Patents

Literature

146results about How to "High initial bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

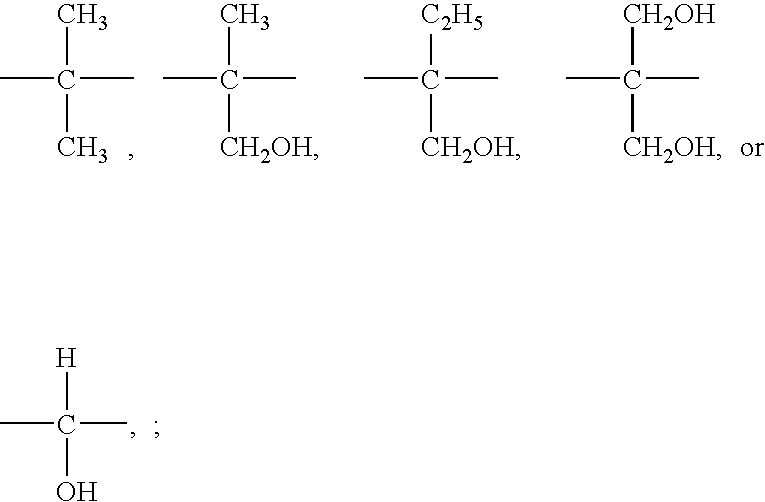

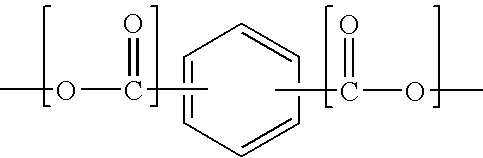

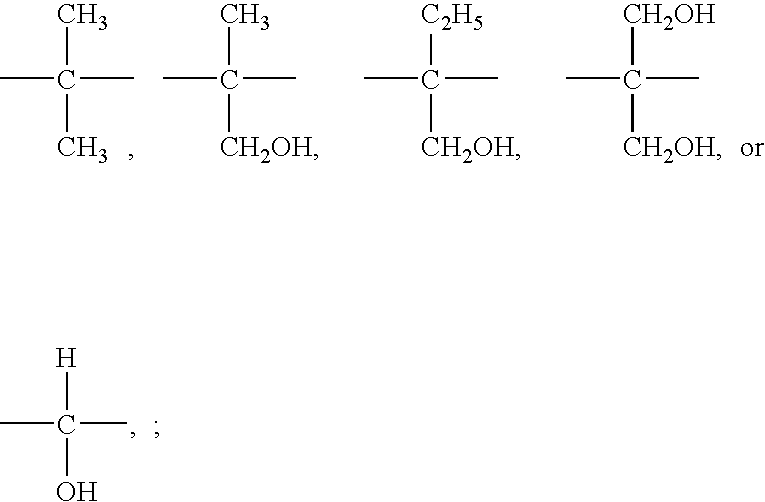

Polyester polyols for polyurethane adhesives

A polyester polyol prepared from a composition including a phthalic acid based material containing more than 10% by weight of ortho-phahalic or derivatives thereof, an aliphatic dicarboxylic acid (e.g., dodecanedioic acid), and a polyol (e.g., a glycol). A polyurethane adhesive, such as a polyurethane reactive hot-melt adhesive, is made using the polyester polyol, which exhibits improved initial bonding strength, shortened setting time, and ability to bond to low surface energy substrates such as ABS. The methods to prepare the polyester polyol and the polyurethane adhesive, and the method to use them are also disclosed.

Owner:OBRIEN MICHAEL E

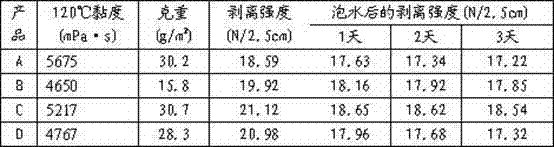

Boiling resistant polyurethane adhesive and method for preparing same

InactiveCN1629245AHigh bonding strengthHigh initial bond strengthPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

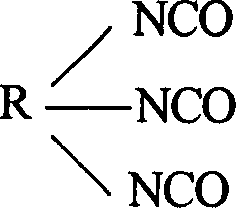

The invention discloses a boiling resistant polyurethane adhesive and method for preparing same, wherein the adhesive comprises by weight ratio 50-90% of main component and 10-50% of curing agent, the main component comprises (A) polyether polyol with hydroxyl value being 10-30mgKOH / g and (B) polyester polyol with hydroxyl value being 30-100mgKOH / g, the curing agent is polyisocyanate prepolymer. The adhesive can be applied for an intaglio gluing dry-type compounding machine.

Owner:广东国望精细化学品有限公司

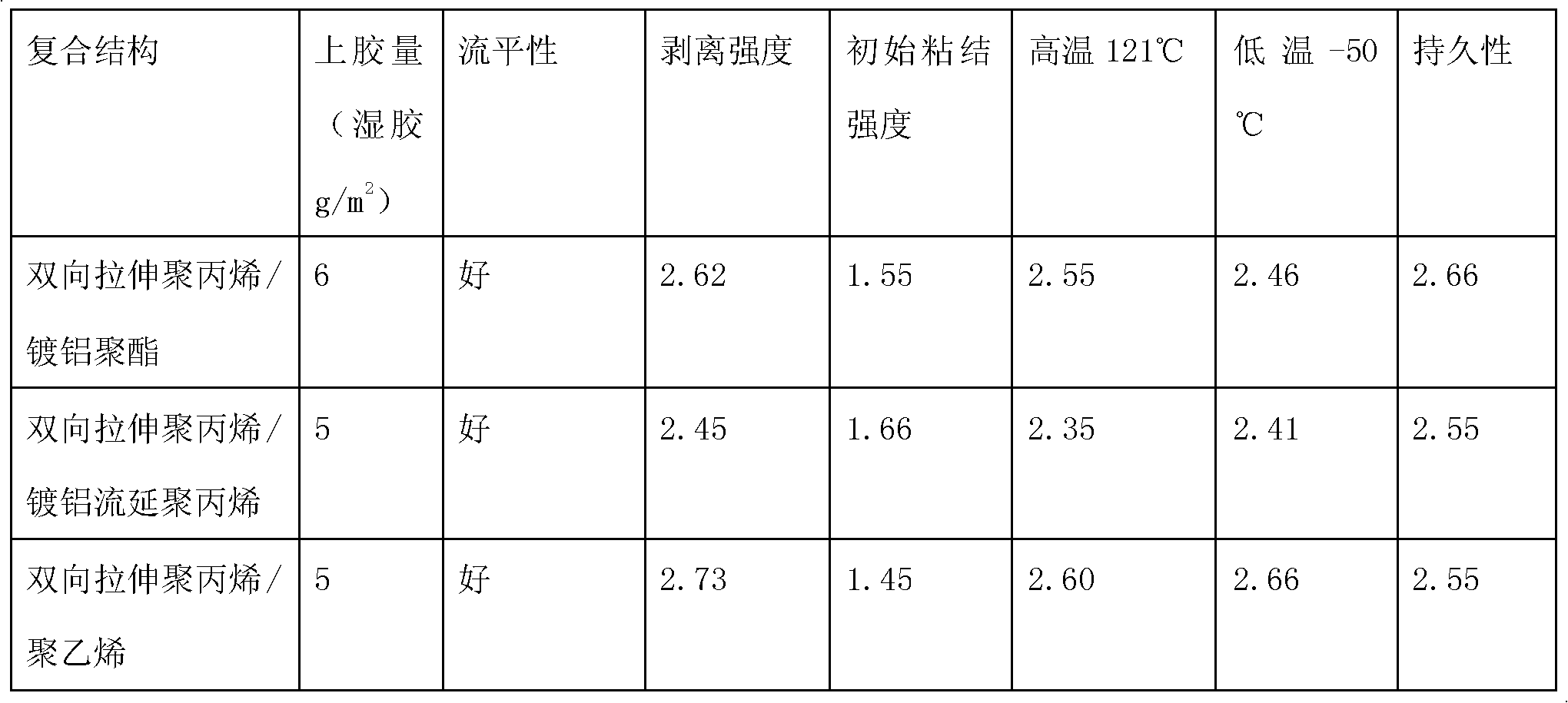

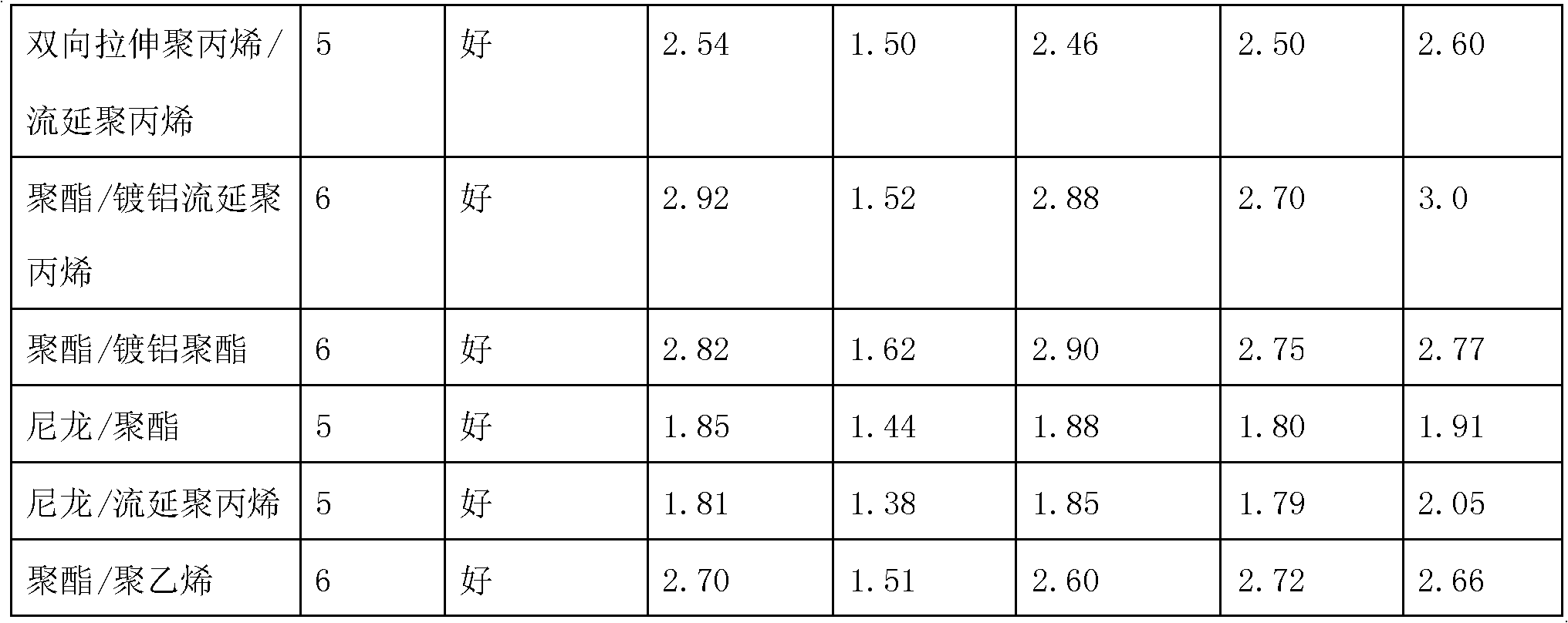

Water-based composite adhesive

InactiveCN102618193AHigh peel strengthGood high and low temperature resistanceEster polymer adhesivesCross-linkWater based

The invention discloses water-based composite adhesive, which contains acrylate emulsion and a cross-linking agent, wherein the weight of the cross-linking agent is 0.1-6 percent of the weight of the acrylate emulsion; the cross-linking agent is any one or a mixture of hexamethylenediamine and adipic acid dihydrazide; and the acrylate emulsion is formed by copolymerizing a terpenes hard monomer, a terpenes soft monomer, a terpenes carboxylic acid monomer, a terpenes functional monomer, a dual-vinyl monomer and a terpenes cross-linking monomer through nuclear shells under an emulsion system. The adhesive is particularly suitable for dry-type composite adhesion between flexible package composite base materials such as a plastic film and a vacuum aluminized film which are processed through corona; has good leveling, fast drying, high transparency, capability of curing at room temperature, high initial strength, excellent peel strength, difficulty in mesh clogging and skinning, wide adaptability and low cost; and can be applied to various machine types, does not contain any organic solvent, can replace solvent adhesive at present completely, and belongs to environment friendly adhesive.

Owner:GUANGDONG RONGYU INDAL

Adhesive, its preparation method and application method

ActiveCN102417804AHigh bond strengthImprove appearance performanceLaminationLamination apparatusSteel platesChemistry

The invention provides an adhesive, its preparation method and an application method. The adhesive contains a resin ingredient and a cured ingredient, wherein the resin ingredient contains a main resin, a flexibilizer and a filling material. The main resin contains a first epoxy resin and a second epoxy resin, wherein epoxy equivalent of the first epoxy resin is 150-300 and softening point of the second epoxy resin is 65-100 DEG C. The cured ingredient contains a normal-temperature curing agent. After the adhesive is coated on the surface of steel plates, the bonding strength between the steel plates is very high without the need of spot welding or riveting.

