Patents

Literature

913results about How to "Improve guidance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

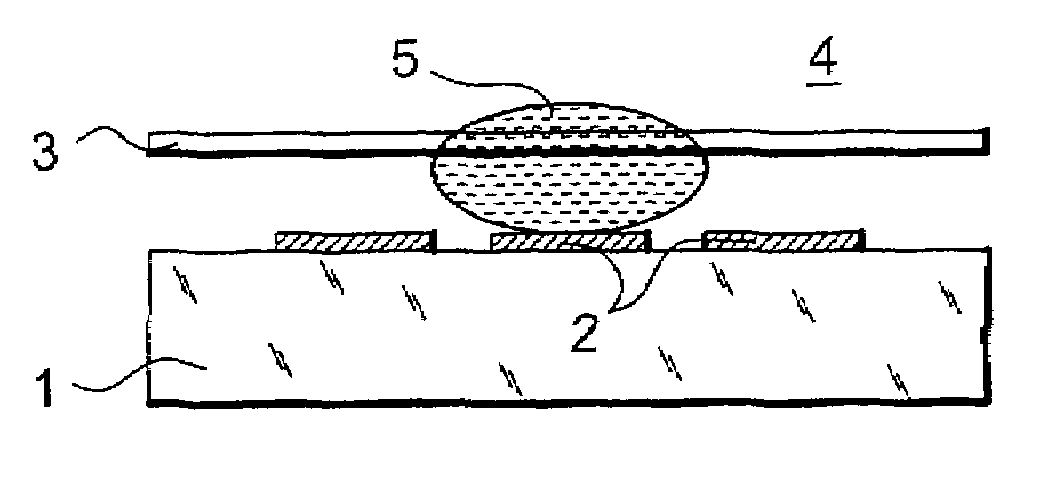

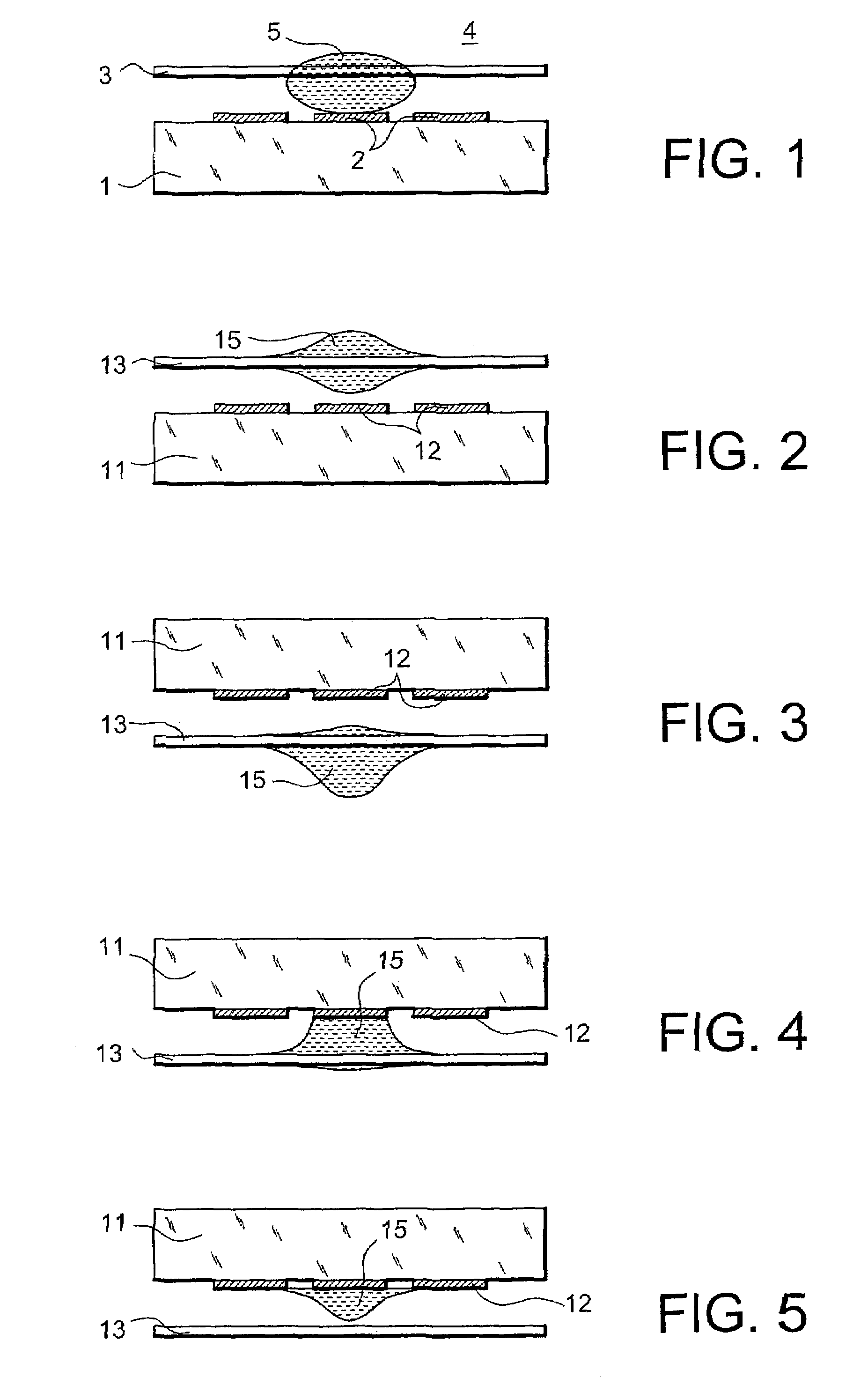

Device for displacement of small liquid volumes along a micro-catenary line by electrostatic forces

ActiveUS7052244B2Improve guidancePrevent evaporationPump componentsLaboratory glasswaresElectricityElectrical control

The invention relates to a device for displacement of at least a small volume of liquid (5) under the effect of an electrical control, including a substrate (1) provided with first electrically conducting means (2), the device also comprising second electrically conducting means (3) arranged facing the first electrically conducting means (2), the first electrically conducting means and the second electrically conducting means possibly being connected to electrical power supply means to enable the application of electrostatic forces to the small liquid volume (5). The second electrically conducting means include at least one conducting wire (3) arranged parallel to the substrate and at a fixed distance from the substrate to enable displacement of the small volume of liquid (5) along said conducting wire (3) under the effect of the applied electrostatic forces.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

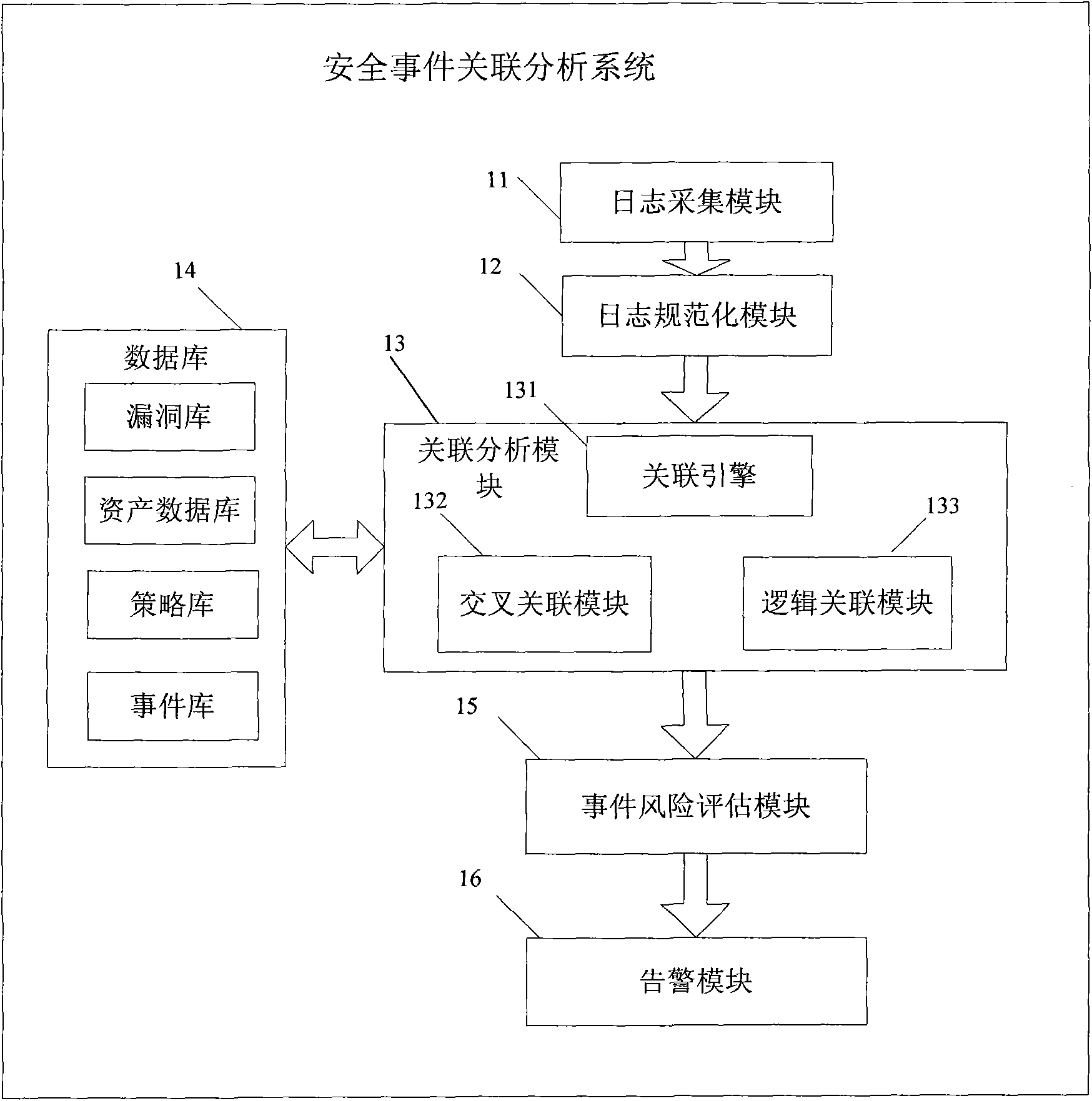

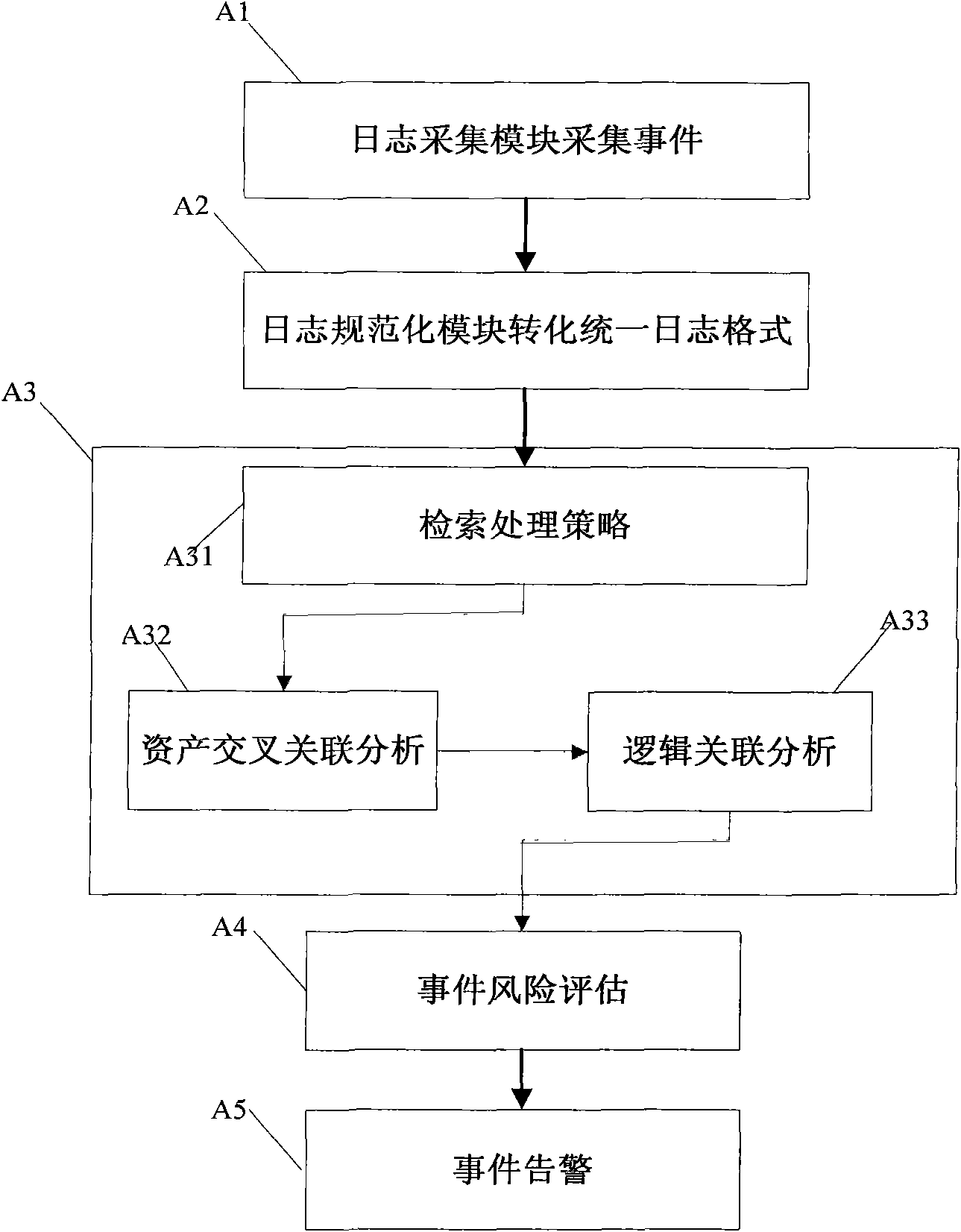

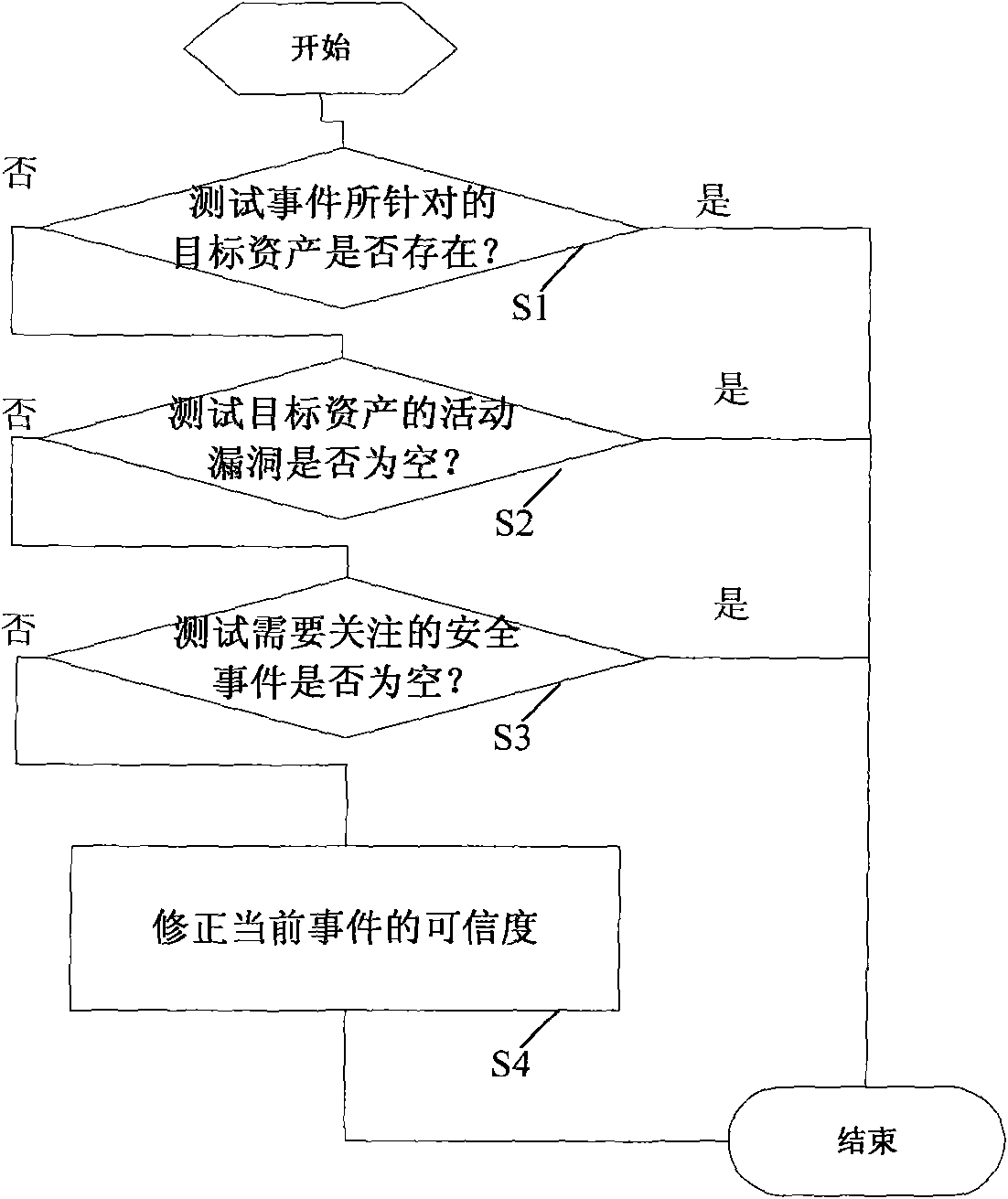

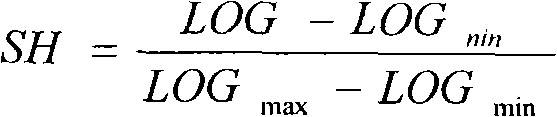

Log correlation analysis system and method

ActiveCN101610174ACalculation speedReduce false alarmsData switching networksEvent correlationCross correlation analysis

The invention provides a log event correlation analysis system and a method, which comprises the steps of: collecting log data, extracting characteristic data of the log data through a preset regular expression, constructing log events with uniform format according to the extracted characteristic data, querying treatment strategies of the log events, implementing cross correlation analysis and event flow logic correlation analysis to the events according to the instruction of strategies, as well as implementing risk evaluation on the log events and automatically responding. The method effectively reduces false-alarm, improves the objectivity of risk evaluation and the warning thereof has higher actual direction on users. The invention also provides a log event correlation analysis system corresponding to the method.

Owner:SHENZHEN Y& D ELECTRONICS CO LTD

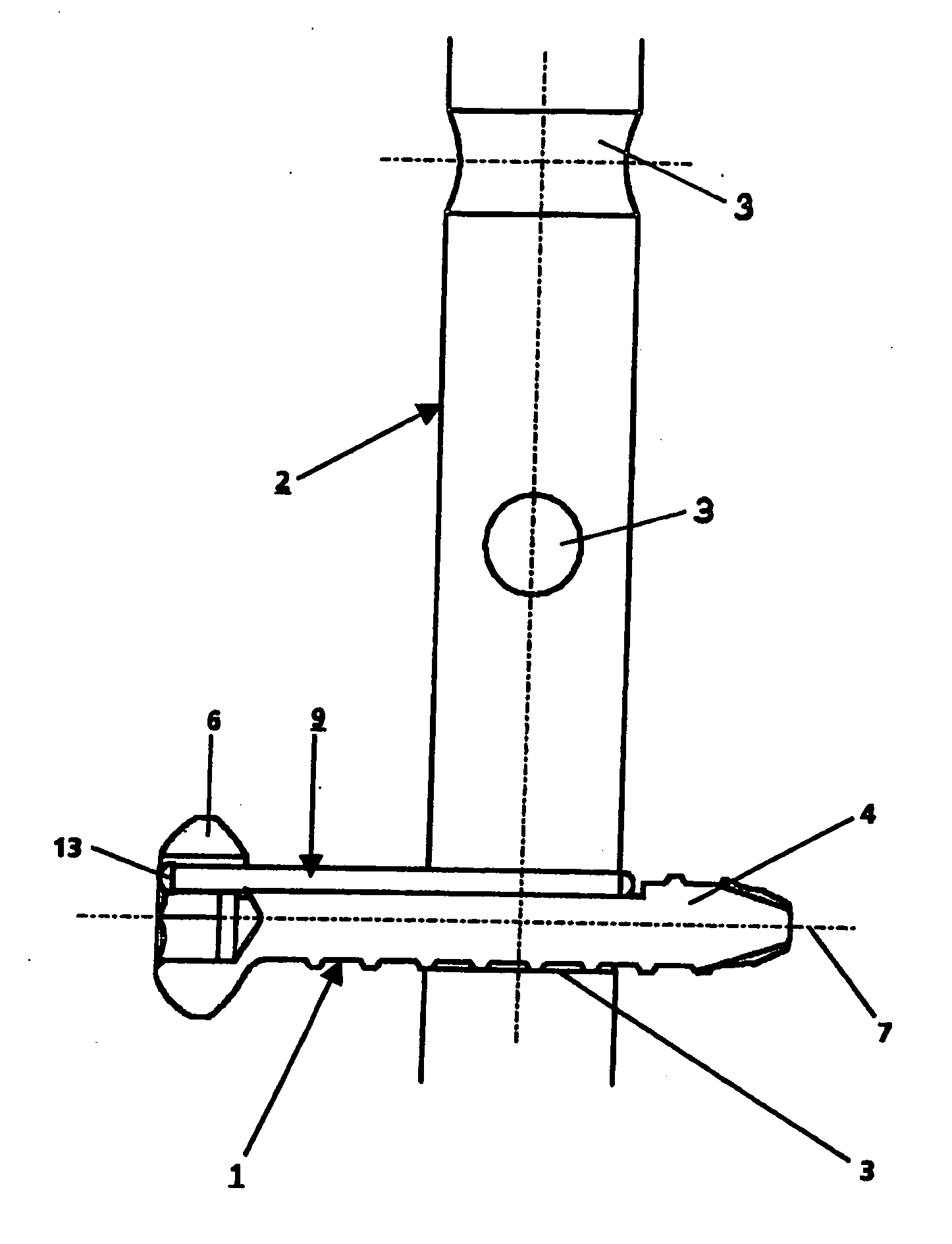

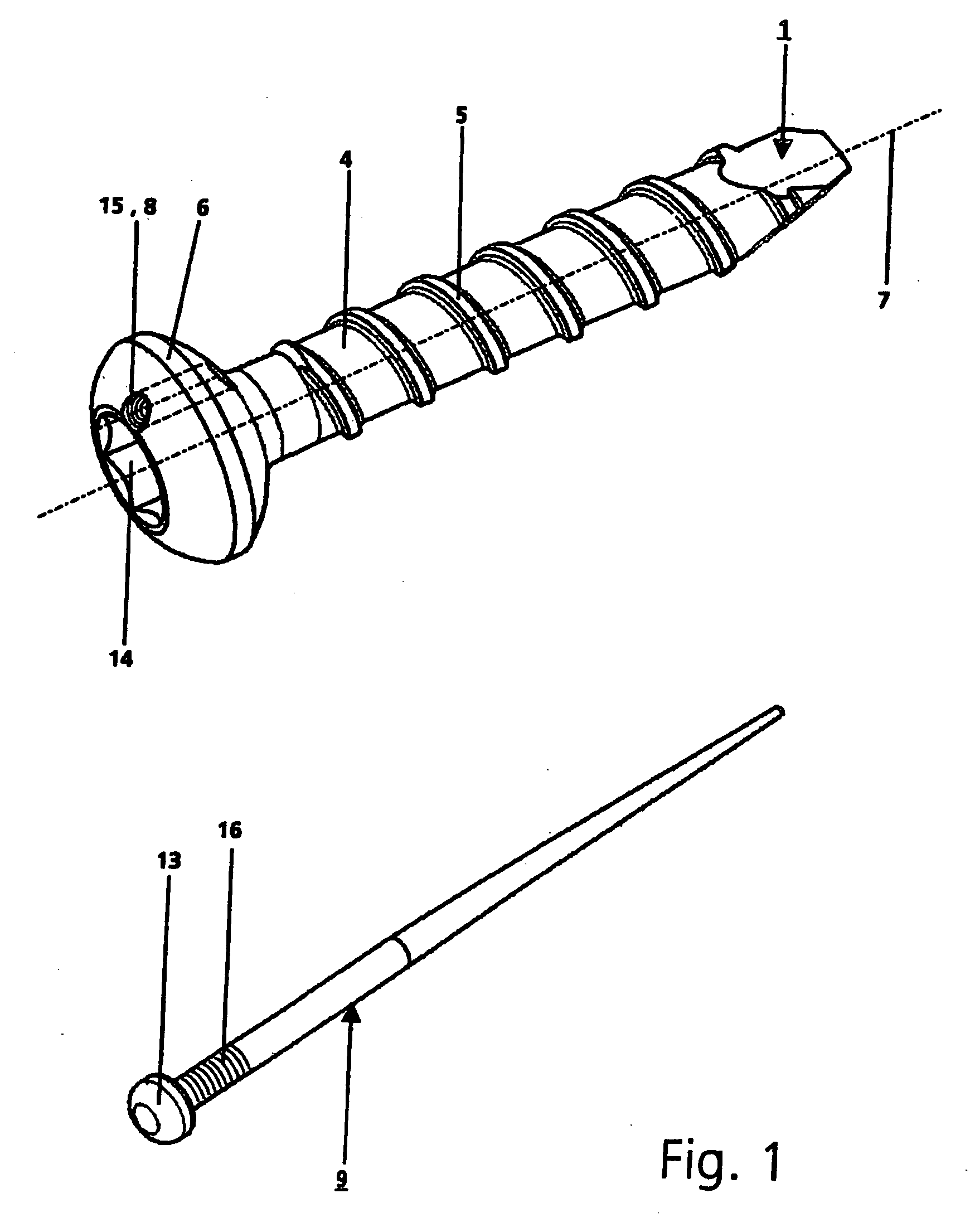

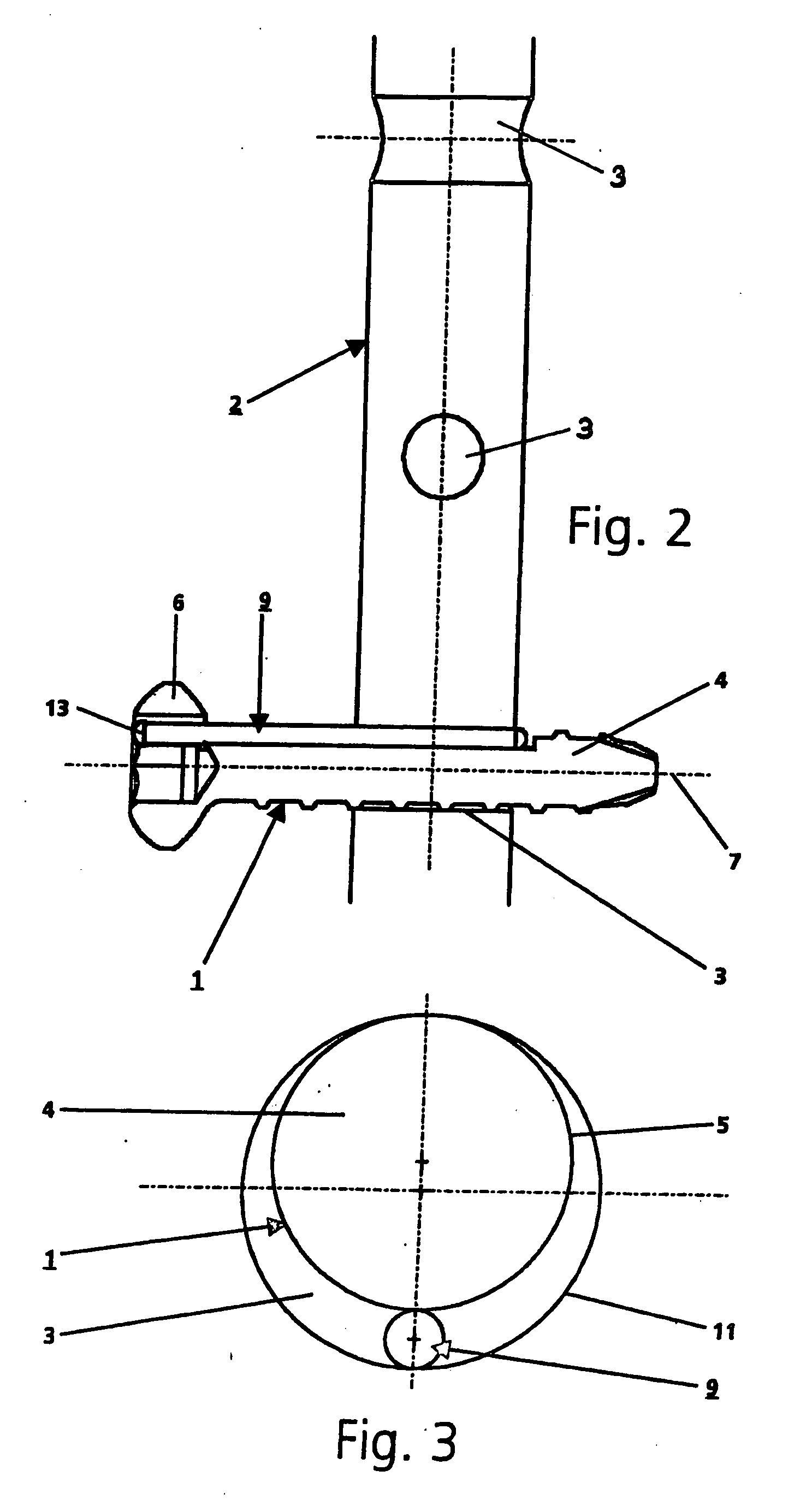

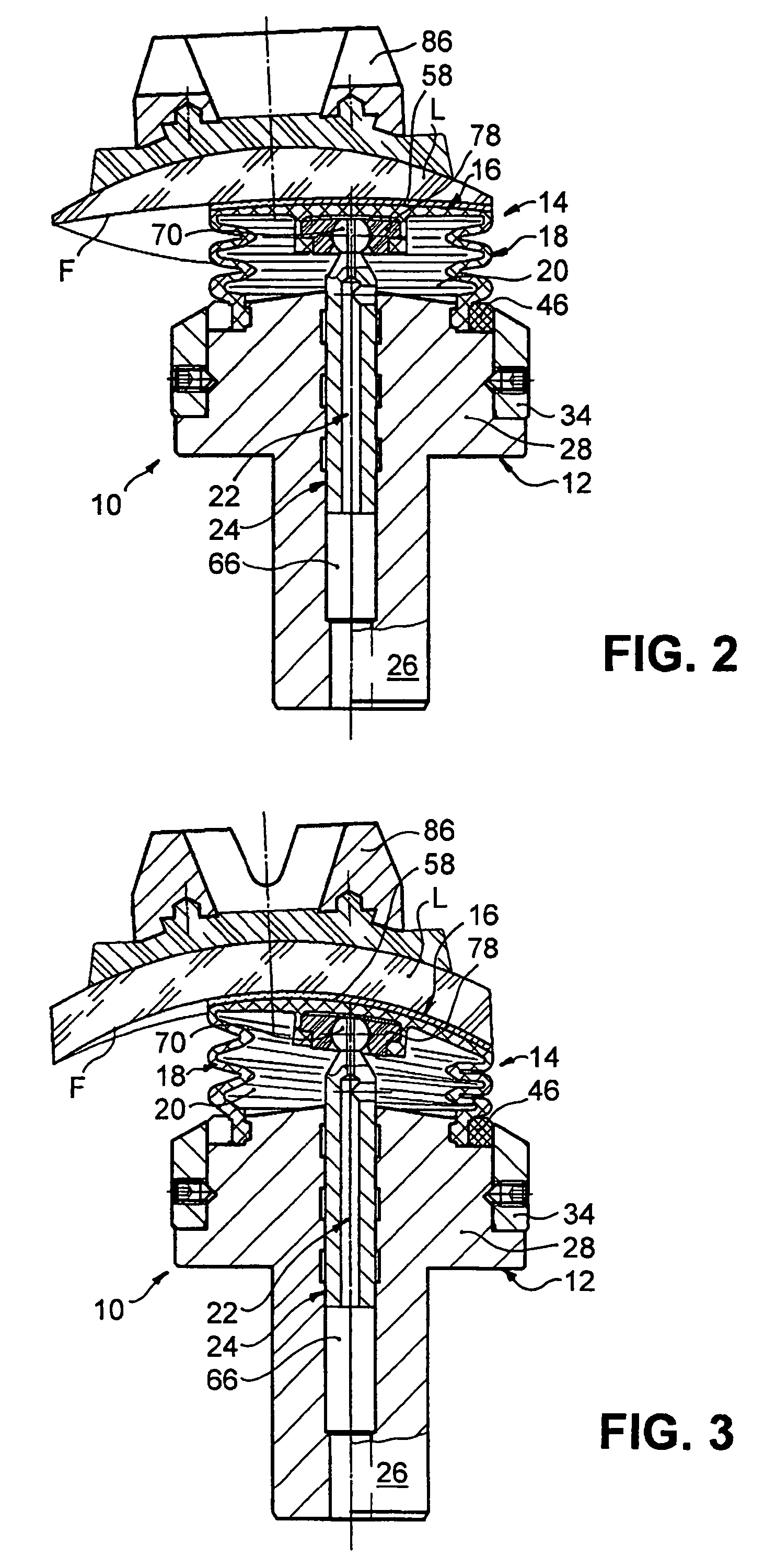

Locking screw for an intramedullary nail

ActiveUS20060064095A1Avoid piercingImprove guidanceInternal osteosythesisJoint implantsEngineeringScrew thread

A locking screw for an intramedullary nail having at least one transverse hole. The locking screw has a central longitudinal axis and includes a screw shank, which is at least partially provided with an external thread, and a screw head. The diameter of the screw head is greater than the outer diameter of the external thread, and the screw head includes a passage extending generally parallel to the longitudinal axis of the screw and the external thread. The passage is configured to receive a longitudinal wedge element. As a result, any gap between the locking screw and the intramedullary nail is eliminated and the screw is wedged in position in the transverse hole of the intramedullary nail.

