Patents

Literature

1087 results about "Diglycidyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diglycidyl ether is a chemical compound used as a reactive diluent for epoxy resin. Other uses include treating textiles and stabilizing chlorinated organic compounds. It is extremely toxic, and can prove fatal or cause permanent damage if inhaled or consumed orally.

Bisphenol a and aromatic glycidyl ether-free coatings

ActiveUS20070036903A1Good metal substrateGood inter-coat adhesionLiquid surface applicatorsSynthetic resin layered productsPolyesterMeth-

Disclosed are Bisphenol A (BPA), Bisphenol F, Bisphenol A diglycidyl ether (BADGE), and Bisphenol F diglycidyl ether (BFDGE)-free coating compositions for metal substrates including an under-coat composition containing a polyester (co)polymer, and an under-coat cross-linker; and an over-coat composition containing a poly(vinyl chloride) (co)polymer dispersed in a substantially nonaqueous carrier liquid, an over-coat cross-linker, and a functional (meth)acrylic (co)polymer. Also provided is a method of coating a metal substrate using the BPA, BPF, BADGE and BFDGE-free coating system to produce a hardened protective coating useful in fabricating metal storage containers. The coated substrate is particularly useful in fabricating multi-part foodstuffs storage containers with “easy-open” end closures.

Owner:SWIMC LLC

Epoxy adhesive having improved impact resistance

InactiveUS20030196753A1Polyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyphenolExpandable microsphere

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

Epoxy adhesive having improved impact resistance

InactiveUS6998011B2Increase resistanceImprove toughnessPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyolNitrile rubber

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

Shape Memory Epoxy Copolymer

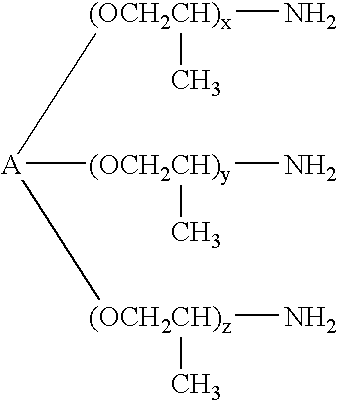

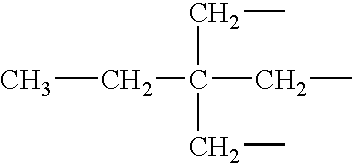

ActiveUS20080269420A1Harden and quickly and repetitivelySoften quickly and repetitivelyHydrogenGlass transition

The shape memory polymers disclosed are a reaction product of at least one reagent containing two active amino-hydrogen or two active phenolic-hydrogen with at least one multifunctional cross linking reagent which contains at least three or more active amino- or phenolic-hydrogen or is a reagent containing at least three glycidyl ether moieties which is then further mixed with at least one diglycidyl ether reagent whereupon the resulting mixture is cured and has a glass transition temperature higher than 00C. This reaction creates crosslinking between the monomers and polymers such that during polymerization they form a crosslinked thermoset network.

Owner:CORNERSTONE RES GROUP

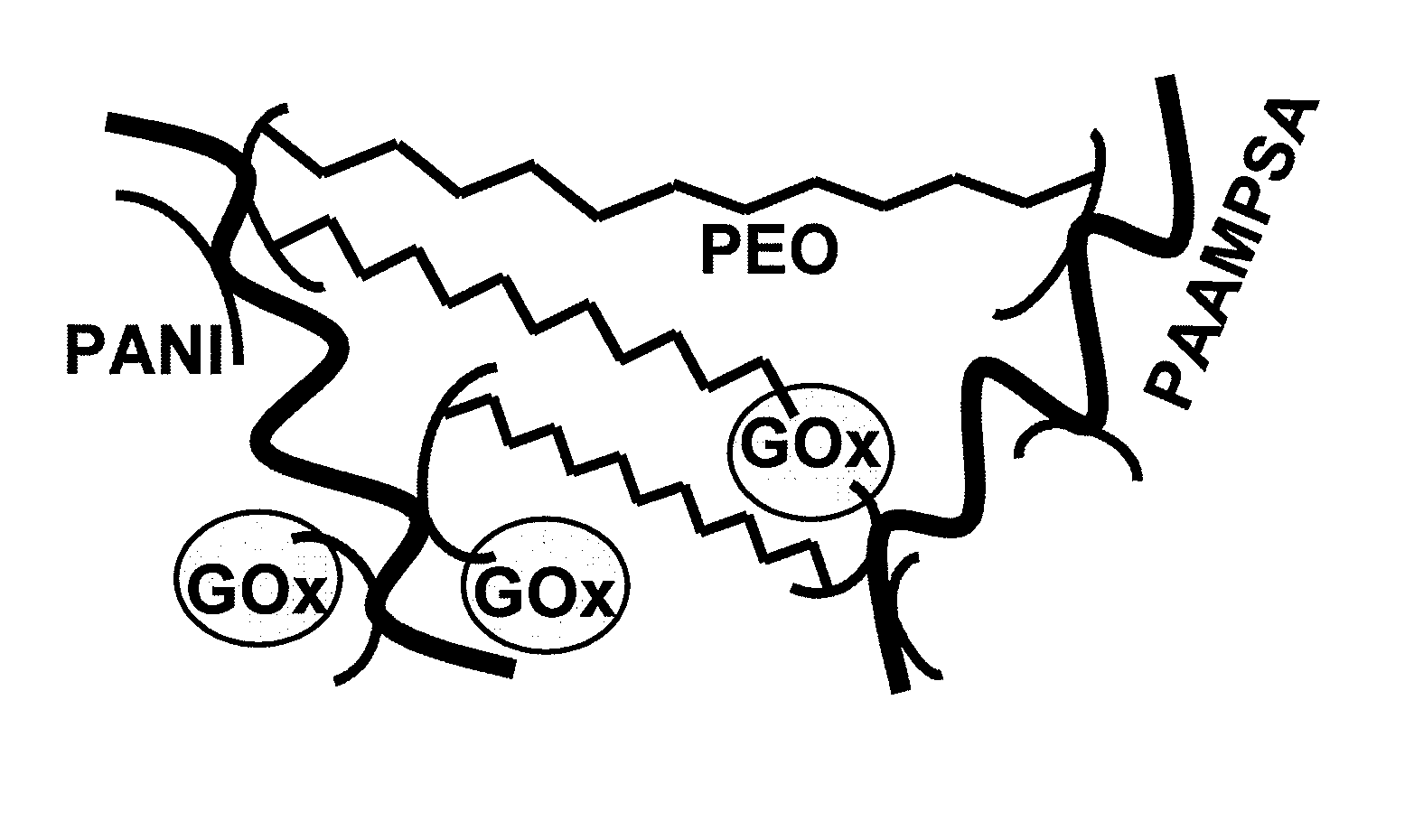

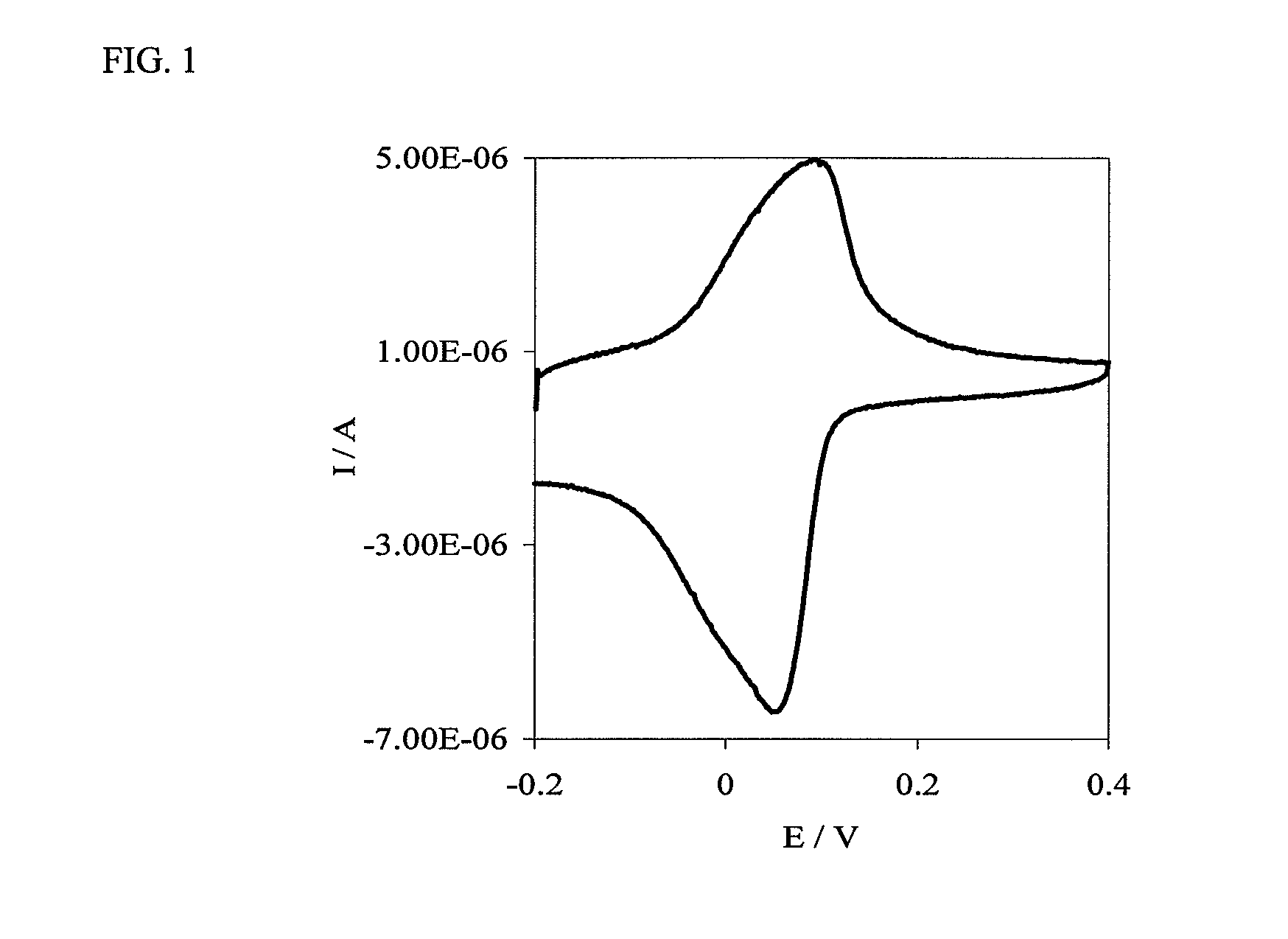

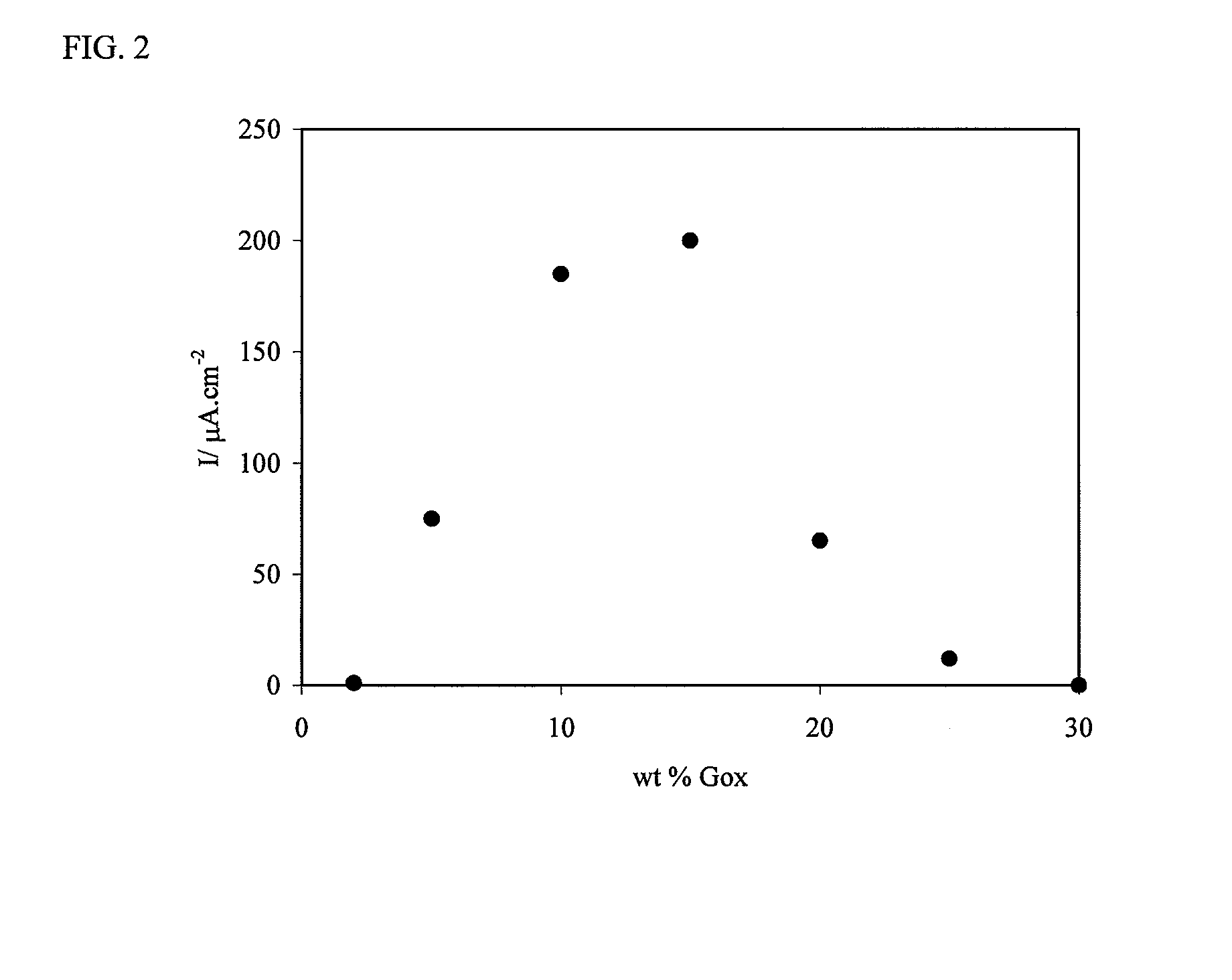

Electron-conducting crosslinked polyaniline-based redox hydrogel, and method of making

ActiveUS20090321277A1Bioreactor/fermenter combinationsBiological substance pretreatmentsRedox enzymesPolymer science

A polymer matrix that may coated on an electrode is created by co-crosslinking (1) an adduct of a polyaniline formed by templated oxidative polymerization on a polymer acid; (2) a water-soluble crosslinker; and (3) a redox enzyme. The polymer matrix may be hydrated, and the absorbed water may make it permeable to, for example, glucose. The polyaniline may be polyaniline itself or a substituted polyaniline; the water-soluble crosslinker may be poly(ethylene glycol) diglycidyl ether, and the redox enzyme may be glucose oxidase. The polymer matrix may be produced by co-crosslinking (1) an adduct of an electrically conductive polymer and a polymer acid; (2) a water-soluble crosslinker; and (3) a redox enzyme in a single step at an about neutral pH, curing by drying. After hydration, the crosslinked polymer matrix may form a 3-dimensional glucose-permeable bioelectrocatalyst, catalyzing the electrooxidation of glucose.

