Patents

Literature

3505results about How to "High energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

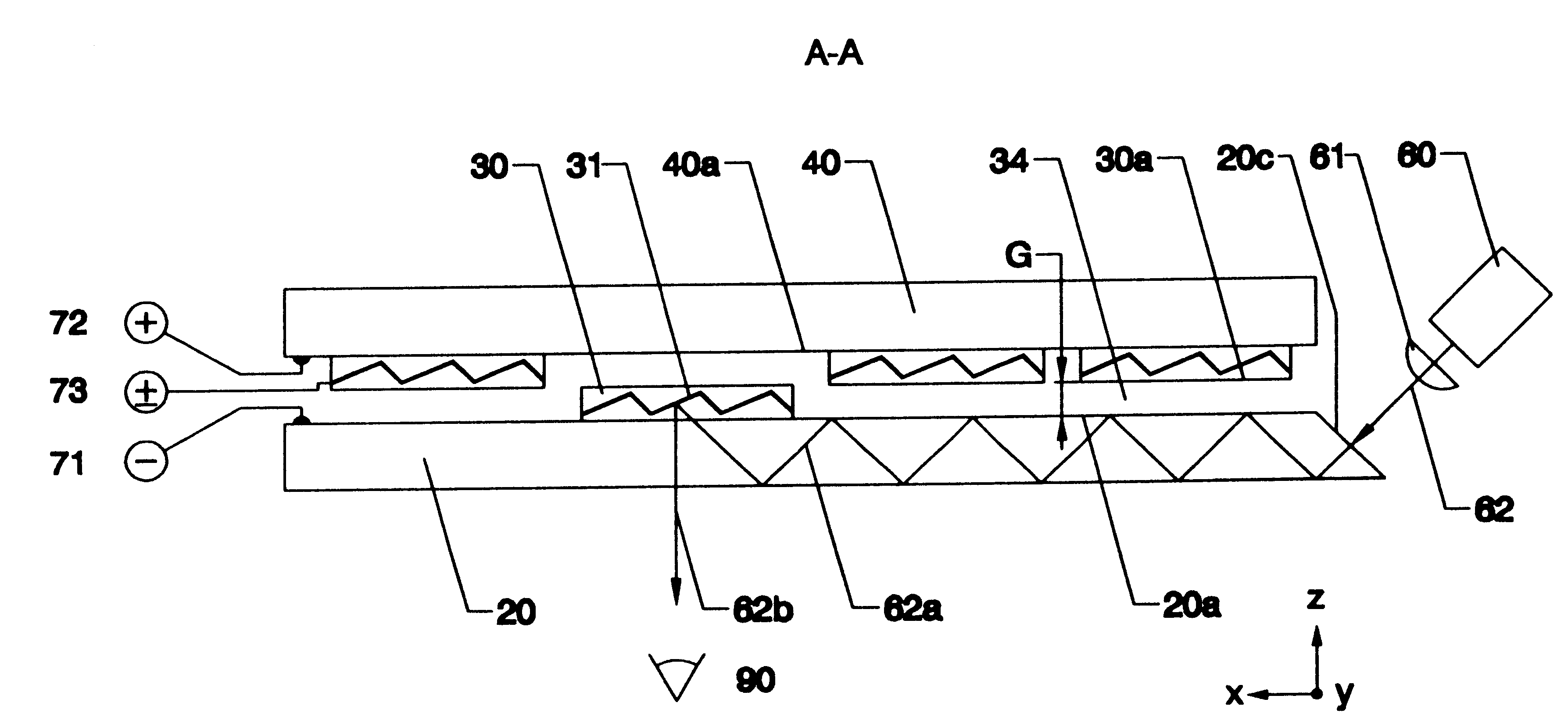

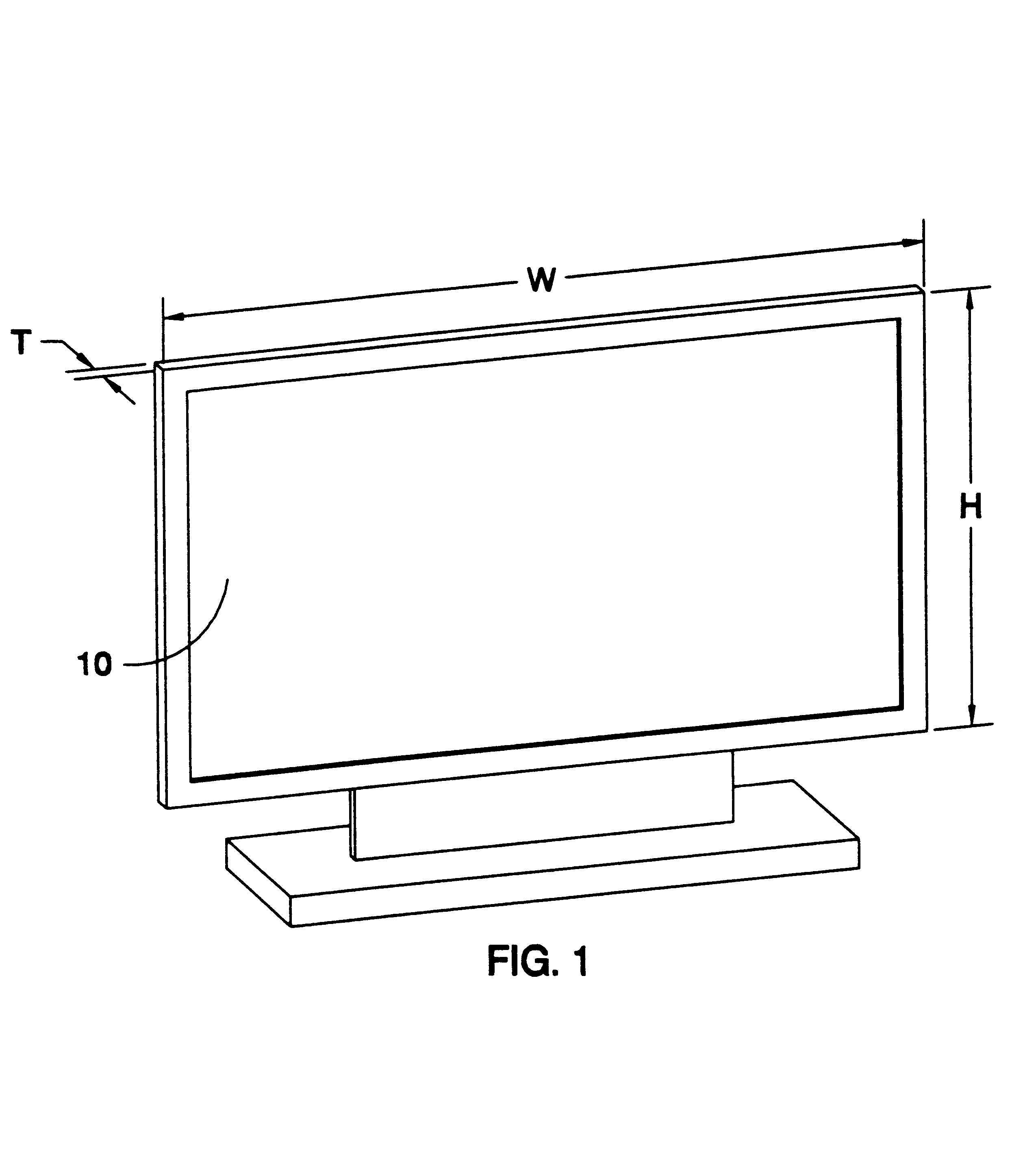

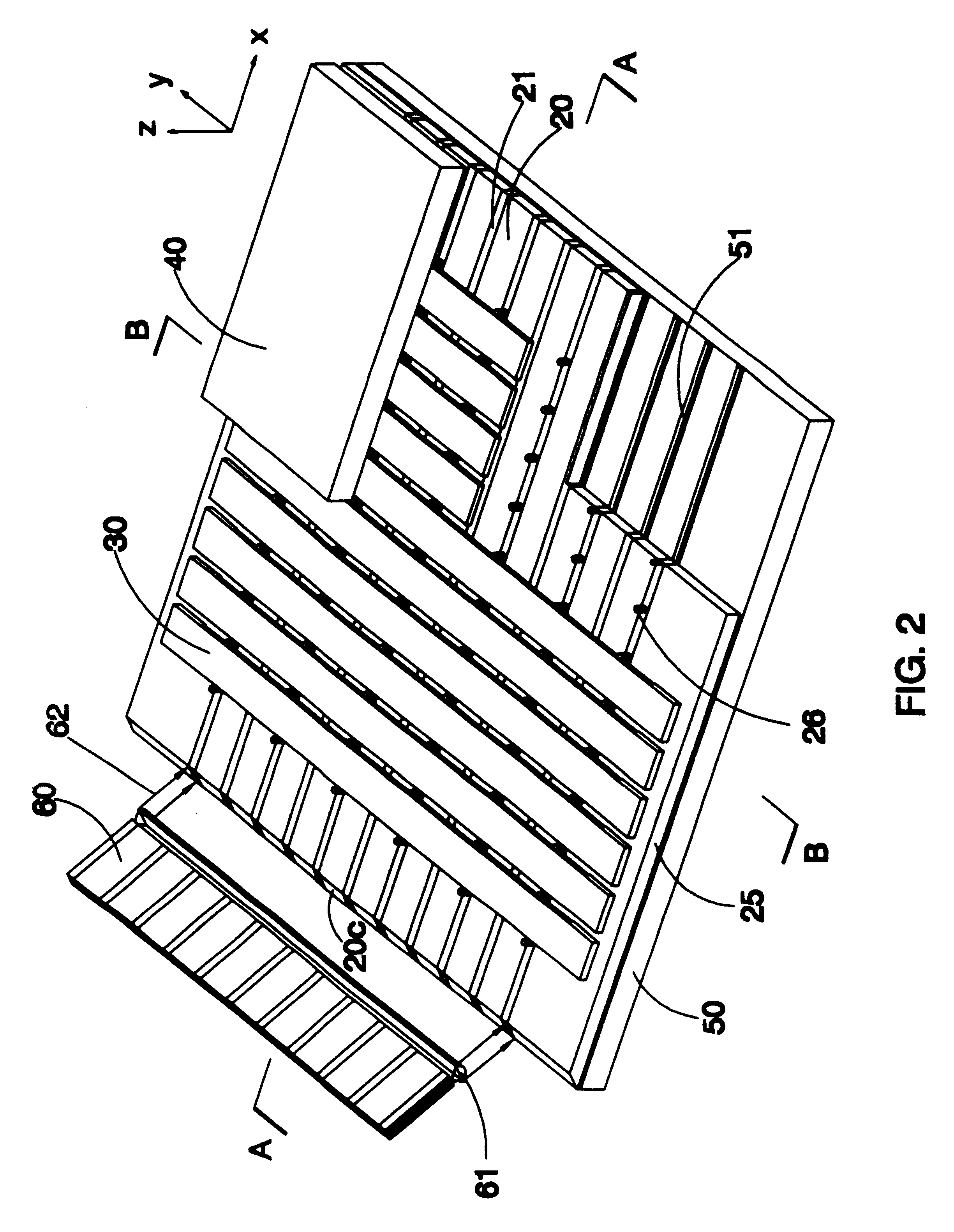

Optical device utilizing optical waveguides and mechanical light-switches

InactiveUS6650822B1High refractive indexReduction factorCoupling light guidesOptical waveguide light guidePhotovoltaic detectorsPhotodetector

An optical device consists of one or more optical waveguides and mechanical light switches 30. When a light switch 30 is turned on, it extracts light beam 62a from a waveguide core 20 and redirect the light beam 62b into free space, it redirects an incoming light beam 80 from free space and injects the light beam 80a into the waveguide core 20, or it performs both functions at the same time, depending on specific applications. On and off states of a light switch 30 are achieved by pulling the light switch 30 into a close vicinity of the waveguide core 20 and by pushing the light switch 30 away from the waveguide core 20, respectively. An interactive fiat-panel display can be built based on this invention. A plurality of parallel channel waveguides forms a display panel. An array of light beams 62a, injected from an array light source 60, propagates along waveguide cores 20 until reaches a location where a light switch 30 is turned on. At this location, the light switch 30 redirects the light beams towards a viewer. An image is produced when the light switches 30 are turned on sequentially while the light-intensity distribution on the array light source 60 is synchronically updated. The panel display is capable of responding to an input optical signal by detecting an incoming light beam 80 from a light pen 100. An array of photodetectors 81 is used to identify the location of the incoming light beam 80 on the display panel and a computer is used to execute a corresponding action accordingly.

Owner:LIFE TECH CORP

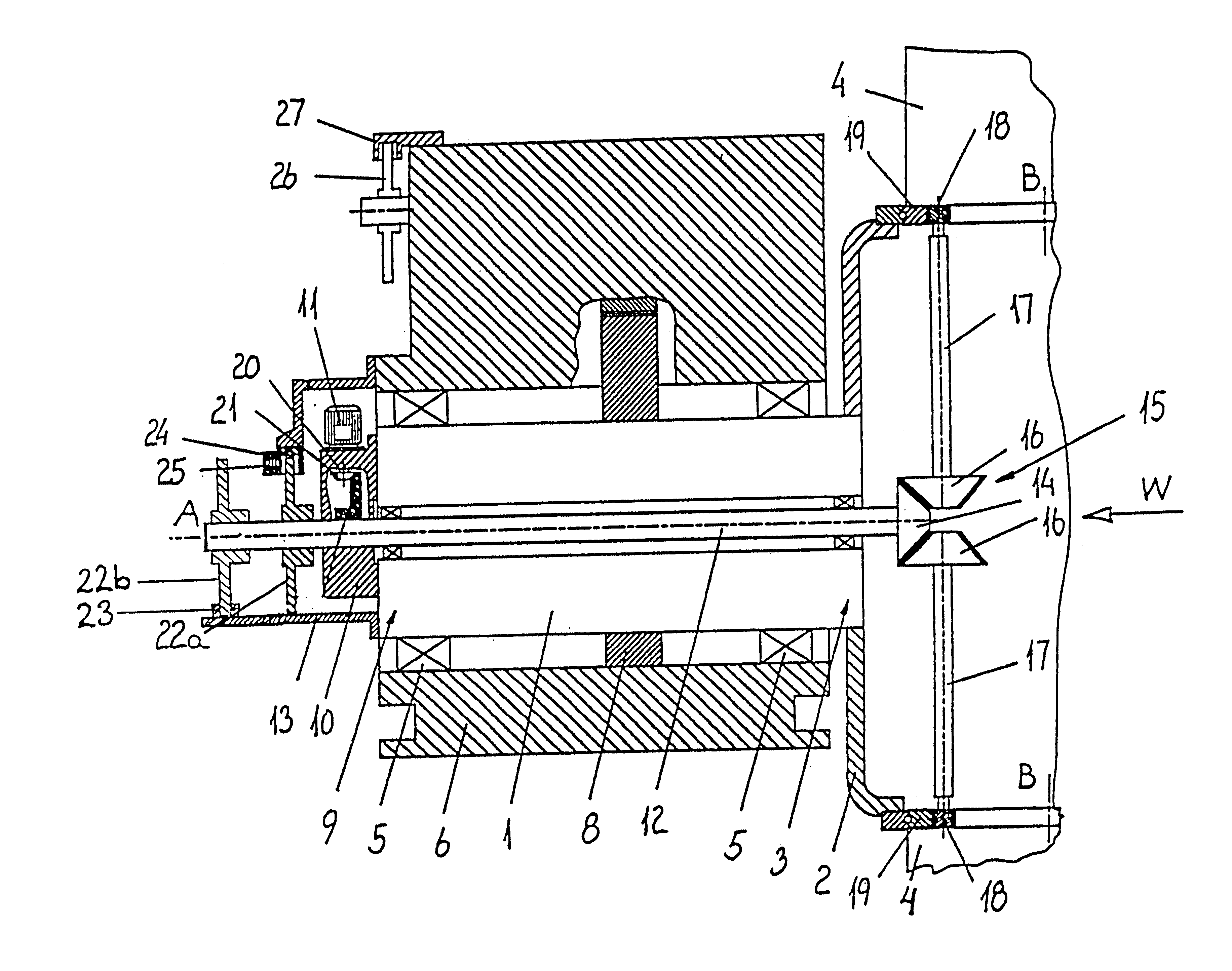

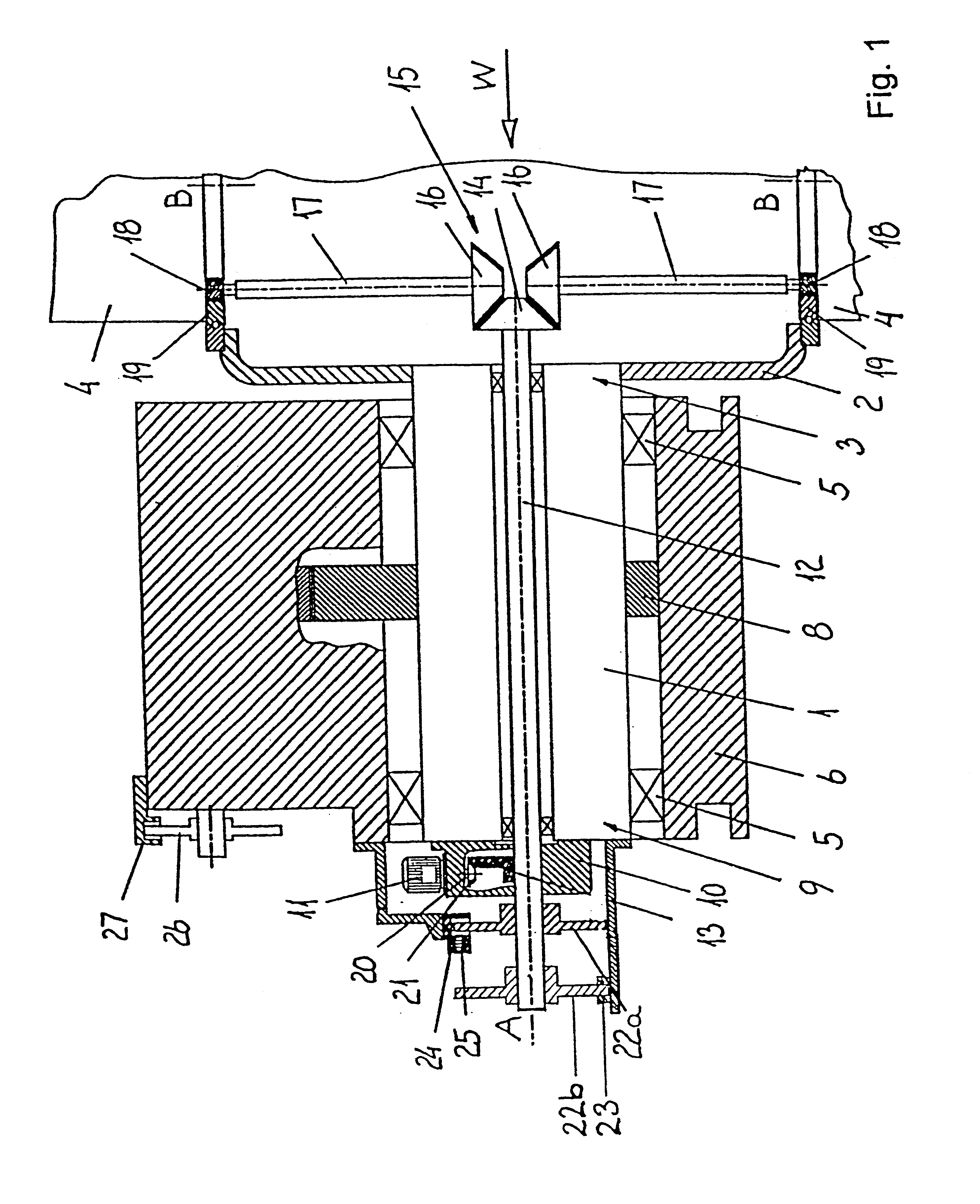

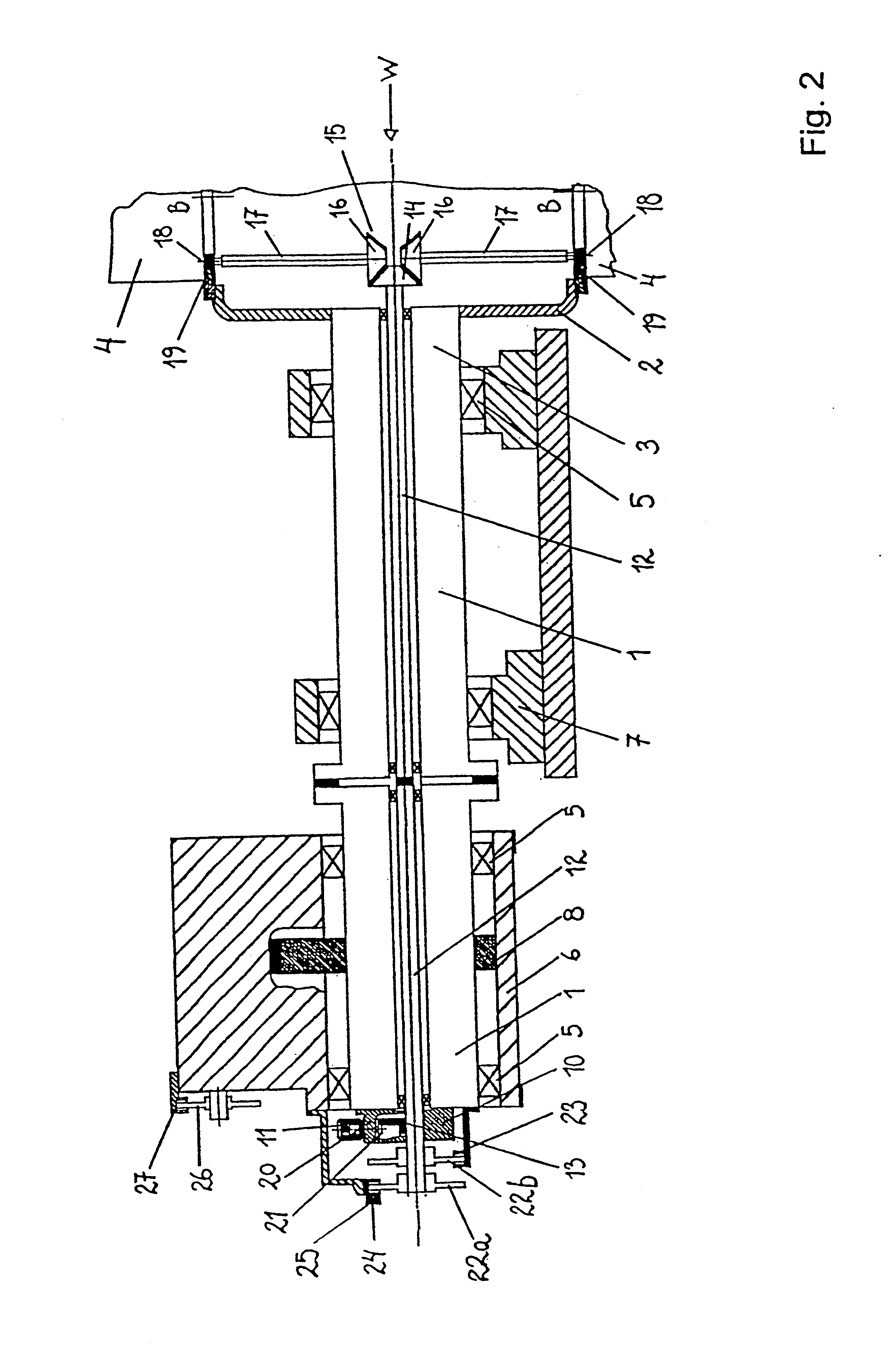

Method and a device for adjusting the pitch and stopping the rotation of the blades of a wind turbine

A method and mechanism for adjusting / controlling the pitch of at least one blade of a wind turbine relative to a wind direction parallel to a longitudinal main shaft of the wind turbine use a mechanism with a motor for rotating drive wheels in the angle gear around a longitudinal blade shaft via drive wheels of an angle gear. The method and mechanism can stop the complete turning of a main shaft of a wind turbine having a motor to rotate a drive pinion in an angle gear via a drive wheel, the angle gear being meant to pitch at least one blade around a longitudinal axis.

