Patents

Literature

1077 results about "Water rinsing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

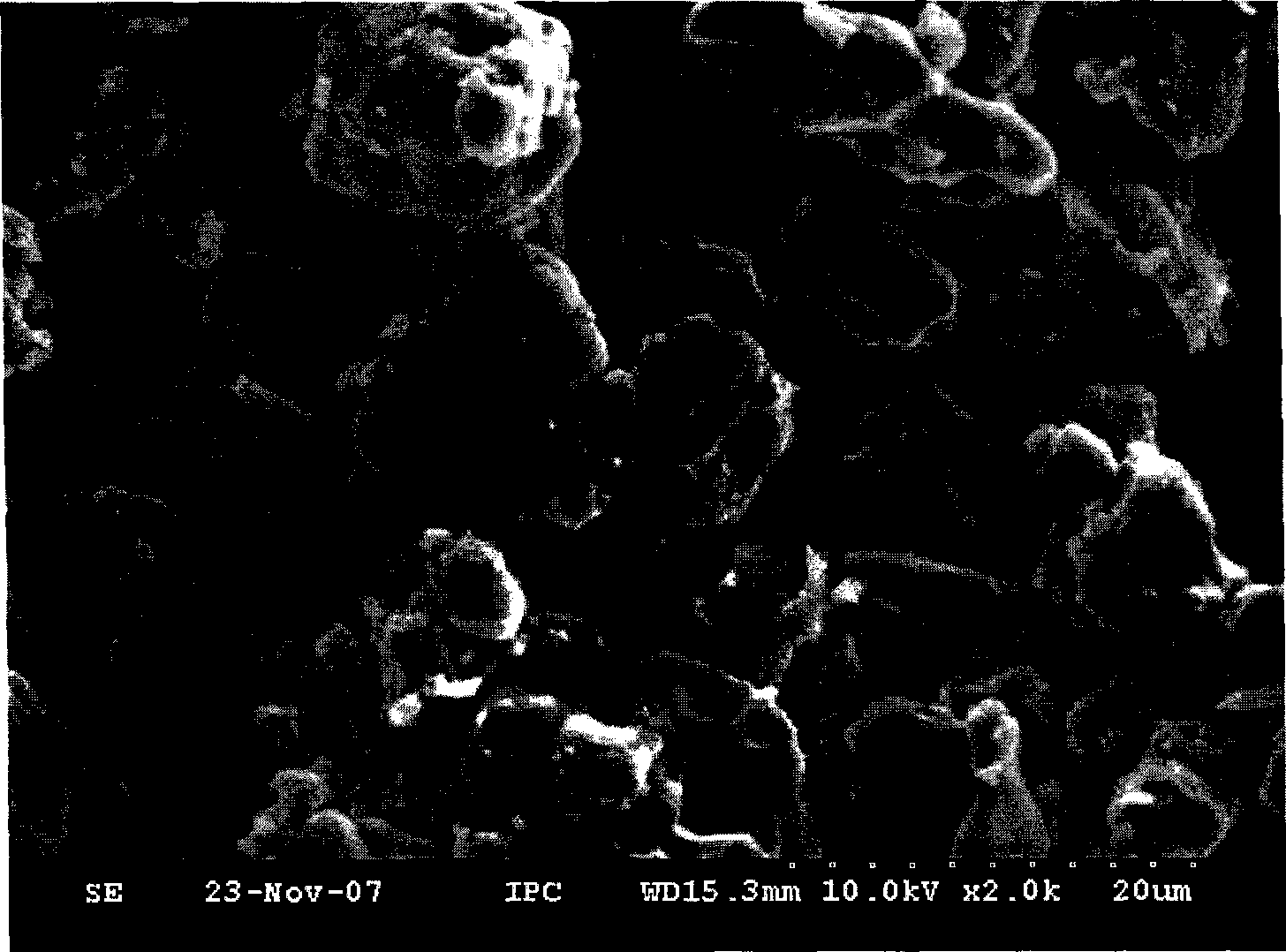

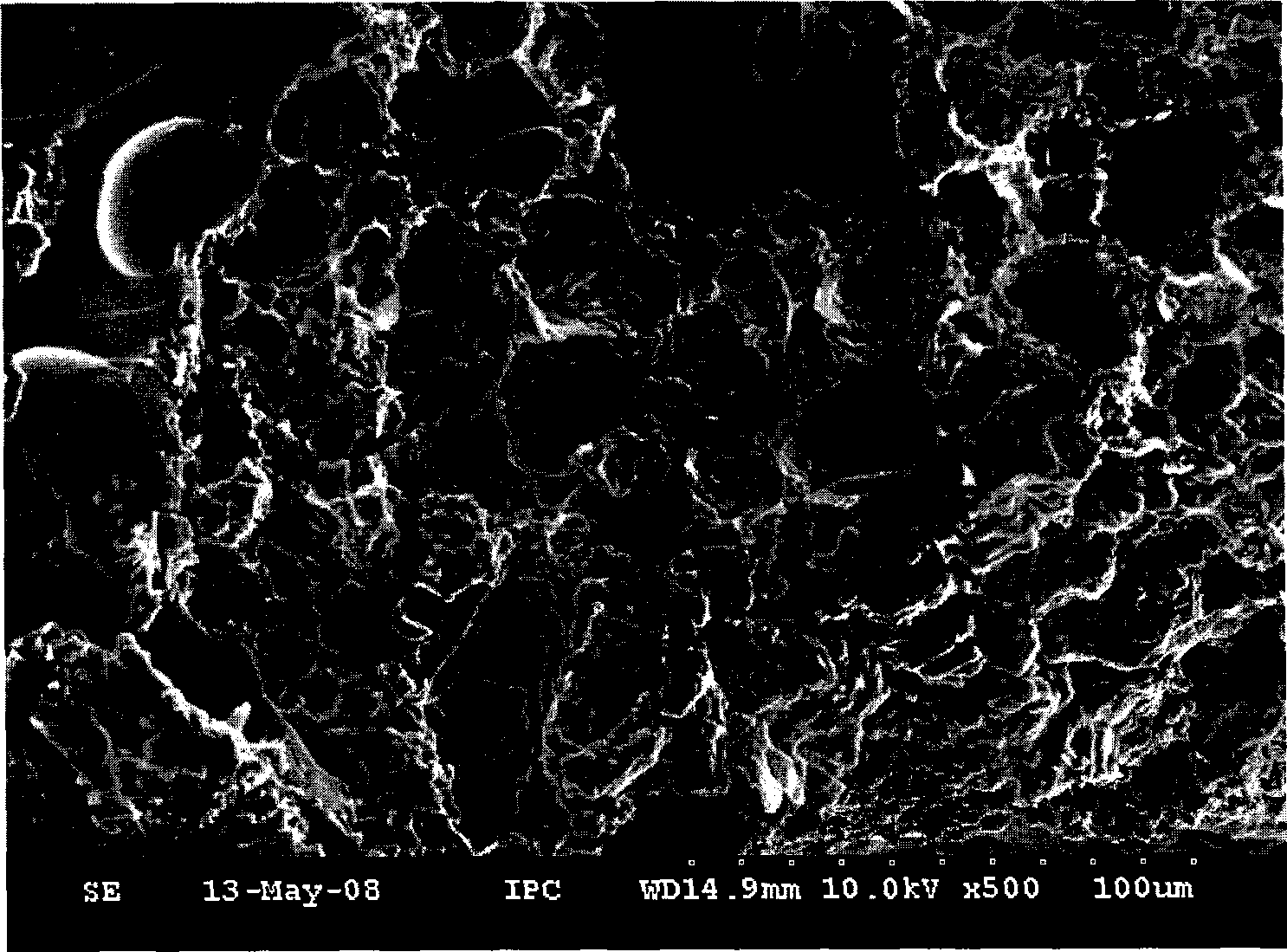

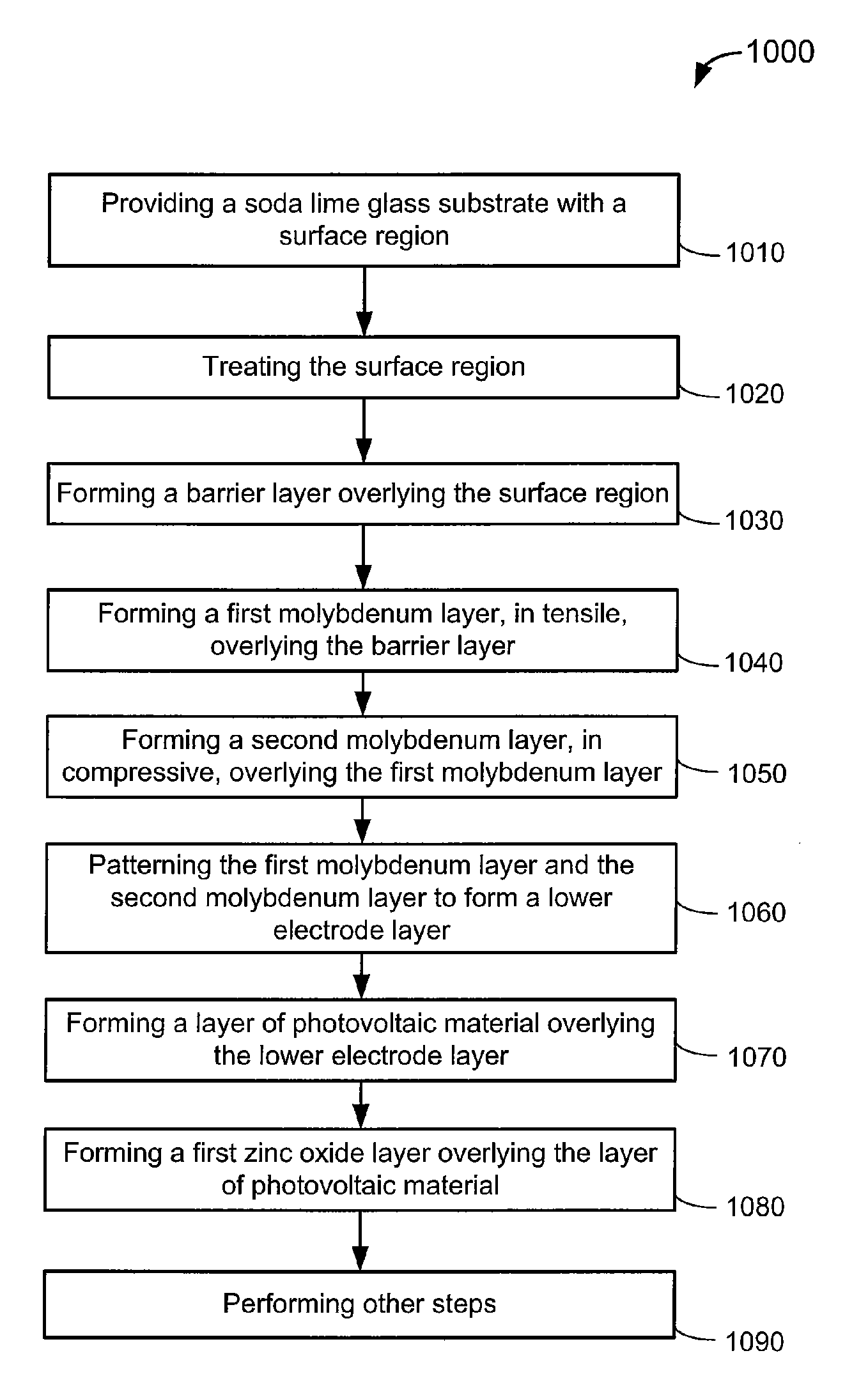

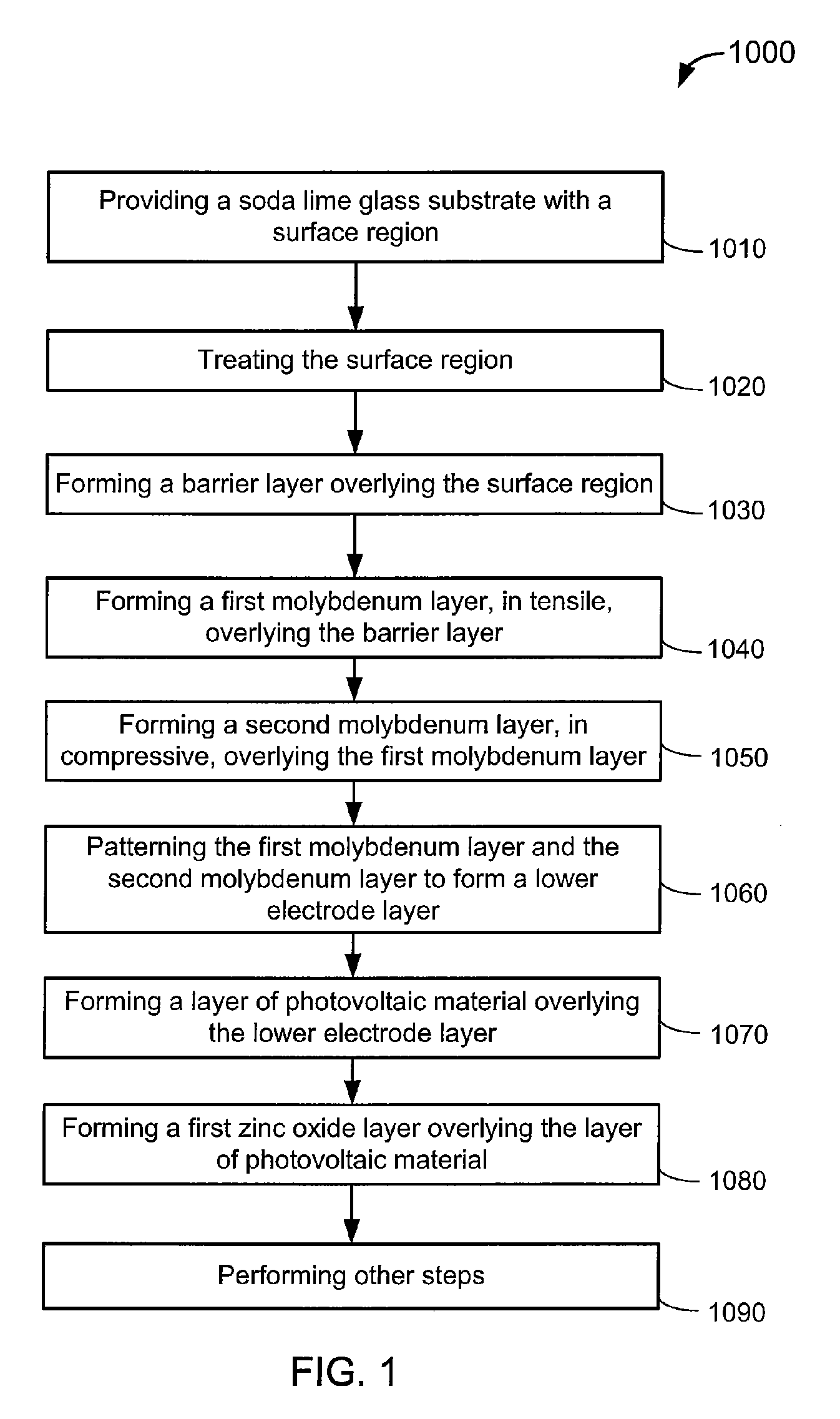

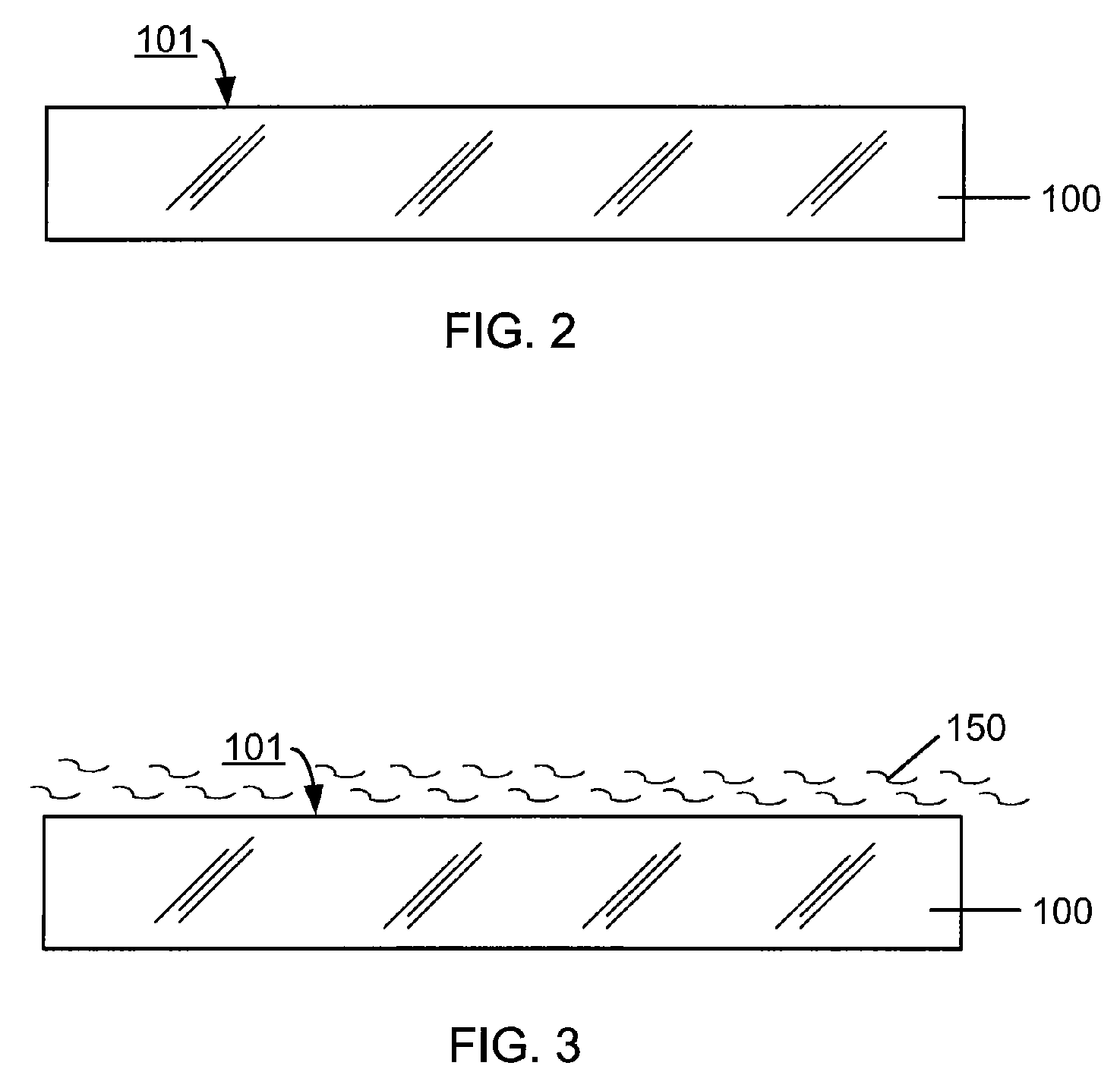

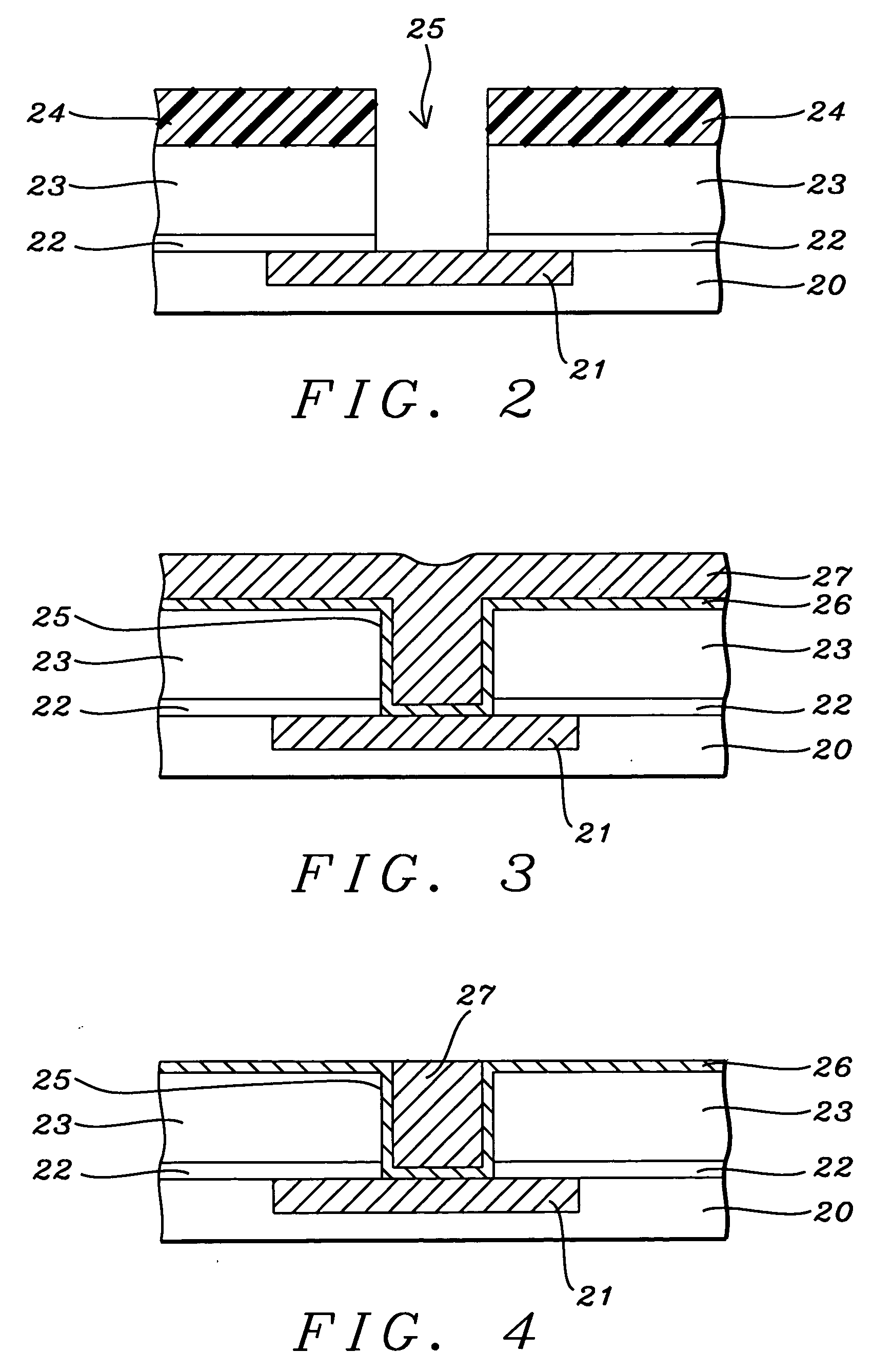

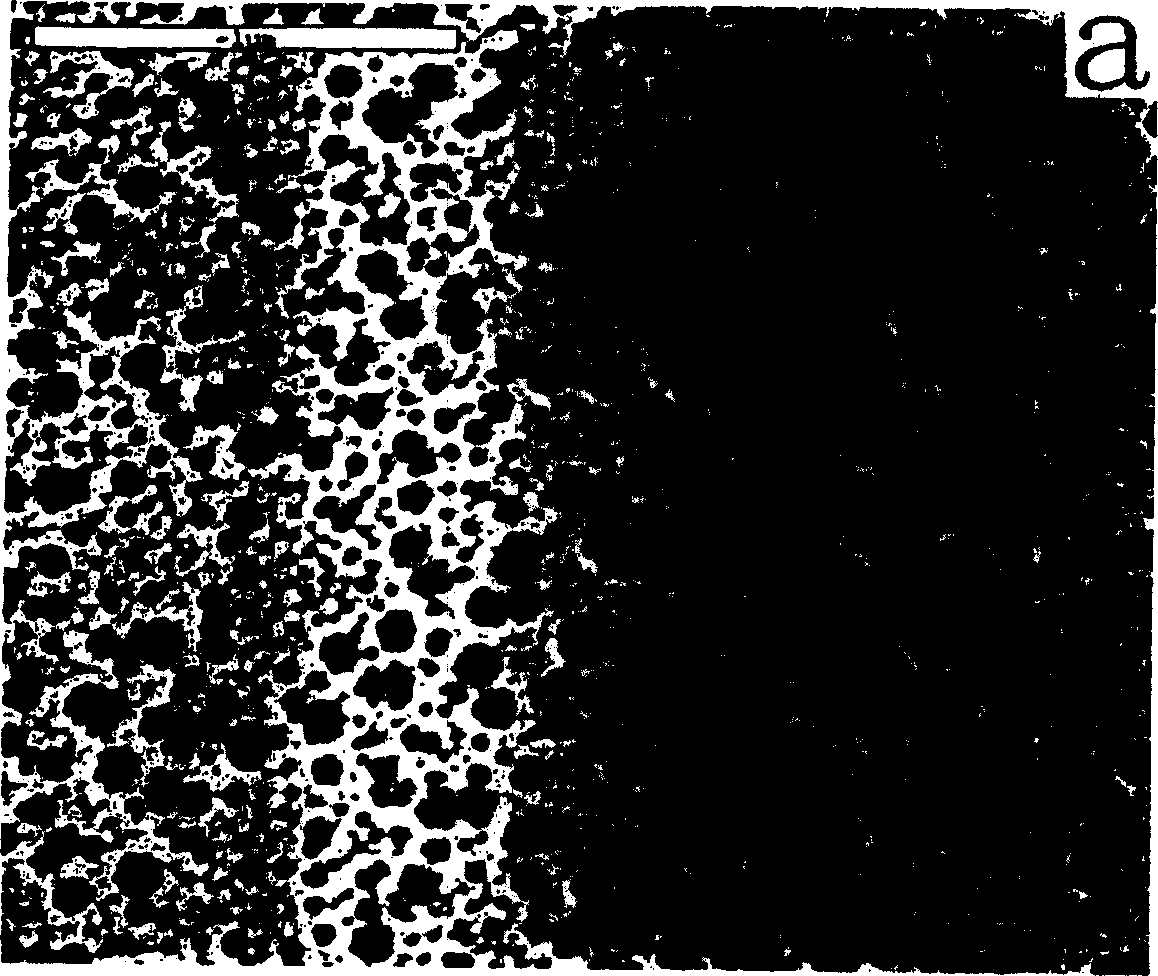

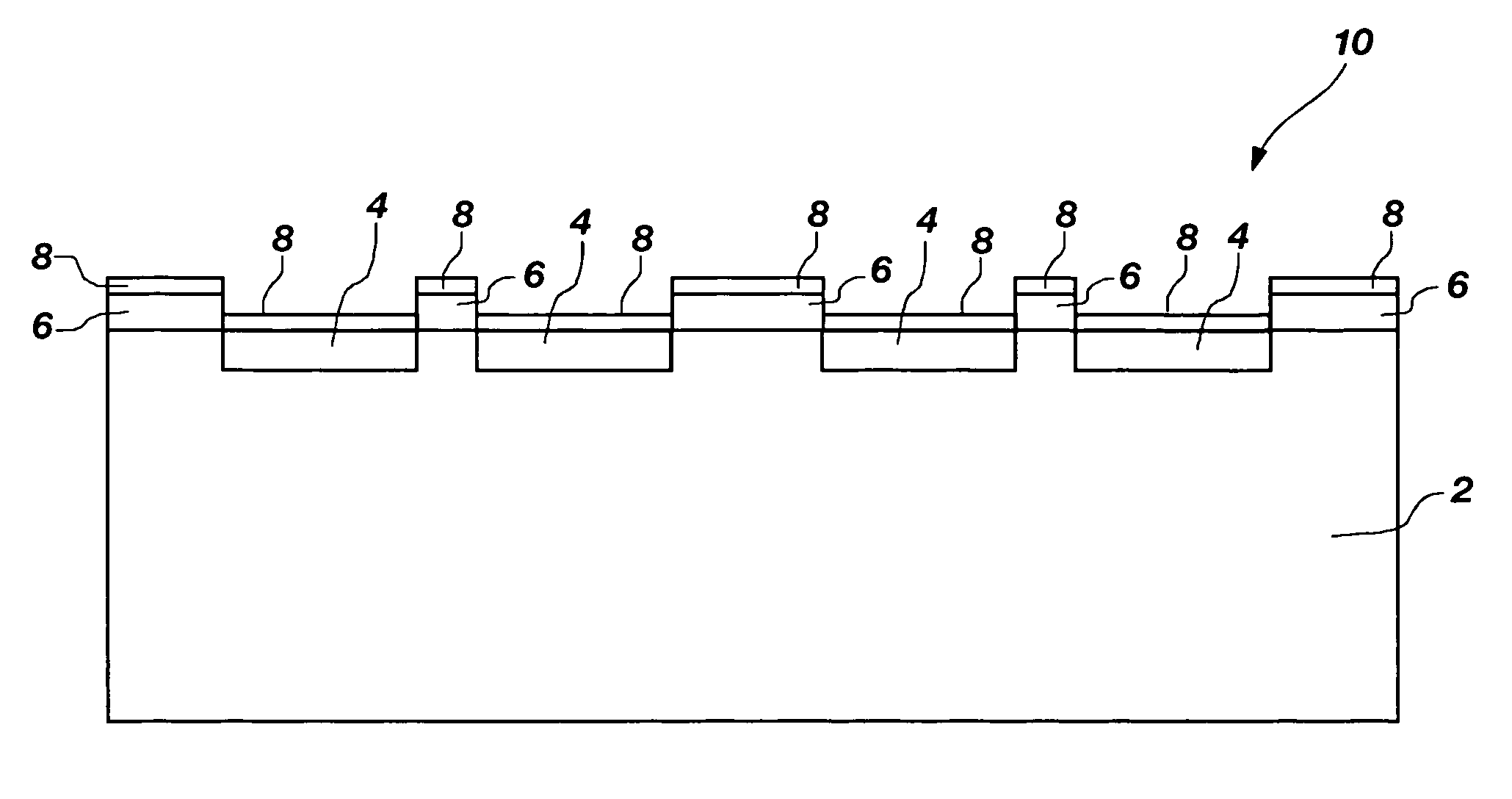

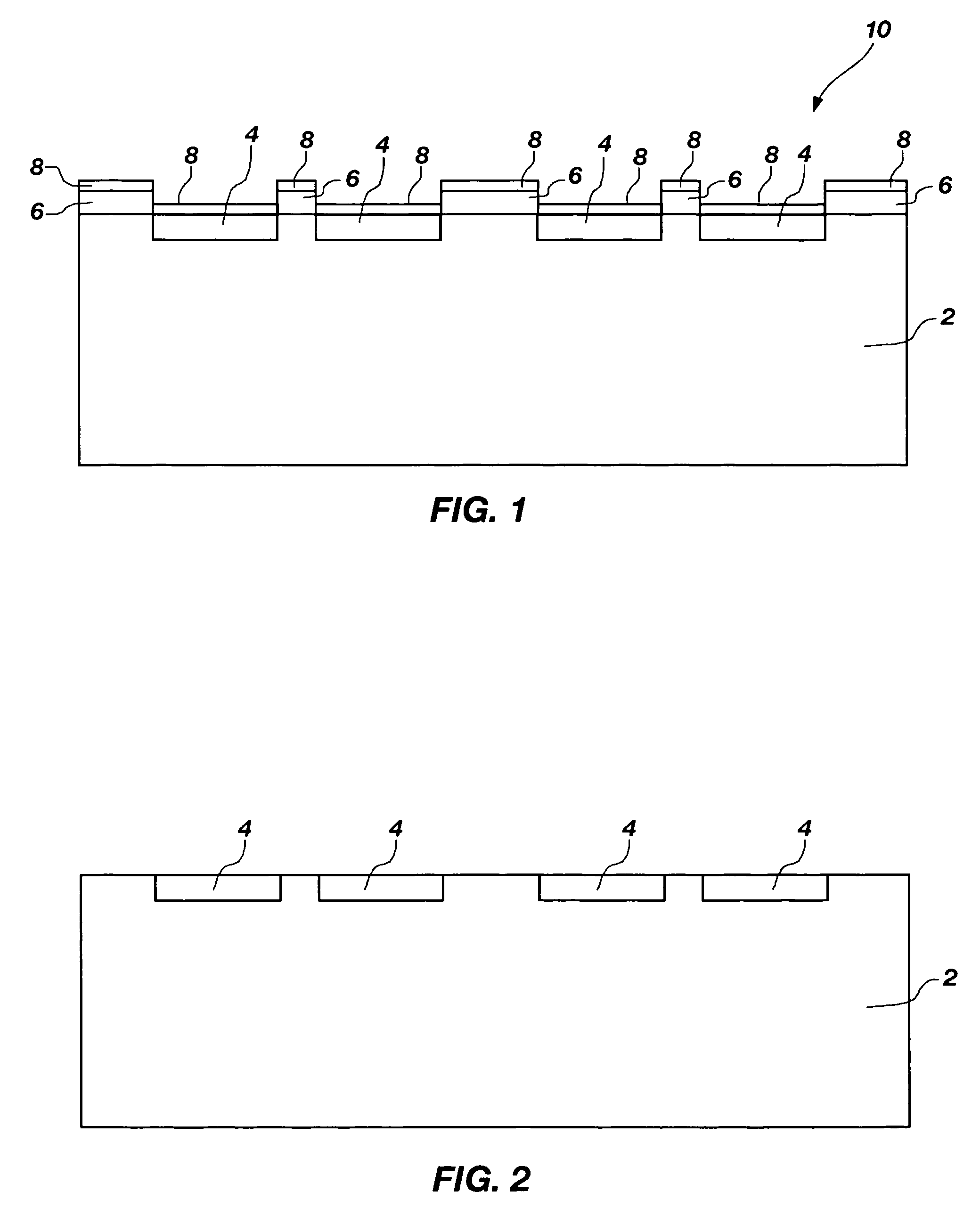

Thin film sodium species barrier method and structure for cigs based thin film photovoltaic cell

InactiveUS20100258179A1Large grainImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptoelectronicsSpecies barrier

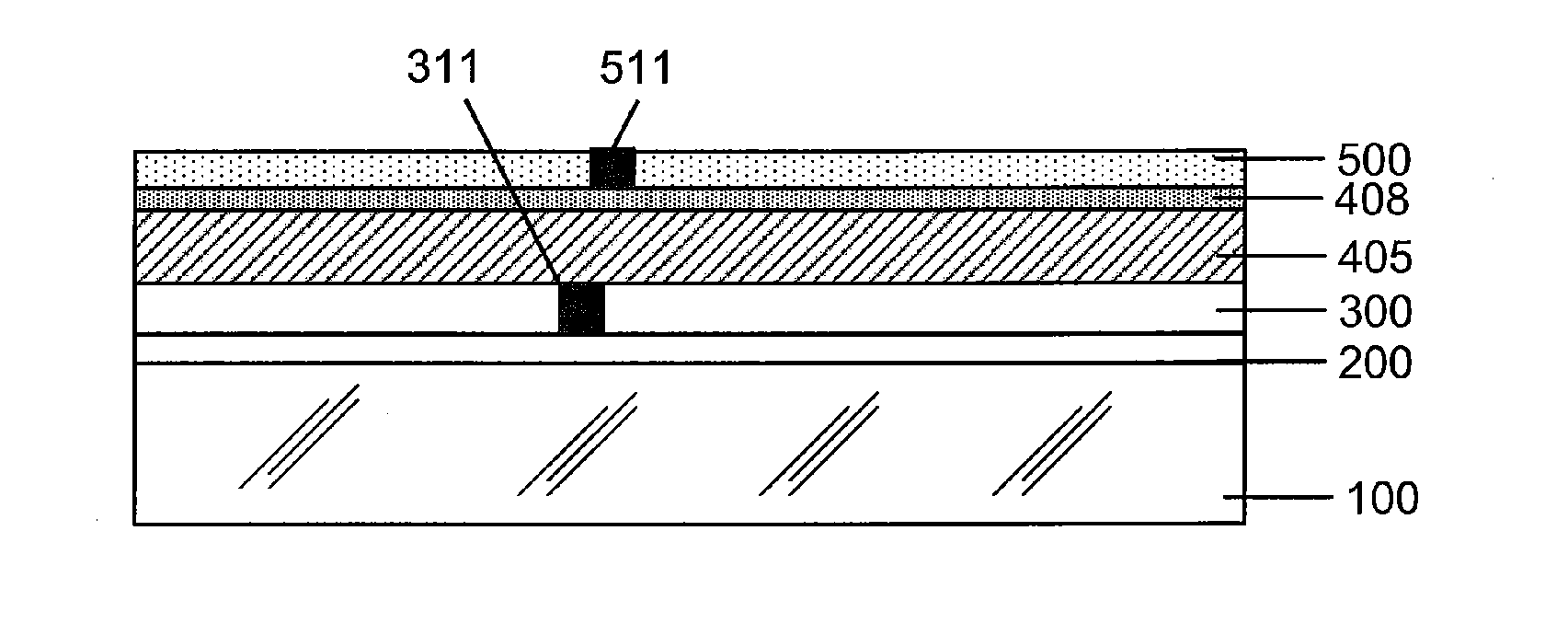

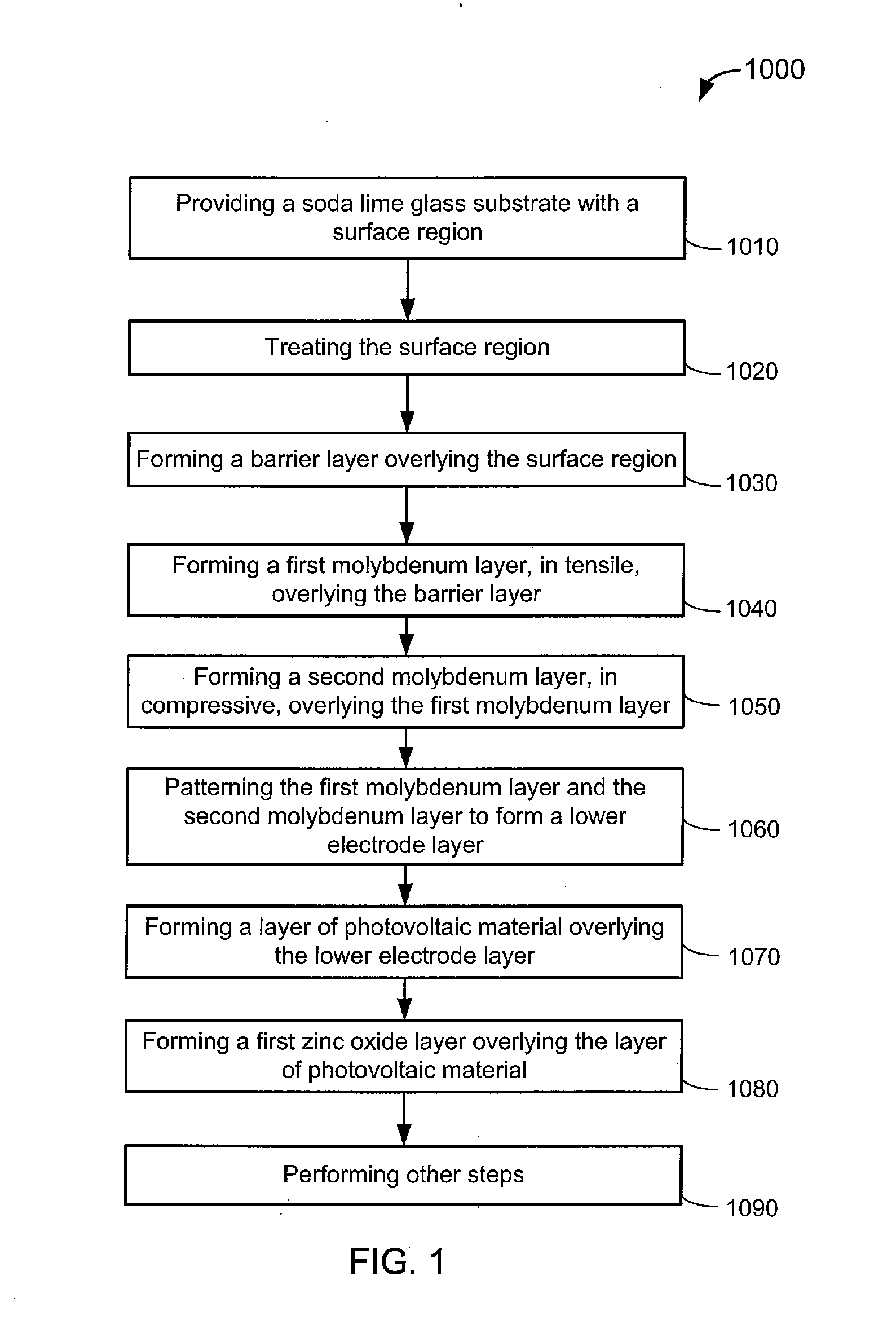

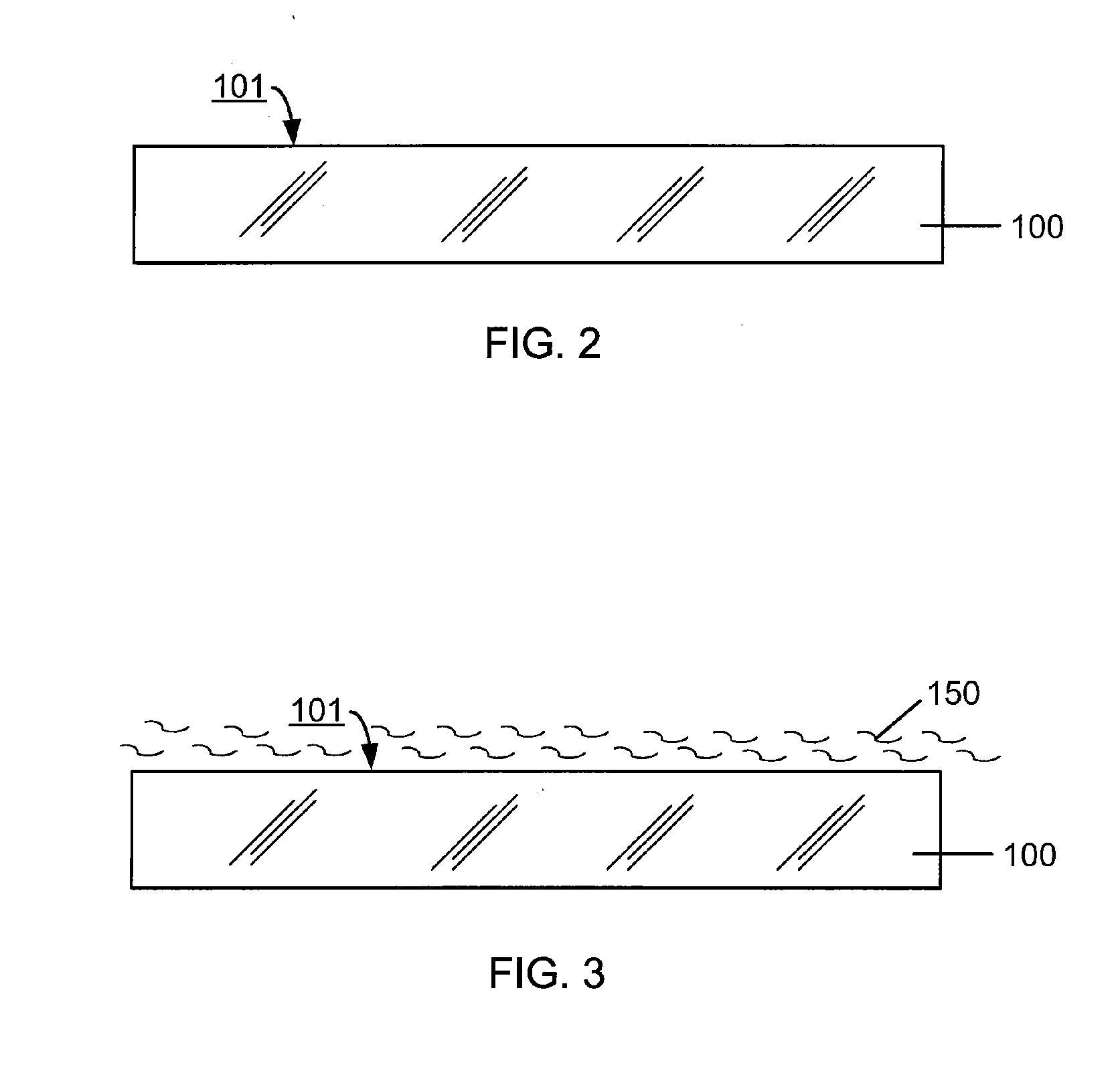

A method for fabricating a thin film solar cell includes providing a soda lime glass substrate comprising a surface region and a concentration of sodium oxide of greater than about 10 wt % and treating the surface region with one or more cleaning process, using a deionized water rinse, to remove surface contaminants having a particles size of greater than three microns. The method also includes forming a barrier layer overlying the surface region, forming a first molybdenum layer in tensile configuration overlying the barrier layer, and forming a second molybdenum layer in compressive configuration using a second process overlying the first molybdenum layer. Additionally, the method includes patterning the first molybdenum layer and the second molybdenum layer to form a lower electrode layer and forming a layer of photovoltaic material overlying the lower electrode layer. Moreover, the method includes forming a first zinc oxide layer overlying the layer of photovoltaic materials.

Owner:CM MFG

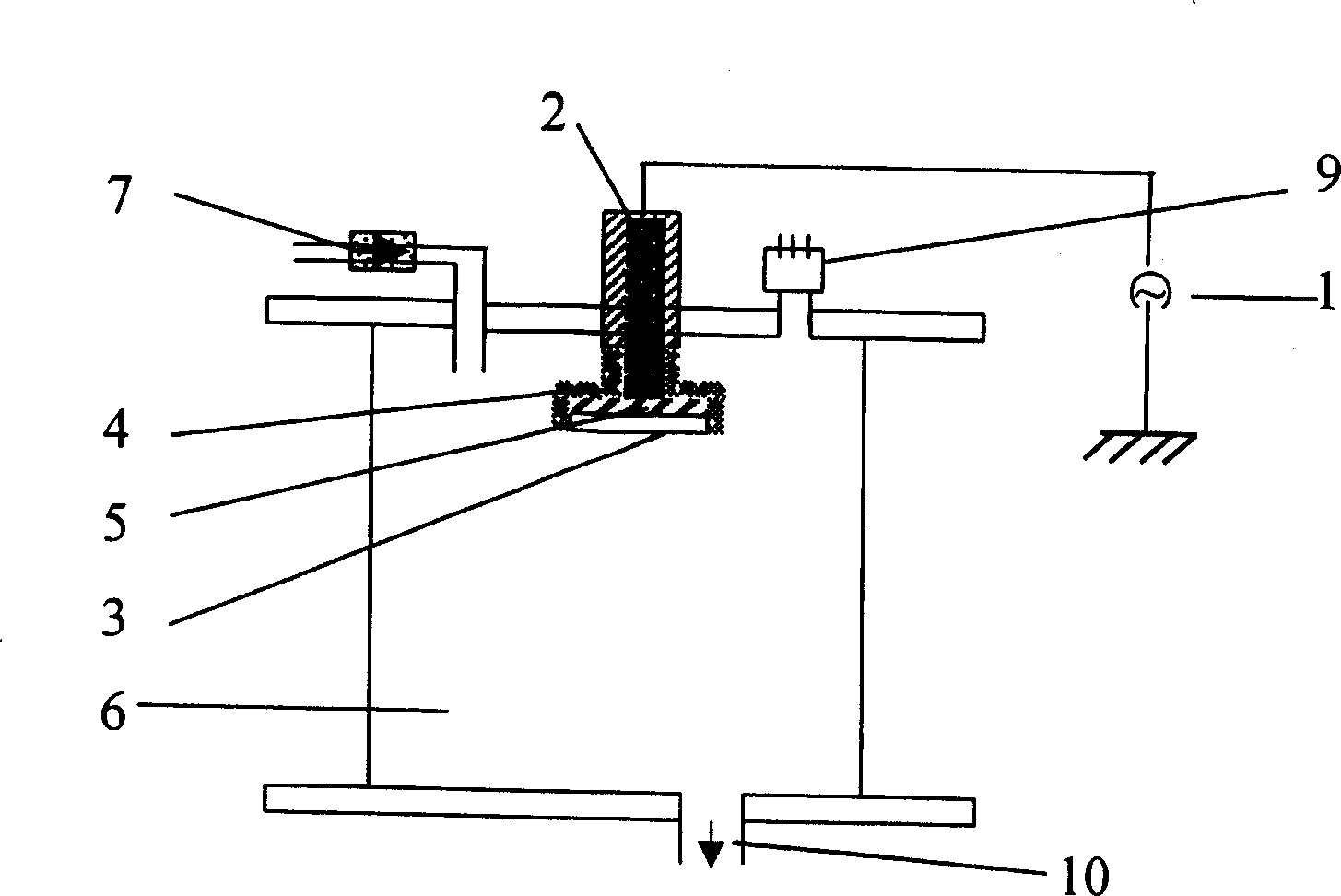

Preparation method and application of polycaprolactone/natural polymer composite porous scaffold

InactiveCN102277737AImprove hydrophilicityEasy to spreadLayered productsFibre typesFiberPolymer science

Preparation method and application of polycaprolactone / natural polymer composite porous scaffold, method: including preparation of polycaprolactone electrospun nanofiber membrane; (1) placing polycaprolactone electrospun nanofiber membrane in alkaline solution reaction, soaking and rinsing in deionized water; (2) putting the fiber membrane obtained in (1) into DMTMM or natural polymer solution of DTMMM to react, immersing and rinsing in deionized water, and then immersing in natural polymer for room temperature reaction, to remove Ionized water soaking and rinsing; (3) Evenly coating and casting the mixed solution of natural polymer materials on the fiber membrane obtained in (2), freeze-drying, and extracting the solvent; (4) Applying the double-layer scaffold obtained in (3) After soaking in the cross-linking room temperature reaction, soaking in deionized water, rinsing, and freeze-drying. The porous scaffold prepared by the invention is stable, has suitable pore diameter, good biocompatibility and fast degradation rate, and can be used for skin and clinical tissue and organ defect repair, reconstruction or wound dressing.

Owner:NANCHANG UNIV

Thickened hard surface cleaner

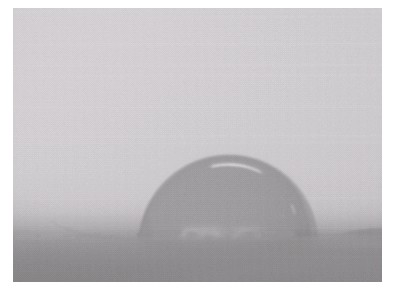

InactiveUS20020082178A1Efficient use ofHigh viscosityInorganic/elemental detergent compounding agentsCationic surface-active compoundsHard-surface cleanerWater rinsing

A low viscosity aqueous cleaning composition provides increasing viscosity upon dilution which provides a high viscosity diluted cleaning composition having solvents compatible with the rod micelle thickener and the cleaning system that clings for an extended period of time in a thickened form containing cleaning system ingredients that can penetrate and remove hard baked-on soils on vertical surfaces in cleaning units. The composition contains active cleaning ingredients (acid, alkaline and enzyme) that, in combination with thickening systems, provide the useful properties. The thickened materials can be applied on cold or hot surfaces and can successfully penetrate, soften and remove baked-on food soil on a variety of surfaces including oven walls, doors and grills, baking dishes, utensils, etc. The material is applied in the form of a thick diluted liquid spray or hot foam directly to the hardened soil, is permitted to penetrate the soil, resulting softened soils are then easily removed by hot or cold water rinse or by mechanical action such as scrubbing, scraping or wiping.

