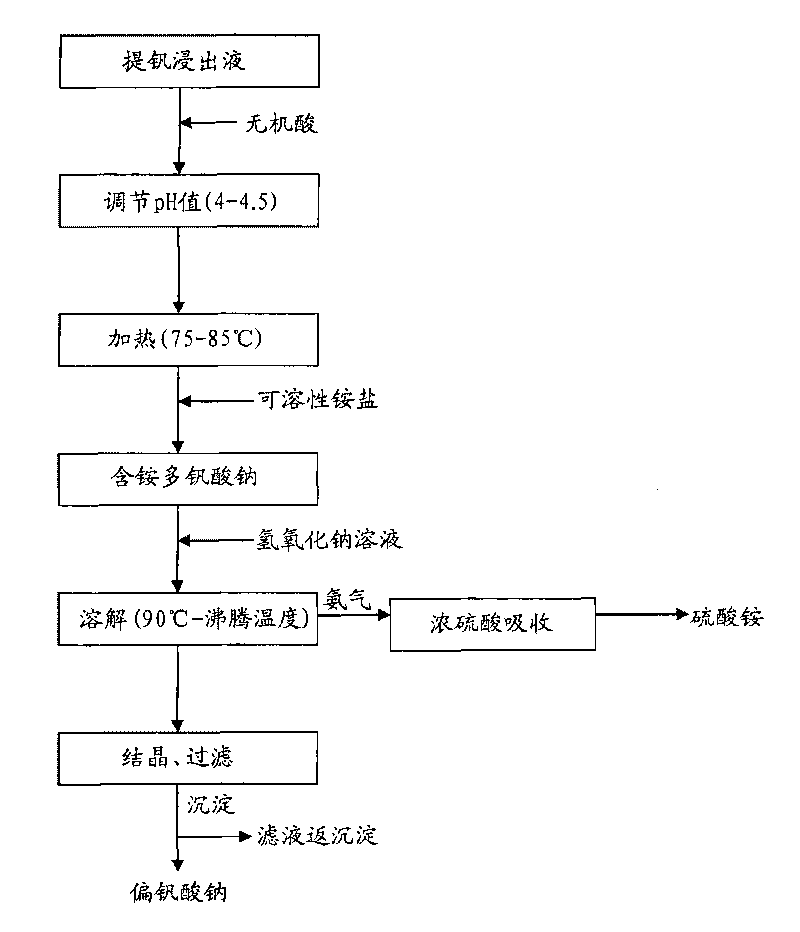

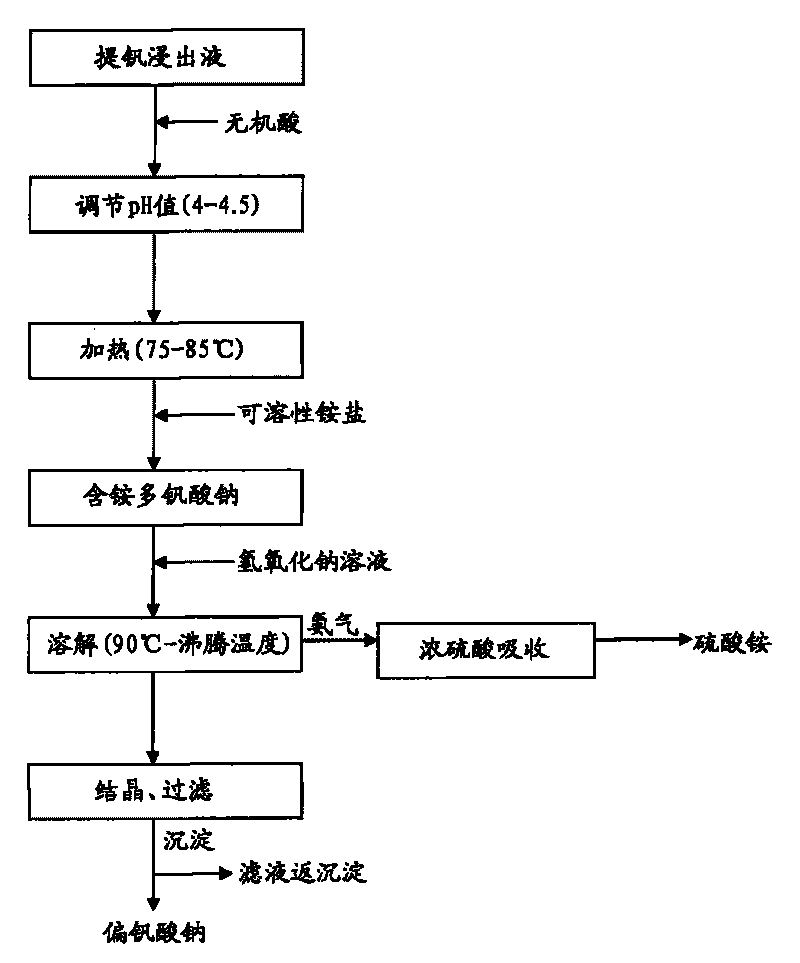

Method for extracting sodium metavanadate from vanadium extraction leaching solution

A sodium metavanadate, sodium vanadium leaching technology, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve problems such as difficult washing, high production cost, and complex leachate components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In the method for preparing sodium metavanadate according to the present invention, the inorganic acid can be at least one of sulfuric acid, hydrochloric acid, nitric acid; the soluble ammonium salt can be at least one of ammonium sulfate, ammonium chloride, ammonium nitrate A sort of.

[0015] According to the method for preparing sodium metavanadate of the present invention, in step (1), the temperature of the precipitated ammonium-containing polyvanadate sodium is 75°C-85°C, and when the precipitation temperature is greater than 85°C, part of the ammonium-containing polyvanadium in the precipitate Sodium acid is converted to ammonium polyvanadate, resulting in Na in the precipitated product + The content decreases and the sulfur content of wrapped impurities in the product increases. When the precipitation temperature is lower than 75°C, the precipitation time is prolonged.

[0016] According to the method for preparing sodium metavanadate of the present invention, ...

Embodiment 1

