Patents

Literature

464 results about "Bending fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bending fatigue is caused by repeated bending stresses that exceed the local fatigue strength in the tensile root fillet of a gear tooth.

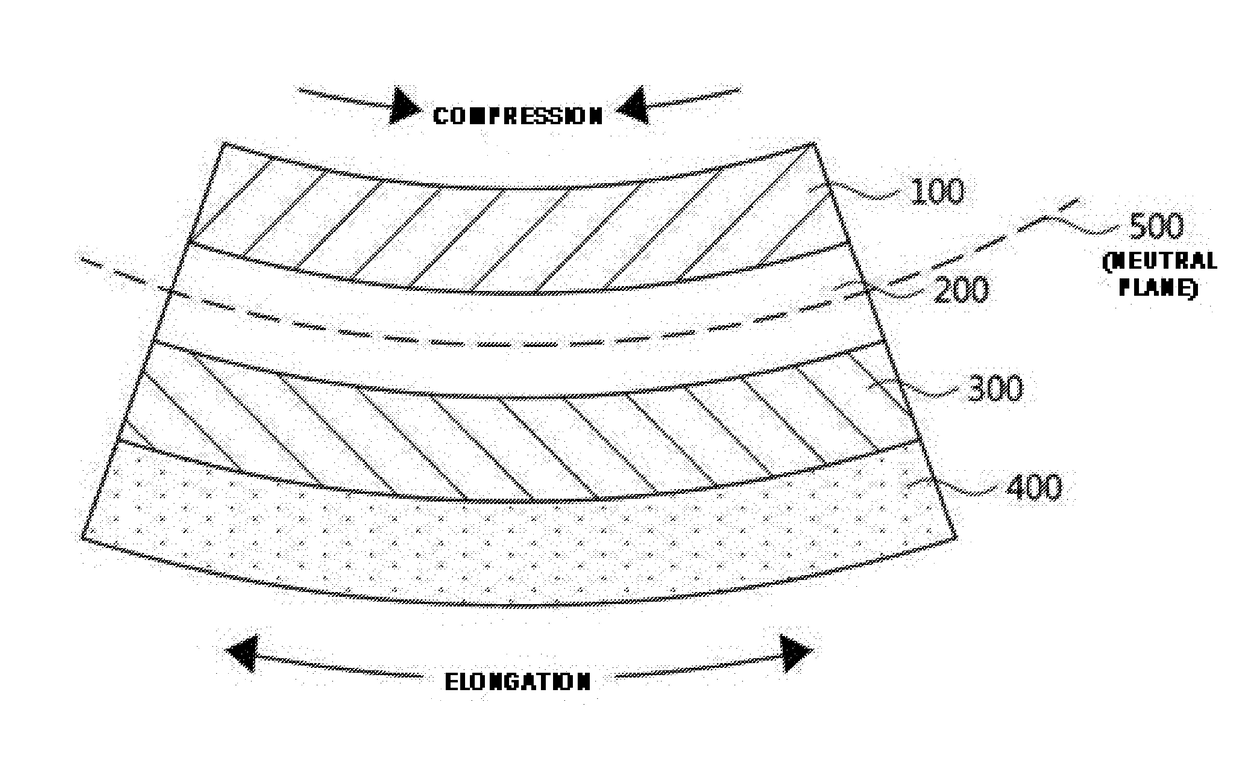

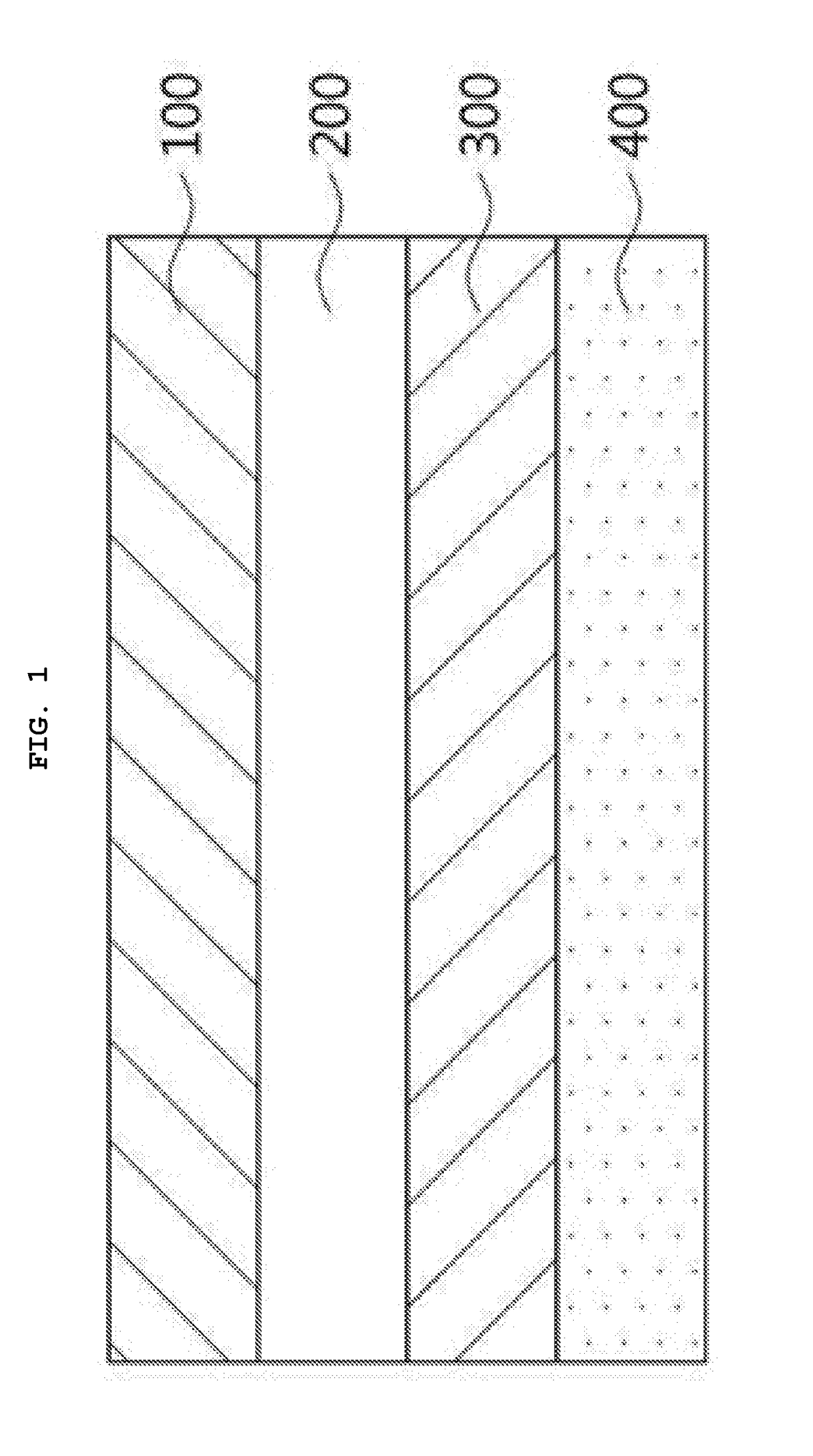

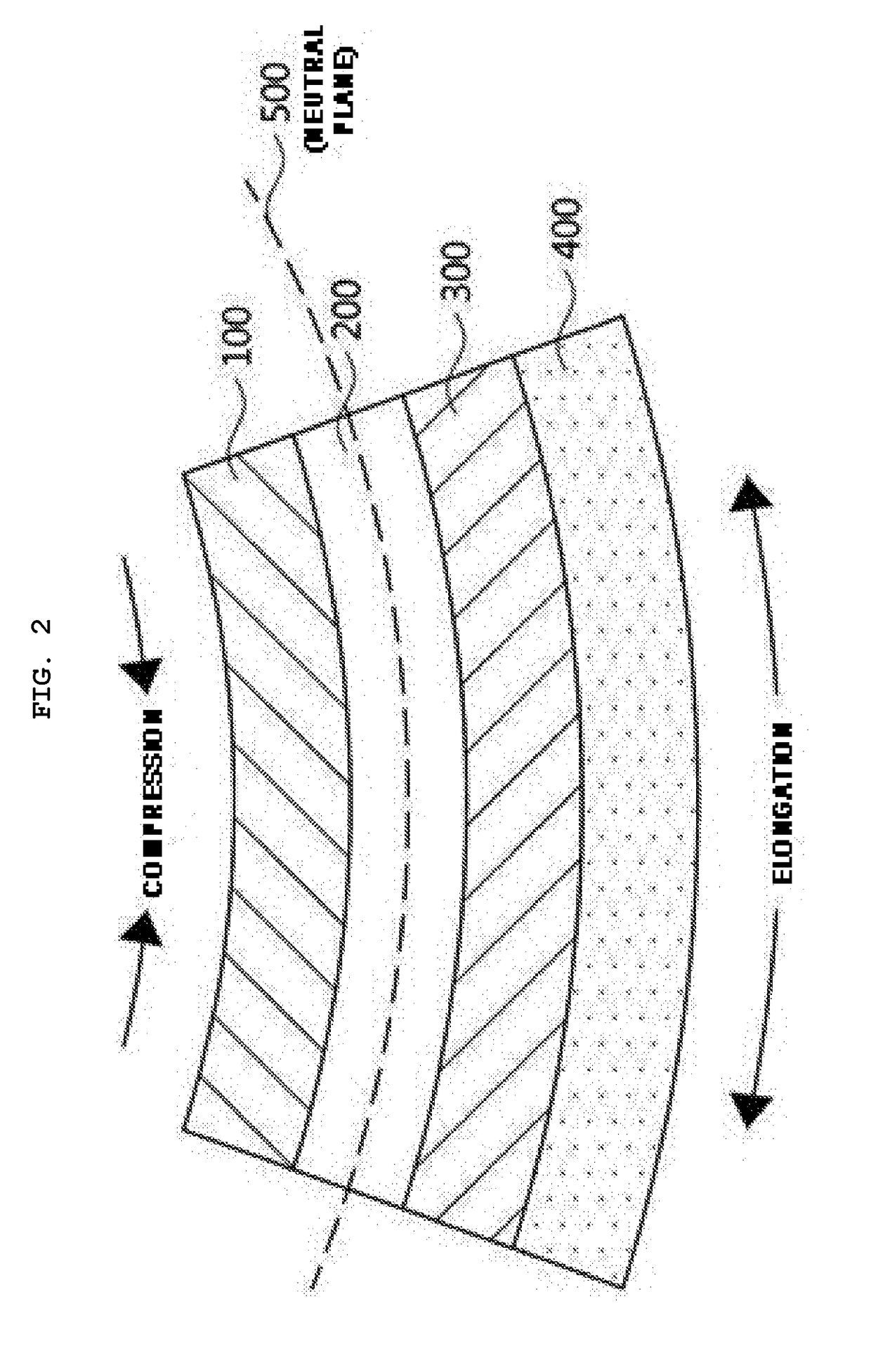

Flexible image display device

ActiveUS20170147117A1Good flexibilityMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingNeutral planeComputer science

Owner:DONGWOO FINE CHEM CO LTD

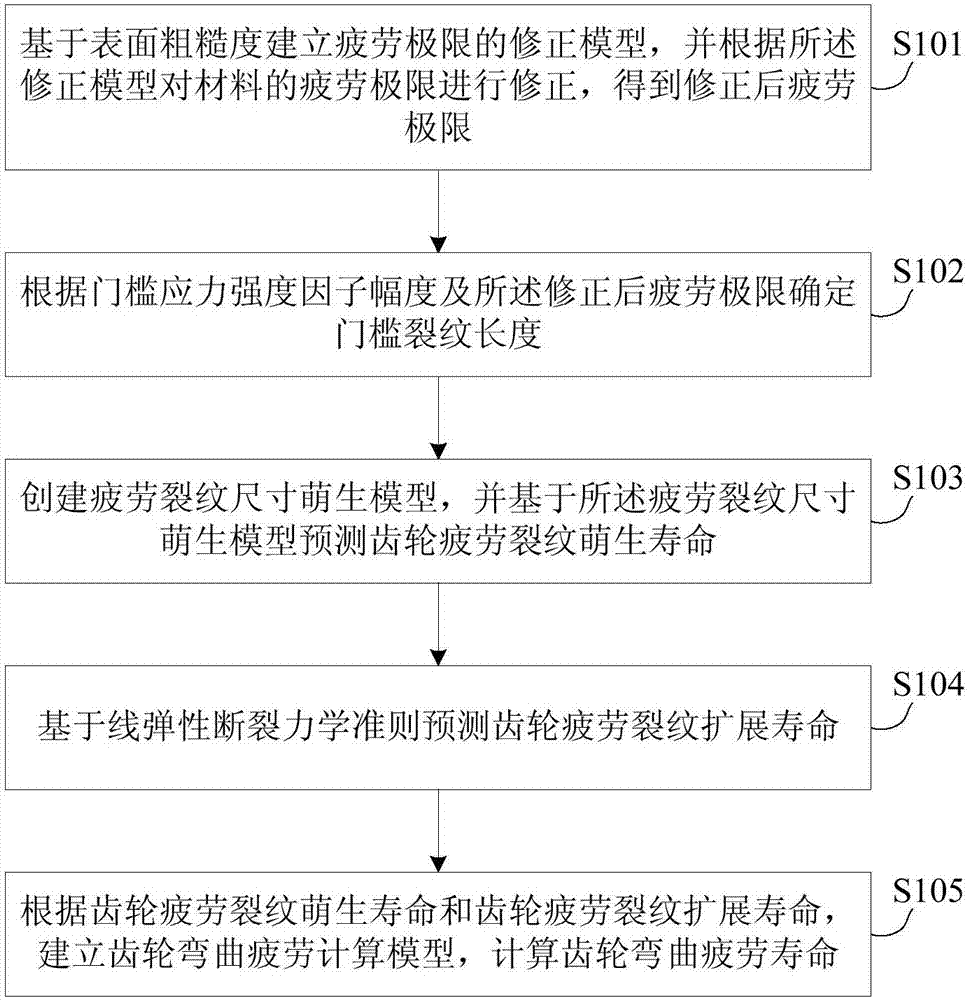

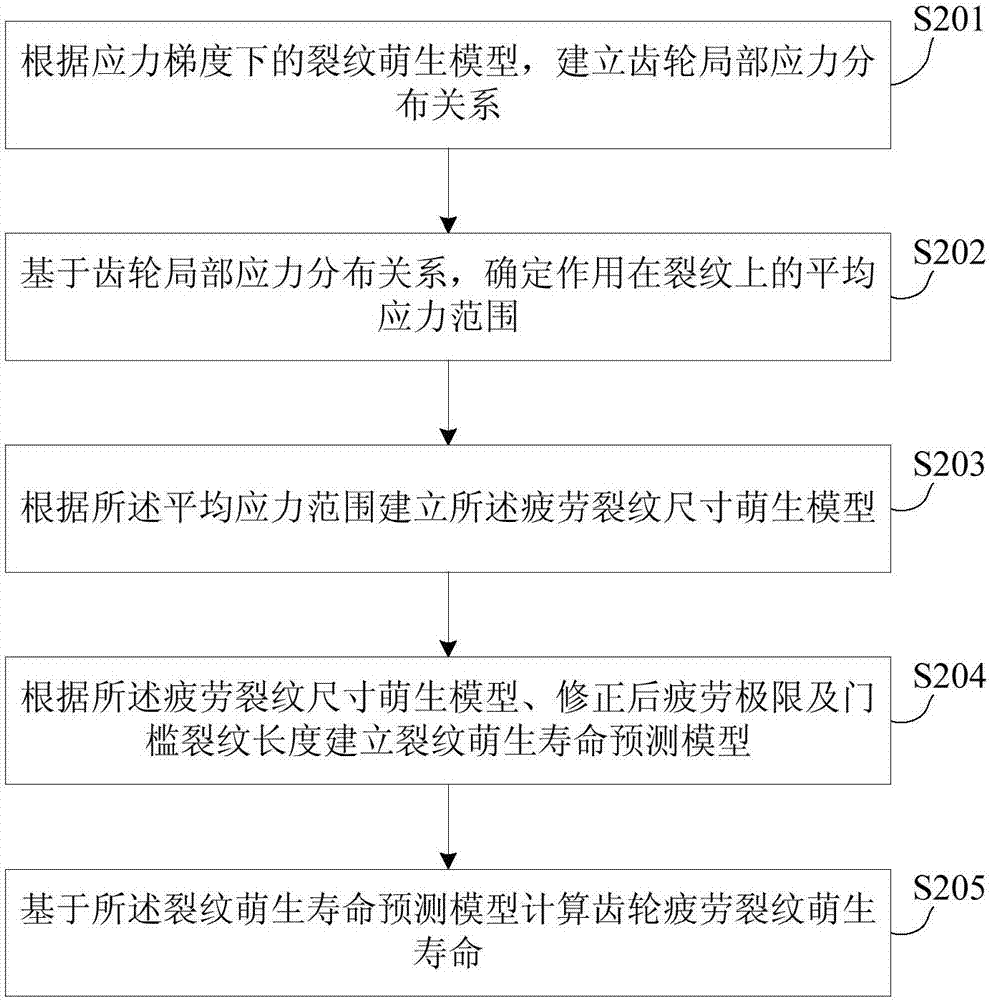

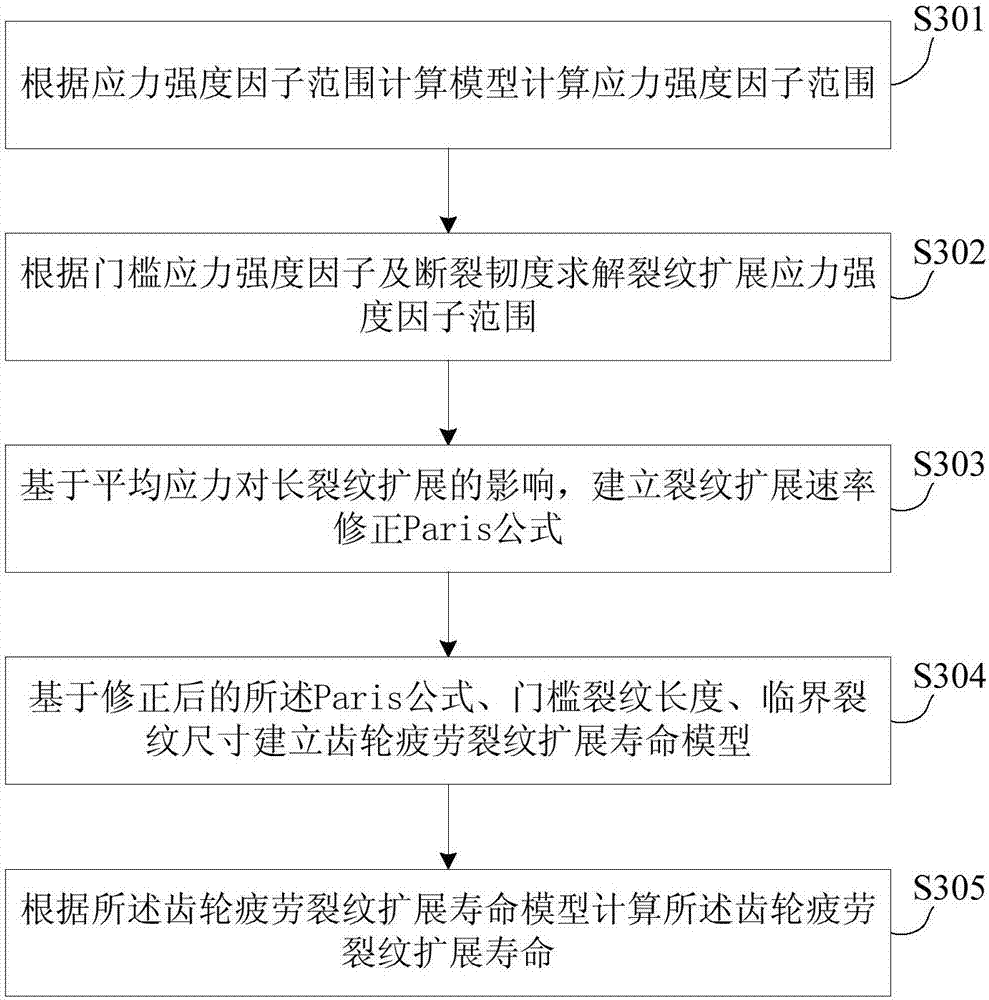

Gear bending fatigue life forecast method and apparatus

ActiveCN106886663ASimplify the operating life prediction processPredicting Flexural Fatigue LifeGeometric CADDesign optimisation/simulationGuidelineSurface roughness

The invention provides a gear bending fatigue life forecast method and a device. The gear bending fatigue life forecast method comprises the steps that a fatigue limit amendment model is built based on the surface roughness, and the fatigue limit of materials is amended according to the amendment model, the fatigue limit after the amendment is obtained; the threshold crack length is determined according to the threshold stress strength factor range and the amended fatigue limit; a fatigue crack size initiation model is created, and gear fatigue crack initiation life is forecasted based on the fatigue crack size initiation model; gear fatigue crack propagation life is forecasted based on the linear elastic fracture mechanics guidelines; according to the gear fatigue crack initiation life and gear fatigue crack propagation life, a gear bending fatigue calculation model is built, to calculate the gear bending fatigue life.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

