Patents

Literature

161results about How to "No post-processing required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

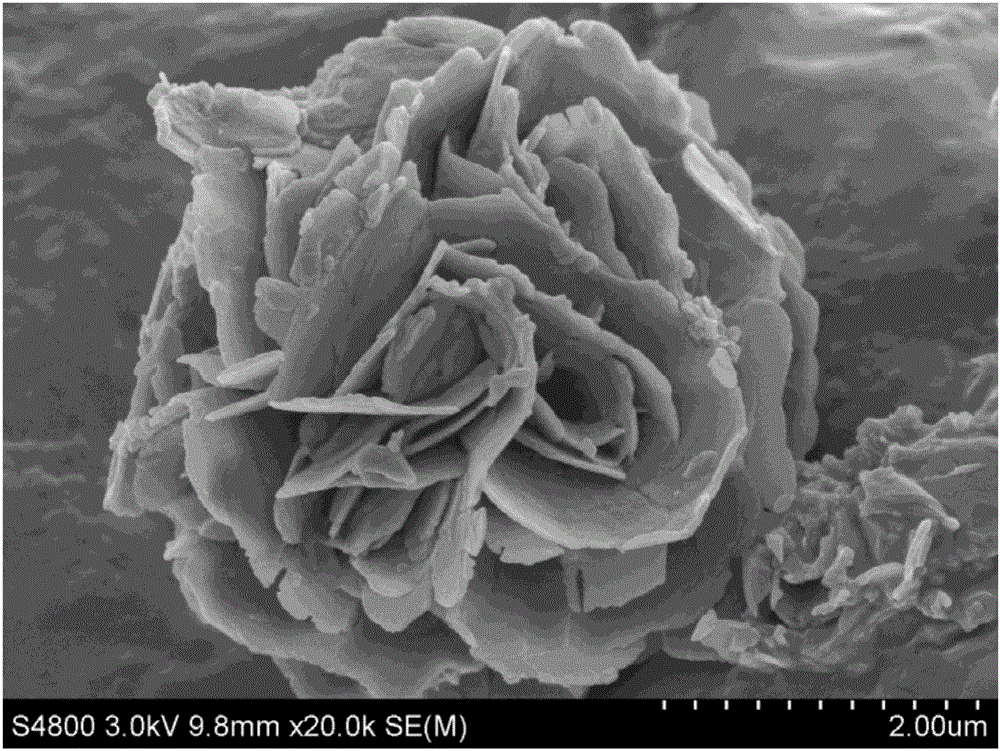

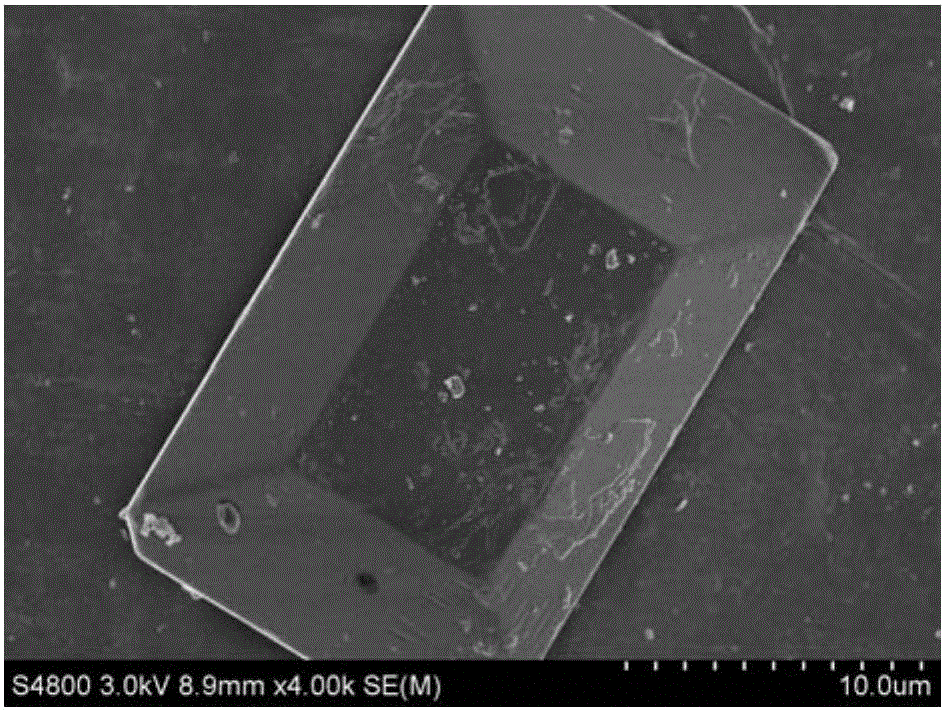

Preparation method and application of nanosheet self-assembled microflower-shaped VS2

ActiveCN105819507AOvercoming high temperatureRaw materials are cheap and easy to getCell electrodesNanotechnologyLithiumSodium hydroxide

The invention provides a preparation method and application of nanosheet self-assembled microflower-shaped VS2. The preparation method comprises the steps that firstly, the pH of a vanadium source solution and the pH of a sulfur source solution are regulated to be 11-14 under the magnetic stirring state through a sodium hydroxide solution; secondly, the solutions are poured into a reaction inner lining, the inner lining is contained in an outer kettle and fixed, and then the outer kettle is placed in a homogeneous reaction instrument; finally, a product obtained after a reaction is cooled, washed, collected and dried, and then the nanosheet self-assembled microflower-shaped VS2 can be obtained. The technology of the method is simple and easy to control, and the prepared nanosheet self-assembled microflower-shaped VS2 is uniform in chemical constitution and high in purity, has a specific self-assembled structure and shows the excellent electrochemical property when the nanosheet self-assembled microflower-shaped VS2 serves as a lithium-sodium ion battery electrode material. In addition, the method has the advantages that the defect that a traditional calcination method is high in temperature is overcome, large equipment and harsh reaction conditions are not needed, the raw materials are cheap and easy to obtain, the cost is low, the yield is high, aftertreatment is not needed, and the method is friendly to the environment and can be suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

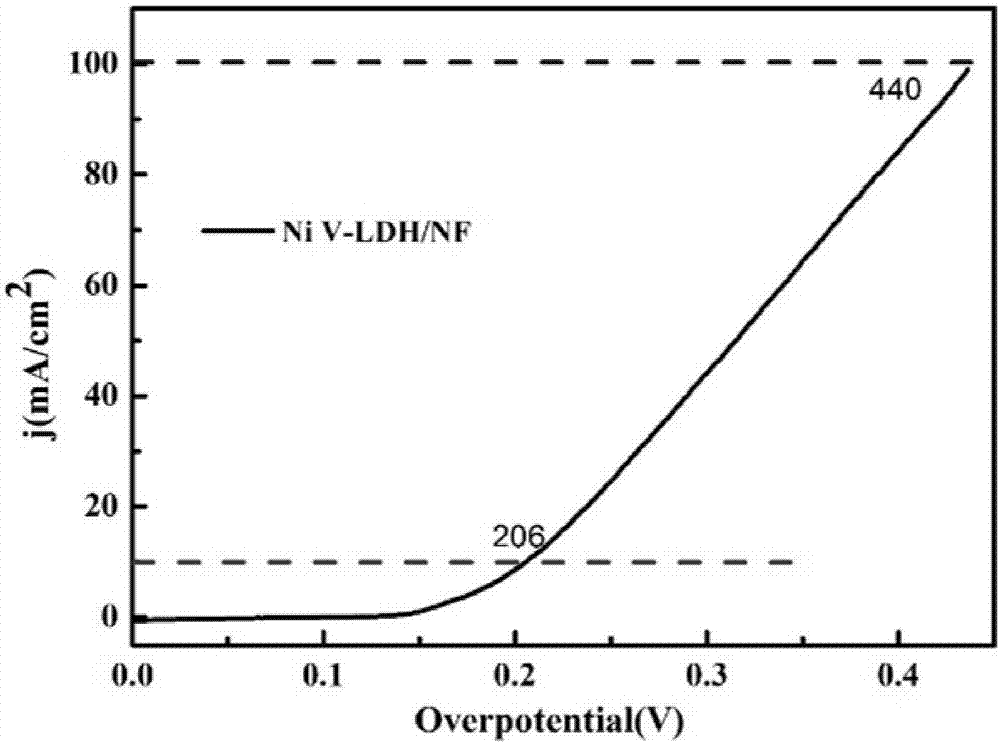

Preparation method of nickel/vanadium layered double hydroxide nano-sheet array water oxidation catalyst

InactiveCN107497444ASynthesis temperature is lowLow costCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectrolysisVacuum drying

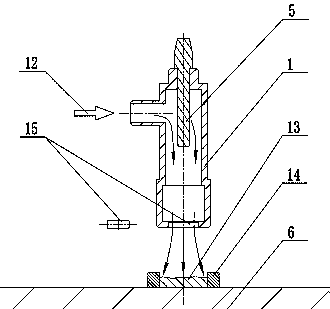

The invention provides a preparation method of a nickel / vanadium layered double hydroxide nano-sheet array water oxidation catalyst. The preparation method includes the steps of: 1) soaking foam nickel in a pure acetone solution for ultrasonic washing, soaking foam nickel in hydrochloric acid for ultrasonic washing, alternately washing the foam nickel with ethanol and deionized water, and finally vacuum-drying the foam nickel to obtain treated foam nickel; 2) simultaneously adding NiCl2.6H2O, VCl3 and Co(NH2)2 to deionized water to obtain a clear solution A; and 3) placing the foam nickel in a reaction lining, pouring the solution A into the reaction lining, sealing the reaction lining, and arranging and fixing the reaction lining in an outer kettle, placing the kettle in a homogeneous-phase reactor to perform hydrothermal reaction, and naturally cooling the reaction product to room temperature; 4) moving the cooled foam nickel product out, alternately washing the foam nickel product with water and alcohol, collecting the product, and vacuum-drying the product to obtain NiV-LDH nano-sheet array. The produce has homogeneous chemical composition, high purity and uniform appearance, and has excellent electrochemical performance when being used as an electrode material for electrolyzing water.

Owner:SHAANXI UNIV OF SCI & TECH

Formation method of two-color or multi-color jacquard warp knitting cloth and warp knitting cloth formed according to same

The invention discloses a formation method of two-color or multi-color jacquard warp knitting cloth. The warp knitting cloth is knitted on a jacquard warp knitting machine. The formation method comprises the following steps that (1) jacquard patterns are designed by the adoption of a computer; (2) knitting is prepared; (3) parameters are input to the jacquard warp knitting machine, knitting is achieved through the machine, and the warp knitting cloth with preset patterns is obtained. The knitted warp knitting cloth can be of two colors or multiple colors, yarns in each color independently form jacquard and other patterns, the appearance is attractive, and the problems of cost and loss increasing, environmental protection, the physical property, quality and the like caused by the fact that the two colors or the multiple colors of the warp knitting cloth is obtained by the adoption of post processing are resolved. Meanwhile, more than seven yarn guide bars are adopted to knit, the formed warp knitting cloth not only has the function of irregular pattern jacquard but also displays different colors of different patterns, patterns of a cloth cover of the warp knitting cloth are complex and changeable, the different colors are mutually combined to form the cloth cover with distinct levels and distinguished in flexibility.

Owner:FUJIAN HUACAI NEW MATERIALS CO LTD

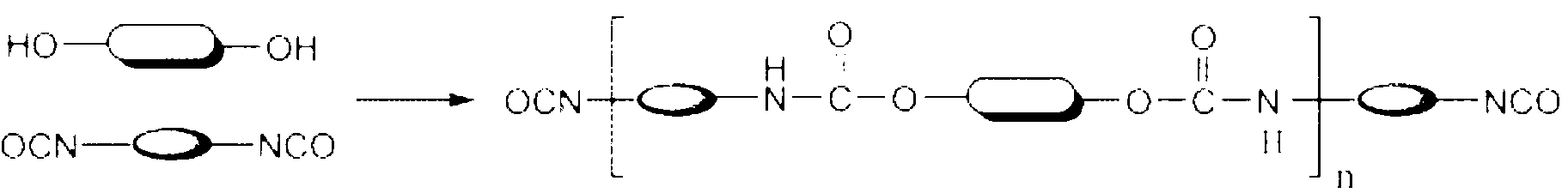

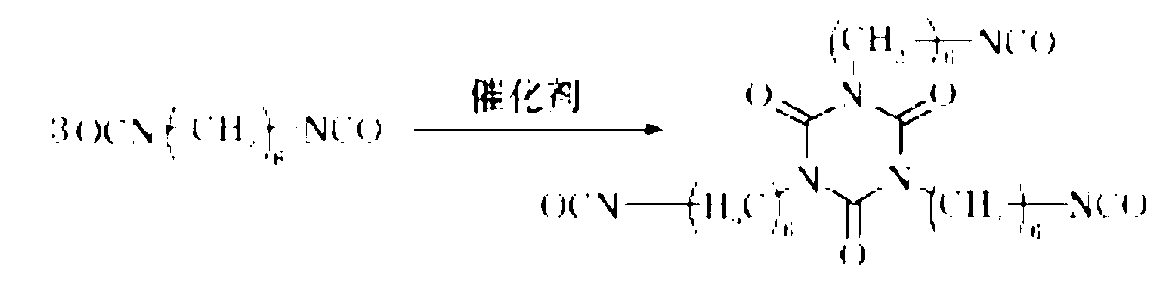

Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

InactiveCN103224605AAdd one step polymerization reactionLow free HDI contentPolyurea/polyurethane coatingsPolymer scienceMeth-

The present invention relates to a polyurethane curing agent with low free isocyanate monomer and a preparation method thereof. The polyurethane curing agent comprises the raw materials in weight percentage as following: 80 - 88 parts of hexamethylene diisocyanate monomer; 12 - 20 parts of polyhydric alcohol; 0.1-0.5 part of catalyst; and 0.1-1.0 part of terminating agent. The invention adopts a two-step chemical conversion reaction, namely, adds one step of polymerization reaction based on one-step addition reaction to remove free isocyanate monomer by a trimer method so as to obtain the 100% solid content, wherein the NCO content is between 21 and 22 %, and the free HDI content is between 0.1 and 1.0 %. According to the present invention, the preparation process of polyurethane curing agent is simplified without post-processing . The polyurethane curing agent of the invention is matched with hydroxyl acrylic resin and polyester resin etc., and the paint film will not be yellowed, and has excellent light resistance, weathering resistance, chemical resistance and gorgeous gloss.

Owner:HUBEI TRASION CHEM IND CO LTD

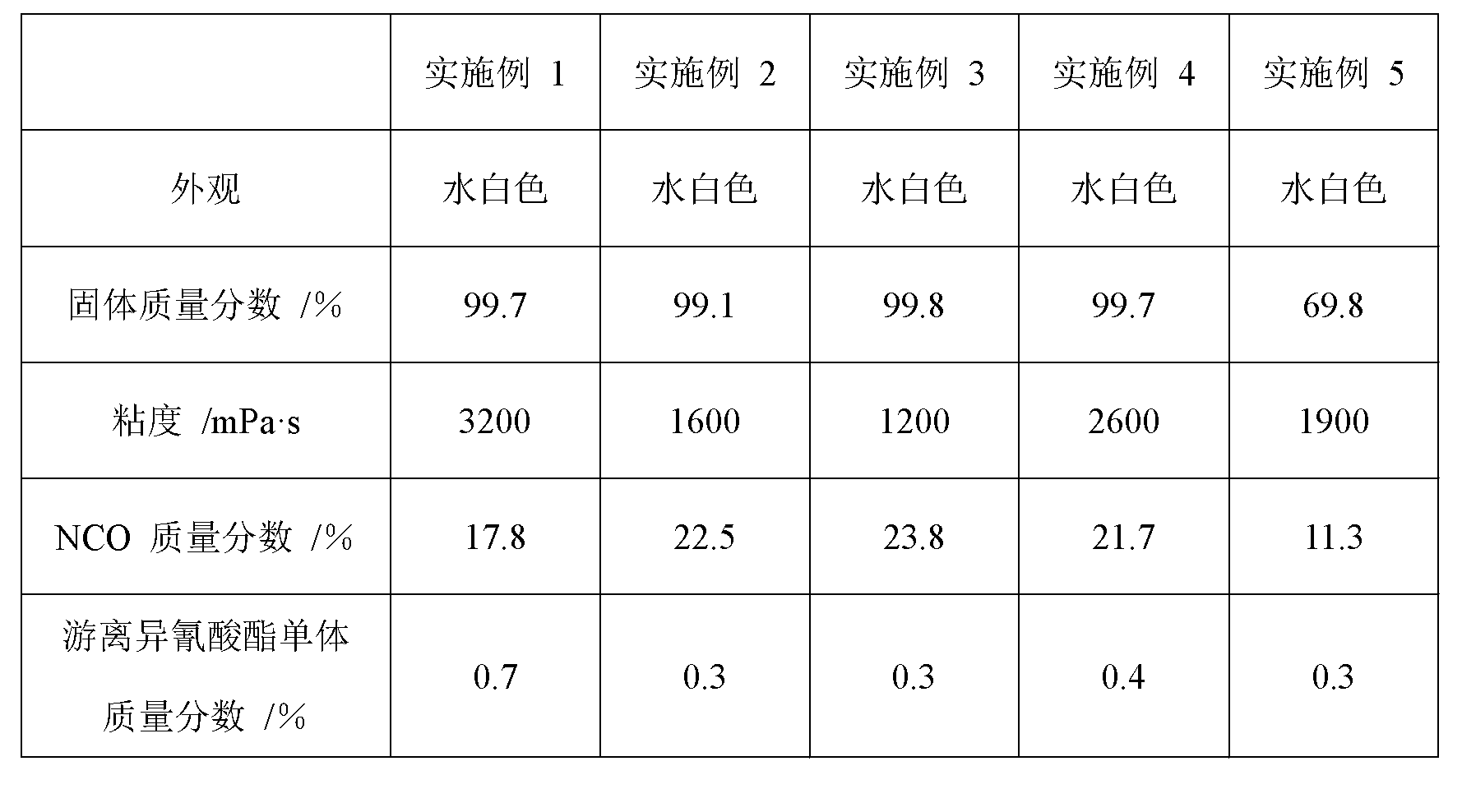

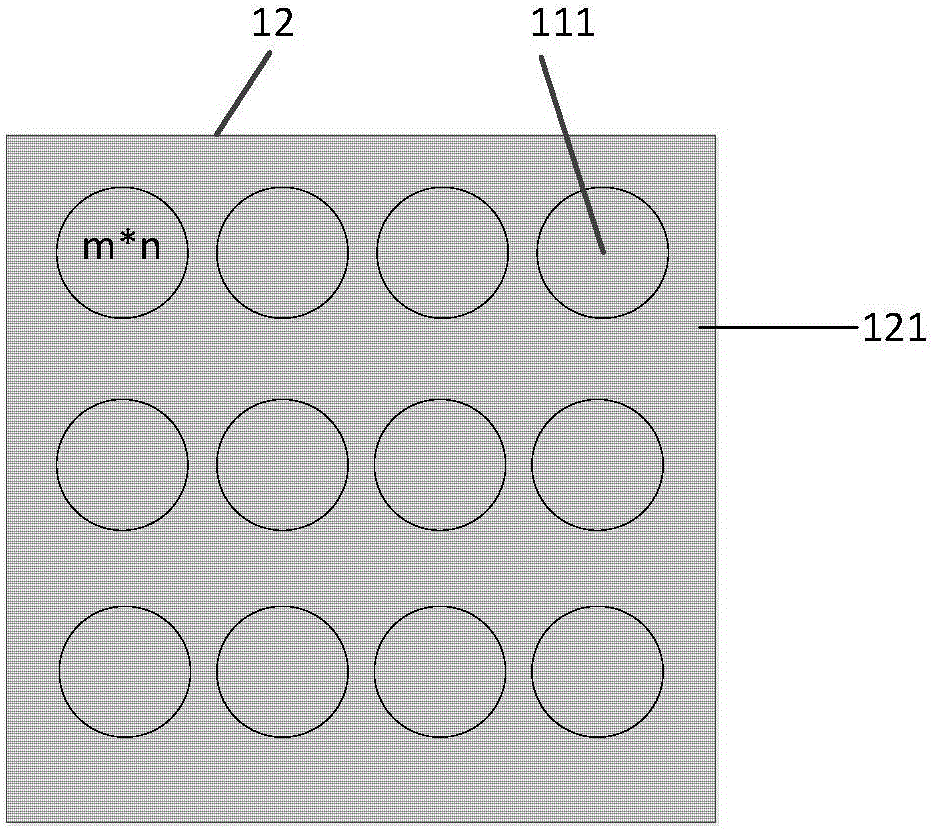

Image shooting device and shooting method thereof

ActiveCN105827922ASimple structureEasy to operateTelevision system detailsColor television detailsCamera lensShooting method

The invention discloses an image shooting device and a shooting method thereof. The image shooting device comprises a liquid crystal lens array, an image sensor and a driving module, wherein the liquid crystal lens array is composed of multiple liquid crystal sub-lenses; a preset distance exists between the liquid crystal lens array and the image sensor; the driving module is electrically connected with the liquid crystal lens array; and the driving module is used for regulating a focal distance of each of the liquid crystal sub-lenses according to the distance between an object of an image obtained by a camera lens of the image shooting device and corresponding each of the liquid crystal sub-lenses when obtaining the image, so that light rays of each object, after passing through the corresponding each of the liquid crystal sub-lenses, are focused on a plane where the image sensor locates. Because the driving module can regulate the focal distance of each of the liquid crystal sub-lenses, different parts of the liquid crystal lens array have different focal distances, and to-be-shot objects at different distances can be focused clearly, thereby obtaining an all-in-focus image. Compared with the existing all-in-focus shooting device, the structure is simple, the response speed is fast, no post-processing is needed and the operation is simple.

