Patents

Literature

251 results about "Sodium metavanadate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium metavanadate is the inorganic compound with the formula NaVO₃. It is a yellow, water-soluble solid. Its natural forms include mineral metamunirite (anhydrous) and a dihydrate, munirite. Both are very rare, metamunirite is now known only from vanadium- and uranium-bearing sandstone formations of central-western USA and munirite from Pakistan and South Africa.

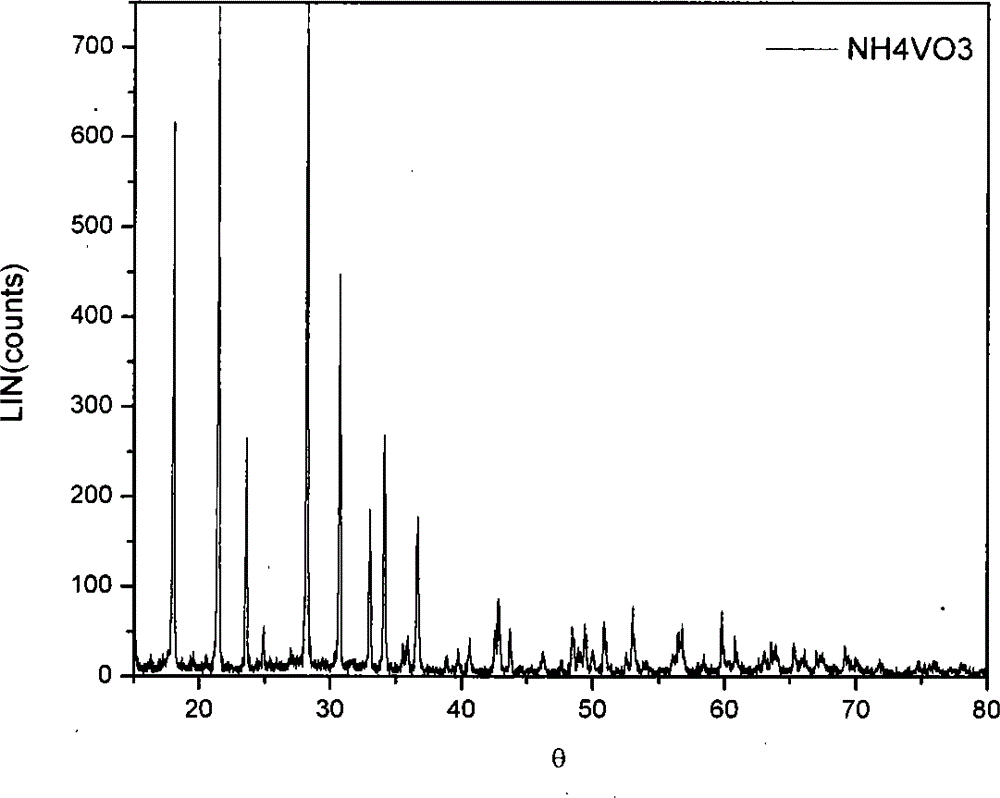

Method for preparing high purity vanadium pentoxide through using ammonium metavanadate

The invention which relates to a method for preparing high purity vanadium pentoxide through using ammonium metavanadate belongs to the wet metallurgy field. The method comprises the following steps: heating and dissolving crude ammonium metavanadate in water, adjusting the pH value to 8-10 with an alkali after dissolving, adding an impurity removing agent to remove impurities, filtering to obtain a sodium metavanadate solution, adding ammonia water or an ammonium salt to the sodium metavanadate solution to precipitate to obtain an ammonium metavanadate precipitate, dehydrating the ammonium metavanadate precipitate, carrying out water washing on the precipitate through using a dilute ammonium salt solution, dehydrating after the wash washing, and roasting to obtain the high purity vanadium pentoxide. Vanadium pentoxide produced through adopting the method of the invention has the advantages of high purity and less impurities, and completely satisfies production requirements of high-end products; and the method of the invention has the advantages of short process flow, simple equipment, low cost and high benefit, and is suitable for the large-scale industrial production.

Owner:崇阳县恒通工贸有限公司

Penicillium, as well as preparation method and application

InactiveCN101434909AReach pollutionReduce pollutionFungiMicroorganism based processesEcological environmentPhosphate

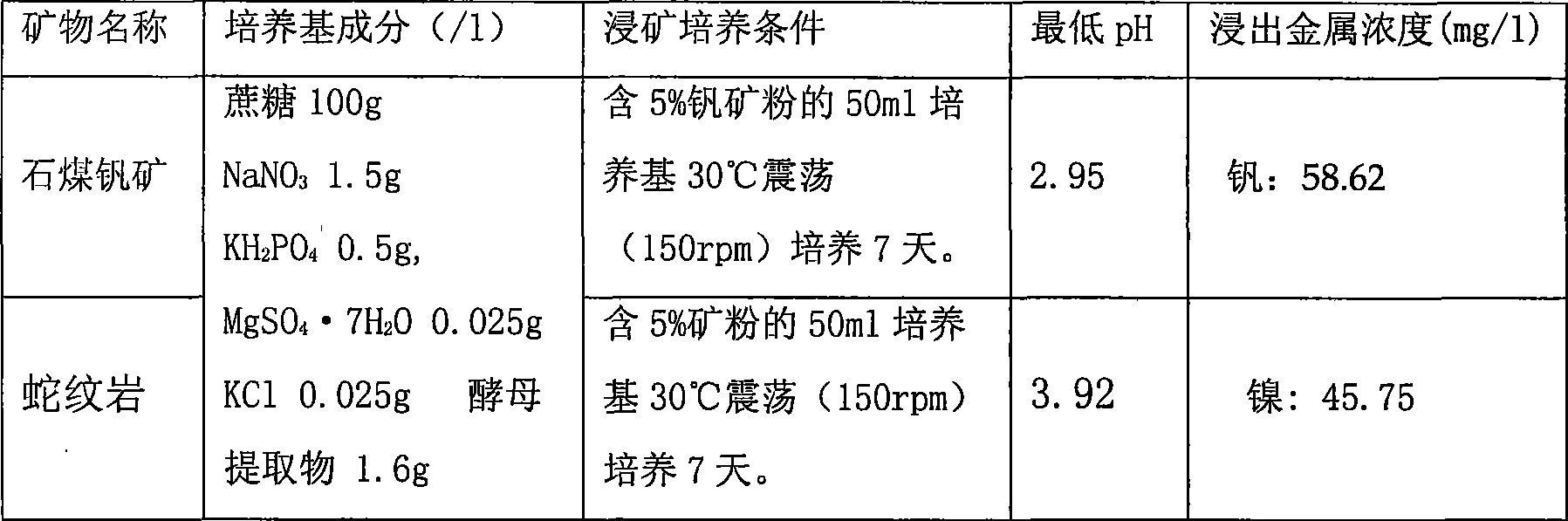

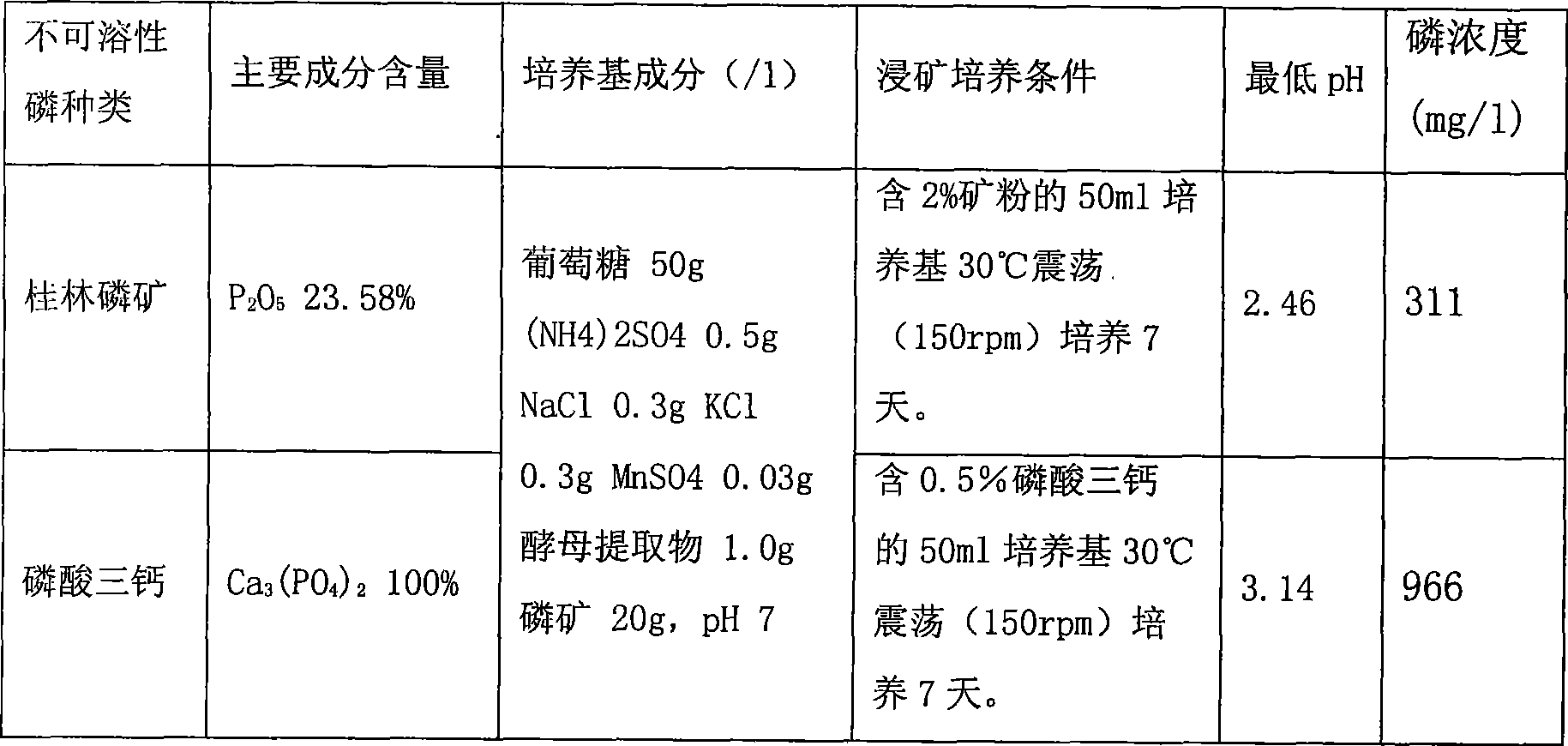

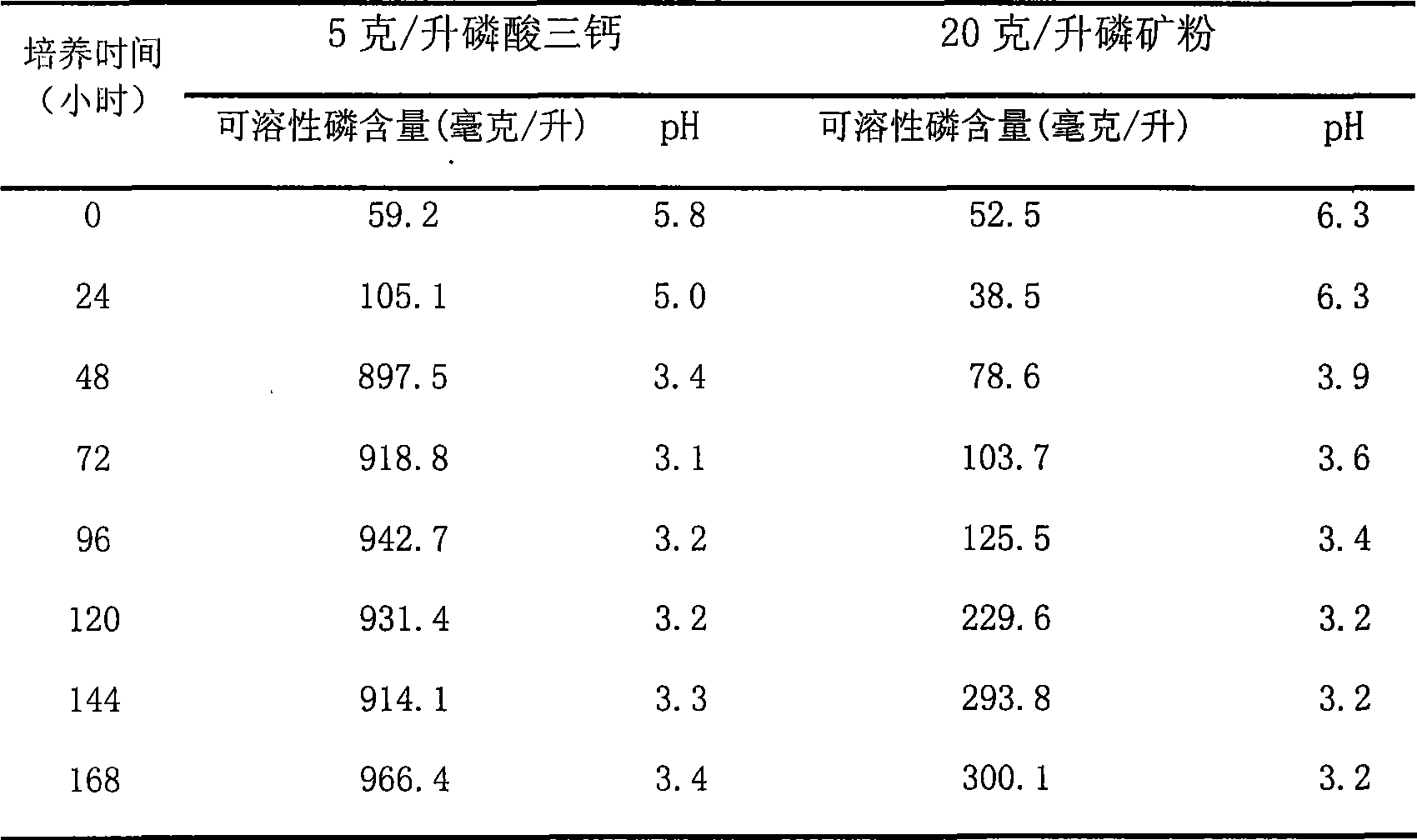

The invention discloses a Penicillium, a preparation method and applications thereof, Penicillium fungus PSM11-5 is separated from a vanadium ore sample; insoluble tricalcium phosphate, sodium metavanadate, cobalt hydroxide and basic nickel carbonate are taken as indicating compounds; and a fungal strain is screened by testing the capability of decomposing the tricalcium phosphate, the sodium metavanadate, the cobalt hydroxide and the basic nickel carbonate. The Penicillium PSM11-5 is Penicillium sp.PSM11-5 CCTCCM208207. The strain is utilized for carrying out biological leaching of phosphorus and biological metallurgy, metals of phosphorus, vanadium, nickel, cobalt and the like are leached from lean ores, discarded ores, submarginal ores, difficult-to-mine ores, difficult dressing ores and refractory ores, thereby fully utilizing the mineral resources, reducing the metallurgical costs and protecting the ecological environment. The PSM11-5 is utilized for leaching the phosphorus from low-grade phosphate rock powder, a biological fertilizer is prepared to be applied to the soil, thereby leading the soil to contain higher content of soluble phosphorus which can be utilized by crops; the strain further leaches insoluble phosphorus which is deposited in the soil before, thereby reducing phosphorus fertilizer and reducing gas pollution caused by the phosphorus fertilizer and water pollution caused by the phosphorus fertilizer.

Owner:WUHAN INST OF VIROLOGY CHINESE ACADEMY OF SCI

Extraction of vanadium and molybdenum compound from refused materials containing vanadium and molybdenum etc. multiple elements

InactiveCN1940096APrecipitation completeStable pHVanadium oxidesProcess efficiency improvementSodium molybdateMolybdenum compounds

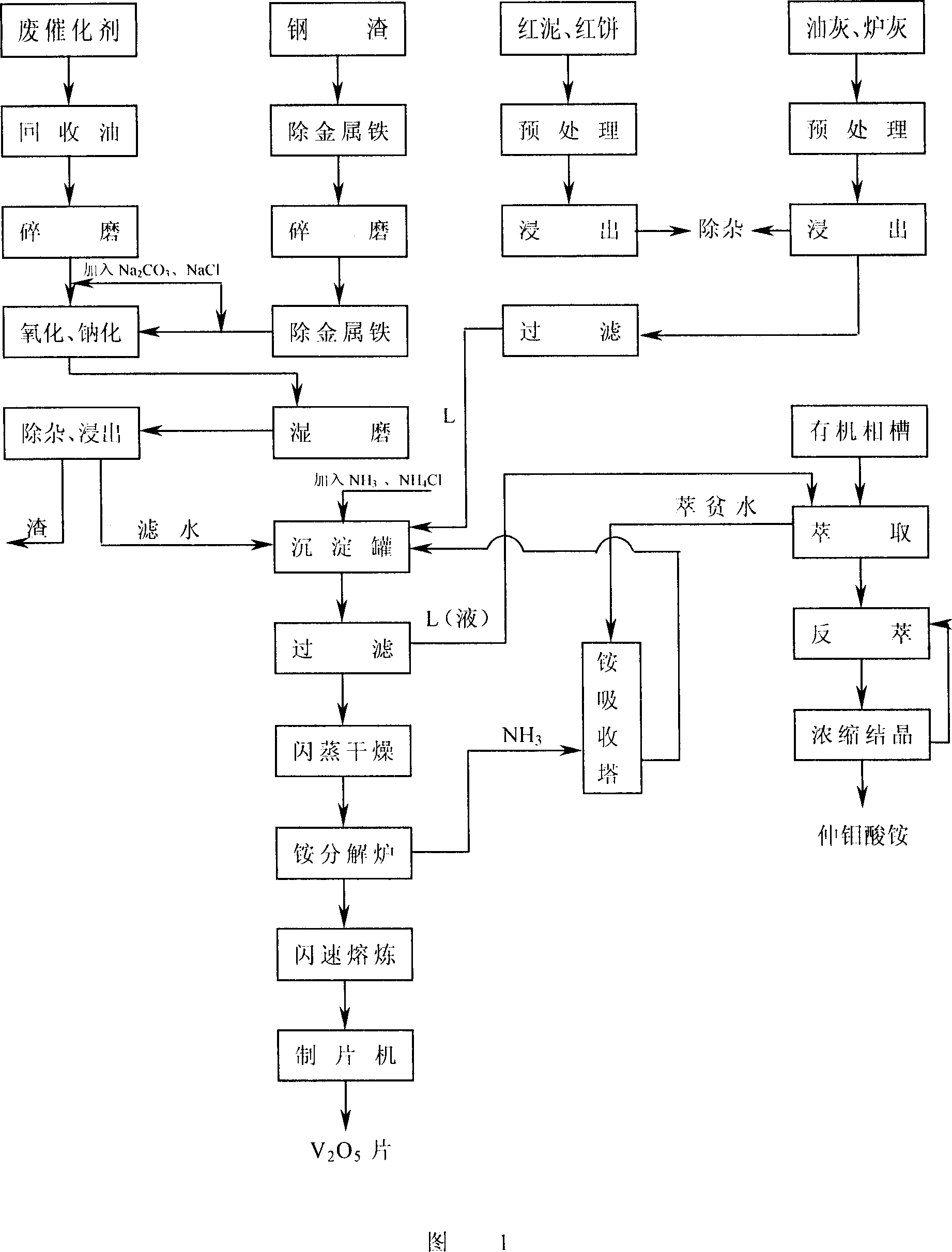

Extraction of vanadium and molybdenum from waste materials is carried out by physically or chemically pre-treating for raw materials by recovered oil, leaching out at a certain pH value, generating soluble sodium metavanadate and sodium molybdate, removing impurities, filtering, solid-liquid separating, precipitating ammonium metavanadate by amine salt, filtering, drying, decomposing, tabletting by smelting furnace to obtain sheeted vanadic anhydride, precipitating ammonium metavanadate filtrate, pouring it into vanadium extraction tank, extracting by organic phase, cleaning by saturated organic phase, reversed extracting, concentrating and crystallizing. It has better vanadium recovery rate and quality and more product yield.

