Ultrasonic wave cleaner for coating of optical lens and treatment method thereof

An optical lens and ultrasonic technology, applied in the direction of using liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of unsafe, polluted environment, large energy consumption, etc., to reduce energy consumption and avoid air pollution. The effect of pollution and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

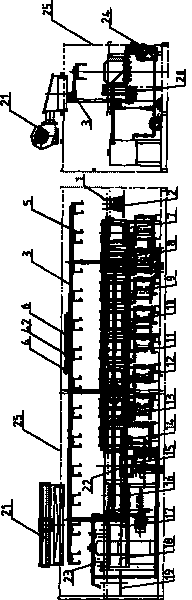

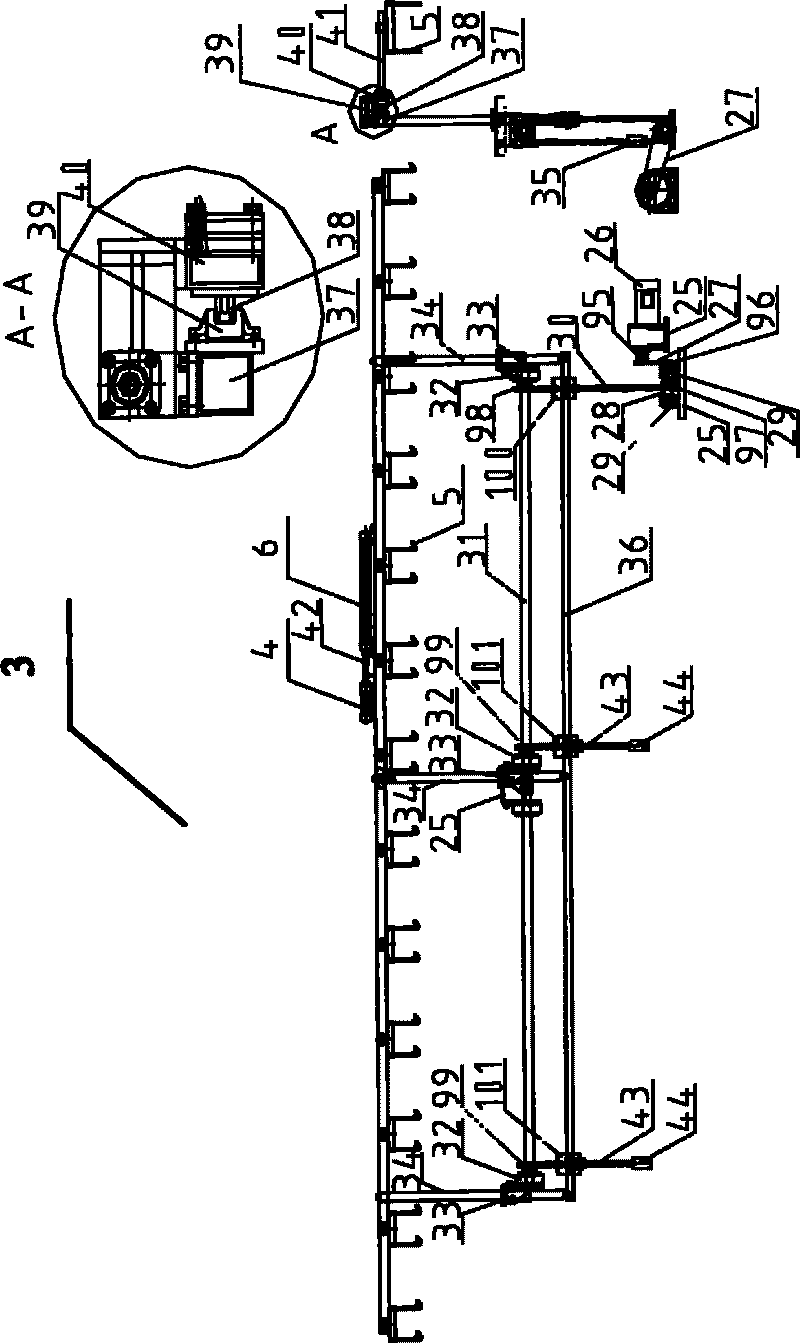

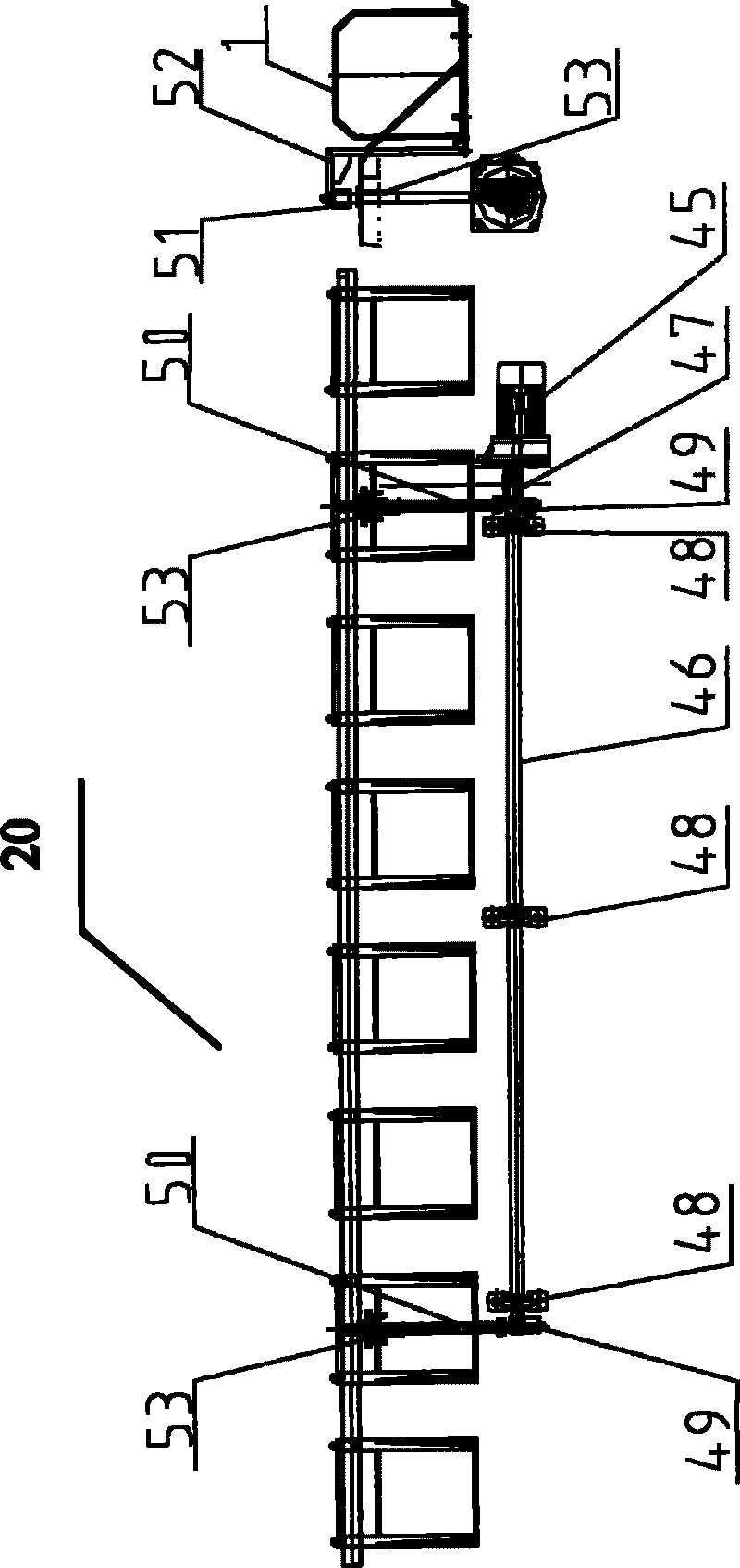

[0019] The present invention will be further described now in conjunction with accompanying drawing

[0020] The cleaning basket 1 is placed on the feeding station 2, the handling device 3 is lowered together with the grab hook 5, and reaches the cleaning basket 1, and the grab cylinder 4 pushes the moving beam 40 to move a fixed stroke in the horizontal direction, so that the grab hook 5 enters the cleaning basket 1 The handle is lowered, the handling device 3 rises to the highest point as a whole, the traverse cylinder 7 pulls the moving beam 40 to move one station horizontally, and the cleaning basket 1 is transported from the feeding station to the cleaning station 7, and the grabbing hook cylinder 4 returns One stroke distance, the conveying device 3 rises to the highest point, and the traverse cylinder 7 promotes the moving beam 40 to return to the starting point, that is, the grapple 5 reaches the top of other stations except the discharging station 19 again. There are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com