Patents

Literature

2986 results about "Brush device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

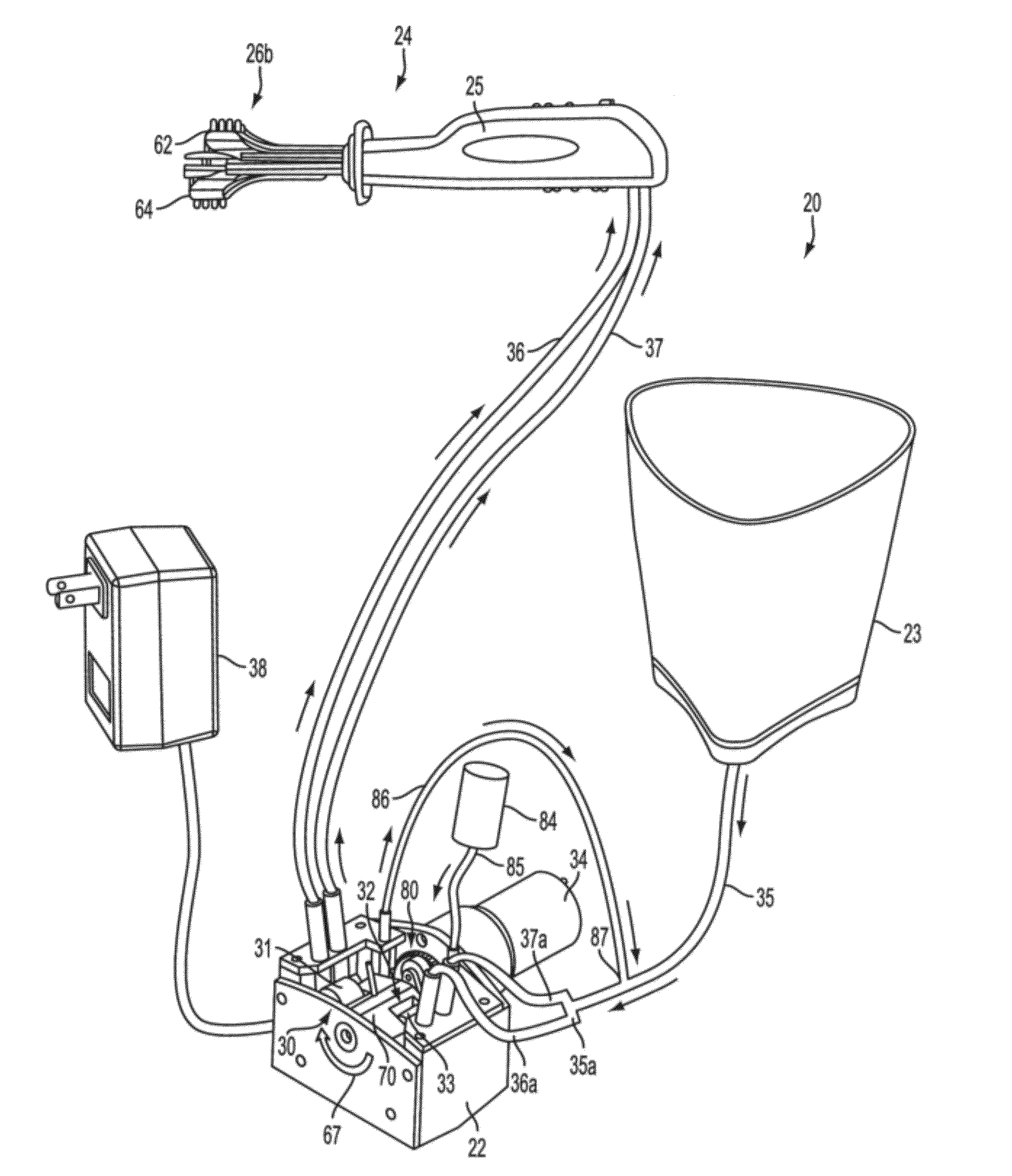

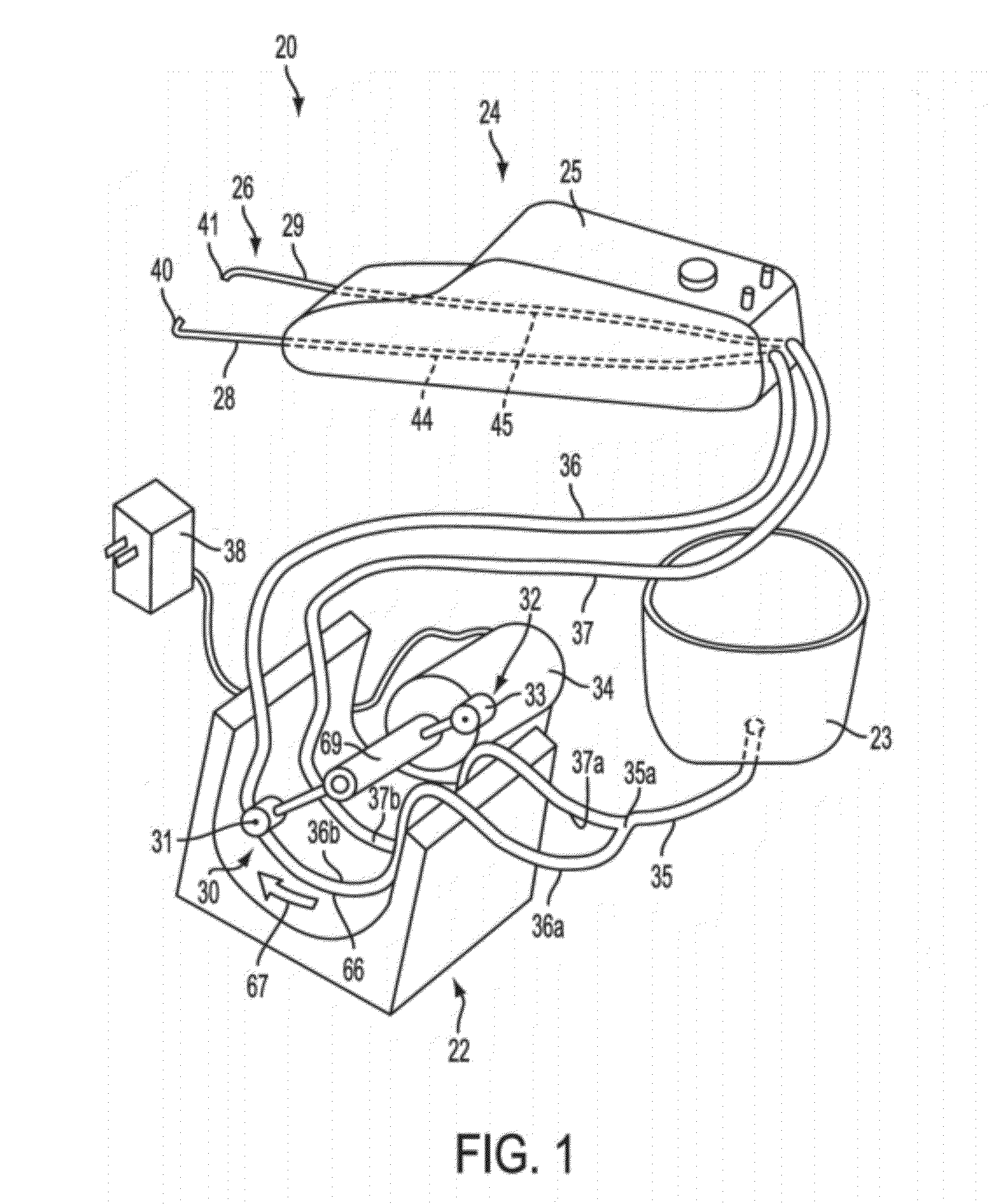

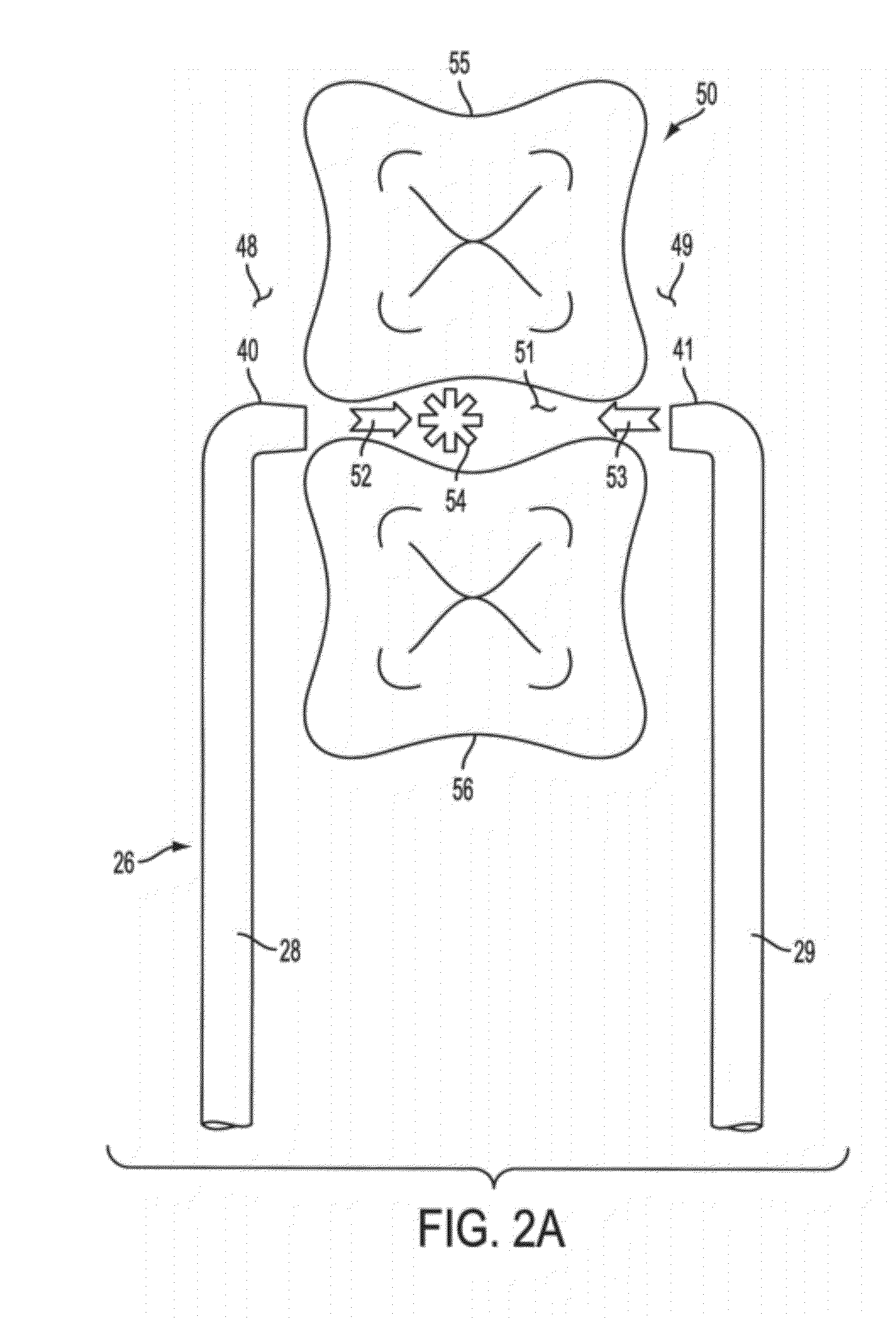

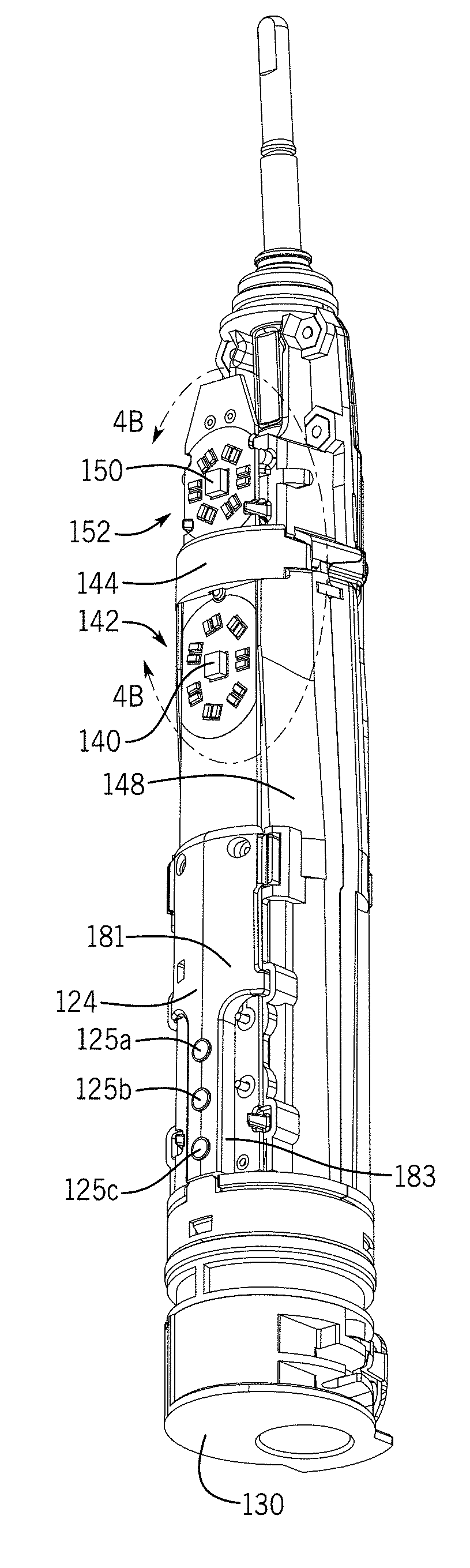

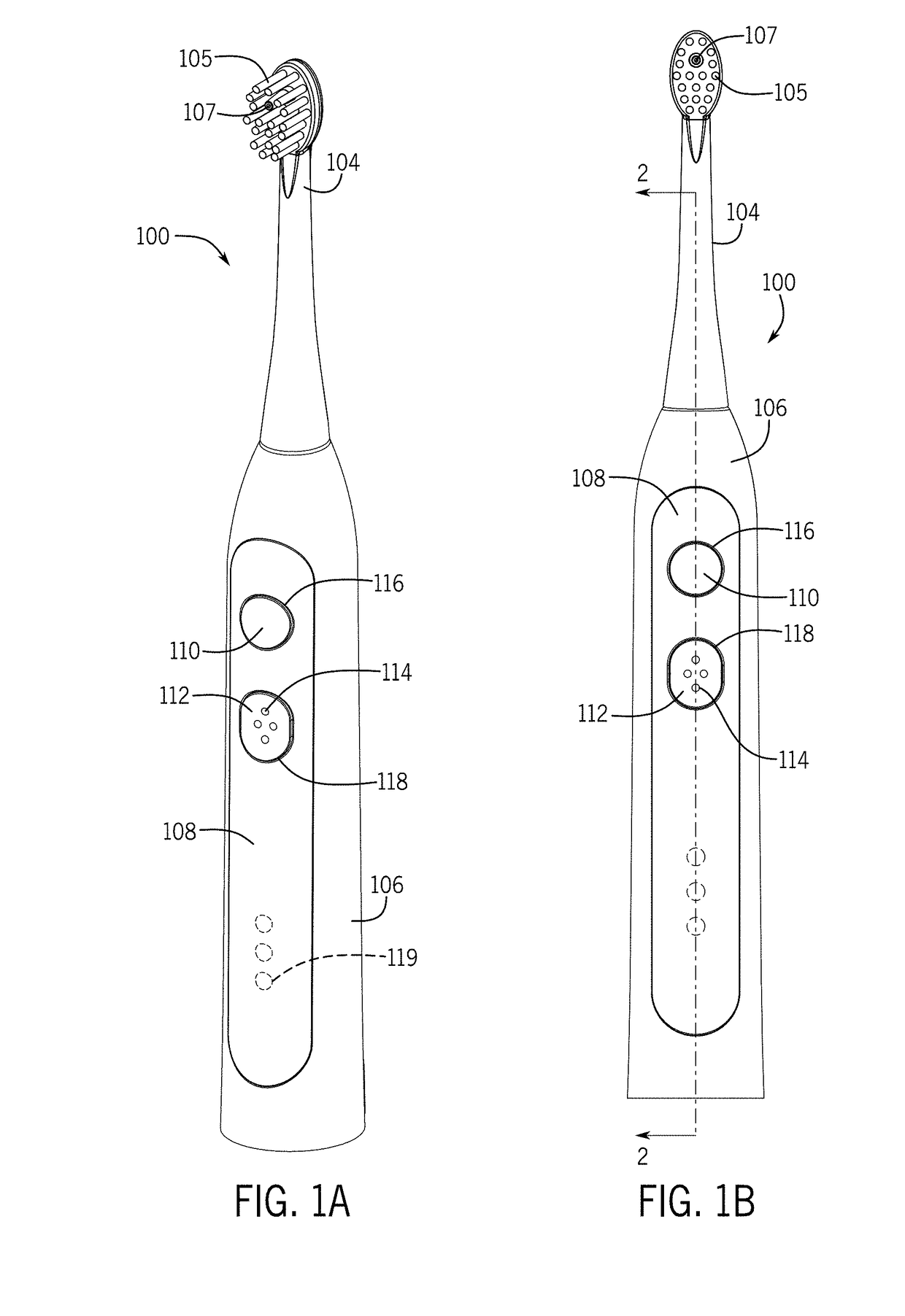

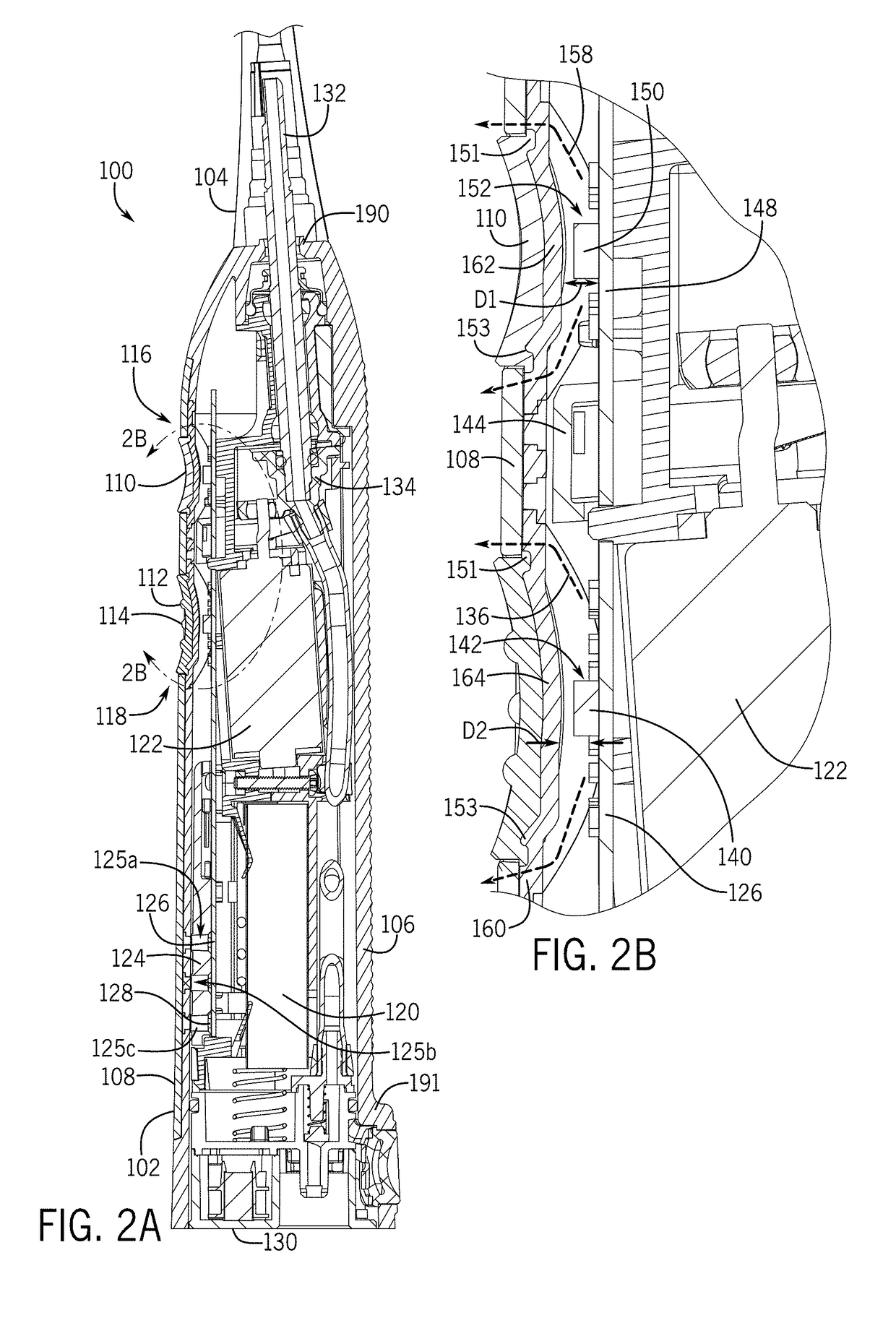

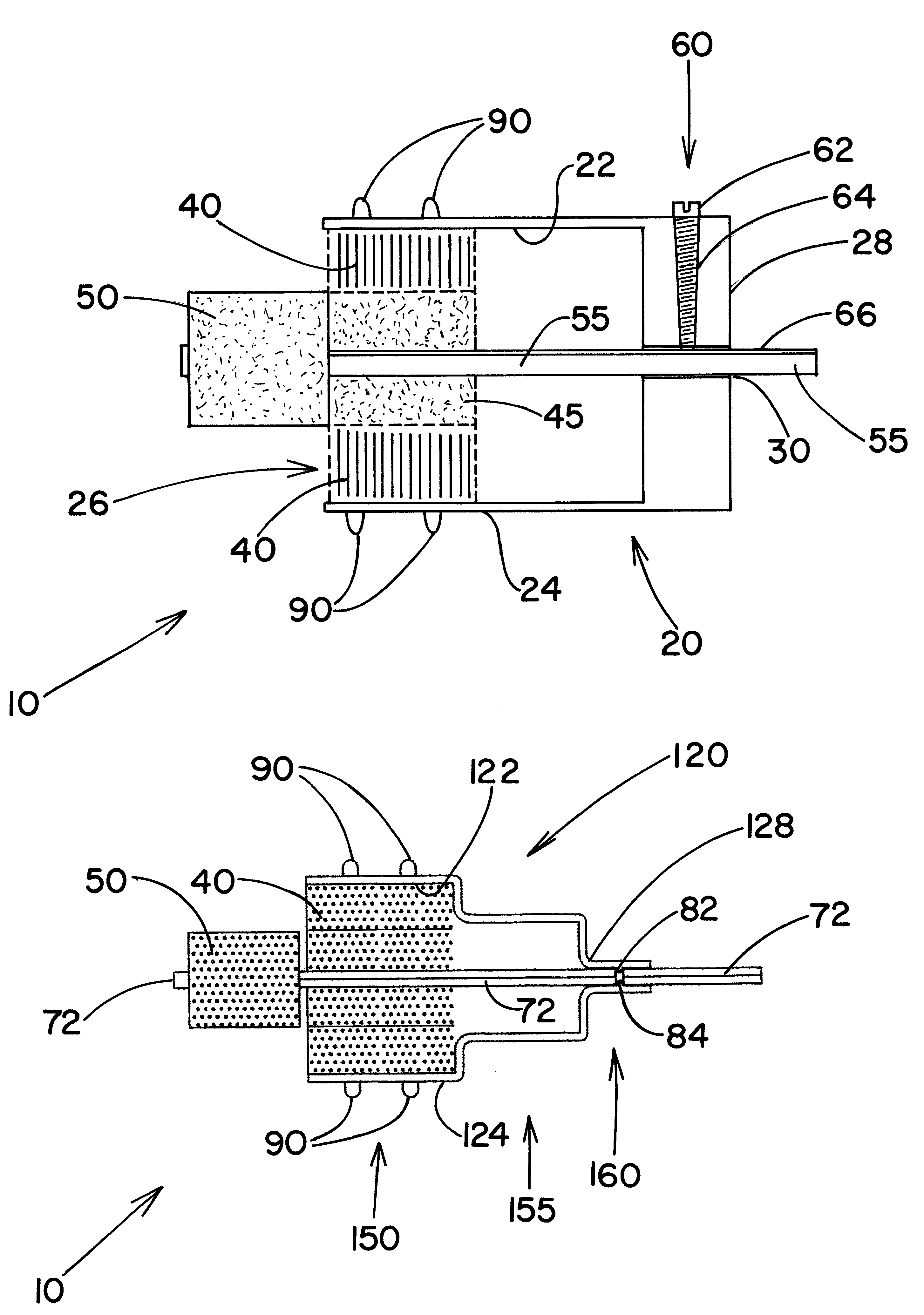

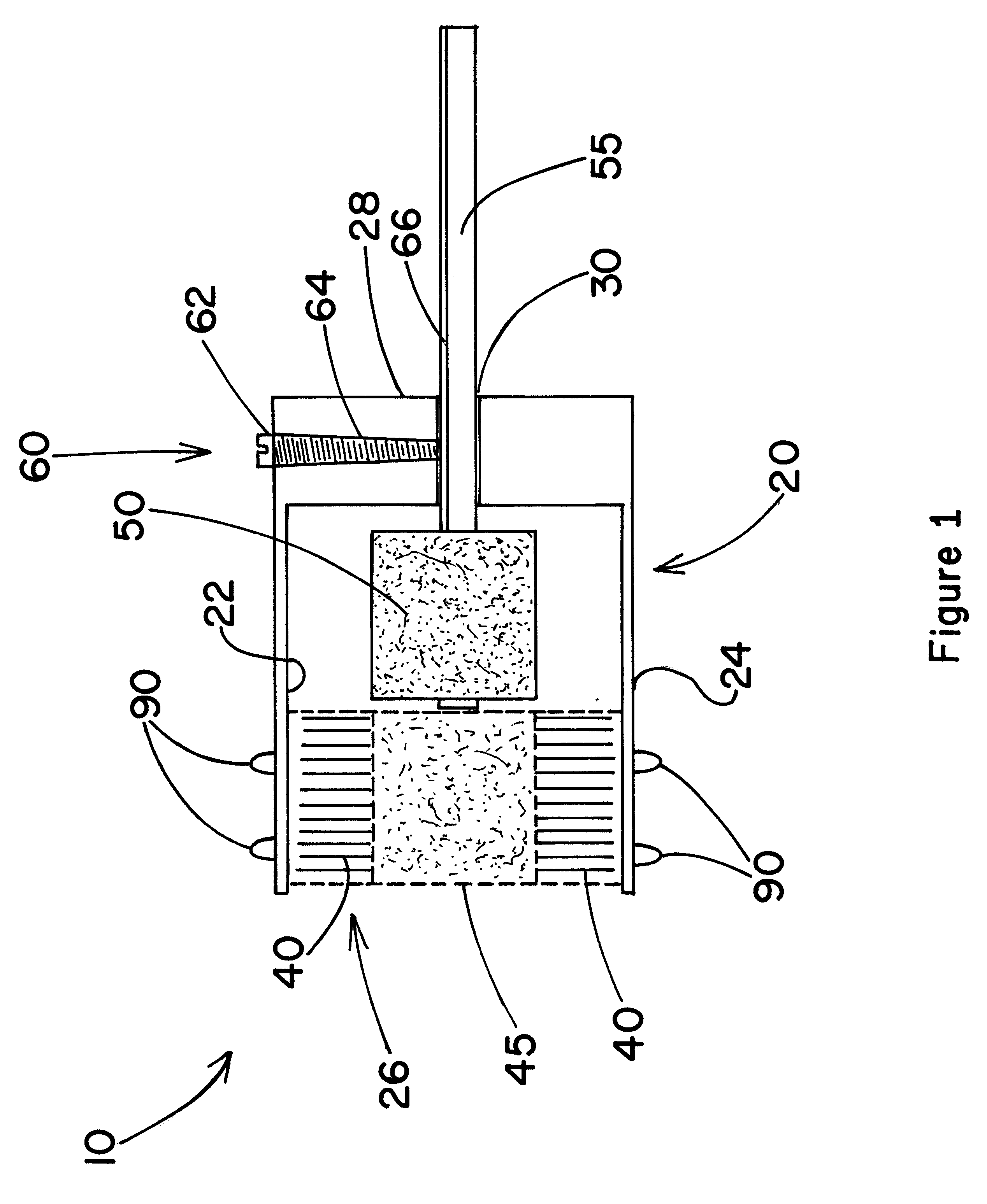

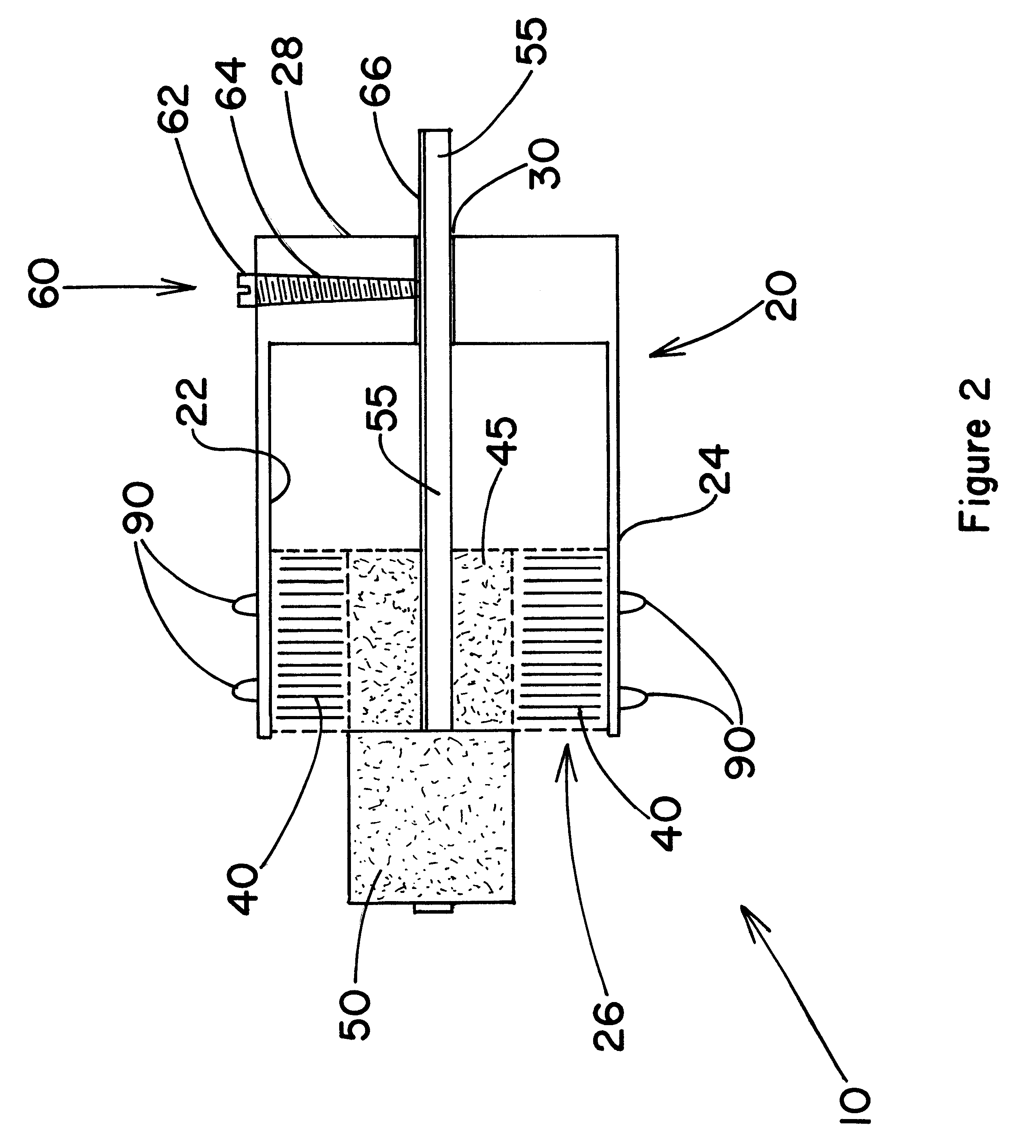

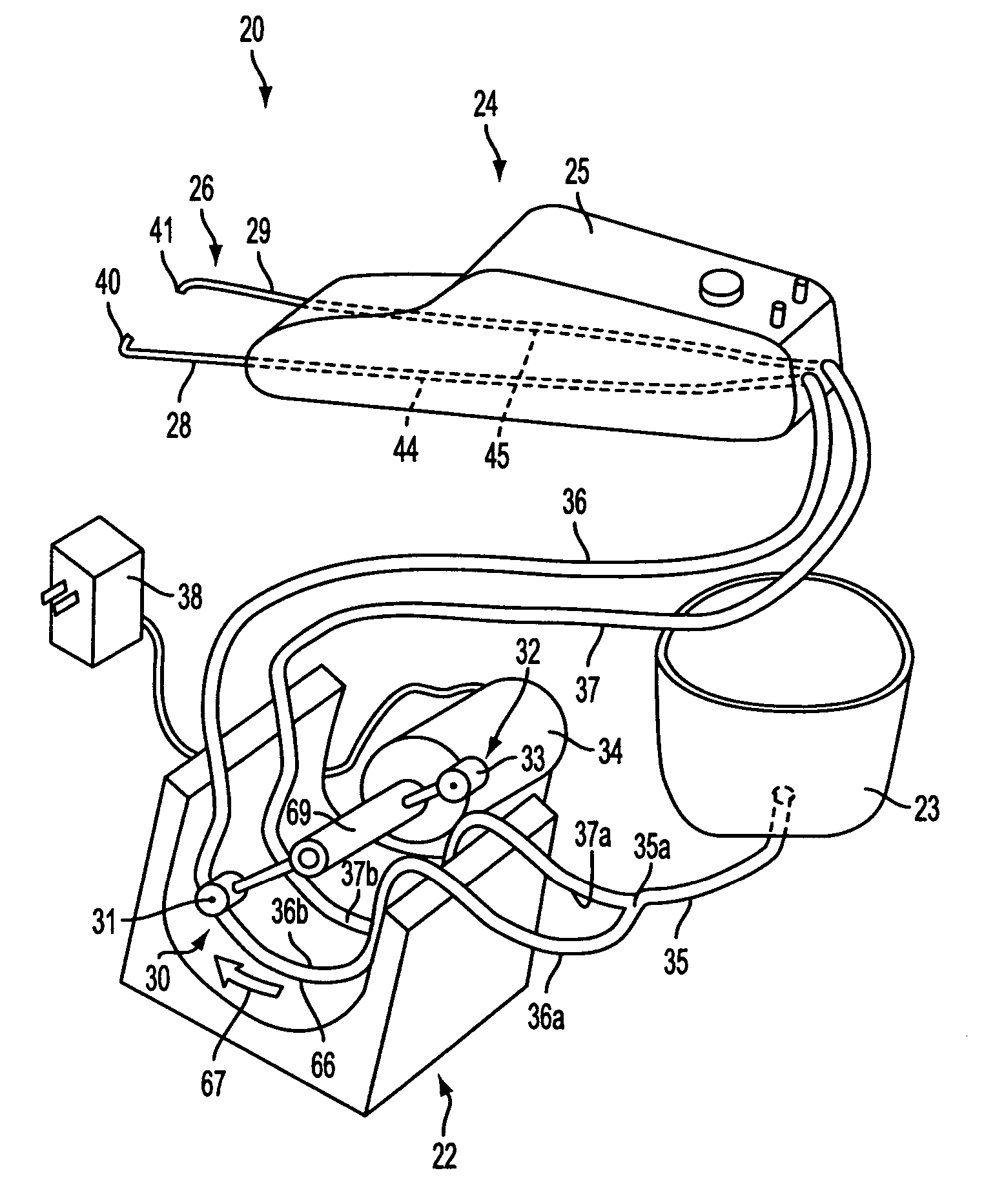

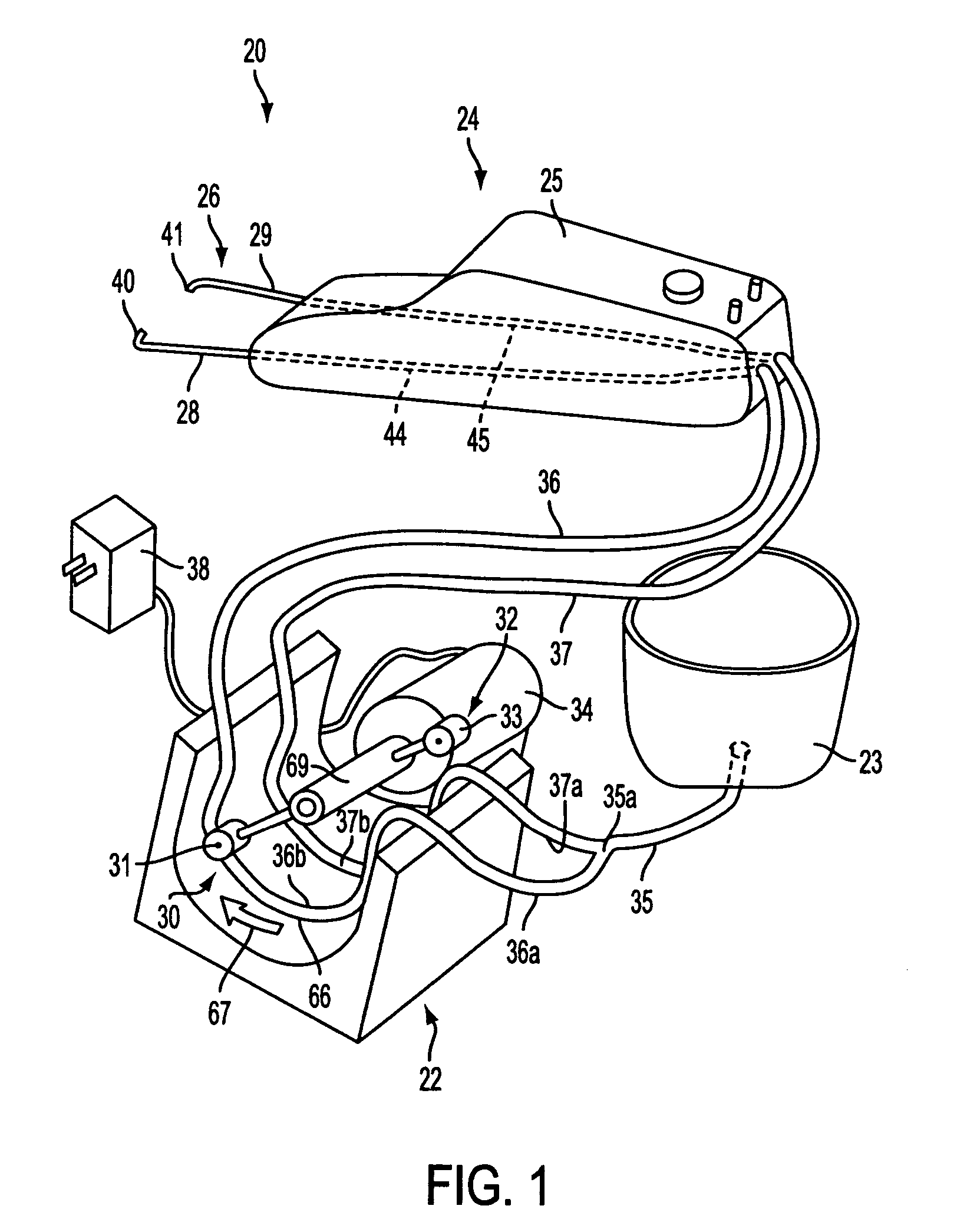

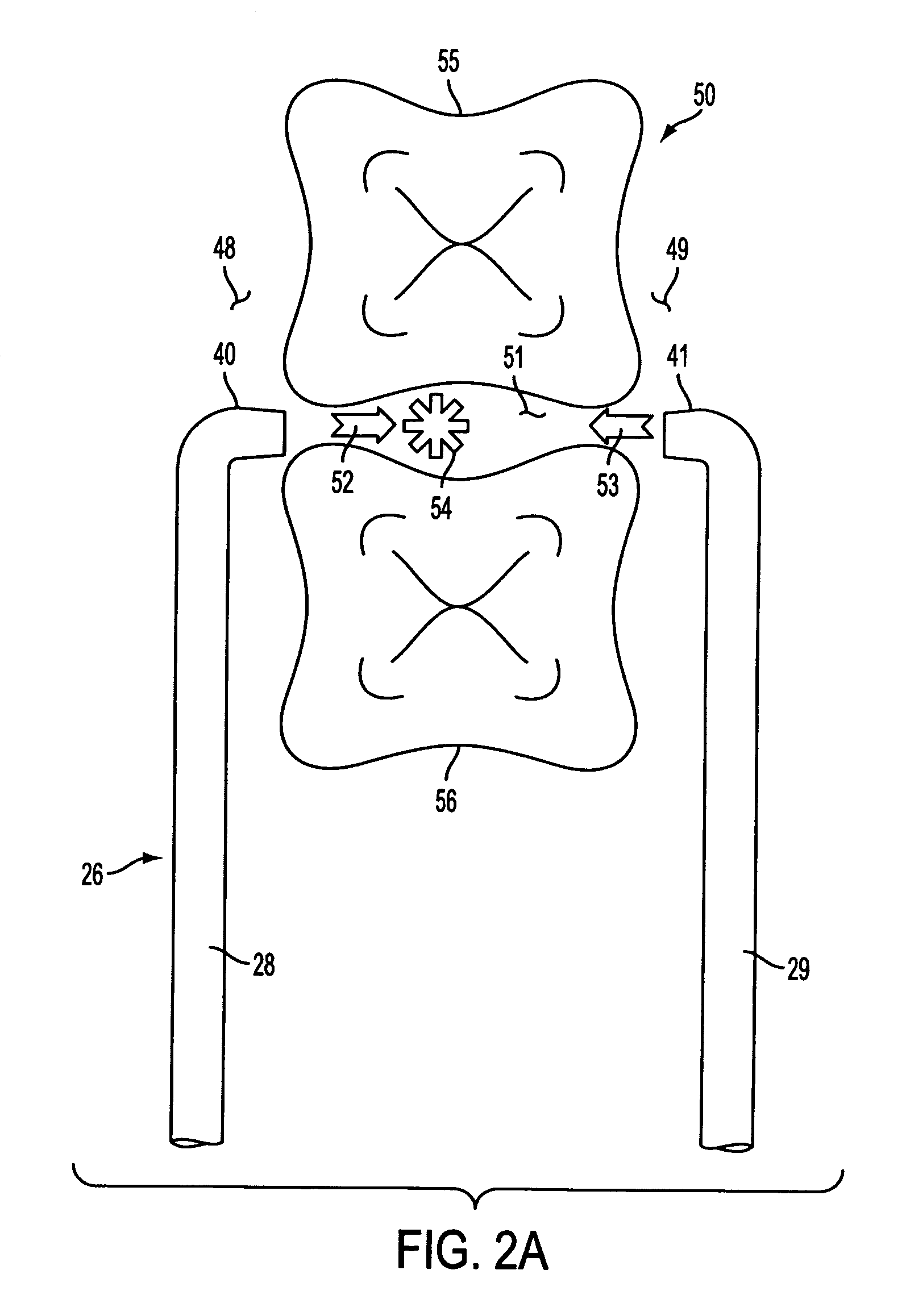

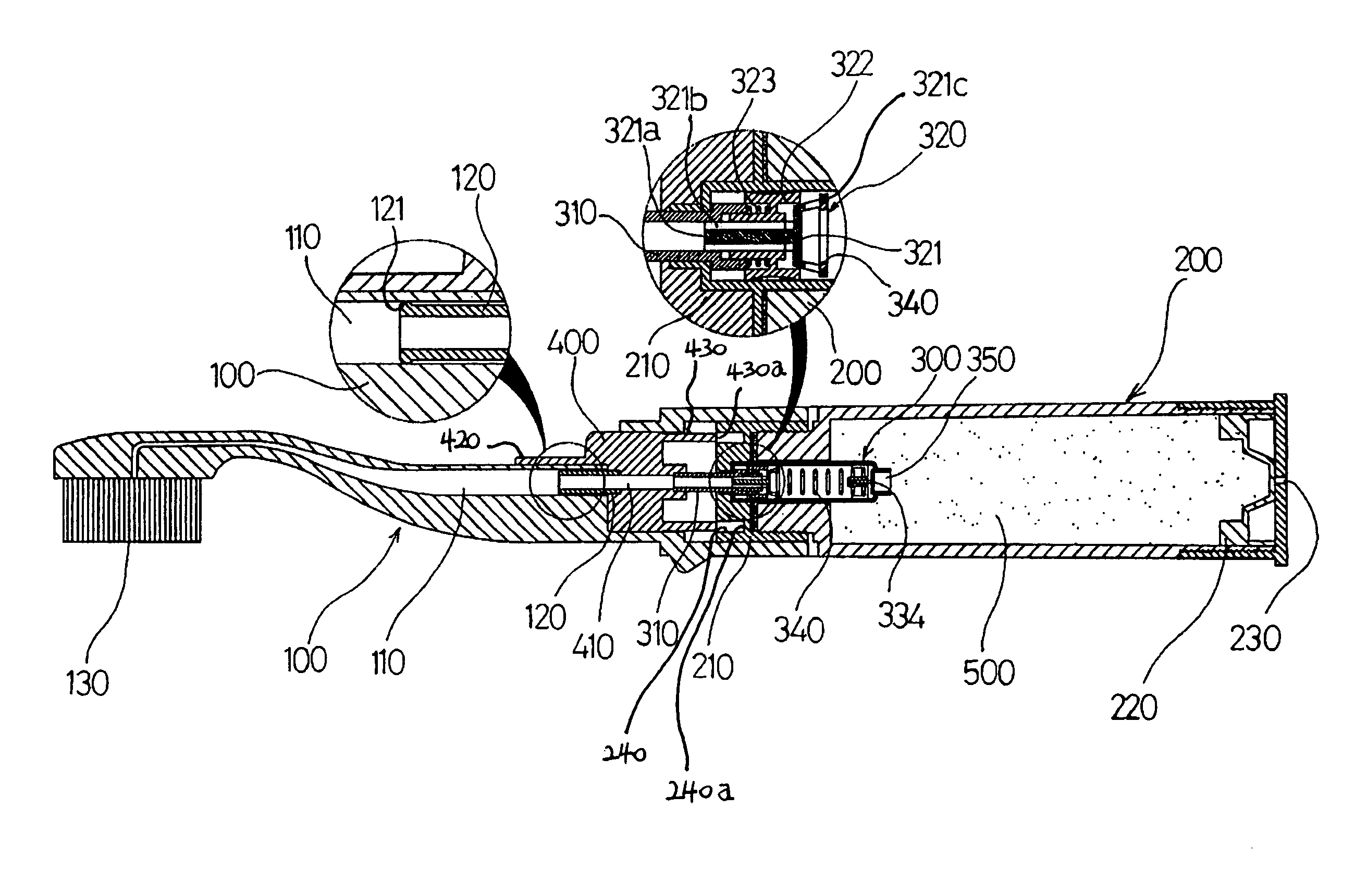

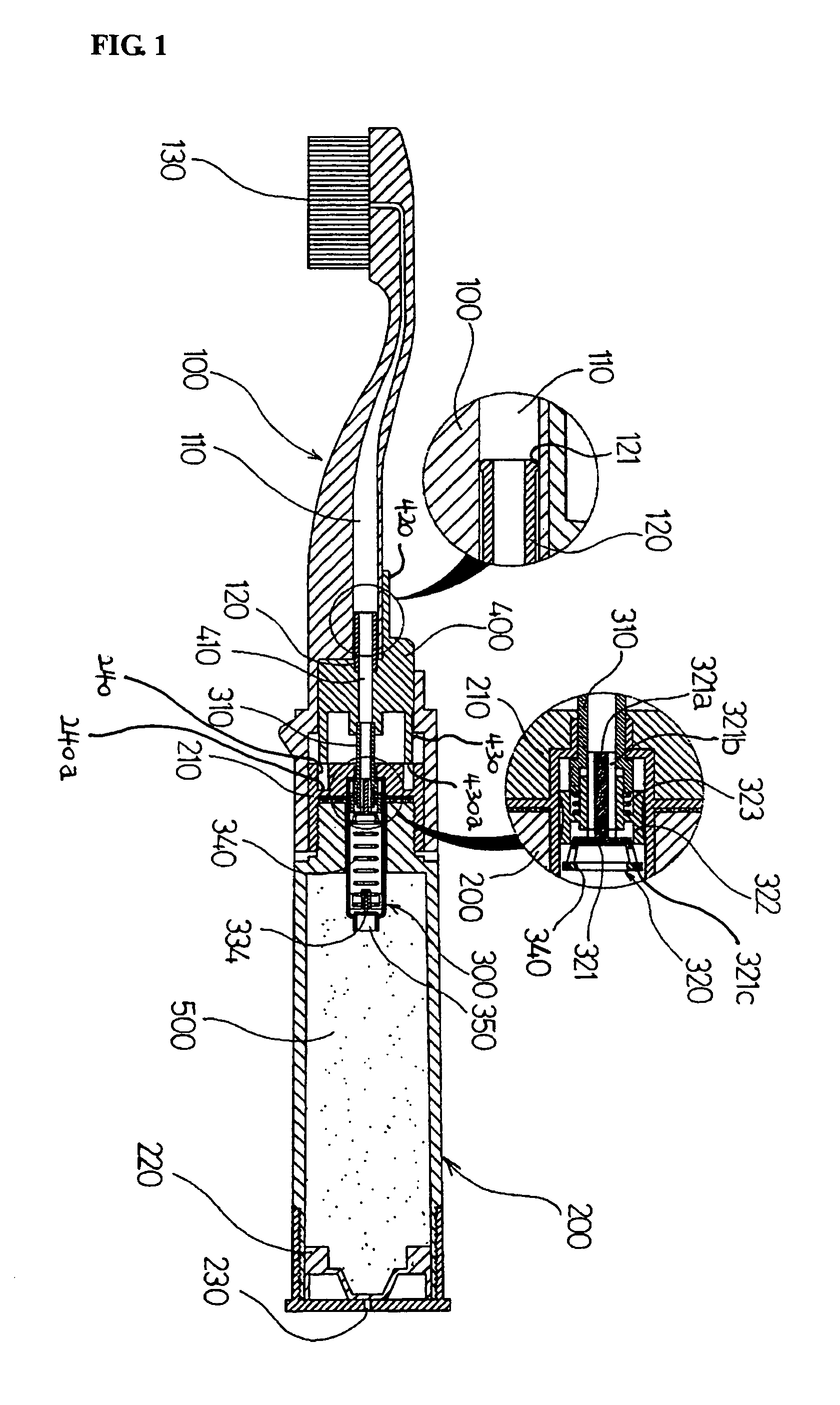

