Patents

Literature

261 results about "Sport utility vehicle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sport utility vehicle (SUV) is a category of motor vehicles that combine elements of road-going passenger cars with features from off-road vehicles, such as raised ground clearance and four-wheel drive.

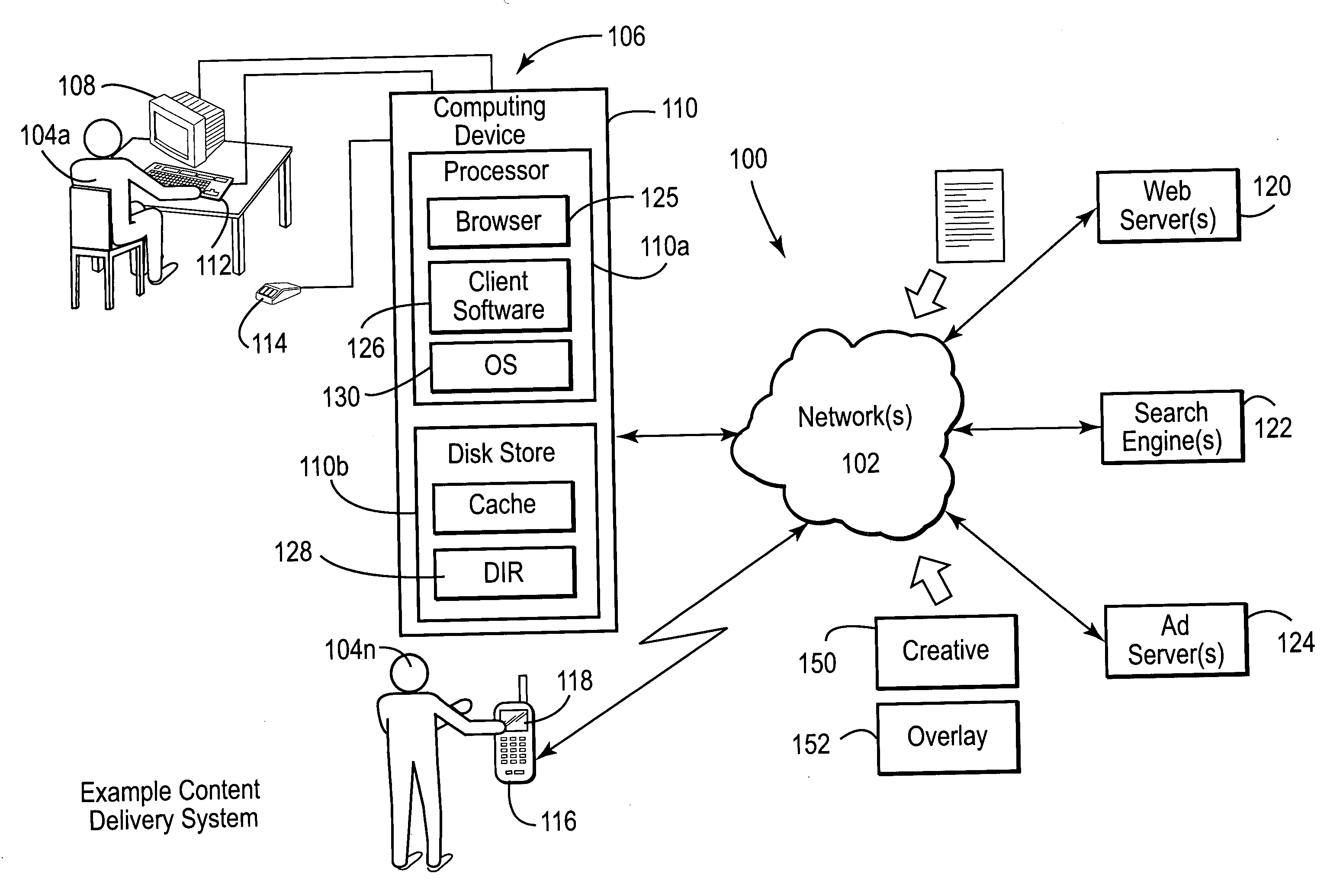

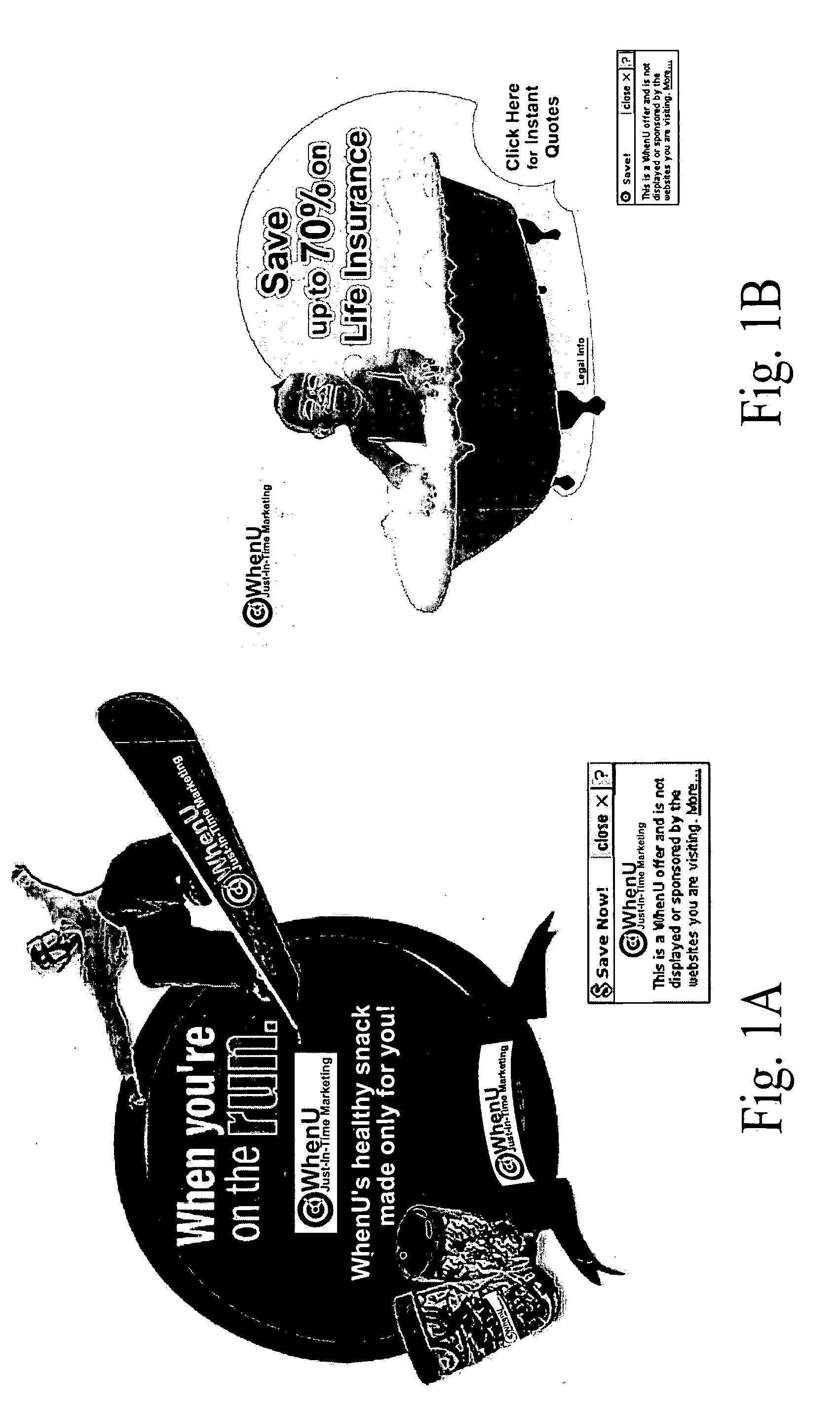

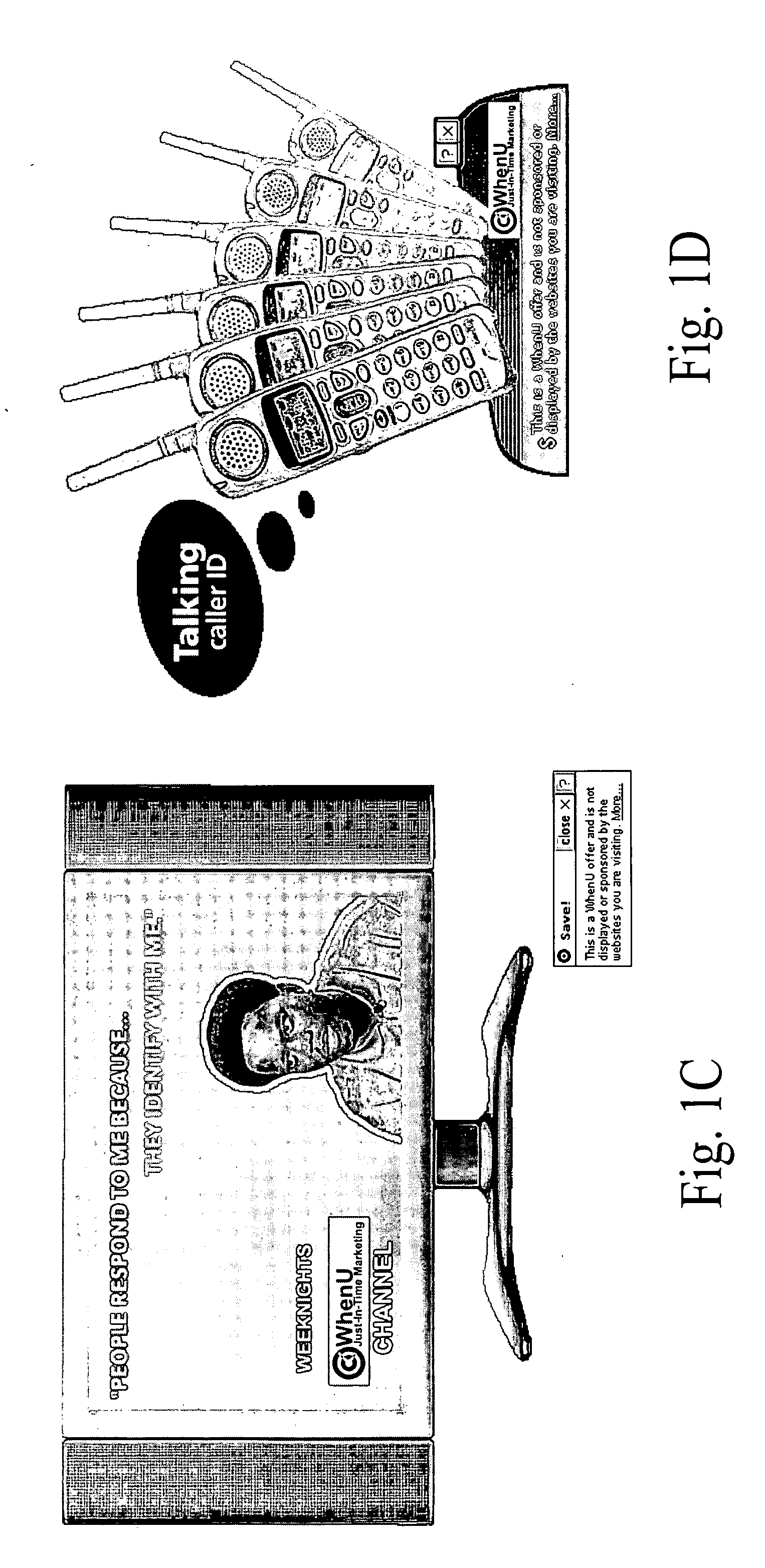

Techniques for remotely delivering shaped display presentations such as advertisements to computing platforms over information communications networks

InactiveUS20060053048A1Raise the possibilityReached efficientlyMarketingWeb browserSport utility vehicle

A high impact desktop or palmtop product placement or “shaper” display presentation technique overcomes disadvantages of previous ad display techniques while providing high consumer interest and increased flexibility for content creators. An advertisement is run in front of or behind a web browser view so it appears with the user's desktop as background, and in a non-rectangular shape that looks nothing like a traditional pop-up or pop-under ad. A “shaper” ad can, for example, have any desired shape such as for example an exact replica of a product being advertised e.g., a cell phone, a Sports Utility Vehicle climbing a mountain, a plasma television set, etc.