Owner:BYD CO LTD

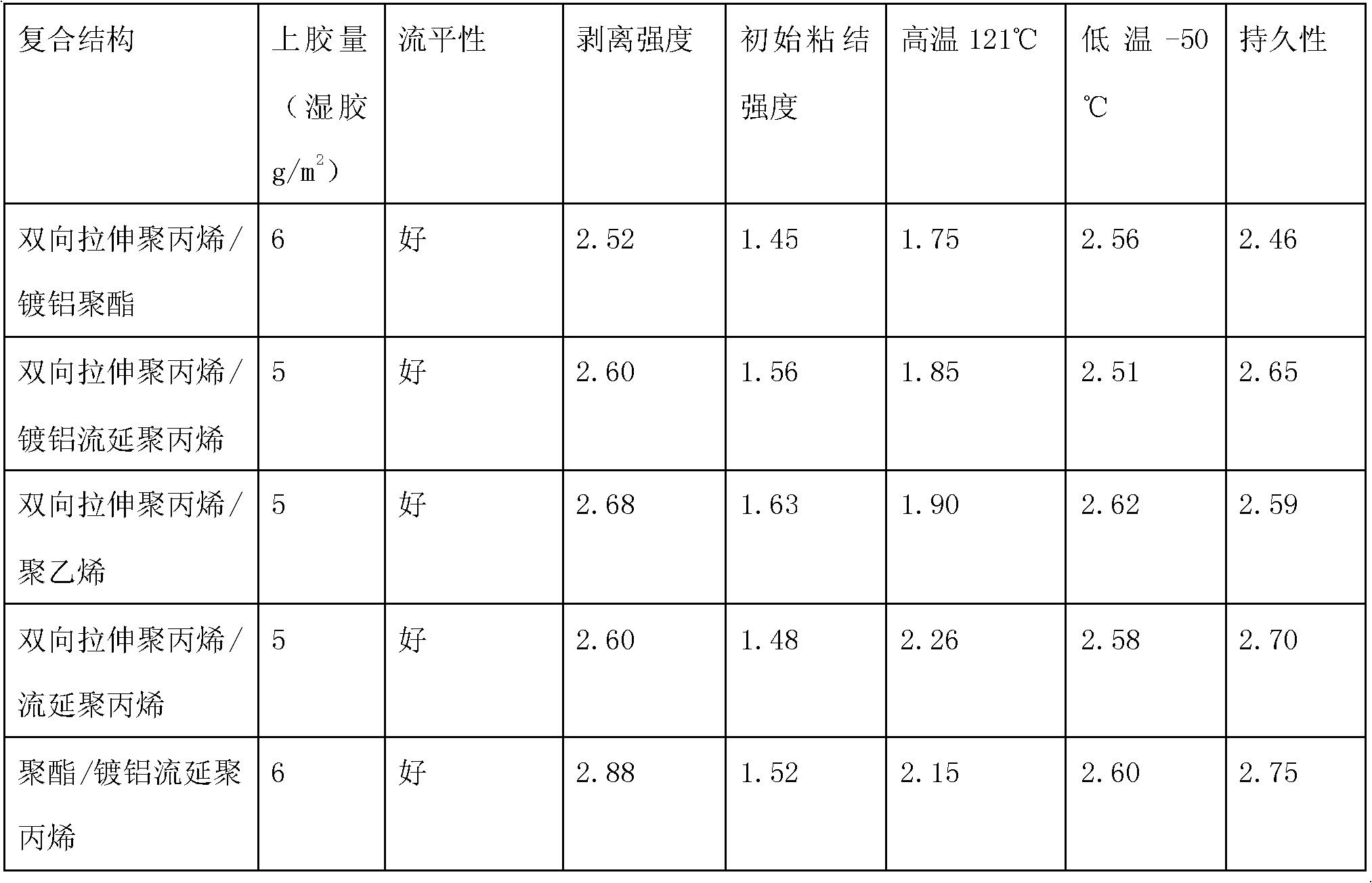

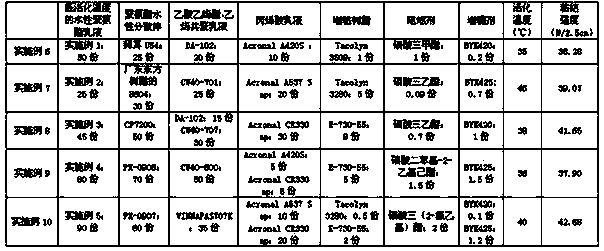

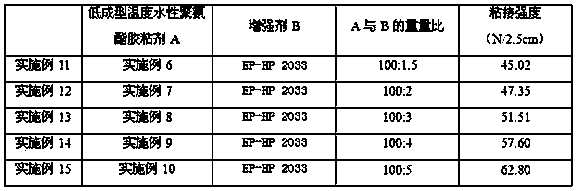

Low-molding-temperature waterborne polyurethane adhesive and preparation method thereof

ActiveCN104031596AImproved sag performanceReduce lossNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a low-molding-temperature waterborne polyurethane adhesive and a preparation method thereof. The low-molding-temperature waterborne polyurethane adhesive is prepared by matching a waterborne polyurethane dispersion, ethylene-vinyl acetate (EVA) emulsion, acrylic emulsion and the like based on low-activation-temperature waterborne polyurethane emulsion, wherein the low-activation-temperature waterborne polyurethane emulsion mainly consists of polyhydric alcohols, diisocyanate, a small molecule alcohol chain extender, a catalyst and a hydrophilic chain extender and has the activation temperature of less than 25 DEG C; the low-molding-temperature waterborne polyurethane adhesive prepared based on the low-activation-temperature waterborne polyurethane emulsion has the activation temperature of 30-60 DEG C, is high in bonding strength, is water-based emulsion, does not contain organic solvents or volatile organic compounds, is green and environment-friendly and can well meet the service requirements of adhesives for automobile roofs. The low-molding-temperature waterborne polyurethane adhesive also can be matched with a certain amount of enhancers, the bonding strength of colloid at the later stage is effectively improved, and the heat resistance of the roof at the later molding stage is guaranteed.

Owner:重庆中科力泰高分子材料有限公司

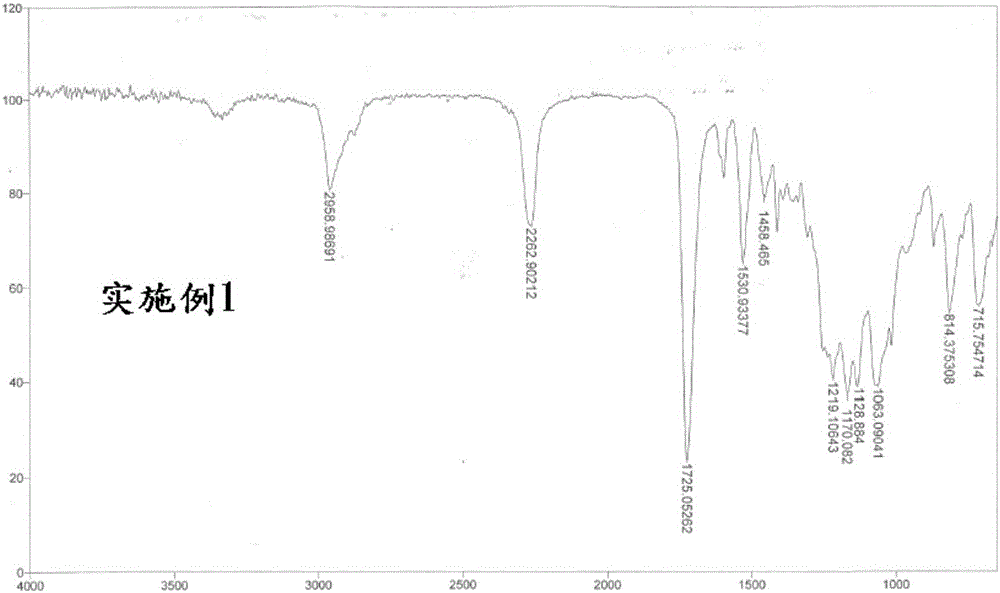

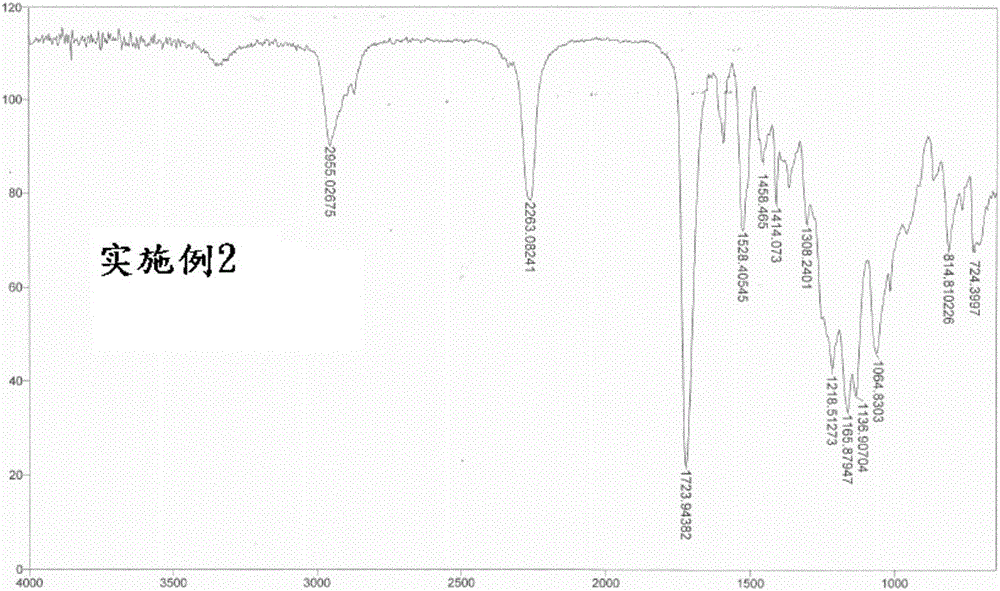

Preparation method of wet curing reaction-type polyurethane hot melt adhesive for textile

ActiveCN103497725AHigh initial bond strengthGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method of a wet curing reaction-type polyurethane hot melt adhesive for a textile. The preparation method mainly comprises the following steps: (1) stirring and mixing polyether polyol 4000E, polyether polyol 3000H and an antioxidant, heating and warming to about 120 DEG C, dewatering for 0.5 hour when the vacuum degree is smaller than 100Pa; (2) adding a tackifying resin, continuing to warm to 135-140 DEG C, dewatering for 1.5 hours when the vacuum degree is smaller than 100Pa; (3) cooling to 87 DEG C, adding 4,4'-diphenyl methane diisocyanate and a catalyst, stirring and reacting for 2 hours when the vacuum degree is smaller than 100Pa; (4) relieving a vacuum state, adding white carbon black, quickly stirring and evenly mixing, and continuing to stir for 10 minutes when the vacuum degree is smaller than 100Pa; and (5) keeping the discharge temperature at 85-100 DEG C, quickly discharging and encapsulating, and then curing for 4 hours under the condition of 80-85 DEG C, so as to obtain a target product. The product is applied to compounding of the textile, and has excellent peel strength, short opening time, good hydrolysis resistance and good storage stability.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

High-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and preparation method thereof

InactiveCN111849408AExtended opening hoursHigh initial bond strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a high-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials inparts by weight: 20-50 parts of polyether polyol, 10-40 parts of crystalline polyester polyol, 5-30 parts of liquid polyester polyol, 10-20 parts of polyisocyanate, 10-35 parts of thermoplastic acrylic resin, 2-15 parts of tackifying resin, 0.1-0.5 parts of a catalyst and 0.1-1 part of an antioxidant. The moisture-curable polyurethane hot melt adhesive provided by the invention has the advantagesof long opening time, high initial adhesion strength, high curing speed, higher final adhesion strength, favorable damp-heat resistance and favorable high / low-temperature impact resistance, and can achieve the goals of no pressure maintaining and high-efficiency production of electronic products.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD +3

Formula of adhesive agent for aircraft tire renewing

ActiveCN101200625AHigh adhesion retentionMeet performance requirementsNatural rubber adhesivesSulfurGasoline

The present invention discloses a prescription of an adhesive used for an aircraft tire retreading. The adhesive considers caoutchouc as the main material and also contains the main auxiliary materials of styrene butadiene rubber, adhesion promoter, adhesive, high abrasion furnace black, high dispersion white carbon black, ketoamine age inhibitor, indiscerptible sulfur and sulfenamide accelerant. The main material and the main auxiliary materials are made into gross rubber according to certain weight portion ratio, and the gross rubber is mixed with gasoline by certain proportion to be made into the adhesive. The adhesive of the prescription has the advantage that the adhesive solves the problem of sticking an old tire body with a retreading component when the aircraft tire is retreaded, which ensures that the aircraft tire does not have the problem of the delamination of the glue material between the old tire body and the retreading component, bulging and other quality problems during the use course, and the tire is safe for using.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Method for preparing high solid content aqueous polyurethane emulsion by continuous process

The invention provides a method for preparing water-borne polyurethane emulsion with high solid content by the continuous method. The method comprises the following steps that: oligomer polylol after vacuum dehydration, isocyanate, a chain extender, a solvent and a catalyst are added into a reactor at a time under the protection of dry nitrogen; the mixture is mechanically stirred and simultaneously controlled at a certain temperature for reaction to a certain degree; the system temperature is reduced to between 20 and 50 DEG C; the hydrophilic chain extender is slowly dripped into a prepolymer which is then added with the solvent so as to prevent gel coagulation caused by overlarge viscosity; the isocyanate-based NCO content in the prepolymer which is generated through reaction is not changed again; and the prepolymer is added with water again to perform emulsion dispersion and undergoes vacuum distillation to remove the solvent, and then the water-borne polyurethane solution is prepared. The water-borne polyurethane solution prepared by the method has high solid content, low viscosity, large initial bonding strength, and good heat resistance, can be used as textile fabric coating agent, shoe coating agent, leather finishing agent, and adhesives used in the fields of wood, architecture, automobile, paper-making, electronics and so on.

Owner:ANHUI UNIVERSITY +1

Synthetic method of waterborne polyurethane adhesive

ActiveCN105400481ARaw materials are easy to getLow costPolyureas/polyurethane adhesivesDispersion stabilityPolyurethane adhesive

A synthetic method of waterborne polyurethane adhesive is as below: reacting dehydrated polyol, an ionic group-containing diol chain extender and diisocyanate in a reactor, then adding a solvent 1 and a catalyst, continuing the reaction, then adding castor oil or modified castor oil and a solvent 2, reacting, adding a neutralizing agent for neutralization to obtain the intermediate, adding a sulfonic acid group-containing diamine chain extender to the intermediate, stirring, then adding deionized water, uniformly dispersing, then adding an aqueous solution of small molecule diamine chain extender, reacting, removing the solvent under vacuum to obtain a milky white waterborne polyurethane dispersion liquid, and preparing glue by using the milky white aqueous polyurethane dispersion liquid, a thickener, a curing agent and a substrate wetting agent to obtain the waterborne polyurethane adhesive. The waterborne polyurethane adhesive provided by the present invention has the advantages of high solid content, good dispersion stability, high initial bonding strength and good resistance to damp-heat aging.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Aqueous silylated urethane compositions, aqueous adhesives for wrapping, and aqueous contact adhesives

InactiveUS20060183845A1Improve securitySatisfactory tackinessPolyureas/polyurethane adhesivesWater basedCarbamate

A water-based silylated urethane composition is used as a water-based adhesive that has high safety, develops satisfactory tackiness in a short time and has excellent initial bond strength. The water-based silylated urethane composition contains following Components (A), (B) and (C): (A) a urethane prepolymer containing an anionic group and a tertiary amino group and having a terminal alkoxysilyl group, the urethane prepolymer (A) being a reaction product of an anionic-group-free polyol compound (A1), an anionic-group-containing polyol compound (A2), a compound (A3) containing a tertiary amino group and an isocyanate-reactive group, a polyisocyanate compound (A4), an alkoxysilane compound (A5) containing an isocyanate-reactive group, and an amine-based chain extender (A6); (B) a basic compound; and (C) water

Owner:KONISHI CO

Primer coating for polyurethane sealant and preparation method thereof

ActiveCN103113819AImprove bindingFast tack strengthPolyurea/polyurethane coatingsSilane compoundsPolyurethane adhesive