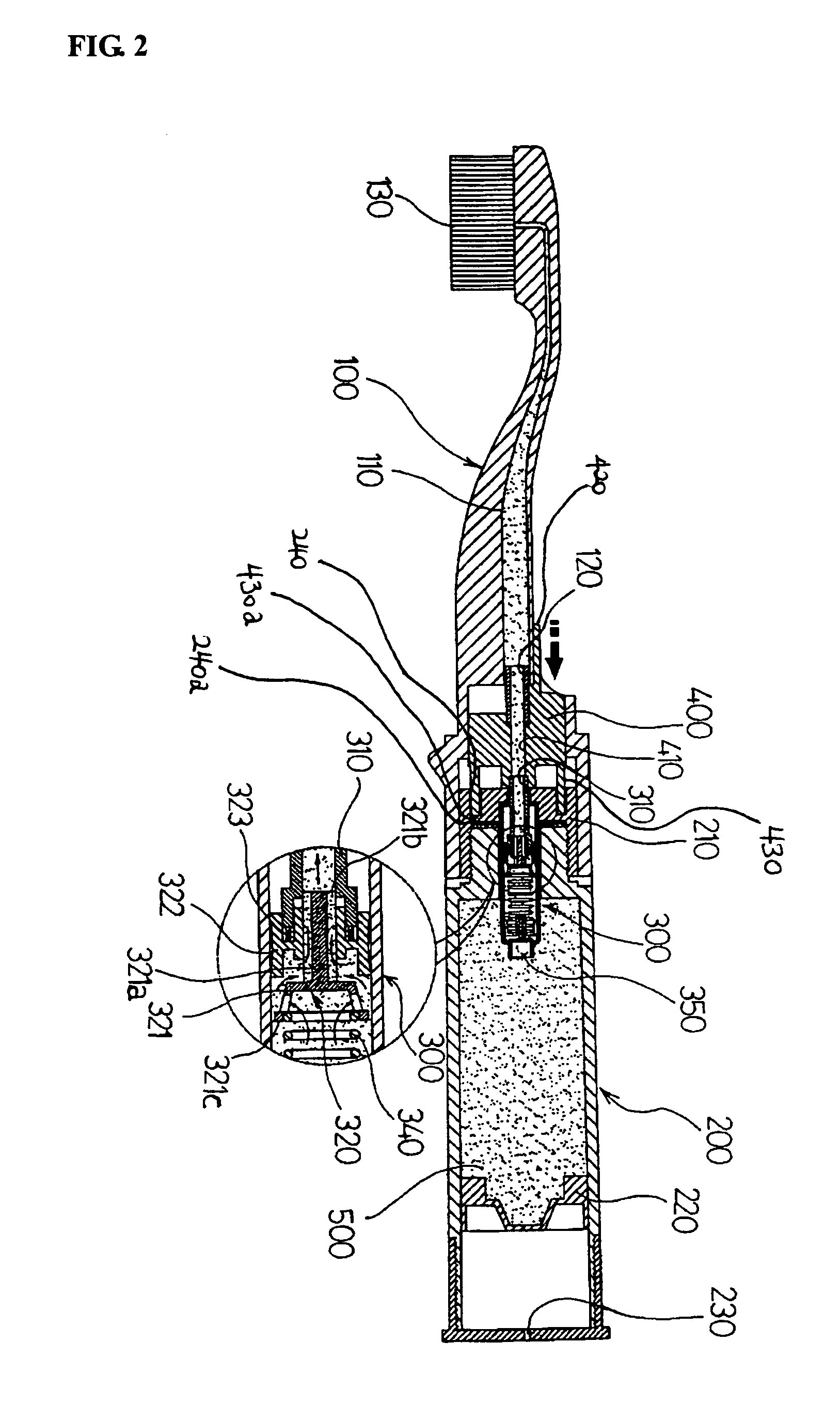

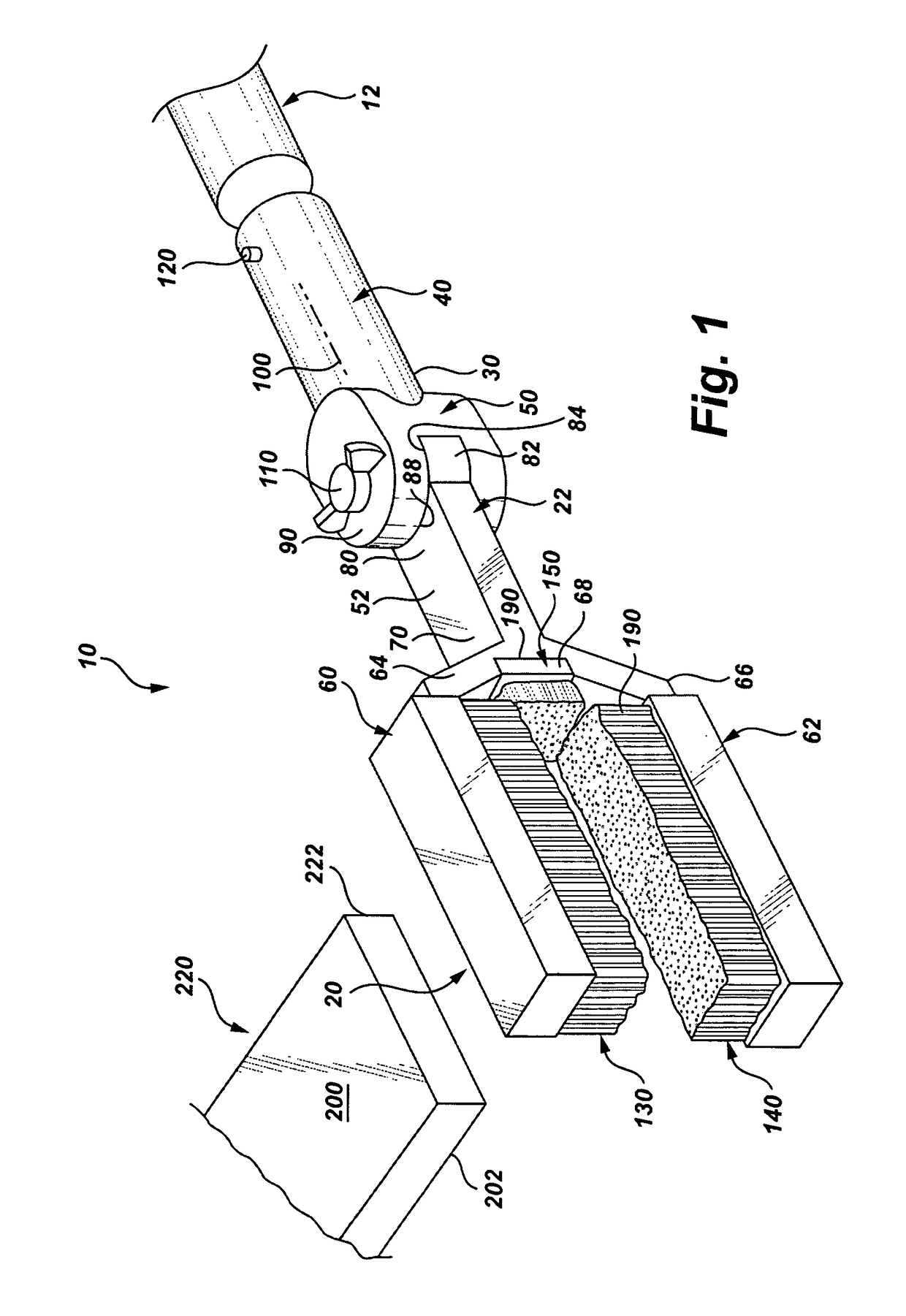

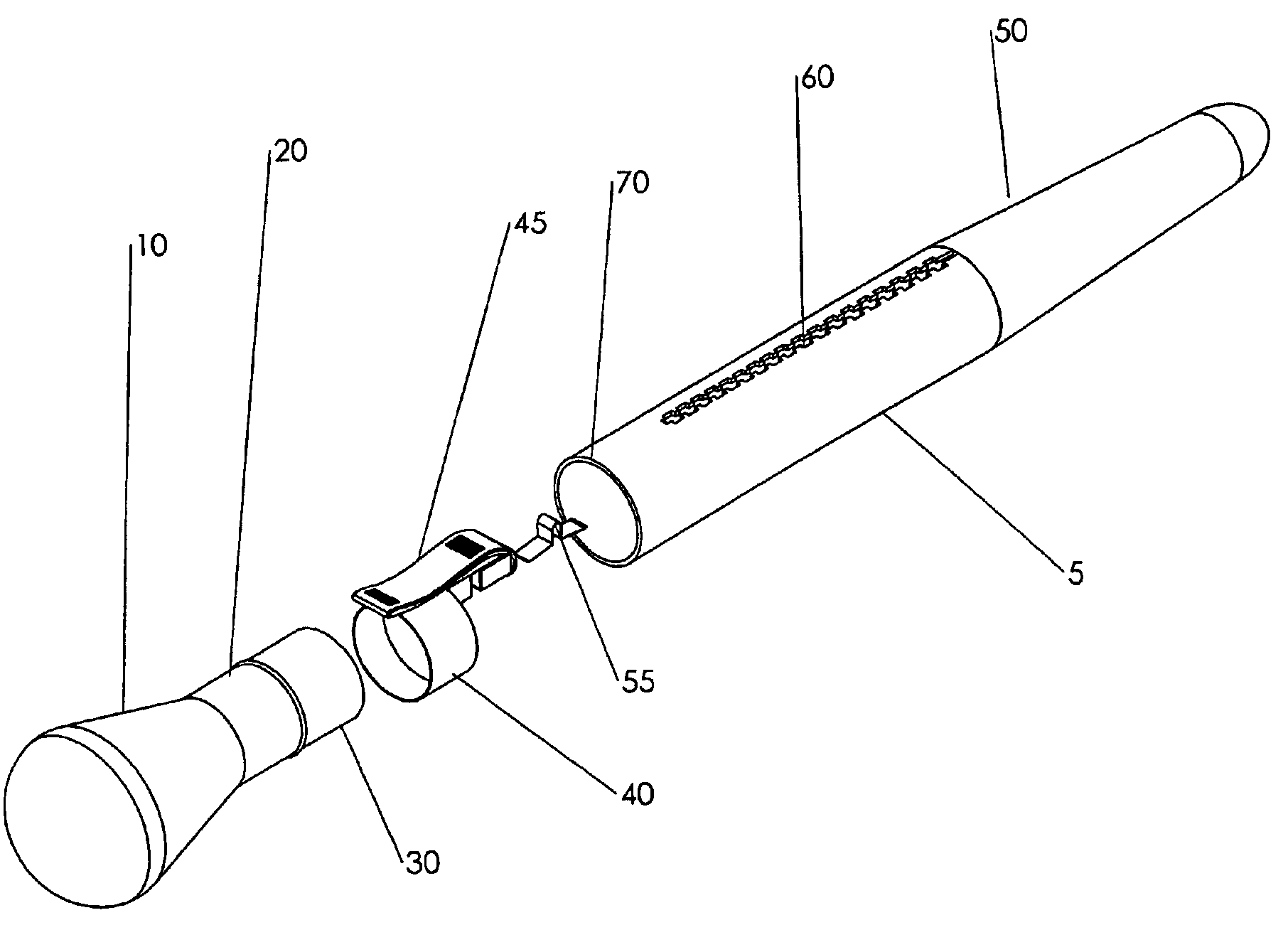

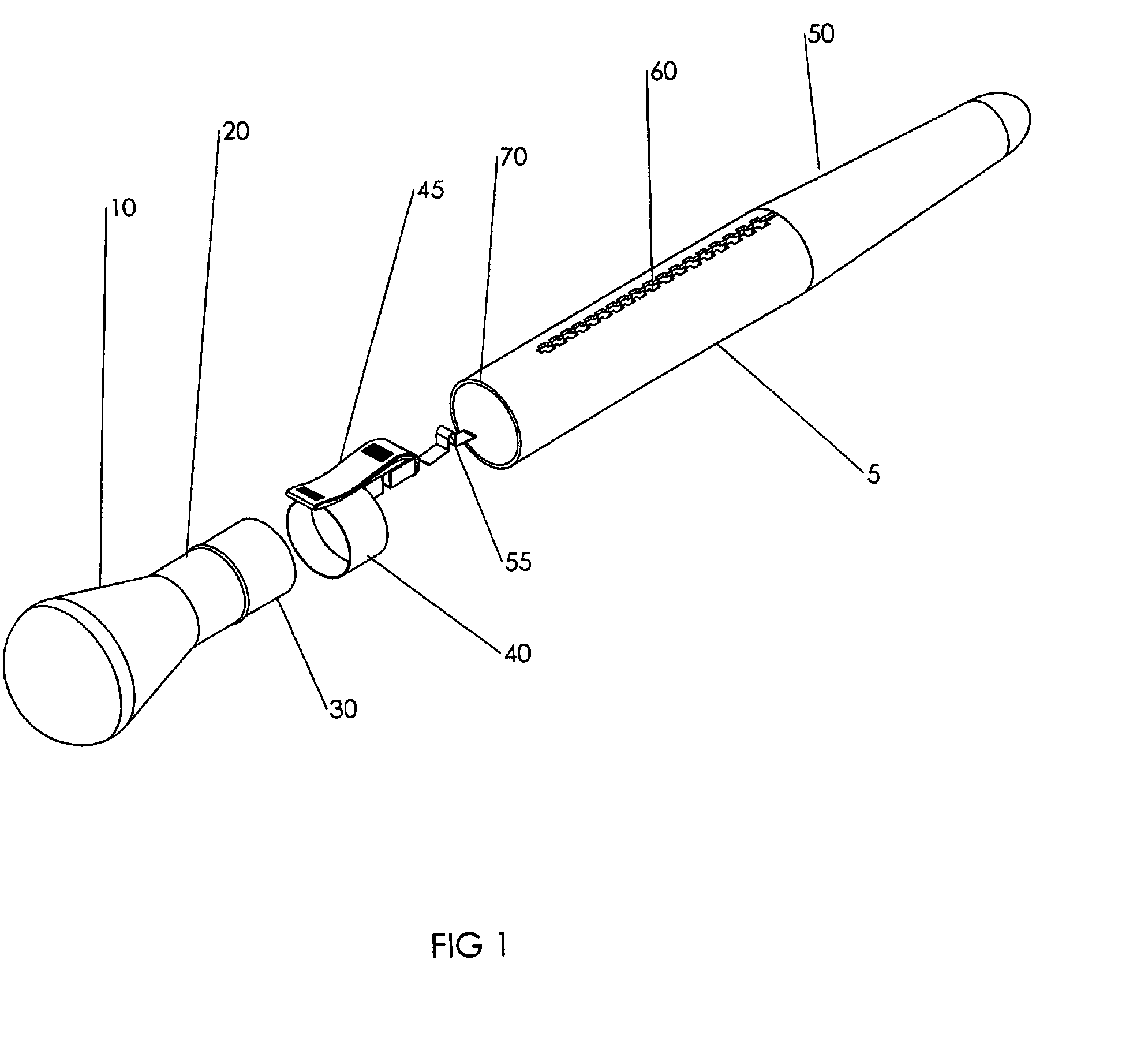

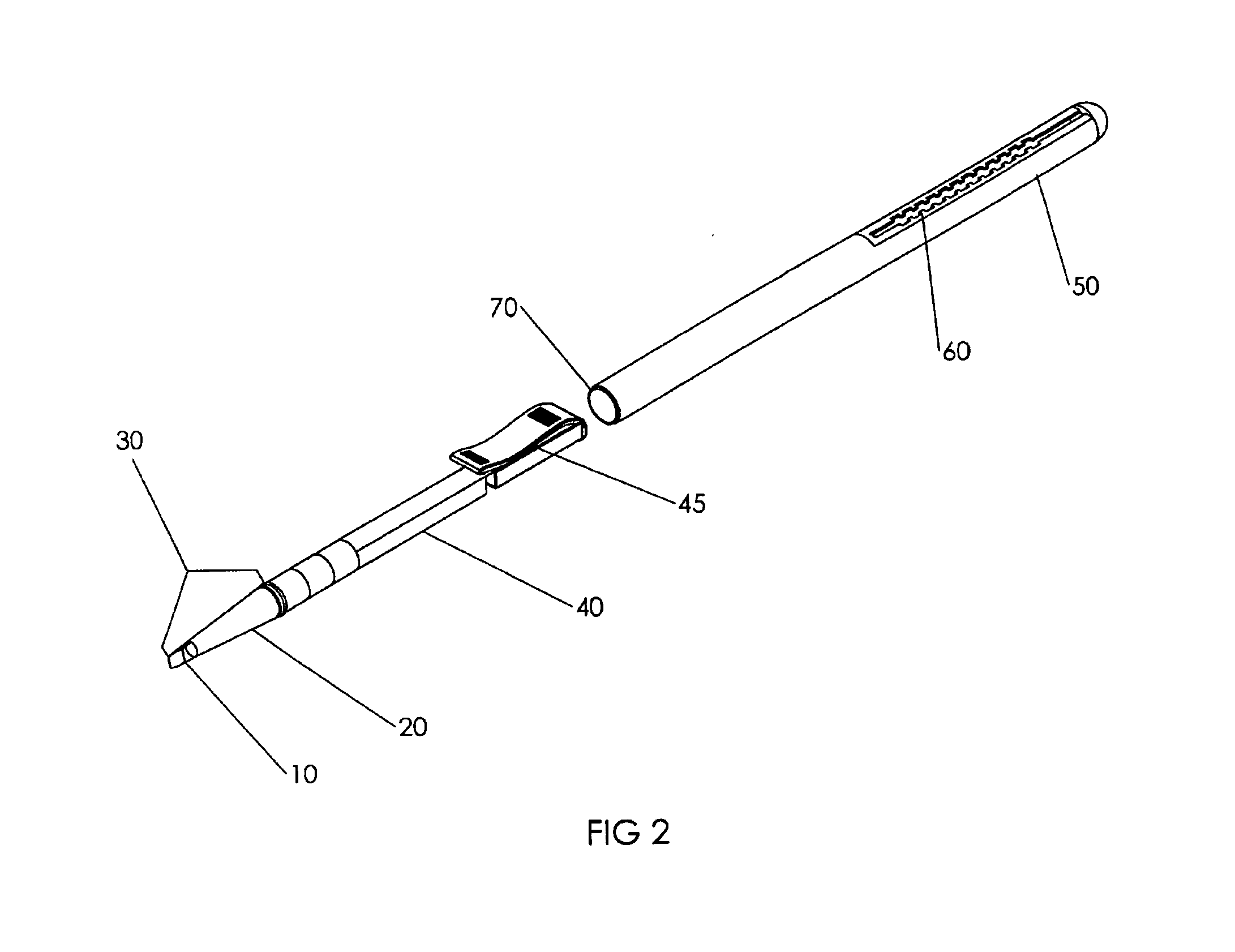

Oral Irrigation and/or Brushing Devices and/or Methods

InactiveUS20120064480A1Promotes Oral HealthPrecise positioningGum massageBristleBrush deviceDentistry

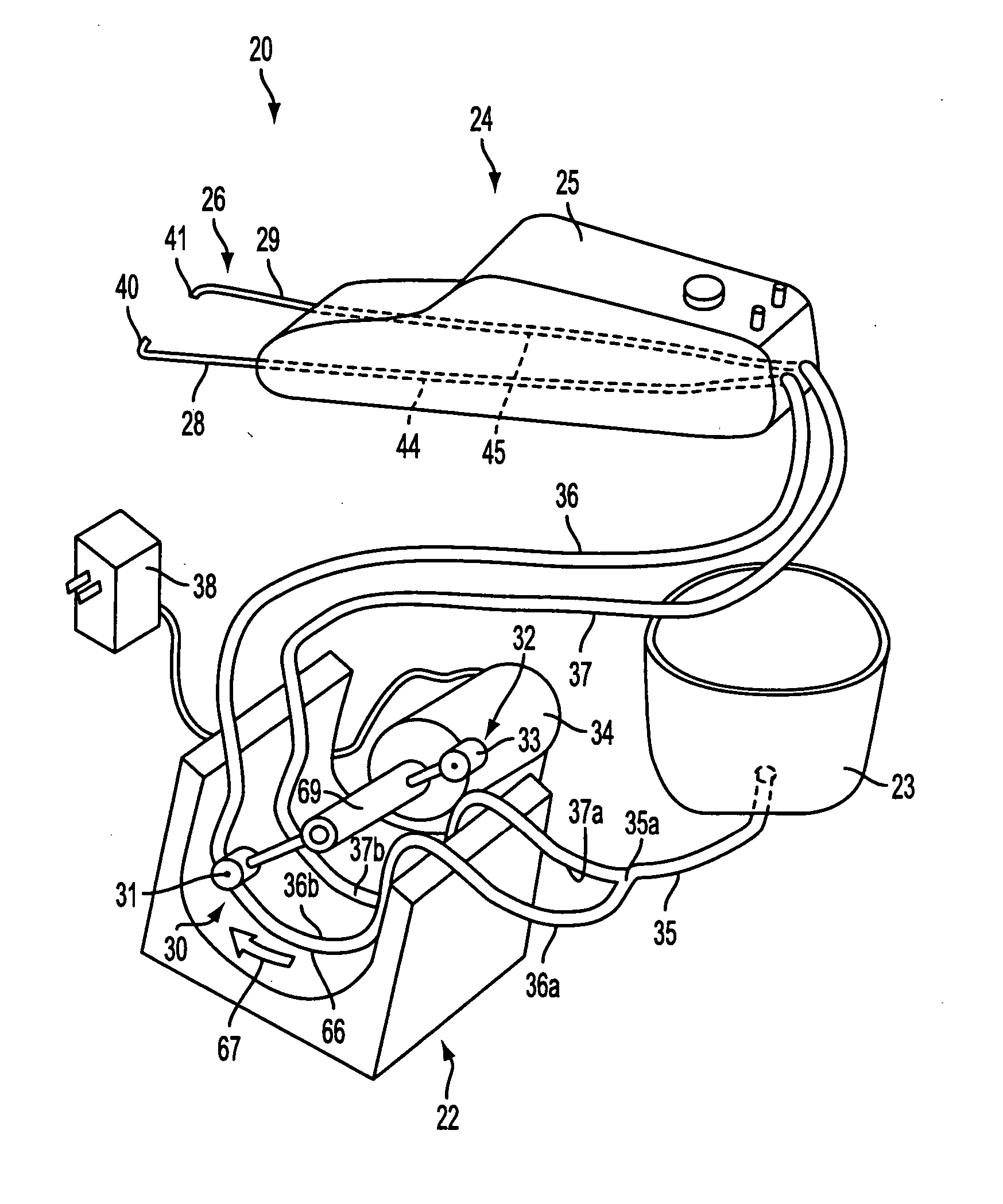

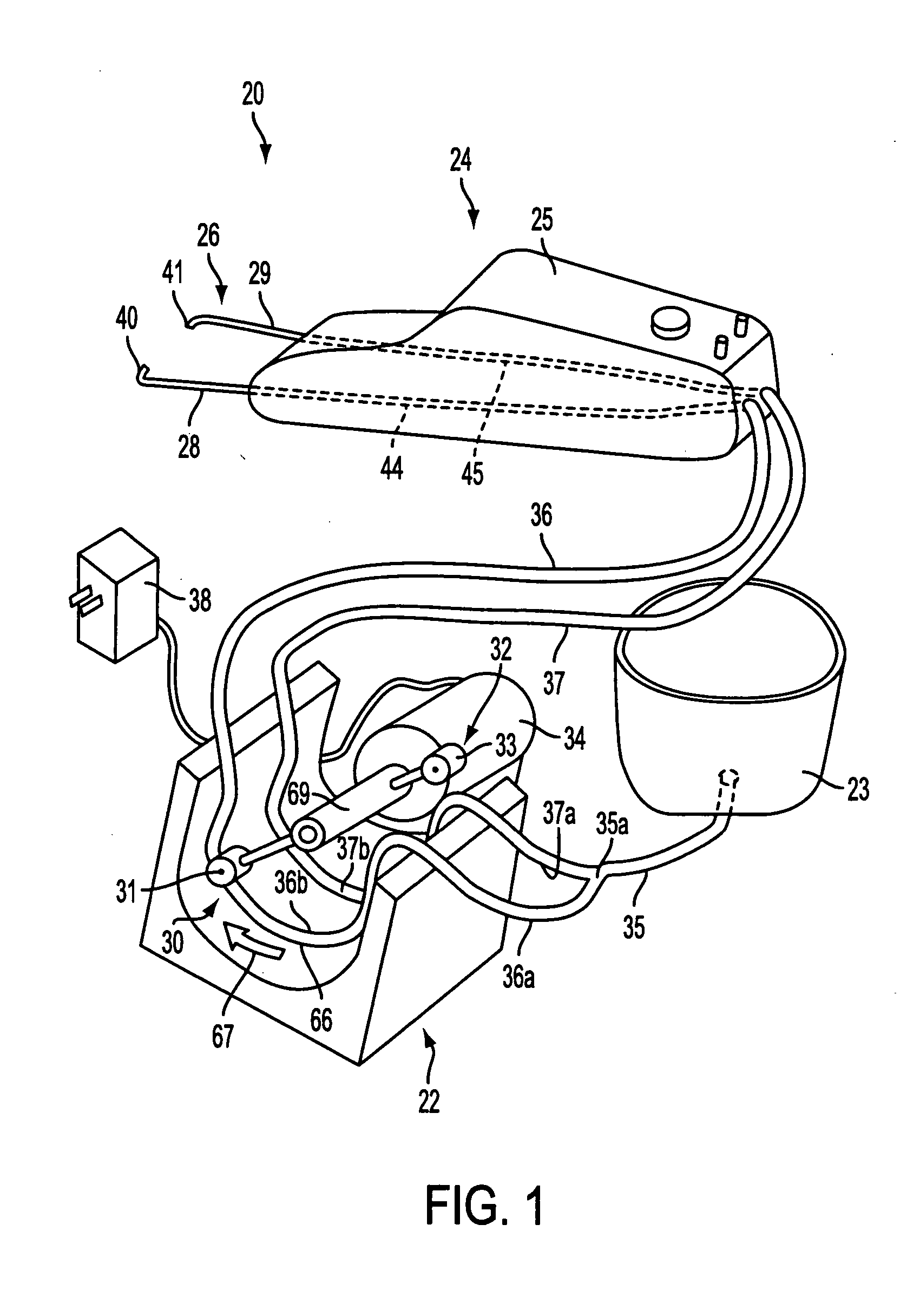

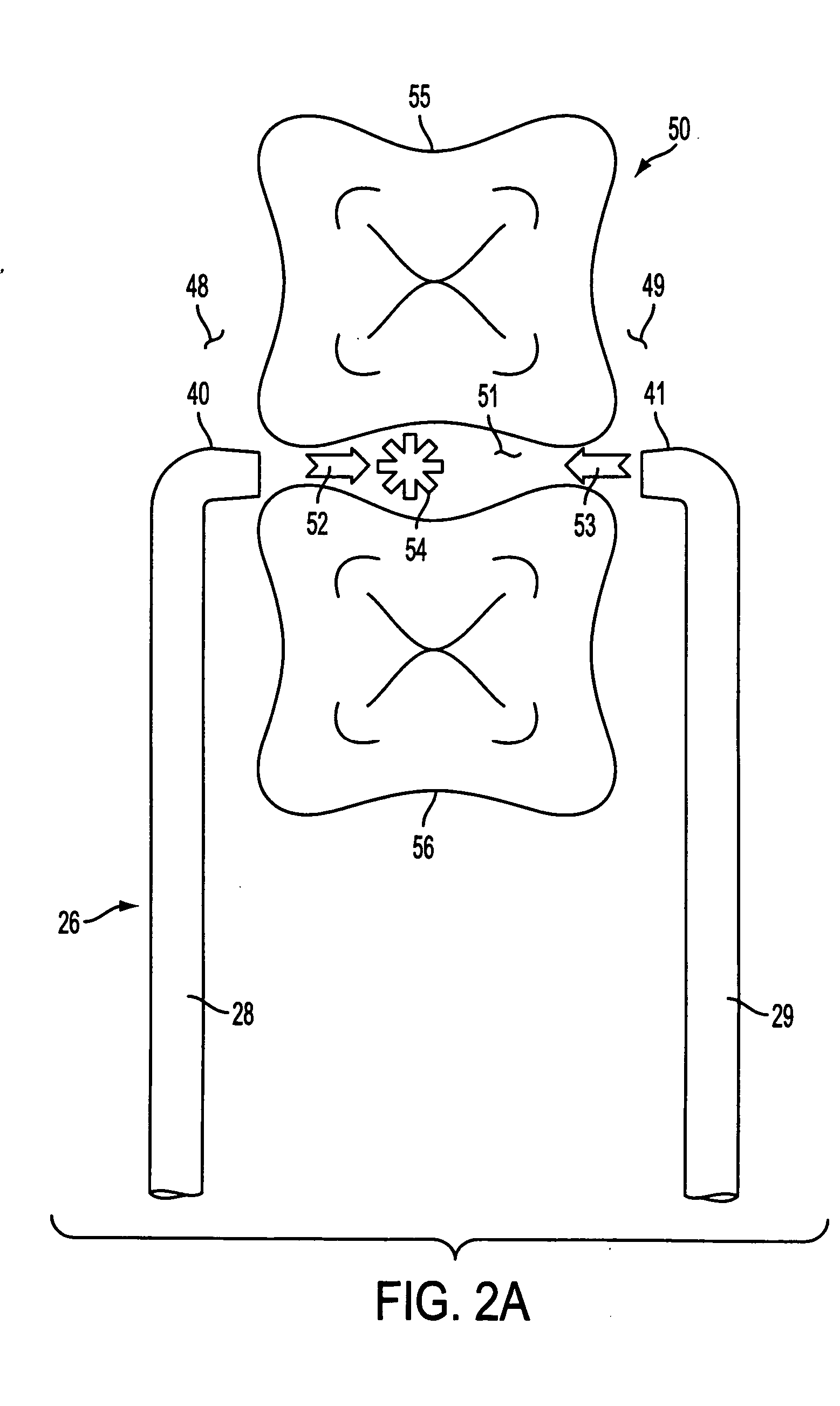

An integrated or combined oral care device having an oral cleaning device including a handle, and one or more cleaning head assemblies and a fluid irrigation assembly attached or attachable to the oral cleaning device.

