Patents

Literature

6260 results about "Megasonic cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Megasonic cleaning is a type of acoustic cleaning, related to ultrasonic cleaning. It is a gentler cleaning mechanism, less likely to cause damage, and is used in wafer, medical implant, and industrial part cleaning.

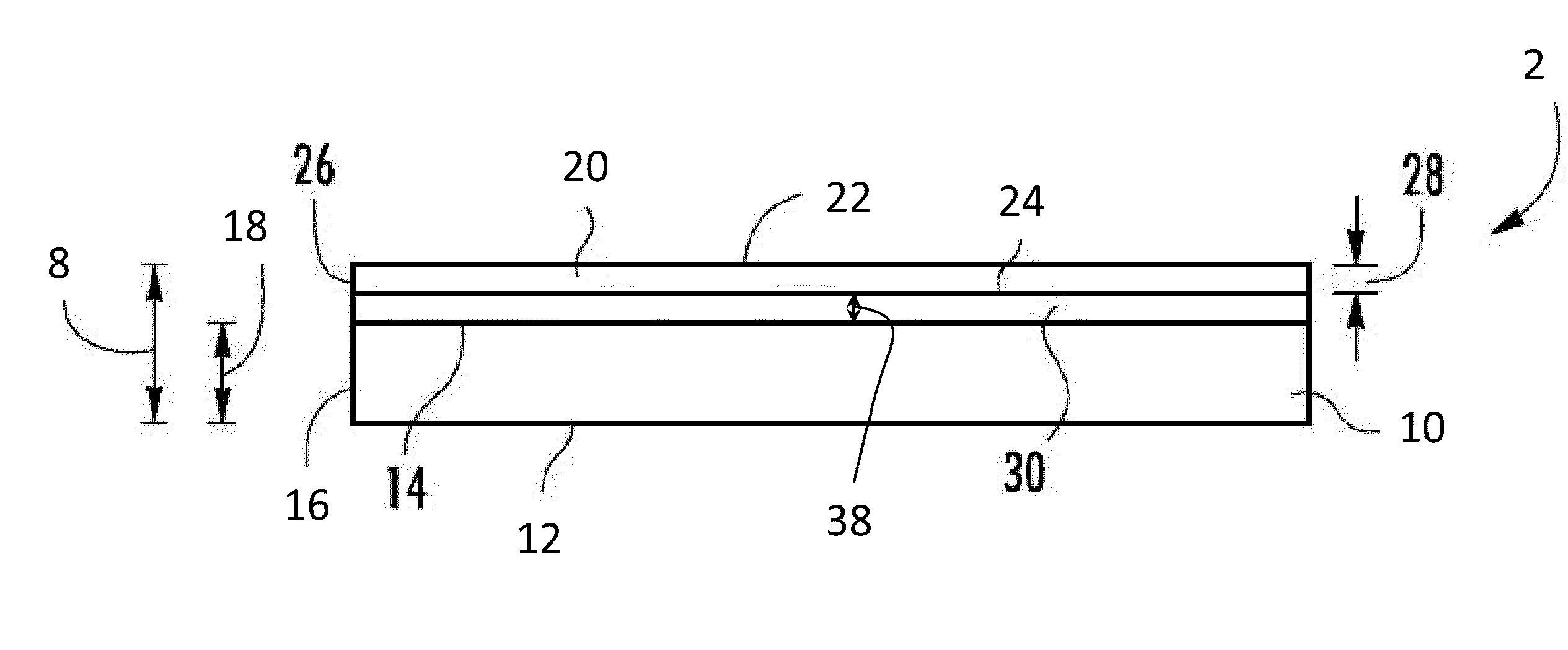

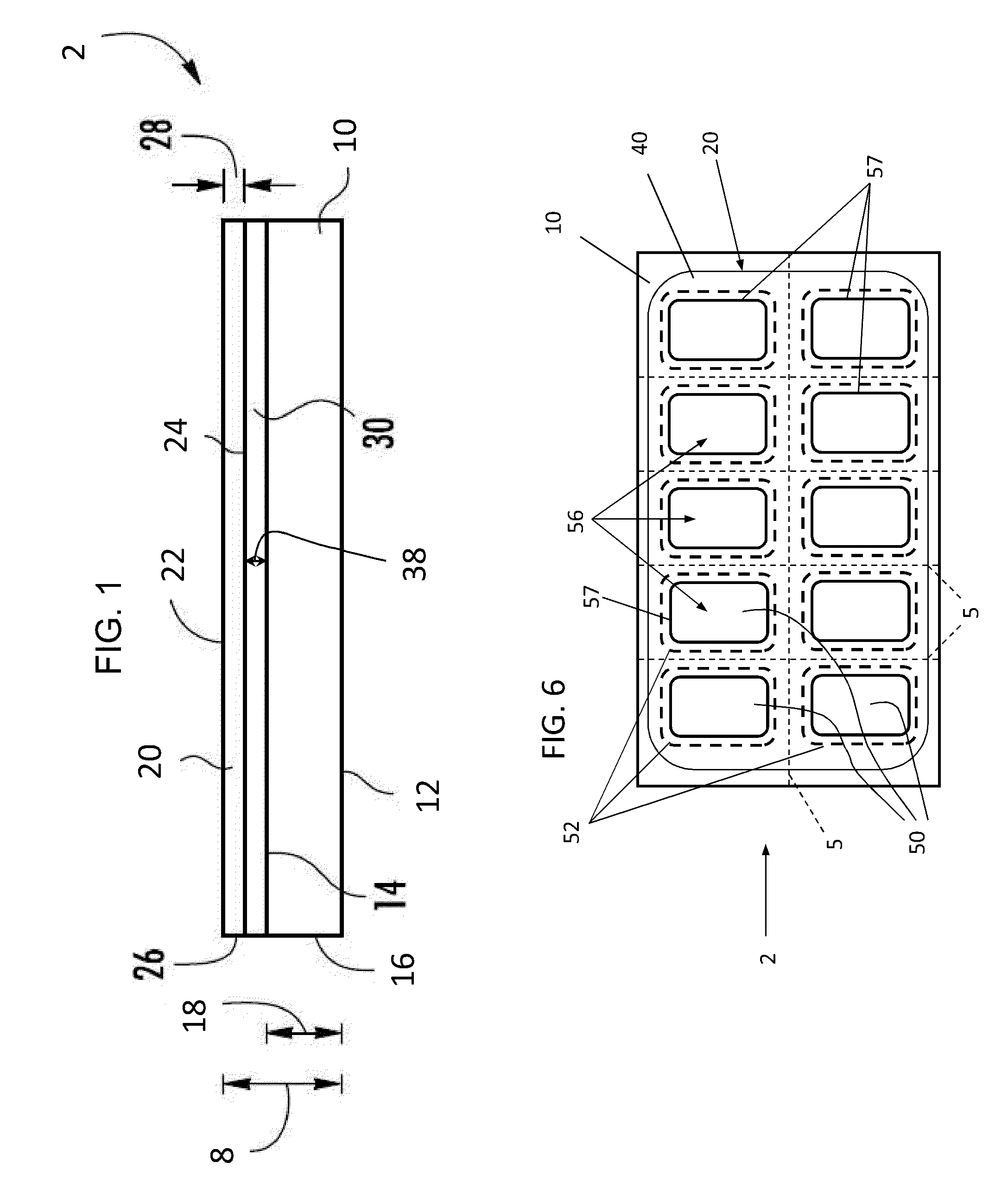

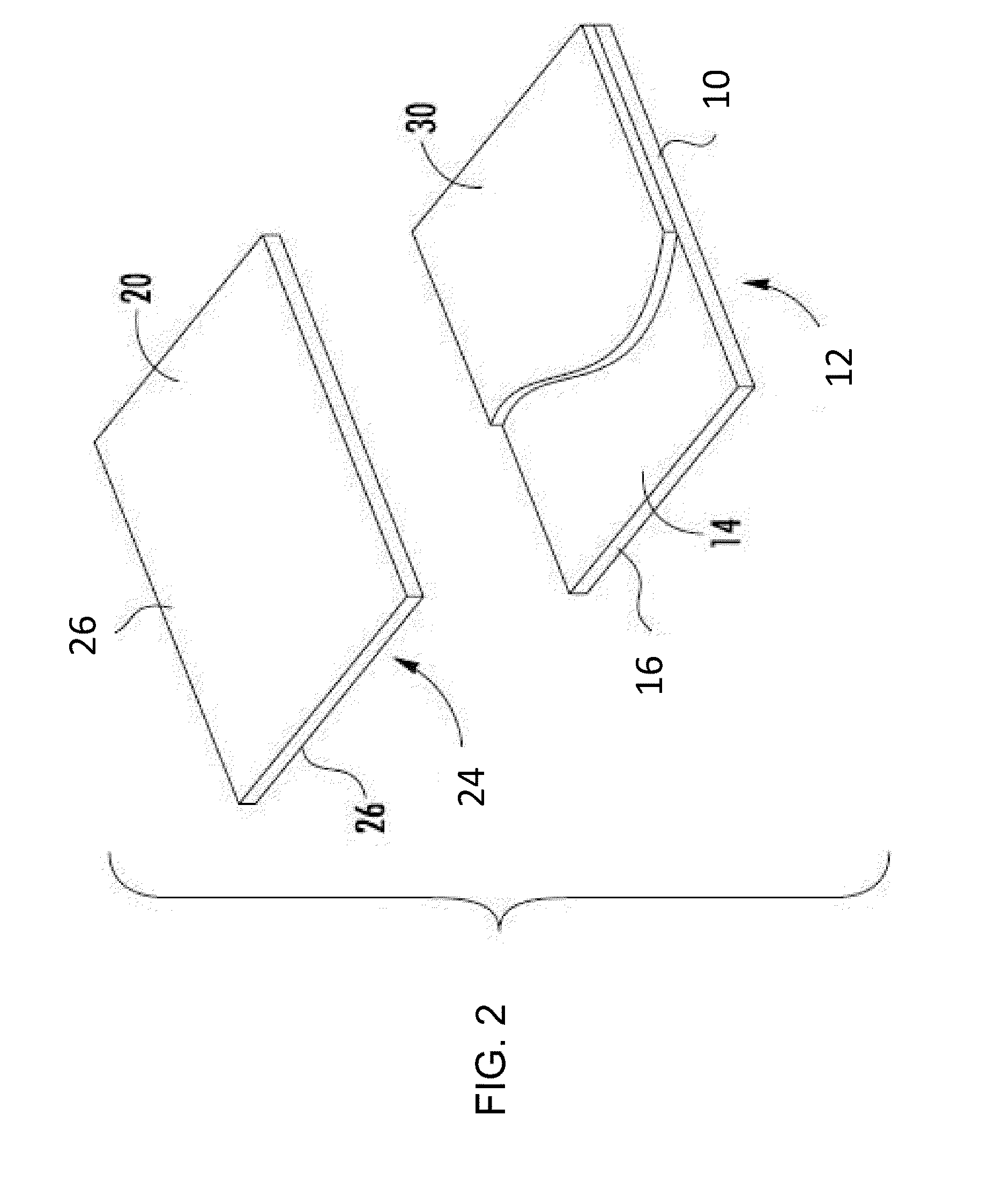

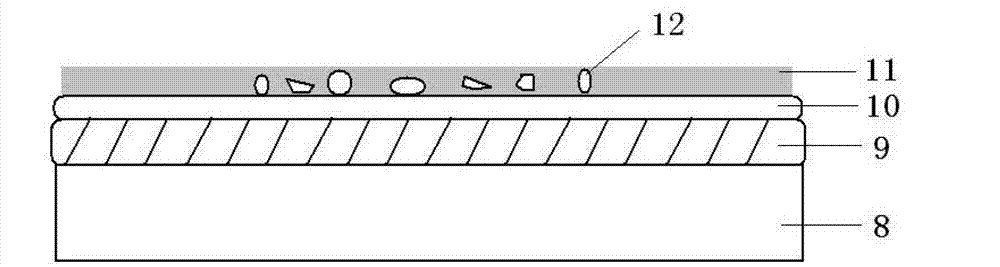

Glass articles and methods for controlled bonding of glass sheets with carriers

ActiveUS20140170378A1Film/foil adhesivesSynthetic resin layered productsMegasonic cleaningRoom temperature

Surface modification layers and associated heat treatments, that may be provided on a sheet, a carrier, or both, to control both room-temperature van der Waals (and / or hydrogen) bonding and high temperature covalent bonding between the thin sheet and carrier. The room-temperature bonding is controlled so as to be sufficient to hold the thin sheet and carrier together during vacuum processing, wet processing, and / or ultrasonic cleaning processing, for example. And at the same time, the high temperature covalent bonding is controlled so as to prevent a permanent bond between the thin sheet and carrier during high temperature processing, as well as maintain a sufficient bond to prevent delamination during high temperature processing.

Owner:CORNING INC

Method for preparing silicon thin film heterojunction solar cell

InactiveCN1588649AAvoid damageReduce hydrogen contentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon thin film

A prepn. method of silicon thin film heterojunction solar cell includes following steps: cleaning substrate, semiconductor cleaning technology is used to do primary cleaing to substrate surface, then do ultrasonic cleaning in deionized water several times; nitrogen blow drying; prepare nitrinsic amorphous silicon layer by heater chemical vapour phase depositing technology, tungsten filament temp. is measured by pyrometer, temp of heater and sample are determined separately by two electric thermo-couples, temp. is controlled by electric temp. controller; to react and grow thin film on substrate surface; to redeposit a transmitting layer on intrinsic amorphous silicon thin film; front and back electrodes forming, sputtering technology is used to form front and back electrodes; finally to proceed vacuum heat annealing process. The thin film produced by the invention has illumination stability, the photoconduction gain can reach to 10 to the power 6 on Am1.5 100mW / cm2 standard illumination.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing multi-metal element doped diamond film

InactiveCN101787512AImprove performanceVacuum evaporation coatingSputtering coatingCathodic arc depositionIon bombardment

The invention discloses a method for preparing a multi-metal element doped diamond film, which is characterized by comprising the following steps: removing a pollution layer on matrix surface by using the ultrasonic cleaning technology, carrying out ion beam bombardment cleaning on the matrix surface by using inert gas ion beam produced by an ion source, carrying out metal ion bombardment cleaning on the matrix surface by using metal ions produced by a cathodic arc source under a condition of high workpiece negative bias, preparing a gradient transition layer by using a cathodic arc deposition or ion beam assisted magnetron sputtering (IBAMS), and synthesizing a multi-metal element doped DLC film on the transition layer by using ion beam deposition and mosaic composite target magnetron sputtering, wherein the ion beam deposition is realized by introducing carbon gas in the ion source; and the mosaic composite target doped multiple metal are used, and the main body material of the mosaic composite target can be any one of Ti, Cr, W, Zr, Nb and Ta, and the mosaic block material is one or more of other metals except the above main body materials.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

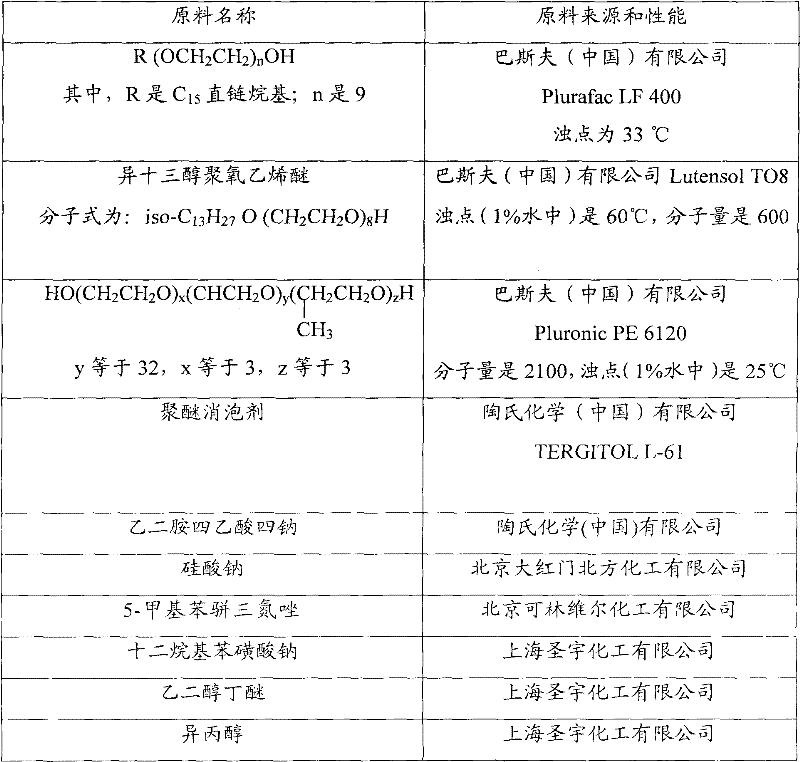

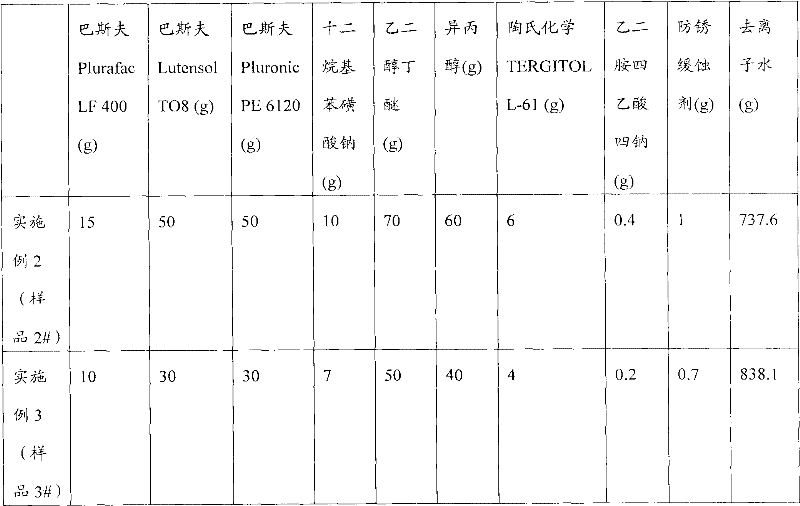

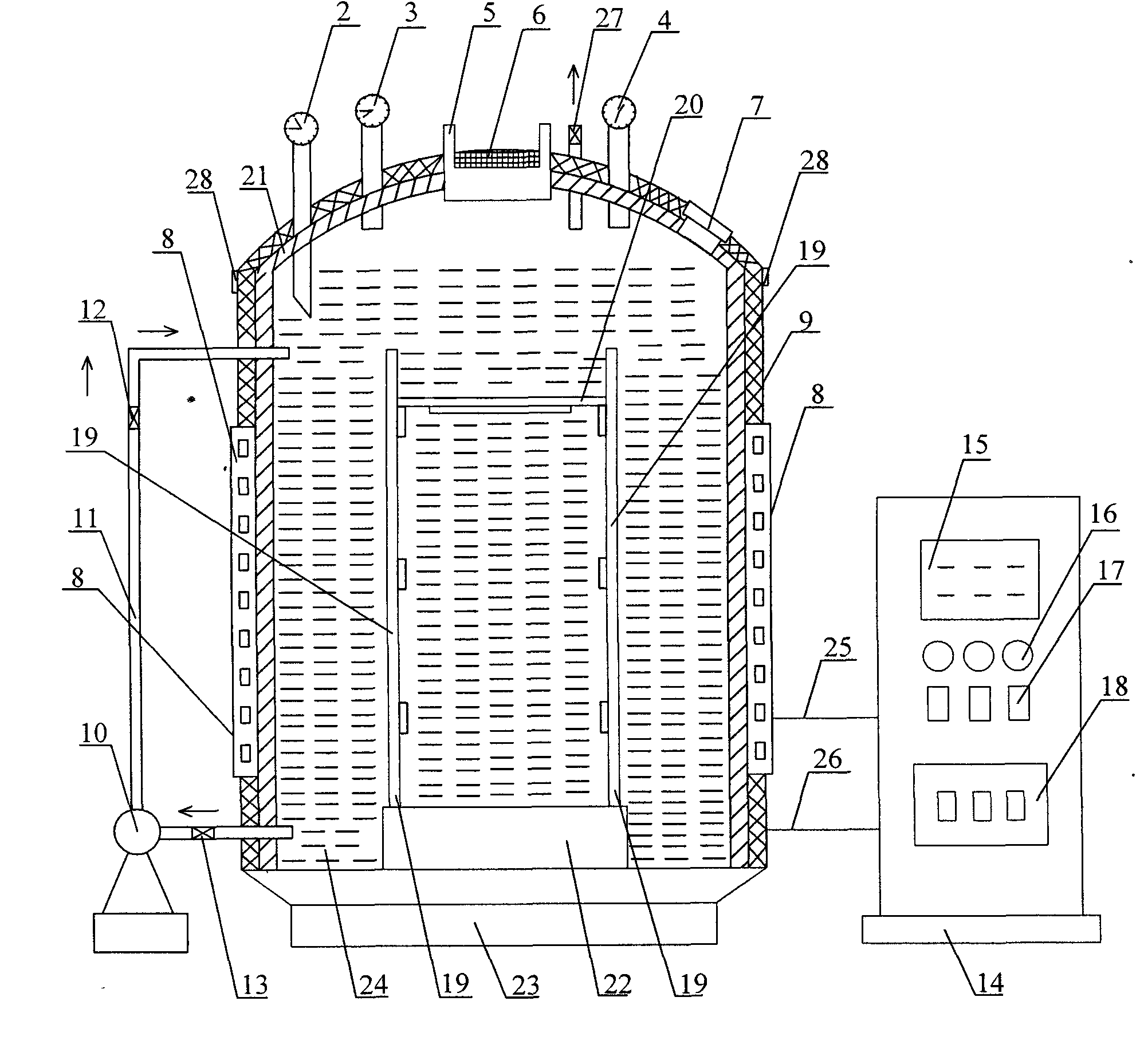

Environment protection efficient water-based circuit board cleaning agent and preparation thereof

InactiveCN101440332ANo pollutionThe raw materials are scientific and reasonableNon-ionic surface-active compoundsOrganic detergent compounding agentsWater basedActive agent

The invention provides an environment-friendly high-efficiency water-based circuit board cleaning agent and a method for preparing the same. The raw material formulation of the cleaning agent comprises a surfactant, a corrosion-retarding active agent, a chelating agent, a defoamer, a cleaning solvent and water. The preparation method comprises the following steps: accurately weighing various raw materials according to the ratio of the formulation, adding the raw materials into a reactor to be stirred evenly, and keeping the mixture stand to obtain the cleaning agent of the invention. The cleaning agent has the advantages of scientific and reasonable raw materials, simple and practicable preparation method, nontoxic and non-corrosive product, no inflammable and explosive properties, non pollution to the environment, high cleaning cleanliness and low cost, is biodegradable, can be cleaned through both immersion and ultrasonic, and has significant economic benefits.