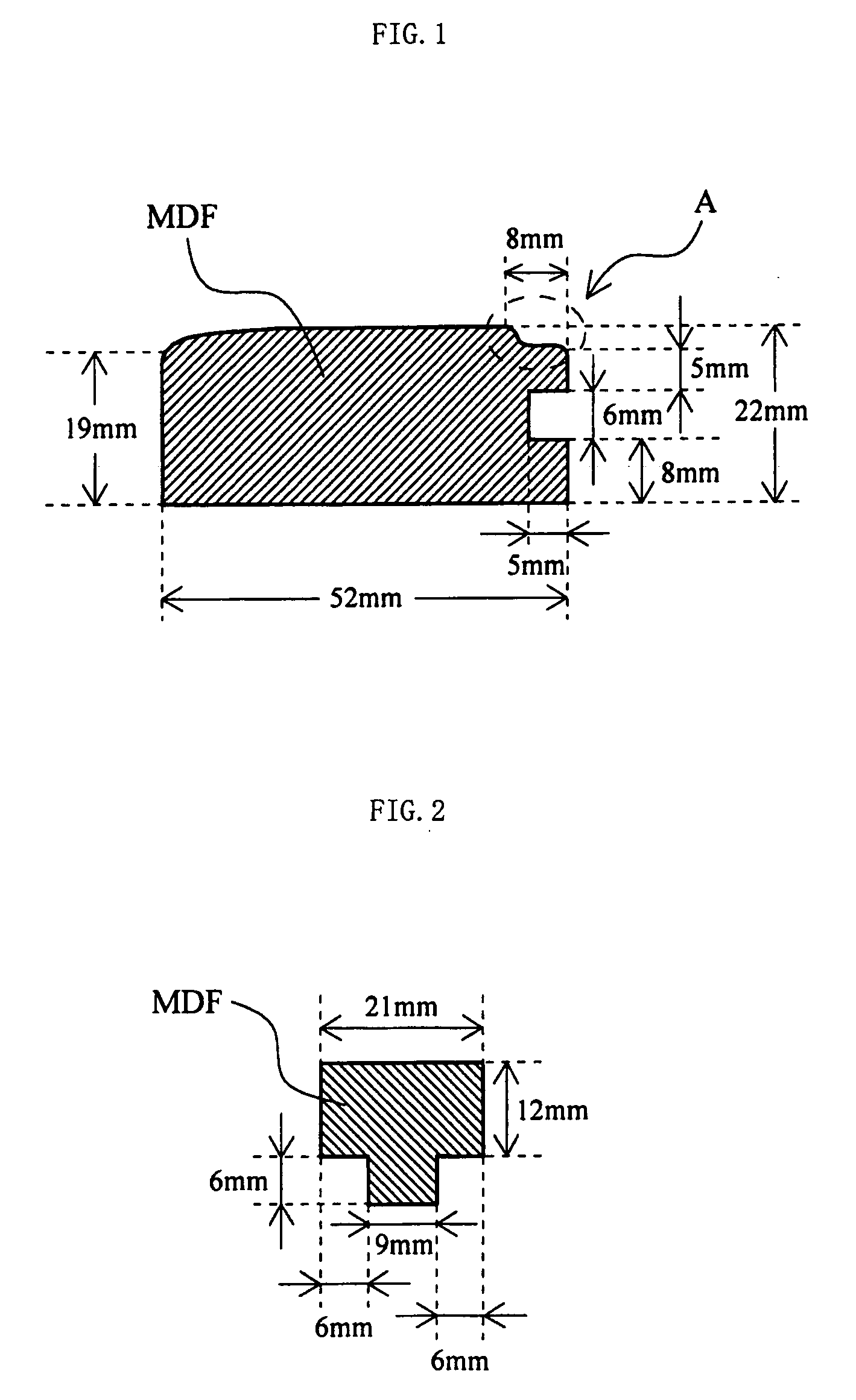

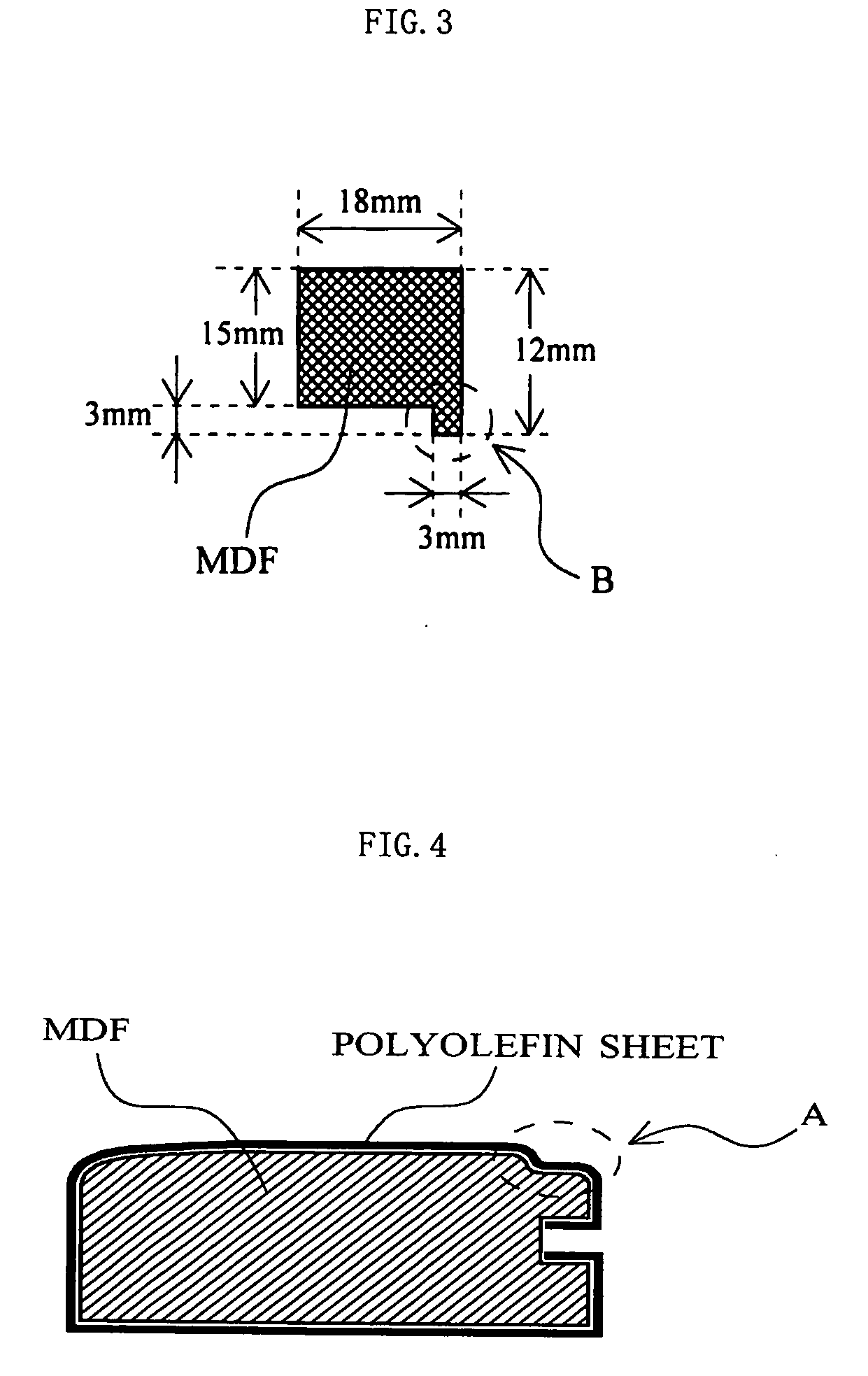

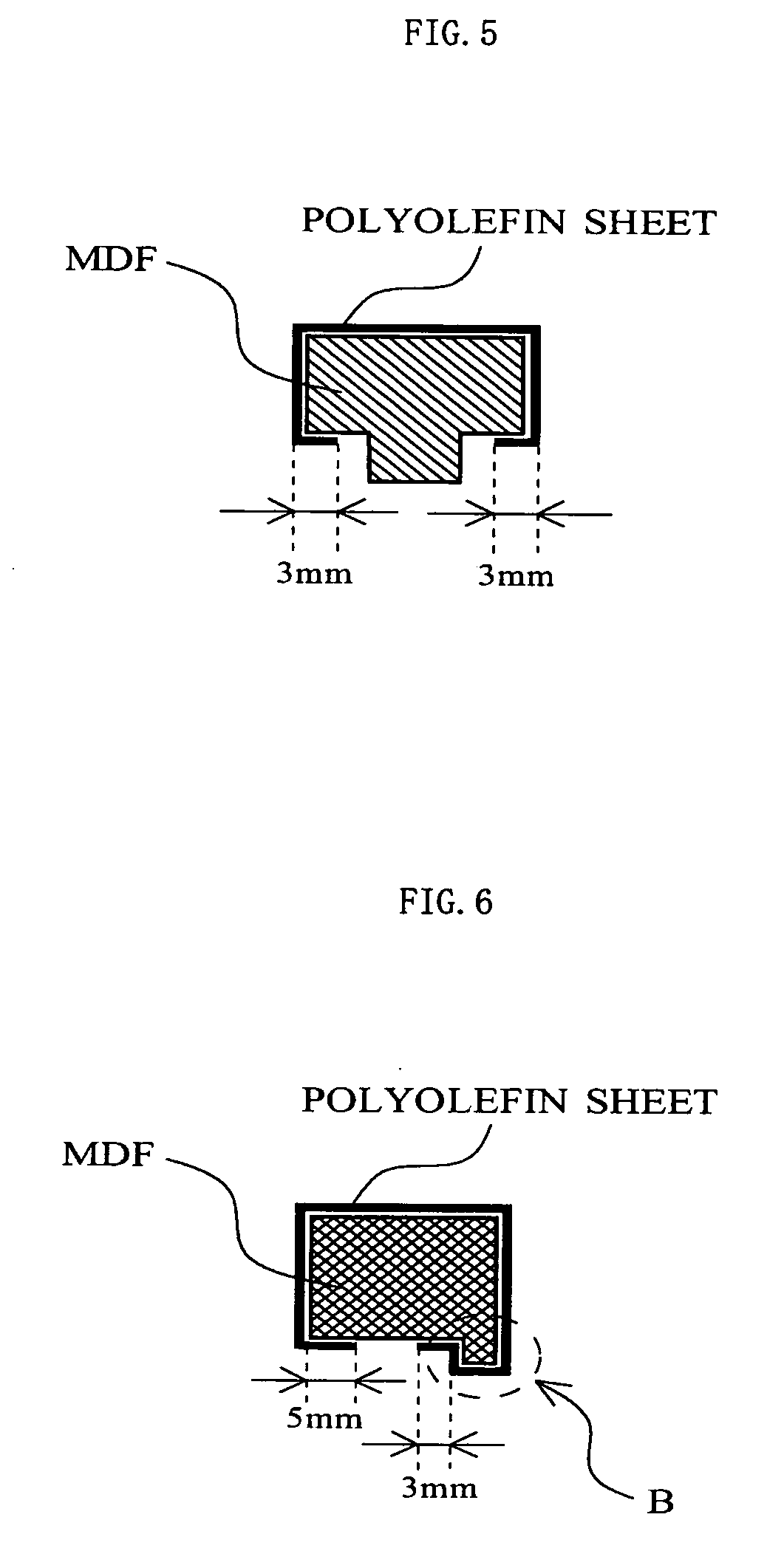

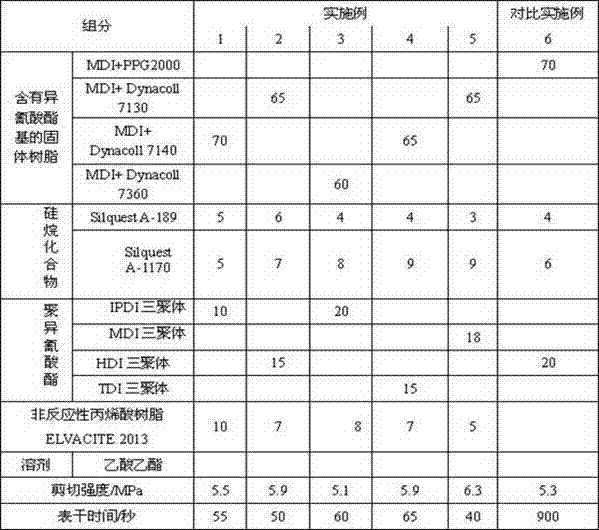

The invention discloses a primer coating for a polyurethane sealant, in particular relates to a primer coating with high initial adhesive strength for the polyurethane sealant and a preparation method thereof and belongs to the technical field of adhesives. The primer coating is prepared from the following raw materials: 50-70 parts of hard resin containing isocyanate groups, 5-15 parts of silane compound, 10-20 parts of polyisocyanate and 5-10 parts of non-reactive thermoplastic resin. The polyurethane primer coating prepared by the method has high initial adhesive strength for different base materials and is high in curing speed and firm in adhesion, the polyurethane adhesive / sealant can be coated without waiting, and the production efficiency of the automobile glass assembly line can be improved.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

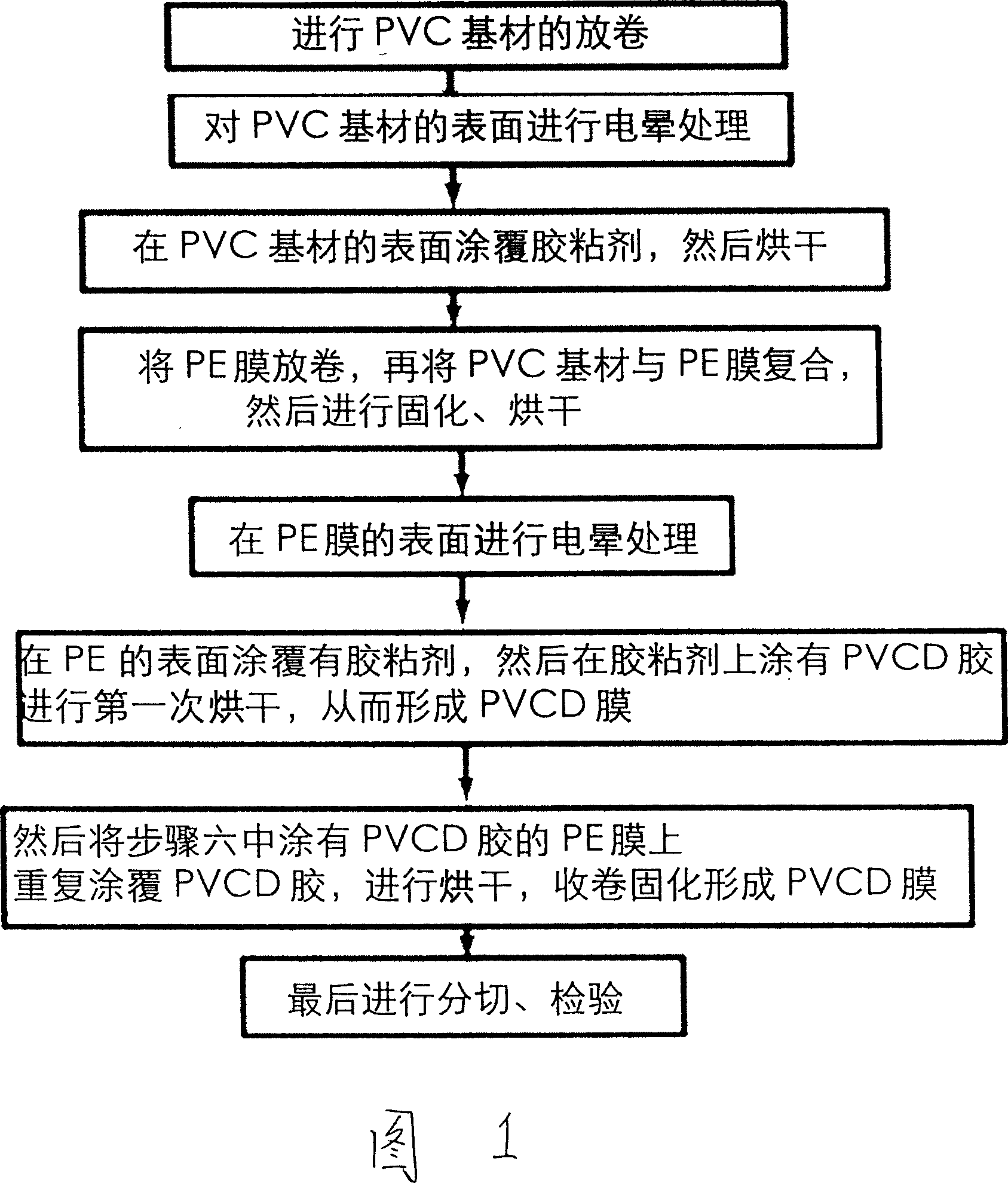

Technology for preparing high-separation, low solvent residue and low resolving-out matter PVC/PE/PVCD solid medicinal composite hard sheet

InactiveCN101024325ASolvent resistantUV resistantLamination ancillary operationsSynthetic resin layered productsManufacturing technologyAdhesive

The invention discloses PVC / PE / PVCD solid medicine using composite hard sheet manufacturing technology. It includes the following steps: unreeling for PVC basis material; corona treatment for its surface; coating adhesive; drying; unreeling for PE film; compositing the PVE basis material and PE film; solidifying; dying; corona treatment for the PE film surface; coating adhesive; coating PVCD glue; drying to form PVCD film; repeating coating the PVCD glue on the PE film; drying; rolling, solidifying to form PVCD film again; patting cut and detecting.