[0023] Take 500mL of sodium roasting leaching solution (concentration of vanadium is 29.23g / L), adjust the pH value of the solution to 4.2 with concentrated sulfuric acid, heat the solution to 75°C, and 4 + : Add (NH 4 ) 2 SO 4 Solid, fully stirred, reacted for 50 minutes, filtered the obtained solid, and washed quickly to obtain ammonium-containing sodium polyvanadate crystals. The obtained ammonium-containing sodium polyvanadate is placed in a sealed reactor, and 100 mL of sodium hydroxide solution is put into it according to the molar ratio of Na:V=0.8, and stirred at 90 ° C until white solids start to precipitate in the solution, and then the solution is Cool to room temperature under stirring condition, filter and dry to obtain 33.3 g of sodium metavanadate solid, the product purity is 99.6%, and the recovery rate is 95%.

Embodiment 2

[0025] Take 500mL of sodium roasting leaching solution (concentration of vanadium is 21.5g / L), adjust the pH value of the solution to 4.5 with concentrated hydrochloric acid, heat the solution to 80°C, and 4 + : Add NH to the solution at a mass ratio of V=1.8 4 Cl solid, fully stirred, reacted for 30 minutes, filtered the resulting solid, and washed it quickly to obtain ammonium-containing sodium polyvanadate crystals. The obtained ammonium-containing sodium polyvanadate was placed in a sealed reactor, and 50 mL of sodium hydroxide solution was dropped in according to the molar ratio of Na:V=0.8, and stirred at 92 ° C until white solids began to precipitate in the solution, and then the solution was Cool to room temperature under stirring condition, filter and dry to obtain 23.3 g of sodium metavanadate solid, the product purity is 99.5%, and the yield is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com