Patents

Literature

724 results about "Product model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

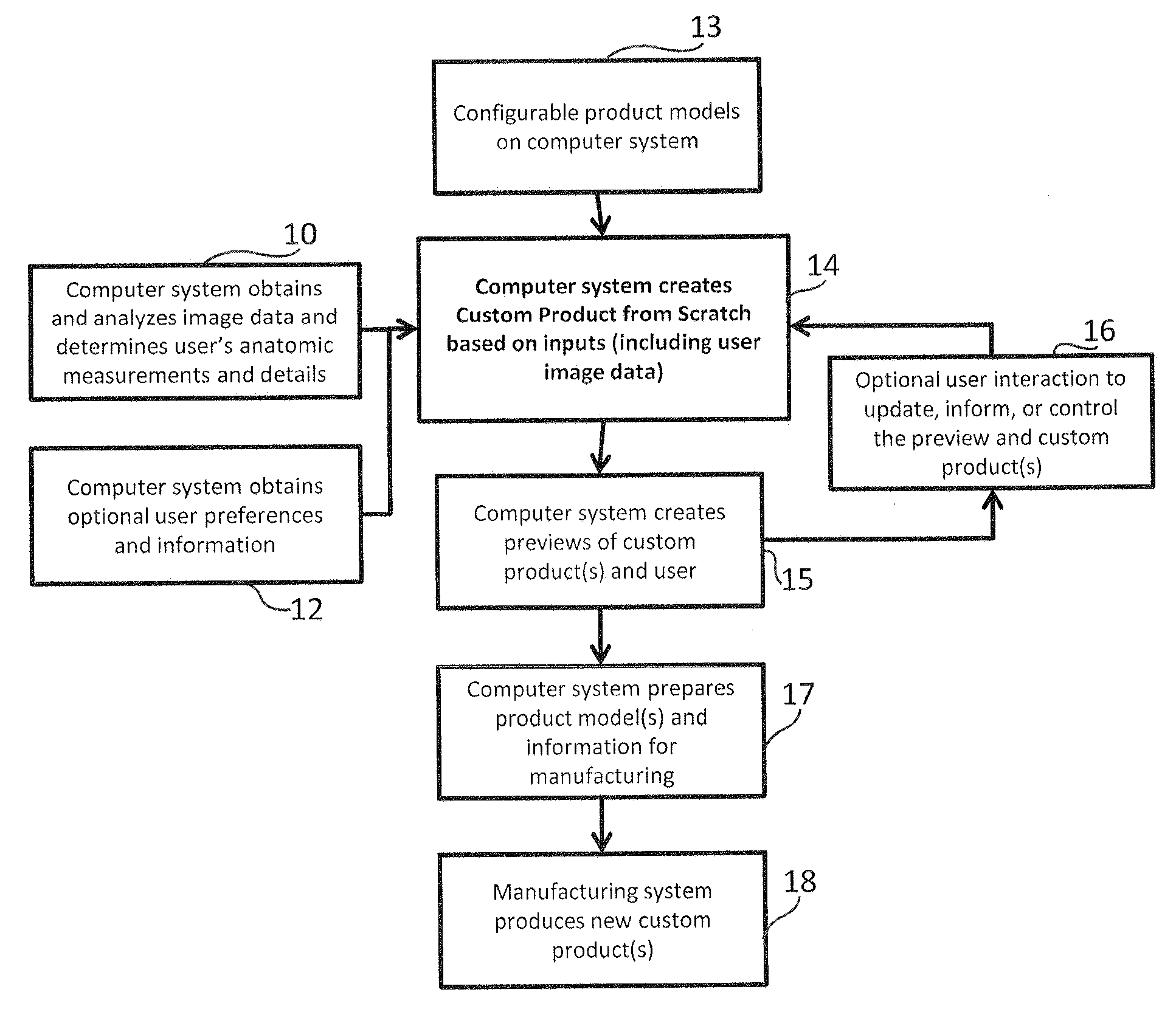

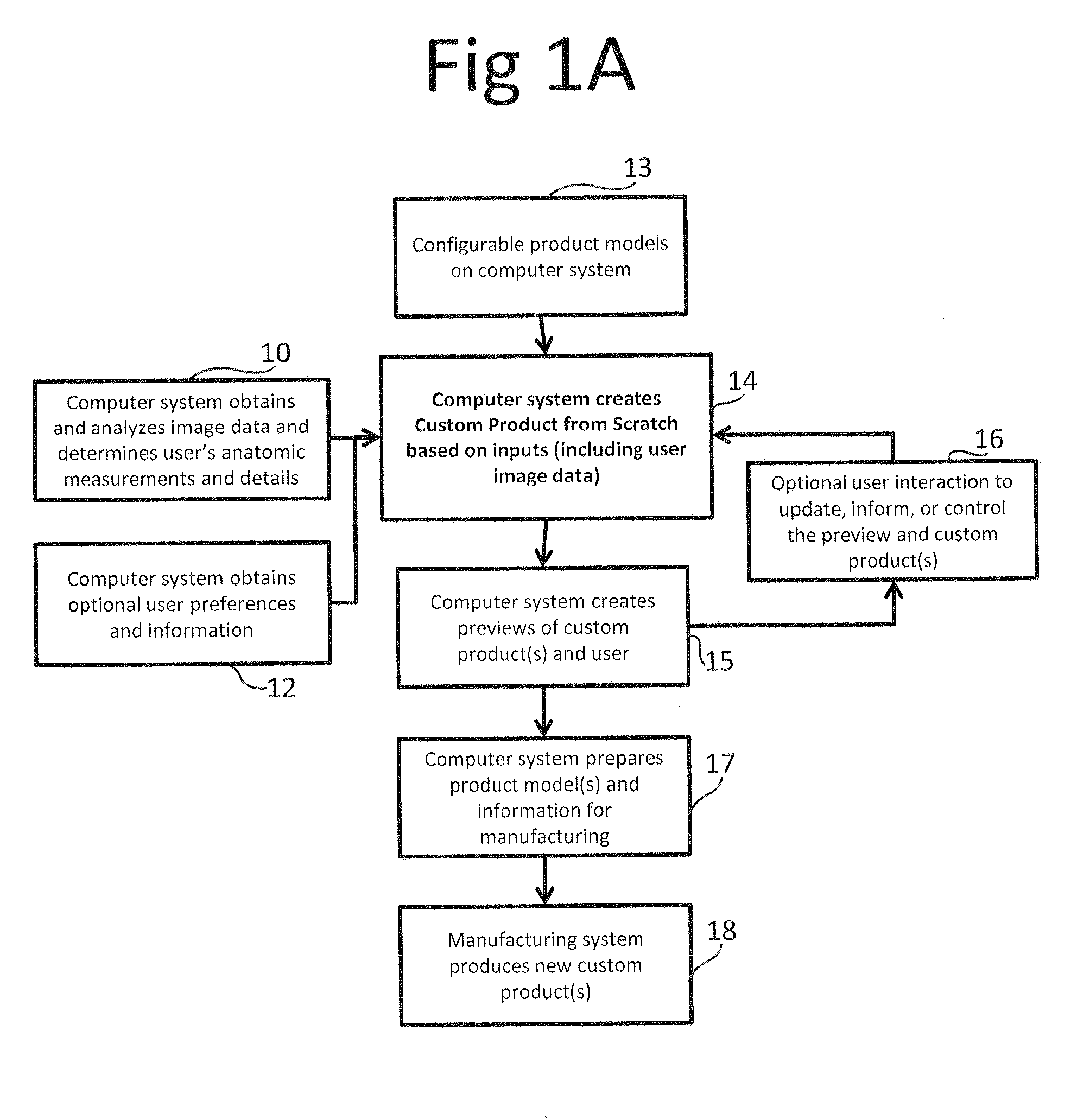

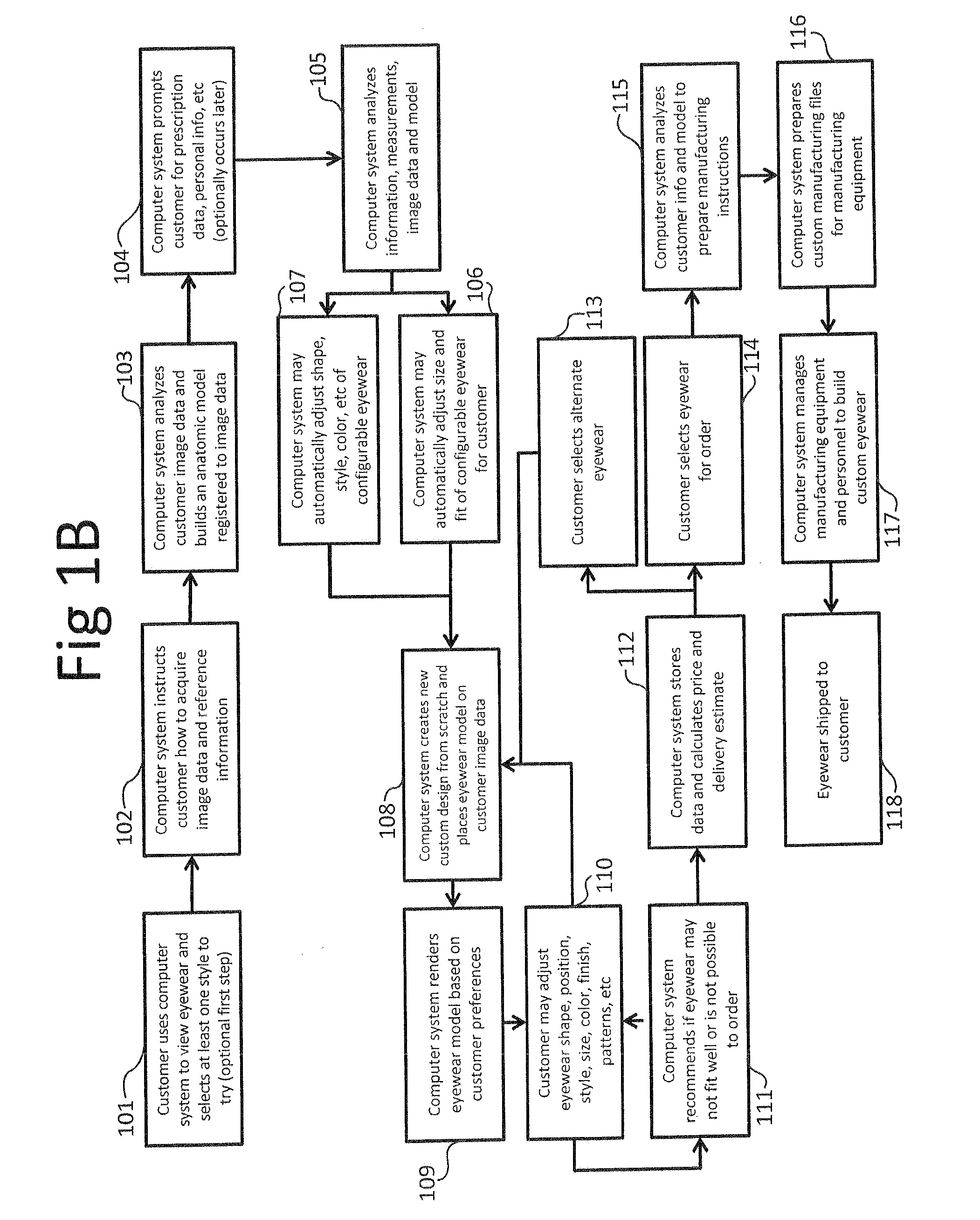

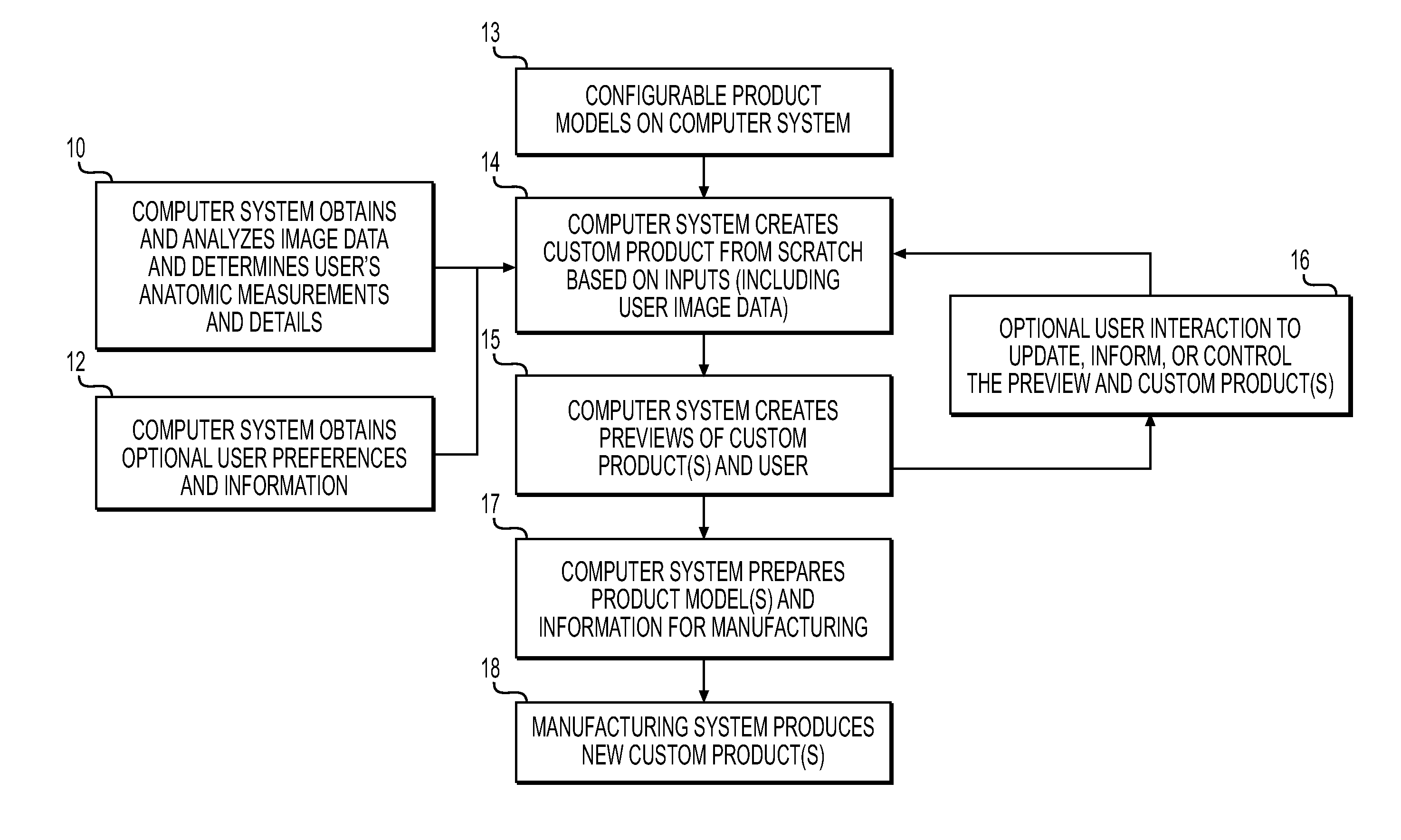

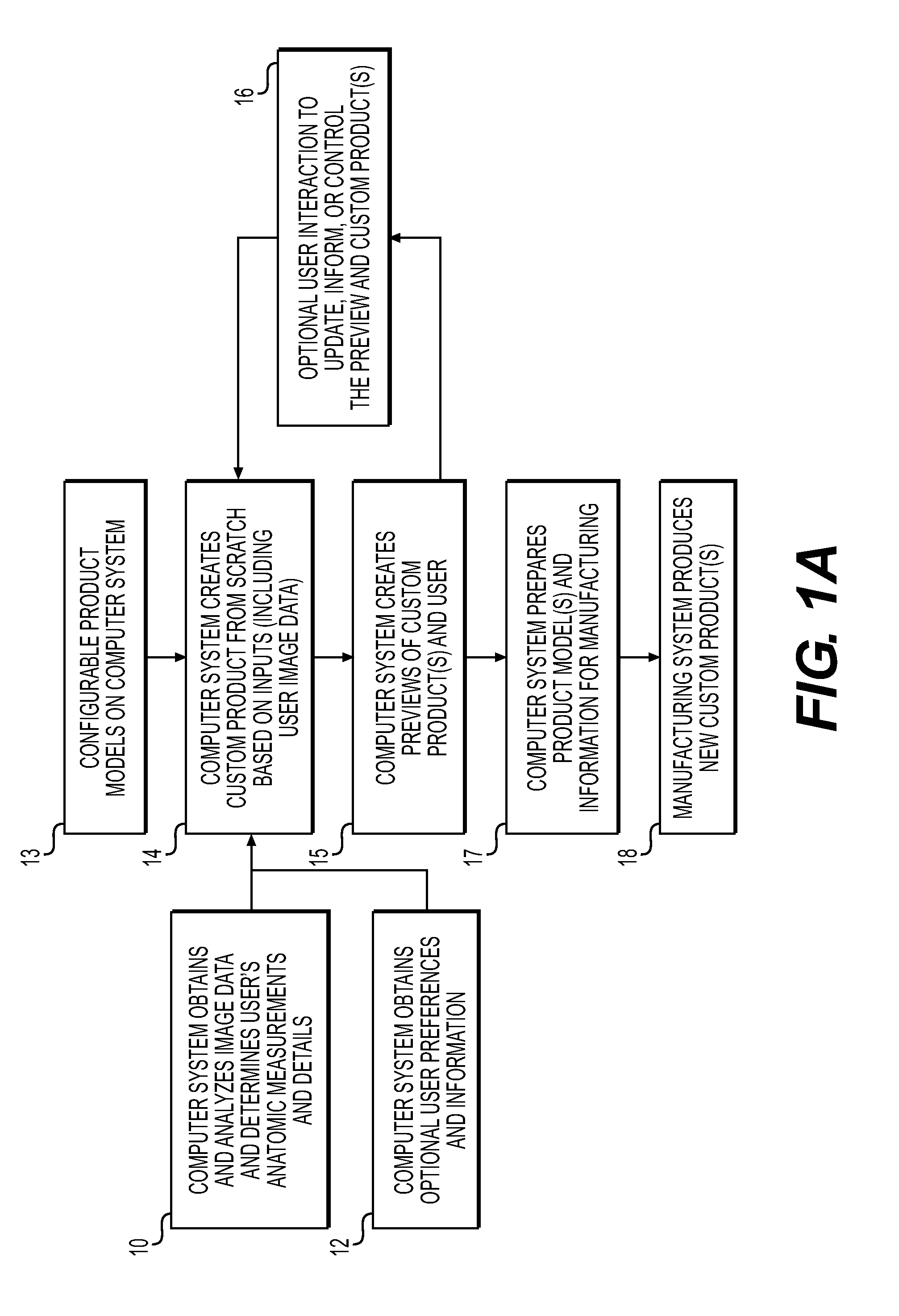

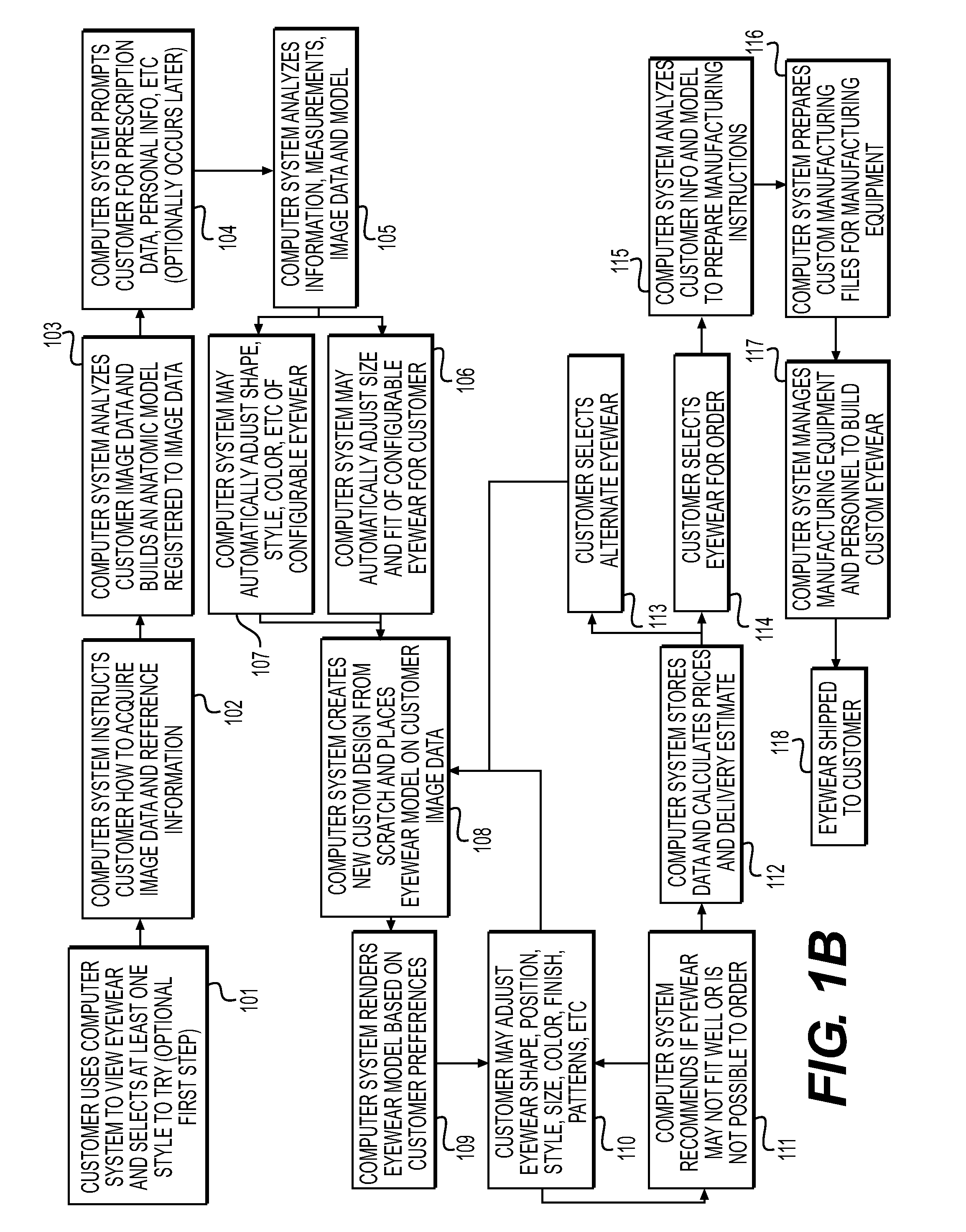

Method and system to create products

Systems and methods for creating fully custom products from scratch without exclusive use of off-the-shelf or pre-specified components. A system for creating custom products includes an image capture device for capturing image data and / or measurement data of a user. A computer is communicatively coupled with the image capture device and configured to construct an anatomic model of the user based on the captured image data and / or measurement data. The computer provides a configurable product model and enables preview and automatic or user-guided customization of the product model. A display is communicatively coupled with the computer and displays the custom product model superimposed on the anatomic model or image data of the user. The computer is further configured to provide the customized product model to a manufacturer for manufacturing eyewear for the user in accordance with the customized product model. The manufacturing system is configured to interpret the product model and prepare instructions and control equipment for the manufacturing of the customized product.

Owner:BIS

System and method for visually representing project metrics on 3-dimensional building models

Provided are a system and method for visually representing project metrics on 3-dimensional product models. The system comprises: a user interface unit for receiving an input of color information, including variations in the colors and color tones of objects to be visualized in response to the course of a project, and output conditions, including a time interval at which an output is required, from a user; a database unit for storing the objects and temporal and / or spatial relationships between the objects; and an image formation unit for determining colors and color tones of the objects according to the project course based on the output conditions input by the user, and forming and outputting 3-dimensional images of the objects by the determined colors and color tones.

