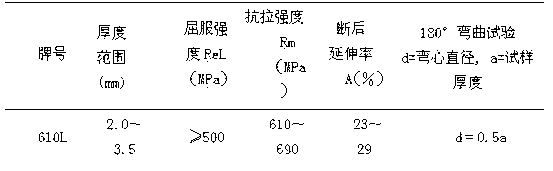

Process for producing hot-rolled acid-pickled 610 L automobile frame steel strip with thin gauge and high elongation

A technology of automobile beam steel and production process, which is applied in the field of automobile steel production technology, to achieve the effect of reducing the weight of the whole vehicle, reducing the thickness of the steel plate, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

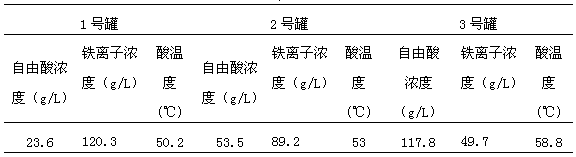

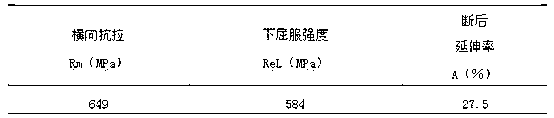

Embodiment 1

[0018] After converter smelting and LF furnace refining, the chemical composition of 610L hot-rolled automobile frame steel strip is controlled as follows: C: 0.08 wt%, Mn: 1.55 wt%, S: 0.007 wt%, P: 0.019 wt%, Si: 0.09 wt% , Als: 0.026 wt%, Nb: 0.047 wt%, Ti: 0.018 wt%, slab thickness 150mm. The casting slab is heated by a walking heating furnace, and the temperature of the slab coming out of the furnace is ≥1280°C. The heating time is 150 minutes. After 5 passes of rough rolling, the thickness of the intermediate billet after rough rolling is 35-40mm. After being coiled by the hot coil box, the head and tail are reversed to reduce the temperature difference between the head and the tail, and then go through 7 passes of finish rolling. To form a steel strip with a thickness of 2.3mm, the temperature of the finishing rolling is controlled within the range of 1030-1070°C, the temperature of the finish rolling is 840±10°C, the strip is cooled in the laminar cooling line, and the...

Embodiment 2

[0027] After converter smelting and LF furnace refining, the chemical composition of 610L hot-rolled automobile frame steel strip is controlled as follows: C: 0.06wt%, Mn: 1.60wt%, S: 0.005wt%, P: 0.015wt%, Si: 0.06wt% , Als: 0.029 wt%, Nb: 0.047 wt%, Ti: 0.018 wt%, slab thickness 150mm. The casting slab is heated by a walking heating furnace, and the temperature of the slab coming out of the furnace is ≥1280°C. The heating time is 150 minutes. After 5 times of rough rolling, the thickness of the intermediate billet after rough rolling is 35-40mm. After being coiled by the hot coil box, the head and tail are reversed to reduce the temperature difference between the head and the tail, and then 7 times of finish rolling. For steel strips with a thickness of 2.6mm, the temperature for finishing rolling is controlled within the range of 1030-1070°C. The final rolling temperature is 840±10°C, the strip is cooled on the laminar flow cooling line, the opening mode of the cooling wat...

Embodiment 3

[0035]After converter smelting and LF furnace refining, the chemical composition of 610L hot-rolled automobile frame steel strip is controlled as follows: C: 0.07wt%, Mn: 1.50wt%, S: 0.009wt%, P: 0.017wt%, Si: 0.06wt% , Als: 0.022 wt%, Nb: 0.050 wt%, Ti: 0.017 wt%, slab thickness 150mm. The casting slab is heated by a walking heating furnace, and the temperature of the slab coming out of the furnace is ≥1280°C. The heating time is 150 minutes. After 5 times of rough rolling, the thickness of the intermediate billet after rough rolling is 35-40mm. After being coiled by the hot coil box, the head and tail are reversed to reduce the temperature difference between the head and the tail, and then 7 times of finish rolling. For steel strips with a thickness of 3.2mm, the temperature for finishing rolling is controlled within the range of 1030-1070°C. The final rolling temperature is 840±10°C, the strip is cooled on the laminar flow cooling line, the opening mode of the cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com