Film covering machine for film covering of ends of catalyst and film covering method of film covering machine

A coating machine and catalyst technology, applied in the field of automatic catalyst production equipment, can solve the problems of unguaranteed coating film quality, poor working environment for workers, corrosiveness, etc., achieve convenient coating, improve automation level, use and The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

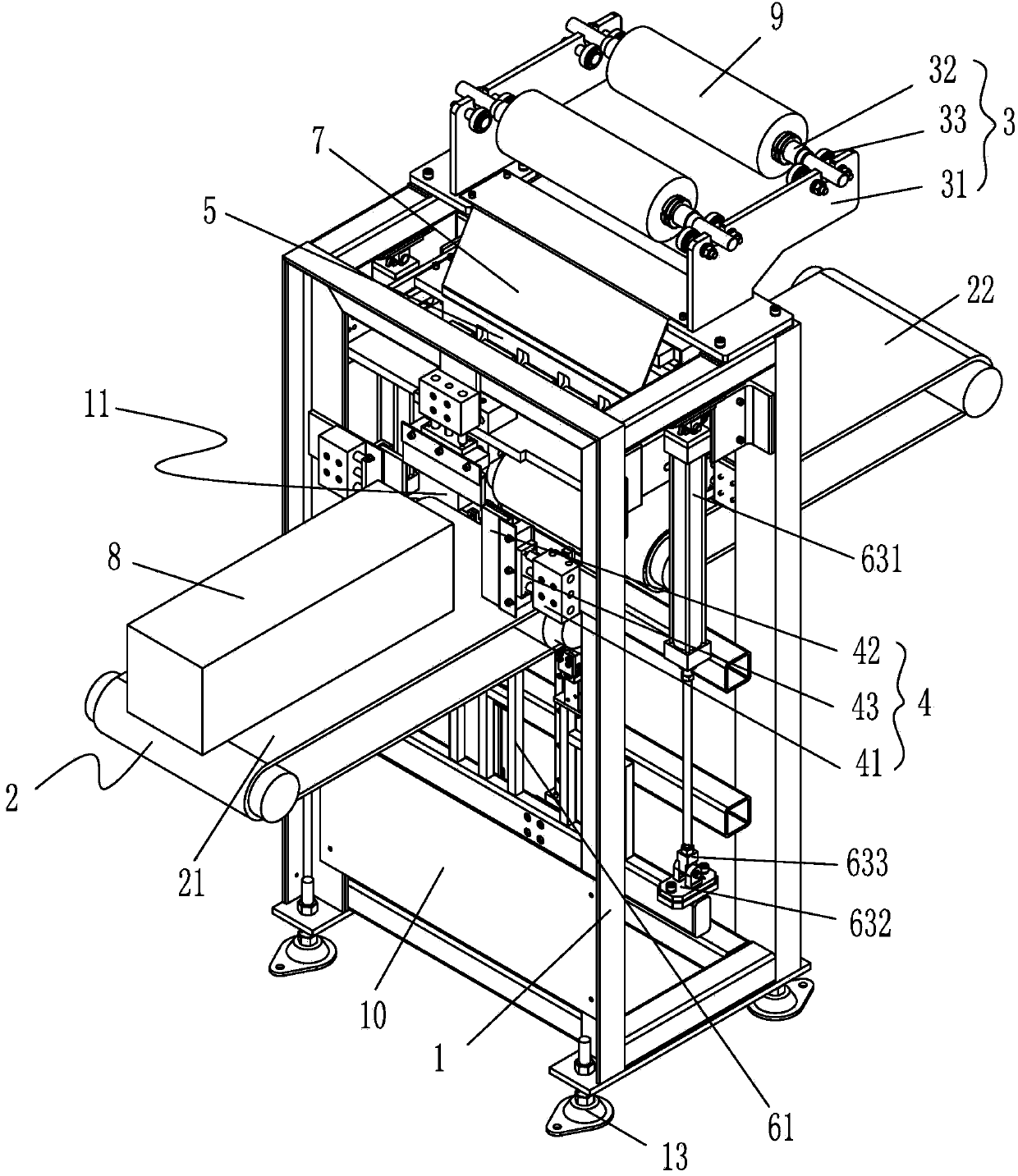

