Patents

Literature

1552 results about "Glass microsphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

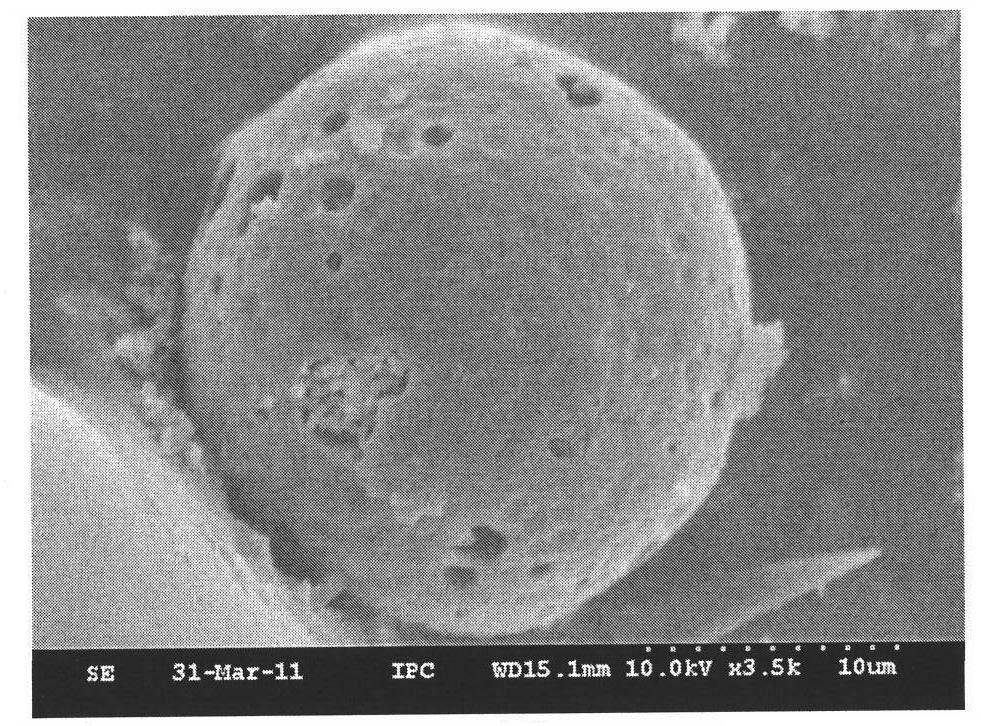

Glass microspheres are microscopic spheres of glass manufactured for a wide variety of uses in research, medicine, consumer goods and various industries. Glass microspheres are usually between 1 and 1000 micrometers in diameter, although the sizes can range from 100 nanometers to 5 millimeters in diameter. Hollow glass microspheres, sometimes termed microballoons or glass bubbles, have diameters ranging from 10 to 300 micrometers.

Catheter guiding system and methods

ActiveUS10376673B2Reduce and spread stressEliminate needHeart valvesCatheterGlass microsphereCatheter device

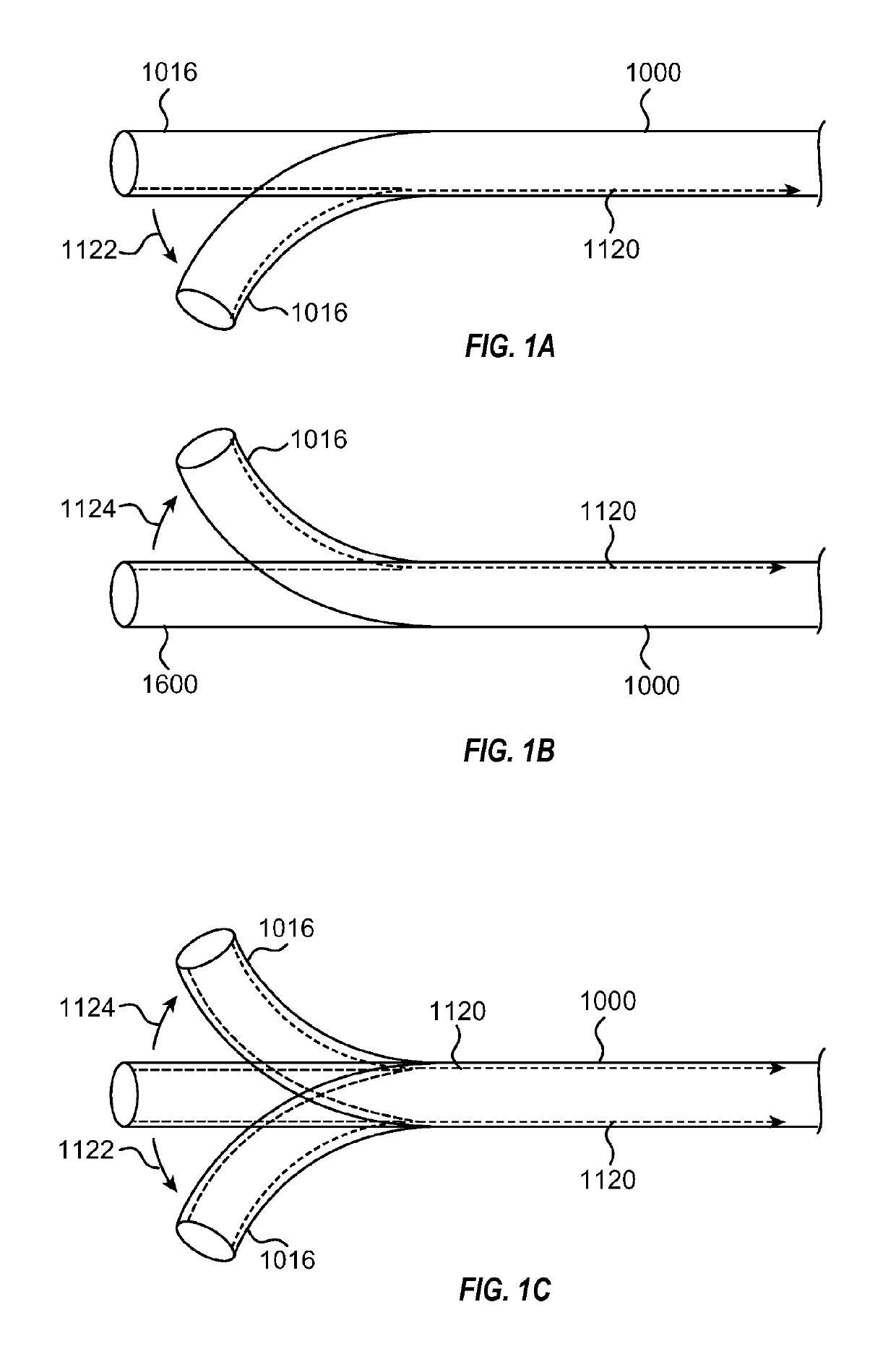

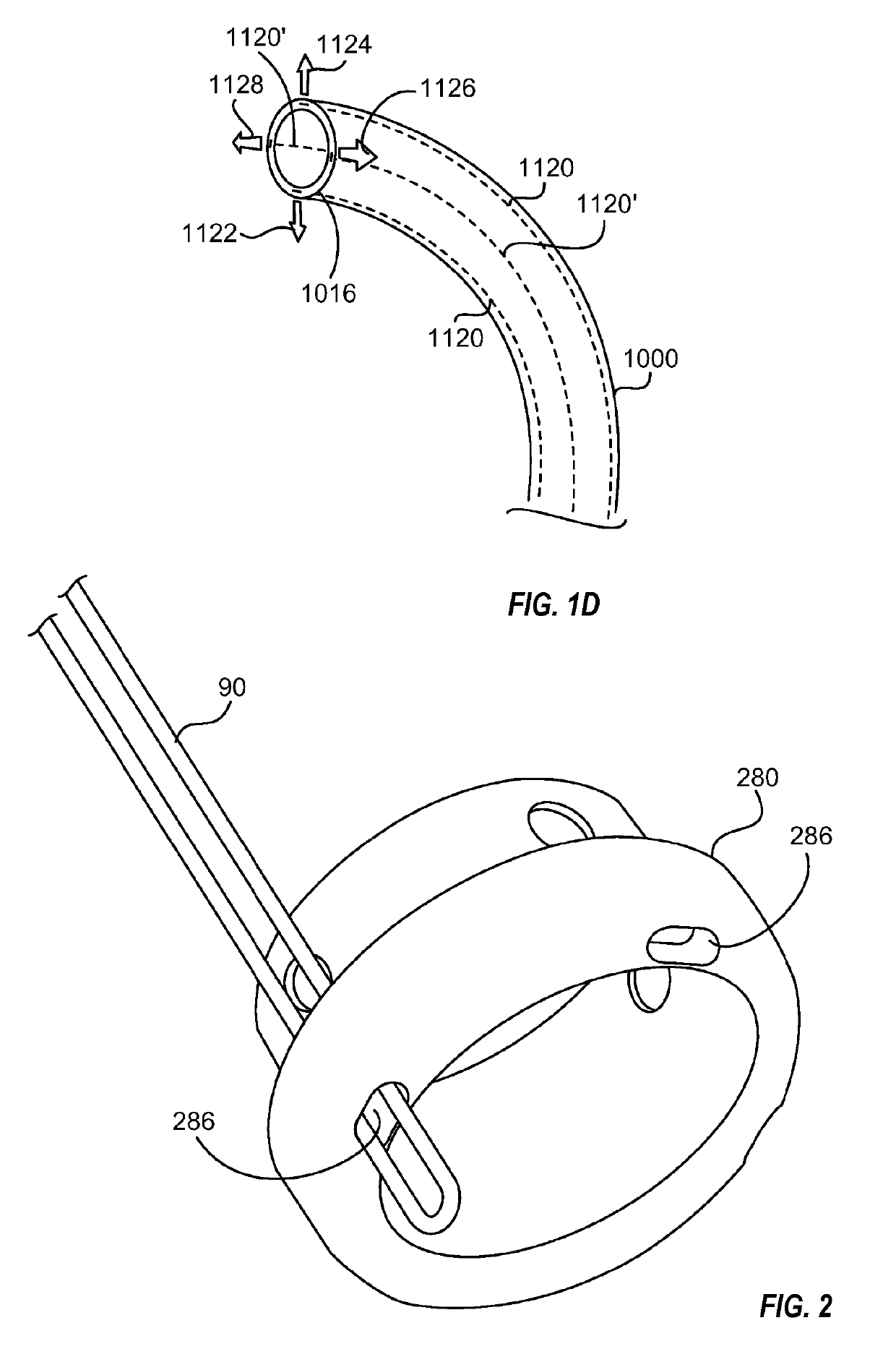

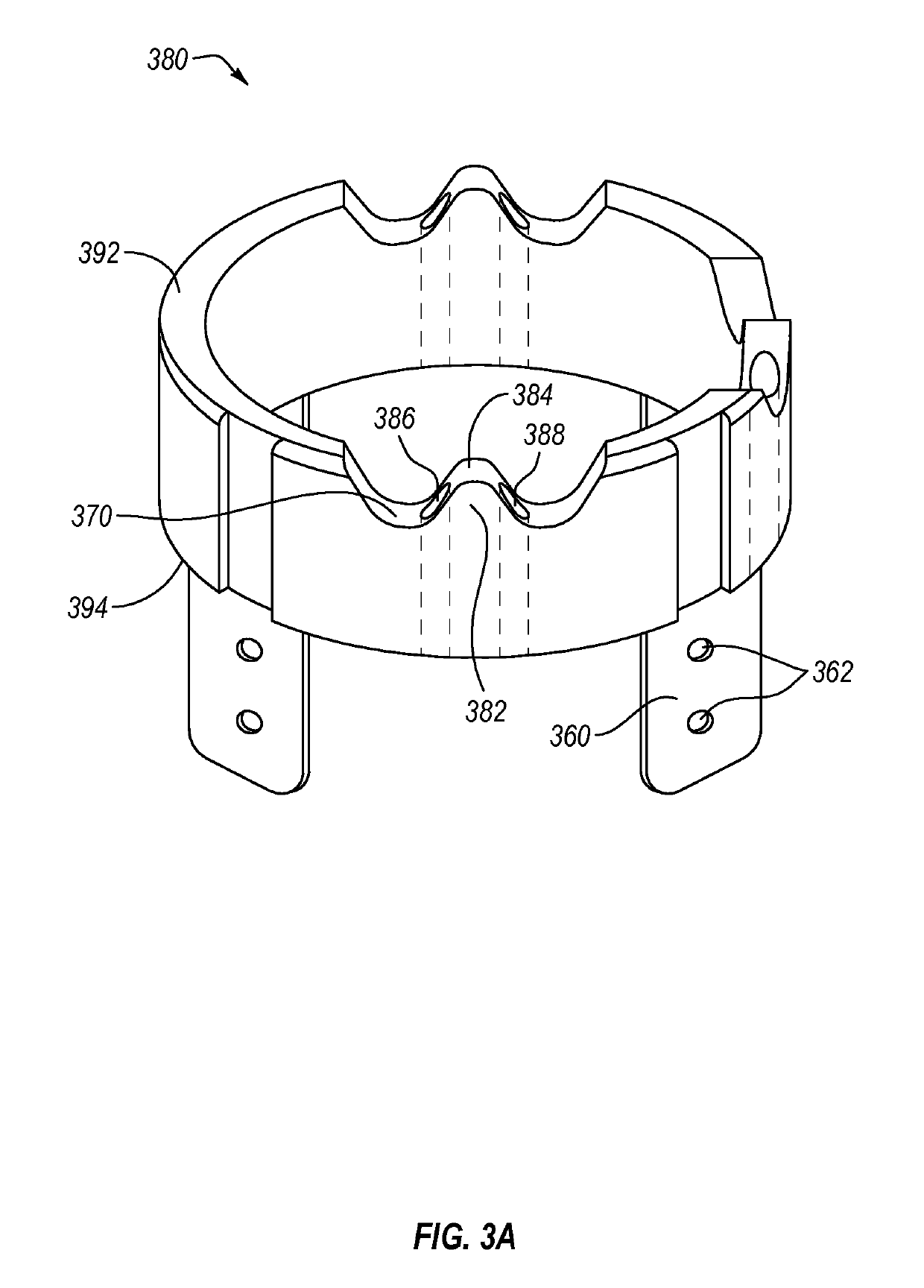

A steerable guide catheter includes a tip ring at a distal end and one or more pullwires configured to engage with the tip ring when put in tension, the pullwire(s) thereby subjecting the steerable guide catheter to a curving or turning force. The tip ring includes a saddle and one or more pullwire channels allowing the pullwire to be looped over the saddle such that when the pullwire is placed under tension, it abuts against the saddle of the tip ring. Some embodiments include additional catheters axially aligned within or outside of the steerable guide catheter, and include a keying feature aligning the rotation of the multiple catheters. The keys of the keying feature can be formed of a polyamide with a glass microsphere filler, and can be thermally welded to the catheter.

Owner:EVALVE

Methods of cementing pipe in well bores and low density cement compositions therefor

The present invention provides methods of cementing pipe in well bores and low density cement compositions having enhanced compressive, tensile and bond strengths upon setting. The composition of the invention are basically comprised of a hydraulic cement, sufficient water to form a slurry and hollow glass microspheres surface treated with a mixture of organosilane coupling agents present in an amount sufficient to produce a cement composition density in the range of from about 6 to about 12 pounds per gallon.

Owner:HALLIBURTON ENERGY SERVICES INC

High SPF transparent or translucent, cytoprotective, biodegradable, UV radiation resistant compositions

ActiveUS20080233060A1Protect the skinEliminating possible endocrine disruption responseCosmetic preparationsToilet preparationsCarrageenanPhospholipid

A composition comprising purified water using ozonation, ionization, or distillation or any combination thereof wherein alcohol may be substituted for, or combined with water at least one emollient including but not limited to chitosan, and aloe vera gel, individually or in any combination; an oil component with spf boosting agents including but not limited to; ethyl macadamiate, non-toxic silicone oil and essential oils, butter milk, waxes impregnated with inorganic sun-block or sunscreen agent and organic / inorganic micronized particles, wood powder and bentonite clay, keratin, either individually or in any combination; at least one inorganic sun-block or sunscreen agent including any metal oxide, glass microsphere, silica and silica compound, and optionally metal oxide pigments with particles that are micronized, submicronized, nanoparticle sized, or otherwise individually or in any combination that can be homogenized in either a water phase, a water-aloe phase, an oil phase or any phase of said composition; at least one emulsifier wherein said emulsifier includes but is not limited to a phospholipid and / or liposome or an aloe vera gel or an ester of coconut oil individually or in any combination, for emulsifying the water, water-aloe, or oil phase in combination with an homogenizer; where any of components are preferably mixed with an homogenizer and where an appropriate thickening agent including but not limited to xanthan gum, carageenan, either individually or in any combination is added as required.