Owner:CRA LABS

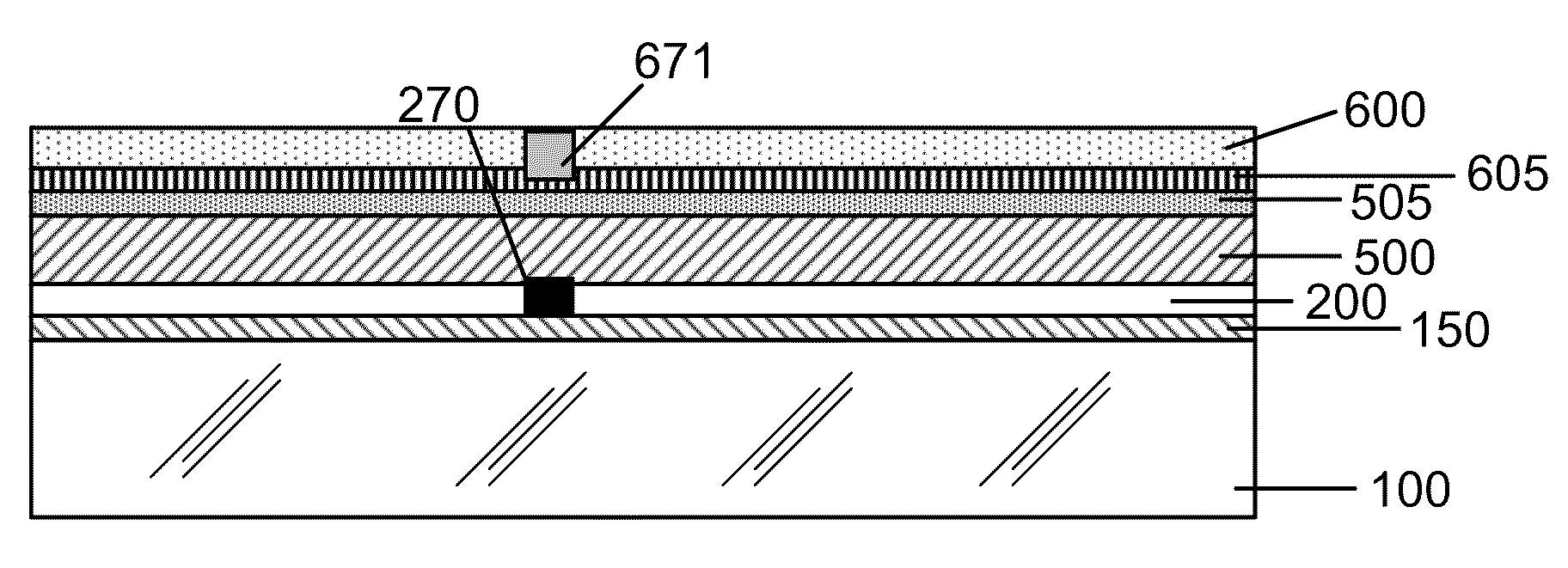

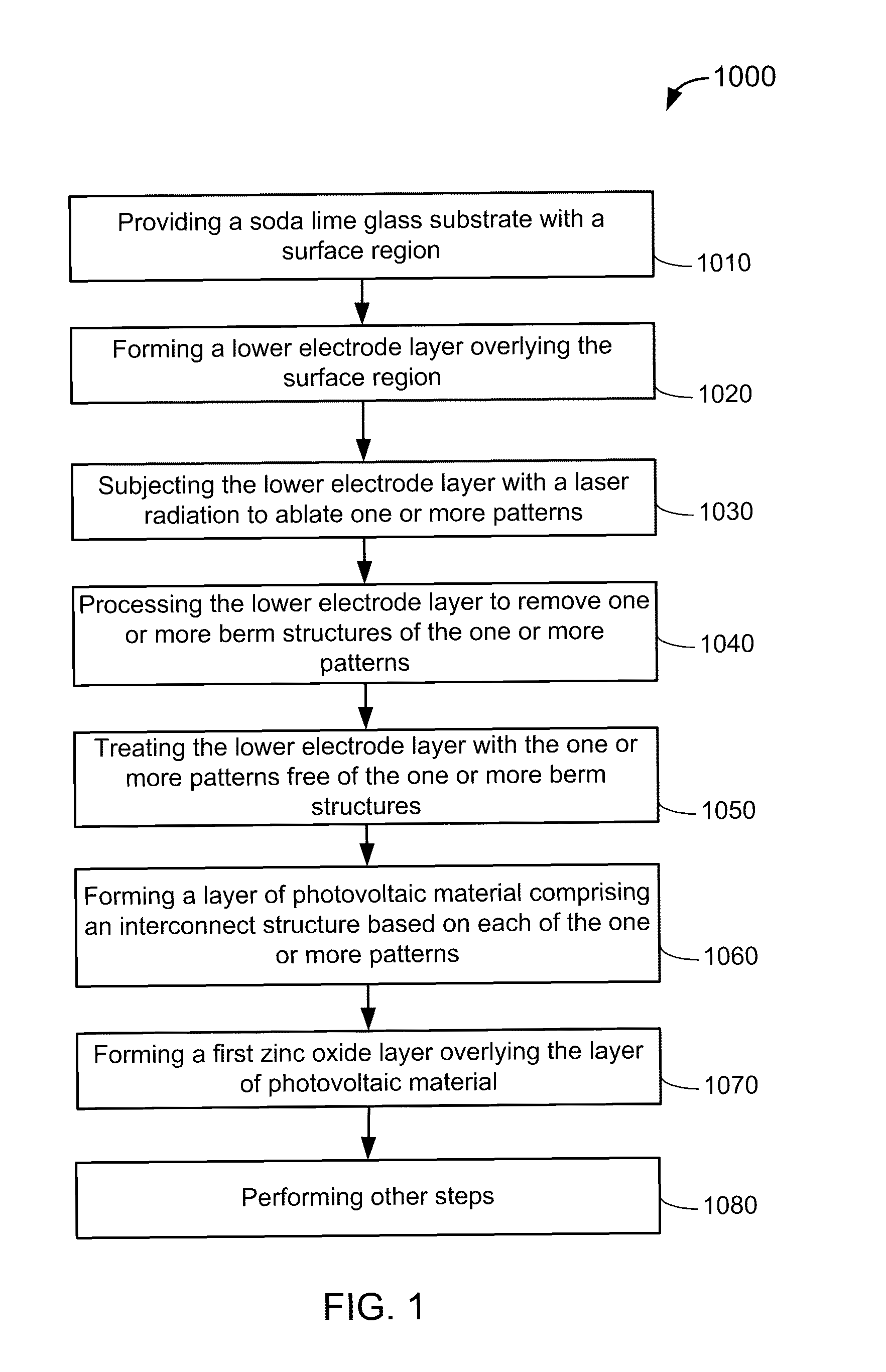

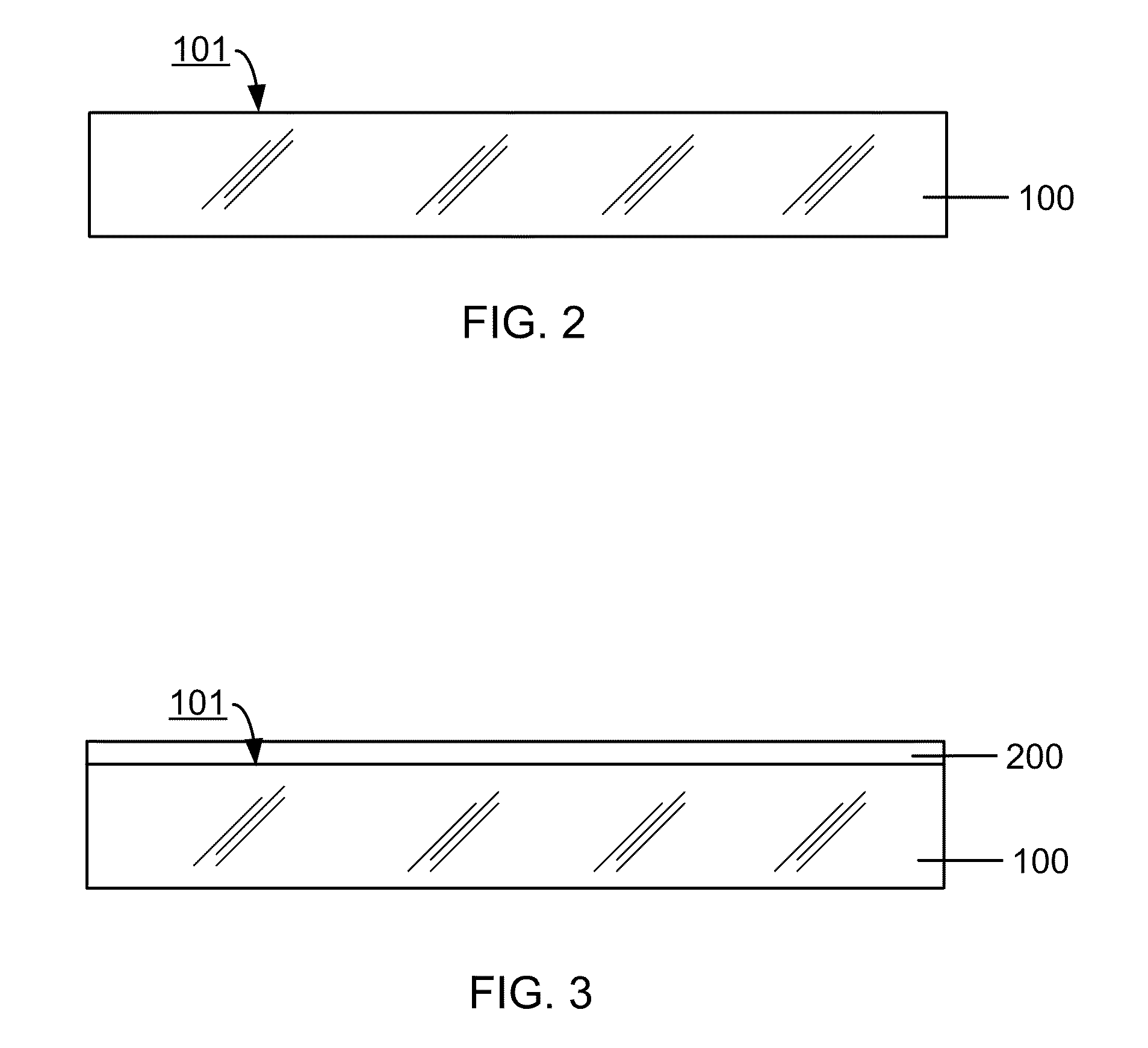

Patterning electrode materials free from berm structures for thin film photovoltaic cells

InactiveUS7863074B2Solid-state devicesSemiconductor/solid-state device manufacturingBrush deviceOptoelectronics

A method for forming a thin film photovoltaic device having patterned electrode films includes providing a soda lime glass substrate with an overlying lower electrode layer comprising a molybdenum material. The method further includes subjecting the lower electrode layer with one or more pulses of electromagnetic radiation from a laser source to ablate one or more patterns associated with one or more berm structures from the lower electrode layer. Furthermore, the method includes processing the lower electrode layer comprising the one or more patterns using a mechanical brush device to remove the one or more berm structures followed by treating the lower electrode layer comprising the one or more patterns free from the one or more berm structures. The method further includes forming a layer of photovoltaic material overlying the lower electrode layer and forming a first zinc oxide layer overlying the layer of photovoltaic material.

Owner:CM MFG

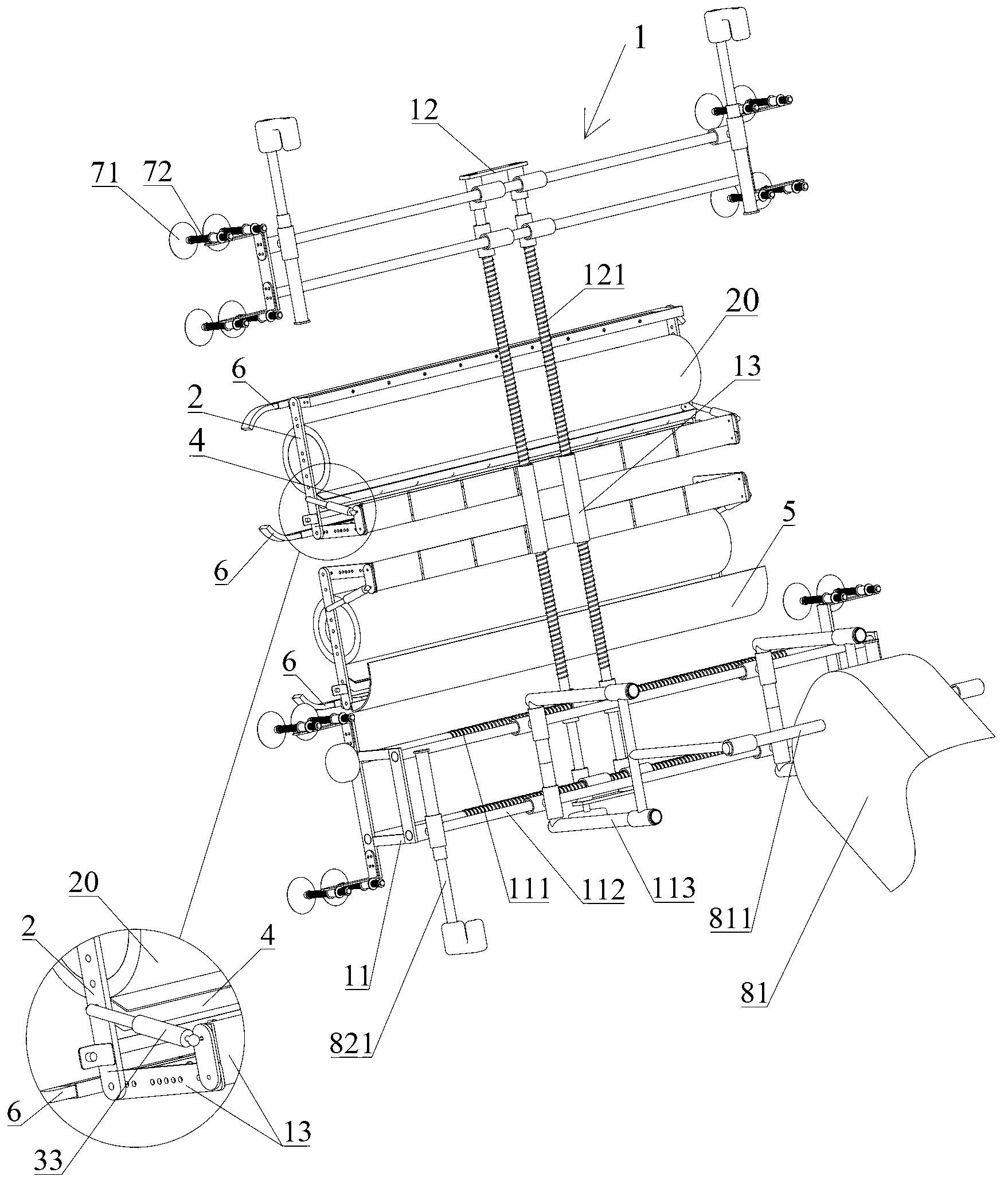

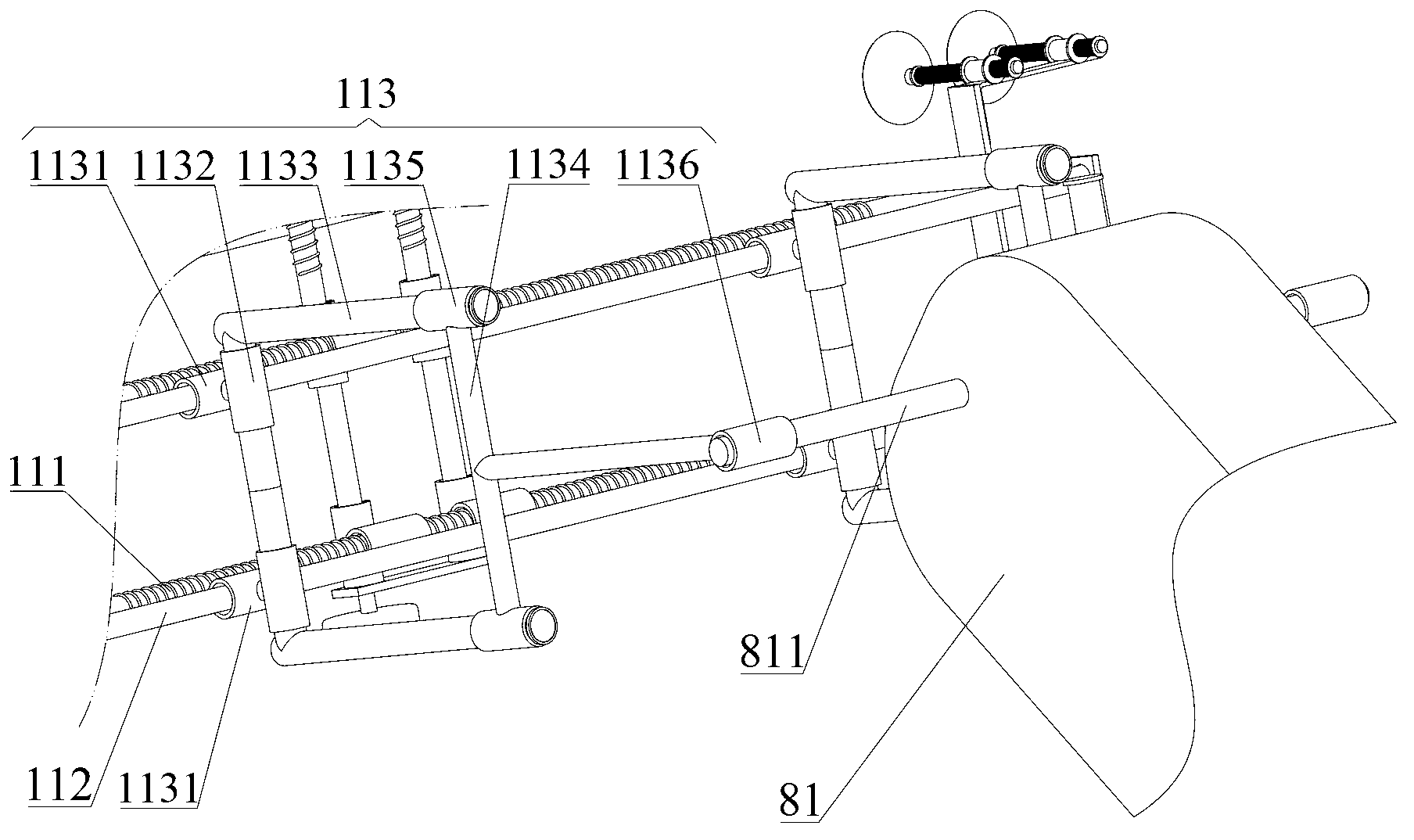

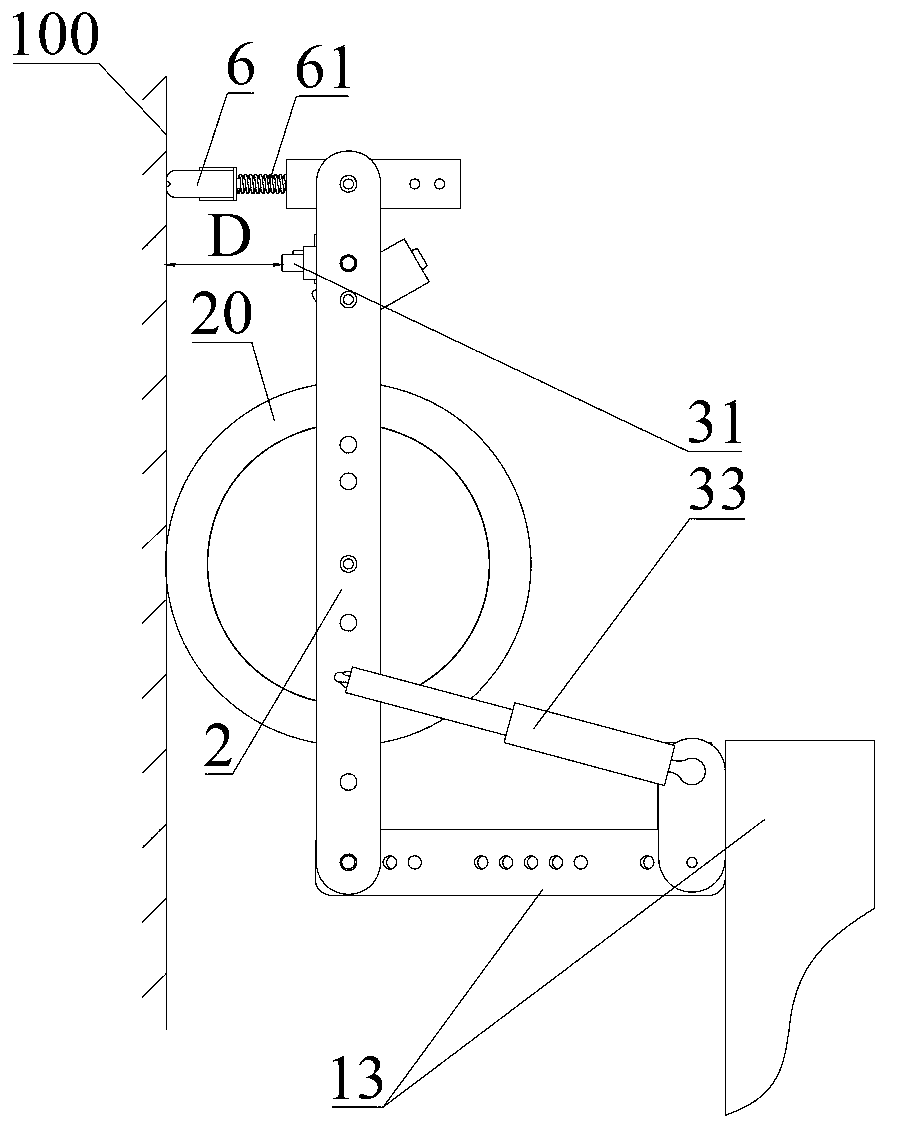

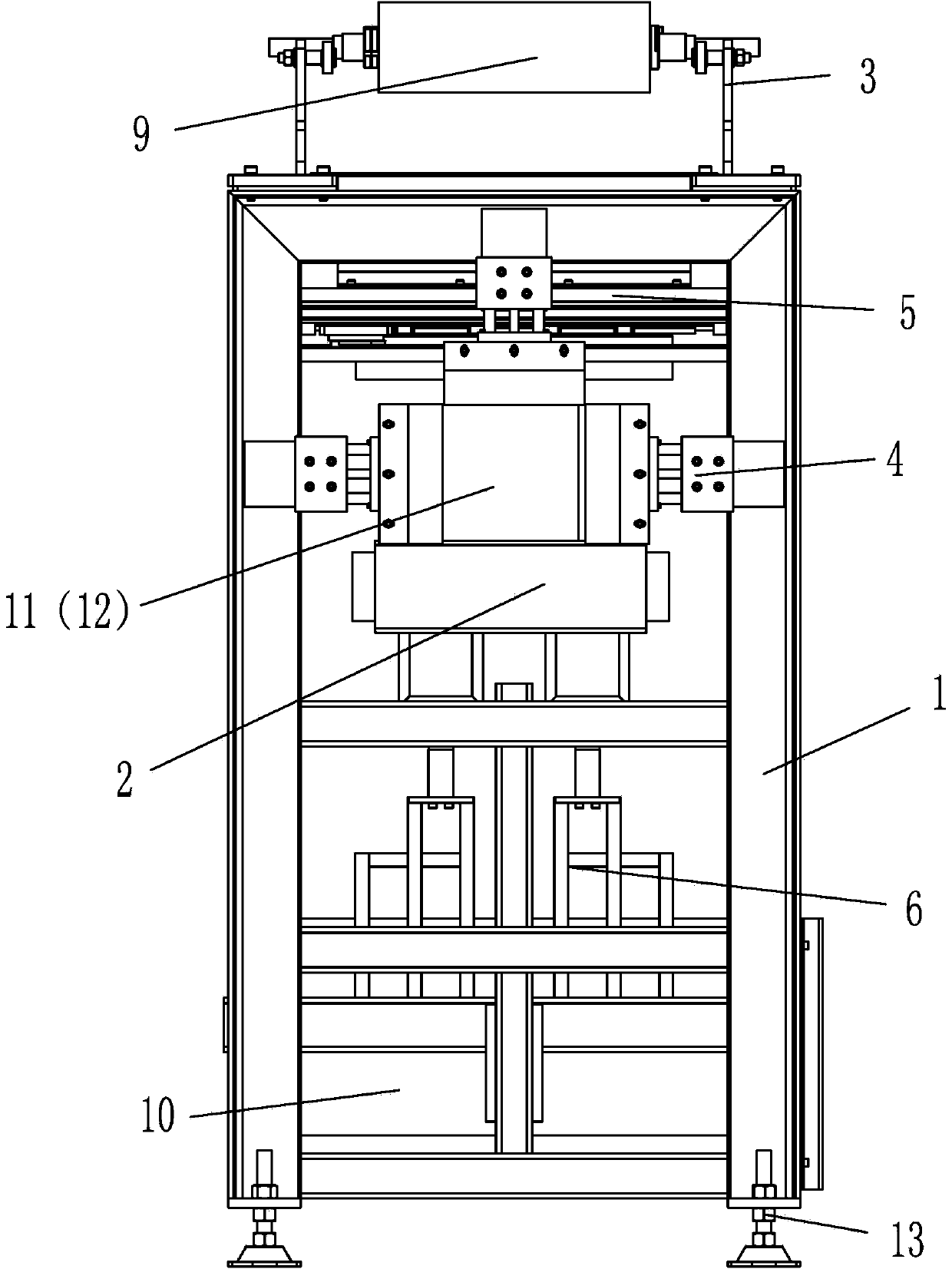

Outer wall cleaning machine

The invention provides an outer wall cleaning machine which comprises a rack and a cleaning brush device arranged on the rack. The cleaning brush device comprises a first support with a cleaning brush, a first distance detecting unit, a first control unit and a first driving mechanism, wherein the first support is movably connected with the rack, the first distance detecting unit is used for measuring the first distance between the first distance detecting unit and a cleaning face, the first control unit is used for controlling the first driving mechanism according to the first distance, and the first driving mechanism is used for driving the first support to carrying out motion. The outer wall cleaning machine can clean a flat cleaning face and a flat cleaning face with protrusions safely and efficiently.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

