Patents

Literature

185results about How to "Improve initial strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

EVA hot melt adhesive composition containing linear hydroxyl-terminated polyurethane resin

InactiveCN101787250AImprove initial strengthIncrease ultimate strengthPolyureas/polyurethane adhesivesWaxAntioxidant

The invention discloses an EVA hot melt adhesive composition containing a linear hydroxyl-terminated polyurethane resin, which comprises the linear hydroxyl-terminated polyurethane resin, an ethylene-vinyl acetate polymer, a tackifier, waxes, an antioxidant, an ultraviolet stabilizer, a filling material, a fire retardant and the like. The EVA hot melt adhesive composition containing the linear hydroxyl-terminated polyurethane resin is used for improving the early strength, the final strength and the high- and low-temperature resistance performances of the EVA hot melt adhesive compositions.

Owner:山东久隆高分子材料有限公司 +1

Aqueous acrylic emulsion, aqueous adhesive for pearlized film composite materials and preparation method thereof

InactiveCN101717467AGood adhesionImprove the level ofEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for pearlized film composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 20-40 wt% of acrylic acid hard monomer and 55-70 wt% of acrylic acid soft monomer and 1-5 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). The polymer obtained by polymerization has higher molecular weight, lower coating viscosity and favorable levelling property; and thus, the polymer has high shear strength and initial strength and can achieve the best bonding strength without curing for a long time.

Owner:BEIJING COMENS NEW MATERIALS

Mortar for concrete base surface repair, and preparation method thereof

The present invention belongs to a building mortar, and particularly relates to a mortar for concrete base surface repair, and a preparation method thereof. The mortar comprises the following raw materials by mass: 20-80 parts of silicate cement, 20-100 parts of sulphoaluminate cement, 80-190 parts of aggregate, 40-100 parts of a mineral admixture, 30-80 parts of an aqueous epoxy emulsion, 0.2-0.5 part of cellulose ether, 0.1-0.5 part of anti-cracking fibers, and 20-85 parts of water. The mortar of the present invention has characteristics of strong adhesion, excellent cracking resistance, excellent compression resistance, high bonding strength, and low price.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

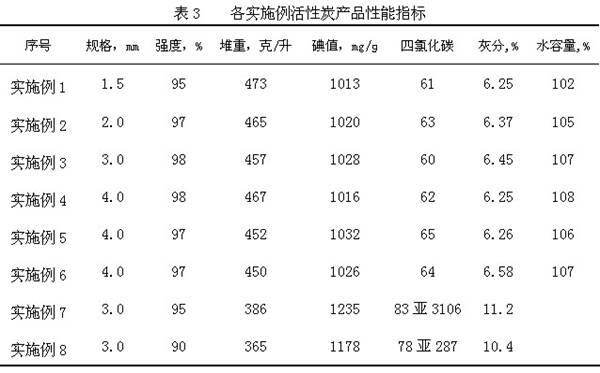

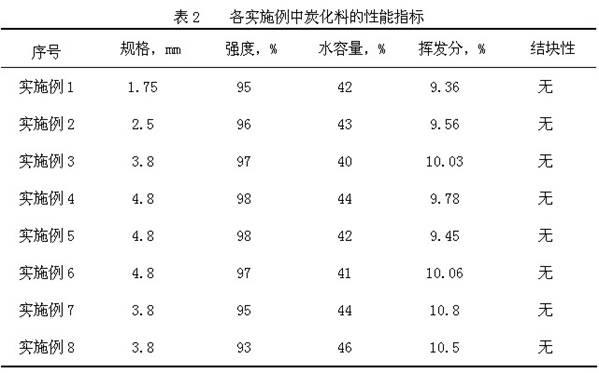

Columnar activated carbon based on coal pitch binders and preparation method of columnar activated carbon

InactiveCN102674341AImprove initial strengthEquivalent mechanical strengthCarbon compoundsActivated carbonUltimate tensile strength

The invention discloses columnar activated carbon based on coal pitch binders. The columnar activated carbon with grain size range of 1.0-10mm is prepared through a preparation method which comprises the steps of: using 100 parts by weight of carbonaceous materials as basic raw materials and 6-30 parts by weight of coal pitch as binders, respectively pulverizing the carbonaceous materials and the coal pitch, mixing the pulverized carbonaceous materials with the pulverized coal pitch, adding 20-50 parts by weight of temporary binders, kneading, molding, drying, carbonizing in a rotary carbonizing furnace and activating in a Slapple activating furnace. Since the temporary binders are used for endowing the molded materials with primary strength and the coal pitch and the pulverized carbon are co-carbonized and solidified and endow the carbonized materials with final mechanical strength, the traditional long-lasting mode of columnar activated carbon coal tar molding production is broken through and the goal of preparing columnar activated carbon by using coal pitch as binders to replace coal tar is realized.

Owner:李钱胜

Preparation method of calcium orthophosphate bone cement degradable to pore in human body

The invention relates to a preparation method for calcium phosphate aggregate cement that can degradate in human body, which comprises: preparing said cement powder by alpha-type tricalcium phosphate, calcium biphosphate and calcium carbonate powder; adding chitose microsphere in prepared analog body fluid, clearing and drying to mix with said solid powder to prepare composite powder; using buffle solution to add baking soda and sodium alginate to prepare solidification liquid; finally, mixing the powder and liquid to prepare composite slurry.

Owner:TSINGHUA UNIV

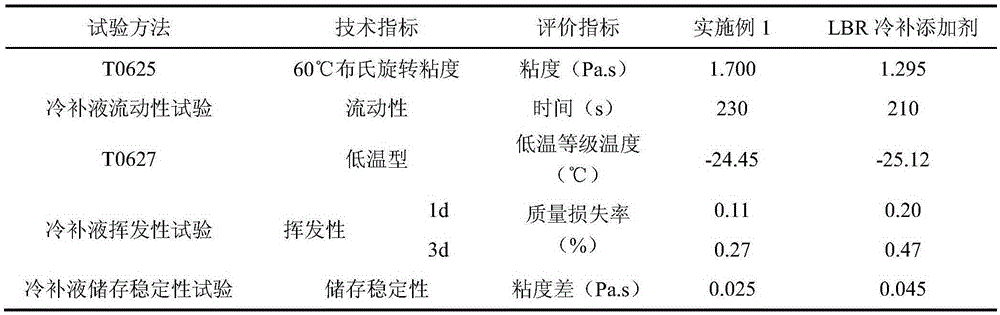

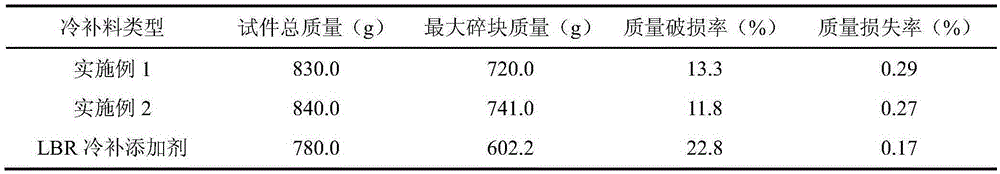

Solvent-type cold-patch asphalt liquid and preparation technology therefor

The invention relates to a solvent-type cold-patch asphalt liquid and a preparation technology therefor. The solvent-type cold-patch asphalt liquid comprises the following substances, by weight, 100 parts of petroleum asphalt, 10-15 parts of diluents, 10-15 parts of heavy oil, 10-15 parts of solvent naphtha, 1-5 parts of tackifier, 1-5 parts of strengthening agent, 0.2-0.8 part of surfactant and 0.5-0.8 part of anti-stripping agent. The above materials form performed polymers respectively and then are mixed uniformly, thus the obtained cold-patch liquid has good dispersibility, the stability of the obtained cold-patch asphalt liquid is raised, the storage stability is excellent, the employed tackifier, strengthening agent and anti-stripping agent can raise adhesion and strengthening effects of asphalt, and the surfactant can improve fluidity of asphalt substantially. The solvent-type cold-patch asphalt liquid is blended with aggregates when used to prepare cold-patch asphalt mixture for repairing pavement pits, no heating is needed during the blending process, the prepared cold-patch asphalt mixture has good initial and molding intensities and water damage resistance, and the construction workability is good.

Owner:CHANGAN UNIV +1

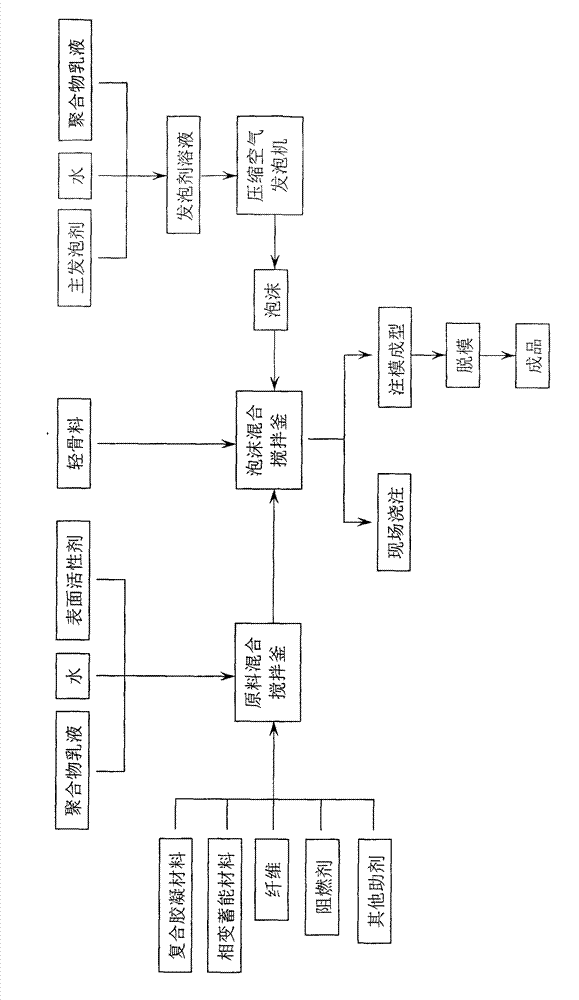

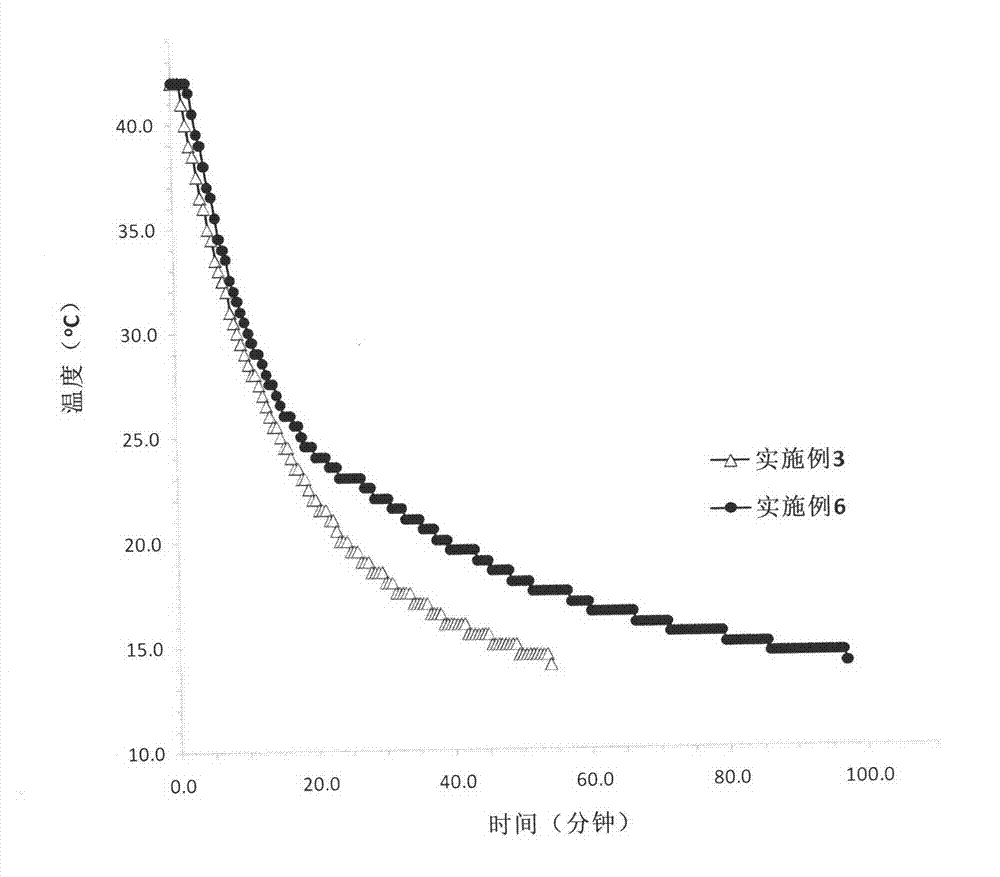

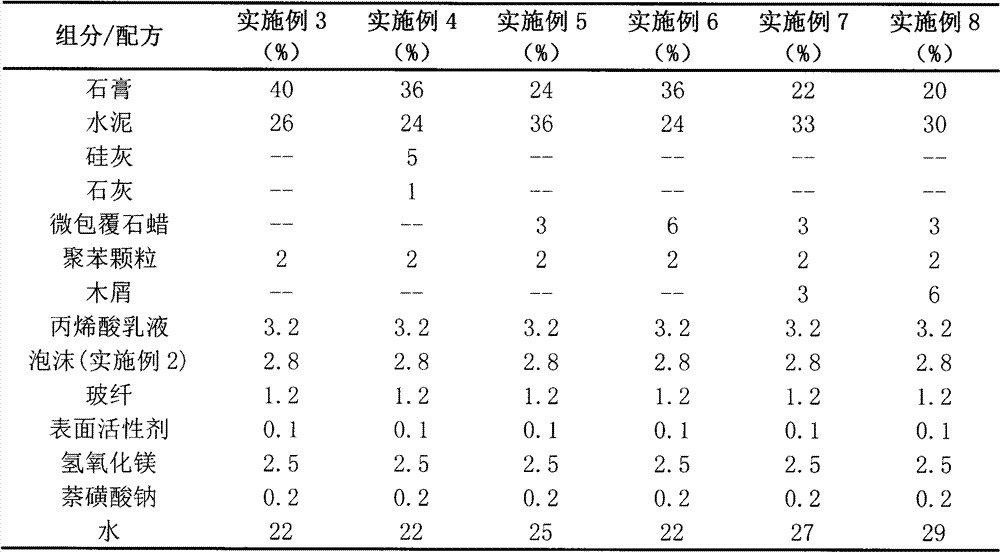

Energy storage energy-efficient foam gypsum cement composite material and preparation method thereof