Owner:DEPUY SYNTHES PROD INC +1

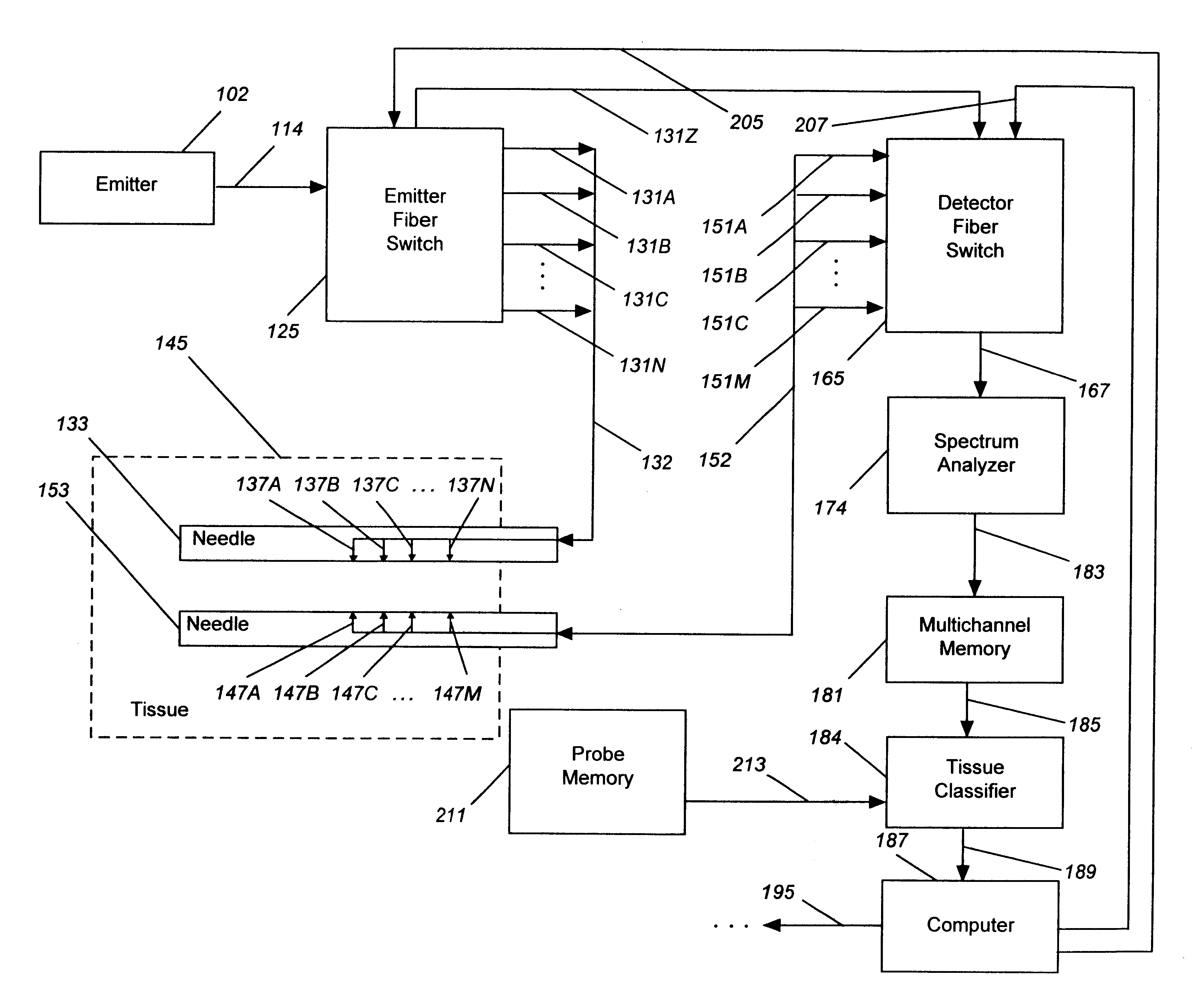

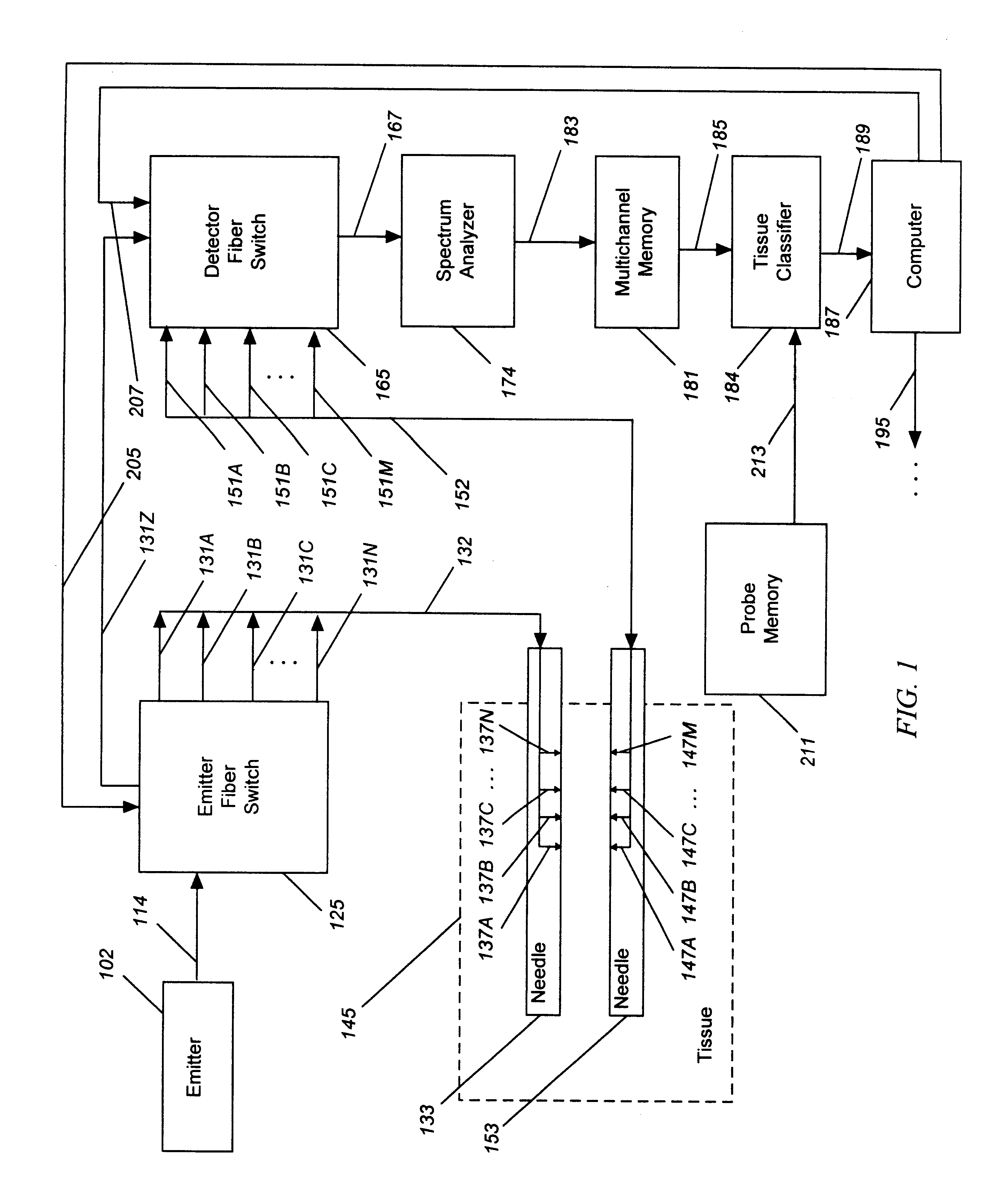

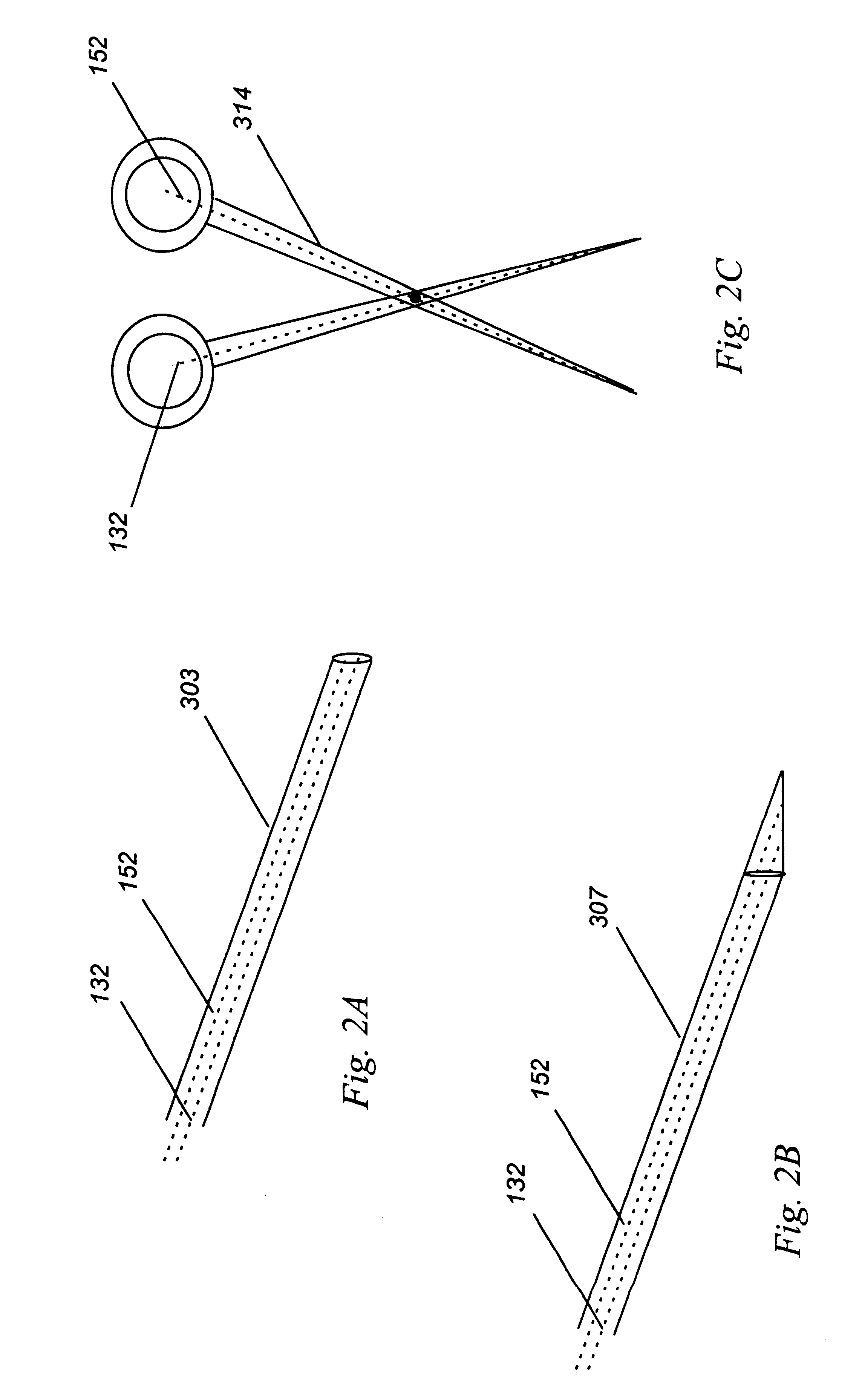

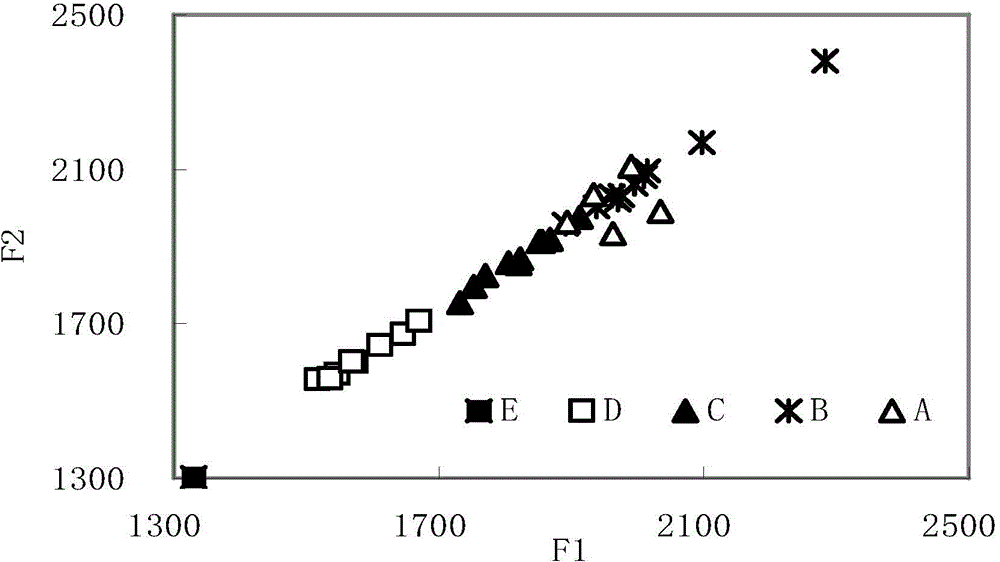

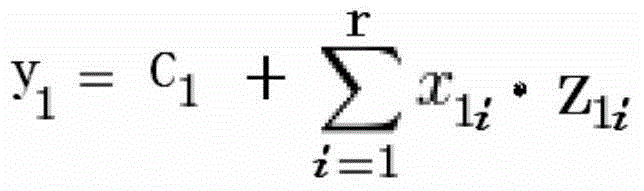

Device and method for classification of tissue

InactiveUS6594518B1Data augmentationIncrease valueDiagnostics using lightDiagnostics using spectroscopyOptical couplingBiological tissue

A diagnostic monitor for classifying biological tissue in which a light emitter (102) is optically coupled to the tissue to be diagnosed (145) and a light detector (174) is optically coupled to the tissue to detect a portion of the light which passes through the tissue. The tissue classifier (184) receives a signal from the detector and provides an optical classification output signal (195), wherein the tissue is classified by type or state, either for detection, localization, or imaging. A method of classifying tissue is also described.

Owner:J FITNESS LLC

Method for dynamic road mapping

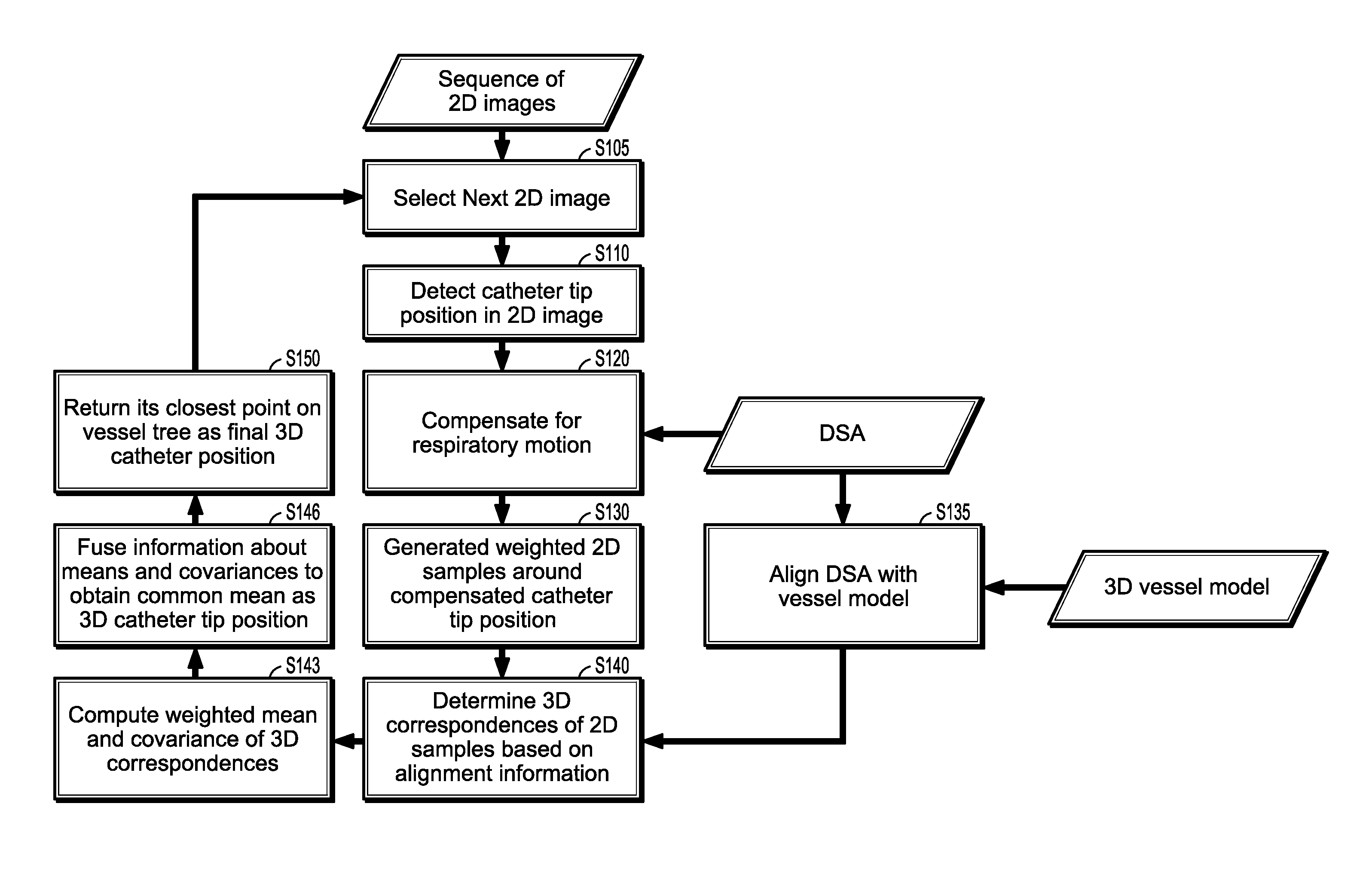

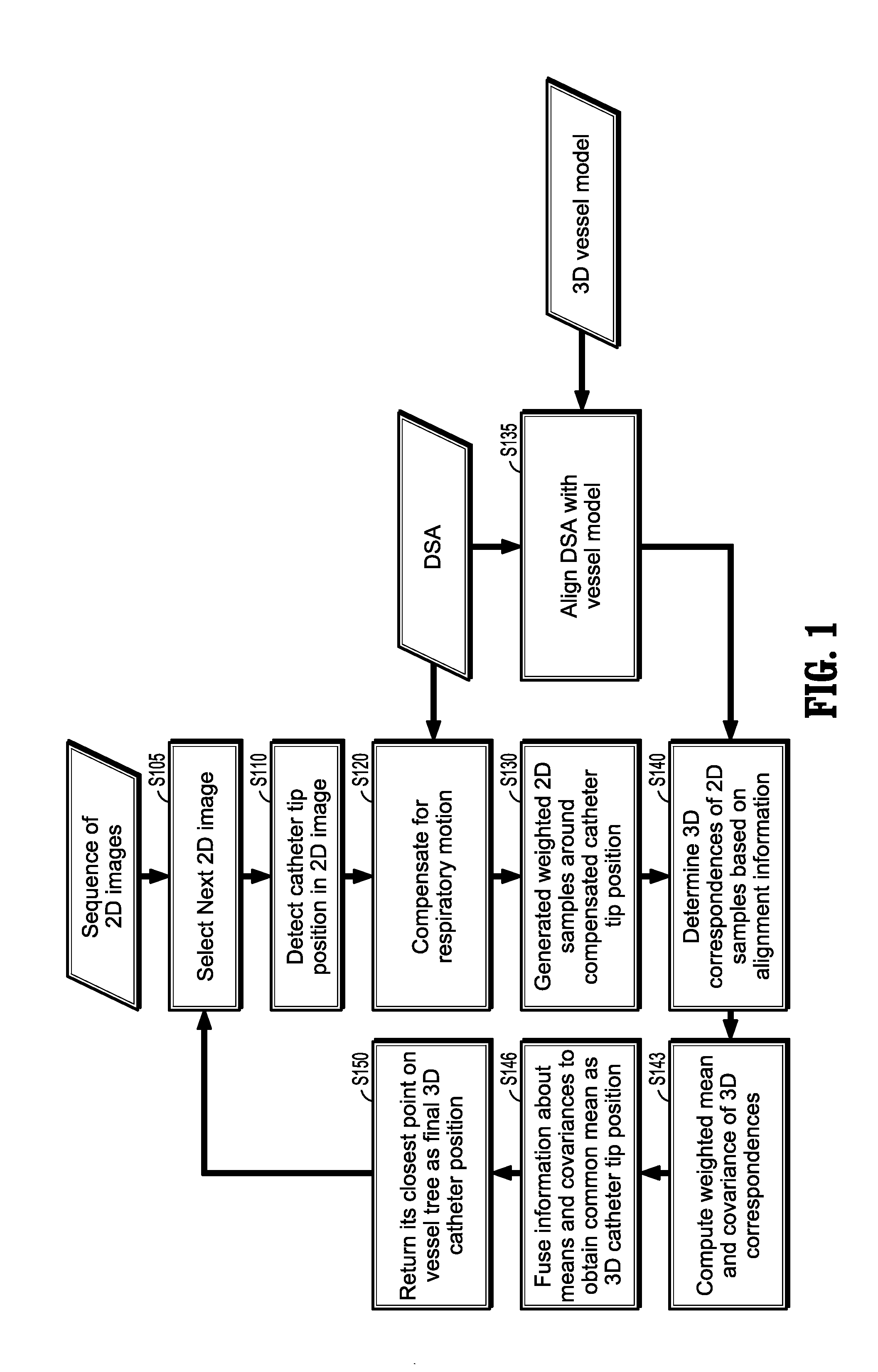

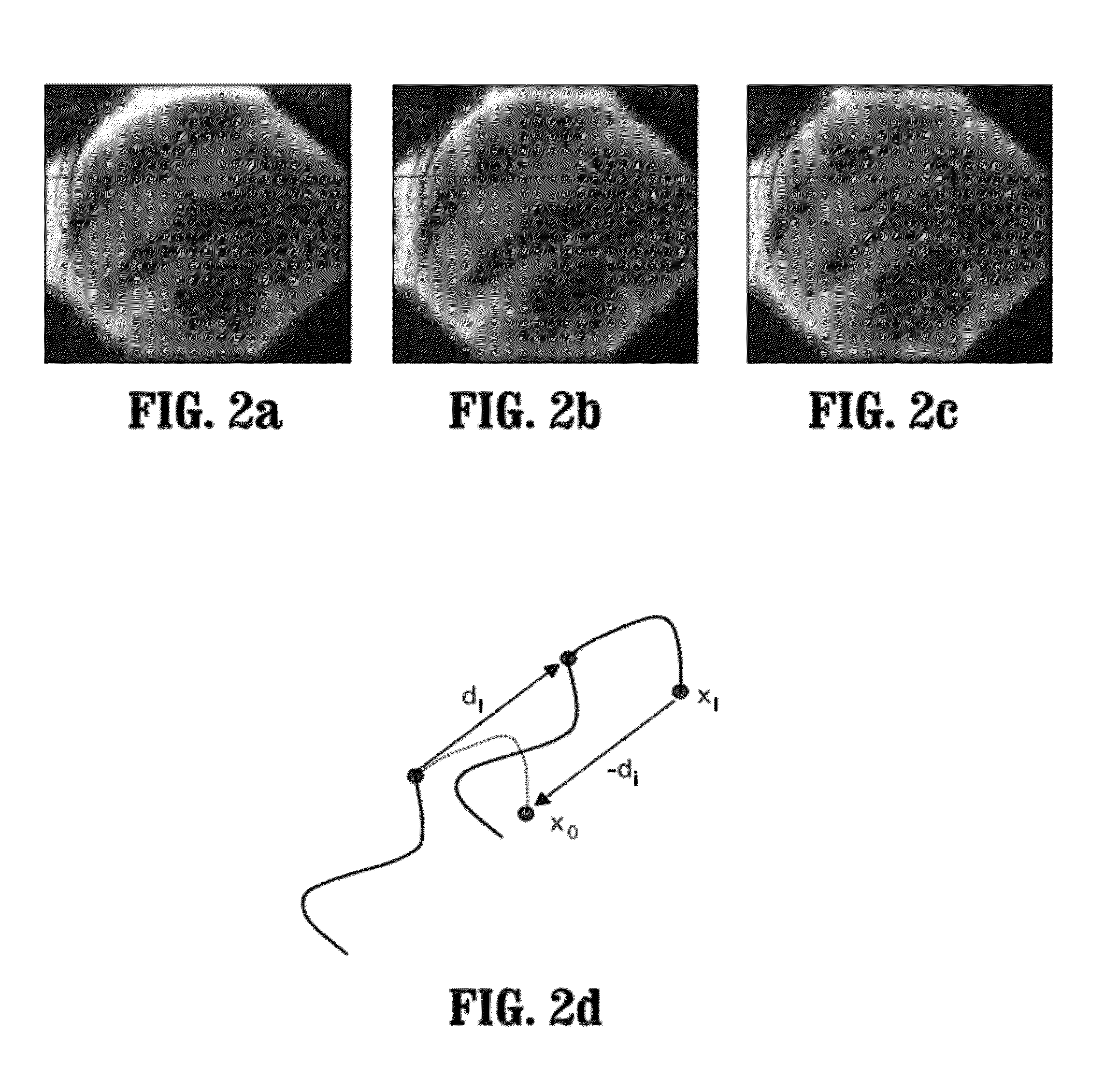

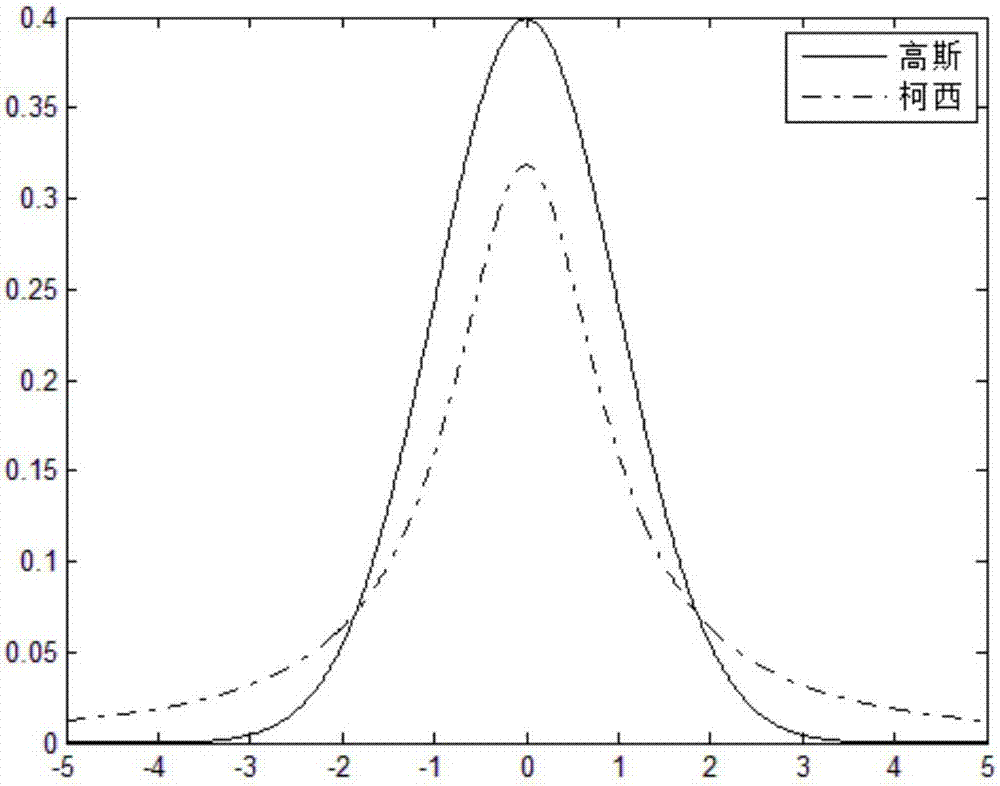

A method of determining a three-dimensional (3D) position of a catheter tip includes: compensating a 2D position of the tip of the catheter for respiratory motion to generate a compensated 2D catheter position, generating weighted sample points around the compensated 2D catheter position, determining correspondent points of the weighted sample points in a 3D image, computing a weighted mean and a weighted covariance of each correspondent point, and determining the 3D position of the catheter tip in the 3D image from a fusion of the weighted means and weighted covariances.