Owner:GRUNE GUERRY L

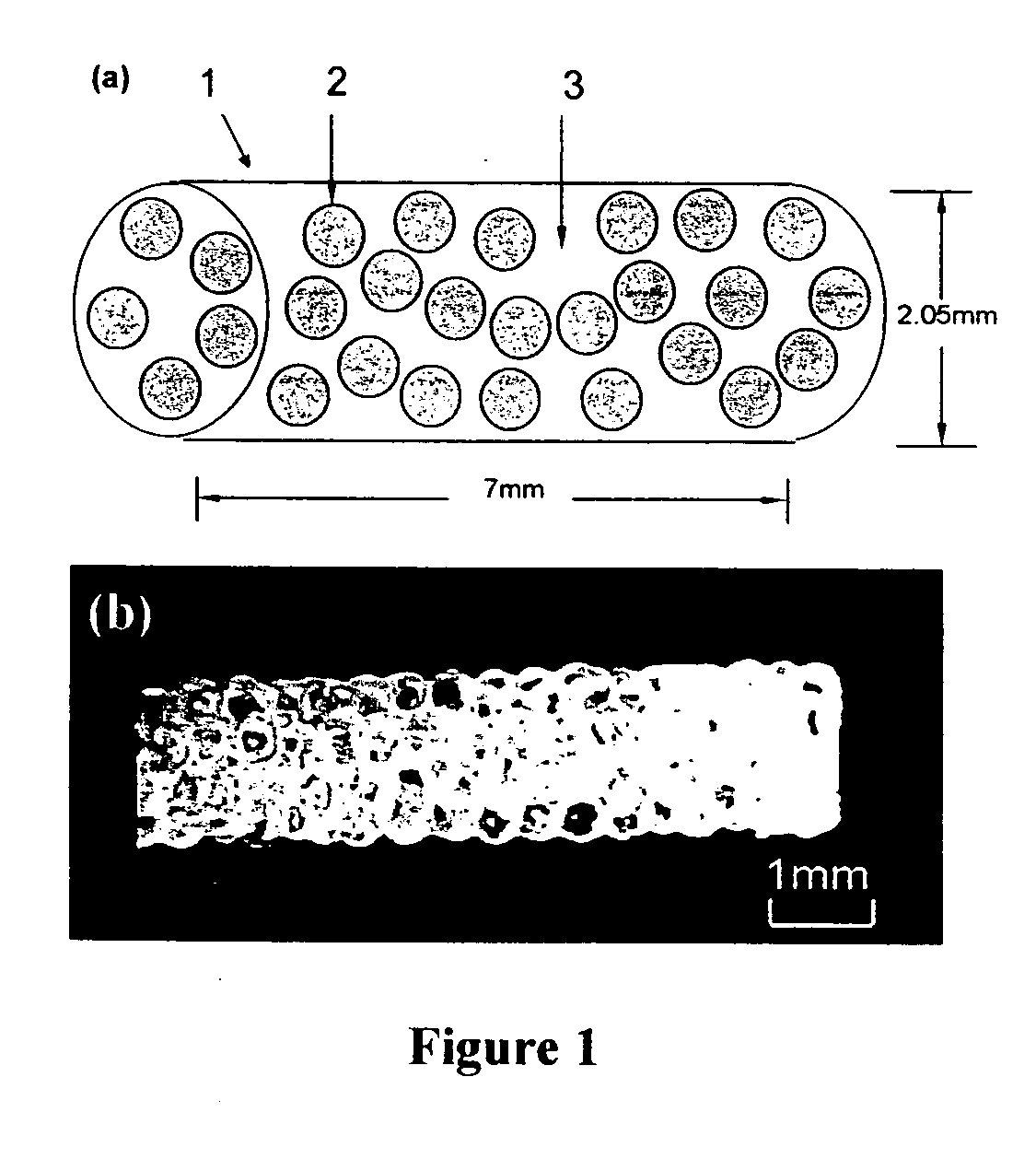

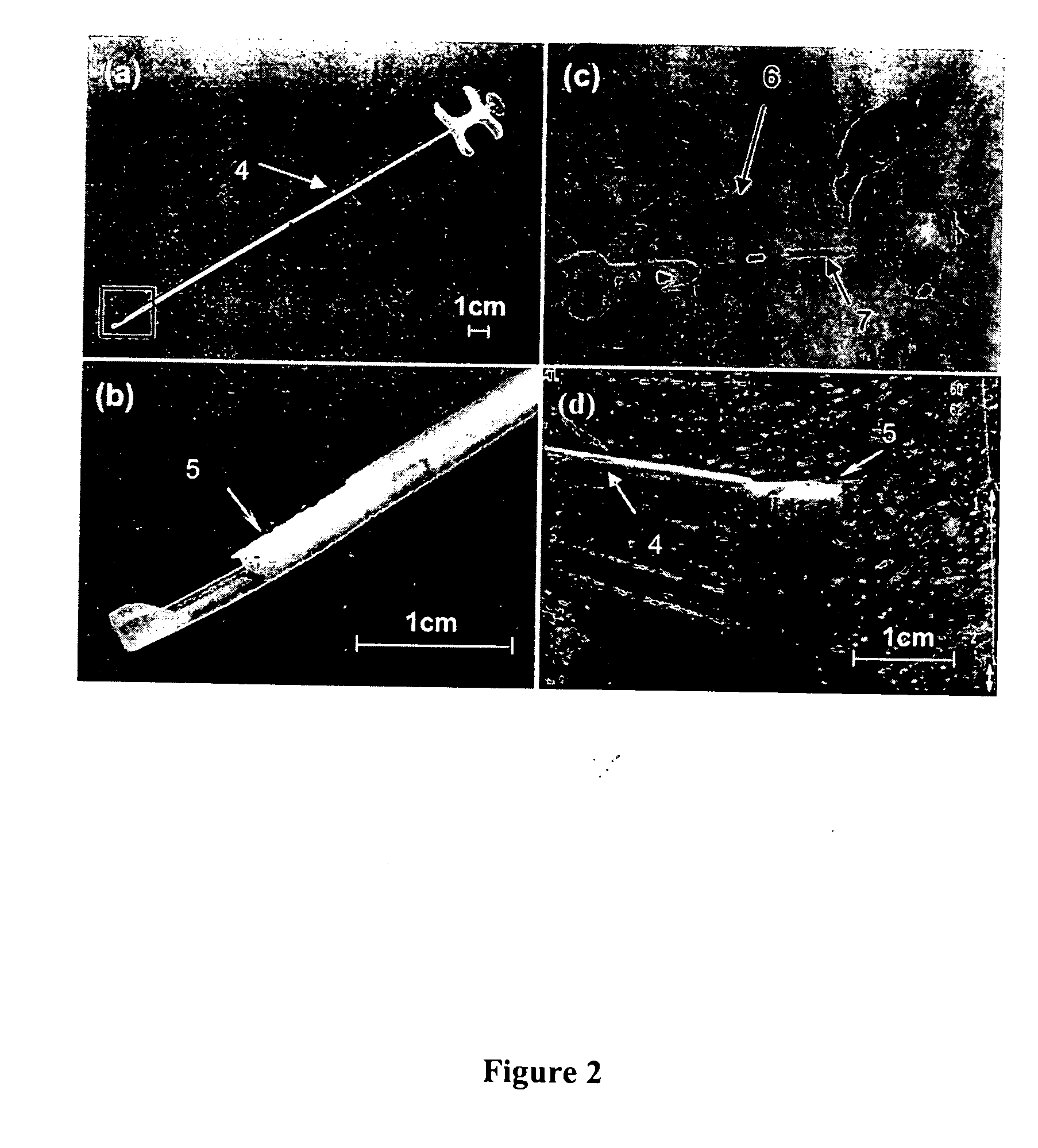

Marker device for X-ray, ultrasound and MR imaging

InactiveUS20060293581A1Sharp contrastEasily introduced into tissueUltrasonic/sonic/infrasonic diagnosticsPowder deliveryDiagnostic Radiology ModalityMicrosphere

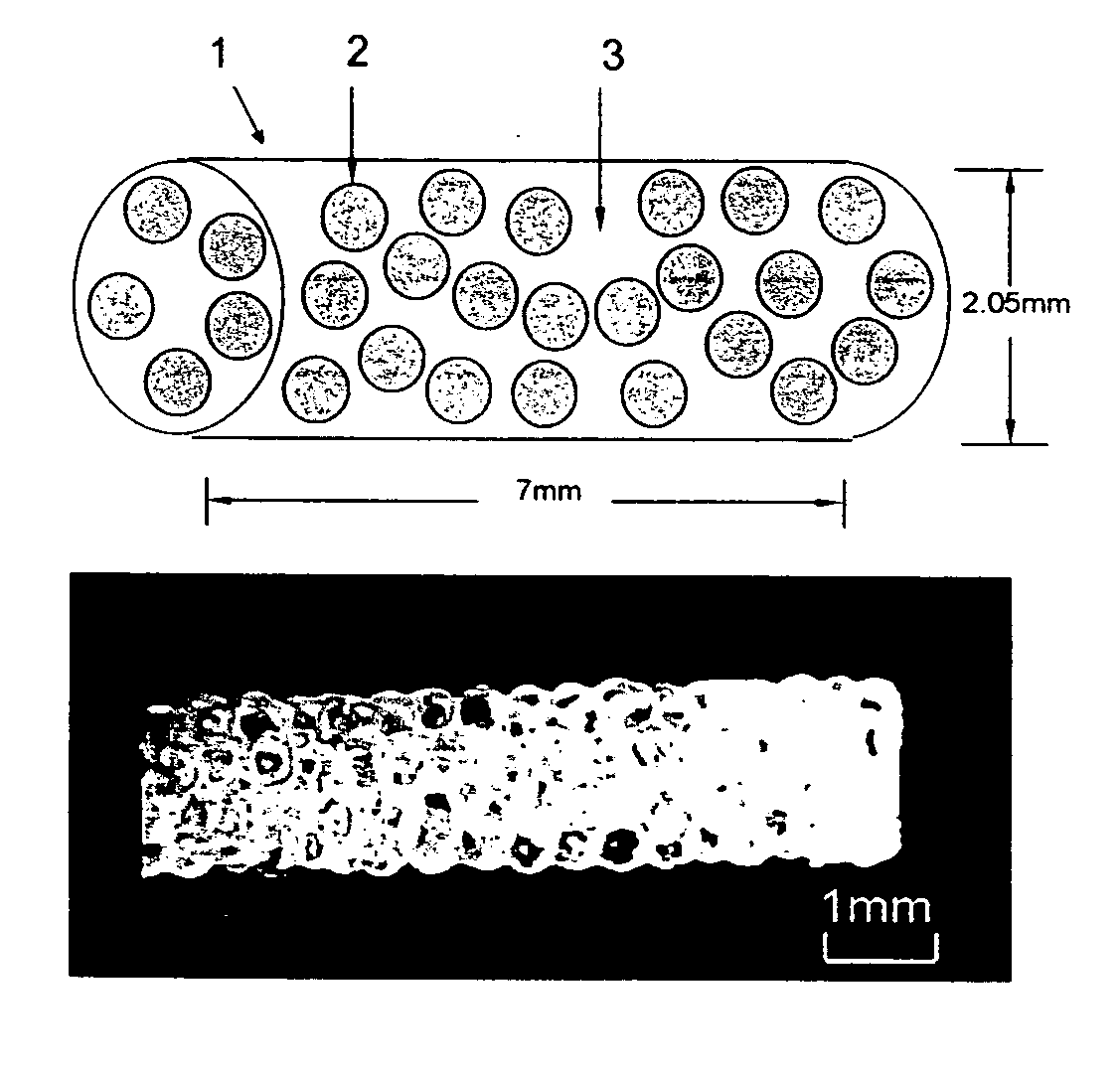

An imaging marker comprised of glass and iron-containing aluminum microspheres in a gel matrix which shows uniformly good contrast with MR, US and X-Ray imaging. The marker is small and can be easily introduced into tissue through a 12-gauge biopsy needle. The concentration of glass microspheres and the size dictate the contrast for US imaging. The contrast seen in MRI resulting from susceptibility losses is dictated by the number of iron-containing aluminum microspheres; while the artifact of the marker also depends on its shape, orientation and echo time. By optimizing the size, iron concentration and gel binding, an implantable tissue marker is created which is clearly visible with all three imaging modalities.

Owner:SUNNYBROOK & WOMENS COLLEGE HEALTH SCI CENT

Light composite material

InactiveCN103087463ASolve the insulation performanceSolve the sound insulationGlass fiberCarbon fibers

The invention relates to a light composite material, and in particular relates to a hollow microspheres and fiber body composite material. The light composite material consists of a base material, the fiber body and hollow microspheres which are uniformly distributed. The proportion of the total volume of the fiber body and hollow microspheres and the base material is (1:5)-(1:1). The base material is thermoplastic or thermosetting resin. The fiber body is at least one of fibrilia, carbon fiber, glass fiber, polypropylene fiber, aramid fiber and basalt fiber. The hollow microspheres are at least one of hollow glass microspheres and hollow ceramic microspheres. The volume ratio of the fiber body and the hollow microspheres is (1:5)-(1:1). The fiber body and the hollow microspheres are bonded together through the base material. According to the light composite material provided by the invention, the problem that current composite material is unsatisfactory in heat insulation, sound insulation, shock absorption and the like because the inner structure is almost a solid structure can be solved.

Owner:CHERY AUTOMOBILE CO LTD

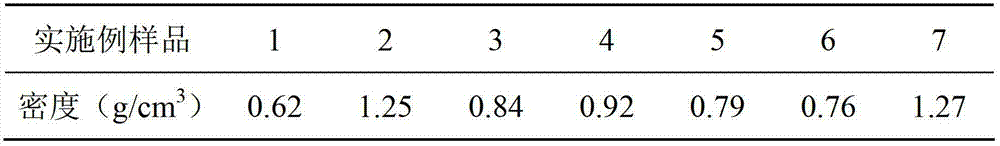

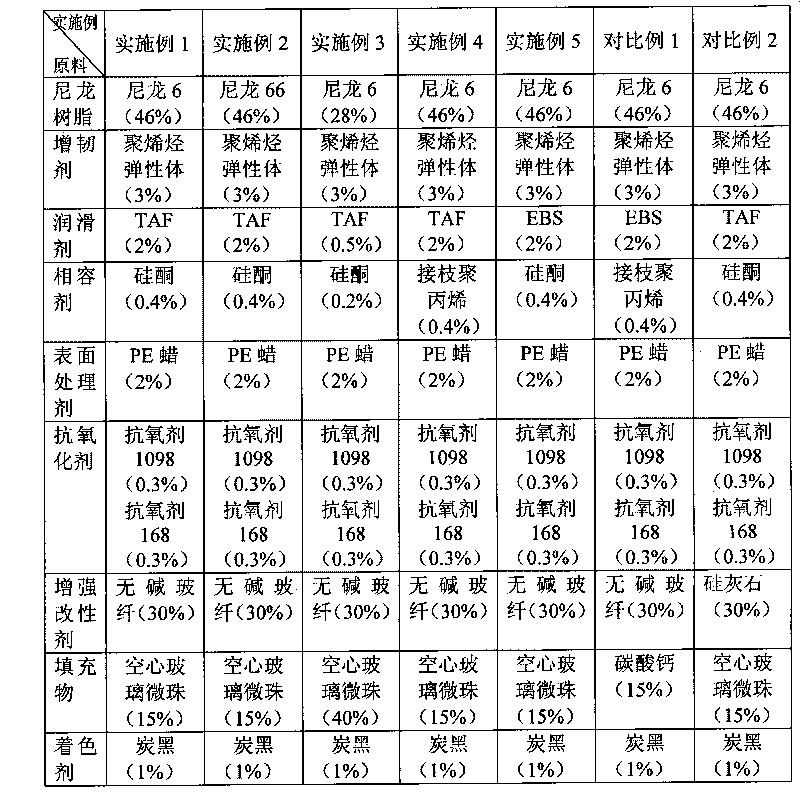

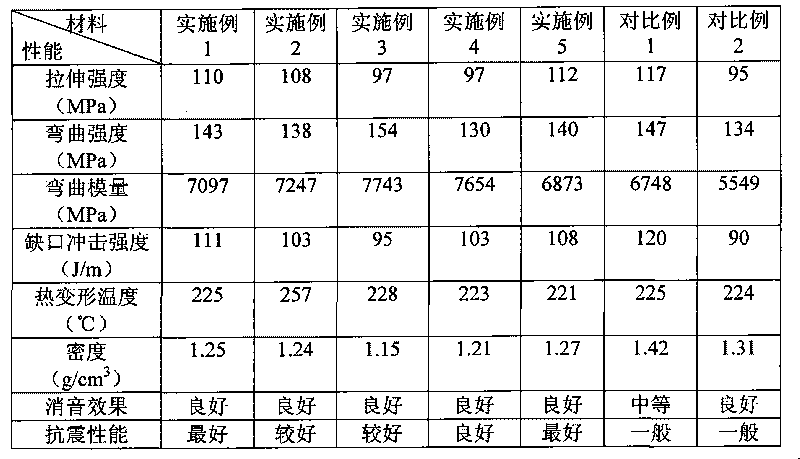

Nylon composition, method for preparing same and application thereof

The invention provides a nylon composition and a method for preparing the same. The raw materials of the nylon composition comprise nylon resin, a toughening agent, a lubricant, a compatilizer, a surface treating agent, an antioxidant, a reinforced modifying agent which is fiber, and filling materials which are hollow glass microspheres. The nylon composition, provided by the invention, can lower the warpage of the materials, prevent the glass fiber from being exposed to the outside, make the surface of the injection moulding piece more smooth and clean, reduce the weight of the injection moulding piece and simultaneously achieves good silencing and shock resistant effects.

Owner:BYD CO LTD

Fire resistant fabric material

A fire resistant fabric material comprising a substrate having an ionic charge which is coated with a coating having essentially the same ionic charge. The coating consists essentially of a filler material comprising clay and a binder material. The substrate is preferably fiberglass, the filler material may further comprise at least one additional filler selected from the group consisting of decabromodiphenyloxide, antimony trioxide, fly ash, charged calcium carbonate, mica, glass microspheres and ceramic microspheres and mixtures thereof and the binder material is preferably acrylic latex.