Owner:HUARUI VANADIUM IND SHENYANG

Method for preparing vanadium pentoxide

The invention relates to a method for preparing vanadium pentoxide and belongs to the field of fine chemical engineering. The purpose of preparation of the vanadium pentoxide is achieved. The method includes the following steps of a, re-dissolution, b, crystallization, c, water addition for dissolution, d, vanadium settlement, and e, calcination, wherein in the re-dissolution step, ammonium polyorthovanadate is dissolved in a sodium hydroxide solution, so that a re-dissolution solution is acquired; in the crystallization step, the re-dissolution solution stands still for 20 h to 40 h at the indoor temperature and filtered, filtrate is acquired and stands at the temperature from 2 DEG C to 5 DEC G so as to be crystallized, and sodium metavanadate solid is acquired; in the step of water addition for dissolution, water is added to the sodium metavanadate solid for dissolution, so that a dissolved solution is acquired; in the vanadium settlement step, ammonium sulfate or ammonium sulfate is added to the dissolved solution, a reaction is conducted at the temperature from 45 DEG C to 65 DEG C for 0.5 h to 2 h, the solution is filtered, and ammonium metavanadate solid is acquired; in the calcination step, the ammonium metavanadate solid is calcined, so that vanadium pentoxide is acquired. According to the method, the vanadium pentoxide with high purity can be obtained, the process is simple, and operation is convenient; in the preparation process, vanadium pentoxide can be prepared by adding a small amount of sodium hydroxide and ammonium salt, raw materials are saved, and the method accords with the industrial policies of energy conservation and emission reduction.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Method for preparing sodium metavanadate/potassium metavanadate

The invention discloses a method for preparing sodium metavanadate / potassium metavanadate, which comprises the following steps: heating sodium modified vanadium extraction leach liquor to 80-90 DEG C, adding calcium chloride saturated solution into the sodium modified vanadium extraction leach liquor with the mass ratio of Ca: V= 1.5: 2, stirring the mixture uniformly while the temperature of 80-90 DEG C is kept, and filtering the mixture after reaction for 30-40 minutes to obtain vanadic acid solid; washing and filtering the obtained vanadic acid solid; putting the washed vanadic acid solid in a container, adding sodium bicarbonate solution or potassium bicarbonate solution with the mass concentration of 20-30% by a molar ratio of CO3<2-> to Ca<2+> in the range of 1 to 1.2 into the container, fully stirring the mixture at temperature of 60-70 DEG C, , filtering the mixture after reaction for 30-40 minutes to obtain calcium carbonate solid and sodium metavanadate or potassium metavanadate solution, evaporating, concentrating, crystallizing, and finally, separating the obtained crystal and dring at a temperature below 40 DEG C to obtain the sodium metavanadate or potassium metavanadate solid.

Owner:PANZHIHUA IRON AND STEEL +1

Method for producing mung bean sprout

InactiveCN101731133APromote growthImprove qualityCultivating equipmentsSoilless cultivationContinuous operationMoisture

The invention relates to a method for producing mung bean sprout, comprising: dipping mung beans and cultivating mung beans. When mung bean sprouts are produced, sowing density is 1847-3079g / m<2>. The method for dipping mung beans comprises: dipping mung beans by chitosan solution of which the deacetylated degree is 80-95%; and after being drained, dipping the mung beans overnight by sodium metavanadate solution of which the concentration is 0-3000 mg / L, and draining the moisture content. The method for cultivating mung beans comprises: putting the dipped mung beans into a seedling culture disk for cultivation; spraying sodium metavanadate solution of which the concentration is 0-3000 mg / L for 3-5 times each day, and spraying 50-150 ml once. The mass percent concentration of potassium permanganate is 1%. The invention has the advantages of simple technology and big handling capacity, can accelerate the growth of mung beans, obviously improves output and can be in continuous operation; in addition, the invention has moderate production condition and high mung bean quality, uses sodium metavanadate solution to dip and cultivate so as to succeed in introducing vanadium element into the mung beans, so that the mung bean has high vanadium content and vanadium containing ratio.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

Method for extracting sodium metavanadate from vanadium extraction leaching solution

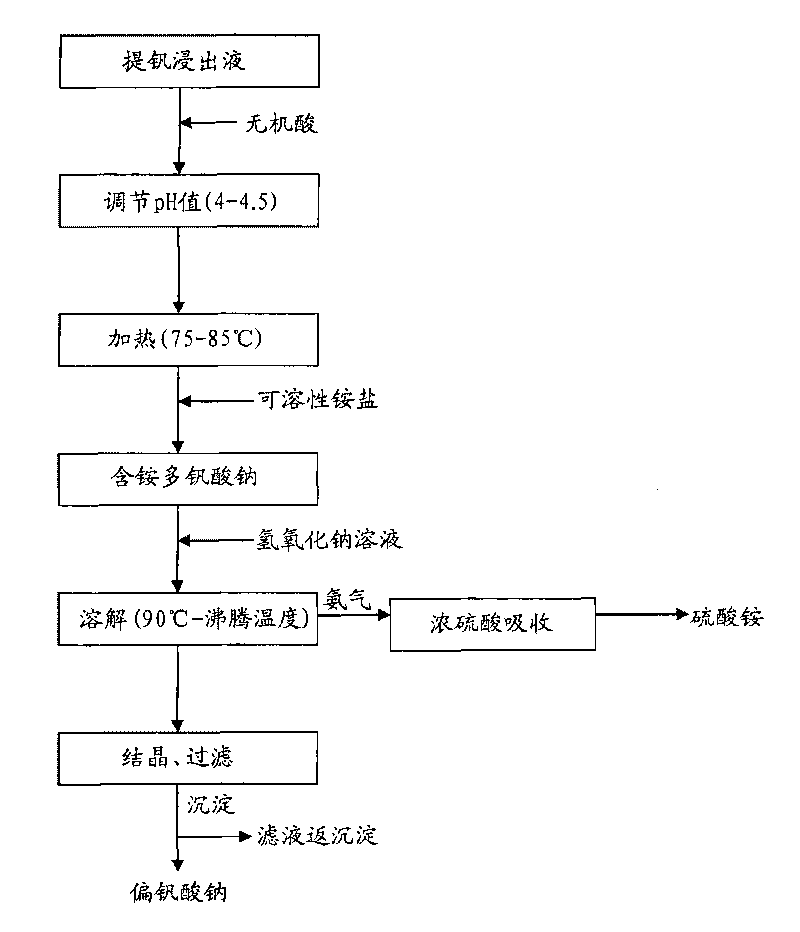

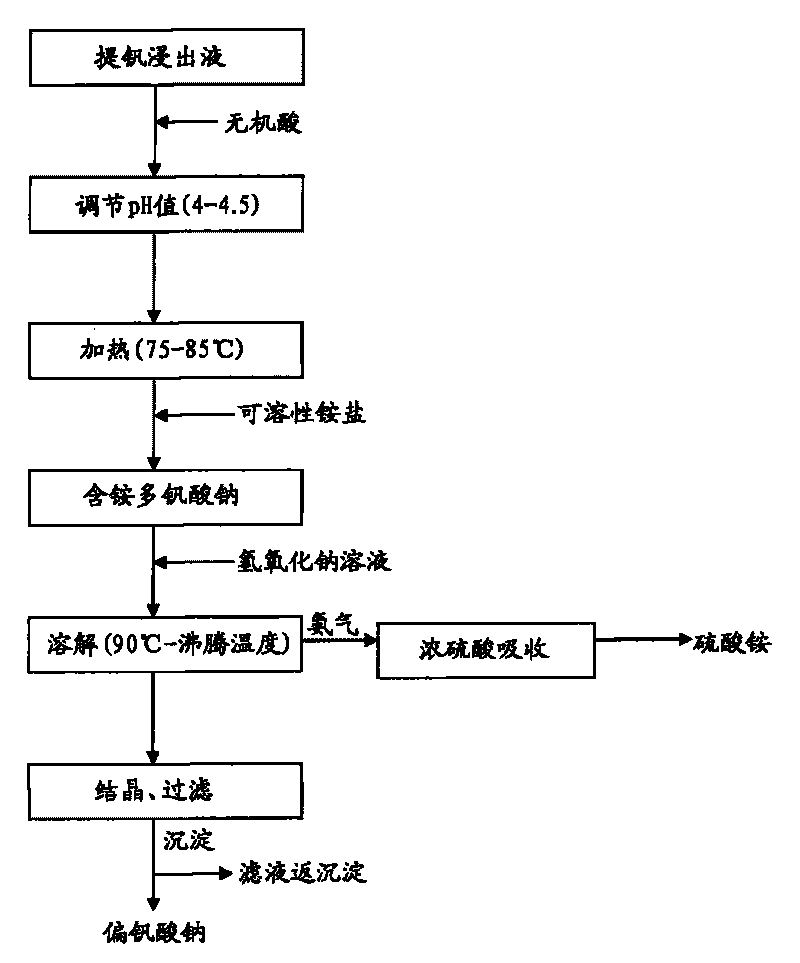

The invention discloses a method for extracting sodium metavanadate from a vanadium extraction leaching solution, comprising the following steps of: adjusting the pH value of the sodium-ionized vanadium extraction leaching solution to 4-4.5 by using inorganic acid, then heating the solution to the temperature of 75-85 DEG C, then adding a soluble ammonium salt into the solution according to the mass ratio of NH4+:V=1.5-2, fully and uniformly stirring, and obtaining sodium polyvanadate containing ammonium after the reaction is finished; putting the obtained sodium polyvanadate containing ammonium into a sealed reactor, adding sodium hydroxide according to the mol ratio of Na:V=0.8-0.9, stirring at the temperature ranging from 90 DEG C to the boiling temperature till the solution starts to precipitate a white or light yellow solid, cooling the solution to the room temperature under the condition of stirring, filtering and drying to obtain a sodium metavanadate solid.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM +1

Method for preparing high-corrosion-resistance colored passivating film on surface of aluminum alloy

ActiveCN103276385AEasy to observeEasy to operateMetallic material coating processesTitaniumPre treatment

The invention discloses a method for preparing a high-corrosion-resistance colored passivating film on the surface of aluminum alloy. The method comprises the following steps of: (1) pretreating the surface of the aluminum alloy; and (2) placing the aluminum alloy treated in the step (1) in conditioning fluid, and impregnating at a constant temperature for a period of time to obtain the yellow passivating film containing zirconium, titanium and vanadium on the surface of aluminum alloy. The aluminum alloy conditioning fluid comprises the following components: 0.1g / L-20g / L of fluotitanic acid, 0.1g / L-30g / L of fluozirconic acid, 0.2g / L-40g / L of sodium metavanadate and 0.1g / L-20g / L of tannic acid. The film generated by the method has a color, is convenient to observe and can rapidly form the passivating film with high corrosion resistance.