Owner:潘惠凯 +1

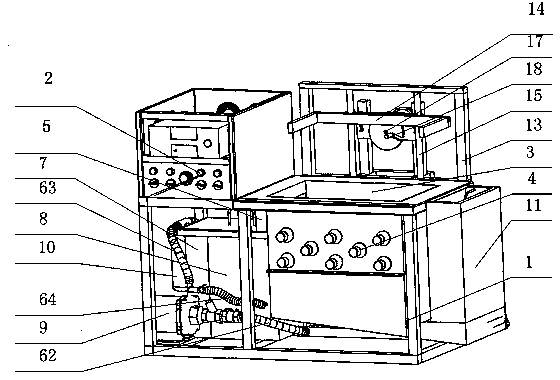

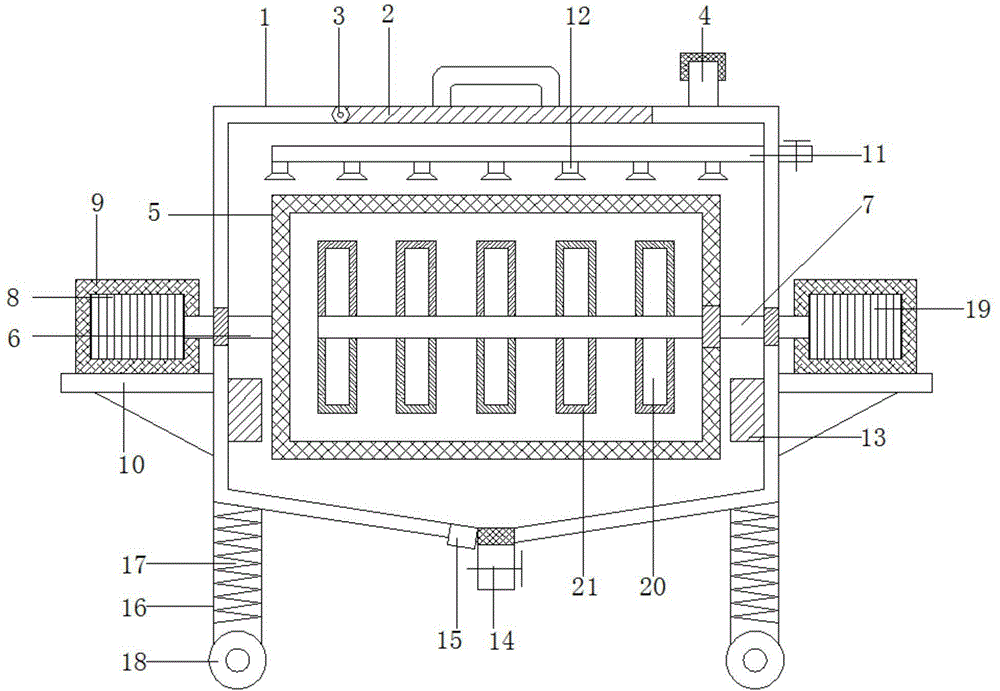

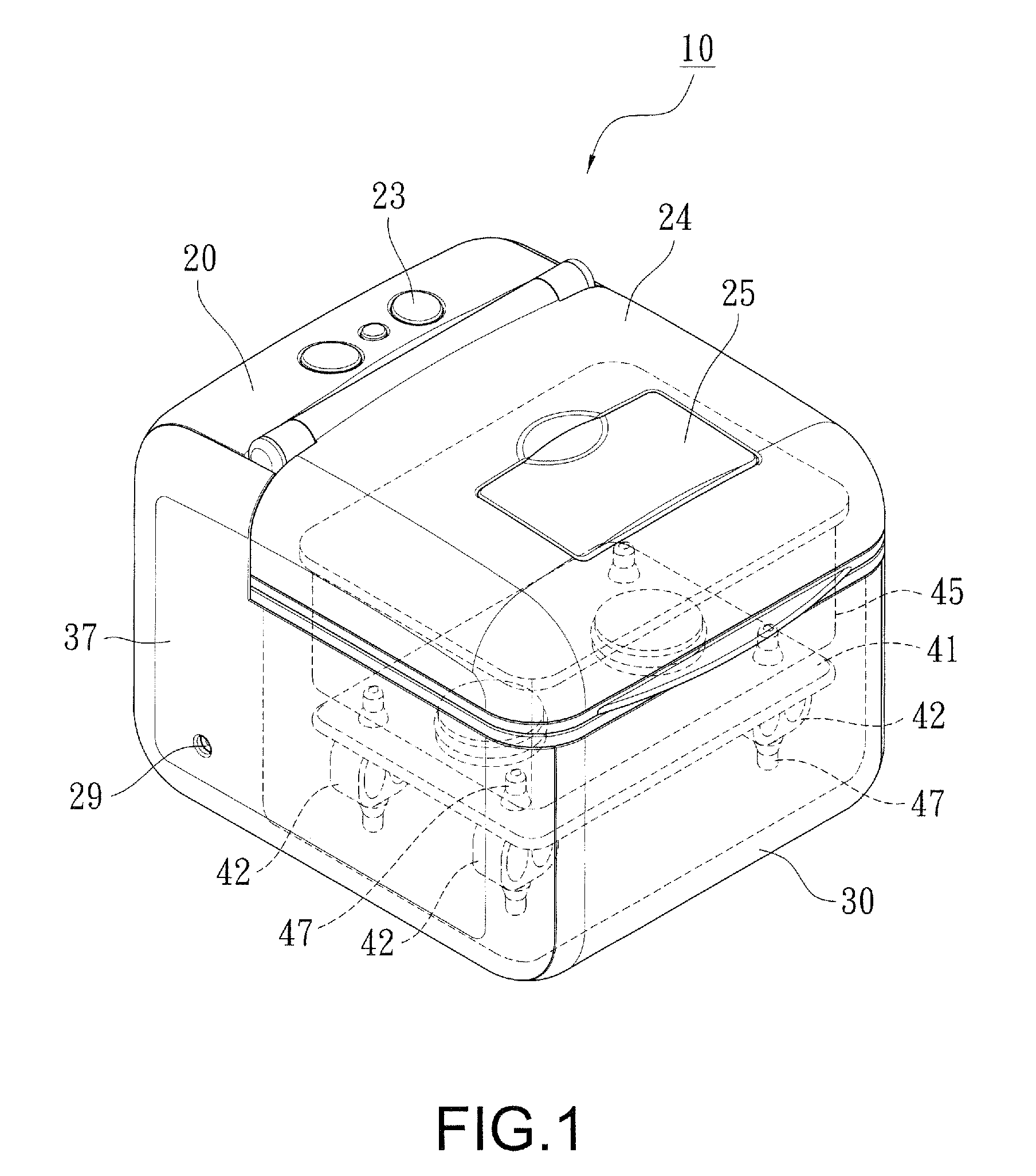

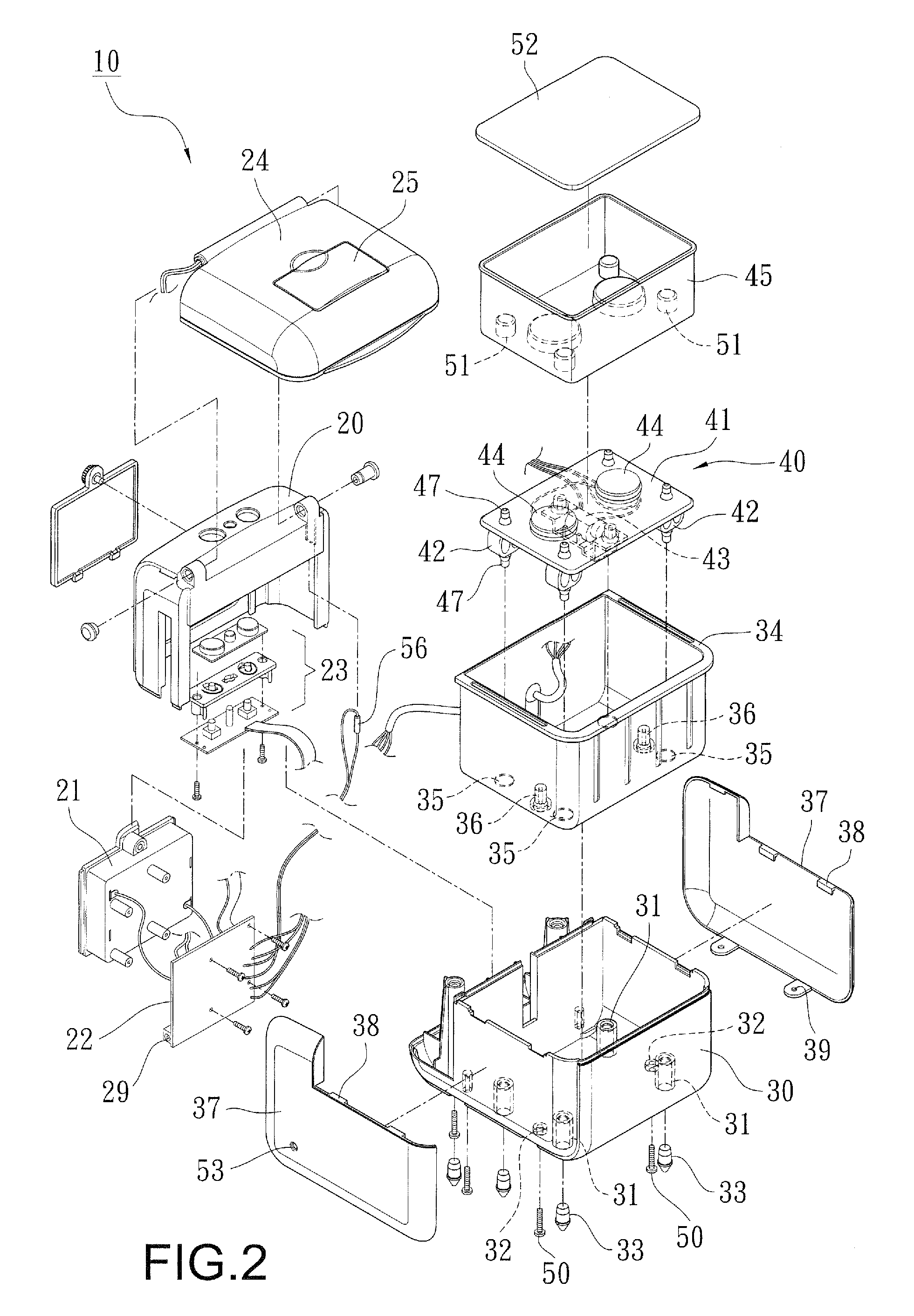

Ultrasonic cleaner

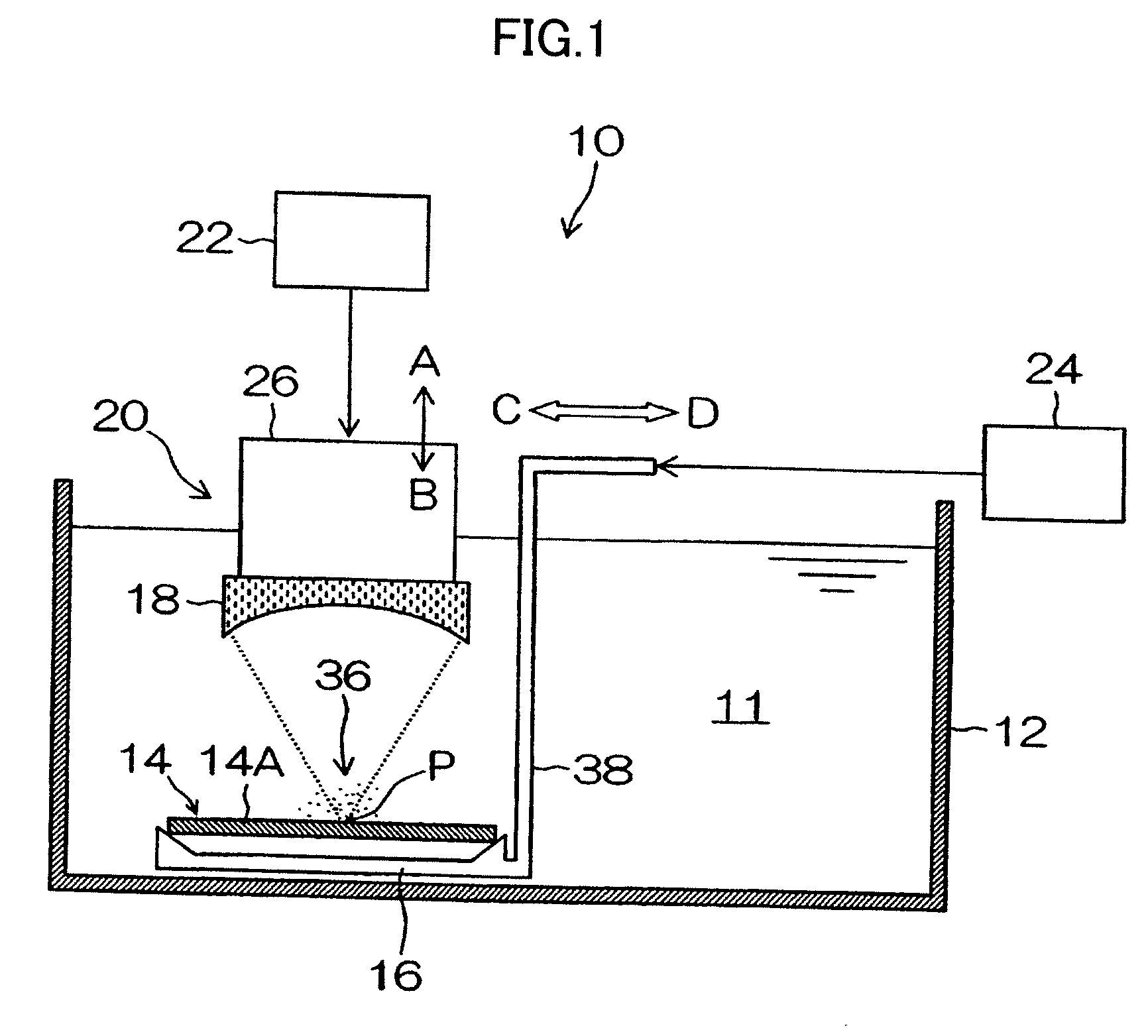

ActiveCN103878143AConsistent cleanlinessReduce replacement cycleCleaning using liquidsFiltrationWater storage tank

The invention discloses an ultrasonic cleaner and belongs to the field of mechanical equipment cleaning. The ultrasonic cleaner solves the problems that cleaning fluid in an existing ultrasonic cleaner cannot remove impurities in time, and the cleaning fluid is wasted. The ultrasonic cleaner comprises a rack (1), an ultrasonic generator (2), a cleaning tank (3) and ultrasonic vibrators (4). A water circulation device is arranged on the outer side of the cleaning tank (3) and comprises an overflow tank (5) arranged on one side of the cleaning tank (3). The water circulation device further comprises the overflow tank, an oil contamination tank (7), a water storage tank (8), a water pump (9), a filter (10) and a water injection tank (11). The bottom of the water injection tank (11) is communicated with the cleaning tank (3). The bottom of the cleaning tank (3) is an inclined plane. The ultrasonic cleaner integrates the functions of heating, ultrasonic waves, circulating filtration, oil-water separation and article movement, the cleaning speed is high, and the cleaning effect is good; besides, the ultrasonic cleaner is multifunctional, low in energy consumption and capable of prolonging the replacement cycle of the cleaning fluid and reducing environmental pollution, thereby being wide in application range.

Owner:台州鸿辰机械制造有限公司

Water-removable coatings for LCD glass

InactiveUS6715316B2Same and smoothnessMaterial nanotechnologyNanostructure manufactureMegasonic cleaningAqueous solution

Owner:CORNING INC

Ultrasonic washing device

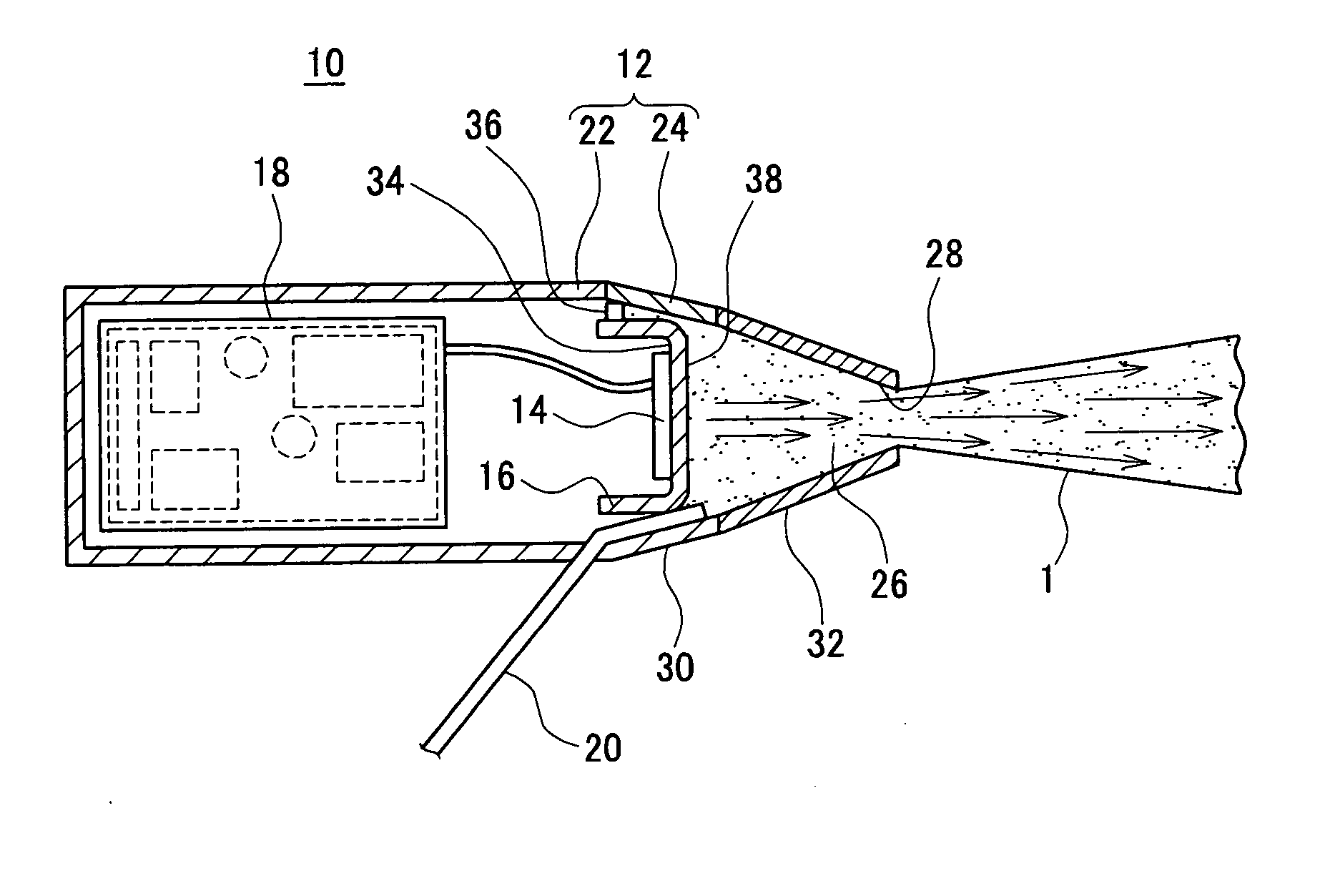

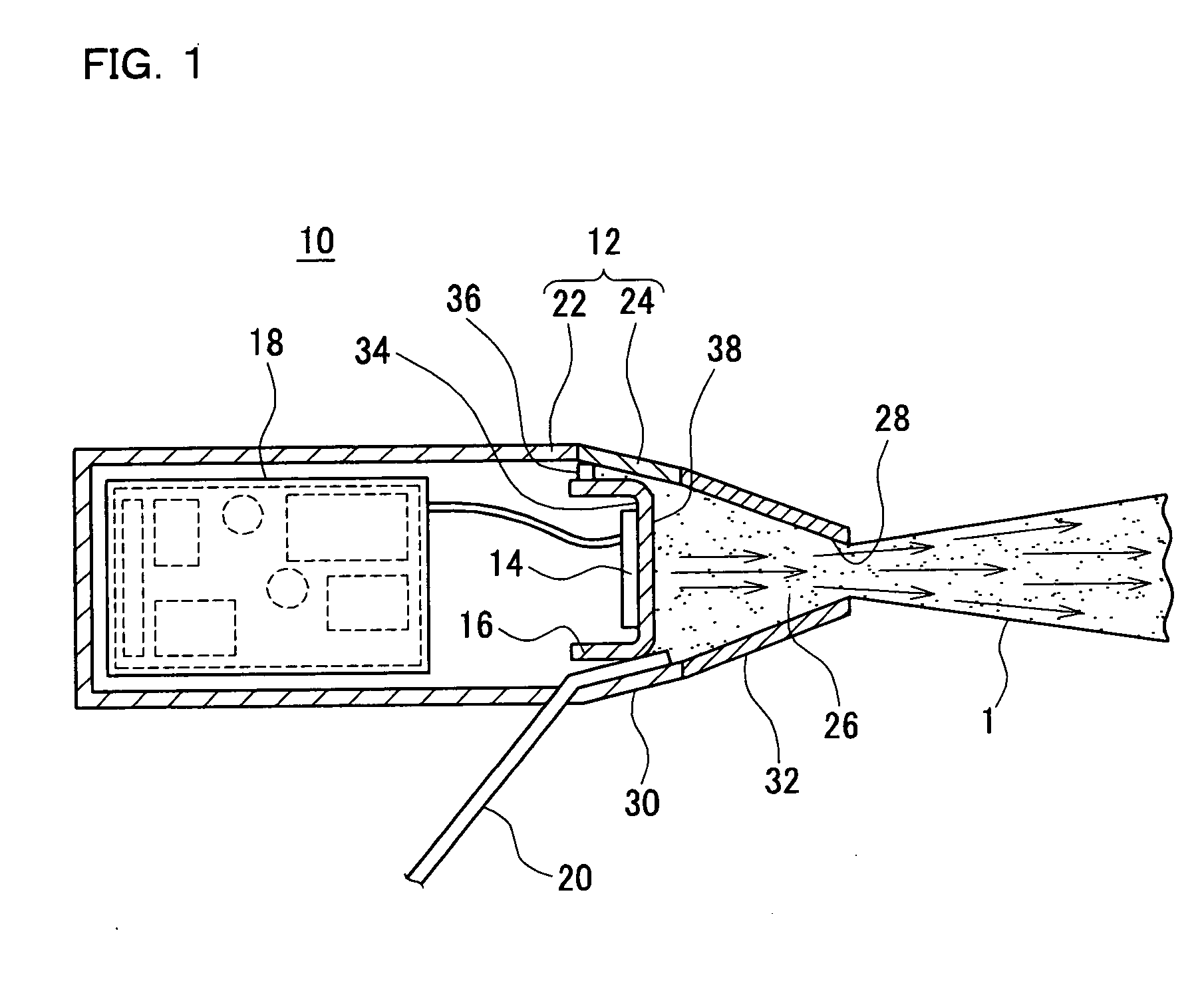

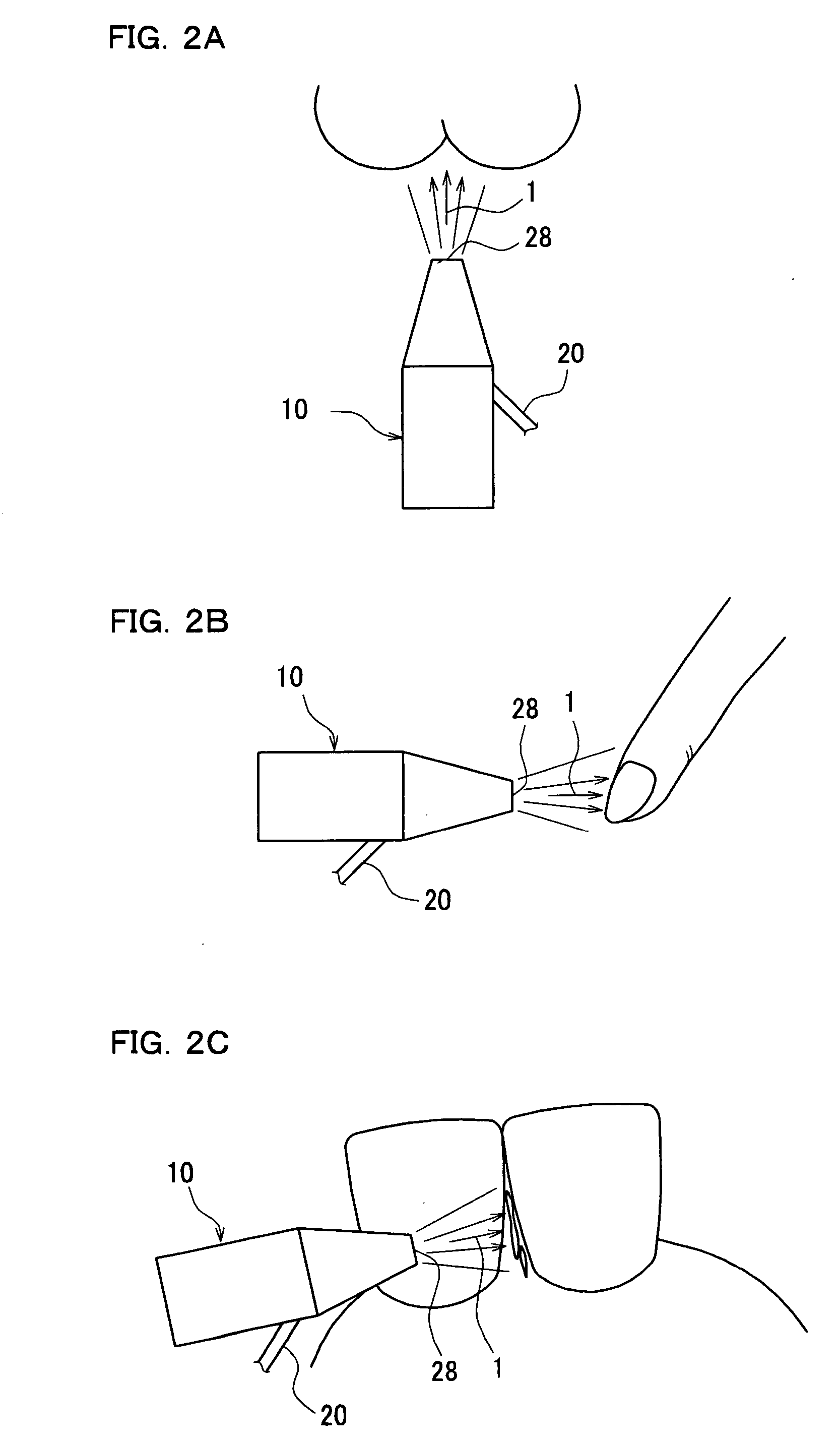

InactiveUS20060191562A1Easy to useLittle energy lossBathroom accessoriesSpray nozzlesSpray nozzleMegasonic cleaning

In an ultrasonic washer for washing by splaying washing toward an object to be washed or a portion to be washed from a front end of a nozzle, a part of an ultrasonic wave propagation member connected to an ultrasonic transducer is protruded into a cavity of the nozzle into which the washing is filled in order to propagate ultrasonic vibration generated by the ultrasonic transducer to the washing efficiently. Furthermore, the ultrasonic wave propagation member is formed so that a cross-sectional area becomes gradually smaller as approaching to the front end thereof, so that the ultrasonic vibration is converged to the end face of the ultrasonic wave propagation member. Still furthermore, a length of the ultrasonic transducer and the ultrasonic wave propagation member is made to be integral multiplication of a half-wavelength of ultrasonic standing wave oscillation, and the end face of the ultrasonic wave propagation member from which the ultrasonic wave is emitted to the washing is disposed at a position of antinode of the ultrasonic standing wave oscillation where the amplitude becomes the largest.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Medlar and red date enzyme and preparation method thereof

InactiveCN104872674AKeep natural colorImprove biostabilityNatural extract food ingredientsFood ingredient functionsRipeningHigh pressure

The invention discloses a medlar and red date enzyme and a preparation method thereof, which belong to the technical field of enzyme preparation. Multi-strain composite fungi powder is adopted as a leavening agent; the medlar and the red date are adopted as main raw materials; dietary fiber, pectin hydrolyzate, seasoner extracting liquor, Chinese herbal medicine extracting liquor, enzyme stabilizer and other multifunctional auxiliary raw materials are scientifically compounded and modified; low-temperature processing technology such as ultrasonic cleaning, cryogenic grinding, microwave-assisted high-voltage pulse electric field processing and ultrasonic ripening are mainly adopted in the whole process, so that the natural colors, the flavor, the taste and the content of the active materials of the medlar and the red date are maintained furthest, the biological stability, the non-biological stability and the biological activity of the medlar and red date enzyme are obviously enhanced, the introduction of chemical addition agent is reduced, and the juicing rate of the medlar and the red date as well as the food safety of the enzyme are improved. Finally, the medlar and red date enzyme with high biological activity, strong stability, strong taste, flavor and appetite, long expiration date and edible safety is prepared.