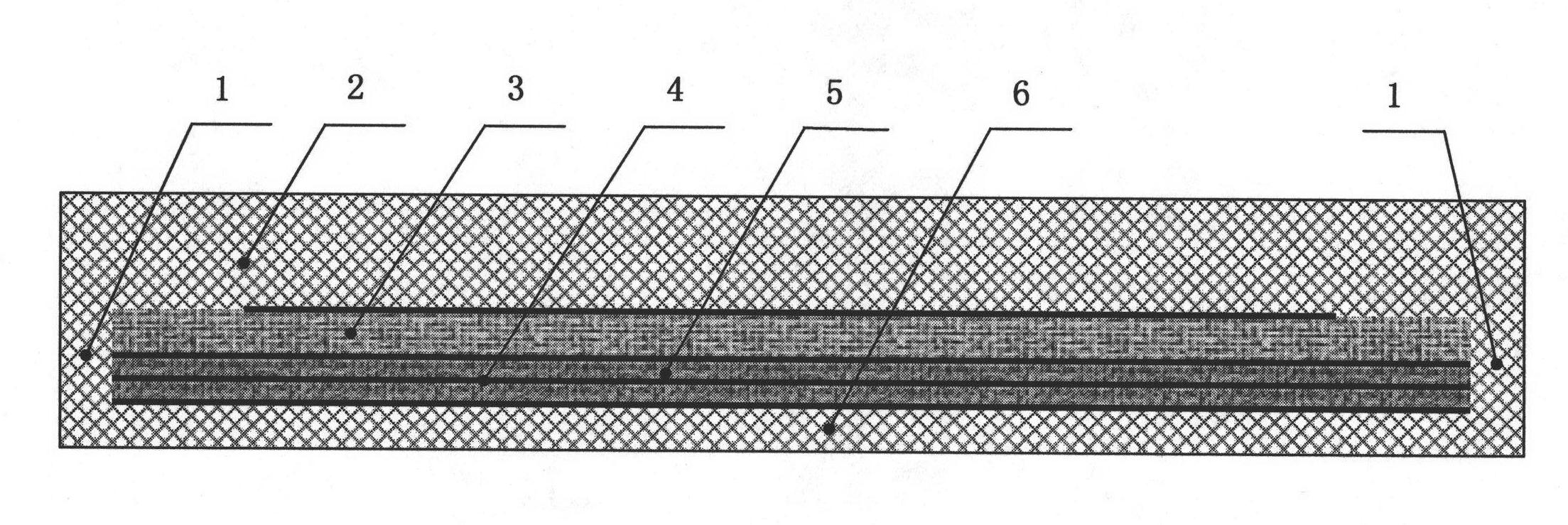

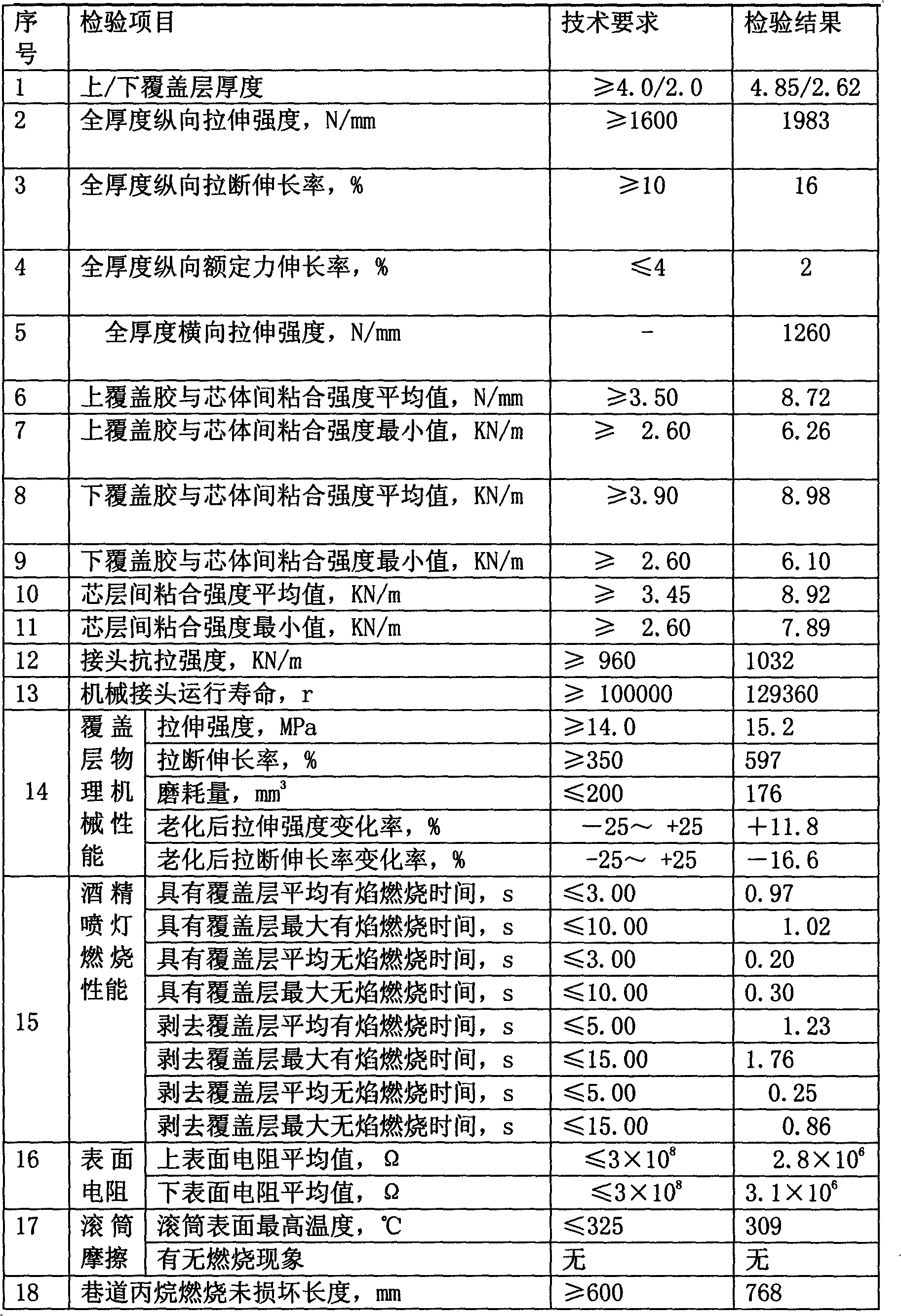

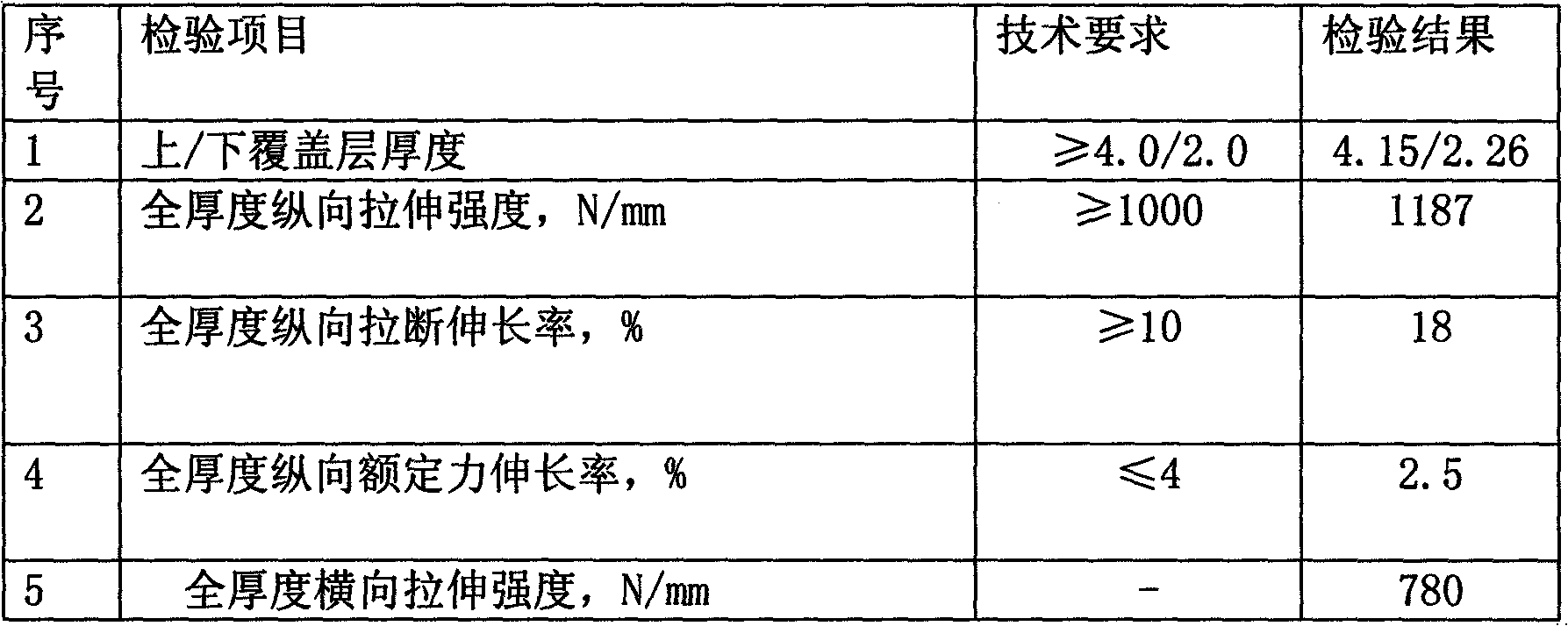

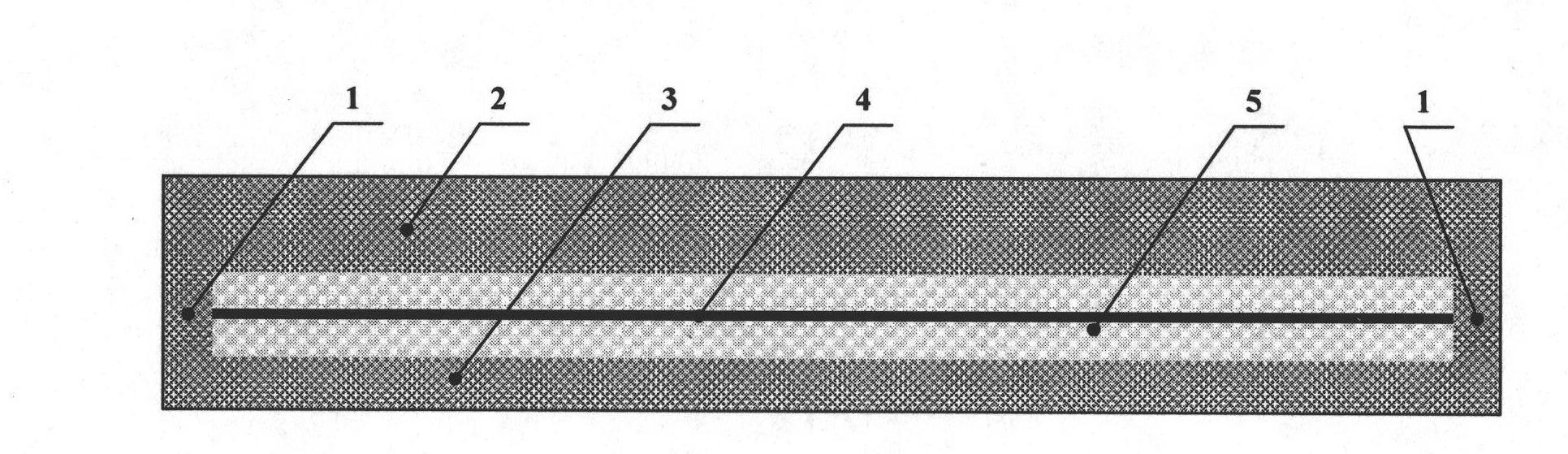

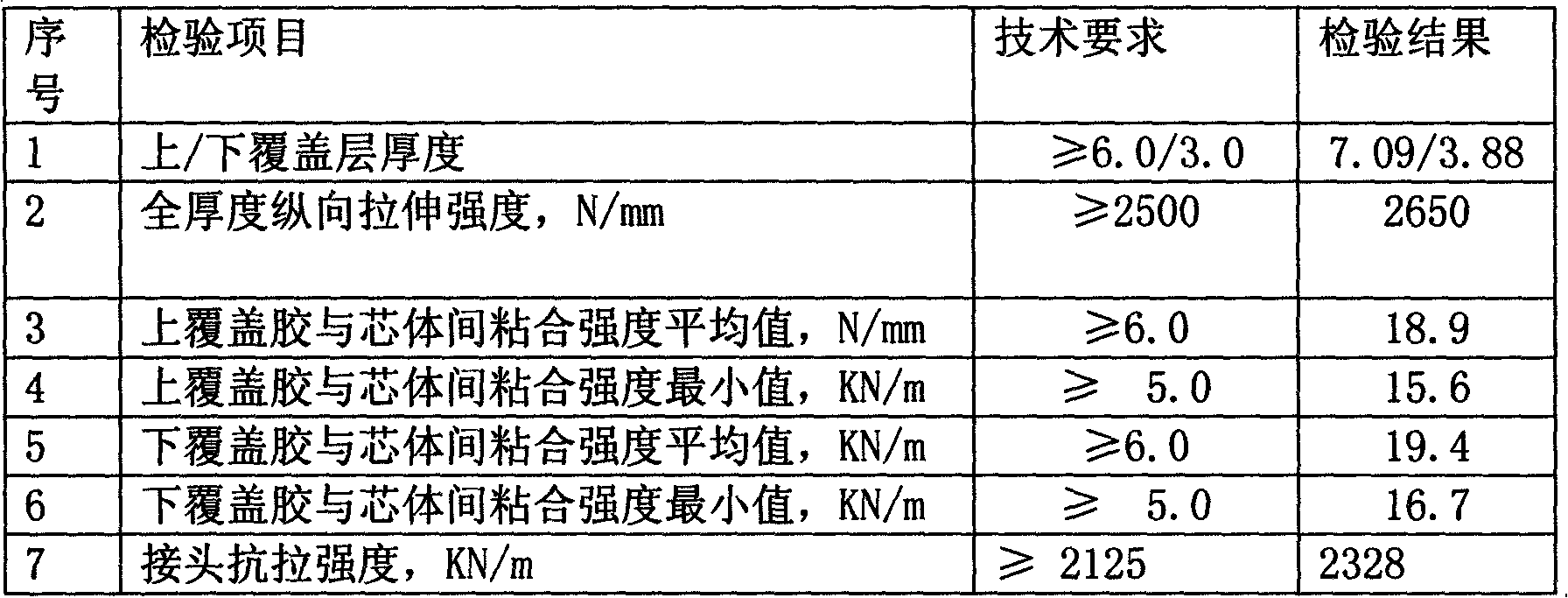

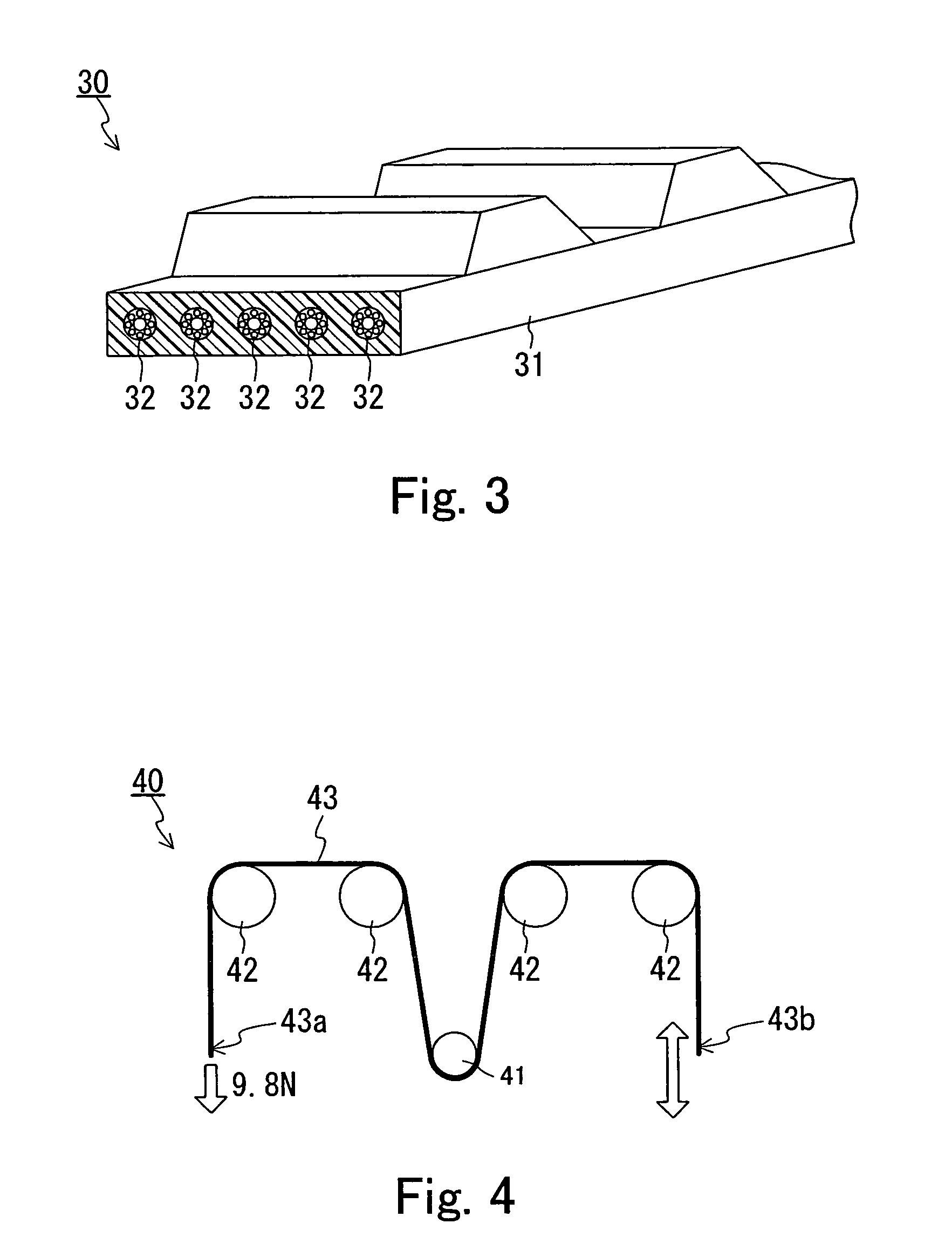

Tube-shaped flame retardant conveying belt with fabric laminations for coal mine

InactiveCN102642693AOptimizing process designReduce dosageNatural rubber adhesivesConveyorsEngineeringFire retardant

The invention discloses a tube-shaped flame retardant conveying belt with fabric laminations for a coal mine, which solves the problem that exiting products are not suitable for usage for underground conveying belts with laminations for coal mines. The conveying belt is characterized by comprising an upper flame retardant covering adhesive layer, a lower flame retardant covering adhesive layer, a side adhesive, skeleton layers, a flame retardant bonding layer and a buffering layer. A flame retardant bonding adhesive is used for bonding among the skeleton layers, among the skeleton layers and buffering layer and between the buffering layer and the upper flame retardant covering adhesive layer to form a whole, and formulas of the flame retardant bonding adhesive and a flame retardant covering adhesive are designed. Flame retardant epoxide resin (EP) canvas which is subjected to flame retardant impregnation processing serves as a skeleton, produced conveying belts have high pipe forming capability, conveying belt bodies have suitable softness, and produced conveying belts can meet turning requirements of tube-shaped conveying belts at different levels and requirements of tube-shaped conveying machines on physical mechanical properties of tube-shaped conveying belts; a flame retardant bonding adhesive material has high infiltration capacity on skeleton materials, after sulfuration, the bonding force of the flame retardant bonding adhesive material is large, dynamic heat is small, and the flame retardant bonding adhesive material has repeated bending fatigue resistance; and abrasion resistant and yielding resistant performance of the flame retardant bonding adhesive material is improved, and the flame retardant performance meets underground flame retardant requirements for coal mines.

Owner:胡世献

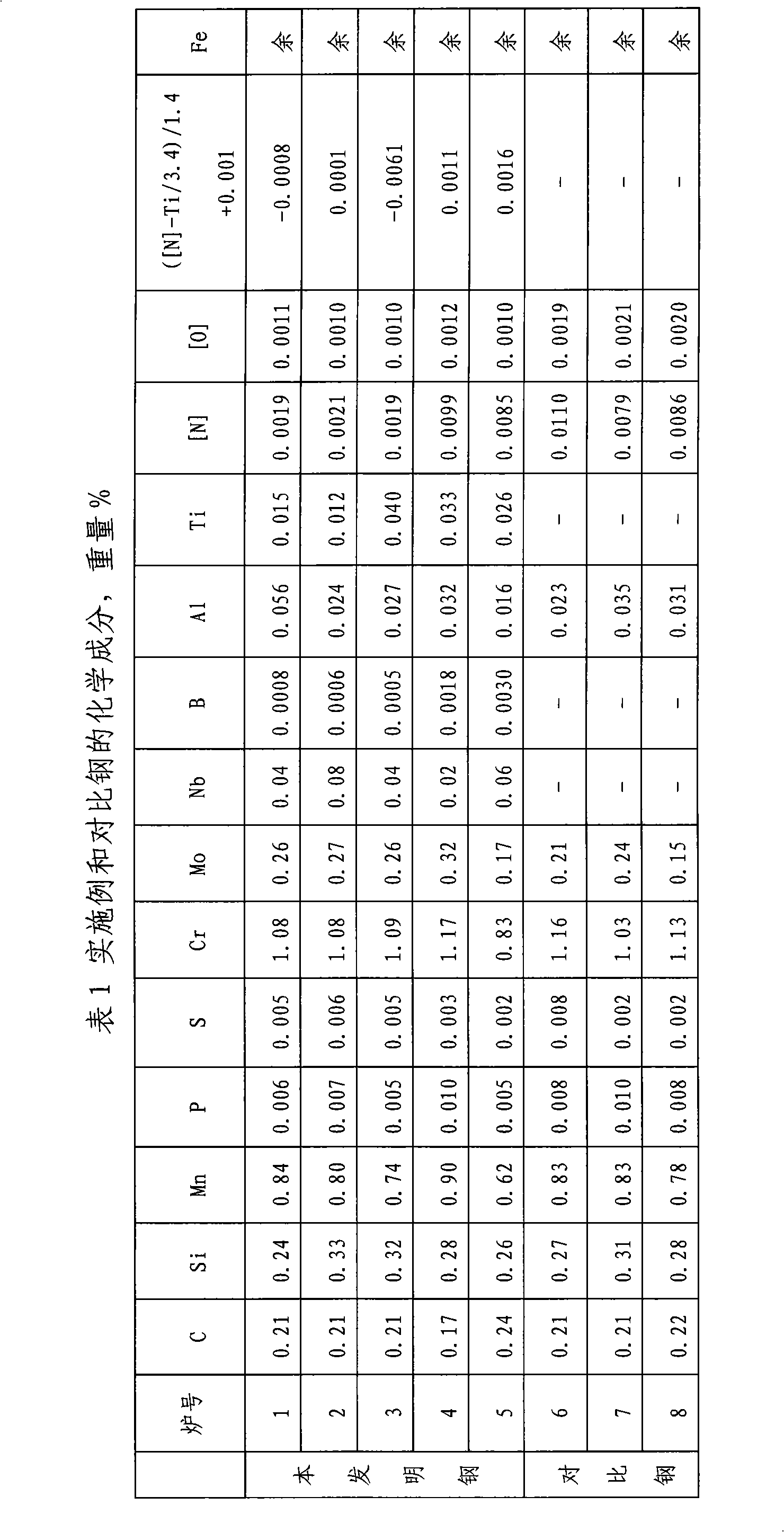

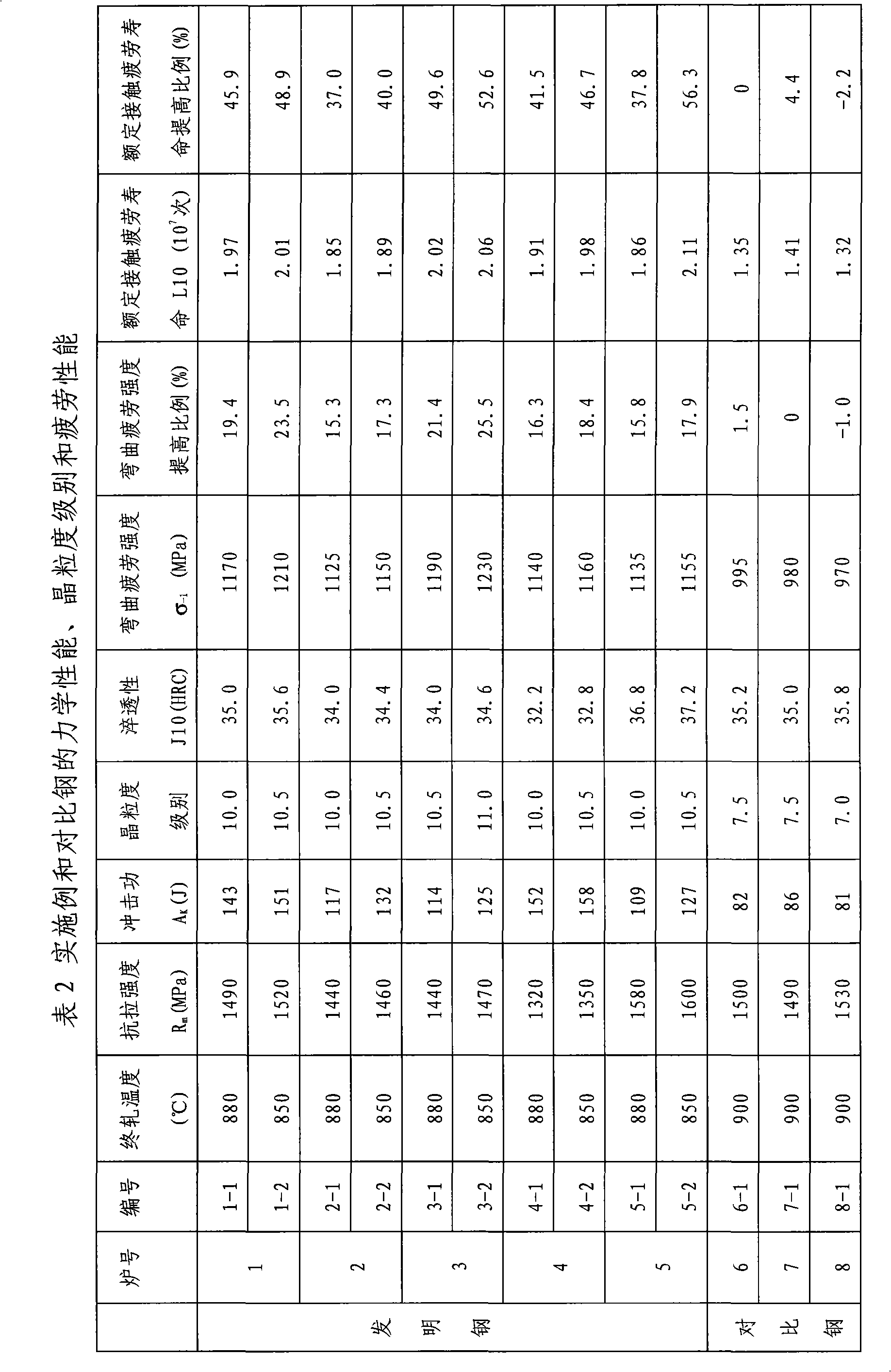

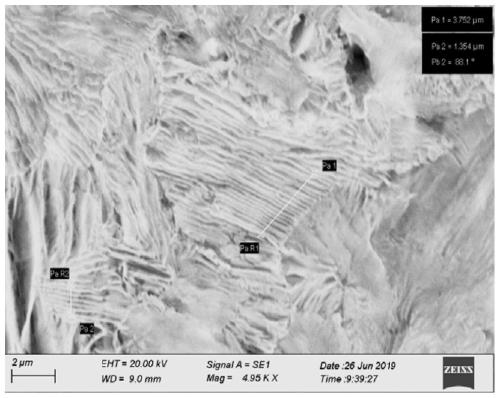

Steel for fine grain carburizing gear and method of manufacturing the same

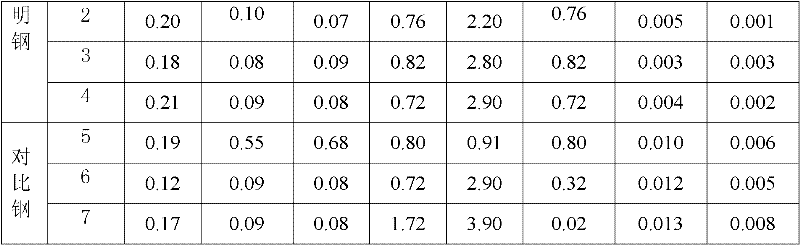

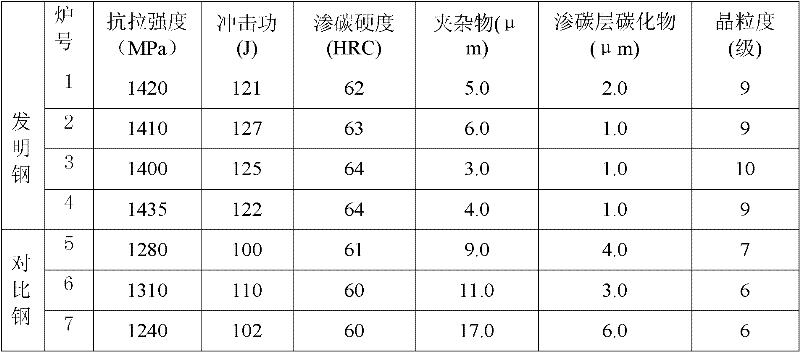

The invention belongs to the alloy steel field, particularly relating to steel for a fine grain carburization gear and a preparation method thereof. The steel comprises the following chemical compositions in weight percentage: 0.15 to 0.25 percent of C, less than or equal to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.80 to 1.20 percent of Cr, 0.15 to 0.35 percent of Mo, 0.02 to 0.08 percent of Nb, 0.0005 to 0.0035 percent of B, 0.02 to 0.06 percent of Al, 0.01 to 0.04 percent of Ti, less than or equal to 0.015 percent of [N], less than or equal to 0.0015 percent of [O], the balance being Fe and inevitable impurities. Meanwhile, Ti is more than or equal to 2[N] and B is more than or equal to ([N] minus Ti / 3.4) / 1.4 plus 0.001; and the rolling production process with the finish-to-gage temperature below 900 DEG C is adopted. Compared with the prior carburization gear steel 20CrMoH, the grain size of the steel after carburizing and quenching exceeds ten grade, the bending fatigue resistance(sigama-1) is improved by more than 15 percent and the contact fatigue life(L10) is improved by more than 30 percent.

Owner:CENT IRON & STEEL RES INST

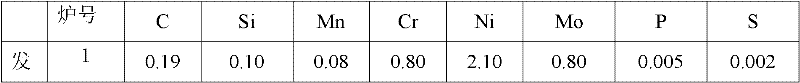

High-toughness carburized bearing steel with ultra-long contact fatigue life and preparation method thereof

The invention relates to a high-toughness carburized bearing steel with ultra-long contact fatigue life and a preparation method thereof, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.16-0.24% of C, at most 0.10% of Si, at most 0.10% of Mn, 0.30-1.50% of Cr, 1.5-4.5% of Ni, 0.30-1.50% of Mo, 0.02-0.10% of Nb, 0.3-0.9% of V, and the balance of Fe and inevitable impurities, wherein [N]+[O]+[H]+P+S<=0.0080%, and Ti<=0.0030%. The invention particularly relates to a high-toughness carburized bearing steel which has the advantages of high shock resistance load, stable dimension and ultra-long contact fatigue life in the serve process. Compared with the prior art, the invention has the advantages of high surface hardness, high core toughness, high dimensional stability, high bending fatigue strength limit and ultra-long contact fatigue life.

Owner:CENT IRON & STEEL RES INST

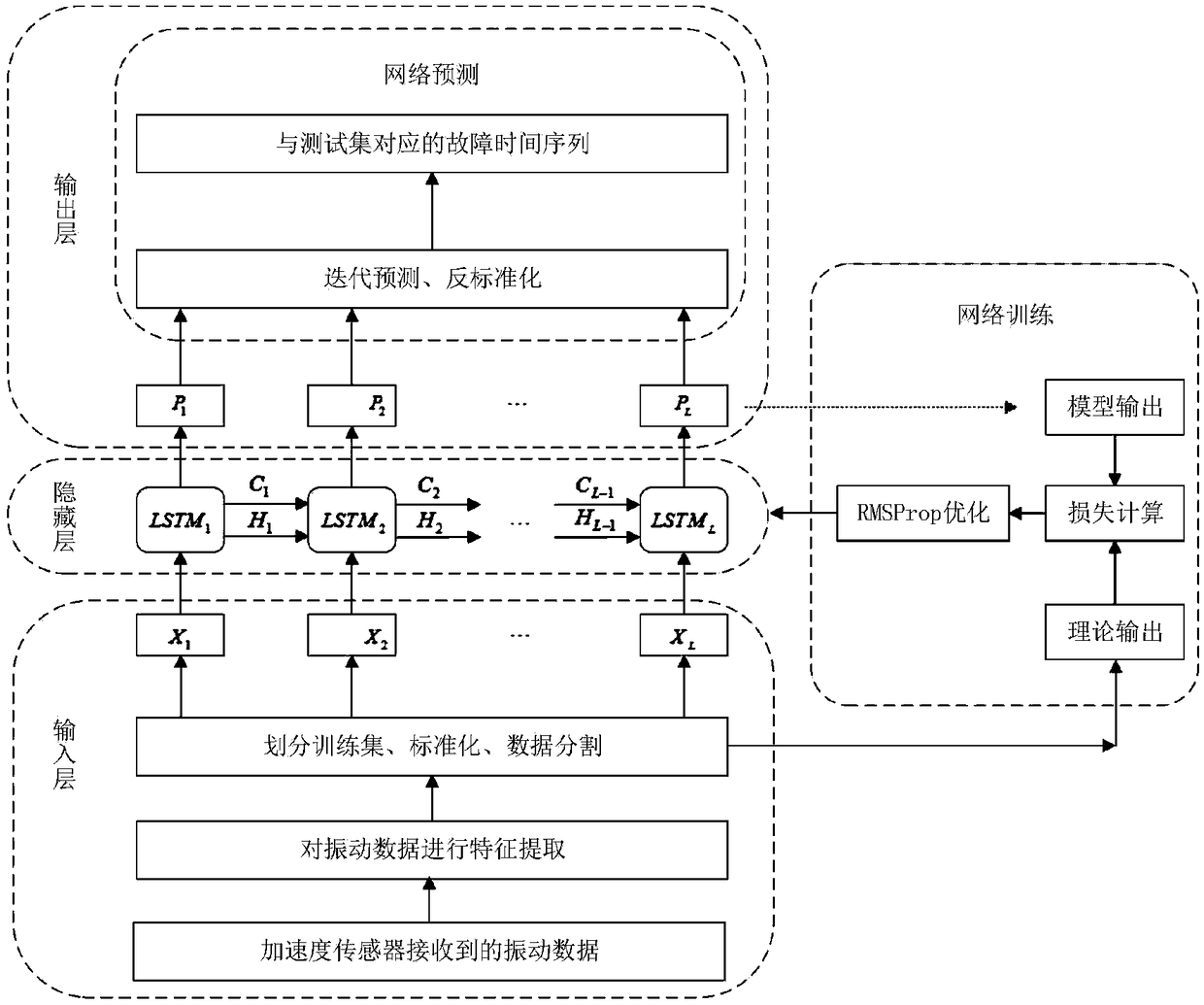

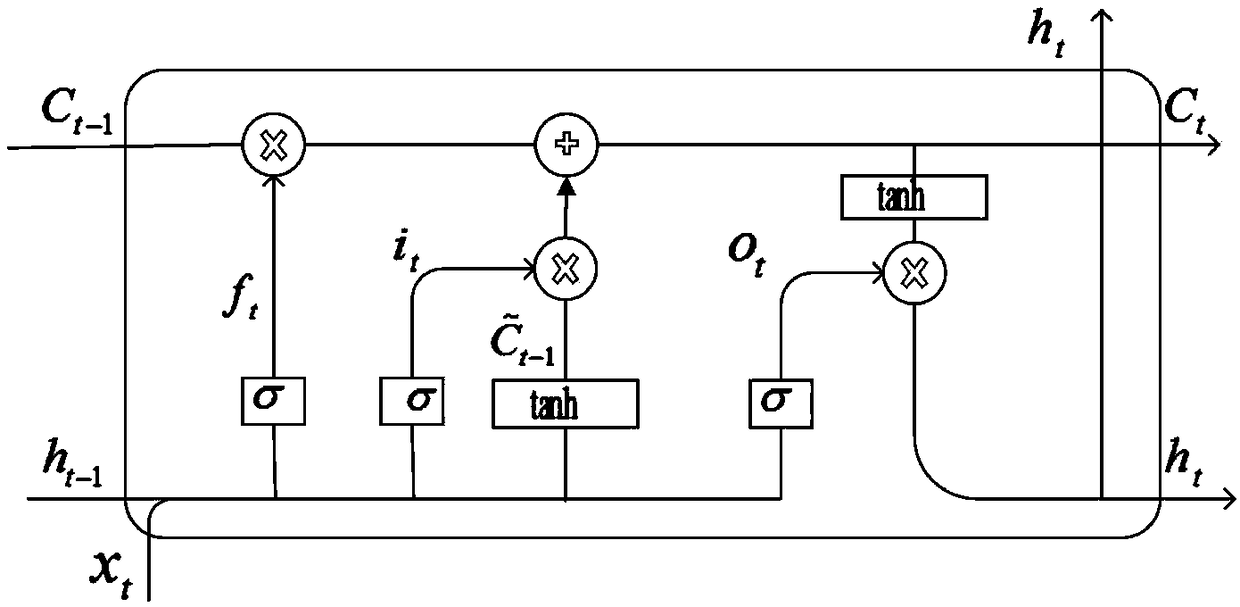

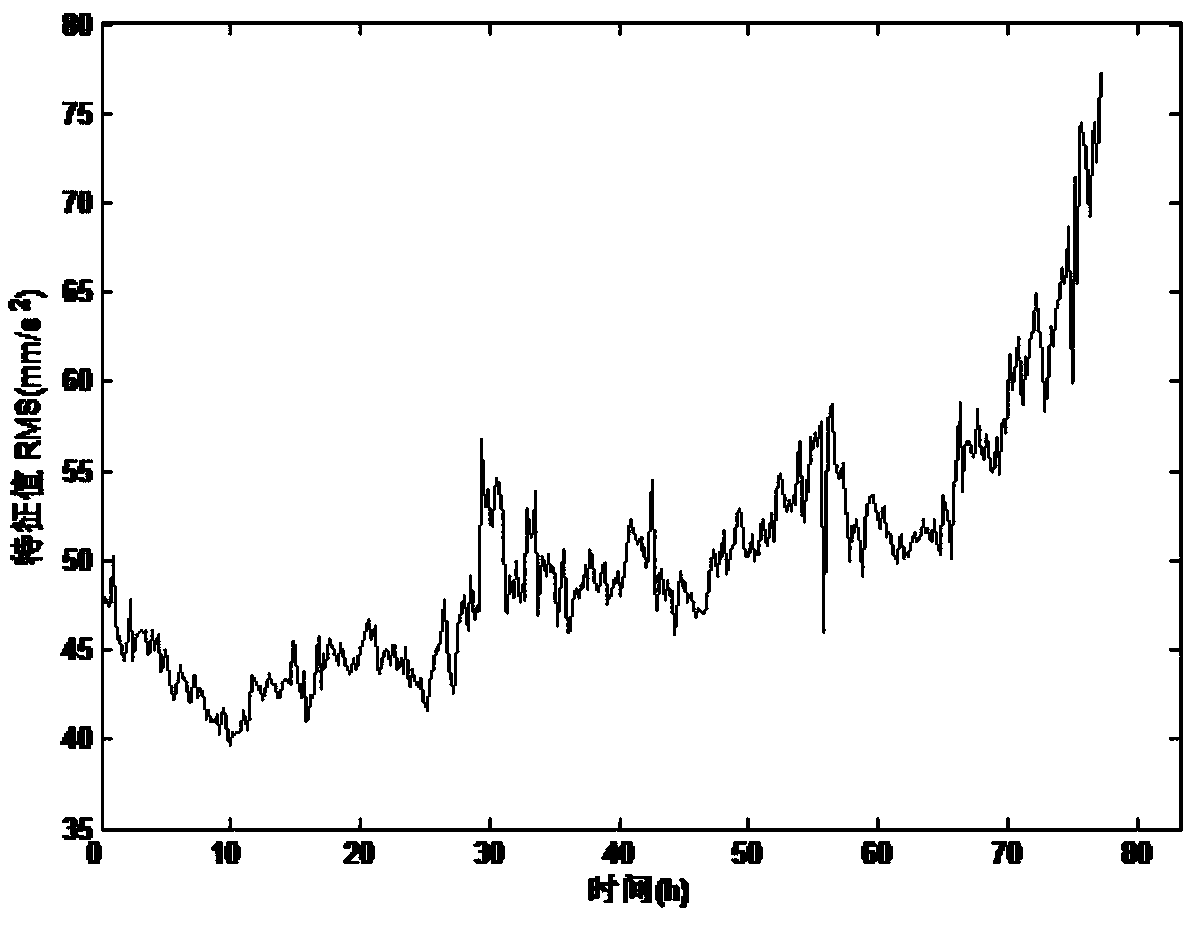

Gear residual life predicting method based on long short-term memory

InactiveCN109343505AImprove accuracyMachine gearing/transmission testingElectric testing/monitoringFeature extractionAlgorithm