Owner:WHENU COM

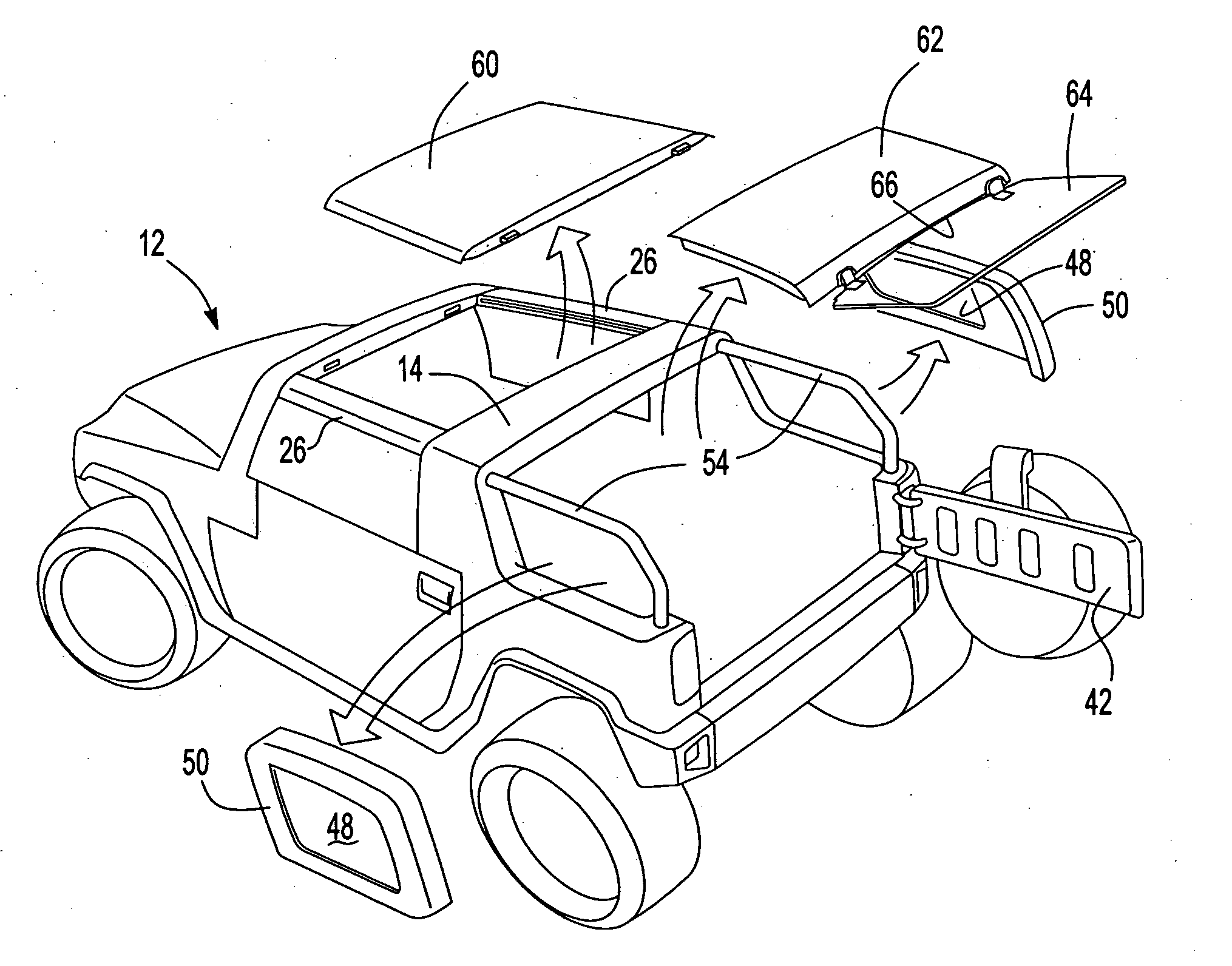

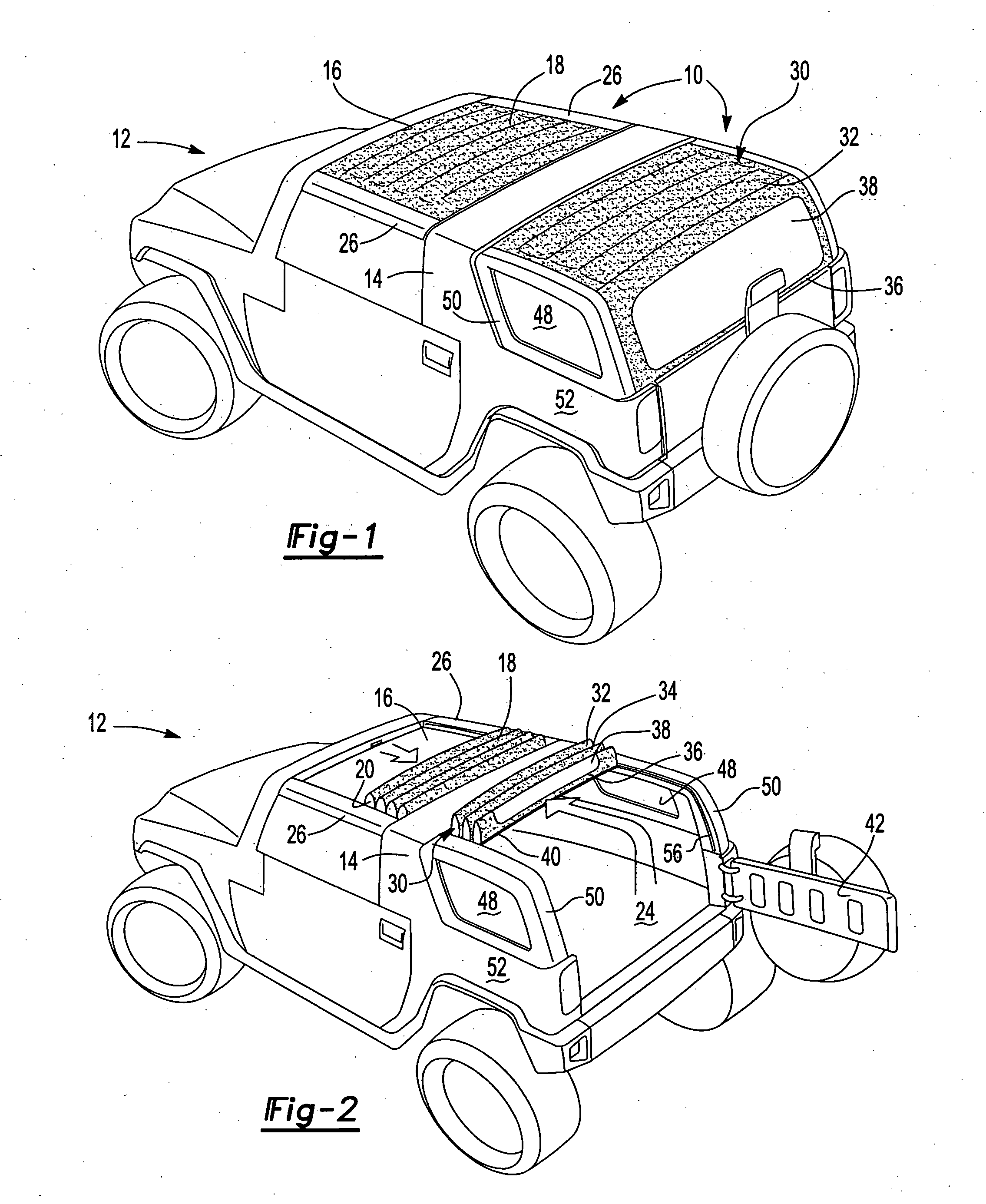

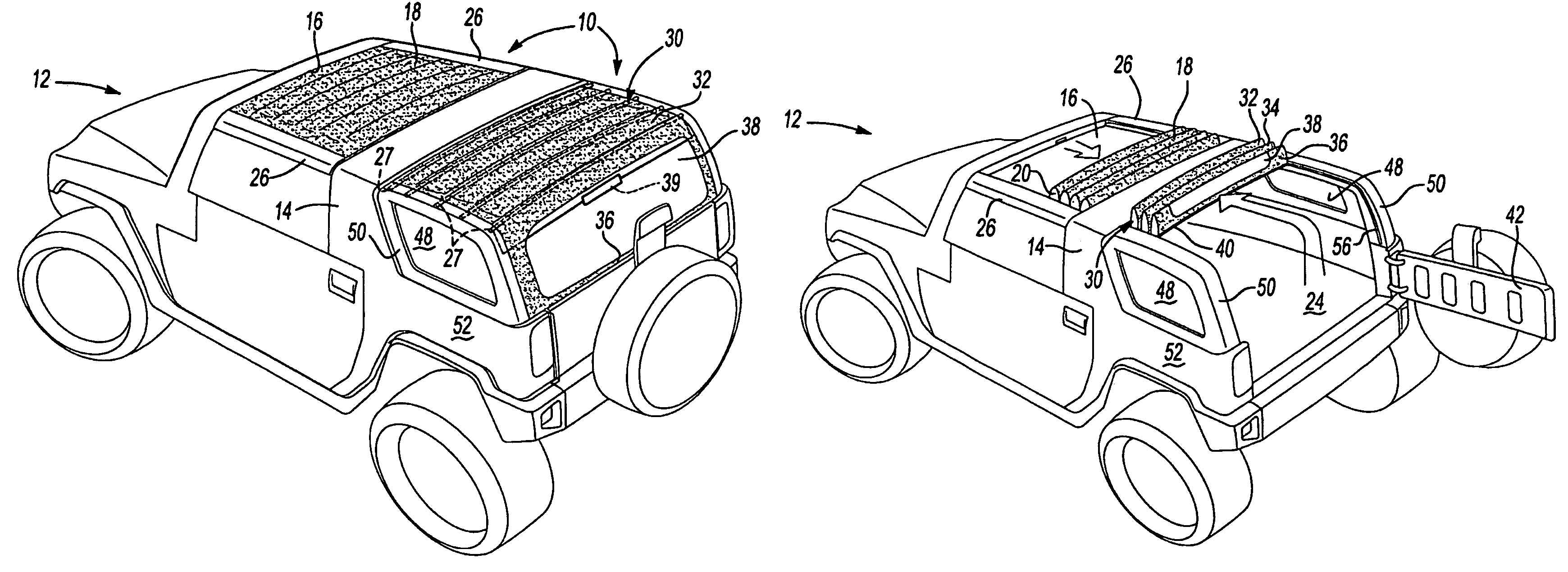

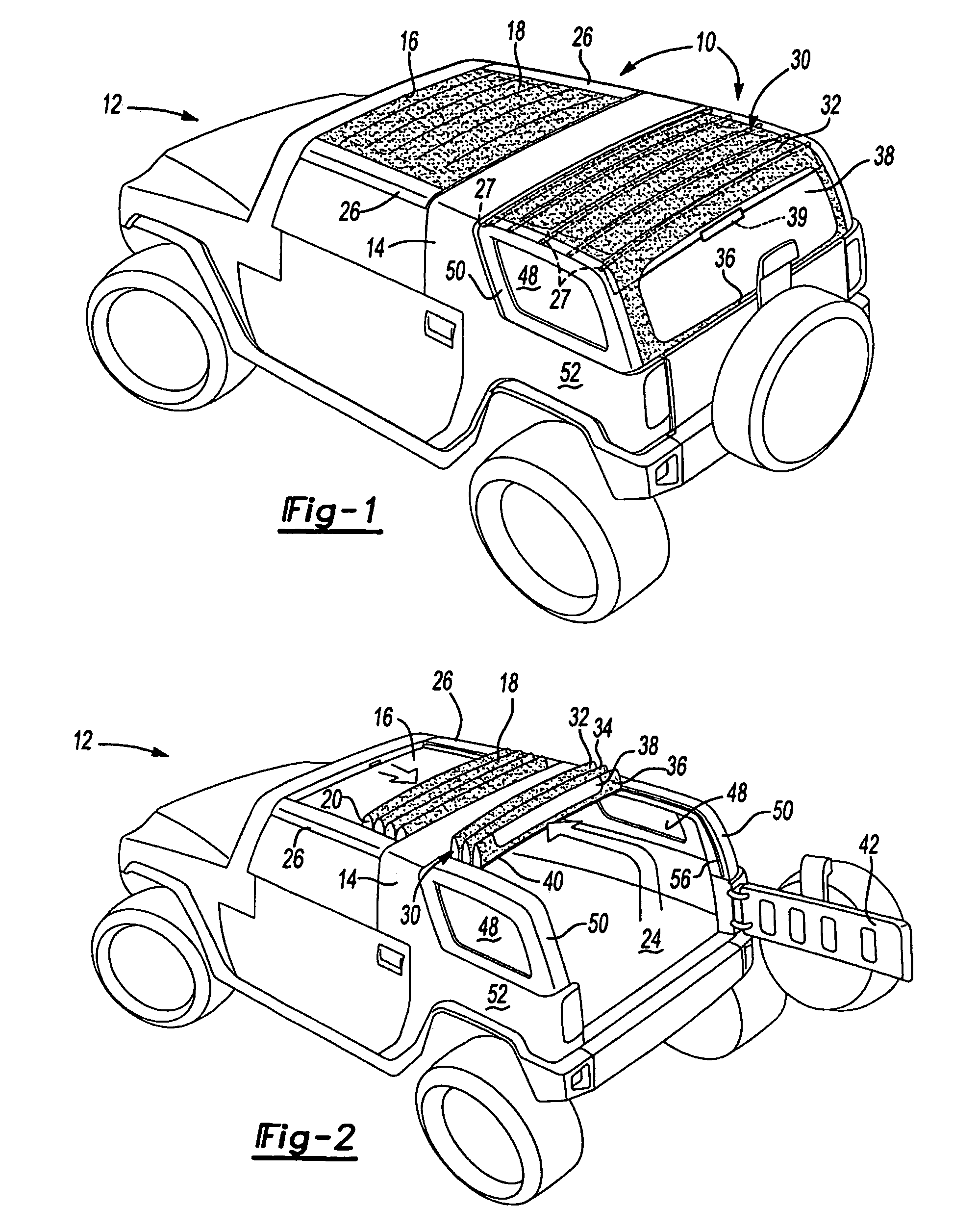

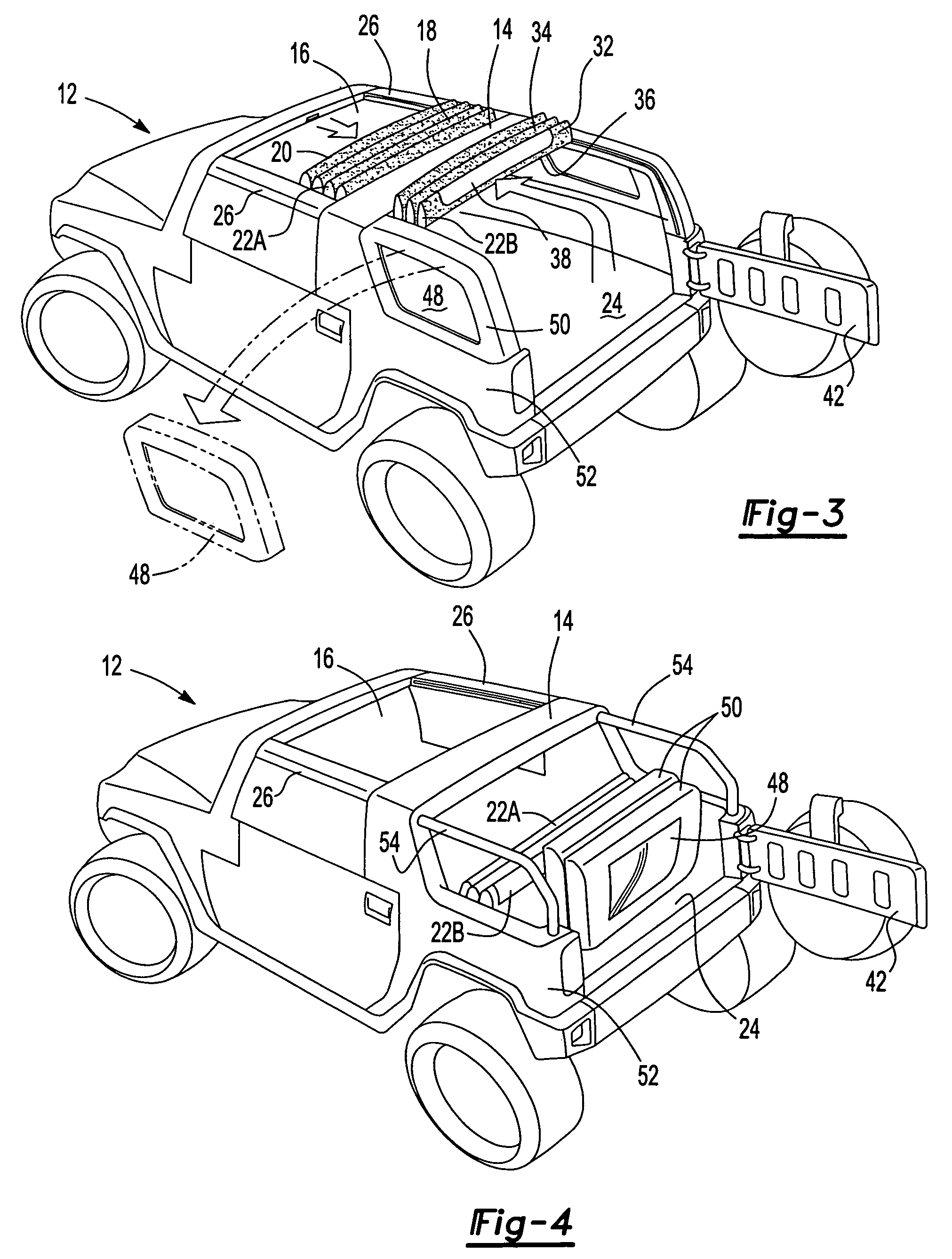

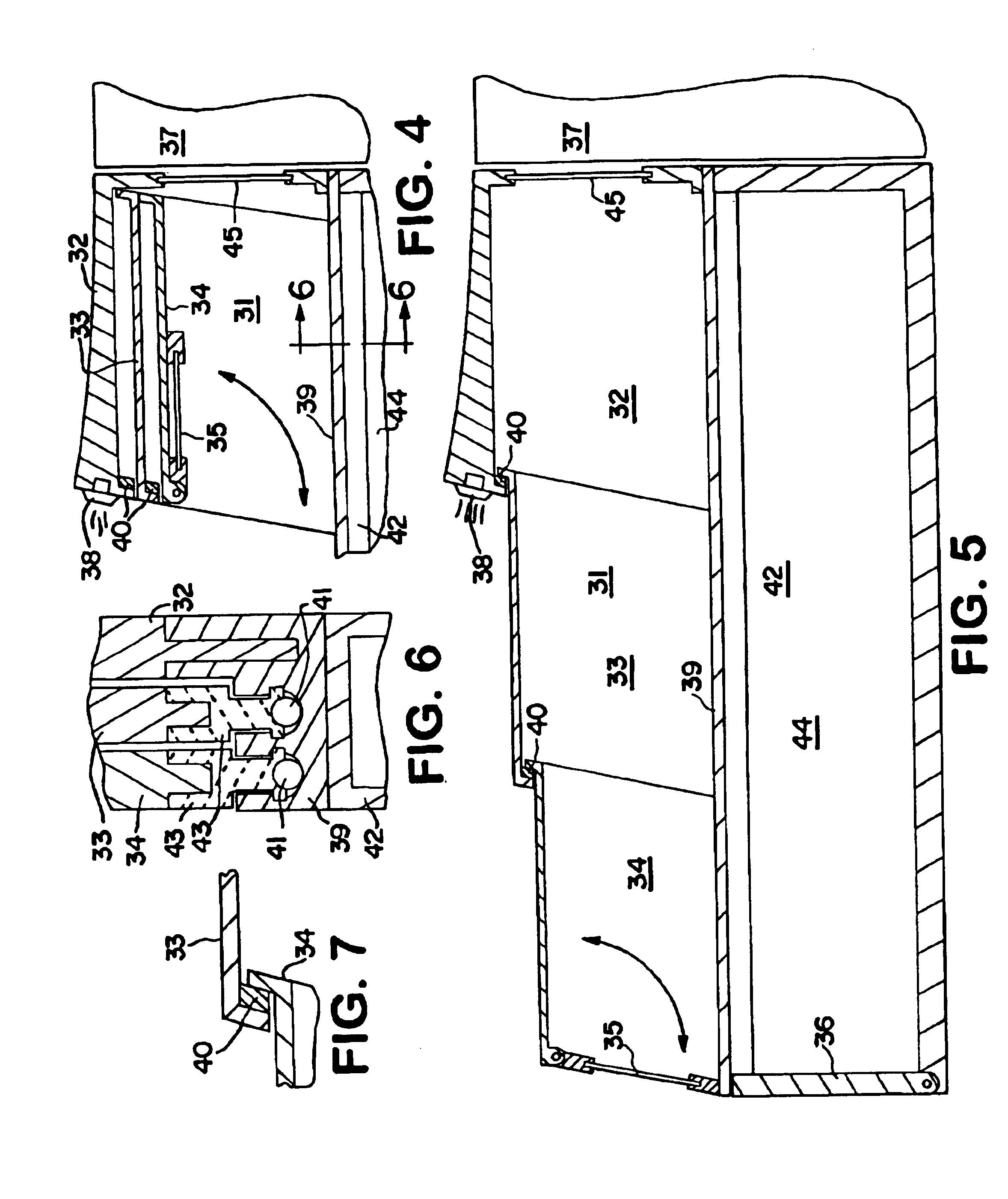

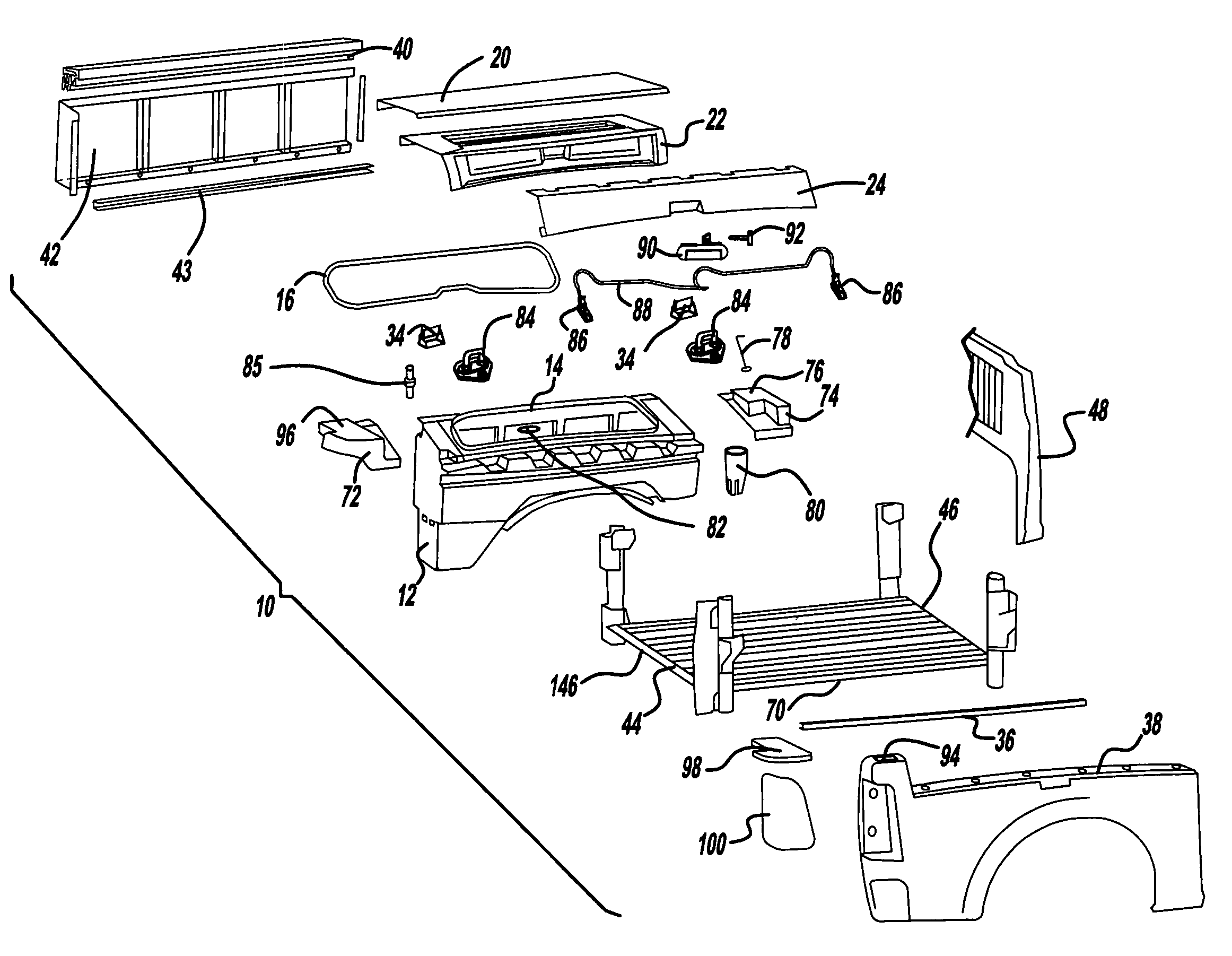

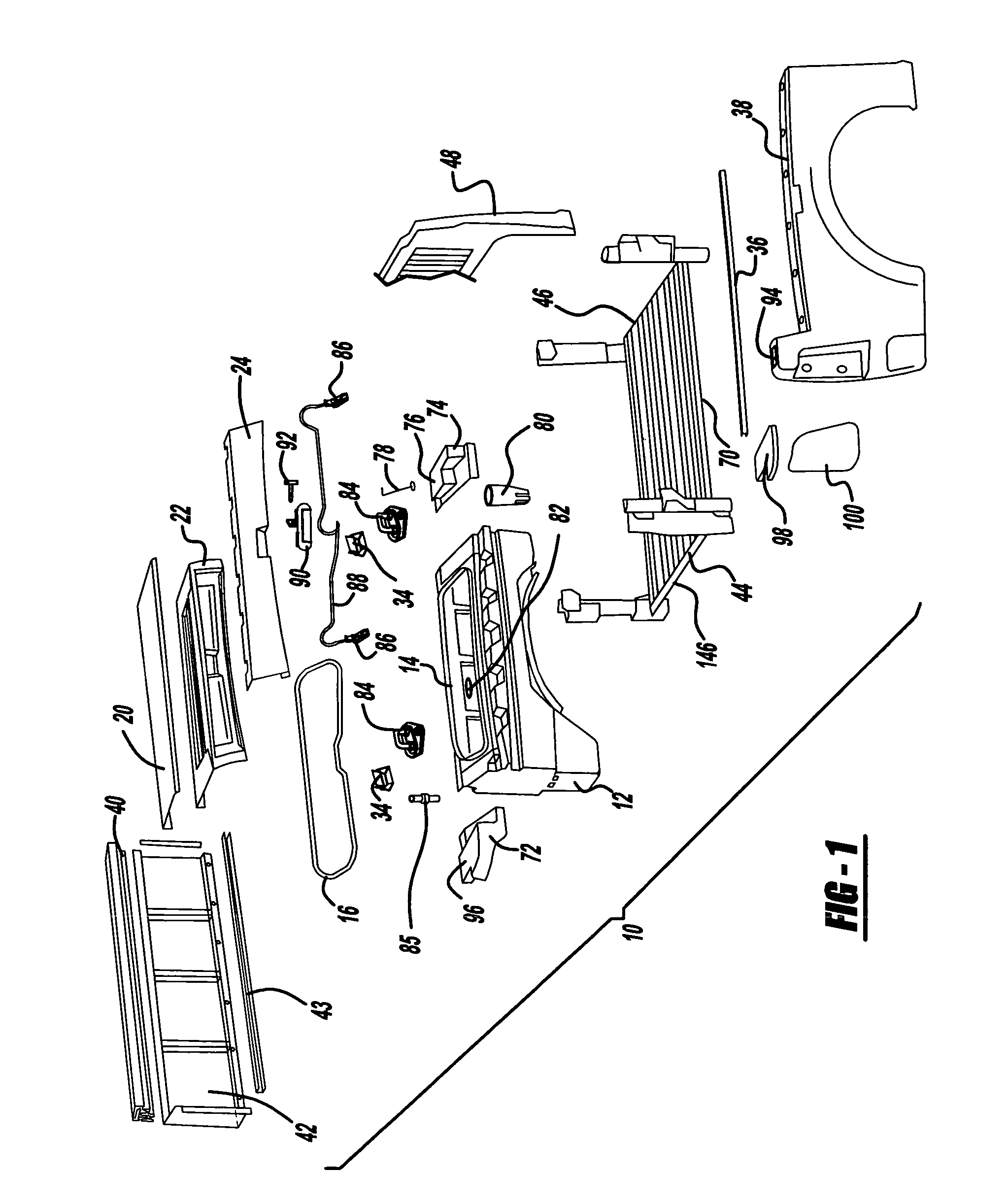

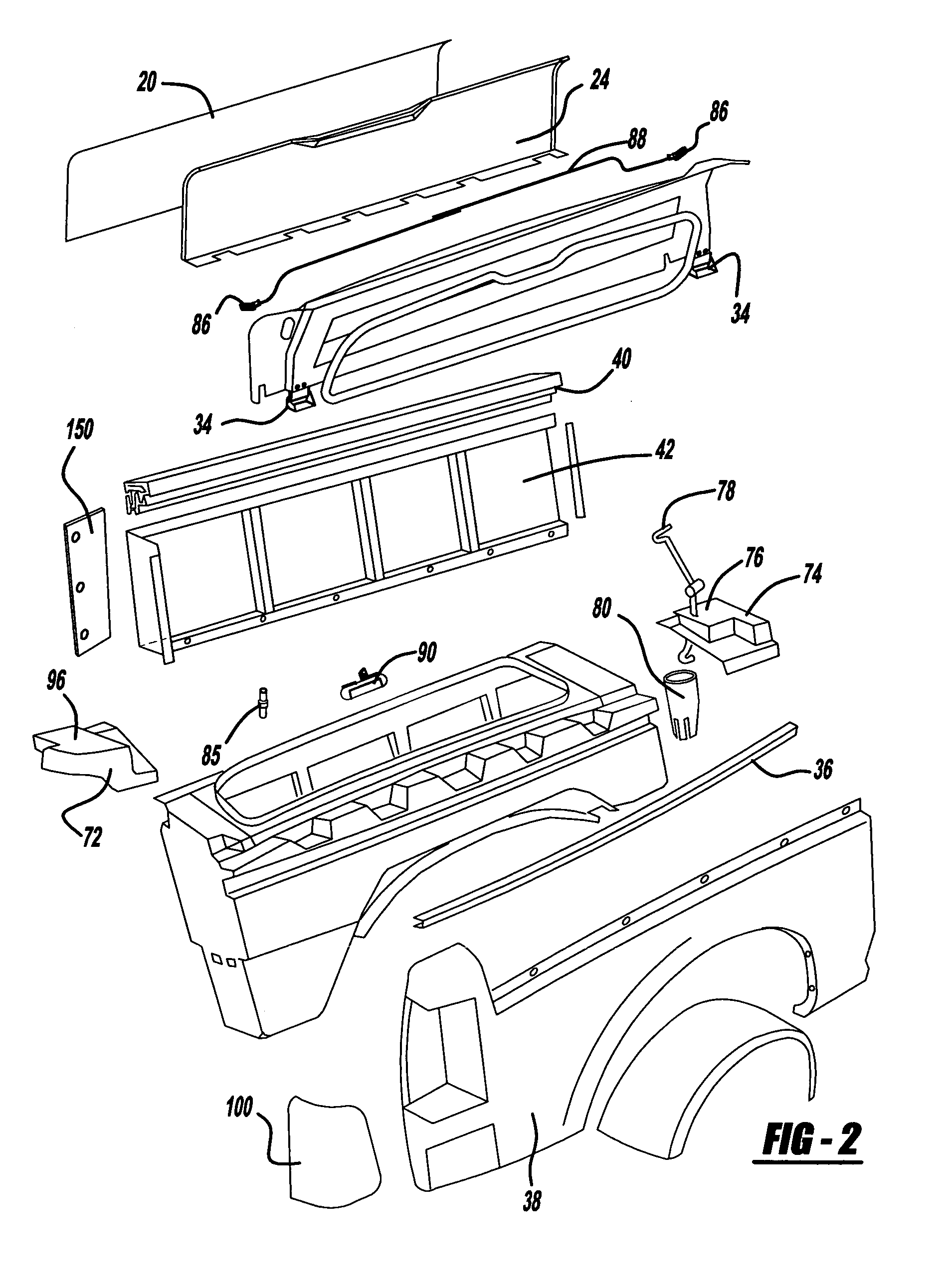

Modular convertible top

A removable top system for a vehicle having a front removable roof section and a rear removable roof section. Different removable roof coverings may be interchangeably combined to provide a complete roof for a sport utility vehicle having a permanent hoop dividing the front and rear roof sections. Soft top and hard top roof coverings are selectively provided. Different retraction mechanisms are disclosed for retracting and storing the removable roof sections.

