Apparatus for testing one-way flexural-tensile fatigue of microstructure

A fatigue test and microstructure technology, applied in microstructure devices, microstructure technology, and the use of repetitive force/pulse force to test the strength of materials, etc., to achieve the effect of improving stress level, easy processing, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the utility model are described below in conjunction with the drawings:

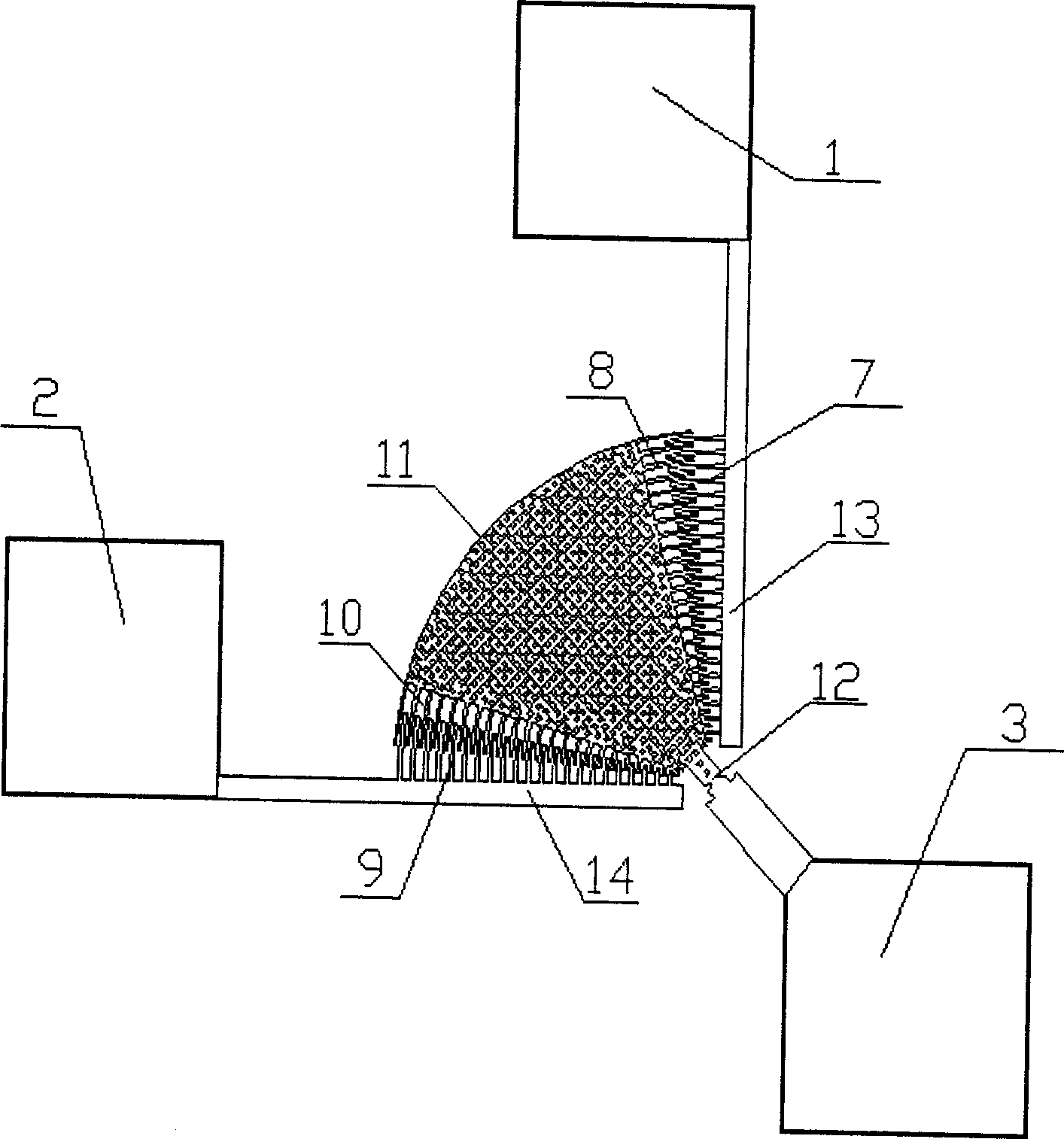

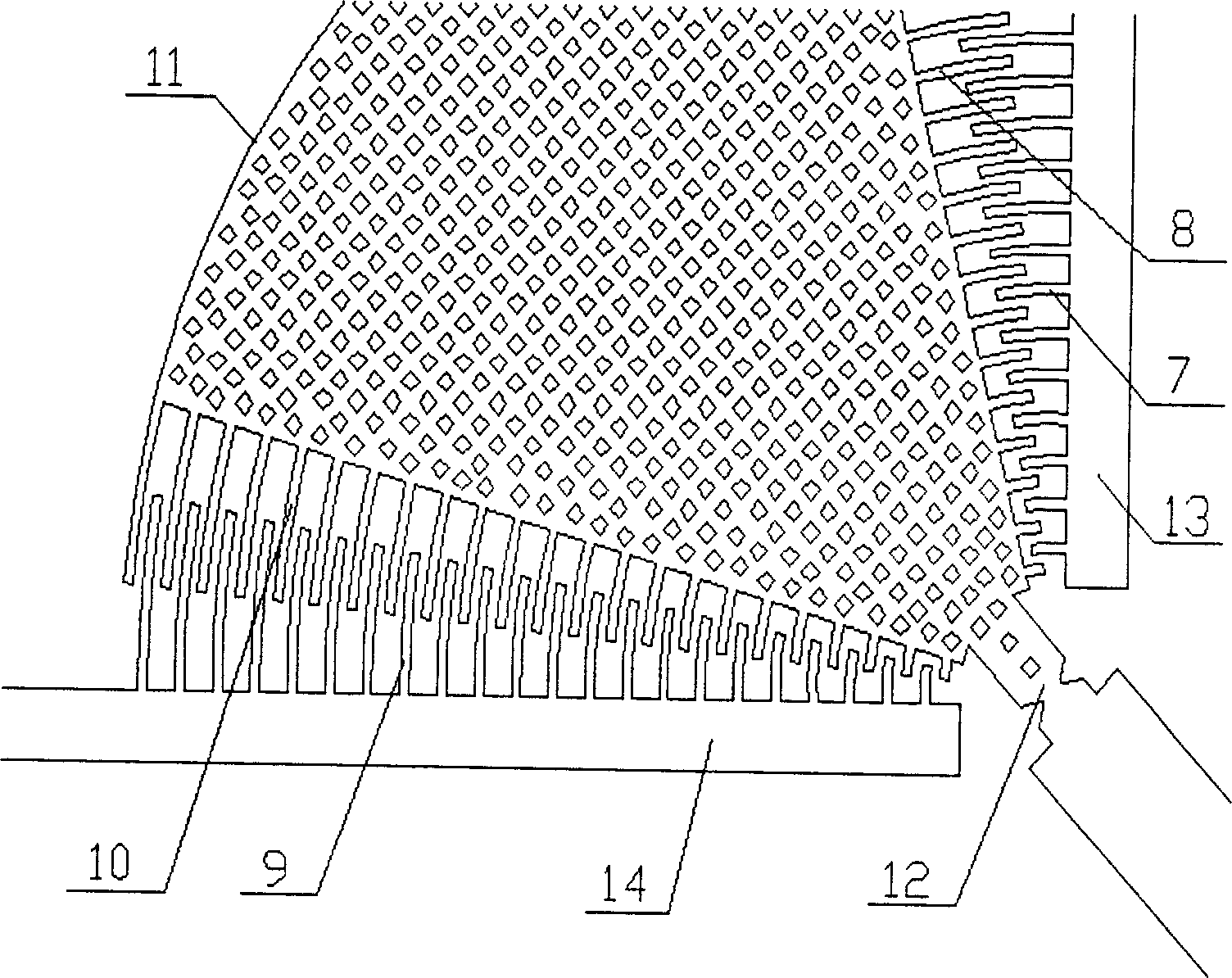

[0037] The schematic diagram of the structure of the microstructure bending and tensile fatigue test device designed according to the basic idea of the technical solution is shown in figure 1 , figure 2 Shown