The invention provides a gear residual life predicting method based on long short-term memory, and belongs to the field of big data and intelligent manufacturing. The problems that the existing RNN algorithm cannot solve long-term dependence and recurrent neural network is prone to gradient exploding or gradient vanishing are solved. The specific steps of using the algorithm are as follows: 1, monitoring the degradation of a power gear in real time with a sensor; 2, extracting features of the gear fatigue state, and evaluating the gear wear degradation performance; 3, establishing a real-timemonitoring data prediction model of the gear bending fatigue based on LSTM; 4,optimizing parameters based on the LSTM prediction model; 5, predicting the gear residual life based on gear state estimation and a known gear fault threshold. The gear residual life predicting method based on long short-term memory has the advantages that the gear degradation state and the real-time residual life can beaccurately predicted, and the basis for predictive maintenance of the gear is provided.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

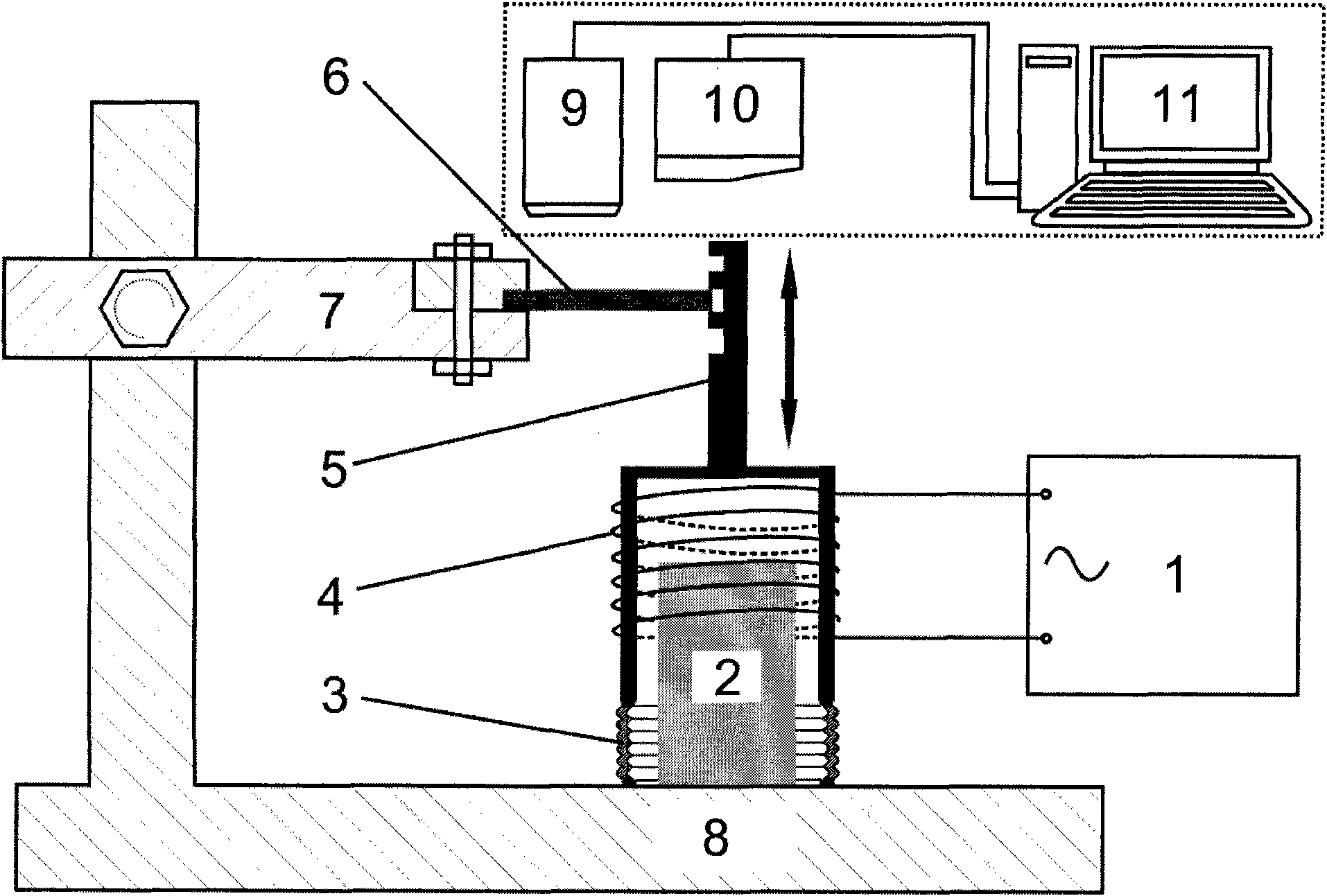

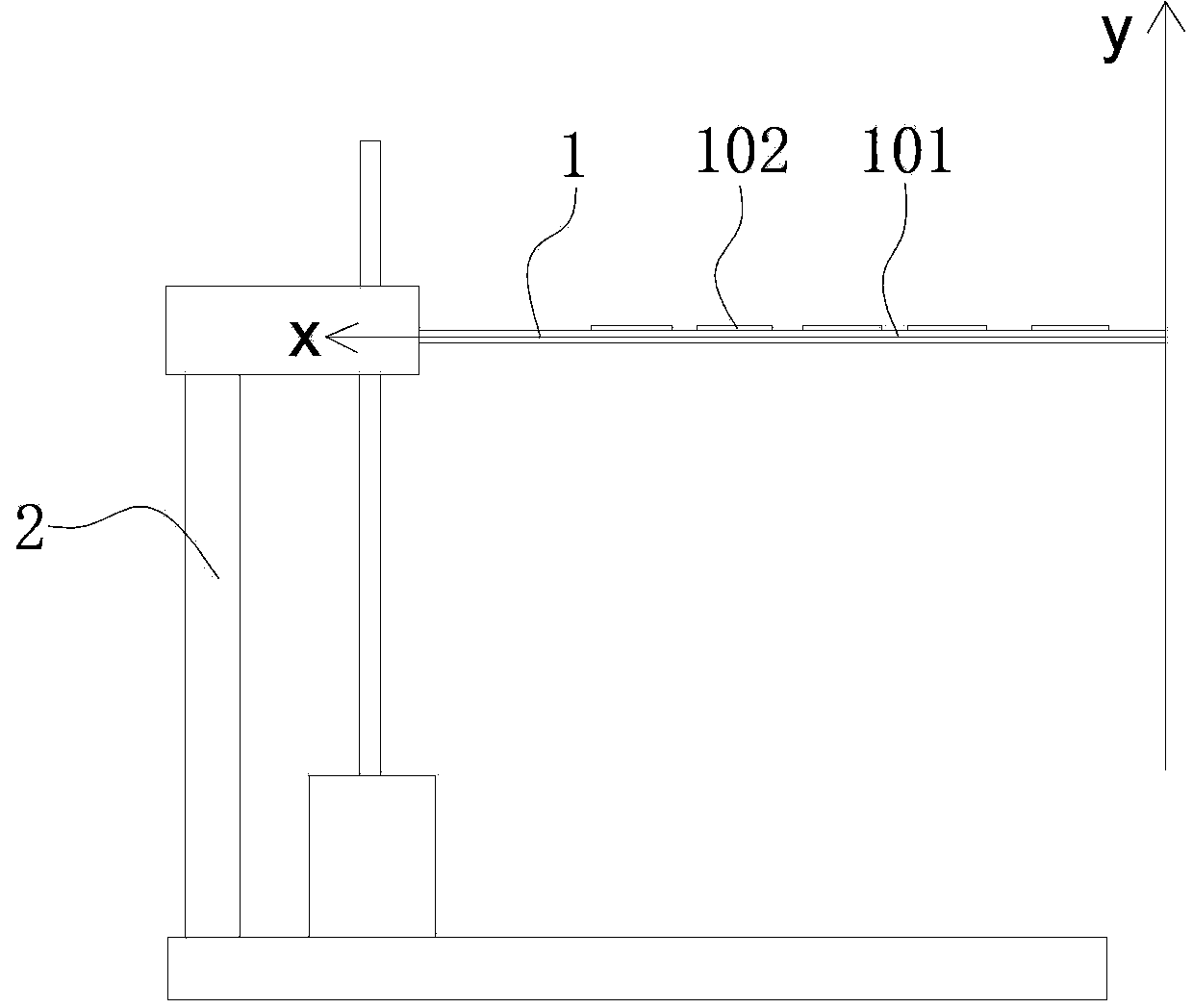

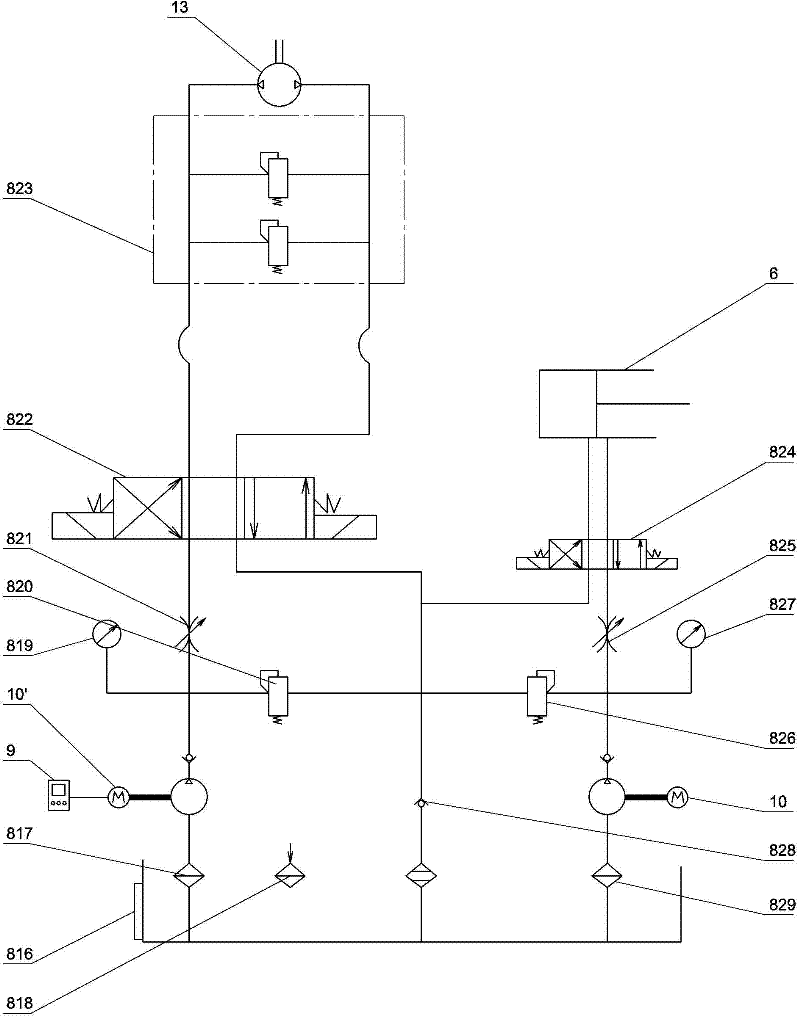

Test system and test method for dynamic bending fatigue property of thin film material

InactiveCN101571467AEasy and fast clampingWide range of loading frequencyMaterial strength using repeated/pulsating forcesVibration testingFatigue loadingEngineering

The invention relates to a test system and a test method for the dynamic bending fatigue property of a small-scale thin film material. The test system comprises an electromagnetic driving part, a sample holding part and a measuring and observing part, and the system provides functions and a test method for dynamic bending fatigue property test for the thin film materials used for various micro / nanoelectronic mechanical systems and supported with matrix or without matrix, the metalized interlinking body foil material used for an integrated circuit and various two-dimensional thin plate type materials and can record in-situ real-time monitoring and analysis to the appearance of the tested sample. The free end of the cantilever beam sample is driven under the electromagnetic force of the electrified coil in the stationary magnetic field to reciprocate relatively to the equilibrium position thereof, thus various types of cyclic fatigue loads can be applied to various material samples, and the precision of the applied fatigue loads can reach the millinewton magnitude. The invention can be used to evaluate the fatigue property and the fatigue crack growth behaviors of various thin film materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

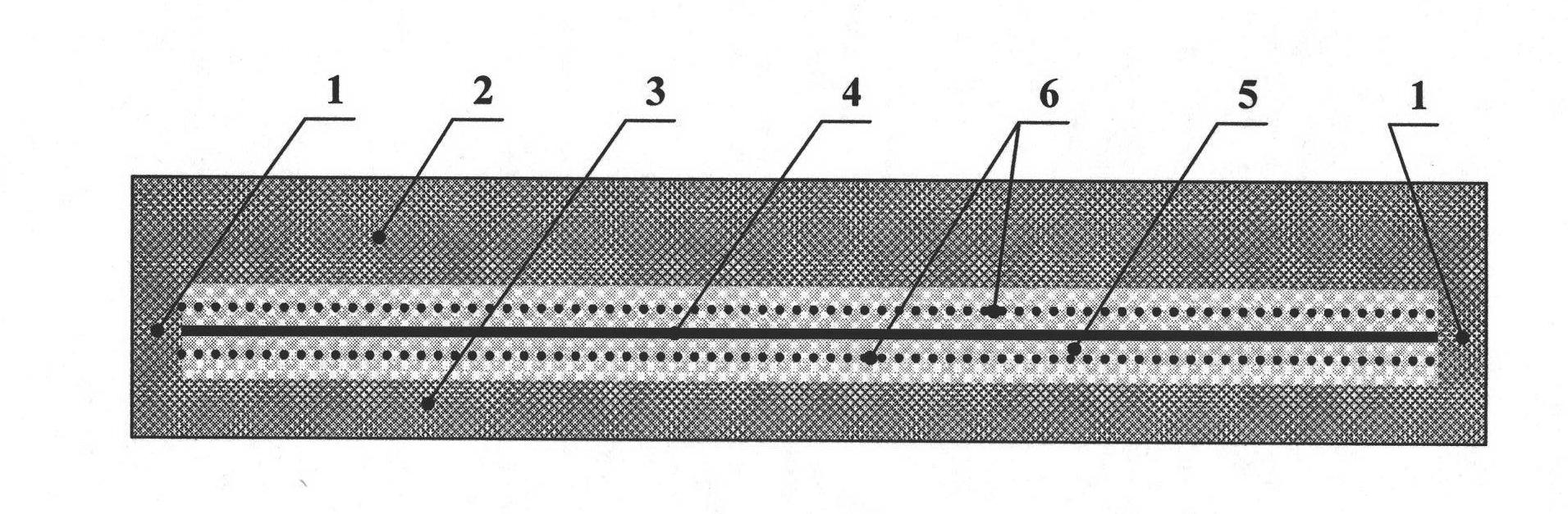

Tubular anti-flaming aramid fiber fabric lamination conveyor belt for coal mine

InactiveCN102658952AStrong tube forming abilityAppropriate softnessConveyorsResistRolling resistance

The invention discloses a tubular anti-flaming aramid fiber fabric lamination conveyor belt for a coal mine, which solves the problem that the conventional conveyor belt is inconvenient to use as a tubular conveyor belt under a coal mine well. The tubular anti-flaming aramid fiber fabric lamination conveyor belt is characterized in that a novel conveyor belt product is produced for being used under the coal mine well through material selection of a framework material, a design of a core body structure, adhesion of an adhesive layer, formulation design of covering the adhesive layer and the like. The tubular anti-flaming aramid fiber fabric lamination conveyor belt provided by the invention uses aramid fiber fabrics as a framework layer, so that a finished conveyor belt has strong pipe formation capability; a belt body has proper flexibility; and the different-level cornering requirements of the tubular belt can be met. A vulcanized anti-flaming bonding adhesive material is large in bonding force, is small in dynamic themogenesis, resists repeated bending fatigue, and has excellent anti-flaming property. An anti-flaming covering adhesive material is compounded by different adhesive types through a modifier and a fire retardant in a synergistic manner, and uses materials such as aramid fiber pulp, a coupling dispersant and an anti-flaming tackifier, so that the strength of the adhesive material is enhanced; the wear resistance and the anti-flexural property can be improved, particularly the cutting resistance is improved; the rolling resistance is reduced; and the requirements on the anti-flaming property under the coal mine well can be met.

Owner:王萍

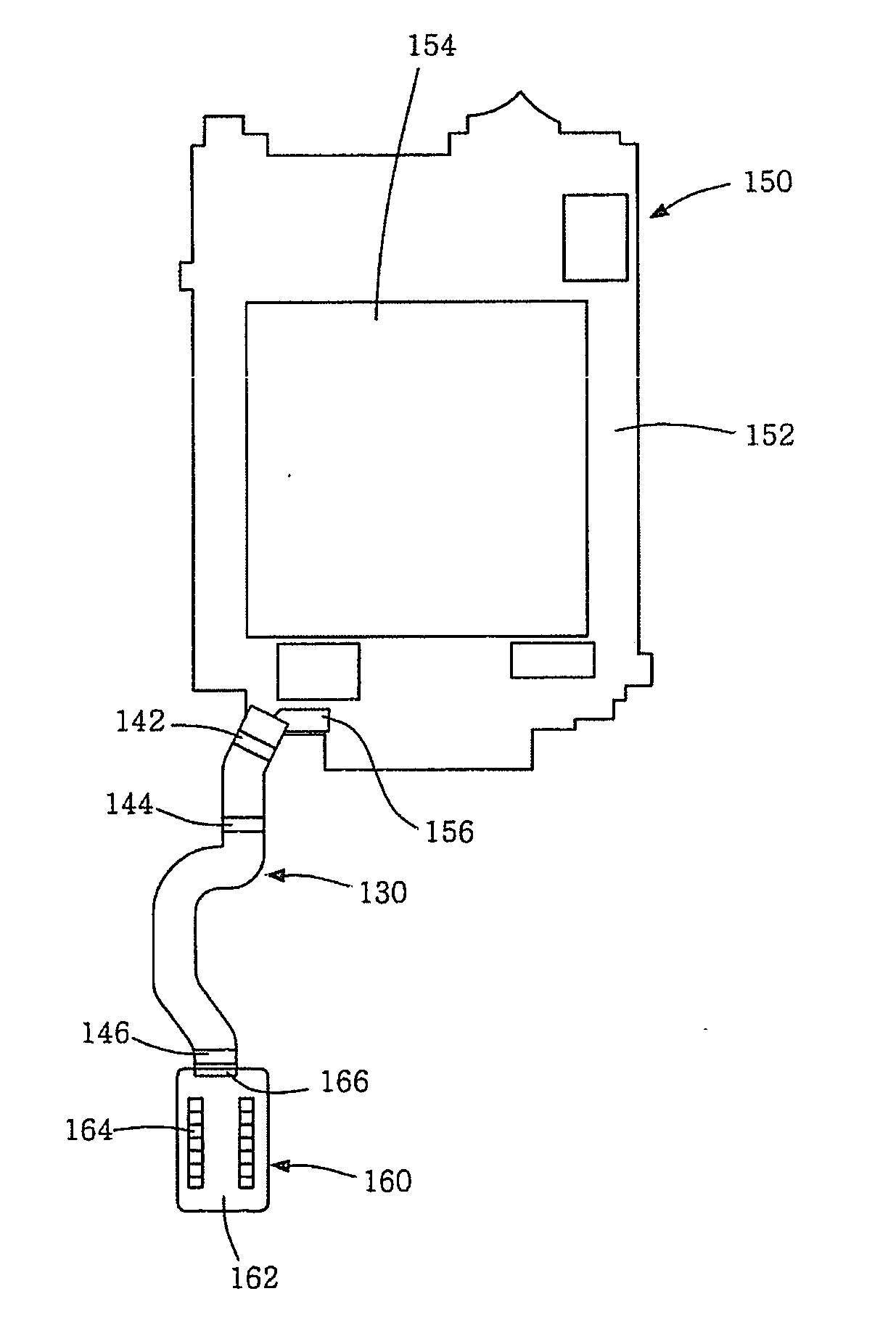

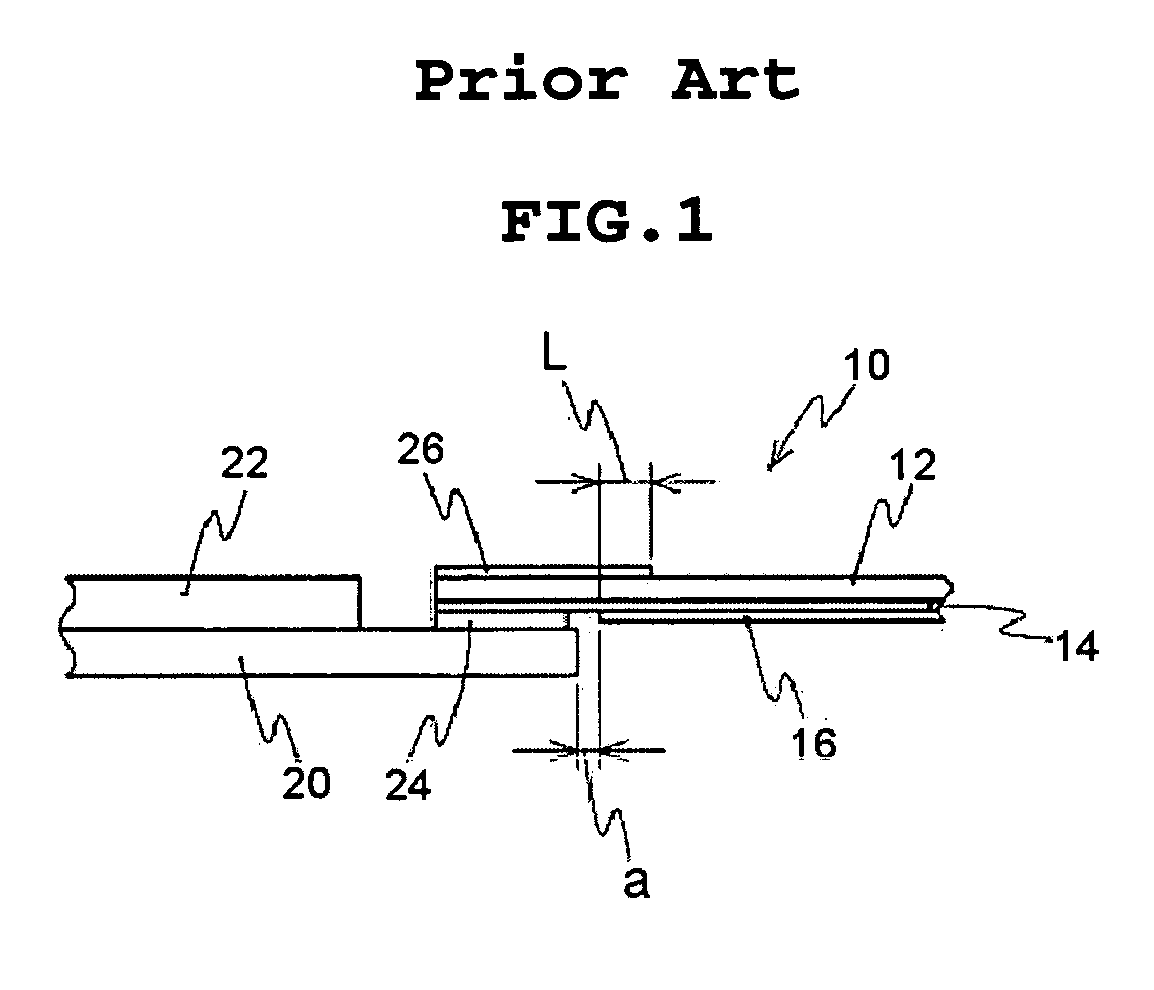

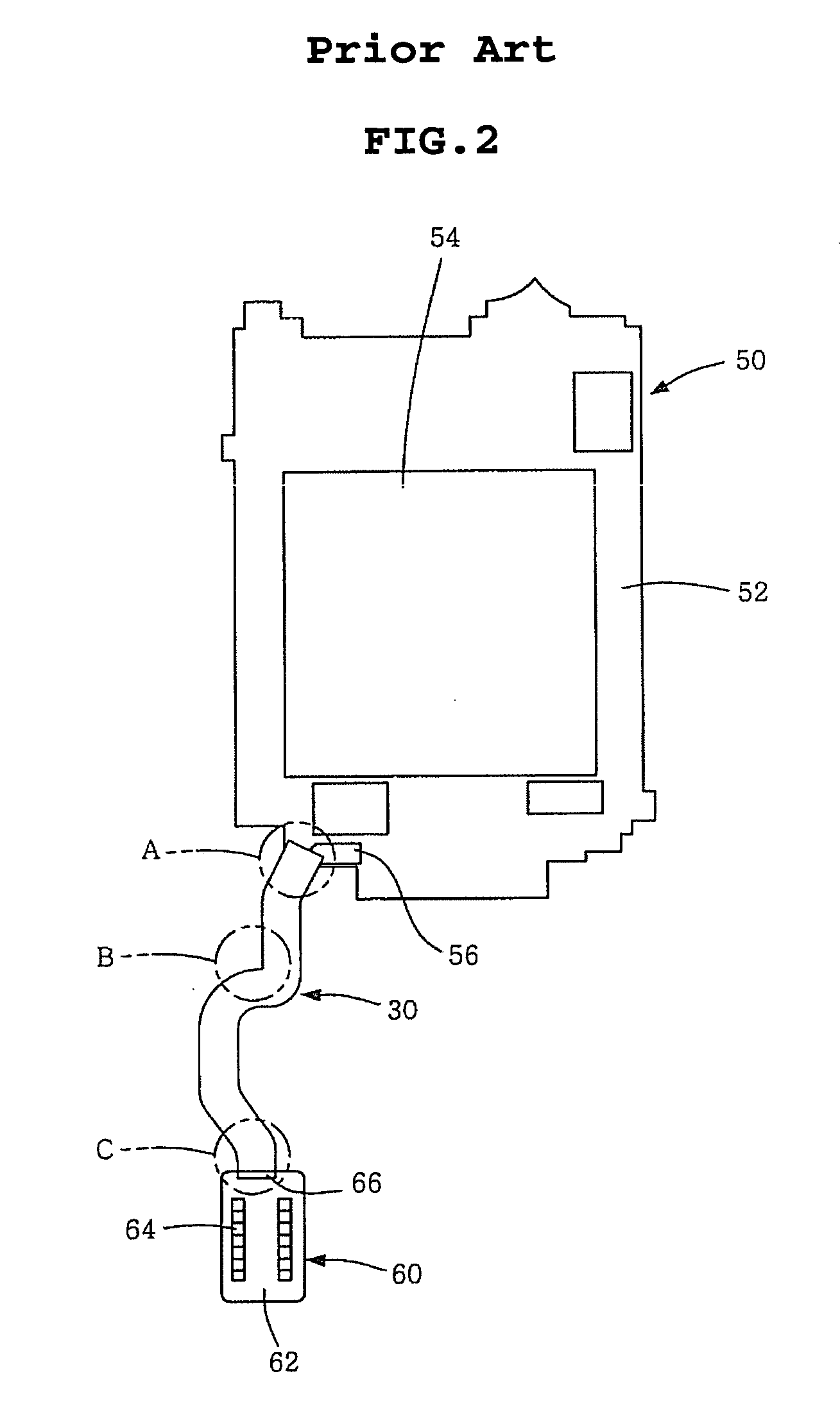

Flexible PCB having surplus bends for electronic equipment

InactiveUS20060213682A1Excellent durability against bending fatigueQuality improvementPrinted circuit aspectsCircuit susbtrate materialsEngineeringRepetitive movements

A flexible PCB is provided with surplus bends so that it can be readily bent according to the repetitive movement thereof, whereby wires formed in the flexible PCB can be prevented from being severed by the bending fatigue accumulated due to the movement. The flexible PCB for use in electronic equipment acts to transmit electrical signals between two rigid PCBs and acts as a structural bridge therebetween, the two rigid PCBs being spaced away from each other and being able to relatively move. The flexible PCB includes: a plurality of wires, each functioning as a passageway for electrical signals; and a soft material-based substrate body in which the wires are formed; and being provided with surplus bends at predetermined positions so as to allow the flexible PCB to resiliently move according to the relative movement of the rigid PCBs.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