Owner:ABBOTT DIABETES CARE INC

Preparation and application of latent nonionic self-emulsifying epoxy curing agent

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

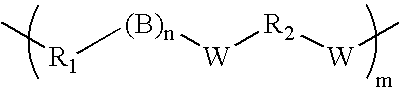

High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

The invention relates to a high slump retaining type polycarboxylic acid water reducing agent with a sustained-release effect and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preserving 5-30 mol% of monomer A, 30-60 mol% of monomer B, 20-55 mol% of monomer C at 60-80 DEG C for 1-3 h under the effect of an initiator, a chain transfer agent and a polymerization inhibitor; copolymerizing the monomers to obtain a polymer with molecular weight of 30000-100000; and then adding alkali to neutralize the polymer, wherein the total amount of the monomers A, B and C is 100 mol%; the monomer C comprises a slump retaining auxiliary 1 and a slump retaining auxiliary 2 according to a mol ratio of 1:20-13:20; the monomer A is isopentene alcohol polyoxyethylene ether, allyl polyethylene glycol, 1-methyl-2-allyl polyethylene glycol or allyl poly diglycidyl ether with polymerization degree n of 20-60; and the monomer B is acrylic acid or methacrylic acid. The high slump retaining type polycarboxylic acid water reducing agent with the sustained-release effect, provided by the invention, has the advantages of excellent slump retaining property, substantially no loss for slump degree within 3 h and wide applicability.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

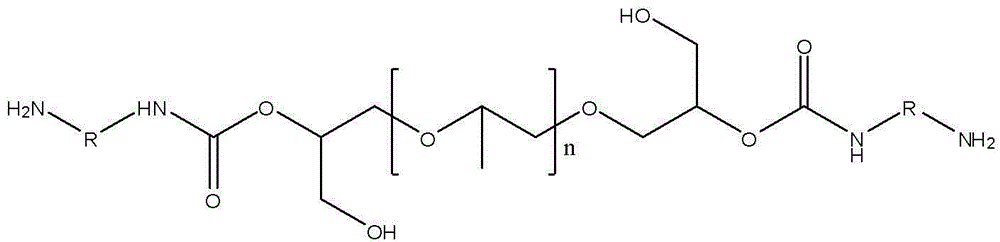

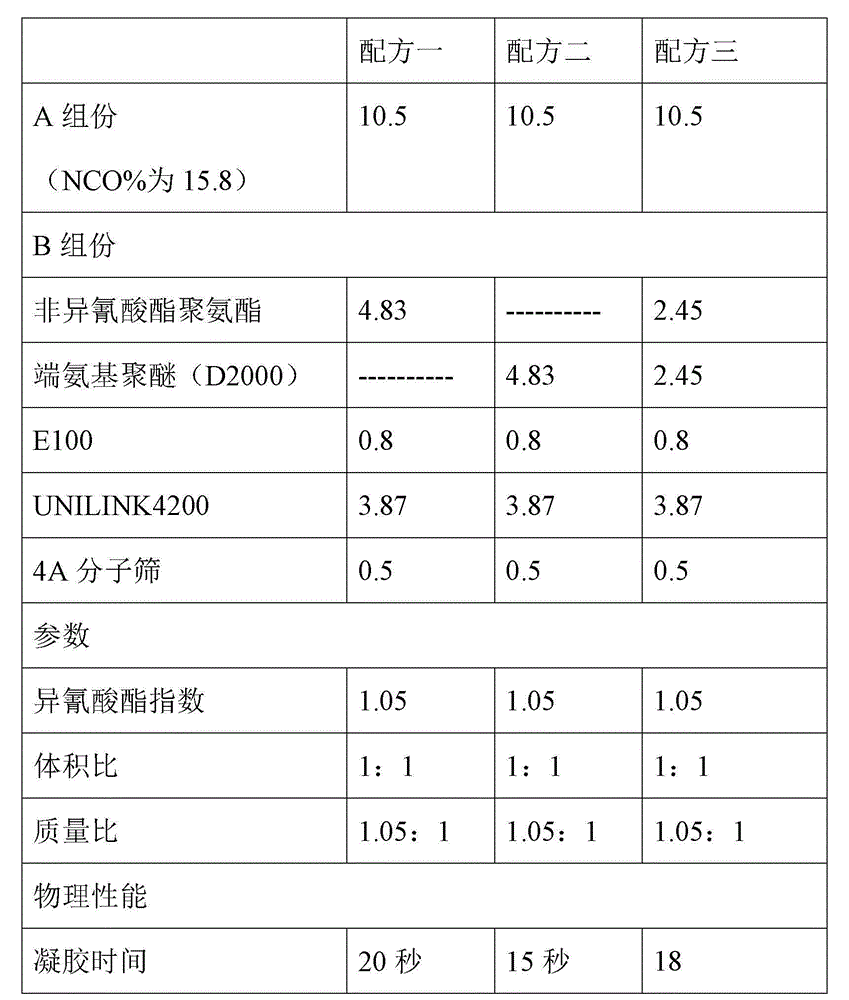

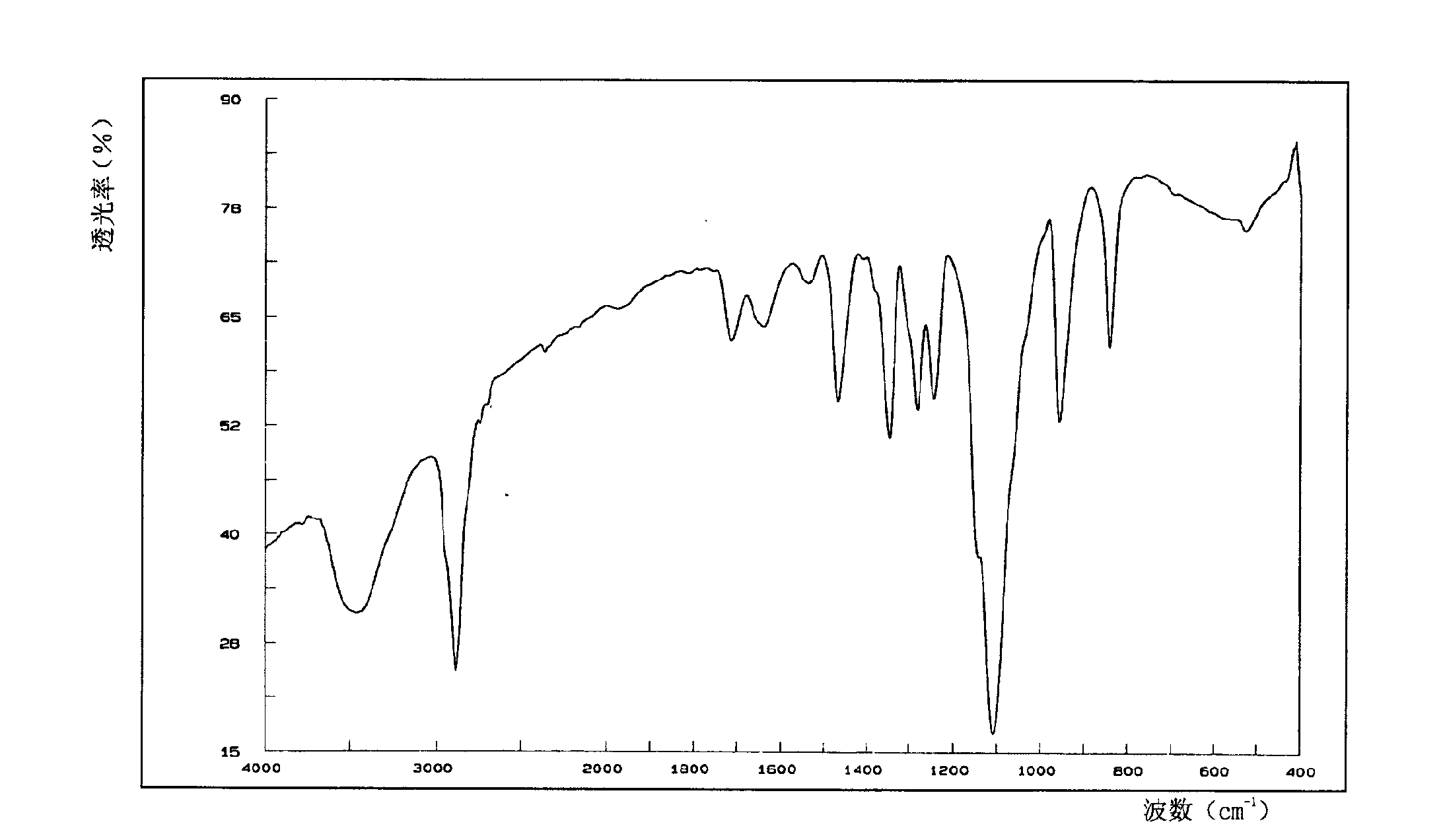

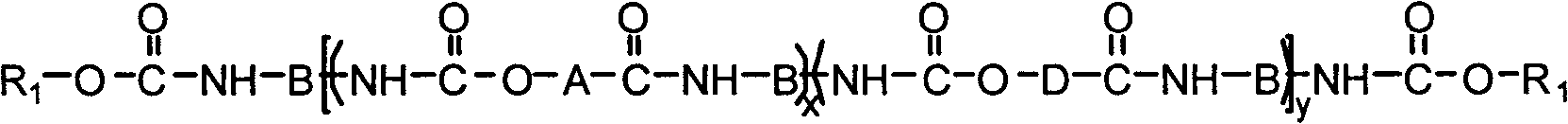

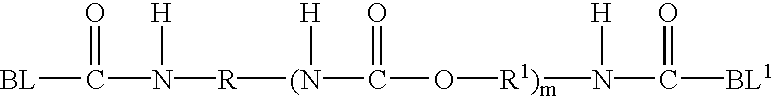

Preparation method of non-isocyanate polyurethane and application of non-isocyanate polyurethane in spraying polyurea

InactiveCN102718964ANo post-processing requiredReduce energy consumptionPolyurea/polyurethane coatingsPotassium iodineHydrolysis

The invention discloses a preparation method of non-isocyanate polyurethane and application of the non-isocyanate polyurethane in spraying polyurea. The preparation method of the non-isocyanate polyurethane comprises the following steps: (1) preparing a polyether diol diglycidyl ether intermediate; (2) preparing a heterogeneous loaded potassium carbonate and potassium iodide catalyst; (3) preparing polyether bicyclo carbonate; and (4) preparing the non-isocyanate polyurethane product. The invention has the advantages as follows: 1, the preparation method is low in energy consumption, free of pollution and low in cost and has a concept of environment friendliness, low-carbon economy and atomic economy; and 2. the prepared non-isocyanate polyurethane, as a amine resin for the spraying polyurea, has better chemical resistance, hydrolysis resistance and the penetration resistance and is superior to amino-terminated polyether in adhesion to substrate and leveling property.

Owner:GUANGXI UNIV FOR NATITIES

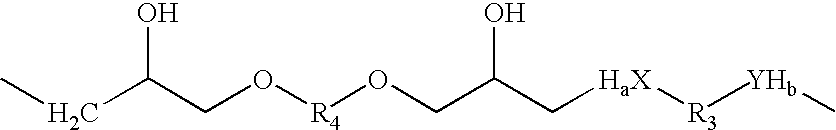

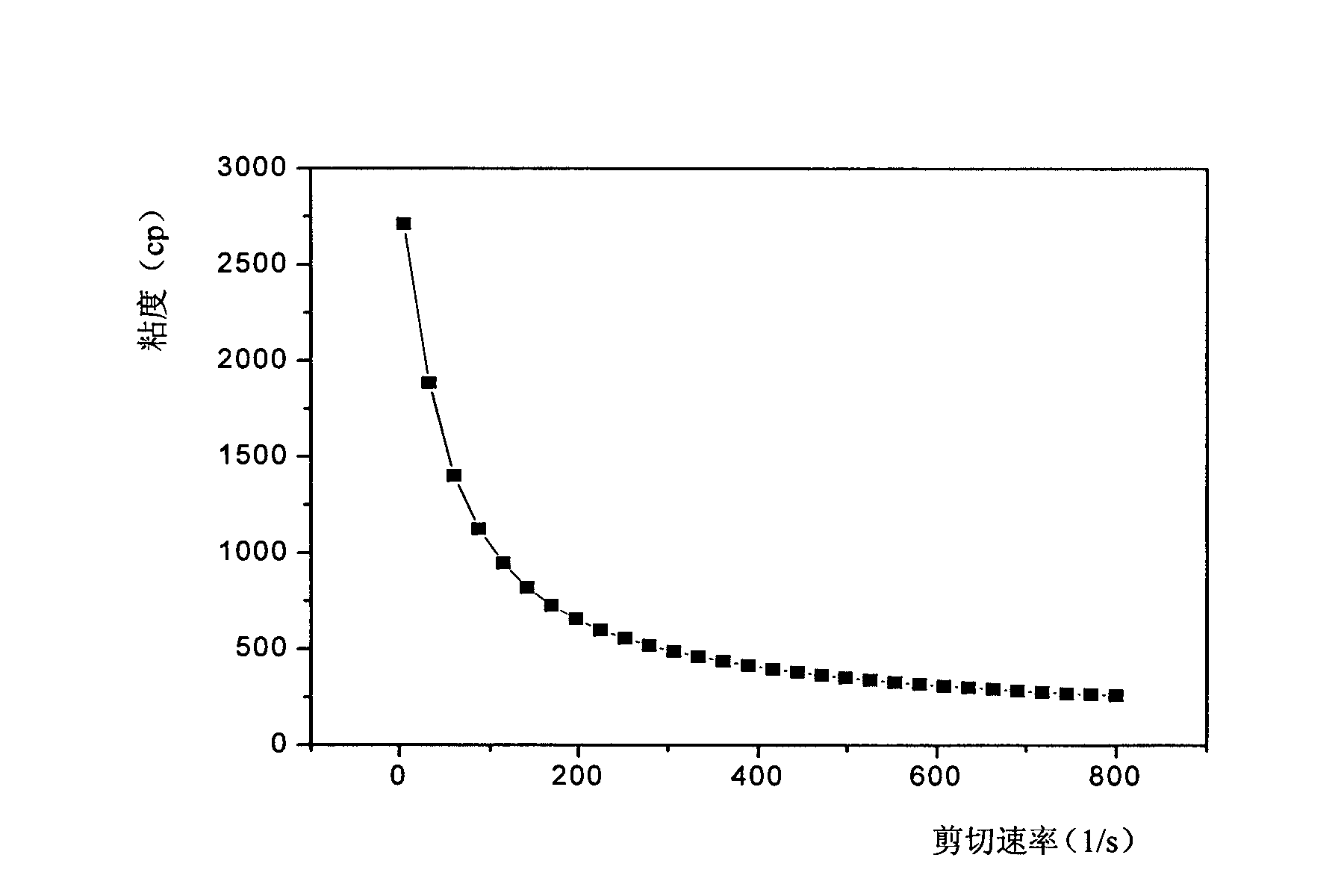

Comb polyurethane associated thickener and preparation method and application thereof