Owner:BOE TECH GRP CO LTD +1

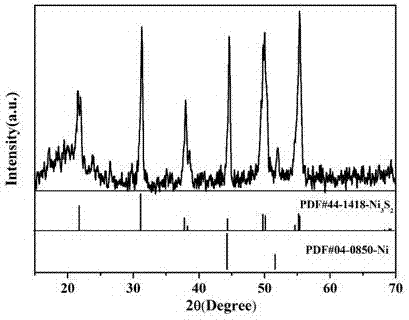

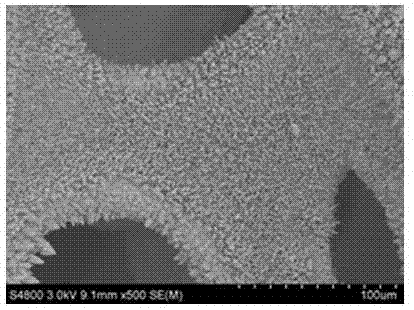

Synthetic method of Ni3S2 microrod array

InactiveCN107324408ASynthesis temperature is lowRaw materials are cheap and easy to getMaterial nanotechnologyElectrode shape/formsSolventPolytetrafluoroethylene

The invention discloses a synthetic method of Ni3S2 microrod array. The synthetic method comprises following steps: 1, nickel foam to be treated is subjected to full ultrasonic cleaning and drying; 2, a vanadium source and a sulfur are dissolved in an appropriate amount of a solvent at a molar ratio of 1: (1-11), and full stirring is carried out so as to obtain a solution A, wherein the concentration of the vanadium source in the solution A is controlled to be 10 to 40mM; 3, the solution A is delivered into a hydrothermal reactor with a polytetrafluoroethylene lining, the nickel foam obtained via pretreatment in step 1 is immersed in the solution A, the hydrothermal reactor is sealed, and solvothermal reaction is carried out at 70 to 200 DEG C for 6 to 30h; and 4, after reaction, the hydrothermal reactor is cooled at room temperature, and an obtained product is washed fully and dried so as to obtain the Ni3S2 microrod array. Operation of the synthetic method is simple; reaction conditions are mild; reaction period is short; the purity of prepared Ni3S2 is high; the morphology is uniform; and excellent electrocatalytic hydrogen evolution performance is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

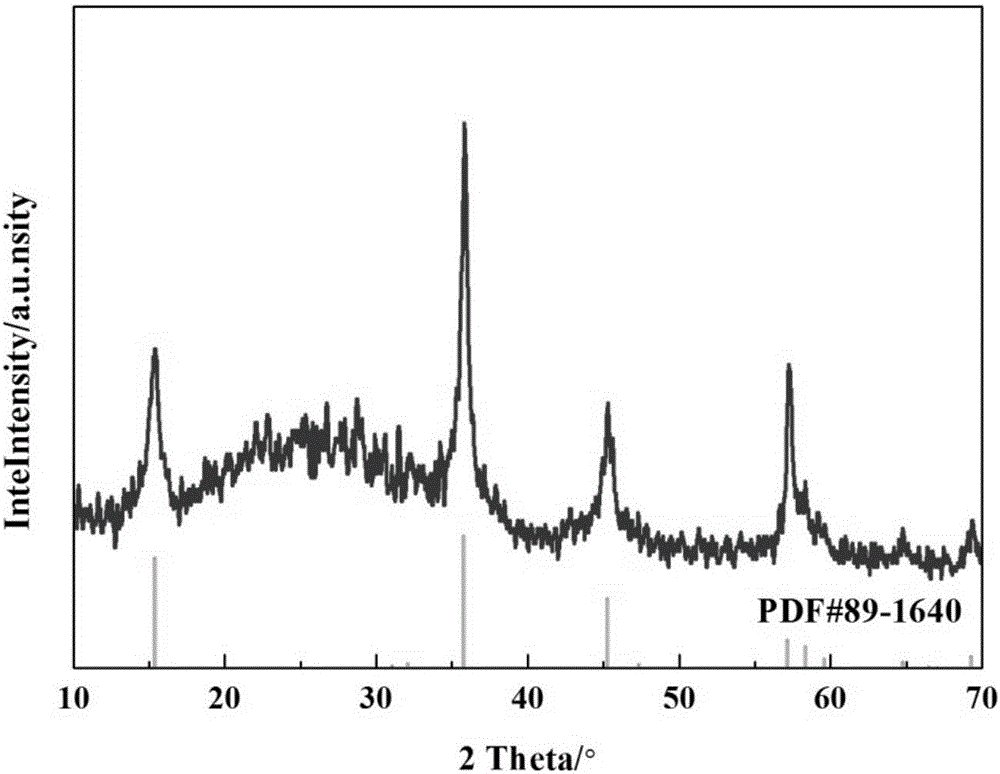

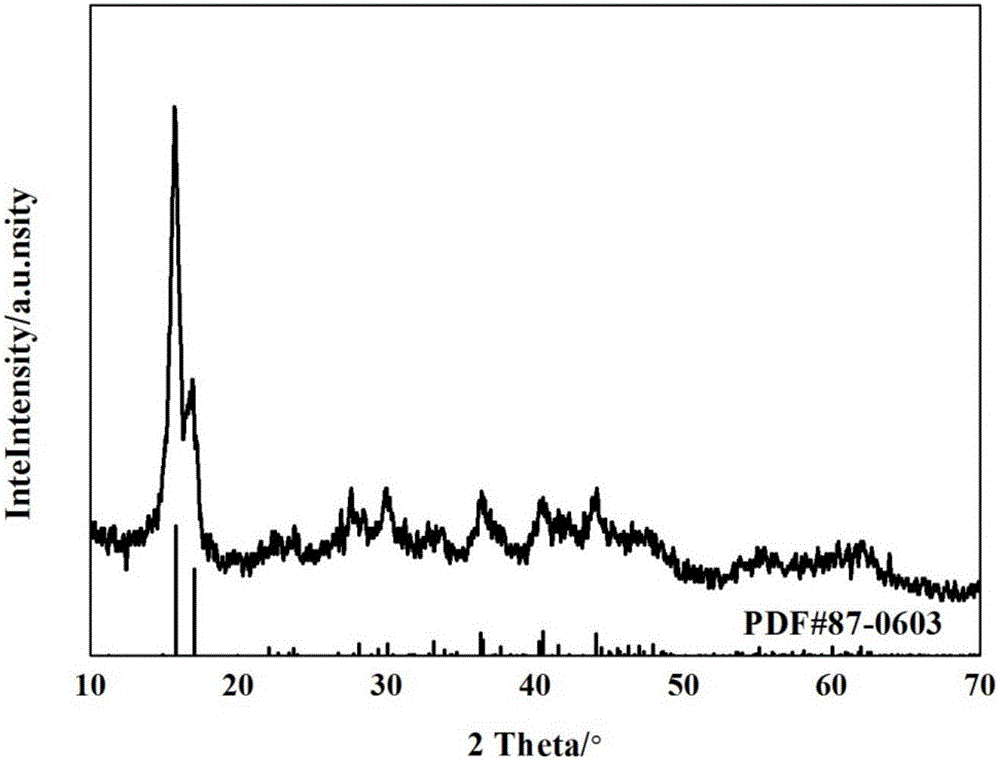

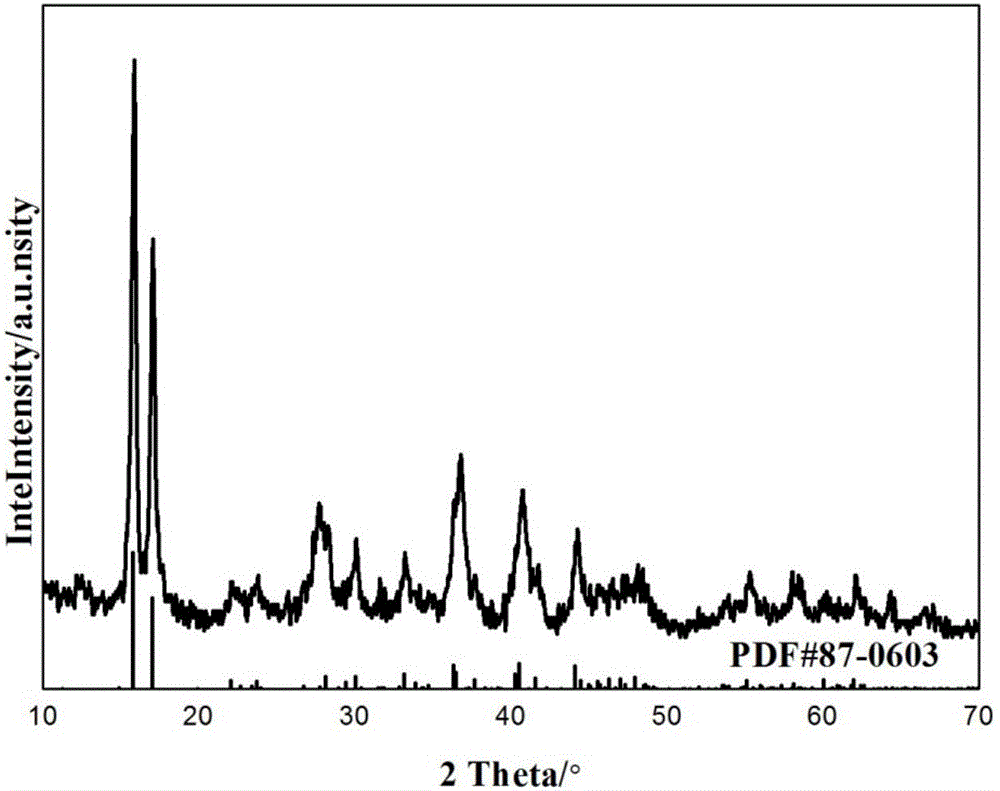

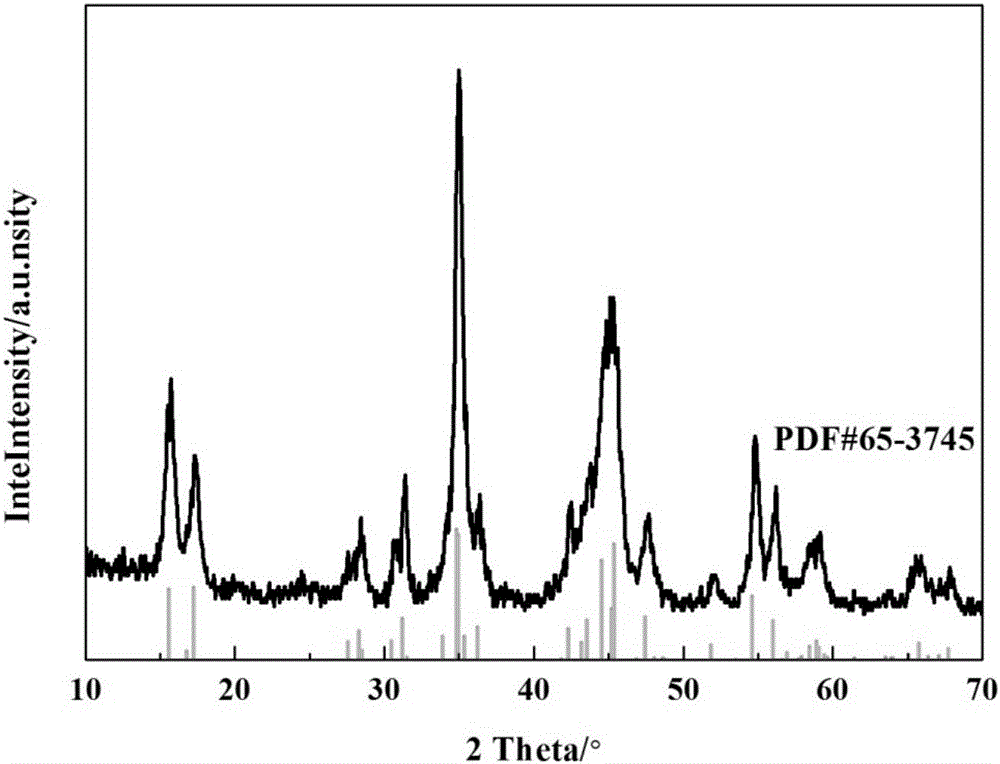

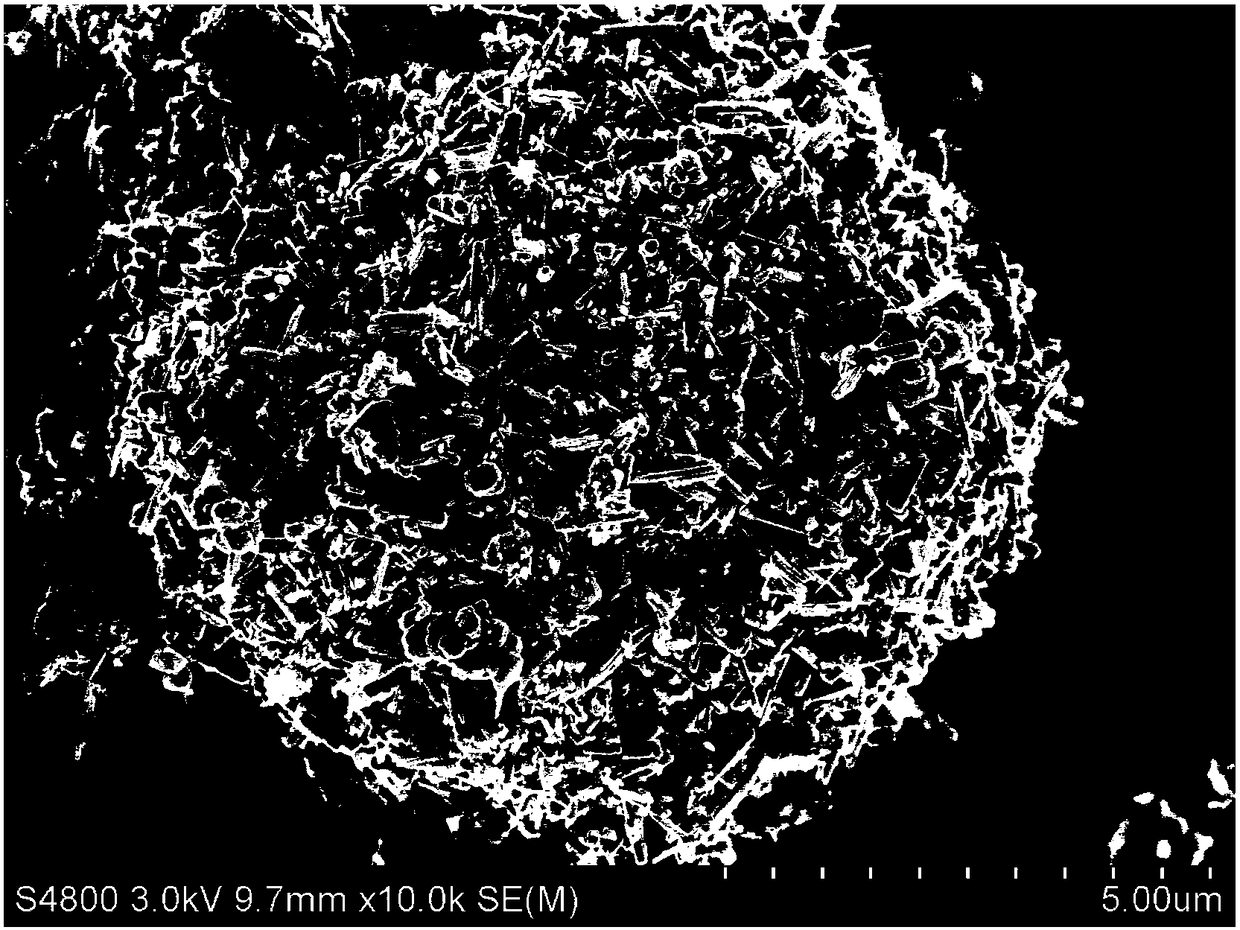

Multilevel-structured VS4 nano-powder, and preparation method and application thereof

ActiveCN105923652AUniform chemical compositionHigh purityPhysical/chemical process catalystsHybrid capacitor electrodesLithiumChemical composition

The invention provides a multilevel-structured VS4 nano-powder, and a preparation method and an application thereof. According to the invention, a vanadium source solution and a sulfur source solution are mixed under stirring, wherein the molar ratio of vanadium to sulfur is controlled at 1:1-1:2, such that a mixed liquid is obtained; the mixed liquid is subjected to a hydrothermal reaction; when the reaction is finished, cooling, washing, collecting and drying are carried out, such that the multilevel-structured VS4 nano-powder is obtained. The process is simple and is easy to control. The prepared VS4 nano-powder has uniform chemical composition and relatively high purity. The nano-powder shows excellent electrochemical performance when used as a lithium / sodium ion battery electrode material. Also, the method overcomes a defect of high temperature of a traditional calcination method, and does not need large equipment and harsh reaction conditions. The raw materials are cheap and are easy to obtain; cost is low; yield is high; no post treatment is needed; and the method is environment-friendly. The method is suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of vanadium tetrasulfide nano-powder and application

InactiveCN105810942ASimple and easy to control chemical compositionUniform chemical compositionCell electrodesSecondary cellsLithiumChemical composition

The invention provides a preparation method of vanadium tetrasulfide nano-powder and an application. The method comprises the following steps: firstly, mixing a vanadium source solution with a sulfur source solution, stirring the mixture until semi-clear and then adding an acid or alkali solution to adjust the pH of a reaction liquid; transferring the reaction liquid to a homogeneous reaction instruction for hydrothermal reaction; and finally cooling the reacted product and then washing, collecting and drying the product to obtain the vanadium tetrasulfide nano-powder. According to the method, the technology is is simple and easy to control; and the prepared vanadium tetrasulfide nano-powder is uniform in chemical composition and relatively high in purity, and demonstrates excellent electrochemical properties when used as an electrode material for a lithium / sodium-ion battery. Furthermore, the disadvantage of a high temperature of a traditional calcination method is overcome; large equipment and harsh reaction conditions are not needed; and the method is cheap and available in raw material, low in cost, high in productivity, free of after-treatment and friendly to environment, and can be suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Anti-electrostatic ceramic material, preparation method thereof and firecrackers lead knitting needle made of material

ActiveCN101786878ALow resistivityImprove flexural strengthCeramic shaping apparatusFuse manufactureFirecrackerMass ratio

The invention discloses an anti-electrostatic ceramic material which comprises the following components in percentage by weight: 68-80 percent of yttria stabilized zirconia, 1-3 percent of silicon dioxide, 10-14 percent of tin oxide, 7-11 percent of zinc oxide, 1-2.5 percent of silicon 1-2.5 percent of silicon carbide. The preparation method of the ceramic material comprises the following steps of: firstly, mixing various raw materials in ultrathin powder state by a ball mill; then drying; melting and blending the dried mixed raw materials with an organic binder according to a mass ratio of (4-9):1; injecting and forming particles obtained by melting and blending to obtain a ceramic blank; and degreasing and sintering to obtain an anti-electrostatic ceramic material. In the method, the firecrackers lead knitting needle is injected and formed by a die. The anti-electrostatic ceramic material and the firecrackers lead knitting needle thereof have the advantages of electrostatic resistance, abrasion resistance, good anti-bending performance, simple preparation process, lower cost, and accurate size of a prepared ceramic product without post-processing.

Owner:JIANGSU JINSHENG CERAMIC TECH

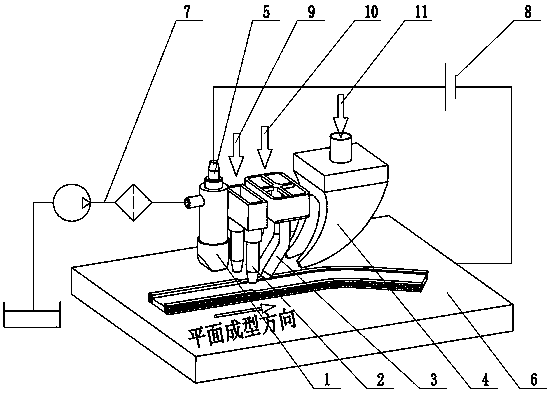

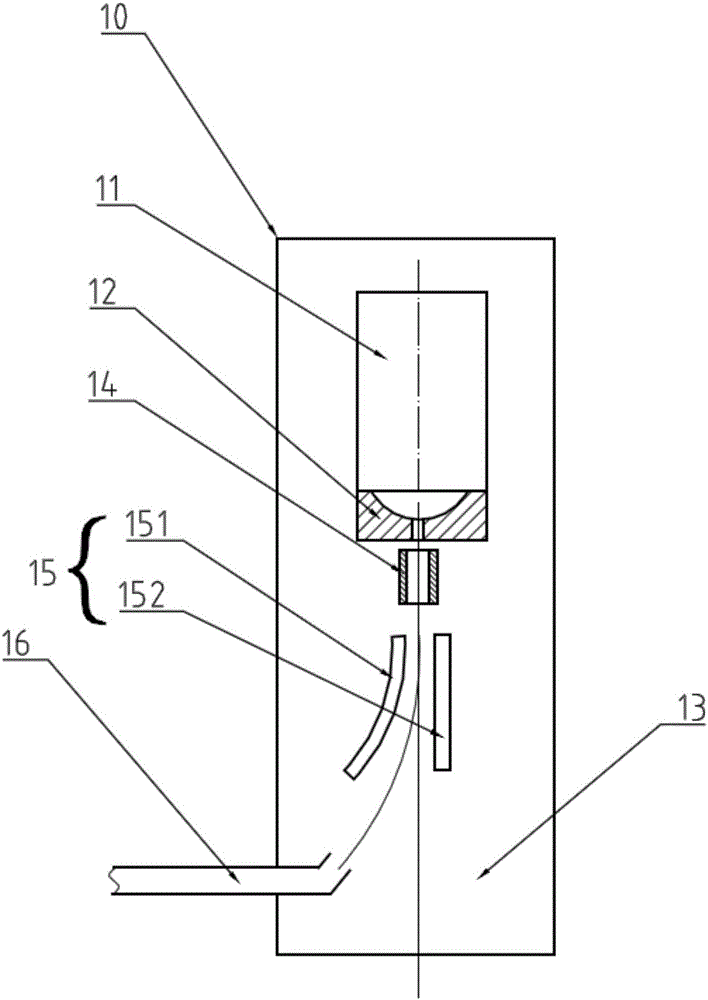

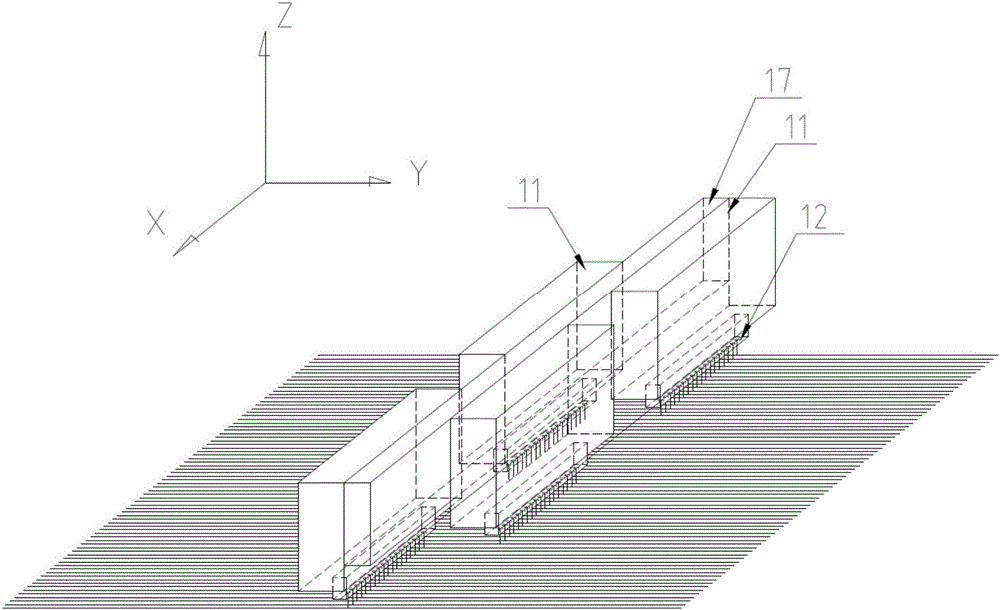

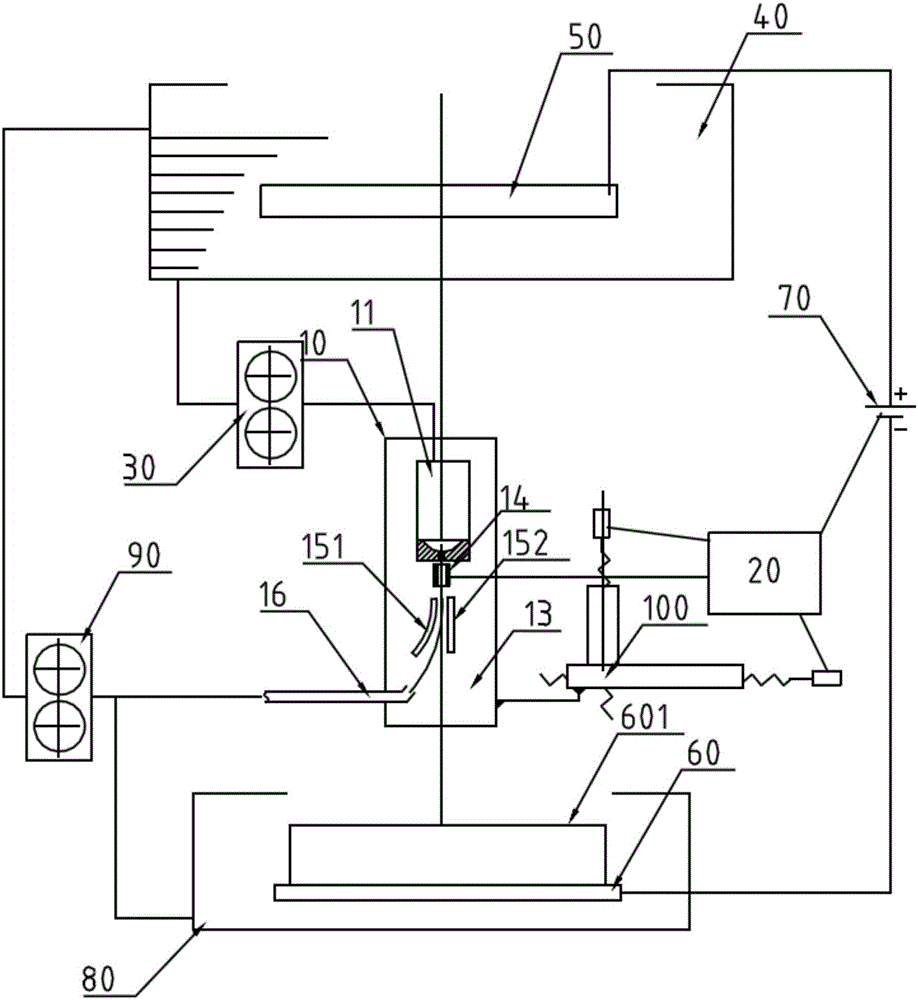

Metal three-dimensional additive manufacturing apparatus and method

ActiveCN108103541AHigh precisionHigh forming precisionCellsAdditive manufacturing apparatusIonJet flow

The invention discloses metal three-dimensional additive manufacturing apparatus and method. The apparatus includes: a jet flow nozzle internally provided with an electric conductor, a film forming nozzle communicated with a high molecular polymer supply source, a gas ejection nozzle communicated with a hot gas source, a cleaning nozzle communicated with a deionized water source, a cathode substrate, an electro-deposition power supply, and an electrolyte cycle filter apparatus. In the apparatus, with scanning movement of the nozzles, the film forming nozzle stacks two rows of film layers on the cathode substrate, the gas ejection nozzle and the cleaning nozzle can rapidly clean and dry the surface of the films, and the jet flow nozzle ejects electrolyte to the zone between the two rows offilm layers on the cathode substrate, thus electro-depositing the metal layer in the localization manner; by increasing the height of the nozzles, the stack film layers and metal layers are added continuously, thus achieving the additive manufacturing of a three-dimensional metal member. The apparatus has simple structure and high efficiency, and can shape the three-dimensional metal member havinghigh compactness and precision.