Owner:徐小圣

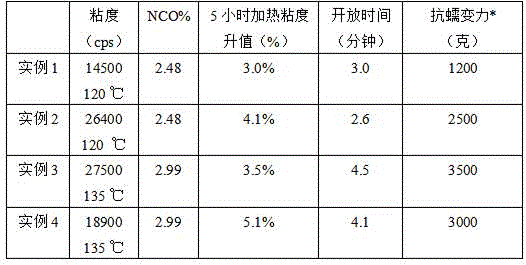

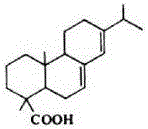

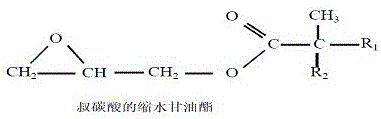

Hot-melt polyurethane adhesive with high initial adhesion and preparation method thereof

InactiveCN106496500AHigh initial bond strengthShort opening hoursPolyureas/polyurethane adhesivesPolyurethane adhesivePrepolymer

The invention provides a hot-melt polyurethane adhesive with high initial adhesion. The hot-melt polyurethane adhesive comprises, by weight, 70 to 90% of polyurethane prepolymer and 10 to 30% of an adhesion promoting agent, wherein the adhesion promoting agent is prepared through addition of rosin acid, one-component or two-component epoxy, and hydrogenated rosin or any cyclic compound with a carboxyl group or natural resin. The invention has the following unique beneficial effects: 1, the active adhesion promoting agent is produced through addition of natural resin or a related cyclic compound with the carboxyl group and epoxy for the first time, and is applied to the reactive polyurethane adhesive; and 2, the novel two-step preparation method has not been reported and used so far. The novel two-step preparation method can prepare a hot-melt polyurethane adhesive product with high initial adhesion without changing a formula for the hot-melt polyurethane adhesive. The hot-melt polyurethane adhesive product has creep resistance reaching the grade of 3, 500 g, and has superior heat stability. Due to high adhesive capability and arbitrarily-adjustable hot opening time of the product, the hot-melt polyurethane adhesive product can be applied to industrial places like the shoemaking industry and engineered floors with high requirements on initial adhesion.

Owner:佛山市顺德区巴德富实业有限公司

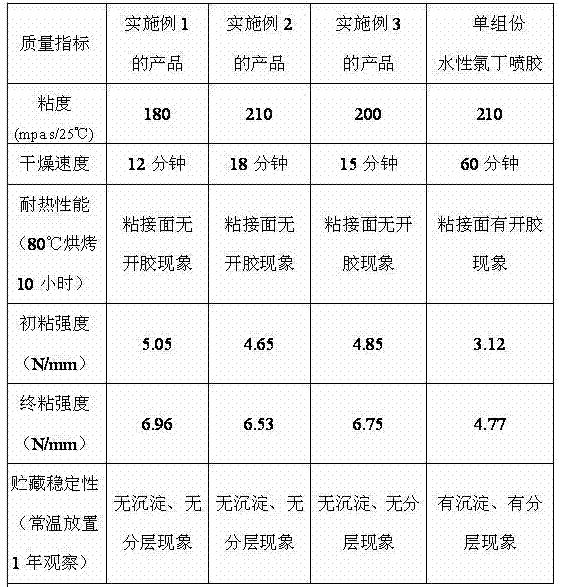

Double-component aqueous neoprene spray glue

ActiveCN103865439AHigh initial bond strengthImprove final bond strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesivePolymethyl methacrylate

The invention provides double-component aqueous neoprene spray glue, aiming at overcoming the defect of the existing aqueous neoprene spray glue. The double-component aqueous neoprene spray glue is characterized in that water is used as a solvent, the total volatile substances account for zero percentage, and the initial adhesive strength is high. The double-component aqueous neoprene spray glue is prepared by two steps: dissolving chloroprene rubber adhesive emulsion, polyurethane emulsion, polymethyl methacrylate emulsion, aqueous tackifying resin and zinc oxide to deionized water to obtain composite emulsion, and then adding aqueous tackifying resin, a stabilizer, a thixotropic agent and an ultraviolet light absorber to the composite emulsion to obtain the finished product of aqueous neoprene spray glue. In spraying, a water-based curing agent is added to the obtained finished product of aqueous neoprene spray glue and uniformly agitated, and the purpose of mixing and using is reached. The double-component aqueous neoprene spray glue has the advantages of being low in toxicity, green, environment-friendly, free of organic volatile substances, fast to dry, high in final adhesive strength, resistant to heat, convenient to construct, high in working efficiency, simple in production process, convenient in operation, and low in cost, and does not pollute the environment during production, so that the requirement on environment protection is met.

Owner:SHANDONG EVERGAIN ADHESIVE CO LTD

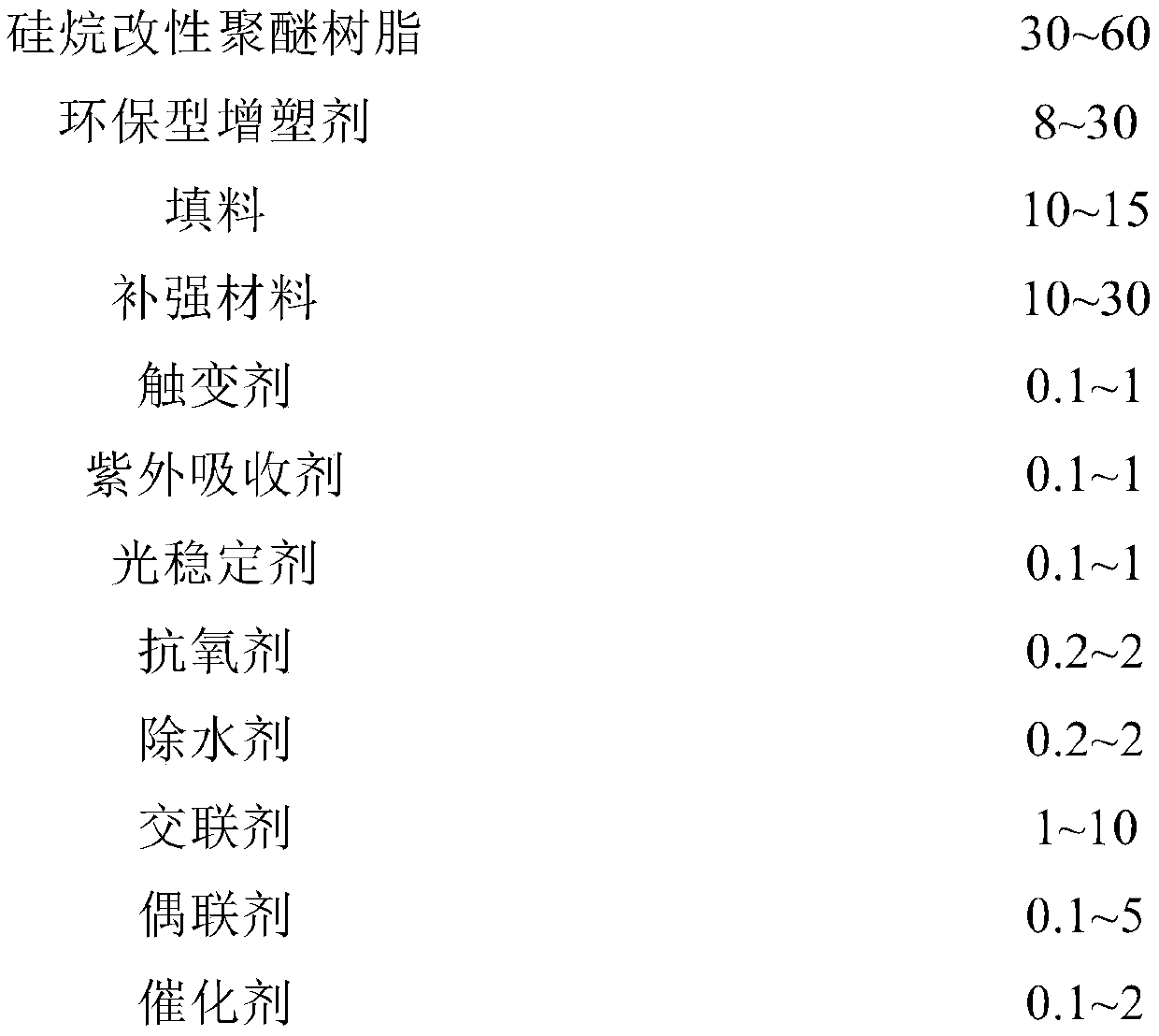

Single-component silane modified polyether sealant used in automobile glass rapid assembling, and preparation method thereof

ActiveCN110105907AQuick Bond PositioningSave operating timeNon-macromolecular adhesive additivesPolyether adhesivesTruckChemistry

The invention discloses a single-component silane modified polyether sealant used in automobile glass rapid assembling. The single-component silane modified polyether sealant used in automobile glassrapid assembling comprises, by weight, silane modified polyether resin of 30 to 60 parts; an environmentally friendly plasticizer of 8 to 30 parts; a filler of 10 to 15 parts; a reinforcing material of 10 to 30 parts; a thixotropic agent of 0.1 to 1; a UV absorber of 0.1 to 1 part; a light stabilizer of 0.1 to 1 part; an antioxidant of 0.2 to 2 parts; a water removal agent of 0.2 to 2 parts; a crosslinking agent of 1 to 10 parts; a coupling agent of 0.1 to 5 parts; and a catalyst of 0.1 to 2 parts. The invention also discloses a preparation method thereof. The sufficient bonding strength of the single-component silane modified polyether sealant is ensured, at the same time, the initial bonding strength of the single-component silane modified polyether sealant is ensured, high bonding speedis achieved, the single-component silane modified polyether sealant is safe, and is friendly to the environment, the bonding effect is excellent, and the single-component silane modified polyether sealant is suitable to be used for rapid assembling of windshield, skylight, and side window glass of vehicles such as passenger cars, delivery vehicles, fire fighting trucks.