Owner:SOUTH CHINA UNIV OF TECH

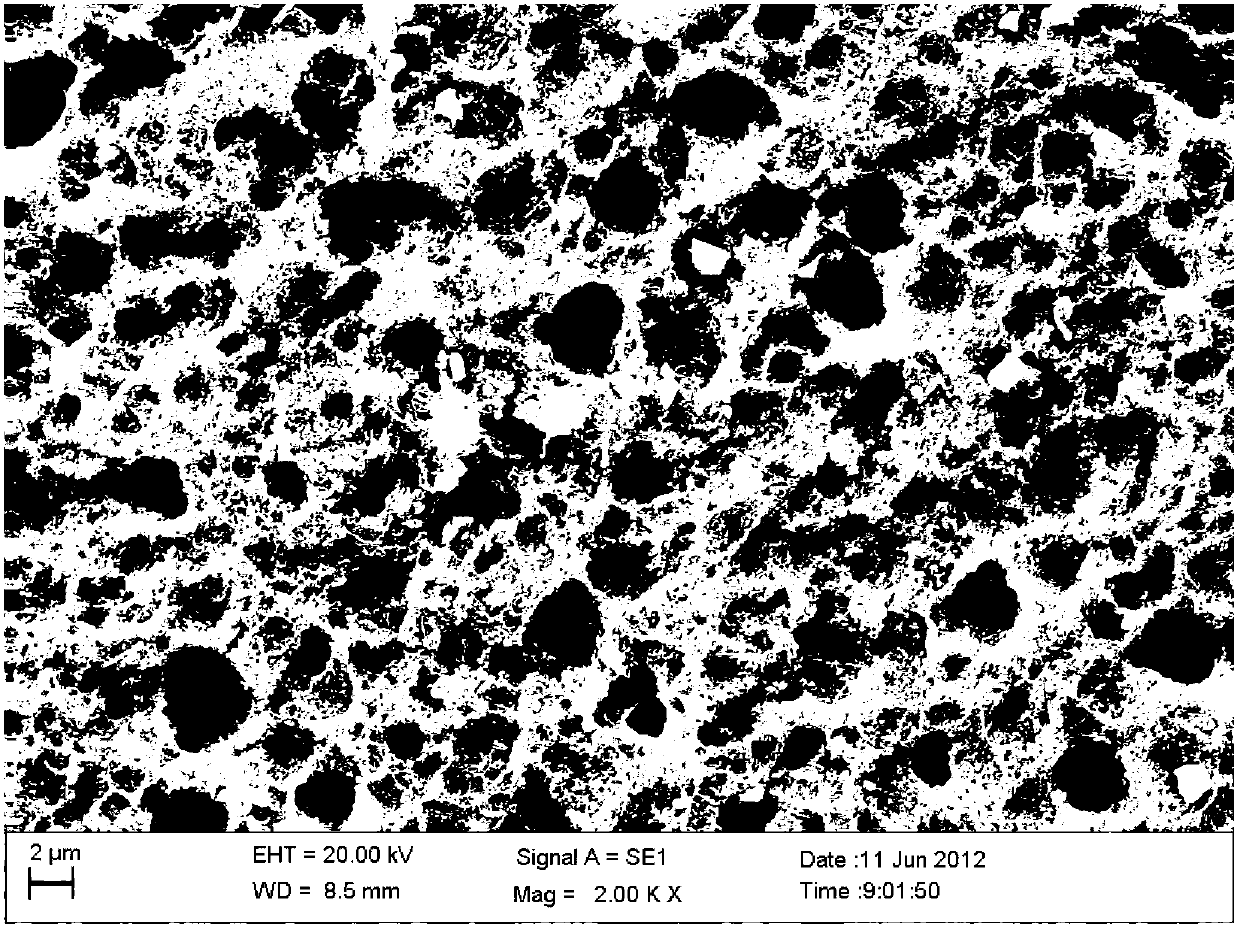

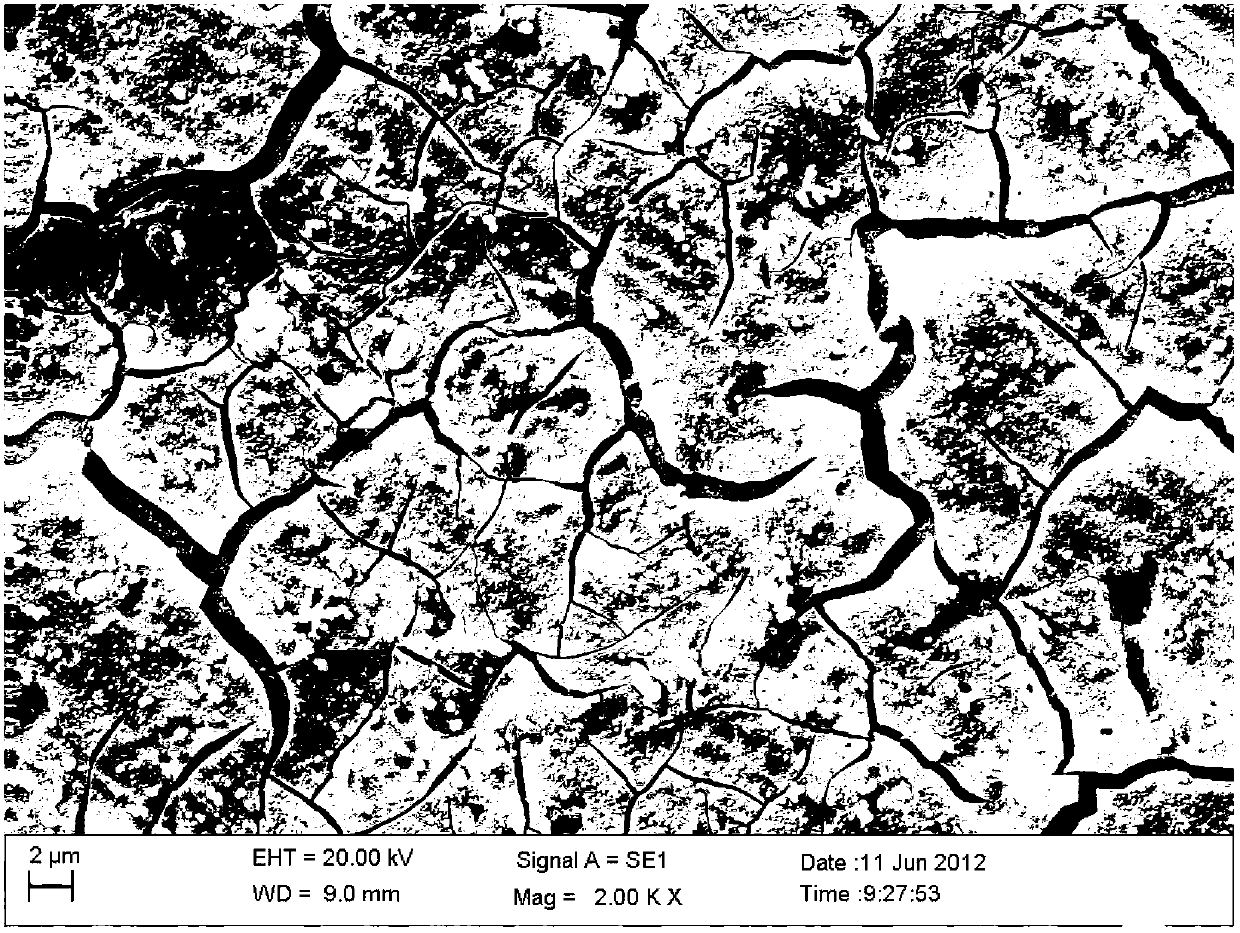

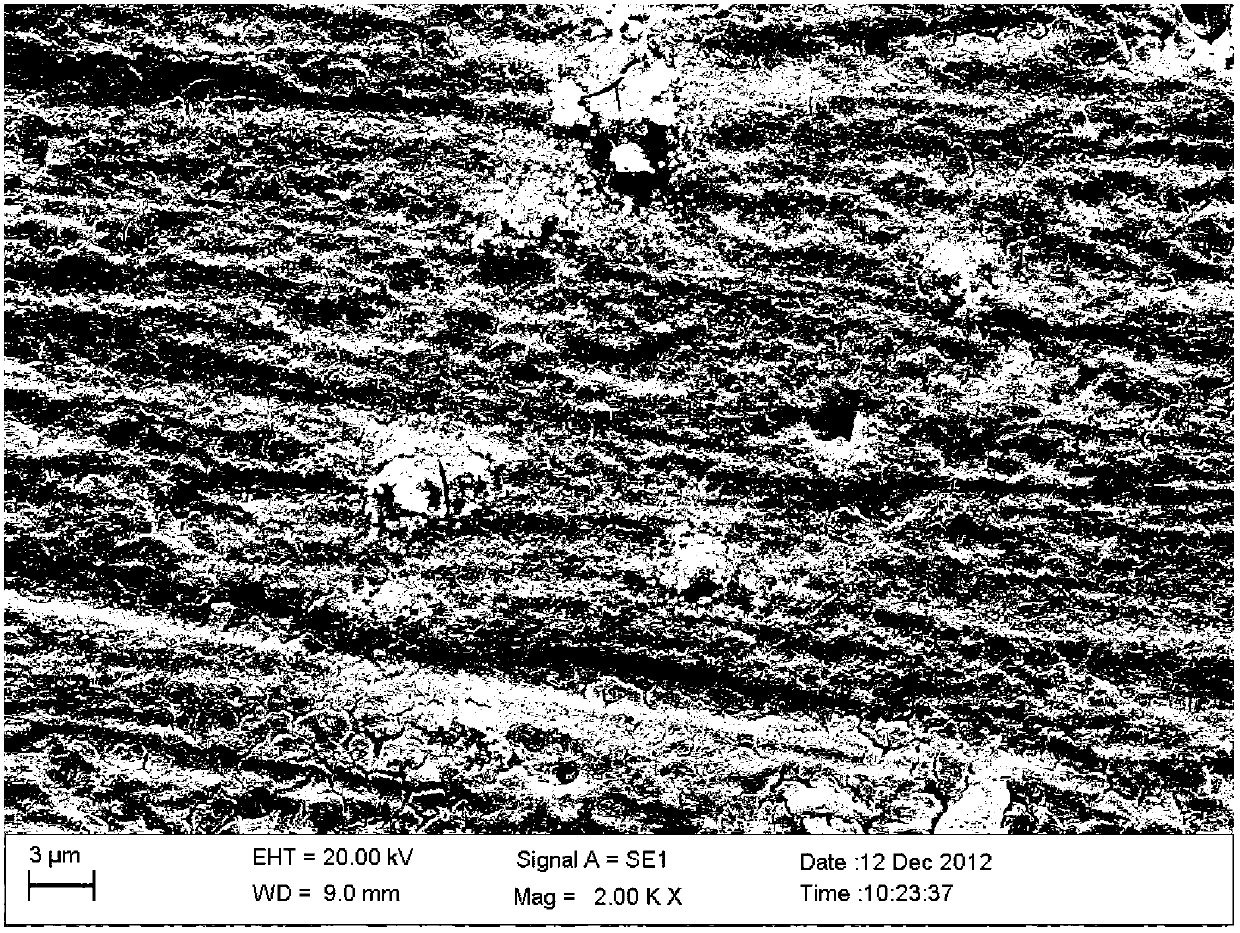

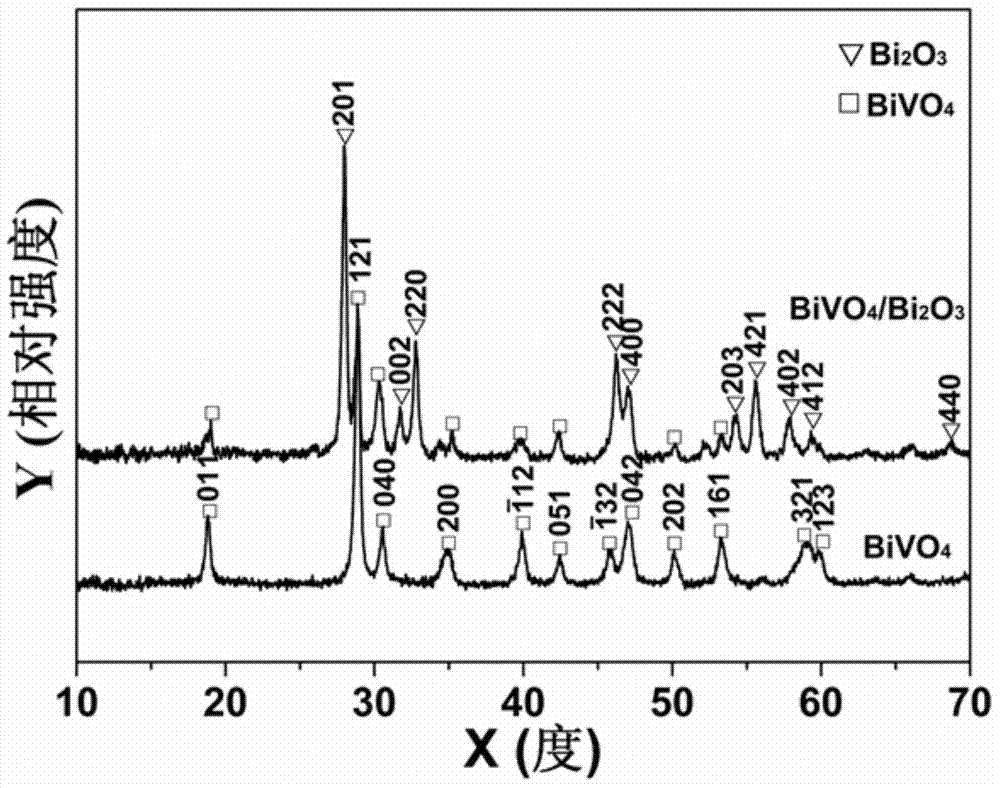

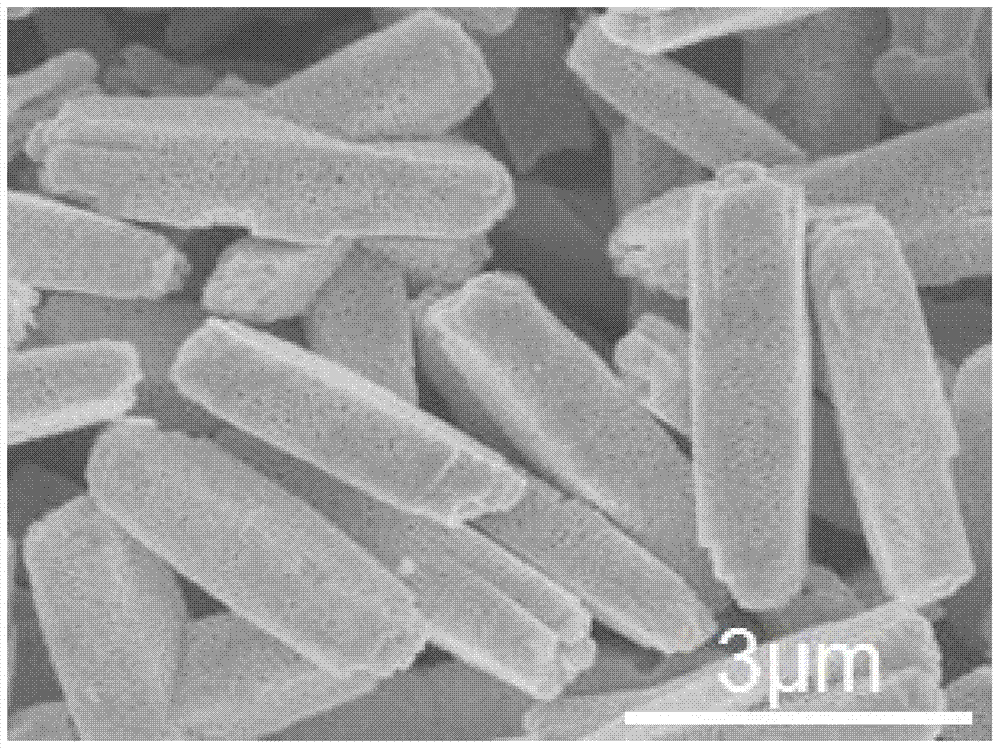

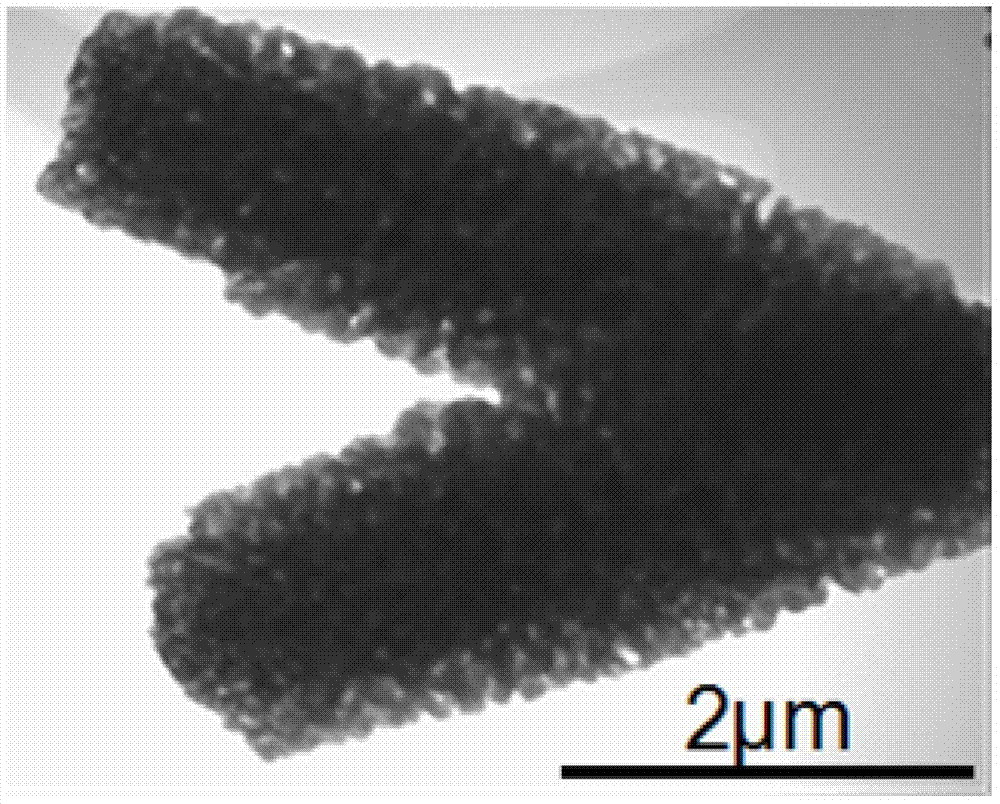

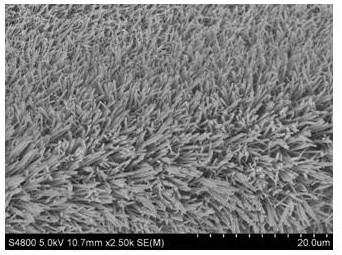

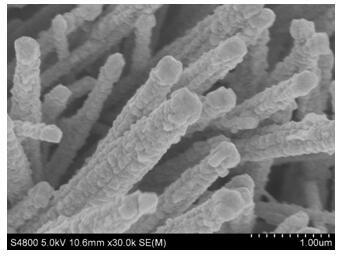

Method for massively preparing mesoporous BiVO4/Bi2O3 composite micro-rod p-n heterojunction photocatalyst

InactiveCN104772134ALow costEasy to controlMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionSurface-active agents

The invention relates to a method for massively preparing a mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst. The method for massively preparing the mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst takes metal inorganic salt-bismuth nitrate pentahydrate (Bi (NO3) 3.5H2O) as a reaction precursor, polyvinylpyrrolidone (PVP) as a surface active agent as well as sodium oxalate (Na2C2O4) and sodium metavanadate (NaVO3) as reactants; the method comprises the steps of feeding the surface active agent into the reaction precursor, carrying out a solvothermal reaction, centrifuging, washing, drying, and carrying out solid-phase reaction calcination on the obtained product at the temperature of 300-400 DEG C to obtain the BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst. The prepared mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst has the length of about 3.5-4.5mu m, the diameter of about 0.7-0.9mu m and the mesoporous average diameter of 30.0nm. The prepared mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst has the characteristics of being low in cost, easy to control, good in repeatability, and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

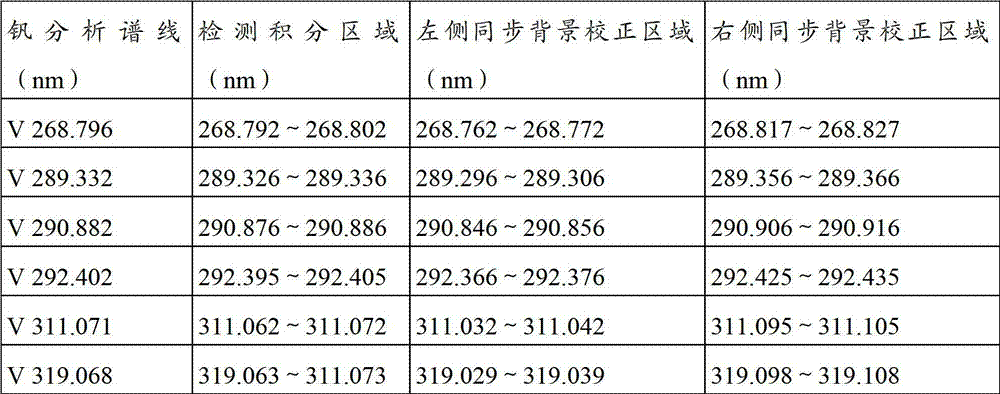

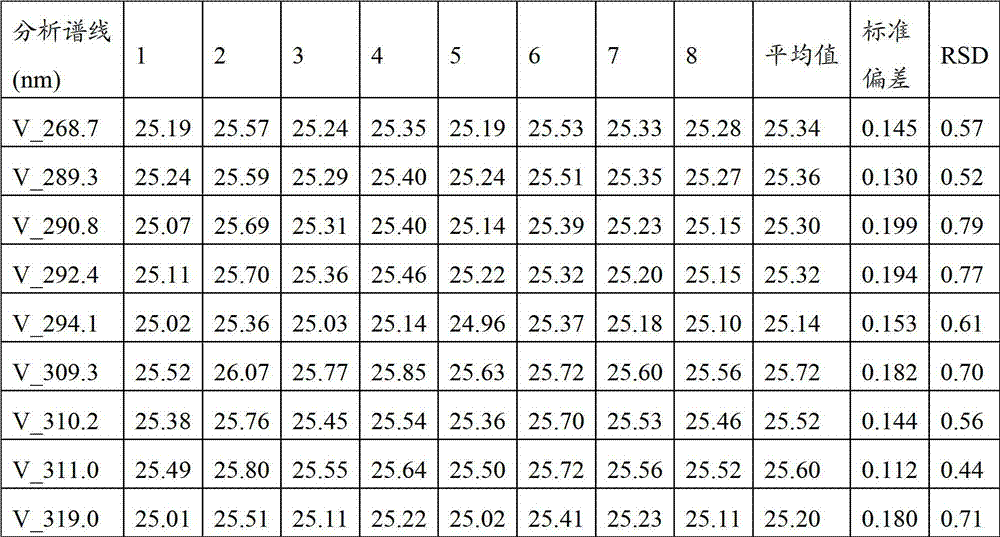

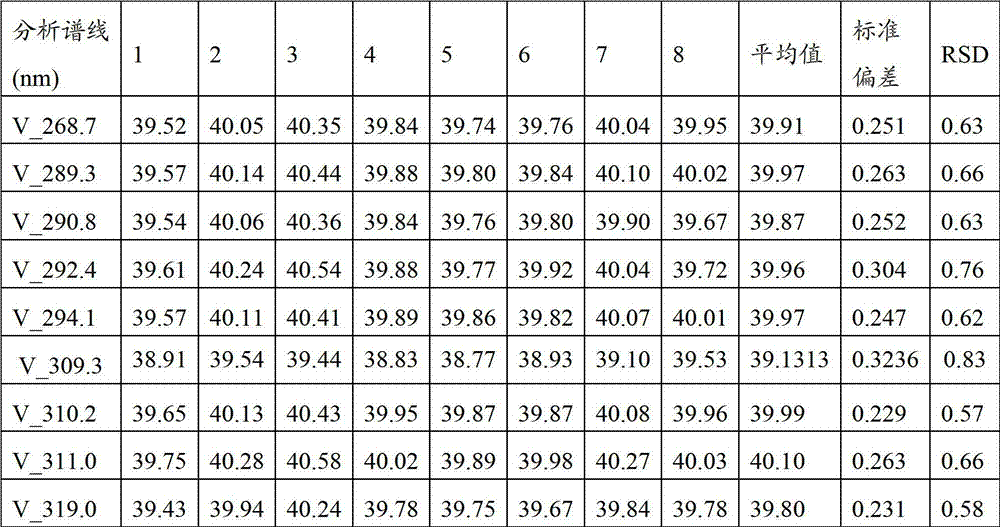

Method for determining content of vanadium

ActiveCN103048309AAccurate measurementAnalysis by thermal excitationSodium metavanadateAnalytical chemistry

The invention provides a method for determining content of vanadium. The method for determining content of vanadium comprises the following steps: digesting a vanadium-containing sample with hydrochloric acid to obtain a vanadium-containing solution, and determining the content of vanadium in the vanadium-containing solution using an inductively coupled plasma atomic emission spectrometer. According to the method, the content of vanadium in sodium metavanadate can be determined fast and accurately.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

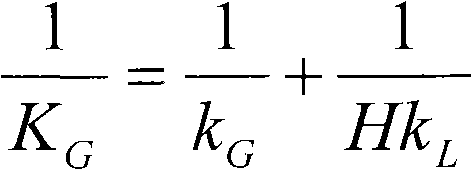

A method for capturing carbon dioxide in mixed gas with composite decarburization solution

InactiveCN102284227APromote absorptionIncrease desorptionCarbon compoundsDispersed particle separationAbsorption capacityChemical reaction

The invention relates to a composite decarburization solution for capturing carbon dioxide in mixed gas, belonging to the technical field of carbon dioxide gas capture. It relates to a composite decarburization solution, which is composed of solvent benzyl alcohol, phenyl alcohol, N-methylpyrrolidone or a mixture thereof, main absorption component MEA, auxiliary absorption components EDA, DETA and TETA, active components PZ and 2, 3-butanedione, the corrosion inhibitor is sodium chromate, and the antioxidant is sodium metavanadate and copper carbonate. Since the composite decarburization liquid uses a mixed solvent, it not only improves the absorption capacity, purification degree and desorption rate of carbon dioxide, expands the reaction temperature range, but also reduces the volume of the desorption tower, greatly reduces regeneration energy consumption, and reduces equipment investment and operating costs. The invention is mainly used for capturing carbon dioxide in various chemical reaction tail gas, ore decomposition gas, combustion flue gas, natural gas, city gas and biogas, and has broad application prospects.

