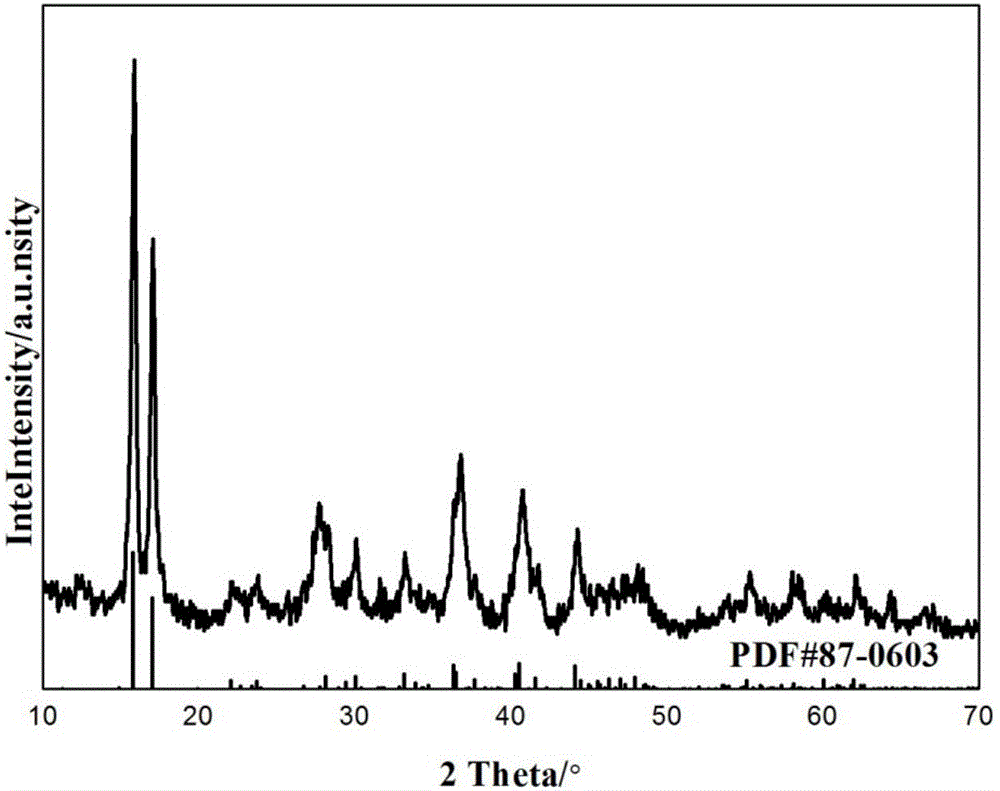

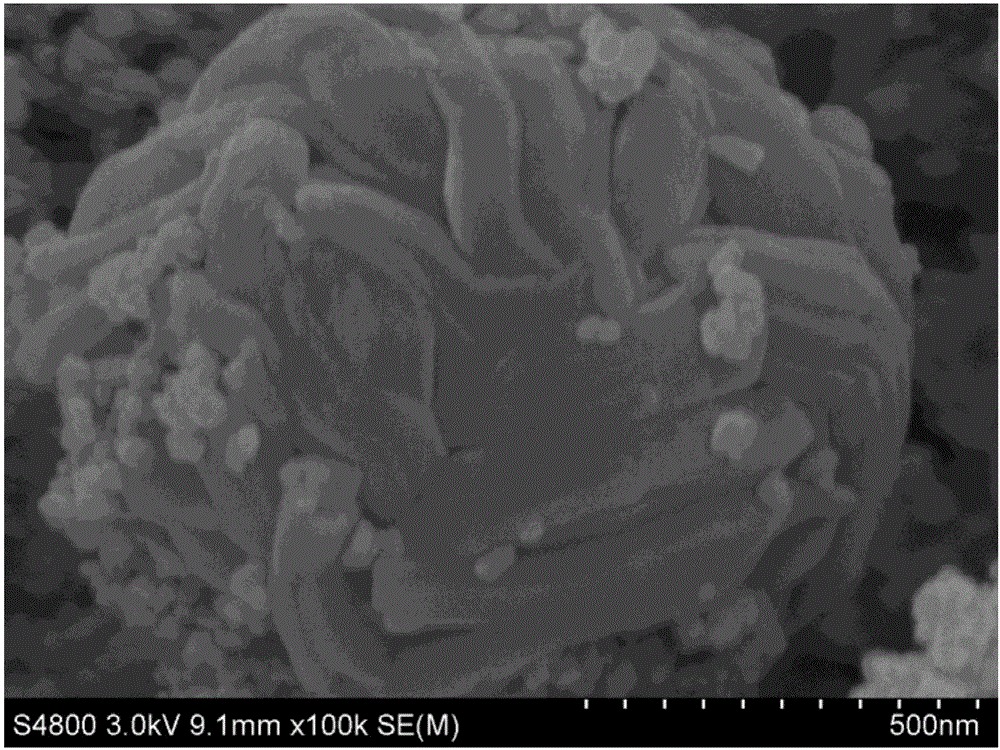

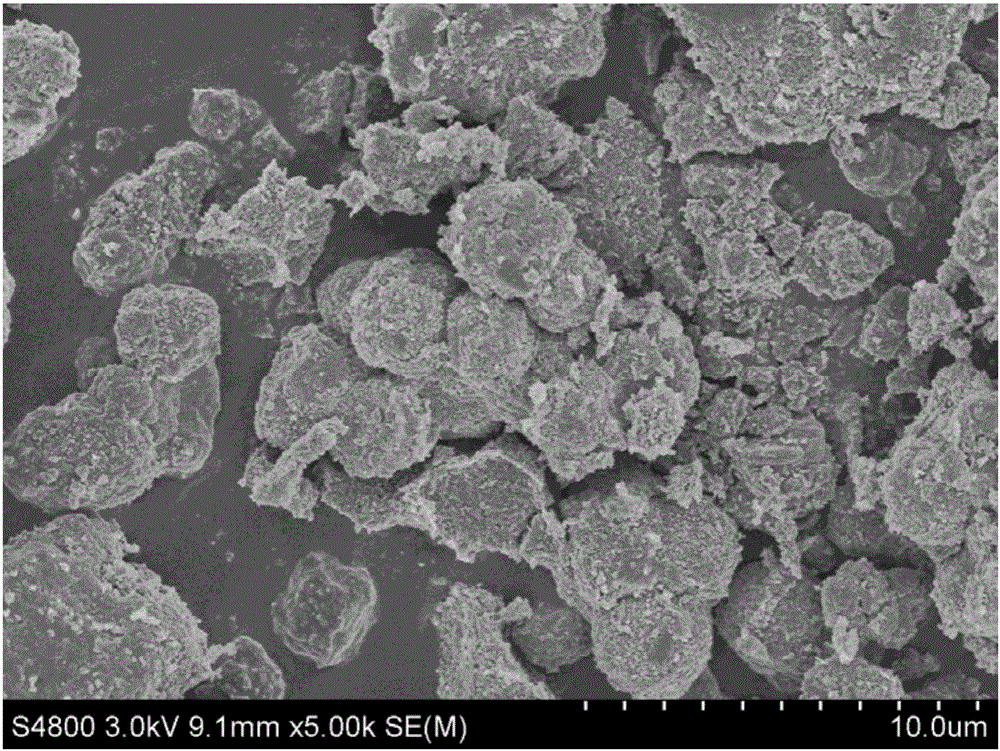

Preparation method of vanadium tetrasulfide nano-powder and application

A nano-powder technology of vanadium tetrasulfide, which is applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of harsh synthesis conditions of vanadium tetrasulfide, slow research progress, difficult to control the reaction, etc., and achieve excellent electrochemical performance. Uniformity in performance, chemical composition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of vanadium tetrasulfide nanopowder, comprising the following steps:

[0024] Step 1: Prepare hydrochloric acid solution and sodium hydroxide solution of certain concentration for adjusting the pH value of the reaction solution. The hydrochloric acid solution can also be sulfuric acid solution, and the sodium hydroxide solution can also be ammonia water or potassium hydroxide solution.

[0025] Step 2: Mix the vanadium source solution and the sulfur source solution, the vanadium-sulfur molar ratio is controlled at 1:2 to 1:10, magnetically stir or ultrasonically disperse until the mixed solution is in a semi-clear state to obtain a suspension A, at this time the vanadium source The concentration is 0.06-0.6 mol / L, the pH of the suspension is adjusted to be acidic or weakly alkaline, the pH value is 1-10, and it is completely dissolved to obtain solution B.

[0026] The vanadium source is one or more of sodium metavanadate, sodium vanadate, ammonium...

Embodiment 1

[0033] Step 1: Prepare a 3mol / L hydrochloric acid solution for adjusting the pH value of the reaction solution.

