Circulating water electrolytic descaling device and descaling method thereof

A technology of circulating water and hydropower, which is applied in the field of circulating water treatment devices and circulating water descaling devices, which can solve the problems of blocked pipes, dismantling and washing of filter screens, incomplete filtration, and inability to reduce the absolute hardness of water quality, etc., and achieves the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

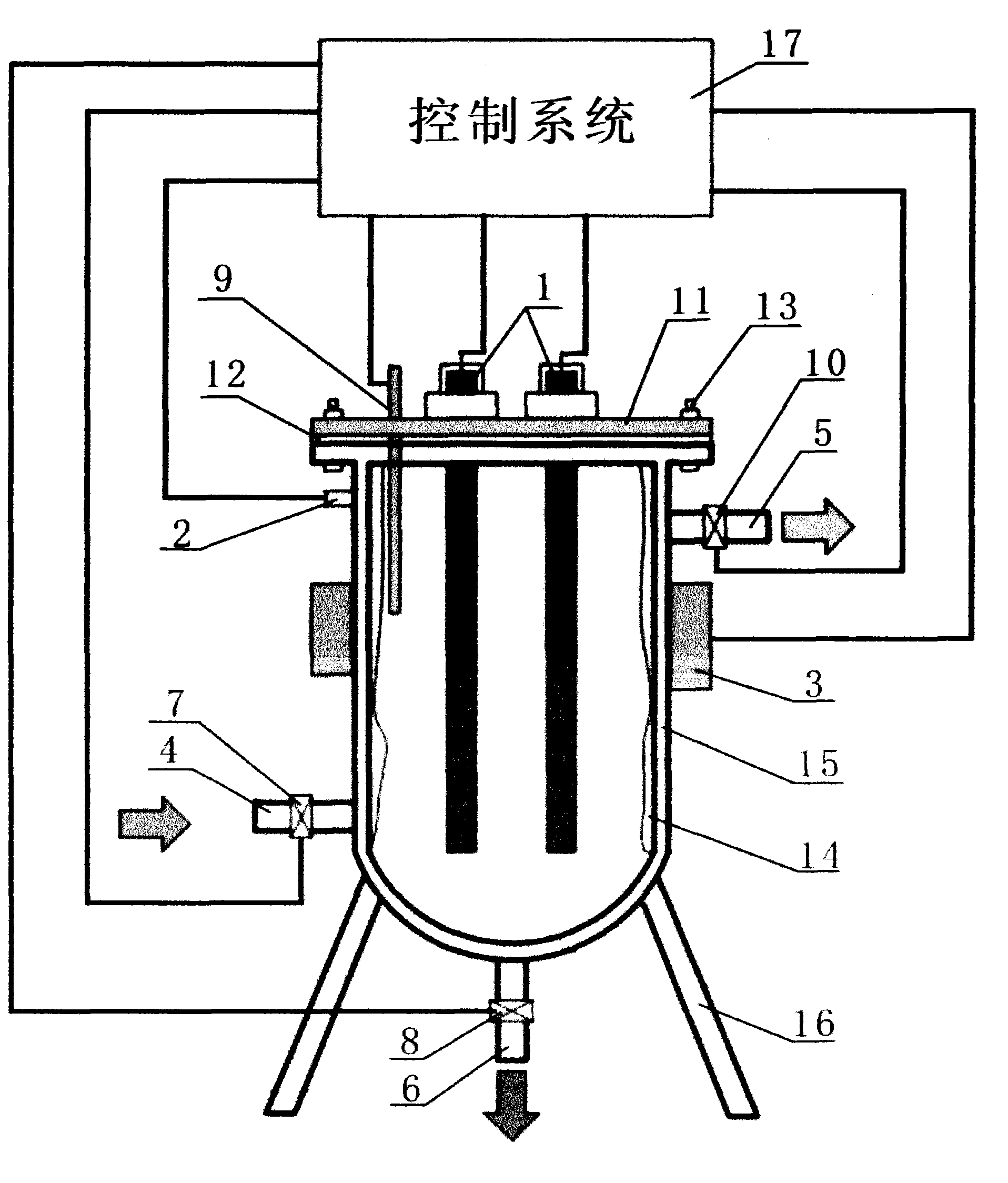

[0015] Circulating water electrolytic descaling device, including reaction chamber 15, water inlet 4 and water inlet valve 7, water outlet 5 and water outlet valve 10, sewage outlet 6 and sewage valve 8, anode 1, control system 17, end cover 11, bracket 16; The reaction chamber 15 is provided with a test electrode 9, the reaction chamber 15 is a metal material, and its inner wall is connected to the cathode terminal 2 as the cathode of the electrolytic reaction; the anode 1 and the test electrode 9 pass through and are fixed on the end cover 11, and the test electrode 9 near the inner wall of the reaction chamber 15, the outer wall of the reaction chamber 15 is coated with an epoxy resin layer and equipped with an ultrasonic cleaner 3, the bottom of the reaction chamber 15 is spherical or conical, and its inner surface is coated with an epoxy resin layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com