Owner:NEG MICON

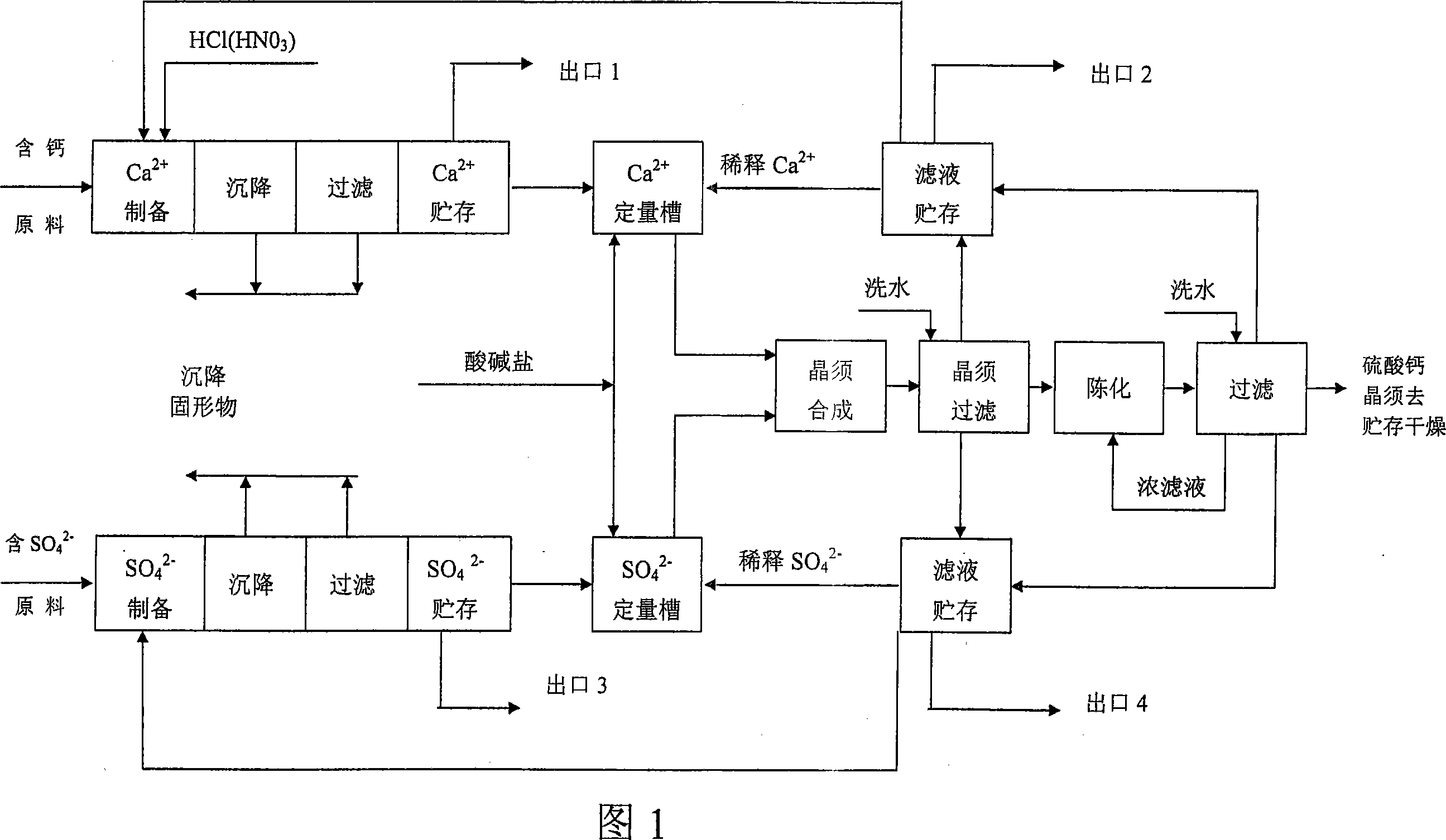

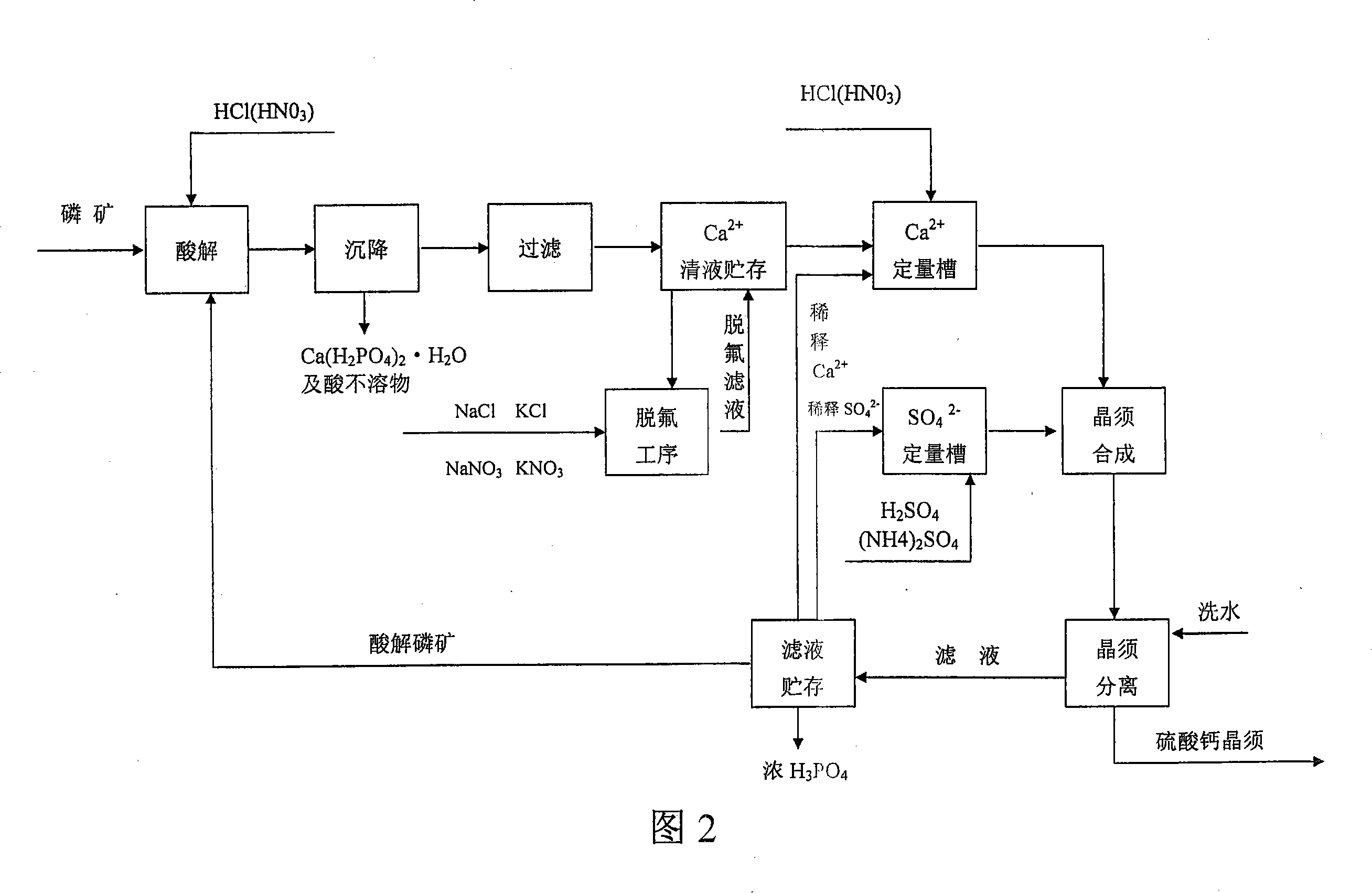

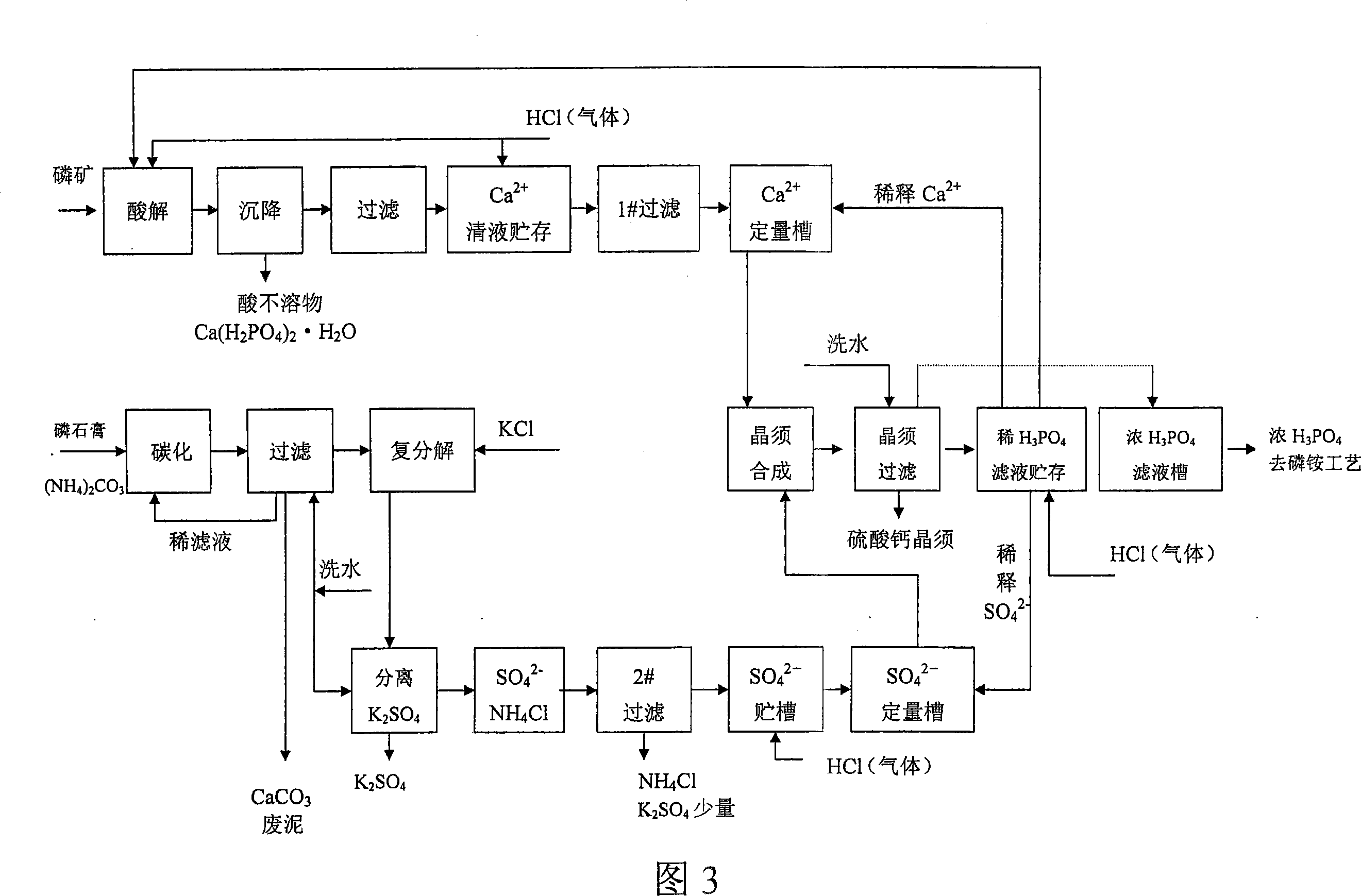

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

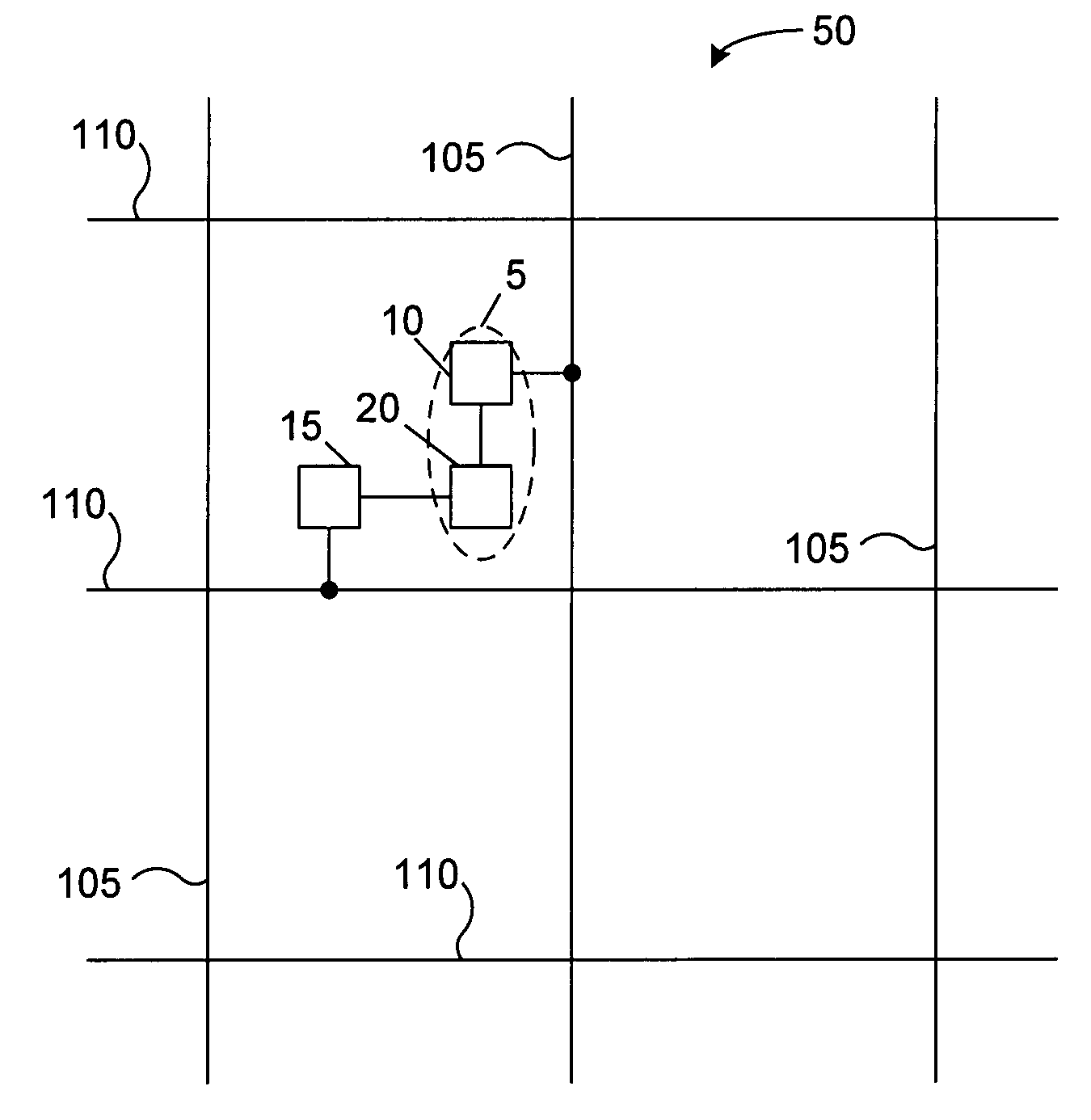

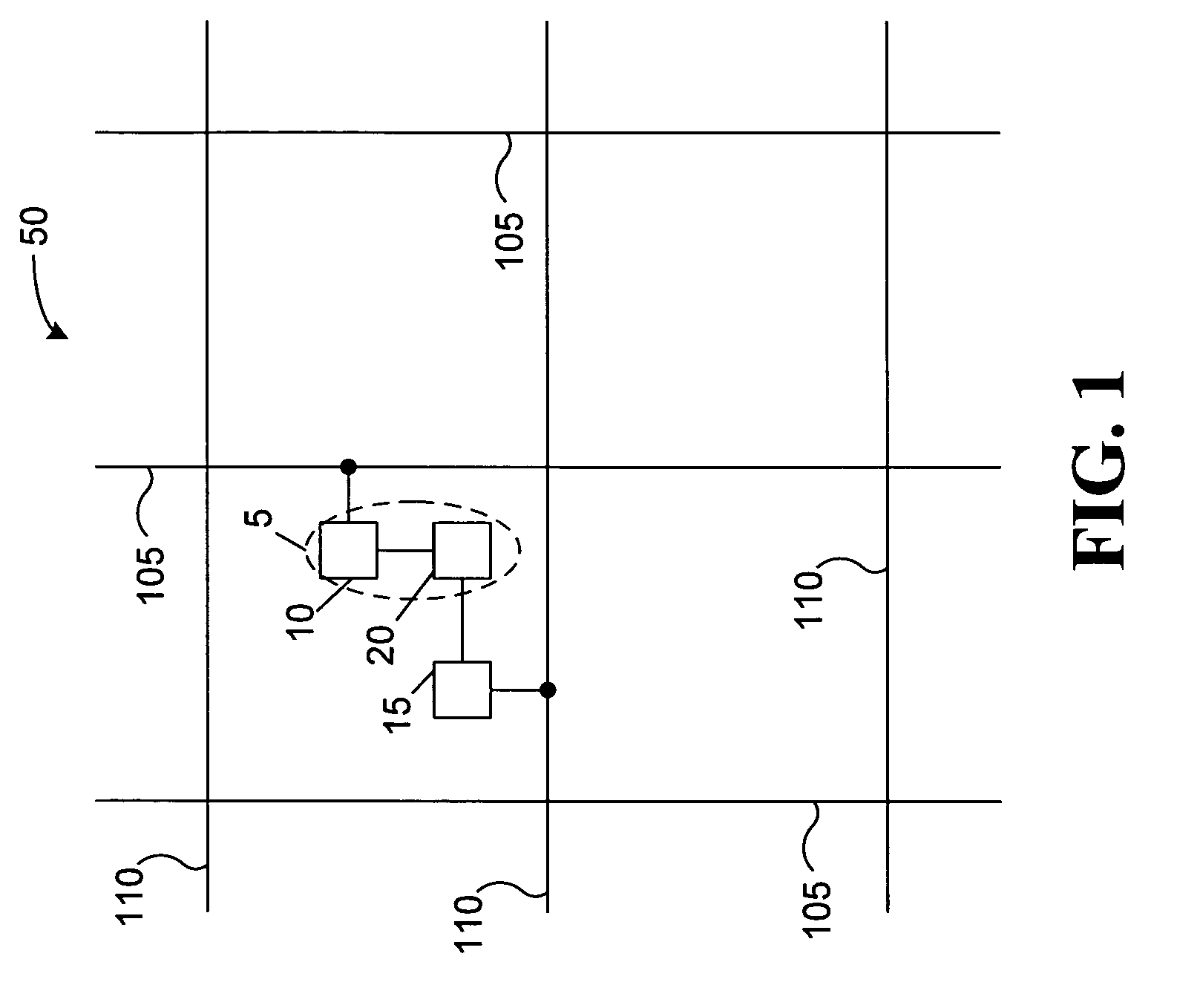

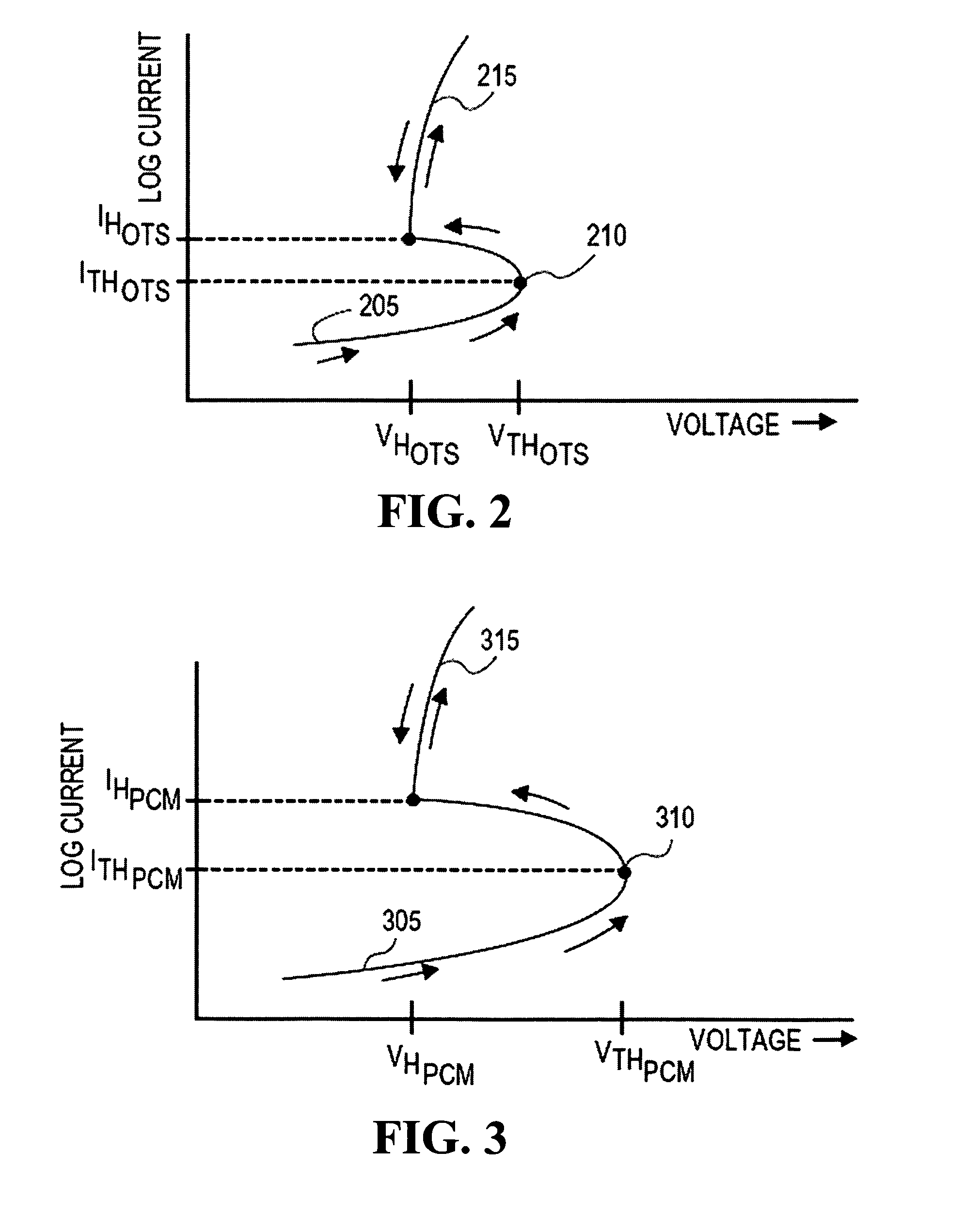

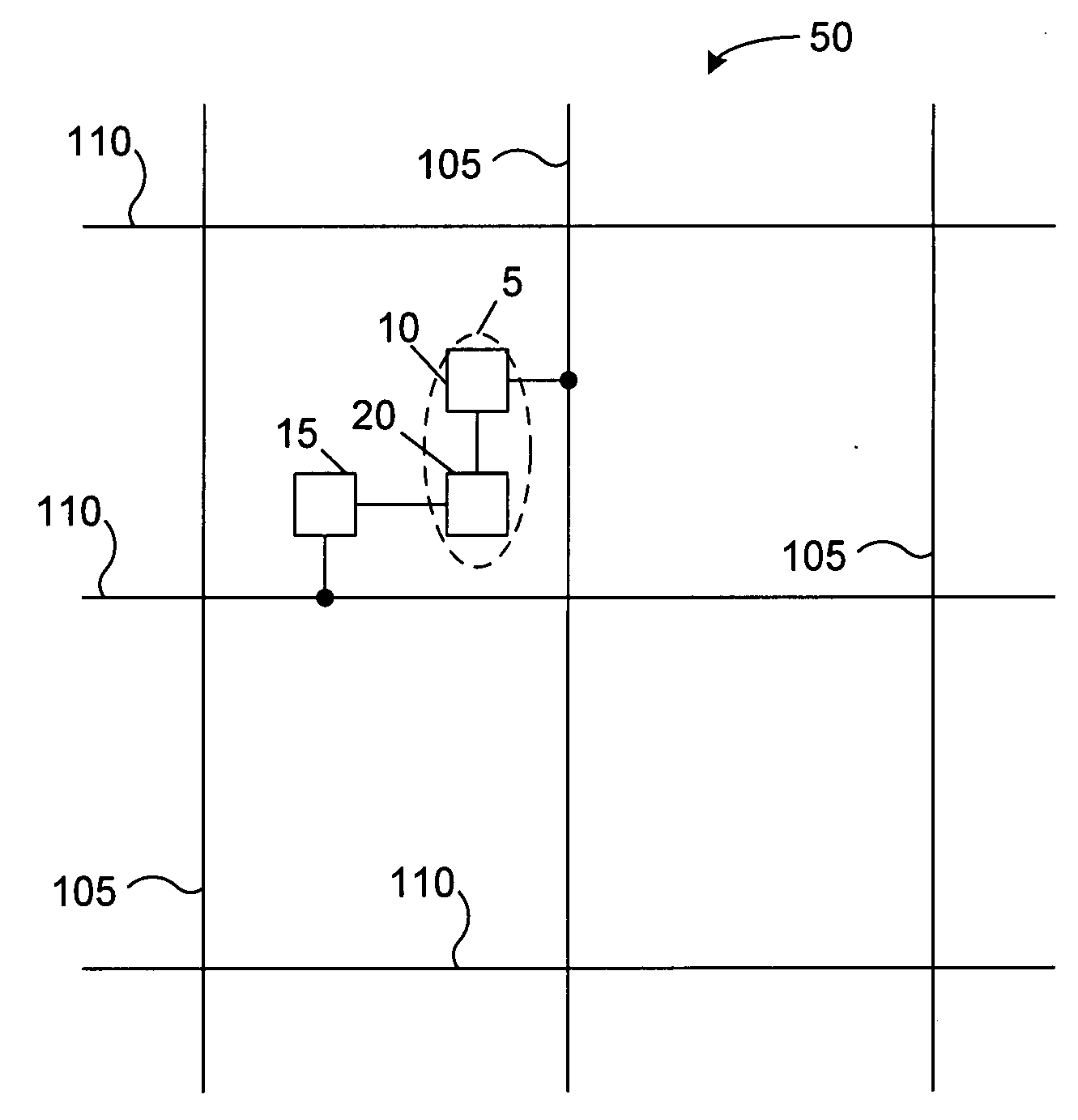

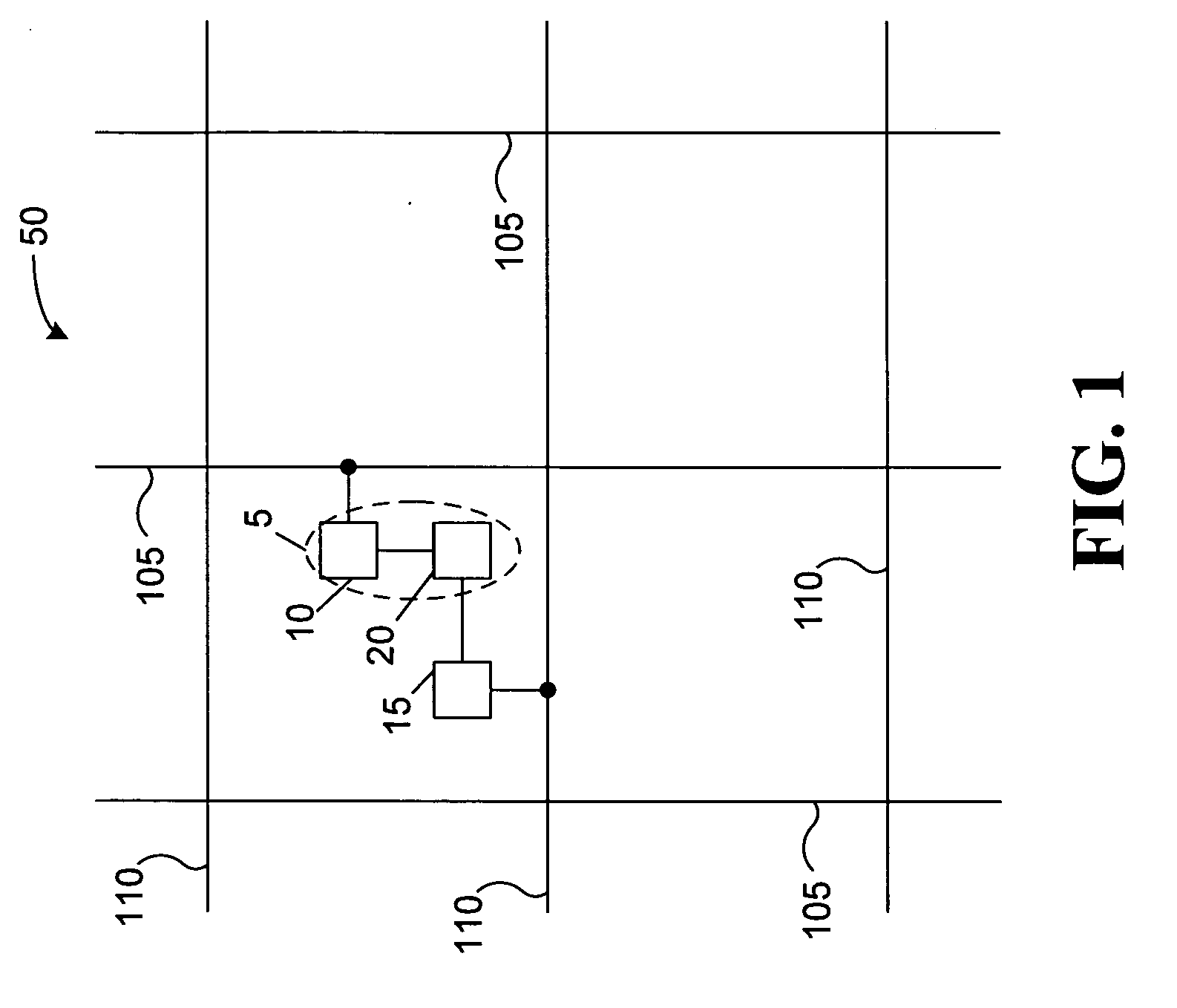

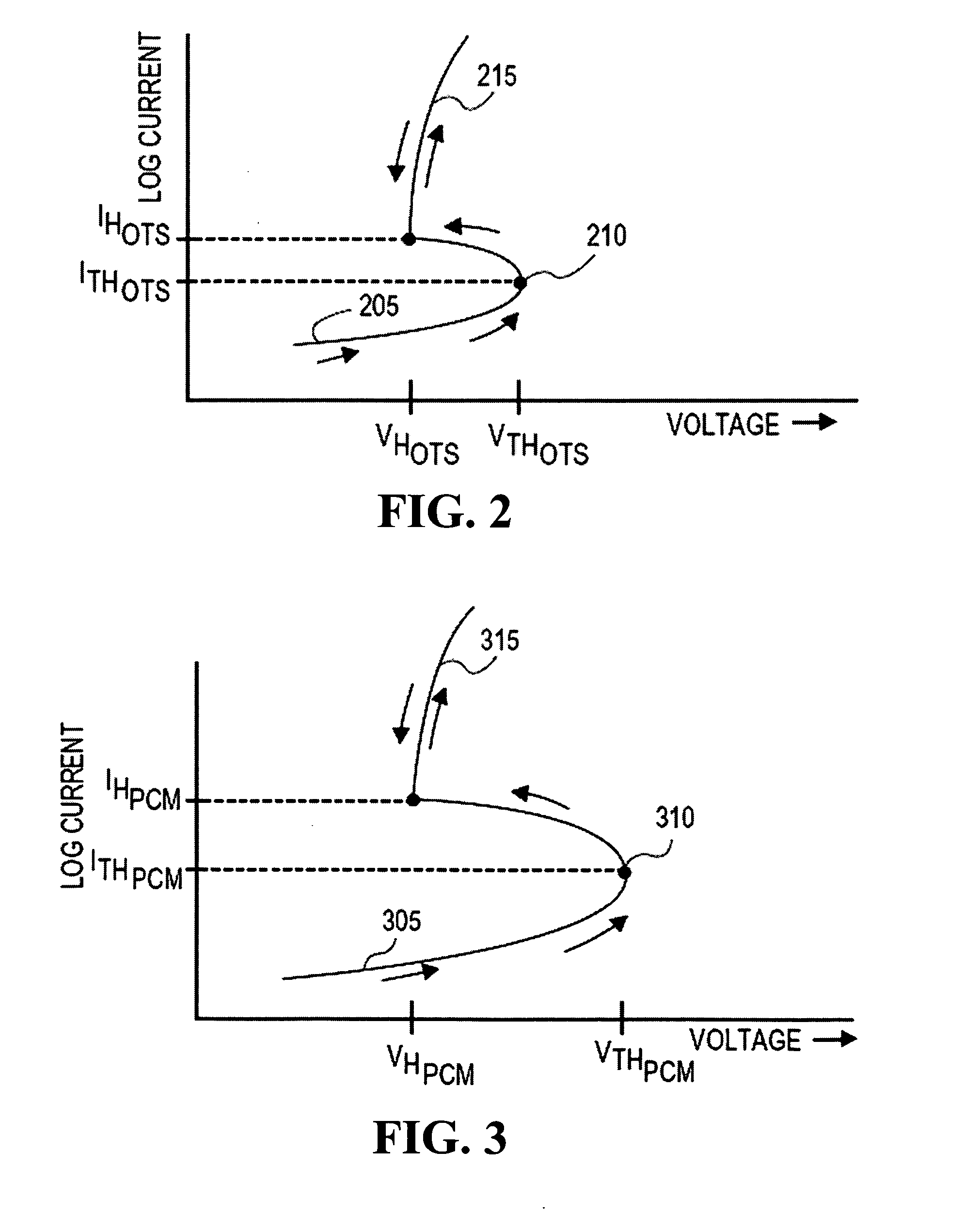

Energy-efficient set write of phase change memory with switch

ActiveUS8385100B2Reduce energy consumptionHigh energy consumptionRead-only memoriesDigital storagePhase-change memoryComputer architecture

Embodiments of apparatus and methods for an energy efficient set write of phase change memory with switch are generally described herein. Other embodiments may be described and claimed.

