Detachable reactive polyurethane hot melt adhesive used for bonding of mobile phone frames and preparation method of adhesive

A hot-melt adhesive and mobile phone frame technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the difficulty of bonding mobile phone frames, increase the difficulty of bonding, waste raw materials, etc. problem, to achieve the effect of high bond strength, short holding time and smooth dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 18.7 parts of polyether polyol, 44.8 parts of polyester polyol, 13.1 parts of acrylic resin, 3.3 parts of tackifying resin, 2.2 parts of TPU, and 0.1 part of phosphoric acid agent into the reactor and heat it to 140°C. Dissolve completely, stir evenly, vacuum and dehydrate, heat and vacuum for 60min, keep the vacuum at -0.1Mpa; cool down to 110℃, vent with nitrogen, add 15.1 parts of pure MDI, keep at 120℃ for 80min, add DMDEE0.2 after nitrogen vent And 2.5 parts of adhesion promoter, continue to keep the temperature at 120°C, react for 45min with the vacuum degree of -0.1Mpa, and then vent the material with nitrogen gas to obtain the removable reactive polyurethane hot-melt adhesive for bonding mobile phone frames.

Embodiment 2

[0040] Weigh 17.4 parts of polyether polyol, 40.6 parts of polyester polyol, 17.4 parts of acrylic resin, 4.6 parts of tackifying resin, 1.2 parts of TPU, and 0.1 part of phosphoric acid agent into the reactor, heat to 140℃, and wait for the solid materials in it Dissolve completely, stir evenly, vacuum and dehydrate, heat and vacuum for 60min, keep the vacuum at -0.1Mpa; cool to 110℃, vent with nitrogen, add 16.3 parts of pure MDI, keep at 120℃ for 80min, add DMDEE0.2 after venting with nitrogen 2. The adhesion promoter is 2.2 parts, the temperature is kept at 120℃, the vacuum degree is -0.1Mpa, and the reaction is 45min, and then the nitrogen is discharged to obtain the removable reactive polyurethane hot melt adhesive for the bonding of mobile phone frame.

Embodiment 3

[0042] Weigh 19.7 parts of polyether polyol, 38.8 parts of polyester polyol, 18.5 parts of acrylic resin, 3.8 parts of tackifying resin, and 0.1 part of phosphoric acid agent into the reactor, heat to 140℃, wait until the solid materials in it are completely melted, and stir evenly After vacuum dehydration, heat preservation and vacuum for 60min, the vacuum degree is kept -0.1Mpa; the temperature is reduced to 110℃, nitrogen is vented, 16.7 parts of pure MDI is added, 120℃ is kept and reacted for 80min, after nitrogen is vented, 0.2 part of DMDEE is added to promote adhesion Add 2.5 parts, continue to keep the temperature at 120°C, react for 45 minutes with a vacuum of -0.1Mpa, and then vent the material with nitrogen to obtain a removable reactive polyurethane hot-melt adhesive for bonding mobile phone frames.

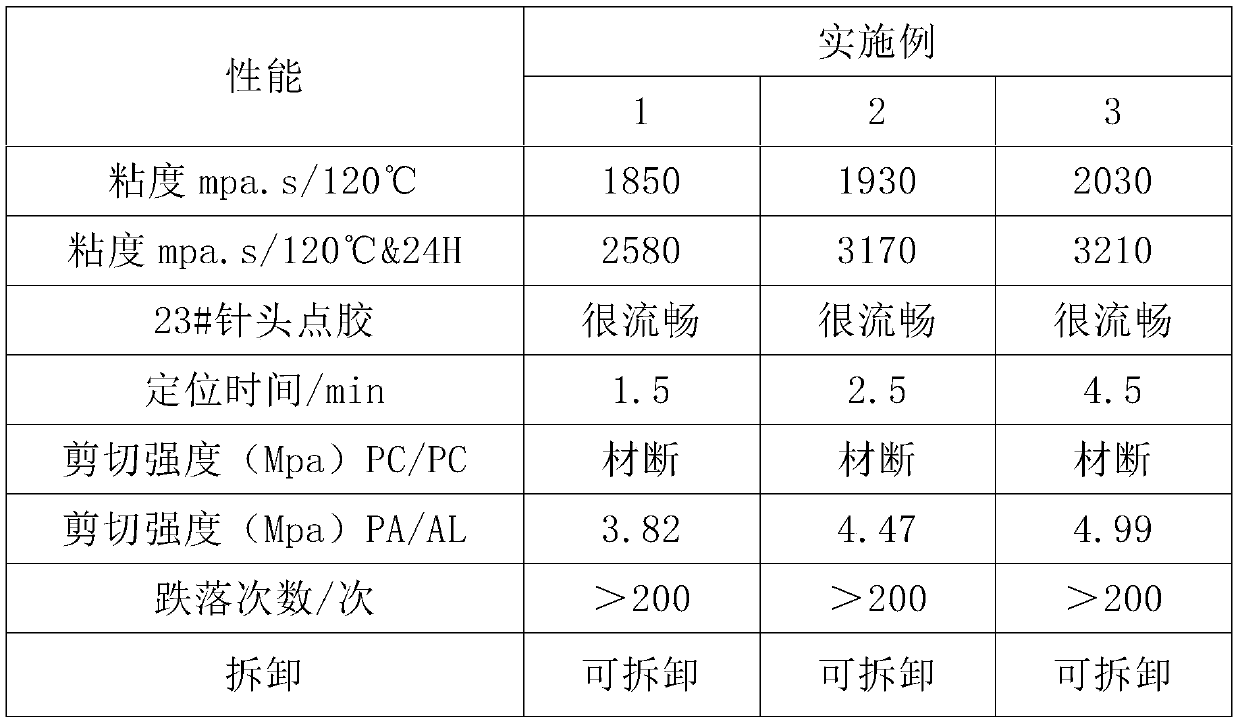

[0043] The test performance results in Examples 1 to 3 are shown in Table 1:

[0044] Table 1: Performance test comparison of detachable reactive polyurethane hot melt adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com