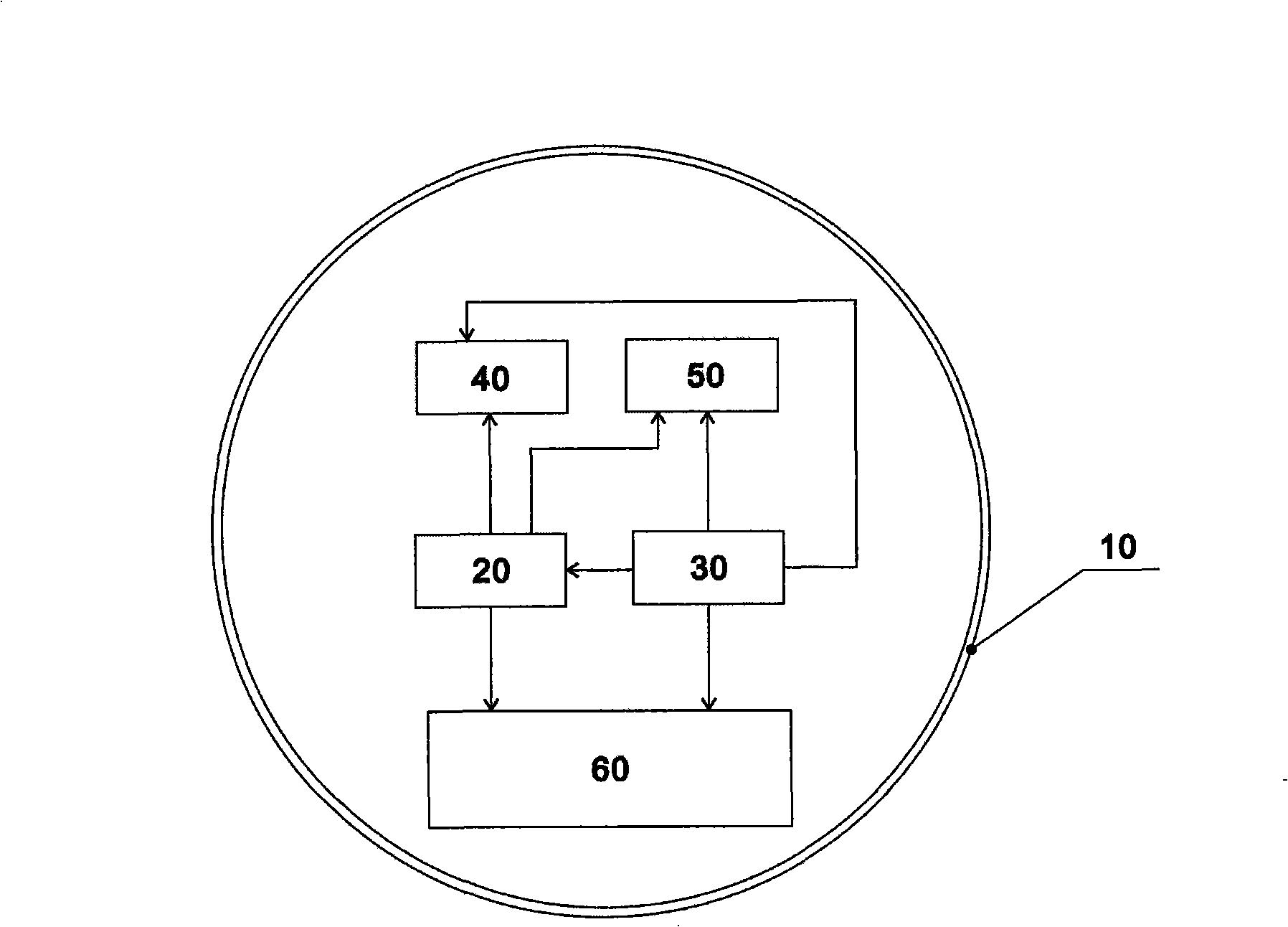

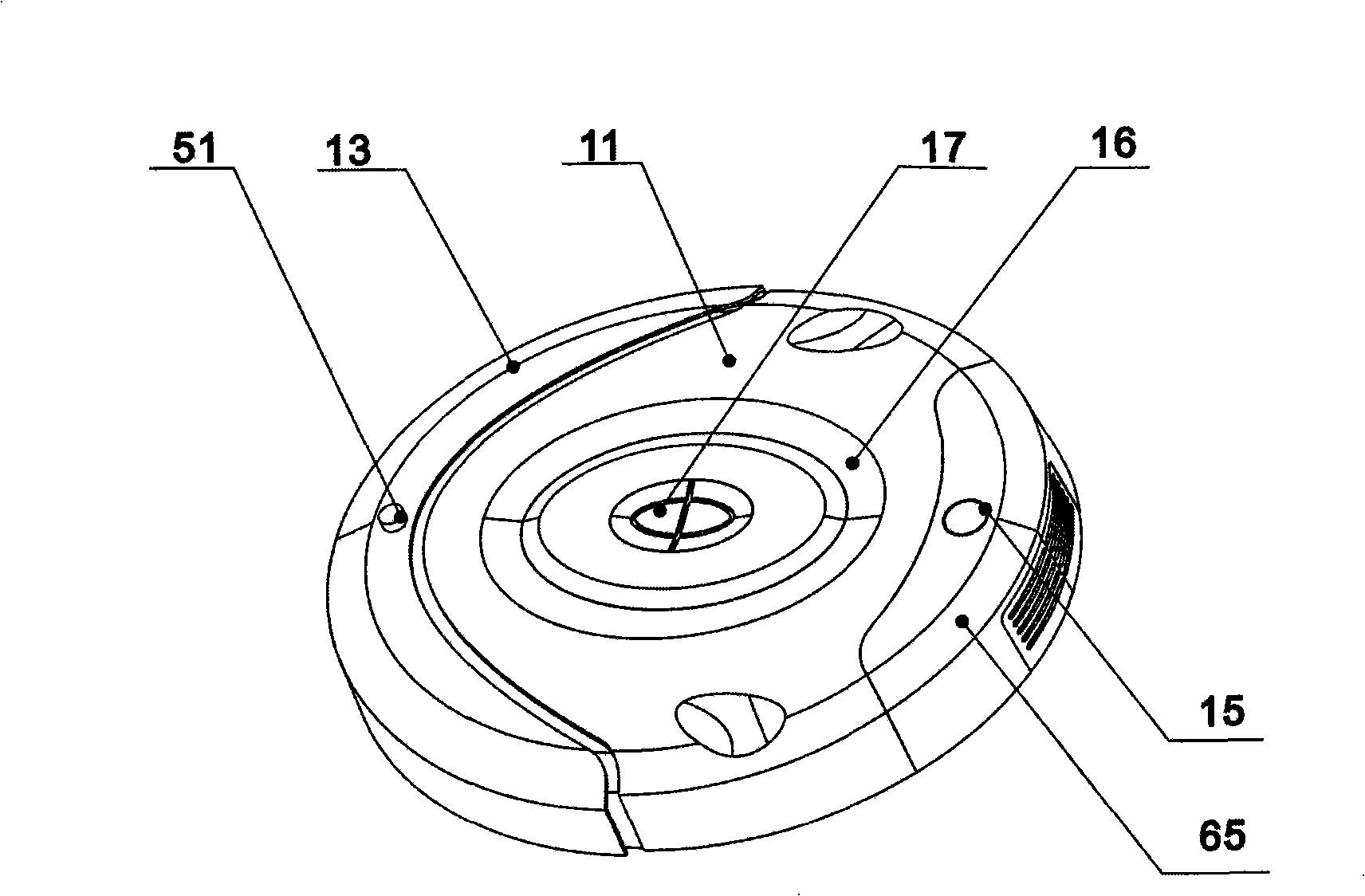

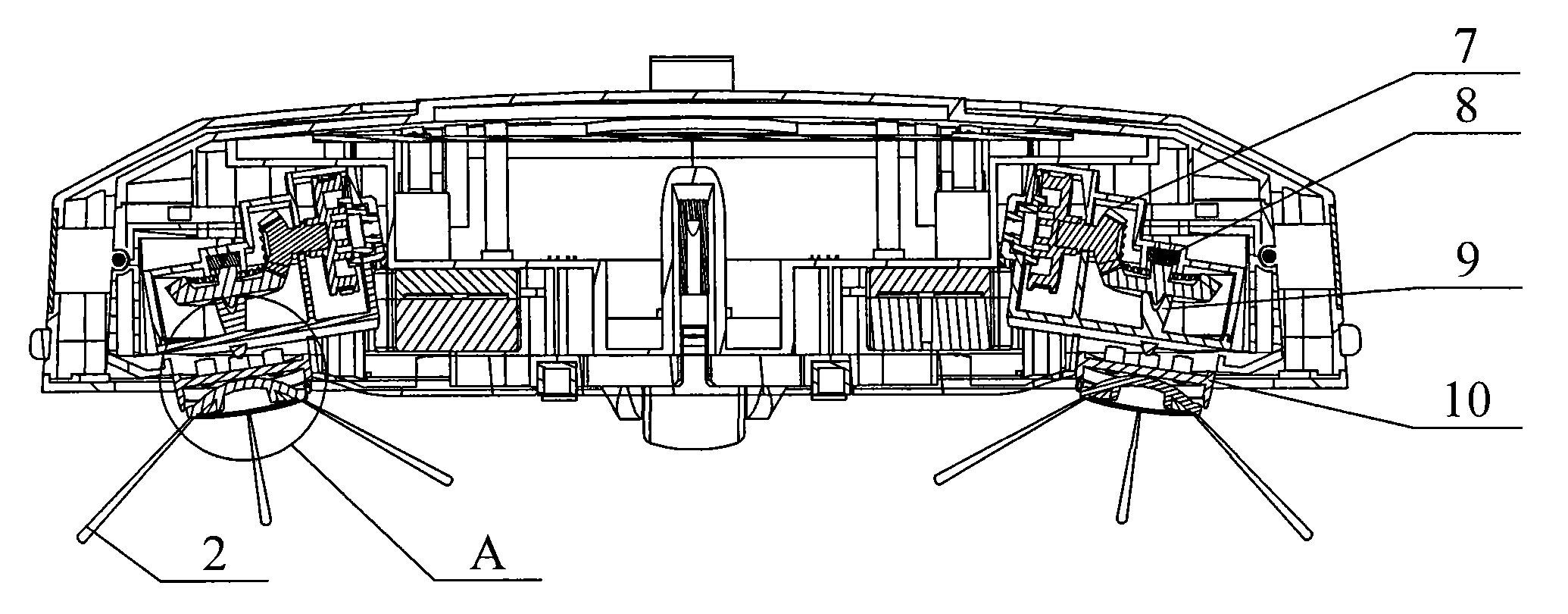

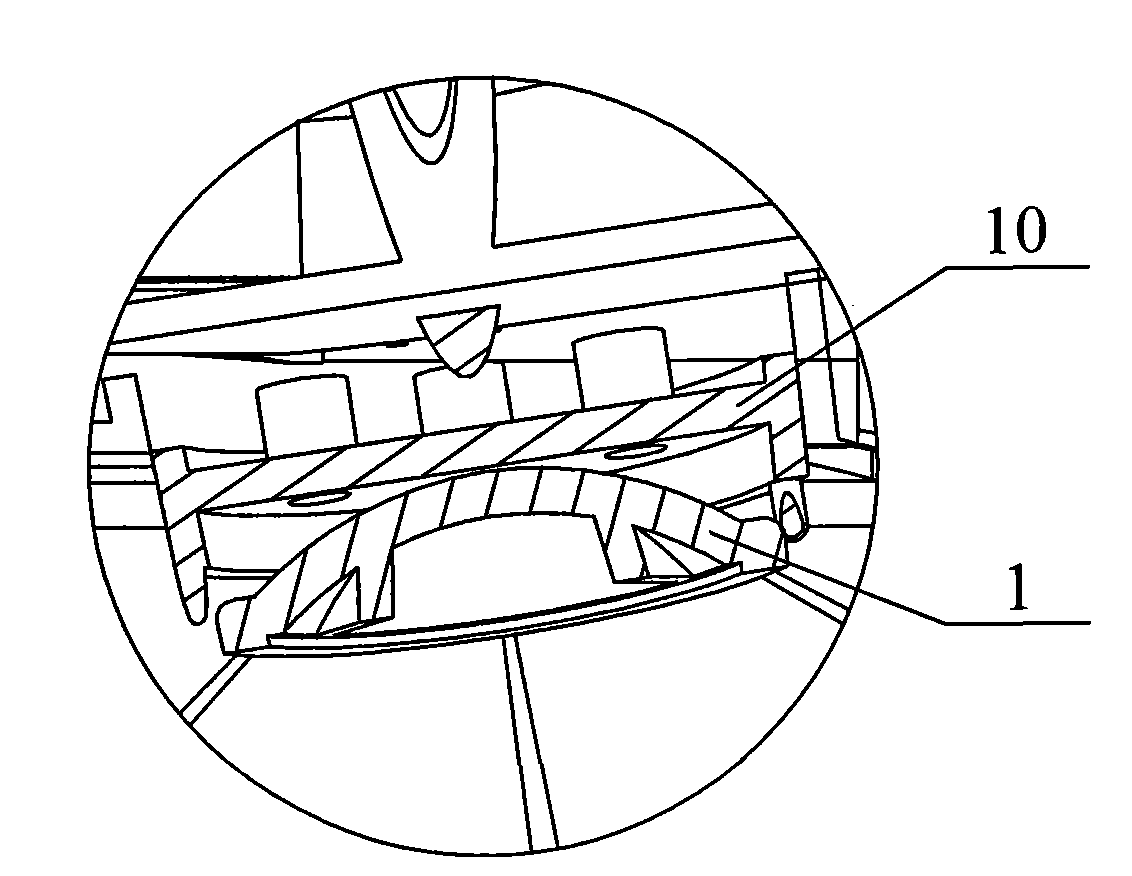

4-segment type sweeping robot

InactiveCN101301186AImprove cleaning qualityImprove reliabilitySuction nozzlesFloor sweeping machinesControl systemEngineering

The invention relates to a four-stage sweeping robot, comprising a power supply system, a motor system, a sensor system, a control system and a sweeping system which are arranged on the rounded base plate, wherein the sweeping system comprises a front main brush device and a rear main brush device respectively on the front portion and the read portion of the base plate, a left side brush device and a right side brush device respectively on the left portion and the right portion of the base plate, and a vacuum dust cleaner device on the back side of the base plate; the front main brush device and the rear main brush device provided with a dust collection chamber respectively and driven by a separated motor, and a side brush and a main brush which share a motor, constitute an independent sweeping system. Two sets of sweeping systems can be operated together or independently. The four-stage sweeping process comprises a step of sweeping dust into the bottom of the robot by the side brush, a step of sweeping dust into the dust collection chamber by the front main brush, a step of sweeping dust into the dust collection chamber by the rear main brush, and a step of drawing residual dust into the filtering chamber by the vacuum cleaner device. The inventive four-stage sweeping robot solves the problems of incomplete cleaning and susceptibility to blockage of the main brush caused by the prior robot design.

Owner:上海中为智能机器人有限公司

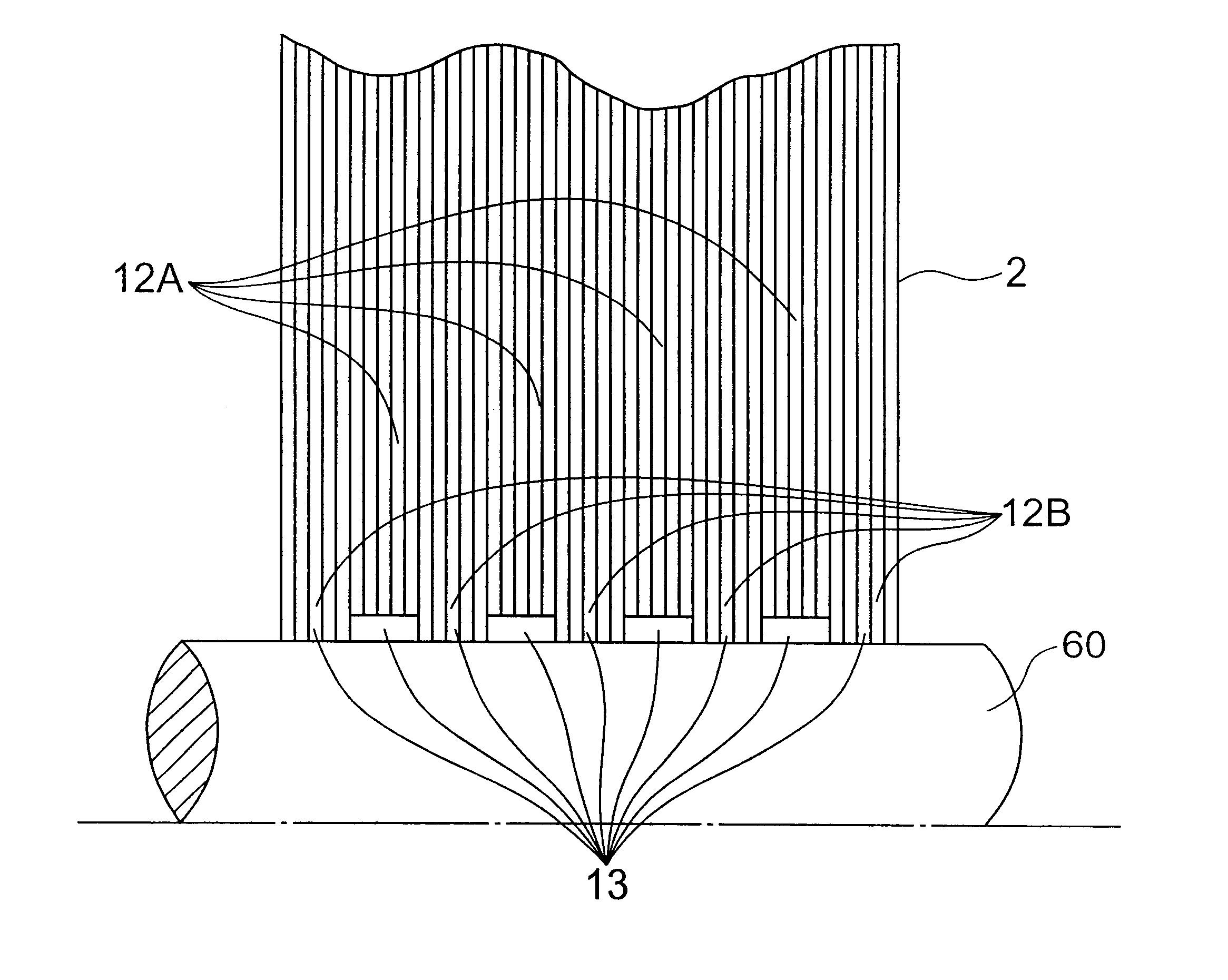

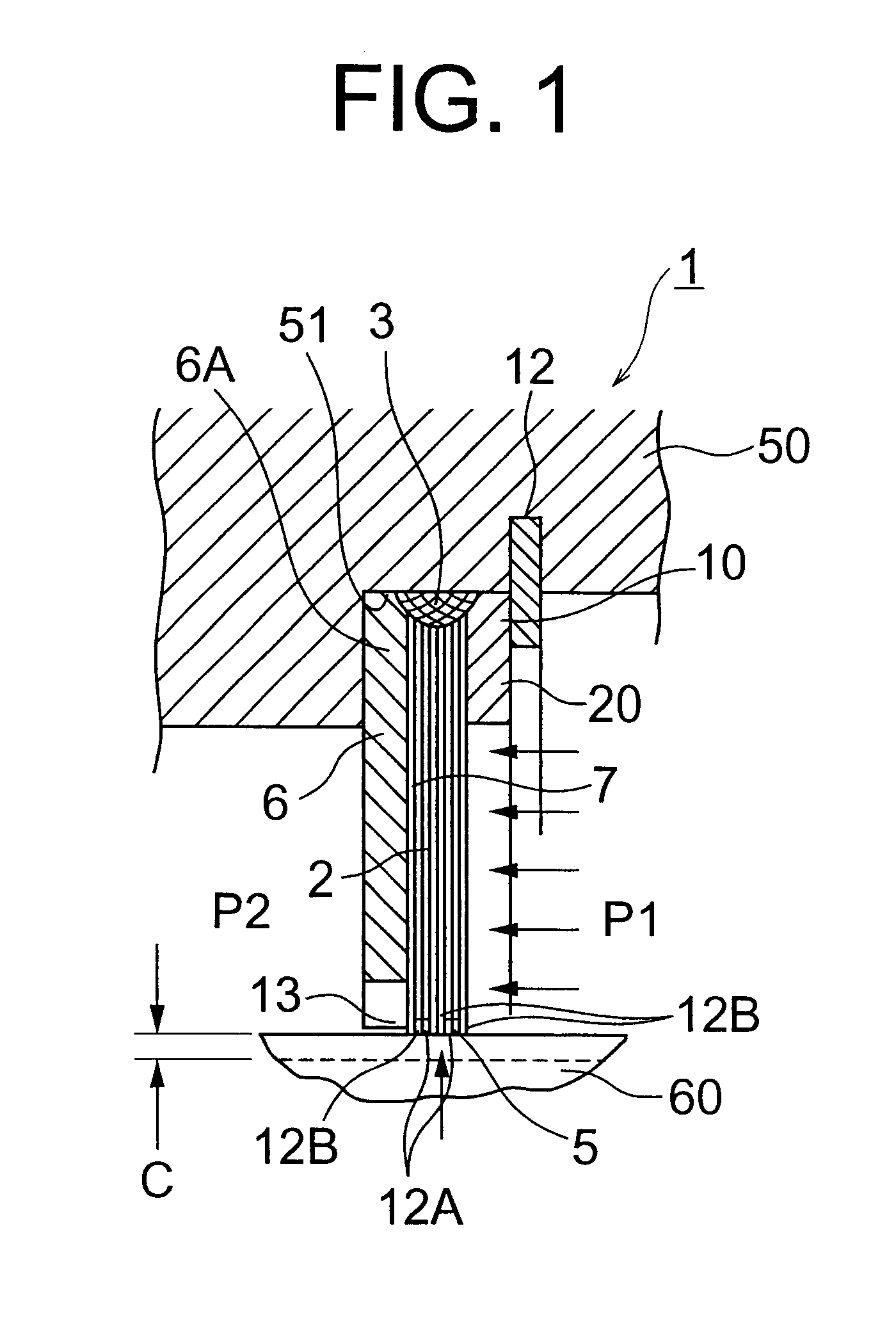

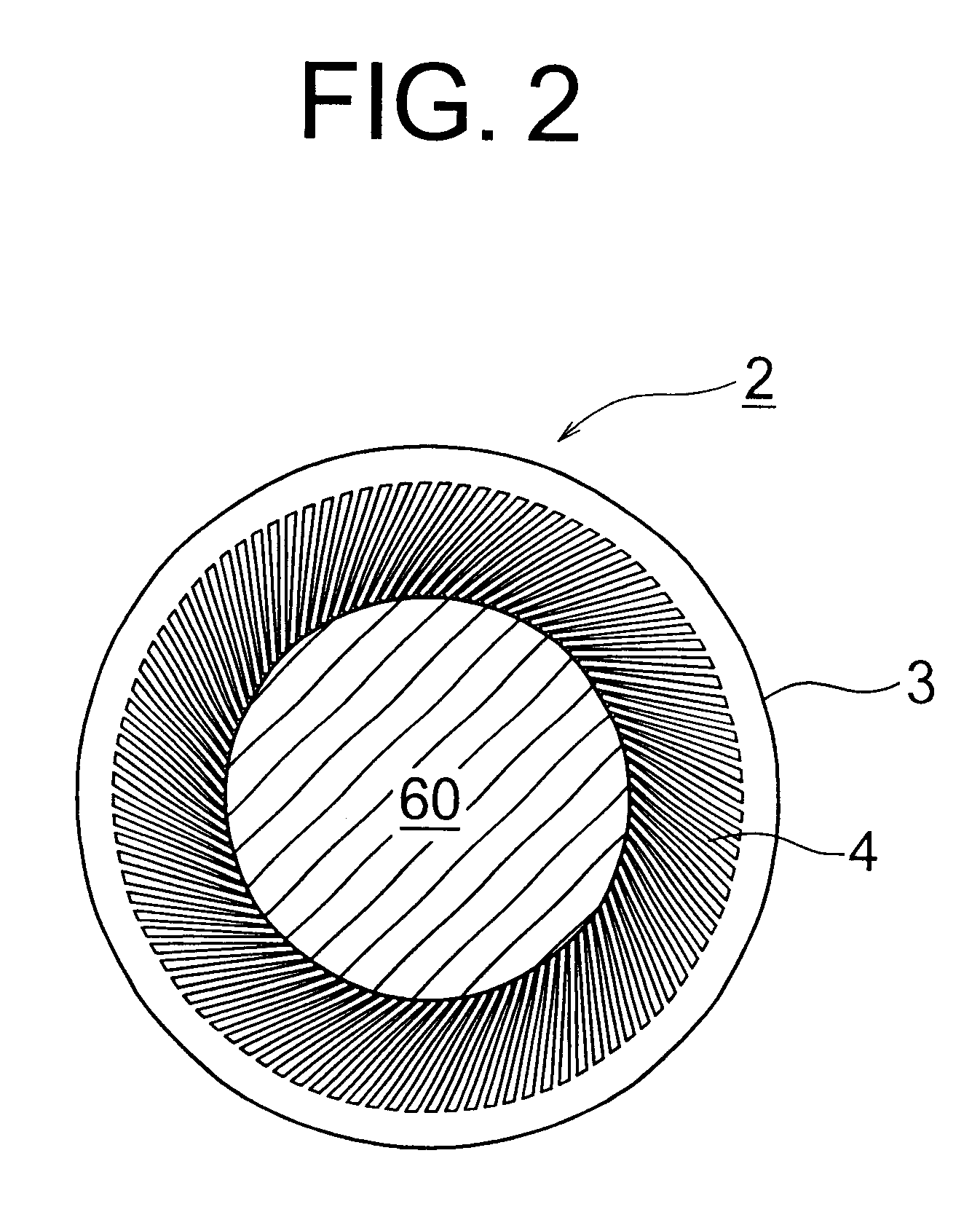

Brush seal device

When a clearance between a rotor and the free end of a brush seal of thin plates becomes larger by oscillation of the rotor or the like, the enlarged clearance is effectively sealed. In order to achieve this effect, in a brush seal device, brush seal units as recess layers and brush seal units as projection layers are stacked in the direction of the pressure of the sealed fluid to form recess and projection portion on its free end. The inner diameter of the recess layer is different from that of the projection layer.

Owner:EAGLE INDS

Brushing device with illumination features

ActiveUS20180168332A1Well formedPlanar light sourcesElectric circuit arrangementsBrush deviceElectrical and Electronics engineering

Owner:WATER PIK INC

Glass-cleaning and drying device

The invention provides a glass-cleaning and drying device suitable for cleaning and drying coated glass. The glass-cleaning and drying device comprises a stand, a conveying mechanism, a tray brush device, a brush device, a water-absorbing component, a drying device and a heat drying device. The conveying mechanism comprises a driving motor and a plurality of conveying rollers arranged in a line, wherein the driving motor drives the conveying rollers to convey coated glass; the tray brush device comprises a lifting mechanism, a plurality of tray brushes and a tray brush driving mechanism; the lifting driver of the lifting mechanism drives the tray brushes to move up and down relative to the coated glass; the tray brush driving mechanism drives the tray brushes to rotate; the clamped transmission roller group of the brush device is arranged between the tray brush device and the brush device for conveying the coated glass in a clamping mode and expelling moisture on the coated glass; the water-absorbing component comprises a water-absorbing roller group which comprises water-absorbing rollers with water absorption in vertical two-to-two correspondence; the drying device comprises air knives and a blower; and the air knives respectively face to the upper surface and the lower surface of the coated glass.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

Adjustable fitting and pipe cleaning brush device

The invention outlined in the disclosure is an adjustable wire brush tool for cleaning either the inside or the outside end of a copper pipe or fitting in preparation for soldering the parts together. The tool includes a hollow cylindrical section with a first wire brush on the interior surface of the section. Attached at one end of the cylindrical section is a slightly smaller cylindrical section sized to hold a second cylindrical twisted steel brush having a hexagonal shaft that extends from the smaller section, opposite the larger cylindrical section. The twisted steel brush and attached shaft can be moved to extend the twisted brush beyond the open end of the larger cylindrical section, for insertion into a fitting to clean the fitting interior surface by attaching a power drill to the shaft and rotating the twisted steel brush attached thereto. To clean the outside of a pipe, the twist brush is retracted into the smaller section and secured to that section with an engaging means. The pipe is inserted into the larger section, and the drill is activated to rotate the shaft and attached larger section to clean the pipe outer surface. The tool overcomes the need for separate tools to perform each task and requires but one drill to perform either task as needed. The tool is sized to handle a particular diameter of pipe and fitting, with sizes ranging from one quarter inch to several inches.

Owner:THE MILL ROSE

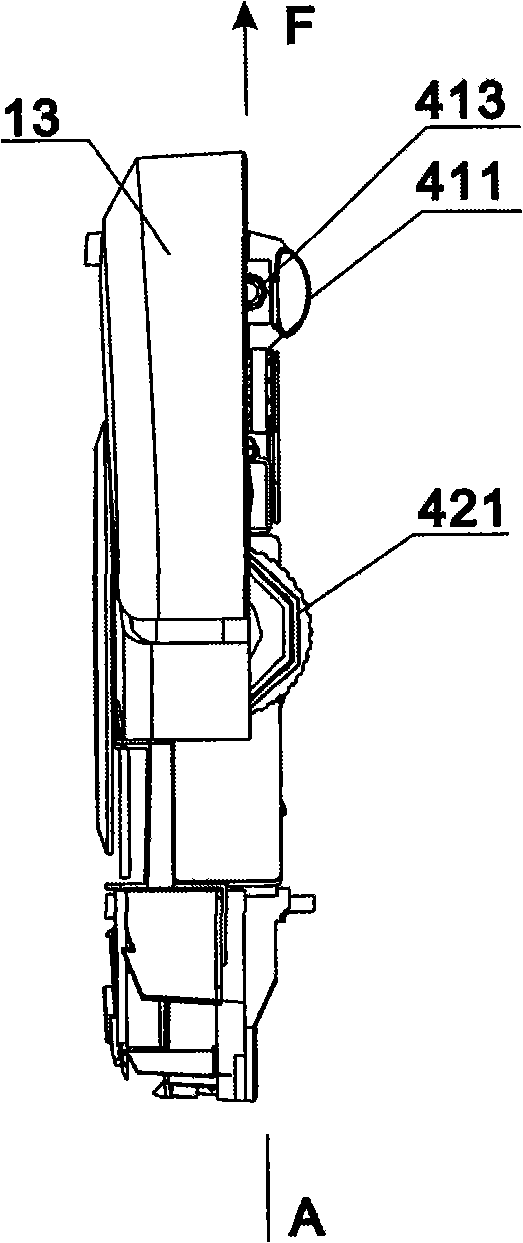

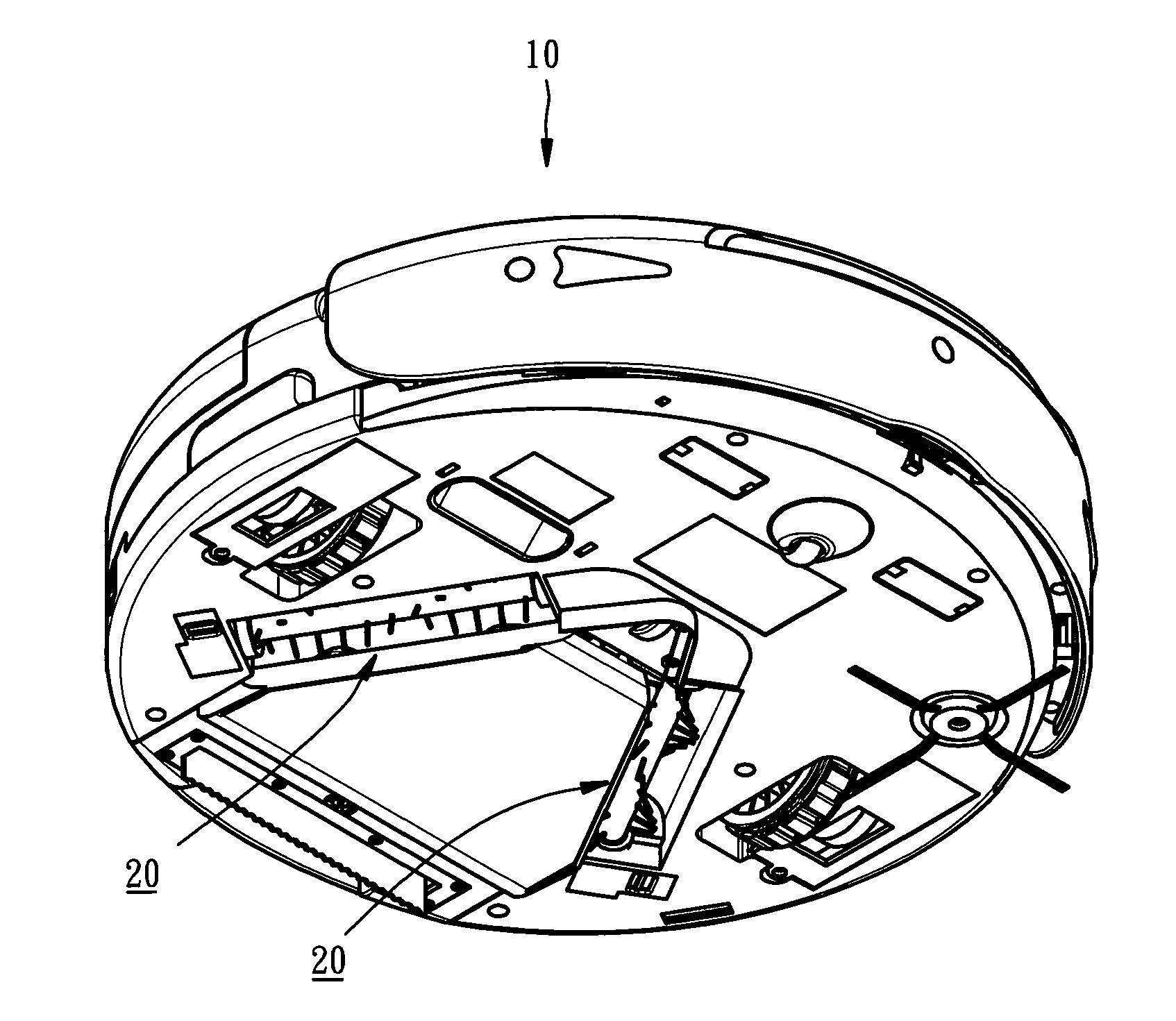

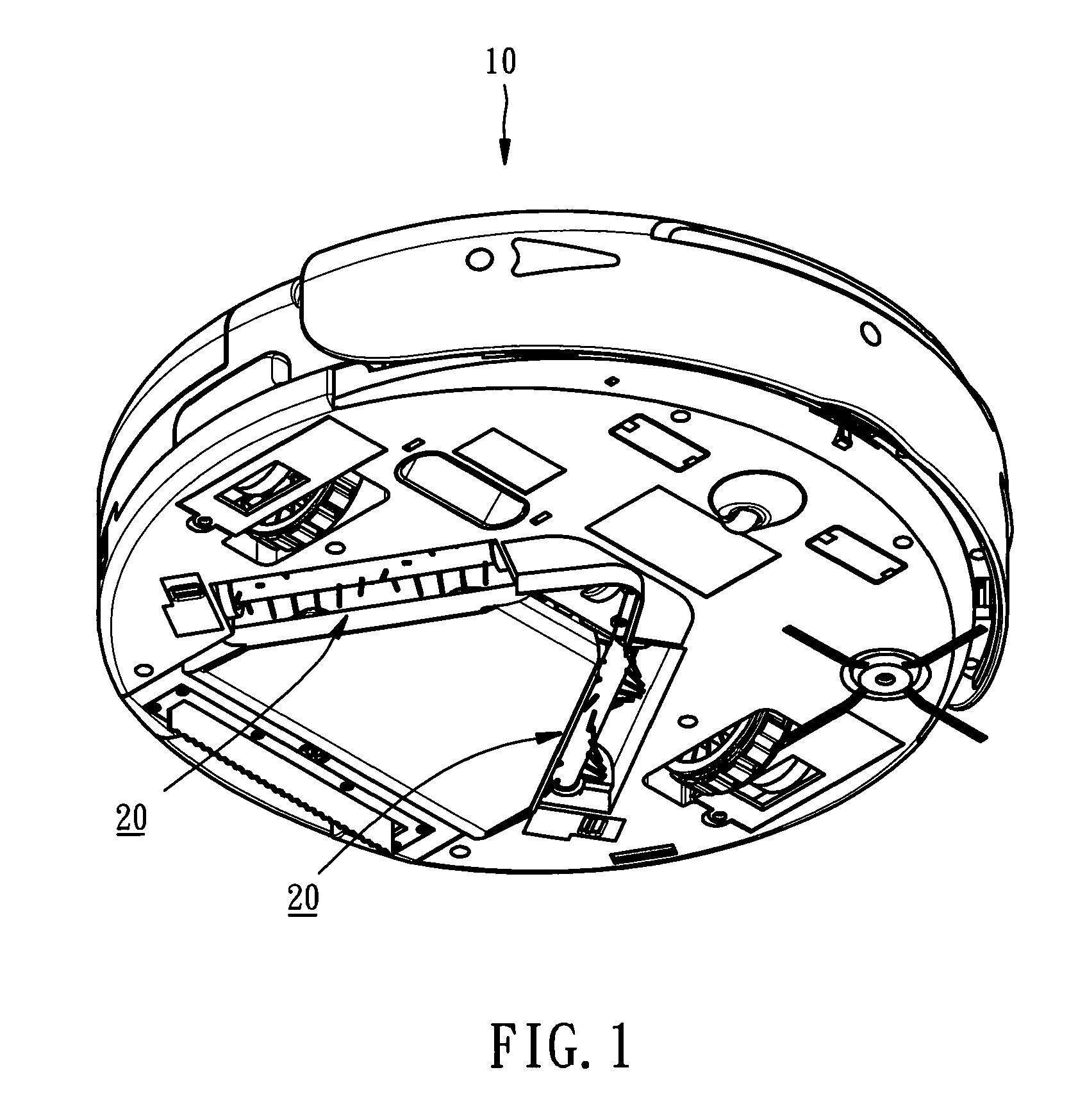

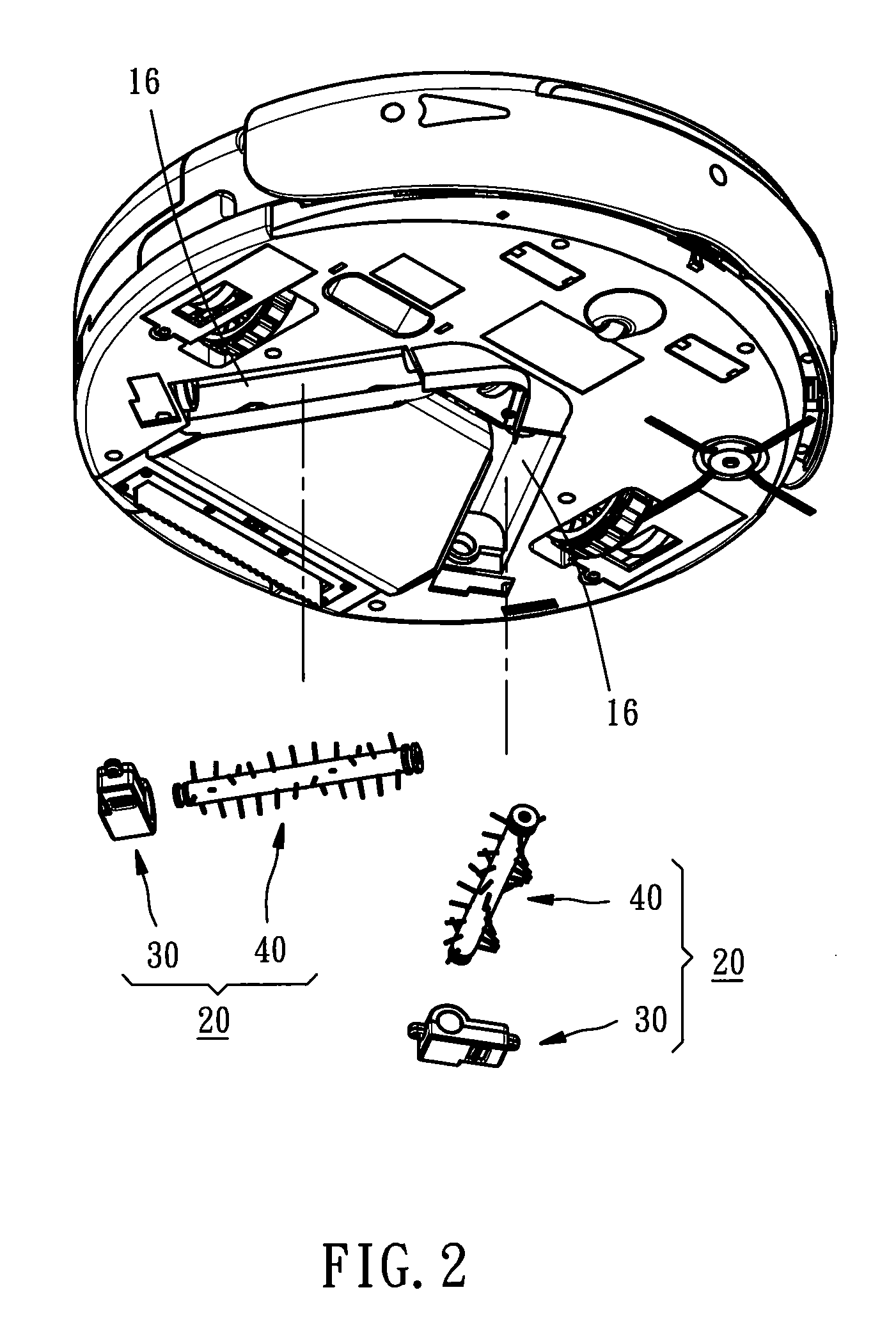

Dust roller brush device for mobile robotic vacuum cleaner

Used in a mobile robotic vacuum cleaner, a detachable roller brush device is disclosed to include a mounting device, and a roller brush having one end thereof detachably connectable to the driving shaft of the driving device and an opposite end thereof rotatably and detachably connectable to the mounting device. Thus, when released the connection between the roller brush and the mounting device, the roller brush can easily be removed from the mobile robotic vacuum cleaner for repair or replacement

