Patents

Literature

4880 results about "Dielectric loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dielectric loss quantifies a dielectric material's inherent dissipation of electromagnetic energy (e.g. heat). It can be parameterized in terms of either the loss angle δ or the corresponding loss tangent tan δ. Both refer to the phasor in the complex plane whose real and imaginary parts are the resistive (lossy) component of an electromagnetic field and its reactive (lossless) counterpart.

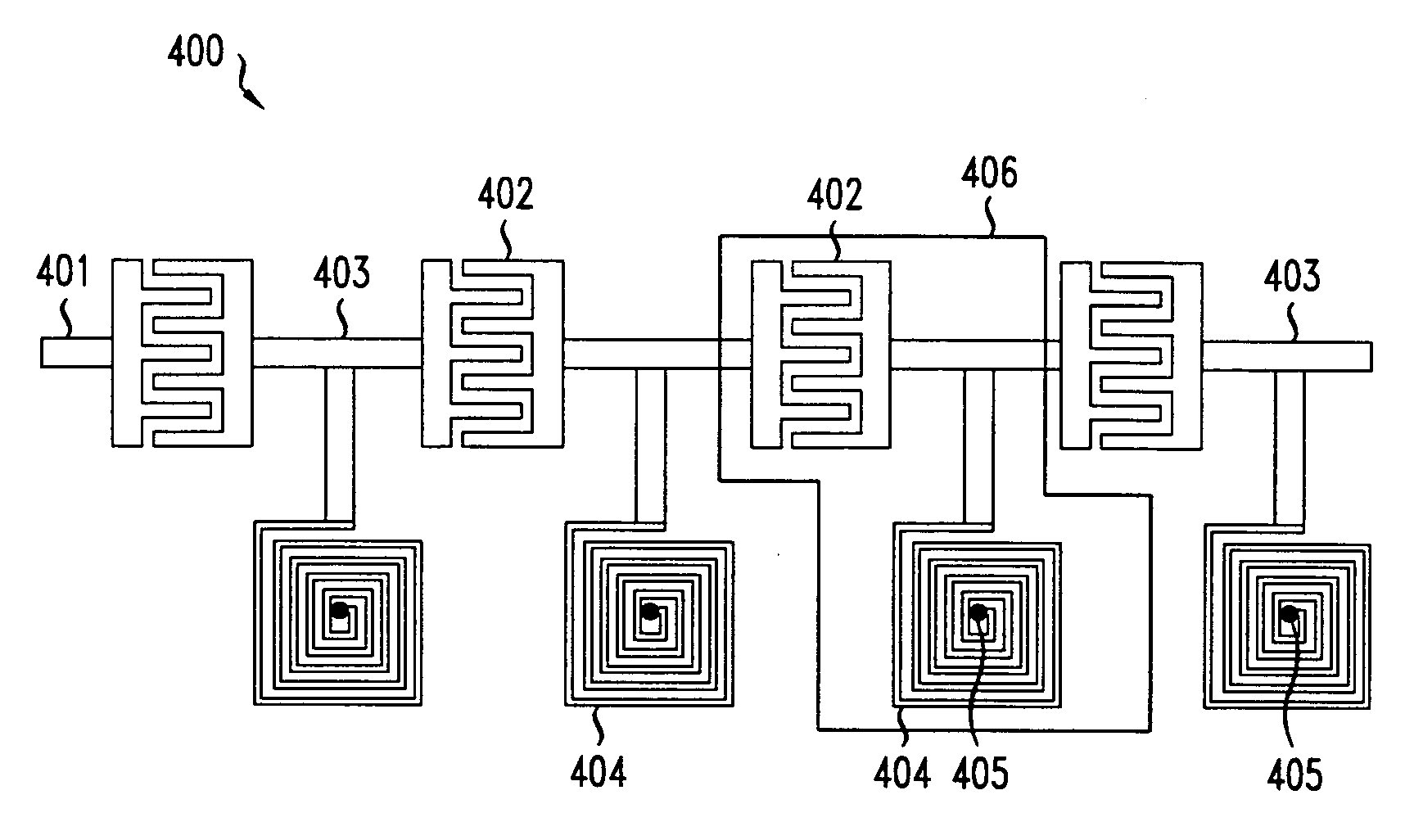

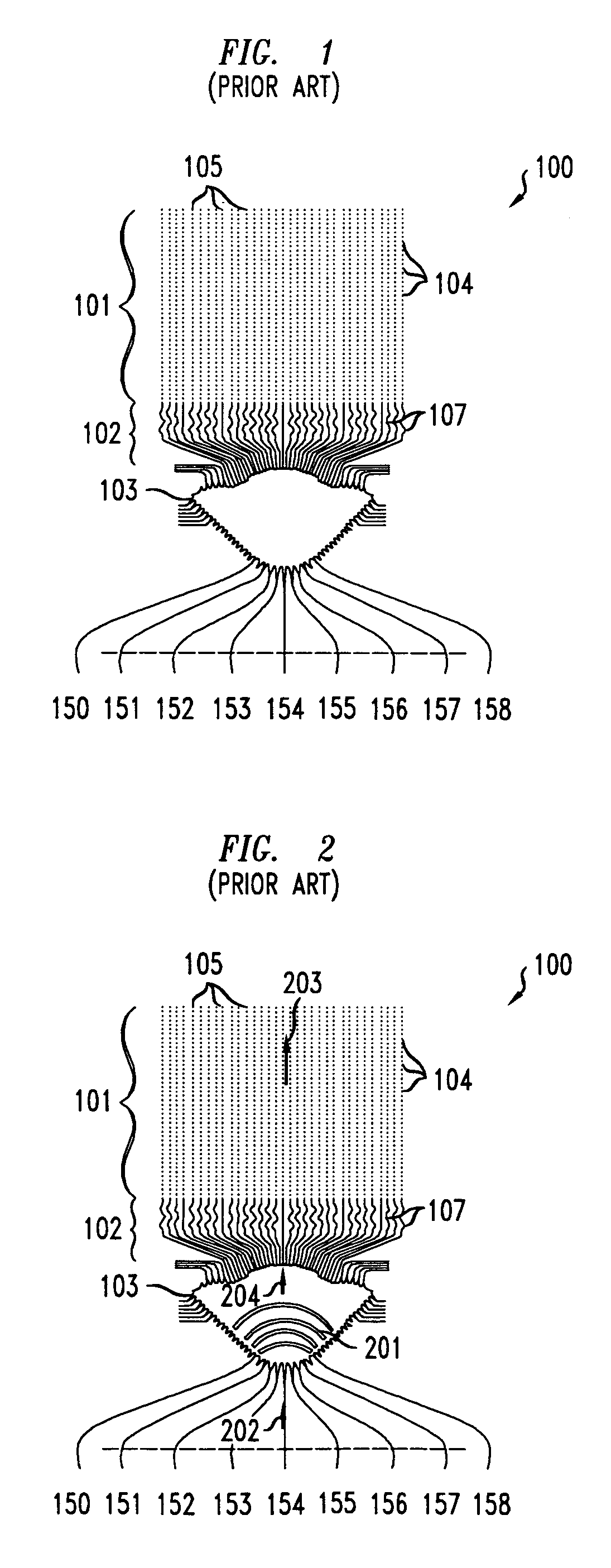

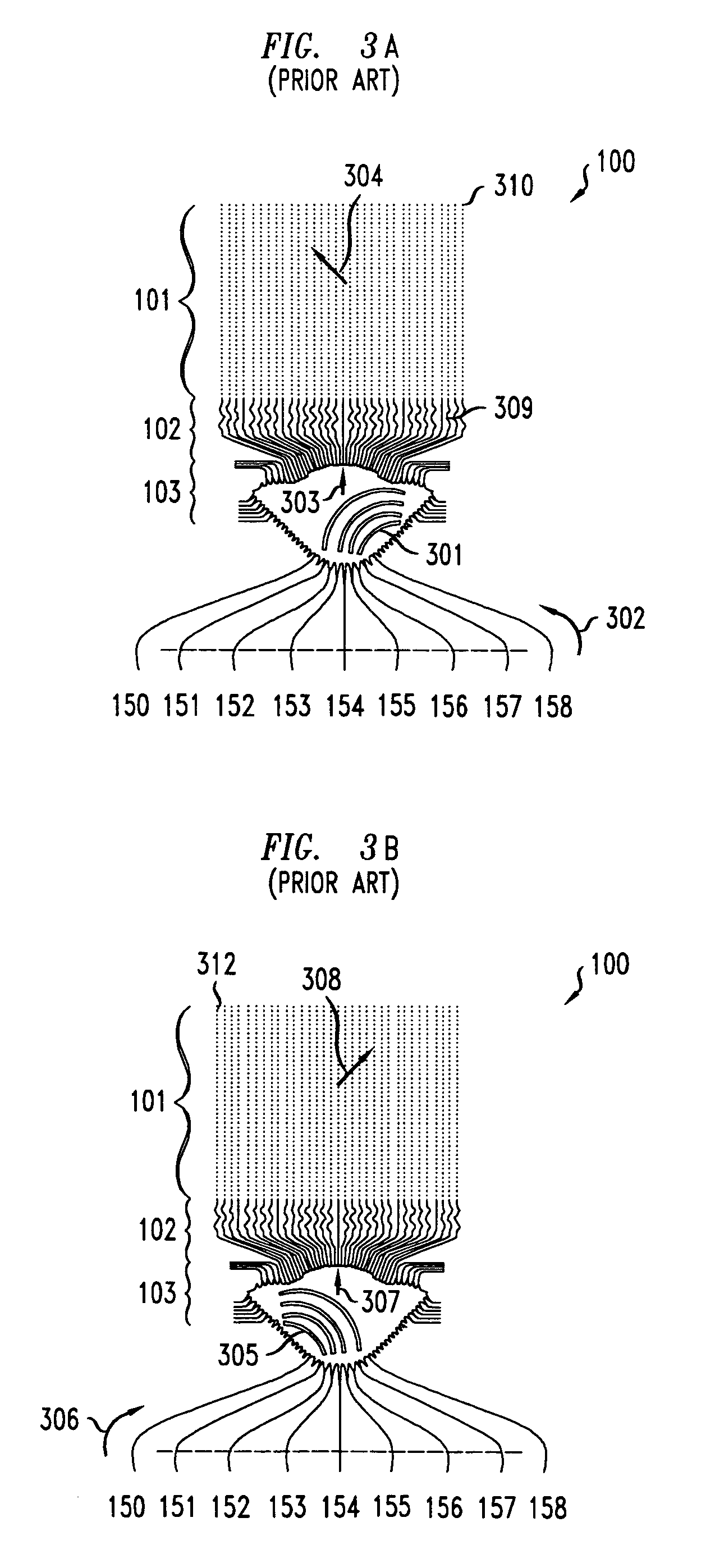

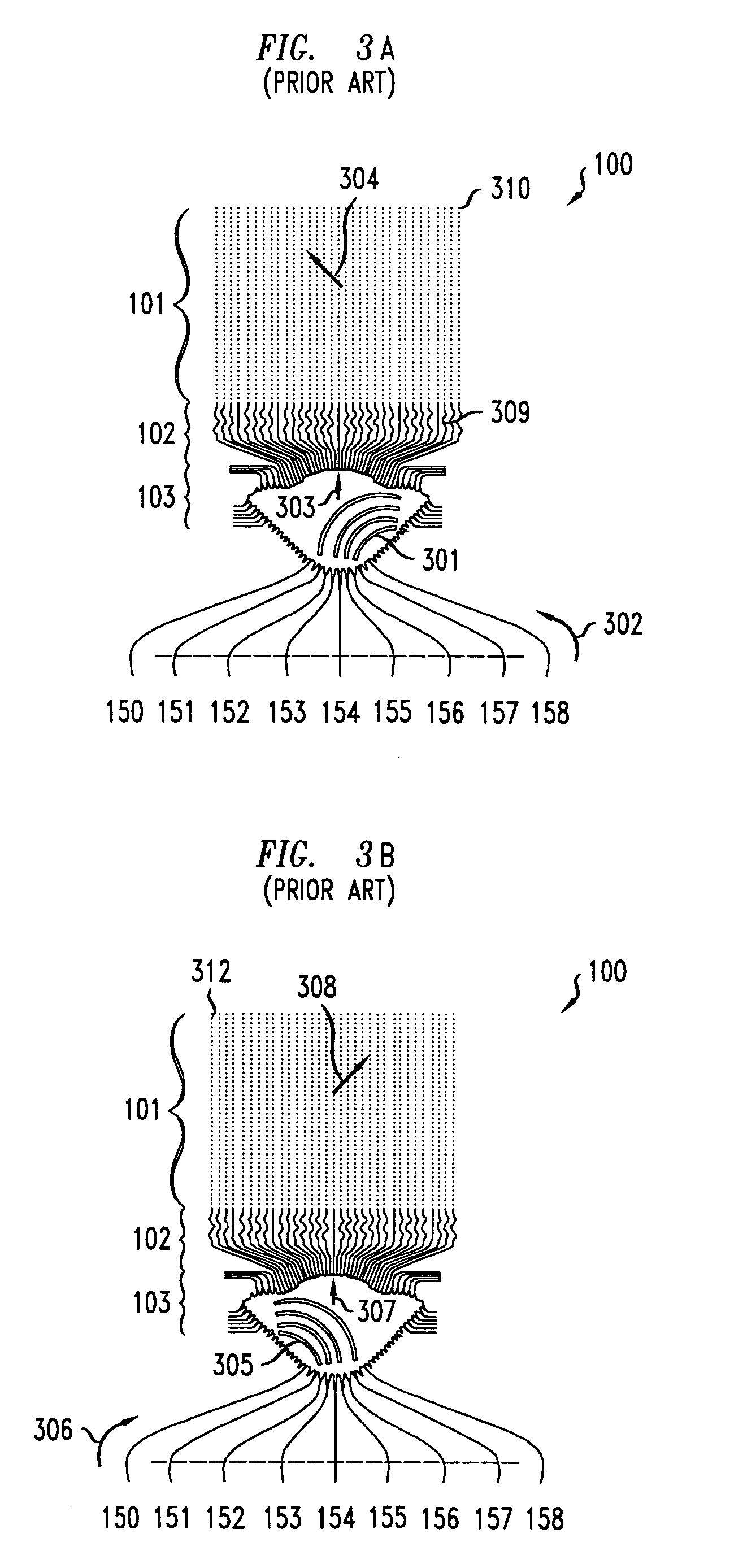

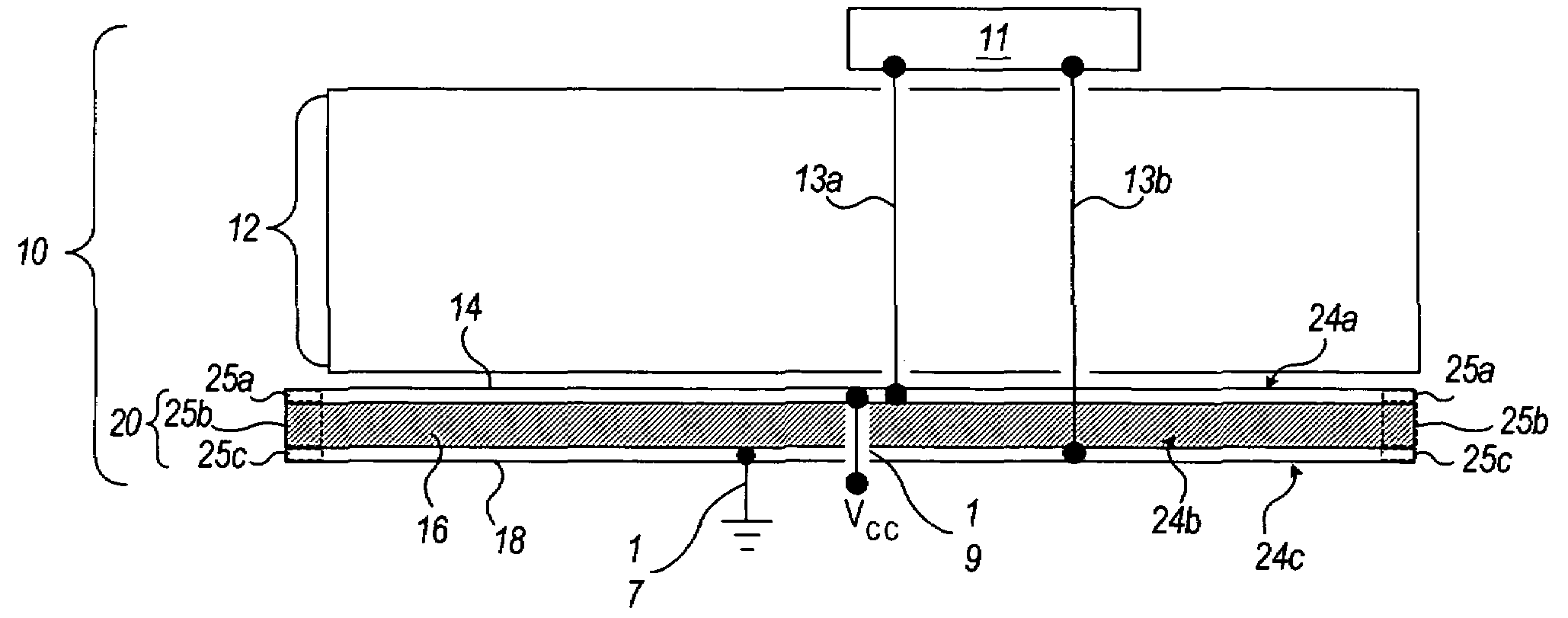

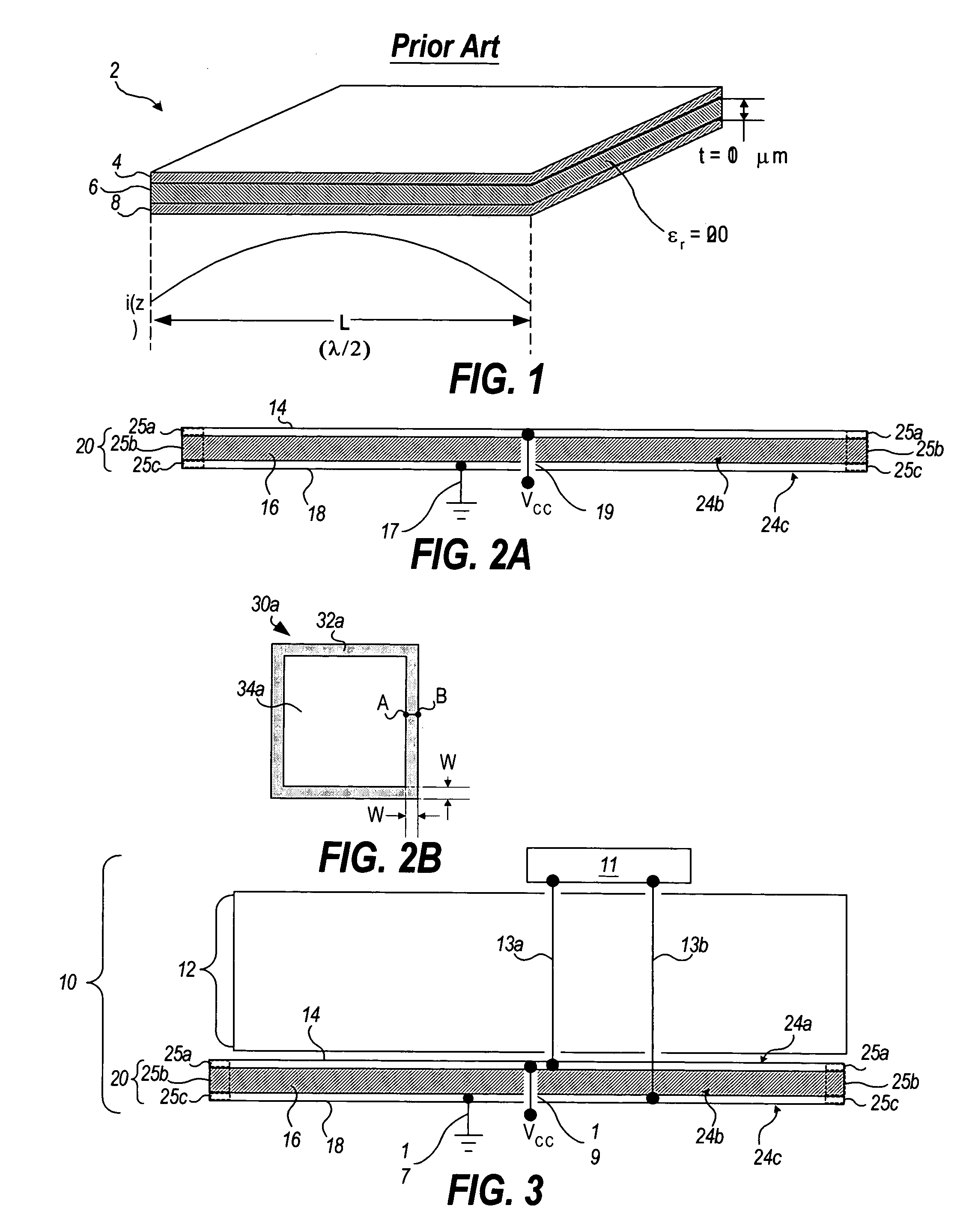

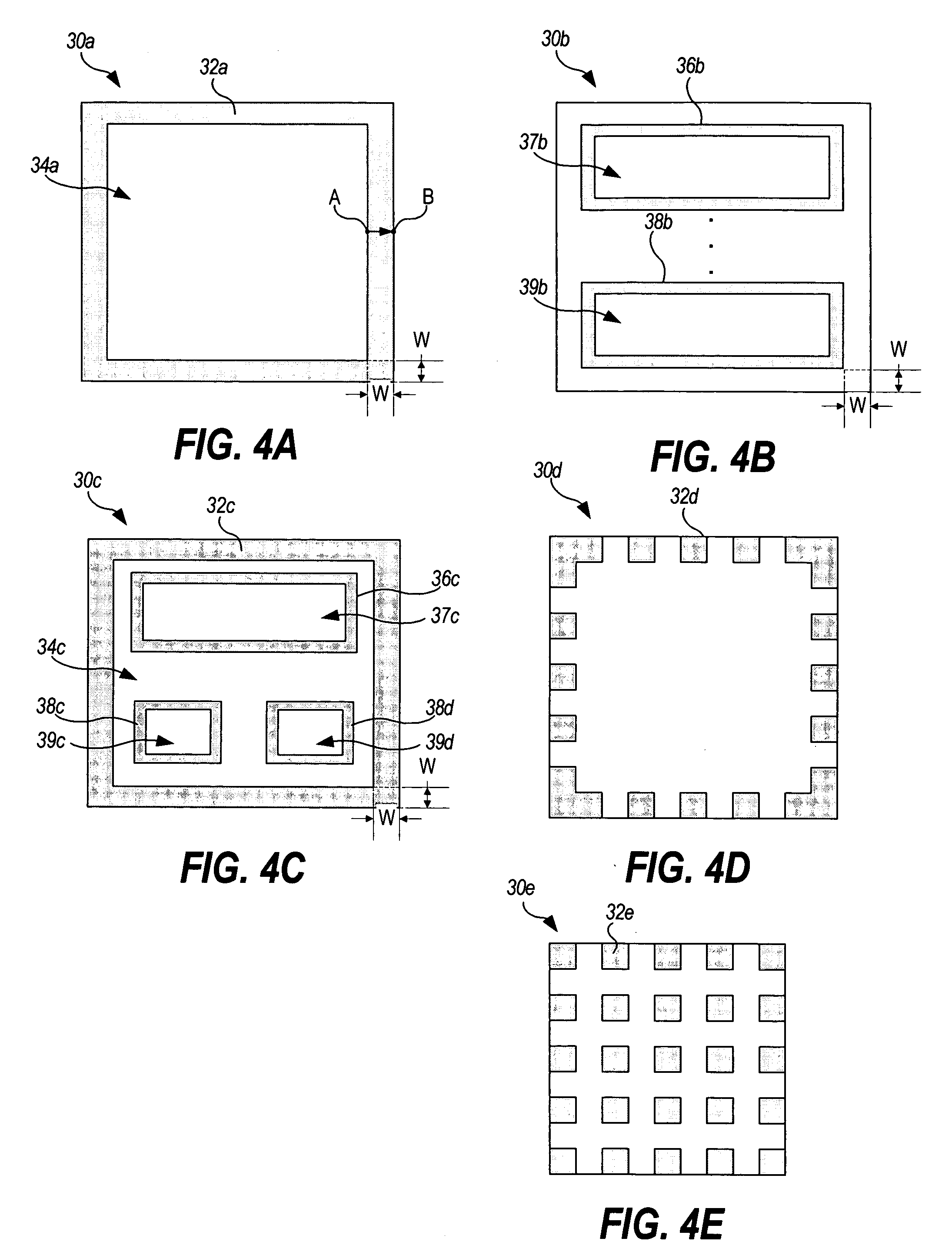

Phased array metamaterial antenna system

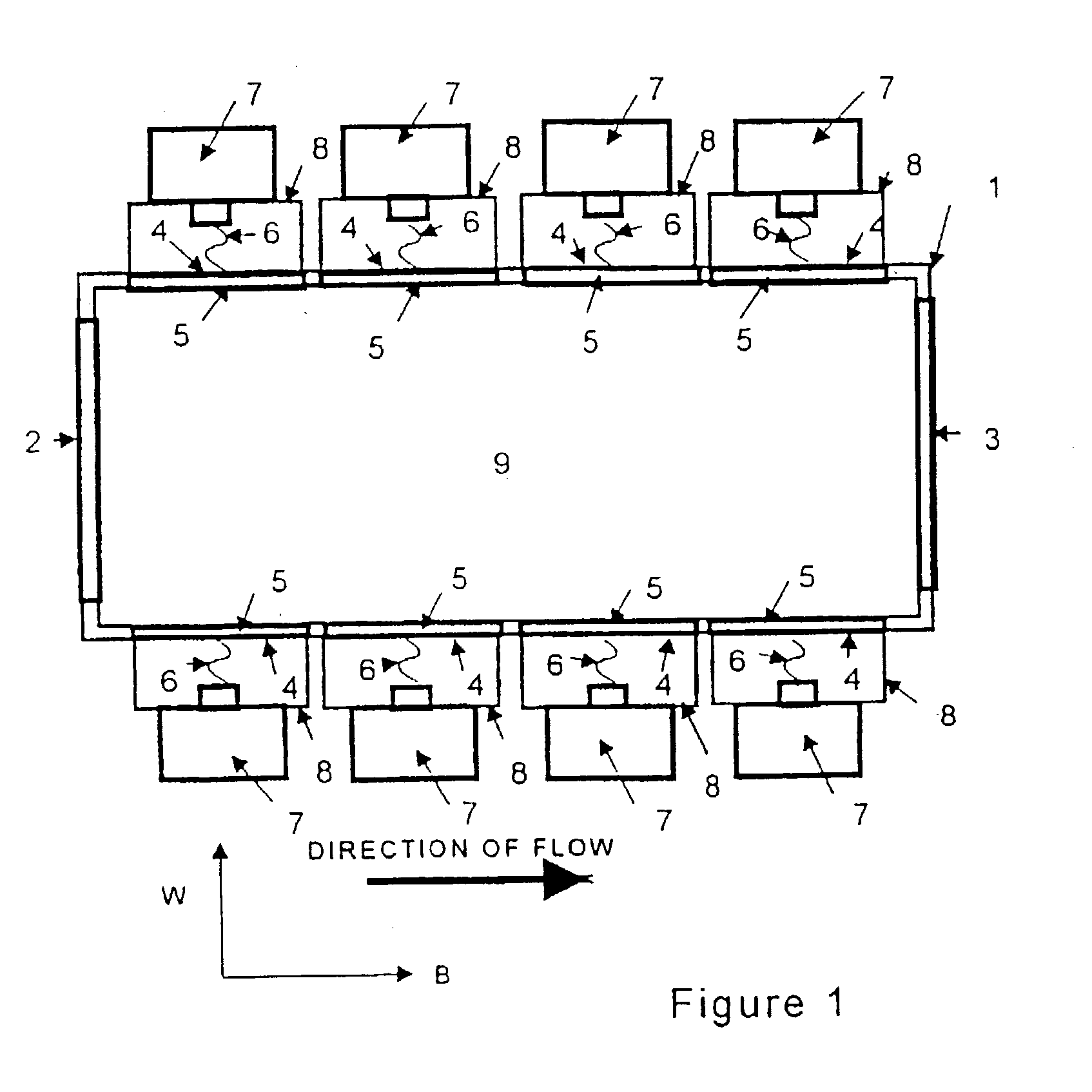

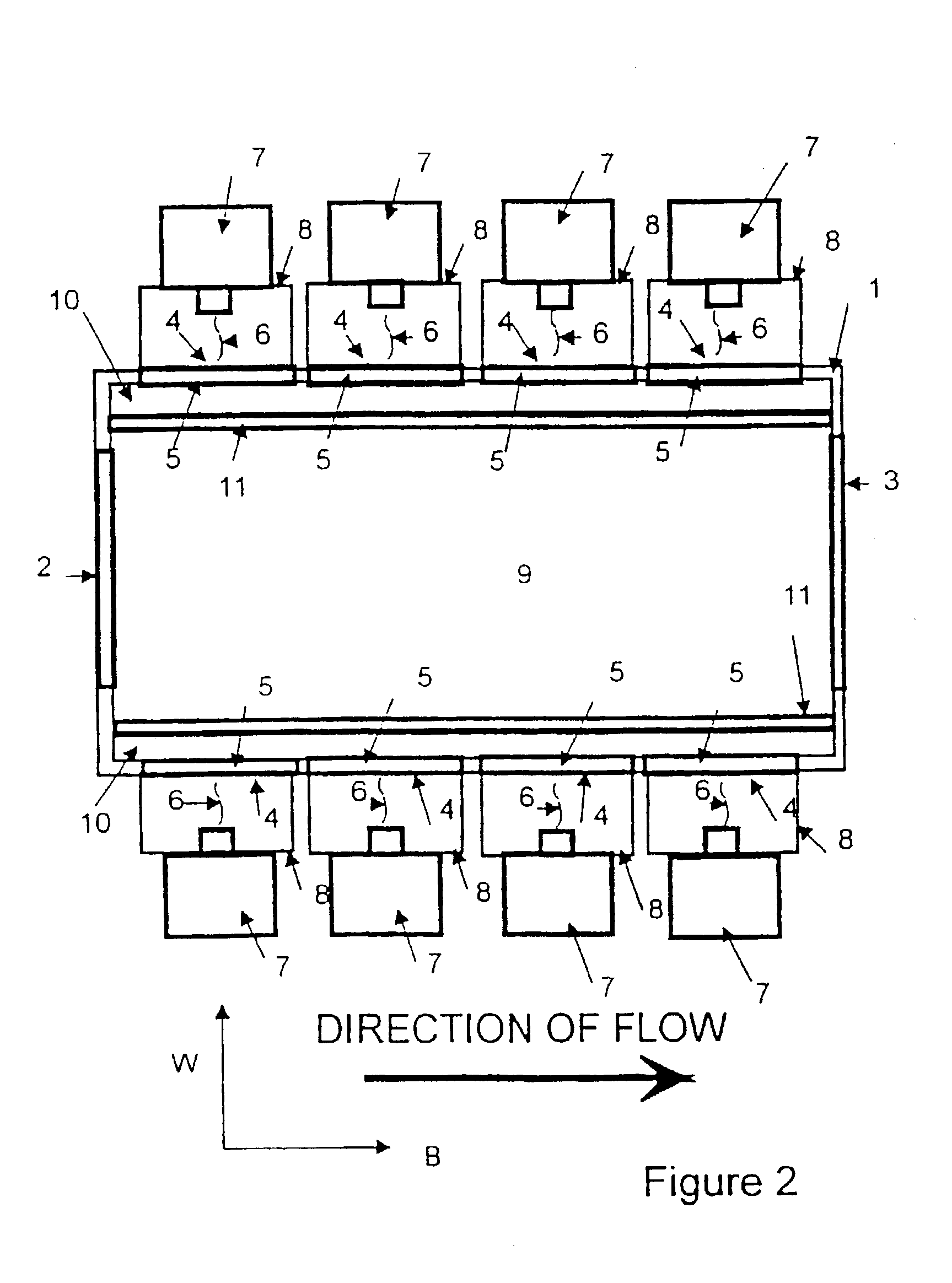

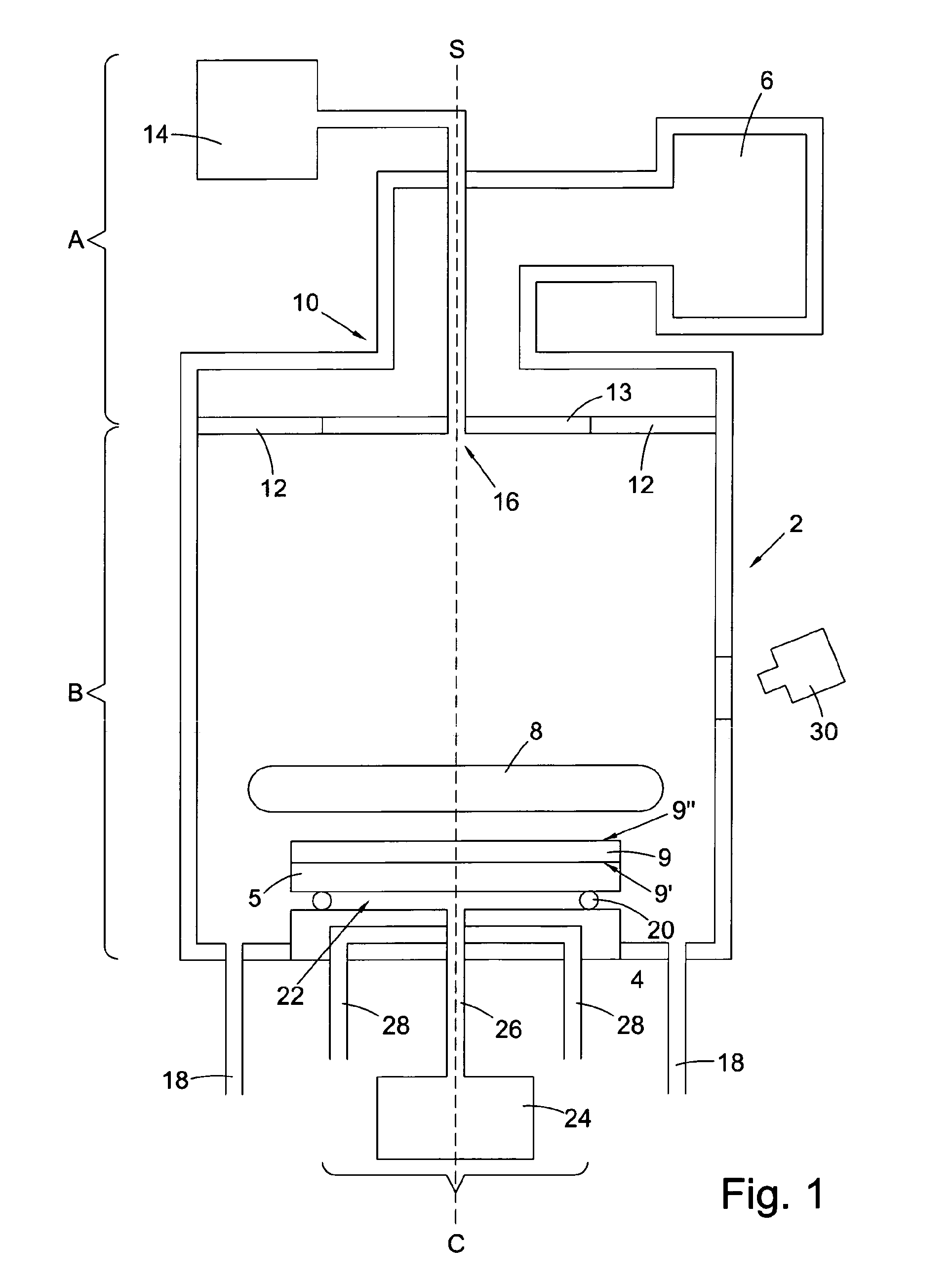

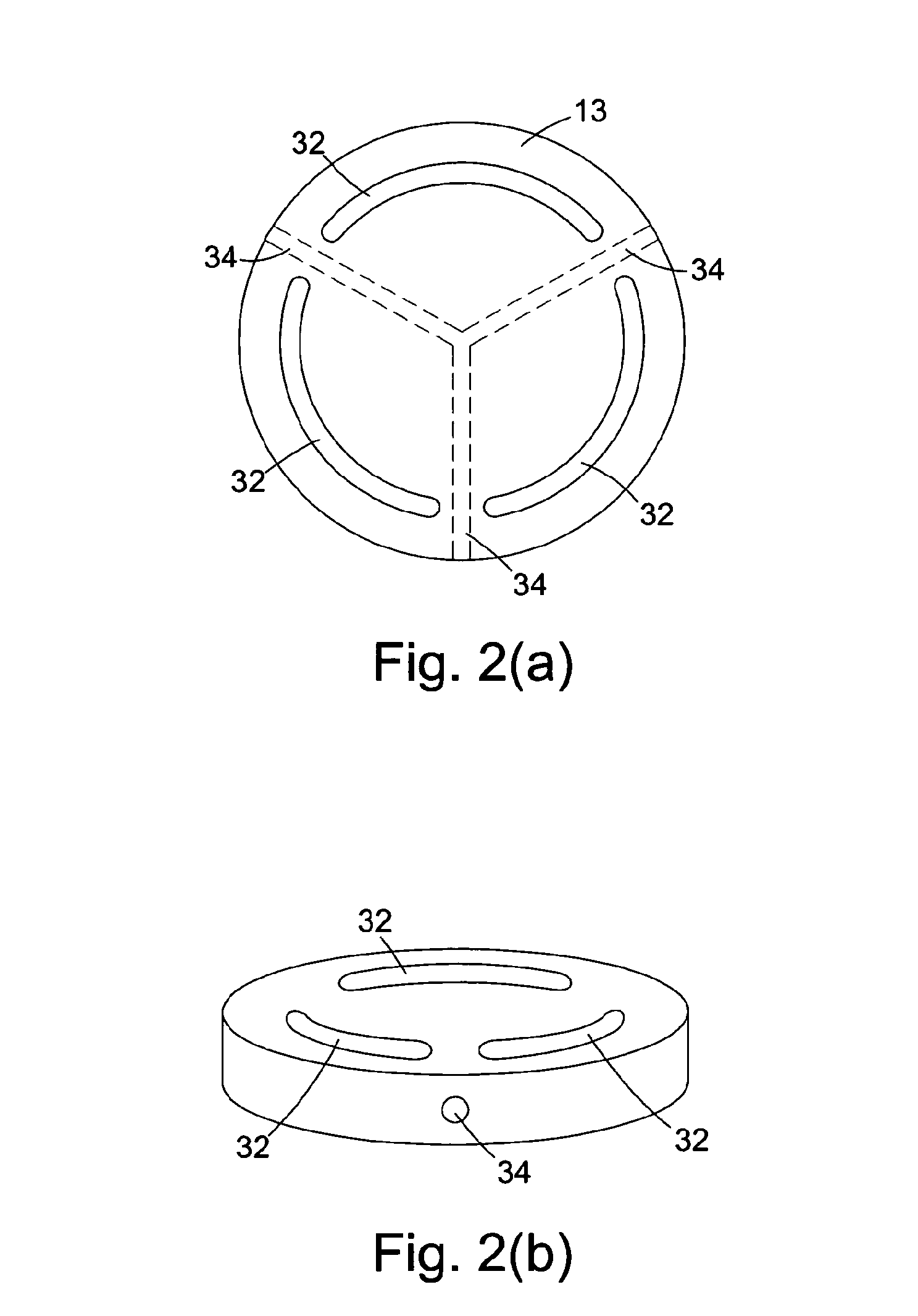

ActiveUS6958729B1Reduce sidelobeIncrease amplitude performanceSimultaneous aerial operationsRadiating elements structural formsSolid substratePhased array

An efficient, low-loss, low sidelobe, high dynamic range phased-array radar antenna system is disclosed that uses metamaterials, which are manmade composite materials having a negative index of refraction, to create a biconcave lens architecture (instead of the aforementioned biconvex lens) for focusing the microwaves transmitted by the antenna. Accordingly, the sidelobes of the antenna are reduced. Attenuation across microstrip transmission lines may be reduced by using low loss transmission lines that are suspended above a ground plane a predetermined distance in a way such they are not in contact with a solid substrate. By suspending the microstrip transmission lines in this manner, dielectric signal loss is reduced significantly, thus resulting in a less-attenuated signal at its destination.

Owner:LUCENT TECH INC

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

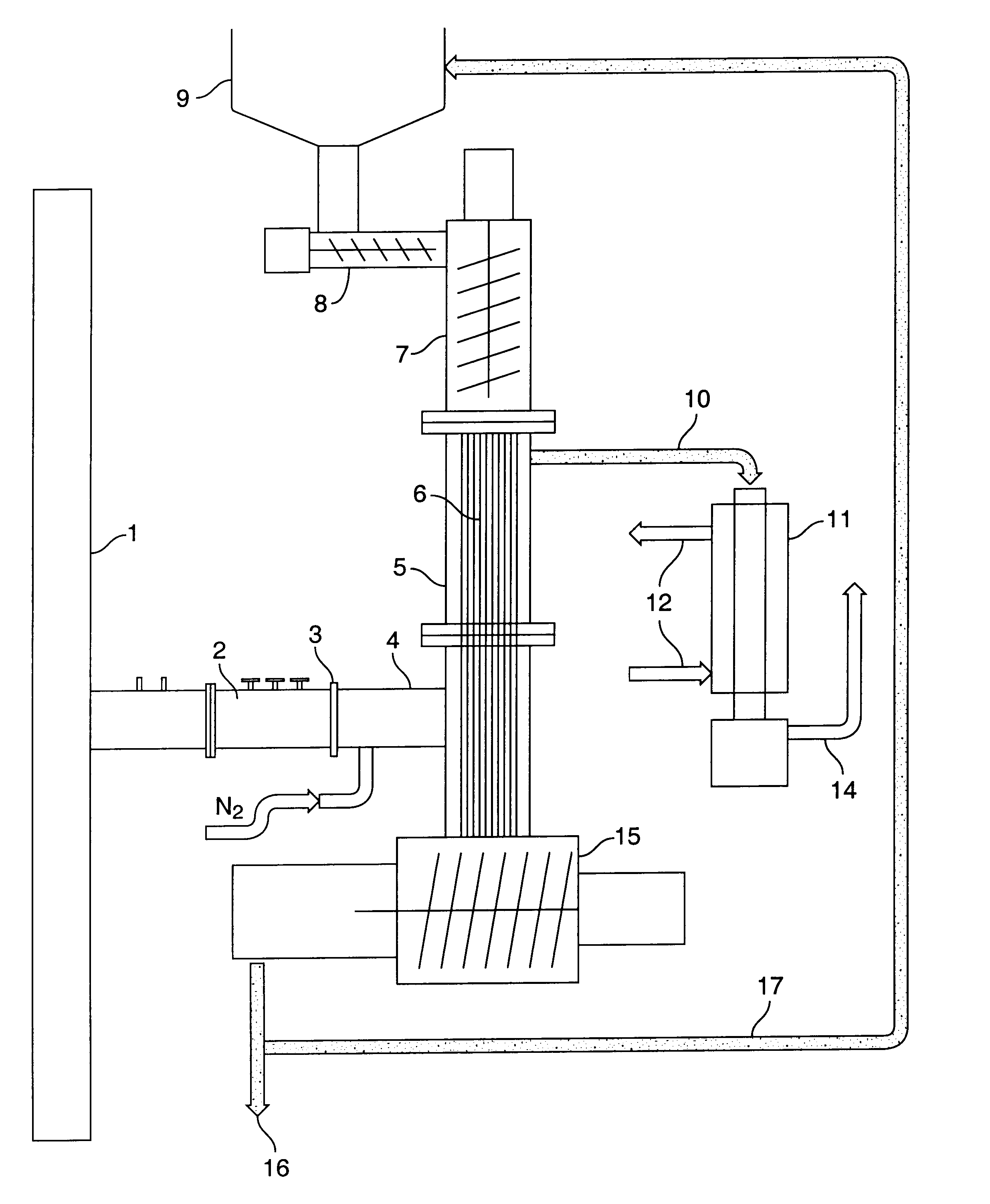

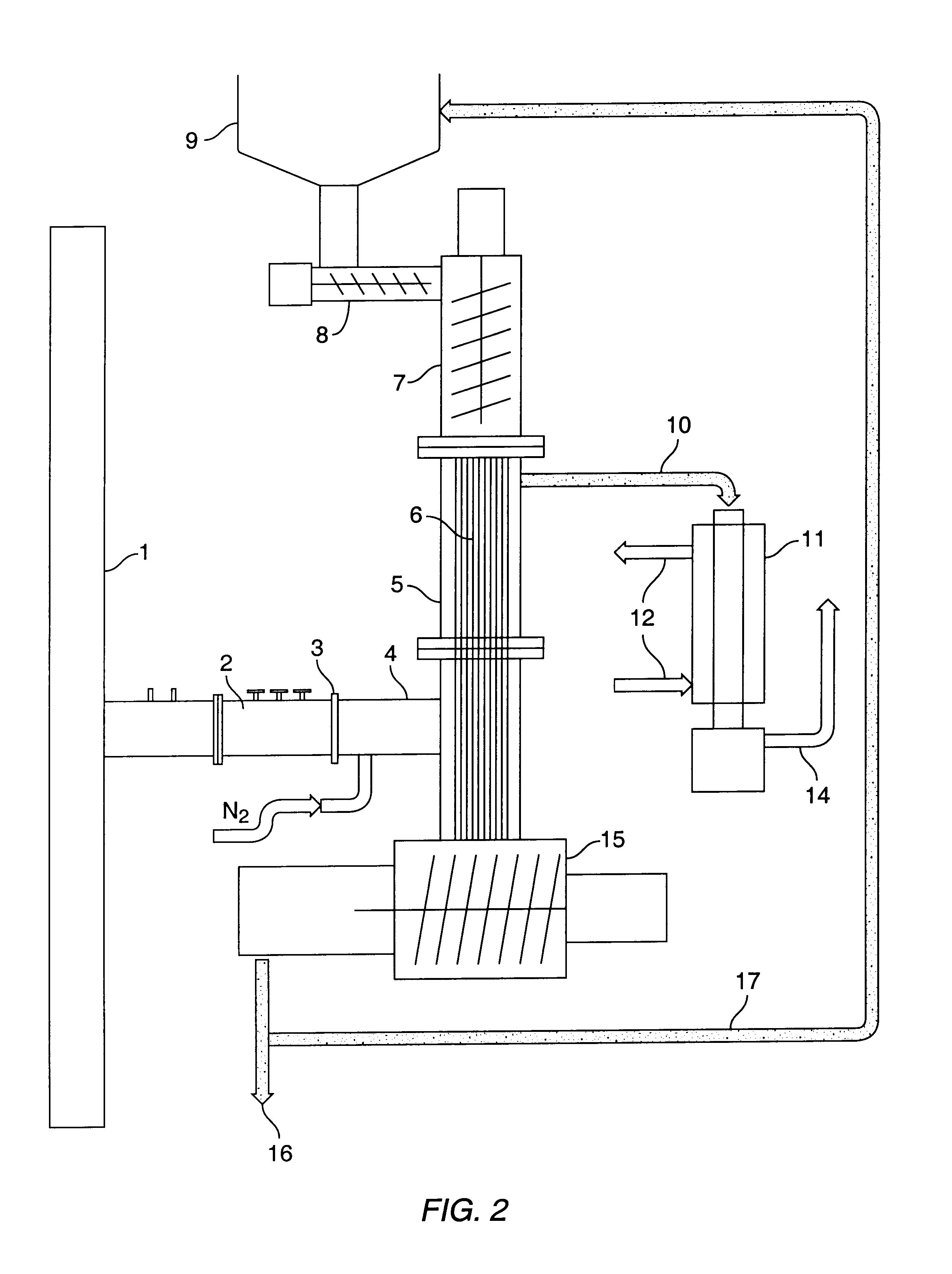

Process and reactor for microwave cracking of plastic materials

InactiveUS6184427B1Indirect and direct heating destructive distillationLiquid hydrocarbon mixture productionRadio frequency energyPlastic materials

A process of activated cracking of high molecular organic waste material which includes confining the organic waste material in a reactor space as a mixture with a pulverized electrically conducting material (sensitizer) and / or catalysts and / or "upgrading agents" and treating this mixture by microwave or radio frequency electro-magnetic radiation. Organic waste materials include hydrocarbons or their derivatives, polymers or plastic materials and shredded rubber. The shredded rubber can be the source of the sensitizer and / or catalyst material as it is rich in carbon and other metallic species. This sensitizer can also consist of pulverized coke or pyrolytically carbonized organic feedstock and / or highly dispersed metals and / or other inorganic materials with high dielectric loss which absorb microwave or radio frequency energy.

Owner:HIGHWAVE ACQUISITION

Tunable dielectric compositions including low loss glass

InactiveUS6905989B2Lower sintering temperatureIncrease varietyFixed capacitor dielectricCeramic layered productsBreakdown strengthStrontium titanate

Tunable dielectric materials including an electronically tunable dielectric ceramic and a low loss glass additive are disclosed. The tunable dielectric may comprise a ferroelectric perskovite material such as barium strontium titanate. The glass additive may comprise boron, barium, calcium, lithium, manganese, silicon, zinc and / or aluminum-containing glasses having dielectric losses of less than 0.003 at 2 GHz. The materials may further include other additives such as non-tunable metal oxides and silicates. The low loss glass additive enables the materials to be sintered at relatively low temperatures while providing improved properties such as low microwave losses and high breakdown strengths.