ActiveCN102765959AImprove fire performancePrevent high temperature penetrationCeramicwareInsulation layerThermal insulation

The invention relates to an energy storage energy-efficient foam gypsum cement composite material and a preparation method thereof. The formula thereof is composed of a composite cementing material, lightweight aggregate, a phase change energy storage material, polymer latex, foam and a foaming agent. The composite cementing material is mainly composed of semi-hydrated gypsum and cement. The preparation method thereof comprises the steps of: preparing a foaming agent solution to prepare stable foam; thoroughly mixing water, polymer emulsion and other liquid state components with the composite cementing material, the phase change energy storage material and other additives such as solid-state components; and sending the solid-liquid mixed slurry to a foam-mixing kettle filled with the lightweight aggregate, while introducing the foam, to prepare the foam gypsum cement composite slurry. The inorganic composite foam material of the present invention has an energy storage function absorbing heat during the day and radiating heat at night, so as to effectively maintain a comfortable indoor temperature, is fire-proof, heat preservative, humidity-adjustable, good in water-resistance, and high in strength, and can be used for manufacturing fireproof insulation layers or fireproof insulation zones for interior and exterior walls of buildings, heat insulation, fire proof and heat preservation wallboards, door panels and core materials, steel structure fireproof cladding materials and the like.

Owner:南京依科国特新材料科技有限公司

Injectable self-curable calcium phosphate bone tissue repairing material and its preparation method and application

The invention discloses a curing calcium phosphate silicate bone tissue restoring material, comprising solid phase and liquid phase. Said solid phase comprises re-crystallized mannite and microcosmic salt mixture with calcium tetrahydrogen phosphate and calcium hydrogen orthophosphate of equal mole. Said liquid phase comprises chitose, citrate, glucose, collagen and water. The invention also relates to the method for preparing said restoring material and its application in bone tissue engineering mount preparation and restoring material for bone coloboma preparation. The restoring material can be degraded inside body, the strength in initial period is high, and degradation speed in later period is fast, so it is favorable to new bone tissue growth.

Owner:JINAN UNIVERSITY

Asphalt mixture for rapid repair of hot-mix-cold-laid pavement

InactiveCN101353481AHigh porosityImprove the compaction effectIn situ pavingsBuilding insulationsDiluentMaterials science

The invention relates to a road restoration asphalt mixture, and discloses a hot-mixing cold-paving road restoration asphalt mixture which comprises modified asphalt, additives and aggregates, wherein, the additives include a diluent, petroleum resin and an anti-stripping agent, the aggregates include coarse aggregate, fine aggregate and mineral powder. While preparing liquid asphalt, using the weight of the modified asphalt as reference, the weight proportion of the diluent is 14 percent to 22 percent, the weight proportion of the petroleum resin is 1.8 to 2.2 percent and the weight proportion of the anti-stripping agent is 0.4 to 0.6 percent. The asphalt mixture of the invention has strong comprehensiveness, performs excellently in poriness, compactibility, initial strength, workability, the strength of formed mixture, anti-water damage property and storage property, can be mixed easily and operated conveniently and is suitable for practical application and generalization.

Owner:TONGJI UNIV

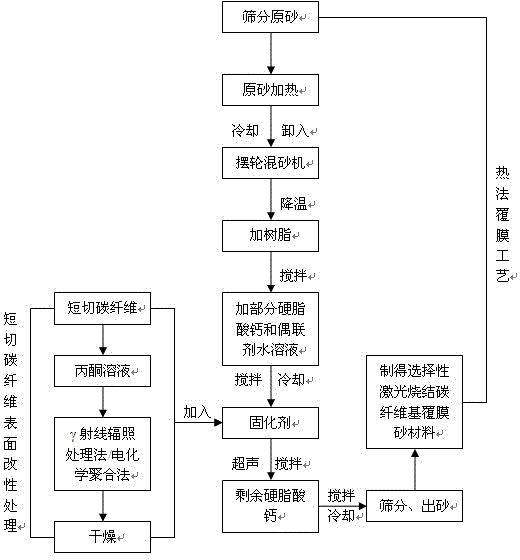

Carbon fiber-based precoated sand material for selective laser sintering and preparation method thereof

InactiveCN104308072AImprove thermal stabilityEnhancement effect is goodFoundry mouldsFoundry coresFiberSelective laser sintering

The invention discloses a carbon fiber-based precoated sand material for selective laser sintering and a preparation method thereof. The carbon fiber-based precoated sand material comprises chopped carbon fibers, crude sand, an organic binder, a curing agent, a lubricant, a coupling agent and a dispersant. The preparation method comprises the following steps of carrying out surface modification treatment on the chopped carbon fibers, heating the crude sand, adding resin, adding a part of calcium stearate and a prepared coupling agent aqueous solution, adding a chopped fiber-containing urotropine curing agent, adding the rest of the calcium stearate, carrying out cooling and carrying out screening and sand discharge to obtain the product. The carbon fiber-based precoated sand material has the advantages that 1, the carbon fibers have thermal conduction effects, limit integral shrinkage of a sintered part to a certain degree and reduce warp phenomenon in molding, and 2, through laser sintering, the precoated sand substantially improves resin precoated sand thermostability, promotes curing reaction of phenolic resin at locals in the sintered layer and between the sintered layers and obviously improves laser sintering forming part blank strength.

Owner:NANCHANG HANGKONG UNIVERSITY

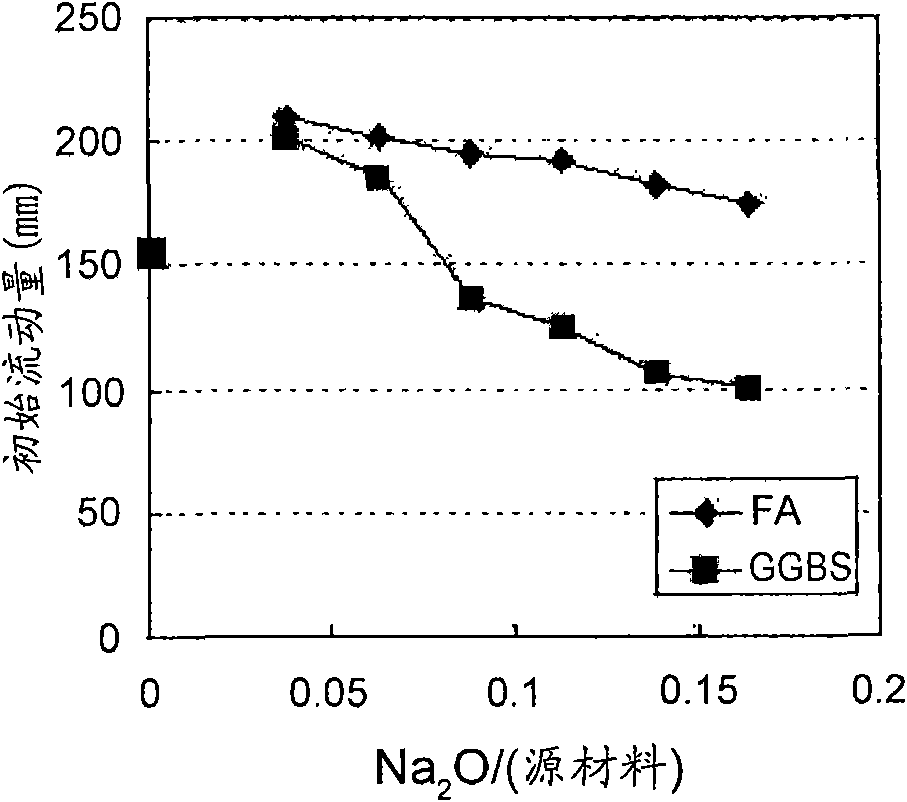

Alkali-activated binder with no cement, method for fabricating mortar using it, and method for fabricating alkali-activated reinforcement mortar with no cement

InactiveCN101687704AImprove initial strengthLow heat of hydrationSolid waste managementCement productionPortland cementKaolin clay

The present invention relates to a cement-free alkali activated binder in which alkaline inorganic materials are appropriately added to an industrial waste such as blast furnace slag, fly ash, meta kaolin and the like, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar. Specifically, the present invention relates to a cement-free alkali activated binder that is not only environmentally friendly as being capable of dramatically reducing the carbon dioxide emission, which has been remained as a problem for producing Portlandcement, but also has an excellent property, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar.

Owner:IND FOUND OF CHONNAM NAT UNIV

A production method of high-strength large-elongation aluminum-clad steel wire

InactiveCN108986989AChange heat treatment temperatureHigh tensile strengthSingle bars/rods/wires/strips conductorsApparatus for heat treatmentWire rodHigh carbon

The invention relates to a production method of high-strength large-elongation aluminum-clad steel wire, comprising the following steps: 1) hot-drawing high-carbon steel wire rod to different wire diameters through cold drawing; 2) carry out lead bath quenching treatment on that steel wire, and carry out on-line pickling and rinsing to obtain a pretreated steel wire; 3) uniformly cover an outer lay of that pretreated steel wire with a layer of aluminum to form a cladding blank; 4) that coat blank is drawn into a super-high-strength aluminum clad steel wire semi-finished product through multiple passes of a bimetal synchronous deformation wire draw machine; 5) age that semi-finished product of the high-strength aluminum-clad steel wire through a high-temperature box. The method of the invention changes the traditional lead bath heat treatment temperature, The tensile strength of Al-clad steel wire is increased by multi-pass synchronous deformation and drawing with small compression ratio, and the elongation of Al-clad steel wire is increased by high temperature aging treatment. The ultimate tensile strength >= 1700 MPa, elongation >= 3. 0%, and other indexes are in accordance with the requirements of Al-clad steel GB / T17937-2009 standard, thereby meeting the requirements of high strength and high elongation and meeting the application requirements.

Owner:HUBEI LONGSKY COMM TECH

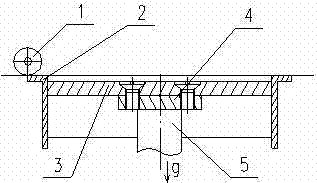

Quick manufacturing method for die-free casting sand mold

InactiveCN102397991AReduce distortionAvoid problems such as high gas productionFoundry mouldsFoundry coresData informationEngineering

The invention belongs to the technical field of casting and discloses a quick manufacturing method for a die-free casting sand mold. The quick manufacturing method comprises the following steps of: paving a layer of phenolic resin coated sand on a worktable by adopting a relevant power paving system in die-free casting sand mold manufacturing equipment controlled by a computer; secondly, driving an injection system of the equipment to inject solvent according to a contour data information instruction of each layer of section of the sand mold, which is acquired by the computer; melting and bonding the injected part of phenolic resin coated sand to form; drying; after finishing the forming of one layer, descending the worktable by a story height; carrying out power pavement, solvent injection and drying of next layer until a casting sand mold solid is formed by stacking and curing layer by layer; removing residual sand; and drying and curing the residual sand to obtain the casting sand mold with high strength. The quick manufacturing method disclosed by the invention has the characteristics of no heating required for initial curing and lower deformation of a sand core; meanwhile, the consumption of resin is reduced, and thus the defect of high gas forming amount of the casting sand mold is avoided. The quick manufacturing method has the advantages of low cost of used solvent, environment friendliness, energy source saving and popularization and application value.

