Preparation method of iron manganese phosphate

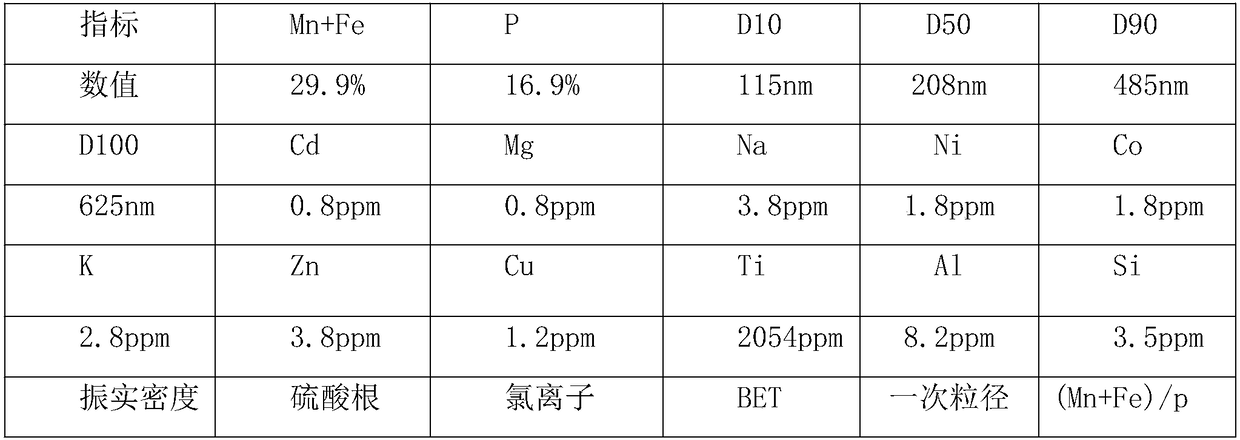

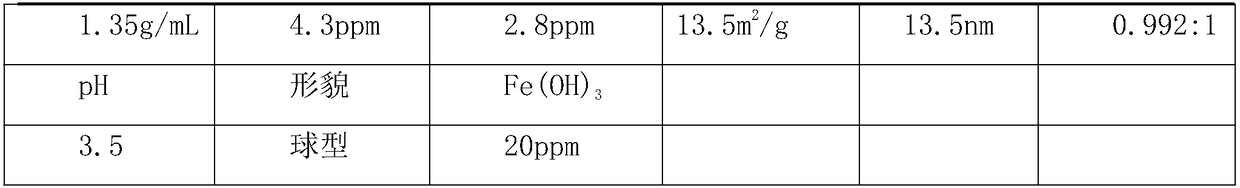

A technology of ferromanganese phosphate and ferromanganese, which is applied in the field of lithium battery new energy materials, can solve the problems of high iron hydroxide content, low phosphorus content, and low purity, and achieve low iron hydroxide content, sulfate radical and chloride ion content The effect of low, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of ferromanganese phosphate, which comprises the following steps:

[0034] (1) prepare bottom liquid, bottom liquid is ammonium bicarbonate solution, and the pH of bottom liquid is 7.08, and manganese sulfate and ammonium ferrous sulfate are made into solution, then mix to obtain ferromanganese mixed solution, prepare ammonium bicarbonate solution, then Add ferromanganese mixed solution and ammonium bicarbonate solution to the bottom solution under stirring, maintain the pH of the process at 7.08, the temperature at 53.5°C, the stirring speed at 220r / min, the total adding time is 145min, and the first 30 minutes of feeding The speed is 1.25 times of the subsequent feeding speed. After the feeding is completed, continue to stir and react for 80 minutes, then raise the temperature to 72.5°C, add ammonia water to adjust the pH of the solution to 7.75, and continue to react for 25 minutes to obtain carbonate slurry;

[0035] (2) The carbonate slurry obt...

Embodiment 2

[0046] A preparation method of ferromanganese phosphate, which comprises the following steps:

[0047] (1) prepare bottom liquid, bottom liquid is ammonium bicarbonate solution, and the pH of bottom liquid is 7.11, and manganese sulfate and ferrous ammonium sulfate are made into solution, mixes then and obtains ferromanganese mixed solution, prepares ammonium bicarbonate solution, and then Add ferromanganese mixed solution and ammonium bicarbonate solution to the bottom solution under stirring, maintain the pH of the process at 7.11, the temperature at 51°C, the stirring speed at 240r / min, the total adding time is 130min, and the first 30 minutes of feeding The speed is 1.45 times of the subsequent feeding speed. After the feeding is completed, continue to stir and react for 80 minutes, then raise the temperature to 73.5°C, add ammonia water to adjust the pH of the solution to 7.75, and continue to react for 18 minutes to obtain carbonate slurry;

[0048] (2) The carbonate slu...

Embodiment 3

[0060] A preparation method of ferromanganese phosphate, which comprises the following steps:

[0061] (1) prepare bottom liquid, bottom liquid is ammonium bicarbonate solution, and the pH of bottom liquid is 7.11, and manganese sulfate and ferrous ammonium sulfate are made into solution, mixes then and obtains ferromanganese mixed solution, prepares ammonium bicarbonate solution, and then Add ferromanganese mixed solution and ammonium bicarbonate solution to the bottom solution under stirring, maintain the pH of the process at 7.11, the temperature at 53.5°C, the stirring speed at 240r / min, the total addition time is 140min, and the first 30 minutes of feeding The speed is 1.35 times of the subsequent feeding speed. After the feeding is completed, continue to stir and react for 80 minutes, then raise the temperature to 72°C, add ammonia water to adjust the pH of the solution to 7.72, and continue to react for 20 minutes to obtain carbonate slurry;

[0062] (2) The carbonate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com