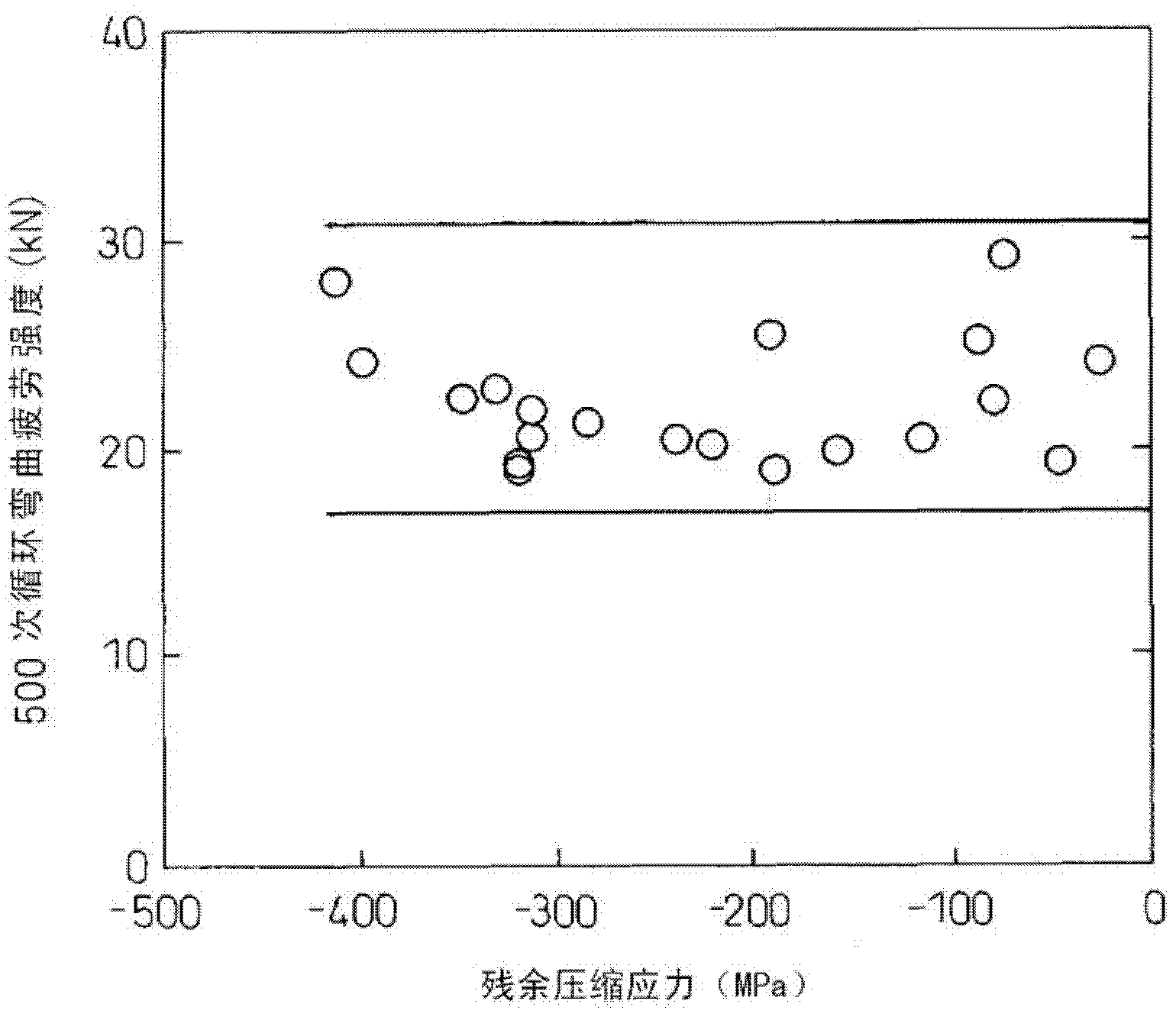

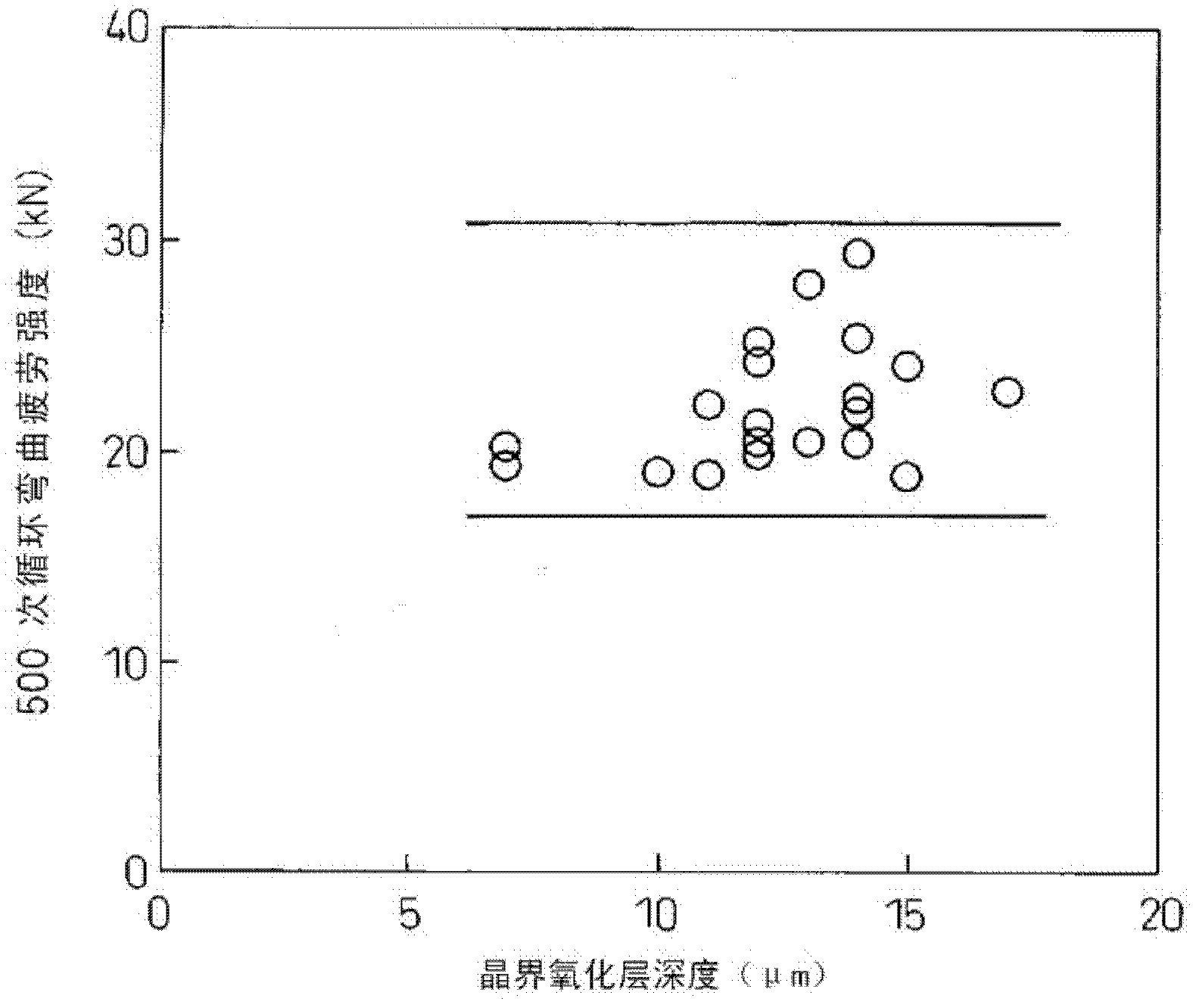

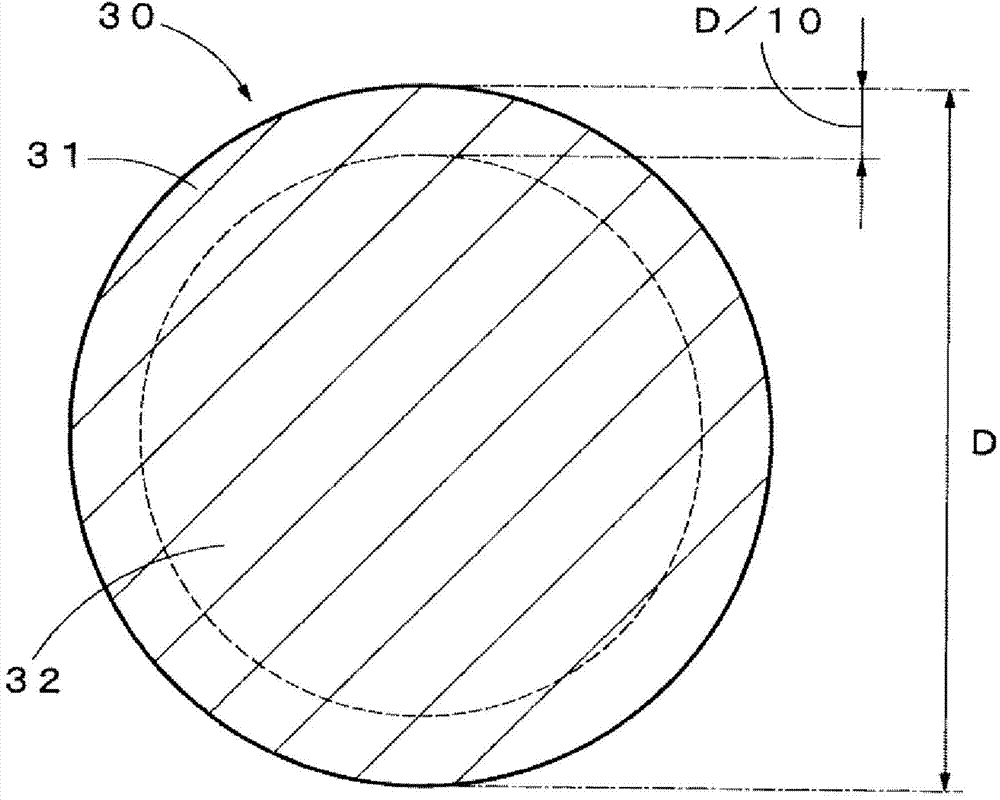

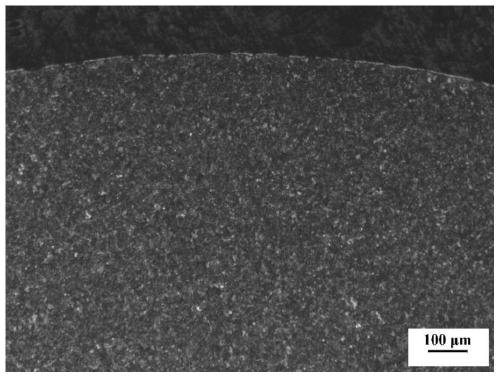

Carburized steel component excellent in low-cycle bending fatigue strength

InactiveCN102471842AGood effectExcellent cyclic bending fatigue strengthPortable liftingSolid state diffusion coatingChemical compositionHardness

To provide a carburized steel component more excellent in low-cycle bending fatigue strength than heretofore. The carburized steel component contains a steel having a chemical composition comprising, by mass, 0.1-0.6% C, 0.01-1.5% Si, 0.3-2.0% Mn, <=0.02% P, 0.001-0.15% S, 0.001-0.03% N, 0.001-0.06% Al, <=0.005% O, and the balance Fe with inevitable impurities, and is subjected to carburizing, quenching and tempering treatments. The steel component has the surface hardness of HV550 to HV800, and the core hardness of HV400 to HV500.

Owner:NIPPON STEEL CORP +1

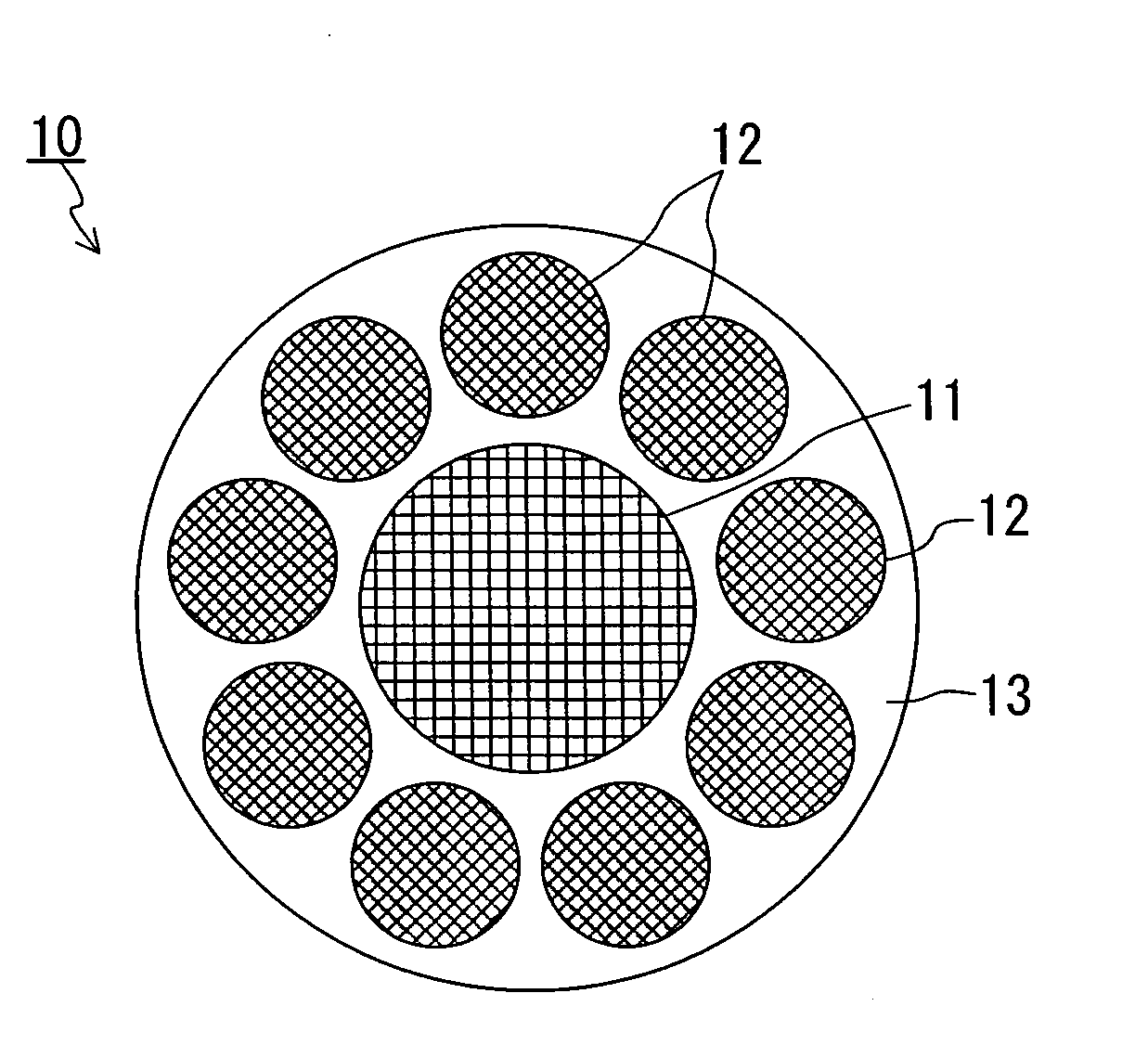

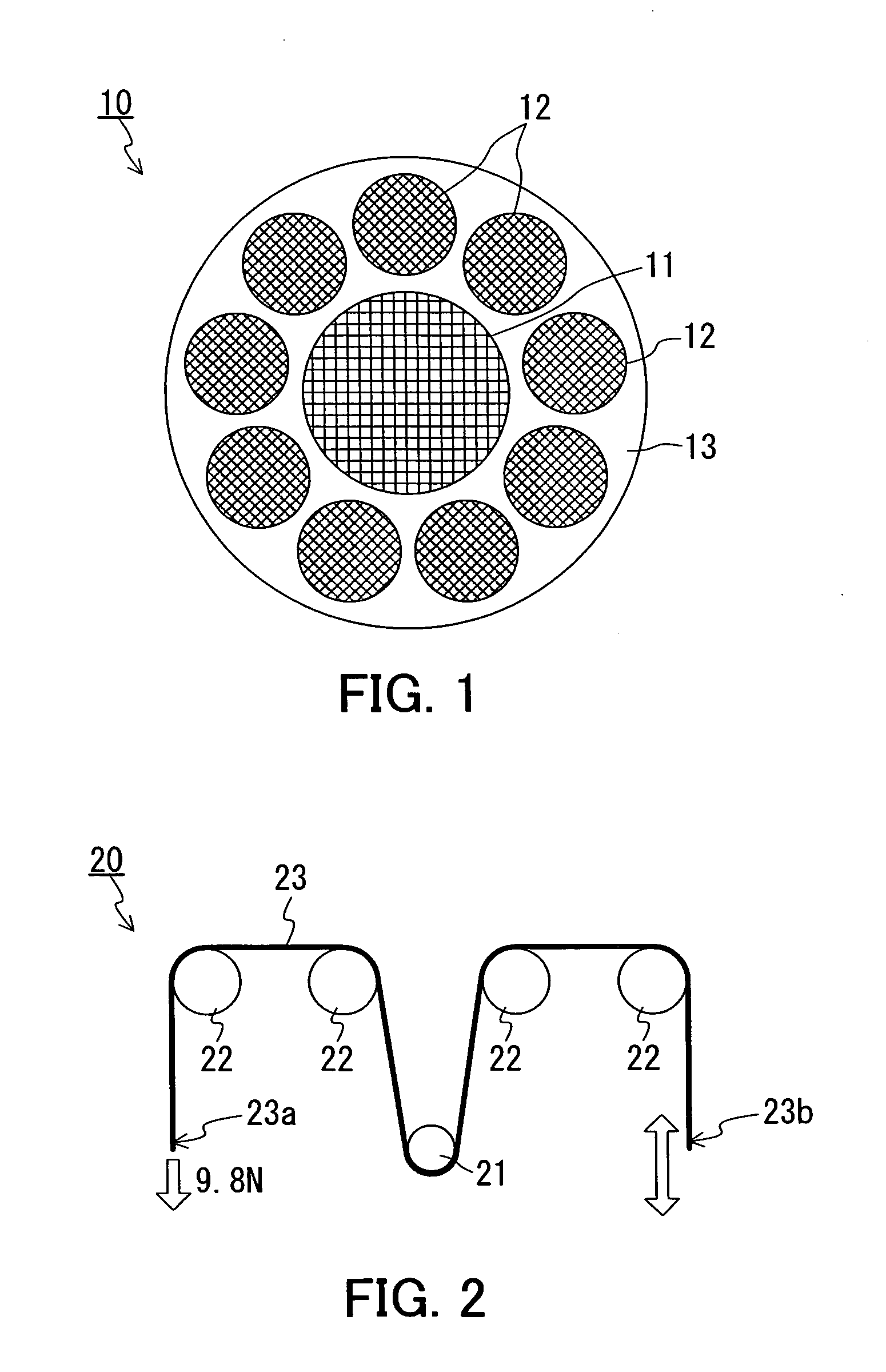

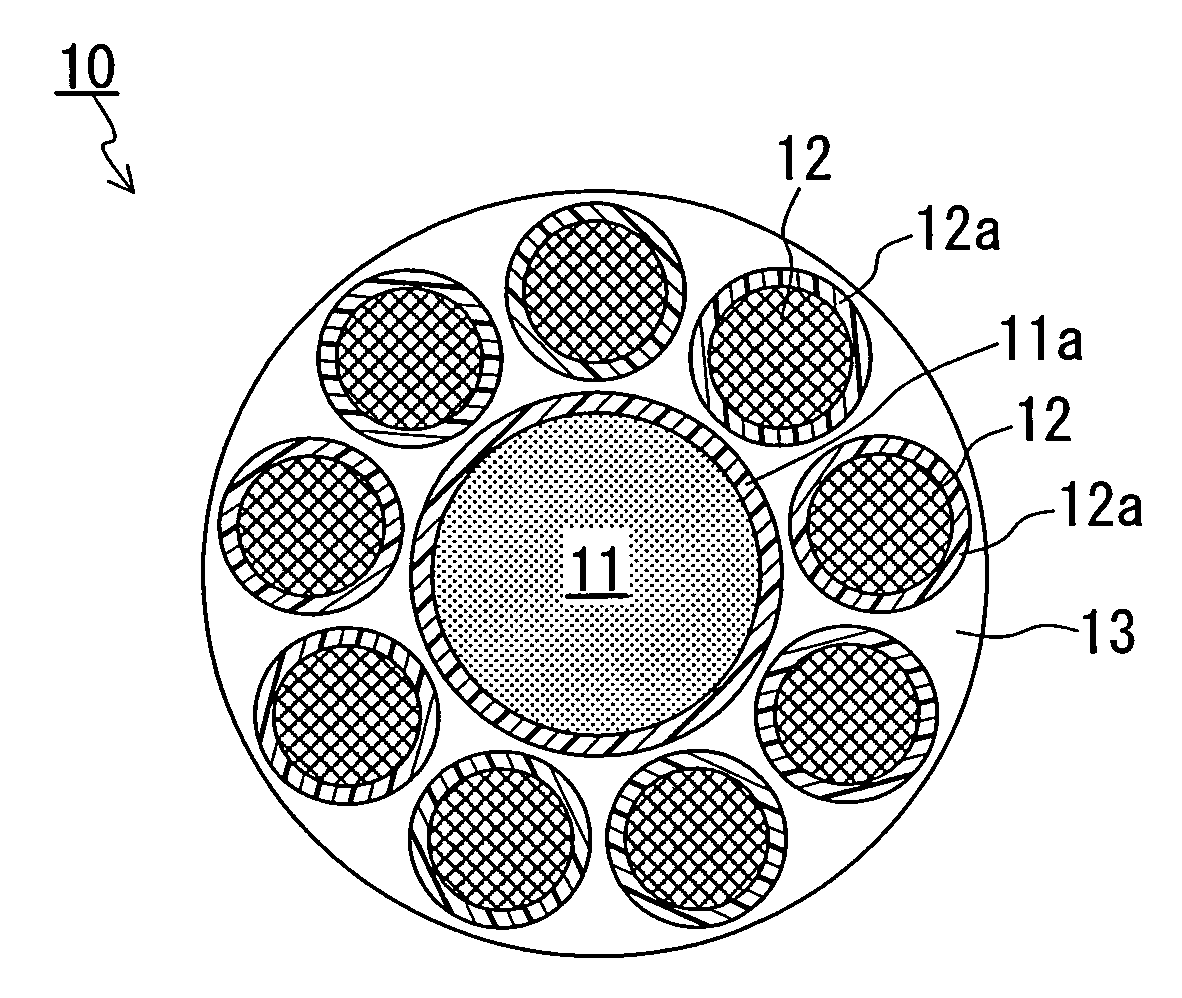

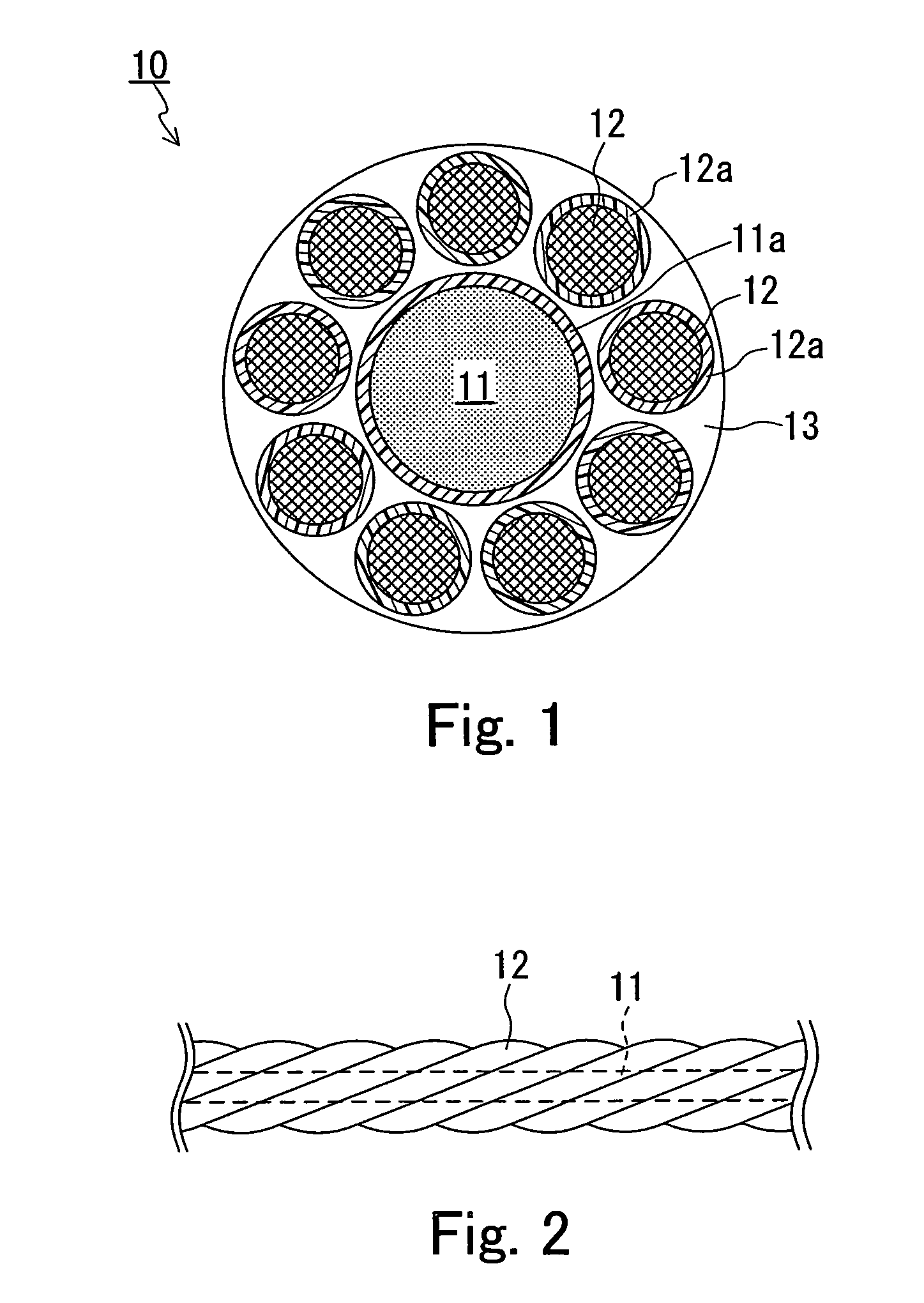

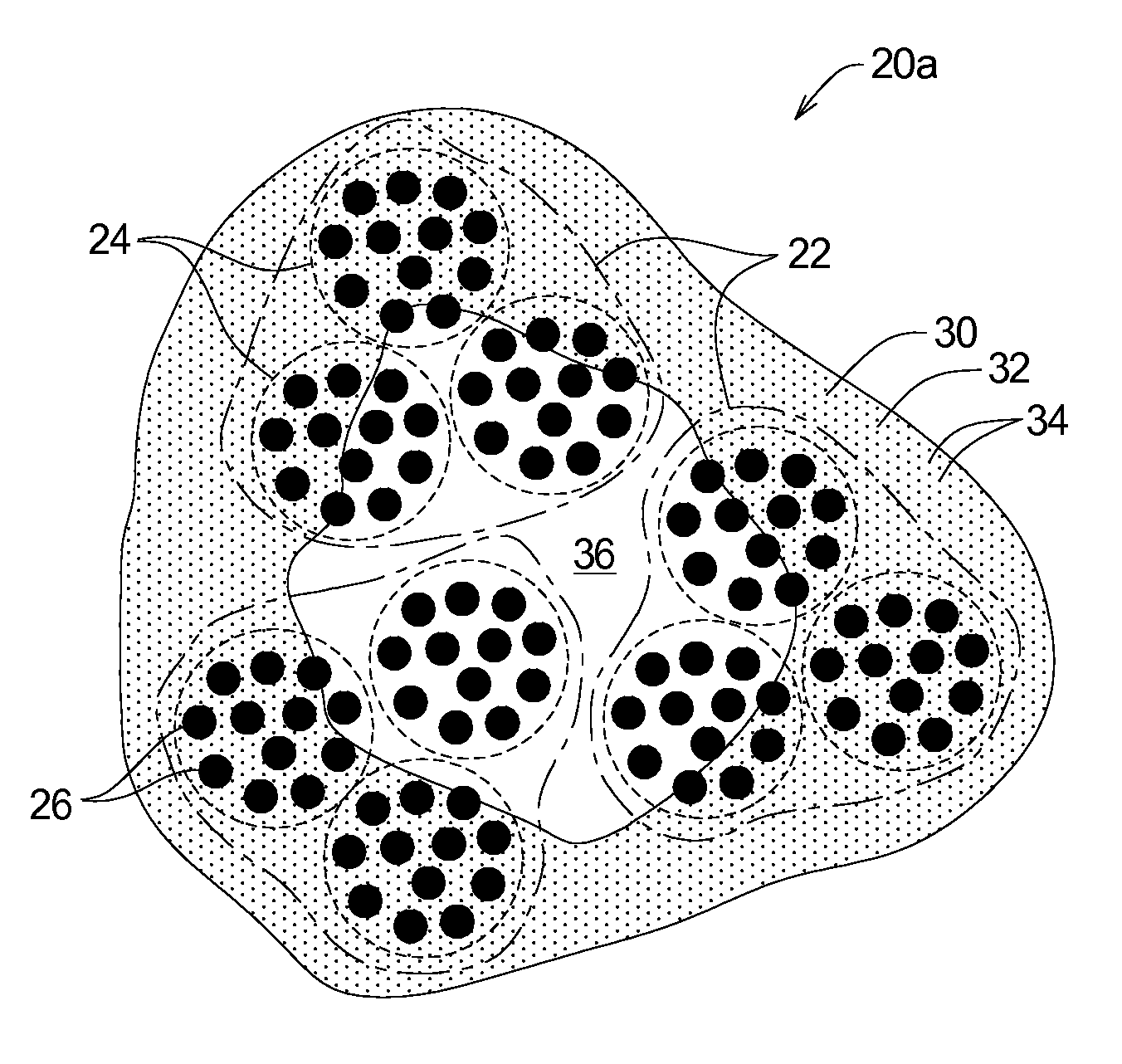

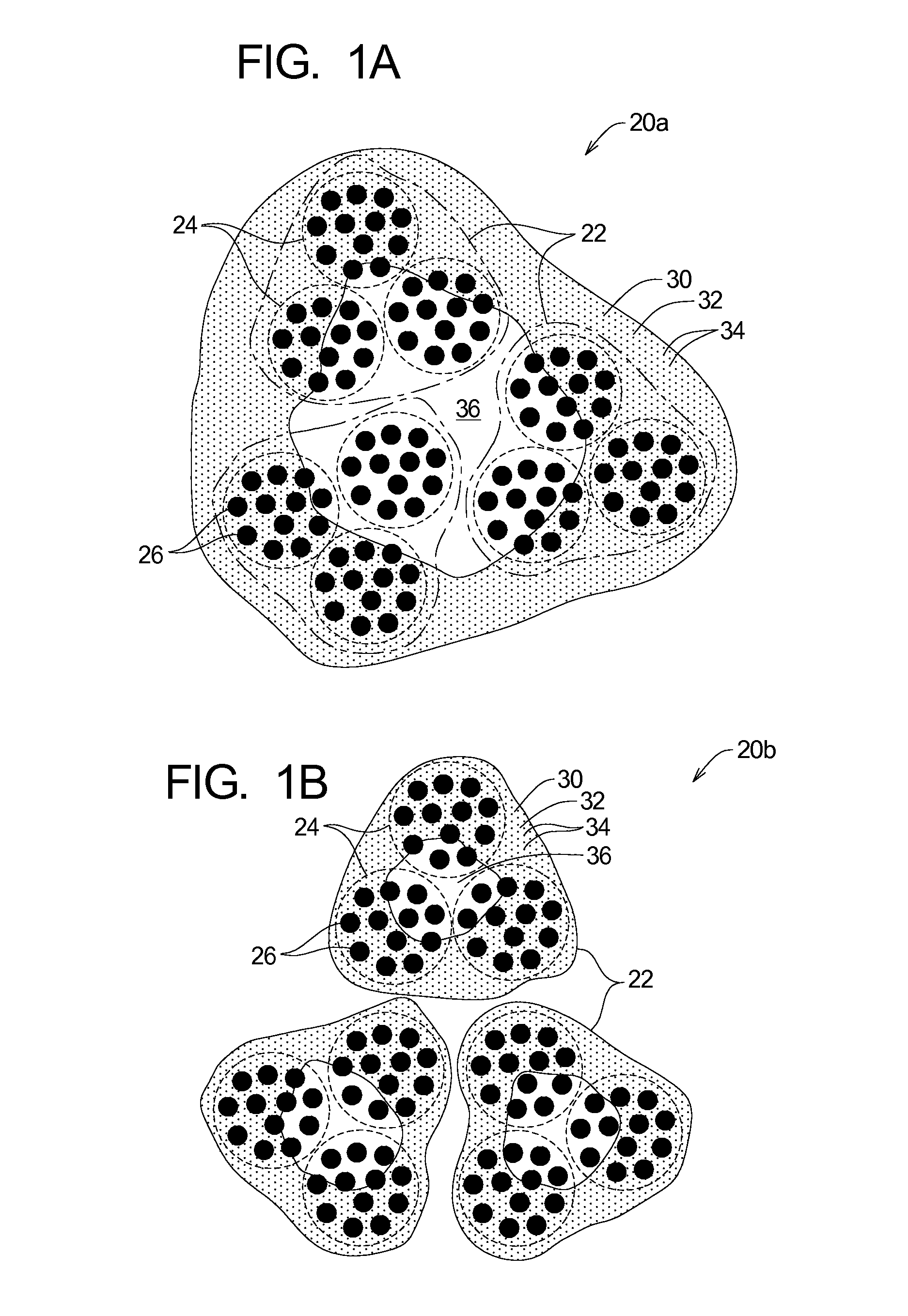

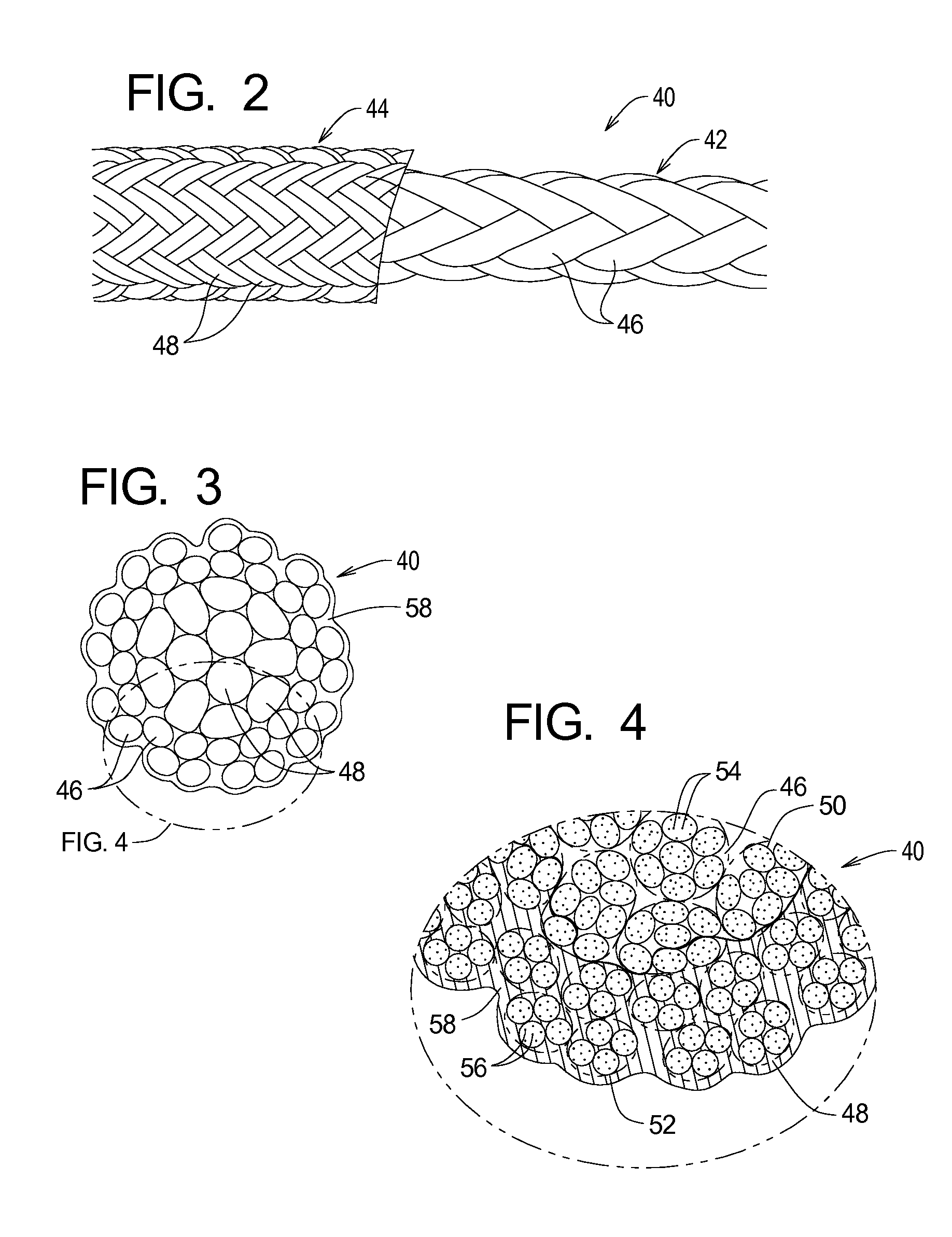

Reinforcing cord for rubber reinforcement and rubber product including the same

A reinforcing cord for rubber reinforcement of the present invention includes reinforcing fibers. The reinforcing fibers include polyarylate fibers 11 and a plurality of outer strands 12 that are arranged around the polyarylate fibers 11. The plurality of outer strands 12 include fibers other than polyarylate fibers. The use of this reinforcing cord for rubber reinforcement makes it possible to obtain a reinforcing cord for rubber reinforcement having high strength, elasticity, and bending fatigue resistance, and a rubber product including the same.

