Patents

Literature

687results about How to "Easy to film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

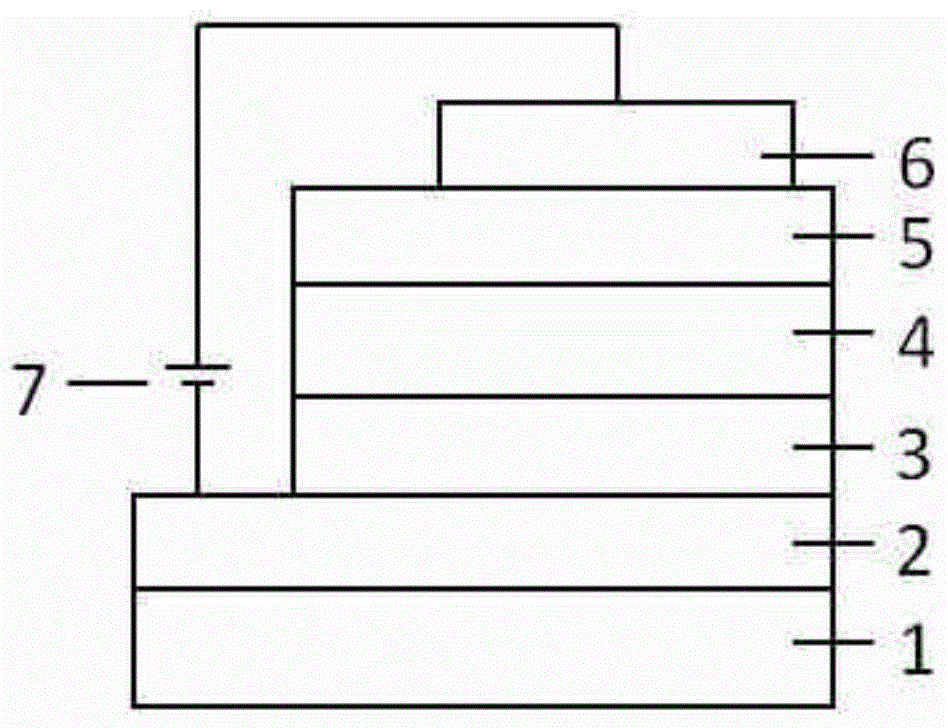

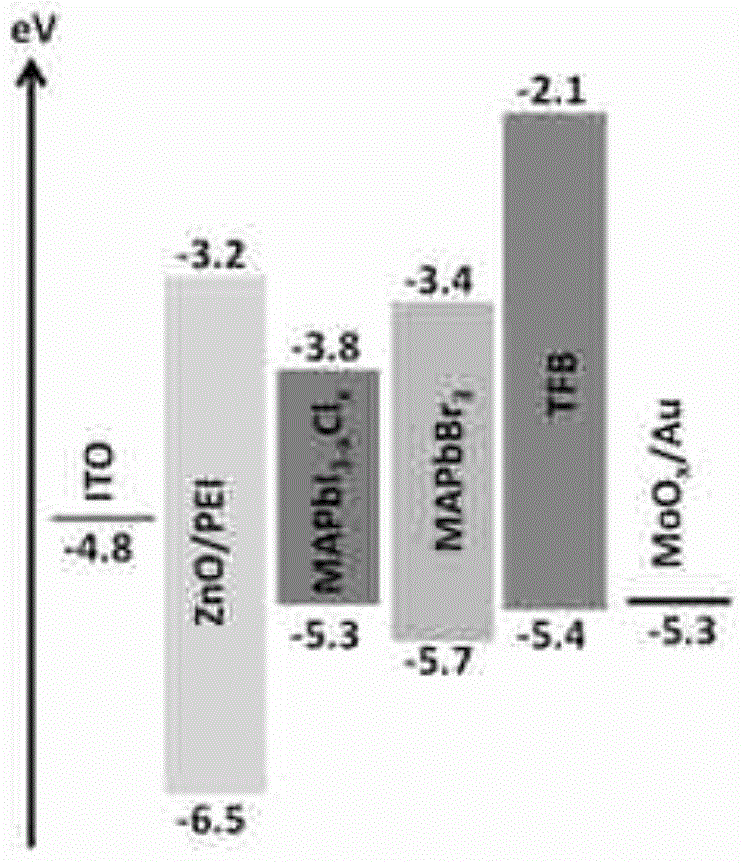

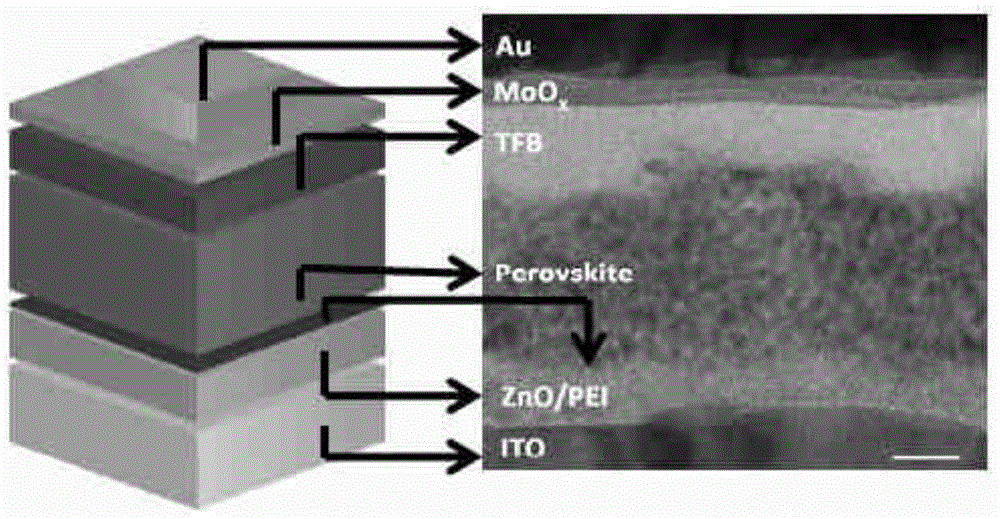

Perovskite type electroluminescence device and preparation method thereof

ActiveCN104681731AIncrease brightnessEasy to filmSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionBlocking layer

The invention discloses a perovskite type electroluminescence device. The device comprises a substrate, a cathode, an electronic transmission-hole blocking layer, a luminescent layer, a hole transmission-electron blocking layer and an anode, wherein the luminescent layer is made of a material of a perovskite structure; the structure of the device can effectively promote injection and transmission of the charge carriers, restrict the sufficient recombination luminescence of the charge carriers / excitons, and adjust the emission color from the near ultraviolet light band, the visible light band to the near-infrared band by means of changing the components of the luminescent material. The electroluminescence device provided by the invention is high in efficiency, low in turn-on voltage, excellent in color saturation and stable in spectrum changed along with the voltage, meanwhile, the perovskite type electroluminescence device is simple in process, low in cost and is suitable for being widely used in the products of the display and illumination field, in particular suitable for the large-sized industrial production of the high-performance electroluminescence devices with low cost and flexible substrate.

Owner:NANJING UNIV OF TECH

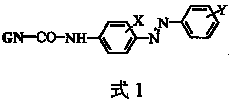

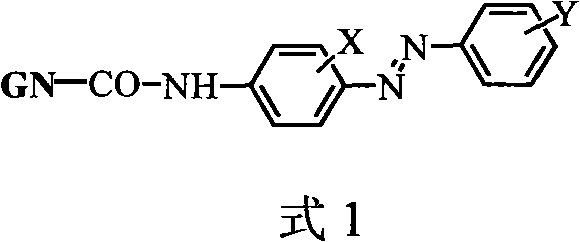

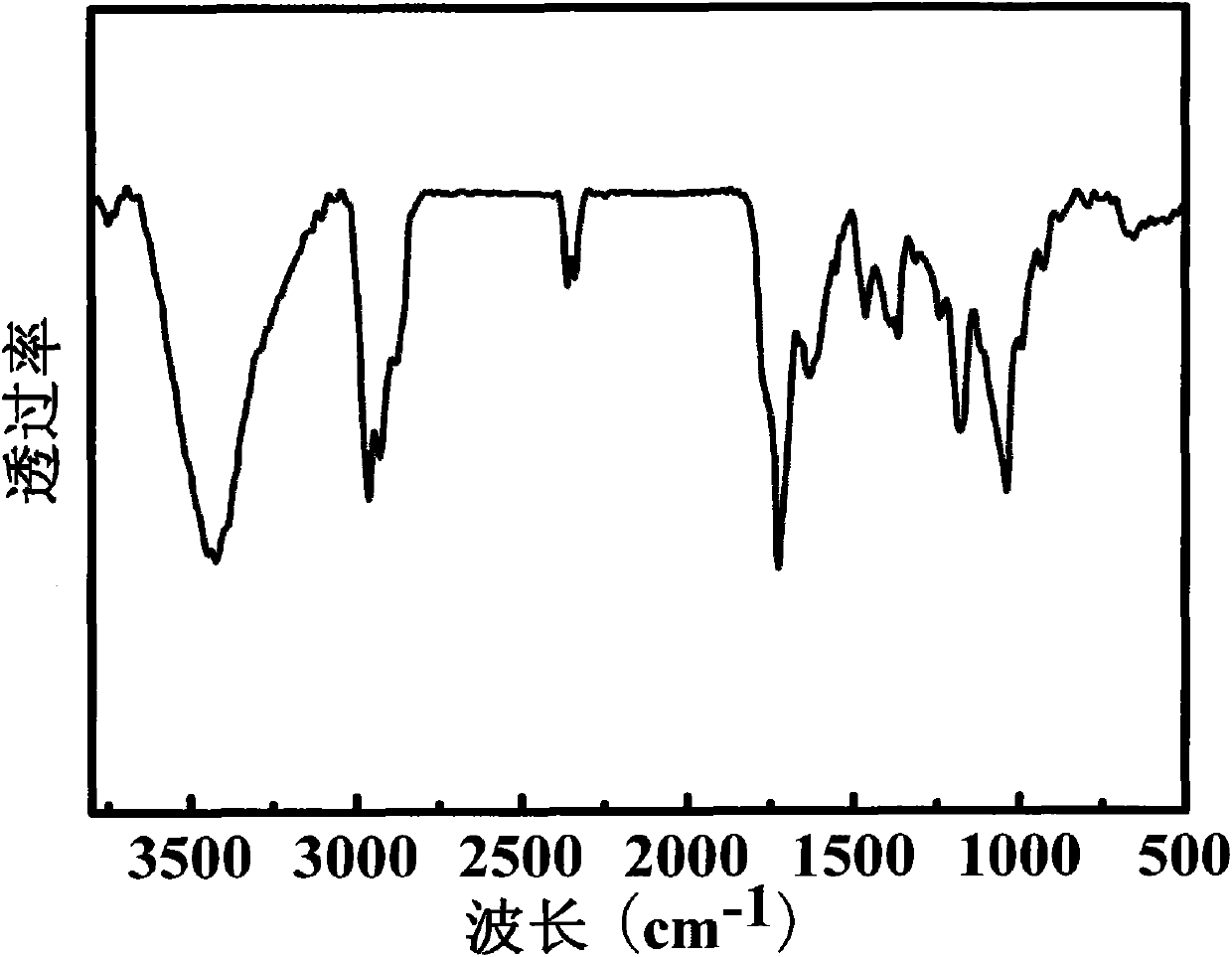

Optical responsive azobenzene graft grapheme material and preparation method thereof

The invention discloses an optical responsive azobenzene graft grapheme material and a preparation method thereof. The structural formula of the material is represented as formula 1. The preparation process comprises the steps of: dispersing graphene oxide and reductive graphene oxide in a single layer graphite structure in thionyl chloride to react to obtain the grapheme material with acyl chloride functional group; reacting azobenzene with amino group with acylated grapheme material in N,N-dimethyl formamide to prepare the optical responsive azobenzene graft grapheme material. The prepared azobenzene graft grapheme material has the advantages of good solubility in organic solvents, easy filming, controllable optical and electrical properties, high photoelectric conversion rate and the like.

Owner:TIANJIN UNIV

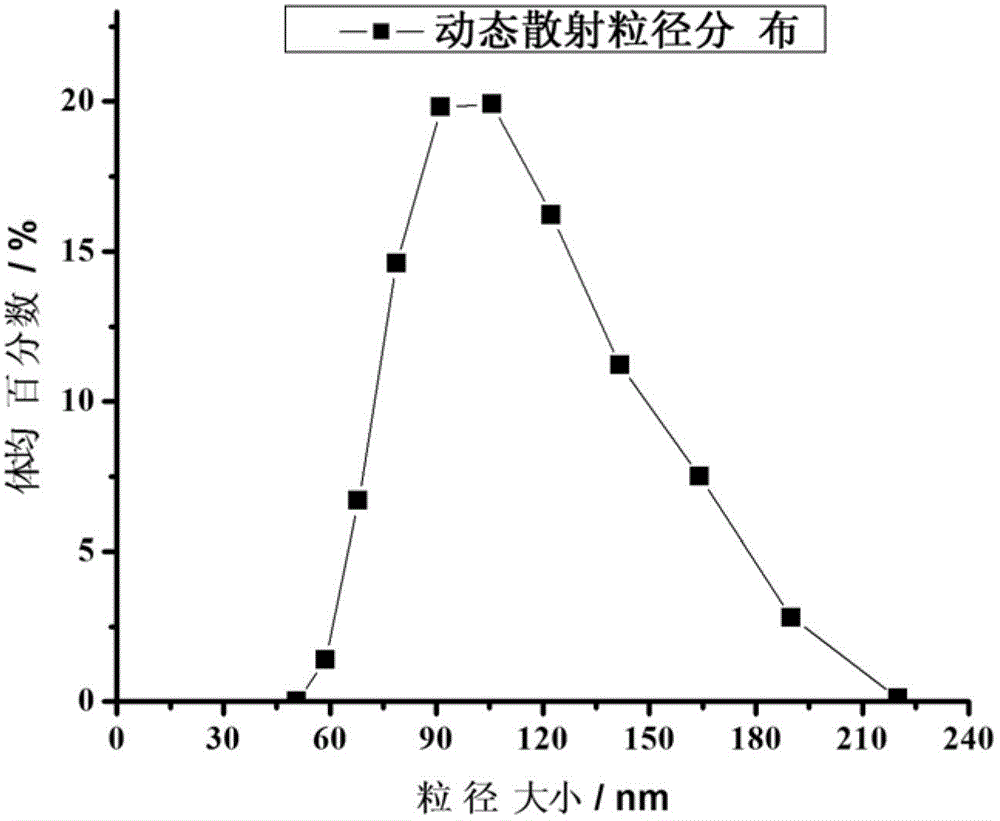

Organic silicon modified acrylate emulsion and preparation method thereof

The invention relates to organic silicon modified acrylate emulsion and a preparation method thereof. A core-shell structure synthesis method is adopted for preparation, a core layer / shell layer glass transition temperature is designed to be -30- -25 DEG C / 0-5 DEG C and lower than conventional core-shell emulsion. The emulsion comprises core-shell emulsion monomers, initiator accounting for 0.4-0.6% of the total mass of the monomers, composite emulsifier accounting for 2.5-4.5% of the total mass of the monomers, pH (potential hydrogen) buffering agent accounting for 0.4-0.6% of the total mass of the monomers and the balance deionized water. The emulsion preparation method includes (1) pre-emulsifying, (2) core-layer emulsion preparation, and (3) core-shell emulsion preparation. The emulsion which is aqueous emulsion is environment-friendly and high in stability, bonding power and tensile strength, has functions of softening, smoothening and the like for surface treatment of fabrics and the like, and is widely applicable to the fields of spinning, papermaking, leather, painting, water-based ink and the like.

Owner:DONGHUA UNIV

Long-acting water-soluble and environmentally-friendly steel structural protective coating

ActiveCN103450719AImprove adhesionHigh reactivityAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceAcrylic coating

The invention provides a long-acting water-soluble and environmentally-friendly steel structural protective coating. The long-acting water-soluble and environmentally-friendly steel structural protective coating is characterized in that a water-soluble inorganic zinc silicate coating is used as a primer of the protective coating; a water-soluble silicon-acrylic coating is used as an intermediate coating; a water-soluble fluorocarbon coating serves as a top coating; the water-soluble inorganic zinc silicate coating comprises the raw materials of high-modulus potassium silicate inorganic nanometer resin and synthesized organic polymer emulsion, wherein the high-modulus potassium silicate inorganic nanometer resin has the modulus of 5.3 to 6.2, and the particle diameter is 5 to 20nm; the synthesized organic polymer emulsion is composed of one or a plurality of water-soluble styrene-acrylic emulsion, water-soluble pure acrylic emulsion, water-soluble silicone acrylic emulsion, water-soluble fluorocarbon emulsion and water-soluble fluoro-silicon emulsion; and the water-soluble silicon-acrylic coating comprises the raw material of a silicon-acrylic matrix, wherein the silicon-acrylic matrix is one of a mixture of silicone acrylic emulsion and pure acrylic emulsion, the mixture of silicone acrylic emulsion and styrene-acrylic emulsion, and silicone acrylic emulsion. By adopting the long-acting water-soluble and environmentally-friendly steel structural protective coating, the corrosion resistance and weather resistance of the protective coating are obviously improved; the corrosion resisting effect can last for 20 years; and the weather resistance lasts for more than 20 years.