Owner:TAHOE RES LTD

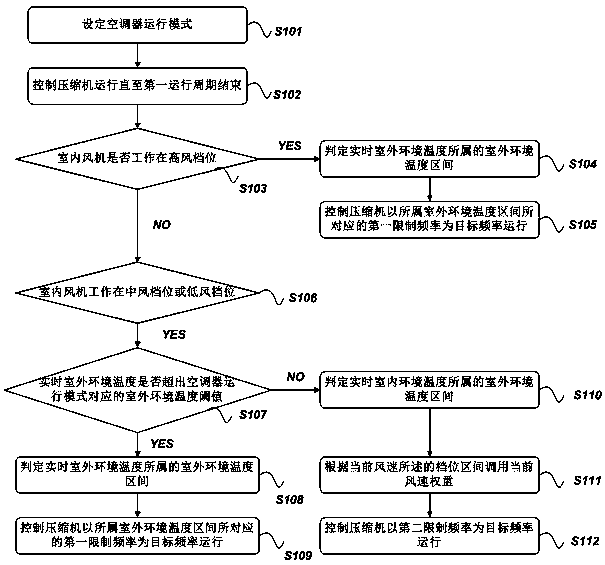

Air conditioner control method and air conditioner

ActiveCN109114729AHigh energy consumptionHigh degree of associationMechanical apparatusSpace heating and ventilation safety systemsEngineeringWind speed

The invention discloses an air conditioner control method. The air conditioner control method comprises the steps that a running mode is set; an air conditioner runs for a first running period and then is stopped; whether an indoor fan works at the high air gear or not is judged; if yes, the outdoor environment temperature interval is judged, and a compressor is controlled to run by taking first limiting frequency corresponding to the outdoor environment temperature interval as target frequency; if the indoor fan works at the middle air gear or the low air gear, whether the real-time outdoor environment temperature exceeds an outdoor environment temperature threshold value corresponding to the air conditioner running mode or not is judged; if yes, the outdoor environment temperature interval is judged, and the compressor is controlled to run at the first limiting frequency corresponding to the outdoor environment temperature interval; and if not, the outdoor environment temperature interval is judged, the current air speed weight is called, and the compressor is controlled to run by taking second limiting frequency as the target frequency. Meanwhile, the invention further disclosesan air conditioner. According to the air conditioner control method and the air conditioner, energy consumption of the compressor is intelligently optimized, and the balance among the human body comfort, the compressor energy consumption and the outdoor environment temperature is achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

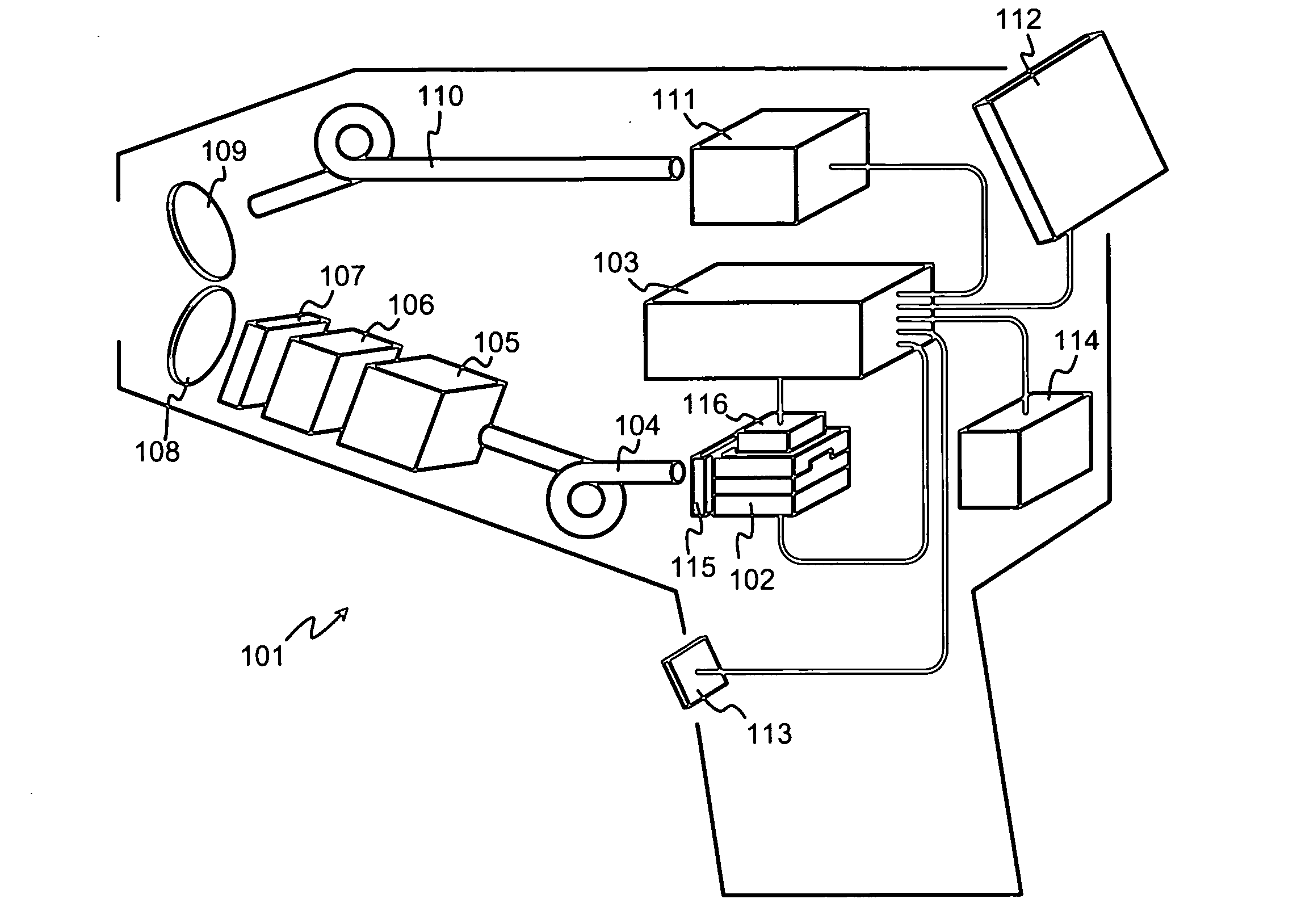

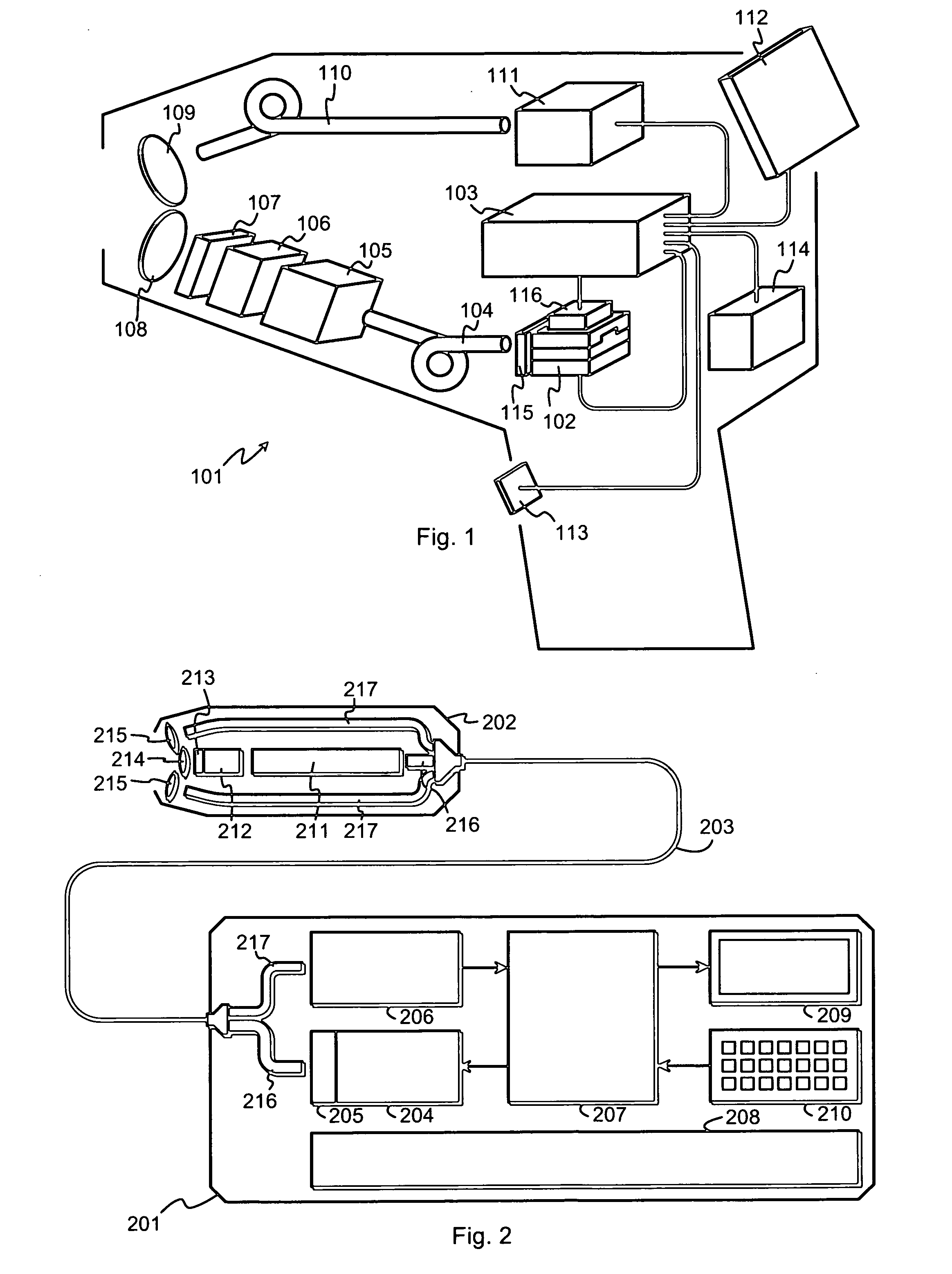

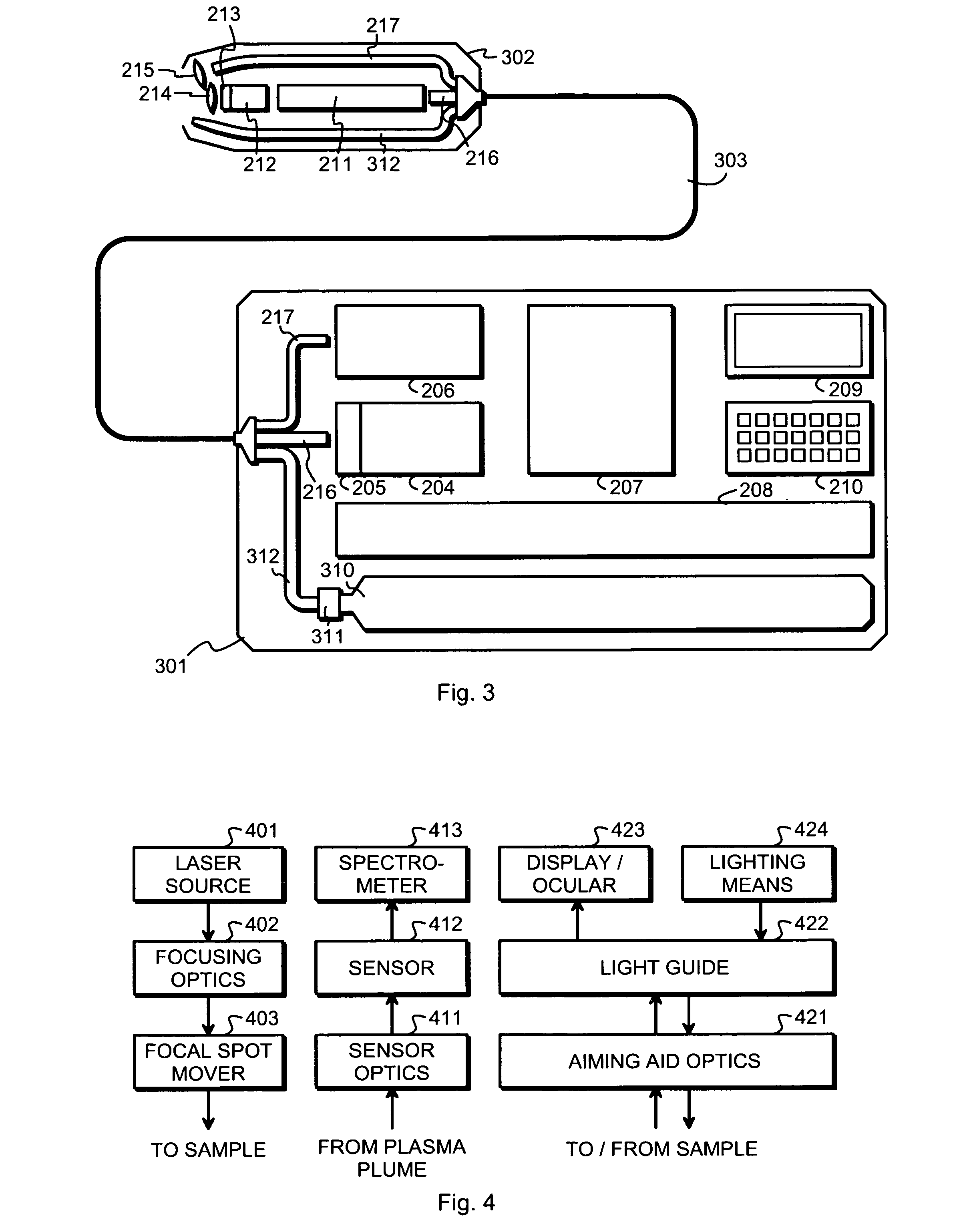

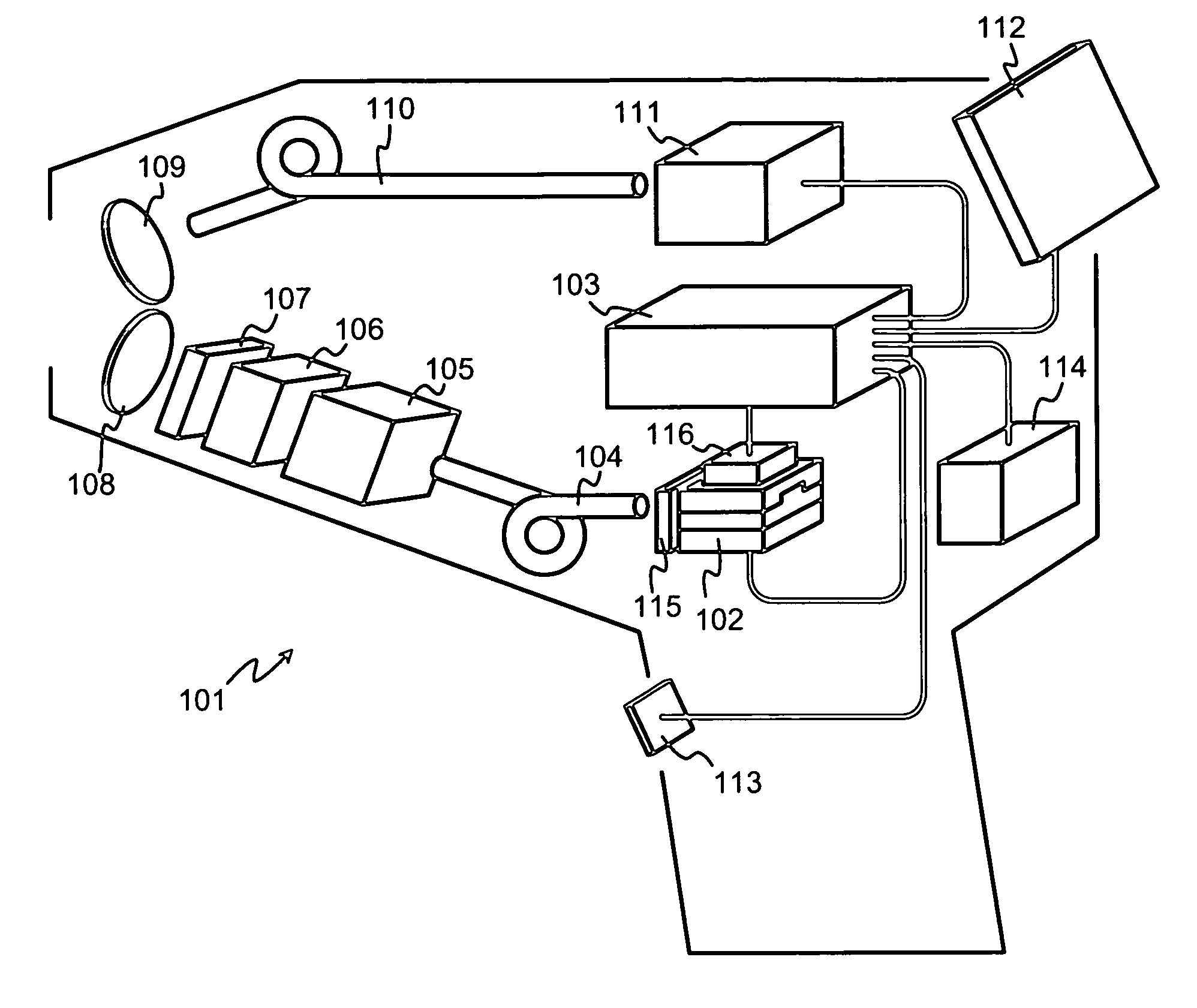

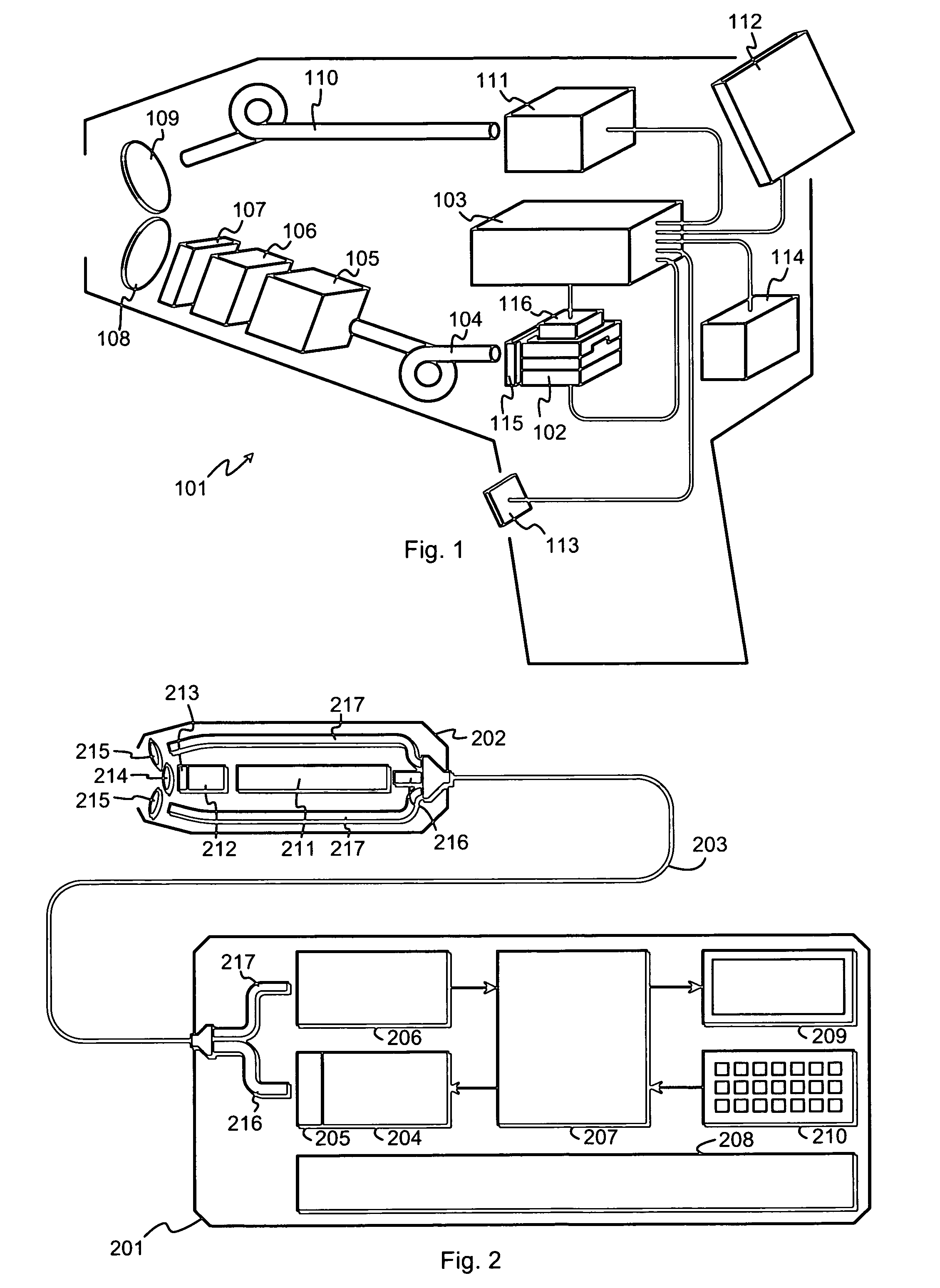

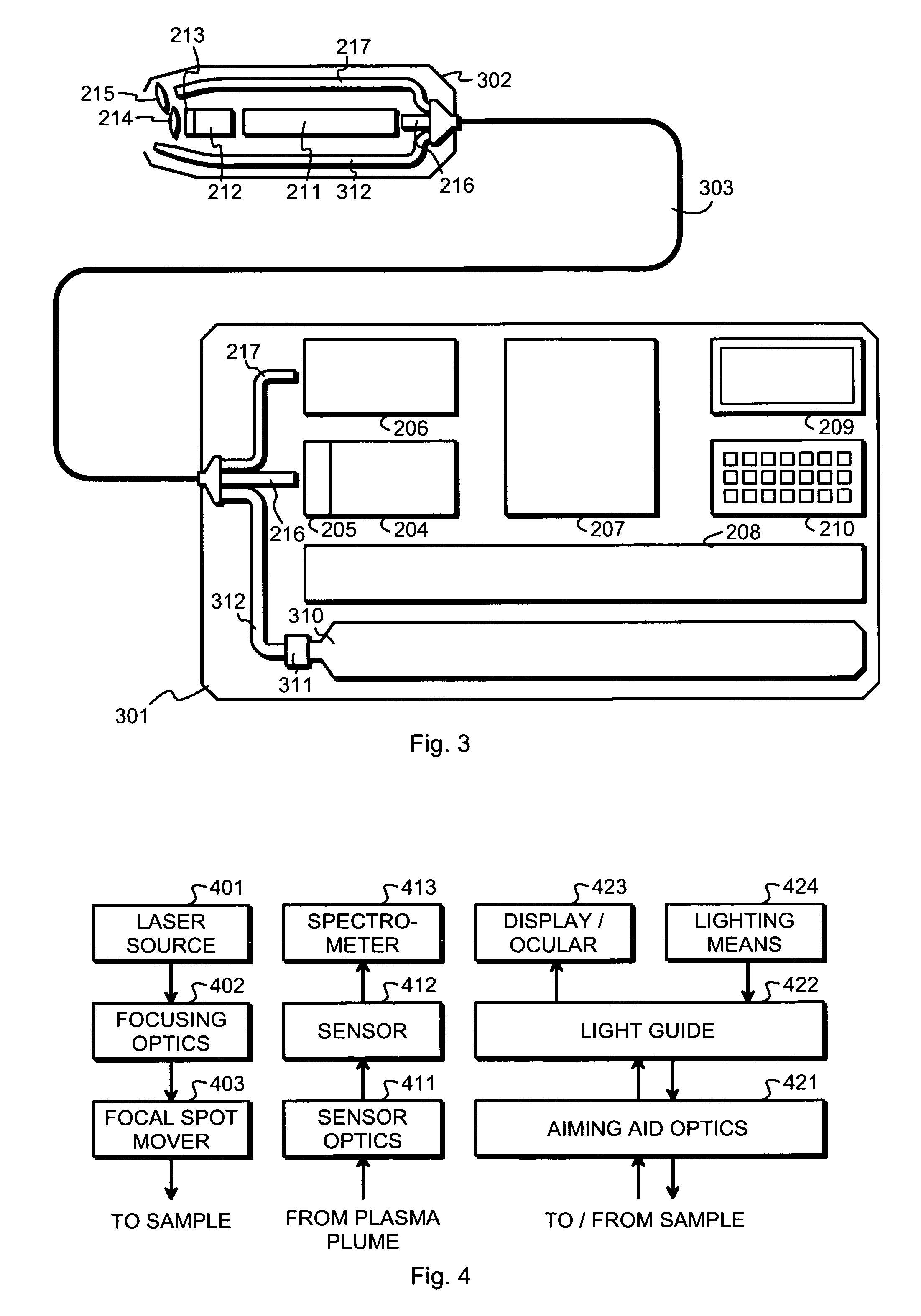

Practical laser induced breakdown spectroscopy unit

ActiveUS20080151241A1Easy to reachHigh energy consumptionRadiation pyrometrySpectrum investigationLaser-induced breakdown spectroscopyLaser beams

An apparatus for performing laser-induced breakdown spectroscopy comprises a handheld unit with a pump laser and a controller. A combination of a solid laser medium and a Q-switch receive a laser beam from said pump laser. Focusing optics focus laser pulses from said combination to a focal spot at a sample. Light collection optics collect light from plasma induced of sample material by focused laser pulses. A spectrometer receives collected light and produces information describing its spectral distribution. A power source delivers electric power to other parts of the apparatus. The pump laser, combination, focusing optics, light collection optics, spectrometer and power source are parts of said handheld unit.