Owner:CHINA YITUO GROUP

Gunning mix for blast furnace tapping channel

The invention relates to a refractory material and particularly relates to a gunning mix for a blast furnace tapping channel, which aims at solving the problems that a channel lining is easily cracked and dropped in the prior art. The gunning mix for the blast furnace tapping channel comprises the following components in parts by mass: 35-45 parts of mullite of which the granularity is 3-5mm, 25-35 parts of corundum of which the granularity is 1-3mm, 12-25 parts of silicon carbide of which the granularity is 0-1mm, 8-12 parts of alumina powder, 6-10 parts of cement, 0.1-0.3 part of explosion-proof fiber, 1-3 parts of graphite and 3-5 parts of iron silicon nitride. According to the gunning mix disclosed by the invention, by adding the explosion-proof agent, the adhesion rate can be increased and the cracking and dropping are prevented, and especially when the high-temperature gunning is carried out, since voids are formed by melting fibers, the porosity is increased to provide a passage for the rapid exhaust of the steam; the gunning mix contains relatively high content of Al2O3 and is suitable for a part with a serious melting loss need to be repaired on the main channel; cement is conductive to improving the initial strength of the gunning mix and thus the gunning mix can withstand relatively high vapor pressure and thus the burst is avoided and the gunning mix has relatively high adhesion force and durability; by adding iron silicon nitride, bonding strength between the oxide and non-oxide is improved; by virtue of the gunning mix disclosed by the invention, the service life of the main channel is prolonged.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

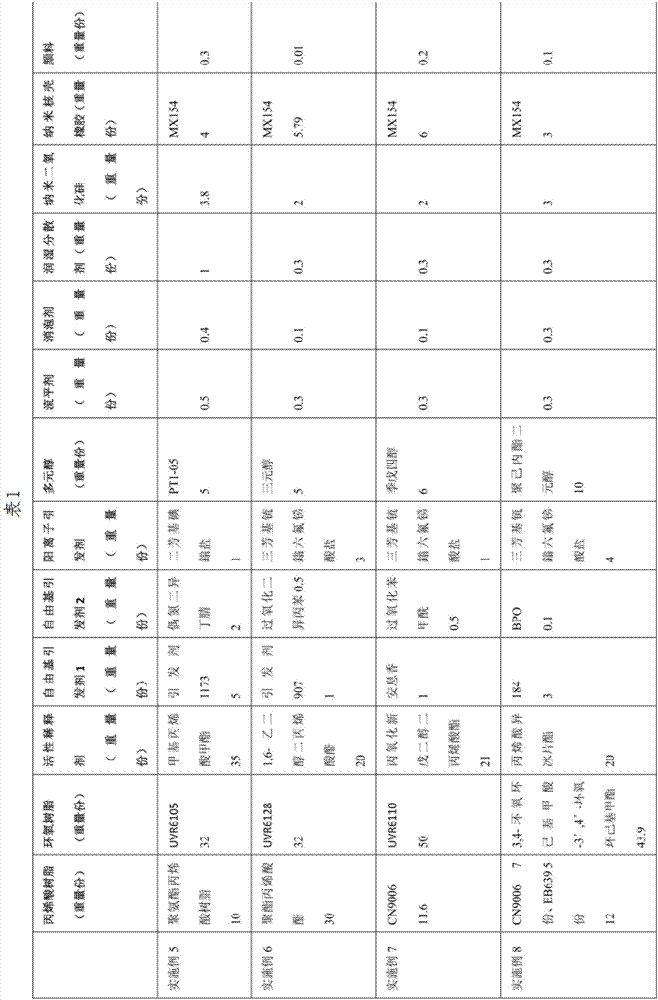

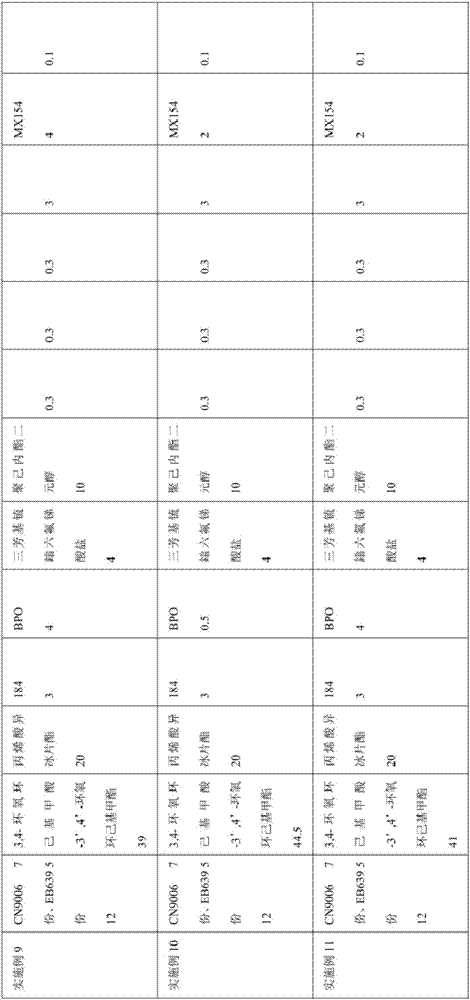

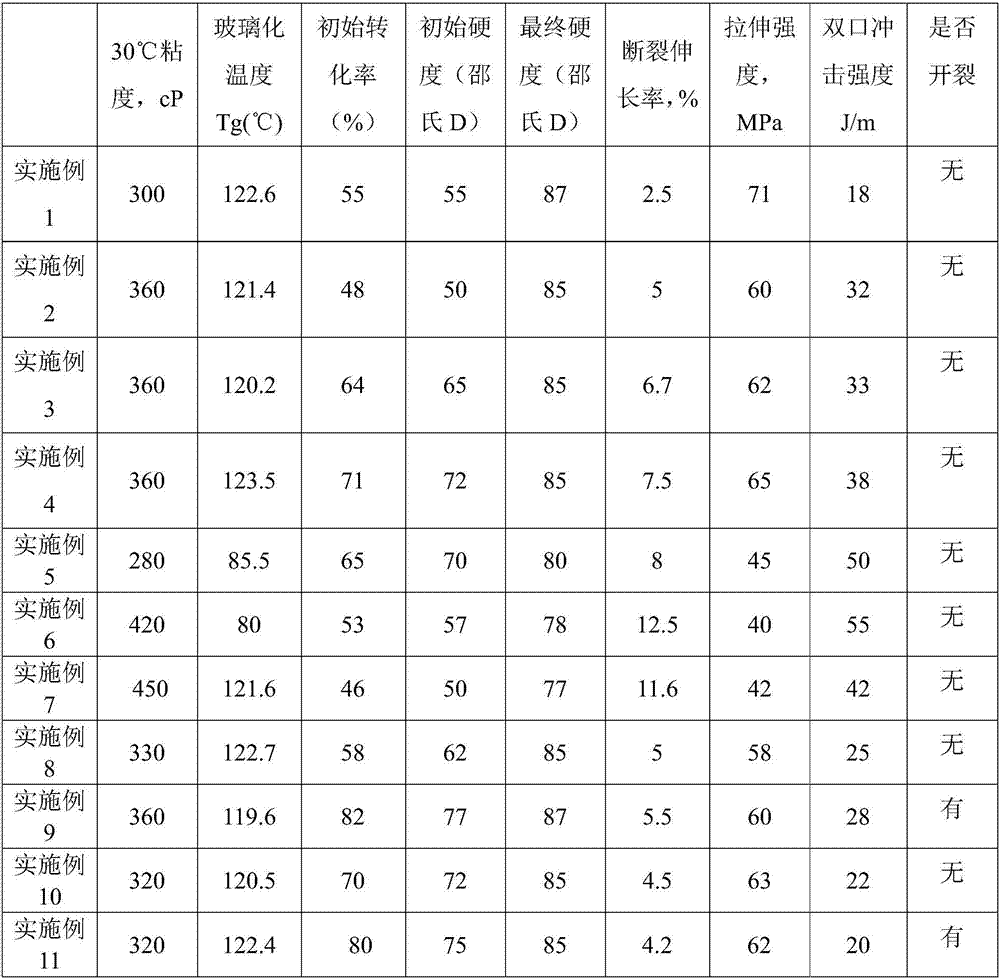

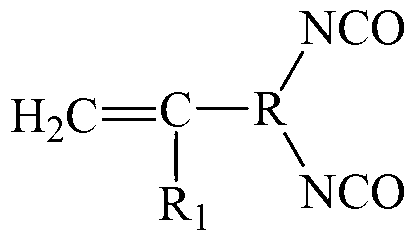

High-temperature-resistant toughened light-cured resin composition and preparation method thereof

ActiveCN107513247AImprove the shortcomings of slow printing speed and low curing efficiencyImprove curing efficiencyAdditive manufacturing apparatusEpoxyAcrylic resin

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

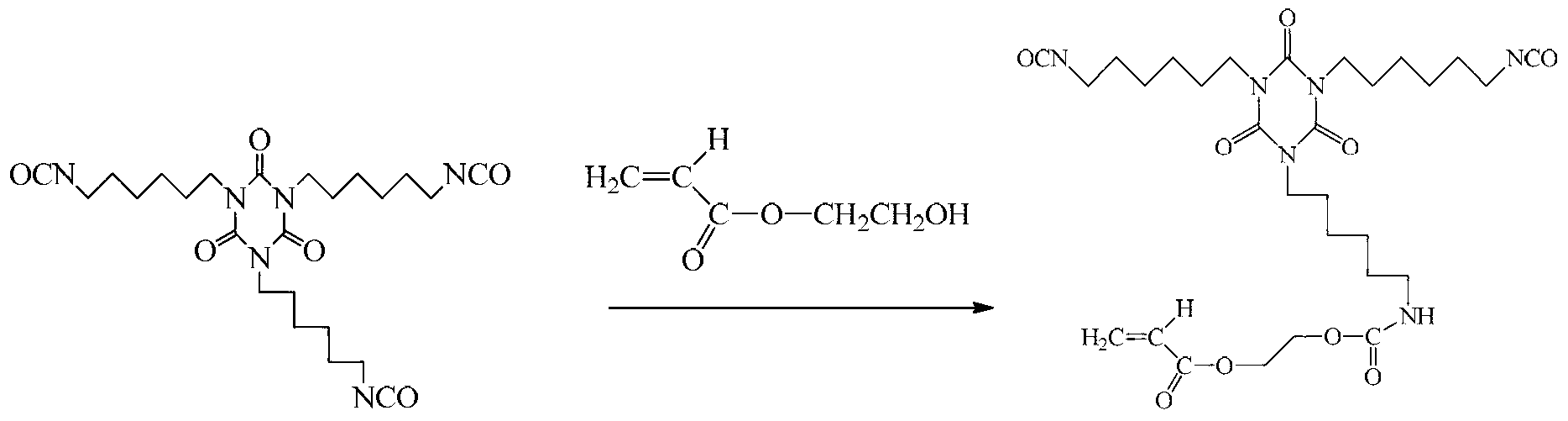

Preparation method of light/humidity dual-curing polyurethane hot melt adhesive

InactiveCN103305174AMulti-step reactionBalance dosagePolyureas/polyurethane adhesivesMolten stateWater vapor

The invention relates to a preparation method of a light / humidity dual-curing polyurethane hot melt adhesive. The preparation method comprises the following steps of: introducing N2 into an HDI (hexamethylene diisocyanate) tripolymer, removing water vapor, carrying out a protective reaction, respectively adding a polymerization inhibitor and a catalyst and dropwisely adding HEA (hydroxyethyl acrylate); after dropwisely adding and reacting, adding polyisocyanate, and stirring uniformly to obtain 3HDI-HEA / polyisocyanate; heating and fusing polyalcohol and stirring for dehydration; adding the 3HDI-HEA / polyisocyanate and the catalyst; discharging after reacting, packaging the sample with an aluminum foil bag for standby application to obtain a light / humidity dual-curing polyurethane hot melt adhesive prepolymer; melting the prepolymer, and adding a photoinitiator, a polymerization inhibitor, a plasticizer and the catalyst, stirring uniformly in a molten state, rising the temperature and removing air bubbles; and ending stirring and discharging to obtain the light / humidity dual-curing polyurethane hot melt adhesive. The obtained hot melt adhesive has high initial bonding strength and final strength.