Owner:WUDA JUCHENG STRUCTURE CO LTD

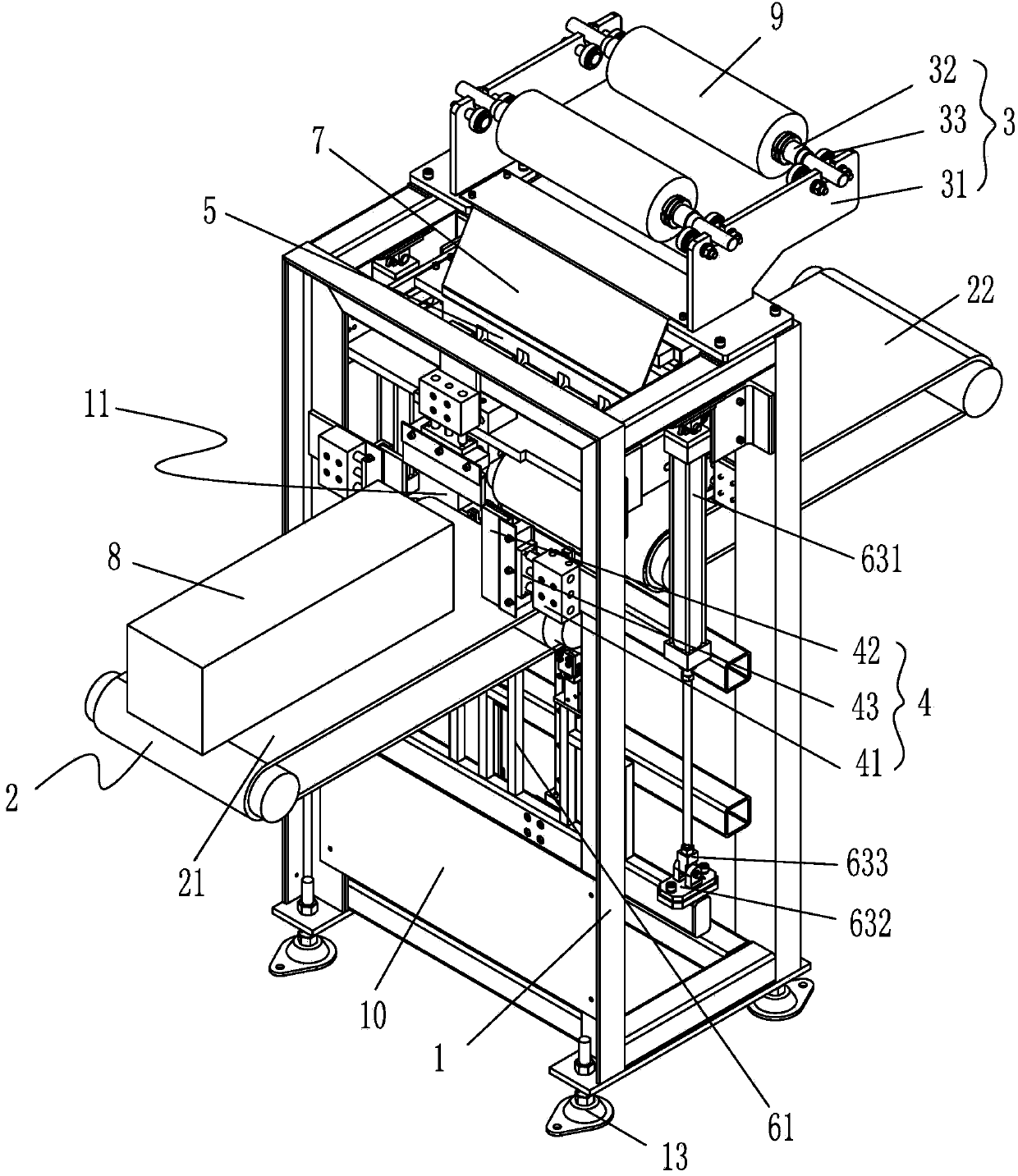

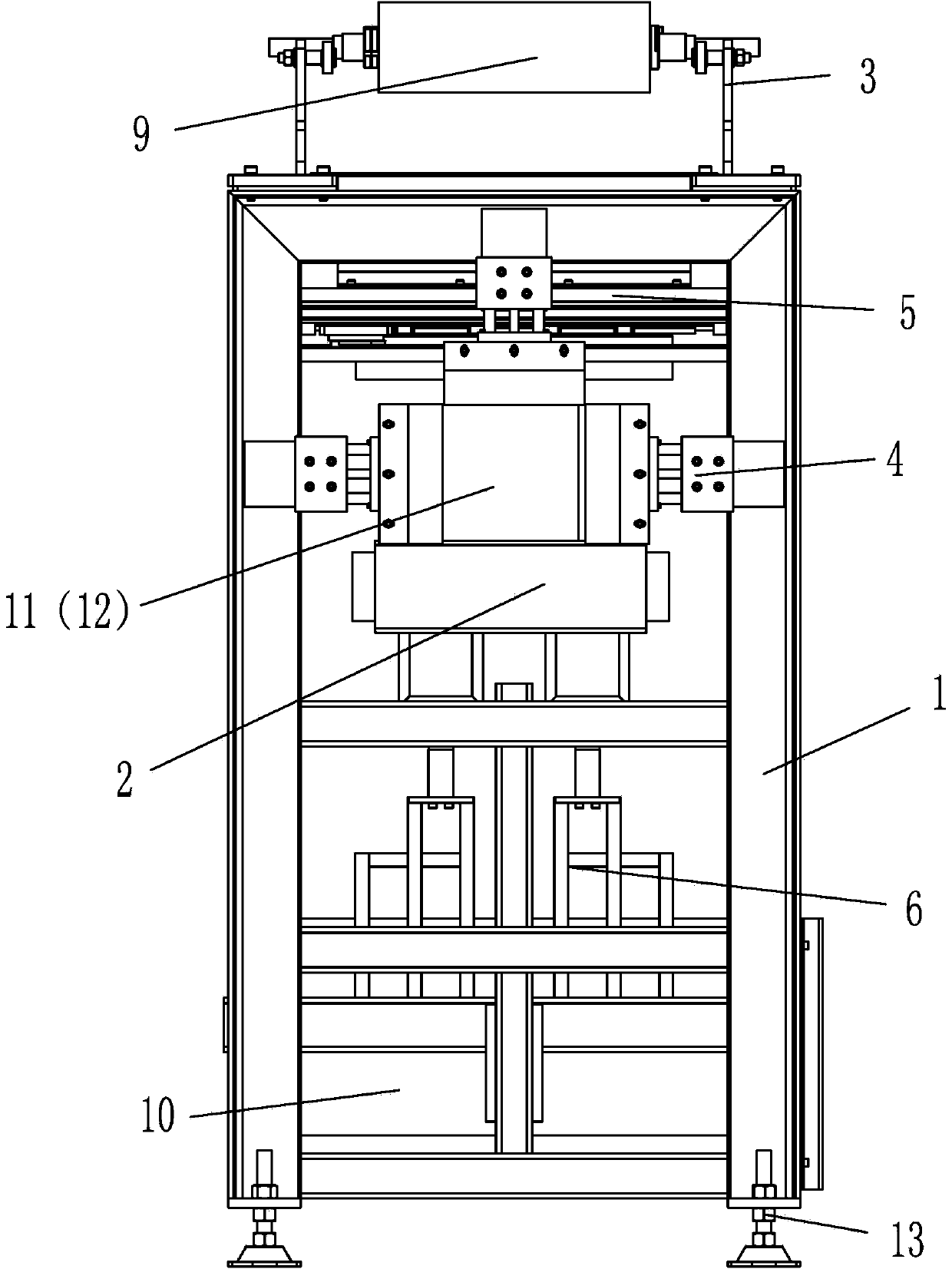

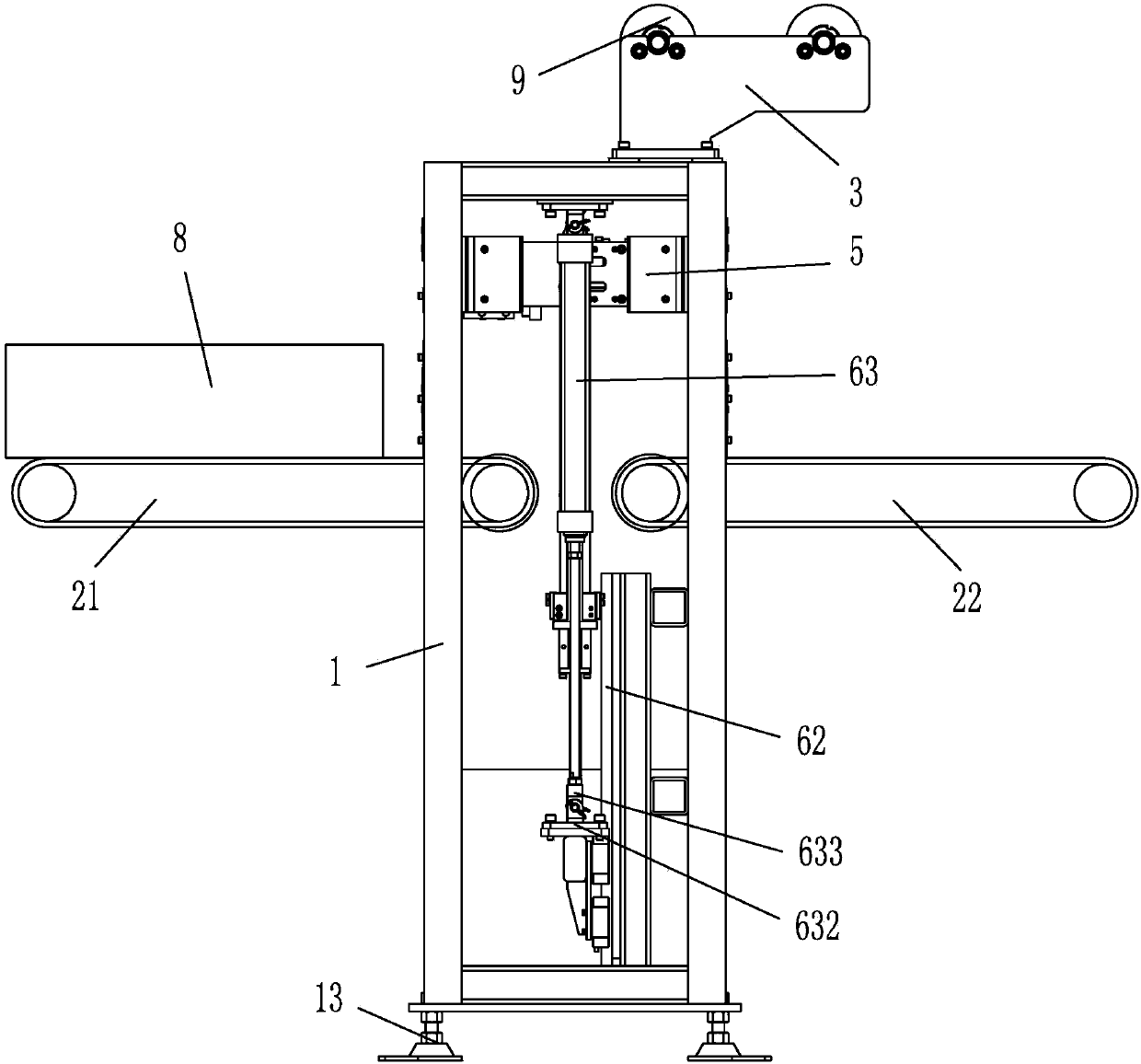

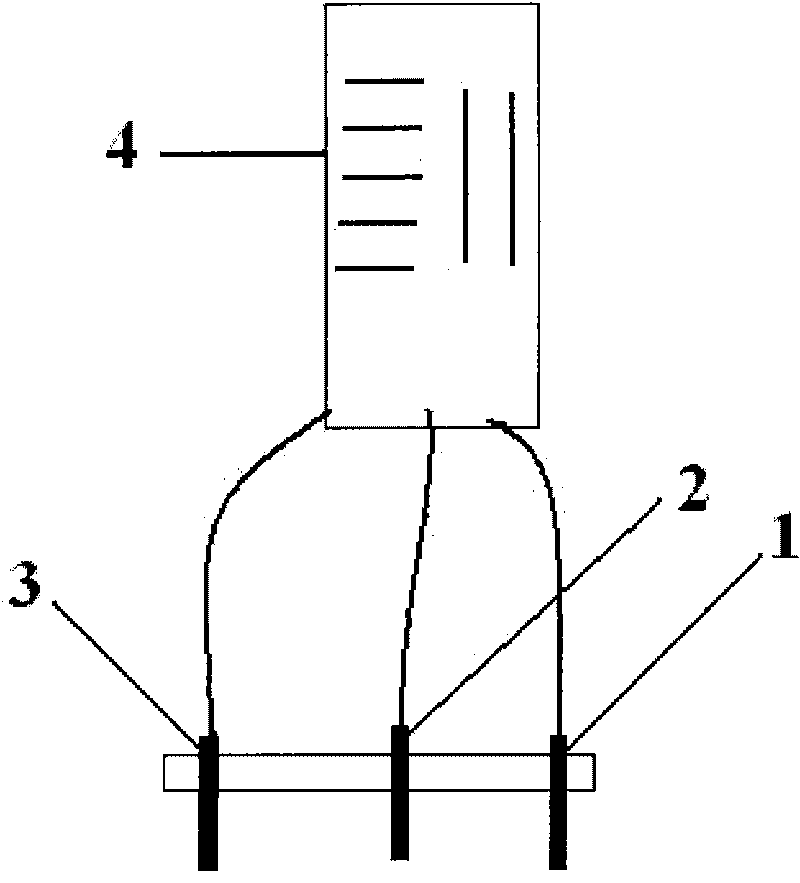

Film covering machine for film covering of ends of catalyst and film covering method of film covering machine

InactiveCN104192345AEasy to replaceMeet needsWrapping material feeding apparatusThin membraneBrush device

The invention provides a film covering machine for film covering of the ends of catalysts and a film covering method of the film covering machine. The film covering machine comprises a machine frame, a conveying device, a film feeding device, a film drawing device, a film brushing device and a film cutting device, wherein the machine frame is provided with a workpiece inlet and a workpiece outlet; the conveying device is used for conveying a workpiece to be covered with a film and comprises a front conveying belt and a rear conveying belt, and the front conveying belt and the rear conveying belt are sequentially arranged corresponding to the workpiece inlet and the workpiece outlet and drive the workpiece to be covered with the film to pass through the machine frame; the film feeding device is installed on the machine frame, used for installing and supporting the film to be arranged, and located above the workpiece inlet and the workpiece outlet; the film drawing device is installed on the machine frame and arranged between the workpiece inlet and the workpiece outlet relative to the film feeding device, and can move vertically along the machine frame; the film brushing device is installed on the machine frame, used for brushing the film to be arranged on the surface of the workpiece to be covered with the film, and arranged at the workpiece inlet and the workpiece outlet relative to the film drawing device; the film cutting device is installed on the machine frame and arranged between the film feeding device and the film brushing device. The invention further discloses the film covering method of the film covering machine.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

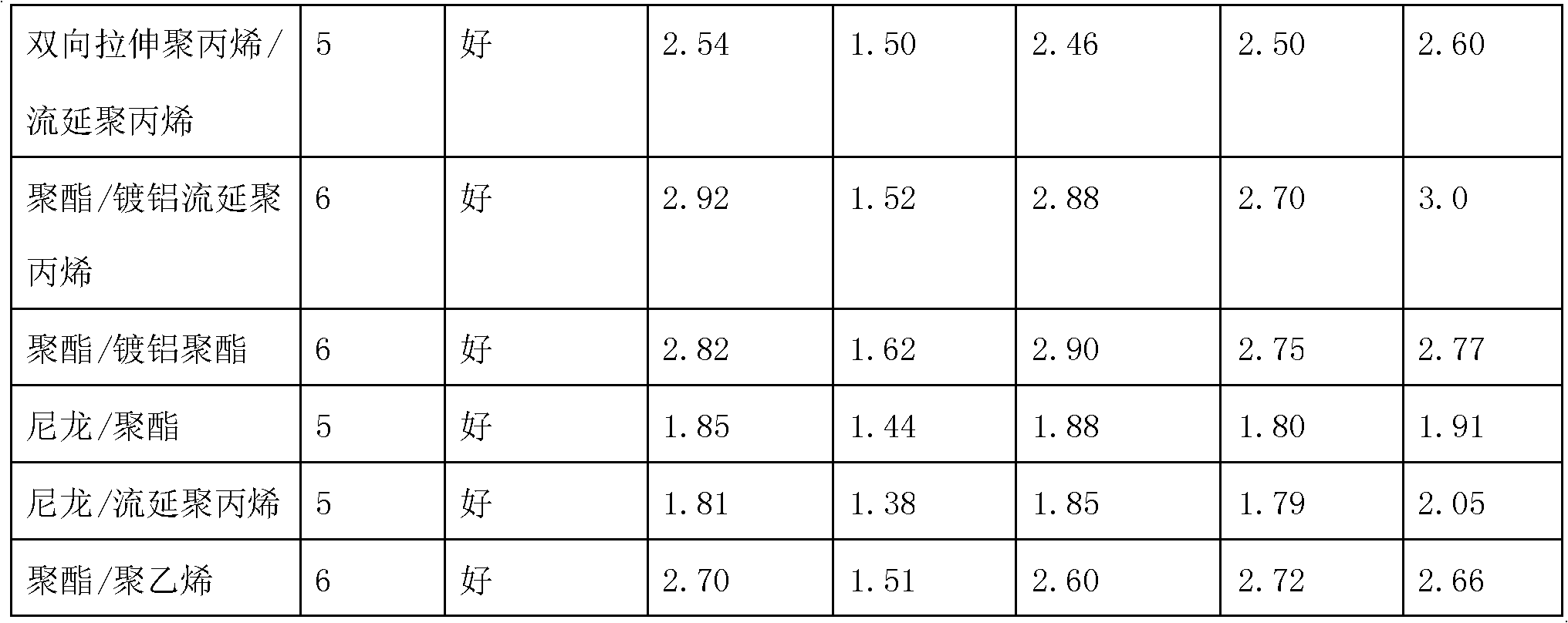

Lithium ion battery electrolyte and high-energy-density lithium ion battery using same

InactiveCN109659614AImproved High Temperature StoragePromote circulationSecondary cells servicing/maintenanceOrganic electrolytesHigh energyElectrical impedance