Owner:HENAN POLYTECHNIC UNIV

Preparation method of cake-piece-shaped N/BiVO4 photocatalyst growing along high-activity (040) crystal orientation

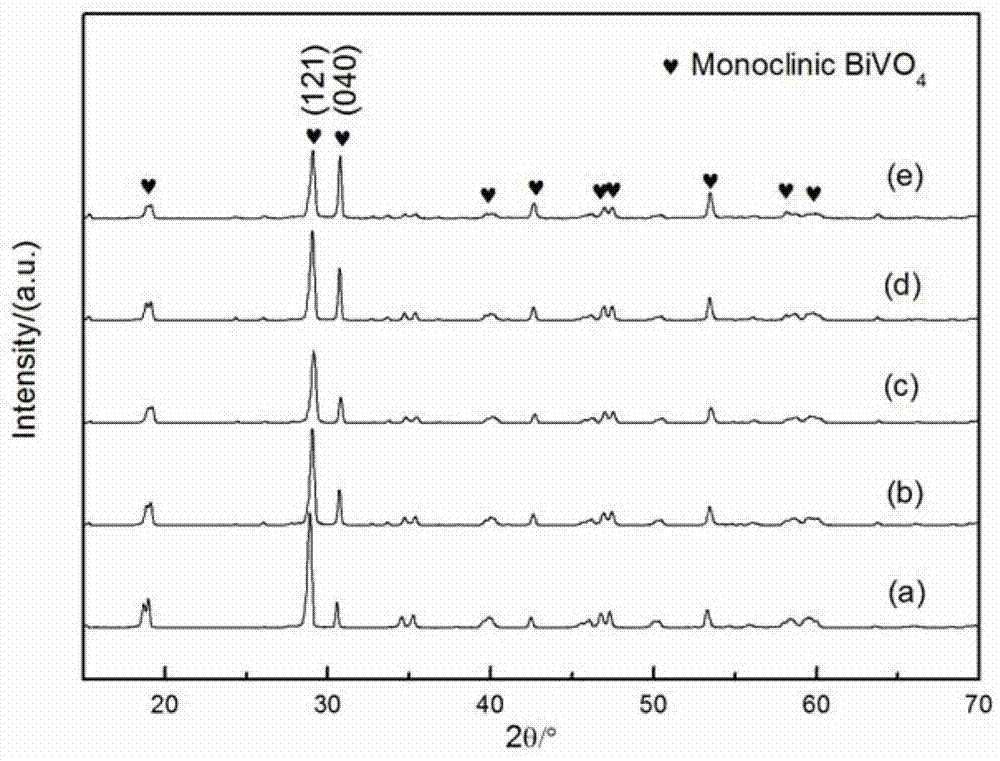

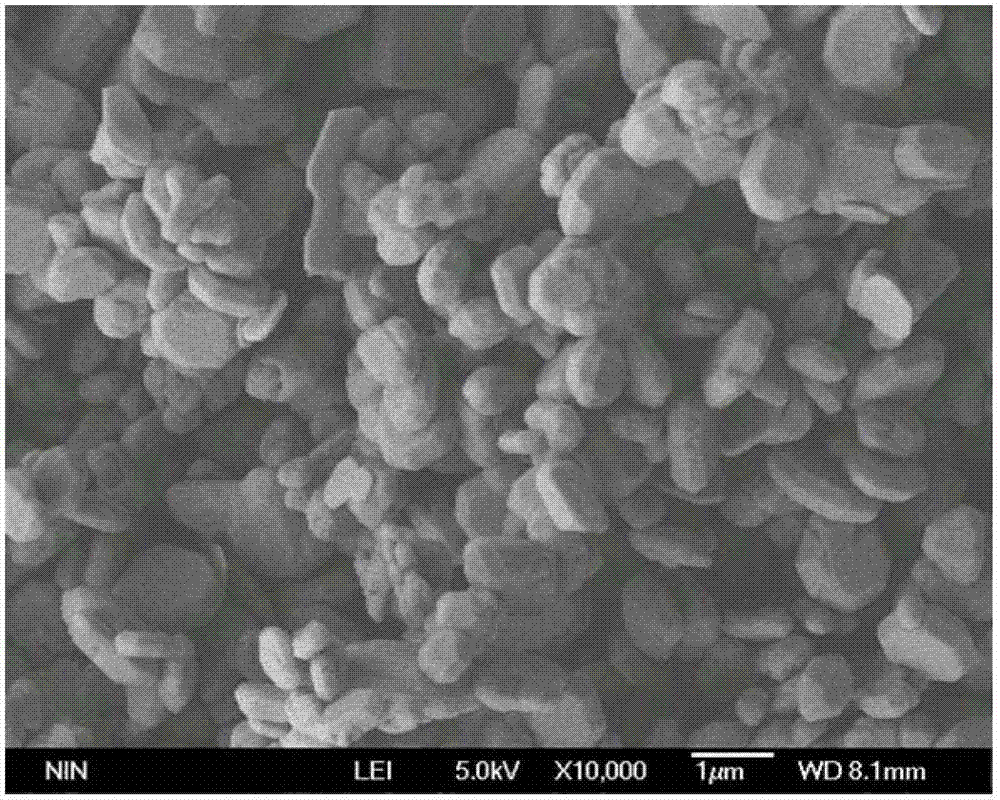

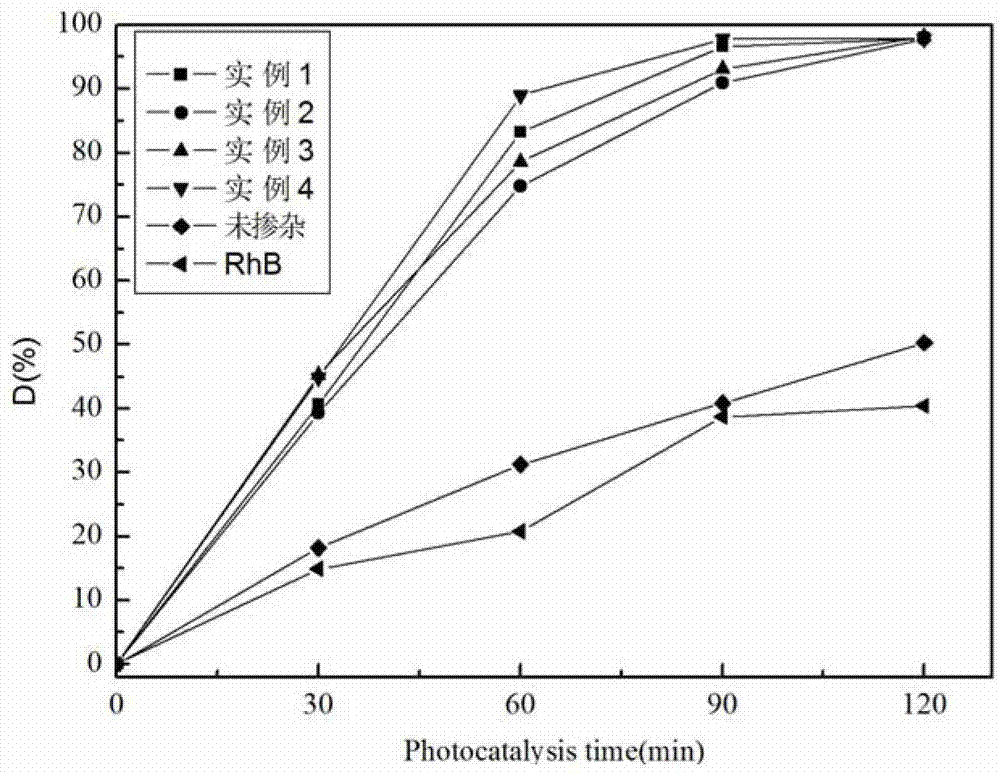

ActiveCN103028390AEasy to prepareUniform particle sizeWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsChemistryCrystal orientation

The invention discloses a preparation method of a cake-piece-shaped N / BiVO4 photocatalyst growing along a high-activity (040) crystal orientation. The method comprises the following steps: mixing a bismuth salt solution with a vanadium salt solution according to a molar ratio Bi:V=1:1, and uniformly stirring to form a mixture A; adding NaN3 into the mixture A according to the molar ratio NaN3:Bi=(0.8-1.1):1, and stirring to form a mixture B; adding NH4Cl and N2H4.H2O into the mixture B according to the molar ratio NaN3: NH4Cl: N2H4.H2O=3:1:1 to form a precursor; and adopting a microwave hydrothermal method to obtain N / BiVO4 powder. The preparation method has the advantages of simplicity in operation and short reaction time, the synthesized N / BiVO4 powder grows along the high-activity (040) crystal orientation, and the particle morphology takes the shape of a cake piece, so that the photocatalytic activity of the N / BiVO4 powder under ultraviolet light and visible light irradiation is higher.

Owner:SHAANXI UNIV OF SCI & TECH

Printing head, printing device and printing method for rapid forming of metal piece

InactiveCN105112965ATo overcome the shortcomings of low printing efficiencyFast printAdditive manufacturing apparatusEtchingEngineering

The invention discloses a printing head, a printing device and a printing method for rapid forming of a metal piece. The printing head comprises a body, a plurality of nozzles, a first electrode and a second common electrode. When the printing head is in the working state, electroplate liquid is sprayed out through the multiple nozzles and sequentially passes through the first electrode and the second common electrode. The printing device is provided with the printing head. According to the printing method, when electrochemical deposition or electrolytic etching is conducted on the electroplate liquid, the electroplate liquid is electrified and is directly sprayed onto a position needing to be printed; in the position which does not need to be printed, the electroplate liquid deflects when flowing through a deflection electric field by changing the electrical characteristic of the electroplate liquid, and the electroplate liquid is prevented from being sprayed onto the position which does not need to be printed. By the adoption of the printing head, the printing device and the printing method for rapid forming of the metal piece, the defects that a three-dimensional (3D) printer for the metal piece in the prior art is low in printing efficiency and low in precision are overcome, and rapid, high-quality and high-precision printing of 3D metal pieces is achieved.

Owner:SHANGHAI SHENGKUANG ELECTROMECHANICAL TECH

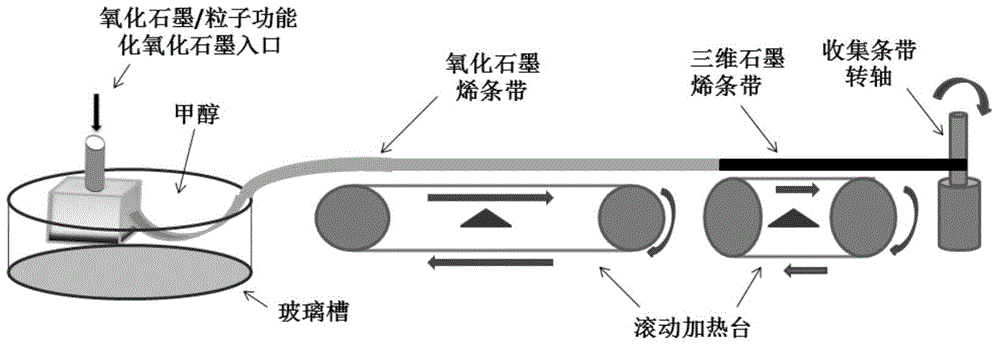

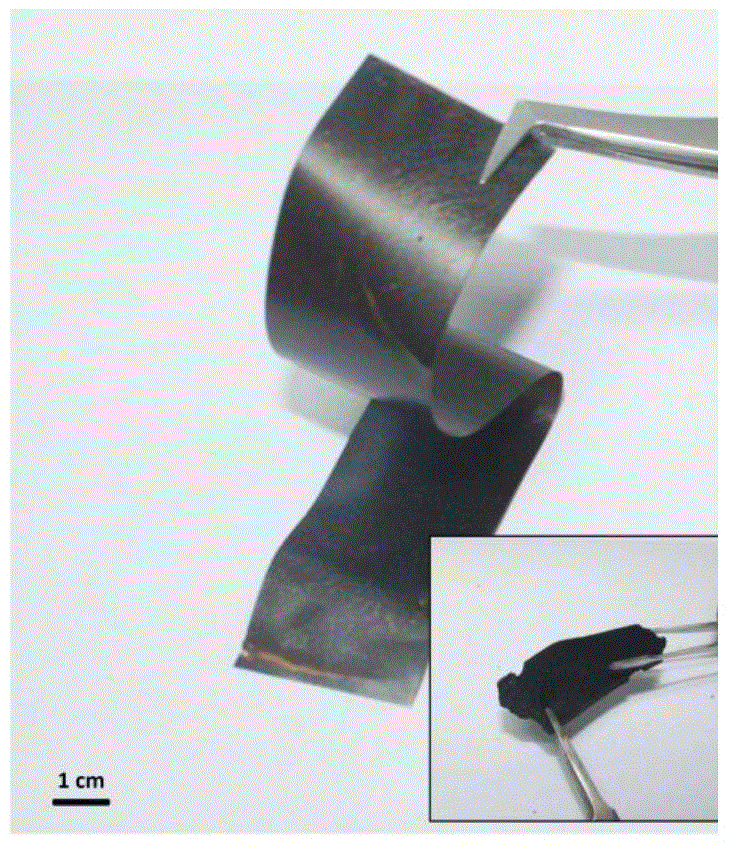

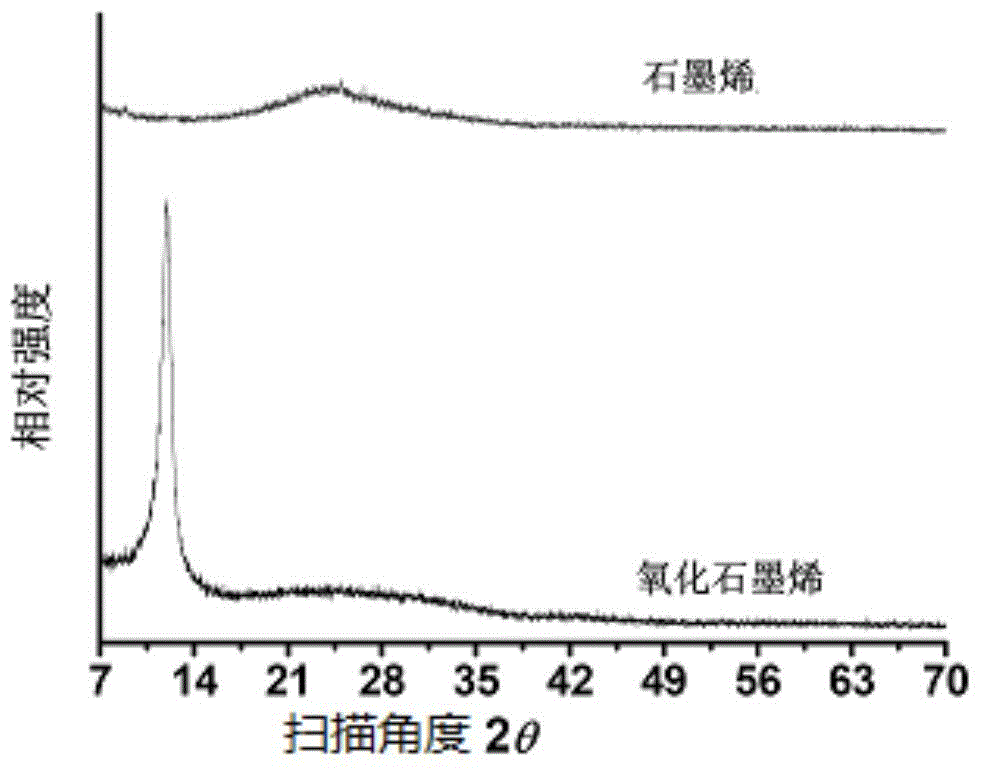

Method for on-scale continuous production of three-dimensional graphene membrane and application

ActiveCN104310381ALow costSynthetic technology is matureMaterial nanotechnologyFerroso-ferric oxidesNanoparticleCvd graphene

The invention discloses a method for on-scale continuous production of a three-dimensional graphene membrane and application, belonging to the field of functional materials. The method comprises the following steps: 1, preparing a graphene oxide solution; 2, stirring and concentrating; 3, soaking a polytetrafluoroethylene bath into methanol; 4, filling the concentrated graphene oxide solution into the polytetrafluoroethylene bath, thereby obtaining graphene oxide strips; 5, leading out the graphene oxide strips from the methanol solution, firstly drying, and further performing reduction expansion, thereby obtaining the three-dimensional graphene membrane; and 6, collecting the three-dimensional graphene membrane, and coiling. The graphene oxide solution and functional nanoparticles are mixed, and the functional three-dimensional graphene membrane can be prepared by performing the above preparation steps. The method is simple in preparation process, environment-friendly, low in cost and applicable to on-scale production, and the three-dimensional graphene membrane prepared by using the method is three-dimensional and porous and has the characteristics of light mass, large specific surface area and good flexibility.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

