Device and method for testing thermo-mechanical fatigue

A thermomechanical fatigue and heating device technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of complex equipment, long heating and cooling cycles, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

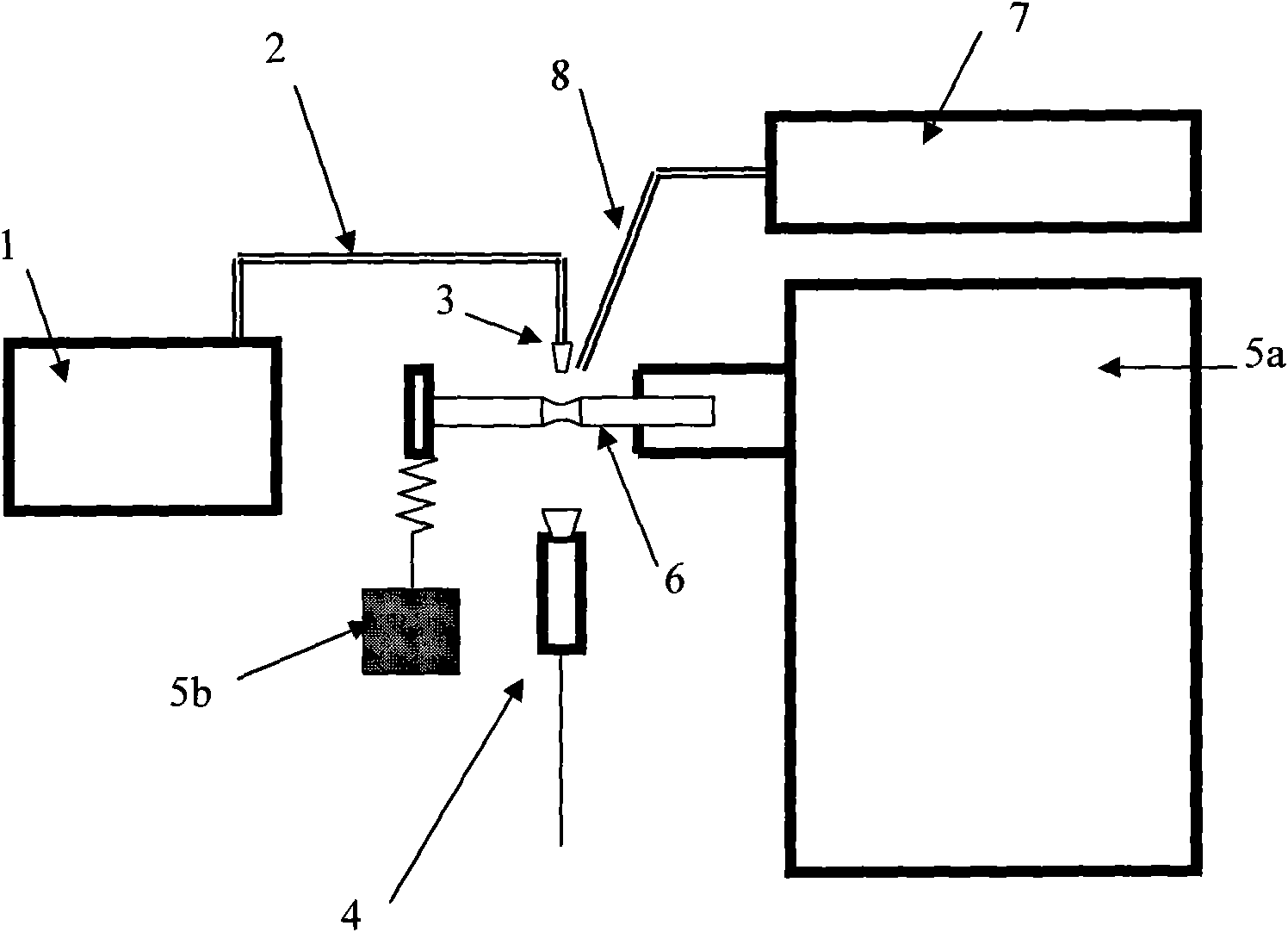

[0033] like figure 1 In the device shown, the loading device is a weight 5b; the sample 6 is set on the rotating shaft of the main body 5a of the rotating bending fatigue machine, and the other end of the sample is mechanically loaded by the weight 5b. The heating device includes a laser light source 1, a focusing lens 2, and may also include a heating device (not shown in the figure) for heating the entire experimental sample. The laser light emitted by the continuous laser light source 1 is transmitted through the optical fiber 2, and then focused on the surface of the sample 6 by the focusing lens 3 to heat the surface of the sample 6. When the overall heating of the test sample is required, the overall heating device can be started to heat the sample. heating. The temperature measuring device is an infrared temperature measuring device, and other temperature measuring devices capable of accurately measuring temperature may also be used. The temperature of the sample heat...

