Bi-component silane modified polyether sealing material and preparation method thereof

A technology of silane-modified polyether and sealing materials, which is applied in polyether adhesives, chemical instruments and methods, and other chemical processes, and can solve the problems of slow deep curing, high-temperature dehydration, and slow surface drying, and achieve production cycle Long-term, low-cost, and small-change effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

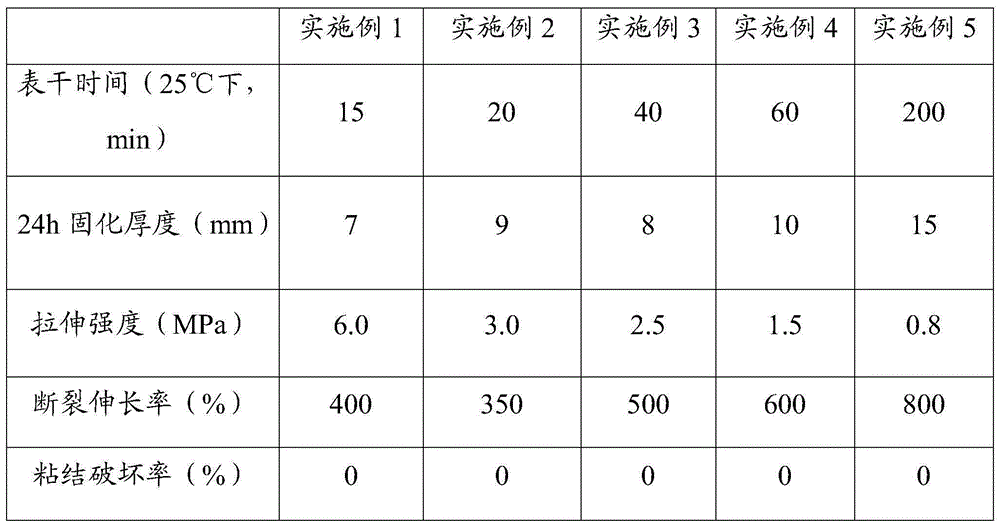

Examples

Embodiment 1

[0033] A two-component silane-modified polyether sealing material, the raw materials of which are composed of:

[0034] Component A: 30 parts of silane-modified polyether (SAT400 from Kaneka Corporation of Japan), 40 parts of filler A (including 30 parts of nano-active calcium carbonate and 10 parts of heavy calcium carbonate), reinforcing filler (hydrophobic gas-phase white carbon Black) 10 parts, toner (carbon black) 15 parts, thixotropic agent (polyamide wax) 0.05 parts, light stabilizer 0.12 parts (including BASF's UV-P 0.02 and 7700.1 parts), crosslinking agent (positive Ethyl silicate) 1 part, coupling agent (N-aminoethyl-γ-aminopropyltriethoxysilane) 0.05 part;

[0035] Component B: 40 parts of plasticizer (PPG), filler B (50 parts of nano-active calcium carbonate, 5 parts of kaolin), 0.03 parts of organotin catalyst (dibutyltin diacetylacetonate), titanium catalyst (diisopropyl Oxygen diacetylacetonate titanium) 2 parts.

[0036] The preparation method of the above-m...

Embodiment 2

[0040] A two-component silane-modified polyether sealing material, the raw materials of which are composed of:

[0041] Component A: 50 parts of silane-modified polyether (SAT40030 parts, S303H20 parts of Japan Kaneka Company), 20 parts of plasticizer (DIDP), extender filler A (including 50 parts of nano-active calcium carbonate and 10 parts of silicon micropowder) 60 parts, 10 parts of reinforcing filler (hydrophobic fumed silica), 10 parts of toner (titanium dioxide), 3 parts of thixotropic agent (including 2 parts of hydrogenated castor oil and 1 part of organic bentonite), 3 parts of light stabilizer (including 3260.5 parts and 7880.5 parts of BASF), 1 part of coupling agent (including 2 parts of γ-methacryloxypropyl trimethoxysilane and 1 part of isocyanatopropyl trimethoxysilane) 3 parts;

[0042] Component B: 30 parts of plasticizer (DIDP), 40 parts of extender filler B (nano-active calcium carbonate), 0.1 part of organotin catalyst (dibutyltin dilaurate), 8 parts of ti...

Embodiment 3

[0047] A two-component silane-modified polyether sealing material, the raw materials of which are composed of:

[0048] Component A: 50 parts of silane-modified polyether (S303H of Japan Kaneka Company), 20 parts of plasticizer (DINP), 60 parts of filler A (nano-active calcium carbonate), reinforcing filler (hydrophobic fumed white carbon) Black) 5 parts, toner (titanium dioxide) 15 parts, thixotropic agent (including 2 parts of polyamide wax and 0.05 parts of organic bentonite) 2.05 parts, light stabilizer (including BASF's UV-90.05 parts and 6220.05 parts) 0.1 parts , 3 parts of crosslinking agent (including 1 part of methyltrimethoxysilane and 2 parts of vinyltrimethoxysilane), 3 parts of coupling agent (1 part of γ-glycidyl etheroxypropyl trimethoxysilane, 1 part of γ-aminopropyl 2 parts of base triethoxysilane coupling agent) 3 parts;

[0049] Component B: 20 parts of plasticizer (DINP), 20 parts of filler B (including 10 parts of heavy calcium carbonate and 10 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com