Owner:NANJING FORESTRY UNIV

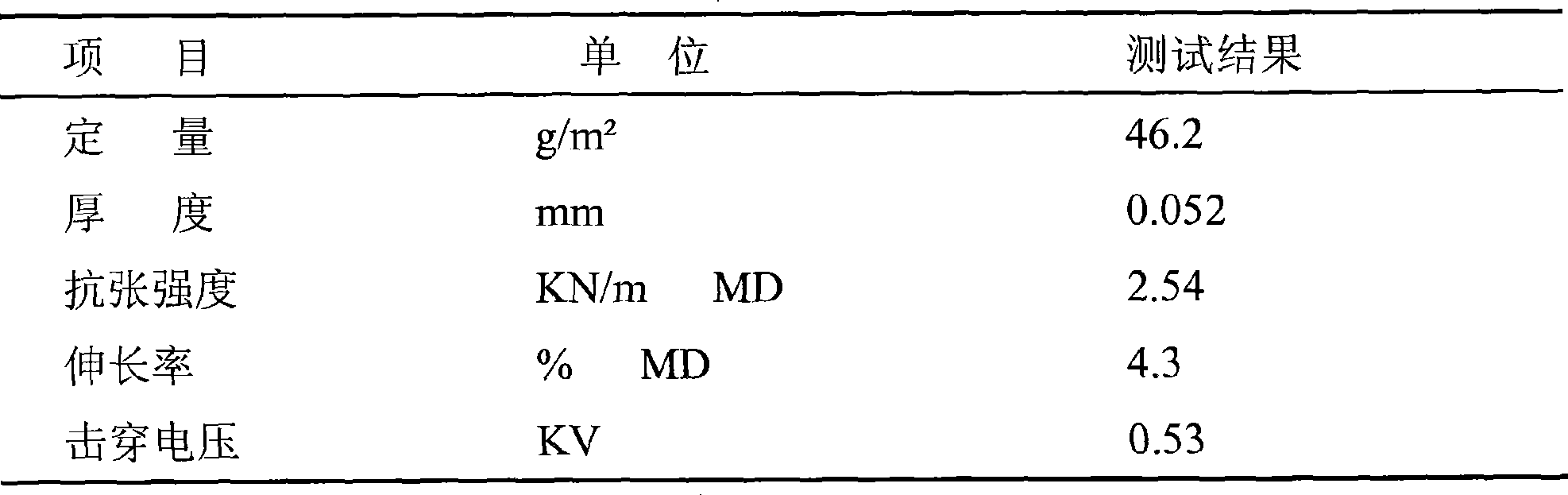

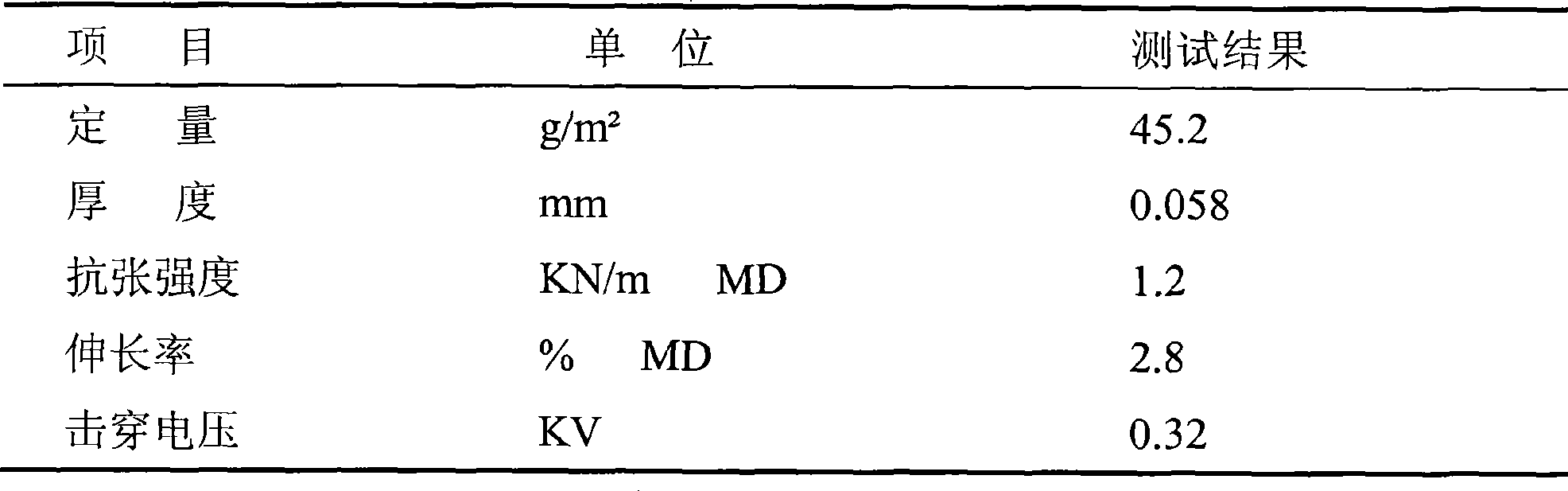

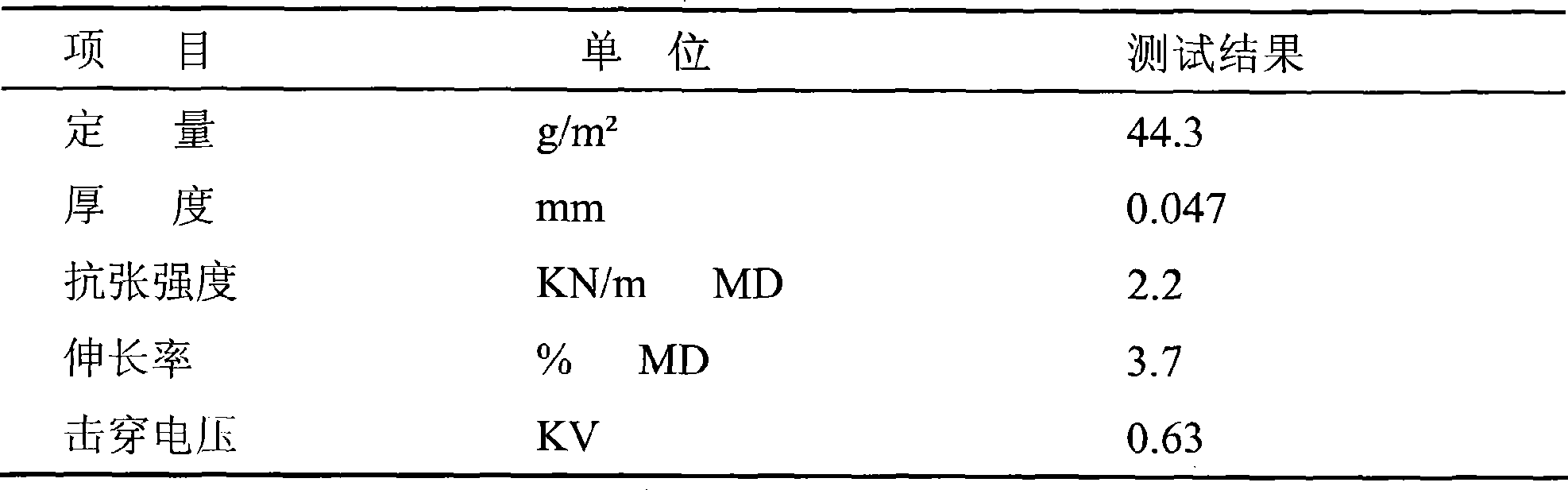

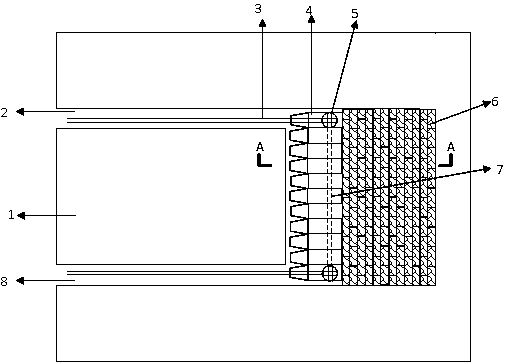

Method for preparing synthetic paper containing polysulfone amide precipitation fibers

ActiveCN101392475AImprove initial strengthImprove heat resistanceSynthetic cellulose/non-cellulose material pulp/paperPhysical paper treatmentSynthetic fiberHigh intensity

The invention provides a synthetic fiber paper, which contains the following ingredients in parts of weight: 5-95 parts of structural fiber and 5-95 parts of splicing fibers, wherein, the structural fiber is polyisophthaloyl metaphenylene diamide fiber and the splicing fiber is polysulfonamide precipitated fiber. The synthetic fiber paper is produced by the following steps: the structural fiber and the splicing fiber are made into be formed by a wet method and hot-rolled to obtain the paper. The synthetic fiber paper provided by the invention has high intensity conservation rate under the high temperature, excellent paper-making overall properties compared with the insulation paper made of full para-fiber, meta-fiber and full polysulfonamide material, and is more suitable for the insulation requirement under high-temperature environment.

Owner:LONGPONT

High initial strength filling mining method

InactiveCN105370279AImprove initial strengthLow costUnderground miningSurface miningCement pasteCoal pillar

The invention relates to a high initial strength filling mining method. The method includes the following steps: crushing municipal garbage, mixing the garbage with a proportional curing agent and pressing the garbage into a filling material; transporting the prepared sealed filling material from the ground to the bottom of the well, and then shipping the filling material to a working face; after coal cutting, support advancing and pushing on the working face, sending the filling material from a gate top by using a mining flatbed truck, sending the filling material into a flexible rail behind a support through a rotating switch of an upper end, unloading the filling material to a goaf area, stacking regularly, and filling the remaining gap with a rapid hardening cement paste material to ensure complete roof contact; and after mining, sealing the goaf area again through boundary coal pillars and stop line coal pillars to ensure zero gas and liquid exchange between the filled area and the unfilled area. The method of the invention solves the problems of municipal garbage disposal and the sources for mining coal filling material, and the filling material has high initial strength and can effectively control the surface subsidence.

Owner:UNIV OF SCI & TECH BEIJING

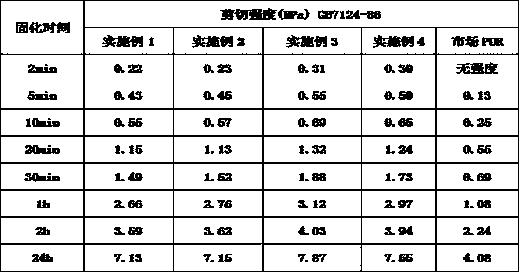

High initial strength reaction type polyurethane hot melt adhesive and preparation method thereof

InactiveCN109181555AEasy to masterEasy to prepareMacromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceInitial strength

The invention discloses a high initial strength reaction type polyurethane hot melt adhesive and a preparation method thereof. The hot melt adhesive is prepared from the following raw materials in parts by weight: 60-90 parts of polyhydric alcohols, 5-40 parts of tackifying resins, 10-15 parts of isocyanate compounds, 0.1-1 part of catalyst and 0.1-1 part of adhesion promoter. The preparation method comprises the following steps: (1) adding polyhydric alcohols and tackifying resins into a reaction vessel, heating in vacuum, melting and dehydrating, thereby acquiring a mixture; (2) adding isocyanate compounds or isocyanate group terminated prepolymer compounds into the mixture acquired in the step (1) and then controlling temperature and performing polymerization reaction, thereby acquiringa polymer; (3) adding a catalyst and an adhesion promoter into the polymer acquired in the step (2), controlling temperature and reacting in vacuum; and (4) placing the prepared hot melt adhesive into a container and filling dry inert gas. The high initial strength reaction type polyurethane hot melt adhesive disclosed by the invention has the advantages of high initial strength, excellent temperature resistance and low production cost. The preparation method is simple and is easy for industrial production.