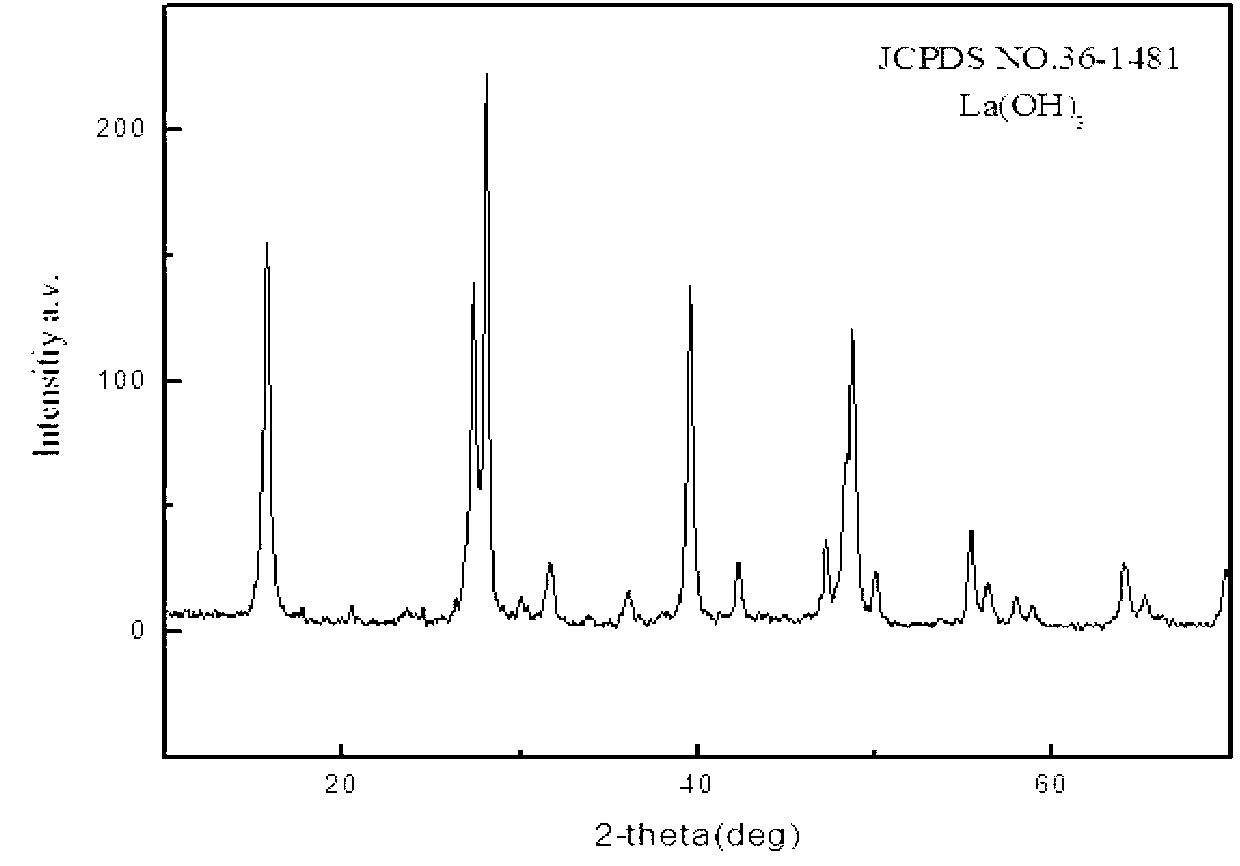

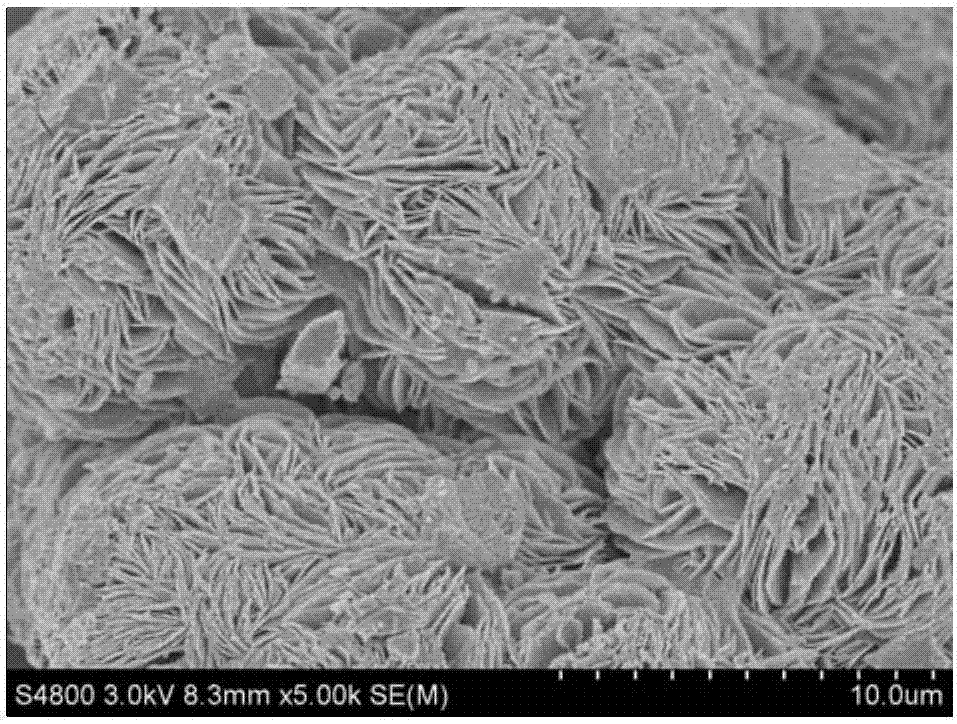

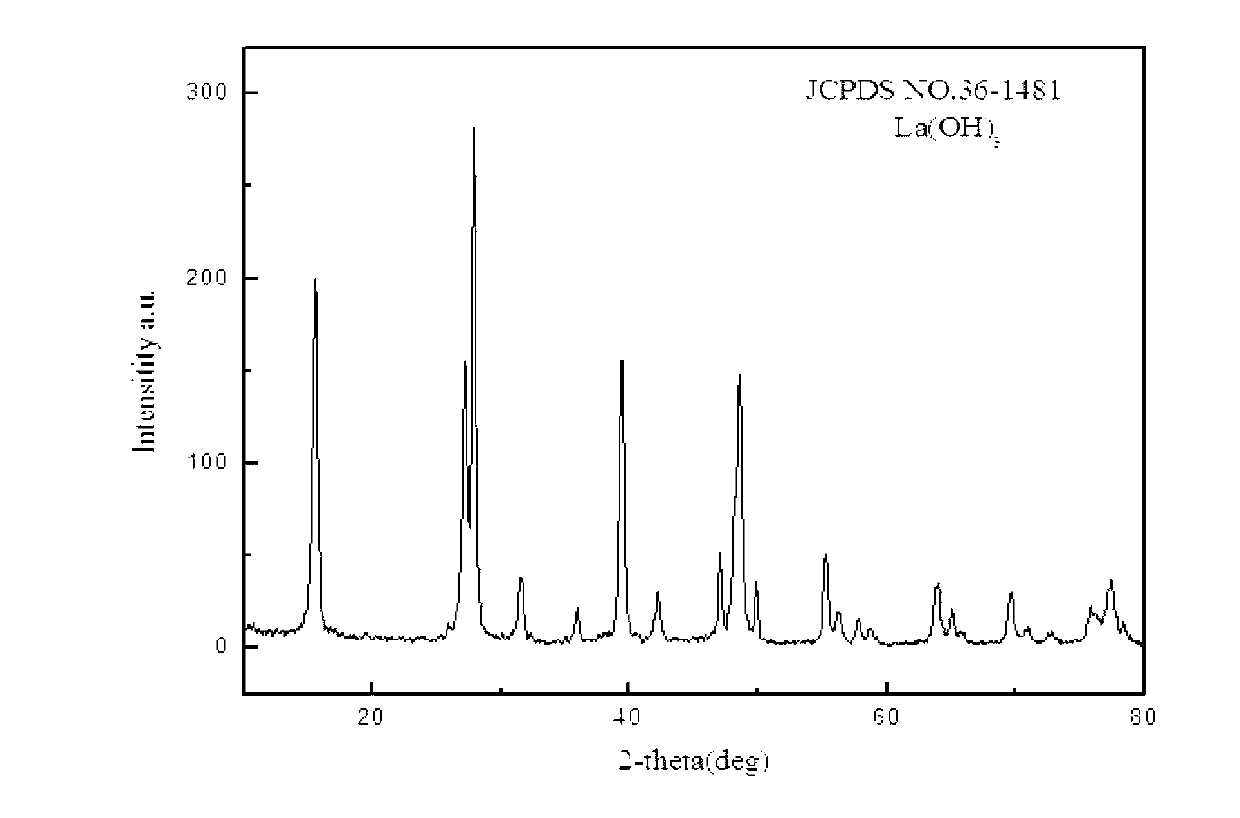

Method for preparing platy lanthanum hydroxide nanocrystalline through microwave-ultrasonic method

InactiveCN102936028AShort reaction timesReduce energy consumptionNanotechnologyRare earth metal compoundsPolyethylene glycolPotassium hydroxide

The invention provides a method for preparing platy lanthanum hydroxide nanocrystalline through a microwave-ultrasonic method. Analytically pure lanthanum nitrate hexahydrate and polyethylene glycol are added in deionized water to obtain a solution B; a potassium hydroxide or sodium hydroxide solution is added in the solution B to form a precursor solution C; the precursor solution C is poured into a four-neck round-bottom flask, the flask is put in a microwave-ultraviolet-ultrasonic trinity synthesis reaction apparatus, microwave heating and ultrasonic combination under a temperature-time mode is selected, the precursor solution C is cooled to the room temperature naturally after reaction is finished, a product is collected through centrifugation and then washed several times by deionized water and absolute ethyl alcohol, and the product is dried to obtain the final product platy lanthanum hydroxide nanocrystalline. The method adopts a simple microwave-ultrasonic preparation process, is short in reaction time period and low in energy consumption, reaction can be finished in liquid phase in one time, and no after-treatment is needed. La(OH)3 particles made by the method are of platy structures and are large in specific surface area, good in dispersibility and excellent in performance.

Owner:SHAANXI UNIV OF SCI & TECH

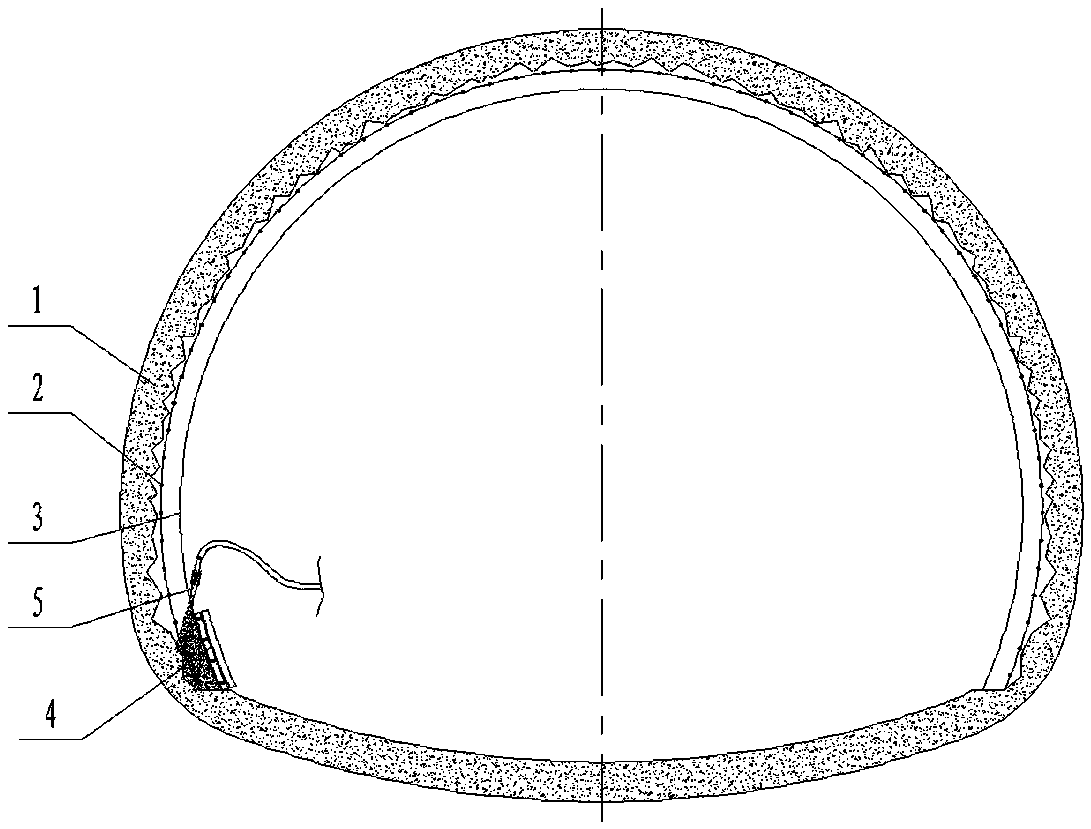

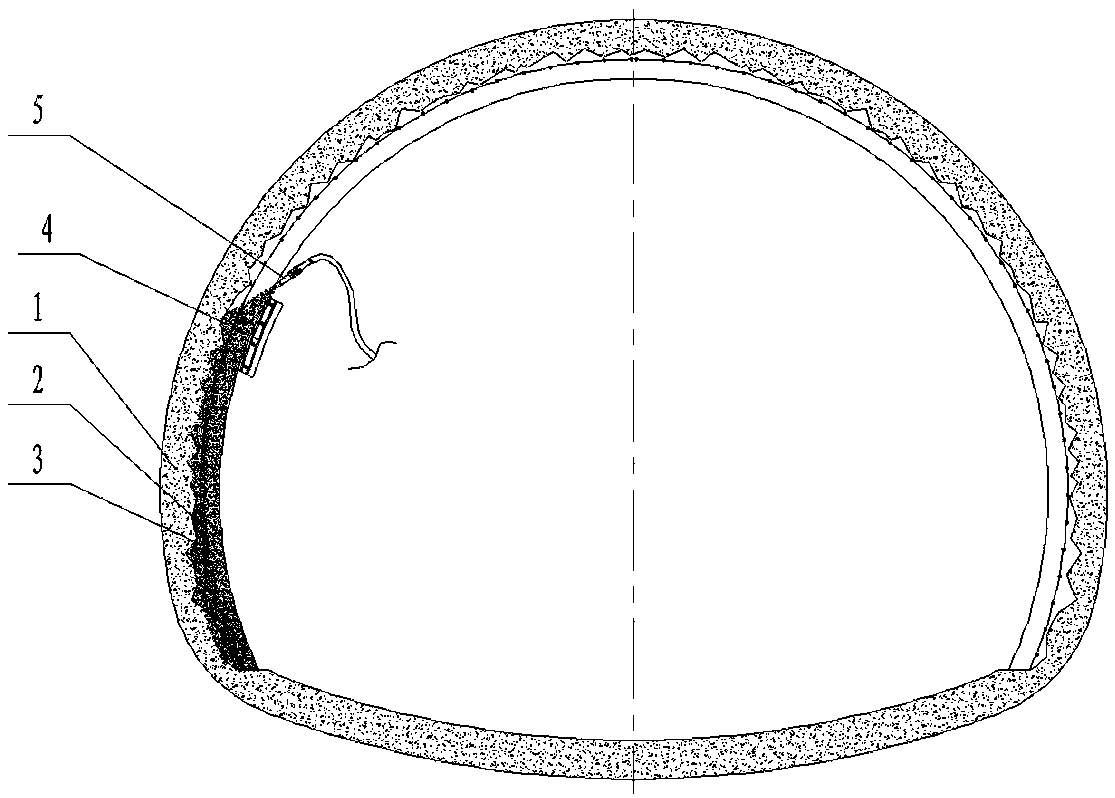

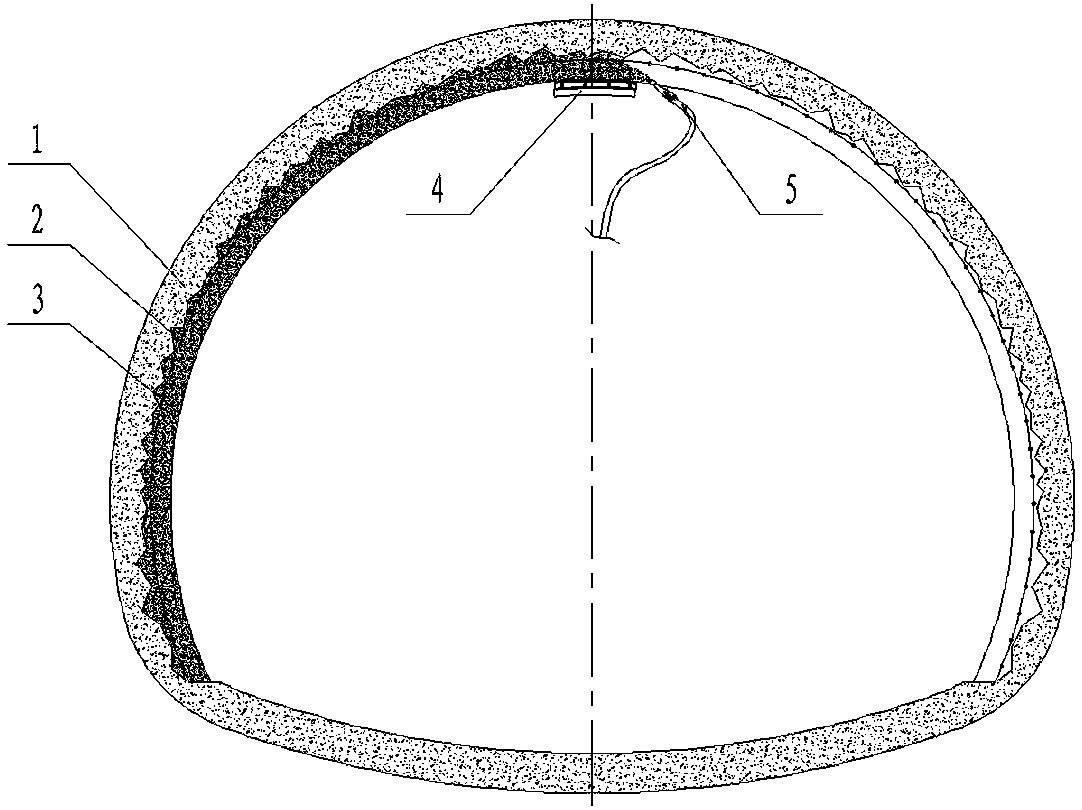

Construction method and support mould for tunnel primary support

The invention provides a construction method and support mould for tunnel primary support. The movable support mould is adopted in tunnel primary support construction; a mould cavity is formed betweenthe support mould and the tunnel excavation face; the support mould moves with the outline of the tunnel excavation face as the moving track; the mould cavity used for forming a tunnel primary support concrete layer is formed through joint cooperation of the movable support mould and the tunnel excavation face; the mould cavity is filled with concrete added with an accelerator, and after the concrete at the bottom of the mould cavity is initially solidified, the support mould moves towards a next station step by step; when the support mould moves, a mould cavity which is newly formed by the support mould in the moving process and the tunnel excavation face is continuously filled with concrete added with an accelerator; and finally, the whole tunnel primary support concrete layer is formed. The construction method and support mould have the beneficial effects that the working time is short, efficiency is high, the using quantity of the accelerators is small, springback is avoided, flatness is high, smoothness is achieved, unevenness is avoided, attractiveness is achieved, and after-treatment is not needed.

Owner:SICHUAN LANHAI ENG EQUIP MFG CO LTD

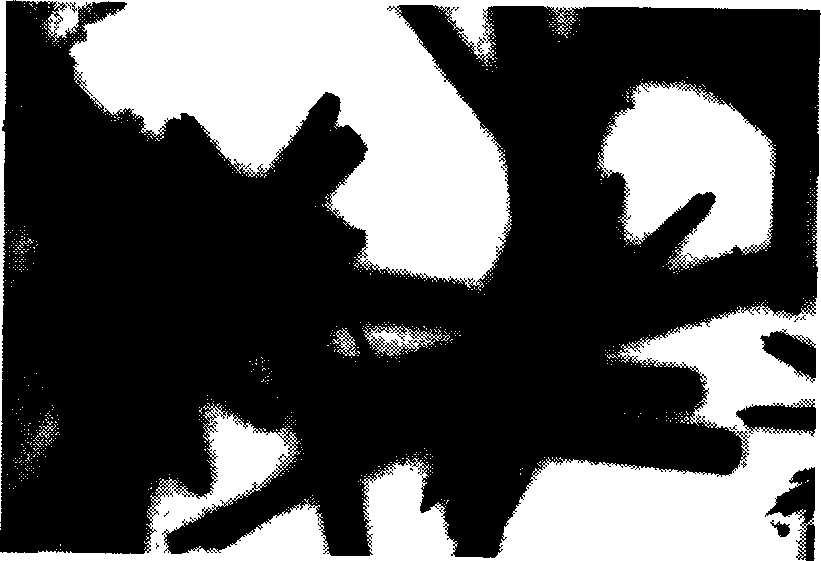

Preparation method and application of nanometer rod-shaped V3S4

ActiveCN105932279AThe process is simple and easy to controlRaw materials are cheap and easy to getMaterial nanotechnologyCell electrodesLithiumSulfur

The invention provides a preparation method and application of a nanometer rod-shaped V3S4. The preparation method comprises the following steps of firstly, carrying out hydrothermal reaction of a vanadium source solution to obtain a vanadium oxide nanometer material, wherein the concentration of a vanadium source is 0.01-0.10mol / L; and finally, roasting the vanadium oxide nanometer material whose mole ratio of vanadium to sulfur is (1:8)-(1:12) and a sulfur source substance in a tubular atmosphere furnace, cooling the roasted sample, and washing, cooling and drying the sample to obtain the nanometer rod-shaped V3S4. The method process is simple and is easy to control, and the prepared V3S4 nanometer powder is uniform in chemical constitution, relatively high in purity and relatively high in crystallinity, and shows excellent performance when taken as a ferromagnetic material and an electrode material of a lithium / sodium ion battery. Meanwhile, by the method, a V3S4 structure is controlled by a two-step method, and the controllable preparation of the nanometer rod-shaped V3S4 is further achieved; and further, the raw material is low in cost and is available, the cost is low, the yield is high, subsequent processing is not needed, and the method is friendly to an environment and can be suitable for mass production.

Owner:SHAANXI UNIV OF SCI & TECH

Bar type zinc oxide granule, preparation method and usage

A rod-shaped zinc oxdie particle (tens nm-several microns) is prepared through preparing the aqueous solution of zinc salt, preparing the aqueous solution of ammonium alcoholate, proportionally mixing them in the preheated secondary water solvent, reaction, ageing, and centrifugal separation. It can be used for preparing photoelectric device, chemical sensor, atomic microscope, or scan tunnel microscope.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

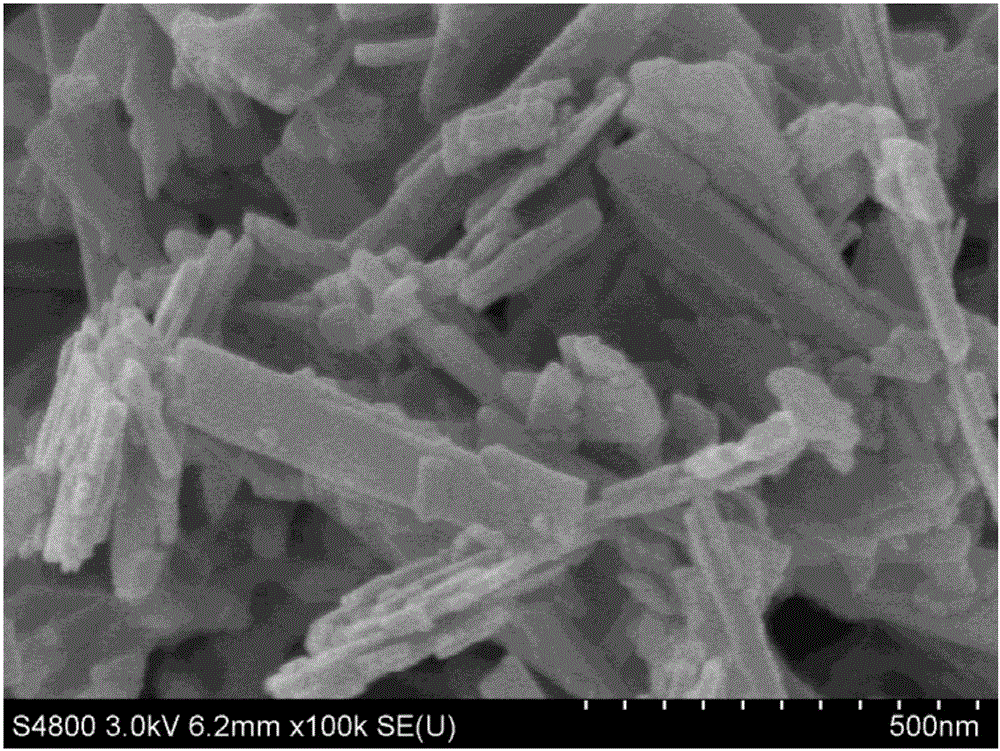

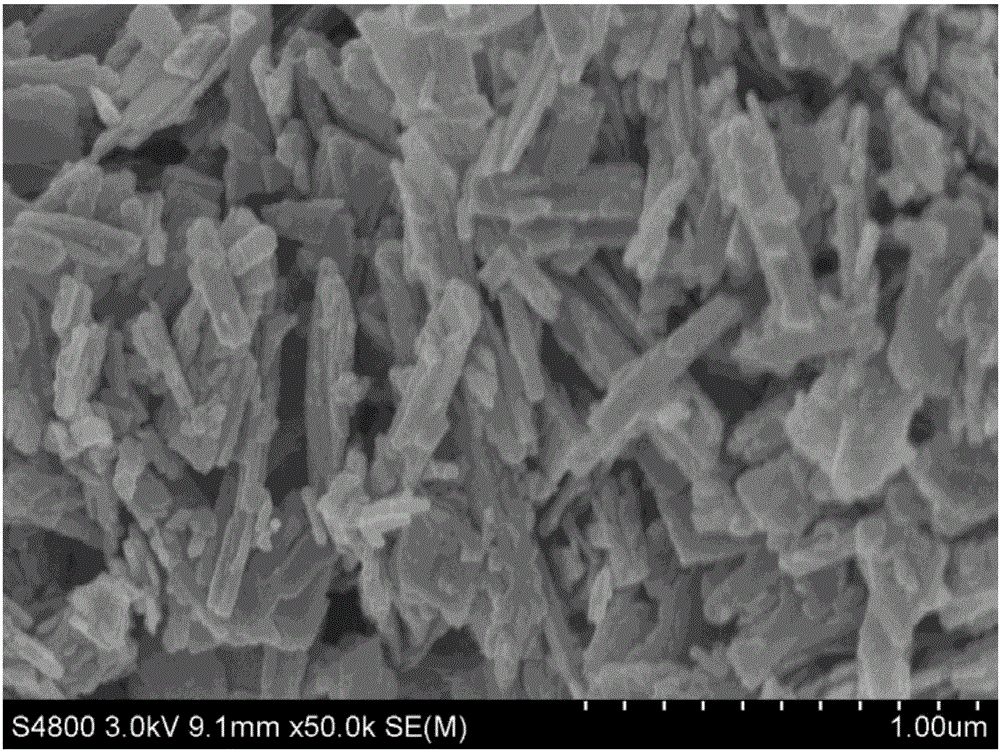

Vanadium disulfide nanosheet coated with oxo-vanadium hydroxide and preparation method and application thereof