The invention provides a lithium ion battery electrolyte and a high-energy-density lithium ion battery using the same. The lithium ion battery electrolyte comprises a non-aqueous organic solvent, a lithium salt and additives. The additives comprise a negative electrode film-forming additive, a nitrile or ether nitrile compound, an acid anhydride compound and a lithium salt type additive. Accordingto the lithium ion battery electrolyte, 0.3-20wt% of the negative electrode film-forming additive such as vinylene carbonate and / or fluorocarbonate can form an excellent SEI film on a carbon-containing negative electrode, a silicon-containing negative electrode or a silicon carbon alloy negative electrode and the like, thereby stabilizing the negative electrode and ensuring excellent battery performance; 0.2-6.5wt% of the nitrile or ether nitrile compound, the acid anhydride compound and a combination of them can complex metal ions of a positive electrode or form a protective film on the surface of the positive electrode, thereby stabilizing the positive electrode and improving battery performance; and the 0.5-3 wt% of the lithium salt type additive in the lithium ion battery electrolytecan lower the impedance of the battery so as to improve the low temperature performance of the battery or improve the high temperature performance of the battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Normal temperature fast filming fluid for aluminium alloy surface and its usage

InactiveCN101021006AReduce pollutionLow costMetallic material coating processesTemperature controlFluoride

The present invention discloses one kind of normal temperature fast filming fluid for aluminum alloy surface and its usage. The filming fluid contains silicate, titanate, peroxide, fluoride and trivalent metal salt. When it is used, the filming fluid is controlled to be in the temperature of 1-40 deg.c and pH value of 2-8, and to be contacted with aluminum alloy for 1-10 min. The filming fluid can form film with high anticorrosive performance and excellent adhering performance, and has less environmental pollution, fast filming speed, low production cost and capacity of being used in industrial production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

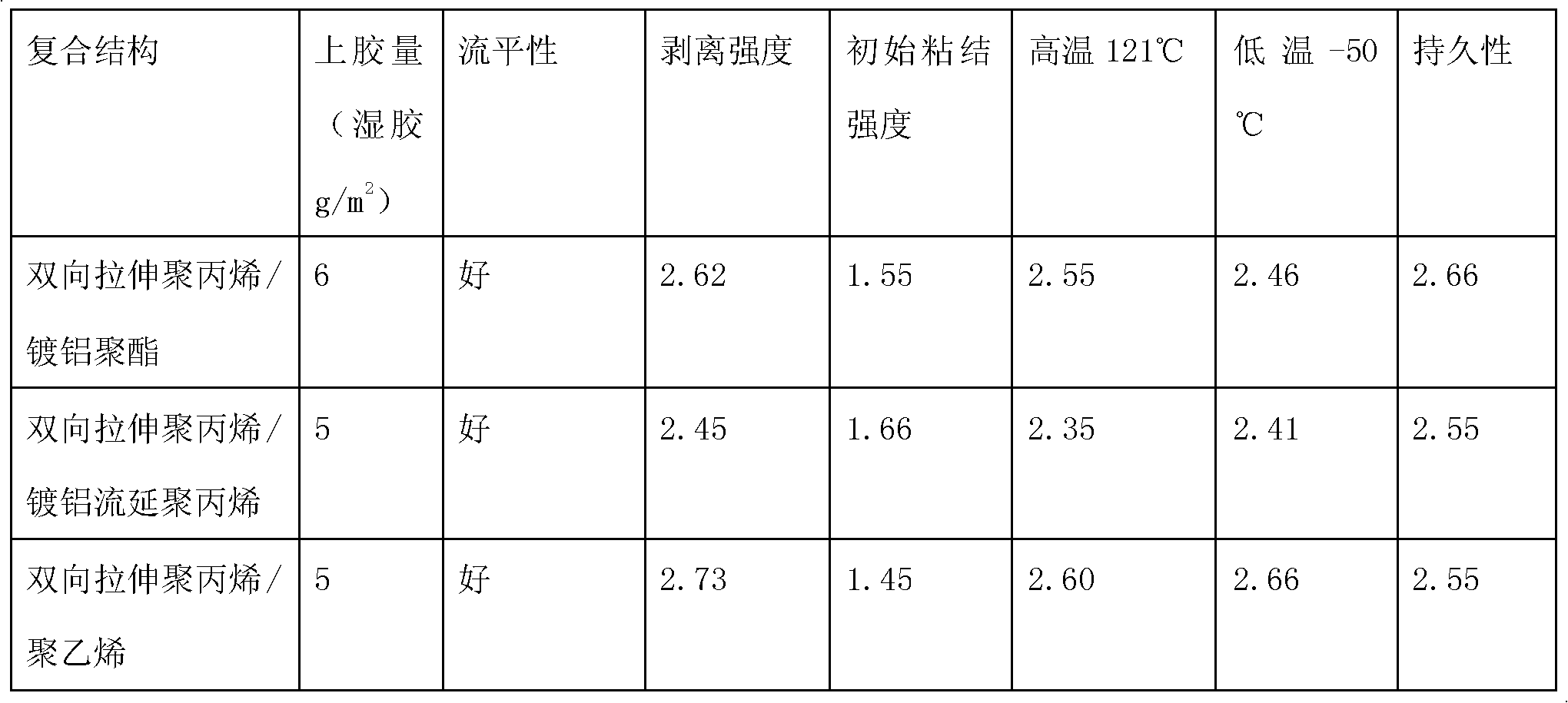

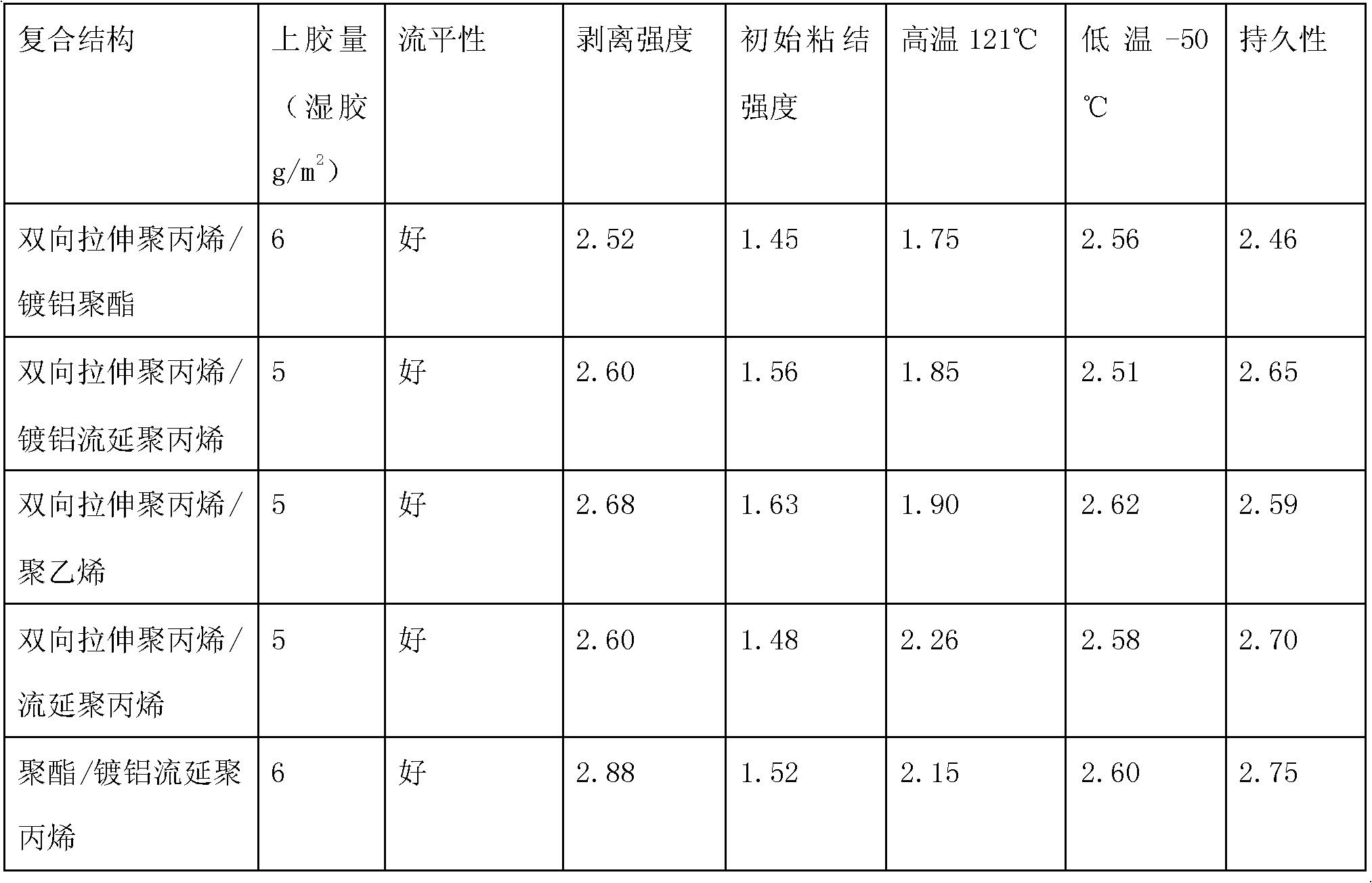

Water-based composite adhesive

InactiveCN102618193AHigh peel strengthGood high and low temperature resistanceEster polymer adhesivesCross-linkWater based

The invention discloses water-based composite adhesive, which contains acrylate emulsion and a cross-linking agent, wherein the weight of the cross-linking agent is 0.1-6 percent of the weight of the acrylate emulsion; the cross-linking agent is any one or a mixture of hexamethylenediamine and adipic acid dihydrazide; and the acrylate emulsion is formed by copolymerizing a terpenes hard monomer, a terpenes soft monomer, a terpenes carboxylic acid monomer, a terpenes functional monomer, a dual-vinyl monomer and a terpenes cross-linking monomer through nuclear shells under an emulsion system. The adhesive is particularly suitable for dry-type composite adhesion between flexible package composite base materials such as a plastic film and a vacuum aluminized film which are processed through corona; has good leveling, fast drying, high transparency, capability of curing at room temperature, high initial strength, excellent peel strength, difficulty in mesh clogging and skinning, wide adaptability and low cost; and can be applied to various machine types, does not contain any organic solvent, can replace solvent adhesive at present completely, and belongs to environment friendly adhesive.

Owner:GUANGDONG RONGYU INDAL

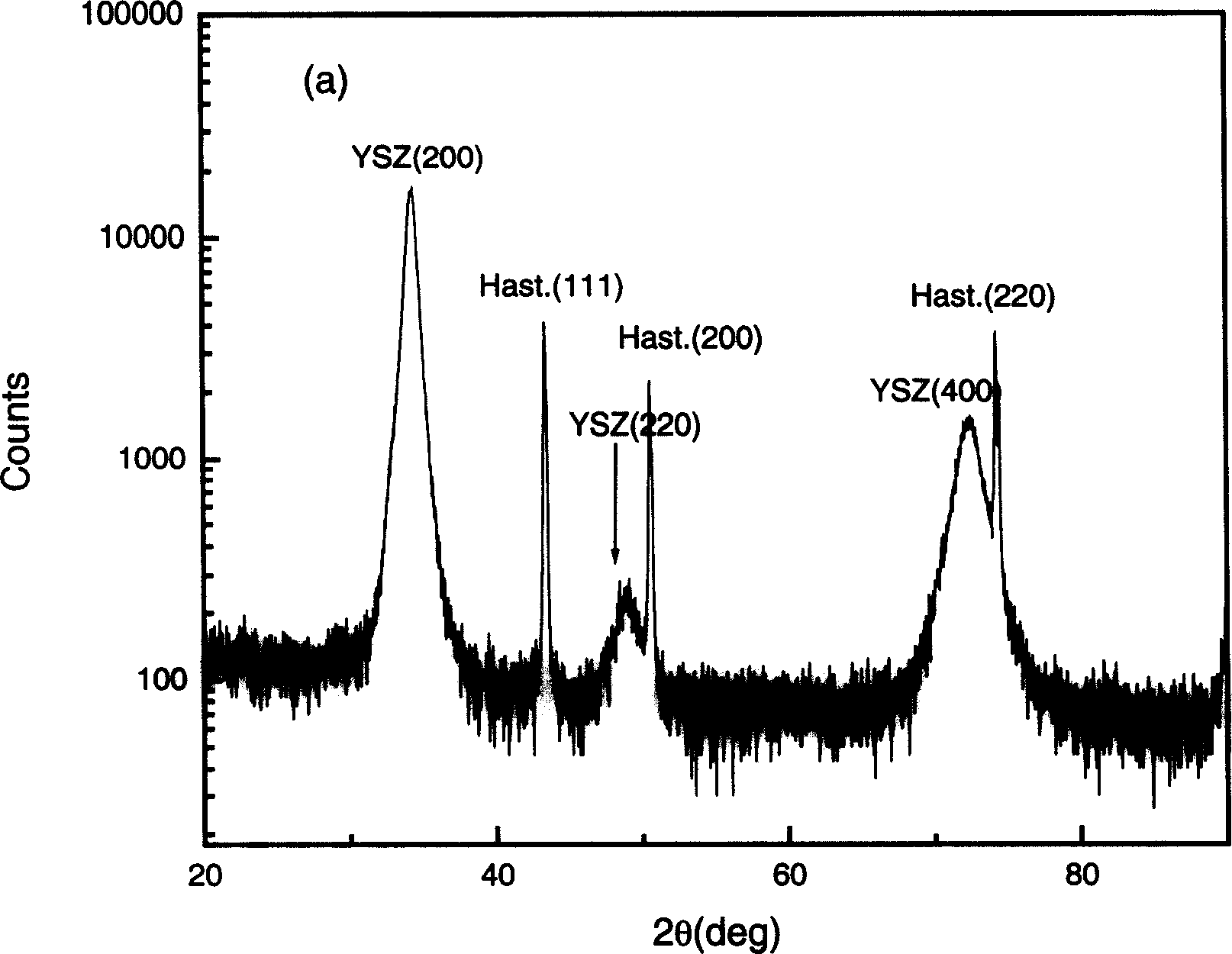

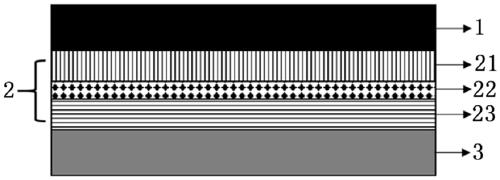

High-temp. superconducting film conductor and preparing method thereof

ActiveCN1719553AEasy to filmImprove film qualitySuperconductors/hyperconductorsSuperconductor devicesIon beam-assisted depositionChemistry

A high temperature super-conduction clad-film conductor and its preparation method relates to the method combining an IBAD technology with chemical solution method filming technology. The clad-film conductor is composed of a super-conduction protection layer, YBCO super-conduction layer, a CeO2 buffer layer, an IBAD YSZ buffer layer and a metal substrate. The method includes preparing a double-shaft buffer layer and an additional buffer layer on the metal basic belt material, then, preparing YBCO super-conduction layer and a lost super protection layer on these buffer layer material substrates to get the high temperature super-conduction clad-film conductor.