Owner:NIPPON SHEET GLASS CO LTD

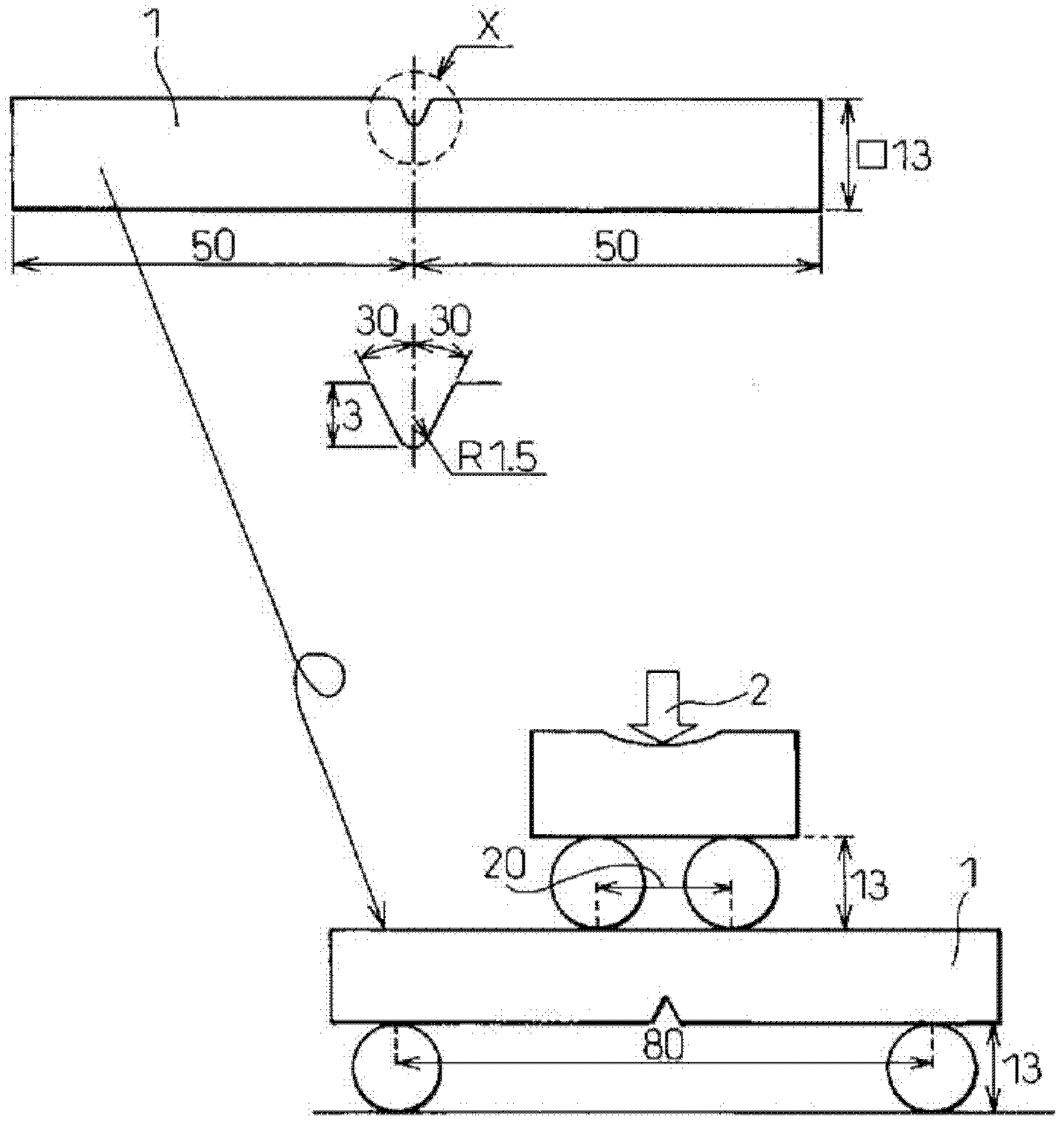

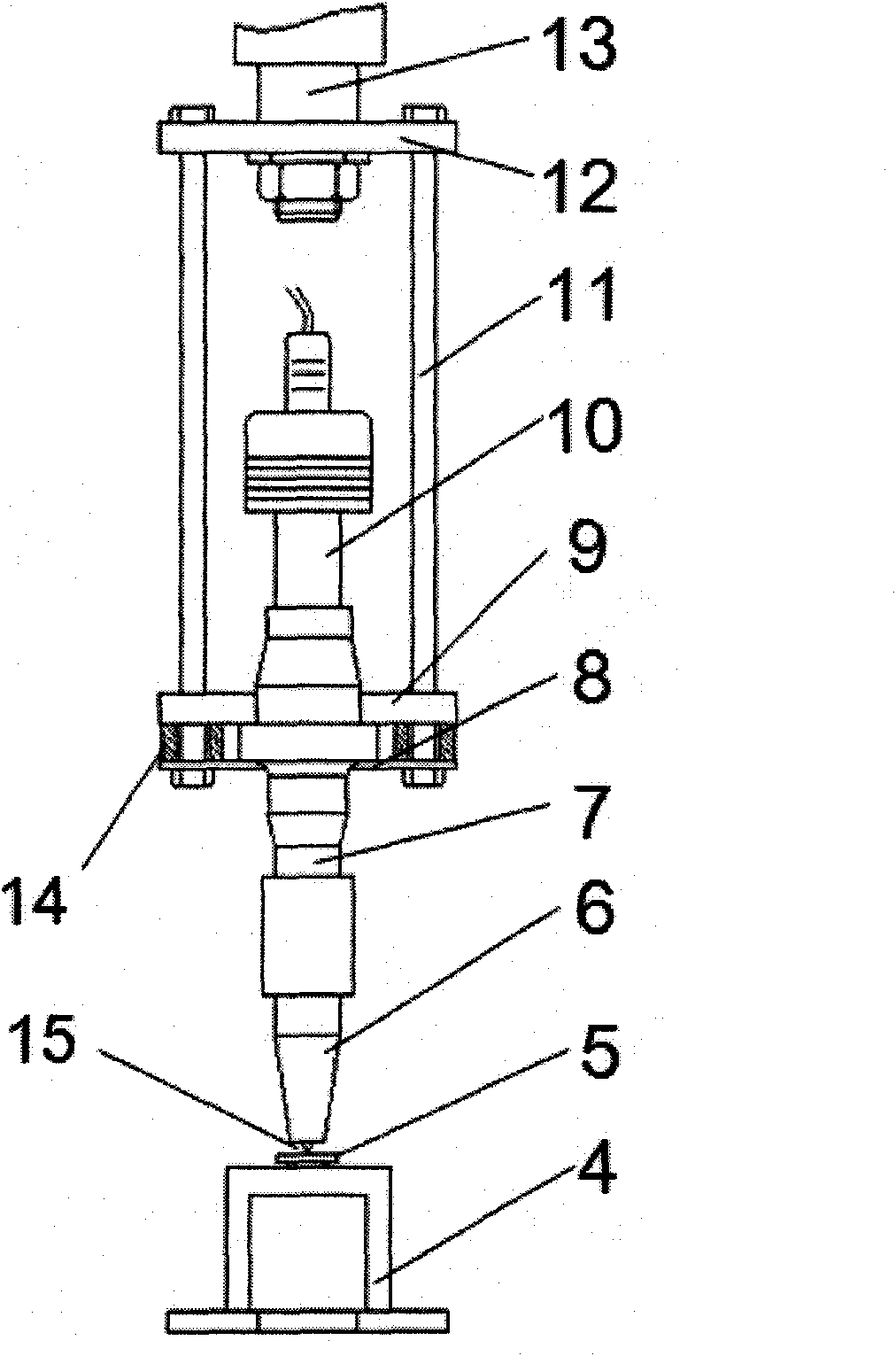

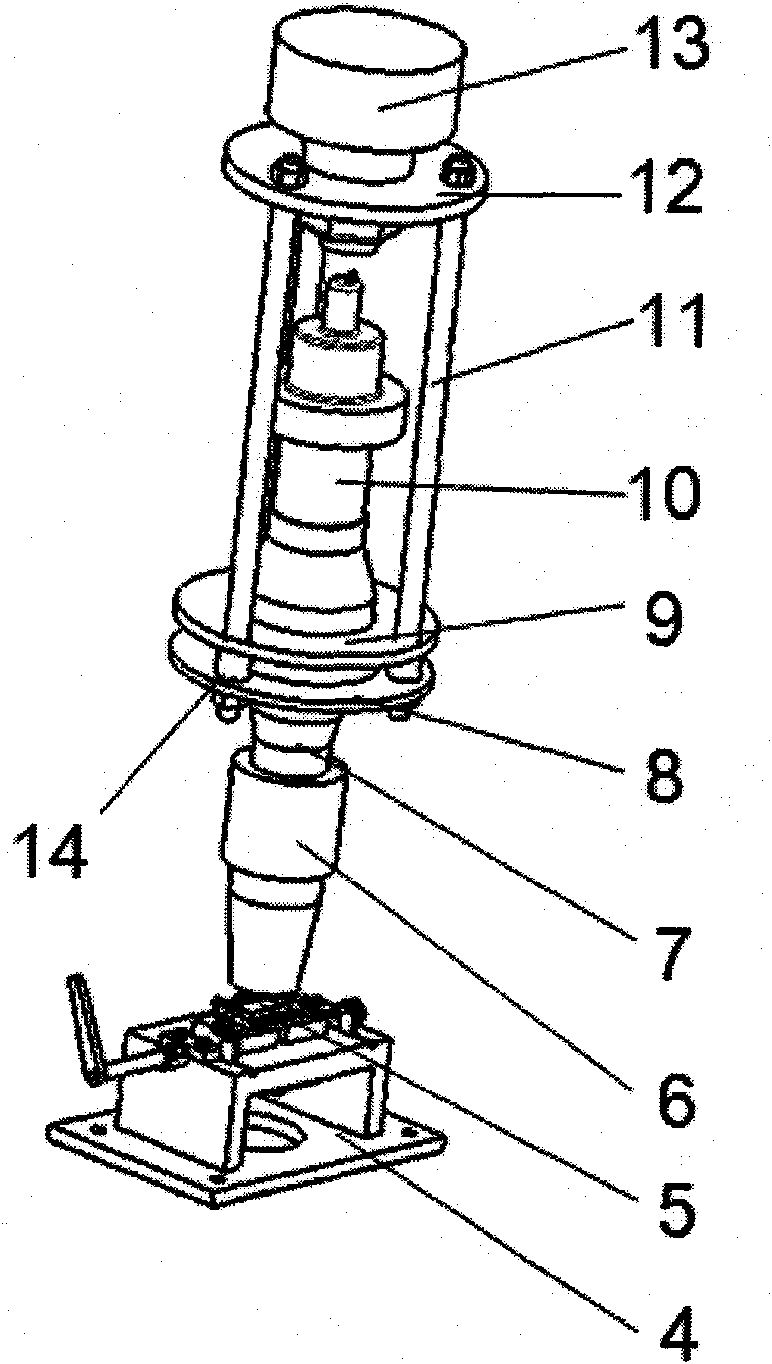

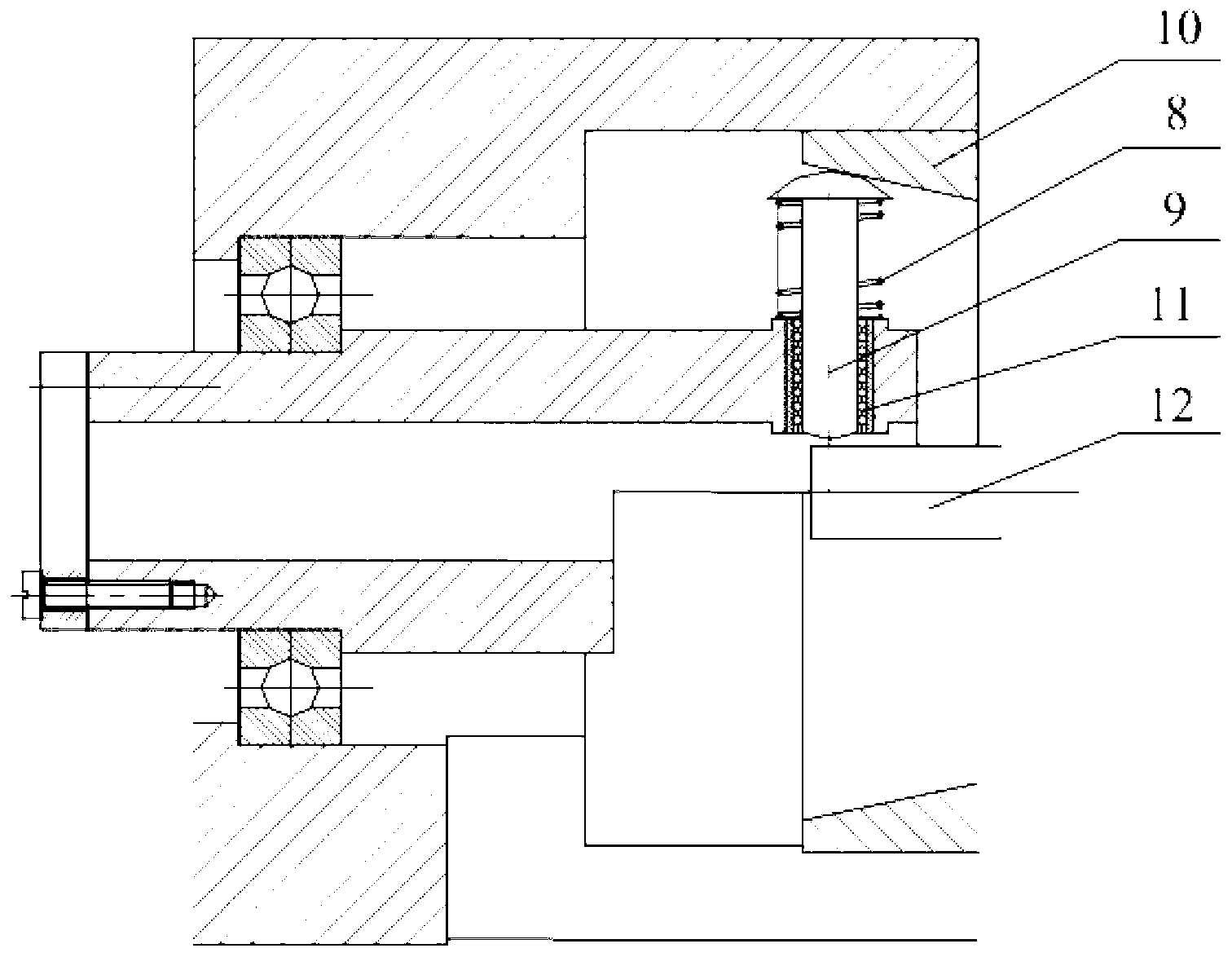

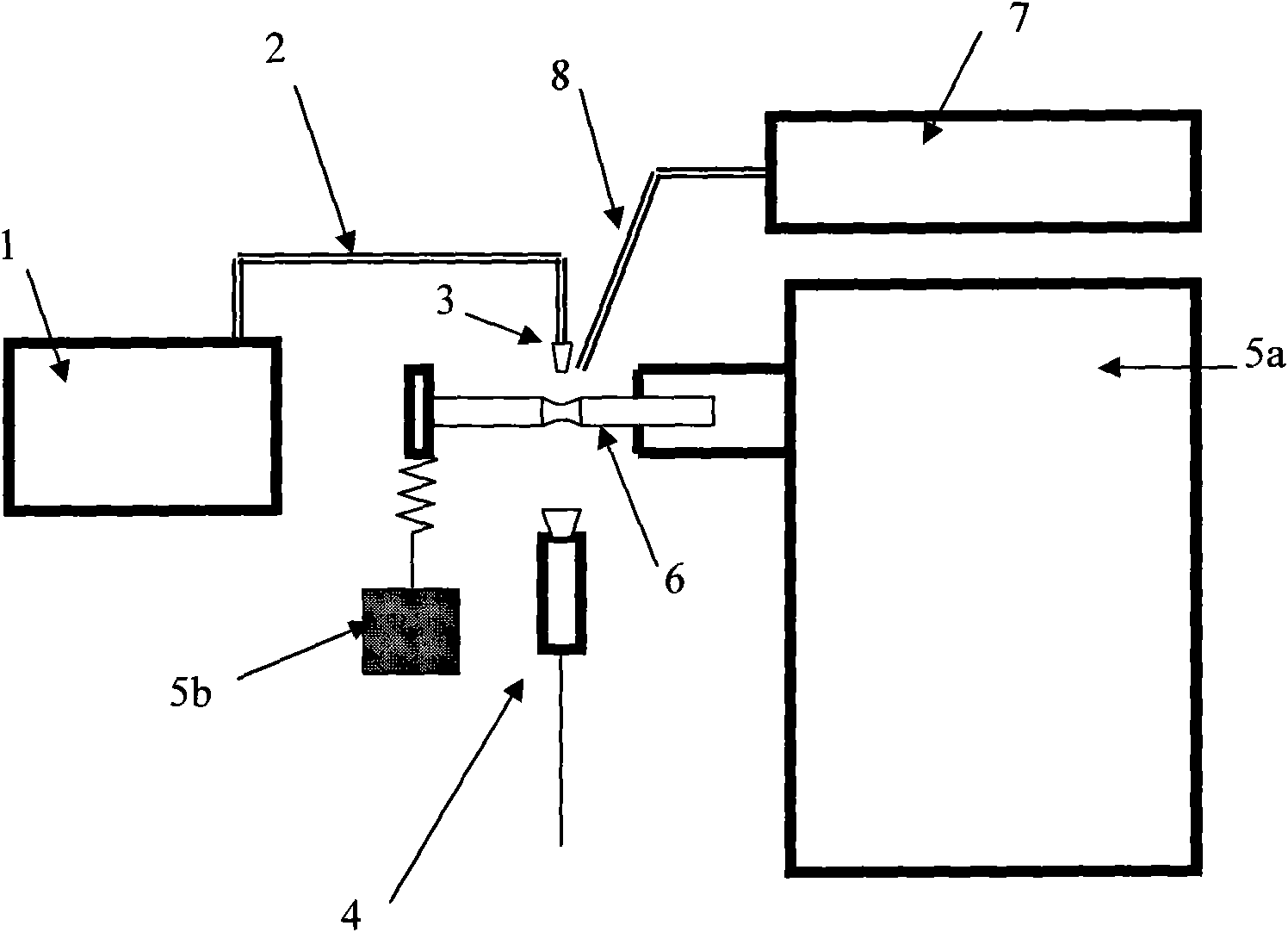

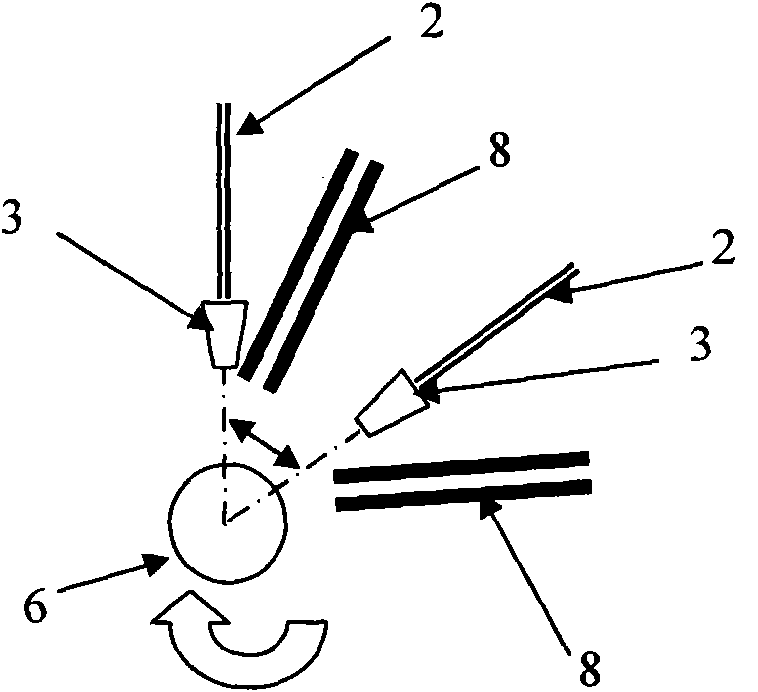

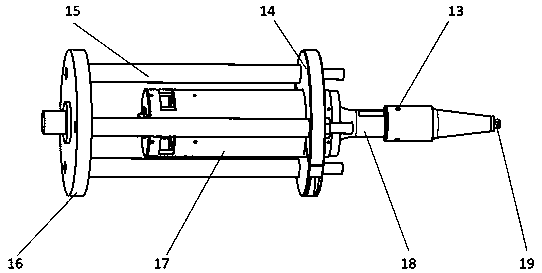

Ultrasonic bending fatigue experimental device

InactiveCN101819114AGuaranteed resonance conditionsAvoid the influence of vibration wavesSubsonic/sonic/ultrasonic wave measurementMaterial strength using steady bending forcesAudio power amplifierResonance

The invention relates to an ultrasonic bending fatigue experimental device, wherein a transducer is positioned in a force transmitter and connected with a connector. The transducer is positioned in the middle of the ultrasonic bending fatigue experimental device; a backing plate and an upper connecting plate as well as a lower connecting plate of the force transmitter are fixedly connected through force transmitting rods. One end of the connector penetrates through the lower connecting plate at the lower end of the force transmitter and is connected with a displacement amplifier, and the other end penetrates through the upper connecting plate and is connected with the transducer. A supporting device is positioned below the displacement amplifier; and a static load force applying device penetrates through the central hole of the backing plate and is fixedly connected with the backing plate. The transducer, the connector, the displacement amplifier and a pressure head form a longitudinal resonance system, and a longitudinal vibration load is transferred to a bending fatigue sample through the pressure head, so that bending vibration is generated by the bending fatigue sample. The position of the supporting point of the bending fatigue sample can be automatically regulated through a positioning guide screw to realize an ultrasonic bending fatigue experiment, the ultrasonic bending fatigue experiments of the samples with different loading loads and different geometrical sizes can be realized, and the ultrasonic bending fatigue experimental device is suitable for carrying out the bending fatigue experiment by utilizing an axial loading ultrasonic fatigue experiment machine.