Owner:HUIZHOU DUV ELECTRONICS MATERIALS

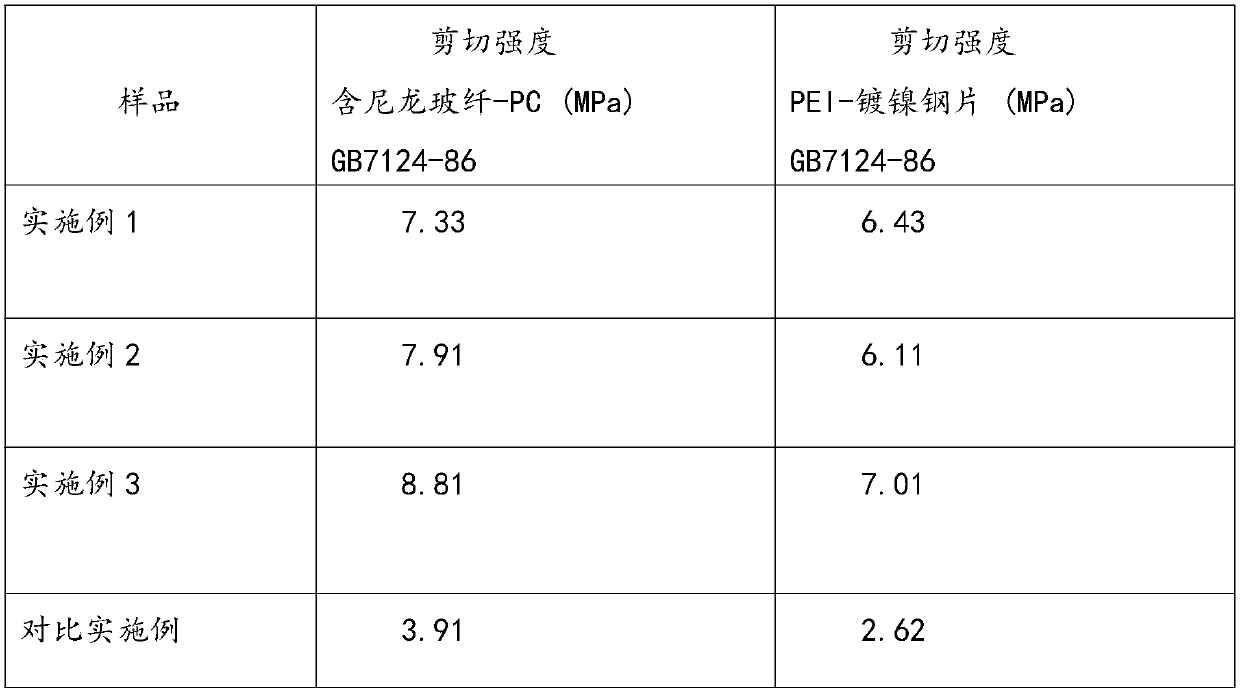

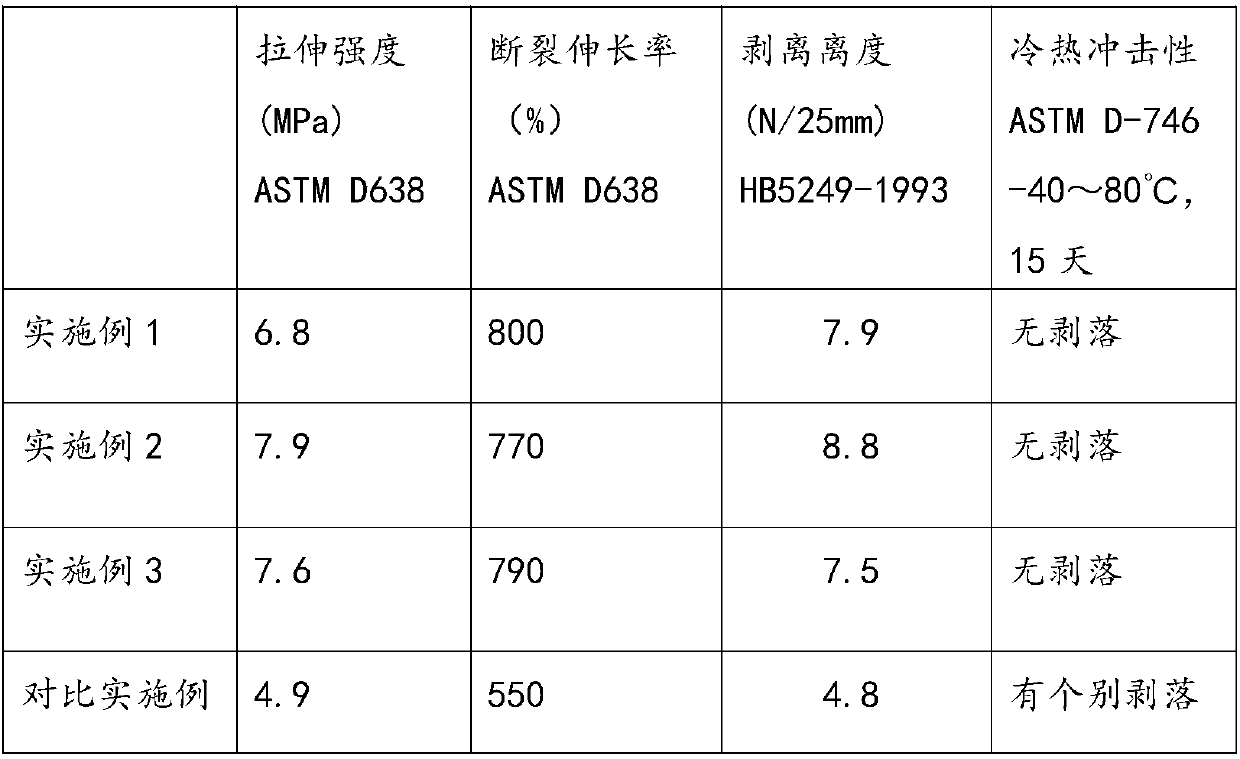

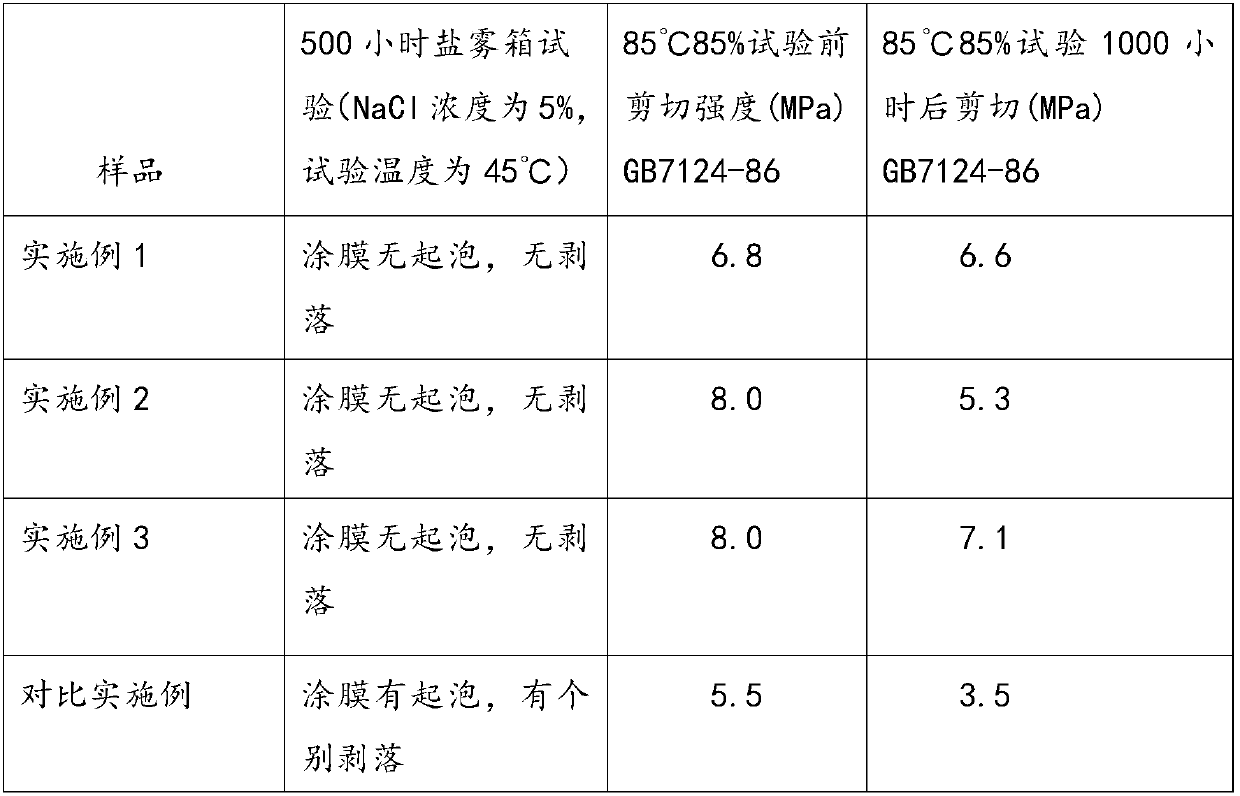

Preparation method of polyurethane hot melt adhesive adhered with lower surface energy material

ActiveCN107652937AExcellent low surface energy adhesive propertiesGood flexibility and bulk tensile strengthPolyureas/polyurethane adhesivesSurface energyExpansion factor

The invention relates to a preparation method of a polyurethane hot melt adhesive adhered with a lower surface energy material. The polyurethane hot melt adhesive prepared by the method provided by the invention has favorable flexibility and body tensile strength, can overcome the influence of an expansion factor difference between different materials, and is uniform in stress distribution so as to adapt to base materials in different types; an anti-dropping performance is good: the times for dropping a roller is higher than 300 times; the adhesion strength is high: the adhesion strength of PEI and a nickel-plated steel disc is higher than 6.0MPa; salt spray resistant and ageing-resistant performances are good: no damage is caused after a salt spray test is carried out for 500 hours, and no remarkable intensity attenuation is caused after a dual-85 test is carried out for 1000 hours.

Owner:YANTAI DARBOND TECH

Industrial solid waste autoclaved aerated concrete block and preparation method thereof

The invention discloses an industrial solid waste autoclaved aerated concrete block and a preparation method thereof. The concrete block uses fly ash, carbide slag, red mud, lime, desulfurized gypsumand cement as main raw materials and aluminum powder, sodium hydroxide, water glass and the dispersing agent silica fume as additives; the coal ash reacts with components in the carbide slag to generate ettringite, so the strength of the concrete block can be enhanced; a large amount of aluminum oxide contained in the red mud can a replace part of lime and undergo a hydration reaction with the cement, and the aluminum oxide in the red mud can react with calcium hydroxide in the carbide slag, so the strength of the block is enhanced; the coal ash, the carbide slag and the red mud react with oneanother to generate hydrated calcium silicate and hydrated calcium aluminate, so the structural compactness of the block can be improved; and the additives can enhance the foaming stability of the aluminum powder and improve the early strength of the block under an alkaline condition. The method is green and environment-friendly, and the waste of non-renewable resources is effectively reduced.

Owner:张延年

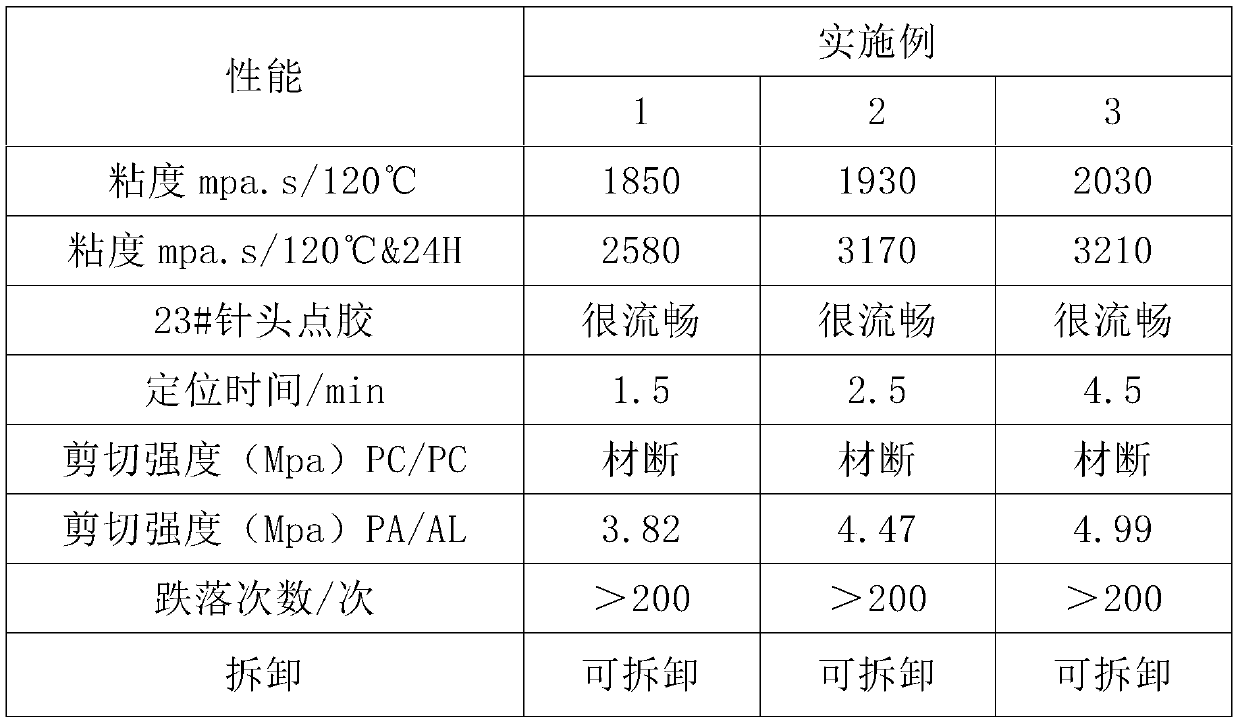

Detachable reactive polyurethane hot melt adhesive used for bonding of mobile phone frames and preparation method of adhesive

PendingCN110016315AImprove cohesive strengthQuick peelPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterAcrylic resin

The invention discloses a detachable reactive polyurethane hot melt adhesive used for bonding of mobile phone frames. The adhesive is characterized by comprising the following components, in percentages by weight: 10-30% of a polyether polyol, 30-50% of a polyester polyol, 15-35% of isocyanate, 15-30% of acrylic resin, 3-10% of tackifying resin, 1-5% of thermoplastic polyurethane (TPU), 0.1-0.5% of a stabilizing agent, 0.1-1% of a catalyst, and 1-5% of an adhesion promoter. The invention also discloses a preparation method of the adhesive. The reactive polyurethane hot melt adhesive provided by the invention has low viscosity, good fluidity, easy dispensing and no drawing; the adhesive has good stability, and the viscosity change does not exceed 50% at 120 DEG C for 24 h; the adhesive hasa fast positioning speed and short pressure holding time; the adhesive has high bonding strength and very good bonding effects on a plurality of plastics and metals; and the adhesive is detachable.