Owner:ELK PREMIUM BUILDING PROD

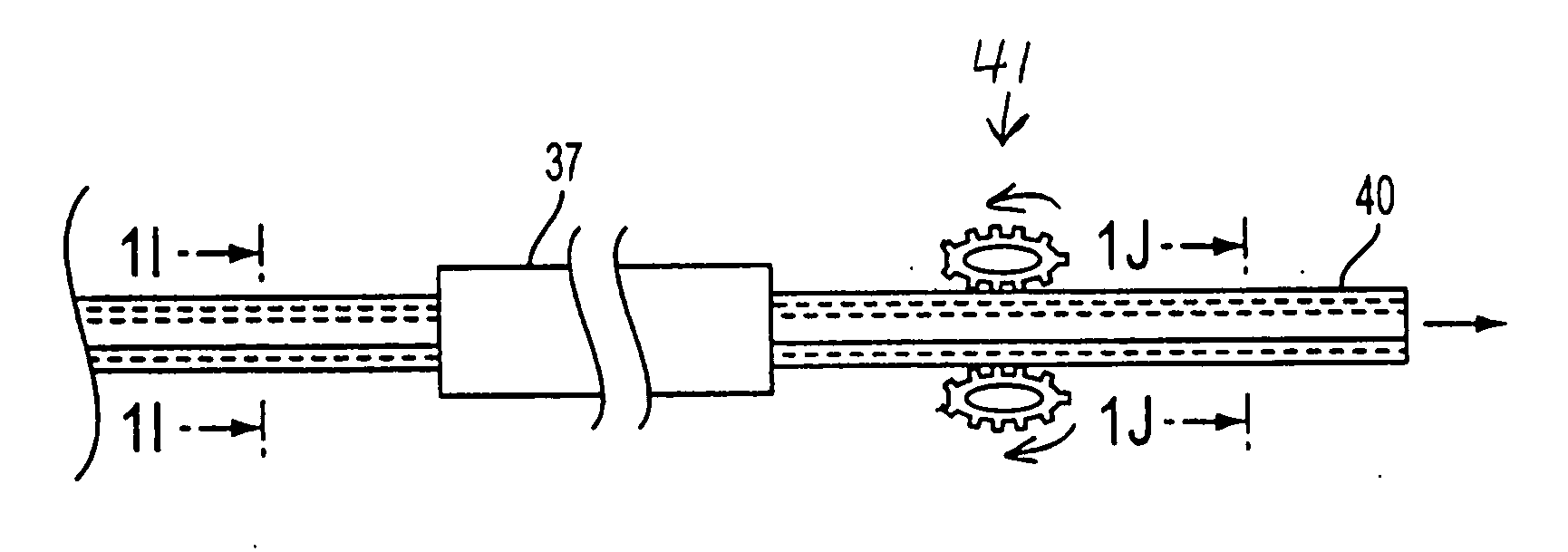

Pneumatic tire having built-in sealant layer and preparation thereof

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G′ (80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G′ (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

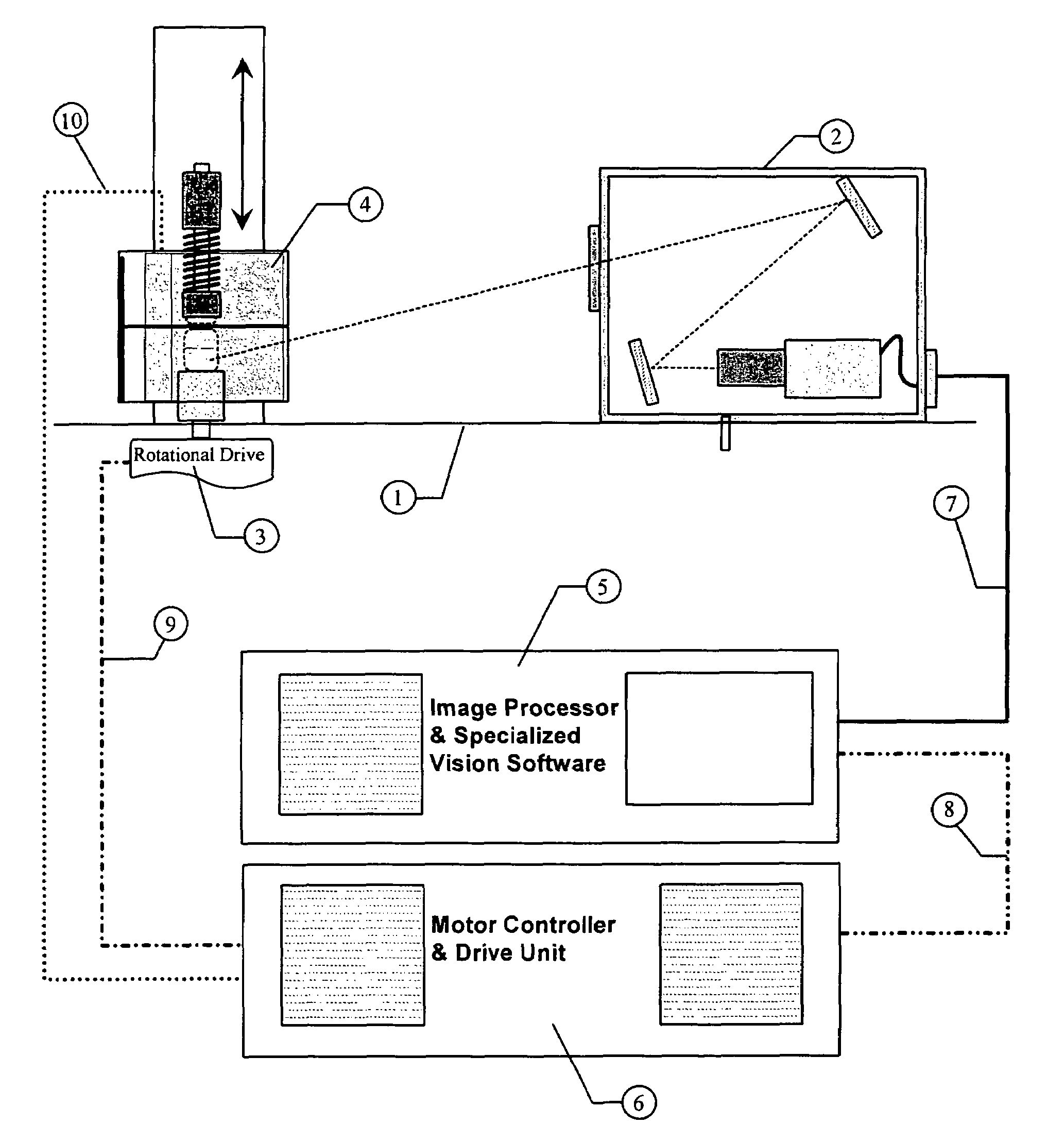

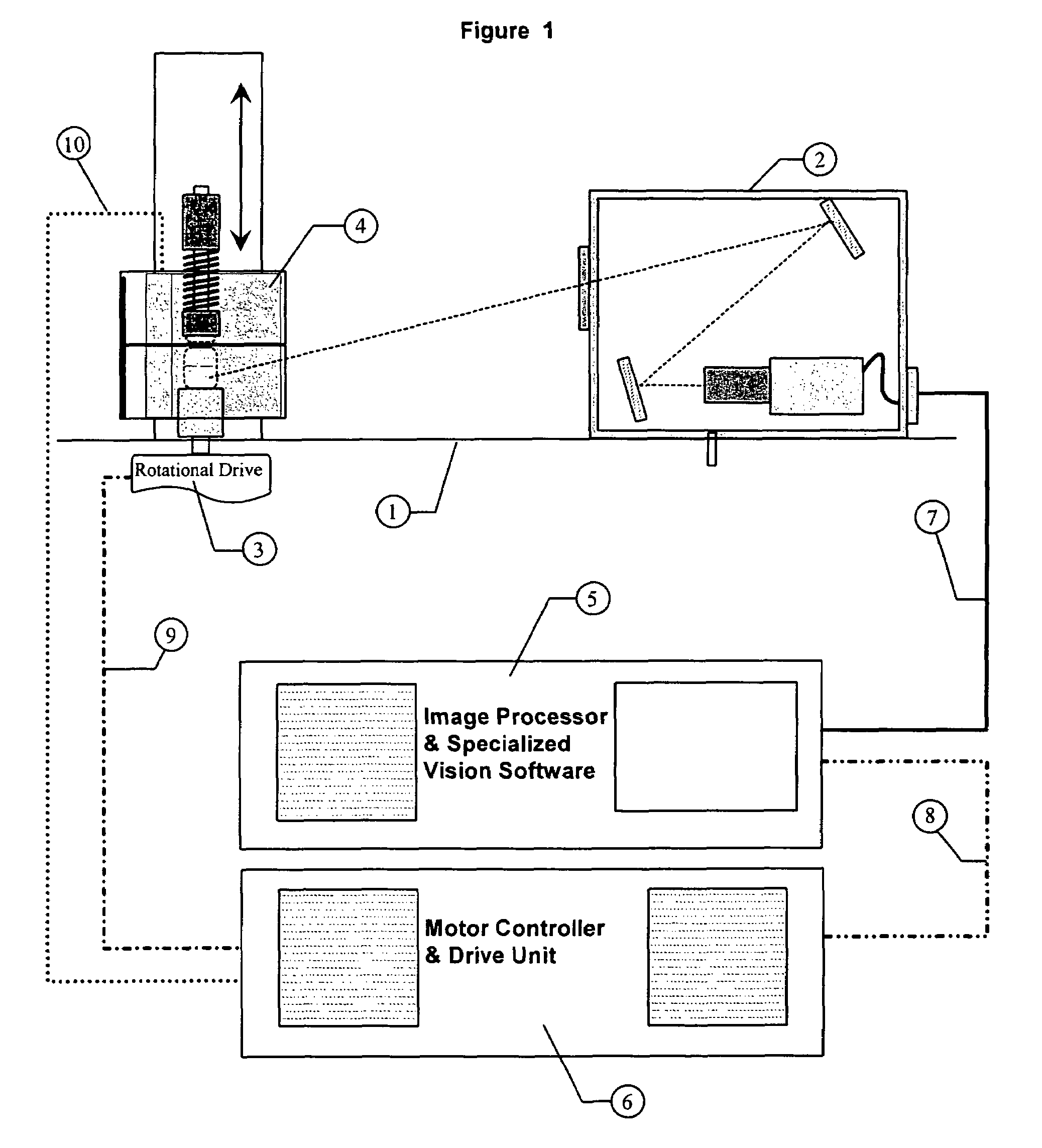

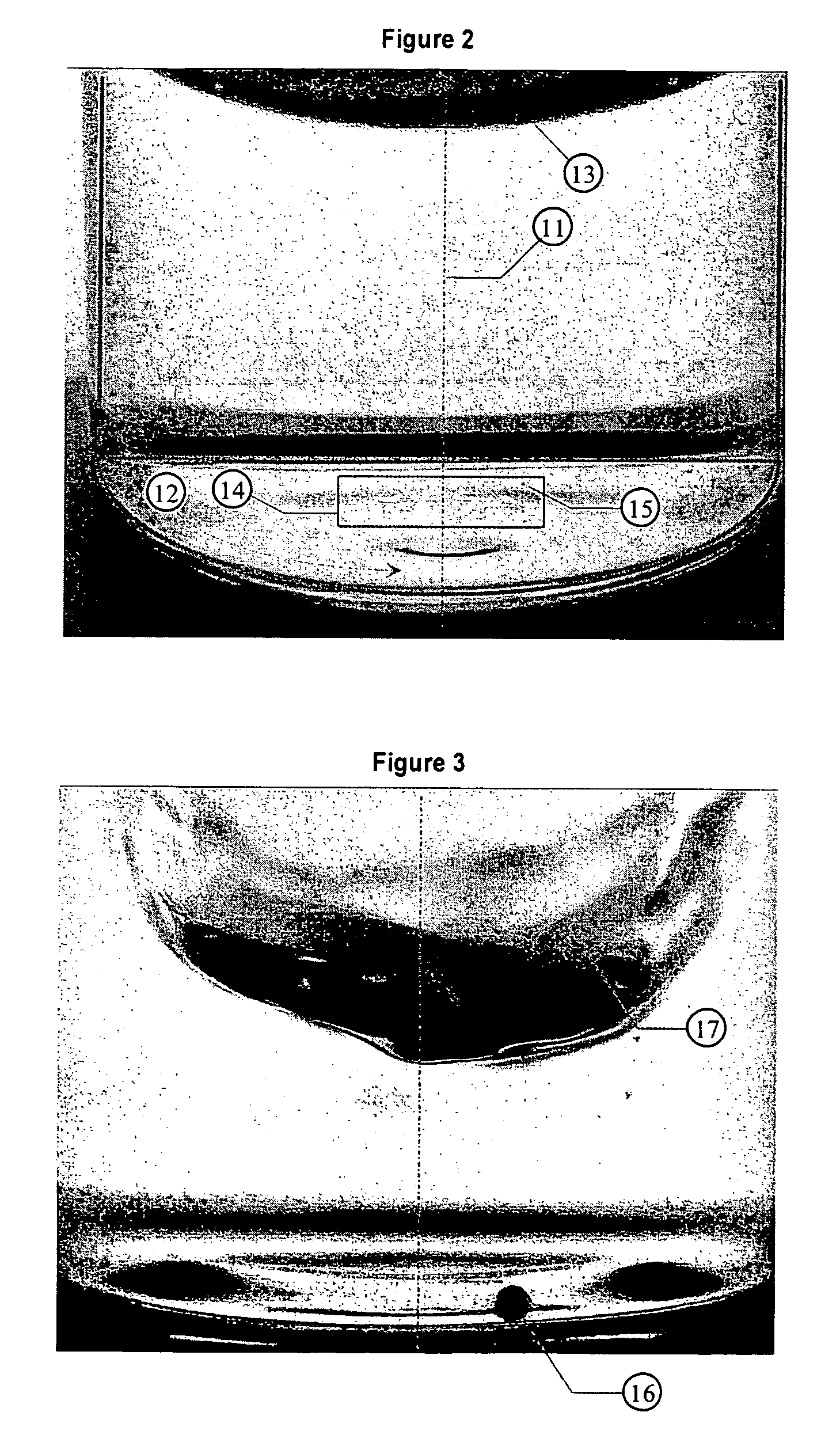

Small container fluid dynamics to produce optimized inspection conditions

ActiveUS7430047B2Improved detection and measurementSmall sizeOptically investigating flaws/contaminationIndividual particle analysisAlgorithmMicrosphere

New methodology, realizable with both manual and new semi-automatic imaging technology, has transformed both the inspection and the batch release Attribute Sampling Inspection for contaminating visible particles in injectable solutions into statistically replicable procedures. In this new non-destructive inspection procedure, a calibration curve relates NIST traceable measurement of maximum particle size to the rejection probability of the particle. Data for this calibration curve is determined with a graduated set of single durable stainless steel and glass microspheres that are sized with NIST traceability. Use of the calibration curve transforms the probabilistic variability of visible particle inspection data described by Knapp into the ‘simply replicable form’ required by the Attribute Sampling Tables. The present invention uses cutting edge imaging technology to achieve 1% sizing accuracy within 10 μm from 50 to 1,000 μm. An improved alternative sizing technique used in this invention uses the particle information to achieve an integral particle sizing function.