Owner:DALIAN UNIV OF TECH

Comprehensive utilization method of stone coal resources

ActiveCN104841682ASolve difficult problemsReduce stackingSolid waste disposalClimate change adaptationBrickCrushed stone

A comprehensive utilization method of stone coal resources comprises the following steps: 1, crushing stone coal, and carrying out ball milling; 2, adding water, adding concentrated sulfuric acid, and stacking for slaking; 3, adding water, mixing, and carrying out solid-liquid separation; 4, sintering tailings to make red bricks or a garbage fertilizer; 5, preparing ammonium alum; 6, separating to prepare calcium sulfate dihydrate; 7, separating to obtain a sodium metavanadate solution; and 8, preparing vanadic anhydride, carrying out solid-liquid separation to obtain a liquid which is a sodium chloride solution, and heating for evaporation to obtain industrial salt. A small amount of sulfuric acid is added in the production process, most sulfuric acid is consumed in the stacking slaking process to form sulfate, and sulfate basically has no corrosion, so special protection is not needed. Ion exchange resin is Dow weak alkaline anion resin containing a weak alkaline group, and has the advantages of good adsorption ability, strong selectivity, good regeneration property, environmental protection, and simple and safe operation.

Owner:张伟峰

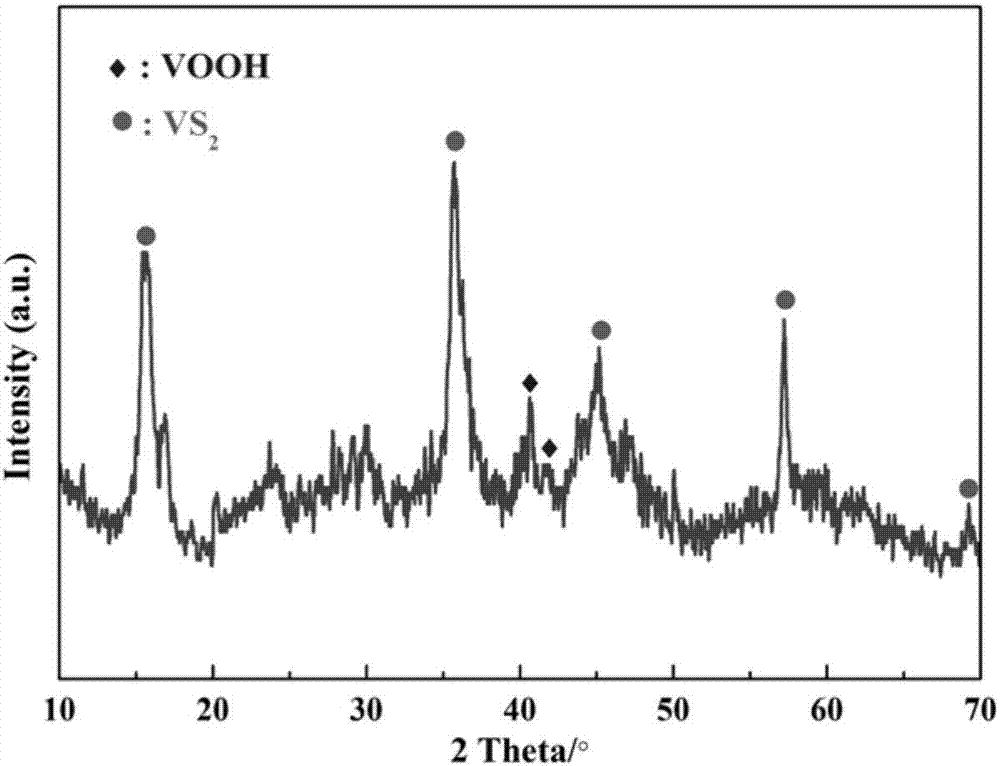

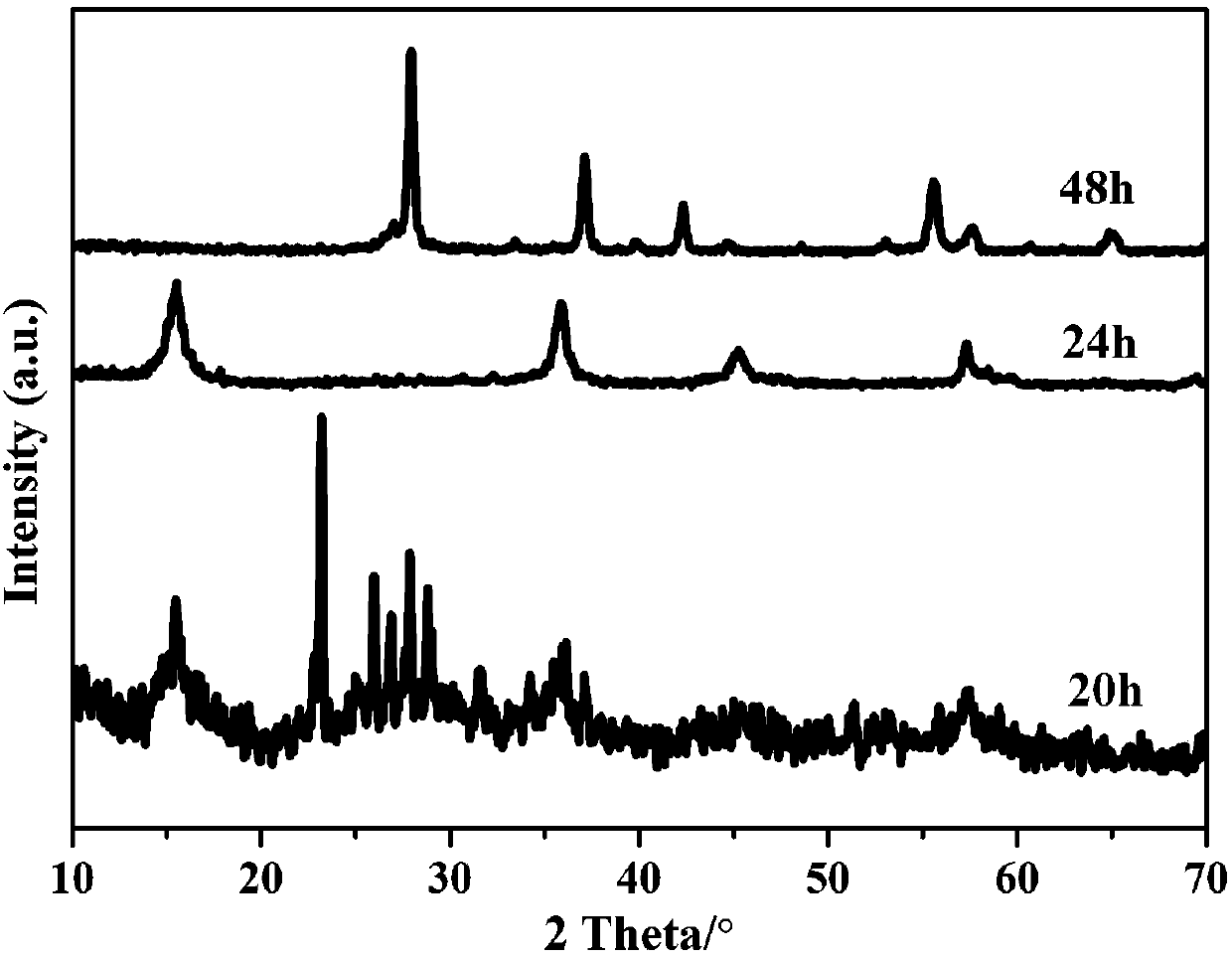

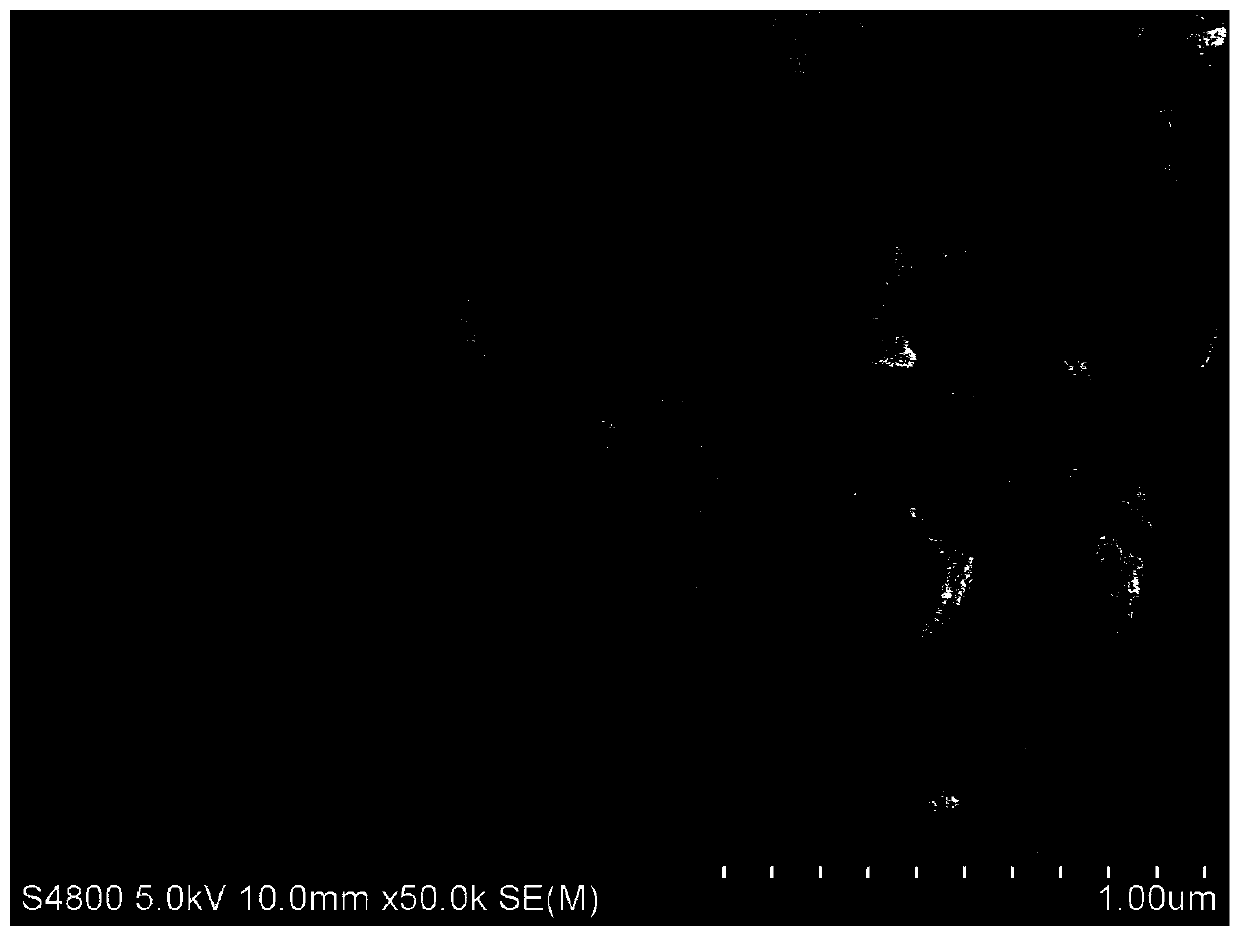

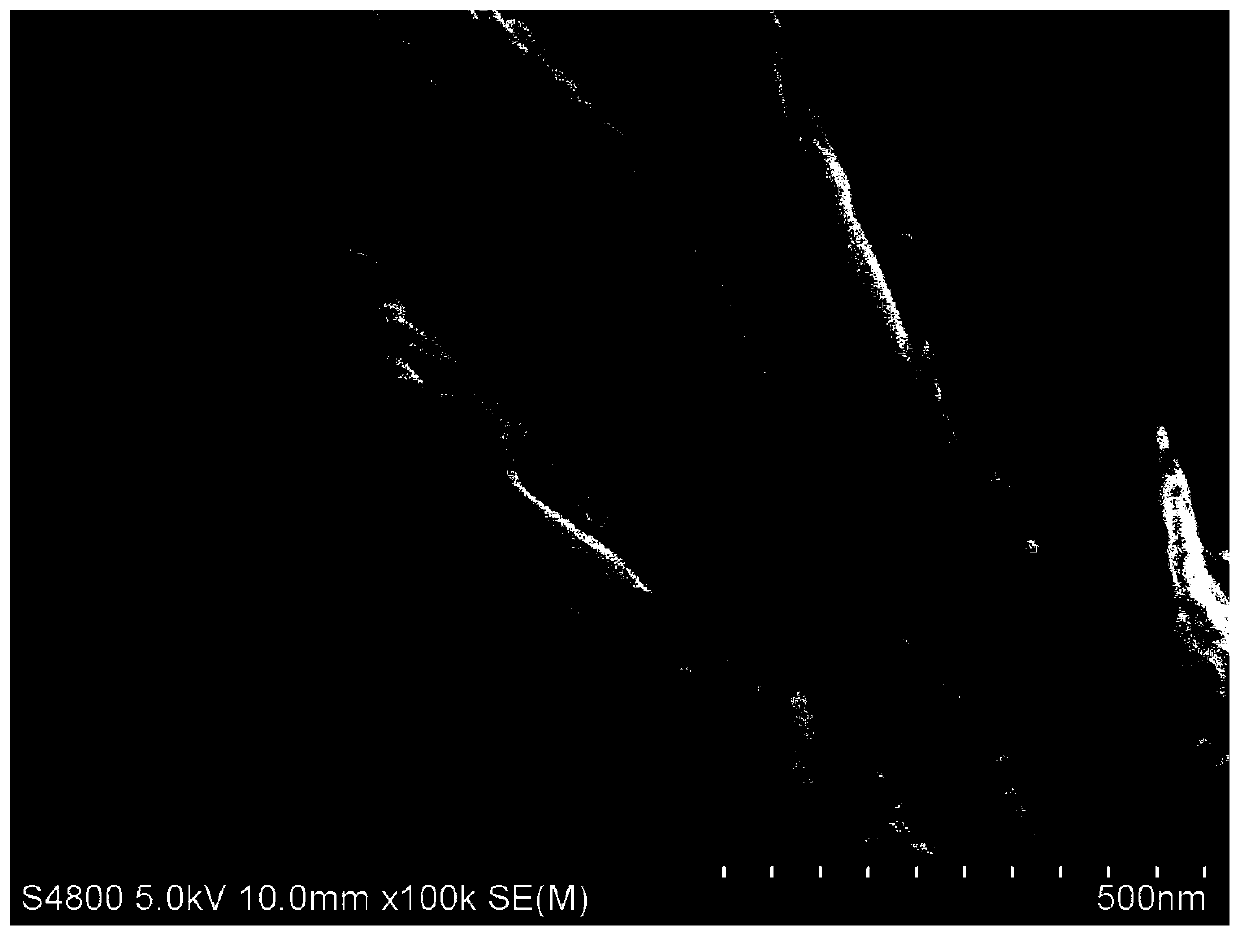

Vanadium disulfide nanosheet coated with oxo-vanadium hydroxide and preparation method and application thereof

ActiveCN107221646AReported electrochemical performanceSynthesis temperature is lowImpregnation manufacturingVanadium disulfideElectrical battery

The invention provides a vanadium disulfide nanosheet coated with oxo-vanadium hydroxide and a preparation method and application thereof. The preparation method comprises the following steps: dissolving sodium metavanadate and thioacetamide in deionized water in a magnetic stirring state simultaneously; then, pouring the solution into a reaction lining for sealing, loading the lining into an outer kettle for fixing, and placing the outer kettle into a homogeneous phase reaction instrument; lastly, cooling a reaction product, washing, collecting and drying to obtain the VOOH-coated VS2 nanosheet. The VOOH-coated VS2 nanosheet prepared by the method has uniform chemical composition, higher purity, uniform appearance and a specific self-assembly structure, and shows superior electrochemical performance when being taken as a sodium-ion battery electrode material. Moreover, by adopting the method, the defect of high temperature in a conventional calcining method is overcome, and large-sized equipment and severe reaction conditions are not needed; the vanadium disulfide nanosheet has the advantages of adoption of cheap and readily-available raw materials, low cost, high yield, no need of posttreatment and environmental friendliness, and can be suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