InactiveCN101633718AReduce application viscosityHigh viscosityCosmetic preparationsCoatings with pigmentsPolymer scienceEmulsion

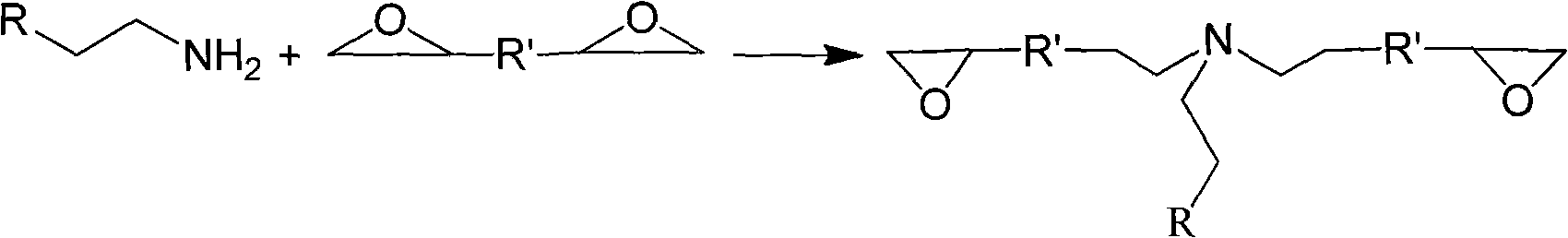

The invention discloses a comb polyurethane associated thickener and a preparation method and an application thereof and the preparation method comprises the following steps: adopting primary amine and diglycidyl ether to react, obtaining hydrophobic diol; then adopting polyether diol, catalyst, diisocyanate, hydrophobic diol and alkanol to react, using precipitate for precipitation after finishing the reaction, drying the precipitation and obtaining the comb polyurethane associated thickener. More than two hydrophobic groups (long chain alkyl) in the molecules of the comb polyurethane associated thickener so that the consistency of the emulsion paint can be greatly improved, the emulsion paint has not only high viscosity under low shear but also low applicable viscosity under high shear, and the quality of the emulsion paint is increased. The polyurethane associated thickener is applicable to thickening the water-containing system and can be used in emulsion paint, varnish, adhesive, leather, papermaking, dyeing and printing, ink, cosmetics and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

BADGE- and BPA-free can coating

ActiveUS7682674B2Suitable flexibilitySuitable resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPolyvinyl chloride

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components:(a) 30 to 90 wt. % of a polyvinylchloride-(PVC)-polymer,(b) 7 to 25 wt. % of an acrylic resin,(c) 3 to 40 wt. % of a crosslinking agent, which is produced from phenol, para-tert.-butylphenol, xylenol or a mixture thereof, and formaldehyde,(d) 0 to 8 wt. % additive,(e) 0 to 50 wt. % pigment and(f) a solvent-component,where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl-ether (“BADGE”) and also substantially free of bisphenol-A-resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

Long chain branched polyester and preparation method thereof

The invention discloses long-chain branched polyester and a preparation method thereof. The long-chain branched polyester is obtained by carrying out esterification and polycondensation on a diacid component A, a diacid component B and a bifunctional branching agent component C such as biglycidyl ester, diglycidyl ether or glycidol and the like. According to the invention, a non-toxic bifunctional branching agent is directly adopted to in situ generate branching points; the preparation method is unique, preparation process is simple and environmentally-friendly, branching reaction is uniform,branching degree is easy to regulate and control, and the high molecular weight long-chain branched polyester can be prepared; and the preparation method can be used for preparation of non-degradablepolyester and preparation of biodegradable polyester, thereby being beneficial to the realization of commercialization. The long-chain branched polyester has the characteristics of long-chain branching and large molecular weight in structure and is beneficial to increase of melt strength and improvements of blow molding and foaming processing performance.

Owner:ZHEJIANG UNIV

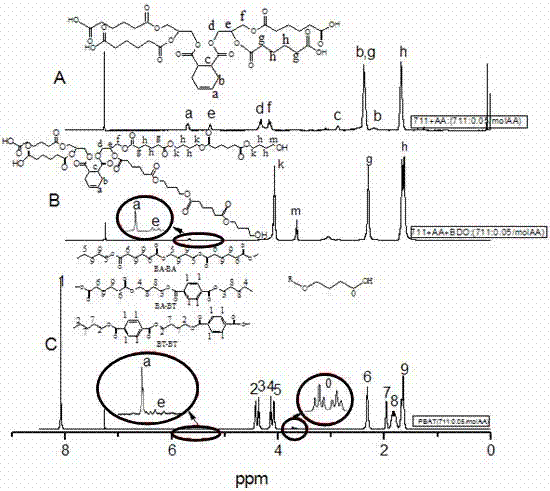

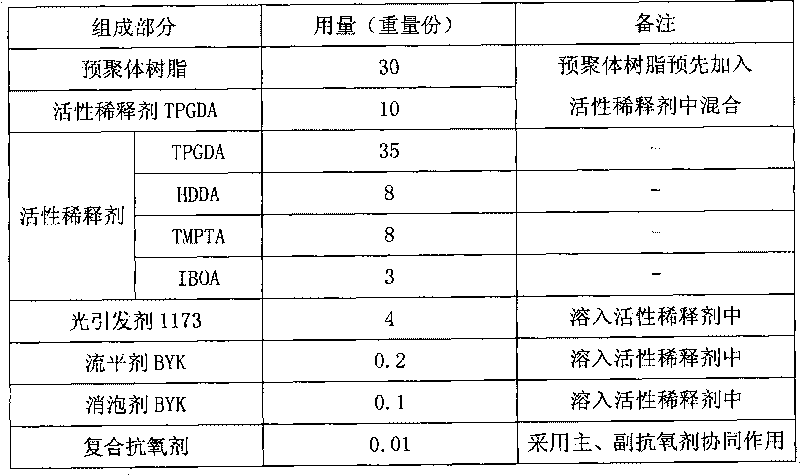

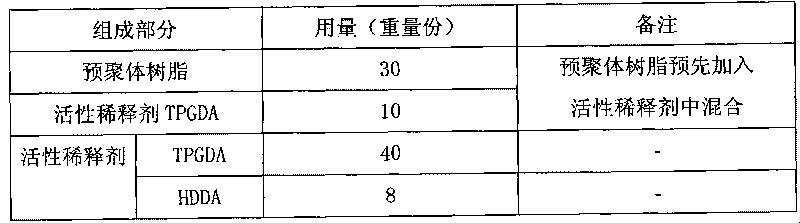

Epoxy acrylate prepolymer resin and preparation method thereof and application in photocurable coating

The invention relates to an epoxy acrylate prepolymer resin and a preparation method thereof and an application in a photocurable coating. The prepolymer has the characteristics of low viscosity, good flexibility, good adhesion and basic colorlessness and can be used for preparing various photocurable coatings and coating various base materials, such as bamboo floor. The epoxy acrylate prepolymer resin is prepared by epoxy resin and methacrylate under the action of the catalyst through ring-opening esterification and is characterized in that the prepolymer resin comprises the following components according to parts by weight: 100 parts of epoxy resin, 35-50 parts of methacrylate, 2-8 parts of long chain saturated dicarboxylic acid, 12-25 parts of polyethylene glycol, 8-12 parts of diglycidyl ether, 0.01-0.05 parts of antioxidant, 0.2-0.5 parts of catalyst and 0.005-0.01 parts of polymerization inhibitor. The viscosity reduction, toughening and modification are carried out for the epoxy acrylate prepolymer resin, the flexibility and strength are improved, the viscosity of the prepolymer resin is effectively reduced, and the prepolymer resin is applicable for preparing the photocurable coatings.

Owner:浙江天和树脂有限公司 +1

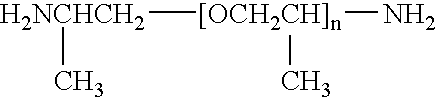

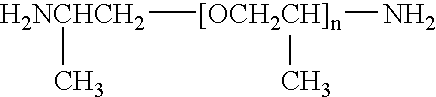

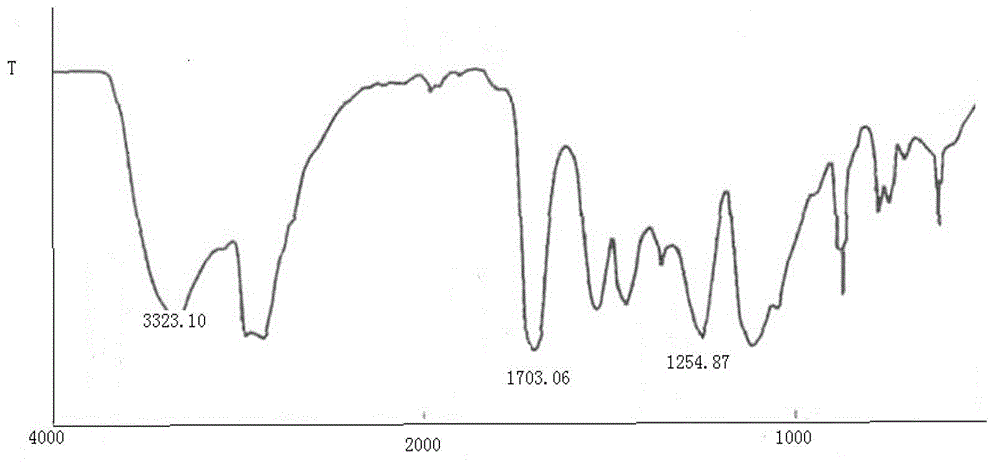

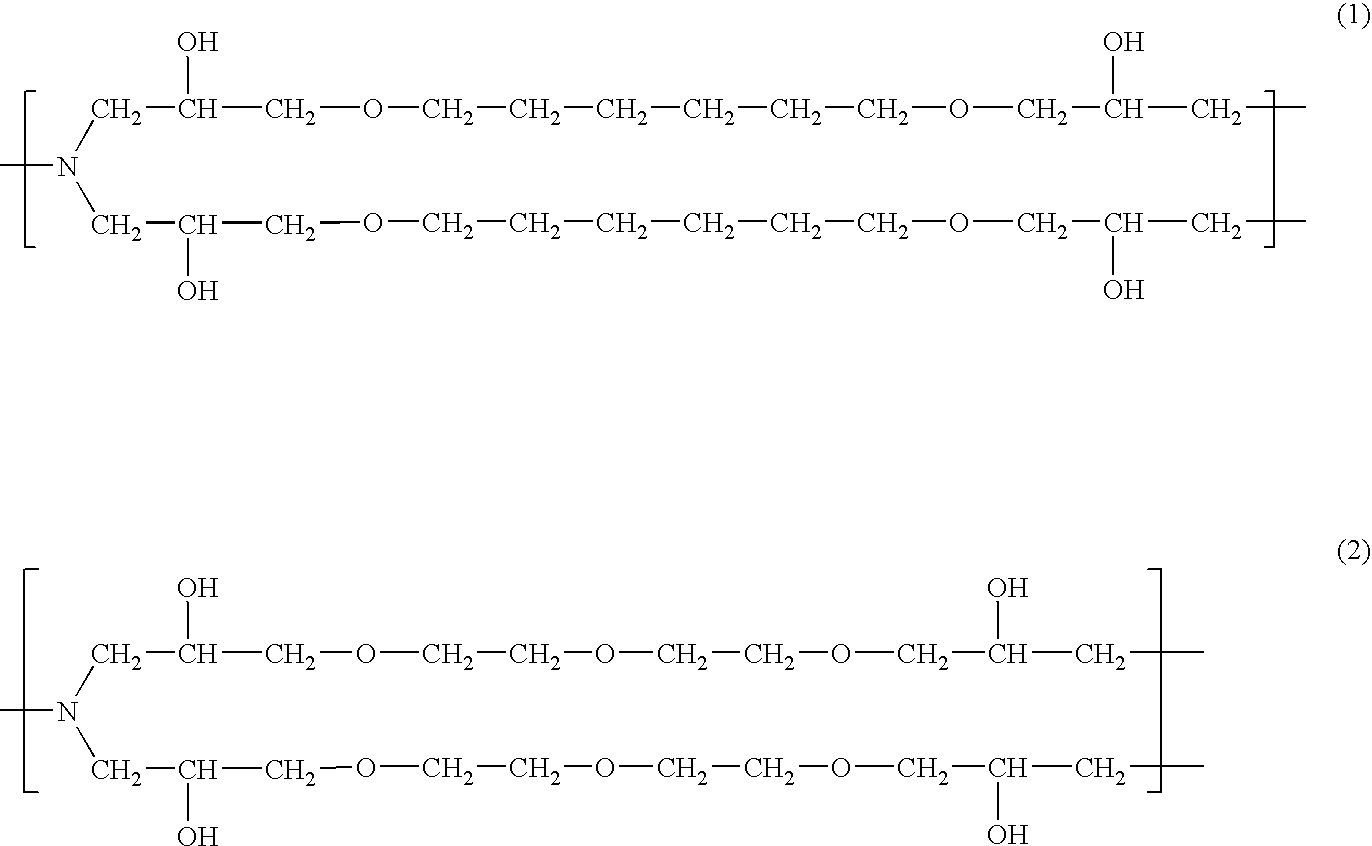

Preparation method of non-ionic room temperature-cured aqueous epoxy curing agent

The invention discloses a process of preparing non-ionic cold curing water- based epoxy curing agent. It comprises following steps: adding polyether polyols diglycidyl ether or polyether epoxide resin or mixture of them into organic solution of aromatic polyamine or aliphatic polyamine for chain extension reaction, then adding epoxide resin solution for futher chain extension reactor; dropping distilled water at 20-90 Deg. C to dilute product until the solid content being 30- 80%, and getting non-ionic cold curing water- based epoxy curing agent. The invention introduces epoxide resin molecular chain segment into curing agent, which increases the compatability between curing agent and epoxide resin, and the water- based epoxy curing agent and liquid epoxide resin are used, they possess function of emulsion liquid epoxide resin. The invention is characterized by easy process and temperate reaction condition.