Owner:NINGXIA JINSHANGQI BIOTECH

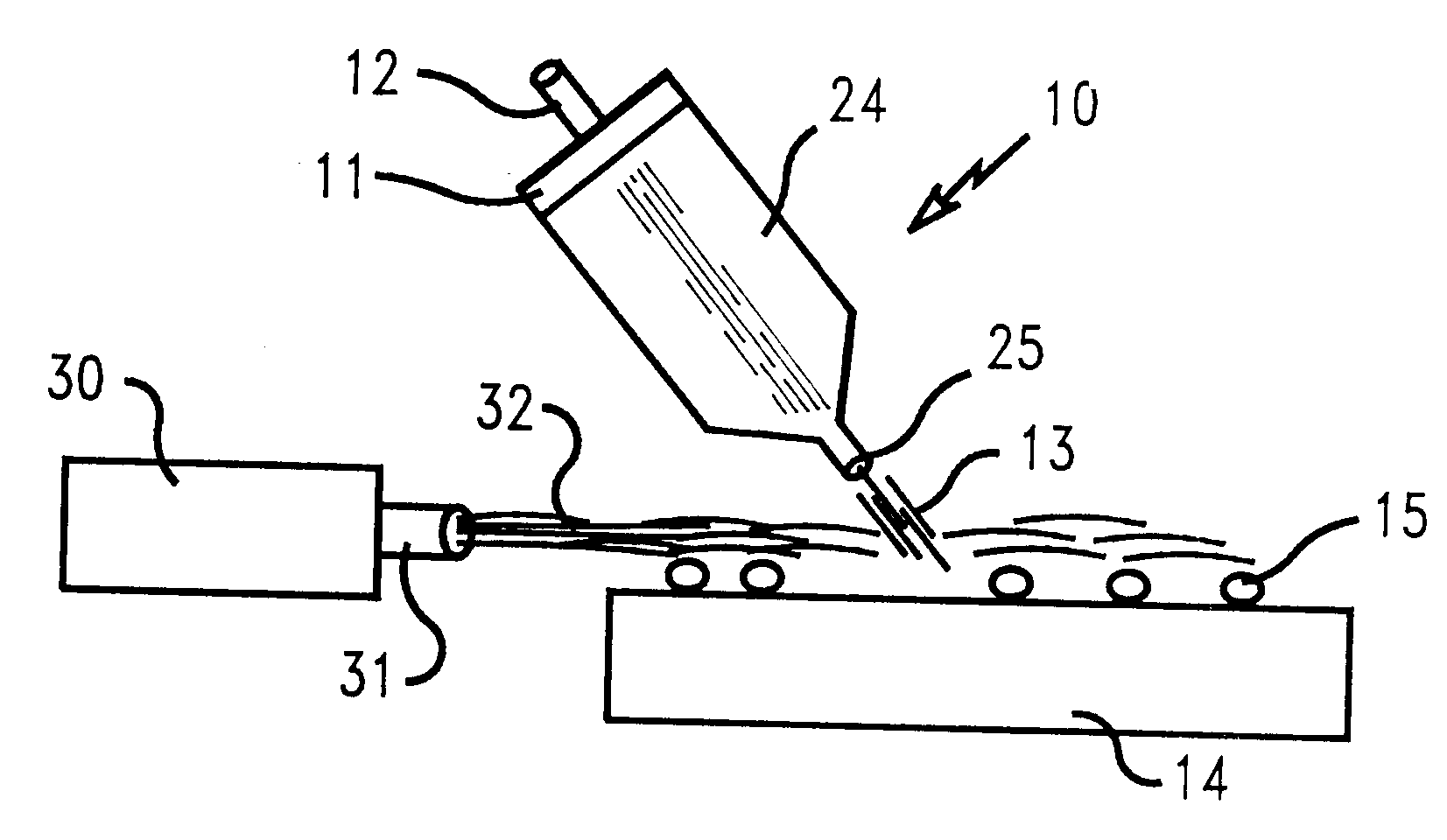

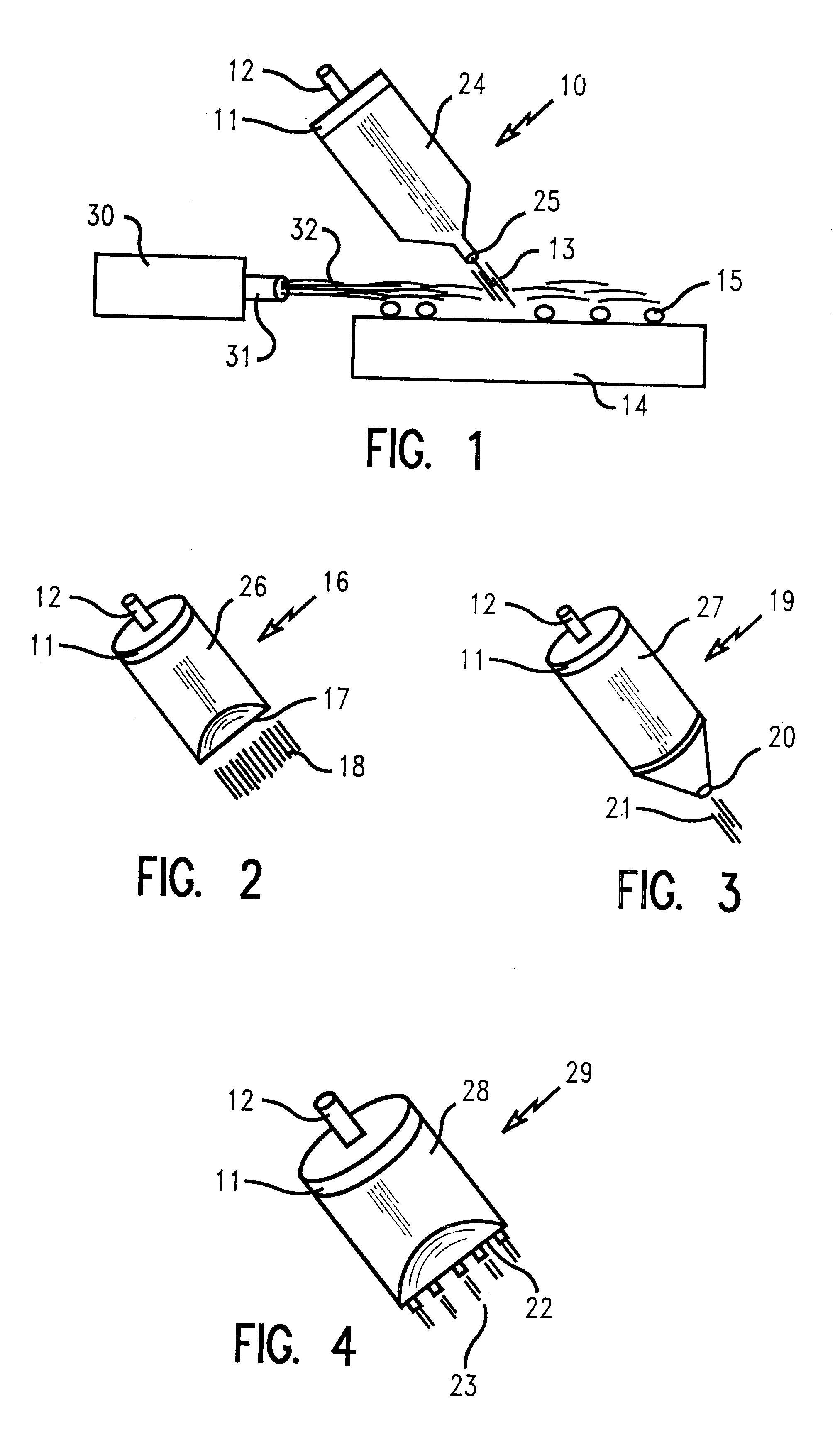

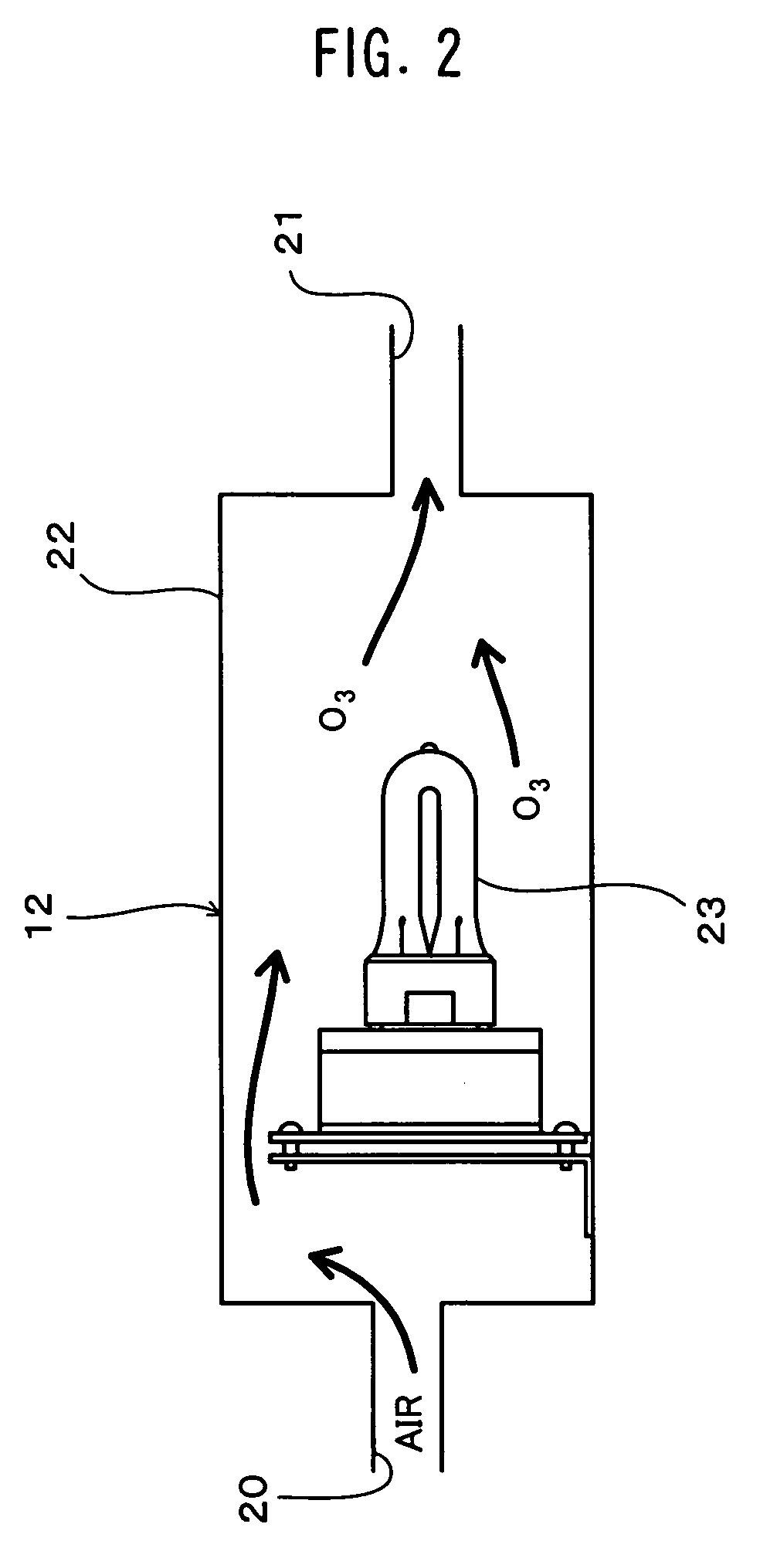

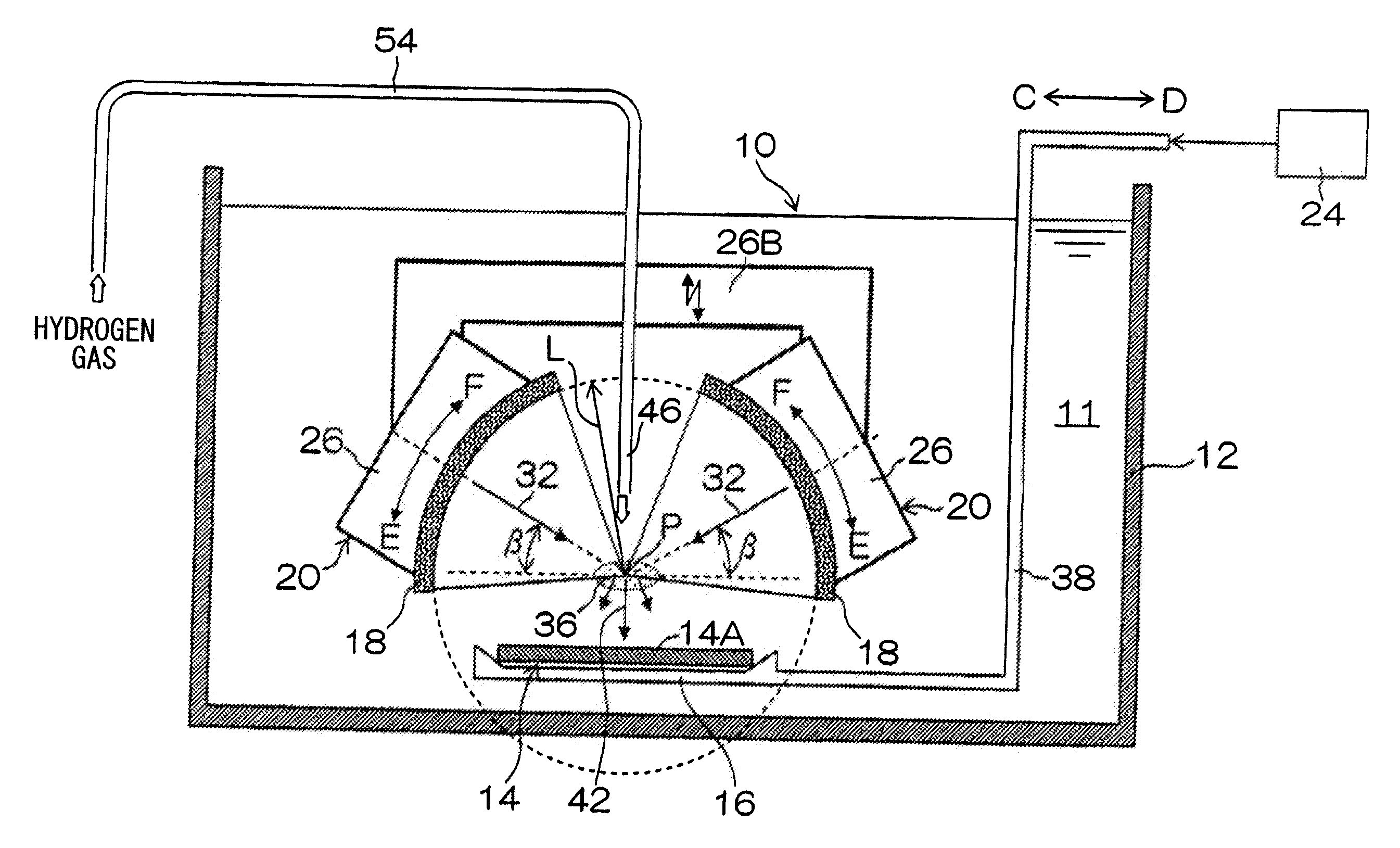

Cleaning with liquified gas and megasonics

InactiveUS6343609B1Semiconductor/solid-state device manufacturingElectrostatic cleaningAcute angleEngineering

An apparatus and method are provided for cleaning (removing) contaminating particles and / or films from substrate surfaces such as semiconductor wafers during the fabrication process for making electronic components. The method and apparatus use a liquified gas contained in a distributor which has been energized with megasonic energy in the distributor and the energized liquefied gas directed as a stream against the surface to be cleaned from an outlet distribution nozzle of the distributor. The stream is preferably impinged on the substrate surface at an acute angle. The preferred liquified gas is carbon dioxide.

Owner:IBM CORP

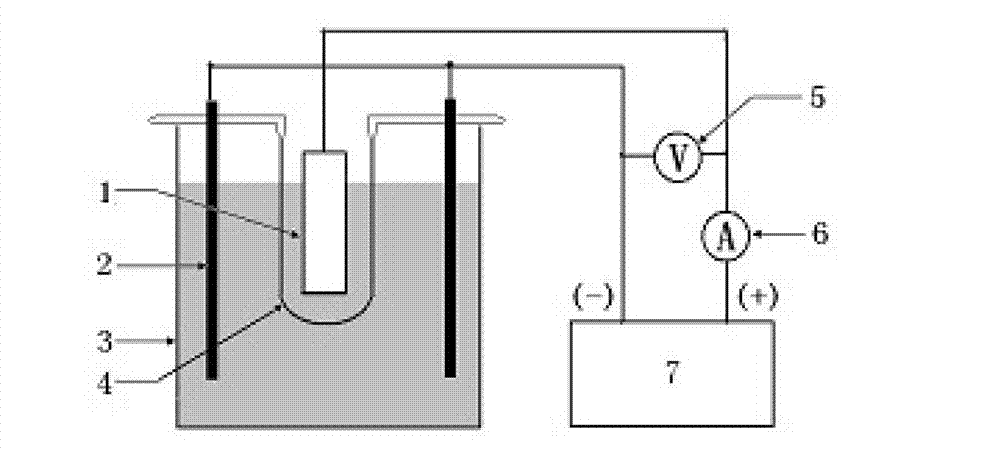

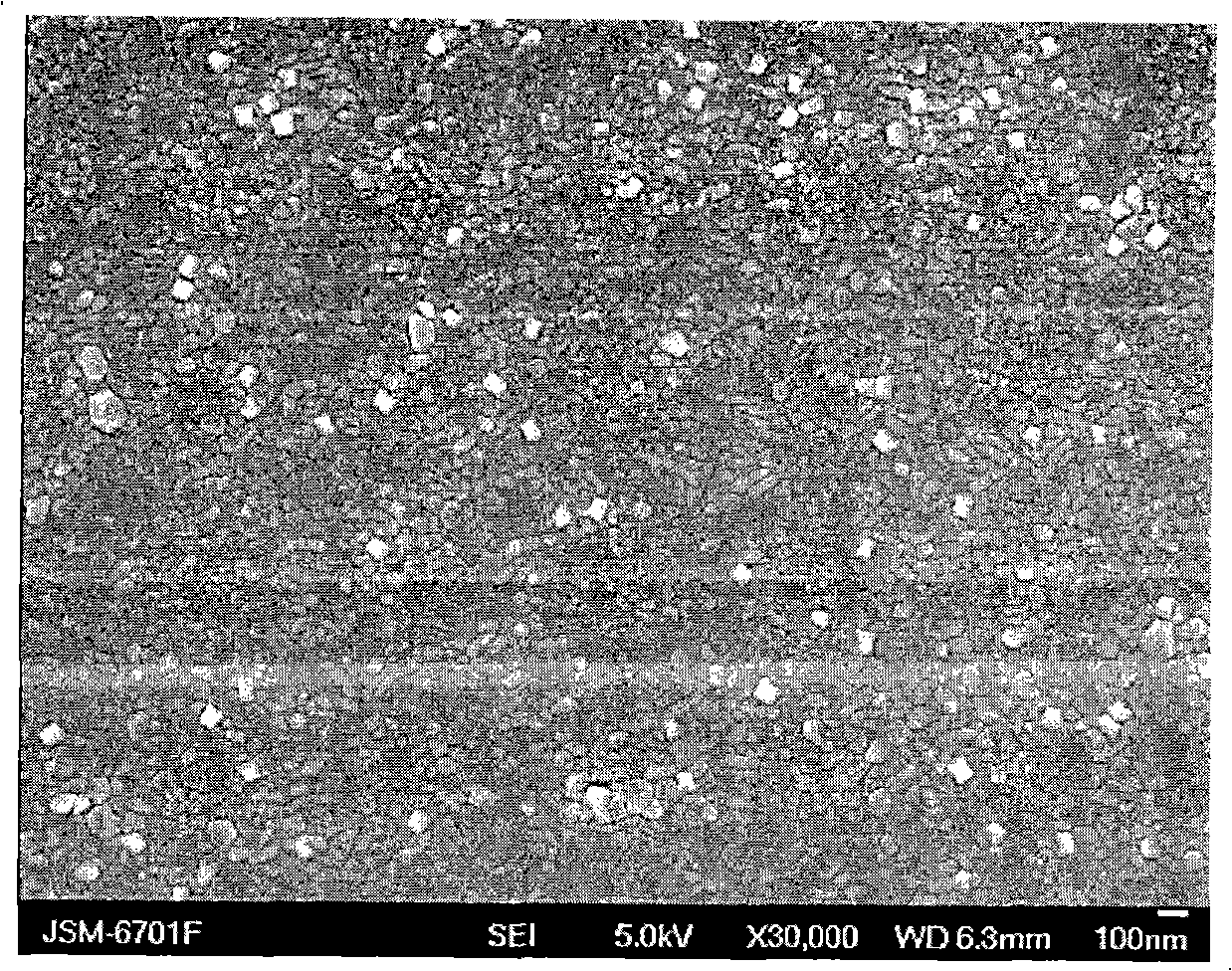

Method of electrolytically extracting and detecting fine inclusions in steel

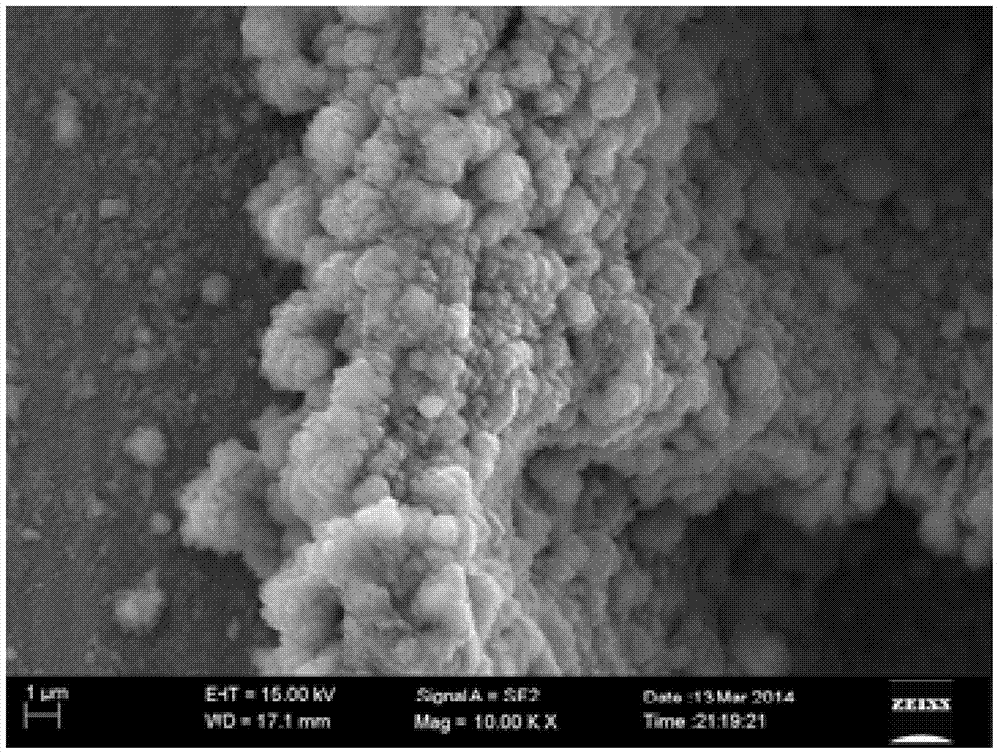

ActiveCN102818723ACollect fast and losslessAvoid lostPreparing sample for investigationTesting metalsElectrolysisScanning electron microscope

The invention discloses a method of electrolytically extracting and detecting fine inclusions in steel, belonging to the technical field of metal physical research methods. The method comprises the following technical steps of: using an organic electrolyte to carry out electrolysis on a steel sample; after electrolysis, washing the electrolyte mixed with the inclusions by absolute ethyl alcohol, and carrying out magnetic separation on the electrolyte by a magnet; separating the electrolyte after magnetic separation and collecting the inclusions by adopting a method of centrifugation by a centrifugal machine; putting the collected inclusions into a solvent easy to volatilize, carrying out ultrasonic dispersion on the inclusions by an ultrasonic cleaner, and then dripping a solution after ultrasonic dispersion on a carrier drop by drop by a trace pipette; and after the solvent volatilizes, putting the carrier which is distributed with the inclusions into a scanning electron microscope to analyze. The method has the advantages that the fine inclusions can be extracted in an undamaged way, the obtained inclusions are good in dispersion under a field of view of the scanning electron microscope, the shapes of the inclusions are perfect, and a good space statistic analysis result can be obtained so as to supply accurate data for a product.