Owner:TSINGHUA UNIV +1

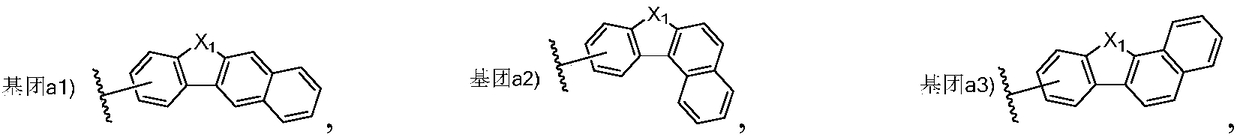

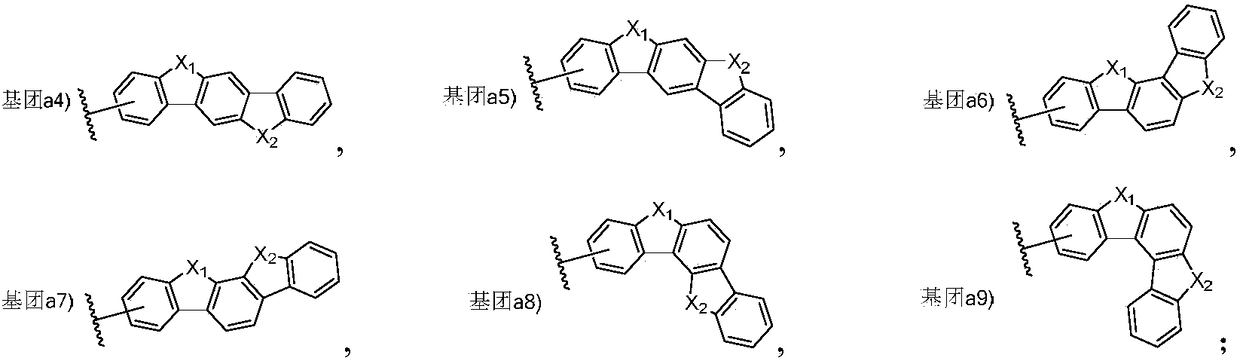

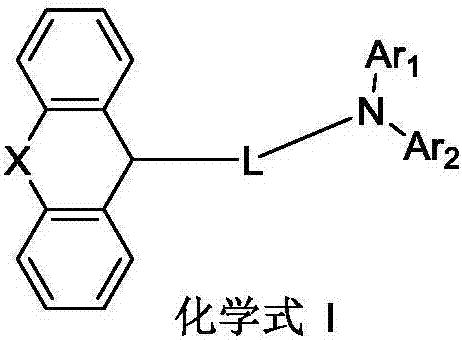

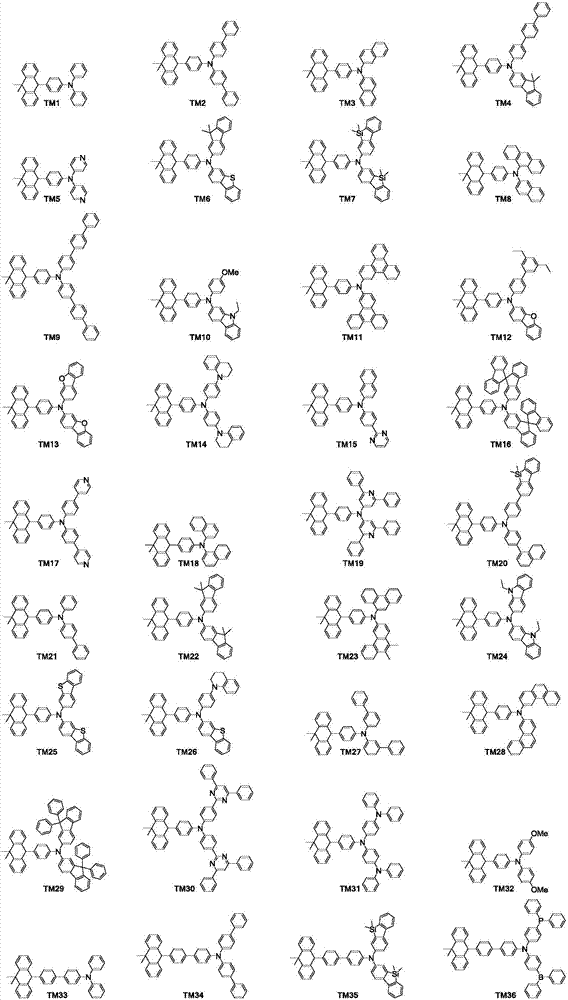

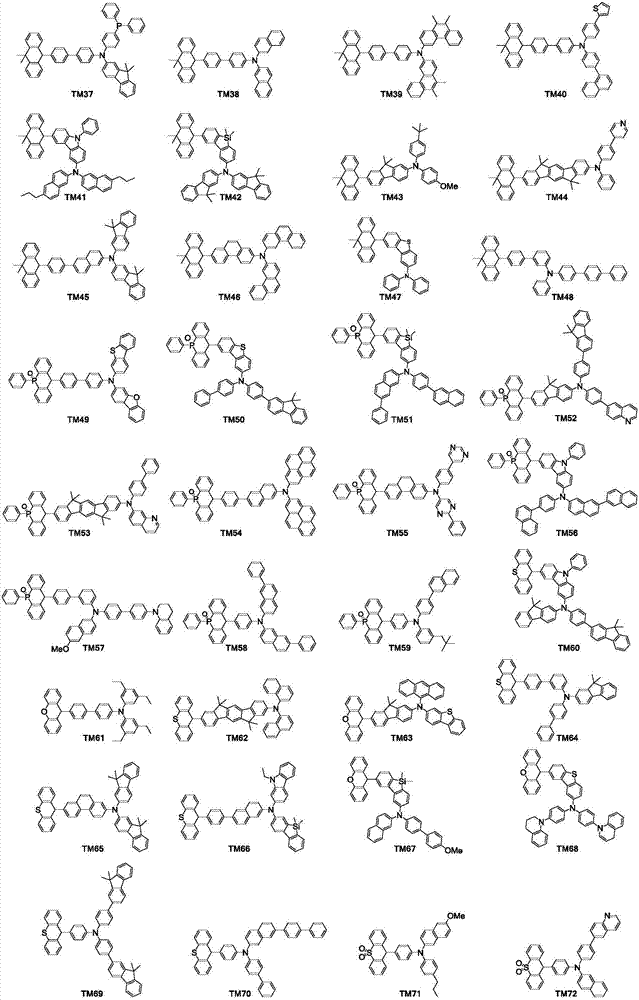

Triarylamine compound and organic electroluminescent device thereof

ActiveCN111808042AHigh triplet energy levelHigh glass transition temperatureOrganic chemistrySolid-state devicesBenzoxazoleRefractive index

The invention provides a triarylamine compound and an organic electroluminescent device thereof, and relates to the technical field of organic photoelectric materials. According to the invention, a substituted or unsubstituted 9-phenyl-fluorene group and a triarylamine group containing benzoxazole / benzothiazole / benzimidazole / benzotriazole undergoes a reaction to obtain the triarylamine compound by9-position (tertiary C) connection of fluorene. The triarylamine compound has a good hole transport capability, is high in glass transition temperature, good in thermal stability, good in film-forming property, high in refractive index and simple to synthesize, can be applied to an organic electroluminescent device to serve as a hole transport layer and / or a covering layer, can effectively solvethe problems of low luminous efficiency and short service life of the organic electroluminescent device, and has the advantages of high luminous efficiency and long service life.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

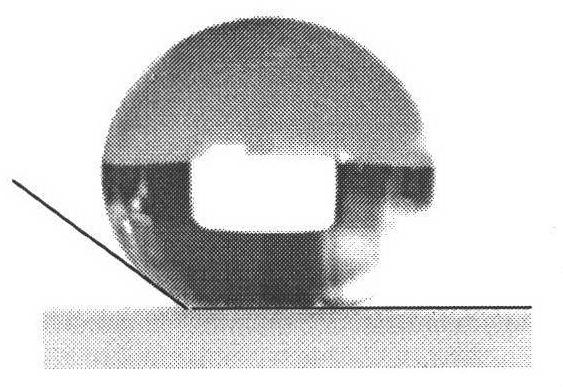

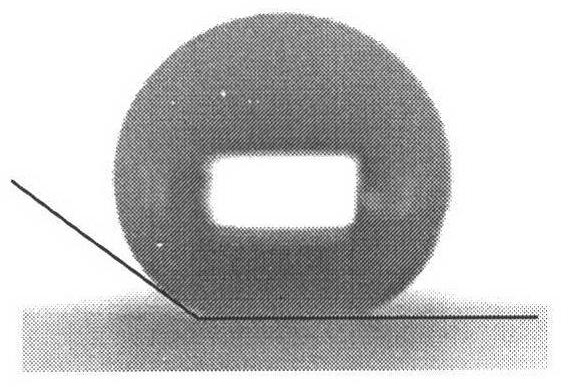

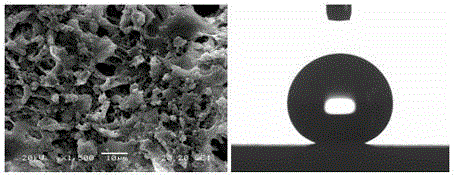

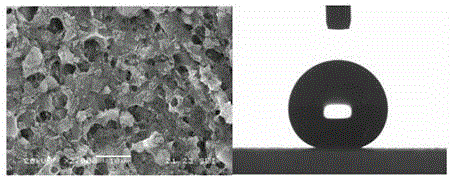

Hydrophobic anti-ice and snow coating of fluorosilicone acrylate copolymer and coating preparation method

InactiveCN102277060AReduce adhesionNot easy to accumulatePretreated surfacesCoatingsMicro nanoChemical treatment

The invention discloses a hydrophobic anti-ice and snow coating of a fluorosilicone acrylate copolymer and a preparation method of the coating. The paint includes ethyl acetate as a solvent, and the solute contained in the solvent is a fluorosilicone acrylate copolymer and a curing agent. The process of preparing the coating with the coating includes using aluminum flakes as the substrate, cleaning the surface with acetone and water, and drying; the coating is sprayed with a spray gun, powered by air, and sprayed at different distances from the surface of the substrate to obtain micro-nano Superhydrophobic coating with raised rough structure. The invention has the advantages of simple coating preparation process, easy-to-obtain raw materials, good film formation, high strength and hardness of the formed coating, and is widely used for surface coating of outdoor facilities such as transportation and power transmission. The coating preparation method is simple, does not require chemical treatment, is easy to industrialize, is suitable for large-area applications, and has high practical value and good anti-ice and snow effect.

Owner:TIANJIN UNIV

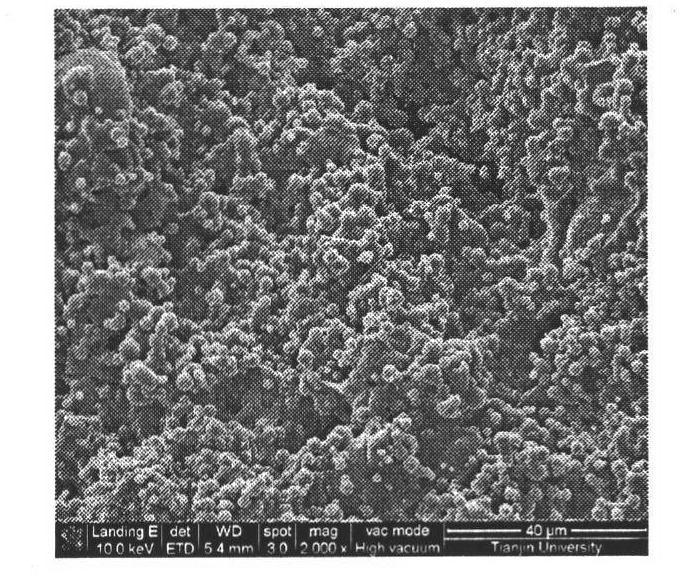

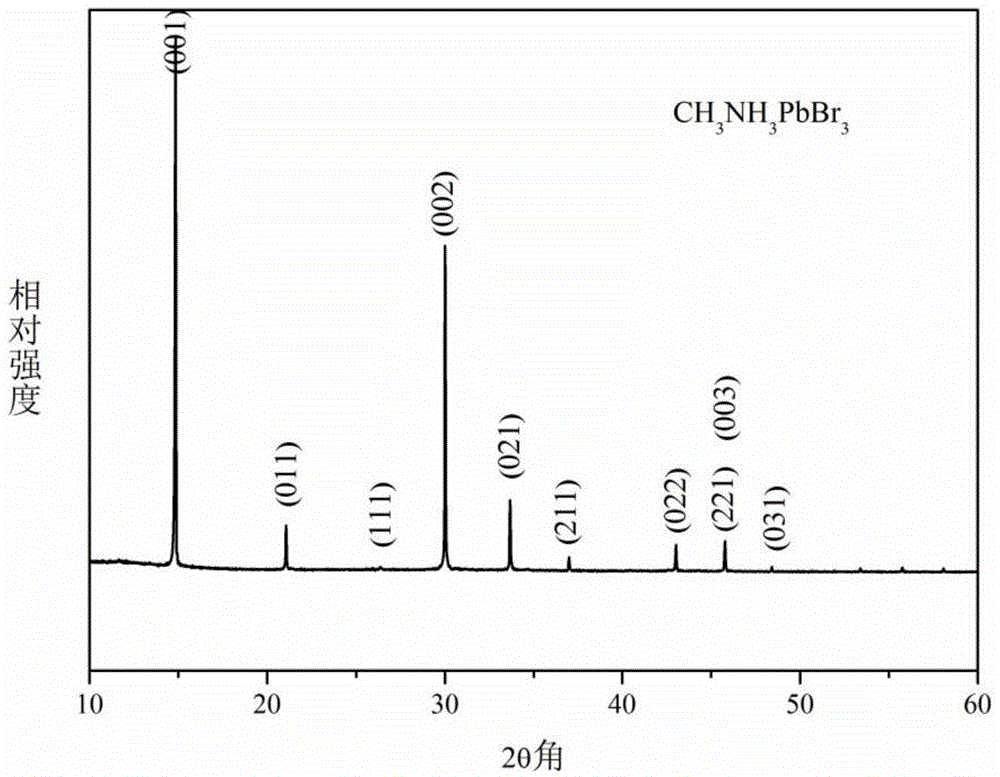

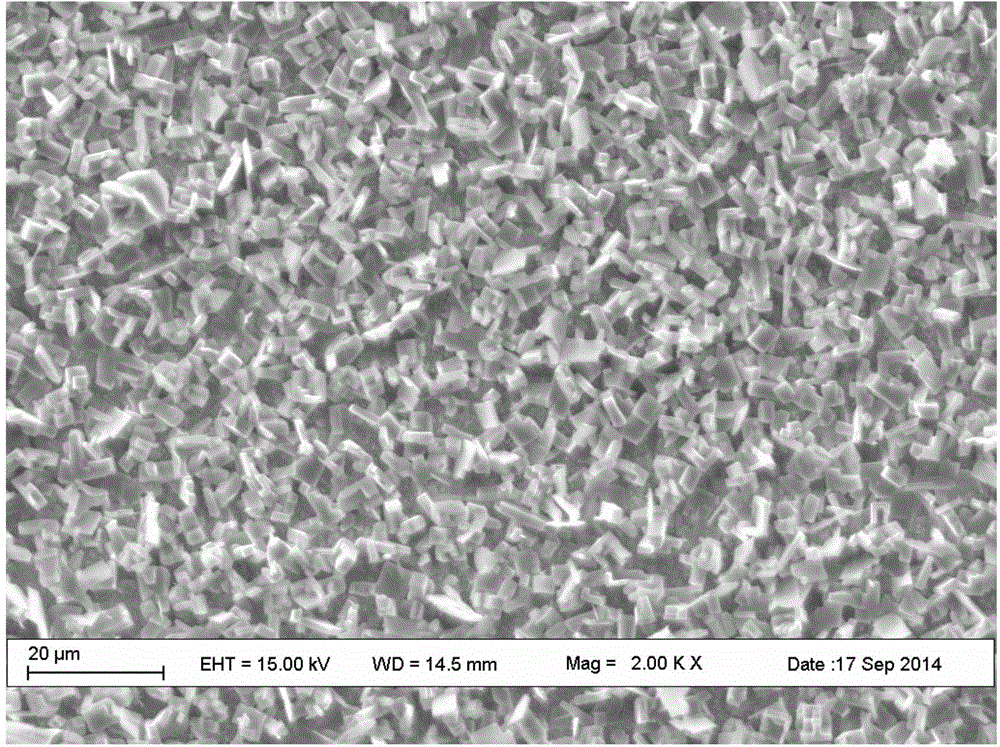

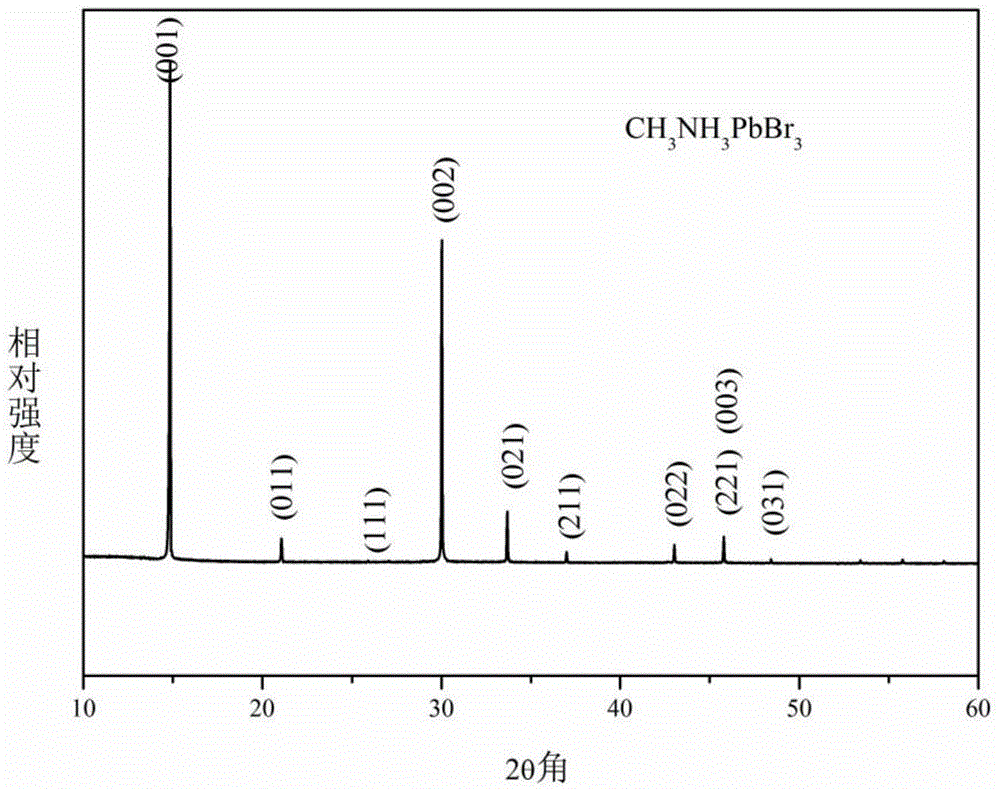

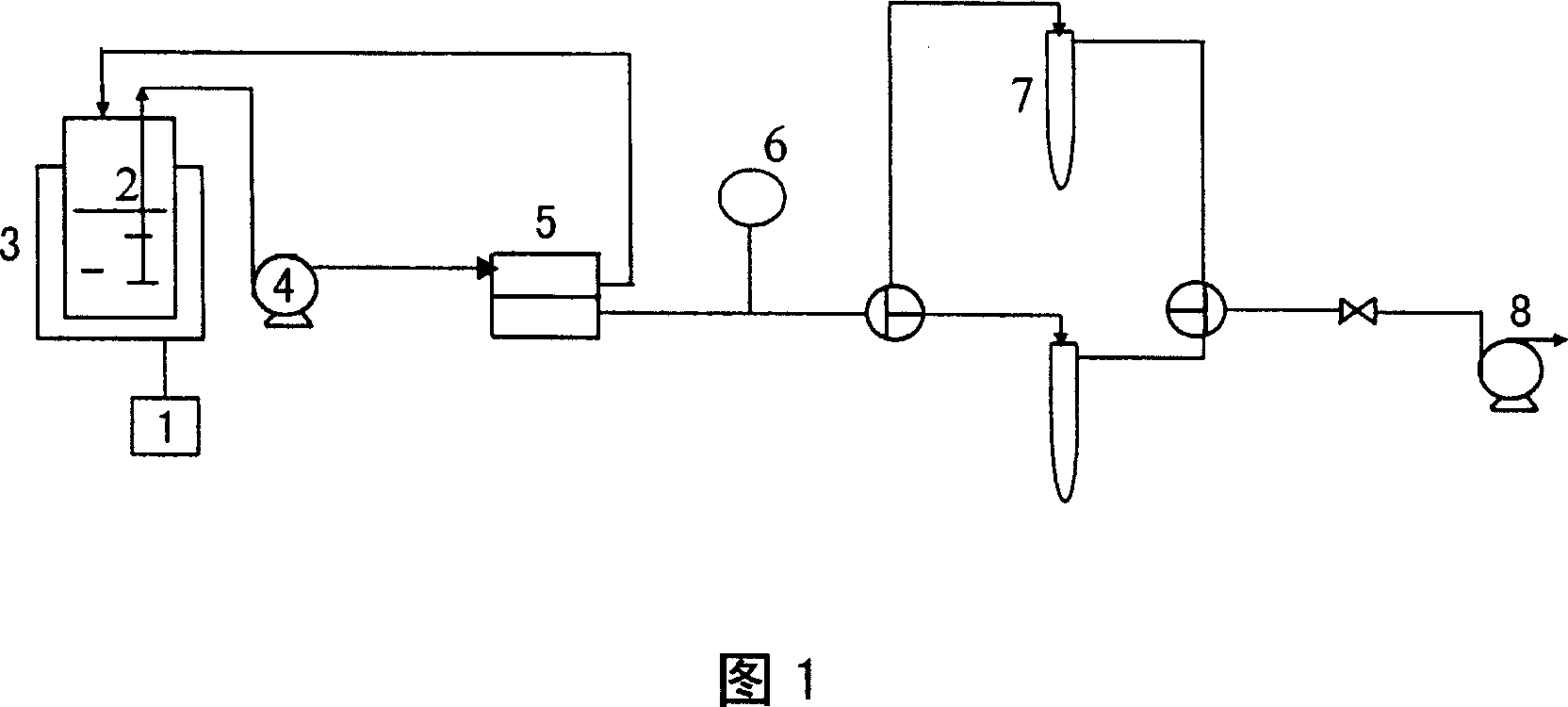

Chemical method for synthesizing perovskite type CH3NH3PbBr3 film material through in-situ large area control based on lead monomer film