Owner:SOUTH CHINA UNIV OF TECH

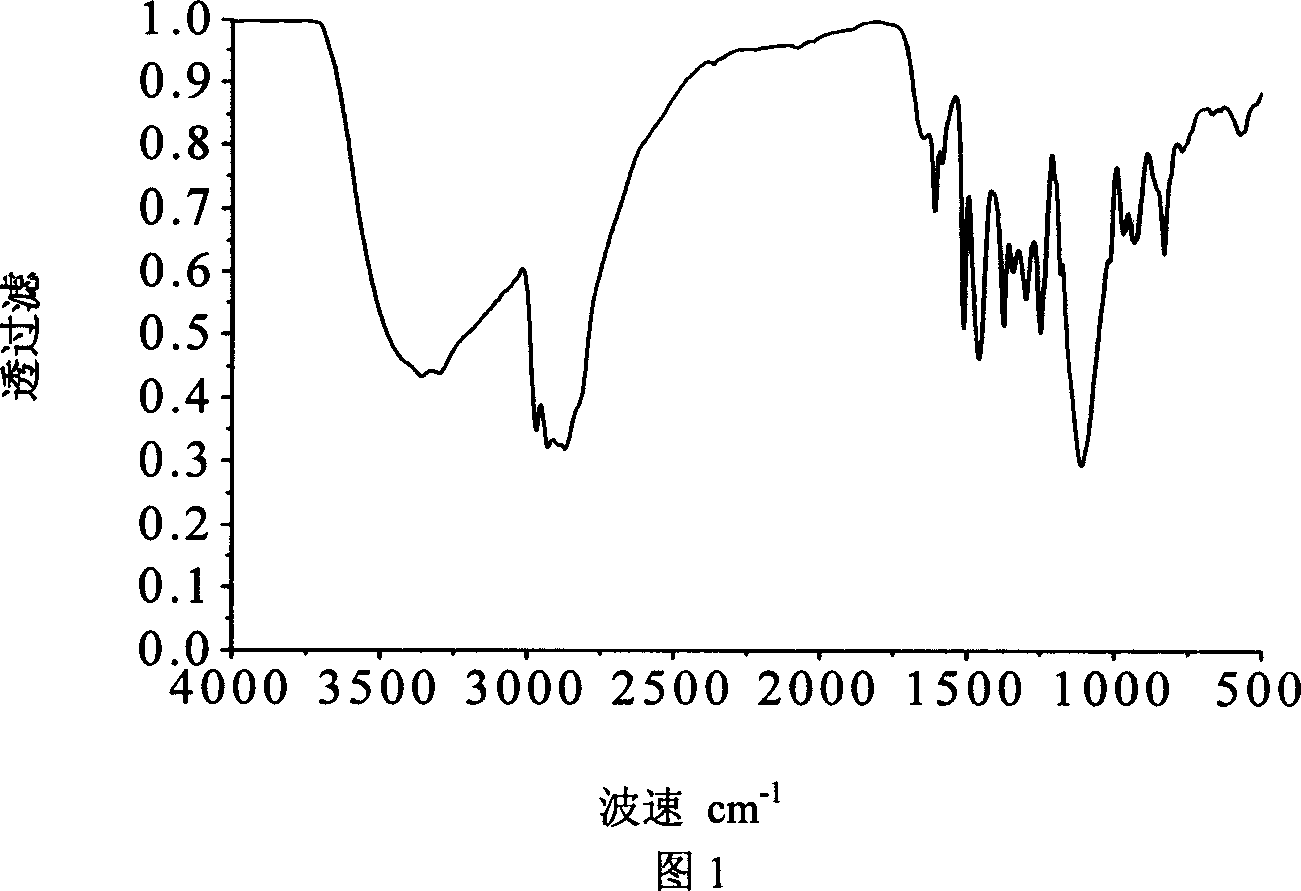

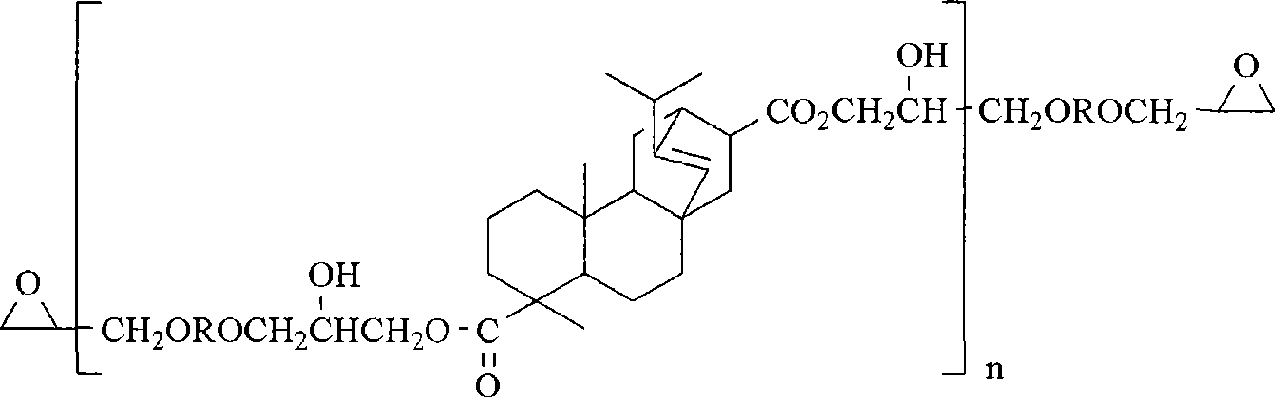

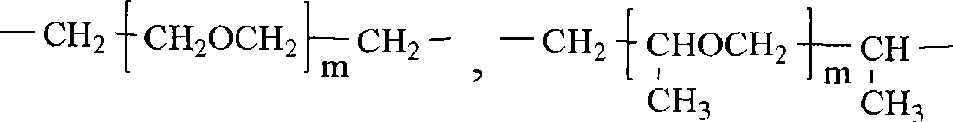

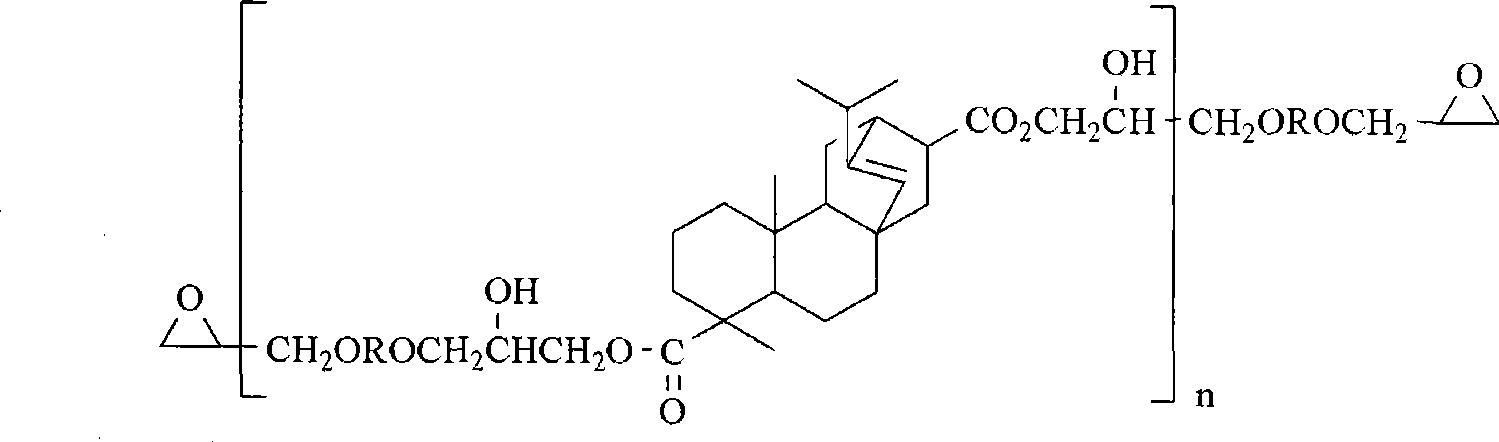

Acrylic acid rosin and epoxy resin prepolymer and preparation method thereof

InactiveCN101544744AImprove brittlenessGood weather resistanceNatural resin chemical modificationNatural productReaction temperature

The invention discloses an acrylic acid rosin and epoxy resin prepolymer and a preparation method thereof. Acrylic acid rosin is molten, diglycidyl ether is added to the molten acrylic acid rosin and reacts with the same under the action of esterification catalyst at the reaction temperature of 120-200 DEG C until the acid number of the reaction system is lower than 10mgKOH / g, the product of reaction is cooled and the acrylic acid rosin and epoxy resin prepolymer is obtained. The acrylic acid rosin and epoxy resin prepolymer is prepared by cheap and available natural products, has excellent mechanical property and uvioresistant property, is especially suitable to manufacture outdoor weather-resisting electric engineering insulating material and can be used as weather-resisting epoxy adhesive, epoxy resin coating, hydrated epoxy coating and the like.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

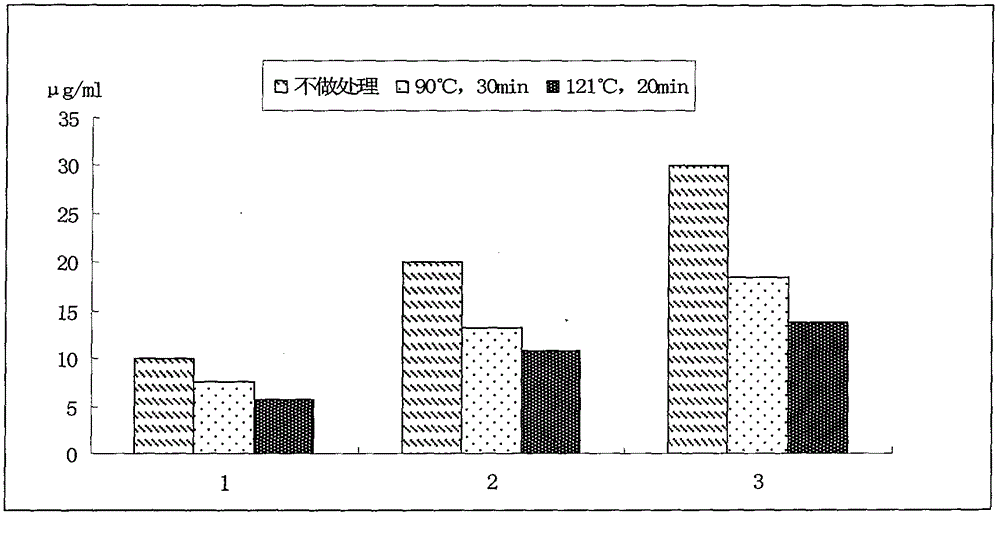

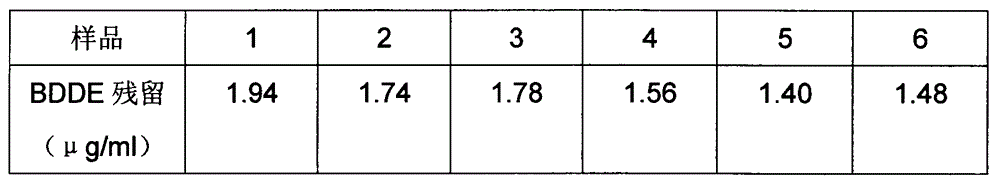

Preparation method of low-temperature secondary cross-linked sodium hyaluronate gel

InactiveCN103146003AImprove cross-linking efficiencyAvoid the disadvantages of yellowingProsthesisHigh concentrationCross linker

The invention relates to a preparation method of 1,4-butanediol diglycidyl ether cross-linked sodium hyaluronate gel. The method comprises the steps of: by taking high-concentration sodium hyaluronate solution as reaction matrix, performing first cross-linking for a longer time under the low-temperature condition by adding less cross-linking agent, then performing secondary deep cross-linking under high-temperature condition, and finally processing and pelleting through short-time dialysis technique, thereby obtaining the sodium hyaluronate gel product. With the method, the cross-linking condition of the high-concentration cross-linking agent under the traditional high-temperature condition can be eliminated, milder secondary depth cross-linking condition is adopted, the reaction efficiency of the less cross-linking agent can be greatly improved, the residual cross-linking agent is more easily removed, and the excellent biocompatibility of the cross-linked sodium hyaluronate gel can be ensured. The method is simple in preparation technique, excellent in controllability and easier to practically produce on large scale.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

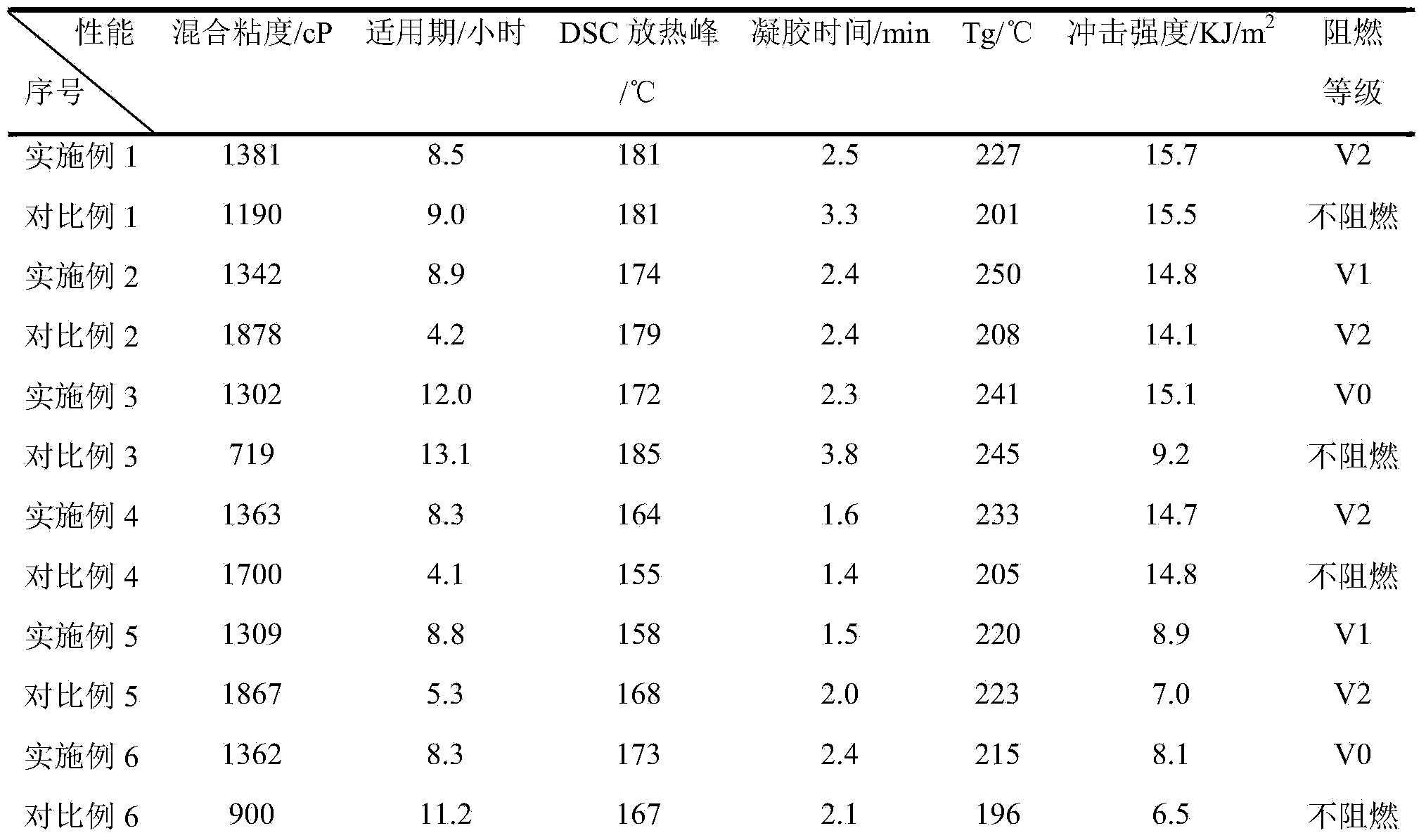

Flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and preparation method thereof

