Patents

Literature

115 results about "Tensile fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

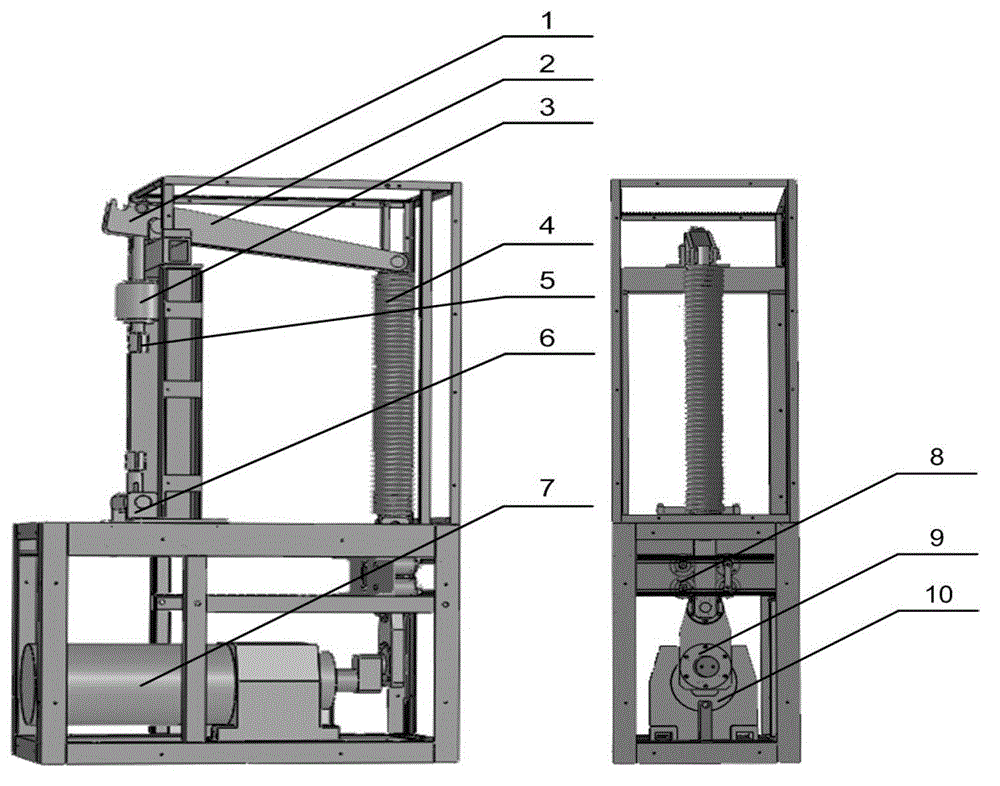

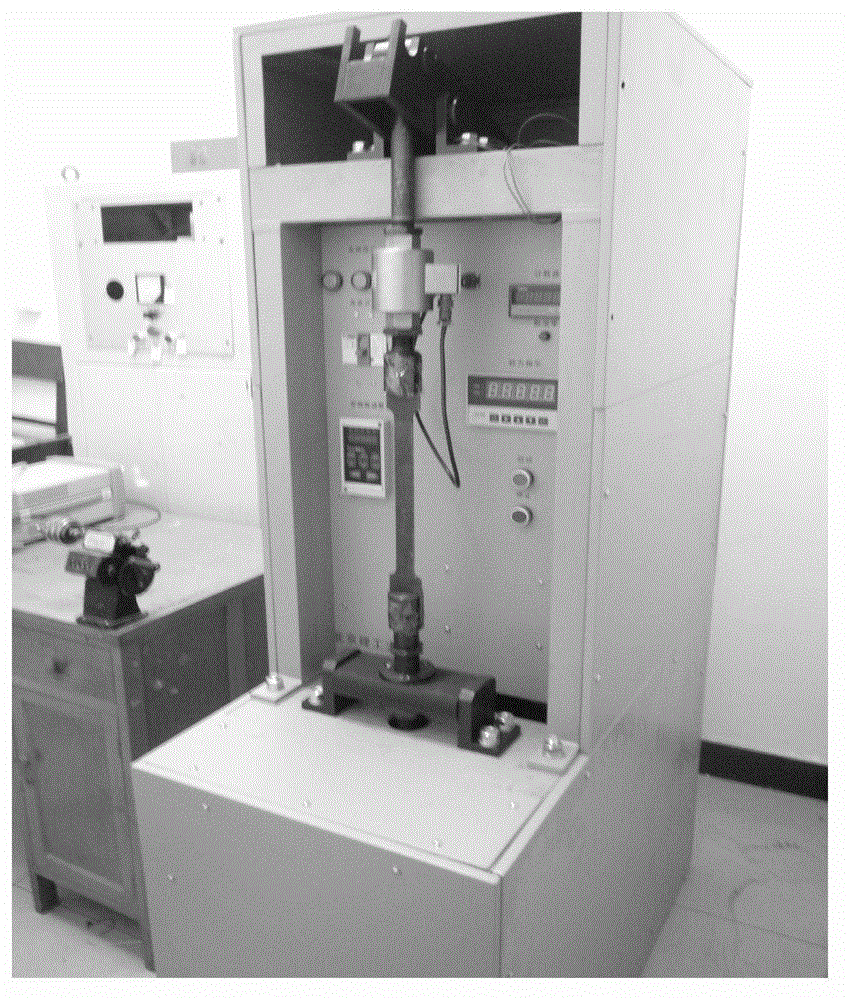

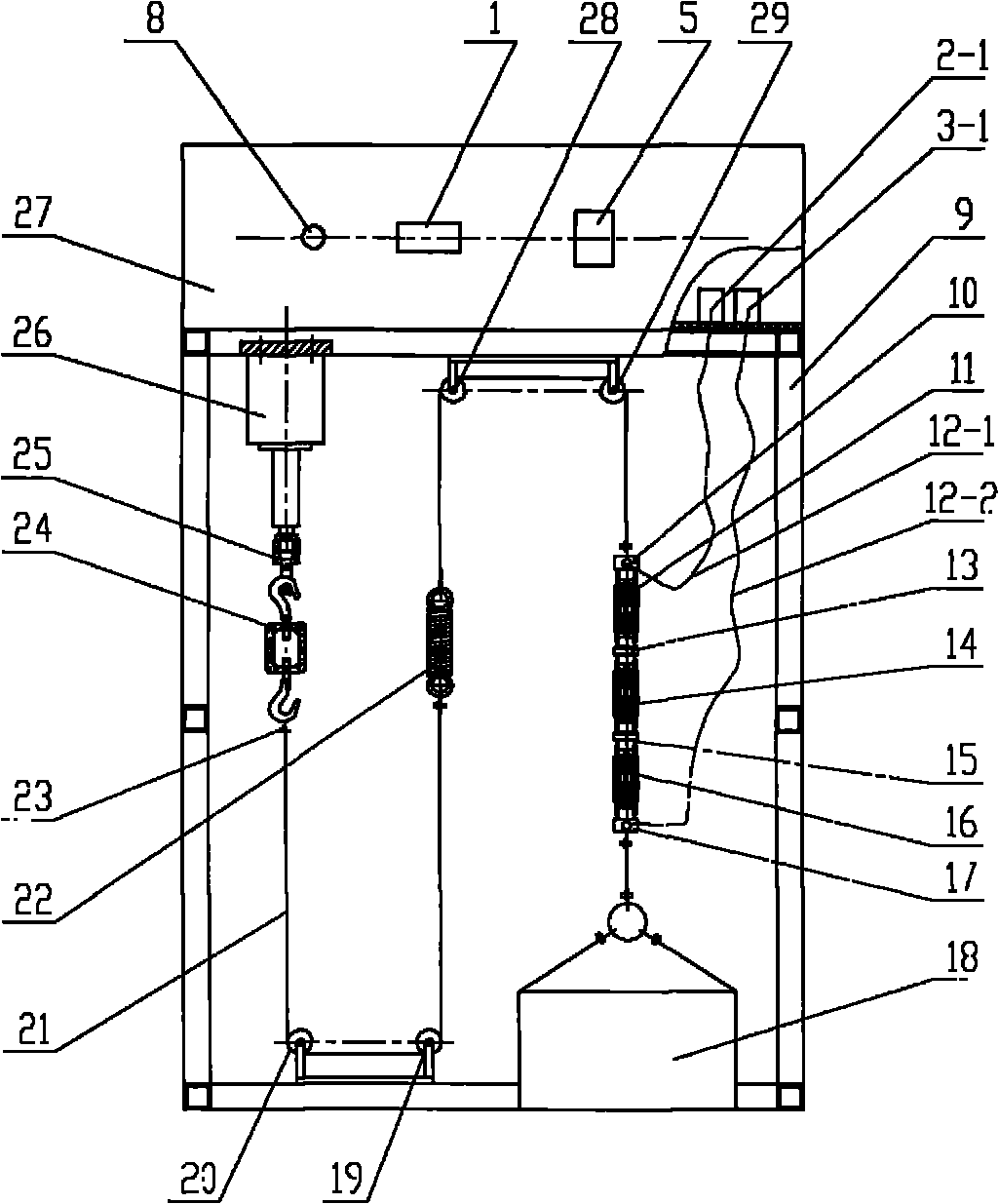

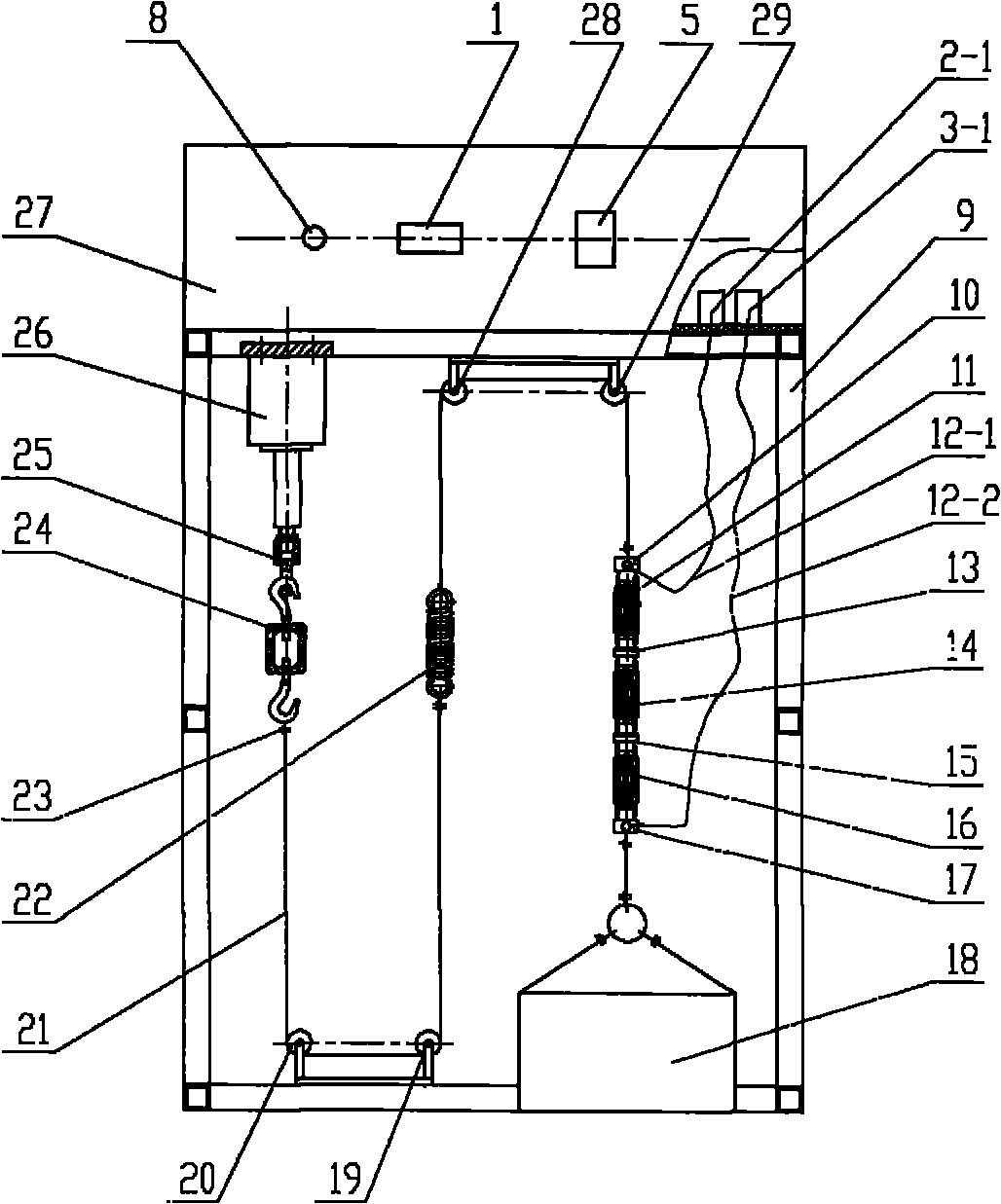

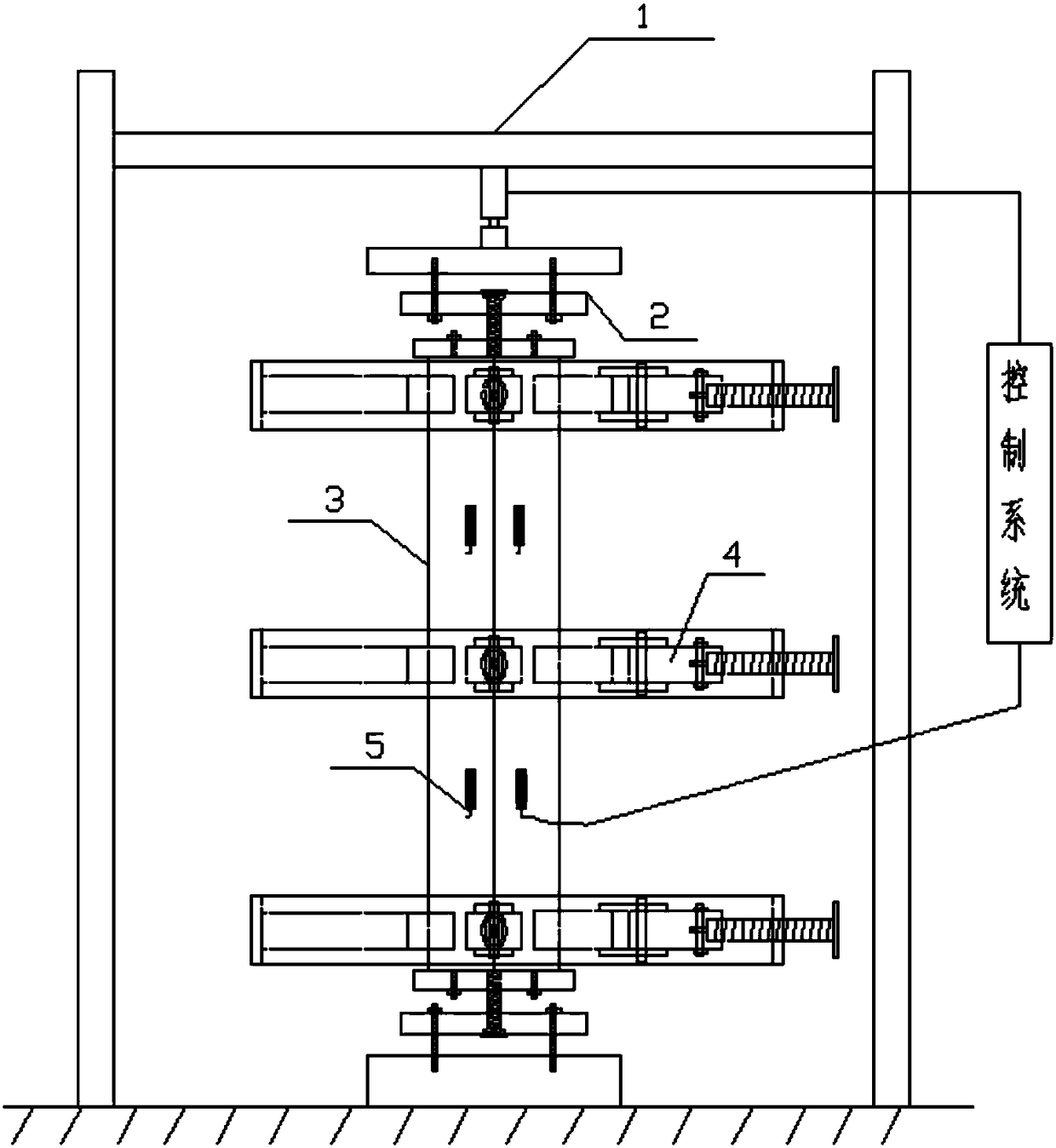

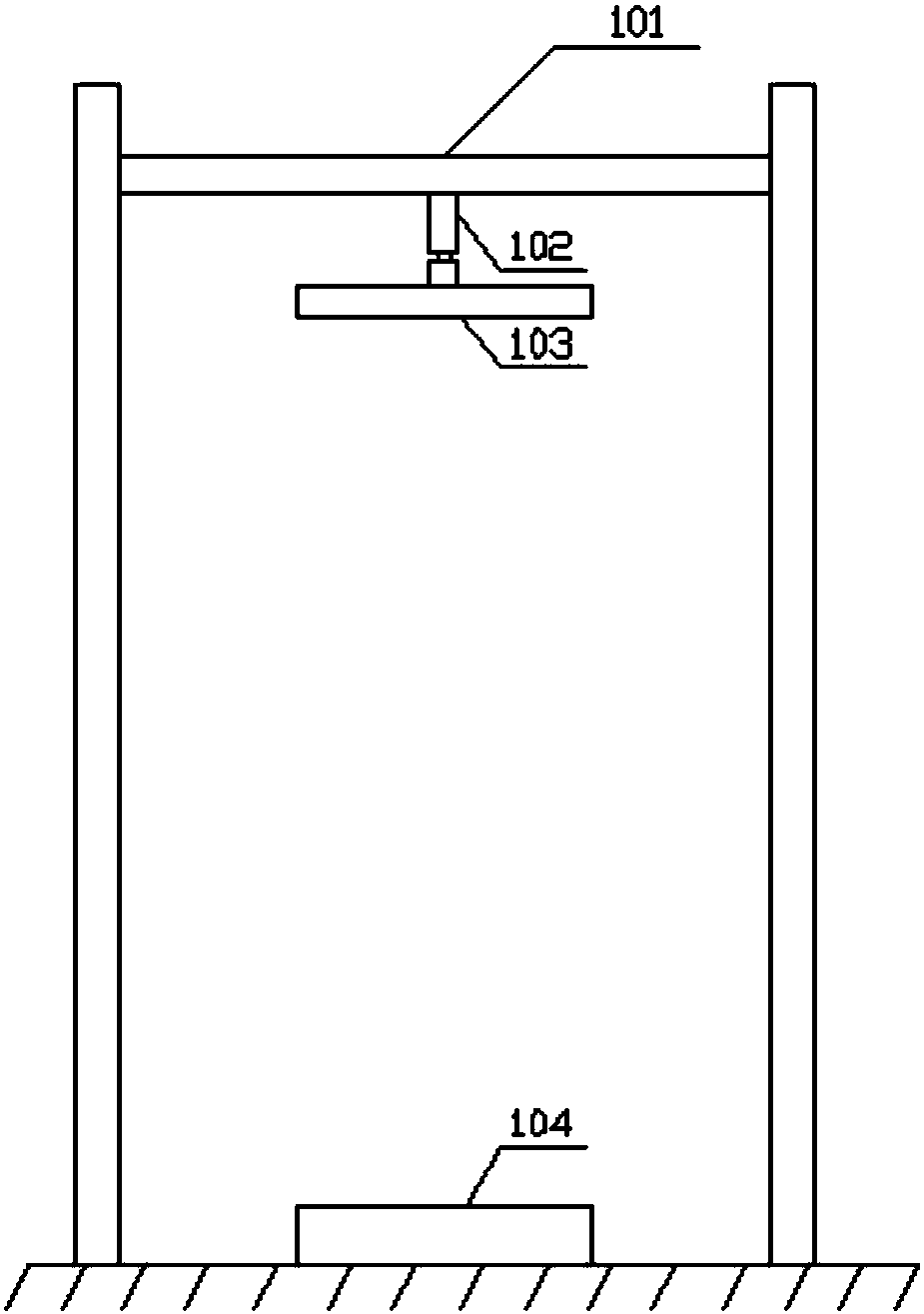

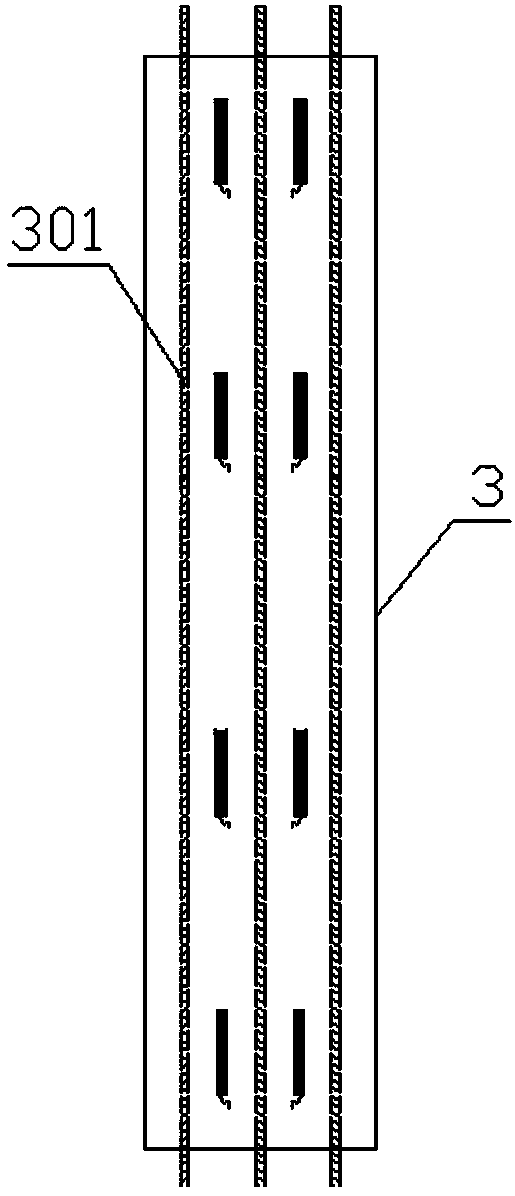

Fatigue testing machine applied to tension test piece and method thereof

InactiveCN101957290AMaximum average displacementMaximum peak displacementMaterial strength using tensile/compressive forcesMechanical componentsPull force