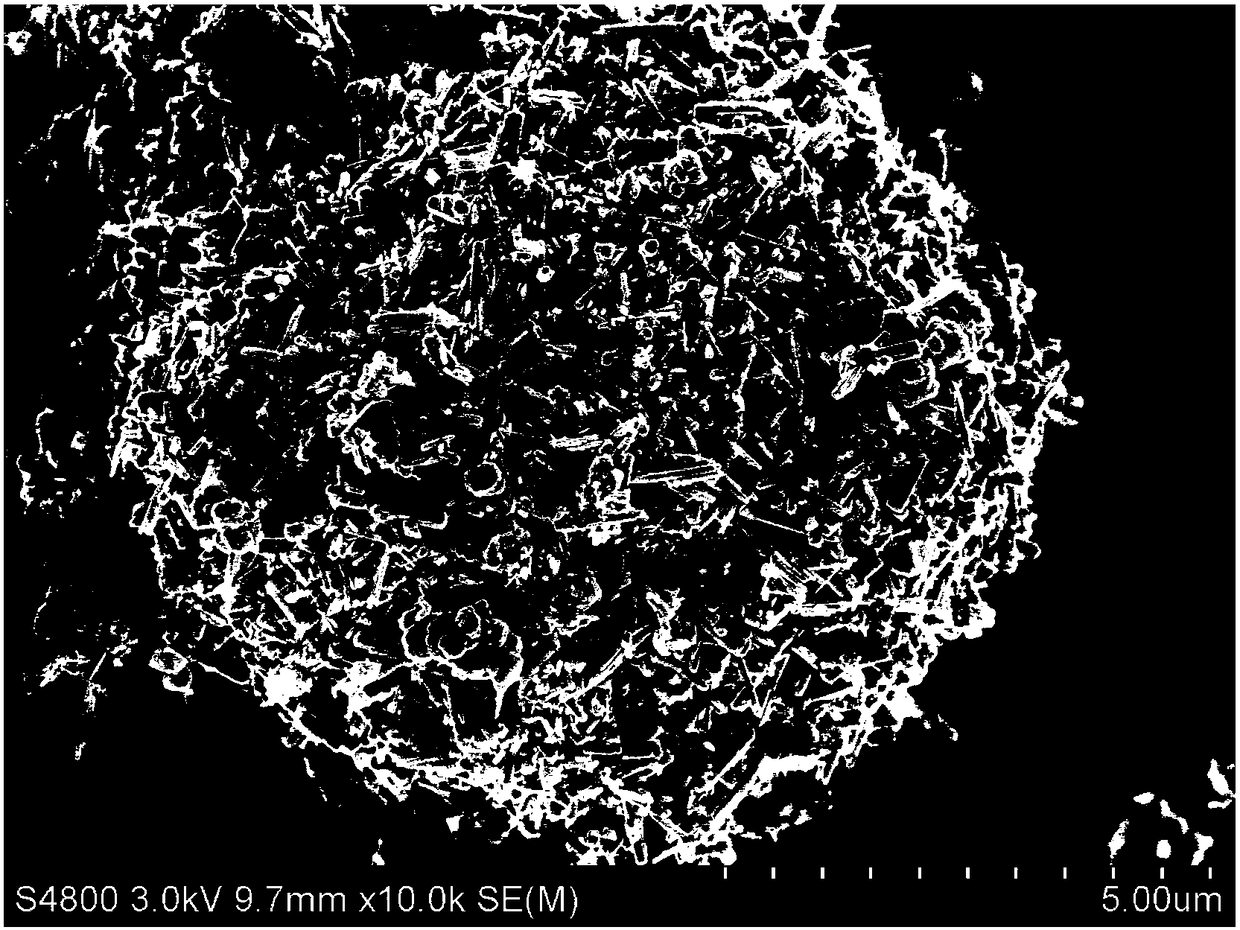

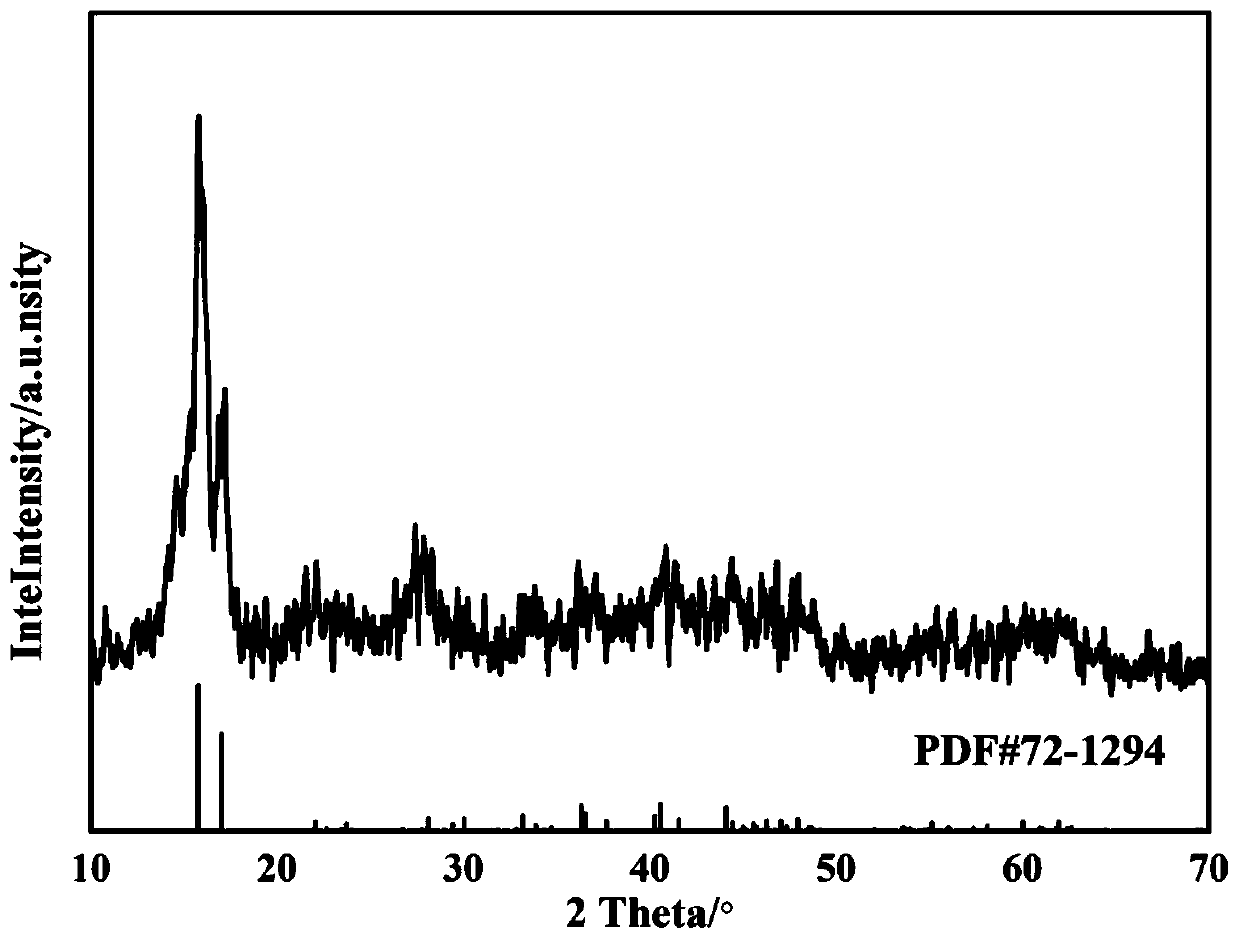

Ultra-small nanosheet self-assembled flower-like VS2 powder and preparation method thereof

InactiveCN108585042AImprove responseReduce the temperatureMaterial nanotechnologyVanadium compoundsReaction temperatureSolvent

The invention relates to an ultra-small nanosheet self-assembled flower-like VS2 powder and a preparation method thereof. The one-step preparation of ultra-small nanosheet self-assembled flower-like VS2 powder is realized by adopting a solvothermal method, using nitrogen methylpyrrolidone as a solvent, respectively using sodium metavanadate and thioacetamide as a vanadium source and a sulfur source, and synergistically controlling the concentration and ratio, reaction temperature and reaction time. The method has the advantages of simple reaction process, low temperature, and easy control, does not require large equipment and harsh reaction conditions, can generate ultra-small and ultra-thin VS2 nanosheets through a structural regulation function of the solvent, and allows the nanosheets to be self-assembled into small-scale flower-like structures in a specific manner. When being applied as a sodium / lithium ion battery negative electrode material and a photo / electrocatalyst, the aboveproduct can exhibit excellent electrochemical performances and catalytic performances.

Owner:SHAANXI UNIV OF SCI & TECH

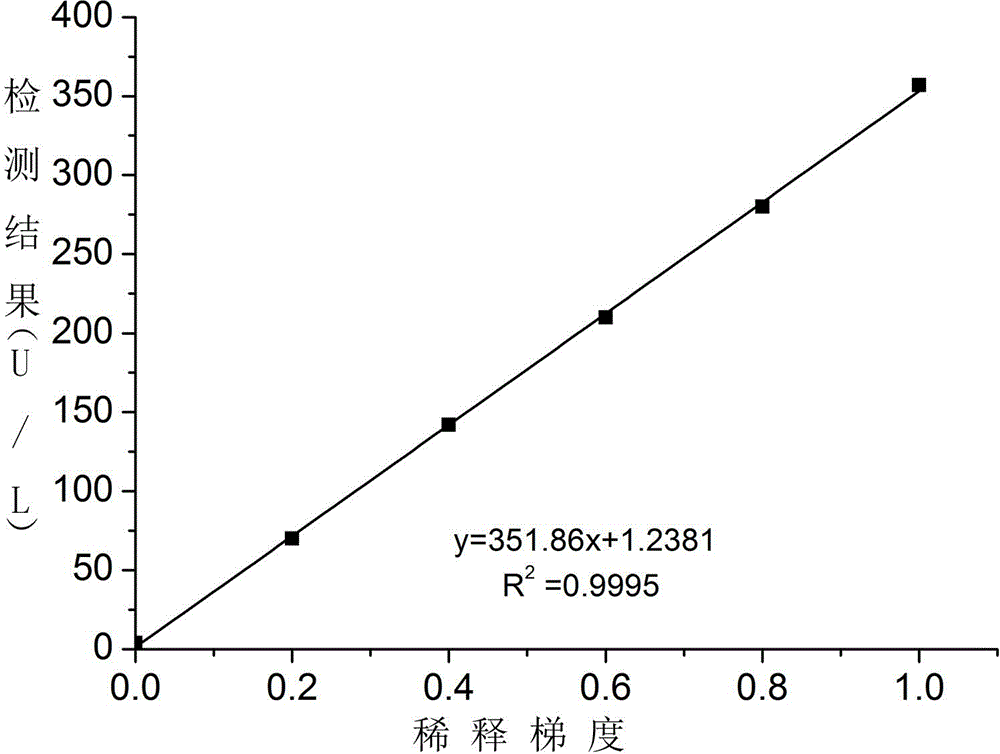

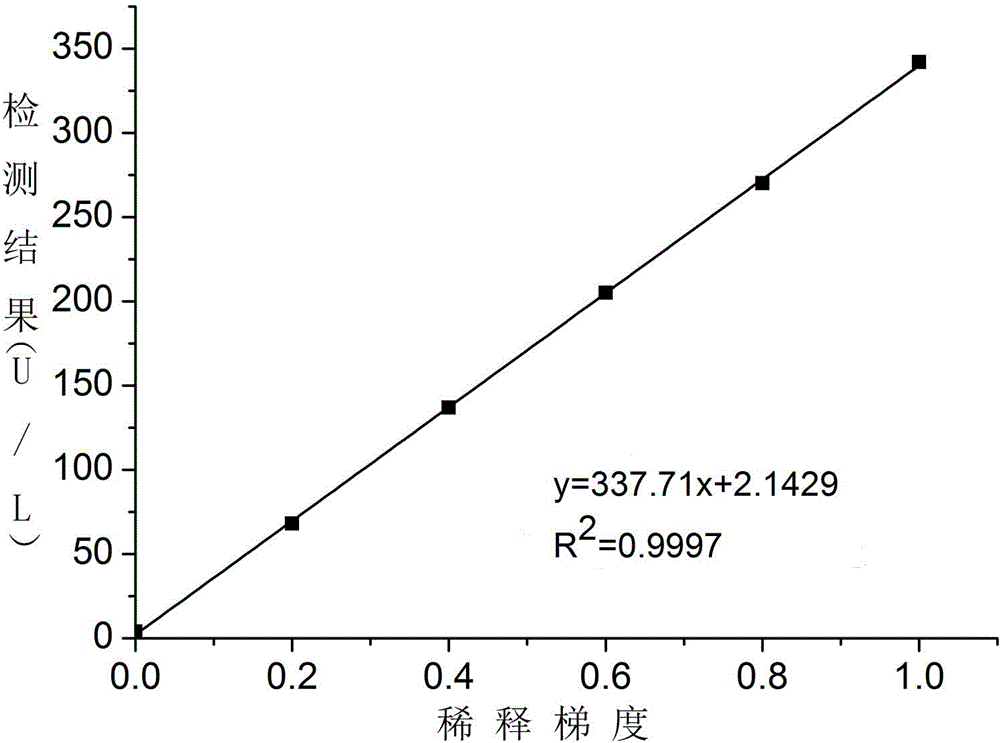

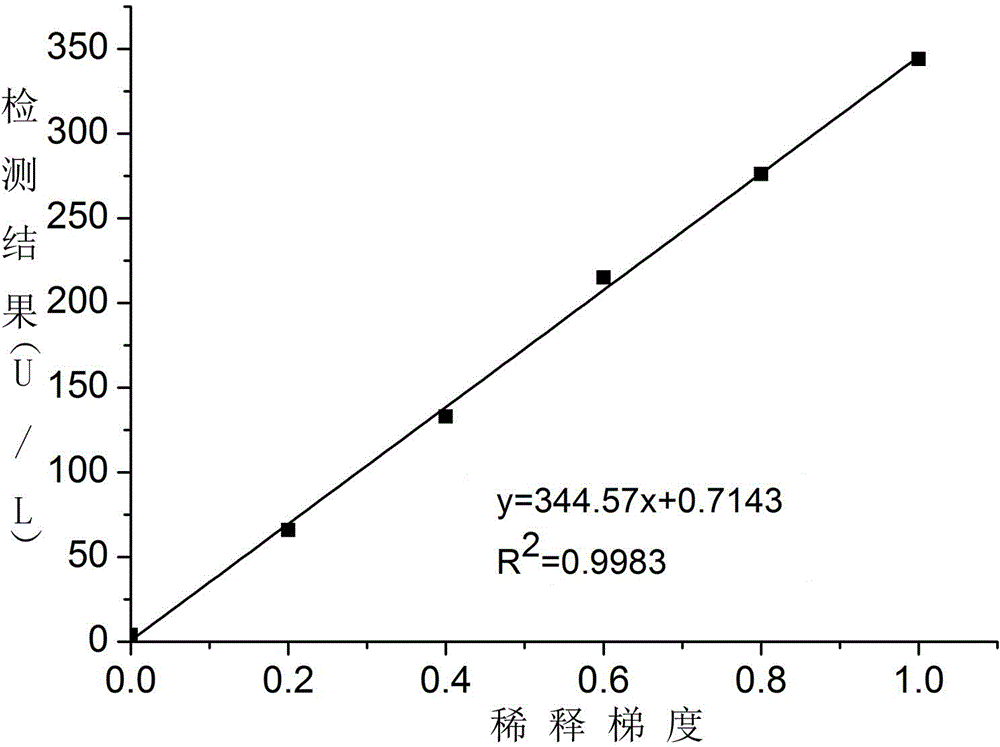

Direct bilirubin detection reagent

ActiveCN104406971AImprove anti-interference abilityImprove accuracyMaterial analysis by observing effect on chemical indicatorHydrazine dihydrochlorideActive agent

The invention discloses a direct bilirubin detection reagent. The detection reagent disclosed by the invention comprises a reagent R1 and a reagent R2 of which the volume ratio is 4:1, wherein the reagent R1 comprises tartaric acid buffer solution, hydrazine dihydrochloride, a surfactant and Proclin300; the reagent R2 comprises phosphate buffer solution, sodium metavanadate and Proclin300. The direct bilirubin detection reagent disclosed by the invention has high anti-interference capacity, high accuracy, higher linearity and high stability, can eliminate interference of interfering substances and indirect bilirubin, is suitable for a full-automatic biochemical analyzer and has high clinical application value.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