The invention discloses a flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and a preparation method thereof. The flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion comprises three components of A, B, and C, and is characterized in that the A component comprises diglycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents; the B component comprises cycloaliphatic acid anhydride, arene poly(acid anhydride), a thermoplastic phenolic resin curing agent, a maleic anhydride-grafted rubber flexibilizer, a polysiloxane toughening modifier, and an epoxy resin curing accelerator; the C component comprises an inorganic fire retardant which has an ultrafine particle size and is subjected to surface modification by a silane coupling agent and a hydrophobic modifier; the weight ratio of the A, B, and C components is that A:B:C=100:50-250:20-150.

Owner:江苏绿材谷新材料科技发展有限公司

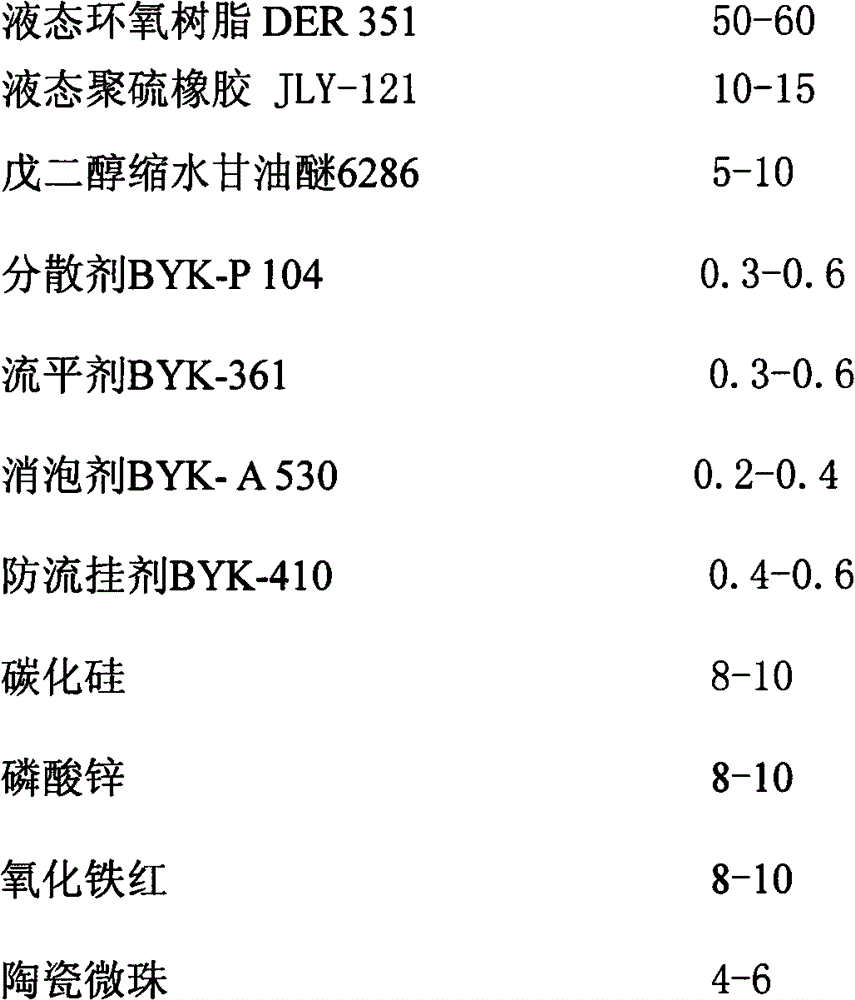

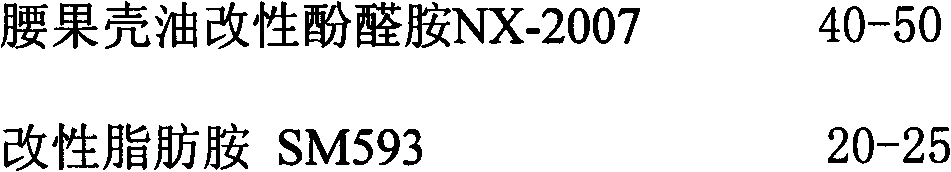

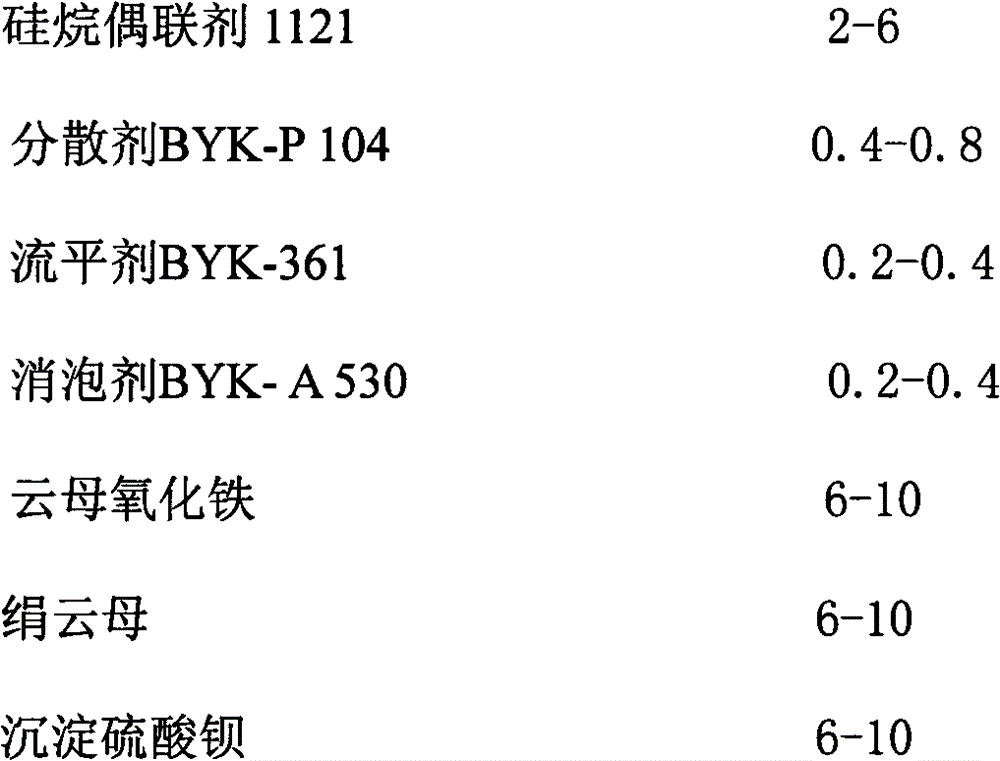

Epoxy anti-corrosive paint used for underwater concrete

InactiveCN102719173AStrong adhesionExcellent abrasion resistanceAnti-corrosive paintsEpoxy resin coatingsMicrosphereSolvent free

The invention discloses epoxy anti-corrosive paint used for underwater concrete. Liquid epoxy resin DER351 is used as a base material; polysulfide rubber is used as a flexibilizer; pentanediol diglycidyl ether 6286 is used as a diluent; zinc phosphate and iron oxide red are used as active anti-corrosive pigment; spherical silicon carbide, ceramic microspheres, mica iron oxide, sericite and precipitate vitriolic barium are used as fillings; cashew shell oil, modified phenolic aldehyde amine and modified aliphatic amine are used as curing agents; and a silane coupling agent 1121 is used as an adhesion promoter. With the cooperation of functional promoters, the raw materials are made into solvent-free double-component epoxy anti-corrosive paint used for underwater concrete through conventional preparation technique equipment. The epoxy anti-corrosive paint used for underwater concrete is highly environmental-friendly and can be directly painted or smeared on damp interfaces of underwater concrete and rapidly solidified into films; the coating has great adhesion and strong abrasion resistance and corrosion prevention. The epoxy anti-corrosive paint used for underwater concrete is widely applied to the corrosion prevention of various underwater concrete facilities.