Owner:KYUMAN SONG

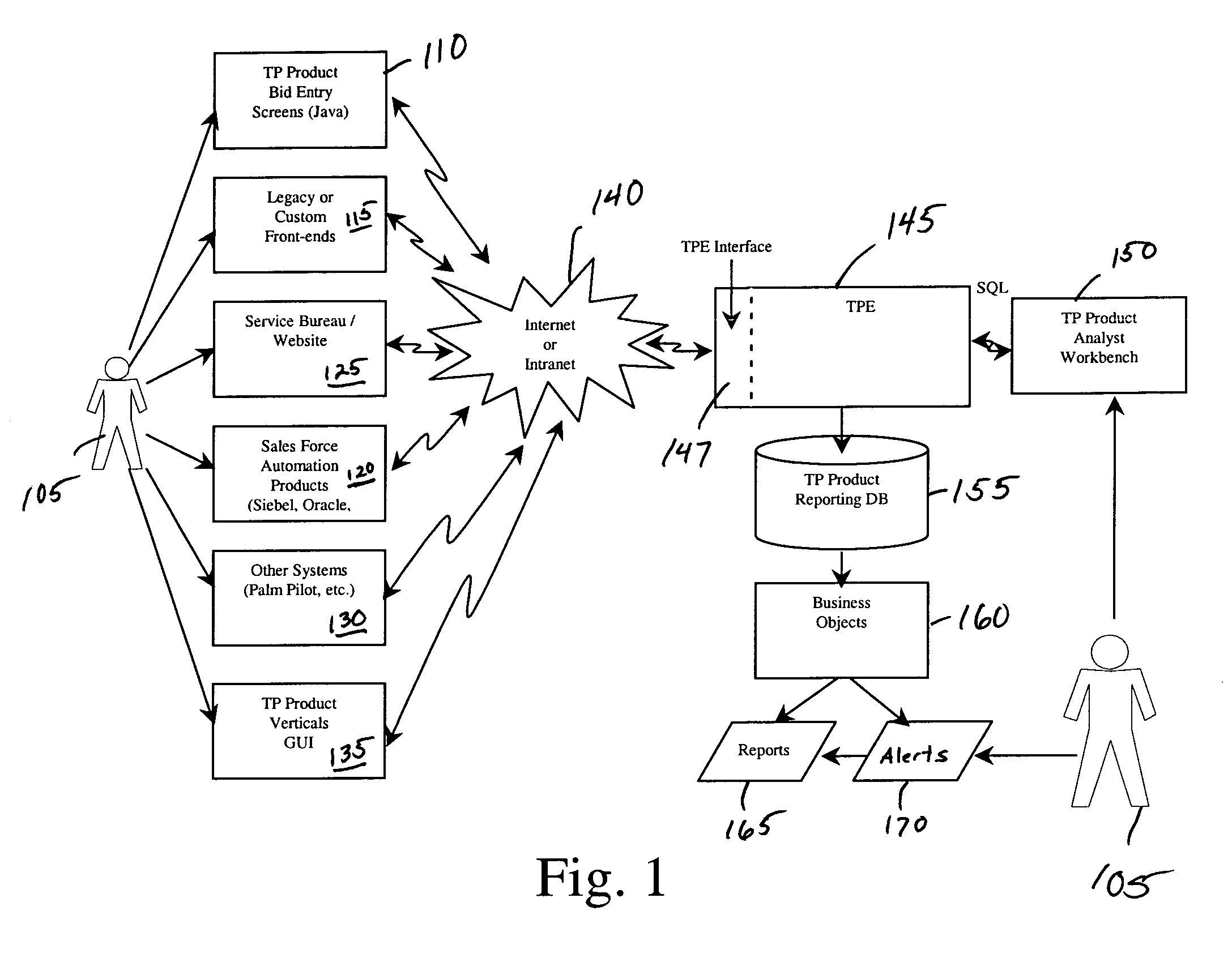

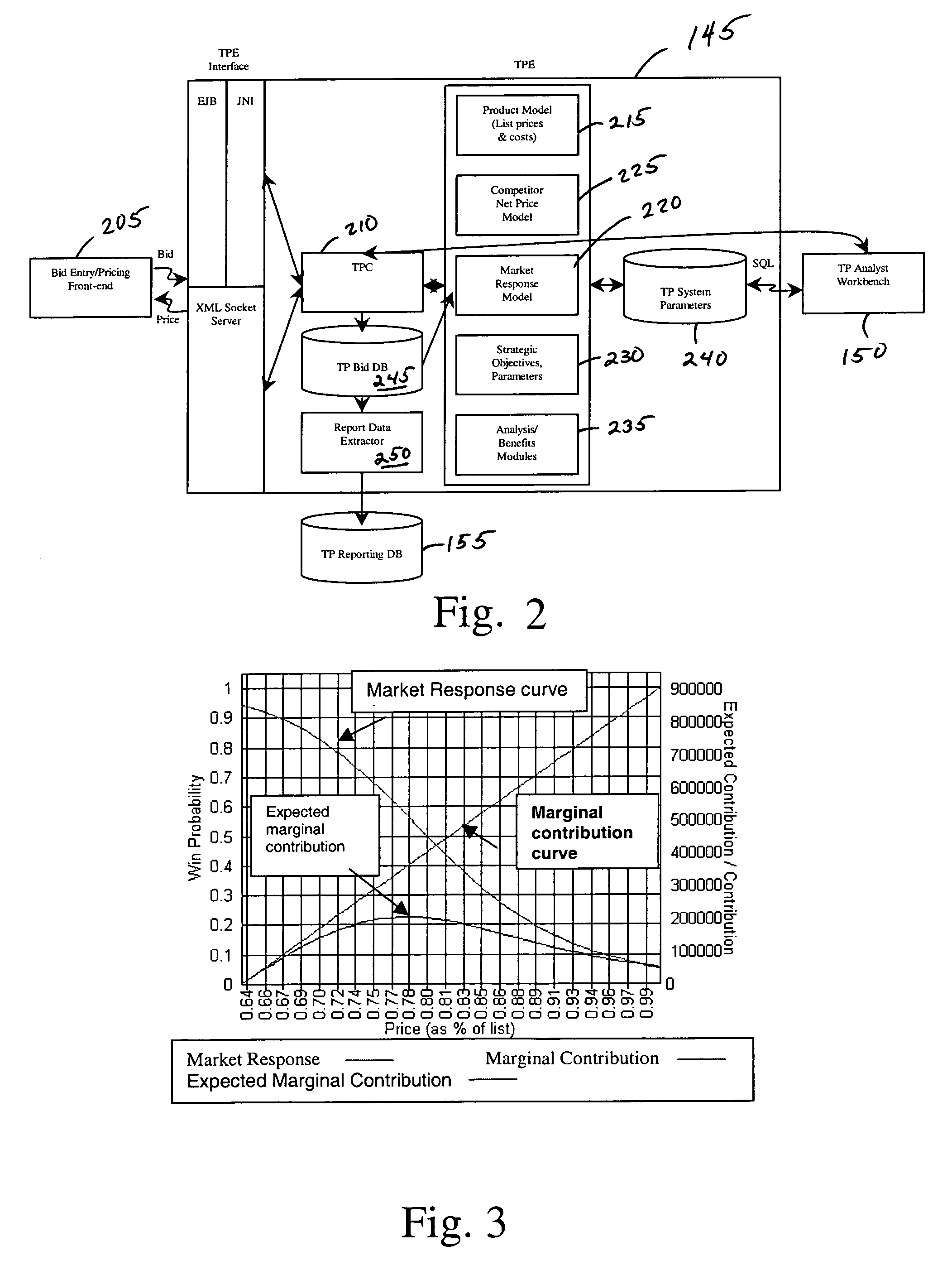

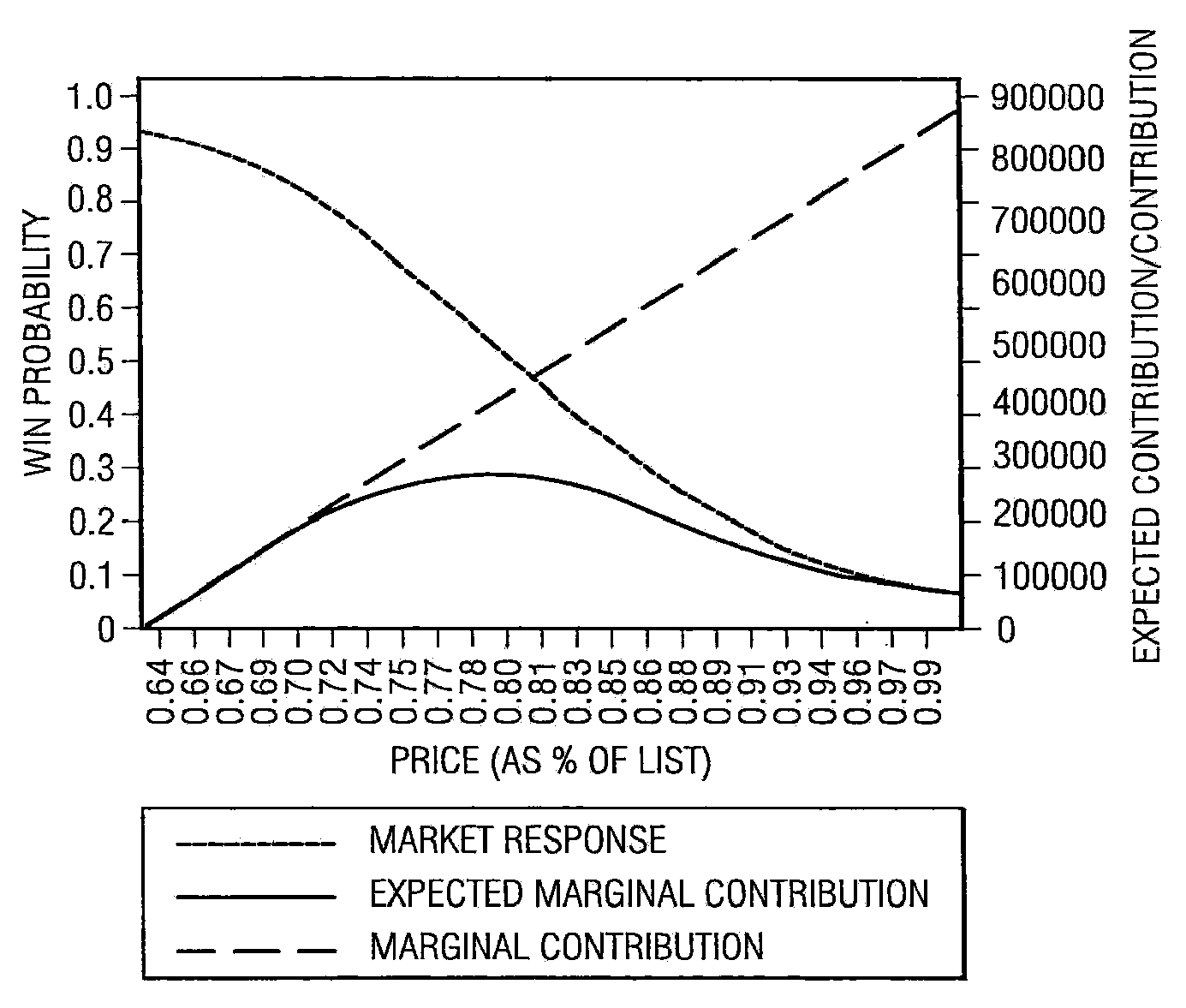

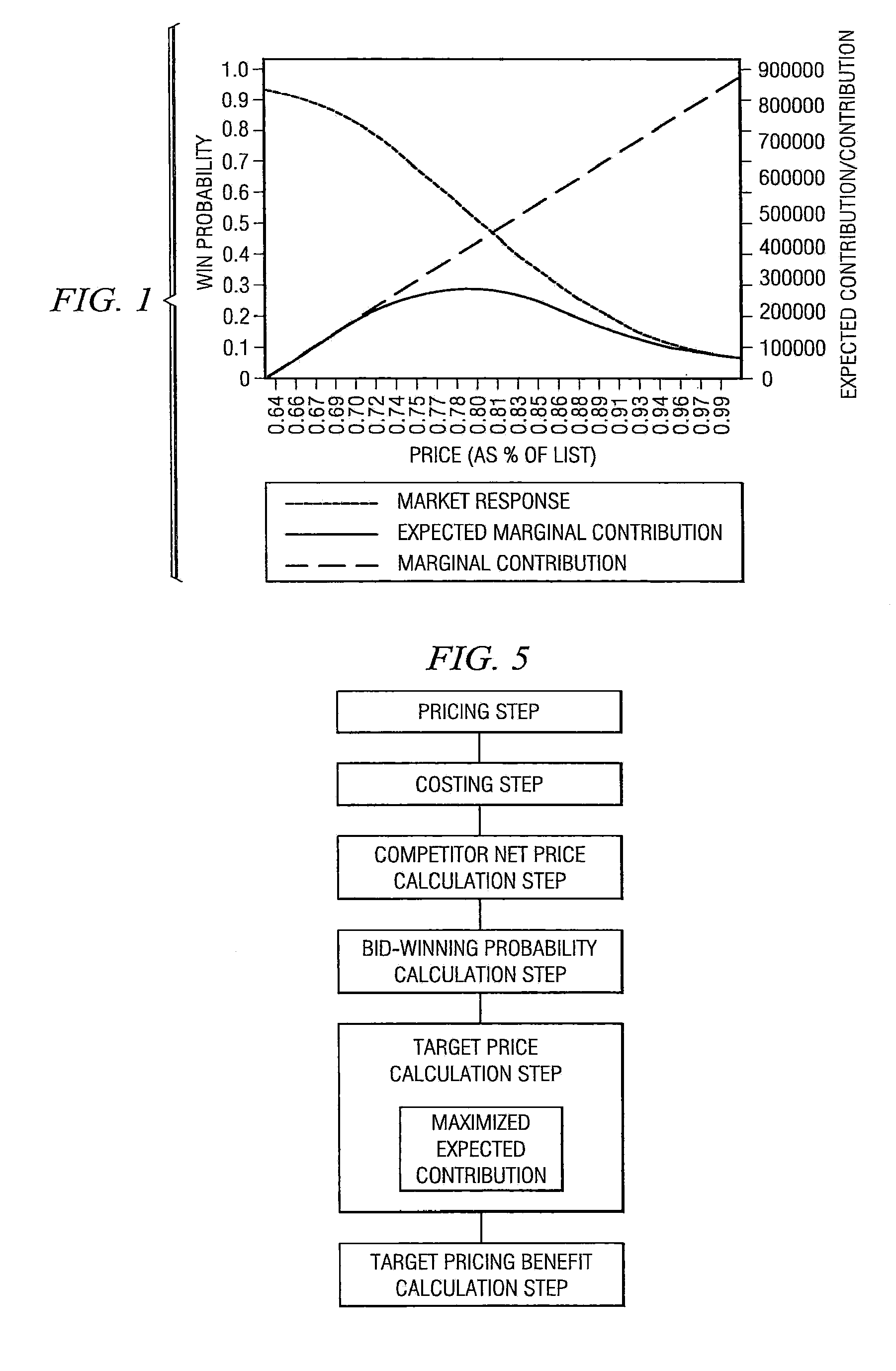

Target pricing system

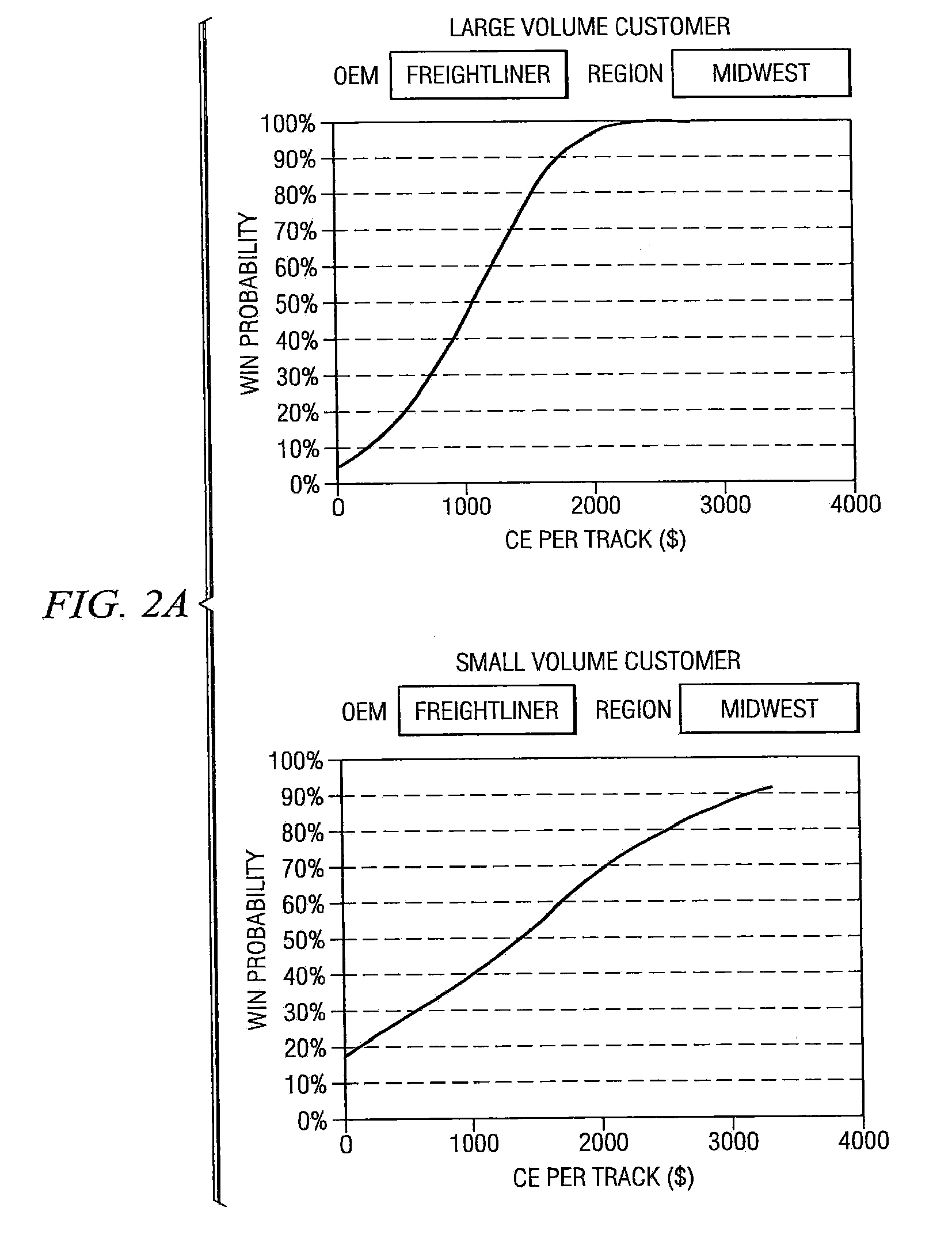

InactiveUS6963854B1Increase profitMaximize expected financial contributionFinanceFlags/bannersComputerized systemData storing

A business process and computer system known as the “Target Pricing System” (TPS) that generates an optimum bid or value for a competitively bid good or service. The system is resident on one or more host processors in connection with one or more data stores, and includes a product model that defines list values for the bid using stored price data and costs the values using stored cost data, a competitor net price model that calculates an equivalent competitor net price for the value, anda market response model that calculates the probability of winning with the value as a function of price. The system further preferably includesan optimization model that computes the target price of an optimal value that maximizes expected contribution for the bid or value. The system alternately further includes a benefits model for calculating the benefits of using target pricing over a pre-existing approach, and strategic objects which each affect the target price.

Owner:JDA SOFTWARE GROUP

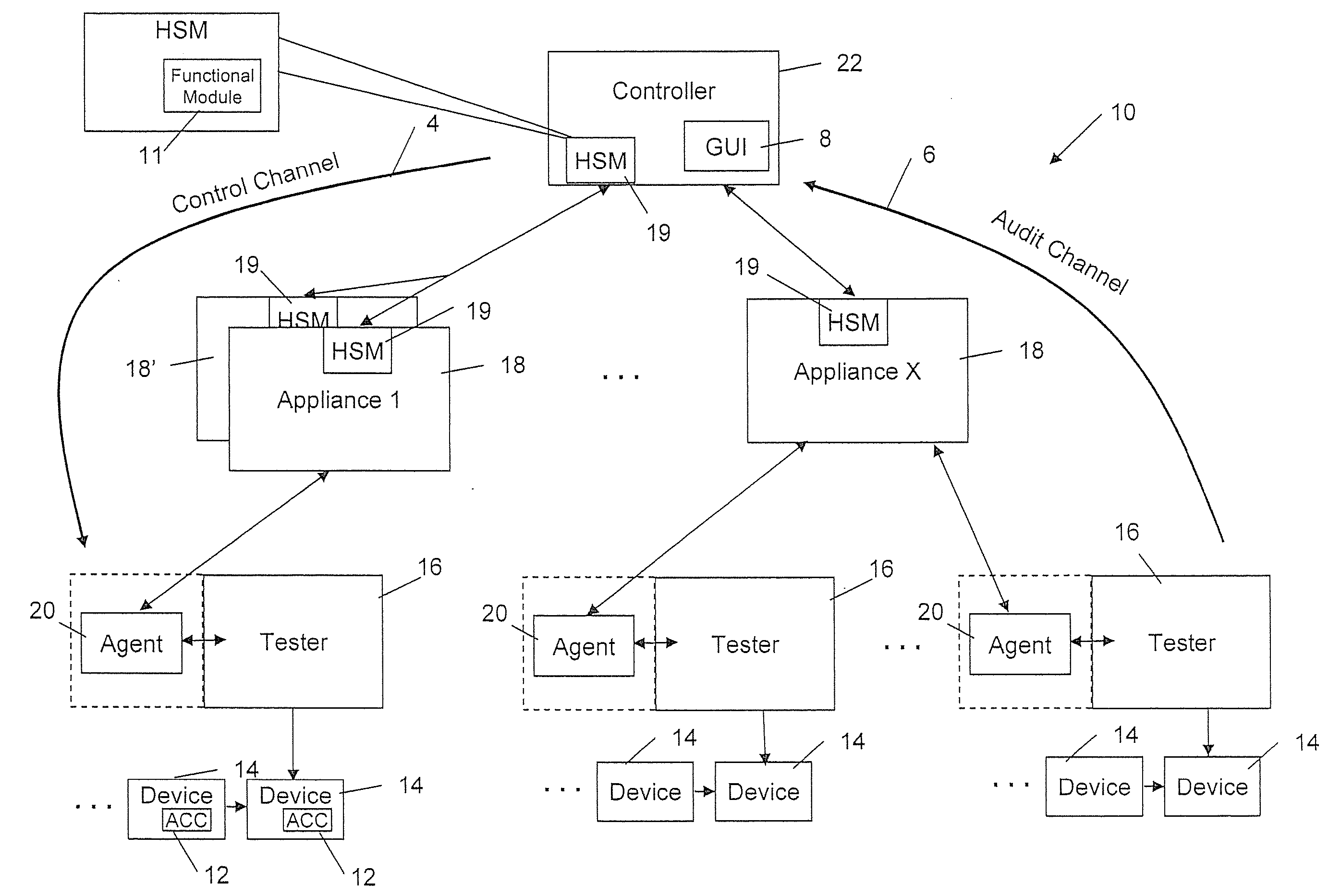

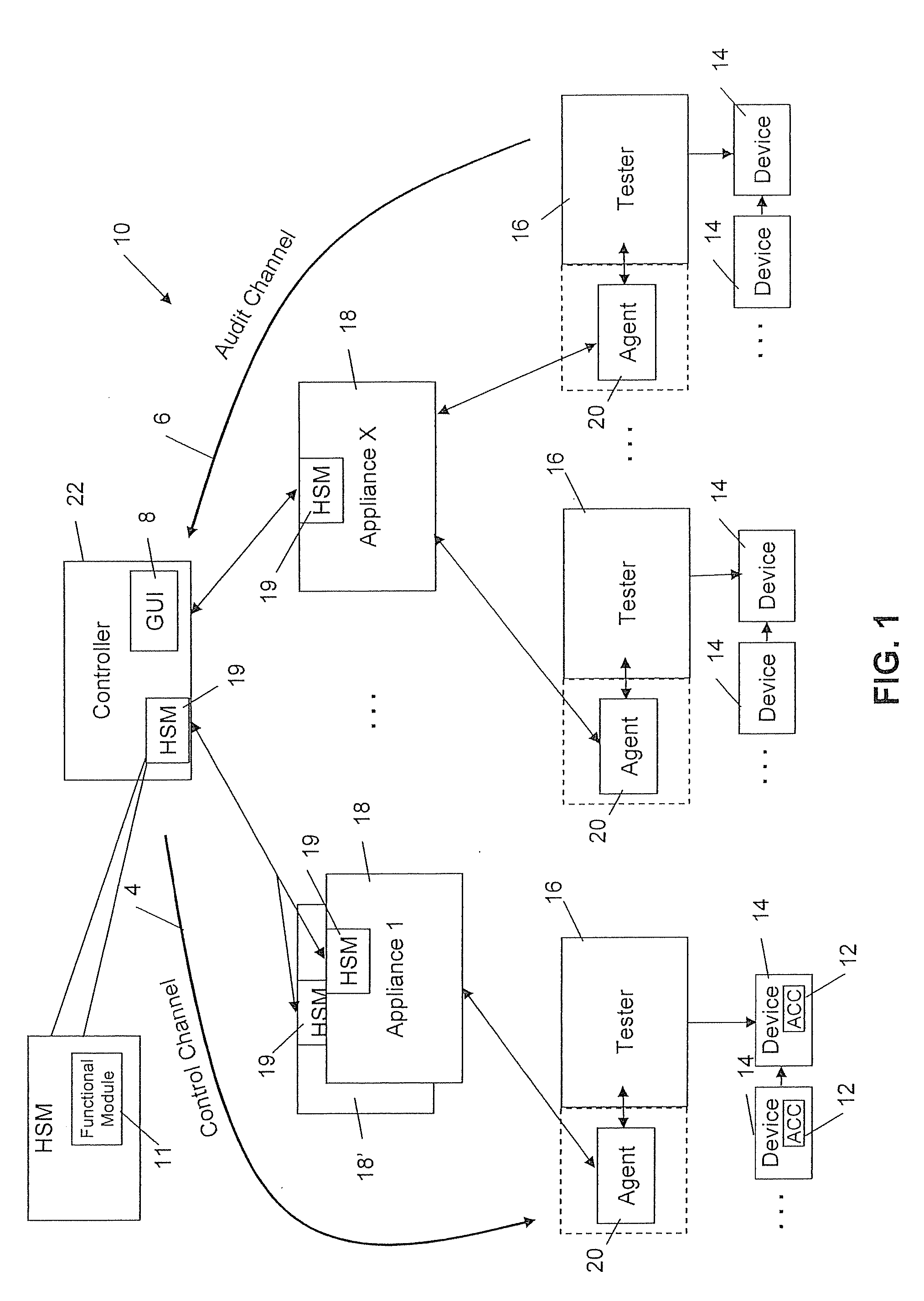

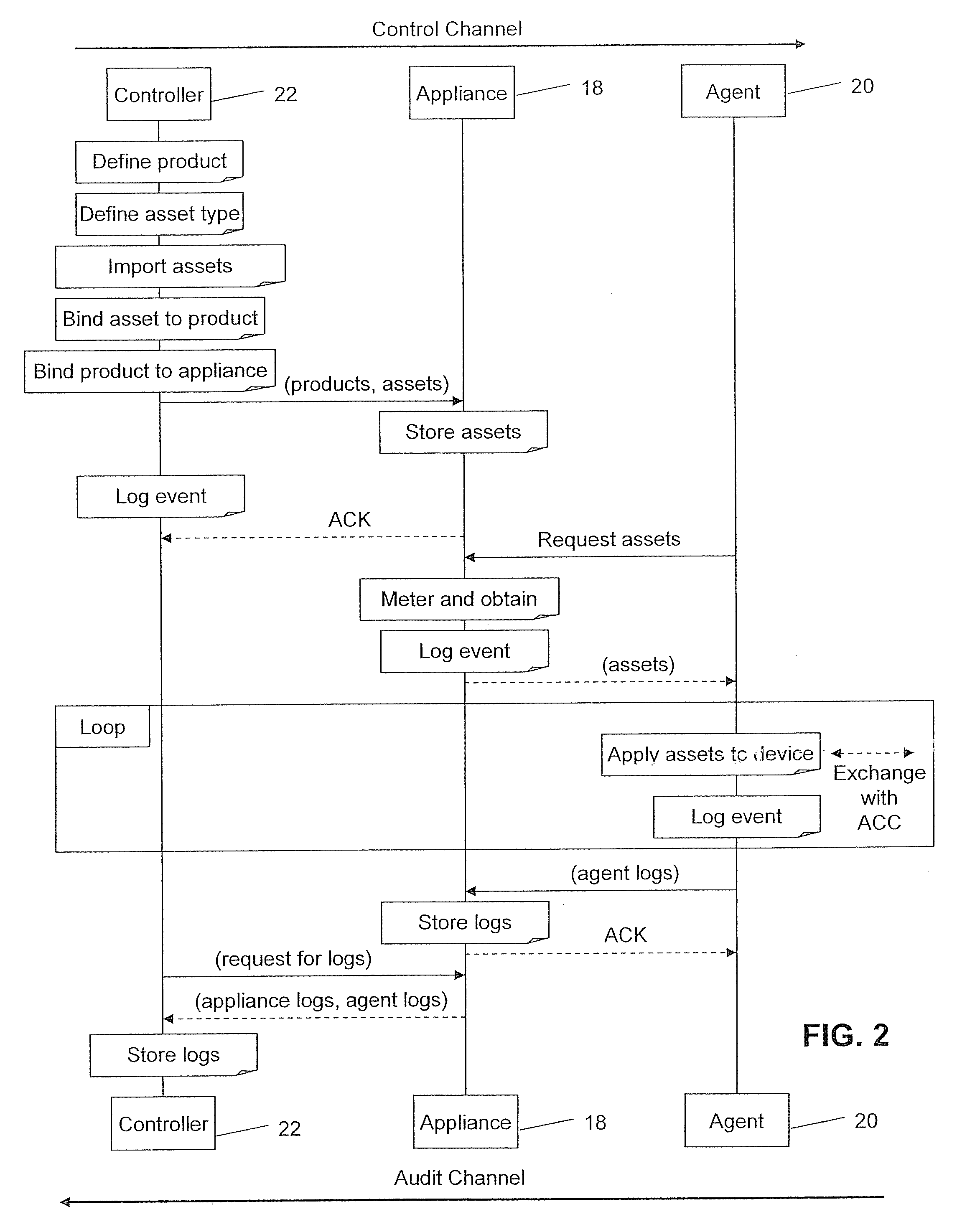

System and method for performing serialization of devices

ActiveUS20110063093A1Reduce in quantityImprove abilitiesSensing detailsForecastingSerializationService module

A serialization service module is provided for configuring an asset management system to provide a secure means of generating, assigning to chips (or other electronic objects or devices), and tracking unique serial numbers. To provide this service, a controller is used to define a product model, then to define one or more serialization schemas to be bound to each product model. Each serialization schema contains a range of serial numbers for a particular product. The serial number schemas are sent over a secure, encrypted connection to appliances at the manufacturer's location. Agents can then request serial number values by product name. The serial numbers are generated by the appliance, metered, and provided to the agents. The serial numbers are then injected sequentially into each die in a chip manufacturing process using the agent.

Owner:MALIKIE INNOVATIONS LTD

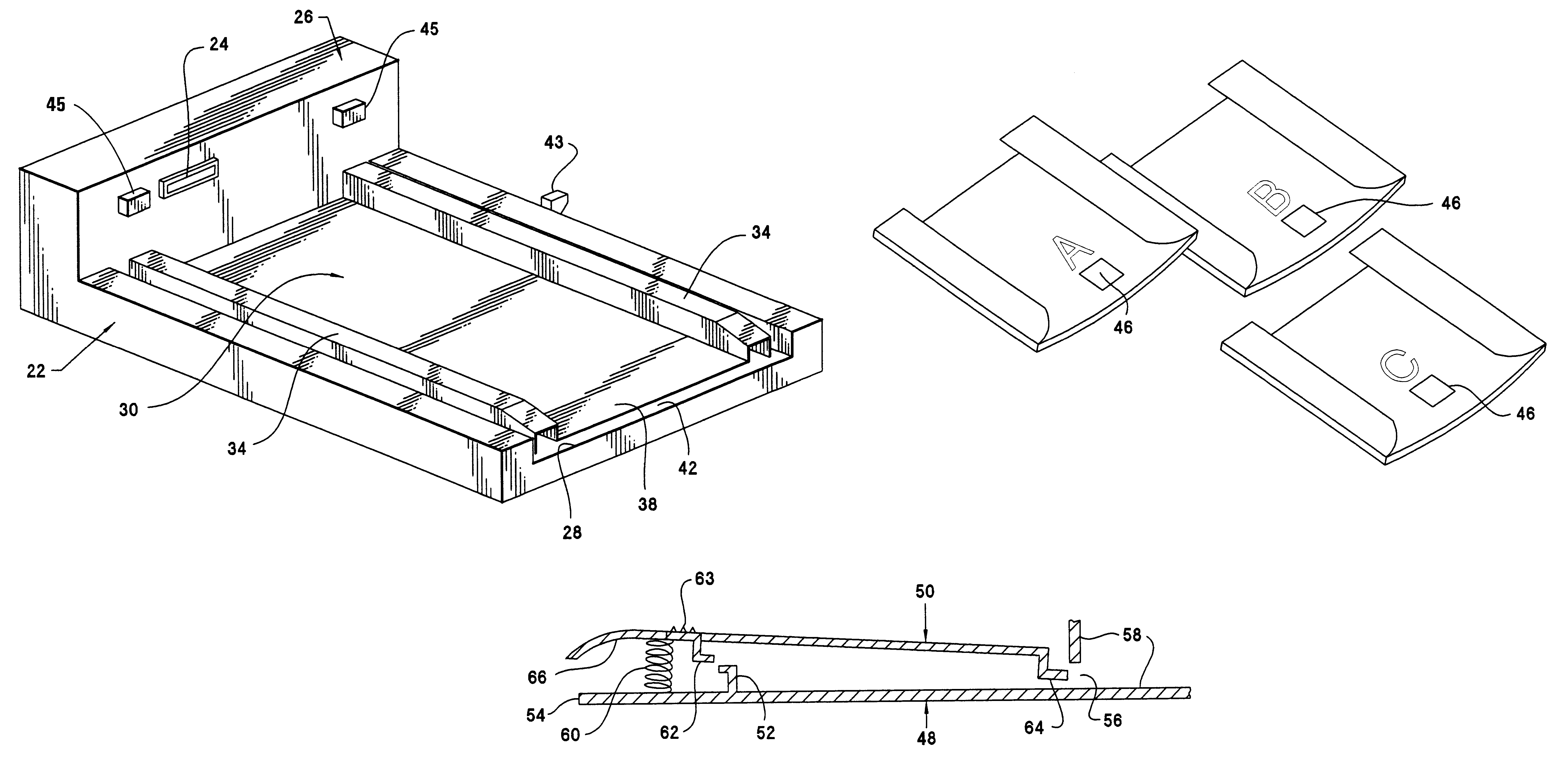

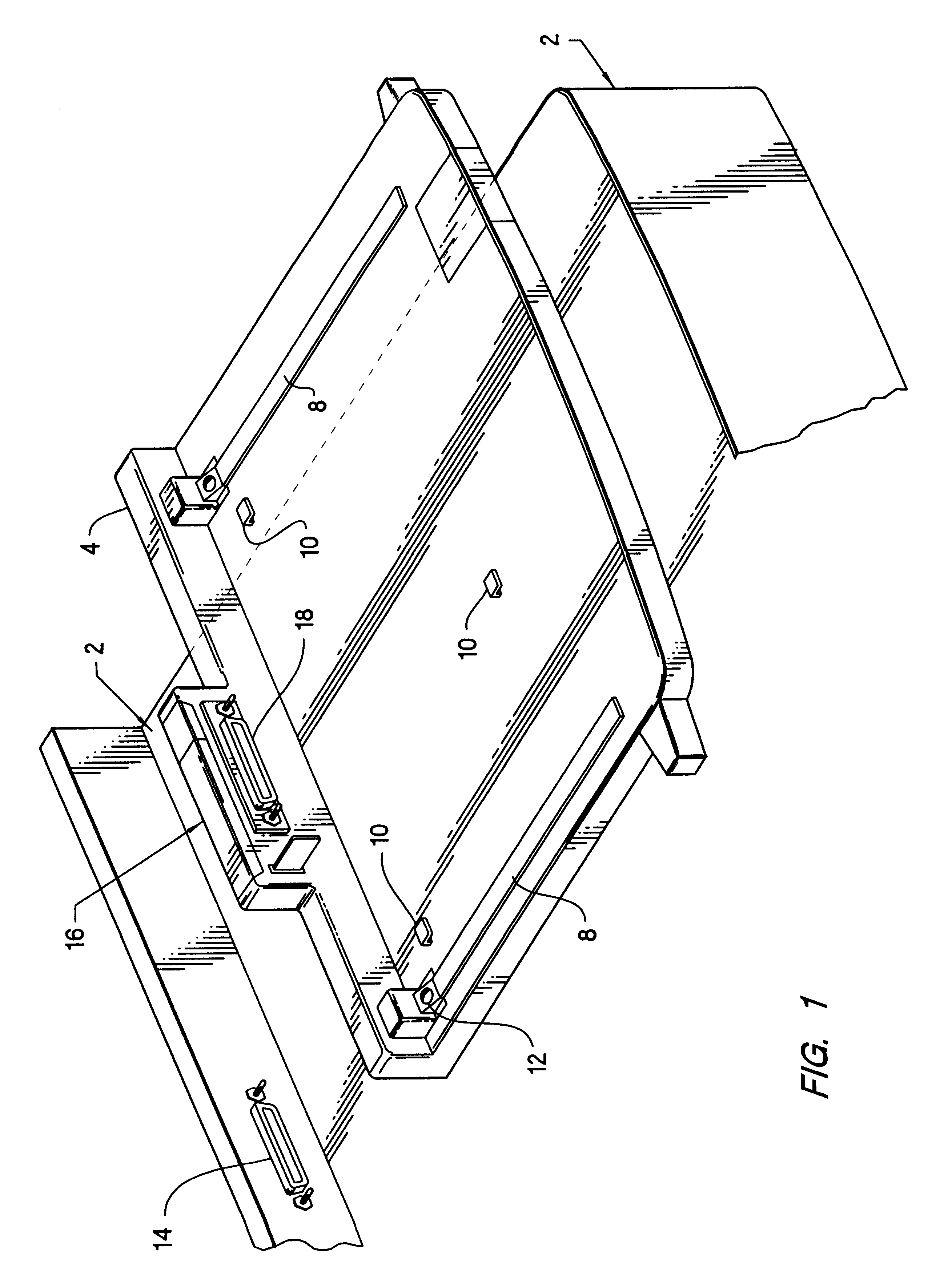

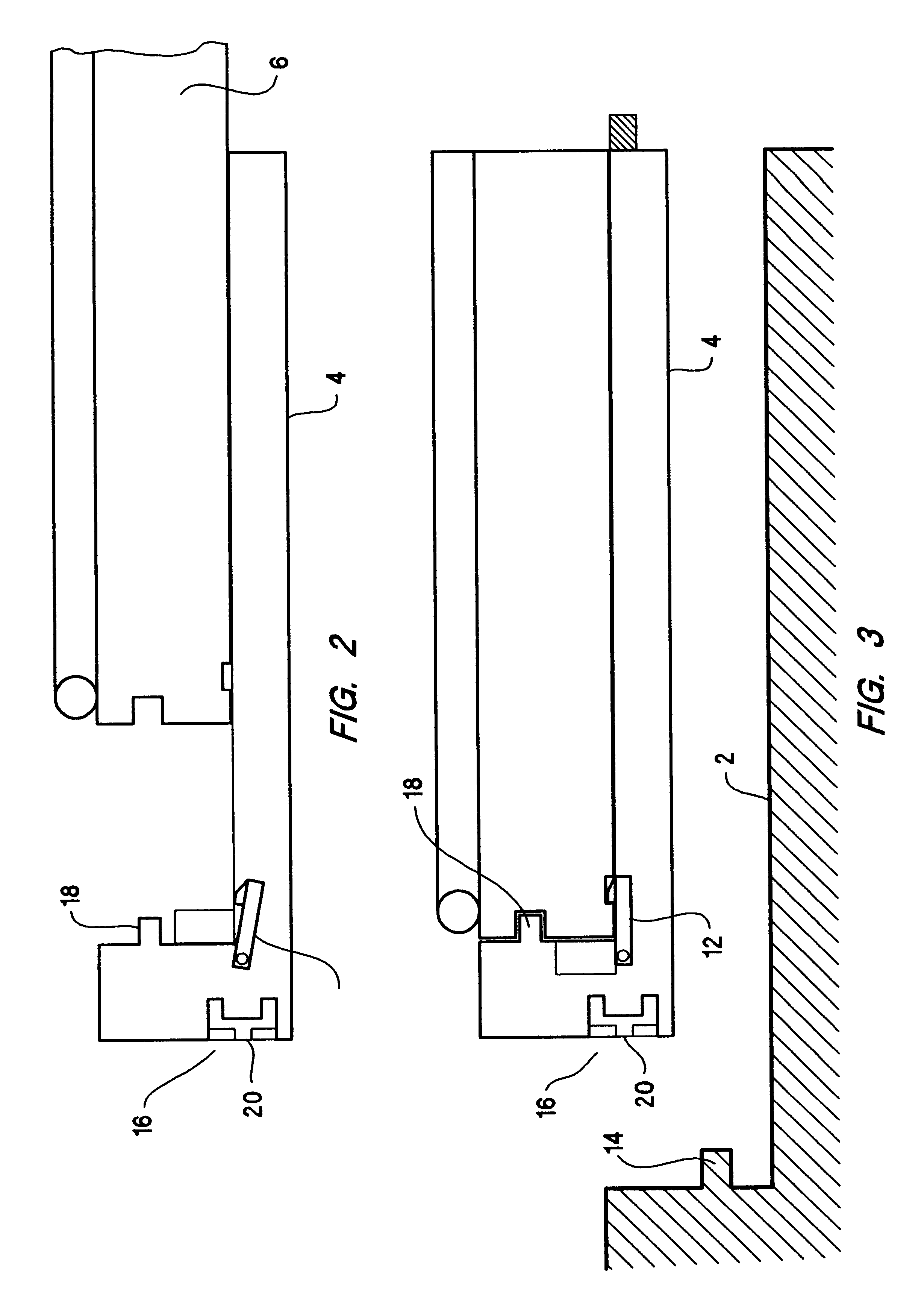

Docking station having a plurality of adapter trays for a plurality of portable computers

InactiveUS6301106B1Few structuresReduce manufacturing costBatteries circuit arrangementsDigital data processing detailsDocking stationProduction line

The invention provides a single docking station structure which is usable for a set of different pieces of equipment having essentially similar interfaces, such as a manufacturer's line of portable ("notebook" or "laptop") computer product models. A common first module supports interfaces with peripheral devices or the like. A model-specific second module, second from a set of second modules that correspond with various models from the line of portable computers, is coupled with the first module to support the portable computer. The second module supports the portable computer, so as to interface it directly with the interface on the first module. The second modules, preferably configured as trays for holding the portable computers, are very simple and inexpensive to manufacture. The trays can be stored next to the docking station (like magazines on a bookshelf). An identification system, which labels the different trays and cross-references them to the corresponding portable computers, allows for future changes in the manufacturer's product line, in which a new model of portable computer requires either a new tray or one of the previously existing trays. The invention is advantageous to manufacturers because it reduces the number and variety of docking station products required for use with the manufacturer's portable computers.