Owner:HITACHI HIGH TECH ANALYTICAL SCI FINLAND OY

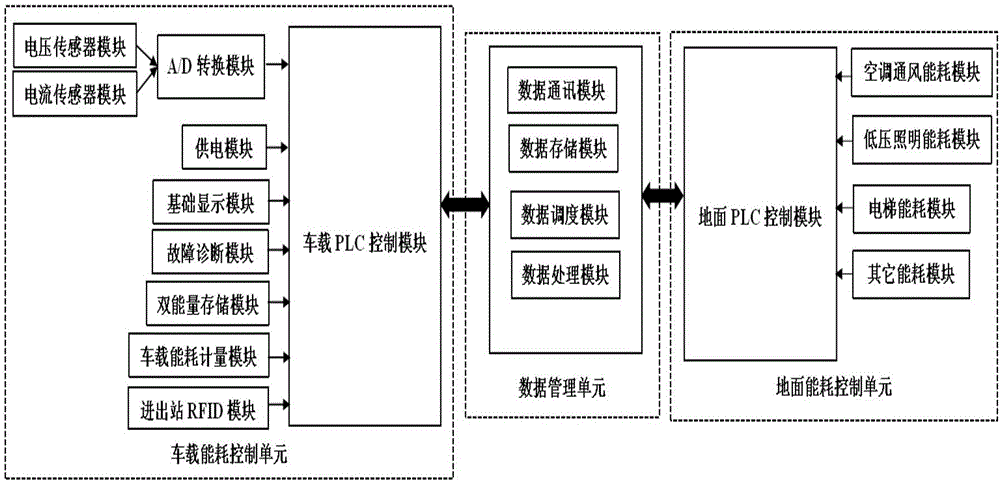

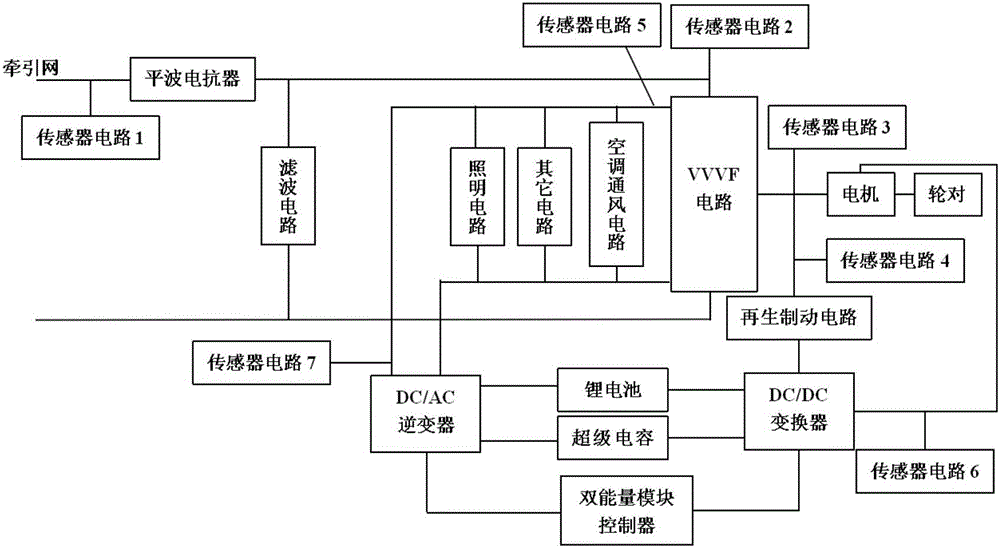

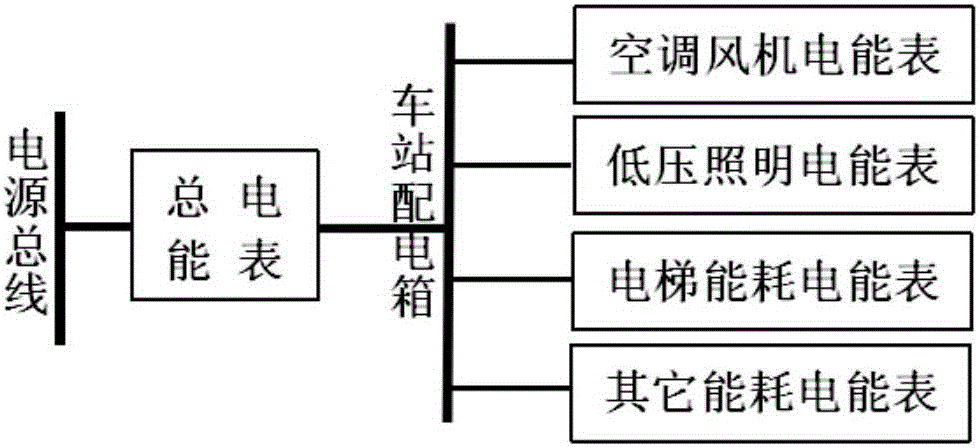

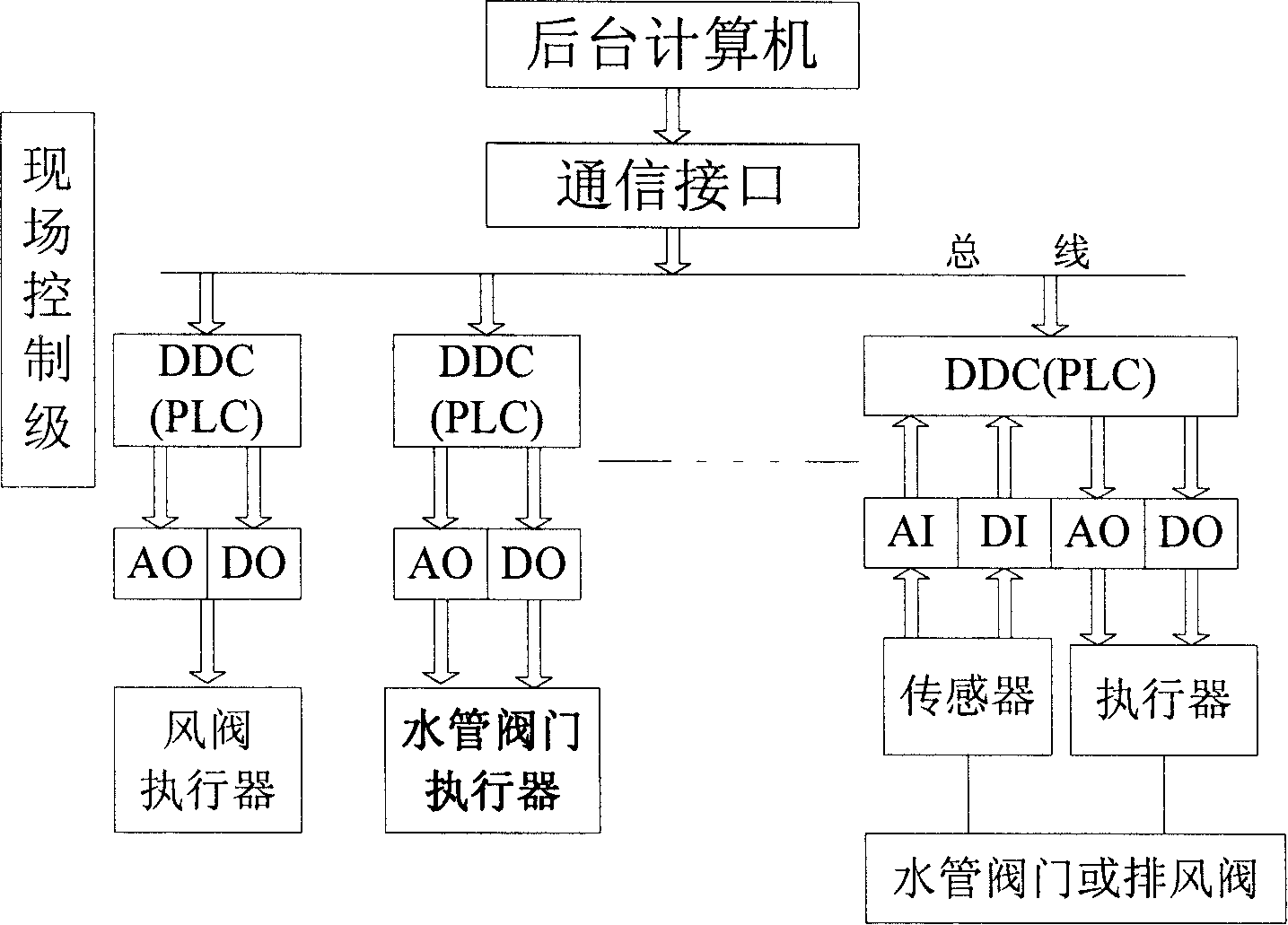

Control system for measuring energy consumption of urban rail transit and evaluation method

InactiveCN106774131AMake up for the disadvantage of low energy densityExtend your lifeElectrical measurementsProgramme control in sequence/logic controllersCapacitanceEnergy control

The invention discloses a control system for measuring the energy consumption of urban rail transit and an evaluation method. The control system comprises a vehicle-mounted energy consumption control unit, a data management unit and a ground energy consumption control unit. The control system has the beneficial effects that the system is a multi-path sampling energyconsumption metering system; drive control is carried out by adopting a permanent-magnet synchronous DC motor; a double-energy control module is built by using a super capacitor and a lithium battery for vehicle-mounted energy conversion control; train force analysis and modeling are not needed; a large quantity of nonlinear analysis or intelligent optimization calculation is not needed; traction energy consumption, regenerative braking energy and auxiliary energy consumption can be measured and monitored by directly utilizing collected voltage and current data; the control system has the functions of real-time storage and display of energy consumption data; the energy consumption data can be uploaded to the ground energy consumption control unit through the data management unit; the labor cost is reduced; the control system has a fault detection function; and the fault can be accurately reported when the system fails.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Surface metallizing method, method for preparing plastic article and plastic article made therefrom

InactiveUS20110281135A1Reduce energy consumptionEasy to performRadiation applicationsPretreated surfacesElectroless platingNickel

The present invention discloses a method for metallizing a plastic surface. The method may comprise the steps of: 1) gasifying the plastic surface to expose the electroless plating promoter; and 2) electroless plating a layer of copper or nickel on the plastic surface, followed by electroplating or a second electroless plating to form a metallized layer on the plastic surface. Further, the present invention discloses a method for preparing a plastic article and a plastic article as manufactured by the method as described.

Owner:BYD CO LTD

Energy-efficient set write of phase change memory with switch

ActiveUS20110134685A1Reduce energy consumptionHigh energy consumptionRead-only memoriesDigital storagePhase-change memoryComputer architecture

Embodiments of apparatus and methods for an energy efficient set write of phase change memory with switch are generally described herein. Other embodiments may be described and claimed.

Owner:TAHOE RES LTD

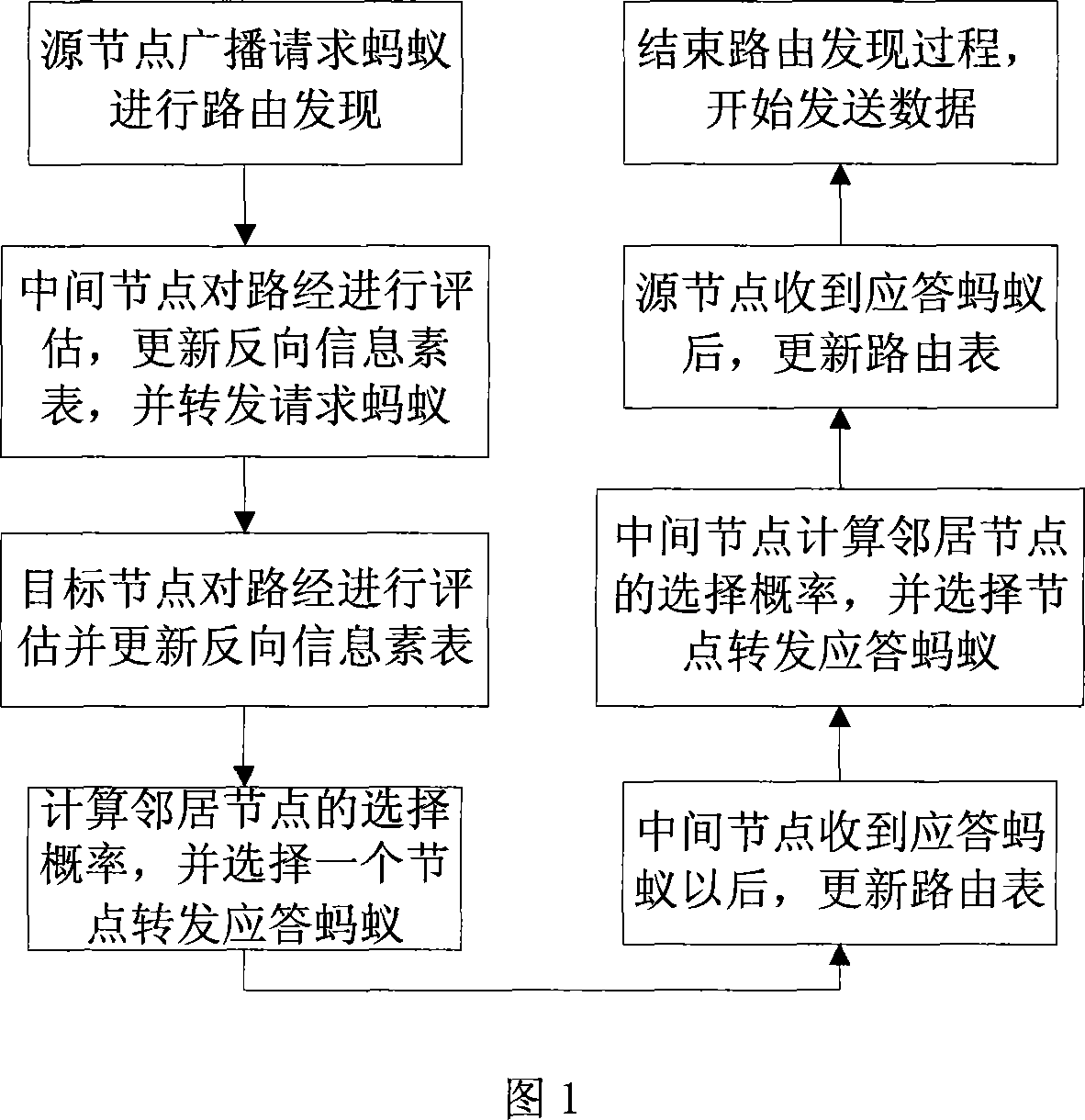

Ant algorithm based wireless self-organized network energy-saving routing method on demand

InactiveCN101083616ASimple structureImprove QoSEnergy efficient ICTData switching networksMethod selectionEnergy consumption

The invention relates to wireless self organized network energy saving needed route method based on ant colony optimization. The route building includes the following steps: broadcasting state information of asking ant to search network and store in each node reverse information pheromone list; responding the anti while receiving the request and selecting one neighbor node as the next step reverse source node; building the route from the source node to destination node. The route maintenance is that energy parameter is inducted; and new route finding process will be forced to do to avoid node from dying untimely while node energy consumption is overmuch.

Owner:SHANGHAI JIAO TONG UNIV

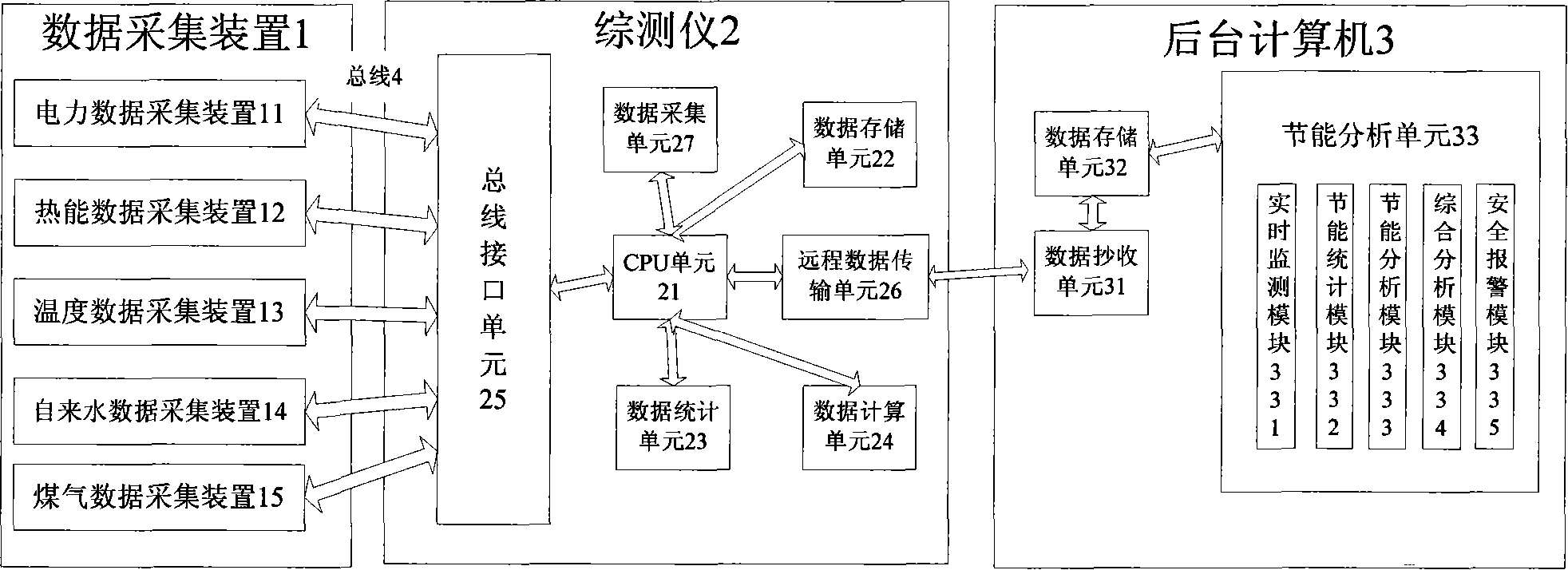

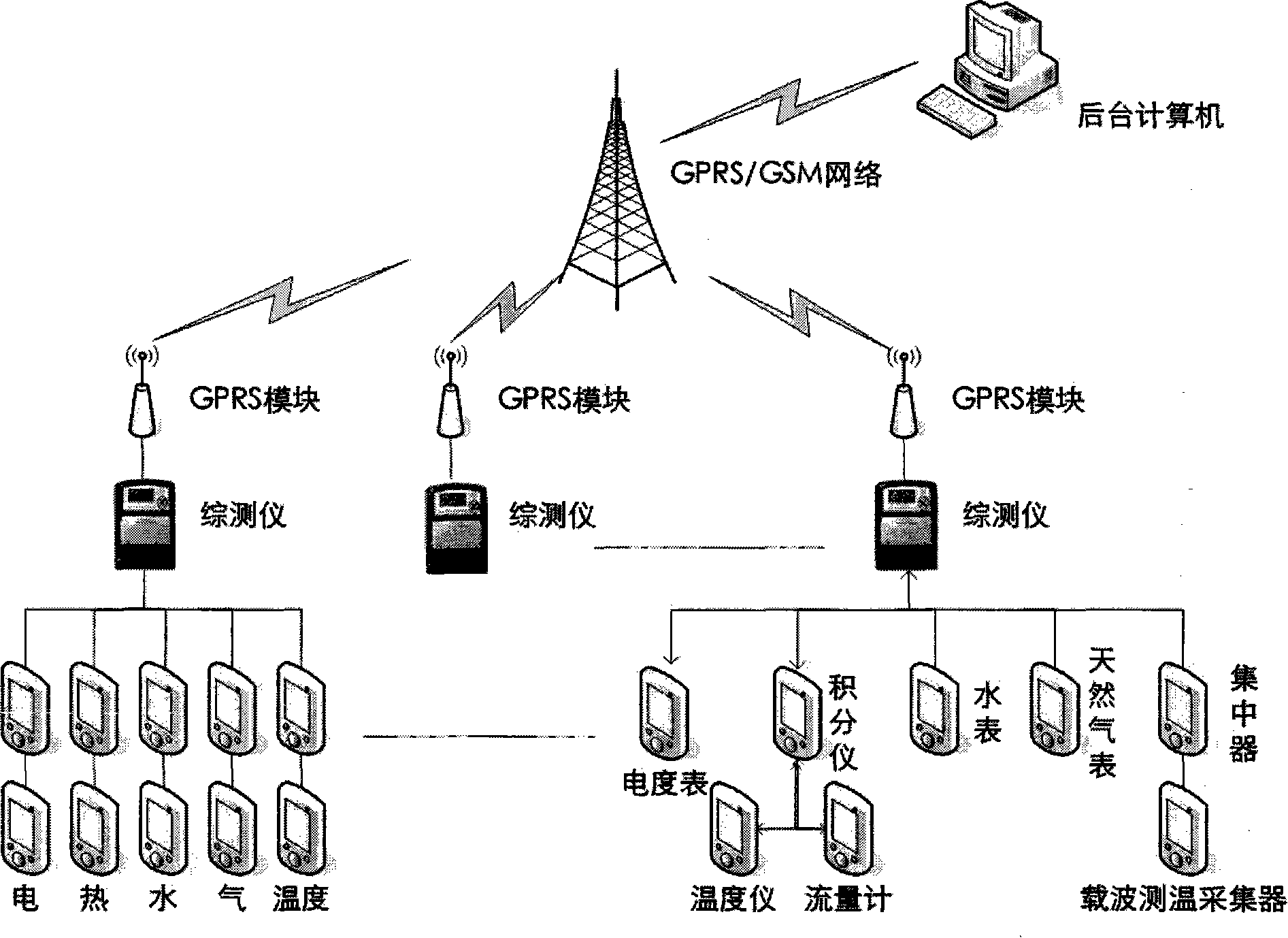

Energy-saving monitoring system

ActiveCN101174364AHigh energy consumptionGood compensationEnergy efficient ICTElectric signal transmission systemsThermal energyData acquisition

The invention discloses an energy-saving monitoring system, which comprises a plurality of data acquisition devices, a synthesis tester connected with the data acquisition devices, and a background computer connected with the synthesis tester; the data acquisition devices comprise electric data acquisition devices, heat energy data acquisition devices, and other devices, and are connected with the synthesis tester through bus lines; the synthesis tester comprises a CPU unit, and a data storage unit, a data statistic unit, data computing unit, a bus interface unit, and a long-distance data transmission unit which are connected with the CPU unit; the background computer comprises a data collecting unit, a data storage Unit, and an energy-saving analysis unit connected with the long-distance data transmission unit of the synthesis tester through the data collecting unit by adopting long-distance transmission means. The invention can effectively reduce the energy source waste through the monitoring to the energy consumption condition, thus realizing the preliminary behavior energy conservation; and completes energy saving renovation and realizes technical energy conservation by using technical means.

Owner:BEIJING JIUZHOU HENGSHENG CONSTR ENG

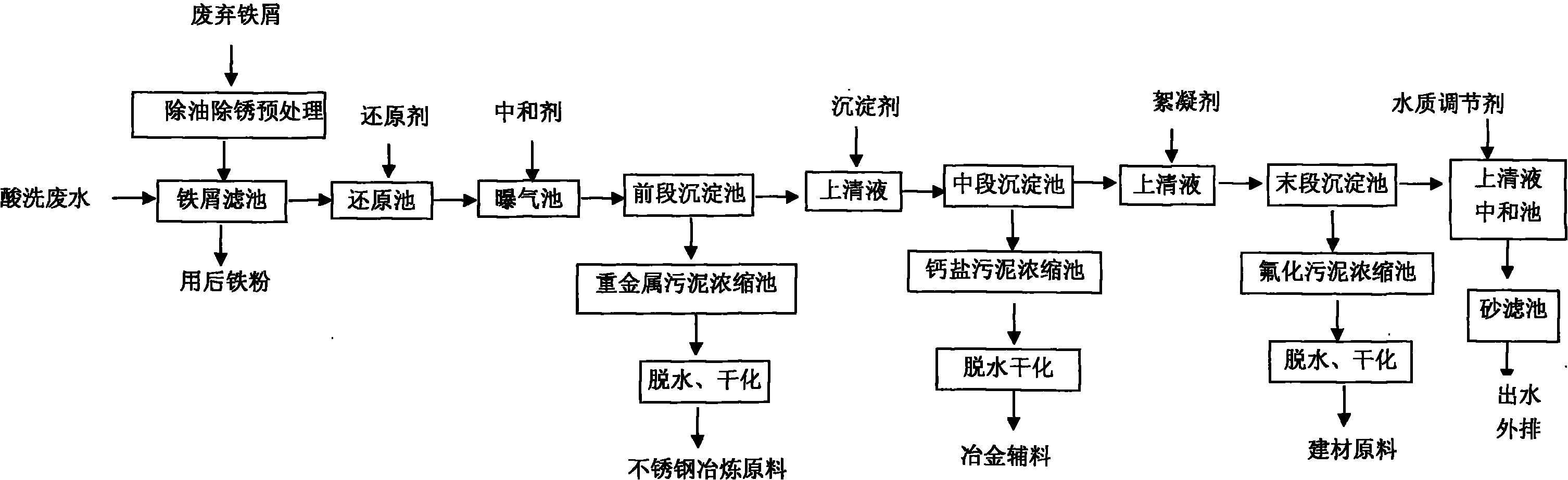

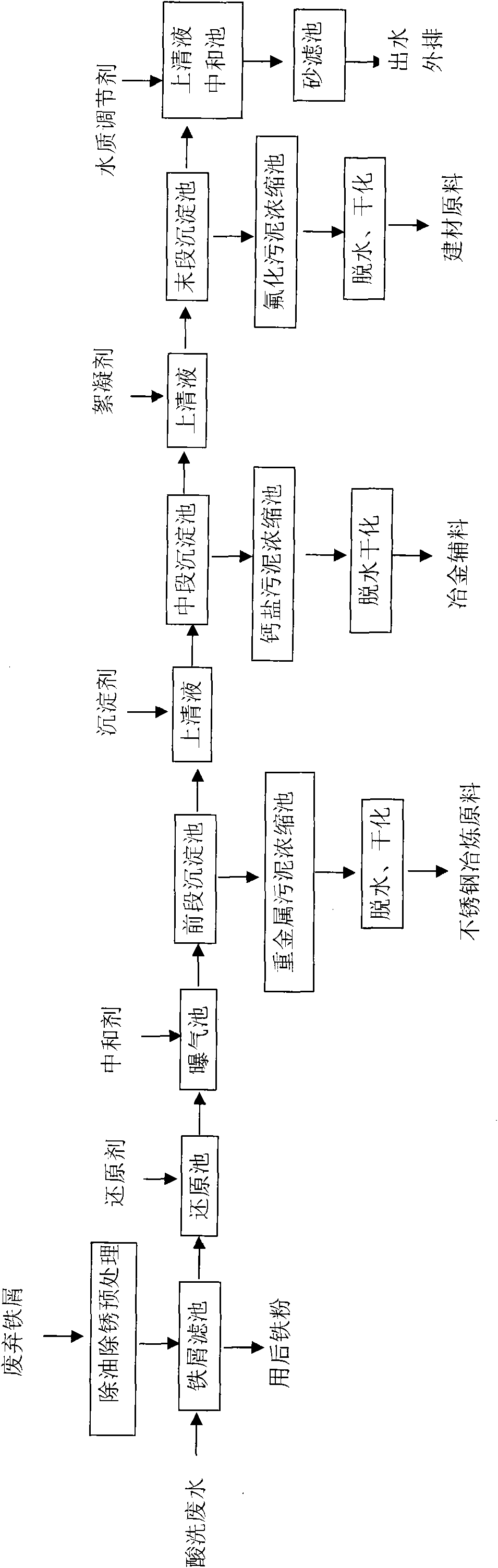

Processing method of stainless steel cold rolling pickling wastewater

ActiveCN101811792AIncrease dosageIncrease productionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processScrapHexavalent chromium

The invention relates to a processing method of stainless steel cold rolling pickling wastewater. The pickling wastewater enters a hexavalent chrome secondary reduction pool after the actions of micro-electrolysis and hexavalent chrome preliminary reduction of a scrap iron filtering pool; the reduced wastewater enters a front-segment precipitation tank after neutralization and aeration, heavy metal sludge is concentrated and dehydrated, and the heavy metal sludge and scrap iron after the use of the scrap iron filtering pool are recycled and used as stainless steel smelting raw materials; middle-segment precipitation is carried out after a primary supernatant acts with a precipitant, and dehydrated and dried fluoride sludge is recycled and used as a metallurgical adjuvant material; final-segment precipitation is carried out after a secondary supernatant continues to act with a flocculating agent to obtain calcium salt which can be used as a building material raw material; and after the three segments of precipitation of acidic wastewater, the final third level supernatant reaches a standard and is discharged through water quality regulation and sand filtering. The invention has the advantages of less investment, low wastewater processing cost, convenient maintenance and the like, and not only can effectively utilize discarded scrap iron of a stainless steel enterprise, but also can greatly lower the subsequent wastewater processing cost and the operating load.