Owner:SHOUGANG CORPORATION

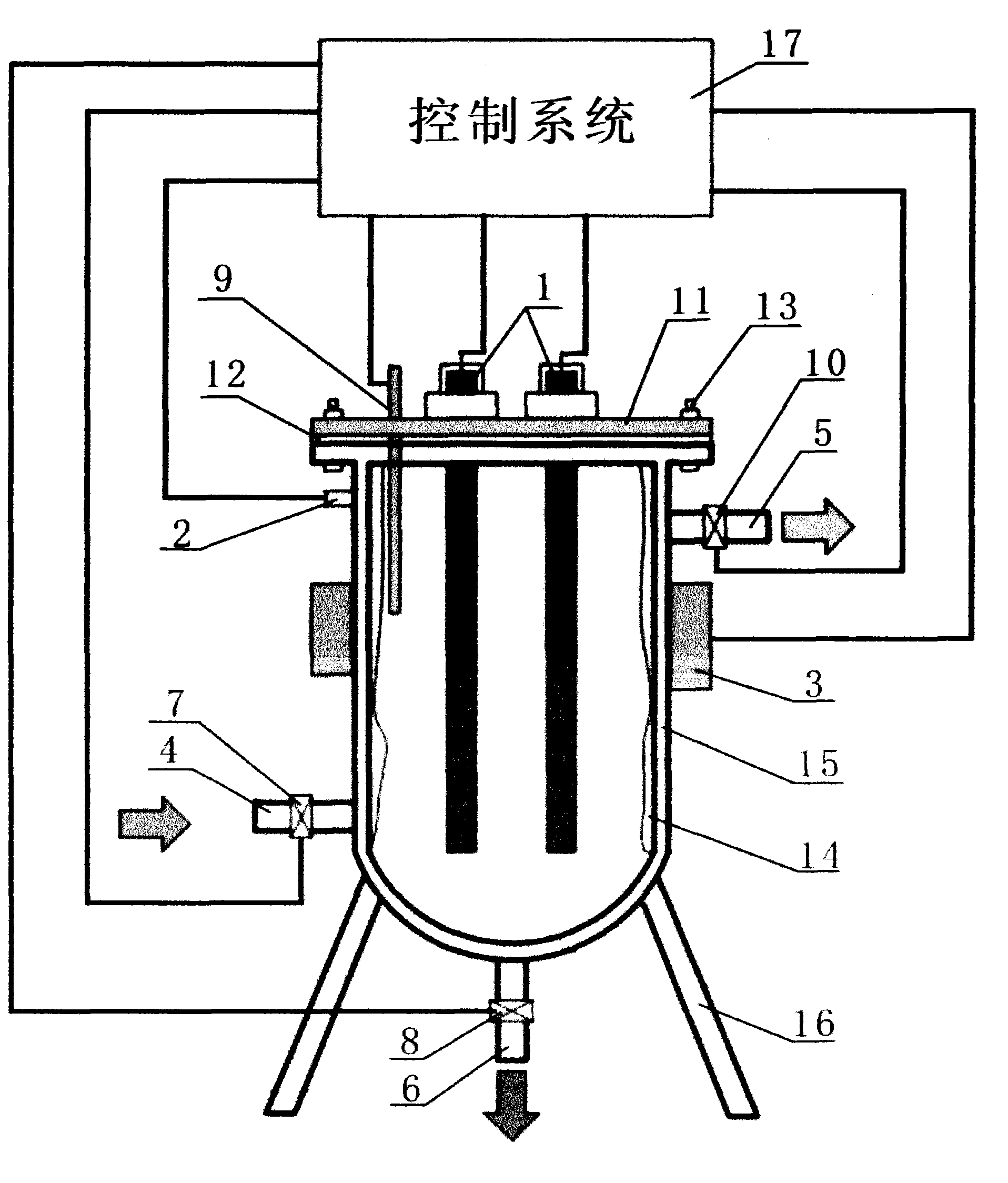

Circulating water electrolytic descaling device and descaling method thereof

InactiveCN101585569ACompact structureWater/sewage treatmentCleaning using liquidsCorrosionMegasonic cleaning

The invention discloses a circulating water electrolytic descaling device and a descaling method thereof, and belongs to the technical field of environment protection. The device comprises a reaction chamber, a water inlet, a water inlet valve, a water outlet, a water outlet valve, a drain outlet, a drain valve, an anode, a control system, an end plate and a bracket. The reaction chamber therein is provided with a test anode, the reaction chamber is made of metal materials, and the inner wall thereof is used as the cathode of an electrolytic reaction and connected with a cathode wiring terminal; the anode and the test electrode pass through the end plate and are and fixed on the end plate, the test electrode approaches the inner wall of the reaction chamber, the outer wall of the reaction chamber is coated with an epoxy resin layer and provided with an ultrasonic cleaner, the bottom of the reaction chamber is spherical or tapered, and the inner surface thereof is coated with the epoxy resin layer. The descaling method comprises an electrolytic descaling process and a cleaning descaling process. The invention uses ultrasonic waves for automatically descaling and cleaning, has the functions of automatically sterilizing, removing alage and softening water quality after descaling, has multiple functions, compact, firm and durable structure, and is suitable for sterilization, algae removal, descaling and corrosion resistance of circulating cooling water.

Owner:CHENGDU FILTRASCALE TECH

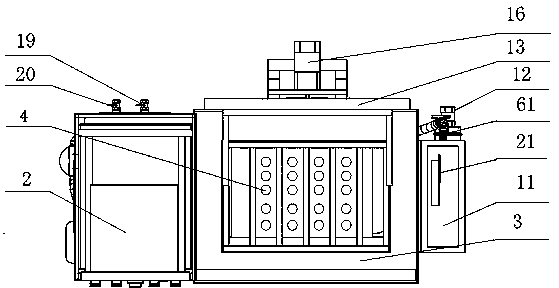

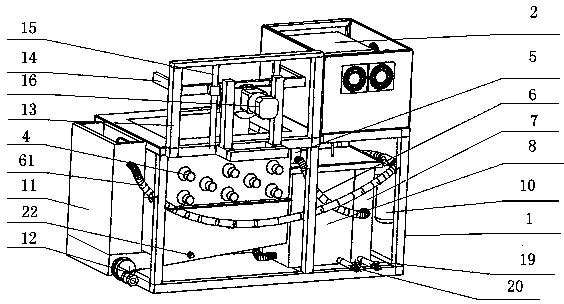

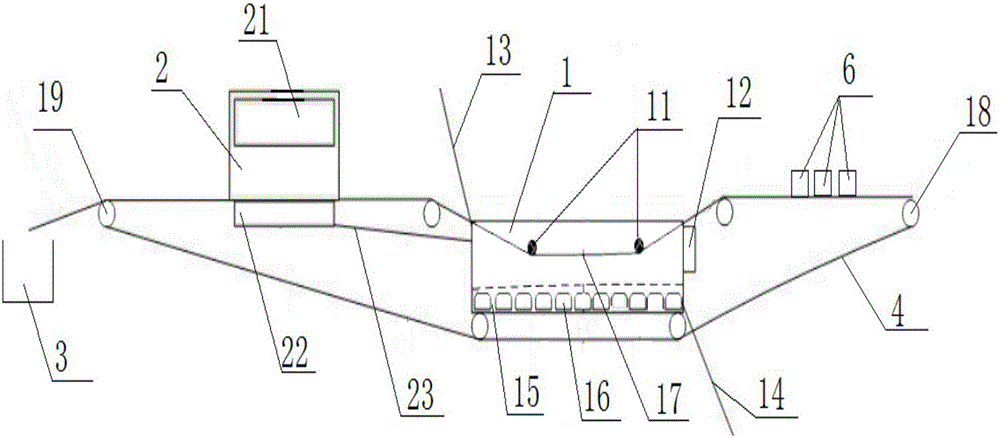

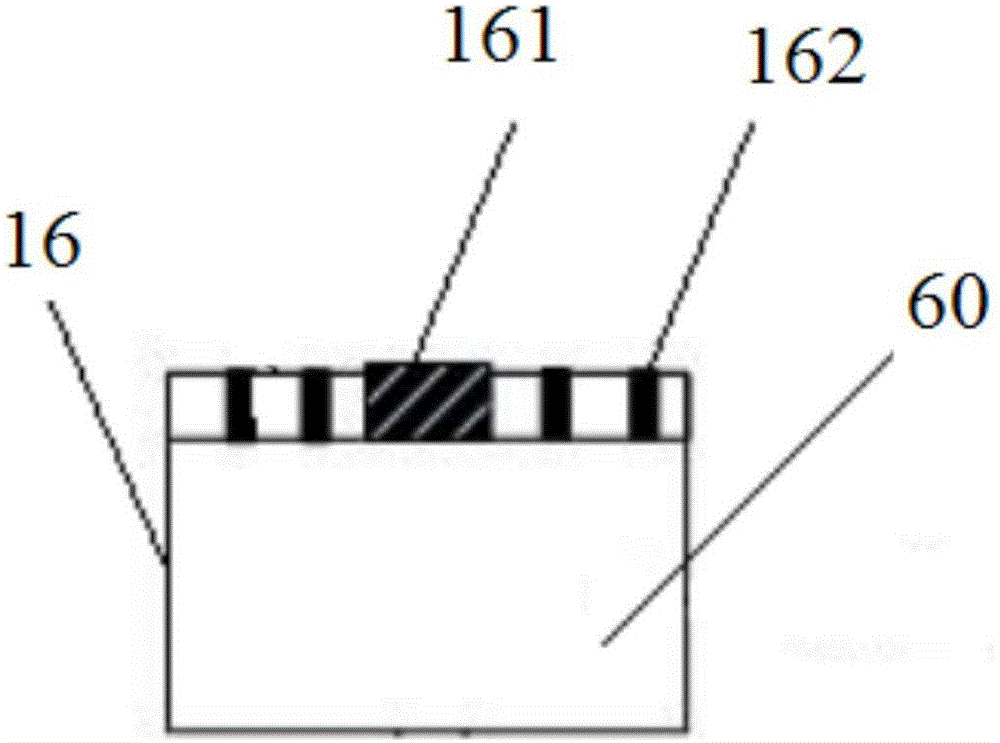

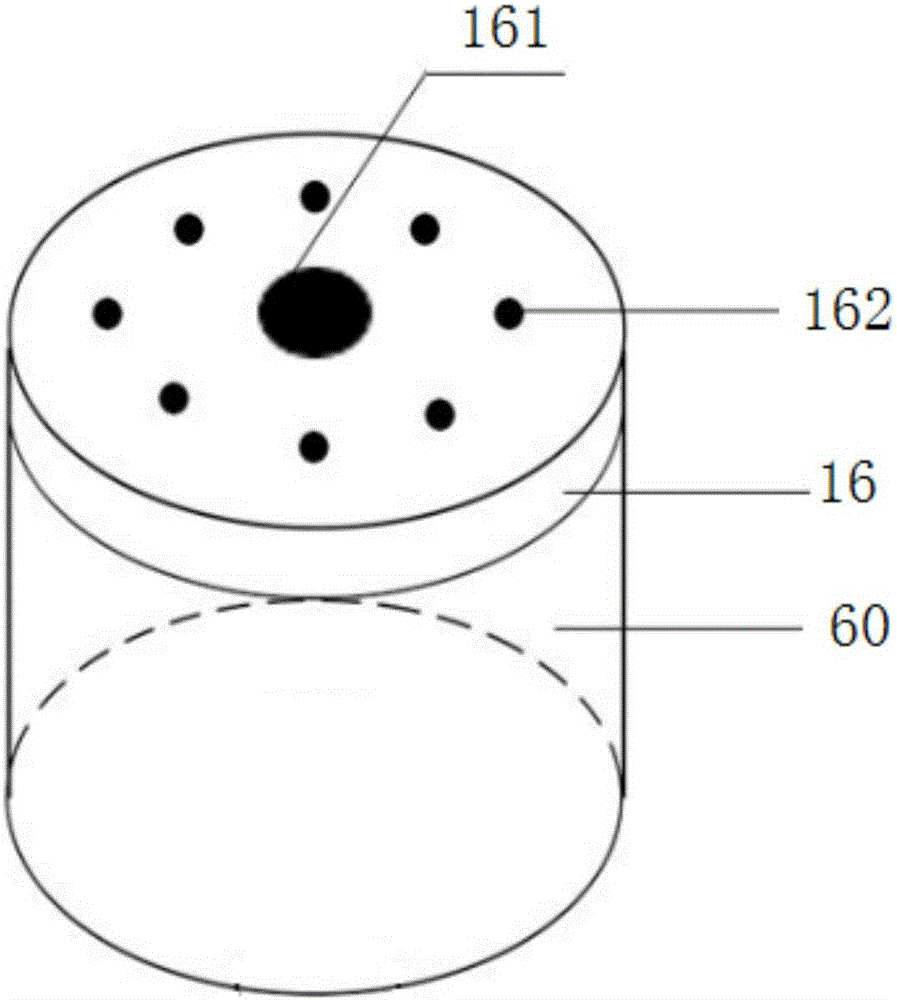

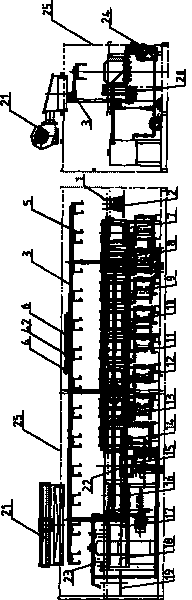

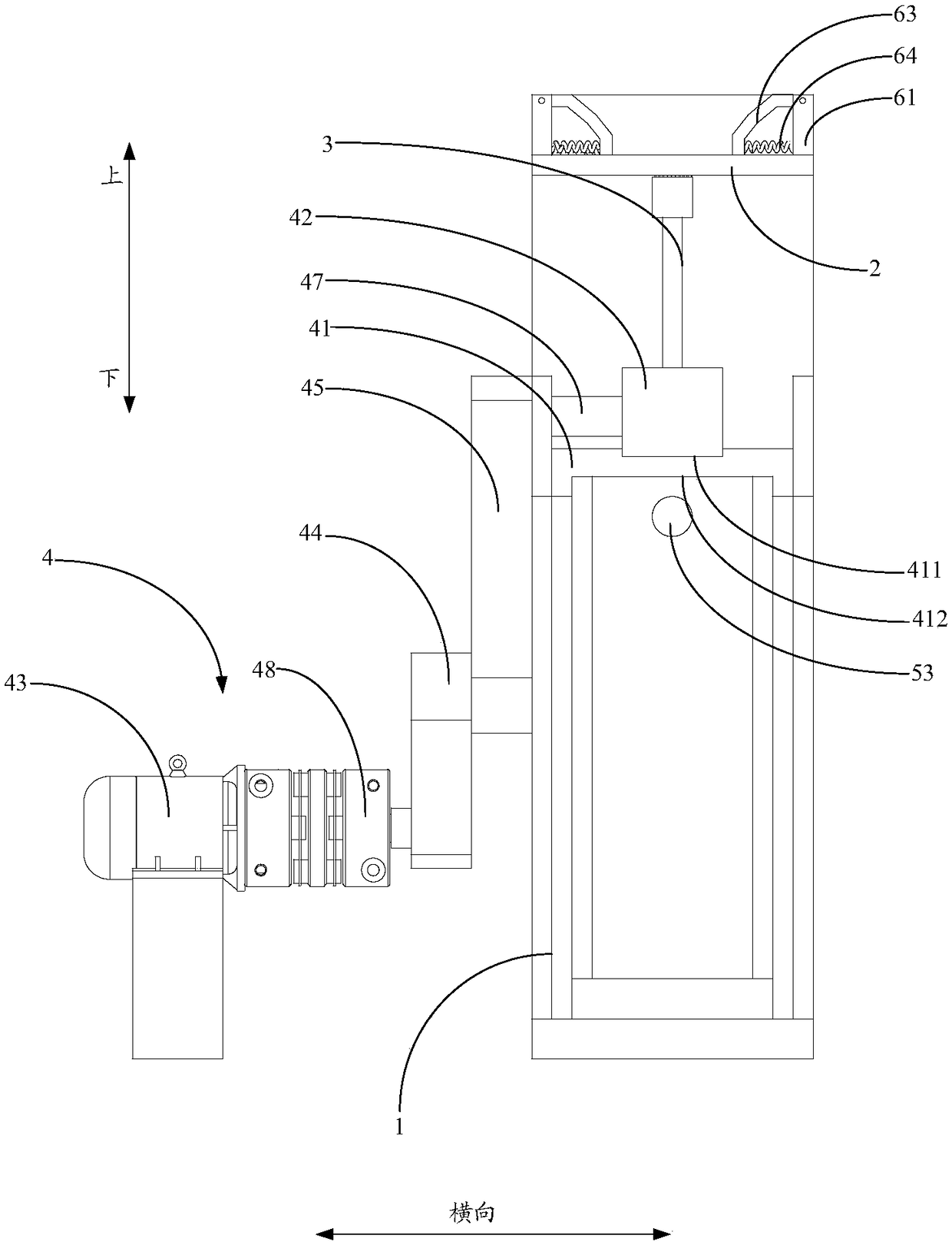

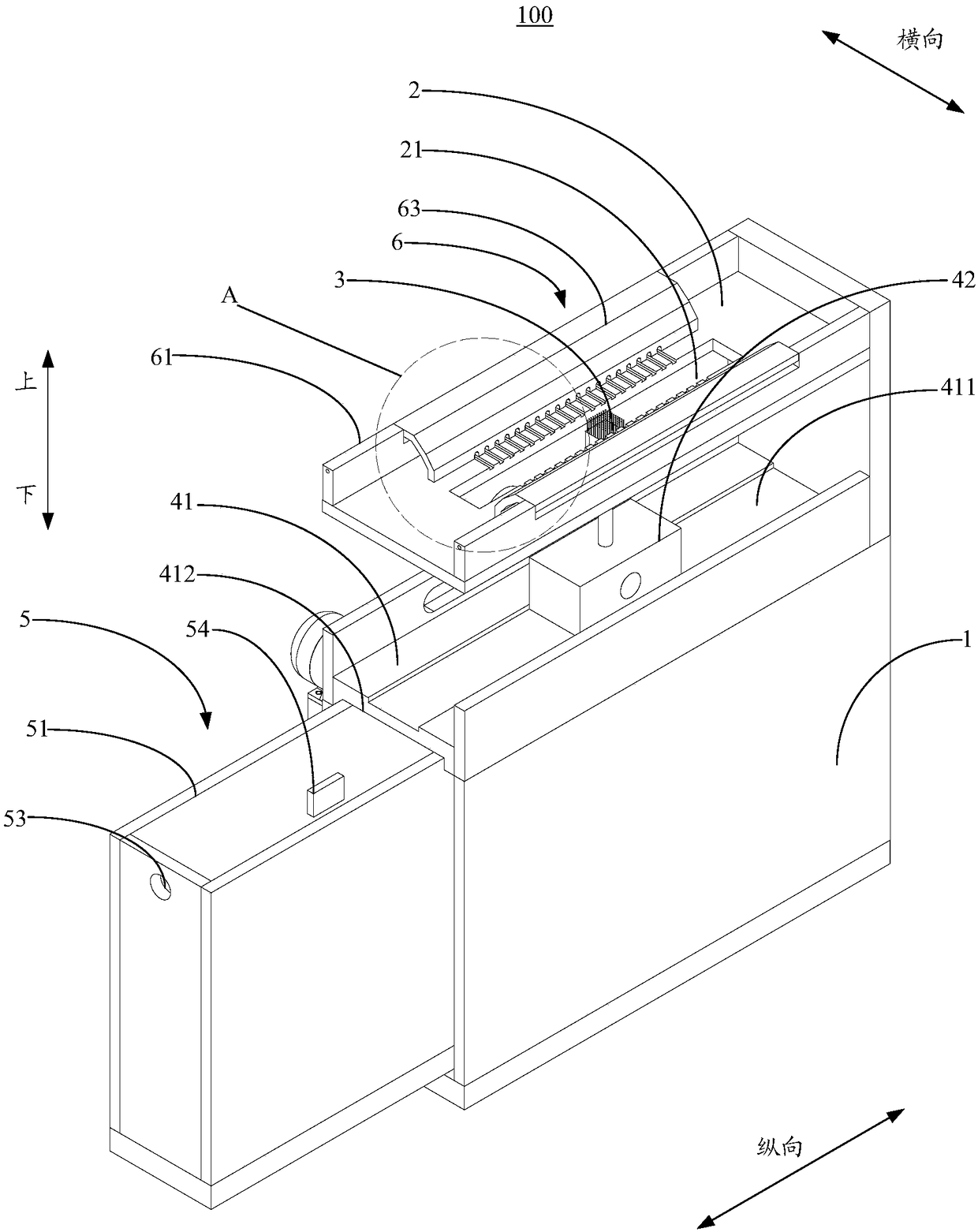

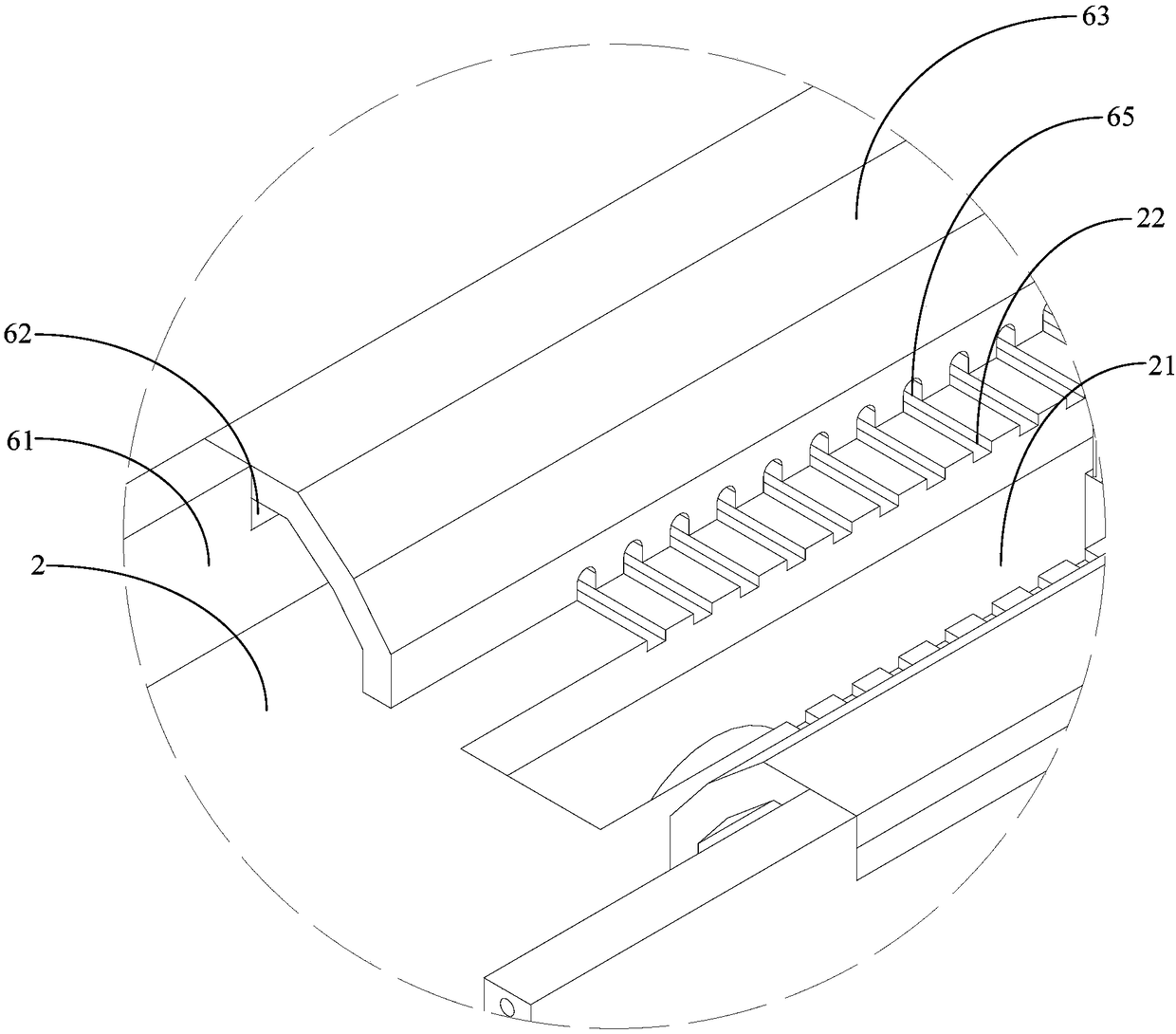

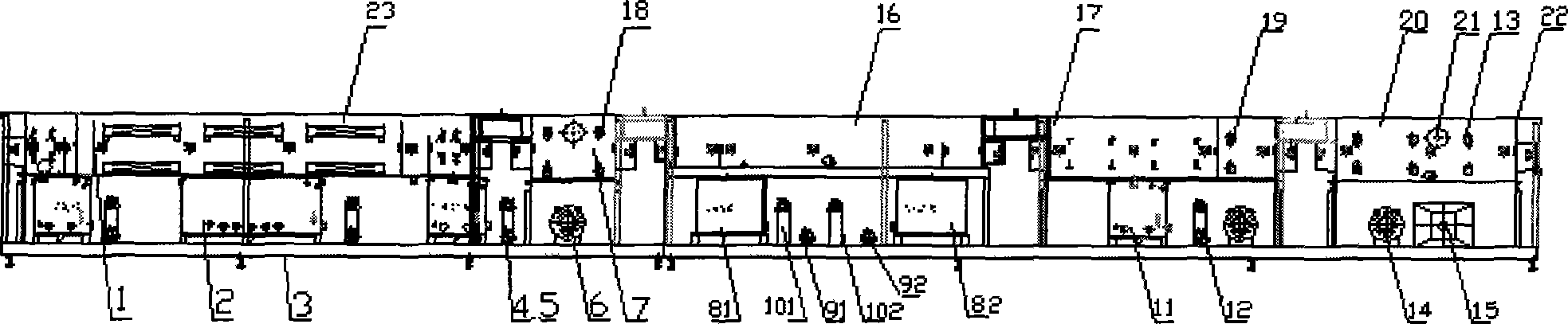

Large automatic ultrasonic dish washing machine

InactiveCN106235981AUltrasonic intensity is highBig impactTableware washing/rinsing machine detailsCleaning equipmentUltrasonic sensorEngineering

The invention discloses a large automatic ultrasonic dish washing machine. The large automatic ultrasonic dish washing machine comprises an ultrasonic washing tank, an air-drying tank and a collecting tank in sequence from front to back. The ultrasonic washing tank is internally provided with ultrasonic emitting head devices and a driving device, and the driving device is connected with the ultrasonic emitting head devices and used for driving the ultrasonic emitting head devices to work. Each ultrasonic emitting head device comprises an ultrasonic transducer and a high pressure air nozzle which enables input high pressure air to form bubbles in a cleaning fluid, each ultrasonic transducer is used for providing energy for the cleaning fluid, the bubbles in the cleaning fluid are broken to produce an impact force, and the impact force is utilized for washing dishes to be washed. The large automatic ultrasonic dish washing machine is simple and exquisite in structure and is used for washing dishes and the like; the high pressure gas is introduced, the strength of ultrasonic waves produced by the emitting head devices is high, the impact force and friction force of the ultrasonic waves produced by breaking of the bubbles are large, no surfactant or detergent is needed, the effect is good, and environmental protection and sanitation are achieved.