Owner:SIEMENS HEALTHCARE GMBH

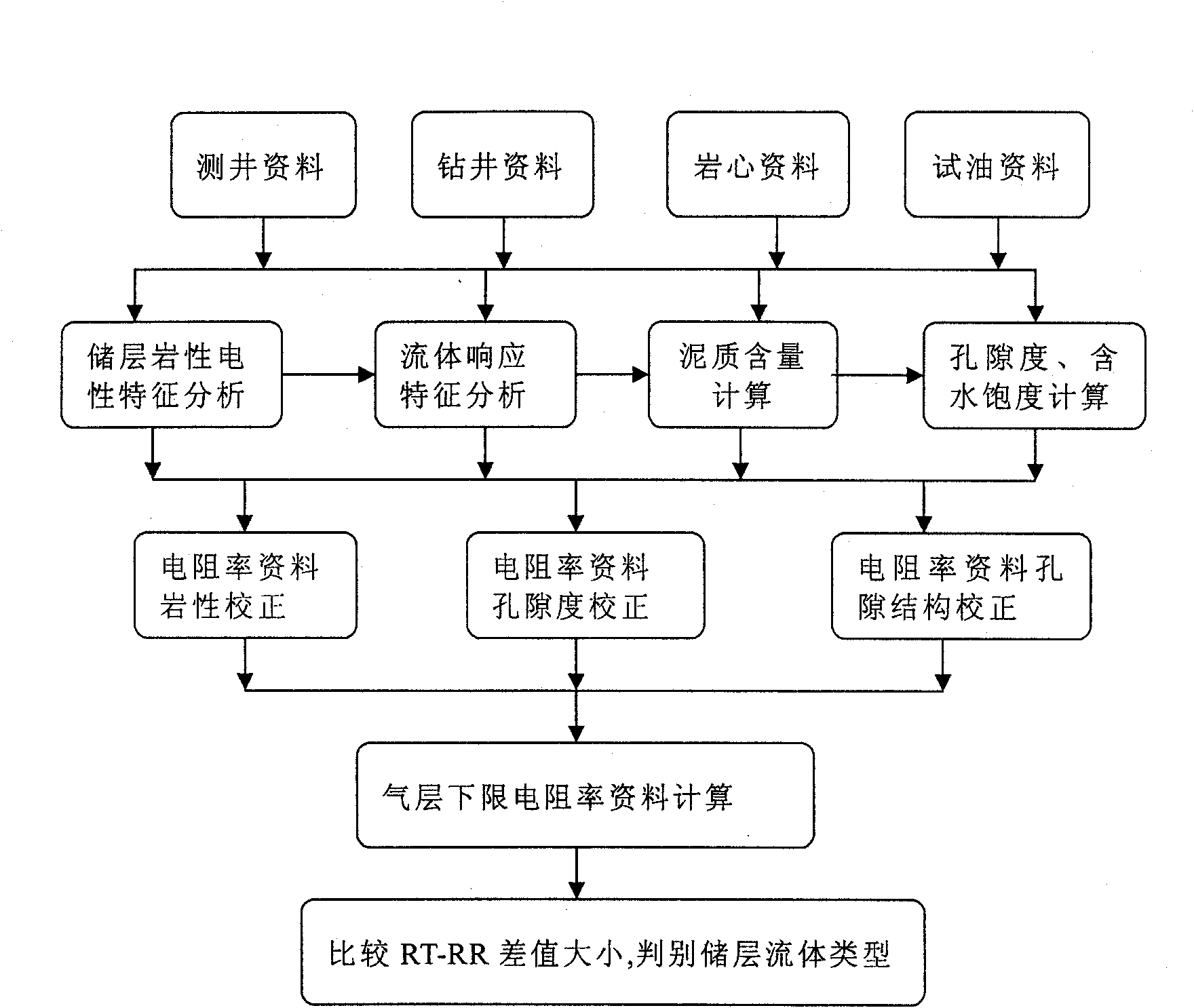

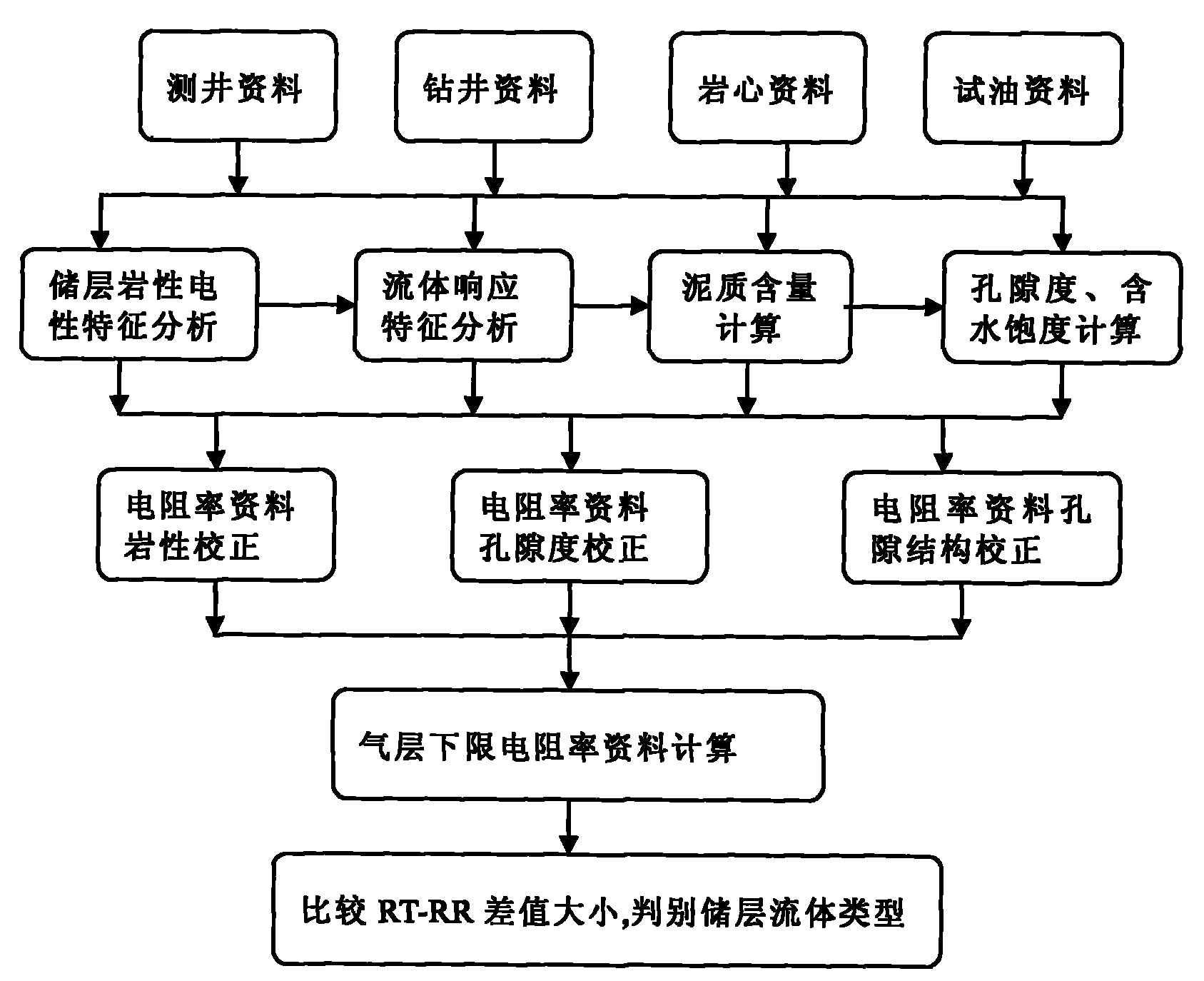

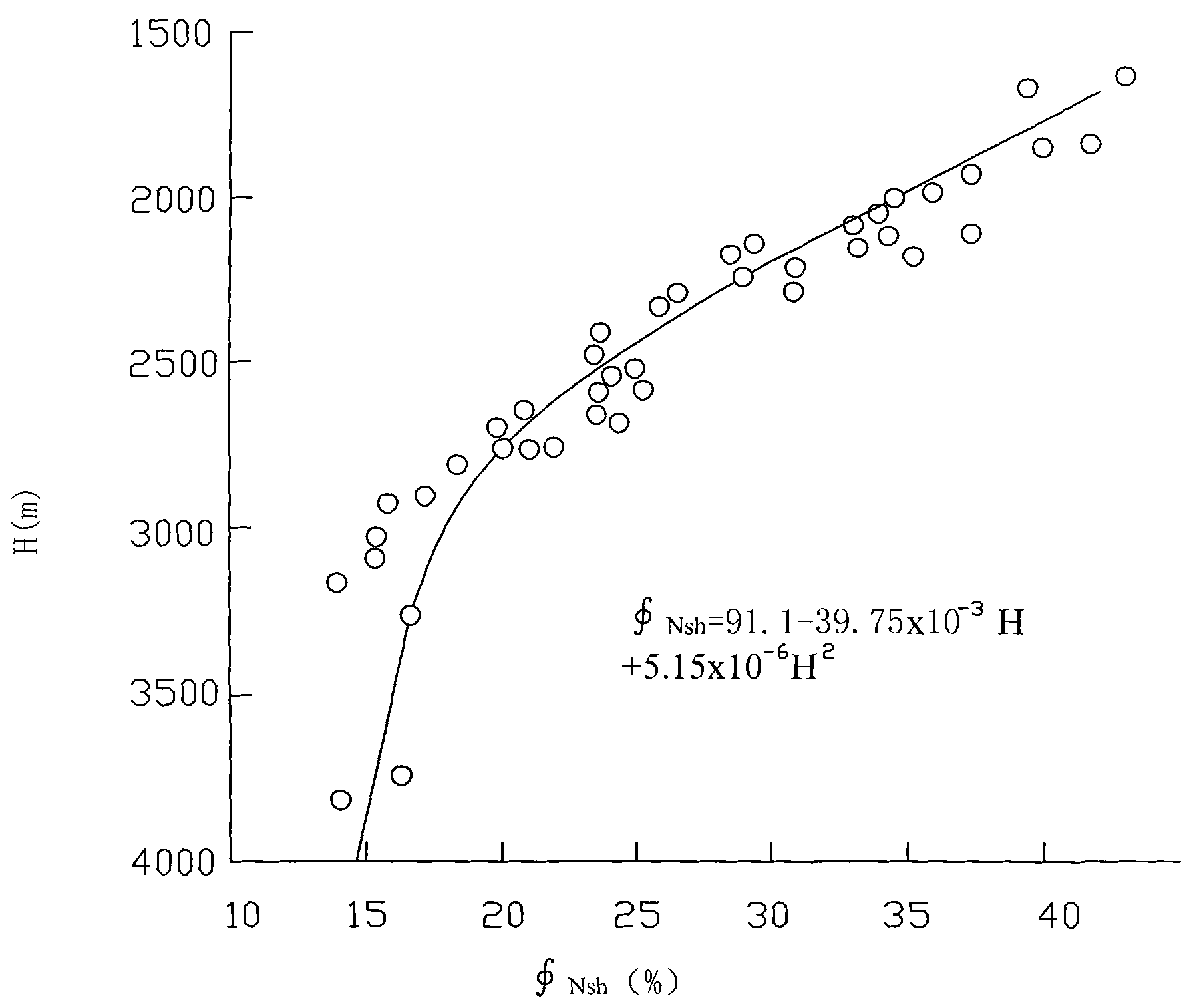

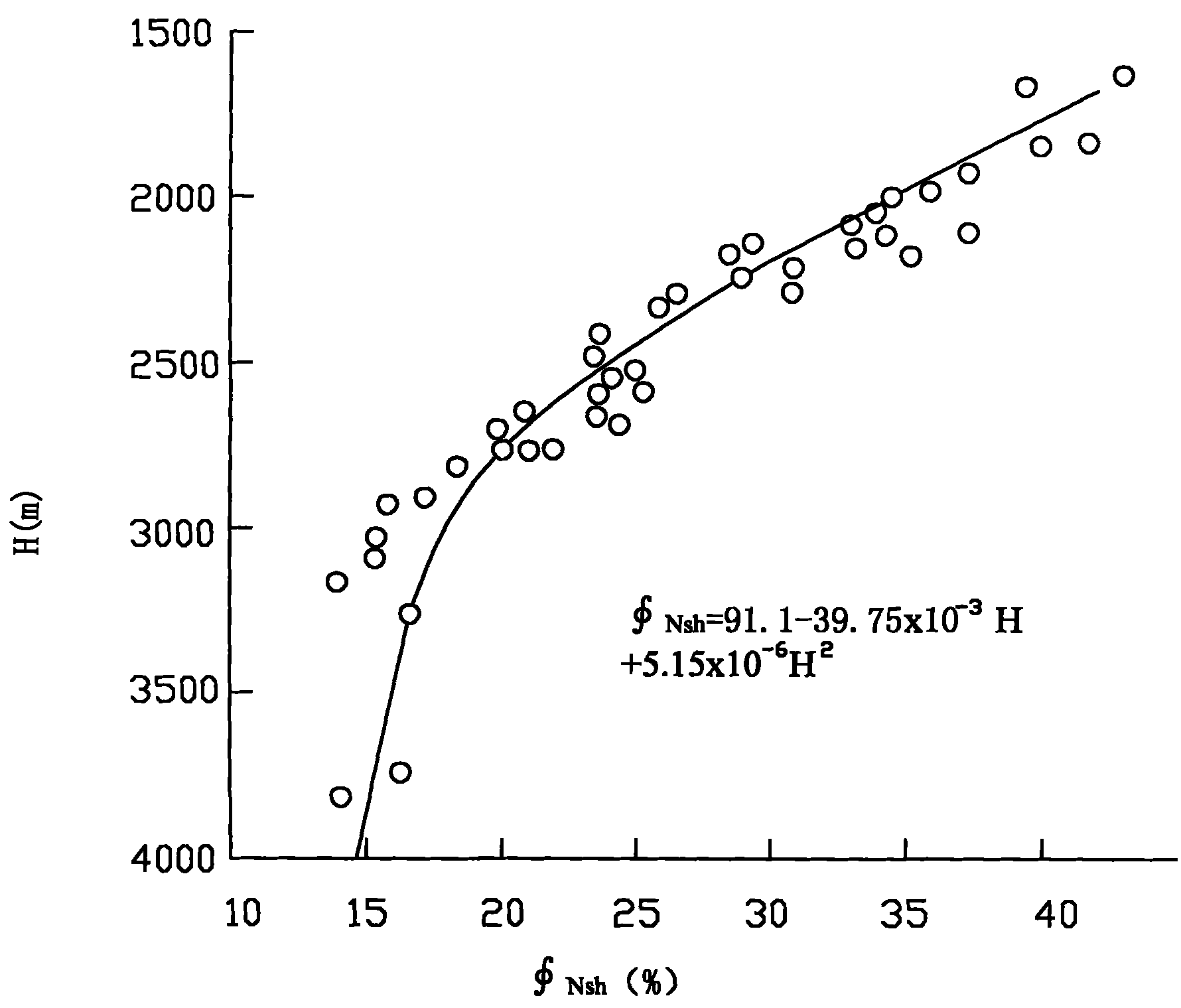

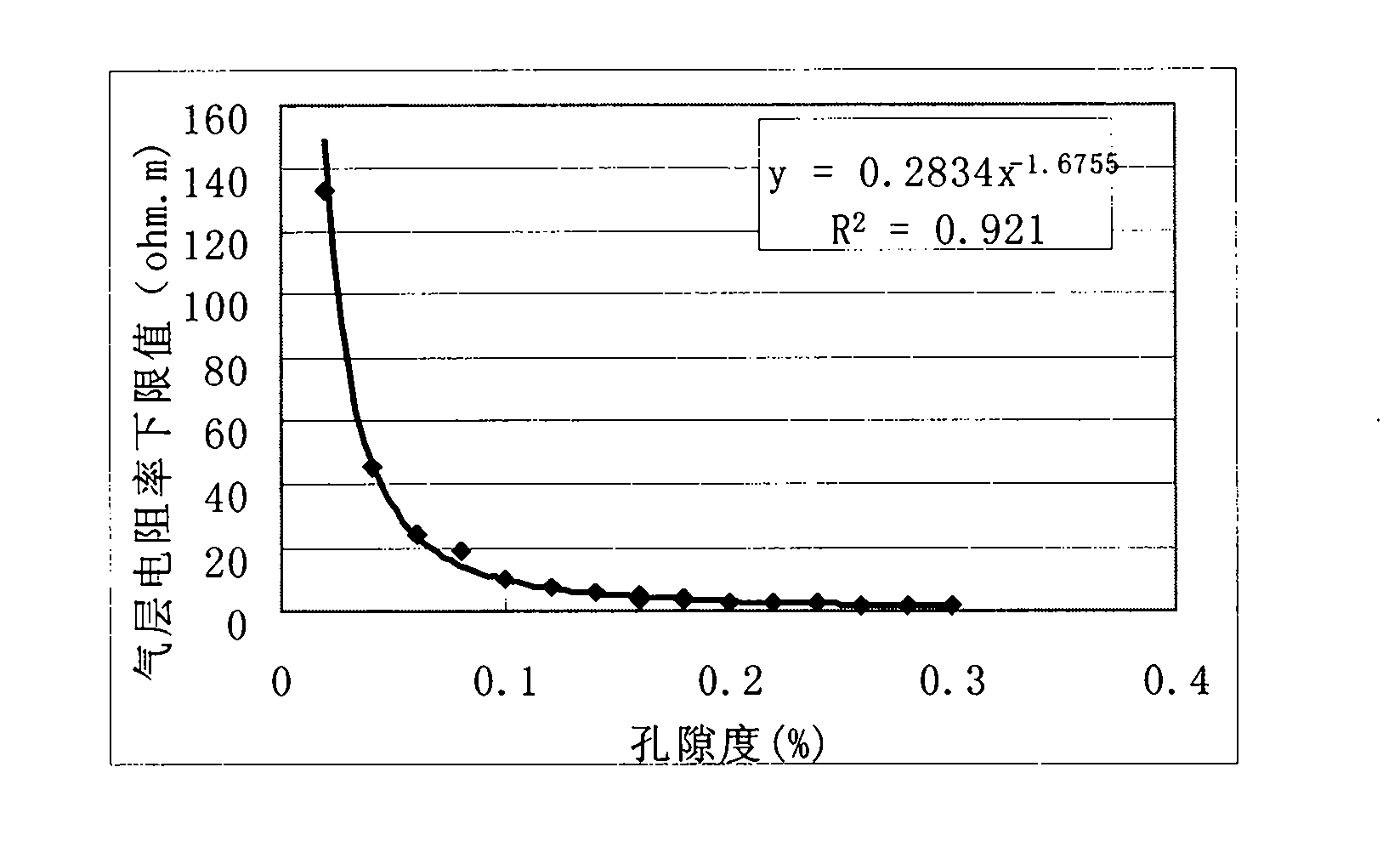

Method for distinguishing reservoir fluid type by adopting resistivity data

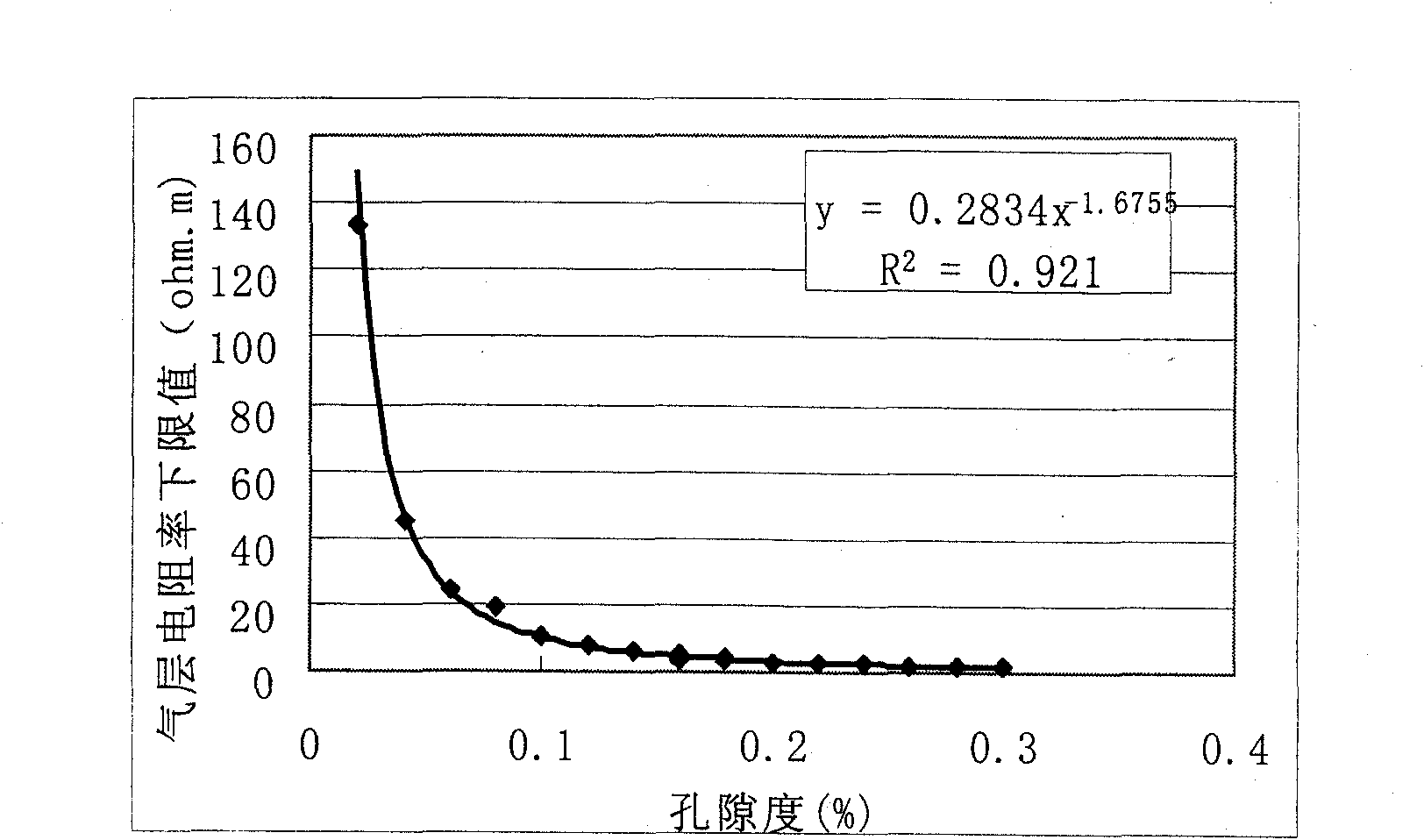

ActiveCN101930082AMastering Real Response PropertiesImprove the identification rateElectric/magnetic detection for well-loggingMaterial resistancePorosityLower limit

The invention discloses a method for distinguishing a reservoir fluid type by adopting resistivity data, relating to the technological field of petroleum and gas logging, geology and core test analysis. The method comprises the following steps of: a. logging by utilizing core data scales and accurately calculating reservoir shale content, rock constituent and porosity; b. eliminating the influence of rock characters and the porosity on resistivity; c. utilizing a core test to obtain the parameters of m, a, n and b reflecting a pore structure, calculating the resistivity lower limit RR of an air layer and eliminating the influence of the pore structure on the resistivity; and d. distinguishing the reservoir fluid type by comparing a deep-induction and deep- lateral resistivity value RT andthe resistivity lower limit RR of the air layer obtained in the step c. The invention eliminates the influence of non-fluid factors of the rock characters, the porosity, the pore structure and the like on the resistivity, and maintains and utilizes the response characteristics of fluids with different resistivities so as to greatly enhance the coincidence rate for distinguishing the reservoir fluid type.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

