Surface modification method for hollow glass tiny bead and uses thereof

A hollow glass microsphere and surface modification technology, applied in the field of preparation of thermal insulation coatings, the field of surface modification of hollow glass microspheres, to achieve the effect of improving heat reflection effect, optimizing speed and ability, and reducing VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

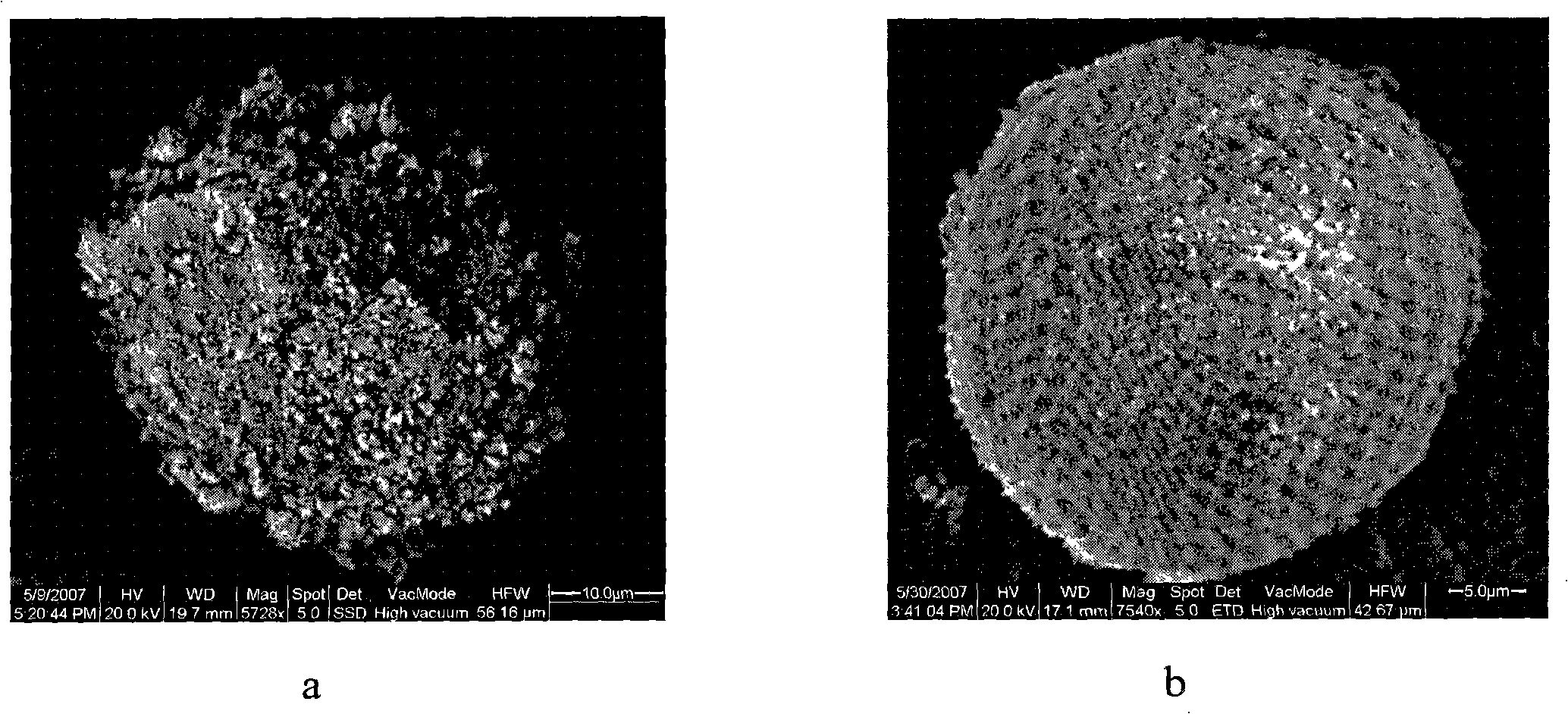

[0045] The concentration of 256.25ml is 0.4mol.L -1 Sodium hydroxide aqueous solution with a particle size of 10-100 μm and a specific surface area of 0.1-0.7 m 2 Add 5g of hollow glass microspheres per gram into a 1000ml flask, and add dropwise 0.3ml of surfactant sodium dodecylbenzenesulfonate aqueous solution with a concentration of 0.1g / ml in the flask, fully stir to make a hollow glass Microbead suspension; in the state of electric stirrer stirring at a constant speed of 60 rpm, maintain the temperature of the reaction system at 60°C, add 256.25ml dropwise to the hollow glass microsphere suspension within 6 hours of reaction time with a concentration of 0.1 mol.L -1 The aqueous solution of titanium sulfate was allowed to stand for 2 hours after the dropwise addition, filtered, washed until no white precipitate was added to the filtrate with 10% aqueous solution of barium chloride, and filtered with suction to obtain wet powder. Dry the wet powder at 100-110°C for 3 ho...

Embodiment 2

[0047] The concentration of 512.5ml is 0.2mol.L -1 Potassium hydroxide aqueous solution with a particle size of 10-100 μm and a specific surface area of 0.1-0.7 m 2 Add 5g of hollow glass microspheres per gram into a 2000ml flask, and add dropwise 0.3ml of surfactant sodium dodecylbenzenesulfonate aqueous solution with a concentration of 0.1g / ml in the flask, fully stir to make hollow glass Microbead suspension: under the state of electric stirrer stirring at a constant speed of 60 rpm, maintain the temperature of the reaction system at 40°C, add 1025ml dropwise to the hollow glass microbead suspension within 8 hours of reaction time with a concentration of 0.05mol .L -1 The titanyl sulfate aqueous solution was left to stand for 2 hours after the dropwise addition, filtered, washed until no white precipitate was added to the filtrate with 15% barium nitrate aqueous solution, and the wet powder was obtained by suction filtration. Dry the wet powder at 100-110°C for 3 hours,...

Embodiment 3

[0049] The concentration of 768.75ml is 0.2mol.L -1 Sodium hydroxide aqueous solution with a particle size of 10-100 μm and a specific surface area of 0.1-0.7 m 2 Add 2.5g of hollow glass microspheres / g into a 2000ml flask, and add dropwise 0.1ml of a surfactant sodium dodecylbenzenesulfonate aqueous solution with a concentration of 0.1g / ml in the flask, stir fully, and make a hollow Glass microbead suspension; under the electric stirrer with 60 revolutions / minute constant speed stirring state, the temperature of maintaining reaction system is 40 ℃, in the reaction time of 8 hours, dropwise add the concentration of 384.38ml in this hollow glass microbead suspension to be 0.1mol.L -1 The aqueous solution of titanium sulfate was left to stand for 2 hours after the dropwise addition, filtered, washed until no white precipitate was added to the filtrate with 15% aqueous solution of barium nitrate, and filtered by suction to obtain a wet powder. Dry the wet powder at 100-110°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com