Owner:GUANGZHOU JOINTAS CHEM

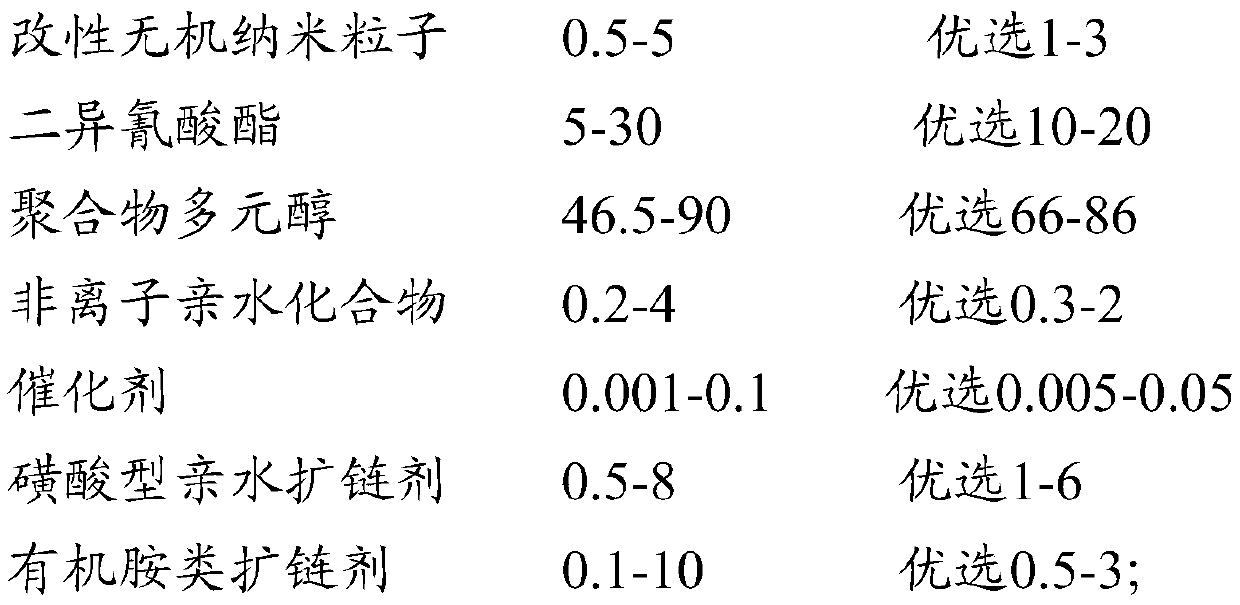

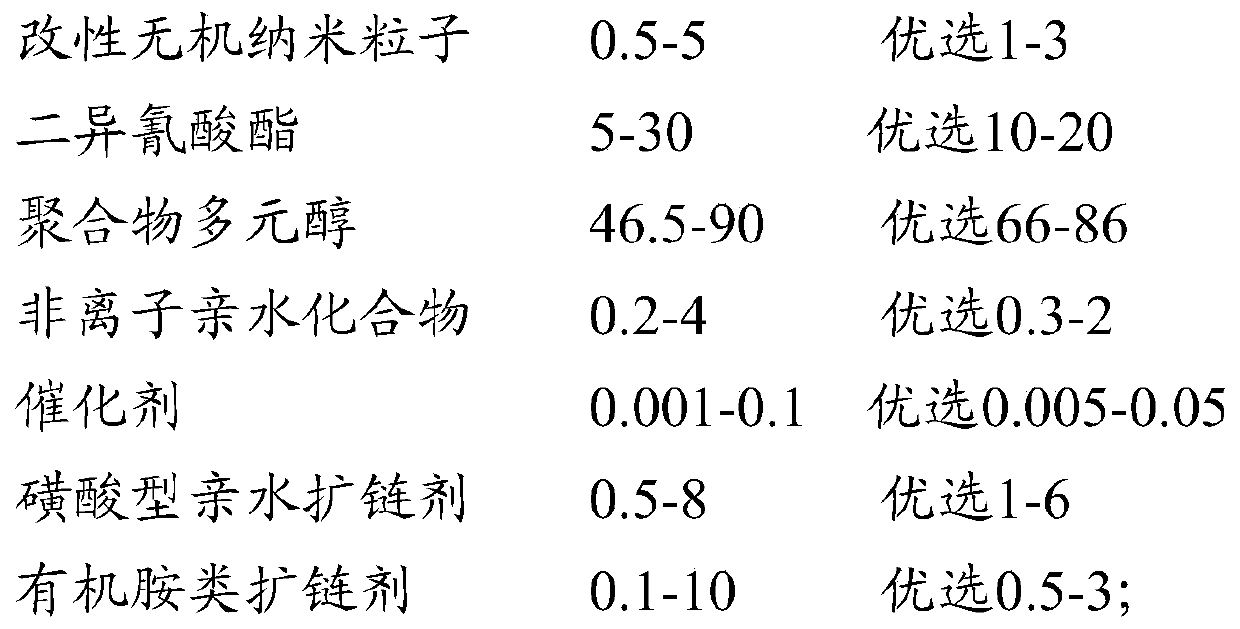

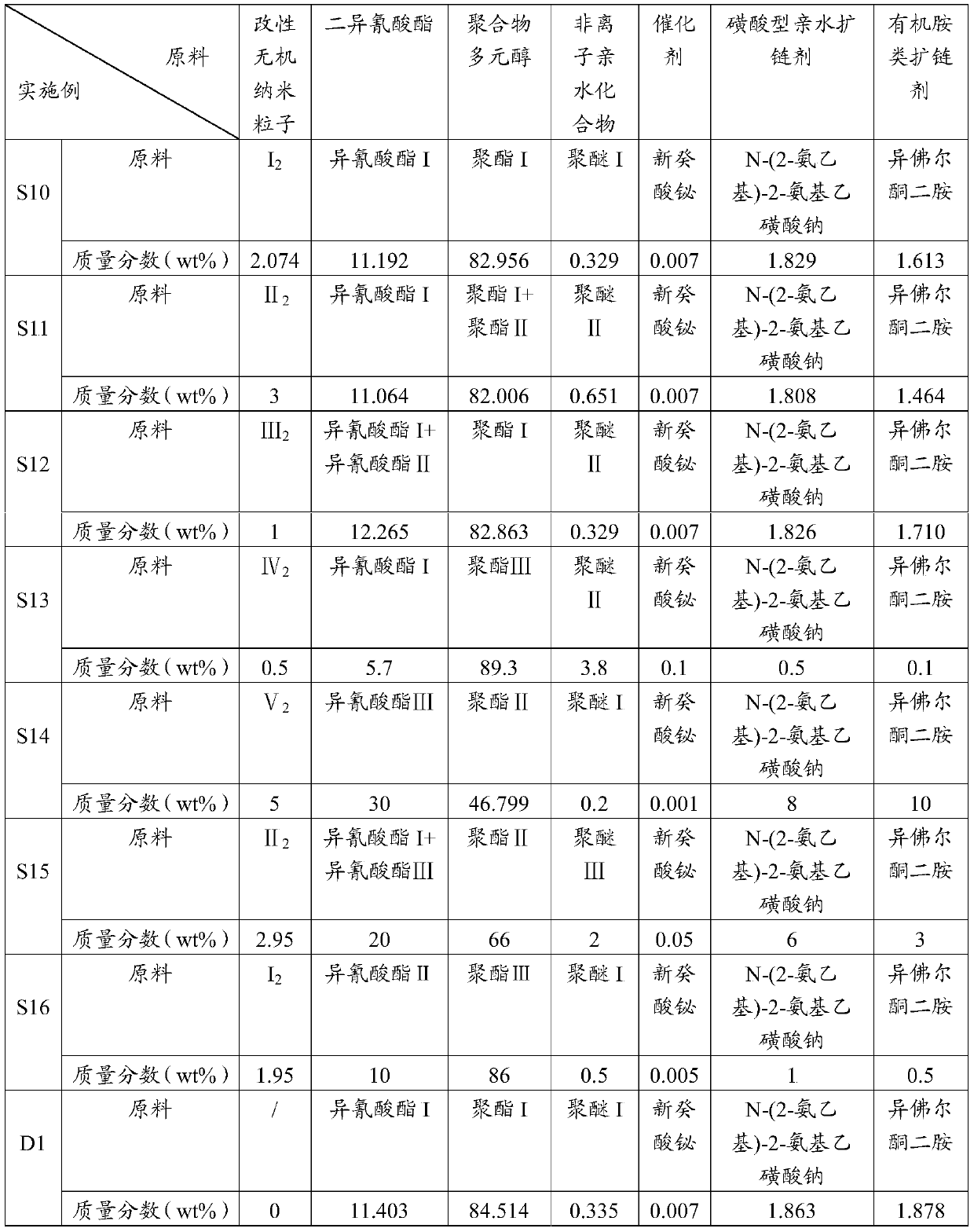

Modified inorganic nano particle, composite waterborne polyurethane resin and application thereof

ActiveCN109796631AImprove performanceTightly boundNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAlcoholHydrolysate

The invention provides modified inorganic nano particles, composite waterborne polyurethane resin, and a preparation method and application thereof. The preparation method of the modified inorganic nano particles comprises the following steps of: (1) preparing a fluorine-containing polyaminosilane coupling agent by using fluorine-containing acrylic acid and a polyaminosilane coupling agent; (2) preparing fluorine-containing polyamino silane coupling agent hydrolysate; (3) preparing dispersion liquid of the inorganic nano particles; (4) preparing the modified inorganic nano particles by using the dispersion liquid of the inorganic nano particles and the fluorine-containing polyamino silane coupling agent hydrolysate. The modified inorganic nano particle composite waterborne polyurethane resin is prepared by the reaction of the following substances: modified inorganic nano particles, diisocyanate, polymer polyhydric alcohol, a nonionic hydrophilic compound, a sulfonic acid type hydrophilic chain extender and an organic amine chain extender. The modified inorganic nano particles and the composite waterborne polyurethane resin thereof have good performance, simple preparation method and wide application.

Owner:WANHUA CHEM GRP CO LTD +1

Special glue for cigarettes

InactiveCN102391798AWater resistantHeat resistantMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesHeat resistanceEngineering

The invention provides special glue for cigarettes. The special glue for cigarettes comprises vinyl acetate, polyvinyl alcohol, dibutyl phthalate, a crosslinking agent Me-10, a copolymerization catalyst Zh-4 and water. The special glue for cigarettes provided by the invention has the characteristics of water tolerance, heat resistance, freezing resistance, high initial adhesive strength and the like. The special glue for cigarettes is applicable to the conventional different models of cigarette machines in China to serve as cigarette glue and can also serve as high-performance general milk-white glue.