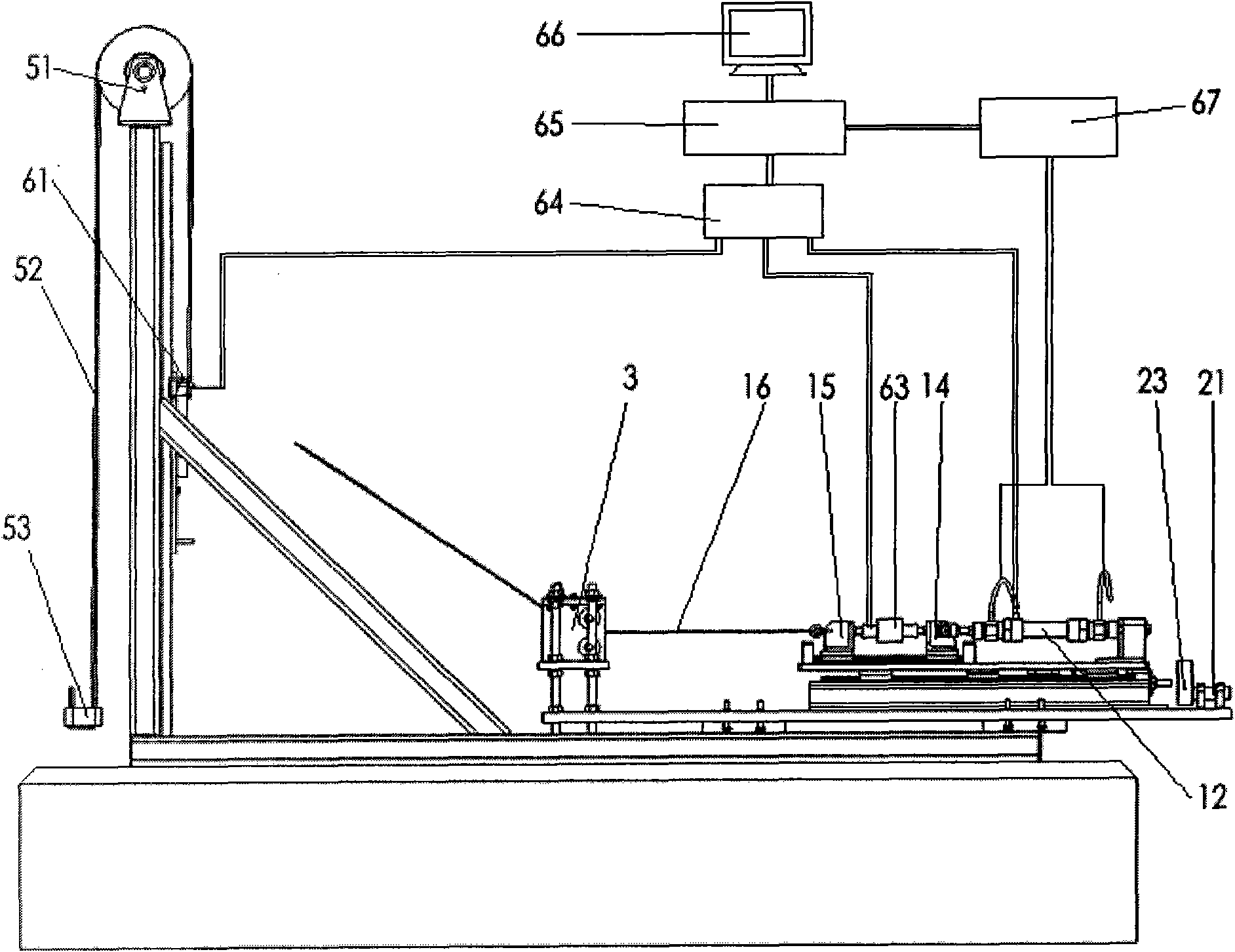

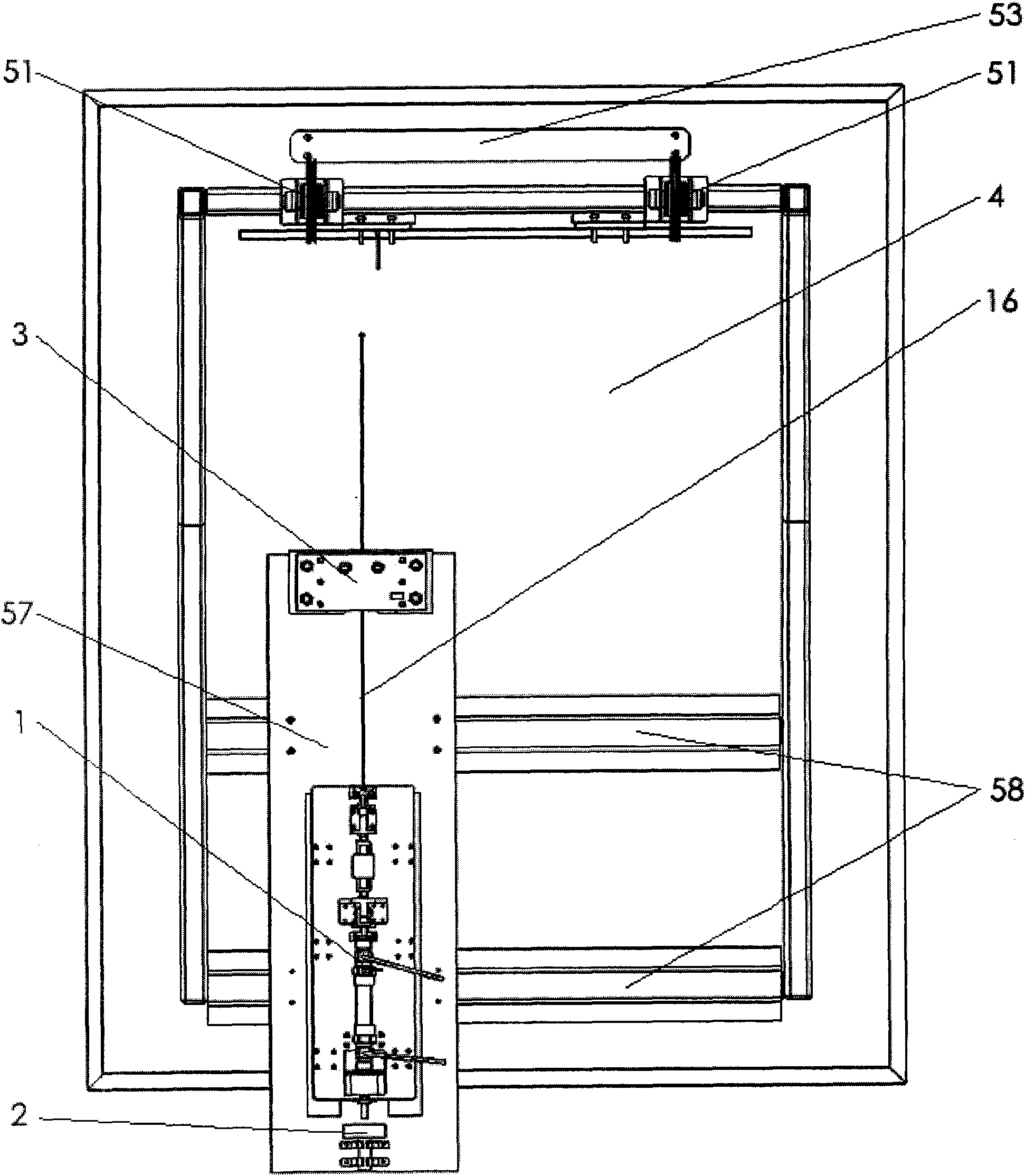

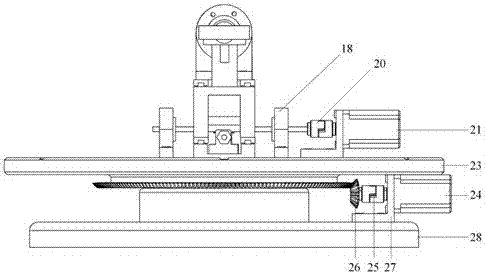

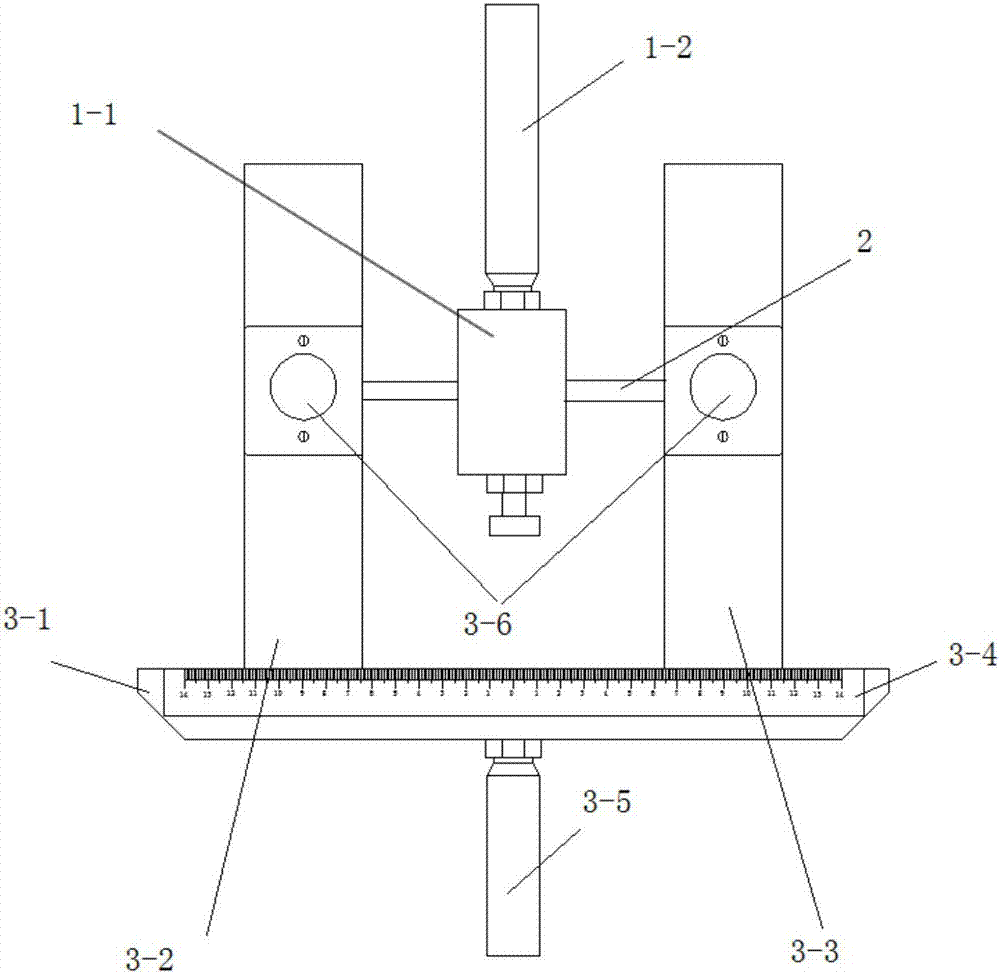

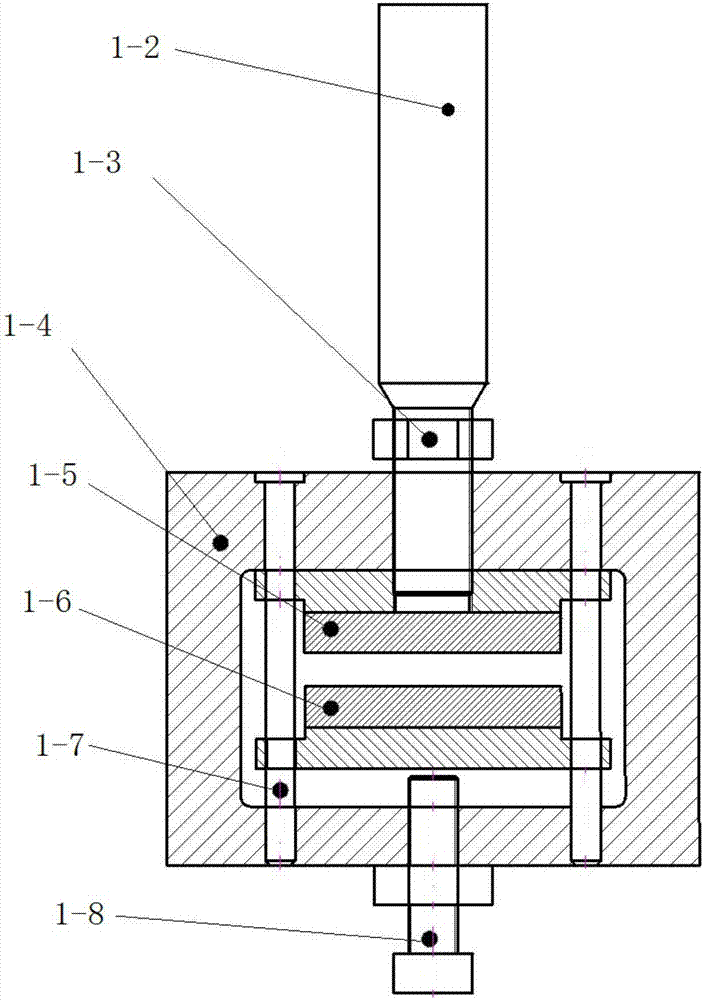

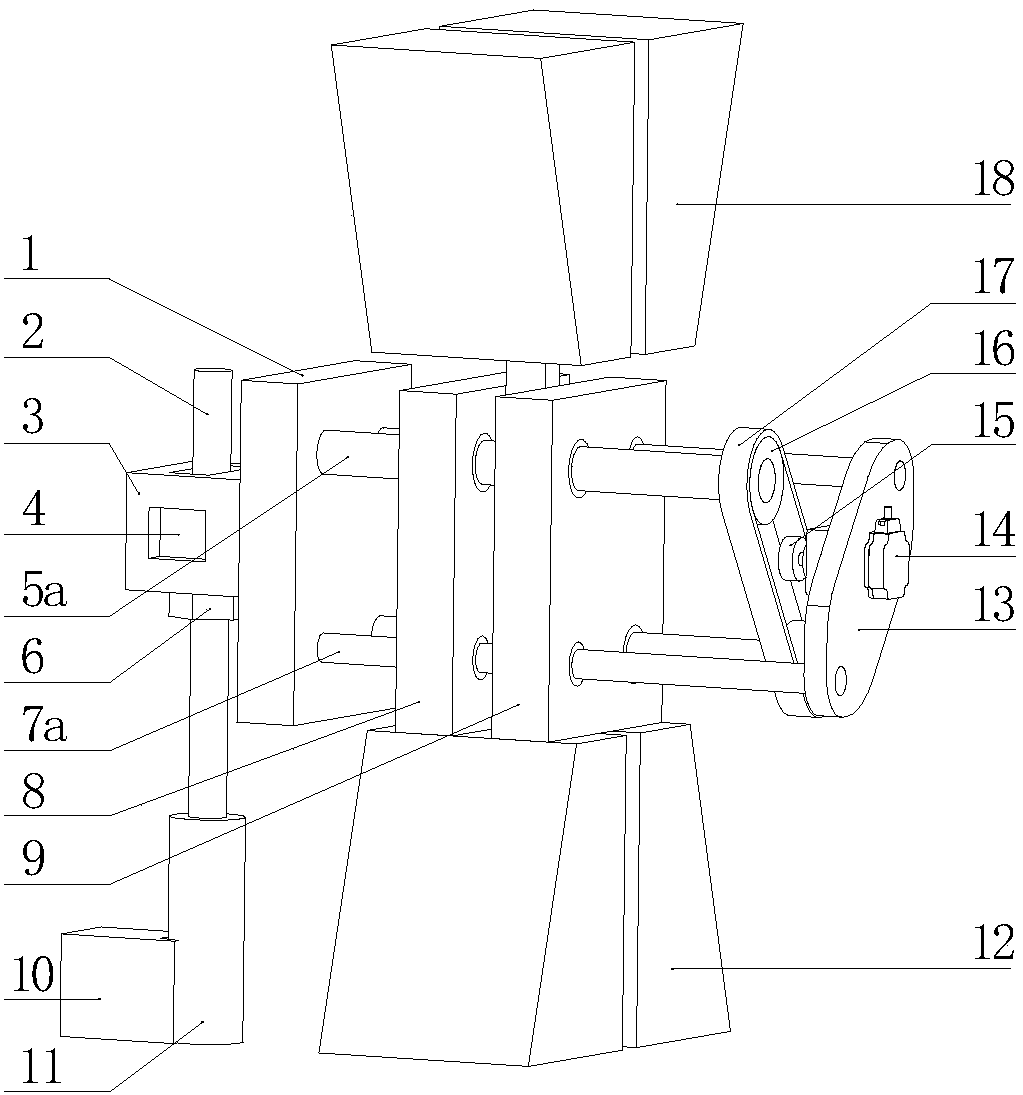

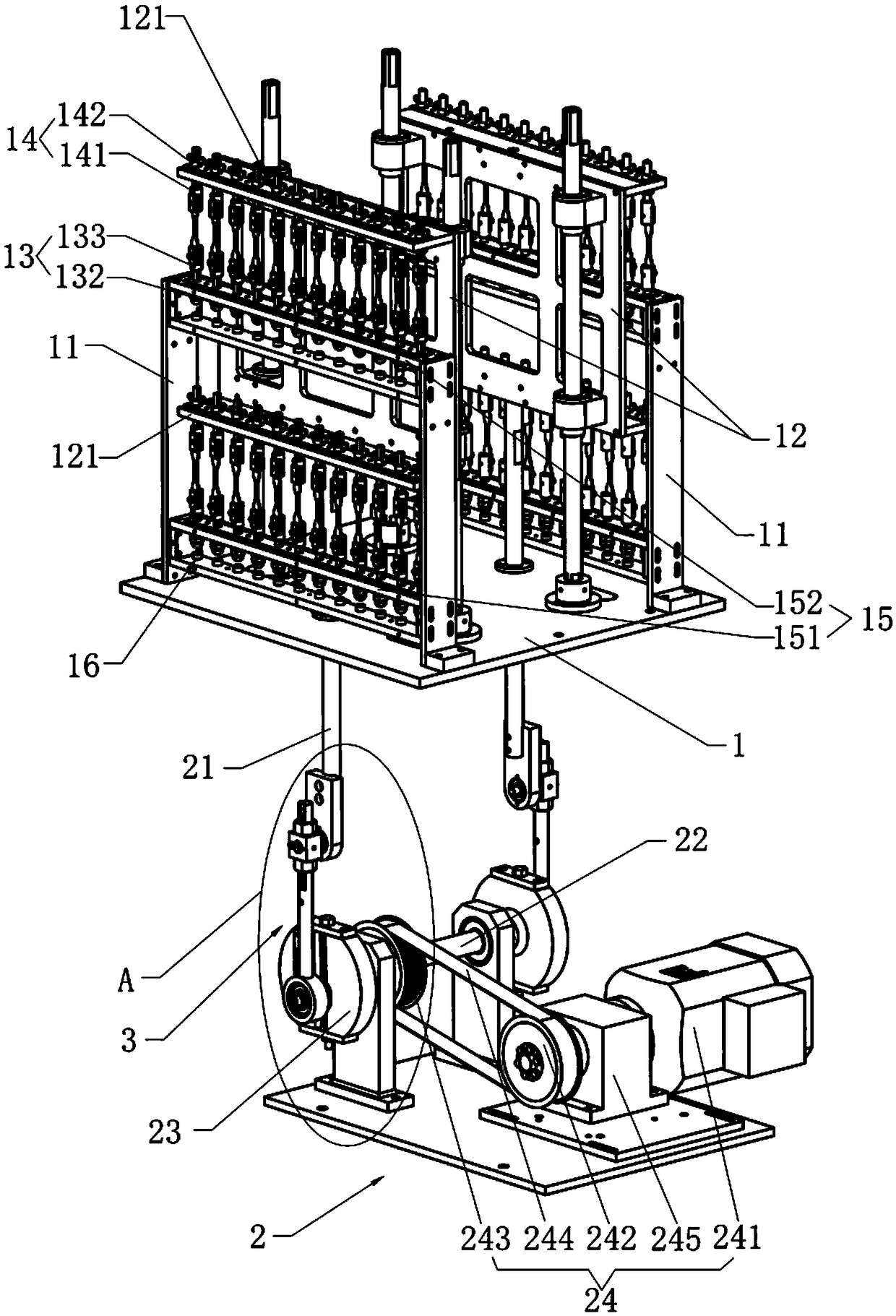

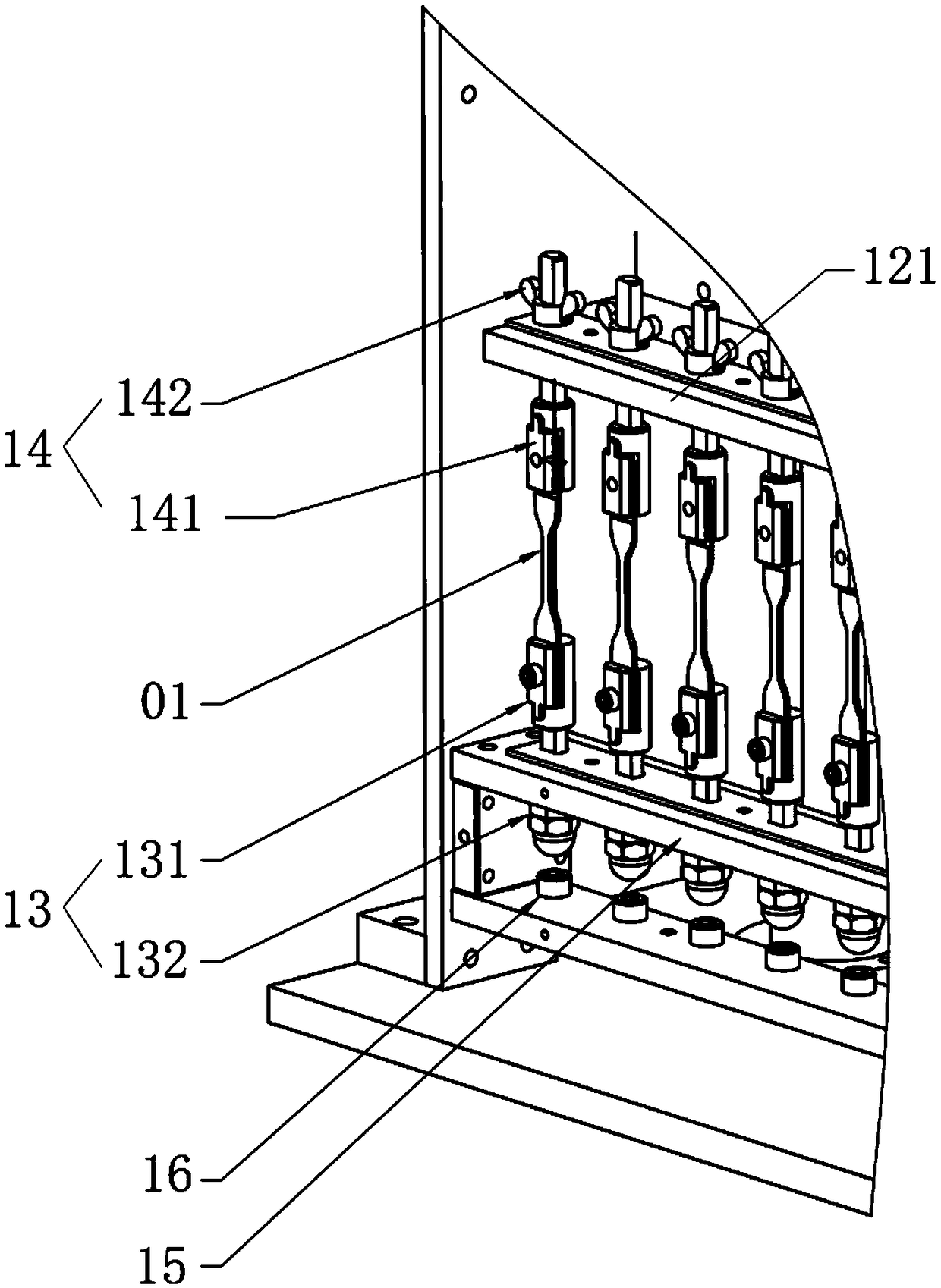

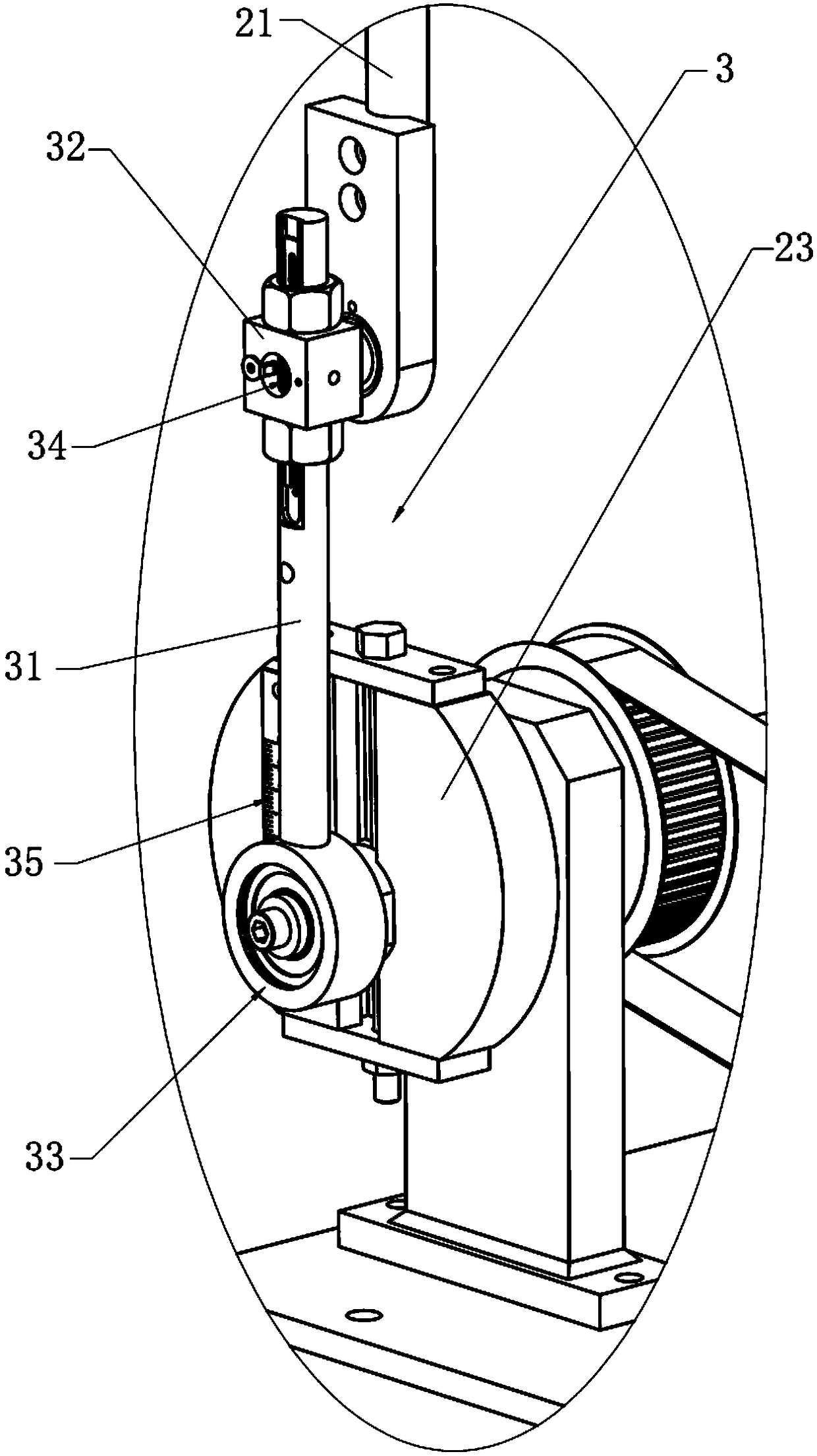

The invention discloses a fatigue testing machine applied to a tension test piece. The fatigue testing machine is mainly used for a tensile test and a tensile fatigue test for mechanical components. The testing machine comprises a fatigue force application mechanism, a pretightening force mechanism, a straightening roller mechanism, a test fixing frame, an auxiliary mechanism and a control system. A power system of the fatigue testing machine comprises the fatigue force application mechanism and the pretightening force mechanism; the tensile force output by the power system is redirected by the straightening roller mechanism and is transmitted to the tension test piece; and the fatigue force application mechanism, the pretightening force mechanism, the straightening roller mechanism and the auxiliary mechanism of the fatigue testing machine are arranged on the test fixing frame. The fatigue testing machine has the advantages of adopting hybrid pneumatic and electric power as the power system of the fatigue testing machine, mastering numerous parameters including the maximum average displacement, the minimum average displacement, peak displacement, the maximum average tension, minimum average tension, minimum fatigue tension, frequency, accumulated test times, accumulated test time and the like, and providing a basis for optimization design of the tension test piece.