Owner:NANTONG JINNIU MACHINERY MFR +1

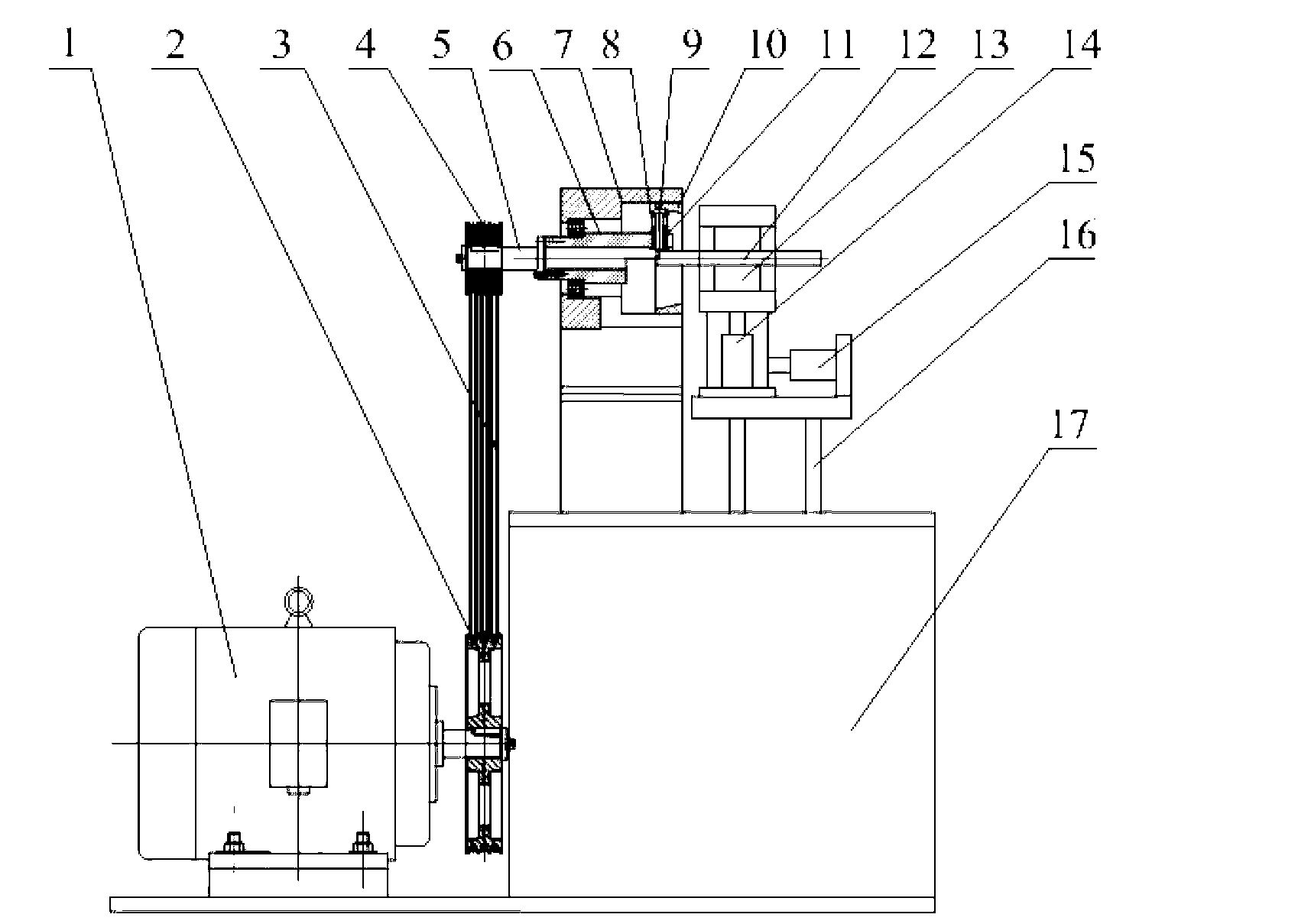

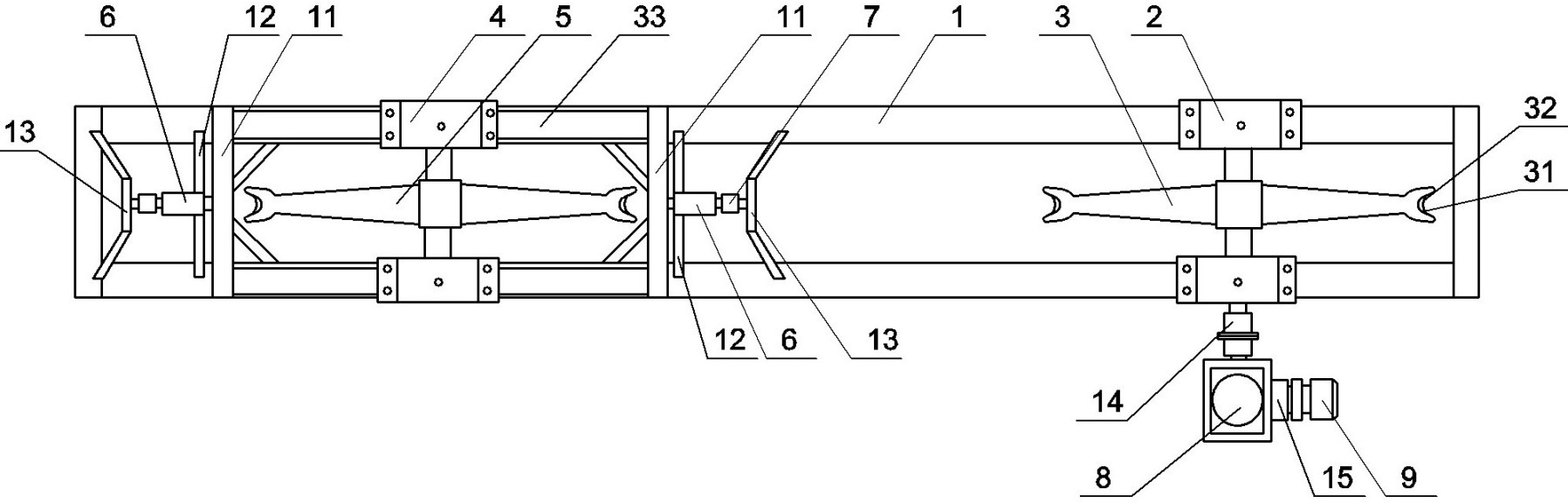

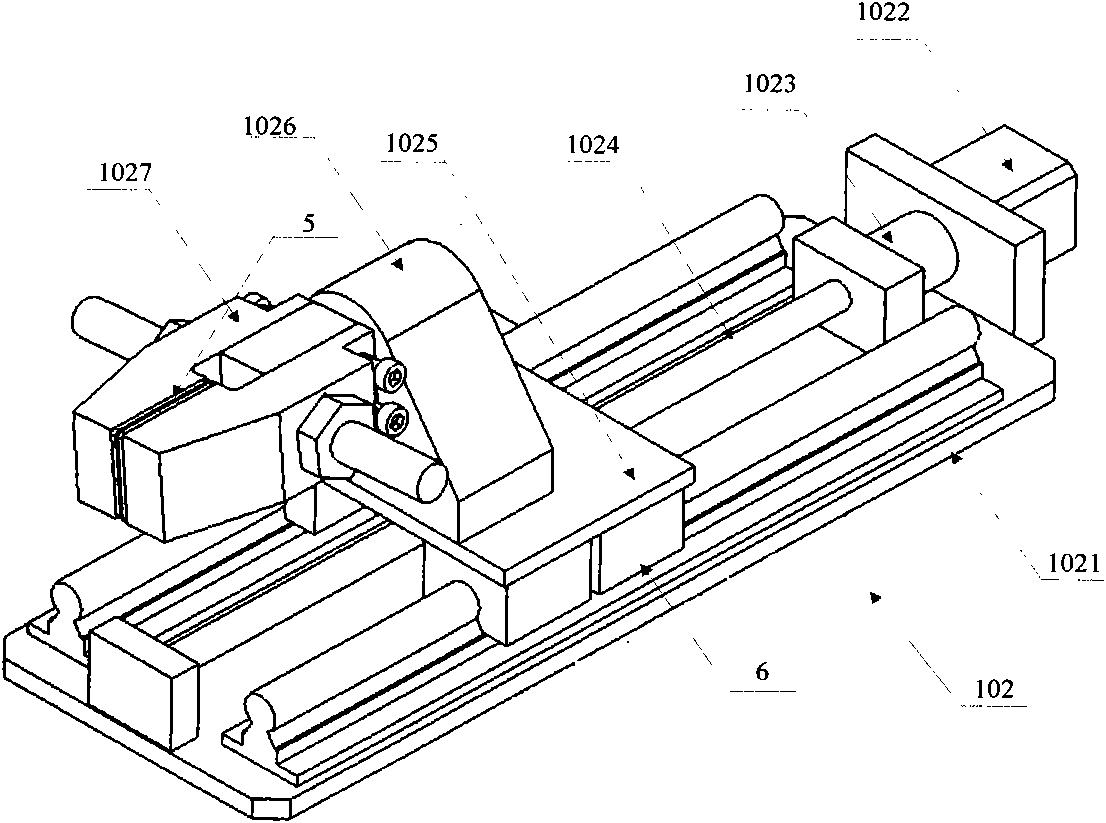

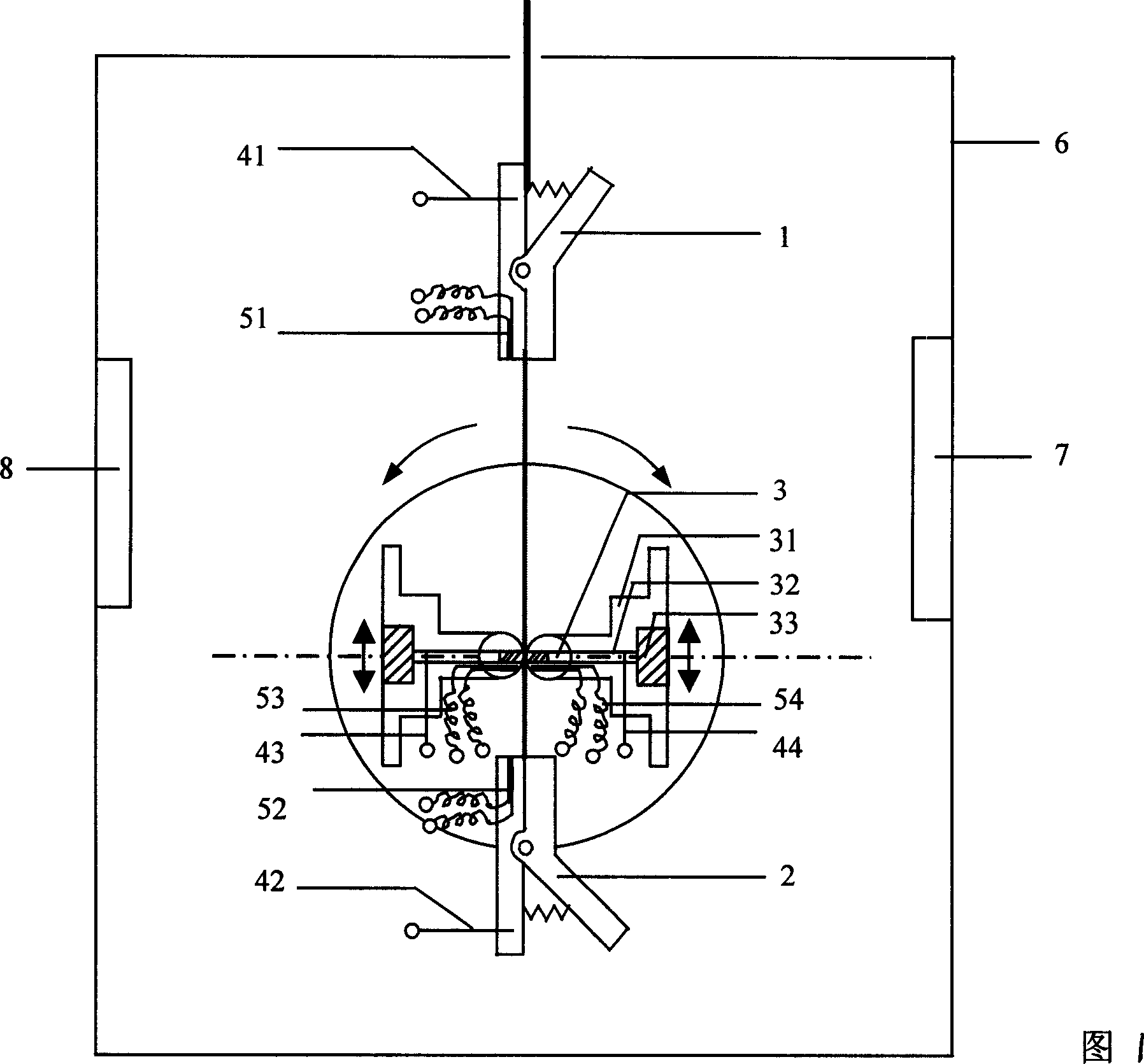

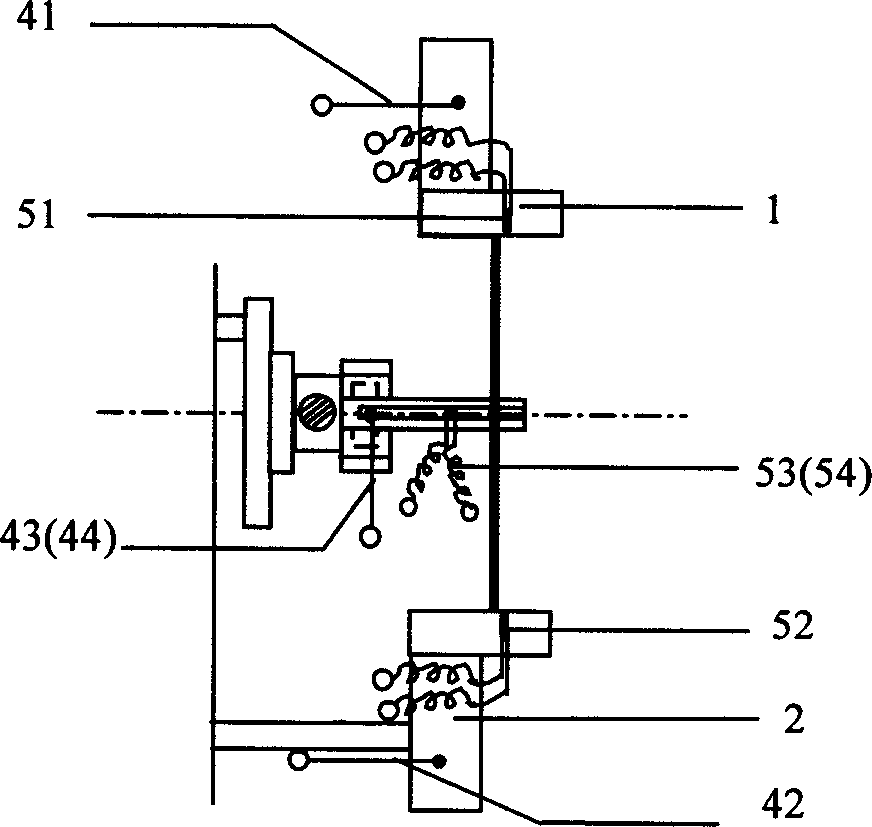

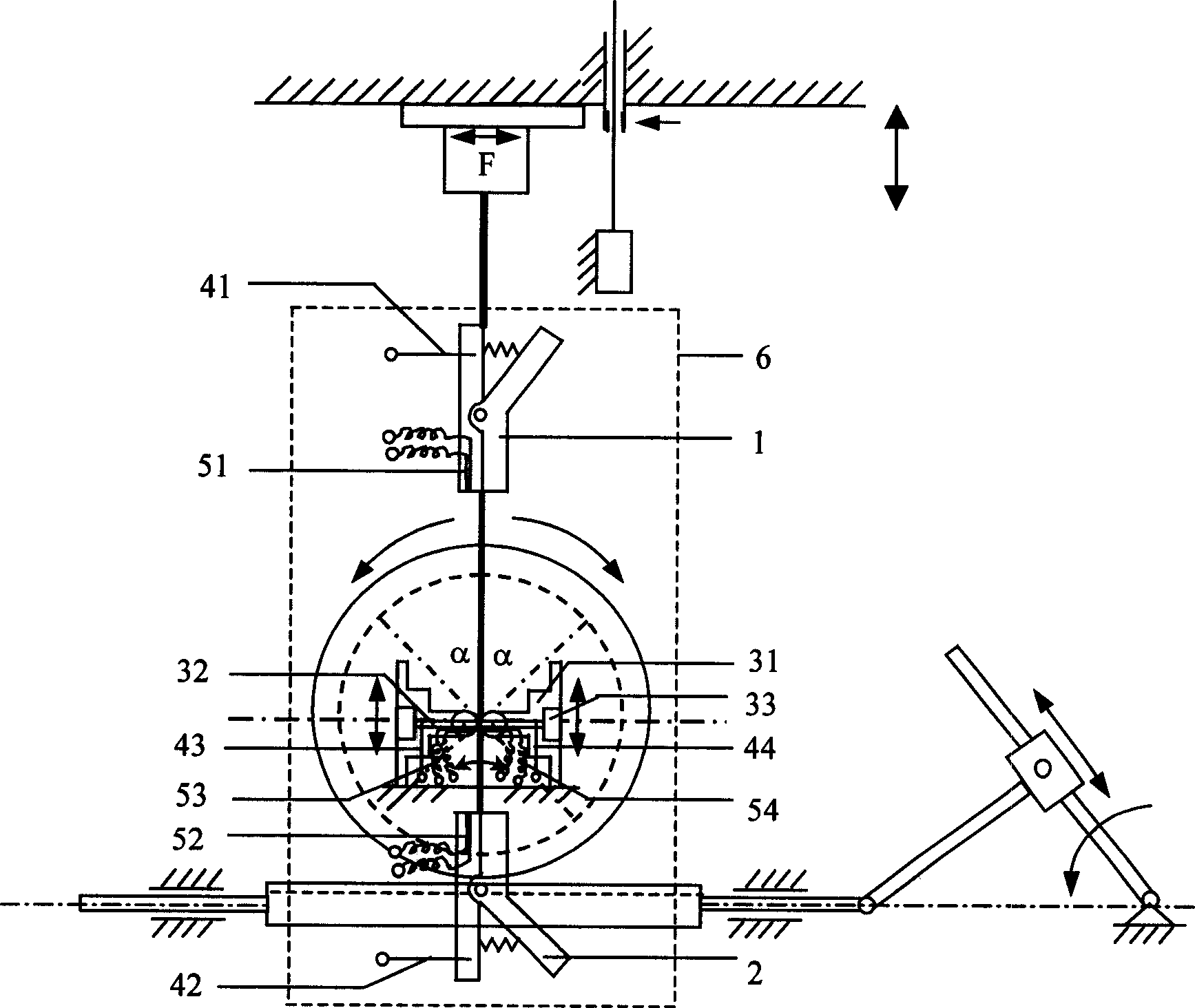

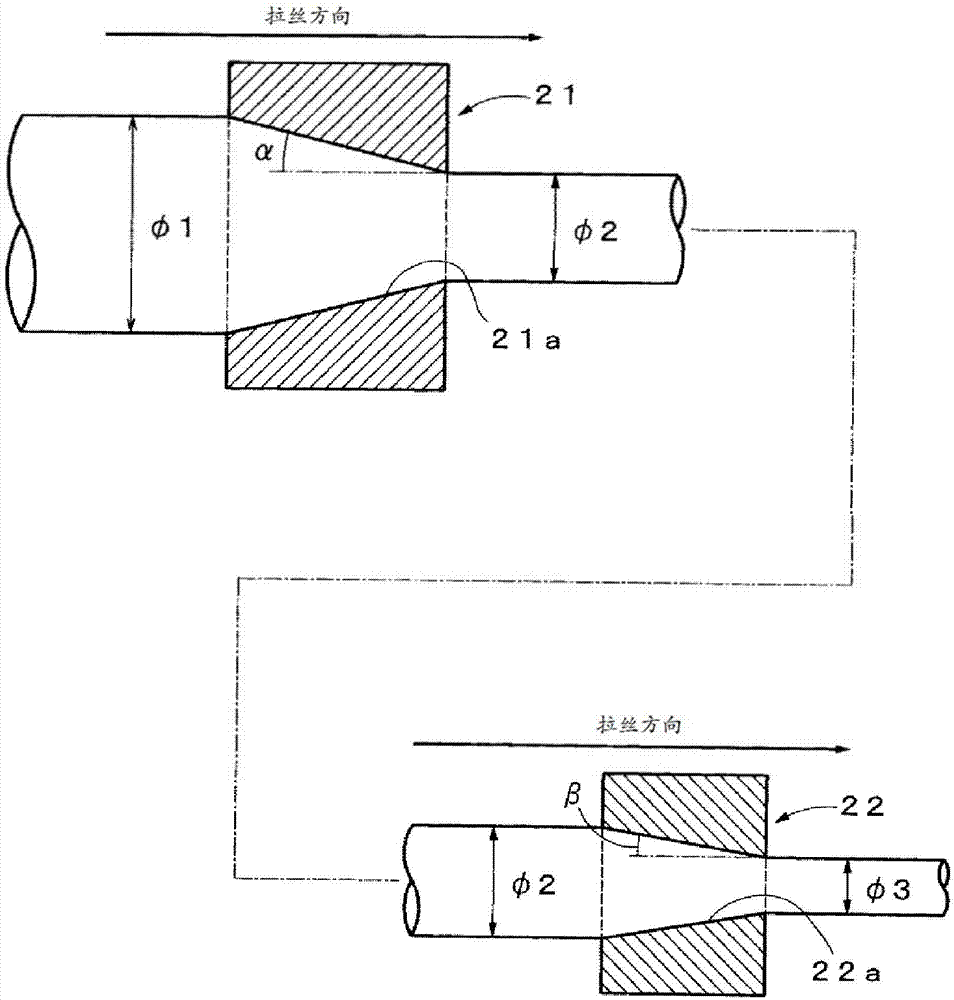

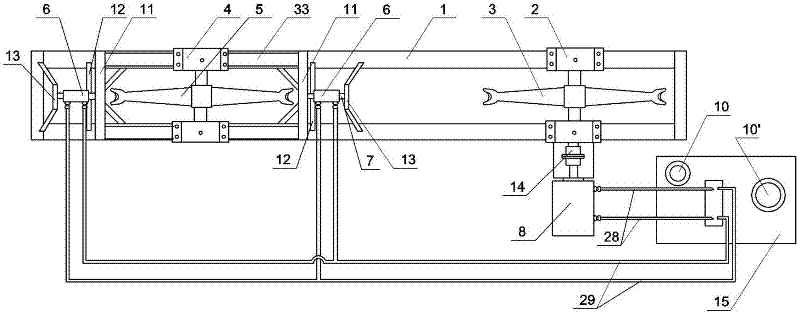

Variable-speed circumferential low-stress bending fatigue crack precise blanking machine and blanking method thereof

InactiveCN103286249AReduce utilizationLower the thresholdPower hammersHandling devicesStress concentrationBall bearing

The invention discloses a variable-speed circumferential low-stress bending fatigue crack precise blanking machine and a blanking method of the variable-speed circumferential low-stress bending fatigue crack precise blanking machine. The variable-speed circumferential low-stress bending fatigue crack precise blanking machine comprises a variable-frequency motor, a large belt pulley, a V-shaped belt, a small belt pulley, a two-stage gear accelerator, a high-speed main shaft, a sliding rail supporting seat, a screw compression spring, a columnar hammer head, a feeding sleeve, a ball guide bushing, metal bars, a clamping hand, a clamping cylinder, a feeding cylinder, a hydraulic clamping feeding mechanism support, a machine body, a seat plate, a servo motor, a speed reducer, a coupler, a ball screw supporting seat, a screw, a nut, a ball screw, a deep groove ball bearing and a key. The variable-speed circumferential low-stress bending fatigue crack precise blanking machine is high in geometric precision of blanking workbanks, free of corner collapse and radial deformation, perpendicular and smooth in fracture section, few in burrs, and high in use ratio of material. The stress concentration effect, the resonance effect and the bending fatigue of an annular V-shaped groove are utilized to enable the critical value of the impact speed of vibration on the metal bars to be lower than the critical value of the speed in the high-speed shearing process, and the blanking machine is applicable to precise blanking of the metal bars of different materials.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

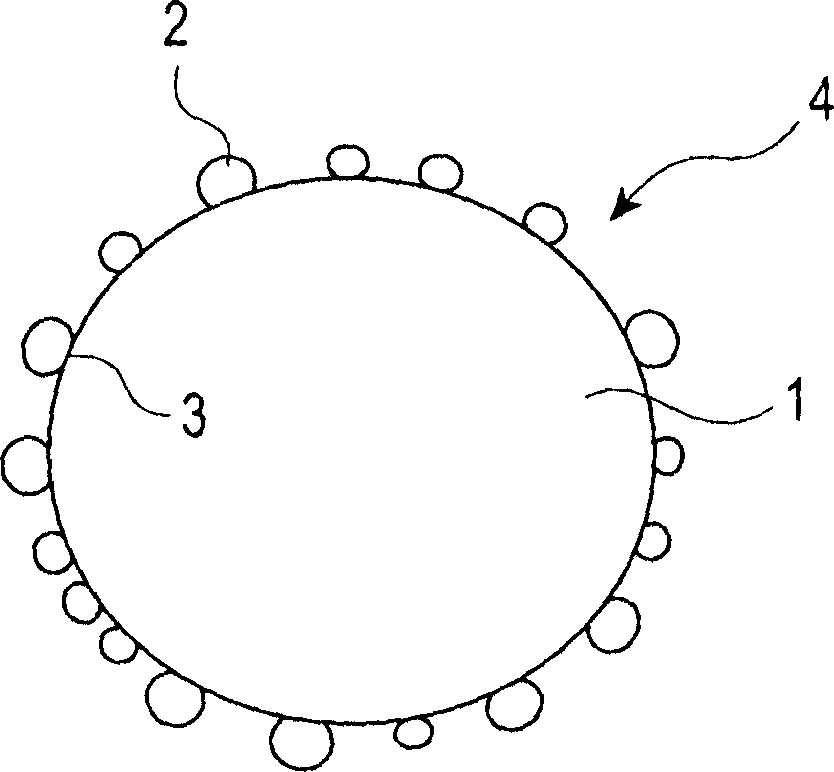

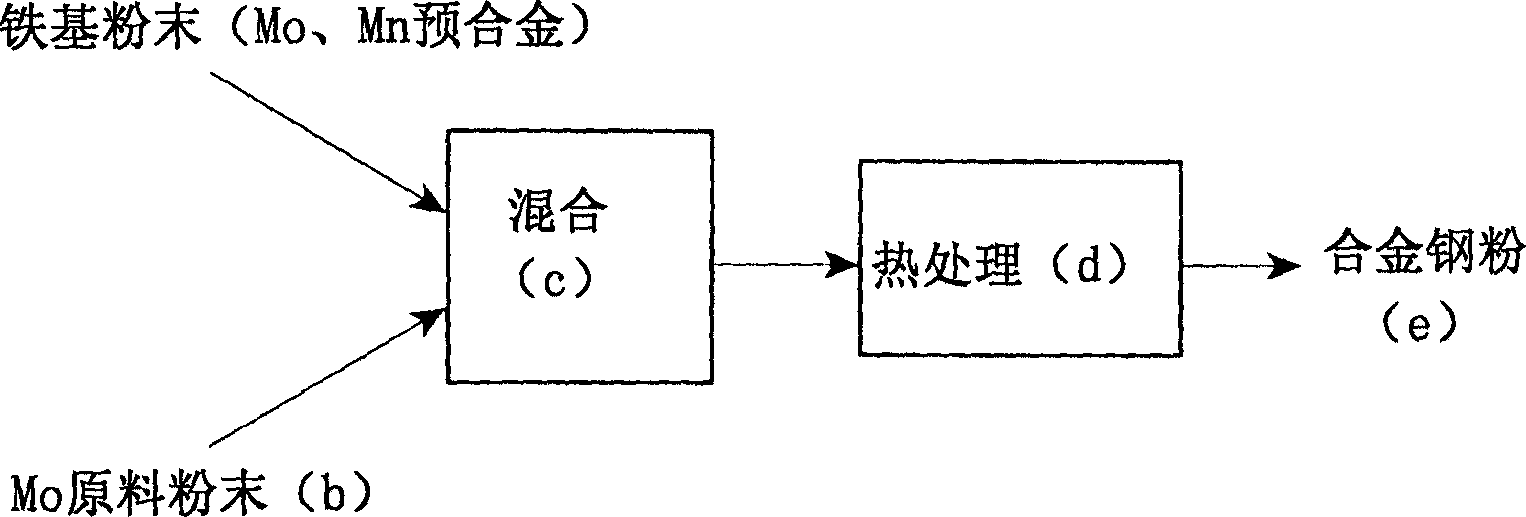

Mixed powder for powder metallurgy

Disclosed is a mixed powder for powder metallurgy which is obtained by diffusing and adhering 0.05-1.0 mass% of Mo over the surface of an iron base powder which contains, as a prealloy, not more than 0.5 mass% of Mn and 0.2-1.5 mass% of Mo, thereby forming an alloy steel powder, and then blending 0.2-5 mass% of an Ni powder and / or 0.2-3 mass% of a Cu powder into the thus-formed alloy steel powder. A dense sintered body having excellent tensile strength and bending fatigue strength can be produced from such a mixed powder.

Owner:JFE STEEL CORP

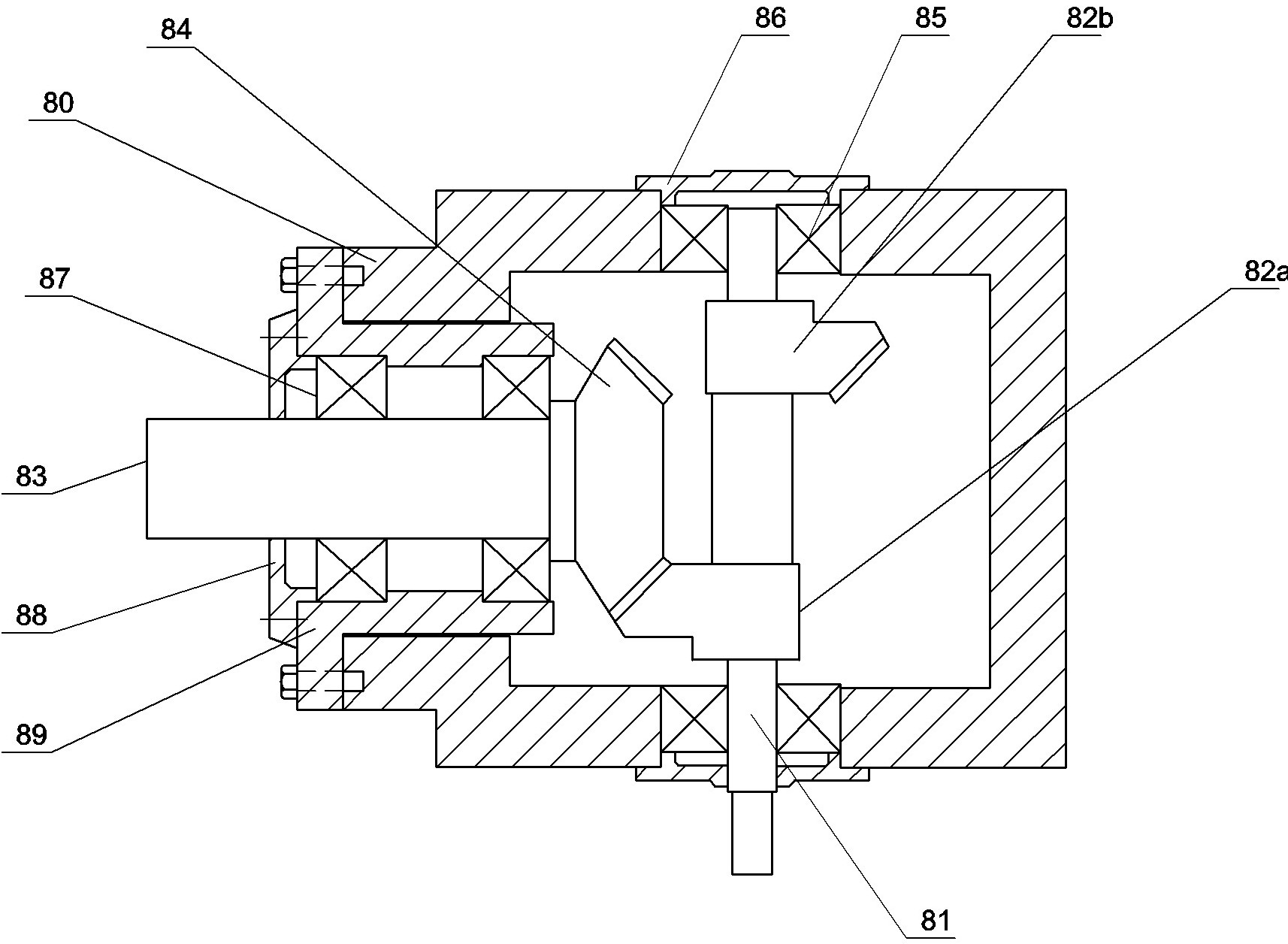

Mechanical horizontal steel wire rope bending fatigue testing machine and mechanical rotation driving device

InactiveCN102323161AConvenience setImprove general performanceToothed gearingsMaterial strength using steady bending forcesPolyesterDrive wheel

The invention discloses a mechanical horizontal steel wire rope bending fatigue testing machine and a ring-shaped combination gasket. 180-degree positive and negative rotating movement of the testing machine is realized by two half umbrella-shaped bevel gears. The machine is matched with a polyester friction gasket according to the rope diameter to carry out bending fatigue test on steel wire ropes with different diameters. The circular arc radius of the polyester friction gasket is consistent with the radius of the section of the tested steel wire rope. The polyester friction gasket can be randomly disassembled and replaced from rope sleeves of a driving wheel and a testing wheel to be installed as required. A constant value load of the machine is realized by a frame structure such as a power device, a pressure sensor, a spring and the like. A heavy method of applying a load by hanging a weight, which is adopted by other like equipment, is changed. The mechanical horizontal steel wire rope bending fatigue testing machine has high accuracy. The 1:1 steel wire rope winding testing wheel is adopted. The mechanical horizontal steel wire rope bending fatigue testing machine is consistent with the actual working condition, has simple and reasonable structure, occupies a small space and has high rigidity and strength, low deformation and small overall size.

Owner:HENAN COAL SCI RES INST

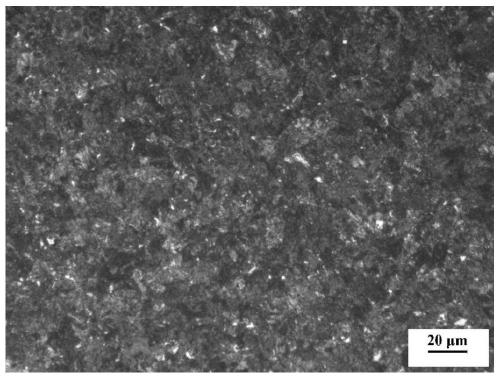

High-strength steel product excelling in fatigue strength and process for producing the same

A high-strength and high-fatigue-strength steel having a base metal strength of 1000 MPa or more and a rotating bending fatigue strength of 550 MPa or more is provided. The steel contains 0.3-0.8 percent by mass of C, 0.01-0.9 percent by mass of Si, 0.01-2.0 percent by mass of Mn, and Fe and unavoidable impurities as the remainder. The steel has a ferrite-cementite structure having a grain size of 7 mum or less or a ferrite-cementite-pearlite structure having a grain size of 7 mum or less. A surface metal of the steel after high-frequency induction quenching has a martensite structure having a prior austenite grain size of 12 mum or less. Alternatively, a surface metal of the steel after nitriding has a fine structure having a ferrite grain size of 10 mum or less.

Owner:JFE STEEL CORP

Reinforcing cord for rubber reinforcement and rubber product including the same

InactiveUS7682274B2Increase resistanceImprove stabilityV-beltsRopes and cables for vehicles/pulleyGlass fiberEngineering

A reinforcing cord of the present invention is a reinforcing cord for rubber reinforcement. The reinforcing cord includes a carbon fiber strand (11) and a plurality of glass fiber strands (12) arranged around the carbon fiber strand (11). The present invention makes it possible to obtain a reinforcing cord having sufficient tensile strength for reinforcing rubber products as well as high dimensional stability and bending fatigue resistance.