Owner:MAGNA CAR TOP SYST GMBH

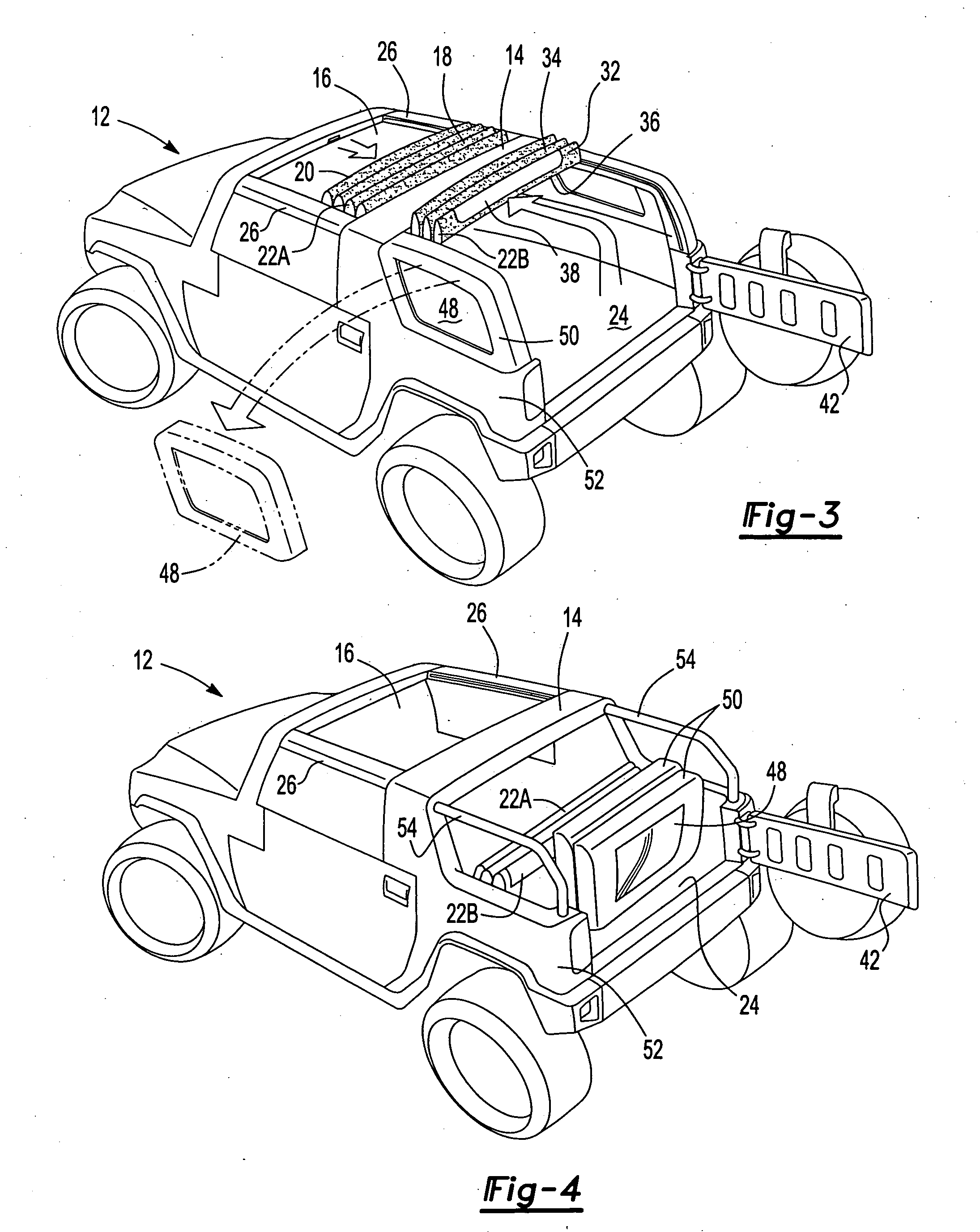

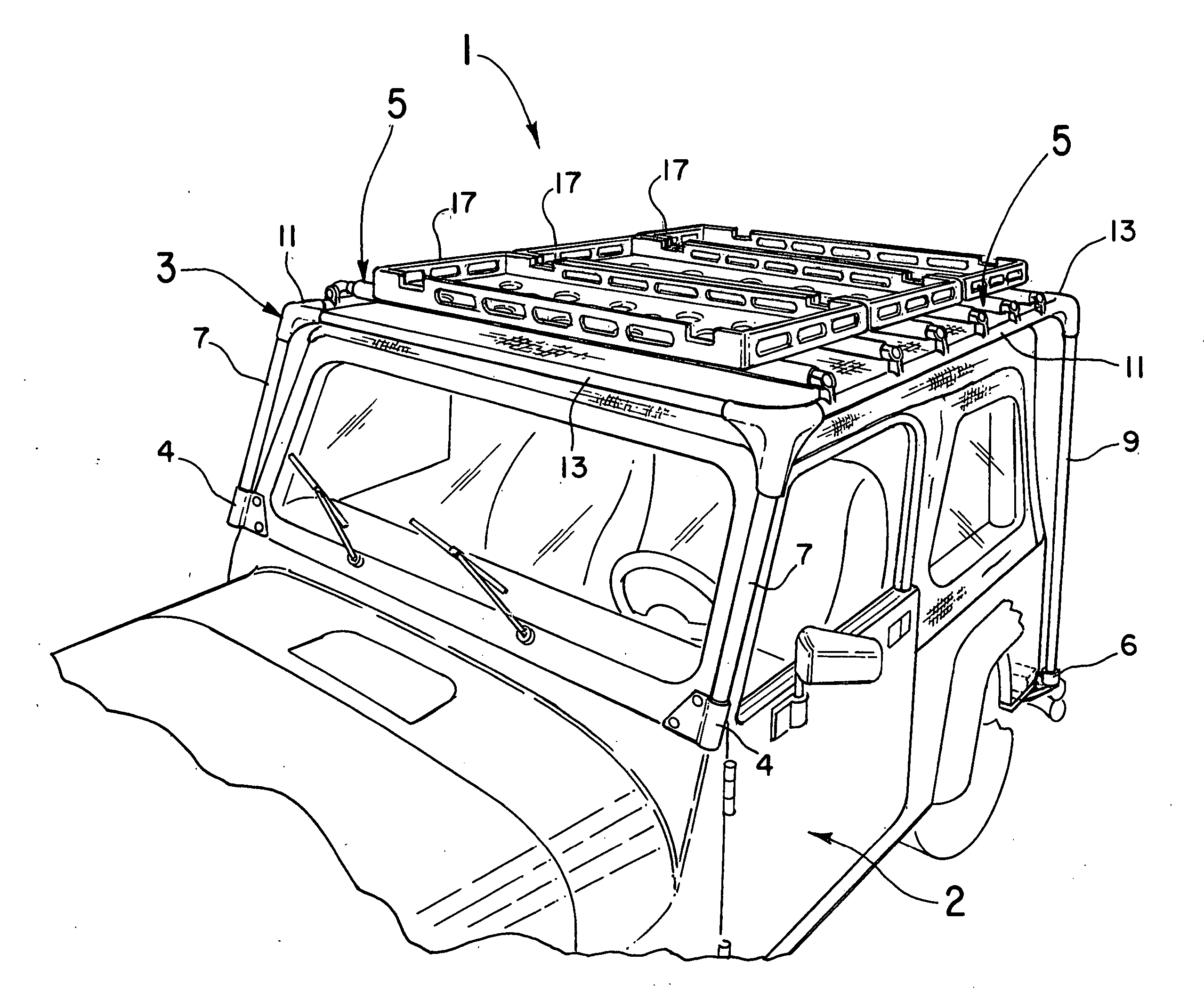

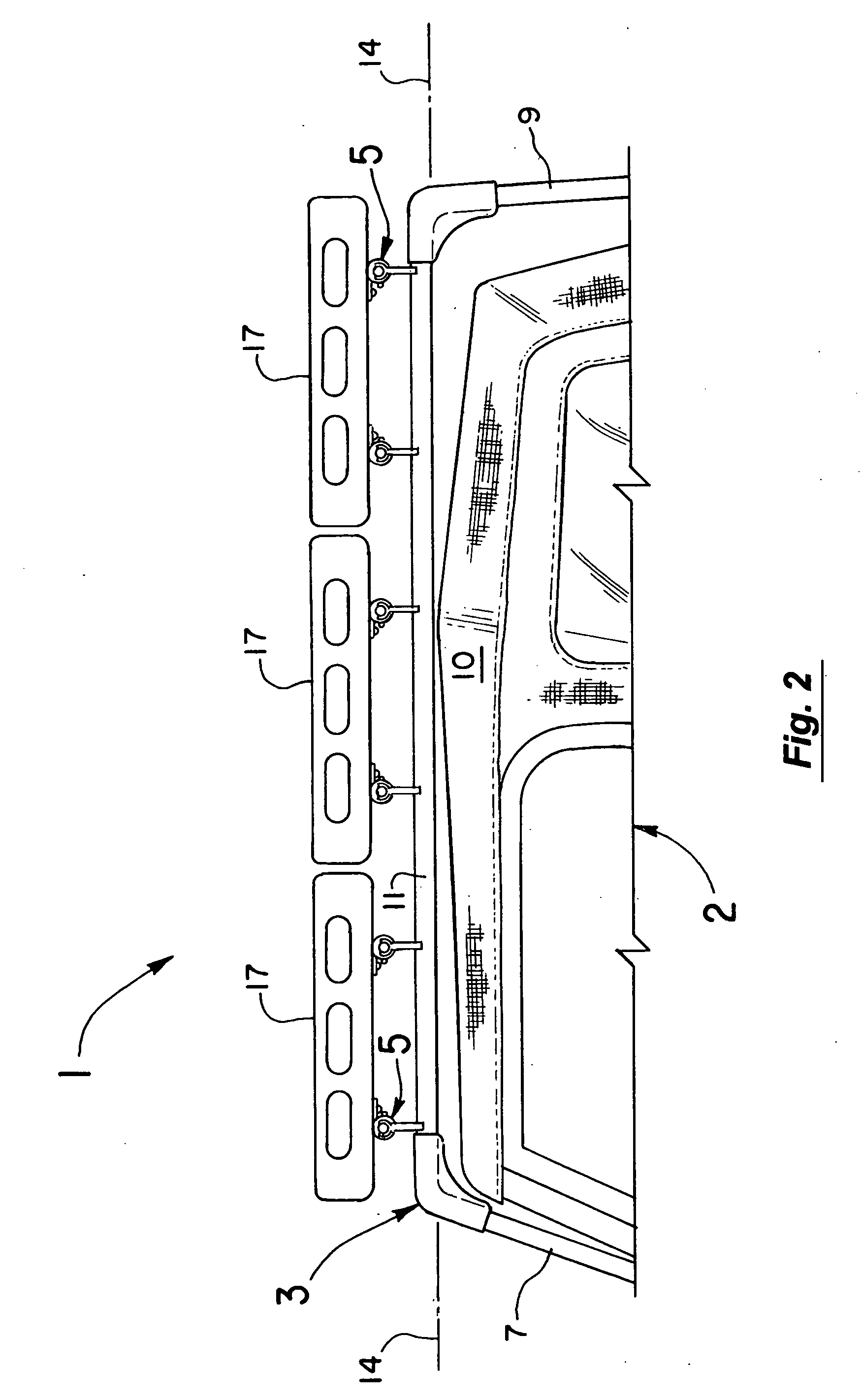

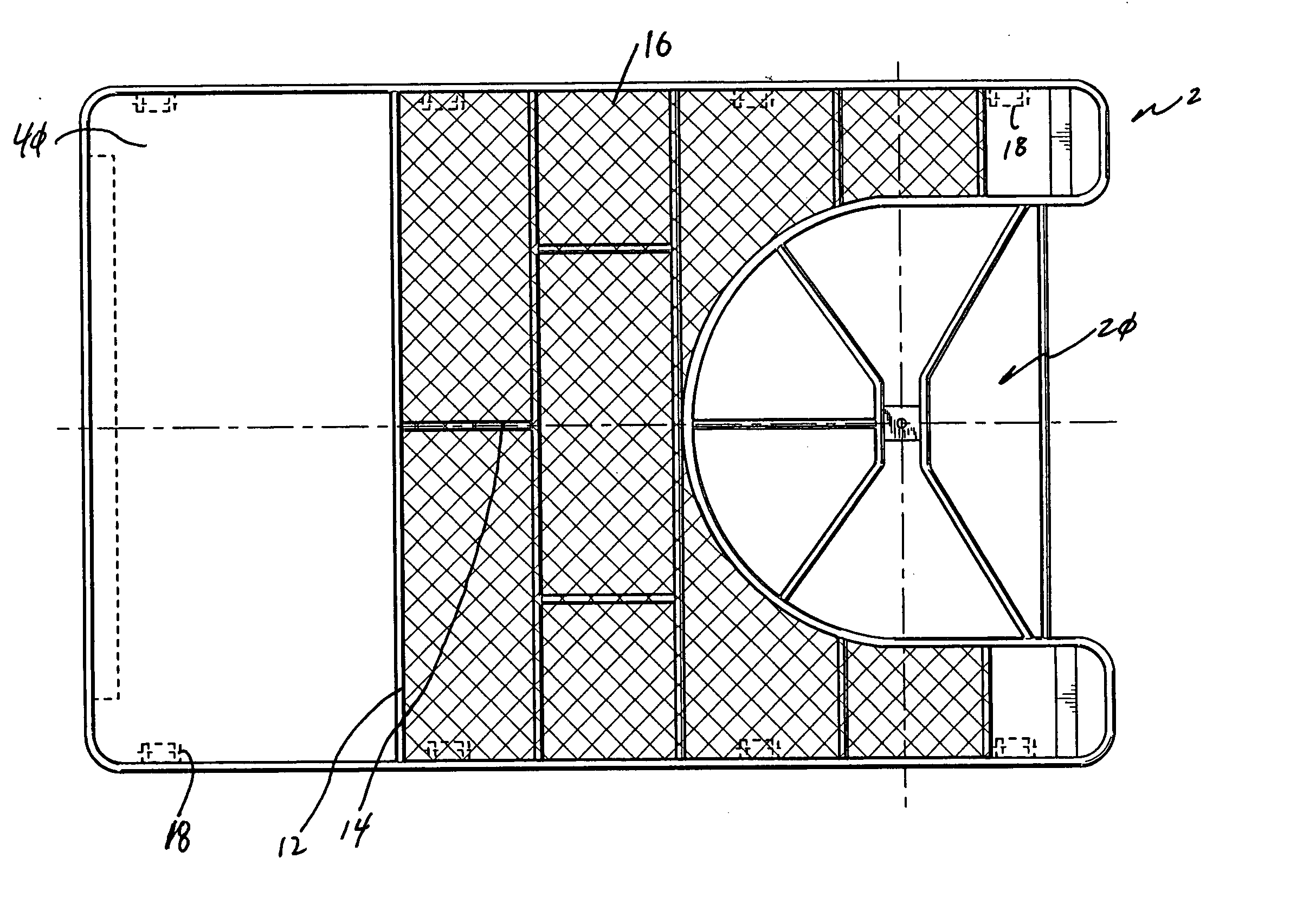

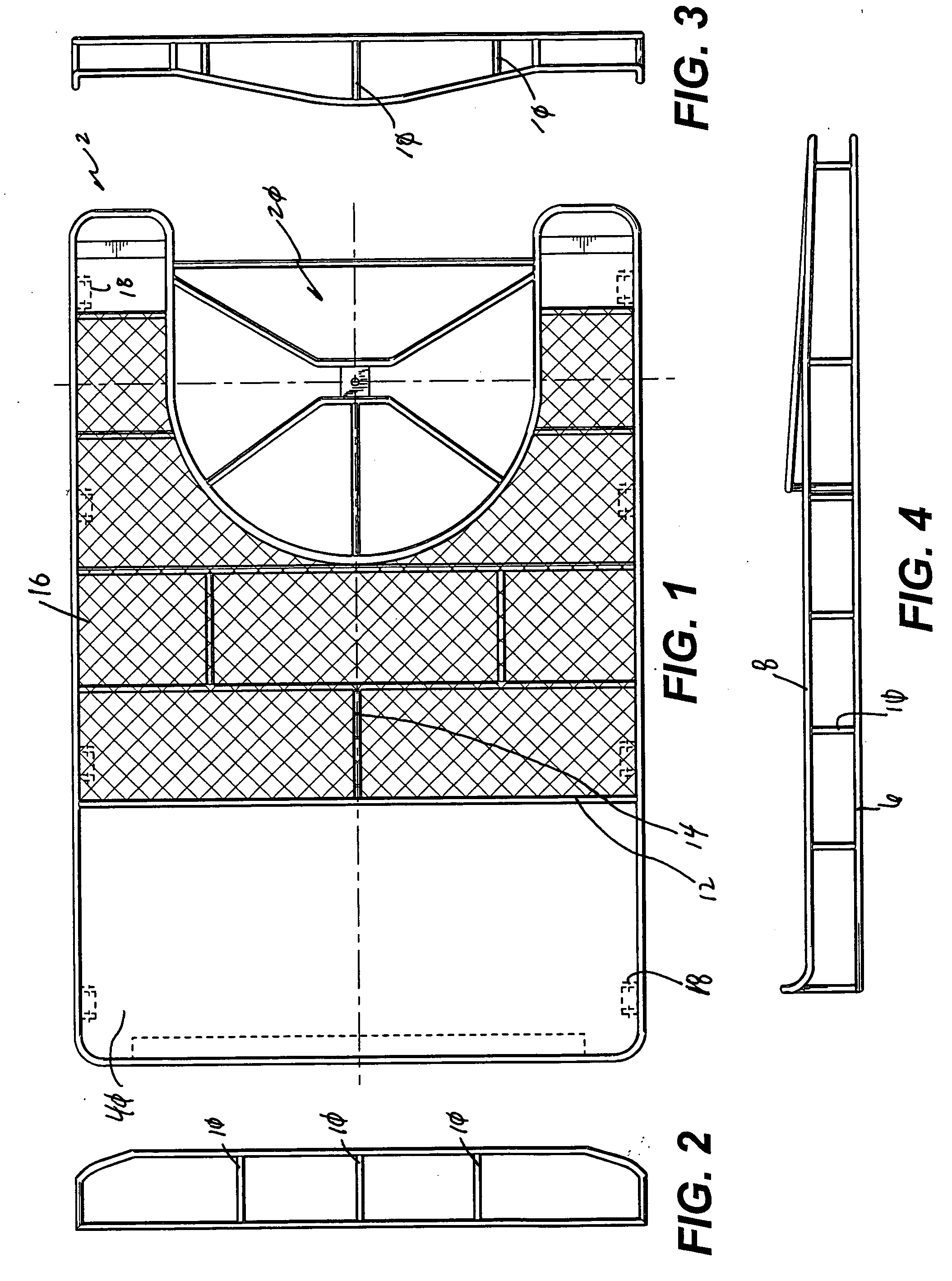

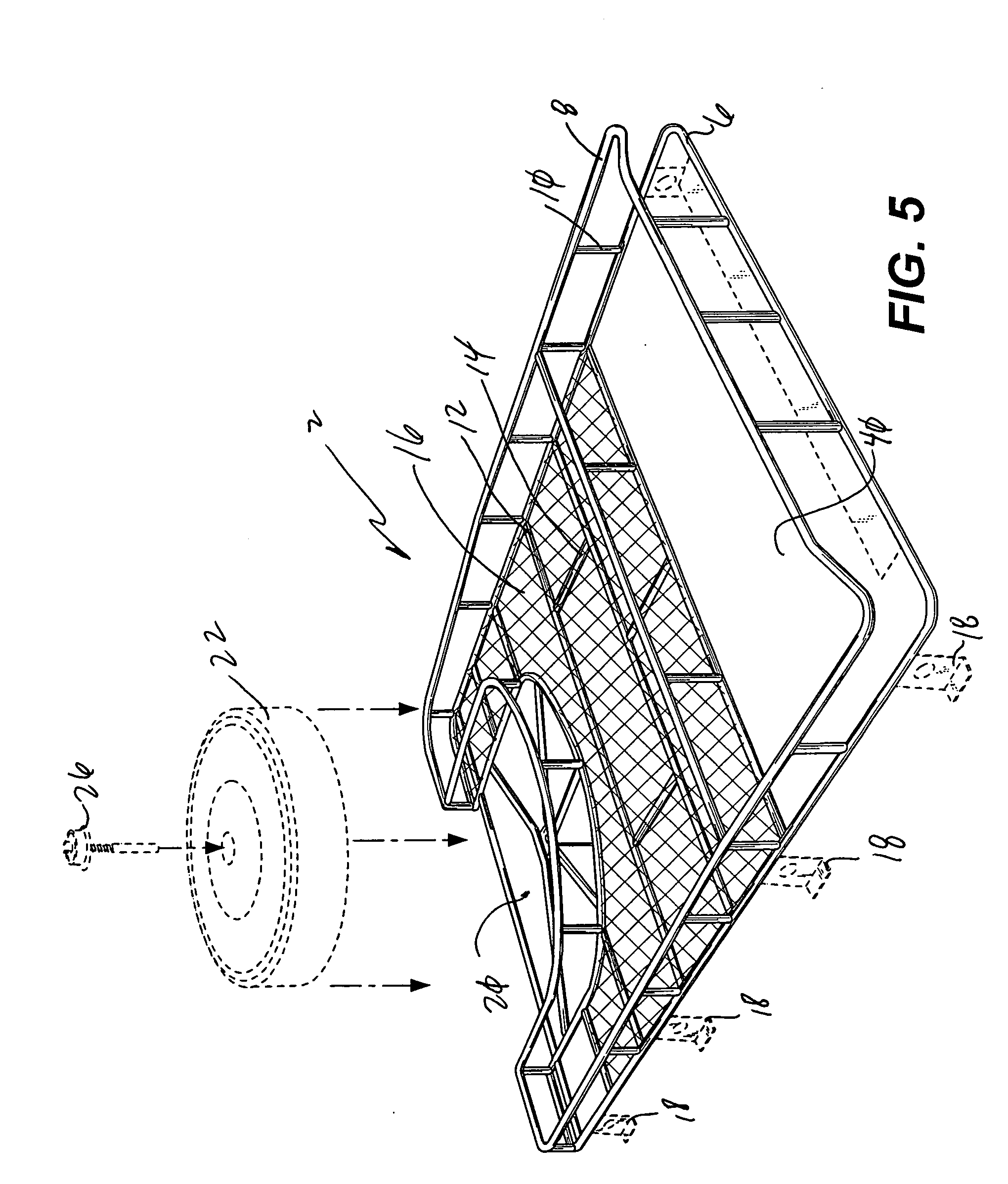

Roof rack for a sport utility vehicle

InactiveUS20050092796A1Easily and quickly pivotedEasy to moveSupplementary fittingsGear wheelSport utility vehicle

A roof rack for a sport utility vehicle. The rack includes a main frame attached to the vehicle and a plurality of rack portions or cross pieces pivotally mounted to the main frame. In use, the rack portions