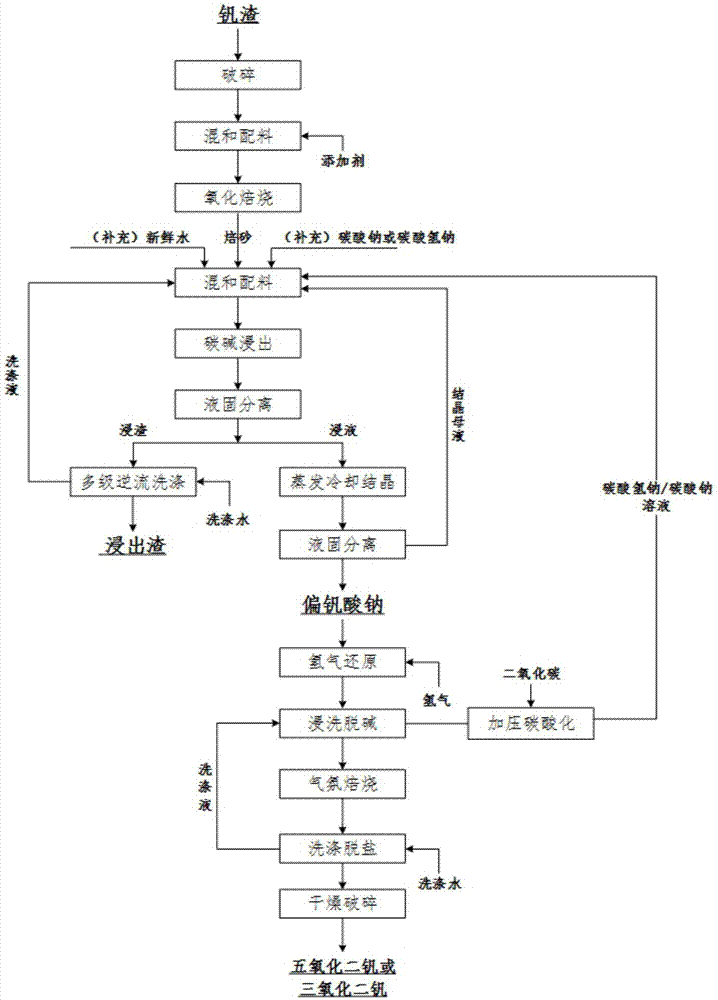

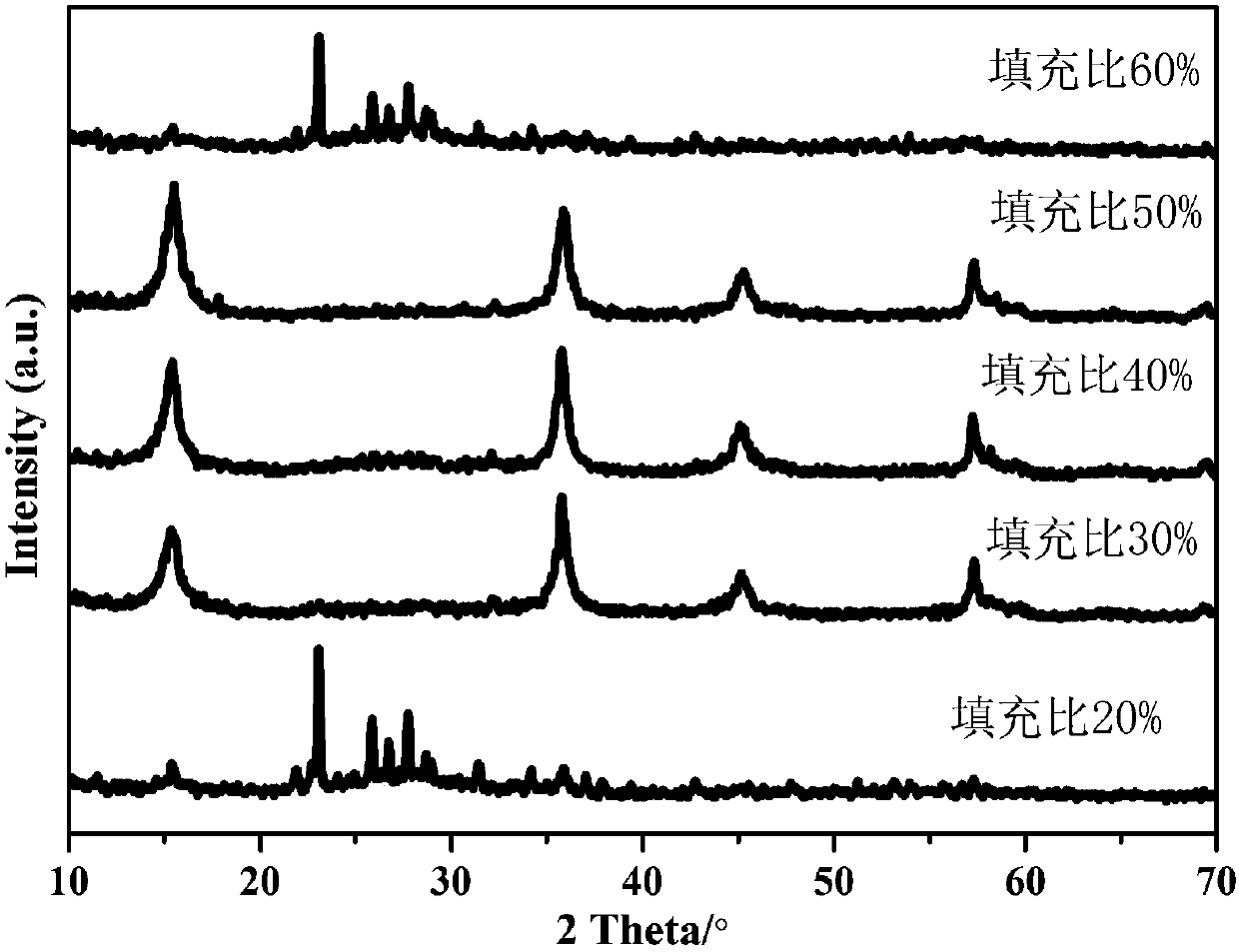

Clean production technique of vanadium oxide by vanadium slag carbocholine leaching-hydrogen reduction process

ActiveCN104120271AImprove leaching rateHigh recovery rateProcess efficiency improvementSlagVanadium oxide

The invention relates to a clean production technique of vanadium oxide by a vanadium slag carbocholine leaching-hydrogen reduction process. The technique comprises the following steps: (1) mixing and proportioning the vanadium slag and additives, and roasting to obtain a roasted product; (2) leaching the roasted product obtained in the step (1) with a carbocholine water solution, and carrying out liquid-solid separation; (3) evaporating the solution separated in the step (2), cooling to crystallize, and separating to obtain a sodium metavanadate crystal; and (4) drying the sodium metavanadate crystal obtained in the step (3), reducing with hydrogen, and carrying out immersion cleaning for dealkalization, atmosphere roasting, washing for desalting, drying and crushing on the reduction product to obtain the vanadium oxide product. The technique has the advantages of high vanadium recovery rate and low impurity content in the leaching solution. The sodium metavanadate is used for directly preparing the vanadium oxide product, thereby avoiding the treatment of the ammonia nitrogen wastewater. The technique is simple and clean, and has the characteristics of no pollution and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

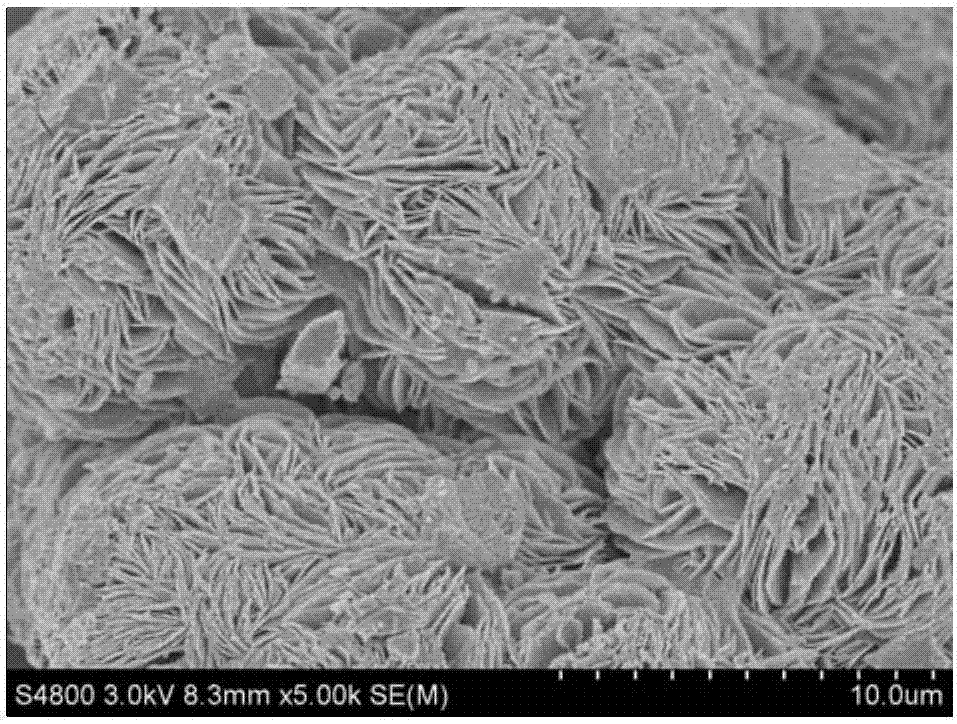

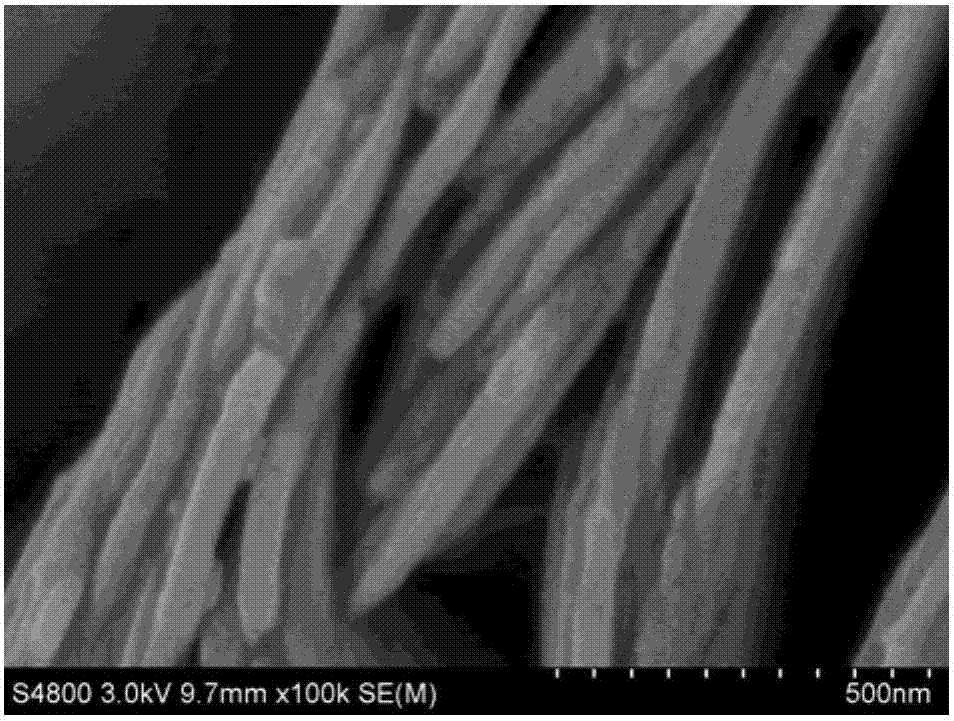

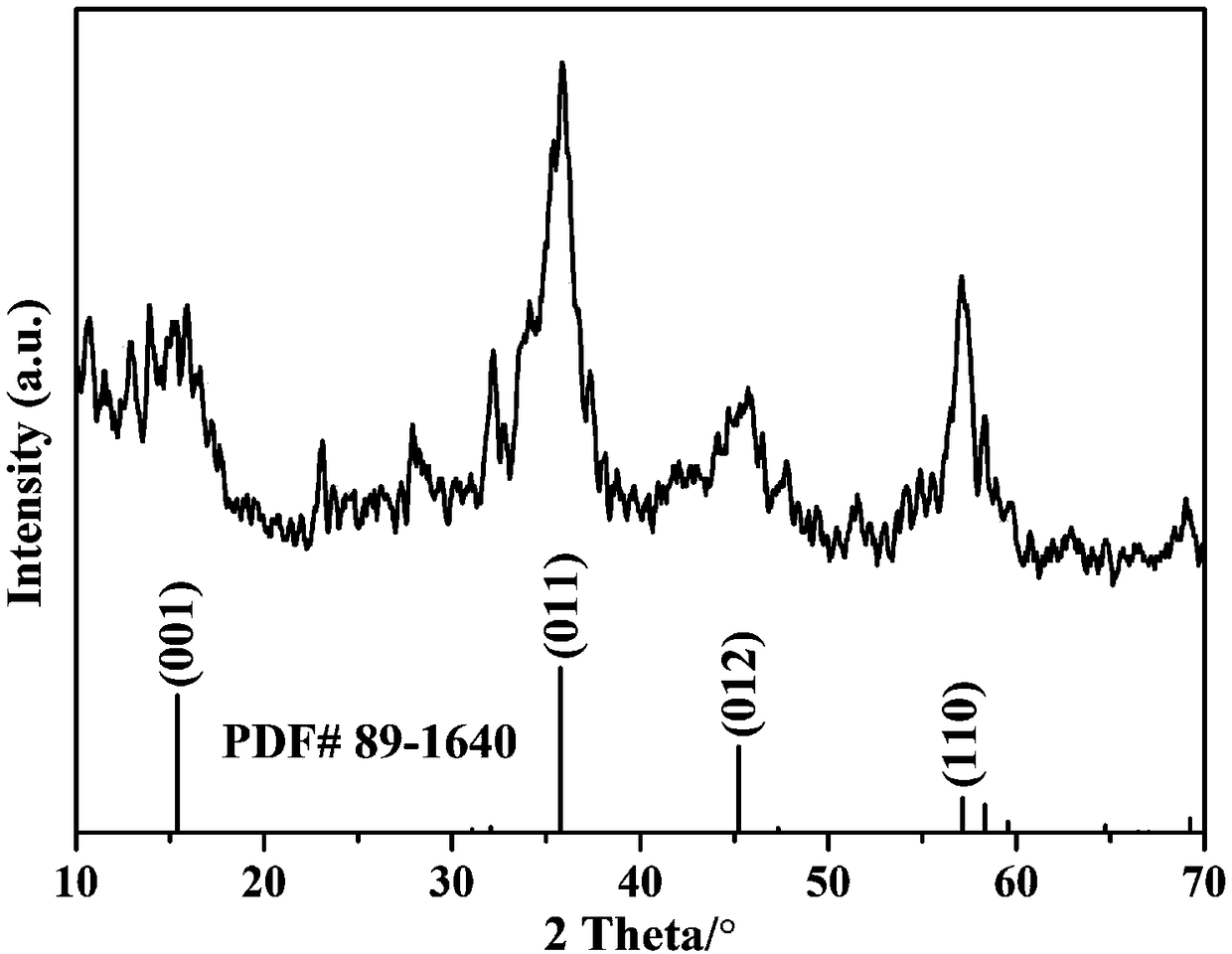

(001)-oriented nanosheet self-assembled three-dimensional VS2 microrod and preparation method thereof

ActiveCN107902697ASynthesis temperature is lowLow costMaterial nanotechnologyVanadium compoundsSingle crystalSolvent

A preparation method of a (001)-oriented nanosheet self-assembled three-dimensional VS2 microrod comprises the following steps: simultaneously adding sodium metavanadate and thioacetamide into anhydrous ethanol to obtain a solution A; and pouring the solution A into a reaction liner, sealing the reaction liner, carrying out a hydrothermal reaction in a homogeneous reactor, naturally cooling the obtained reaction product to room temperature, taking out the obtained cooled reaction product, alternately cleaning the product with water and alcohol, collecting the product, and drying the product toobtain the (001)-oriented nanosheet self-assembled three-dimensional VS2 microrod. The center of the microrod is obtained through mutually interlacing large VS2 nanosheets in a radial form, the edgeof the microrod is formed by small flaky VS2 nanosheets, the nanosheets are monocrystalline structures and grow along the (001) crystal face orientation, the diameter of the microrod is 2-15 [mu]m, and the thickness of the nanosheets is 5-20 nm. The highly-pure three-dimensional self-assembled VS2 is synthesized through a one-step solvothermal technology. The method has the advantages of simple reaction process, low temperature, easiness in control, and no large devices or strict reaction conditions.

Owner:SHAANXI UNIV OF SCI & TECH

Preparing method for sodium metavanadate

ActiveCN103422111ALower pHReduce the burden onElectrolysis componentsVanadium compoundsElectrolysisAmmonium metavanadate

The invention discloses a preparing method for sodium metavanadate. The preparing method comprises the steps: a sodium vanadate solution as an anode electrolyte solution undergoes ionic membrane electrolysis, a sodium metavanadate solution with a pH value of 7.0-8.0 and the molar ratio between sodium and vanadium being 0.95-1.05 according to sodium element and vanadium element is obtained at an anode under the ionic membrane electrolysis condition. According to the preparation method of sodium metavanadate, vanadium pentoxide does not need to be firstly prepared, sodium metavanadate can be directly prepared by the sodium vanadate solution, and thus the production steps are simplified; moreover, because sulfuric acid does not need to be employed to adjust the pH value and ammonium sulfate does not need to be employed to precipitate ammonium vanadate, vanadium precipitation wastewater containing sodium sulfate and ammonium sulfate is not produced, and thus the burden on the environment is reduced; and because the vanadium precipitation wastewater containing sodium sulfate and ammonium sulfate is not produced, the vanadium precipitation wastewater does not need to be processed, and thus the production cost is reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

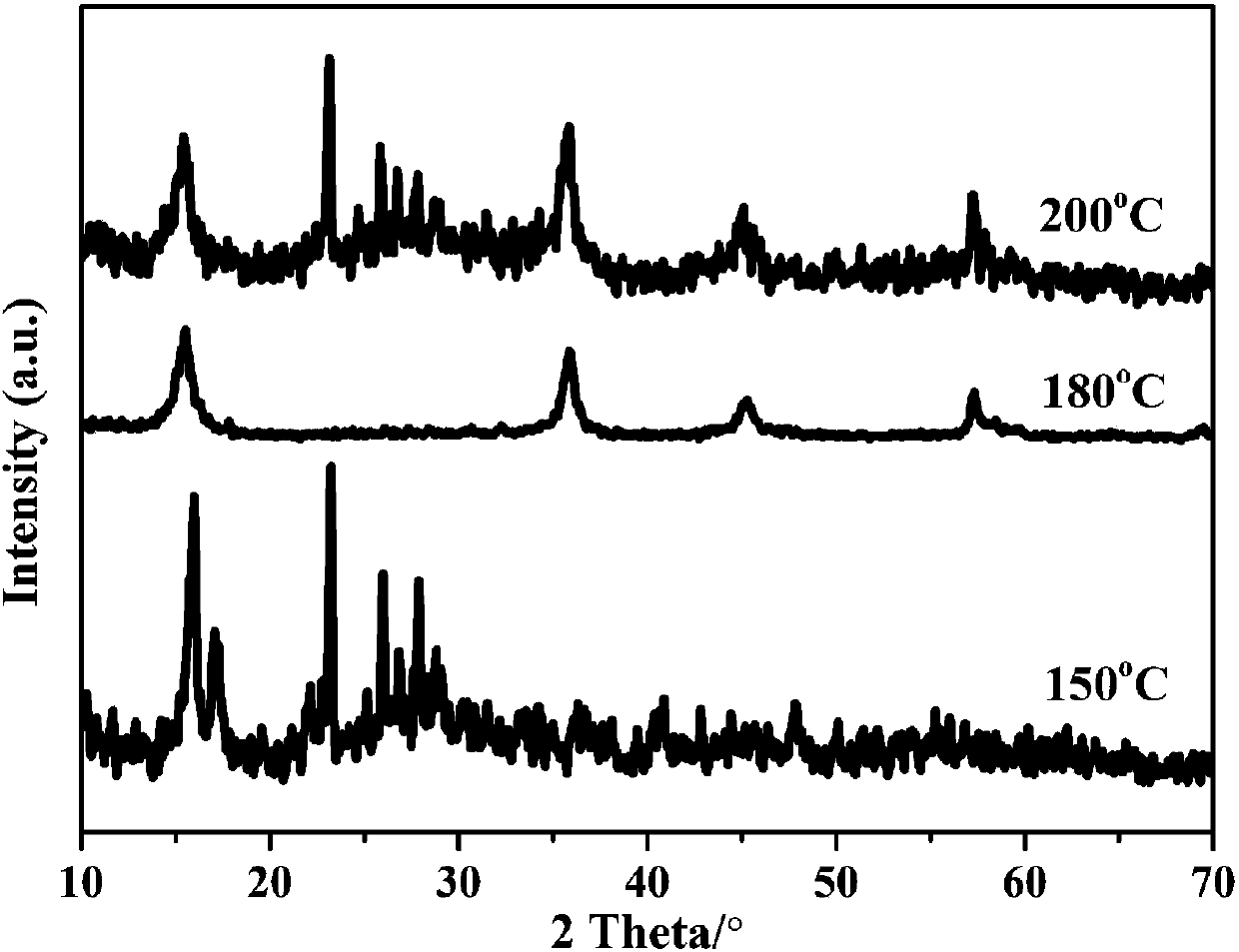

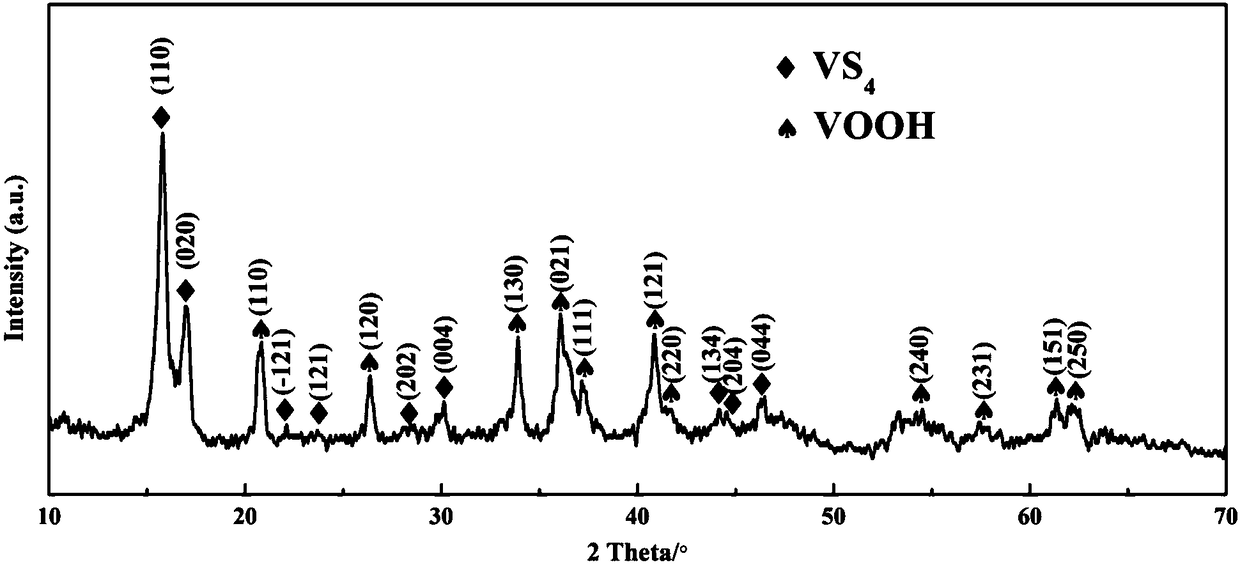

VOOH/VS4 micrometer composite powder as well as preparation method and application of VOOH/VS4 micrometer composite powder