Owner:曾仲林 +1

Efficient vegetable cleaning machine

The invention discloses an efficient vegetable cleaning machine. The efficient vegetable cleaning machine comprises a cleaning machine main body, a cleaning barrel and a cleaning brush layer, wherein a cover board is arranged on the upper surface of the cleaning machine main body, the left end of the cover board is fixedly connected with the inner wall of the upper side of the cleaning machine main body through a rotating shaft, a liquid inlet pipe is arranged at the right end of the upper side of the cleaning machine main body, and the cleaning barrel is horizontally arranged in the center in the cleaning machine main body. According to the efficient vegetable cleaning machine disclosed by the invention, motors drive the cleaning barrel horizontally arranged to rotate so as to turn over and clean vegetables, and besides, the rotating shaft drives the cleaning brush layer to rotate backwards to scour the vegetables, so that the cleaning effect and the cleaning efficiency of the cleaning machine are greatly improved; in addition, ultrasonic cleaning and spraying of cleaning liquid are used for cleaning the vegetables, so that the cleaning efficiency is further improved, and sanitation and hygiene of the vegetables are ensured; the cleaning machine can freely and conveniently move, so that the convenience and the practicality are high; springs can effectively reduce the vibration of a machine body, so that the mechanical stability of the machine body is improved; in addition, when the cleaning machine works, the noise is small.

Owner:苏晓玲

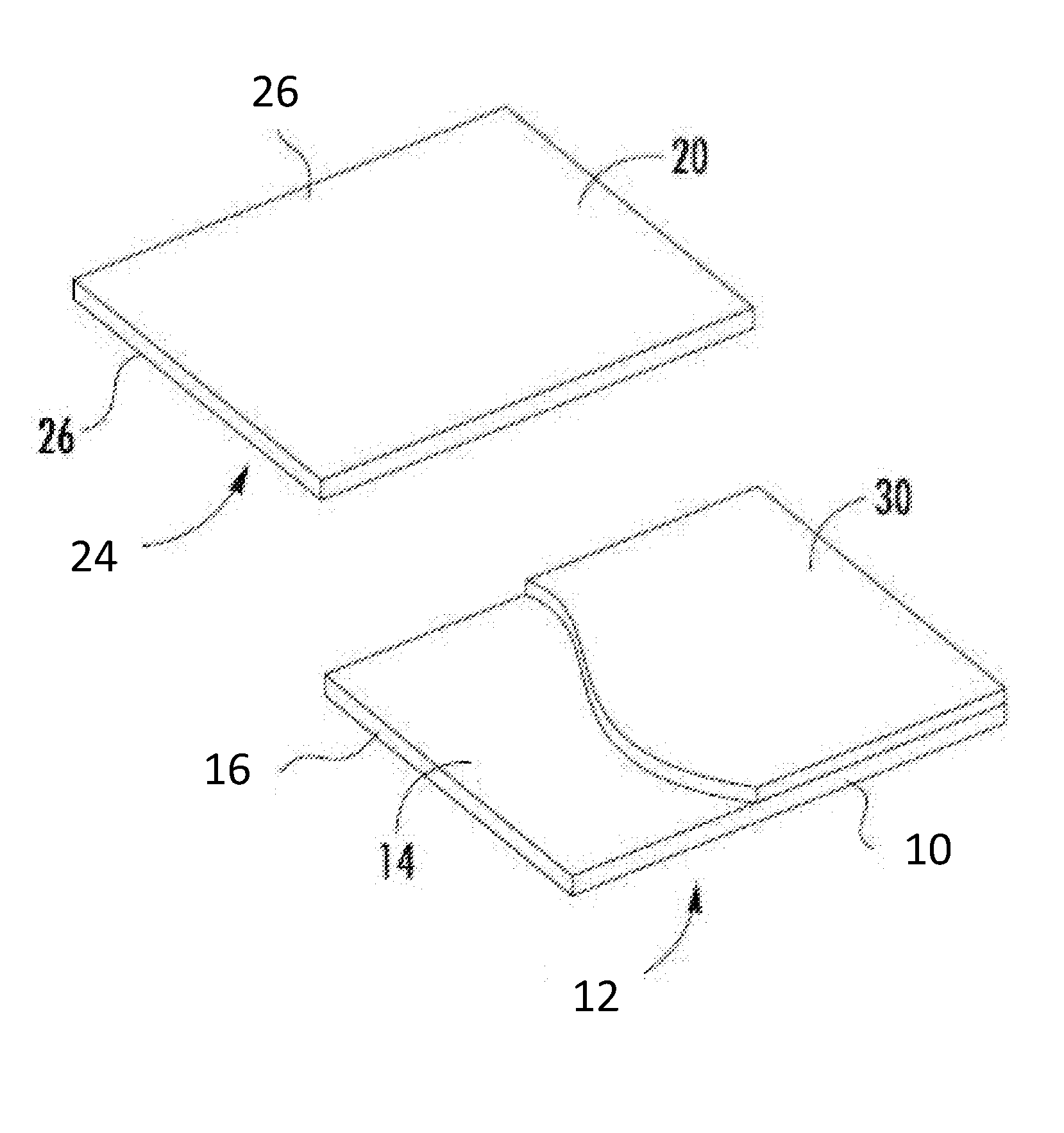

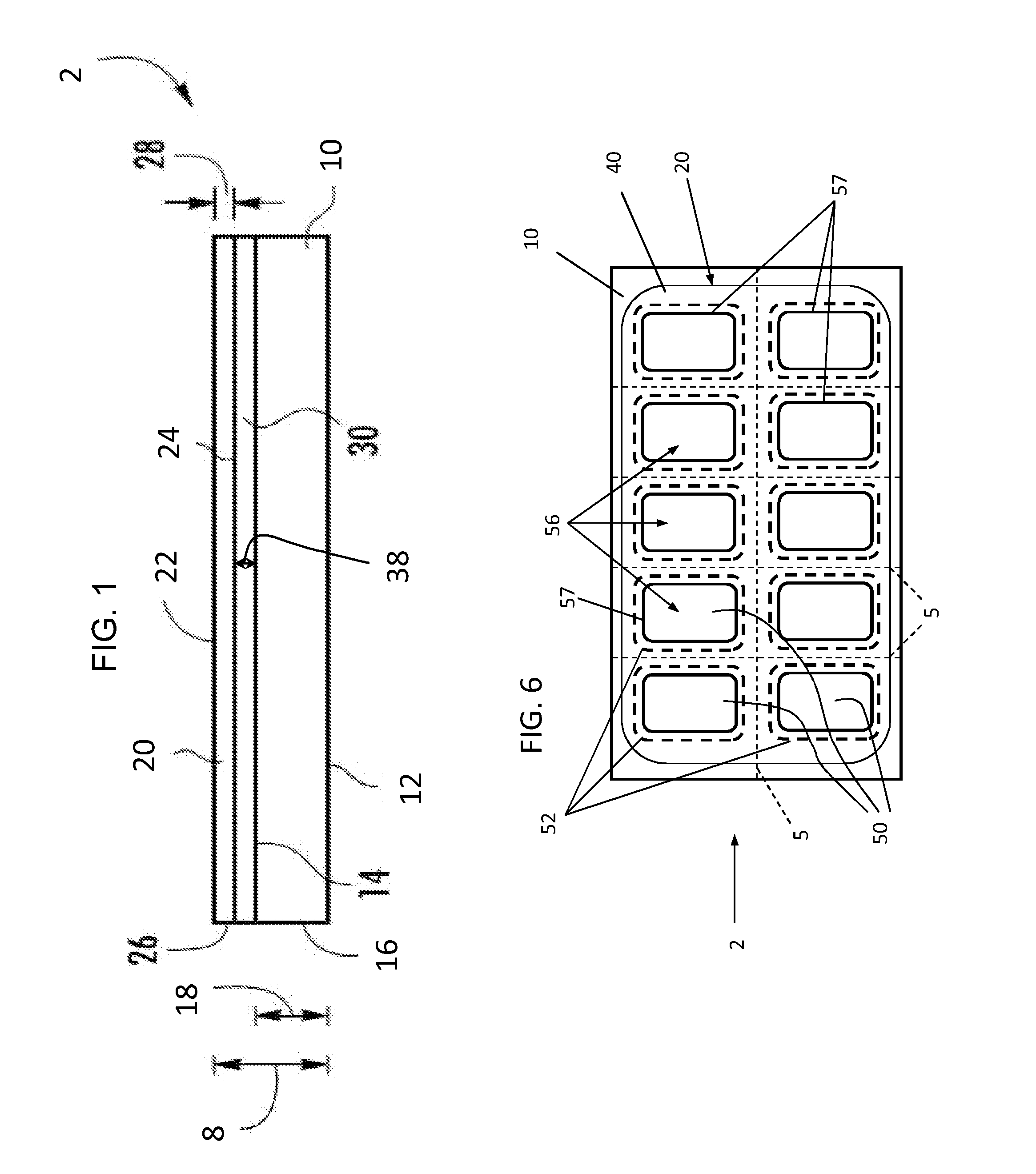

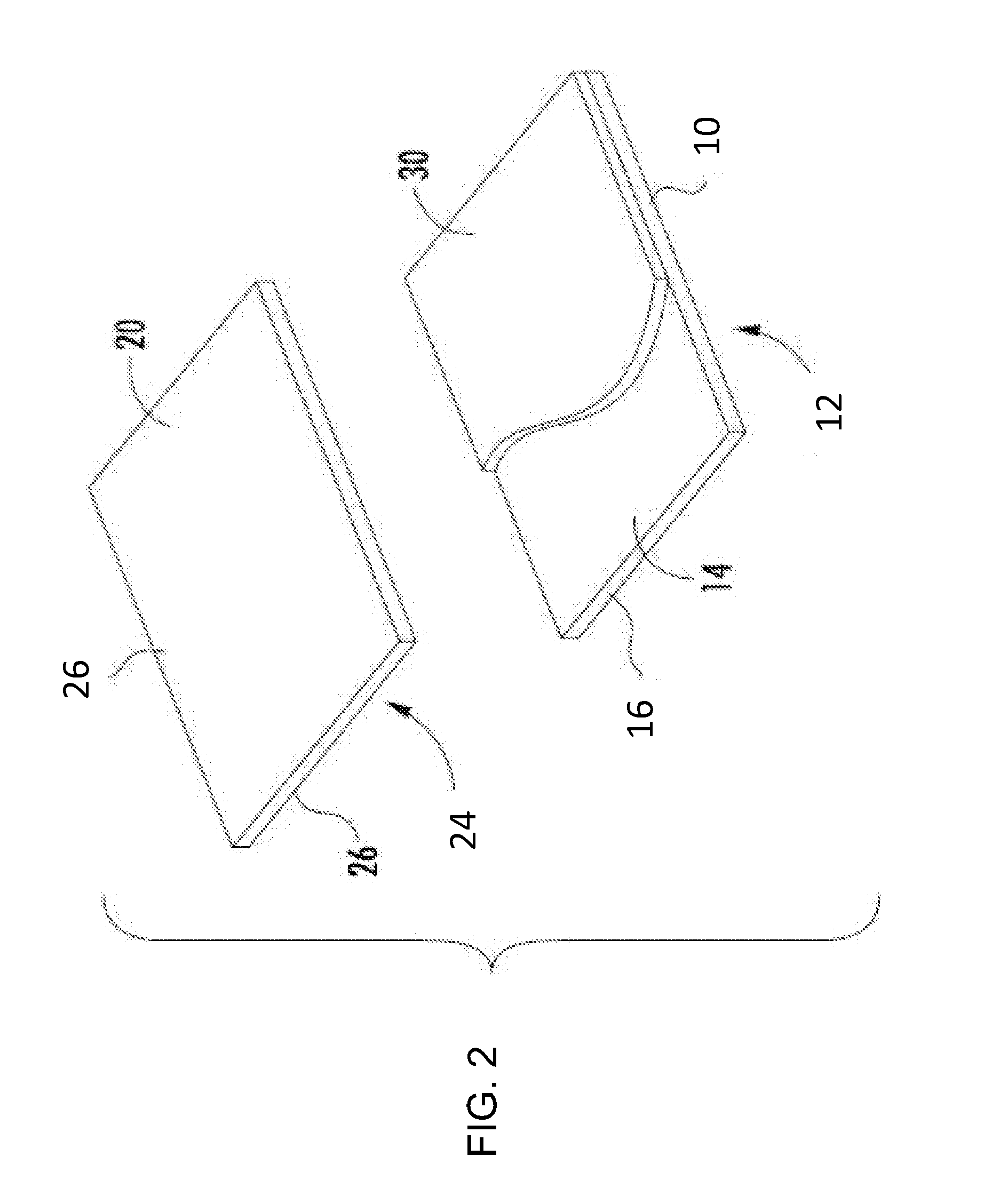

Glass and methods of making glass articles

InactiveUS20150329415A1Liquid surface applicatorsSynthetic resin layered productsMegasonic cleaningRoom temperature

Surface modification layers (30) and associated heat treatments, that may be provided on a sheet (20), a carrier (10), or both, to control both room-temperature van der Waals (and / or hydrogen) bonding and high temperature covalent bonding between the thin sheet and carrier. The room-temperature bonding is controlled so as to be sufficient to hold the thin sheet and carrier together during vacuum processing, wet processing, and / or ultrasonic cleaning processing, for example. And at the same time, the high temperature covalent bonding is controlled so as to prevent a permanent bond between the thin sheet and carrier during high temperature processing, as well as maintain a sufficient bond to prevent delamination during high temperature processing.

Owner:BELLMAN ROBERT ALAN +4

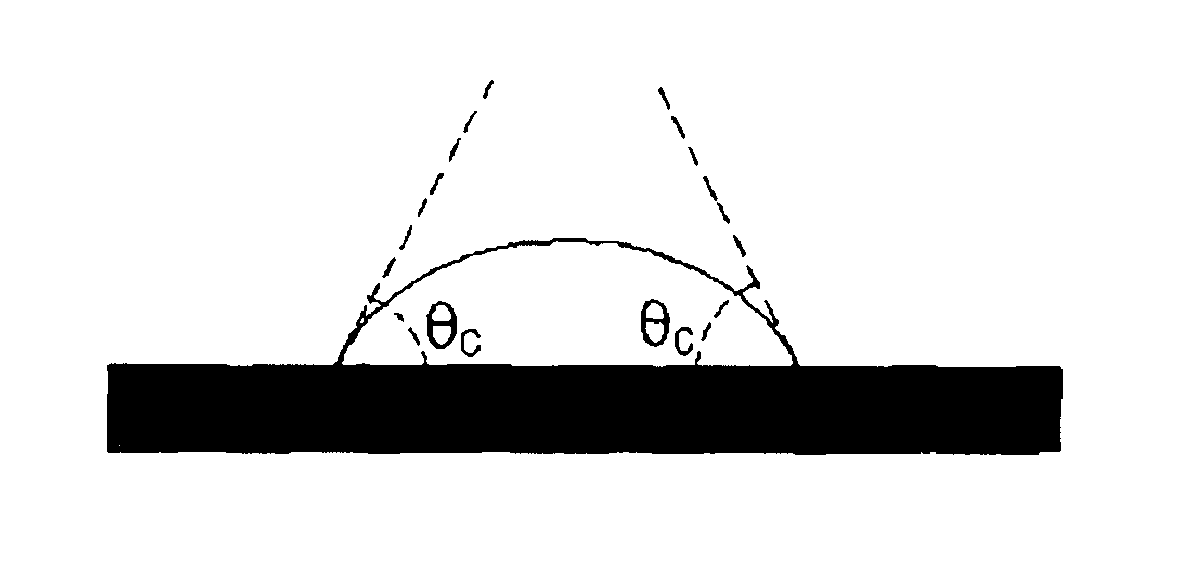

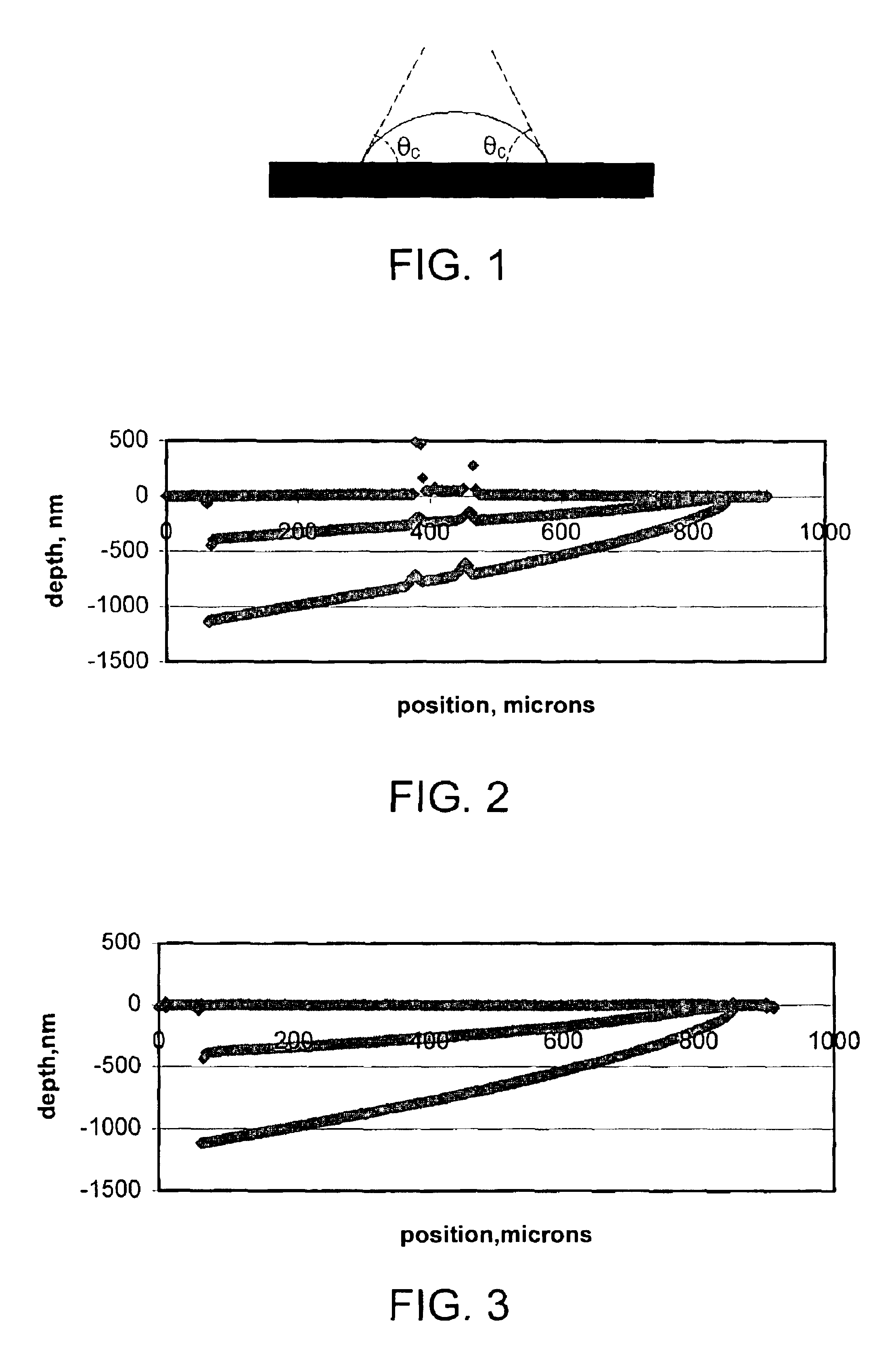

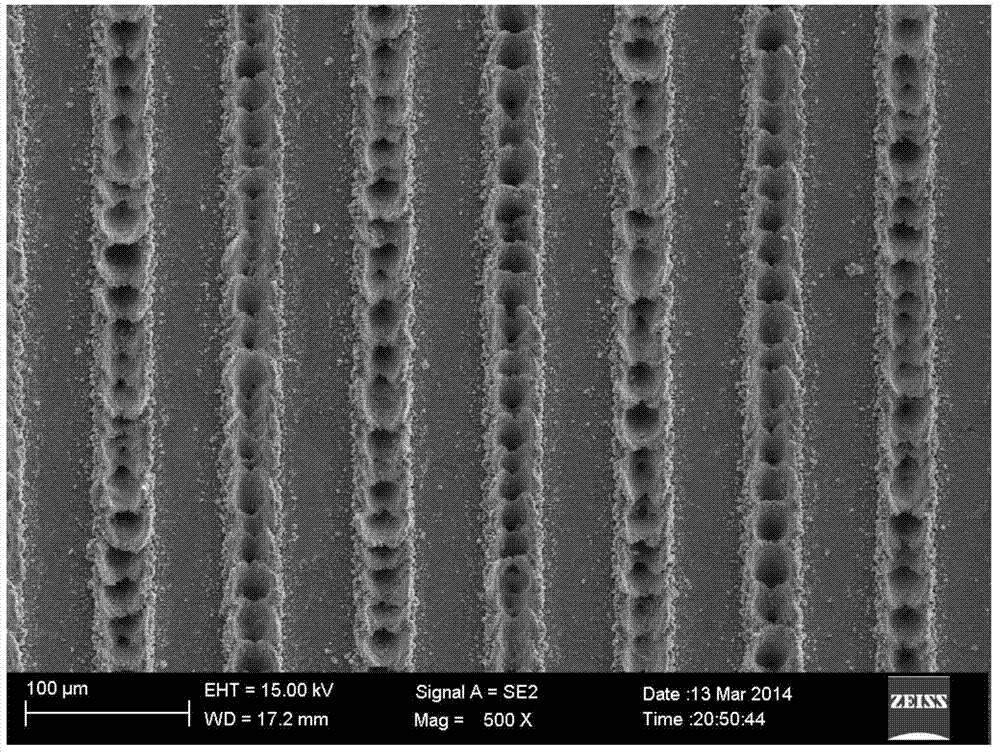

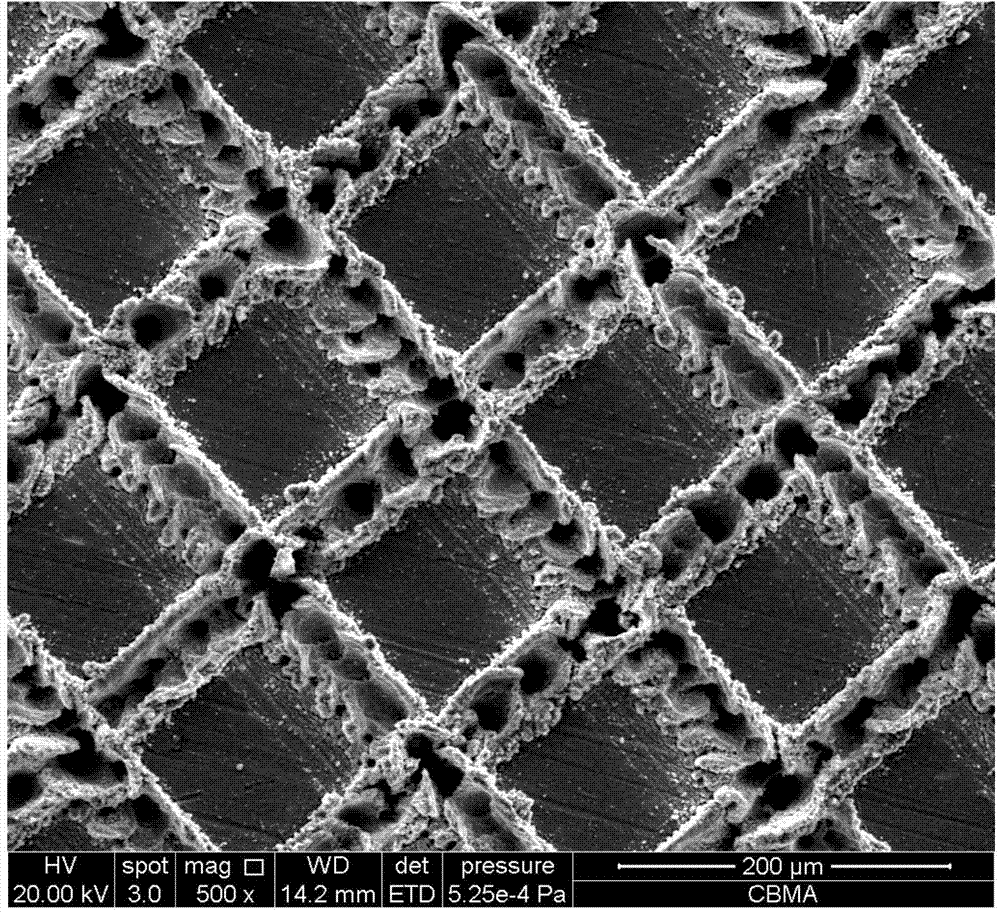

Preparation method of super-hydrophobic micro-nano structure on titanium alloy surface