ActiveCN105369232AEasy to operateAdapt to the needs of industrial applicationsMetallic material coating processesPhysical chemistryThin membrane

Owner:XUCHANG UNIV

Super-concentrated clothes washing sheet

InactiveCN105238584AEasy to filmEasy to carryInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBetaineFatty alcohol

The invention provides a super-concentrated clothes washing sheet. The super-concentrated clothes washing sheet comprises the following components in percentages by weight: 10-30% of a film forming agent, 1-10% of kaolin, 1-10% of silicon dioxide, 3-40% of sodium lauryl sulfate, 0.5-10% of fatty acid diethanol amide, 0.1-10% of dodecanol polyoxyethylene ether sodium sulphate, 0-10% of lauric acid betaine, 0-10% of fatty alcohol polyoxyethylene ether, 0-10% of polyalcohol, 0.1-5% of a chelate agent, and 1-50% of deionized water. Active components, the film forming agent and the like are scientifically collocated, so that the super-concentrated clothes washing sheet is easy to form a film.

Owner:GUANGZHOU LANJIEBAO BIOTECH CO LTD

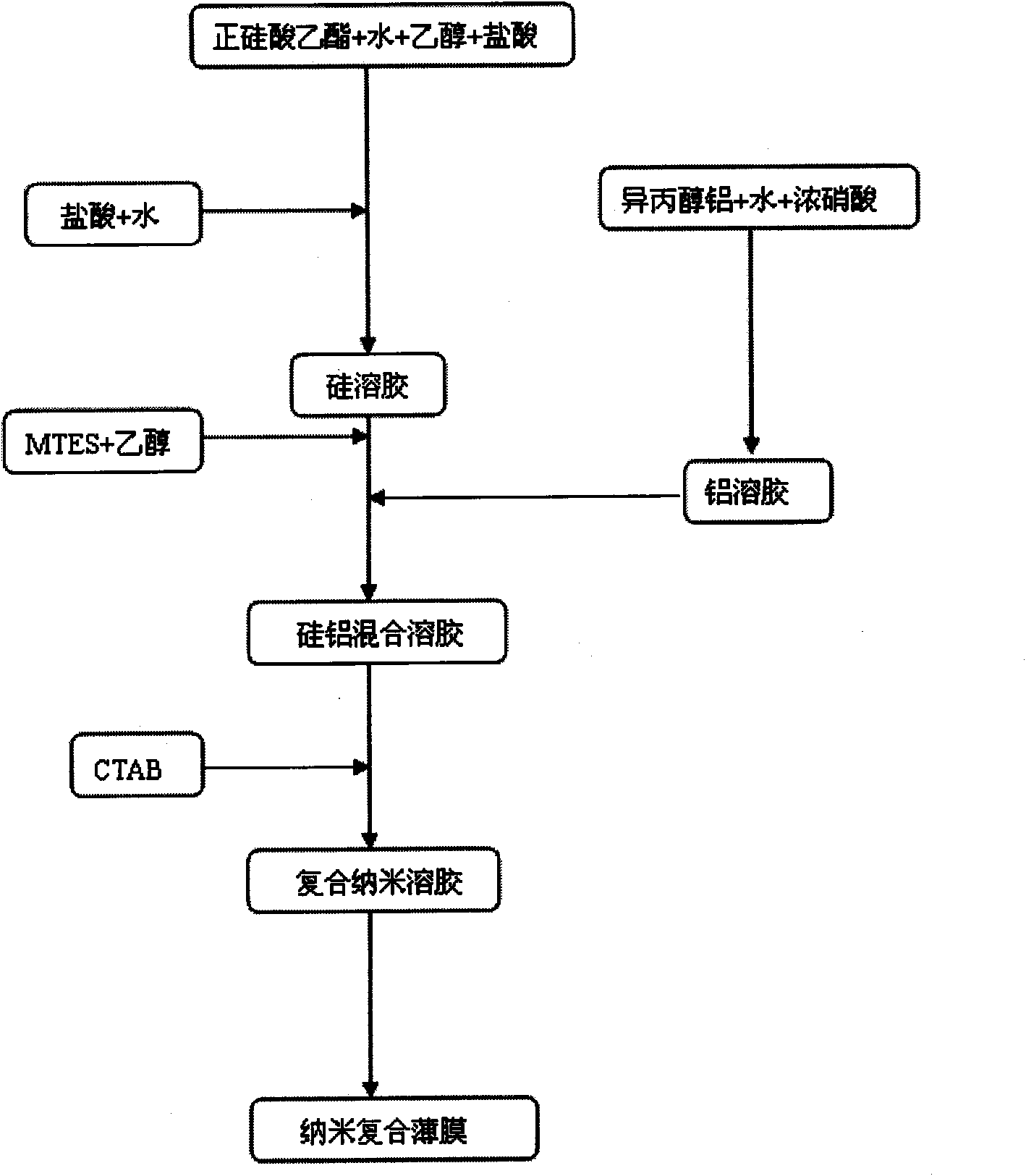

Nanometer composite hydrophobic hard transparent film and preparation method thereof

InactiveCN101629066AReduce the temperatureImprove mechanical propertiesOther chemical processesAviationComposite film

The invention discloses a nanometer composite hydrophobic hard transparent film and a preparation method thereof, belonging to the nanometer technical field. The preparation method of the nanometer composite hydrophobic hard transparent film comprises the preparation of silicon dioxide sol, the preparation of aluminium sol, the preparation of composite sol, film-plating and other steps. The hardness of the finally obtained nanometer composite hydrophobic hard transparent film of the invention can reach 5h which is detected by a QHQ type pencil hardness gauge and SL100 type static contact angle admeasuring apparatus, and the hydrophobic angle can reach 115 degrees so that the nanometer composite film has excellent mechanical properties and hydrophobic function. The obtained nanometer composite hydrophobic hard transparent film in the invention can be used on the surface of different devices so as to prevent or reduce the adhesion of steam, ice and snow and other pollutants and has broad application prospect in national defense, aviation, aerospace, everyday life and other industrial fields.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

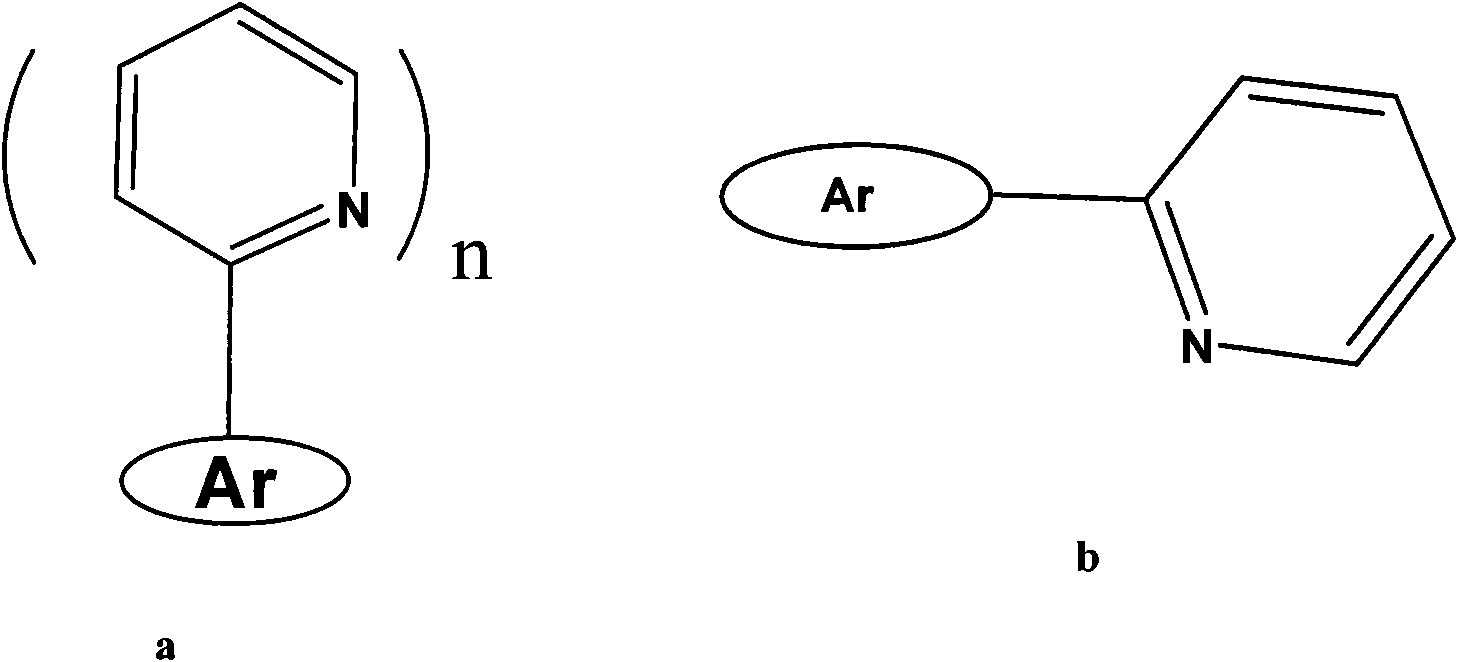

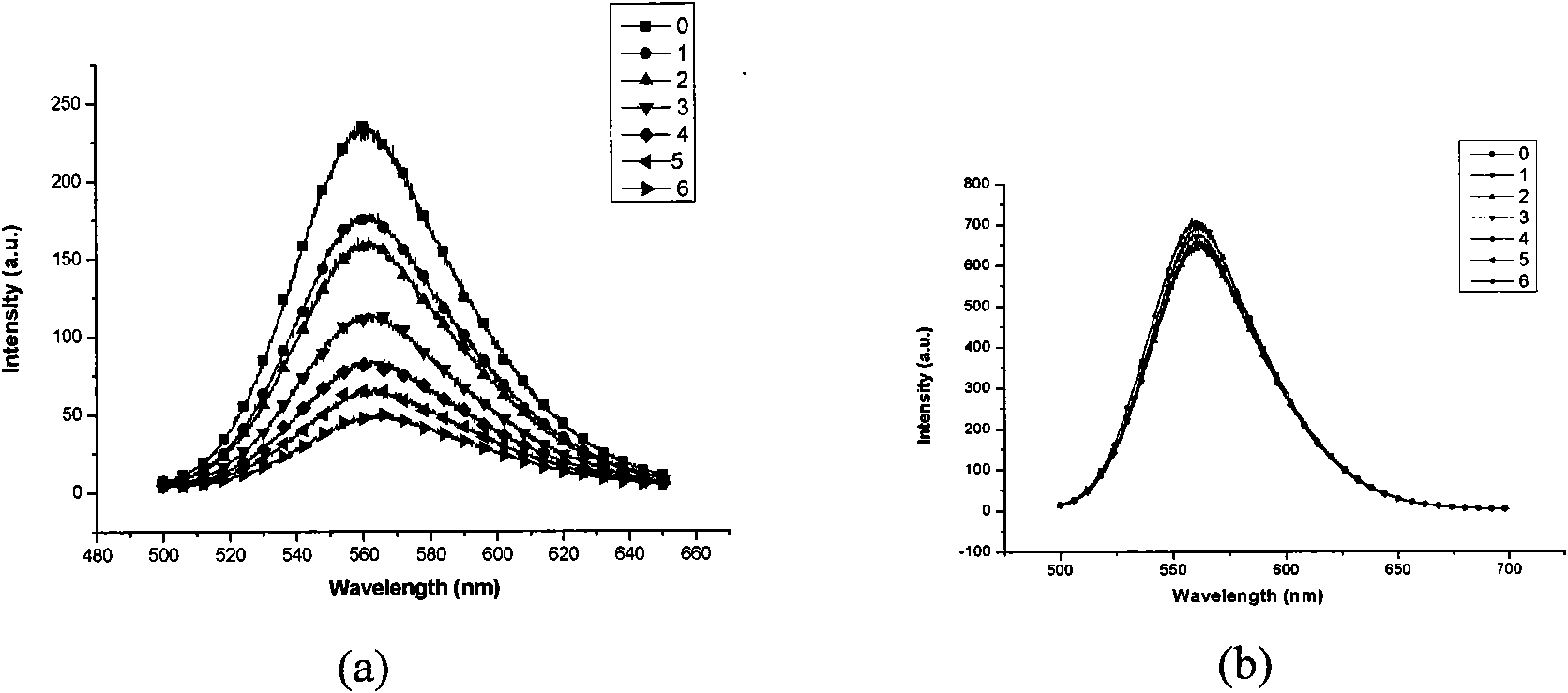

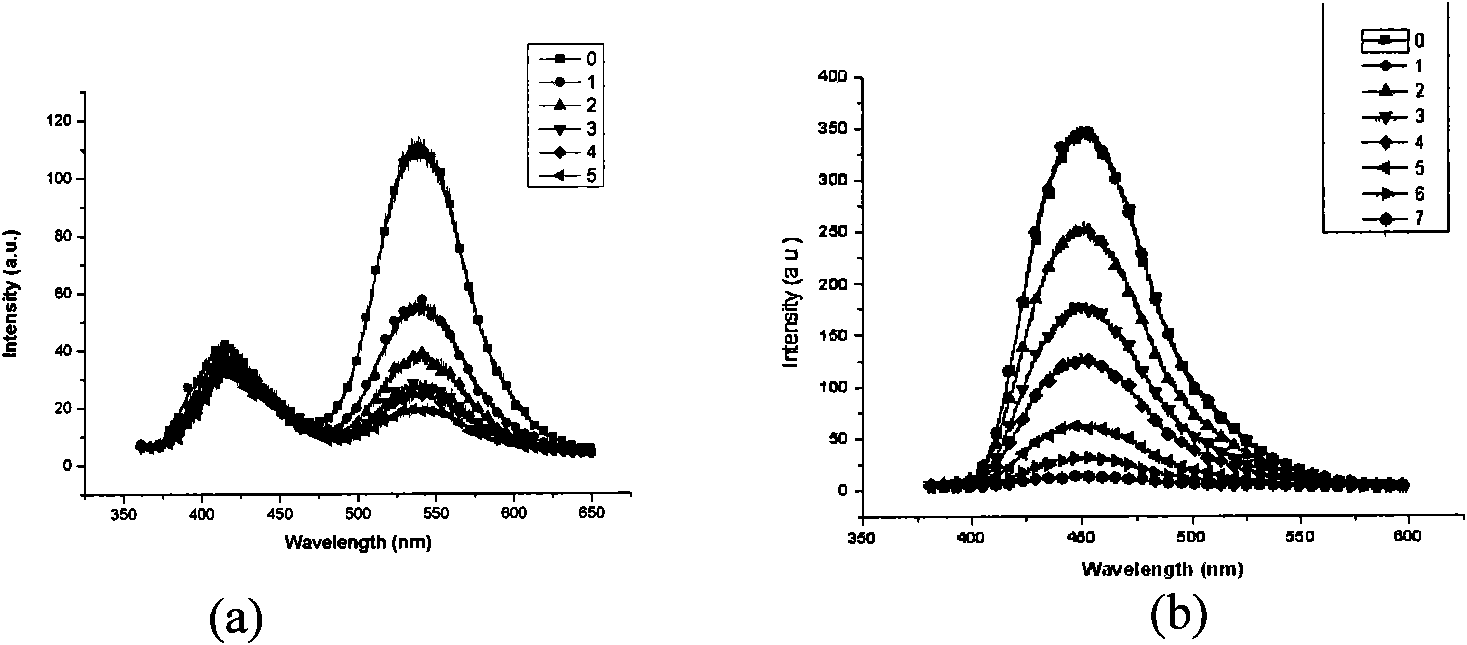

Fluorescent sensing material with sensing function to phenyl amine compounds, method and application thereof

InactiveCN101550234AEfficient detectionQuick responseFluorescence/phosphorescenceFluorescenceChemical compound

The invention relates to a fluorescent sensing material with sensing function to phenyl amine compounds, the method and the application thereof. The invention is characterized in that: Aryl is connected with pyridyl to form fluorescent sensing material, the fluorescent sensing material comprises line type, star type and dendritic aryl pyridine; the number of the pyridine units is a positive integer from 1 to 150. The preparation method comprise two steps: synthesizing aryl boric acid or boron ester compound and synthesizing aryl pyridine compound. The fluorescent sensing material provided in the invention is used to detect phenyl amine compounds.