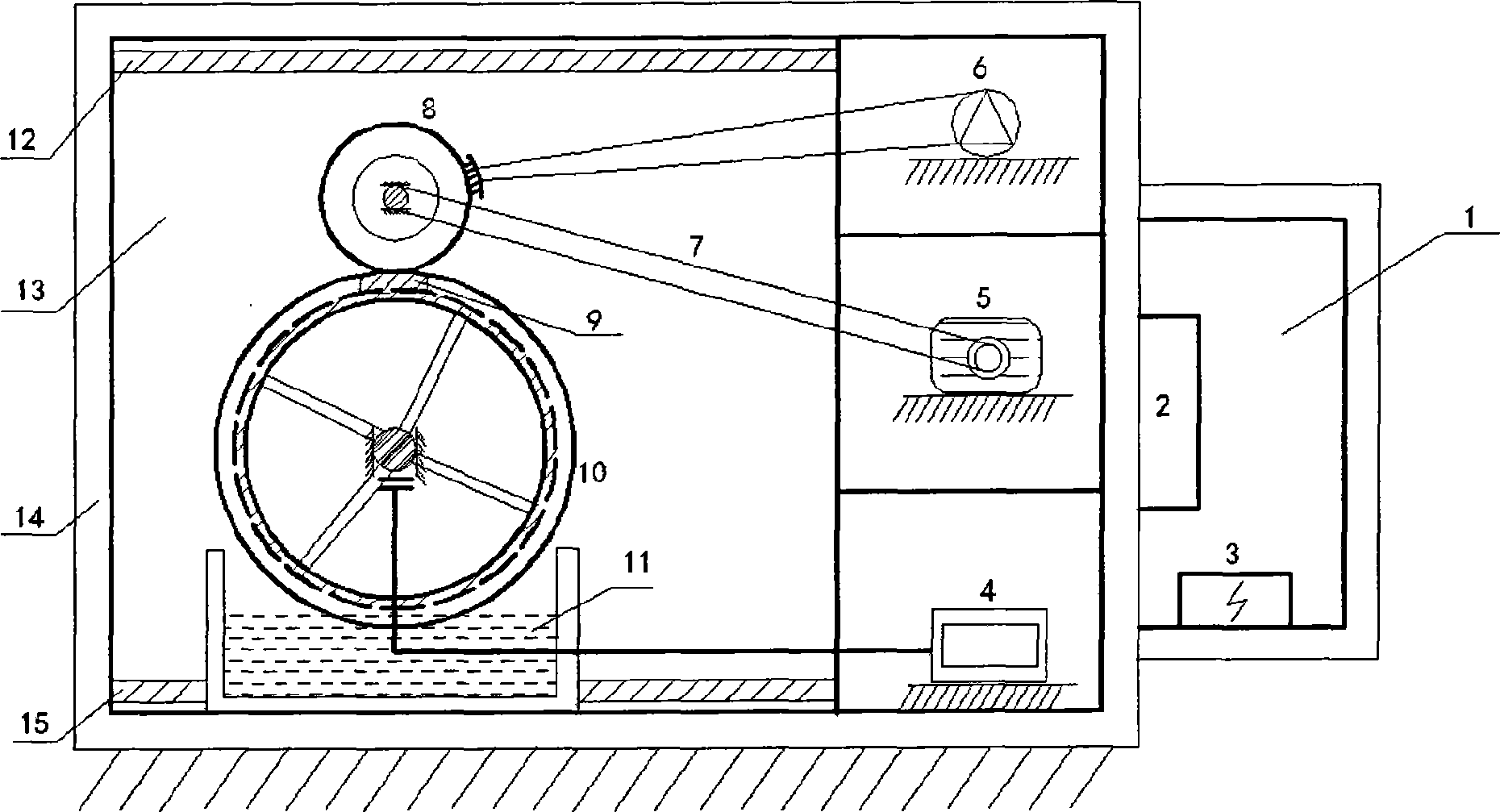

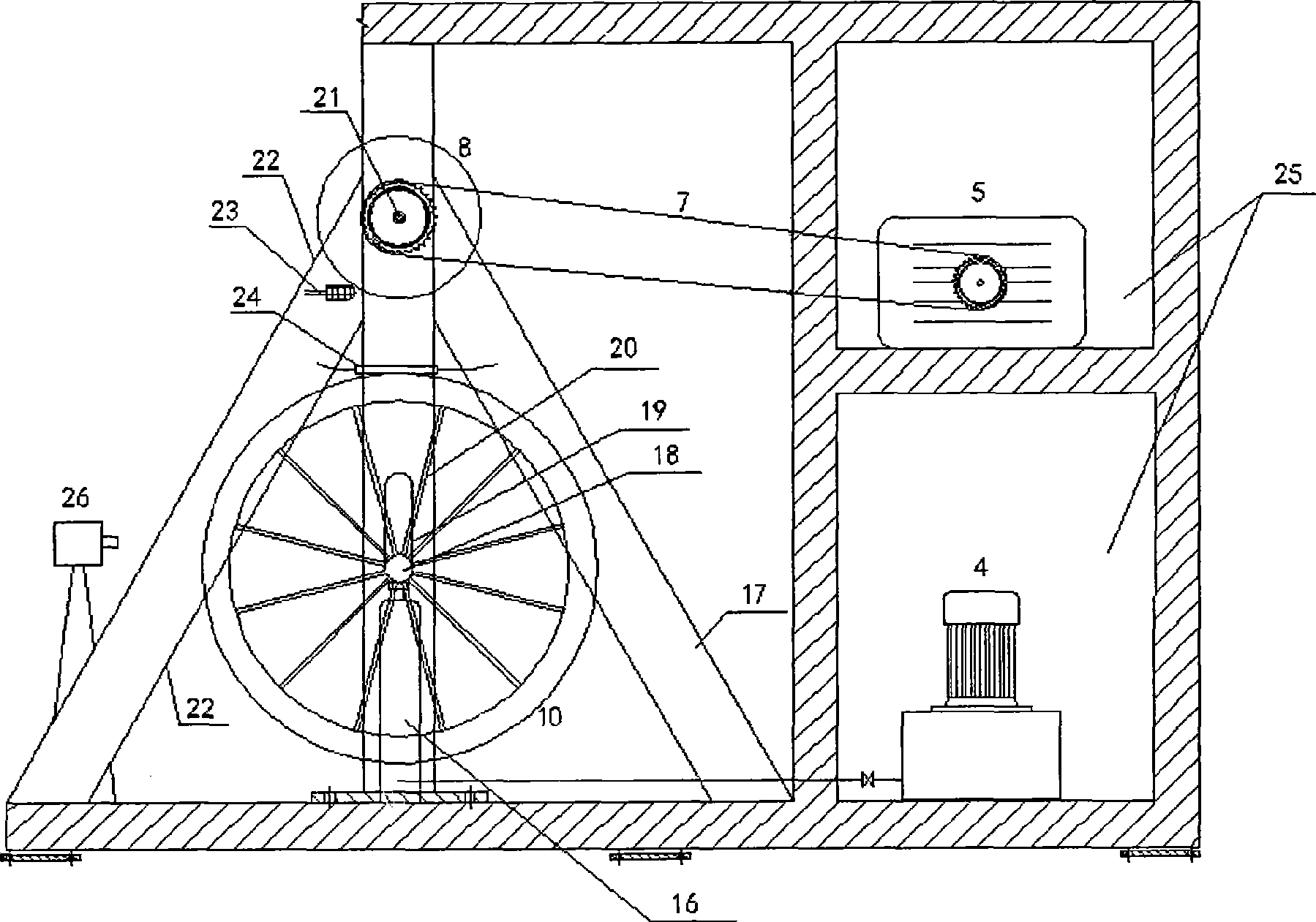

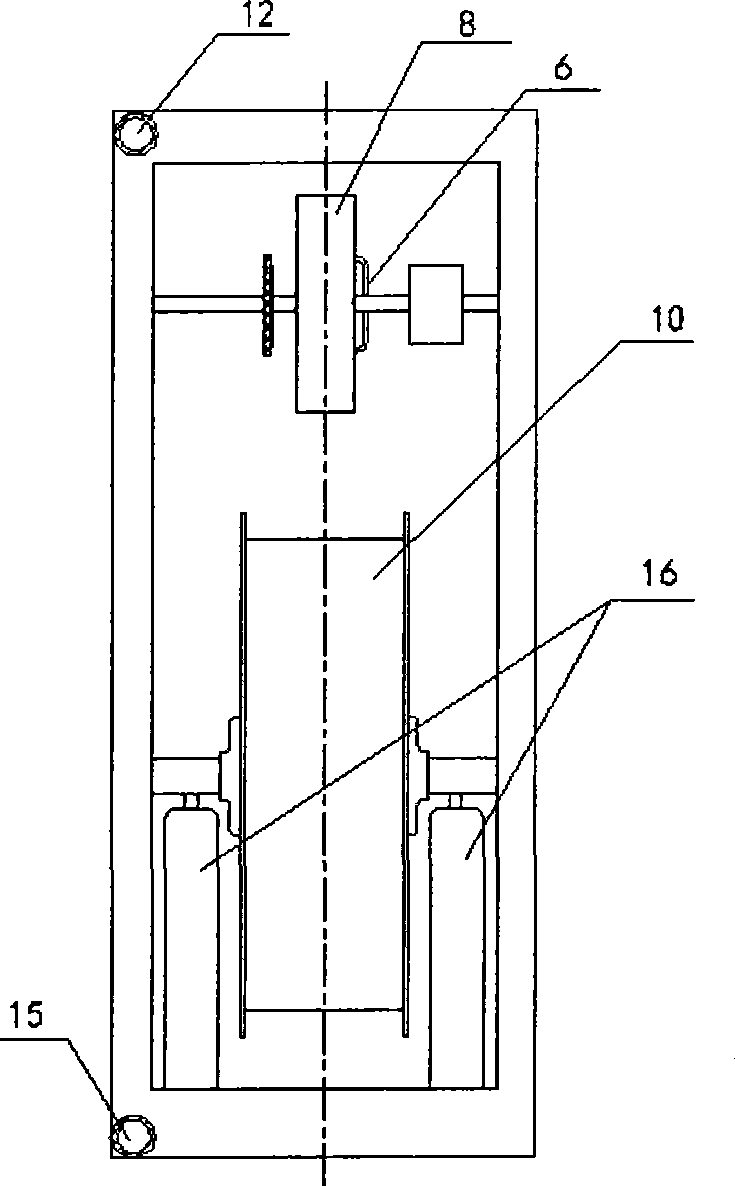

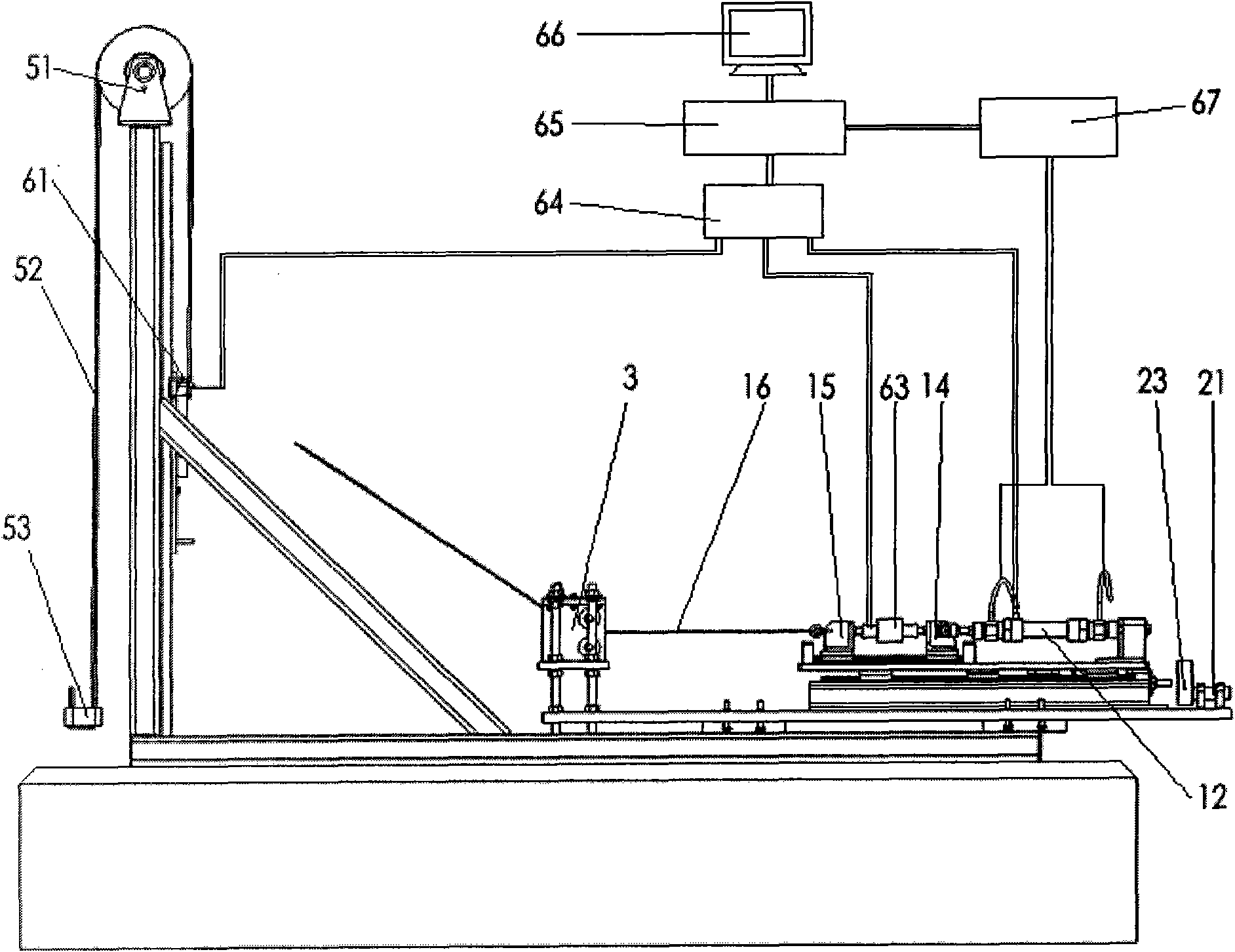

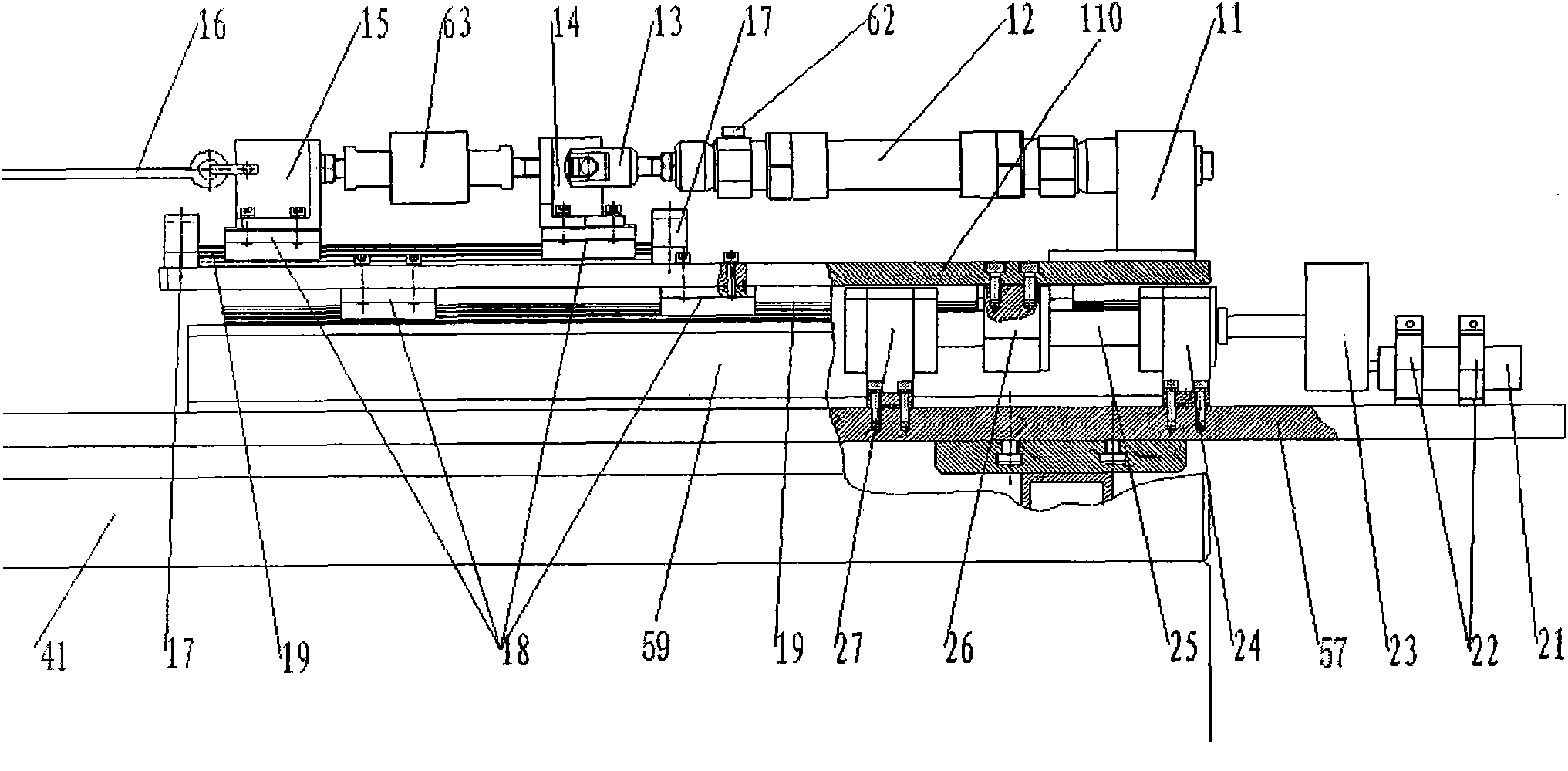

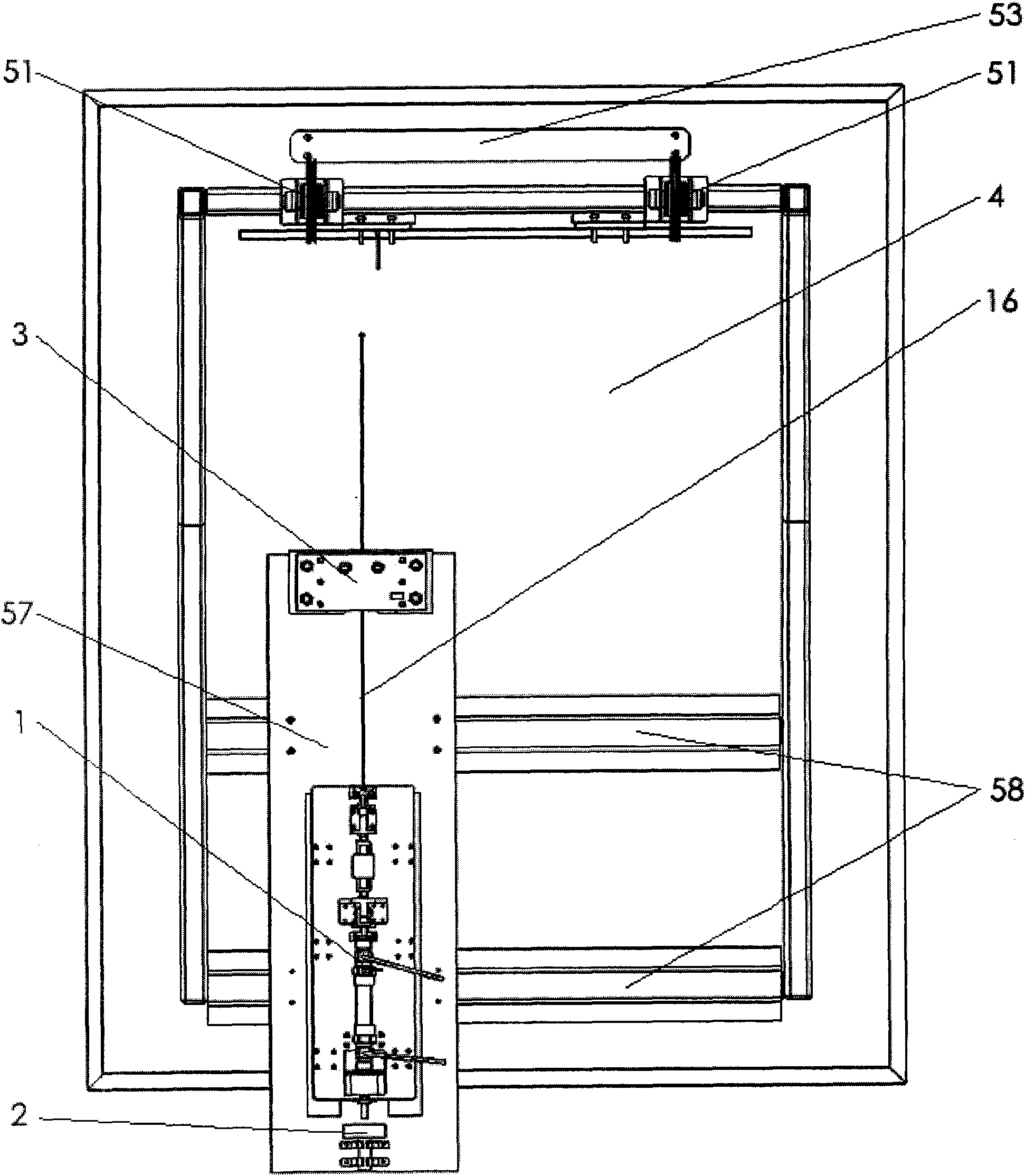

Method for testing accelerating and loading of main drive wheel type pavement materials and device

InactiveCN101532934AImprove guidanceImprove applicabilityMaterial strength using tensile/compressive forcesUsing mechanical meansWater bathsDrive wheel

The invention discloses a method for testing accelerating and loading of main drive wheel type pavement materials and a device thereof. The device comprises a control console, a PLC control box, an electronic box, a hydraulic device, a motor, a brake, a driving chain and chain wheel, a drive wheel, a driven wheel, a water bath tank, a circulated air inlet duct, a thermostatic chamber, a test cabinet and a circulated air outlet duct; the control console is positioned on the outside of the test cabinet; the hydraulic device is connected with the driven wheel; the motor is connected with the drive wheel via the driving chain and chain wheel; the drive wheel is fixed on a bracket; the driven wheel is positioned in a guide slot; the water bath tank is arranged right below the driven wheel; a ranging laser is positioned on one side of the driven wheel; one end of the drive wheel is provided with a microphone and the bottom thereof is provided with a torque sensor; the contact surface of the drive wheel and a test piece is provided with a pressure sensor; two tachometers are fixed on the bracket and are respectively positioned on the outsides of the drive wheel and the driven wheel. The device has simple structure, low prices, flexible use and good reliability.

Owner:SOUTH CHINA UNIV OF TECH

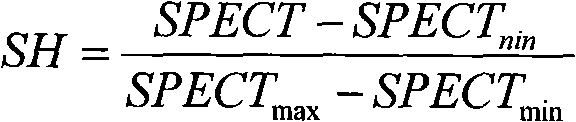

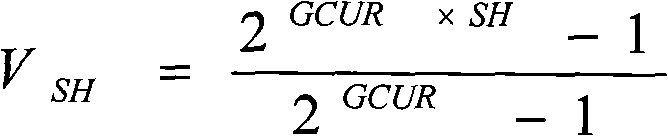

Method for judging reservoir fluid type of difference between density porosity and neutron porosity

ActiveCN101832133AImprove the identification rateImprove guidanceBorehole/well accessoriesLithologyRock core

The invention discloses a method for judging the reservoir fluid type of a difference between density porosity and neutron porosity and relates to the technical fields of oil and gas logging and geology and core test analysis. The method comprises the following steps: 1) accurately calculating the shale content, the rock composition, the density porosity and the neutron porosity of a reservoir bycore data calibrating logging and logging data environmental correction; 2) removing the influence of factors of lithology, well diameter and mud invasion on density and neutron data; and 3) establishing standards for judging the reservoir fluid type by utilizing the response difference of the density and the neutron data to gas and formation water and by comparing the values of the density porosity and the neutron porosity. When the invention judges the reservoir fluid type by utilizing the density and the neutron data, non-fluid influencing factors, such as lithology, borehole conditions, mud invasion and the like are removed, therefore, influence features of different fluids to the density and the neutron data can be truly reflected, and the coincidence rate for judging the reservoir fluid type can be enhanced to above 90 percent from the existing 70 percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

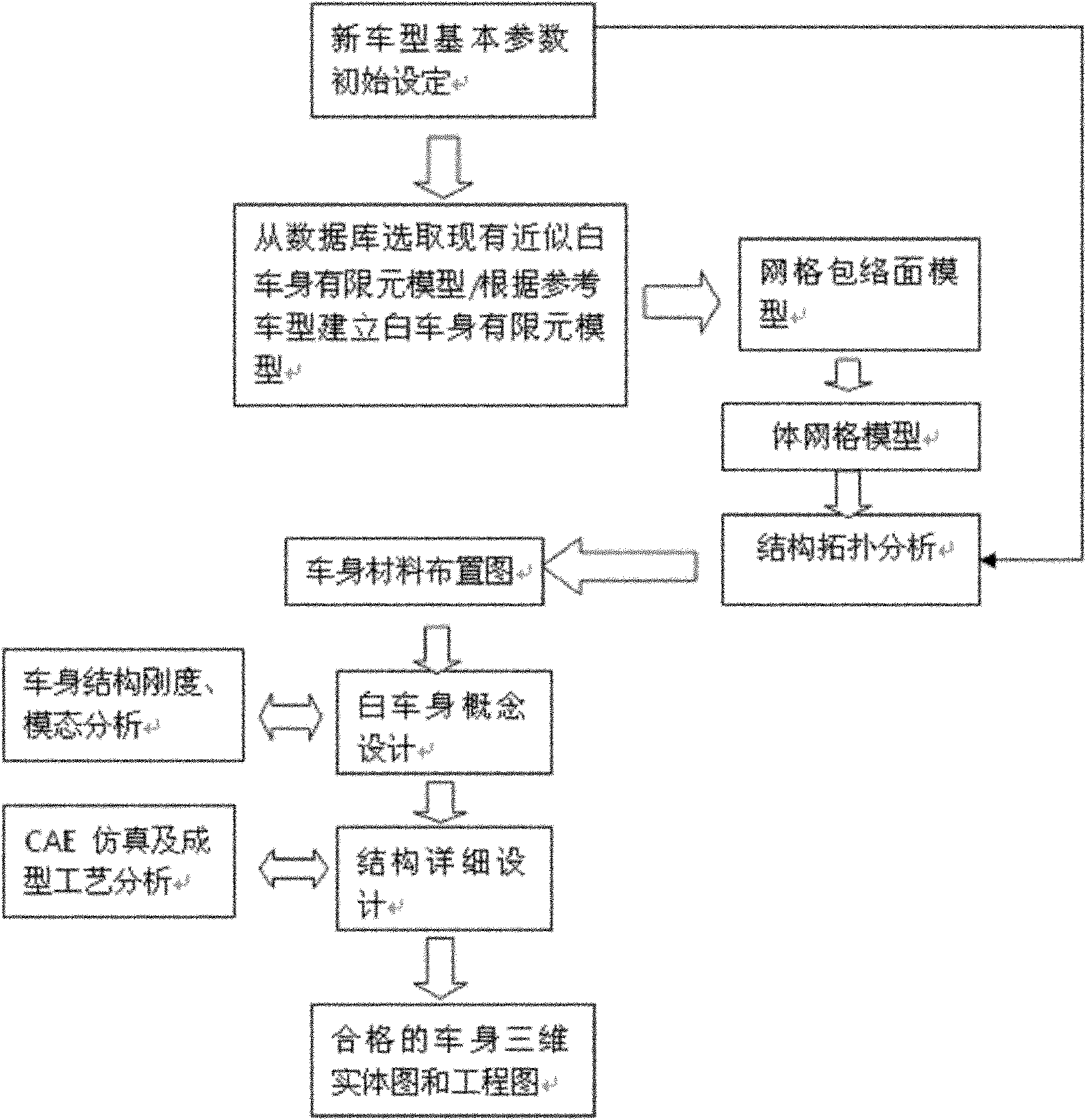

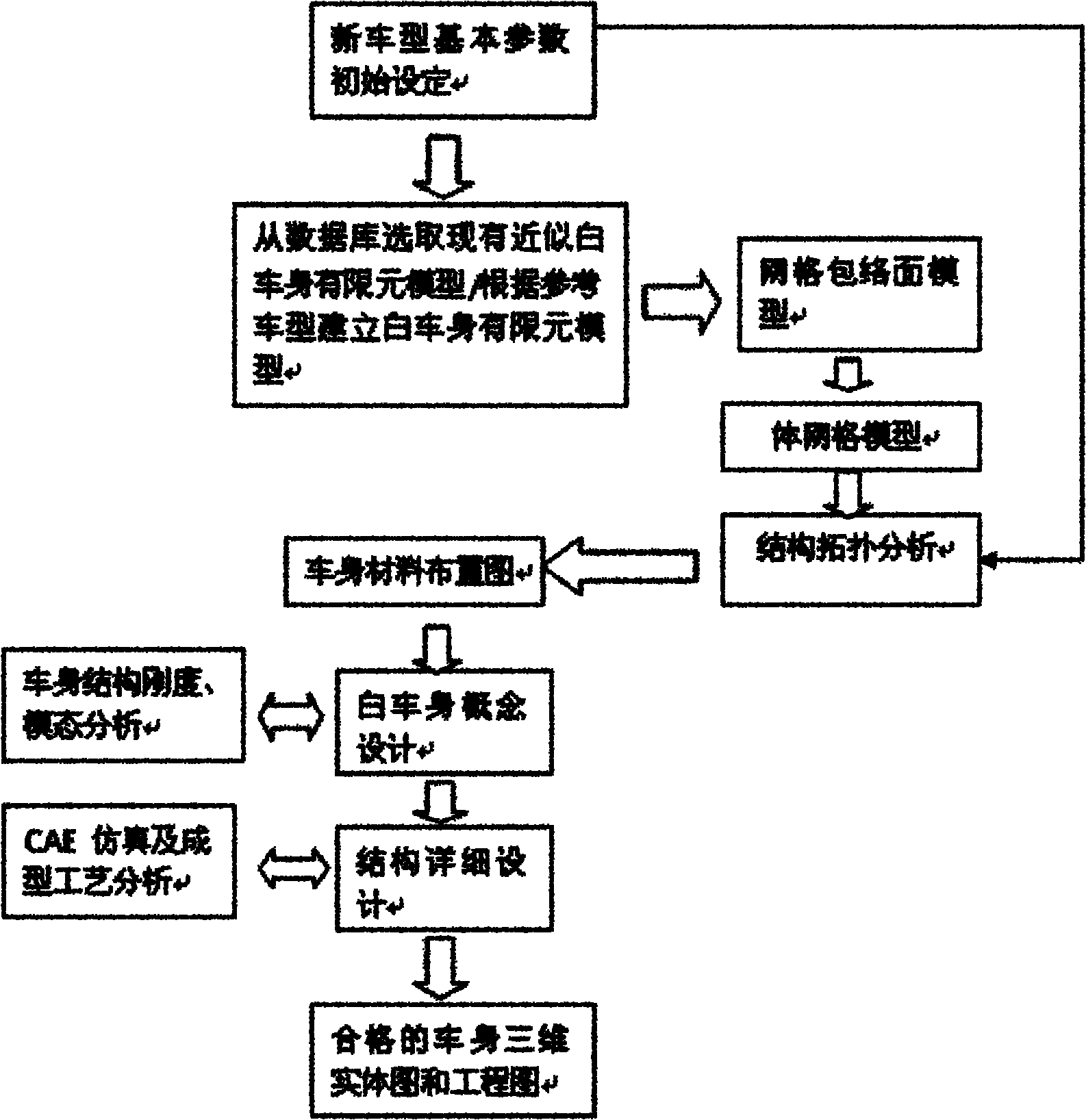

Method for designing automobile body structure layout

InactiveCN102012958AImprove guidanceShorten the development cycleAerodynamics improvementSpecial data processing applicationsElement modelTopology optimization

The invention relates to a method for designing automobile body structure layout. The method comprises the following steps of: 1) initially setting the parameters of a new type automobile, 2) choosing the white automobile body finite element models having similar structures and sizes, or directly building a white automobile body finite element model, 3) generating a grid enveloped model according to the white automobile body finite element model, 4) generating a body grid model according to the grid enveloped model, 5) topologically optimizing and analyzing according to a target parameter based on the body grid model, 6) according to an analyzed result and drawing an automobile body material layout diagram, 7) designing conception according to the layout diagram, and 8) designing the layout structure in detail according to the data of the conception design, performing simulating analysis of strength, NVH and impact performance CAE and formability process analysis according to the data of the detailed design of the layout structure, and modifying so as to acquire a three-dimensional digitized product model fit for volume production. The automobile body structure layout has the advantages of shortened developing period and lowered researching and developing cost.

Owner:CHERY AUTOMOBILE CO LTD

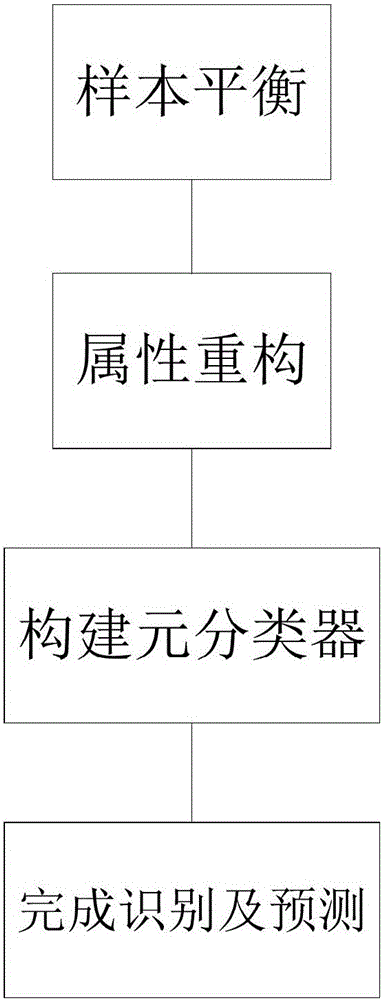

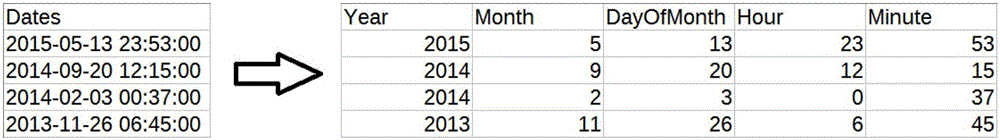

Criminal identification and forecast method

InactiveCN106096623AInability to handle limitationsHigh computational complexityData processing applicationsCharacter and pattern recognitionSupport vector machineSentence processing

The invention provides a criminal identification and forecast method. The method adopts a data pre-processing method in data mining; aiming at criminal information such as data, street address, criminal police zone, week, criminal type, criminal description and sentence processing, attribute reconstruction, feature extraction and feature selection are performed, the correlation between the criminal information is mined, a characteristic factor with maximum difference is generated, and the correlation between the characteristics factor and a criminal result, namely the criminal type is generated; and then a model integrating Gaussian Naive Bayes, a neural network, Logistic regression, regularized regression, K neighbor, random forest, a support vector machine and an XGBoost learning algorithm is built to obtain an element classifier based on a weighted voting classifier having highlight classification and favorable clustering effect, reconstructed data is analyzed, processed and identified, a criminal condition of a city in future is forecasted, an individual criminal map of the city is drawn, and the effects of promoting and regulating city public security and management are further achieved.

Owner:SUN YAT SEN UNIV +2

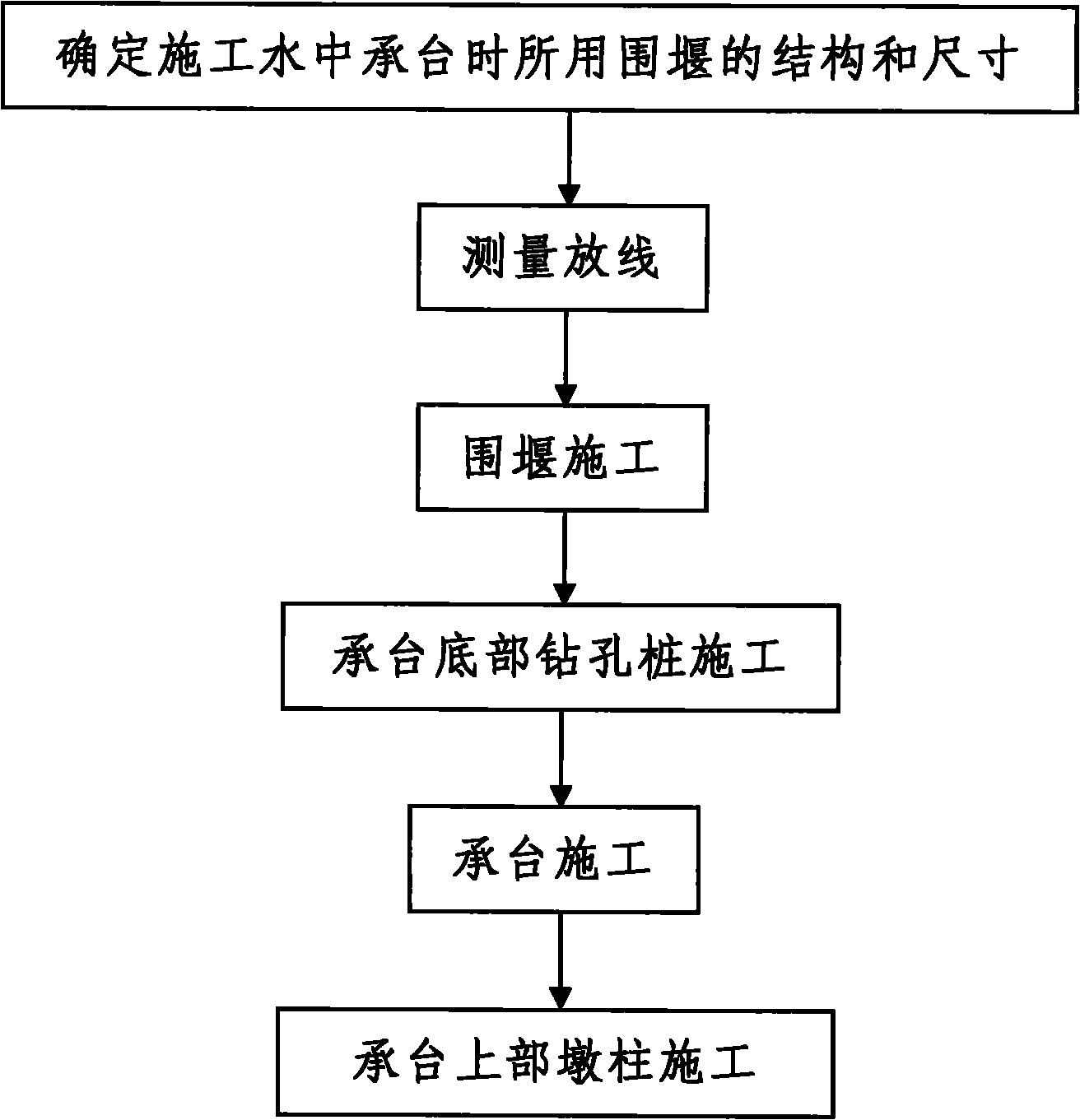

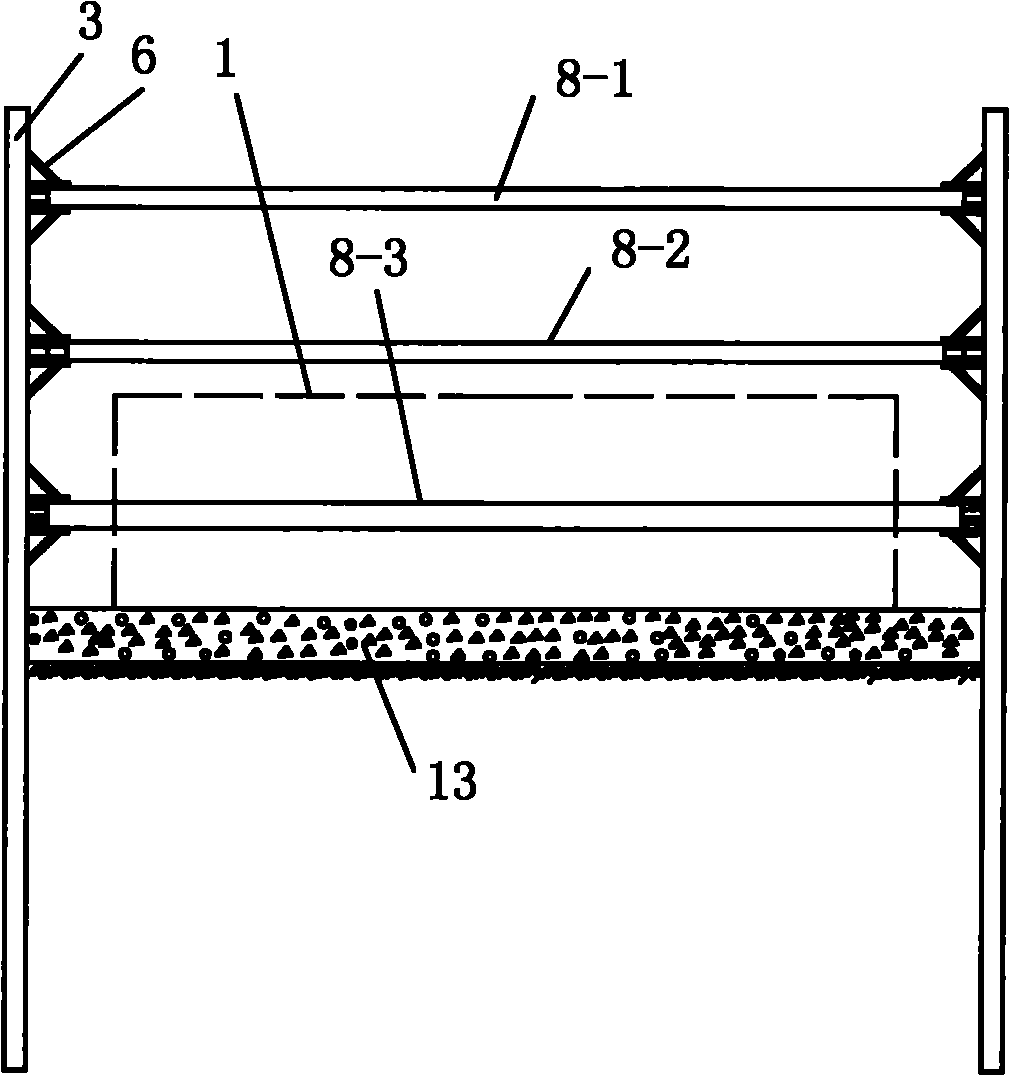

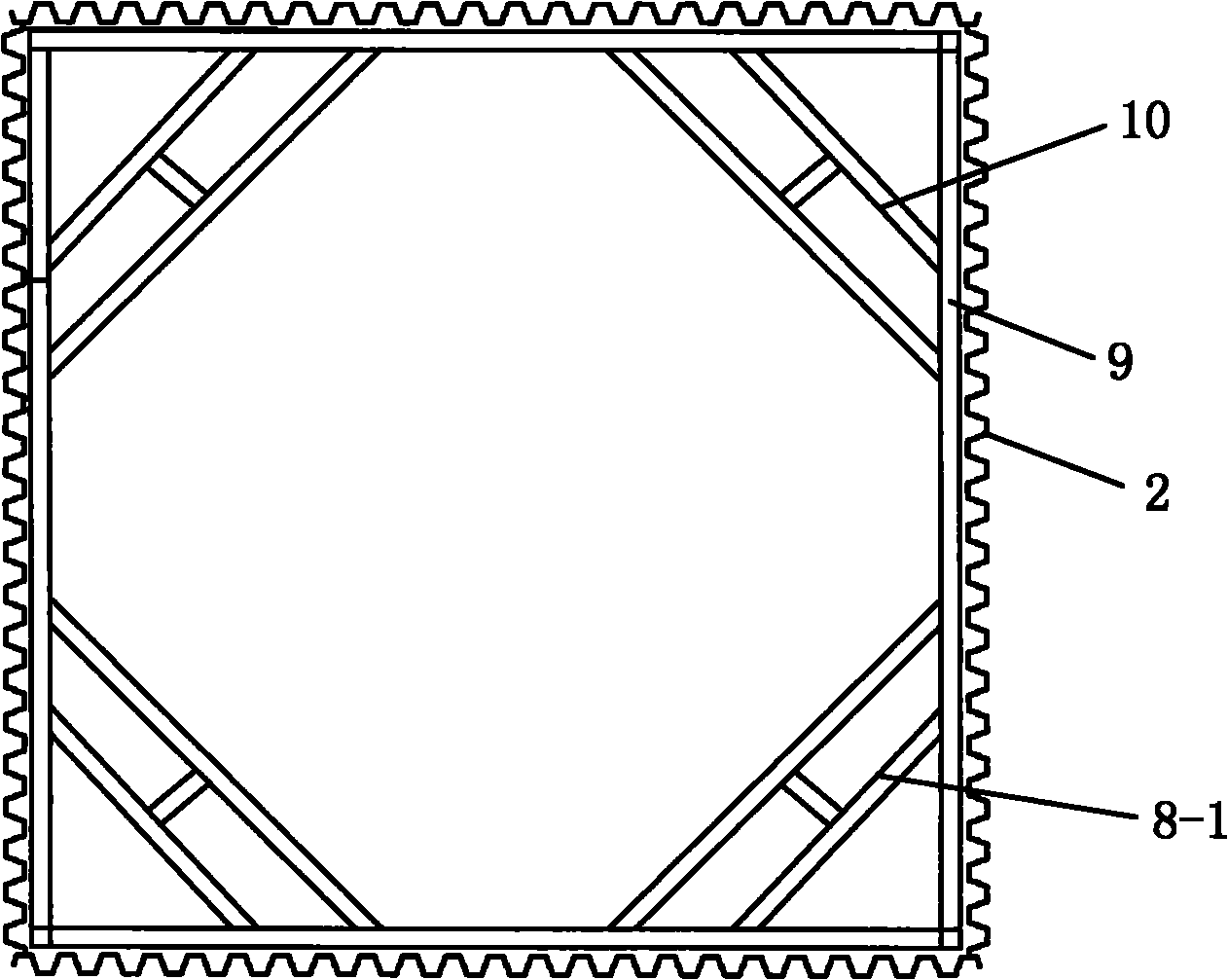

Construction technology of steel sheet pile cofferdam for Yellow River Channel internal support table construction

The invention discloses a construction technology of a steel sheet pile cofferdam for Yellow River Channel internal support table construction. A construction support table is an underwater support table arranged in a Yellow River Channel. The technology comprises the following steps of firstly, determining a structure and the size of a used cofferdam in the process of underwater support table construction; secondly, surveying and setting out; thirdly, constructing the cofferdam; fourthly, constructing a bored pile at the bottom of the support table; fifthly, constructing the support table: carrying out forming construction of the underwater support table on the top of the bored pile after construction when the bored pile construction is finished, and finishing integrative construction of the bored pile and the underwater support table; and sixthly, constructing a pier column at the upper part of the support table. The invention has the advantages of reasonable design, convenient construction and low construction cost, carrys out construction by adopting an integrative construction method of the support table and the bored pile and can efficiently solve the defects of long construction period, large investment, needs of setting up a plurality of construction platforms, large construction difficulty and the like in the successive construction process of the bored pile and the support table in the traditional construction process of the steel sheet pile cofferdam.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Index screening and processing method for evaluating quality of tobacco leaves

ActiveCN104063599AThe method is simple and easyEasy to operateSpecial data processing applicationsBiologyDiscrimination function

The invention discloses an index screening and processing method for evaluating quality of tobacco leaves. The method is characterized by comprising the following steps: determining 21 tobacco leaf quality indexes, screening the quality evaluation indexes by utilizing a main component analysis and relevant analysis way, grading the quality evaluation indexes by utilizing probability distribution, determining quality evaluation index weight by utilizing a layering analysis way, establishing a tobacco leaf quality judgment function by utilizing a K-average value clustering and multi-category gradual judgment analysis way, and detecting the accuracy of the judgment function. The tobacco leaf quality index which can accurately analyze and evaluate the tobacco leaf quality can be more systematically and comprehensively screened from the tobacco leaf quality indexes of multiple base units.