Owner:BAOSHAN IRON & STEEL CO LTD

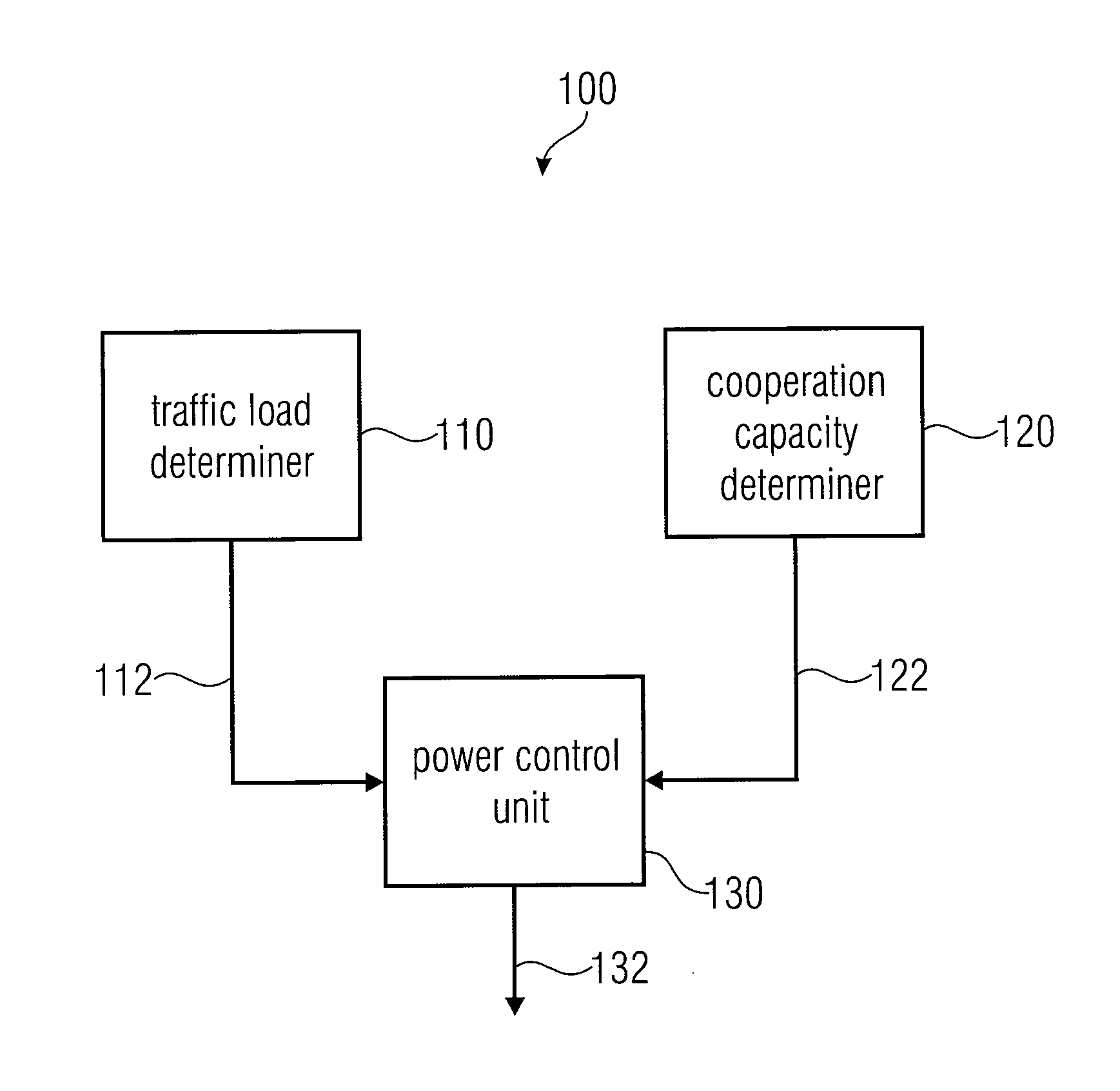

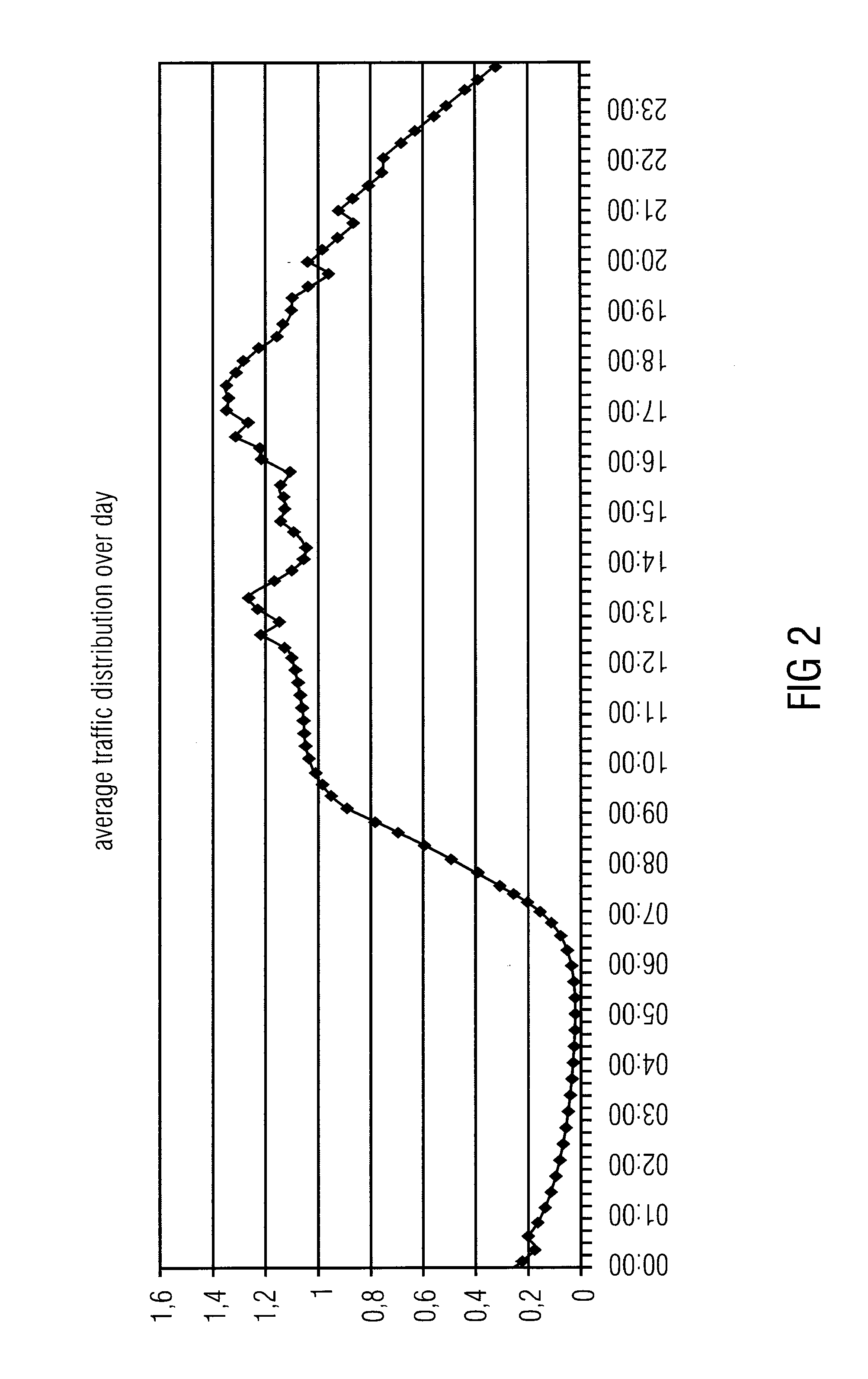

Apparatus and method for controlling a node of a wireless communication system

InactiveUS20120165063A1Traffic load within the wireless communication is lowReduce in quantityPower managementEnergy efficient ICTCommunications systemTraffic load

An apparatus for controlling a node of a wireless communication system has a traffic load determiner, a cooperation capacity determiner and a power control unit. The traffic load determiner determines a traffic load in the wireless communication system and the cooperation capacity determiner determines an available cooperation capacity of the node with another node of the wireless communication system. Further, the power control unit activates or deactivates an antenna of a node based on the determined traffic load and the determined available capacity.

Owner:NTT DOCOMO INC

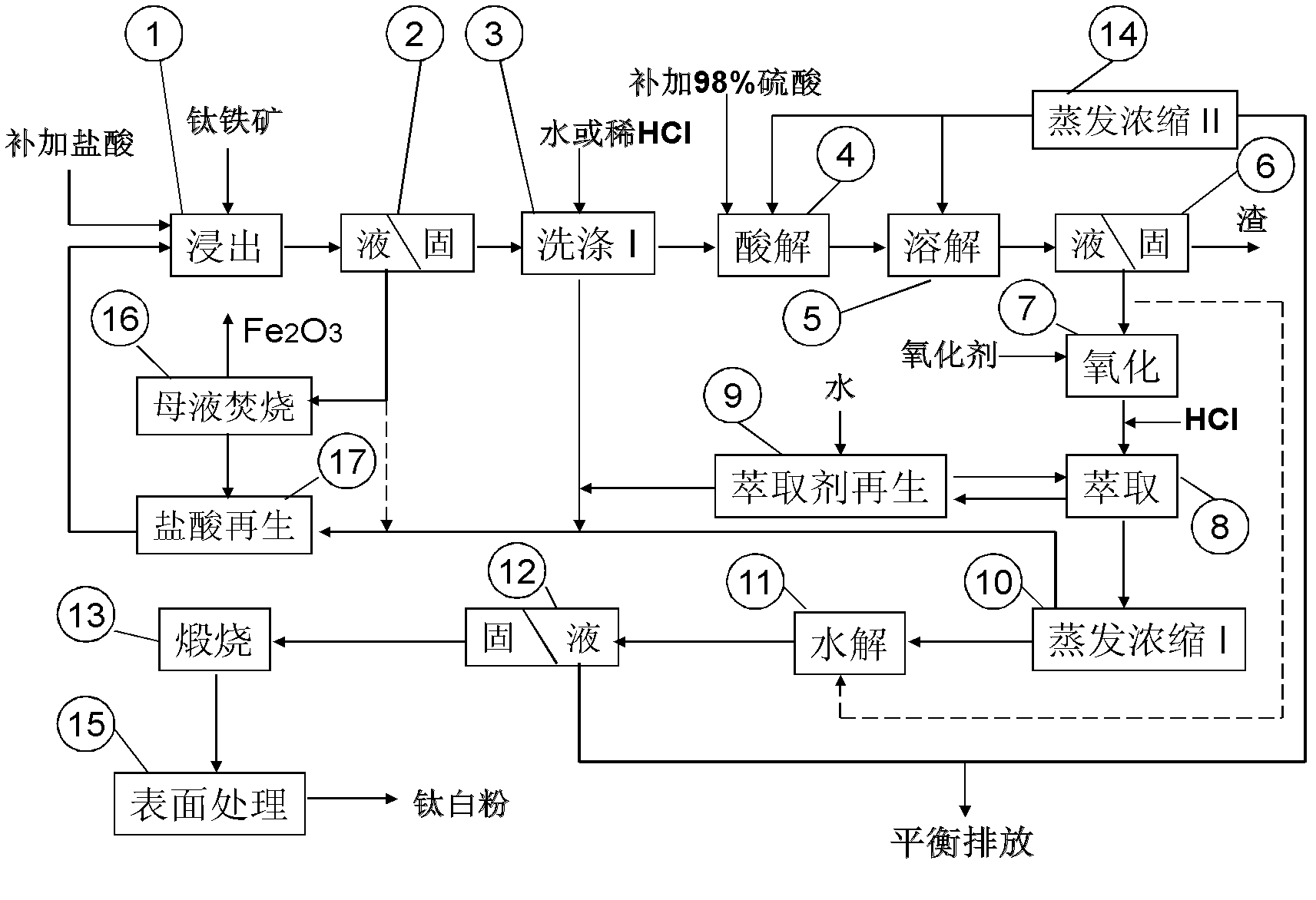

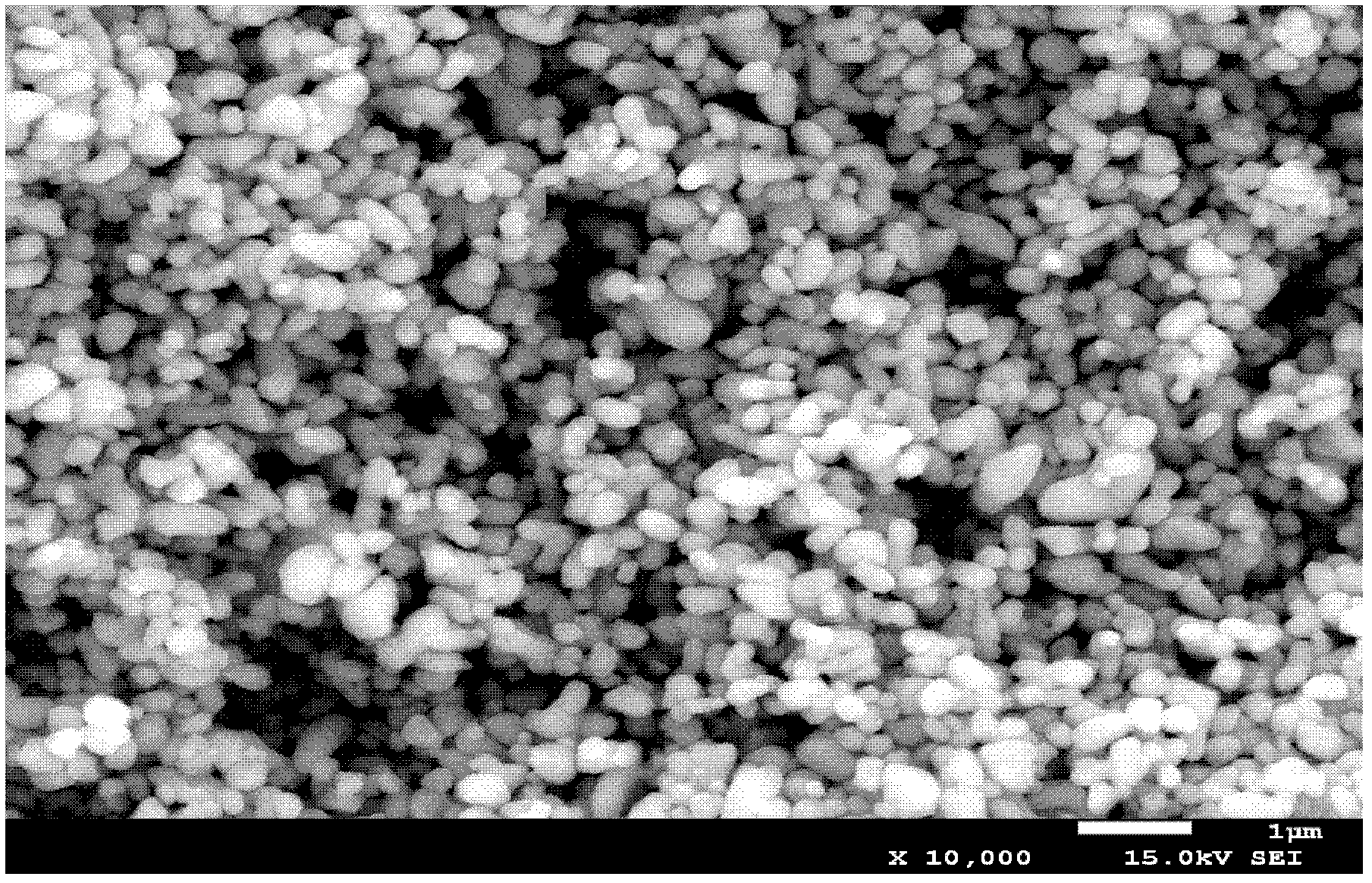

Method for preparing titanium white

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

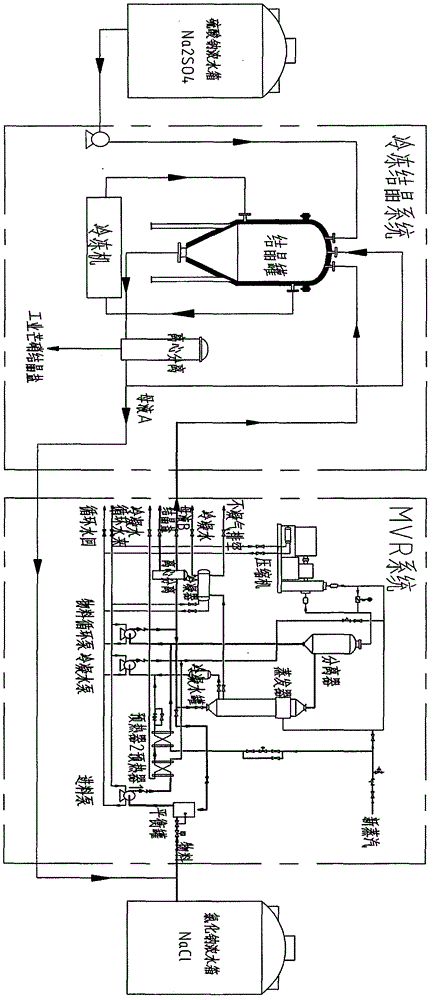

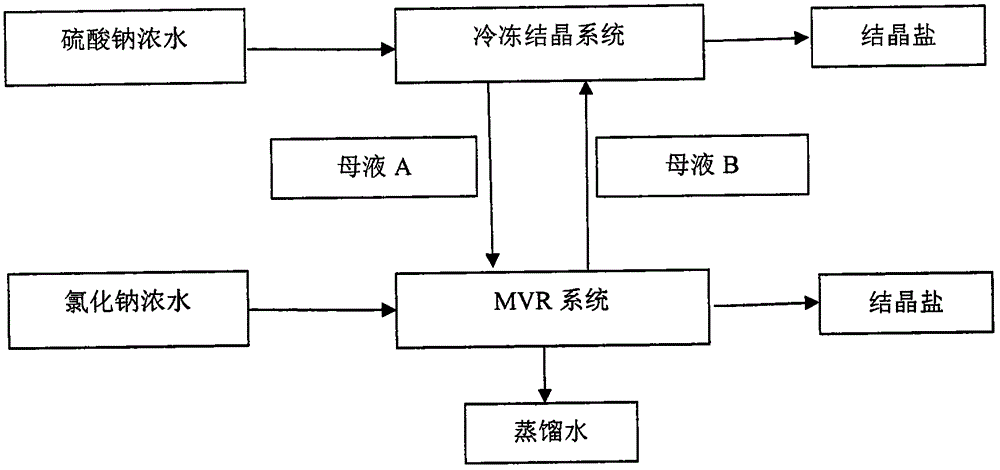

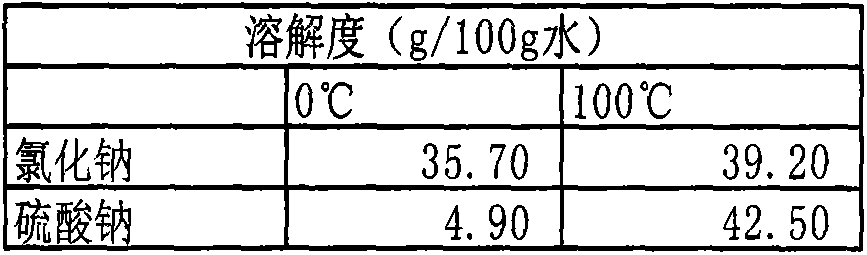

Crystallization treatment method and device of high salt wastewater

ActiveCN104692575AHigh energy consumptionHigh operating costsAlkali metal sulfite/sulfate purificationMultistage water/sewage treatmentResource utilizationWastewater

The invention relates to a crystallization treatment method and device of high salt wastewater and belongs to the technical field of water treatment. The method is characterized in that after sodium sulfate concentrated water is treated by a freezing crystallization system, generated mother liquor A enters into an MVR system for evaporative crystallization; after sodium chloride concentrated water is treated by the MVR system, generated mother liquor B enters into a freezing crystallization system for freezing crystallization, and the mother liquor can be treated in a circulation overlapping manner; a drain outlet of the MVR system of the device is connected with a liquid inlet of a crystallization tank in the freezing crystallization system through a pipeline and the drain outlet of the freezing crystallization system is connected with a liquid inlet pipe of the MVR evaporative crystallization system. The method has the advantages that the mother liquor is treated by a freezing crystallization technology and an MVR evaporation crystallization technology in a circulation overlapping manner, so that the problems of zero emission and resource utilization are solved, and therefore, the energy consumption is effectively reduced and the operating cost is lowered.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

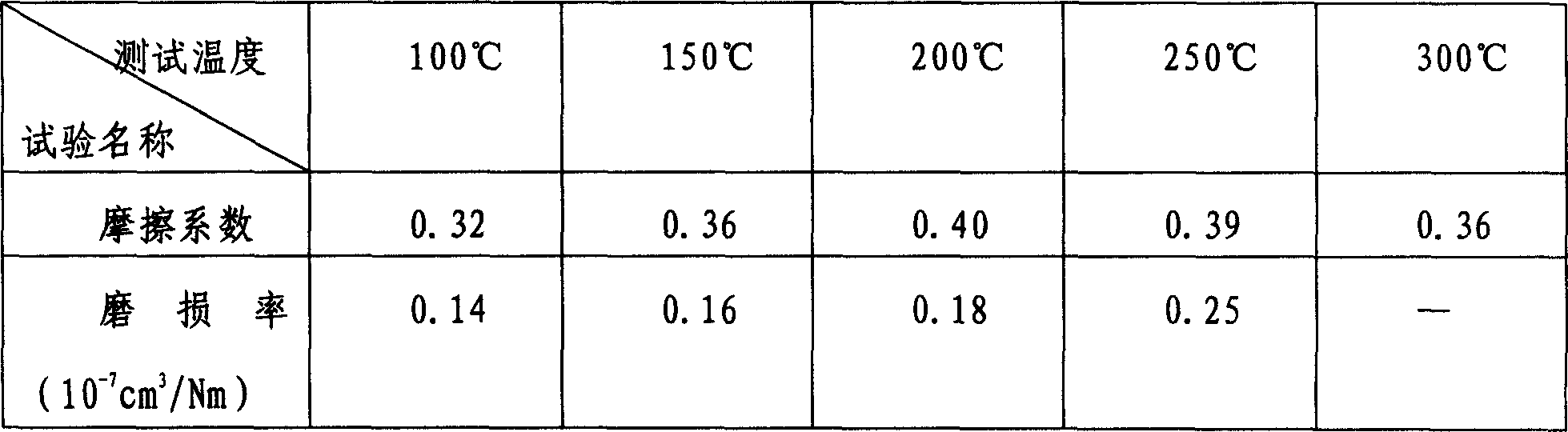

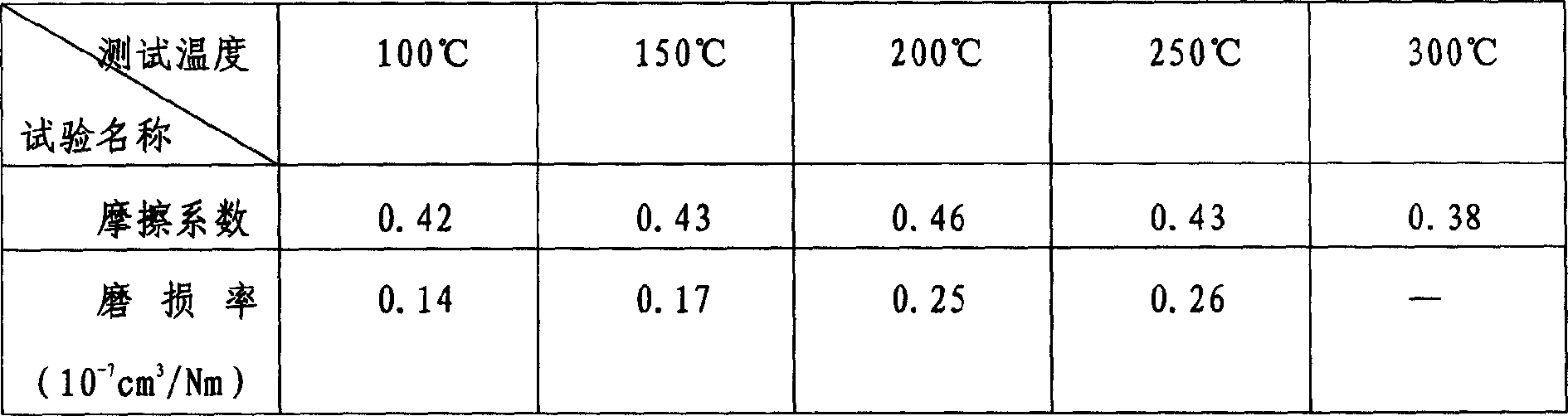

Automotiv non-asbestos high strength braking friction disk, and its prodn. method

InactiveCN1563735AImprove heat resistanceEnhancement effect is goodFriction liningHeat resistanceMetal fibers

The wearing piece of non-asbestos high srength material applies the high molecular compound, phenolic ressin as the agglomerant. The metal fiber or organic fiber is strengthen component. The stuffing applies regulator with frictional properties and barium sulfate, black lead, alumina as accessory ingredient. The production possesses excellent characteristic of physical chemical and mechanical and thermo-stability.