Owner:陈瑜

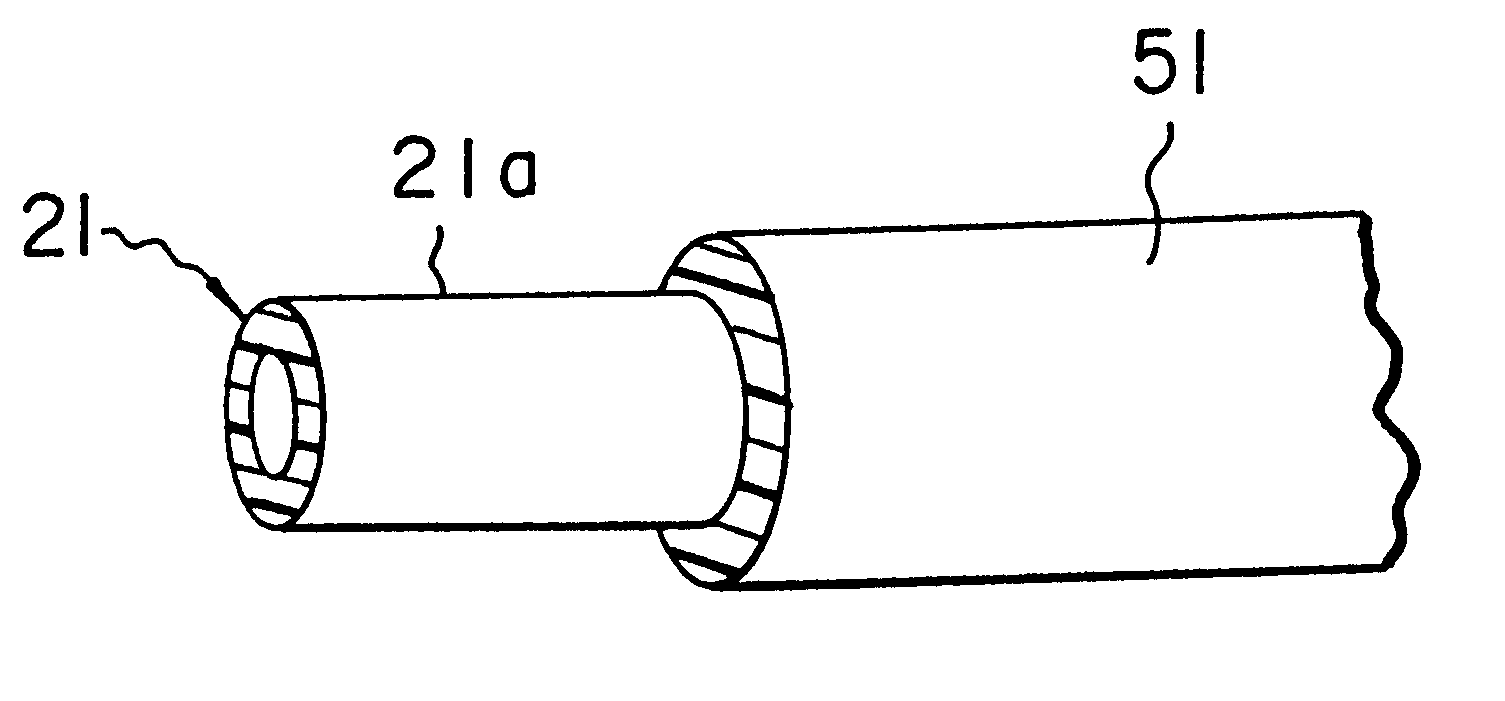

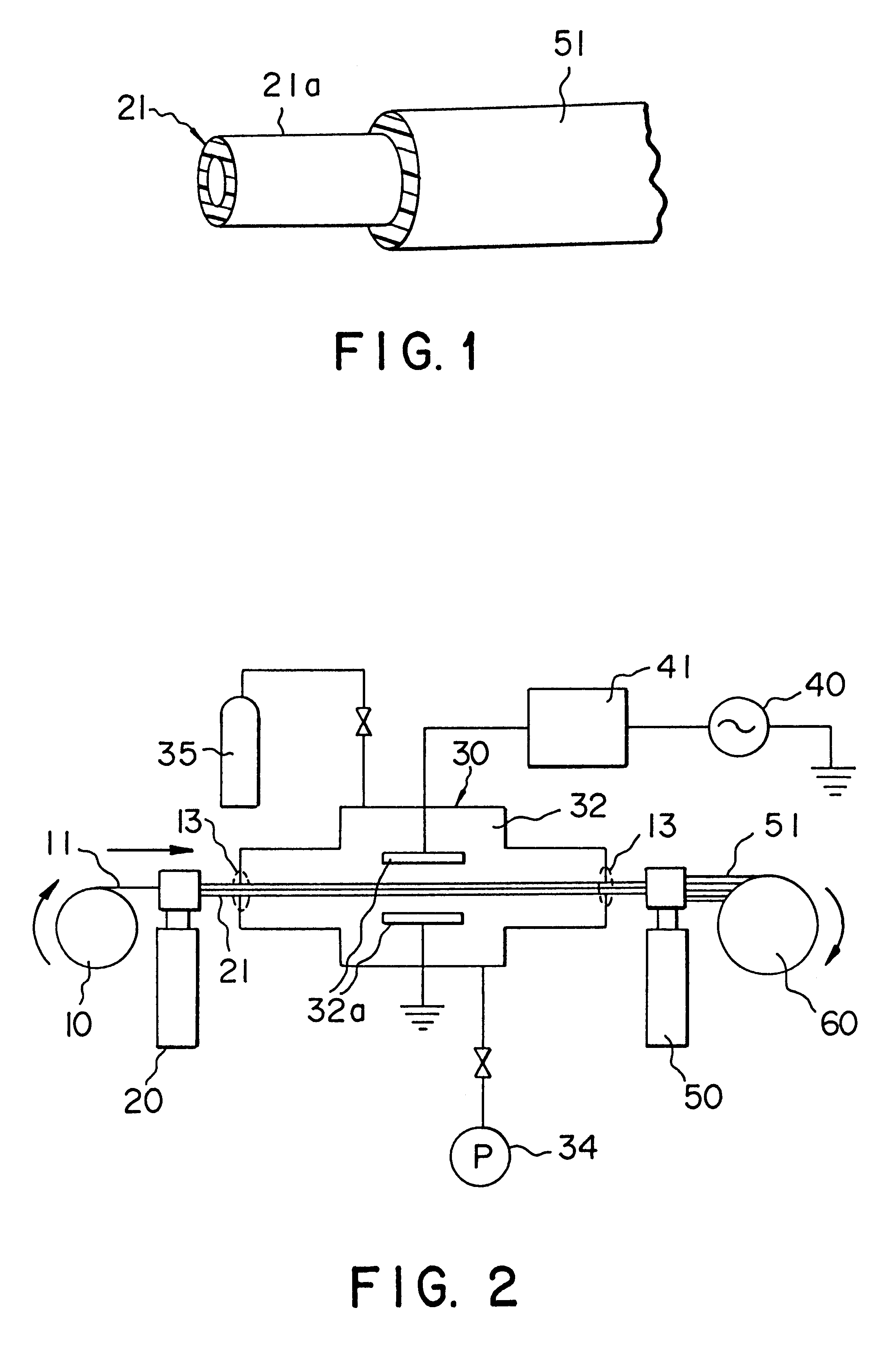

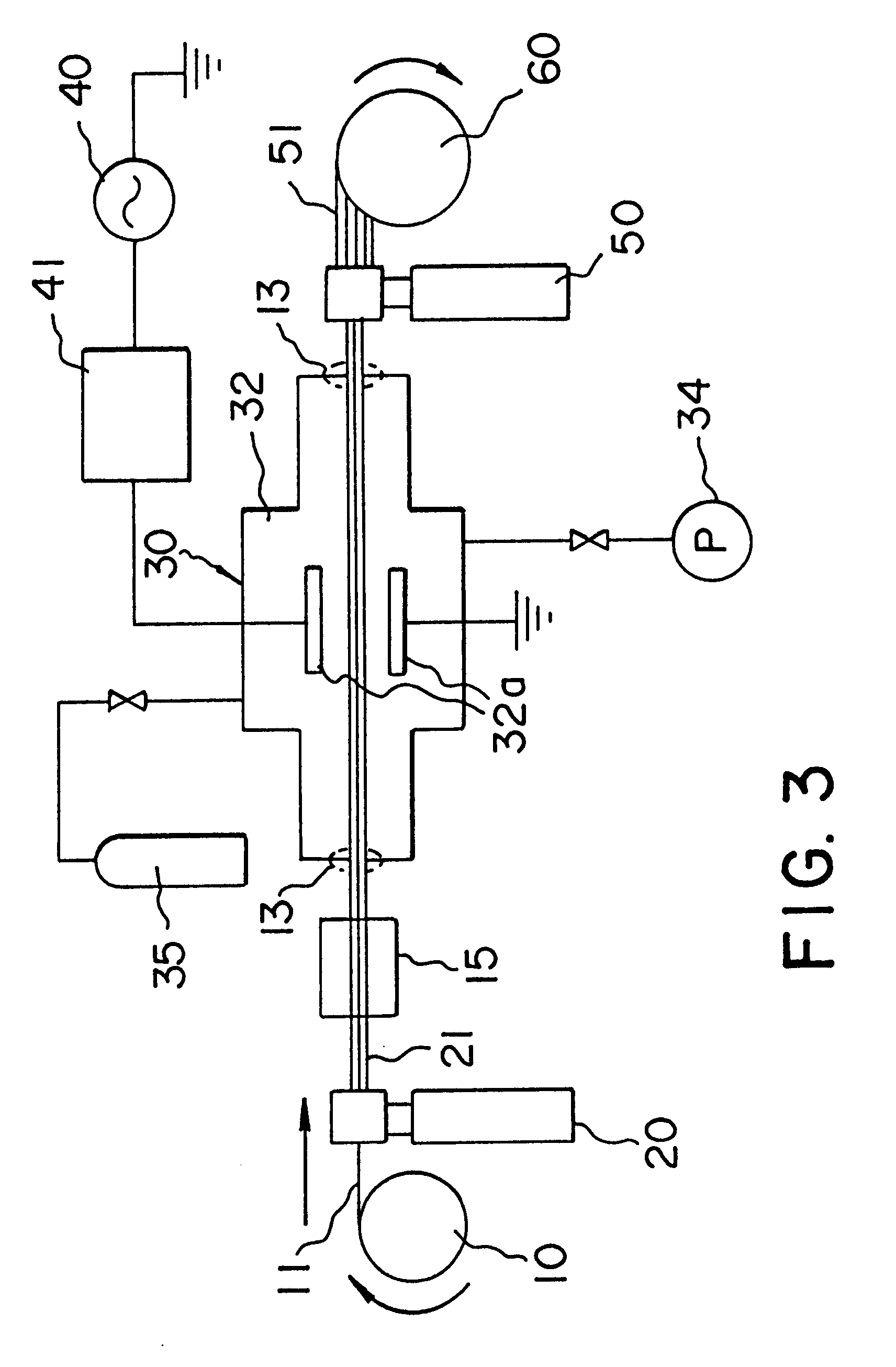

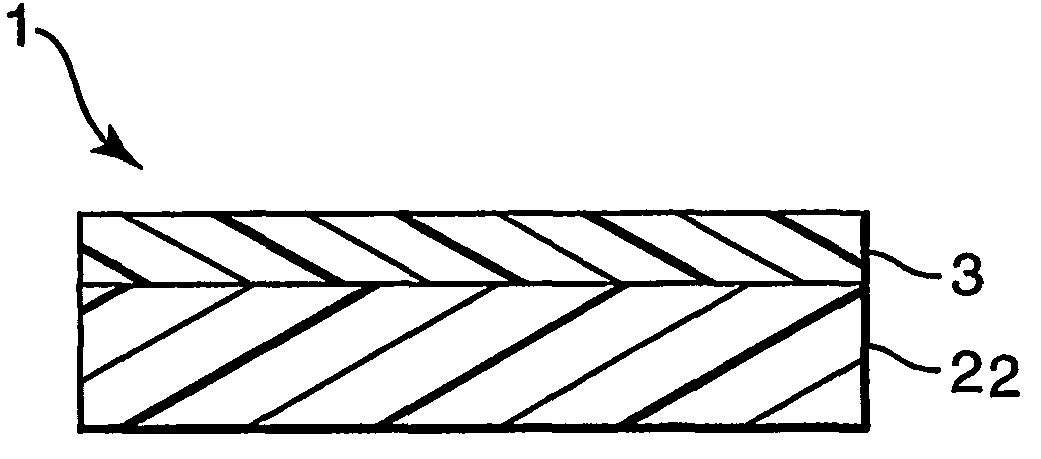

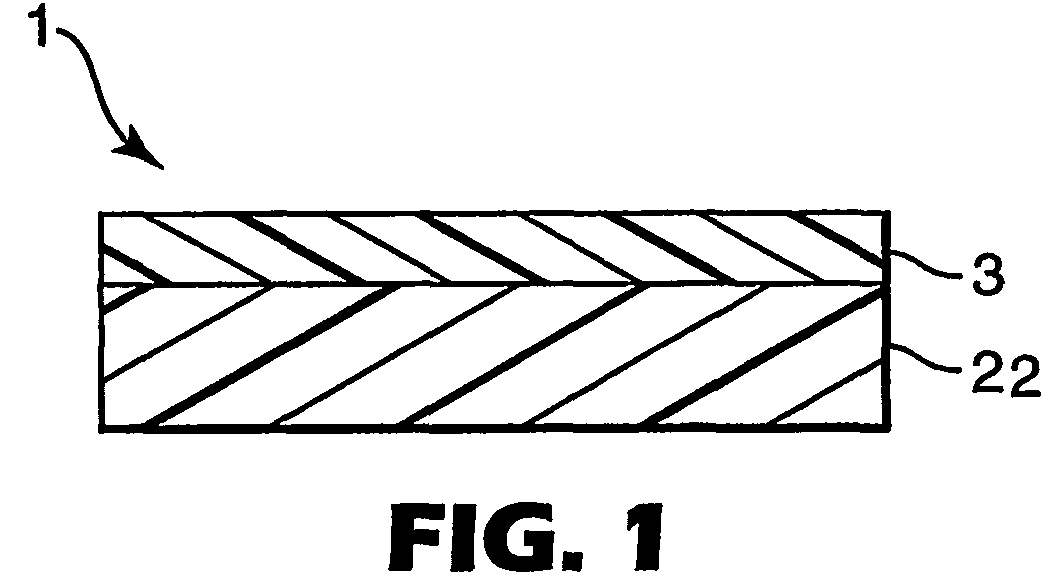

Fuel hose and method of its production

InactiveUSRE38087E1High initial bond strengthEasy to manufacturePreformed elementsCoatingsSurface layerEngineering

The fuel hose of this invention is a fuel hose comprising a tubular fluororesin inner ply and, as laminated onto the peripheral surface thereof, a thermoplastic resin or rubber outer ply, the tubular fluororesin inner ply having been molded from a fluororesin with an F / C ratio, i.e. ratio of the number of fluorine atoms (F) to the number of carbon atoms (C), of not greater than 1.6 and the peripheral surface layer of the fluororesin inner ply having been modified into the following treated layer (A).(A) a layer with a distribution of oxygen atoms and having an F / C ratio, i.e. ratio of the number of fluorine atoms (F) to the number of carbon atoms (C), of not greater than 1.12 and an O / C ratio, i.e. ratio of the number of oxygen atoms (O) to the number of carbon atoms (C), of not less than 0.08.In this fuel hose of the invention, the treated layer (A) of the tubular fluororesin inner ply has a remarkably increased adhesive affinity for thermoplastic resin and rubber, with the result that the bond strength between the tubular fluororesin inner ply and the thermoplastic resin or rubber outer layer is as high as not less than 1.2 N / mm.

Owner:SUMITOMO RIKO CO LTD

Plasticizer-resistant pressure-sensitive adhesive composition and adhesive article

InactiveUS7744998B2High initial bond strengthMaintain bond strengthLayered productsAmide/imide polymer adhesivesMeth-Plasticizer

There is provided a pressure-sensitive adhesive composition which has a high initial adhesive strength to an adherend containing a plasticizer and can maintain the adhesive strength even after long-term use. A plasticizer-resistant pressure-sensitive adhesive composition comprising a copolymer obtained by polymerizing a monomer mixture comprising (a) an aromatic-containing (meth)acrylate monomer, (b) a nitrogen-containing vinyl monomer, and (c) an alkyl(meth)acrylate monomer, an alkyl group of which has 4 to 14 carbon atoms.

Owner:3M INNOVATIVE PROPERTIES CO

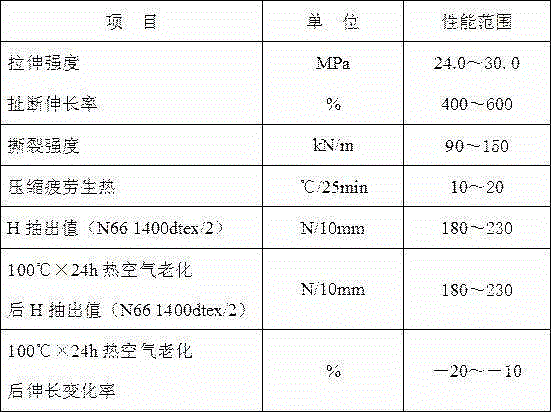

Aviation tire reinforcing layer adhesive of high adhesive strength

The invention discloses an aviation tire reinforcing layer adhesive of high adhesive strength, prepared through two-stage mixing performed by a mixer by using main materials: 80-90% of ribbed smoked sheet 1#, 10-20% of styrene butadiene rubber 1500, 30-40% of new process high structural and high wear resistant carbon black, 5-10% of silica, and silane coupling agent KH-560, adhesion promoter AIR-201, adhesive SL-3090, p-phenylenediamine antioxidant 4010NA, antioxidant RD, sulfenamide accelerator and scorch retarder CTP, . The invention has properties of high initial adhesive strength, high adhesive after aging, high tensile strength, high tensile modulus and low heat production, and can meet property requirements of high speed and high load of future new model tires; and the adhesive strength between rubber before and after aging and nylon cord is high, has high hardness and tensile, low heat production, and can improve the dynamic property of tires, thereby preventing tires from delaminating, blowing up and rejecting of tread, and improving the safety performance of aviation tires.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Cohesive glue for flexible decorative tile and manufacturing method thereof

ActiveCN101701138AHigh initial bond strengthLight weightEster polymer adhesivesHydrocarbon polymer adhesivesAntioxidantUltraviolet

The invention relates to cohesive glue for a flexible decorative tile and a manufacturing method thereof; the cohesive glue is composed of the following raw materials by weight proportion: 0.3-1.5 percent of water-retaining agents, 28-48 percent of water, 0.3-2 percent of thickeners, 48-68 percent of polymer latex, 0-0.35 percent of ultra-violet absorber, 0-0.42 percent of antioxidant, and 0.7-4.2 percent of film-forming additives; the manufacturing method is that: 1-3 percent of the water-retaining agents, 93-97 percent of water and 1-4 percent of the thickeners are mixed to prepare water-holding thickening liquid for spare, and then 94-98 percent of the polymer latex, 0-0.5 percent of the ultra-violet absorber, 0-0.6 percent of the antioxidant and 1-6 percent of the film-forming additives are mixed to prepare polymer film-formation weather-proofing modified liquid for spare, and 30-50 percent of the water-holding thickening liquid and the polymer film-formation weather-proofing modified liquid are formulated to prepare the cohesive glue for the flexible decorative tile. The cohesive glue has the advantages of no taste, no toxicity, high first sticking intensity, low volume weight and rapid construction speed.

Owner:烟台同化防水保温工程有限公司

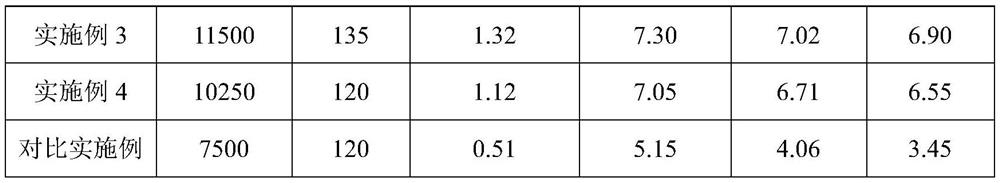

Method for preparing single-component high-heat-resistance aqueous polyurethane adhesive

InactiveCN102153984BImprove cohesive strengthHigh heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a preparation method of a single-component high-heat-resistance aqueous polyurethane adhesive, which comprises the following steps: reacting polyester polyol and nano silicon dioxide with diisocyanate to form an isocyanate group(-NCO)-terminated prepolymer; adding a hydrophilic chain extender and a polylol monomer for further reaction; performing chain extension by using small-molecular-weight glycol; regulating the pH value of the reaction solution by neutralizing with triethylamine, adding acetone in an amount which is 5 to 40 percent based on the weight of the polyester polyol to lower the viscosity of the material, and dispersing the solution into light blue semi-transparent emulsion with deionized water; and finally, removing the acetone serving as the solventunder vacuum to obtain the single-component high-heat-resistance aqueous polyurethane adhesive. The single-component aqueous polyurethane adhesive prepared by the method is environmentally-friendly, the solid content of the single-component aqueous polyurethane adhesive can reach 50 percent, the cohesive strength of the single-component aqueous polyurethane adhesive is high, and the single-component aqueous polyurethane adhesive can meet a high-strength adhesion requirement; and more importantly, the tolerable temperature of the adhesive is as high as over 160 DEG C, and the adhesive can be used without adding a curing agent.