Owner:ZHEJIANG UNIV

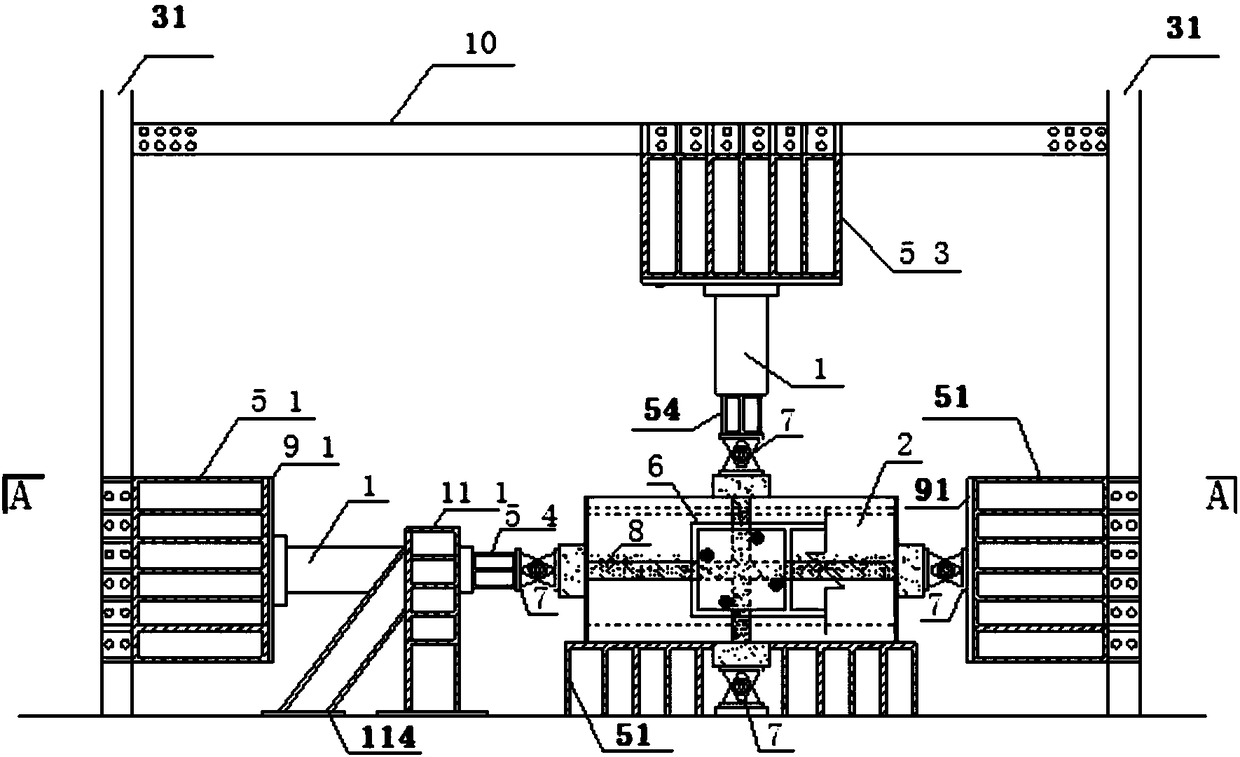

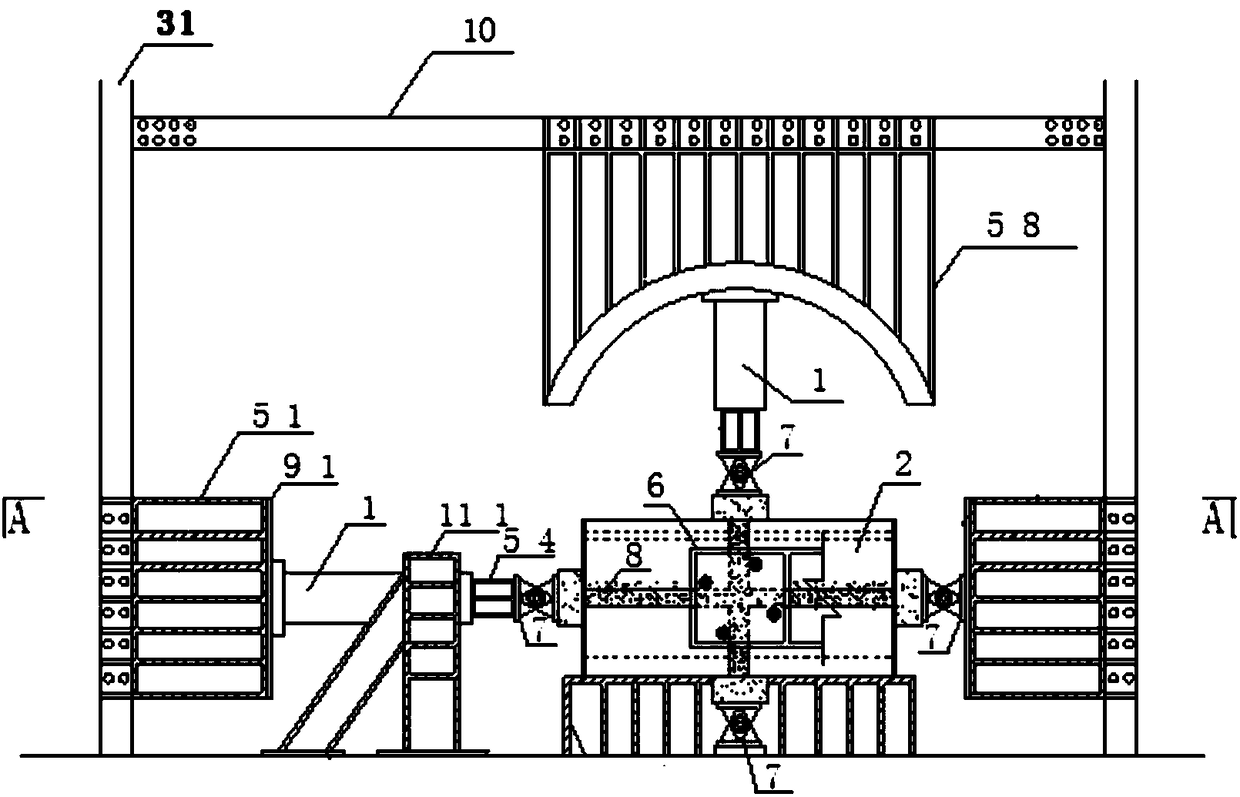

Multilevel static-dynamic coupling mechanical loading device for high-frequency fatigue test

ActiveCN107340190ARealize static and dynamic couplingMeet the requirements of large driving loadsMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesFatigue loadingElectric machine

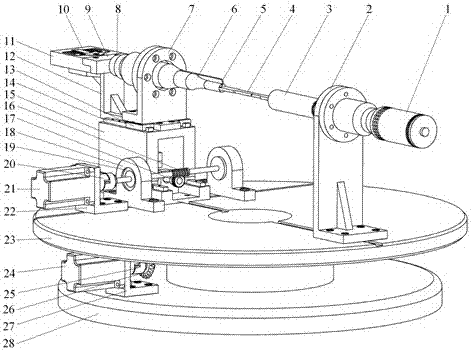

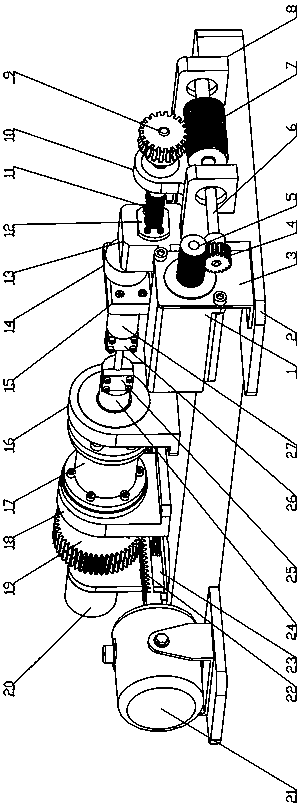

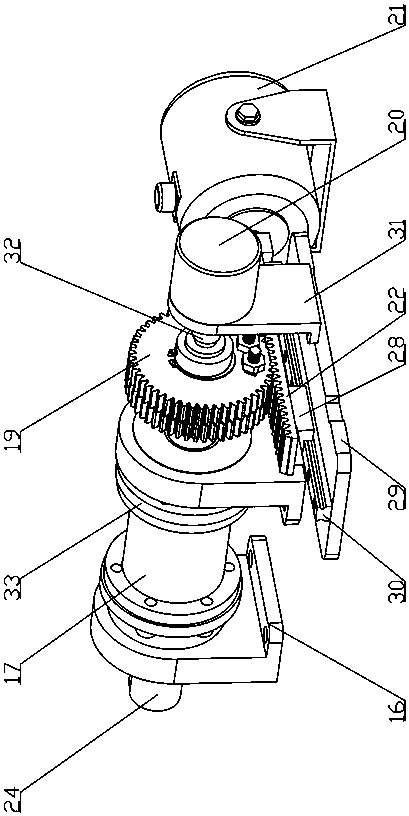

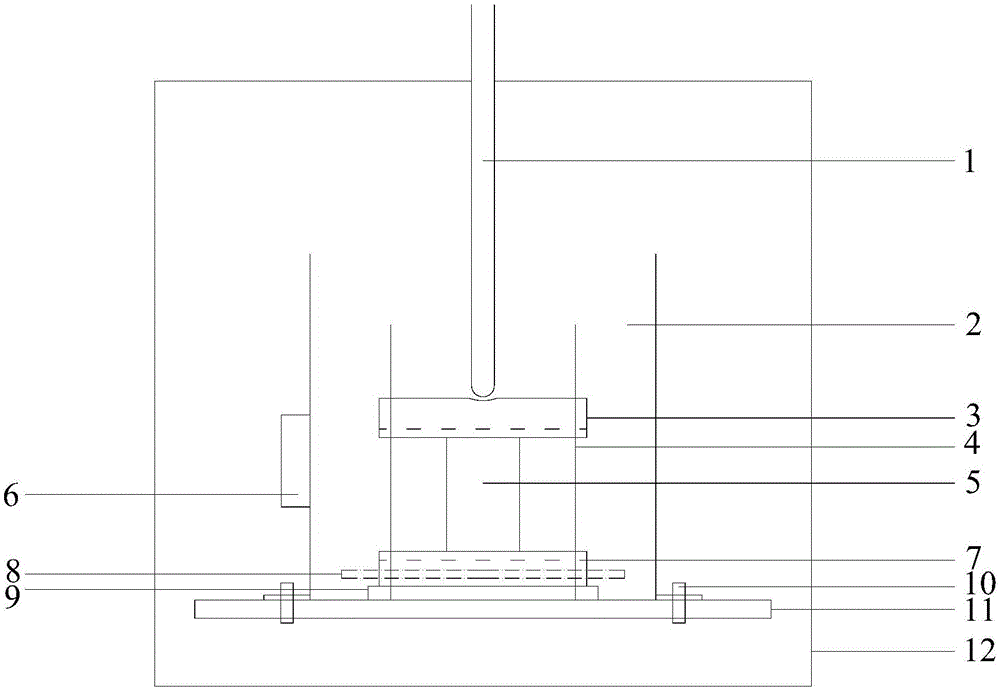

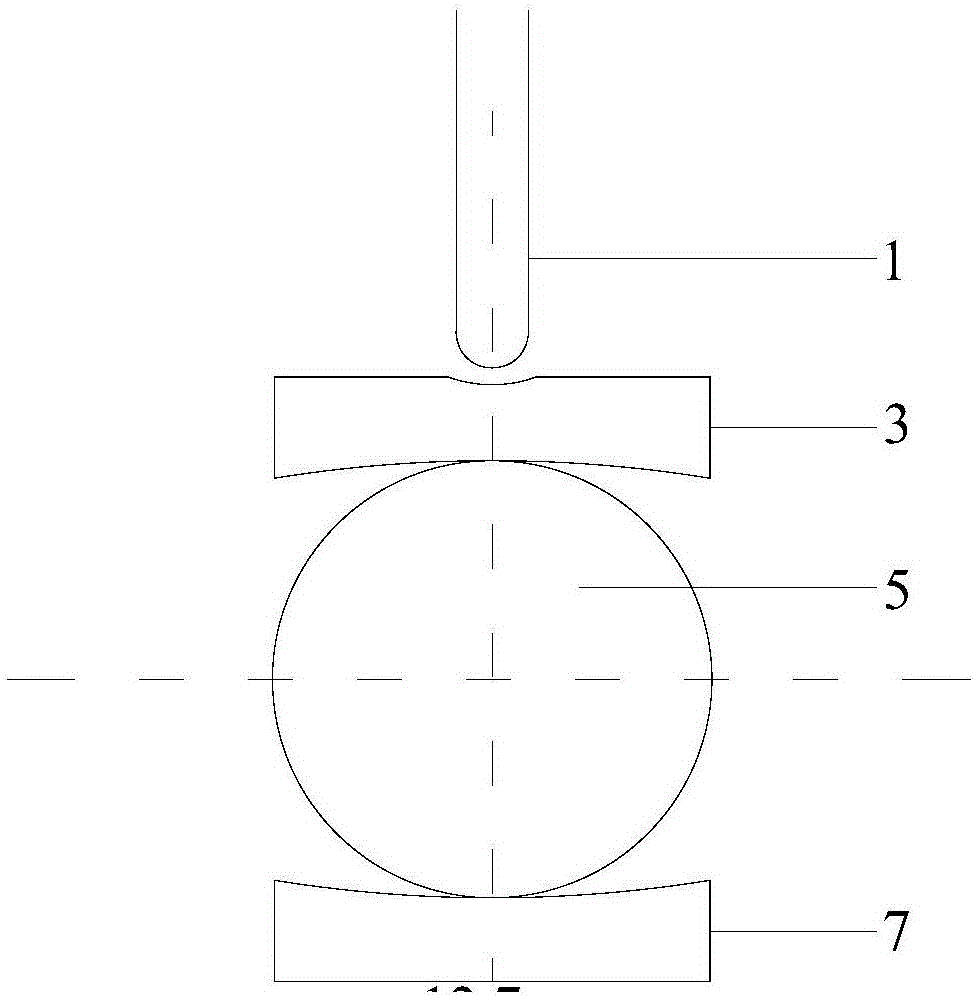

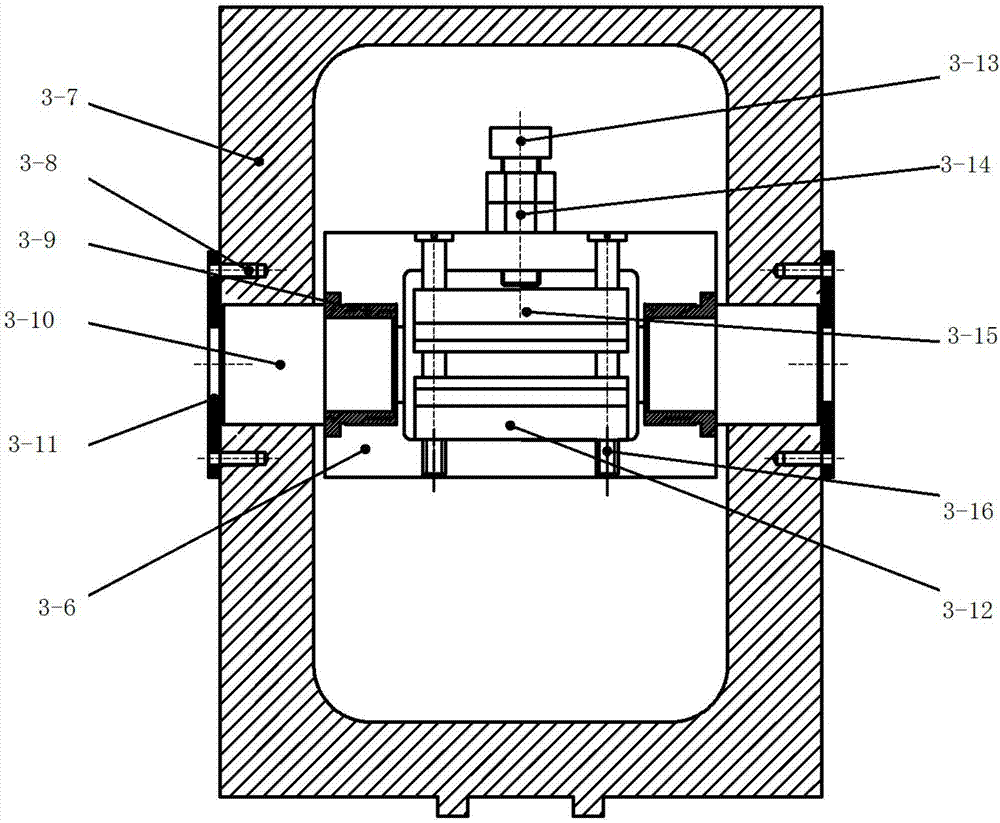

The invention relates to a multilevel static-dynamic coupling mechanical loading device for a high-frequency fatigue test, and belongs to the fields of scientific instruments and mechanical property tests of materials. The device comprises a high-frequency fatigue loading unit, a low-frequency fatigue loading unit, a tensile loading and detection unit and a synchronous rotating unit. The device realizes tensile fatigue loading through a servo motor, a piezoelectric stack and an ultrasonic vibrator assembly, and simultaneously realizes detection of load and displacement through a mechanical sensor and an optical fiber displacement sensor. The motor drives a rotating mechanism by a motor to realize real-time dynamic crystal diffraction characterization performed on a sample by a synchronous radiation light source. Moreover, a dual-V gap feature defect sample can realize a composite load test mode of tensile-sheering or tensile-bending and the like close to the actual stress form of a material. The multilevel static-dynamic coupling mechanical loading device provided by the invention is compact in structure, and can integrate multiple test methods, thereby providing an effective test tool for the high-frequency fatigue test of the material.

Owner:JILIN UNIV

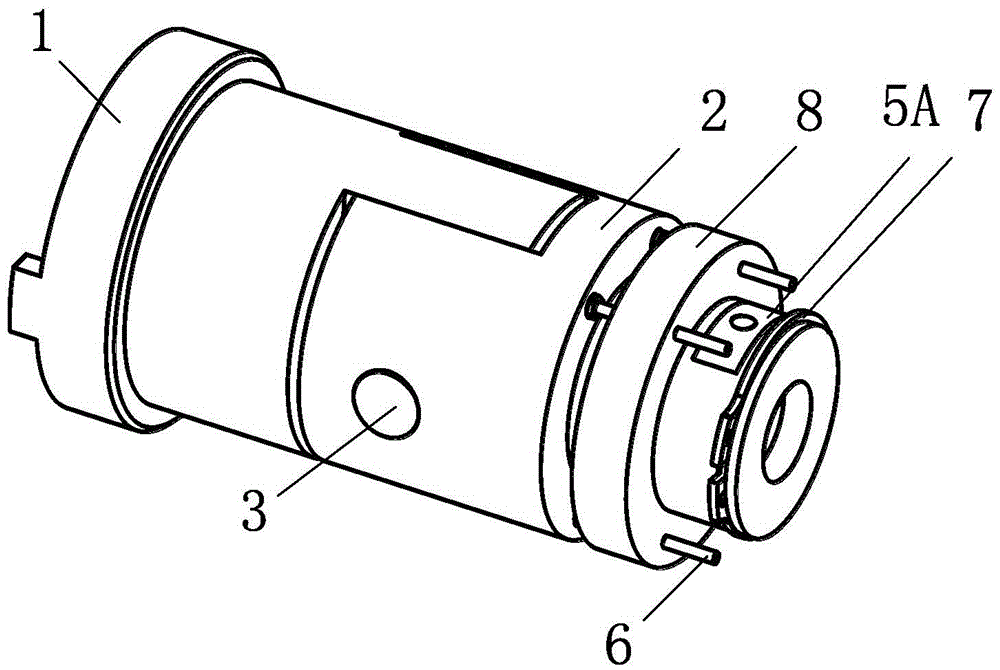

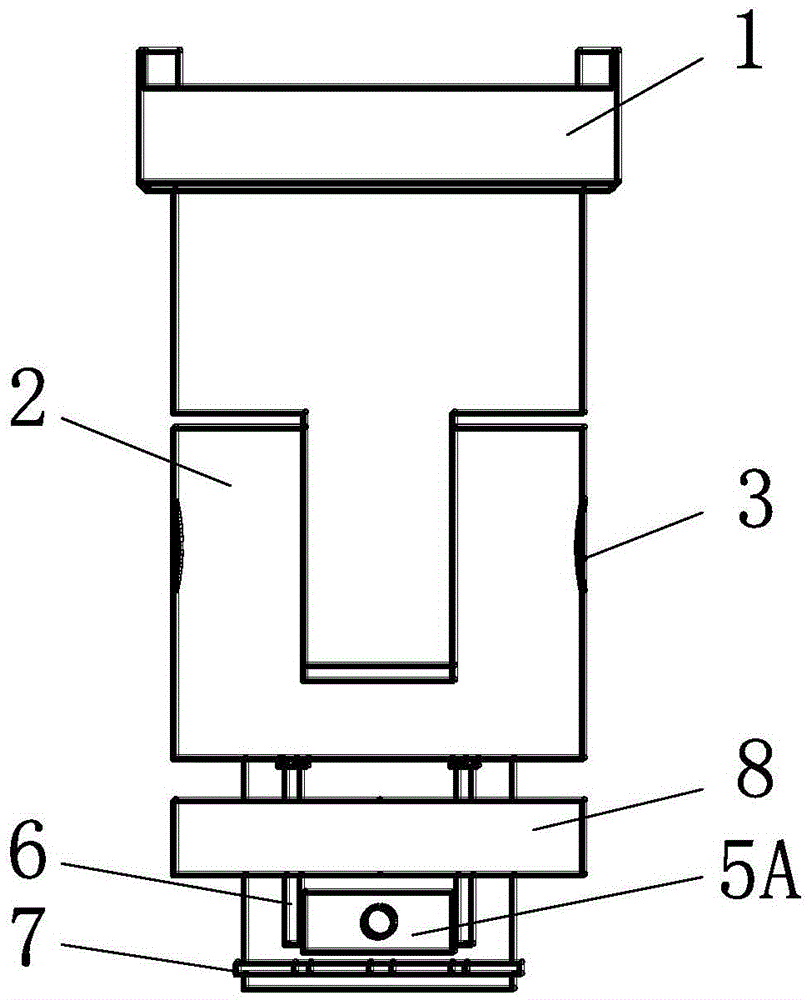

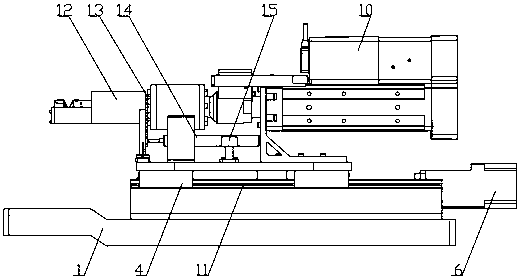

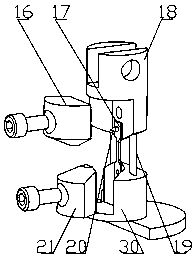

Dynamic torsional fatigue mechanical property test device in tensile preload

PendingCN107703006AImprove test accuracySimple structureMaterial strength using tensile/compressive forcesTorsion fatigueCoupling