Owner:NXP USA INC

Large area optical quality synthetic polycrystalline diaond window

ActiveUS20140349068A1Improve optical qualityPrecise design toleranceSynthetic resin layered productsDiamondDielectric lossRoom temperature

A polycrystalline chemical vapour deposited (CVD) diamond wafer comprising: a largest linear dimension equal to or greater than 70 mm; a thickness equal to or greater than 1.3 mm; and one or both of the following characteristics measured at room temperature (nominally 298 K) over at least a central area of the polycrystalline CVD diamond wafer, said central area being circular, centred on a central point of the polycrystalline CVD diamond wafer, and having a diameter of at least 70% of the largest linear dimension of the polycrystalline CVD diamond wafer: an absorption coefficient ≦0.2 cm−1 at 10.6 μm; and a dielectric loss coefficient at 145 GHz, of tan δ≦2×10−4.

Owner:ELEMENT SIX TECH LTD

Phased array metamaterial antenna system

ActiveUS20050225492A1Low Sidelobe PerformanceReduce sidelobeRadiating elements structural formsWaveguidesSolid substratePhased array

An efficient, low-loss, low sidelobe, high dynamic range phased-array radar antenna system is disclosed that uses metamaterials, which are manmade composite materials having a negative index of refraction, to create a biconcave lens architecture (instead of the aforementioned biconvex lens) for focusing the microwaves transmitted by the antenna. Accordingly, the sidelobes of the antenna are reduced. Attenuation across microstrip transmission lines may be reduced by using low loss transmission lines that are suspended above a ground plane a predetermined distance in a way such they are not in contact with a solid substrate. By suspending the microstrip transmission lines in this manner, dielectric signal loss is reduced significantly, thus resulting in a less-attenuated signal at its destination.

Owner:LUCENT TECH INC

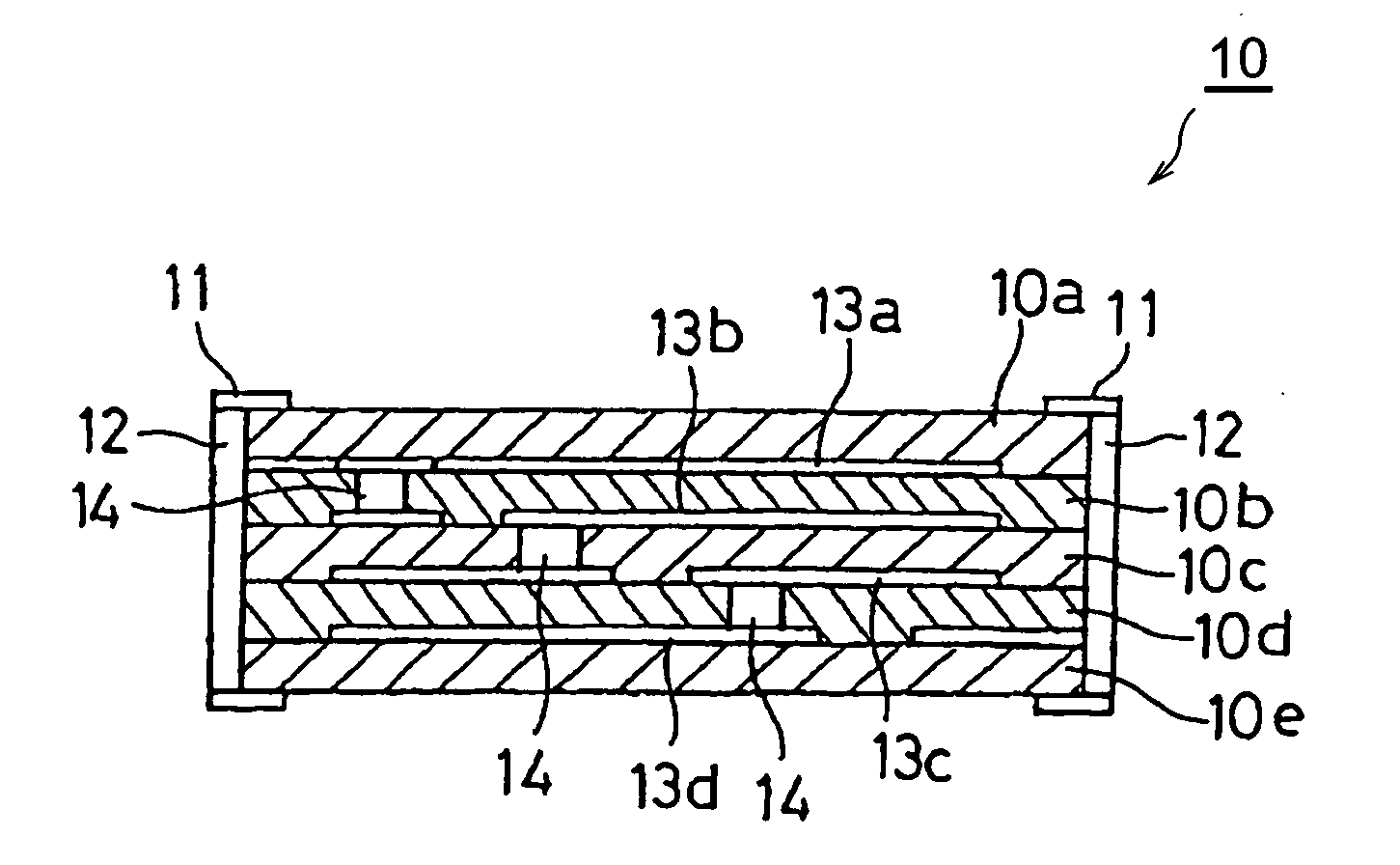

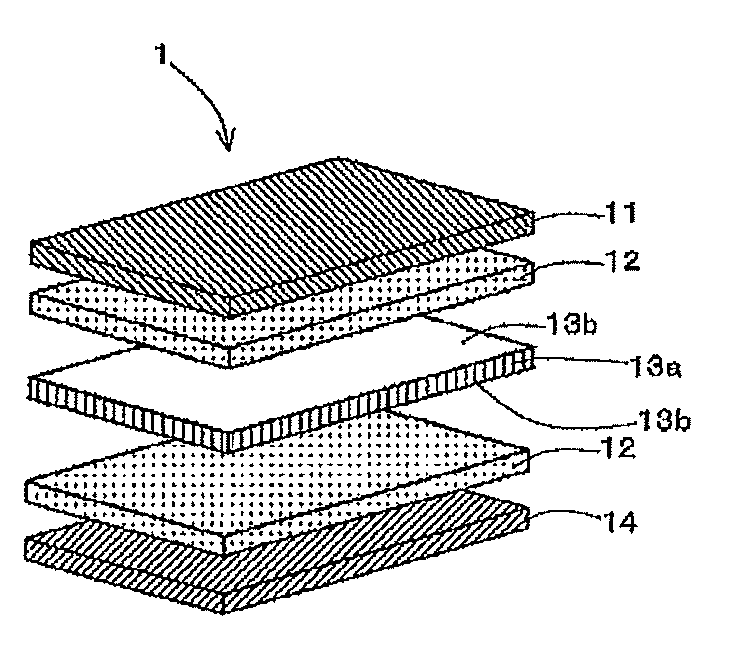

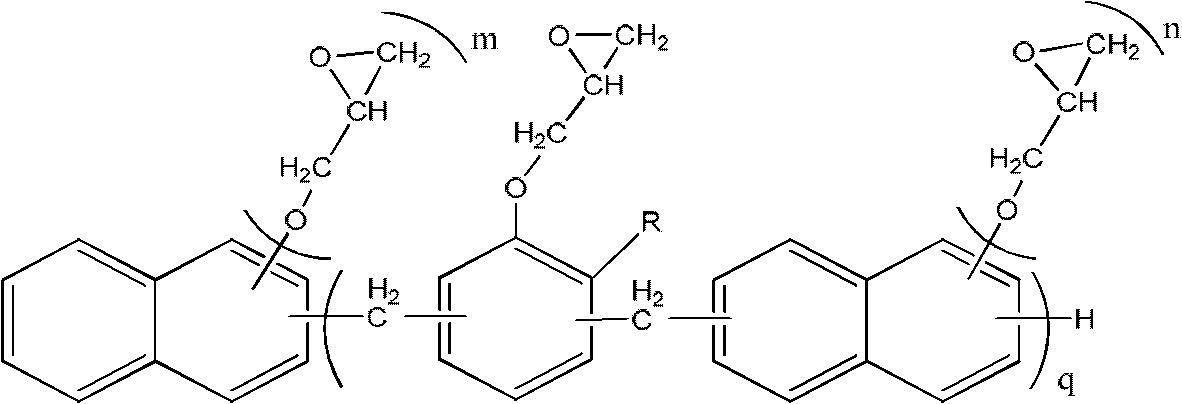

Resin composition, cured resin, sheet-like cured resin, laminated body, prepreg, electronic parts and multilayer boards

InactiveUS20050003199A1Maintain electrical propertiesHigh dielectric constantSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEpoxyDielectric loss

The invention provides electronic parts which comprise a composite dielectric layer composed of an organic insulating material and a dielectric ceramic powder having a larger relative dielectric constant than the organic insulating material, and which also comprise conductive element sections forming inductor elements, etc., wherein the organic insulating material comprises a cured resin obtained by curing reaction of an epoxy resin with an active ester compound obtained by reaction between a compound with two or more carboxyl groups and a compound with a phenolic hydroxyl group. The dielectric ceramic powders of the described electronic parts have larger relative dielectric constants than the organic insulating materials, and the organic insulating materials have low dielectric loss tangents. It is possible to adequately reduce time-dependent dielectric constant changes in the high-frequency range of 100 MHz and above even with prolonged use at high temperatures of 100° C. and higher, while it is also possible to satisfactorily prevent deformation and other damage to the electronic parts during their handling.

