Method for processing ternary material by being clad with lithium ferric manganese phosphate

A technology of lithium iron manganese phosphate and ternary materials, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as the reduction of energy density of mixed electrodes, improve coagulation, reduce alkalinity, and reduce residual alkali. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for coating and processing ternary materials with lithium manganese iron phosphate, comprising the following process:

[0035] 1. Preparation of LFMP precursor slurry: Weigh Li respectively in proportion 2 CO 3 2.62g, C 2 h 2 FeO 6 2H 2 O2.55g, MnO4.02g, H 3 PO 4 6.94g, 20g ascorbic acid, 120g alcohol, stir and mix for 0.5h under protective atmosphere;

[0036] 2. Mixing of raw materials: Weigh 100g ternary material (LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ) was added to the above slurry, the slurry was vacuum-dried at 120° C. for 12 hours after continuing to stir for 2 hours.

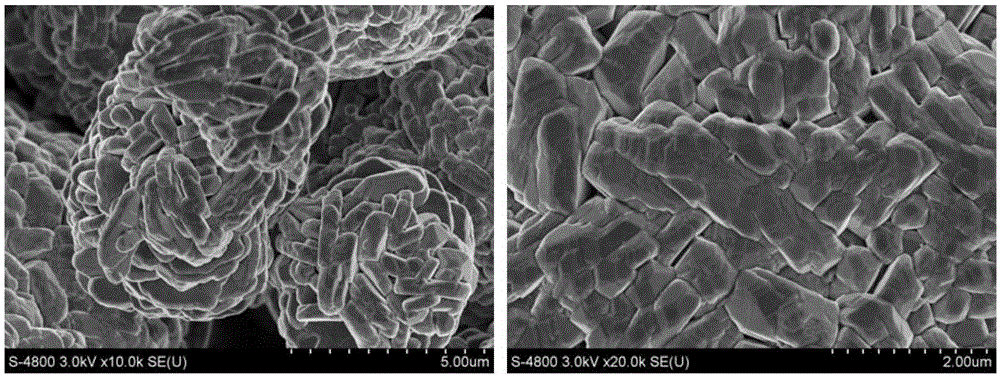

[0037] 3. Preparation of ternary material / lithium manganese iron phosphate composite positive electrode material: Put the dried mixed material into an argon protective atmosphere sintering furnace, keep it at 400°C for 2h, then raise the temperature to 600°C for 12h, and cool it with the furnace After 280 mesh sieves, ternary material / lithium manganese iron phosphate (LiFe 0.2 mn 0.8 P...

Embodiment 2

[0039] A method for coating and processing ternary materials with lithium manganese iron phosphate, comprising the following process:

[0040] 1. Preparation of LFMP precursor slurry: Weigh LiH 2 PO 4 3.66g, FeCl 2 0.32g, MnC 2 o 4 0.1g, NH 4 h 2 PO 4 5.98g, 5g ascorbic acid, 150g alcohol, stirred and mixed for 0.5h under protective atmosphere;

[0041] 2. Mixing of raw materials: Weigh 100g ternary material (LiNi 0.5 co 0.2 mn 0.3 o 2 ) into the above slurry, continue to stir for 2 hours, then vacuum dry the slurry at 120°C for 12 hours;

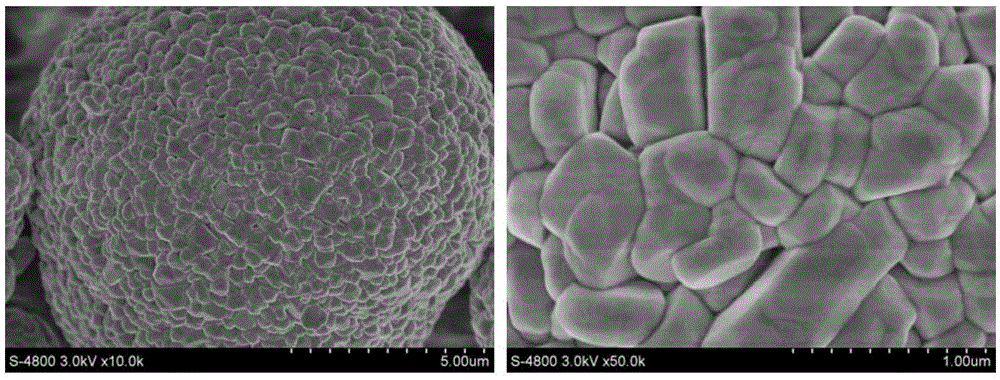

[0042]3. Preparation of ternary material / lithium manganese iron phosphate composite positive electrode material: Put the dried mixed material into an argon protective atmosphere sintering furnace, keep it at 350°C for 3h, then raise the temperature to 500°C for 16h, and cool it with the furnace After 280 mesh sieves, ternary material / lithium manganese iron phosphate (LiFe 0.8 mn 0.2 PO 4 ) Composite cathode material.

Embodiment 3

[0044] A method for coating and processing ternary materials with lithium manganese iron phosphate, comprising the following process:

[0045] 1. Preparation of LFMP precursor slurry: Weigh CH 3 COOLi41.88g, FeSO 4 ·7H 2 O88.34g, MnCO 3 36.53g, (NH 4 ) 2 HPO 4 83.88g, 50g ascorbic acid, 375g alcohol, stirred and mixed for 0.5h under protective atmosphere;

[0046] 2. Mixing of raw materials: Weigh 100g ternary material (LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ) into the above slurry, continue to stir for 2 hours, then vacuum dry the slurry at 120°C for 12 hours;

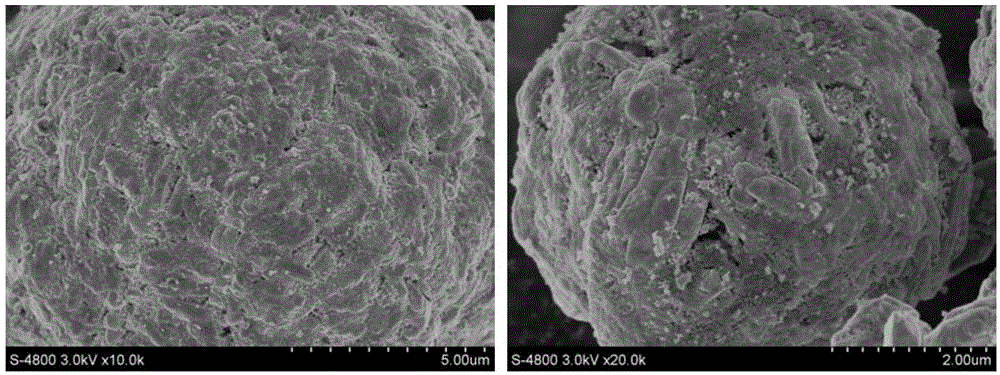

[0047] 3. Preparation of ternary material / lithium manganese iron phosphate composite positive electrode material: put the dried mixed material into an argon protective atmosphere sintering furnace, keep it at 400°C for 2h, then raise the temperature to 600°C for 12h, and cool it with the furnace After 280 mesh sieves, ternary material / lithium manganese iron phosphate (LiFe 0.5 mn 0.5 PO 4 ) Composite cathode materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com