Owner:APPLIED PHYSICS INST OF GUANGXI ACADEMY OF SCI

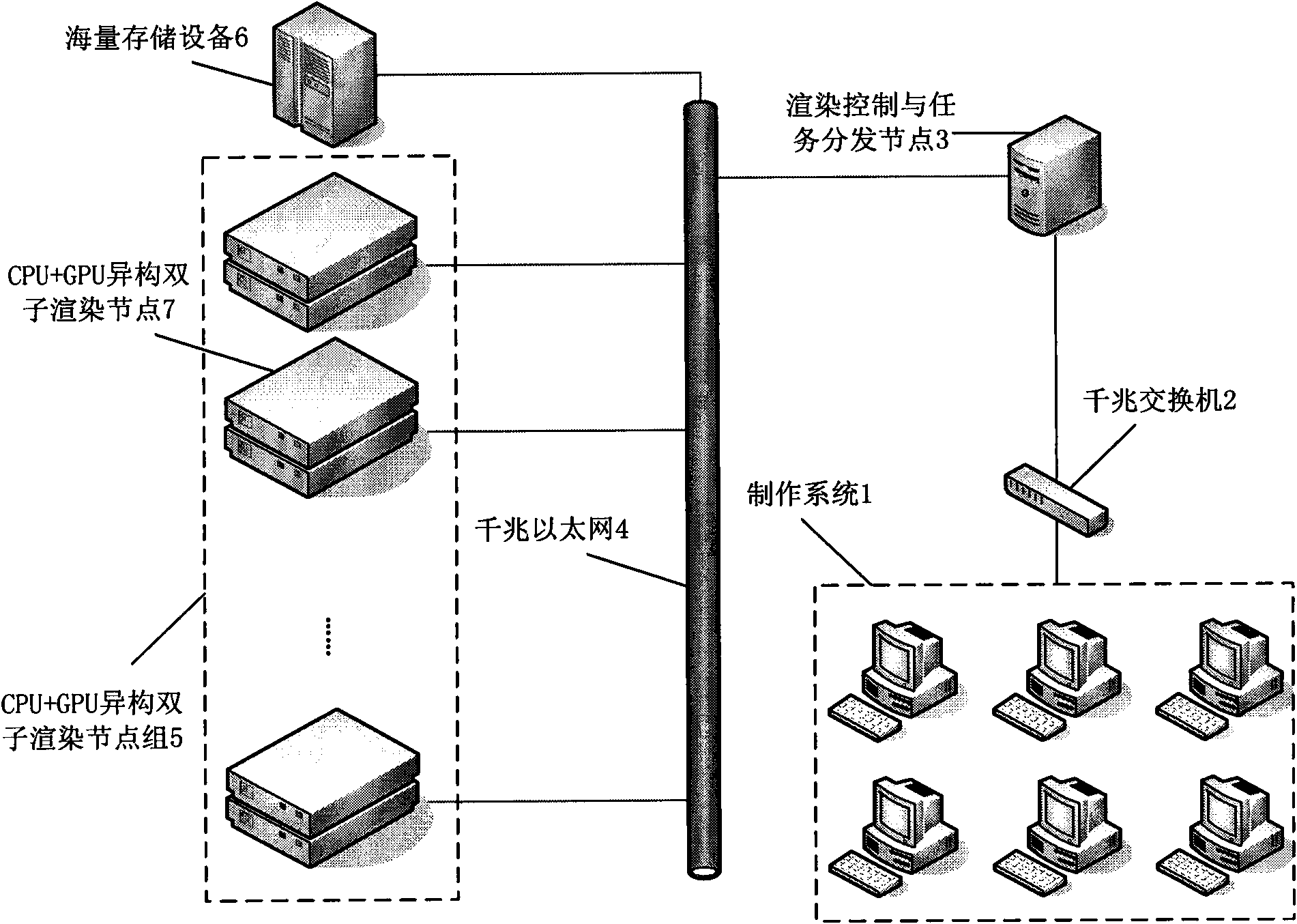

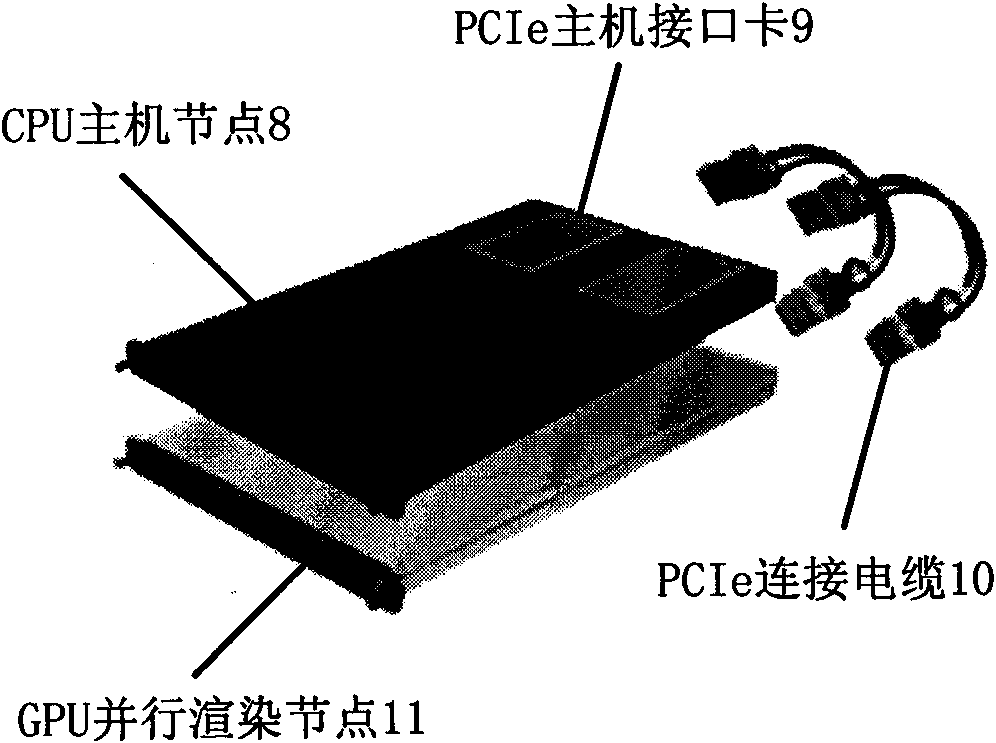

Render farm based on CPU cluster

InactiveCN101587583AImprove performanceHigh energy consumptionProcessor architectures/configurationData switching networksSupercomputerVideo image

The present invention discloses a render farm based on CPU cluster. A distributed parallel cluster rendering system is constructed with high-efficiency low-energy-consumption CPUs so that the computing power obtains and even exceeds the computing performance of a supercomputer. The invention settles a batch rendering problem in the digital innovation producing process. Through using the render farm based on the CPU cluster according to the invention, the producing of the three-dimensional cartoon, special effect of video image, architecture designing, etc. can be completed with a high efficiency. The render farm based on CPU cluster according to the invention further has the advantages of increasing the rendering speed for more than 40 times, reducing the investment cost of building the render farm for 20%-70%, and saving the energy consumption in the production process for 60%-80%.

Owner:CHANGCHUN UNIV OF SCI & TECH

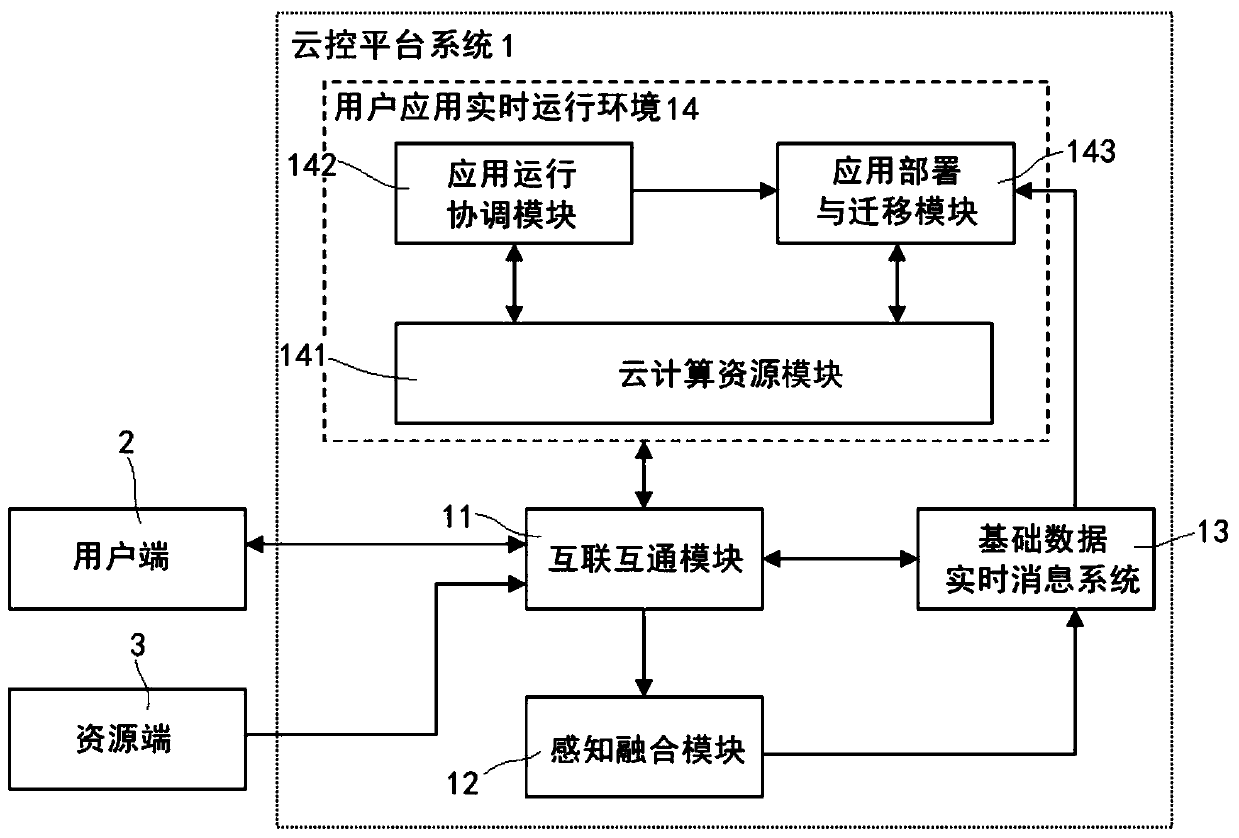

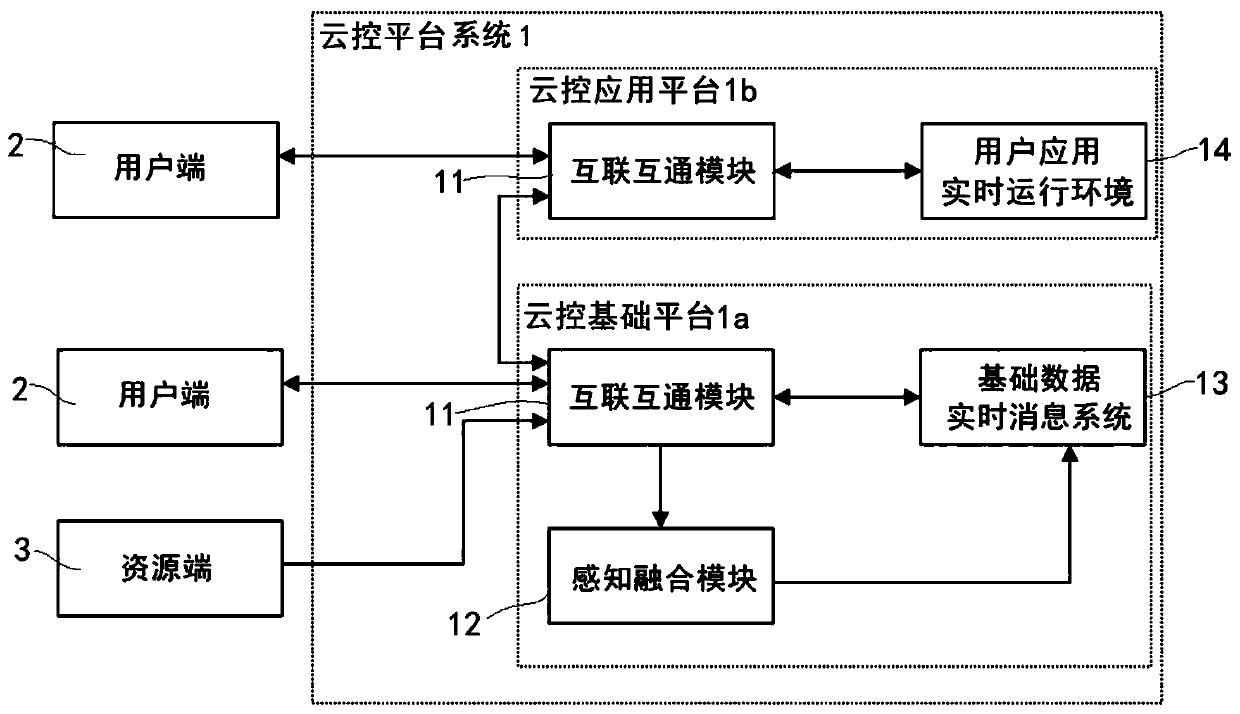

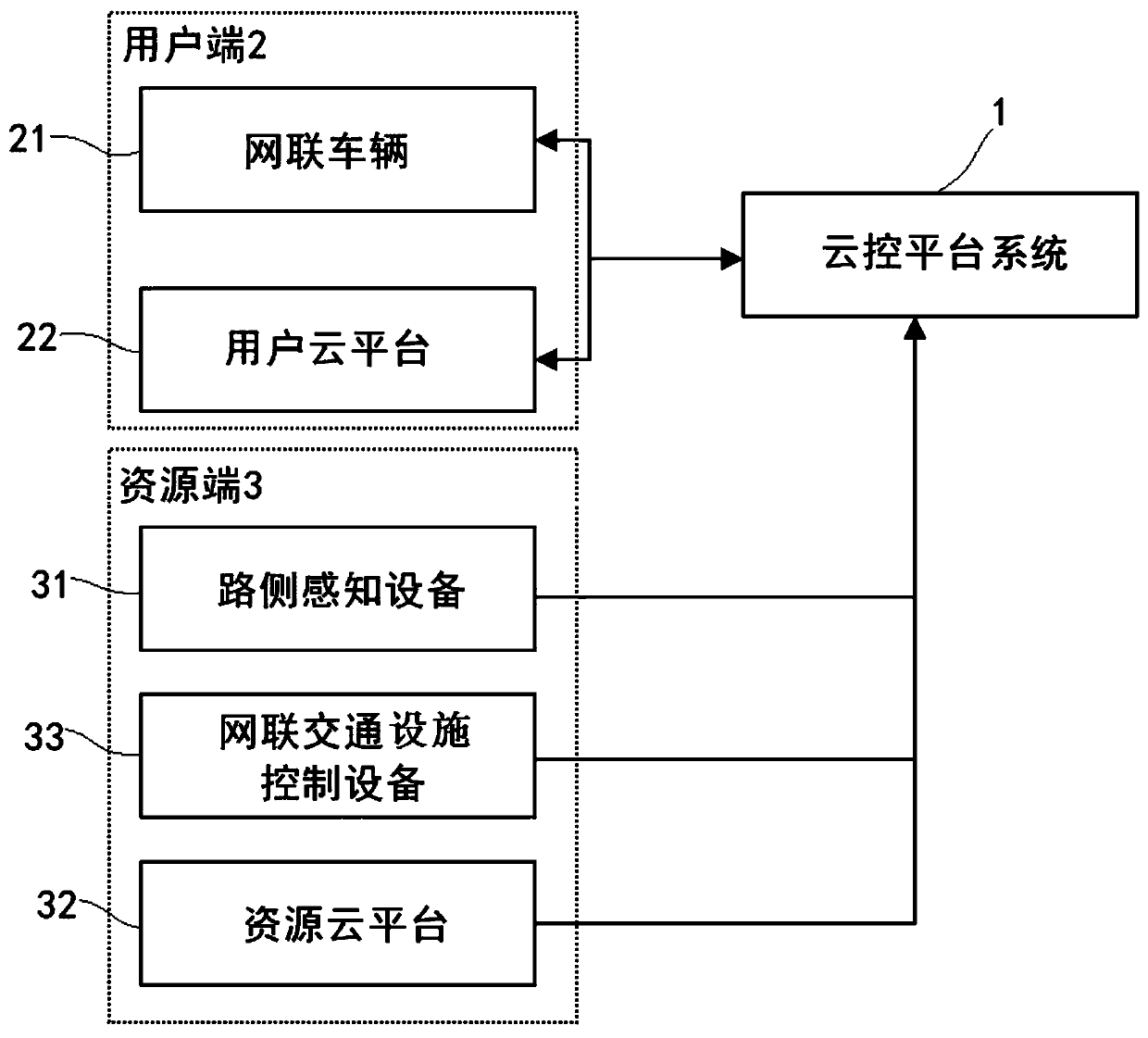

A cloud control platform system for vehicle-vehicle and vehicle-road collaboration and a collaboration system and method

ActiveCN109714730AImprove securityImprove efficiencyParticular environment based servicesBroadcast service distributionNetwork connectionDistributed computing

The invention discloses a cloud control platform system for vehicle-vehicle and vehicle-road collaboration and a collaboration system and method. The cloud control platform system comprises an interconnection and intercommunication module (11), a perception fusion module (12), a basic data real-time message system (13) and a user application real-time operation environment (14). The user application real-time operation environment (14) provides a real-time optimized cloud computing environment for the user application on the cloud control platform system (1) according to the requirements of each network connection application on real-time performance and time delay, and performs real-time deployment and migration on the user application based on working conditions; And the interconnectionand intercommunication module (11) regulates and controls the external communication of the cloud control platform system (1) according to the working condition, or regulates and controls the externalcommunication used by the user application by sending an instruction.

Owner:TSINGHUA UNIV +1

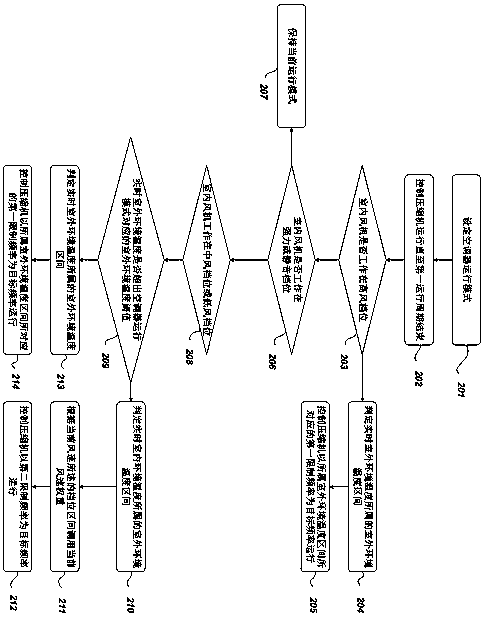

Practical laser induced breakdown spectroscopy unit

ActiveUS7394537B1High energy consumptionReduce energy consumptionEmission spectroscopyRadiation pyrometryLaser-induced breakdown spectroscopyLaser beams

An apparatus for performing laser-induced breakdown spectroscopy comprises a handheld unit with a pump laser and a controller. A combination of a solid laser medium and a Q-switch receive a laser beam from said pump laser. Focusing optics focus laser pulses from said combination to a focal spot at a sample. Light collection optics collect light from plasma induced of sample material by focused laser pulses. A spectrometer receives collected light and produces information describing its spectral distribution. A power source delivers electric power to other parts of the apparatus. The pump laser, combination, focusing optics, light collection optics, spectrometer and power source are parts of said handheld unit.

Owner:HITACHI HIGH TECH ANALYTICAL SCI FINLAND OY

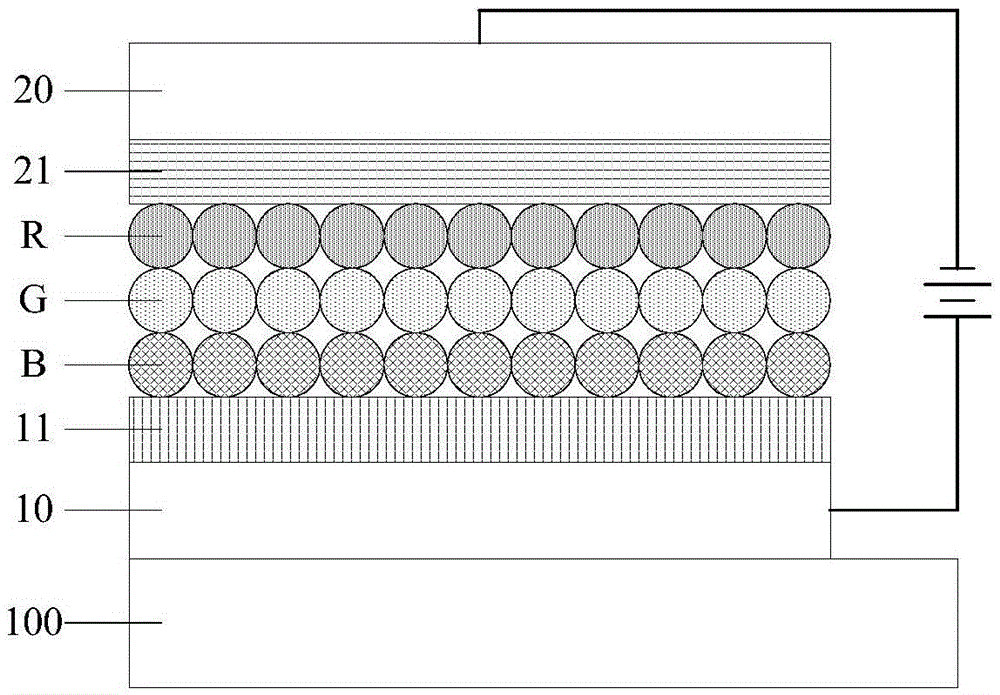

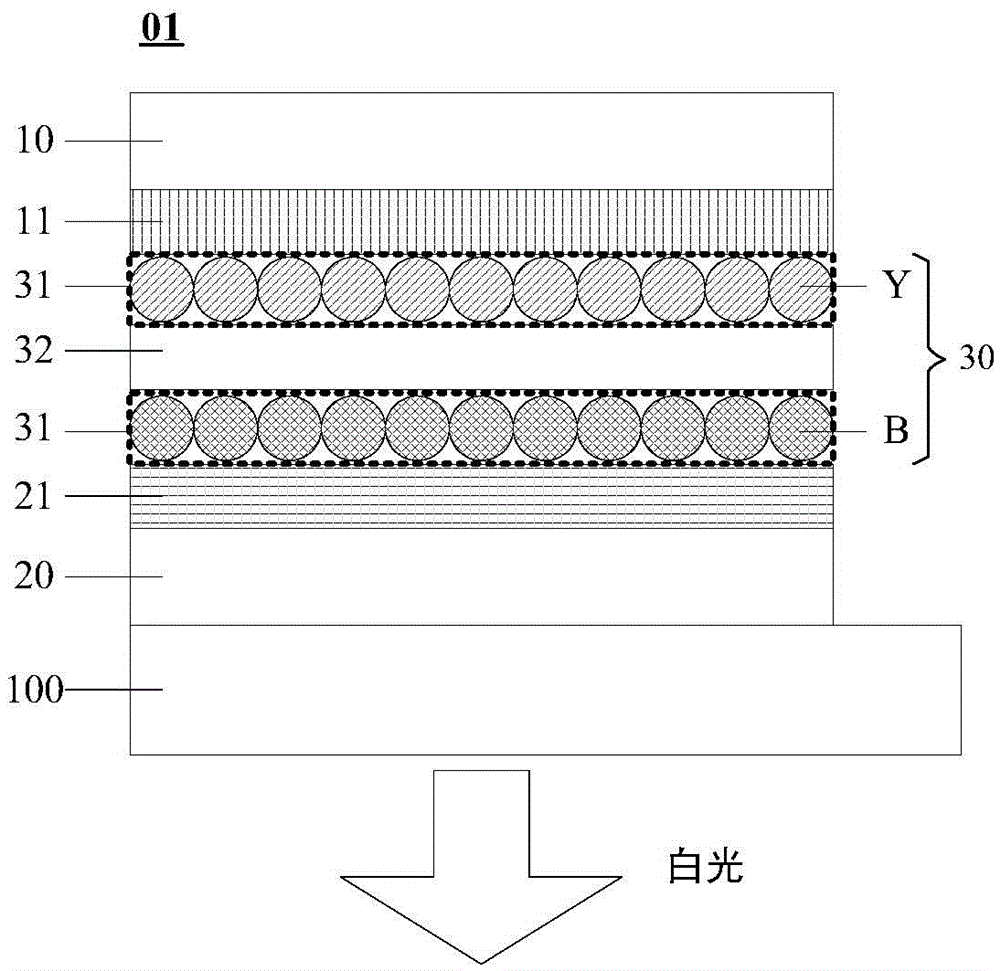

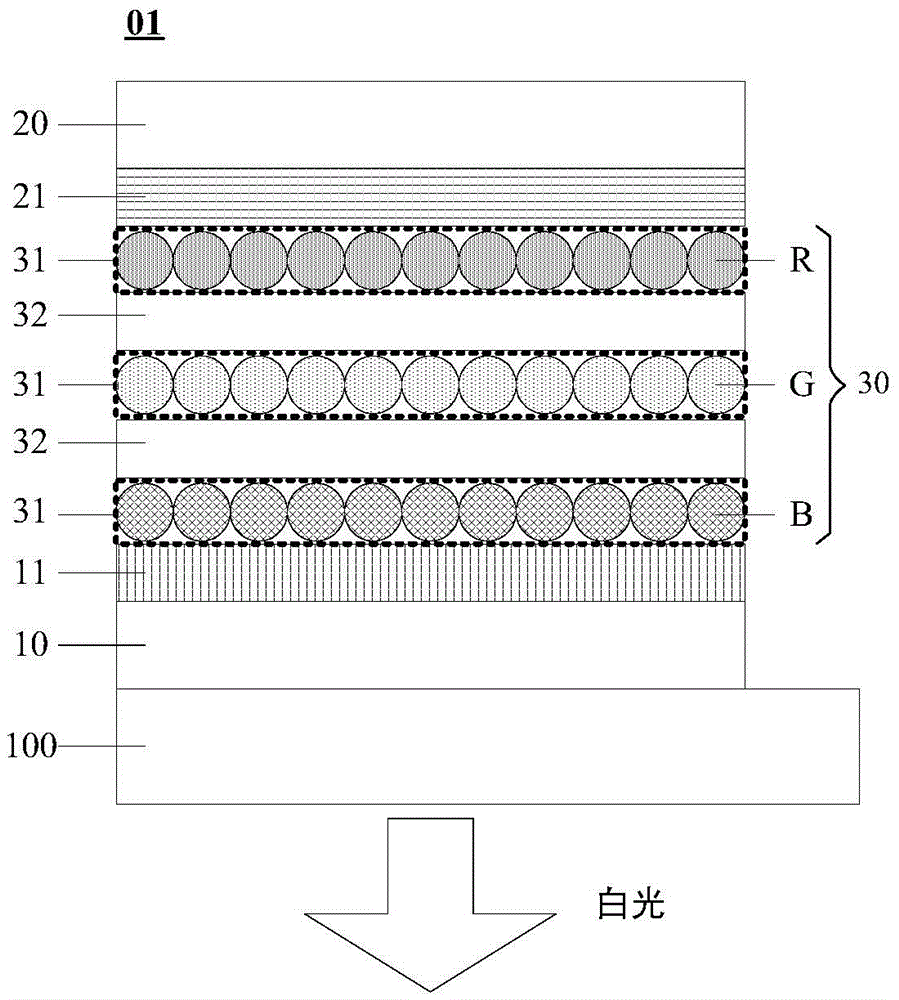

Light-emitting device and preparation method thereof as well as display device

ActiveCN105552244AThe luminous effect does not diminishImprove luminosityNanotechElectroluminescent light sourcesHigh energyDisplay device

Embodiments of the invention provide a light-emitting device and a preparation method thereof as well as a display device, relating to the field of display technologies and solving a problem of light-emitting color cast due to high-energy exciton transfer in the light-emitting device while reducing the energy consumption of the device. The light-emitting device comprises an anode and a cathode which are opposite, a hole transfer layer close to the anode, an electron transfer layer close to the cathode and a light-emitting function layer arranged between the hole transfer layer and the electron transfer layer, wherein the light-emitting function layer comprises at least two layers of quantum dot light-emitting layers capable of emitting different colors of light and a transparent insulating layer arranged between any two adjacent layers of quantum dot light-emitting layers. The method is used for preparing the light-emitting device and the display device comprising the light-emitting device.

