Dry cleaning device and dry cleaning method

A technology for cleaning equipment and cleaning agents, applied in cleaning methods and utensils, cleaning methods using gas flow, cleaning with electrostatic methods, etc., can solve problems such as damage and scratches, and achieve high cleaning quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

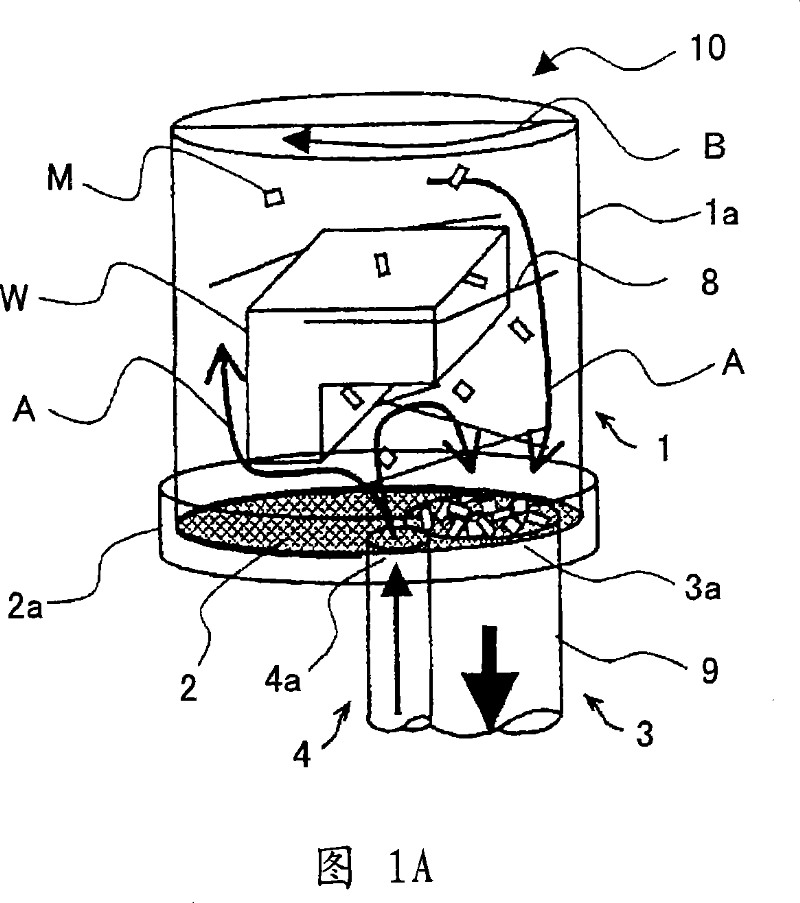

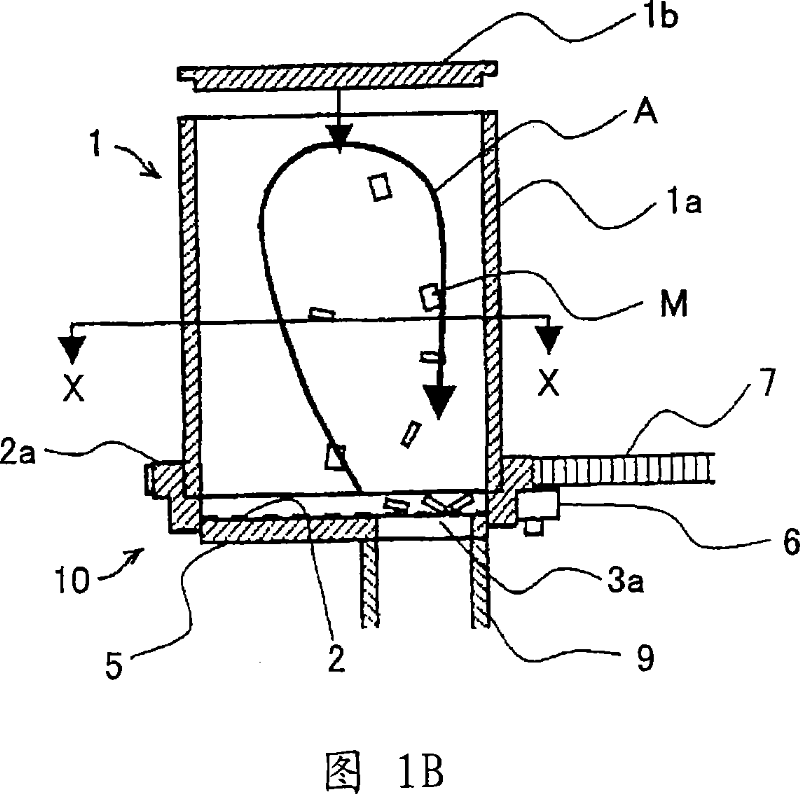

[0080] A first embodiment of the present invention will be described with reference to FIGS. 1A and 1B and FIGS. 2A and 2B. In the following, each unit of the device will be explained first.

[0081] The cleaning box 10 is made by using a disc-shaped cover portion 1b at the top, a cylindrical side wall portion 1a, a disc-shaped mesh member 2 at the bottom, a mesh member cover 5 partially covering the mesh member 2, and a mesh member for holding the mesh member. The holding unit 2a of the piece 2, which together form a closed space, except for leaving a certain opening.

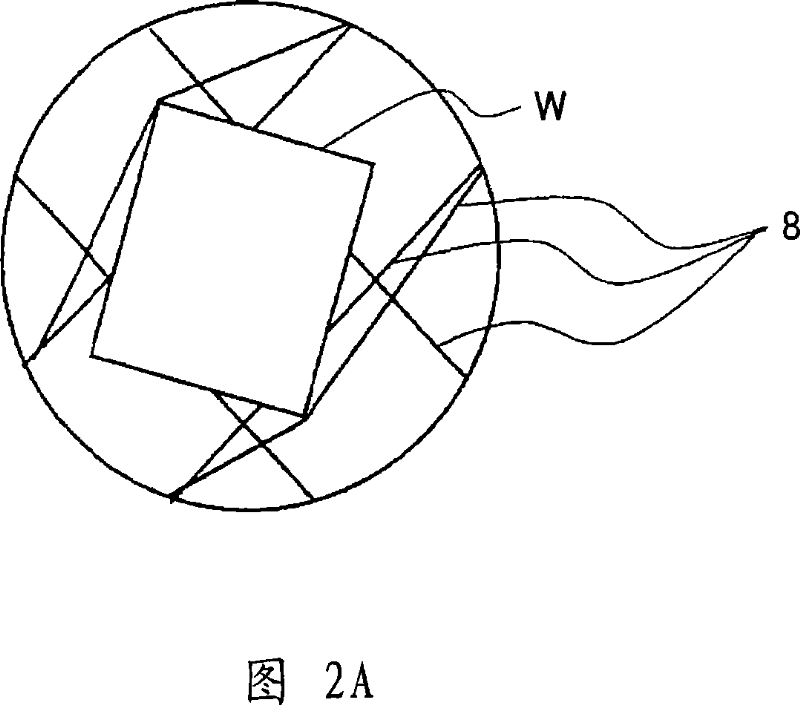

[0082] The side wall portion 1a is a cylindrical member fixedly mounted to the holding unit 2a. When the holding unit 2a rotates, the side wall portion 1a also rotates jointly with the cover portion 1b. The side wall portion 1a is provided with a workpiece holding unit 8, which will be described in detail below.

[0083] The side wall portion 1a is slidably engaged with the holding unit 2a so that the side ...

no. 2 example

[0126] 7A and 7B show the construction of the second embodiment of the present invention. Fig. 7A is a plan view of the cleaning tank, and Fig. 7B is a partially cutaway side view.

[0127] The direction of rotation D of the suction duct 9 , the base plate 11 , the support column 12 , the upper plate 13 , the rotation shaft bushing 14 , the rotary drive unit 15 and the suction duct 9 is shown. In this embodiment, the grid 2 is fixed, while the suction opening and the inlet are rotated. Hereinafter, each unit will be explained.

[0128] The mesh member 2 as a separation unit does not allow the passage of the cleaning agent M, but allows the passage of the dust which has not been removed. The grid 2 has a cylindrical basket shape and is fixedly mounted to the upper plate 13 . The mesh cover 5 covers the outer periphery of the cylindrical mesh 2, thereby separating the clean box 10 from the outside air. The mesh cover 5 is rotated while its inner wall is positioned adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com