Owner:TDK CORPARATION

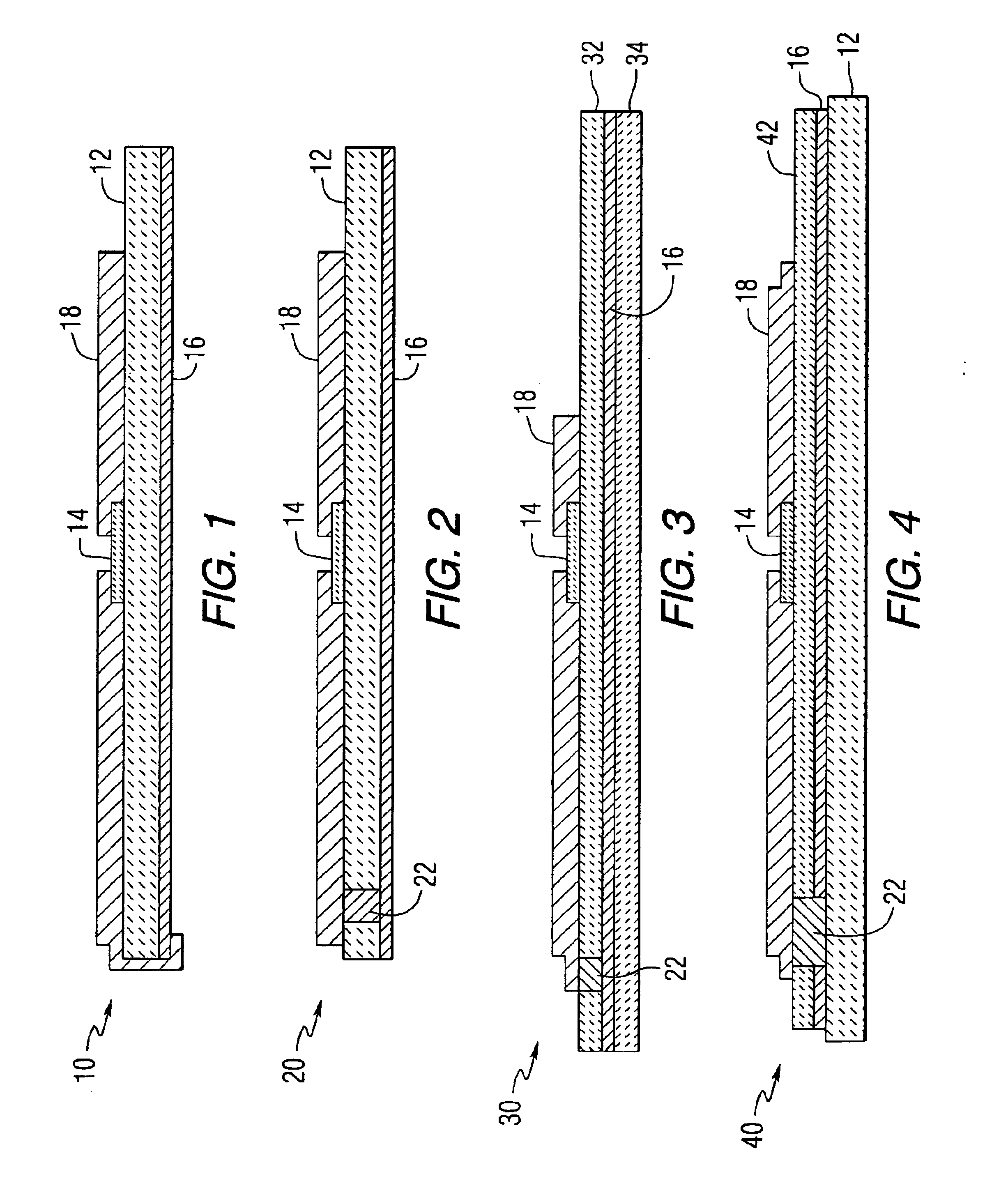

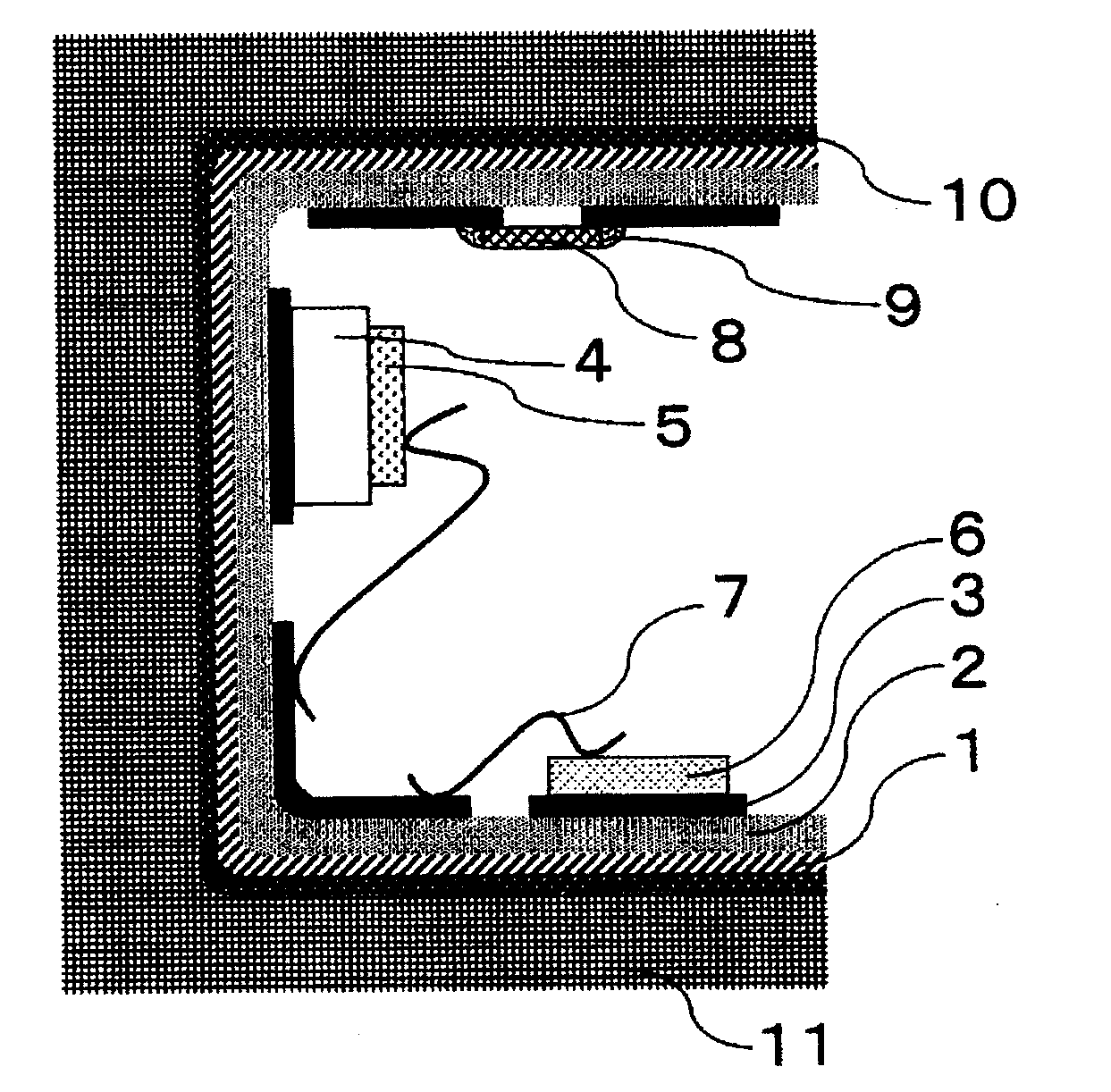

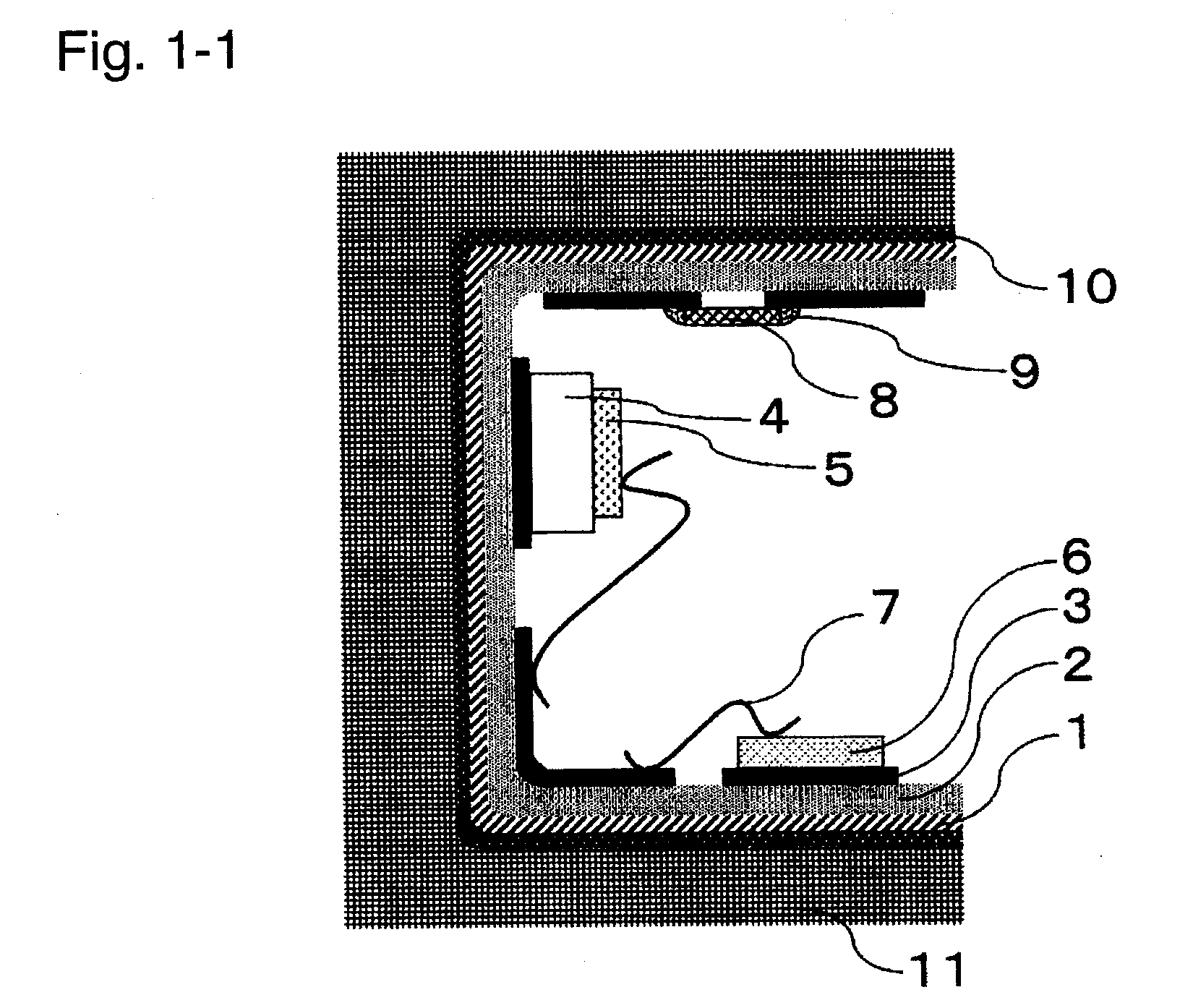

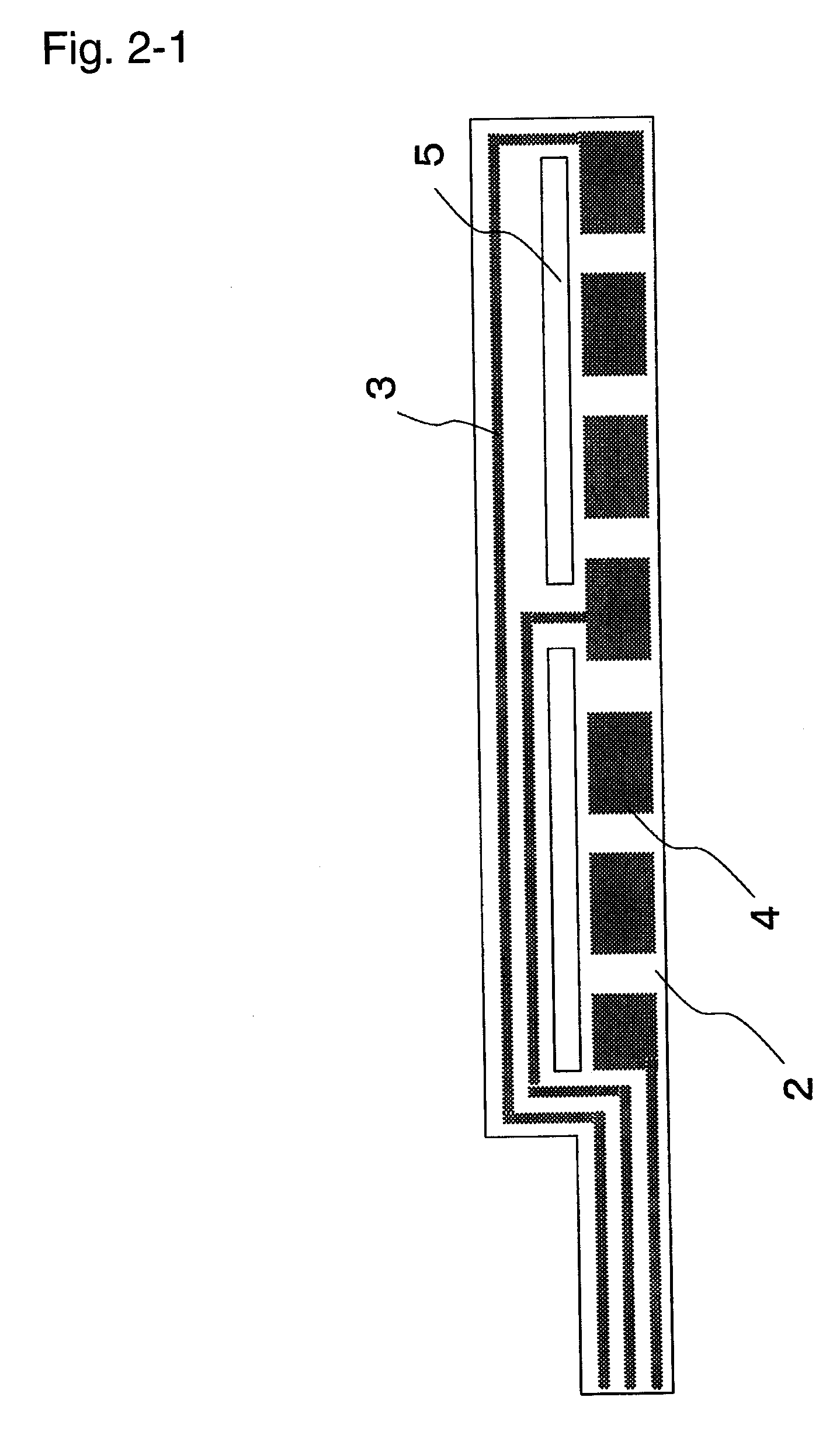

Metal base circuit board, LED, and LED light source unit

ActiveUS20090032295A1Easy to bendSmall sizePoint-like light sourcePrinted electric component incorporationThin metalMetal foil

To provide a thin metal base circuit board which can be not only installed on a flat portion but also closely attached to a side or bottom surface of a case or to a stepped or curved portion and which is excellent in heat dissipation performance, electrical insulating performance and flexibility; a process for its production; and a hybrid integrated circuit, an LED module and a bright, ultra-long-life LED light source employing it.A metal base circuit board having insulating layers and conductive circuits or metal foils alternately laminated, characterized in that the thickness of each conductive circuit or metal foil is from 5 μm to 450 μm, each insulating layer is made of a cured product of a resin composition comprising an inorganic filler and a thermosetting resin, and the thickness of each insulating layer is from 9 μm to 300 μm; and a hybrid circuit board employing it. The metal base circuit board wherein a coverlay is provided, and a layer having a magnetic loss or a layer having a dielectric loss is laminated on the surface of the coverlay. A LED light source unit having at least one light-emitting diode (LED) mounted on the conductive circuit.

Owner:DENKA CO LTD

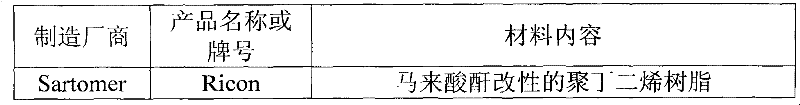

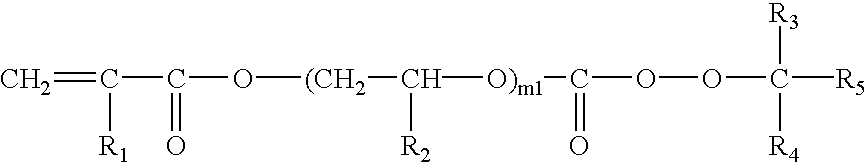

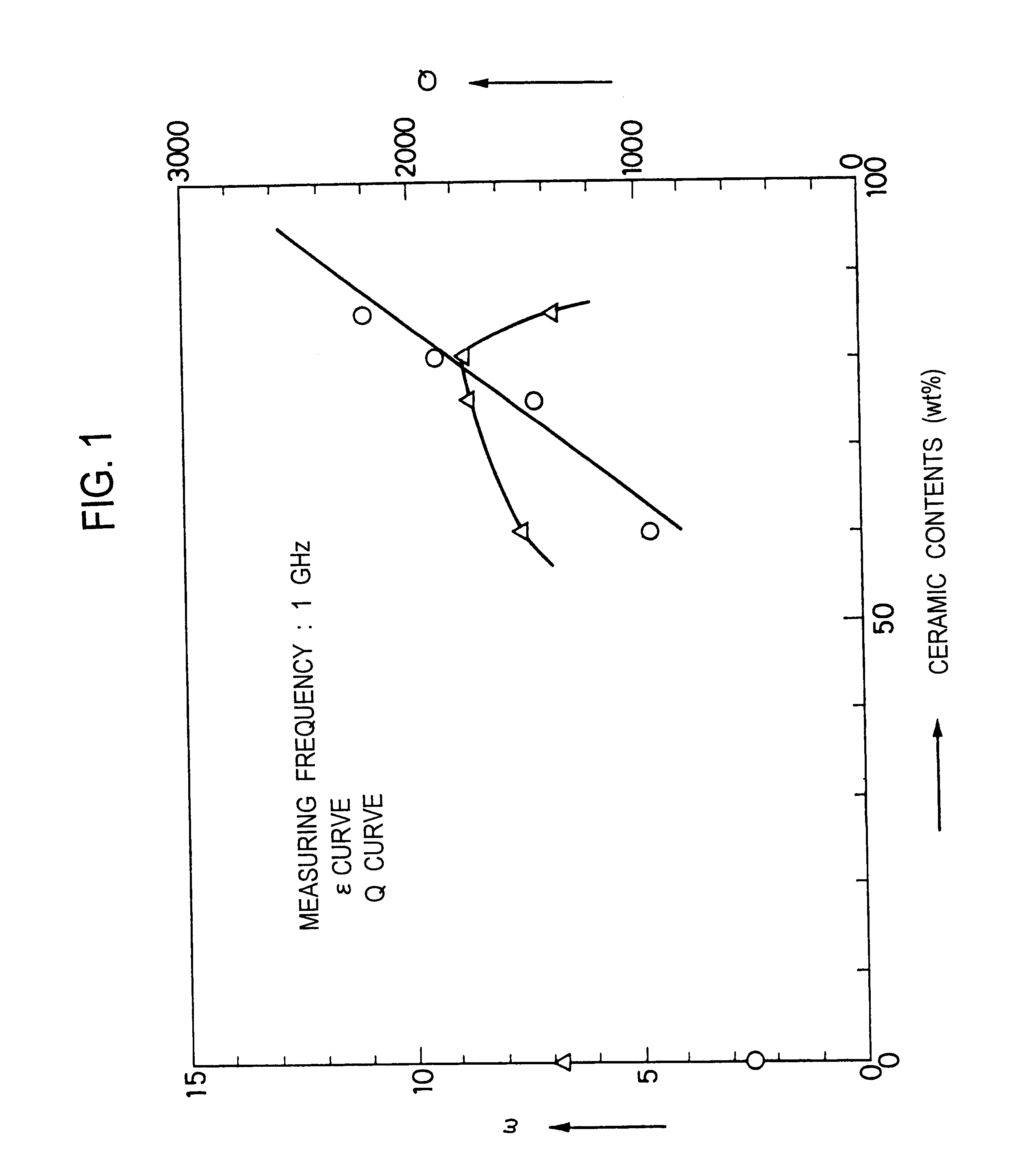

Composite material, high-frequency circuit substrate therefrom and manufacture method thereof

ActiveCN102161823AHigh peel strengthImprove the sticky problemPrinted circuit manufactureCircuit susbtrate materialsDouble bondCopper foil

The invention relates to a composite material, a high-frequency circuit substrate therefrom and a manufacture method thereof. The composite material comprises thermoset mixture, glass fiber cloth, power filler, a fire retardant and a curing initiator, wherein the thermoset mixture comprises more than one kind of vinyl liquid resin and polyphenyl ether resin; the molecular weight of the vinyl liquid resin is below 10000, and the vinyl liquid resin is provided with a polar functional group; the molecular weight of the polyphenyl ether resin is less than 5000, and the molecular tail end of the polyphenyl ether resin is provided with unsaturated double bonds. The high-frequency circuit substrate manufactured with the composite material comprises multiple layers of semi-solidified sheets and copper foils, wherein the semi-solidified sheets are mutually overlaid, and the copper foils are respectively pressed on two sides. The composite material disclosed by the invention causes the semi-solidified sheets to be easily manufactured and have high adhesive bonding force with the copper foils. The high-frequency circuit substrate manufactured by the material has the advantages of low dielectric constant, low dielectric loss angle tangent, good heat resistance and simple technical operation. Thus, the composite material disclosed by the invention is suitable for manufacturing the circuit substrate of the high-frequency electronic equipment.