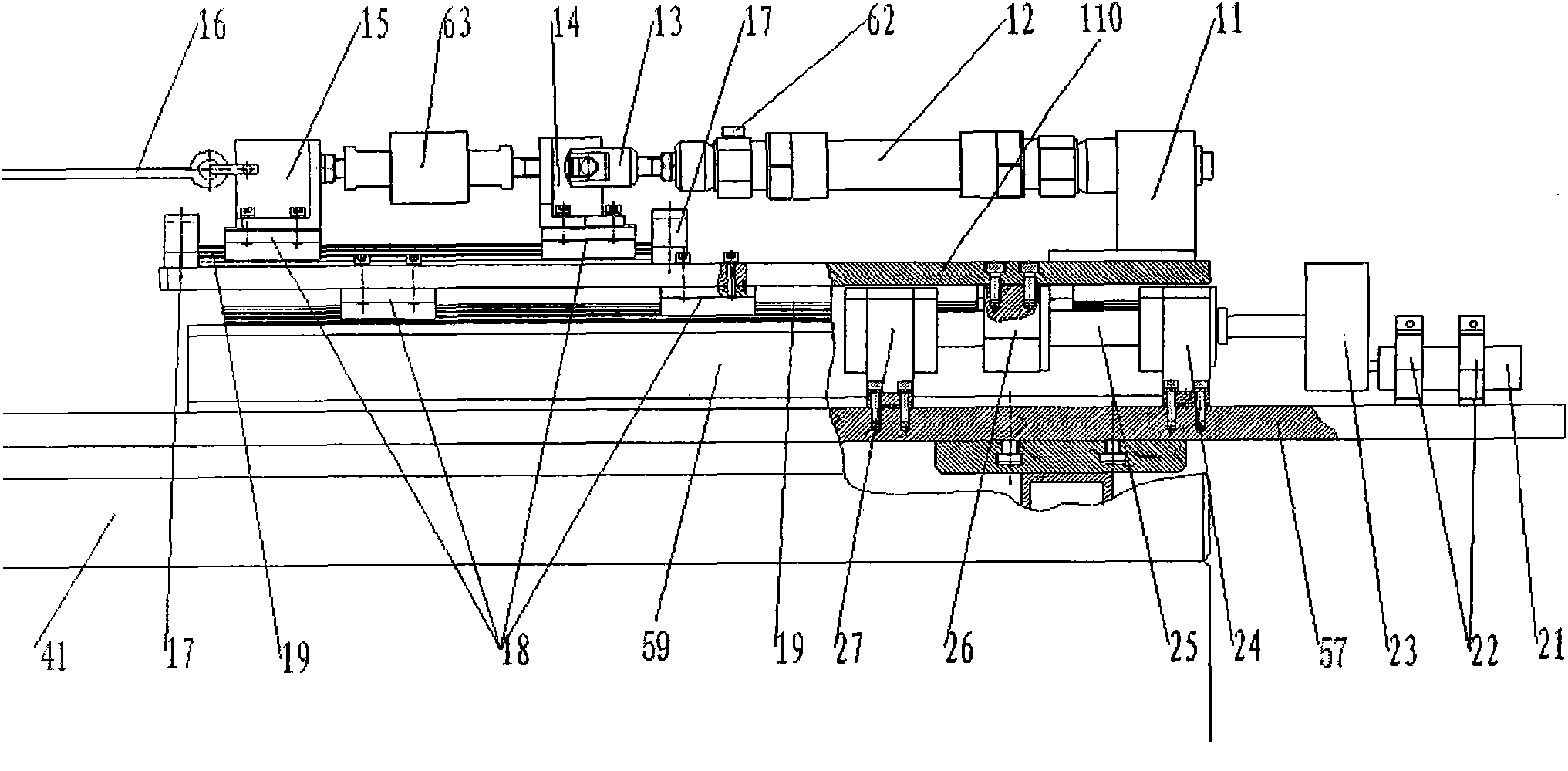

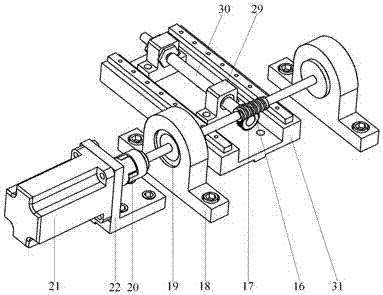

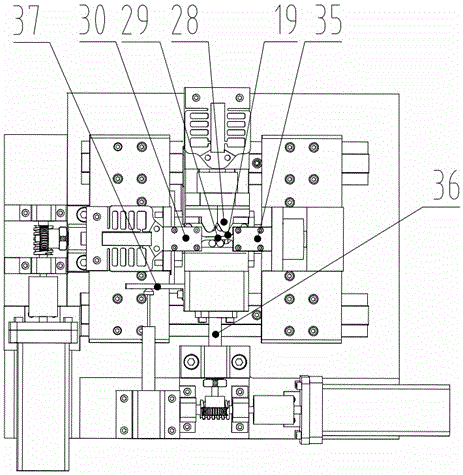

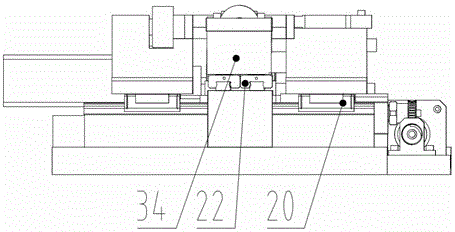

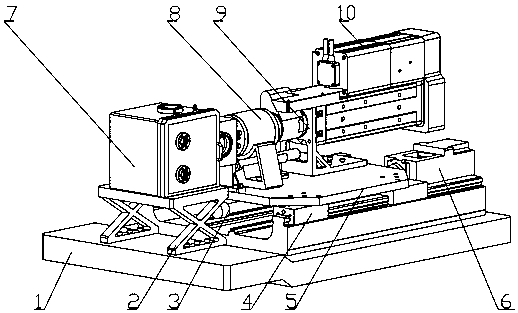

The invention relates to a dynamic torsional fatigue mechanical property test device in a tensile preload, and belongs to the technical field of a precise instrument. The test device is in horizontalarrangement and comprises a tensile unit, a torsional fatigue unit, a force signal and displacement signal detecting unit and a test piece clamping unit, wherein the tensile unit and the torsional fatigue unit are respectively arranged at two sides of test pieces, and are positioned on the same axial line as the test pieces; the tensile unit, the torsional fatigue unit, the force signal and displacement signal detecting unit and the test piece clamping unit are all arranged on a bottom plate; a magnetic field and a heat field are loaded between the tensile unit and the torsional fatigue unit for realizing the force thermomagnetic coupling loading. The dynamic torsional fatigue mechanical property test device has the advantages that the test precision is relatively high; the structure is relatively simple; the realization is easy; the torsional fatigue compound loading under the tensile and torsional fatigue and the tensile preload can be realized; the thermomagnetic coupling loading ofthe force can be realized; the microstructure change such as crack extension during the torsional fatigue bearing of a material can be observed in real time.

Owner:JILIN UNIV

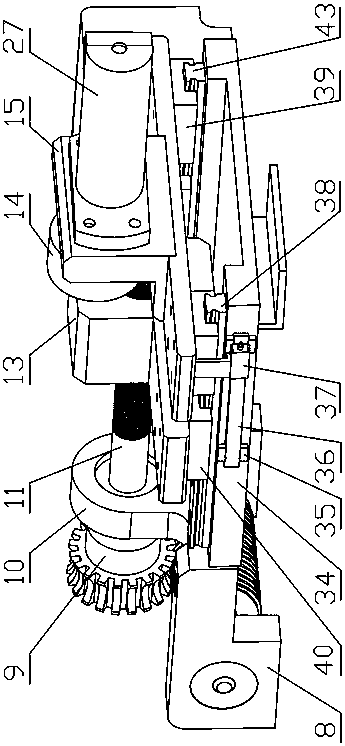

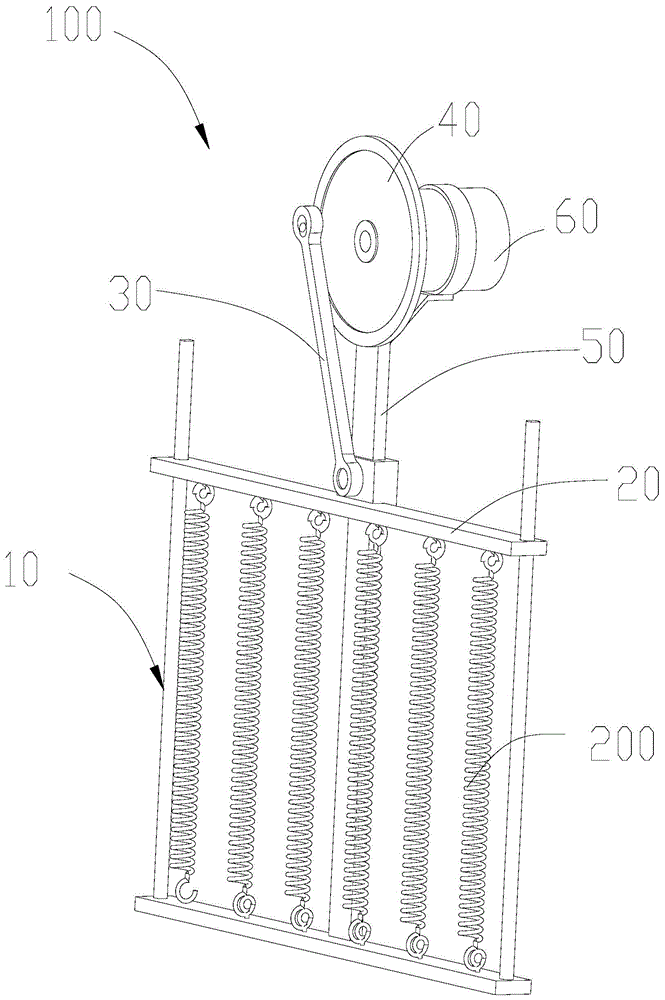

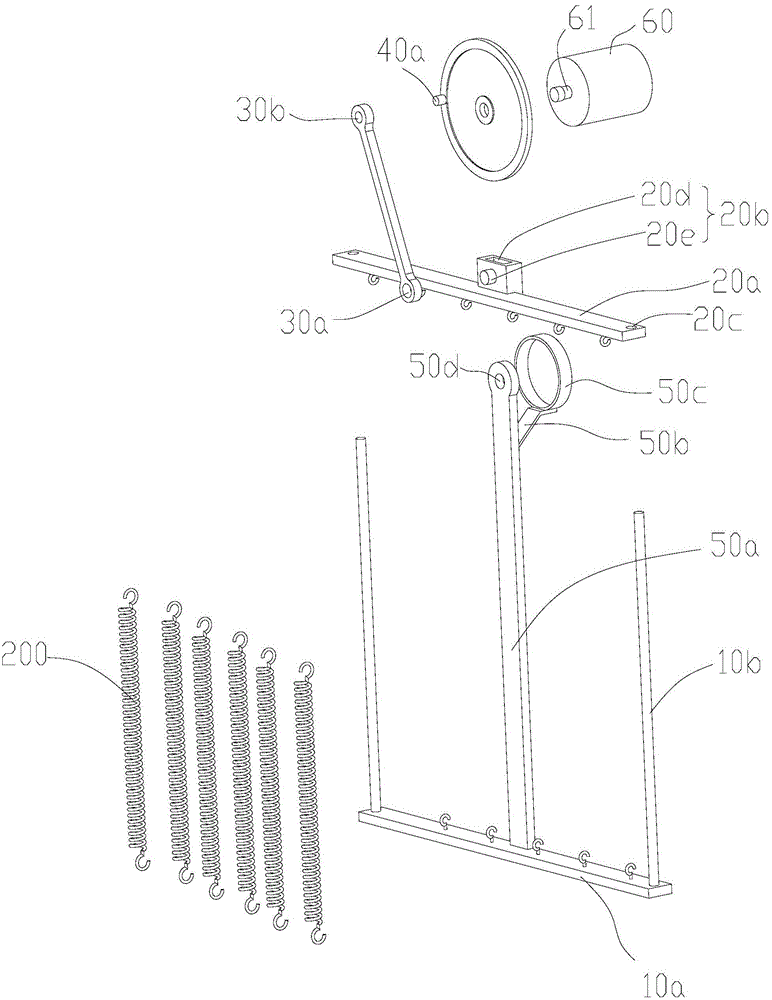

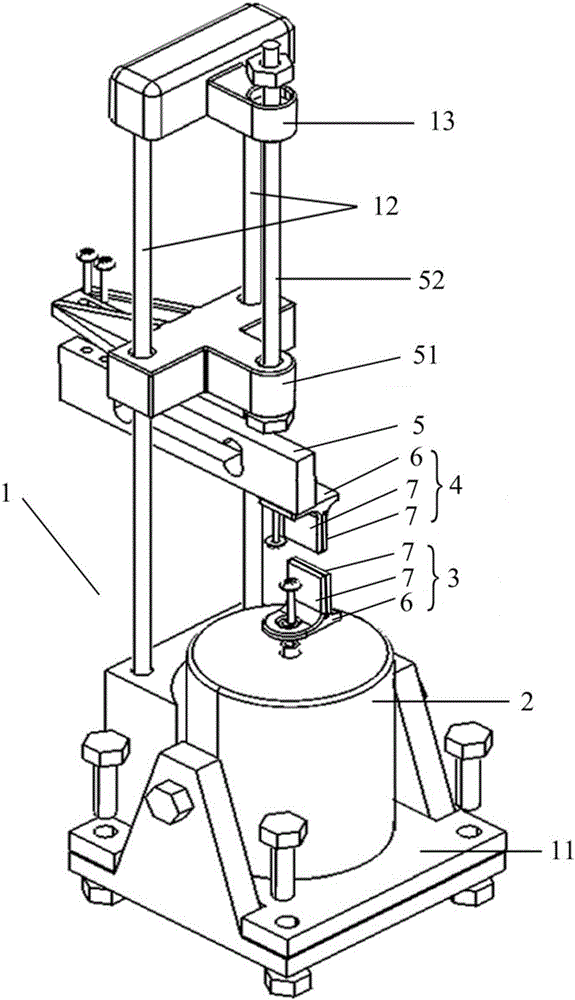

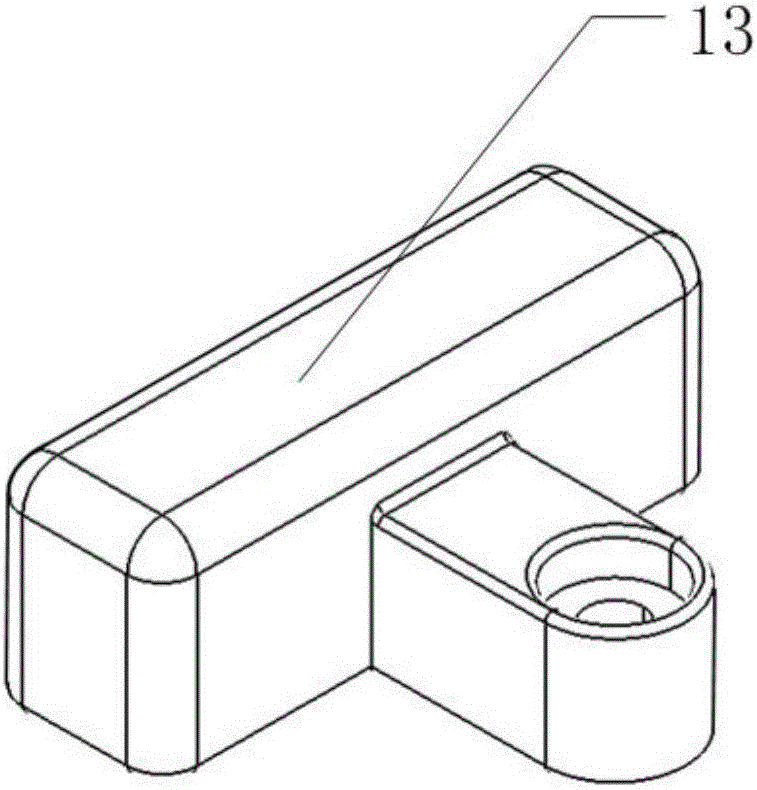

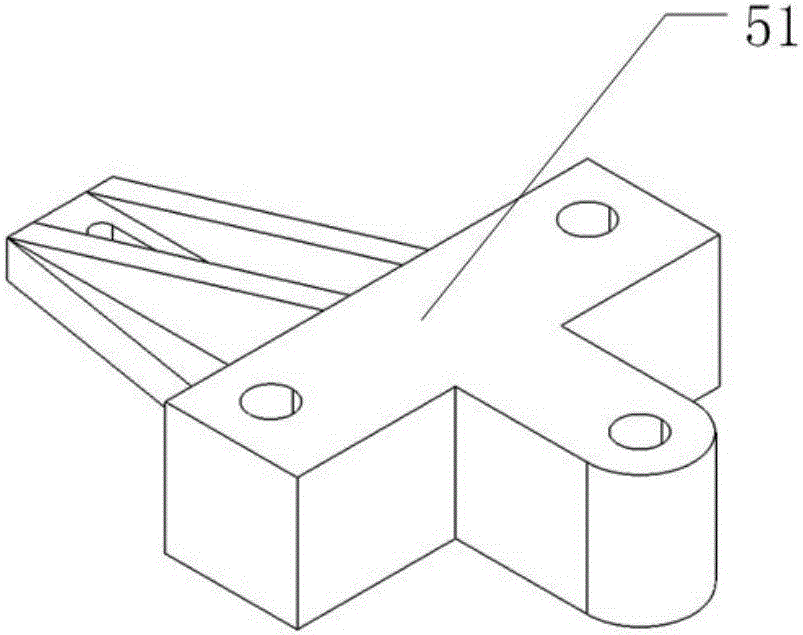

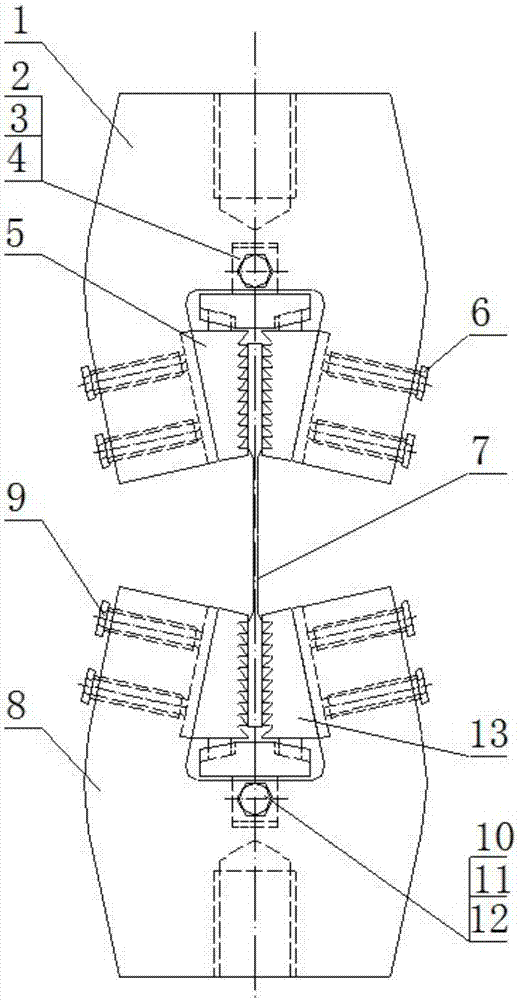

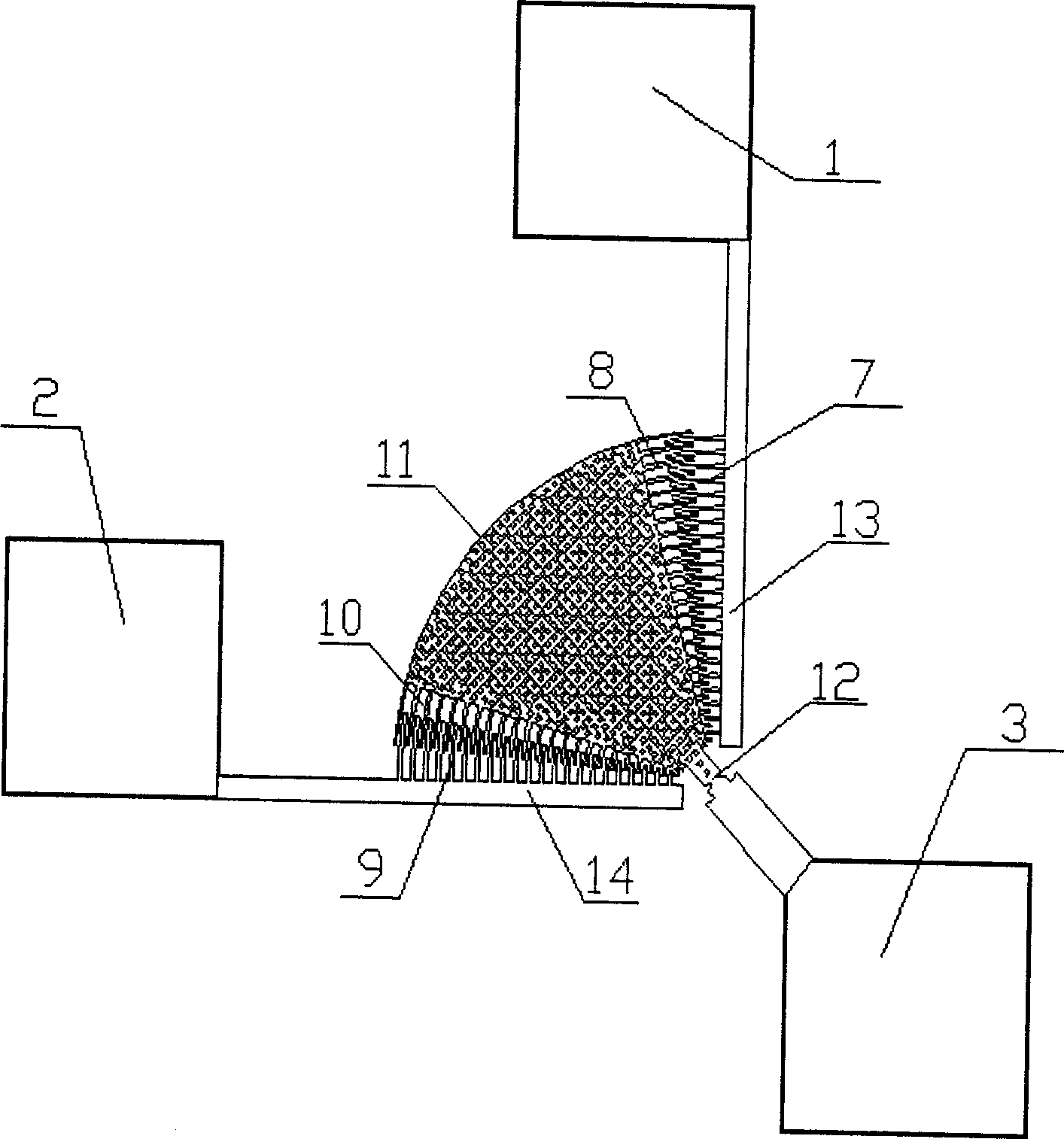

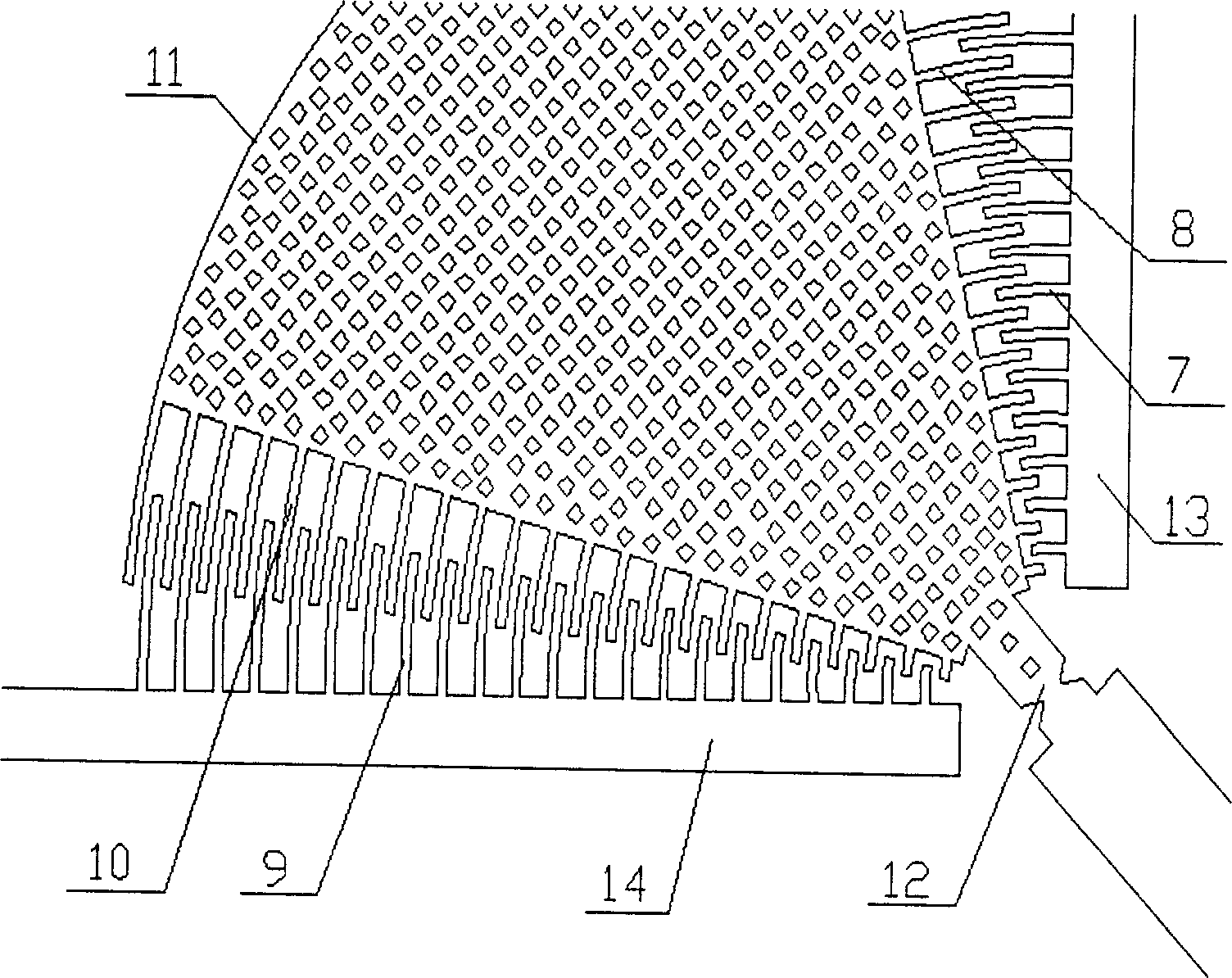

Spring-lever energy storage type fatigue tension test machine

InactiveCN102914478ALow costReduce the impact of vibration shockMaterial strength using repeated/pulsating forcesReduction driveEngineering