[0034] Step 2: Weigh sodium metavanadate and thioacetamide and dissolve them in deionized water, then mix the vanadium source solution and the sulfur source solution, the molar ratio of vanadium to sulfur is controlled at 1:4, and then at a speed of 700r / min Stir magnetically for 30 minutes until the solution is in a semi-clear state to obtain a suspension A. At this time, the concentration of the vanadium source is 0.1mol / L, and then add hydrochloric acid solution dropwise to the suspension A until the pH value of the solution reaches 1 to obtain a solution B. The magnetic stirring can be replaced by ultrasonic dispersion.

[0035] Step 3: Transfer the solution B to the hydrothermal reaction liner, add an external kettle, place it in a homogeneous reactor, and react at a synthesis temperature of 180°C for 24 hours.

[0036] Step 4: After the hydrothermal reaction...

Embodiment 2

[0040] Step 1: Prepare 5 mol / L hydrochloric acid solution for adjusting the pH value of the reaction solution.

[0041] Step 2: Weigh sodium metavanadate and thioacetamide and dissolve them in deionized water, then mix the vanadium source solution and the sulfur source solution, the molar ratio of vanadium to sulfur is controlled at 1:2, and then at a speed of 700r / min Stir magnetically for 30 minutes until the solution is in a semi-clear state to obtain a suspension A. At this time, the concentration of the vanadium source is 0.06mol / L, and then add hydrochloric acid solution dropwise to the suspension A until the pH value of the solution reaches 7 to obtain a solution B. The magnetic stirring can be replaced by ultrasonic dispersion.

[0042] Step 3: Transfer the solution B to the hydrothermal reaction liner, add an external kettle, place it in a homogeneous reactor, and react at a synthesis temperature of 180°C for 24 hours.

[0043]Step 4: After the hydrothermal reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com