Owner:EGENPOWER

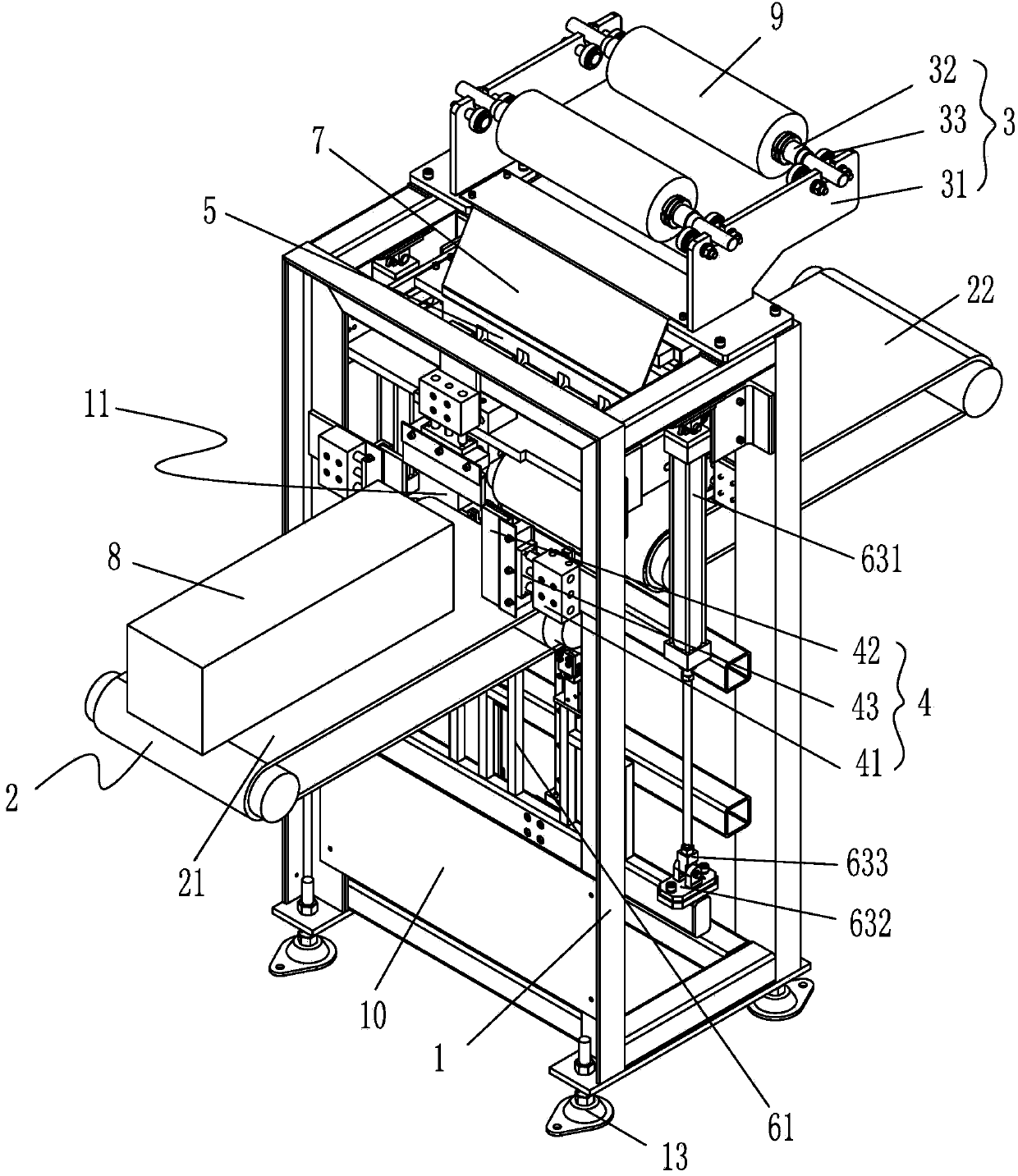

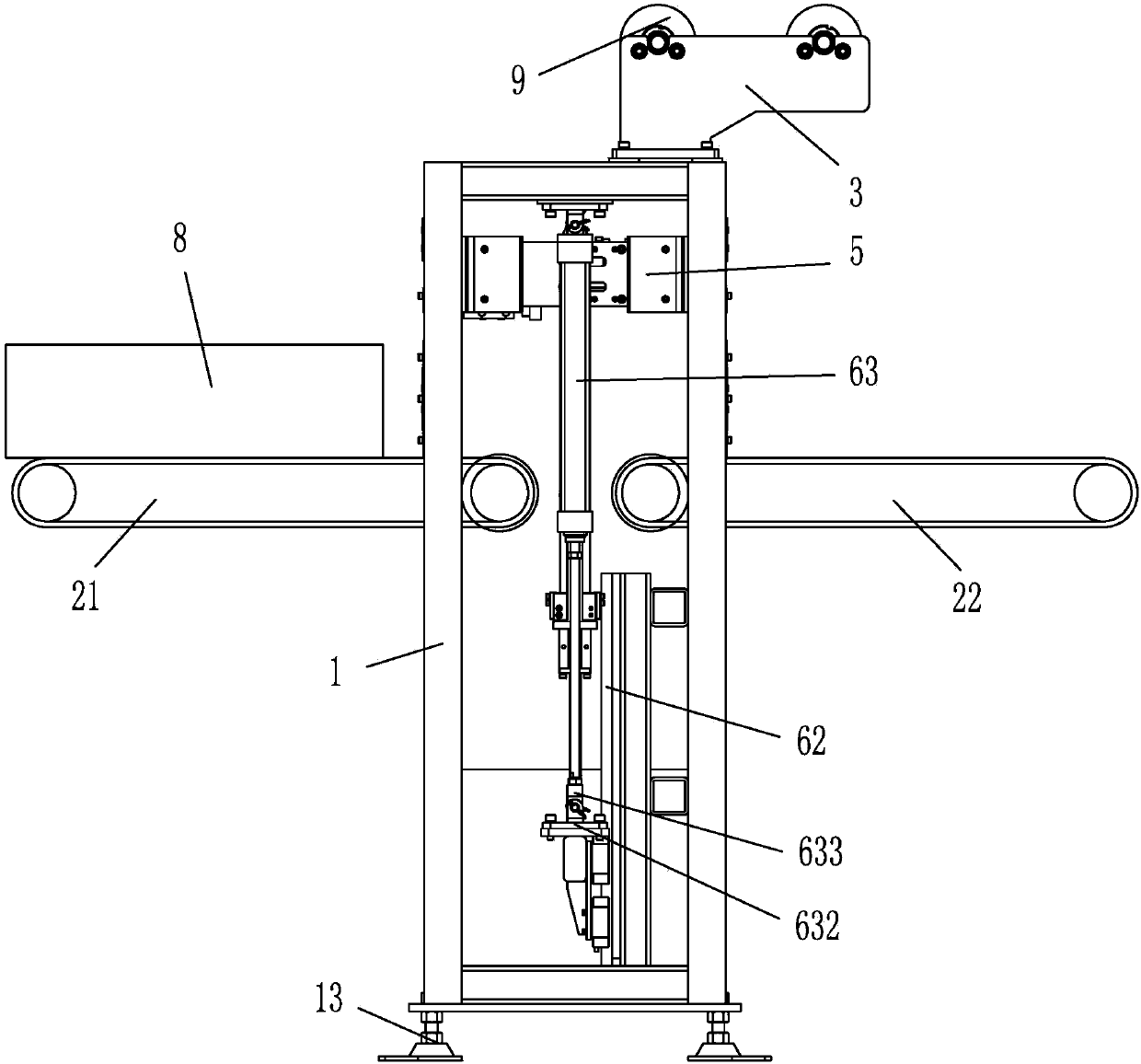

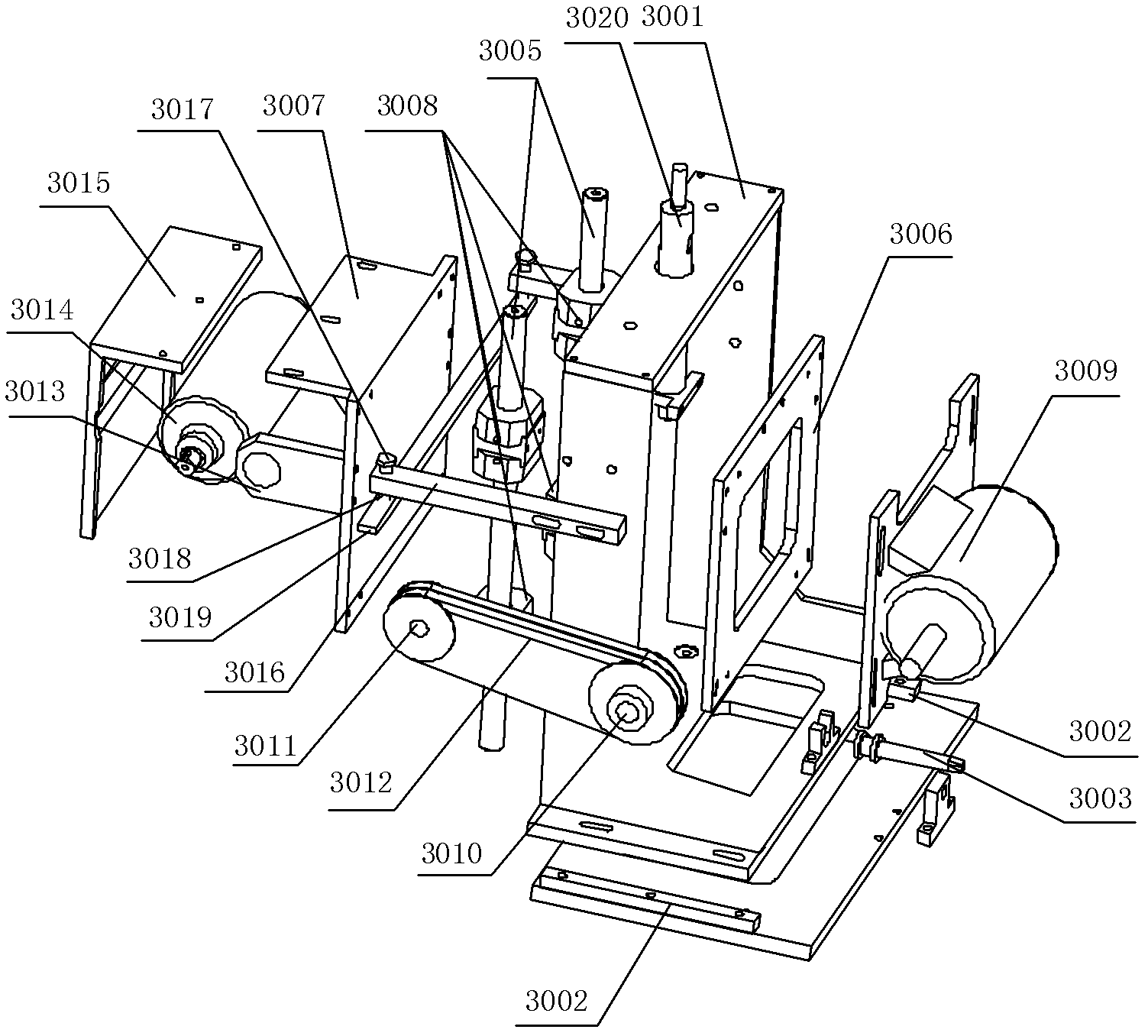

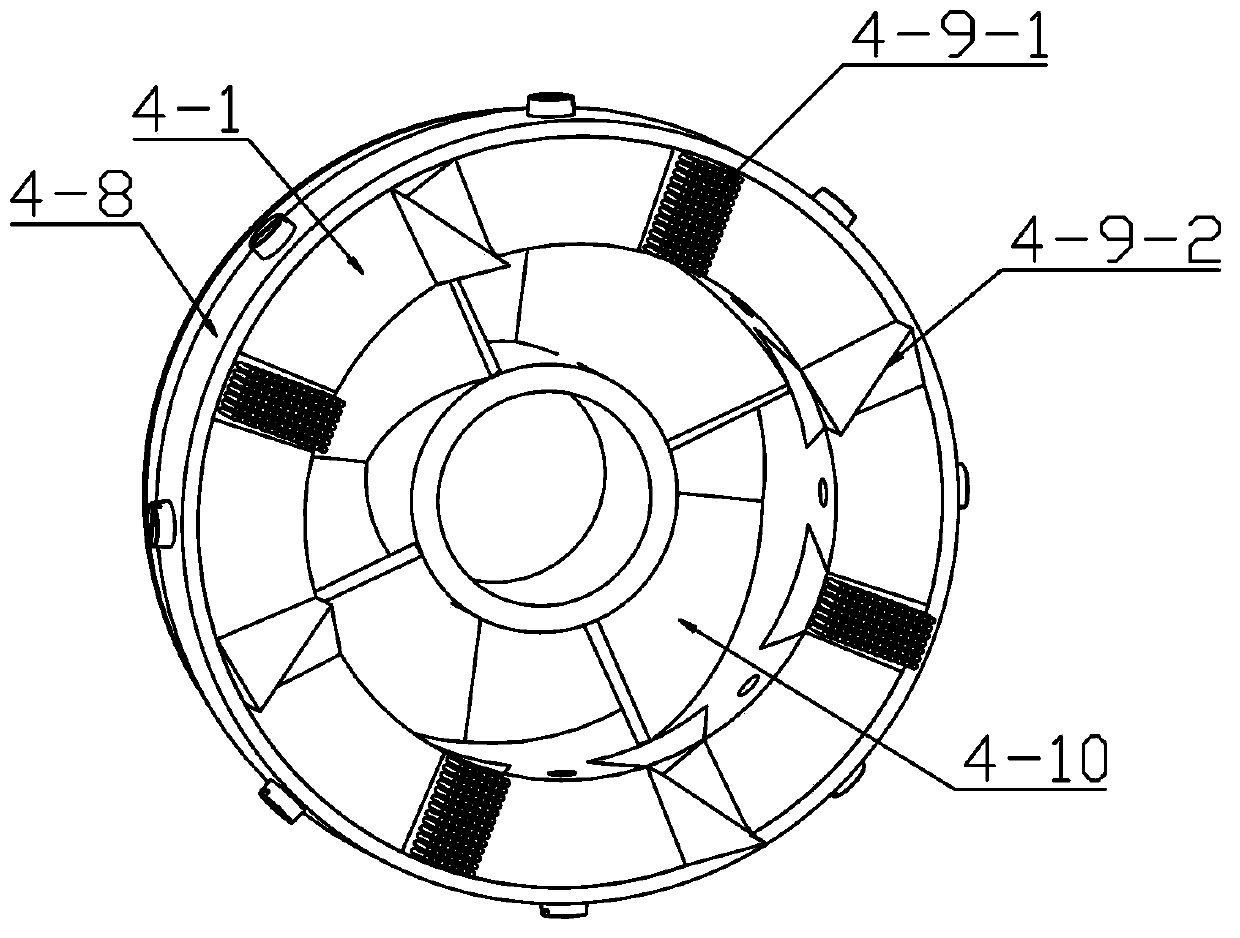

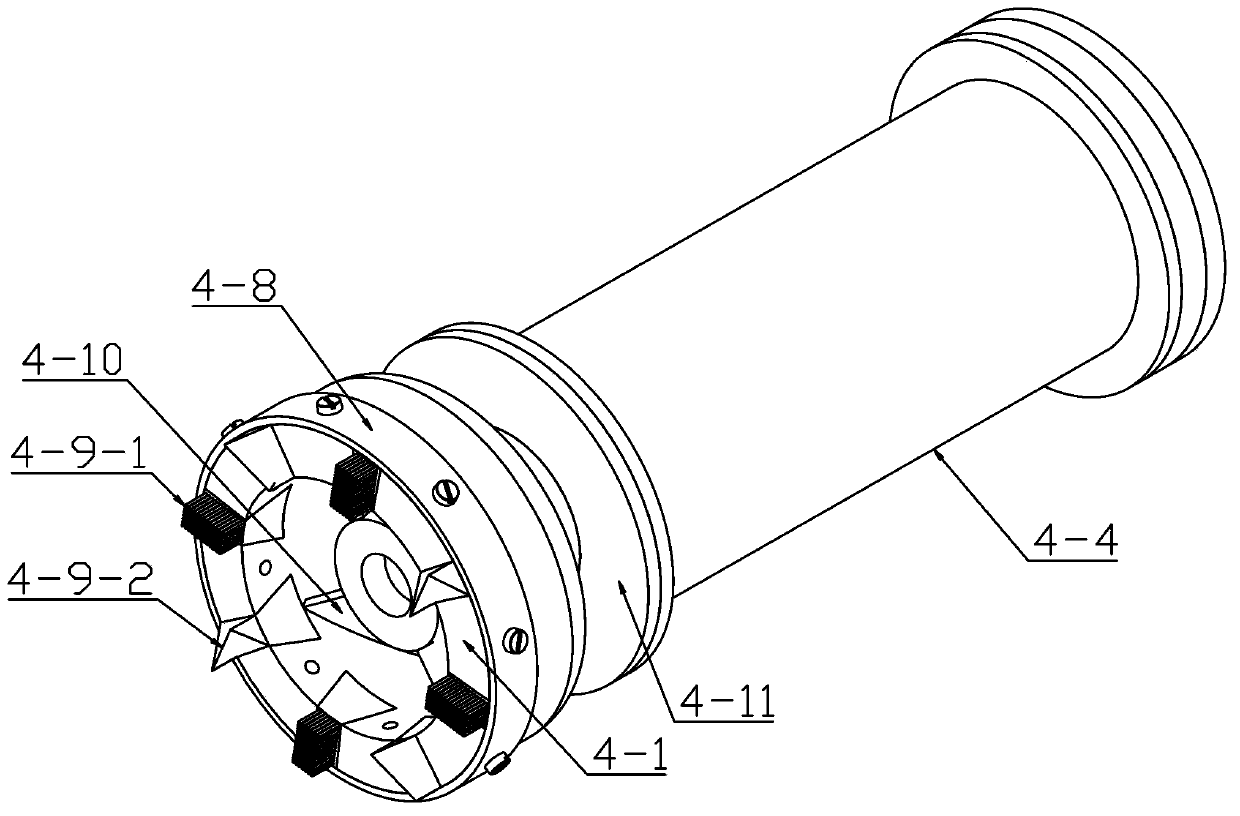

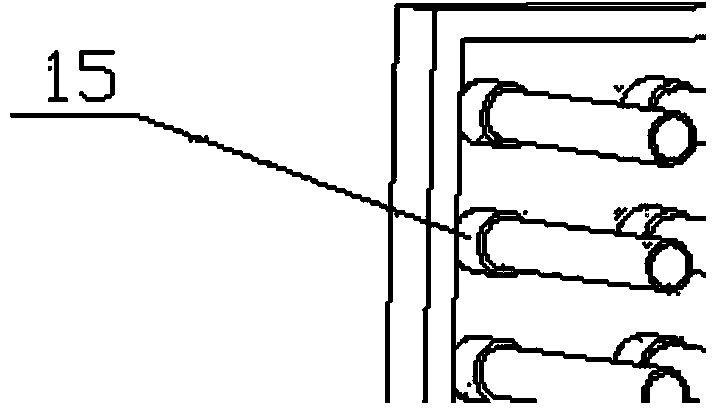

Film covering machine for film covering of ends of catalyst and film covering method of film covering machine

InactiveCN104192345AEasy to replaceMeet needsWrapping material feeding apparatusThin membraneBrush device

The invention provides a film covering machine for film covering of the ends of catalysts and a film covering method of the film covering machine. The film covering machine comprises a machine frame, a conveying device, a film feeding device, a film drawing device, a film brushing device and a film cutting device, wherein the machine frame is provided with a workpiece inlet and a workpiece outlet; the conveying device is used for conveying a workpiece to be covered with a film and comprises a front conveying belt and a rear conveying belt, and the front conveying belt and the rear conveying belt are sequentially arranged corresponding to the workpiece inlet and the workpiece outlet and drive the workpiece to be covered with the film to pass through the machine frame; the film feeding device is installed on the machine frame, used for installing and supporting the film to be arranged, and located above the workpiece inlet and the workpiece outlet; the film drawing device is installed on the machine frame and arranged between the workpiece inlet and the workpiece outlet relative to the film feeding device, and can move vertically along the machine frame; the film brushing device is installed on the machine frame, used for brushing the film to be arranged on the surface of the workpiece to be covered with the film, and arranged at the workpiece inlet and the workpiece outlet relative to the film drawing device; the film cutting device is installed on the machine frame and arranged between the film feeding device and the film brushing device. The invention further discloses the film covering method of the film covering machine.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

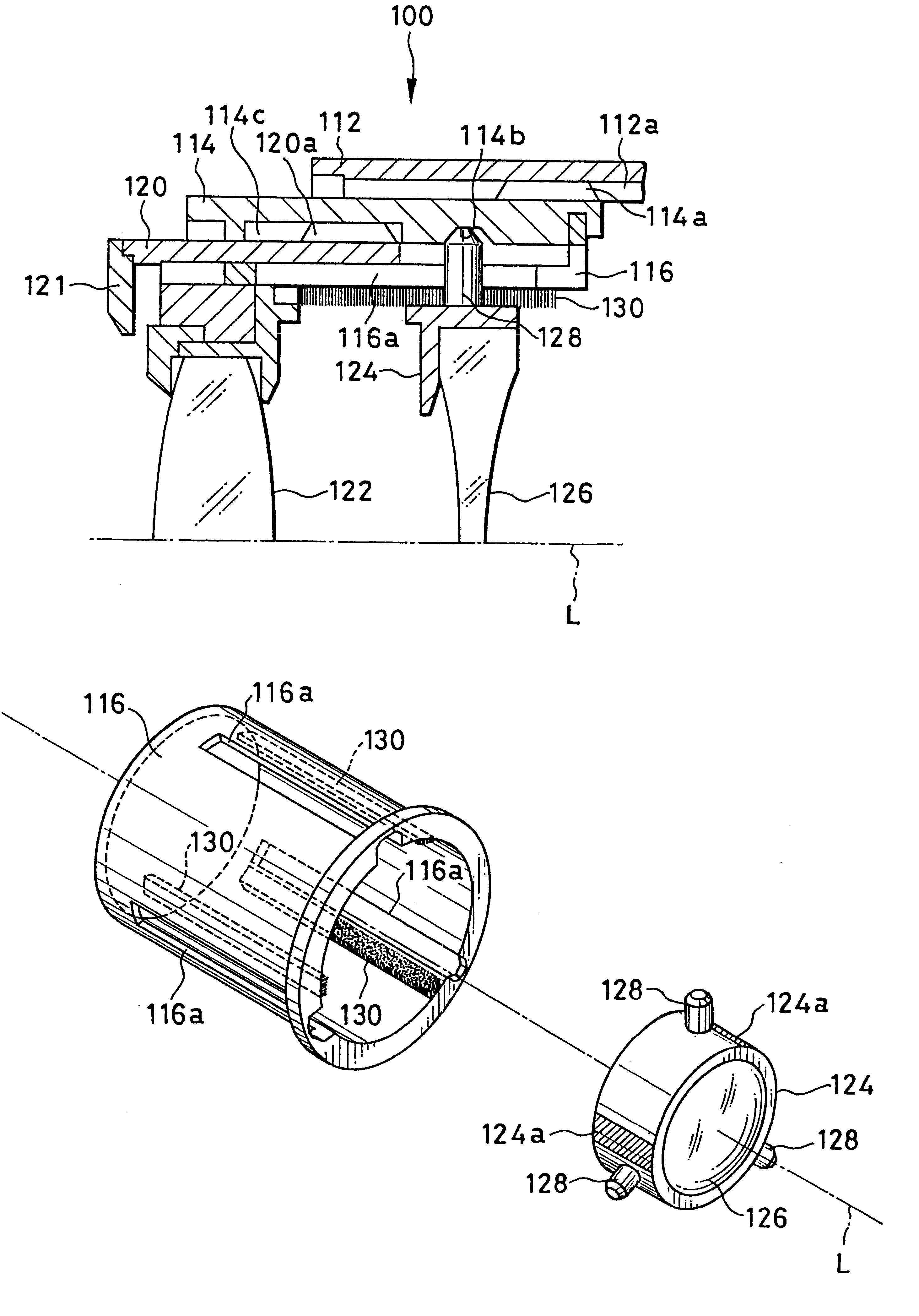

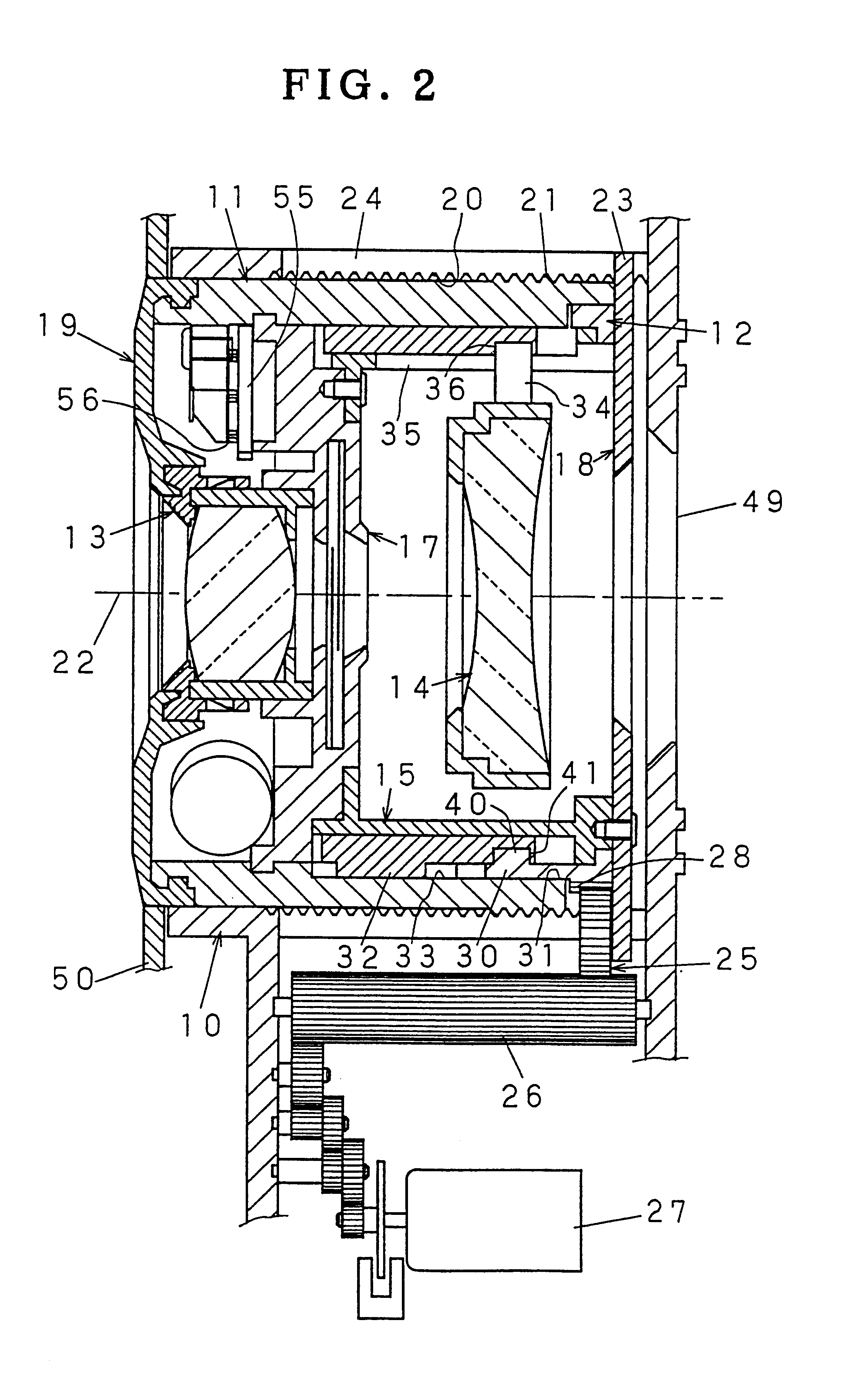

Zoom lens device with zooming position detector

A zoom lens device has a zooming position detector consisting of a code plate and a brush device. The code plate is mounted to a front face of a shutter unit that is attached to a front end of an axial movement barrel. The axial movement barrel is located inside a helical movement barrel so as to be immovable in the axial direction relative to the helical movement barrel, but is rotated relative to the helical movement barrel for zooming. The brush device is mounted to an inner peripheral portion of a lens barrel that is located near the face of the shutter unit and rotates relative to the face of the shutter unit, such that the electric contact strips brush the code plate while the shutter unit rotates relative to the lens barrel for zooming. A zooming position of the zoom lens device is determined based on output signals from the brush device.

Owner:FUJIFILM CORP

"Air cushion effect" soft oral care brush

InactiveUS6671919B2Reduce the degree of impactUsed easily and comfortably and effectivelyCarpet cleanersBrush bodiesMassageEngineering

Owner:DAVIS COLIN G

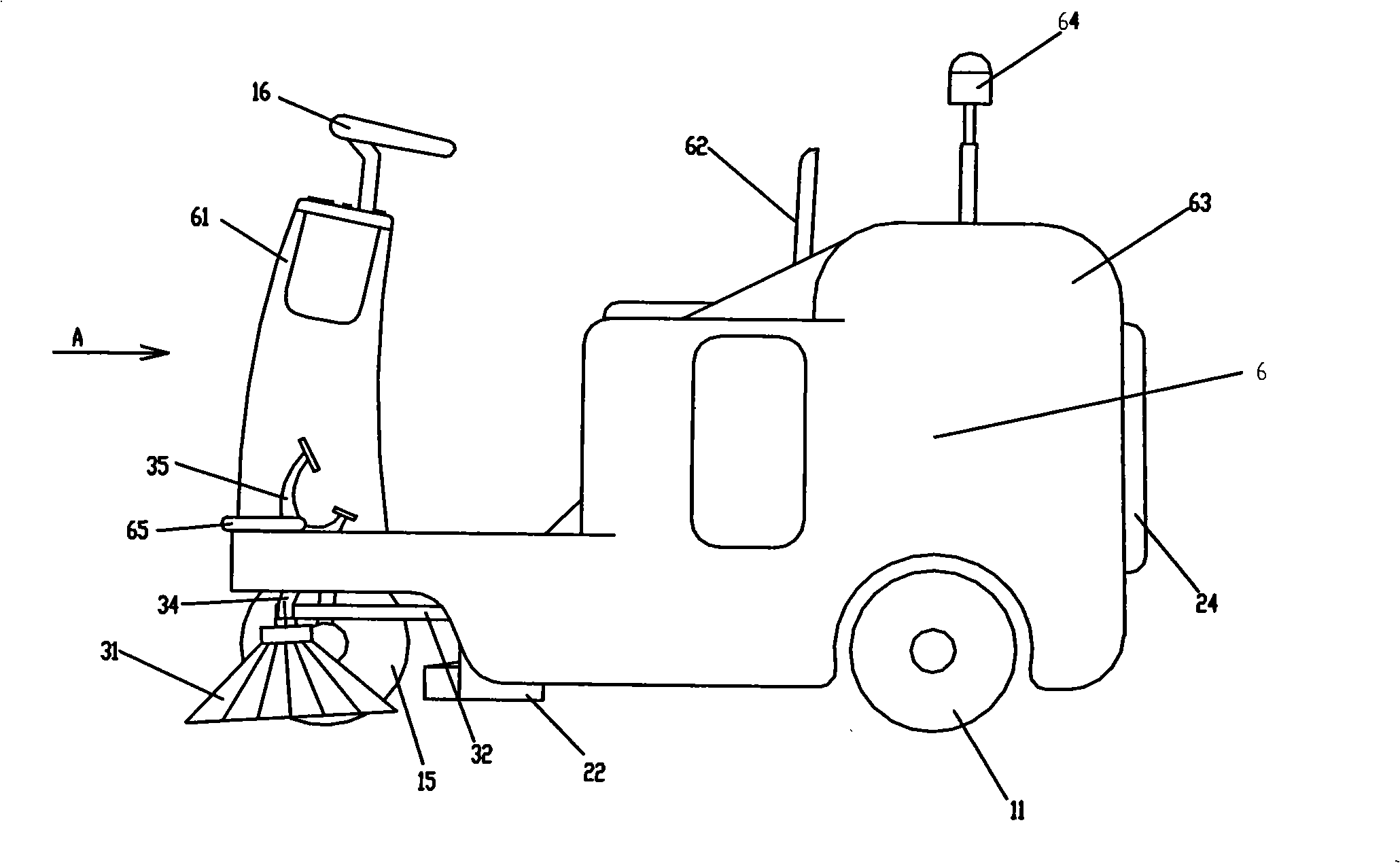

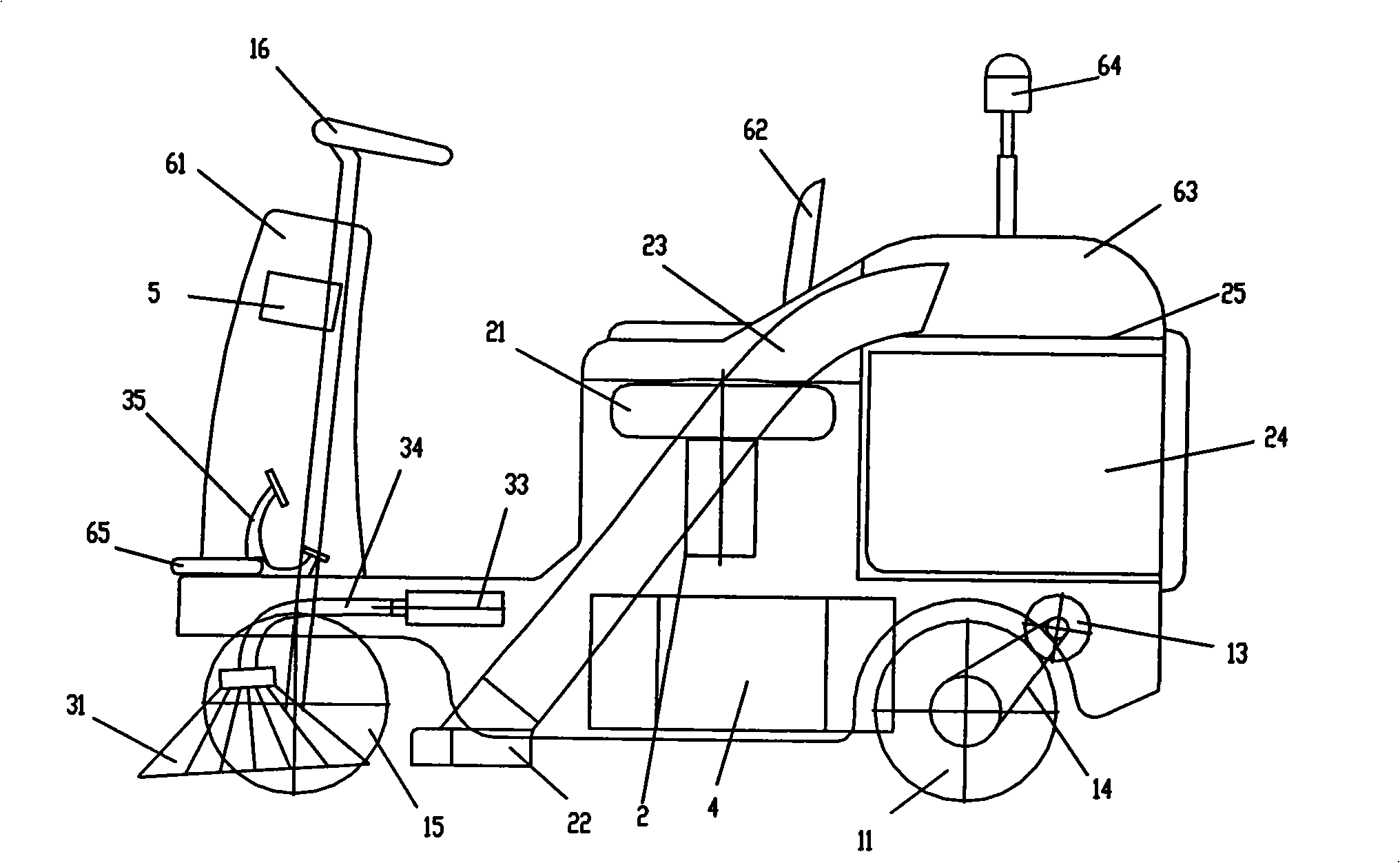

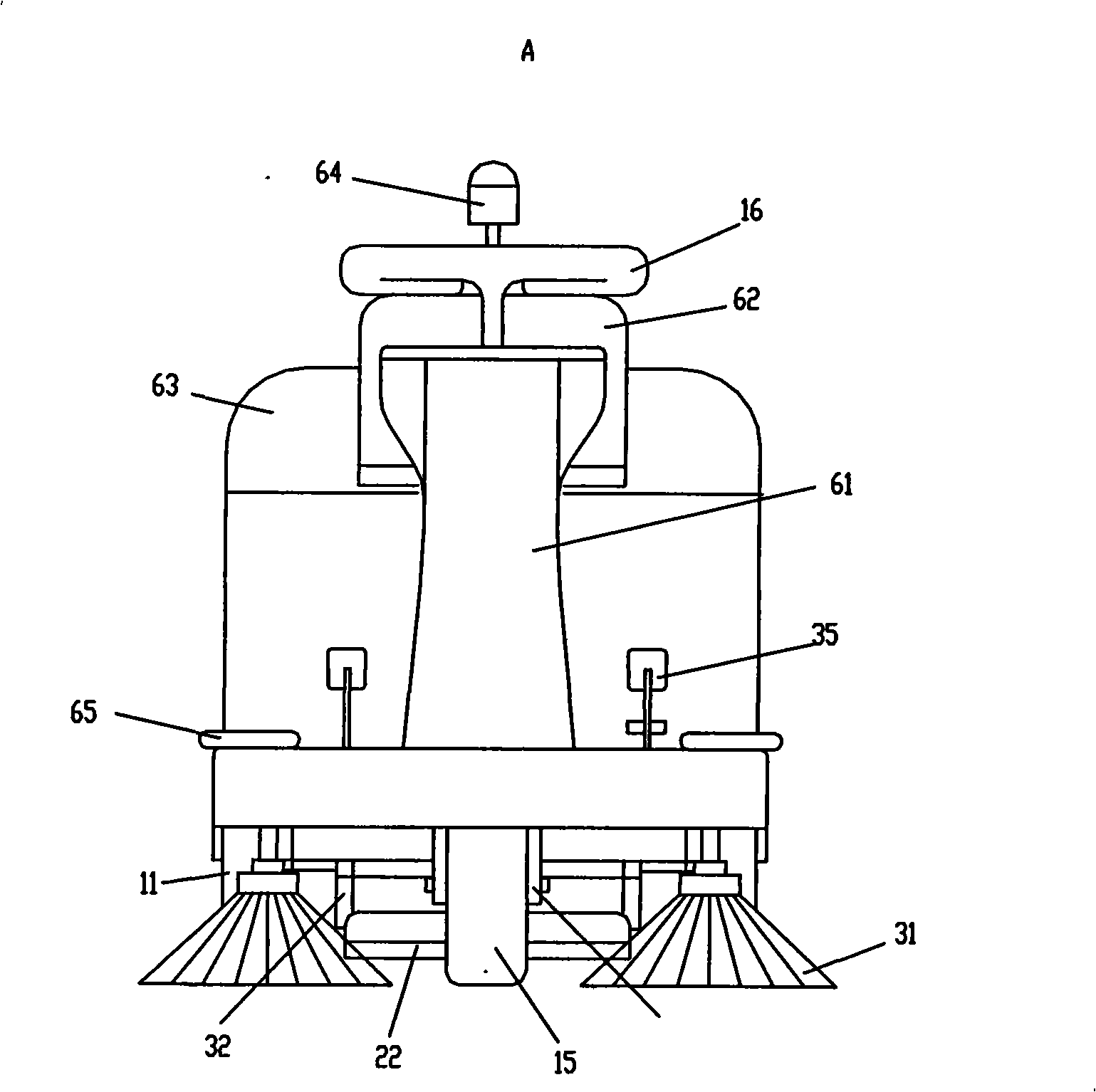

Miniature electric suction sweeping type ground sweeper

The invention discloses a mini-electronic absorbing-sweeping style ground-sweeping truck which has the advantages that the structure is simple; the use is convenient; the manufacturing cost is low; the pollution can be avoided and the applicable sites are wide, etc. The ground sweeping truck has the structure that: the ground-sweeping truck is provided with an electro-tricyle walking device, an electronic dust exhaust device, a double sweeping-brush device, a power package, a control system and a truck body; wherein, the electro-tricyle walking device is arranged on the lower part of the truck body, and the double sweeping-brush device is arranged on the front part of the truck body and a suction inlet of the electric dust exhaust device is arranged on the truck body and a discharging outlet is communicated with a dust box at the back of the truck body; the power supply unit is arranged on the side of the truck body to provide power for each device of the ground-sweeping truck.

