A composite binder of silicon carbon negative electrode material for lithium ion battery and its preparation method and application

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of negative electrode material pulverization, poor mechanical properties, battery failure, etc., achieve low cost, convenient operation, and avoid falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

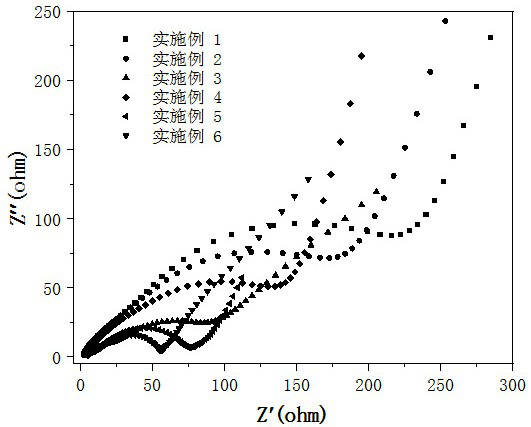

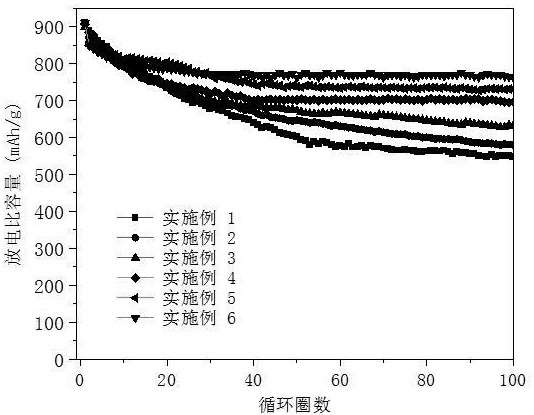

Embodiment 1

[0019] The preparation method of the silicon-carbon negative electrode material composite binder of the present embodiment is as follows:

[0020] (1) Take 2 g of polyacrylamide with a molecular weight of 45 W, add it to 20 mL of 10 wt% sodium hydroxide aqueous solution, stir at a speed of 100-500 rpm, and fully dissolve it for 5 h at room temperature;

[0021] (2) Take 0.1 g of 1,4-butanediol diglycidyl ether, add it to the above solution, and fully react for 2 h at a stirring speed of 100~500 rpm and 35 °C;

[0022] (3) The mass ratio of polyacrylamide:1,4-butanediol diglycidyl ether is 1:0.05;

[0023] (4) After the reaction, dialyze to neutrality in a dialysis bag, and dry at 70°C in vacuum. The product is configured into a 10 wt% aqueous solution to obtain a composite binder;

[0024] Take the binder prepared above. According to the ratio of active material: binder: conductive agent = 8: 1: 1, weigh 0.8 g of silicon carbon anode material, 0.1 g of conductive agent SP, ...

Embodiment 2

[0027] The preparation method of the silicon-carbon negative electrode material composite binder of the present embodiment is as follows:

[0028] (1) Take 2 g of polyacrylamide with a molecular weight of 45 W, add it to 20 mL of 30 wt% sodium hydroxide aqueous solution, stir at a speed of 100-500 rpm, and fully dissolve it for 5 h at room temperature;

[0029] (2) Take 0.2 g of epichlorohydrin, add it to the above solution, and fully react for 3 hours at a stirring speed of 100~500 rpm and 30 °C;

[0030] (3) The mass ratio of polyacrylamide: epichlorohydrin is 1:0.1;

[0031] (4) After the reaction, dialyze to neutrality in a dialysis bag, and dry at 70°C in vacuum. The product is configured into a 10 wt% aqueous solution to obtain a composite binder;

[0032] Take the composite binder prepared above. According to the ratio of active material: binder: conductive agent = 8: 1: 1, weigh 0.8 g of silicon carbon anode material, 0.1 g of conductive agent SP, and 0.1 g of compo...

Embodiment 3

[0035] The preparation method of the composite binder for the silicon carbon negative electrode material of the present embodiment is as follows:

[0036] (1) Take 2 g of polyethyleneimine with a molecular weight of 45 W, add it to 20 mL of 30 wt% sodium hydroxide aqueous solution, stir at a speed of 100-500 rpm, and fully dissolve it for 5 h at room temperature;

[0037] (2) Take 0.2 g of epichlorohydrin, add it to the above solution, and fully react for 3 h at a stirring speed of 100-500 rpm and 30 °C;

[0038](3) The mass ratio of polyethyleneimine: epichlorohydrin is 1:0.1;

[0039] (4) After the reaction, dialyze to neutrality in a dialysis bag, and dry at 70°C in vacuum. The product is configured into a 10 wt% aqueous solution to obtain a composite binder;

[0040] Take the composite binder prepared above. According to the ratio of active material: binder: conductive agent = 8: 1: 1, weigh 0.8 g of silicon carbon anode material, 0.1 g of conductive agent SP, and 0.1 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com