Owner:ECOLAB INC

Expansion type flame-retardant coatings glue and use thereof in textile finishing

ActiveCN101498100AImprove washing resistanceResistance to Mechanical ImprovementVegetal fibresCross-linkPolymer science

The invention discloses an intumescent flame retardant coating gum and the application thereof on fabric finishing. When the traditional intumescent flame retardant is applied to fabric, the fabric is not resistant to water rinse, water immersion or transfer, the flame retardant can lose or degrade under the action of luminous rays, heat, moisture and mechanical external force, and the flame retardant properties are reduced. The intumescent flame retardant coating gum comprises a flame retardant coating base gum and a carbon source, and is characterized in that the flame retardant coating base gum is prepared by mixing ammonium polyphosphate, melamine and 4A zeolite, adding organic alcohol, coating the mixture by more than two silane coupling agents for modification, drying the mixture after removing the organic alcohol to obtain a composite flame retardant, adding water, a non-ionic surface active agent, a binding agent and a cross-linking agent to the composite flame retardant, and grinding and dispersing the mixture; the carbon source is aqueous polyacrylic ester containing hydroxyl groups or aqueous polyurethane containing hydroxyl groups or a modifier of the former two. The invention obviously improves the performance of the flame retardant coating gum on flame retardant fabric for resistance to water rinse, transfer, light, heat and friction.

Owner:传化智联股份有限公司 +2

Thickened hard surface cleaner

InactiveUS6268324B1Efficient use ofHigh viscosityInorganic/elemental detergent compounding agentsCationic surface-active compoundsHard-surface cleanerWater rinsing

A low viscosity aqueous cleaning composition provides increasing viscosity upon dilution which provides a high viscosity diluted cleaning composition having solvents compatible with the rod micelle thickener and the cleaning system that clings for an extended period of time in a thickened form containing cleaning system ingredients that can penetrate and remove hard baked-on soils on vertical surfaces in cleaning units. The composition contains active cleaning ingredients (acid, alkaline and enzyme) that, in combination with thickening systems, provide the useful properties. The thickened materials can be applied on cold or hot surfaces and can successfully penetrate, soften and remove baked-on food soil on a variety of surfaces including oven walls, doors and grills, baking dishes, utensils, etc. The material is applied in the form of a thick diluted liquid spray or hot foam directly to the hardened soil, is permitted to penetrate the soil, resulting softened soils are then easily removed by hot or cold water rinse or by mechanical action such as scrubbing, scraping or wiping.

Owner:ECOLAB USA INC

Cleaning solution for substrate for semiconductor device and cleaning method

InactiveUS20060270573A1Good water rinsabilityEasy to cleanOrganic detergent compounding agentsDetergent mixture composition preparationDevice materialOrganic base

To provide a cleaning solution for a substrate for a semiconductor device capable of removing particle contamination, organic contamination and metal contamination at the same time without corroding the substrate surface, and further having good water rinsability and capable of making the substrate surface highly clean in a short time, and a cleaning method. A cleaning solution for a substrate for a semiconductor device, which comprises an organic acid as component (a), an organic alkaline component as component (b), a surfactant as component (c) and water as component (d) and which has a pH of at least 1.5 and less than 6.5. A method for cleaning a substrate for a semiconductor device, which comprises cleaning a substrate for a semiconductor device having a Cu film and a low dielectric constant insulating film on its surface and having CMP treatment applied thereto, by means of the above cleaning solution for a substrate for a semiconductor device.