Owner:山东鲁得贝车灯股份有限公司

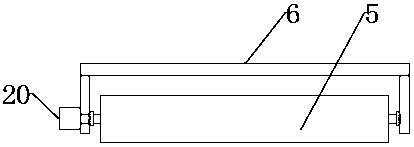

Cloth processing equipment for weaving

InactiveCN108374278ATimely stereotypesImprove qualityMechanical cleaningPressure cleaningEngineeringBrush device

The invention discloses cloth processing equipment for weaving. The cloth processing equipment comprises a dustproof box, a material inlet roller, a material outlet roller, a float hair attracting device, a float hair brushing device, a humidifying device and a wrinkle eliminating device. The float hair attracting device comprises a dust collector, an air pipe and an attracting head. The float hair brushing device comprises a first electric push rod, a mounting board and a hairbrush roller. The humidifying device comprises a water tank, a hard water pipe, a booster pump and a nozzle. The wrinkle eliminating device comprises a second electric push rod, a mounting box, a heater and a winkle eliminating board. The cloth processing equipment is provided with the float hair attracting device and the float hair brushing device, thereby eliminating the float hair on the surface of the cloth and preventing entering of the float hair into body of personnel through breathing in postprocessing oftextile. The cloth processing device is provided with the humidifying device and the wrinkle eliminating device for performing ironing and wrinkle elimination on the humidified cloth. The cloth is pulled out of the bottom of the wrinkle eliminating board through the pulling force of the material outlet roller and is stretched. The wrinkle-eliminated cloth is cooled and molded in air, thereby ensuring in-time cloth fixing after wrinkle elimination and improving cloth quality.

Owner:陈雪莲

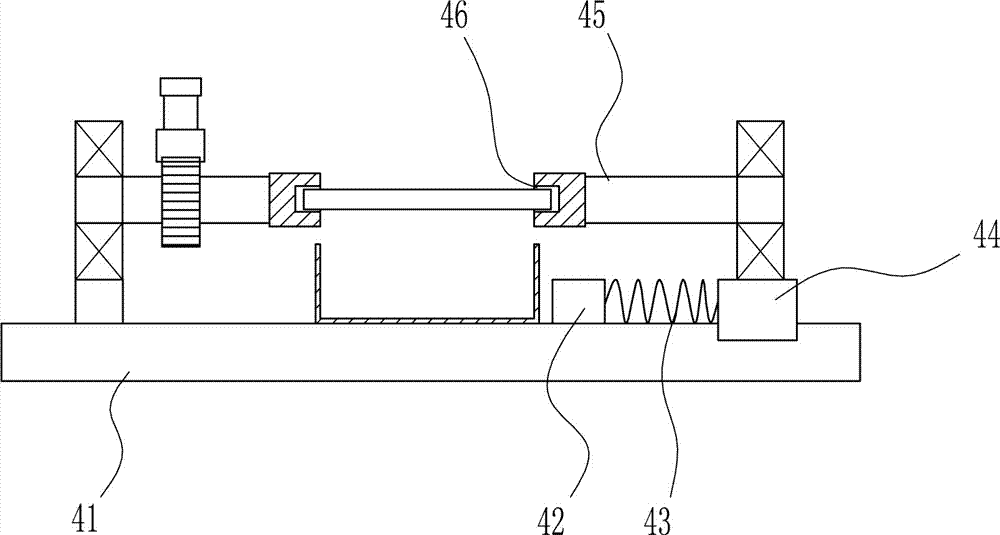

Automatic glue brushing device for brake pad manufacture

InactiveCN106944298AEasy to take outEasy to placeLiquid surface applicatorsCoatingsEngineeringBrush device

The invention relates to a glue brushing device, in particular to an automatic glue brushing device for brake pad manufacture. The automatic glue brushing device for the brake pad manufacture carries out automatic glue brushing and is simple to operate and high in safety degree. The automatic glue brushing device for the brake pad manufacture comprises a bottom plate, a glue prevention frame, a rotating mechanism, a clamping mechanism, a lifting mechanism, a glue discharge mechanism and the like; a forward and backward movement mechanism, the rotating mechanism and the clamping mechanism are arranged on the top surface of the bottom plate from back to front sequentially; the lifting mechanism is arranged in front of the bottom of the forward and backward movement mechanism; the glue discharge mechanism is arranged on the right side and at the bottom of the lifting mechanism; and a hair brush is arranged at the bottom of the glue discharge mechanism. The effects of the automatic glue brushing and high safety are achieved, the rotating mechanism can rotate a brake pad so that the brake pad can be changed to the non-brushed surface to be coated with glue, and the position of the brake pad is fixed through the clamping mechanism.

Owner:重庆云瑞智能自动化设备有限公司

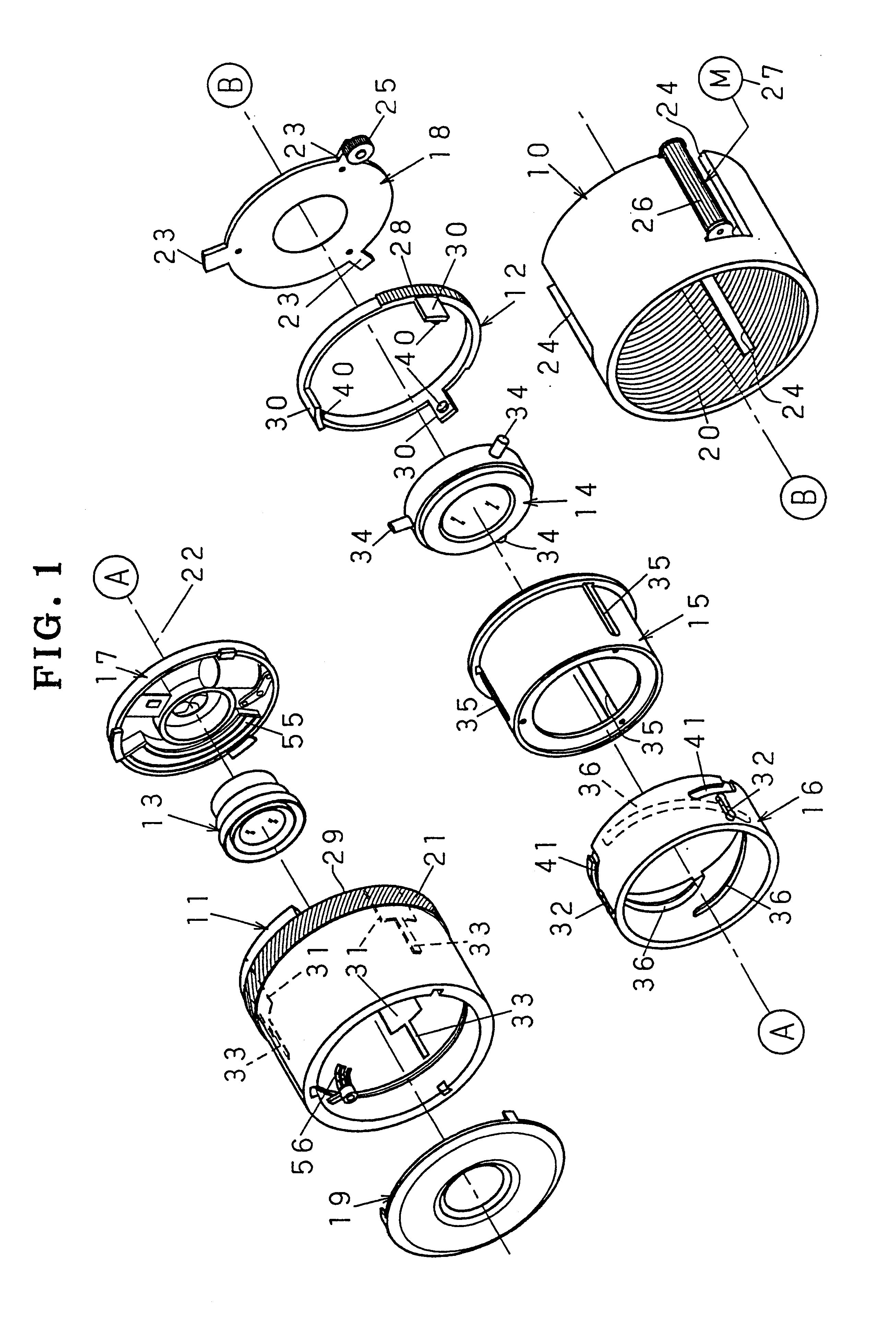

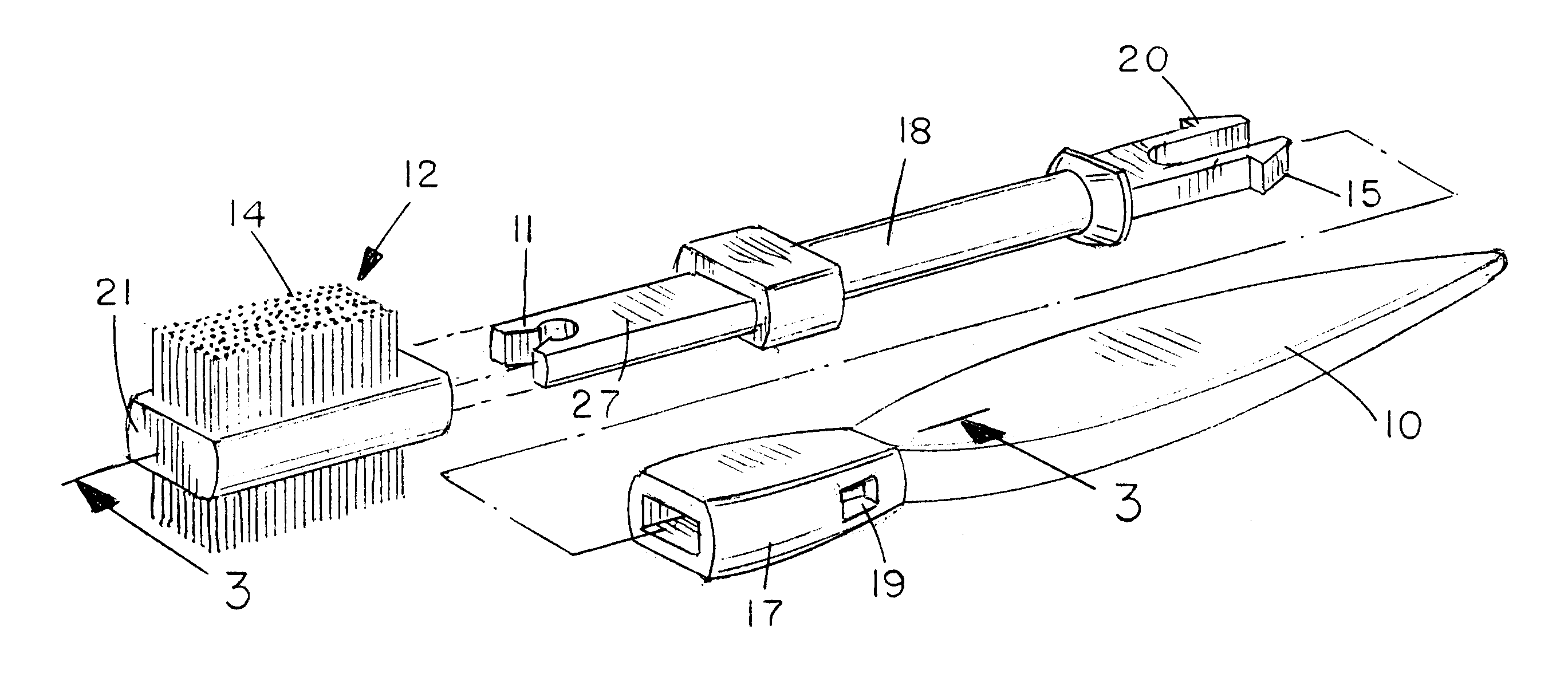

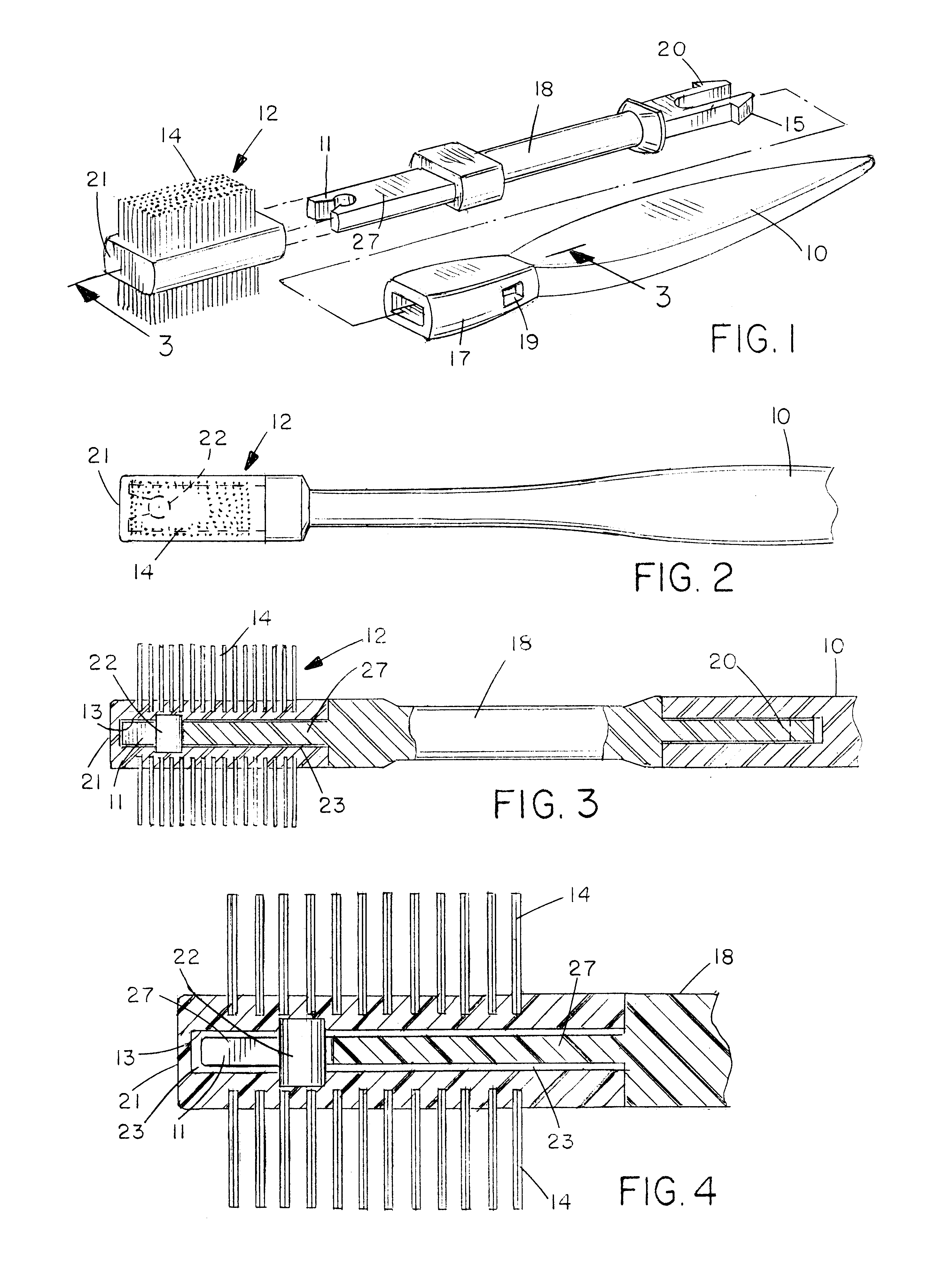

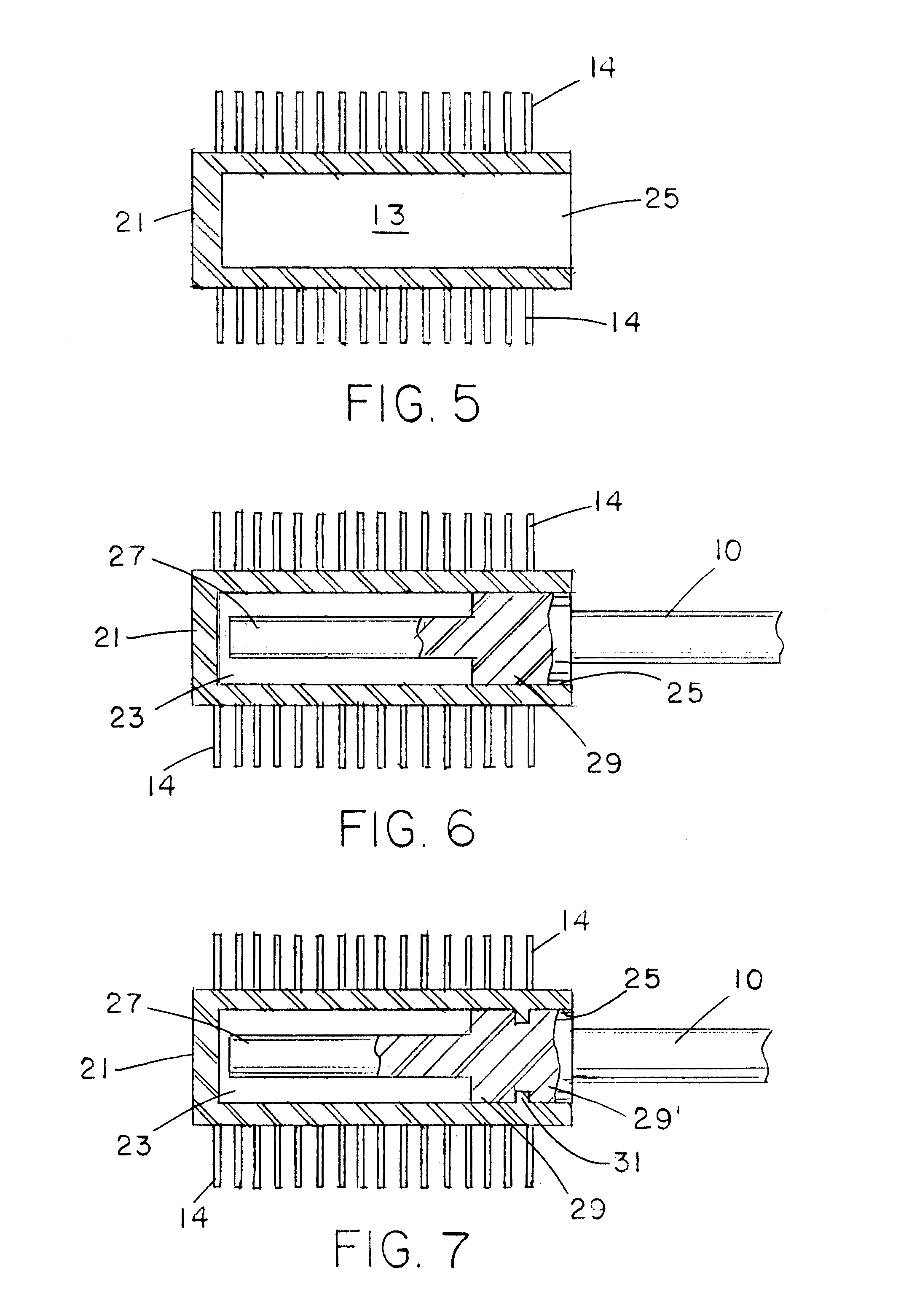

Oral irrigation and/or brushing devices and/or methods

An oral hygiene device having, in one embodiment, a unique, peristaltic pump water streaming or jet action; and in another embodiment, a multi-headed toothbrush may also be disposed on the end of a handle on which the jet nozzle or nozzles are disposed.

Owner:CRA LABS

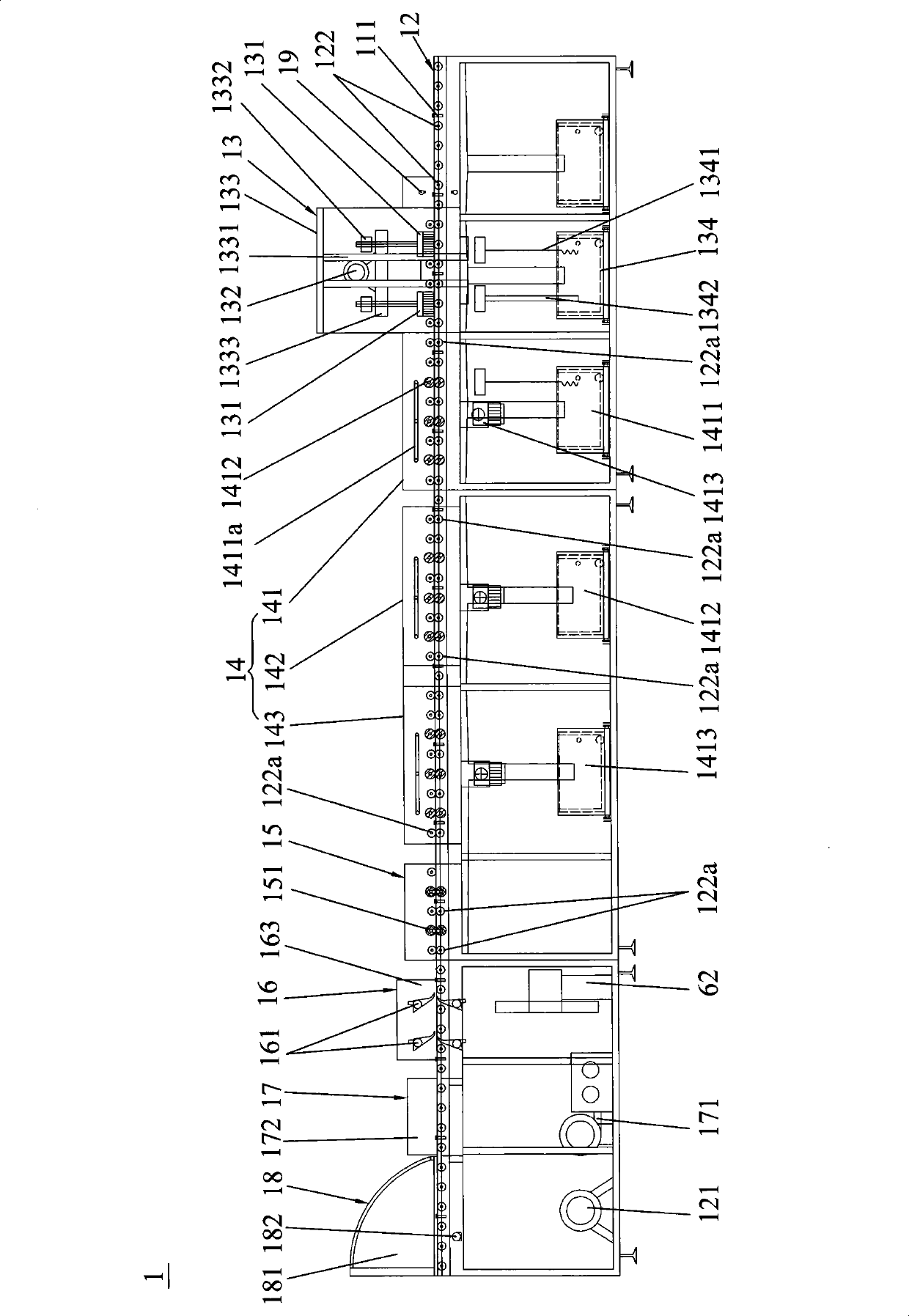

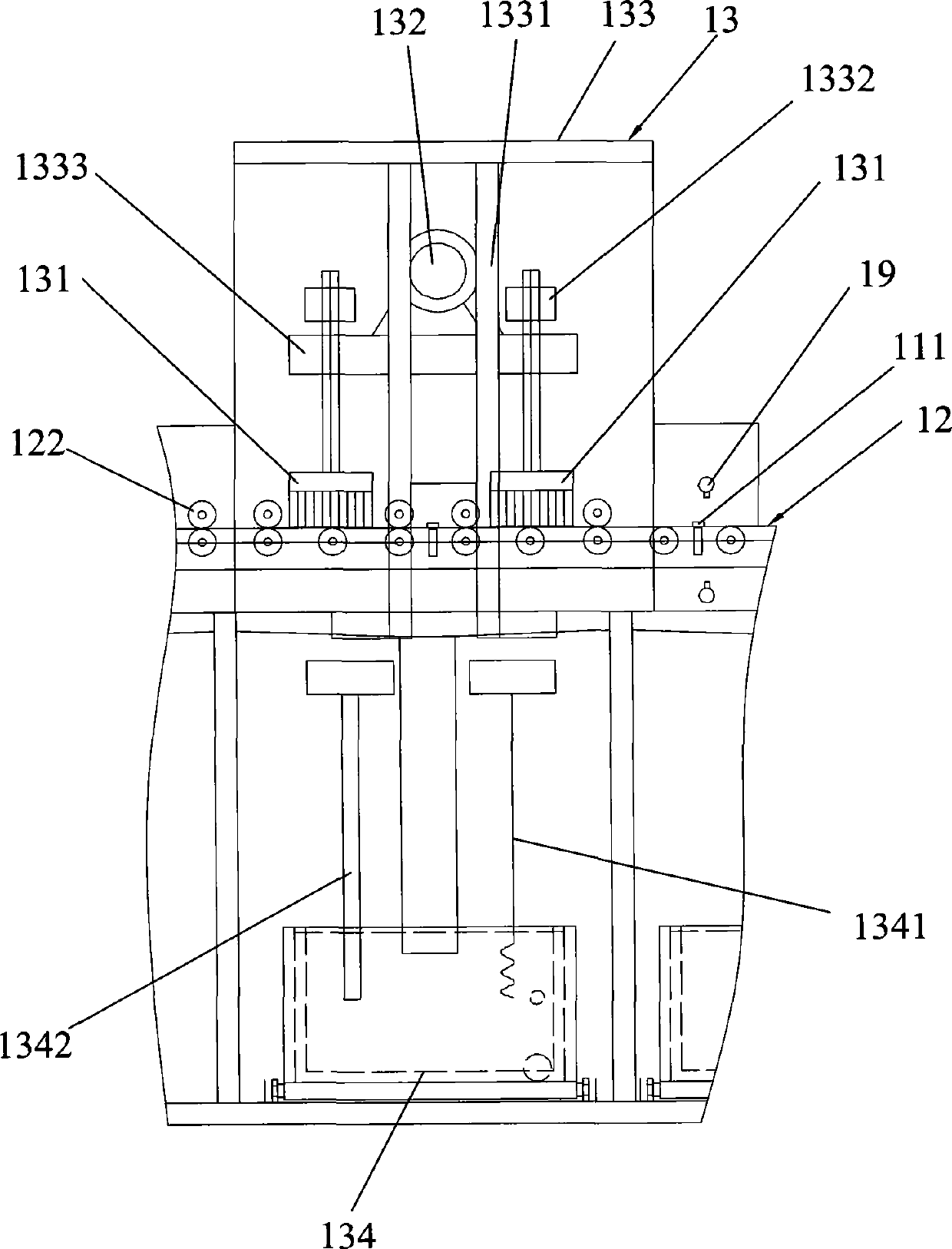

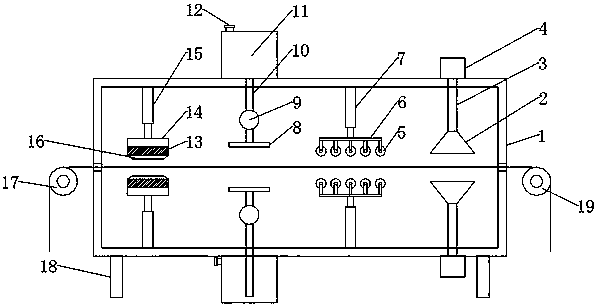

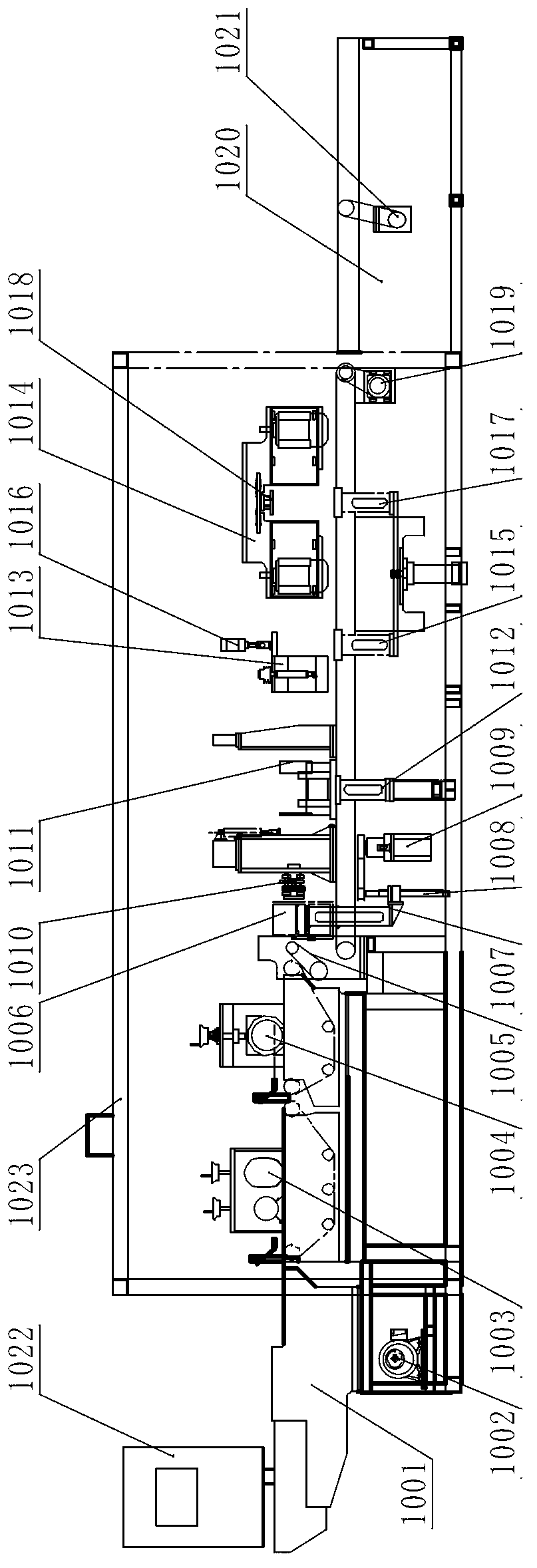

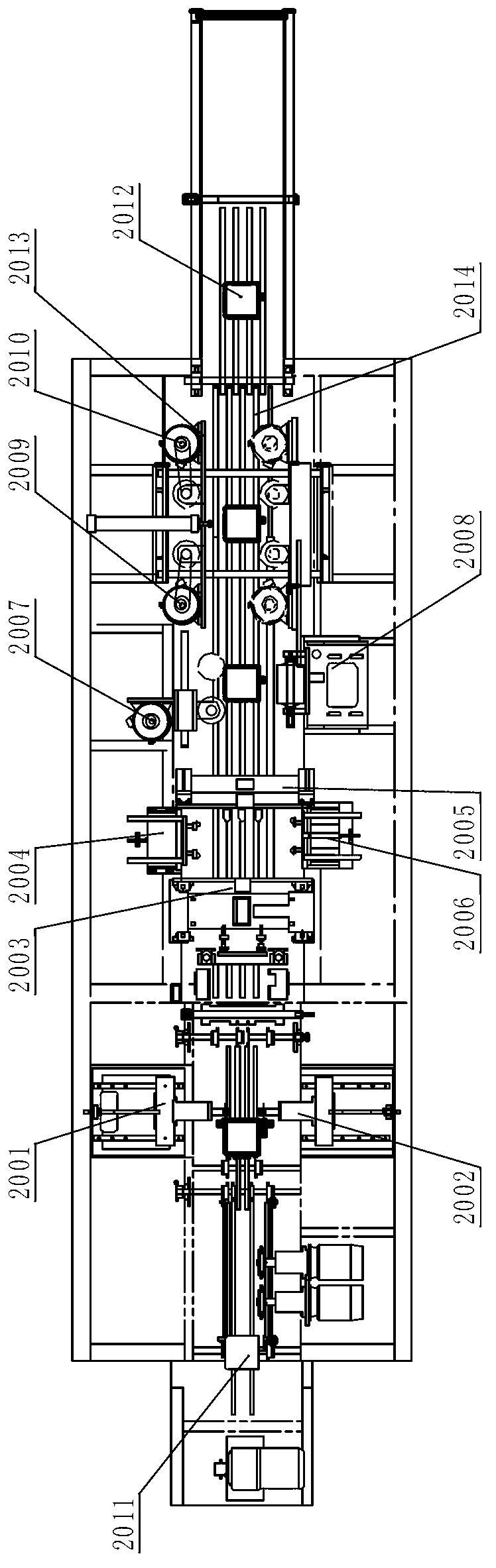

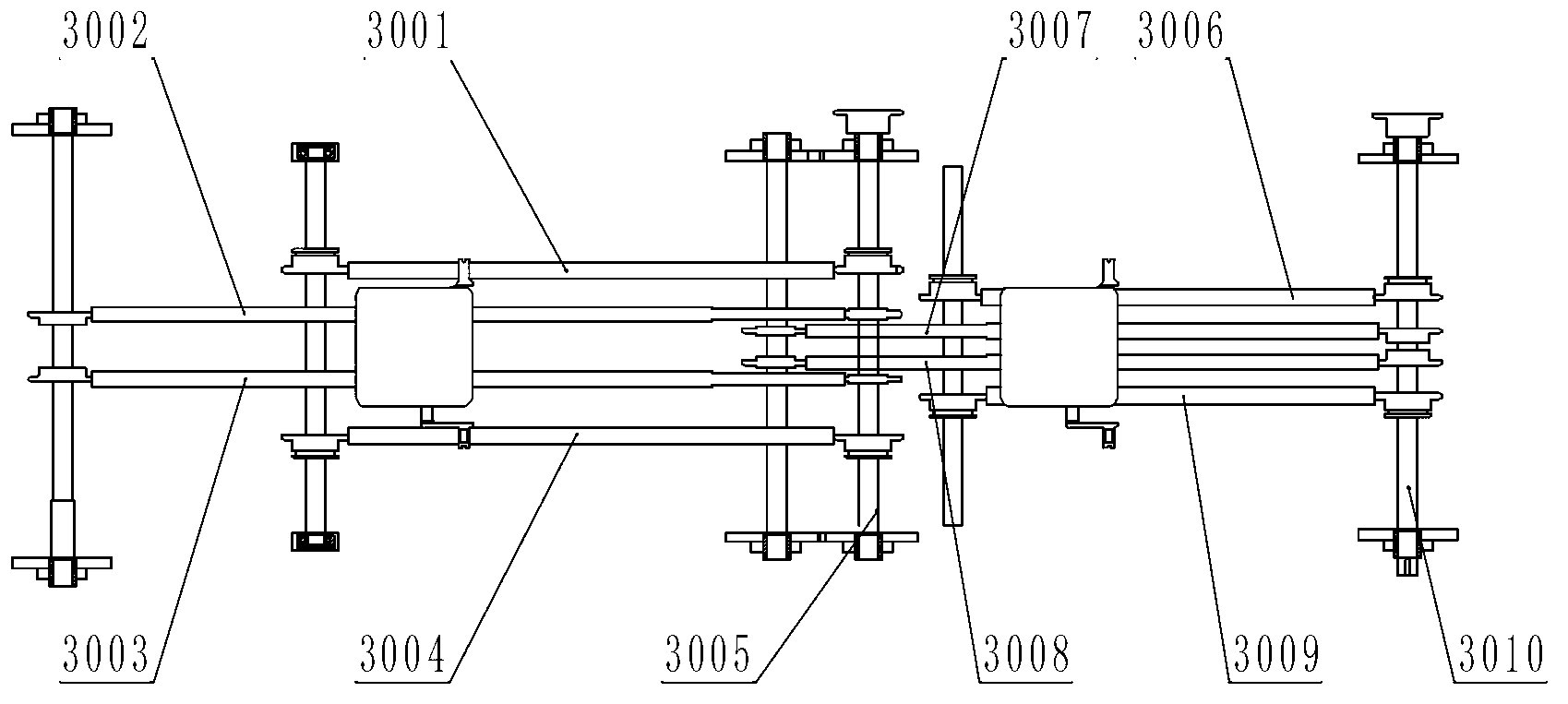

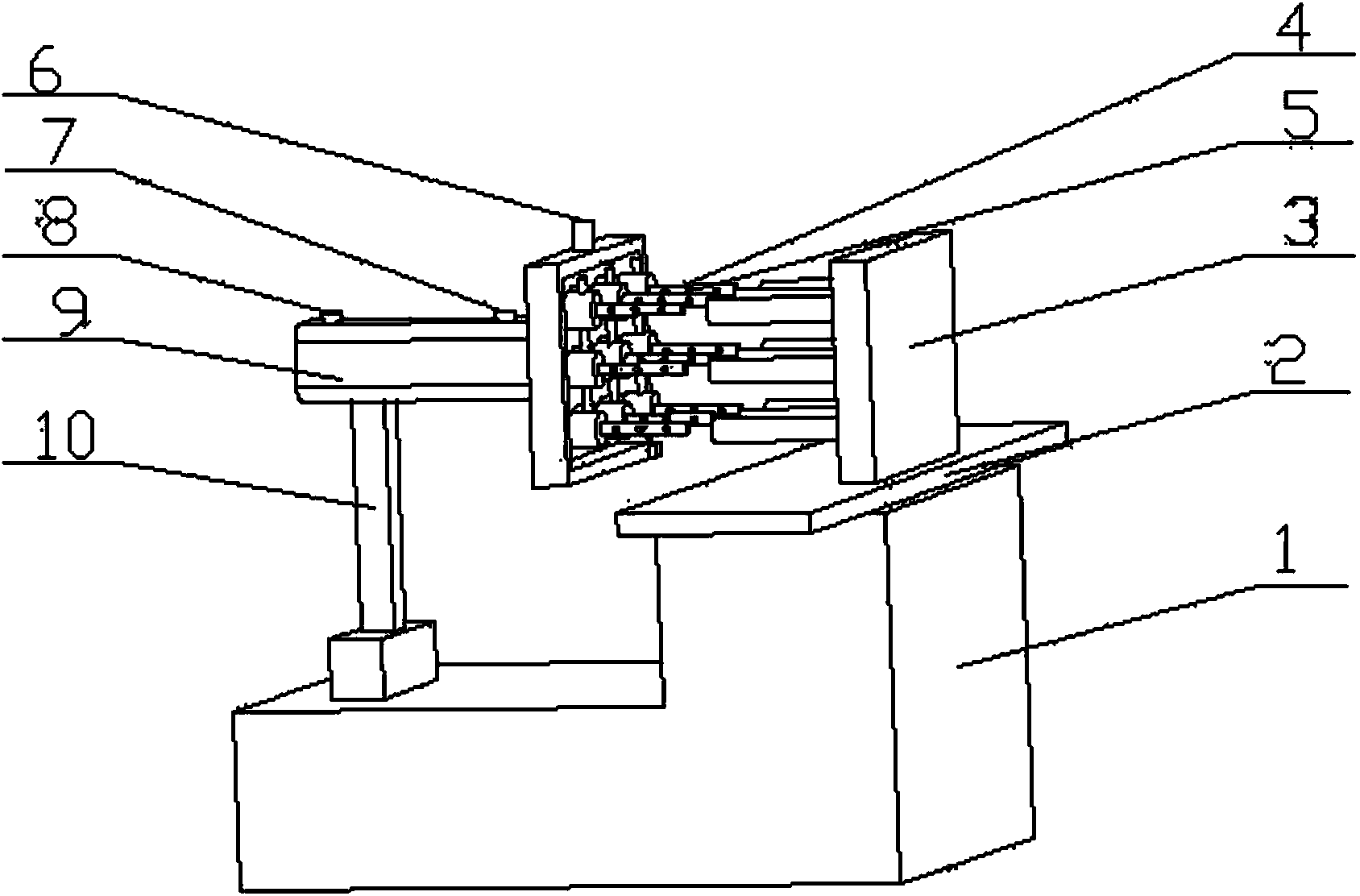

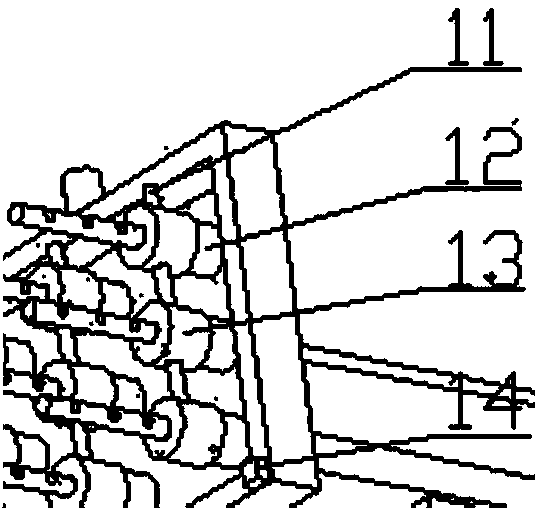

Automatic lug brushing-cutting and frame-brushing machine for storage battery plate