with the gear or carrying trays supported on them can be pivoted to one side of the vehicle and out of the path of the normal movement of the vehicle top including any sunroof. The top or sun roof can then be easily and quickly moved as intended between its open and closed positions without having to unload and reload the stored gear or other items.

Owner:BESTOP

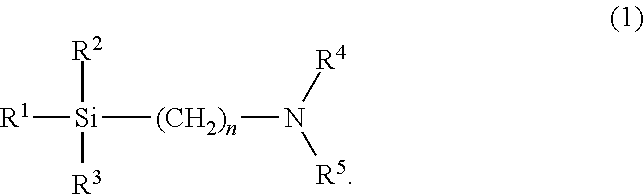

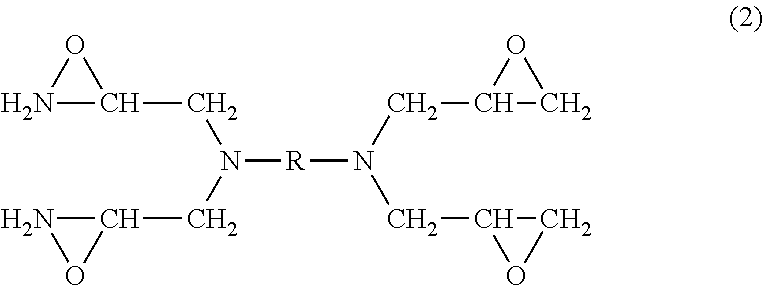

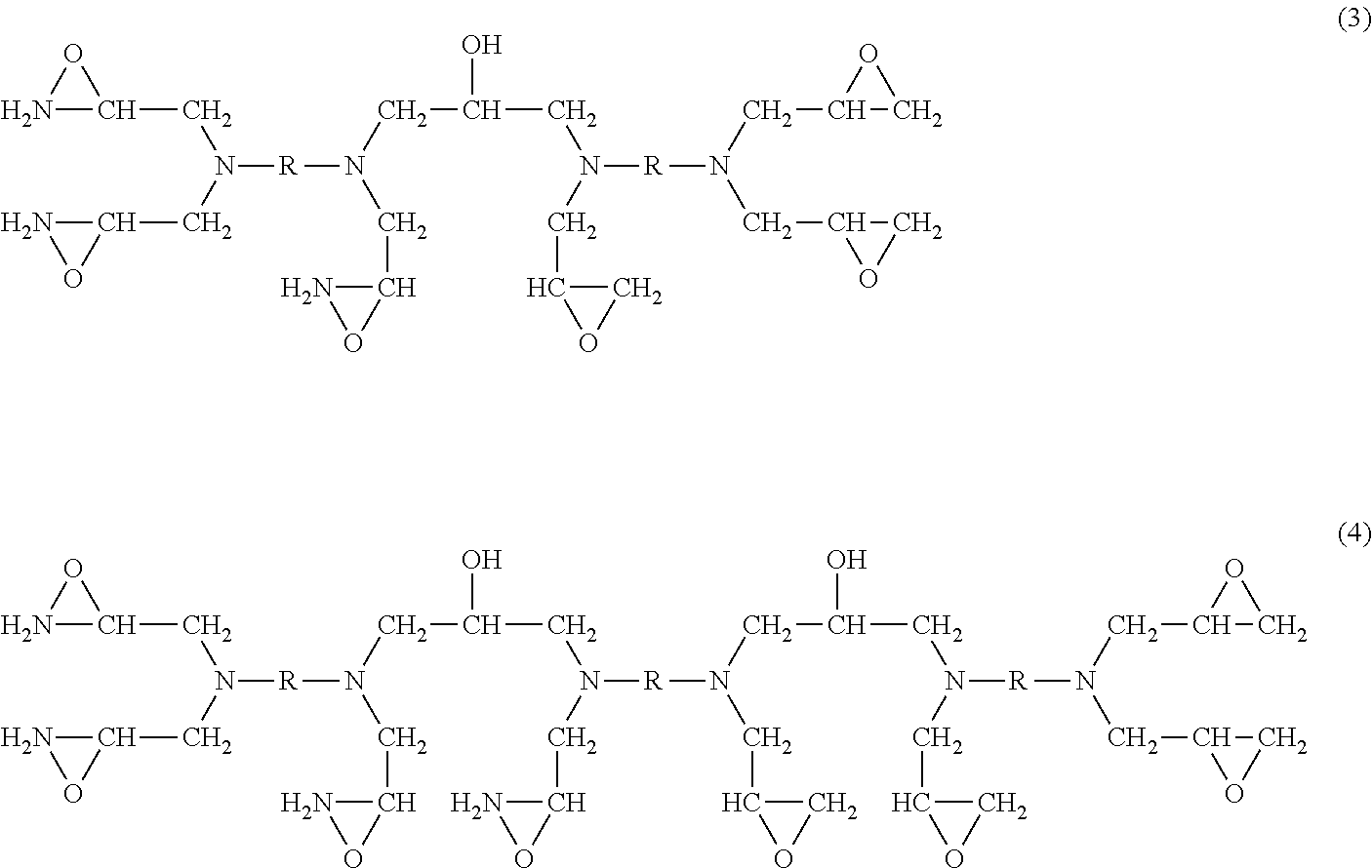

Rubber composition for tread, and pneumatic tire

ActiveUS20130331498A1Improve wear resistanceImprove wet grip performanceSpecial tyresNitrogenEngineering