Owner:BOE TECH GRP CO LTD

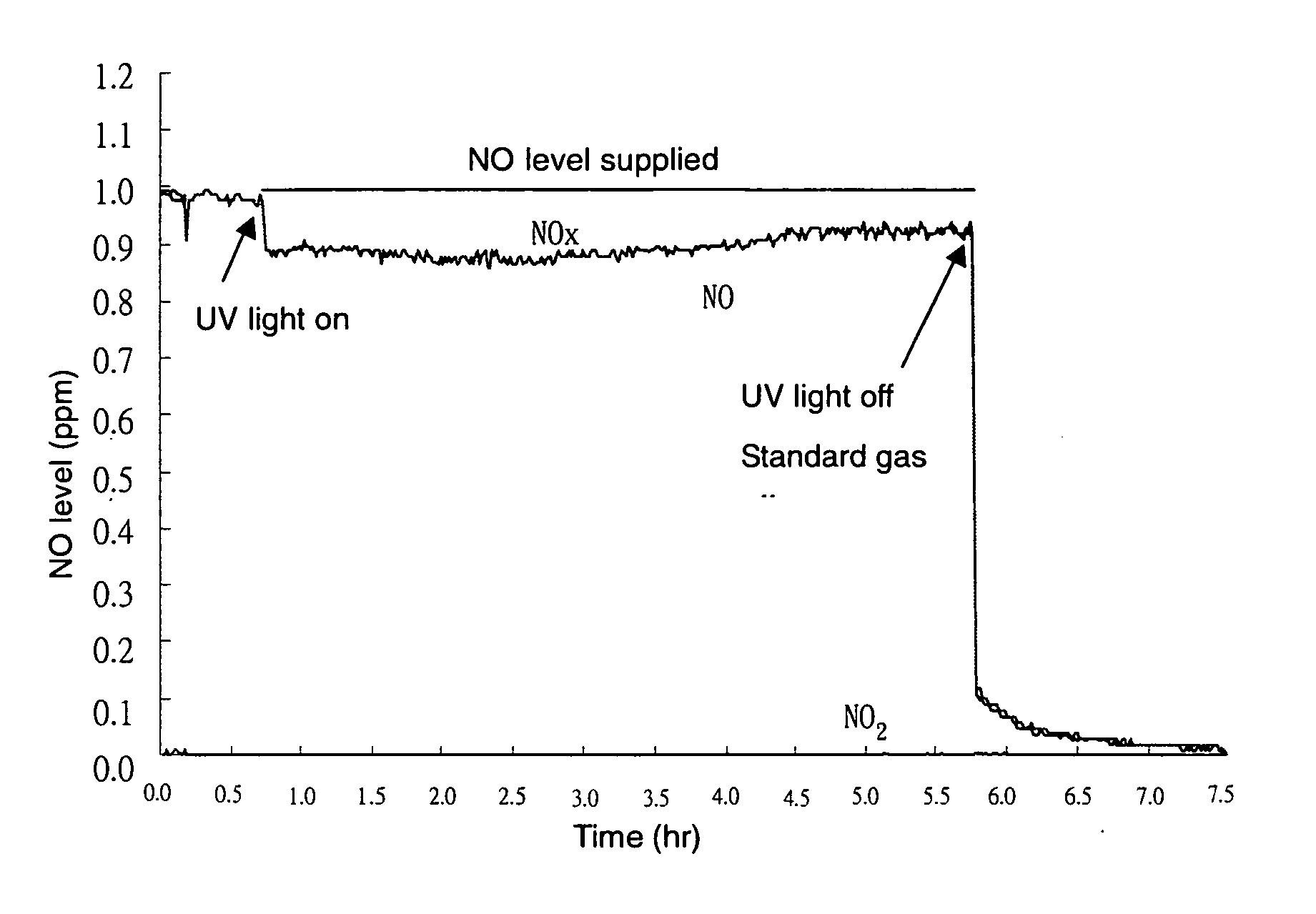

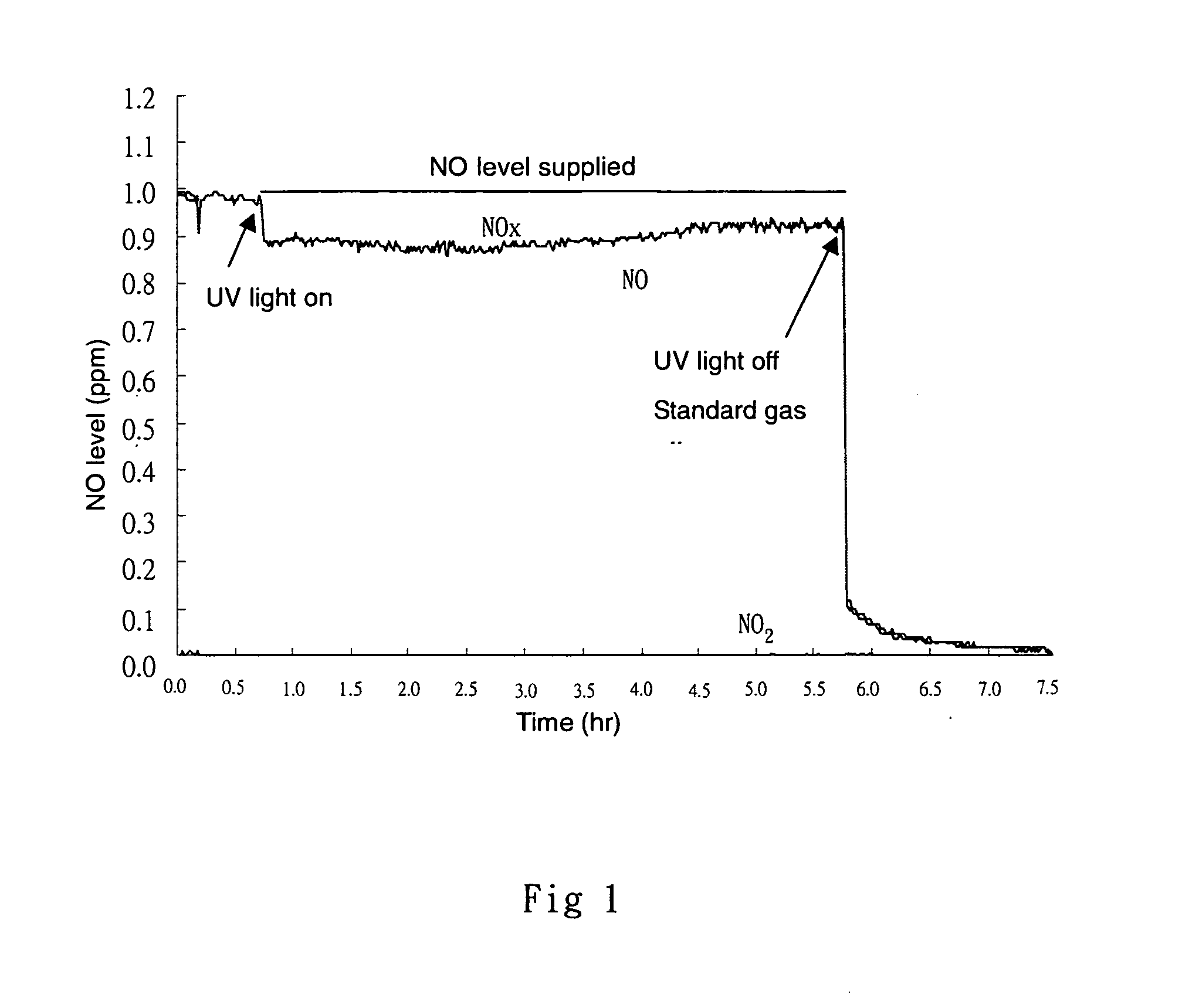

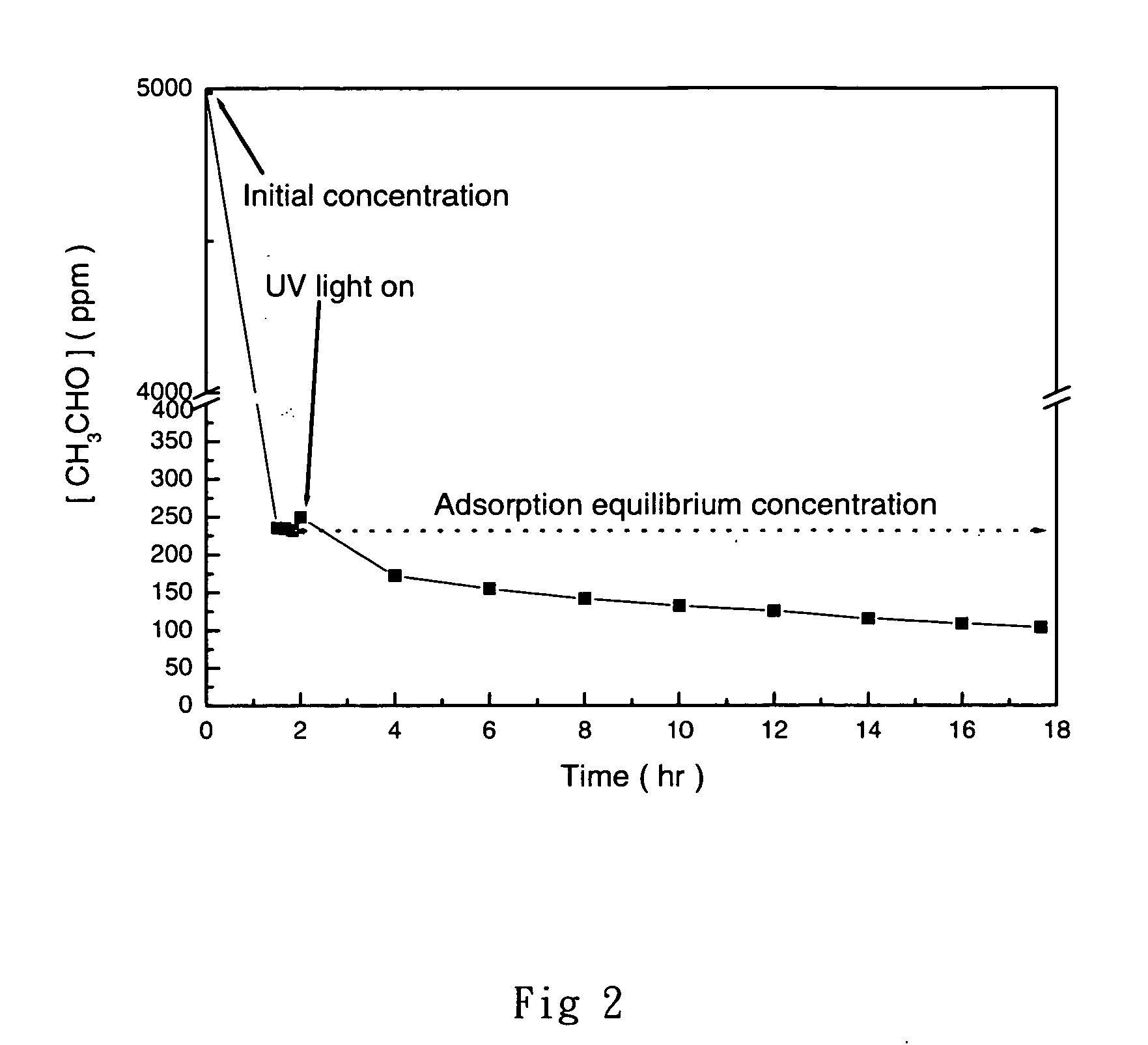

Photocatalytic composite material, method for producing the same and application thereof

InactiveUS20070149397A1High energy consumptionEasy to cleanMolecular sieve catalystsWater treatment compoundsPhoto catalysisEnergy consumption

The present invention relates to a photocatalytic composite material, a method for producing the same and application thereof. This invention can maintain the activity of a photocatalytic adsorbent and reduce energy consumption by immersing an adsorbent material into a nano-photocatalyst sol to immobilize the nano-sized photocatalyst on the surface of the adsorbent material without a high-temperature calcinations step or using an adhesive agent. Besides, immobilizing the photocatalytic composite material onto a filter can be applied to the equipment for cleaning environment.

Owner:IND TECH RES INST

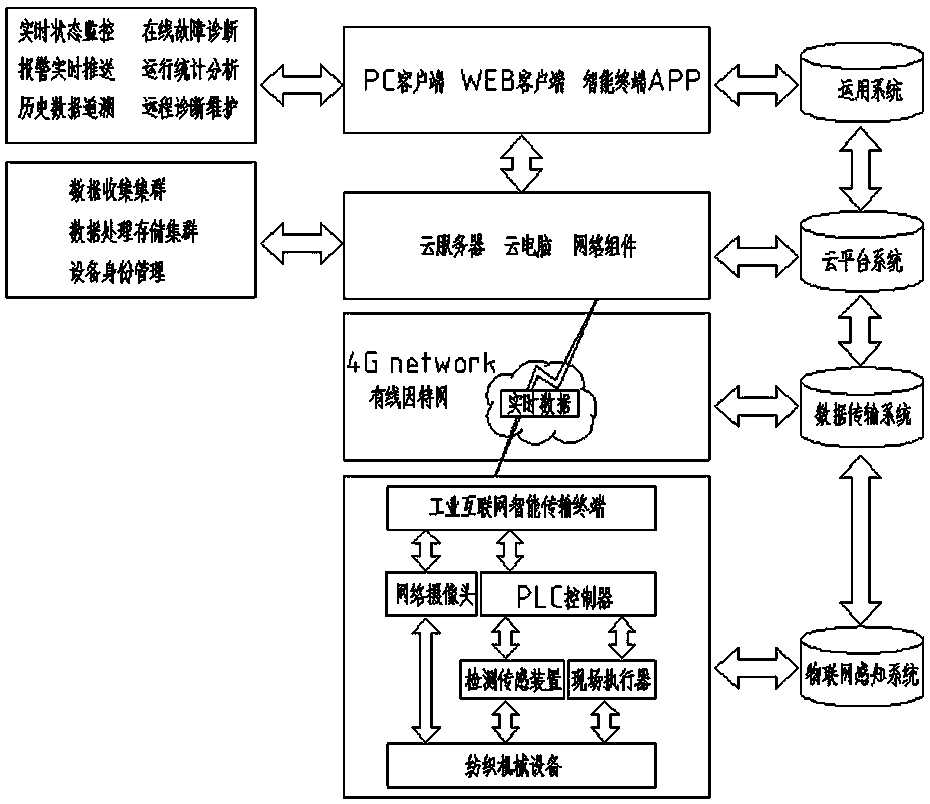

Remote operation and maintenance system for textile machine, and implementation method for remote operation and maintenance system

PendingCN109246223AResume normal productionRealize remote diagnosisClosed circuit television systemsTransmissionStatistical analysisThe Internet

The invention discloses a remote operation and maintenance system for a textile machine, and an implementation method for the remote operation and maintenance system. The system comprises a textile machine IOT (Internet of Things) sensing system, a data transmission system, a cloud platform system and an operating system. The textile machine IOT sensing system comprises a textile machine device, aPLC controller, an industrial Internet intelligent transmission terminal connected with the PLC controller, a web camera installed on the textile machine device, a detection sensing device installedin textile machine device and a field actuator. The system achieves the real-time condition monitoring service, operation statistical analysis service, fault / abnormal condition alarm service, device failure rate distributed analysis service, online fault diagnosis service, remote maintenance and real-time video surveillance service of the textile machine device. The system realizes remote diagnosis and maintenance of the textile machine through taking the textile machine IOT sensing system and industrial cloud platform as the basis, centralizes and integrates the original piecemeal management,and promotes the whole life cycle management of equipment.

Owner:HAINING TEXTILE MACHINERY FACTORY

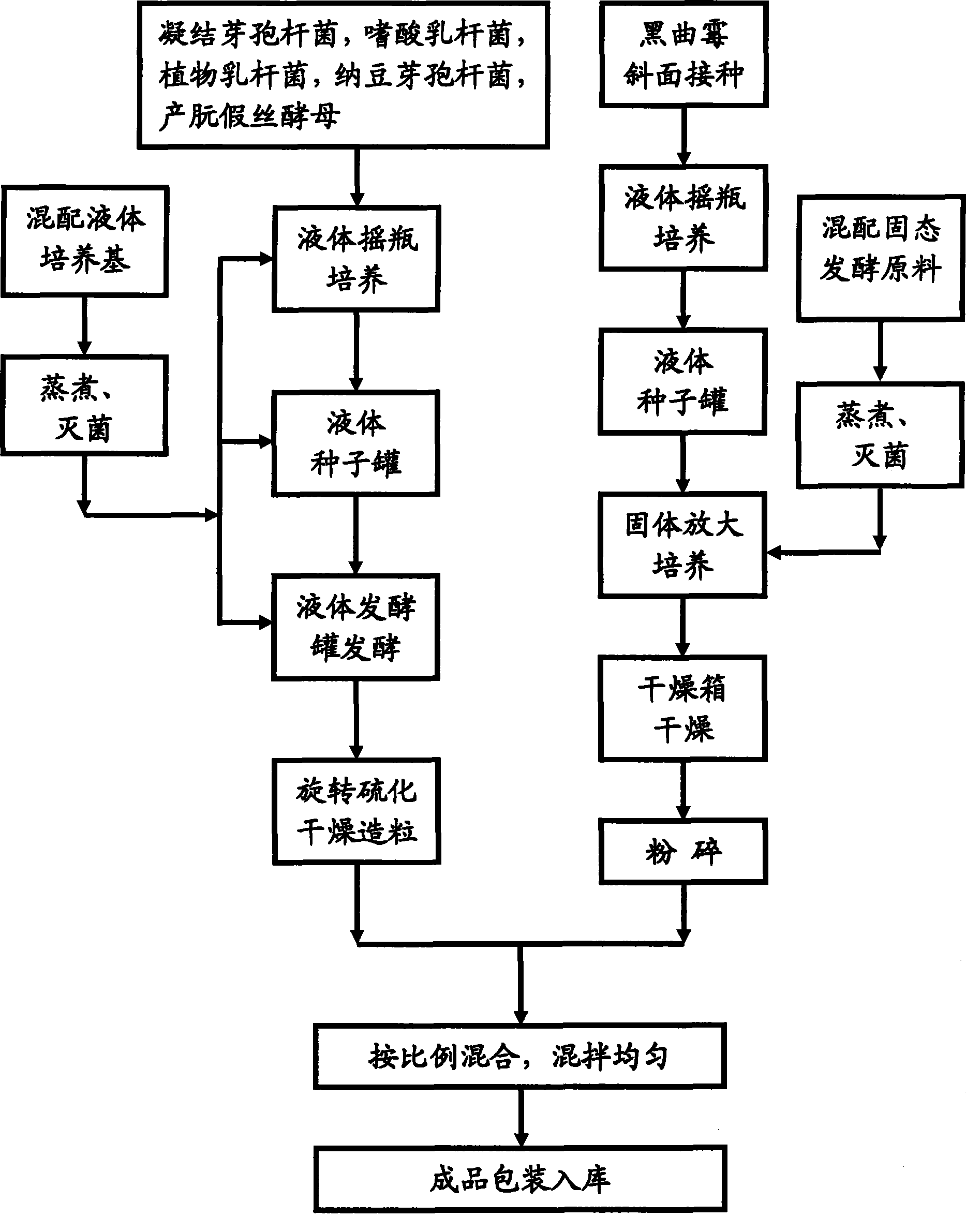

Additive agent for feeding microorganism viable bacteria and production method

InactiveCN101473896AIncrease food intakeImprove digestibilityAnimal feeding stuffDiseaseMicroorganism

The invention relates to a feeding addition agent for microorganism viable bacteria and a preparing method thereof. The addition agent consists of 1.5-2.5 parts of bacillus coagulans viable bacteria powder, 0.5-2.0 parts of lactobacillus acidophilus viable bacteria powder, 1.0-2.5 parts of lactobacillus plantarum viable bacteria powder, 0.5-2.5 parts of bacillus natto viable bacteria powder, 0.5-1.5 parts of candida utili viable bacteria powder and 2-4.5 parts of aspergillus niger viable bacteria powder. Each gram of the content of viable bacteria is as follows: bacillus coagulans is not less than 1.0*10cfu / g; lactobacillus acidophilus is not less than 1.0*10cfu / g; lactobacillus plantarum is not less than 1.0-10cfu / g; bacillus natto is not less than 1.0*10cfu / g; aspergillus niger is not less than 1.0*10cfu / g; and candida utili is not less than 1.0*10cfu / g. The invention has the advantages that the composition is reasonable, the preparation method is scientific, the usage scale is wide, the operation is simple and easy to master, and the cost is low. In addition, the invention can be used as the feeding stuff agent for various poultries, thus increasing the use ratio of the feeding stuff addition agent and strengthening the anti-disease ability of the poultries.

Owner:北京阔利达生物技术开发有限公司 +1

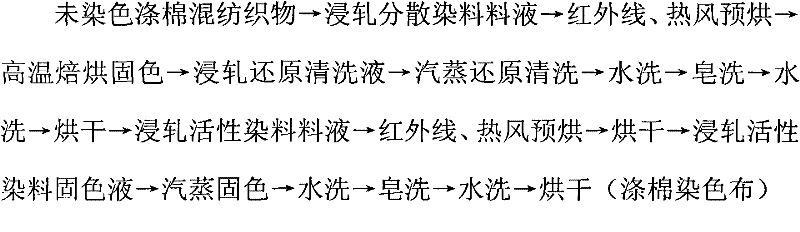

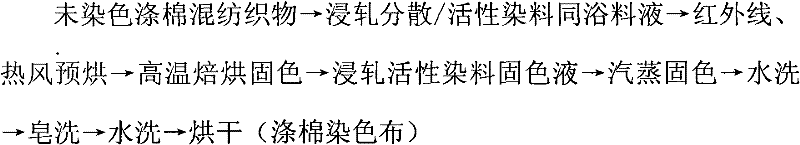

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

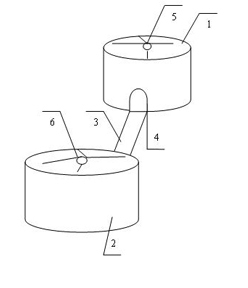

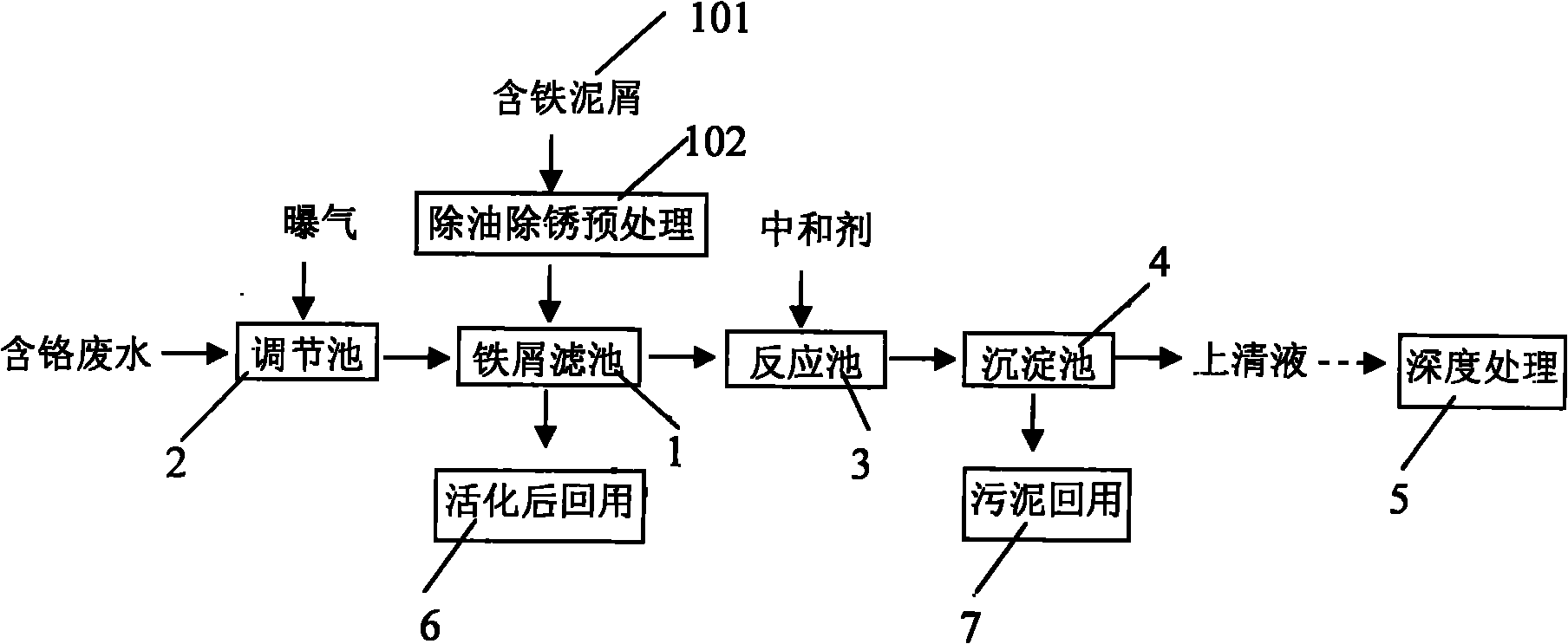

Pretreatment process of chromium-containing wastewater

InactiveCN101811793AIncrease productionDrive up processing costsWater contaminantsMultistage water/sewage treatmentElectrolysisResource utilization

The invention relates to a pretreatment process of chromium-containing wastewater, which comprises the following steps that: 1) scrap iron filter tank is established, iron-containing spare is mixed with carbon-containing particles and porous filler to form a scrap iron filter tank after being washed by alkali so as to remove the oil and being washed by acid to remove the rust and to be activated; 2) chromium-containing wastewater is introduced into the scrap iron filter tank to be undertaken the micro electrolysis reaction after being aerated by an adjusting tank, and pH value and the oxidation reduction potential level ORP value are adjusted by acid liquid, so major hexavalent chrome is reduced to trivalent chromium; 3) the water which is discharged from the filter tank is guided to a reaction tank, neutralizing agent is added, heavy metal complex-precipitation happens, and discharged water is guided into a sedimentation tank; 4) after the majority of heavy metal pollutant inside the sedimentation tank is removed, the upper clean liquid is undertaken the advanced treatment and is discharged after reaching the standard. The pretreatment process not only realizes the resource utilization of waste scrap iron and waste acid liquid, but also greatly reduces the cost of the medicine, reduces the quantity of the following mud, and is easier to realize the resource utilization of the produced mud.