ActiveCN103066245AReduce deformation, loose lugs and other defectsReduce pollutionLead-acid accumulator electrodesOperational costsEngineering

The invention relates to a lug brushing-cutting and frame brushing machine for a high-dense storage-battery plate, and particularly relates to equipment for automatically brushing and cutting lugs and brushing four sides of a high-dense pole plate in the lead-acid battery production process. The lug brushing-cutting and frame brushing machine is a streamline device which formed by successive connection of a plate delivering device, a pole plate conveying device, a lug brushing device, a lug cutting device, a transition device, a laminating device, a reshaping device, a frame brushing device and a plate folding device, and the streamline device automatically cooperates under electric control. The lug brushing-cutting and frame brushing machine provided by the invention achieves the automatic lug brushing-cutting and frame brushing of a high-dense lead alloy pole plate, and finishes the transition of a production flow from a semi-automation operation to a full automatic serialization operation, so that labour operation intensity and operational cost are greatly reduced, the labour productivity is improved, and the damage to human bodies caused by the environmental pollution and lead dust can be alleviated.

Owner:武汉深蓝自动化设备股份有限公司

Oral irrigation and/or brushing devices and/or methods

An oral hygiene device having, in one embodiment, a unique, peristaltic pump water streaming or jet action; and in another embodiment, a multi-headed toothbrush may also be disposed on the end of a handle on which the jet nozzle or nozzles are disposed.

Owner:CRA LABS

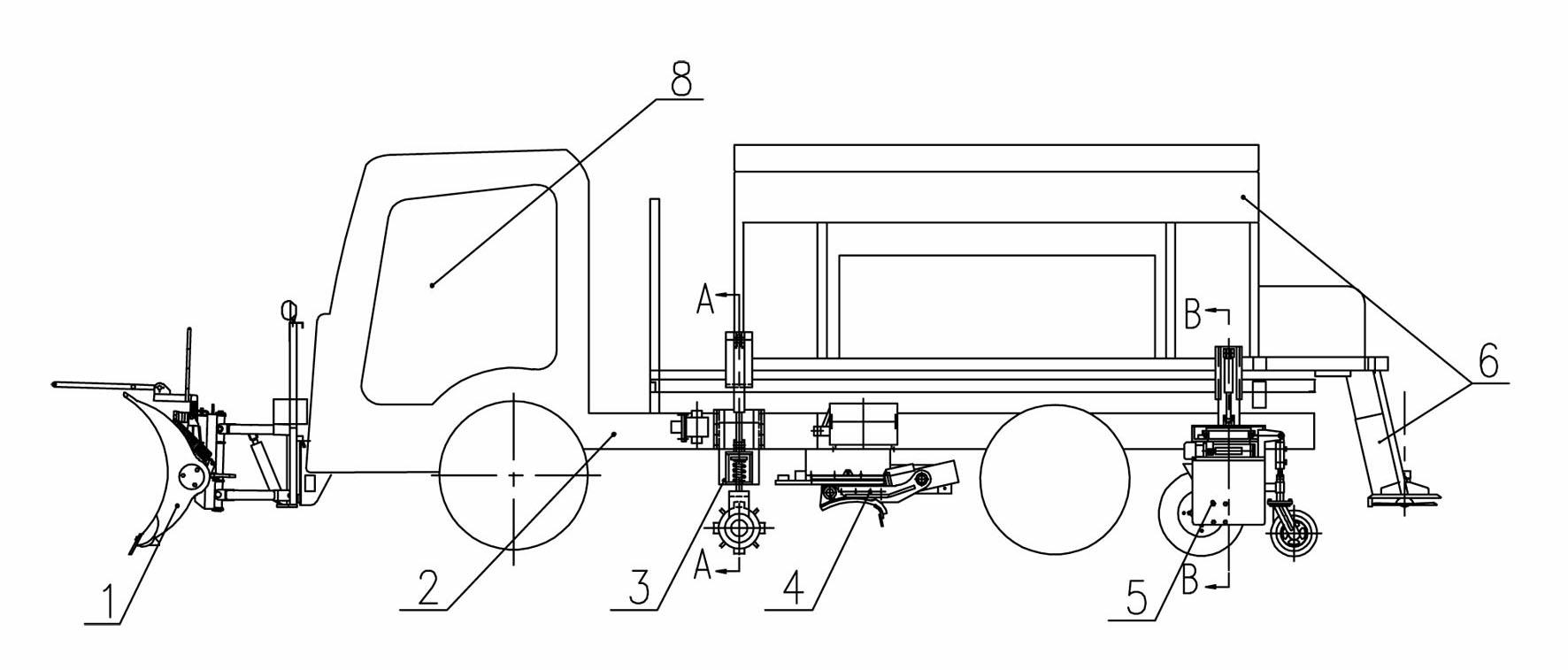

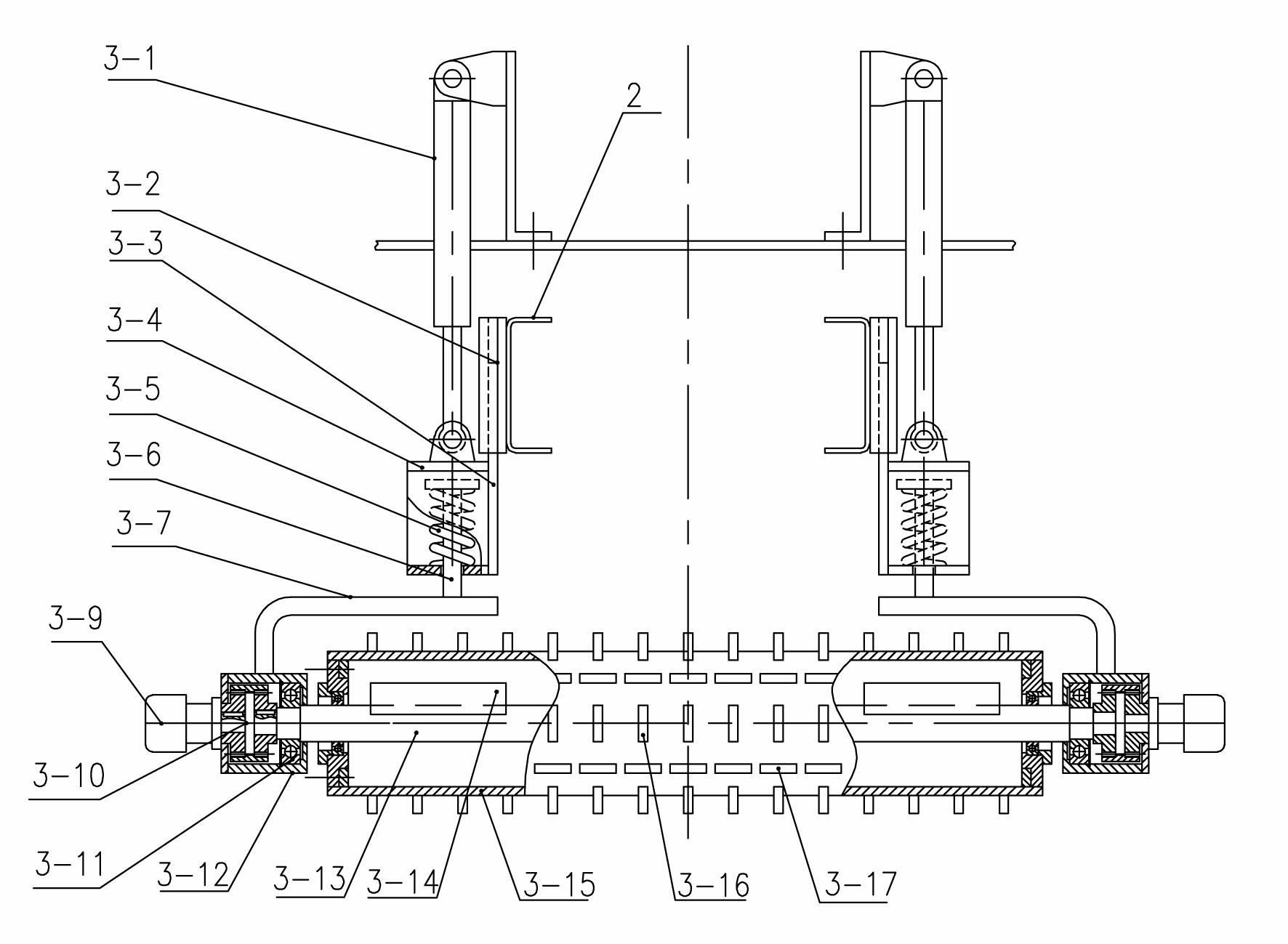

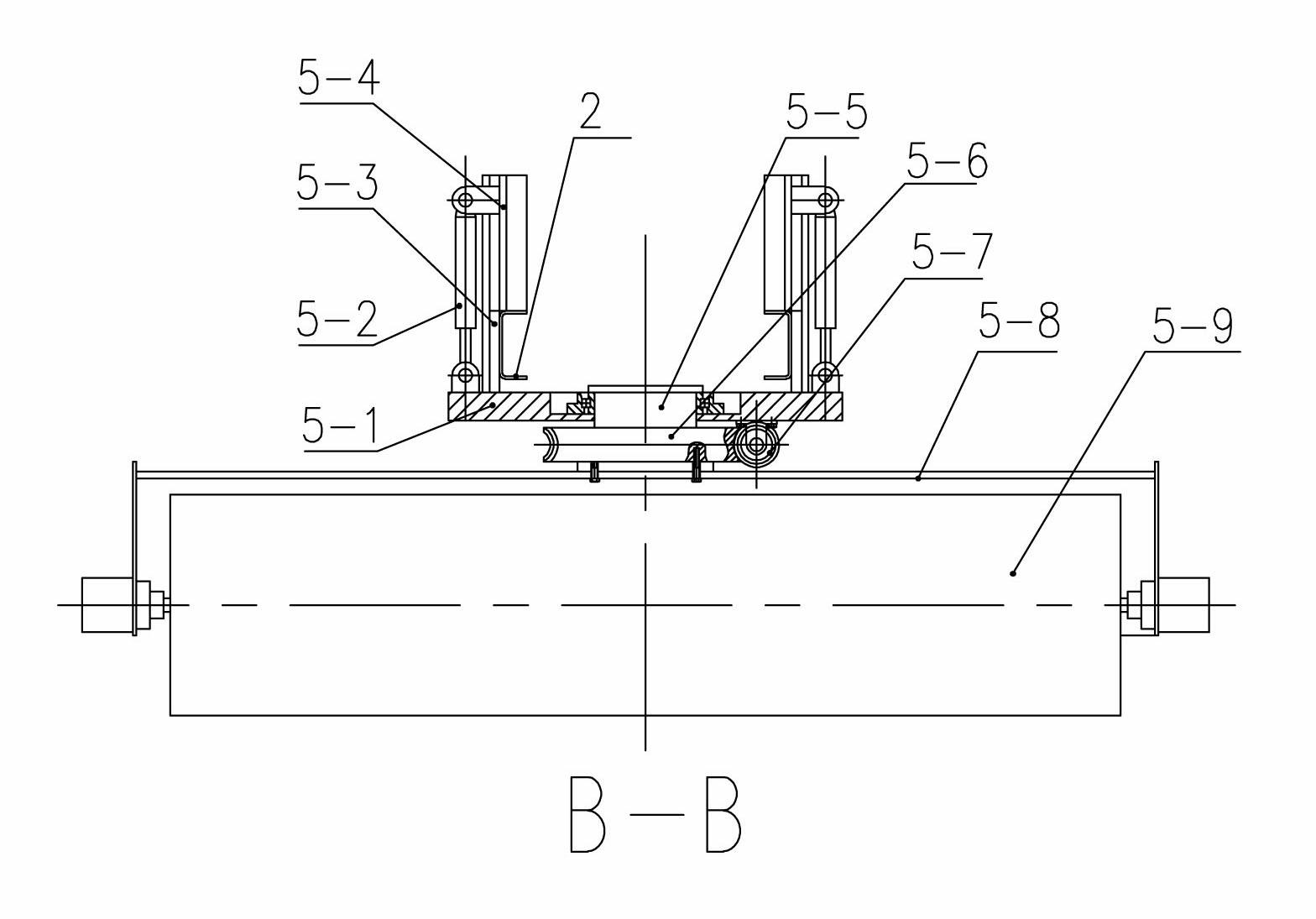

Vehicle-mounted multifunctional snow remover

ActiveCN102094401AImprove snow removal qualityFast snow removalSnow cleaningHydraulic motorSnow removal

The invention belongs to the technical field of snow removal equipment for removing snow on a road and spreading a snow-melting agent, and in particular to a vehicle-mounted multifunctional snow remover. The vehicle-mounted multifunctional snow remover comprises a vehicle cab, a snow removal shovel device, a vehicle chassis, a hydraulic pump station, a snow-melting agent spreader and a swing ventral shovel device, wherein, the swing ventral shovel device is arranged in the middle part of the vehicle chassis; an ice-breaking roller device is arranged in the front of the swing ventral shovel device, and a snow-sweeping roller brush device is arranged in the back of the swing ventral shovel device; the ice-breaking roller device consists of an ice-breaking roller chute, an ice-breaking roller slide rail, a spring seat, a spring bar, a spring, an ice-breaking roller and an ice-breaking roller lift cylinder; and the snow-sweeping roller brush device consists of a roller brush chute, a roller brush slide rail, a support plate, a support axle, a worm wheel, a roller brush frame, a roller brush assembly, a worm, a roller brush rotating-angle adjustment hydraulic motor and a roller brush lift cylinder. The vehicle-mounted multifunctional snow remover has the advantages of completing the four procedures of pushing snow, breaking ice, sweeping and spreading the snow-melting agent once, improving the snow removal effect, accelerating the snow removal speed and protecting the original asphalt pavement from damage.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

Tooth brush device

InactiveUS6948875B1Increase supplyEffectively brush his teethCarpet cleanersFloor cleanersBrush deviceEngineering

A toothbrush device is provided, which includes a brush, a toothpaste storing case, and a push-button pump disposed between the brush and the toothpaste storing case; a first check valve disposed between the toothpaste storing case and the pump, a second check valve disposed between the first check valve and the toothpaste storing case, and a first spring disposed between the first and second check valves; wherein the first check valve includes a second spring and a piston in sequence in a direction away from the pump, and has a working element which includes a rod with movement grooves at a first end thereof and a securing part at a second end thereof.

Owner:CHOI RYAN KYUNG SOO +1

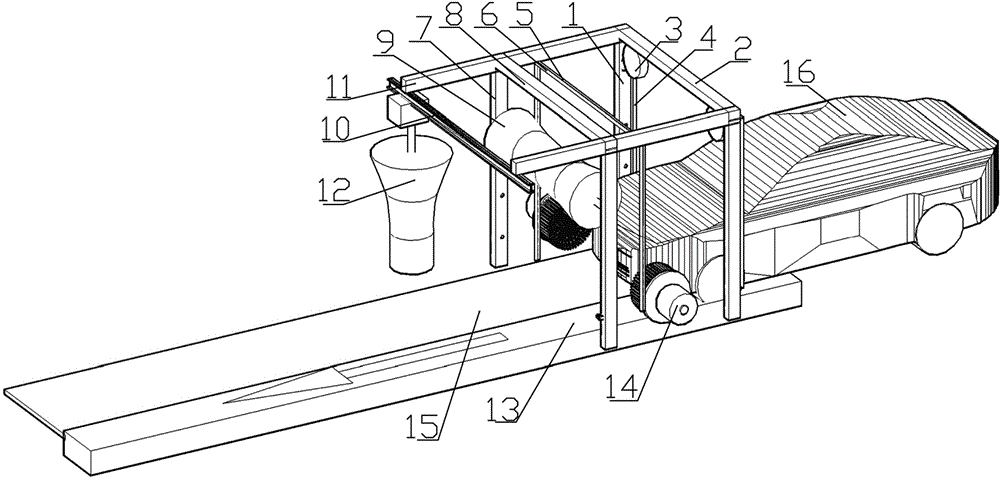

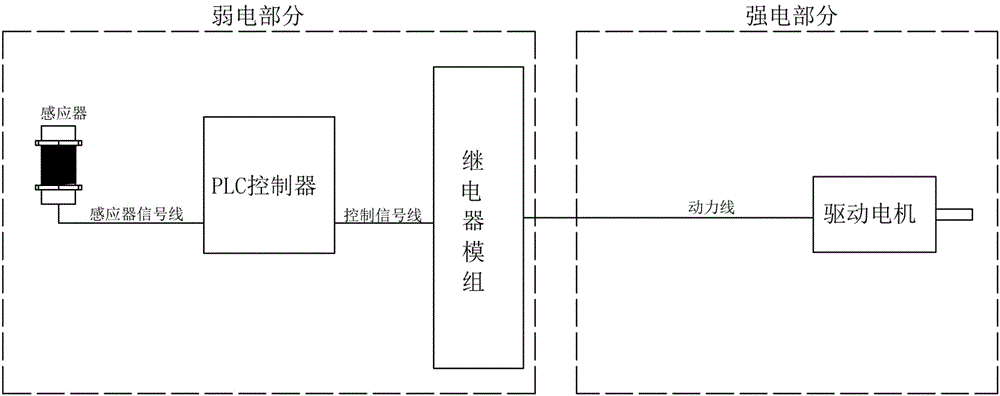

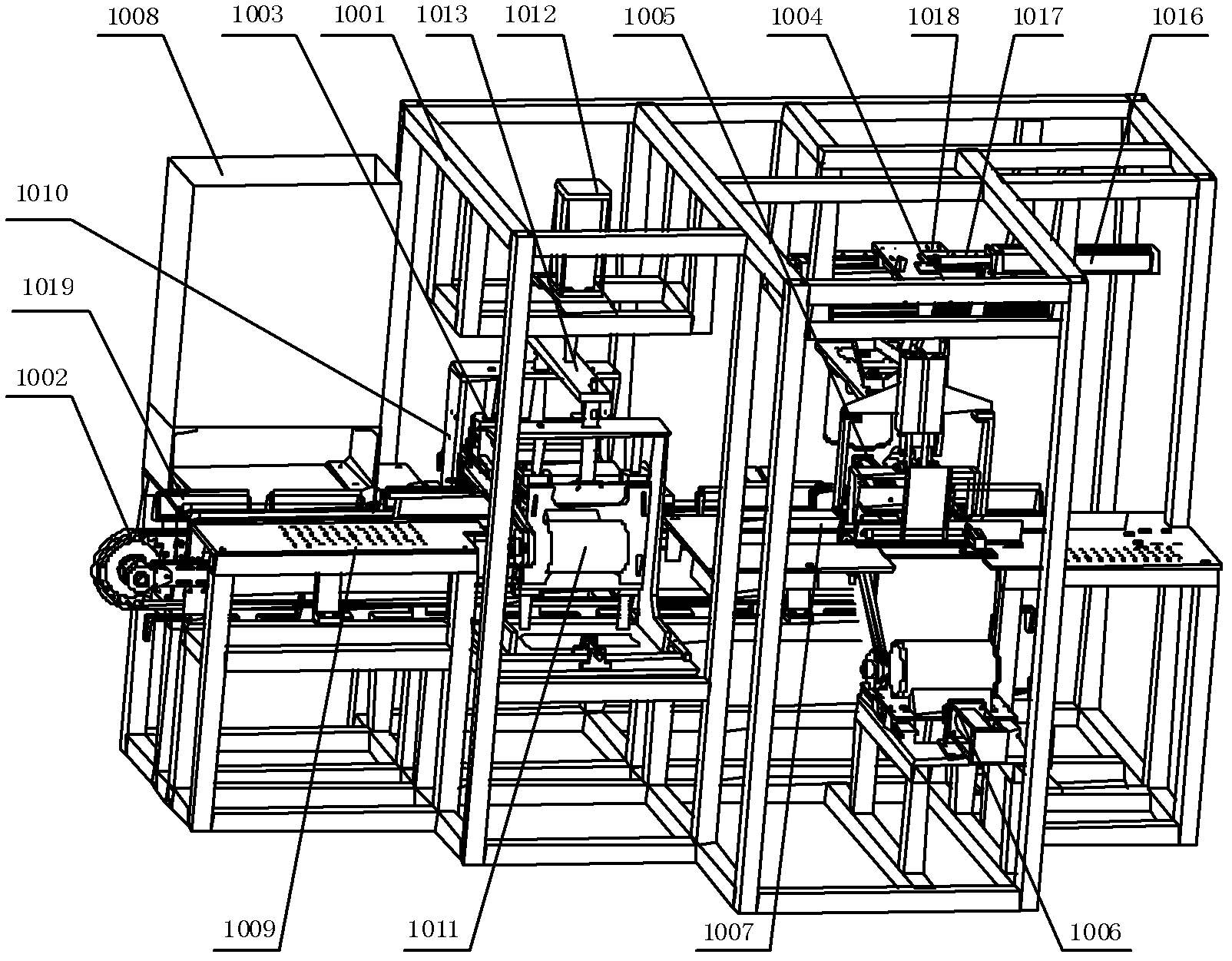

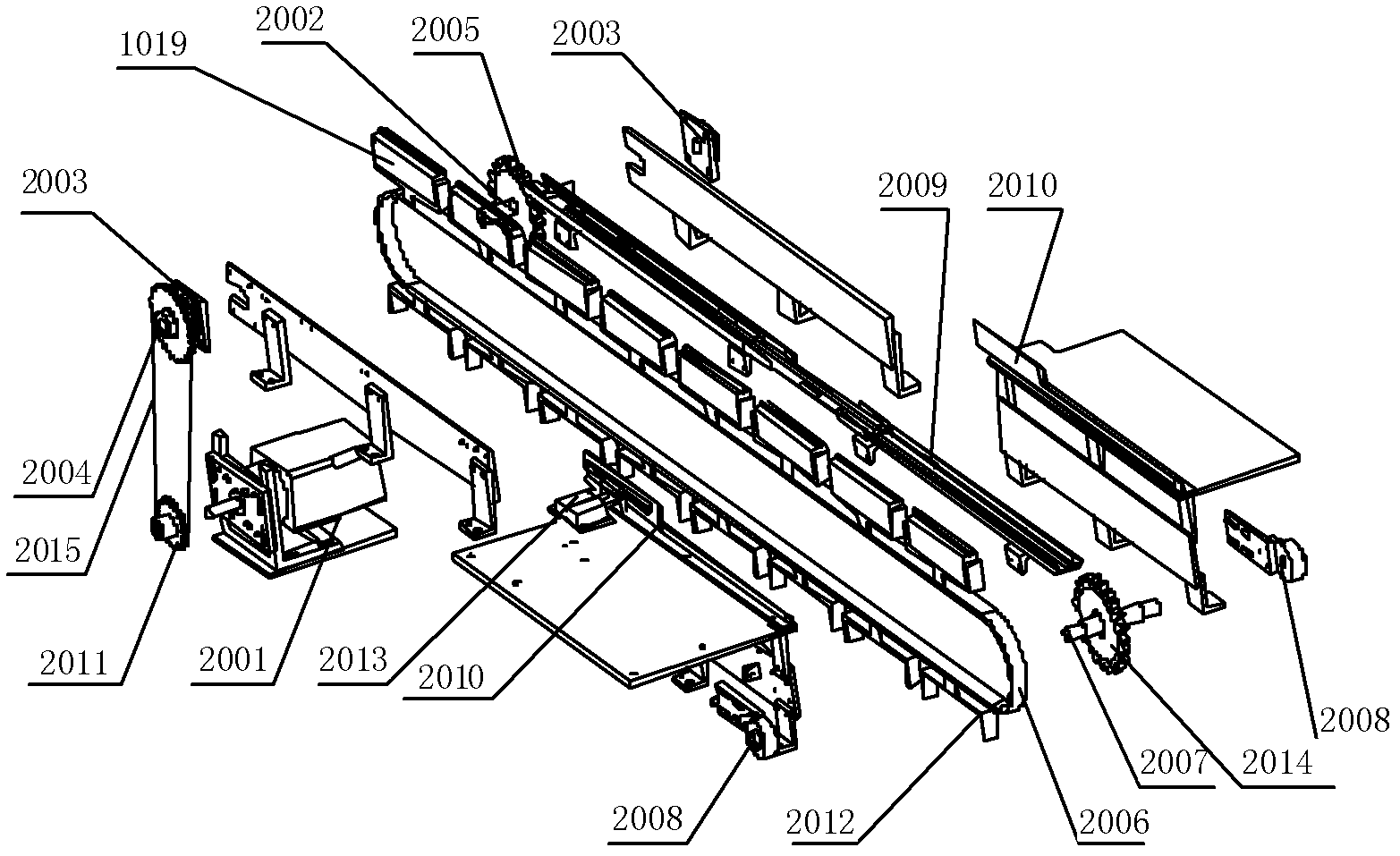

Equipment and method for intelligently automatically cleaning vehicle

ActiveCN105857264AAvoid damageSimple mechanical structureCleaning apparatus for vehicle exteriorsFailure rateGrounding grid

The invention relates to equipment and a method for intelligently automatically cleaning vehicles. The equipment comprises a pull guide rail. The pull guide rail is arranged on a side of a ground grid, a first upright column is vertically mounted at the right end of the ground grid, a first transverse beam is fixedly connected with the top of the first upright column, a second upright column is mounted at the rear of the first upright column, a second transverse beam is fixedly connected with the top of the second upright column, longitudinal beams are mounted between the first transverse beam and the second transverse beam, and a third transverse beam is mounted at the tail ends of the longitudinal beams. A second water spray pipe and a water wax spray pipe are arranged between the first transverse beam and the second transverse beam, and a top brush device is mounted on the second upright column. A vertical brush device is mounted on the third transverse beam. Wheel brush devices are symmetrically mounted on the side surfaces of the pull guide rail and are positioned between the first upright column and the second upright column. The equipment and the method have the advantages that mechanical structures can be simplified, power consumption and water consumption can be reduced, failure rates of machinery can be decreased, and the later-stage maintenance cost can be saved; the equipment is additionally provided with an automatic control system, accordingly, the vehicles can be fully automatically cleaned, and the work efficiency can be improved.

Owner:李勇

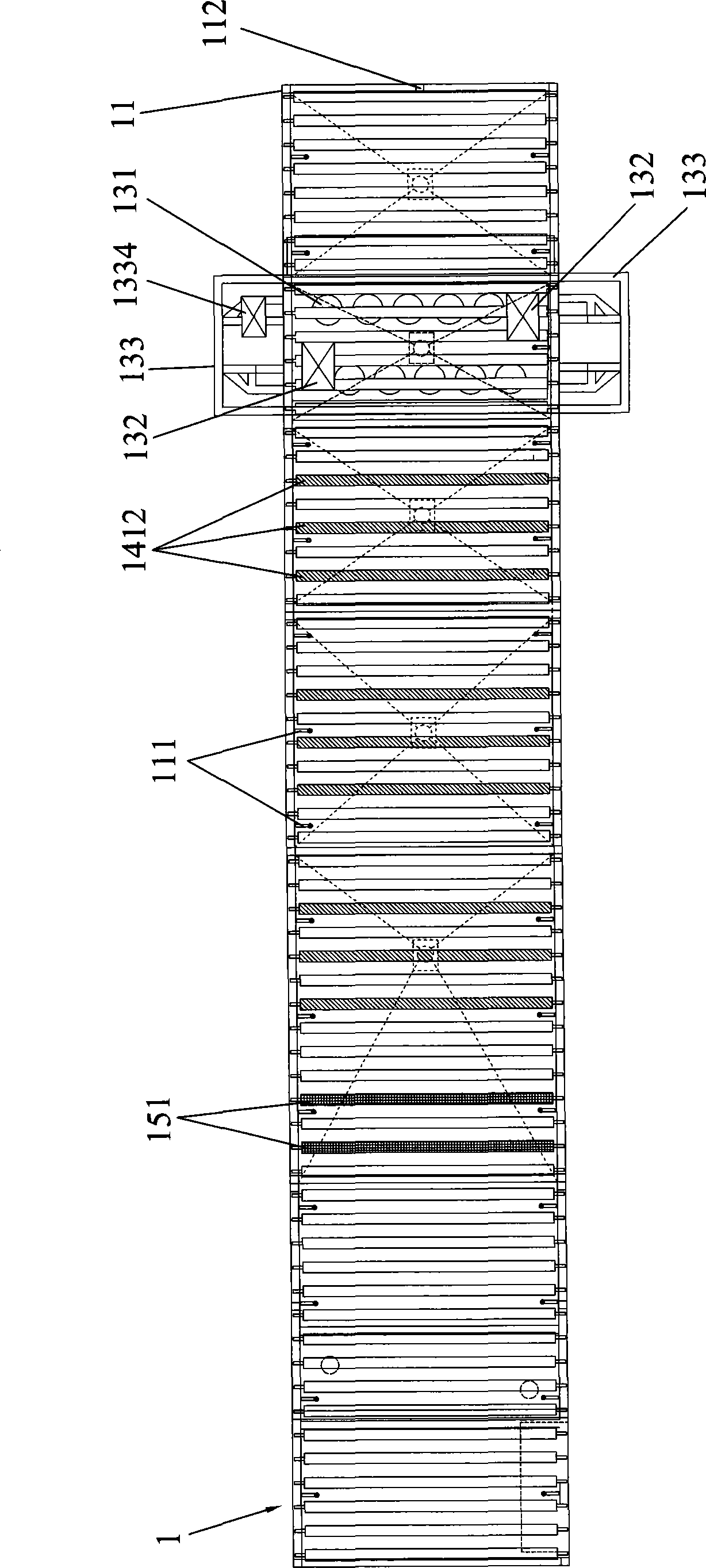

Automatic edge brushing machine for pipelined battery plate

InactiveCN102626891AEdge grinding machinesElectrode manufacturing processesDevice formMedium density

The invention relates to an automatic edge brushing machine for a pipelined battery plate, and particularly to equipment for brushing the four edges of a plate automatically in production process of a lead-acid battery. The invention discloses a frame brushing machine which is a pipelined device formed by connecting a rack, a plate running device, a side edge brushing device, an upside edge brushing device, a plate pushing device, a downside edge brushing device and a plate receiving device in sequence. The pipelined device coordinates automatically under electrical control. With the frame brushing machine provided by the invention, automatic edge brushing of low- and medium-density lead alloy plates is realized, the transformation of the production process from a semi-manual labor to an automatic operation is fulfilled, production intensity and operation cost of a manual operation are greatly reduced, labor productivity is improved, and pollution to environment and harm to human bodies caused by lead dust are reduced.