Owner:北京国泰瑞华精藻硅特种材料有限公司

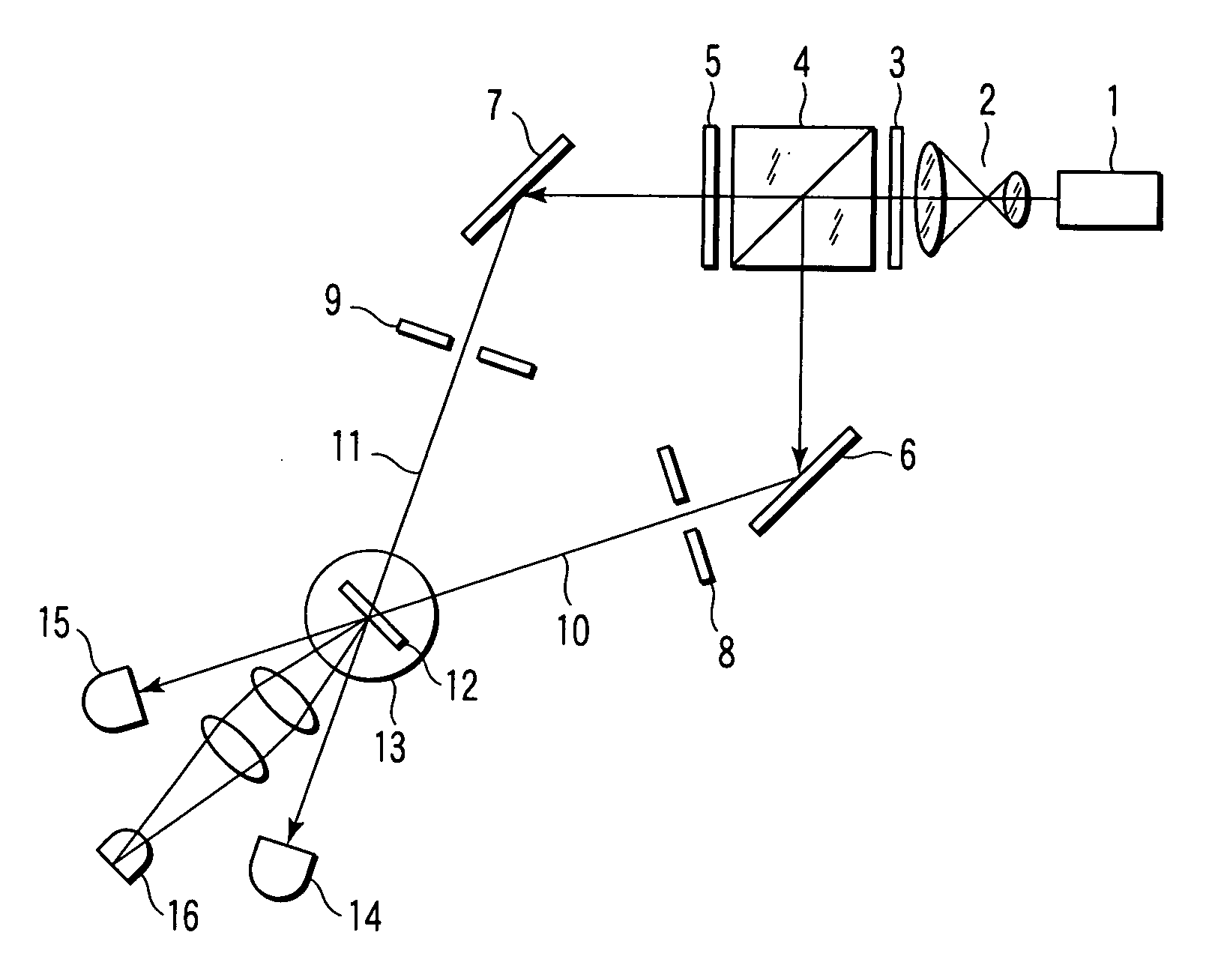

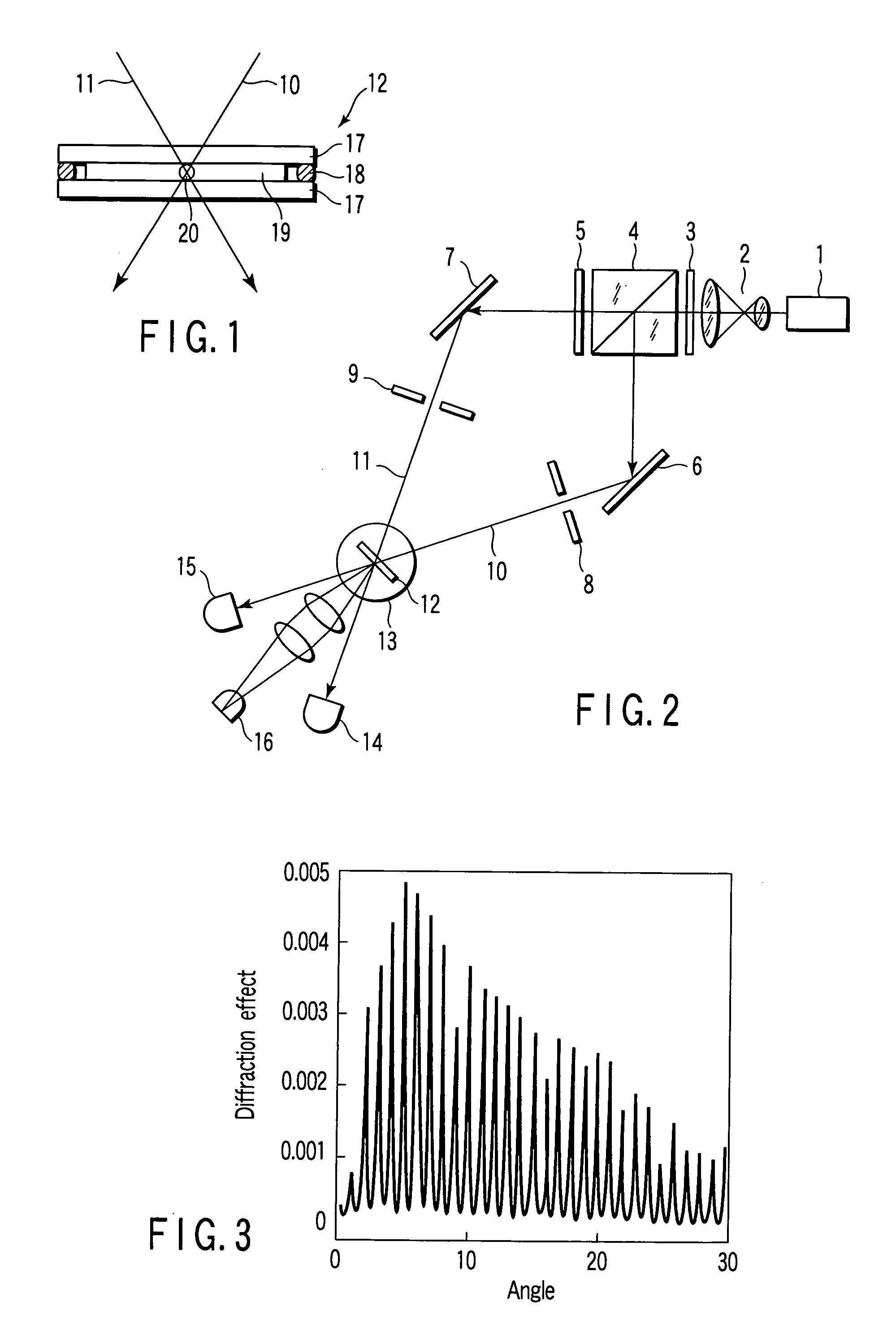

Holographic recording medium

Disclosed is a holographic optical recording medium, comprising a recording layer containing a three dimensionally cross-linked polymer matrix, a radically polymerizable compound, and a photo radical polymerization initiator, the three dimensionally cross-linked polymer matrix comprising a cured material of a reaction product between a diglycidyl ether and an amine, the diglycidyl ether being selected from the group consisting of 1,6-hexanediol diglycidyl ether and diethylene glycol diglycidyl ether.

Owner:KK TOSHIBA

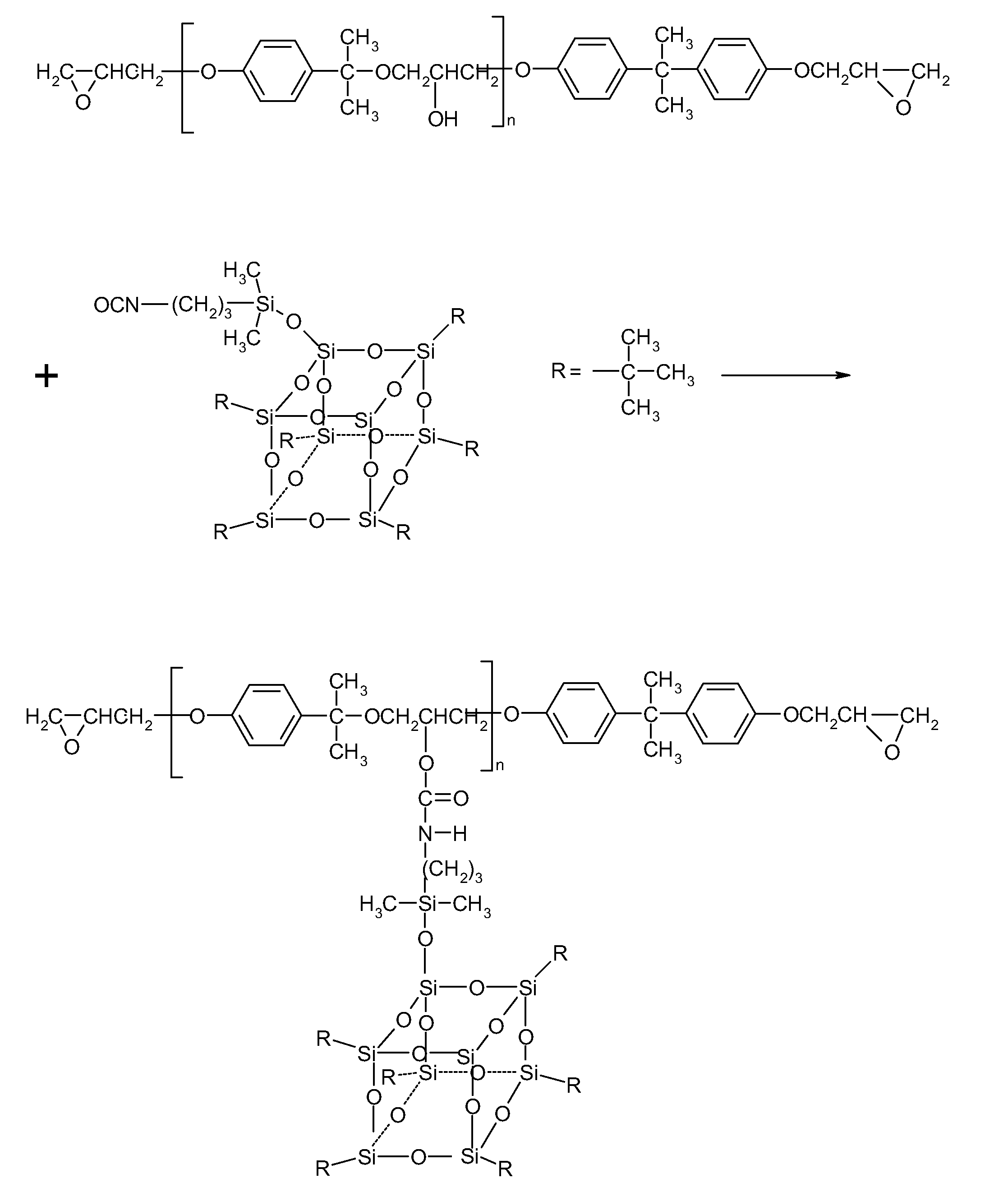

Epoxy resin containing side-chain-tethered caged POSS and preparation method thereof as well as epoxy resin material containing POSS-epoxy and preparation method thereof

ActiveUS20100087616A1High glass transition temperatureHigh temperature resistanceSide chainDiglycidyl ether

An epoxy resin containing side-chain-tethered caged POSS and a preparation method thereof as well as epoxy resin material containing POSS-epoxy and a preparation method thereof are disclosed. The epoxy resin containing side-chain-tethered caged POSS (POSS epoxy) is formed by tethering of POSS group to the side chain of the diglycidyl ether of bisphenol A (DGEBA) epoxy resin. The preparation method of the POSS epoxy includes a step of reacting epoxy resin with caged POSS to form epoxy resin containing side-chain-tethered caged POSS (POSS-epoxy). The preparation method of epoxy resin material containing POSS-epoxy includes a step of reacting DGEBA epoxy resin with POSS-epoxy to get epoxy resin material containing POSS-epoxy. The POSS-epoxy is distributed evenly in the epoxy resin material with POSS-epoxy.

Owner:NAT CHUNG SHAN INST SCI & TECH

Reversible repair functional matrix resin for pultrusion and preparation method of matrix resin

InactiveCN104194269AMeet the requirements of pultrusion processImprove axial tensile strengthEpoxyDiphenylmethane

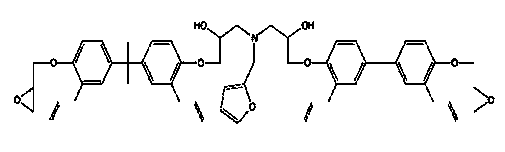

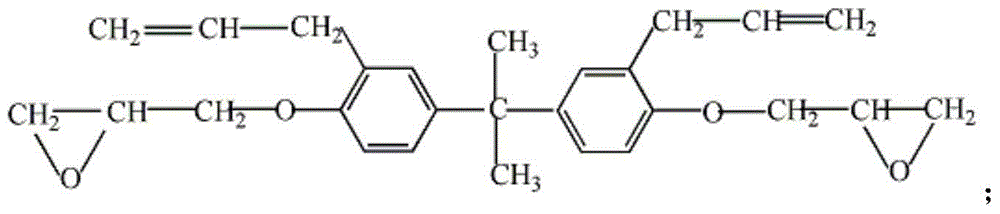

The invention discloses a reversible repair functional matrix resin for pultrusion and a preparation method of the matrix resin. The matrix resin is prepared from the following raw materials in parts by weight: 30-60 parts of 4,4'-diallylbisphenol A diglycidyl ether epoxy resin, 20-35 parts of furfuryl amine, 15-30 parts of 4,4'-bismaleimide diphenylmethane, 0-25 parts of liquid epoxy resin and 5-15 parts of curing agent. The preparation method comprises the following steps: dissolving the 4,4'-diallylbisphenol A diglycidyl ether epoxy resin in a formula amount into a solvent, slowly adding the furfuryl amine into a reaction container for reacting, adding the 4,4'-bismaleimide diphenylmethane, liquid epoxy resin and curing agent, reacting and mixing for a hour, performing reduced pressure distillation to remove the solvent, and cooling. The reversible repair functional matrix resin for pultrusion and the preparation method of the matrix resin disclosed by the invention have the beneficial effects that the matrix resin has good molding manufacturability, the molecular structure contains furan and imide structures, the heating and repairing functions of the prepared composite material can be realized by virtue of a Diels-Alder reversible reaction, and the matrix resin also has the advantages of high strength and high heat resistance.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

Fibroin reinforcement process of fragile silk

InactiveCN101487189AGood colorDoes not affect appearanceAnimal fibresProtein solutionAging resistance

The invention provides a silk protein reinforcing method for fragile silk, comprising the steps as follows: A) the fragile silk with the weight ratio of 1:30-200 is put in a silk protein solution with the weight percentage of 0.1-5% and dipped for 1min to 2h at the temperature of 20-35 DEG C and then taken out and naturally dried; B) the fragile silk is put in ethylene glycol diglycidyl ether solution with the weight percentage of 0.001-10%, dipped for 1min to 2h at the temperature of 20-35 DEG C and then taken out; C) after the treatment, the fragile silk is solidified for 24h to 2h at the temperature of 20-60 DEG C; and D) after natural drying, the silk reinforced by the silk protein molecular is obtained. The method has the advantages of simple method, convenient operation, not affecting the appearance of the silk relic, partly recovering the true luster of the relic, having outstanding advantages on high-temperature ageing resistance, and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Preparation of hyperbranched polyetheramine-grafted GO adsorbent used for heavy metal and dye adsorption as well as application thereof

ActiveCN104707579AOther chemical processesWater/sewage treatment by sorptionPolymer scienceGlycidyl ethers

The invention relates to a preparation method of a hyperbranched polyetheramine-grafted GO adsorbent used for heavy metal and dye adsorption as well as an application thereof. The hyperbranched polyetheramine-grafted GO adsorbent is characterized in that polyether diglycidyl ether and a polyamine monomer are employed to prepare the hyperbranched polyetheramine HPEA, an alkalescence catalyst grafting oxidation graphene GO is used, so that the hyperbranched polyetheramine-grafted oxidized graphene GO-HPEA. The adsorbent preparation method is simple and easy, the adsorption quantity for the heavy metal ion or cation dye can be more than 500mg / g, and the hyperbranched polyetheramine-grafted GO adsorbent has the advantages of easy solid-liquid separation and repeatable utilization, and can be used for high efficiency treatment of heavy metal and dye in waste water.

Owner:UNIV OF JINAN

Synthesis method of water-absorbent resin with novel structure

ActiveCN106987075AHigh absorption rateHigh pressure absorption capacityCross-linkAbsorption capacity

The invention discloses a synthesis method of water-absorbent resin with a novel structure. The synthesis method is characterized by comprising, by weight, 200-300 parts of acrylic acid, 1-5 parts of cross-linking agents, 700-800 parts of deionized water, 0.5-2 parts of oxidation reduction initiating agents, 50-80 parts of octylene glycol, 10-80 parts of ethyl alcohol, 5-15 parts of butanediol diglycidyl ether, 20-40 parts of aluminum sulfate, 2-5 parts of silicon dioxide and sodium hydroxide solution. According to the synthesis method, the acrylic acid is firstly polymerized at the indoor temperature and then neutralized by the aid of the sodium hydroxide solution, triple cross-linking treatment of the surface is performed, so that the water-absorbent resin has high gel intensity and pressurizing absorption capacity, good liquid passing performance and water retention capacity and fundamentally solves the problem that gel intensity and absorption ratio cannot be completely considered, and the synthesized water-absorbent resin is quite excellent in performance and has high infiltration speed, super-low reverse osmosis and super-dry and comfortable surfaces when being applied to paper diapers.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Epoxy resin-based autodeposition coatings

InactiveUS6833398B2Improve moisture and corrosion resistanceExpand coverageSynthetic resin layered productsThin material handlingAdductMetal

Autodeposited coatings useful for protecting metal surfaces and in production of rubber-to-metal composites are obtained by curing adducts based on epoxy resins which are adhered to the metal surface. One or more epoxy resins, such as for example, the combination of a diglycidyl ether of bisphenol A and a flexibilizing epoxy resin, may be prereacted to form an adduct of higher average molecular weight than the starting epoxy resins. Said adduct may then be dispersed in water, with the resulting dispersion being used in an autodeposition bath composition.