Owner:GUANGDONG SHENGYI SCI TECH

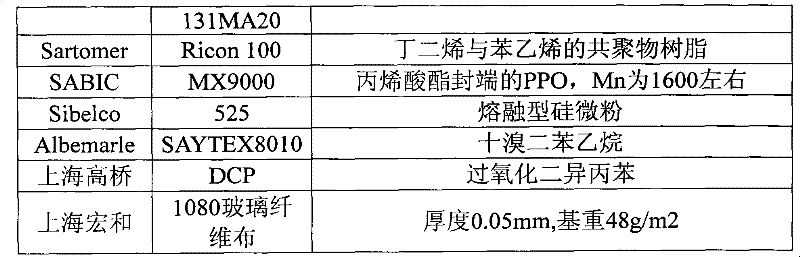

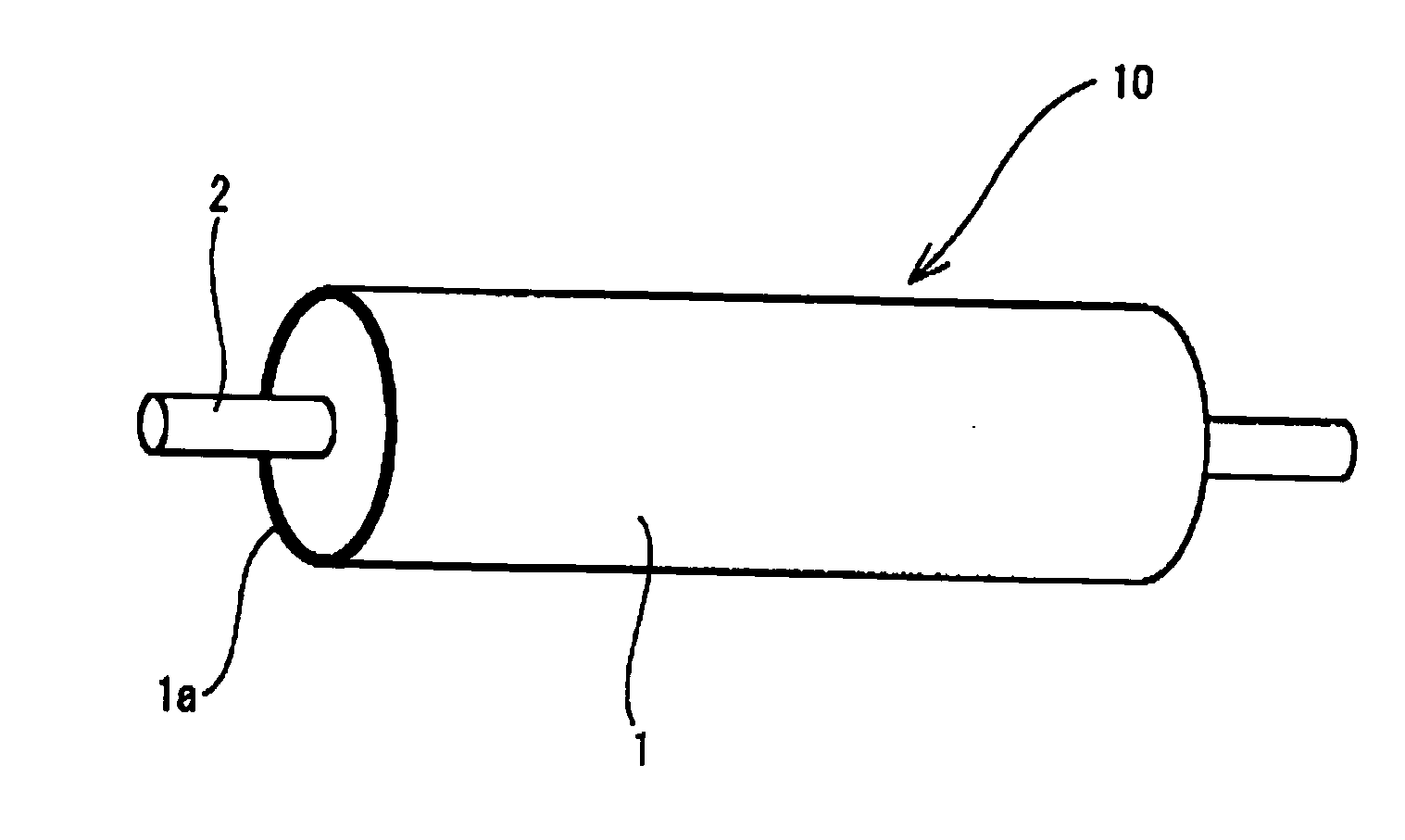

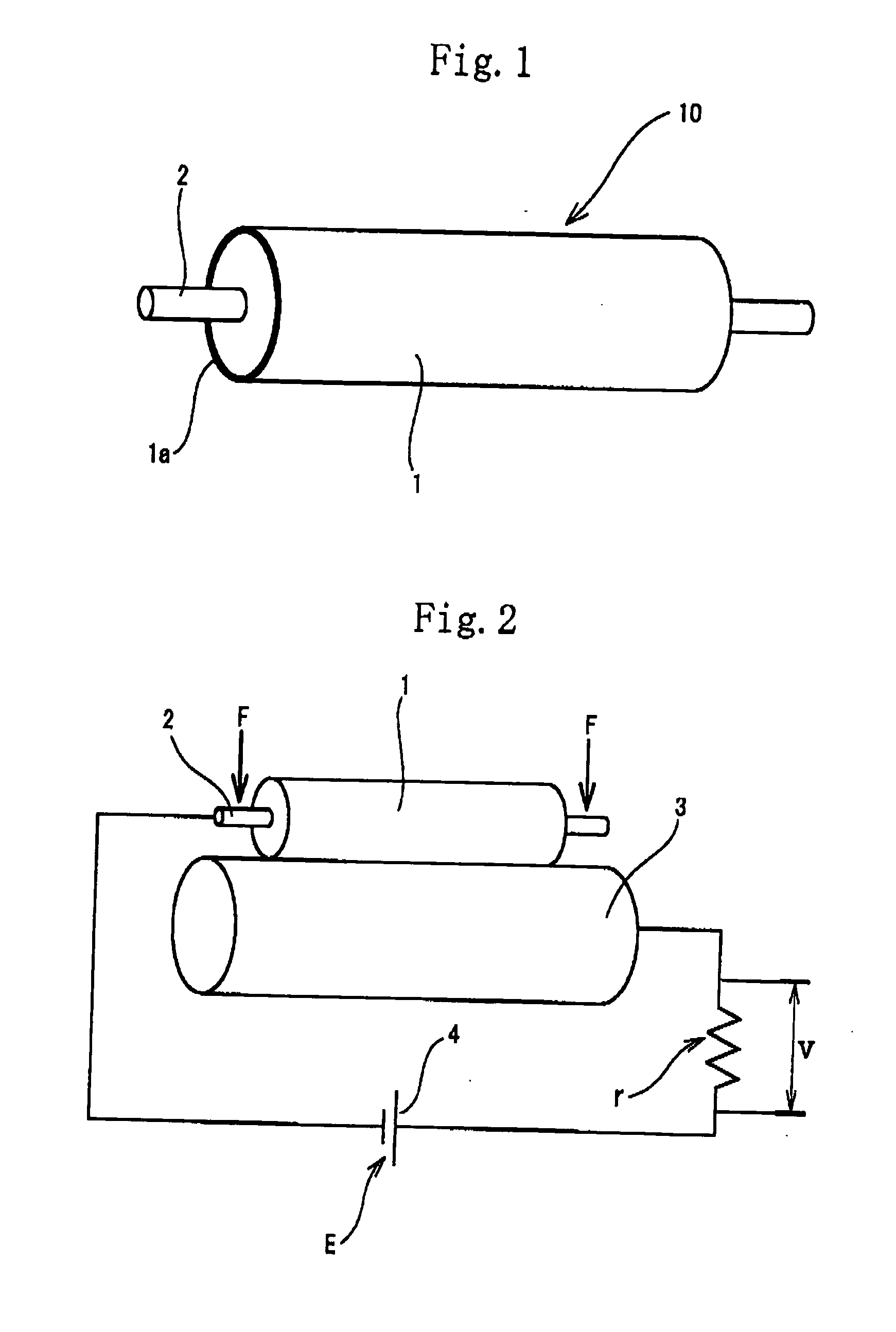

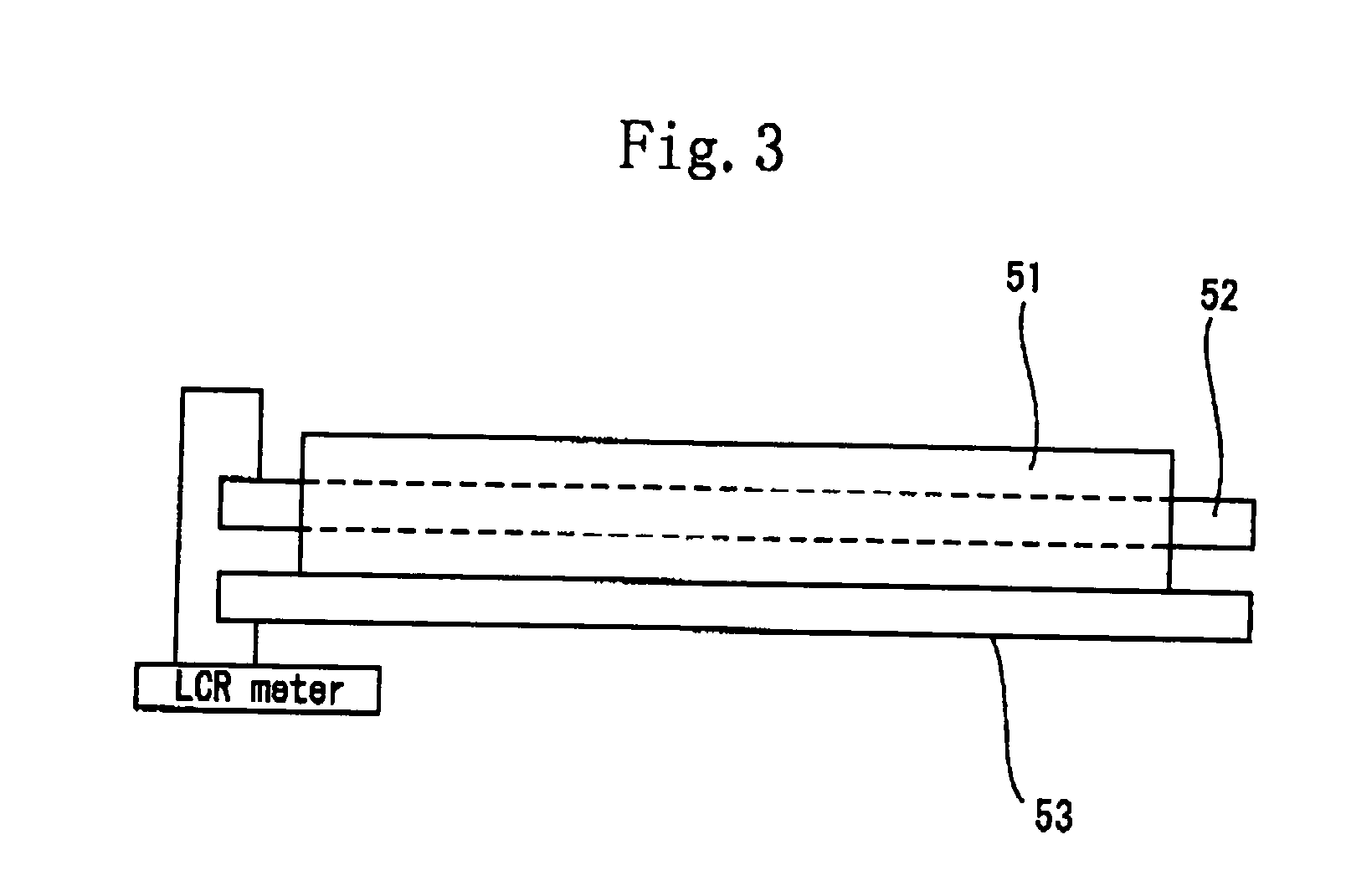

Semiconductive rubber member

InactiveUS20060269327A1Electrical charge on becomes highPrevent leakageElectrographic process apparatusCorona dischargeDielectric lossAC - Alternating current

A conductive rubber roller 10 having a conductive rubber layer 1, containing chloroprene rubber, which composes an outermost layer thereof. When an alternating current is applied to the conductive rubber roller 10 at a voltage of five and a frequency of 100 Hertz, a dielectric loss tangent is 0.1 to 1.8.

