Preparation method of non-ionic room temperature-cured aqueous epoxy curing agent

A room temperature curing, water-based epoxy technology, applied in the field of epoxy resin curing agent, can solve the problems of complex preparation process, pH value sensitivity, coating film performance decline, etc., achieve simple preparation process, mild reaction conditions, and improve compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

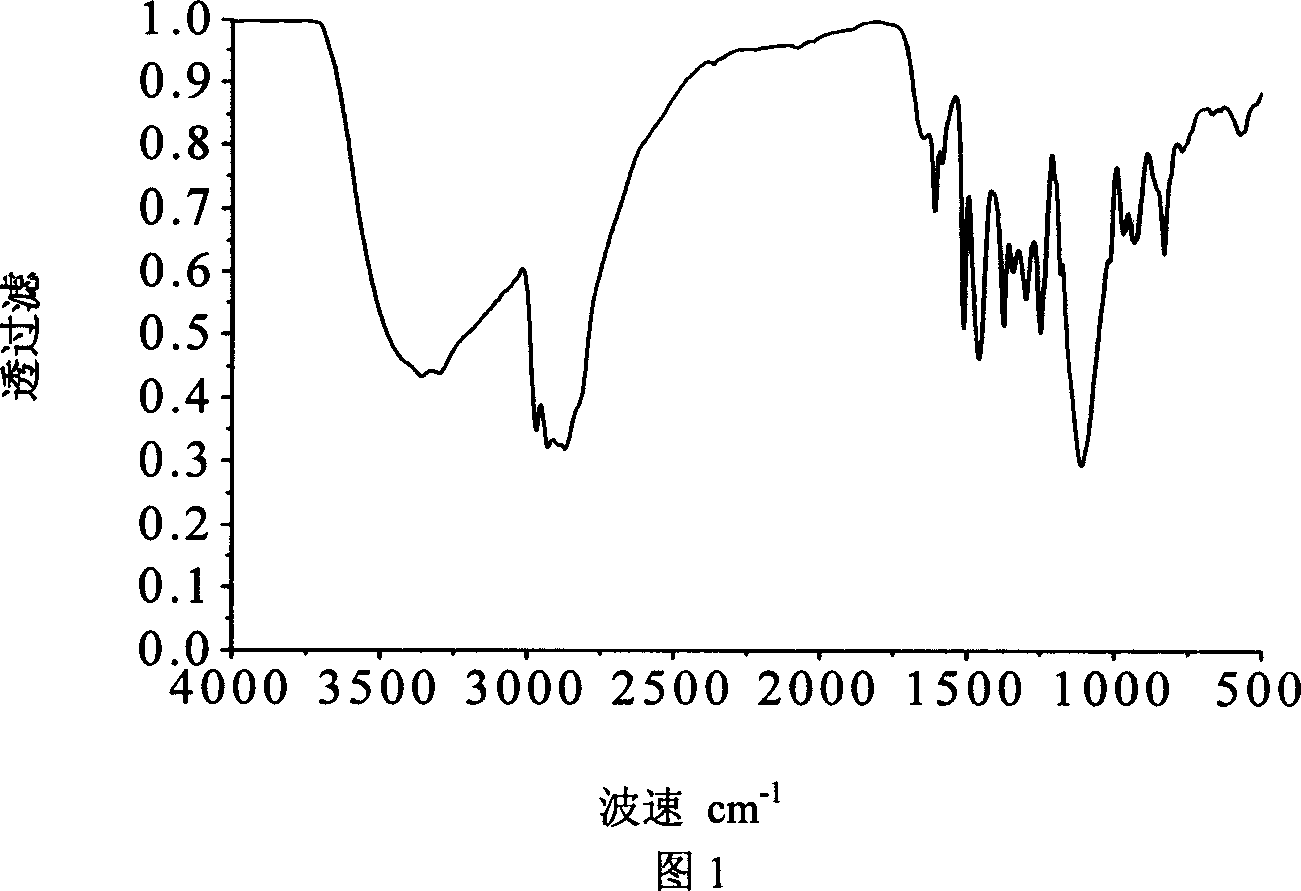

Image

Examples

Embodiment 1

[0022] Under the protection of dry nitrogen, 0.6 mol of triethylenetetramine was put into a 1000 mL four-necked reaction flask filled with 110 mL of propylene glycol methyl ether solution. The four-necked reaction flask is equipped with a reflux condenser, a thermometer and a stirrer. The stirring paddle type is an anchor impeller stirring paddle, the stirring speed is about 500rm-1, and the heating form is a water bath constant temperature. When the temperature in the reaction bottle rises to 65°C, add 0.2 moles of polyether polyol diglycidyl ether (NPER-032) dropwise at a rate of 60 mL per hour to the reaction bottle for reaction, and then keep it warm for 2 hours after the dropwise addition about.

[0023] After the excess triethylenetetramine was removed by distillation under reduced pressure, in the aforementioned reaction device, when the temperature in the reaction bottle was 65°C, 0.1 mole of liquid epoxy resin EPON828 was added dropwise at a rate of 60 mL per hour to...

Embodiment 2

[0026] Under the protection of dry nitrogen, put 0.6 mole of ethylenediamine into a 1000 mL four-necked reaction flask filled with 120 mL of propylene glycol methyl ether solution. The 1000mL four-necked reaction flask is equipped with a reflux condenser, a thermometer and a stirrer. The stirring paddle type is an anchor impeller stirring paddle, and the stirring speed is 500rm -1 Left and right, the heating form is a constant temperature in a water bath. When the temperature in the reaction bottle rises to 70°C, add 0.3 moles of polyether polyol diglycidyl ether (NPER-032) dropwise at a rate of 60 mL per hour to the reaction bottle for reaction, and then keep it warm for 2 hours after the addition is complete. about.

[0027] After decompression distillation to remove excess ethylenediamine, in the aforementioned reaction device, when the temperature in the reaction bottle is 65°C, add 0.15 moles of liquid epoxy resin EPON828 dropwise at a rate of 60 mL per hour to the abov...

Embodiment 3

[0029] Under the protection of dry nitrogen, put 0.6 mol of diethylenetriamine into a 1000 mL four-necked reaction flask filled with 100 mL of propylene glycol methyl ether solution. The four-necked reaction flask is equipped with a reflux condenser, a thermometer and a stirrer. The stirring paddle type is an anchor impeller stirring paddle, the stirring speed is about 500rm-1, and the heating form is a water bath constant temperature. When the temperature in the reaction bottle rises to 60°C, add 0.2 moles of polyether polyol diglycidyl ether (NPER-032) dropwise at a rate of 60 mL per hour to the reaction bottle for reaction, and then keep it warm for 2 hours after the dropwise addition about.

[0030] After the excess diethylenetriamine was removed by distillation under reduced pressure, in the aforementioned reaction device, when the temperature in the reaction bottle was 65°C, 0.1 mole of liquid epoxy resin E-51 was added dropwise at a rate of 60 mL per hour to The react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com