Owner:康达新材料(集团)股份有限公司

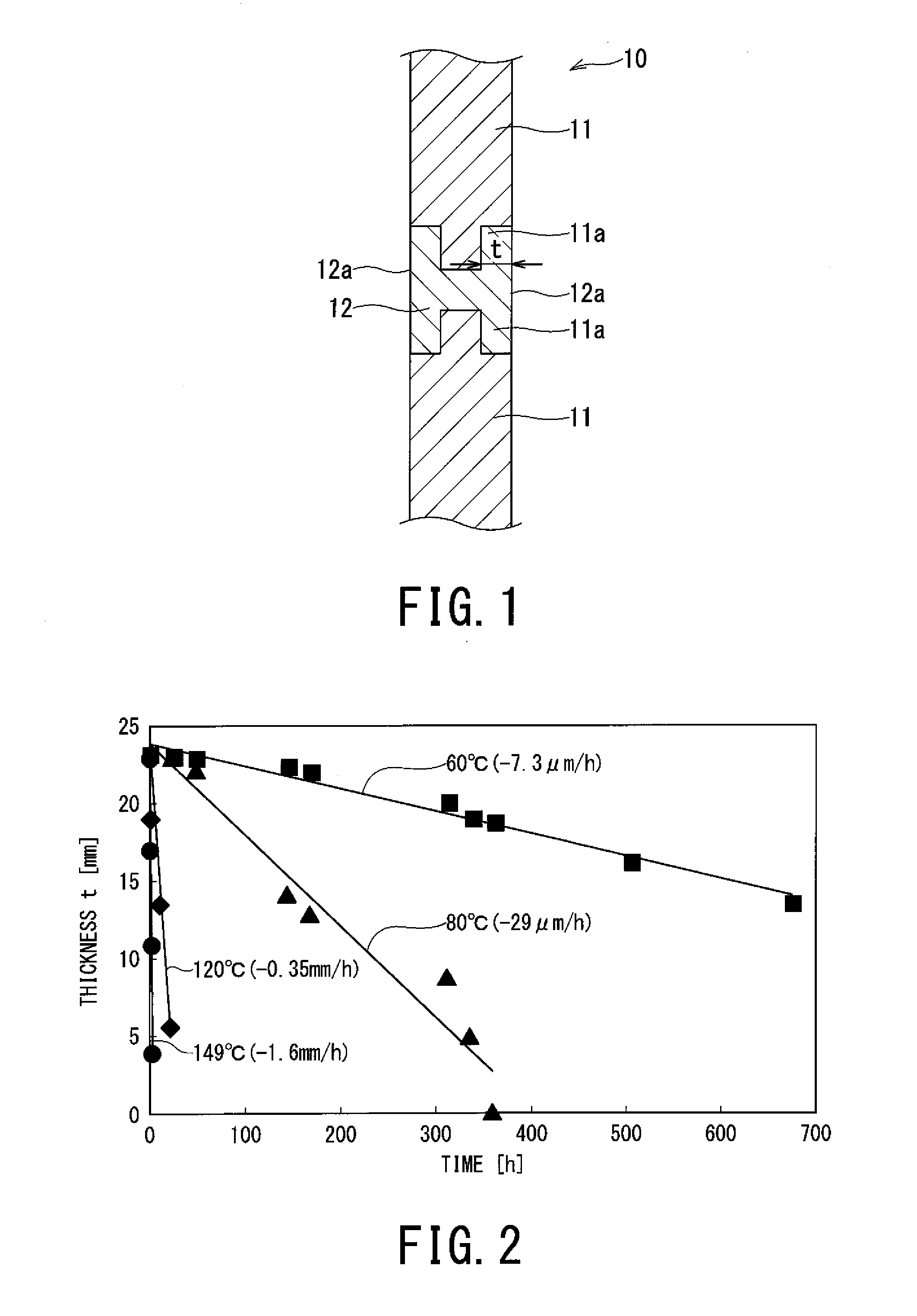

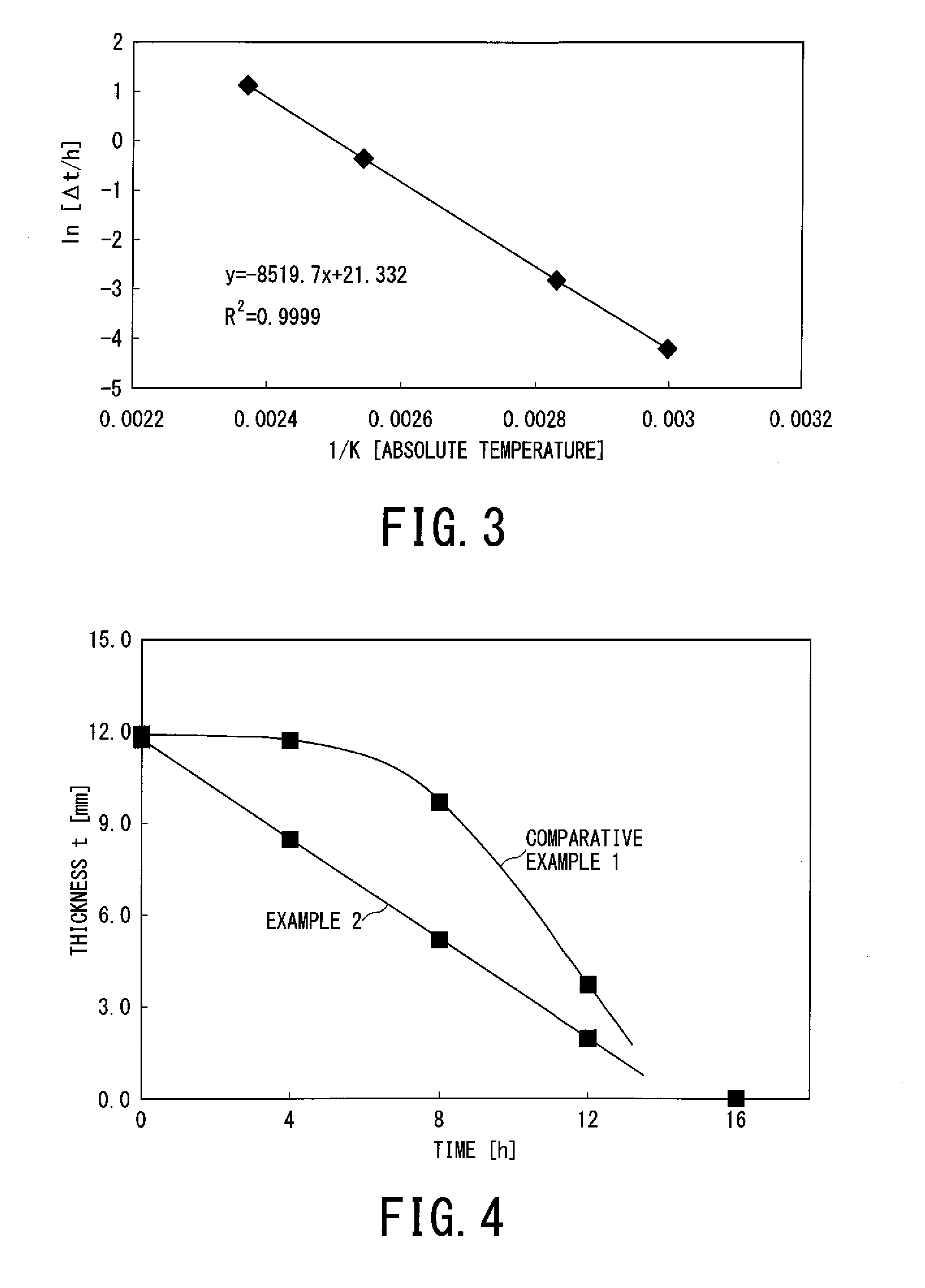

Member for hydrocarbon resource collection downhole tool

ActiveUS20150096741A1Precise designImprove initial strengthDrilling rodsConstructionsReduction rateResource recovery

A downhole tool member for hydrocarbon resource recovery, comprising a shaped body of a polyglycolic acid resin having a weight average molecular weight of at least 70,000, having an effective thickness which is ½ or more of a critical thickness of surface decomposition, and exhibiting a thickness reduction rate in water which is constant with respect to time. As a result, it has become possible to more accurately design the strength and time up to the collapse of the downhole tool member which forms the whole or a part of a downhole tool for developing or repairing downholes for recovery of hydrocarbon resources, such as oil and gas.

Owner:KUREHA KAGAKU KOGYO KK

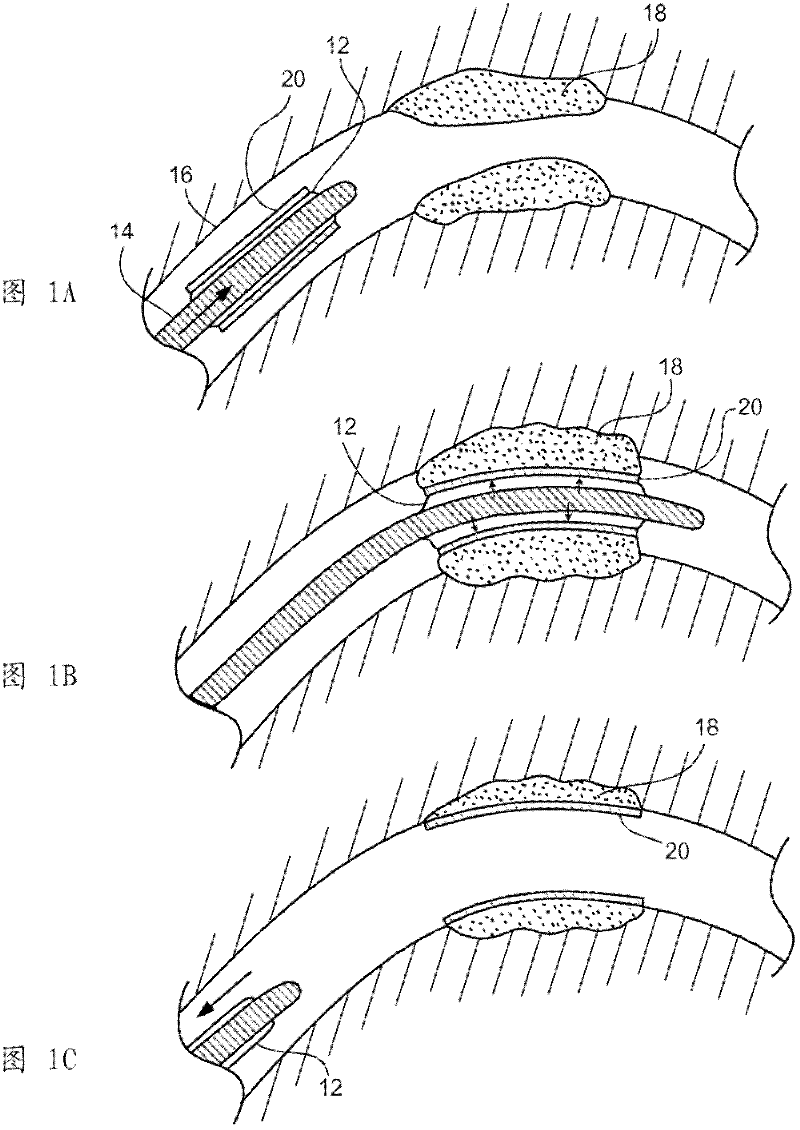

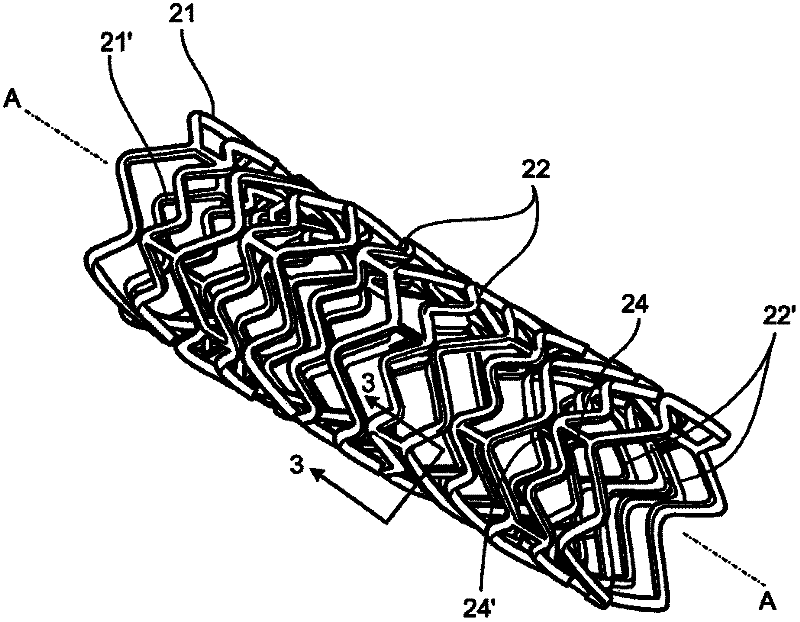

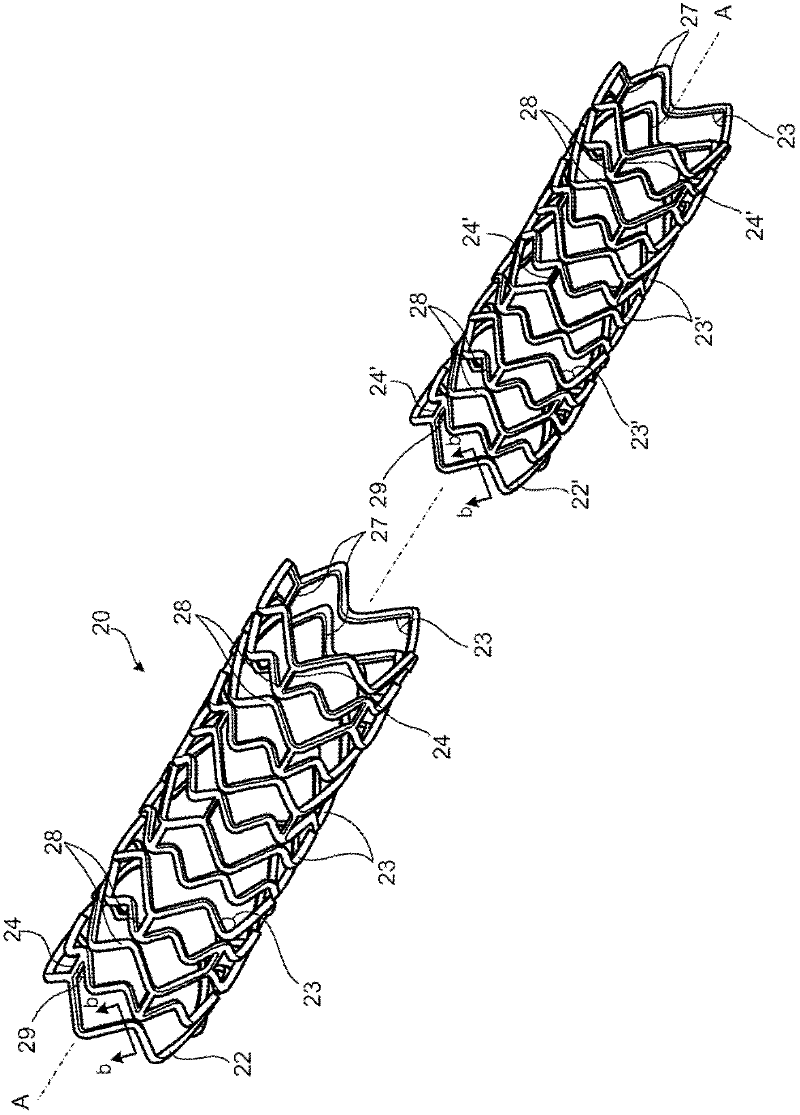

Bioerodible endoprosthesis

InactiveCN102458315AFavorable mechanical propertiesFavorable biodegradabilityStentsProsthesisMedicineInsertion stent

A stent includes a first tubular element formed of a first bioerodible metal composition and second tubular element formed of a second biodegradable metal composition. The first and second tubular elements are concentrically arranged; and the first and second bioerodible metal compositions are different