Owner:HENKEL KGAA

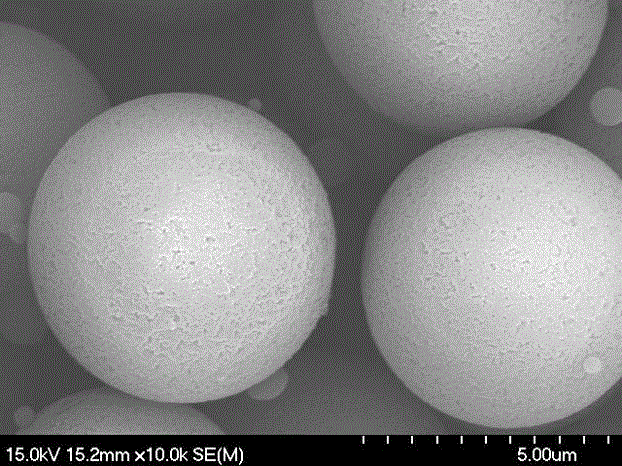

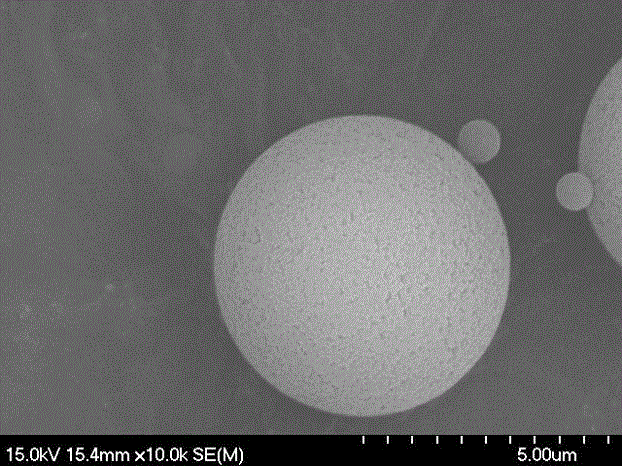

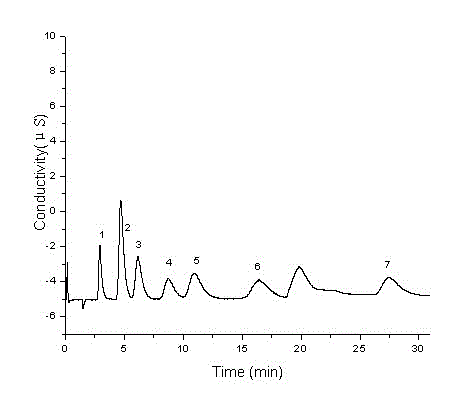

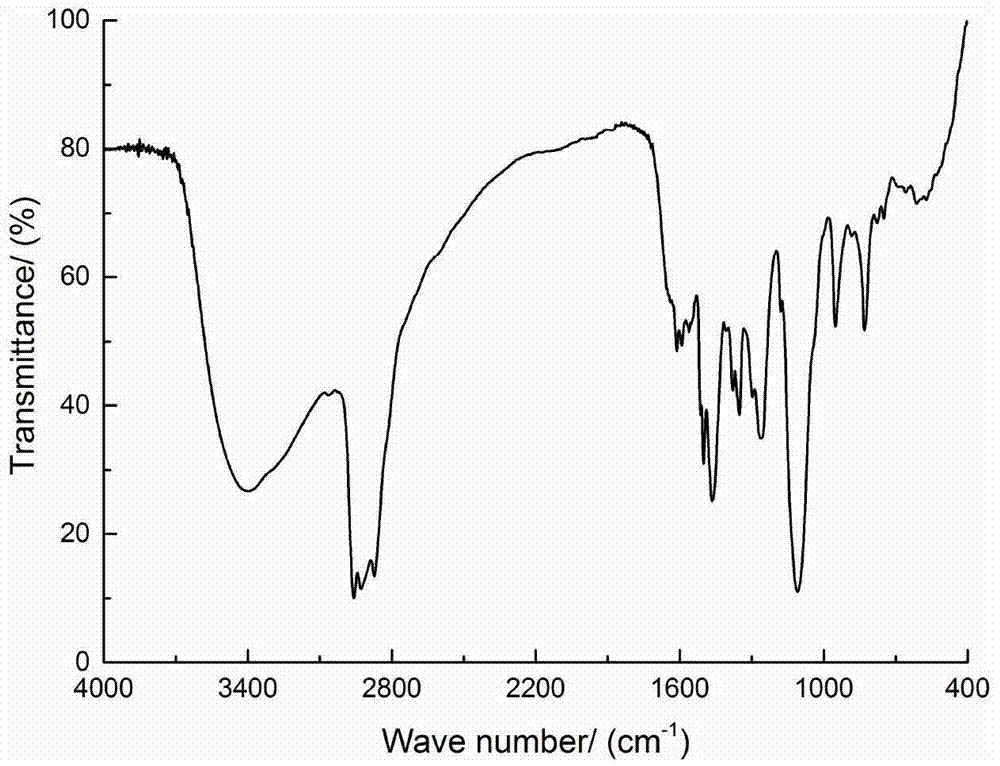

Preparation method of surface-grafting anion chromatography stationary phase

InactiveCN102941074ALow costNarrow particle size distributionOther chemical processesGlycidyl methacrylateMicrosphere

The invention relates to an anion chromatographic column a preparation method thereof, particularly relates to a preparation method of a surface-grafting anion chromatography stationary phase. The method disclosed herein is characterized by: preparing monodispersed linear polystyrene microspheres seeds by dispersion polymerization, activating the seeds, then synthesizing polystyrene-divinyl benzene-glycidyl methacrylate microballoons by one-step seed swelling method, and extracting to remove the pore forming agent; adopting multi-step grafting synthetic method, taking methylamine and 1,4-butanediol diglycidyl ether as raw materials, and introducing a large amount of positively charged quaternary ammonium groups as the anion exchange functional group to the surface of the prepared polystyrene-divinyl benzene-glycidyl methacrylate microballoons; and packing by homogenate method. According to the invention, the method disclosed herein has the advantages of low cost and simple process, the prepared filling material has uniform granularity and has no need to be screened, and the particle size distribution is narrow.

Owner:ZHEJIANG UNIV

Epoxy resin composition, prepreg, and fiber reinforced composite material

It is an object of the present invention to provide a fiber reinforced composite material combining good properties such as toughness and impact resistance and to provide an epoxy resin composition to obtain this. This object is achieved by the an epoxy resin composition comprising the following [A], [B], [C], and [D]:[A] a diglycidyl ether-type epoxy resin having a molecular weight of 1,500 or more;[B] an epoxy resin in which an SP value of a structural unit thereof is greater by 1.5 to 6.5 than an SP value of a structural unit of [A];[C] a diglycidyl ether-type epoxy resin having a molecular weight of 500 to 1,200; and[D] an epoxy resin curing agent,in a ratio that satisfies the following formulas (1) to (4):0.2≦A / (A+B+C+E)≦0.6; (1),0.2≦B / (A+B+C+E)≦0.6; (2),0.15≦C / (A+B+C+E)≦0.4; and (3),0≦E / (A+B+C+E)≦0.2, (4)wherein A, B, and C represent weights of [A], [B], and [C], respectively, and E represents a weight of an epoxy resin other than [A], [B], and [C].

Owner:TORAY IND INC

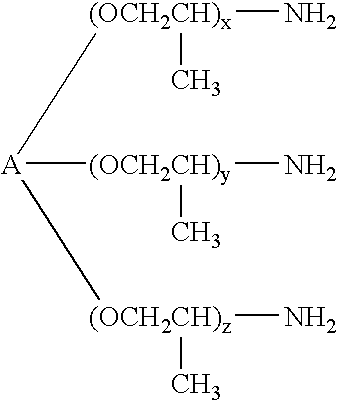

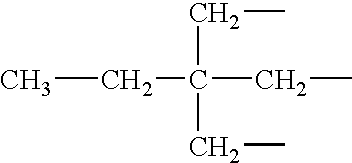

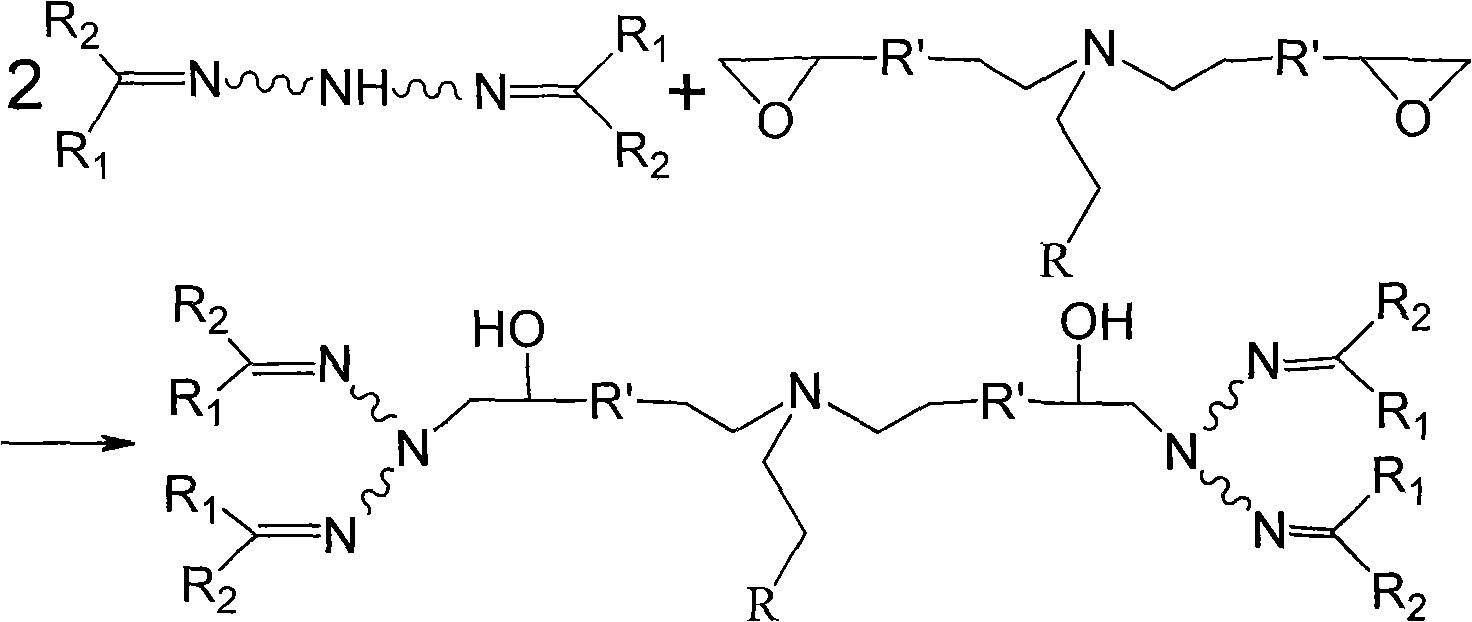

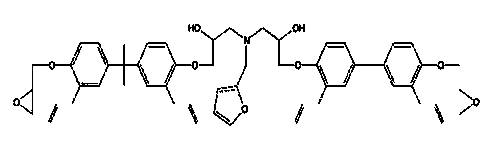

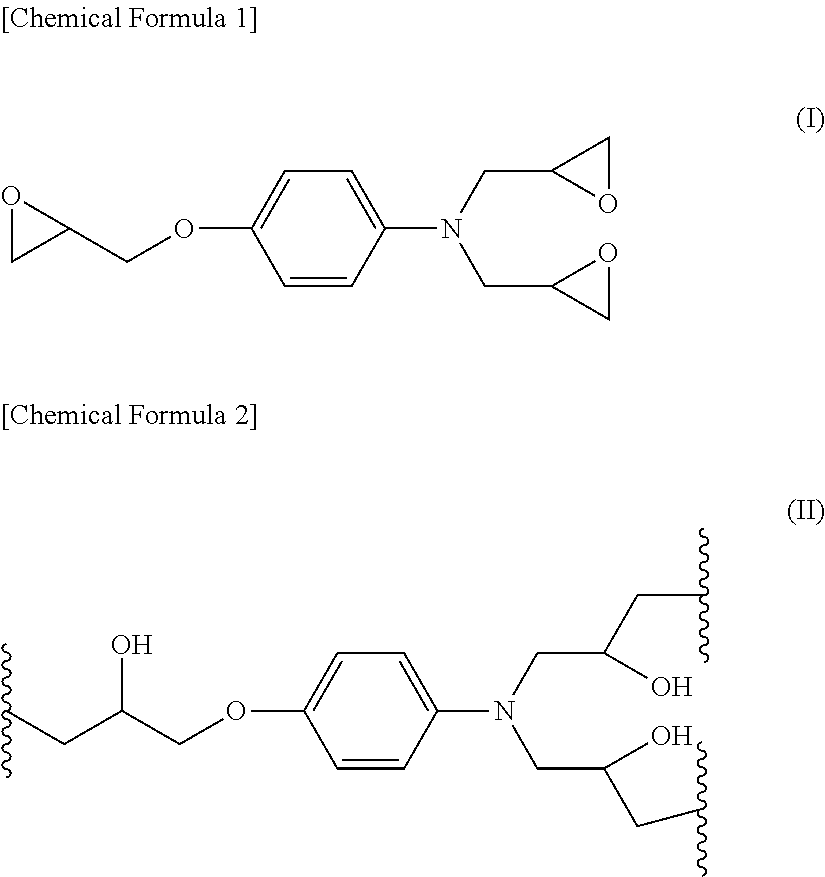

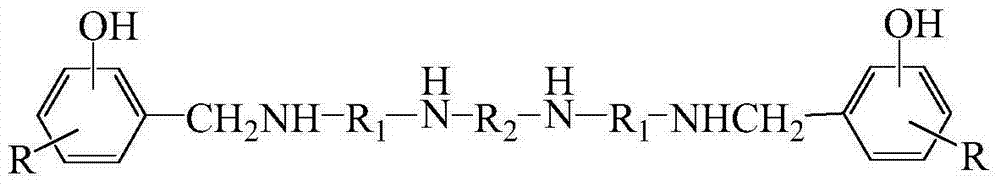

Nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure and preparation method thereof

InactiveCN104262589AThe synthesis process is simpleThe synthesis process is simple and controllableOrganic compound preparationAmino-hyroxy compound preparationWater basedEpoxy