ActiveCN108126712AImprove responseReduce the temperaturePhysical/chemical process catalystsCell electrodesMicrosphereSingle crystal

The invention discloses a VOOH / VS4 micrometer composite powder as well as a preparation method and application of the VOOH / VS4 micrometer composite powder. The preparation method comprises the steps:simultaneously adding sodium metavanadate and thioacetamide into deionized water to obtain a solution A; then, dropwise adding an aqueous ammonia solution into the solution A to obtain a solution B; pouring the solution B into a reaction liner, and then, carrying out sealing for a hydrothermal reaction; next, taking out a product cooled after being reacted, alternately cleaning the product by using water and alcohol, and then, collecting the product; and freezing the cleaned product, and then, drying the product to obtain the VOOH / VS4 micrometer composite powder. The VOOH / VS4 micrometer composite powder prepared according to the preparation method is composed of uniform spheroidal structures of which the diameters are about 10mu m, parts of spheroidal structures are gathered, the insides of microspheres are formed by self-stacking micrometer VS4 short rods of which the diameters are 0.5-1.0mu m and the length is 1.0-2.0mu m, and the outsides of the microspheres are randomly formed fromVOOH long rods having the diameters of 50-200nm and single-crystal structures. The VOOH / VS4 micrometer composite powder is applied to the fields of lithium / sodium ion batteries and photo / electric catalysis. The VOOH / VS4 micrometer composite powder shows excellent electrochemical properties and catalytic property when being applied as an anode material of a sodium / lithium ion battery and a photo / electric catalyst.

Owner:SHAANXI UNIV OF SCI & TECH

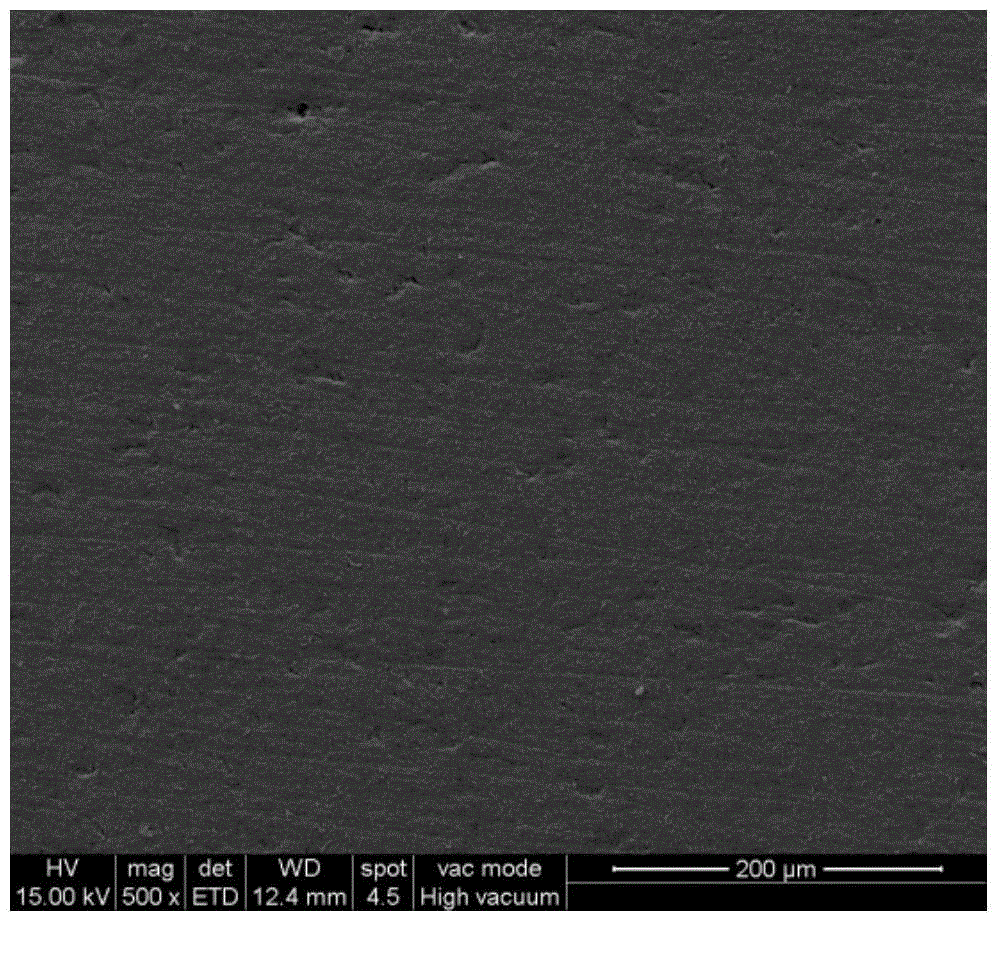

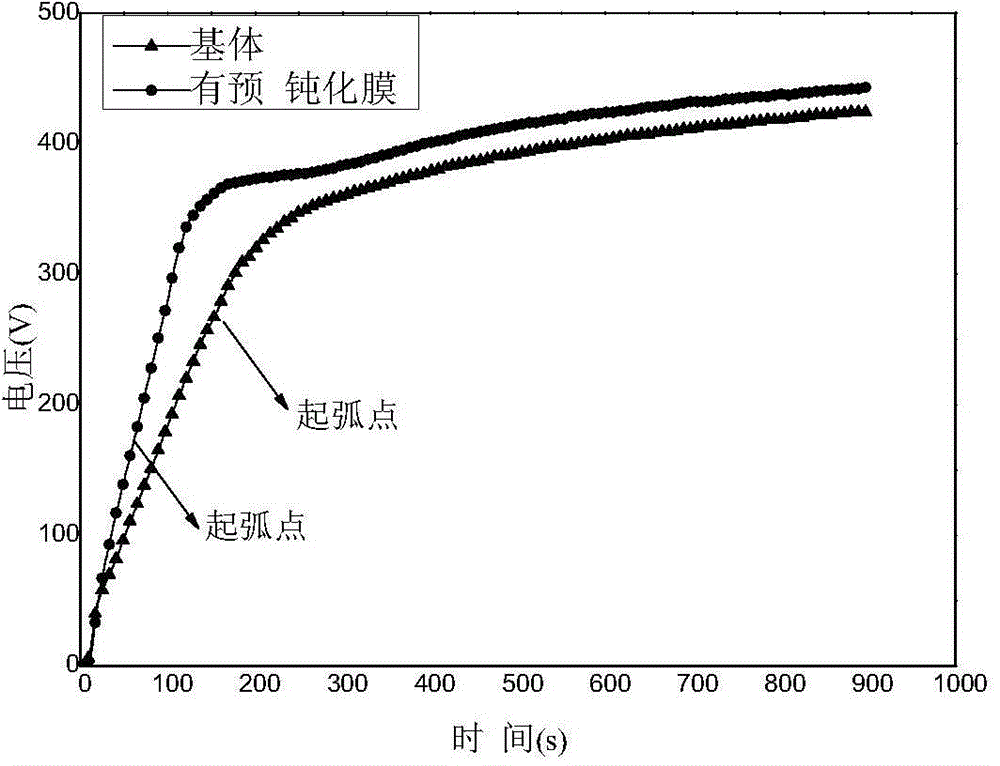

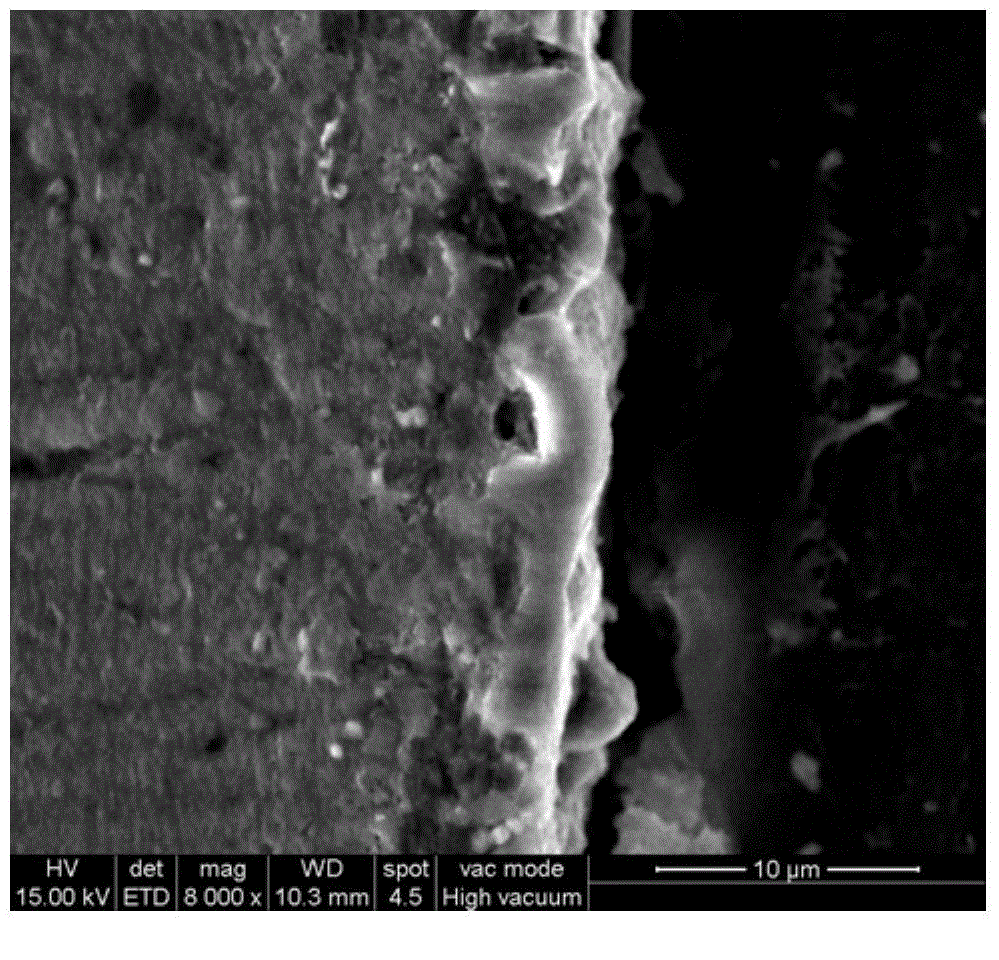

Method for lowering unit energy consumption of high-silicon aluminum alloy microarc oxidation

ActiveCN104911664AShorten arcing timeReduce the adverse effects of micro-arc oxidationAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for lowering unit energy consumption of high-silicon aluminum alloy microarc oxidation. According to the method, a Ti / Zr pre-passivating film is firstly prepared on the surface of the high-silicon aluminum alloy, and then microarc oxidation treatment is performed. The process of preparing the Ti / Zr pre-passivating film on the surface of the high-silicon aluminum alloy comprises the following steps: (1) pretreating the high-silicon aluminum alloy; (2) preparation of the Ti / Zr passivating film on the surface of the high-silicon aluminum alloy: (2-1) preparing a passivating liquid: every liter of deionized water contains 1-5g of tannin, 1-4g of hydrofluotitanic acid, 1-2g of fluorozirconic acid and 1-4g of sodium metavanadate; and (2-2) immersing the high-silicon aluminum alloy in the passivating liquid, and treating at 25 DEG C for 1-4 minutes. The method lowers the adverse effect of silicon on microarc oxidation, and has the effects of shortening the arcing time in the cast aluminum-silicon alloy microarc oxidation process and lowering the unit energy consumption under the conditions of simple technique, high efficiency and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application of vanadium tetrasulfide @ reduced graphene oxide composite powder

ActiveCN109888223ASynthesis temperature is lowLow costPhysical/chemical process catalystsCell electrodesAlcoholOxide composite

The invention relates to a preparation method of vanadium tetrasulfide @ reduced graphene oxide composite powder. The preparation method comprises the steps of: weighing 20 to 120mg of graphene oxideinto 58 to 62ml of deionized water to carry out ultrasonic processing to obtain black solution A uniformly dispersed; weighing 0.9 to 1.1g of sodium metavanadate and 3.5 to 3.7g of thioacetamide, simultaneously adding into the solution A, and carrying out magnetic stirring to obtain solution B; after pouring the solution B into a reaction liner, sealing up, then placing the liner in an outer kettle, after fixing the outer kettle, placing the outer kettle into a homogeneous reactor, and then performing a reaction under a rotational speed condition; after a hydrothermal reaction is ended, naturally cooling the reaction kettle to the room temperature, then taking out a cooled product after the reaction, and after alternatively cleaning the product with water and alcohol, collecting the product; and placing the collected product into a cold well of a freezer dryer to carry out freezing, then placing the frozen product into a tray, covering a sealing hood, and after vacuumizing and drying,collecting the product to obtain the vanadium tetrasulfide @ reduced graphene oxide composite powder. The preparation method has the characteristics of simple reaction process, low temperature, easiness for control and no requirement for large-sized equipment and harsh reaction conditions.

Owner:SHAANXI UNIV OF SCI & TECH

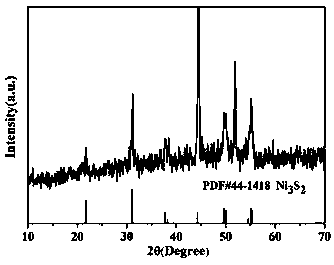

Vanadium-modified Ni3S2 nano-rod array electrode material and preparation method thereof

InactiveCN109261168ALow costShort reaction cyclePhysical/chemical process catalystsElectrodesSolventSodium carbamate

The invention provides a vanadium-modified Ni3S2 nano-rod array electrode material which has a scale-shaped surface appearance formed by self-assembling particles. A preparation method comprises the following steps: immersing metal nickel in a suspension solution containing a vanadium source, a sulfur source and ammonium fluoride, and carrying out solvothermal reaction; then, calcining a product of the solvothermal reaction to obtain the nano-rod-shaped vanadium-modified Ni3S2 electrode material. The vanadium source is vanadiumoxy acetylacetonate, sodium metavanadate, sodium vanadate, sodium vanadate dodecahydrate, ammonium metavanadate or vanadium pentoxide; the sulfur source is thiourea, thioacetamide, sodium sulfide, sodium oiethyl dithiocarbamate or a sulfur elementary substance. A nano-rod structure formed by self-assembling the particles has a secondary-grade unit so that catalytic active sites of the material are effectively increased; compared with a block-shaped catalyst, theresistance of the material is effectively reduced and the material can be used as an excellent electro-catalytic oxygen production electrocatalyst.

Owner:SHAANXI UNIV OF SCI & TECH

Synthetic method of 5-bromo-2-chlorobenzoic acid

ActiveCN108250060AReduce pollutionReduce manufacturing costOrganic compound preparationCarboxylic compound preparationBenzoic acid2-Chlorobenzoic acid

The invention discloses a synthetic method of 5-bromo-2-chlorobenzoic acid. The method comprises the following steps of by taking salicylic acid as a starting material, performing bromination reactionto obtain 2-hydroxyl-5-bromo-benzoic acid, and then performing chlorination reaction to obtain the 5-bromo-2-chlorobenzoic acid, wherein a bromination system adopted by the bromination reaction is tetrabutyl ammonium bromide / oxygen / sodium metavanadate, a catalyst is aluminium tribromide, and a solvent is 1,4-dioxane; and a chlorinating agent is carbon tetrachloride, and a catalyst is molybdenum hexacarbonyl. The method provided by the invention adopts the cheap salicylic acid which is wide in source as the starting material and prepares the 5-bromo-2-chlorobenzoic acid through two-step reaction of bromination and chlorination, is novel in synthetic route, relatively low in production cost, relatively small in environmental pollution and very suitable for industrial mass production. According to the method, through the bromination reaction and the chlorination reaction, by selecting proper reagents, relatively high reaction yield and product purity can be obtained.