Owner:SUMITOMO RUBBER IND LTD

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

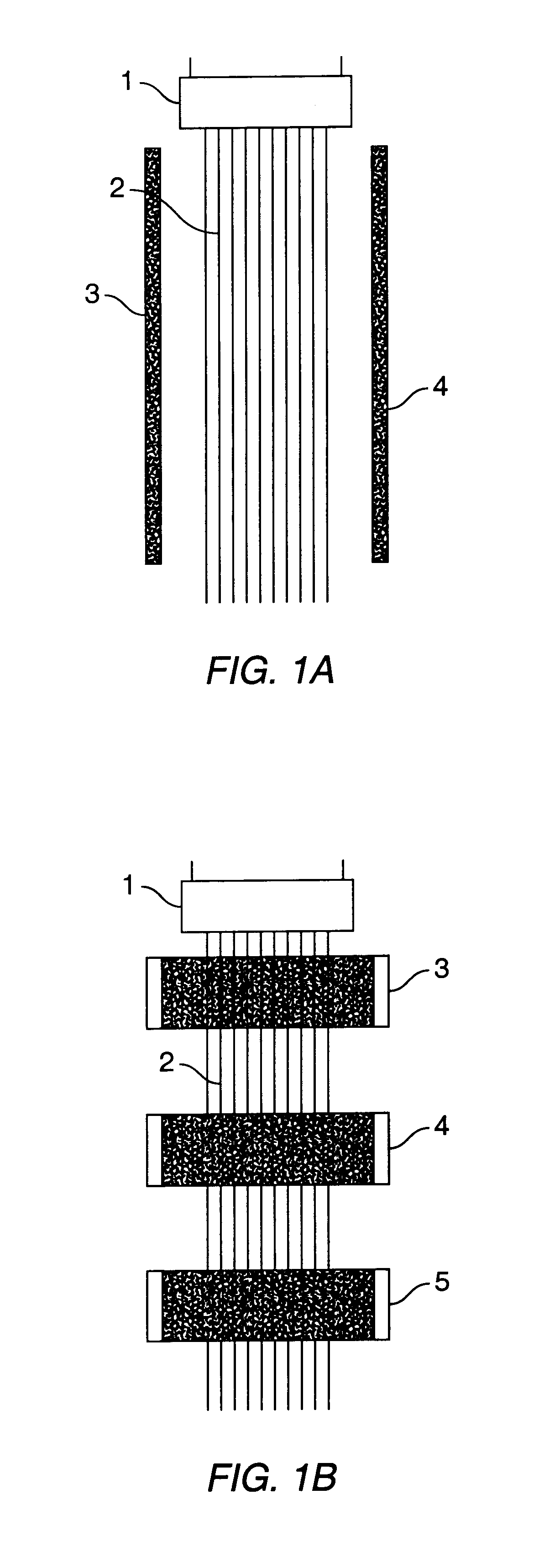

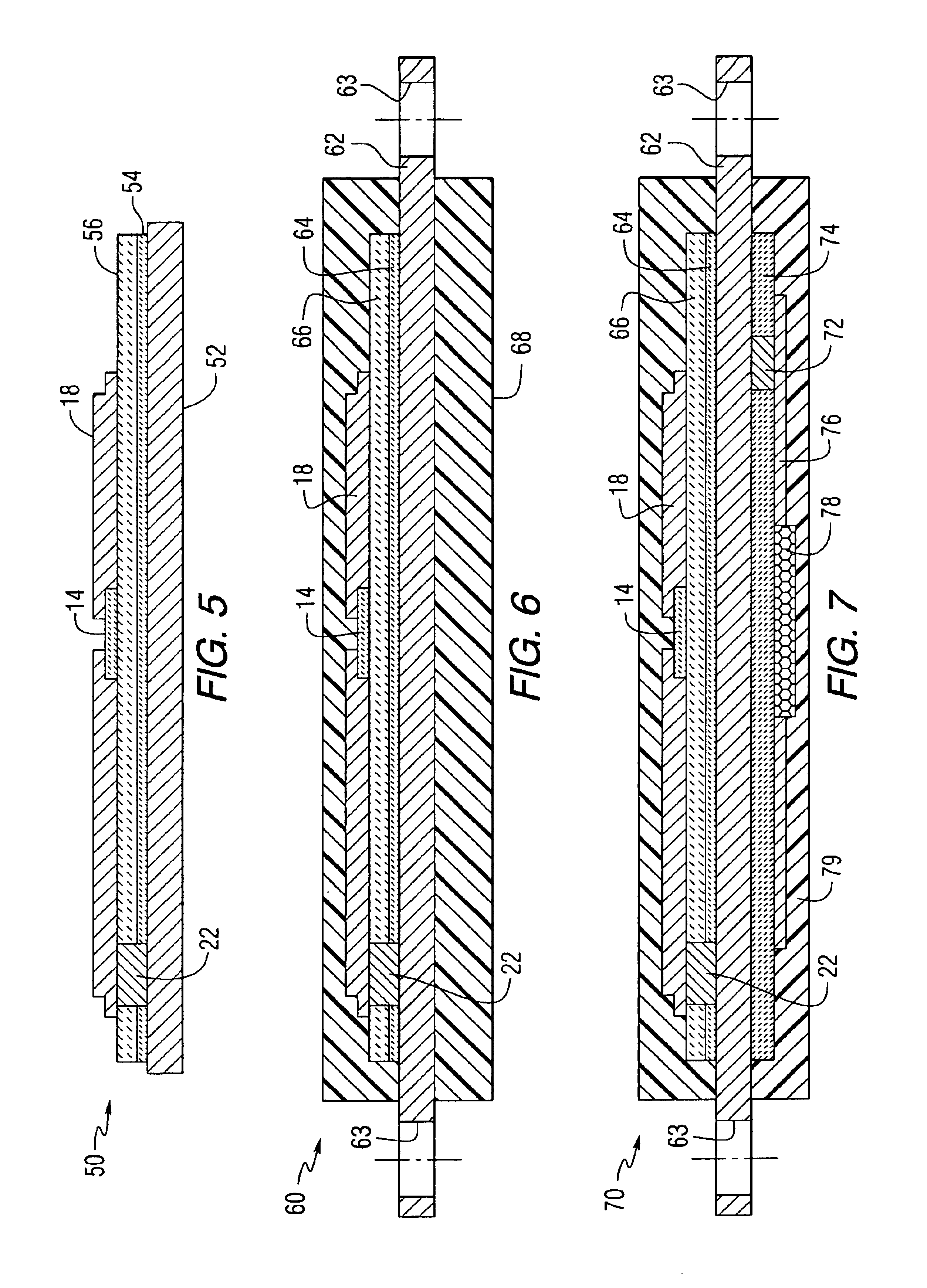

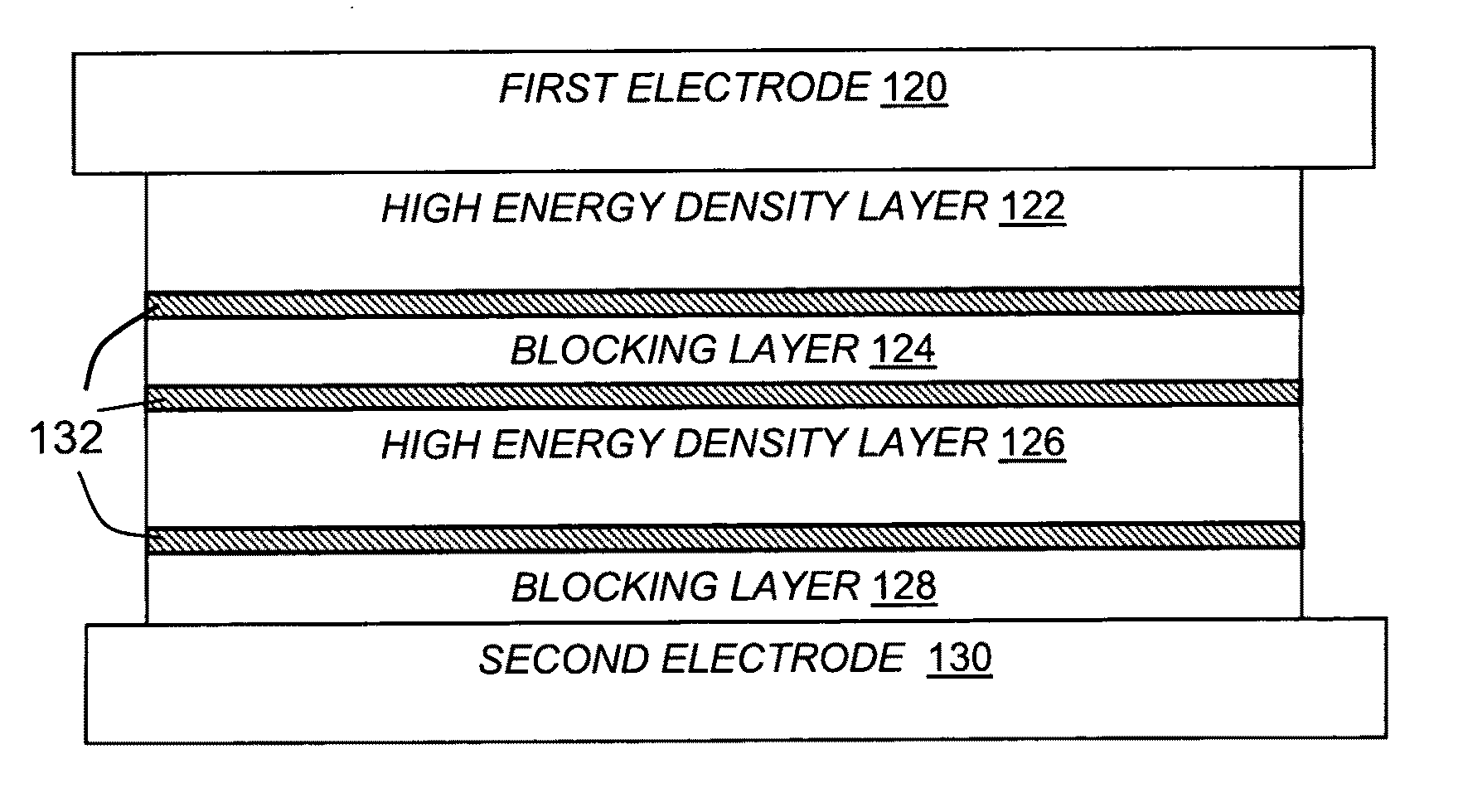

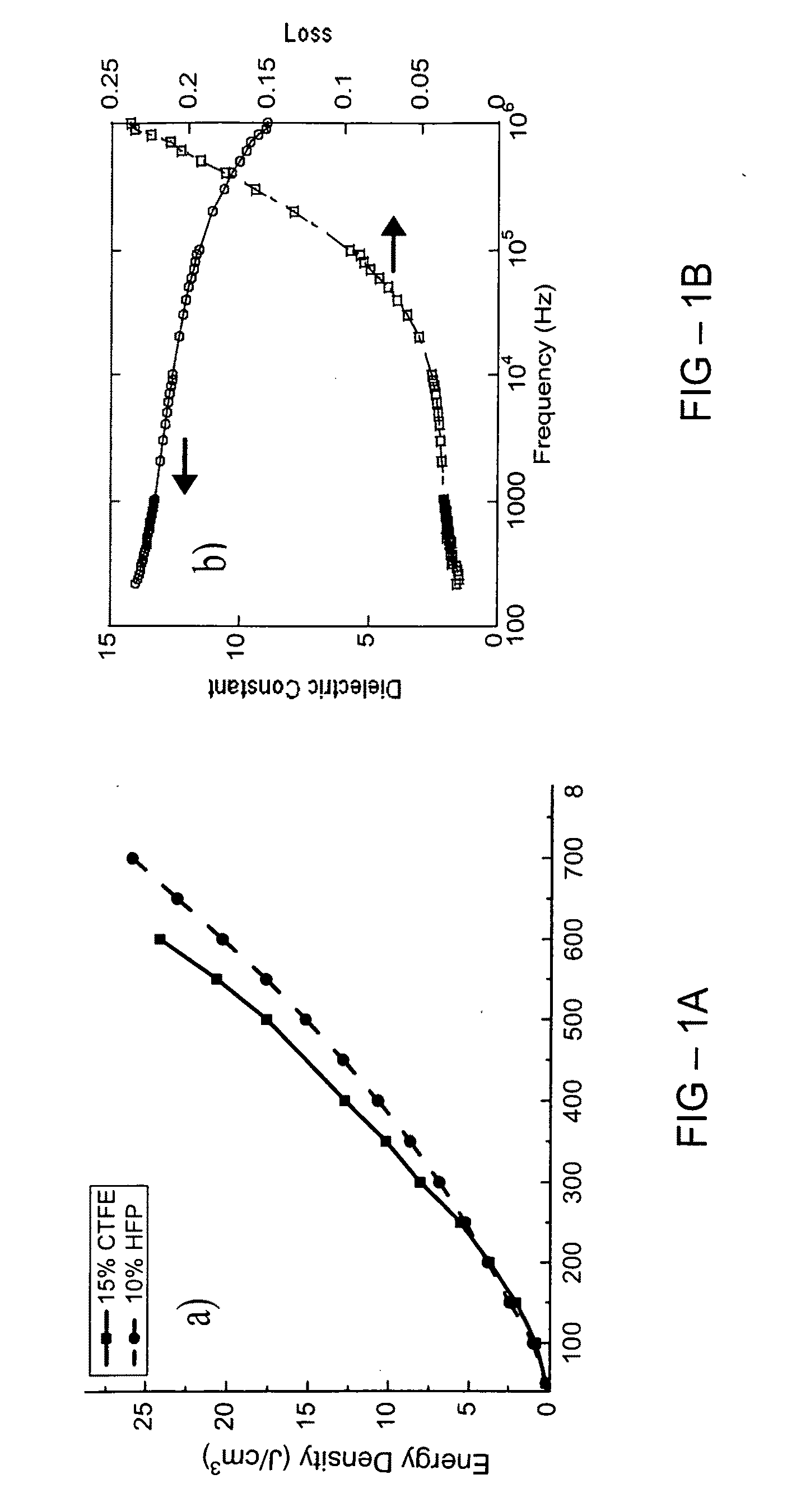

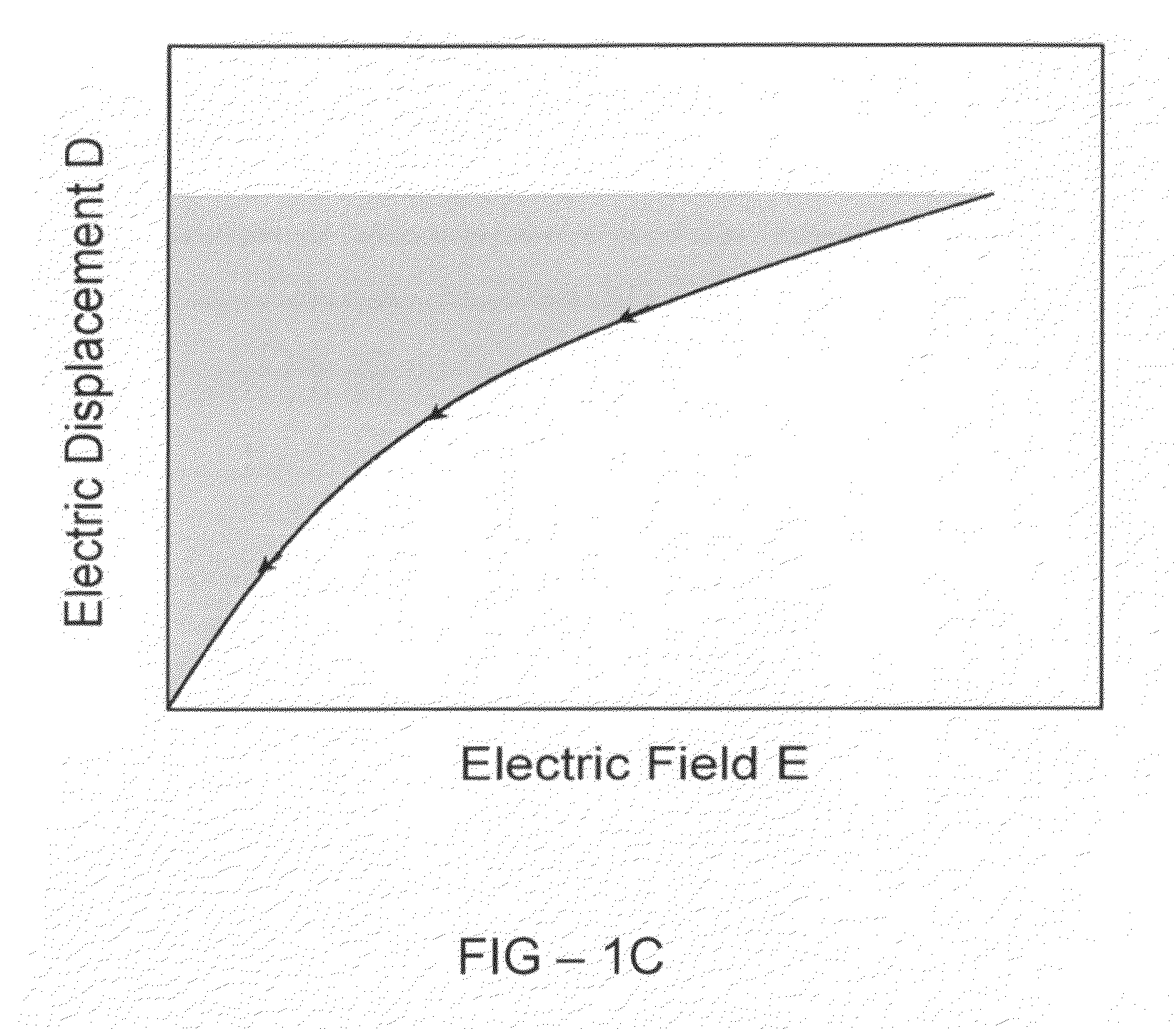

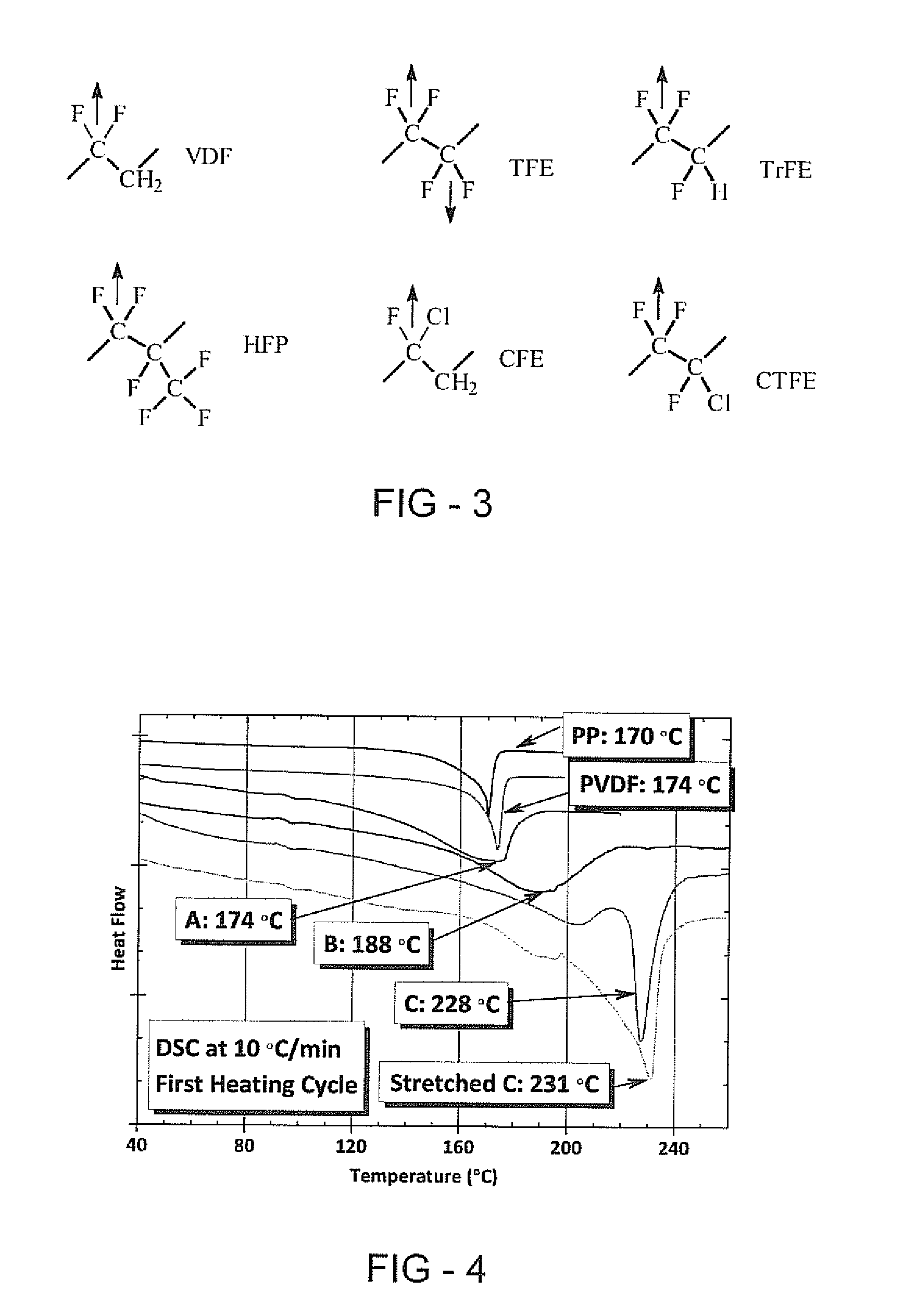

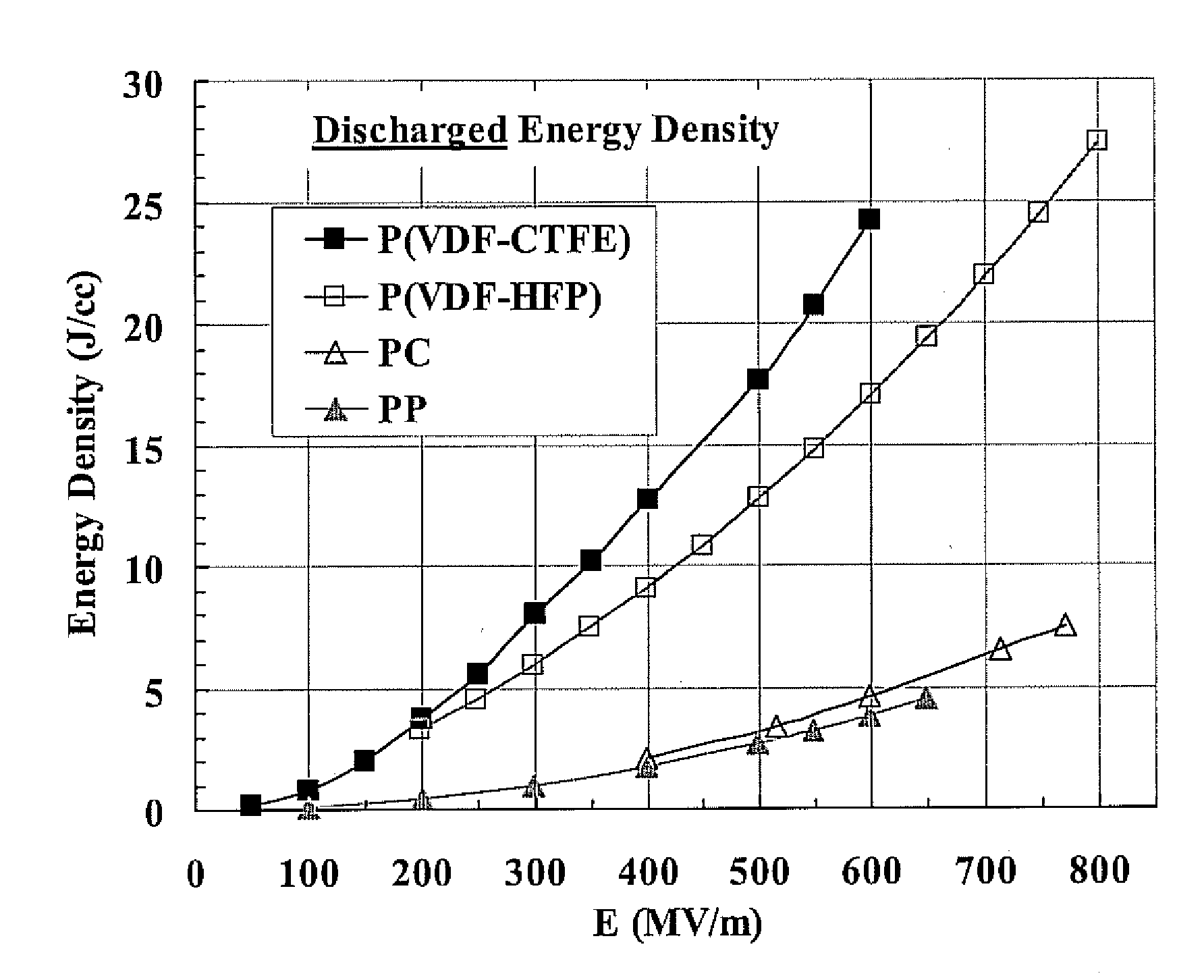

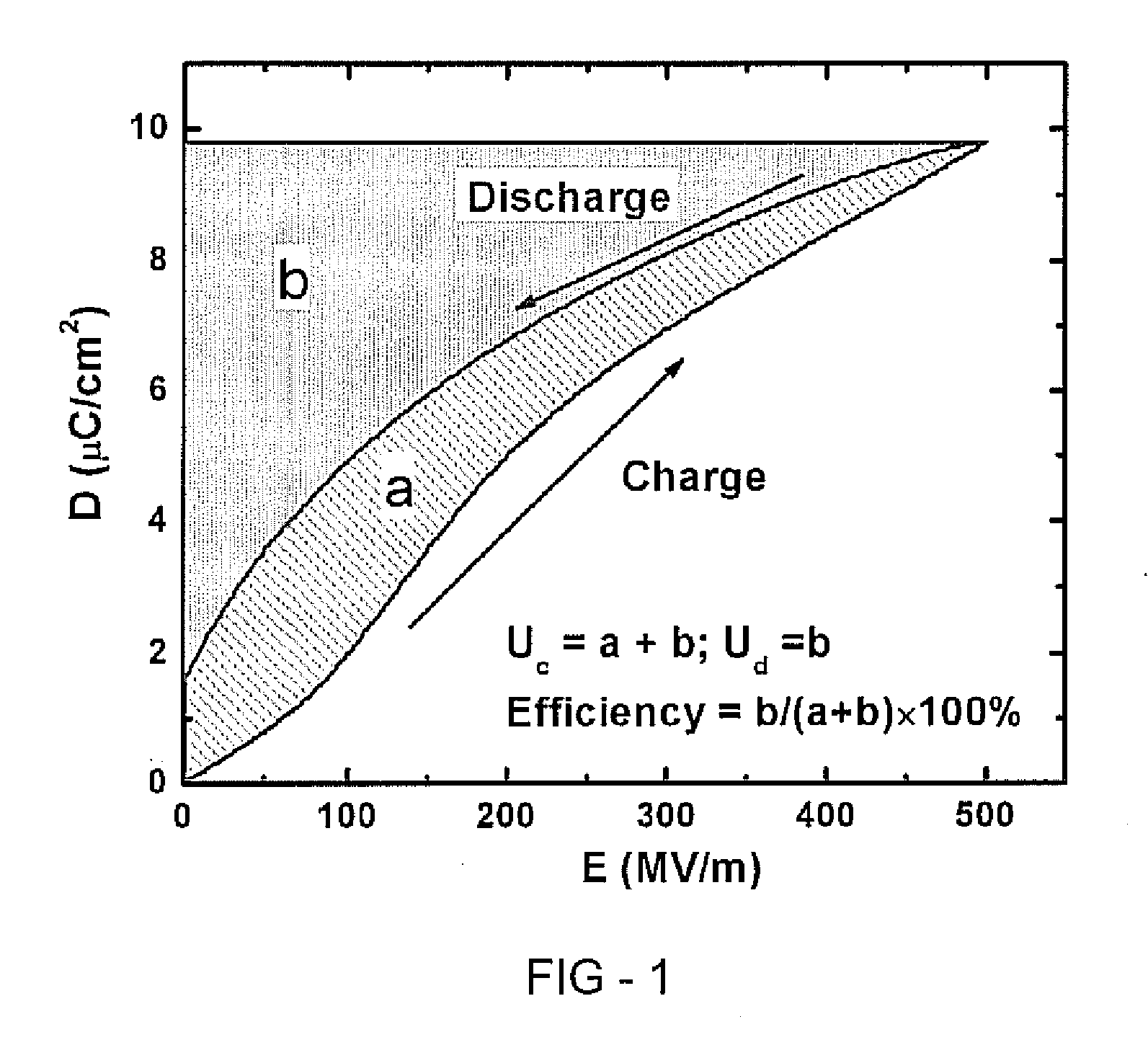

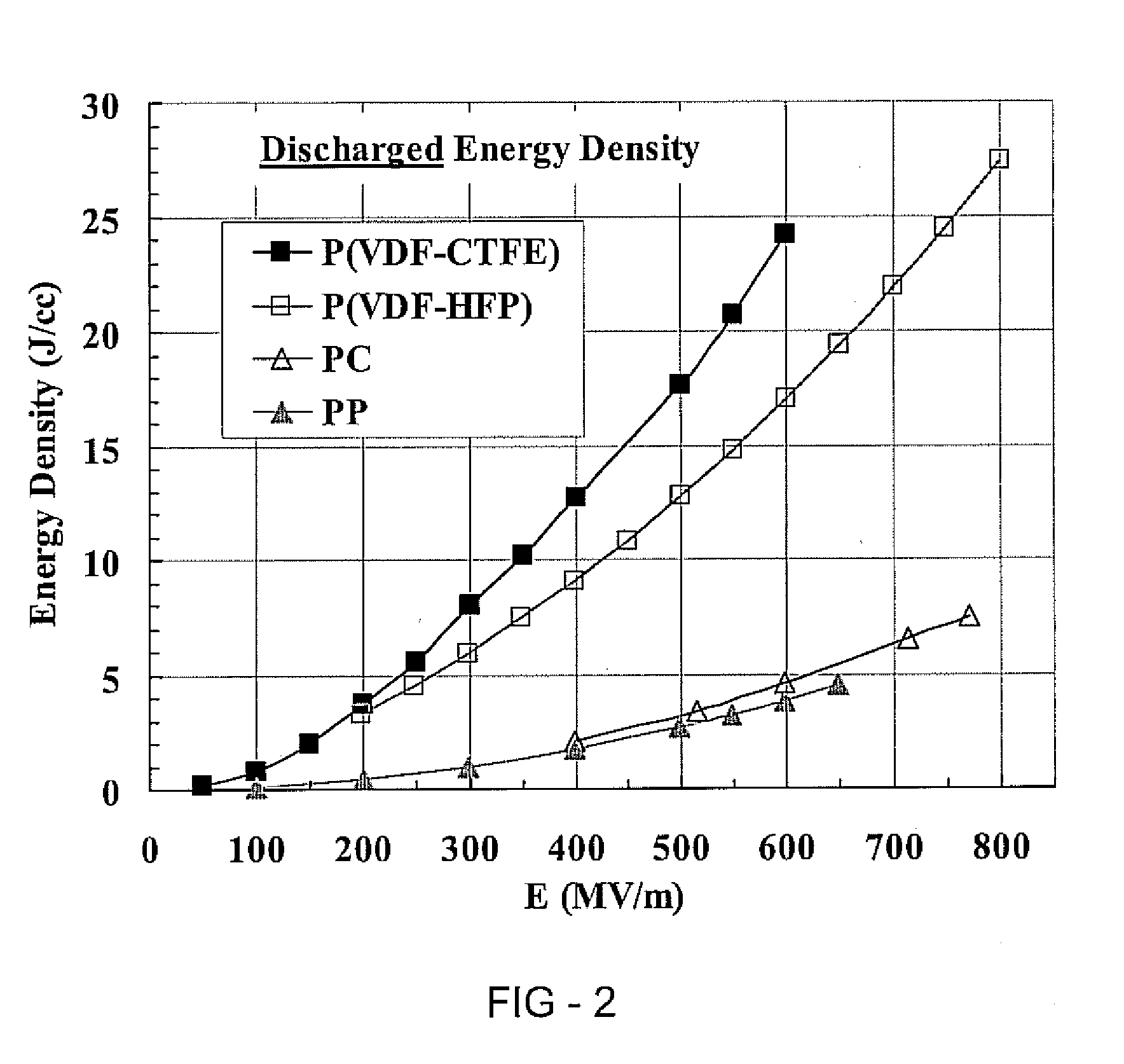

Methods to improve the efficiency and reduce the energy losses in high energy density capacitor films and articles comprising the same

InactiveUS20110110015A1Reduce conduction lossHigh breakdown strengthThin/thick film capacitorFixed capacitor dielectricCapacitanceDielectric loss

A multilayer film useful for capacitive applications comprises a high energy density layer and a dielectric blocking layer. In some embodiments, a conducting film is located between the high energy density layer and the blocking layer. The high energy density layer may be a fluoropolymer, such as a polymer or copolymer of poly-1,1-difluoroethene or a derivative thereof. The multilayer film may have high energy density (for example,. >8 J / cm3) and low dielectric loss, for example less than 2%, and preferably less than 1%.

Owner:PENN STATE RES FOUND

Electric heating tube made of hexagonal boron nitride and mixed heat conducting material thereof

ActiveCN101854750ALong life and high qualityImprove insulation performanceChemical industryHeat-exchange elementsHexagonal boron nitrideHeat conducting

The invention belongs to the technical field of electric heating tube manufacture, and relates to an electric heating tube using hexagonal boron nitride or mixture of hexagonal boron nitride and magnesium oxide as a heat conducting material, in particular to a mixed heat conducting material for a novel electric heating tube. A main body structure comprises a metal tube body, a mixed filler, a resistance wire and accessories comprising a fixed plate, porcelain beads, sealant, a plastic plug, a leading-out bar, a terminal electrodes and screws; a cavity structure of the metal tube body is invariantly bent into a circular, elliptical or spiral geometric structure; parallel structures at two end sections of the metal tube body are fixed on the fixed plate in an interval penetration mode, and fixed screws are arranged at two ends of the fixed plate; and the resistance wire is fixed and electrically connected on the central axis of the cavity of the metal tube body and parallel to two end points on two sides of the tube wall, and the mixed filler is filled between the resistance wire and the side wall of the metal tube body. The electric heating tube has the advantages of high stability and heat conducting efficiency, high-temperature softening prevention in inert gas, long service life, high quality, good insulating property, low dielectric constant and dielectric loss, and safe use.

Owner:QINGDAO EASYTOUSE ELECTRONICS

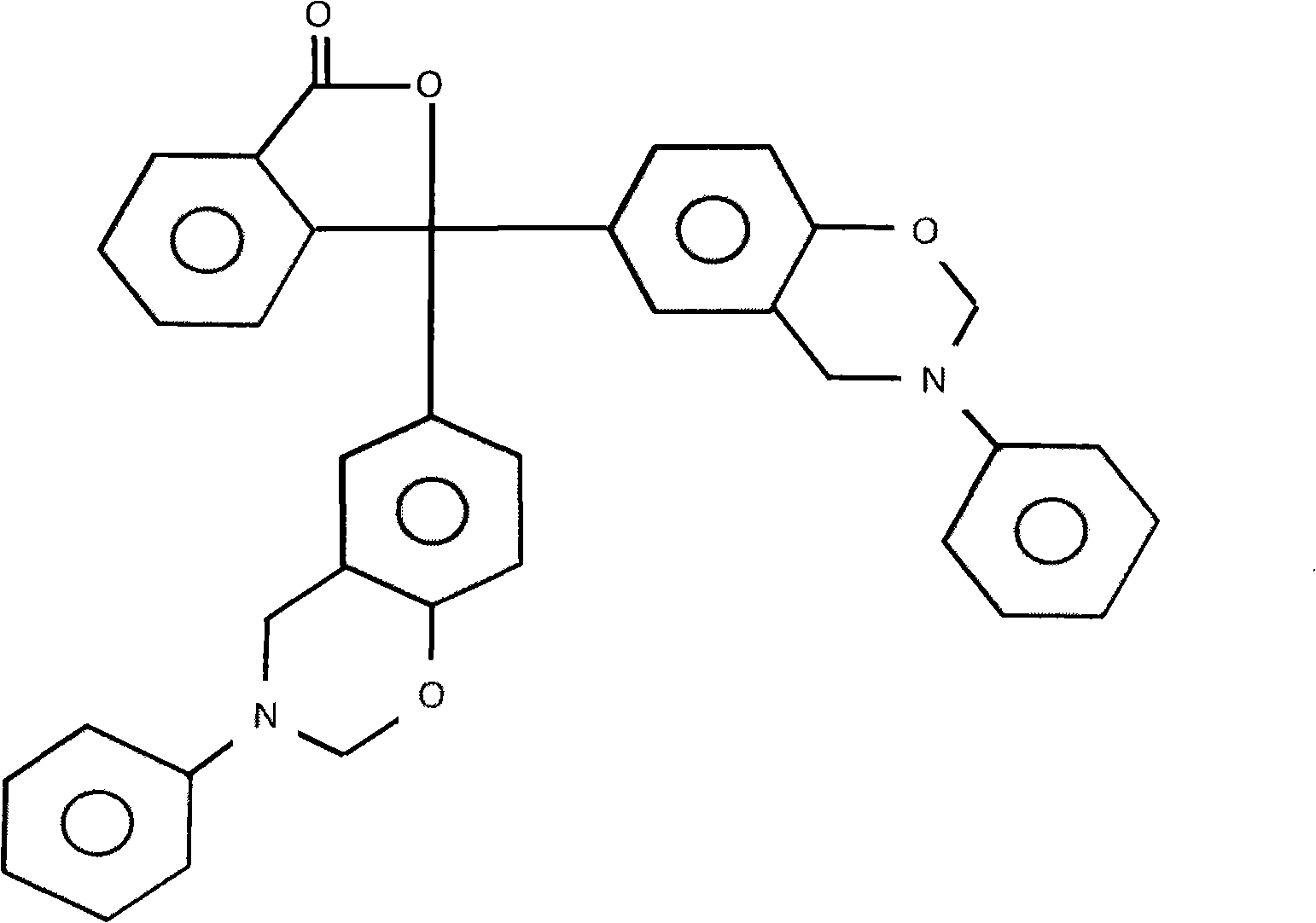

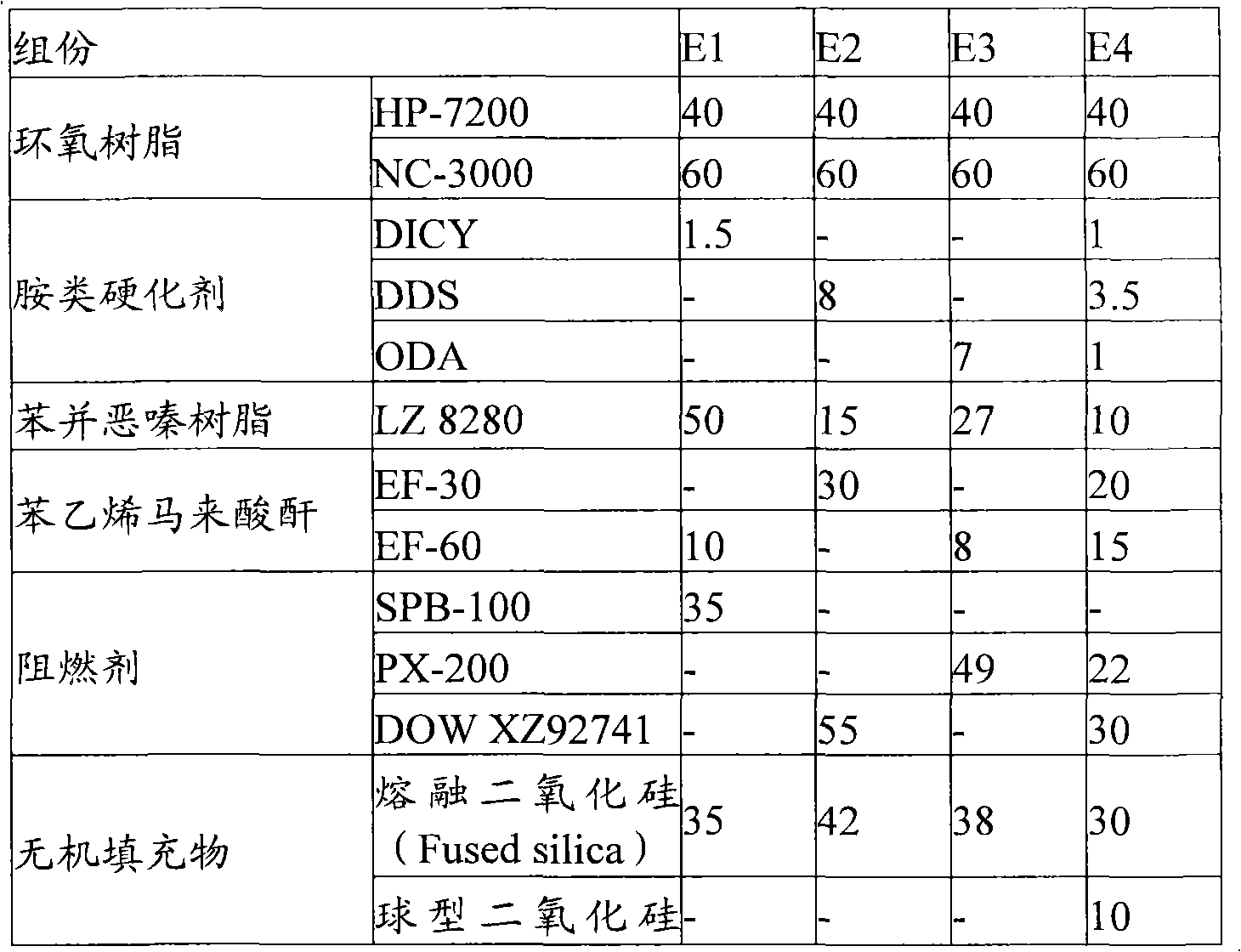

Halogen-free resin composition and copper clad laminate and printed circuit board applying the same

ActiveCN103131131ALow dielectric propertiesLow heat resistanceCircuit susbtrate materialsEpoxySheet film

The invention provides halogen-free resin composition, and a copper clad laminate and a printed circuit board applying the halogen-free resin composition. The halogen-free resin composition comprises, by weight, (A) 100 parts of epoxy resin, (B) 1 part -100 parts of benzoxazine resin, (C) 1part -100 parts of styrene maleic anhydride, (D) 0.5 part -30 parts of amine curing agents, and (E) 5-150 parts of halogen-free flame retardants. By means of the specified constituents and ration, the halogen-free resin composition achieves the purposes of low dielectric constant, low dielectric loss, high heat resistance, and high flame resistance, can be manufactured into semi-solidified rubber pieces or resin films, and then achieves the purposes of being applied to the copper clad laminate and the printed circuit board.