ActiveCN107221646AReported electrochemical performanceSynthesis temperature is lowImpregnation manufacturingVanadium disulfideElectrical battery

The invention provides a vanadium disulfide nanosheet coated with oxo-vanadium hydroxide and a preparation method and application thereof. The preparation method comprises the following steps: dissolving sodium metavanadate and thioacetamide in deionized water in a magnetic stirring state simultaneously; then, pouring the solution into a reaction lining for sealing, loading the lining into an outer kettle for fixing, and placing the outer kettle into a homogeneous phase reaction instrument; lastly, cooling a reaction product, washing, collecting and drying to obtain the VOOH-coated VS2 nanosheet. The VOOH-coated VS2 nanosheet prepared by the method has uniform chemical composition, higher purity, uniform appearance and a specific self-assembly structure, and shows superior electrochemical performance when being taken as a sodium-ion battery electrode material. Moreover, by adopting the method, the defect of high temperature in a conventional calcining method is overcome, and large-sized equipment and severe reaction conditions are not needed; the vanadium disulfide nanosheet has the advantages of adoption of cheap and readily-available raw materials, low cost, high yield, no need of posttreatment and environmental friendliness, and can be suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

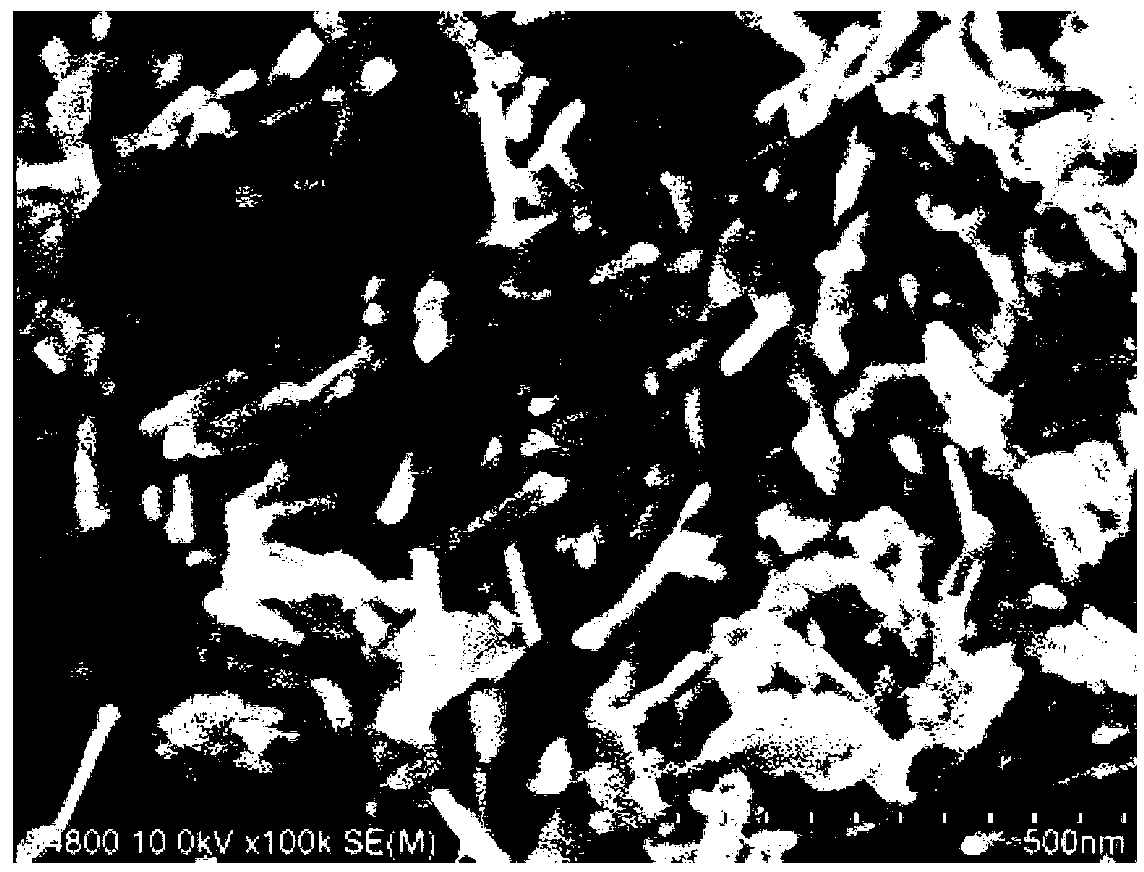

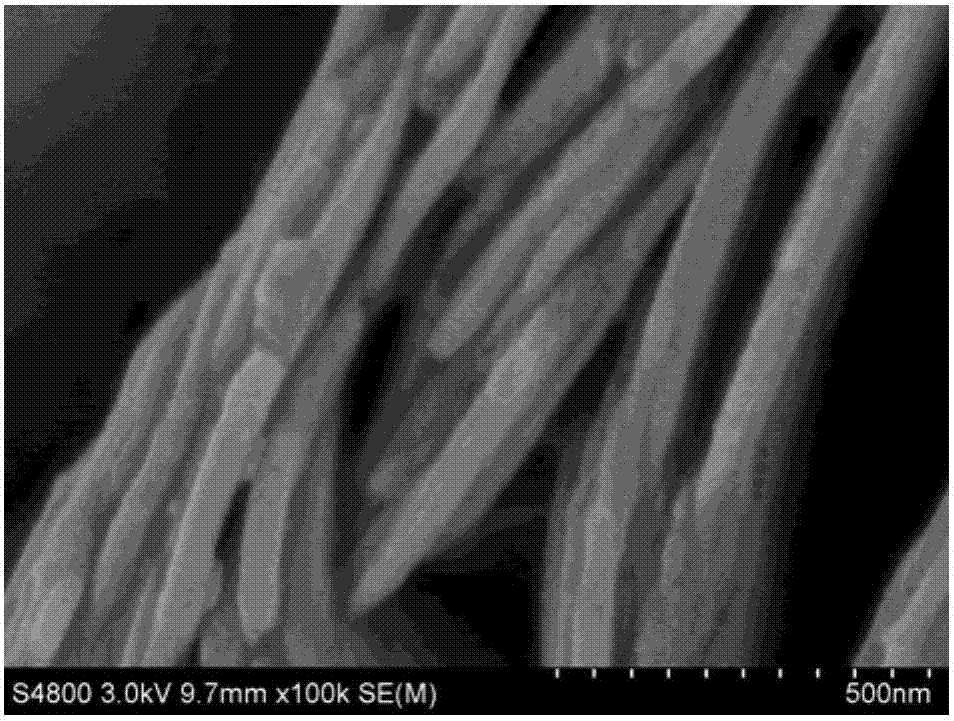

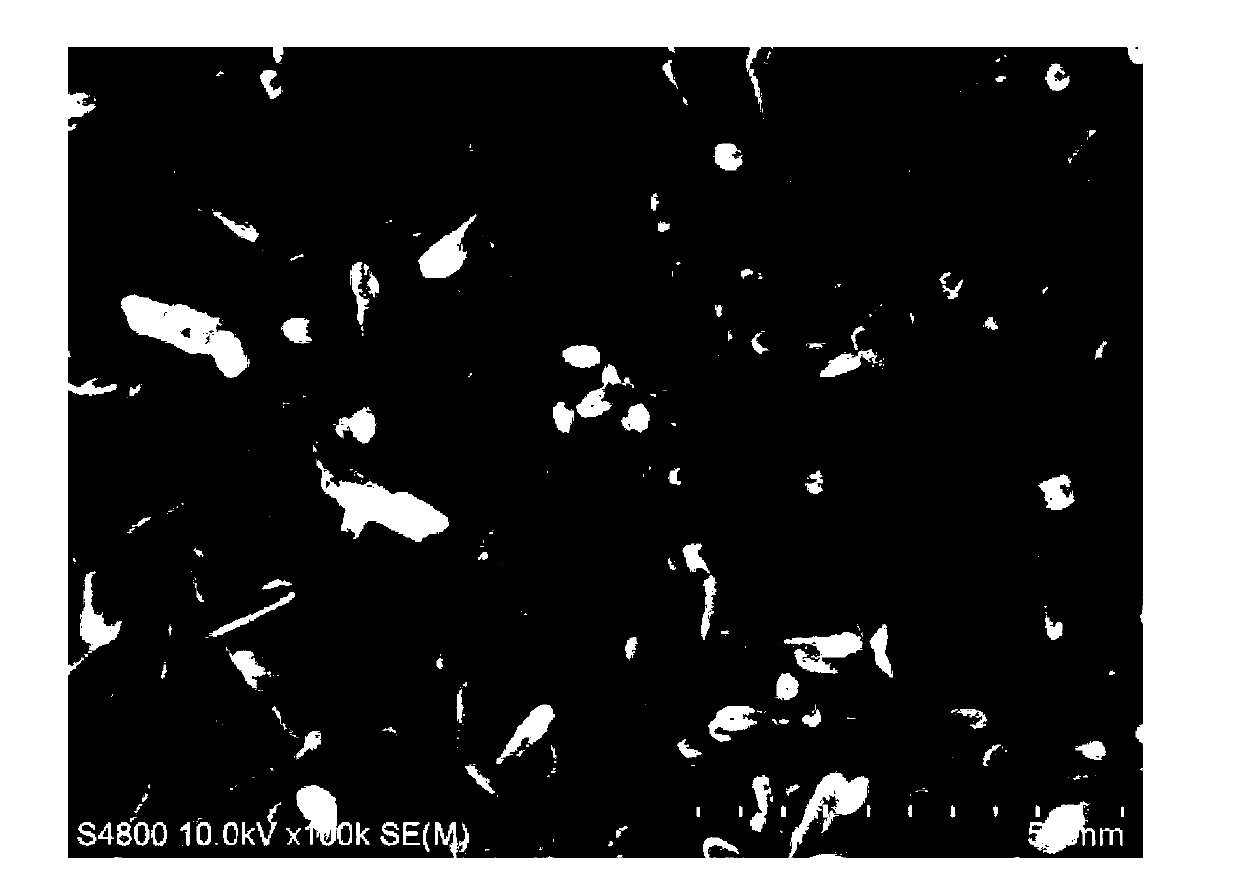

Preparation method of bar-shaped lanthanum hydroxide nanocrystal

ActiveCN102942203AShort reaction timesReduce energy consumptionMaterial nanotechnologyRare earth metal compoundsDispersityEthylenediamine

The invention provides a preparation method of a bar-shaped lanthanum hydroxide nanocrystal. The method comprises the following steps of: adding nona-lanthanum sulfate and ethylenediamine tetraacetic acid into deionized water respectively to obtain a solution B; adjusting the pH of the solution B to 8.0-12.0 with an ammonia water solution to obtain a precursor solution C; pouring the precursor solution C into a four-neck round-bottom flask, putting the four-neck round-bottom flask into a microwave-ultraviolet ray-ultrasonic wave three-in-one synthesis reaction instrument, selecting a microwave heating-ultraviolet irradiation combined reaction in a temperature-time mode, and naturally cooling to the room temperature after the reaction; and centrifugally collecting a product, washing repeatedly with deionized water and absolute ethyl alcohol respectively, and drying to obtain a final product, i.e., bar-shaped lanthanum hydroxide nanocrystal. A simple microwave-ultraviolet ray synthesis method preparation process is adopted, so that the method has the advantages of short reaction time period, low energy consumption, low cost, convenience in operating, one-time completion of a reaction in a liquid phase, and no need of subsequent treatment. La(OH3) particles prepared with the method have bar-shaped structures, are small in size, have high dispersity, and can be applied in the catalysis field and the optics field.

