Patents

Literature

836 results about "Manganese phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese(II) phosphate is an inorganic compound with the chemical formula Mn 3 (PO 4) 2. It has industrial importance as a constituent of manganese based phosphate conversion coatings. Formation. Manganese phosphates often combine with iron phosphates through paragenesis.

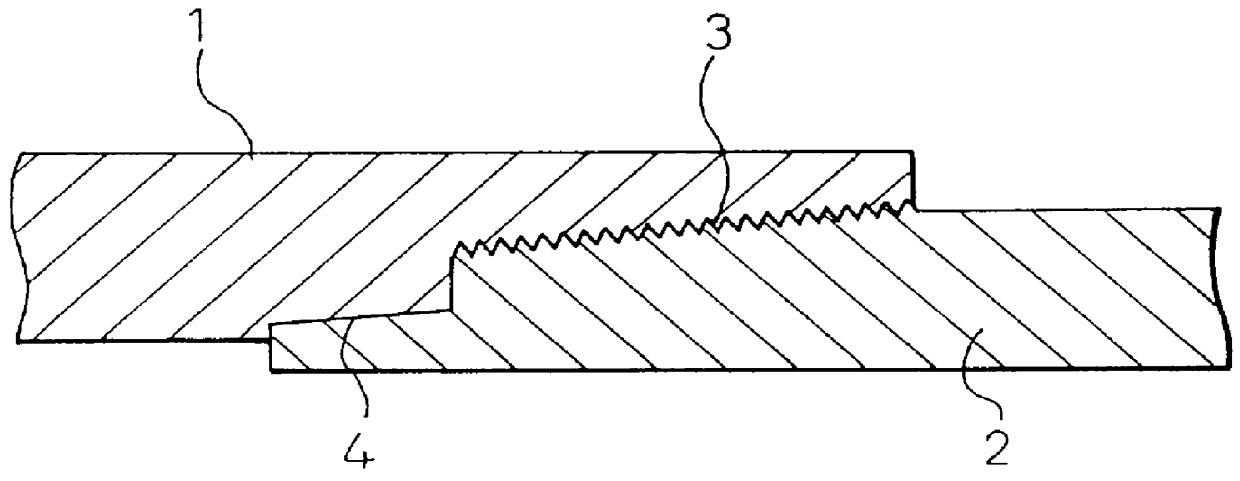

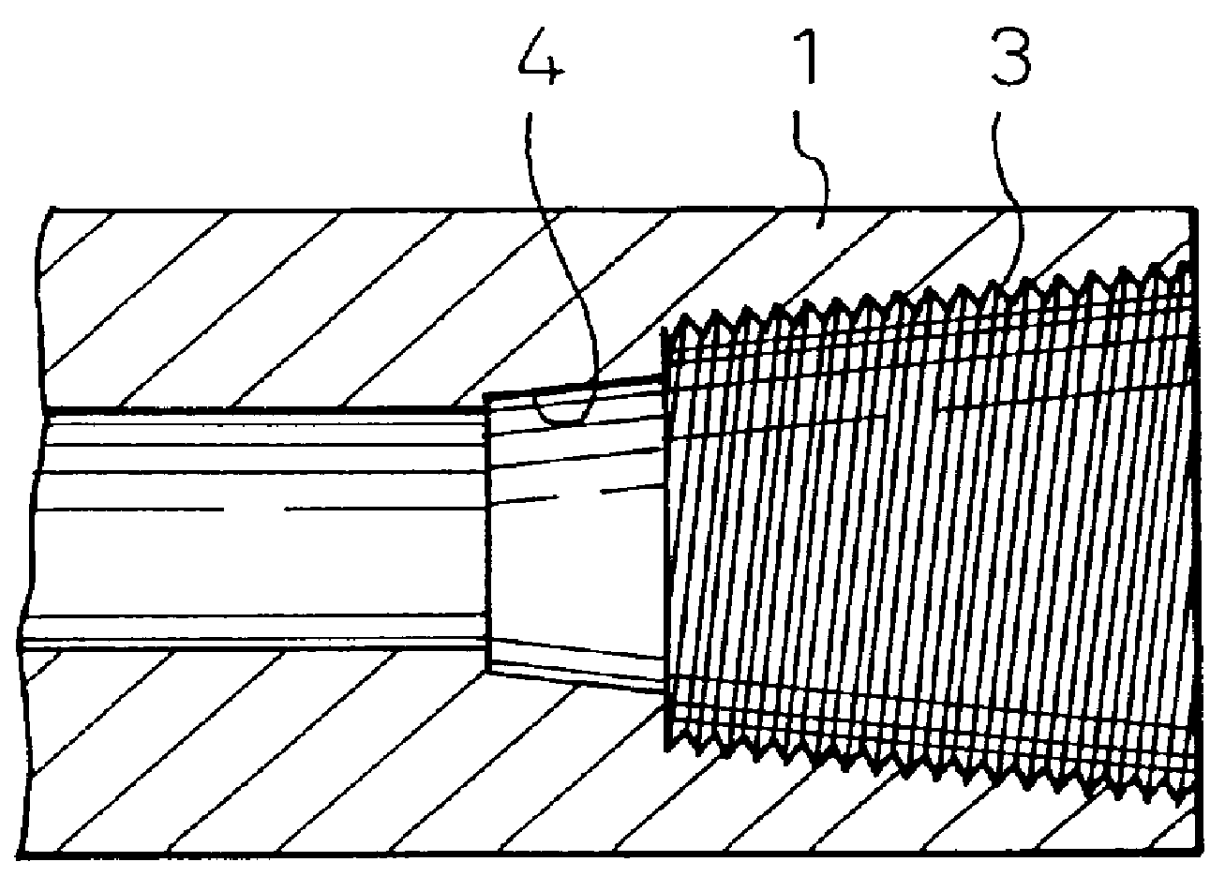

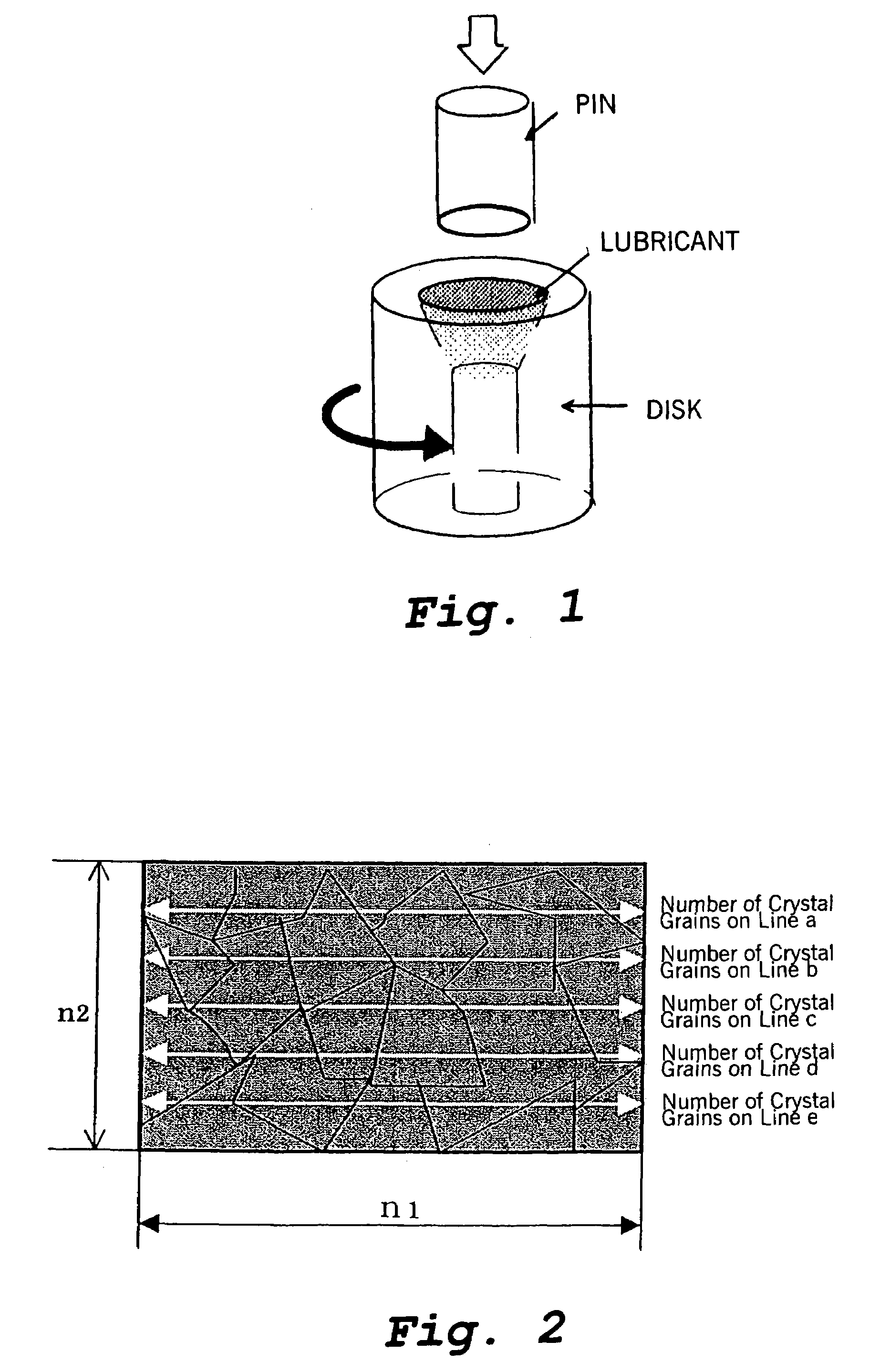

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

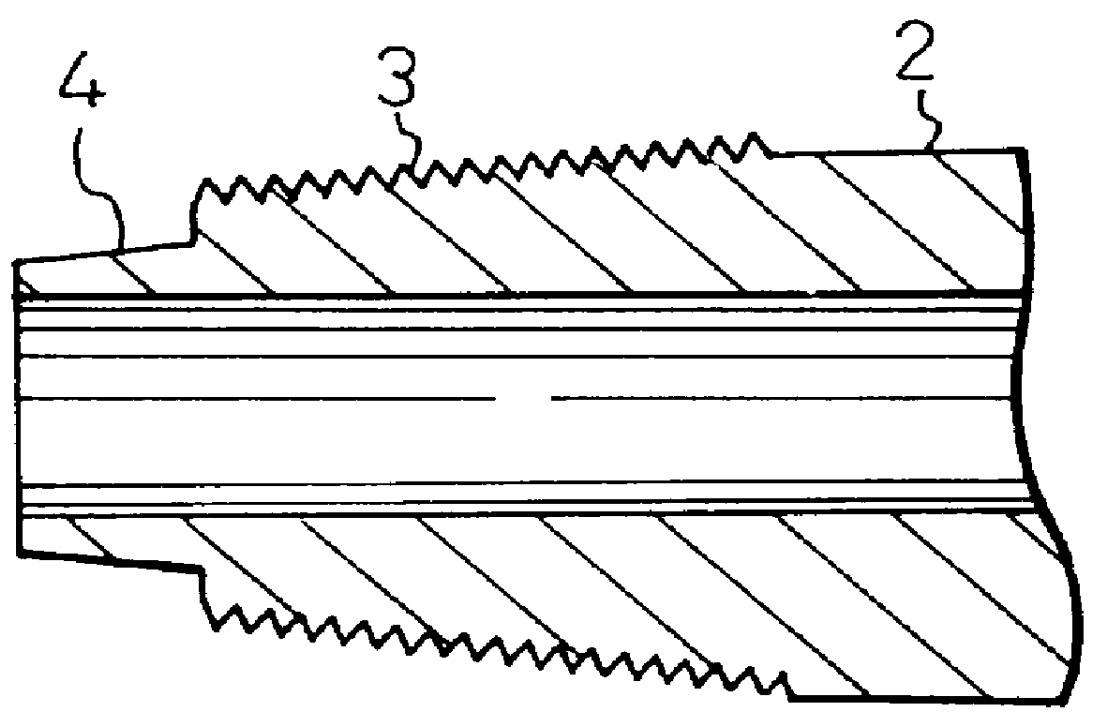

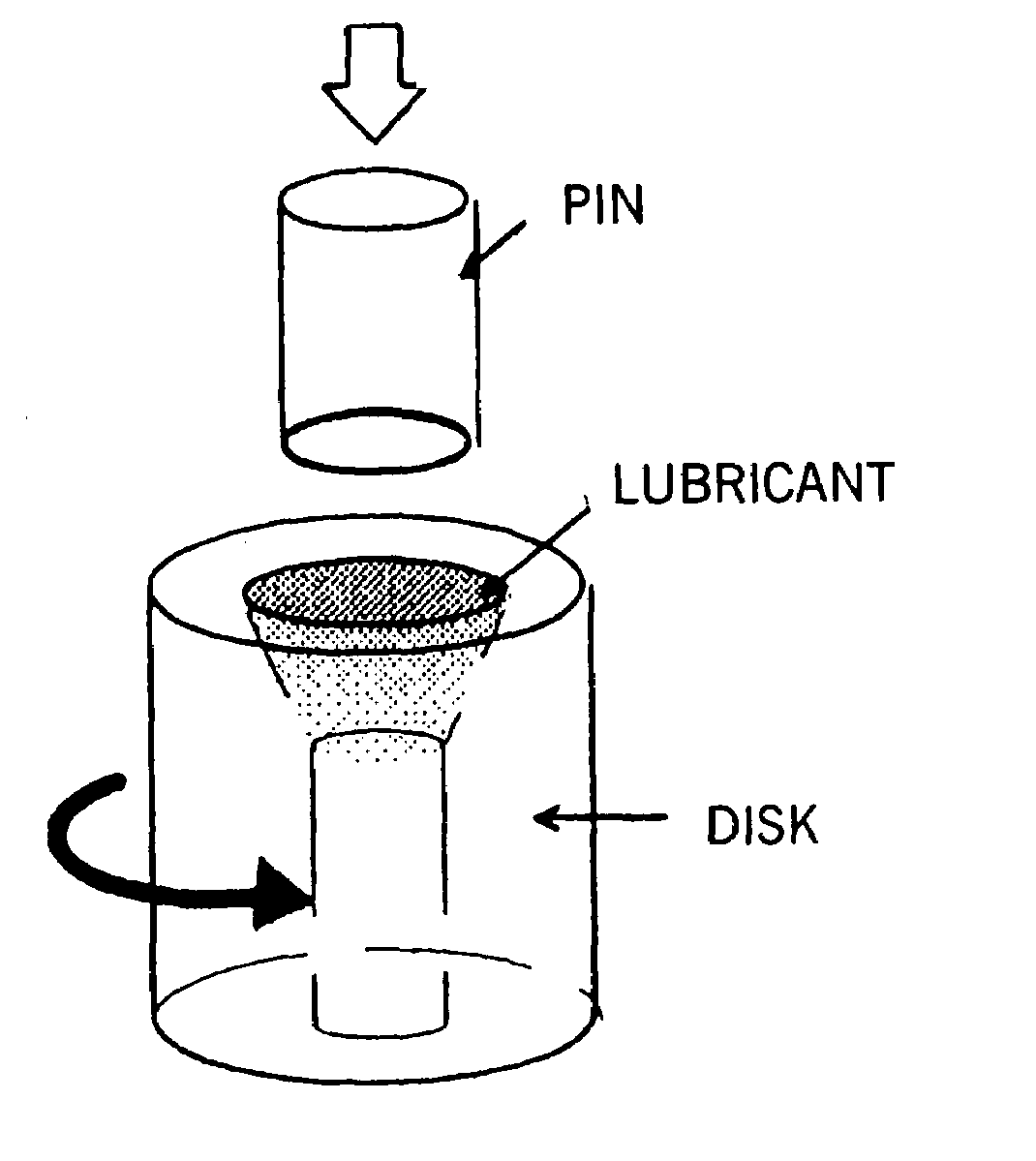

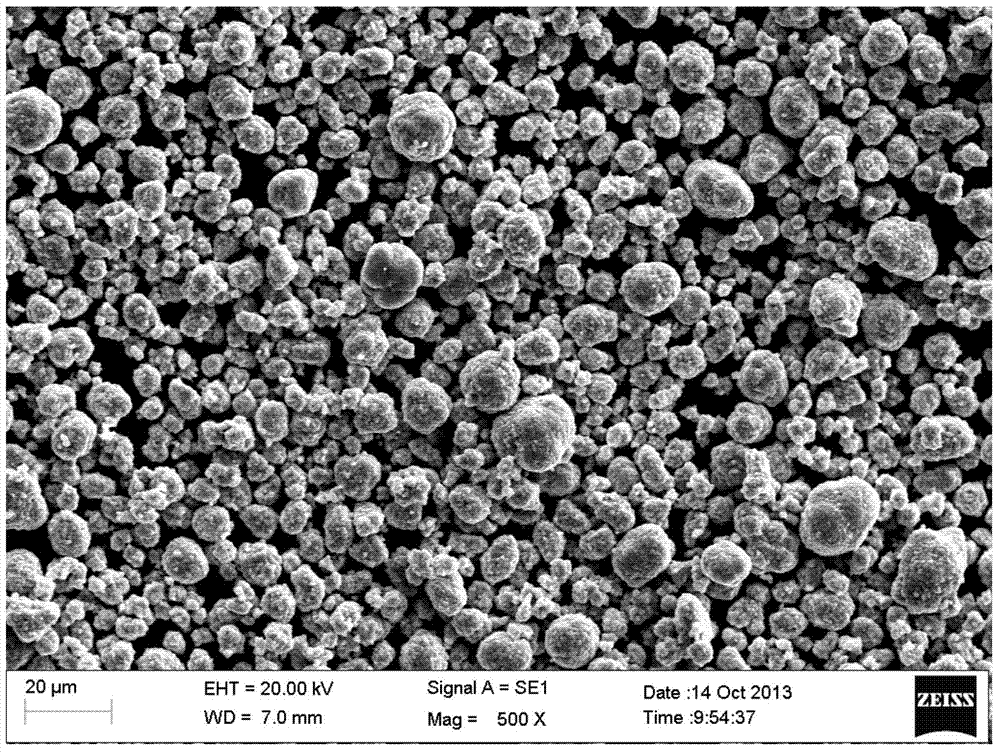

Surface conditioning prior to chemical conversion treatment of a steel member

ActiveUS7666266B2Optimized diameterShort timeOther chemical processesCorrosion preventionPotassiumMaterials science

By subjecting a threaded joint for OCTG (oil country tubular goods) to surface conditioning with an aqueous solution of potassium tetraborate or sodium tetraborate prior to manganese phosphate chemical conversion treatment, a manganese phosphate chemical conversion coating having coarse crystal grains with an average crystal grain diameter of 10-110 micrometers is formed on the surface of the steel member which may be any steel including a high Cr steel. This manganese phosphate chemical conversion coating can hold a large amount of a liquid lubricant, and it is effective at preventing the occurrence of galling at the time of makeup of a threaded joint for OCTG.