Provided are a rubber composition for treads that has both excellent abrasion resistance and good wet grip performance and also offers good fuel economy and elongation at break, and a pneumatic tire (particularly for passenger vehicles and for sport utility vehicles) formed therefrom. The rubber composition includes, based on 100% by mass of a rubber component, 40-75% by mass of BR and 25-55% by mass of SBR; and includes, per 100 parts by mass of the rubber component, 40-120 parts by mass of a silica having a nitrogen adsorption specific surface area of 160-270 m2 / g, and 15-50 parts by mass of a carbon black having a nitrogen adsorption specific surface area of 100-250 m2 / g, wherein a ratio of a total content of silica to a total content of SBR is 0.70-2.50, and a ratio of a total content of carbon black to a total content of BR is 0.25-0.75.

Owner:SUMITOMO RUBBER IND LTD

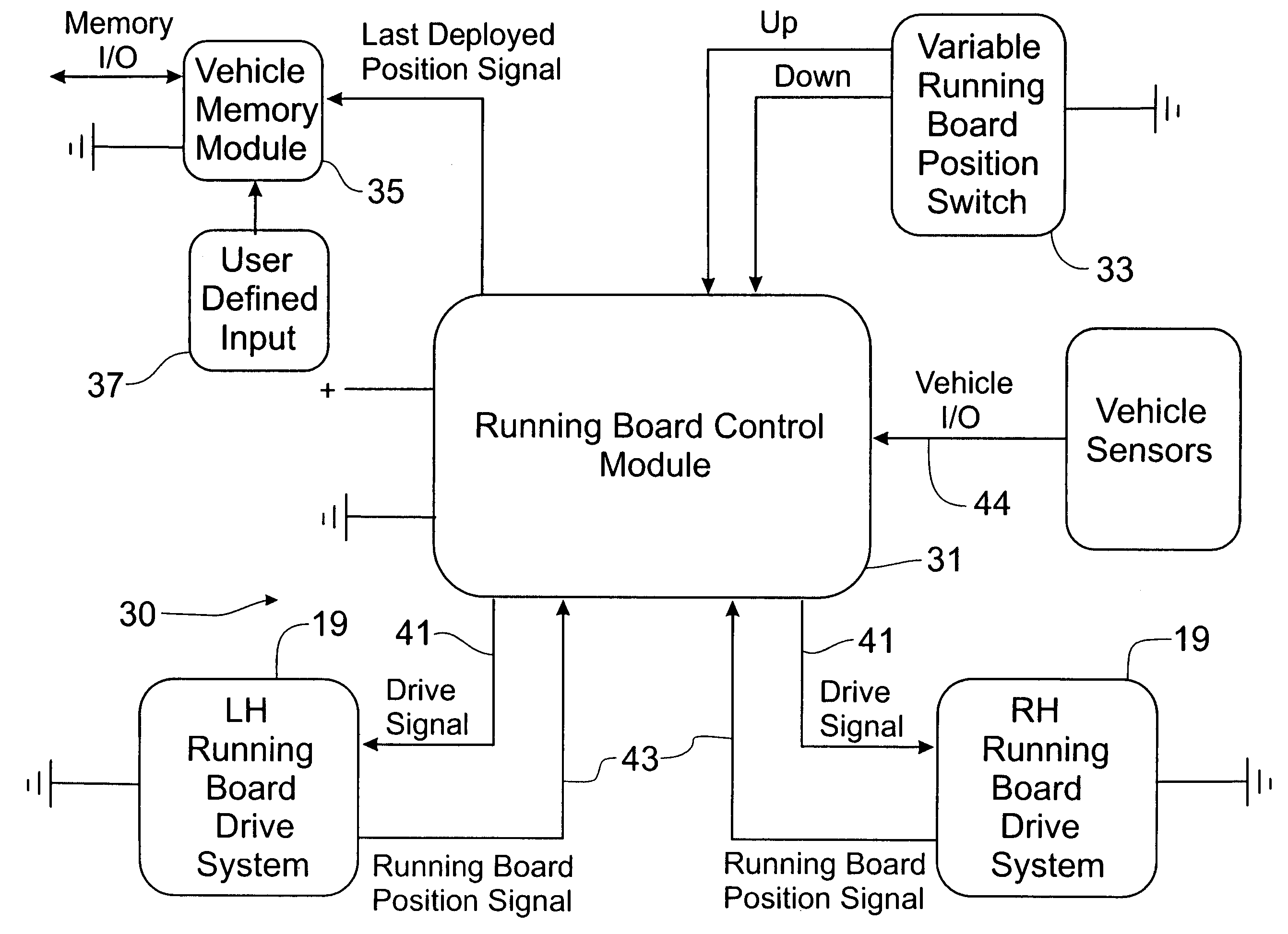

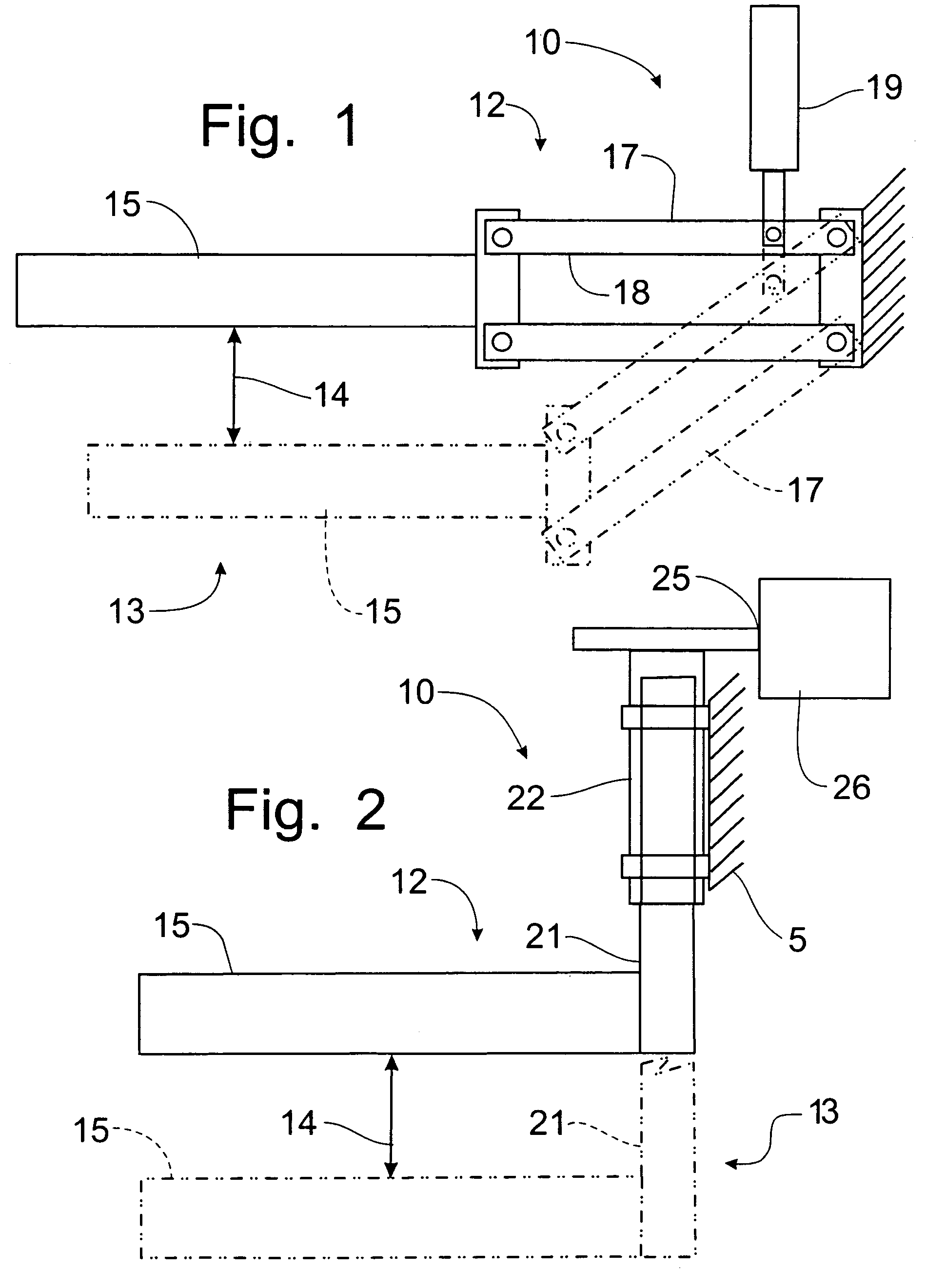

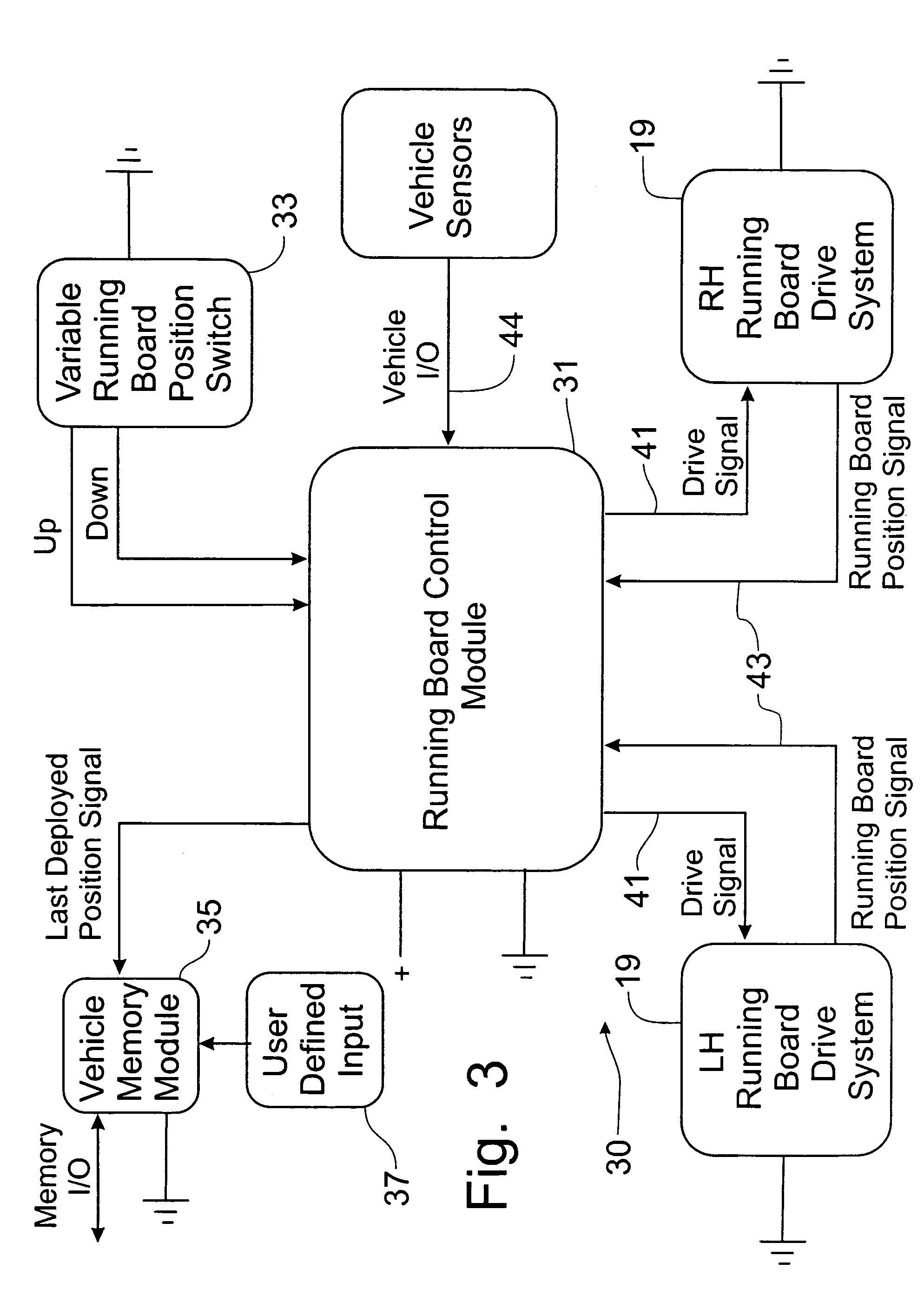

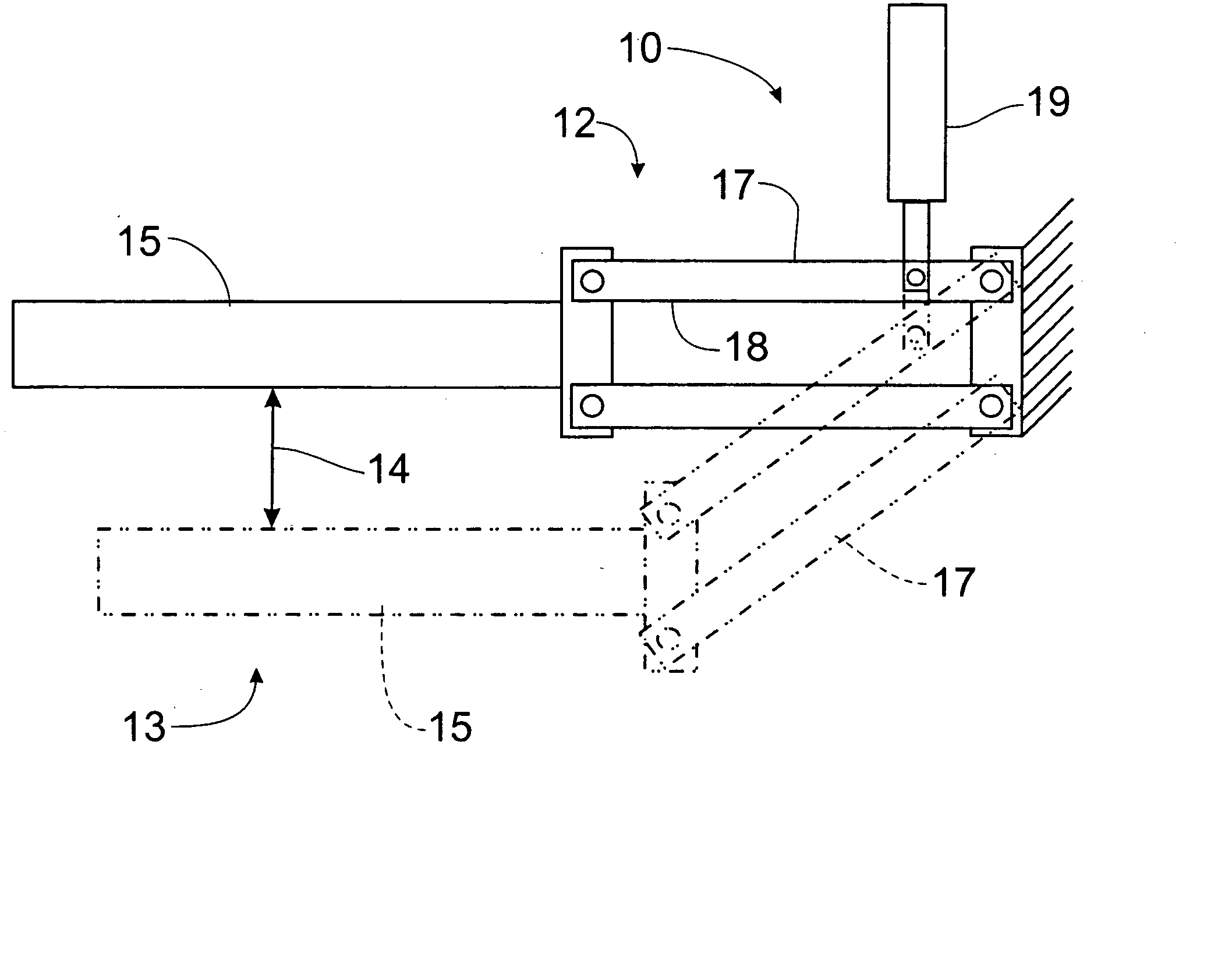

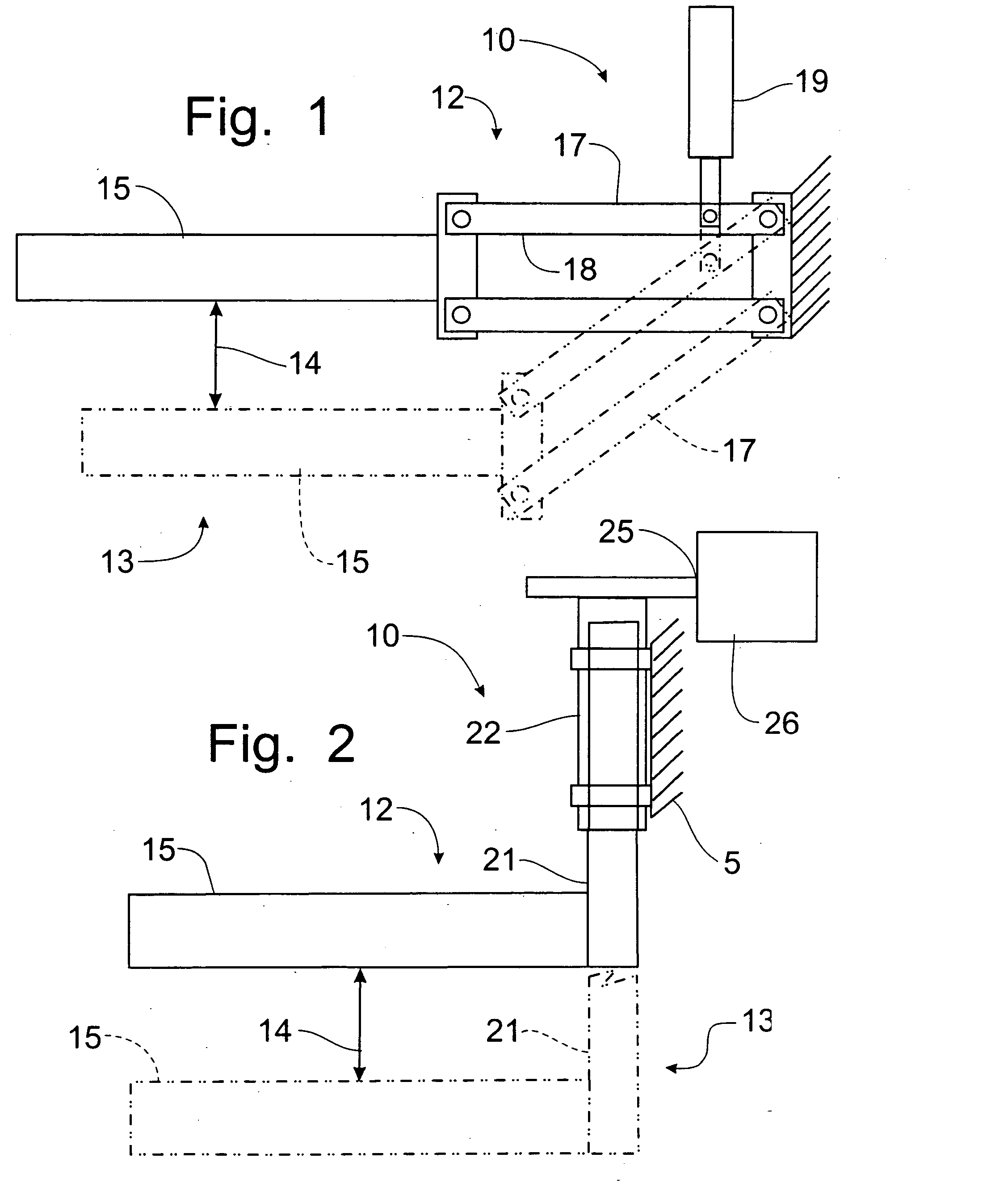

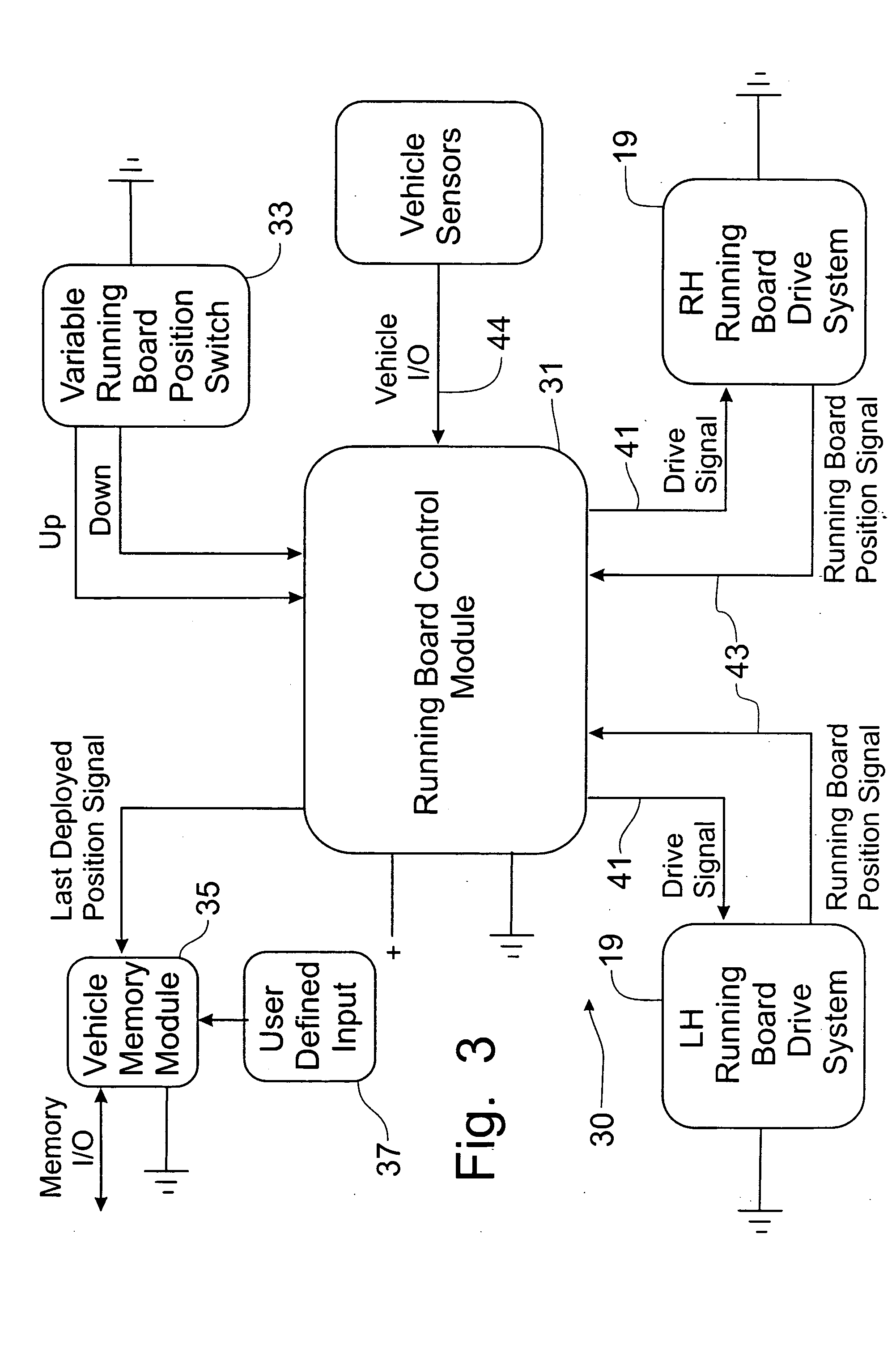

Memory function for powered running boards

ActiveUS7070194B2Convenient heightReliable constructionSteps arrangementMobile vehicleOperating point