Owner:武汉深蓝自动化设备股份有限公司

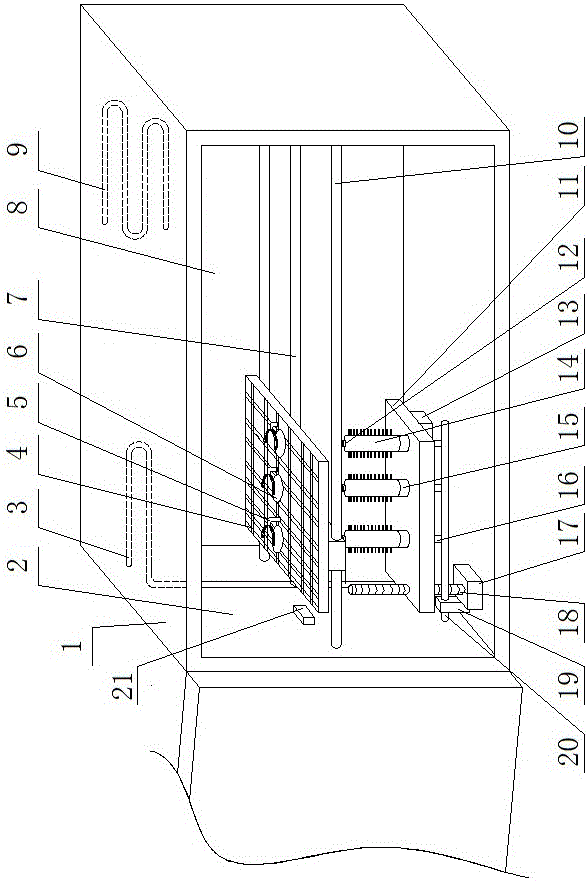

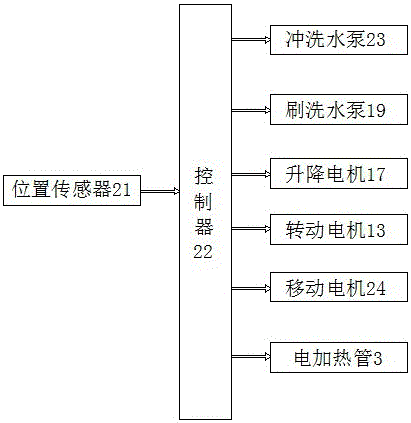

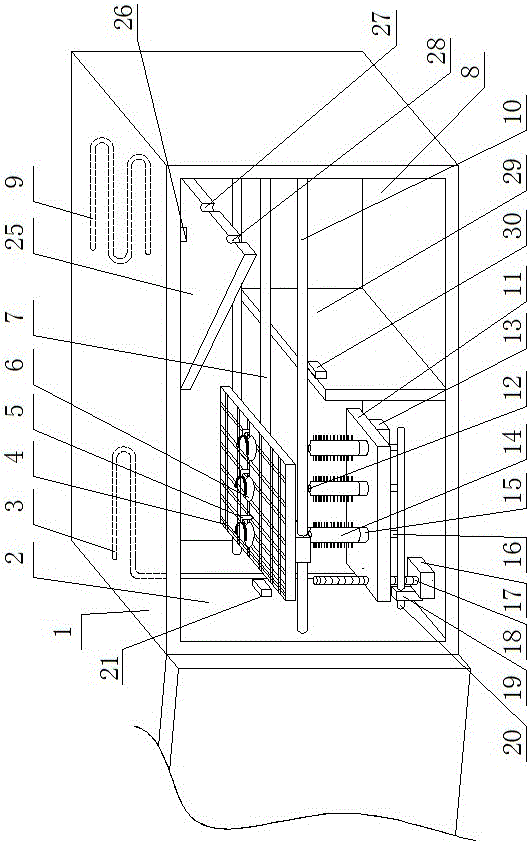

Test tube cleaning and drying device for chemical tests

InactiveCN106363000AAchieve cleaningAchieve immediate storageHollow article cleaningHeating arrangementChemical testEngineering

The invention discloses a test tube cleaning and drying device for chemical tests and belongs to the field of test tube cleaning and drying devices. The technical problems that test tubes cannot be cleaned thoroughly and cannot be stored immediately after being cleaned are solved. As for the structure, the test tube cleaning and drying device comprises a box body. The interior of the box body is divided into a cleaning cavity and a drying cavity, and the cleaning cavity communicates with the drying cavity in the left-right direction. A test tube moving device is fixed in the box body. A grid-shaped test tube fixing plate is fixed to the test tube moving device. A plurality of brushing holes are formed in the test tube fixing plate. A test tube fixing clip is fixed in the position of each brushing hole in the test tube fixing plate. The cleaning device comprises a flushing device and a brushing device. The flushing device is fixed to the position above the test tube fixing plate. The brushing device is fixed below the test tube fixing plate. A drying device body is fixed to the position above the test tube fixing plate. The test tube moving device, the flushing device, the brushing device and the drying device body are all connected to a controller. By the adoption of the test tube cleaning and drying device, the test tubes can be cleaned thoroughly and dried.

Owner:赵靖宇

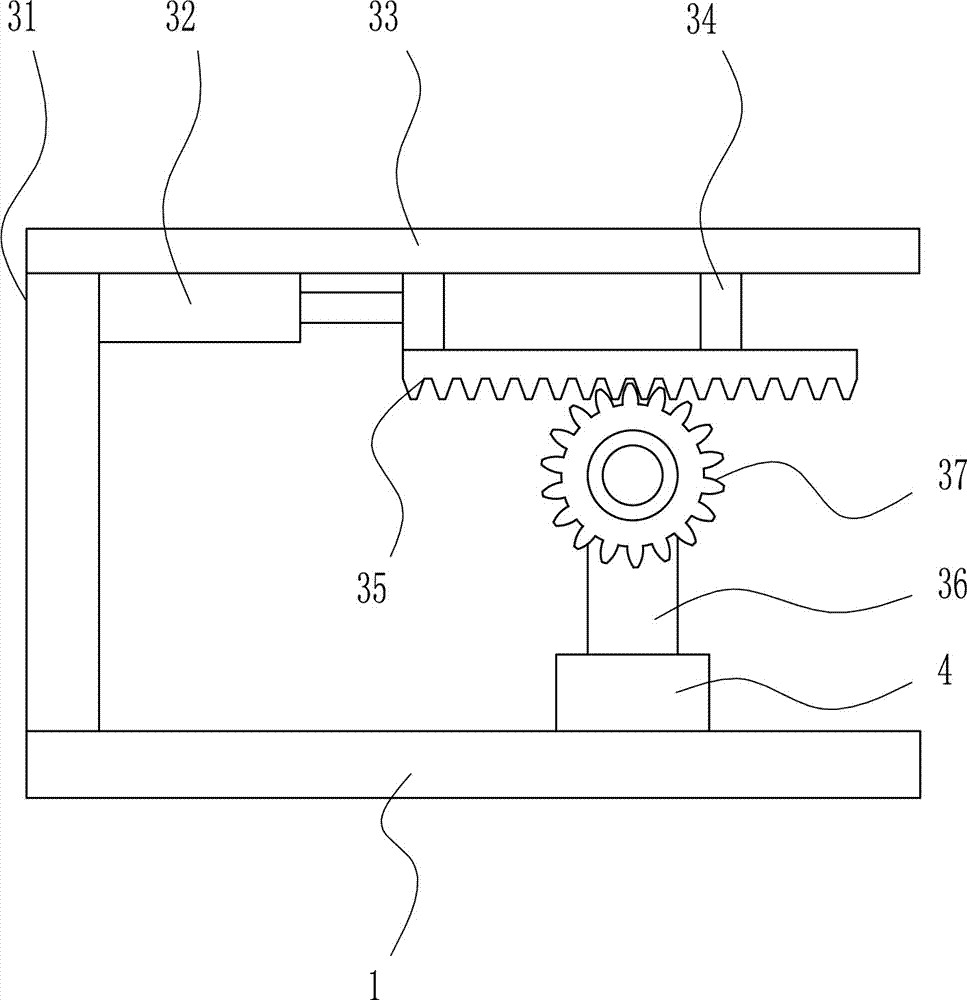

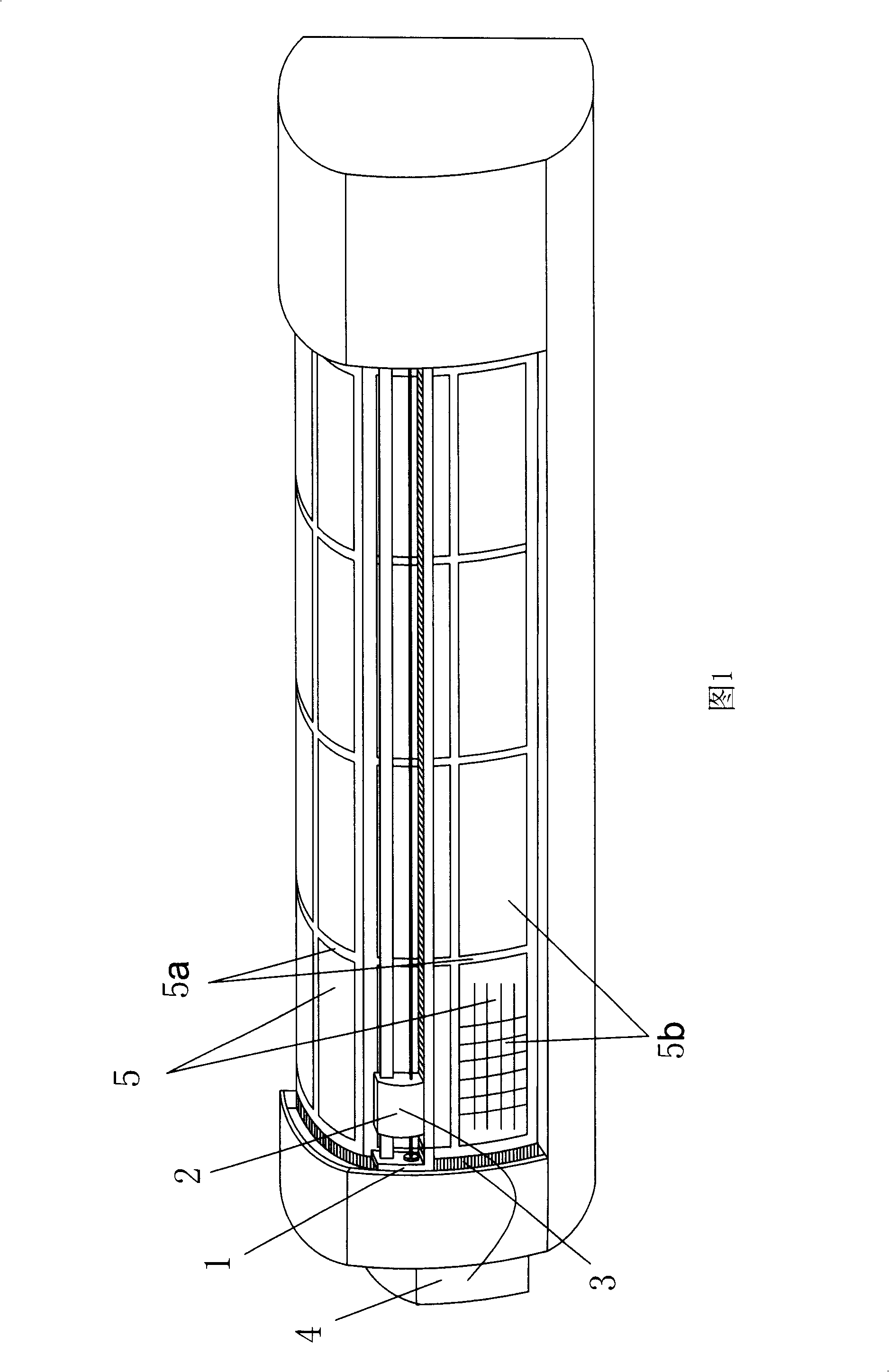

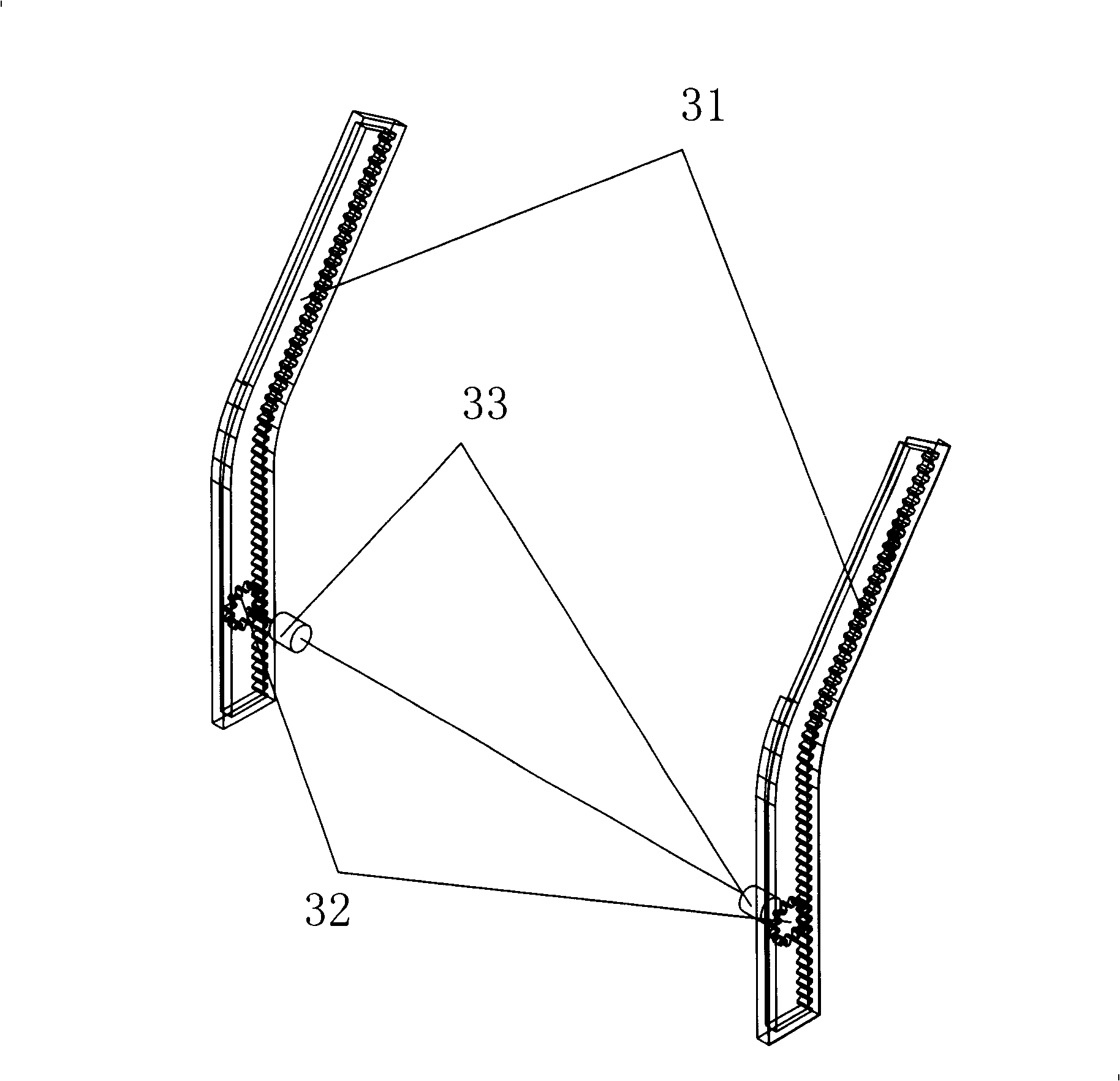

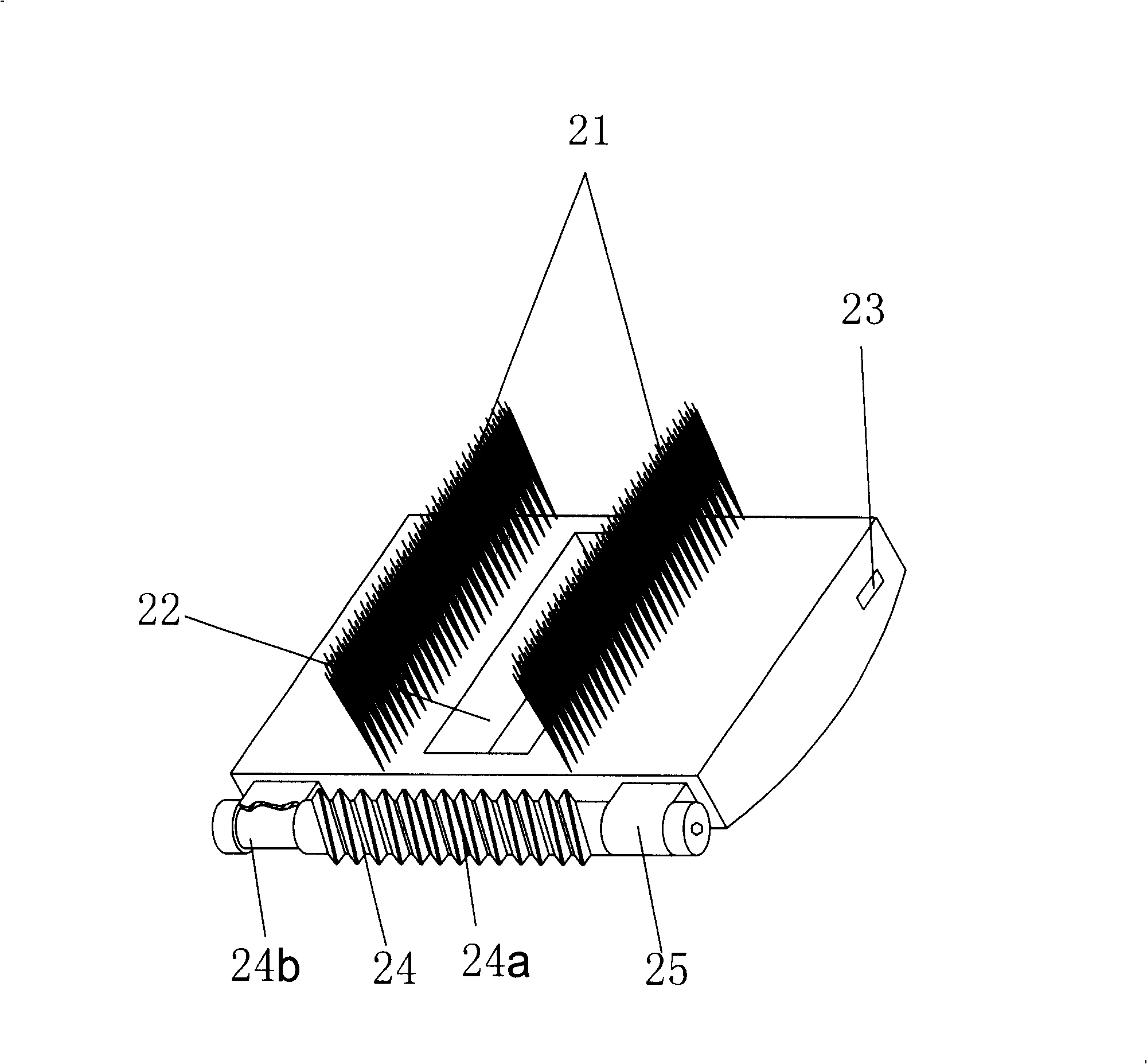

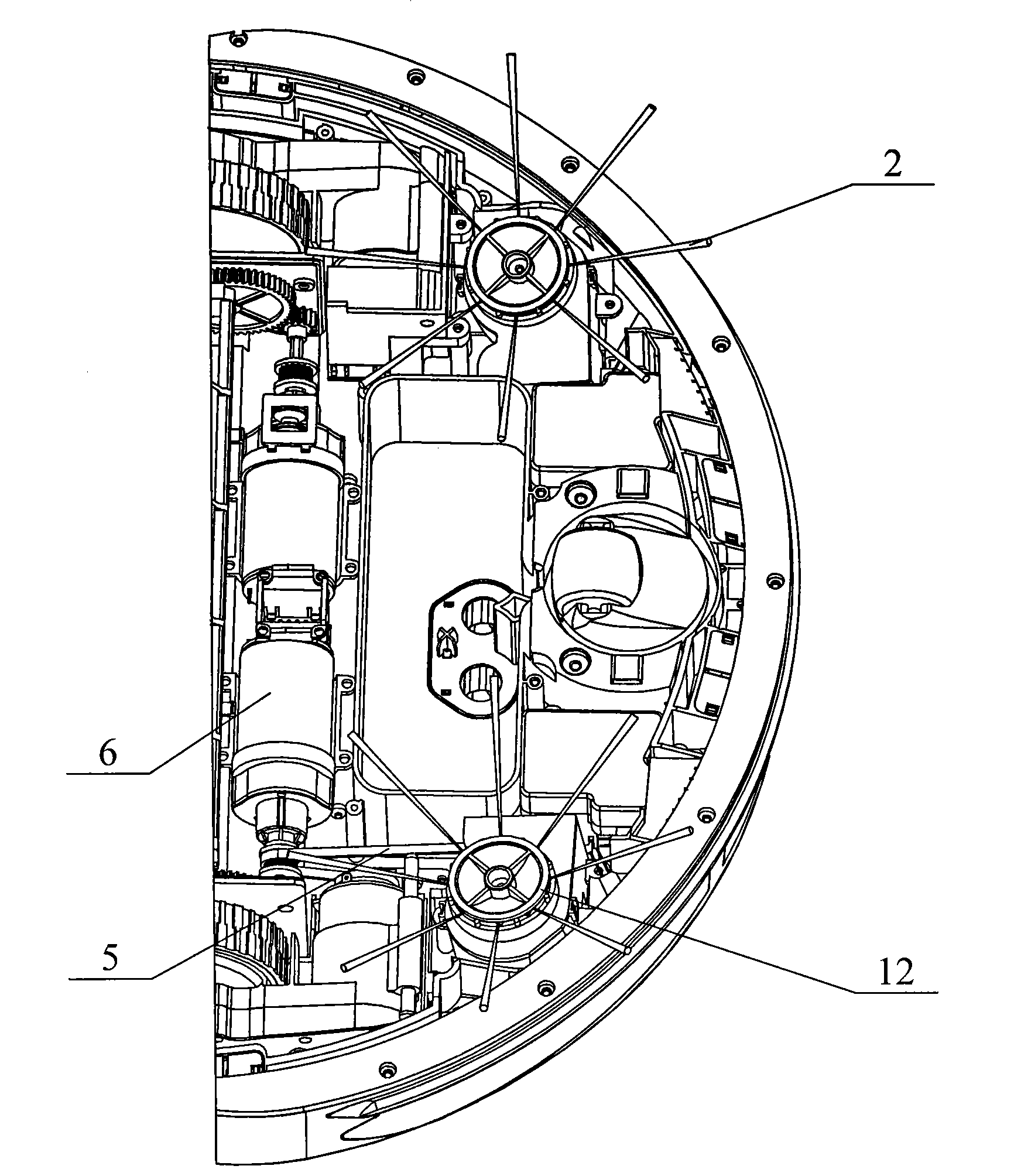

Self-cleaning device of air conditioner dirt filtrating screen

ActiveCN101270902AStable structureDispersed particle filtrationLighting and heating apparatusBrush deviceAir conditioning

The invention relates to an air-conditioning strainer mesh self-cleaning device, in particular to an air-conditioning strainer mesh self-cleaning device in which a rack- pinion device or a belt wheel device can be used as a drive device. The device consists of a brush device which is used to clean the dust of the air-conditioning strainer mesh, a main body used to carry the brush device, and a dust cleaning device used to absorb the dust; wherein, the brush device and the dust cleaning device are connected through a dust absorption hose; the main body is provided with a drive device and a track device; wherein, the drive device is used to drive the above-mentioned main body to perform reciprocal movements in the vertical direction along the surface of the air conditioning; the track device is used to drive the brush device to perform reciprocal movements in the horizontal direction on the main body; the brush device is provided with at least two rows of brushes as well as at least a dust absorption port. By adopting the above-mentioned structure and the technical proposal, the device can automatically remove the dust on the air-conditioning strainer mesh completely in a relatively short time; the structure of the device becomes reliable and durable.

Owner:HAIER GRP CORP +1

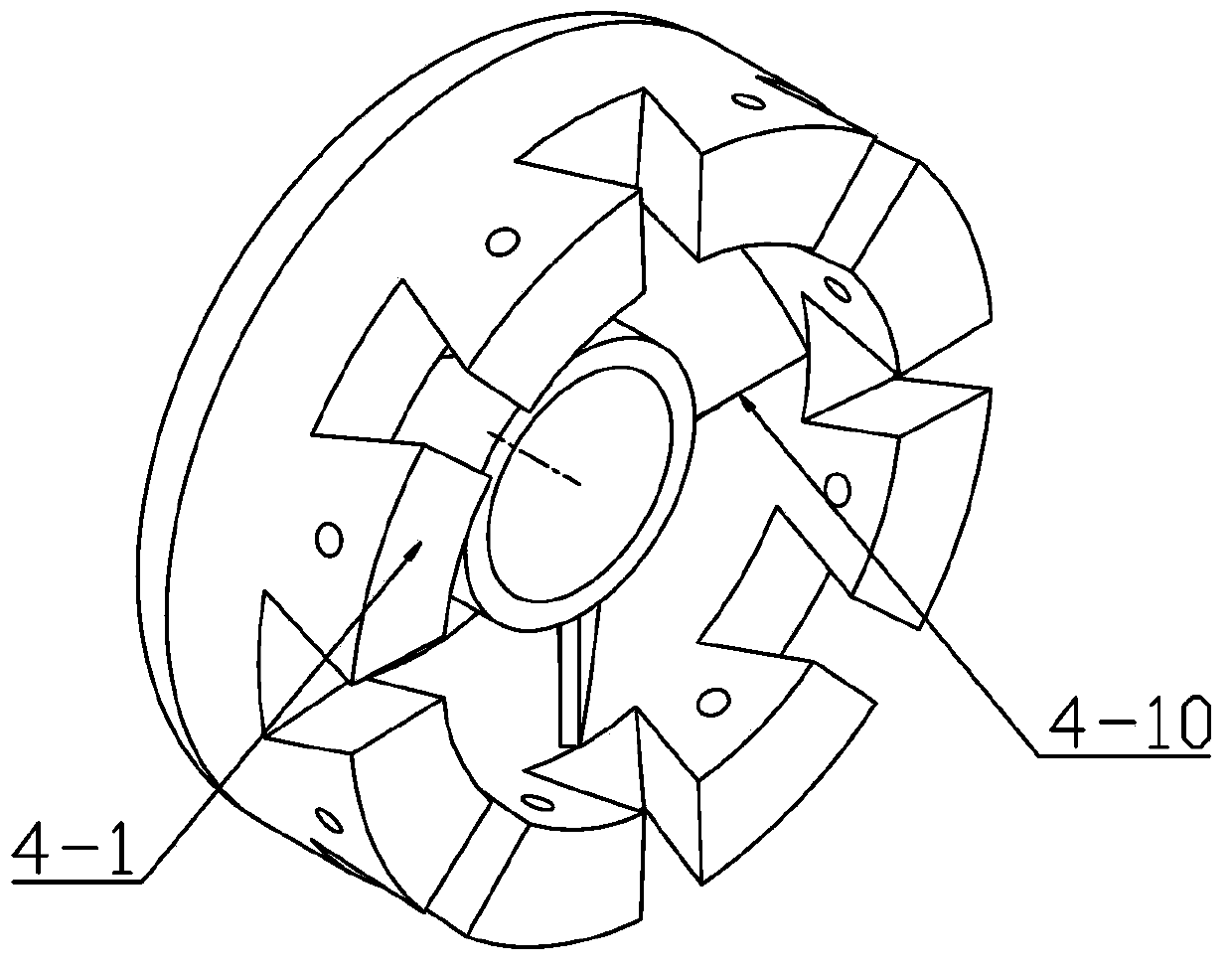

Side brush device of cleaning robot

InactiveCN101884512AImprove work performanceEasy to cleanSuction nozzlesFloor sweeping machinesGear wheelBrush device

The invention relates to a side brush device of a cleaning robot, which is arranged on two sides of the bottom of the cleaning robot. A side brush main body consisting of brush hair, a brush handle and a brush cover is connected with a motor and driven by the motor to rotate around a central shaft of the side brush main body. The side brush device is characterized in that the side brush main body has 2 to 20 holes for mounting the brush hair and the rotary central shaft of the side brush main body is inclined at an angle of 2 to 45 degrees towards the inner side of the bottom of the cleaning robot. Holes for mounting the brush hair are formed on the four sides of the brush cover, and the brush hair is expanded and inclined towards a conical direction after insertion. The side brush main body and the motor are connected by a pulley, a synchronous belt gear or a worm. The side brush main body is convenient to mount and dismantle and arranged on left and right sides of the front end of the cleaning robot. The bottom part of the cleaning robot is provided with one or more side brushes which are rotary or fixed. The side brush device for the cleaning robot overcomes a defect that the conventional non-inclined brushes on the two sides push in a rotary way and cannot clean sundries stacked by the wall or in dead corners.

Owner:上海中为智能机器人有限公司

Pool cage beam brush

A brush device can be releasably attached to a distal end of a pool broom and has a plurality of strategically placed brushes which brushingly engage the surfaces of the beams of a pool cage to clean those surfaces. The brushes are mounted on a head that can be angularly adjusted so the brushes will engage the cage surfaces in a manner which is conducive to thorough cleaning of those surfaces. The brushes are releasably mounted so they can be removed for cleaning or replacement.

Owner:RUH II GARY ROBERT

Underwater brushing detection robot

The invention relates to an underwater brushing detection robot, comprising a frame, a control system, an electric appliance sealed chamber, a walking mechanism, a brushing device, a propulsion device and a disease visual detection device, wherein the electric appliance sealed chamber, the walking mechanism, the brushing device, the propulsion device and the disease visual detection device are installed on the frame, the walking device comprises two walking units which are respectively installed on the two sides of the frame, the brushing device is installed on the bottom of the frame, the electric appliance sealed chamber is arranged in the frame, the control system is installed in the electric appliance sealed chamber, and the walking mechanism, the brushing device, the propulsion device and the disease visual detection device are respectively connected with the control system. The beneficial effects of the robot provided in the invention reside in that: the underwater robot can agilely and conveniently walk underwater, can clean the soft or hard impurities deposited on water conservancy facilities by a self-mounted brushing function, avoids leakage detection and false detection, and provides favorable guarantee of safety operation of the water conservancy facilities.

Owner:HOHAI UNIV CHANGZHOU

Chemical test tube cleaning device

The invention discloses a chemical test tube mechanical cleaning device, and belongs to the field of chemical supplies. The chemical test tube cleaning device is composed of an automatic rotation water spraying hairbrush, motors, small-sized cylindrical water channels, a stand column, a tube brushing machine base platform, an air cylinder, air holes, a conveyor belt, an operating platform and a micro sensor. The stand column is used for supporting the upper air cylinder, an air cylinder piston is connected with a tube brushing device, and one end of a test tube brush is connected with the motors. The motors are separated from a water inlet in the tail portion of the test tube brush through the small-sized cylindrical water channels. The rotation hairbrush is in a thin-wall hollow type, six small water spraying holes are punched in the working position of the hairbrush, two water inlet holes are punched in the hollow positions, corresponding to the small-sized cylindrical water channels, of the hairbrush, an outer water inlet is formed in the upper portion of a test tube brush box, and the micro sensor is placed at the lower right corner of the test tube brush box. Nine novel rubber plugs are mounted inside a test tube clamping box, and the conveyor belt is used for conveying the test tube box so that cleaning can be achieved. The chemical test tube cleaning device has the advantage that a large number of test tubes can be efficiently cleaned through the device.

Owner:孙香兰

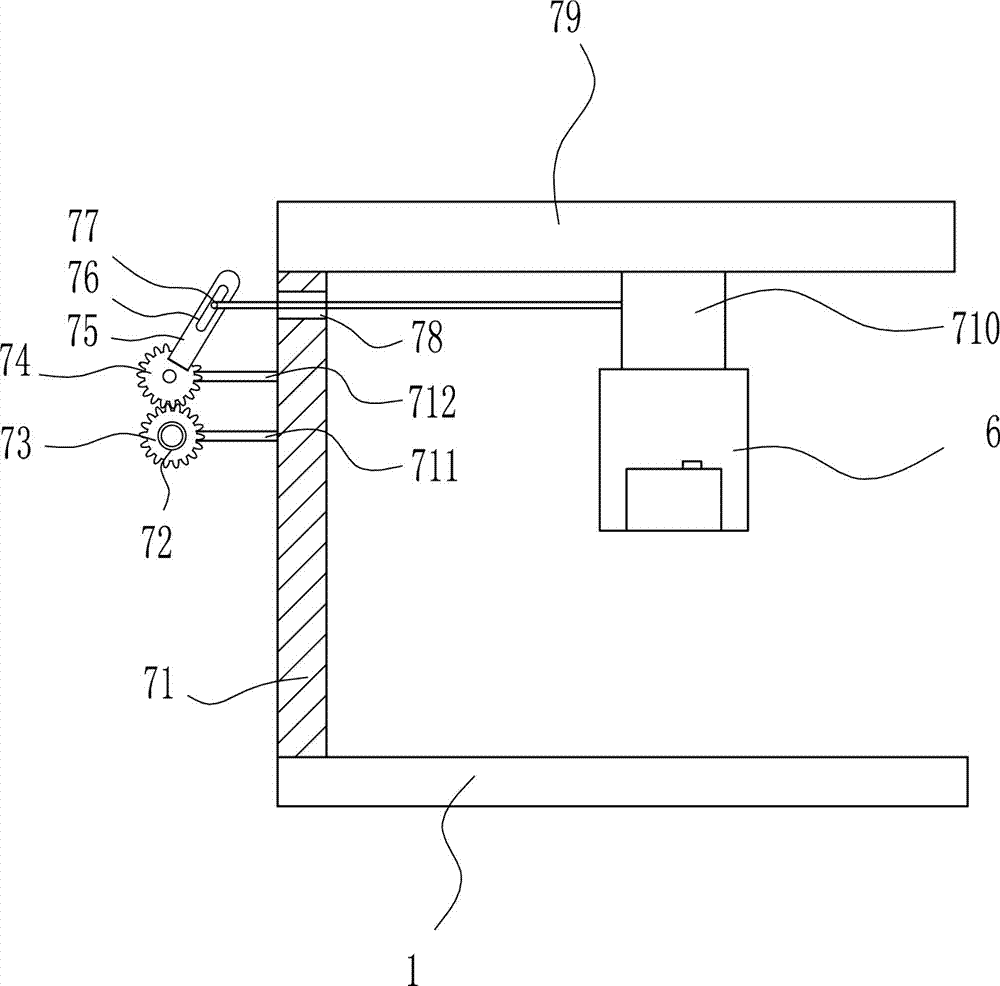

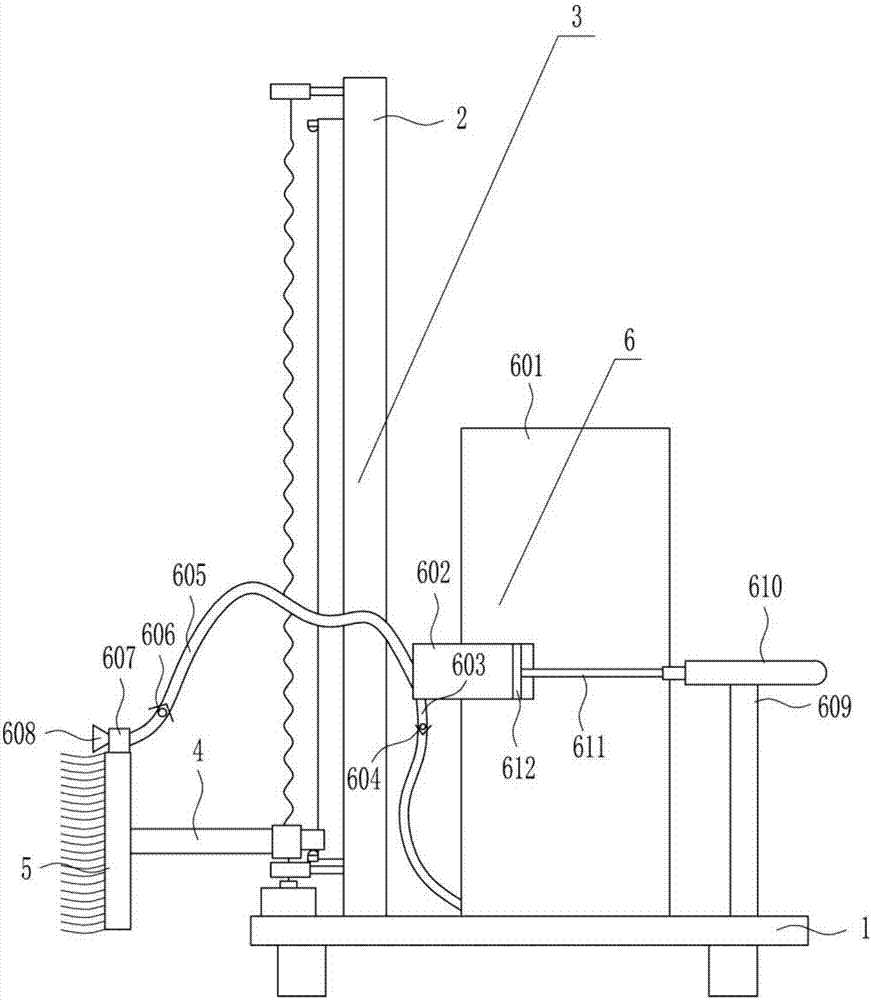

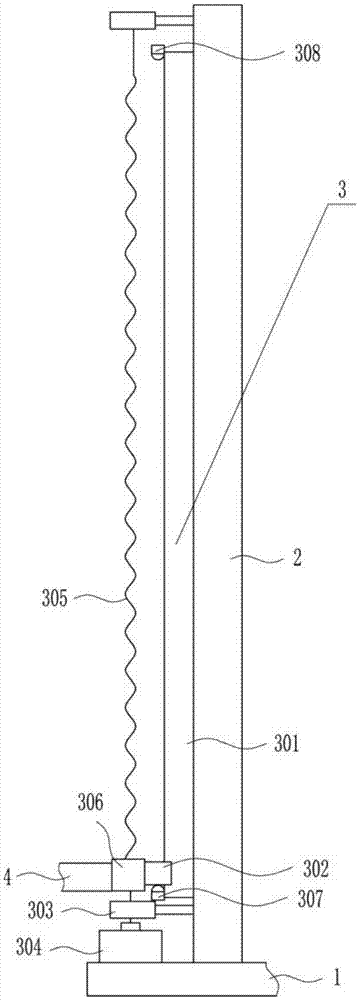

Wall paint brushing device for decoration

InactiveCN107447960ADry fastUniform concentrationBuilding constructionsBrush deviceUltimate tensile strength

The invention relates to a wall brushing device for decoration, in particular to a wall paint brushing device for decoration, and aims to provide the wall paint brushing device for decoration, which can reduce the labor intensity, improve the brushing efficiency and the decoration efficiency and protect the body health. In order to solve the technical problem, the wall paint brushing device for decoration comprises a cart and the like, wherein a supporting plate is vertically arranged on the left side of the top of the cart; an up-and-down movement mechanism is arranged on the left side surface of the supporting plate; a cross bar is connected to the movement part of the up-and-down movement mechanism; the left end of the cross bar is connected with a brush; and a paint spraying device is arranged at the top, at the right side of the supporting plate, of the cart. The wall paint brushing device for decoration achieves the effects of reducing the labor intensity, improving the brushing efficiency and the decoration efficiency and protecting the body health.

Owner:戚展鹏

Multihead Artist and Make-up Brush

InactiveUS20100043815A1Easy to replaceQuick connect/disconnectBristle carriersCurling devicesPolymer scienceBrush device

Owner:SWITCHPRO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com