Owner:山西省应用化学研究所

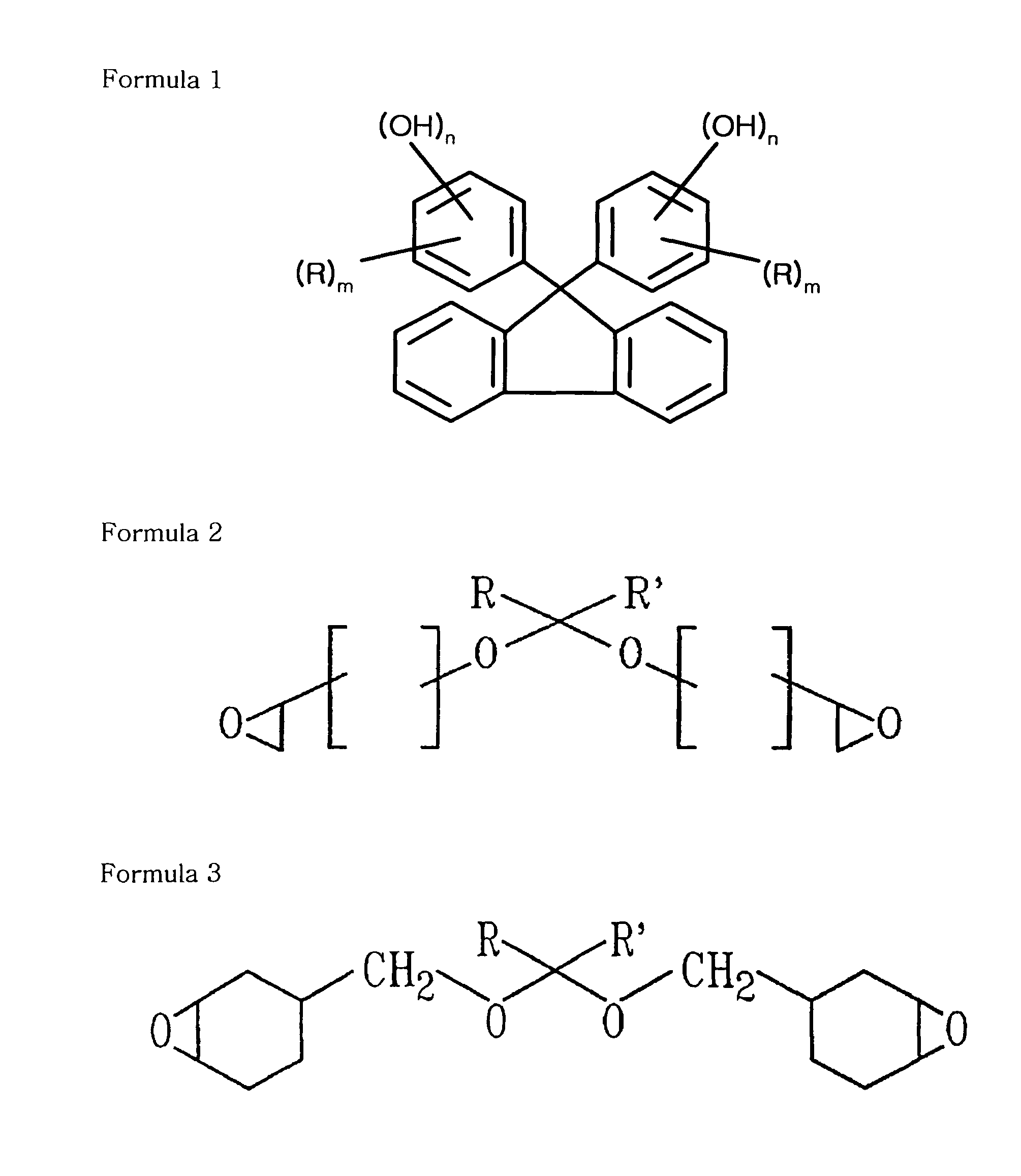

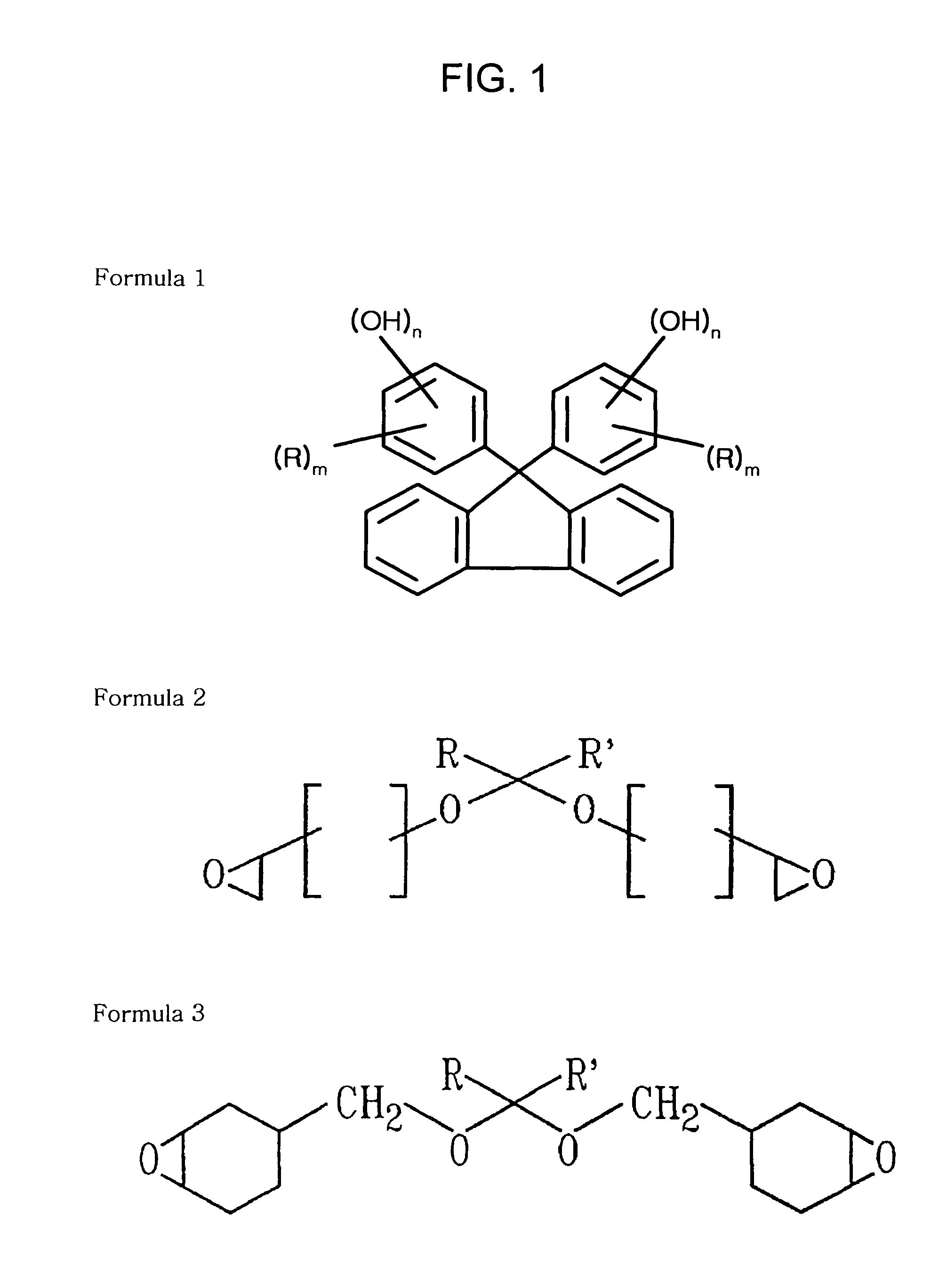

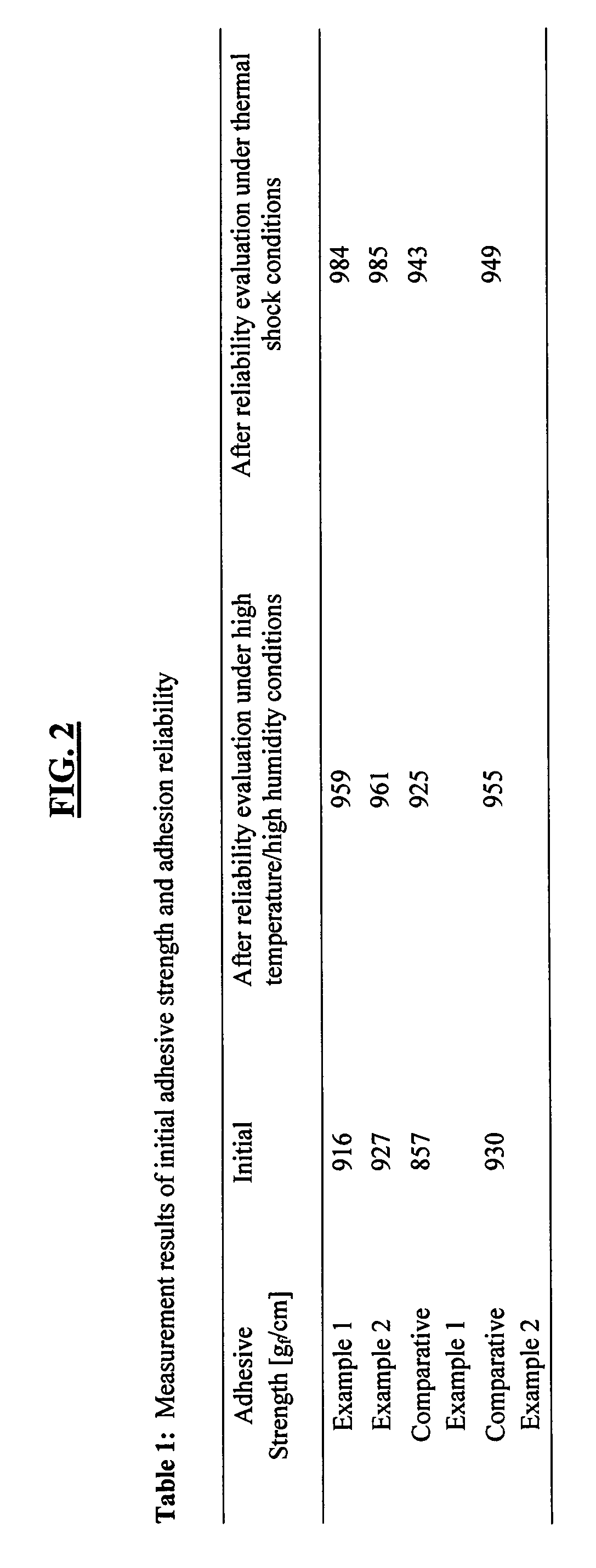

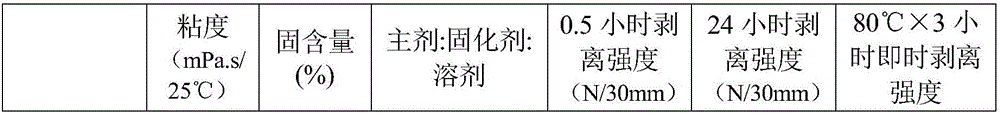

Anisotropic conductive film composition, anisotropic conductive film including the same, and associated methods

ActiveUS8034261B2Improve conductivityHigh initial bond strengthConductive materialNon-conductive material with dispersed conductive materialAnisotropic conductive filmPolymer resin

An anisotropic conductive film composition includes a polymer resin, a first epoxy resin including at least one of a bisphenol epoxy resin, a novolac epoxy resin, a glycidyl epoxy resin, an aliphatic epoxy resin, and an alicyclic epoxy resin, a second epoxy resin including an acetal epoxy resin, an epoxy resin curing agent, and conductive particles.

Owner:KUKDO ADVANCED MATERIALS CO LTD

Thermal-resistant PVC (Polyvinyl Chloride) composite double-component polyurethane adhesive and preparation method thereof

InactiveCN106753161AStir wellHigh affinityPolyureas/polyurethane adhesivesPolyurethane adhesivePolyvinyl chloride

The invention discloses a thermal-resistant PVC (Polyvinyl Chloride) composite double-component polyurethane adhesive which comprises a polyurethane prepolymer as a main agent and comprises raw materials, namely, oligomer polyhydric alcohols, hydroxyl chloride vinyl acetate resin, a chain extender, polyisocyanates, a catalyst A and a solvent in a mass ratio of 100:(5-20):(0-20):(10-30):(0-0.05):(300-800), wherein the viscosity of the adhesive is 1000-20000cps / 25 DEG C, the solid content of the adhesive is 20-50%, a curing agent is a polyurethane prepolymer of a mono-isocyanate group which is synthesized from polyisocyanates and a polyhydroxy compound by using a prepolymerization method, the content of the polyisocyanates is 10-15wt%, and the solid content is 70-80%. Due to addition of the hydroxyl chloride vinyl acetate resin which has very good affinity with a PVC substrate, a prepared primary product is very high in adhesion strength, good in plasticizer resistance effect, very good in peeling strength, very high in tearing load and very good in thermal resistance.

Owner:JIAXING HEXIN CHEM IND

Adhesive hydrogel and use thereof

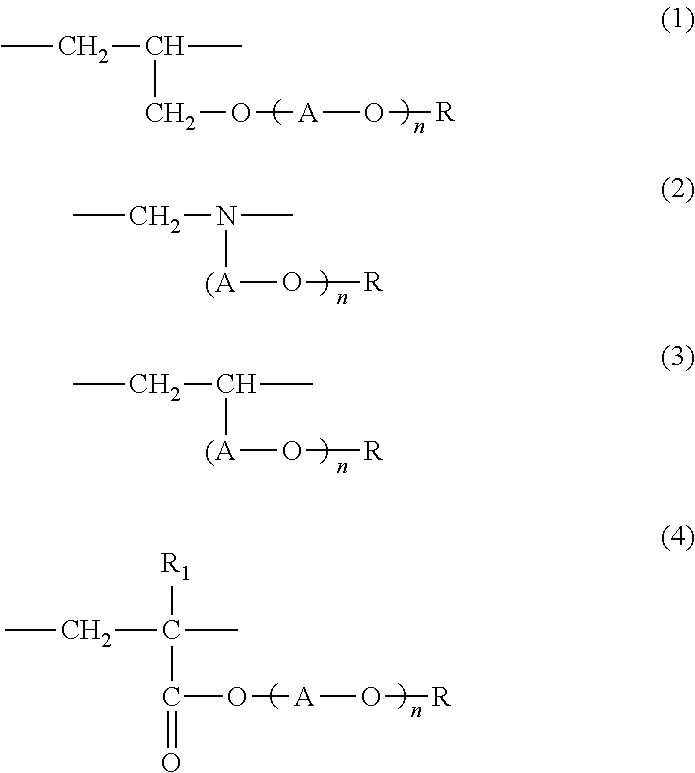

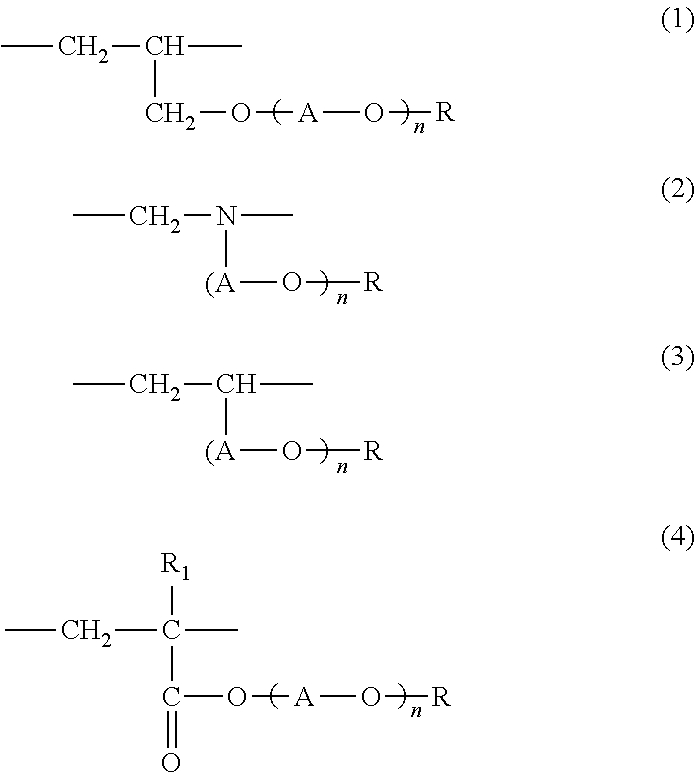

ActiveUS20140296418A1High initial bond strengthImprove adhesion strengthNon-macromolecular adhesive additivesChemical liquid solidificationPolymer scienceSide chain

An adhesive hydrogel contains: a polymer matrix of a copolymer of a monofunctional monomer and a crosslinking monomer (a); another polymer component; water; and a polyhydric alcohol, wherein: either a structural unit derived from the monofunctional monomer contained in the polymer matrix or the other polymer component or both contain a structural unit derived from at least one compound (b) selected from the group consisting of ethylenically unsaturated carboxylic acids, ethylenically unsaturated carboxylic acid salts, and ethylenically unsaturated carboxylic acid derivatives having a hydroxyl group, an acid group, a salt thereof, an amino group, and / or an ammonium group; and the other polymer component contains a polymer compound (c) with a side chain having an oxyalkylene group or a polyoxyalkylene group.