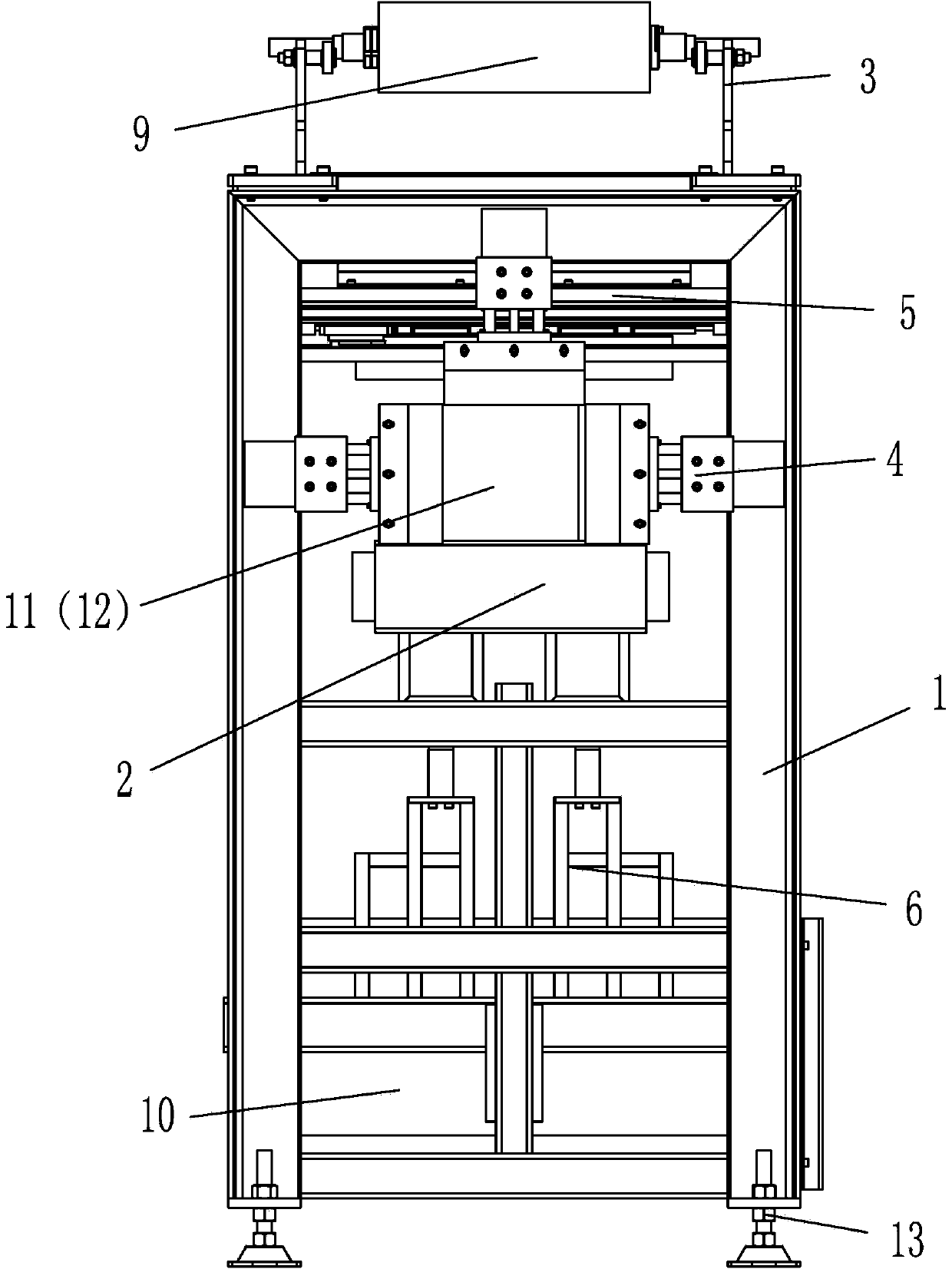

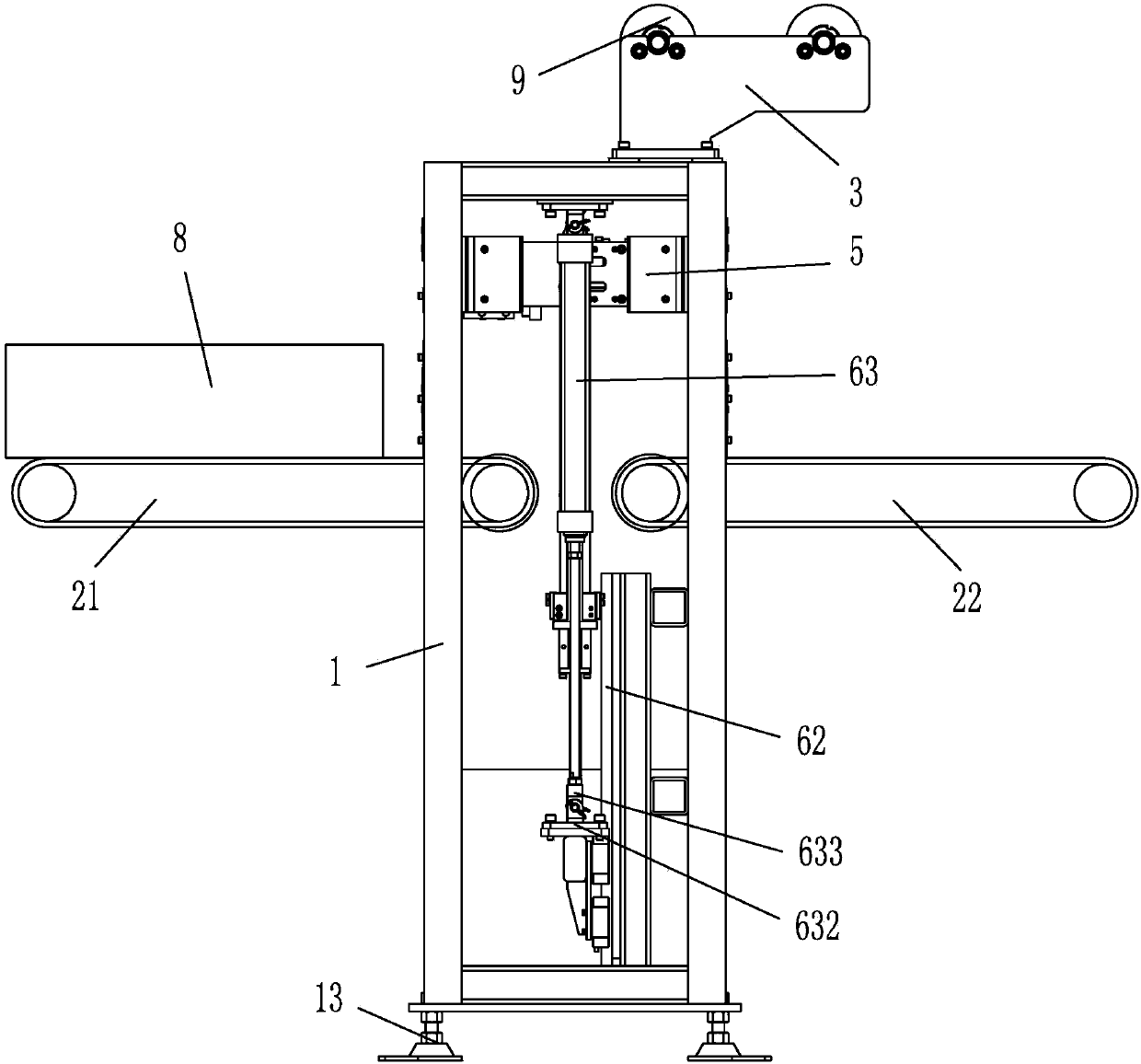

[0103] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0104] see Figure 1-Figure 3 , figure 1 It is a structural schematic diagram of a laminating machine according to an embodiment of the present invention, figure 2 It is a front view of a laminating machine according to an embodiment of the present invention, image 3 for figure 2 left view of . The present invention is used for the coating machine of catalyst end coating, comprises: Frame 1, as the basic structural part of whole equipment assembly, the parts and components of film coating machine are all assembled with this piece as a reference, and this frame 1 is for example It is a frame structure, preferably a welded structure, and its two sides are respectively provided with a workpiece inlet 11 and a workpiece outlet 12, and four adjustable feet 13 are installed at the bottom of the frame to adjust the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com