The invention relates to a novel mechanical structure design scheme, which is used for testing test pieces made of various metal and alloy materials at room temperature and bearing tension fatigue characteristic, fatigue life and fatigue crack expansion test of mechanical parts (such as various mechanical connecting pieces). According to the scheme, a motor drives a speed reducer to rotate, the spring is subjected to energy storage by an eccentric shaft coupler and a crank connecting rod mechanism, the spring is controlled by four guide wheels to do vertical reciprocating motion, the potential energy of the spring is converted into moment through a lever, and extension and compression of the spring are reinforced by a lever mechanism, so that tension bars are separated vertically and the stretching effect is achieved; and force amplitude is changed through connecting points at different positions of the lever, so that fatigue tension tests of different frequency and different amplitude are realized. The invention is simple in structure and low in manufacturing cost, adopts a mechanical structure, can meet the basic performance requirement of the fatigue tension test, and can be applied to the tensile fatigue test under the lab environment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

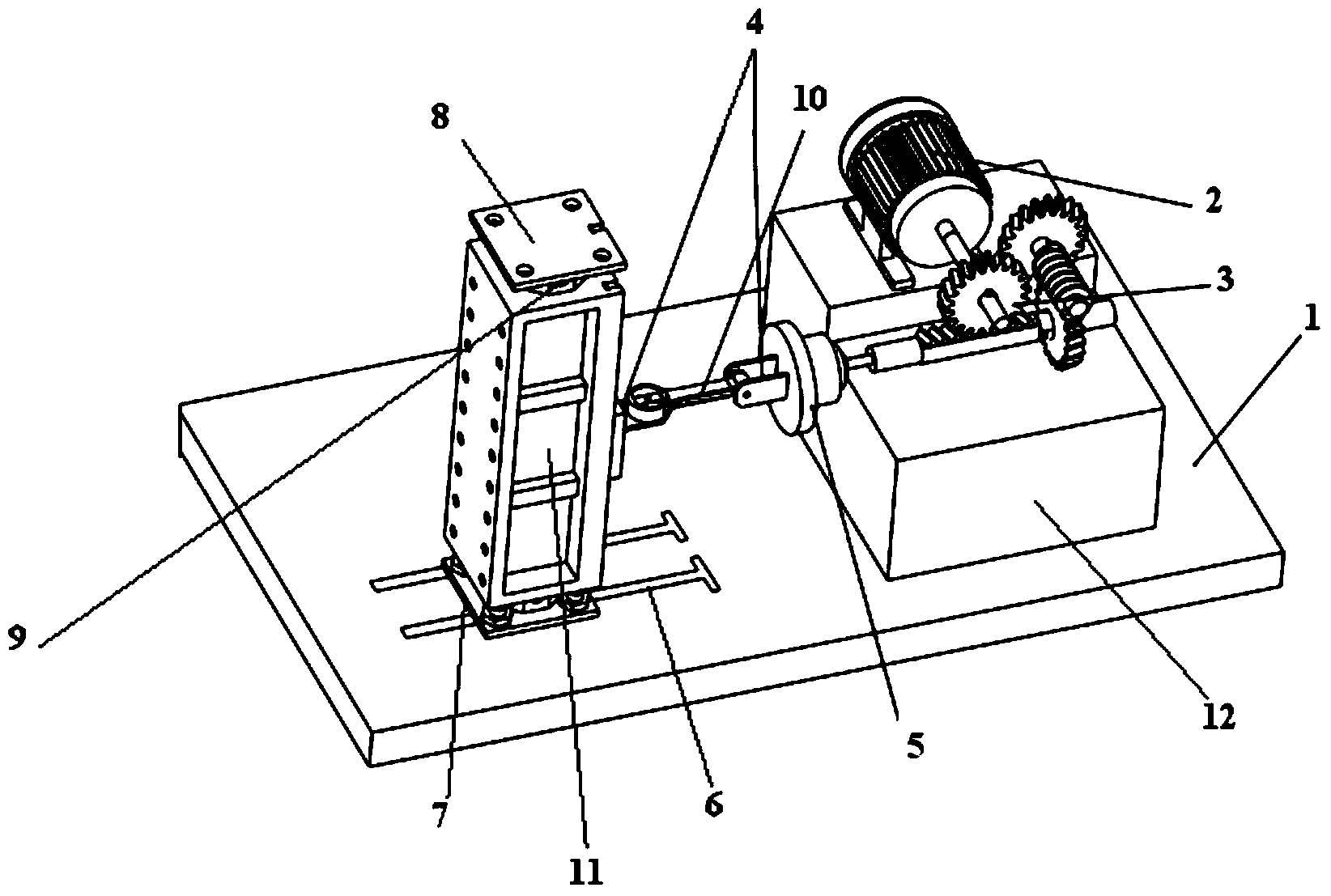

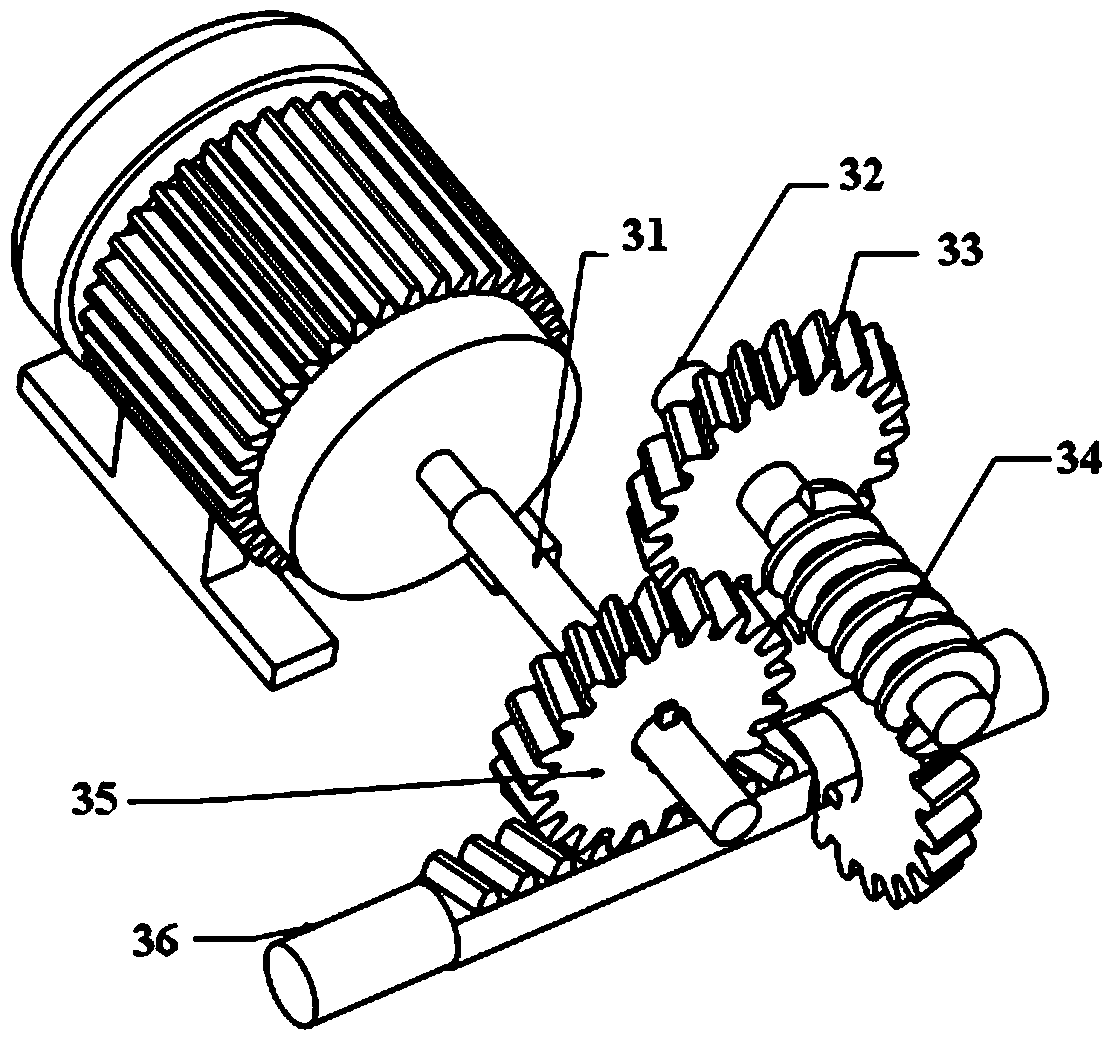

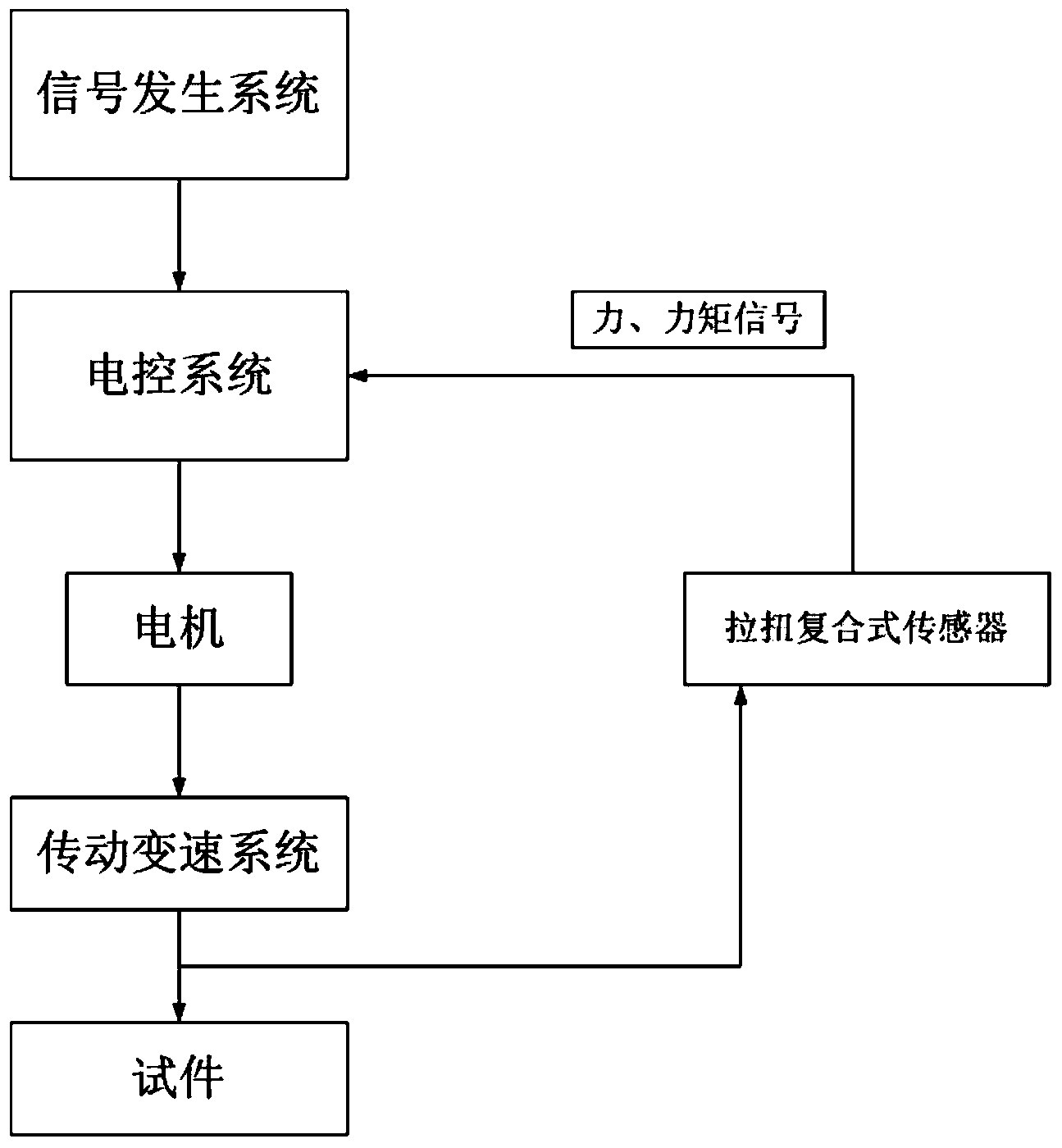

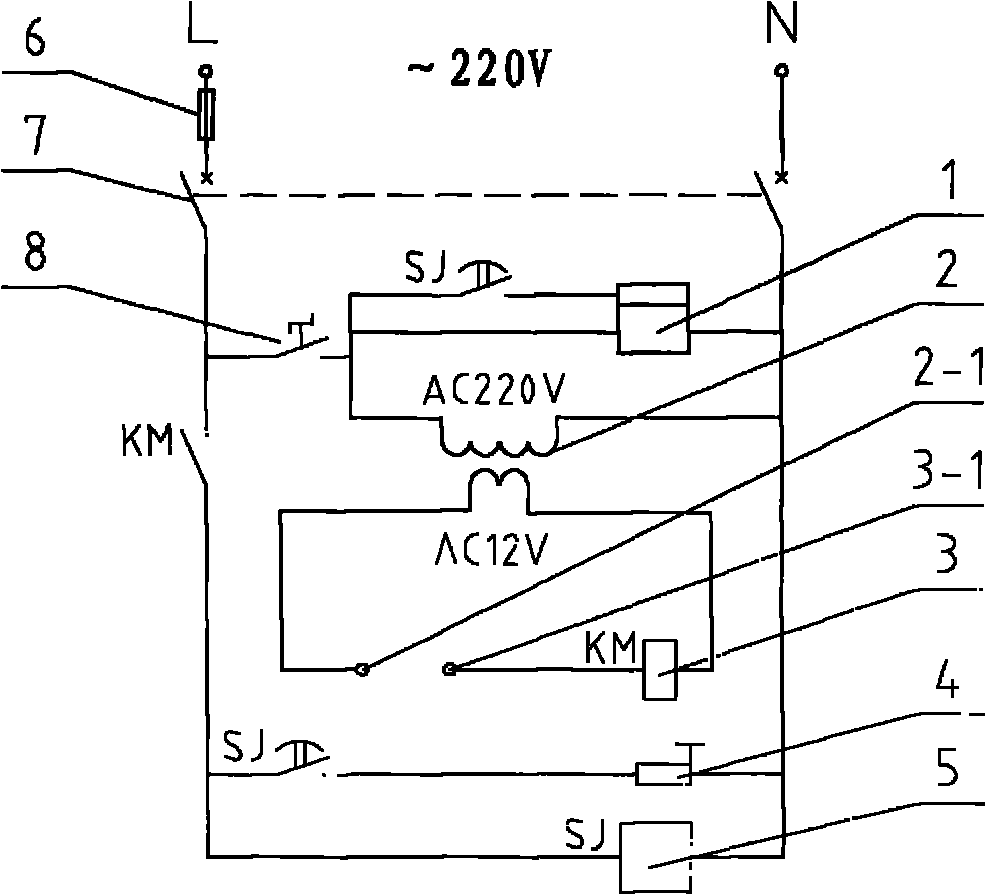

Tensile fatigue and torsional fatigue testing machine for automobile parts

InactiveCN104359773ARealize tension and compressionRealized Torsional Fatigue TestMaterial strength using repeated/pulsating forcesElectronic control systemElectric machinery

The invention relates to a tensile fatigue and torsional fatigue testing machine for automobile parts. The tensile fatigue and torsional fatigue testing machine comprises a supporting platform, a motor, a test piece, a general fixture, an installing upright post, a base, an electronic control system, a signal generating system, a composite tension and torsion sensor and a transmission speed change system, wherein the motor and the transmission speed change system are arranged on the base; an input end of the transmission speed change system is fixedly connected with an output shaft of the motor; the composite tension and torsion sensor is arranged at an output end of the transmission speed change system; the composite tension and torsion sensor is connected with the electronic control system through a circuit; the signal generating system is sequentially connected with the electronic control system and the motor through a circuit. Compared with the prior art, the tensile fatigue and torsional fatigue testing machine has the advantages as follows: the tensile fatigue and torsional fatigue testing machine can conveniently perform a tensile fatigue test and a torsional fatigue test on the automobile parts, so that the periods for the fatigue tests are greatly shortened, and thus a basis for shortening the developing period of the whole automobile is provided.

Owner:TONGJI UNIV

Test method and device thereof for reciprocating tensile fatigue testing of safety break-away valves for oiling machines

InactiveCN101975694AMaterial strength using tensile/compressive forcesCushioningReciprocating motion

The invention provides a test method for reciprocating tensile fatigue testing of safety break-away valves for oiling machines, which belongs to the technical field of assembly and testing of the safety break-away valves for the oiling machines. A two-way time relay is used for controlling the reciprocating motion of a piston rod of a cylinder with a valve, tensile force F born on the tested safety break-away valve can be gradually increased from 0N to the gravity of a heavy hammer via 3S-5S by utilizing the cushioning action of a spring, time is delayed for 3S-5S, and the tensile force F born on the tested safety break-away valve is gradually reduced from the gravity of the heavy hammer to 0N via 3S-5S, thereby constituting a reciprocating tensile fatigue test cycle, displaying 1 on a counter, and testing in such as way; when the repeated cycles reach 10000 and the tested safety break-away valves are not broken away, the batch of the safety break-away valves can be judged to be qualified; when the cycles are less than 10000 and any one of the tested safety break-away valves is broken away, the batch of the safety break-away valves can be judged to be unqualified. The test method has novel design and high working efficiency, and can find the quality hidden troubles of products in time and avoid the economic loss and the safety accidents.

Owner:ZHEJIANG CHUNHUI INTELLIGENT CONTROL

A spring tensile fatigue test device

InactiveCN104697871AEfficient testing of tensile fatigue propertiesSimple structureMaterial strength using repeated/pulsating forcesTest efficiencyCircular disc

A spring tensile fatigue test device is disclosed. The spring tensile fatigue test device comprises a support, a sliding bar, a first connecting bar, a circular disc and a supporting bar. The support is U-shaped, and is connected to the sliding bar in a sliding manner. Both ends of each spring to be tested are respectively connected to the support and the sliding bar. The first end of the first connecting bar is fixedly connected to the sliding bar, and the second end of the first connecting bar is fixedly connected to the edge of the circular disc. The circular disc rotates around a center shaft. The supporting bar is used for supporting the circular disc. The spring tensile fatigue test device can effectively test the tensile fatigue performance of the spring to be tested, and is simple in structure, high in testing efficiency and capable of largely reducing manual labor.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Multi-node fatigue failure test device for steel beam columns and concrete beam columns

ActiveCN108181191AMaterial strength using tensile/compressive forcesMaterial strength using steady torsional forcesServo actuatorTest beam

The invention discloses a multi-node fatigue failure test device for steel beam columns and concrete beam columns. The device comprises a steel frame system, an electro-hydraulic servo actuator, a test beam column and a test furnace, wherein the test beam column is arranged in the test furnace; the steel frame system is arranged on the periphery of the test furnace; a horizontal fatigue load device, a vertical fatigue load device and a torsional fatigue load device are sequentially arranged between the steel frame system and the test beam column, the horizontal fatigue load device is arrangedin the horizontal direction of the test beam column, the vertical fatigue load device is arranged in the vertical direction of the test beam column, and the torsional fatigue load device is arranged above the test beam column. The eccentric tensile fatigue load to the steel beam columns and the concrete beam columns can be met, the eccentric size can be set according to experimental requirements,and all that is required is to change the relative position of a column head and the test beam column; the fatigue failure test device can also meet requirements of nodes such as cross type, T type, Ltype and the like of the steel beam columns and the concrete beam columns.

Owner:CHINA UNIV OF MINING & TECH

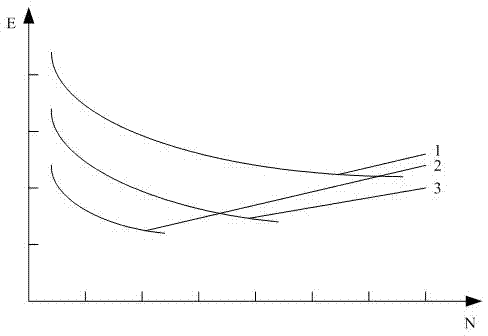

Method for estimating remaining life of asphalt pavement of freeway

InactiveCN102565312AEstimated maintenance timingAccurately predict maintenance timingMaterial testing goodsTensile strainStiffness modulus

The invention discloses a method for estimating the remaining life of an asphalt pavement of a freeway. The method comprises the following steps of: building a corresponding computation model in a Bisar program according to an asphalt concrete pavement structure to be predicted, and calculating the tensile strains which are applied to the bottoms of various structural layers of the asphalt pavement under the action of a standard load by taking the thicknesses and moduli of the structural layers as calculation parameters; performing core drilling on a hard shoulder, an overtaking lane and a running lane of the asphalt pavement of the freeway on the spot respectively; performing indirect tensile fatigue tests with strain control on core samples of the lanes; and acquiring relation curves of indirect tensile stiffness moduli and load action times in the process of the fatigue tests, comparing the fatigue test curves of the lanes, combining the asphalt pavement to build traffic volume data since the opening of the freeway which are obtained through counting, and predicting the remaining fatigue lives of the lanes of the asphalt pavement. By the method, the remaining fatigue lives of asphalt pavements can be accurately predicted, and the long-term human randomness of the selection of the maintenance time of the pavements is avoided.

Owner:HOHAI UNIV

A kind of elastic fabric fatigue test method

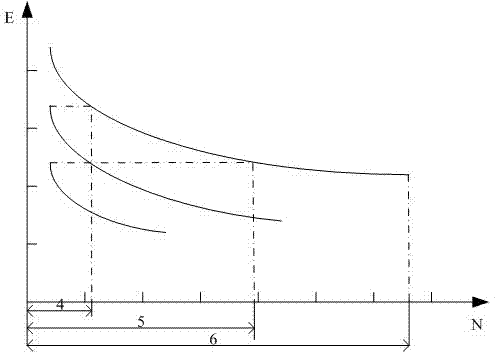

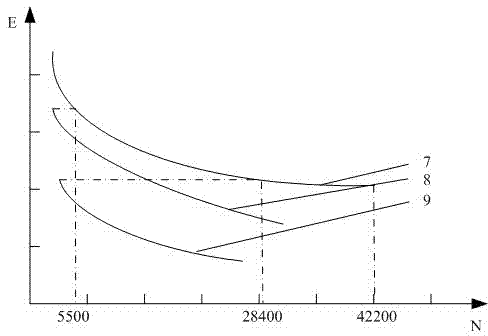

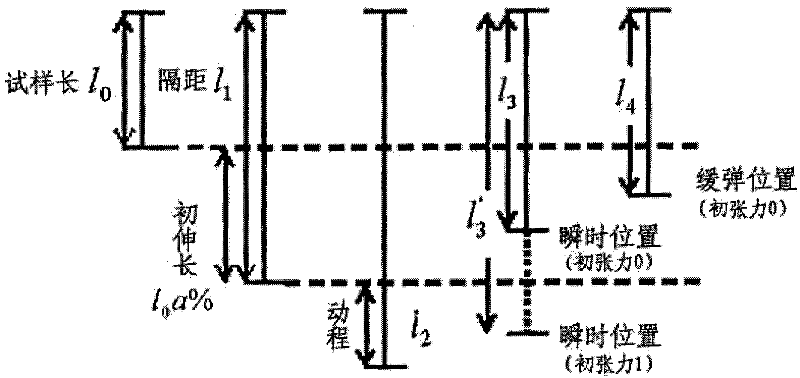

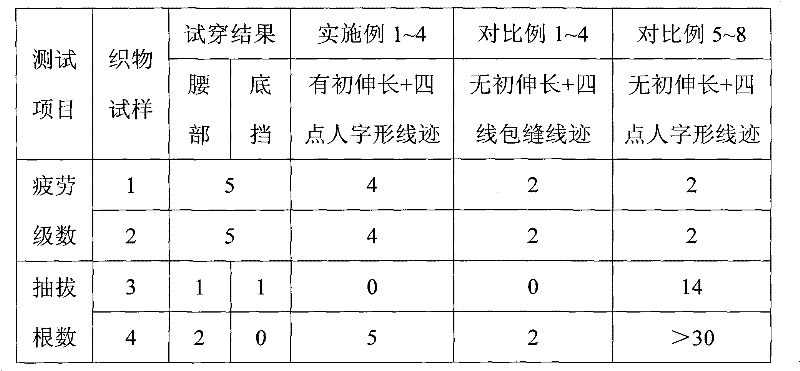

InactiveCN102262015AAvoid fatigueAvoid dissatisfactionMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesYarnTensile fatigue

The invention relates to an elastic fabric fatigue testing method, which is characterized in that: a testing sample is stitched with a four-point herringbone trace pattern, and an elastic yarn extracting test is carried out; the testing method is a tensile fatigue testing method with a primary elongation; the testing apparatus used in the testing method is an elastic fabric fatigue testing apparatus. The testing method provided by the invention comprises steps of sample preparing, parameter configuring, sample adjusting, fatigue testing, fatigue evaluating, and the like. The testing method provided by the invention is fast, accurate, and is easy to operate. In prior arts, no problem is shown in elastic fabric fatigue tests and extracting tests. However, problems occur during actual wearing, and consumers are unsatisfied. With the method provided by the invention, the phenomenon can be effectively avoided, such that economic loss of most enterprises due to the reason can be recovered.