Owner:BUDD GERALD WALTER +1

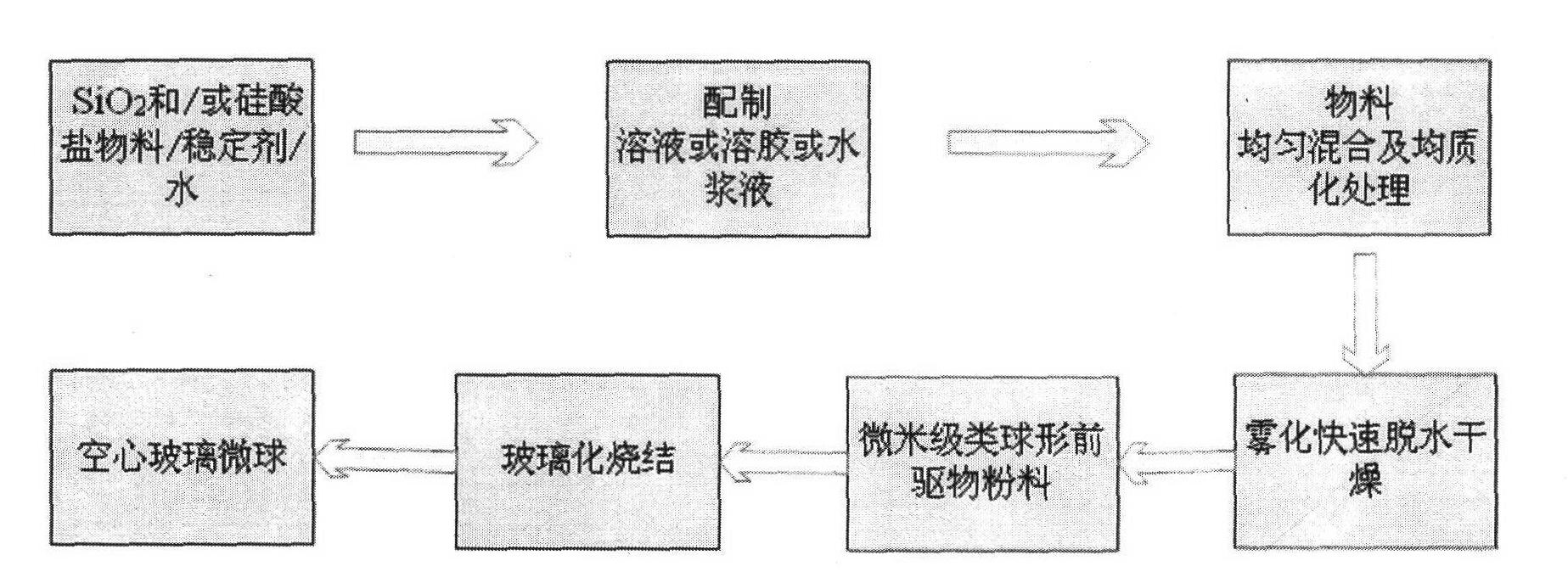

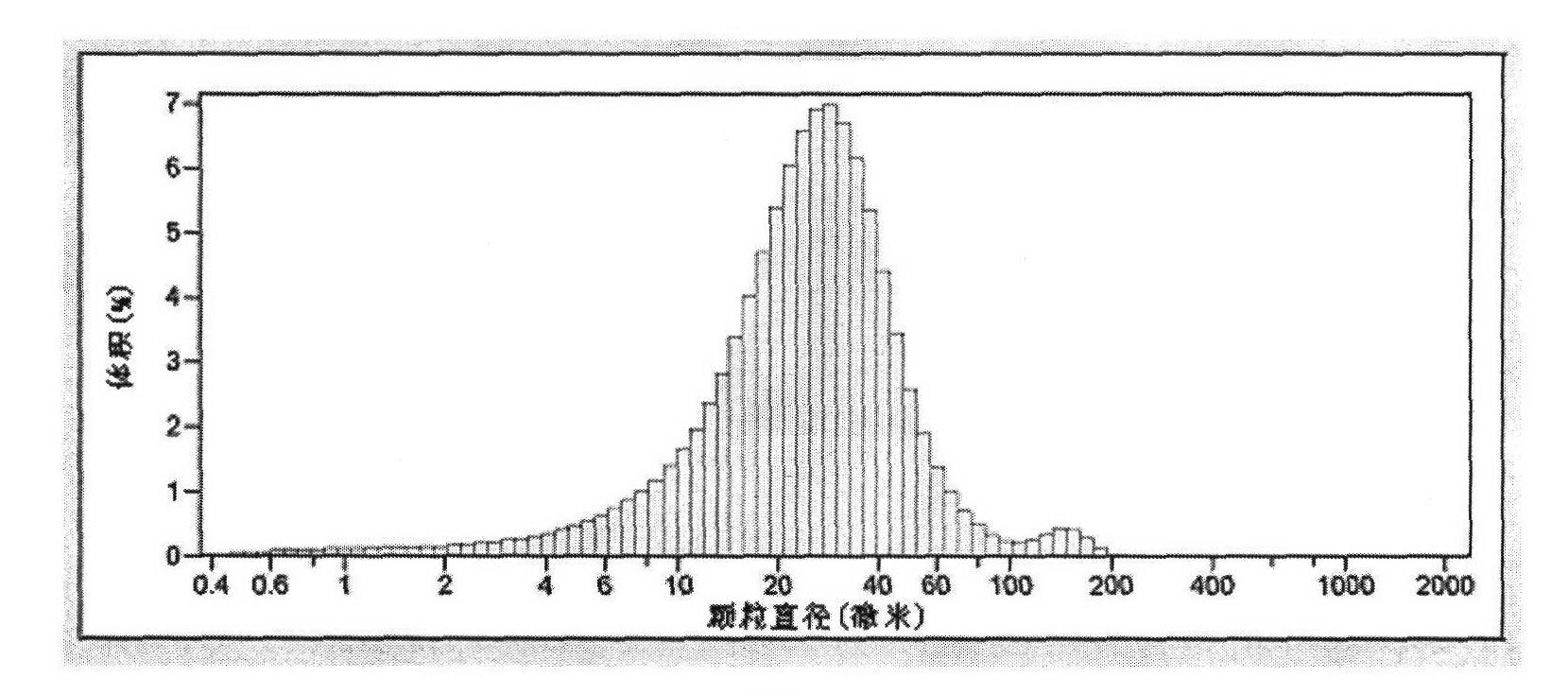

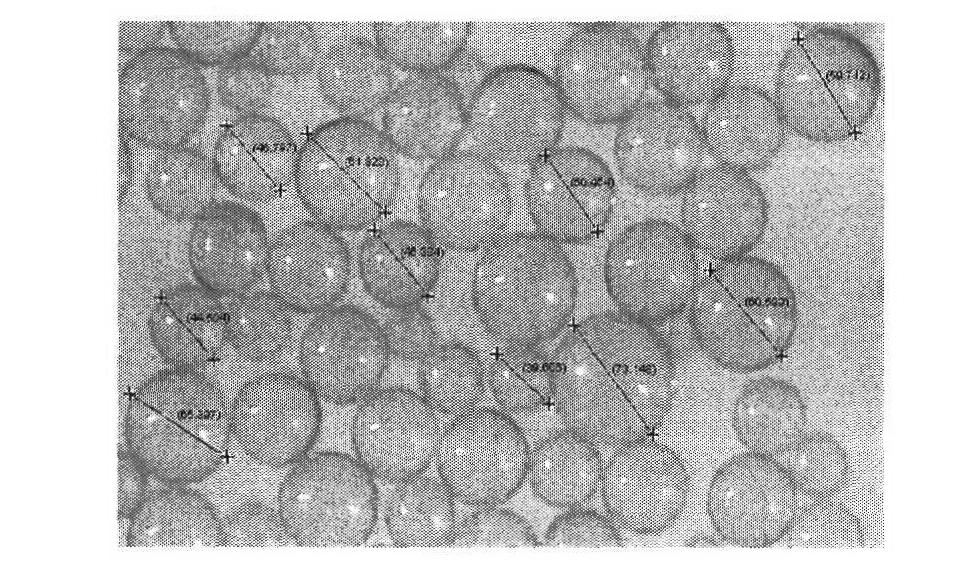

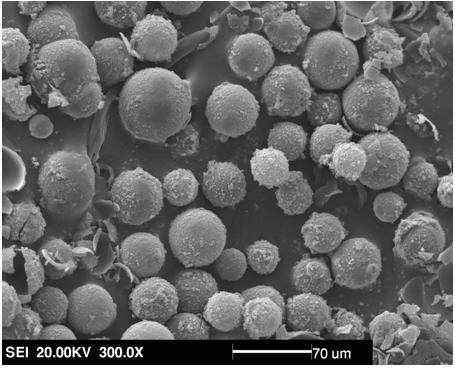

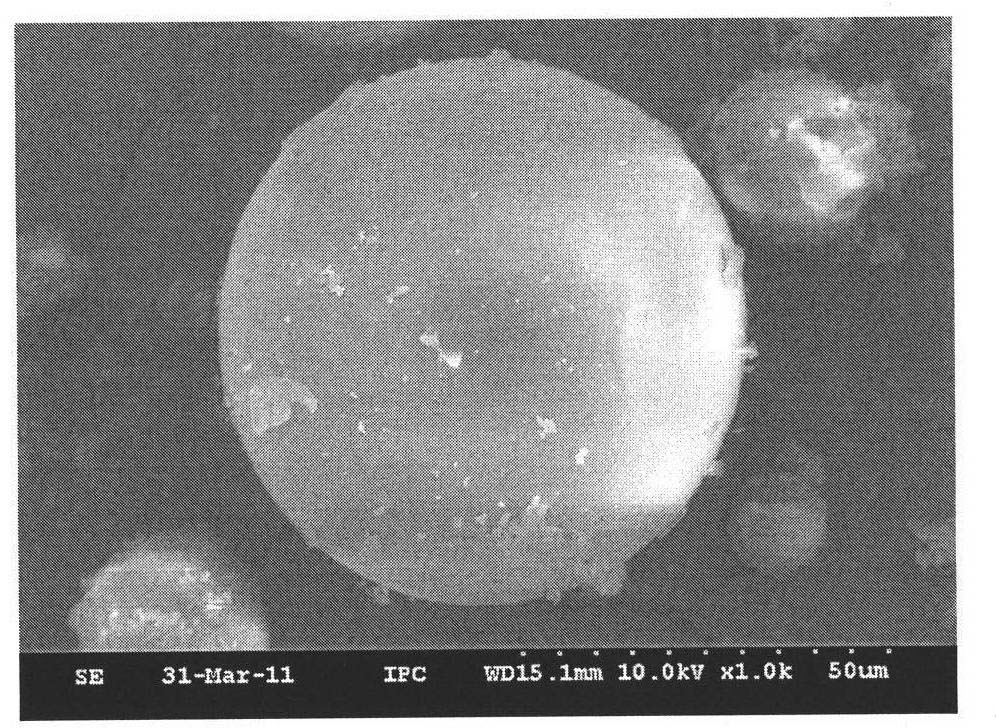

Soft chemical preparation method for hollow glass micro-balloon, prepared hollow glass micro-balloon and application thereof

ActiveCN102583973AHigh strengthHigh compressive strengthGlass shaping apparatusMicron scalePolymer science

The invention belongs to the technical field of a soft chemical method. According to the invention, the method is used for overcoming the defects that the traditional solid-phase glass powder method for preparing a hollow glass micro-balloon is high in energy consumption, long in technical process and difficult in controlling grain size distribution and the hollow glass micro-balloon prepared according to a liquid-phase atomizing method is high in alkalinity, easy to absorb water, high in strength and easy to break, and the like. A liquid material system is compounded through a chemical reaction; after the system is homogenized, the system is quickly atomized, dewatered and dried, thereby obtaining approximate spherical precursor powder with required grain size and corresponding distribution; and the powder is treated under high temperature at 600-1100 DEG C, thereby obtaining a micron-scale hollow glass micro-balloon with the volume floating rate being above 90%, the SiO2 content (weight) being 55-88%, the true density being 0.1-0.7g / cm<3> and the compression strength being 1-50MPa. The method is low in energy consumption, free from fusion and sintering, and high in yield. The prepared hollow glass micro-balloon is high in compression strength, light in weight, low-alkali, waterproof, excellent in fluidity and dispersibility, and suitable for various high-performance light compound materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

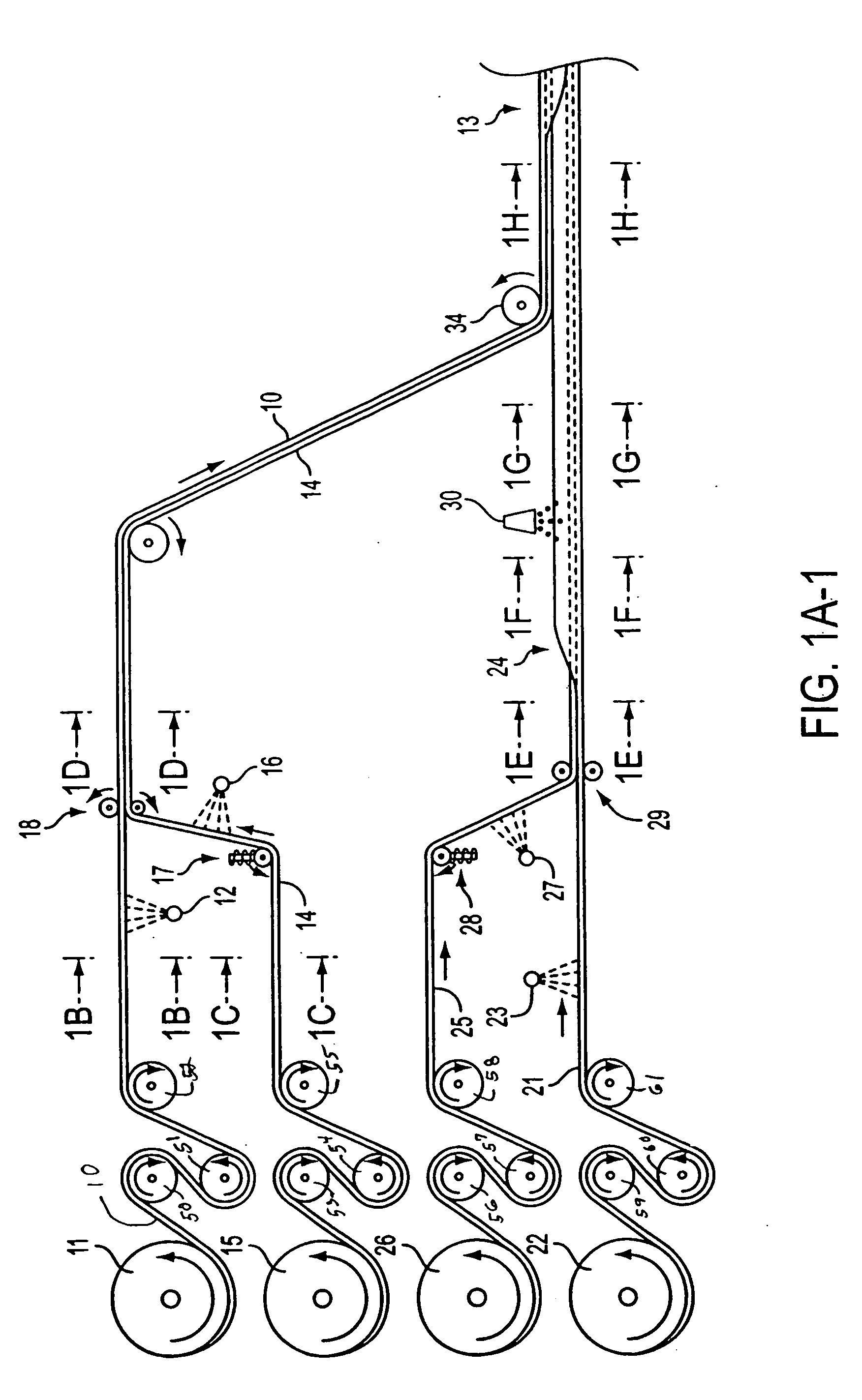

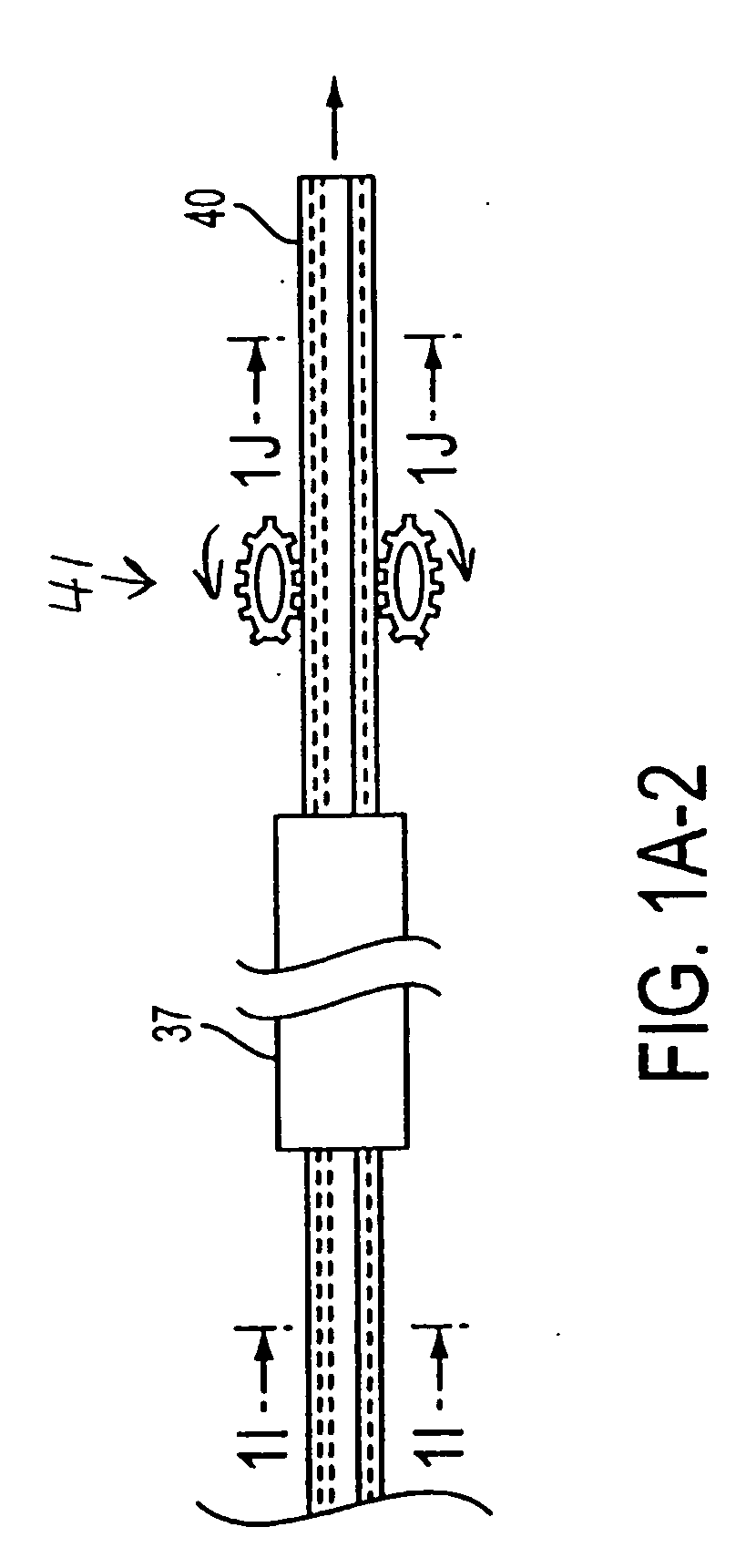

Composite structural material and method of making same

InactiveUS20070113759A1Conserve costIncrease the proportionSynthetic resin layered productsPaper/cardboard layered productsPolyesterEpoxy

A composite structural material suitable, for example, as a replacement for wooden boards, is disclosed. It comprises a dimensionally stable core material ensheathed in a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one layer of parallel cords (19) bonded to at least one layer of a rigidified web material (10) selected from the group consisting of paper and cloth. Suitable core materials include polyurethane foam (38), optionally filled with particles (32) of granulated rubber, expanded perlite, expandable polymer beads, and / or glass microspheres. The parallel cords (19) preferably are supplied in the form of a strip of polyester cloth, as the warp cords thereof. The web material (10) preferably is kraft paper that is rigidified with an epoxy resin.