Owner:上海球球云环保科技有限公司

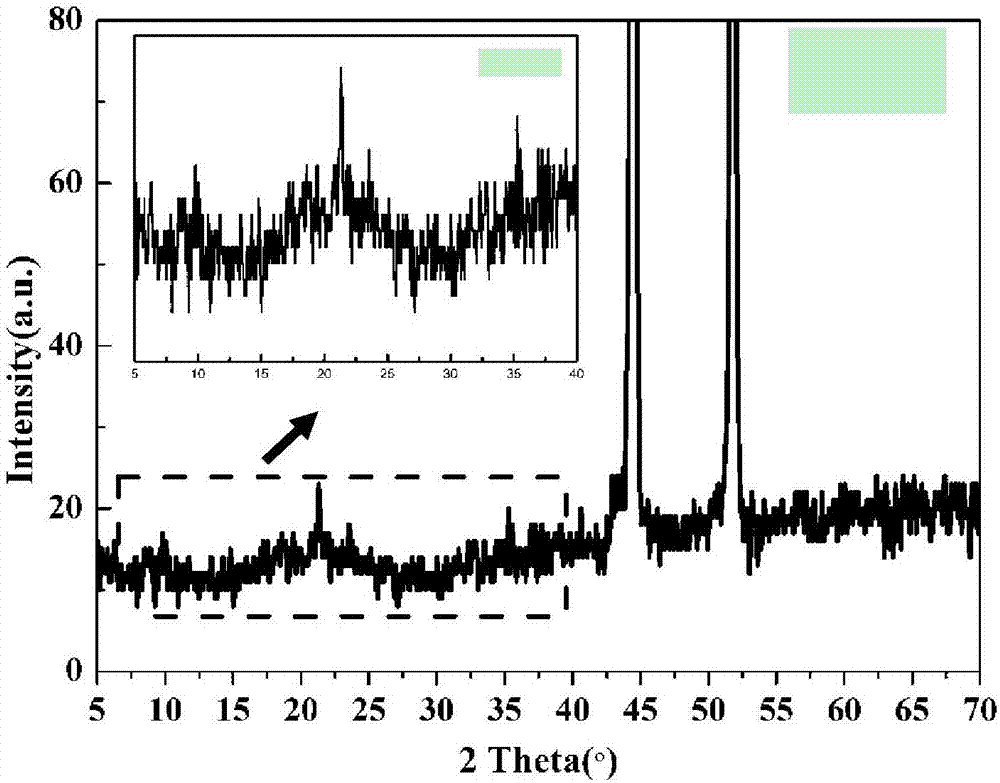

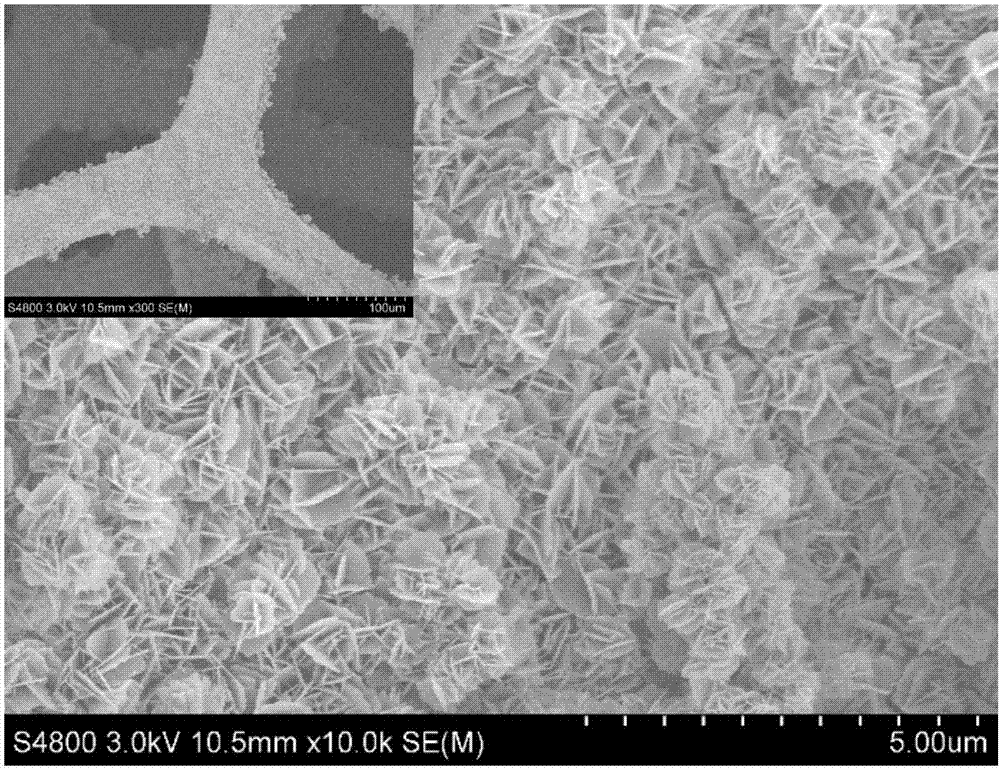

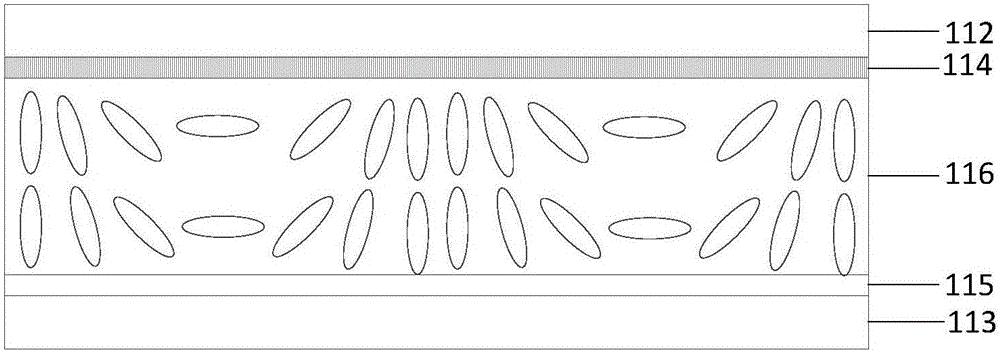

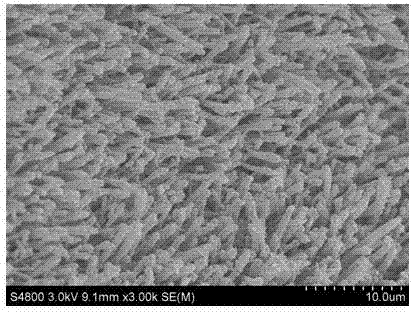

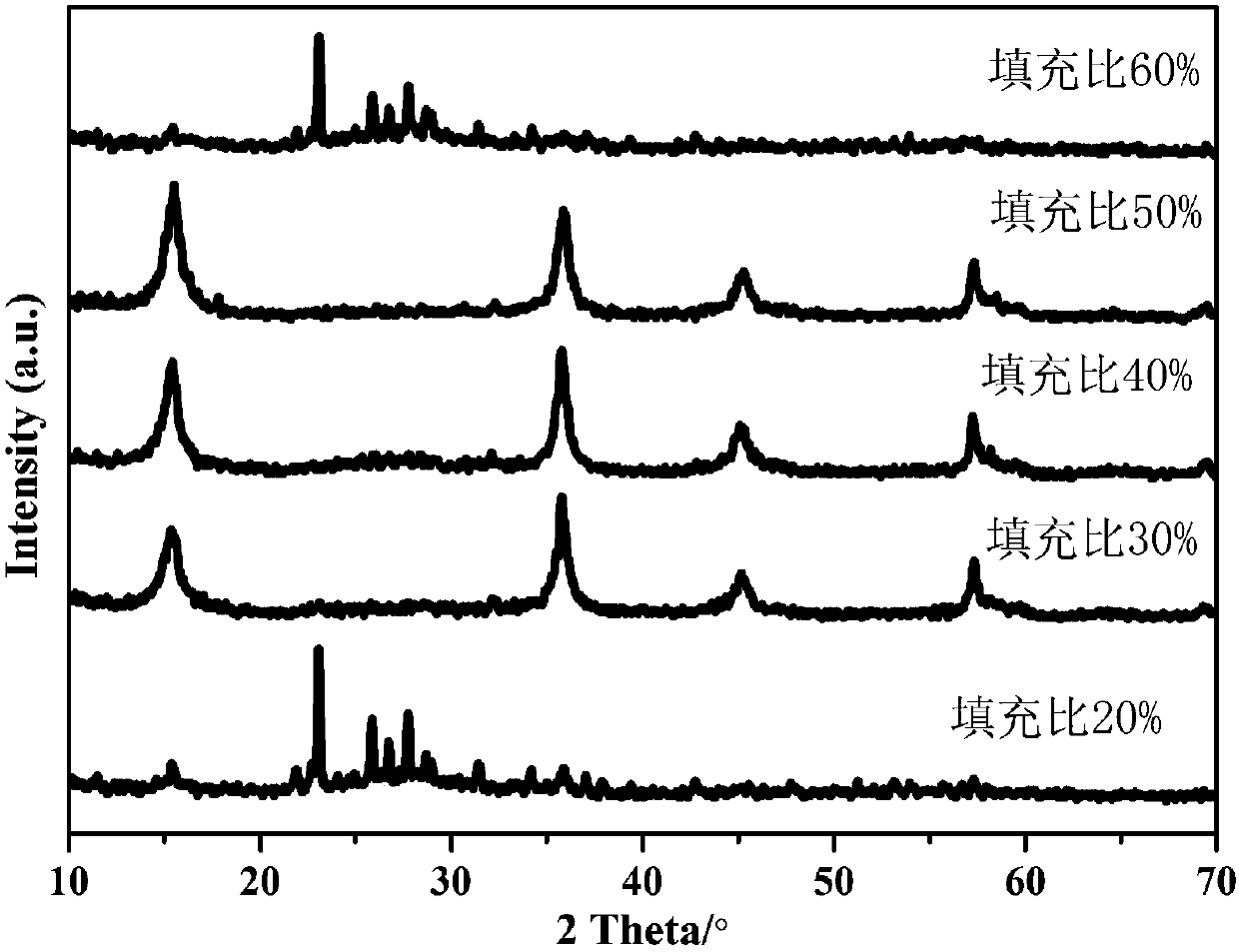

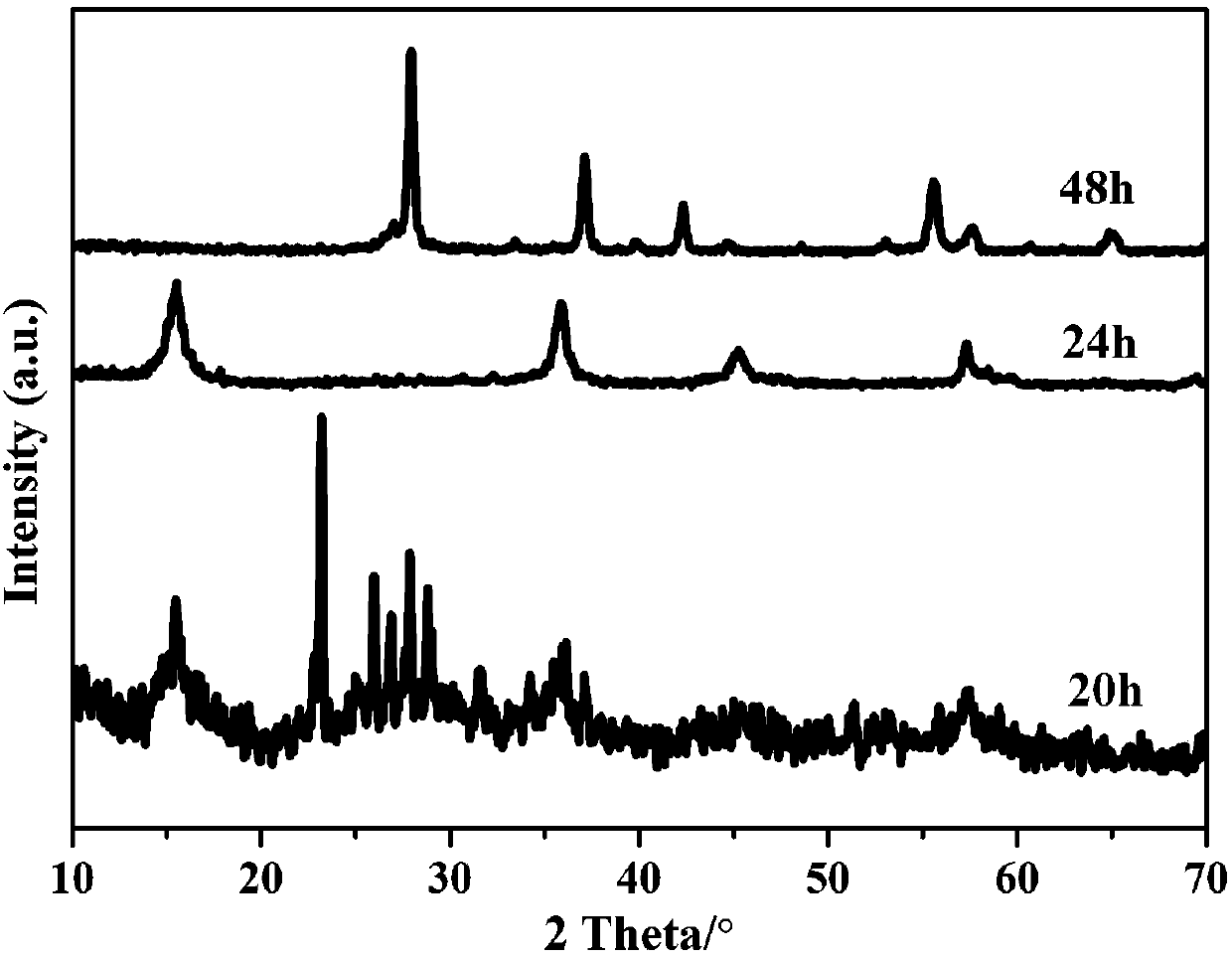

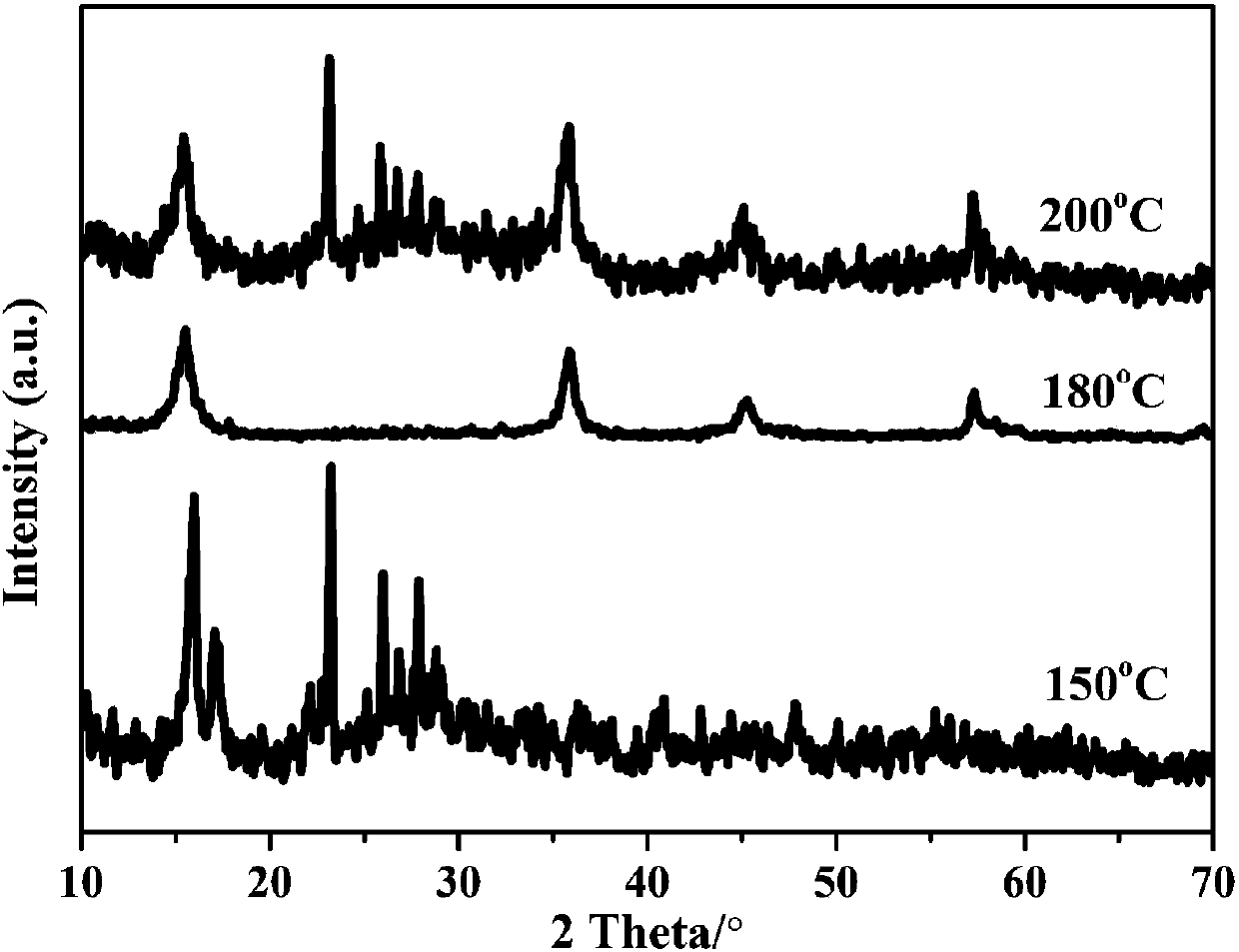

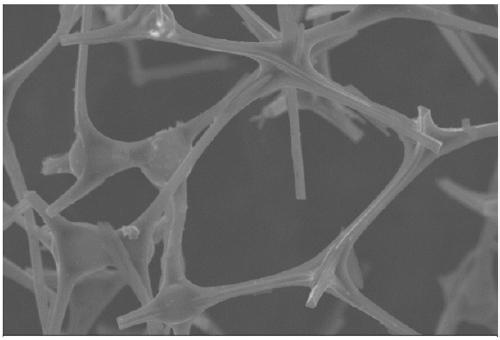

(001)-oriented nanosheet self-assembled three-dimensional VS2 microrod and preparation method thereof

ActiveCN107902697ASynthesis temperature is lowLow costMaterial nanotechnologyVanadium compoundsSingle crystalSolvent

A preparation method of a (001)-oriented nanosheet self-assembled three-dimensional VS2 microrod comprises the following steps: simultaneously adding sodium metavanadate and thioacetamide into anhydrous ethanol to obtain a solution A; and pouring the solution A into a reaction liner, sealing the reaction liner, carrying out a hydrothermal reaction in a homogeneous reactor, naturally cooling the obtained reaction product to room temperature, taking out the obtained cooled reaction product, alternately cleaning the product with water and alcohol, collecting the product, and drying the product toobtain the (001)-oriented nanosheet self-assembled three-dimensional VS2 microrod. The center of the microrod is obtained through mutually interlacing large VS2 nanosheets in a radial form, the edgeof the microrod is formed by small flaky VS2 nanosheets, the nanosheets are monocrystalline structures and grow along the (001) crystal face orientation, the diameter of the microrod is 2-15 [mu]m, and the thickness of the nanosheets is 5-20 nm. The highly-pure three-dimensional self-assembled VS2 is synthesized through a one-step solvothermal technology. The method has the advantages of simple reaction process, low temperature, easiness in control, and no large devices or strict reaction conditions.

Owner:SHAANXI UNIV OF SCI & TECH

Three-dimensional carbon material and preparation method thereof, as well as metal lithium composite electrode and preparation method thereof

ActiveCN109052359AConductiveLarge specific surface areaMaterial nanotechnologyCell electrodesHigh current densityLithium

The invention discloses a method for preparing a three-dimensional carbon material. The method comprising: S1) soaking a sponge in a soluble catalyst precursor aqueous solution, after drying, obtaining a soaked sponge; the soluble catalyst being a salt compound of iron series element; S2) heating the soaked sponge in a protective atmosphere and keeping the temperature, and obtaining the three-dimensional carbon material. Compared with the prior art, according to the invention, the sponge is used as a solid carbon source, the sponge adsorbs catalyst precursor in an early stage, and then in theprotective atmosphere, the sponge is pyrolyzed and carbonized, the catalyst is generated in situ, and the carbon nanotube grows at the same time; the three-dimensional carbon material with the carbonnanotube winding a carbonized sponge framework is prepared, the method is simple without requiring post processing; moreover, the three-dimensional carbon material maintains the elasticity and the three-dimensional framework structure of the sponge, has certain conductivity, also has a larger specific surface area and rich void structures, and after depositing metal lithium, and the three-dimensional carbon material maintains the elasticity and the three-dimensional framework structure of the sponge can achieve high current density and high surface capacity without dendrite formation.