Owner:MITSUBISHI CHEM CORP

Thin film sodium species barrier method and structure for cigs based thin film photovoltaic cell

InactiveUS8217261B2Large grainImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationBarrier methodWater rinsing

Owner:CM MFG

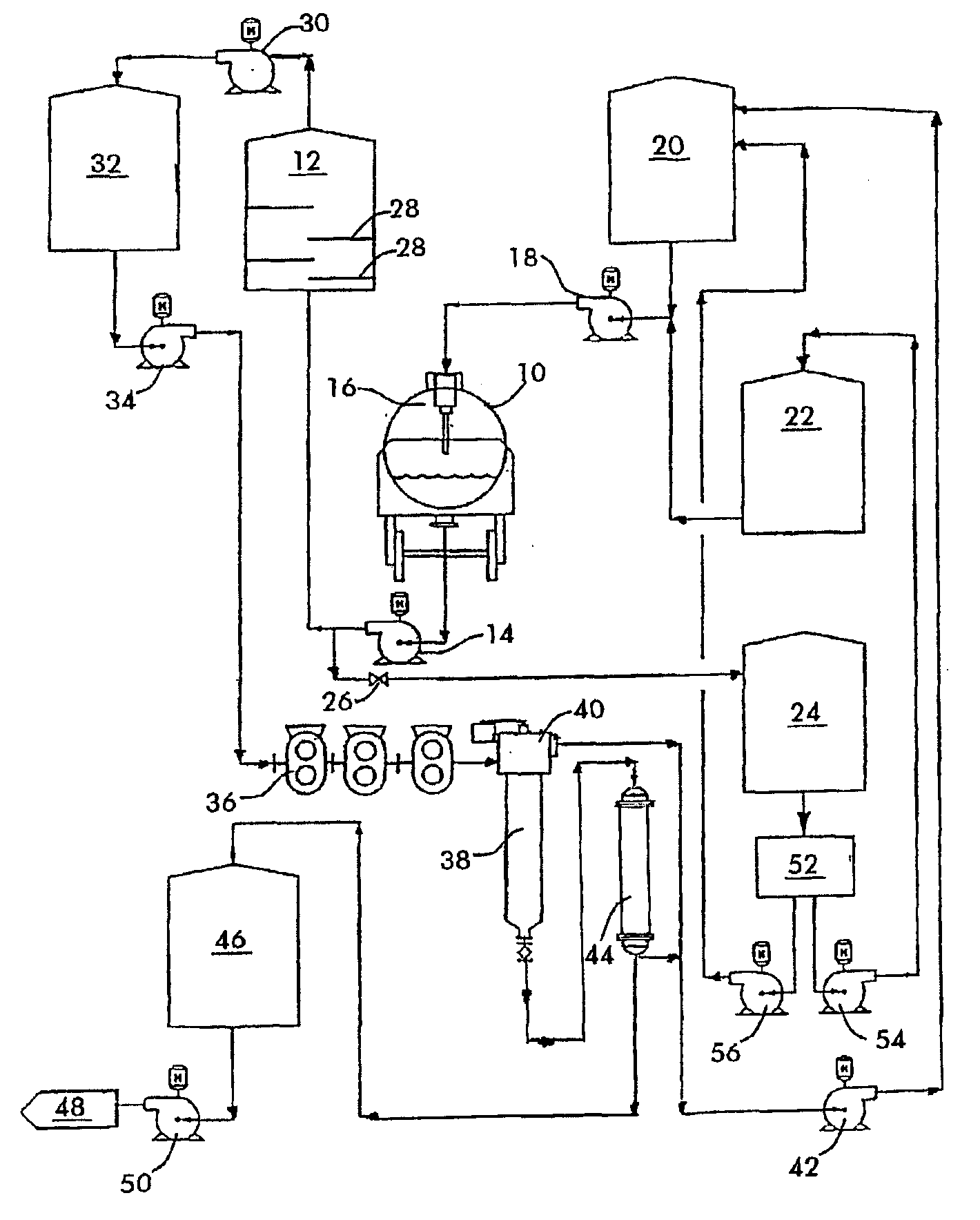

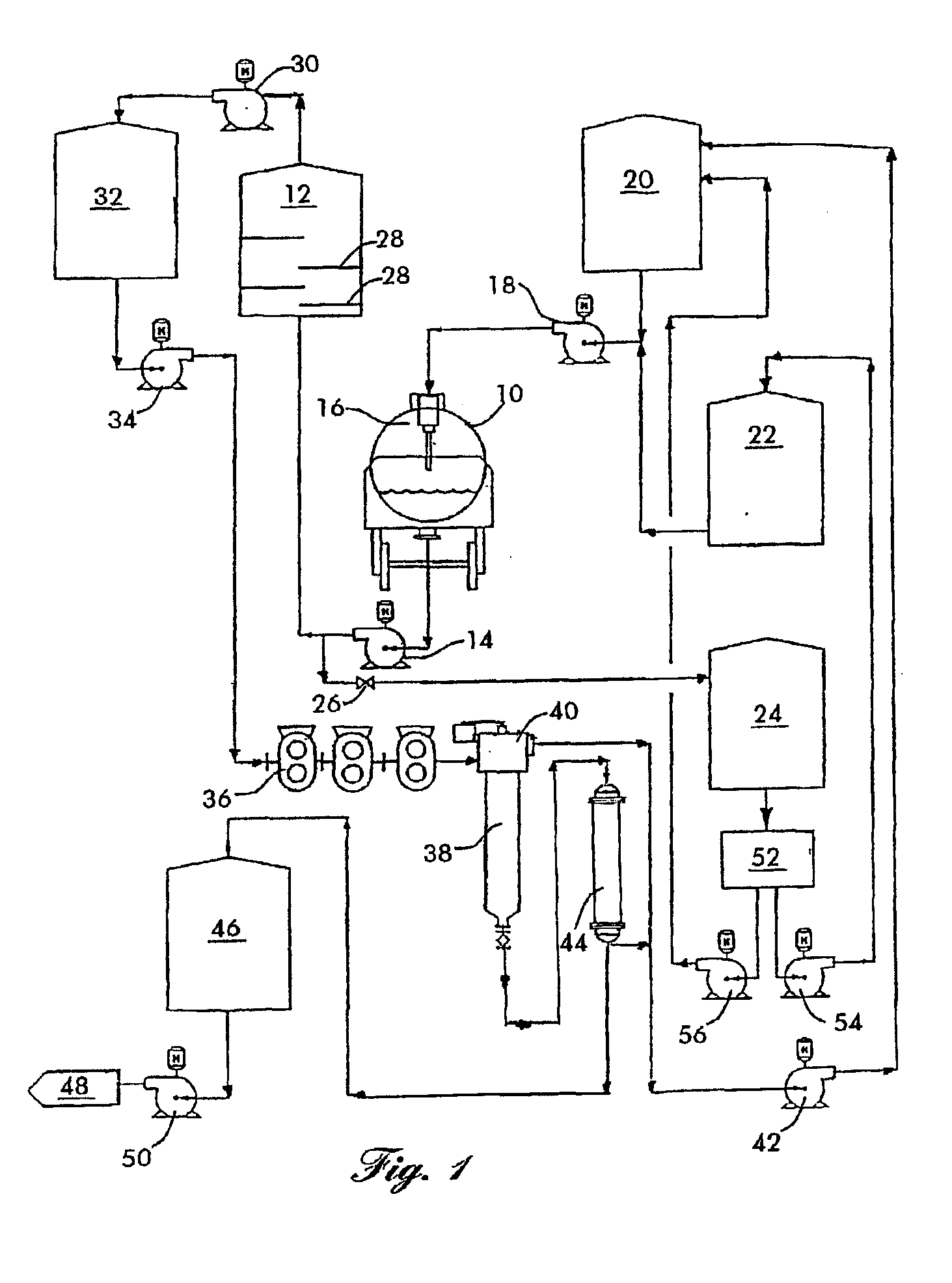

Closed loop cleaning system

InactiveUS6858090B2Hollow article cleaningLiquid hydrocarbon mixture productionDistillationPetroleum product

Railroad tank cars that have contained petroleum products are cleaned of asphalt residues by a closed cleaning system. An initial spray of terpene-based solvent is followed by a water rinse. The solvent extracts hydrocarbons from the asphalt residue. The solvent and hydrocarbon are separated by filtration, stratification, and distillation, allowing reuse of clean solvent and sale of marketable oil products. The rinse water is cleaned by filtration and evaporation of solvent residues, allowing reuse of the water. The asphalt solids such as residual inorganics are removed by filtration as a dry product suited for disposal in a landfill.

Owner:HEBERT SHIRLEY A

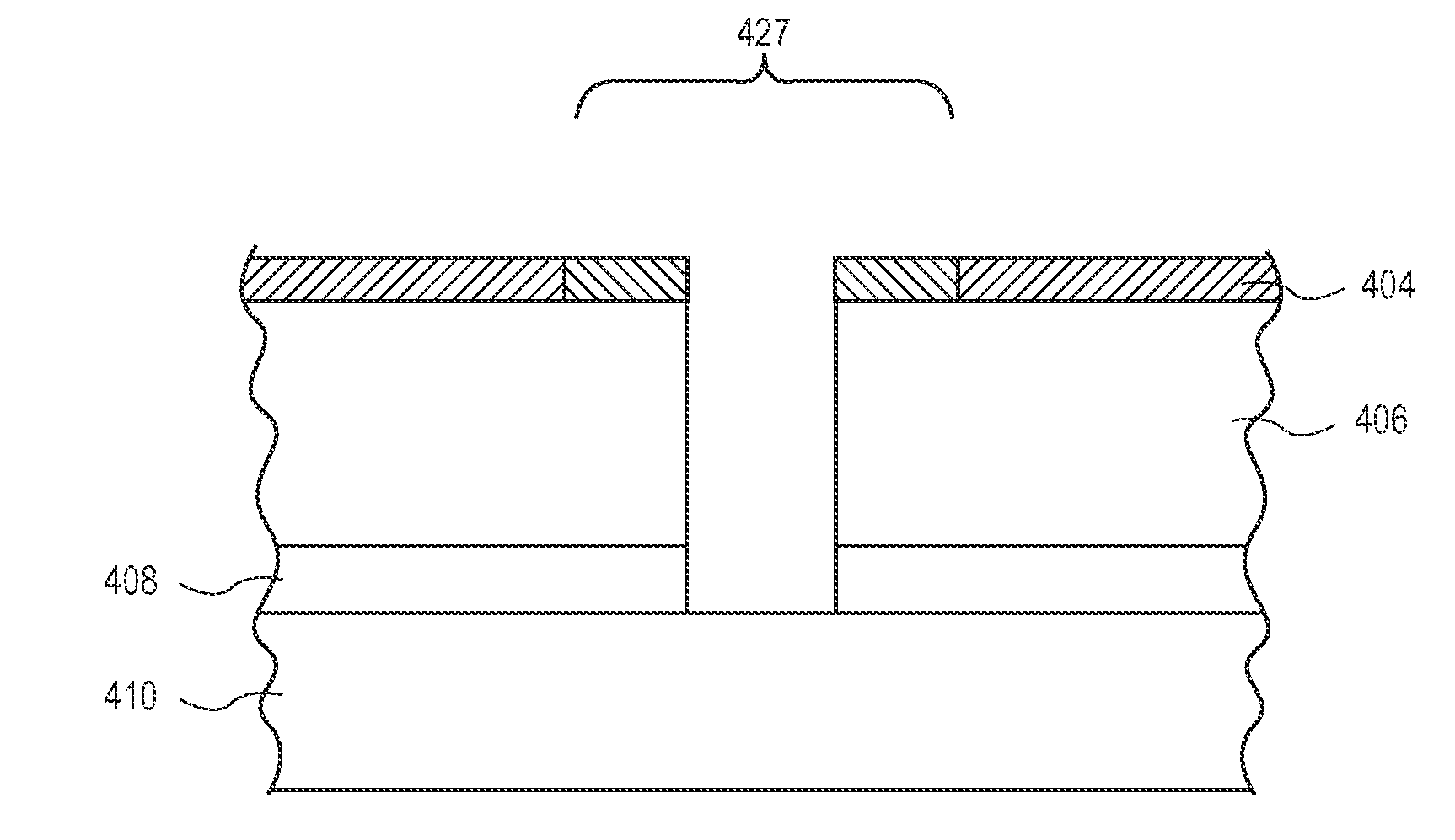

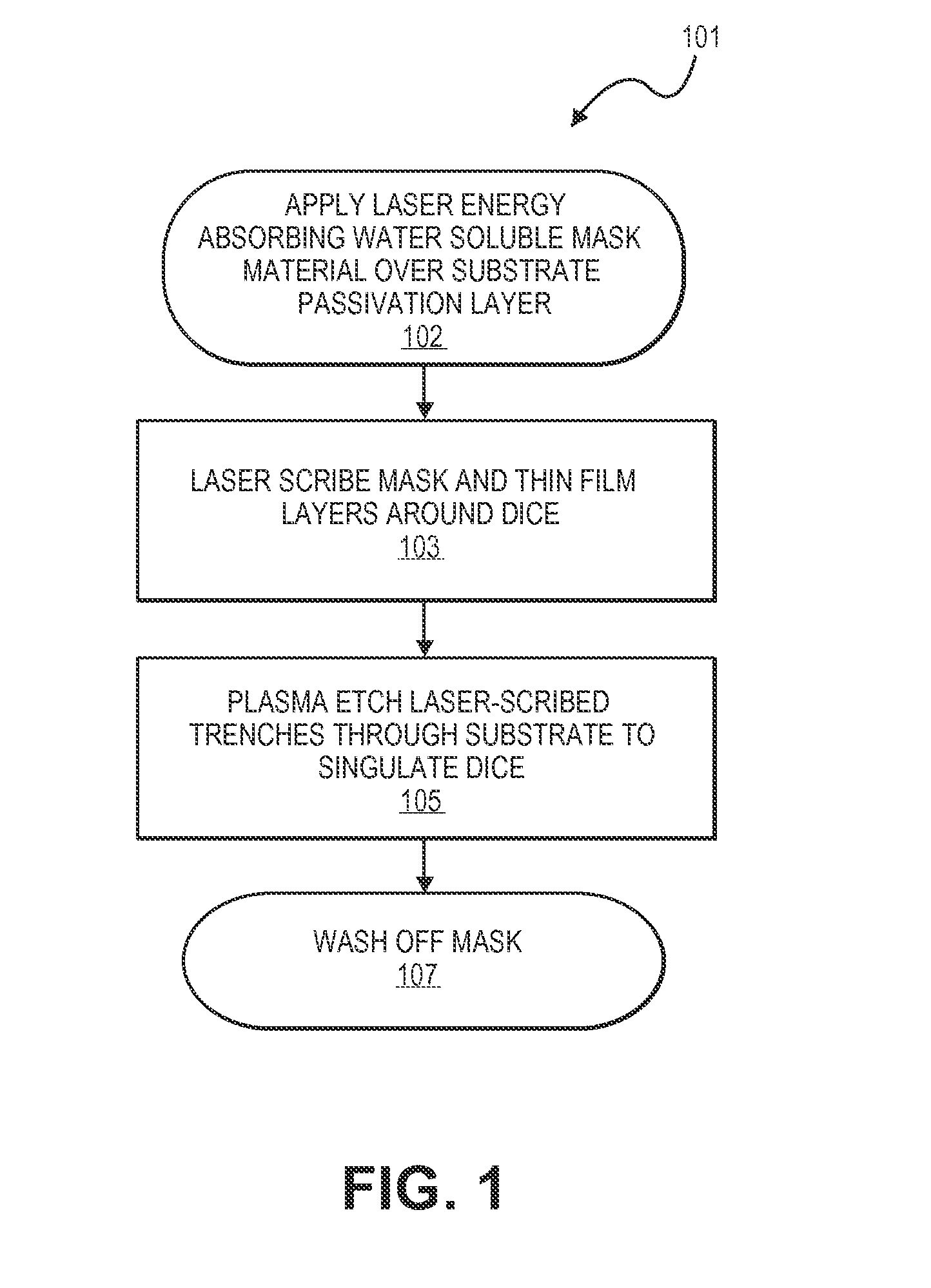

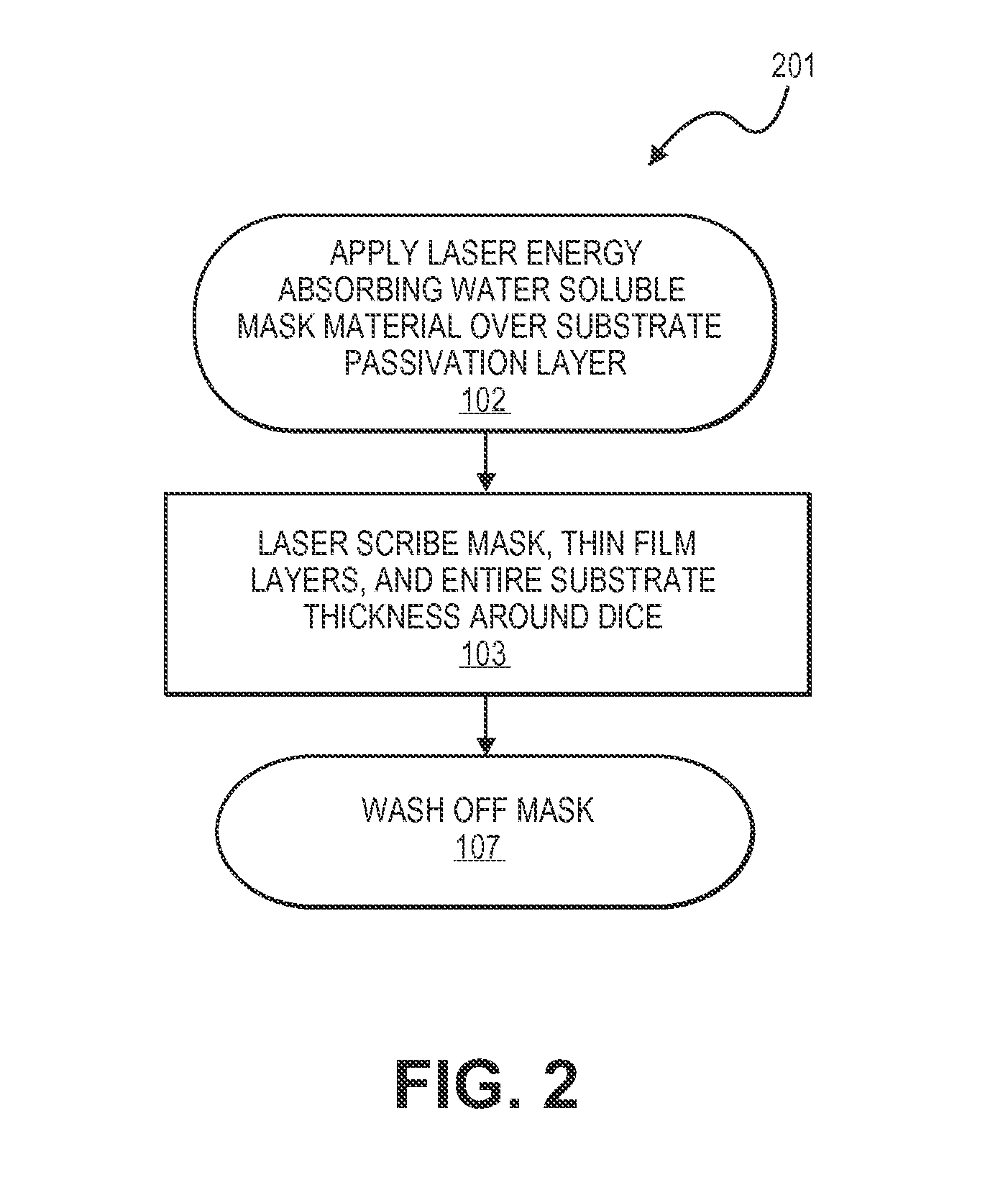

Substrate laser dicing mask including laser energy absorbing water-soluble film

InactiveUS20140273401A1Improve edge qualitySemiconductor/solid-state device detailsSolid-state devicesWater rinsingWater soluble

Methods of dicing substrates having a plurality of ICs. A method includes forming a mask comprising a laser energy absorbing material layer soluble in water over the semiconductor substrate. The laser energy absorbing material layer may be UV curable, and either remain uncured or be cured prior to removal with a water rinse. The mask is patterned with a laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the substrate between the ICs. The substrate may then be plasma etched through the gaps in the patterned mask to singulate the IC with the laser energy absorbing mask protecting the ICs for during the plasma etch. The soluble mask is then dissolved subsequent to singulation.

Owner:APPLIED MATERIALS INC

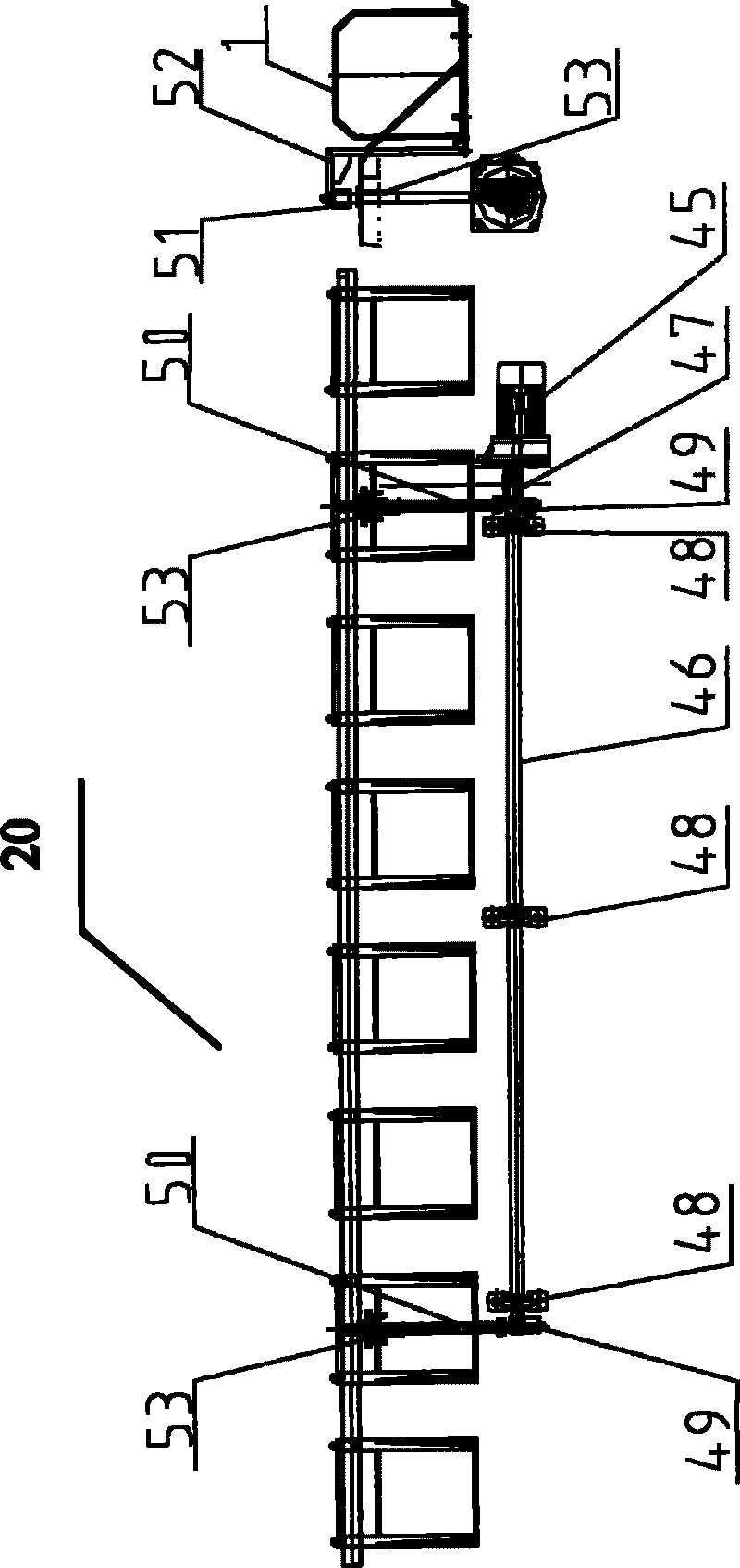

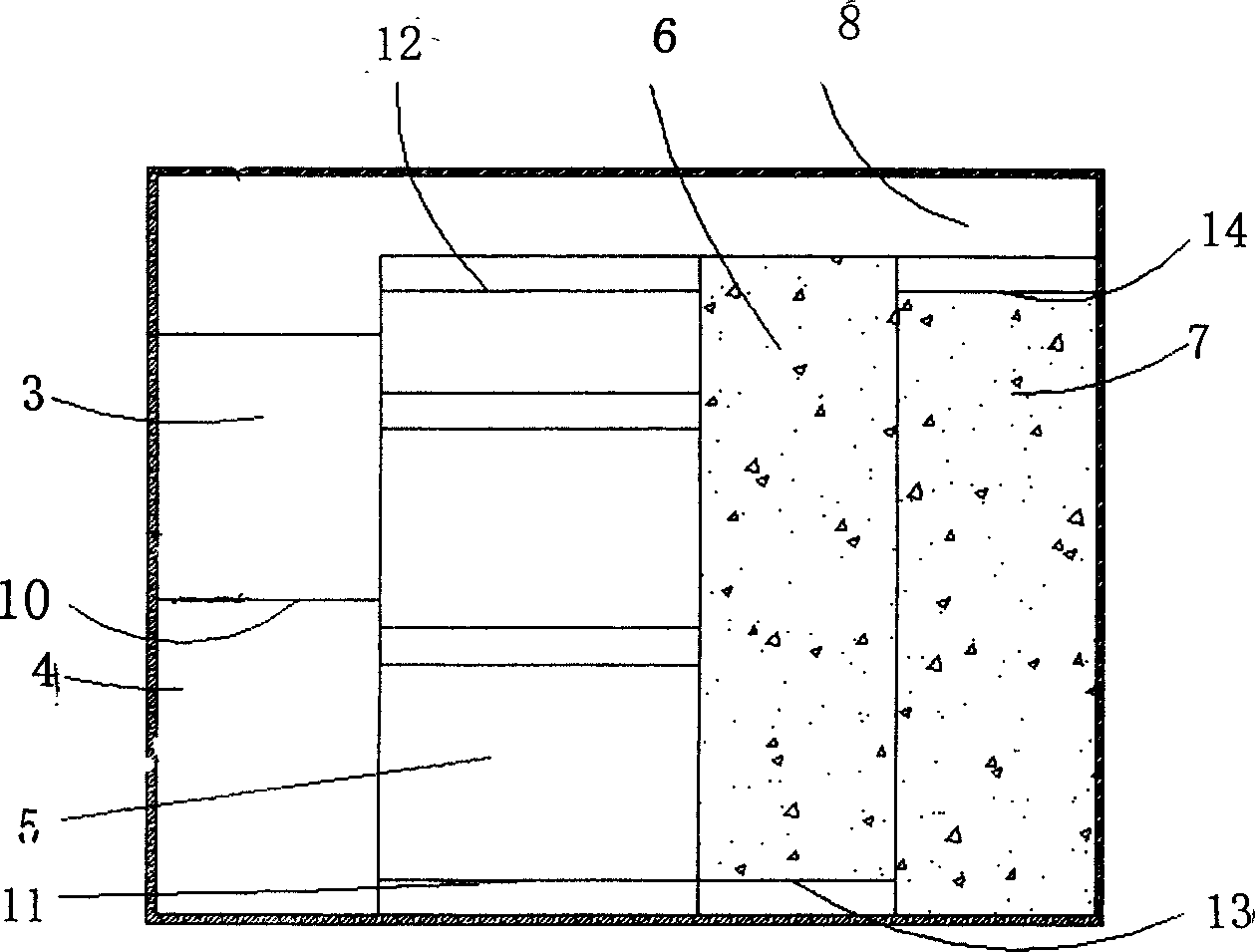

Ultrasonic wave cleaner for coating of optical lens and treatment method thereof

The invention discloses an ultrasonic wave cleaner for a coating of an optical lens and a treatment method thereof, which belong to the fields of metal surface treatment technology, vacuum coating technology and optical technology. The ultrasonic wave cleaner is characterized by performing ultrasonic alkali cleaning, pure water rinsing and ultrasonic pure water rinsing on the optical lens in cleaning medium under the condition of pendular motion respectively, slowly and perpendicularly lifting the optical lens or ensuring that a liquid slowly descends to break away from a workpiece when running water is circularly filtered, and using hot air to dry the optical lens under quiescent conditions. A structure of the ultrasonic wave cleaner is that: a conveyer is provided with traveling girders, the girders are provided with grab hooks, and the hooks are suspended with washing baskets; and different working procedures are finished by different devices, namely a liquid tank body is matched with a pendulous device, a dehydration device and a drying device to finish respective working procedures. The ultrasonic wave cleaner and the method have the advantages that the ultrasonic wave cleaner and the method do not use inflammable, explosive and toxic organic solvents to wash, reduce energy consumption, avoid the air pollution in workshops, can effectively improve the cleanliness of products, and ensure that the adhesive force of the coating of the optical lens is remarkably improved.

Owner:SHANGHAI MINGXING KAICHENG ULTRASONIC TECH

Nano water-based cleaning agent and preparing method thereof

InactiveCN102816660AReduce cleaningSave energySurface-active non-soap compounds and soap mixture detergentsWater basedDissolution

The invention relates to the technical field of industrial cleaning agents, is an improvement of the prior art, and particularly relates to a nano water-based cleaning agent and a preparing method thereof. The cleaning agent comprises, by weight, 2.0% to 18.0% of saponifiers, 5.0% to 30.0% of surfactants, 0.05% to 0.5% of inhibiters, 0.05% to 0.5% of nano defoamers, 0.2% to 1.0% of water-soluble nano silica and the balance deionized water, wherein the total weight percentage is 100%. The nano water-based cleaning agent and the preparing method thereof are characterized in that bubbles during a cleaning process are few, water rinsing is not needed after cleaning, the cleaning procedure is reduced, and the energy is saved and the cost is reduced; and volatile organic solvents are not contained, cleaned objects are not corroded, the application range is wide, and heat dissolution is not needed during the preparation so that energy is saved. The nano water-based cleaning agent and the preparing method thereof are practical and large in market potential.

Owner:PERFECTION SCI & TECH DONGGUAN +1

Copper CMP defect reduction by extra slurry polish

InactiveUS20050106872A1Reduce in quantityLower Level RequirementsSemiconductor/solid-state device manufacturingWater rinsingSlurry

An oxide polishing process that is part of a CMP process flow is disclosed. After a copper layer is polished at a first polishing station and a diffusion barrier layer is polished at a second polishing station, a key sequence at a third polish station is the application of a first oxide slurry and a first DI water rinse followed by a second oxide slurry and then a second DI water rinse. As a result, defect counts are reduced from several thousand to less than 100. Another important factor is a low down force that enables more efficient particle removal. The improved oxide polishing process has the same throughput as a single oxide polish and a DI water rinse method and may be implemented in any three slurry copper CMP process flow.