Owner:ELITE MATERIAL

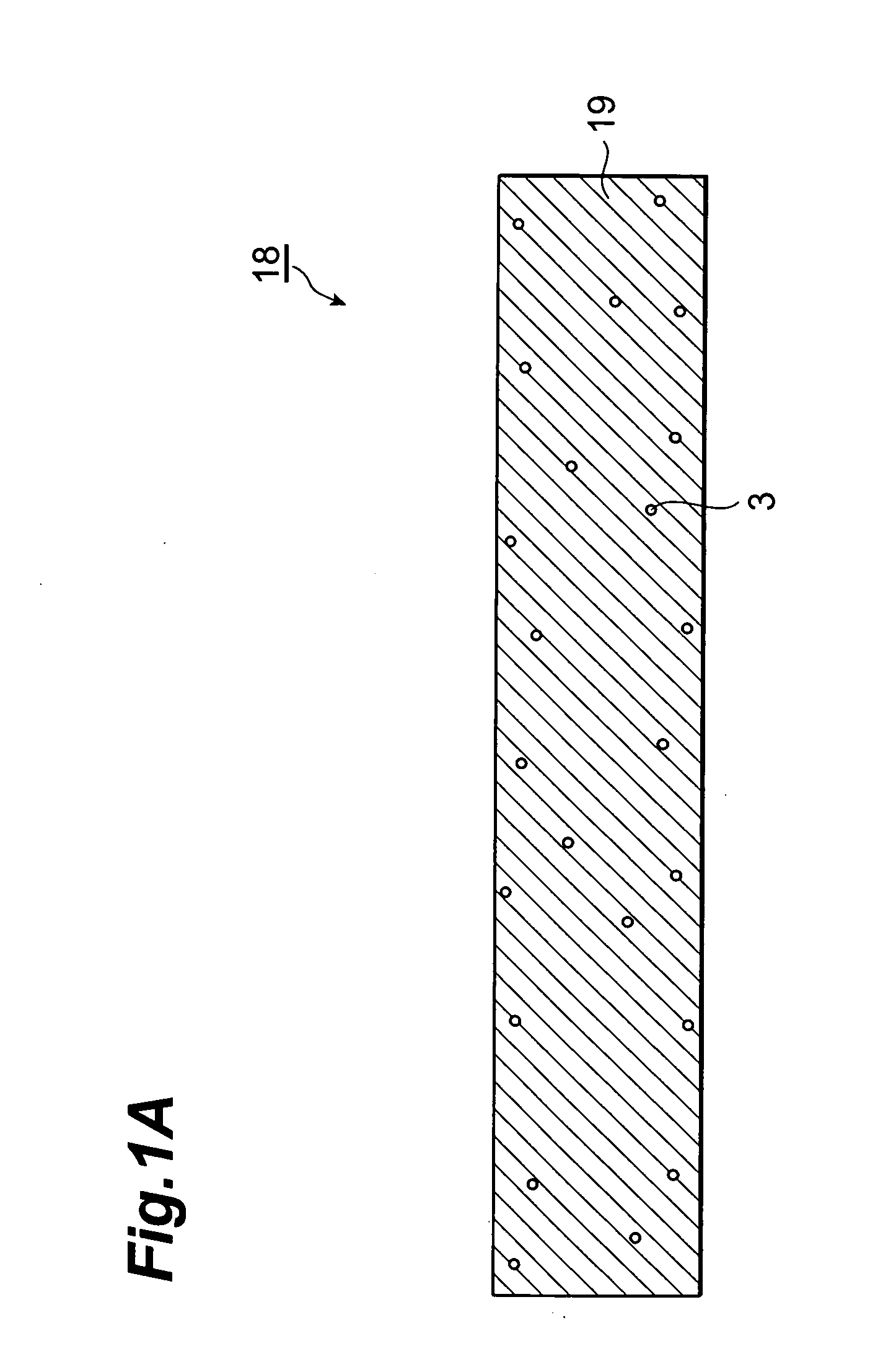

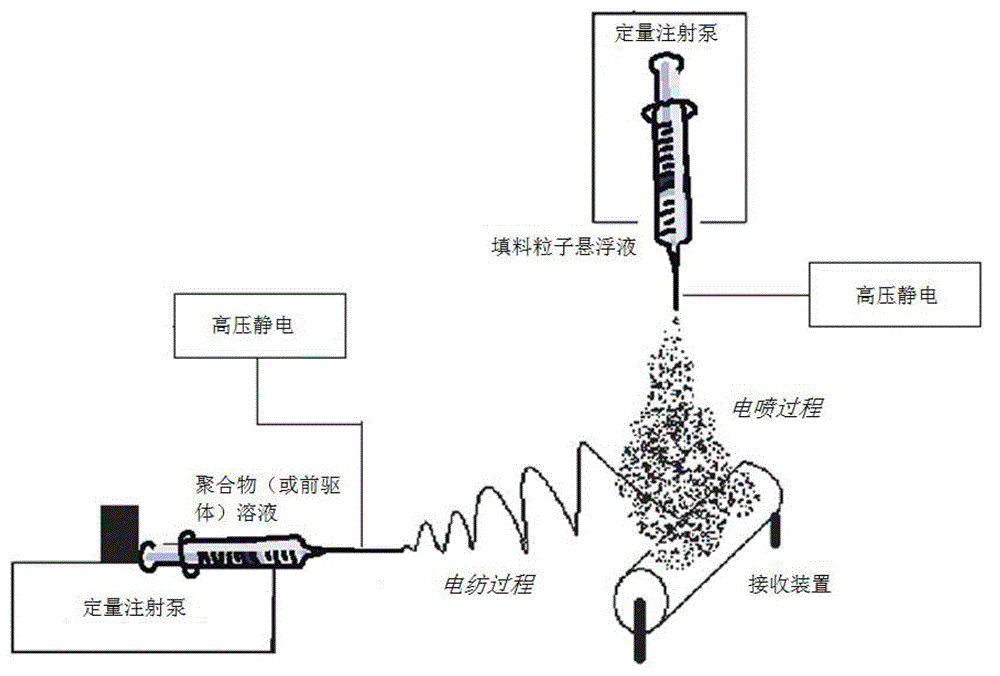

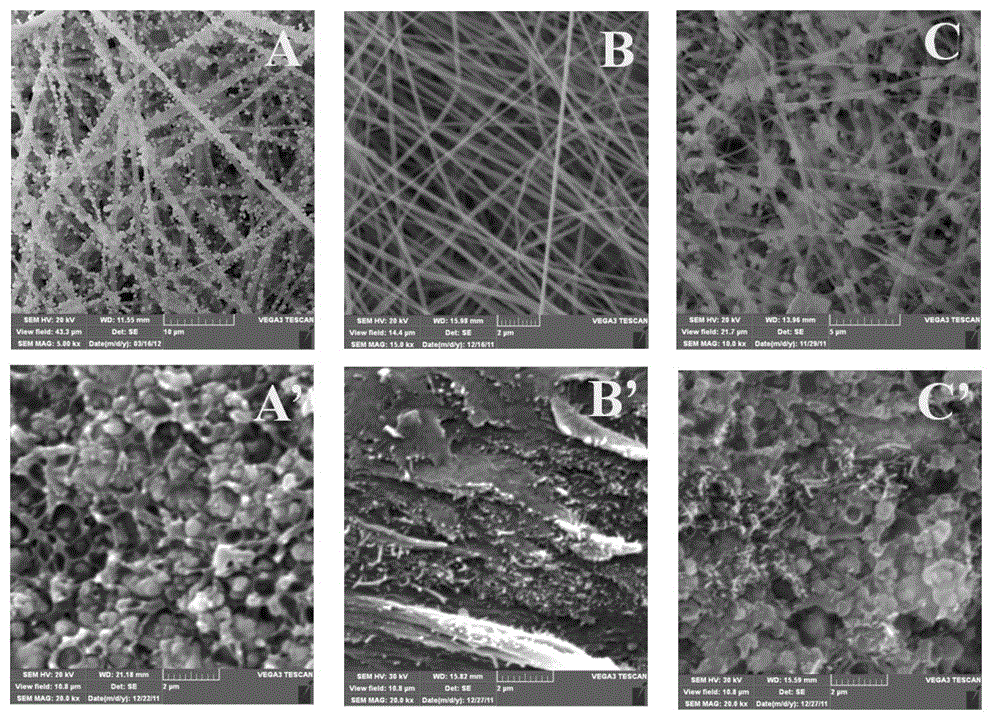

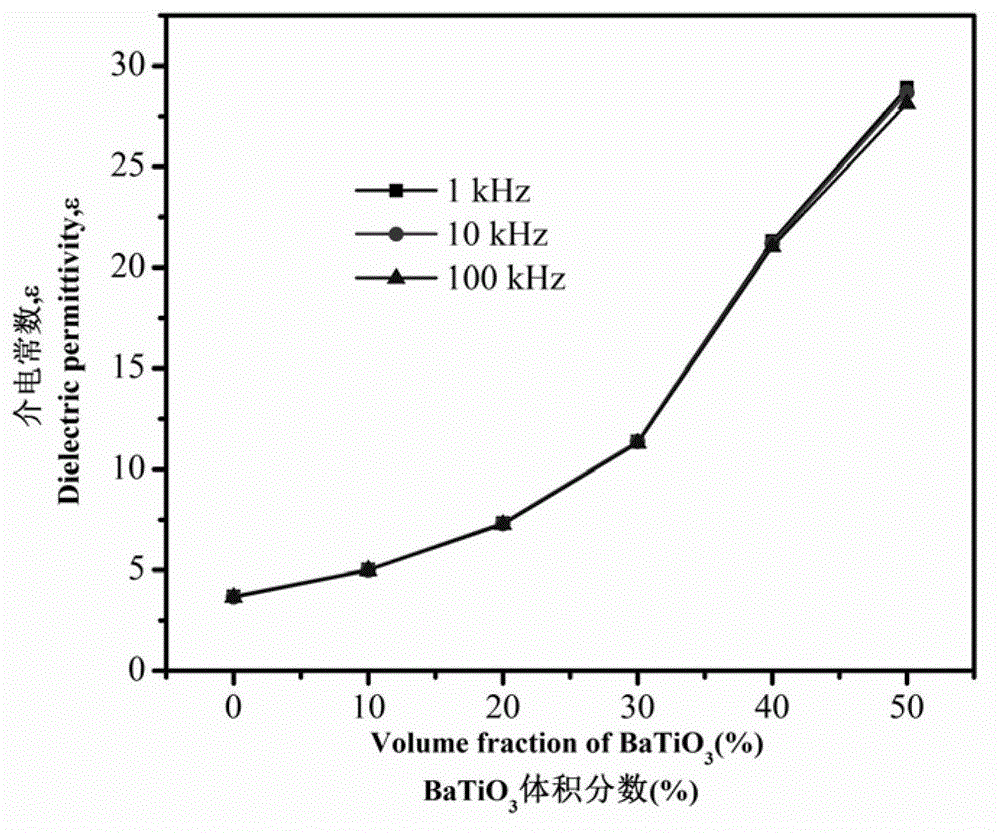

Method for preparing high dielectric constant polymer-based nano composite material

InactiveCN103147226AHigh dielectric constantControllable dielectric constantNon-woven fabricsFiberMatrix solution

The invention provides a method for preparing high dielectric constant polymer-based nano composite material. The method comprises the following steps: performing electrostatic spinning on a polymer matrix solution and simultaneously performing electrostatic spraying on a filler particle suspension; simultaneously receiving the products of the electrostatic spinning and the electrostatic spraying through a common receiving device to obtain a composite fiber membrane; and finally obtaining the high dielectric constant polymer-based nano composite material with filler particles uniformly dispersed after the composite fiber membrane is processed through a hot-pressing processing technique. The composite material prepared by the invention has the characteristics of high dielectric constant, low dielectric loss and the like; and at the same time the dielectric constant of the composite material can be adjusted through adjusting the content of the filler particles in the polymer matrix. The invention has the advantages of simple process, convenient operation and little environment pollution, can well solve the problem that the filler particles is uniformly dispersed in the polymer matrix, and is expected to the microelectronic industry as dielectric material and the like for preparing embedded capacitors.

Owner:JIANGXI NORMAL UNIV

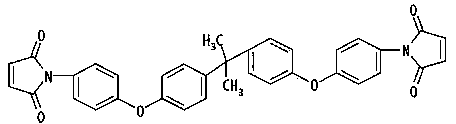

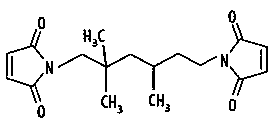

Low dielectric material

InactiveCN103965606ASmall coefficient of thermal expansionLow water absorptionDielectric lossThermal expansion

The invention relates to a low dielectric material. The low dielectric material includes, by weight, 40-80 parts of polyphenyl ether with the number average molecular weight Mn of 1000-4000, the weight average molecular weight Mw of 1000-7000 and the Mw / Mn ratio of 1.0-1.8, 5-30 parts of bimaleimide and 5-30 parts of a polymer additive, and the Dk value and the Df value of the low dielectric material are 3.75-4.0 and 0.0025-0.0045 respectively. The low dielectric material can be applied to semi-cured films or circuit substrate insulating layers, and has the characteristics of high Tg, low thermal expansion coefficient, low water absorption rate, and excellent dielectric properties like dielectric constant (Dk) and dielectric loss (Df).

Owner:ITEQ CORP

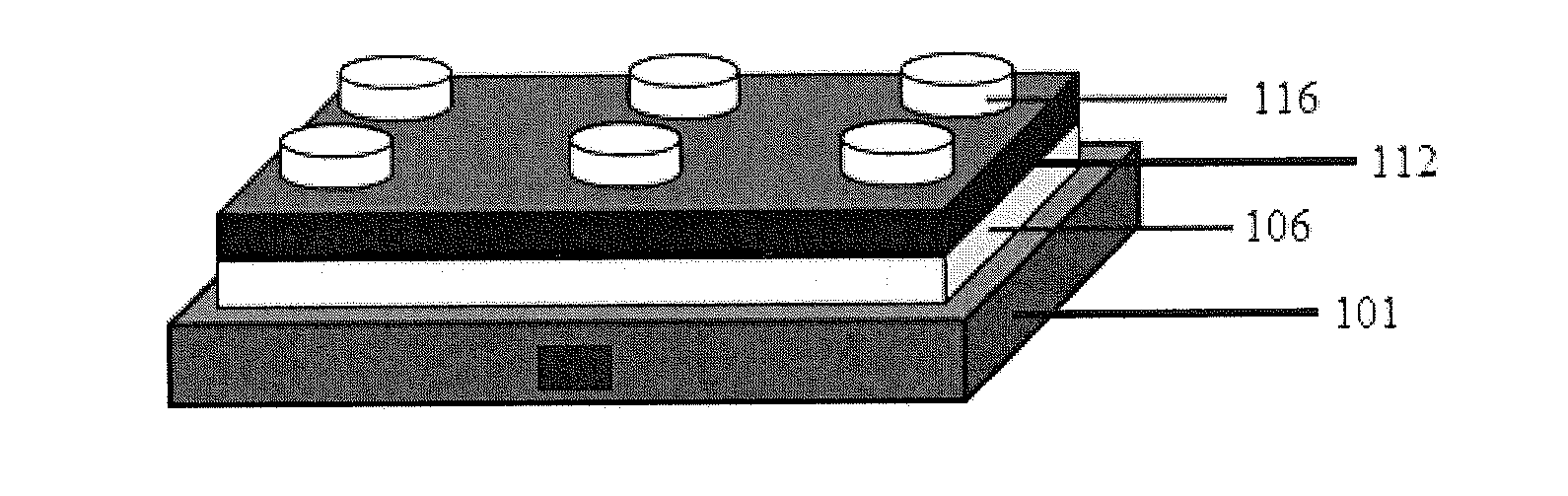

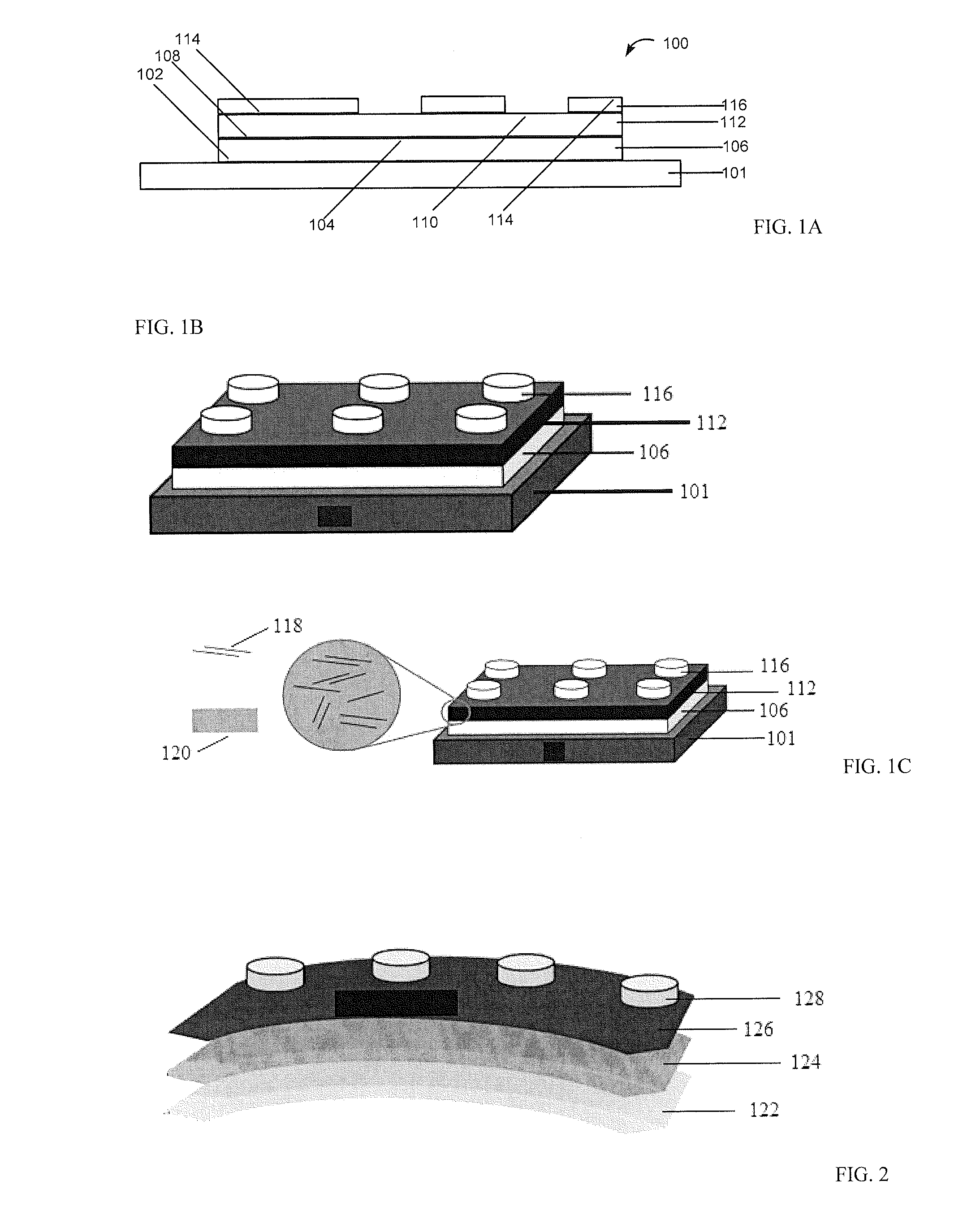

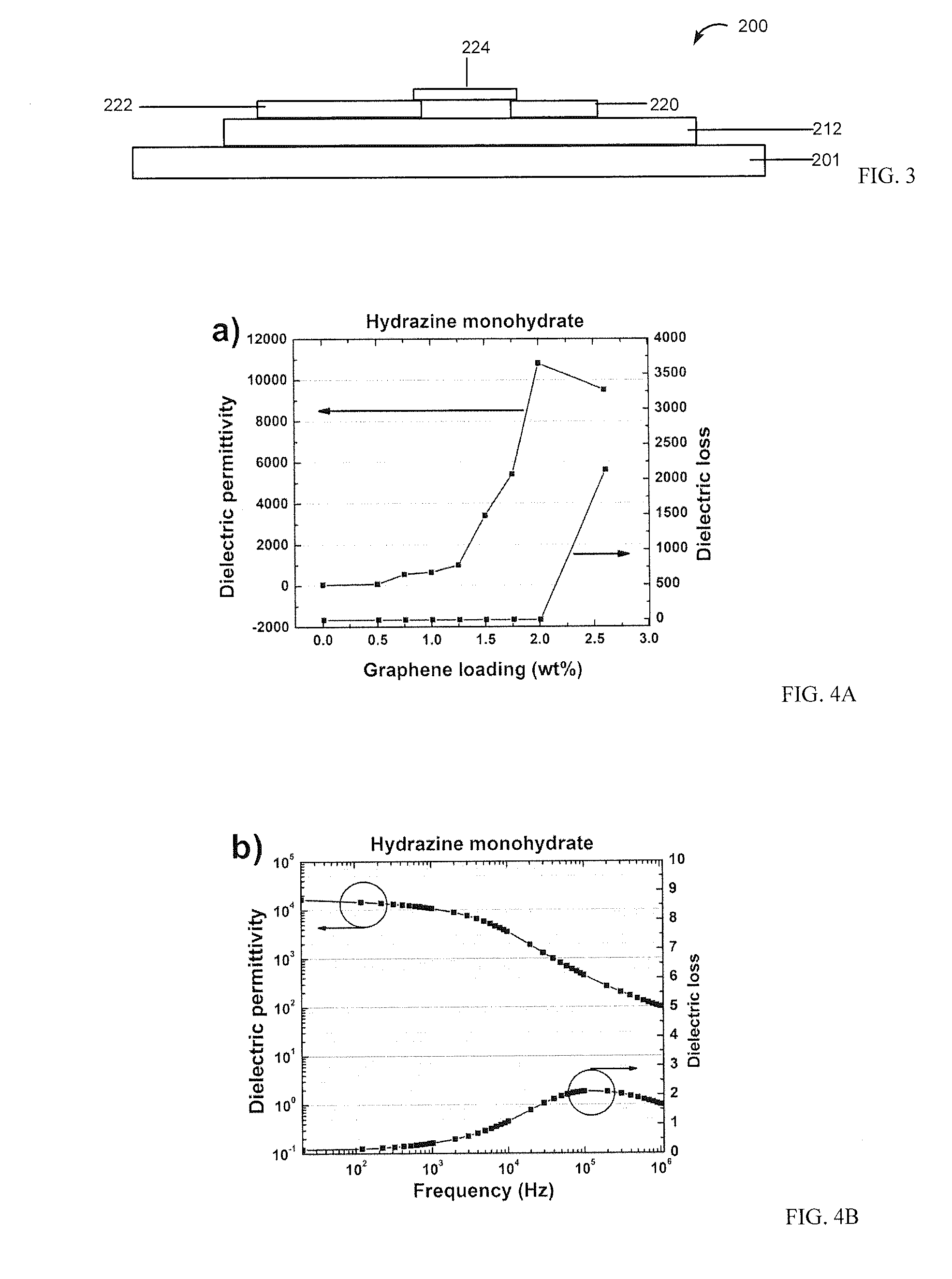

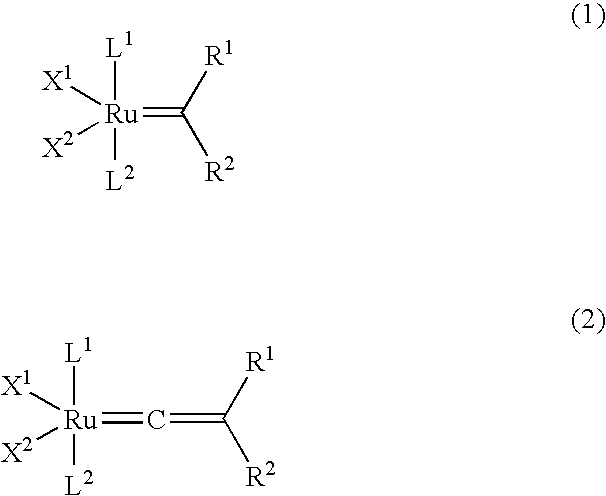

Graphene-based composite materials, method of manufacture and applications thereof

Disclosed herein is a composite material comprising a relaxor ferroelectric material and a hydrazine-reduced graphene oxide, wherein the weight ratio of the composite material to the hydrazine-reduced graphene oxide is 9:1 to 200:1. The composite materials have high dielectric permittivity and low dielectric losses and can be used to manufacture various high dielectric permittivity components.

Owner:SAUDI BASIC IND CORP SA

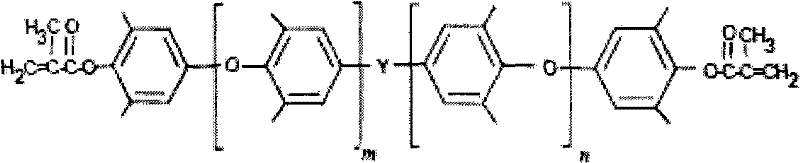

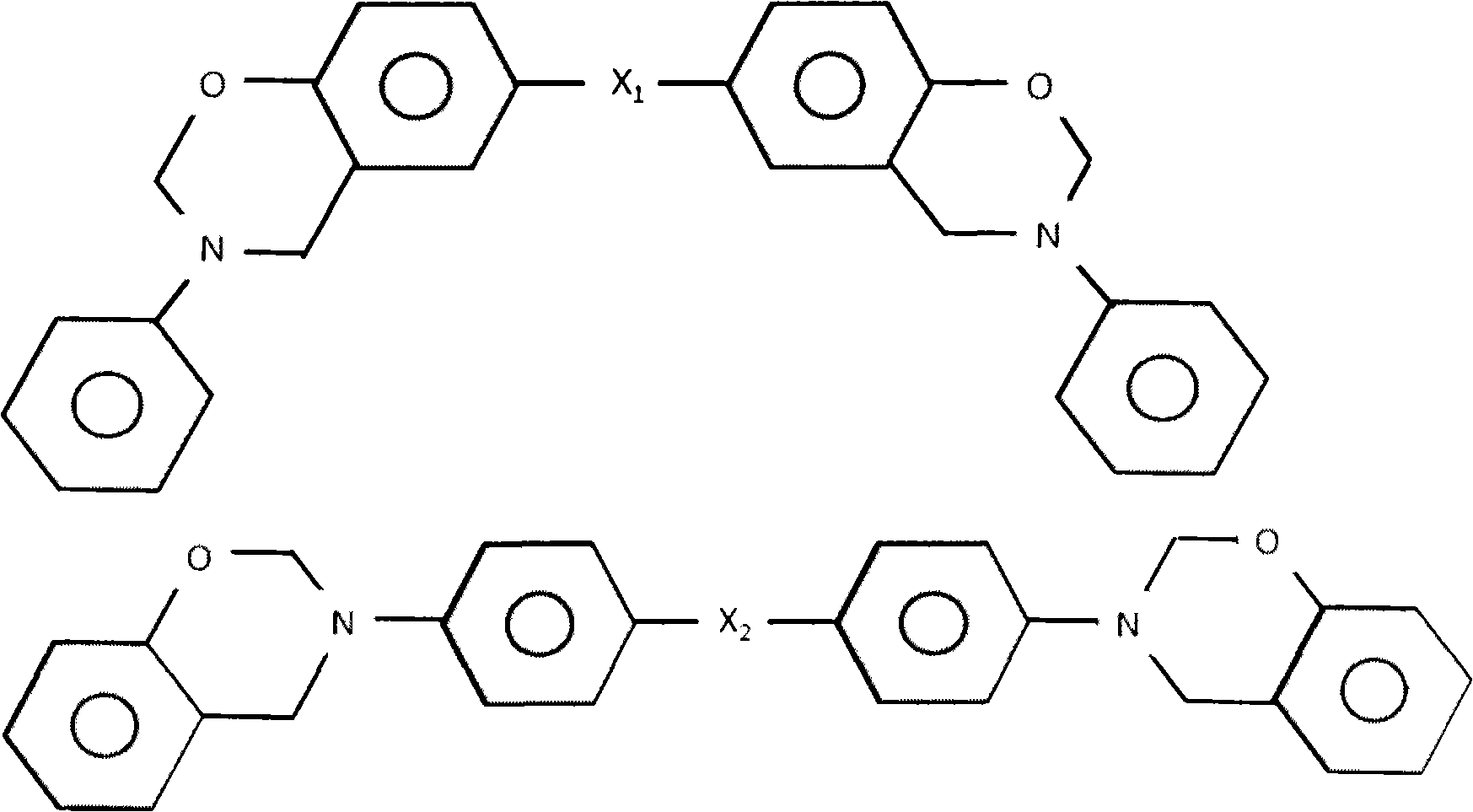

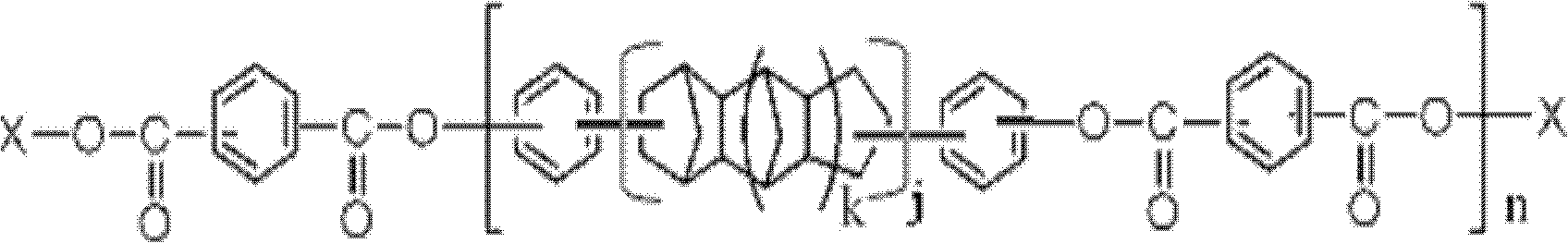

Composite dielectric material composition, and film, substrate, electronic part and molded article produced therefrom

InactiveUS6420476B1Acceptable performanceImprove performancePlastic/resin/waxes insulatorsOther chemical processesHydrogenHydrogen atom

The invention has for its object to provide a composite dielectric material having any desired dielectric constant selectable from a relatively wide range in a high-frequency band and a low dielectric loss tangent, and a film, substrate, electronic part or molded or otherwise formed article using the same. To accomplish this object, there is provided a composite dielectric material composition comprising a heat-resistant, low-dielectric polymeric material that is a resin composition comprising one or two or more resins having a weight-average absolute molecular weight of at least 1,000, wherein the sum of carbon atoms and hydrogen atoms in said composition is at least 99%, and some or all resin molecules have a chemical bond therebetween, and a filler. A film, substrate, electronic part or molded or otherwise formed article is obtained using this composition.