Owner:BAOSHAN IRON & STEEL CO LTD

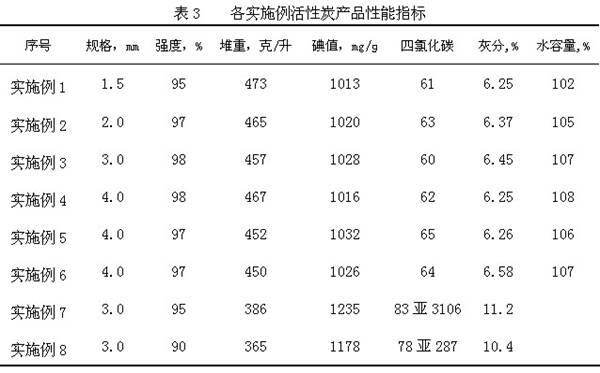

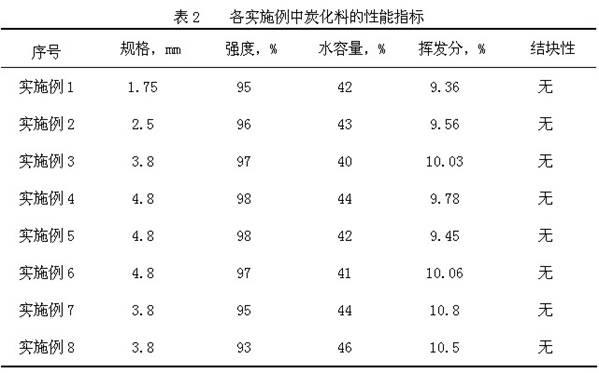

Columnar activated carbon based on coal pitch binders and preparation method of columnar activated carbon

InactiveCN102674341AImprove initial strengthEquivalent mechanical strengthCarbon compoundsActivated carbonUltimate tensile strength

The invention discloses columnar activated carbon based on coal pitch binders. The columnar activated carbon with grain size range of 1.0-10mm is prepared through a preparation method which comprises the steps of: using 100 parts by weight of carbonaceous materials as basic raw materials and 6-30 parts by weight of coal pitch as binders, respectively pulverizing the carbonaceous materials and the coal pitch, mixing the pulverized carbonaceous materials with the pulverized coal pitch, adding 20-50 parts by weight of temporary binders, kneading, molding, drying, carbonizing in a rotary carbonizing furnace and activating in a Slapple activating furnace. Since the temporary binders are used for endowing the molded materials with primary strength and the coal pitch and the pulverized carbon are co-carbonized and solidified and endow the carbonized materials with final mechanical strength, the traditional long-lasting mode of columnar activated carbon coal tar molding production is broken through and the goal of preparing columnar activated carbon by using coal pitch as binders to replace coal tar is realized.

Owner:李钱胜

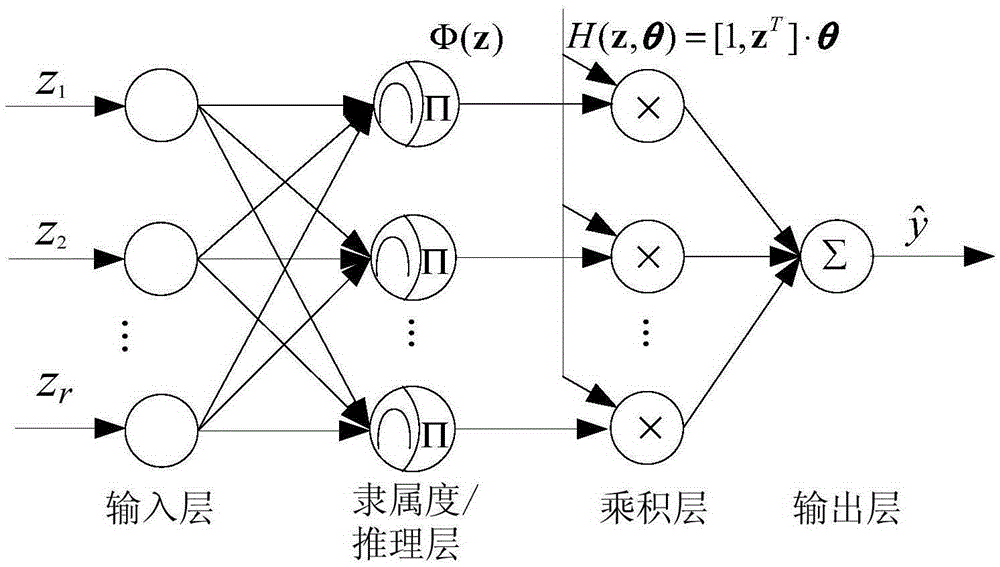

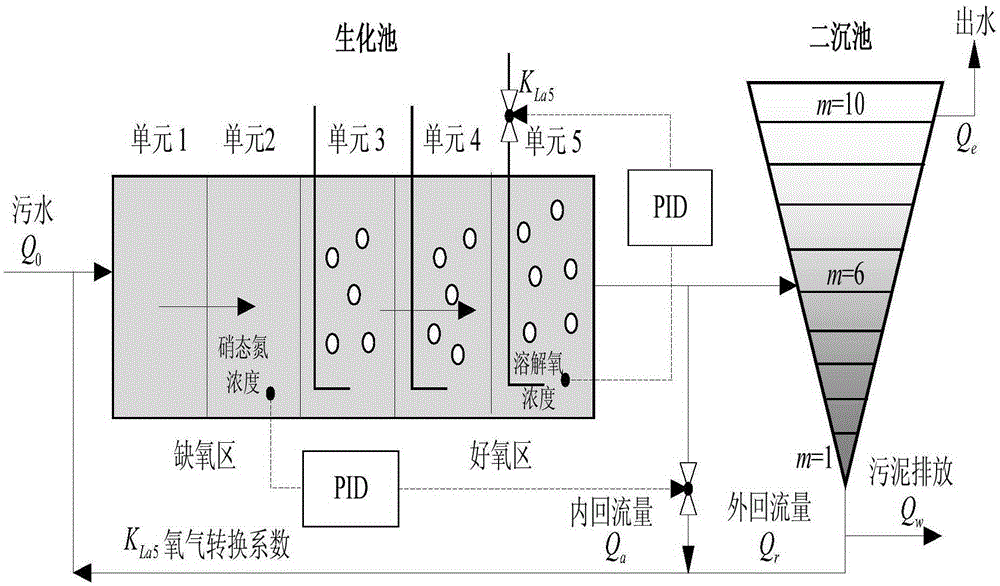

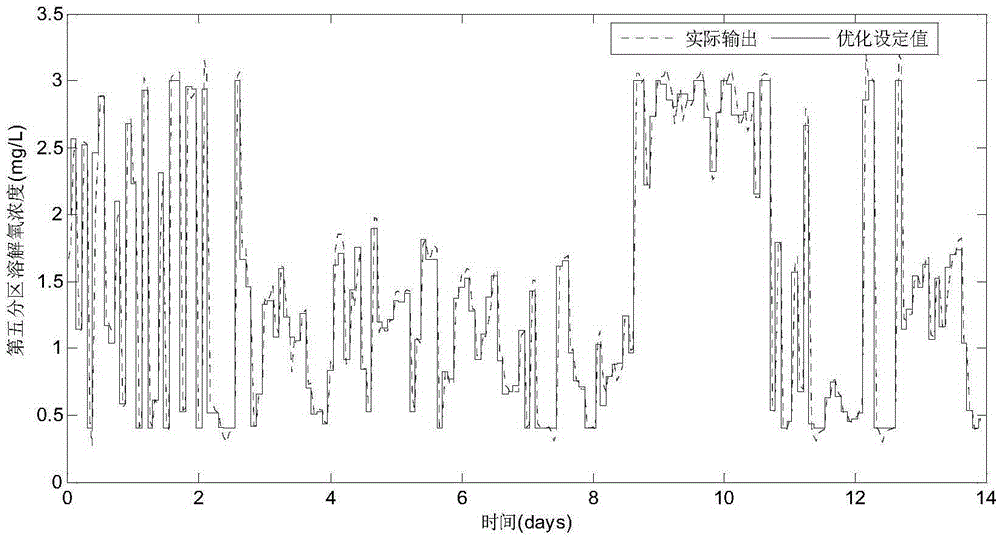

Sewage processing process dynamic multi-target optimization control method

ActiveCN105404151AHigh energy consumptionImprove water quality indicatorsAdaptive controlProcess dynamicsNerve network

The invention discloses a sewage processing process dynamic multi-target optimization control method, belongs to the field of water research and also belongs to the field of intelligent control, for simultaneously optimizing energy consumption and water quality indexes under the condition that the water quality reaches the standard. First of all, a sewage processing process multi-target optimization model is constructed through a nerve network online modeling method for solving the problem of lack of accurate mathematic description between an optimization variable and a performance index; secondly, based on the established optimization model, a Pareto optimal solution of the problem is obtained through a multi-target optimization algorithm, and according to decision information, one satisfactory optimization solution is determined from a Pareto solution set, i.e., optimization set values of a dissolved oxygen concentration and a nitrate nitrogen concentration; and finally, a bottom controller realizes a tracking task of the optimization set value. The method provided by the invention can effectively reduce the energy consumption and the operation cost of a sewage processing process under the condition that the water quality reaches the standard.

Owner:BEIJING UNIV OF TECH

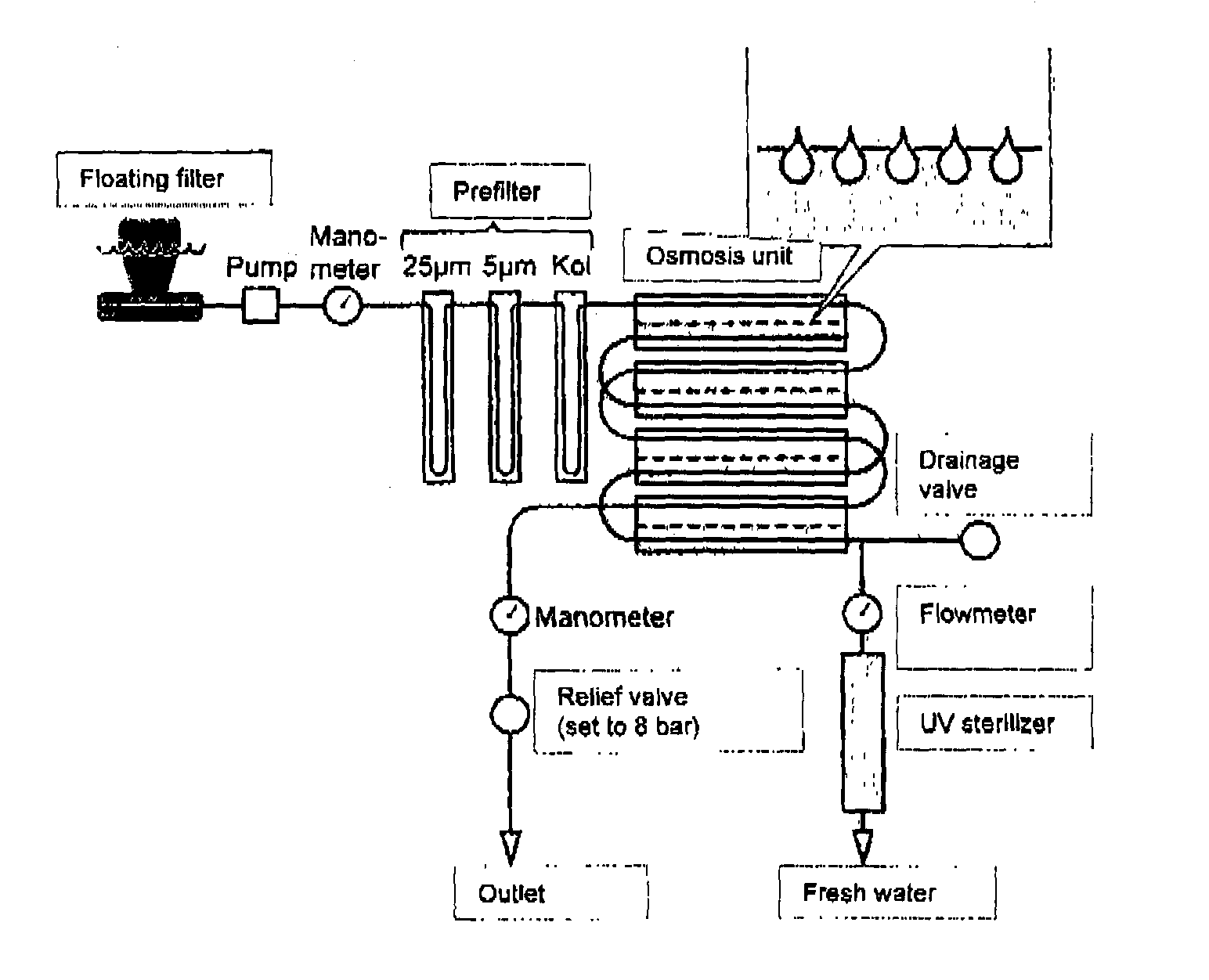

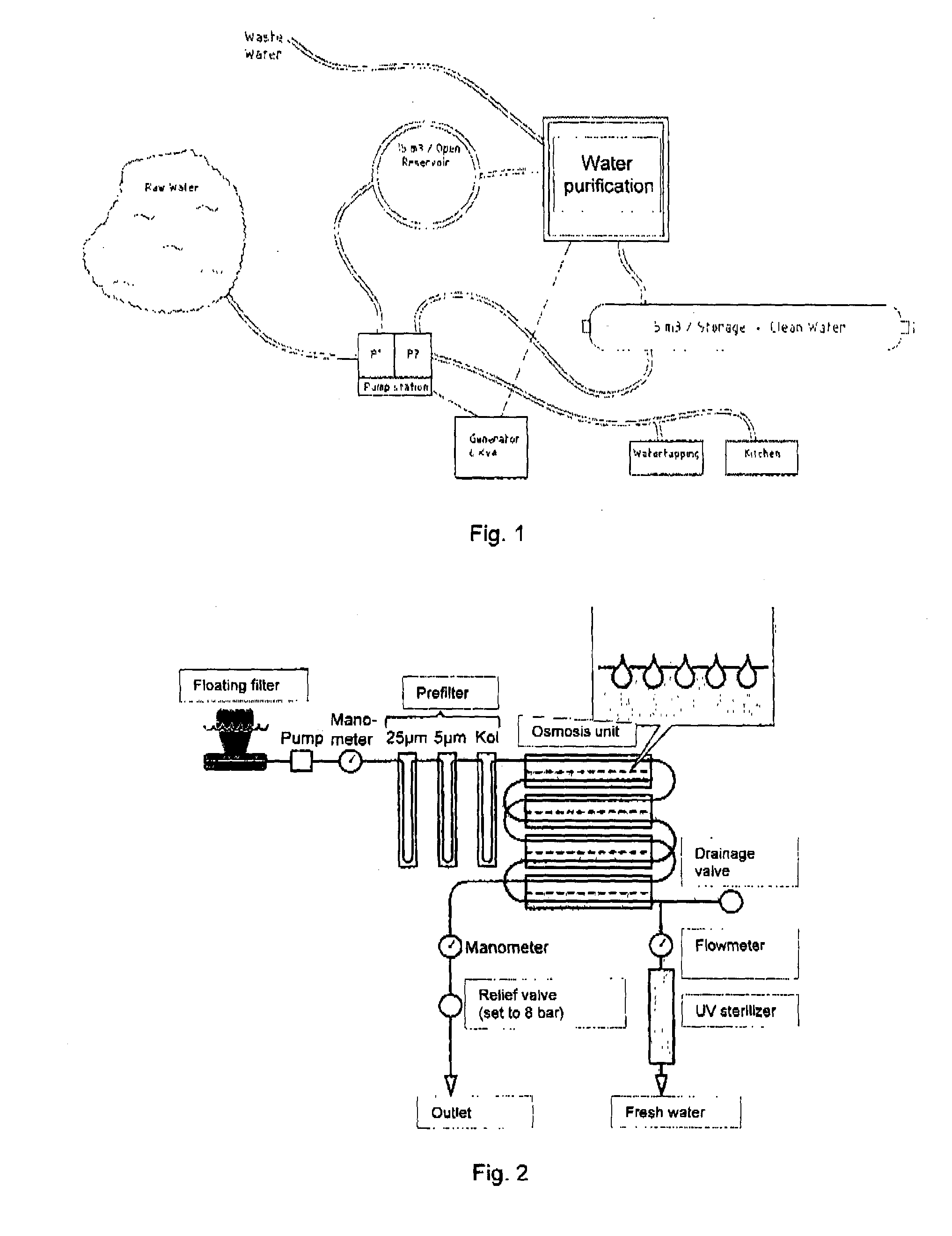

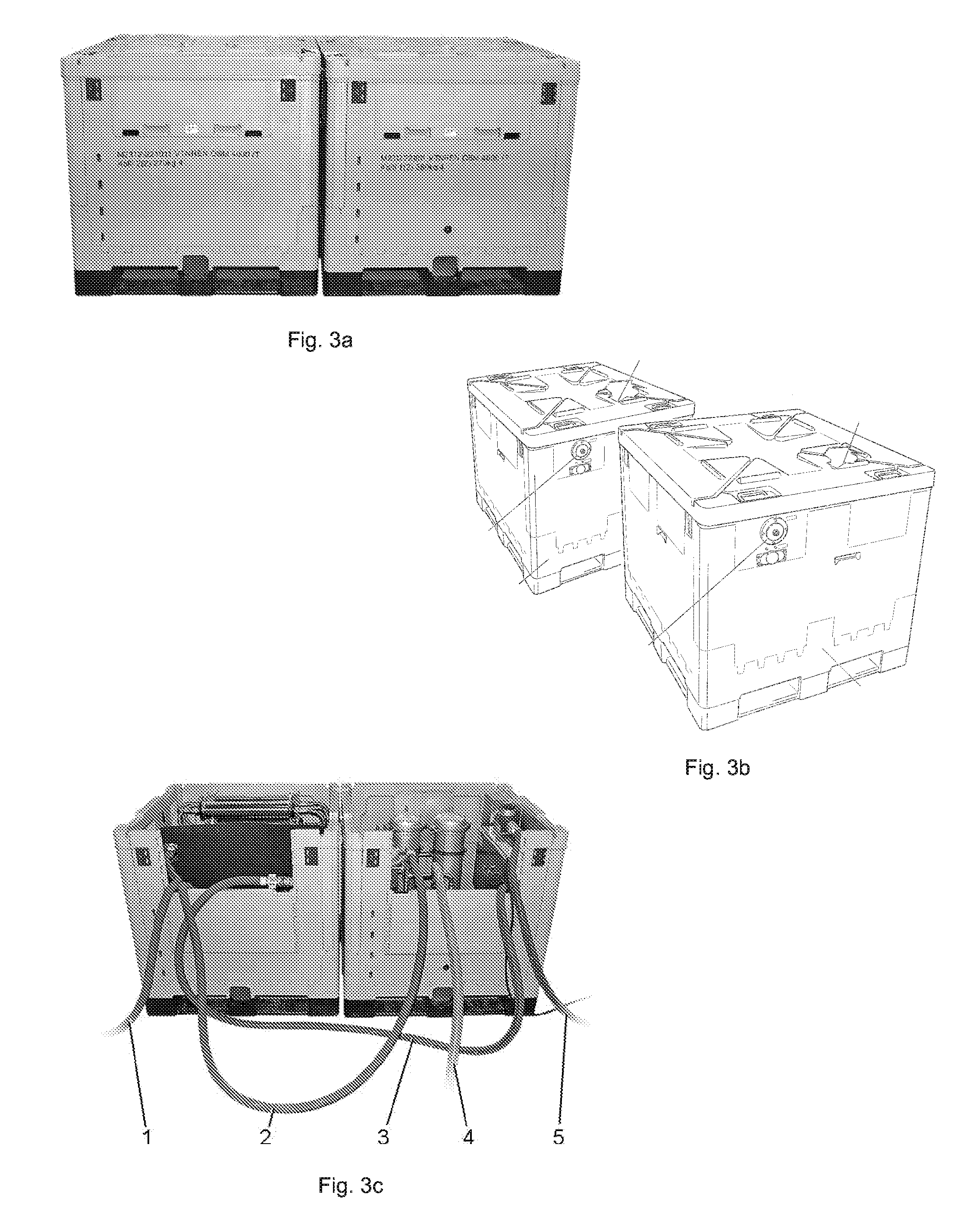

Mobile Water Purification System

InactiveUS20140021115A1Increase productionHigh energy consumptionWater/sewage treatment by irradiationGeneral water supply conservationReverse osmosisCross-flow filtration

The present invention relates to a mobile water purification system employing crossflow filtration, such as reverse osmosis filtration. One embodiment of the invention discloses a mobile water purification system comprising a housing, a pump unit and a piping system for providing fluid communication between a water inlet, a pre-filtration unit, a crossflow filtration unit, a disinfection unit and an outlet for supply of purified water, wherein the pre-filtration unit comprises sediment / cartridge filtrations means and dechlorination means, the cross-flow filtration unit comprises a plurality of parallel and / or sequentially arranged membrane filters, and the piping system is reconfigurable such that the crossflow filtration unit can be bypassed. The present water purification system is adapted to be deployed in remote areas substantially anywhere in the world.

Owner:PURE H2O

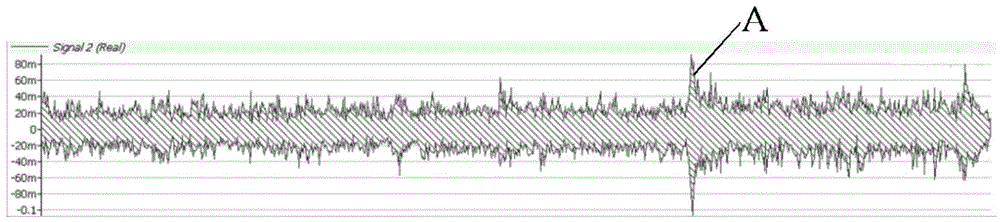

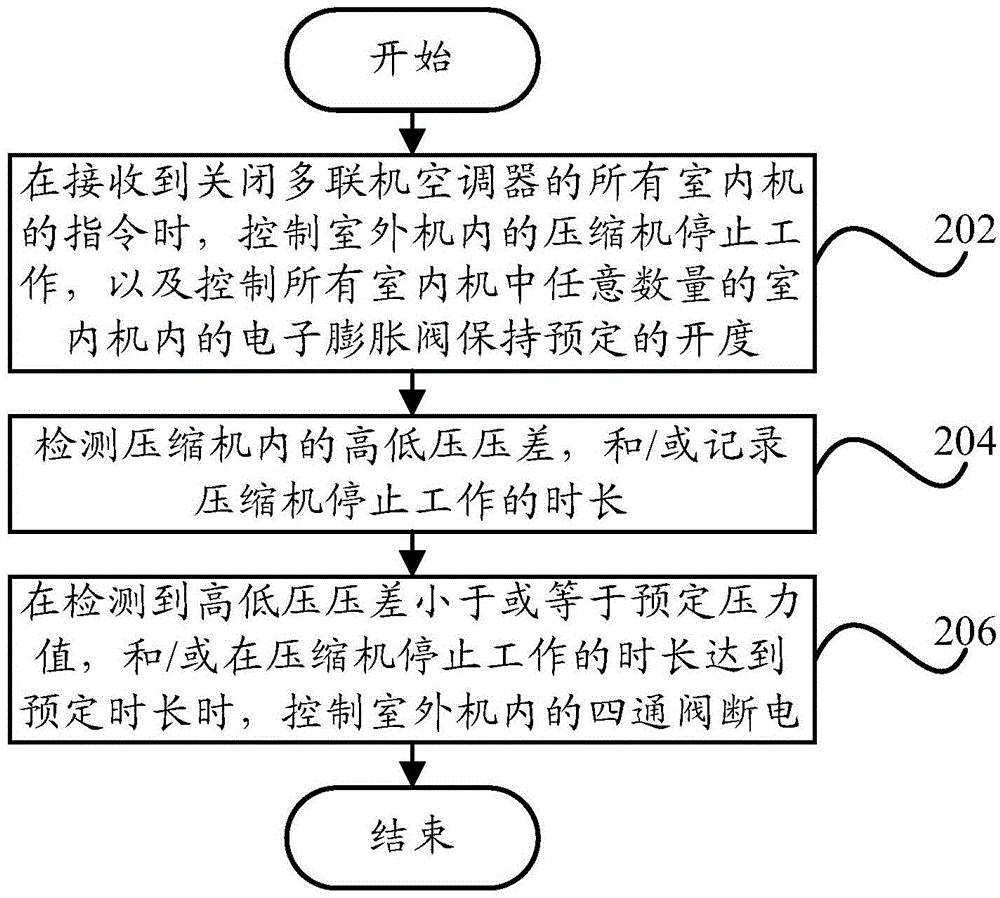

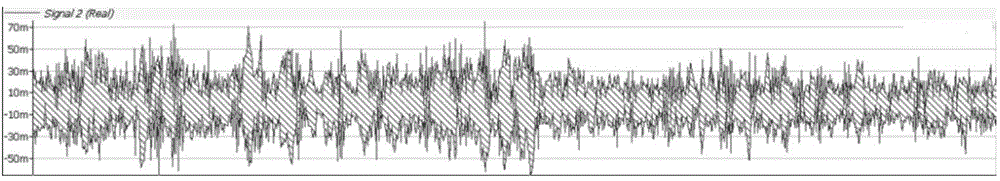

Control method and system of variable refrigerant flow (VRF) air conditioner

ActiveCN104101054AHigh energy consumptionBalance high and low pressure differencesSpace heating and ventilation safety systemsLighting and heating apparatusFour-way valveControl system

The invention provides a control method and system of a variable refrigerant flow (VRF) air conditioner. The VRF air conditioner comprises an outdoor unit and a plurality of indoor units. An electronic expansion valve is mounted in each indoor unit. The control method includes: when an instruction for turning off all the indoor units of the VRF air conditioner is received, controlling the compressor of the outdoor unit to stop operation, and controlling an optional number of electronic expansion valves in all the indoor units to keep a preset openness; detecting the difference of high pressure and low pressure in the compressor, and / or recording the duration of operation stopping; when the detected pressure difference is smaller than or equal to a preset pressure value and / or the duration of operation stopping reaches preset duration, controlling the four-way valve in the outdoor unit to deenergize. By the control method, when all the indoor units of the VRF air conditioner are turned off, air flow impact noise can be avoided while air conditioner energy consumption can be lowered under the premise that the difference of the high pressure and the low pressure in the compressor is balanced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com