Owner:NIPPON STEEL CORP

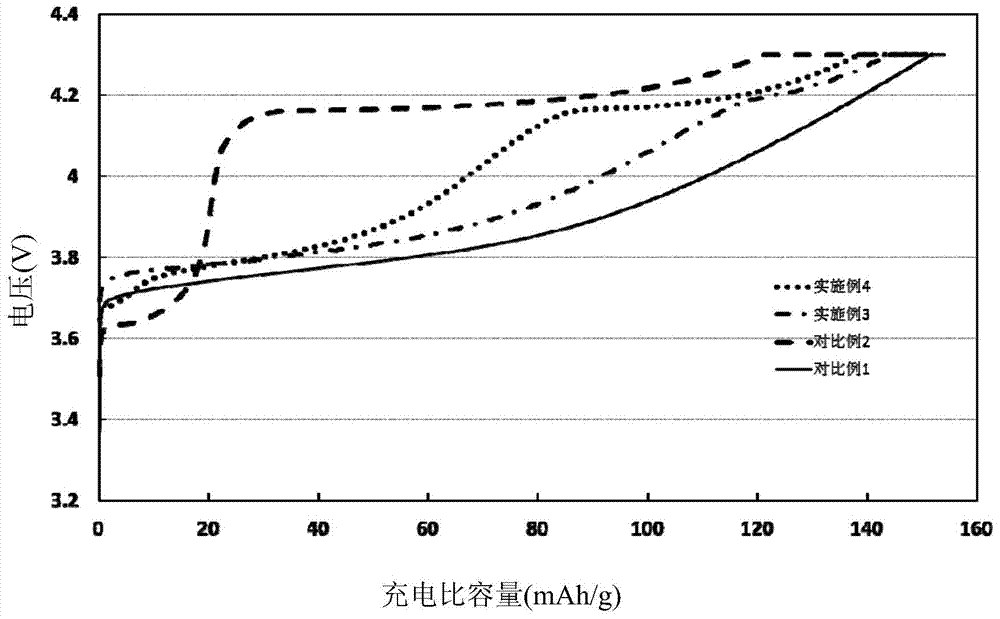

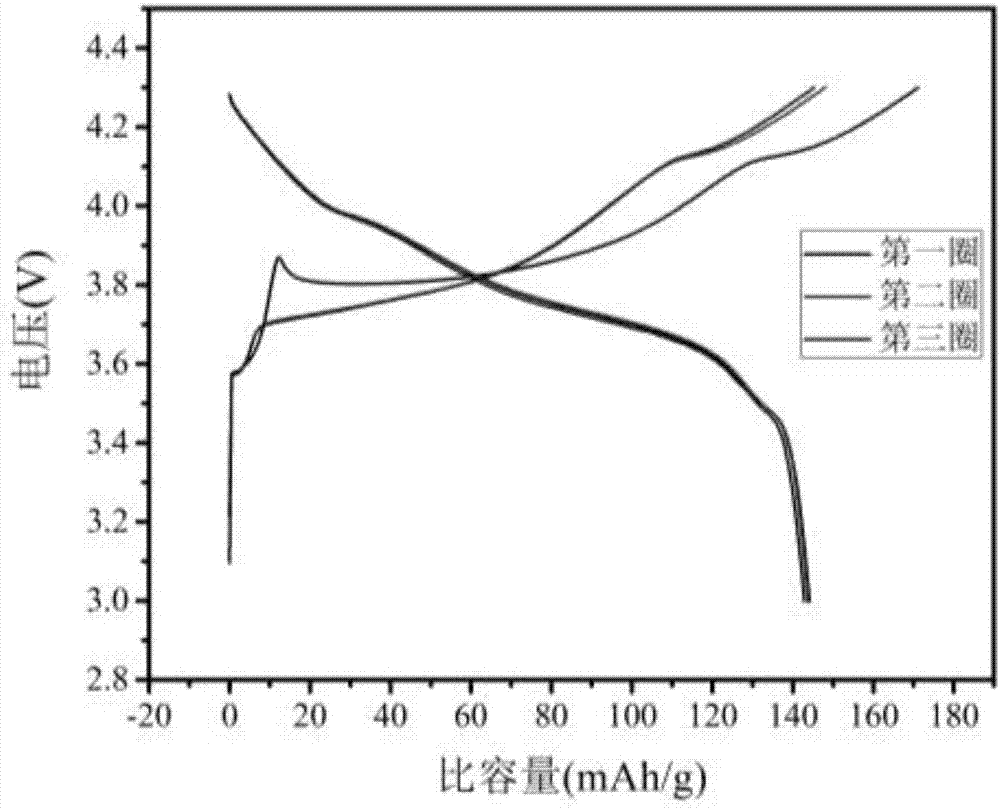

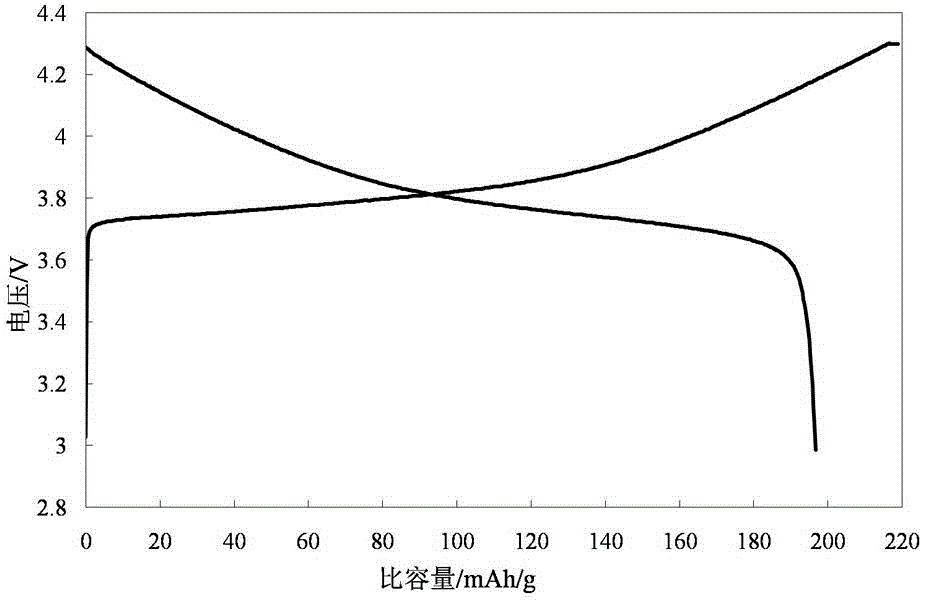

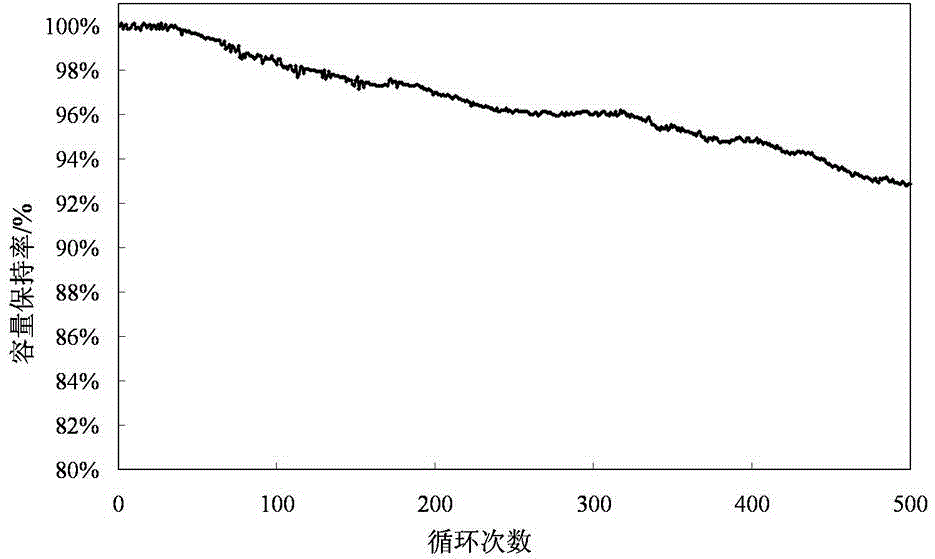

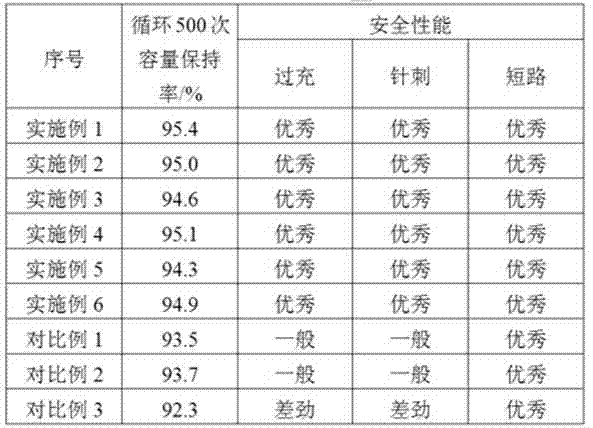

Mixed positive electrode material, positive plate using the same, and lithium ion battery

ActiveCN104300123AIncrease energy densityStable thermal decompositionCell electrodesSecondary cellsHigh energyManganese

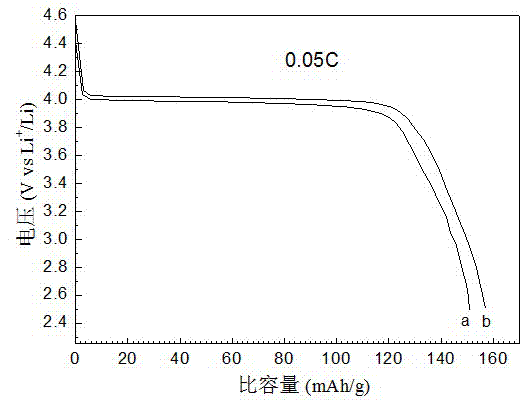

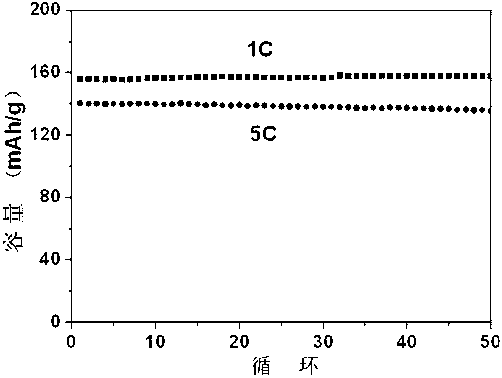

The invention discloses a mixed positive electrode material, a positive plate using the same, and a lithium ion battery. The mixed positive electrode material comprises the following component by weight: 50-90 parts of a nickel-cobalt-manganese ternary material and 10-50 parts of lithium-manganese-iron phosphate. The mixed positive electrode material provided by the invention combines the nickel-cobalt-manganese ternary material with high energy density and lithium-manganese-iron phosphate with high safety performance, and plays complementary advantages of nickel-cobalt-manganese and lithium-manganese-iron phosphate, so that comprehensive performances of the positive electrode active material are improved. The positive plate prepared by using the mixed positive electrode material increases the safety performance and cycle performance of the lithium ion battery, increases average voltage of the lithium ion battery, and keeps relatively high energy density; and the lithium ion battery using the positive plate has excellent electrochemical performances, high energy density and high safety performances and long cycle life, and is suitable for popularization and application.

Owner:中创新航科技(江苏)有限公司

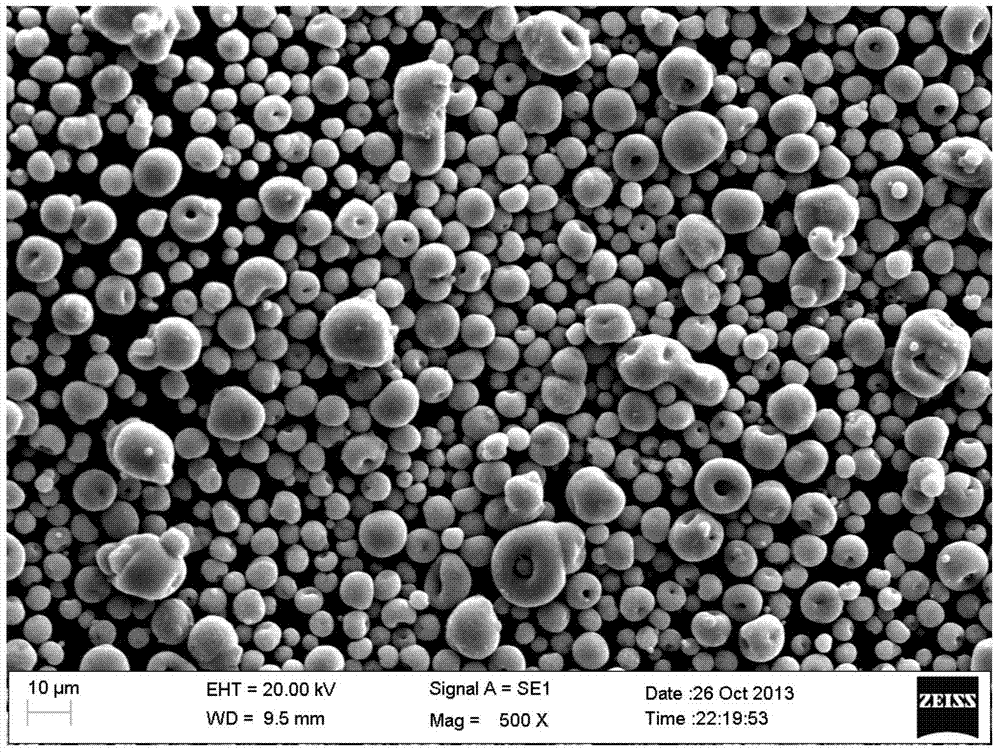

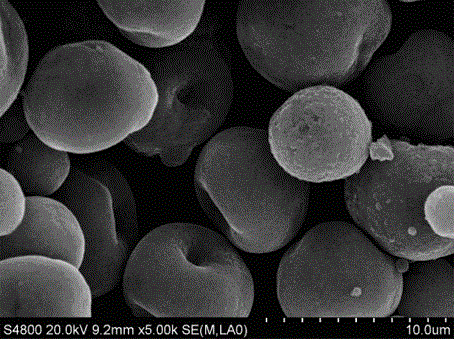

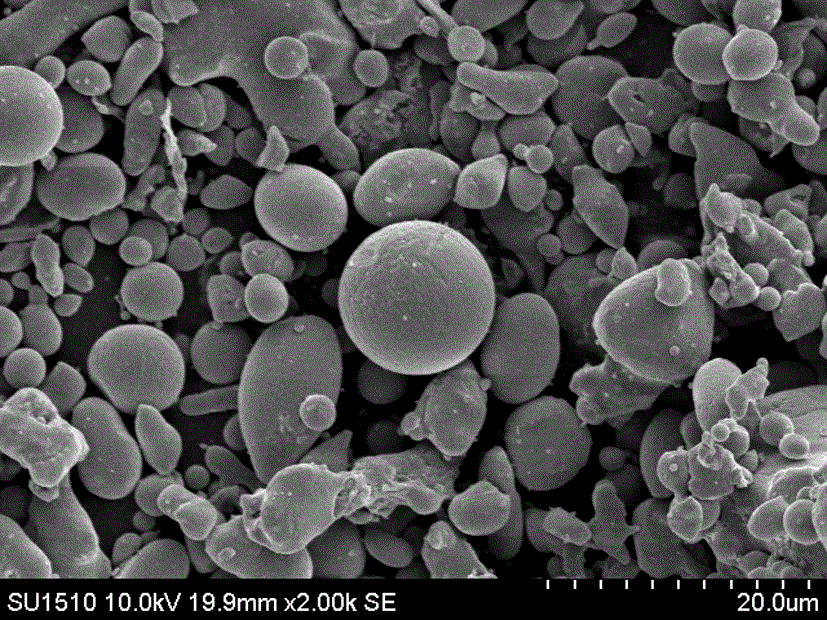

Method for preparing high-density spherical lithium iron phosphate and lithium iron manganese phosphate

InactiveCN1632970AWide variety of sourcesImprove conductivityElectrode manufacturing processesLithium compoundsFerrous ammonium phosphatePersulfate

This invention discloses a high-density ball ferric phosphate lithium and manganous phosphate iron lithium process method used in lithium ion battery positive electrode material in energy material process technique field. The process method comprises the following steps: to use ferric persulfate, phosphor or complex builder or manganese sulfate to process the mixture liquid; to react with the hartshorn solution to generate ball ferrous phosphate ammonium or manganese phosphate ferrous front driver; to mix it with lithium carbonate with mole proportion of one to one after washing and drying; under protection of nitrogen gas and after 600 to 900 degrees for 8 to 48 hours to get the ferric phosphate lithium or manganese phosphate ferrous.