Owner:CODA CAPITAL MANAGEMENT GROUP

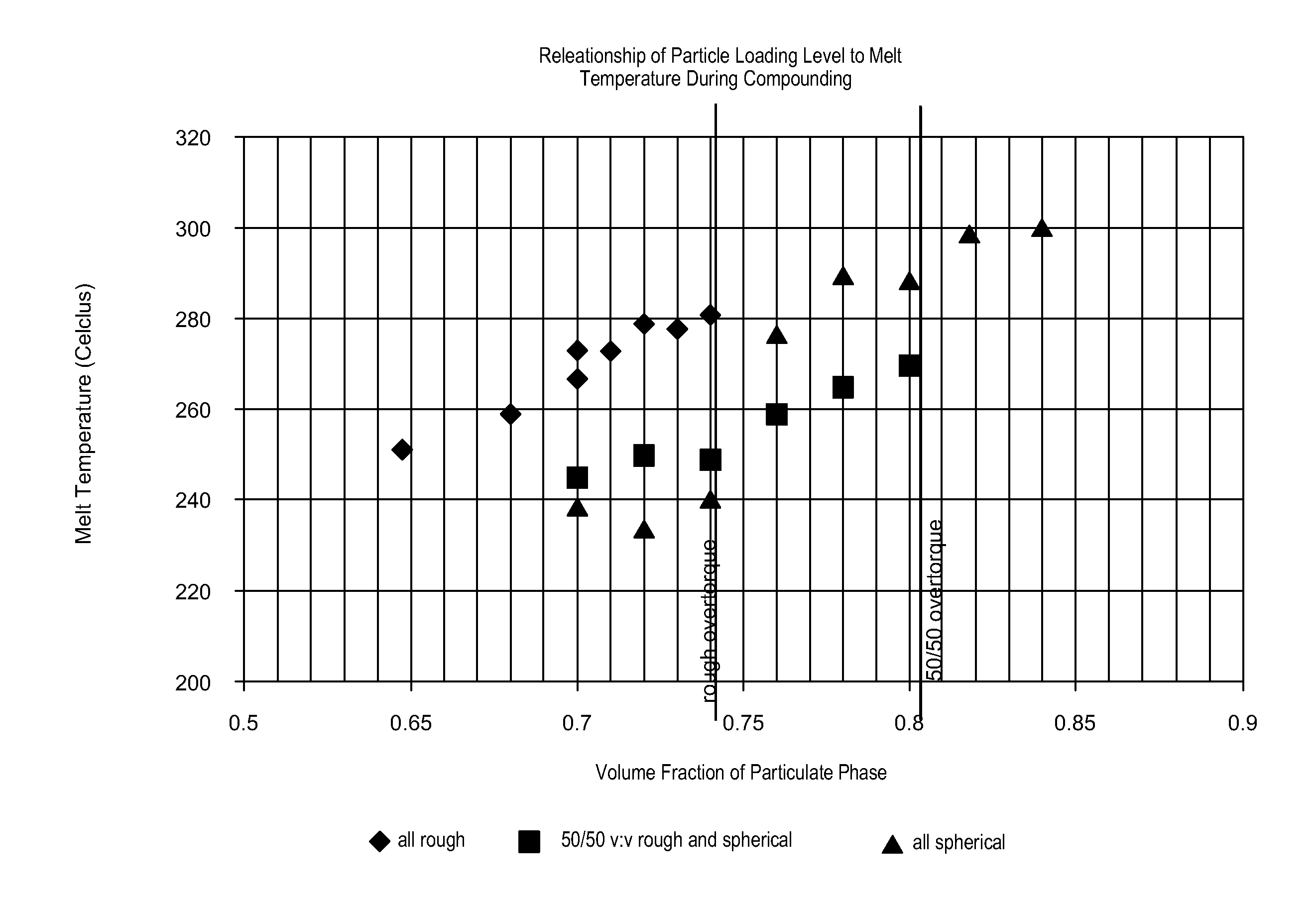

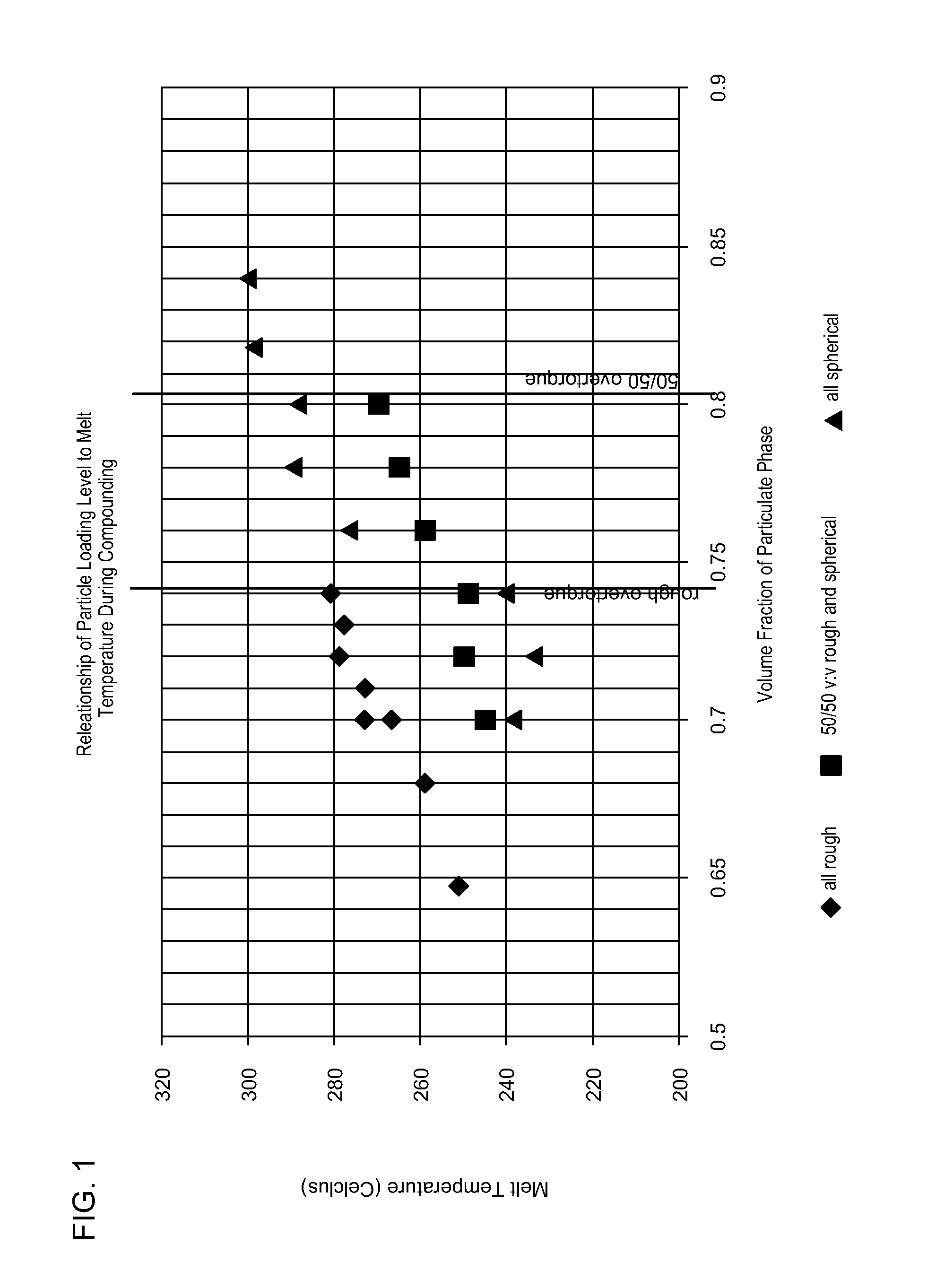

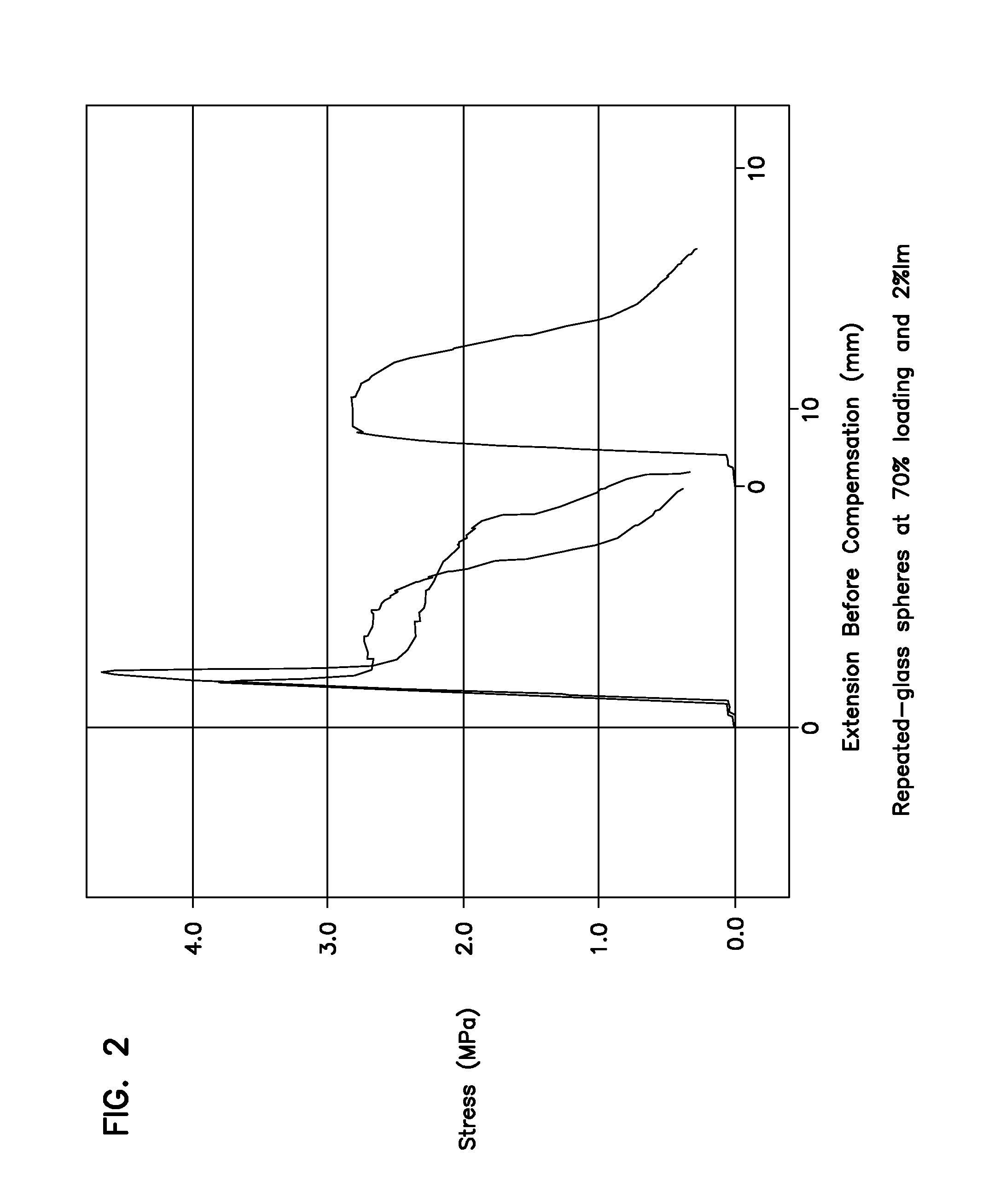

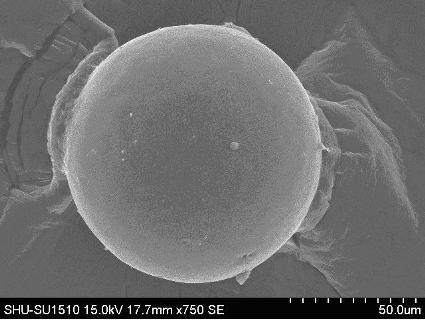

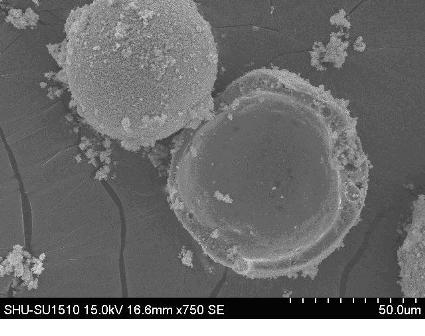

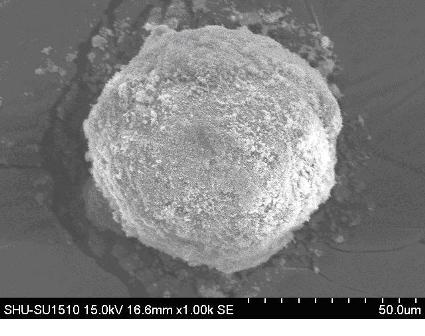

Reduced Density Glass Bubble Polymer Composite

The invention relates to a hollow glass microsphere and polymer composite having enhanced viscoelastic and rheological properties.

Owner:TUNDRA COMPOSITES LLC

Method for preparing hollow glass microsphere coating titanium dioxide

InactiveCN102002263AEasy to depositExtended service lifePigment treatment with organosilicon compoundsReflecting/signal paintsFiltrationDistilled water

The invention discloses a method for preparing titanium dioxide for coating surfaces of hollow glass microspheres. The method comprises: washing the hollow glass microspheres with alkali liquor to remove impurities and etching to improve activity; performing surface activation and modification by using a silane coupling agent; mixing the activated hollow glass microspheres and distilled water in a mass ratio of 1:10; fully stirring at 40 to 90 DEG C; in the stirring process, dripping solution of titanium sulfate at a constant speed with in 2 to 6 hours according to a mass ratio of the hollow glass microspheres to the titanium sulfate of 1:0.8-1:1.6; slowly adding alkali liquor, keeping the pH value of the reaction system between 5 and 7, and stirring first at a speed of 400r / min for the first 1 / 5 of reaction time and then at a speed of 100 to 300r / min for the rest 4 / 5 of reaction time; and after the reaction is finished, standing, performing suction filtration, washing with distilled water, drying and calcining. The hollow glass microspheres coated with the titanium dioxide can serve as filler for reflective and thermal-insulation coating. Compared with common hollow glass microspheres, the hollow glass microspheres can be used for preparing and synthesizing high-performance coating combining various thermal-insulation mechanisms.

Owner:SHANGHAI UNIV

Pneumatic tire having built-in sealant layer and preparation thereof

ActiveUS20040159386A1Improve abilitiesImprove efficiencyOther chemical processesSpecial tyresFiberVulcanization

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G'(80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G' (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