Owner:上海新微科技发展有限公司

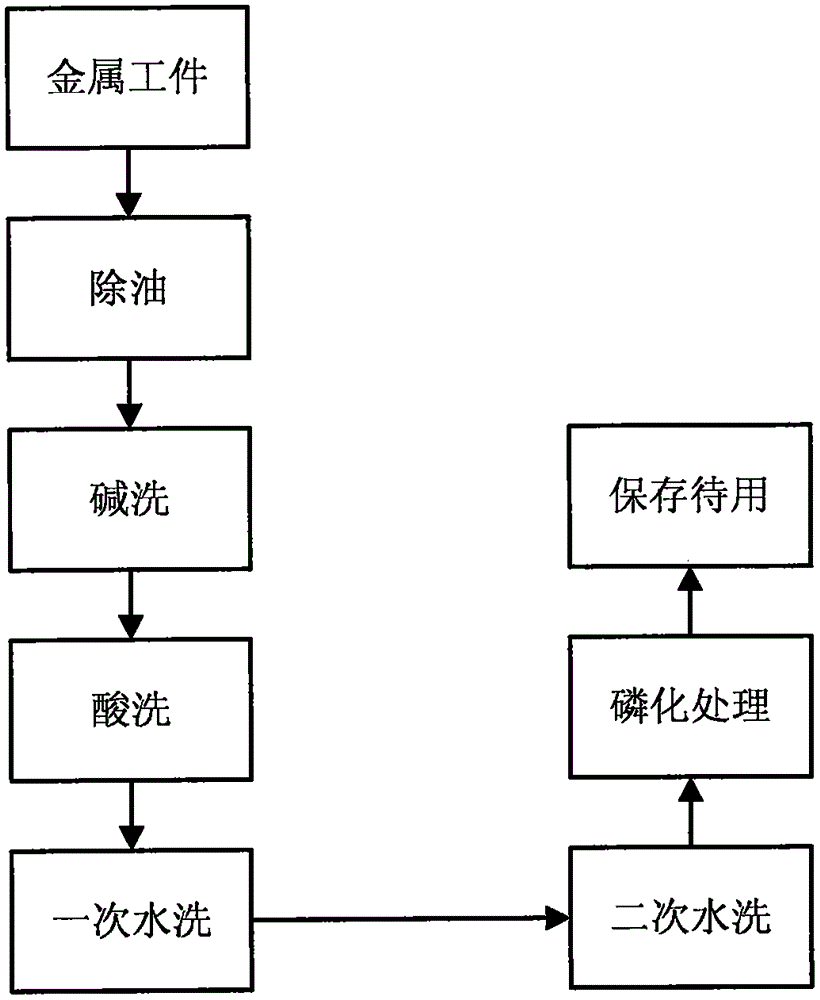

Before-coating metal surface treatment method

ActiveCN105369271AImprove permeabilityFast film formationMetallic material coating processesNonferrous metalAcid washing

The invention discloses a before-coating metal surface treatment method. The before-coating metal surface treatment method comprises such steps as oil removal, alkali washing, acid washing, two times of water washing and phosphorization. Adopted environment-friendly alkaline cleaning liquid has the technical effects of energy conservation and environmental protection, and has an excellent cleaning effect on both black metal and nonferrous metal; adopted phosphorization liquid has such advantages as quick film formation, strong paint film bonding force, good corrosion resistance, capability of operating through brushing or spraying, simple operation and low cost; the prepared phosphorization liquid reduces phosphorization liquid sediments, and guarantees the quality of phosphorized film; and the film layers are uniform and exquisite, so that the metal surface treatment method can realize the before-coating metal surface treatment more environment-friendly and more efficiently, and has active effects on the coating process and the coating quality.

Owner:苏州天成涂装系统股份有限公司

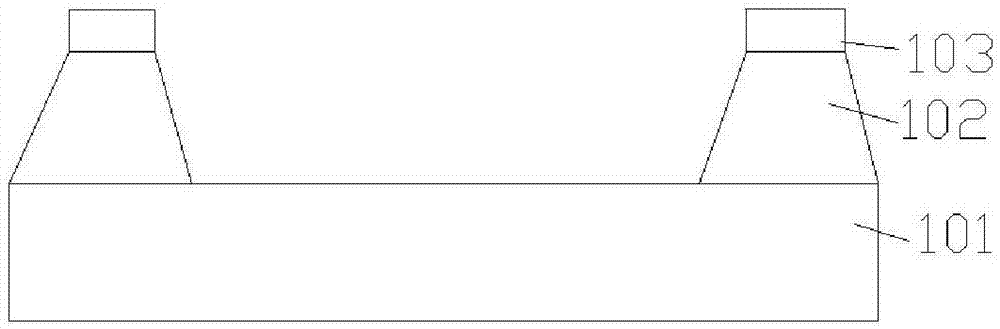

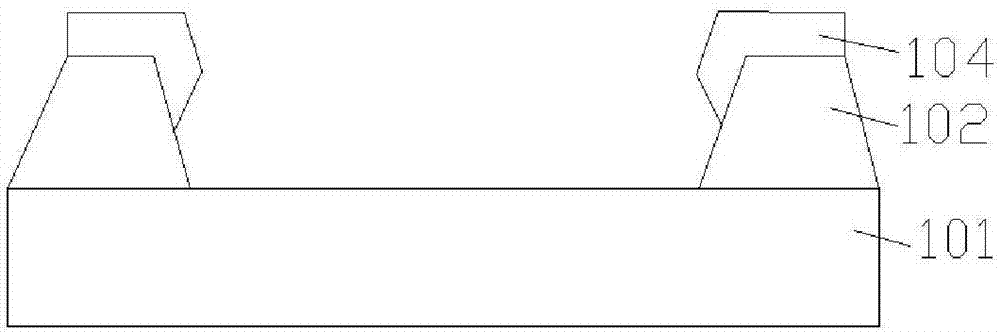

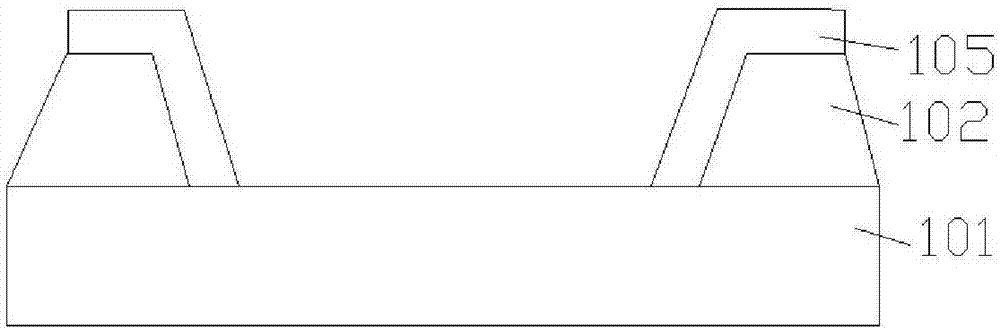

Pixel defining layer and manufacturing method thereof

ActiveCN107248523AEasy to prepareReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

According to the invention, a first defining layer of a pixel defining layer comprises dam bodies locally covering a substrate; second defining layers are arranged at the tops of the dam bodies; and the second defining layers are made of a lyophobic material. A manufacturing method of the pixel defining layer disclosed by the invention comprises the steps of: preparing the first defining layer on the substrate; preparing one layer of lyophobic material on the substrate and the first defining layer; and by the etching process, removing the lyophobic material between the dam bodies to obtain the second defining layers covering the dam bodies of the first defining layer. According to the pixel defining layer disclosed by the invention, hydrophobic layers are arranged at the tops of the dam bodies, and a material of the substrate has the lyophilic property, so that the requirements for top lyophobicity and bottom lyophilic property of the pixel defining layer are met; and the manufacturing method of the pixel defining layer disclosed by the invention is simple, low in manufacturing cost and very simple and convenient in process flow.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

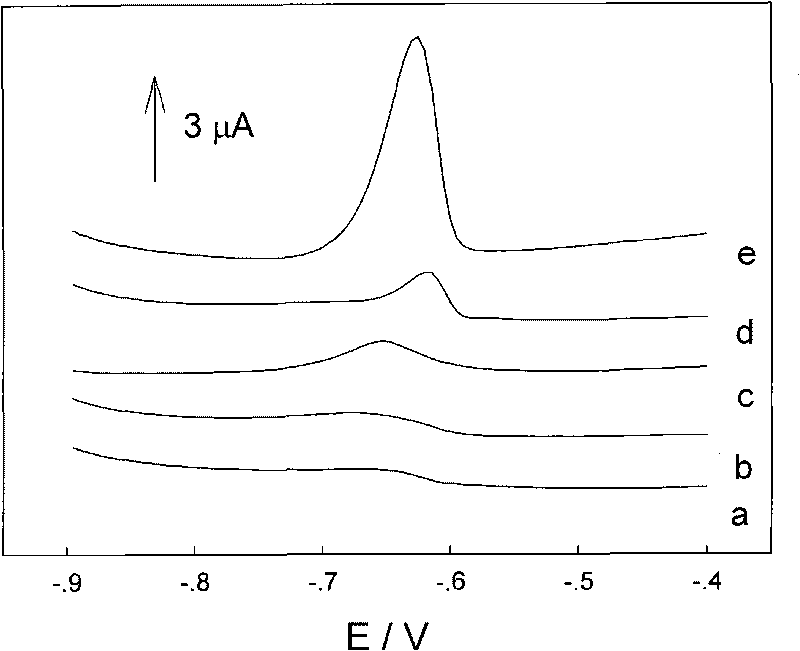

Electrochemical sensor for determining concentration of heavy metal ions in water sample

ActiveCN101706471AGood choiceHigh sensitivityMaterial analysis by electric/magnetic meansIon exchangeAuxiliary electrode

The invention relates to a sensor, in particular to an electrochemical sensor for determining the concentration of heavy metal ions in a water sample. The electrochemical sensor specifically comprises a working electrode, a reference electrode and an auxiliary electrode, and the working electrode, the reference electrode and the auxiliary electrode are respectively connected to a control potential meter through conducting wires; the working electrode consists of a polytetrafluoroethylene pipe and a carbon electrode clamped therein, the bottom end of the carbon electrode is connected with a lead wire for leading out, and a sensitive membrane is arranged at the top end of the carbon electrode; and the sensitive membrane consists of a nano-functional absorbing material, a heavy metal ion carrier and an ion exchange agent, 1-20mmol of nano-functional absorbing material, 0.5%-5% by weight of the ion exchange agent and the 0.5-10mmol of the ion carrier are added in each liter of dispersant and evenly mixed, and then 1mu L-30mu L of the mixture is taken and evenly coated on the surface of the carbon electrode. The electrochemical sensor has low cost, simple technology, high selectivity and sensitivity and good stability, and can be extensively applied in the detection of the heavy metal ions in waste water, fresh water, sea water, daily necessities and body fluid.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Star-shaped adamantane derivative molecular glasses, and preparation method and application thereof

ActiveCN103804196AEasy to synthesizeAchieve separationOrganic compound preparationCarboxylic acid esters preparationAlkoxy groupPerylene derivatives

The invention discloses star-shaped adamantane derivative molecular glasses having the following structure shown in the description, wherein substituents R1-R12 are respectively hydrogen, hydroxy, alkoxy or acid sensitivity substituents; the substituents R1-R12 can be different or the same, but the substituents at a same benzene ring cannot both be hydrogen. The invention also discloses a preparation method of the star-shaped adamantane derivative molecular glasses. The method is simple in synthesis process, products of the steps of a reaction all can be separated from the system through a recrystallization or precipitation method. The molecular glasses can be used as photoresist main body materials made into thin films, and also can be used for photoetching.

Owner:国科天骥(北京)新材料技术有限责任公司

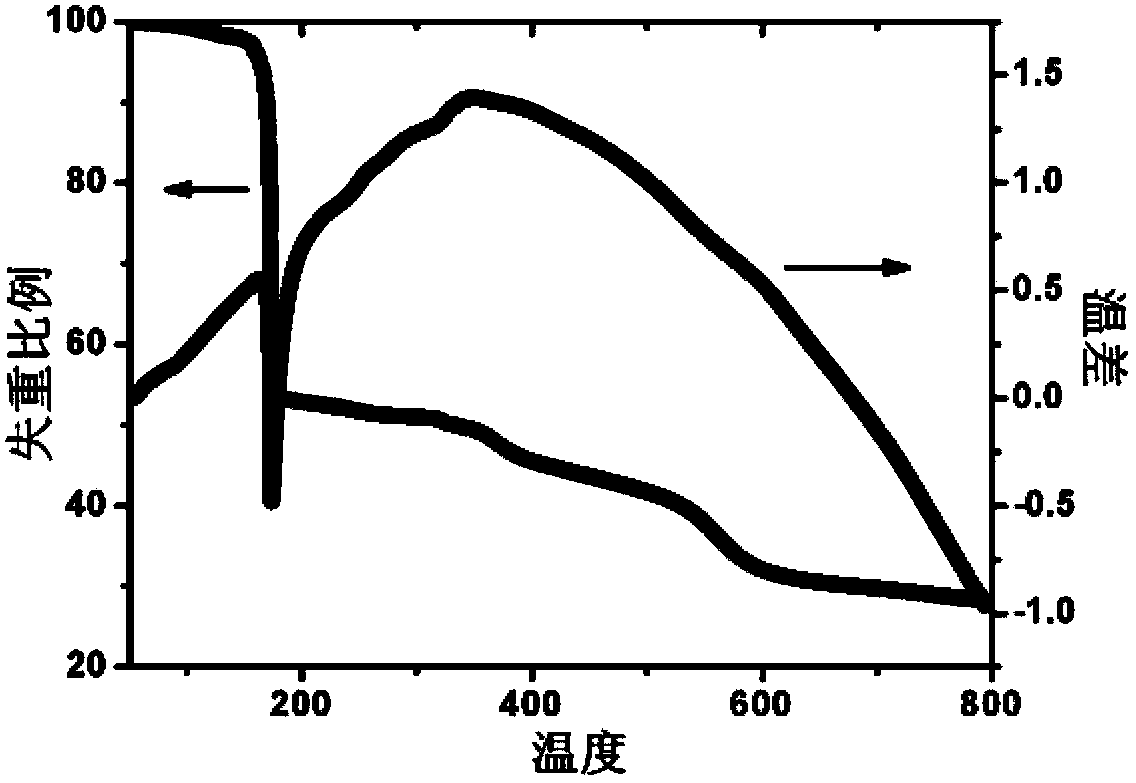

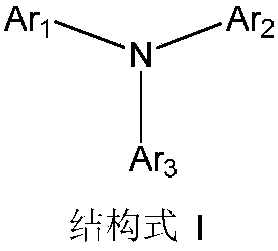

Triarylated amine derivative and organic electroluminescence device with same

InactiveCN108341795AIncreased conjugated systemHigh hole mobilityOrganic chemistrySolid-state devicesOrganic electroluminescencePerylene derivatives

The invention discloses a triarylated amine derivative and an organic electroluminescence device with the same, and relates to the technical field of organic photoelectric materials. The triarylated amine derivative has a large conjugated system, thereby having high hole mobility and presenting good hole transmissibility; in addition, the triarylated amine derivative has high thermal stability anddissolubility and is beneficial for material film forming. The organic electroluminescence device comprises a cathode, an anode and one or more organic matter layers. The organic matter layers are located between the cathode and the anode. At least one of the organic matter layers contains the triarylated amine derivative. The organic electroluminescence device has low driving voltages, high light-emitting efficiency, light-emitting luminance and long service life.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

High molecular waterproof coating and preparation method thereof

The invention relates to a waterproof coating, in particular to a high molecular waterproof coating and a preparation method thereof. The high molecular waterproof coating is prepared from a powder material and a liquid material in the weight ratio of (1-5):1, wherein the powder material comprises the following components in parts by weight: 0.1-5 parts of reactive polysiloxane compound, 1-5 parts of polypropylene chopped fiber, 10-50 parts of quartz powder, 30-70 parts of calcium carbonate and 1-15 parts of bentonite; and the liquid material comprises the following components in parts by weight: 30-80 parts of polyvinyl acetate emulsion, 0.5-5 parts of thickening agent, 0.5-5 parts of sterilizing agent, 0.1-3 parts of organic silicon antifoaming agent and 10-40 parts of water. The high molecular waterproof coating has the advantages of no pollution to human bodies and the environment, readily-available raw materials, low cost, easiness for preparing, convenience for construction, safety, environment friendliness, excellent physical property, strong bonding force, high extensibility, prevention of water and rust and the like, and can be applied to waterproofness of indoor and outdoor buildings.