Owner:TSINGHUA UNIV

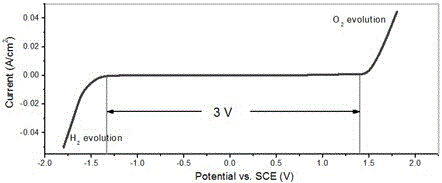

Water system high-voltage mixed ion secondary battery based on zinc-lithium ferric manganese phosphate

InactiveCN105826520AIncrease capacityExcellent rate performanceCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention relates to a water system high-voltage mixed ion secondary battery. A positive pole material of the battery is a high-voltage battery positive pole material, namely zinc-lithium ferric manganese phosphate (LiFe1-xMnxPO4), the element zinc serves as the majority of a negative pole material, and electrolyte is a liquid-state or gel-state material which is formed by lithium bis(trifluoromethane sulfonimide) (LiTFSI) and soluble zinc salt as solute and water as solvent and has ionic conductivity. The battery is based on the energy storage mechanisms of a dissolution-out / deposition reaction of zinc ions (Zn2+) on a negative pole and a reversible embedding / ejection reaction of the zinc ions (Zn2+) on a positive pole, meanwhile, through the water-in-salt electrolyte formed by high-concentration LiTFSI, the electrochemical water decomposition process is inhibited, a potential window of the water system electrolyte is remarkably broadened, the zinc-lithium mixed ion secondary battery has the advantages of being high in capacity, long in cycling life, safe, environmentally friendly, low in cost and the like, and the battery can be applied to the fields such as consumer electronic equipment, electromobiles and large-scale energy storage.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

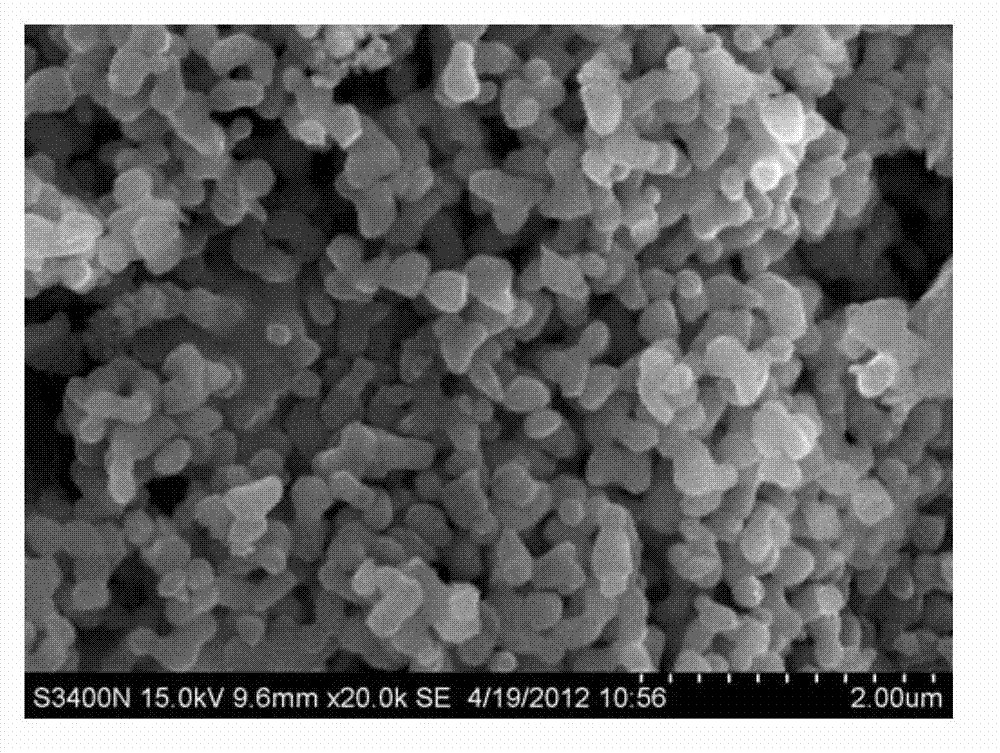

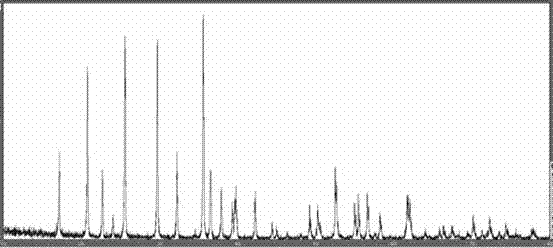

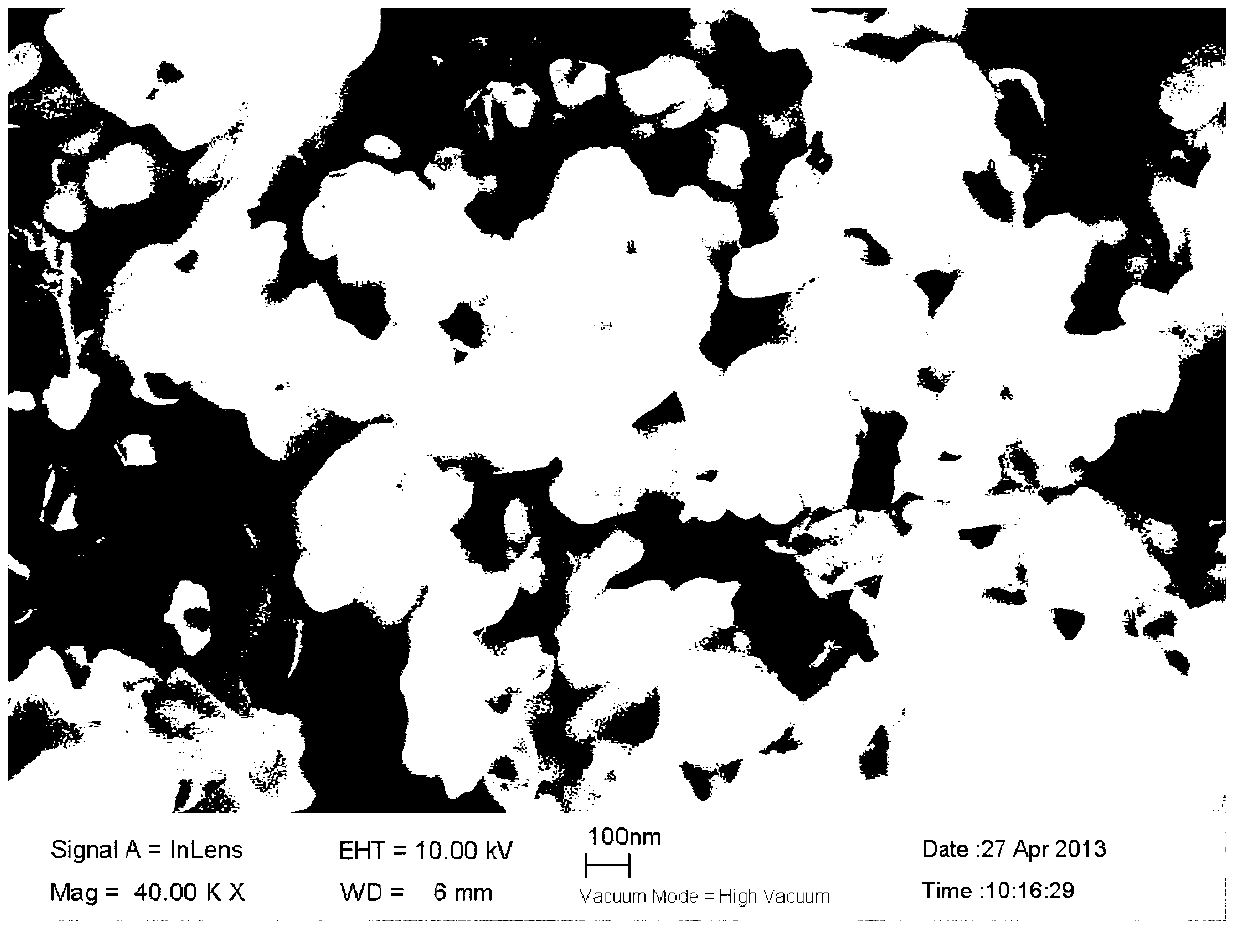

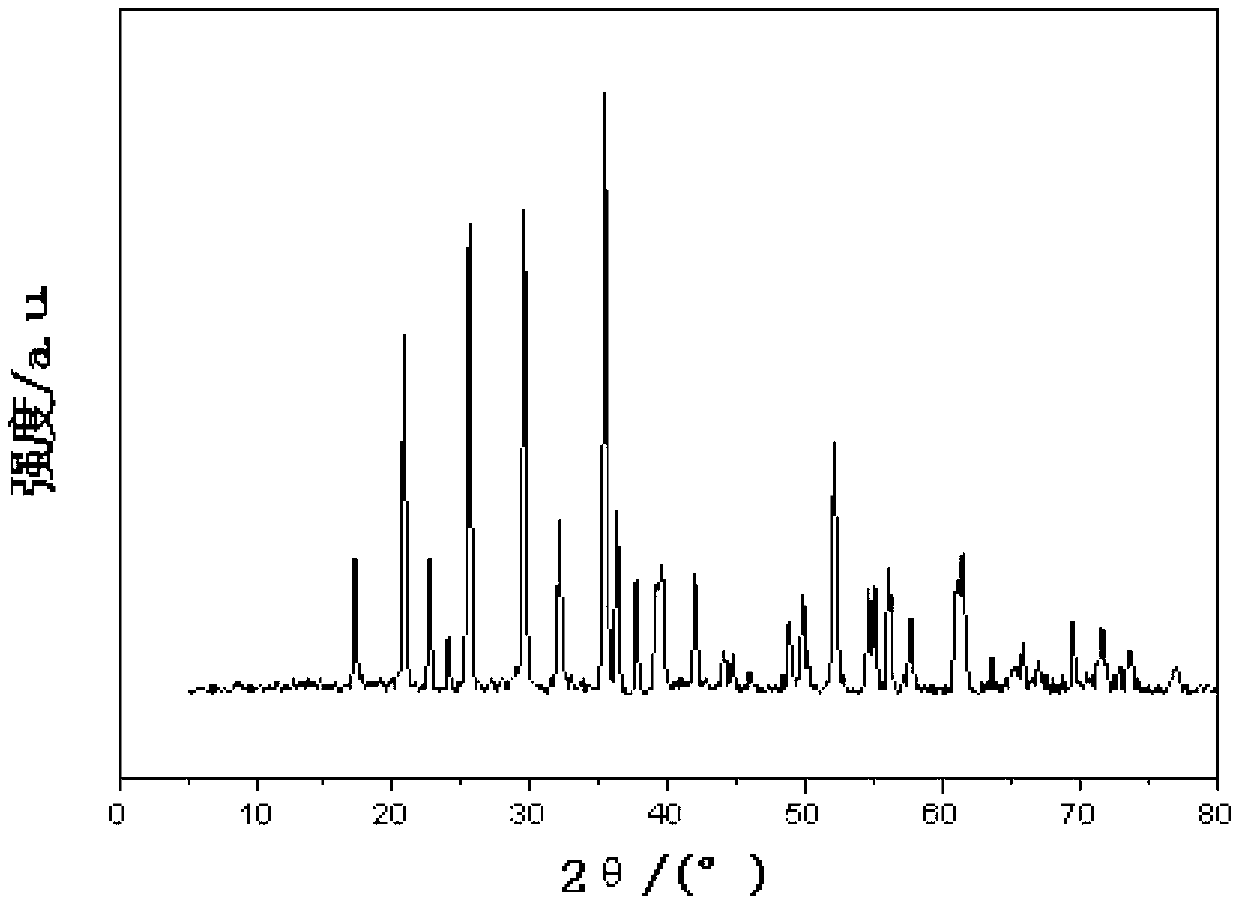

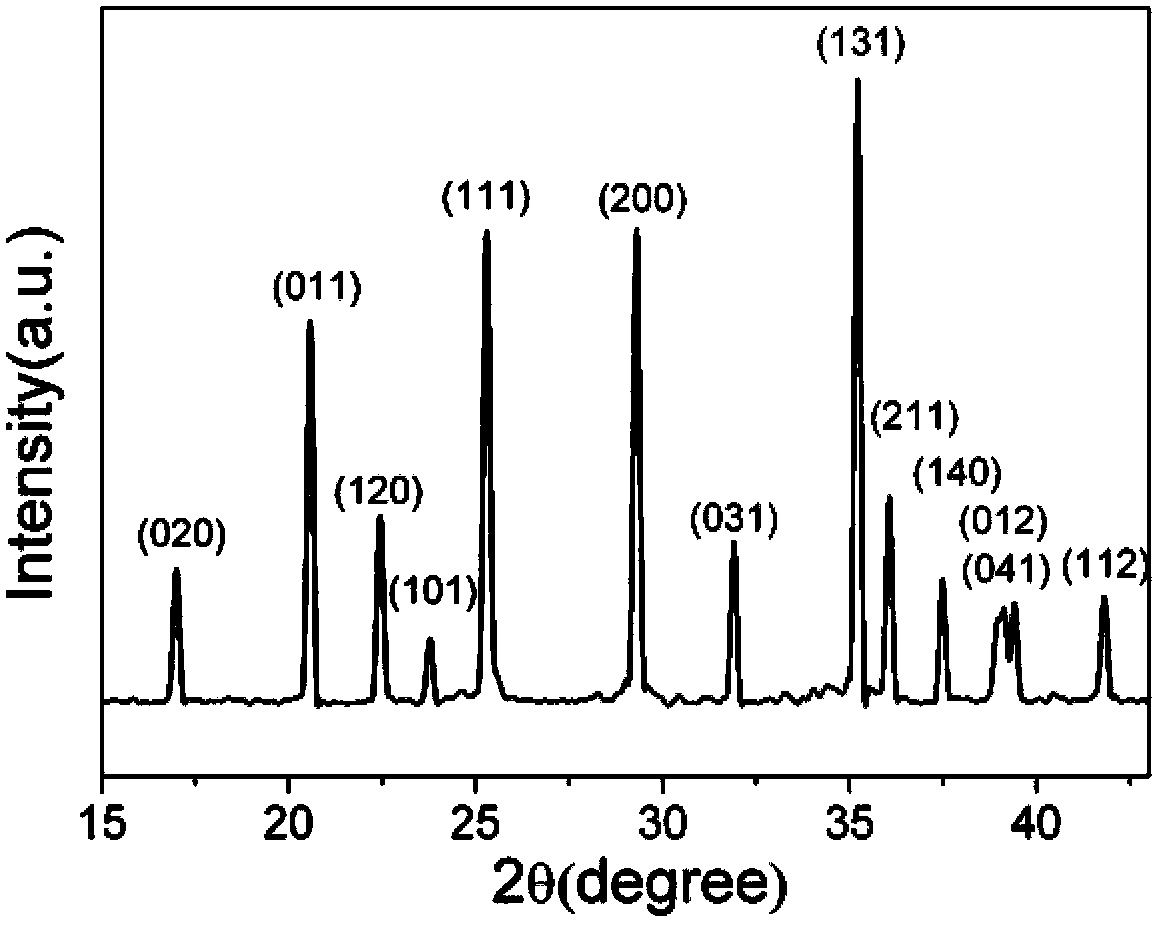

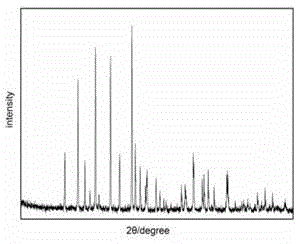

Preparation method of nano-grade lithium manganese phosphate anode material

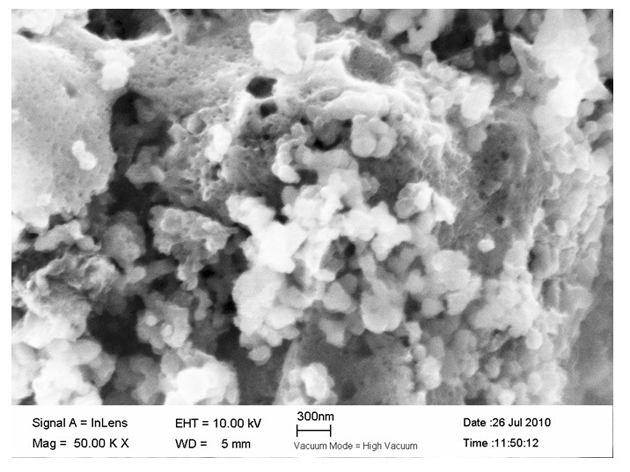

The invention discloses a preparation method of a nano-grade lithium manganese phosphate anode material, comprising the following steps of: preparing a lithium source, a manganese source, a phosphorus source and a doping element compound into a solution in a mol ratio of Li: Mn: P: the doping element of (0.9-1): (0.9-1): (0.9-1): (0-0.1); adding a complexing agent and adding a carbon source into the solution to obtain a uniform colloid; drying the colloid to obtain precursor powder; heating the precursor powder under a protective atmosphere to obtain nano powder; and sintering the nano powder under a protective atmosphere to obtain the nano-grade lithium manganese phosphate anode material. The method belongs to one of a liquid-phase method; each element is at an ion or molecule state in a synthesizing process and the mixing is more uniform; on the basis of the existing liquid-phase method, the synthesizing time is further shortened, a production process is simplified and the cost is reduced; and the nano grade and the purity of a synthesized product are high, the grain diameter is 10-400 nm and the electrochemical performance is good.

Owner:FOSHAN DYNANONIC

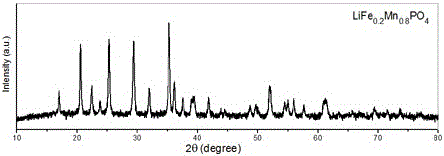

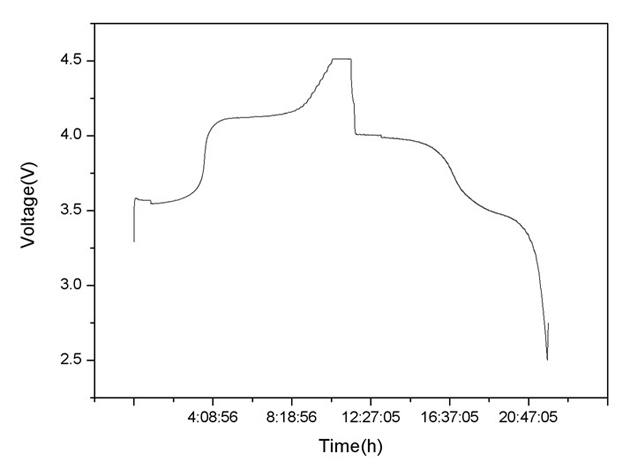

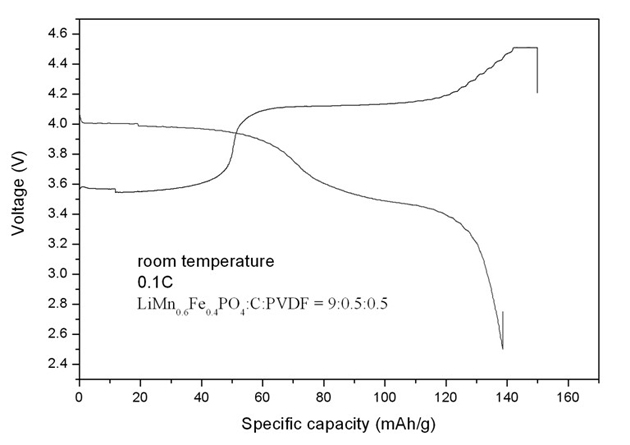

Lithium ferric manganese phosphate as cathode material of lithium ion battery and preparation method thereof

The invention relates to a lithium ferric manganese phosphate as a cathode material of a lithium ion battery and a preparation method thereof, belonging to the technical field of lithium ion batteries. The lithium ferric manganese phosphate as the cathode material has a chemical composition: Li1-yMyFel-xMnxPO4. The preparation method of the lithium ferric manganese phosphate as the cathode material comprises the following steps of: (1) synthesizing a precursor: placing raw materials into a container; adding a dispersant; grinding and dispersing 1-3 hours at rotation speed of 1000-2500r / min; and drying and grinding pasty paste; (2) preburning: heating to the temperature of 350-550 DEG C according to a heating rate of 1-10 DEG C / min; preburning 3-20 hours at constant temperature; cooling to room temperature along with a furnace; and preparing the lithium ferric manganese phosphate; and (3) coating carbon at high temperature: mixing and dispersing the lithium ferric manganese phosphate, a carbon source and the dispersant 1-3 hours; after drying, heating to the temperature of 600-850 DEG C by using a heating rate of 1-10 DEG C / min; insulating 3-20 hours; cooling to room temperature along with the furnace; and preparing the lithium ferric manganese phosphate. The invention has the advantages of simple technology, low cost of batteries, high safety of cathode materials, high thermal stability, electric conductivity increase, and the like.