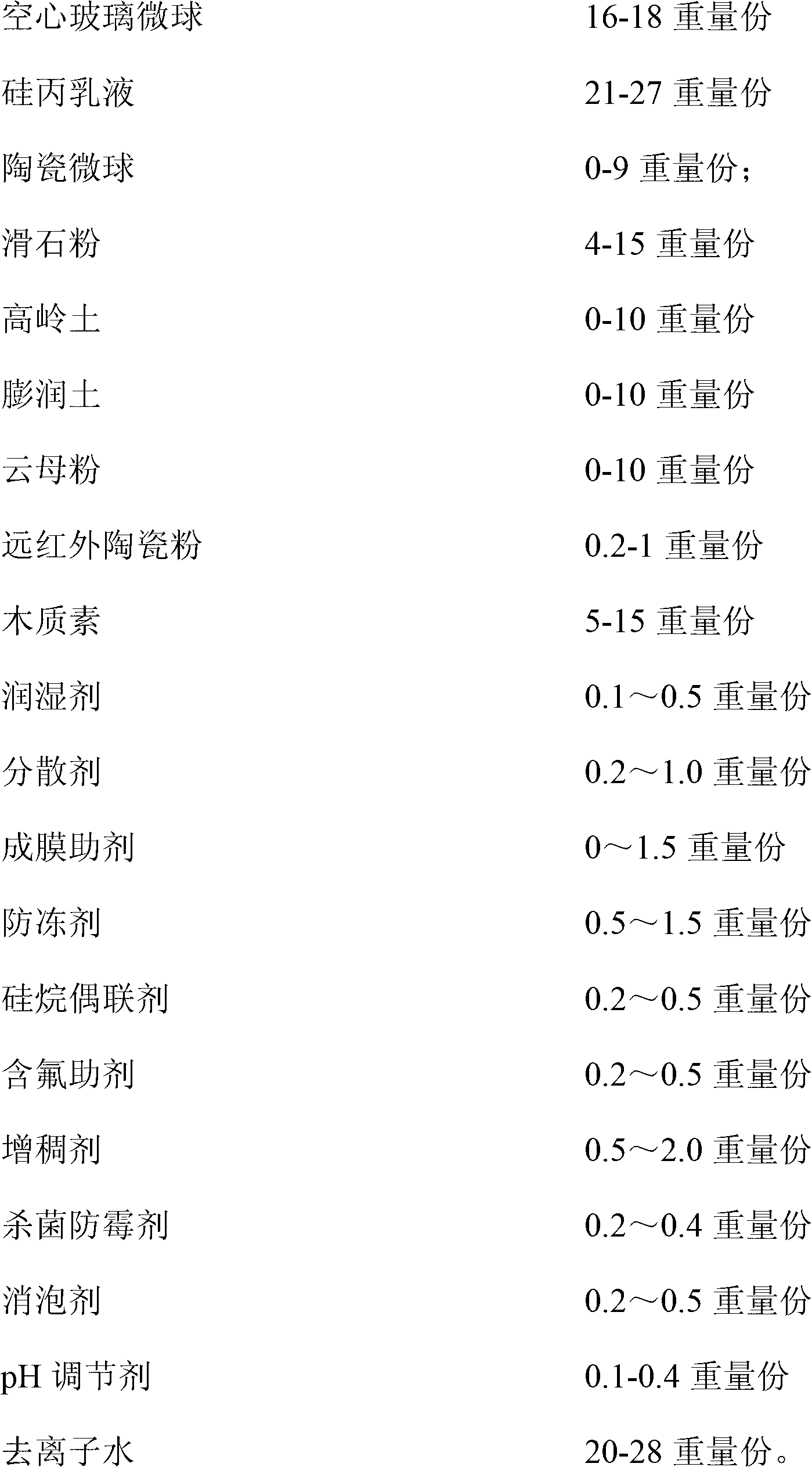

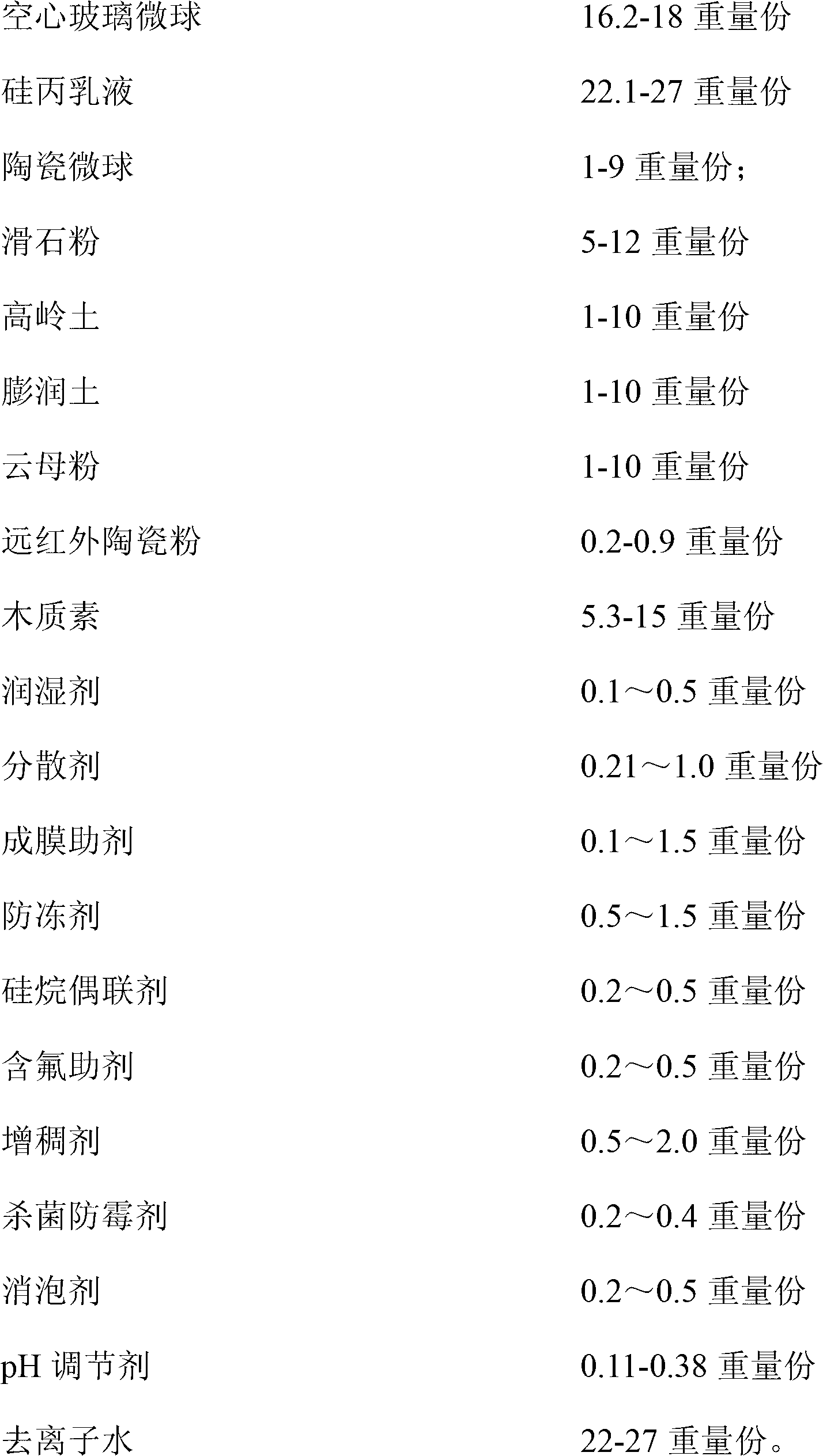

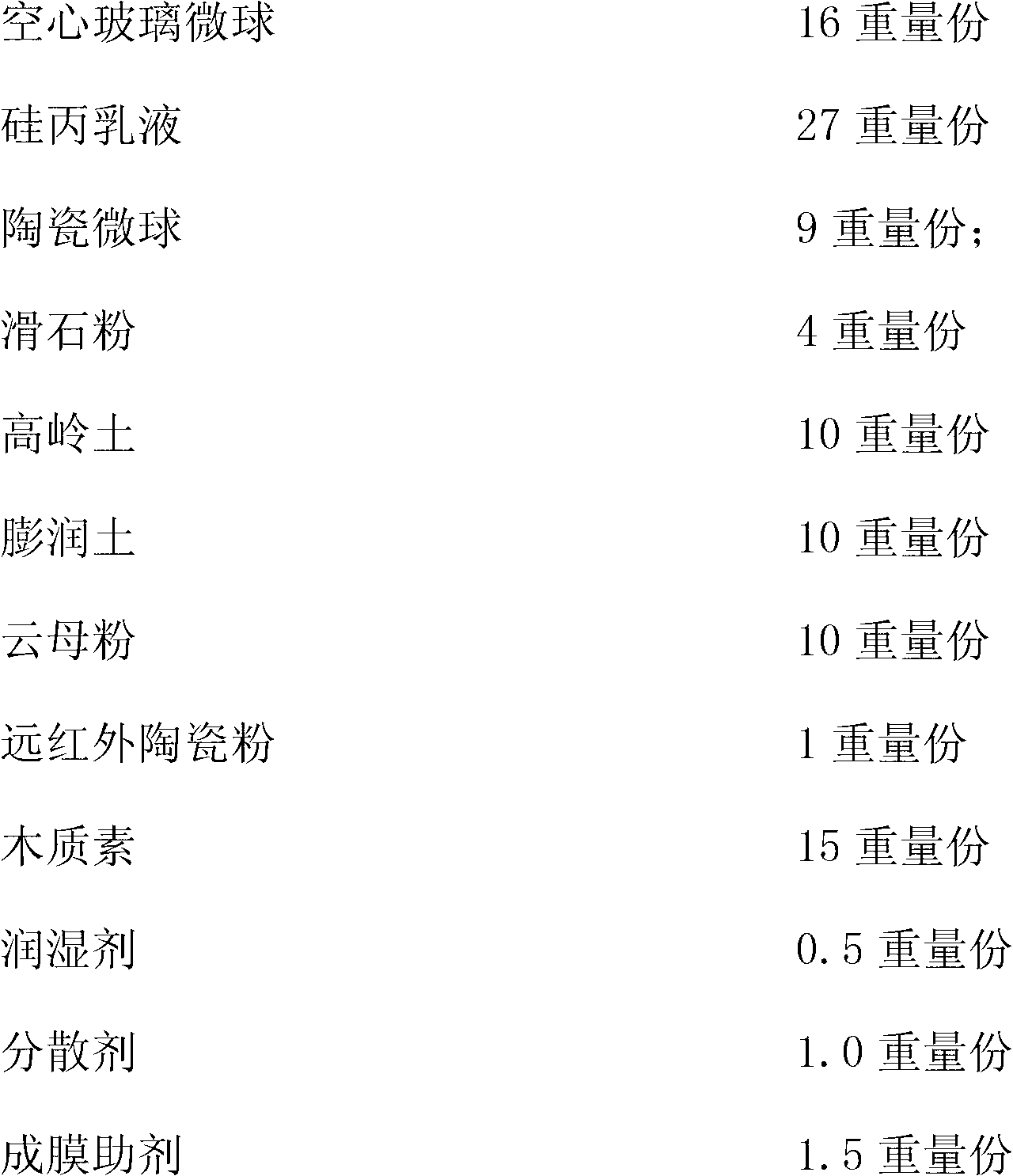

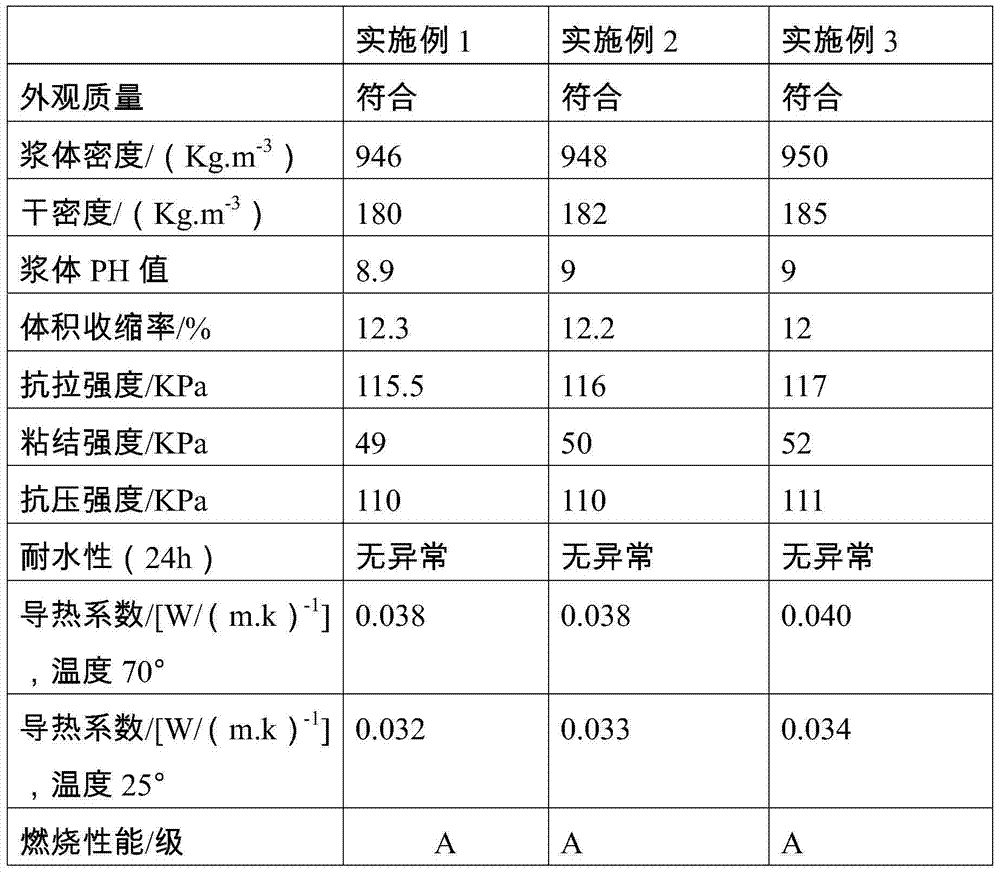

Waterproof thermal insulation coating composition and preparation method thereof

InactiveCN102702904AStir wellHigh solar reflectanceAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

The invention relates to a waterproof thermal insulation coating composition, which comprises an aggregates, a substrate, an auxiliary filling and an assistant, and is characterized in that the aggregates are hollow glass microspheres, and the substrate is silicone acrylic emulsion; in the thermal insulation coating composition, 6-18 parts by mass of hollow glass microspheres and 21-27 parts by mass of silicone acrylic emulsion are provided. According to the invention, the silicon acrylic emulsion is selected, so that the thermal insulation coating has excellent thermal insulation property, and good waterproof and antifouling performance, and the waterproof and antifouling performance is more excellent for fluorine-containing silicone acrylic emulsion.

Owner:TIANCHANG JULONG TRAVEL PAINT

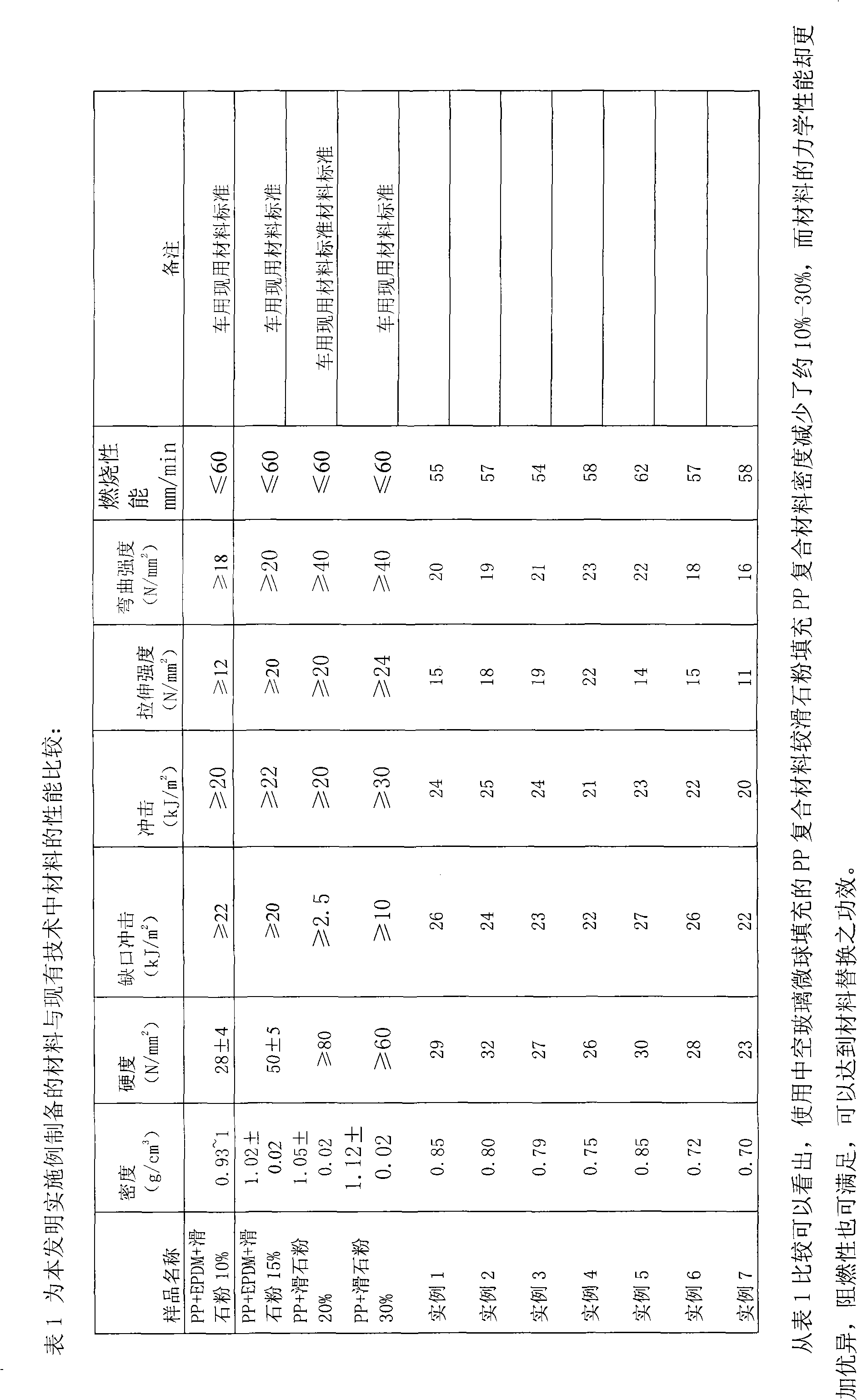

Polypropylene composite material and preparation method thereof

The invention discloses a polypropylene composite material and a preparation method thereof, wherein the formulation of the polypropylene composite material comprises the components by weight percent: 40-70% of polypropylene, 5-30% of toughening agent, 10-40% of hollow glass microspheres, 0.2-5% of photo-thermal stabilizing agent, 0.1-5% of coupling agent, 0.5-5% of compatilizer, 0.1-5% of processing agent and 2-15% of flame retardant agent. The preparation method of the polypropylene composite material comprises the steps that: mixing the raw materials, soaking the hollow glass microspheres in the coupling agent, drying, mixing, pelleting and obtaining the polypropylene composite material. By adding the hollow glass microspheres with high strength, the invention reduces the density of the PP material, improves the strength and the dimensional stability of the PP material, has important significance for reducing the weight of plastics, especially for lightening the weight of automobiles as well as saving energy and reducing emission in the plastic material used for the automobiles.

Owner:CHERY AUTOMOBILE CO LTD

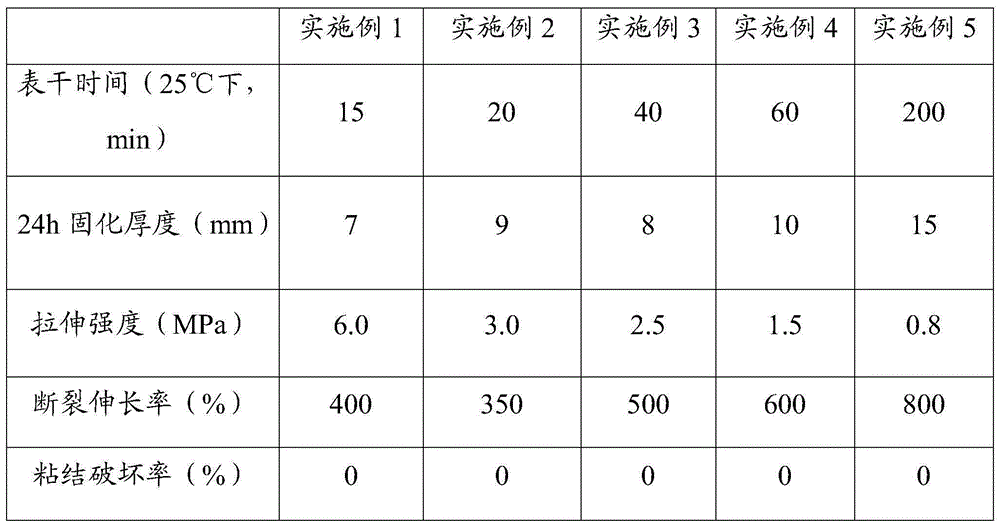

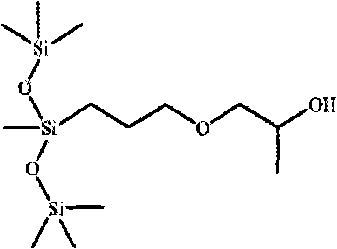

Bi-component silane modified polyether sealing material and preparation method thereof

ActiveCN105219337AHarm reductionOvercoming Temperature Relying on Moisture CuringNon-macromolecular adhesive additivesOther chemical processesCross-linkPlasticizer

The invention discloses a bi-component silane modified polyether sealing material and a preparation method thereof. The bi-component silane modified polyether sealing material comprises silane modified polyether, a plasticizer, an incremental filler A, a reinforcing filler, a toner, a thixotropic agent, a light stabilizer, hollow glass microspheres, a cross-linking agent, a coupling agent, an incremental filler B, an organic tin catalyst and a titanium catalyst. According to the bi-component silane modified polyether sealing material, organic tin is partially replaced with the titanium catalyst and is low in content, so that the harm of organic tin can be reduced; the production process is simple, a high temperature dehydration process is omitted, and the cost is low; the external and internal parts of a glue layer are simultaneously cured by virtue of moisture of the glue layer during curing, so that the defects that single-component silane modified polyether sealing glue is cured from outside to inside by virtue of moisture and the dept curing is slow are overcome, and the variation of curing rate along the external environment is small, so that the production efficiency is greatly improved; the bi-component silane modified polyether sealing material has good construction stability and can be widely applied to the fields of buildings, automobiles, locomotives, electric products and the like.

Owner:GUANGZHOU BAIYUN CHEM IND

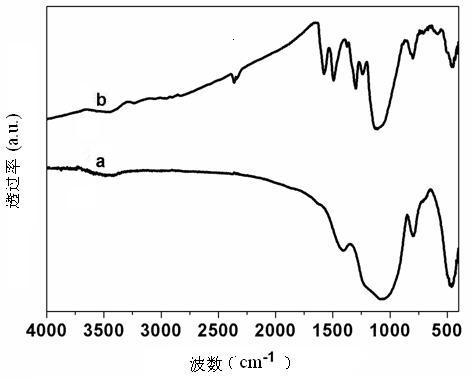

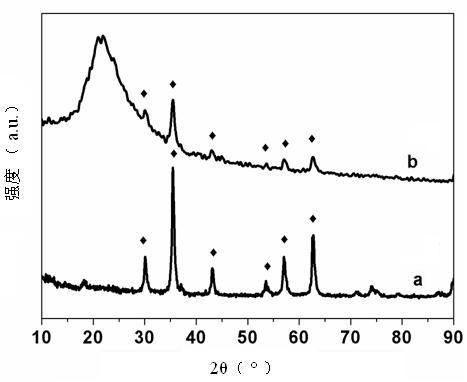

Method for preparing magnetic ferroferric oxide/conductive polyaniline light-weight composite hollow microspheres

InactiveCN101885915AGood dispersionNot easy to reuniteMicroballoon preparationMicrocapsule preparationConductive polymer compositeMicrosphere

The invention provides a method for preparing magnetic ferroferric oxide / conductive polyaniline light-weight composite hollow microspheres, which relates to a method for preparing a magnetic ferroferric oxide / conductive polyaniline composite material. The invention solves the problems of high density and easy agglomeration of the traditional magnetic nanometer particle / conductive polymer composite material. The method comprises the following steps of: regulating ferrous chloride and ferric chloride solutions to be alkaline, adding sodium dodecyl benzene sulfonate and reacting to obtain ferroferric oxide; and modifying hollow glass microspheres by using poly(diallyldimethylammonium chloride) solutions after alkaline cleaning, then reacting the hollow glass microspheres with the ferroferric oxide, sequentially immersing obtained solid particles by using the poly(diallyldimethylammonium chloride) solutions and polystyrene sulfonic acid solutions, then adding the solid particles to aniline solutions, initiating polymerization by using ammonium persulfate, and washing and drying the solid particles to obtain the composite hollow microspheres. The composite hollow microspheres have both conductivity and magnetism, the density is 0.78-0.8g / cm<3>, and the composite hollow microspheres are not easy to agglomerate and are used for fields of military equipment stealth technology and civil anti-electromagnetic radiation.