Owner:CHINA TOBACCO JIANGSU INDAL

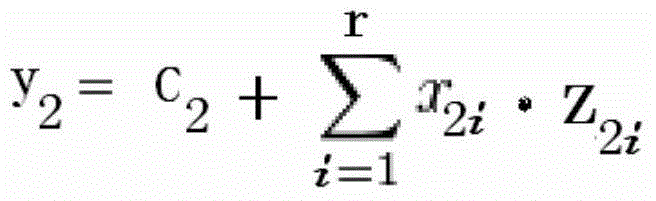

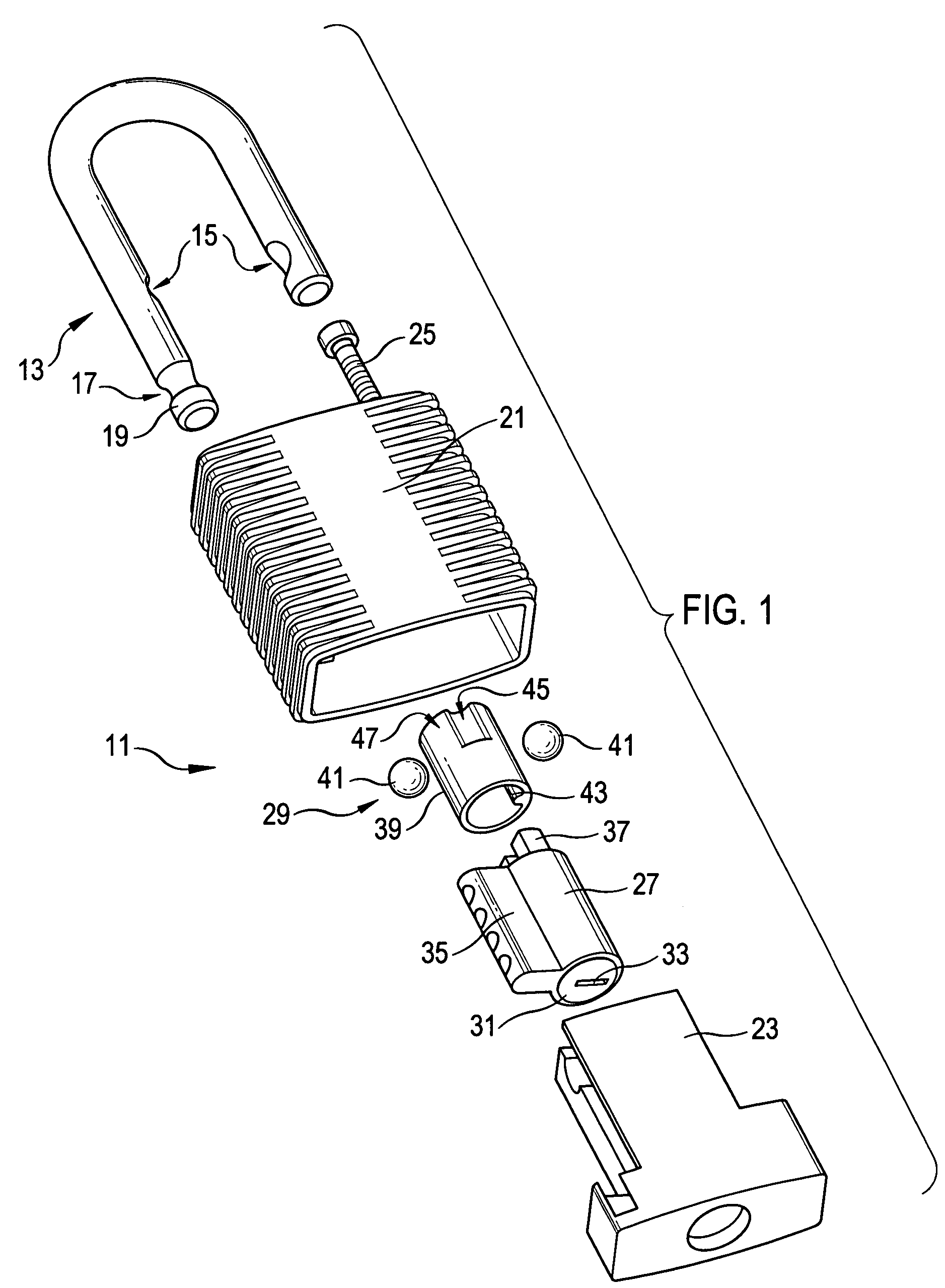

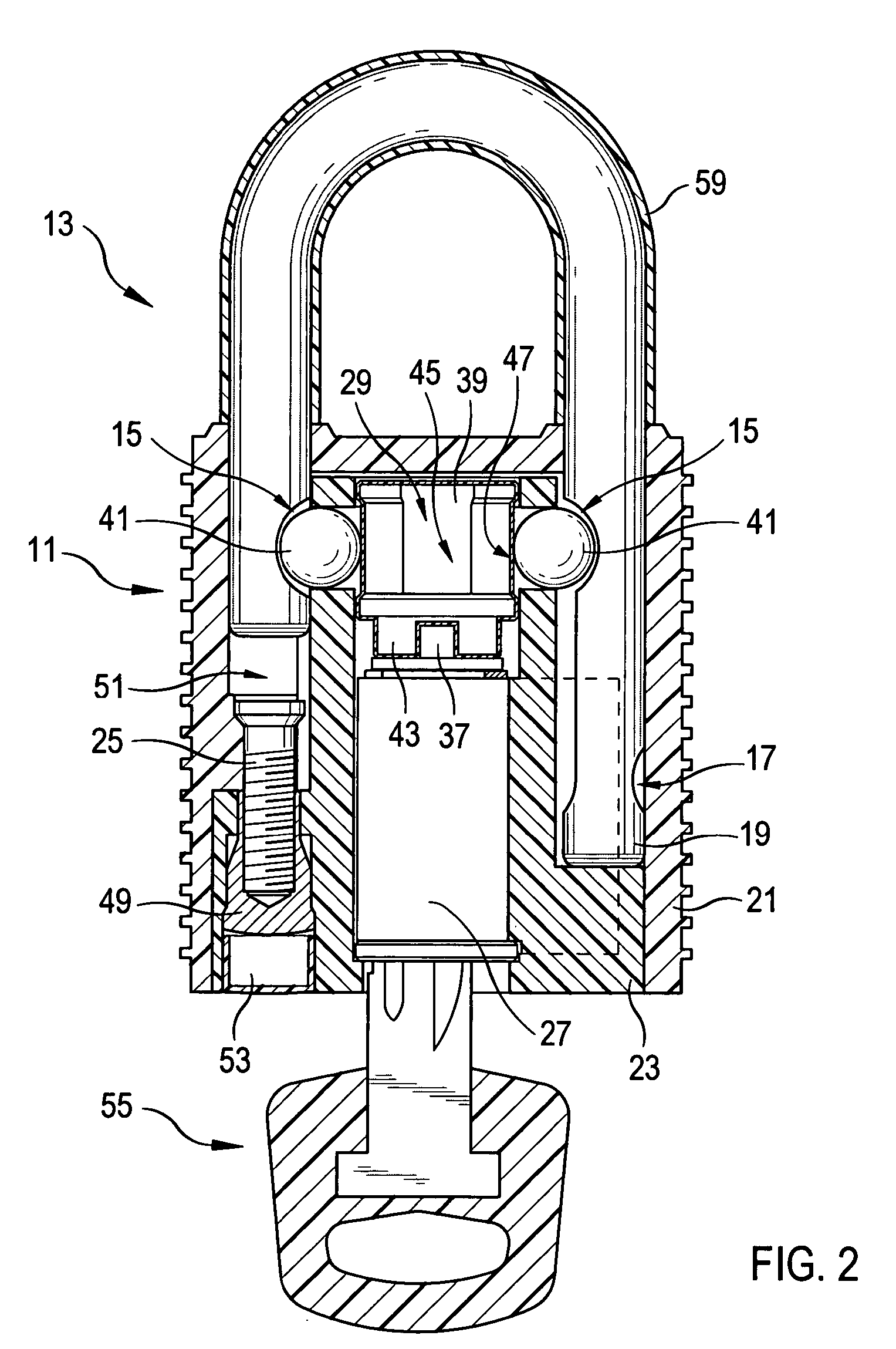

Padlock

ActiveUS7278283B2Improve mechanical stabilityImprove guidancePadlocksCarpet fastenersEngineeringElectrical and Electronics engineering

Owner:ABUS AUGUST BREMICKER SOEHNE AG

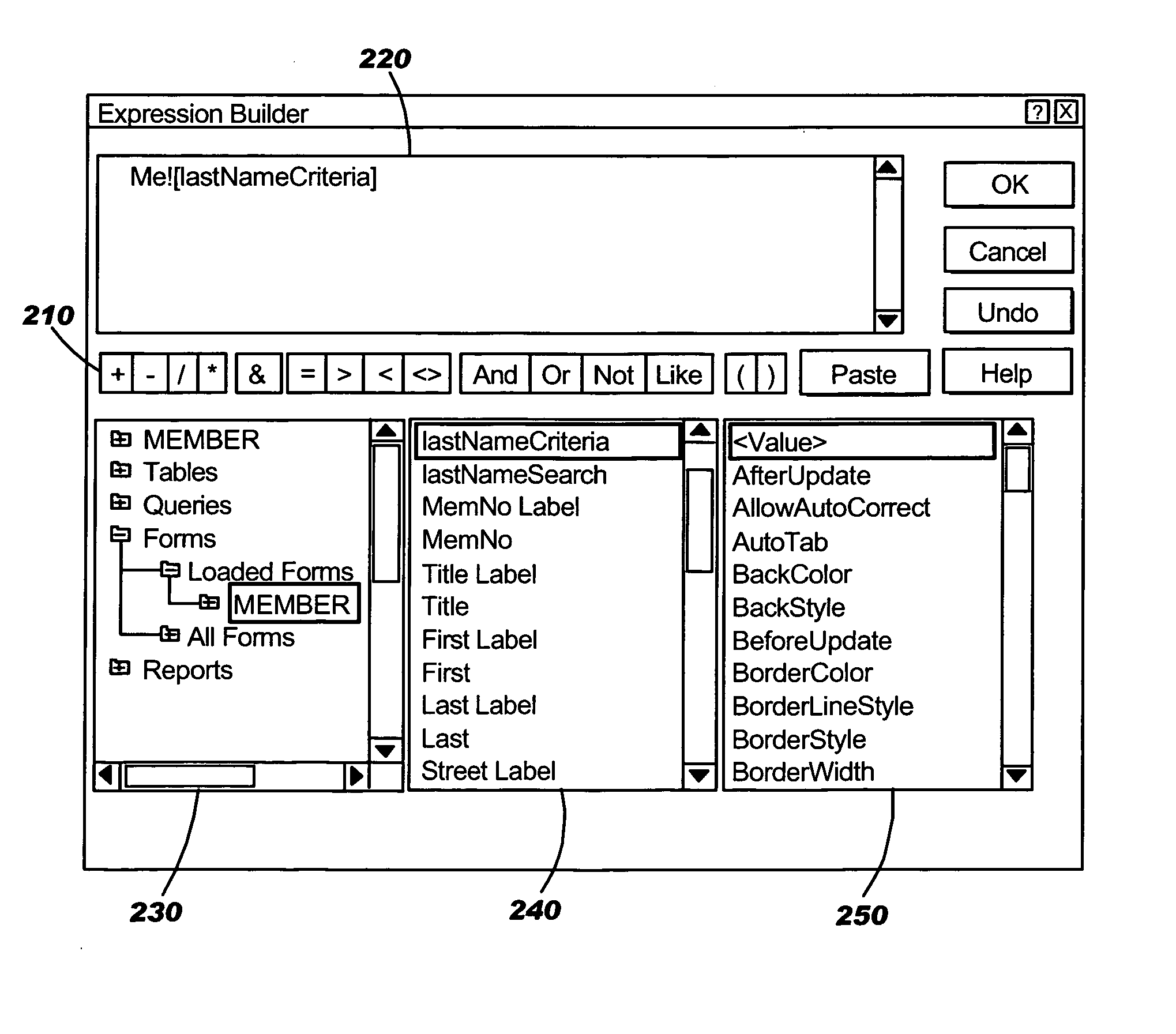

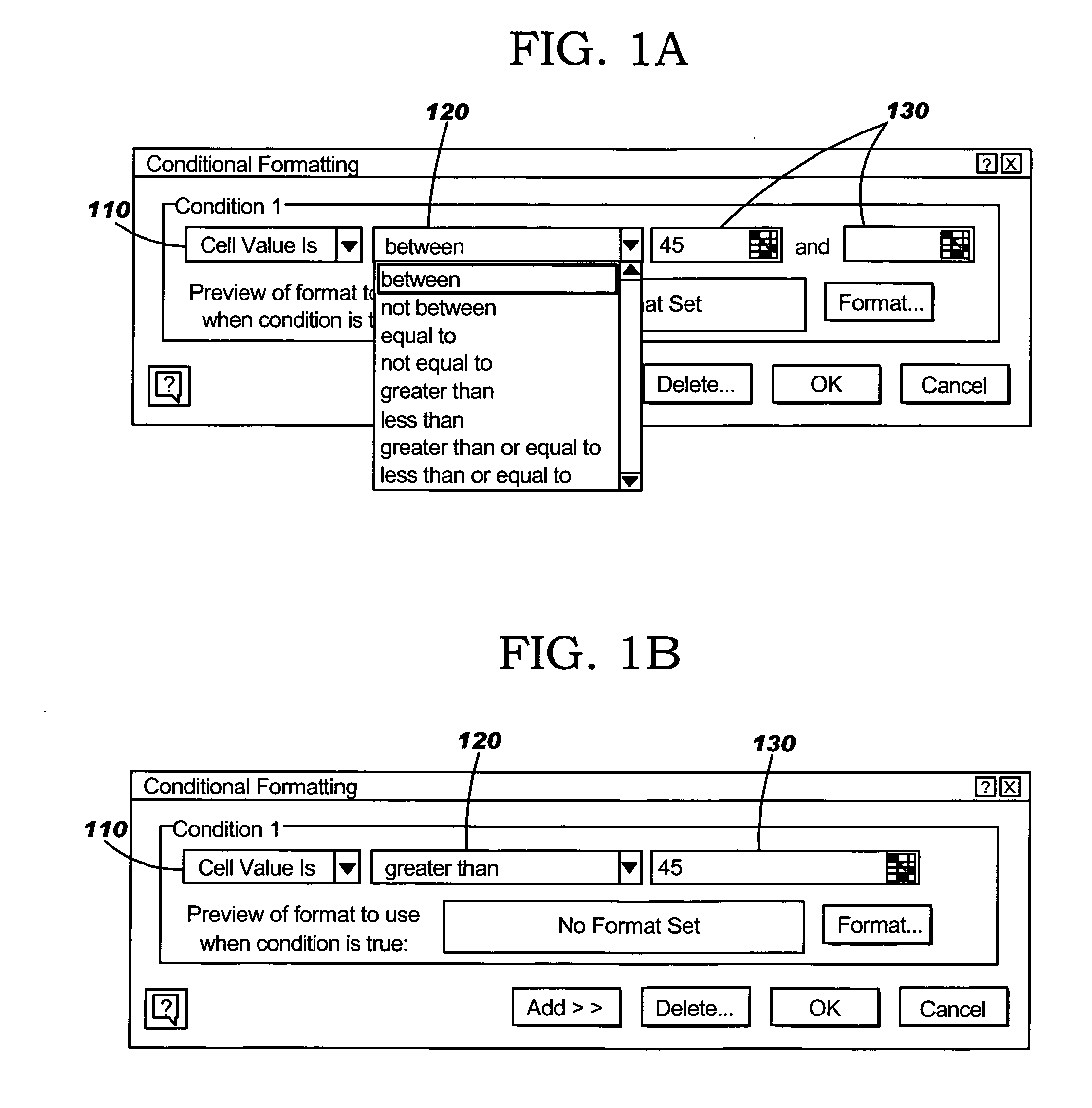

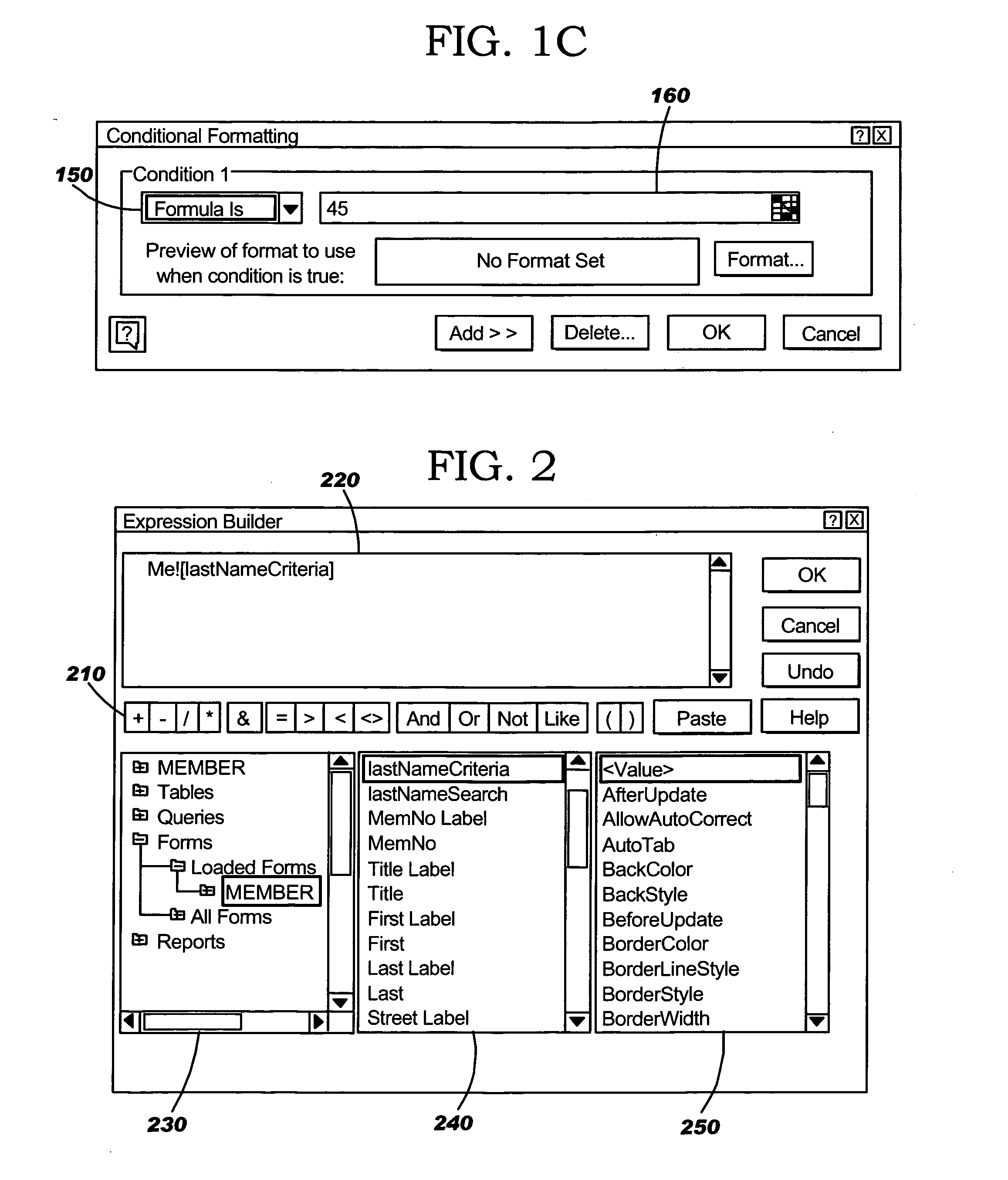

Apparatus and method for providing a condition builder interface

InactiveUS20060224959A1Less sophisticatedReduce usageData processing applicationsText processingConditional expressionHuman–computer interaction

An apparatus and method for providing a user interface through which a user may generate a conditional expression are provided. The user interface provides guidance to a user as to the proper parts of the conditional expression to include in the conditional expression as the user constructs the conditional expression. Thus, as the user completes parts of the conditional expression, the guidance that is offered is updated based on the current context of the conditional expression. This guidance may include listings of variables, attributes and / or functions that are most appropriate to be entered next in the conditional expression, help text, and the like.

Owner:IBM CORP

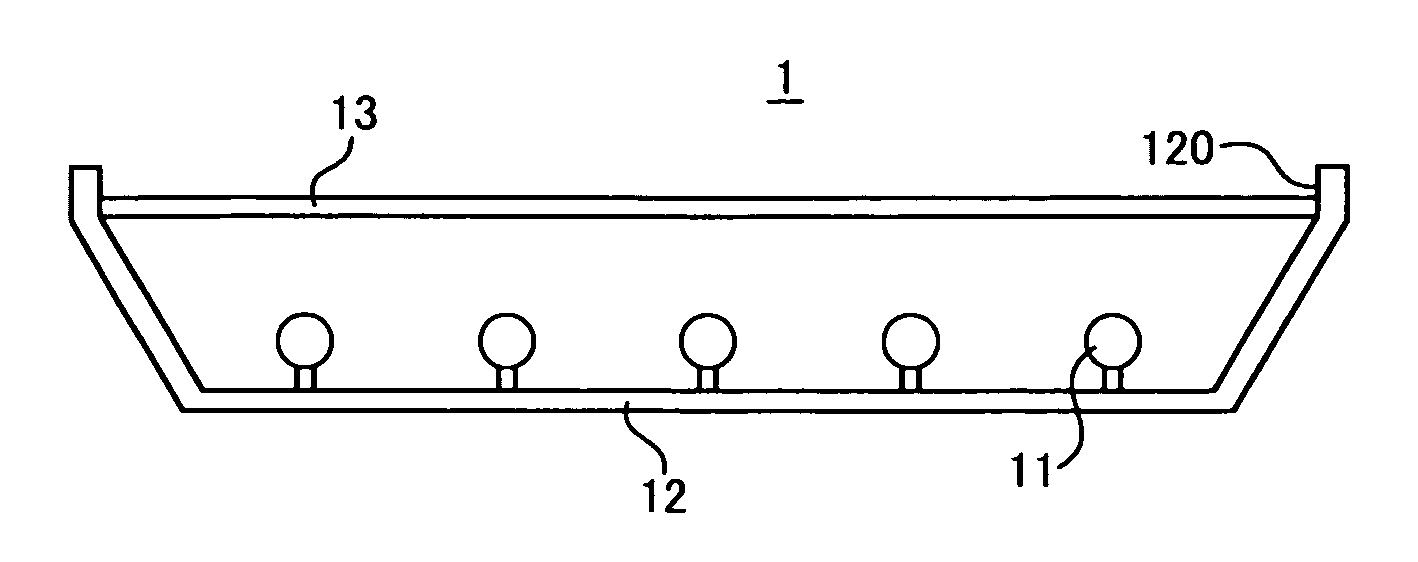

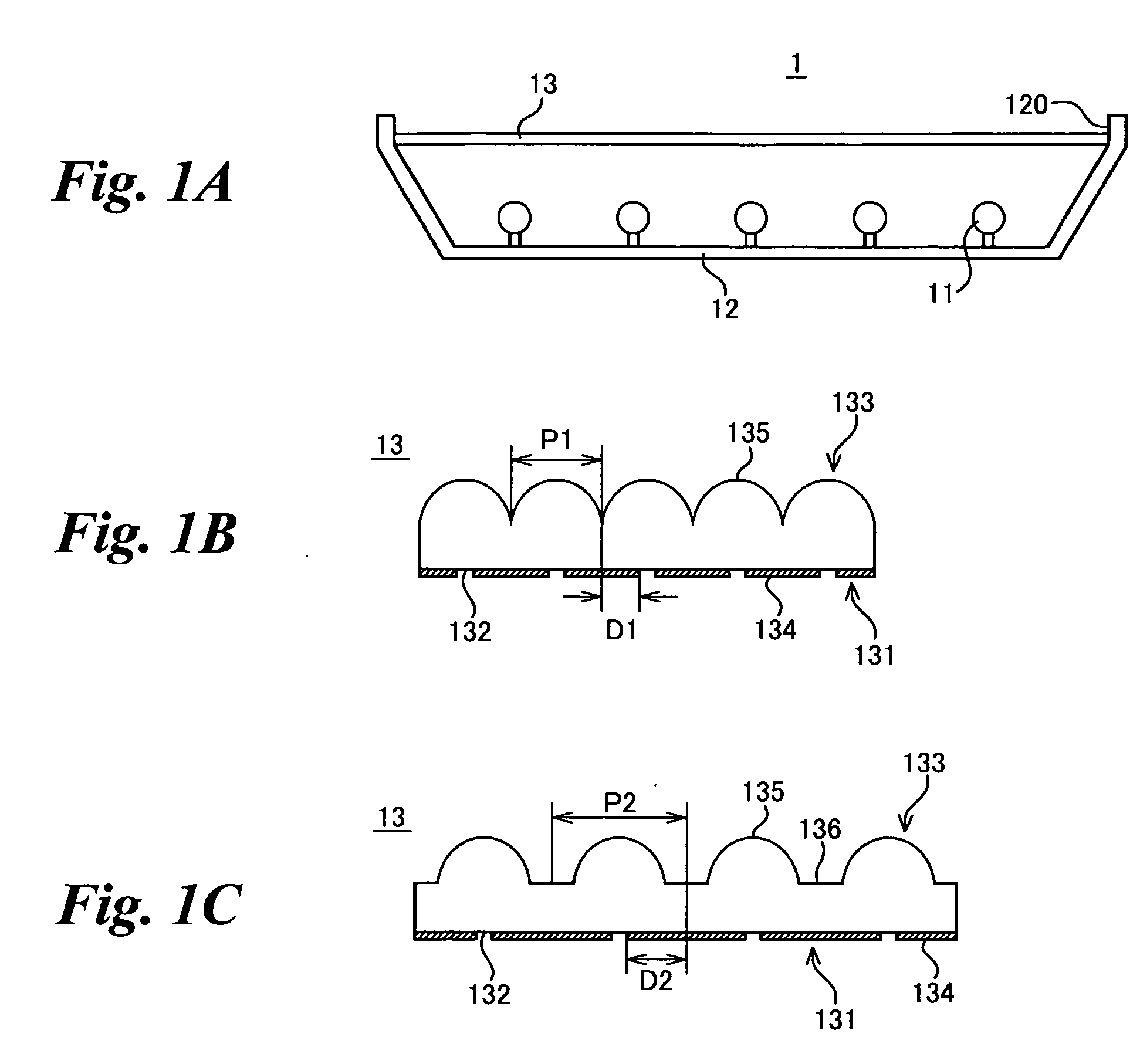

Lighting apparatus and display apparatus

ActiveUS20060285312A1Broad freedomEasily manufactureOptical light guidesIlluminated signsLight sourceOptical axis

The lighting apparatus includes a light source, a housing that contains the light source inside and has an exit port for outputting light from the light source, and an optical sheet that is placed in the exit port. The optical sheet includes a lens structure that is placed at a light exit side and aligns an output direction of incident light from the light source, a reflector that is placed at a light incident side and reflects light emitted by the light source, and a light transmitting opening that exists in the reflector and transmits incident light from the light source. The light transmitting opening is placed in a position deviated from an optical axis of the lens structure. The display apparatus includes the lighting apparatus.