Owner:SEKISUI PLASTICS CO LTD

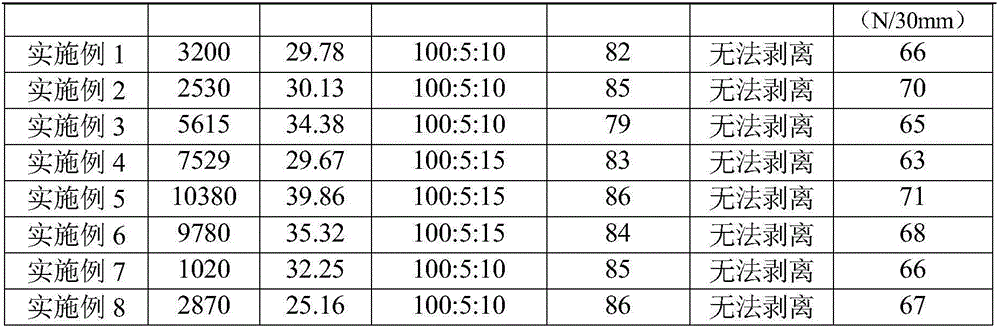

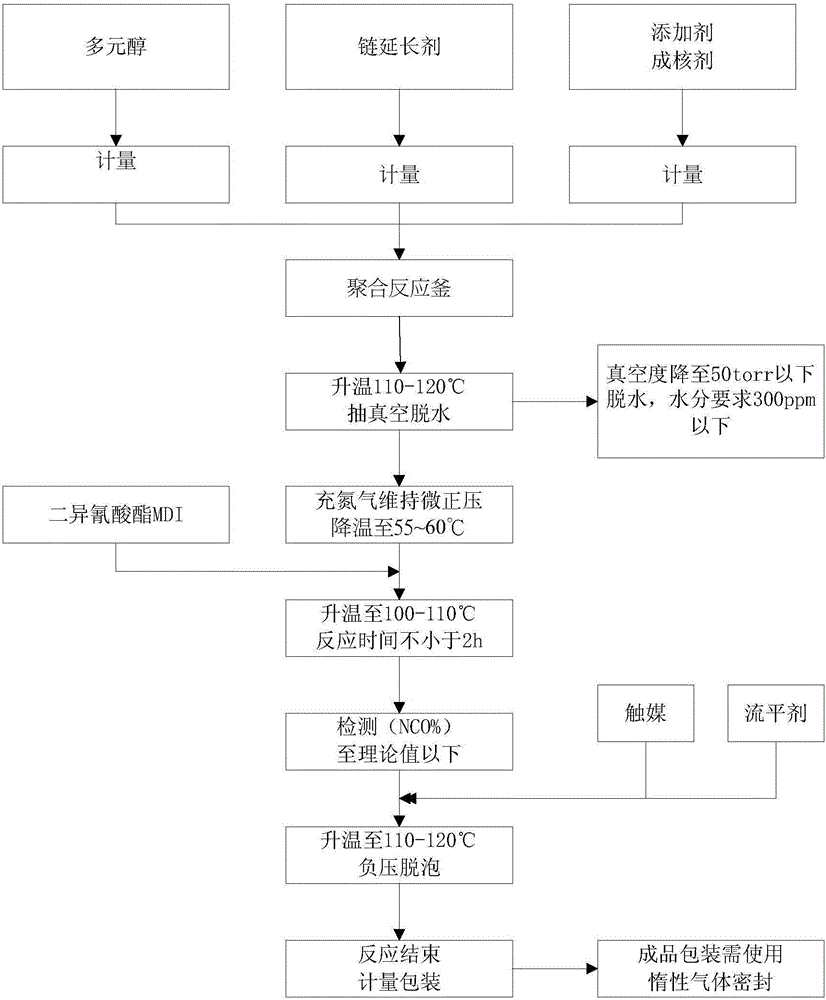

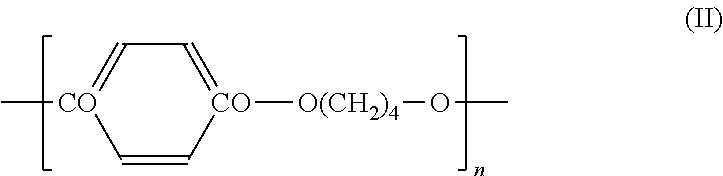

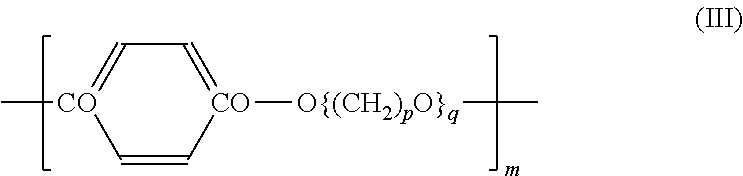

Preparation method and application of moisture reaction type polyurethane hot-melt adhesive for composite floor

The invention disclose a preparation method and application of moisture reaction type polyurethane hot-melt adhesive for a composite floor and belongs to the technical field of macromolecule material preparation .According to the method, polyester polyol, diisocyanate and chain extender are adopted as basic raw materials, auxiliary agents such as accelerant, a flatting agent and a nucleating agent are combined, and a high temperature polymerization reaction is conducted, so that the moisture reaction type polyurethane hot-melt adhesive (PUR) is obtained .A product prepared through the method is the one-component moisture reaction type polyurethane hot-melt adhesive, no cross-linking agent is used for hardening, and instead, an NCO functional group with the resin molecular chain tail end reactive is adopted for reacting with moisture to achieve cross-linking .The solid content of the product is 100%, no solvent is contained, no solvent is used in the technological process, a baking channel does not need to be arranged, cost is lowered, and no safety or environmental protection problem exists .In addition, the polyurethane adhesive product produced through the method is high in cohesive energy, good in initial adhesion and excellent in heat resistance, weather resistance, hydrolysis resistance and aging resistance after being cured and can be widely applied to processing of building decorative materials.

Owner:高鼎精细化工(昆山)有限公司

Moisture-Curable Hot Melt Adhesive

ActiveUS20180298254A1High initial adhesive strengthLong open timeFurniture partsVehicle componentsPrepolymerIsocyanate

The object of the present invention is to provide a moisture-curable hot melt adhesive having high initial adhesive strength, long open time, excellent coating property and reduced stringing property. The present invention relates to a moisture-curable hot melt adhesive comprising (A) a urethane prepolymer having a terminal isocyanate group, (B) a metallocene-based polyolefin having a viscosity of 10,000 mPa·s or less at a temperature of 170° C. and (C) a polyester-polyether copolymer.

Owner:HENKEL KGAA

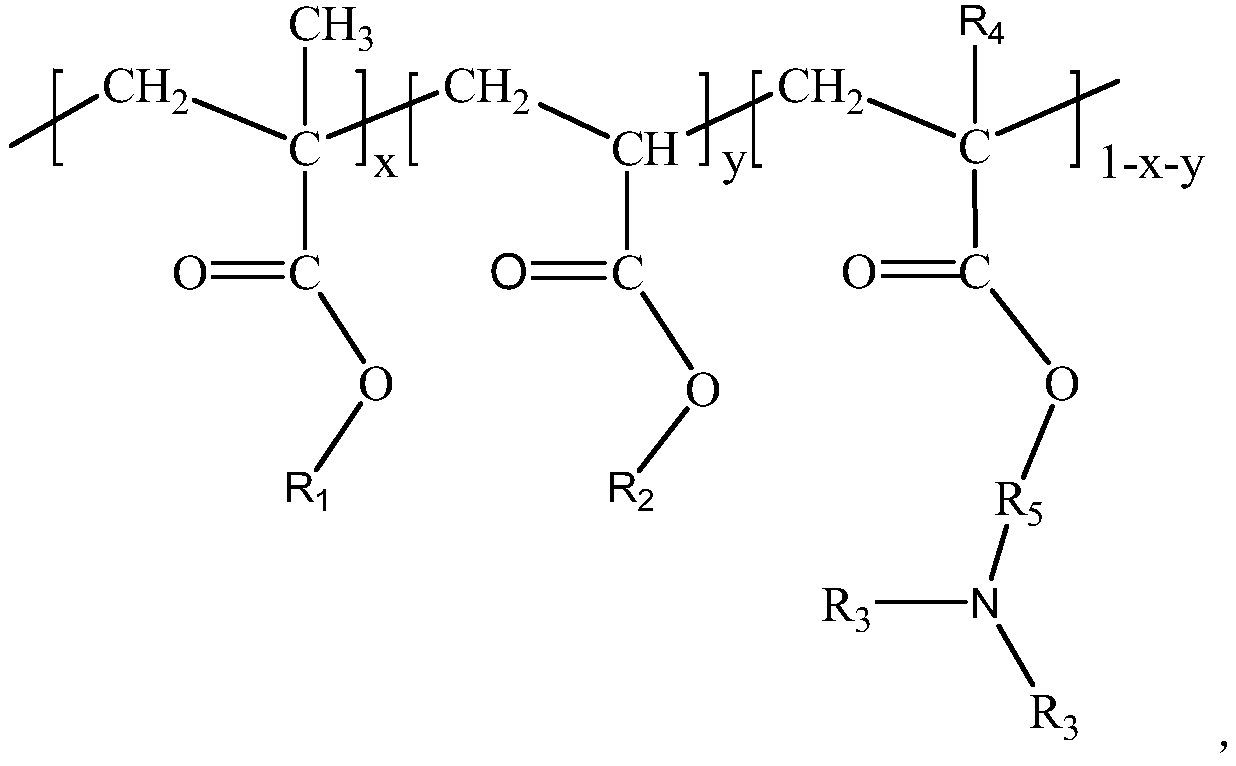

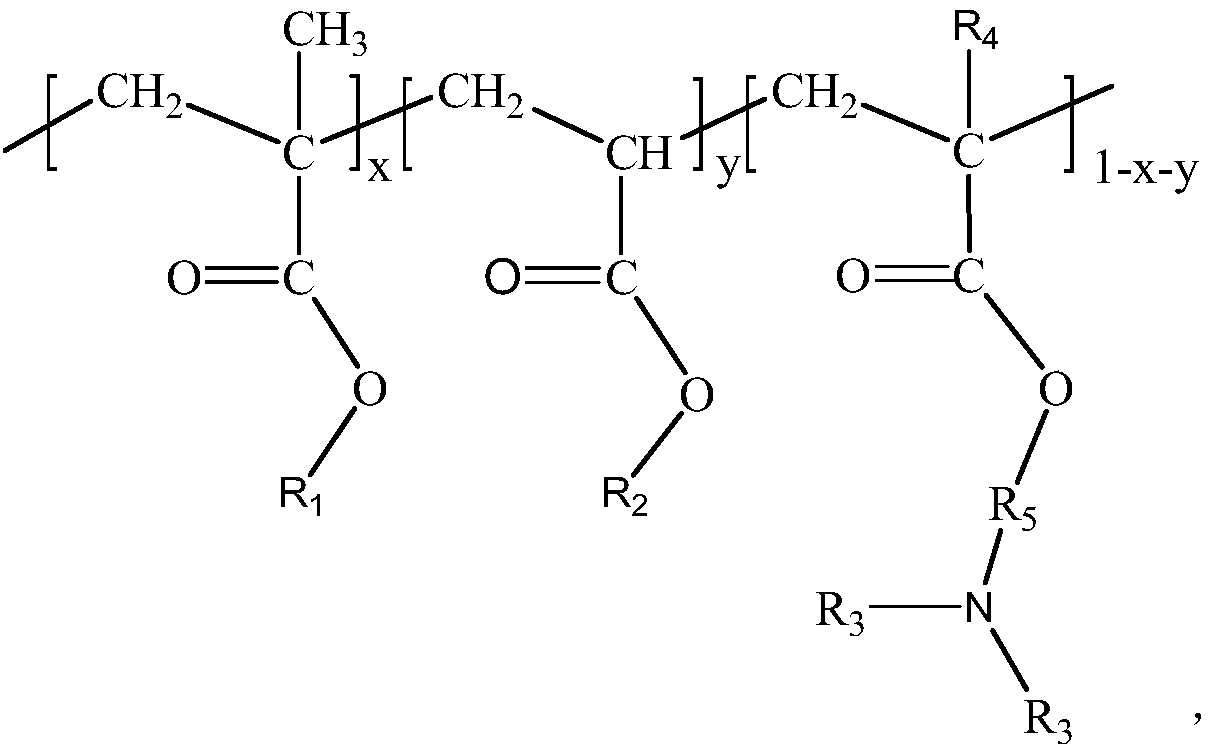

Tertiary-amine-group-containing polyacrylic acid resin modified reaction-type polyurethane hot melt glue and preparation thereof

InactiveCN109762505AImprove initial bond strengthModerate viscosityPolyureas/polyurethane adhesivesChemistryBonding strength

The invention relates to tertiary-amine-group-containing polyacrylic acid resin modified reaction-type polyurethane hot melt glue and preparation thereof. The hot melt glue is prepared from the following raw material components in parts by weight: 10-40 parts of polyester polyol, 10-40 parts of polyether polyol, 10-30 parts of polyisocyanates, 1-40 parts of tertiary-amine-group-containing polyacrylic acid resin, 0.01-1 part of a catalyst and 0.05-5 parts of a silane coupling agent. Compared with the prior art, the bonding strength of various base materials is greatly improved, especially the initial bonding strength and the final bonding strength of metal and non-polar plastic base materials are greatly improved; and meanwhile, the viscosity and the opening time are moderate, a process iseasy to use and operate, and the using requirements of different industrial application fields can be met.

Owner:EAST CHINA UNIV OF SCI & TECH

Dual-curing polyurethane hot melt adhesive and preparation and using methods thereof

ActiveCN109401719AGood compatibilityHigh initial bond strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterChemistry

The invention discloses a dual-curing polyurethane hot melt adhesive and preparation and using methods thereof. The dual-curing polyurethane hot melt adhesive is prepared from a main material and an auxiliary material, wherein the main material is prepared from the flowing raw material components: polyester polyol, polyether polyol, a chemical modifier, isocyanate and a chain extender, and the auxiliary material is prepared from the flowing raw material components: a physical modifier, a catalyst, a silane coupling agent, a photoinitiator, an antioxygen and white carbon black. According to thetechnical scheme, the UV light / wet dual-curing polyurethane hot melt adhesive has the advantages of a wet curing polyurethane hot melt adhesive and an ultraviolet curing hot melt adhesive and meanwhile overcomes the disadvantages of the wet curing polyurethane hot melt adhesive and the ultraviolet curing hot melt adhesive; and the UV light / wet dual-curing polyurethane hot melt adhesive is synthesized through the chemical modifier and adopts an acrylate diluent as aiding to be blended to improve compatibility of the components, and a polyurethane hot melt adhesive product which is high in initial bonding strength, good in tenacity, high in weather resistance and convenient to construct is obtained.

Owner:SHANGHAI ZHIGUAN HIGH POLYMER MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com