Owner:HARBIN INST OF TECH

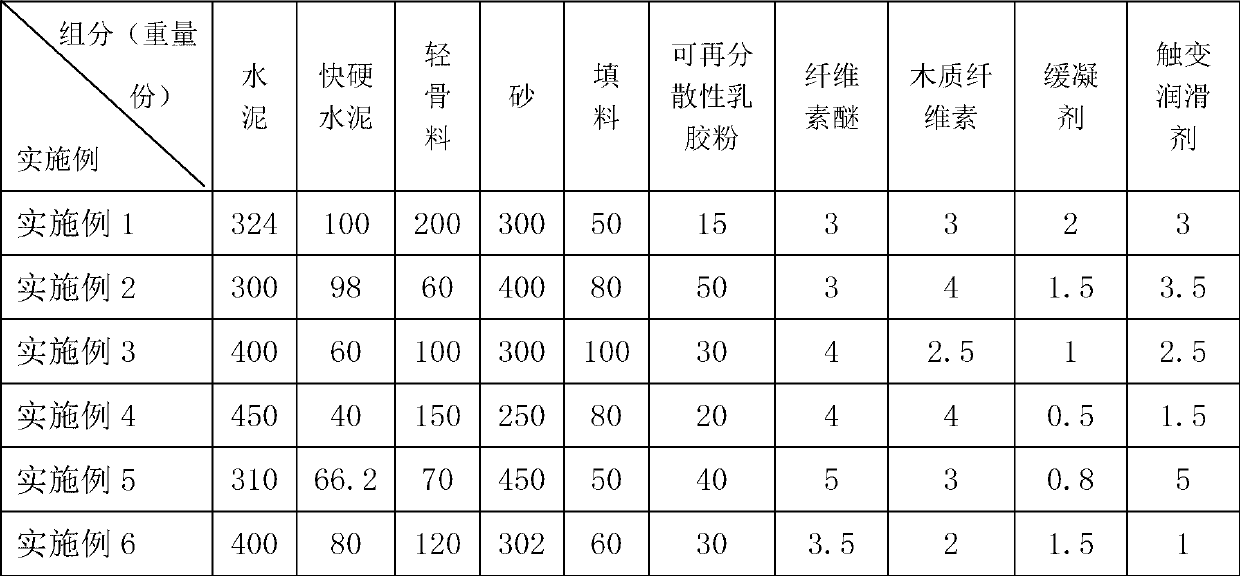

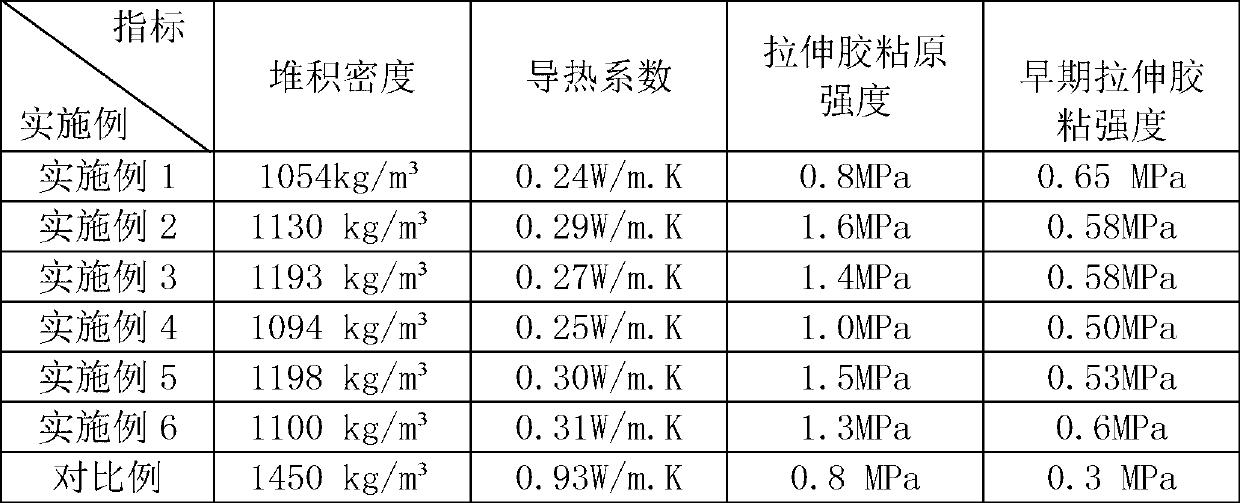

Binding mortar with light weight and high droop resistance and preparation and use methods

The invention provides binding mortar with light weight and high droop resistance, which consists of the following components in parts by weight: 300-450 parts of cement, 40-100 parts of rapid hardening cement, 60-200 parts of lightweight aggregate, 250-450 parts of sand, 50-100 parts of filling material, 15-50 parts of re-dispersible emulsion powder, 3-5 parts of cellulose ether, 2-4 parts of lignocellulose, 0.5-2 parts of retarder and 1-5 parts of thixotropic lubricant. The lightweight aggregates are glass microspheres, or hollow glass microspheres or ceramsite sand, of which the particle size is below 1.2mm and loose bulk density is below 0.8Kg / L. The invention has lower mortar density, good droop resistance, lower thermal conductivity and certain thermal insulation performance; the binding mortar can be hardened quickly, and the requirement of carrying out subsequent construction quickly is satisfied; the elastic modulus of the mortar is small, and deformation resistance is strong; and the mortar uses multiple polymer additives, and base materials have strong adaptability and strong binding performance.

Owner:深圳广田高科新材料有限公司

High strength aluminosilicate hollow glass microsphere and preparation method thereof

The invention discloses a high strength aluminosilicate hollow glass microsphere and a preparation method thereof. The hollow glass microsphere is characterized by comprising the following chemical components by mass percent: 60-75% of SiO2, 10-15% of Al2O3, 10-15% of Na2O, 1-3% of CaO, 0-1% of MgO, 0.02-0.5% of S, 0-3% of R2O and 0-3% of Fe2O3, wherein R in R2O is an alkali metal except Na. The density of the hollow glass microsphere is 0.2-0.6g / cm<3>, the compressive strength is 3-130MPa, the grain size is not greater than 80mu m, the floating rate is not less than 95%, and the softening temperature is not less than 750 DEG C. The hollow glass microsphere disclosed by the invention not only can be used in the fields in which common hollow glass microspheres are applied, but also is suitable for the high temperature and high pressure fields having special requirements in which the common hollow glass microspheres can not be applied. The hollow glass microsphere can be the hollow glass microsphere solid buoyancy material used 1000m, 2000m, 4500m and below under water, the hollow glass microsphere used for cementing wells with depth beyond 6000m during oil drilling and the hollow glass microsphere used for plastic hot extrusion molding.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Powder paint with high surface harness and decoration

ActiveCN101942262AGood compatibilityHigh hardnessPowdery paintsEpoxy resin coatingsMicrosphereHigh surface

The invention discloses powder paint with high surface harness and decoration. The powder paint contains one or more 100% fluorocarbon resin by weight, one or more glass microspheres and ceramic microballons as well as a characteristic inorganic filler taking nephelinite as a main component. Compared with the prior art, the fluorocarbon resin of the invention has good compatibility with a film-forming resin, and the coating embodies excellent decorative effect.

Owner:黄山华佳表面科技有限公司

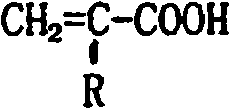

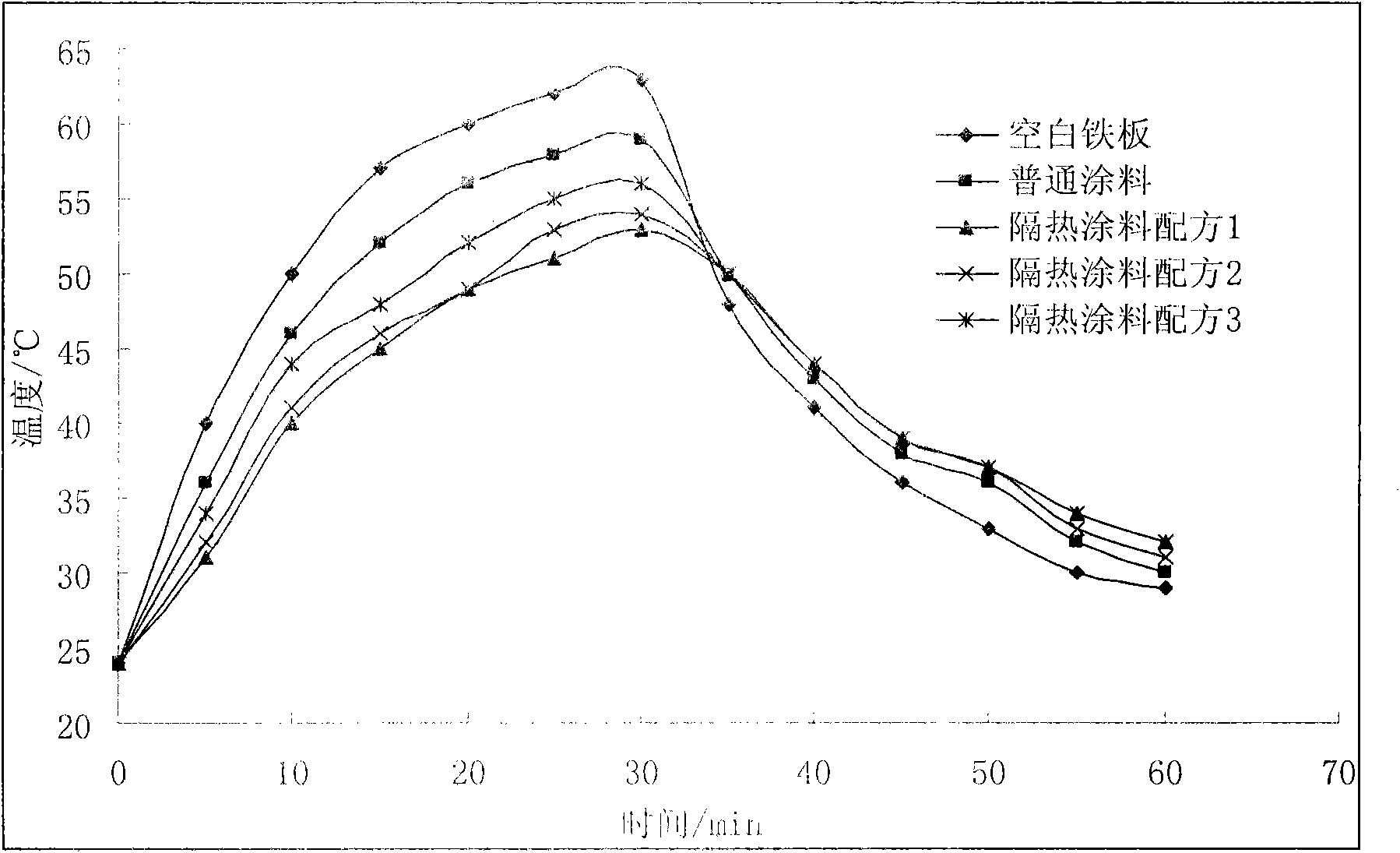

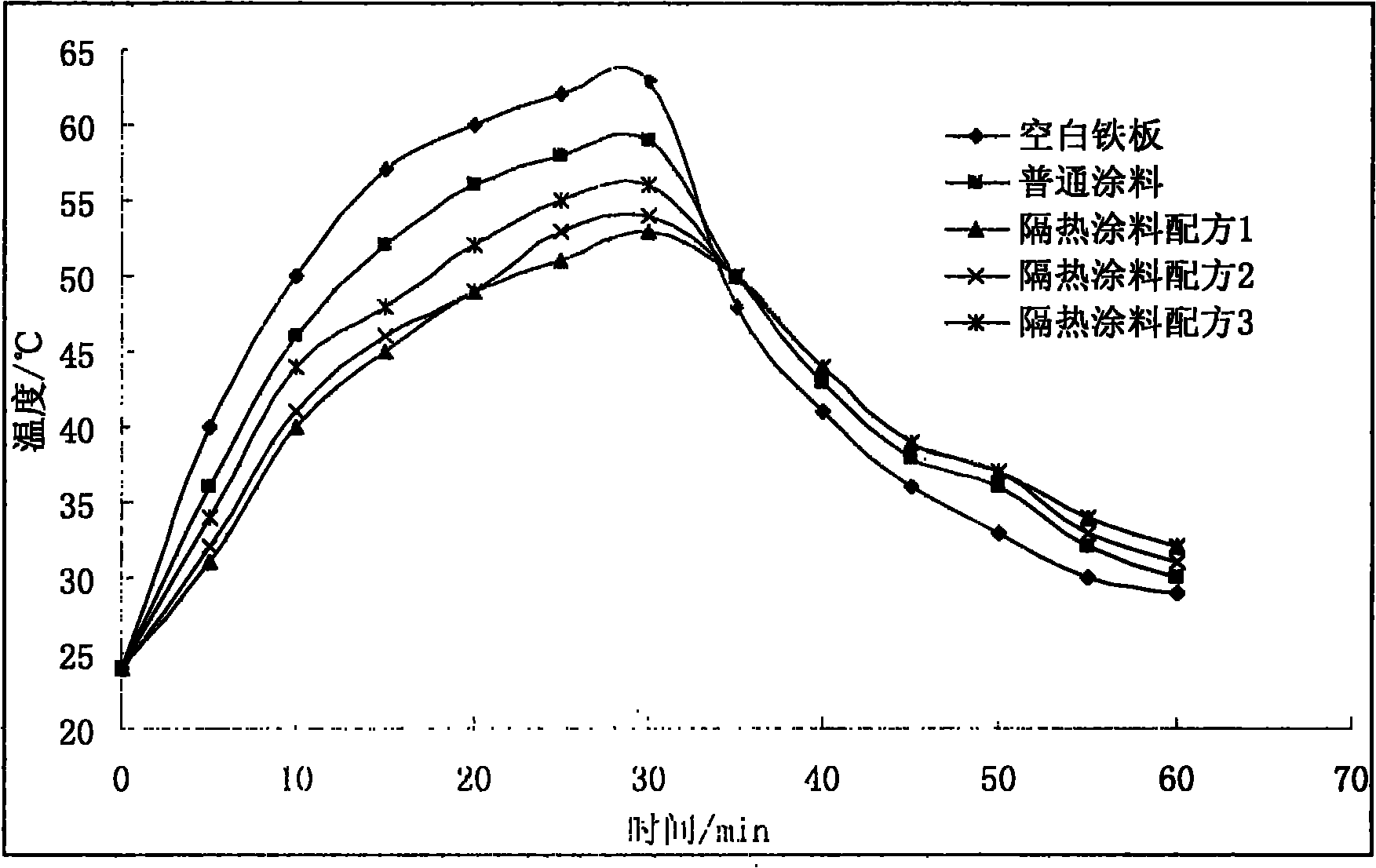

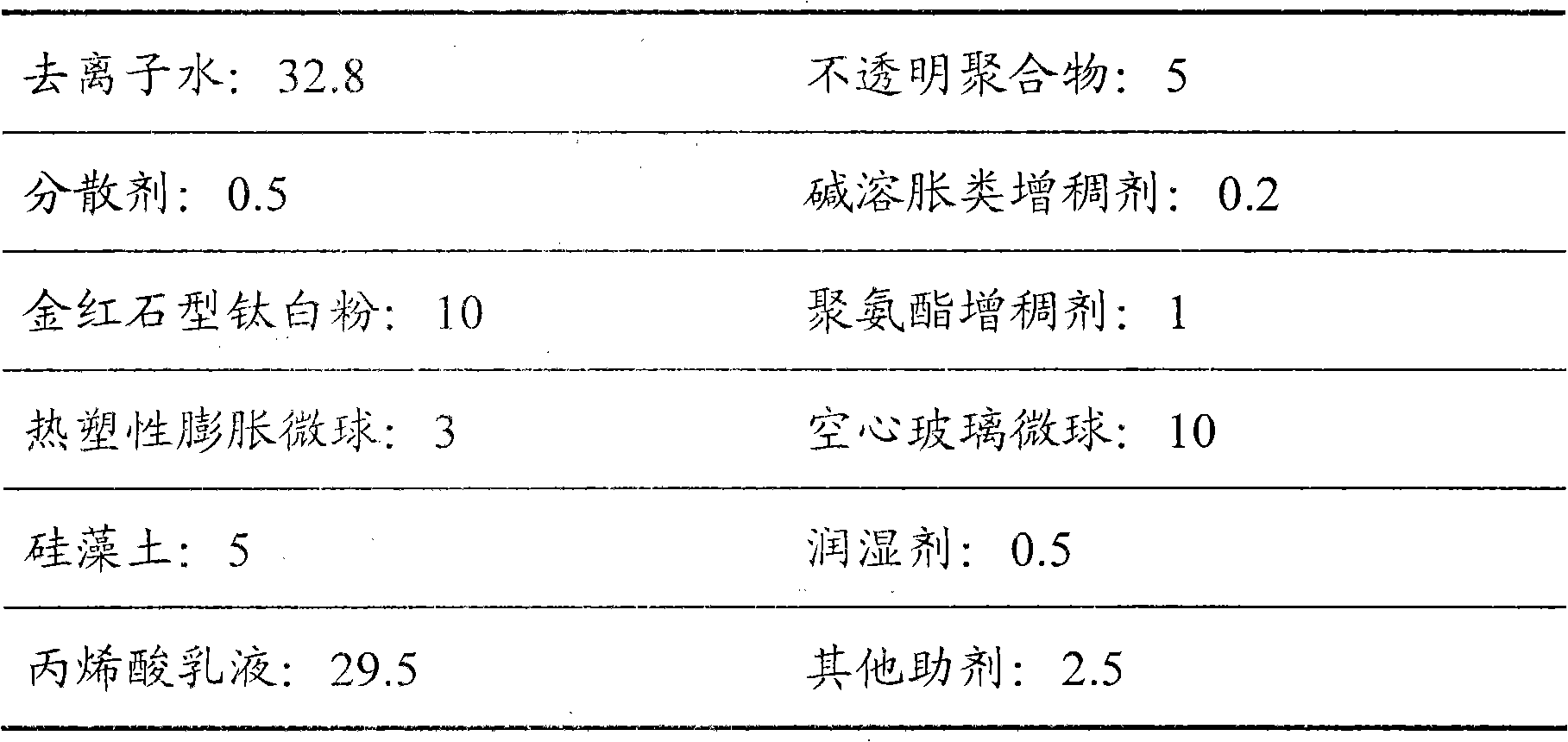

Heat-insulating coating for inner wall

The invention discloses a heat-insulating coating for an inner wall. The heat-insulating coating comprises the following components in percentage by weight: 20 to 40 percent of acrylic acid latex, 0.1 to 5 percent of moistening agent, 0.1 to 5 percent of dispersing agent, 5 to 20 percent of diatomite, 5 to 10 percent of hollow glass microsphere, 5 to 25 percent of titanium white powder, 0.1 to 5 percent of thickening agent, 1 to 10 percent of swelling microsphere, 3 to 10 percent of opaque polymer and 20 to 40 percent of water. The novel heat-insulating coating for the inner wall has the characteristics of slow temperature rise during heating and slow temperature drop during heat emission, and can properly adjust the indoor temperature and make the housing environment more comfortable; and, the aqueous latex is used, so that the heat-insulating coating is safe to the human body and the environment, and belongs to green environmentally-friendly product.

Owner:CHINA PAINT MFG CO SHENZHEN

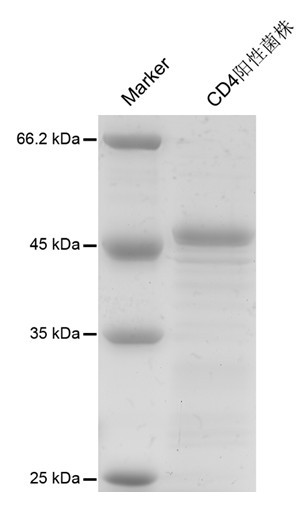

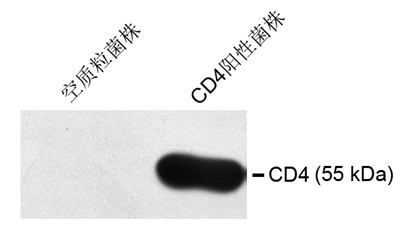

Human immunodeficiency virus affinity adsorption column, and preparation method and uses thereof

InactiveCN102631891ARich sourcesQuality improvementIon-exchange process apparatusOther blood circulation devicesMicrosphereHuman immunodeficiency

The invention discloses a human immunodeficiency virus (HIV) affinity adsorption column, comprising a column body and at least one activated affinity microsphere located in the column body, wherein the activated affinity microsphere is connected with a human immunodeficiency virus affinity protein, and the affinity protein can be bound with human immunodeficiency virus. The affinity protein comprises a main receptor CD4 molecule, a gp120 antibody, an auxiliary receptor CXC chemokine receptor 4 (CXCR-4) and a CC chemokine receptor 5 (CCR-5). The affinity microsphere may be a glass microsphere with the size of 1mm, a chitosan crosslinking microsphere with the diameter more than 500 microns, or a gluosan microsphere. The human immunodeficiency virus affinity adsorption column disclosed by the invention is applicable for eliminating the human immunodeficiency virus in the blood of HIV patients, and relieving and treating the immunodeficiency syndrome of HIV patients; and compared with the traditional treatment methods, the immunoadsorption column has high safety, good specificity, small toxic or side effects and good operation simplicity.