Owner:TAIWAN SEMICON MFG CO LTD

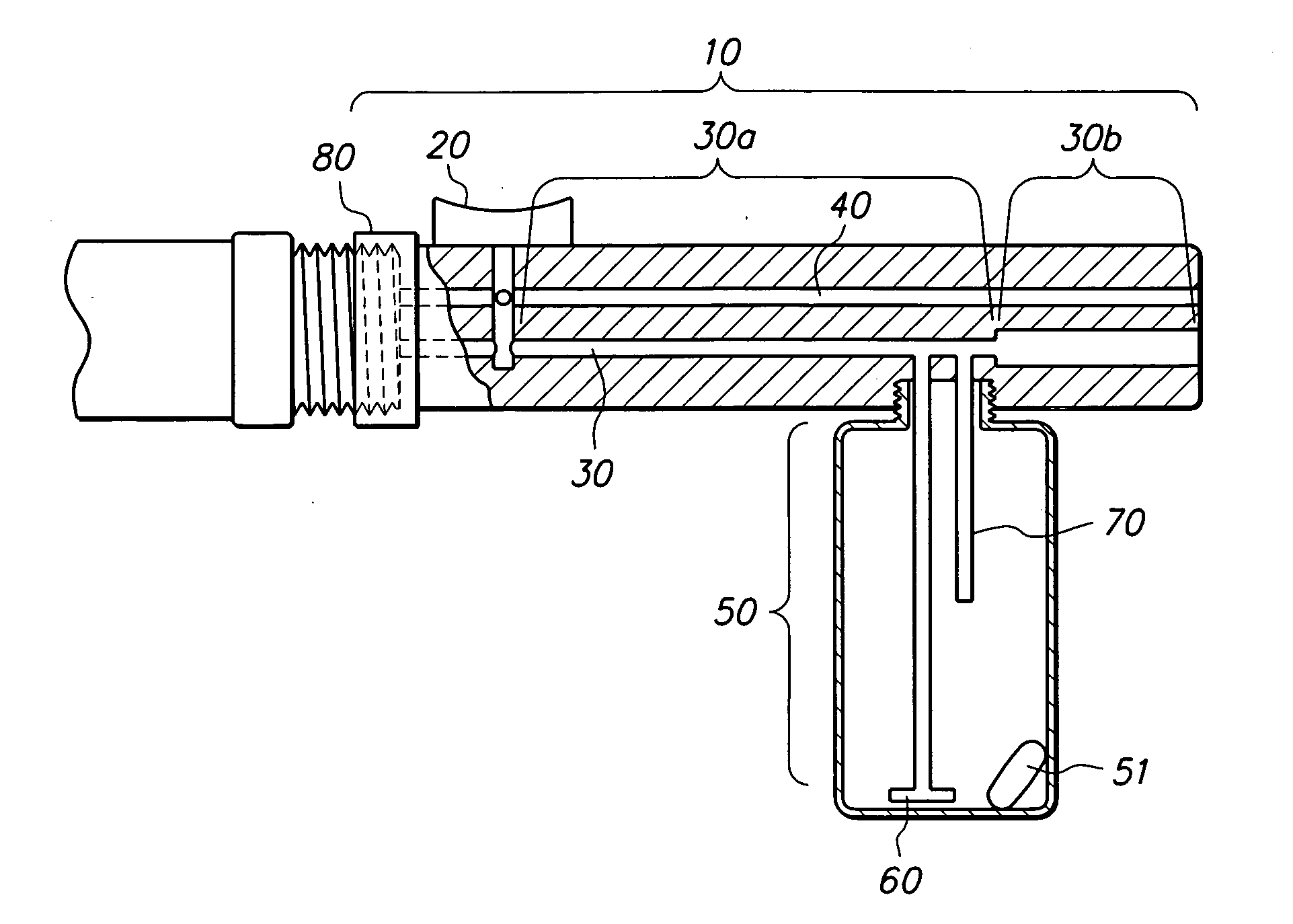

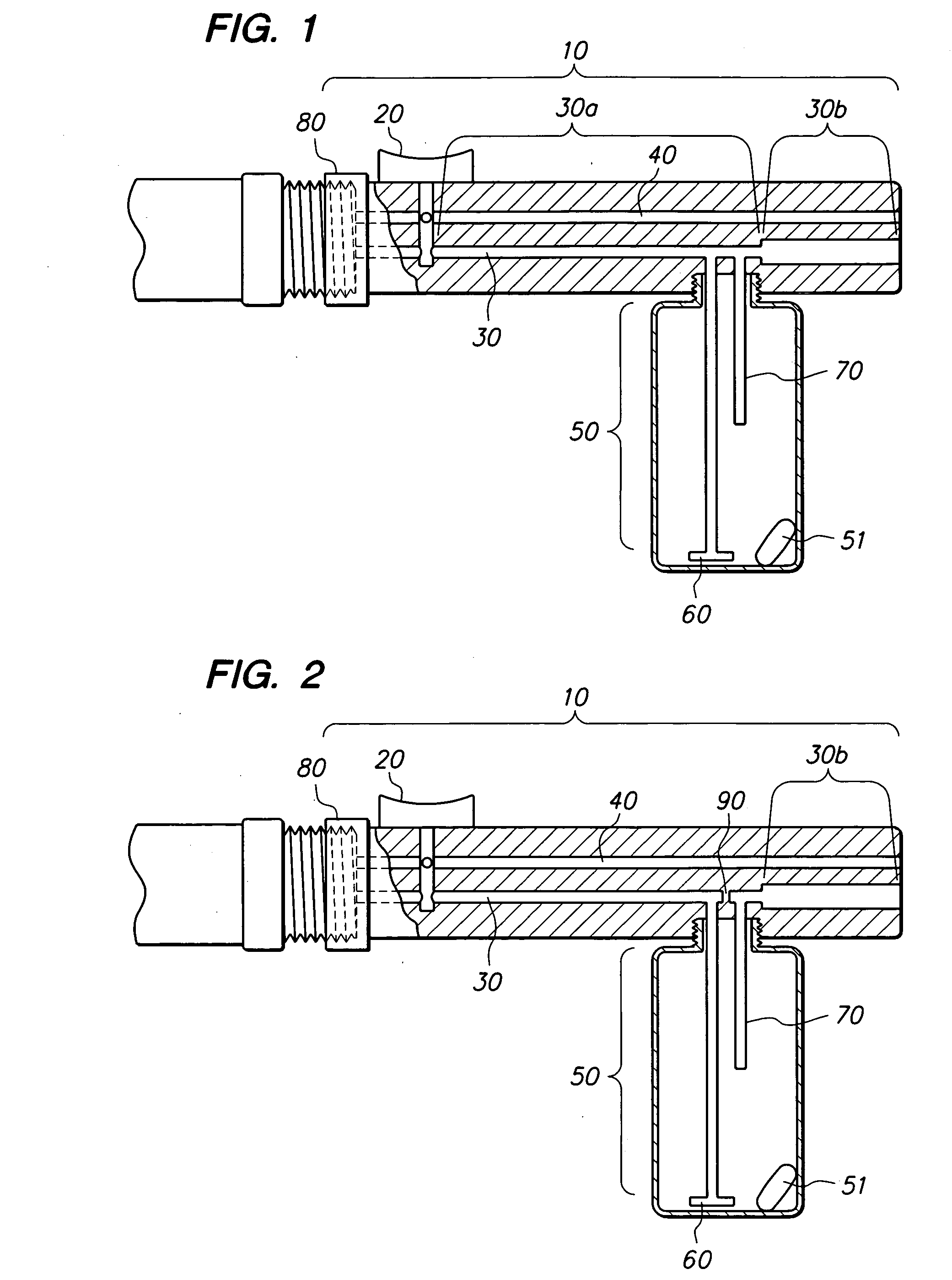

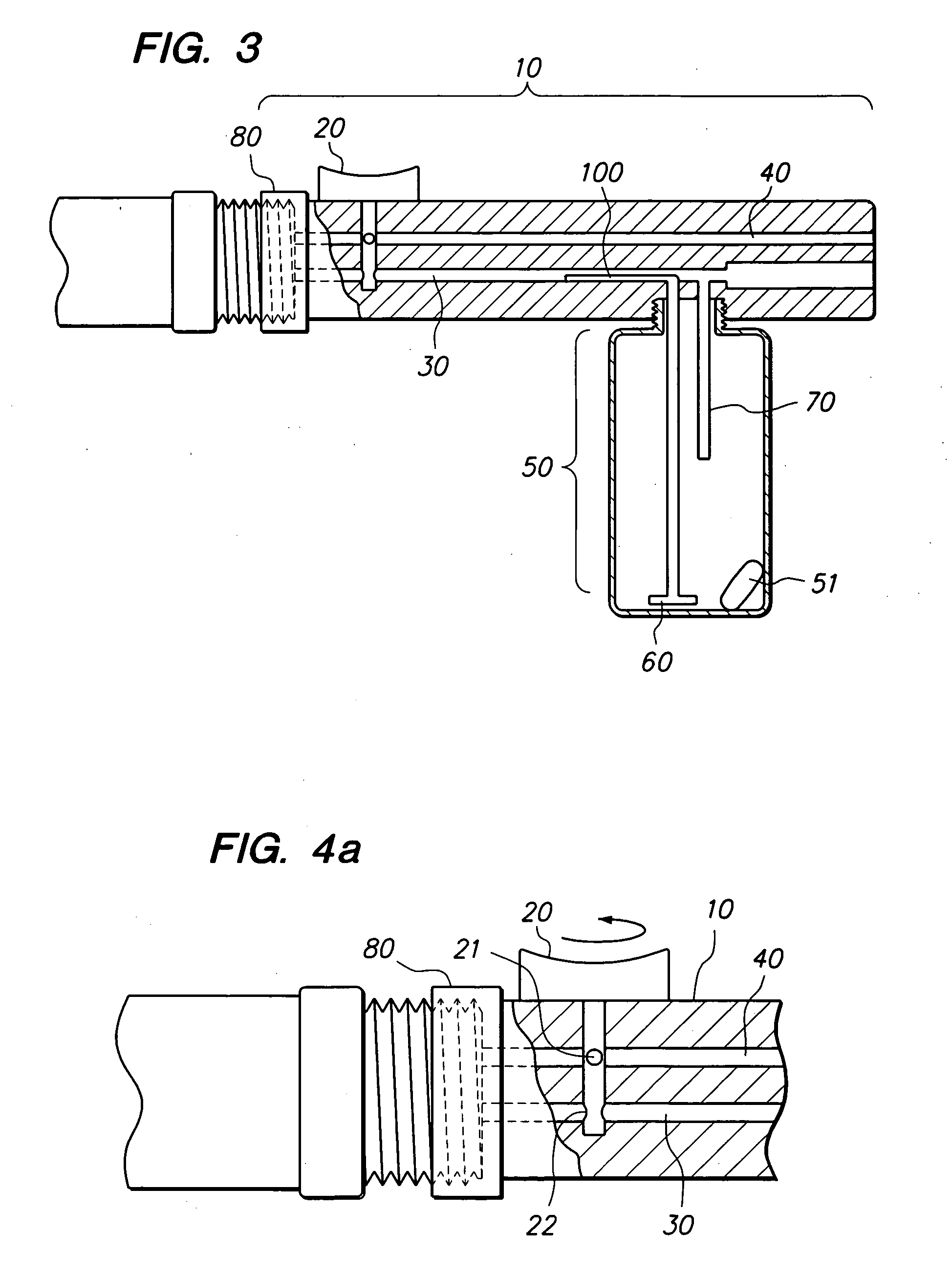

Multi-barreled sprayer for selective spraying a plurality of substances and / or rinse water

A multi-barreled sprayer for applying a diluted product such as a diluted cleaning solution to a surface for cleaning thereof and rinsing the diluted product from the surface by spraying a water-only rinse onto the surface from the sprayer. The sprayer can include a flow meter therein for providing a desired product dilution ratio. To provide different spray patterns for the water rinse or diluted product, the sprayer can include a shroud having shaped exit holes. The sprayer includes separate flow paths for the water-only rinse and the diluted product. The flow path for the diluted product includes a mixing chamber in which concentrated tablet product is diluted and mixed with water supplied by a garden hose, for instance. A rotatable valve allows selective application of water or diluted product. Additional embodiments include a trigger assembly that allows selective application of water for either of the water-rinse or diluted product application.

Owner:THE CLOROX CO

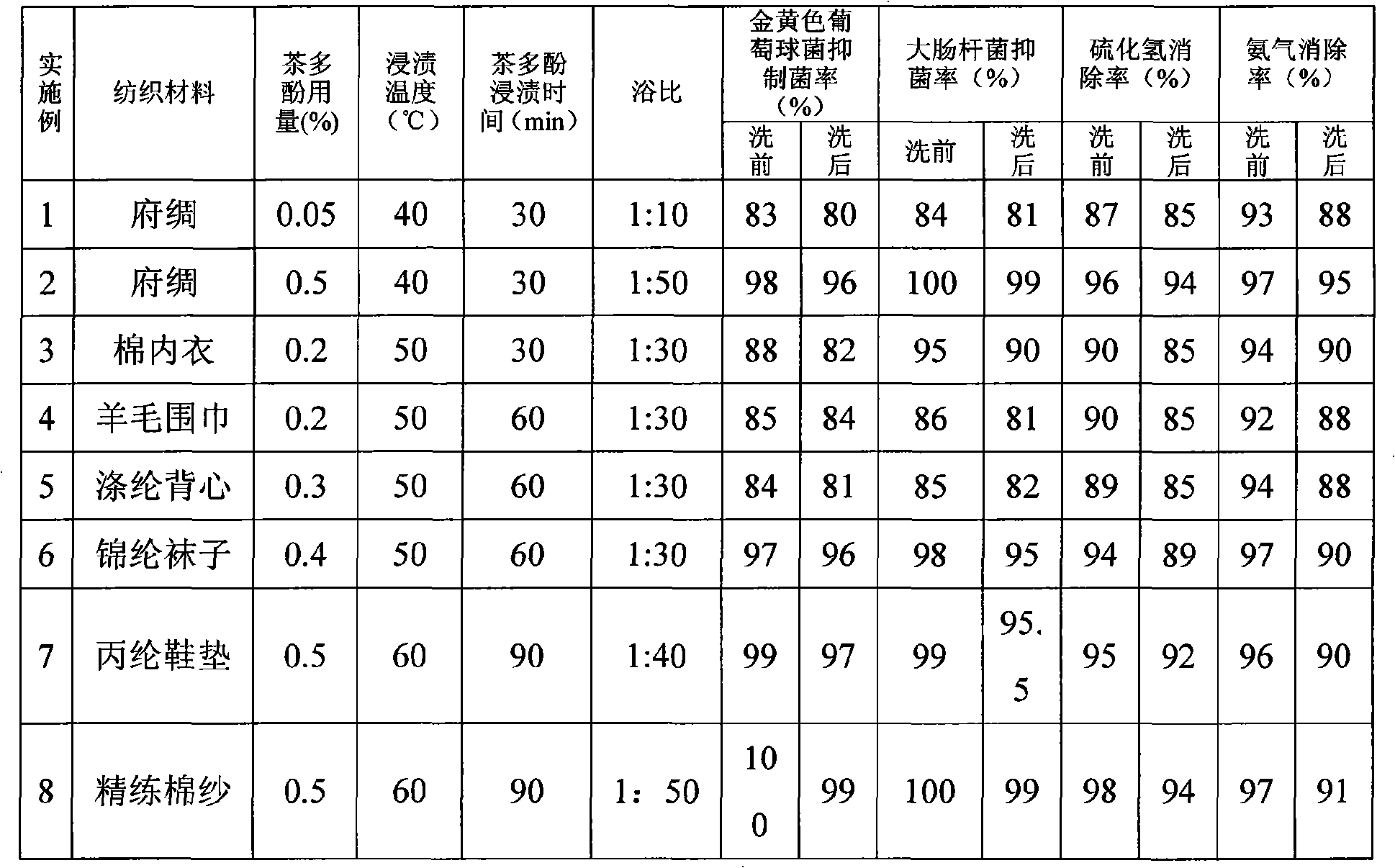

Preparation of environment-friendly type antibiotic and odor removing textile

The invention discloses a preparation method of an environment-friendly, antisepsis and deodorant fabric product and comprises following steps: (1) a fabric material or a fabric product is soaked and processed in a tea polyphenol solution with the concentration of 0.05 to 0.5 percent by weight for 30 to 90 minutes, the weight ratio of the fabric material or the fabric product to the tea polyphenol solution is between 1 : 10 to 50, and the soaking temperature is 40 to 60 DEG C; (2) a metallic ion solution that is equimolar with the tea polyphenol is added, and the fabric material or the fabric product is soaked and processed for 60 minutes, water rinsed, and then parched or dried. The preparation method of the environment-friendly, antisepsis and deodorant fabric product is applicable to various fibers such as multiple kinds of natural fibers like cotton hemp, wool and dacron, and synthesized chemical fibers. The preparation method can be adopted to produce various antisepsis and deodorant garment materials, home-textile materials (such as bedding fabrics, decorative sofa materials and carpets), socks and foot pads. The antisepsis and deodorant fabric of the invention is characterized by environmental protection, high efficiency and wash resistance, etc., and the preparation method thereof is characterized by simple technique and low processing cost, etc.

Owner:ZHEJIANG SCI-TECH UNIV

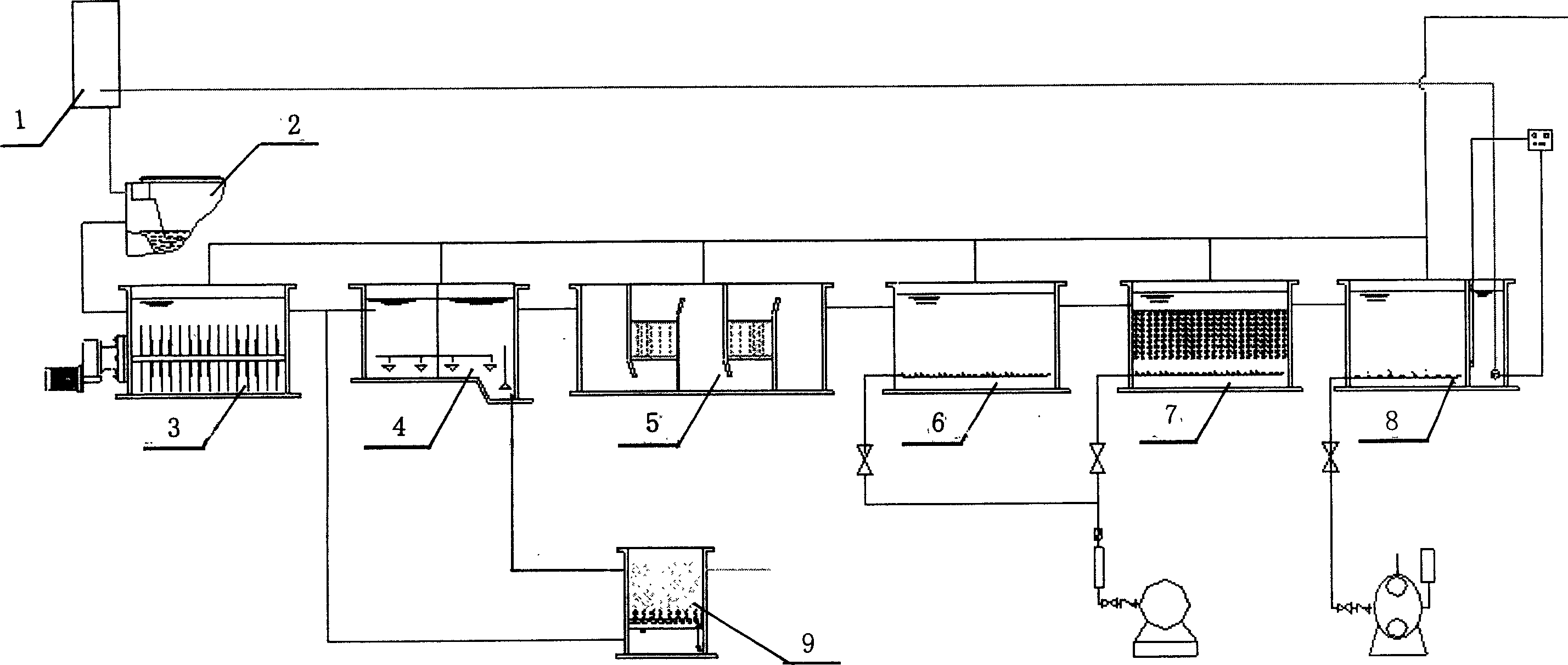

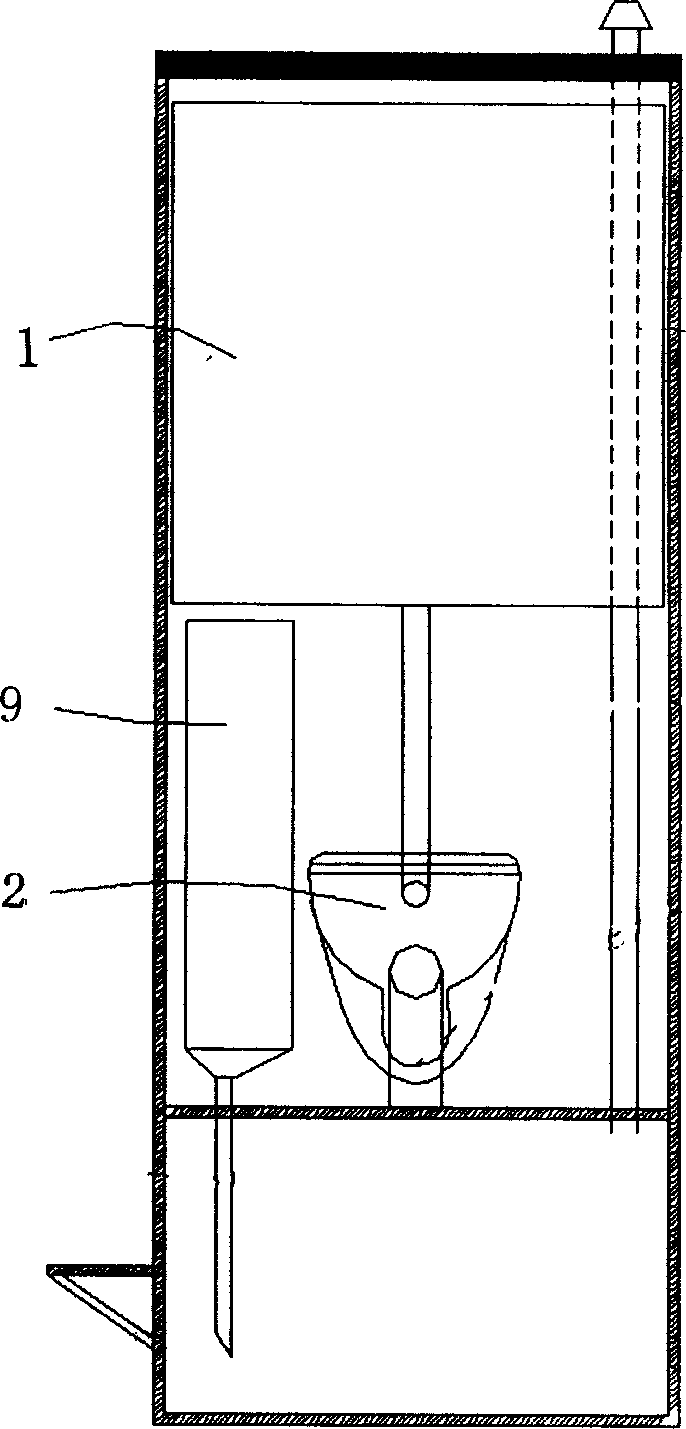

Circulating water flushing ecological toilet and sewage treatment method thereof

InactiveCN1594763AExpand conceptBroaden the field of applicationFlushing devicesLavatory sanitoryHuman wasteFeces

The invention discloses a circulating water flushing ecological toilet and sewage treatment method thereof. The high-position water tank orderly connects to the latrine, grinder-mixer, solid and liquid separator, anaerobic reacting device, facultative reacting device, aerobic reacting device and ozone disinfection device. The ozone disinfection device connects to the high-position water tank by water pump. The invention breaks the localization that the toilet depends on the water and the ecological toilet contaminant is treated elsewhere, conquers the secondary pollution of the transporting, collecting and packing materials for ecological no water toilet, improves the efficiency of the dejection treatment in situ and innocuous treatment degree, fully applies the abundant microbe resource in the dejection.

Owner:NANJING UNIV

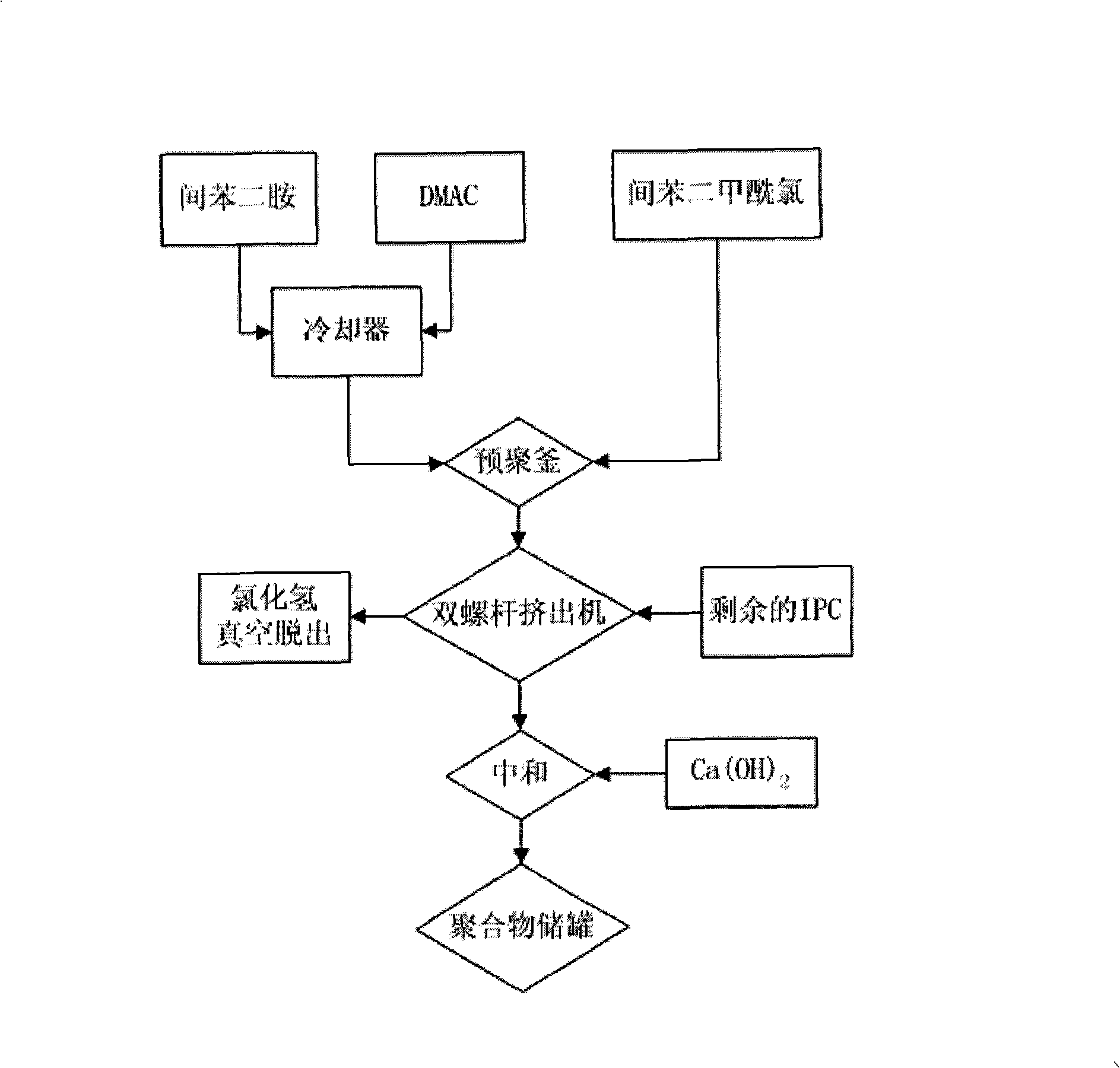

Preparation of low salt-containing aramid fiber 1313spinning solution and process for spinning fibre by wet method

ActiveCN101285214AWell mixedHigh molecular weightWet spinning methodsSpinning solutions preparationPolymer scienceDry heat

The invention relates to a method for spinning aramid fiber 1313 with low salt content by wet spinning. The method comprises the following steps of: prepolymerizing m-phenylenediamine (MPD) and part m-phthaloyl chloride (IPC); adding the preformed polymer and the rest m-phthaloyl chloride into a double-screw extruder to extrude the aramid fiber 1313 containing chlorine hydride; extruding spinning dope into a aqueous coagulation bath after neutralizing the chlorine hydride with calcium hydroxide; crimping and cutting coagulated tows into the required fiber length via hot water drawing, water rinsing, drying, dry-heat drawing and heat setting after being taken out of the coagulation bath to receive a finished fiber. The method is convenient and simple, can improve the molecular weight of products and the evenness of polycondensate, and reduce the salt content of the final spinning solution.

Owner:DONGHUA UNIV +1

Residue removal by CO2 water rinse in conjunction with post metal etch plasma strip

InactiveUS6328905B1Decorative surface effectsSemiconductor/solid-state device manufacturingResistSolubility

Methods of removing resist residues from semiconductor workpiece surfaces are provided. In one aspect, a method of removing resist from a surface of a workpiece is provided that includes the steps of exposing the workpiece to a plasma and rinsing the workpiece with CO2 and water in a processing chamber to dissolve the resist. Reliance on post plasma strip solvent rinses for resist removal is eliminated. The combination of CO2 with post-plasma strip water rinse increases the solubility and thus the removal rate of resist residues.