Owner:UNIV OF SCI & TECH OF CHINA

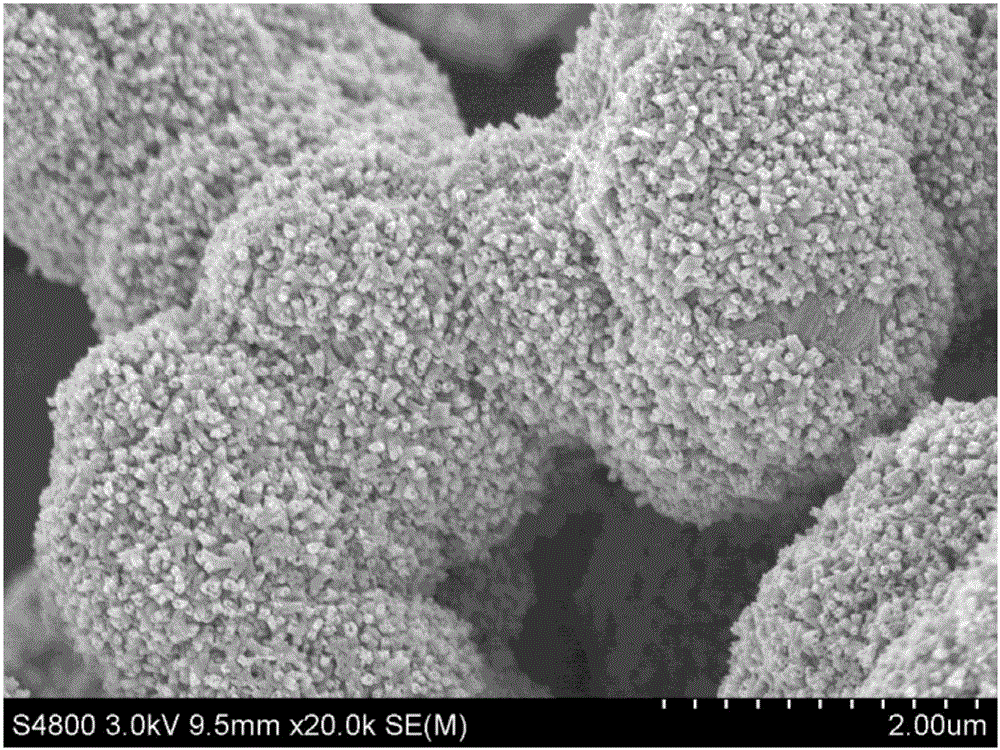

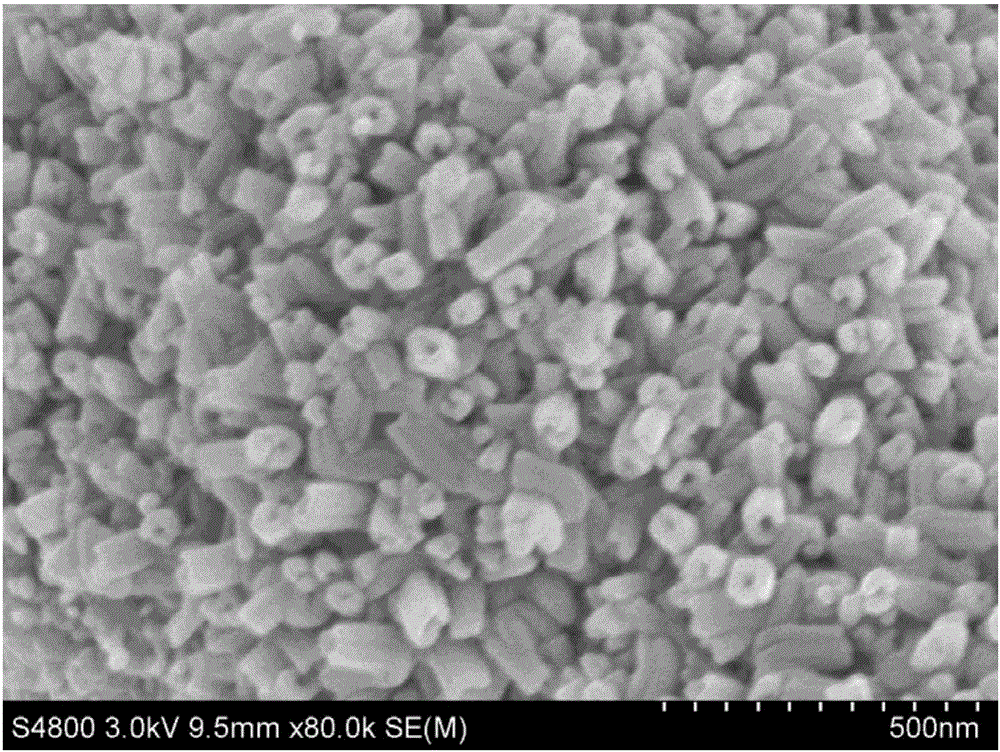

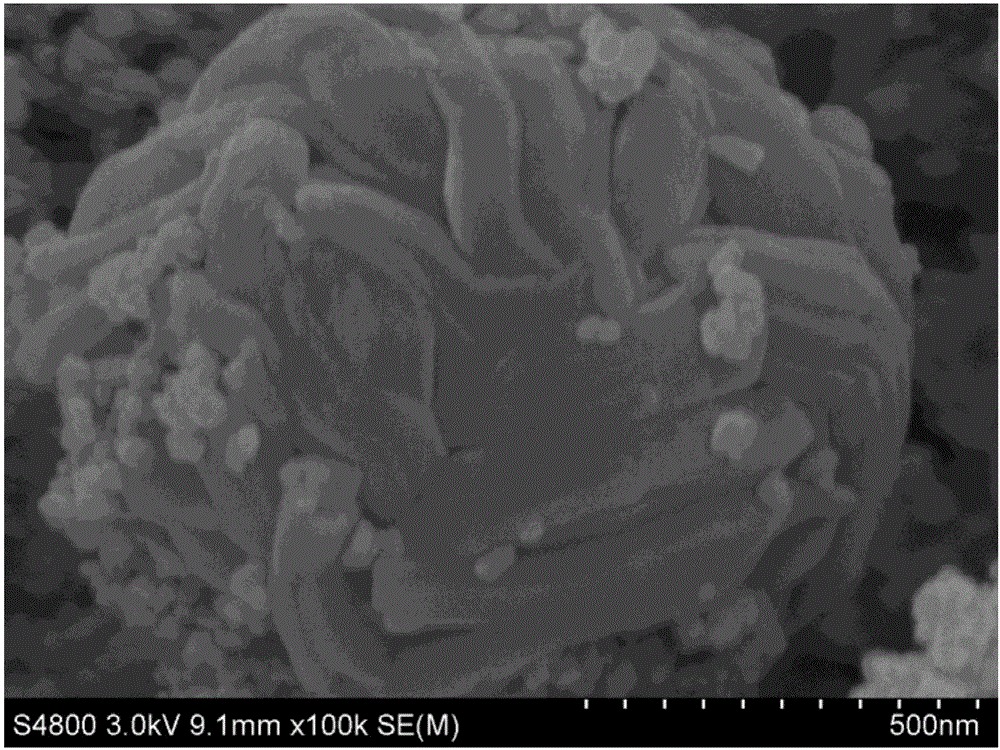

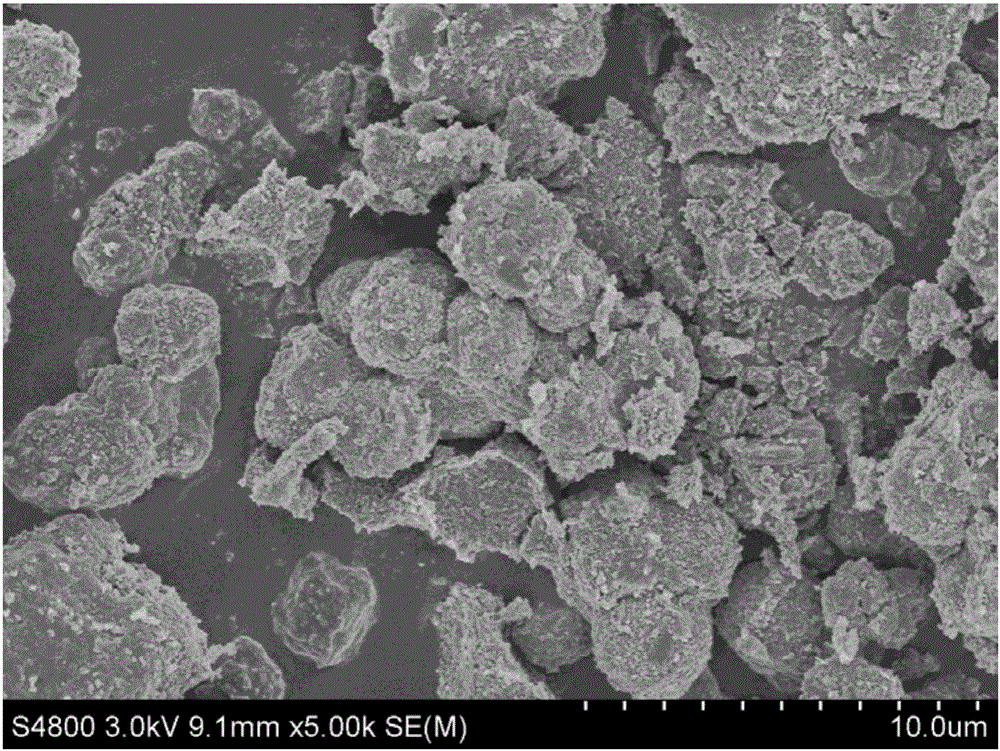

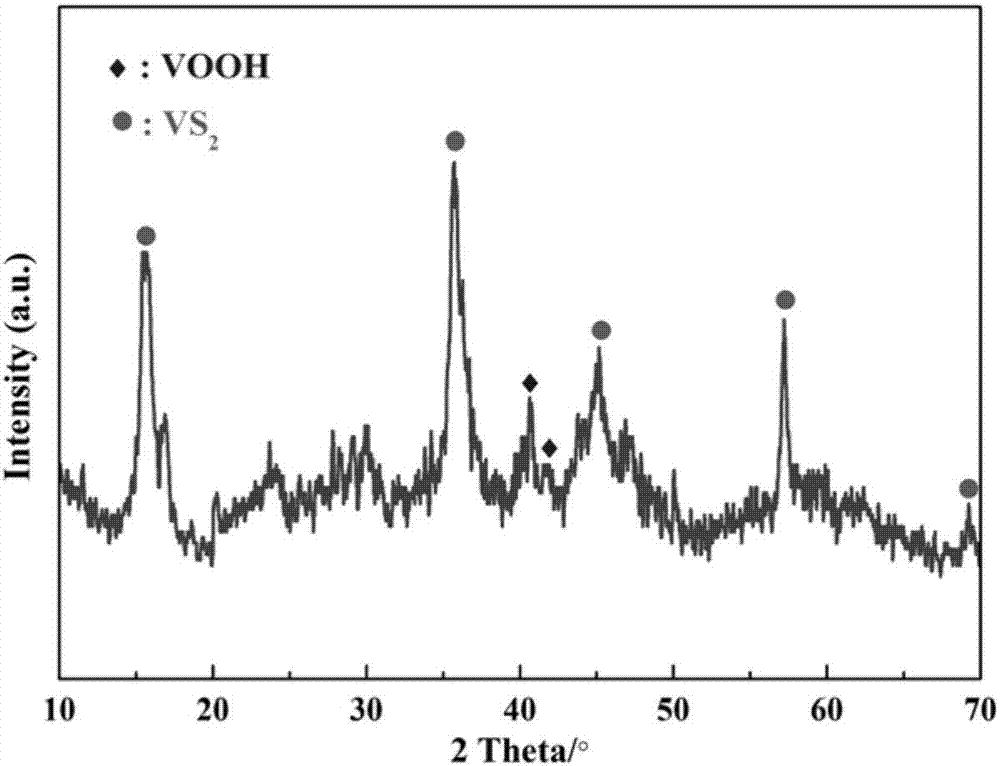

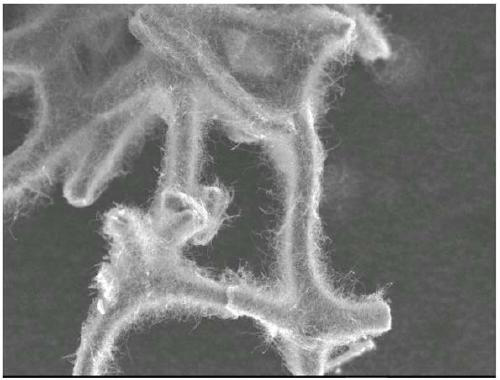

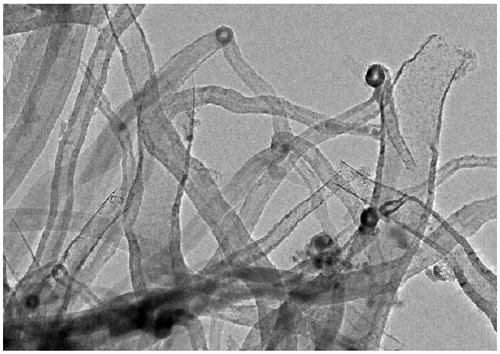

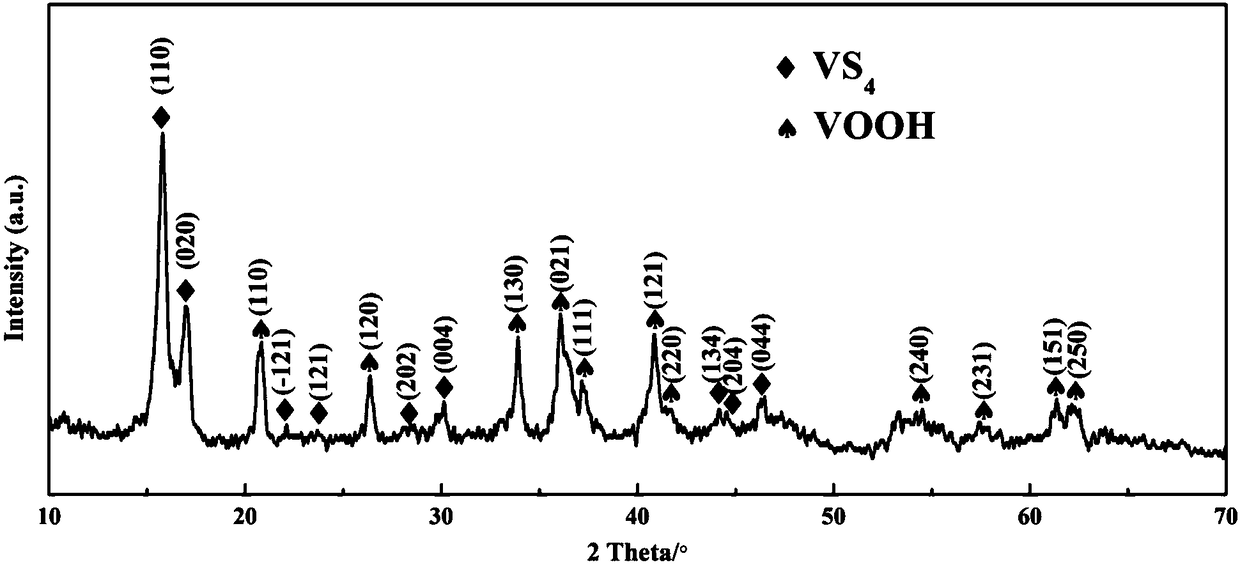

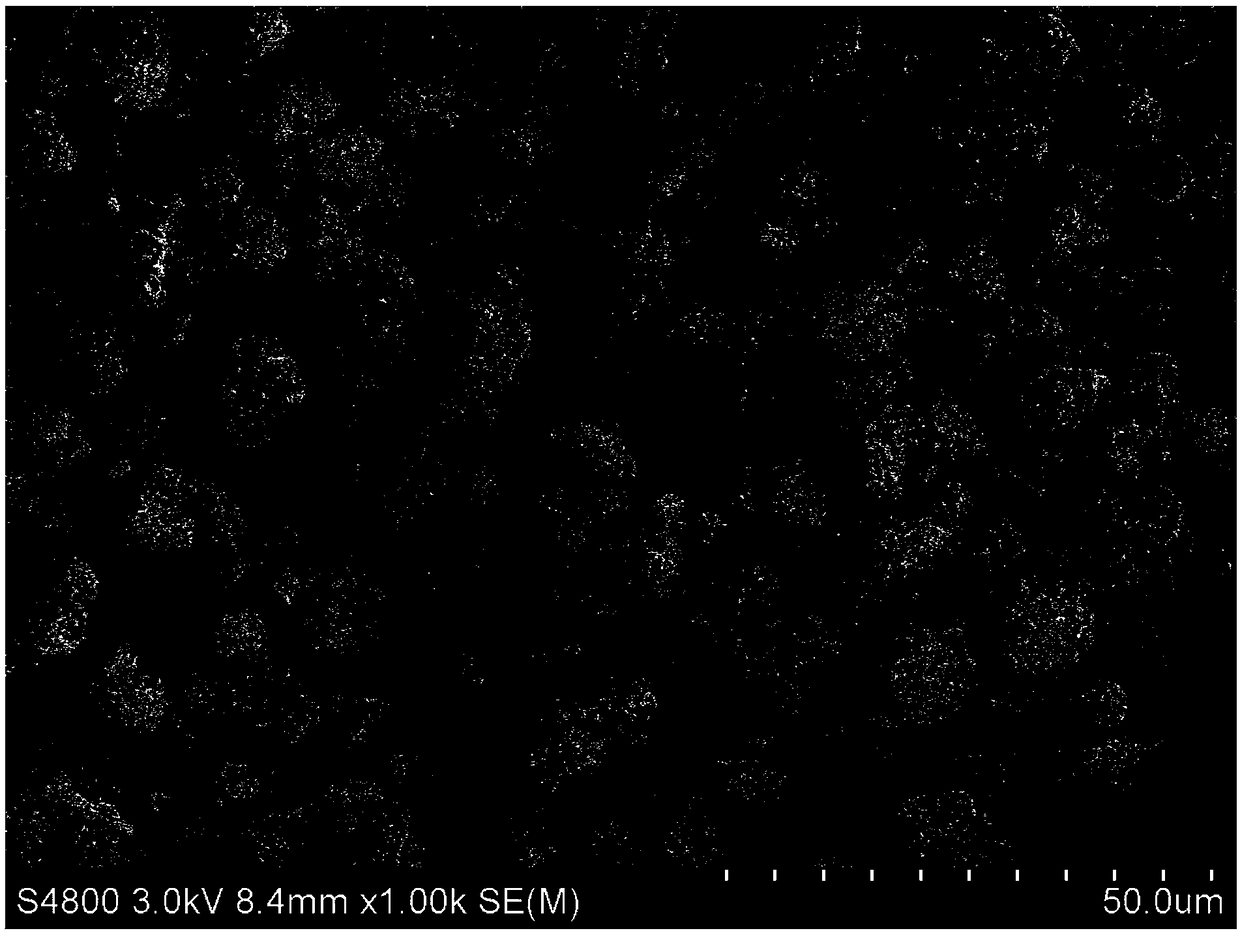

VOOH/VS4 micrometer composite powder as well as preparation method and application of VOOH/VS4 micrometer composite powder

ActiveCN108126712AImprove responseReduce the temperaturePhysical/chemical process catalystsCell electrodesMicrosphereSingle crystal

The invention discloses a VOOH / VS4 micrometer composite powder as well as a preparation method and application of the VOOH / VS4 micrometer composite powder. The preparation method comprises the steps:simultaneously adding sodium metavanadate and thioacetamide into deionized water to obtain a solution A; then, dropwise adding an aqueous ammonia solution into the solution A to obtain a solution B; pouring the solution B into a reaction liner, and then, carrying out sealing for a hydrothermal reaction; next, taking out a product cooled after being reacted, alternately cleaning the product by using water and alcohol, and then, collecting the product; and freezing the cleaned product, and then, drying the product to obtain the VOOH / VS4 micrometer composite powder. The VOOH / VS4 micrometer composite powder prepared according to the preparation method is composed of uniform spheroidal structures of which the diameters are about 10mu m, parts of spheroidal structures are gathered, the insides of microspheres are formed by self-stacking micrometer VS4 short rods of which the diameters are 0.5-1.0mu m and the length is 1.0-2.0mu m, and the outsides of the microspheres are randomly formed fromVOOH long rods having the diameters of 50-200nm and single-crystal structures. The VOOH / VS4 micrometer composite powder is applied to the fields of lithium / sodium ion batteries and photo / electric catalysis. The VOOH / VS4 micrometer composite powder shows excellent electrochemical properties and catalytic property when being applied as an anode material of a sodium / lithium ion battery and a photo / electric catalyst.

Owner:SHAANXI UNIV OF SCI & TECH

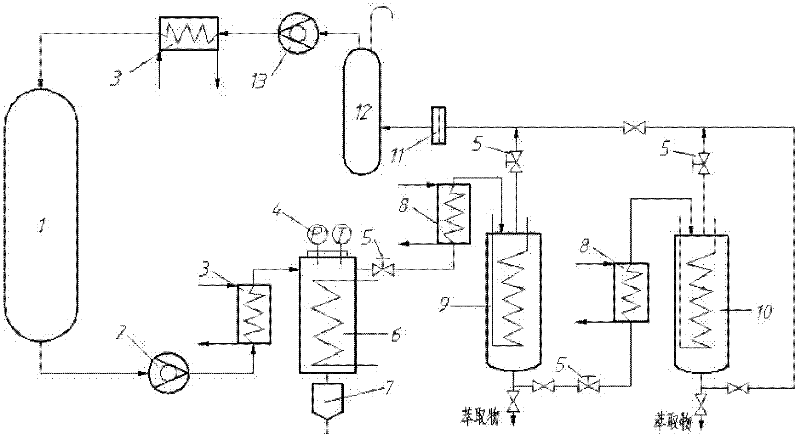

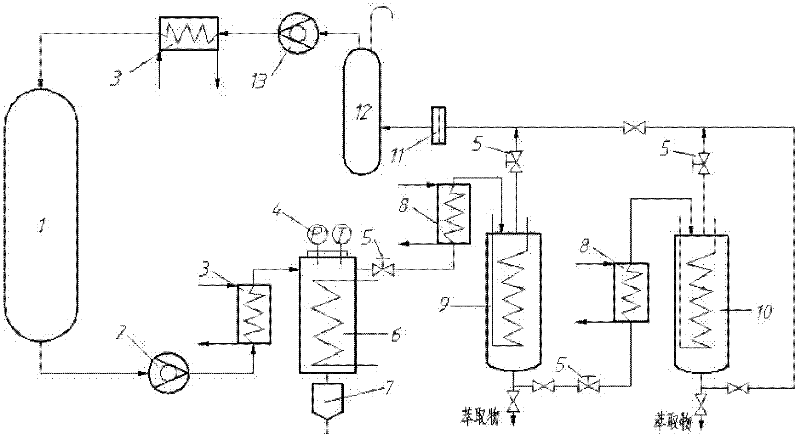

Method for extracting microalgal oil by supercritical CO2 isothermal transformation technology

The invention relates to a method for extracting microalgal oil by supercritical CO2 isothermal transformation technology. The method comprises the steps of: removing impurities in dried microalgae, and then crushing and grinding; putting the ground microalgae dry powder into an extraction kettle, filling supercritical CO2 into the extraction kettle, and extracting under the conditions that the pressure is 12-25MPa, the temperature is 34-42 DEG C and the time is 150-180min; carrying out isothermal decompression separation on the supercritical CO2 containing solute successively by two stages of separators; and collecting fatty acid oil extract separated out from the bottoms of the two stages of separators to obtain the product. According to the method, organic solvent is not needed in the whole process, so that no residual solvent exits in the extract, and oxidation and thermal cracking are not caused in the extraction process; the oil is high in yield and purity; the product is excellent in quality; the whole set of technology is simple in operation and does not have corresponding post-processing requirement. Meanwhile, the method prevents the microalgal oil from poisoning the human body and polluting the environment in the extracting process.

Owner:GUANGXI UNIV

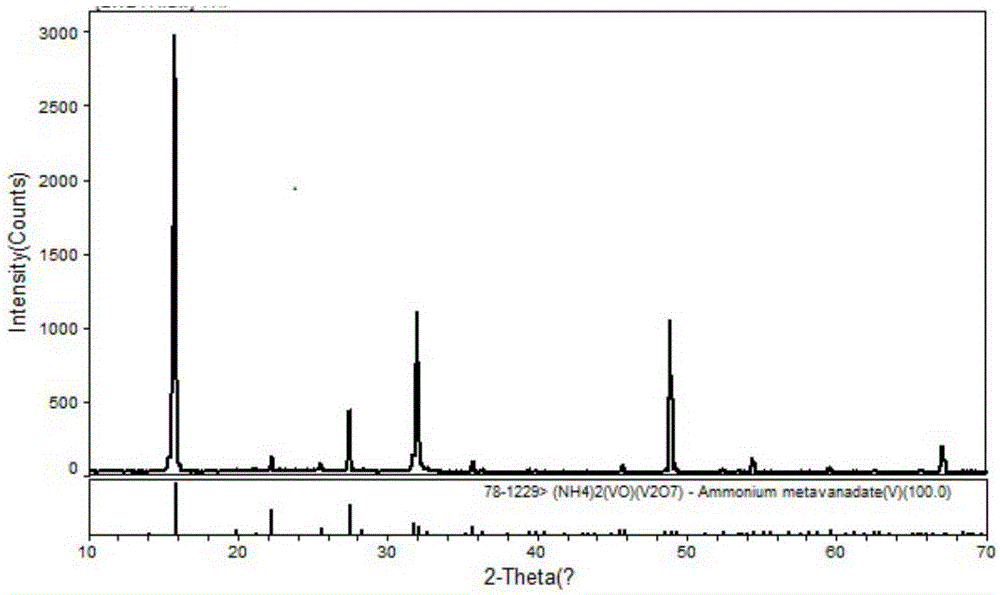

Preparation method of nanosheet self-assembled frustum-shaped (NH4)2V3O8

ActiveCN105932278ASmall sizeUniform chemical compositionMaterial nanotechnologyCell electrodesLithium-ion batteryFrustum

The invention provides a preparation method of a nanosheet self-assembled frustum-shaped (NH4)2V3O8. The preparation method comprises the following steps of firstly, dissolving vanadium pentoxide in deionized water to prepare a suspension liquid A, afterwards adding ammonia water and ethylene glycol to the suspension liquid A, and magnetically stirring the suspension liquid until the suspension liquid is clear to obtain a solution B; secondly, loading the solution B in a hydrothermal reaction kettle, placing the hydrothermal reaction kettle in a homogeneous reaction device, and naturally cooling the homogeneous reaction device after hydrothermal reaction; and finally, washing the product with water and alcohol, collecting and drying the product to obtain the nanosheet self-assembled frustum-shaped (NH4)2V3O8. The method process is simple and is easy to control, and the prepared (NH4)2V3O8 is uniform in microcrystal chemical constitution and relatively high in purity, and shows favorable electrochemical performance when taken as a positive electrode material of a lithium ion battery. Further, by the method, a large-size device and a severe reaction condition are not needed, the raw material is low in cost and is available, the preparation cost is low, the yield is high, subsequent processing is not needed, and the method is friendly to an environment and can be suitable for mass production.

Owner:SHAANXI UNIV OF SCI & TECH

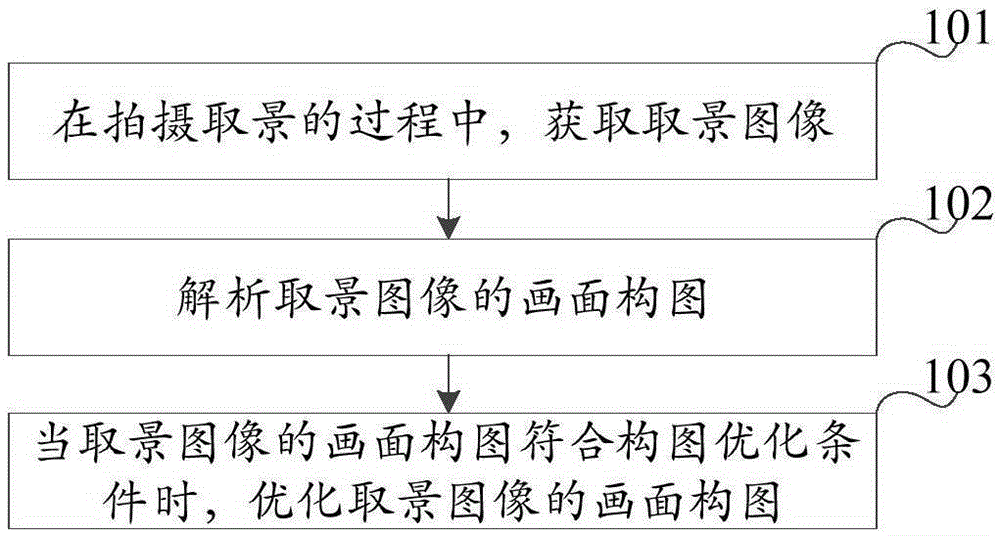

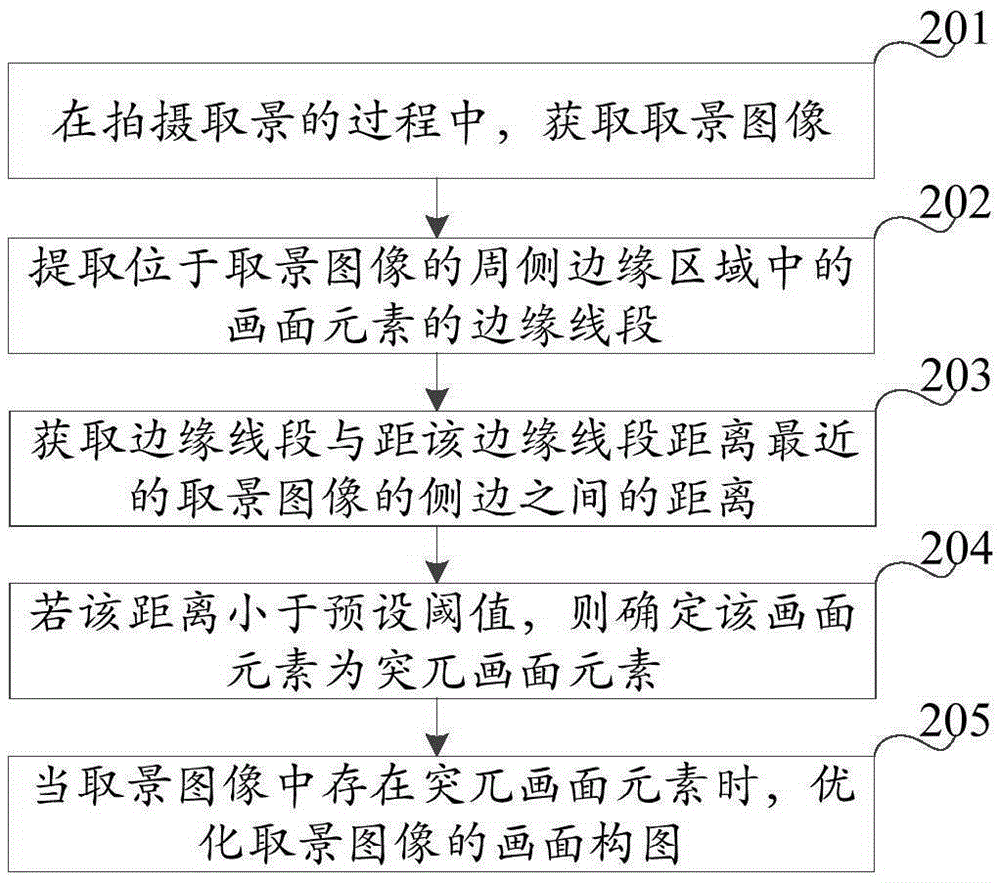

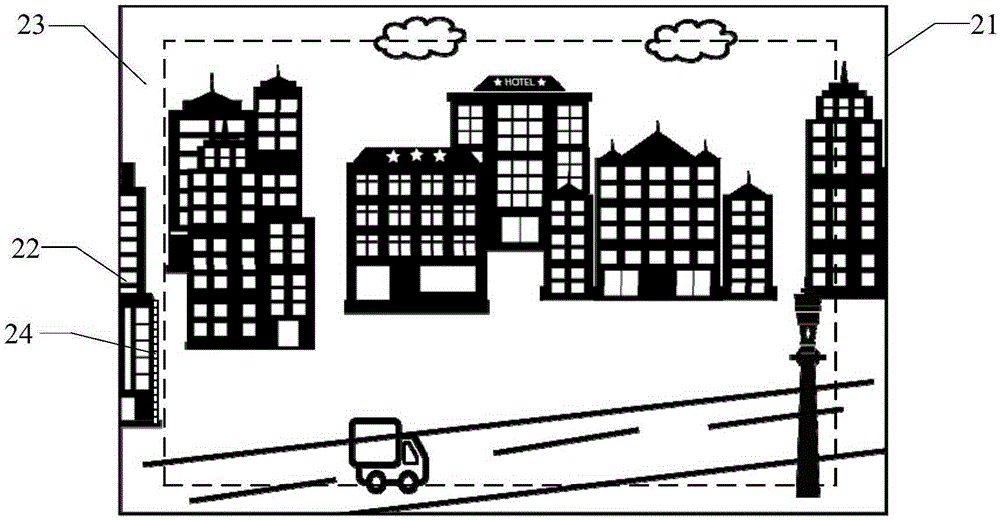

Image shooting method and device

ActiveCN105323491AQuality improvementNo post-processing requiredTelevision system detailsColor television detailsShooting methodComputer vision

The invention relates to an image shooting method and device, and belongs to the technical field of image shooting. The method includes the steps of: obtaining a framing image in a shooting framing process; analyzing composition of the framing image; and when the composition of the framing image satisfies composition optimization conditions, optimizing the composition of the framing image. The image shooting method provided by the invention solves the problem that in related technologies, optimization of the composition of an image that is shot in a later period is complicated in operation and needs to cost much time and energy; and the method realizes optimization of the composition of the framing image in the shooting framing process, thereby directly obtaining a composition-optimized high-quality image during shooting, and later processing is not needed.

Owner:XIAOMI INC

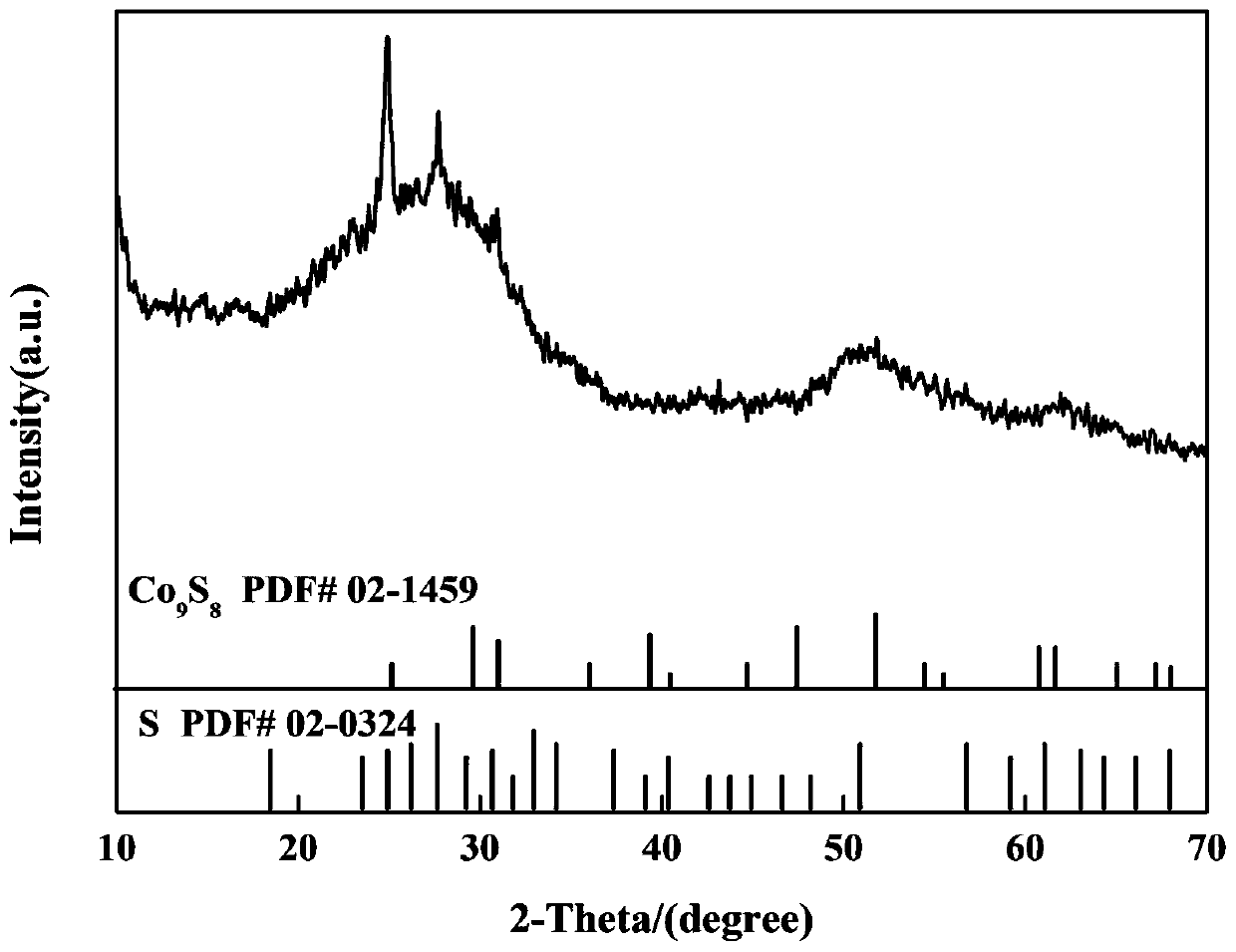

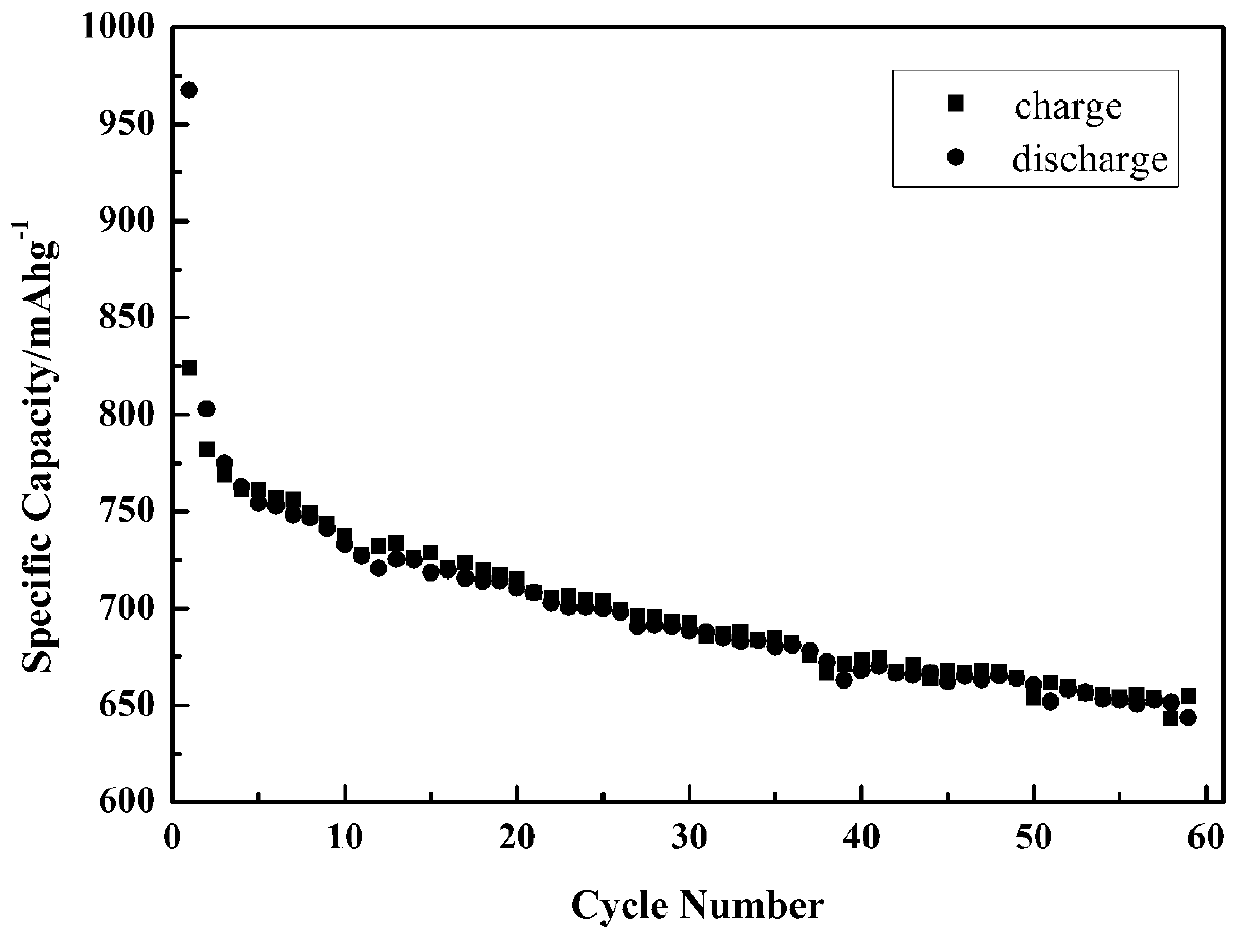

Preparation method of sheet-like cobalt sulfide composite flexible carbon cloth electrode material