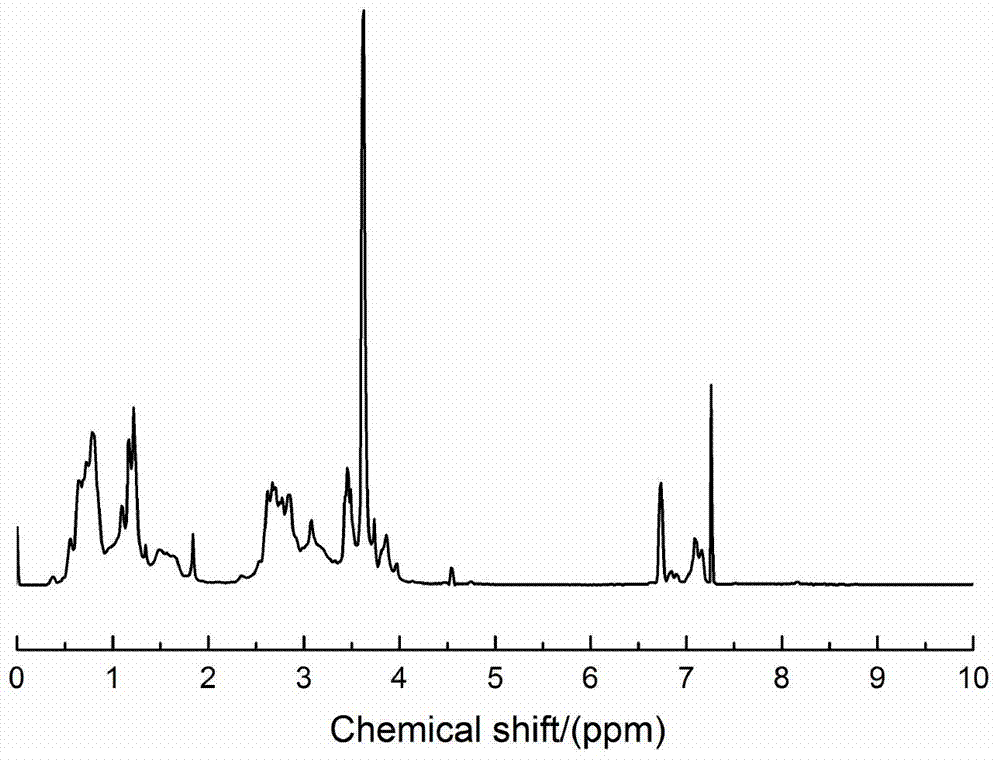

The invention discloses a nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure, of which the molecular general formula is disclosed in the specification. The preparation method comprises the following steps: 1) adding alkyl phenol, polyamine and formalin in a solvent to carry out Mannich reaction, and removing the solvent and byproduct after the reaction finishes, thereby obtaining Mannich amine containing primary amine group; and 2) sufficiently reacting the Mannich amine containing primary amine group with diglycidyl ether, cooling after the reaction finishes, adding water, and sufficiently dispersing to obtain an emulsion, thereby obtaining the product. The synthesis technique is simple and pollution-free; the synthesized curing agent does not need to perform salification reaction to implement self-emulsifying action by using organic acid; the epoxy curing agent has the advantages in the Gemini surfactant and has the characteristics of excellent wettability, excellent emulsibility, excellent stability and the like; and the epoxy curing agent can directly emulsify and cure the liquid epoxy resin, and can also cure an epoxy resin dispersion solution.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

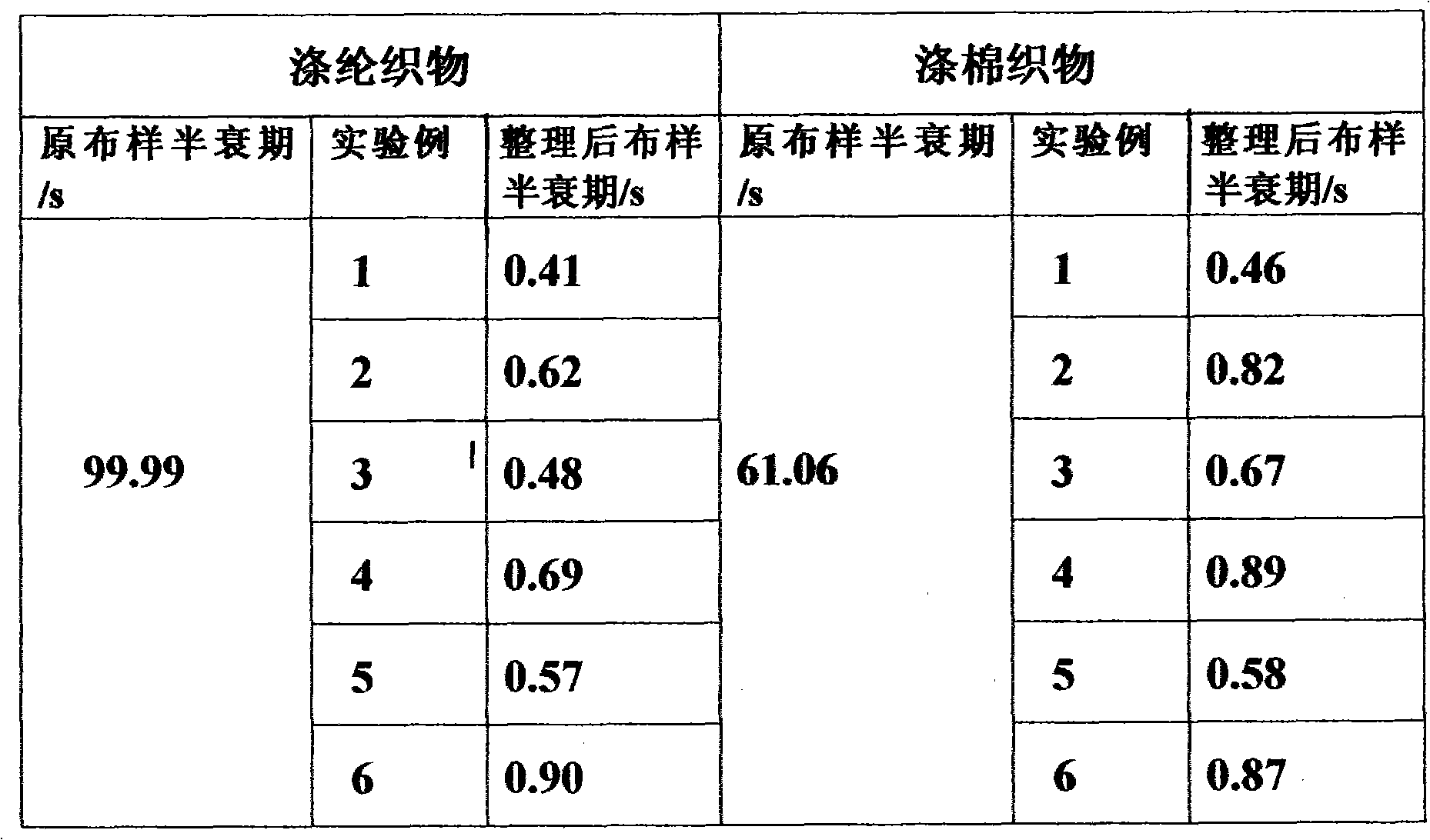

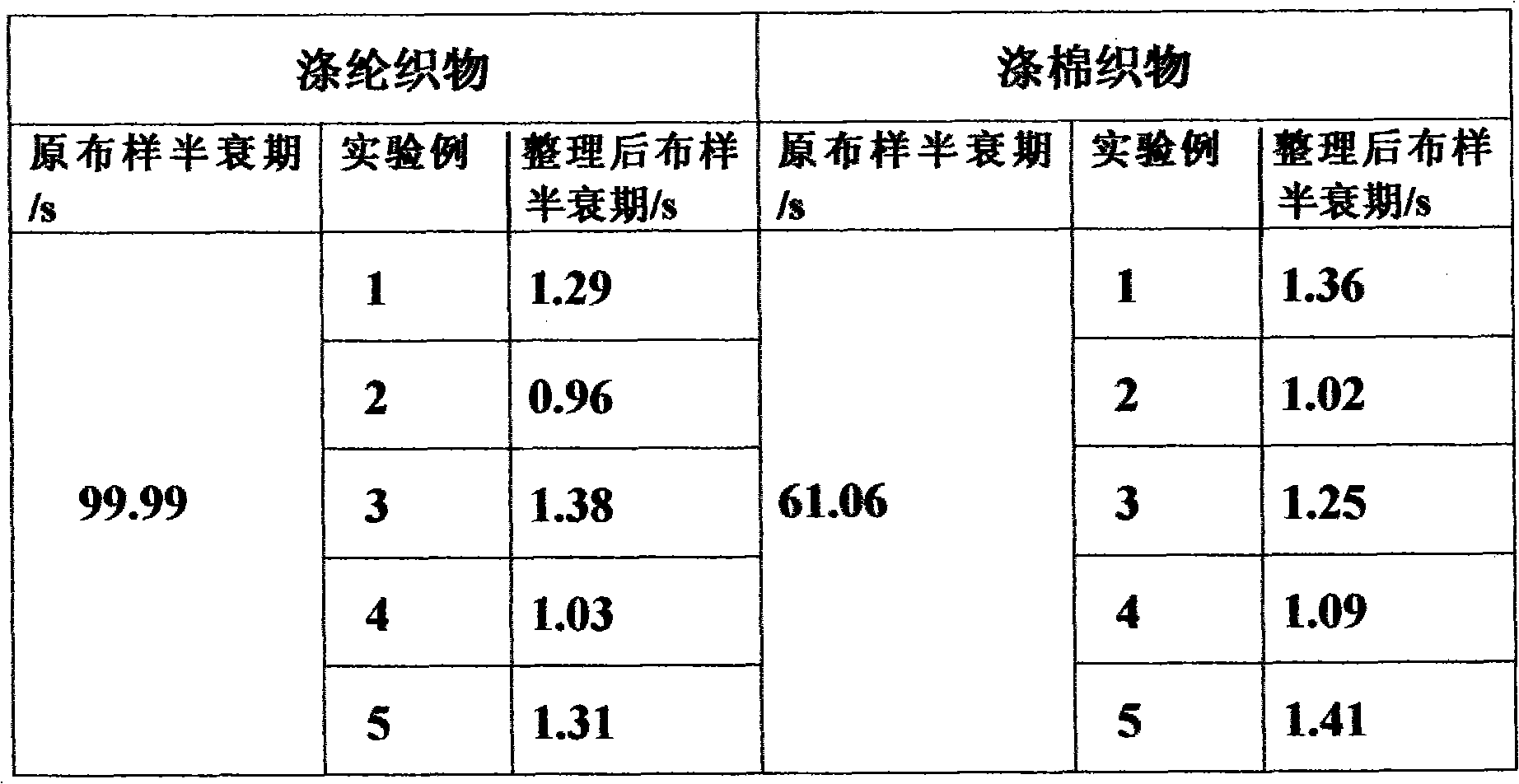

Durable antistatic finishing agent for fabrics and preparation method

The invention relates to a durable antistatic finishing agent for fabrics and a preparation method. The durable antistatic finishing agent is reactive cationic polyurethane water emulsion with a structure of an epoxy group, a closed isocyanate group, a hydrophilic polyethenoxy ether chain segment and a quaternary ammonium salt cationic group. The preparation method comprises the following steps: (1) preparing polyurethane prepolymer with the hydrophilic polyethenoxy ether chain segment and a structure containing tertiary amine group; (2) adding propanetriol diglycidyl ether or trimethylolpropane glycidyl ether and sealant into the polyurethane prepolymer to prepare crosslinking reactive polyurethane; (3) adding a quaternizing agent into the crosslinking reactive polyurethane to prepare crosslinking reactive cationic polyurethane; and (4) adding water into the crosslinking reactive cationic polyurethane to prepare the reactive cationic polyurethane water emulsion, wherein the mass ratio of the reactive cationic polyurethane to the water is 1:2-6.

Owner:郯城县福尔美工艺品厂

Preparation and application of fibroin strengthening protecting agent

The invention discloses a preparation of a protective agent for reinforcing fibroin and an application thereof. The protective agent is formed by two parts of fibroin solution and an auxiliary agent, namely, an ethylene glycol diglycidyl ether aqueous solution, and the preparation of the protective agent is that A) silk fiber is put into Na2CO3 solution and boiled for degumming; B) the silk fiber after the treatment is put into a CaCl2 solution for dissolution at high temperature, and then dissolving liquor is cooled and filtered, and filtrate is put into a dialysis bag and arranged in deionized water for dialysis to obtain pure fibroin solution; C) the obtained fibroin solution is arranged in a spray drier for spraying and drying to form soluble fibroin powder, and reserved for later use; D) the soluble fibroin powder is used for preparing the fibroin solution by the deionized water; and E) the ethylene glycol diglycidyl ether aqueous solution is prepared; when in use, the fibroin solution is sprayed on silk to be reinforced and then the ethylene glycol diglycidyl ether aqueous solution is sprayed on the silk to be reinforced; the preparation can substantially improve the strength of fragile silk and is applied to the protection of silk cultural relics, and has the advantages of simple method, convenient operation, no influence on the appearance of the silk cultural relics, and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Thermosetting resin composition, and prepreg and laminated board made from thermosetting resin composition

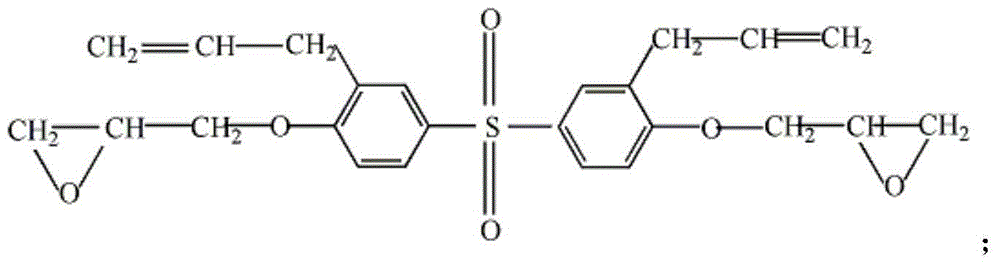

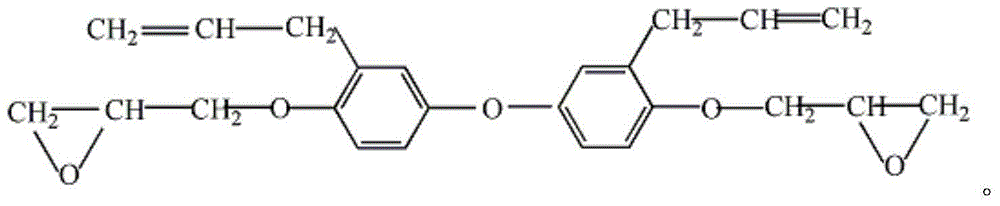

ActiveCN104861652AImprove toughnessHigh peel strengthSynthetic resin layered productsLaminationBottleFire retardant

The invention discloses a thermosetting resin composition. The thermosetting resin composition comprises the following solids by weight: (a) a modified bismaleimide prepolymer, (b) a curing accelerator, (c) a fire retardant, and (d) inorganic fillers. A preparation method of the modified bismaleimide prepolymer comprises the following step: heating bismaleimide and a composite allyl compound in a reaction bottle, wherein the composite allyl compound is composed of a first-class allyl compound and a second-class allyl compound, the first-class allyl compound is selected from one or more of diallyl bisphenol A, diallyl bisphenol S, allyl phenoxy resin and diallyl diphenyl ether, and the second-class allyl compound is selected from one or more of diallyl bisphenol A diglycidyl ether, diallyl bisphenol S diglycidyl ether and diallyl diphenyl ether diglycidyl ether. A laminated board integrates high heat resistance, high toughness, low water absorption, excellent dielectric property and good fire resistance.

Owner:SHENGYI TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com