Owner:ADVANCED MICRO DEVICES INC

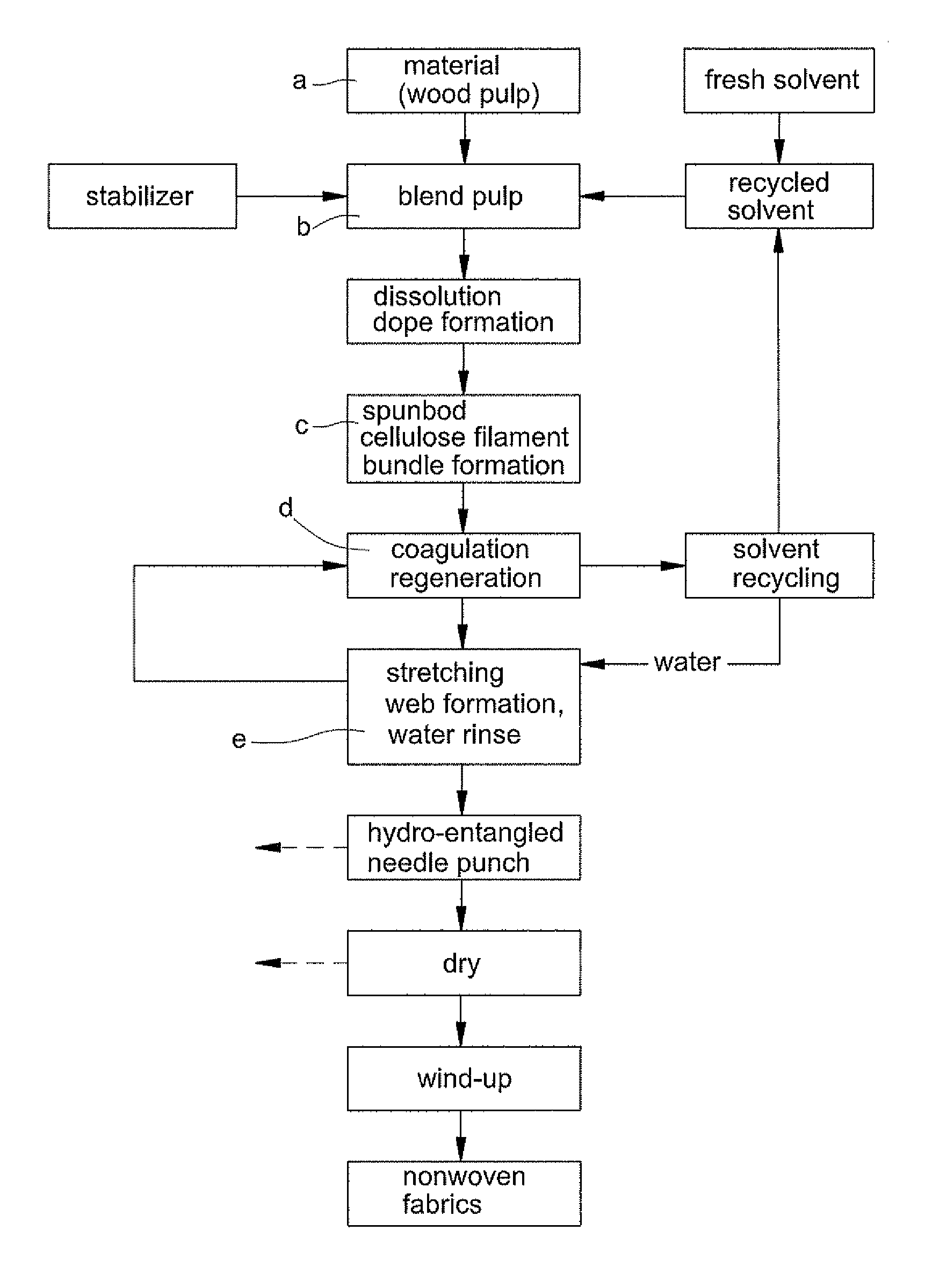

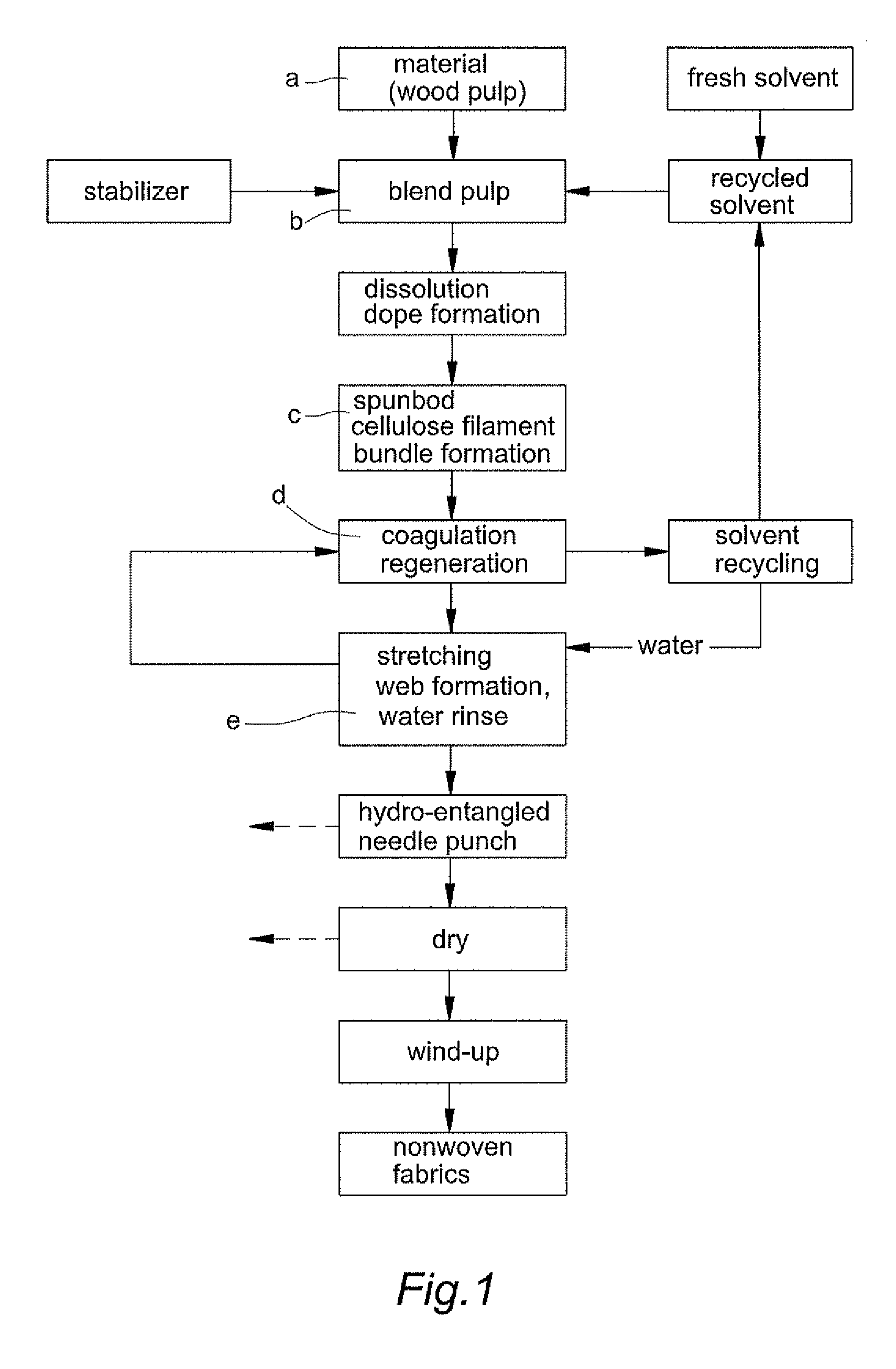

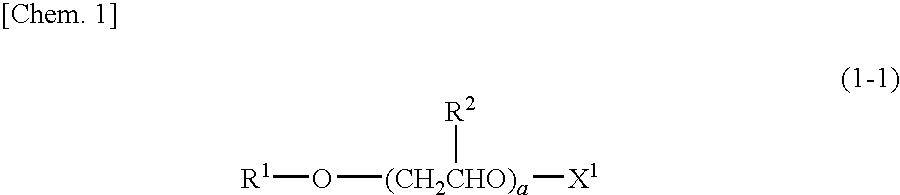

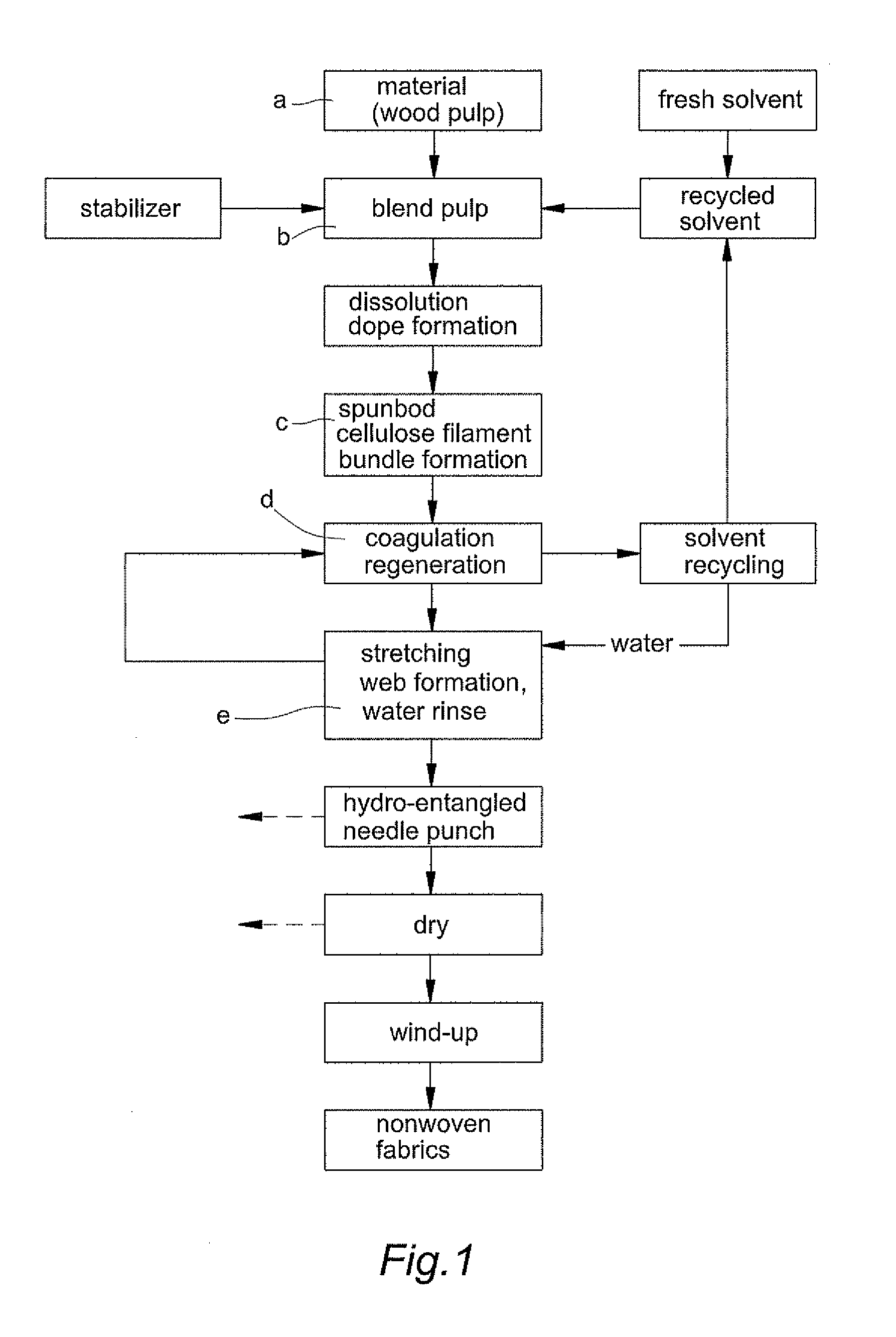

Spunbond wetlaid method for producing non-woven fabrics from natural cellulose

ActiveUS8366988B2Reduce manufacturing costDegree of air permeabilityArtificial filaments from cellulose solutionsPattern makingPunchingWater rinsing

Owner:LIN CHIH HSIN

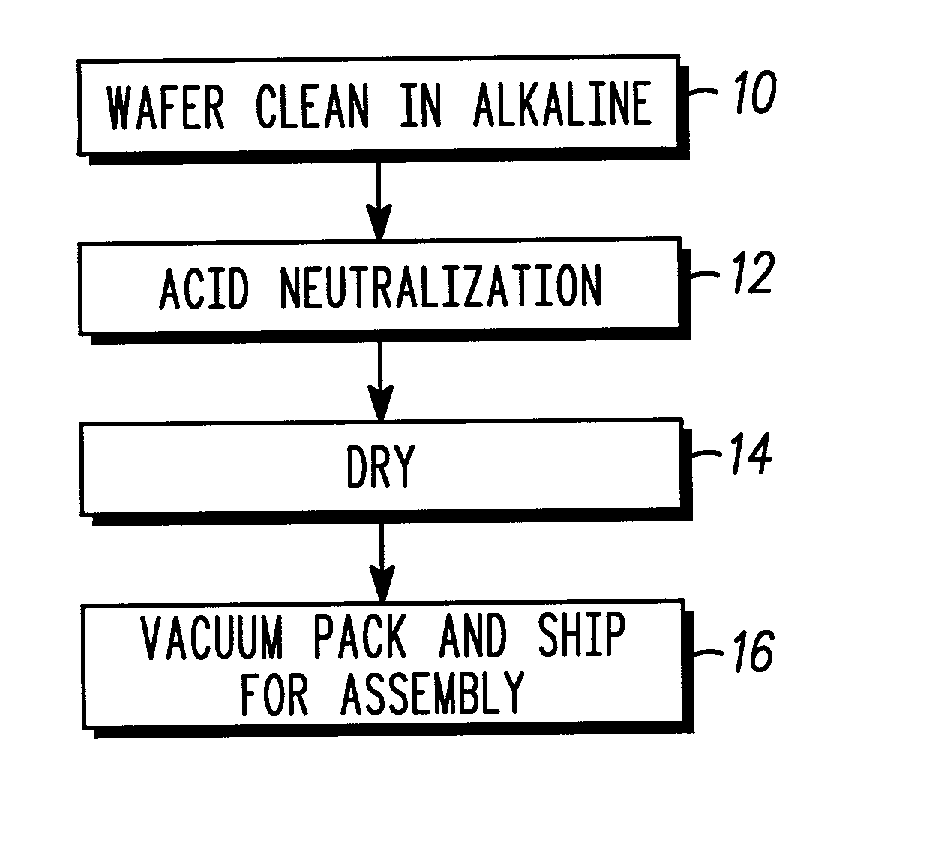

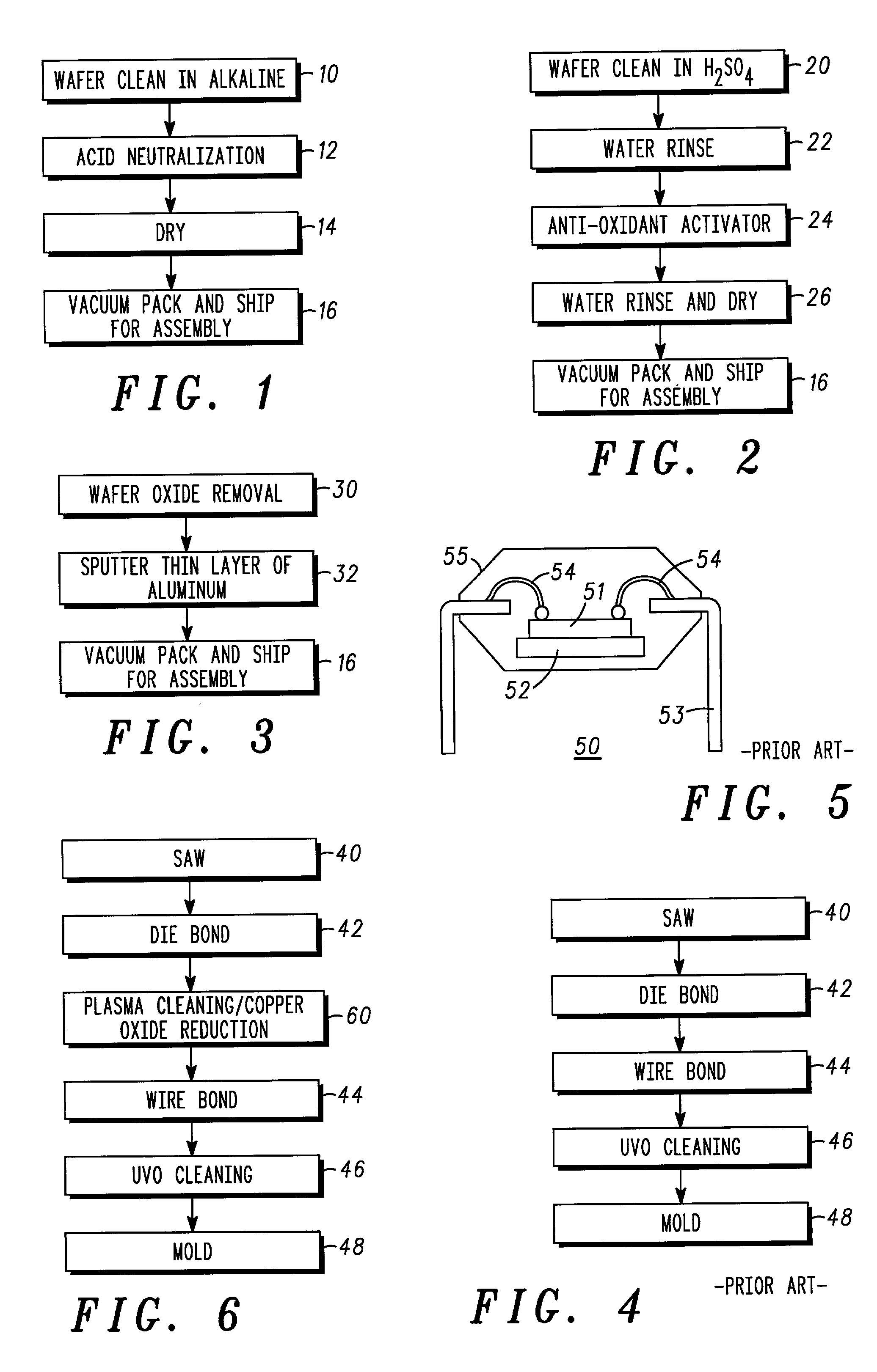

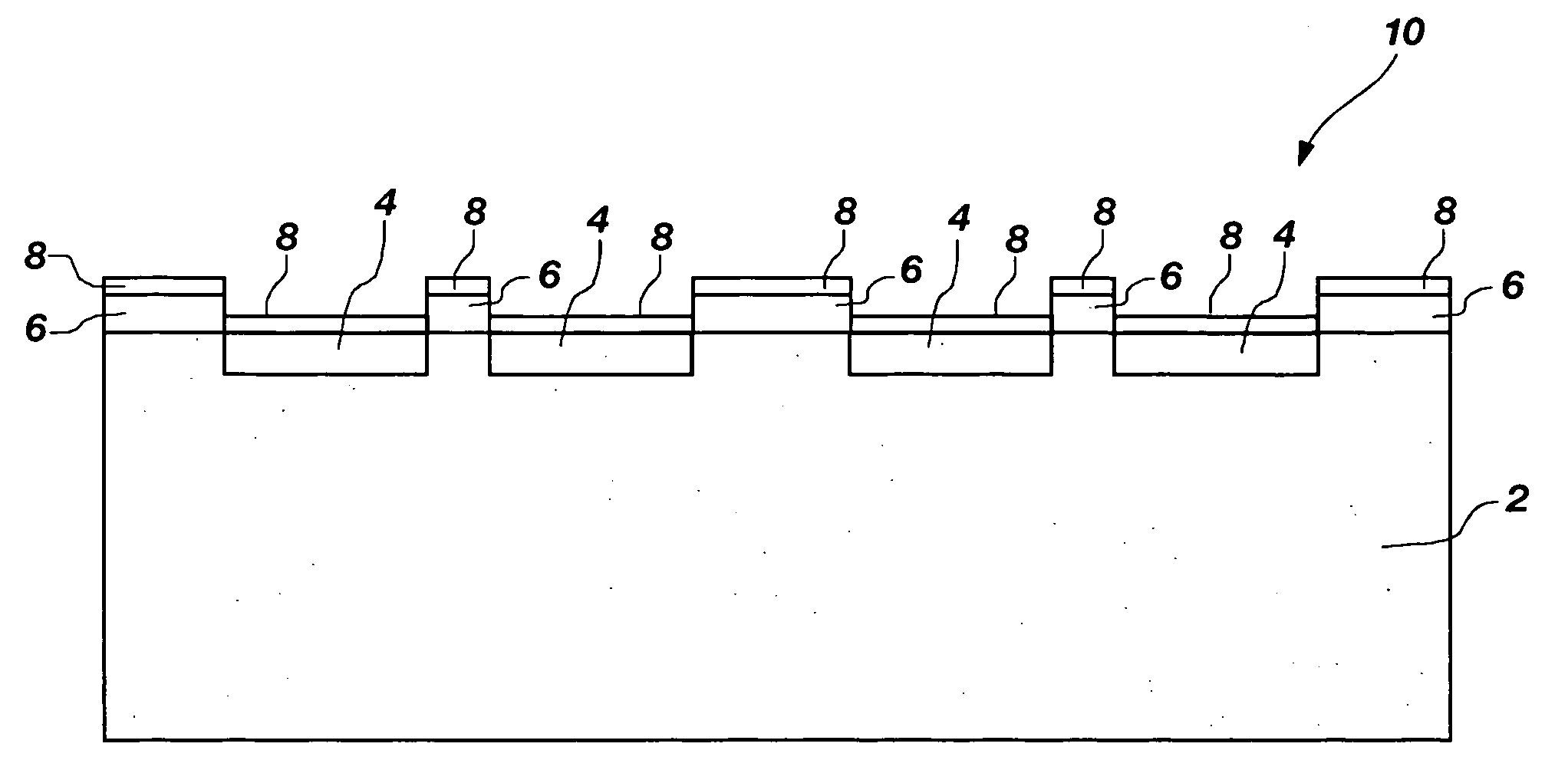

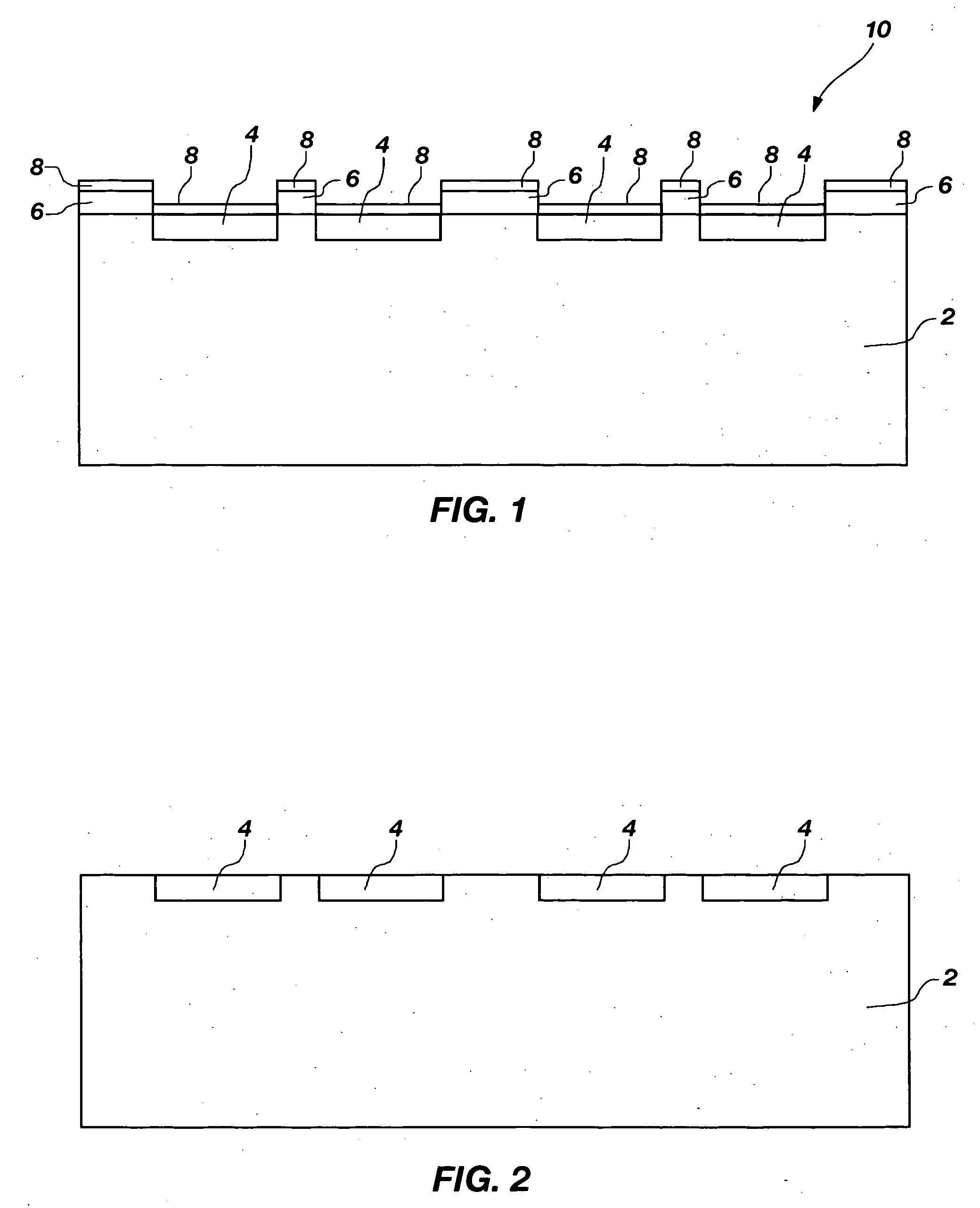

Method of preparing copper metallization die for wirebonding

InactiveUS20020127825A1Semiconductor/solid-state device detailsSolid-state devicesLead bondingAnti oxidant

A method of preparing a semiconductor wafer having a integrated circuits formed on it that have pads formed of copper includes the steps of removing oxide from the copper pads and then the vacuum packing the wafer in a shock-proof container. The oxide may be removed from the copper pads in a number of ways. A first way includes cleaning the wafer in an alkaline solution, performing acid neutralization on the cleaned wafer, and then drying the wafer. A second way includes cleaning the wafer with an acid solution, rinsing the acid cleaned wafer with water, applying an anti-oxidant activator to the surface of the copper pads, rinsing the wafer with water after the application of the anti-oxidant activator, and then drying the water rinsed wafer. Yet a third way includes plasma cleaning the copper pads using a combination of about 5-10% Hydrogen and about 90-95% Argon and then sputtering a very thin layer of aluminum on a surface of the copper pads. The layer of aluminum has a thickness of about 1-5 nanometers.