InactiveCN110010875AImprove performanceImprove electrochemical performanceCell electrodesSecondary cellsFiberCarbon fibers

The invention relates to a preparation method of a sheet-like cobalt sulfide composite flexible carbon cloth electrode material. The method comprises the steps of: adding analytically pure cobalt nitrate hexahydrate into a mixed solution of isopropanol and glycerol to obtain a solution A; adding analytically pure thioacetamide into deionized water to obtain a solution B; mixing the solution A andthe solution B to obtain a precursor solution C; adding CBTA into the solution C to obtain a solution D; performing anodic oxidation pretreatment on the carbon cloth; and completely soaking the pretreated carbon cloth into the solution D, putting the solution D and the carbon cloth into a hydrothermal reaction kettle for hydrothermal reaction, and taking out the carbon cloth for cleaning and freeze-drying to obtain the sheet-like cobalt sulfide composite flexible carbon cloth electrode material. The carbon fibers can form a conductive framework network to increase the contact area with an electrolyte and provide growth attachment points and buffer volume expansion space for active materials. The sheet-like cobalt sulfide composite flexible carbon cloth electrode material has a good electrochemical performance.

Owner:SHAANXI UNIV OF SCI & TECH

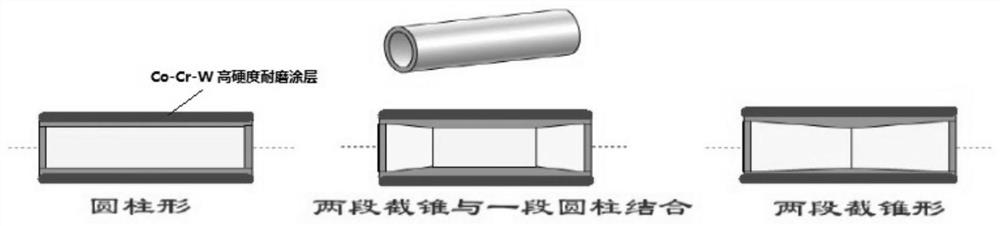

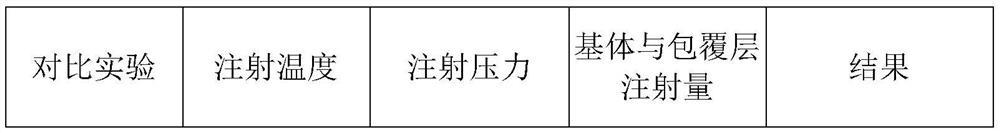

High-hardness wear-resistant piston pin and preparation method thereof

The invention discloses a high-hardness wear-resistant piston pin and a preparation method thereof. The preparation method comprises the following steps of firstly, respectively mixing matrix material powder and Co-Cr-W alloy powder with a binder, and performing granulation to obtain a matrix material feed and a high-hardness wear-resistant coating material feed; then, sequentially injecting the matrix material feed and the Co-Cr-W alloy coating material feed into a mold cavity by using an injection molding technology to obtain a product green body; removing the binder in the green body through catalytic debinding and thermal debinding processes; and finally, performing co-sintering densification to obtain the Co-Cr-W series high-hardness wear-resistant piston pin. The process is simple, the bonding performance of a coating layer and a matrix is good, and the piston pin has the characteristics of high hardness and wear resistance.

Owner:湖南英捷高科技有限责任公司

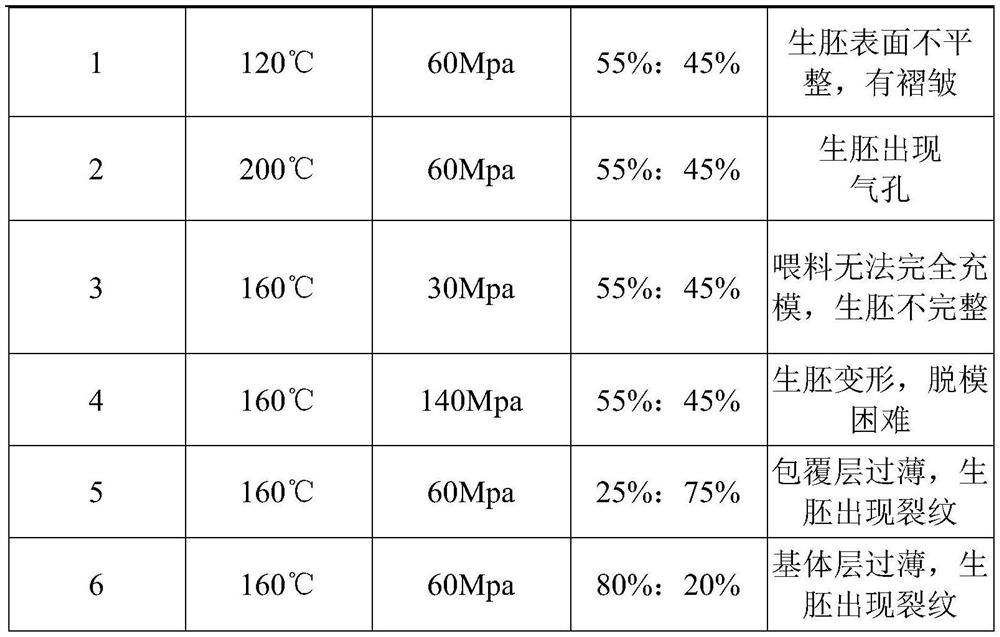

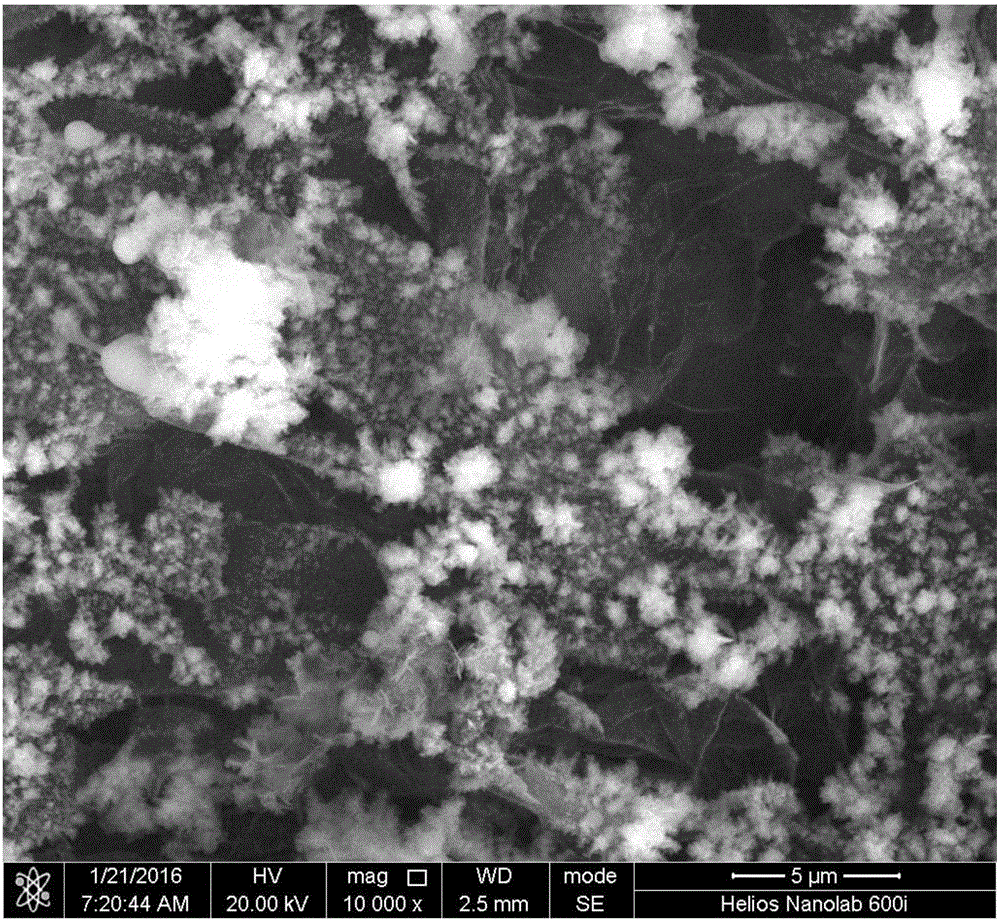

Preparation method of nickel sulfide/graphene/cobalt sulfide three-dimensional composite hydrogen storage material

ActiveCN105895869AGenerate uniformCreate a uniform structureAlkaline accumulatorsCell electrodesAcetic acidFreeze-drying

The invention provides a preparation method of a nickel sulfide / graphene / cobalt sulfide three-dimensional composite hydrogen storage material, relates to a method for preparing the three-dimensional composite hydrogen storage material and aims at solving the technical problem that an existing cobalt sulfide composite material cannot be used as an electrochemical hydrogen storage electrode. The method comprises the following steps: (1) preparing a graphene oxide disperse solution; (2) adding cobaltous acetate and sulphur to the graphene oxide disperse solution to prepare a mixed solution; (3) preparing a mixed dispersion liquid in a ball-milling manner; (4) cleaning nickel foam; and (5) adding the mixed dispersion liquid to a hydrothermal kettle, adding glucose, immersing the nickel foam into the mixed dispersion liquid, carrying out hydrothermal reaction and then carrying out cleaning and freeze drying on the product to obtain the nickel sulfide / graphene / cobalt sulfide three-dimensional composite hydrogen storage material. The specific surface area of the composite hydrogen storage material is 67-78m<2> / g; the preparation method is simple; the reaction period is short; final treatment is not needed; the hydrogen storage property is high; and the nickel sulfide / graphene / cobalt sulfide three-dimensional composite hydrogen storage material can be directly applied to the field of electrochemical hydrogen storage as the hydrogen storage electrode.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

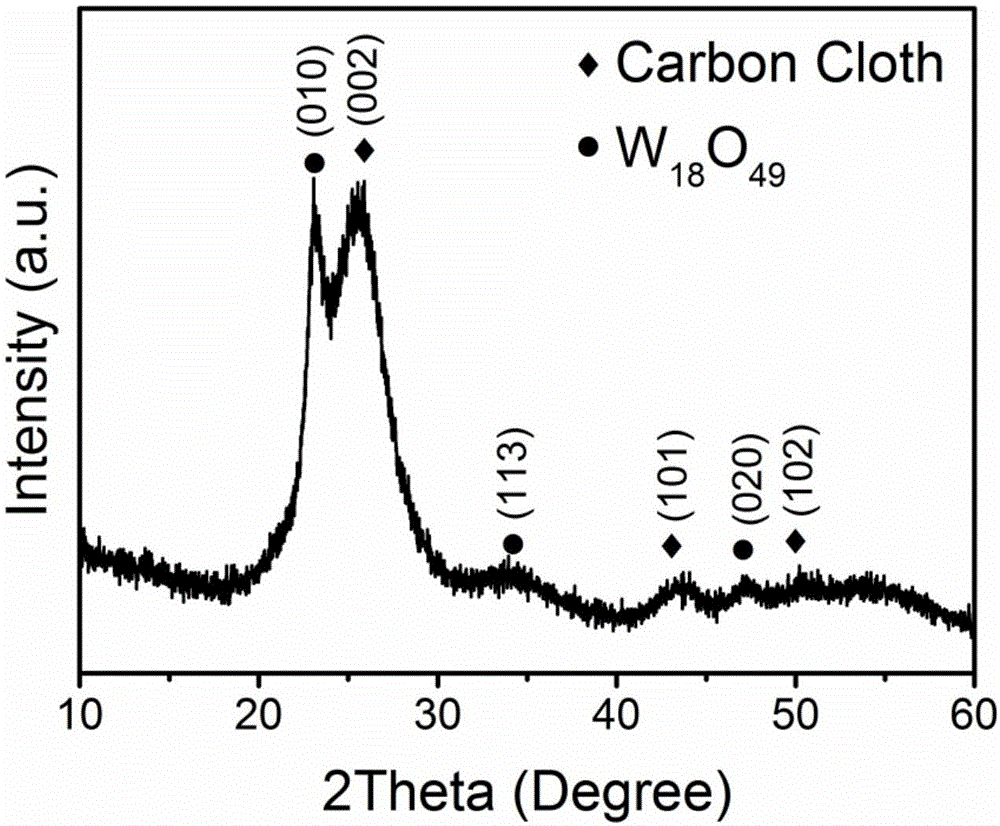

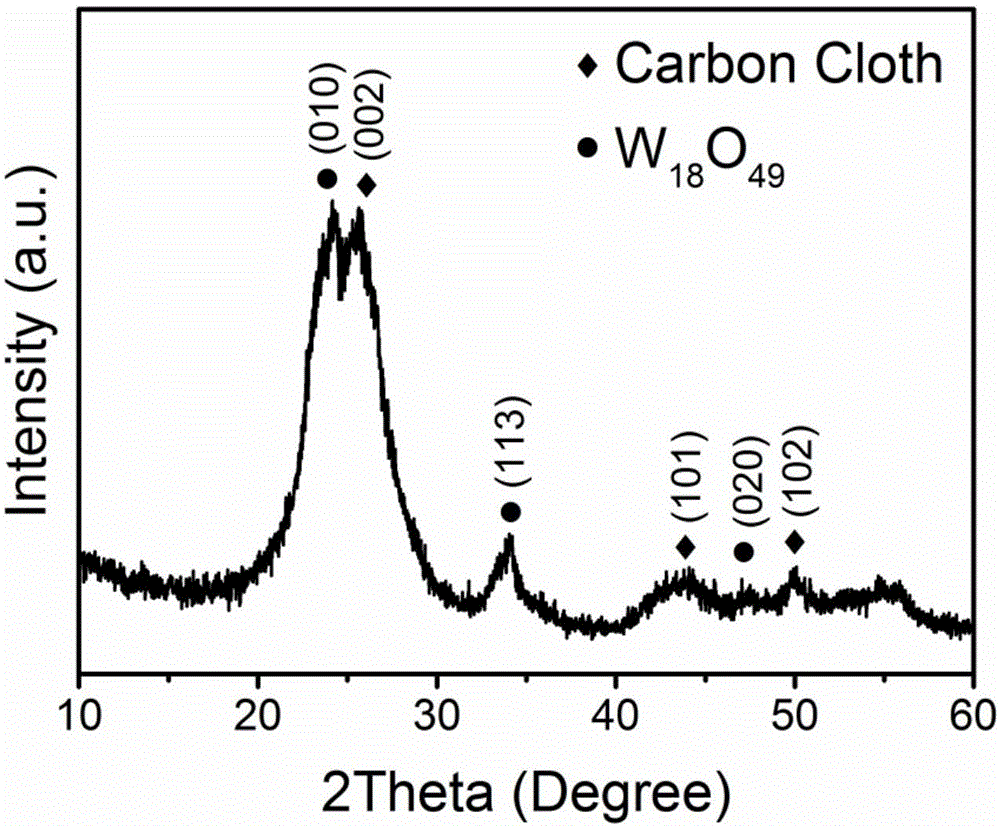

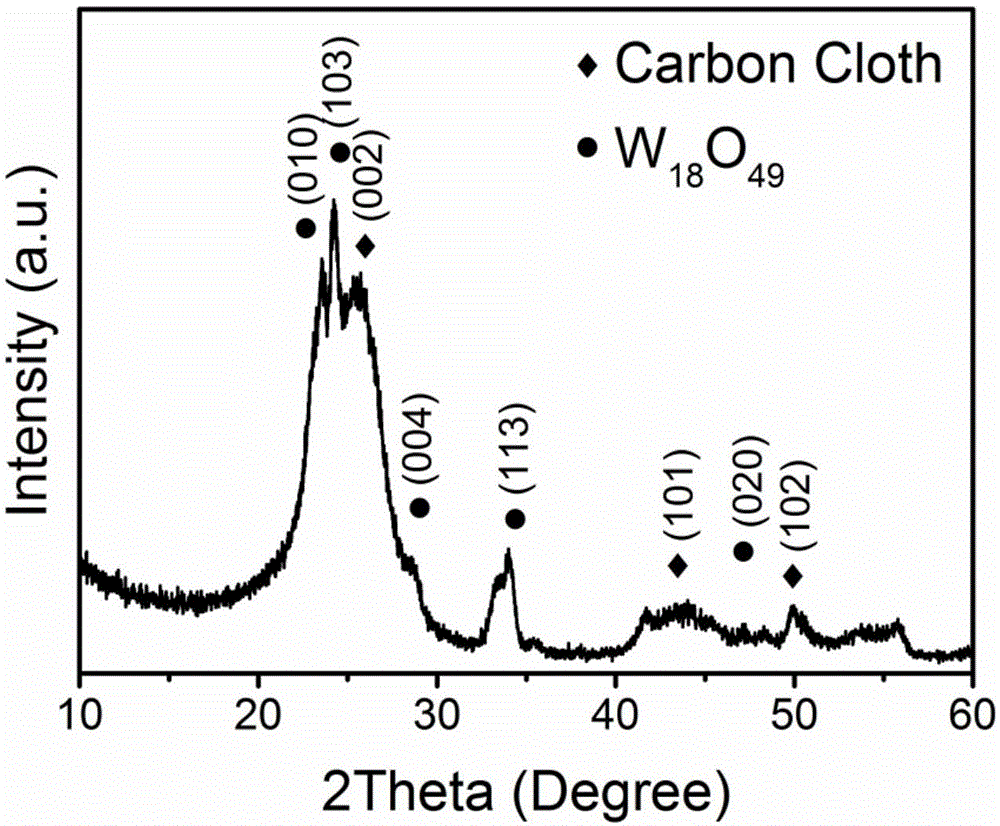

W18O49 coated carbon fiber composite material and preparation method thereof

The invention discloses a W18O49 coated carbon fiber composite material and a preparation method thereof. The W18O49 coated carbon fiber composite material takes carbon fibers as a reaction source and the W18O49 coated carbon fiber composite material is produced by adopting a solvothermal method; a monoclinic W18O49 nano-material grows on the carbon fibers through the solvothermal method in a coating manner; in a solvothermal preparation process, any template and any catalyst are not needed; the technology is simple, the yield is high and the cost is low, so that the W18O49 coated carbon fiber composite material is suitable for batch production; the W18O49 nano-material directly grows on carbon cloth and the prepared nano composite material has a uniform shape and coating tightness and can be used as photocatalysis, electrocatalysis, solar cell, flexible sensor, field emission and lithium-ion battery negative electrode materials.

Owner:NORTHWEST UNIV

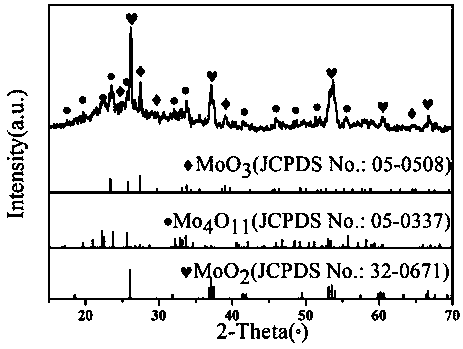

Three-phase system molybdenum oxide MoO3/Mo4O11/MoO2 nano electrode material and preparation method thereof

ActiveCN107739053ARaw materials are cheap and easy to getLow costCell electrodesSecondary cellsSynthesis methodsReaction temperature

The invention discloses a synthesis method of a three-phase system molybdenum oxide MoO3 / Mo4O11 / MoO2 lithium-ion battery negative electrode material. The synthesis method comprises the following steps: 1) dissolving a molybdenum source into an enough ethanol-water mixed solvent according to a formula amount; sufficiently stirring and regulating the pH (Potential of Hydrogen) to 1 to 5 by utilizinghydrogen acid; 2) carrying out solvothermal reaction on a product, wherein the reaction temperature is 60 DEG C to 150 DEG C and the time is 3h to 24h; 3) after finishing reaction, cooling a product,and washing and drying; 4) carrying out heat treatment on the product for 2h to 4h in an inert atmosphere at 300 DEG C to 500 DEG C, so as to obtain a target product MoO3 / Mo4O11 / MoO2. The invention discloses the MoO3 / Mo4O11 / MoO2 material; MoO2 and Mo4O11 have metal-like conductivity; on the basis, a relatively high theoretical capacity and a unique lamellar structure of the MoO3 also have extremely great advantages.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com