Owner:BEIJING INST OF CLOTHING TECH

Tensile fatigue test machine

ActiveCN106813981AMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFiberStress conditions

The invention relates to the technical field of a fatigue test device, in particular to a tensile fatigue test machine. The tensile fatigue test machine comprises a bracket, a vibration exciter, a lower clamping head, an upper clamping head and a force sensor; the vibration exciter and the force sensor are arranged on the bracket; the lower clamping head is connected with a top rod of the vibration exciter and can synchronous move along with the top; the upper clamping head is connected with the force sensor and used for conducting the stress condition to the force sensor; the lower clamping head and the upper clamping head are arranged at intervals in the axial direction of the top rod. The tensile fatigue test machine solves the problem that the tensile fatigue test device for monofilaments does not exist in the prior art; the test machine is small in volume and high in flexibility; each accessory can be replaced according to the requirement, is high in matching property and wide in application range, and has high stability and reusability.

Owner:HARBIN INST OF TECH

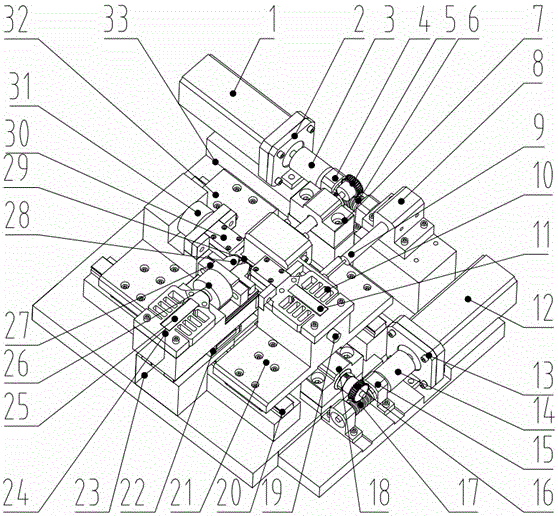

Tensile fatigue-four-point flexural fatigue in-situ mechanical testing device and testing method thereof

PendingCN106769452AReduce volumeCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesElectricityFatigue loading

Owner:YANCHENG INST OF TECH

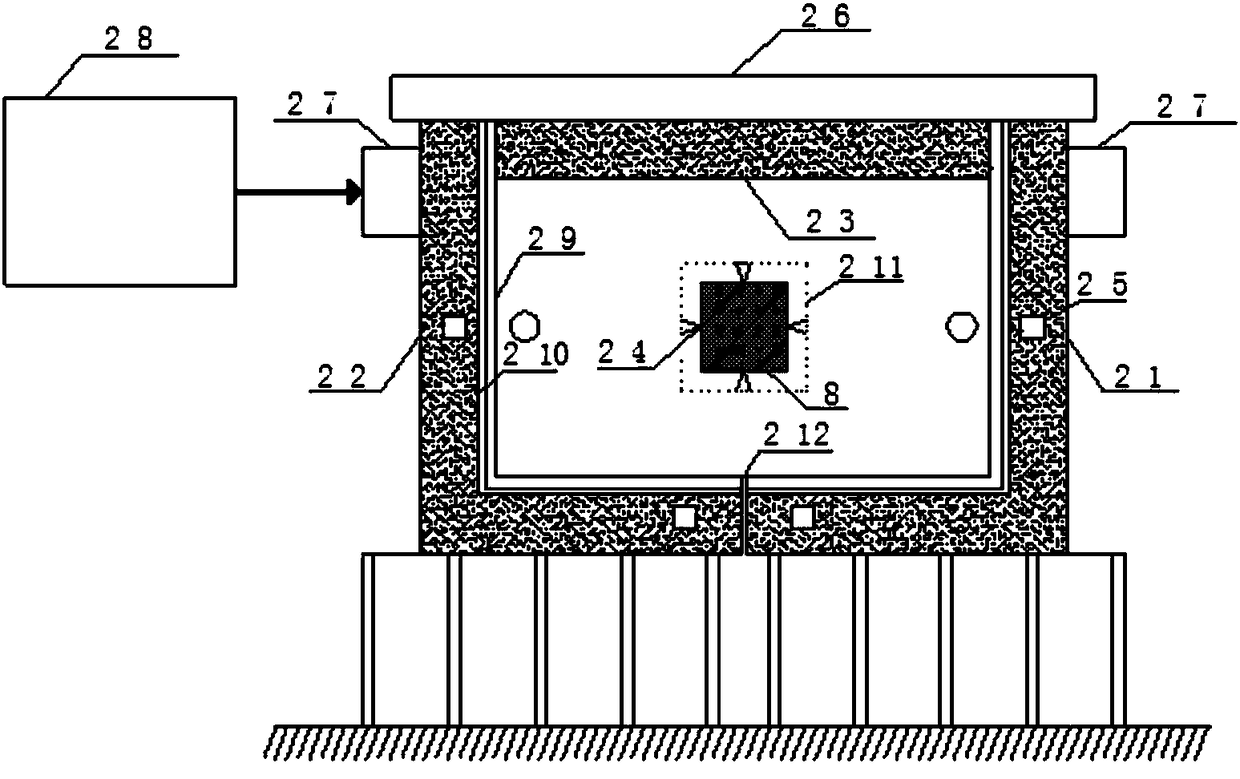

Experimental device used for evaluation of water stability of bituminous mixture and experimental method

InactiveCN106596285ARealize a realistic simulationA true reflection of water stabilityMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesTemperature controlExperimental methods

The invention discloses an experimental device used for evaluation of water stability of a bituminous mixture and an experimental method. The experimental device comprises dynamic load loading equipment, a working box, an indirect tensile test device, a temperature control device and fixed equipment. The experimental device can simulate an external environment of the bituminous mixture in the practical use condition. By adopting a method of conducting an indirect tensile fatigue test in the experimental device, the evaluation of water stability performance of the bituminous mixture under multi-field coupling of stress field, temperature field, waterpower field and dynamic change is achieved, and a fatigue life is used to evaluate the water stability performance of the bituminous mixture in different use environments. The experimental device and the experimental method can be used for studying the water stability performance of the bituminous mixture in the practical use environment, and have very good evaluating effectiveness.

Owner:SOUTHEAST UNIV

Three point bending fatigue testing apparatus

ActiveCN106950107AFunction increaseExpand the scope of testingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesClassical mechanicsTensile fatigue

The invention provides a three point bending fatigue testing apparatus, which can enrich the functions of a tensile fatigue testing machine so that the tensile fatigue testing machine can carry out three point bending fatigue tests. A rotatable clamping mechanism design is adopted; the bending fatigue tests with a negative stress ratio can be carried out effectively, the boundary conditions of a three point bending experiment can be satisfied, the experiment range is enlarged; a conventional three point clamp is optimized, the apparatus cost is reduced, and the sample positioning problem is solved. The adopted clamping structure can prevent a test piece from sliding during the long term fatigue experiment process; the upper clamping structure of the clamping structure is adjustable so as to clamp test pieces with different thicknesses; the clamping structure is composed of a roller and a trapezoidal block; the roller is in line contact with a test piece during the experiment process and is convenient to replace so as to guarantee the experiment accuracy; the trapezoidal block can prevent the interference on the test piece during the experiment process; and a load can be effectively applied on the test piece during the bending fatigue experiment process (with a negative stress ratio) through the combination of an upper press head and a lower press head.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

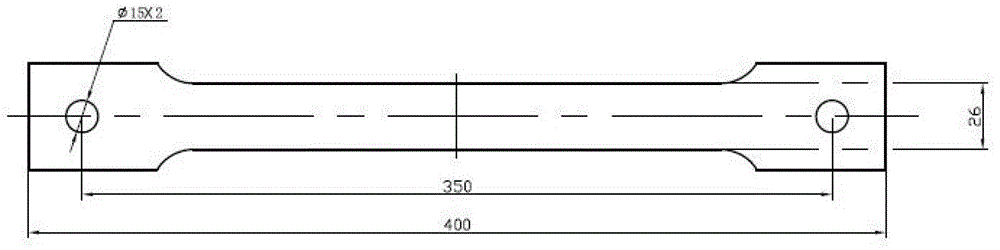

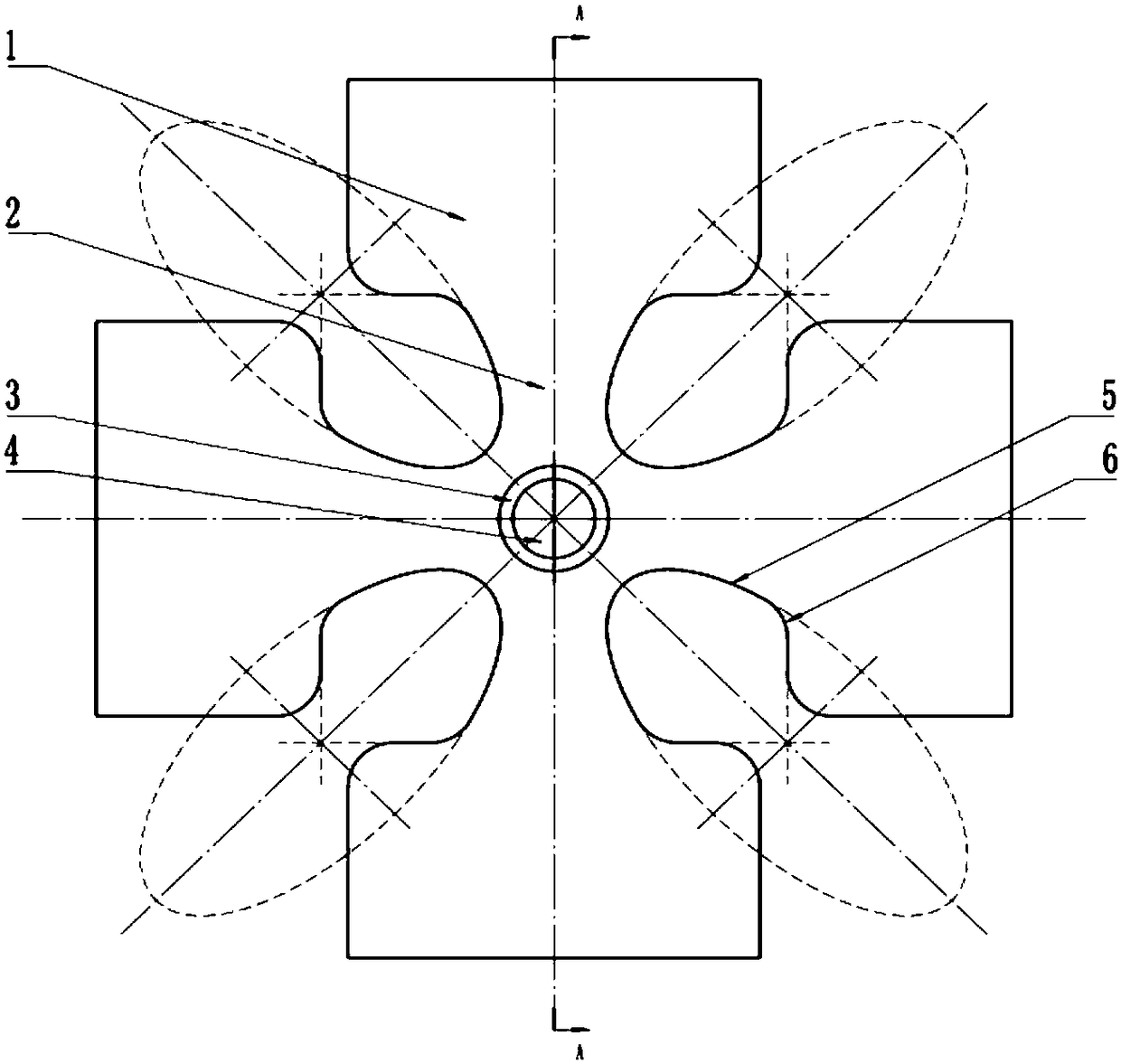

Biaxial tensile fatigue test piece with conic curve transition and test method thereof

InactiveCN108458940AUniform stress and strainReduce the impactMaterial strength using repeated/pulsating forcesAxis of symmetryCircular cone

The invention discloses a biaxial tensile fatigue test piece with conic curve transition and a test method thereof. The whole test piece is in a cross shape and is provided with four loading arms; theends of the four loading arms are integrated into a central area, the other ends of the four loading arms are integrated into a clamping area, a transition area formed by a conic curve is arranged between roots of every two adjacent loading arms, the axis of symmetry of the conical curves at least coincides with one axis of symmetry of the test piece, and a thickness reducing area is arranged between the transition area and the central area and thinned by adopting double arcs or a spline curve or a single arc. The test piece has the advantages that by adopting a conic curve transition mode, the stress strain in the central area is more uniform, and the influence between every two adjacent loading arms is reduced as much as possible; through the design of smooth transition and central areathinning, breakage and cracking of the test piece in the test process occur in the central area at first.

Owner:SOUTHEAST UNIV

Connecting rod material for engines in powder metallurgy and preparation method thereof

The invention discloses a connecting rod material for engines in powder metallurgy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 0.5-1.5% of Mo, 0.5-1.5% of Cr, 0.5-1.0% of Mn, 0.5-1.0% of Si, 1.5-2.0% of Ni, 1.0-2.0% of Cu, 0.4-0.8% of C and the balance of Fe. The preparation method comprises the following steps: mixing, rolling, sintering, carrying out fine die forging, quenching and tempering. The forging density of the material is greater than 7.6g / cm<3>, the tensile strength is greater than 1060 MPa, the yield strength is greater than 600 MPa, the symmetrical cyclic tensile fatigue strength is greater than 350 MPa, and the fatigue life is stably 5 million revolutions.

Owner:CENT SOUTH UNIV

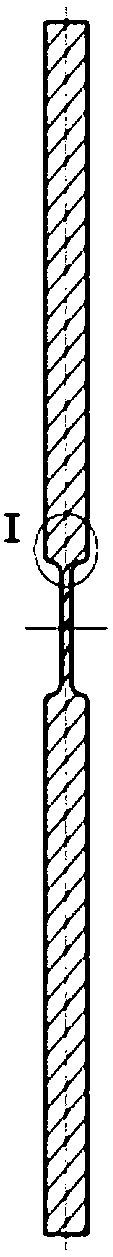

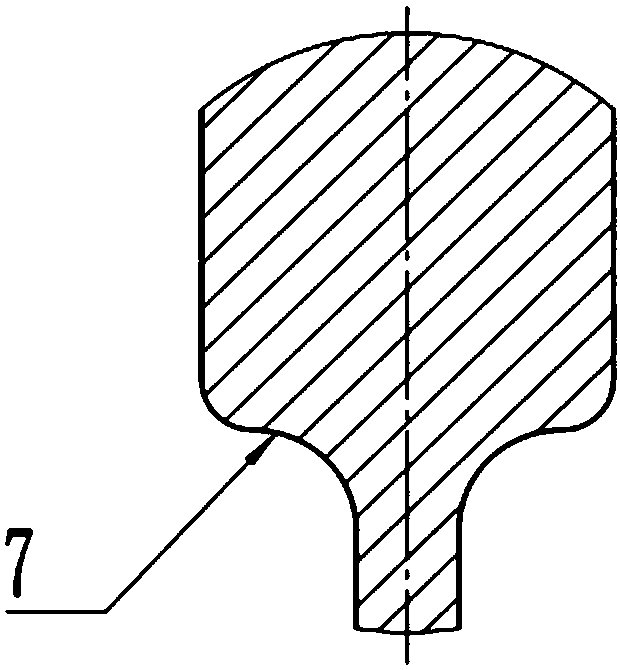

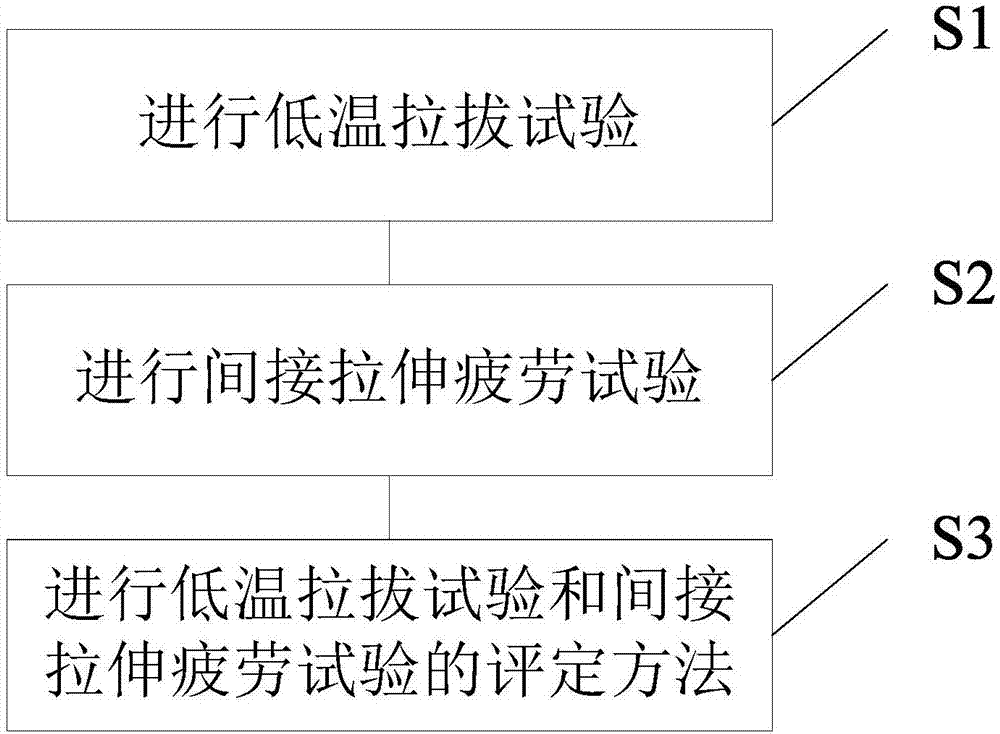

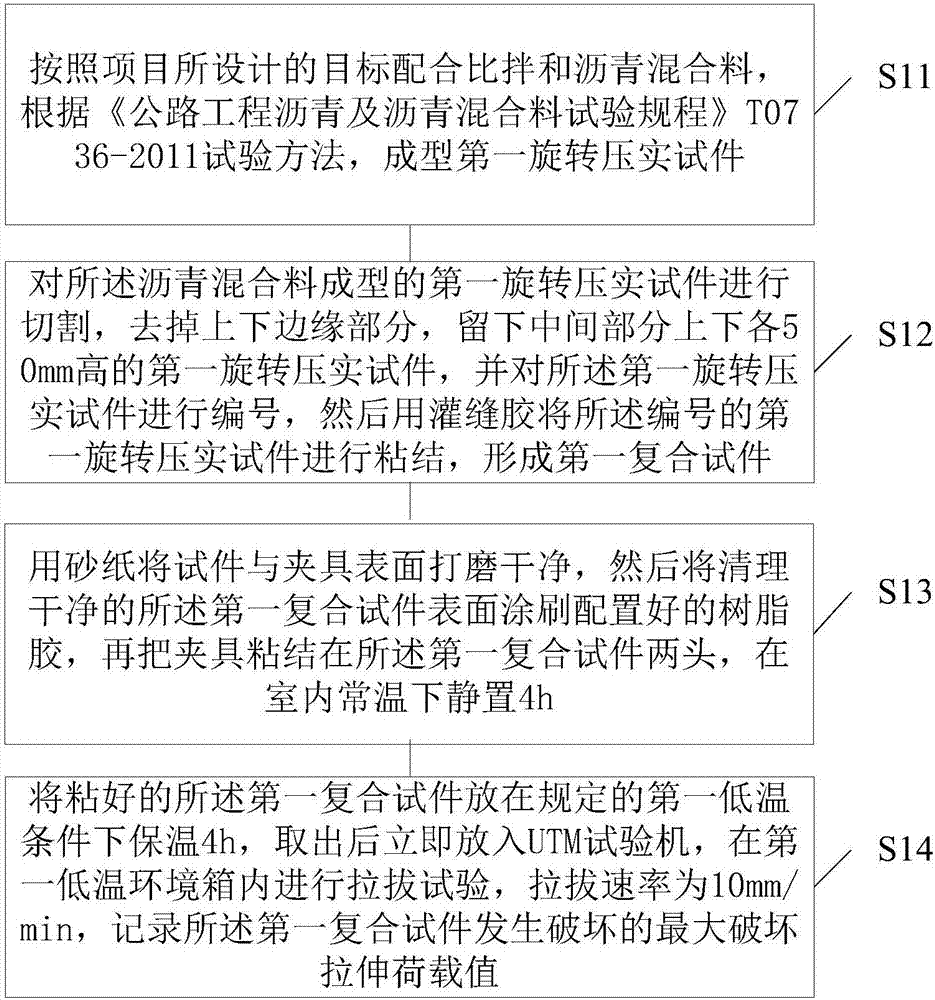

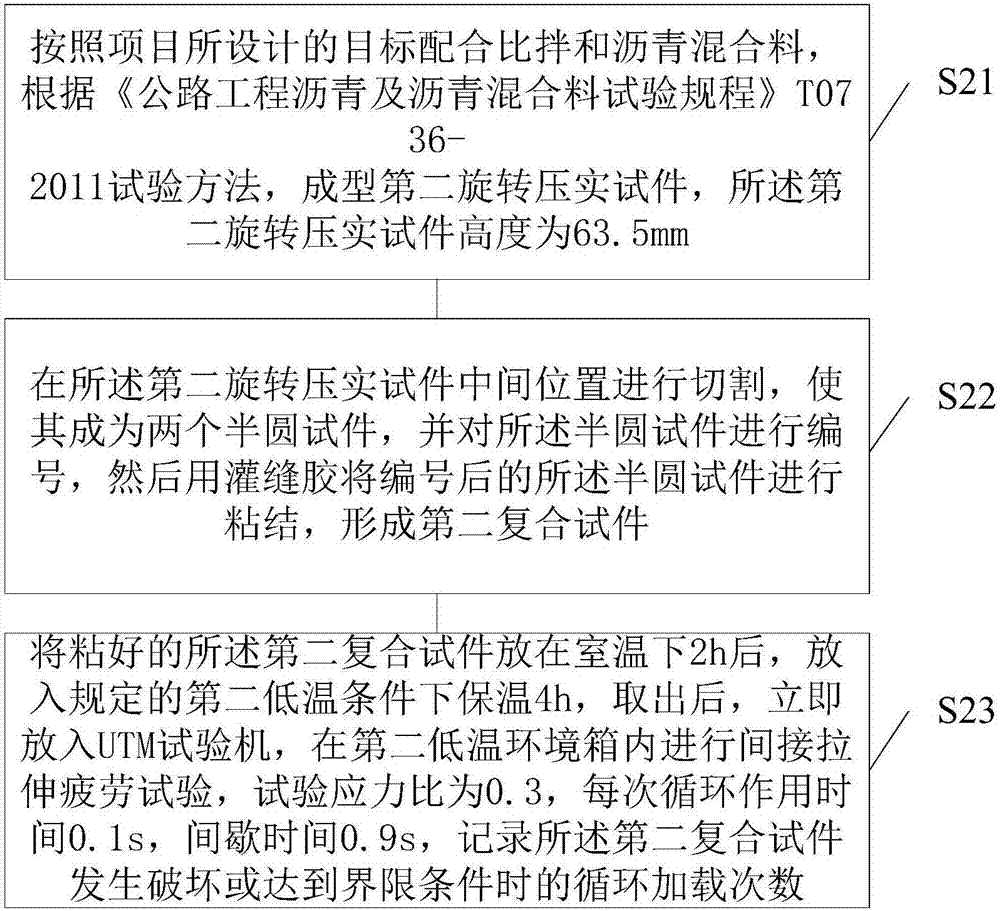

Method for evaluating low-temperature performance and fatigue performance of crack filling adhesive for asphalt pavement

InactiveCN107014706AHigh simulationThe test data is accurate and reliableMaterial strength using repeated/pulsating forcesAdhesiveTensile fatigue

The invention belongs to the technical field of preventive maintenance of highway asphalt pavements and particularly relates to a method for evaluating the low-temperature performance and the fatigue performance of a crack filling adhesive for an asphalt pavement. The method comprises the following steps of (1) carrying out low-temperature drawing test; (2) carrying out indirect tensile fatigue test; and (3) carrying out evaluation on the low-temperature drawing test and the indirect tensile fatigue test. The low-temperature drawing test is used for simulating the cracking resistance of the pavement repaired by the crack filling adhesive under the tension action of an external force under the most unfavorable low-temperature condition; and the indirect tensile fatigue test is used for simulating the anti-fatigue performance of the pavement repaired by the crack filling adhesive under the action of an external load. The method for evaluating the low-temperature performance and the fatigue performance of the crack filling adhesive for the asphalt pavement is closer to the actual pavement crack repairing condition and is capable of quantitatively and quickly judging the low-temperature performance and the fatigue performance after cracks of the asphalt pavement are repaired with the crack filling adhesive.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE BUILDING MATERIALGRP +1