Owner:TIANCHANG JULONG TRAVEL PAINT

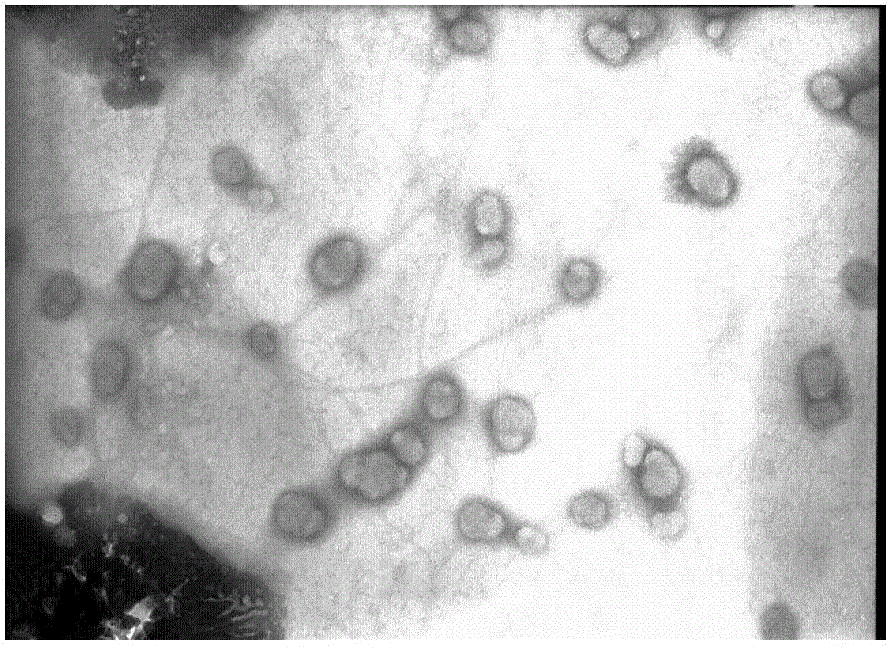

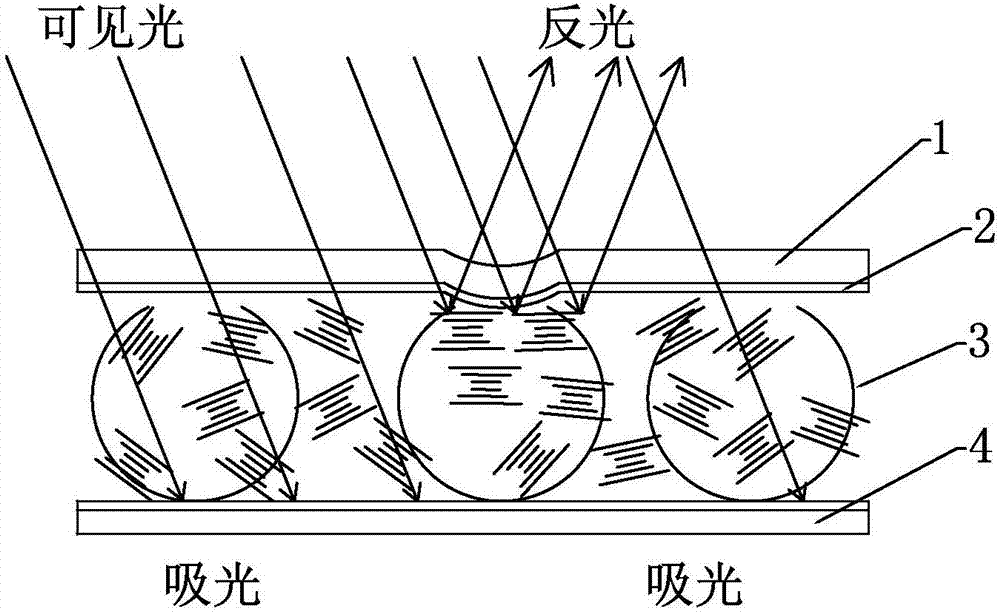

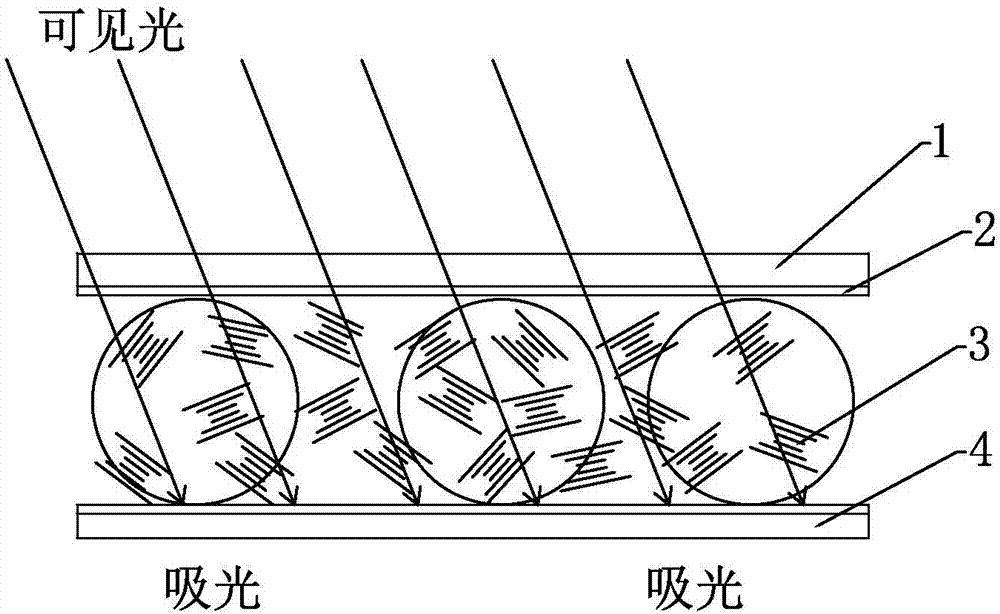

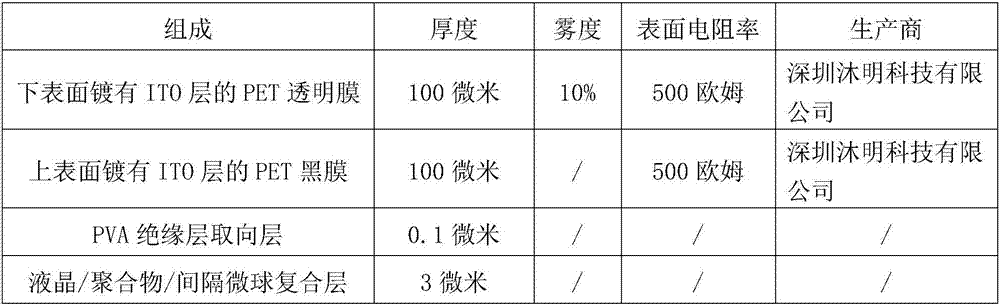

Liquid crystal composite film with writing display function and preparation method thereof

ActiveCN107300818ABig advantageIncrease frictionNon-linear opticsComposite filmLiquid-crystal display

The invention belongs to the field of liquid crystal display and particularly discloses a liquid crystal composite film with a writing display function and a preparation method thereof. The liquid crystal composite film with the writing display function comprises a PET transparent film, a PVA insulating orientation layer, a liquid crystal / polymer / interval microsphere composite layer and a PET black film sequentially from top to bottom. The lower surface of the PET transparent film is coated with an ITO layer, and the upper surface of the PET black film is coated with an ITO layer. The liquid crystal composite film with the writing display function and the preparation method thereof have advantages that due to addition of the PVA insulating orientation layer, short circuit risks of two conductive layers are avoided, and accordingly the rate of finished products is sharply increased, service lives of the products are greatly prolonged, production cost is reduced, and the driving voltage of the liquid crystal film is lowered to increase key technical indexes such as brightness and contrast ratio of the film.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP +1

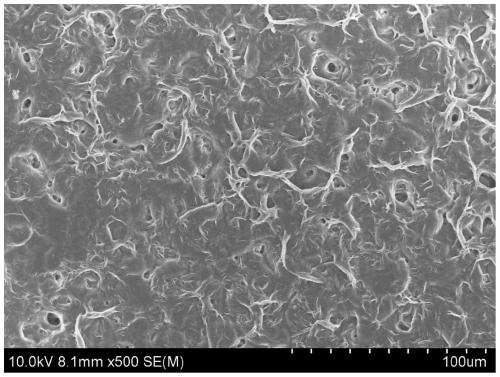

Nano silver-polyvinylidene fluoride composite separation membrane and preparation method thereof

InactiveCN102302903AIncrease water fluxHigh retention rateSemi-permeable membranesNanoparticlePolyvinylidene difluoride

The invention discloses a nano silver-polyvinylidene fluoride composite separation membrane and a preparation method thereof. The separation membrane is obtained by modifying a polyvinylidene fluoride membrane with nano silver. According to the invention, two dispersion methods namely a physical method and a chemical method are simultaneously adopted in the preparation process, so that nano particle reaches an ideal dispersion effect in the polyvinylidene fluoride separation membrane and a reliable guarantee is provided for the excellent property of the membrane. In the invention, a noble metal nano silver the price of which is relatively low is added, and the amount of nano silver is regulated, so that the mechanical property, antibiotic property and pollution resistance of the polyvinylidene fluoride separation membrane are greatly improved, the water flux and trapping rate of the polyvinylidene fluoride separation membrane are also improved, the service life of the membrane is prolonged, and the membrane has high performance-to-price ratio.

Owner:UNIV OF JINAN

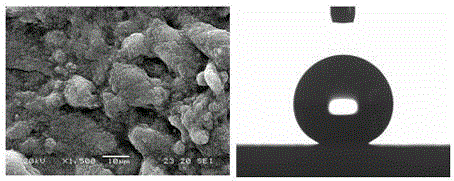

Preparation method of SiO2/polymer combined superhydrophobic coating

The invention discloses a preparation method of a SiO2 / polymer combined superhydrophobic coating. The preparation method comprises the following steps: adding a polymer into an organic solvent, and stirring till the polymer is dissolved completely to obtain a transparent solution I; adding hydrophobic nano silicon dioxide and a coupling agent, continuing stirring or carrying out ultrasonic dispersion till hydrophobic nano silicon dioxide is dispersed uniformly, adopting a pulling film forming method to obtain a uniform superhydrophobic coating, and drying the superhydrophobic coating at room temperature to obtain the product, wherein the addition proportion of the polymer to the organic solvent, hydrophobic nano silicon dioxide and the coupling agent is 1.6g:(40 to 50ml):(2.0 to 2.4g):1.0g. The preparation method has the advantages that the operation is simple; the raw materials are cheap and highly available; the repeatability is high; the prepared product has the advantages of both the polymer and inorganic nano particles, and is excellent in performance; each contact angle between the prepared product and water is 160 degrees or above; the roll angle of a water droplet on the surface of the coating is equal to or smaller than 10 degrees; a film made of the coating is uniform and suitable for various substrates.

Owner:HENAN UNIVERSITY

Organic luminescence compound and organic luminescence device thereof

InactiveCN107986975AIncreased conjugated systemHigh hole mobilitySilicon organic compoundsGroup 5/15 element organic compoundsSolubilityOrganic light emitting device

The invention discloses an organic luminescence compound and an organic luminescence device thereof, and relates to the technical field of an organic photoelectric material. A conjugated system of theorganic luminescence compound is great, so that higher hole mobility is realized; good hole transmission performance is shown. In addition, the organic luminescence compound provided by the inventionalso has good thermal stability and solubility; the film forming of the material is facilitated. The organic luminescence device using the organic luminescence material as an organic matter layer hasthe advantages that the driving voltage is lower; the luminescence efficiency and luminescence brightness are high; the service life is longer.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