Owner:WUHAN UNIV

Novel fireproof coating exclusively for tunnel

The invention relates to the fireproof coating technology, in particular to a novel fireproof coating exclusively for tunnel. A high performance tunnel fireproof coating which conforms the requirements of the I type tunnel fire-resistant experimental test of Chinese GB50016-2006 Code for Fire Protection Regulations of Building Design and the tunnel RABT fire-resistant experimental test of GA / T714-2007 Rapid heating Fire-resistant Test Methods of Fire Protection Materials for Structural Elements for protecting a tunnel fire in China are lacked. The invention reaches the above two standards, comprising the following compositions by weight percentage: 30-40% of high alumina cement and Portland cement, 17-26% of expanded vermiculite, 7-13% of expanded perlite, 4.5-8% of mica, 4-10% of meerschaum, 4-10% of wollastonite in powder, 3.5-4.5% of glass microspheres, 3.5-5.8% of aluminum hydroxide, 5-6.2% of magnesium hydroxide, 0.2-0.4% of polypropylene staple, 0.2-0.3% of a high efficiency water reducing agent and 4-10% of redispersible latex powder.

Owner:JIANGXI LONGZHENG SCI & TECH DEV

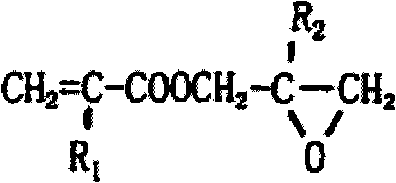

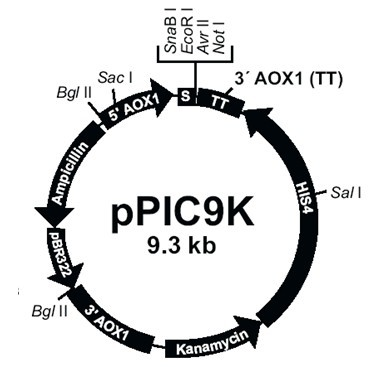

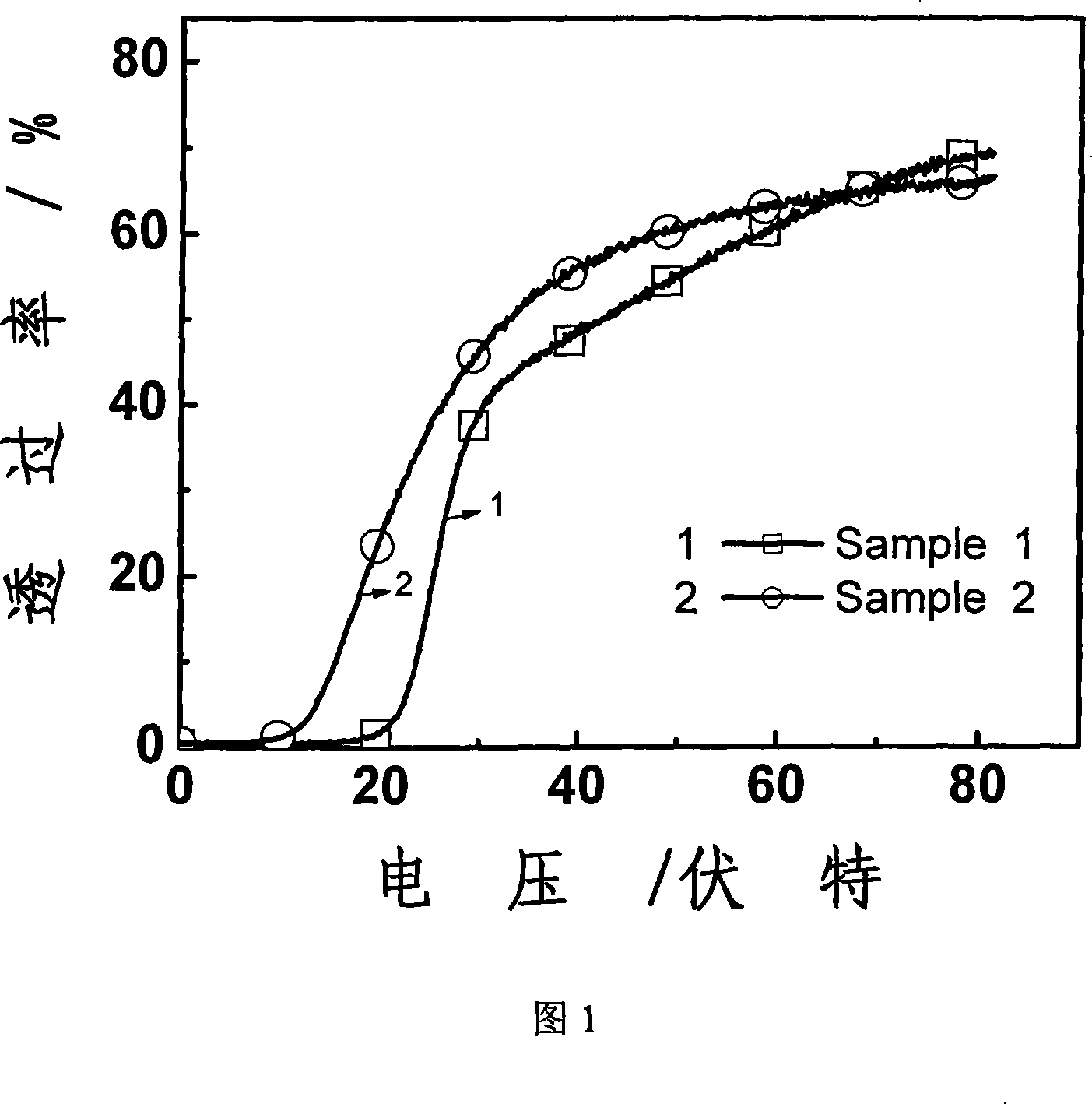

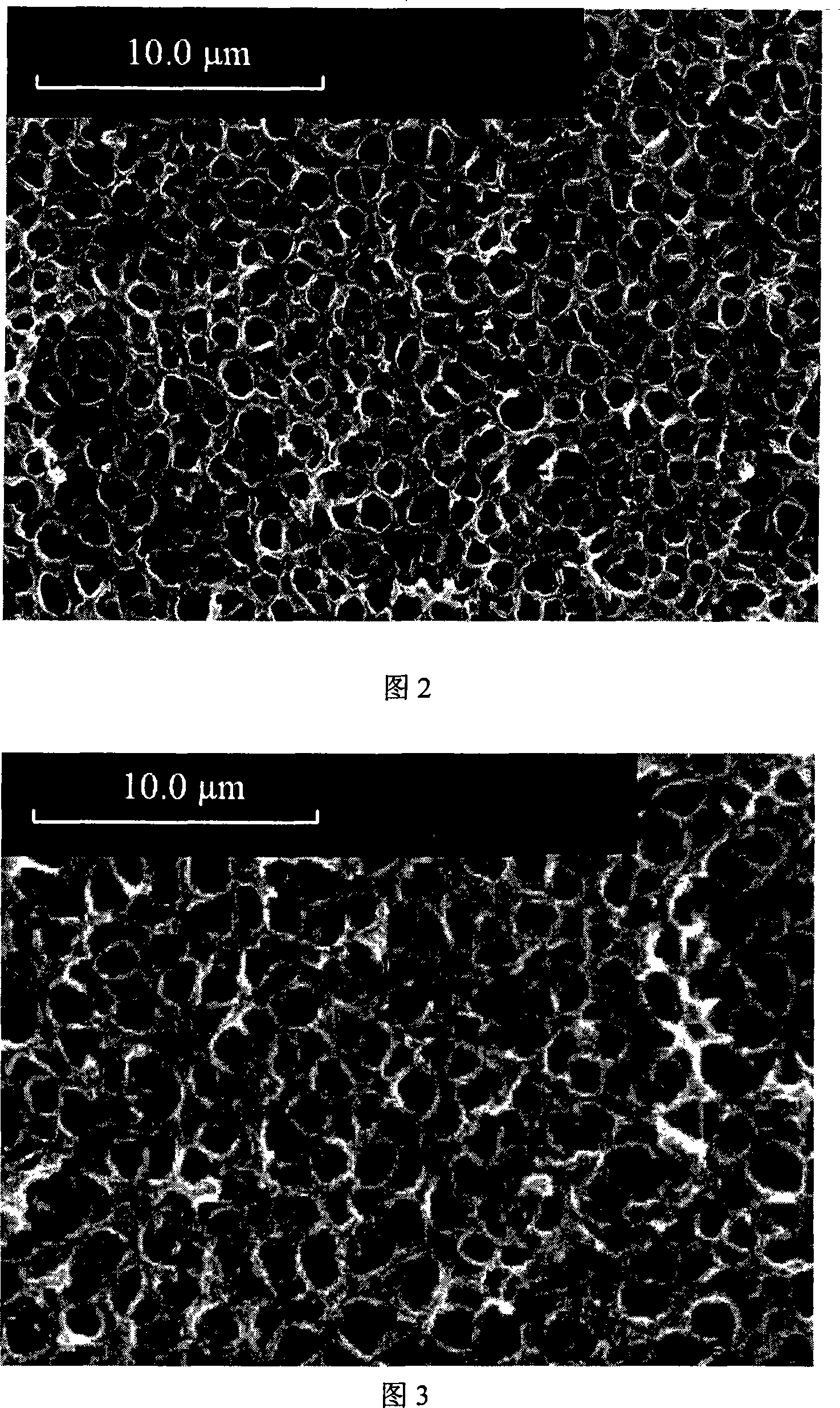

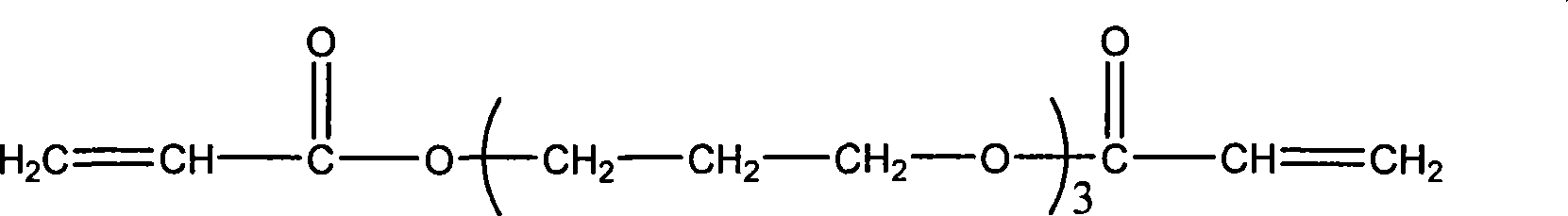

Method for preparing polymer dispersion liquid crystal material by ultraviolet-heating step-polymerization process

ActiveCN101225308AIncrease crosslink densityImprove interfacial adhesionLiquid crystal compositionsUltraviolet lightsPolymer network

The invention in particular relates to a preparation method of polymer dispersing liquid crystal film by an ultraviolet irradiating-heating plus stepwise initiated polymerization and phase separation method, belonging to the functional material field, which is applied in the preparation of electric controlled intelligent glass. The preparation method is characterized in that: the nematic liquid crystal, the monomer which can be polymerized under ultraviolet light, the light initiator, the thermal polymerized monomer and the glass microsphere is blended and then are clipped between two pieces of transparent conductive film plated with indium tin oxide, and then film with the thickness of 20 Mum if formed and is irradiated by the ultraviolet light with the wavelength of 365nm at 0 to 25 degrees; the intensity of the ultraviolet light is 20.0mW / m<2> and the illumination time is 1 to 10 minutes; the thermal polymerization temperature is 60 to 100 degrees, the holding time is 5 to 8 hours, at last the PDLC film is prepared by solidification. The polymer dispersing liquid crystal film has the advantages that: because of the stepwise polymerization crosslinking reaction which is carried out by selecting the monomer polymerized by ultraviolet and thermal polymerized monomer and irradiating and heating under ultraviolet light, the electro-optic performance the PDLC film is improved, the network strength of the polymer is enhanced, meanwhile, the bonding force of the interface between the polymer network and the ITO film are reinforced.

Owner:UNIV OF SCI & TECH BEIJING

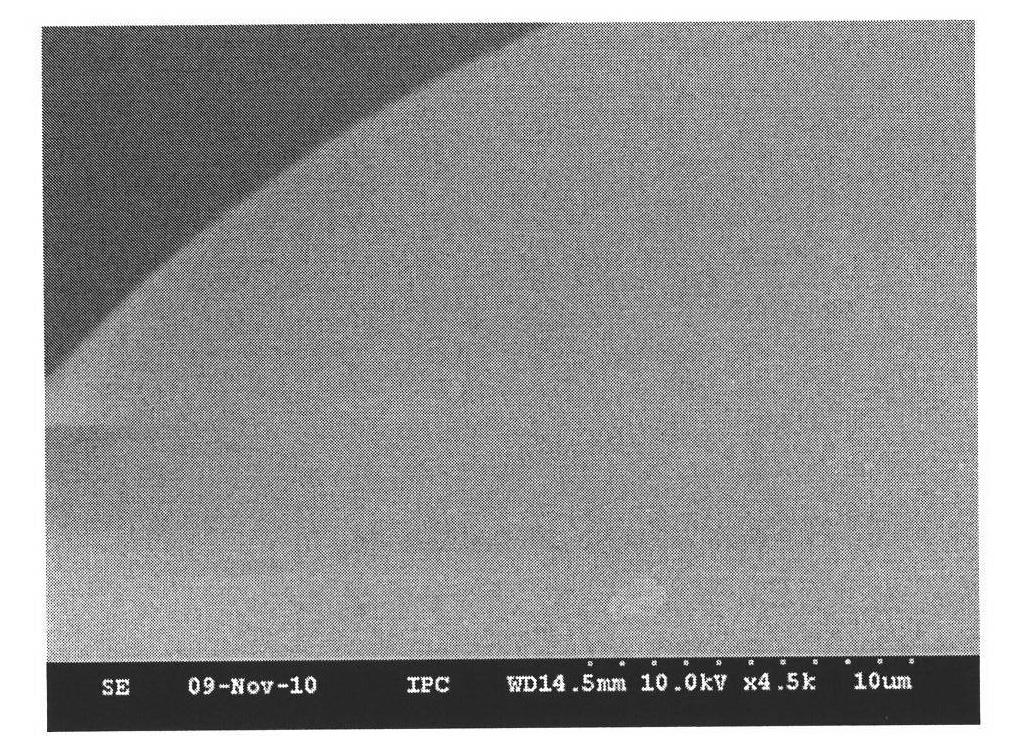

Surface chemical plating treatment process for hollow glass microsphere, plated metal hollow glass microsphere and application thereof

The invention relates to the technical field of a composite material with a core shell structure and provides a surface chemical plating treatment process for hollow glass microspheres. The surface chemical plating treatment process comprises the following steps: carrying out alkaline wash and hydrogen peroxide wash before plating to coarsen and hydroxylate the surface of the hollow glass microsphere; and carrying out chemical plating on the processed hollow glass microsphere to obtain a metal-plated hollow glass microsphere. In the method, complex preprocessing technology, such as sensitization, activation and the like in the existing method, can be simplified, and the use of expensive stannous chloride and palladium chloride which are not environmentally-friendly is avoided. Compared with the existing hot alkaline liquor processing method, the process provided by the invention has the advantages that possible microsphere fracture caused by the long-time soaking in the alkaline liquor can be avoided, and the surface hydroxylation efficiency of the hollow glass microsphere can be greatly increased by using hydrogen peroxide. The hollow glass microsphere processed with the method is easy to plate. The obtained metal-plated hollow glass microsphere has the advantages of a complete metal layer, light weight, good electrical conductivity and the like. When the obtained metal-plated hollow glass is used as a filler, material density can be lowered, cost is lowered, mechanical property is enhanced, and the plated metal hollow glass microsphere is applied to the aspects of staticelectricity coating, electromagnetic wave interference coating, wave adsorption coating and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

Manufacturing method of porosity reference block for composite material

ActiveCN104407060AUniform porosity distributionSmall sizeMaterial analysis using sonic/ultrasonic/infrasonic wavesNon destructivePorosity

The invention provides a manufacturing method of a porosity reference block for a composite material. The manufacturing method comprises the following steps: (1) overlays of a prepreg are designed according to thickness requirements of the porosity reference block, and glass microspheres are uniformly sprayed on each overlay; (2) a paved workpiece is put into an autoclave to be solidified, the solidified workpiece undergoes trimming to form the reference block, the reference block undergoes ultrasonic non-destructive testing, and an ultrasonic decay signal of the reference block is determined; (3) a porosity test panel with real pore flaws is prepared, the test panel is detected by an ultrasonic fault detector, an area which is the same with the ultrasonic decay signal of the reference block in the Step (2) is found out in the test panel, and the area is marked; and (4) the selected area in the Step (3) undergoes metallographic microscopic analysis and numerical value of porosity is determined.

Owner:SHANGHAI AIRCRAFT MFG +1

Nanometer heat-insulating outer wall coating and preparation method thereof

InactiveCN103788798AGood safety and fire performanceEnvironmental protection and energy savingCoatingsWater basedFiber

The invention provides a nanometer heat-insulating outer wall coating and a preparation method thereof. The nanometer heat-insulating outer wall coating comprises the following components in parts by weight: 5-10 parts of deionized water, 1-2 parts of ethylene glycol, 3-5 parts of fibers, 3-5 parts of diatomite, 30-40 parts of acrylic emulsions, 15-25 parts of glass microballoons, 20-40 parts of 20% silicon dioxide aerogel water-based slurry and 1.4-2.9 parts of auxiliary agents. The nanometer heat-insulating outer wall coating provided by the invention is prepared by matching multiple auxiliary agents by taking the self-crosslinking acrylic emulsions as film-forming materials and SiO2 aerogels, hollow glass microspheres and aluminum silicate chopped fibers as fillers. The coating achieves the heat insulation by adopting nanopores, and has the advantages of thin construction layer, good safety property and fire resistance, environmental friendliness, energy conservation, high performance-price ratio and the like.

Owner:BEIJING XINYUAN YONGLI INTEGRATION HOUSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com