Owner:TDK CORPARATION +1

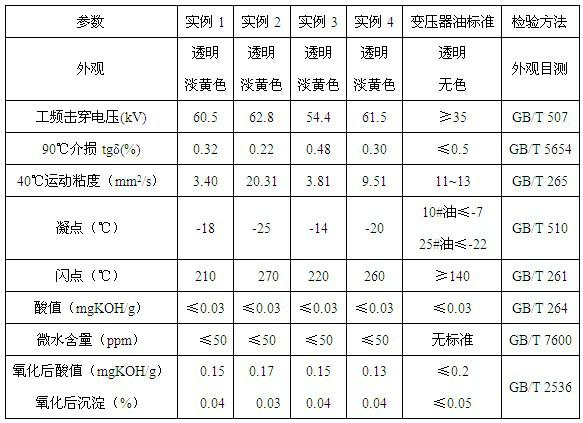

Vegetable insulating oil, and preparation method of vegetable insulating oil

InactiveCN102682869AImprove performanceReduce the temperatureLiquid organic insulatorsBase-materialsVegetable oilAnti oxidant

The invention relates to vegetable insulating oil based on vegetable oil, and a preparation method of the vegetable insulating oil. The insulating oil is prepared by the steps of using refined vegetable oil as raw material, carrying out ester exchange reaction on low-molecular alcohol, refining and washing after the reaction, rinsing, distilling under reduced pressure in order to remove water and alcohol, de-coloring, de-acidifying, filtering, de-watering deeply, finally adding antioxidant and pour point depressant. The insulating oil prepared by the method has the characteristics of high flashing point, low viscosity, low pour point, low acidity, low brackish water content, excellent dielectric constant, low dielectric loss and high breakdown voltage and has good physical and chemical performance and electrical performance.

Owner:CHINA ELECTRIC POWER RES INST

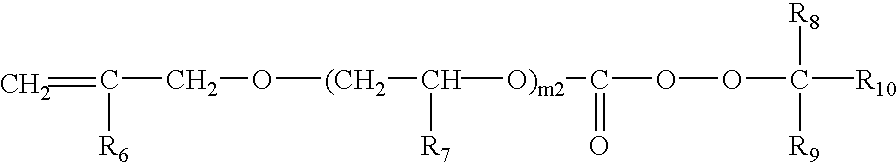

Polymerizable composition and formed article using the same

A polymerizable composition which comprises a cycloolefin monomer (A), a filler (B), a polymer (C) having a carboxyl group or a carboxylic acid anhydride group and having an acid value of 0.1 to 100 mgKOH / g, and a metathesis polymerization catalyst (D). The polymerizable composition comprises a cycloolefin monomer and a large amount of a filler, and has a low viscosity and is excellent in fluidity, and further can provide a molded product which is excellent in the lowness of dielectric constant, the lowness of dielectric loss tangent, the lowness of linear expansion coefficient, high heat resistance and adhesiveness, and further is free of bubble inclusion.

Owner:ZEON CORP

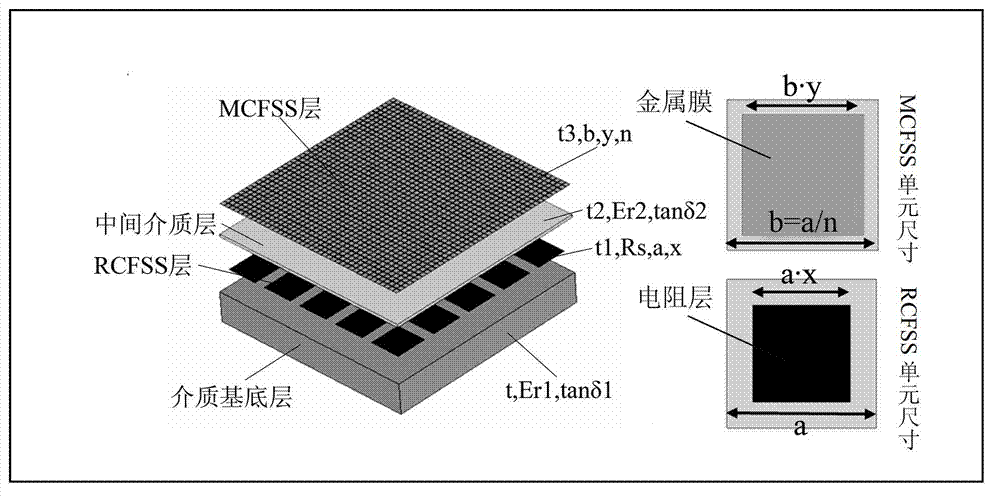

Radar-infrared combined stealth material and preparation method thereof

ActiveCN103158299ASimple structureThe overall thickness is thinLamination ancillary operationsLaminationElectricityScreen printing

The invention discloses a radar-infrared combined stealth material and a preparation method thereof. The radar-infrared combined stealth material orderly comprises a metal-type capacitive frequency selection surface layer, a middle medium layer, a resistance-type capacitive frequency selection surface layer and a medium base layer from top to bottom. The metal-type capacitive frequency selection surface layer and the resistance-type capacitive frequency selection surface layer have matrix structures. The metal-type capacitive frequency selection surface layer adopts metals having low infrared emissing ability. The middle medium layer and the medium base layer have dielectric constants of 3-10 and dielectric loss of 0.01 to 0.50. The preparation method comprises the following steps of preparing a metal film by screen printing processes, carrying out etching of the metal-type capacitive frequency selection surface layer on the metal film by a PCB technology, preparing the resistance-type capacitive frequency selection surface layer on the medium base layer by the screen printing processes, and binding the layers into an integral body by a binder by the vacuum bag molding process. The radar-infrared combined stealth material has a simple structure, is light and thin and has a good stealth effect.

Owner:NAT UNIV OF DEFENSE TECH

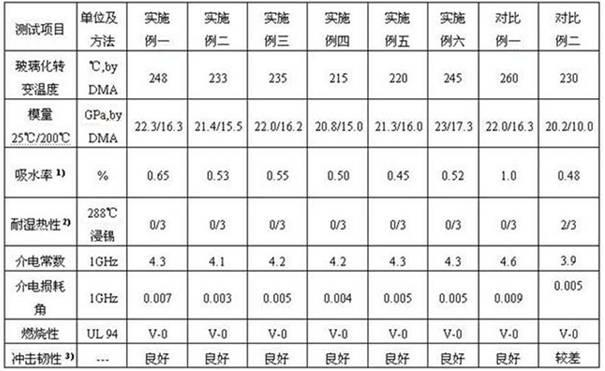

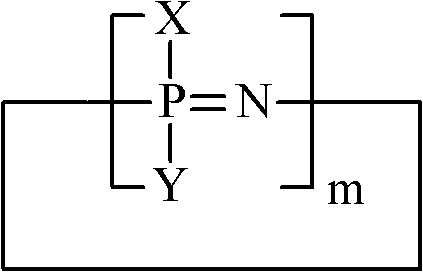

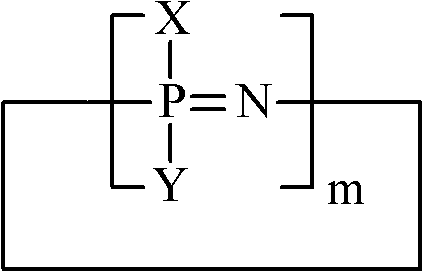

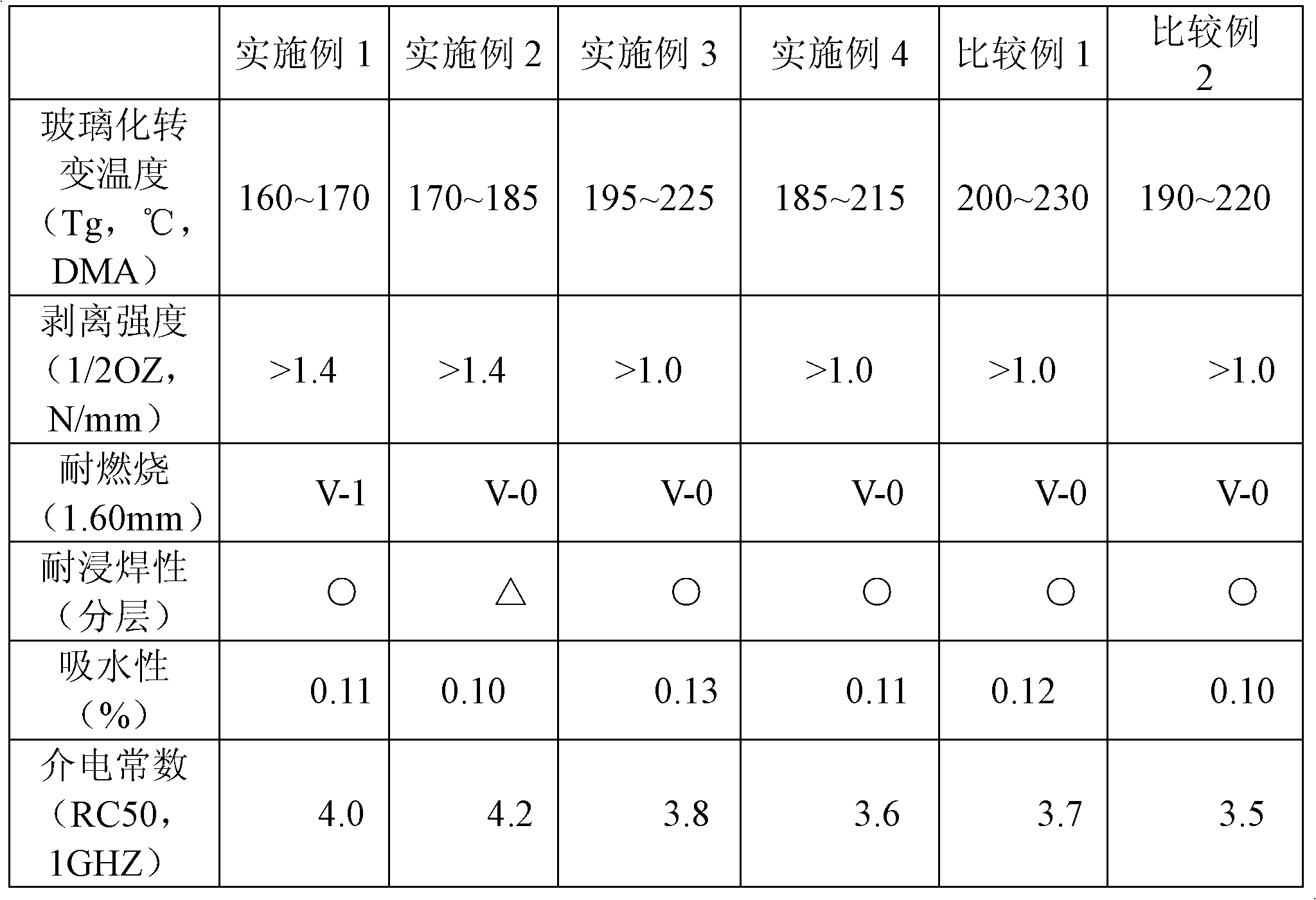

Thermosetting resin composition, prepreg and laminated board

ActiveCN102115600AExcellent heat and humidity resistanceImprove heat resistanceGlass/slag layered productsMetal layered productsEpoxyDielectric loss

The invention discloses a thermosetting resin composition, which is characterized by comprising the following components in part by weight: 8 to 80 parts of allyl modified bismaleimide resin prepolymer, 15 to 60 parts of cyanate resin and 5 to 40 parts of halogen-free epoxy resin, wherein the allyl modified bismaleimide resin prepolymer is prepared by reacting bismaleimide resin with an allylcompound at the temperature of between 110 and 160DEG C for 20 to 100 minutes, and a weight ratio of the bismaleimide resin to the allylcompound is 100:(30-120). The composition can be used for preparing a prepreg and a laminated board. The composition and the laminated board have excellent humidity resistance, high heat resistance, low water absorption rate, high modulus, lower dielectric constant and dielectric loss, and good processing toughness, and can realize halogen-free flame retardancy.

Owner:SHENGYI TECH SUZHOU

Pressure-sensitive adhesive sheet for optical use

InactiveUS20120094037A1Not adversely affectAvoid misuseLiquid crystal compositionsEster polymer adhesivesCapacitanceDielectric loss

Provided is a pressure-sensitive adhesive sheet for optical use which less suffers from a misoperation-causing change in capacitance upon application to an optical member.The pressure-sensitive adhesive sheet for optical use includes a pressure-sensitive adhesive layer and has a dielectric constant of from 2 to 8 at a frequency of 1 MHz and a dielectric loss tangent of more than 0 and 0.2 or less at a frequency of 1 MHz. The pressure-sensitive adhesive sheet for optical use preferably has a dielectric constant at a frequency of 1.0×106 Hz being 60% or more of that at a frequency of 1.0×104 Hz. In addition, the pressure-sensitive adhesive sheet for optical use preferably has an absolute value of difference between the dielectric loss tangent at a frequency of 1.0×106 Hz and that at a frequency of 1.0×104 Hz of 0.15 or less.