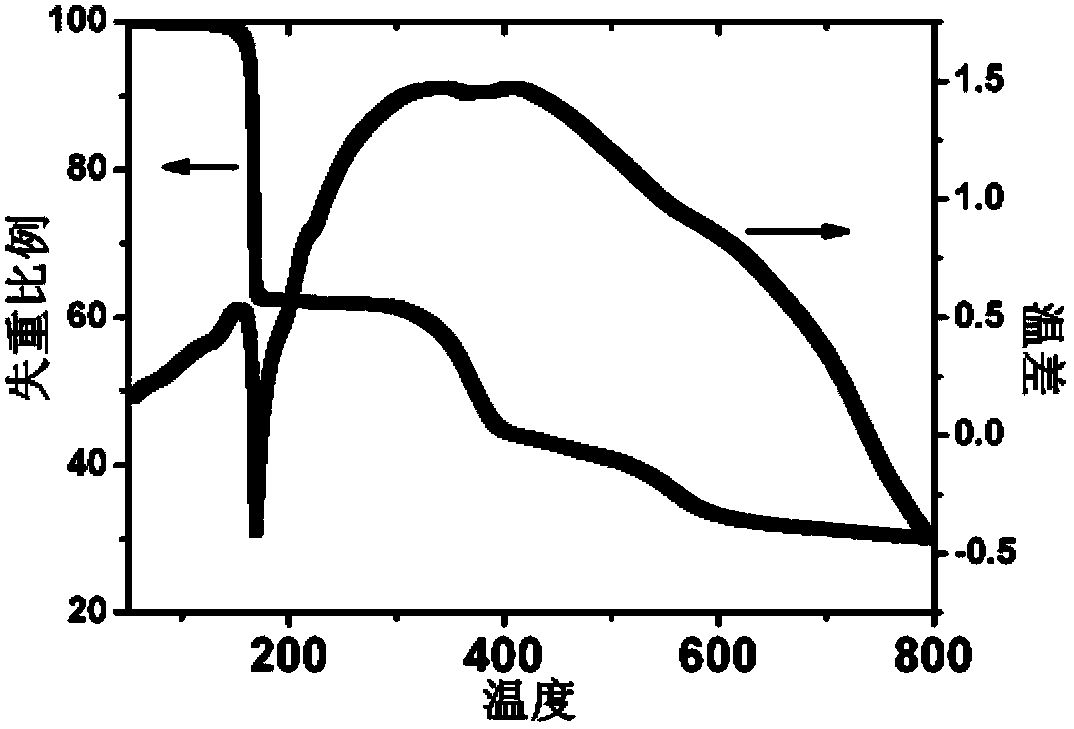

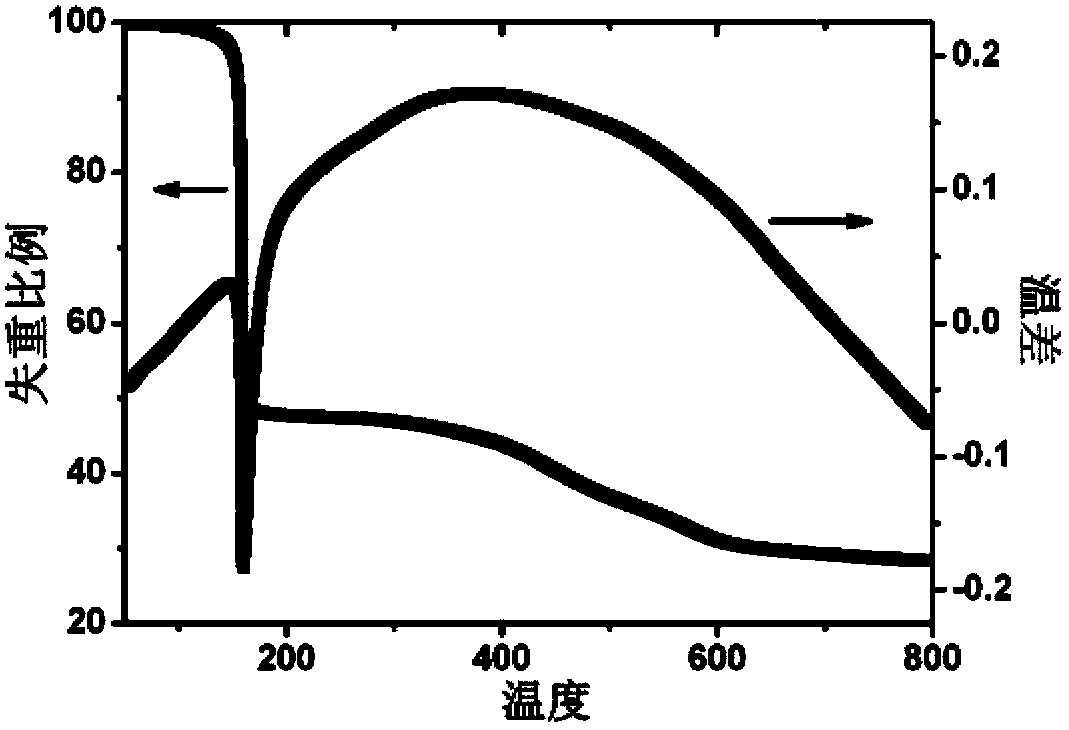

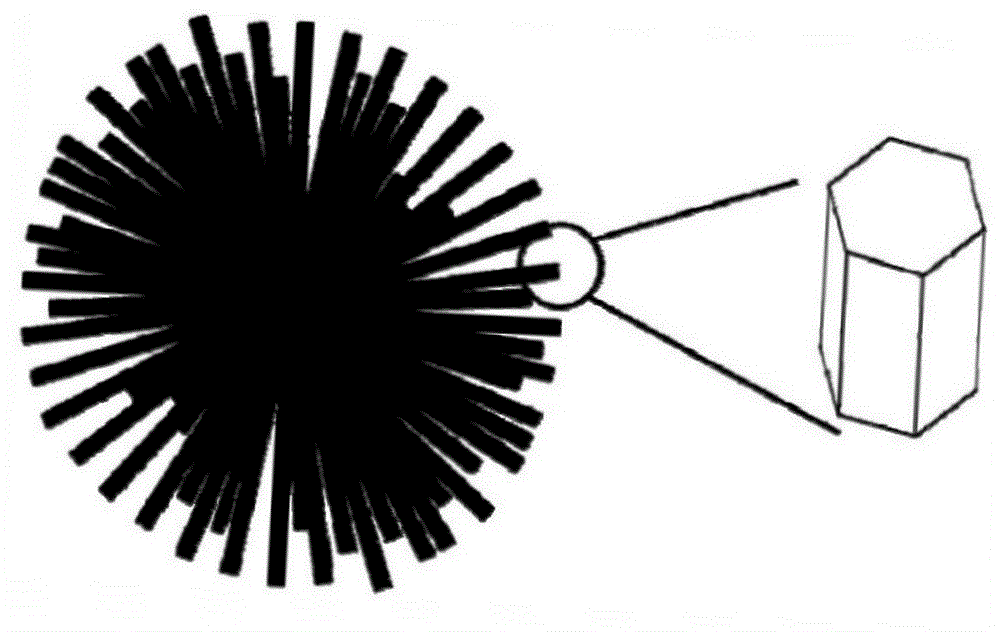

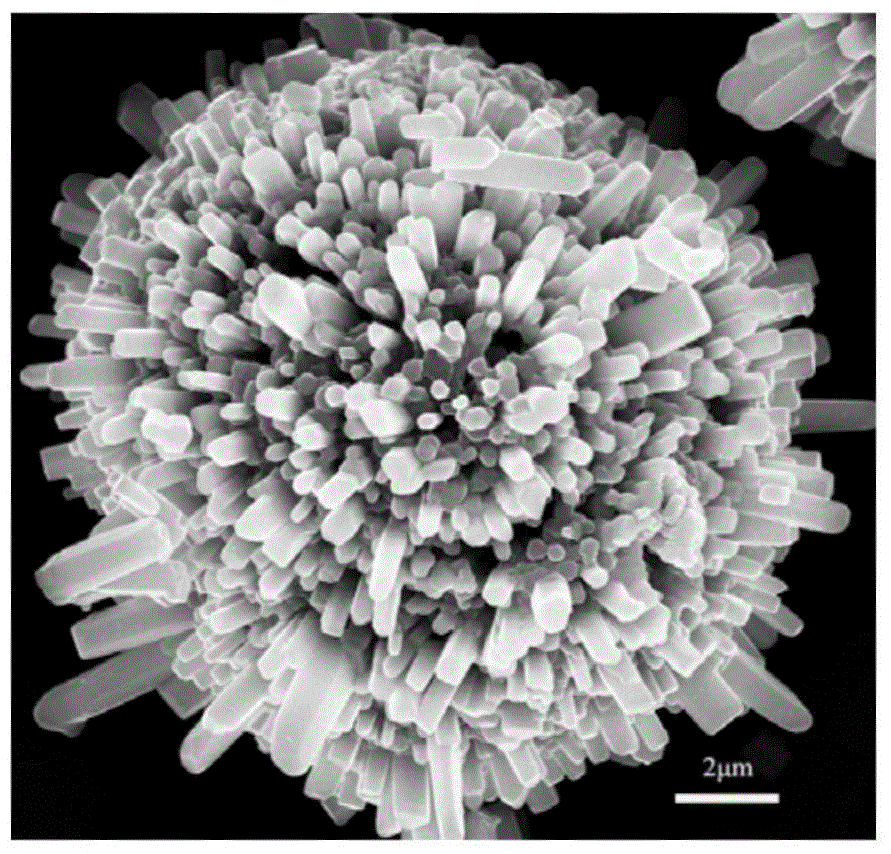

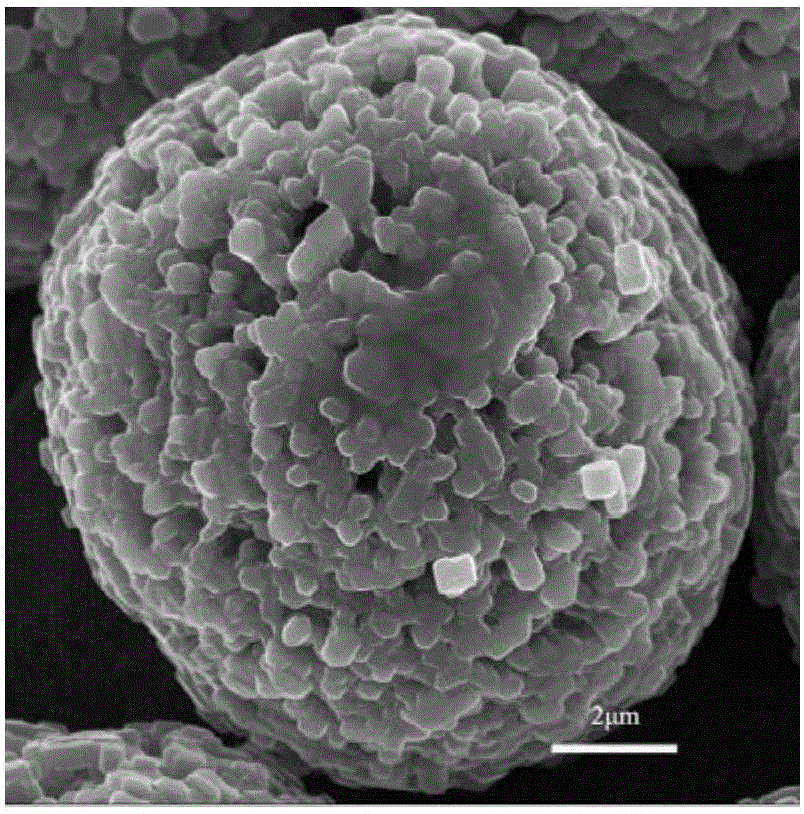

Urchin-like sodium-containing lithium-rich layered cathode material and preparation method thereof

ActiveCN106711434ASimple preparation processImprove uniformityCell electrodesLithium-ion batteryBall mill

An urchin-like sodium-containing lithium-rich layered cathode material and a preparation method thereof belong to the field of a lithium ion battery electrode material and a preparation technology. The chemical composition of the material is Li1.2-zNazMn0.54Co0.13Ni0.13O2 (z is greater than or equal to 0.03 and less than or equal to 0.1), and the urchin-like structure is formed by hexagonal-prism-shaped primary particles. The method is prepared by the following steps: a transition metal composite carbonate (MCO3, M=Mn, Co, Ni) precursor is prepared by a coprecipitation method; through high-temperature roasting, transition metal composite oxide (MOx, M=Mn, Co, Ni) is obtained; and the transition metal composite oxide, a lithium source and a sodium source undergo ball-mill mixing, and finally high-temperature roasting is carried out so as to obtain the product. The invention has the following advantage: the material has good rate capability and cycling stability. During high-temperature roasting of the mixture of the transition metal composite oxide, the lithium source and the sodium source, by the influence of sodion on crystal growth orientation, the urchin-like sodium-containing lithium-rich layered material is obtained. In addition, the preparation process is simple.

Owner:BEIJING UNIV OF CHEM TECH

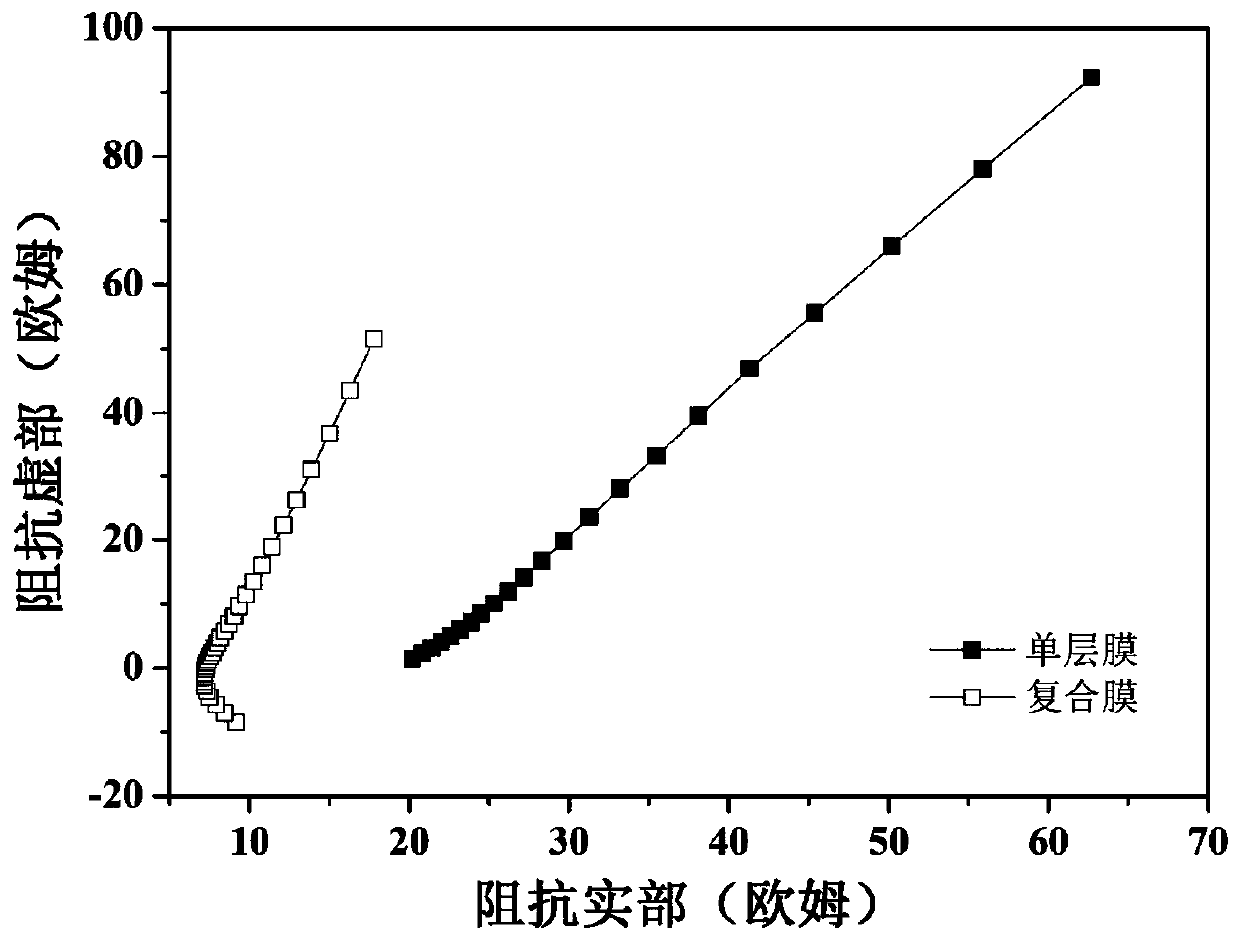

Composite solid-state electrolyte membrane, preparation method and solid-state lithium battery

InactiveCN111430788AImprove cycle stabilityImprove capacity playMaterial nanotechnologySolid electrolytesSolid state electrolytePolyvinyl chloride

The invention discloses a composite solid-state electrolyte membrane, a preparation method and a solid-state lithium battery. The composite solid-state electrolyte membrane comprises a support membrane, an organic-inorganic composite coating A coated on the surface of the positive electrode side of the support membrane, and an organic-inorganic composite coating B coated on the surface of the negative electrode side of the support membrane, wherein the coating A comprises an organic polymer A, a lithium salt and a nano inorganic solid electrolyte, and the organic polymer A is one or more thantwo of polyvinylidene fluoride, a polyvinylidene fluoride copolymer, polyacrylonitrile and polyvinyl chloride; the coating B comprises an organic polymer B, a lithium salt and a nano inorganic solid electrolyte; and the organic polymer B is one or more than two of polyoxyethylene, polypropylene carbonate, polycarbonate and poly trimethylene carbonate. Aiming at different requirements of positive and negative electrode layers in the solid-state lithium battery on the electrolyte membranes, the graphene oxide membrane is used as a support, and the electrolyte membranes containing different polymer groups are designed on the two sides of the graphene oxide membrane respectively so that the comprehensive performance of the battery is further improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Preparation method of polyvinyl chitosan mixed film

InactiveCN101007243AHigh mechanical strengthGood chemical stabilitySemi-permeable membranesAcetic acidMethyl carbonate

The invention involves a preparation method used for separating the polyvinyl alcohol / chitosan mixing film of methanol / dimethyl carbonate, the preparation process is as follows: 1) dissolving the polyvinyl alcohol with the deionized water as solvent in 80 ~ 100 degree C and gaining uniform casting film solution which polyvinyl alcohol concentration is 5wt%; 2) dissolving the chitosan with the glacial acetic acid and deionized water as solvent in 20-40DEG C and gaining uniform casting film solution which chitosan concentration is 1wt%; 3) according certain radio mixing the ratio of PVA and chitosan solution uniformly and debubbling; 4) making film on the glass plate with casting method; 5) thermal treating the film 2~4 hours in 120 ~ 150 degree C. Compared with traditional separation methods, the method has some characteristics such as high one-time separation degree, simple precess, low energy consumption and pollution-free.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

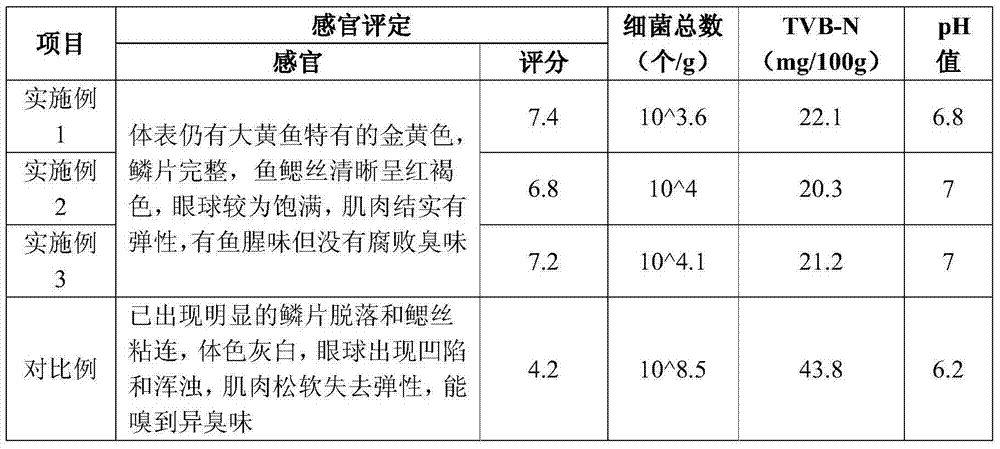

Coating preservation method of pseudosciaena crocea

ActiveCN104322650AGuaranteed food qualityGuaranteed sensory qualityMeat/fish preservation by coatingCold airComposite film

The invention dislcoses a coating preservation method of pseudosciaena crocea. The method includes following steps: (1) pre-treatment; (2) a soaking process; (3) a film-forming process; and (4) a packaging and refrigerating process. In the method, a sodium bicarbonate solution with a mass percentage concentration being 0.5-1% is employed for washing the pseudosciaena crocea, a composite film-forming preservative agent is developed on the basis of biochemical characteristics of the pseudosciaena crocea and an air-drying film-forming operation is carried out through cold air. The coating preservation method in operation process, is less in equipment investment, is environmentally-protective and safe, is suitable for industrialized production and can greatly prolong a preserving time of the pseudosciaena crocea on the premise of ensuring an edible quality and a sensory quality of the pseudosciaena crocea. The method is significant in preserving effect and is high in film-forming efficiency.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

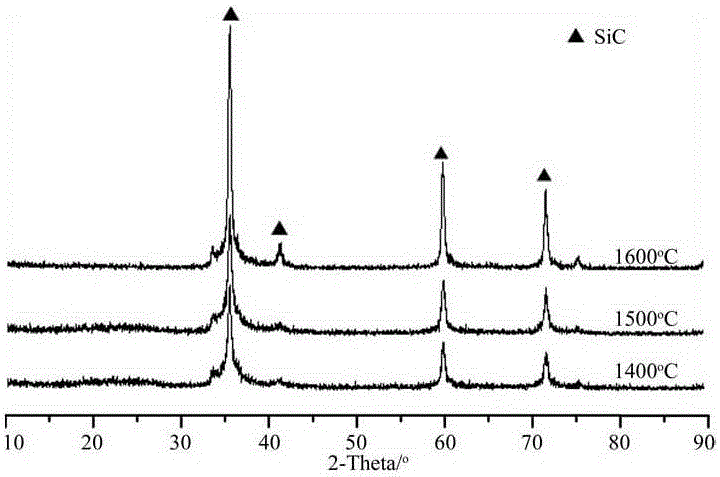

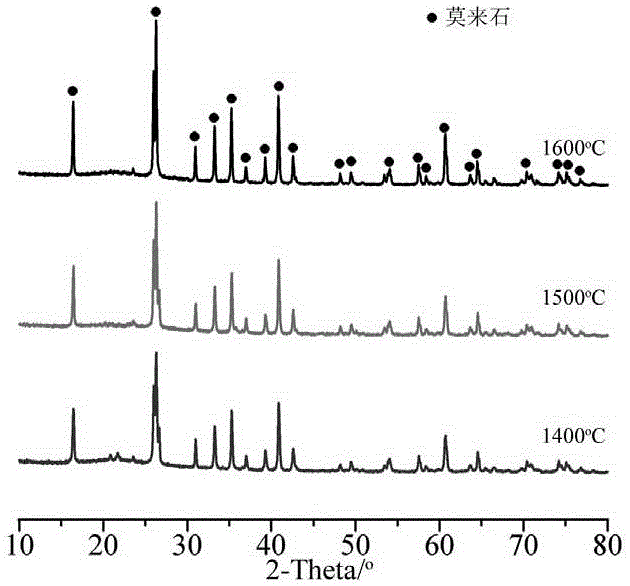

Surface coating system of fiber reinforced ceramic matrix composite material and preparation method therefor

The present invention provides a surface coating system of fiber reinforced ceramic matrix composite material, wherein the surface coating system is arranged on the substrate surface of the fiber reinforced ceramic matrix composite material and comprises a Sic coating layer, a mullite coating layer and a yttrium silicate coating layer laid in order from bottom to top. The preparation method comprises the following steps of preparing sludge raw materials of the Sic coating layer, the mullite coating layer and the yttrium silicate coating layer respectively, and preparing the Sic coating layer, the mullite coating layer and the yttrium silicate coating layer. The present invention is used for the surface coating system of the fiber reinforced ceramic matrix composite material, has the advantages of high density, high temperature resistance and anti-oxidation.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com