Owner:天津斯特兰能源科技有限公司

Method for producing iron lithium manganese phosphate composite positive electrode material used in lithium ion battery through carbon reduction

The invention discloses an iron lithium manganese phosphate composite positive electrode material used in a lithium ion battery, and a preparation method thereof. The method provided by the invention is mainly aimed at improving the performance of a lithium ion battery positive electrode material. The method comprises specific steps that: a lithium source is mixed with an iron source, a manganesesource, a phosphorous source, a reducing agent, and doped elements; the mixture is subject to a reaction, such that a compound of an iron lithium manganese phosphate precursor, a lithium source, manganese phosphate, ferric phosphate, phosphate and doped elements is prepared; the compound is mixed with a lithium source and a reducing agent carbon source; and the mixture is sintered under a protective atmosphere, such that the iron lithium manganese phosphate composite positive electrode material is obtained. The method provided by the invention is advantaged in simple technology, low material cost, low production cost, short production period, and low energy consumption. The method can be applied in large-scale productions. The product prepared with the method is advantaged in high bulk density, good conductivity and high specific capacity.

Owner:济宁市无界科技有限公司

Preparation method of metal doped lithium manganese phosphate/graphene/carbon composite material

ActiveCN103346319AImprove electrochemical performanceReduce polarizationCell electrodesCarbon compositesSolvothermal reaction

The invention discloses a preparation method of a metal doped lithium manganese phosphate / graphene / carbon composite material. By adopting the method, the graphene is added in the preparation process of the lithium manganese phosphate to replace partial conductive carbon black; and a precursor which is a mixture of three solutions is transferred to a reaction tank and is subjected to solvothermal reaction at 160-300 DEG C for 1-20 hours to obtain the graphene in-situ composite lithium manganese phosphate material. According to the preparation method disclosed by the invention, the surface-contact compounding of graphene and lithium manganese phosphate is achieved by taking advantage of the flexibility characteristic of graphene, and the electronic conductivity of the lithium manganese phosphate is improved by taking advantage of the extremely high conductivity of graphene. By adopting the preparation method disclosed by the invention, not only is the intrinsic electronic conductivity of the composite material improved, but also a graphene film layer with extremely high conductivity is uniformly coated on the surface of the lithium manganese phosphate material, the graphene and the conductive carbon black together form a three-dimensional conductive network, and therefore the electrochemical performance of the lithium manganese phosphate material is obviously improved, and the composite material can be used as the anode material of a lithium ion battery.

Owner:HEBEI UNIV OF TECH

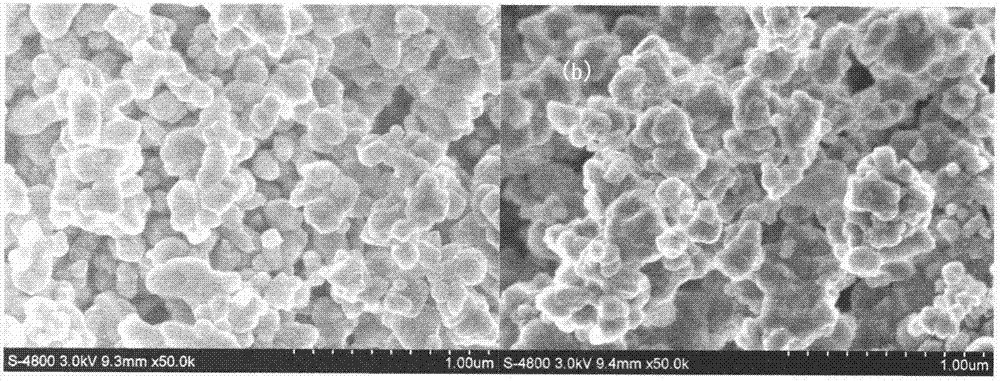

Lithium manganese ferric phosphate-ternary material composite positive electrode material and preparation method therefor

ActiveCN107546379AImprove stabilityImprove cycle performanceCell electrodesSecondary cellsPhosphateManganese

The invention discloses a lithium manganese ferric phosphate-ternary material composite positive electrode material and a preparation method therefor. Lithium manganese ferric phosphate nanoparticlesare fixed on the surfaces of the ternary material granules through a mechanical fusion method to form a tight porous coating layer; therefore, the problem of easy segregation caused by different densities of the ternary material and the lithium manganese ferric phosphate positive electrode material when the mixed paste of the ternary material and the lithium manganese ferric phosphate positive electrode material is needed in the paste mixing stage in the use process of the ternary material and the lithium manganese phosphate positive electrode material can be solved; and by virtue of tight coating of the lithium manganese ferric phosphate on the surface of the ternary material, a stable core-shell structure can be obtained, so that the surface of the ternary material (particularly a high-nickel ternary material) can be protected by the lithium manganese ferric phosphate material, degradation of the ternary material caused by absorption of water contents in the environments can be prevented, direct contact between the ternary material and an electrolyte in the battery can be lowered, and the stability and cyclicity of the ternary material are improved.

Owner:中科致良新能源材料(浙江)有限公司

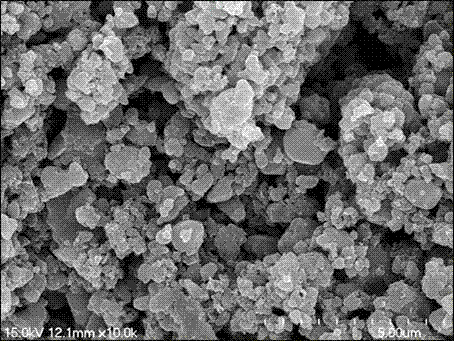

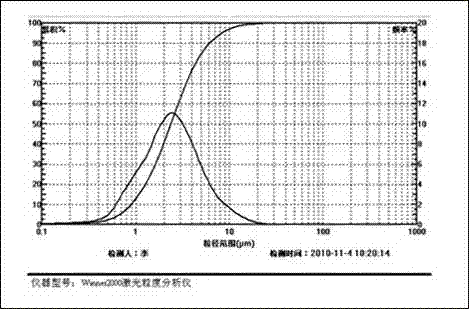

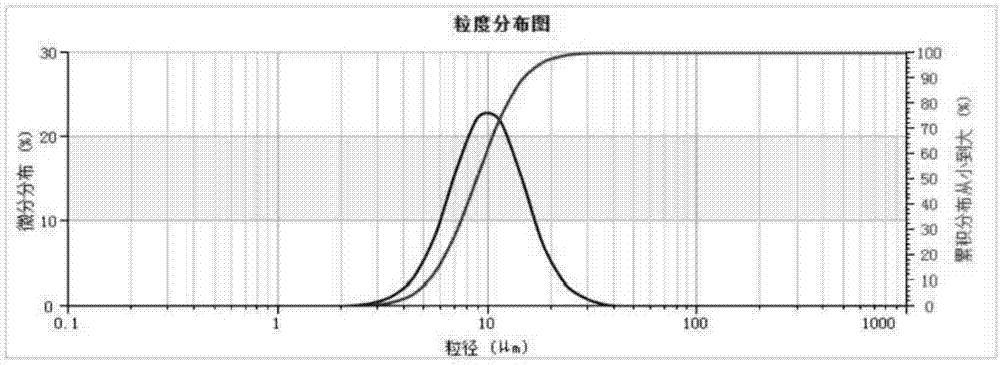

Battery grade iron and manganese phosphate and preparation method thereof

The invention relates to battery grade iron and manganese phosphate and a preparation method thereof. The chemical composition of the battery grade iron and manganese phosphate is MnxFe(1-x)PO4, wherein x is greater than or equal to 0.1 and smaller than or equal to 0.9; the preparation method comprises the steps of adopting a hydrothermal oxidation-coprecipitation technology, putting a soluble phosphorus source, iron source and manganese source solution into a reaction kettle according to the chemical composition MnxFe(1-x)PO4 of the iron and manganese phosphate, adding a surfactant and nitric acid, controlling the system pH value to be within 1 to 4, stirring for 2 to 48 h at 100 to 250 DEG C, so as to perform hydrothermal reaction, obtaining turbid liquid containing MnxFe(1-x)PO4.yH2O precipitate, naturally cooling the turbid liquid to room temperature, filtering, washing and drying, obtaining MnxFe(1-x)PO4.yH2O, performing high-temperature roasting at 250 to 700 DEG C, and then obtaining the battery grade iron and manganese phosphate not containing crystal water. The method is simple and practicable, and is easy to realize scale production, the prepared iron and manganese phosphate has the advantages that size distribution is uniform, the purity is high, and iron and manganese elements realize atomic-scale uniform distribution, and the battery grade iron and manganese phosphate a belongs to the optimal precursor for preparing lithium ferric manganese phosphate battery materials.

Owner:杨志宽

Carbon coated lithium manganese phosphate/lithium iron phosphate core-shell structure material as well as preparation method thereof

The invention discloses a carbon coated lithium manganese phosphate / lithium iron phosphate core-shell structure material as well as a preparation method thereof. The constitutional general formula of the core-shell structure material is LiMnFe(1-x)PO4.a[LiFeyMn(1-y)PO4], wherein the constitutional general formula of a core material is LiMnxFe(1-x)PO4, and the constitutional general formula of a shell material is LiFeyMn(1-y)PO4, x is greater than or equal to 0.8 but less than or equal to 1, y is greater than or equal to 0.8 but less than or equal to 1, and a is greater than or equal to 0.2 but less than or equal to 0.5. Meanwhile, the core-shell structure material further comprises 0.2-50wt% of carbon element which is distributed in the shell. The method comprises the following steps: firstly, carrying out solid phase sintering of a lithium manganese phosphate / manganese phosphate material; and then, after ball-milling and mixing the material with ferric salt, phosphate, a lithium source and the like, sintering in a protective atmosphere to obtain a target product. The carbon coated lithium manganese phosphate / lithium iron phosphate core-shell structure material as an anode material for a lithium ion battery, disclosed by the invention, has higher volume and better cycling stability, is concise in process, easy to operate, high in efficiency, and beneficial to industrial production on a large scale.