Owner:NITTO DENKO CORP

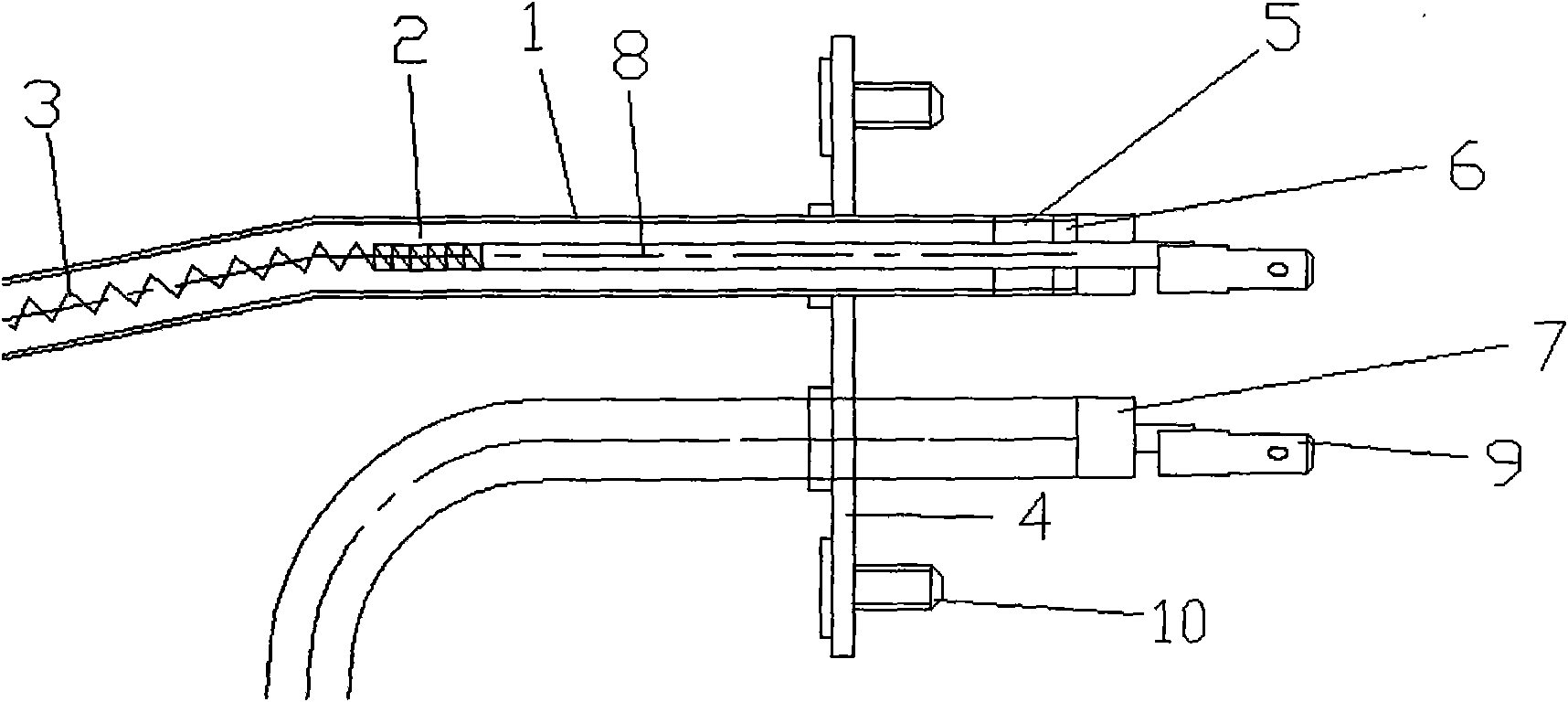

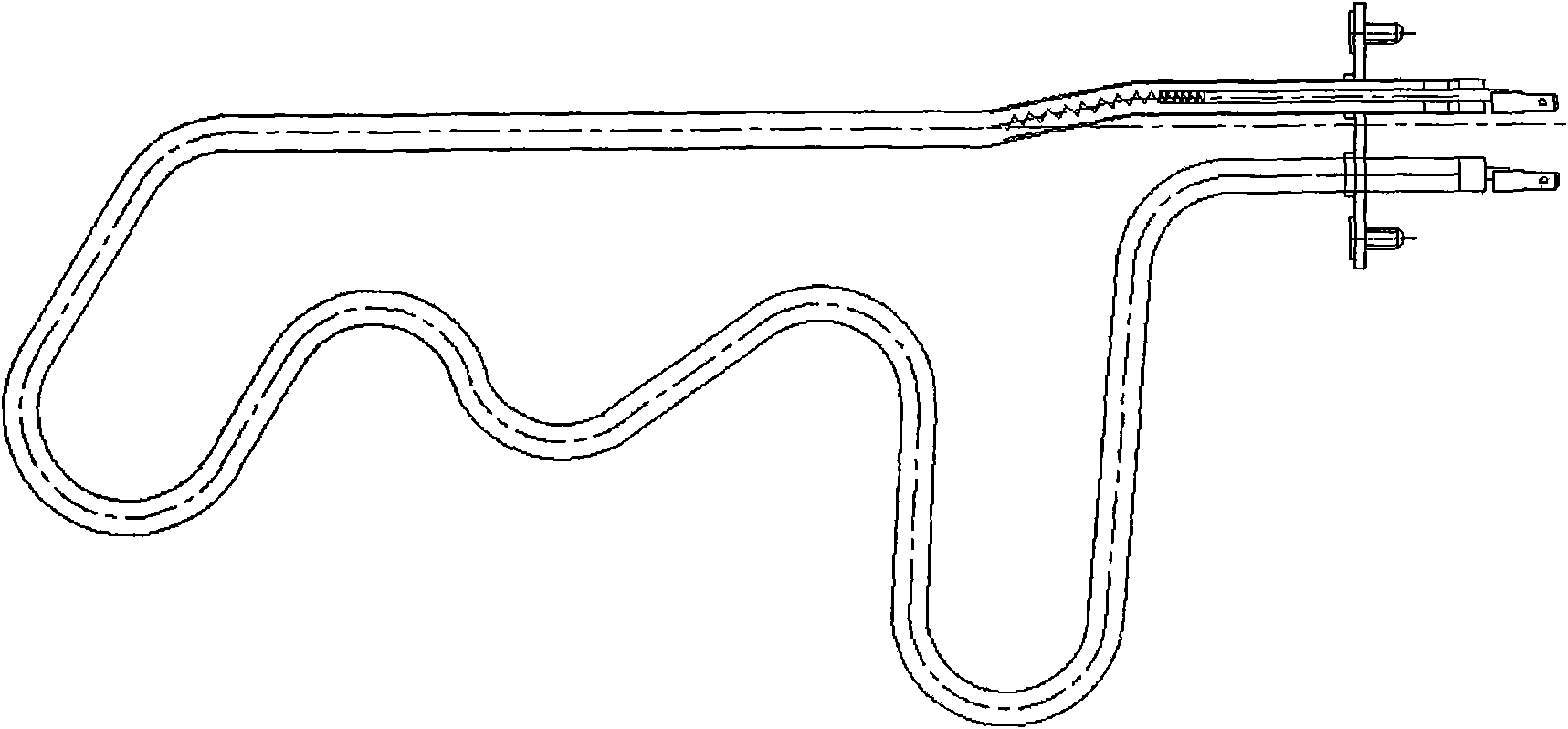

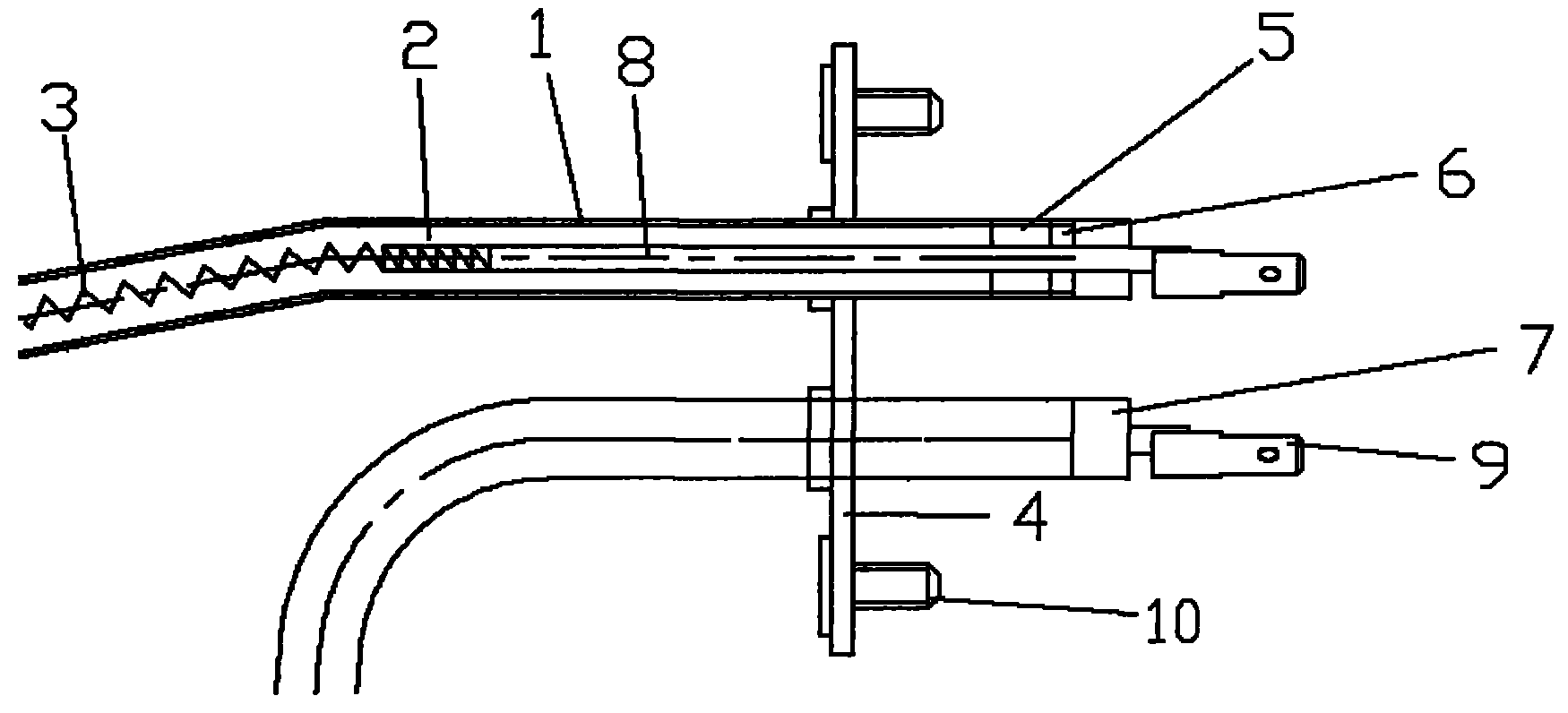

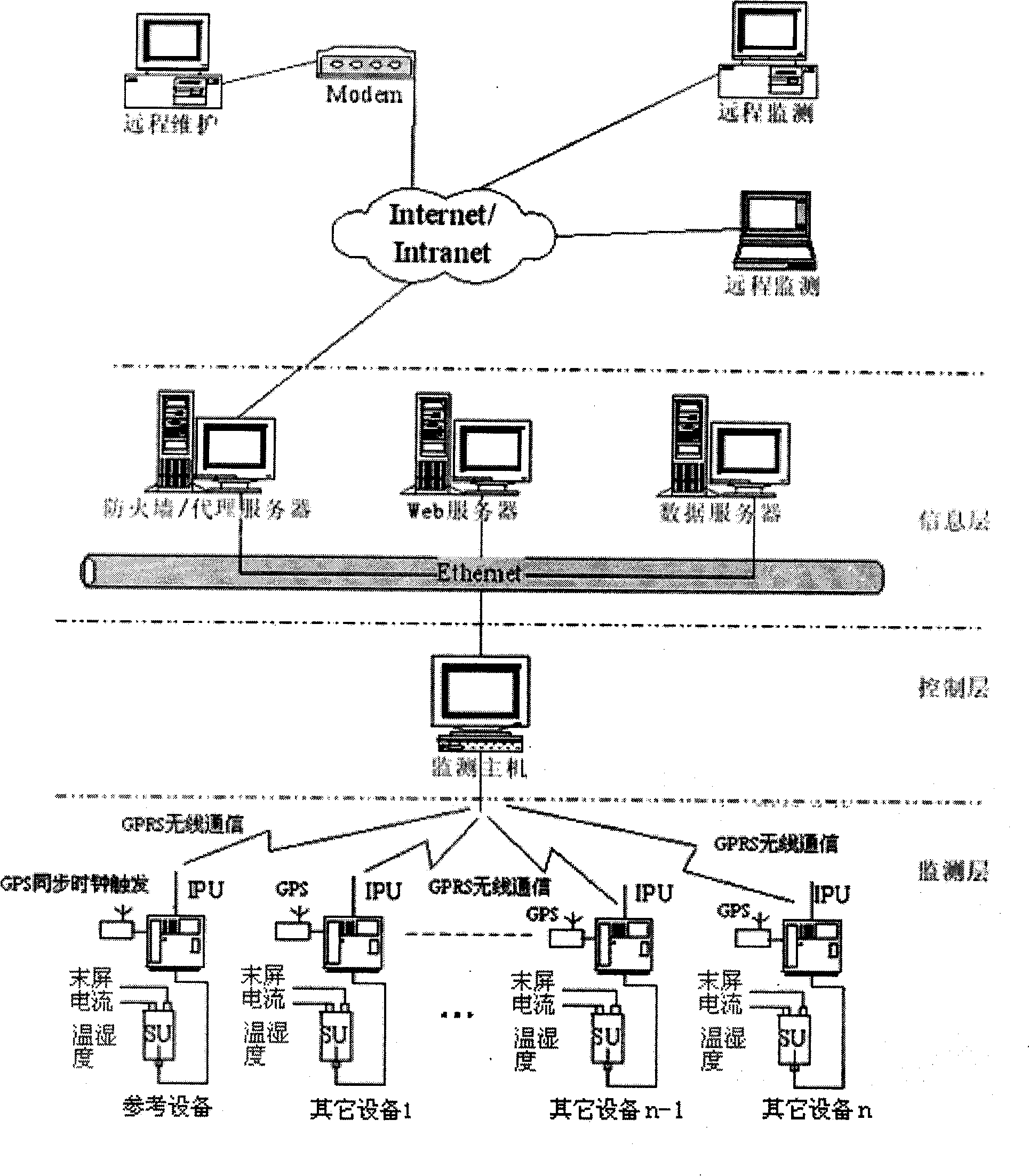

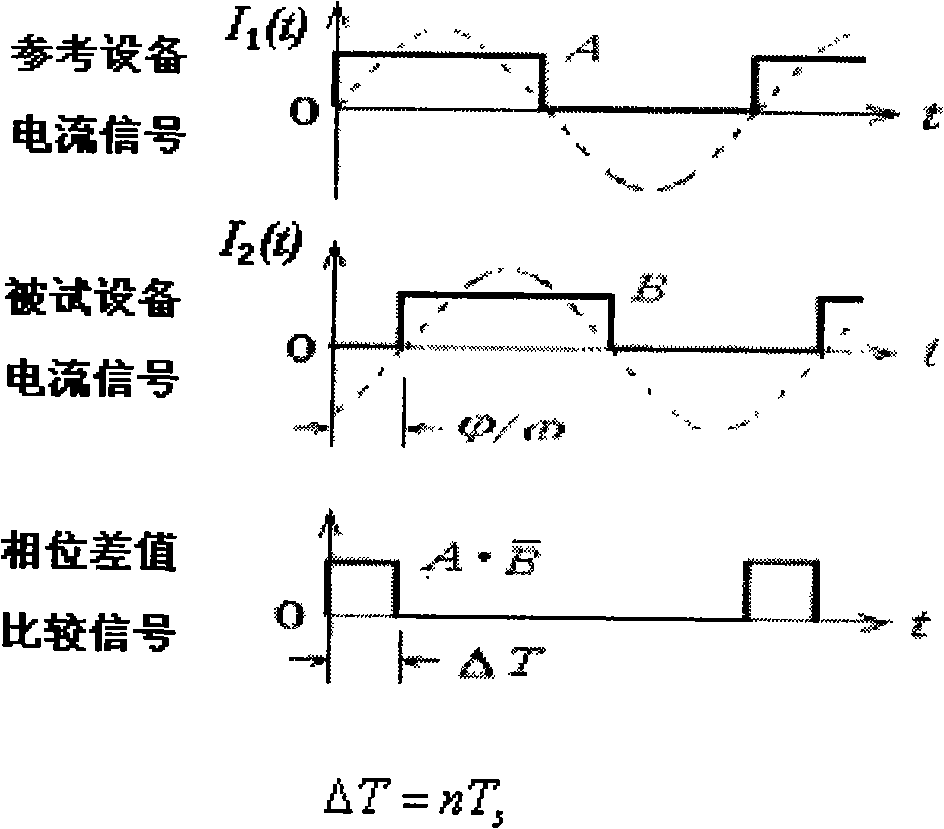

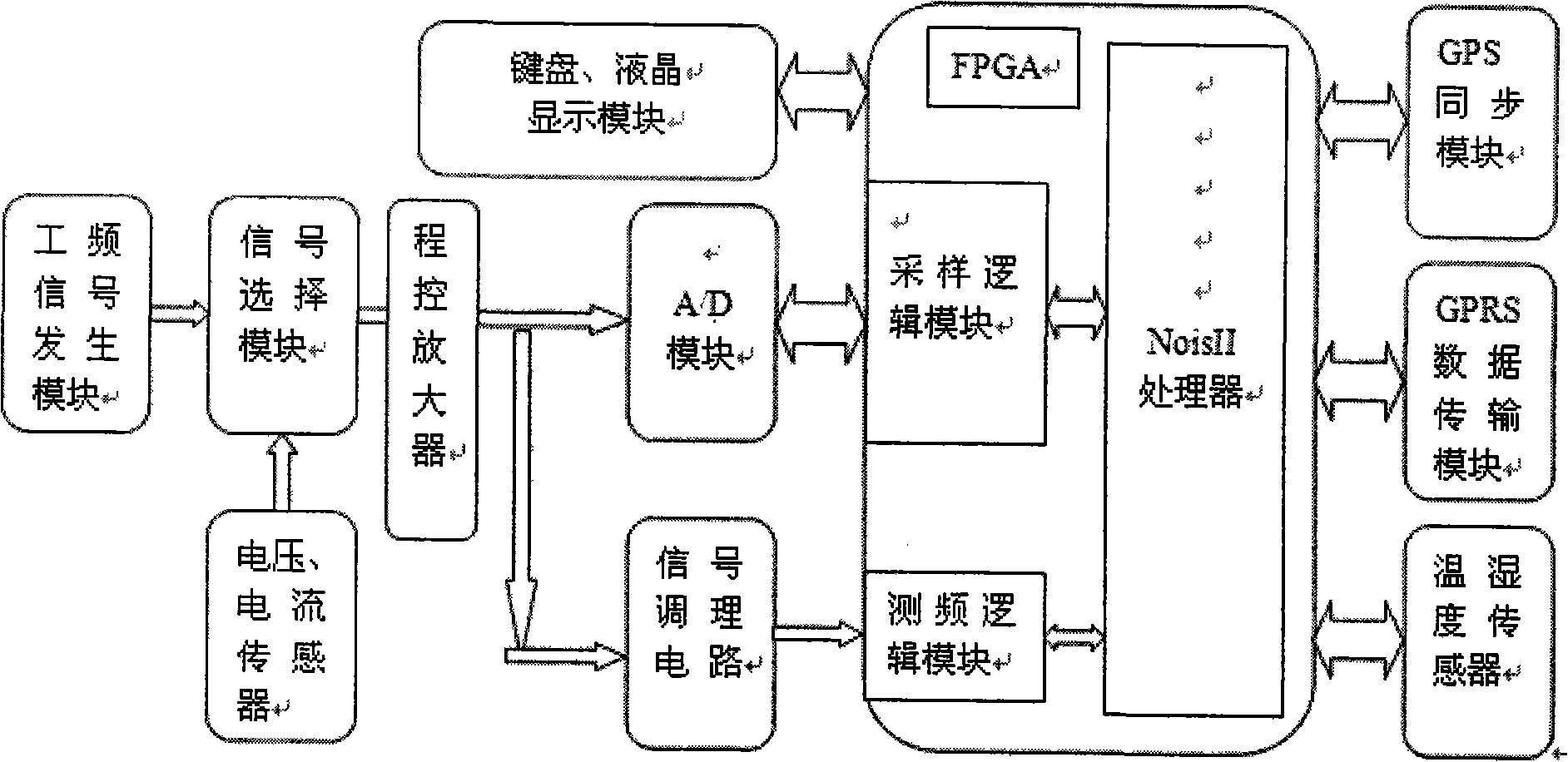

On-line monitoring system for capacitive equipment dielectric loss angle

InactiveCN101493485AAvoid Transmission AttenuationImprove reliabilityResistance/reactance/impedenceInformation layerControl layer

The invention relates to a monitoring system for power transmission and transforming equipment, in particular to a capacitive equipment dielectric loss angle online monitoring system. The system is characterized by at least comprising a microprocessor, a leakage current signal acquisition module, a GPS synchronization module, a wireless communication module, an A / D sampling unit, and a frequency measurement sampling unit; in structure, a centralized management mode is used, a wireless data transmission technology and an Internet network technology are applied, and a layered distributed structure is achieved; according to the functional requirements, the invention divides the system into a monitoring layer, a control layer and an information layer. The manufacturer and operating management department (client) can visit the system in different places by only installing browser software and thus easily achieve remote maintenance and monitoring.

Owner:巨元智能电气(浙江)有限公司

Capacitor having high temperature stability, high dielectric constant, low dielectric loss, and low leakage current

InactiveUS20110228442A1Physical improvementGood chemical propertiesFixed capacitor dielectricStacked capacitorsMetal foilPolymer thin films

Examples of the present invention include high electric energy density polymer film capacitors with high dielectric constant, low dielectric dissipation tangent, and low leakage current in a broad temperature range. More particularly, examples include a polymer film capacitor in which the dielectric layer comprise a copolymer of a first monomer (such as tetrafluoroethylene) and a second polar monomer. The second monomer component may be selected from vinylidene fluoride, trifluoroethylene or their mixtures, and optionally other monomers may be included to adjust the mechanical performance. The capacitors can be made by winding metallized films, plain films with metal foils, or hybrid construction where the films comprise the new compositions. The capacitors can be used in DC bus capacitors and energy storage capacitors in pulsed power systems.

Owner:NOVASENTIS +1

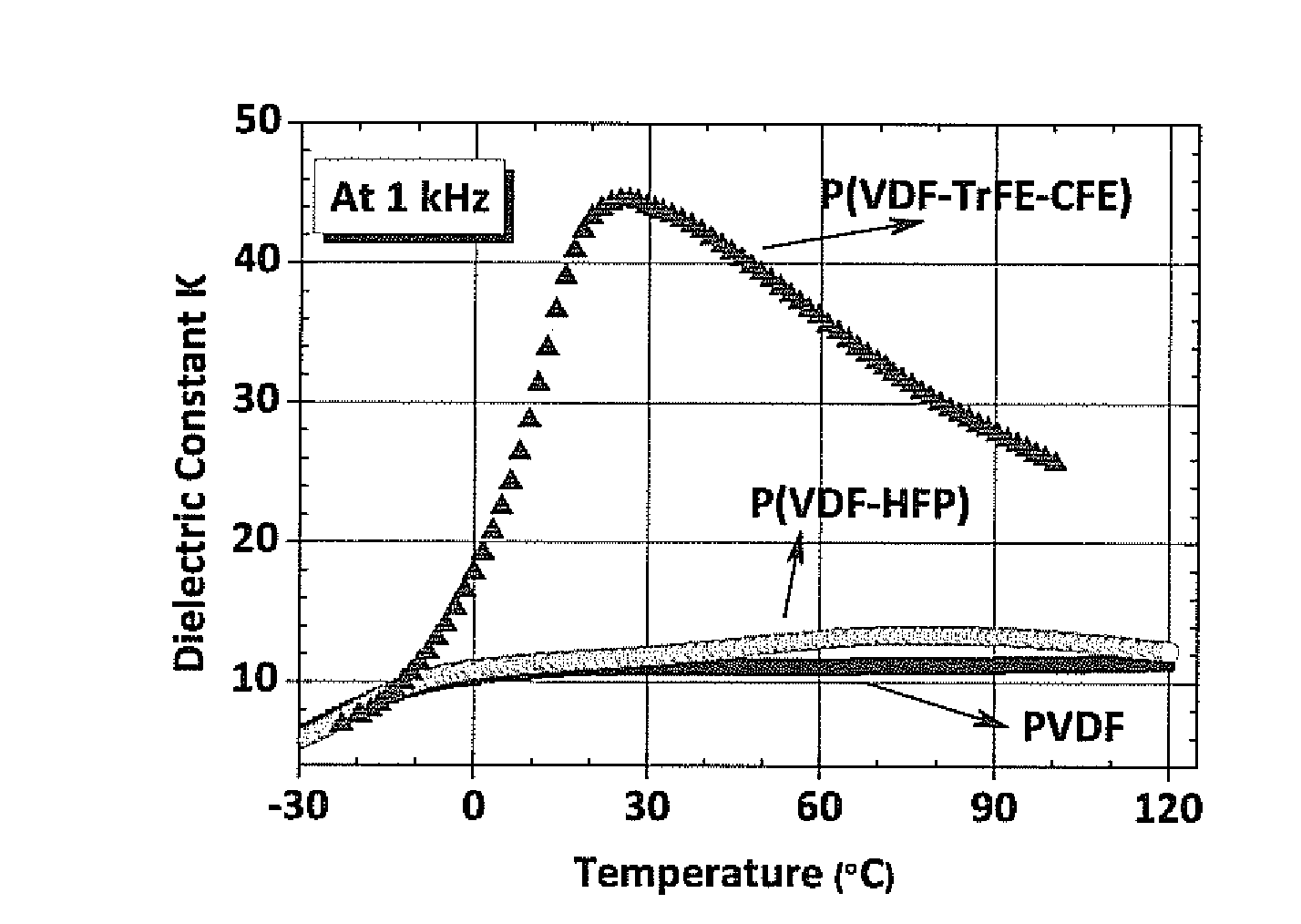

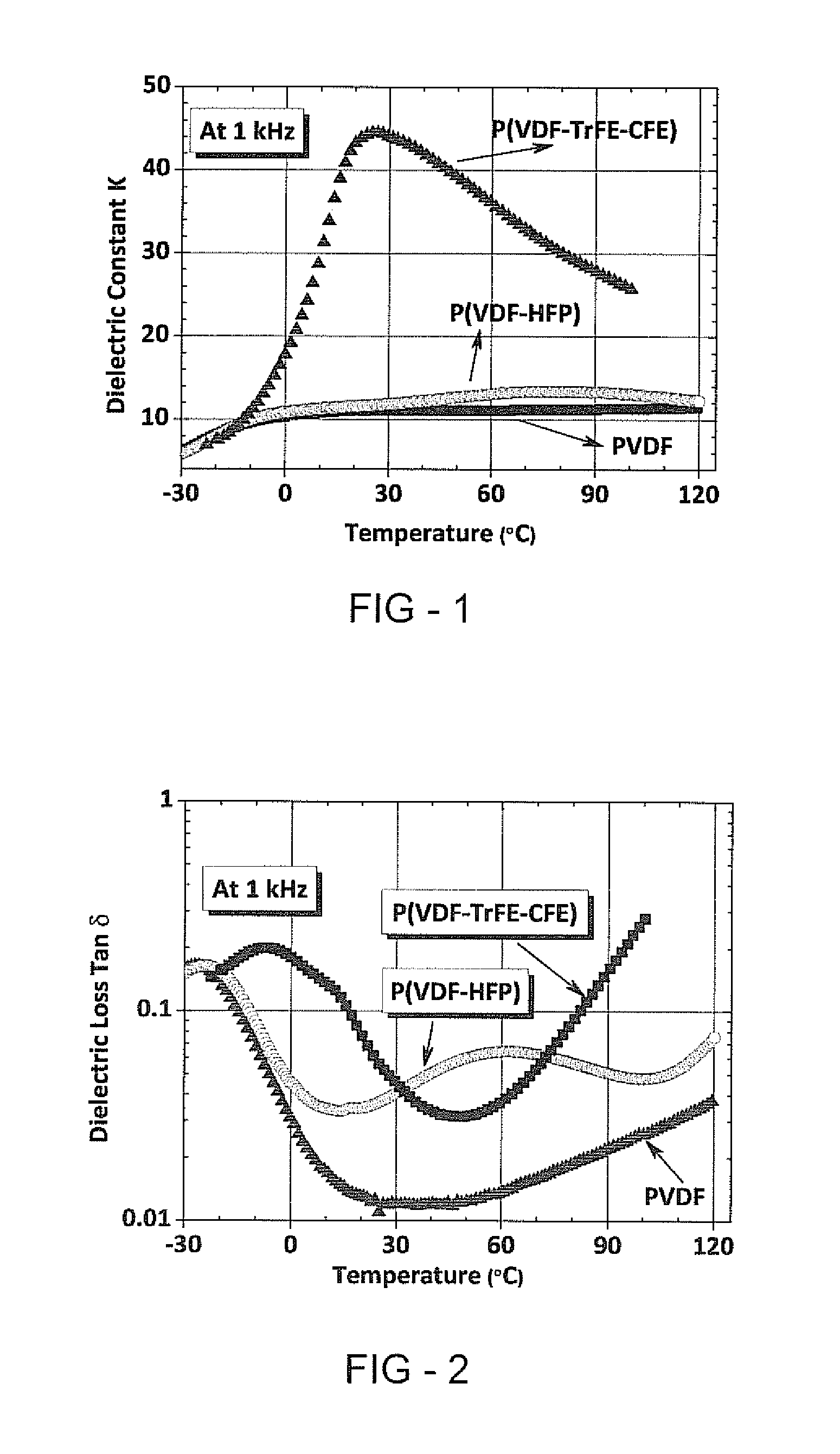

High electric energy density polymeric compositions, methods of the manufacture therefor, and articles comprising the same

InactiveUS20100067172A1Improve efficiencyFast dischargeFixed capacitor dielectricVehicular energy storagePolymer capacitorPolymer science

Examples of the present invention relate generally to high electric energy density polymer film capacitors with high charge-discharge efficiency and fast discharge speed. For example, a high energy density polymer capacitor may be fabricated using a polymer blend comprising one or more high dielectric constant PVDF-based polymers (including homopolymers, copolymers and / or terpolymers) and one or more other polymer with low dielectric loss and high volume resistivity compared to the one or more PVDF-based polymers. An example film capacitor may comprise a high temperature fluoropolymer with dielectric loss lower than 0.2% and good film manufacturability. Polymer films can be stretched and orientated at least in one direction to make thinner films with improved performance. Film capacitors can be made by winding metallized films, plain films with metal foils, or using a hybrid construction where the dielectric films comprise the new compositions. Capacitors can also have a multilayer construction where the films are metallized.

Owner:NOVASENTIS

Halogen-free resin composition as well as copper foil substrate and printed circuit board applying same

ActiveCN103013110AWith flame retardant functionWon't happenCircuit susbtrate materialsSheet filmCopper foil

The invention provides a halogen-free resin composition which comprises (A) 100 parts of cyanate ester resin, (B) 5-50 parts of styrene maleic anhydride, (C), 5-100 parts of polyphenyl ether resin, (D) 5-100 parts of maleimide resin, (E) 10-150 parts of nitrogenous compound, and (F) 10-1000 parts of inorganic filler. As the composition comprises components in special proportion, the halogen-free resin composition is low in dielectric constant, low in dielectric loss, high in heat resistance and high in flame resistance. The halogen-free resin composition can be prepared as a semi-cured film or a resin film, so that the composition can be applied to a copper foil substrate and a printed circuit board.

Owner:ELITE MATERIAL

Epoxy resin composition as well as prepreg and copper-foil-clad laminated board prepared by using same

InactiveCN102443138AHigh glass transition temperatureHigh functionalitySynthetic resin layered productsMetal layered productsEpoxyDielectric loss

The invention relates to an epoxy resin composition as well as a prepreg and a copper-foil-clad laminated board prepared by using the same. The epoxy resin composition comprises the following essential components: (A) epoxy resin containing a naphthol structure, (B) an active ester serving as a curing agent, and (C) a curing accelerant. Because epoxy resin at least contains the naphthol structure in the molecular structure, the epoxy resin composition provided by the invention has higher functionality degree and high glass transition temperature; at the same time, the naphthol group structure is introduced to the molecular structure, thus the cured product has low water absorptivity and low expansion coefficient; due to the active ester serving as the curing agent, the advantages that the a polar group is not generated during the reaction between the active ester and epoxy, thus the dielectric properties are excellent and moisture and heat resistance are good are fully exerted; and in addition, because of the epoxy resin containing the special naphthol structure, the hydroscopicity of the resin cured product is further reduced and the dielectric loss value of the cured product is lowered. The prepreg and the copper-foil-clad laminated board provided by the invention have excellent dielectric properties, moisture and heat resistance and high glass transition temperature.

Owner:GUANGDONG SHENGYI SCI TECH

Halogen-free resin composition and method for preparing copper-clad plate from the halogen-free resin composition

ActiveCN102977551ASmall dielectric lossImprove electrical performanceSynthetic resin layered productsLaminationDielectric lossHeat resistance

The invention discloses a halogen-free resin composition and a method for preparing a copper-clad plate from the halogen-free resin composition. Based on the total weight part of solid ingredients of the halogen-free resin composition, the halogen-free resin composition comprises, by weight, 5 to 50 parts of reaction-type allylphenoxycyclotriphosphazene or vinylphenoxycyclotriphosphazene, 15 to 85 parts of a thermosetting resin, 1 to 35 parts of a crosslinking curing agent, 0 to 5 parts of a crosslinking curing accelerator and 0 to 100 parts of a filling material. Through introduction of reaction-type allylphenoxycyclotriphosphazene or vinylphenoxycyclotriphosphazene having very low water absorbency into the thermosetting resin, the halogen-free resin composition can satisfy halogen-free flame-retardation requirements, improve system electrical properties, and realize non-halogenation of a high-frequency high-speed substrate material. The copper-clad plate prepared from the halogen-free resin composition satisfies halogen-free requirements, has excellent heat resistance and moisture resistance and has a low dielectric loss.

Owner:GUANGDONG SHENGYI SCI TECH

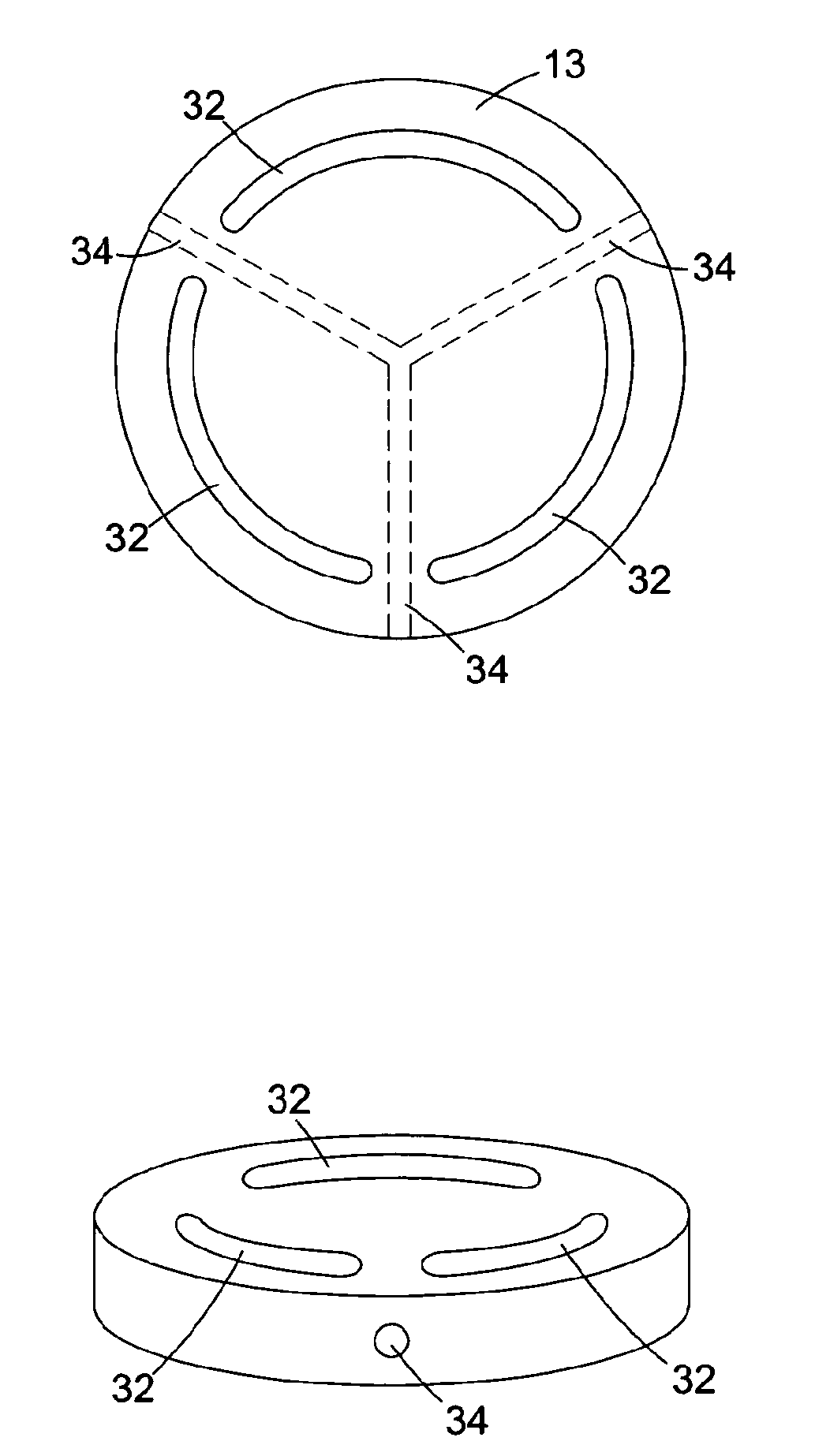

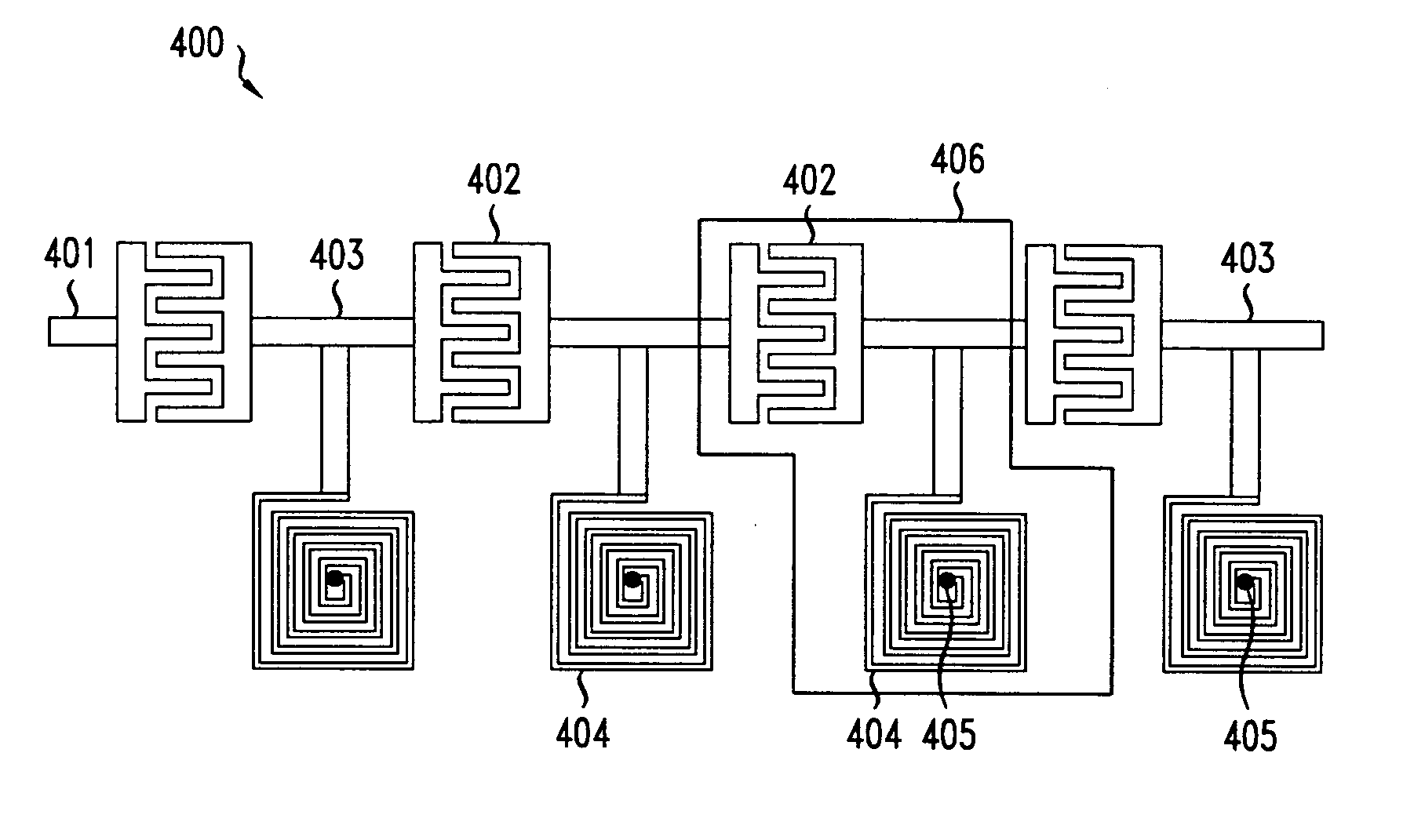

Integral charge storage basement and wideband embedded decoupling structure for integrated circuit

InactiveUS7428136B2Limit upper frequency usefulnessMinimizing restrictionThin/thick film capacitorFixed capacitor dielectricRadiation lossCapacitance

A capacitive structure and technique for allowing near-instantaneous charge transport and reliable, wide-band RF ground paths in integrated circuit devices such as integrated circuit dies, integrated circuit packages, printed circuit boards, and electronic circuit substrates is presented. Methods for introducing resistive loss, dielectric loss, magnetic loss, and / or radiation loss in a signal absorption ring implemented around a non-absorptive area of one or more conductive layers of an integrated circuit structure to dampen laterally flowing Electro-Magnetic (EM) waves between electrically adjacent conductive layers of the device are also presented.

Owner:GEOMAT INSIGHTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com