Owner:HEWLETT PACKARD DEV CO LP

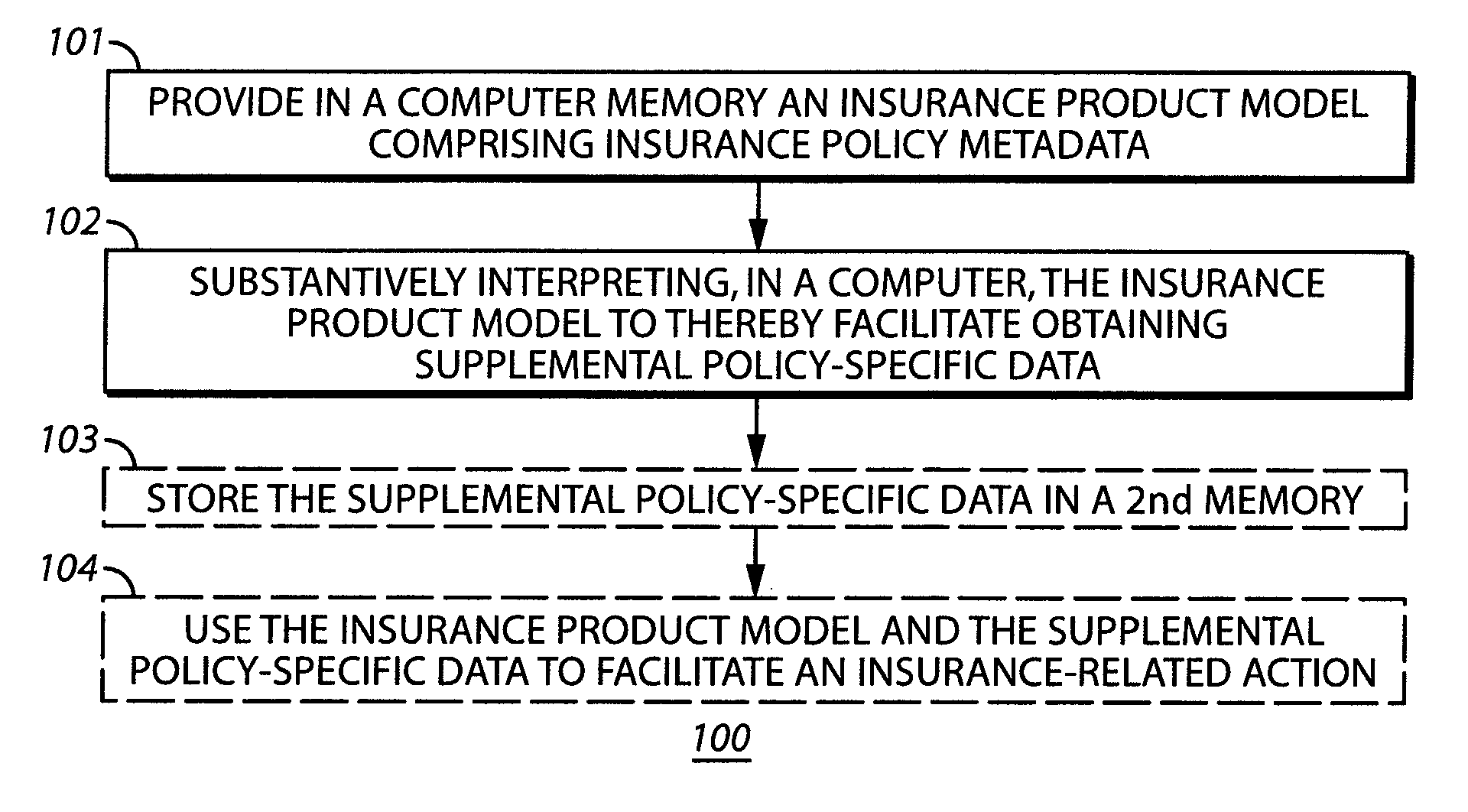

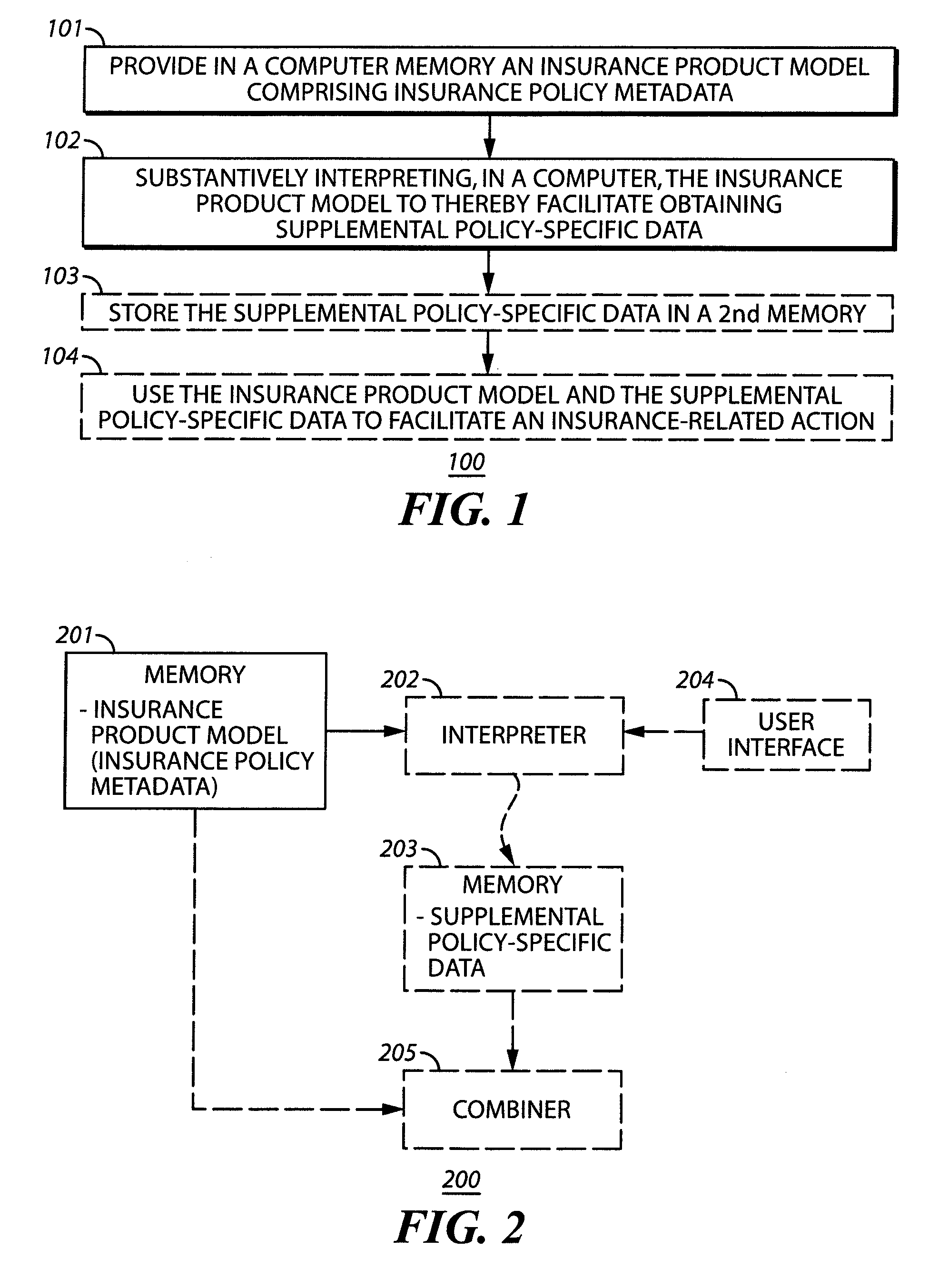

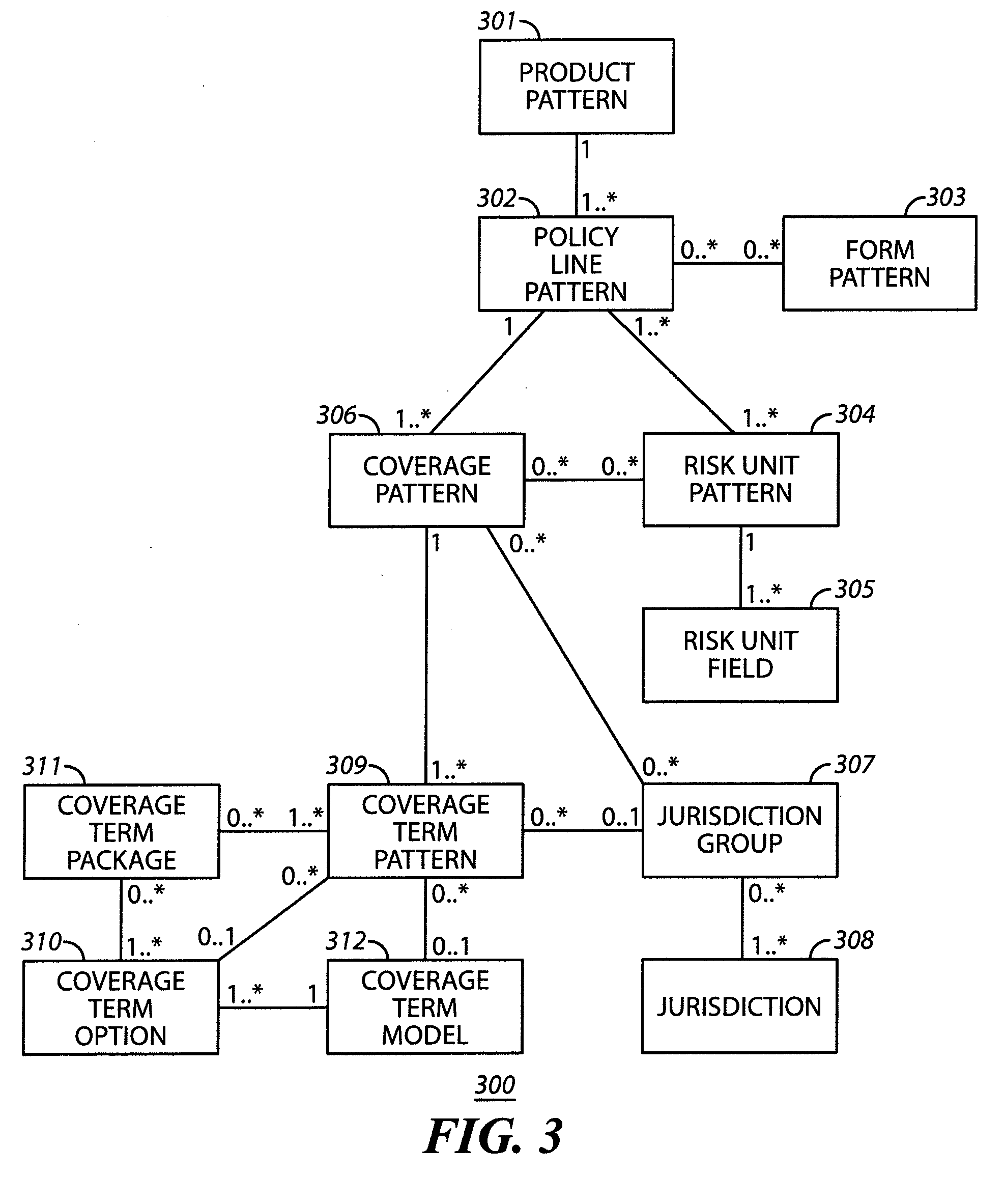

Insurance product model-based apparatus and method

An insurance product model comprising insurance policy metadata is provided (101) in a computer memory. The insurance policy metadata may comprise, at least in part, data that describes information that comprises a given corresponding insurance policy. A computer then serves to substantively interpret (102) this insurance product model to facilitate obtaining supplemental policy-specific data. The supplemental policy-specific data and the insurance policy metadata comprise separate and discrete data models and may, if desired, be stored (103) separately from one another. So configured, these teachings further support using (104) the insurance product model and the supplemental policy-specific data to facilitate an insurance-related action.

Owner:GUIDEWIRE SOFTWARE

Target pricing method

Owner:JDA SOFTWARE GROUP

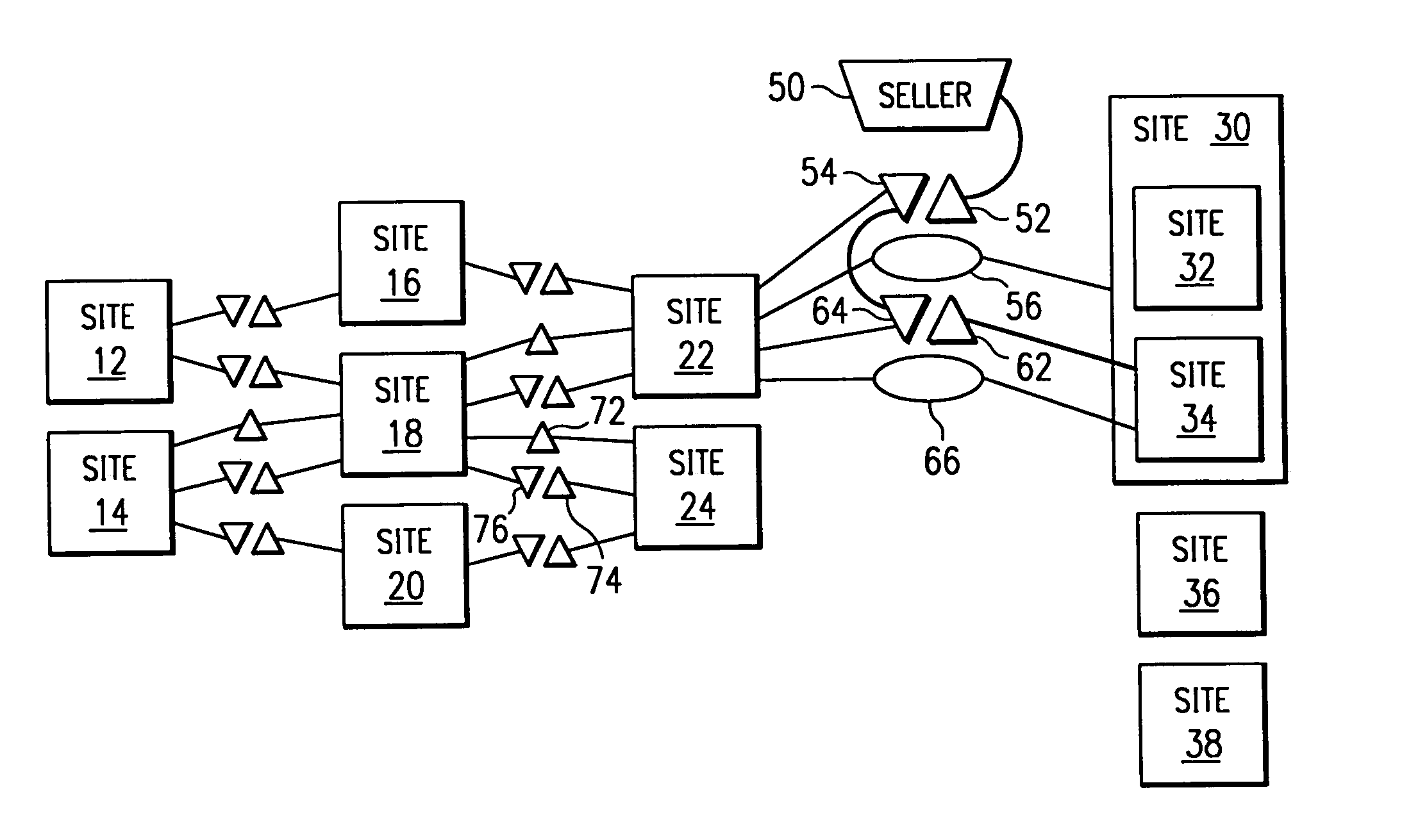

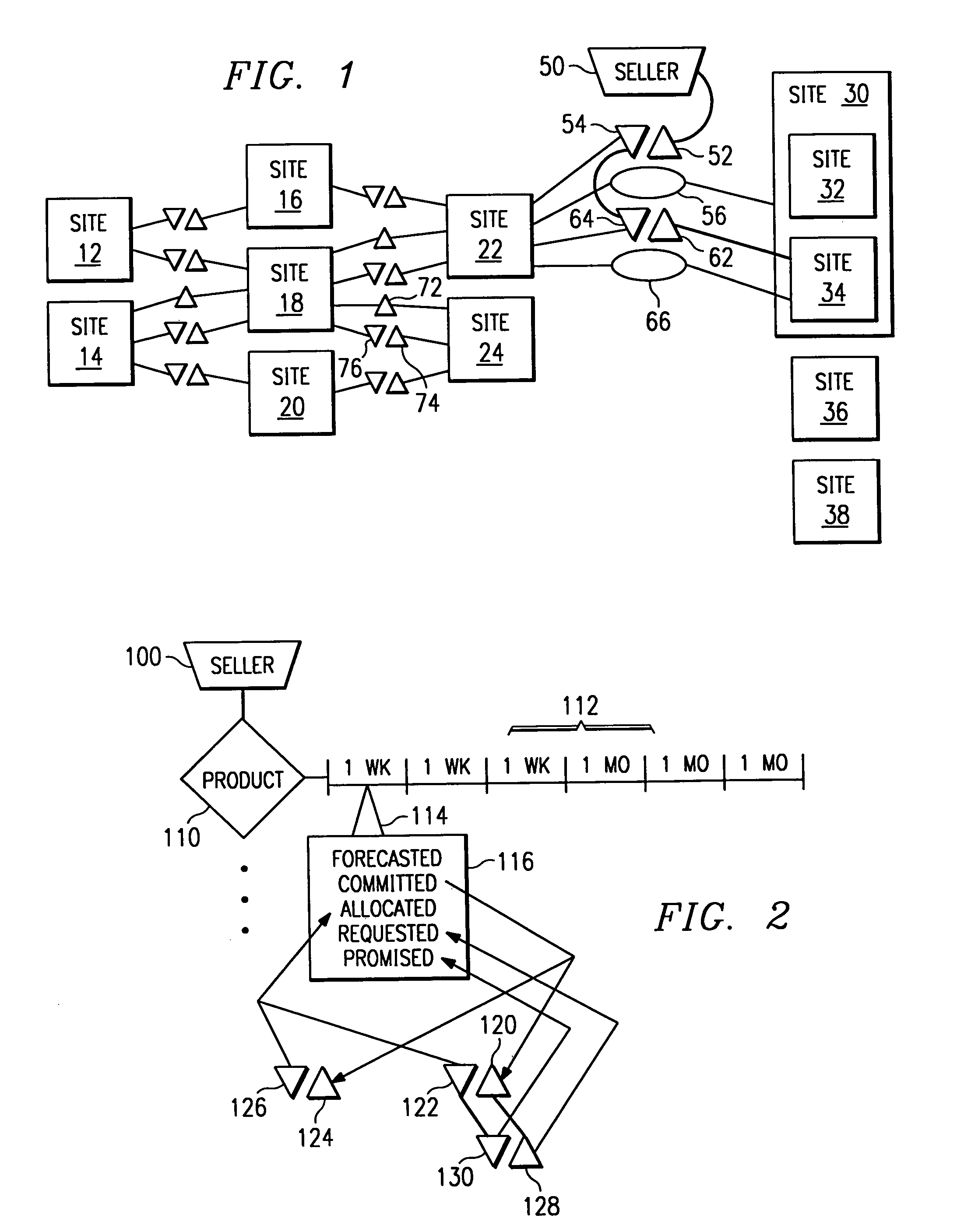

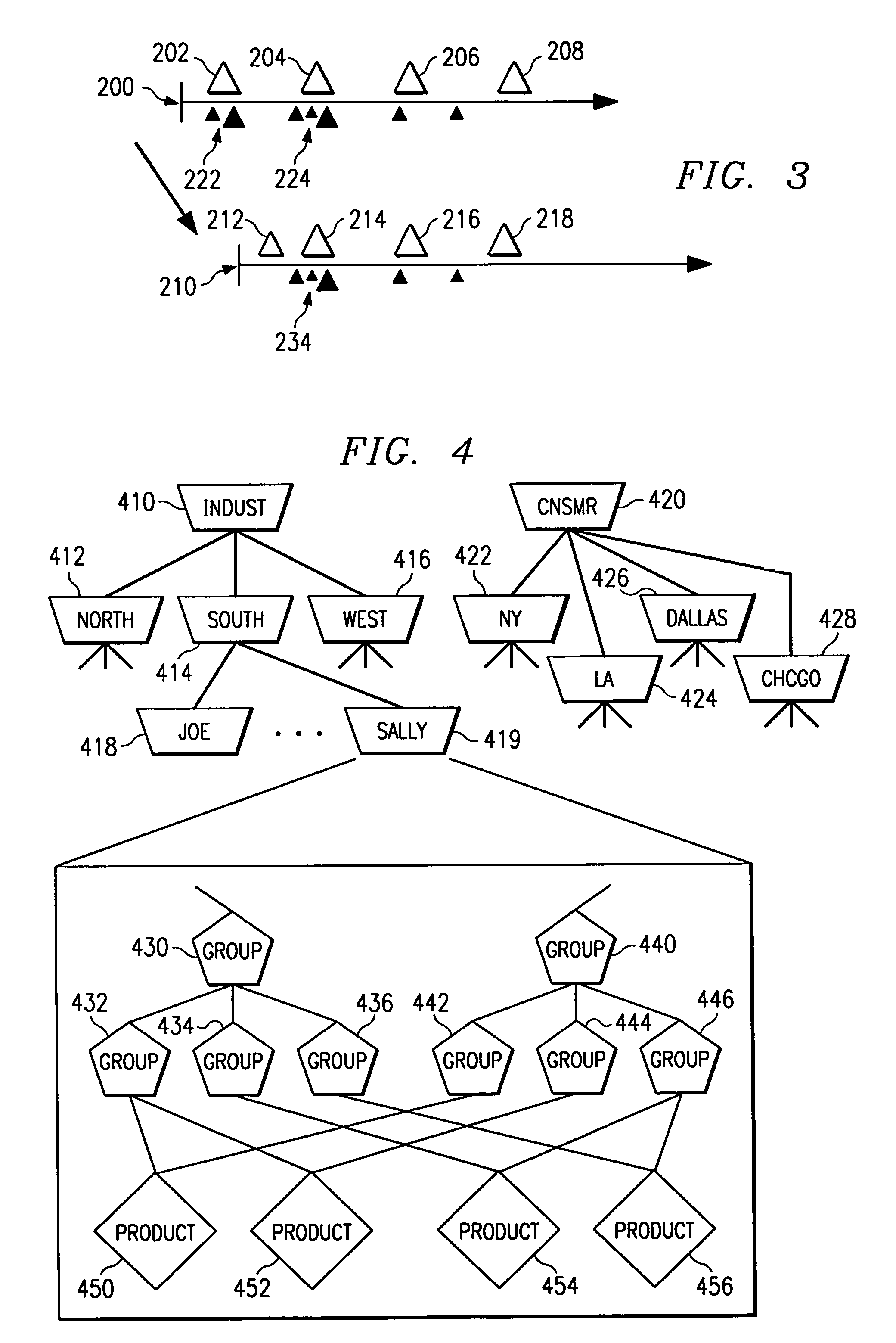

System and method for allocating manufactured products to sellers

InactiveUS7085729B1Eliminate and reduce disadvantageEliminate and reduce and problemCash registersResourcesSoftware systemGeneric Product

A software system is provided for managing available to promise (ATP) and making promises to fulfill customer requests. The software system includes a plurality of generic product models (600) each representing a generic product. Each generic product model (600) specifies one component of a plurality of possible components. A plurality of specific product models (602) each represent a specific product and each specify all components of the specific product. Each component specified by each specific product model (602) is specified by one of the generic product models (600) such that each specific product model (602) is related to a subset of the generic product models (600). A customer request matching a specific product then can be fulfilled by available-to-promise of the specific product or by available-to-promise of all related generic products. In addition, an organization in a seller hierarchy can retain product and designate first-come-first-served product. The organization also can define an ATP horizon to specify when forecasted product is actually available. Further, the organization can use an automatic allocation policy to allocate to members, and some forecast entries can be designated zero-ATP entries.

Owner:JDA SOFTWARE GROUP

Method and system to create products

Systems and methods for creating fully custom products from scratch without exclusive use of off-the-shelf or pre-specified components. A system for creating custom products includes an image capture device for capturing image data and / or measurement data of a user. A computer is communicatively coupled with the image capture device and configured to construct an anatomic model of the user based on the captured image data and / or measurement data. The computer provides a configurable product model and enables preview and automatic or user-guided customization of the product model. A display is communicatively coupled with the computer and displays the custom product model superimposed on the anatomic model or image data of the user. The computer is further configured to provide the customized product model to a manufacturer for manufacturing eyewear for the user in accordance with the customized product model. The manufacturing system is configured to interpret the product model and prepare instructions and control equipment for the manufacturing of the customized product.

