Preparation method of polyurethane fiber with tensile fatigue resistance

A technology of polyurethane fiber and fatigue performance, applied in the field of polyurethane fiber to achieve the effect of improving tensile fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

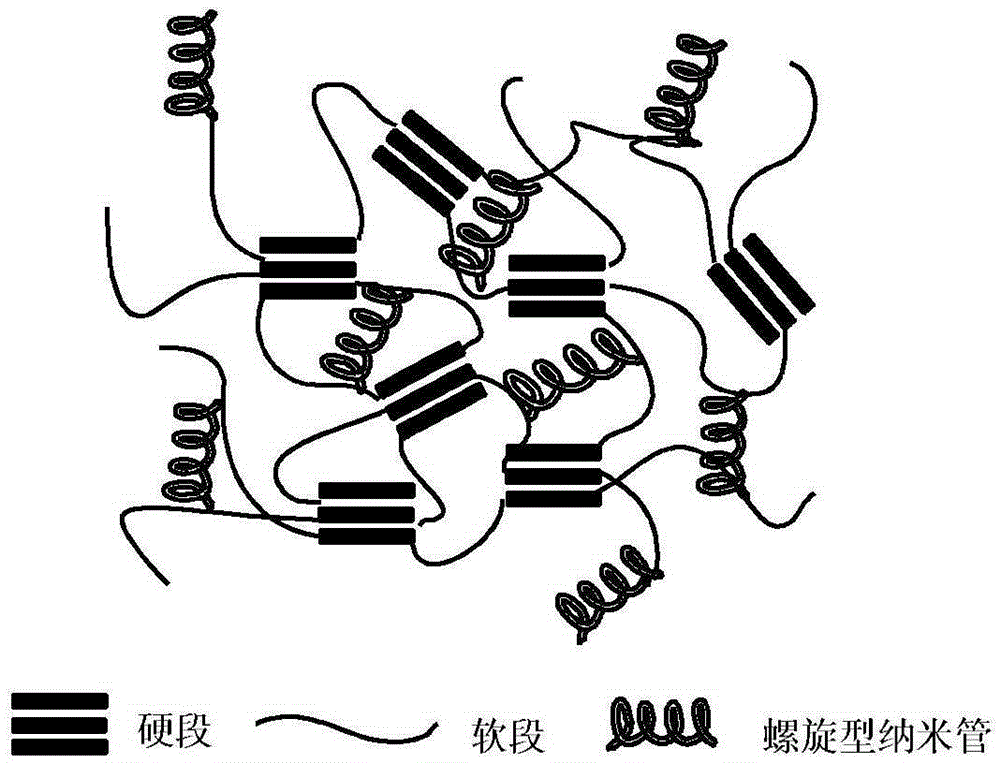

Method used

Image

Examples

Embodiment 1

[0035] Disperse 15 grams of spiral carbon nanotubes in 300 grams of dimethylacetamide, add 2 grams of polyvinylpyrrolidone at the same time, and use a 500-watt ultrasonic oscillator to vibrate for 4 hours to make a spiral-shaped carbon nanotube with a mass concentration of 5%. Carbon nanotube dispersion;

[0036]2 kg of PTMG, 0.8 kg of 4,4'-diphenylmethane diisocyanate (MDI) and 3.6 kg of DMAC were prepolymerized at 60 degrees Celsius for 3 hours; the prepolymerized product was dissolved and diluted by adding 4.0 kg of DMCA, and Cool to 18 degrees Celsius; then slowly drop ethylene glycol, propylenediamine, diethylenetriamine mixed liquid as the chain extender reactant, and the agent reaction control agent is methanol. After the chain extension reaction is completed, add a helical carbon nanotube dispersion, an antioxidant, a light stabilizer, and a lubricant, and stir for 36 hours to obtain a polyurethane spinning solution;

[0037] Then the polyurethane spinning solution is...

Embodiment 2

[0039] Disperse 40 grams of spiral-shaped silicon nanotubes in 600 grams of dimethylacetamide, add 5 grams of polyvinylpyrrolidone at the same time, and use a 500-watt ultrasonic oscillator to vibrate for 6 hours to make a spiral-shaped silicon nanotube with a mass concentration of 6.7%. Silicon nanotube dispersion;

[0040] 3.5 kg of PTMG, 1.0 kg of 4,4'-diphenylmethane diisocyanate (MDI) and 5.2 kg of DMAC were prepolymerized at 53 degrees Celsius for 4 hours; the prepolymerized product was dissolved and diluted by adding 4.0 kg of DMCA, and Cool to 25 degrees Celsius; then slowly drop ethylenediamine, propylenediamine, and glycerol mixed liquid as the chain extender reactant, and the agent reaction control agent is n-butanol. After the chain extension reaction is completed, add a helical silicon nanotube dispersion, an antioxidant, a light stabilizer, and a lubricant, and stir for 48 hours to obtain a polyurethane spinning solution;

[0041] Then the polyurethane spinning ...

Embodiment 3

[0043] Disperse 50 grams of spiral silicon dioxide nanotubes in 500 grams of dimethylacetamide, add 8 grams of polyvinylpyrrolidone at the same time, and use a 500-watt ultrasonic oscillator to vibrate for 4.5 hours to make a mass concentration of 10%. Helical silica nanotube dispersion;

[0044] 3.2 kg of PTMG, 0.73 kg of 4,4'-diphenylmethane diisocyanate (MDI) and 3.2 kg of DMAC were prepolymerized for 3.5 hours at 38 degrees Celsius; the prepolymerized product was dissolved and diluted by adding 4.8 kg of DMCA, and Cool to 6 degrees Celsius; then slowly drop 1,4-butanediol, 1,5-pentanediamine, and glycerol mixed liquid as a chain extender reactant, and the agent reaction control agent is n-pentanol. After the chain extension reaction is completed, add a helical silica nanotube dispersion, an antioxidant, a light stabilizer, and a lubricant, and stir for 40 hours to obtain a polyurethane spinning solution;

[0045] Then the polyurethane spinning solution is squeezed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com