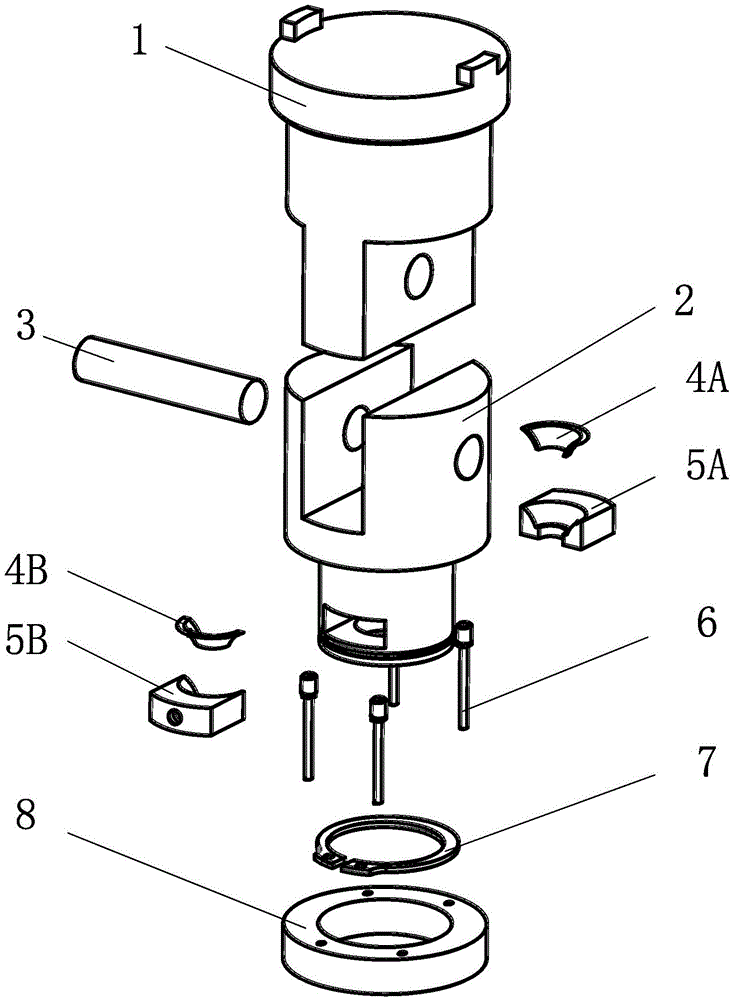

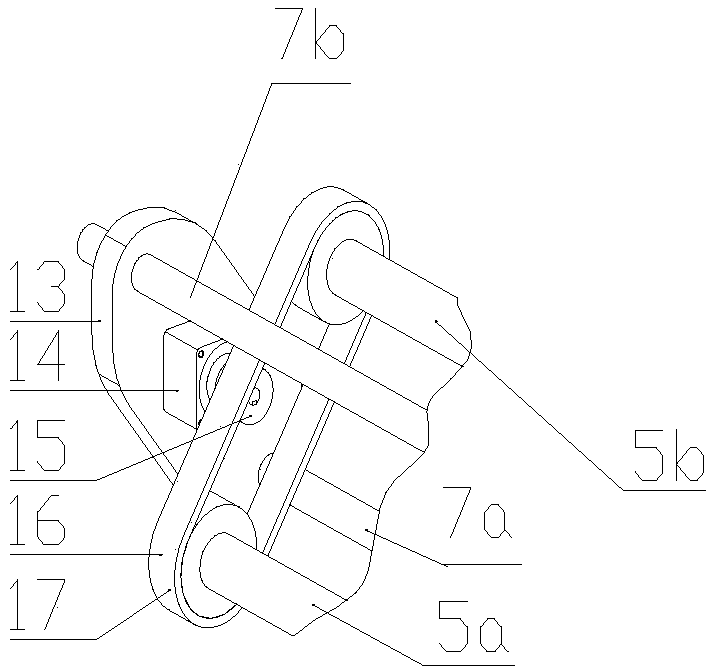

Rapid-assembling and dissembling split clamp used for fatigue test

ActiveCN105527157ASelf-adaptive to centering errorMedium error automatic offsetStrength propertiesTensile fatigueSoftware engineering

The invention relates to a rapid-assembling and dissembling split clamp used for fatigue test, and belongs to the field of material performance test. The split clamp is used for testing the tensile fatigue life of a metal material. Fatigue life test of a component or material is needed to improve the reliability of a part and enhance the safety of a machine device. In the practical test process, inconsistence of the practical bearing load and the design load of the test piece, caused by errors existing in the test piece processing and clamping process and extra load possibly generated in the test process, has influences on the test precision. The test piece fatigue life test clamp is provided to solve the above problem, adopts split design, has centering self-adaptability, and can effectively solve the centering error in the clamping process; and when test piece is replaced, dismounting of a clamp body is not needed, the test piece clamping is fast, the centering precision is consistent, the workload of centering detection is reduced, and the test process is accelerated.

Owner:BEIHANG UNIV +1

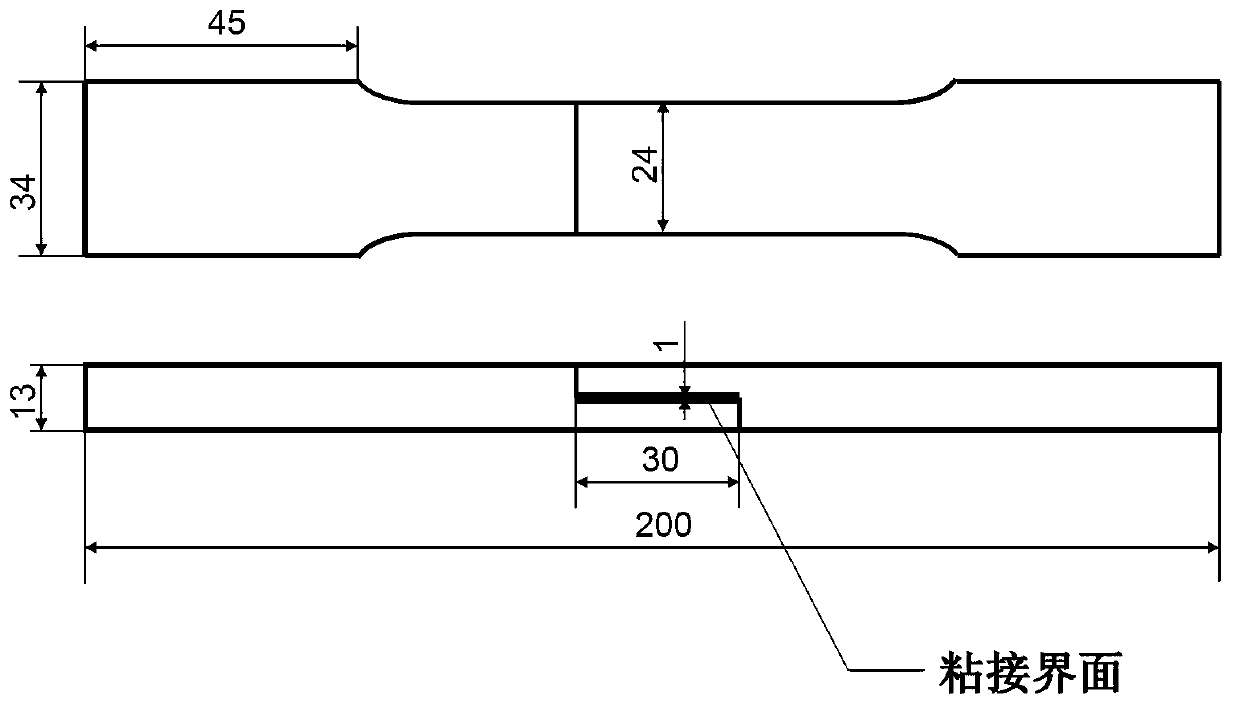

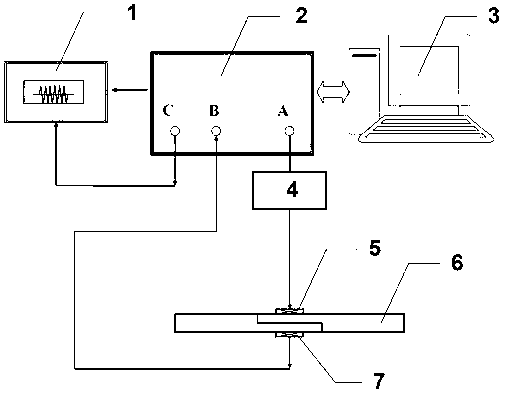

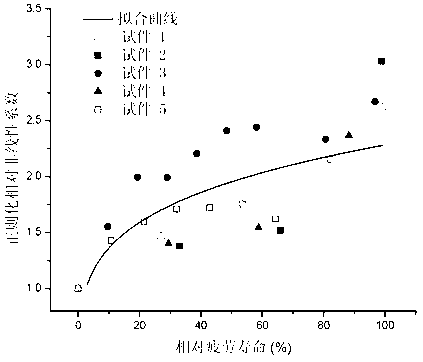

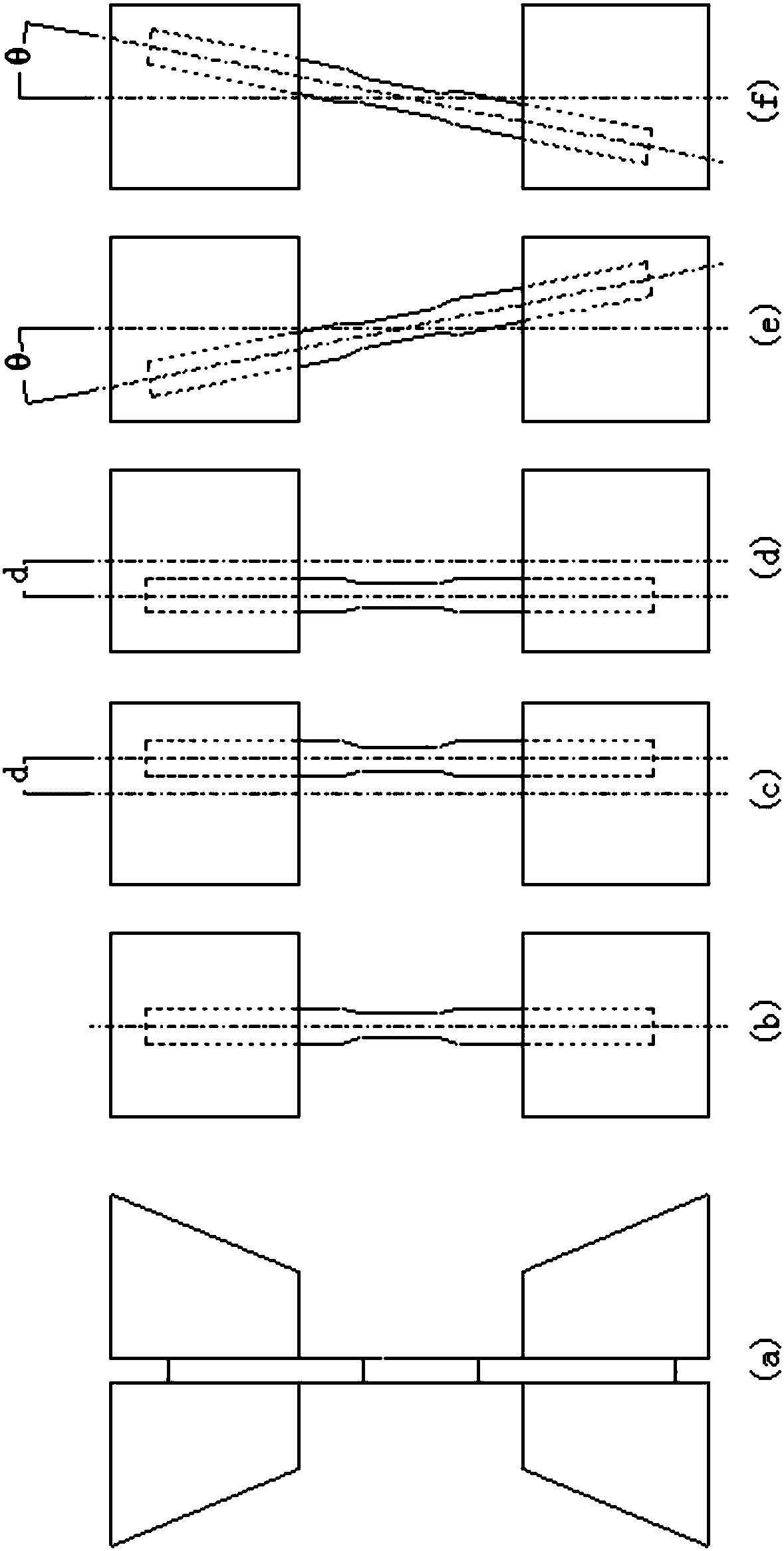

Ultrasonic nondestructive evaluation of early-stage fatigue damage of bonding interface

InactiveCN103278567AEnsure the safety of industrial operationAvoid major operational accidentsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFatigue damageFatigue loading

The invention relates to an ultrasonic nondestructive evaluation of the early-stage fatigue damage of a bonding interface, and relates to a method for evaluating the early-stage fatigue damage of the bonding interface by utilizing an ultrasonic detecting technology. The method comprises the following steps: selecting a test specimen with a bonding structure; measuring the initial nonlinear coefficient of the bonding interface by utilizing a nonlinear ultrasonic testing system; carrying out the tensile fatigue loading on the test specimen and performing nonlinear ultrasonic testing for every thirty times until the test specimen is damaged; dividing the number of the final fatigue loading times by the number of the fatigue loading times, so as to obtain the value of the relative fatigue life; dividing the initial nonlinear coefficient by the nonlinear coefficient, so as to perform normalization; then repeating the operations by selecting another four test specimens; and by taking the normalized nonlinear coefficient as the y-coordinate and the value of the relative fatigue life as the x-coordinate, expressing the normalized nonlinear coefficient values of the five test specimens in the coordinate, so as to obtain a fitting relationship curve chart of the normalized nonlinear coefficient and the relative fatigue life, wherein the greater the normalized nonlinear coefficient is, the more serious the fatigue damage degree of the bonding interface is.

Owner:BEIJING JIAOTONG UNIV

In-situ centering clamping device and method for plate specimen of tensile fatigue tester

PendingCN108489806AGuaranteed coaxialityEnsure consistencyMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesTensile fatigueEngineering

The invention discloses an in-situ centering clamping device and method for a plate specimen of a tensile fatigue tester. The device comprises upper flat clamping blocks and lower flat clamping blockswhich are used for clamping the upper and lower ends of the plate specimen, a side clamping mechanism used for clamping the two sides of the plate specimen and a clamping driving mechanism used for driving the side clamping mechanism are arranged between the upper flat clamping blocks and the lower flat clamping blocks, one side of the side clamping mechanism is fixedly connected with a height and transverse direction adjustment mechanism used for adjusting the side clamping mechanism vertically and transversely, and the lower part of the height and transverse direction adjustment mechanism is fixed to the middle plane of a clamping head of the tensile fatigue tester through a switch-type magnetic base. By means of the device, the coaxiality of the plate specimen on a clamp is guaranteed,the centering accuracy purpose during plate specimen installation of the tensile fatigue tester is achieved, and the consistency and the accuracy of a test result are ensured; moreover, based on thepremise that same functions are achieved, the device is conciser, the production cost is greatly reduced, and the reliability of the device is greatly improved.

Owner:TIANJIN UNIV

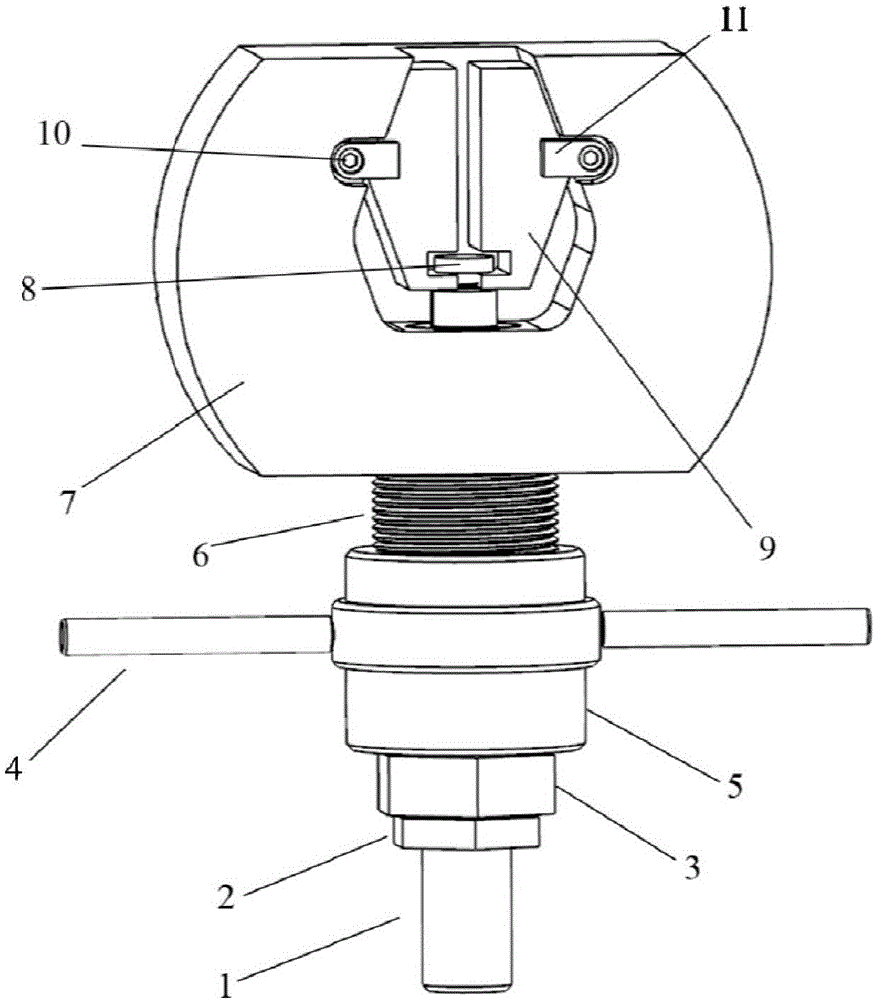

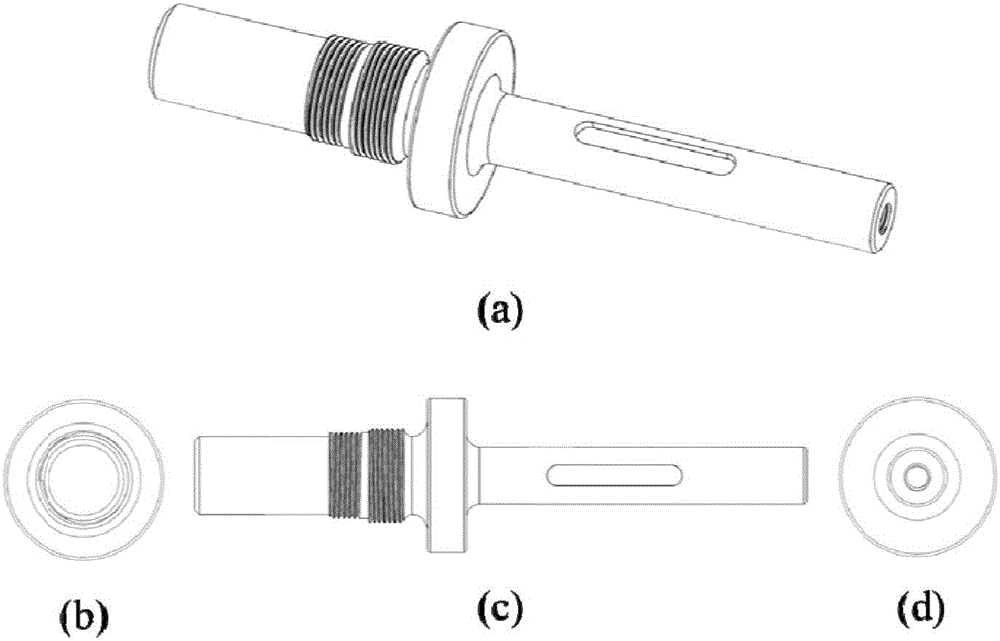

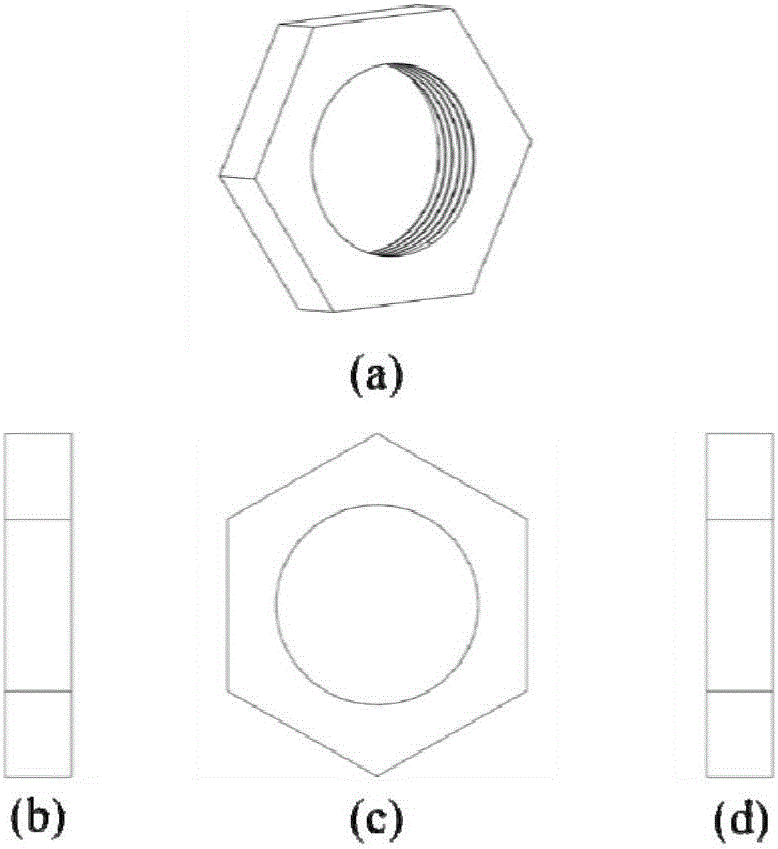

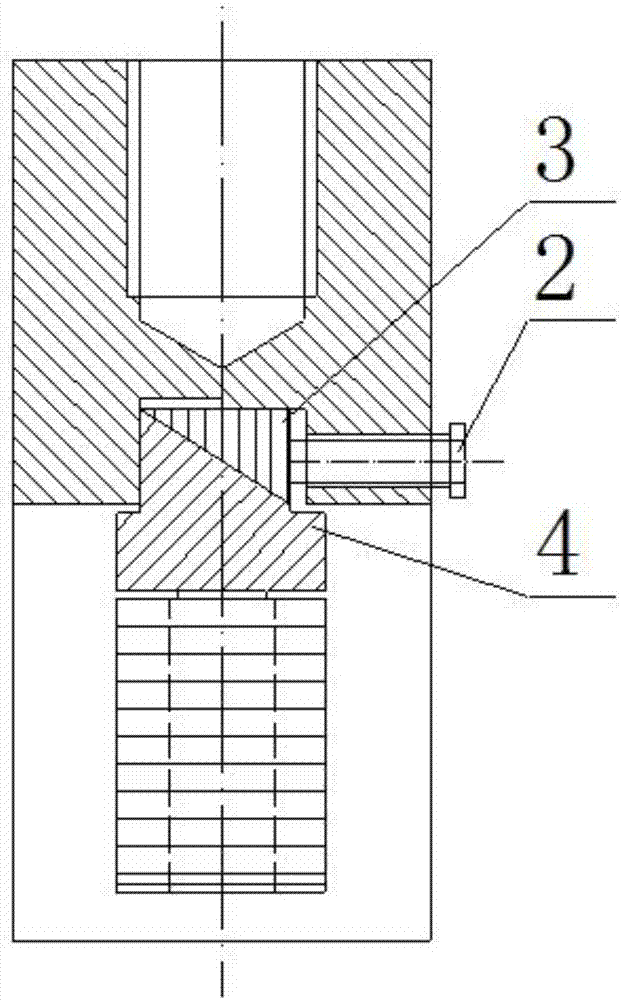

High temperature tensile fatigue test fixture for panel test piece and method

ActiveCN106840867AStable clampingAchieving Stretch FatigueMaterial strength using tensile/compressive forcesTensile fatigueTest fixture

The invention discloses a high temperature tensile fatigue test fixture for a panel test piece and a method. The clamping for the panel test piece in a high temperature test is realized, so that the tensile fatigue test for the panel test piece can be performed under a high temperature condition. A hydraulic chuck of a fatigue machine is used for clamping an optical rod end of a central shaft and is connected with a connecting rod through a sleeve; a fixing nut is arranged on the central shaft; the fixing nut is used for limiting the downward movement of the sleeve; the connecting rod is fixed with the sleeve through a screw; the connecting rod is in threaded connection with a wedge-shaped chuck body; the central shaft passes through a through hole in the middle of the connecting rod; a shaft end is connected with a guiding platform; the guiding platform is located in a groove between two wedge-shaped clamp blocks and is used for guiding the wedge-shaped clamp blocks to move up and down; the test piece is clamped by the wedge-shaped clamp blocks in the wedge-shaped chuck body; the bottoms of the wedge-shaped clamp blocks are propped by the top end of the guiding platform; the two sides are in contact with the wedge-shaped plane in the wedge-shaped chuck body; the upwards movement of the wedge-shaped clamp blocks is limited. The high temperature tensile fatigue test fixture can meet the requirement for stably clamping the panel test pieces in various sizes and can realize the single-shaft tensile fatigue under the high temperature condition.