Owner:BIS

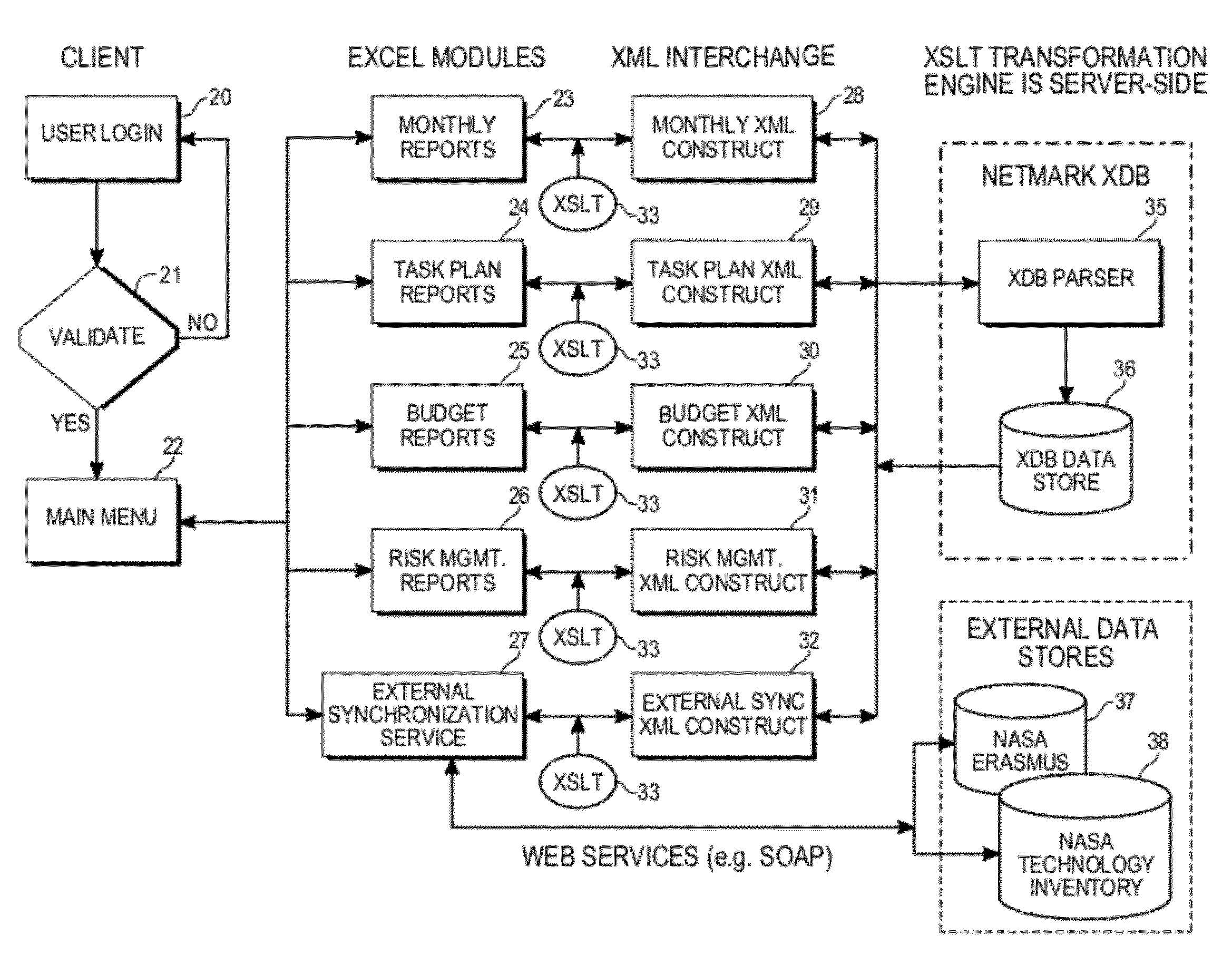

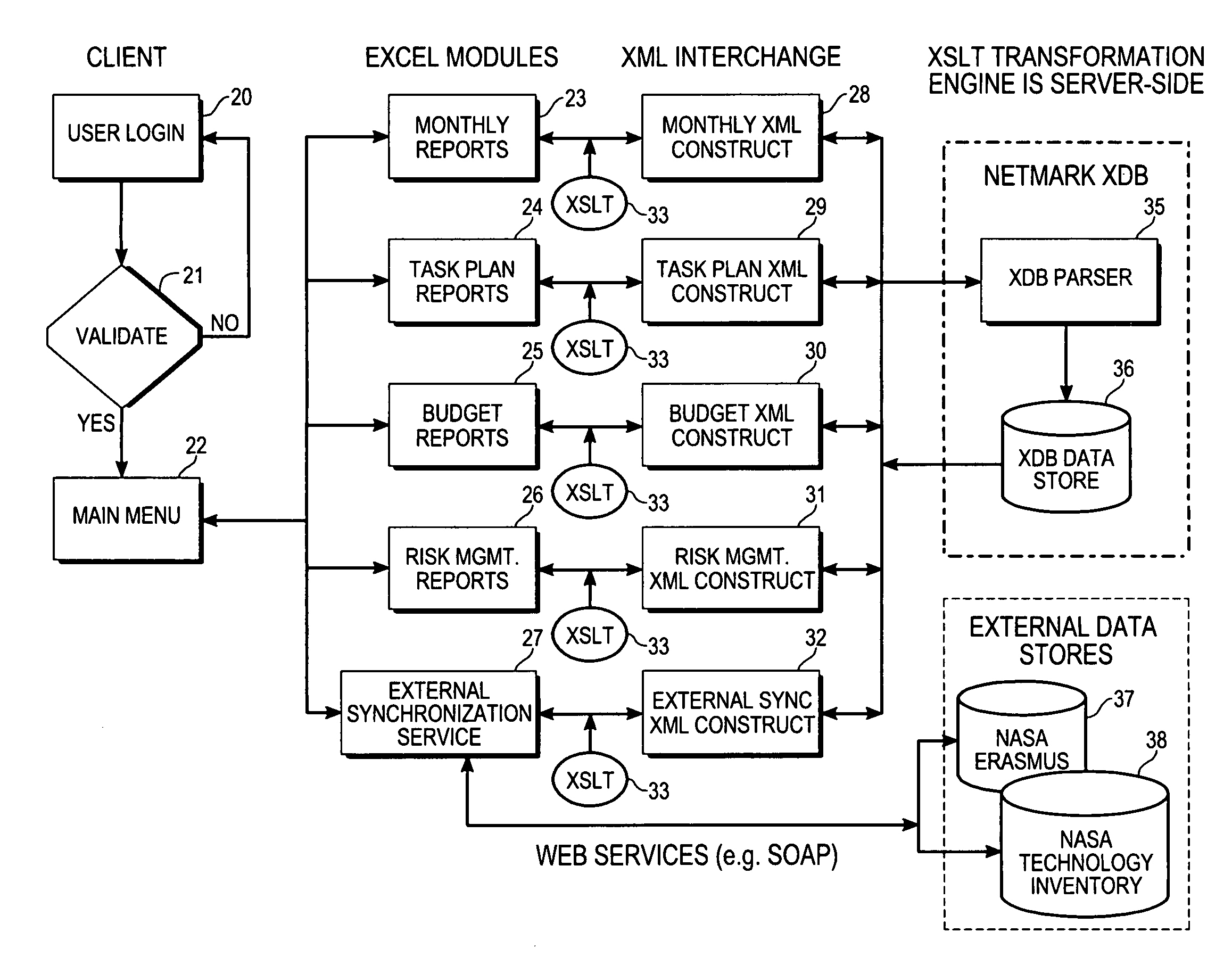

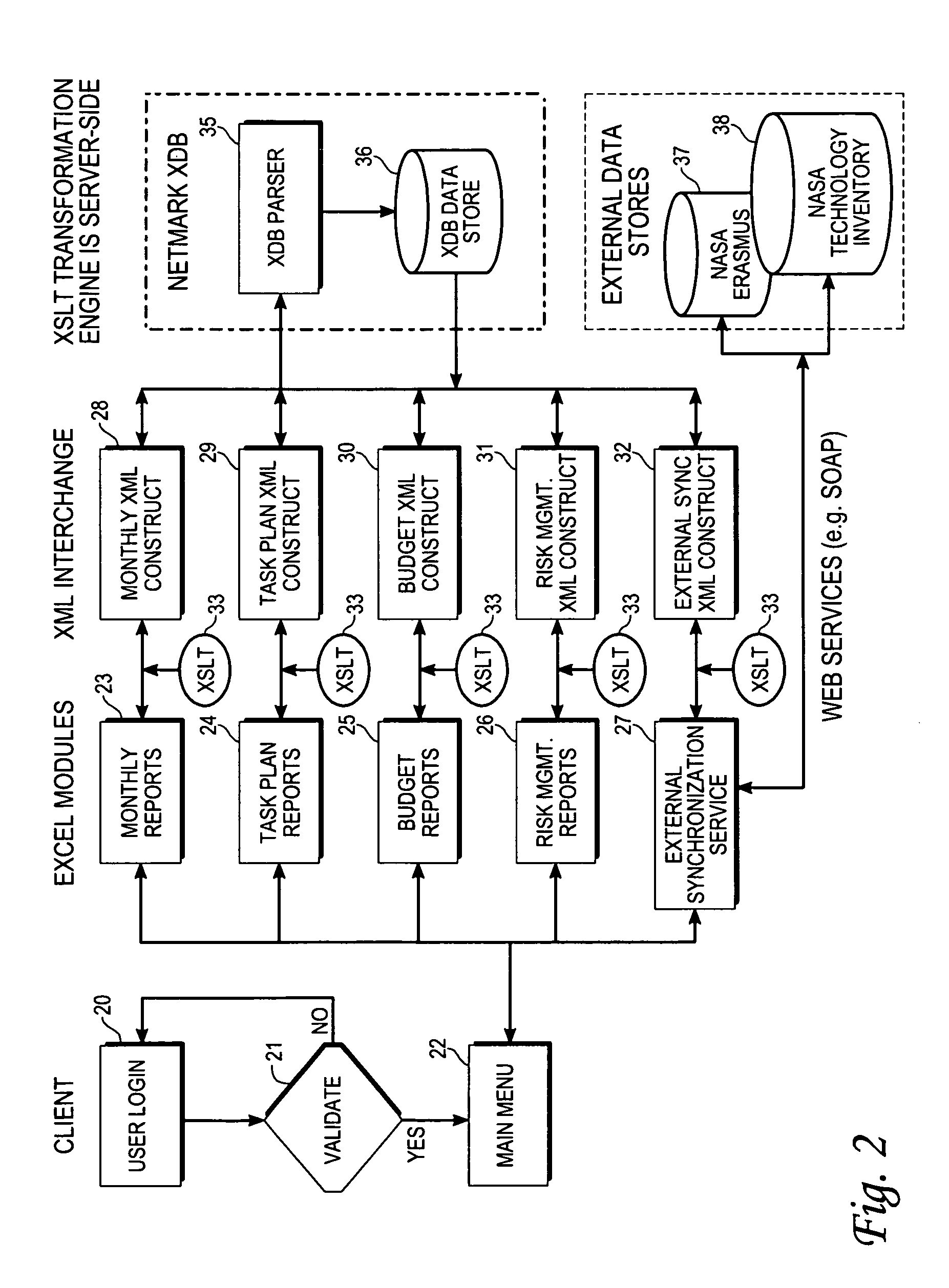

Enhanced project management tool

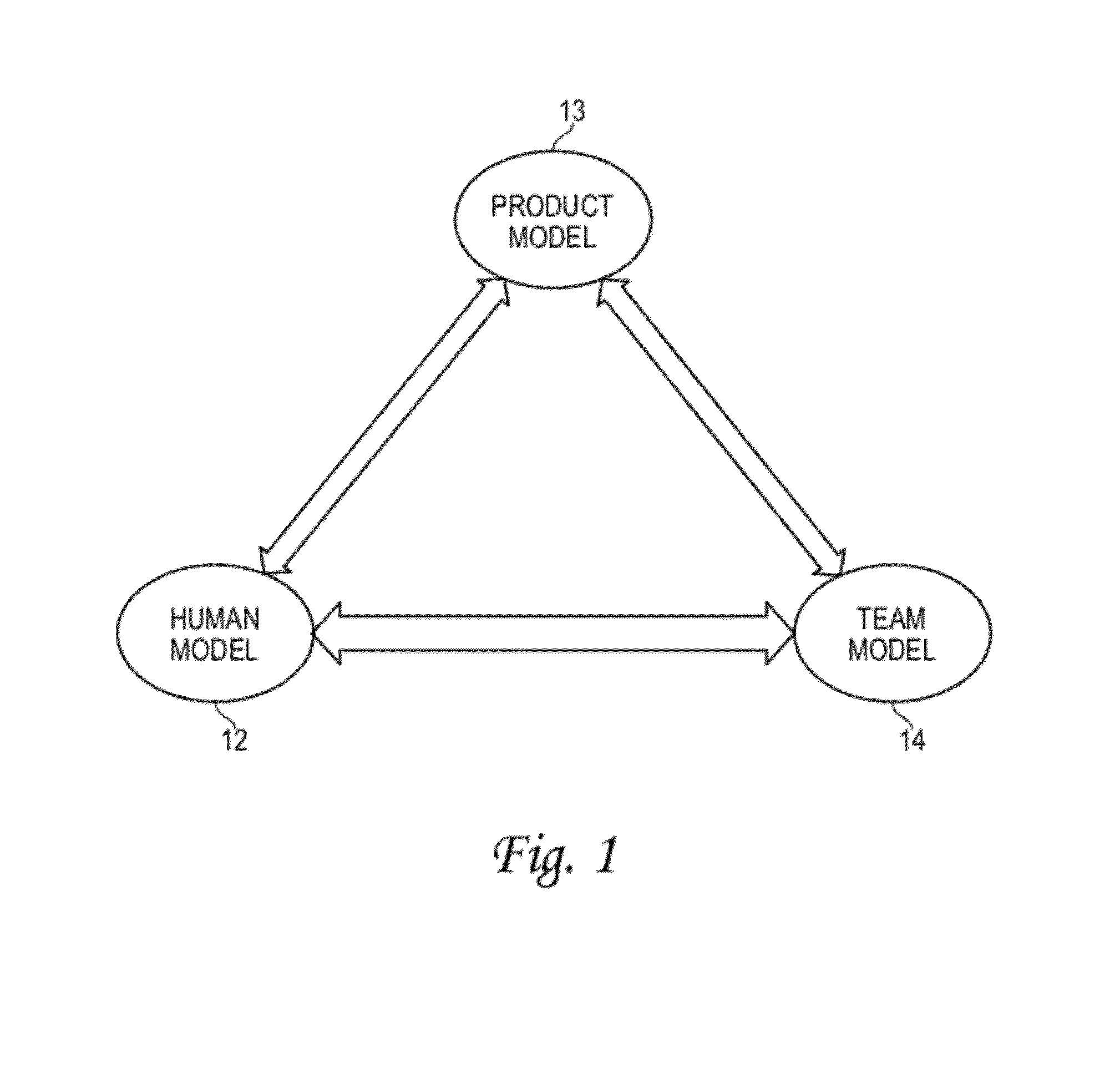

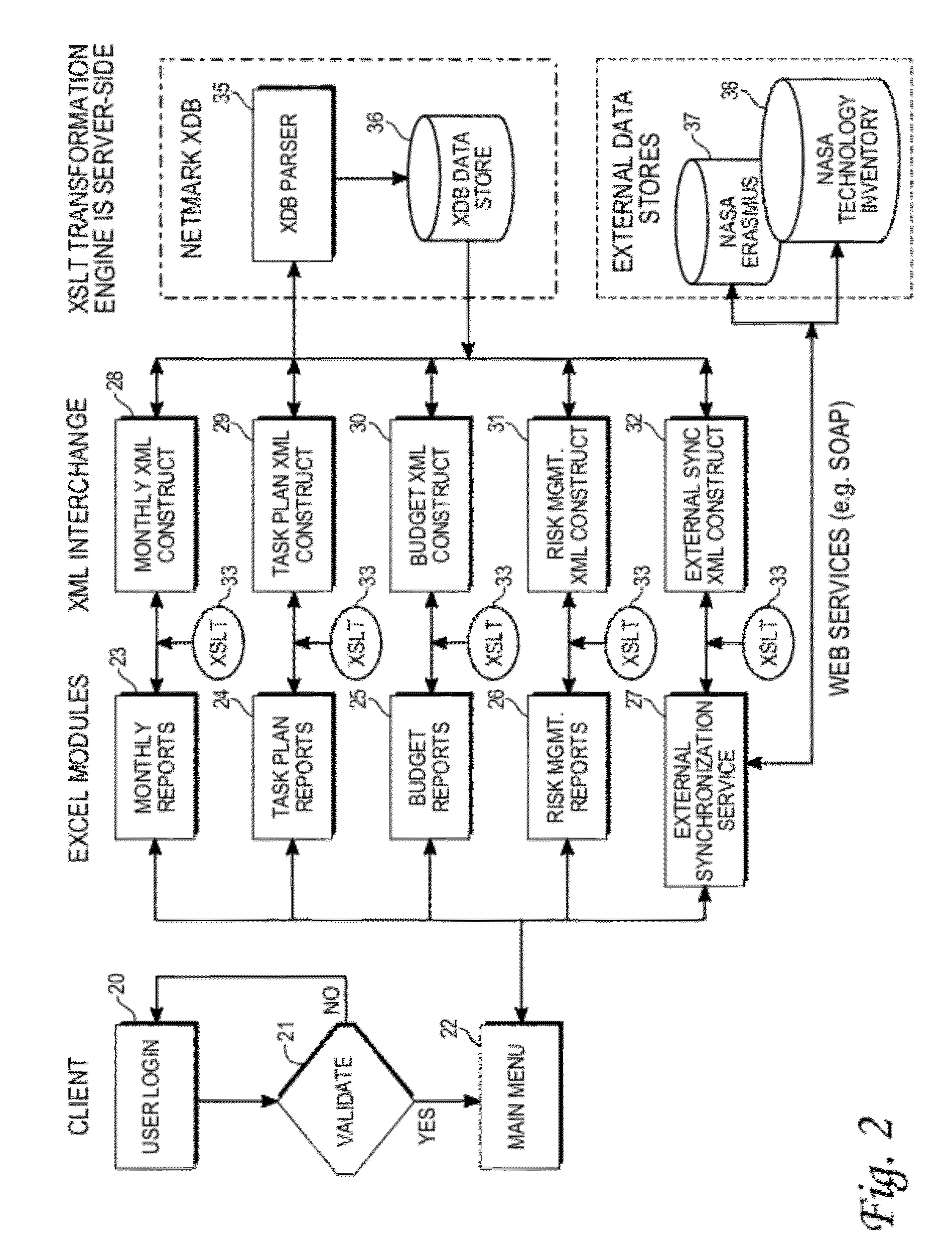

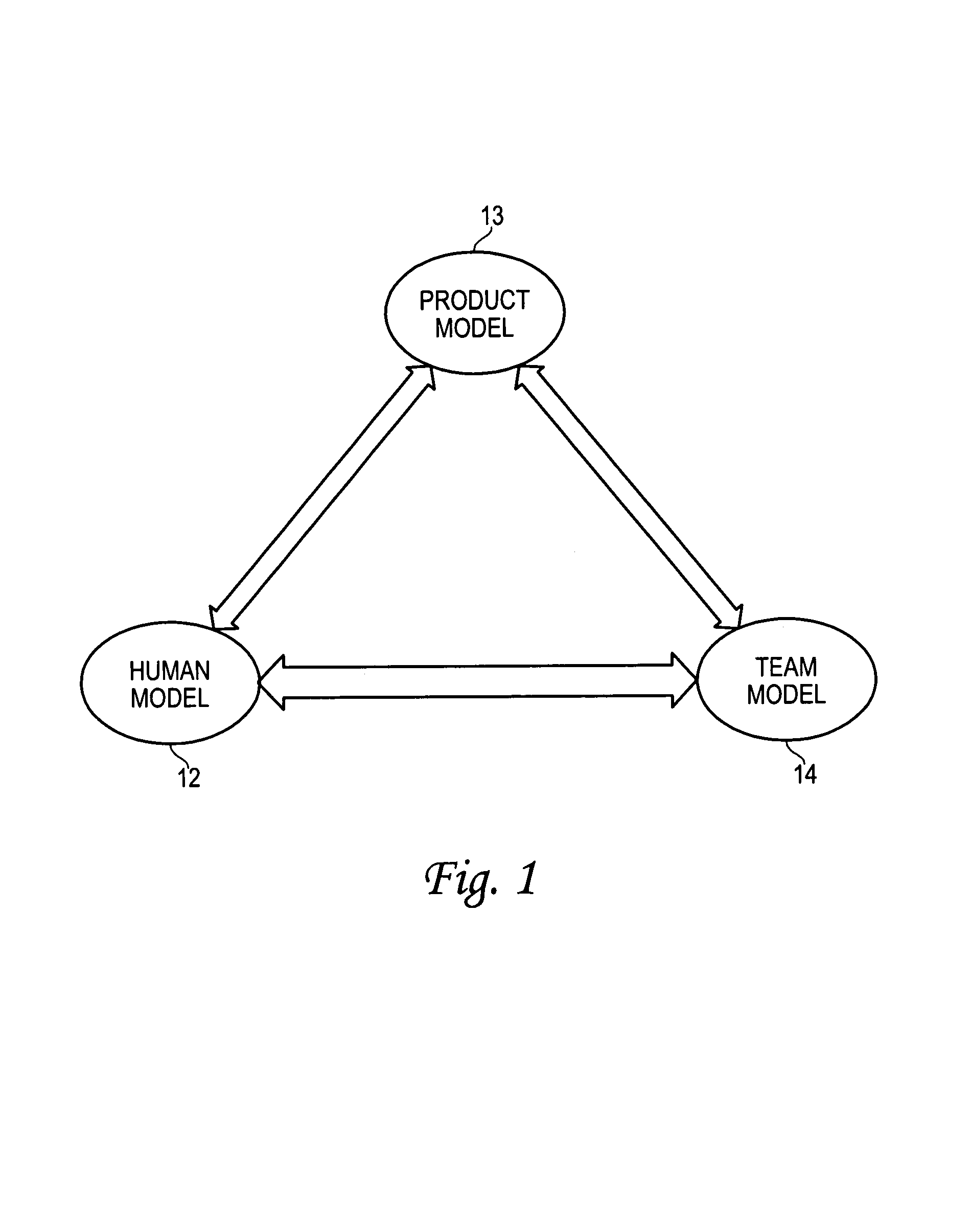

ActiveUS8224472B1Facilitates tool-to-tool (or database-to-database) queriesResourcesSpecial data processing applicationsProject analysisSkill sets

A system for managing a project that includes multiple tasks and a plurality of workers. Input information includes characterizations based upon a human model, a team model and a product model. Periodic reports, such as one or more of a monthly report, a task plan report, a schedule report, a budget report and a risk management report, are generated and made available for display or further analysis or collection into a customized report template. An extensible database allows searching for information based upon context and upon content. Seven different types of project risks are addressed, including non-availability of required skill mix of workers. The system can be configured to exchange data and results with corresponding portions of similar project analyses, and to provide user-specific access to specified information.

Owner:NASA

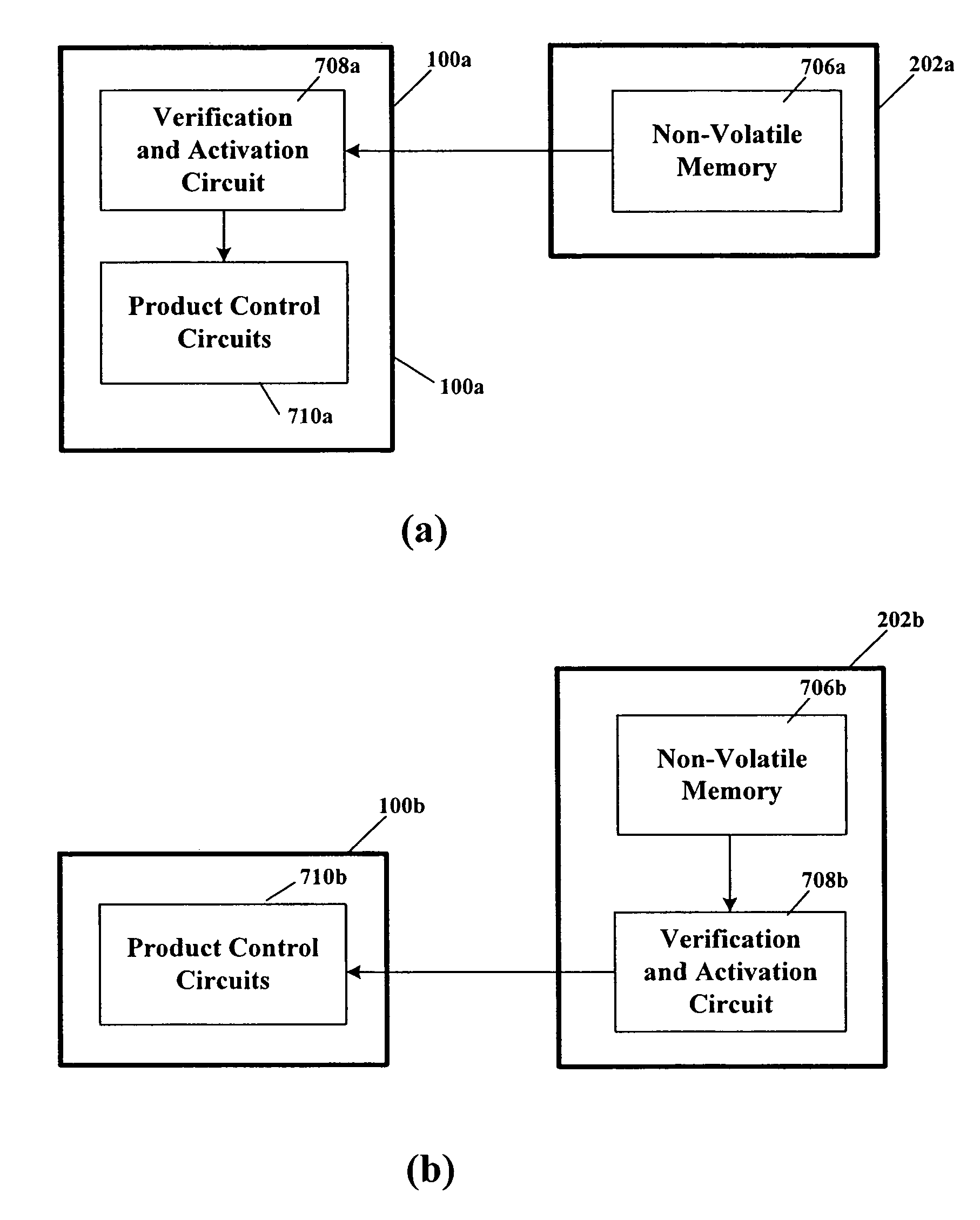

Product verification and activation system, method and apparatus

InactiveUS20050240498A1Unauthorized useAnimal feeding devicesUser identity/authority verificationOptical scannersElectrical connection

A verification and activation module for a product remembers where the product was purchased, the purchase date, purchase price, length of warranty, name and address of purchasing consumer, etc. The verification and activation module may enable operation of the product, enable operation of a replacement product and disable a defective product that has been replaced under warranty or after an out of warranty service exchange. It may be removable from the product and may be packed separately or installed in the product. It may be programmed at the time of product purchase using wireless means, e.g., radio frequency identification (RFID), infrared (IRD), or by direct electrical connection to a programmer at the point of sale. An optical scanner at the point of sale may be used to scan information from a UPC label on the product package and either through the wireless or direct electrical connection can program the verification and activation module from the scanned UPC and other information and additional information, e.g., store name and location, purchase price, purchase date, serial number of product, manufacturer, product model number, warranty duration, consumer name, address and other desired information. The verification and activation module may include a non-volatile memory. Warranty, repair and replacement histories may be retained for later retrieval in the non-volatile memory of the verification and activation module. The verification and activation module may also be used for security purposes to render the product inoperable if a certain security condition is not met.

Owner:THALER ARNOLD

Using context to update product models (as amended)

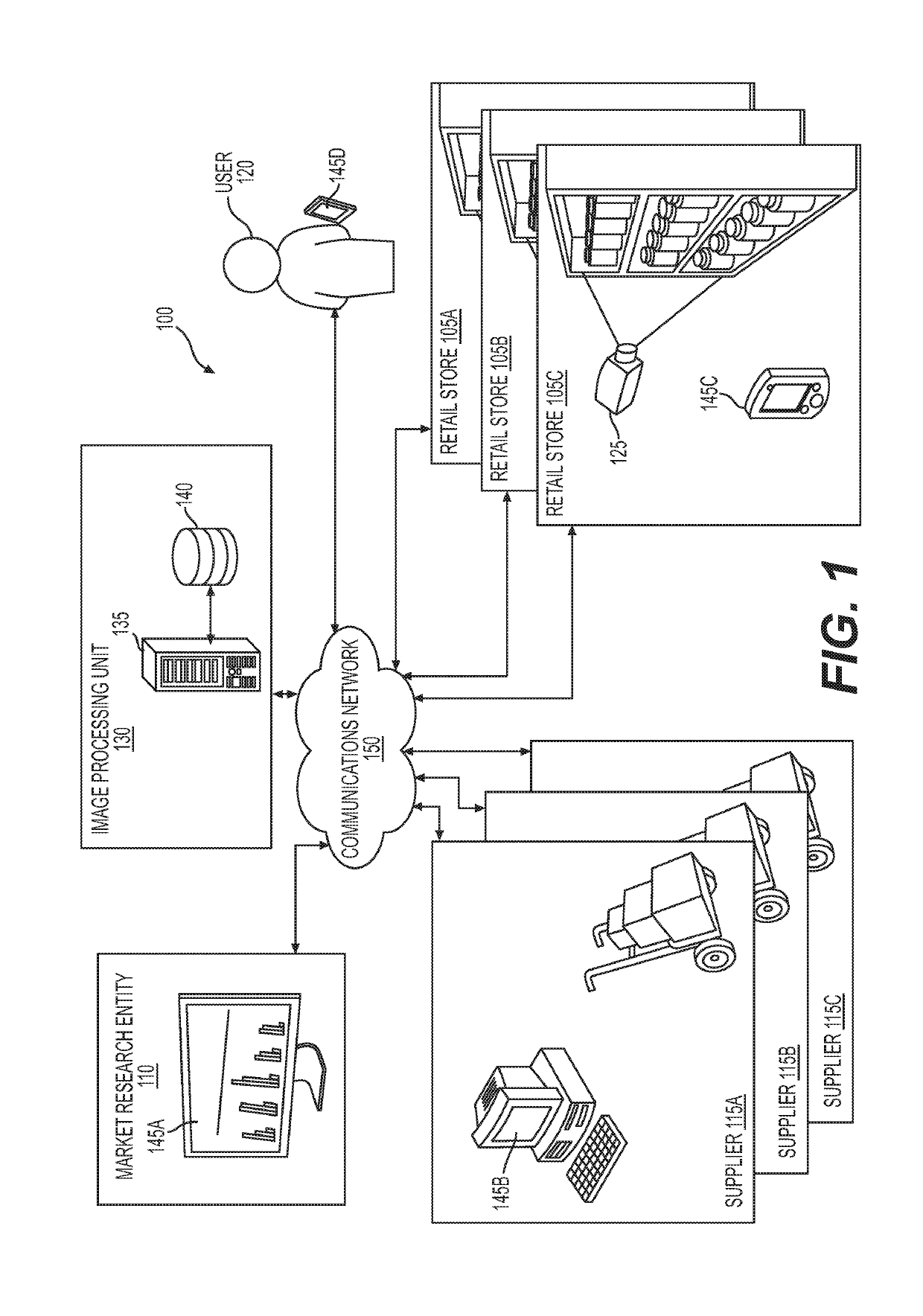

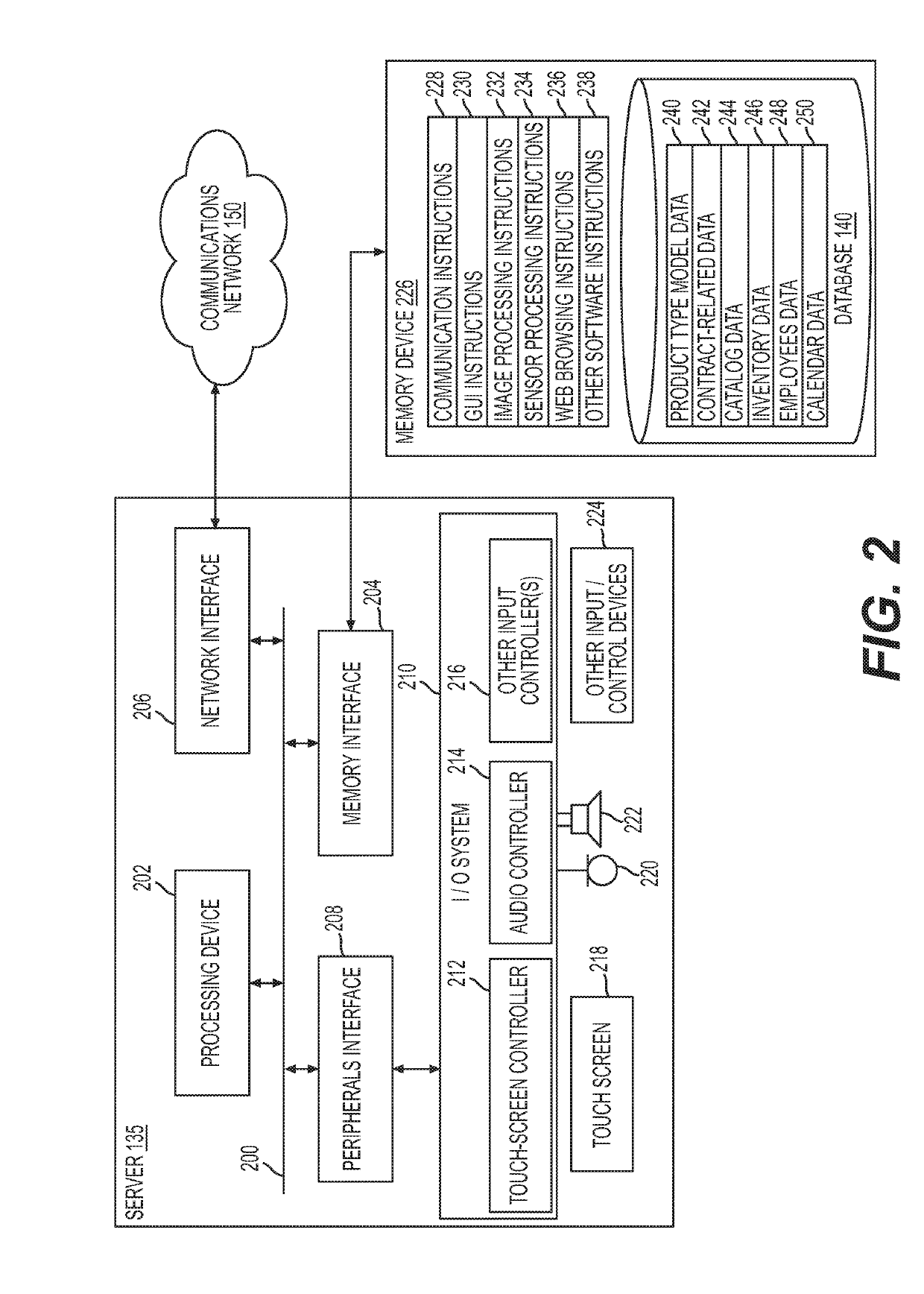

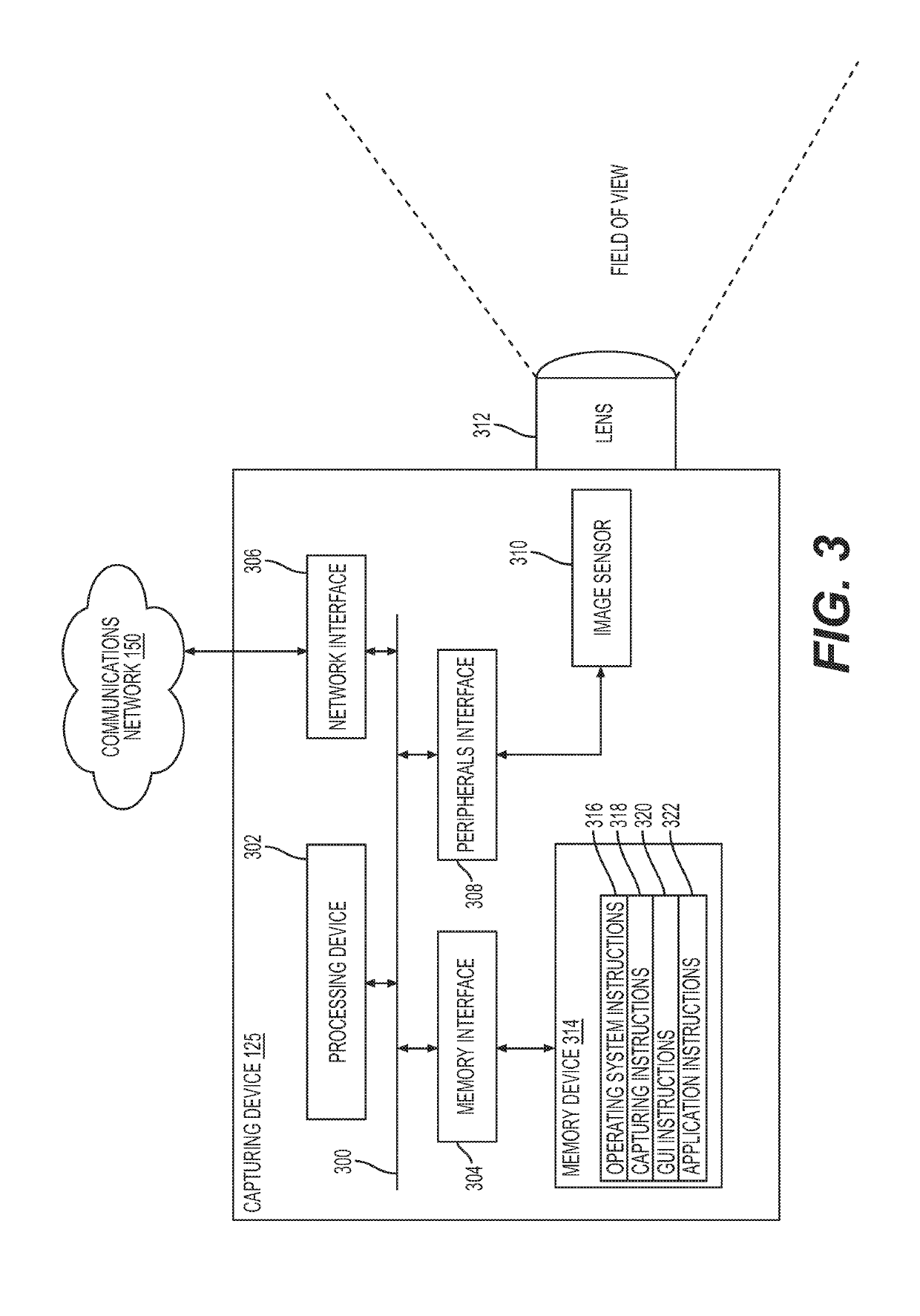

ActiveUS20190213212A1Increasing future saleImage enhancementImage analysisImaging analysisProduct base

A system for processing images captured in a retail store is provided. The system may include a processor configured to: access a database storing a group of product models; receive an image depicting at least part of a store shelf having a plurality of products of a same type displayed thereon; analyze the image and determine a first candidate type of the products based on the group of product models and the image analysis; determine a first confidence level associated with the first candidate type; when the first confidence level is below a confidence threshold, determine a second candidate type of the products using contextual information; determine a second confidence level associated with the determined second candidate type of the plurality of products; and when the second confidence level is above the confidence threshold, initiate an action to update the group of product models stored in the database.

Owner:TRAX TECH SOLUTIONS

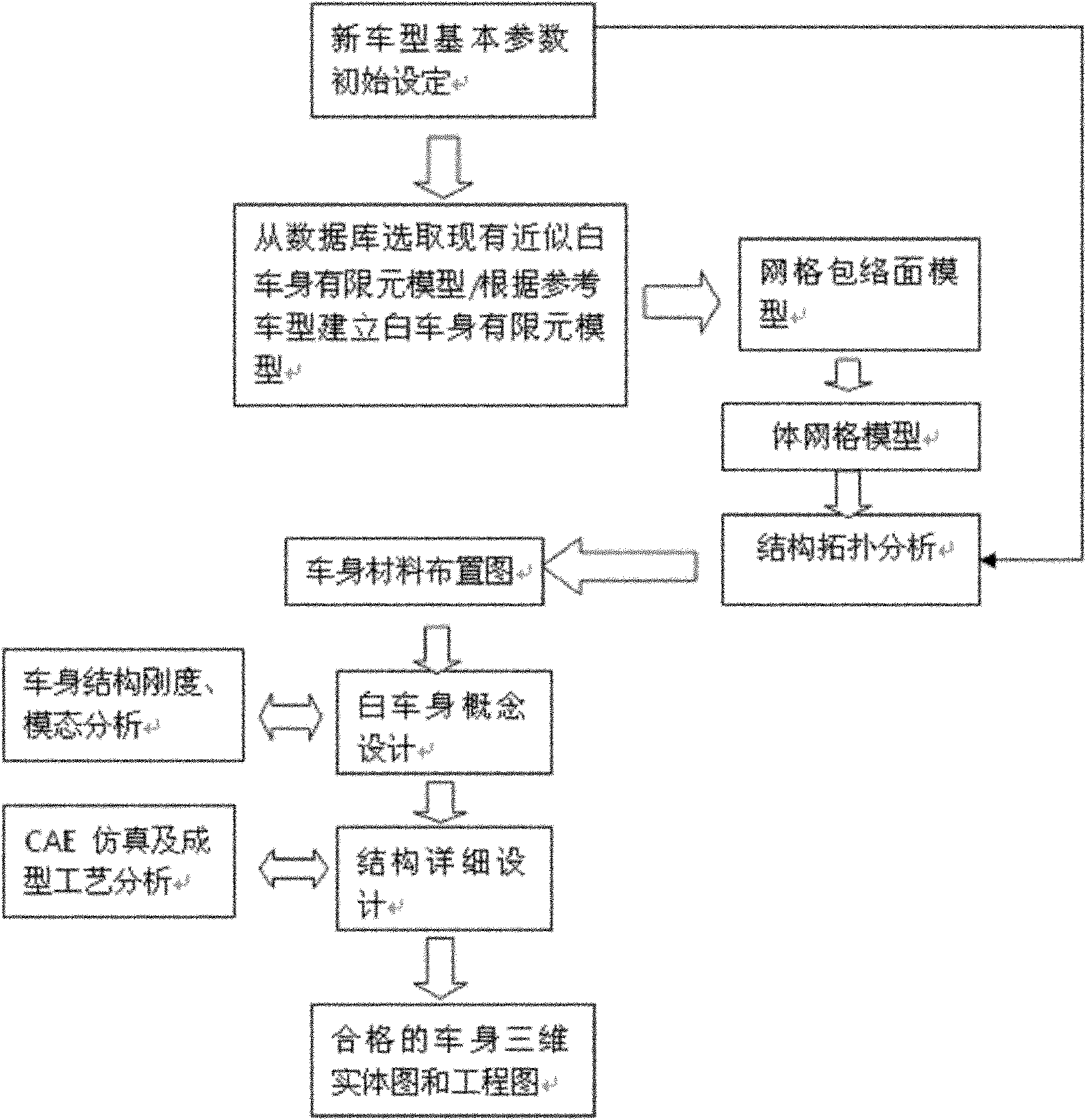

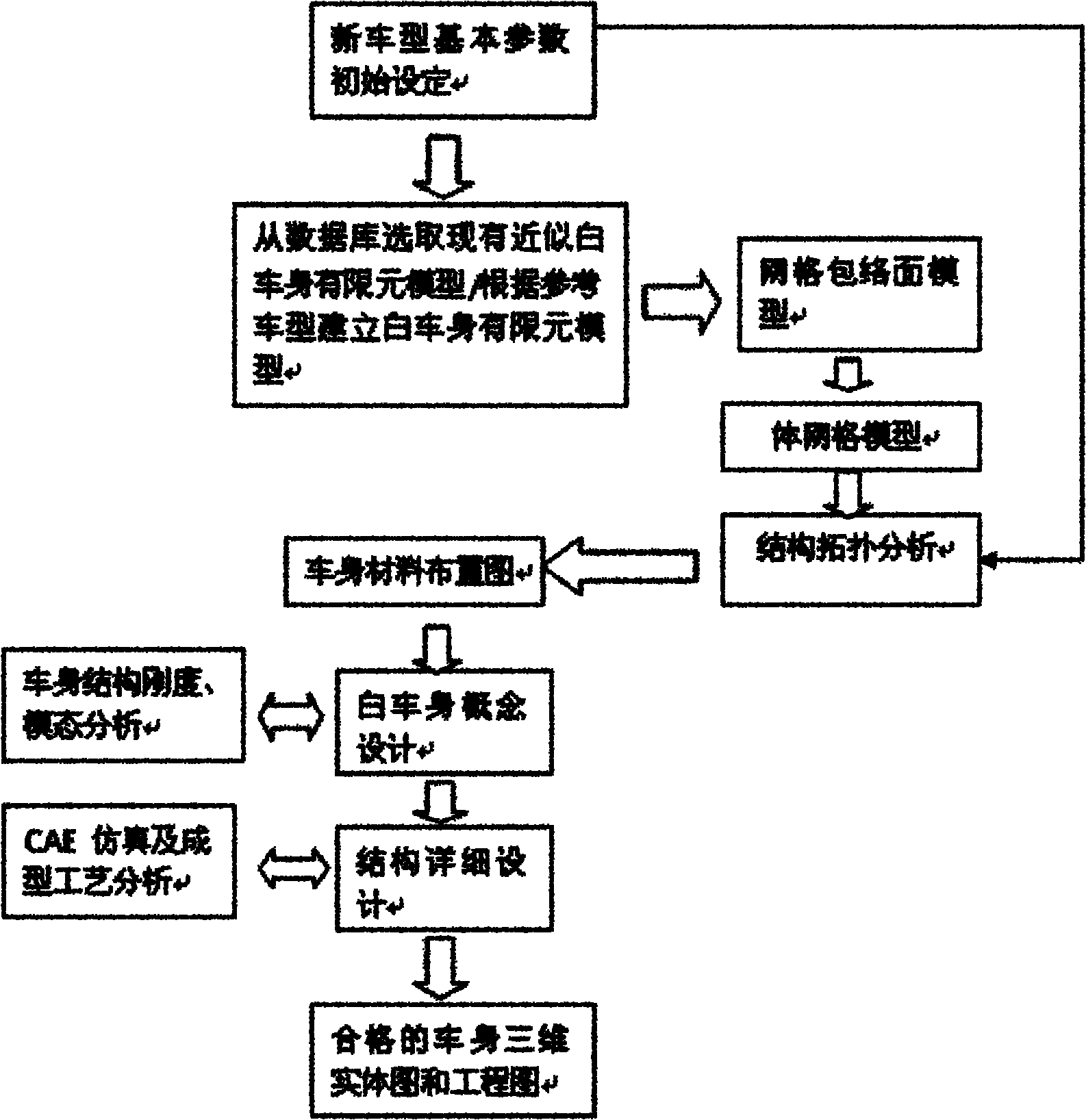

Method for designing automobile body structure layout

InactiveCN102012958AImprove guidanceShorten the development cycleAerodynamics improvementSpecial data processing applicationsElement modelTopology optimization

The invention relates to a method for designing automobile body structure layout. The method comprises the following steps of: 1) initially setting the parameters of a new type automobile, 2) choosing the white automobile body finite element models having similar structures and sizes, or directly building a white automobile body finite element model, 3) generating a grid enveloped model according to the white automobile body finite element model, 4) generating a body grid model according to the grid enveloped model, 5) topologically optimizing and analyzing according to a target parameter based on the body grid model, 6) according to an analyzed result and drawing an automobile body material layout diagram, 7) designing conception according to the layout diagram, and 8) designing the layout structure in detail according to the data of the conception design, performing simulating analysis of strength, NVH and impact performance CAE and formability process analysis according to the data of the detailed design of the layout structure, and modifying so as to acquire a three-dimensional digitized product model fit for volume production. The automobile body structure layout has the advantages of shortened developing period and lowered researching and developing cost.