The invention provides a preparation method of a super-hydrophobic micro-nano structure on a titanium alloy surface. The preparation method comprises the following steps: performing ultrasonic cleaning on a titanium alloy sample respectively with acetone and anhydrous alcohol, to obtain a titanium alloy sample with a clean surface; performing femtosecond laser photoetching processing on the surface of the titanium alloy sample with the clean surface, to obtain the titanium alloy sample with the surface having the super-hydrophobic micro-nano structure in one step, wherein a femtosecond laser beam is fixed and perpendicular to the surface of a processed material, the single pulse energy of the femtosecond laser beam is 100mu J-800mu J, the pulse width is 100fs-500fs, the central wavelength is 500nm-1000nm, the repetition frequency is 500Hz-2kHz, and the size of the etched facula of the femtosecond laser beam is 0.5mum-300mum; the surface of the titanium alloy sample moves relative to the etched facula of the femtosecond laser beam along the three-dimensional directions x, y and z, the motion positioning precision in x and y directions is 50nm-100nm, and the motion positioning precision in z direction is 5nm-10nm.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

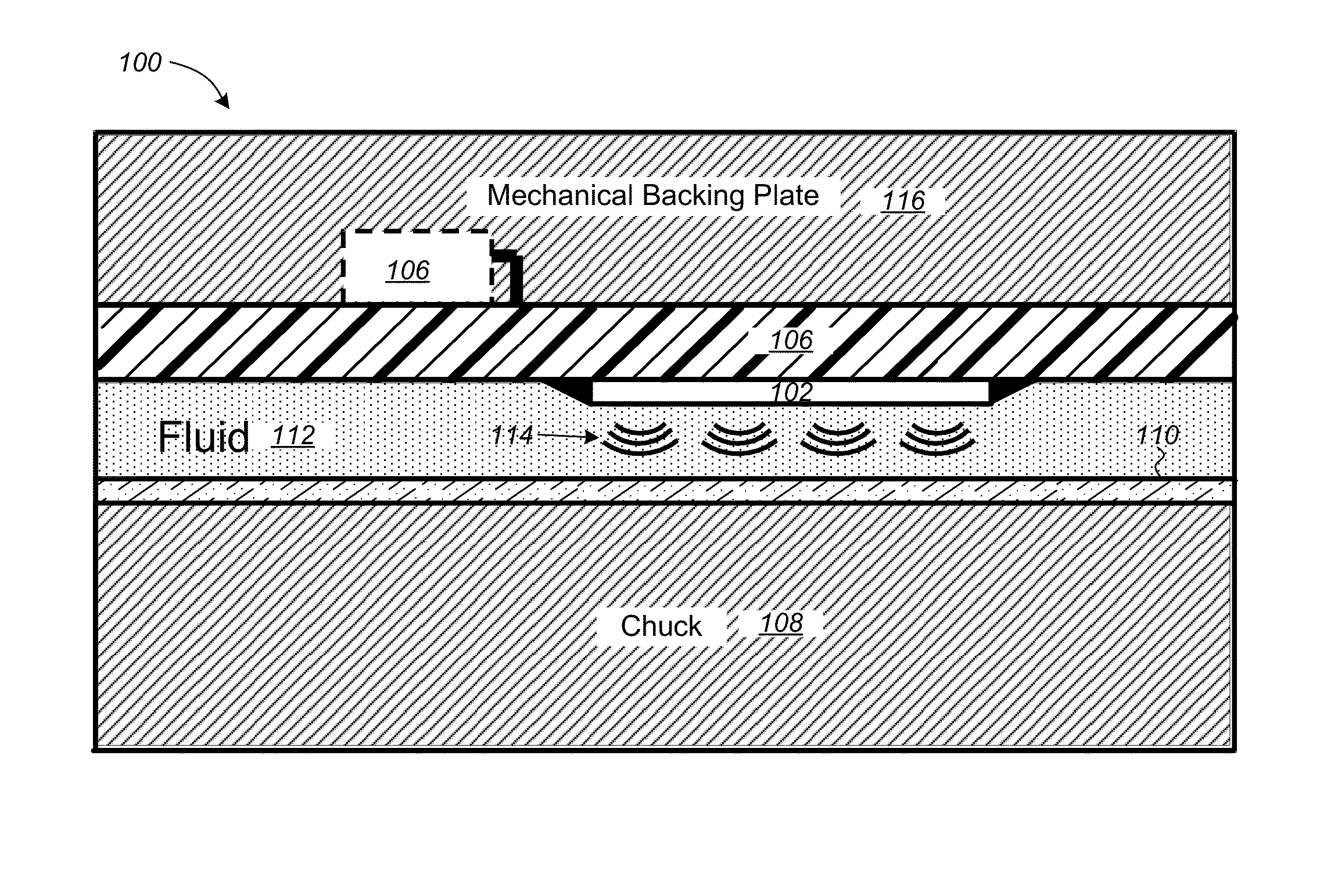

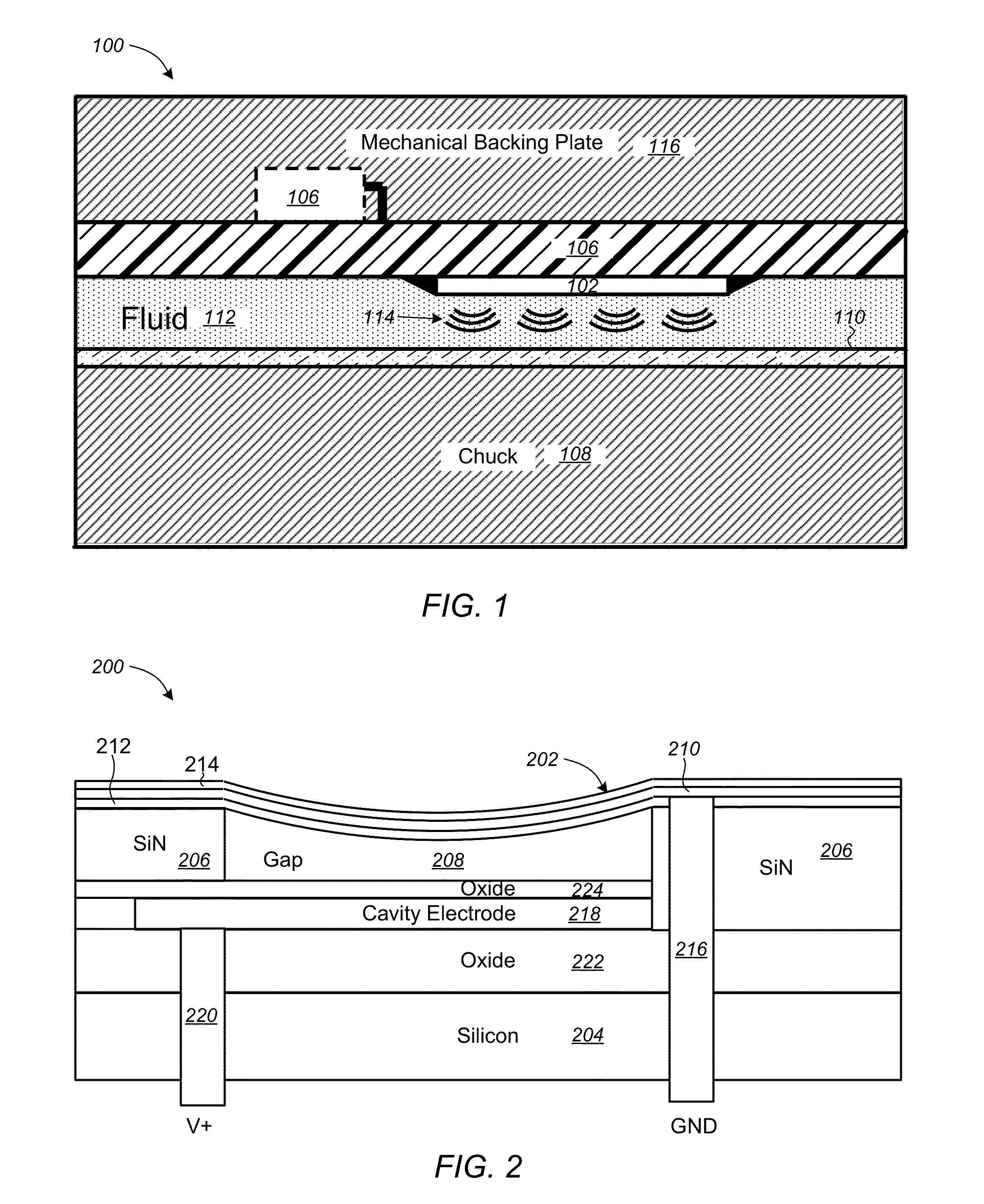

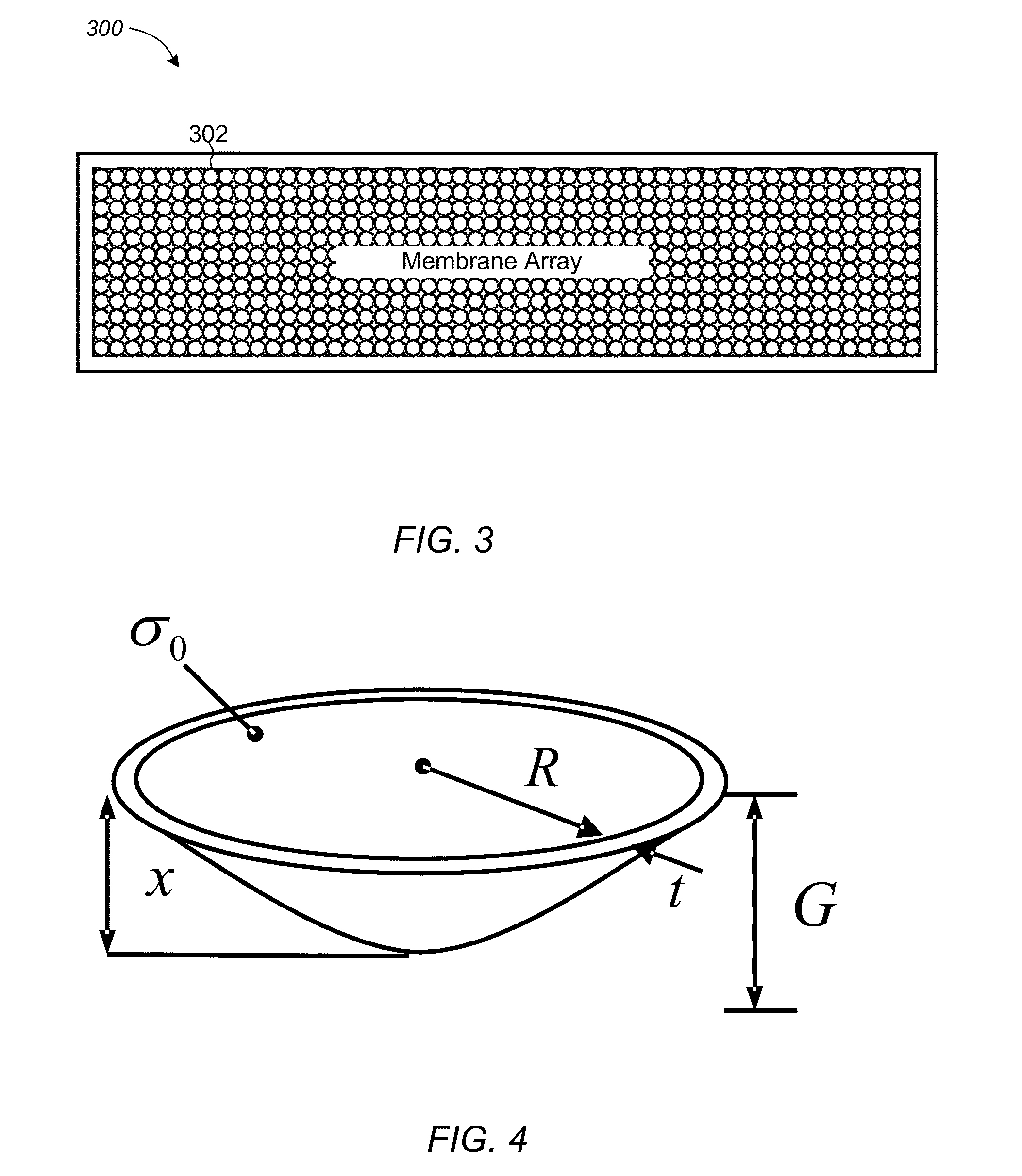

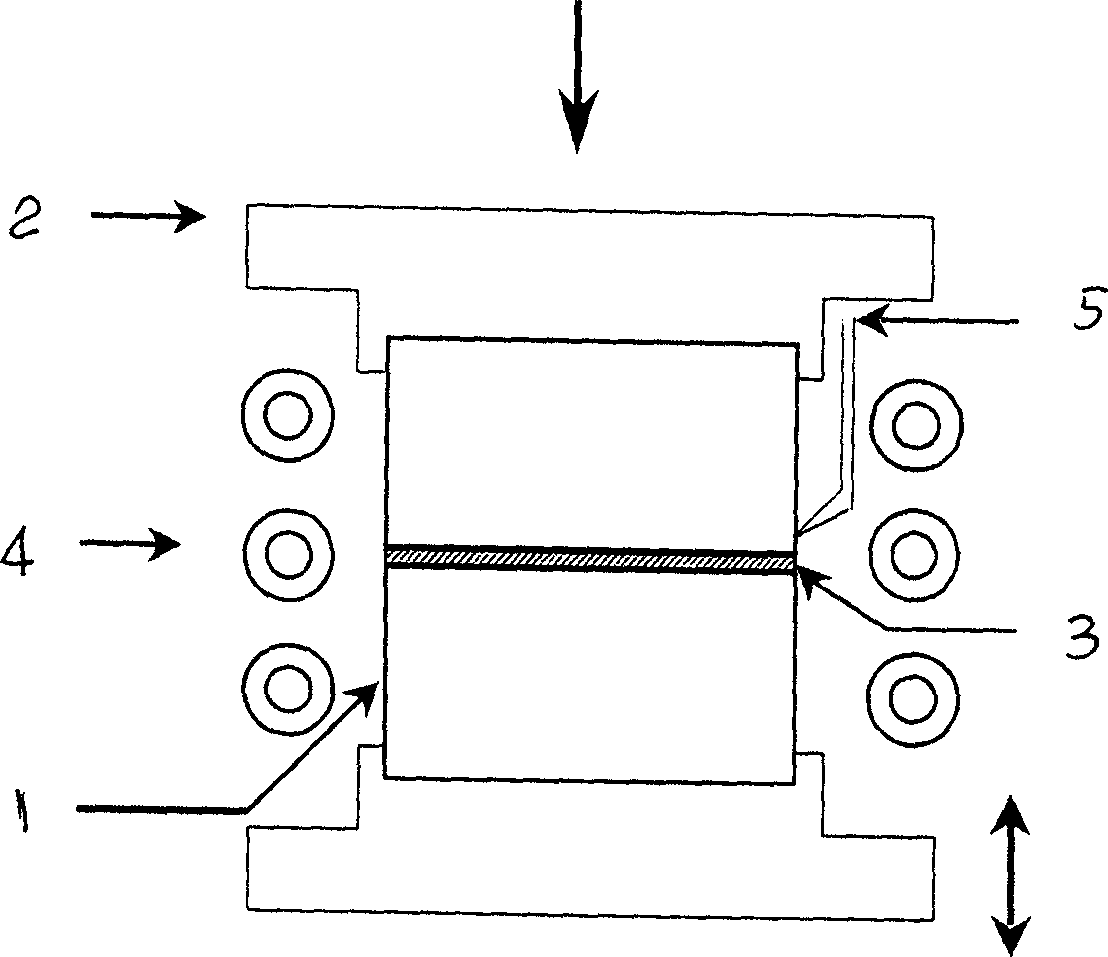

Microelectromechanical system megasonic transducer

ActiveUS8957564B1Piezoelectric/electrostriction/magnetostriction machinesElectrostatic cleaningUltrasonic sensorMegasonic cleaning

Megasonic cleaning systems and methods of fabricating and using the same are provided. In one embodiment, the system comprises a plurality of Micro-Electromechanical System (MEMS) transducers, each transducer including a movable membrane with a membrane electrode coupled to a first potential disposed above and spaced apart from an upper surface of a die including a cavity electrode coupled to a second potential, the membrane including multiple layers including a polysilicon layer between a top silicon nitride layer and a bottom silicon nitride layer, and the membrane electrode includes the polysilicon layer; a chuck on which a target workpiece is positioned; and a fluid to couple sonic energy from the plurality of MEMS transducers to the target workpiece. Other embodiments are also provided.

Owner:SILICON LIGHT MACHINES CORP

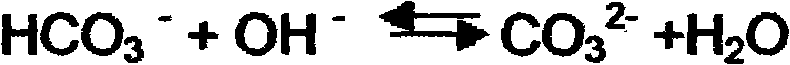

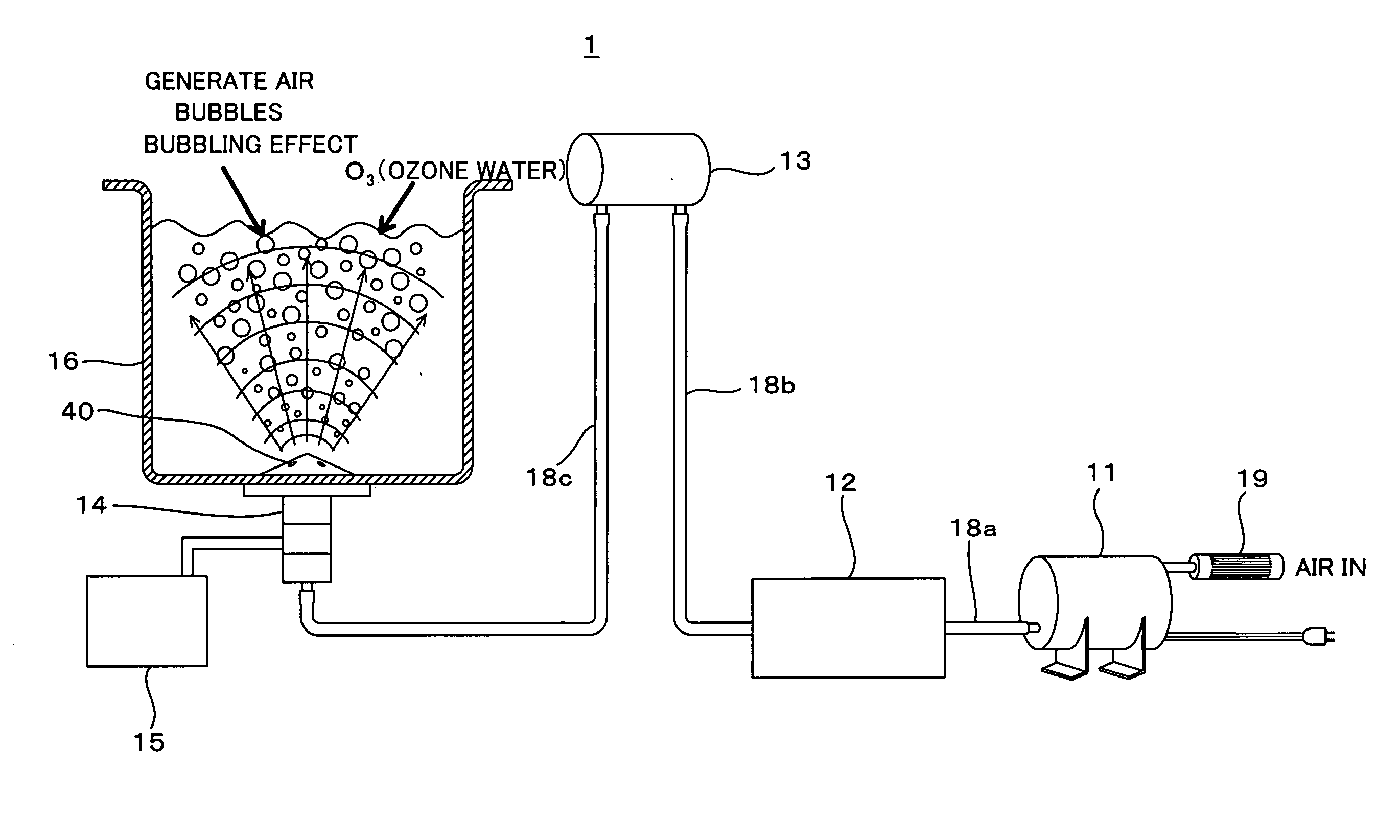

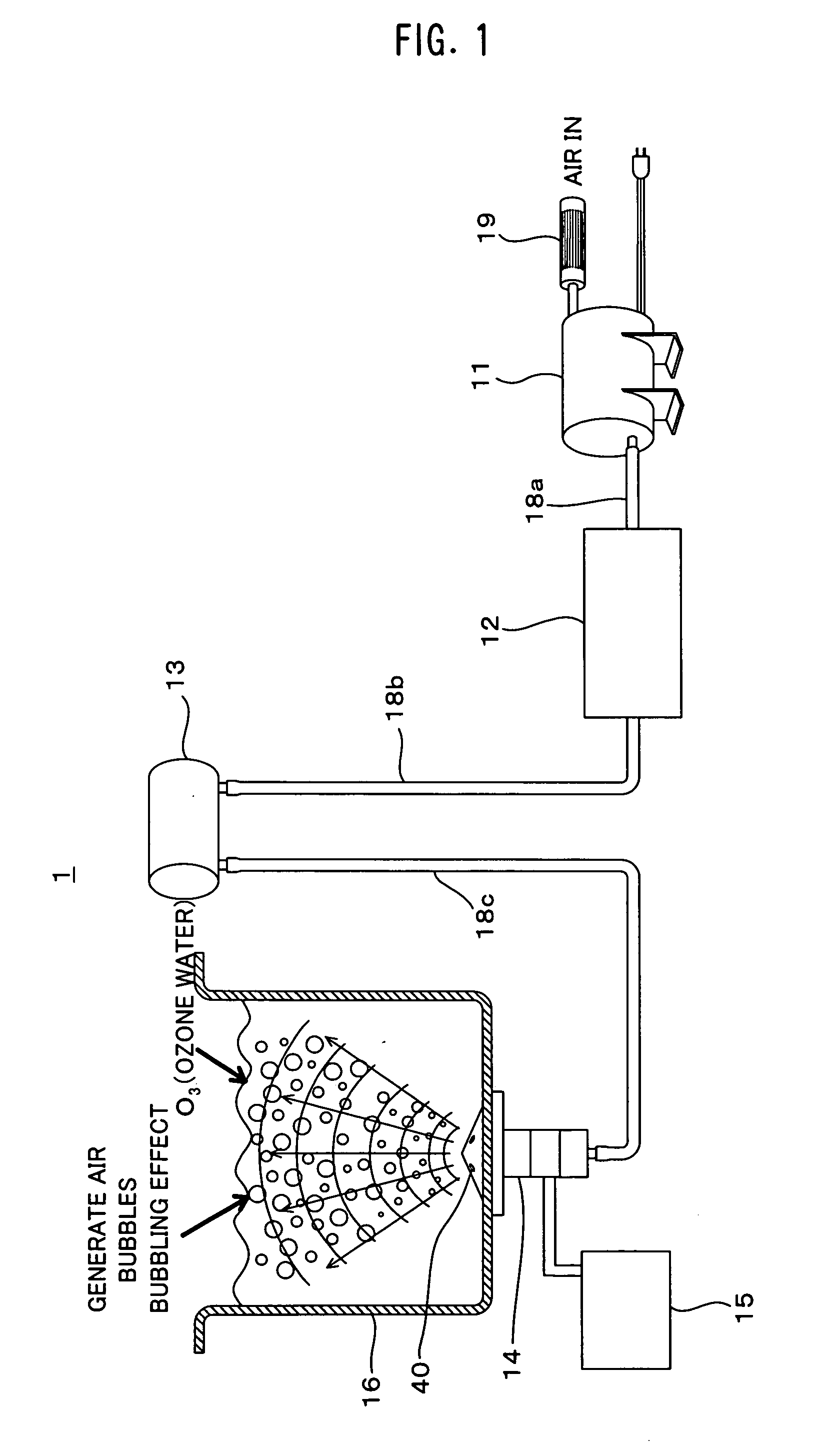

Ultrasonic Cleaning Method and Device

InactiveUS20080289971A1Clean and sterilize medical appliancesFrom normal temperature solutionsLiquid separation by electricitySilver electrodeMegasonic cleaning

An ultrasonic cleaning method and an ultrasonic cleaning device are provided, which are capable of performing simultaneously cleaning and sterilization of medical appliances or the like, and which can also be used for washing hands for disinfection without any special waste water treatment. The ultrasonic cleaning method for cleaning an object to be cleaned by using an ultrasonic wave includes the steps of putting cleaning fluid and the object to be cleaned in a cleaning tank (16), and applying ultrasonic vibrations to the cleaning fluid from an ultrasonic vibration member disposed in the cleaning tank (16) while ejecting air containing ozone into the cleaning fluid. The vibration portion has a communicating conduit 40 that opens at the surface thereof, and air containing ozone is discharged into the cleaning fluid from the communicating conduit. A silver electrode is disposed in the cleaning fluid, and electrolytic sterilization by silver ions is performed for the object to be cleaned adding to sterilization by ozone.