Owner:中科致良新能源材料(浙江)有限公司

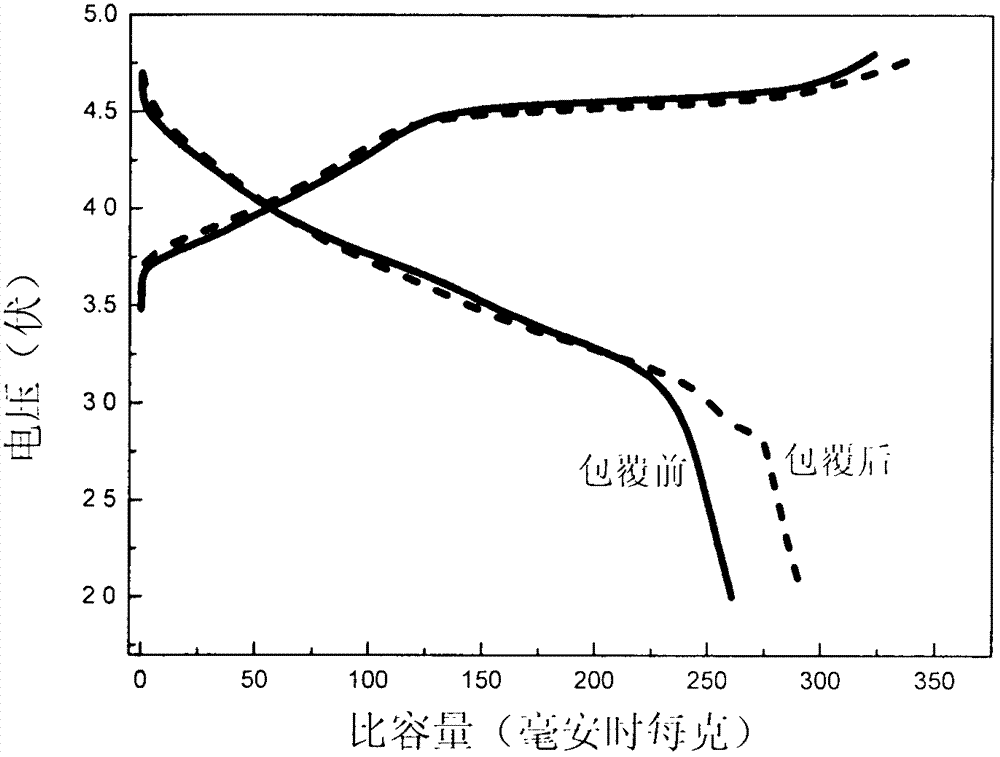

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

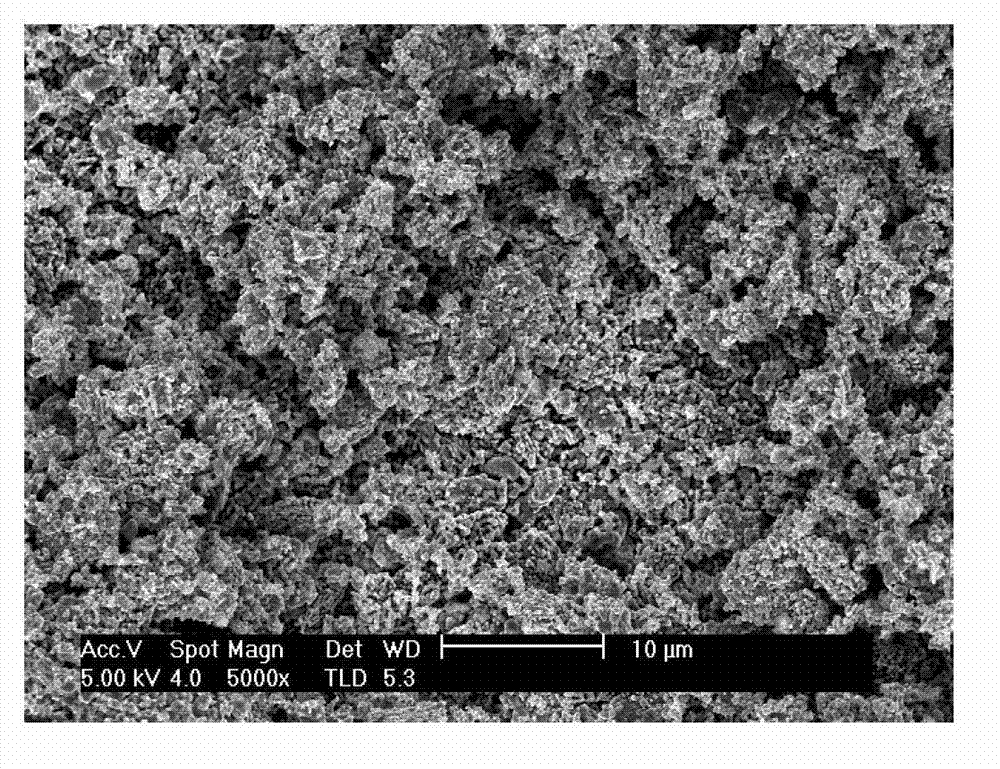

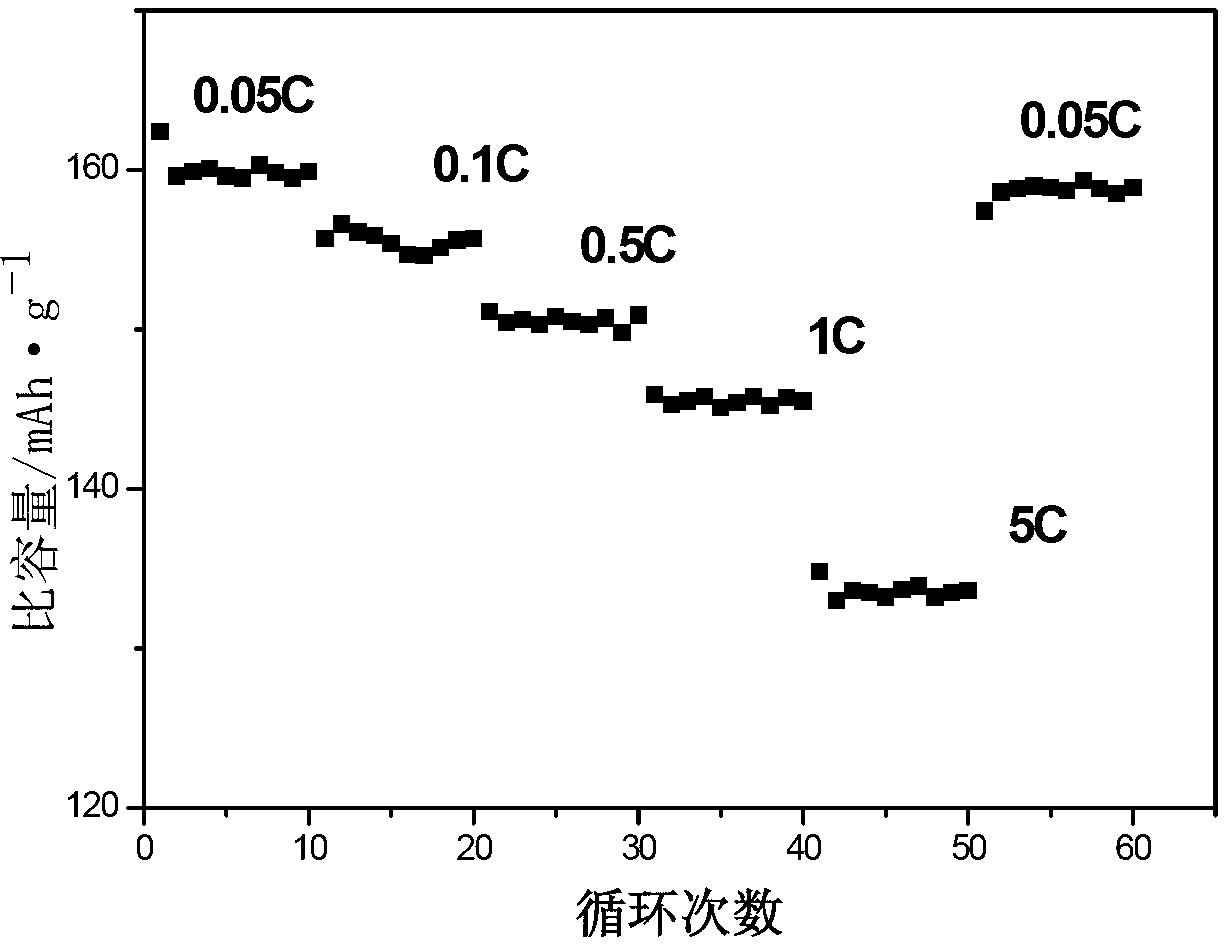

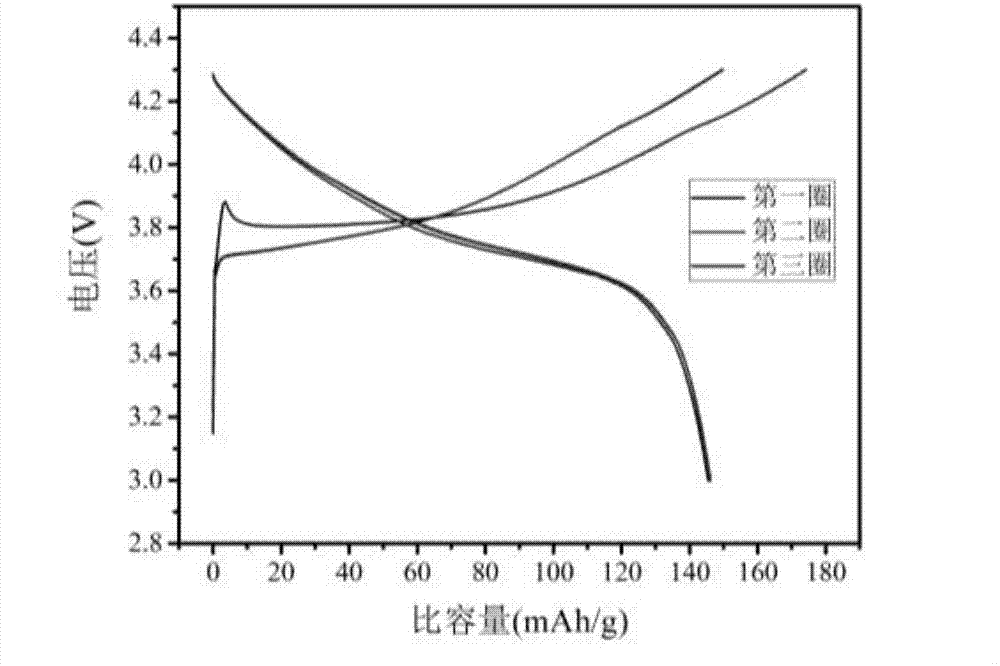

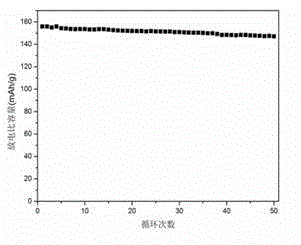

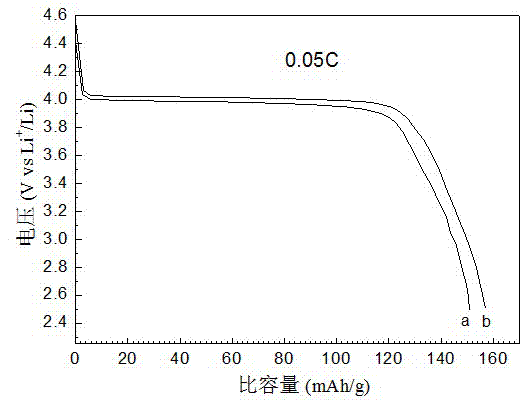

Method for preparing manganese lithium phosphate/carbon composite material by manganese phosphate

ActiveCN101673819ALow costThe synthesis process is simpleElectrode manufacturing processesCarbon compositesManganese

The invention discloses a method for preparing manganese lithium phosphate / carbon composite material by manganese phosphate, belonging to the technical field of energy material, comprising the following steps: firstly, preparing active manganese phosphate (MnPO4), secondly mixing the active manganese phosphate with lithium source and adding carbon source, ball milling and spray drying the materials, conducting heat treatment on the dried powder in the presence of protective atmosphere, heating to 300-850 DEG C and roasting for 2-12 hours and naturally cooling to obtain the manganese lithium phosphate / carbon composite material. The preparation method has low cost and simple synthesis technology, is applied to industrial production; the prepared manganese lithium phosphate / carbon composite material has a primary particle average diameter of 40-500 nm; the synthetic manganese lithium phosphate / carbon composite material has good electrochemical property when taken as the anode material ofthe lithium battery, high specific capacity and nice circulating performance at the conditions of room temperature and large current density; and the specific discharge capacity with 0.1 C multiplyingpower is more than 130 mAh / g.

Owner:TSINGHUA UNIV

Lithium manganese phosphate clad lithium-rich layered oxide cathode material as well as preparation and application thereof

ActiveCN103035906AInhibition of dissolutionAvoid corrosionCell electrodesSecondary cellsManganesePhosphoric acid

The invention relates to a LiMnPO4 clad lithium-rich layered oxide Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 (M is at least one of Ni or Co, wherein x is more than 0 and not less than 0.33) and a preparation method thereof. The Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 is dipped in water solution containing Li, Mn and PO43- (the mol ratio is 1: 1: 1), is continuously stirred for 3-8 hours in an opening container at the temperature of 60-90 DEG C to prepare solid powder, then is dried for 2-24 hours at the temperature of 100 DEG C, and is roasted for 5-10 hours at the temperature of 300-600 DEG C to prepare the LiMnPO4 clad lithium-rich layered oxide Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 cathode material, wherein the mass ratio of the LiMnPO4 to the Li[Li(1-2x) / 3MxMn(2-x) / 3]O2 is 3-10 wt%. The electrode material prepared by the method has the characteristics of high electrochemical capacity, good circulating stability, excellent rate capacity and the like, and has the advantages of simple preparation process, low cost and good reproducibility.

Owner:NANKAI UNIV

Security lithium ion battery positive plate as well as preparation method thereof

ActiveCN103811727AImprove long cycle lifePromote absorptionMaterial nanotechnologySecondary cellsVolume variationManganese

The invention discloses a security lithium ion battery positive plate as well as a preparation method thereof. The positive plate is of a multi-layer structure, and comprises the following active substances: lithium manganese phosphate LiMnPO4, nickel-cobalt-manganese ternary material Li(NixCOyMnz)O2 (0x being more than 0 and smaller than or equal to 0.8, y being more than 0 and smaller than or equal to 0.4, and Z being more than or equal to 0 and less than or equal to 0.4, and x+y+z being equal to 1), as well as a high-temperature-resistant nano material, namely A12O3 or SiO2; the mass percentage of the active substances is that the high-temperature resistant A12O3 or SiO2 ceramic material:LiMnPO4:Li(NixCOyMnz)O2 is equal to (1%-5%):(1%-98%): (1%-98%). The preparation method of the positive plate can be in a sandwiched structure, and also the surface of aluminum foil can be coated with lithium manganese phosphate LiMnPO4 and the Nickel-Cobalt-Manganese ternary material Li(NixCOyMnz)O2 by adopting a mechanical mixing mode, and the surface of aluminum foil can be coated with a layer of high-temperature-resistant nano material; the lithium ion battery prepared by the plate with the structure has favorable safety performance; the long cycle performance and the safety performance of the lithium ion battery can be improved obviously by utilizing the opposite crystal cell volume variation characteristics of different active substances in the charge and discharge processes as well as the excellent liquid retention capability to electrolyte by A12O3 or SiO2.

Owner:SHANGHAI AEROSPACE POWER TECH

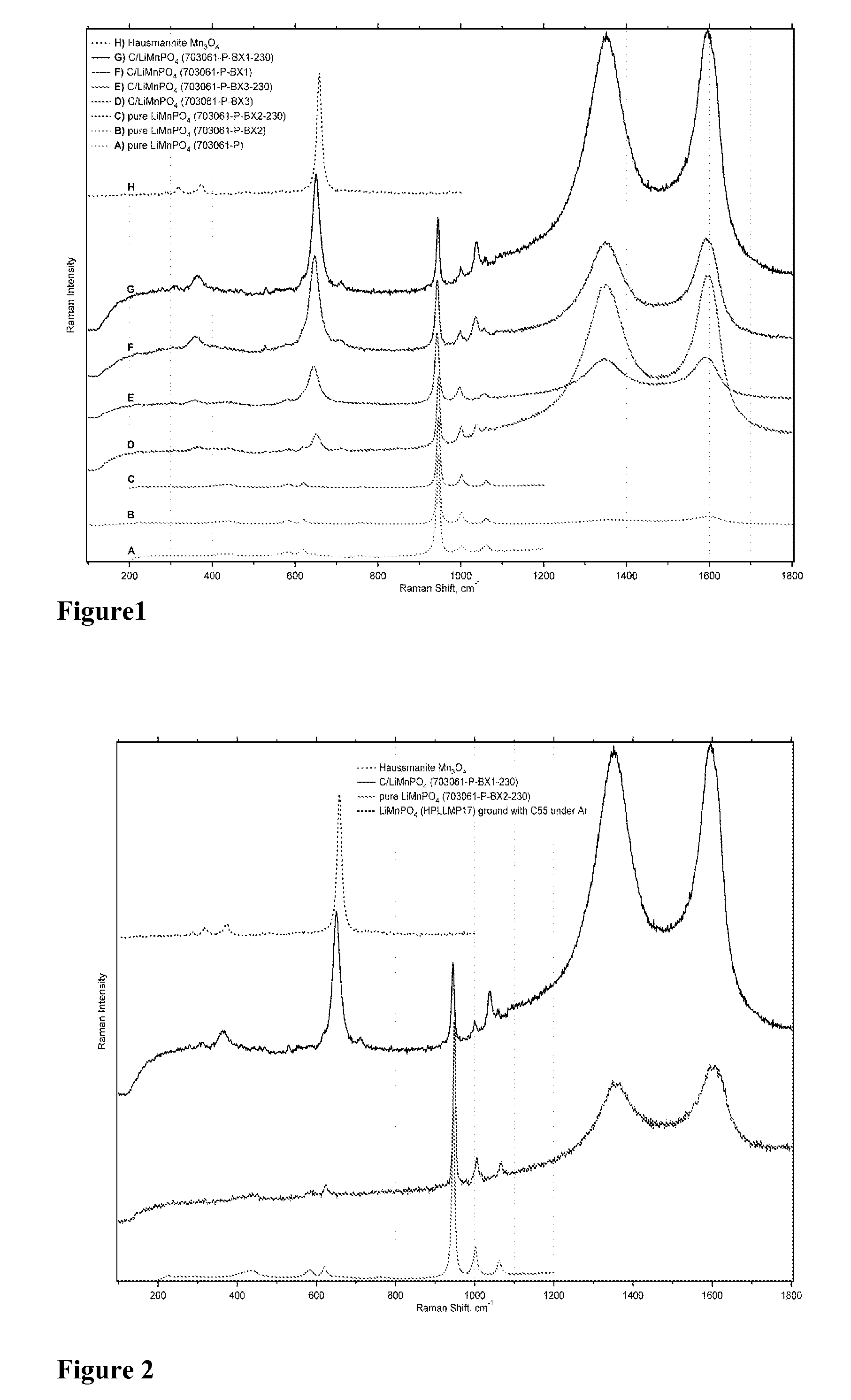

Carbon coated lithium manganese phosphate cathode material

InactiveUS20100178562A1Secondary cellsNon-aqueous electrolyte accumulator electrodesCarbon layerPhosphate

The present invention concerns a carbon coated lithium metal phosphate material containing a manganese oxide layer between the LiMnPO4 material or the C / LiMn1-x ZxPO4 material, where Z═Fe, Co, Ni, Mg, Ca, Al, Zr, V, Ti and x=0.01-0.3, and the carbon layer.

Owner:DOW GLOBAL TECH LLC

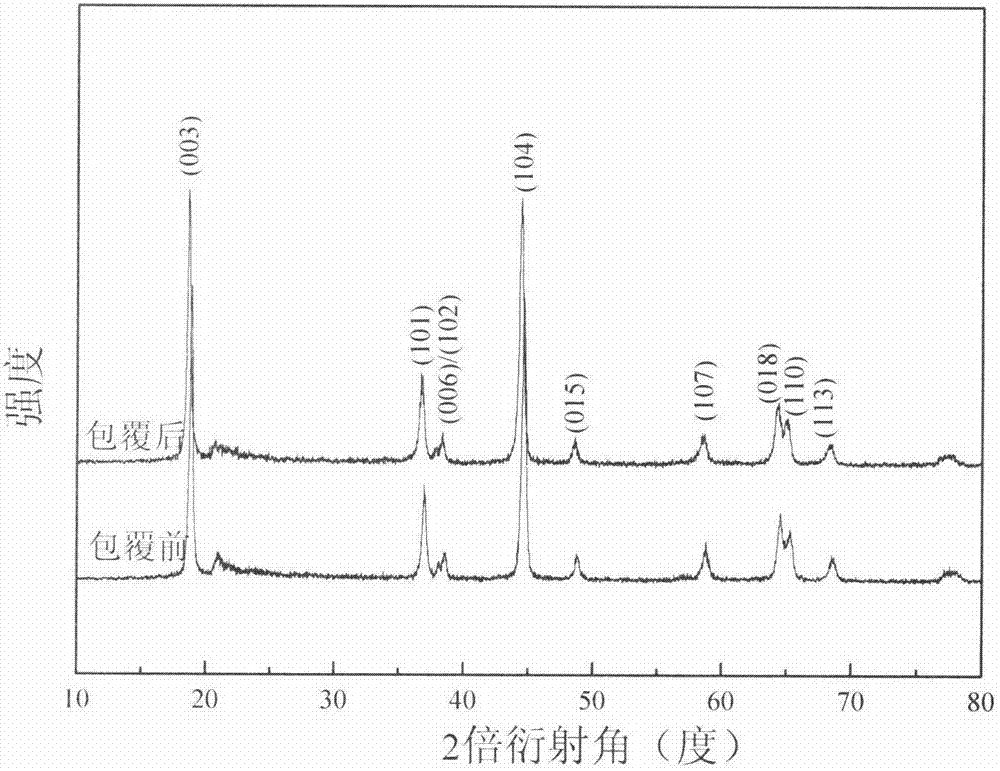

Method for processing ternary material by being clad with lithium ferric manganese phosphate

InactiveCN105406069AGood coating consistencyImprove consistencyCell electrodesSecondary cellsManganeseSlurry

The invention relates to a method for processing a ternary material by being clad with lithium ferric manganese phosphate. The invention belongs to the technical field of a cathode material of lithium ion batteries. The method for processing the ternary material by being clad with the lithium the ferric manganese phosphate comprises the steps of 1, preparation of LFMP precursor slurry: respectively weighing iron, manganese, lithium and phosphorus sources in proportion required by 0.1-100g LFMP, weighing 0-50g ascorbic acid, and adding a dispersion solvent, wherein the solid content is 10%-80%; 2, mixture of materials: weighing 100g ternary material with the constitute of Li(z)Ni(1-x-y)Co(x)Mn(y)O(2), or the mixture of two or more constitutes with the above proportion, adding the slurry, mixing the slurry and the mixture, and carrying out vacuum drying; 3, preparation of the ternary material / lithium ferric manganese phosphate composite cathode material: putting the materials into an argon protective atmosphere sintering surface, keeping warm at the temperature of 250-400 DEG C for 2-6h, then heating to 500-700 DEG C and keeping for 6-16h, cooling along with the furnace, and sieving. The method provided by the invention has the advantages of being simple in technology, convenient to operate, accordant in material performance, small in influence on cell capacity density, and being capable of improving safety performance of the ternary material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

