4-segment type sweeping robot

A cleaning robot, four-stage technology, applied in the direction of manual sweeping machines, motor vehicles, suction nozzles, etc., can solve the problems that the auxiliary brush is easy to accumulate dust, fall on the floor, block the auxiliary brush, etc., and achieve enhanced cleaning effect. The effect of improving cleaning quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

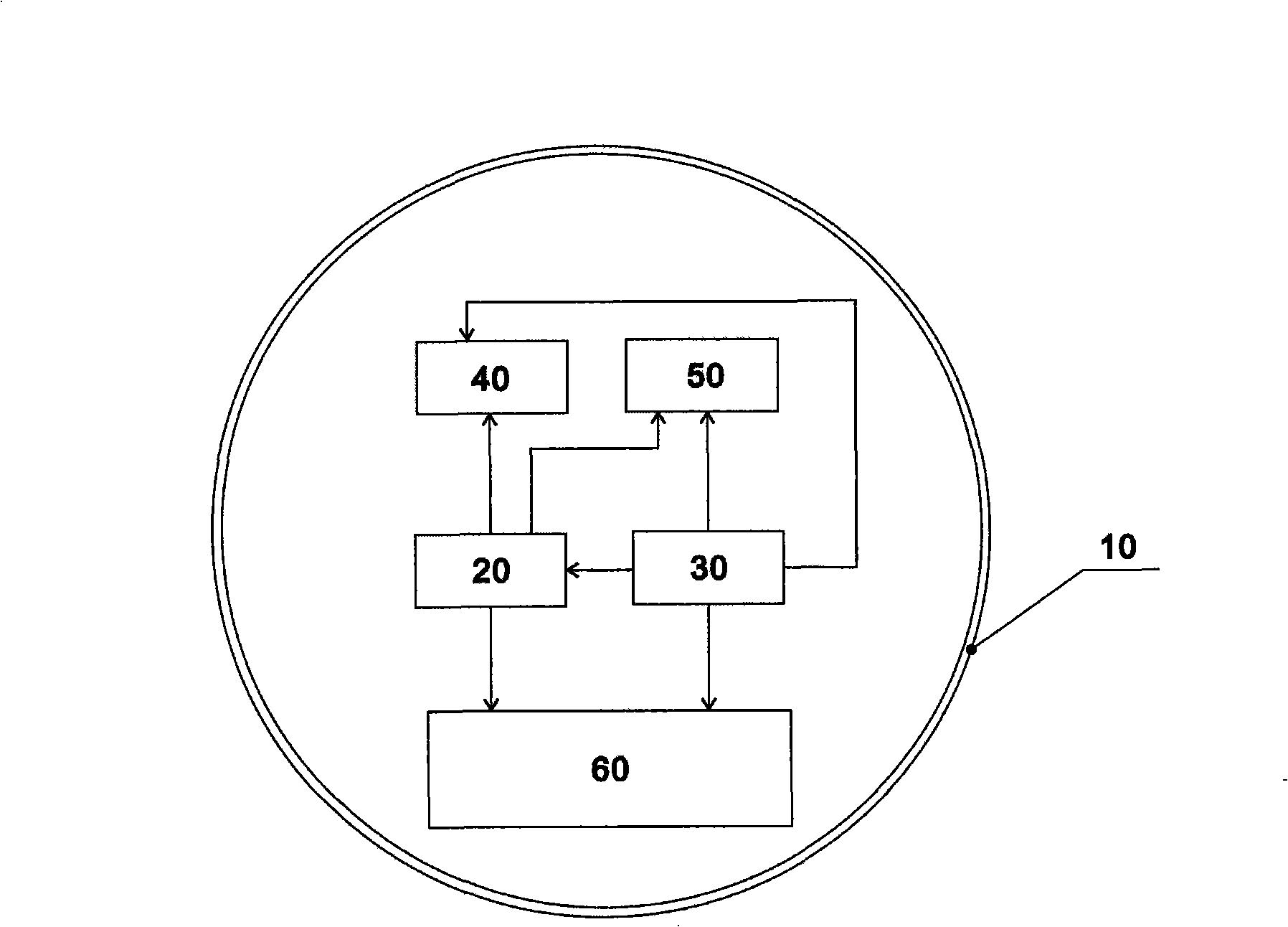

[0027] refer to figure 1 , a four-stage cleaning robot, mainly composed of a housing 10, a control system 20, a power supply system 30, a motion system 40, a sensor system 50 and a four-stage cleaning system 60. A control system 20 , a power supply system 30 , a motion system 40 , a sensor system 50 and a four-stage cleaning system 60 are connected with the housing 10 to form a robot system.

