Halogen-free flame-retardant epoxy resin composition, flexible copper clad laminate made therefrom and preparation of the flexible copper clad laminate

A flexible copper clad laminate and epoxy resin technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of exudation or migration of small molecular fillers, poor mechanical properties of plates, uneven dispersion of fillers, etc. Mechanical properties, excellent dimensional stability, the effect of enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

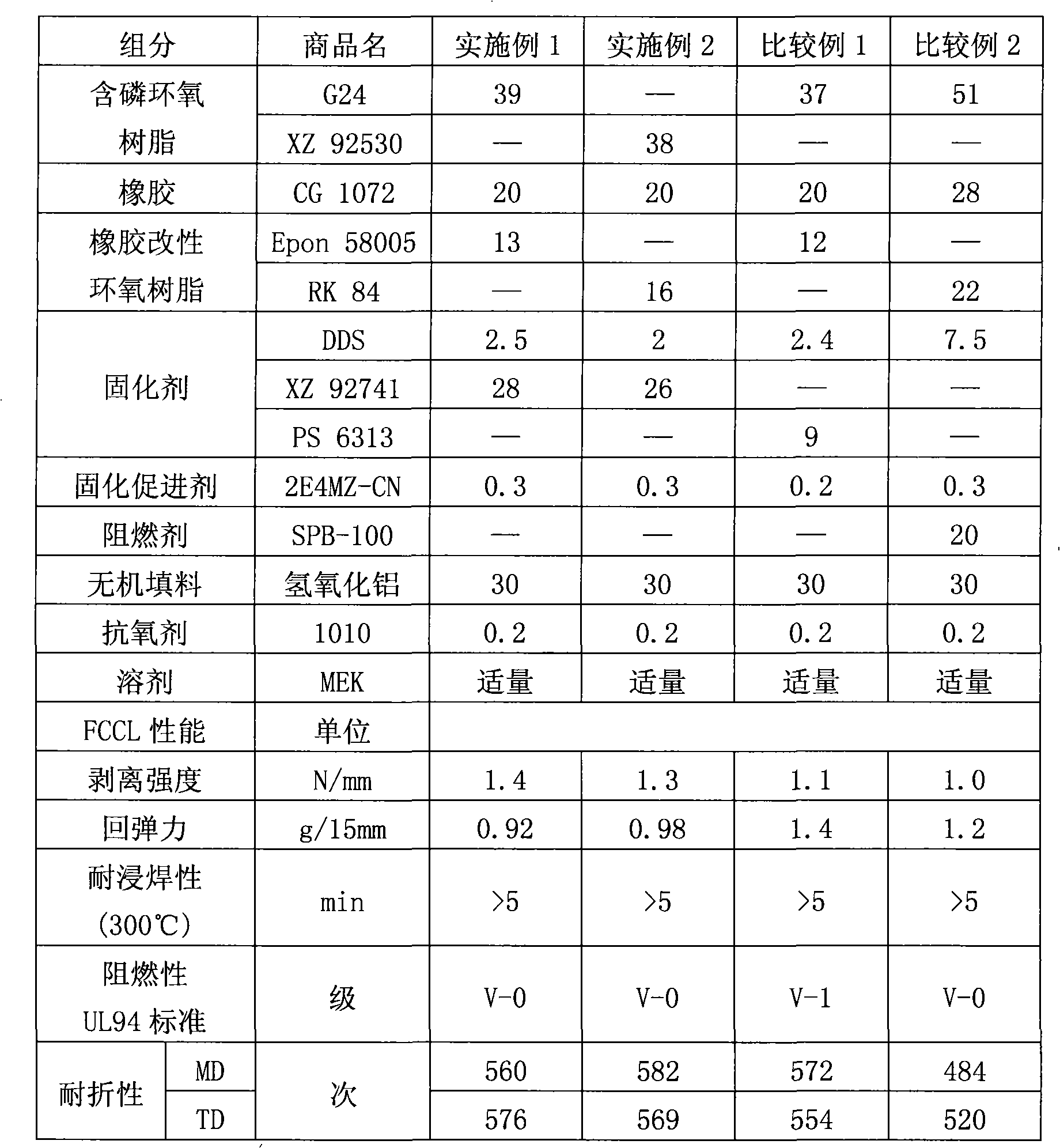

Embodiment 1

[0059] Phosphorus-containing epoxy resin (commercial model G-24, epoxy equivalent 340g / eq, phosphorus content 2.4 mass %, manufactured by Jiangshan Jianghuan Chemical Industry Co., Ltd.) 39 parts by weight; synthetic rubber (commercial model Nipol 1072, acrylonitrile content 27 mass %, manufactured by Zeon Corporation) 20 parts by weight; rubber-modified epoxy resin (commercial model Epon Resin 58005, elastomer content 40 mass %, Hexion Specialty Chemicals, Inc. manufactured) 13 parts by weight; phosphorus-containing phenolic resin (commercial product Model XZ 92741, phosphorus content 9 mass %, manufactured by Dow Chemical Company) 28 parts by weight; Diaminodiphenyl sulfone 2.5 parts by weight; 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN) 0.30 Parts by weight; 30 parts by weight of aluminum hydroxide (average particle diameter of 1 to 5 μm, purity above 99%); 0.20 parts by weight of antioxidant (product model 1010, manufactured by CIBA GEIGY Co.). The solid content of t...

Embodiment 2

[0061] Phosphorus-containing epoxy resin (product model XZ 92530, epoxy equivalent 340g / eq, phosphorus content 3.0 mass%, manufactured by Dow Chemical Company) 38 parts by weight; synthetic rubber (commodity model Nipol 1072, acrylonitrile content 27 mass%, Zeon Corporation manufacturing) 20 weight parts; Rubber-modified epoxy resin (commodity model Hy RK84, elastomer content 32 mass %, CVC Specialty Chemicals Inc., manufacture) 16 weight parts; Phosphorus-containing phenolic resin (commercial model XZ92741, phosphorus content 9 mass %, manufactured by Dow Chemical Company) 26 parts by weight; Diaminodiphenyl sulfone 2.0 parts by weight; 0.30 parts by weight of 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN); Aluminum hydroxide ( 30 parts by weight of an average particle diameter of 1 to 5 μm, and a purity of 99% or more); 0.20 parts by weight of an antioxidant (product model 1010, manufactured by CIBA GEIGY Co.). The solid content of the glue solution is adjusted to 40% wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com