Owner:MAXELL HLDG LTD

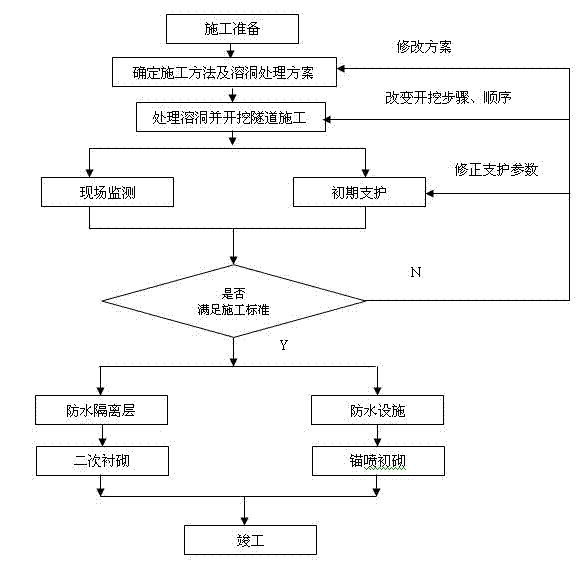

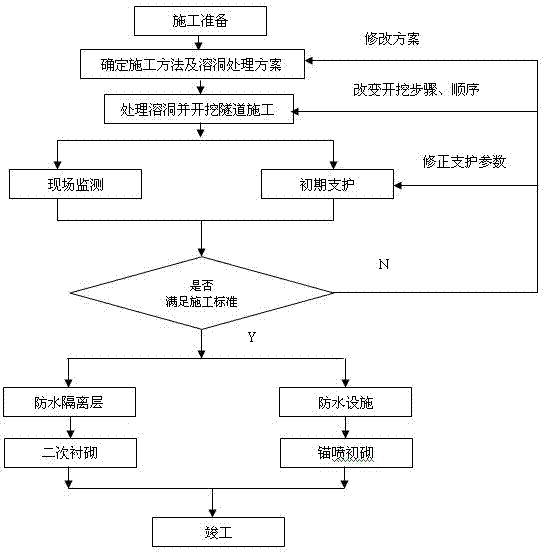

Construction technology for allowing tunnel to pass through ultra-large karst cave

ActiveCN102383806ADo not delay the construction periodQuality assuranceUnderground chambersFoundation engineeringShotcreteMesh reinforcement

The invention relates to a construction technology for allowing a tunnel to pass through a karst cave, and in particular relates to a construction technology for allowing a tunnel to pass through an ultra-large karst cave. The technology at least comprises the following steps of: 1) performing simple bridge treatment on the underground part of the karst cave; 2) performing primary support, namelyarranging a support wall at one side of the karst cave; 3) forming parallel guide holes; 4) performing bottom treatment; 5) treating the tunnel hole body at the inlet section of the karst cave; 6) filling C25 early strength sprayed concrete within 1 meter at the top of the support wall, and arranging phi 50 small grouting conduits with the lengths of 3 meters in the concrete, wherein the distancebetween the small conduits is 1.5 meters; 7) supporting the arch part and the side wall surrounding rock of the karst cave by adopting phi 22 cartridge anchor rods arranged in a plum blossom shape and at a distance of 150cm*150cm, hanging phi6 reinforcing meshes at a distance of 15cm*15cm, and spraying C25 early strength concrete with the thickness of 15 centimeters; 8) treating the accumulation of the karst cave; and 9) monitoring and measuring when the tunnel passes through the ultra-large karst cave. The construction technology for allowing the tunnel to pass through the ultra-large karst cave is simple in process, convenient for construction, low in cost, scientific, effective, energy-saving and environmentally-friendly.

Owner:CCCC SHEC DONGMENG ENG CO LTD

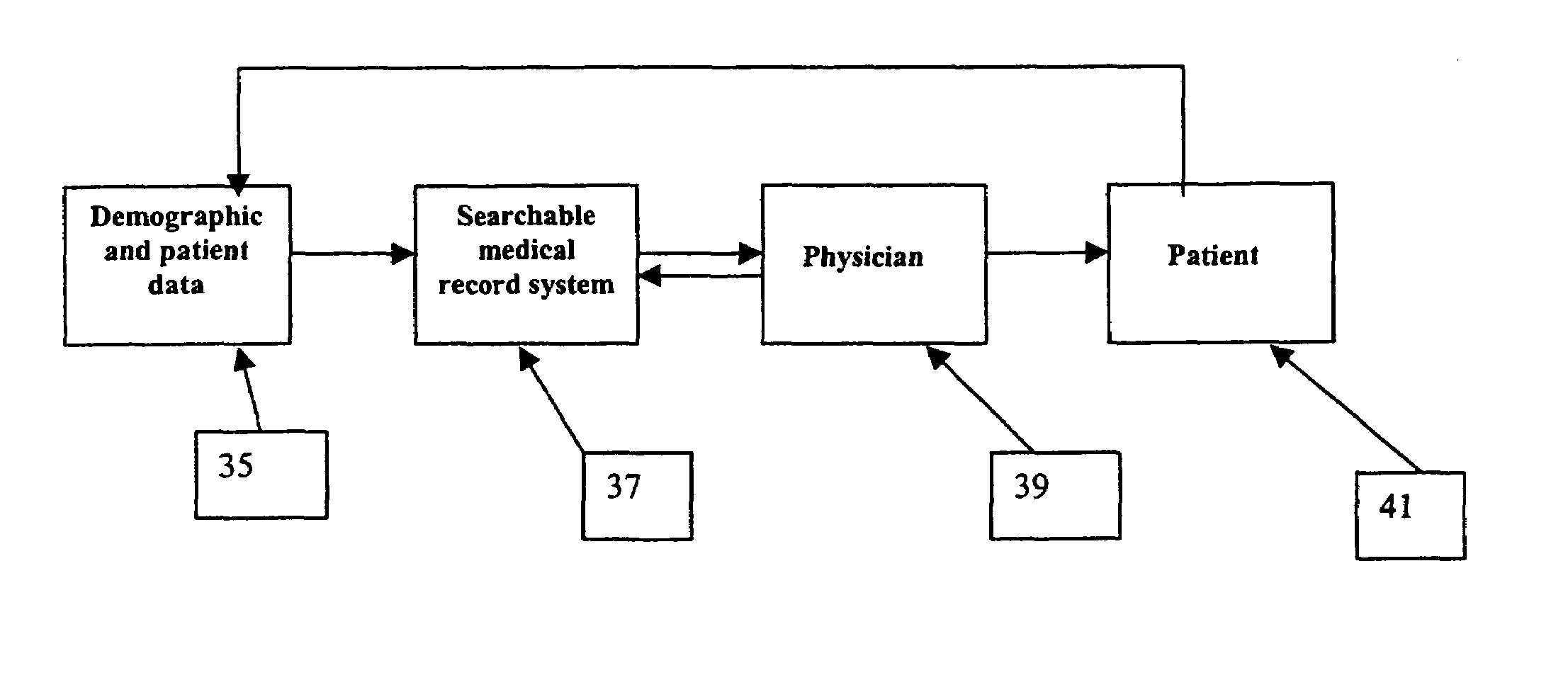

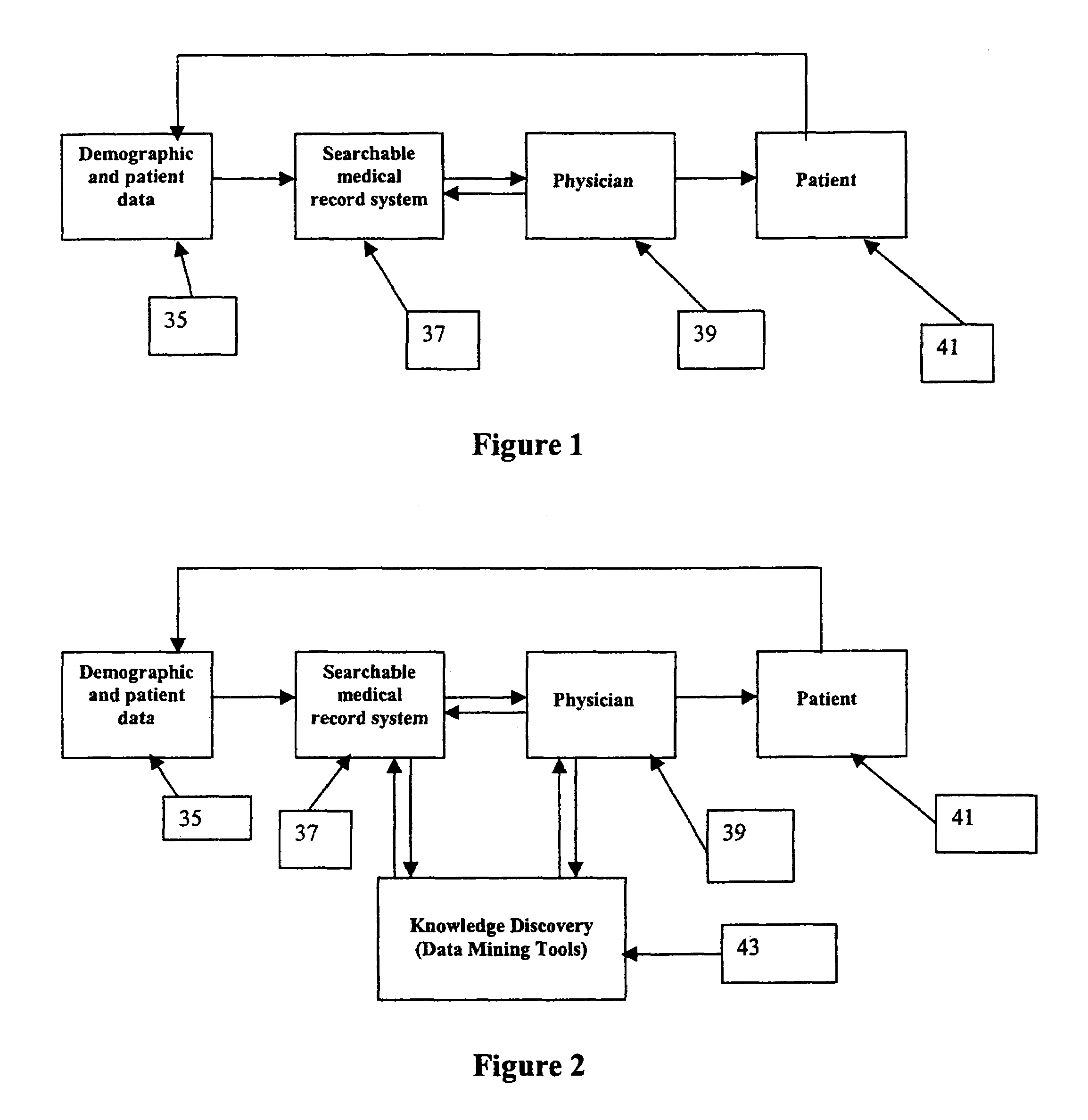

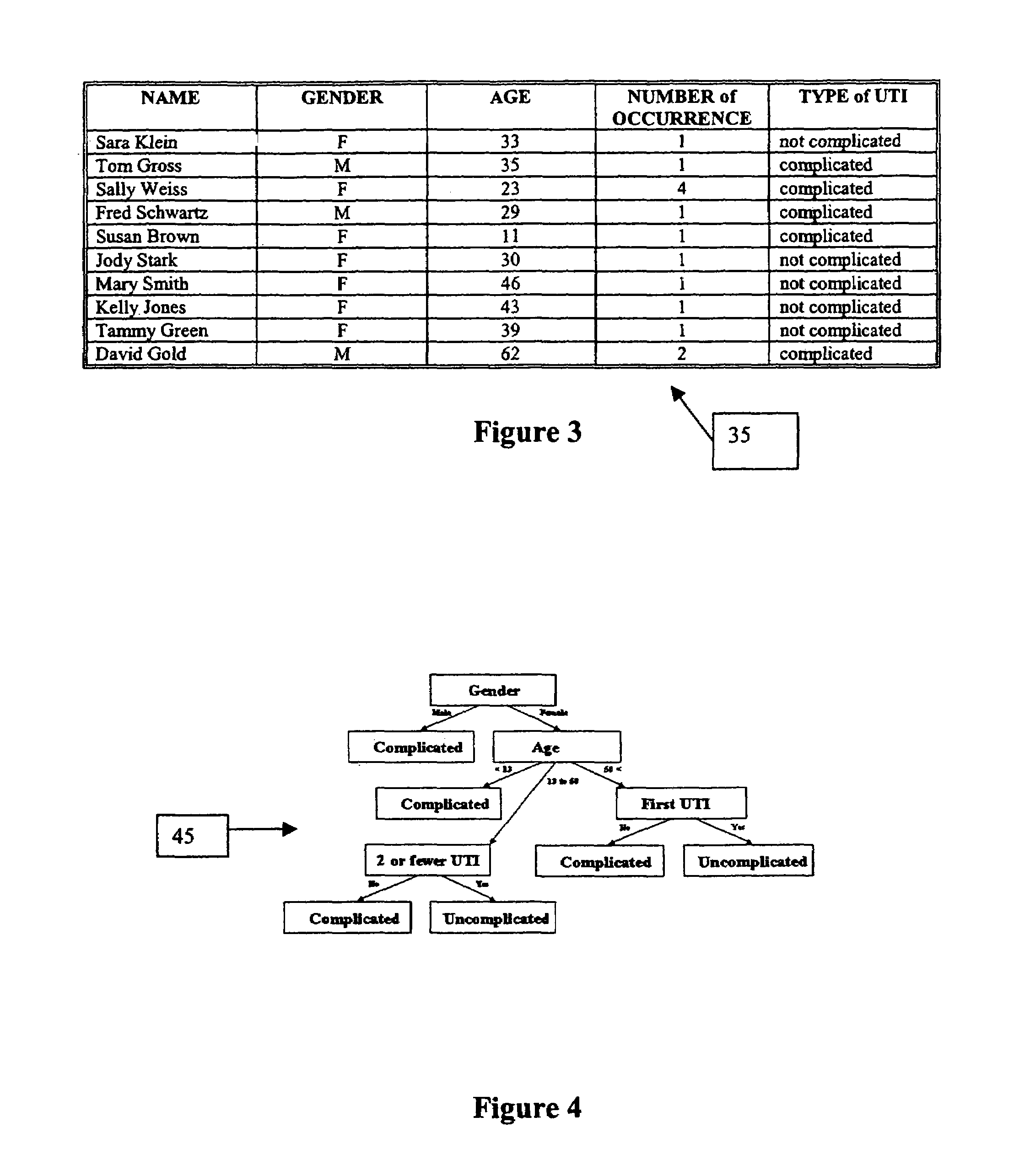

Methods and kits for managing diagnosis and therapeutics of bacterial infections

InactiveUS7418399B2Type accurateEffective treatmentMedical data miningComputer-assisted medical data acquisitionMedical recordData dredging

A method for the construction and utilization of a medical records system capable of providing a continuous data stream of epidemiological data to the records system via kits provided to the symptomatic population to obtain and record an epidemiological profile in a searchable database by applying data mining or automated intelligence techniques whereby, when a valid epidemiological profile is established in the database, automated diagnosis and prescription of treatment may be had for patients presenting similar symptoms. Knowledge discovery techniques may further operate on the database to provide suggested courses of treatment for a virtual class of patients, epidemic threat awareness, and knowledge of drug resistance mutations by a pathogen without direct query of the database.

Owner:NORTHWESTERN UNIV +1

Method for discriminating type of reservoir fluid by using resistivity data

InactiveCN102012526AMastering Real Response PropertiesImprove the identification rateElectric/magnetic detection for well-loggingAcoustic wave reradiationLithologyPorosity

The invention discloses a method for discriminating the type of reservoir fluid by using resistivity data, which relates to the technical field of oil and gas logging as well as geology and core experiment analysis, and comprises the steps of: a, logging the well through scaling core data, and correctly calculating the mud content, the rock constituents and the porosity of the reservoir fluid; b, eliminating the influence from the lithology and the porosity to the resistivity; c, obtaining m, a, n and b by using core experiment to reflect the parameters of the pore structure, calculating the lower limit RR of the gas-layer resistivity, and eliminating the influence from the pore structure to the resistivity; and d, discriminating the type of the reservoir fluid through comparing a deep lateral resistivity RT in deep induction with the lower limit RR of the gas-layer resistivity obtained in the step c. The method eliminates the influence from the non-fluid factors such as the lithology, the porosity, and the pore structure and the like to the resistivity, and retains and utilizes the response characteristics of different fluids for the resistivity so as to greatly improve the coincidence rate of the discriminating the type of the reservoir fluid.

Owner:四川西德电器有限公司

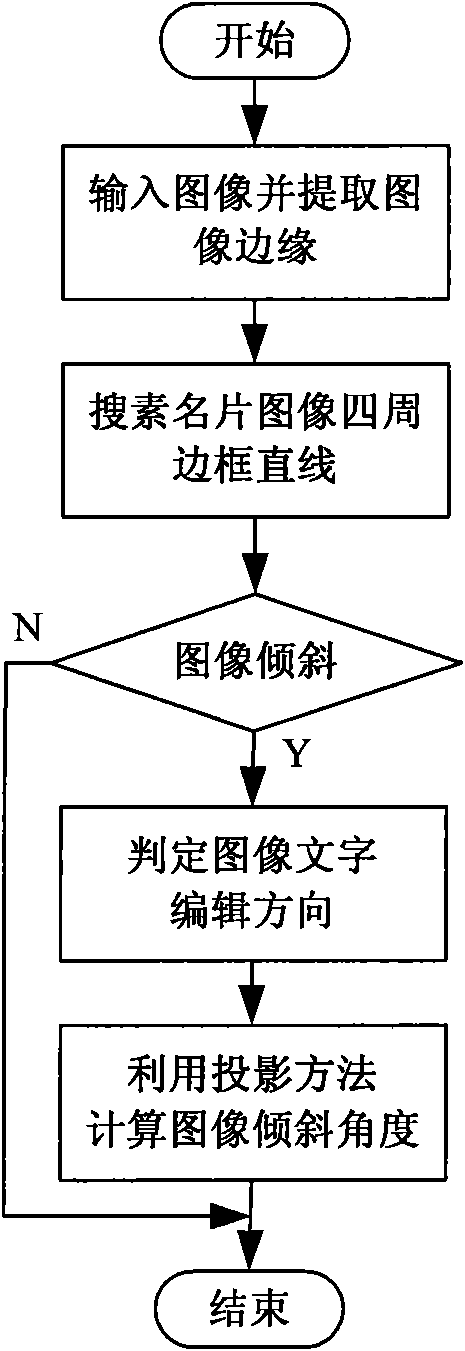

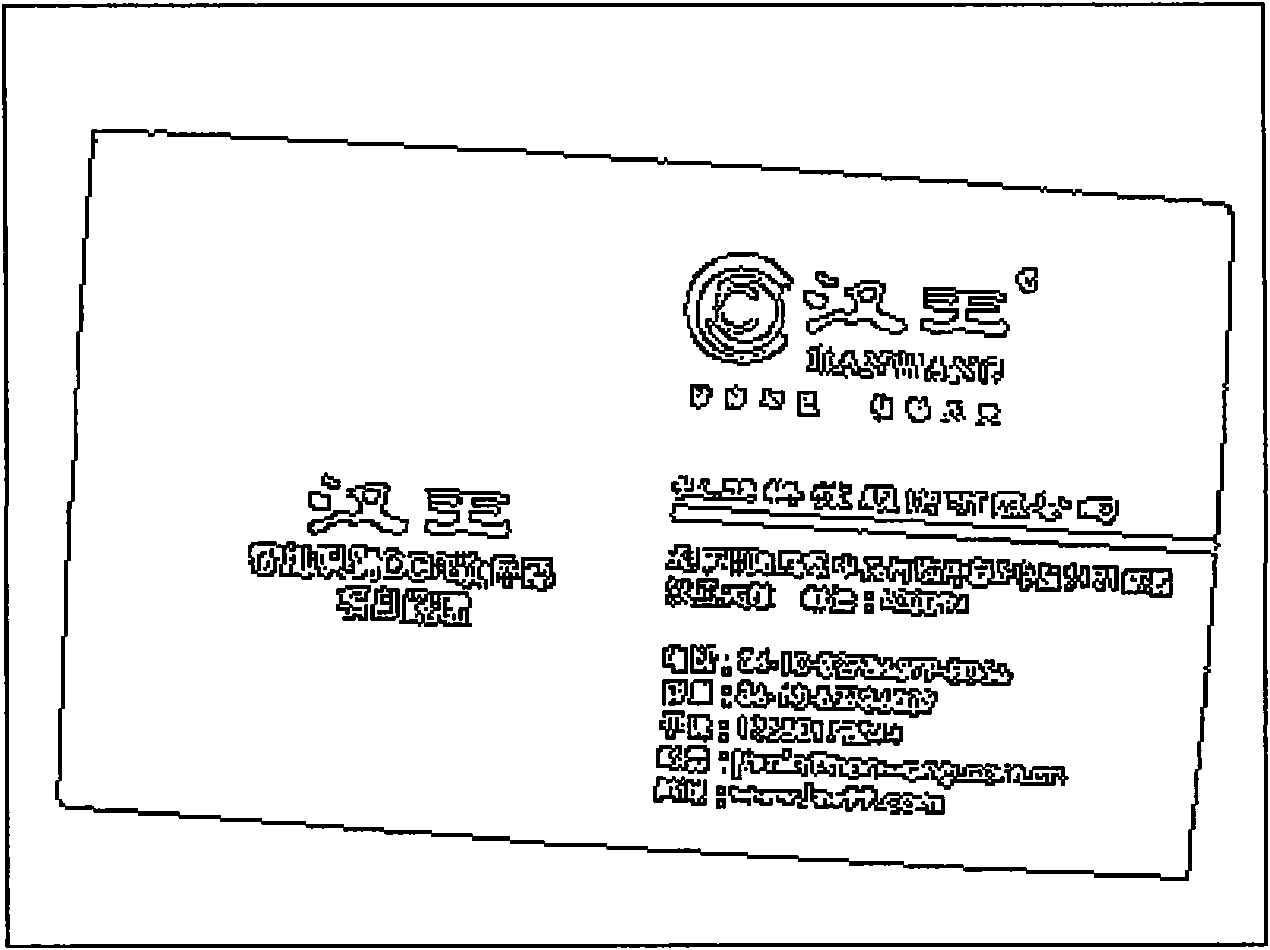

Method and device for measuring image inclination angle of business card

ActiveCN101770575AAccurate tilt angleImprove guidanceCharacter and pattern recognitionBusiness cardComputer graphics (images)

The invention relates to a method and a device for measuring image inclination angle of a business card, which belong to the technical field of OCR. The method extracts the edge image of a business card image at first, searches the peripheral frame line of a business card in the edge image, judges if the image is inclined according to the inclination degree of the peripheral frame line, judges word editing direction thereof for the inclined picture, projects along the word editing direction and calculates the inclination angle of the image by projection characteristic. Judging the inclination of the image by collecting the peripheral frame line of the image, the invention can divide the images into an inclination type and an aclinal type quickly and process the two types respectively. The invention quickly judges the word editing direction by comparing the characteristics of projection histograms in the horizontal direction and the vertical direction. The determination of the word editing direction is greatly useful for calculating the inclination angle by projecting and analyzing the layout of the business card image.

Owner:HANVON CORP

Independent study system and detection method

InactiveCN104680859AGood effectImprove learning effectElectrical appliancesLibrary scienceUser Friendly

The invention provides an independent study system for assisting a user in reinforcement learning of the teaching knowledge point after class; learning contents stored in a cloud server are classified by six levels, and teaching contents are displayed by various modes, so that a whole brain thinking method (a mind map) and a whole brain memory method are adopted to be synchronized with subjects in primary and middle schools, and all the knowledge points can be put into practice; the independent examination is detailed to keywords, so that knowledge disconnection is avoided, and the knowledge continuity is high; meanwhile, the interactivity of the study system is obviously improved by a voice identifier; furthermore, the independent study system can monitor study attitudes of users and a study environment and make a linkage response; the intelligence and the user-friendly performance are improved.

Owner:绵阳点悟教育科技有限公司

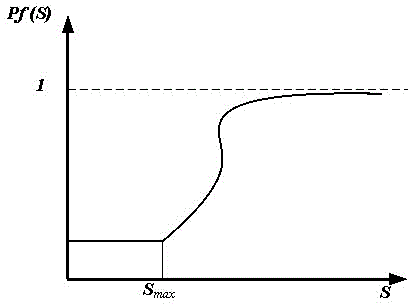

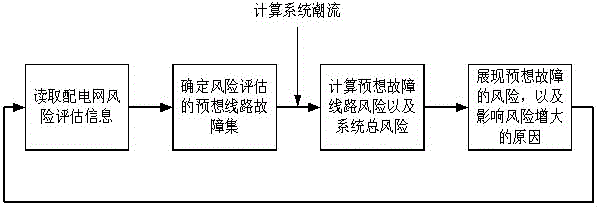

Intelligent power distribution network online risk assessment method

InactiveCN104574217ARealize real-time monitoringEasy to buildData processing applicationsMathematical modelPower grid

The invention discloses an intelligent power distribution network online risk assessment method. Through comprehensive analysis of online data and historical data, an assessment mathematic model is established, and a visually-displayed risk assessment diagram is finally formed. According to targeted power grid data collection and through comprehensive analysis of the online data and the historical data, the data can be monitored in real time, analysis models expanded on the basis of a large number of existing database devices of a power grid are easy to establish, according to the actual condition of the power grid, the risk pre-warning level is instructed simply, visually and clearly in the mode that a two-dimensional chart and different colors are matched, and therefore practicality is high. Prediction models of a system can be edited according to different formula computing methods, flexibility is large, a data report can be updated and stored through a network platform, the current requirement of a user is met, and the method can adapt to changes of development and management modes of an industry and updating of the technology.

Owner:STATE GRID CORP OF CHINA +1

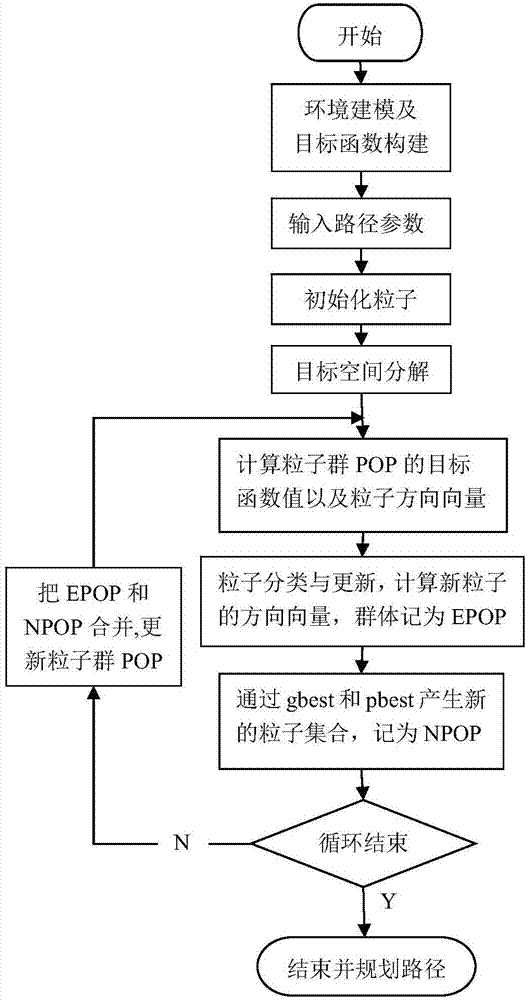

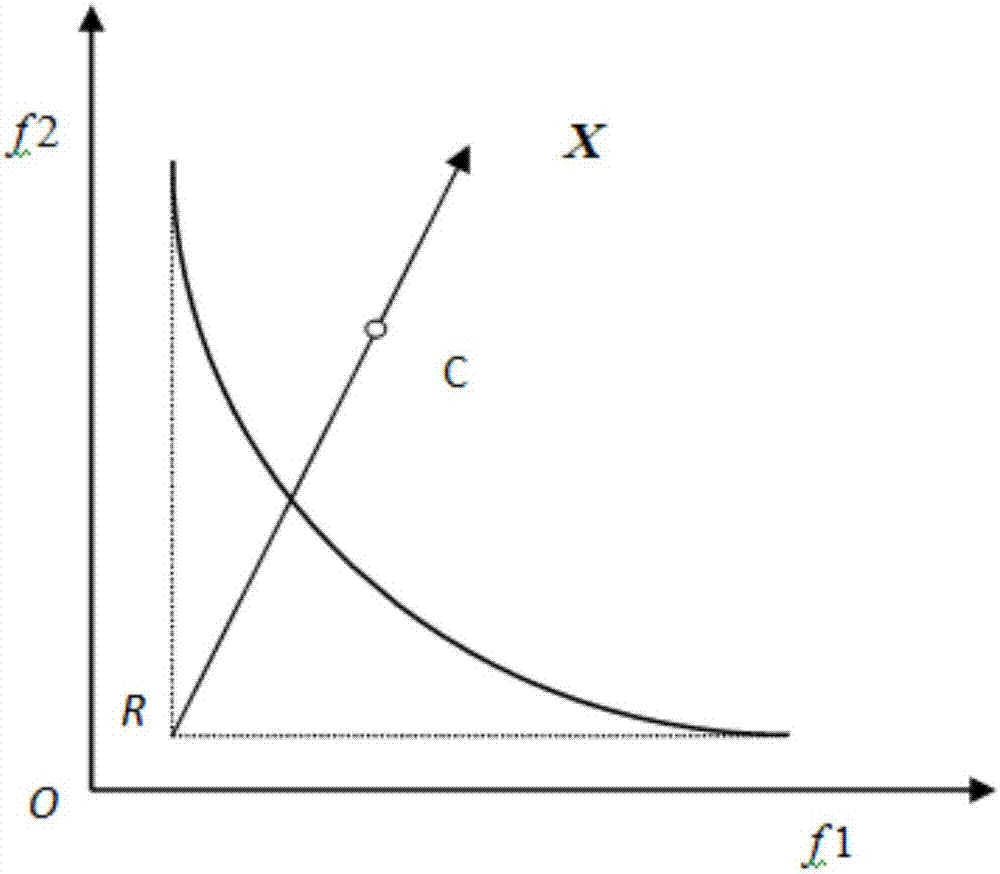

Unmanned vehicle path planning method based on improved multi-objective particle swarm algorithm

ActiveCN107992051AAdded ability to trend towards the true Pareto frontRaise the possibilityPosition/course control in two dimensionsVehiclesGlobal optimumDirection vector

The invention belongs to the technical field of intelligent unmanned vehicles and control, and in particular relates to an unmanned vehicle path planning method based on an improved multi-objective particle swarm algorithm. The method mainly comprises the steps of performing environment modeling and objective function construction, inputting path parameters, initializing information on effective particles, performing target space decomposition, calculating objective function values and particle direction vectors, using new adaptive value formulas for particle classification update, calculatingnew particle direction vectors, using information on global optimum and individual optimal particles to generate a new generation of particles, and performing circulation; when the maximum number ofiterations is reached, stepping out, and planning an optimal unmanned vehicle path according to an optimal solution set. According to the unmanned vehicle path planning method, the optimal path suitable for the unmanned vehicle driving can be quickly planned by using global or local position information in the complex environment and state parameters of a pending unmanned vehicle.

Owner:北京艾上智能科技有限公司

Fatigue testing machine applied to tension test piece and method thereof

InactiveCN101957290AMaximum average displacementMaximum peak displacementMaterial strength using tensile/compressive forcesMechanical componentsPull force

The invention discloses a fatigue testing machine applied to a tension test piece. The fatigue testing machine is mainly used for a tensile test and a tensile fatigue test for mechanical components. The testing machine comprises a fatigue force application mechanism, a pretightening force mechanism, a straightening roller mechanism, a test fixing frame, an auxiliary mechanism and a control system. A power system of the fatigue testing machine comprises the fatigue force application mechanism and the pretightening force mechanism; the tensile force output by the power system is redirected by the straightening roller mechanism and is transmitted to the tension test piece; and the fatigue force application mechanism, the pretightening force mechanism, the straightening roller mechanism and the auxiliary mechanism of the fatigue testing machine are arranged on the test fixing frame. The fatigue testing machine has the advantages of adopting hybrid pneumatic and electric power as the power system of the fatigue testing machine, mastering numerous parameters including the maximum average displacement, the minimum average displacement, peak displacement, the maximum average tension, minimum average tension, minimum fatigue tension, frequency, accumulated test times, accumulated test time and the like, and providing a basis for optimization design of the tension test piece.

