Fatigue testing machine applied to tension test piece and method thereof

A technology of fatigue testing machine and test pieces, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficulties and long periods of time, and achieve increased comparability, clear and reliable test purposes sex increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

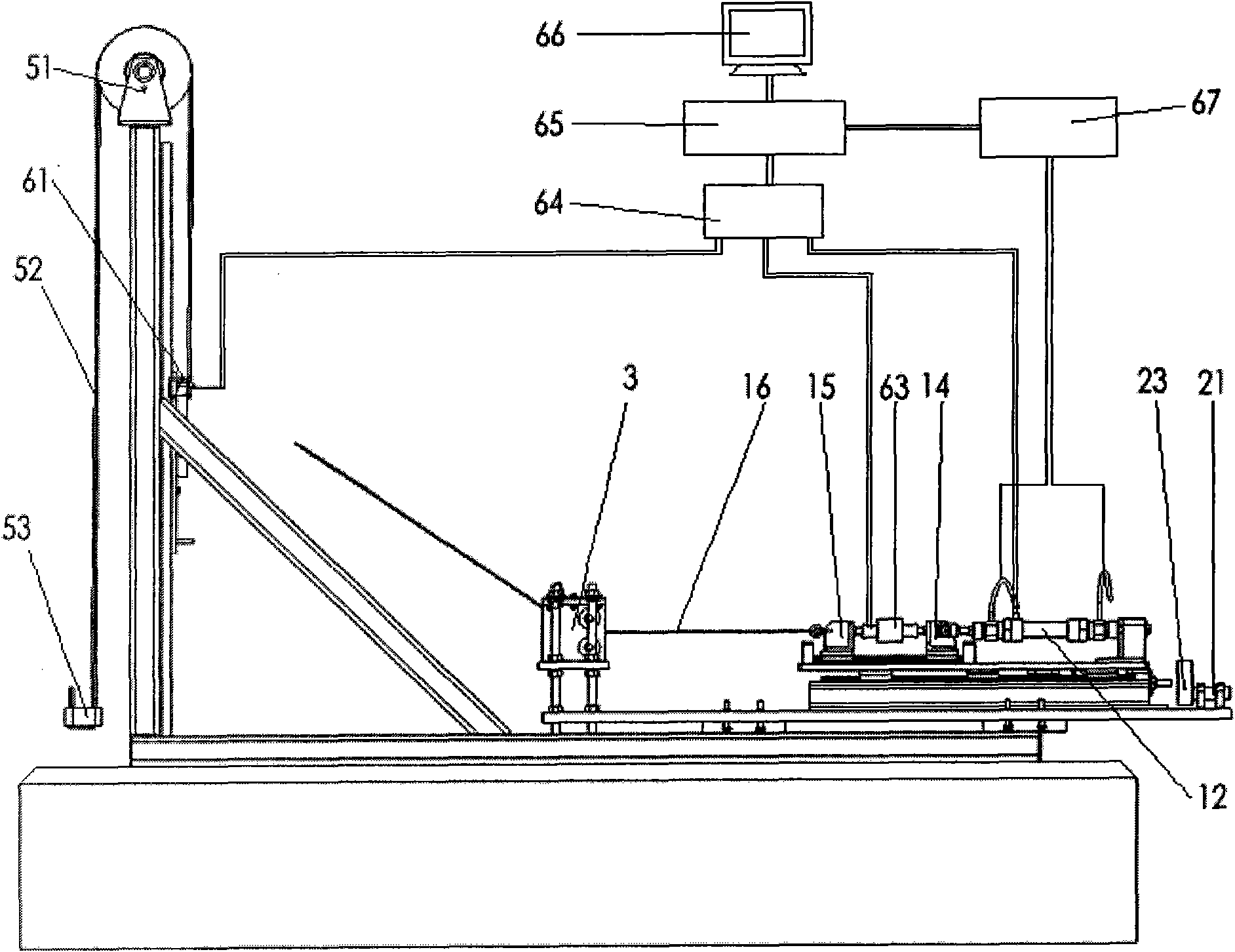

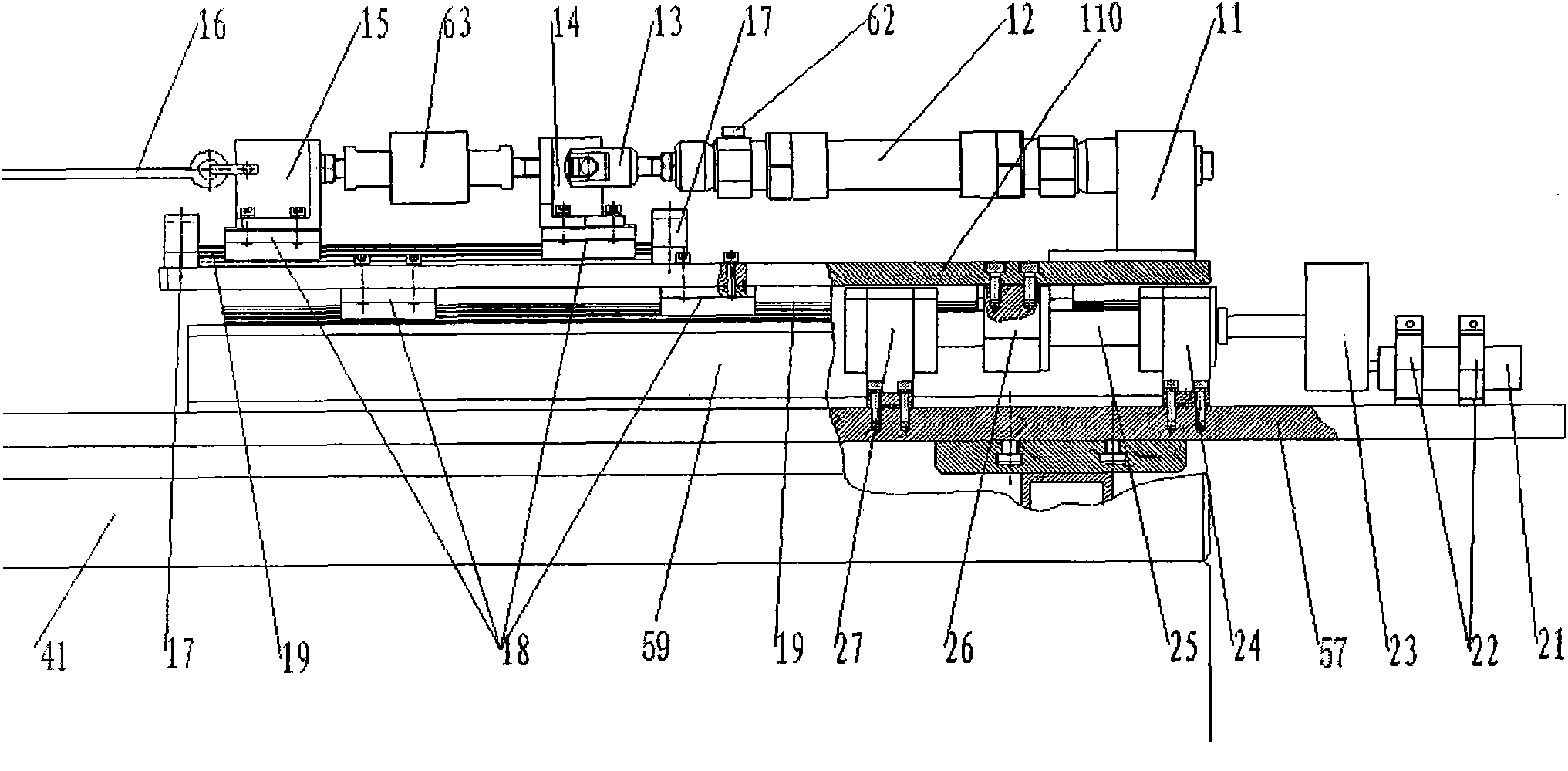

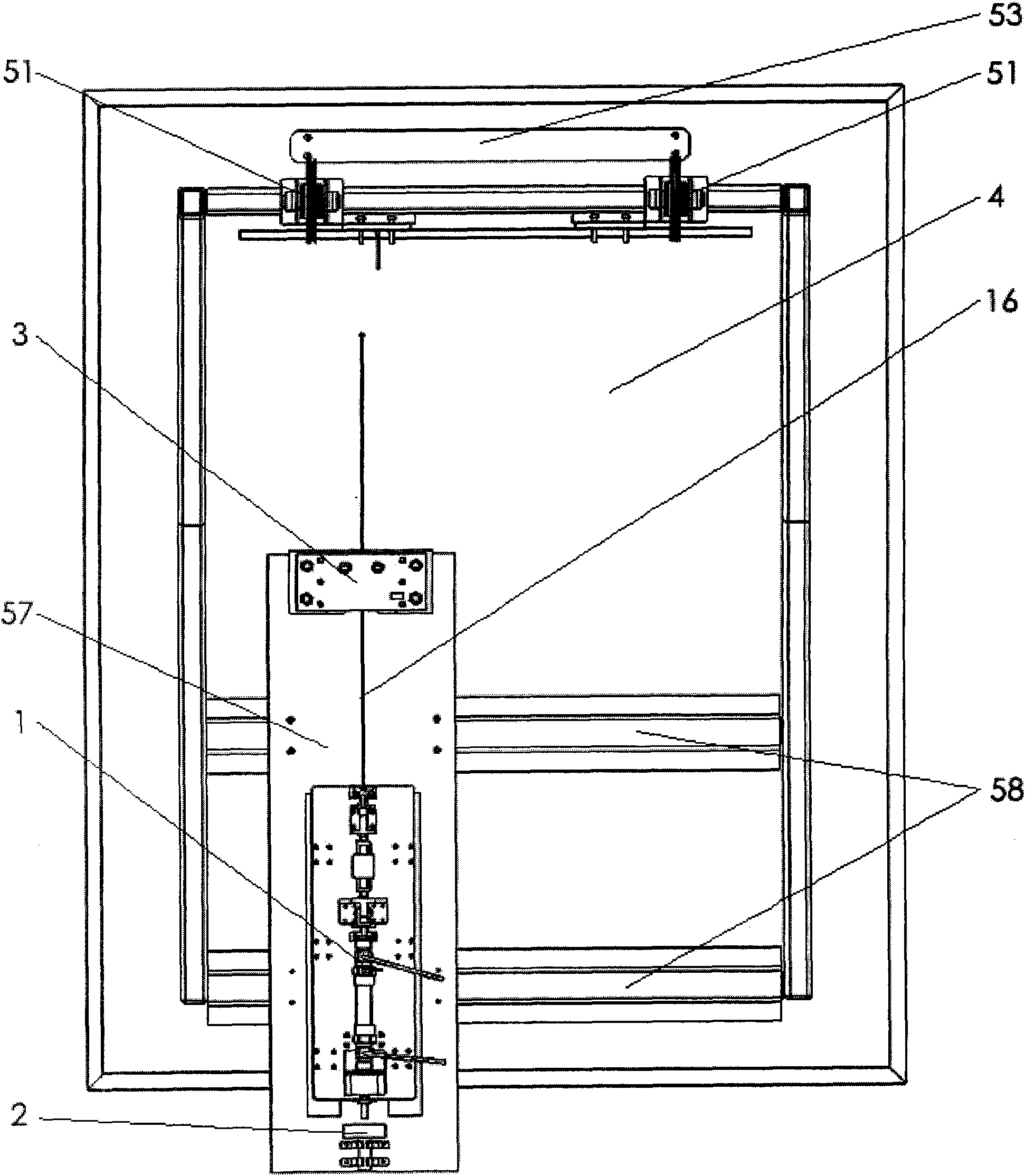

[0034] A fatigue testing machine suitable for tensile test pieces, comprising a fatigue force applying mechanism 1, a pre-tightening force mechanism 2, a straightening roller mechanism 3, a test fixing frame 4, an auxiliary mechanism 5 and a control system 6.

[0035]Fatigue force application mechanism 1 includes support 11, pneumatic muscle 12, connector 13, rear support frame 14, front support frame 15, steel wire rope 16, limit block 17, slider 18, guide rail 19 and sliding support plate 110, wherein: The support 11 is fixed on the sliding support plate 110, the rear end of the pneumatic muscle 12 is connected with the support 11, the front end of the pneumatic muscle 12 is connected with the connector 13, the connector 13 is connected with the rear support frame 14, and the rear support frame 14 is connected with the control The rear end of the tension sensor 63 of the system 6 is connected, the front support frame 15 is connected with the front end of the tension sensor 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com