Owner:BOSTON SCI SCIMED INC

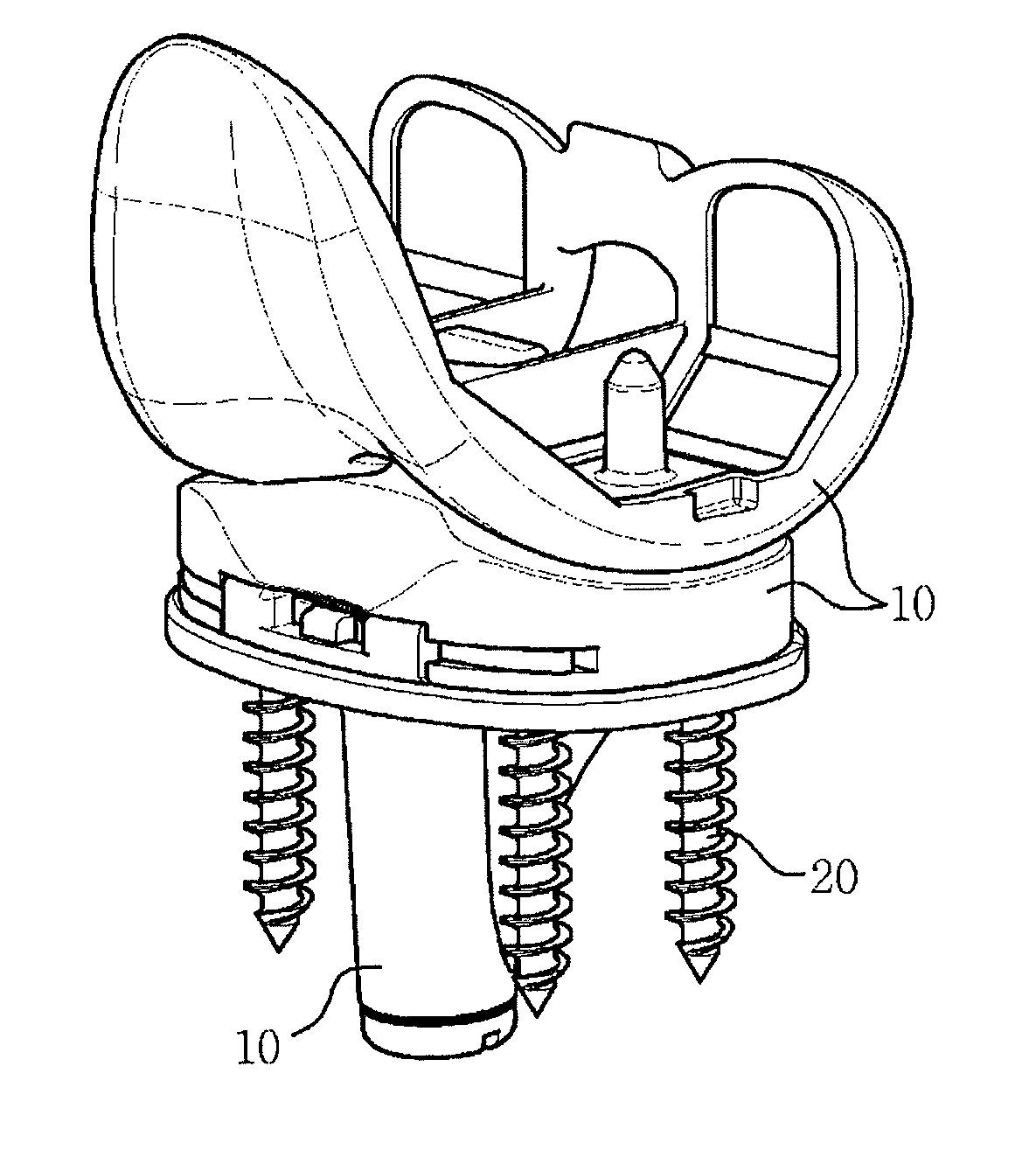

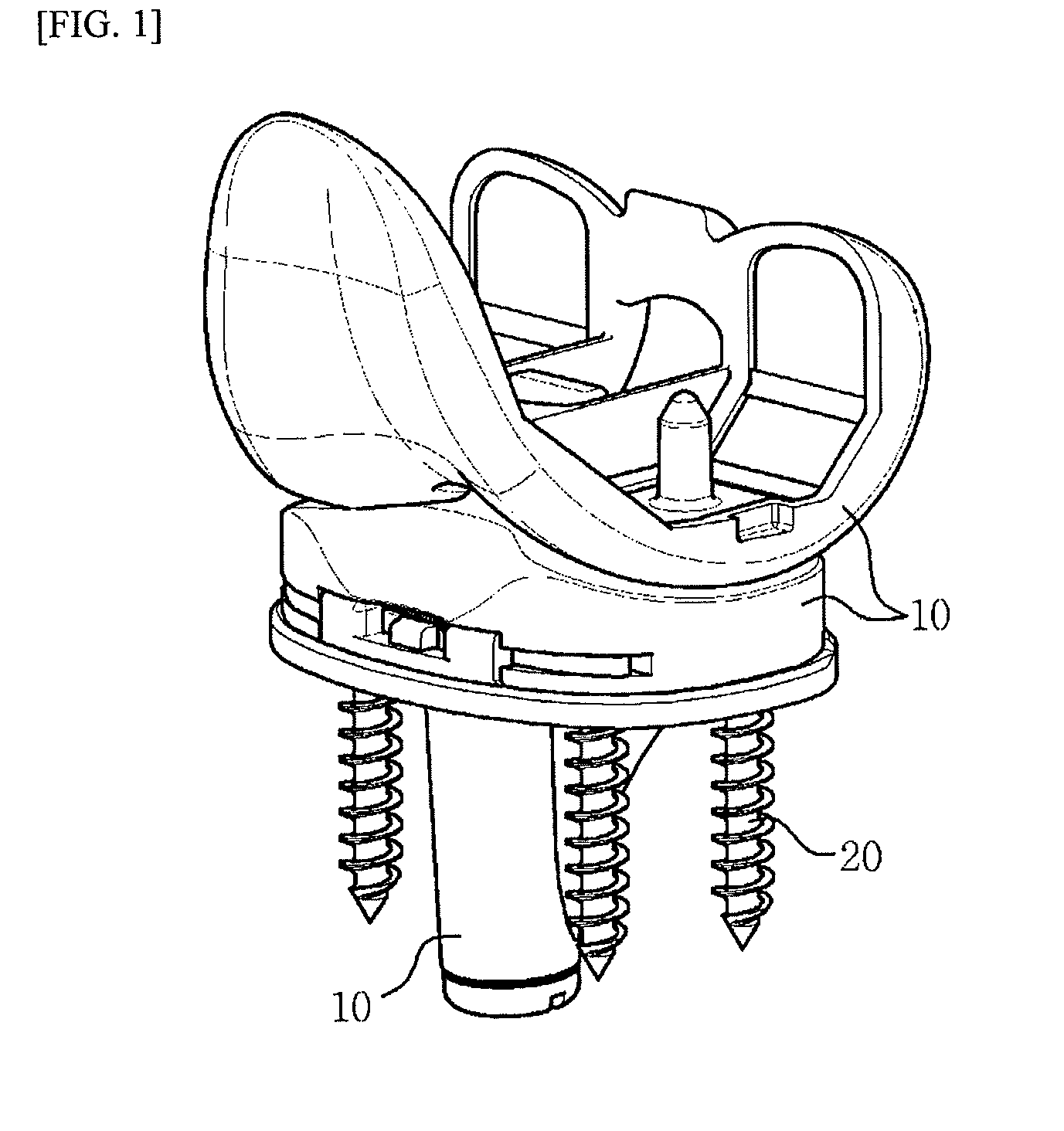

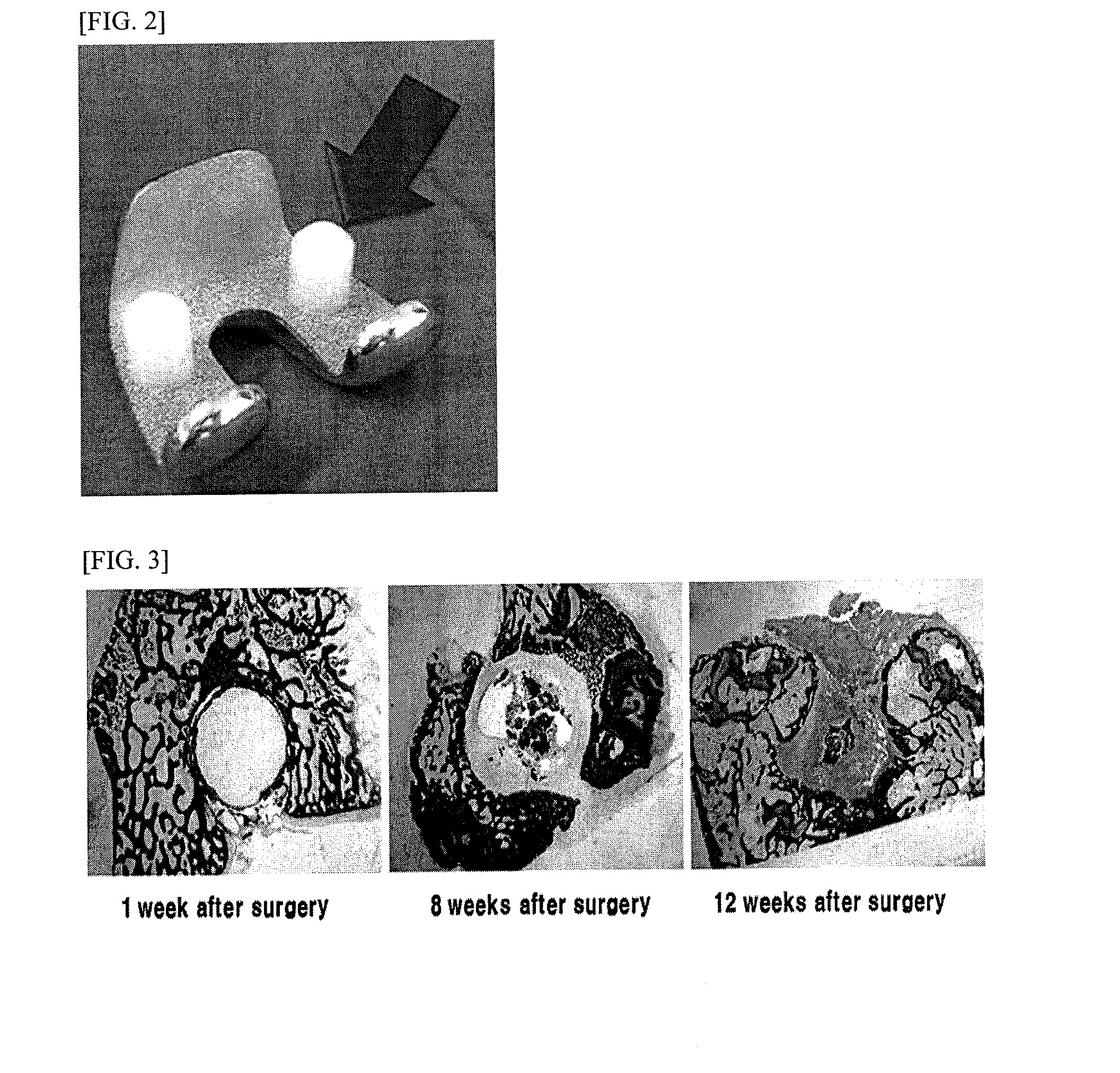

Implant

InactiveUS20130131814A1Improve initial strengthInitial bending strengthSurgeryJoint implantsArtificial jointsMedicine

The present invention provides an implant, which is used to fix an artificial joint in bone, including a biodegradable magnesium alloy.

Owner:U & I INC

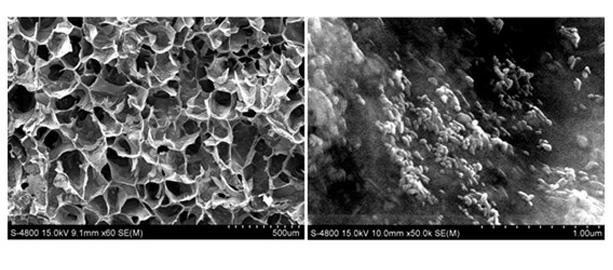

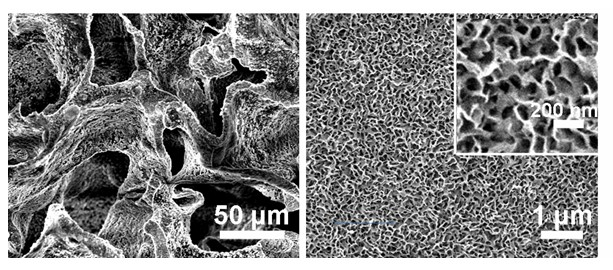

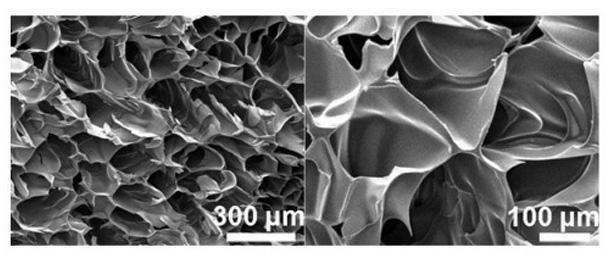

Natural polymer-hydroxyapatite bone tissue engineering scaffold material with secondary three-dimensional network structure and seed-crystal induction preparation method thereof

InactiveCN102107022AOvercoming the inability to form hydroxyapatiteEffective reinforcementProsthesisBone tissue engineeringBone tissue

The invention discloses a natural polymer-hydroxyapatite bone tissue engineering scaffold material with a secondary three-dimensional network structure and a preparation method thereof. The method comprises the following steps of: mixing hydroxyapatite nanorods and a natural polymer, crosslinking by utilizing a non-toxic crosslinking agent, namely genipin, freeze-drying to prepare a porous natural polymer scaffold with nanometer seed crystals, then biomineralizing by utilizing simulation body fluid, and forming a layer of hydroxyapatite nanometer three-dimensional network structure on the walls of porous channels of the natural polymer scaffold with a micron-level three-dimensional network structure under the induction of the seed crystals. The natural polymer-hydroxyapatite bone tissue engineering scaffold material with the secondary three-dimensional network structure not only has good biocompatibility, but also is non-toxic and has high bioactivity, which indicates that the materials are expected to be widely used in repair medicine.