Owner:NIPPON SHEET GLASS CO LTD

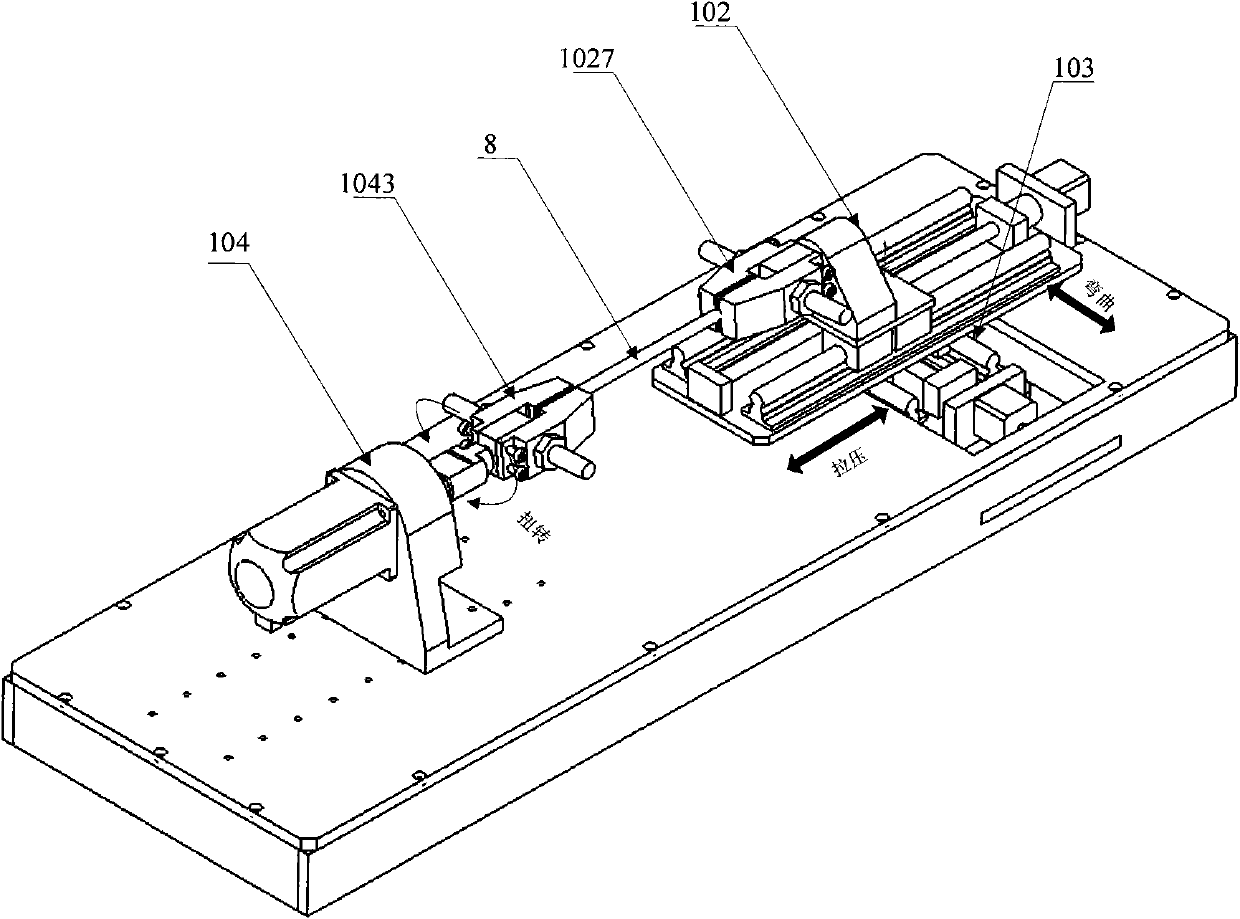

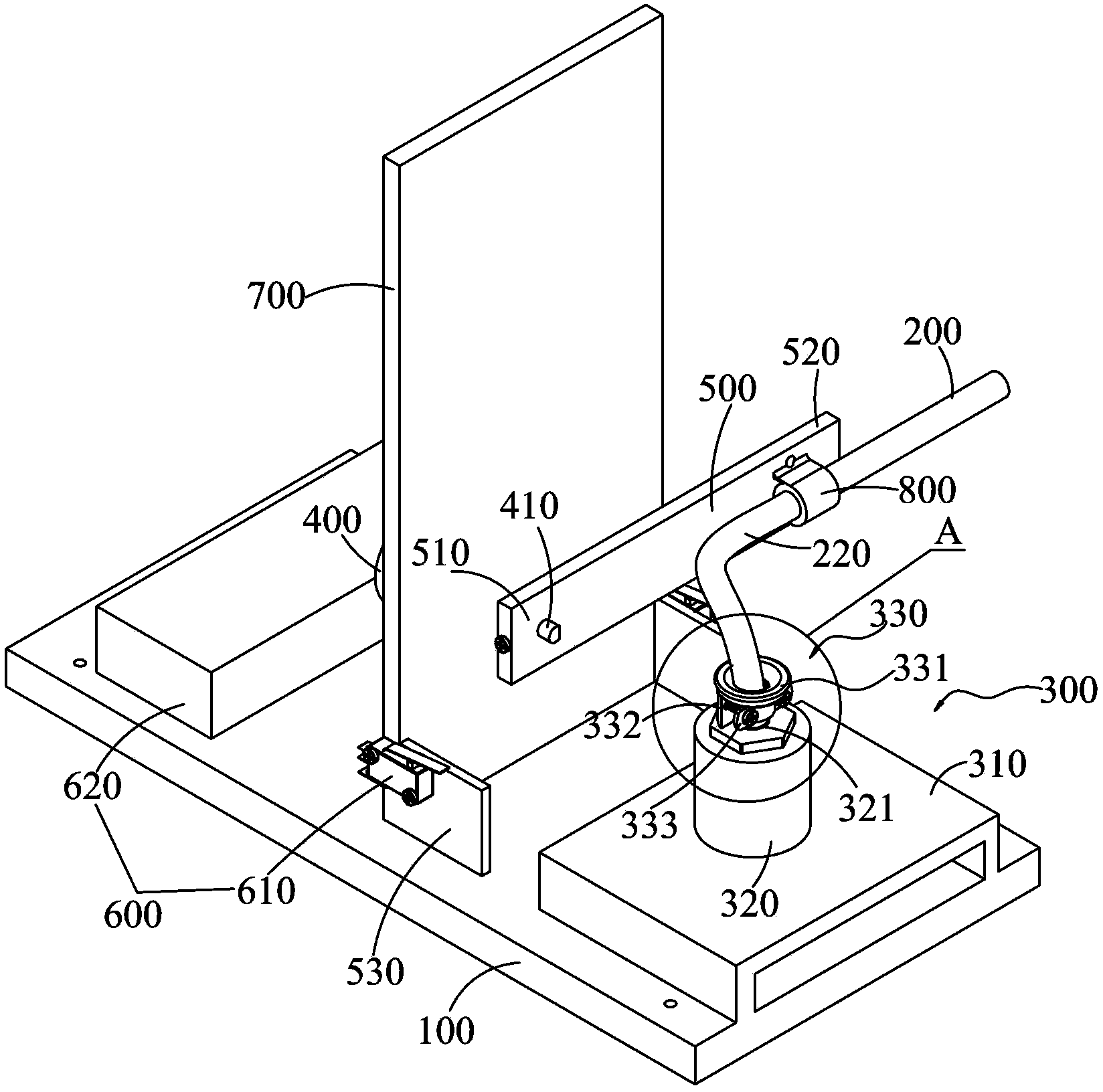

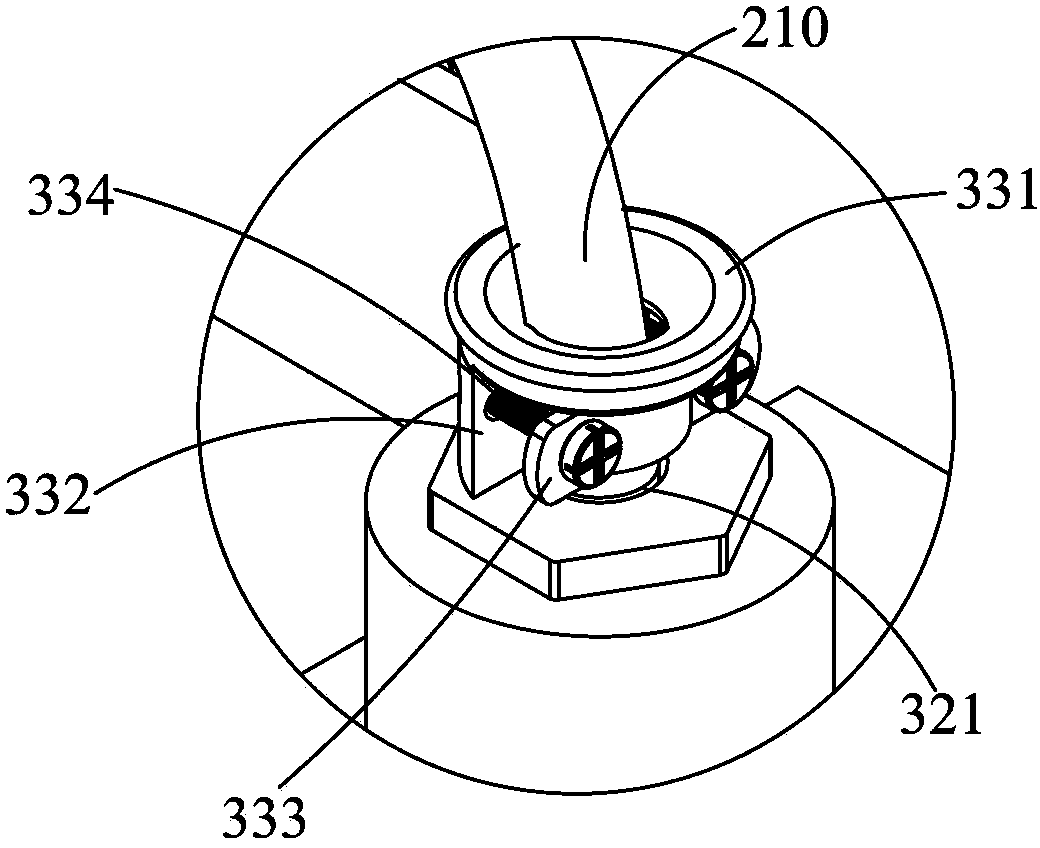

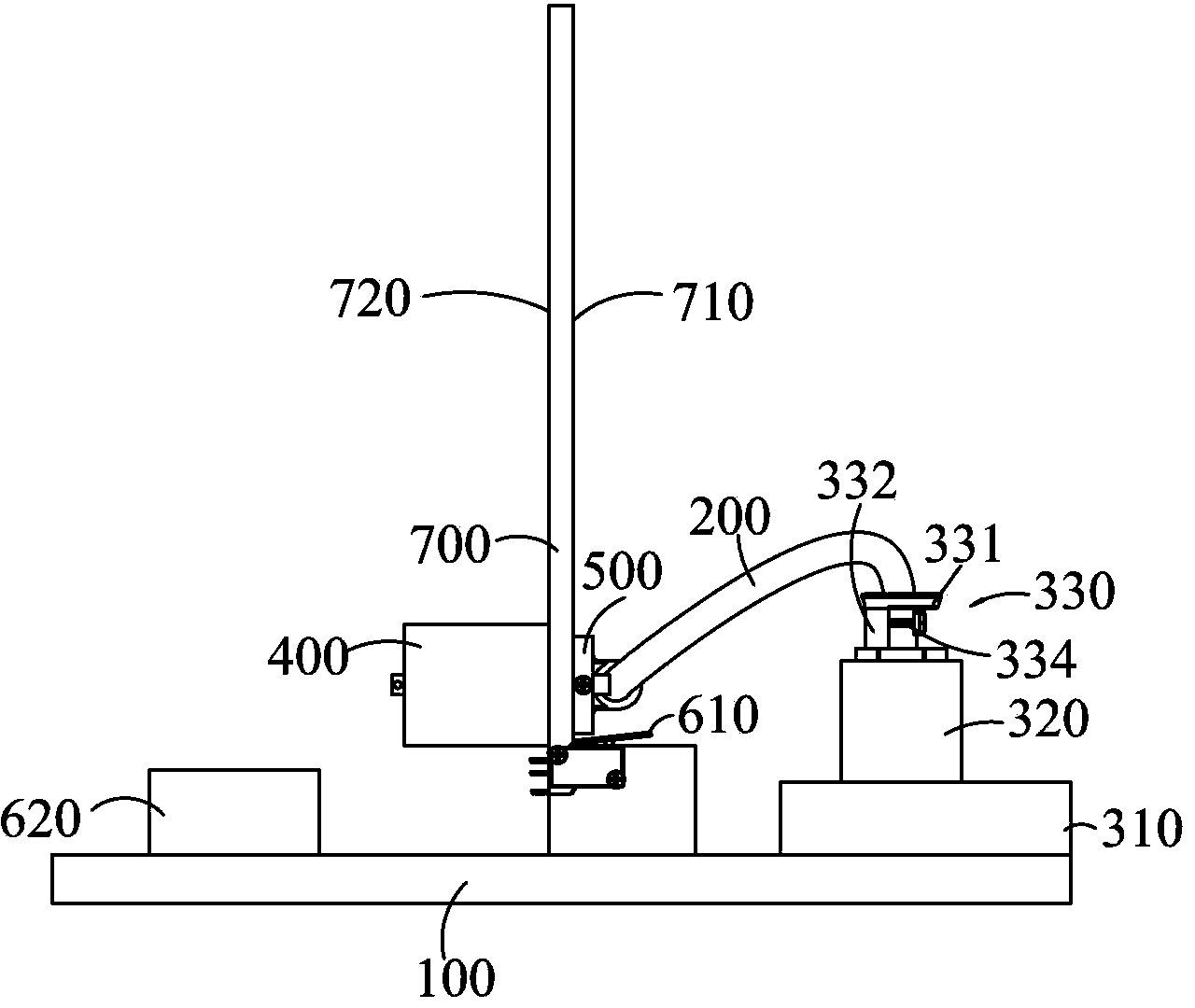

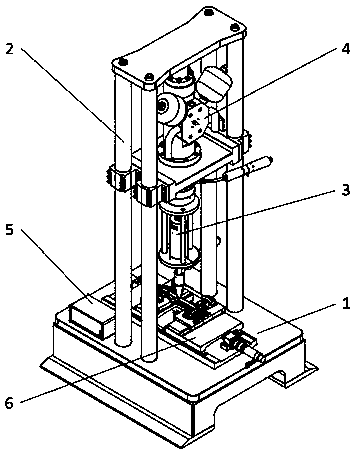

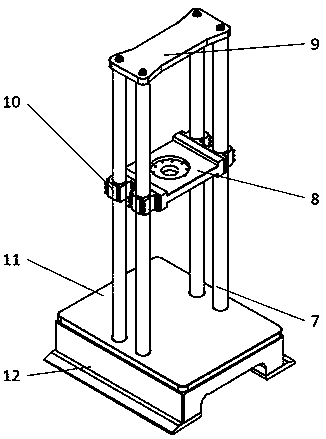

Bone biomechanical measurement device

InactiveCN101886995AEasy to measureImprove adaptabilityMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMeasurement deviceData acquisition

The invention discloses a bone biomechanical measurement device. The device is used for measuring single parameters of bones such as three mechanical parameters of bone pull pressure, torsion and bending; the fatigue parameter measurement comprises measurement of bone pull pressure, torsion and bending fatigue parameters; and the composite mechanical property measurement is the mechanical property measurement when the bone is subjected to composite stress. The bone biomechanical measurement device comprises a host system and a control system; the host system comprises a host mechanical system, a servo motor controller for driving a servo motor, a pull pressure sensor for measuring pull pressure of the bone, a bending pressure sensor for measuring the bending force of the bone, and a displacement sensor for measuring the pull pressure of the bone to generate pull pressure deformation; and the control system comprises a programmable controller, a data acquisition controller and a measurement control processor. The bone biomechanical measurement device not only realizes the measurement of single mechanical properties when the bone is acted with pull pressure, torsion and bending respectively, but also realizes the fatigue mechanical property measurement of the bone and the composite mechanical property measurement when the bone is acted with pull pressure, torsion and bending at the same time.

Owner:BEIHANG UNIV

Multifunctional measuring method and device for flexible material bending fatigue

InactiveCN1614417AReasonable functionSimple partsMaterial thermal conductivityTextile testingElectrical resistance and conductanceData acquisition

A detection device adds four temperature transducers, four electrodes and resistance measuring unit on positioning needle and clamp head of device stipulated in application number 200410053598.7 as well as adds data collection card, measuring module, etc. The detection method includes using bending point temperature obtained by heating or cooling to pressure sample flextual fatigue at different temperature and measuring heat and electric conduction property between sample points under the flexural fatigue action.

Owner:DONGHUA UNIV

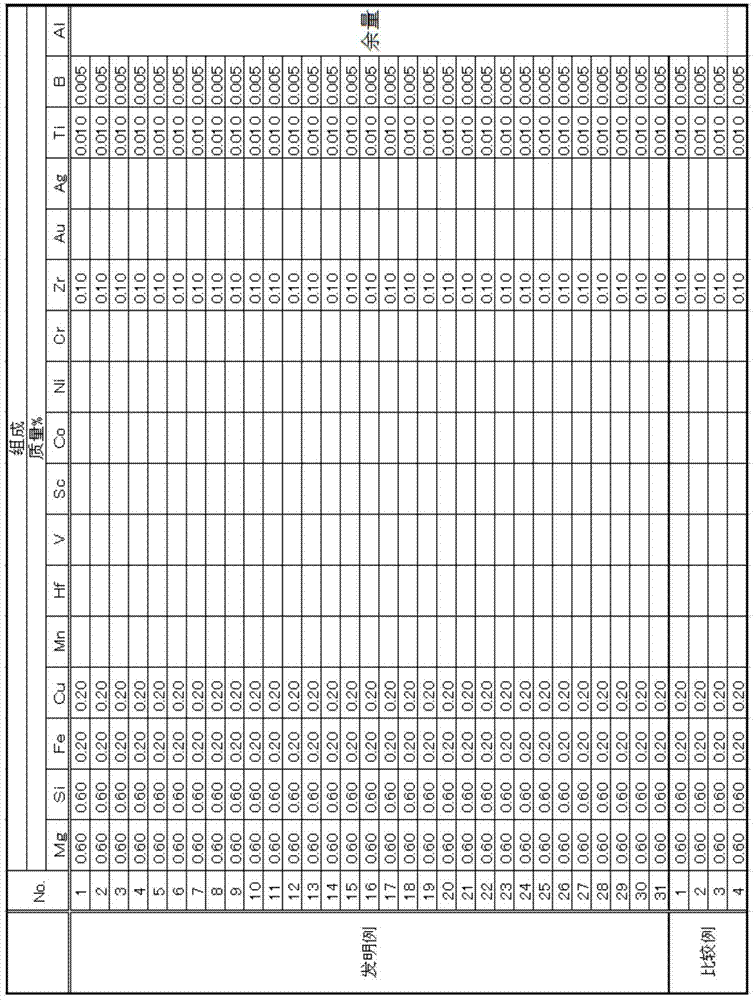

Aluminum alloy conductor, alum1inum alloy stranded wire, sheathed wire, wire harness, and method for manufacturing aluminum alloy conductor

ActiveCN104781431AShock resistantImproved bending fatigue resistancePlastic/resin/waxes insulatorsSingle bars/rods/wires/strips conductorsHigh conductivityElectrical resistivity and conductivity

Owner:FURUKAWA ELECTRIC CO LTD +1

Rope structure with improved bending fatigue and abrasion resistance characteristics

A rope structure adapted to engage an external structure comprising a primary strength component and a coating. The primary strength component comprises a plurality of fibers. The coating comprises a lubricant portion and a binder portion that fixes the lubricant portion relative to at least some of the fibers. The coating is applied to the primary strength component such that the lubricant portion reduces friction between adjacent fibers and reduces friction between fibers and the external structure.

Owner:SAMSON ROPE TECH

Cable bending fatigue testing device

InactiveCN103424323AEasy to operateReduce work intensityMaterial strength using repeated/pulsating forcesElectric machineryEngineering

The present invention relates to a testing technology, and provides a cable bending fatigue testing device including a base, a fastening device, a motor and a control device. An output shaft of the motor horizontally directly faces to the fastening device, and the output shaft is fixedly provided with a movable plate which can swing in the forward direction and the reverse direction with forward rotation and reverse rotation of the output shaft. One end of a cable to be tested is fastenedly fixed on the fastening device, the other end of the cable to be tested is bent and then is fixed on the movable plate and can be bent back and forth in the forward direction and the reverse direction with the forward swing and the reverse swing of the movable plate, both sides of the movable plate are each provided with a travel switch, the travel switches are connected with the control device, and a counting unit is arranged in the control device. According to the invention, one end of the cable to be tested is fixed through the fastening device, the other end of the cable to be tested is bent and then is connected with the movable plate and is cyclically bent in the forward direction and the reverse direction under the drive of the output shaft of the motor, furthermore, counting is carried out through the control device, and thus the bending fatigue strength of the cable to be tested can be tested; with the testing device, operations are simple and reliable, the work intensity is reduced, and the work efficiency is improved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

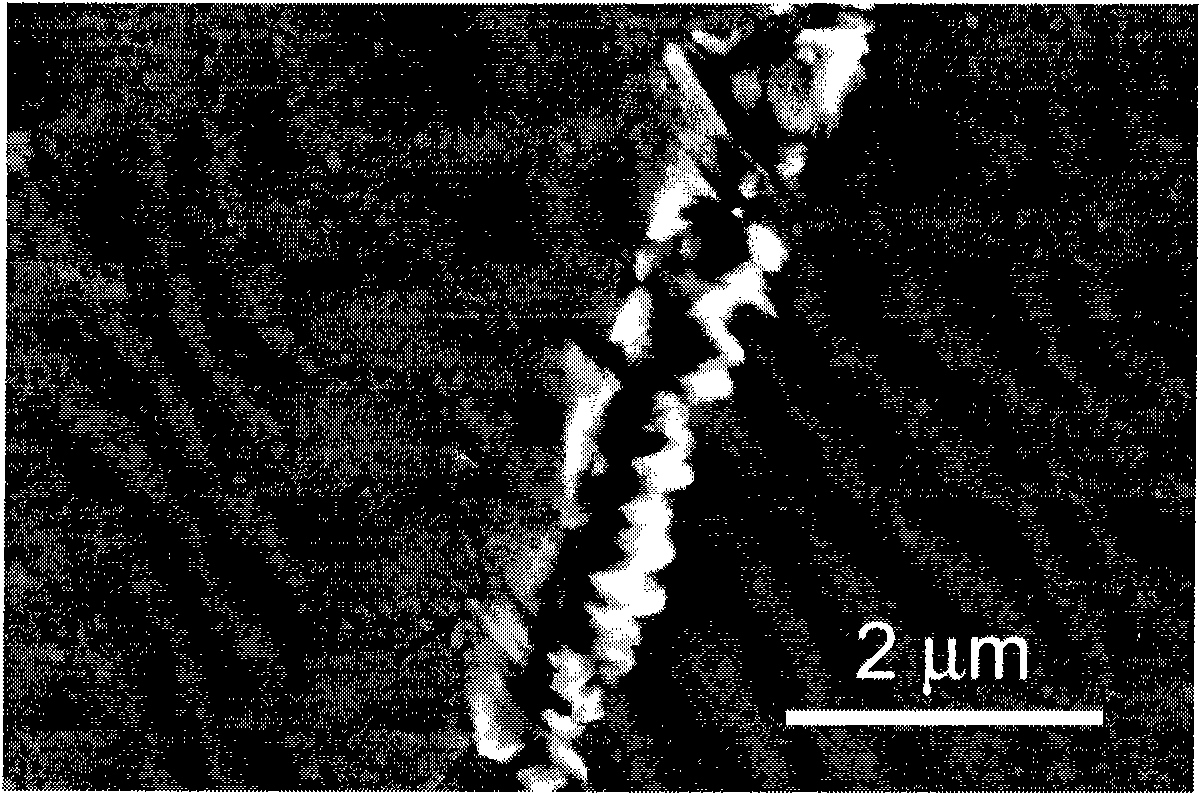

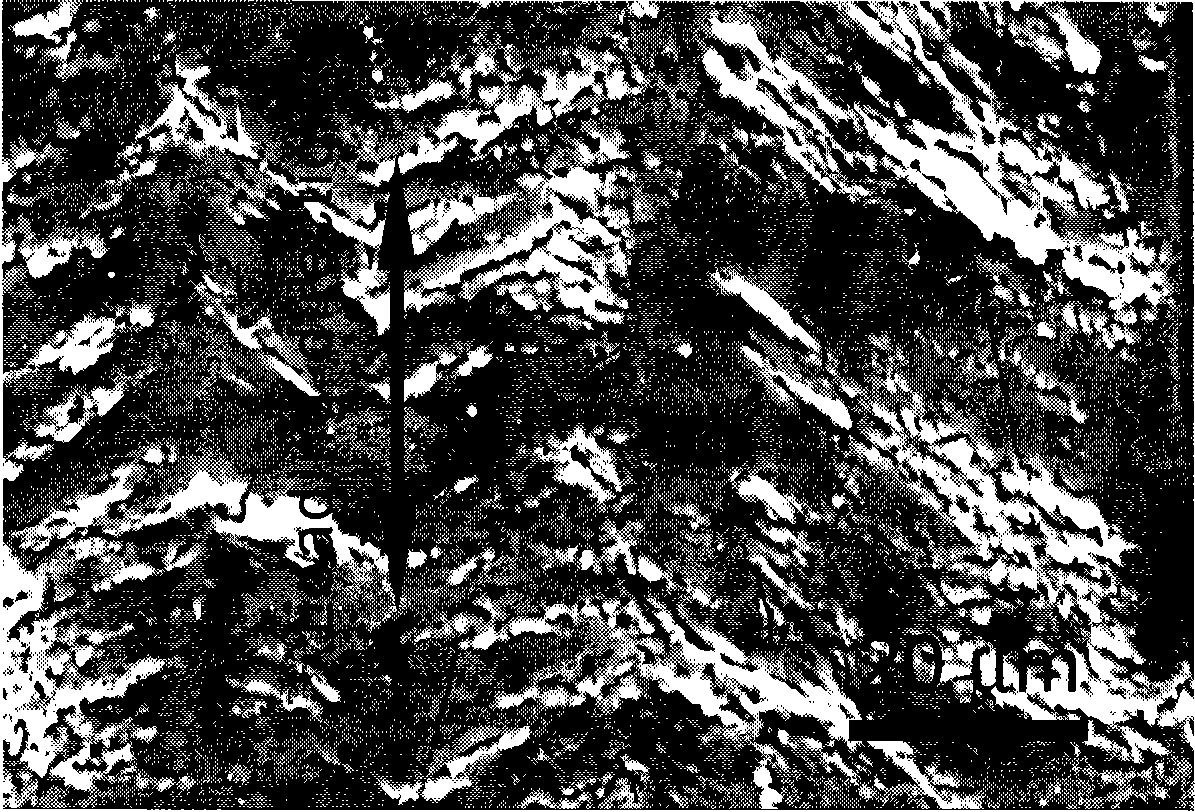

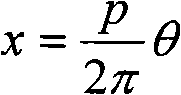

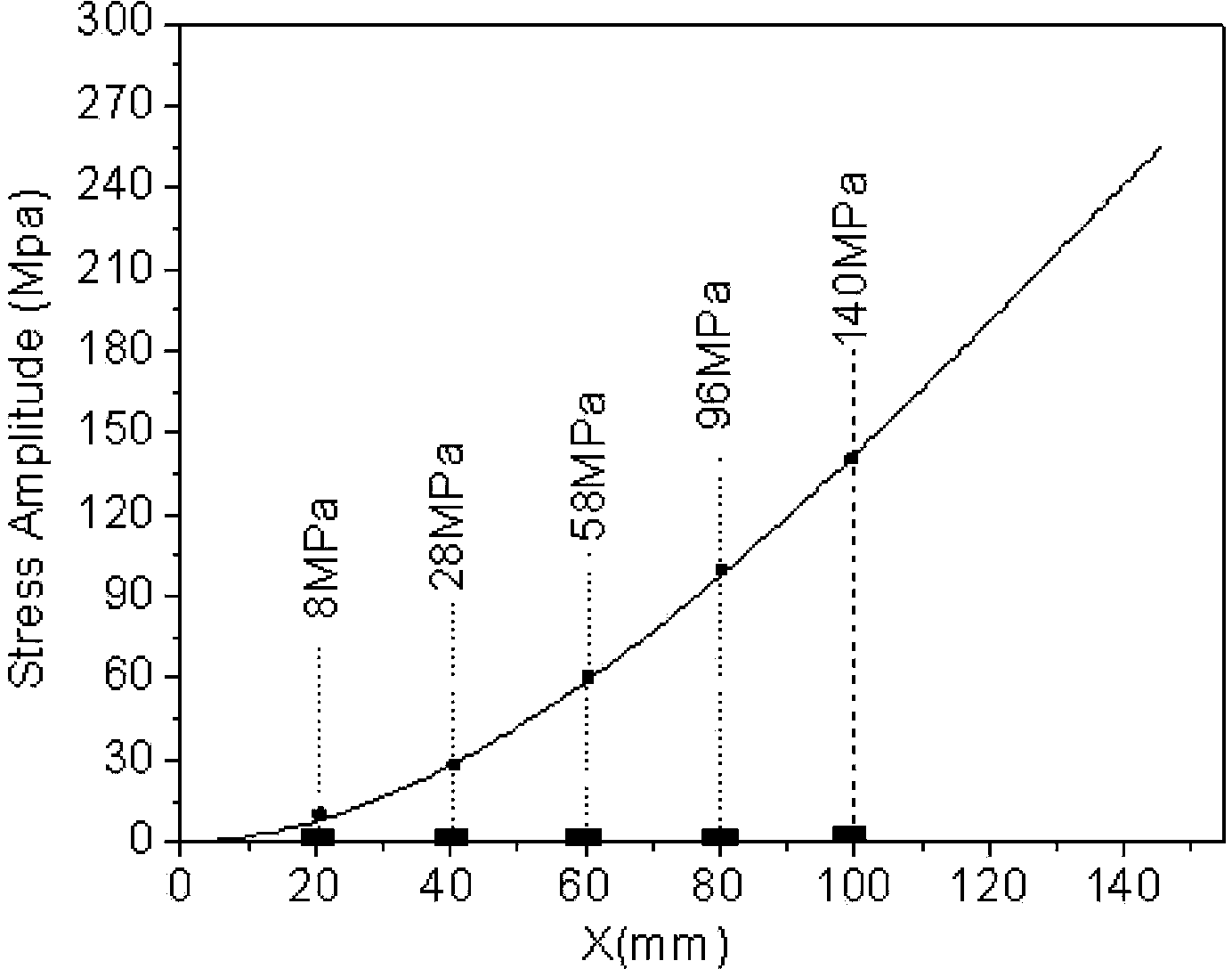

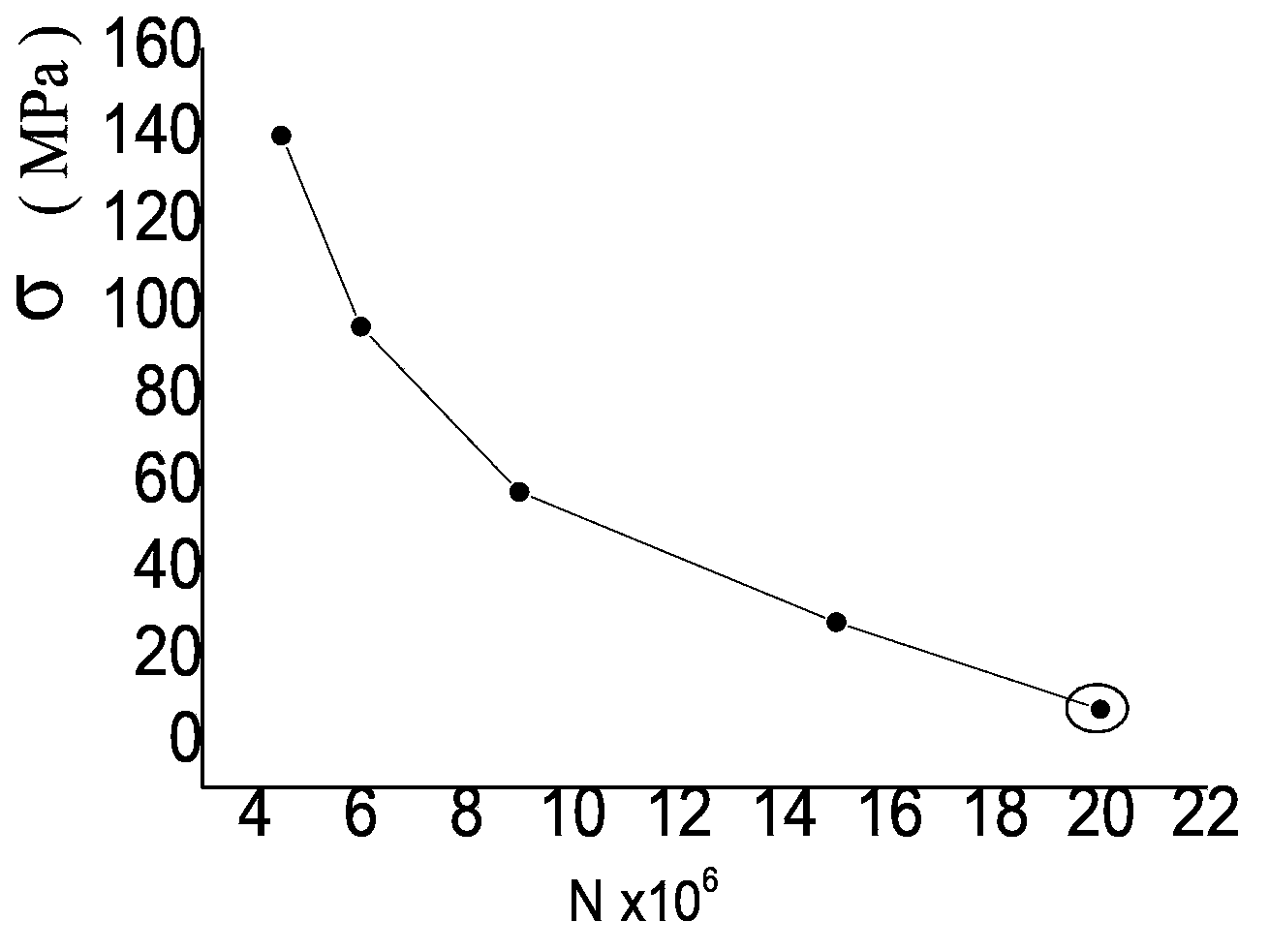

Test method for testing bending fatigue life of film

InactiveCN103364285AQuick and easy access to bending fatigue lifeWide applicabilityMaterial strength using repeated/pulsating forcesEngineeringLife time

The invention discloses a test method for testing bending fatigue life of a film, which is wide in applicability, simple to operate and capable of quickly and conveniently obtaining the bending fatigue life of a film. The test method comprises the following steps of: continuously applying alternating load for stretching and compressing on a film deposited on the surface of a test specimen through the bending vibration of the test specimen, analyzing the amplitude change of the test specimen from a free end to a fixed end to determine the alternating stress amplitude of the film, observing whether the film on the surface of a cantilever beam cracks or drops after the cantilever beam vibrates for a special time t0 each time, measuring the fatigue life time of the film, and drawing an S-N curve. The test method is wide in adaptability and very simple to operate, and can be used for simultaneously researching the bending fatigue behaviors of a film material under different stress amplitudes within one test period, greatly saving the time and cost for drawing the S-N curve and quickly and conveniently obtaining the bending fatigue life of the film. The test method is suitable for generalization and application in the field of fatigue property tests of film materials.