[0038] figure 1 Is the positive overall picture, figure 2 It is a partial enlarged view of the main structure of the front.

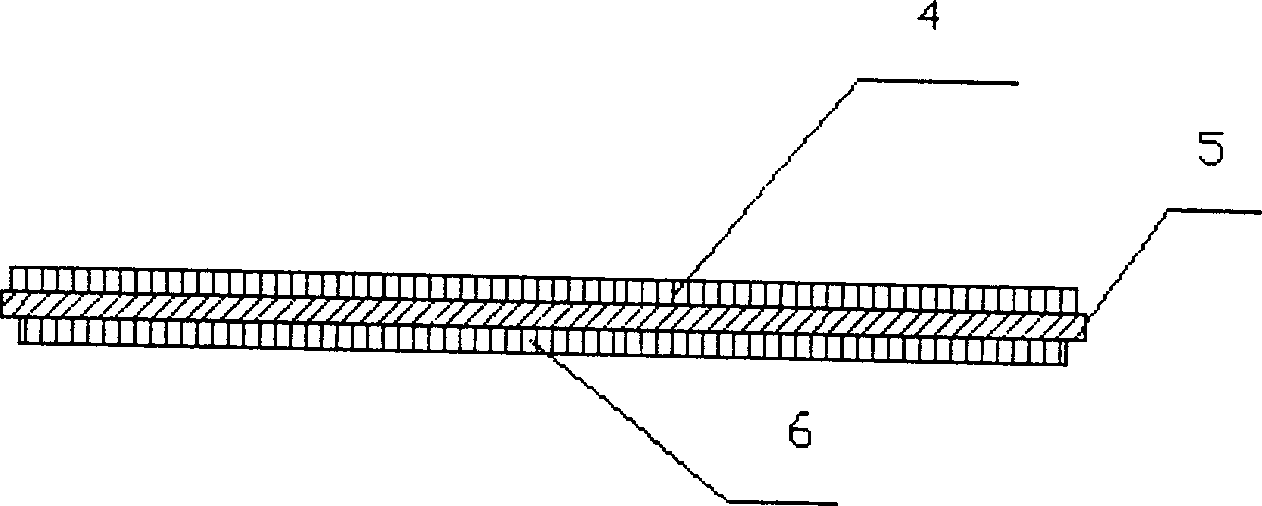

[0039] See figure 1 As shown, 1, 2, and 3 are three electrodes; the surface of each electrode is a layer of metal called metal layer 4, the purpose is to enhance the conductivity, the metal layer is a polysilicon structure layer 5, the main structure of the device In this layer, below the polysilicon structure layer is the anchor layer 6. Please refer to the cross-sectional view of each structure layer of the electrode image 3 ; The entire electrode is anchored on the silicon wafer substrate through the anchor layer.

[0040] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com