Owner:ZHEJIANG UNIV

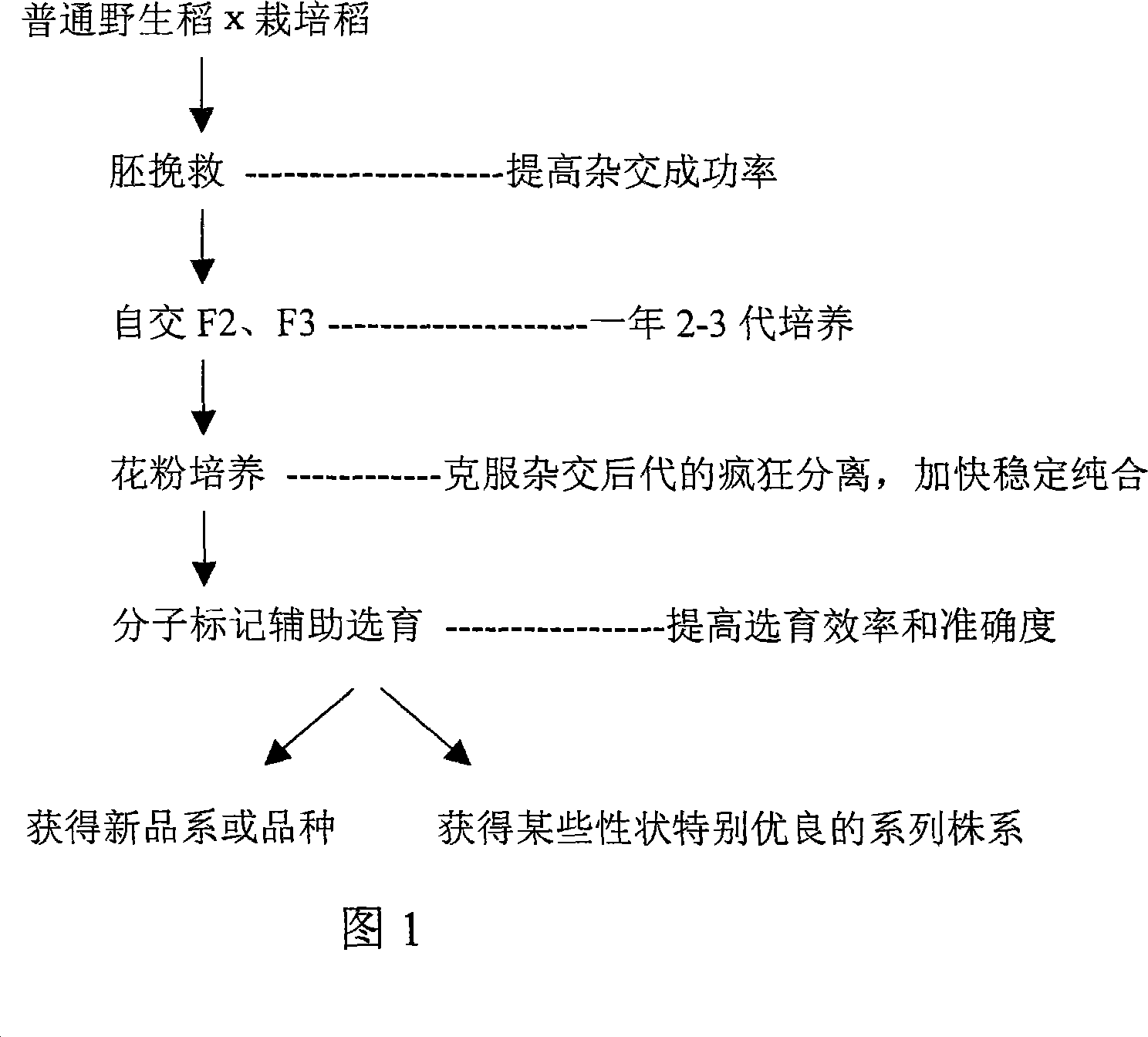

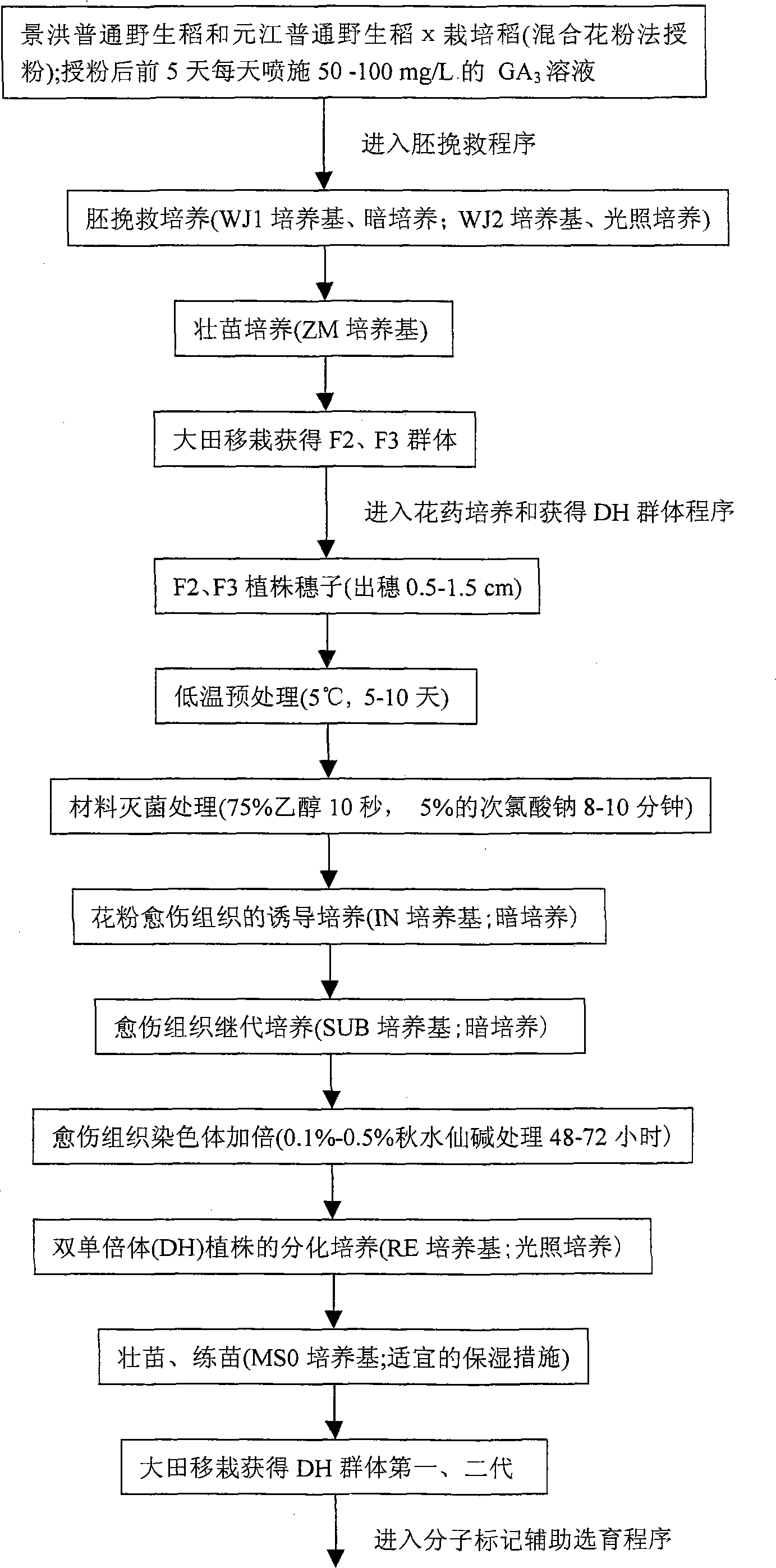

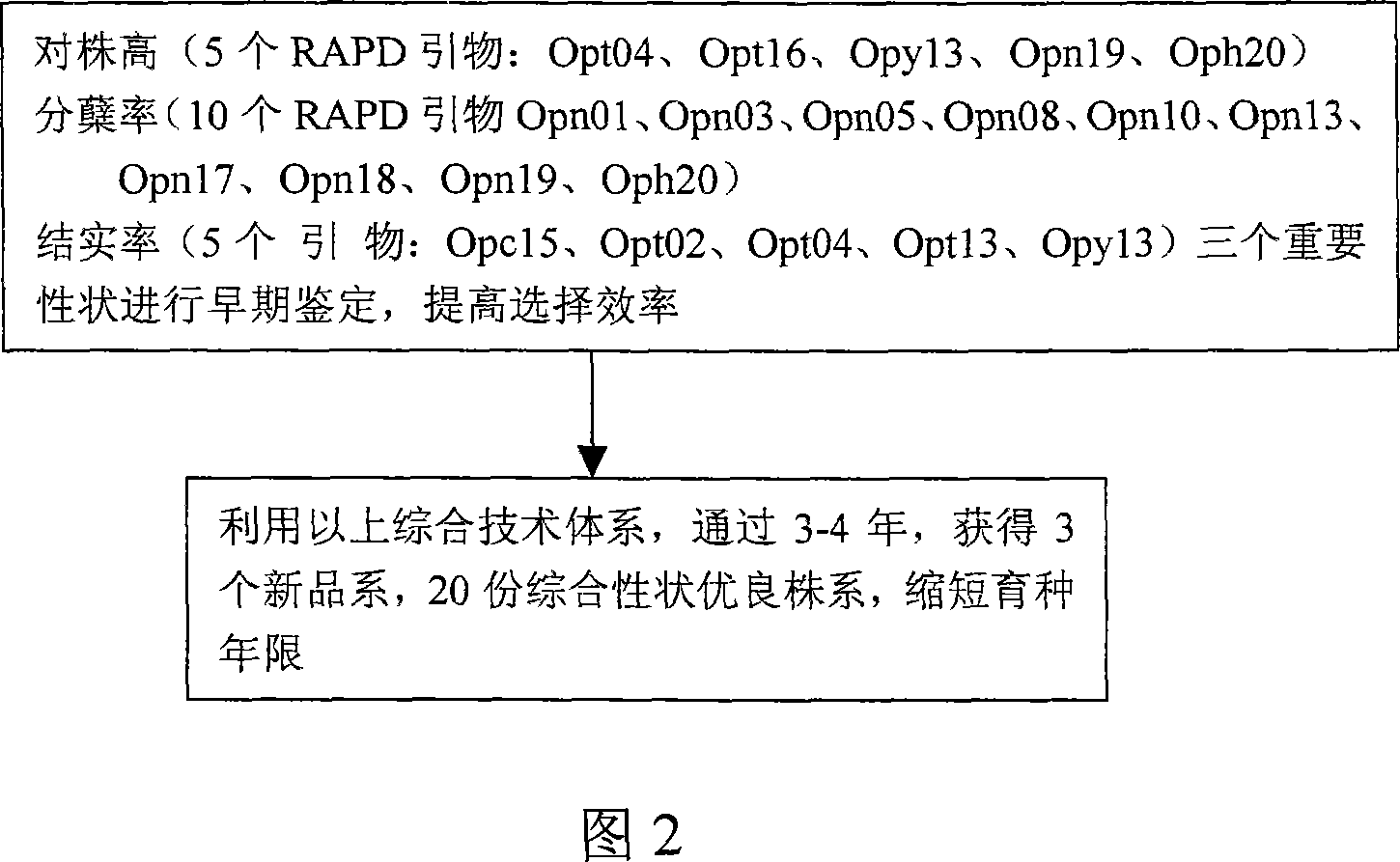

Wild-rice distant hybridization high-efficient cultivating superior progeny method

InactiveCN101142894AStable homozygousAccelerated homozygosityMicrobiological testing/measurementHorticulture methodsAgricultural sciencePollen

The invention relates to a method for high-efficiently cultivating excellent later generation of the wild rice distant hybridization , which is to cultivate the wide rice distant-hybridization high-efficient excellent later generation through the hybridization of the cultivated rice, the embryo rescue, the strong seedling culture, the pollen culture and the molecular marker assisted selection of the hybridization later generation of the cultivated rice and the wide rice. The survival rate of the distant hybridization of the invention is high; the hybrid progeny is backcrossed at the preliminary period and then self-bred, thus being beneficial to overcome the reproductive barrier caused by the different genome in the hybrid progeny of the wide rice and the cultivated rice, and to stabilize more genetic characters of the wide rice inside the cultivated rice; the pollen culture can accelerate the stability of the purification of the hybrid progeny; with the established molecular marker assisted selection, the breeding can be accurately performed without being influenced by the environmental conditions and being restricted by the growth and development period.

Owner:云南省农业科学院生物技术与种质资源研究所

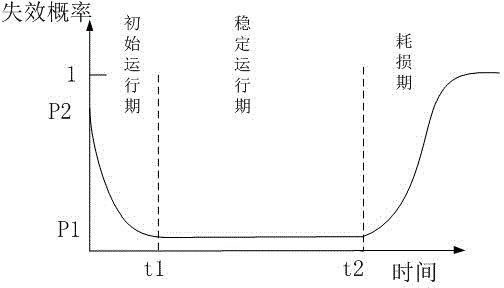

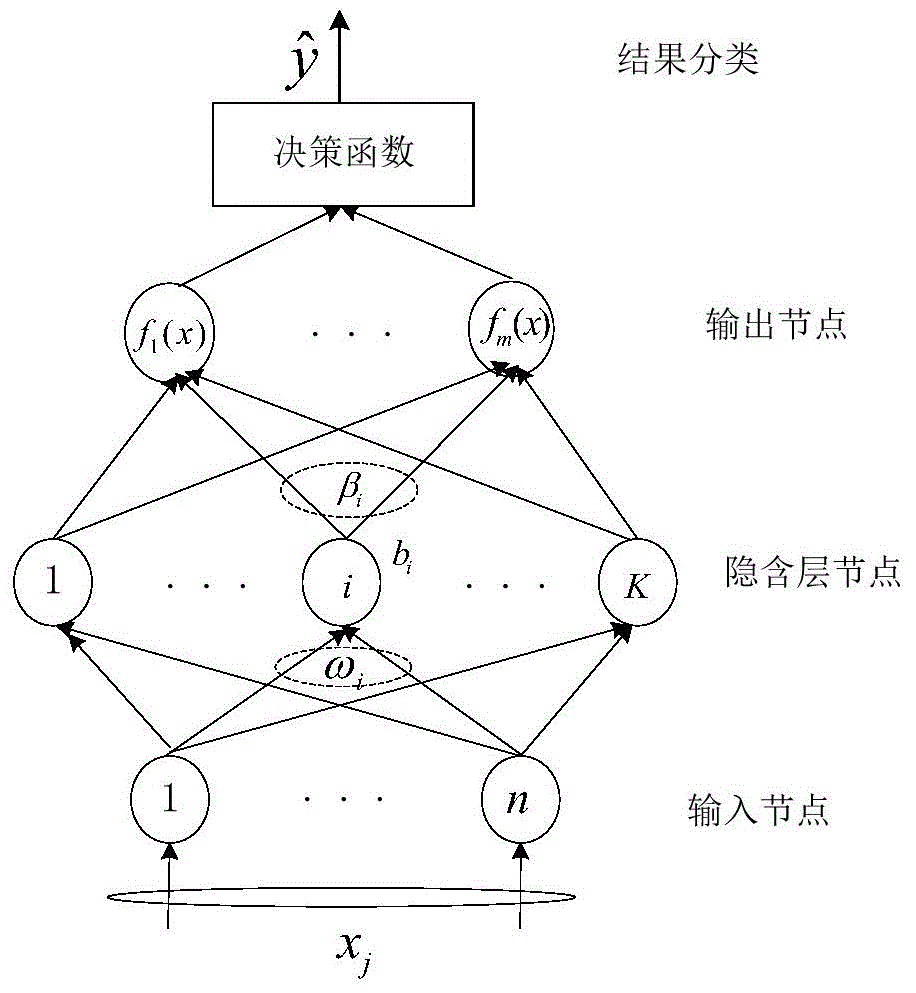

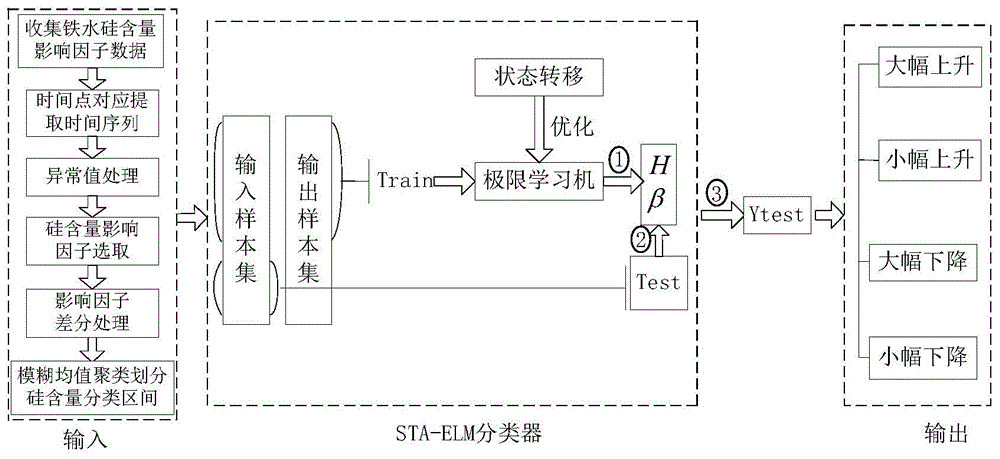

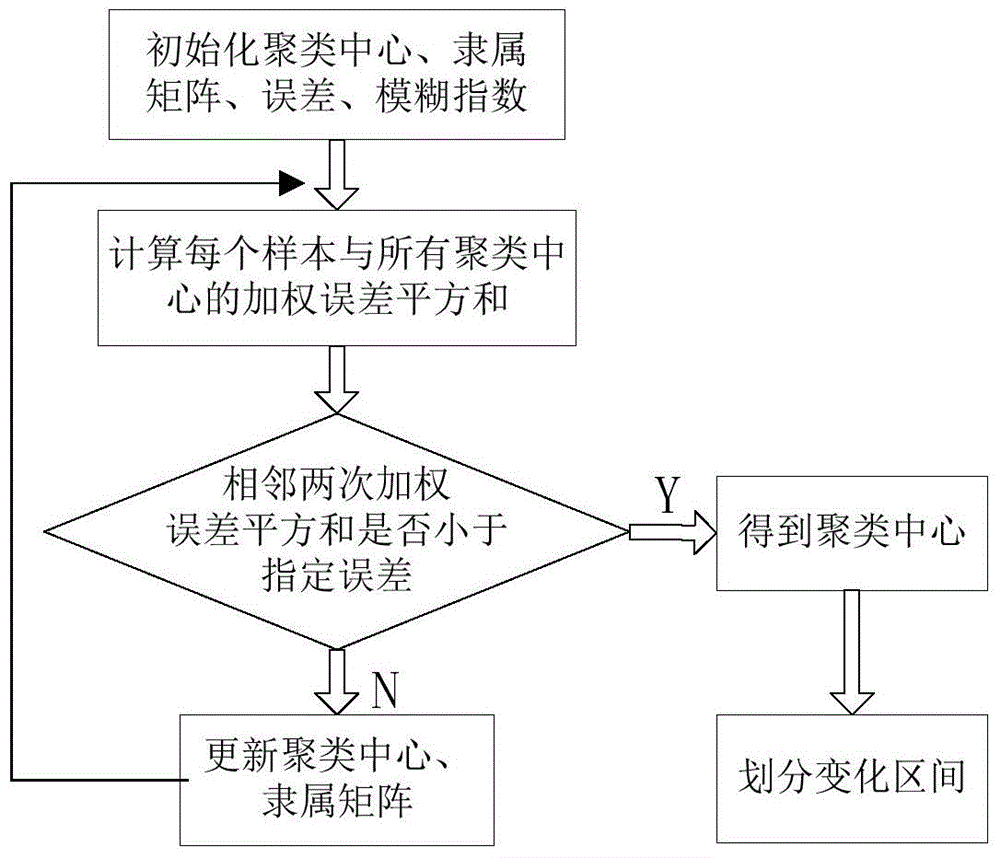

Blast furnace molten iron silicon content four-classification trend prediction model establishing method and application

ActiveCN104899463AImprove hit rateImprove guidanceSpecial data processing applicationsLearning machineTrend prediction

The invention relates to a blast furnace molten iron silicon content four-classification trend prediction model establishing method and application and belongs to the technical field of automatic detection. The method comprises acquiring historical data; performing data pre-processing; determining model input variables and output variables; clustering molten iron silicon content samples through a fuzzy mean clustering method effectively to obtain model output variable four-classification trend change block division standards; establishing the four-classification trend prediction model through an extreme learning machine. By means of the model, the silicon content change trend can be predicted, the trend change amplitude can be obtained, that is, four-classification trend change conditions of sharp rise, small rise, sharp decrease and small decrease of the molten iron silicon content of the next furnace can be predicted. Guidance for blast furnace operators to determine furnace conditions in advance, take measures of small adjustment, early adjustment and the like and prevent rapid changes of the furnace conditions.

Owner:CENT SOUTH UNIV

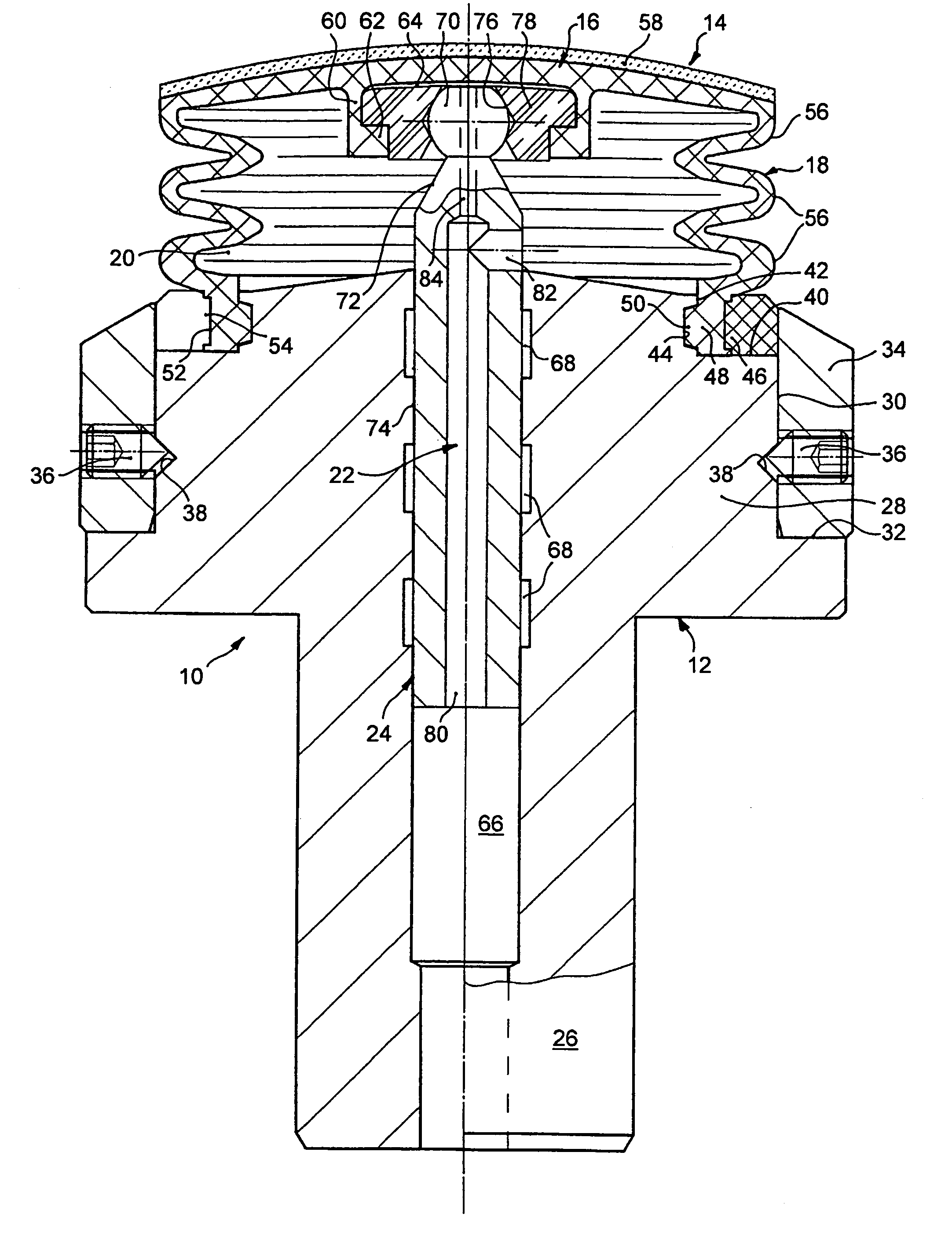

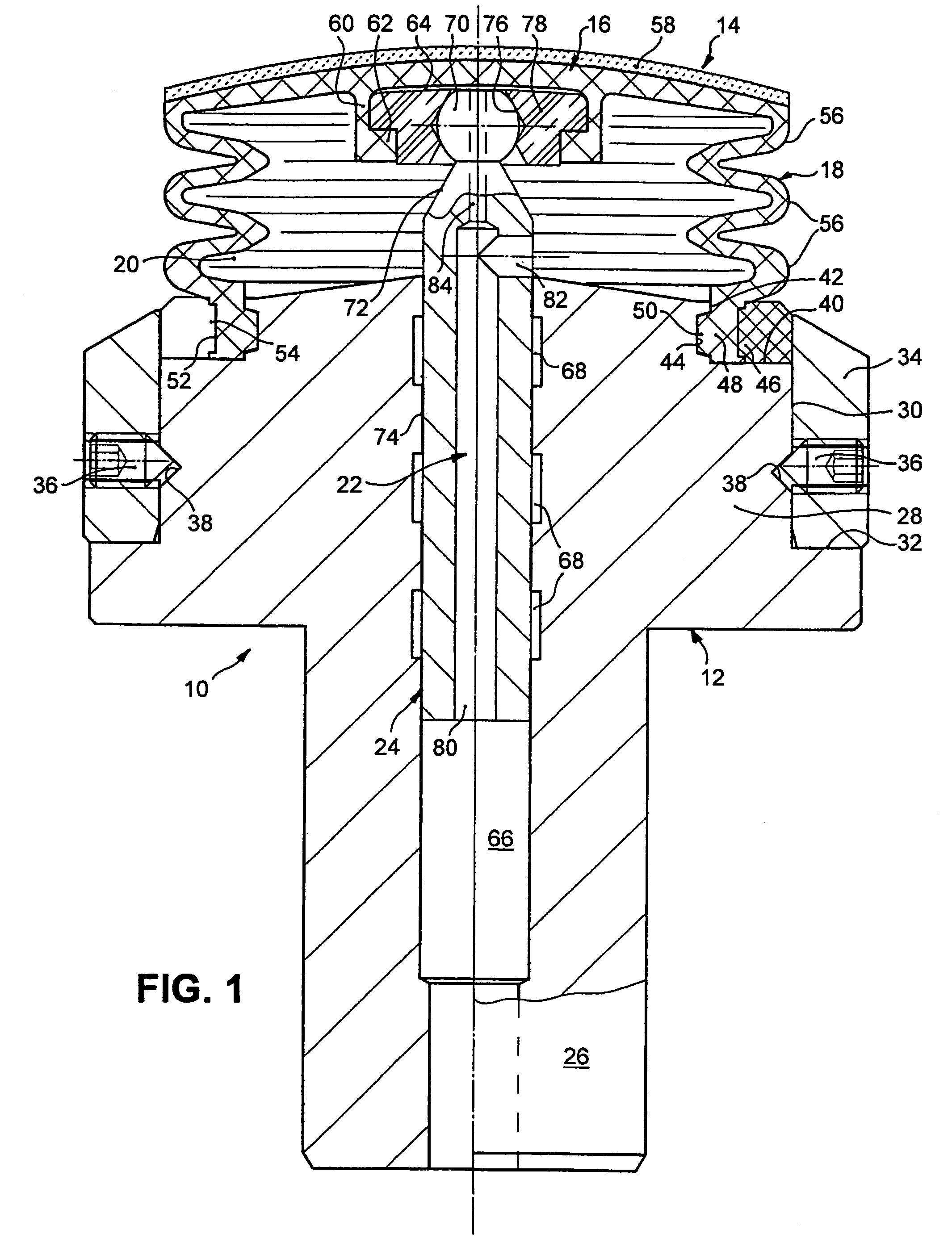

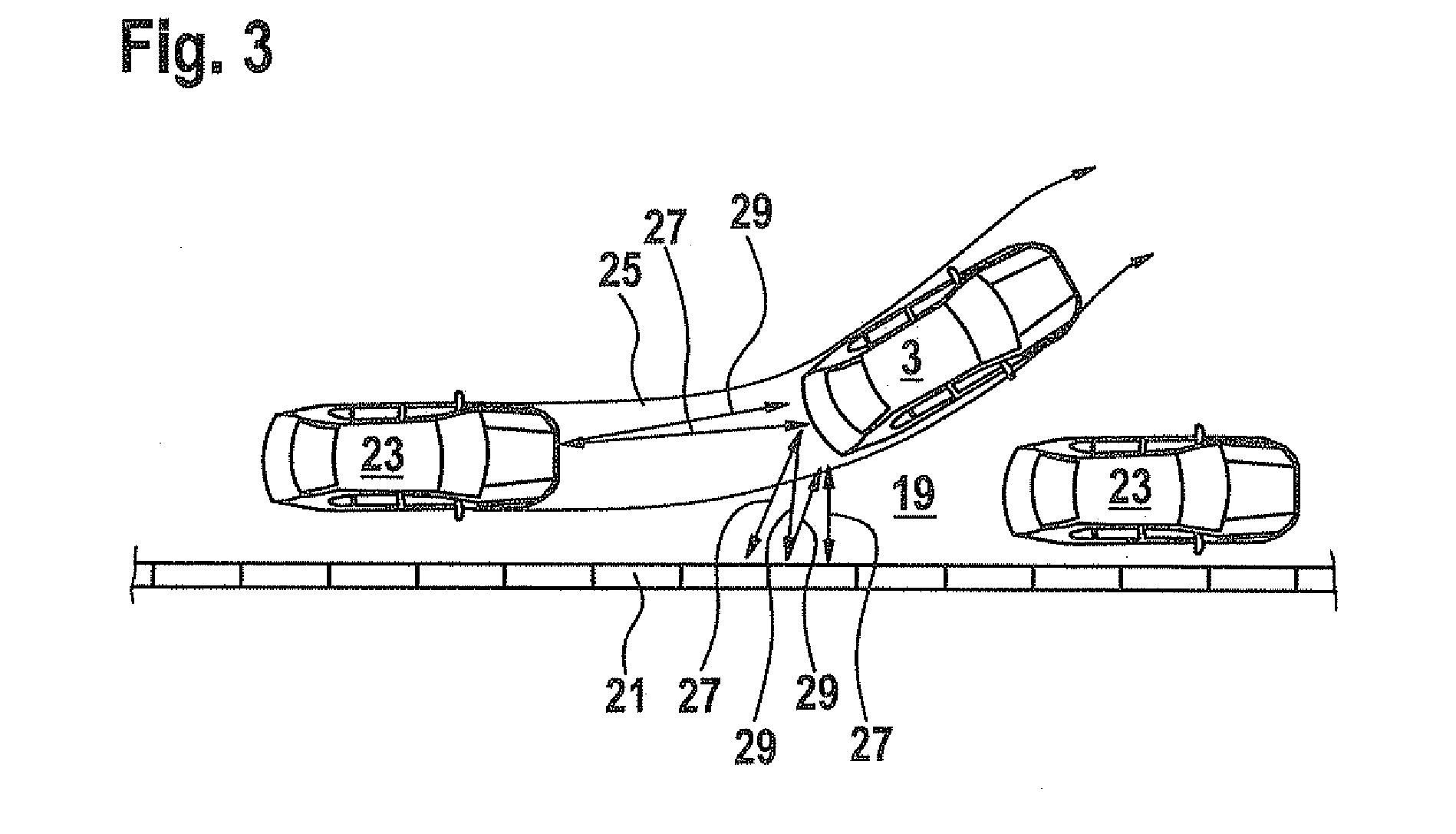

Tool for fine machining of optically active surfaces

ActiveUS7066794B2Good adaptabilityReliable functionEdge grinding machinesOptical surface grinding machinesElastic membraneMachine tool

A tool (10) is disclosed for fine machining of optically active surfaces (F), with a base body (12) that can be attached to a tool spindle of a machine tool, and an elastic membrane (14) that has a machining section (16) to which connects a gaiter section (18) by means of which the membrane is attached to the base body such that it can be rotated therewith. The base body and the membrane delimit a pressure medium chamber (20) which via a channel (22) can be optionally pressurized with a pressure medium in order to apply a machining pressure via the machining section during machining of the optically active surface. A guide element (24) guided longitudinally mobile on the base body is actively connected with the machining section so that the machining section can be moved in the longitudinal direction of the guide element and held in the transverse direction to the guide element, although under an elastic deformation of the gaiter section it is tilt-mobile in relation to the guide element. The result is a tool of simple design and reliable function which has an excellent adaptability to a wide range of geometries to be machined.