Owner:SOUTHWEST JIAOTONG UNIV

Vehicle wheel steel and smelting method

The invention relates to a wheel steel and a smelting method thereof. The wheel steel comprises elements of carbon, silicon, manganese, niobium, phosphor, oxygen, sulfur and iron, etc. By adopting the steps of hot metal pretreatment, converter smelting, refining outside the converter and conventional rolling, the wheel steel is smelted. The components of the alloy are controlled by means of micro alloying and calcium treatment, etc. The indexes of the yield strength, the tensile strength and the bending fatigue life of the wheel made from the wheel steel are all higher than that of the existing wheel steel, furthermore, the wheel steel can be further thinned; therefore, cars adopting the wheel made from the wheel steel can achieve energy saving.

Owner:BENGANG STEEL PLATES

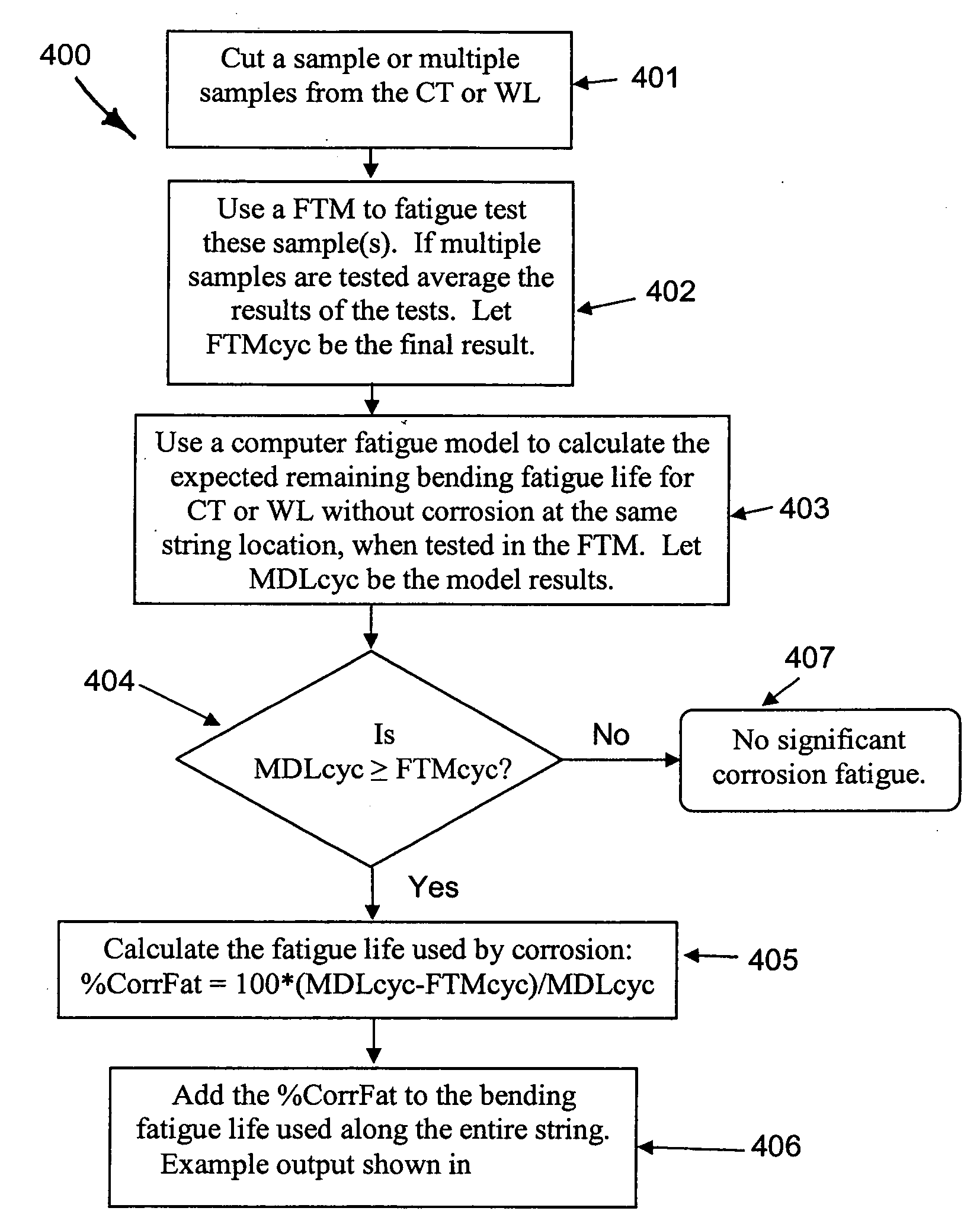

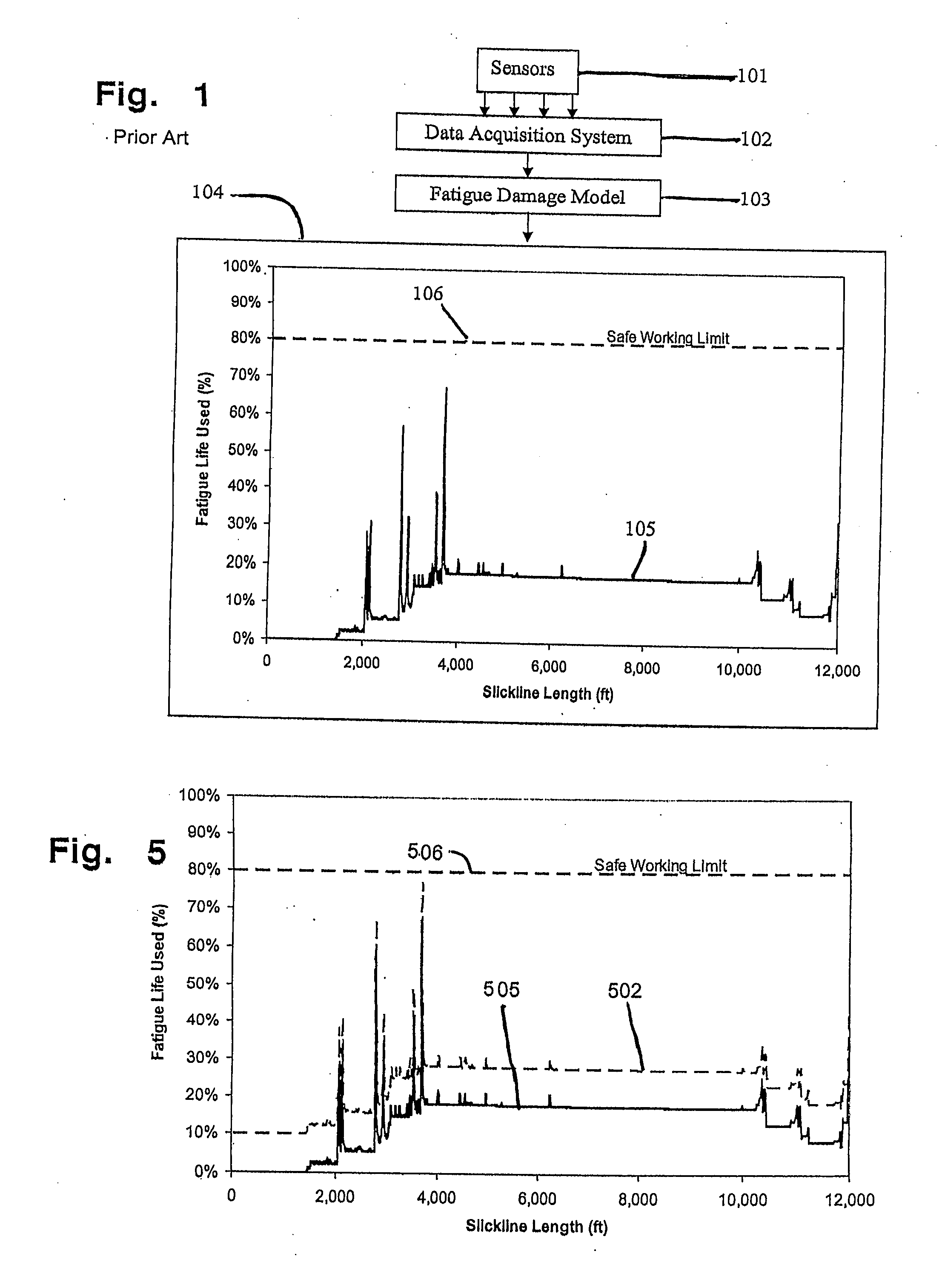

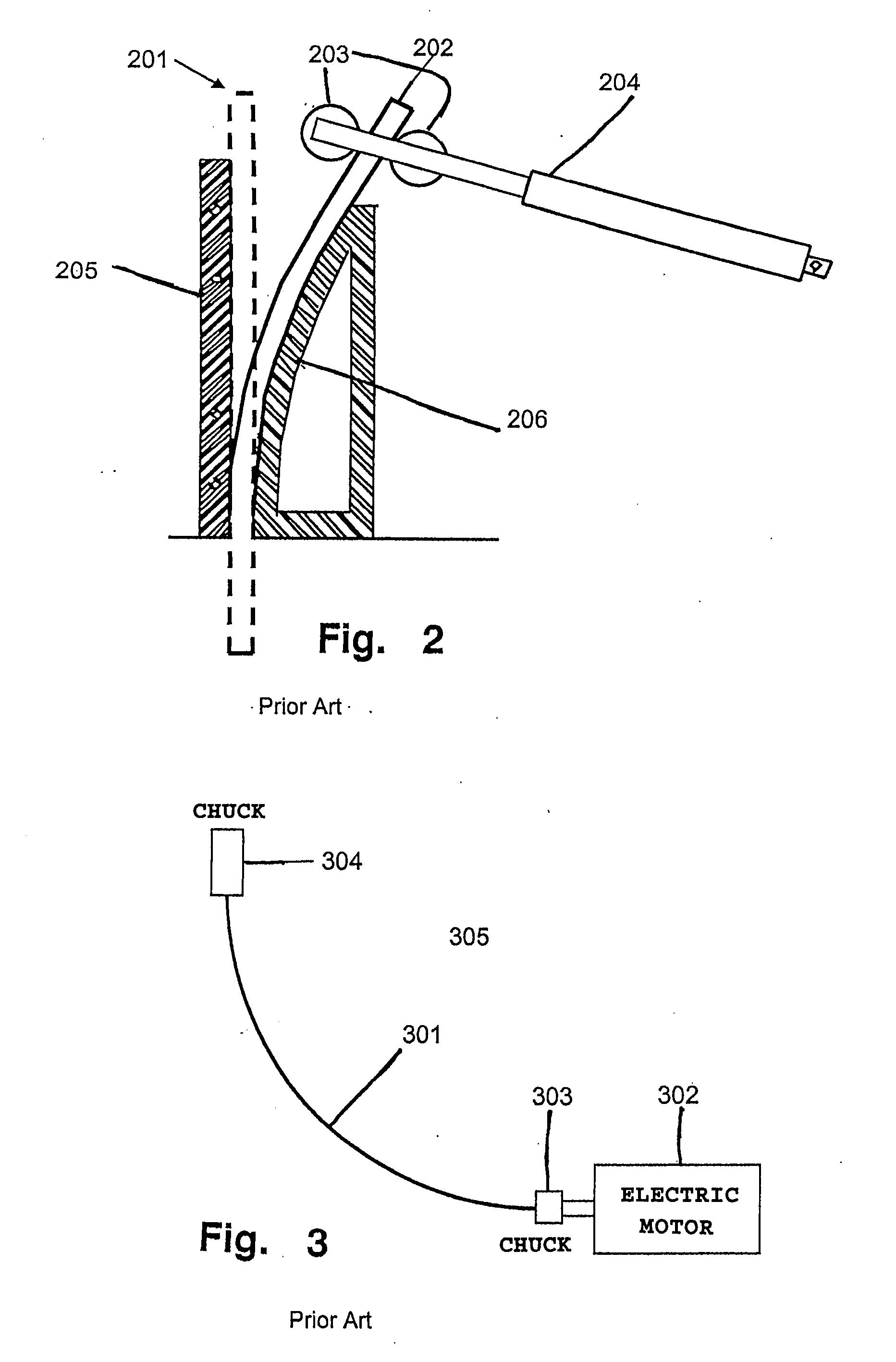

Fatigue measurement method for coiled tubing & wireline

A method for determining fatigue life reduction in a string; the method, in at least certain aspects, including providing at least one sample from a string that has been subjected to corrosion, fatigue testing the at least one sample to determine a measured remaining fatigue life, calculating an expected remaining bending fatigue life for the at least one sample, and comparing the measured remaining fatigue life to the expected remaining bending fatigue life to determine the extent of reduction in fatigue life of the string.

Owner:COILED TUBING ENG SERVICES

Spring steel wire rod with cryogenic drawing performance, spring steel wire, spring and manufacturing method thereof

ActiveCN111041372AImprove mechanical propertiesReduce depthProcess efficiency improvementWire rodTempering

The embodiment of the invention provides a spring steel wire rod with cryogenic drawing performance, a spring steel wire, a spring and a manufacturing method thereof, and relates to the field of wirerods. The spring steel wire rod with cryogenic drawing performance comprises the following chemical components in percentage by mass: 0.32%-0.40% of Si and 0.016%-0.030% of Als. The manufacturing method of the spring steel wire comprises the steps that the spring steel wire rod is directly subjected to cold drawing, and the maximum reduction rate of drawing reaches 95%; the drawn steel wire is subjected to low-temperature stress relief annealing treatment, the percentage reduction of area is greater than or equal to 35% and the bending fatigue life is greater than or equal to 20 times. The low-alloy spring steel wire rod with good comprehensive mechanical properties is developed, the wire rod can be directly cold-drawn to produce a thin spring steel wire with large deformation without intermediate annealing, the cold-drawn steel wire can be directly wound into the spring without oil quenching and tempering treatment, the requirement for bending fatigue resistance of the steel wire canalso be met and the production cost is greatly reduced.

Owner:SGIS SONGSHAN CO LTD

Method for quenching of steel member, quenched steel member, and agent for protecting quenched surface

InactiveUS20100163138A1High hardnessEasy to slideVacuum evaporation coatingSputtering coatingContact pressureInorganic compound

A technique for increasing mechanical strength, such as contact pressure strength, and abrasion resistance and bending fatigue strength, of mechanical and / or structural parts by using surface hardening treatment. A quenched steel member, wherein a hard nitride layer is formed on the surface of a steel material, and an inorganic compound layer containing at least one metal oxide selected from the group consisting of Ti, Zr, Hf, V, Nb, Ta, Cr, W, Mo and Al is formed on the hard nitride layer.

Owner:NIHON PARKERIZING

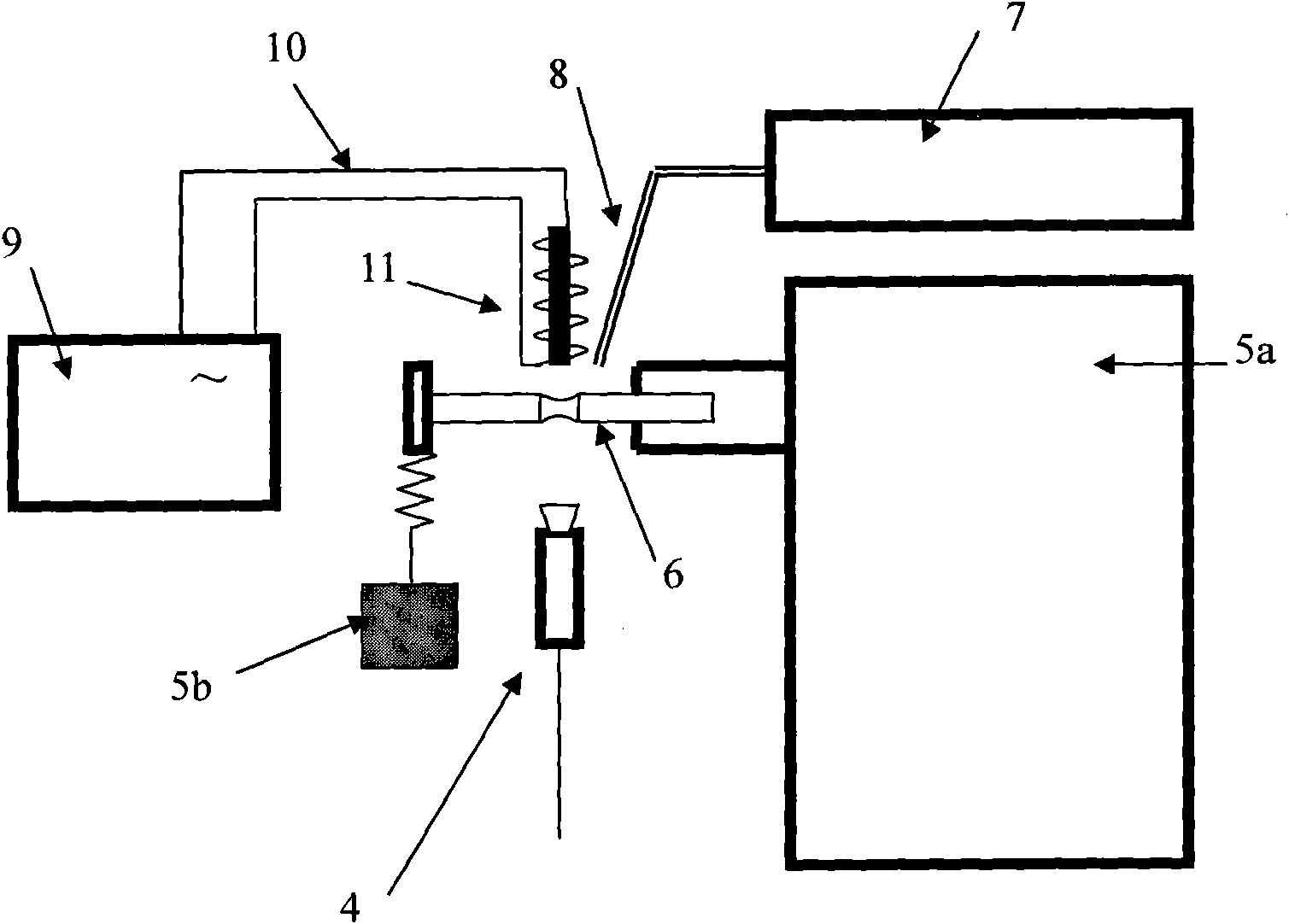

Device and method for testing thermo-mechanical fatigue

InactiveCN101876611AShort heating and cooling cyclesFast heat conductionMaterial strength using repeated/pulsating forcesPhase differenceTemperature waveform

The invention relates to a device and a method for testing thermo-mechanical fatigue. The device comprises a rotary bending fatigue loading device, a heating device for applying a temperature load to a fatigue sample, a sample surface gaseous environment control device and a temperature measurement device. Through the device and the method in combination with the conventional device and the conventional method for rotary bending fatigue and high-speed heating, the temperature load effect of different phase differences on the sample is ensured under the condition of rotary bending fatigue loading. The mechanical load of the fatigue sample is applied and controlled by the rotary bending loading device, while the temperature load is applied and controlled by the heating device and the temperature measurement device; and the phase difference of a temperature waveform and a mechanical load waveform is controlled by the number and the positions of the heating ends of the heating device. The thermo-mechanical fatigue testing device of the invention has the advantages of simple structure, low energy consumption and the capability of realizing rapid temperature rise and drop and accurate phase difference control between the mechanical load waveform and the temperature waveform.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Device and method for testing fatigue mechanical property of material under tensile-bending composite load

PendingCN109883833ARealize in-situ monitoringNovel structureMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesScientific instrumentEngineering

The invention relates to a device and a method for testing the fatigue mechanical property of a material under a tensile-bending composite load, and belongs to the field of precision scientific instruments and material testing. The device comprises a vibration isolation base, a supporting frame, an ultrasonic loading module, a hydraulic loading module, a tensile loading module and an ultrasonic flaw detection module; the supporting frame is connected with the vibration isolation base; the hydraulic loading module is connected with the supporting frame through a connecting flange; the ultrasonic loading module is connected with the hydraulic loading module through a thread; and the tensile loading module and the ultrasonic flaw detection module are arranged on the vibration isolation base.The device has the advantages as follows: high-frequency and high-load cross-range loading can be realized; ultrahigh-frequency bending fatigue loading and tensile-bending static dynamic composite load loading can be realized; and the tensile loading module can ensure accurate centering of tested material samples. The tested material samples made of different materials and having different sizes can be subjected to high-frequency fatigue testing under the static dynamic composite load; and a reliable means is provided for service performance analysis of key materials in aerospace and numerousfields.

Owner:JILIN UNIV

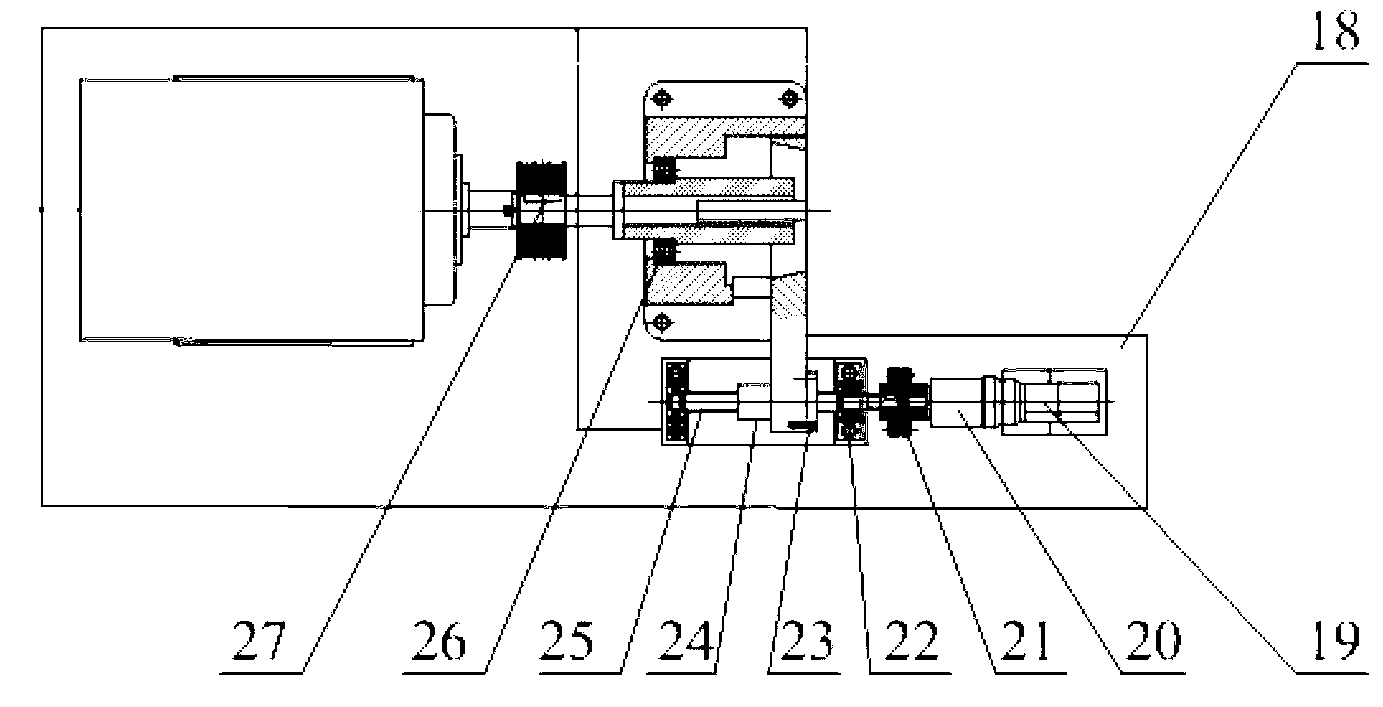

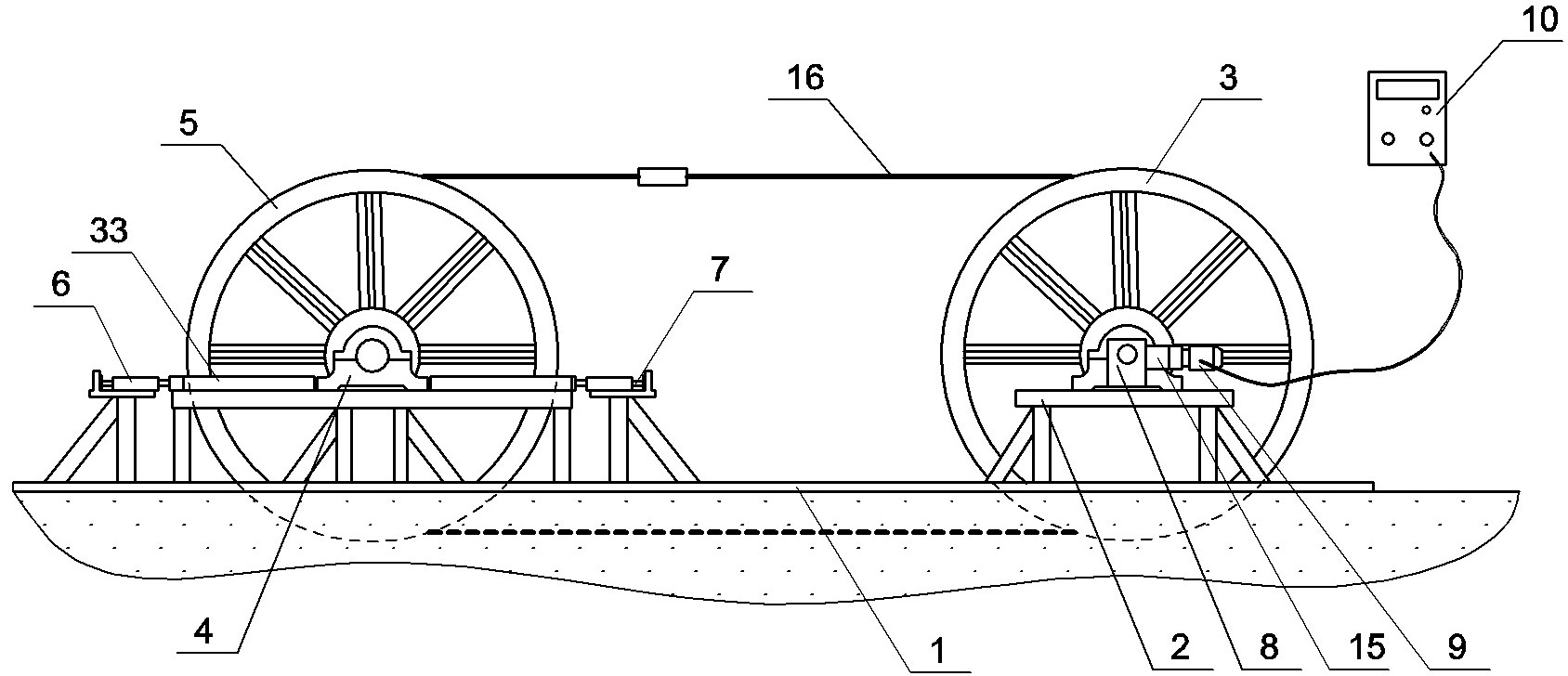

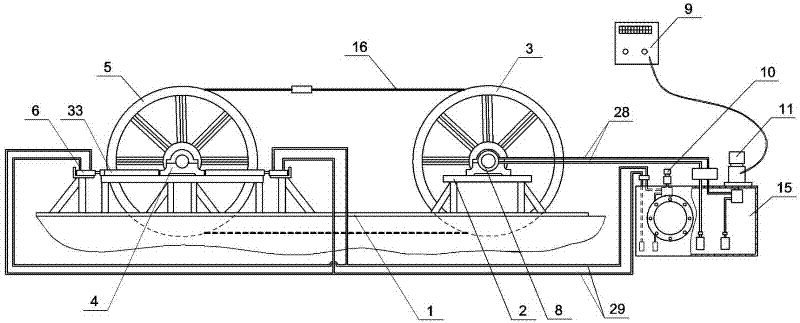

Hydraulic horizontal steel wire rope bending fatigue testing machine and annular combined gasket

ActiveCN102305742AConvenience setImprove general performanceMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesPolyesterDrive wheel

The invention discloses a hydraulic horizontal steel wire rope bending fatigue testing machine and an annular combined gasket. A driving wheel is fixedly arranged at one end of a base of the fatigue testing machine; an experiment wheel is movably arranged at the other end of the base; a rotating shaft of the driving wheel is connected with an output shaft of a rotary driving device through a coupler; an input shaft of the rotary driving device is connected with a power machine; and the power machine is also connected with a photoelectric counter and an electric cabinet. Polyester friction gaskets of the machine are matched according to rope diameters; bending fatigue tests of steel wire ropes with different diameters are carried out; the arc radii of the polyester friction gaskets are matched with the section radii of tested steel wire ropes; and the steel wire ropes can be freely replaced and arranged in rope slings of the driving wheel and the experiment wheel according to the requirements. Fixed-value loads of the machine are realized by frame structures of a power device, a pressure sensor, a spring and the like, and the method is different from a cumbersome method for applying the load by hanging a weight, which is adopted by other similar equipment.

Owner:河南省煤科院检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com