Owner:BEIHANG UNIV

Damage quantitative evaluation method of reinforced concrete test piece

InactiveCN108535100ASimple and fast operationImprove test stabilityMaterial strength using tensile/compressive forcesResidual strainFatigue damage

The invention relates to a damage quantitative evaluation method of a reinforced concrete test piece. The damage quantitative evaluation method comprises the following steps: step I: pouring a test piece; step II: performing the pretreatment before the test; step III: connecting an induction system to a dynamic strain gauge, and performing pre-loading; step IV: applying the load according to a predetermined repeated loading rule, recording stress-strain data, reading residual strain on the surface of the concrete after a unloading standing target time after the test is ended, and calculating the residual strain (shown in description) of the concrete at the initial tensile fatigue damage state, accumulated residual strain sigma rc of the concrete at an initial state of the tensile fatigue damage corresponding to the tensile damage of the concrete and the residual strain sigma r of the concrete after N times of circulation of the tensile fatigue load; and step V: quantifying the damage quantitative of the single-axis tensile concrete by adopting a residual strain method according to the consistence of a damage development rule and a fatigue deformation rule of the concrete. The damage quantitative evaluation method of the reinforced concrete test piece is simple in operation and high in test stability.

Owner:ZHEJIANG UNIV OF TECH

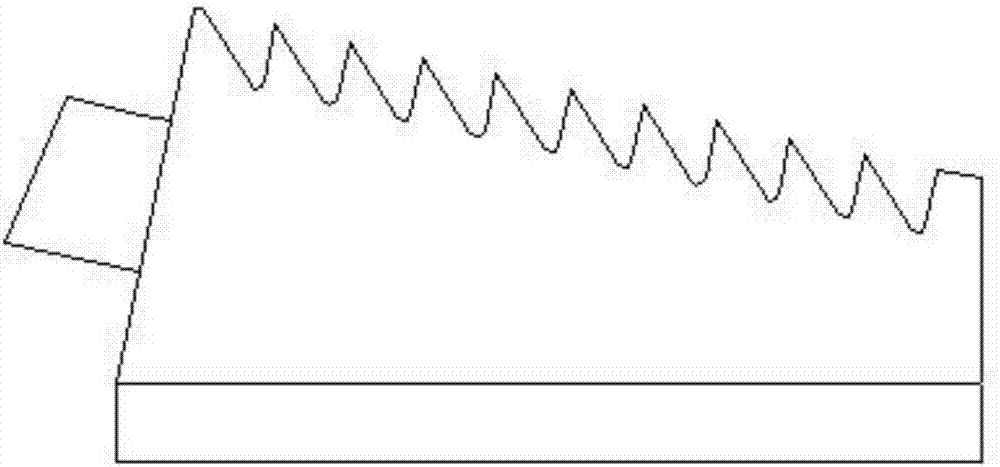

Composite material low temperature performance test fixture assembly

InactiveCN107228795ASuitable for low temperature stretchingApplicable mechanicsStrength propertiesTensile fatigueEngineering

The invention relates to a material mechanical property testing apparatus and provides a composite material low temperature performance test fixture assembly. The fixture assembly comprises two fixtures having the same structures. The fixture comprises a clamping sliding block for clamping a sample, a driven sliding block for transmission of the vertical displacement, a transition sliding block for transmission of the horizontal displacement, a braking bolt for producing a braking force and a forced clamping bolt for forcibly clamping the sample. The two sides of the clamping sliding block are provided with teeth and bosses. The teeth of the two clamping sliding blocks are opposite. The driven sliding block is a raised part having a smooth slope as the top end. The transition sliding block is provided with a smooth slope fitting to the transition sliding block so that a friction pair is formed. The fixture assembly is suitable for low temperature tension and tensile fatigue mechanical tests on the fiber-reinforced composite material sample, can prevent slipping of the composite material at a low temperature and can prevent clamped section damage. In the experiment, along with increasing of test tension, the resistance to the fixture teeth is increased and the clamping force is improved so that the effect of clamping is further guaranteed.

Owner:ZHEJIANG UNIV

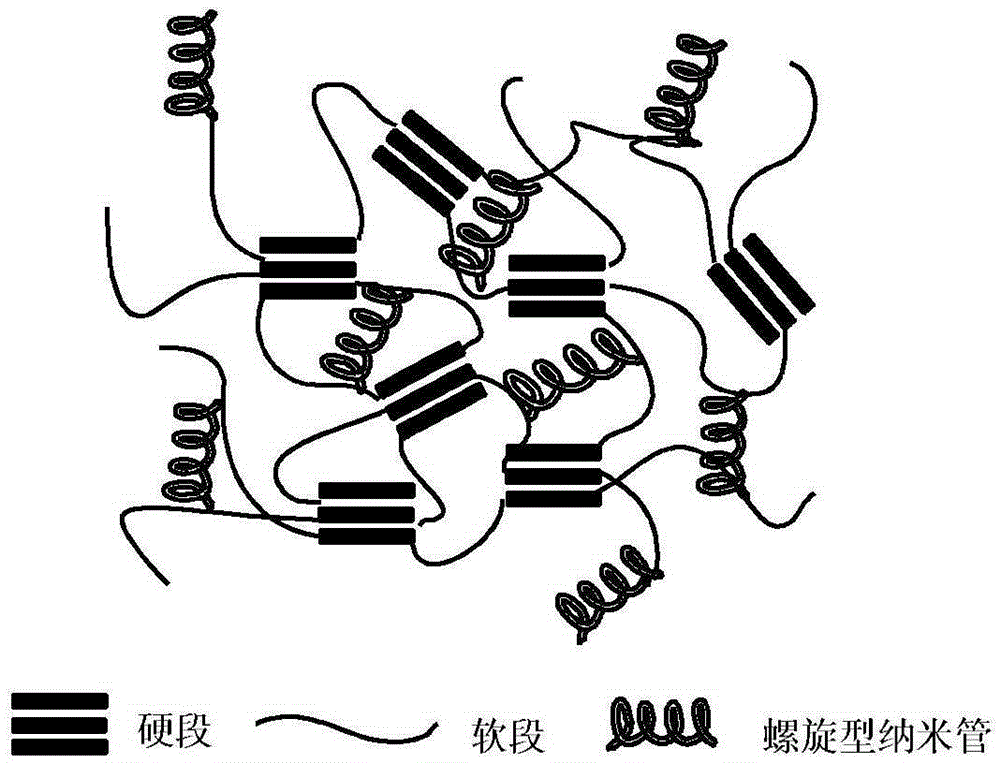

Preparation method of polyurethane fiber with tensile fatigue resistance

ActiveCN105386152AImproved tensile fatigue resistanceEvenly dispersedMonocomponent synthetic polymer artificial filamentArtifical filament manufactureElastic networkFiber

The invention discloses a preparation method of a polyurethane fiber with tensile fatigue resistance. According to the method, a screw-type nanotube is added to the polyurethane fiber for the first time. The method specifically comprises the following steps of firstly, using a high molecular surfactant and sonic oscillation treatment to do surface modification and dispersion processing on the screw-type nanotube, so as to prepare uniform and stable screw-type nanotube dispersion liquid; then uniformly mixing the dispersion liquid and other auxiliaries with a polyurethane solution; finally, forming the polyurethane fiber through a high-temperature channel evaporation solvent. According to the technical method, spring-effect of the screw-type nanotube is utilized to build a firmer elastic network structural system, so the tensile fatigue resistance of the polyurethane fiber is obviously promoted.

Owner:ZHEJIANG HUAFENG SPANDEX

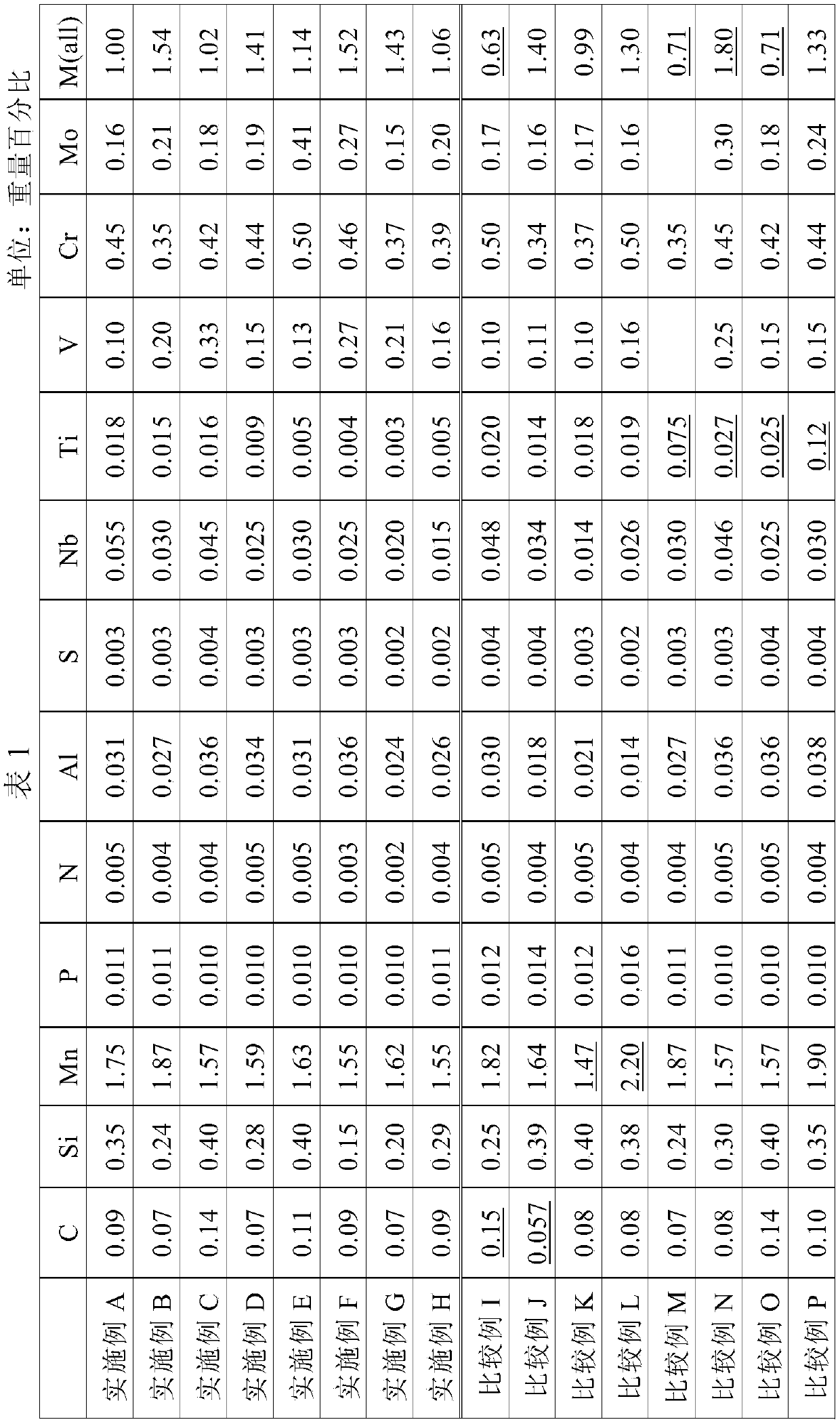

High-strength long-service-life rack steel

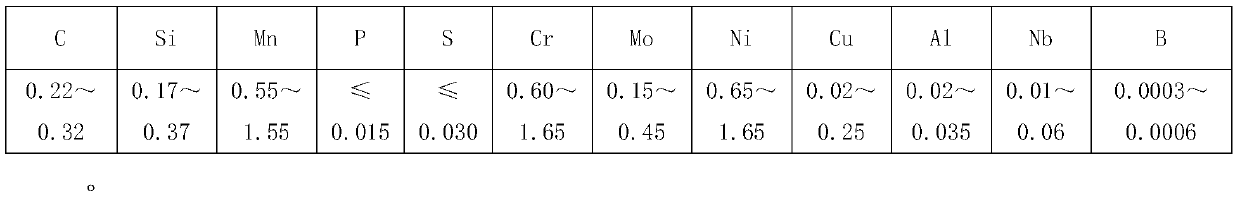

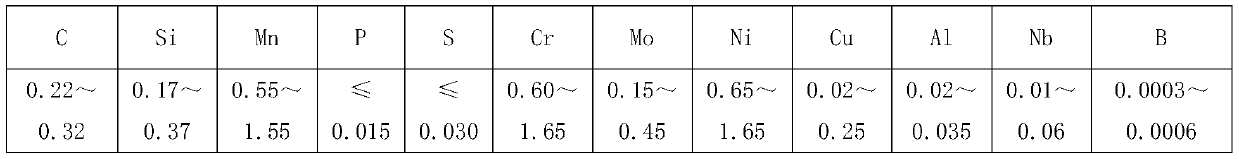

The invention relates to a high-strength long-service-life rack steel. After the steel is subjected to quenching and low-temperature tempering treatment, the tensile strength Rm is larger than or equal to 1650 MPa, and the symmetric tensile fatigue strength Sigma-1 is larger than or equal to 750 MPa. A great amount of data regression analysis is carried out through testing the contribution of the chemical elements to tensile strength and impact toughness, the chemical components are redesigned, so that the tensile strength and the fatigue strength of the rack steel are obviously improved, and the rack steel comprises the following components of, in percentage by mass, 0.22%-0.32% of C, 0.17%-0.37% of Si, 0.55%-1.55% of Mn, less than or equal to 0.015% of P, less than or equal to 0.030% of S, 0.60%-1.65% of Cr, 0.15%-0.45% of Mo, 0.65%-1.65% of Ni, 0.02%-0.25% of Cu, 0.02%-0.035% of Al, 0.01%-0.06% of Nb, 0.0003%-0.0006% of B.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Super-high-strength hot-rolled steel plate and steel belt with good fatigue and broaching performance and manufacturing method of steel plate and steel belt

ActiveCN110643894AHigh strengthImprove hole reaming effectFurnace typesHeat treatment furnacesTensile fatigueBroaching

Owner:BAOSHAN IRON & STEEL CO LTD

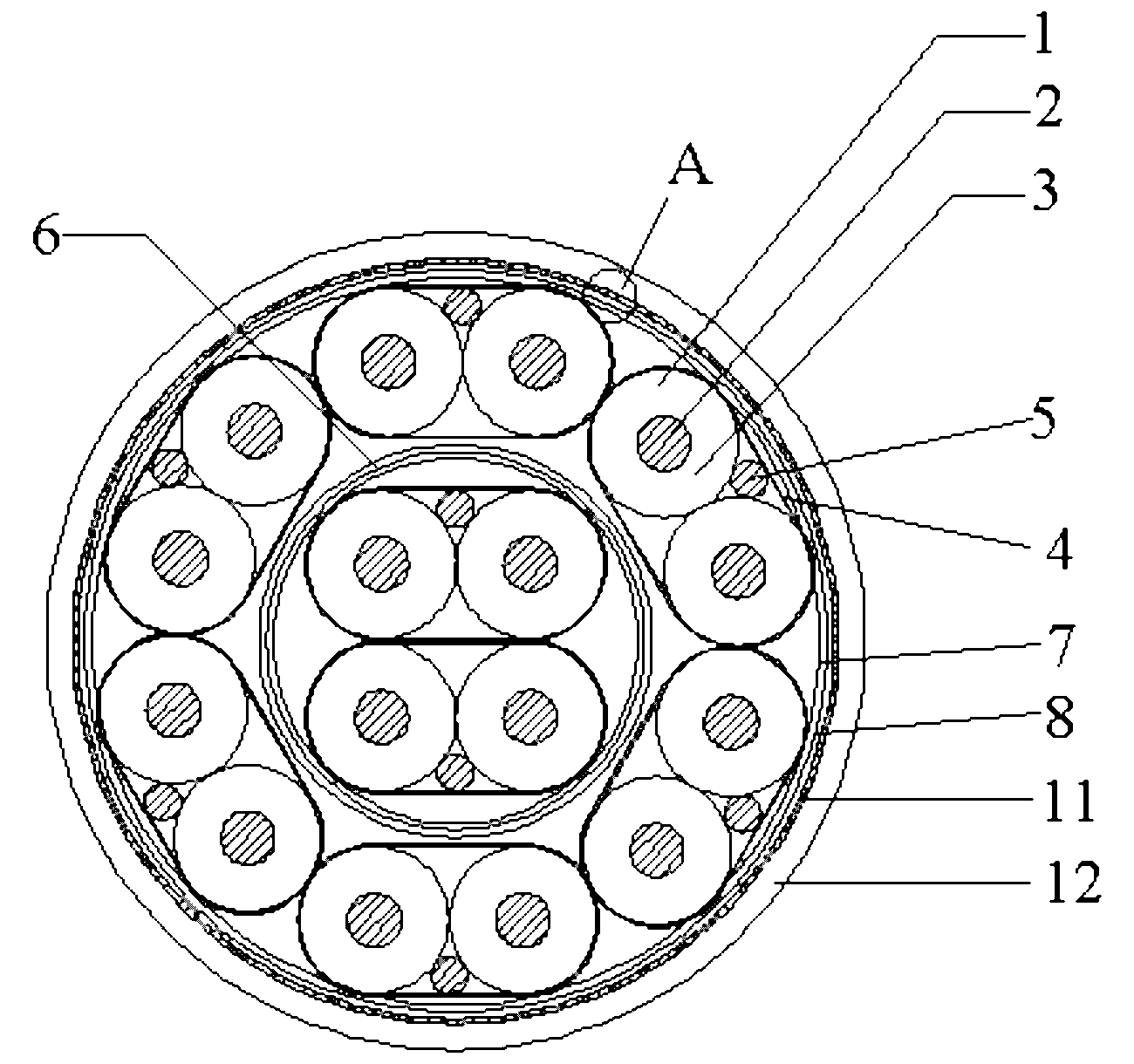

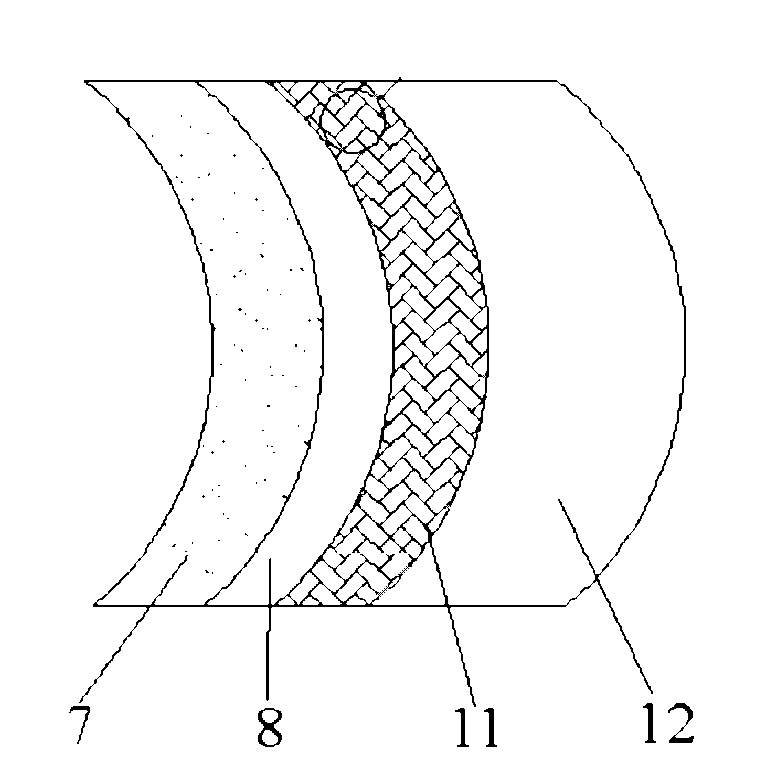

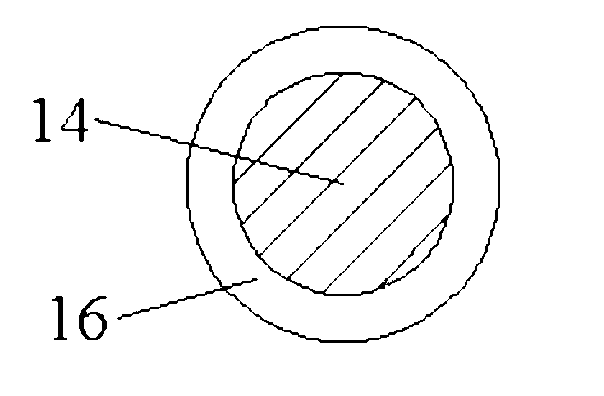

Tensile high-speed data cable

InactiveCN102231301AAdjust DC ResistanceAdjust the diameterNon-insulated conductorsPlastic/resin/waxes insulatorsPolyesterCopper conductor

The invention discloses a tensile high-speed data cable, which comprises eight copper conductor pairs, a second insulating layer, a polyester tape layer, a second aluminum composite layer and a braided shielding layer, wherein the second insulating layer coats two copper conductor pairs of the eight copper conductor pairs; the other six copper conductor pairs in the eight copper conductor pairs are adhered to the second insulating layer; the polyester tape layer is coated on the other six copper conductor pairs in the eight copper conductor pairs; the second aluminum composite layer is coated on the polyester tape layer and consists of a polyester film layer and an aluminum film layer which is coated on the surface of the polyester film layer; the braided shielding layer is coated on an aluminum foil layer and comprises a plurality of strands of aramid fibers of which the sections are circular; a flat copper wire of which the section is rectangular and which is coated with a tin layer is lapped on the aramid fibers; and the braided shielding layer is braided by the plurality of strands of aramid fibers. By the high-speed data cable, the tensile fatigue resistance is improved, and the shielding performance of the cable is improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Tensile fatigue tester

PendingCN108732049ARealize clampingImprove detection efficiencyMaterial strength using repeated/pulsating forcesTest efficiencyTensile fatigue

The invention relates to the technical field of detection equipment, in particular to a tensile fatigue tester. The tensile fatigue tester comprises a worktable, at least one fixed seat arranged on the worktable, at least one sliding seat movably arranged on the worktable and a sliding seat lifting driving mechanism for driving the sliding seat to reciprocate up and down relative to the fixed seat, wherein the fixed seat is provided with a plurality of lower clamps and a limiting plate for preventing the lower clamps from moving upward; the sliding seat is provided with a plurality of upper clamps, the upper clamps and the lower clamps are arranged correspondingly, and a stop test touch block is arranged below each lower clamp. The tensile fatigue tester provided by the invention is simpleand compact in structure and high in testing efficiency, and can detect and test a plurality of samples simultaneously and can detect rejected products from the samples so as to remedy defects of anexisting tensile device, so that the detection efficiency of samples of large batches is improved effectively.

Owner:东莞市恒宇仪器有限公司 +1

High-temperature tensile-fatigue mechanical property tester and method based on electric cylinder drive

ActiveCN108519291AHigh measurement accuracySimple structureNuclear energy generationMaterial strength using tensile/compressive forcesCouplingTensile fatigue

The invention relates to a high-temperature tensile-fatigue mechanical property tester and method based on electric cylinder drive and belongs to the field of mechanical property testing. The high-temperature tensile-fatigue mechanical property tester and method based on electric cylinder drive comprises a mobile platform, a high-temperature module and a test module, the test module is directly driven by an electric cylinder; the intermediate transmission links are few to achieve tensile and fatigue single load and tensile fatigue composite loading. The high-temperature module adopts a double-cavity high-temperature heating furnace, and the clamping specific unit of the test module can be driven by the movable platform after reaching the specified temperature by the double-cavity high-temperature heating furnace and enters the heating cavity to perform relevant mechanical property tests so as to meet the test requirements of the specific materials. The high-temperature tensile-fatiguemechanical property tester had the advantages that the structure is simple, the transmission link is small, the measuring precision is high, and effectively solves the problem of the influence of thethermal deformation on the mechanical property test during the temperature loading process and provides. a new method to reveal the mechanical properties of materials under the coupling of temperaturefield and composite load and has great practical significance to guide future resource exploration, aerospace and so on.

Owner:JILIN UNIV

Apparatus for testing one-way flexural-tensile fatigue of microstructure

InactiveCN1789960AEliminate sample loading cardEliminates the hassle of alignmentMaterial strength using repeated/pulsating forcesMicrostructural devicesVibration amplitudeControl equipment

The invention discloses a microstructure unidirectional bending fatigue test device, which is characterized by the following: the driving comb couple is set on one side of hung vibration block and the test comb couple is set to detect the vibration amplitude on the other side; the outside wall of driving and test comb couples is fixed on the silicon base through anchor fixing layer, which connects the driving electrode to generate periodic electrostatic force and test electrode of sensing circuit; the end of hung vibration block connects one end of sample to produce alternating stress; the other end connects the ground electrode; the sample integrates with the driving and detecting device; the driving electrode connects the output probe of power amplifier; the test electrode is leaded by probe to connect the input end of terminal control equipment after the probe is switched in the amplitude measuring circuit. The device adapts the research based on micronanometer technique on the MEMS system.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com