Owner:NORTH STAR INNOVATIONS

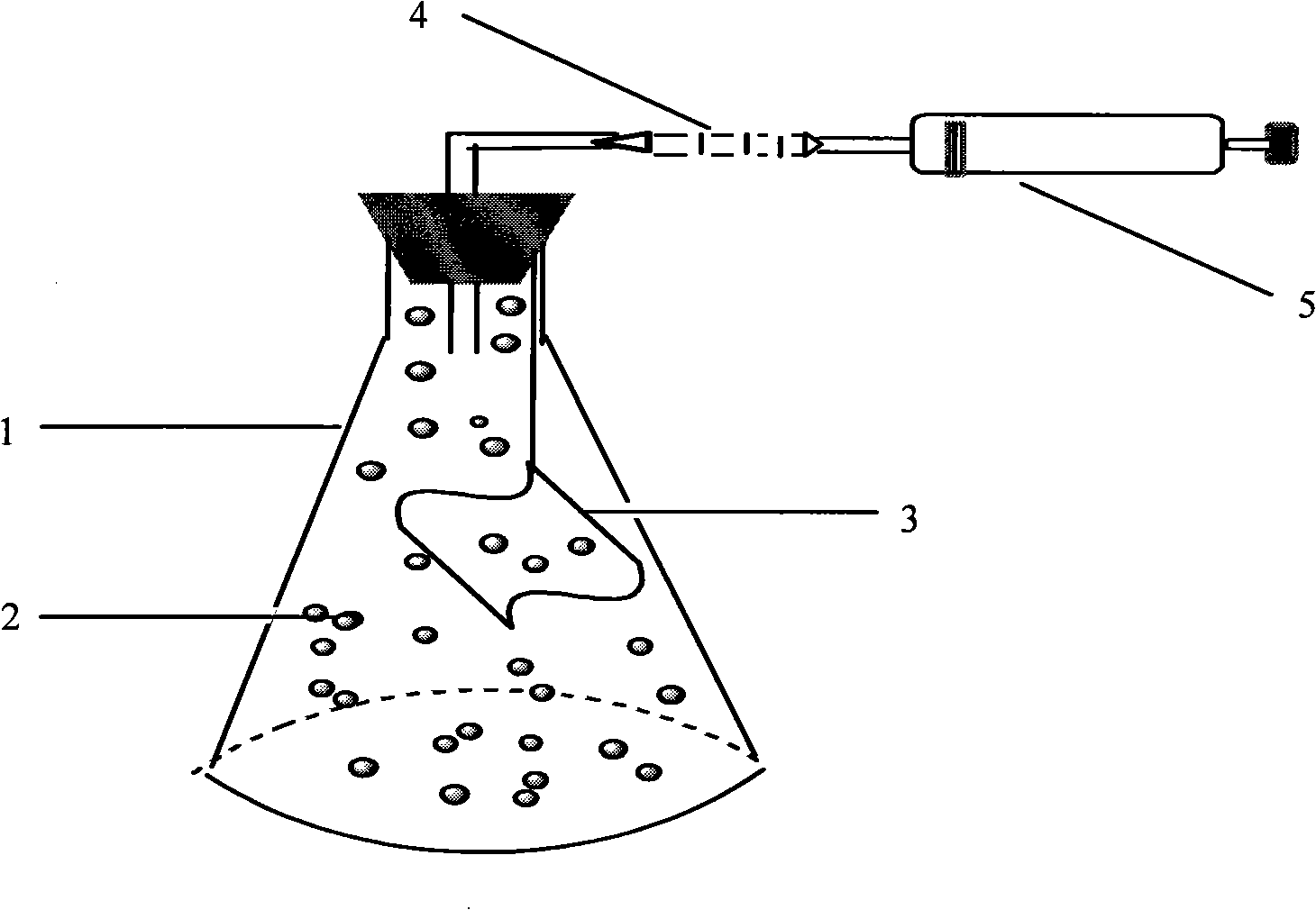

Photosynthetic bacterium immobilizing process

InactiveCN1810966AHigh activityGood dispersionOn/in organic carrierOn/in inorganic carrierWater rinsingWater quality

The photosynthetic bacterium immobilizing process includes preparing zeolite powder of 120-200 mesh, adding sodium alginate solution of 500-1000 mpa.s viscosity and concentrated photosynthetic bacterium liquid in the weight ratio of 1:0.03 to 0.05:0.2-0.3, mixing through stirring, pelletizing, hardening in 20-40 g / L concentration CaCl2 solution, and final clear water rinsing to obtain the product. The process has great photosynthetic bacterium immobilizing amount, high immobilizing efficiency, and high activity of the immobilized photosynthetic bacterium, and the product can deposit fast to water bottom for degrading organic pollutant and purifying water without loss.

Owner:刘军义 +2

Method of photoresist strip for plasma doping process of semiconductor manufacturing

ActiveUS20070243700A1Sure easySemiconductor/solid-state device manufacturingSemiconductor devicesDopantHexafluoroethane

A method of forming an intermediate semiconductor device is disclosed that comprises providing a semiconductor substrate, forming a photoresist layer on the semiconductor substrate, implanting a dopant into the semiconductor substrate, and removing a dopant-containing layer from the photoresist layer. The dopant-containing layer includes dopant residuals and a carbon-rich crust and may be formed during implantation. The dopant-containing layer may be removed from the photoresist layer by exposing the dopant-containing layer to a water rinse, a chlorinated plasma or to a fluorinated plasma. The water rinse may include deionized water that is maintained at a temperature that ranges from approximately 25° C. to approximately 80° C. The fluorinated plasma may be formed from a gaseous precursor selected from the group consisting of nitrogen trifluoride, carbon tetrafluoride, trifluoromethane, hexafluoroethane, sulfur hexafluoride, and mixtures thereof. A method of forming an ultrashallow junction is also disclosed.

Owner:MICRON TECH INC

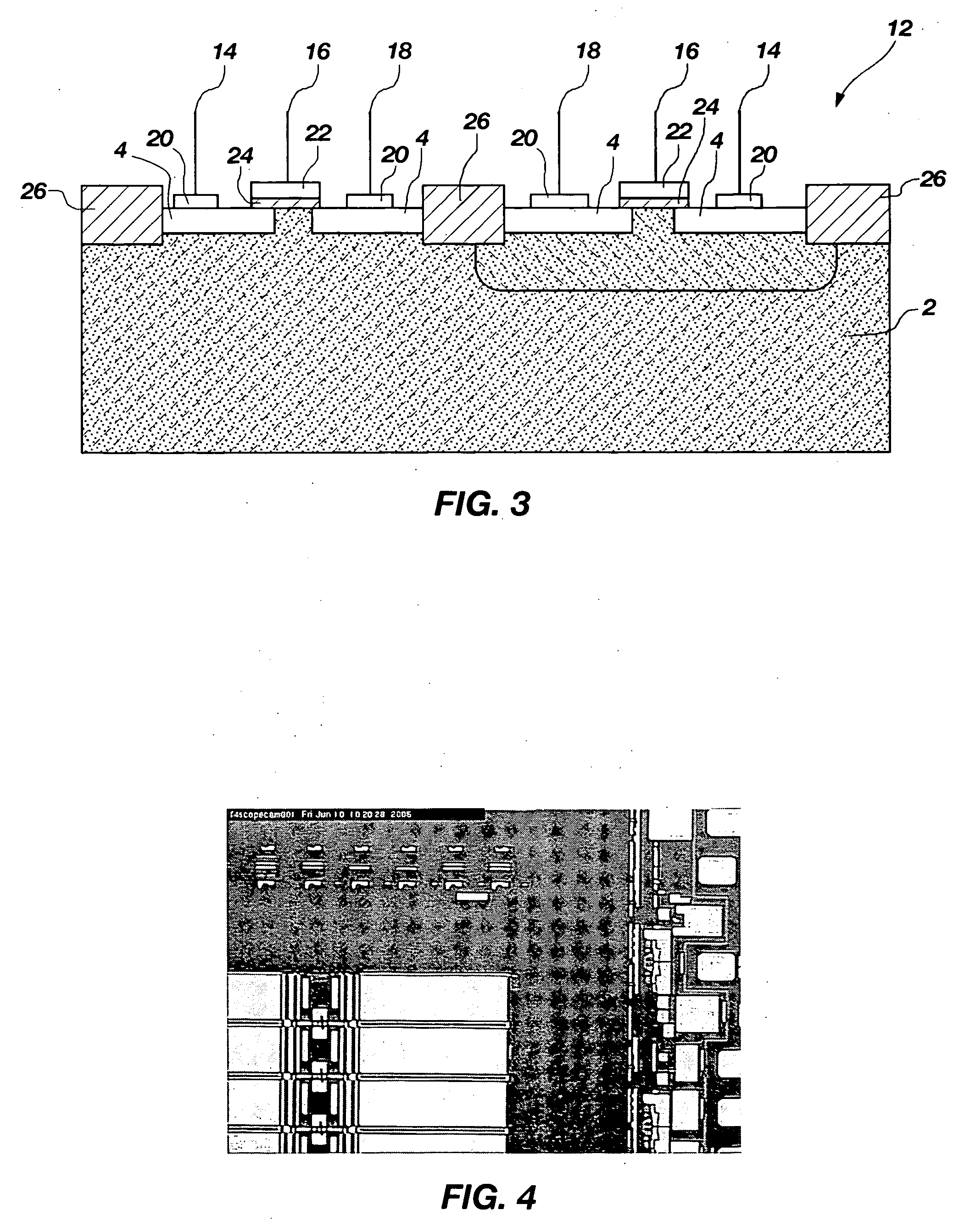

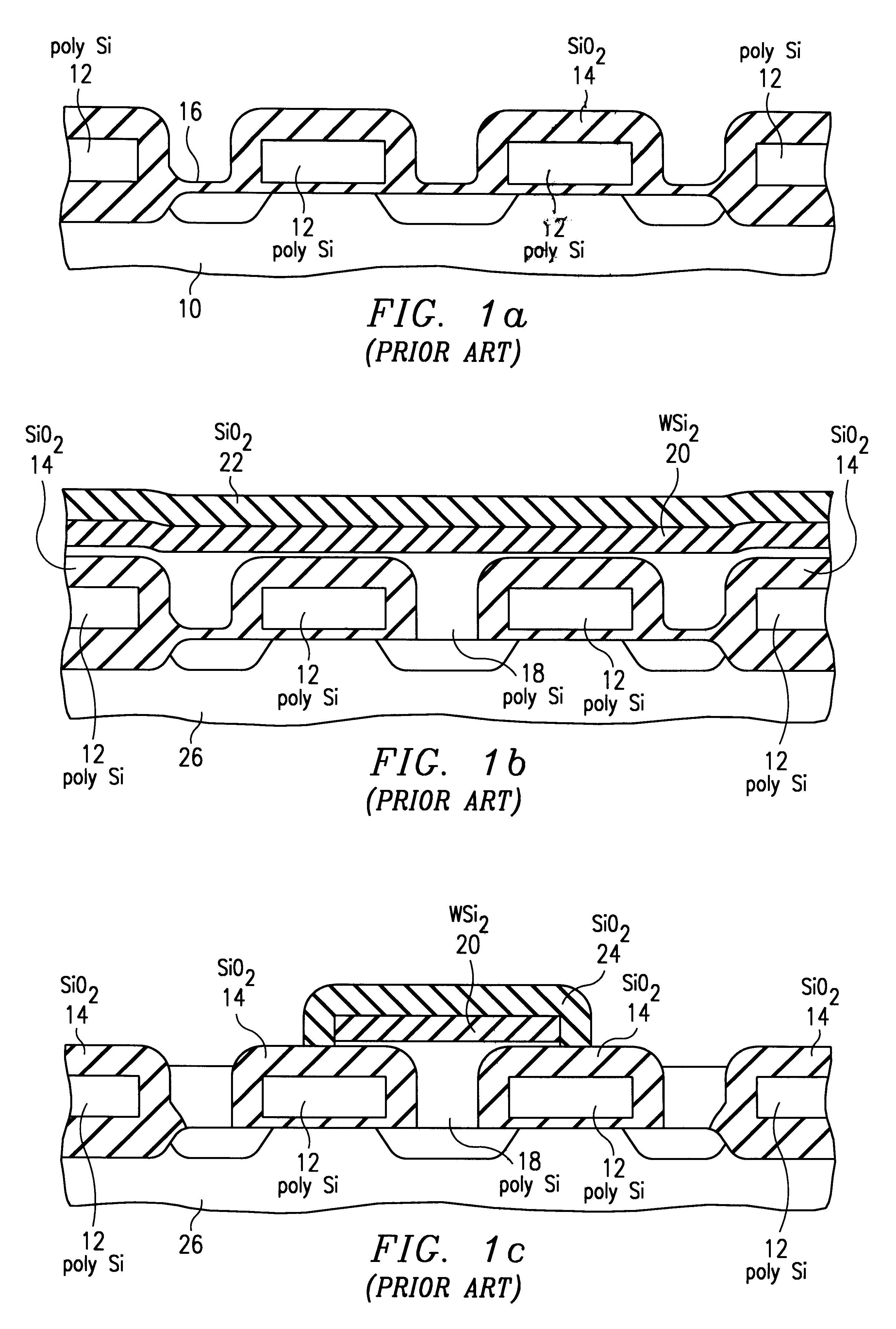

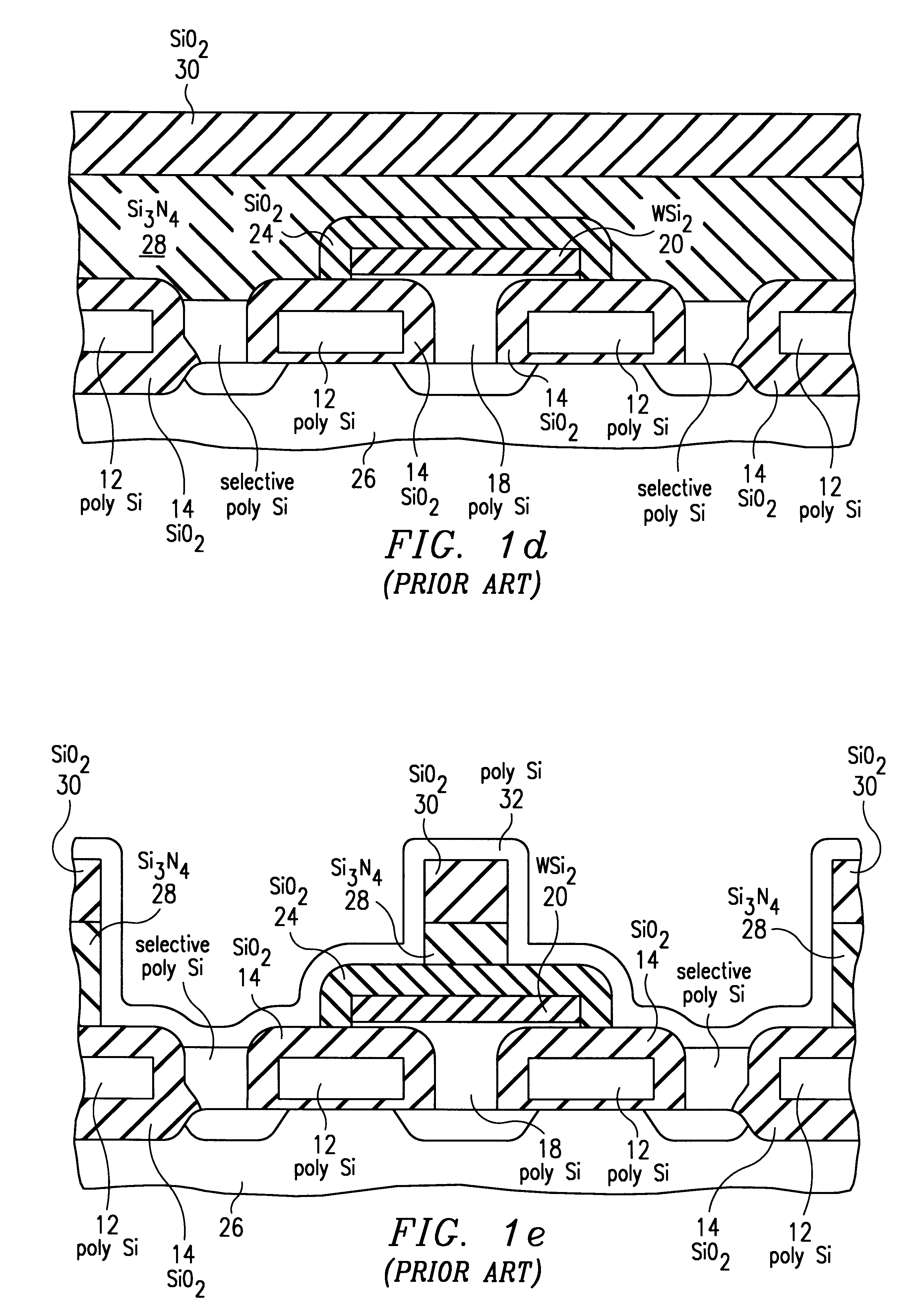

Two step oxide removal for memory cells

InactiveUS6174817B1Reduce particlesMinimizesTransistorSolid-state devicesHydrofluoric acidWater vapor

Hydrofluoric acid (HF) mixed with water and often buffered with ammonium fluoride is a standard silicon dioxide wet etchant which is followed by a rinse. An improved silicon dioxide etch is vapor HF which may be followed by a water vapor rinse. The invention discloses a further improved silicon dioxide etch. Following an initial exposure to vapor HF for oxide removal, a first insitu water rinse occurs. A second exposure to vapor HF then occurs and is followed by a second insitu water rinse. Water, rather than water vapor, aids in freeing particles from the wafer surface. During both the water rinses, the wafer may be rotated at increasing speeds to aid in sweeping particles from wafer surface. The process may be practiced in a commercially available reactor and is suitable for ULSI devices having complex topographies, such as, for example, 64 megabit DRAMs employing crown type memory cells.

Owner:TEXAS INSTR INC

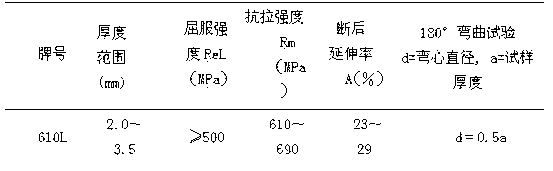

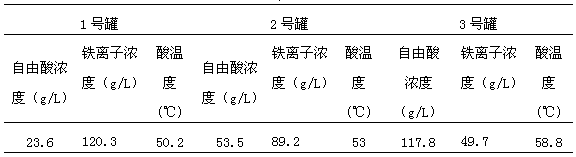

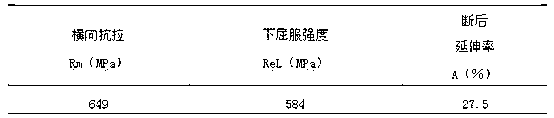

Process for producing hot-rolled acid-pickled 610 L automobile frame steel strip with thin gauge and high elongation

The invention relates to a process for producing a hot-rolled acid-pickled 610 L automobile frame steel strip with thin gauge and high elongation and belongs to the technical field of production processes of steel for automobiles. According to the technical scheme, the process specifically comprises a hot rolling production process and an acid pickling process of an automobile frame steel strip, wherein the hot rolling process comprises the steps of heating, rolling, cooling and the like; and the acid pickling process comprises the following steps of: performing three-section continuous hydrochloric acid pickling and five-section water rinsing on the automobile frame steel strip on a continuous acid pickling production line so that the acid-pickled automobile frame steel strip with gray or offwhite surface and metallic luster on the surface can be obtained; next, drying the surface of the acid-pickled automobile frame steel strip and electrostatically spraying anti-rust oil on both sides of the steel strip, and then coiling and packing the automobile frame steel strip to obtain the finished product. The thin-gauge 610 L automobile frame steel produced by using the process disclosed by the invention is used for substituting 510 L automobile frame steel, so that the thickness of a used steel plate as well as the weight of the whole automobile and fuel consumption of the automobile are reduced while the strengths of the frame and related parts are improved; and therefore, the hot-rolled acid-pickled 610 L automobile frame steel strip provided by the invention plays an important role in reducing the weight of vehicles such as SUV (Sport Utility Vehicle) vehicle and pickup truck. Besides, the acid-pickled surface has metallic luster and thereby has excellent electrophoretic paint coating performance.