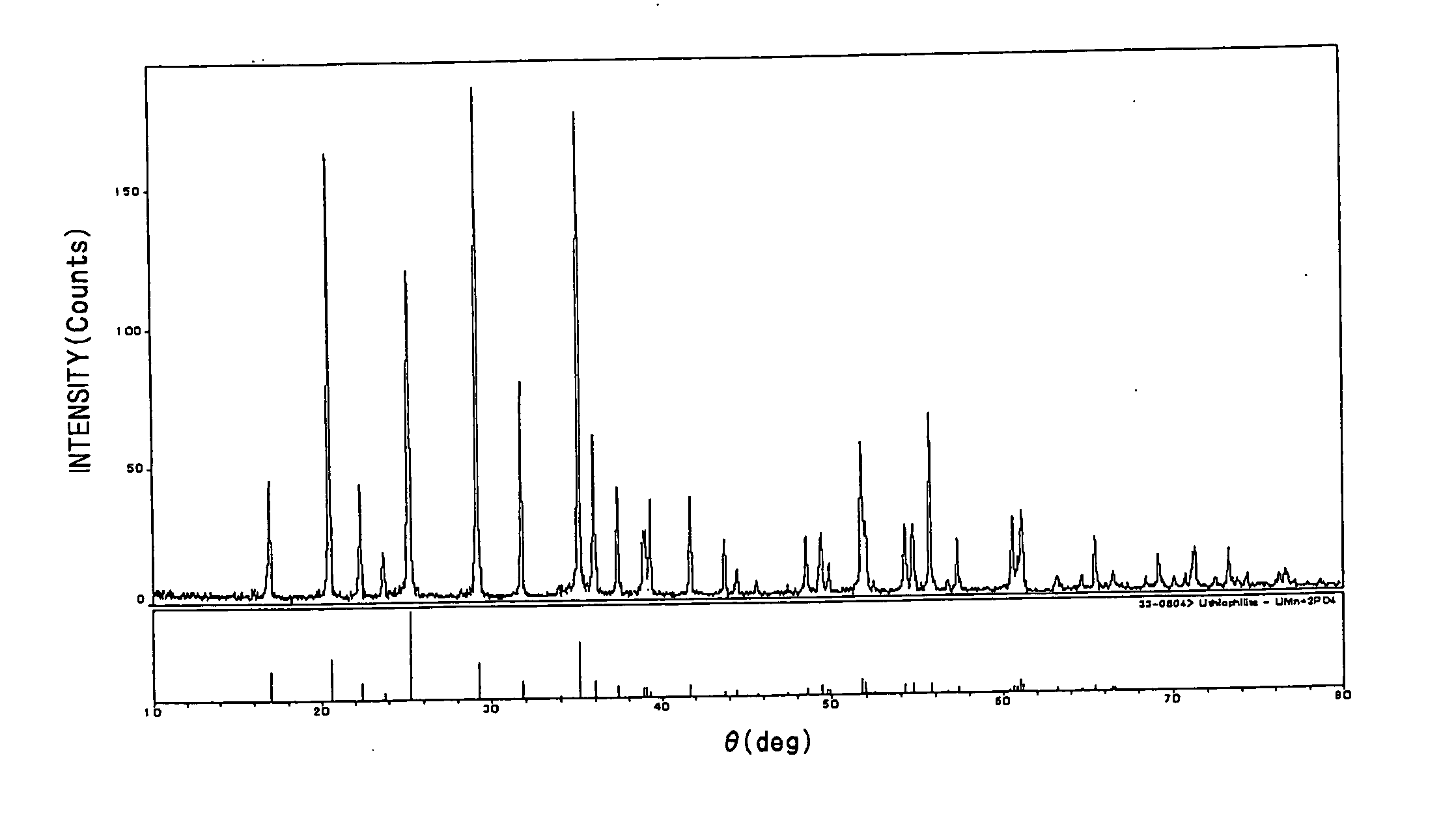

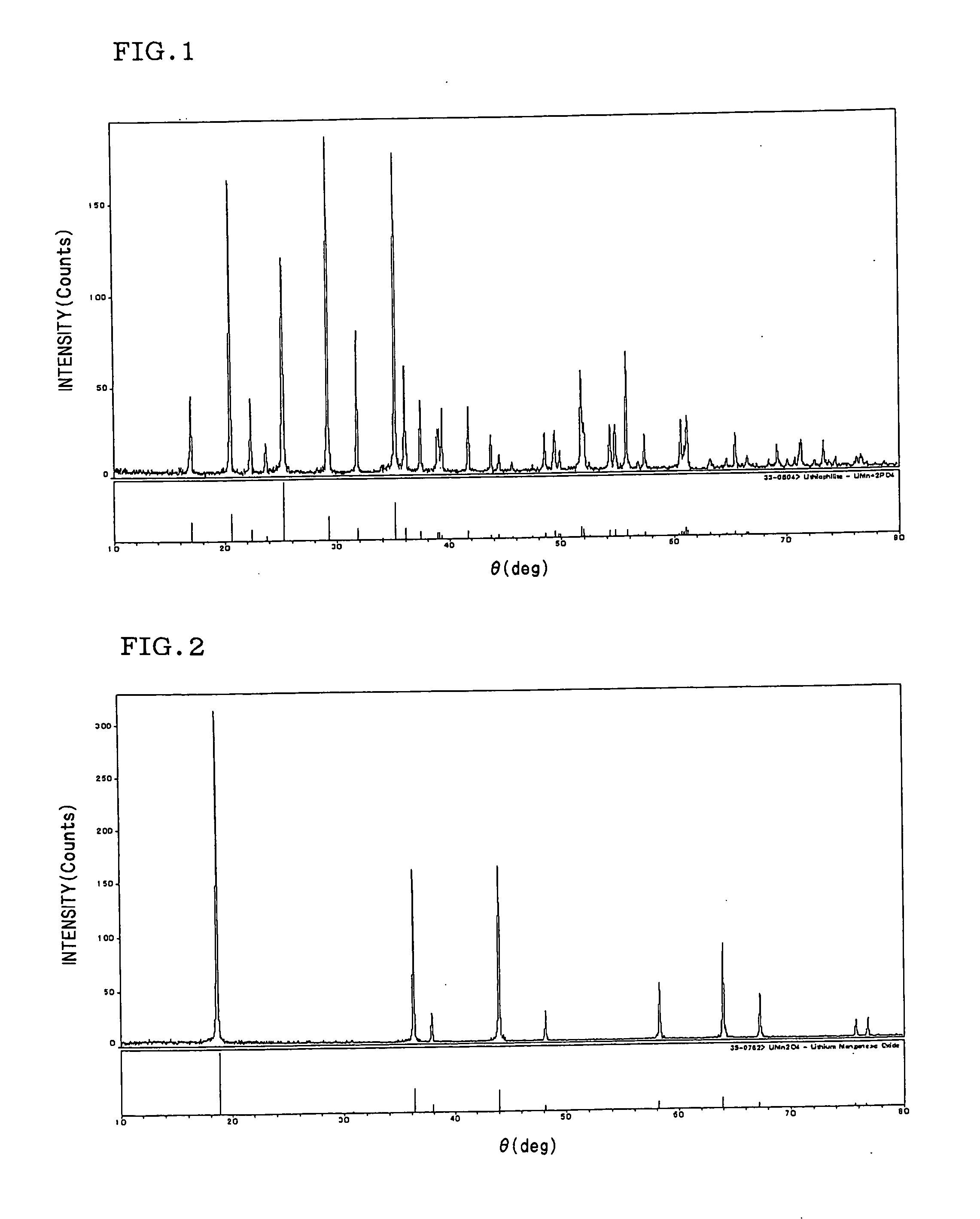

Positive electrode for non-aqueous electrolytic secondary cell and non-aqueous electrolytic secondary cell

ActiveUS20060222946A1Improve featuresIncrease capacityNon-aqueous electrolyte accumulatorsPositive electrodesSpinelManganate

There is disclosed a positive electrode for a non-aqueous electrolytic secondary cell and a non-aqueous electrolytic secondary cell exhibiting a high potential of a 4 V region, and having a high capacity, safety, excellent cycle characteristic, and satisfactory high-temperature characteristic, wherein a positive electrode active material is a mixture of olivine type lithium manganese phosphate and spinel type lithium manganate.

Owner:KYUSHU UNIV +1

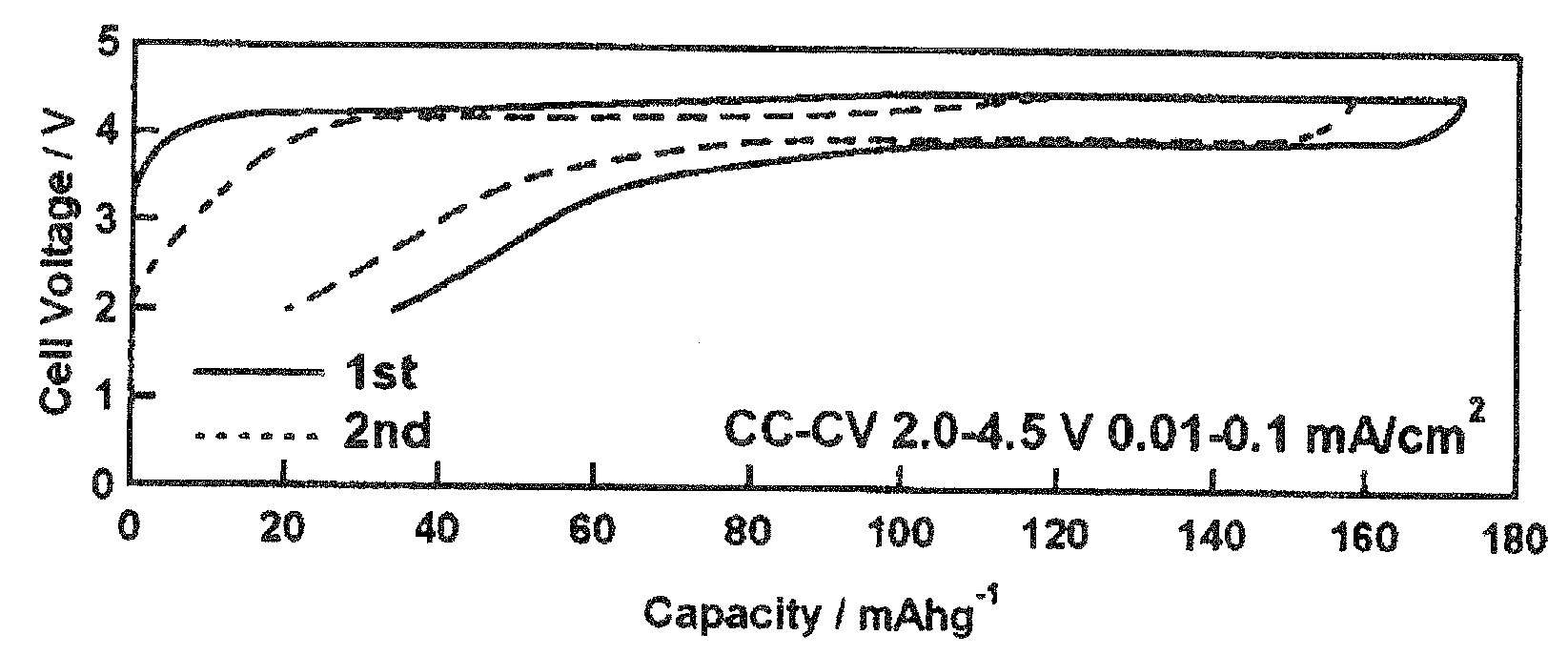

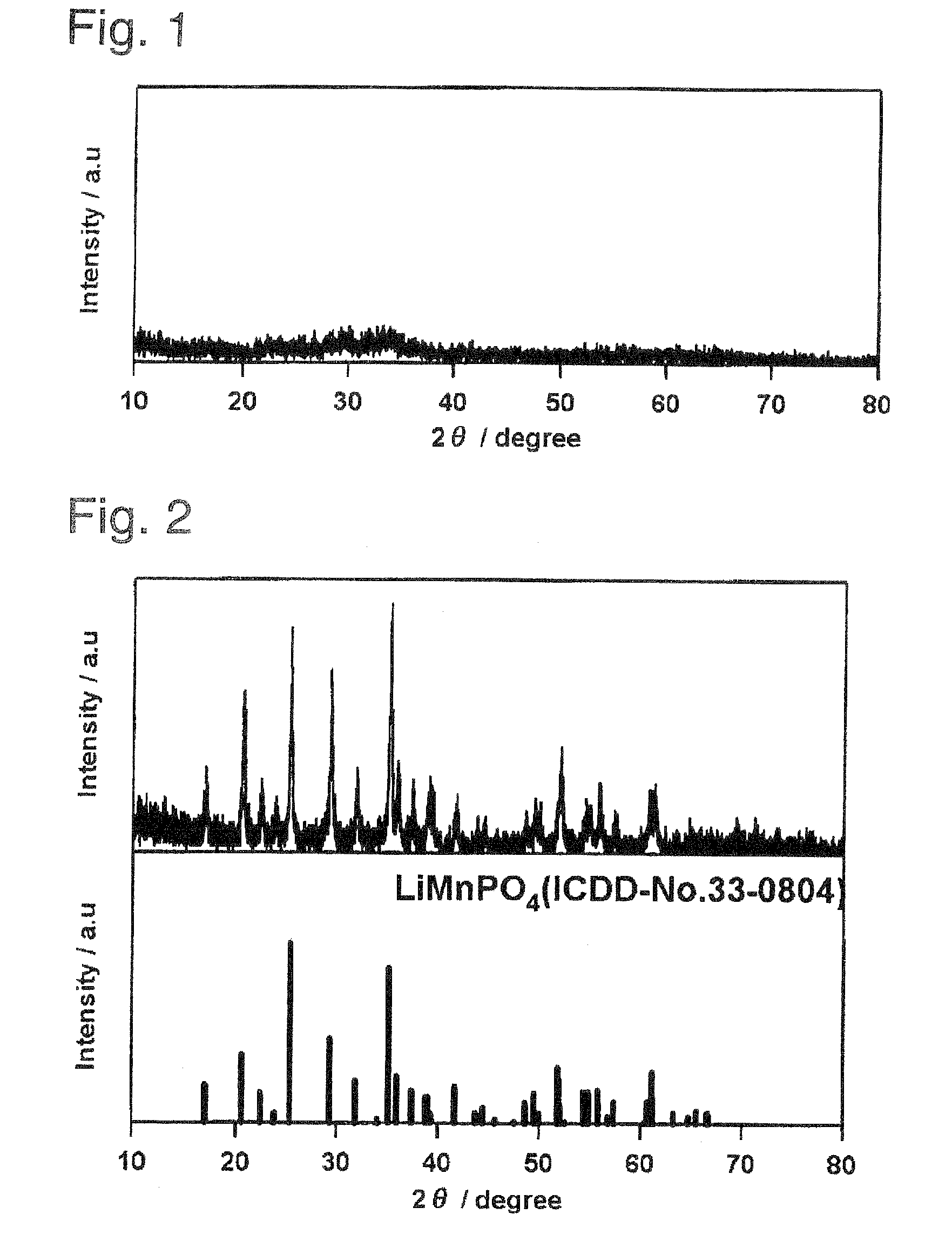

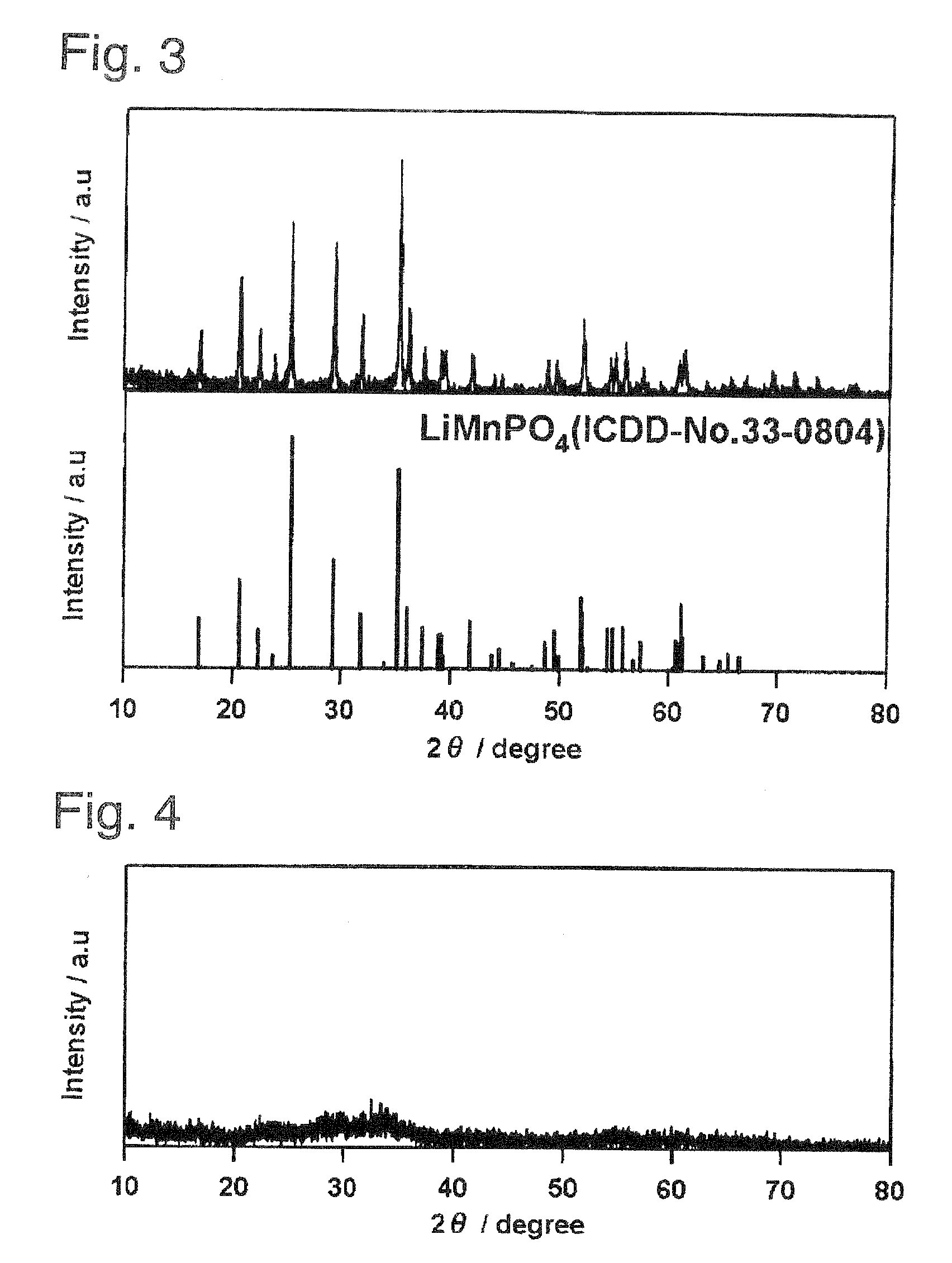

Method of producing positive electrode active material and nonaqueous electrolyte battery using the same

ActiveUS20090130559A1Easy to mass produceElectrode manufacturing processesFinal product manufactureSolid solutionCarbon source

The present invention provides a positive electrode active material that has rate characteristics suitable for nonaqueous electrolyte batteries and particularly nonaqueous electrolyte secondary batteries, a method by which this positive electrode active material can be easily mass produced, and a high-performance nonaqueous electrolyte battery that has a positive electrode active material obtained by this method.The present invention relates to a method of producing a positive electrode active material, the method comprising a step of mixing a carbon source with lithium manganese phosphate LiMnPO4 or a compound LiMn1-xMxPO4 (where, 0≦x<1 and M is at least one metal element selected from the group consisting of Co, Ni, Fe, Zn, Cu, Ti, Sn, Zr, V, and Al) containing lithium manganese phosphate LiMnPO4 as a solid solution composition, and heat treating the obtained mixture under an inert gas atmosphere.

Owner:KANTO DENKA IND CO LTD +1

Lithium iron vanadium manganese phosphate nano oxide compound anode material and preparation method thereof

ActiveCN102891316AHigh crystallinityImprove conductivityCell electrodesCrystallinityLithium-ion battery

The invention relates to a lithium iron vanadium manganese phosphate nano oxide compound anode material and a preparation method thereof. The lithium iron vanadium manganese phosphate nano oxide compound anode material comprises a component A and a compound B carbon source, wherein the component A comprises 95-99.9wt% of lithium iron vanadium manganese phosphate compound Lix+3y+zFexV2yMnz(PO4)x+3y+z and 0.1-5wt% of nano oxide; and the component B carbon source accounts for 0.5-35wt% by mass of the lithium iron vanadium manganese phosphate compound Lix+3y+zFexV2yMnz(PO4)x+3y+z in the component A. The preparation method of the compound anode material comprises the steps of: firstly weighing a lithium source, an iron source, a vanadium source, a manganese source and a phosphorus source according to proportions, uniformly ball-grinding and mixing, pre-sintering after tabletting, crushing, adding the nano oxide and the component B carbon source, ball-grinding, calcining, crushing and refining. The lithium iron vanadium manganese phosphate nano oxide compound anode material provided by the invention has better crystallinity and conductivity as well as high specific capacity, and has wide application prospects in the field of lithium ion batteries.