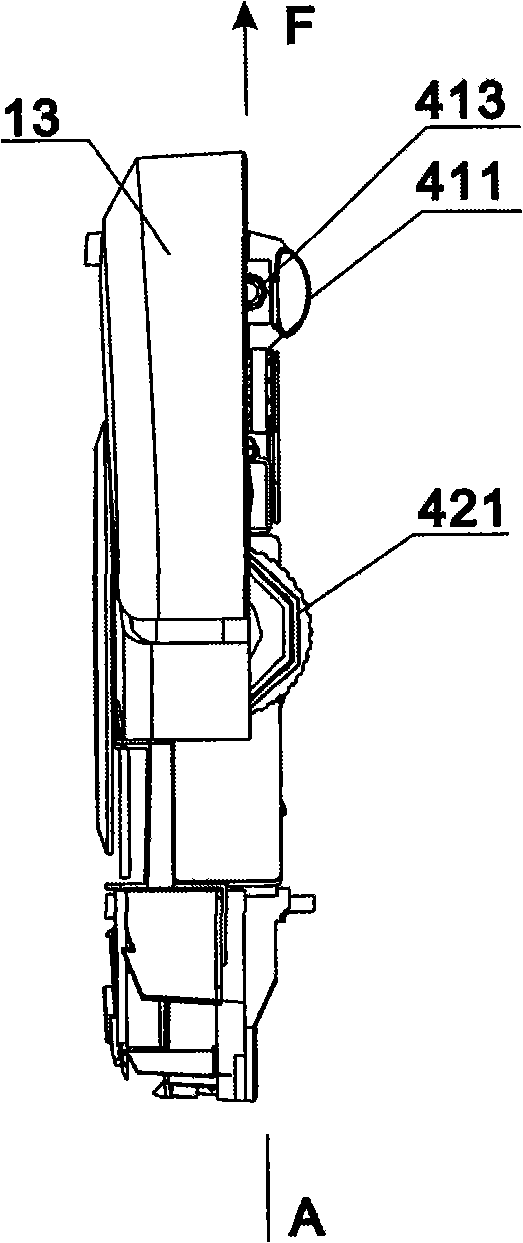

[0028] Because the front and rear of the robot are to be referred to, the lines marked F and A in the drawings mentioned below refer to the axis of symmetry of the robot, and F refers to the front.

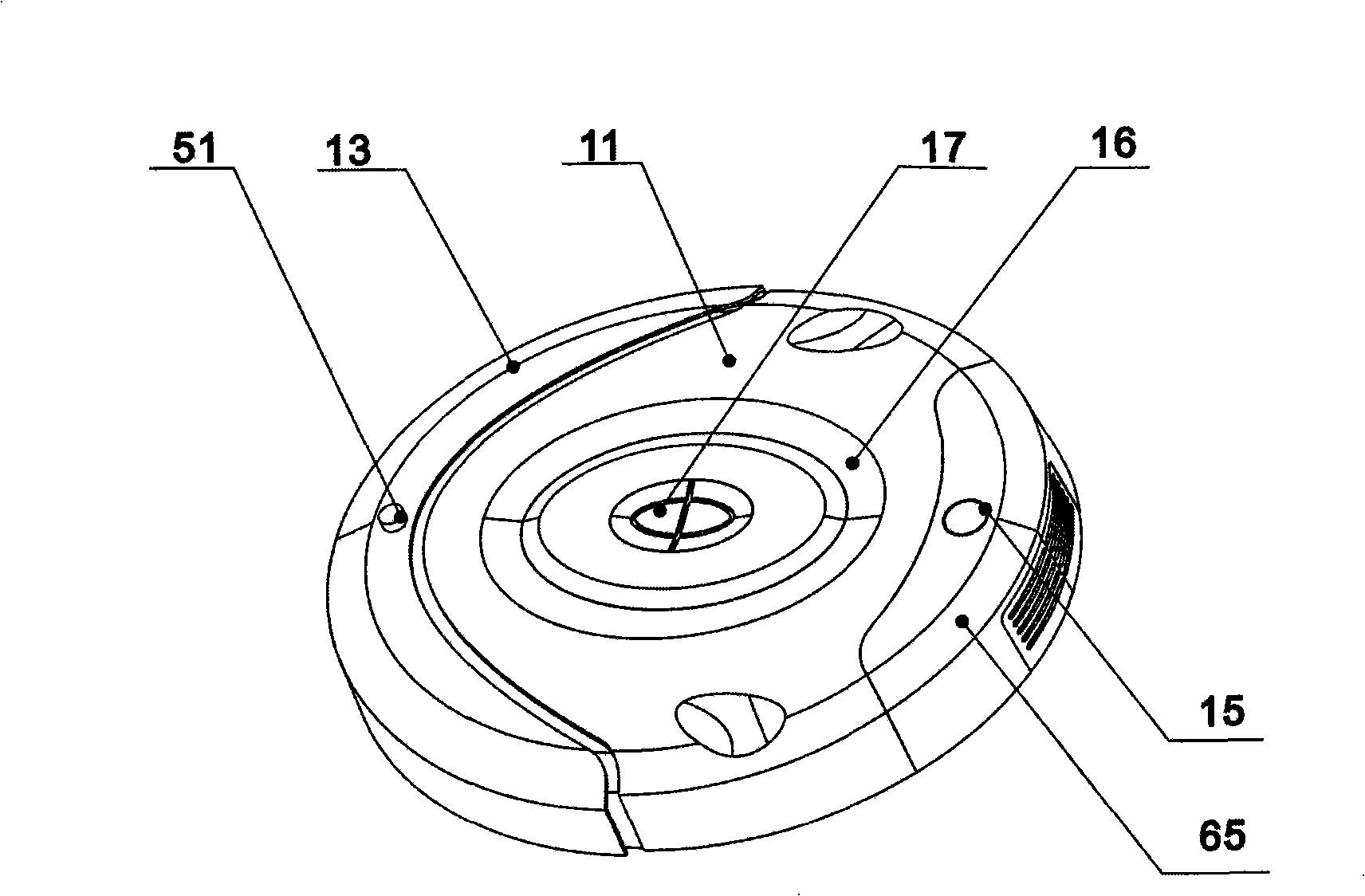

[0029] refer to figure 2 , 3 and 4, the casing 10 is mainly composed of an upper cover 11 , a chassis 12 , a collision ring 13 , a turning partition 14 , and a decorative plate 16 . The control system 20 , the power supply system 30 , the motion system 40 , the sensor system 50 and the four-stage cleaning system 60 are all mounted on the chassis 12 . The chassis 12 is in the shape of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com