Owner:CHERY AUTOMOBILE CO LTD

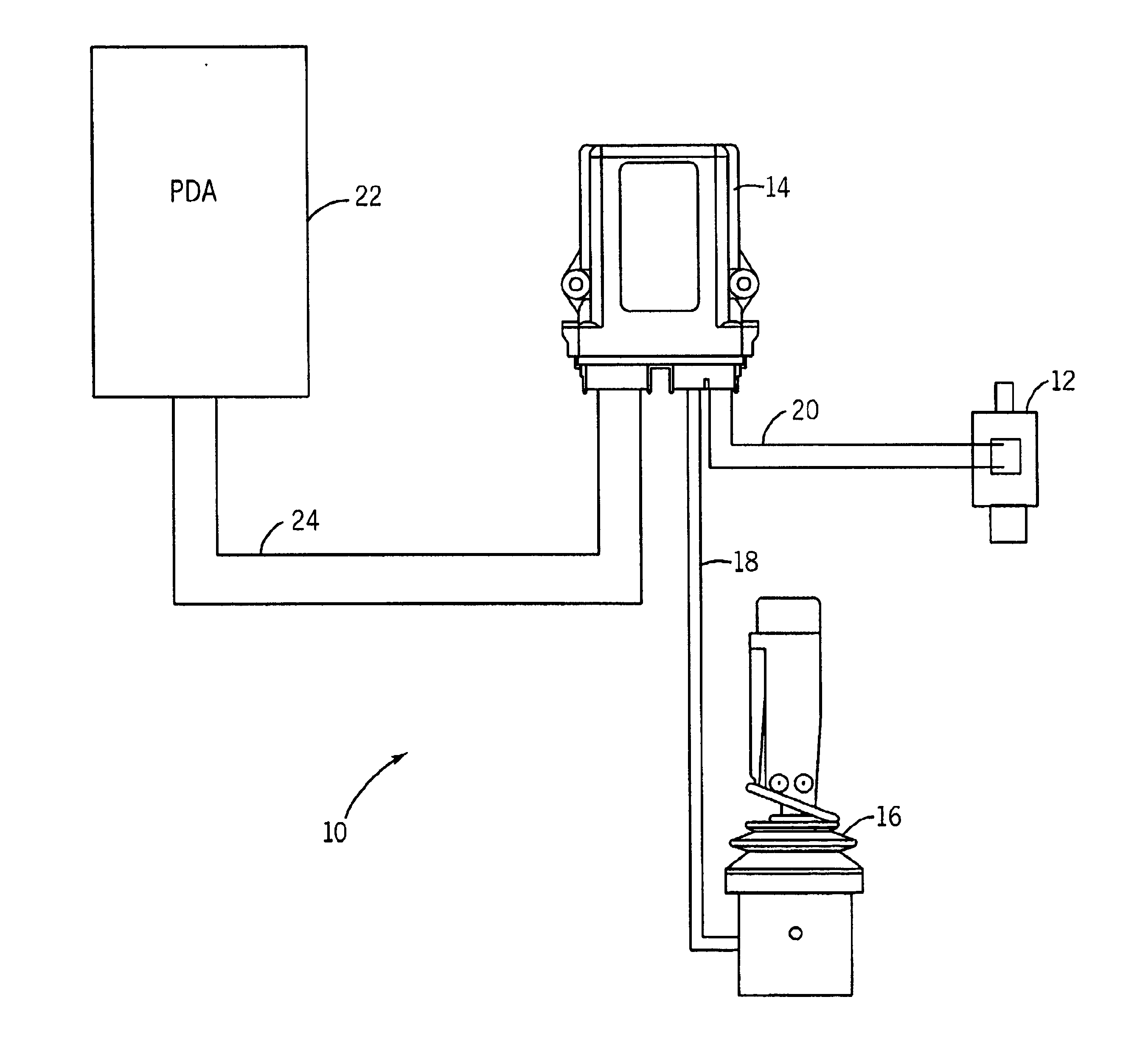

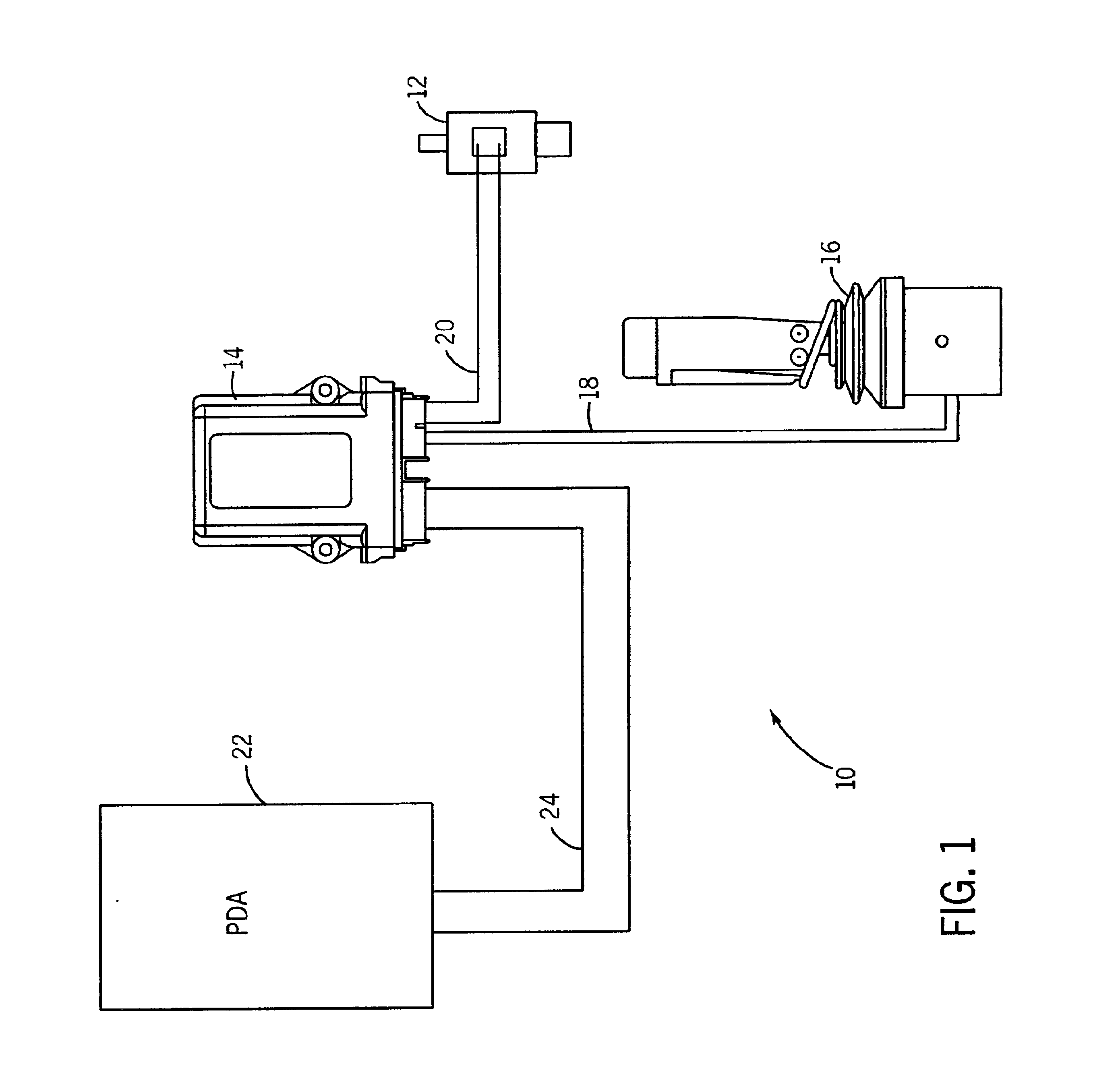

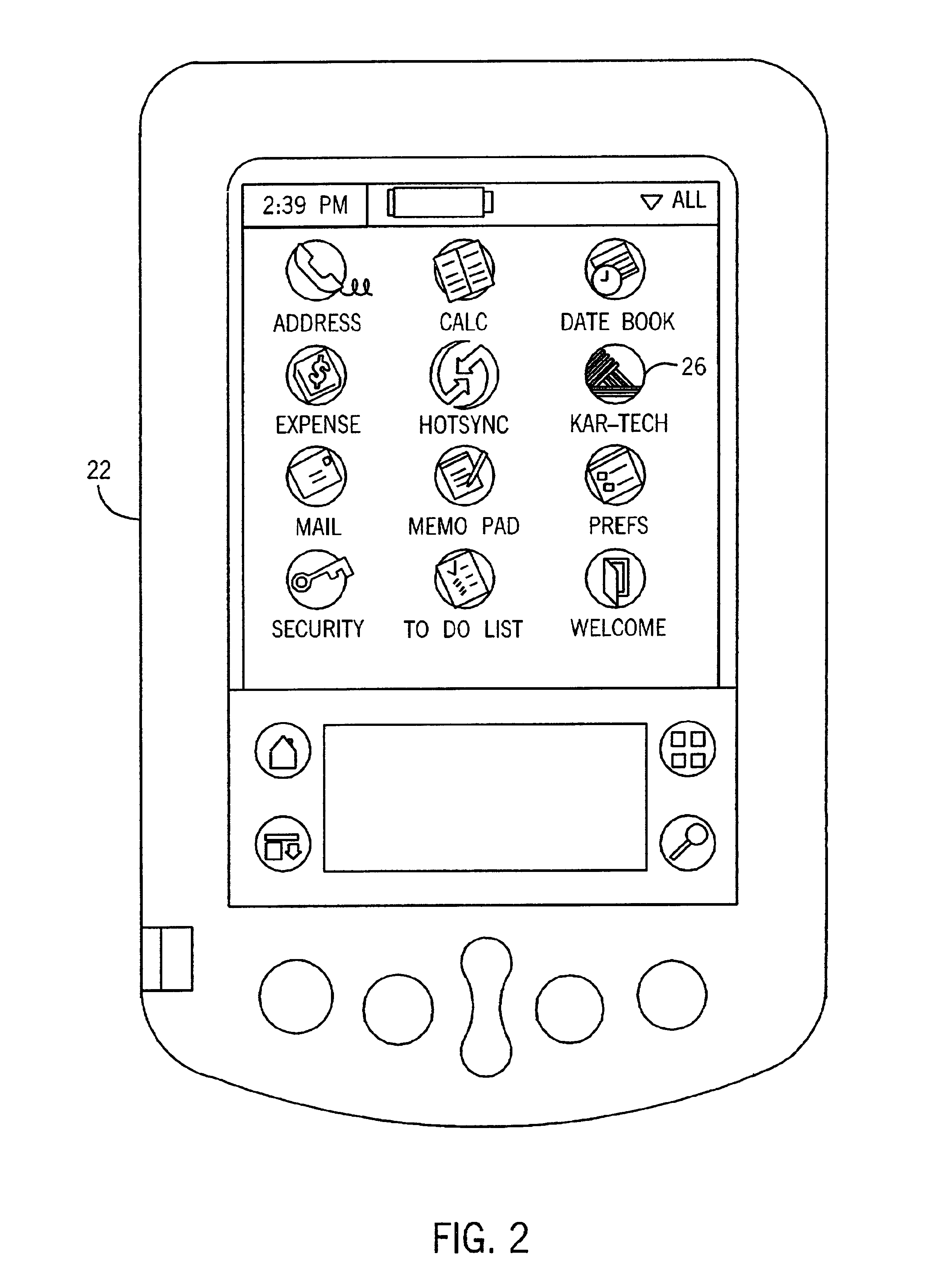

PDA monitoring and diagnostic system for industrial control

InactiveUS6907302B2OptimizationEasy to configureComputer controlSimulator controlComputer moduleOutput device

A system and software for controlling output devices used in association with machinery is disclosed. The system includes a control module which may be connected to a personal digital assistant (PDA), personal pocket PC, personal computer, organizer, cell phone, or other data storage device. The data storage device has programmed within it particularized manufacturer information for various input devices and output devices available on the market. The system allows an operator to select a particular manufacturer, as well as product information, including product model number and operating parameters. The machine can then be calibrated such that the input device being used, as well as the output device manufacturer information, is used to dynamically adjust, monitor or perform diagnostics on the machine. The system allows for on-site calibration of the machine controllers. The invention contemplates the use of any output device used with the operation of the machine or any input device used to input information or operation instructions to the machine. The software may be programmed into any personal electronic device or may be connected to a driver or controller associated with the machine to be regulated.

Owner:KAR TECH

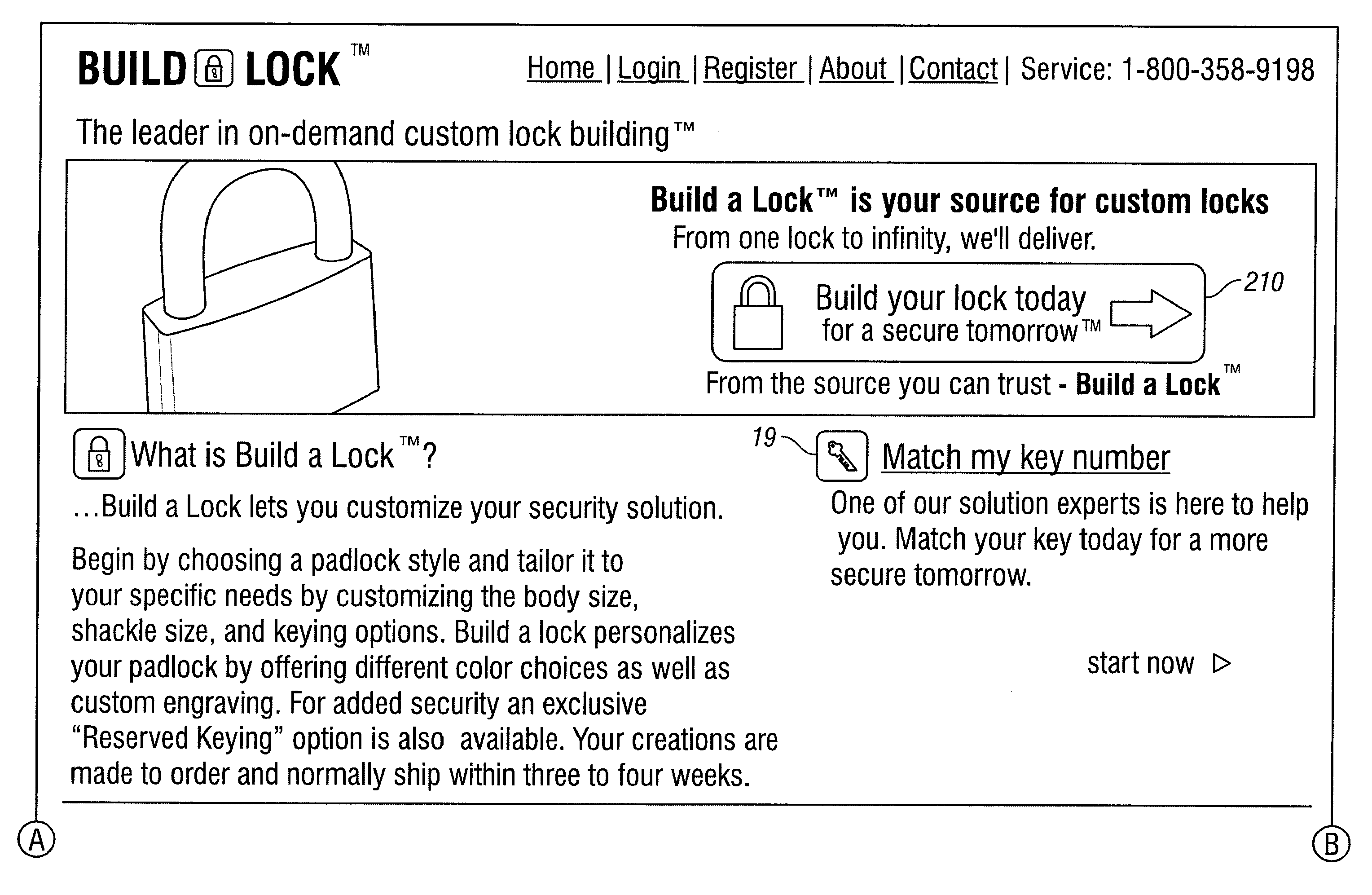

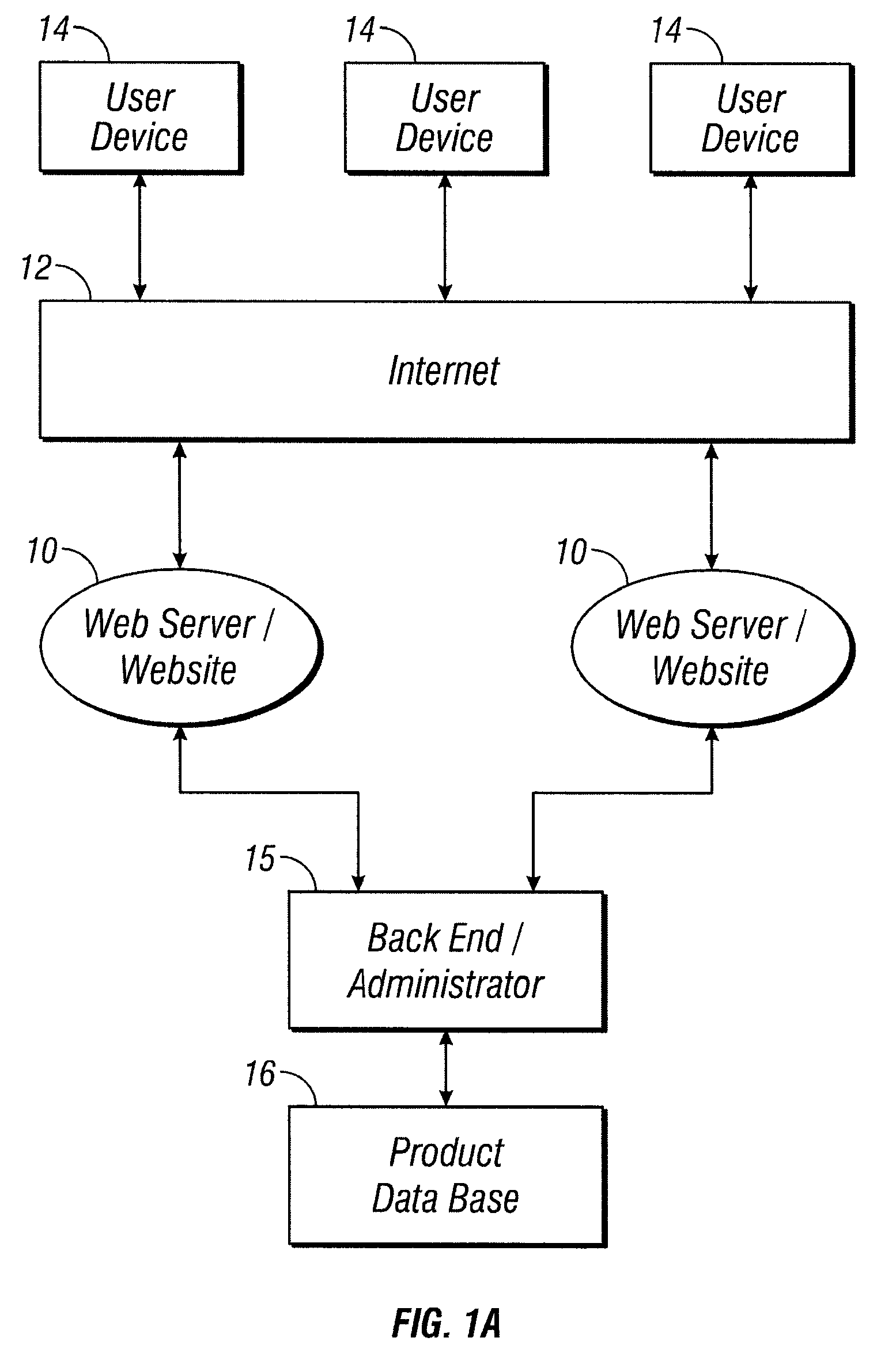

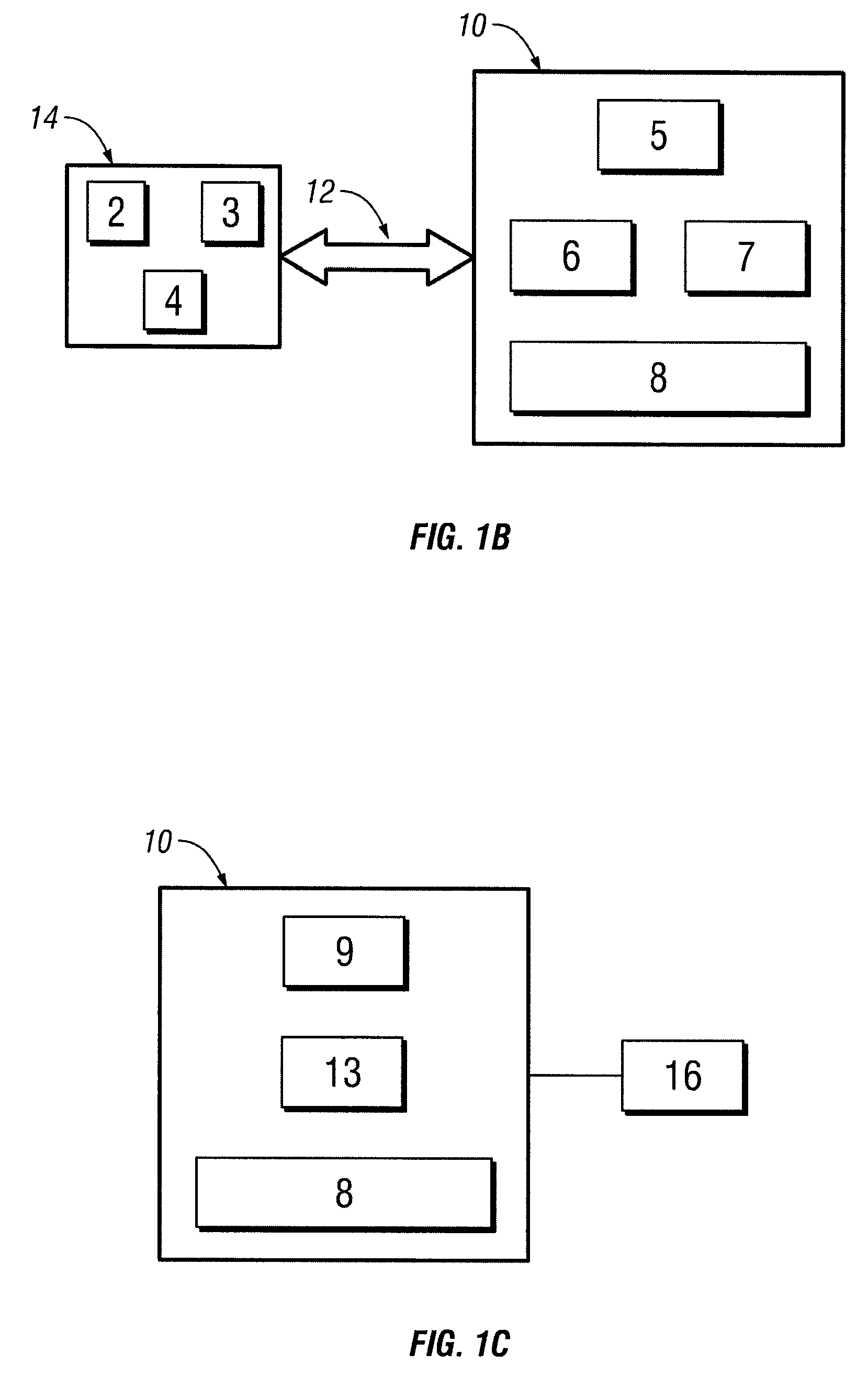

Online ordering system and method for keyed devices

ActiveUS20090271295A1Easy to orderCommerceInput/output processes for data processingProduct orderUser input

An online product ordering system first displays images of different product categories, such as different types of padlocks, and then displays all product models available in a category when the user clicks on a selected category image. The user selects a product model and then customizes various aspects of the selected model. In the case of a padlock, the user can select a shackle type and bumper type from available options, with images of each option displayed to the user for selection purposes, and may order a customized plate with user entered text or other indicia. In the case of a padlock, the user may enter their existing key number and the padlock can be customized to open with the user's existing key.

Owner:HODGE PRODS

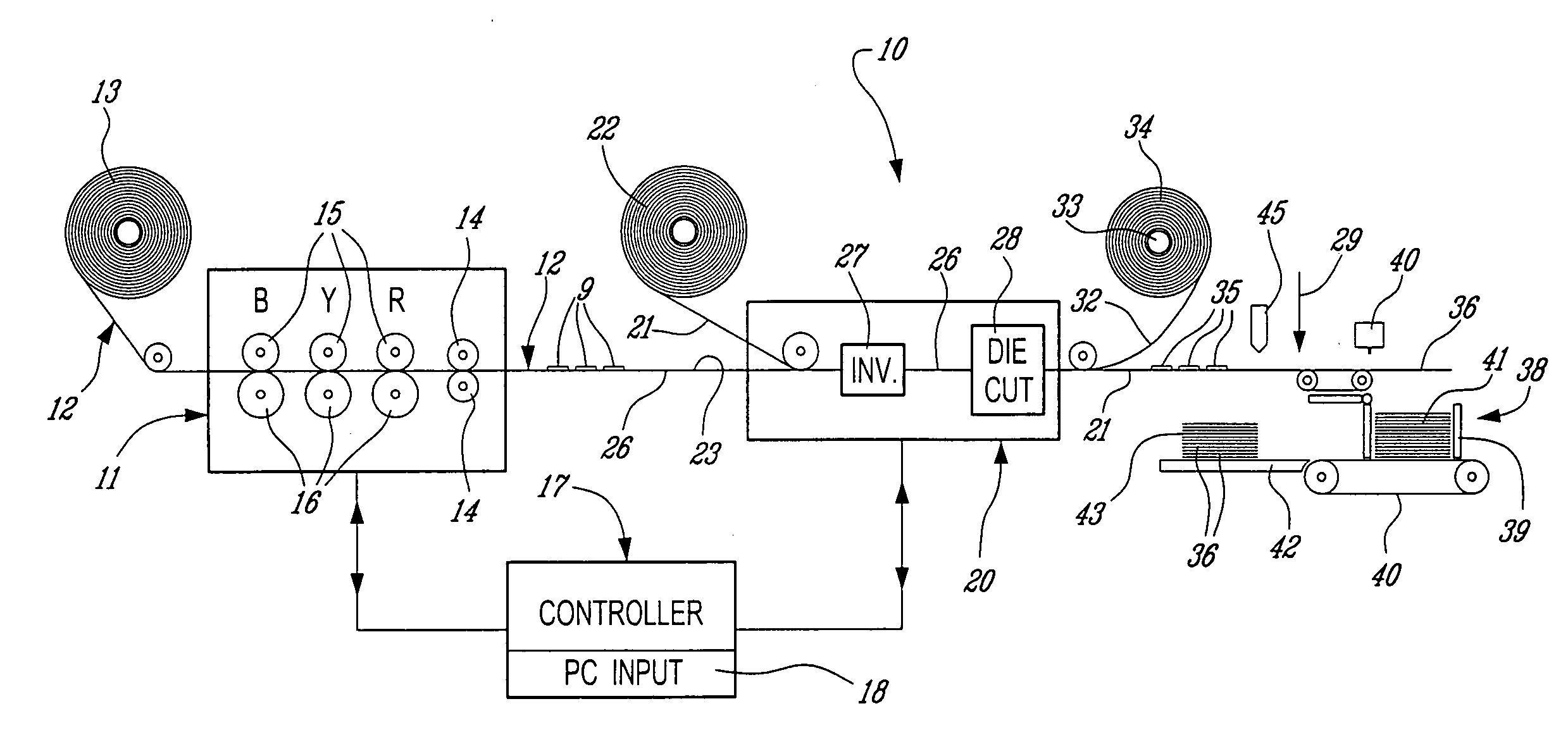

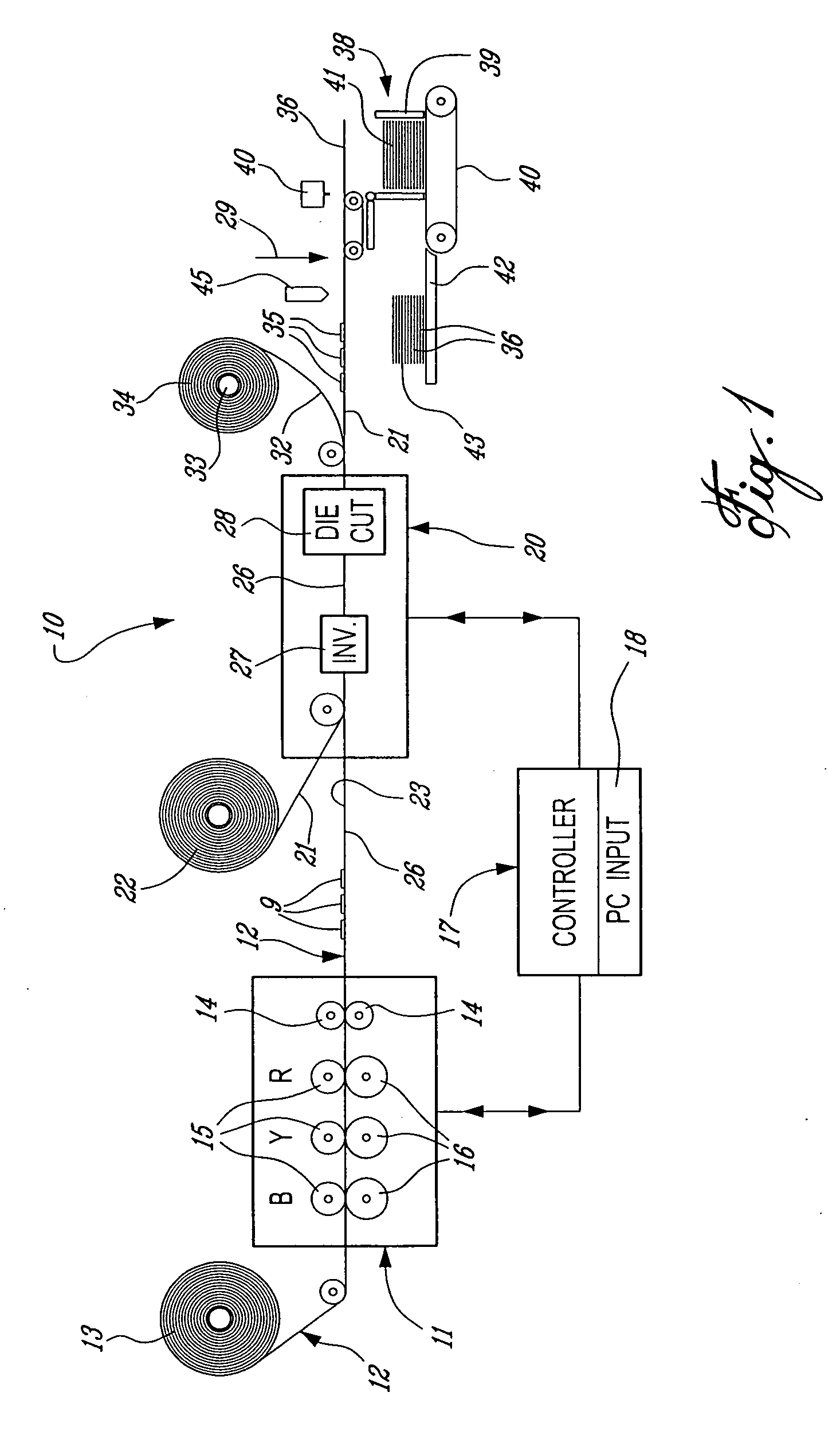

Method and system for manufacturing label kits comprised of carrier sheets having labels of specific shape removably retained thereon

InactiveUS20060233995A1Improve efficiencyStampsLamination ancillary operationsComputer printingControl data

A method and a system for the manufacture of label kits is described. Each kit comprises a one or more of carrier sheets having one or more labels of specific shape and containing specific information associated with a specific product or parts thereof on which they are to be affixed. The labels have an adhesive backing removably retained on a surface of the carrier sheet. The user person that applies the labels to the specific product, or parts thereof, does not have to go through a selection process in determining which of one or more labels should be applied to a single part of the specific product. The kit overcomes this selection process and provides error-proofing and improvements in the efficiency of current assembly processes where specific products vary along an assembly line requiring different labels applied from one assembly to the next, such as in the assembly of automotive vehicles. Parts or assemblies require differing language and content on labels depending on the country or region of shipment. Varying product models or option content requires different labels from part to part or assembly to assembly. The system uses a digital printer and a laminator die-cutting machine which is computer controlled with the data being automatically printed and labels automatically cut into a web whereby to form detachable labels, some having a UV protected clear or opaque synthetic or paper surface material face sheet. The carrier sheets are cut from the web and individually place or stacked into kits or piles to form label kits containing a predetermined number of such labels associated with a specific product or part with the carrier sheets potentially containing a tracking code identifying the specific kit to the product.