Owner:HEBEI IRON AND STEEL

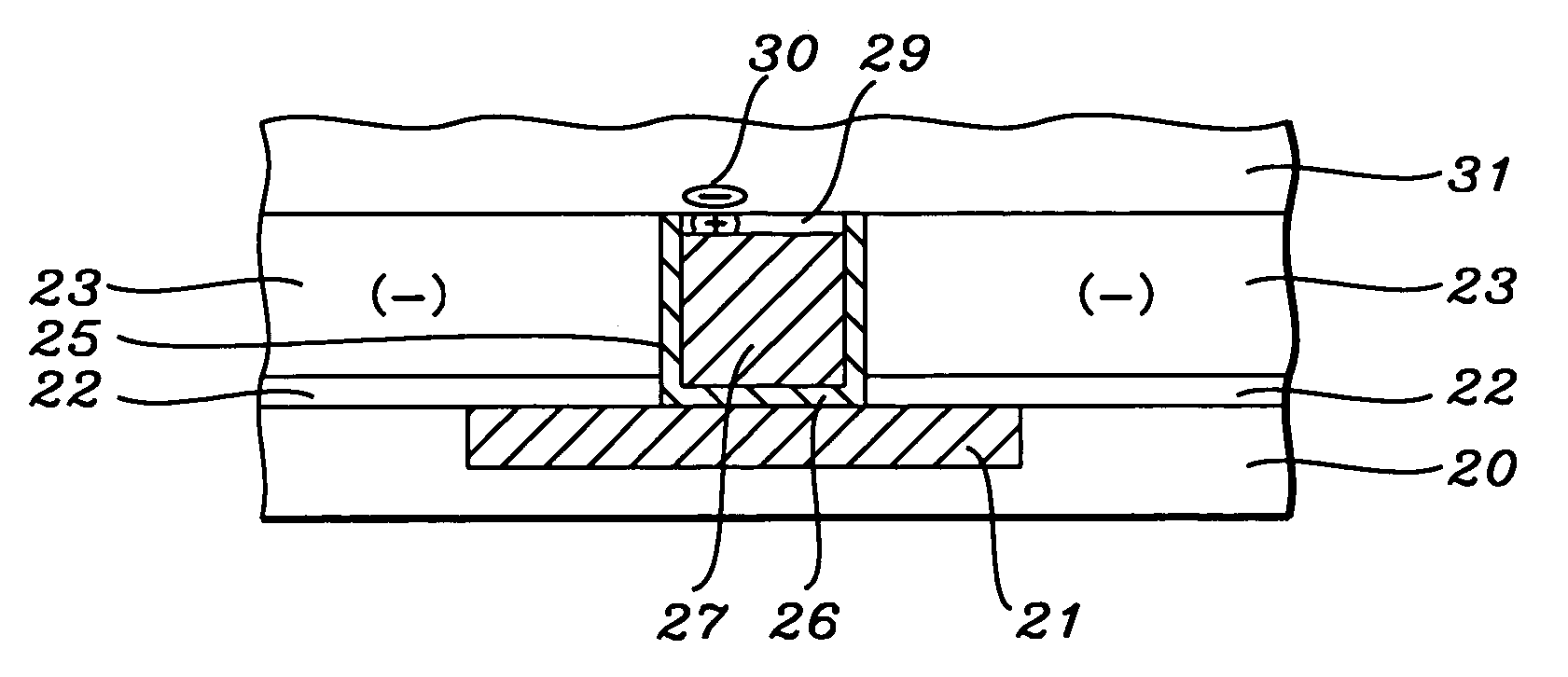

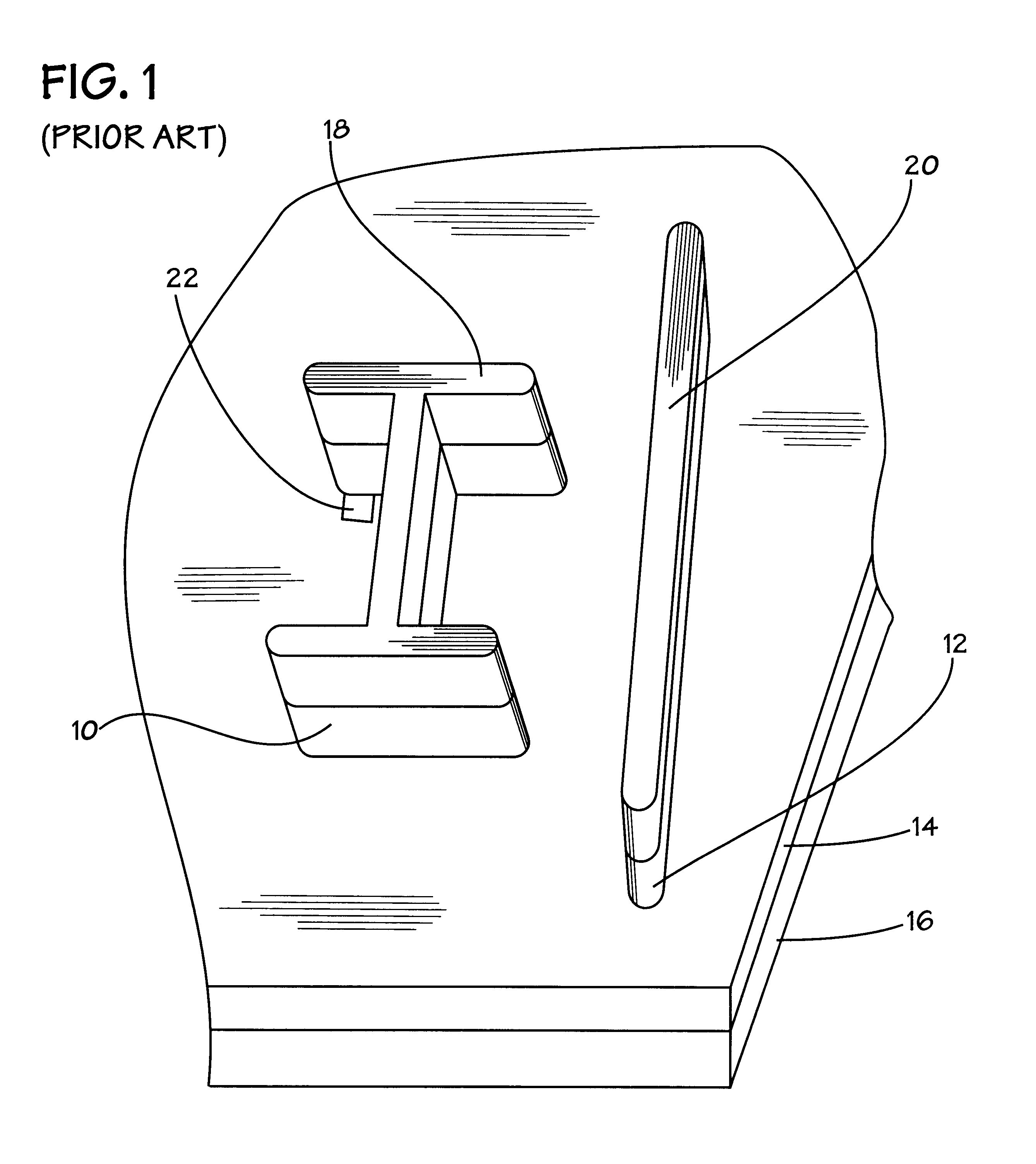

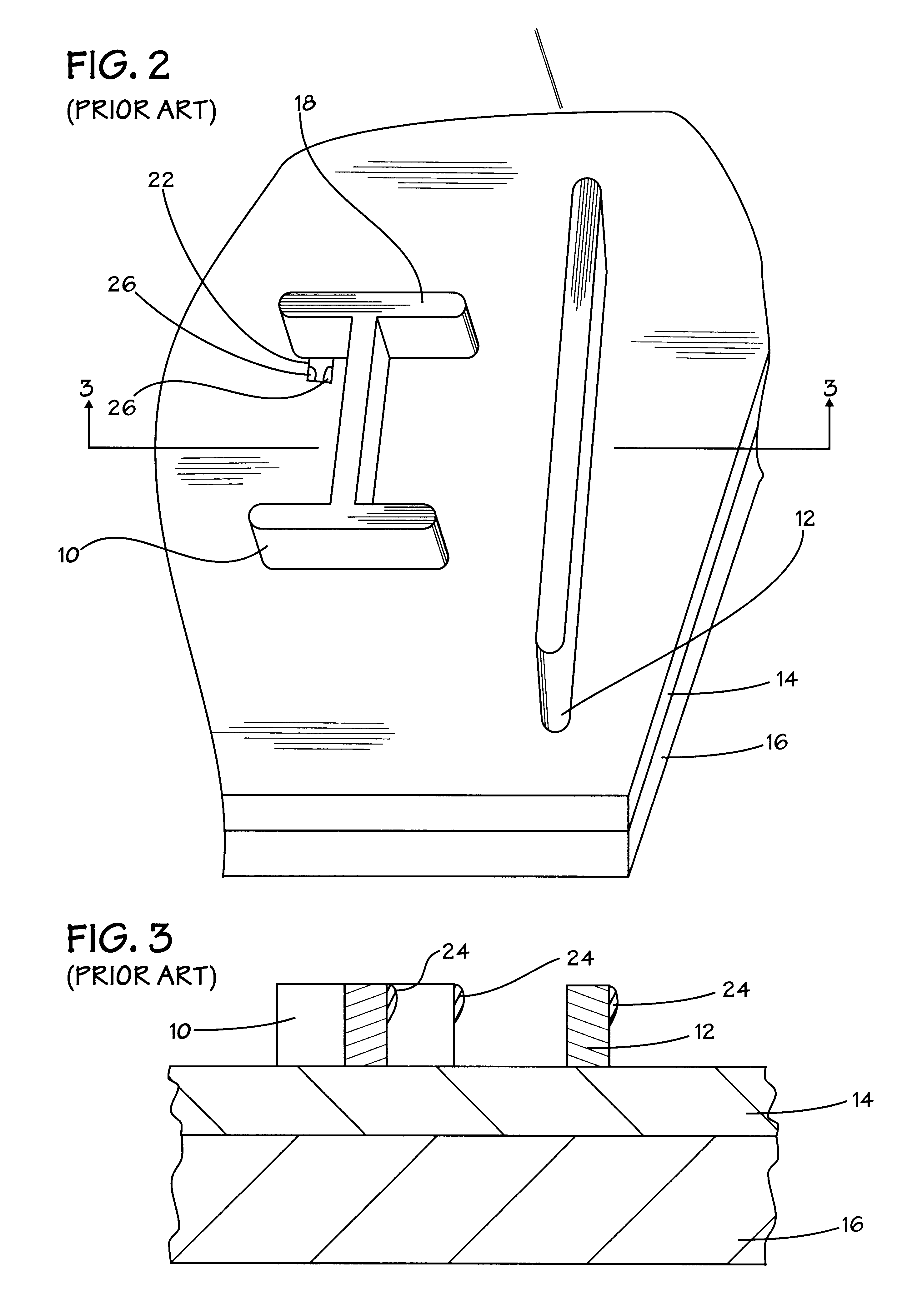

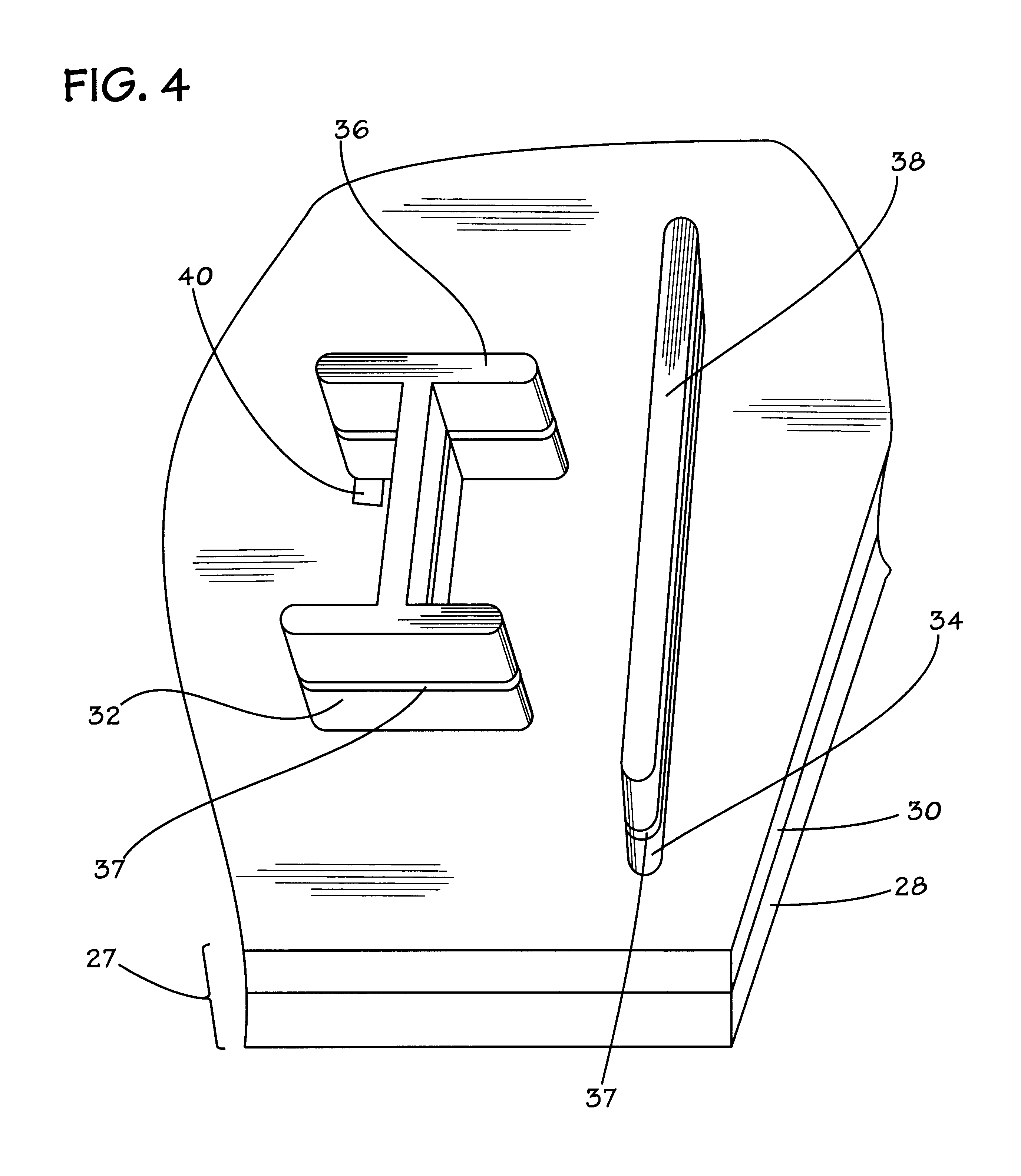

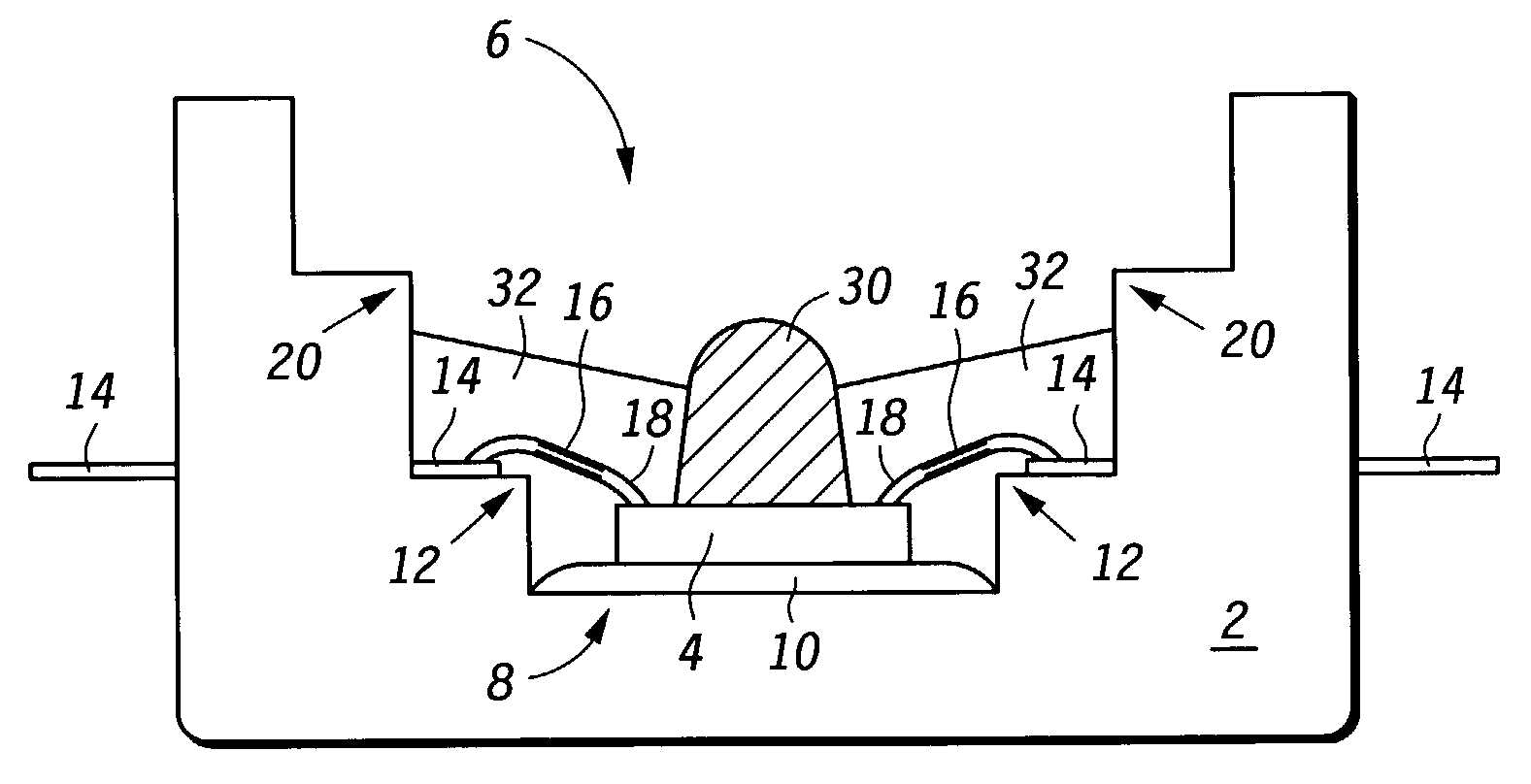

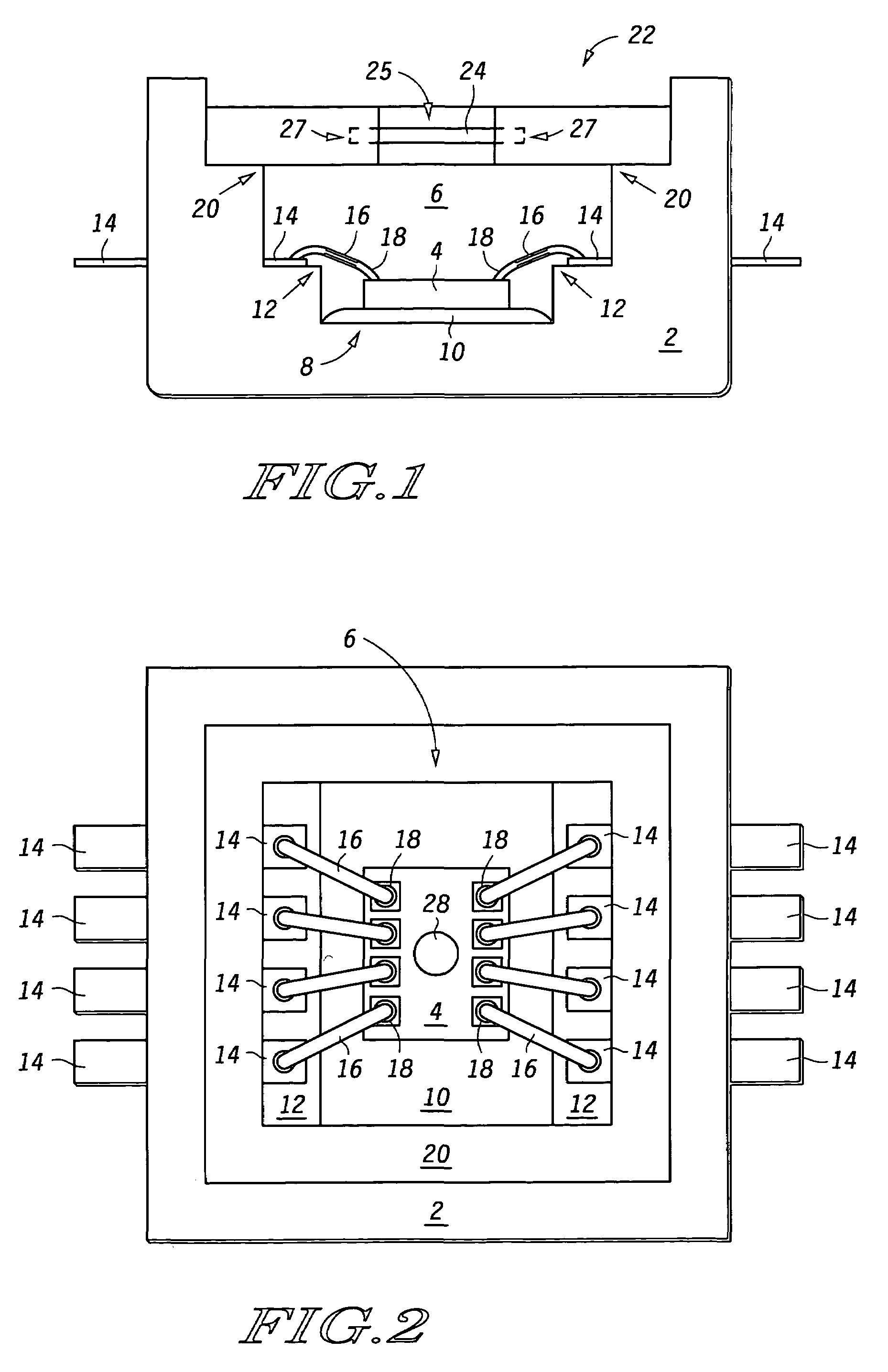

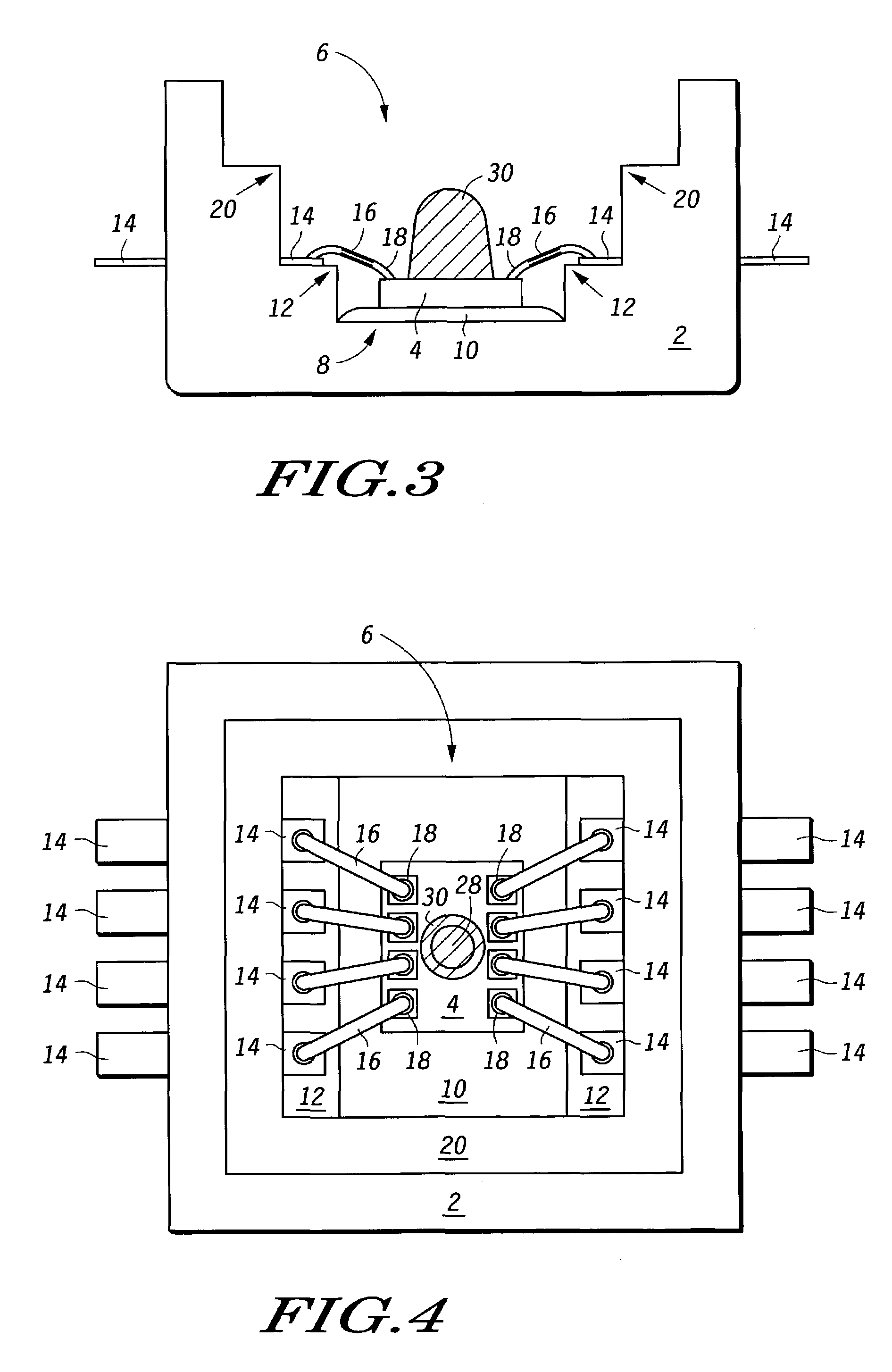

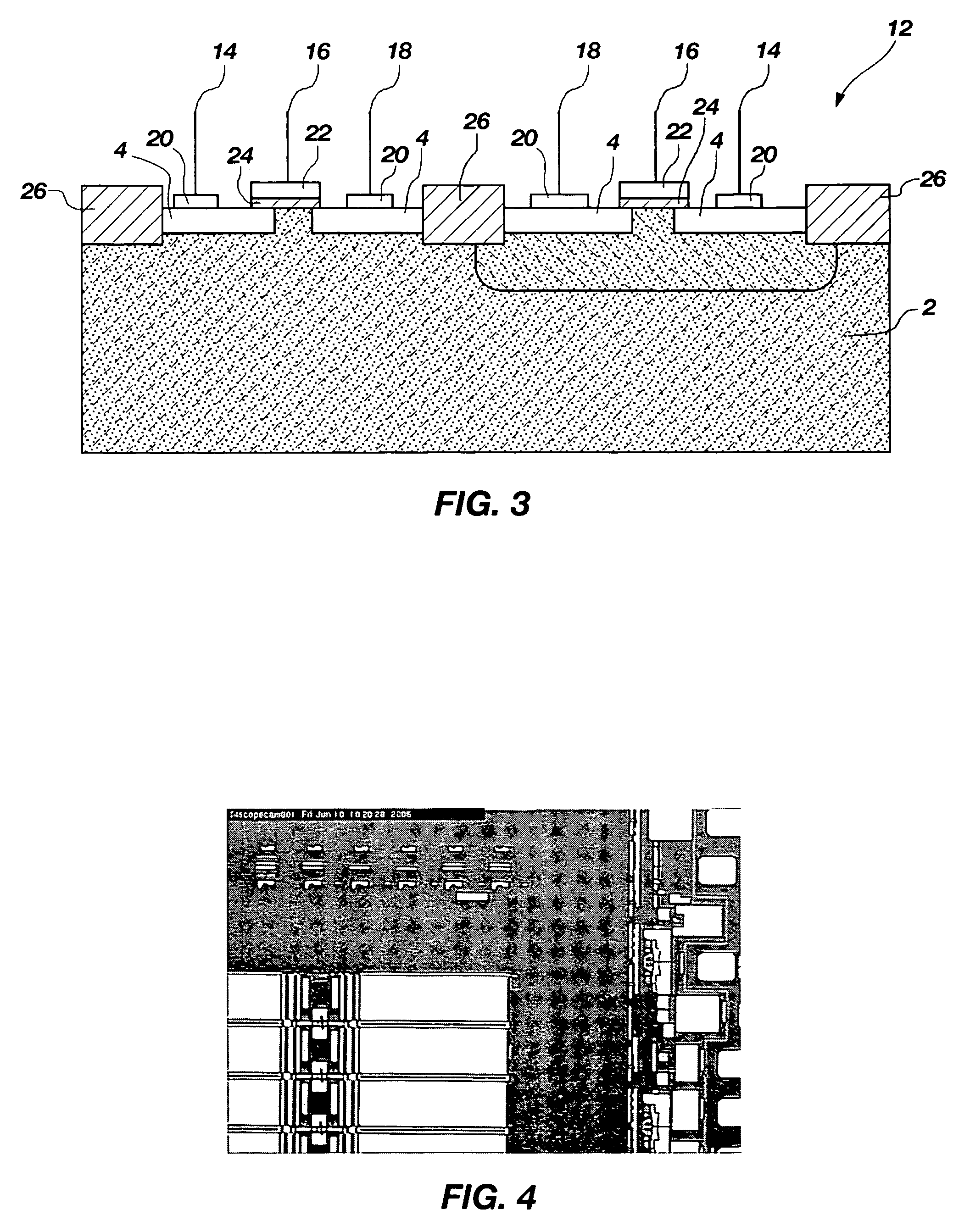

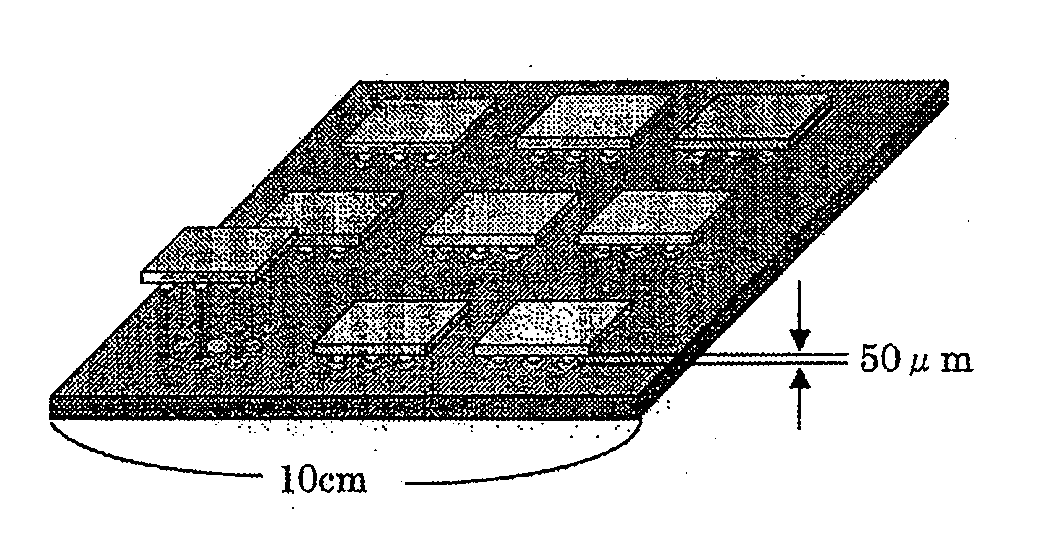

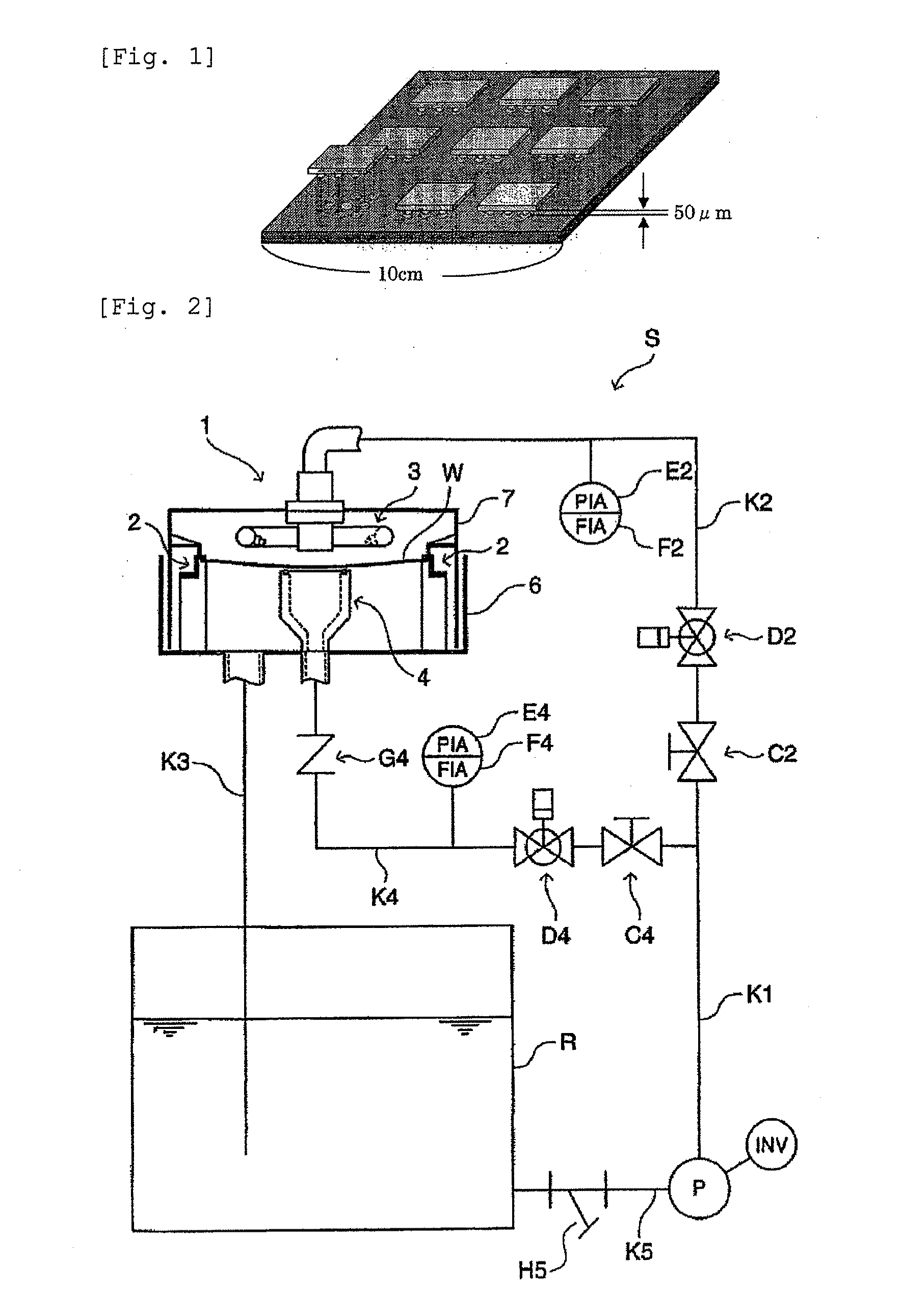

Method and structure for fabricating sensors with a sacrificial gel dome

InactiveUS7014888B2Fluid pressure measurement by electric/magnetic elementsSolid-state devicesWater rinsingEngineering

A method and structure that protects interior electrical components of a pressure sensor (4) from corrosive particles using a sacrificial gel dome (30) to form a vent (34) in a protective gel (32) that covers electrical components that can be corroded such as wires (16), bond pads (18), and electrical leads (14). Sacrificial gel dome (30) is dispensed over a diaphragm (28) of pressure sensor (4) to form vent (34) enabling diaphragm (28) to sense pressure variations without the influence of protective gel (32). Sacrificial gel dome (30) is removed through a water rinsing process (42) to expose vent (34).

