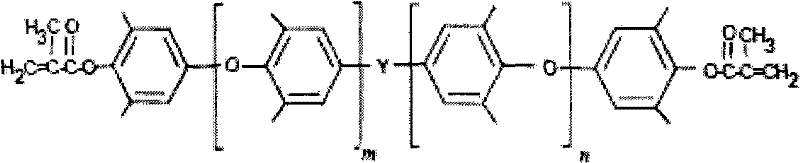

Composite material, high-frequency circuit substrate therefrom and manufacture method thereof

A composite material and mixture technology, used in circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of difficult to meet high temperature, low ratio of rigid structure benzene rings, difficult process operation, etc. The effect of low loss tangent, improved peel strength and convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

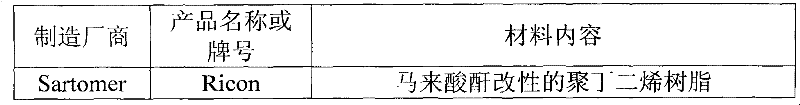

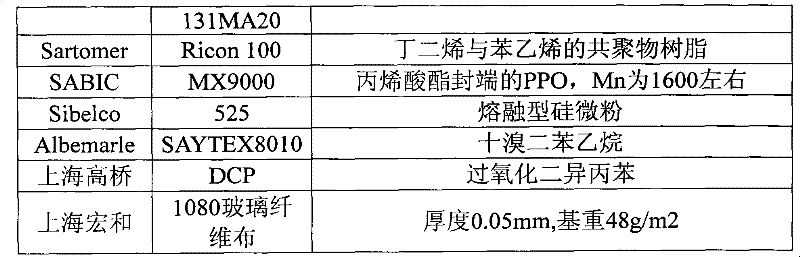

Embodiment 1

[0066] 55.6 parts by weight of maleic anhydride modified polybutadiene resin (Ricon 131MA20), 44.4 parts by weight of acrylate-terminated PPO (MX9000), 85 parts by weight of silicon dioxide (525), 32 parts by weight of The flame retardant decabromodiphenylethane (SAYTEX8010) of parts by weight, the initiator dicumyl peroxide (DCP) of 6.5 parts by weight mixes, adjusts to suitable viscosity with solvent xylene, stirs and mixes evenly, makes filler Uniformly dispersed in the resin to obtain a glue solution. Immerse the above glue with 1080 glass fiber cloth, and then dry to remove the solvent to make a prepreg, because the prepreg is not sticky, and the process is easy to operate. Stack eight prepregs that have been made, and laminate copper foil with a thickness of loz (ounces) on both sides, and cure in a press for 2 hours at a curing pressure of 50Kg / cm 2 , The curing temperature is 190°C. The physical data are shown in Table 3.

Embodiment 2

[0068] The manufacturing process is the same as in Example 1, and the ratio of the composite material and its physical property data are shown in Table 3.

Embodiment 3

[0070] The manufacturing process is the same as in Example 1, and the ratio of the composite material and its physical property data are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com