Owner:中科(马鞍山)新材料科创园有限公司

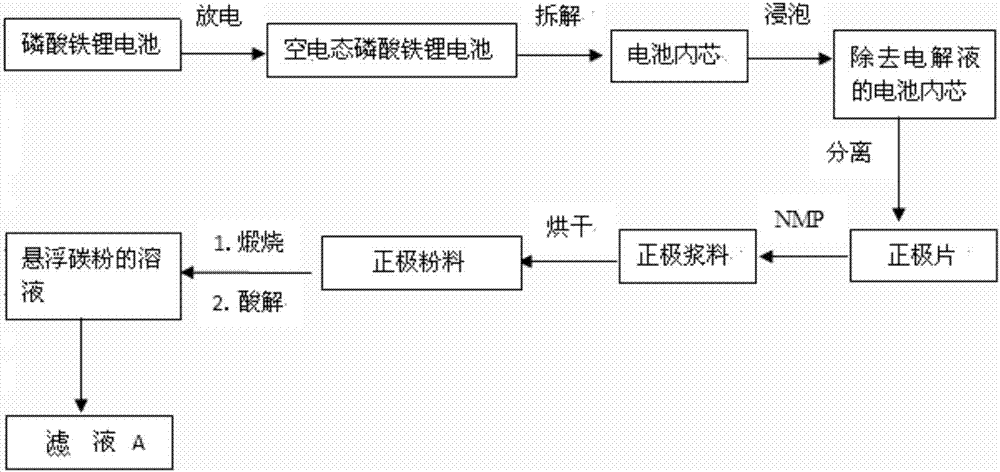

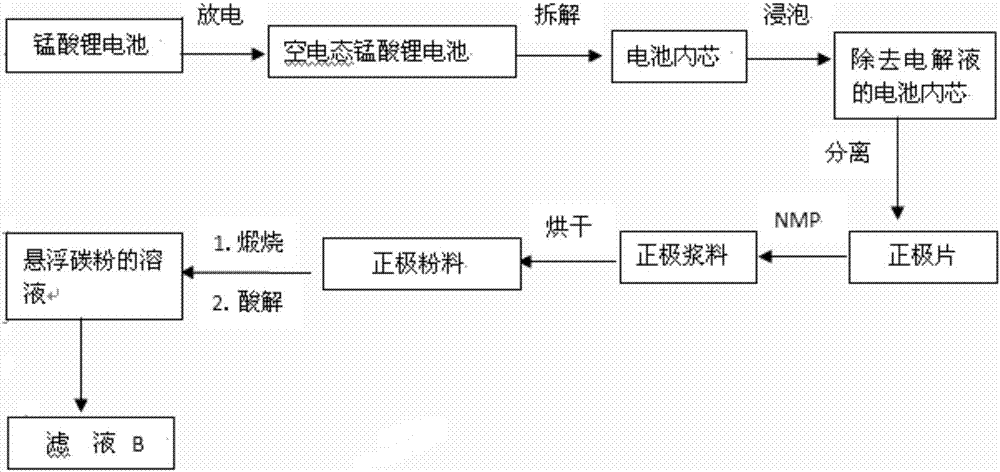

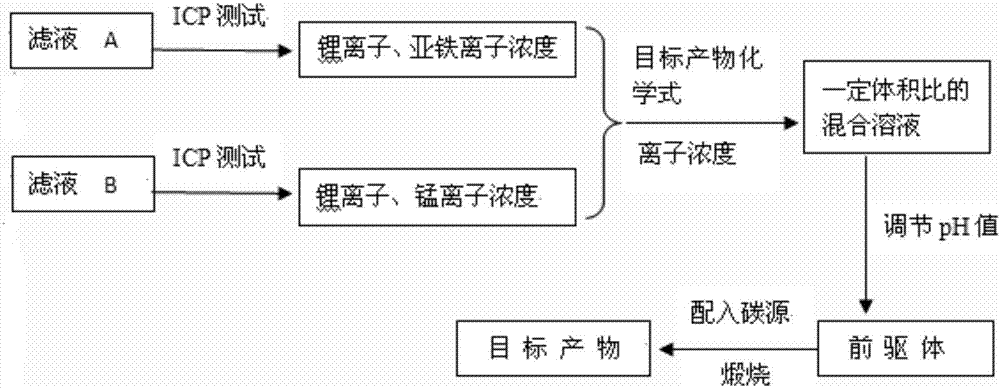

Method of recycling waste lithium iron phosphate battery and lithium manganate battery

ActiveCN106997975AReduce manufacturing costWaste accumulators reclaimingProcess efficiency improvementPower batteryLithium vanadium phosphate battery

The invention discloses a method of recycling waste lithium iron phosphate battery and lithium manganate battery. The method comprises the following steps of carrying out discharging, disassembling, soaking with an organic solvent, calcining, acid hydrolysis and filtering and the like on the lithium iron phosphate battery and the lithium manganate battery respectively, then mixing filtrates of anode materials of the two kinds of batteries according to a certain ratio, regulating a pH value of a solution to obtain a lithium iron manganese phosphate precursor, adding the lithium iron manganese phosphate precursor in a carbon source, and carrying out high-temperature calcining synthesis reaction to obtain the carbon-cladding lithium iron manganese phosphate anode material. By adopting the method provided by the invention, an anode material of the waste lithium iron phosphate battery and an anode material of the waste lithium manganate are treated by proper chemical means to be used as a manganese source, an iron source, a phosphorus source and a lithium source for synthesizing high-energy density anode material lithium iron manganese phosphate, so that the preparation cost of the lithium iron manganese phosphate is lowered, the recycling efficiency is high, the treatment speed is fast, and a brand new reference mode can be provided for a power battery enterprise to treat waste power batteries.

Owner:ANHUI ANKAI AUTOMOBILE

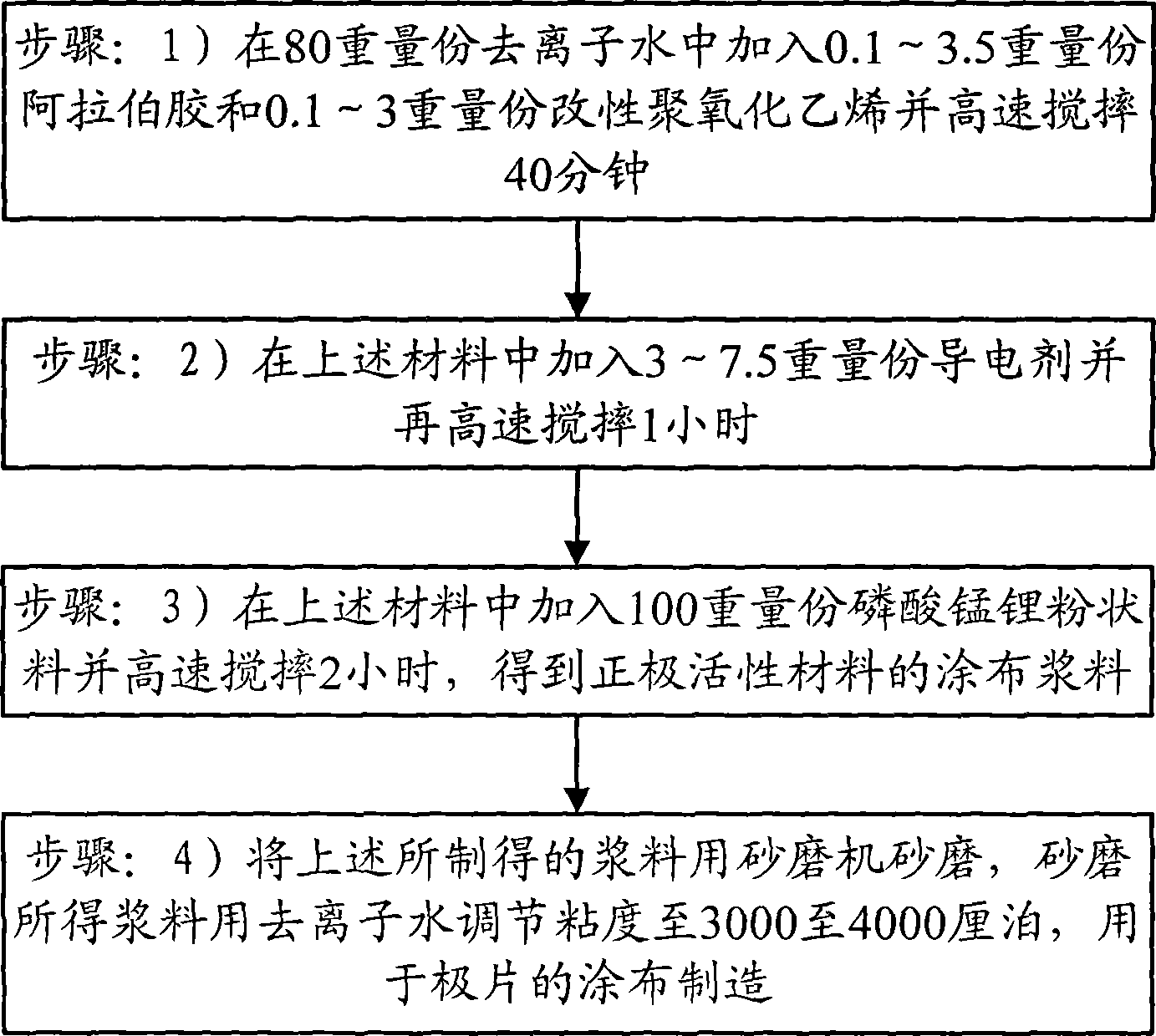

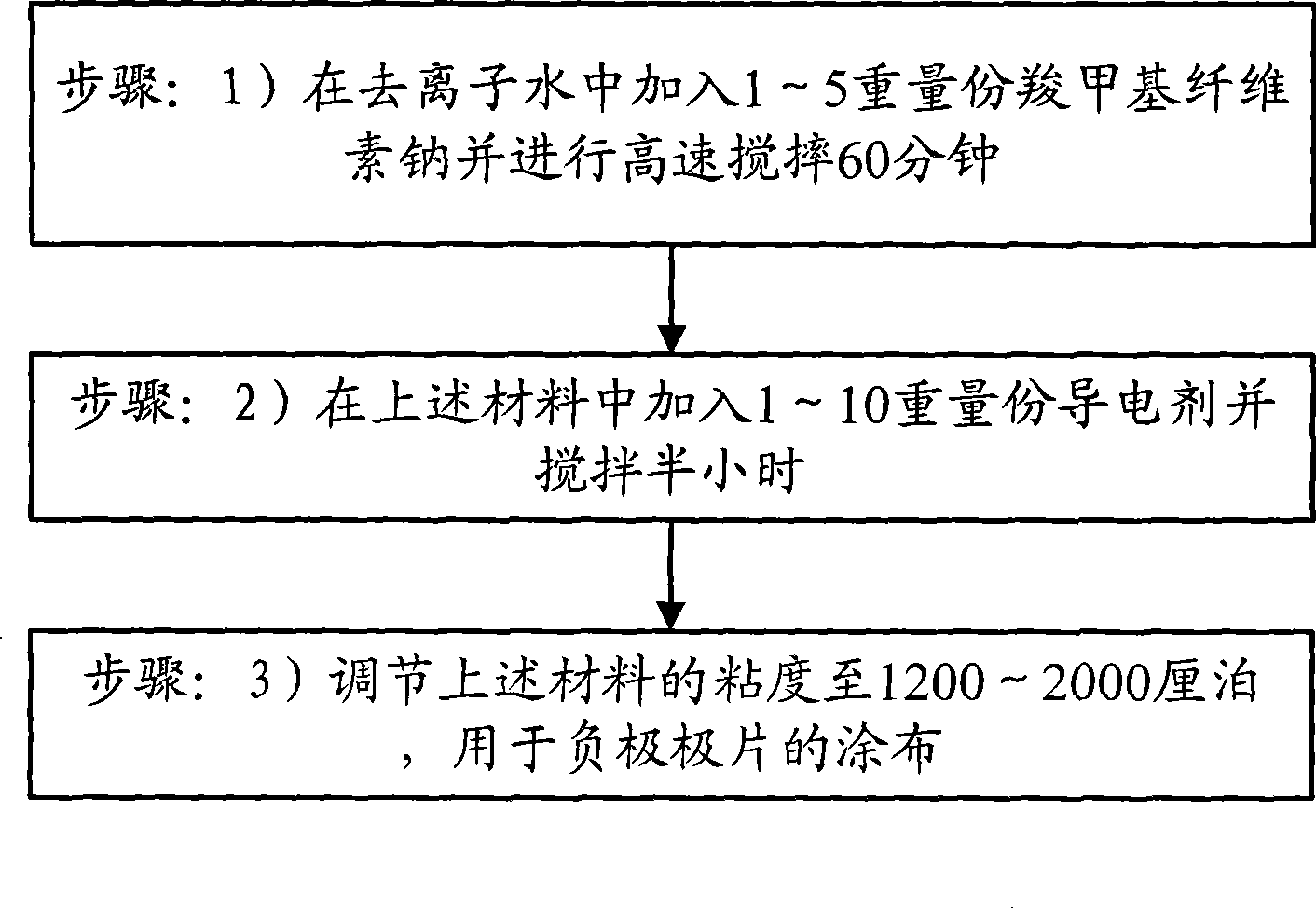

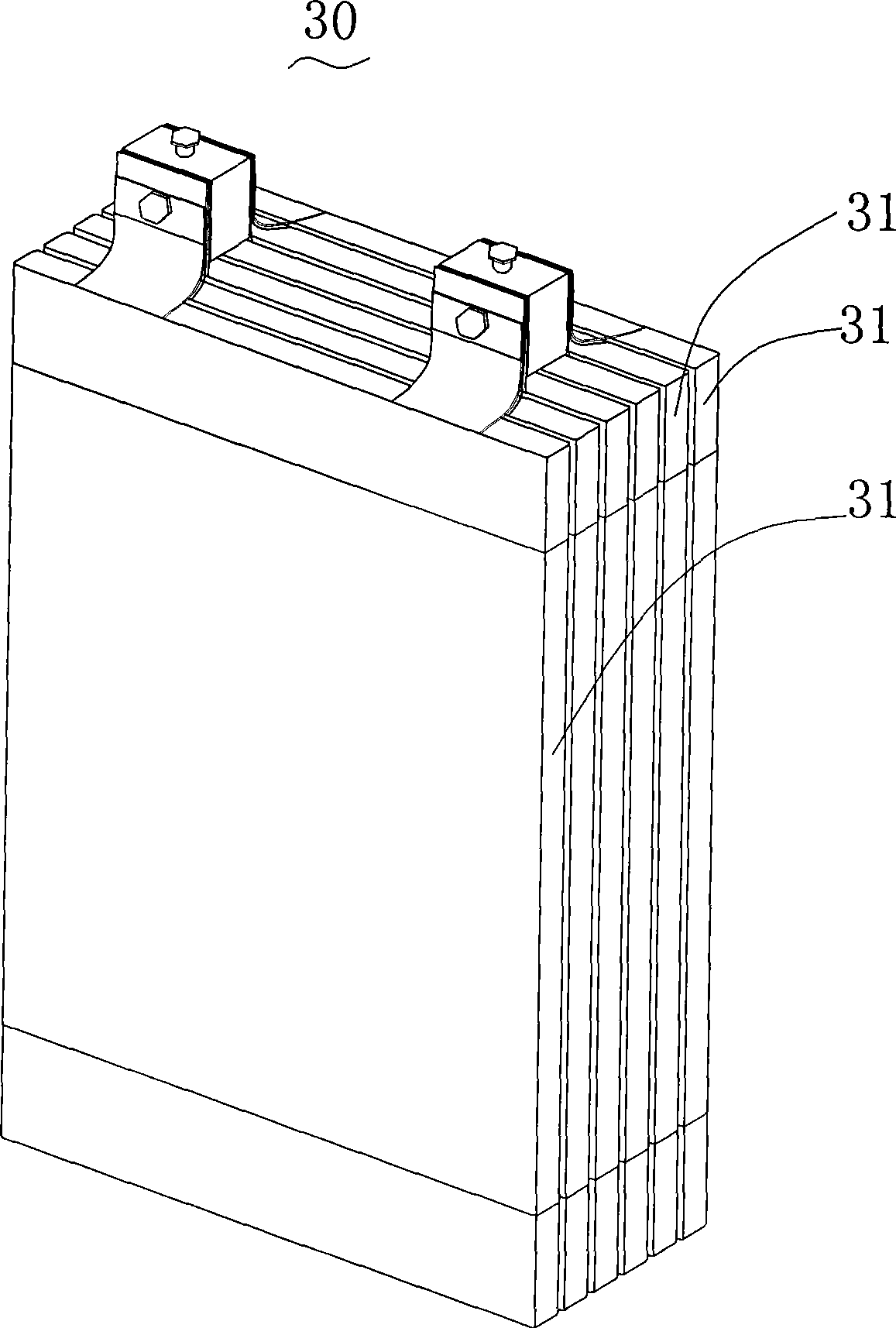

Lithium manganese phosphate or lithium manganese silicate power cell, positive and negative pole manufacturing method thereof

InactiveCN101504994AAvoid technical issues with distortionImprove securityElectrode manufacturing processesSecondary cellsPolyethylene glycolSlurry

The invention discloses a lithium manganese phosphate or lithium manganese silicate power type battery and a method for manufacturing an anode and a cathode of the battery. The battery comprises the anode and the cathode; a material for preparing the anode comprises lithium manganese phosphate or lithium manganese silicate; and a material for preparing the cathode comprises lithium titanate. The method for manufacturing the anode comprises the following steps that: 0.1 to 3.5 weight portions of acacia and 0.1 to 3 weight portions of modified polyethylene glycol oxide are added into 80 weight portions of deionized water and subjected to high-speed stirring for 40 minutes; the materials are added with 3 to 7.5 weight portions of a conducting agent and subjected to high-speed stirring for 1 hour; the materials are added with 100 weight portions of a lithium manganese phosphate or lithium manganese silicate powdery material and subjected to high-speed stirring for 2 hours to obtain coating slurry of an active material of the anode; and the coating slurry is used for coating and manufacturing a polar sheet. The invention initially provides a lithium ion secondary battery system which is formed by the lithium manganese phosphate or lithium manganese silicate anode and the lithium titanate cathode and has safety and high-efficiency discharging capacity.

Owner:国安新能源(荆门)有限公司

Method for manufacturing high insulation resistor FeSiCr metal soft-magnetic material

ActiveCN106816252AAvoid unevennessOvercoming inhomogeneityInductances/transformers/magnets manufactureMagnetic materialsChromium phosphateMetal

The invention discloses a method for manufacturing a high insulation resistor FeSiCr metal soft-magnetic material. The method includes melting; gas and water combined atomization; screening; powder classification matching; mixing; powder passivating; stirring and coating; pelletizing; compression moulding; and sintering. (6) powder passivating: preheating powder to the temperature of 75-90 DEG C, adding a mixed solution of 0.1-0.35 wt% of manganese phosphate and 0.1-0.35 wt% of chromium phosphate with respect to the powder, performing stirring for 10-15 min, performing drying at the temperature of 120 DEG C for 2 hours, and performing screening through a 100-mesh screen. The method can effectively overcome the defects that the insulation resistance is low, the withstand voltage is low, and the coating layer is not even and is not compact in the conventional processes; and according to the high insulation resistor FeSiCr metal soft-magnetic material acquired by the method, the insulation resistance IR is greater than 1G Ohm, the withstand voltage is greater than 100 V, and the magnetic conductivity is 60 (1+ / -20%).