Owner:NORTH STAR INNOVATIONS

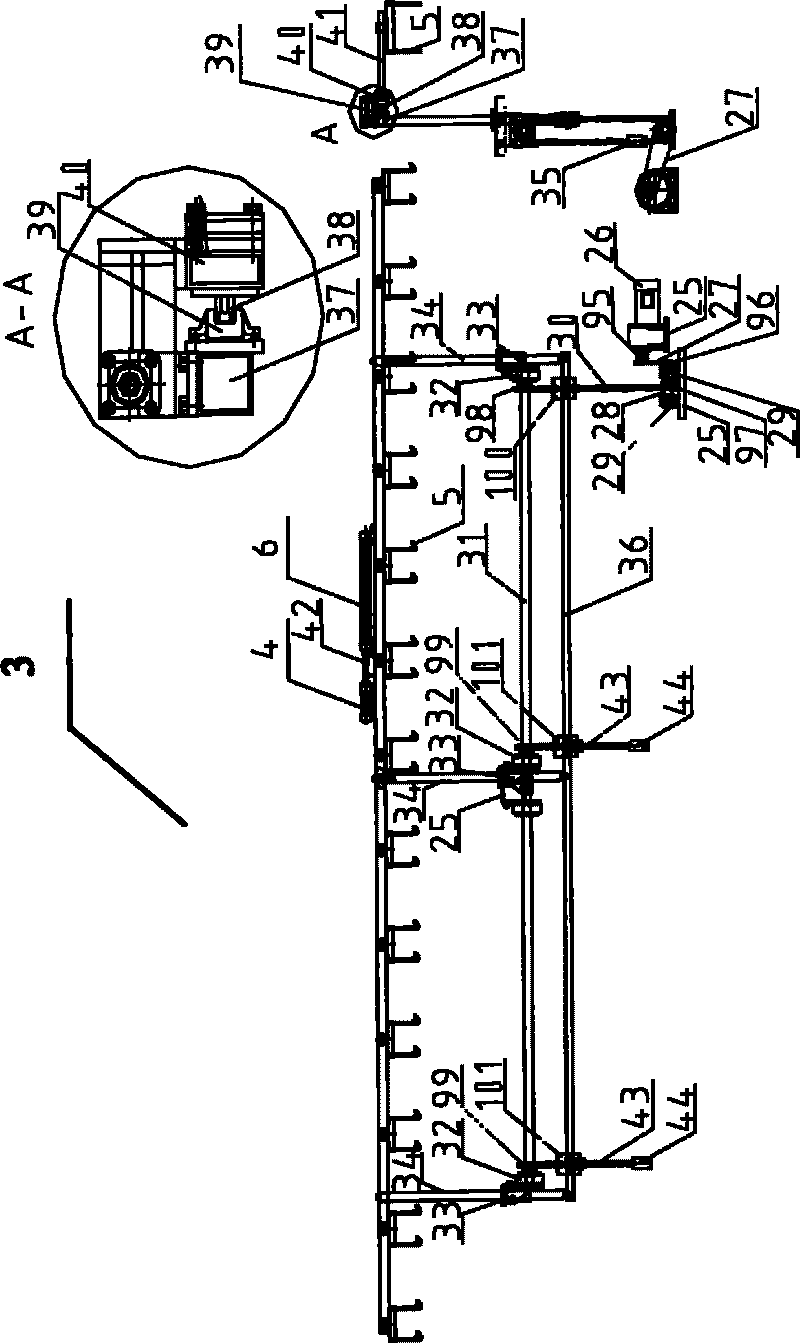

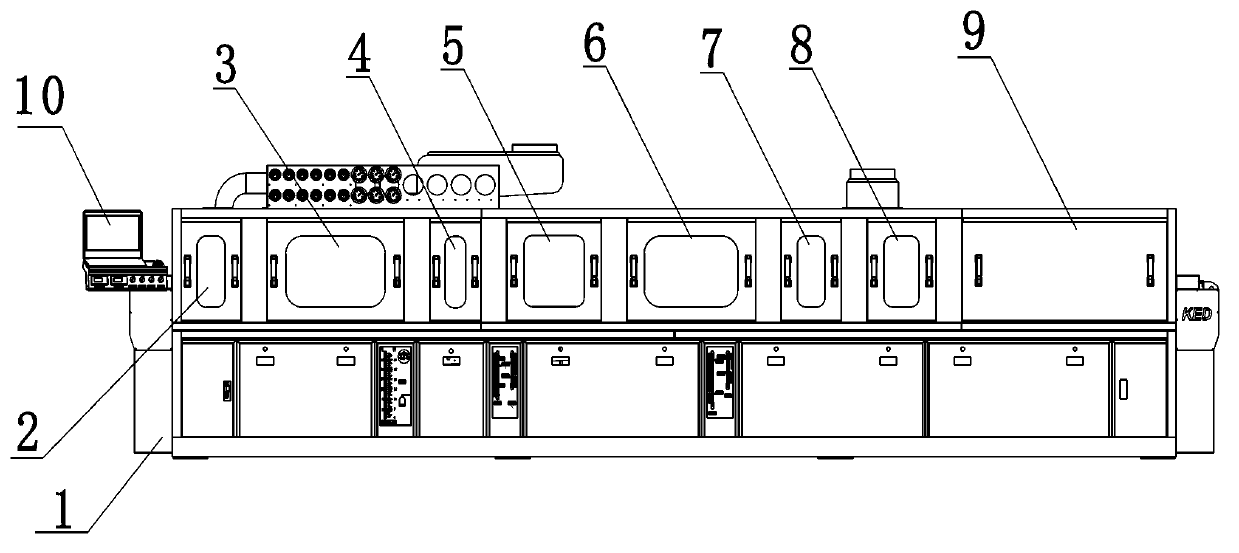

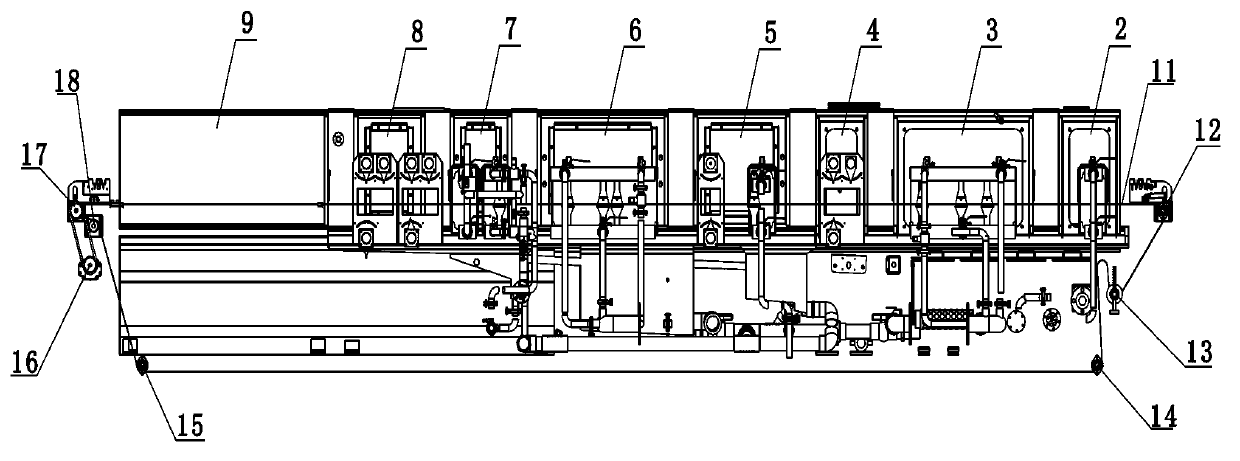

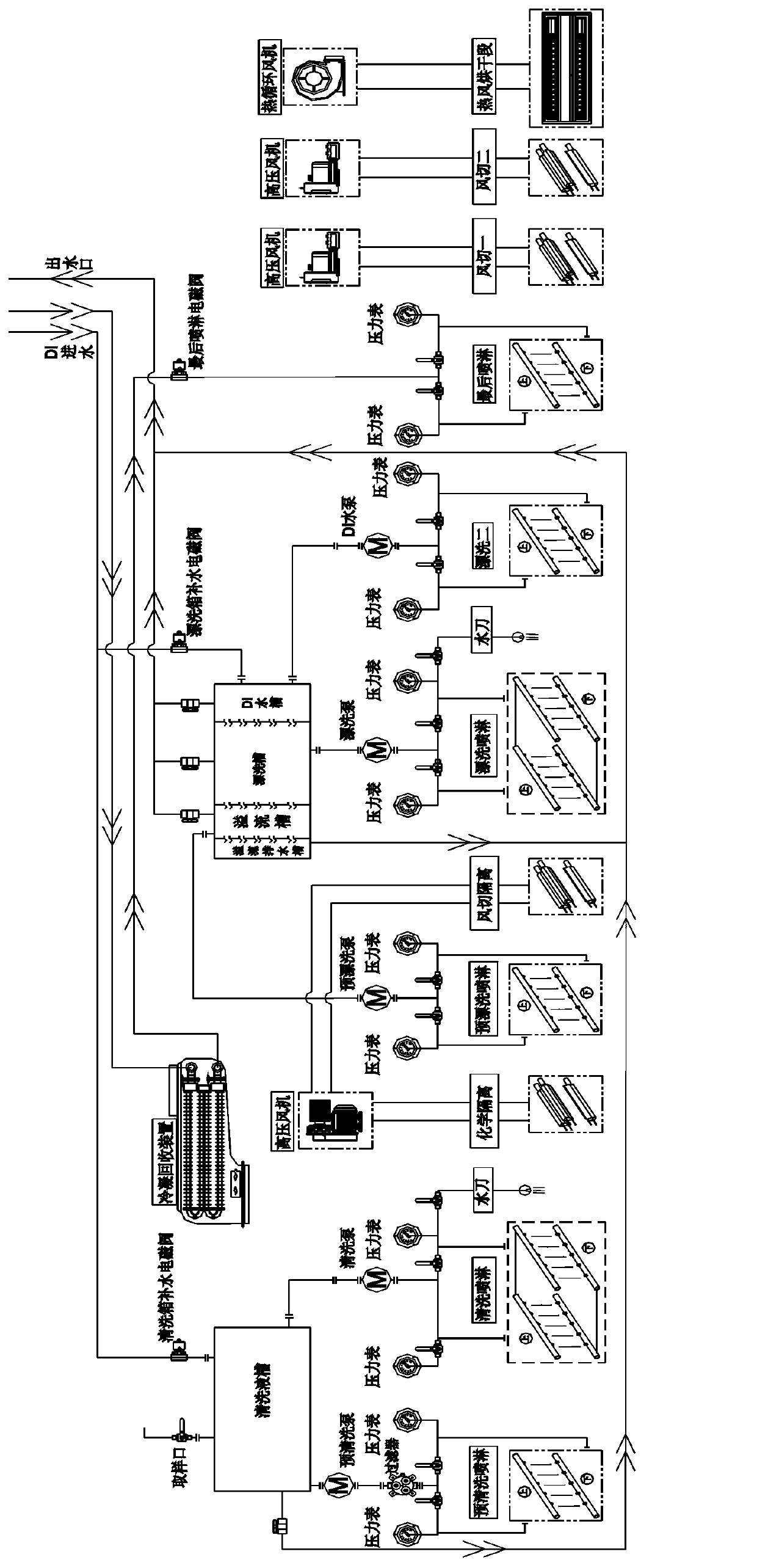

Printed circuit board assembly (PCBA) on-line cleaning machine

InactiveCN102989709ARealize fully automatic online cleaningComprehensive cleaningCleaning using liquidsWater rinsingWind shear

The invention discloses a printed circuit board assembly (PCBA) on-line cleaning machine which comprises a machine body. A mesh belt for transmitting a PCBA board is arranged in the machine body, and a chemical pre-cleaning room, a chemical cleaning chamber, a chemical diaphragm chamber, a digitally integrated (DI) water pre-cleaning chamber, a DI water rinsing chamber, a spraying chamber, a wind shear drying chamber and a hot air drying chamber are arranged above the mesh belt and sequentially arranged along the operation direction of the mesh belt. The PCBA on-line cleaning machine drives the PCBA board through the mesh belt to sequentially perform chemical pre-cleaning, chemical cleaning, chemical isolation, DI water pre-rinsing, DI water rinsing, spraying, wind shear drying, hot air drying and the like from left to right, achieves full-automatic on-line cleaning of the PCBA board, enables the PCBA board to be comprehensively cleaned and rinsed and improves the cleaning and rinsing quality.

Owner:深圳市凯尔迪光电科技有限公司

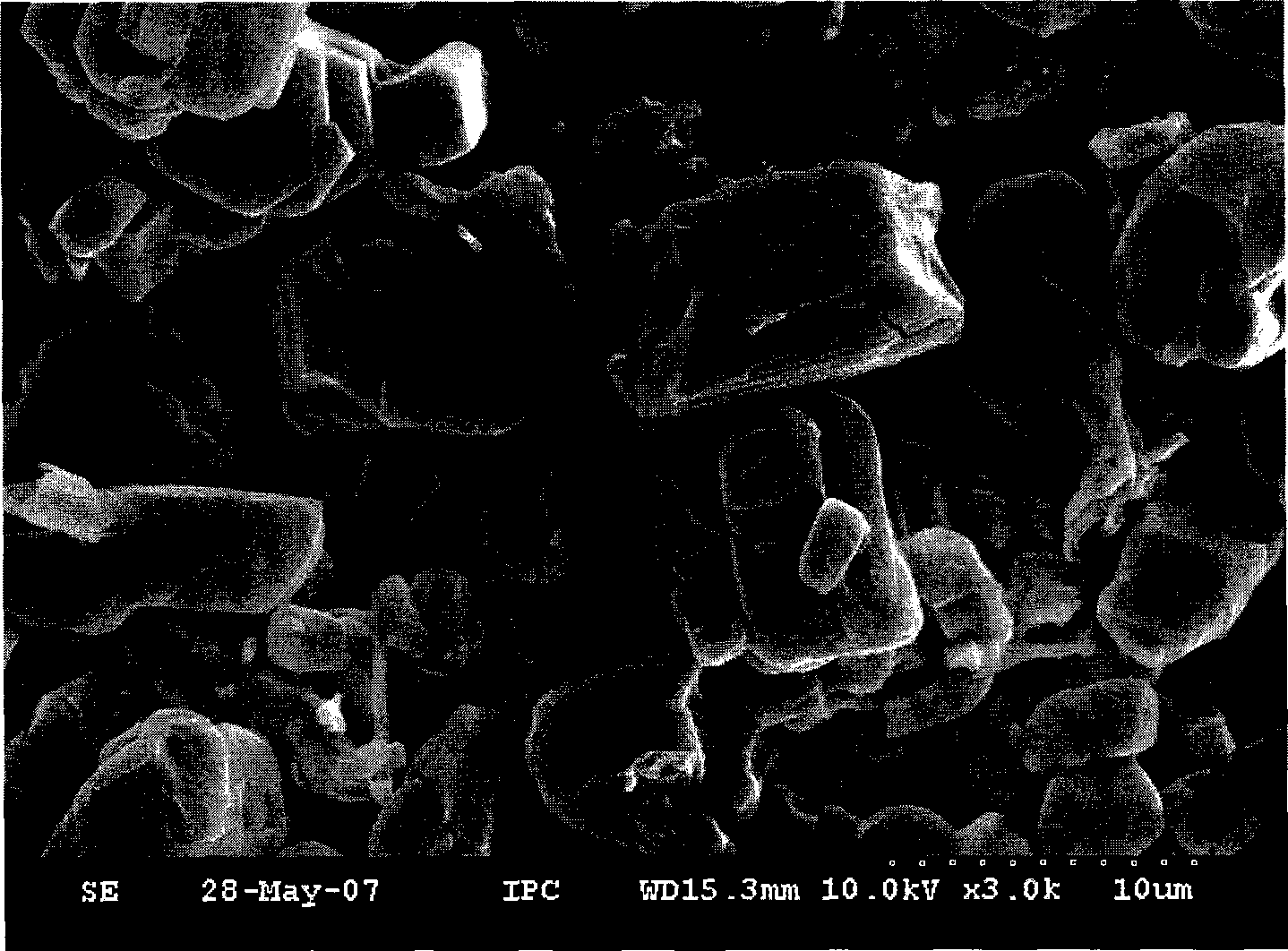

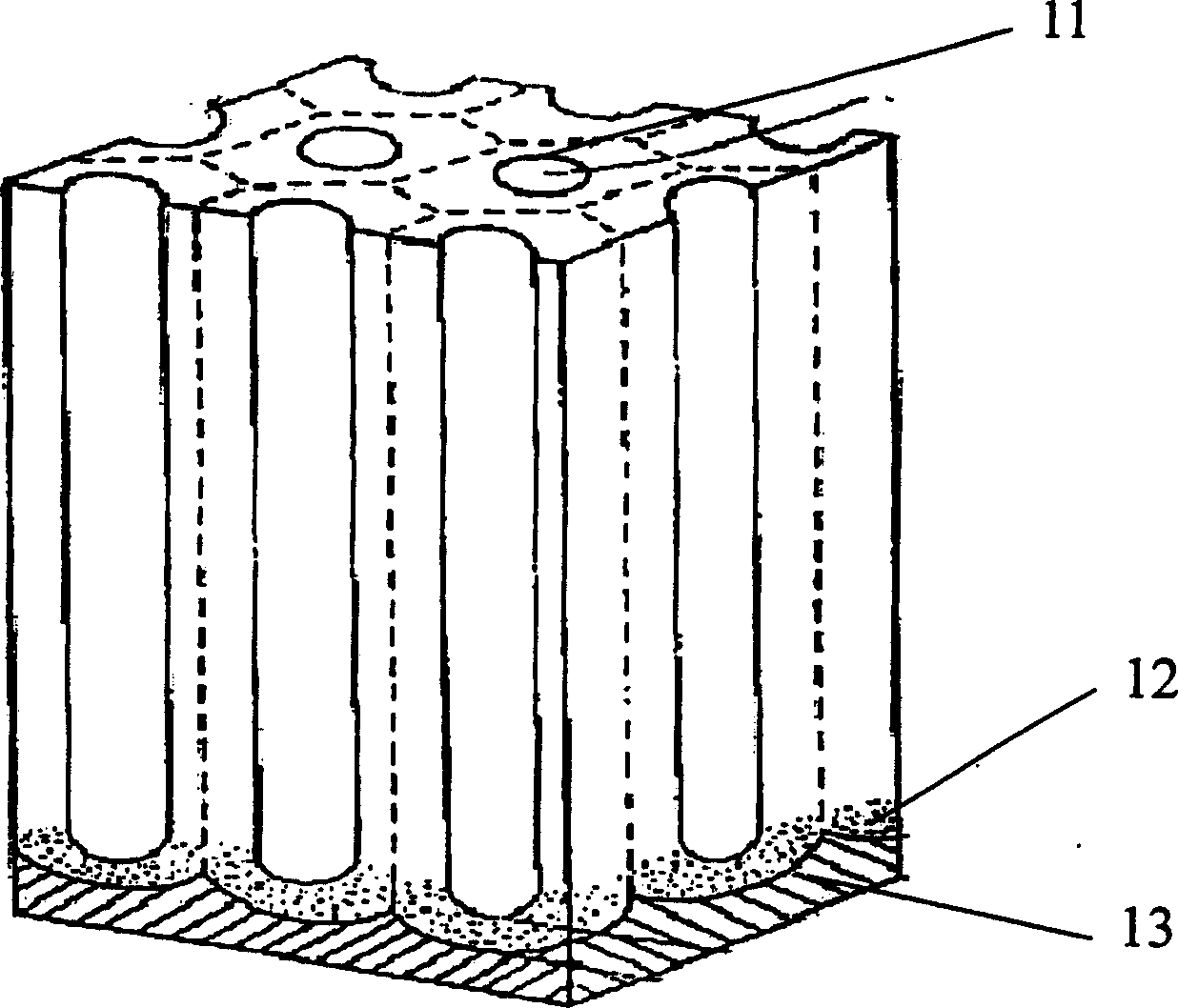

Production process of alumina template with nano holes

The present invention is the production process of aluminum template with nano holes, and is especially the combined anode oxidation and ion bombardment process of producing aluminum template with nano holes in high density and high order. The technological process includes annealing aluminum foil, cleaning, electrochemical polishing, anode oxidation in water solution of oxidizing acid, such as sulfuric acid, oxalic acid, phosphoric acid, to form alumina film, ion bombardment to form holes in the film physically, water rinsing and stoving. The technological process is simple and low in cost, and the holes are densely distributed in certain order and have controllable shape and size of several nano to 100 nano. The said template may be used widely in direct assembling of nano device except its traditional industrial application.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method of photoresist strip for plasma doping process of semiconductor manufacturing

ActiveUS7737010B2Semiconductor/solid-state device manufacturingSemiconductor devicesHexafluoroethaneDopant

A method of forming an intermediate semiconductor device is disclosed that comprises providing a semiconductor substrate, forming a photoresist layer on the semiconductor substrate, implanting a dopant into the semiconductor substrate, and removing a dopant-containing layer from the photoresist layer. The dopant-containing layer includes dopant residuals and a carbon-rich crust and may be formed during implantation. The dopant-containing layer may be removed from the photoresist layer by exposing the dopant-containing layer to a water rinse, a chlorinated plasma or to a fluorinated plasma. The water rinse may include deionized water that is maintained at a temperature that ranges from approximately 25° C. to approximately 80° C. The fluorinated plasma may be formed from a gaseous precursor selected from the group consisting of nitrogen trifluoride, carbon tetrafluoride, trifluoromethane, hexafluoroethane, sulfur hexafluoride, and mixtures thereof. A method of forming an ultrashallow junction is also disclosed.

Owner:MICRON TECH INC

Method for improving wool fire-retardancy with biological enzyme

InactiveCN101509193AConform to modern green environmental protection requirementsMild reaction conditionsBiochemical fibre treatmentAnimal fibresYarnBiotechnology

A method for improving flame retardance of wool by bioenzyme treatment is disclosed, belonging to the field of textile biotechnology. The invention utilizes a catalytic action of transglutaminase (MTG) to graft a type of compounds containing primary amino groups and a large number of phosphorus elements onto the wool so as to improve the flame retardance of the wool, the technological procedures comprise: pretreatment, treatment with a phosphoric finishing agent containing the MTG, water rinsing and drying. Wool yarns and fabrics treated by the inventive technology can not only be improved in the flame retardance, but also be enhanced in some other performances to a certain extent, in particularly the strength of the wool yarns and the fabrics is enhanced to play a role of powerful repair, which is outstandingly superior to other flame-retardant finishing agents or flame-retardant finishing technologies. In addition, in contrast to chemical finishing, the invention is healthier and more environmentally-friendly due to the employment of bioenzyme technique and the pollution-free treatment technology.

Owner:JIANGNAN UNIV

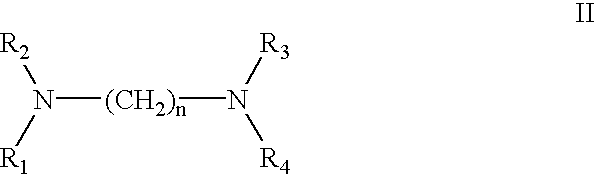

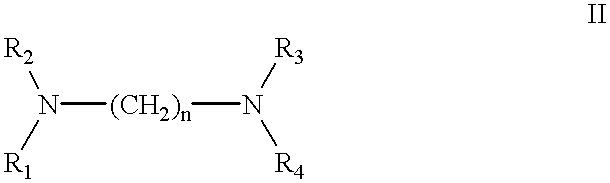

Cleaner composition for removing lead-free soldering flux, and method for removing lead-free soldering flux

InactiveUS20100180917A1Excels in safetySuitable for cleaningNon-surface-active detergent compositionsDetergent mixture composition preparationOrganic solventWater rinsing

The object of the present invention is to provide a novel cleaner composition that not only reduces ignition by flame and has a small influence on the environment, but that also has an excellent property of dissolving flux residues adhered on narrow portions or in narrow gaps in an object to be cleaned that was subjected to soldering with a lead-free solder, and reduces recontamination of the object in the water-rinsing process. The present invention uses a halogen-free organic solvent (A) represented by a specific Formula; an amine-based compound (B) represented by a specific Formula; a chelating agent having no amino group (C); and, as required, water.

Owner:ARAKAWA CHEM IND LTD

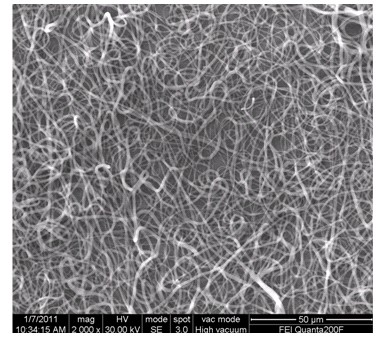

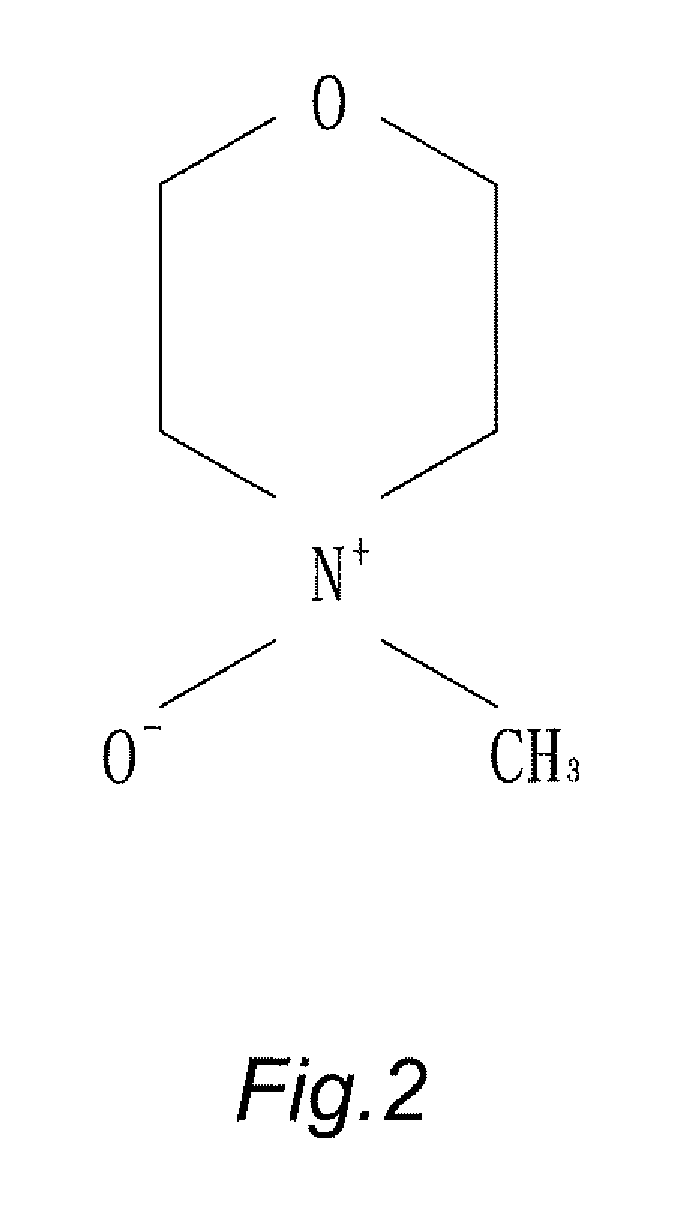

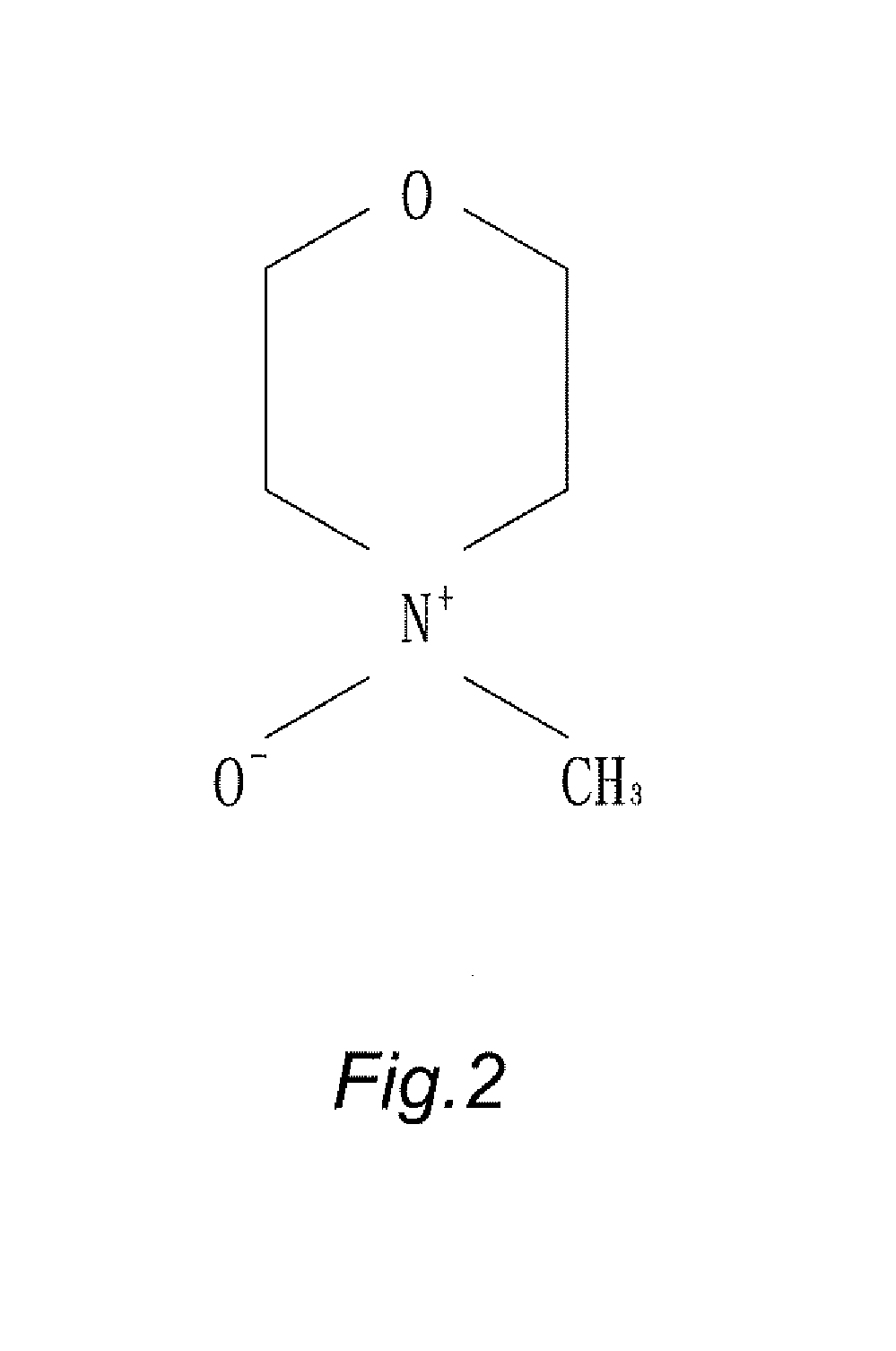

Spunbond wetlaid method for producing non-woven fabrics from natural cellulose

ActiveUS20110156303A1Reduce manufacturing costShort processMonocomponent cellulose artificial filamentWet spinning methodsPunchingWater rinsing

The present invention provides a “spunbond wetlaid method for producing non-woven fabrics from natural cellulose” using pulp as raw material and N-methylmorpholine N-oxide (NMMO) as solvent for dissolving into dope. Then, the dope is extruded out of a spinneret to form filament bundle by spunbond method. The dope is extruded out of a spinneret bank of grouped spinnerets to form filament bundle for further stretching process under quench condition. The filament bundle is coagulated with regeneration in a coagulating solution. The coagulated filament bundle is rapidly stretched under high pressure by an air draw-off machine. The stretched filament bundle is collected and stacked on a collecting net as web nonwoven. After post treatments of water rinsing, hydro-entangled needle punching, drying, winding-up and the like have been orderly applied then final product of nonwoven fabrics with continuous filament are produced from natural cellulose.

Owner:LIN CHIH HSIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com