Owner:DURAMARK TECH INC

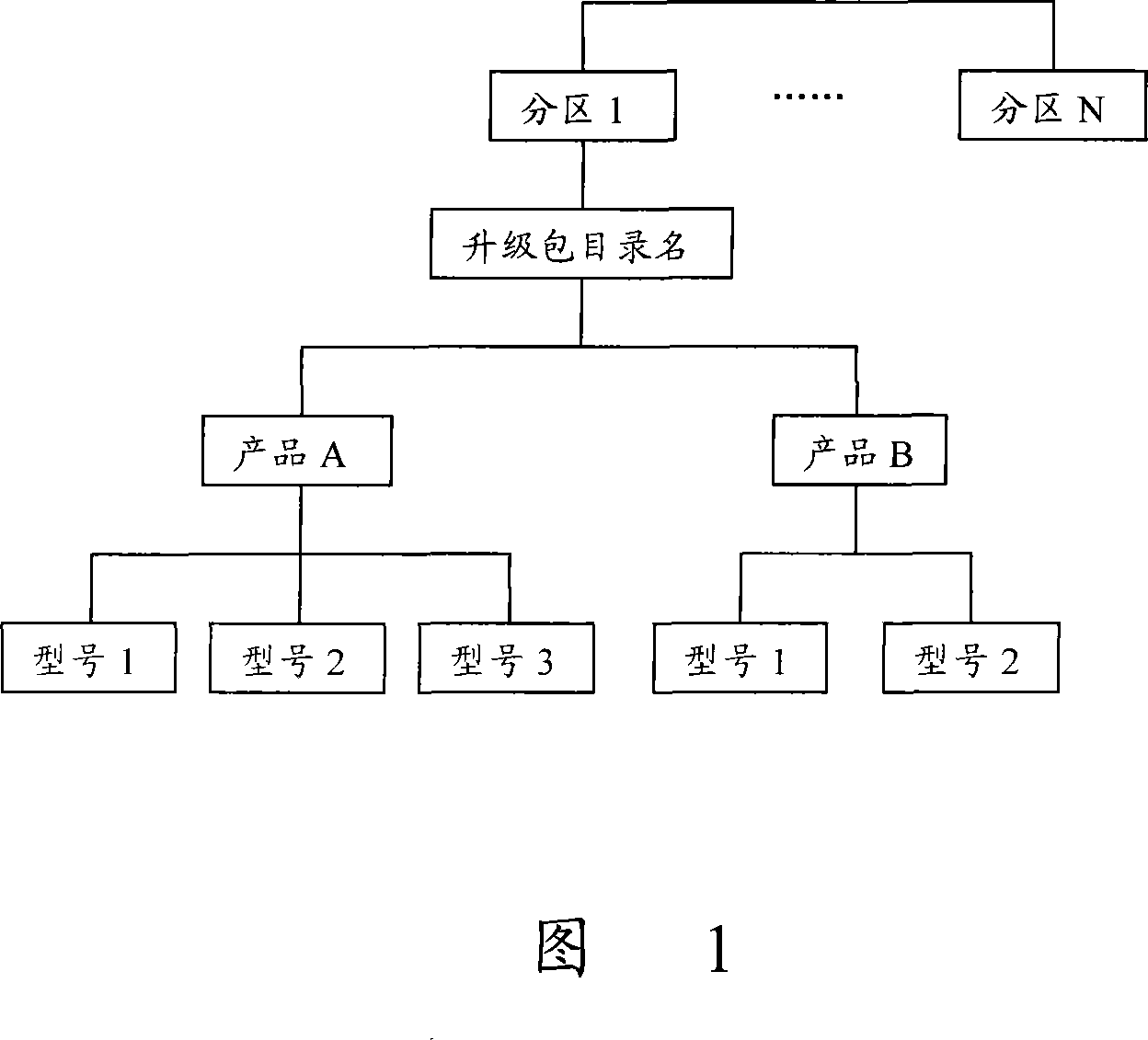

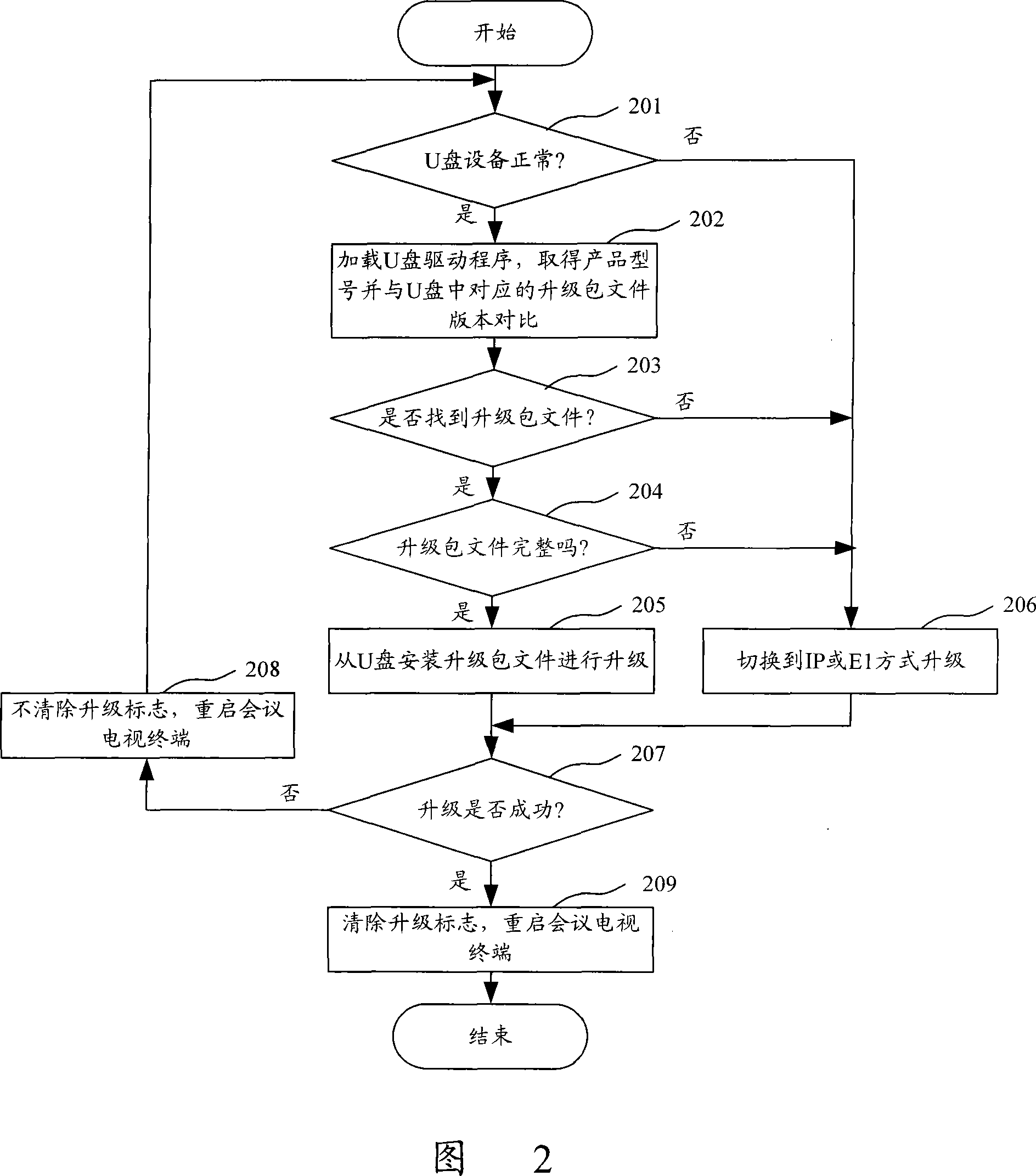

Method for upgrading conference television terminal

ActiveCN101198009AImprove securityImprove confidentialityTelevision conference systemsTwo-way working systemsDedicated lineUSB

The invention discloses an upgrading method of a conference television terminal. A universal serial bus (USB) interface is arranged in the conference television terminal, upgrading package files are stored in a U disk according to the rules of U disk partition and directory, product model, etc., the U disk is inserted into the USB interface when upgrading, and an upgrading procedure of the conference television terminal can automatically identify and load the upgrading package files to a self memory to complete the upgrading process. The method of the invention can not only realize switching between the USB upgrading mode and the prior IP network, E1 dedicated line upgrading mode, but also realize dynamic upgrading of the terminal without depending on the network and overcome the defect of the prior upgrading mode.

Owner:ZTE CORP

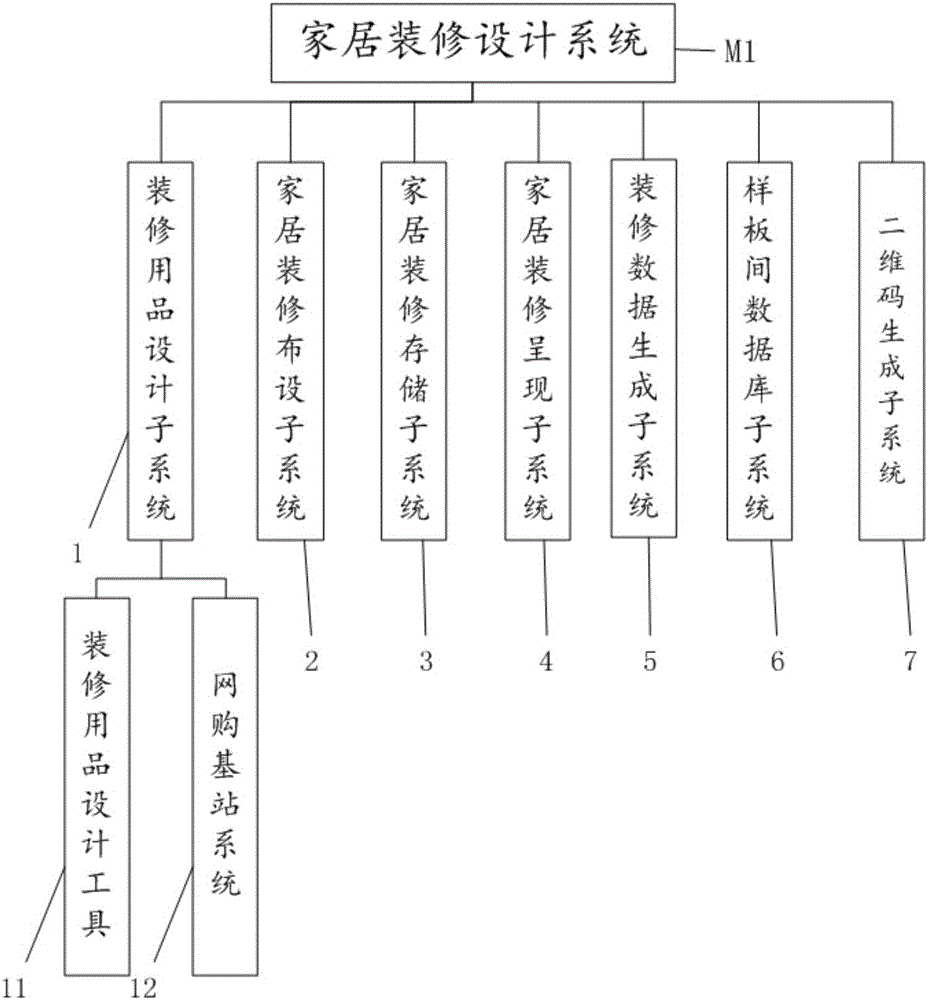

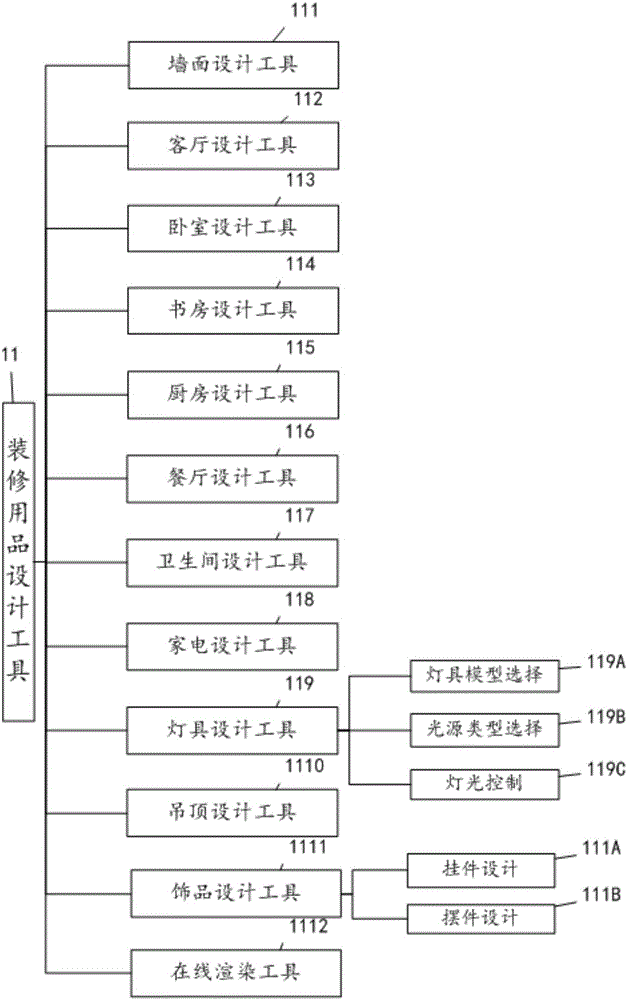

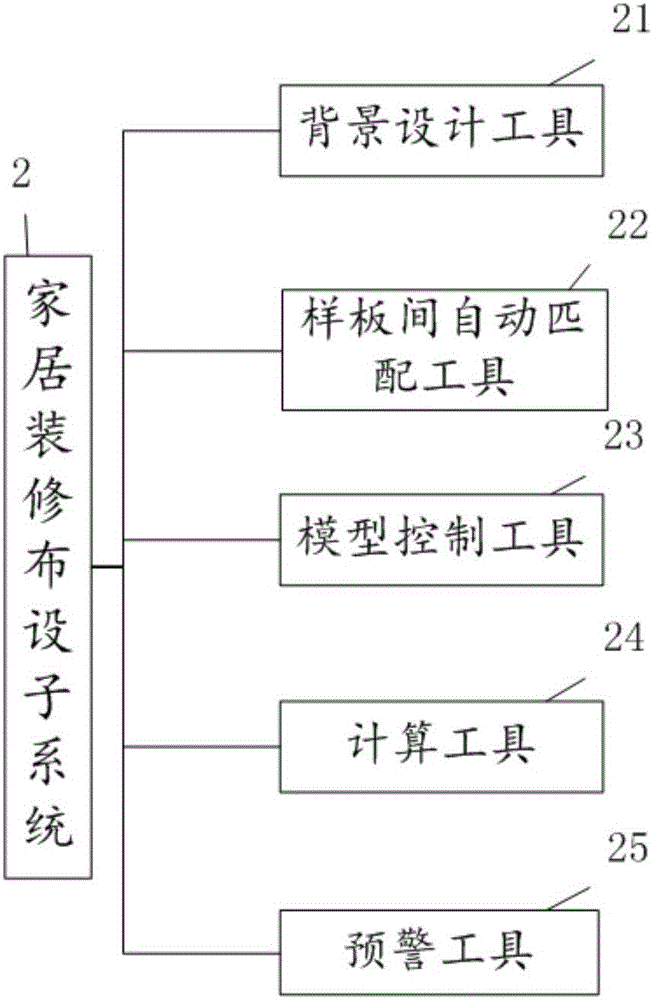

Home decoration design system and method

InactiveCN106055762AConvenient direct purchaseReduce biasSpecial data processing applicationsData informationEngineering

The present invention discloses a home decoration design system and method. The home decoration design system comprises a decoration product design subsystem for designing decoration product models; a home decoration laying subsystem for simulating the decoration process; a home decoration storage subsystem for storing data information; a home decoration presentation subsystem for clients to experience three-dimensional scenes; a decoration data generation subsystem for generating drawings and decoration budget sheets; a two-dimensional code generation subsystem for the clients to preview the home decoration effect; and a prototype room database subsystem for the clients to directly take existing home decoration model cases. A simple and easy home decoration design means is provided for the common clients, design precision is high, simulation scenes are lifelike, and the home decoration design system and method are suitable for the customized, networked and convenient trend of the home decoration design.

Owner:HENAN LIANJIA NETWORK TECH CO LTD

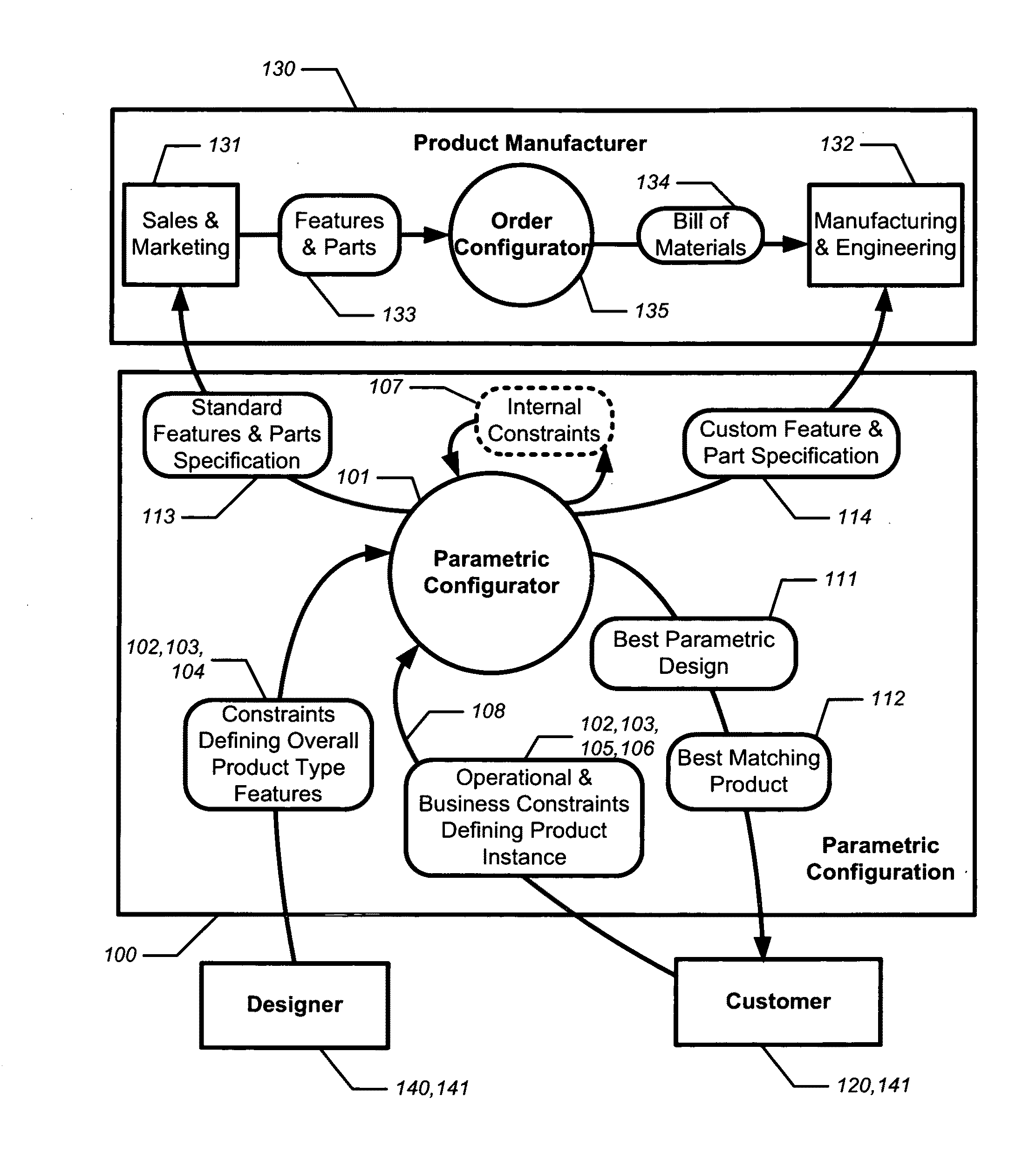

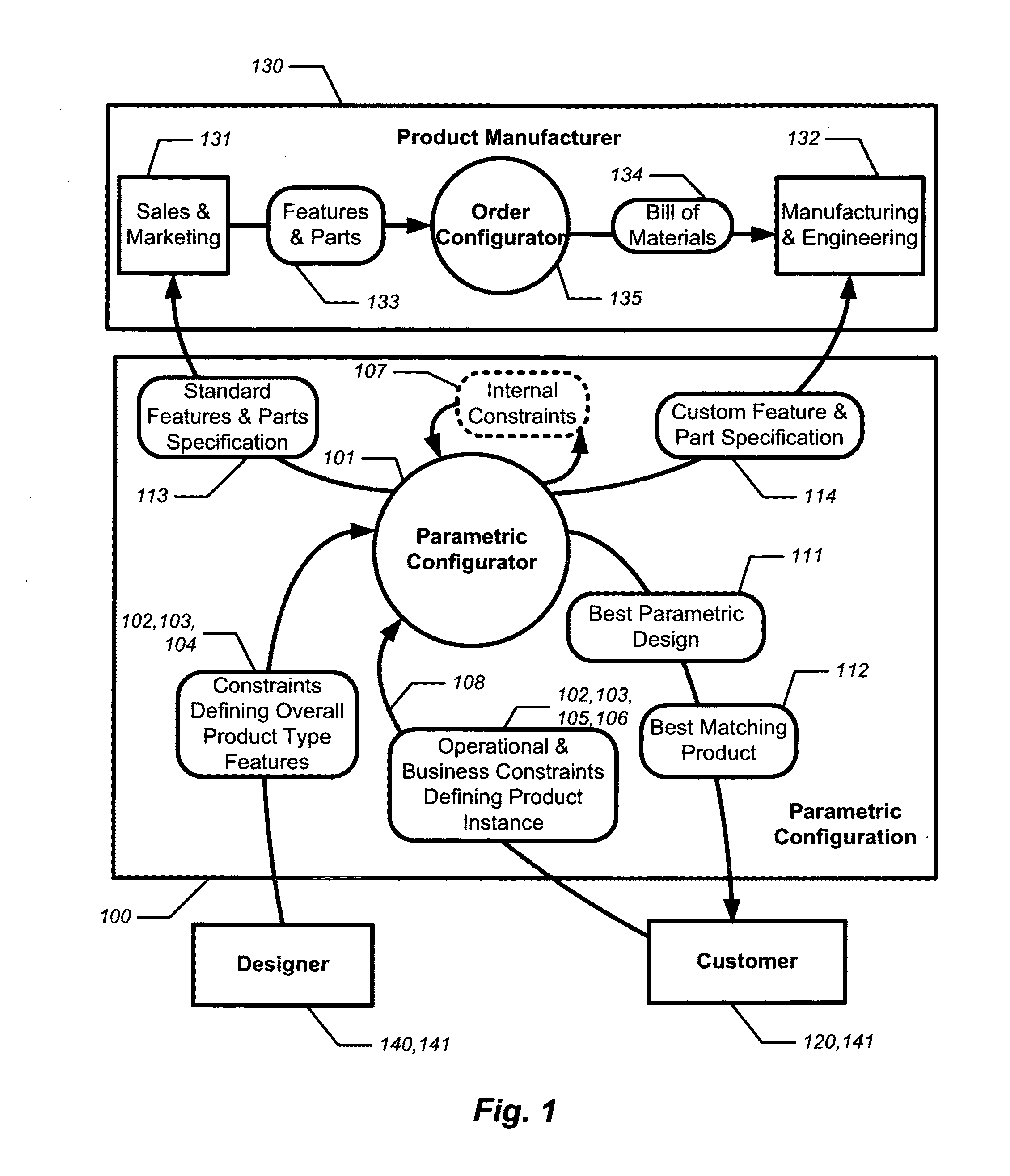

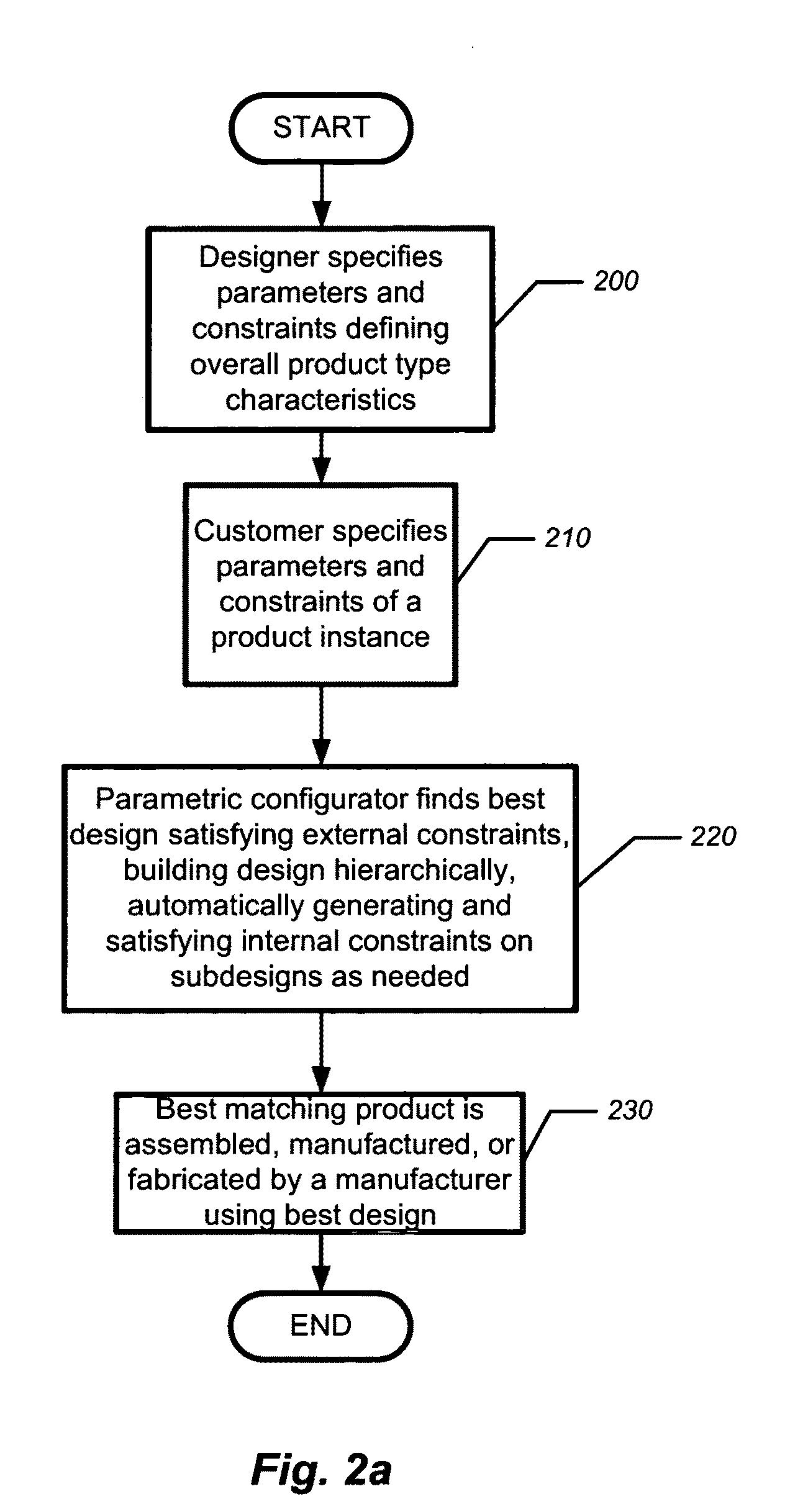

Parametric configurator for product design: system and method

ActiveUS20110098835A1Designing can be facilitatedGeometric CADDigital data processing detailsConfiguration languageData management

The present invention is a system and method for parametric configuration of a complex product. The system includes a parametric configurator, a parametric configuration language, and a parametric data management system. The parametric configuration language facilitates the solution of a design using constraints on geometric, physical, technological, operational, or business parameters. The parametric configurator includes a hierarchical solver that partitions a design into a plurality of subdesigns; provides the choice to collectively or independently optimize sets of subdesigns; and rolls back the solution process to an earlier subdesign when a given subdesign is determined to not be viable. The parametric data management system accesses data on a tangible digital medium, the data including constraints, product models, and product model instances. The method transforms the physical and geometrical constraints into a concrete product design. The completed design can be used to generate a parts and features list from a manufacturer, to generate a quote, or to assemble, manufacture, or fabricate the product.

Owner:CERTUSOFT

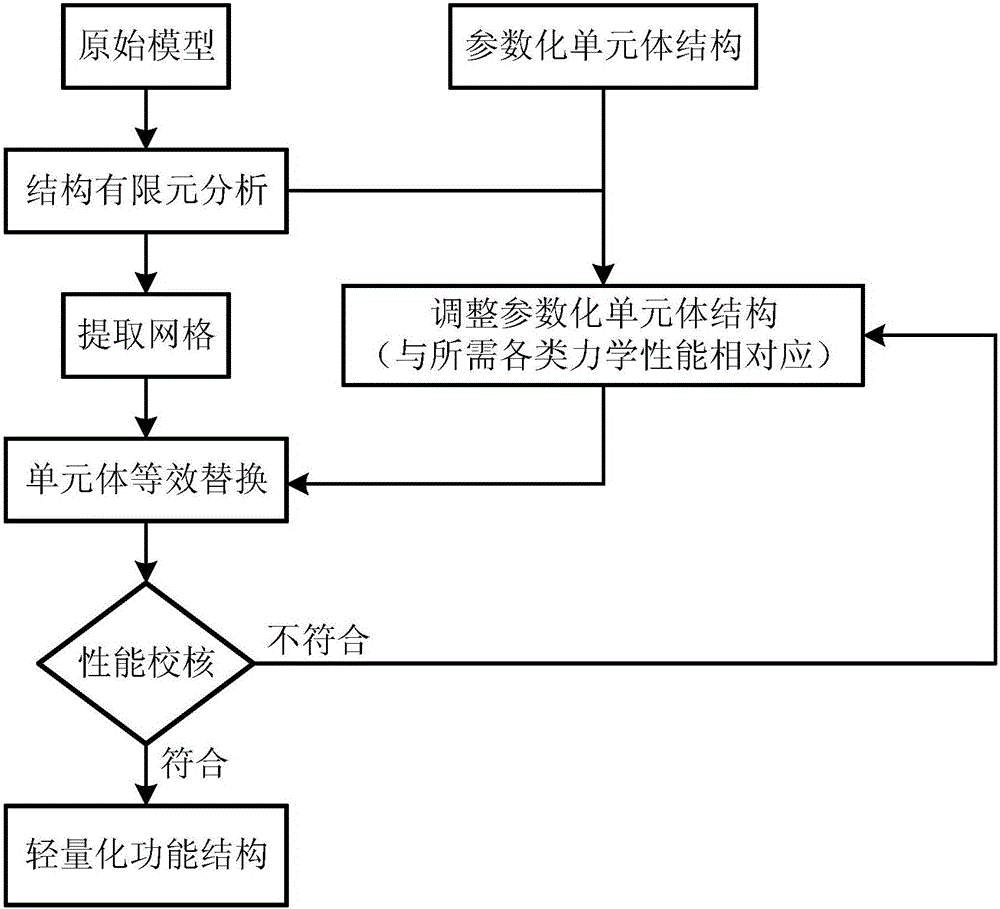

Additive manufacturing-based product lightweight design method

ActiveCN105912803AReasonable and efficient lightweight designReasonable and efficient manufacturingGeometric CADDesign optimisation/simulationElement analysisFinite element analyse

The invention discloses an additive manufacturing-based product lightweight design method. The method comprises the following steps: 1, establishing a parametric porous structure database, and establishing corresponding relationships between various parametric structures and mechanical property; 2, carrying out finite element analysis on an original product model structure; 3, adjusting a parametric unit structure to satisfy difference demands, for the mechanical property, of different mesh regions in the product; 4, carrying out filling replacement on the regions with excess performance in the products by using a lightweight unit structure; 5, carrying out mechanical property check on a lightweight product structure through finite element analysis. According to the method disclosed in the invention, the finite element analysis and the gradient distribution design of a parametric porous structure are combined, and different lightweight strategies are adopted in allusion to the performance demands of different parts of function parts under the premise of satisfying the mechanical property, so that the reasonable and efficient lightweight design is realized, and lightweight products can be prepared by using an additive manufacturing method.