Owner:SATISLOH GMBH

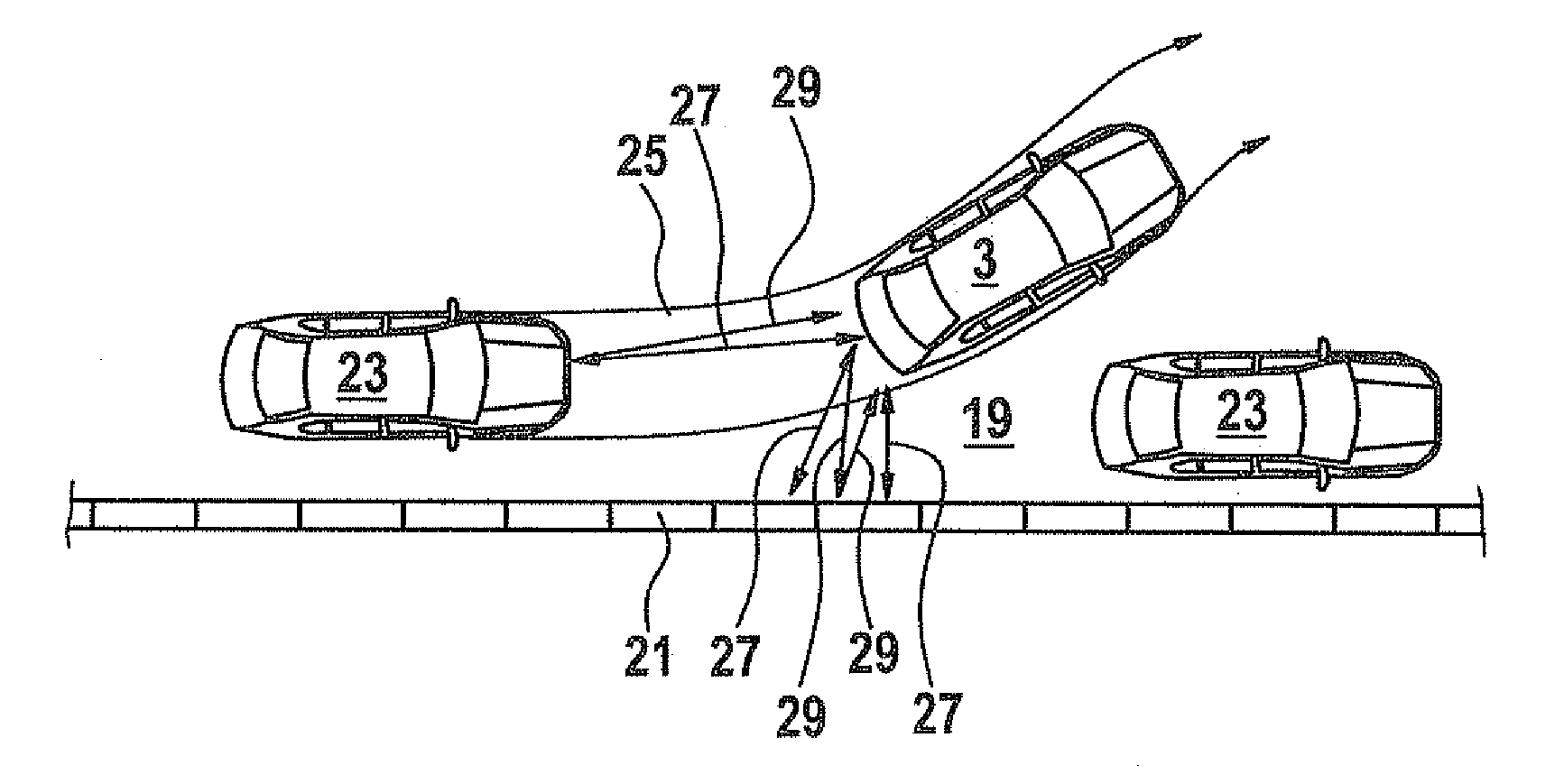

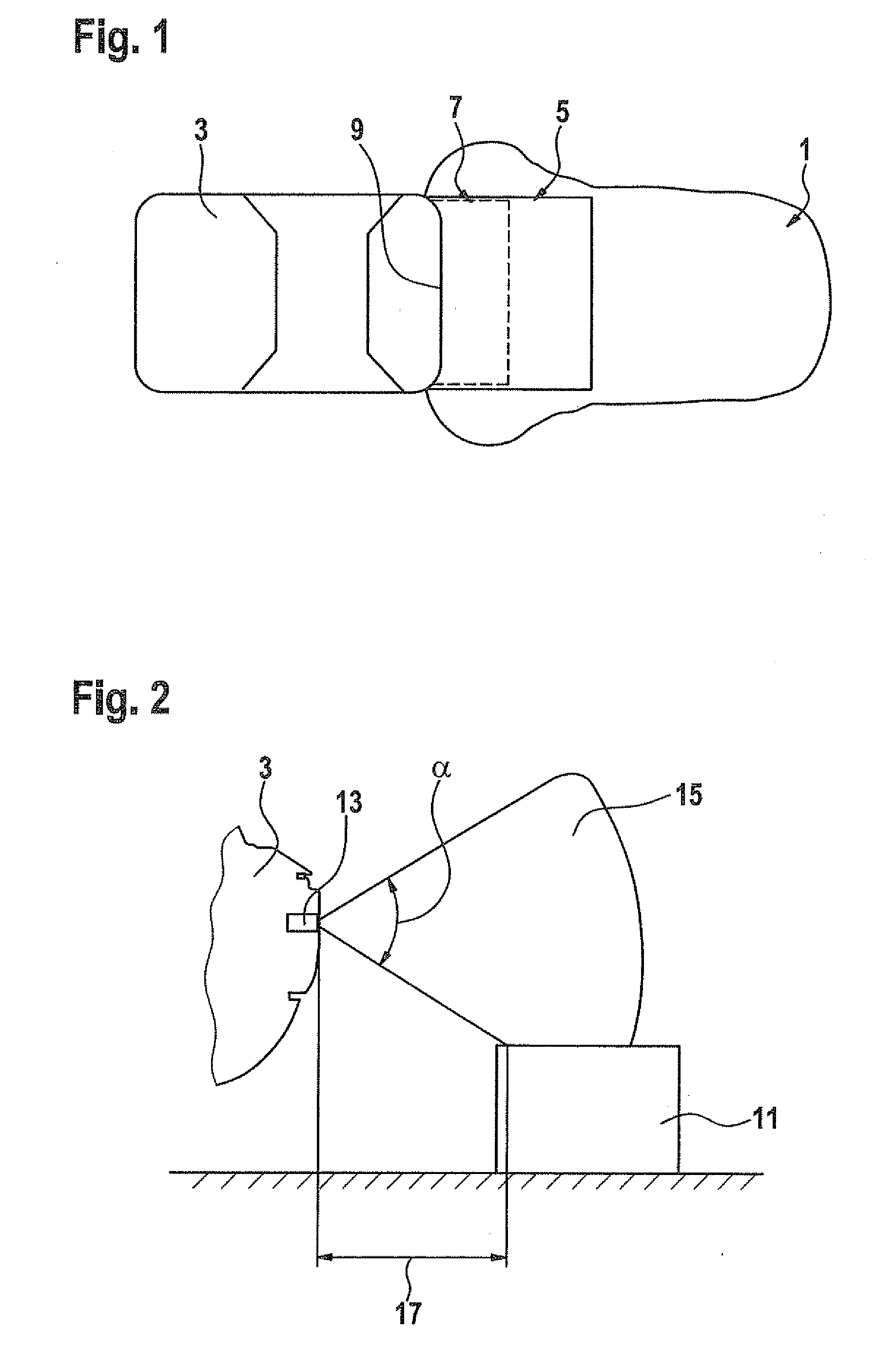

Method For Detecting Objects Having a Low Height

ActiveUS20110121994A1Large safety distanceBig distanceIndication of parksing free spacesSteering partsComputer graphics (images)In vehicle

A method for detecting objects having a low height, using a system for obstacle detection in vehicles, the system for obstacle detection including distance sensors for ascertaining the distance from objects and an arrangement for evaluation.The method includes performing the following: (a) continually recording the distance from an object using the distance sensors or recording the distance from an object at specified intervals, (b) checking whether the object continues to be recorded by the distance sensors when approaching the vehicle, in response to falling below a specified distance, or whether it vanishes from the detection range of the distance sensors, (c) detecting the object, which vanishes from the detection range of the distance sensors, as being an object of low height. Also described is a method for supporting a driver during a driving maneuver.

Owner:ROBERT BOSCH GMBH

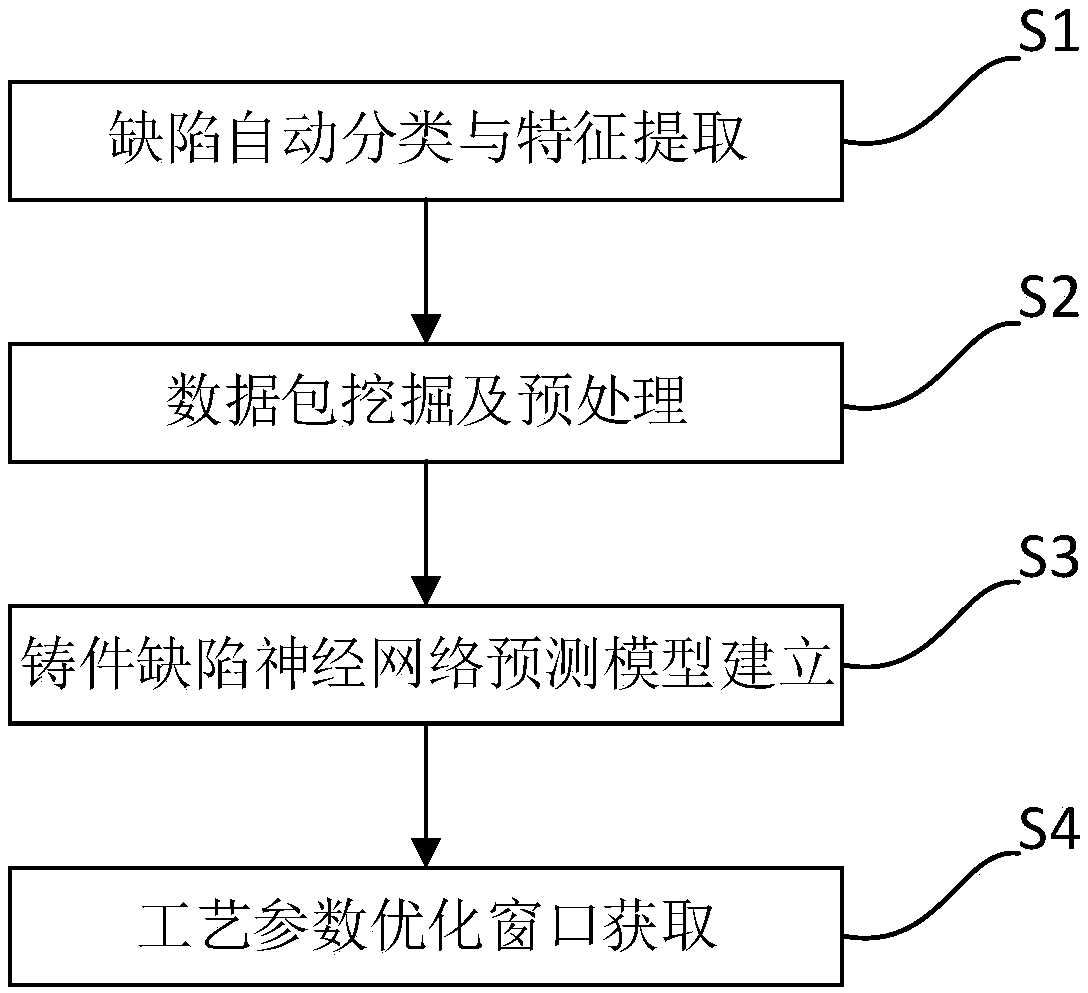

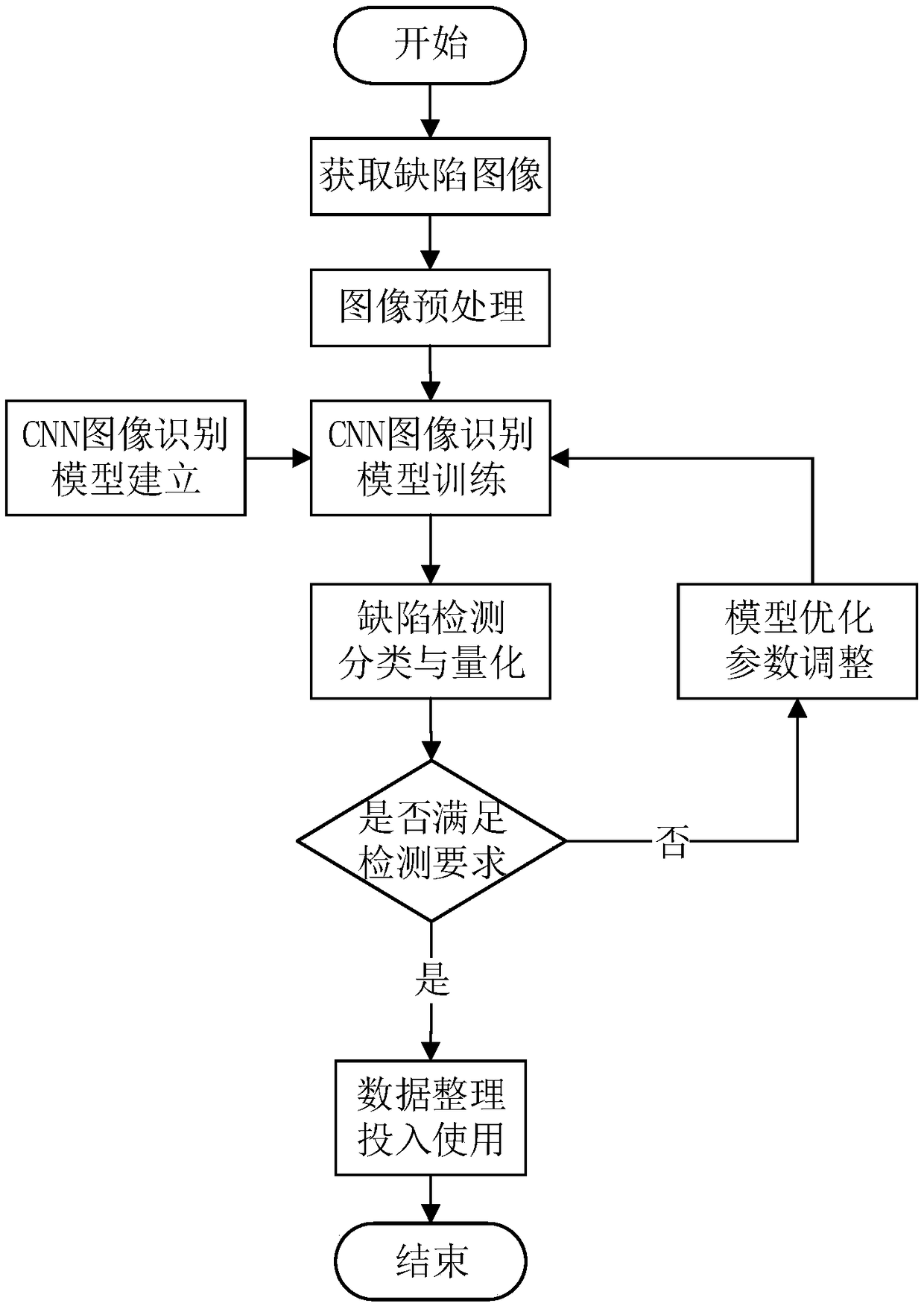

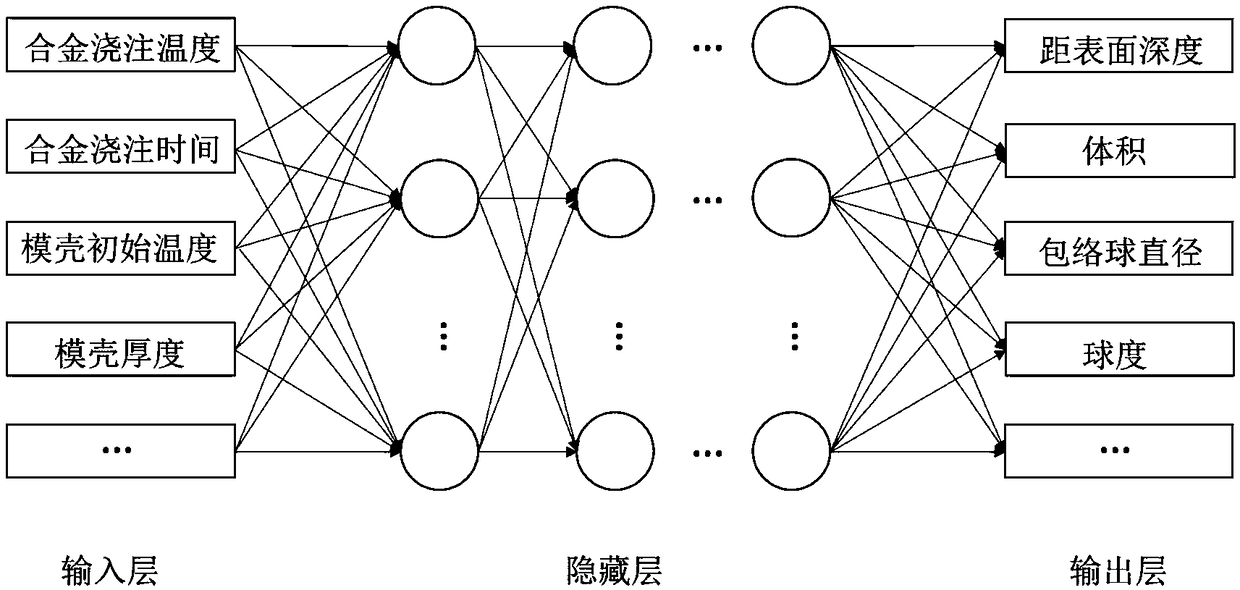

Foundry technology parameter optimization method based on casting defect prediction model

ActiveCN108897925AGood accuracy and robustnessHigh process parameter optimization windowGeometric CADImage enhancementCasting defectNetwork packet

The invention belongs to the related technical field of foundry technology optimization and discloses a foundry technology parameter optimization method based on a casting defect prediction model. Themethod comprises the steps that defect information reflecting the technology level of a casting as a detected object is automatically extracted, and then defects are subjected to qualitative classification and quantitative management; a data package composed of three parts of multi-source data including production data, technology data and detection data is collected and stored; based on the datapackage, a depth neural network is adopted for establishing and optimizing the casting defect prediction model; an orthogonal test is designed to input a technology parameter combination into the model, a sensibility mechanism of key parameters for hole loose defect evolution is researched, and a key technology parameter optimization window is acquired. By means of the method, the intelligent prediction process of the casting defects can be executed, the multi-source data in the whole foundry technology can be related and applied, the optimization result is obtained by a higher-precision modecorrespondingly, and accordingly the quality of the final casting is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

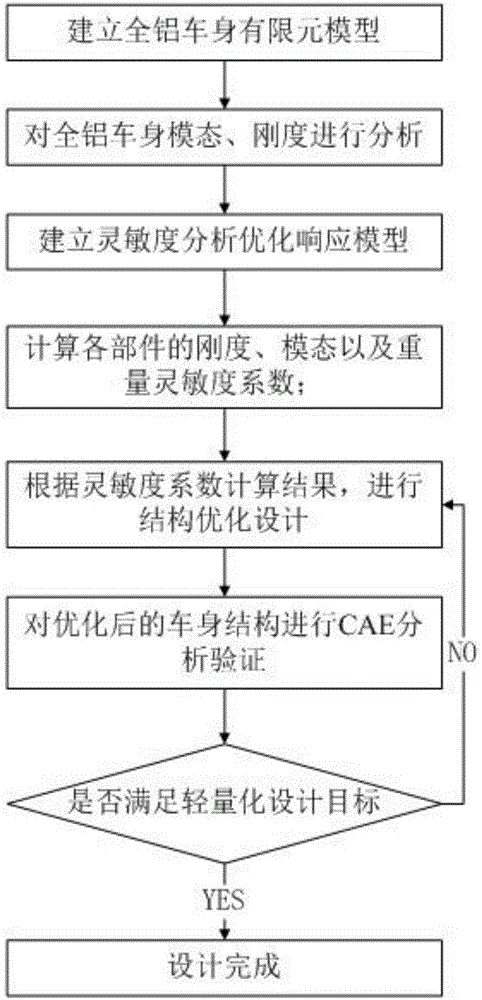

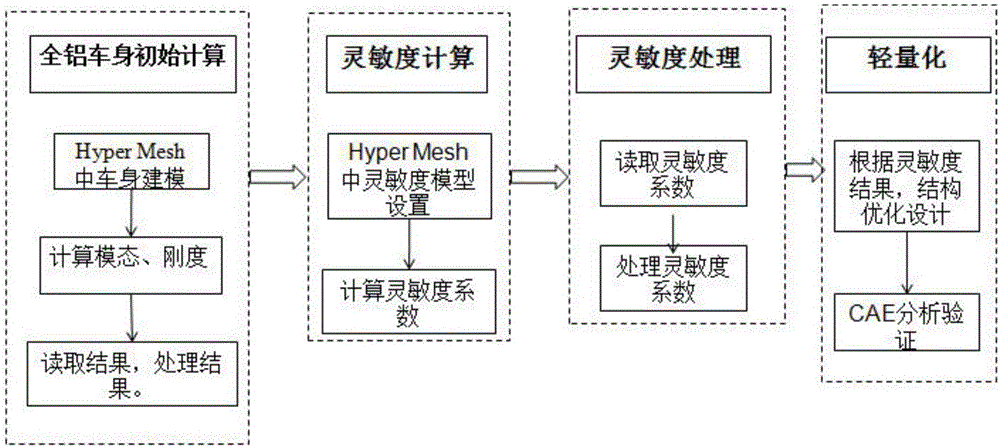

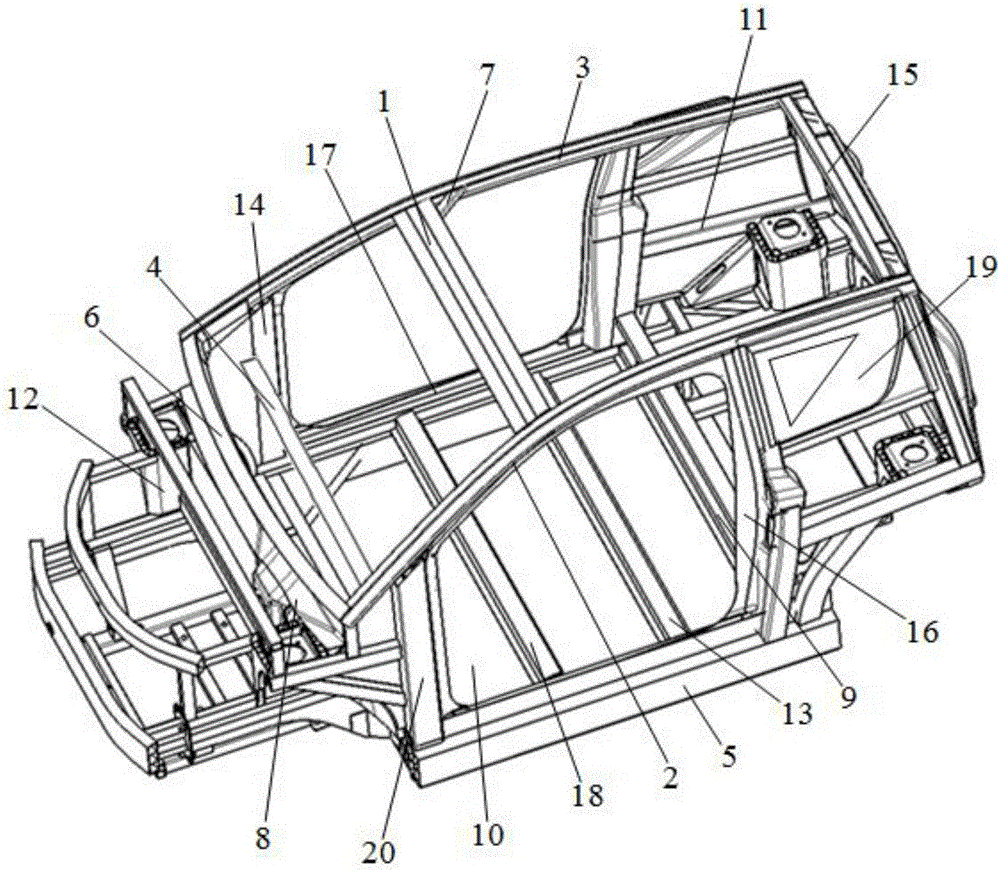

Aluminum body lightweight design method based on sensitivity and CAE analysis

InactiveCN106844874AStrong engineering practicabilityImprove guidanceGeometric CADInternal combustion piston enginesOptimal designDesign objective

The invention discloses an aluminum body lightweight design method based on sensitivity and CAE analysis. The method comprises the following steps of 1, building an aluminum body finite element model; 2, analyzing modality and rigidity of an aluminum body; 3, building a sensitivity analysis optimization response model; 4, calculating a rigidity sensitivity coefficient, a modality sensitivity coefficient and a weight sensitivity coefficient of all components of the aluminum body; 5, according to a calculation result of the sensitivity coefficient, performing structural optimal design; 6, performing CAE analysis validation on the optimized aluminum body structure, judging whether the lightweight design objective is met or not; if yes, completing designing; if not, executing the step 5 again till the lightweight design objective is met. All structures capable of achieving the lightweight objective in the whole aluminum body structure can be analyzed, it can be efficiently verified that the optimized structure meets the requirement for modality and rigidity or not, and the efficient and reliable aluminum body lightweight design is achieved.

Owner:SUZHOU AUTO TECH +1

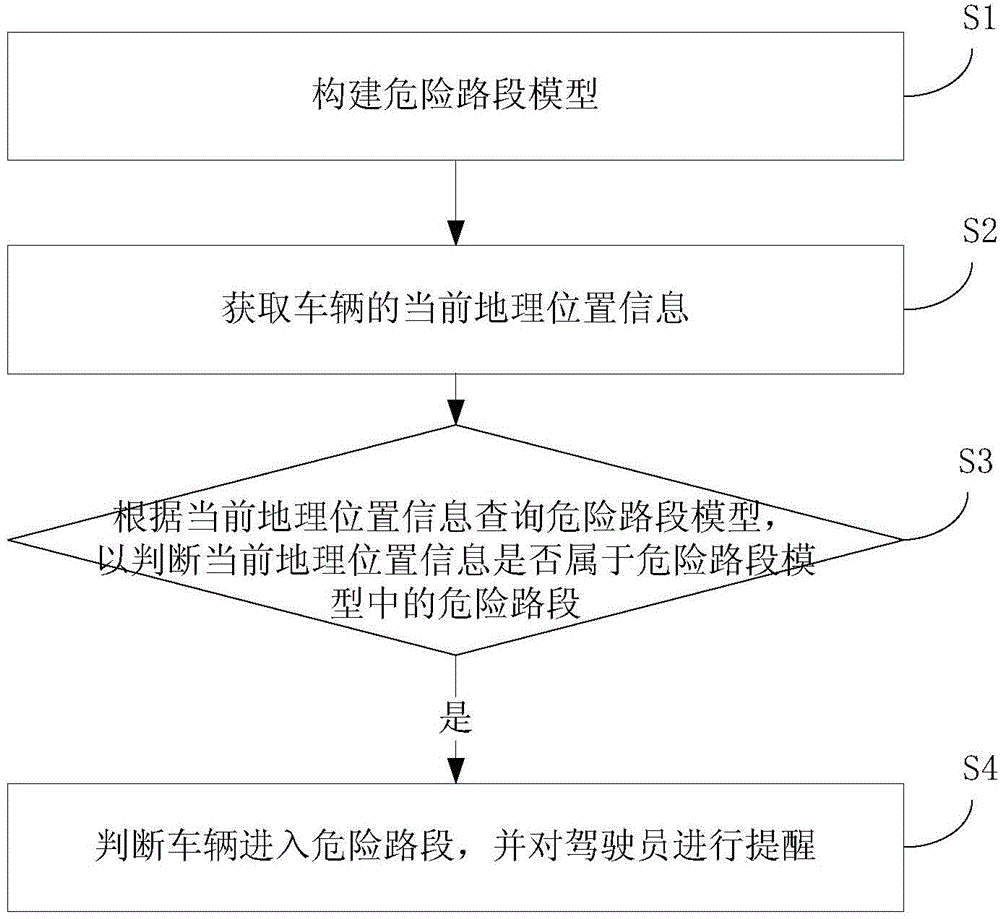

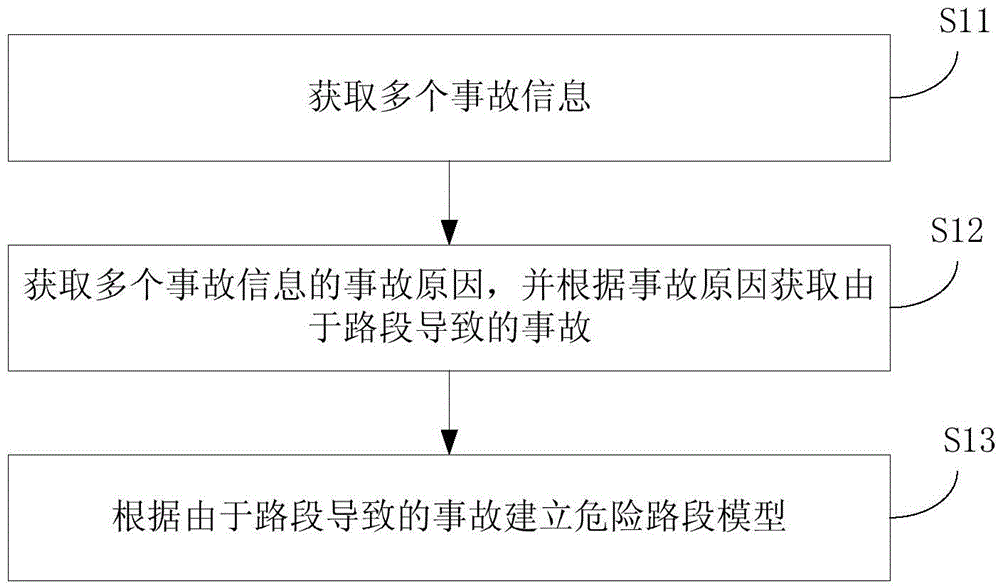

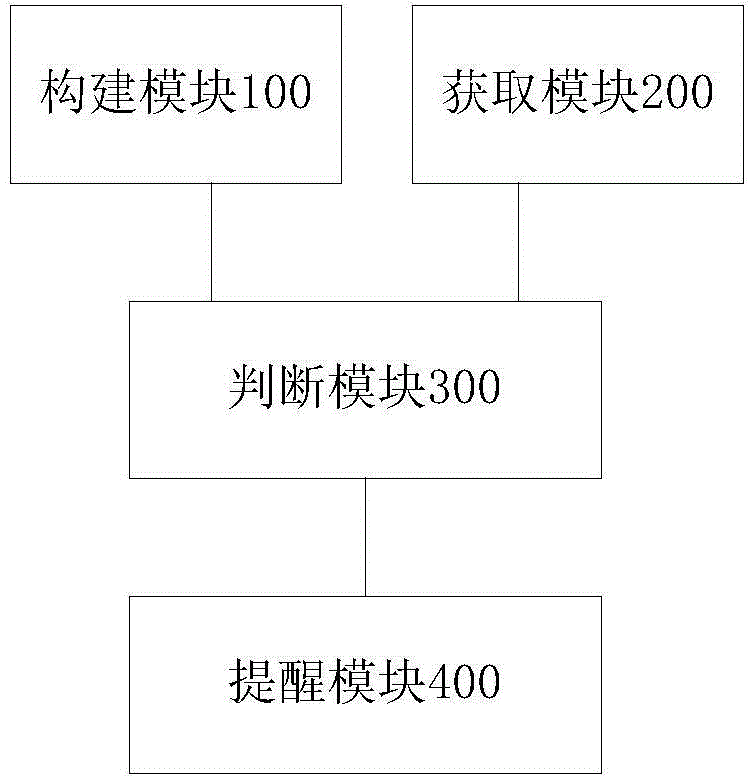

Vehicle safety early warning method, apparatus and vehicle

InactiveCN105788311AImprove guidanceReduce incidenceArrangements for variable traffic instructionsAnti-collision systemsEngineeringDriving safety

The invention discloses a vehicle safety early warning method, an apparatus and a vehicle. The method includes the following steps: establishing a dangerous road model; acquiring current geographic location information of the vehicle; based on the current geographic location information, checking the dangerous road model so as to determine whether the current geographic location information belongs to dangerous roads in the dangerous road model; if the current geographic location information belongs to the dangerous roads in the dangerous road model, determining that the vehicle enters a dangerous road, and altering the driver of the vehicle. According to the embodiments of the invention, the vehicle safety early warning method can provide excellent guidance for the driver when it is determined that the driver is entering the dangerous road, which reduces accident occurrence rate, increases driving safety and substantially increases user driving experience.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com