Owner:TDG HLDG CO LTD

Method for recycling and preparing lithium iron manganese phosphate from positive electrode materials of waste lithium iron phosphate batteries

ActiveCN104609385ASolving Recycling ProblemsIncrease specific energySolid waste disposalWaste accumulators reclaimingPhosphoric acidLithium-ion battery

The invention discloses a method for recycling and preparing lithium iron manganese phosphate from positive electrode materials of waste lithium iron phosphate batteries. The method comprises the following steps: (1) discharging remnant electric quantities of the waste lithium iron phosphate batteries, disassembling the batteries, taking positive electrode sheets, washing, drying, roasting and separating lithium iron phosphate from aluminum foils; (2) by controlling the addition of acid, carrying out acid leaching on separated lithium iron phosphate, and filtering to separate insoluble iron phosphate and iron oxide to obtain a filtrate; (3) analyzing the filtrate, adjusting the molar ratio of the elements, namely, nLi to (nFe+Mn) to nP to 1: 1: 1 and adding a manganese source and a phosphorus source; and adjusting the pH to obtain a precipitate; drying the precipitate, adding a carbon source and mixing to obtain a pre-sintered material; and (4) carrying out solid sintering treatment on the pre-sintered material under non-oxidizing atmosphere to obtain the lithium iron manganese phosphate serving as the lithium ion battery positive electrode material. The method has the advantages of simplicity in process, environmental friendliness, good product properties and the like.

Owner:北京赛德美资源再利用研究院有限公司

Manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and preparation method thereof

ActiveCN102412398AStable structureImprove conductivityMaterial nanotechnologyCell electrodesPtru catalystPhysical chemistry

The invention provides a manganese phosphate lithium and carbon nanometer pipe situ compounding anode material and a preparation method thereof. The chemical formula of the material is Li ( Mn 1-xMx) PO4, wherein the x is 0-0.1, M is a transition metal Fe, Co or Ni; a carbon nanometer pipe is uniformly distributed in manganese phosphate lithium grains in a synthetic process of the manganese phosphate lithium; a transition metal compound is adopted as a catalyzer and an alloying element so as to catalyze pyrolytic hydrocarbon gas and prepare a situ carbon nanometer pipe compound manganese phosphate lithium material; the preparation method provided by the invention has the advantages that the preparation method is simple, the cost is cheap, the manganese phosphate material purity is high, a structure is full, the conductivity is high, and the electrochemistry performance is excellent.

Owner:DONGFANG ELECTRIC CORP LTD

Efficient multi-element compound fertilizer

InactiveCN101591202APromote stoutnessPromote absorptionSuperphosphatesAlkali orthophosphate fertiliserPhosphateInsect pest

The invention discloses an efficient multi-element compound fertilizer, which consists of hexanoic acid 2-(diethylamino) ethyl ester, polypeptide chelated potassium, polypeptide L-aspartate potassium, urea, potassium chloride, diammonium phosphate, calcium superphosphate, potassium dihydrogen phosphate, calcium-magnesium phosphate fertilizer, ammonium chloride, thiamine, zinc chloride, borax, ferrous sulphate, copper sulphate, manganese sulfate, sodium molybdate, cobalt chloride and silicon-manganese phosphate fertilizer. The efficient multi-element compound fertilizer has the advantages of promoting the growth of crops, improving the disease resistance of the crops, resisting falling, insect pests and frozen injury, improving the fertilizer effect, improving the soil, accelerating the growth of branches and leaves, reinforcing the photosynthesis, accelerating the growth of roots, enhancing the drought resistant capacity, improving the yield of the crops and improving the quality of fruits. The yield of grain crops is averagely increased by more than 26 percent, the yield of economic crops is averagely increased by more than 33 percent, and the yield of vegetable crops is averagely increased by more than 42 percent.

Owner:孙承环

Nitrogen-phosphorus expansion flame retardant containing flame retardant synergist and preparation method thereof

The invention discloses a nitrogen-phosphorus expansion flame retardant containing a flame retardant synergist and a preparation method thereof. The nitrogen-phosphorus expansion flame retardant containing the flame retardant synergist is characterized in that 90-99.95 percent of the nitrogen-phosphorus expansion flame retardant and 0.05-10 percent of the flame retardant synergist are evenly mixedaccording to the mass; the nitrogen-phosphorus expansion flame retardant comprises a nitrogen-phosphorus compound expansion flame retardant or / and a nitrogen-phosphorus simple substance expansion flame retardant; and the flame retardant synergist is selected from lanthanum phosphate, cerous phosphate, manganese pyrophosphate, ferric phosphate and / or ferric pyrophosphate. The nitrogen-phosphorus expansion flame retardant containing the flame retardant synergist can be suitable for anti-flaming of polyolefin, polyester or phenyl polymer, thereby overcoming the defects of low flame retardant efficiency, large addition quantity, and the like in the prior nitrogen-phosphorus expansion flame retardant, reducing the adverse effect of flame retardant property of a matrix due to the hygroscopicityof a flame retardant agent and reducing the adverse effect of mechanical property of the matrix due to the flame retardant agent with both convenience of production and use.

Owner:UNIV OF SCI & TECH OF CHINA

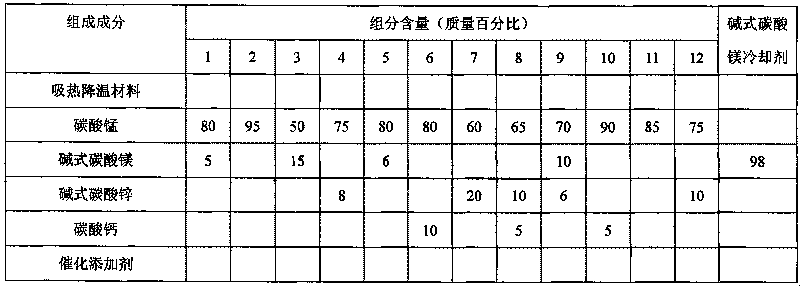

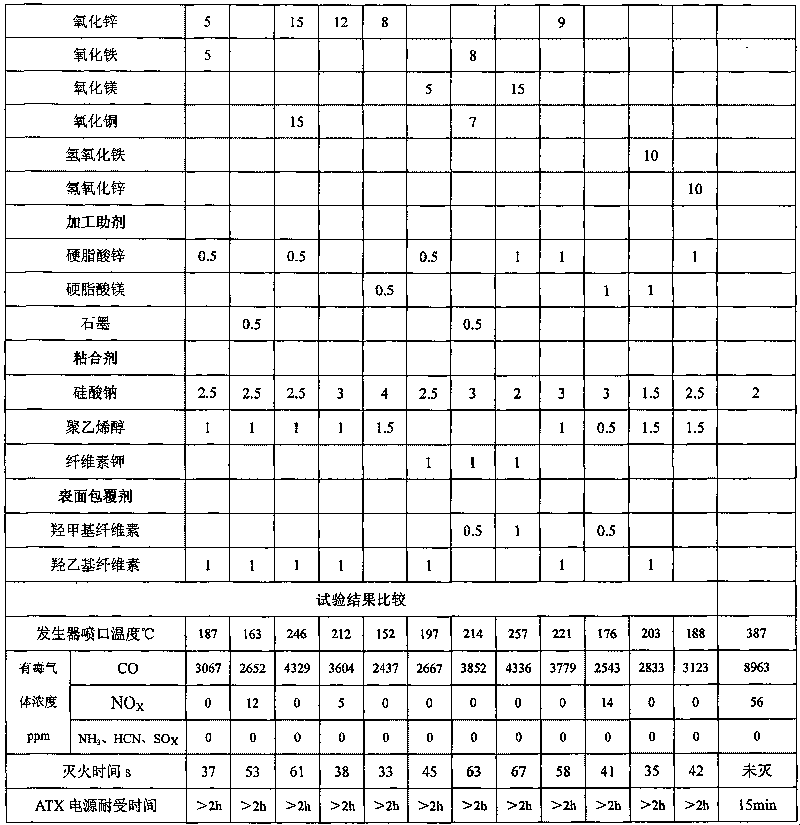

Catalytic chemical coolant for hot aerosol and preparation method thereof

InactiveCN101757760AImprove cooling efficiencyLow toxicityFire extinguisherHydroxyethyl celluloseFilm material

The invention relates to a catalytic coolant used in a hot aerosol fire extinguishing device and a processing technique of the catalytic coolant. As to the coolant, heat absorption cooling components mainly include manganese carbonate or manganese oxalate, manganese phosphate, potassium manganate, metal carbonate of a family I, a family II and a transition family, basic carbonate, oxalate and the like; a metal oxide or a hydroxide are adopted as a catalyst, an oxidant and a reinforcing filling; stearate, graphite and the like are adopted as a processing aid; composite solution of alkalis silicate and a water soluble polymer is adopted as an adhesive; and film materials such as hydroxymethyl or hydroxyethyl cellulose are adopted as a surface coating agent. The processing technique includes the steps of mould pressing, squeezing, pelletizing, coating and forming. Compared with the prior art, the catalytic coolant not only has high intensity and good cooling effect, but also can reduce secondary damage of an extinguishing agent and eliminate the content of poisonous gases in an extinguishing agent product so as to improve the environmental safety of the extinguishing agent.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

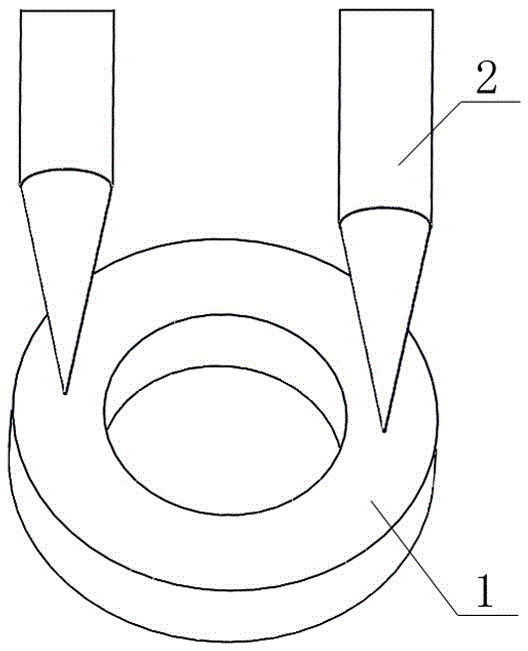

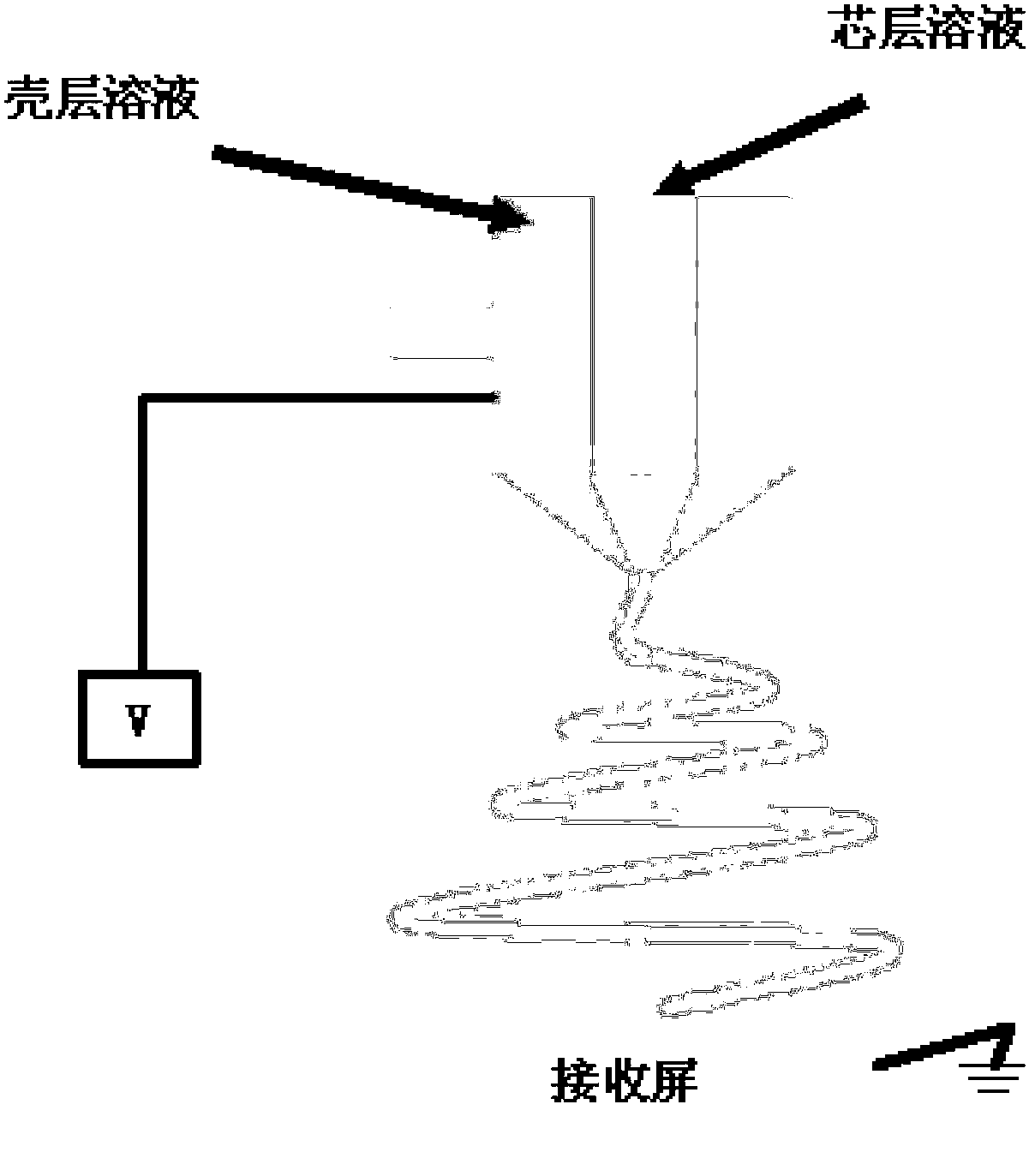

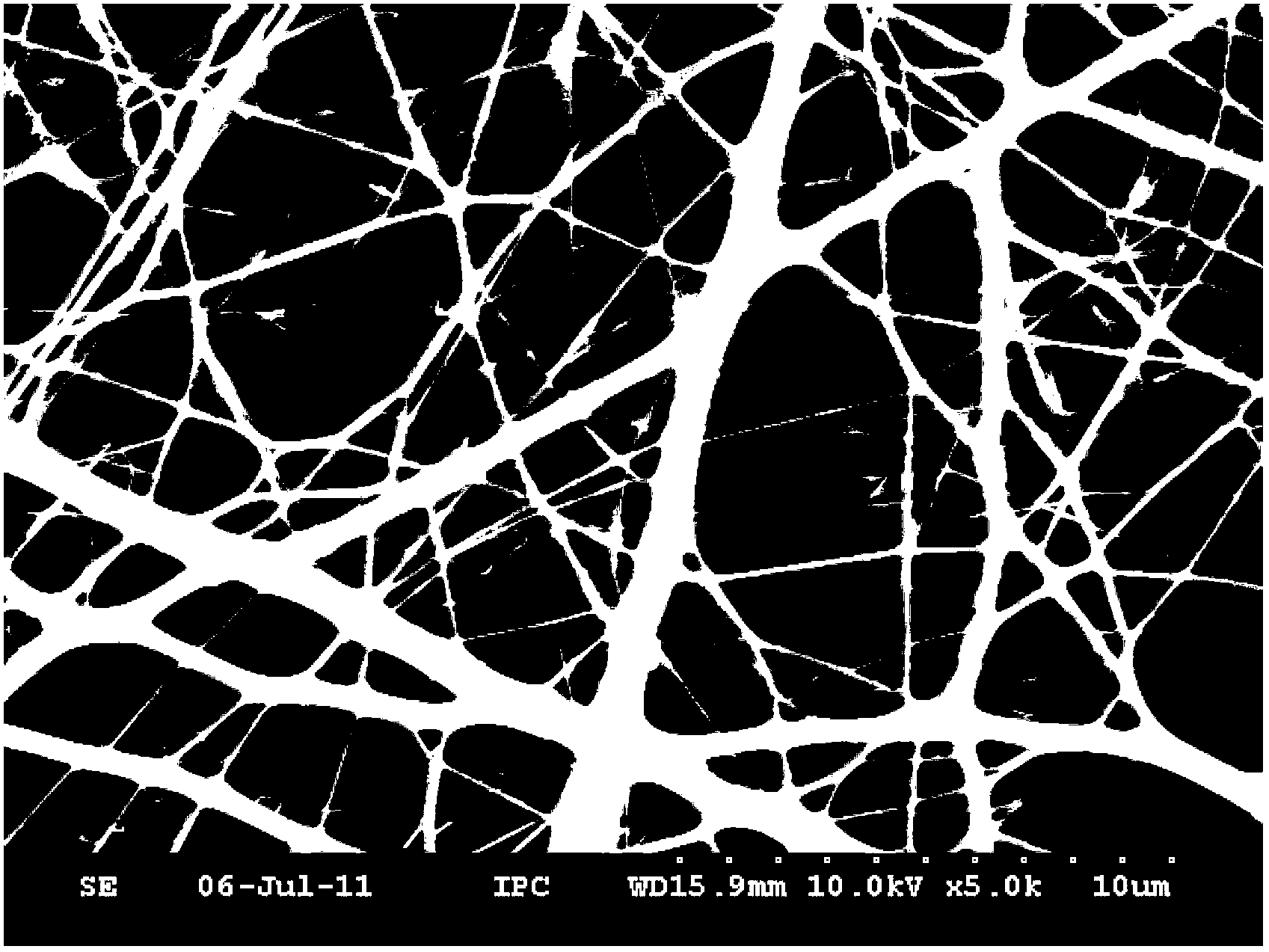

Lithium ferric manganese phosphate as cathode material of nanometer fibrous lithium ion battery and preparation method of lithium ferric manganese phosphate

The invention relates to lithium ferric manganese phosphate as a cathode material of a novel nanometer fibrous lithium ion battery. The lithium ferric manganese phosphate is prepared according to the following steps that iron source compounds, manganese source compounds, phosphorus source compounds, lithium source compounds and macromolecular polymers are used as raw materials, the manganese source compounds easily eroded by electrolyte are dispersed in core layer solution, the more stable iron source compounds are dispersed in case layer solution, and an electrostatic spinning method is adopted. The method for preparing composite materials has the advantages that on one hand, a voltage platform of lithium ion positive electrode materials can be improved, and the specific capacity density and the specific power density of the materials can be greatly improved; and on the other hand, because manganese elements are wrapped in a material core layer, the defects that in the existing preparation technology of the cathode material of the manganese-element-containing lithium ion battery, manganese elements are easily dissolved by electrolyte, the structure is not stable enough, the collapse is easily caused, and the volume attenuation is caused are overcome, and meanwhile, because of the nanometer fiber morphology character, the specific capacity and specific power density and the multiplying power circulation performance of the materials are greatly improved.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com