Owner:SOUTH CHINA UNIV OF TECH

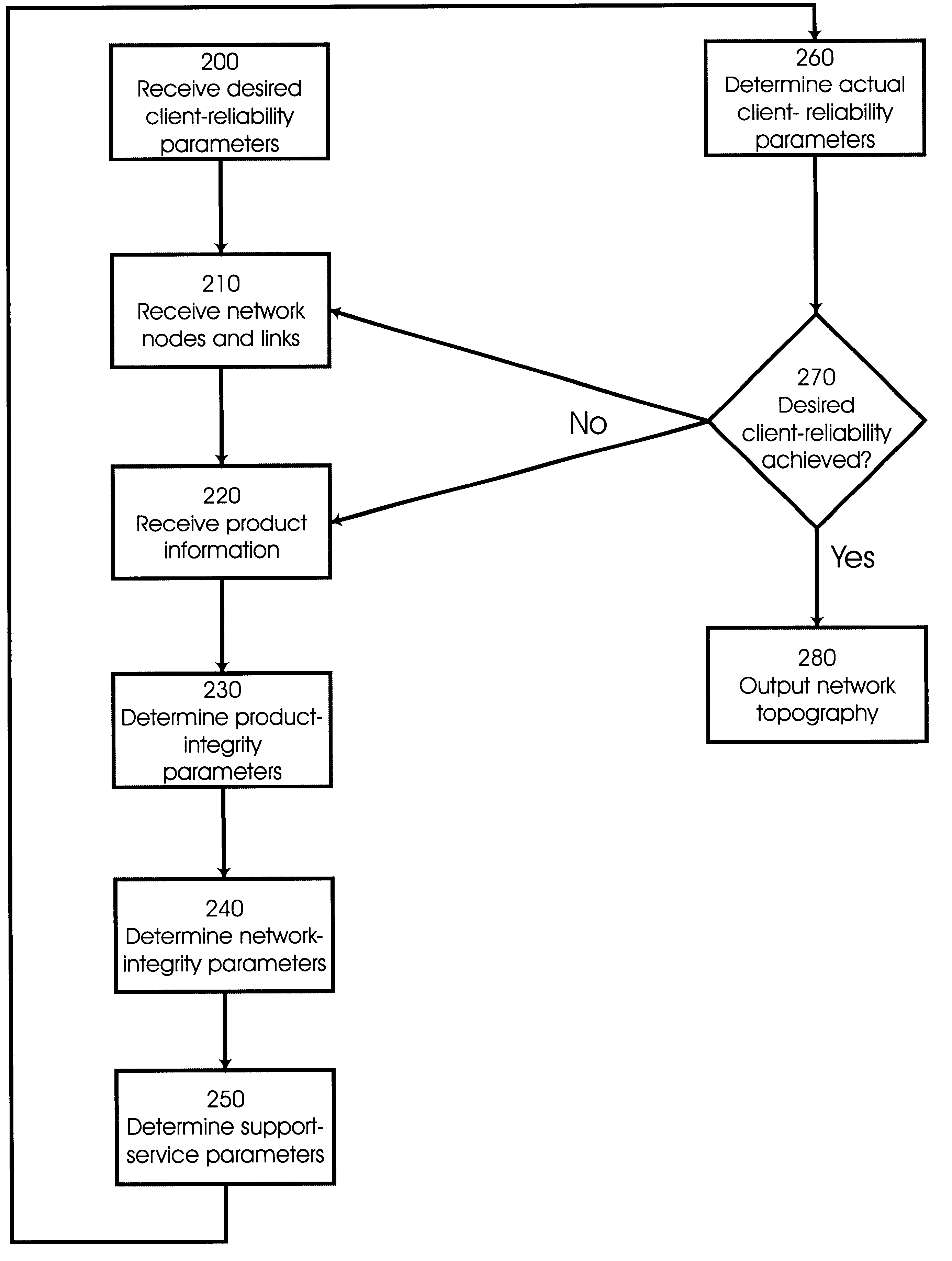

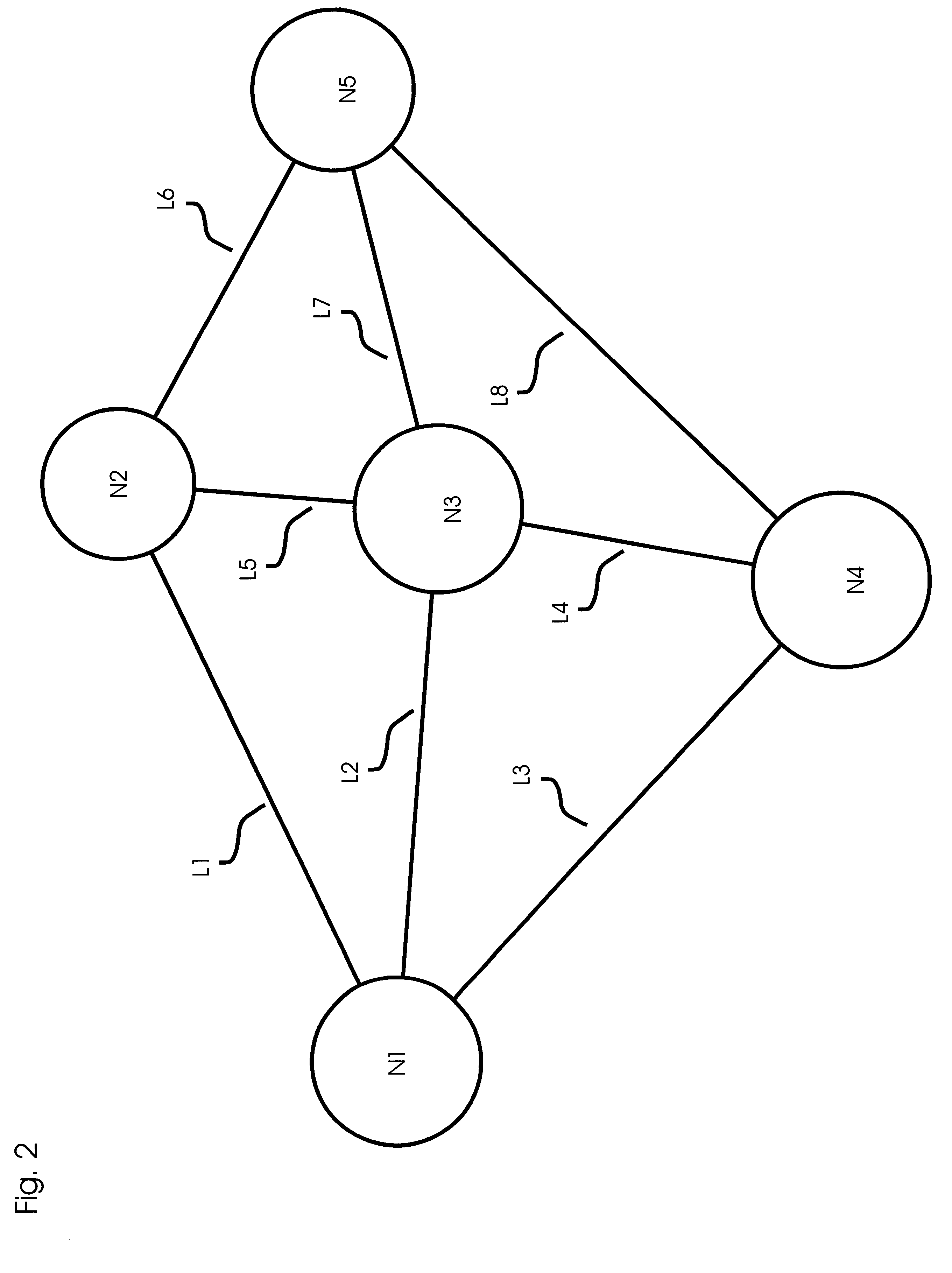

Method and system for designing a network

InactiveUS6857014B1Multiple digital computer combinationsData switching networksNetwork managementDependability

The present invention provides a novel system and method for designing a network. The system is preferably a computer operable to allow a user to input the nodes and links of a network, and to input product information associated with the nodes and links. The computer also stores product-reliability models corresponding to the hardware information. The computer is operable to perform operations that consider the nodes, links, product models to determine a set of reliability performance parameters. The computer can be further operable to vary certain reliability parameters to determine the impact from the perspective of an end-user or other type of network client. One method can include the collection of desired client requirements from the end-user and designing various network configurations to conform with the desired client requirements. Thus, the present invention can be used, and to optimize network designs. Another application is to incorporate the tool in network management product to be used to build or enhance existing networks. This function could be both static as well as dynamic. Thus, the present invention can also be used for other purposes such as modifying, monitoring or optimising existing networks.

Owner:RPX CLEARINGHOUSE

Project management tool

A system for managing a project that includes multiple tasks and a plurality of workers. Input information includes characterizations based upon a human model, a team model and a product model. Periodic reports, such as a monthly report, a task plan report, a budget report and a risk management report, are generated and made available for display or further analysis. An extensible database allows searching for information based upon context and upon content.

Owner:NASA

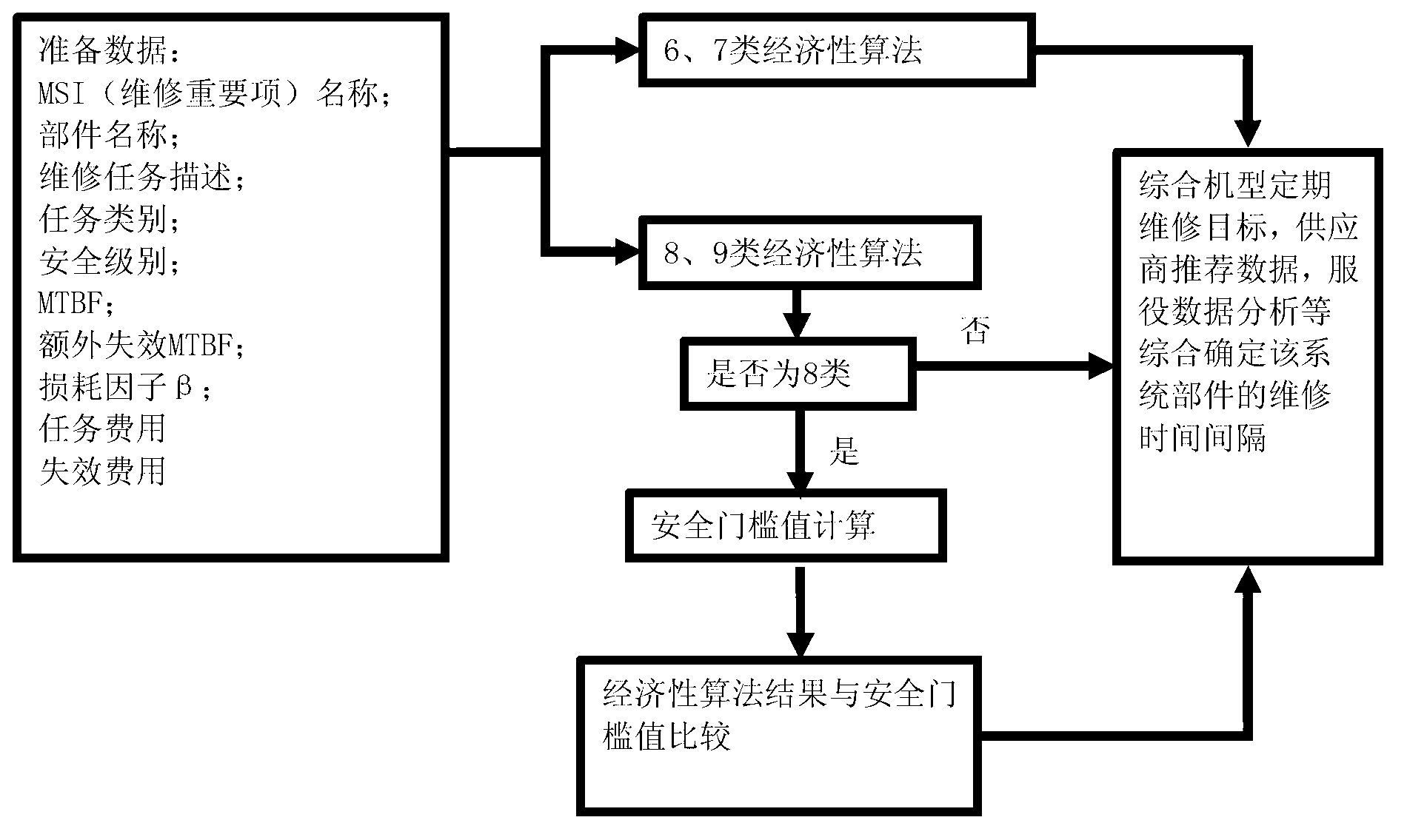

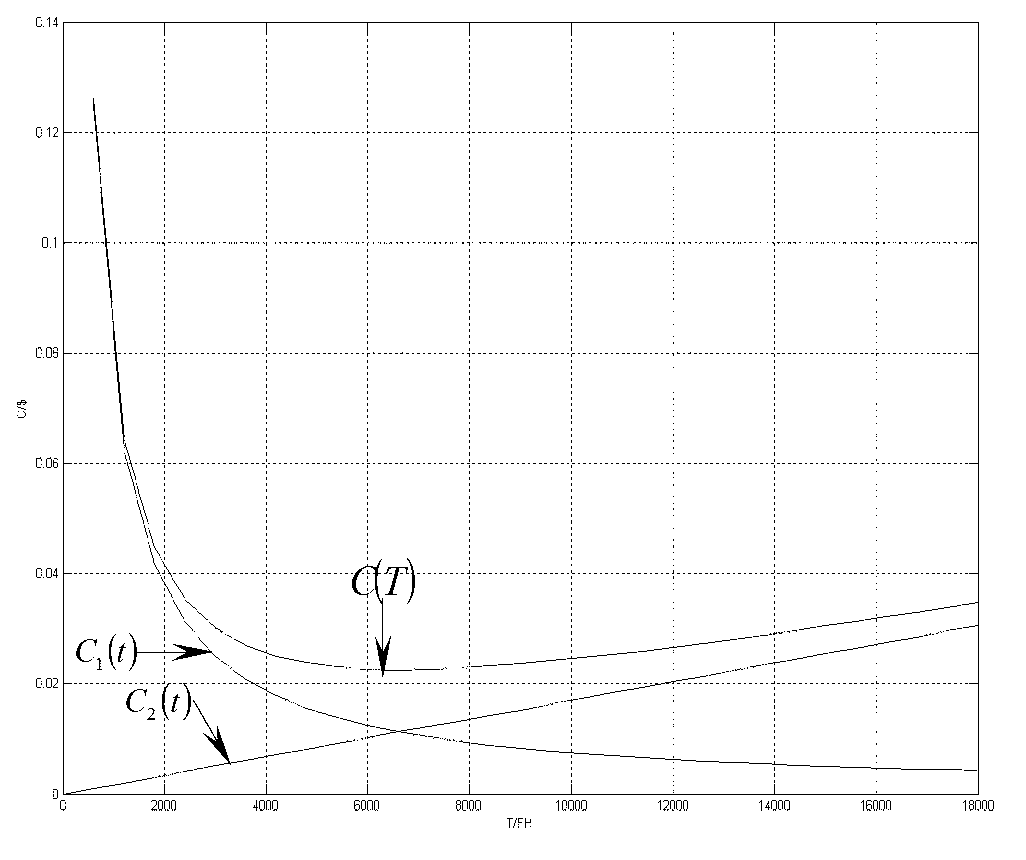

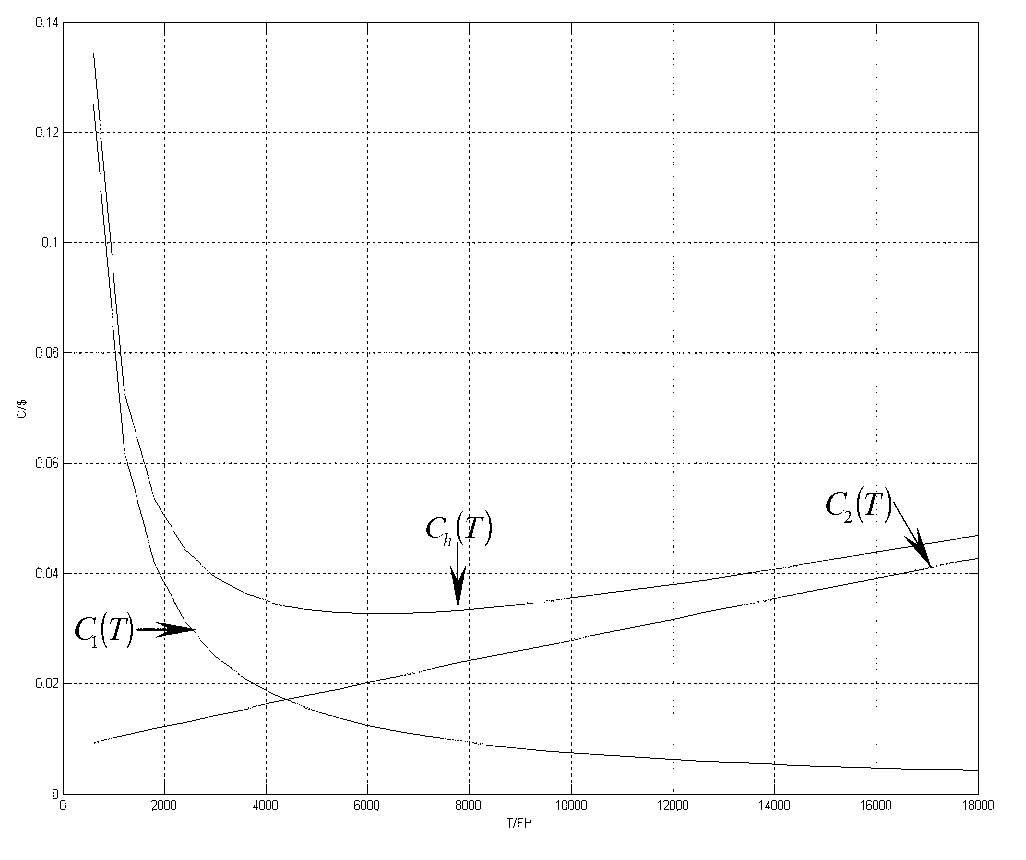

Method for calculating maintenance time interval of civil aircraft system

InactiveCN103020422ASolve the problem of maintenance intervalsSpecial data processing applicationsAviationRepair time

A method for calculating the maintenance time interval of a civil aircraft system belongs to the technical field of aviation. The method selects economy (cost / hour) as an optimization object, wherein as for safety tasks, two methods are used to calculate the time intervals of corresponding maintenance tasks, safety and economy are emphasized particularly, and the economy arithmetic recommended scope, safety threshold and product model regular checking target value are taken into comprehensive consideration to determine the task time interval. The method is economy-centered, is limited by safety and takes reliability as input idea, so as to recommend a reasonable maintenance time interval. A working group comprehensively takes supplier recommended value, engineering recommended value, history maintenance data, similar system part data, industrial experience point, the recommended value of the method and the like into consideration to make a decision, so that an optimum maintenance time interval judgment is made. The method is used for solving the problem that the civil aircraft cannot accurately judge the system part maintenance time interval due to the lack of a large number of service data during a maintenance review board report (MRBR) formulation process.

Owner:AVIC SAC COMML AIRCRAFT

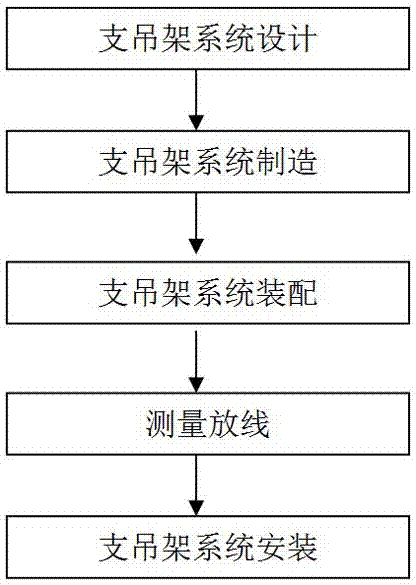

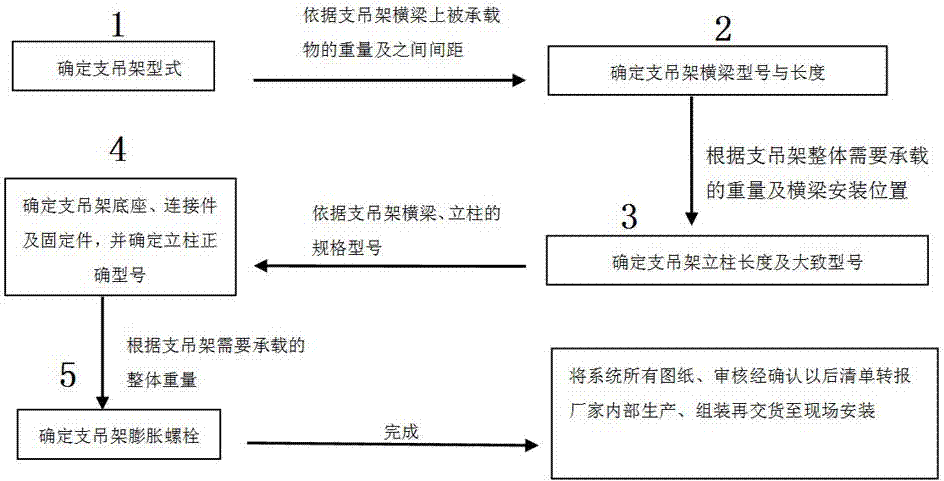

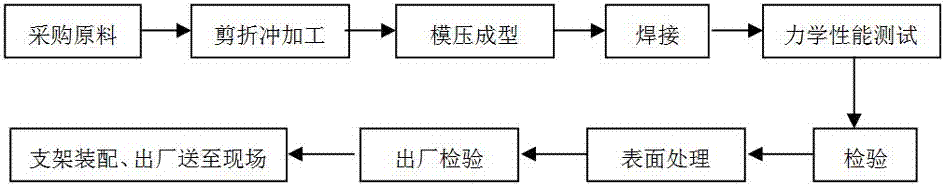

Assembly type building pipeline supporting and lifting frame system installation method based on BIM

ActiveCN106989211AReduce work intensityEnsure site safetyGeometric CADPipe supportsPunchingLight pollution

The invention discloses an assembly type building pipeline supporting and lifting frame system installation method based on a BIM. The installation method includes the steps that supporting and lifting frame design and stress analysis are conducted, the supporting and lifting frame connecting and fixing manner is determined, and a supporting and lifting frame design drawing is obtained; the drawing is guided into BIM software, and three-dimensional modeling is conducted; adjustment optimization is conducted on supporting and lifting frame arrangement, arrangement design, stress calculation and product model selecting of supporting and lifting frames are completed; part drawings and assembling drawings of all assemblies are generated, and factory production of the assemblies is achieved accordingly; measuring paying-off of the supporting and lifting frame system is conducted on the spot, and structure punching operation is conducted accordingly; and the supporting and lifting frames are formed through assembling, and installation is completed. By means of the assembly type building pipeline supporting and lifting frame system installation method based on the BIM, energy can be obviously saved, steel is saved, air pollution, noise pollution and light pollution brought by field feeding, cutting, welding, drilling and the like are avoided during installation, the manufacturing cost is reduced, meanwhile, the field safety of a constructor is ensured, and the work intensity of a laborer is effectively lowered.

Owner:ZHONGYIFENG CONSTR GRP

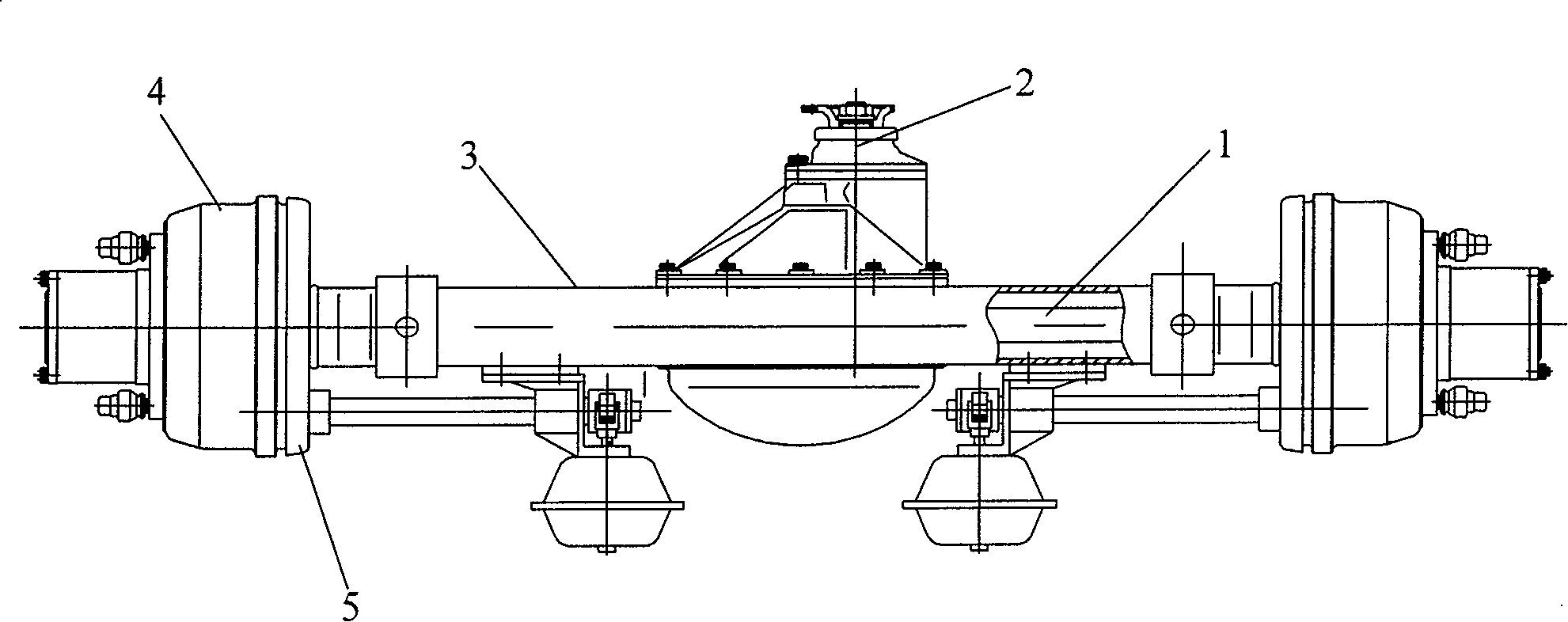

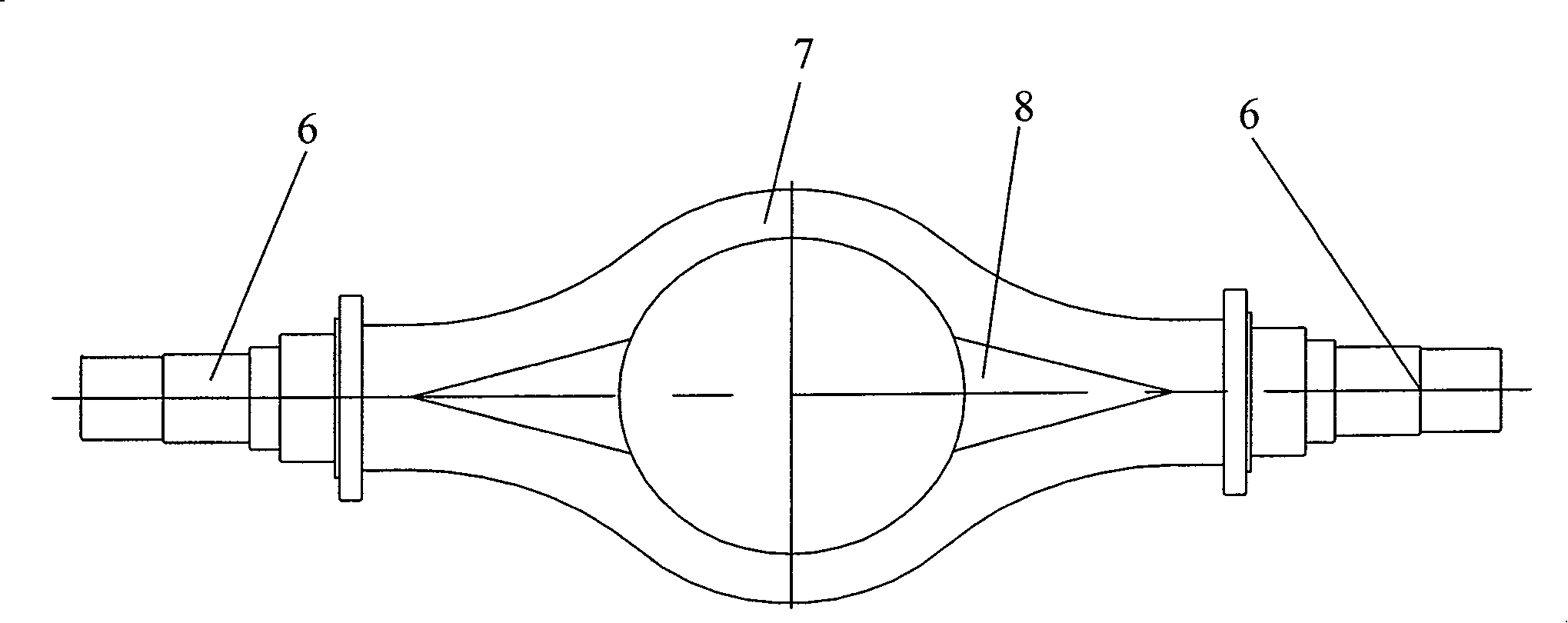

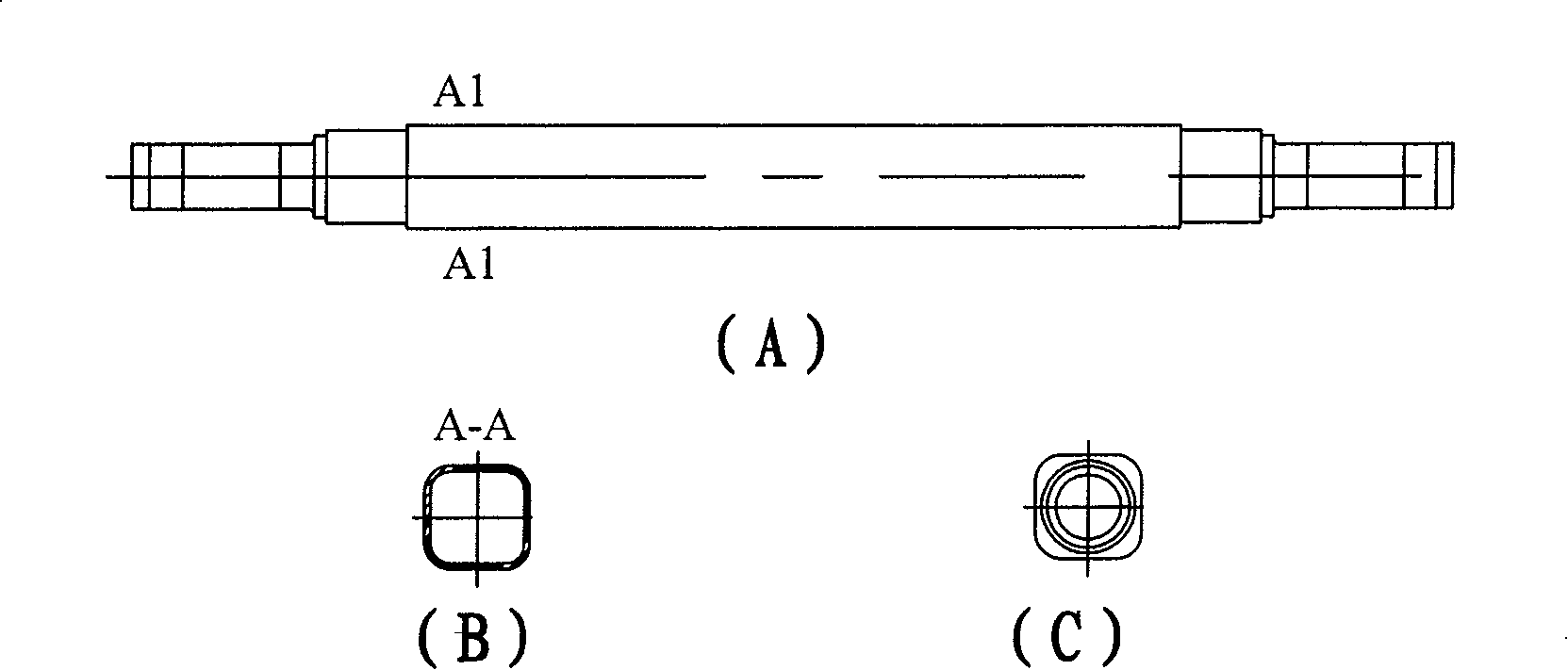

Roll type cold pressing processing method and device for vehicle driving axle housing

InactiveCN101185946ASimple structureHigh mechanical strengthExtrusion control devicesRams/plungersAxial pressureEngineering