Owner:SHANDONG UNIV

Normal temperature repair asphalt solution additive and preparation method thereof

ActiveCN103804924AImprove solubilityNo segregationRoads maintainenceBuilding insulationsReducerPetroleum

The invention discloses a normal temperature repair asphalt solution additive and a preparation method thereof. The additive comprises the following components by mass percentage: 30%-35% of asphalt, 10%-15% a softener, 5%-10% of diesel, 5%-10% of a polymer, 0.25%-0.5% of sulphur, and 29.5%-49.75% of a viscosity reducer. Through simple blending of the additive provided by the invention and pavement petroleum asphalt, a high performance normal temperature repair asphalt solution can be prepared. The mixed normal temperature repair mixture has performance fully meeting relevant specification requirements, is applicable to the environment temperature, can truly achieve all-weather repair, and practical application proves that the performance is excellent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rice straw reinforced foam concrete and method for preparing same

InactiveCN108046840AOffset drying shrinkageRetain Toughening PropertiesCeramicwareFoam concreteFiber

The invention discloses rice straw reinforced foam concrete and a method for preparing the same. The rice straw reinforced foam concrete comprises dry-basis gelling components. The dry-basis gelling components comprise, by weight, 15-75 parts of ordinary silicate cement, 10-25 parts of fly ash, 10-55 parts of mineral waste residue micro-powder, 5-15 parts of steel slag powder and the like. The method includes adding an appropriate quantity of water and foaming agents to prepare concrete slurry; adding modified rice straw fibers on the basis of the concrete slurry; carrying out mold filling, shaping and curing for 28 d to obtain the rice straw reinforced foam concrete which is reinforced and toughened foam concrete. The rice straw reinforced foam concrete and the method have the advantagesthat the rice straw reinforced foam concrete is light, heat-insulation and crack-resistant, is toughened, is quite suitable for mass concrete construction such as mine backfilling and also can be applied to producing novel wall materials, heat can be preserved by the rice straw reinforced foam concrete, dry shrinkage can be prevented, and the like.

Owner:江苏德智重工有限公司 +1

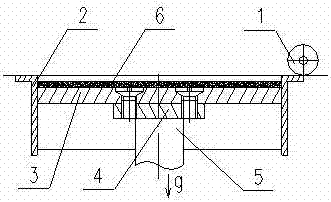

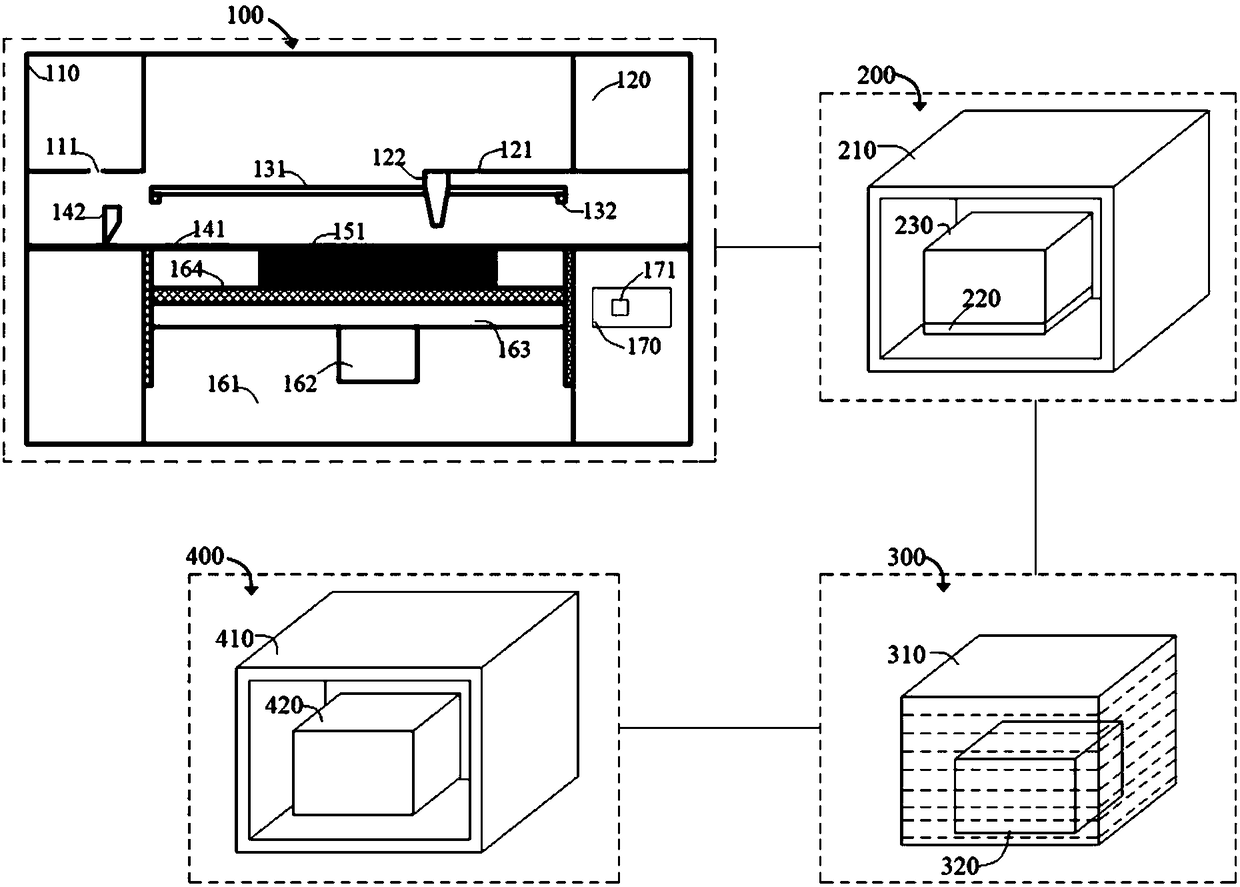

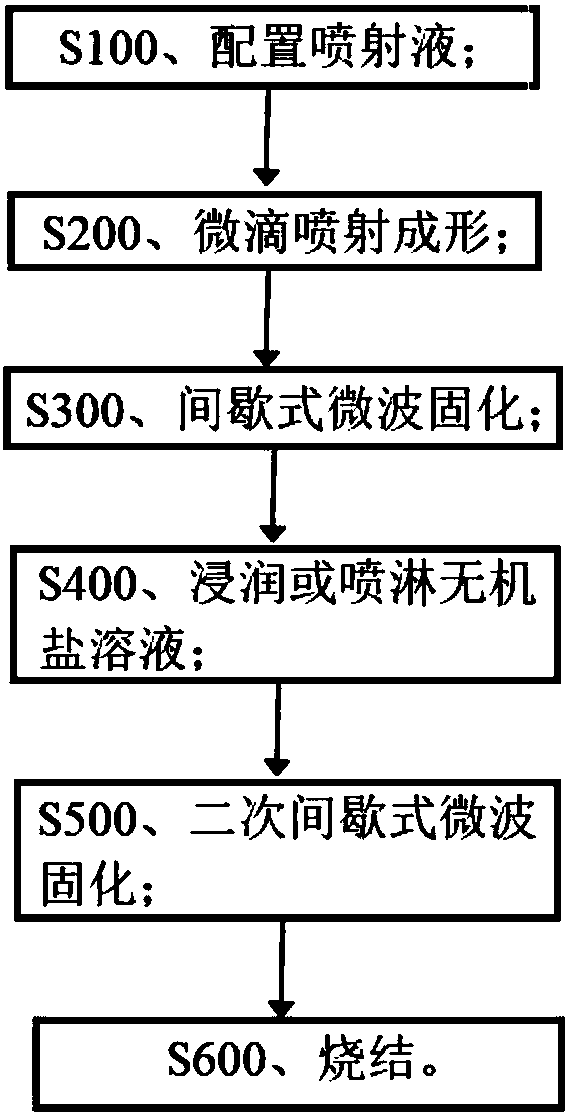

Microwave curing moulding system of water-soluble moulding core

ActiveCN108339942AAvoid scratchingGuaranteed StrengthFoundry mouldsMoulding machinesWater solubleMicrowave curing

The invention discloses a microwave curing moulding system of a water-soluble moulding core and belongs to the technical field of casting. The microwave curing moulding system comprises a moulding sand spraying unit, a moulding core curing unit, a moulding core immersion unit and a moulding core sintering unit, wherein the moulding sand spraying unit comprises a liquid mixing bin, a liquid spraying device and a material spreading device. The liquid mixing bin is used for storing mixed spraying liquid. The material spreading device is used for spreading sand. The liquid spraying device sprays spraying liquid to spread moulding sand layer by layer in accordance with the layer thickness of 0.01-1mm. The spraying liquid enables the moulding sand to aggregate and to coagulate to a to-be-cured moulding core. The moulding core curing unit is used for conducting microwave heating for the to-be-cured moulding core to cure the to-be-cured moulding core to a cured moulding core. The moulding coreimmersing unit is used for immersing the cured moulding core. The moulding core sintering unit is used for sintering the to-be-sintered moulding core. The microwave curing moulding system realizes moulding core fast producing without moulds. The moulding core curing unit adapts microwave heating realizing synchronous heating both interiorly and exteriorly. The intermittent microwave heating method enables inner layer water to be evaporated completely. Thus, the strength of the moulding core is ensured.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

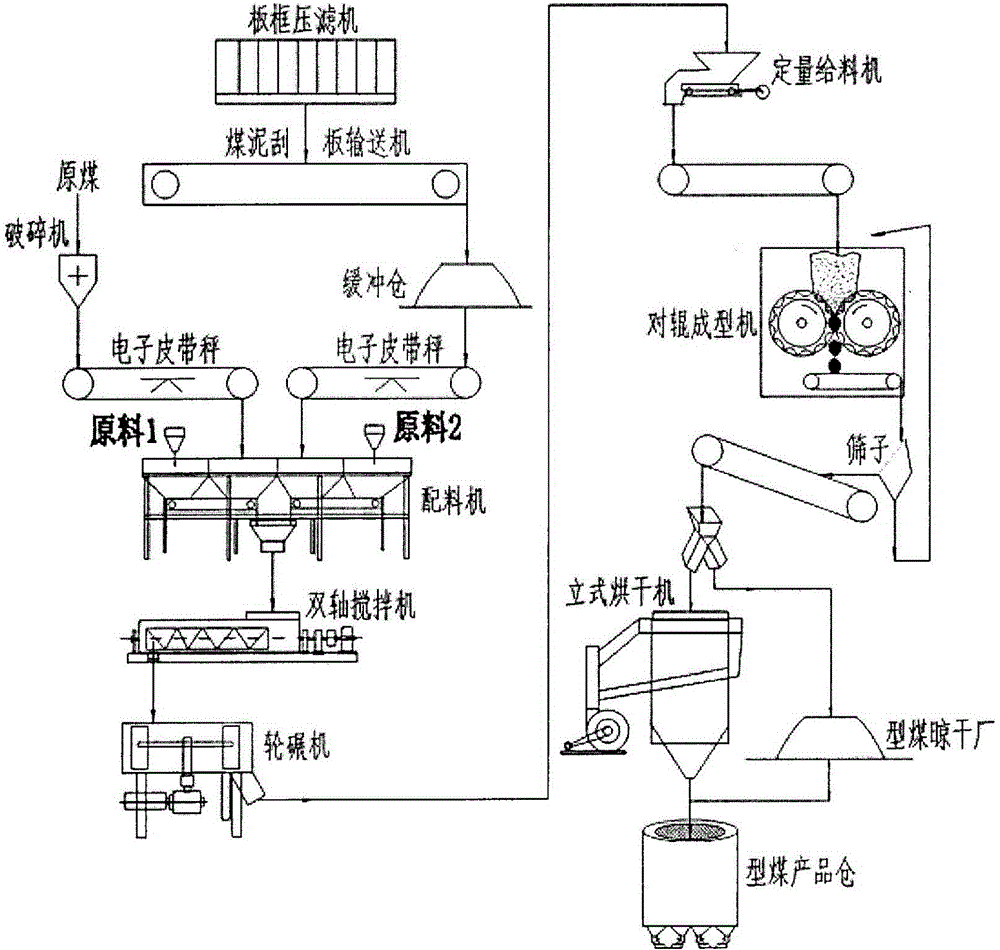

Process of directly forming and utilizing coal slime of coal cleaning plant

The invention discloses a process of directly forming and utilizing coal slime of a coal cleaning plant. The process comprises the following steps: directly transporting the coal slime from a filter-pressing workshop of the coal cleaning plant to a dosing machine; adding a certain amount of raw coal and an adhesive in percentage by mass; adopting a double-roller forming machine or a screw extruder to form after stirring and uniformly mixing. According to the process disclosed by the invention, the filter-pressing coal slime is not needed to be dried, and can be directly transported to a forming site, so that the coal slime is prevented from occupying land and being polluted. The forming process is simple, a briquette coal product is good in mechanical strength, so that the calorific value of the coal slime briquette coal can be adjusted by matching with the raw coal, and therefore, the use requirements of different users are satisfied. The process disclosed by the invention can be used for effectively solving the problems that the coal slime of the coal cleaning plant is in excess of demand, occupies land, and is polluted.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com