Embodiment 2

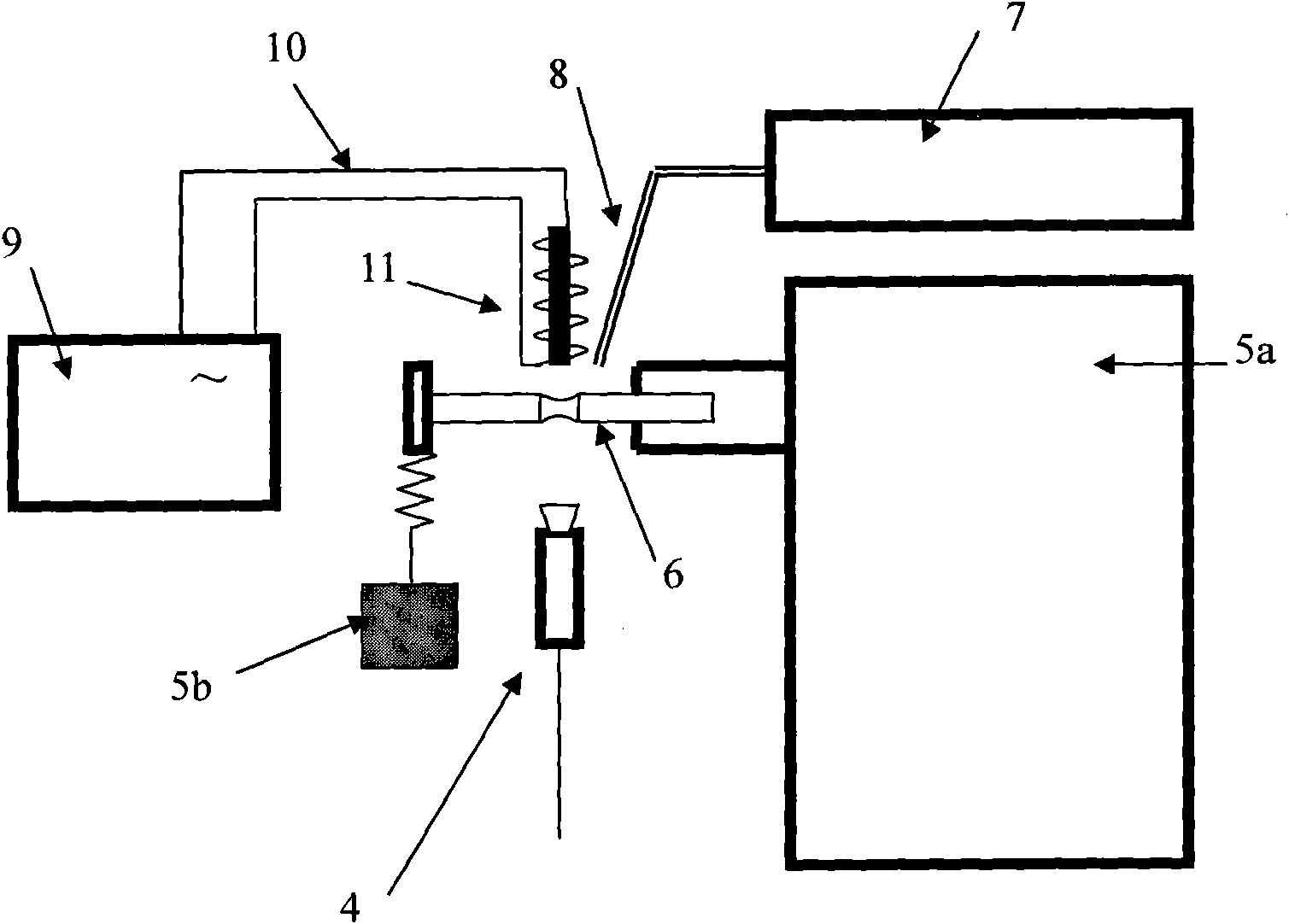

[0046] like image 3In the device shown in , the sample 6 is set on the rotating shaft of the main body 5a of the rotating bending fatigue machine, and the other end of the sample is mechanically loaded by the weight 5b. In the present embodiment, the heating device is: an AC power supply and an induction coil; the AC power supply 9 is connected to the induction coil 11 through a wire 10, and the induction coil 11 generates a high-frequency electromagnetic field to excite an induced current on the surface / subsurface of the sample 6, thus affecting the surface of the sample. for heating. The temperature of the sample heating point is measured by an infrared temperature measuring device 4 . The ambient gas stored in the gas source 7 is sprayed onto the surface of the sample through the gas nozzle 8 to control the ambient atmosphere of the thermomechanical fatigue process.

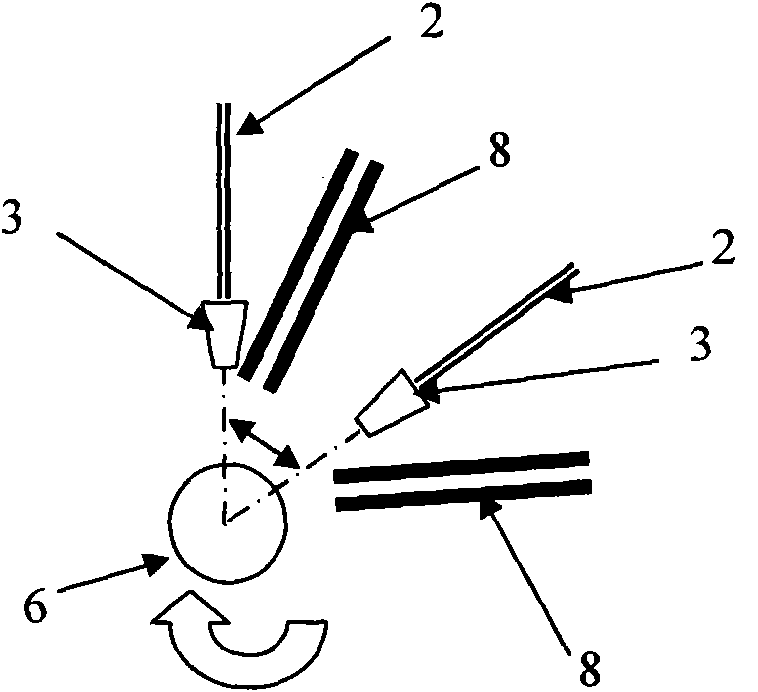

[0047] like Figure 4 As shown, the induction coil 11 and the gas nozzle 8 can be arranged from differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com