Owner:KAGOSHIMA SUPERSONIC TECHN LAB

Method for producing aluminum plate-fin heat exchanger

InactiveCN1943973AHigh strengthLow strength, good cleaning qualityDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesShielding gasNitrogen

The process of producing aluminum plate-fin heat exchanger includes the steps of blanking, washing, mounting, brazing, argon arc welding and pressure test. The present invention adopts numerically controlled lathe with high machining precision for blanking; ultrasonic washing for high washing efficiency and high washing quality; continuous high purity nitrogen protected brazing for high brazing quality; and argon arc welding with welding robot for high welding quality and high production efficiency.

Owner:管保清 +1

Health-care blackberry and mulberry compound fruit wine and brewing method thereof

InactiveCN101845379AReasonable nutritionImprove textureAlcoholic beverage preparationDiseaseFruit wine

The invention relates to a blackberry and mulberry compound fruit wine and a brewing method thereof. The method comprises the following steps of: sorting blackberries and mulberries as raw materials, cleaning the raw materials by using deionized water matched with ultrasonic waves and mixing by according to a certain proportion; then pumping the mixture into heating equipment to heat to 40 DEG C to 50 DEG C, and carrying out enzymolysis, component adjustment, sterilization, compound yeast fermentation, clarification, allocation, filtering and formation of compound fruit wine; and checking and packaging the compound fruit wine into products. The brewing method makes the fragrances of the blackberries and the mulberries complement with nutrient components to prepare the health-care blackberry and mulberry compound fruit wine with the advantages of powerful fruit flavor, ruddy color and luster, sweet vinosity, reasonable nutrition and good texture, and the health-care blackberry and mulberry compound fruit wine has the functions of resisting aging, blacking hair and hairdressing, preventing and resisting cancers and enhancing immunities, especially has an obvious effect on preventing cardiovascular and cerebrovascular diseases, and can improve the immunities of human bodies and be is beneficial to health when frequently drunk by people.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

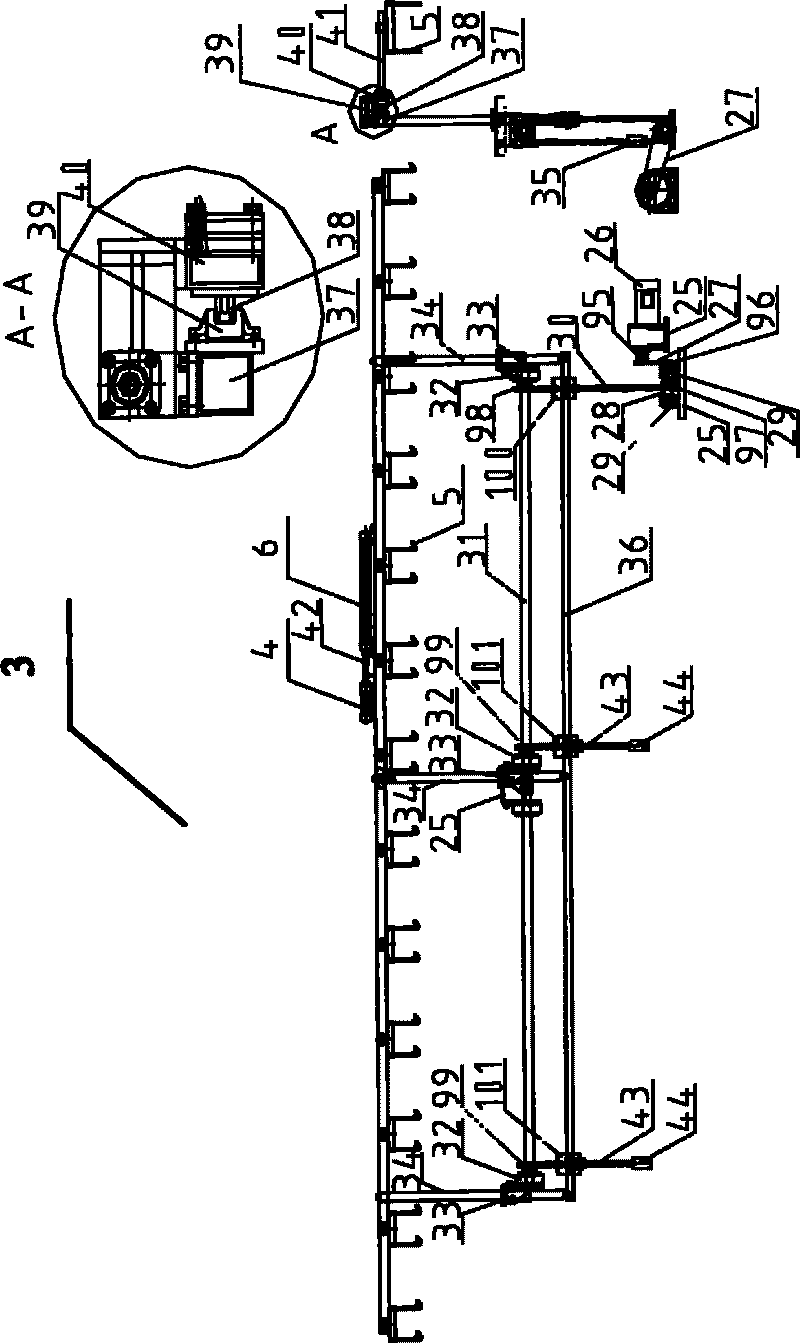

Ultrasonic wave cleaner for coating of optical lens and treatment method thereof

The invention discloses an ultrasonic wave cleaner for a coating of an optical lens and a treatment method thereof, which belong to the fields of metal surface treatment technology, vacuum coating technology and optical technology. The ultrasonic wave cleaner is characterized by performing ultrasonic alkali cleaning, pure water rinsing and ultrasonic pure water rinsing on the optical lens in cleaning medium under the condition of pendular motion respectively, slowly and perpendicularly lifting the optical lens or ensuring that a liquid slowly descends to break away from a workpiece when running water is circularly filtered, and using hot air to dry the optical lens under quiescent conditions. A structure of the ultrasonic wave cleaner is that: a conveyer is provided with traveling girders, the girders are provided with grab hooks, and the hooks are suspended with washing baskets; and different working procedures are finished by different devices, namely a liquid tank body is matched with a pendulous device, a dehydration device and a drying device to finish respective working procedures. The ultrasonic wave cleaner and the method have the advantages that the ultrasonic wave cleaner and the method do not use inflammable, explosive and toxic organic solvents to wash, reduce energy consumption, avoid the air pollution in workshops, can effectively improve the cleanliness of products, and ensure that the adhesive force of the coating of the optical lens is remarkably improved.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH

Lobster cleaning machine

ActiveCN108174910AAchieve cleaningImprove cleaning efficiencyShrimp/lobster processingMegasonic cleaningEngineering

The invention discloses a lobster cleaning machine which comprises an engine base, a lobster spreading plate, a cleaning brush, a water spraying device, a driving device, an ultrasonic cleaning vesseland a water supply device, wherein the lobster spreading plate is mounted on the engine base and a brushing tank used for enabling abdomens of lobsters to be exposed downwards runs through the lobster spreading plate; the cleaning brush is mounted at the brushing tank upwards and movably arranged in a horizontal direction; the water spraying device is used for spraying water to the abdomens of lobsters on the lobster spreading plate; the ultrasonic cleaning vessel is arranged on the engine base; and the water supply device is used for supplying water to the water spraying device and the ultrasonic cleaning vessel. According to the technical scheme provided by the invention, the cleaning brush can be driven by the driving device to brush the abdomens of lobsters on the lobster spreading plate, and the lobsters are wholly cleaned by the ultrasonic cleaning vessel, so that a manual cleaning link is reduced. By combining two manners such as cleaning by the cleaning brush and ultrasonic cleaning, the cleaning effect and the cleaning efficiency are greatly increased.

Owner:WUHAN POLYTECHNIC UNIVERSITY

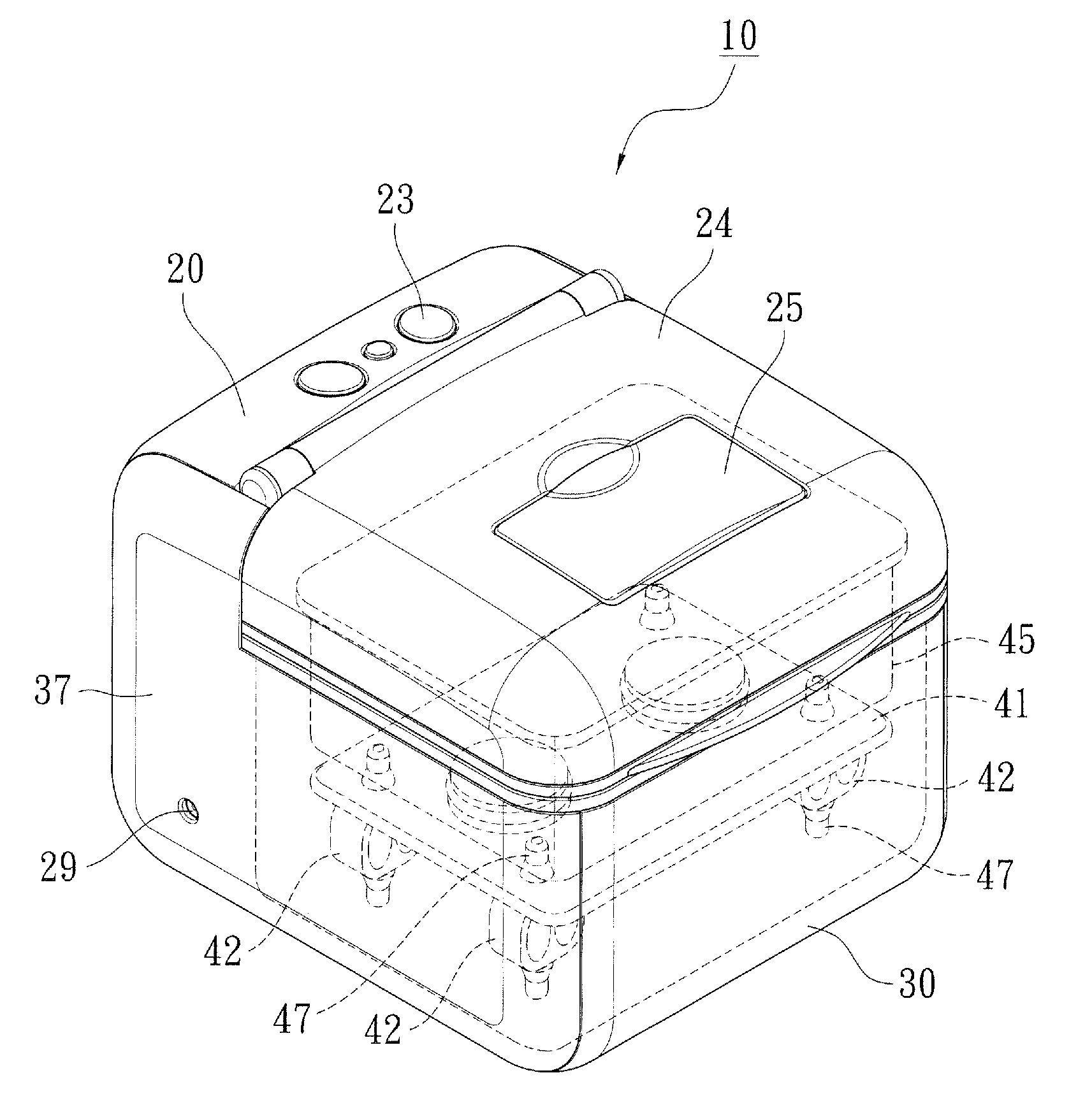

Vibrating and ultrasonic washer

InactiveUS20100326484A1Simple structureSmall sizeLavatory sanitoryCleaning using liquidsUltrasonic generatorMegasonic cleaning

A vibrating and ultrasonic washer which is composed of a case externally provided with a cover and a switch button, and interiorly provided with control circuits, a UV sterilizing light and a vibration device; wherein the vibration device includes pluralities of support mats, a vibration motor and / or at least an ultrasound generator and a washing tank; the vibration motor and / or at least one ultrasound generator is / are provided on a base board and controlled by the control circuits; the base board is connected into the case via the pluralities of support mats; the washing tank is stacked on the base board; thereby the articles to be washed can be put in the washing tank to accomplish cleaning and sterilizing purposes via the vibration waves and / or ultrasound.

Owner:WU CHIH HSIEN

Filling composite welding flux vibrating liquid phase welding method for non-continuous strengthening aluminium base composite material

InactiveCN1792531AStrong welding flexibilityReduce performanceWelding/cutting media/materialsSoldering mediaComposite constructionButt joint

A liquid-phase vibration welding method by filling composite flux for noncontinuously reinforced Al-base composition includes such steps as abrading two surface to be welded, ultrasonic washing in acetone, drying in the air, fixing by fixture in opposite mode, filling composite flux between two surfaces, heating to smelt the flux, vibrating while pressing, and cooling.

Owner:HARBIN INST OF TECH

Method of manufacturing vacuum composite film coating on surface of neodymium iron boron magnet

InactiveCN101403093AAvoid the disadvantages of brittlenessImprove anti-corrosion performanceVacuum evaporation coatingSputtering coatingComposite filmChemical plating

The invention relates to the technical filed of vacuum plating, in particular to a preparation method for conducting vacuum compound plating on the surface of a neodymium iron boron magnet, which is characterized in that the preparation method comprises the following steps: A. pre-treatment, the mixed liquor of washing liquid and purified water is used for conducting oil removal and parting medium washing to the magnet surface in an ultrasonic wave cleaner; B. ion cleaning and activation, the pre-treated neodymium iron boron magnet which is dried at 80-100 DEG C for 5-10 minutes undergoes bombardment activation of a glow plasma in vacuum environment, so as to increase surface activation energy; and C. vacuum plating, vacuum plating treatment is conducted to the neodymium iron boron magnet washed by ions in a vacuum chamber, and a metal plating is prepared on the surface. The deposited metal film on the surface of the neodymium iron boron magnet has the advantages of good stability, high bonding force and tightness, stronger anti-corrosion performance in cold and hot alternation environment. Furthermore, in the physical vapor deposition plating process, the plating thickness is affected much less by the magnet workpiece corner than in electroplating and chemical plating, and the pollution problem is avoided in the preparation process.

Owner:兰州大成科技股份有限公司

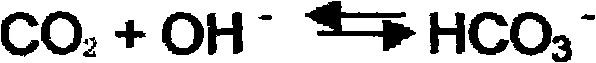

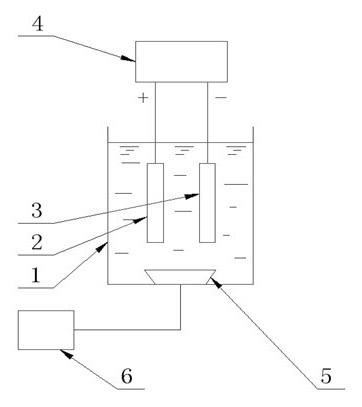

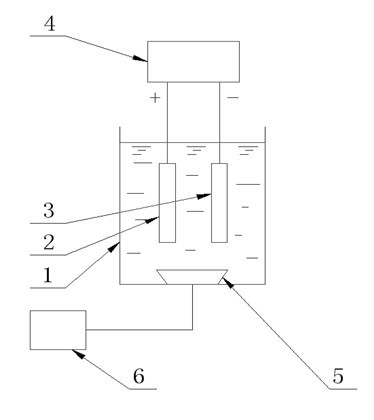

Method and device for pre-treating oil field sewage by ultrasonic oxidation united with electrochemical oxidation

InactiveCN102070222APromote oxidationImprove the bactericidal effectWater/sewage treatment with mechanical oscillationsWater/sewage treatment by oxidationElectrolysisElectrochemistry

The invention relates to a method and a device for pre-treating oil field sewage by ultrasonic oxidation united with electrochemical oxidation, and belongs to the sewage treatment of oil field exploration and production. The invention discloses (1) an ultrasonic and electrochemical cooperated composite oxidation method for oxidizing and degrading organic pollutants in an oil field, wherein the frequency of the ultrasonic wave is 20 to 500Hz; and current density is 50 to 5000A / m<2>; and the invention also discloses (2) an ultrasonic washing method for washing cathode scales which are oxidized in a united electrochemical mode. The device is a composite oxidizing electrolytic bath device, wherein an electrolytic bath, an anode and a cathode are arranged in the composite oxidizing electrolytic bath device; and particularly an ultrasonic device is arranged on the electrolytic bath. The invention has the advantages of reducing and avoiding medicament doping, avoiding the medicament resistance of biological species in a water body and the phenomena of a discontinuous electrolysis process, a poor electrolysis effect and the like caused by the cathode scales in the traditional electrochemical electrolysis, ensuring the stable quality of discharged water and a better purification effect, and lowering water treatment cost.

Owner:广州金川环保设备有限公司

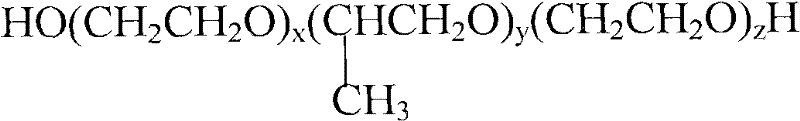

Neutral cleaning agent and preparation method thereof

InactiveCN102399642AReduce surface tensionBest damage-free cleaningOrganic detergent compounding agentsNon-ionic surface-active compoundsWater basedLinear alkylbenzene

The invention provides a neutral water-based cleaning agent and a preparation method thereof. The neutral water-based cleaning agent comprises the following components in percentage by mass: 0.5-1.5%, preferably 1%, of aliphatic alcohol alkoxy surfactant, 1-5%, preferably 3%, of aliphatic alcohol polyoxyethylene ether surfactant, 1-5%, preferably 3%, of ployether surfactant, and 0.5-1%, preferably 0.7%, of linear alkyl benzene sodium sulfonate. In the invention, as nonionic surfactants are compounded with anionic surfactants, surface tension of the cleaning agent is reduced, and pH of the cleaning agent is kept neutral; the neutral water-based cleaning agent disclosed by the invention has a good cleaning effect on polar and nonpolar pollutants, and can achieve an unexpected beneficial effect in cleaning slits by adopting physical cleaning means such as ultrasonic cleaning, high-pressure spraying, brushing and the like.