Owner:梅利红

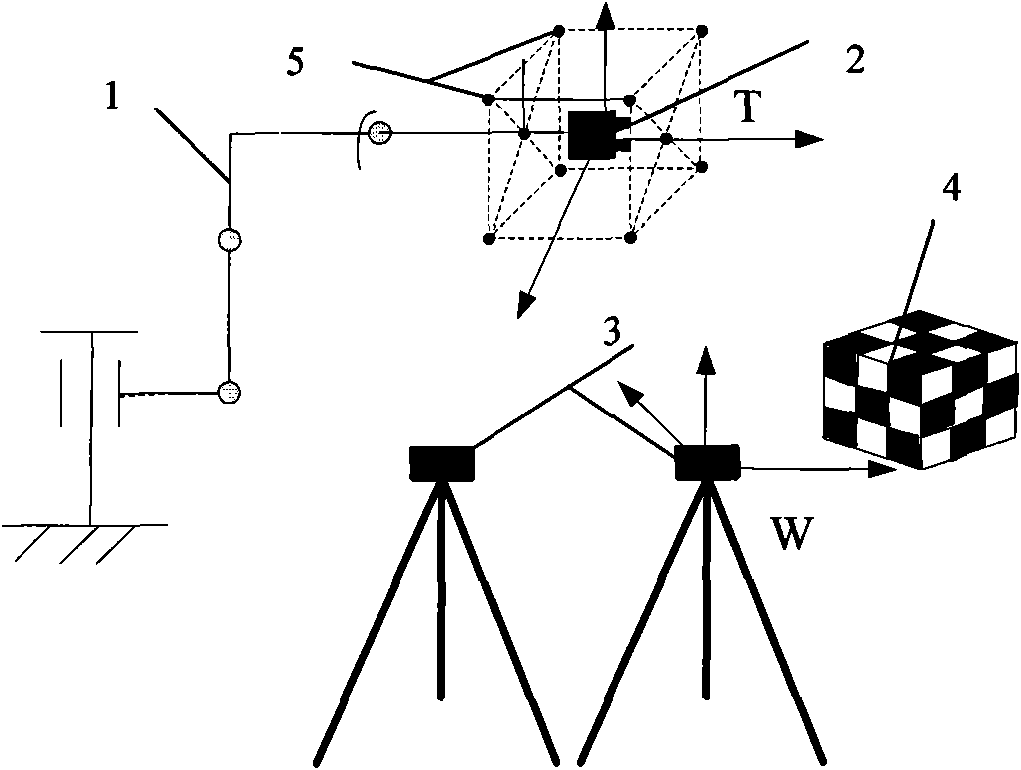

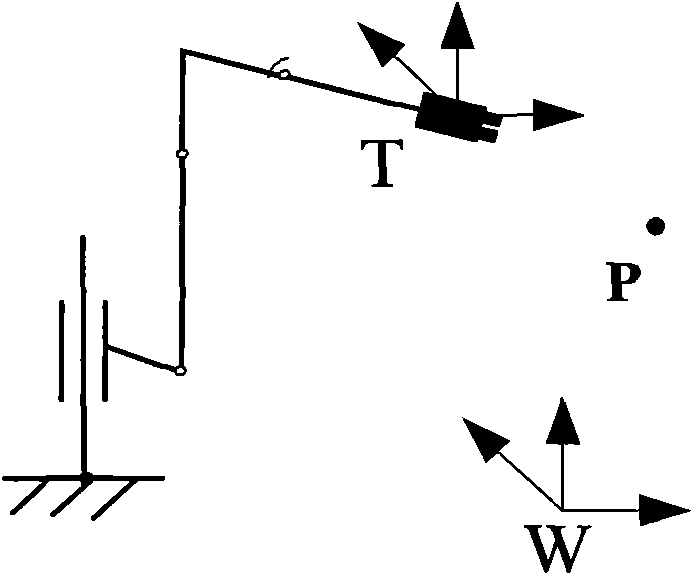

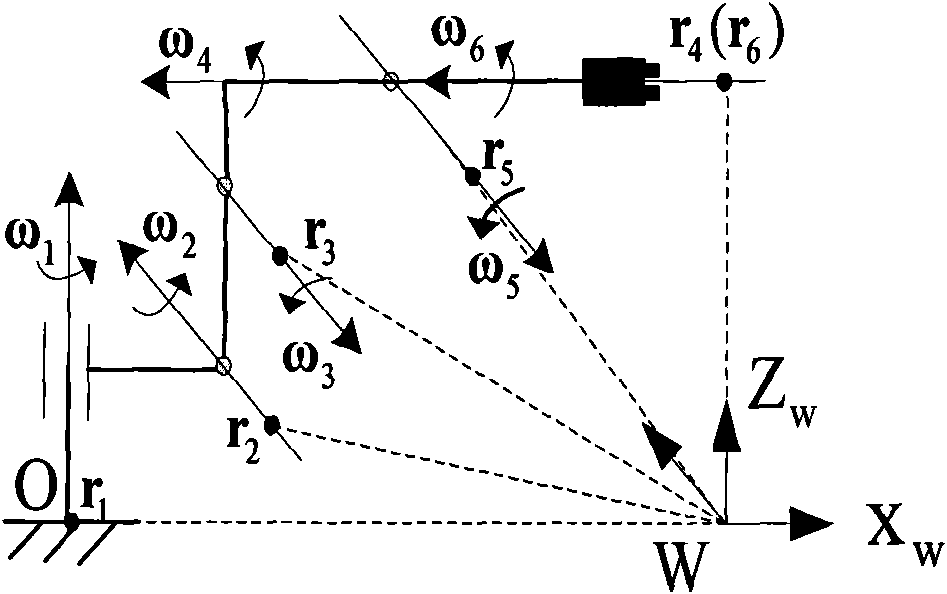

Robot calibration method based on exponent product model

ActiveCN102022989AHigh precisionImprove stabilityMeasurement devicesManipulatorClassical mechanicsIndustrial robotics

The invention discloses a robot calibration method based on exponent product model, comprising the following steps: providing an industrial robot, a measuring instrument independent of the robot, an end three-dimensional imaging device and a three-dimensional calibration block; building a robot kinematics model according to the mode of combination of spinor theory and exponent product; giving closed-form solution of all joint parameters; directly solving the joint spinor parameters by utilizing a linear method; compensating the nominal value of joint angle of the robot, thus avoiding the conversion of a coordinate system and a measuring coordinate system of the robot. In addition, the calibration process is simple, and calibration can be realized through the method that all joints rotate once and the coordinate values of n numbered mark points (n is more than or equal to 3) are measured simultaneously. The robot calibration method in the invention is realized simply, has good stability, and low introduced external error.

Owner:青岛卓信通智能科技有限公司

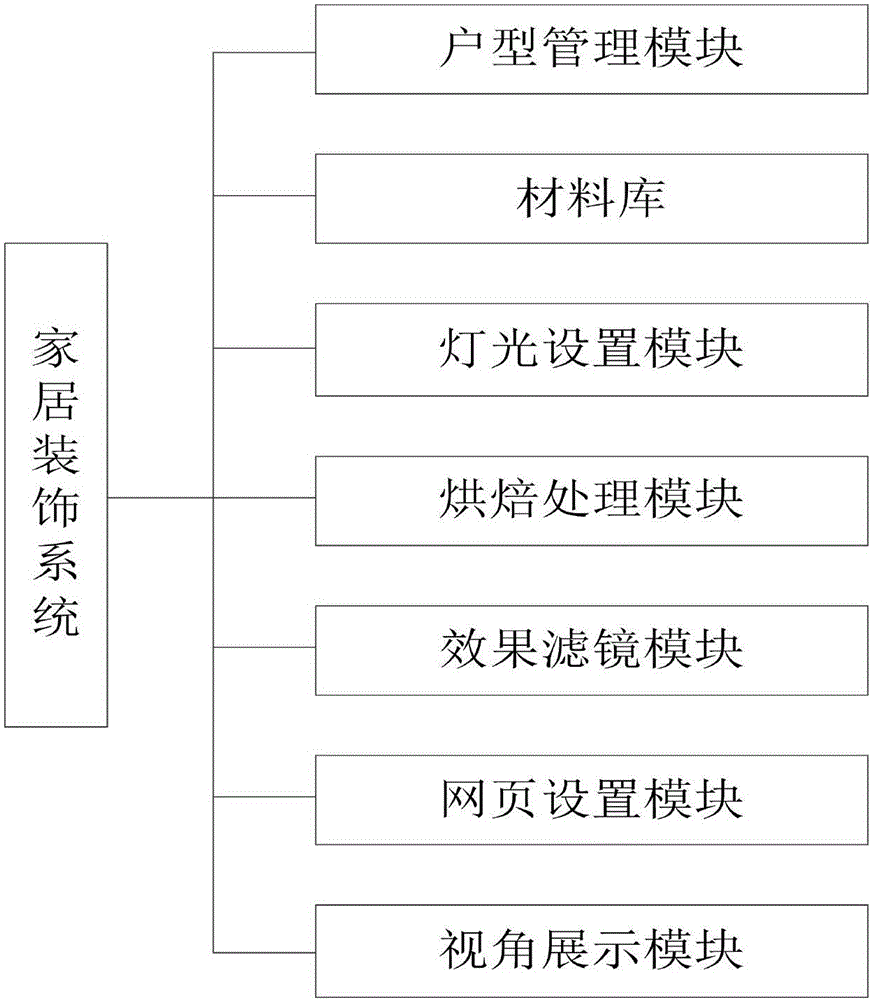

Unreal engine technology-based home decoration system

InactiveCN105741194AEasy decorationAdjust lighting effectsData processing applications3D-image renderingThird partyEnvironment effect

The invention relates to an unreal engine technology-based home decoration system. The system comprises a house type management module, a material library, a light setting module, a roasting module, an effect filter module, a webpage setting module and a visual angle display module, wherein the house type management module is used for importing user type planes to generate three-dimensional application models and carrying out change, adjustment, movement and rotation operations on product models; the material library comprises a preset material library, preset products and self-selected materials; the light setting module comprises an automatic light setting function and is capable of simulating natural lights, simulating the outdoor environment effects and adjusting various light effects; the baking module comprises a cloud processing function and a local rendering function; the effect filter module comprises a preset filter library, an effect simulation unit, a sound simulation unit and a scene presetting unit; the webpage setting module is connected with a third-party webpage; and the visual angle display module comprises a roaming setting unit and a rendering drawing unit. Through the system, different decoration effects can be changed through one key, and the home decoration can be easily finished.

Owner:赵云

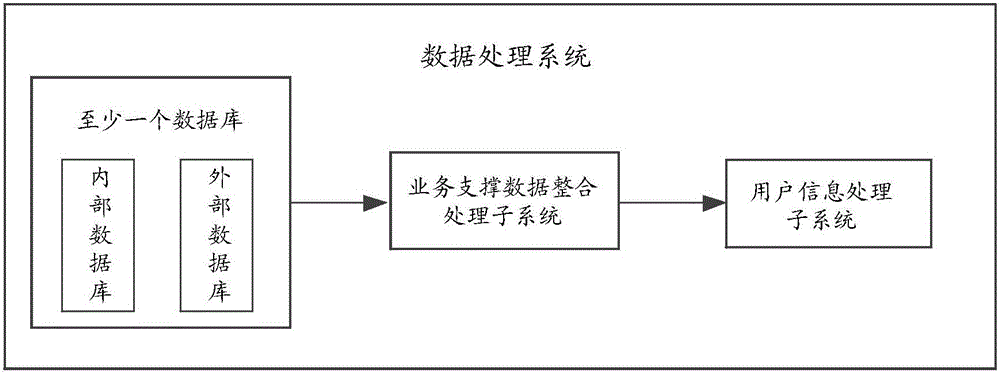

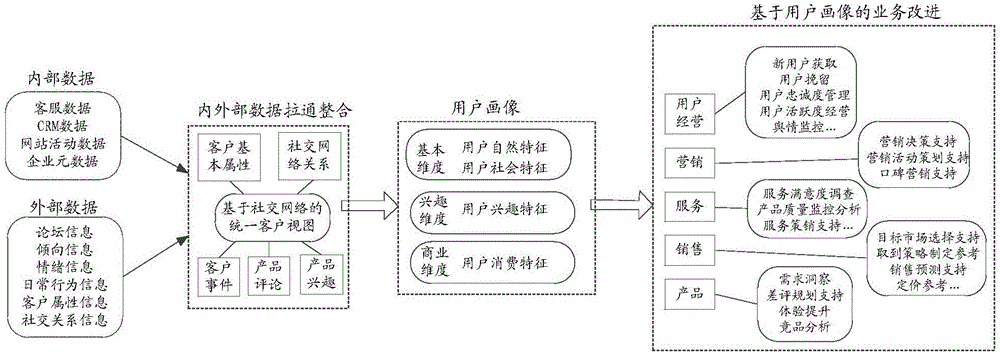

Data processing system

InactiveCN105930540AEasy to handleOther databases queryingSpecial data processing applicationsData processing systemData set

The invention provides a data processing system, which is used for solving the technical problem of poor data processing capacity in a data processing process in the prior art. The system comprises at least one database, a service supporting data integrating processing subsystem and a user information processing subsystem; the database is used for storing customer data which are related to a customer and product data which are related to a product, wherein the customer data comprise customer basic attribute data, customer consuming behavior data, evaluation data of the customer to the product and customer human network relationship data; the product data comprise product model number data, product propagation name data and product network alias data; the service supporting data integrating processing subsystem is used for acquiring the customer data and the product data from the at least one database, and integrating and classifying the acquired data to acquire at least one classification of service data; the user information processing subsystem is used for acquiring and processing the at least one classification of the service data from the service supporting data integrating processing subsystem, acquiring a user description data set, and determining at least one speculative result based on the user description data set.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

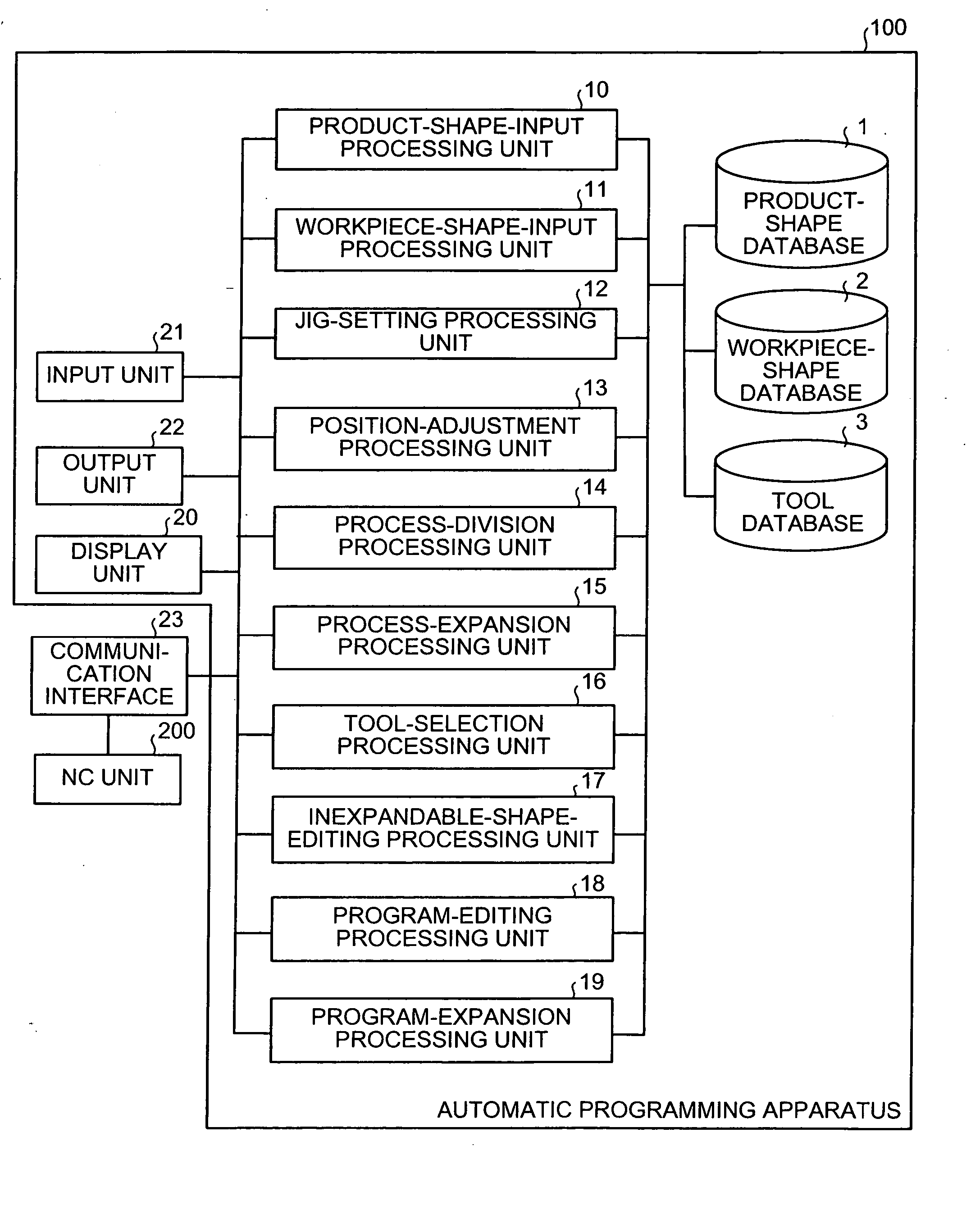

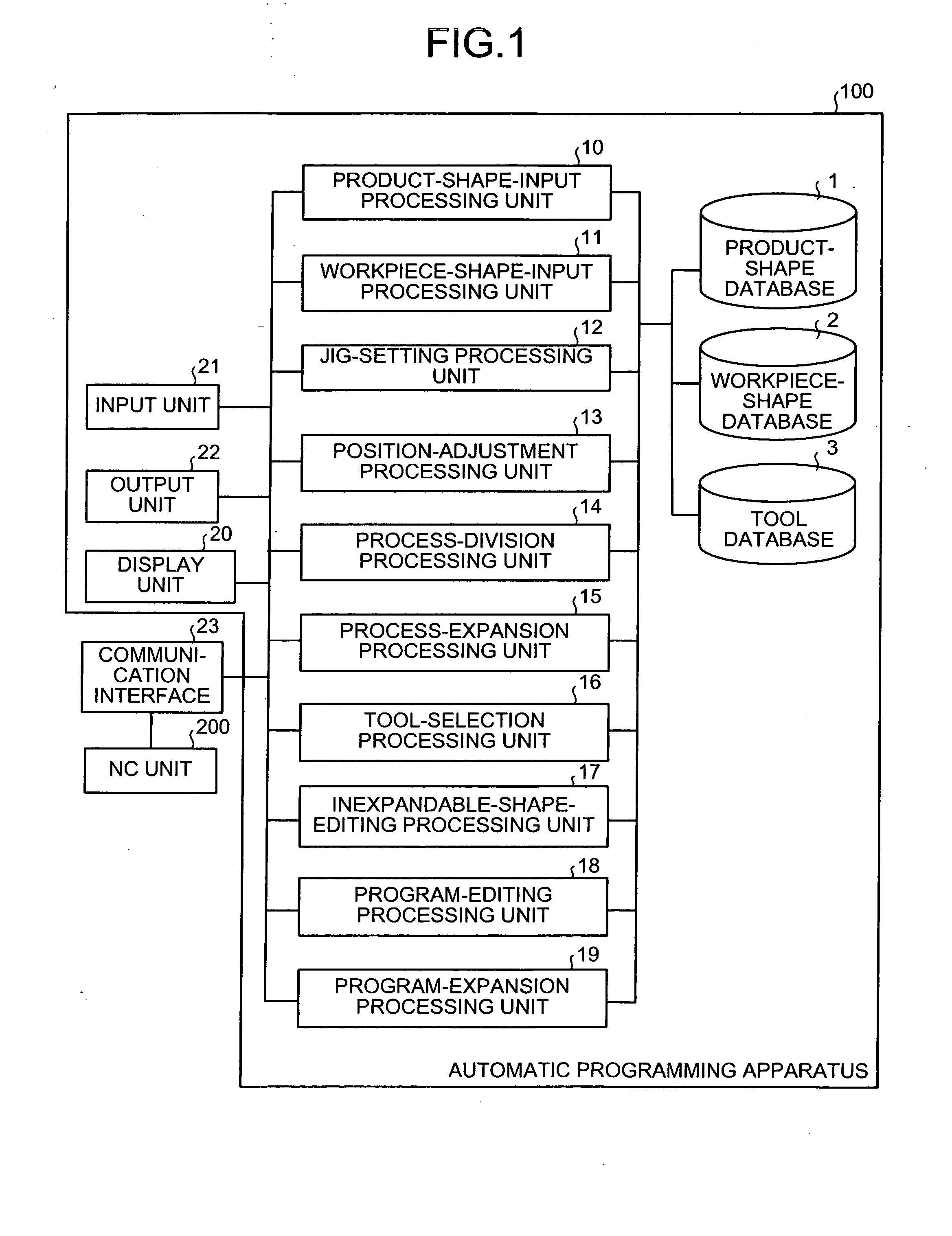

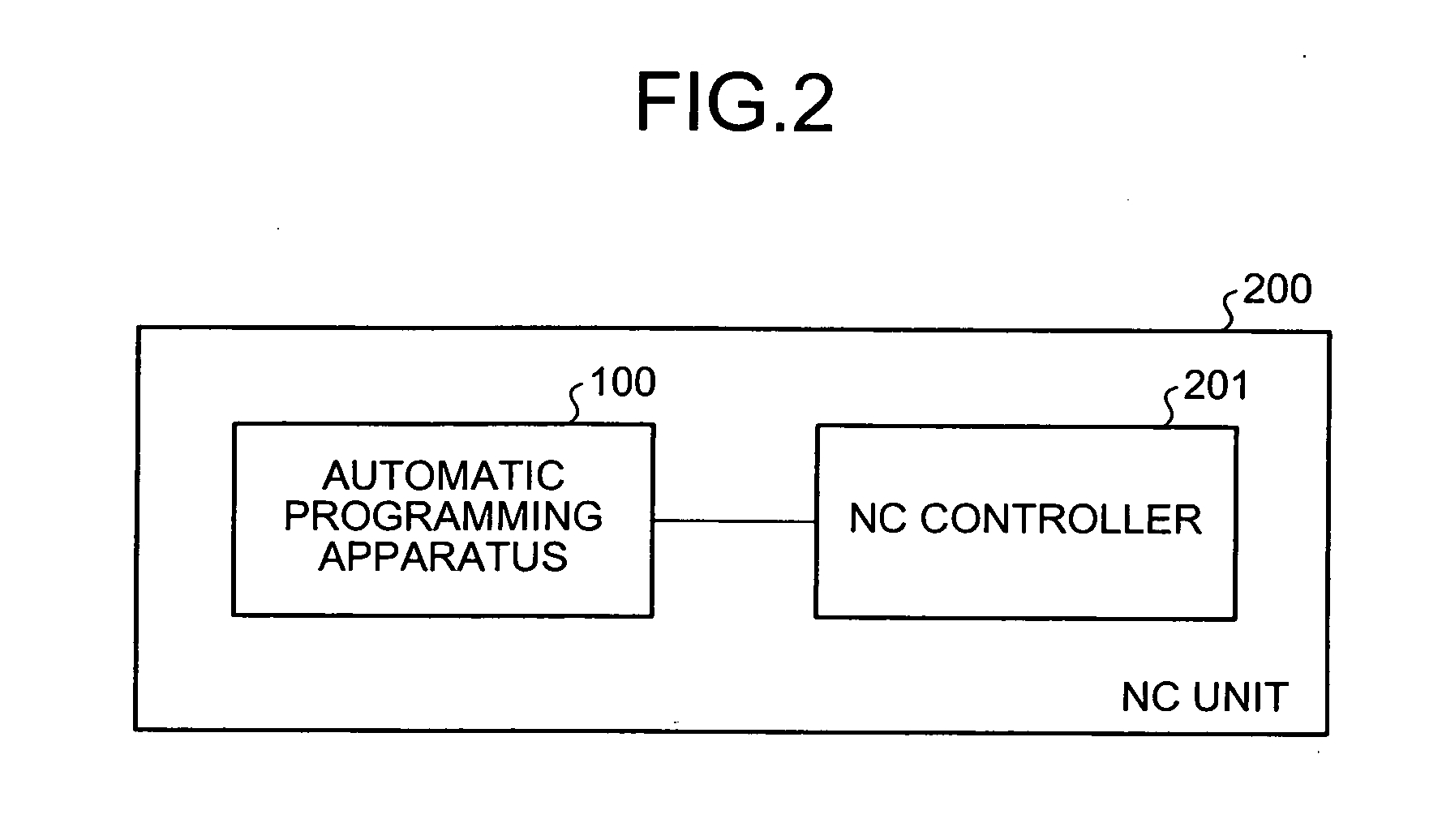

Automatic Programming method and device

ActiveUS20070027571A1Easy to operateAutomatic control devicesData processing applicationsMechanical engineeringAutomatic programming

Workpiece data involving a product shape and having a smallest diameter for lathe turning around a turning axis is selected from the workpiece database, by comparing dimension data of a workpiece model with dimension data of a product model in a state in which the product model is arranged on the turning axis and the workpiece model is arranged so that a center axis of each workpiece matches a center of the turning axis. The workpiece model for lathe turning is created based on the selected workpiece data.

Owner:MITSUBISHI ELECTRIC CORP

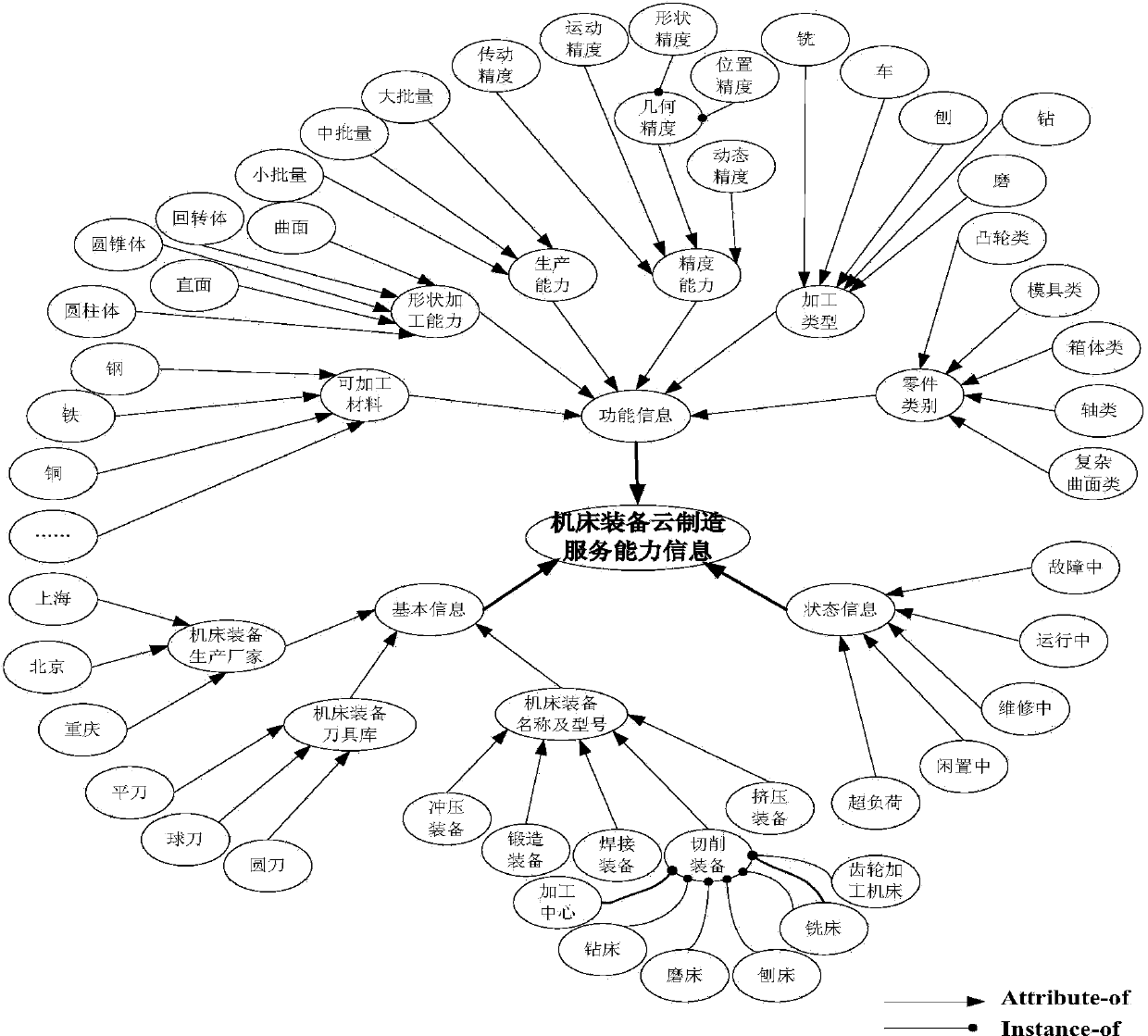

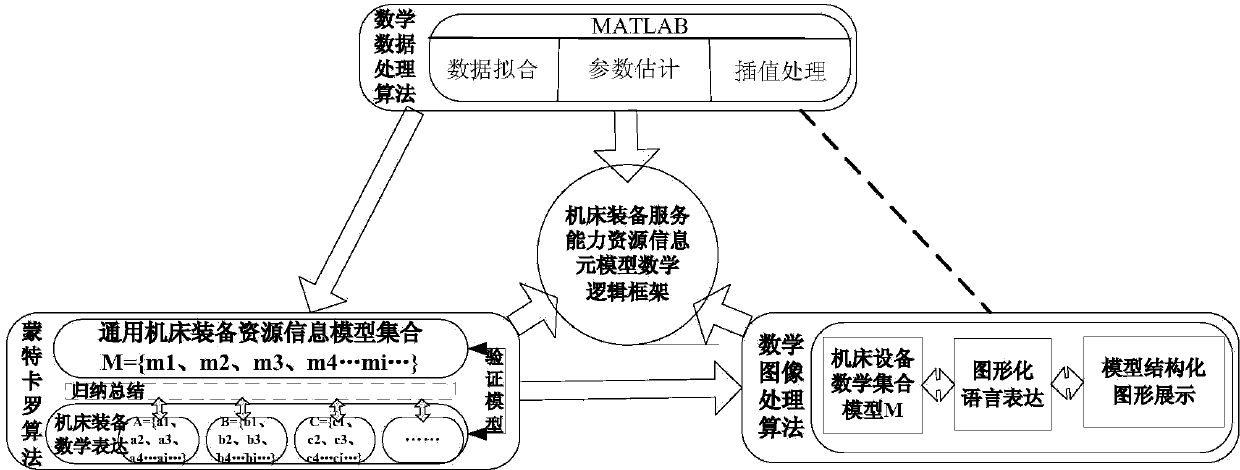

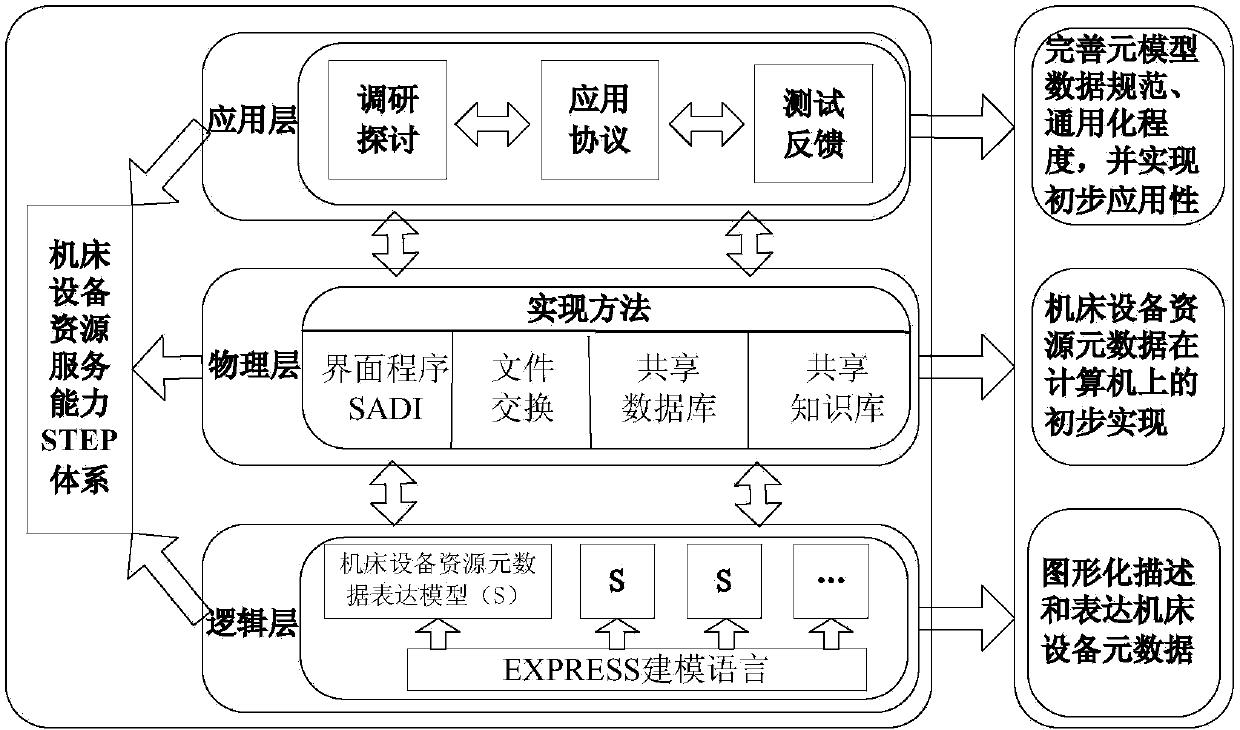

Machine tool equipment service capability modeling method in cloud manufacturing environment

InactiveCN103473407ASolve the problem of how to display graphicallyImprove data normalizationSpecial data processing applicationsPersonalizationVirtualization

The invention relates to a machine tool equipment service capability modeling method in a cloud manufacturing environment, and belongs to the technical field of information. The machine tool equipment service capability modeling method is a machine tool equipment information standardization description method including a substance information analyzing and extracting method, a mathematical modeling technique and an STEP (standard for the exchange of product model data) technique. The machine tool equipment service capability modeling method includes creating a uniform machine tool equipment cloud manufacturing service capability model through analyzing and extracting, logic framework building and virtual standardization describing of machine tool equipment information, and configuring model information parameters in an individualized way. The machine tool equipment service capability modeling method can lay a foundation for realization of techniques like visualized packaging and displaying of machine tool equipment, establishing of machine tool equipment resource libraries and intelligent semantic-based matching of machine tool equipment resources in the cloud manufacturing environment. The machine tool equipment service capability modeling method has the advantages of high virtualized simulation degree, high universality and good expandability; by the machine tool equipment service capability modeling method, service enterprises can be effectively supported to provide cloud manufacturing services conveniently and users can be effectively supported to find and match better resources intelligently.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com