Owner:江苏尚莱特医药化工材料有限公司

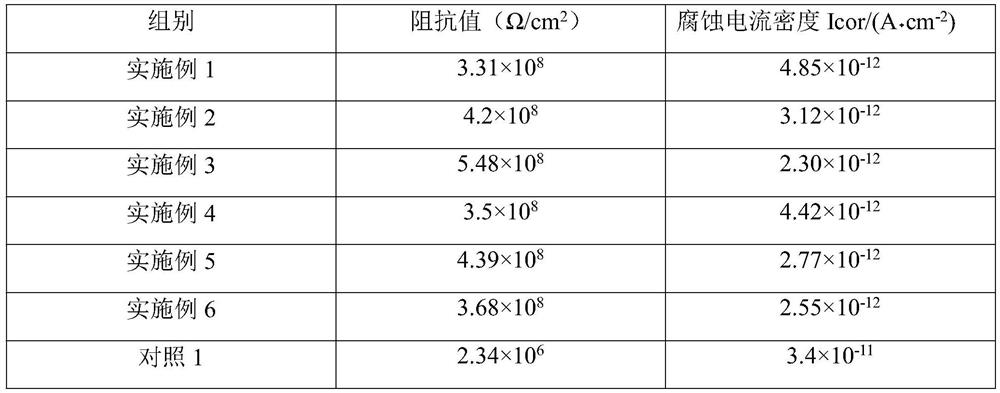

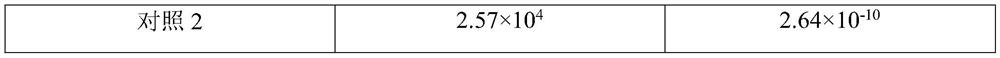

Preparation method and application of modified anti-corrosion super-hydrophobic integrated coating

InactiveCN112300697AChange the proportion of fillerReduce manufacturing costAnti-corrosive paintsAluminium chlorideTitanium oxide

The invention belongs to the technical field of preparation of anticorrosive coatings, and particularly relates to a preparation method and application of a modified anticorrosive super-hydrophobic integrated coating, the method comprises the following steps: respectively preparing a graphene titanium dioxide compound from graphene and tetrabutyl titanate, preparing a zinc-aluminum hydrotalcite anticorrosive material from sodium metavanadate, zinc chloride and aluminum chloride, preparing a PDMS organic emulsion from polydimethylsiloxane and tetrahydrofuran, then performing surface modification on the graphene titanium dioxide compound through dopamine hydrochloride and a zinc-aluminum hydrotalcite anticorrosive material to obtain a dopamine modified composite material, and finally, preparing the modified anticorrosive super-hydrophobic integrated coating from the dopamine modified composite material and a PDMS organic emulsion. Performance tests show that compared with a conventionalmarine anticorrosive coating, the coating prepared by the invention has better anticorrosive and super-hydrophobic effects, is applied to the field of marine corrosion prevention, and can effectivelyprolong the service life of the coating on a protective substrate.

Owner:SUN YAT SEN UNIV

Method for preparing silicon protective in-situ deposition photocatalytic functional textile

InactiveCN102517887AEfficient killingAvoid agglomeration efficiency dropWater/sewage treatment by irradiationFibre treatmentPollutionSodium hydroxide

The invention relates to a method for preparing a silicon protective in-situ deposition photocatalytic functional textile. The method comprises the following steps of: (1) preparing silicon protective anti-oxidation finishing liquor, and treating a textile by using the silicon protective anti-oxidation finishing liquor to obtain a treated textile; (2) in an inert environment, respectively adding bismuth nitrate and ethylene diamine tetraacetic acid into an alkali buffer solution, and dripping a wetting agent to obtain a solution A; in the inert environment, adding sodium metavanadate into an alkali buffer solution, and adding a sodium hydroxide solution and deionized water to obtain a solution B; (3) adding the solution B into the solution A to obtain a photocatalytic precursor solution; and (4) dipping the treated textile obtained in the (1) into the photocatalytic precursor solution to react, drying, treating in boiling water, and thus obtaining the silicon protective in-situ deposition photocatalytic functional textile. The preparation method is simple and low in cost, does not require new equipment, and is easy for industrialized production; and the flexible photocatalytic environment purification material has a good organic pollutant degrading effect, has no secondary pollution, and can be used for a long term.

Owner:DONGHUA UNIV

Method for preparing ammonium metavanadate from vanadium-containing material

The invention provides a method for preparing ammonium metavanadate from vanadium-containing material. The method comprises the steps of a, mixing the vanadium-containing material and sodium modifying agents, roasting the mixtures and then soaking the mixtures in water for forming solutions containing the sodium metavanadate; b, adding ammonium source substances into the solutions containing the sodium metavanadate, guiding CO2 into the solutions and obtaining NH4VO3 through sediment; c, separating the NH4VO3 obtained through sediment from mother solutions for obtaining the NH4VO3; and d, mixing the mother solutions subjected to separation in the step c with new vanadium-containing material and the sodium modifying agents, repeating the step a, the step b and the step c and preparing the ammonium metavanadate from the new vanadium-containing material. According to the method for preparing the ammonium metavanadate from the vanadium-containing material, no waste water is generated, waste liquid can be recycled, and therefore the production cost can be lowered, and the environmental pollution can be reduced; the yield of vanadium is high.

Owner:HUZHOU OCHEM CHEM

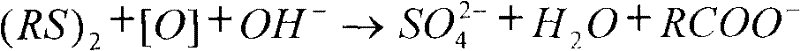

An absorbent for removing sulfide and ammonia in malodorous gas

ActiveCN102266711ALow costImprove performanceDispersed particle separationPotassium sodium tartratePotassium hydroxide

The invention provides an absorbent for removing sulfide and ammonia in malodorous gas and a preparation method thereof, so as to solve problems of incapability of simultaneously removing sulfide and ammonia in malodorous gas and high operating costs in a prior art. The absorbent is prepared from raw materials of water, sodium hydroxide or potassium hydroxide, ethylene diamine tetraacetic acid (EDTA) or potassium sodium tartrate, p-benzoquinone or tannin, vanadic anhydride or sodium metavanadate, ethanolamine and sodium hypochlorite, according to the method provided by the invention. The absorbent can absorb acid gases containing sulfur, such as hydrogen sulfide, mercaptan, and thioether, etc., and ammonia gas, and has a high removal rate, low costs and a wide usage range.

Owner:CHINA PETROCHEMICAL CORP +1

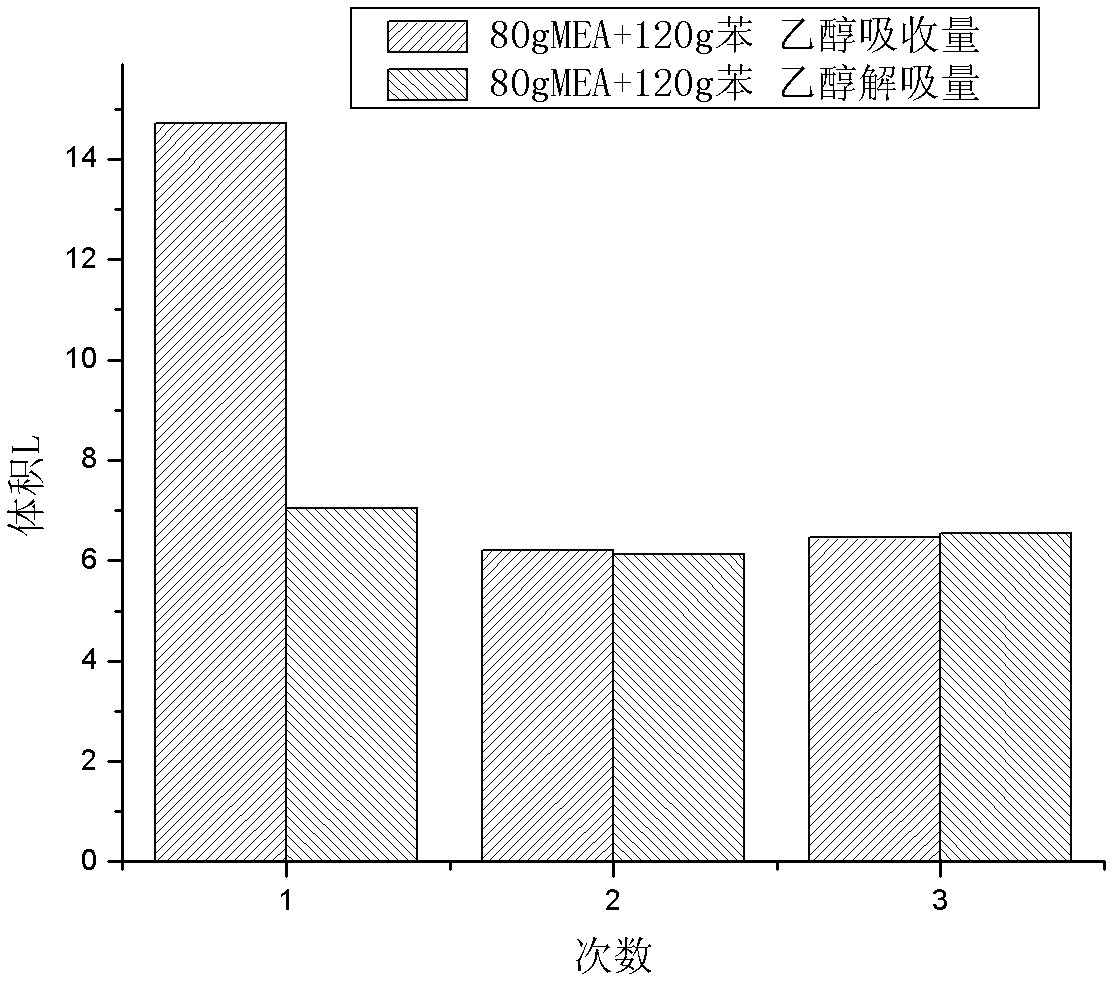

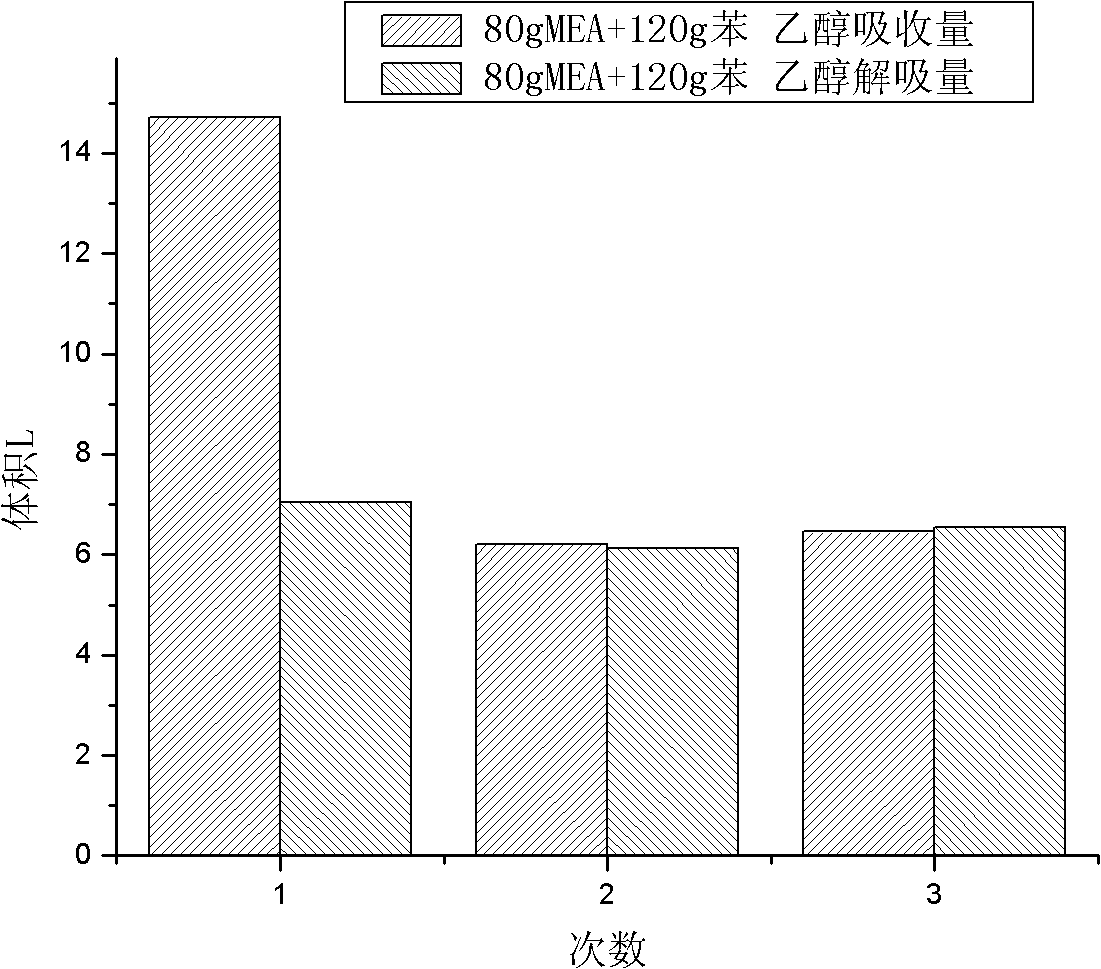

Composite absorbent used for smoke decarbonization

InactiveCN102743954AHigh absorption loadFast absorption rateDispersed particle separationAntioxidantDiethylenetriamine

The invention discloses a composite absorbent used for smoke decarbonization and composed of the following components by mass: 15%-30% of absorption main body, 4%-10% of activating agent and 0.05%-1% of antioxidant and water as the balance. The absorption main body is ethanolamine MEA or N-methyl-diethanolamine MDEA, the activating agent is diethylenetriamine (DETA), and the antioxidant is sodium metavanadate. The absorbent is high in absorption load, high in absorption rate, good in regenerability, low in corrosivity and capable of effectively reducing device corrosion and the like, saves cost and reduces energy consumption. The absorbent is suitable for smoke decarbonization with CO2 density as 1%-40%, and is wide in CO2 density adaptation face.

Owner:CHONGQING UNIV

Bismuth vanadate modified boron nitride nanosheet composite material and preparation method thereof

InactiveCN105688966APromote migrationImprove migration efficiencyMaterial nanotechnologyPhysical/chemical process catalystsWater bathsBismuth vanadate

The invention discloses a bismuth vanadate modified boron nitride nanosheet composite material. According to the bismuth vanadate modified boron nitride nanosheet composite material, bismuth vanadate is loaded onto boron nitride nanosheets which serve as a catalyst carrier, wherein the mole ratio of the boron nitride nanosheets to the bismuth vanadate is 1: (0.01 to 0.6). The invention also discloses a preparation method of the bismuth vanadate modified boron nitride nanosheet composite material. The preparation method comprises the steps of dissolving bismuth nitrate pentahydrate into a 10% nitric acid solution, then, adding the boron nitride nanosheets and sodium metavanadate into the solution so as to obtain a mixture solution, carrying out ultrasonic uniform stirring on the mixture solution, and then, carrying out drying by distillation in water bath; then, carrying out treatment in a muffle furnace, thereby obtaining the bismuth vanadate modified boron nitride nanosheet composite material. According to the composite material disclosed by the invention, by using that the boron nitride nanosheets have certain electronegativity due to nitrogen vacancies of the surfaces of the boron nitride nanosheets, photon-generated holes entrained by bismuth vanadate after illumination excitation are attracted so as to promote hole transporting, and then, the transport efficiency of photon-generated carriers is increased; in addition, the large specific surface area of the boron nitride nanosheets is beneficial to the improvement on the adsorption performance of a composite system, and then, the increase of photocatalytic efficiency is facilitated.

Owner:SHAANXI UNIV OF SCI & TECH

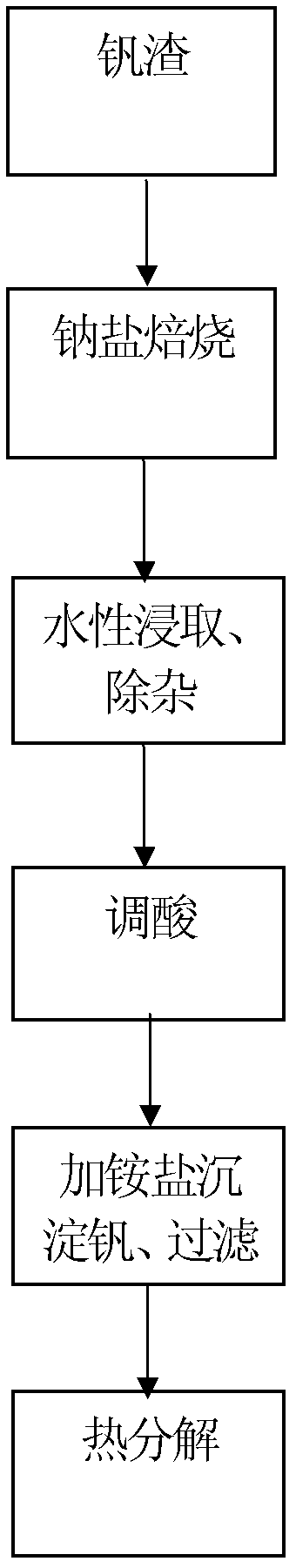

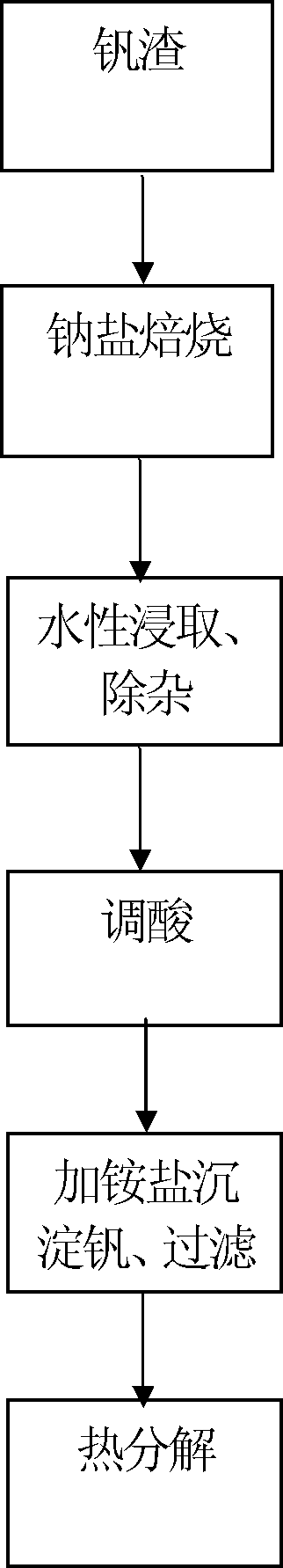

Vanadium extracting method

InactiveCN102534267AEfficient recyclingReduce vanadium contentProcess efficiency improvementSlagVanadate

The invention discloses a vanadium extracting method, which comprises the following steps that: vanadium slag is adopted as a raw material, and the vanadium slag is subjected to sodium-salt-added roasting, water leaching and impurity removing so as to obtain a sodium metavanadate solution; the obtained sodium metavanadate solution is subjected to adjusting acid, adding ammonium salt to precipitate vanadium and filtering so as to obtain poly ammonium vanadate; and the obtained poly ammonium vanadate is prepared into V2O5 powder through thermal decomposition. According to the vanadium extracting method disclosed by the invention, a vanadium resource in the vanadium slag can be effectively recycled.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com