Owner:英泰沃斯(苏州)新材料有限公司

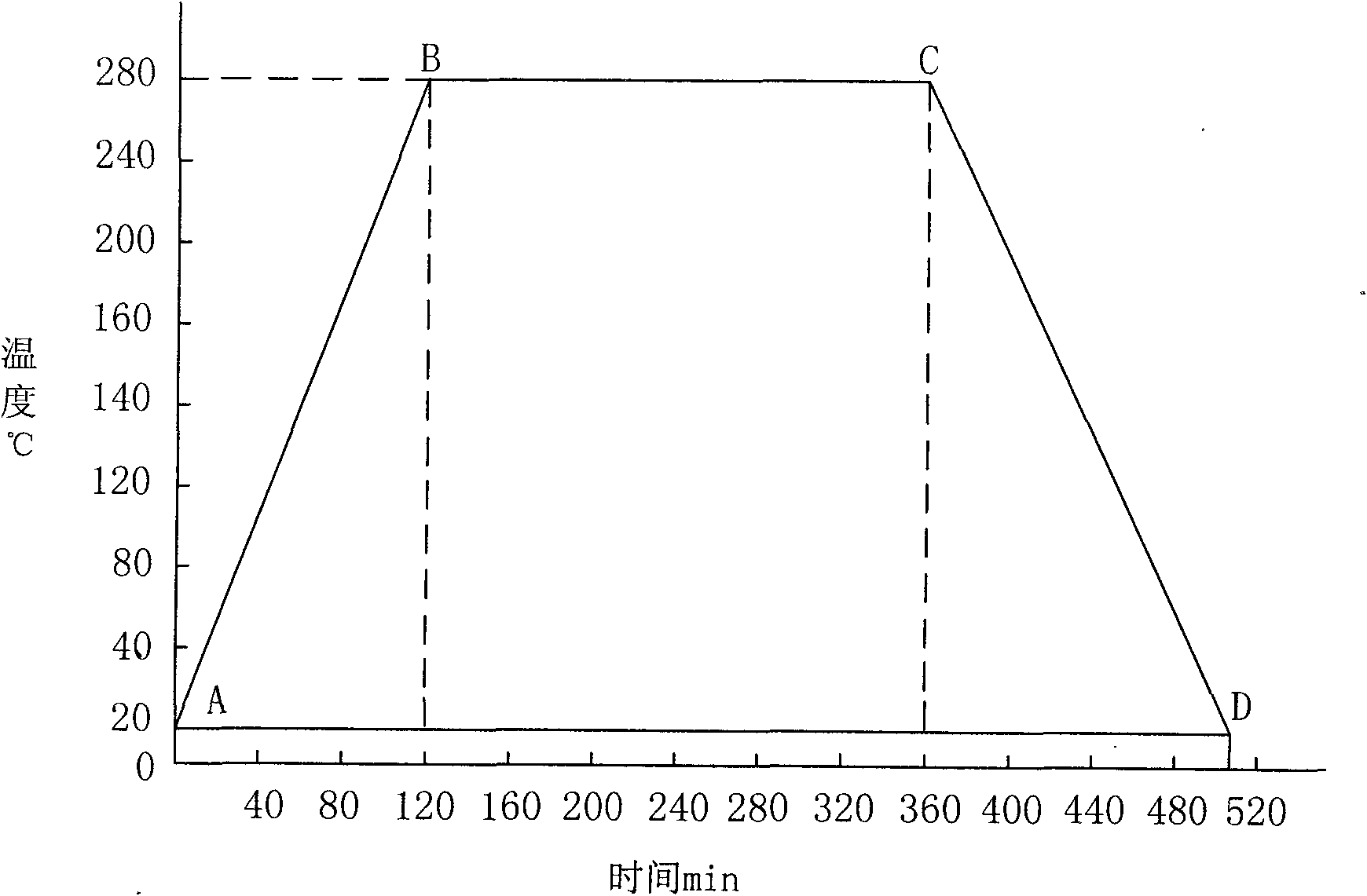

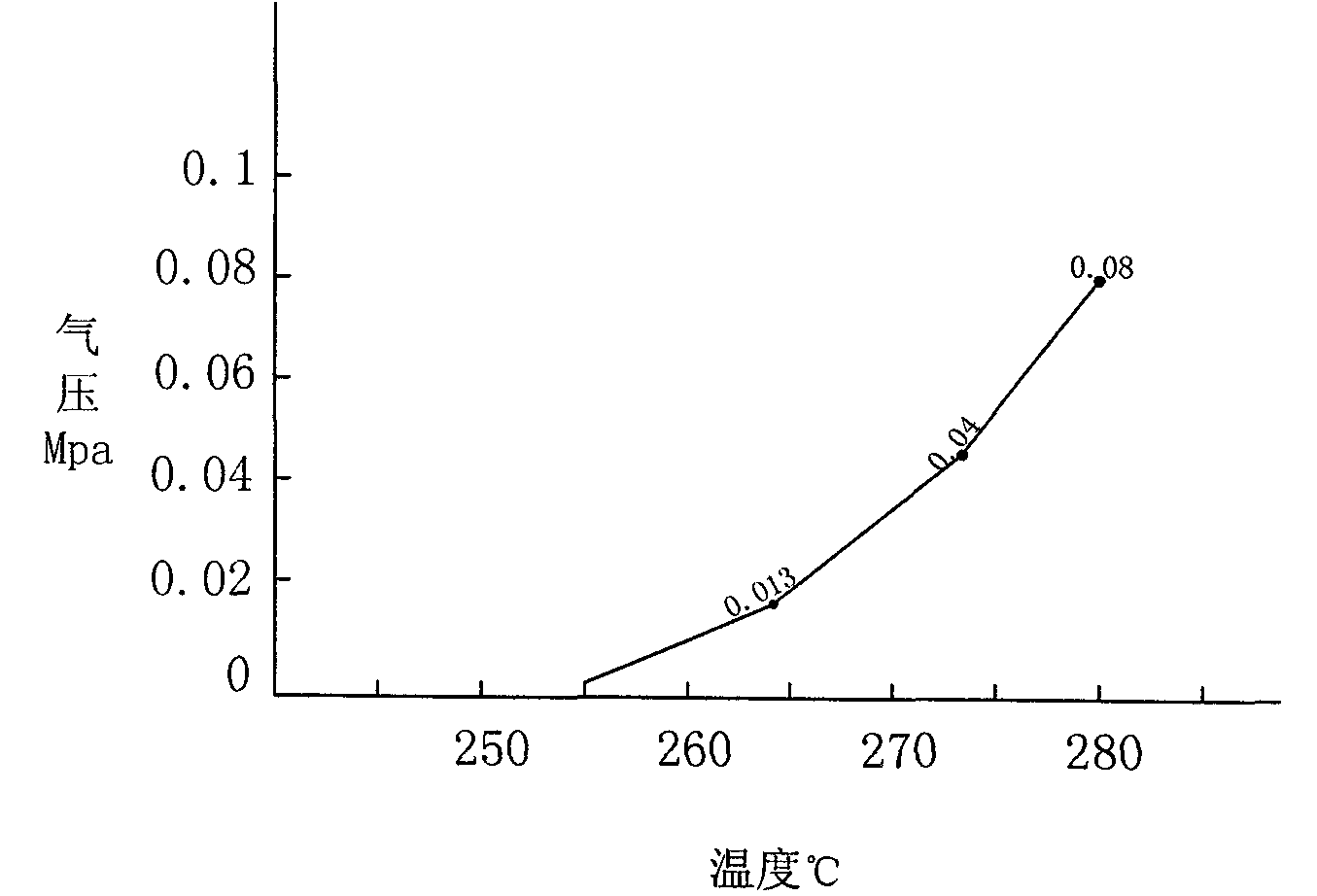

Method for cleaning polyphenylene sulfide melt spinning spinneret

The invention relates to a method for cleaning a polyphenylene sulfide melt spinning spinneret. Regarding that high polymer has the characteristics of high decomposition temperature, organic and inorganic solvent insolubility, based on the actual condition that the polyphenylene sulfide is firmly attached on the spinneret and is hard to clean, according to the principle that structural components of chemical substances are similar and compatible, the method adopts biphenyl-biphenyl ether served as cleaning agent to complete cleaning of the spinneret in a cleaning kettle at 280 DEG C and 0.08MPa under cleaning agent out-kettle circular flowing, and finally completes cleaning of the spinneret through calcining of a calcinator, ultrasonic cleaning and compressed air drying. The cleaning method has short technical process, few used equipment, good cleaning effect and cleaning rate of spinneret attachment reaching 99.999 percent, ensures that the spinneret has no phenomena of deformation, corrosion or decarburization, and is a perfect cleaning method for the polyphenylene sulfide melt spinning spinneret. Components and parts of other spinning machines attached with polyphenylene sulfide high polymer also can be cleaned by using the method.

Owner:TAIYUAN UNIV OF TECH

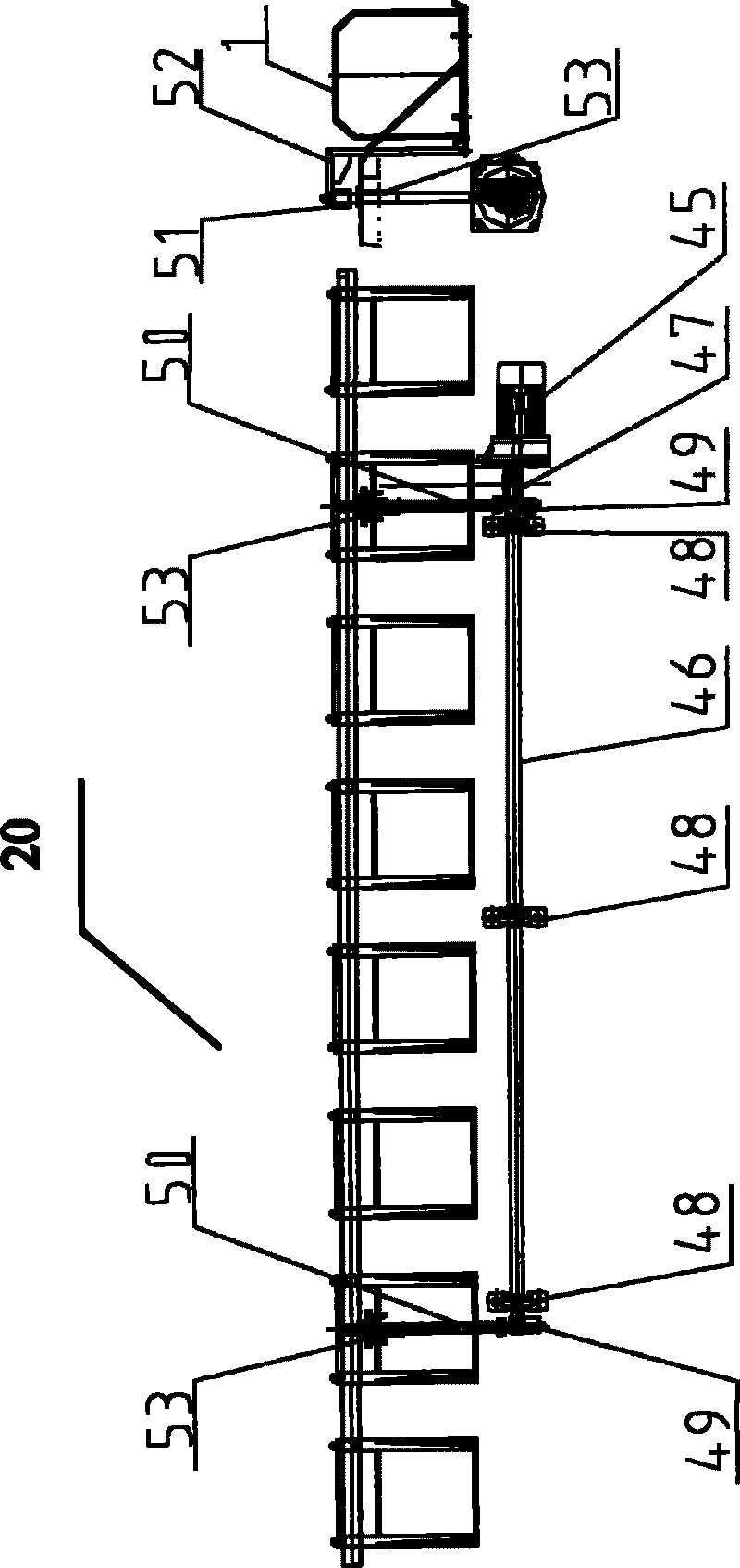

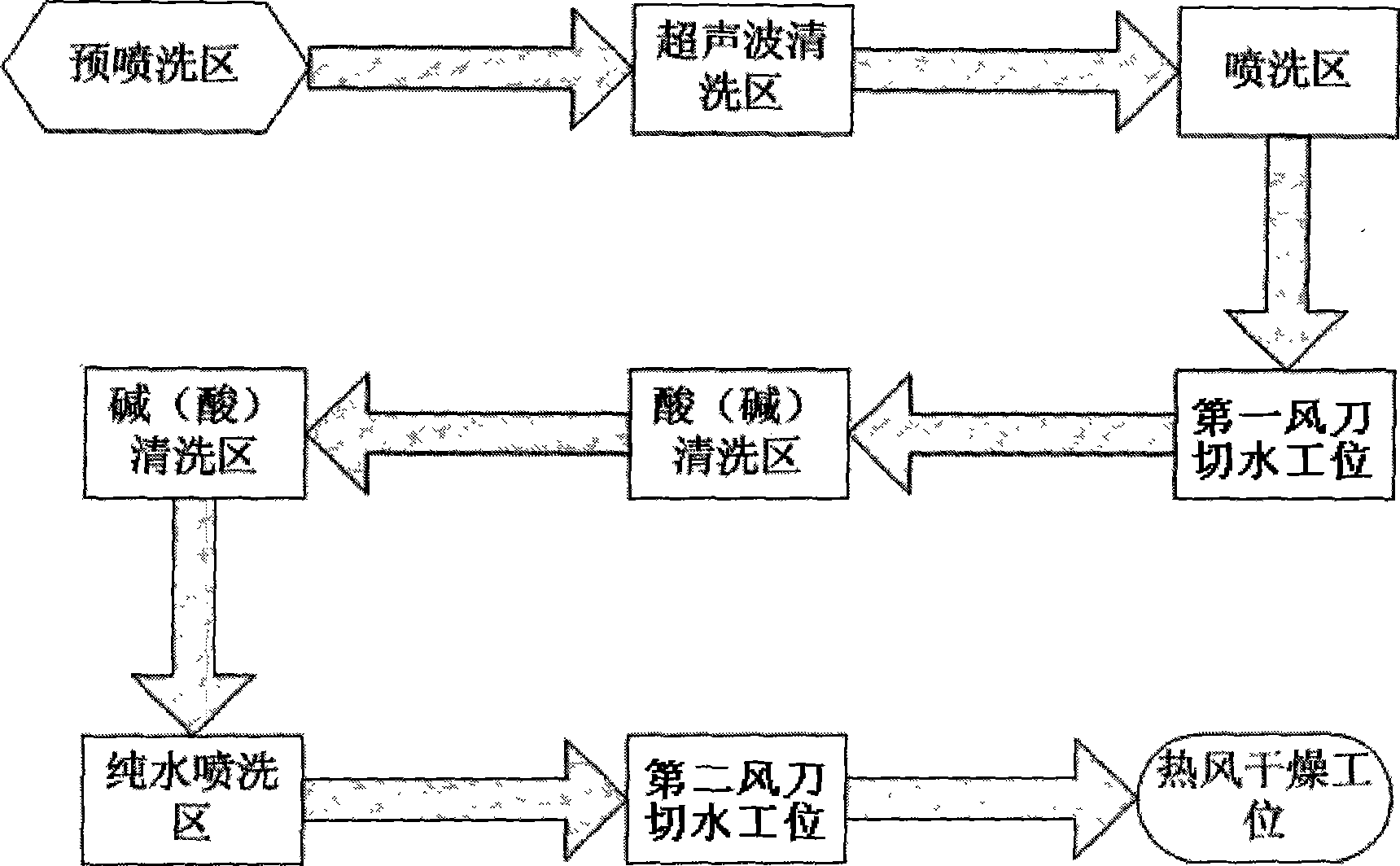

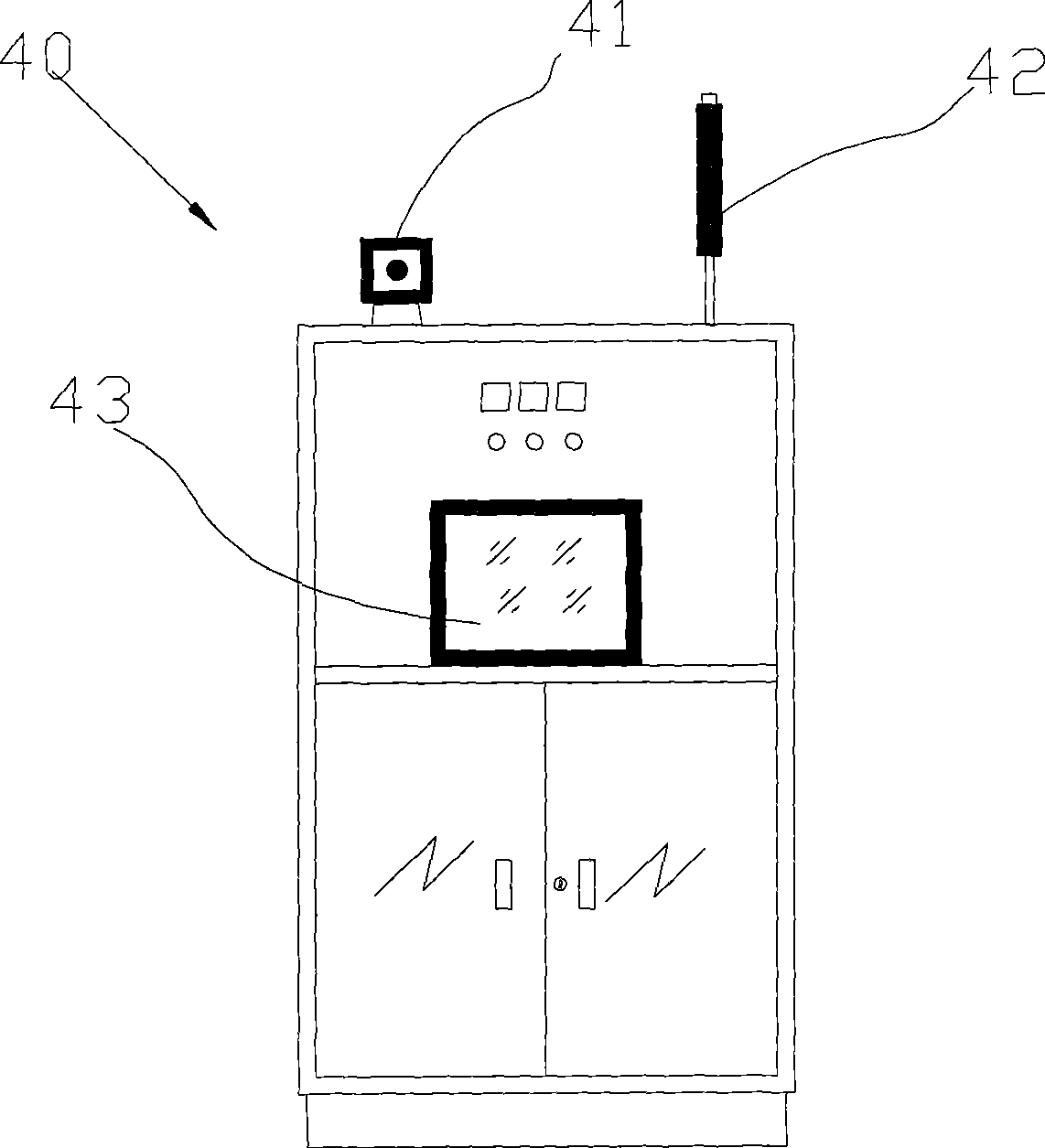

Continuous cleaning equipment system for strip

InactiveCN101474621AReduce manufacturing costMeet production requirementsDrying using combination processesDrying solid materials with heatWater savingMegasonic cleaning

The invention discloses a continuous belt material cleaning equipment system, comprising a station of a pre-spray cleaning area, a station of an ultrasonic cleaning area, a station of a spray cleaning area, a station for a first air knife water shearing, a station of an acidic or alkaline cleaning area, a station of a pure water spray cleaning area, a station for a second air knife water shearing and a station for hot air drying which are connected in turn and arranged on a frame; the stations are electrically connected with a PLC controller; the PLC controller detects and controls input of the belt material from the station of the pre-spray cleaning area; and the belt material is then output after ultrasonic cleaning, spray cleaning, air drying, acid and alkaline cleaning, pure-water cleaning and drying. The system adopts the PLC controller to automatically control and detect the production process without additional auxilians. The system has the function of removing oil and oxide on the surface of the belt material; and the secondary products meet the requirements of electronic-grade product manufacturing. Washing agent is used to carry out internal circle cleaning without discharging, thereby satisfying environment-friendly manufacturing. The system adopts a method combining rinsing and pre-rinsing, so as to reach the goal of water saving and energy saving.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

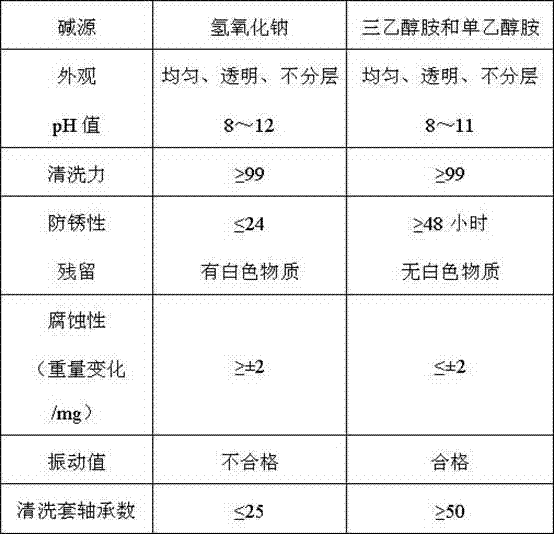

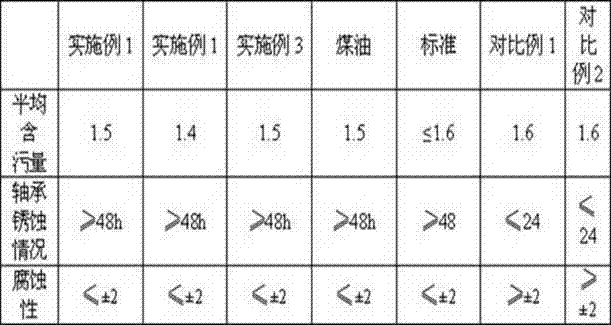

Metal bearing water-based cleaning agent and preparation method and application thereof

The invention discloses a metal bearing water-based cleaning agent and a preparation method and application thereof. The cleaning agent comprises the following components in percentage by mass: 2 to 8 percent of fatty alcohol polyoxyethylene ether, 2 to 8 percent of alkylphenol polyoxyethylene ether, 3 to 10 percent of fatty acid alkanolamide, 5 to 25 percent of triethanolamine oleate, 10 to 22 percent of triethanolamine, 5 to 18 percent of monoethanolamine, 0.5 to 3 percent of alkyl sodium sulfonate, 0.01 to 0.5 percent of benzotriazole, 1 to 2 percent of disodium ethylene diaminetetraacetate and 3.5 to 71.49 percent of water. During use, the cleaning agent is prepared into 2 to 10 percent working solution, and a bearing part is ultrasonically cleaned, rinsed, subjected to spray washing and dried to meet the cleaning degree standard and the finished product vibration value standard. The product is environment-friendly, does not influence a bearing material, is prepared from readily available raw materials, has low cost, can replace the conventional cleaning gasoline and kerosene, reduces the potential safety hazard, avoids environmental pollution, and saves energy.

Owner:白马轴承技术(洛阳)有限公司 +1

Ultrasonic cleaning apparatus

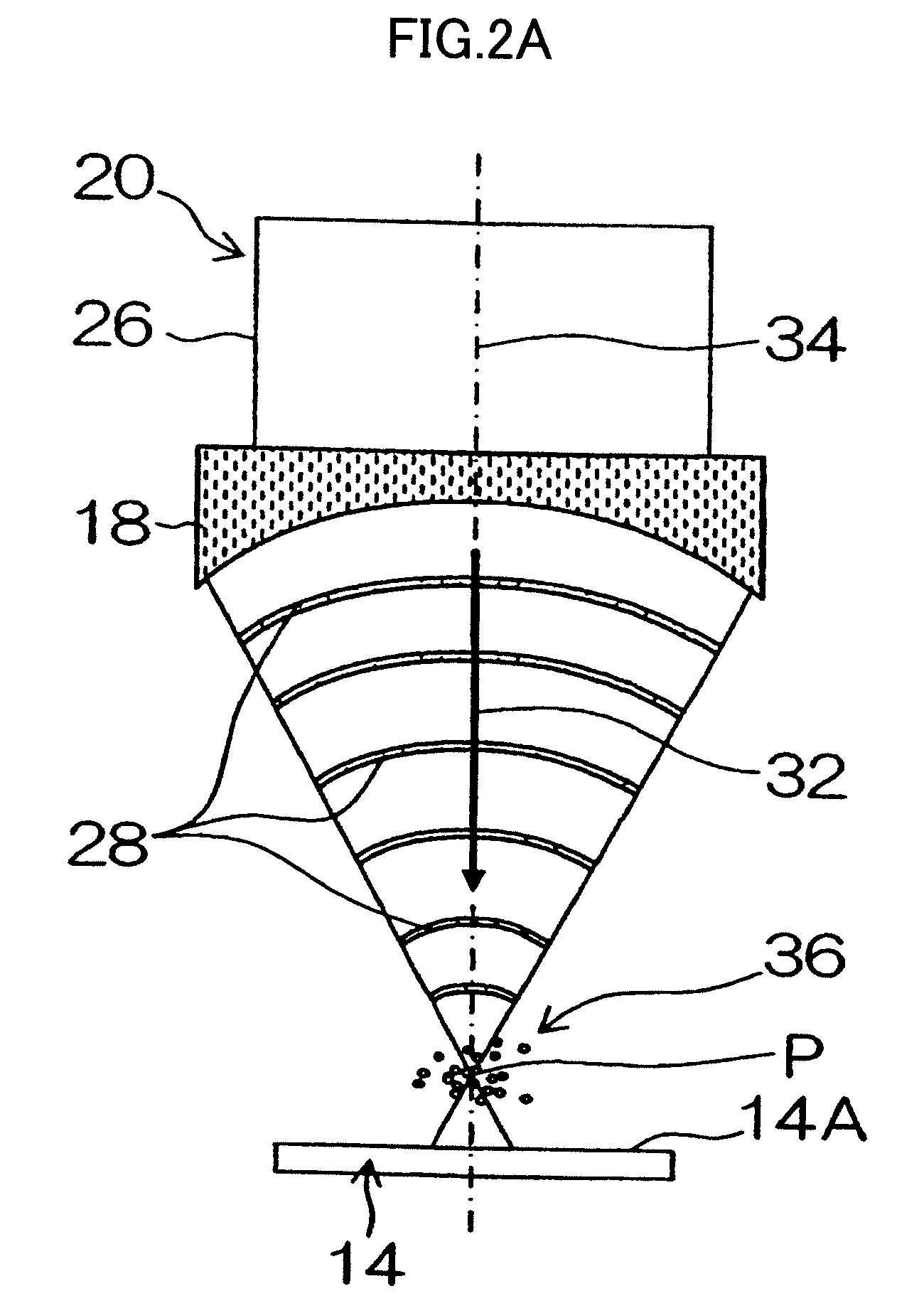

InactiveUS20090025761A1Efficient removalEasy to cleanFlow mixersTransportation and packagingMegasonic cleaningUltrasound

An ultrasonic cleaning apparatus which performs ultrasonic cleaning of a contamination attached to a surface of an object to be cleaned, by using a cleaning liquid to which ultrasonic waves are applied has a cleaning bath pooling the cleaning liquid, a support base on which the object to be cleaned is supported in the cleaning liquid, ultrasonic wave generation device for alternately focusing first ultrasonic waves having a frequency of 1 to 10 MHz and second ultrasonic waves having a frequency equal to or lower than ½ of that of the first ultrasonic waves toward the object to be cleaned, a focus position adjustment device of adjusting the distance between a focus position for the focus and the surface of the object to be cleaned, and moving device of moving at least any one of the ultrasonic wave generation device and the support base so that the effect on the surface of the object to be cleaned of the ultrasonic waves generated by the ultrasonic wave generation device is uniform.

Owner:HITACHI PLANT TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com