Owner:FORD GLOBAL TECH LLC

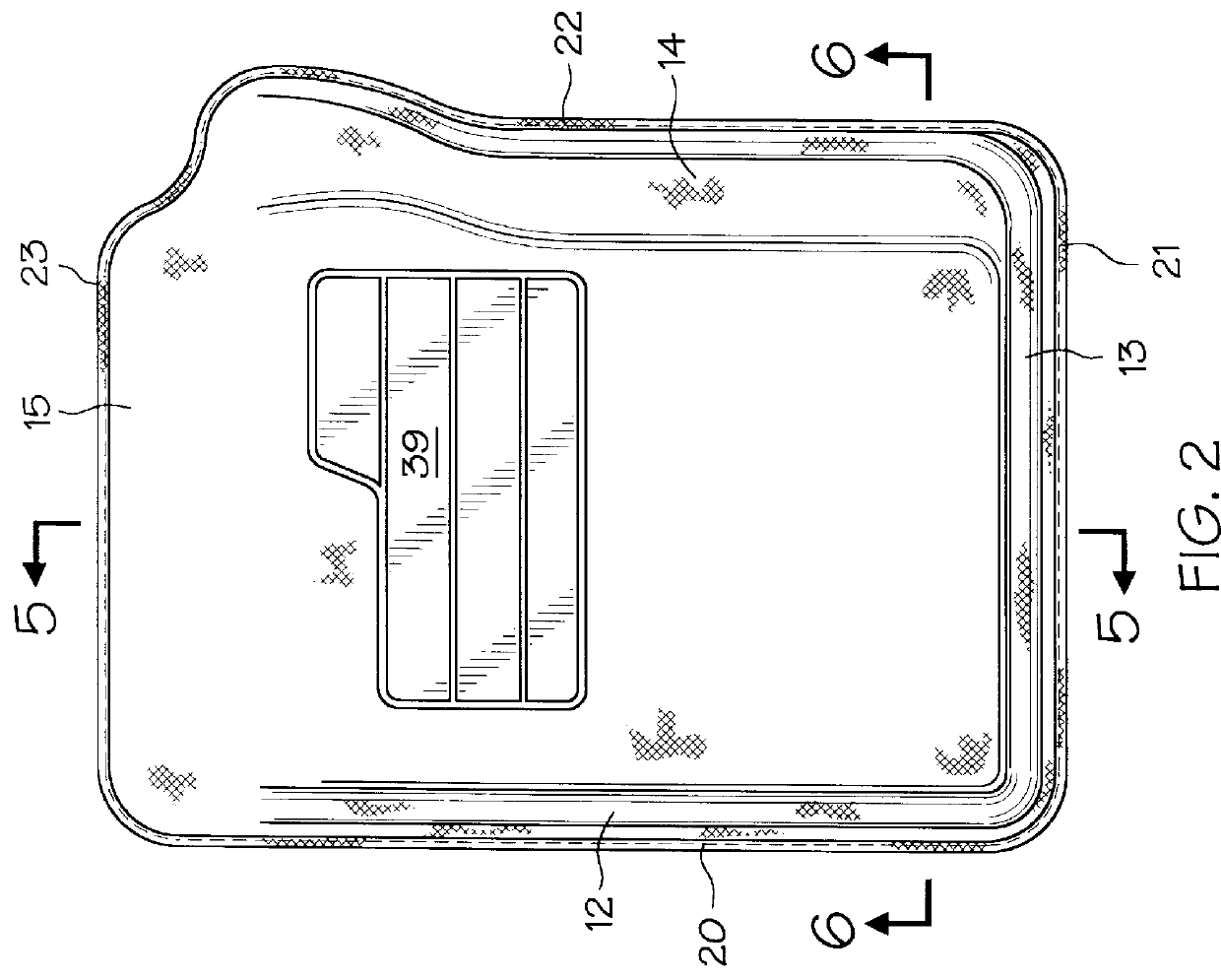

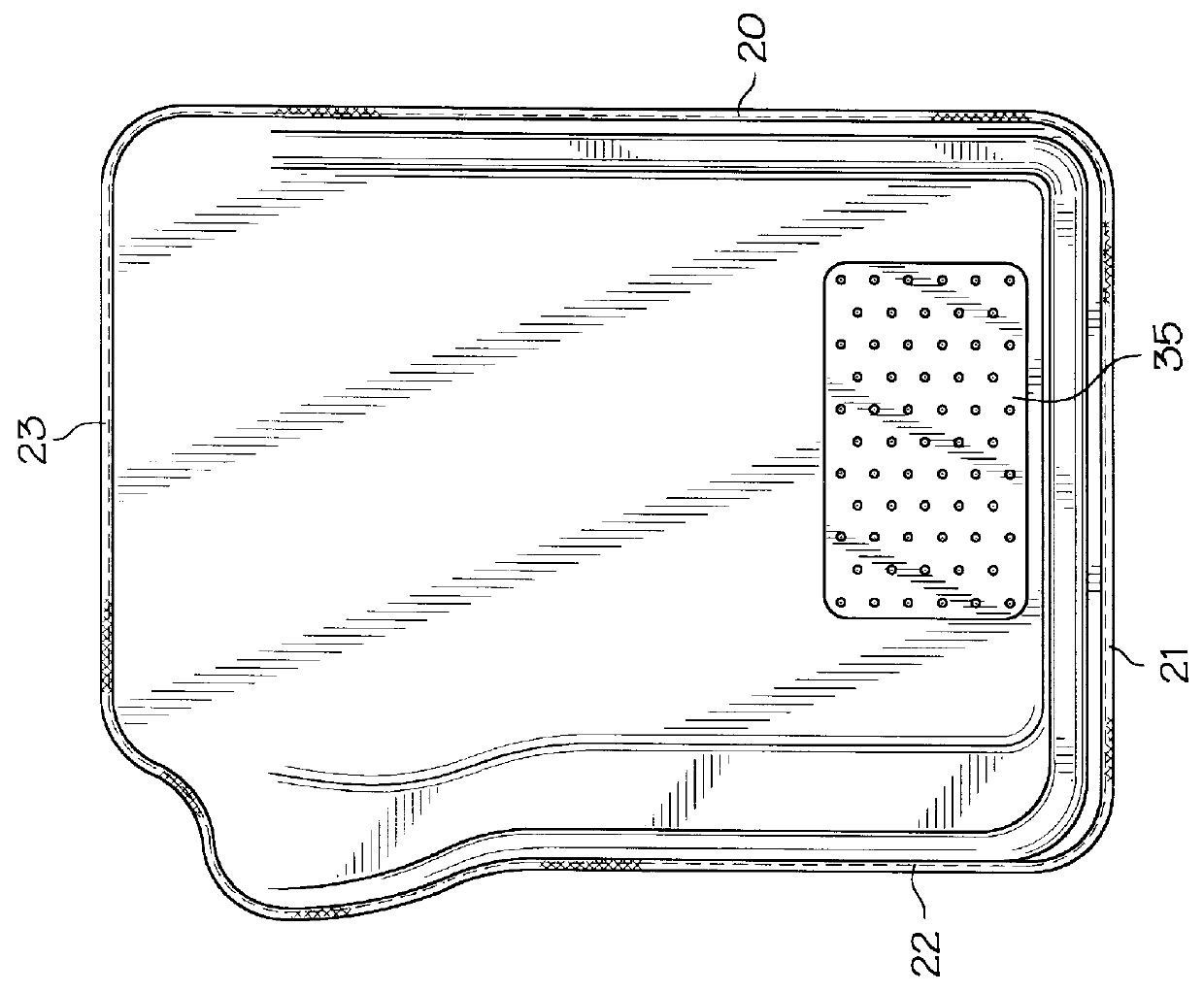

Auxiliary molded floor mats

An auxiliary molded floor mat is produced to fit the carpeted floor compartment area of a van, pickup truck, sport utility vehicle or other vehicle having a floor which is substantially flat and even with a door sill. The floor mat is a one piece composite of a tufted carpet layer, a thermoplastic mid-layer and a non-slip substrate bottom layer. The floor mat has a flat base with raised walls near each of its outside edges which form a tray-like central area. At least one of the raised walls is double walled with a substantially horizontally extending floor engaging peripheral lip. Molding of the composite imparts a desired contoured shape which neatly fits the vehicle's floor compartment area without substantial folds or wrinkles. The tray-like central area of the floor mat catches debris. It is readily cleaned simply by removing the full mat from the vehicle.

Owner:HUSKY LINERS INC

Modular convertible top

A removable top system for a vehicle having a front removable roof section and a rear removable roof section. Different removable roof coverings may be interchangeably combined to provide a complete roof for a sport utility vehicle having a permanent hoop dividing the front and rear roof sections. Soft top and hard top roof coverings are selectively provided. Different retraction mechanisms are disclosed for retracting and storing the removable roof sections.

Owner:MAGNA CAR TOP SYST GMBH

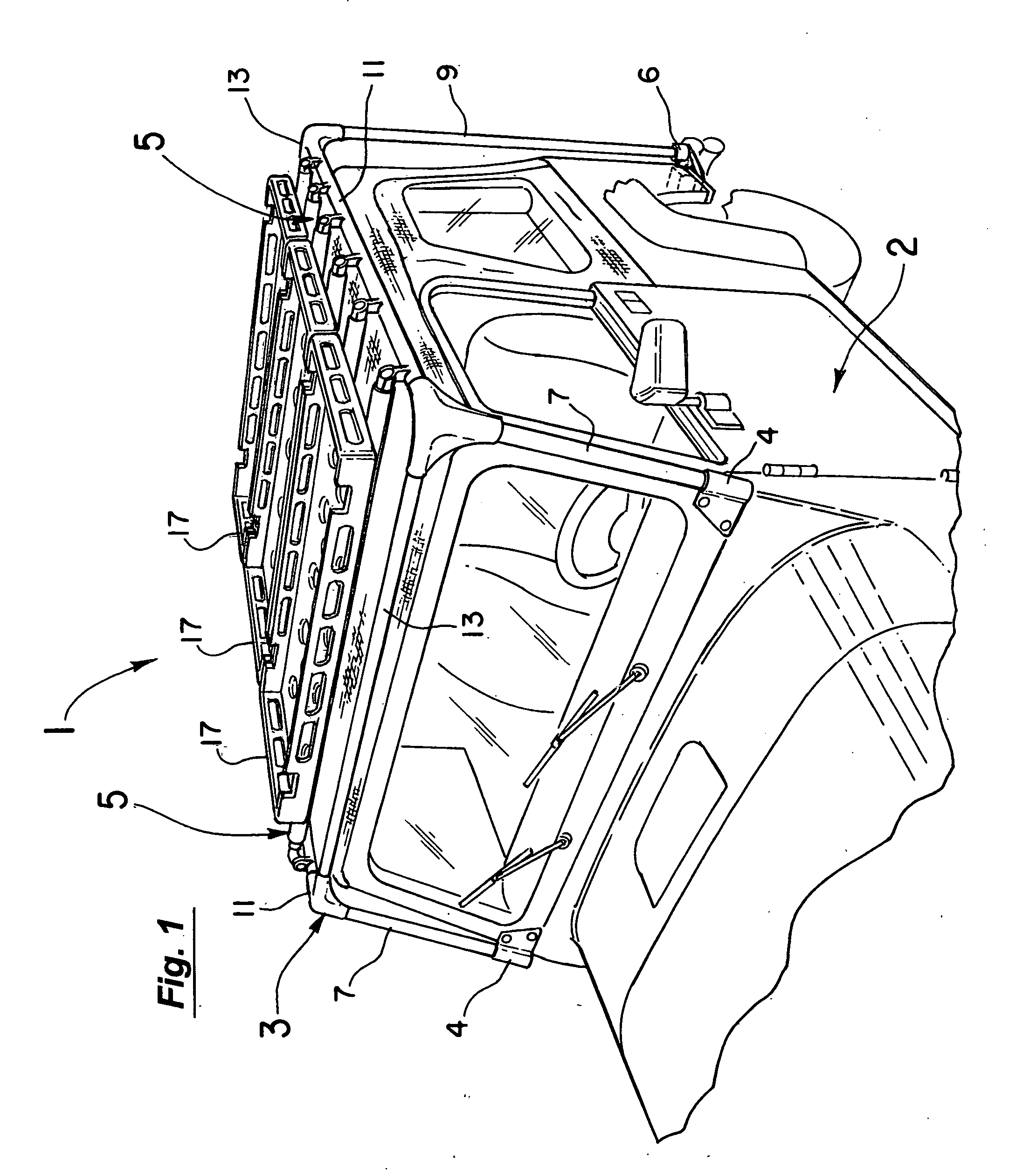

Multi-purpose storage rack for a sport utility vehicle

InactiveUS20050082326A1Reduce generationLow profileSupplementary fittingsSpare wheel arrangementsInterconnectionSport utility vehicle

A storage rack is provided that is adapted for interconnection with the roof of a sports utility vehicle. More specifically, the present invention consists of a lower support structure and an upper support structure separated by a plurality of vertical supports, wherein the lower support structure traverses the width of the roof and is adapted to support luggage or other items. In addition, one embodiment of the present invention includes a novel tire storage area wherein a spare tire of the vehicle may be stowed and easily removed based on a distinct geometry.

Owner:BADILLO PAUL

Lubrication system for right-angle drives used with utility vehicles

ActiveUS20080230289A1Closely spacedMinimizes numberDrip or splash lubricationElectric propulsion mountingReducerEngineering

A bearing lubrication device in a right angle gear reducer includes a gear housing having an interior portion and a lubricating fluid reservoir therein. An oil slinger, rotating pinion shaft, pinion shaft housing, and bearings for supporting the pinion shaft within the pinion shaft housing work together to provide a continuous supply of oil to the bearings. The pinion shaft includes two radially and longitudinally extending passageways therethrough which supply oil from a recess in one end of the pinion shaft to the bearings. Oil is slung from the reservoir into the recess of the rotating pinion shaft where it is forced outwardly and through the passageways to a chamber formed by the rotating pinion shaft, shaft housing and bearings. The roller bearings pump the oil from the chamber back to the fluid reservoir. Oil passageways in the shaft housing enable the return of oil from one bearing set.

Owner:FAIRFIELD MFG CO INC

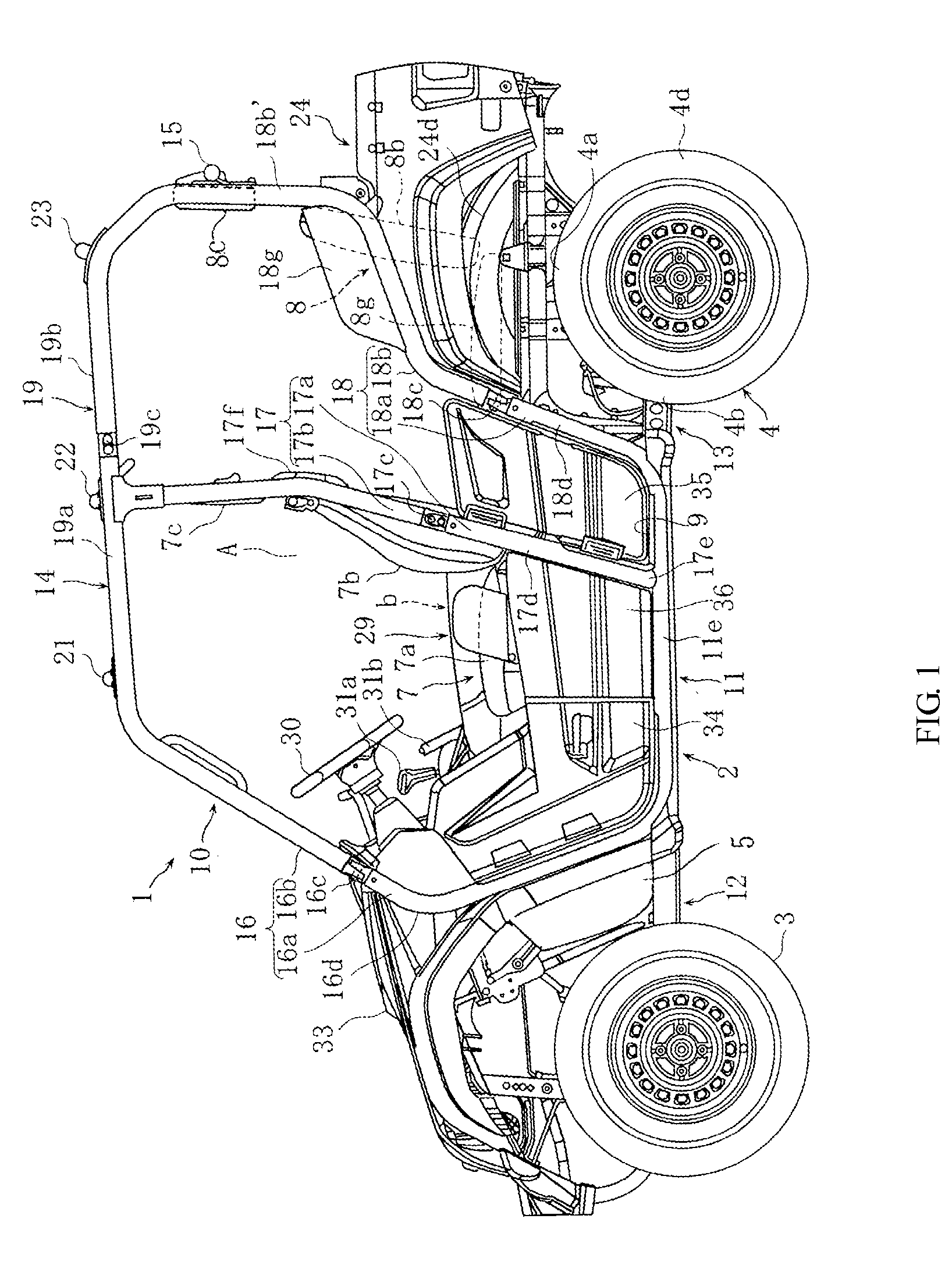

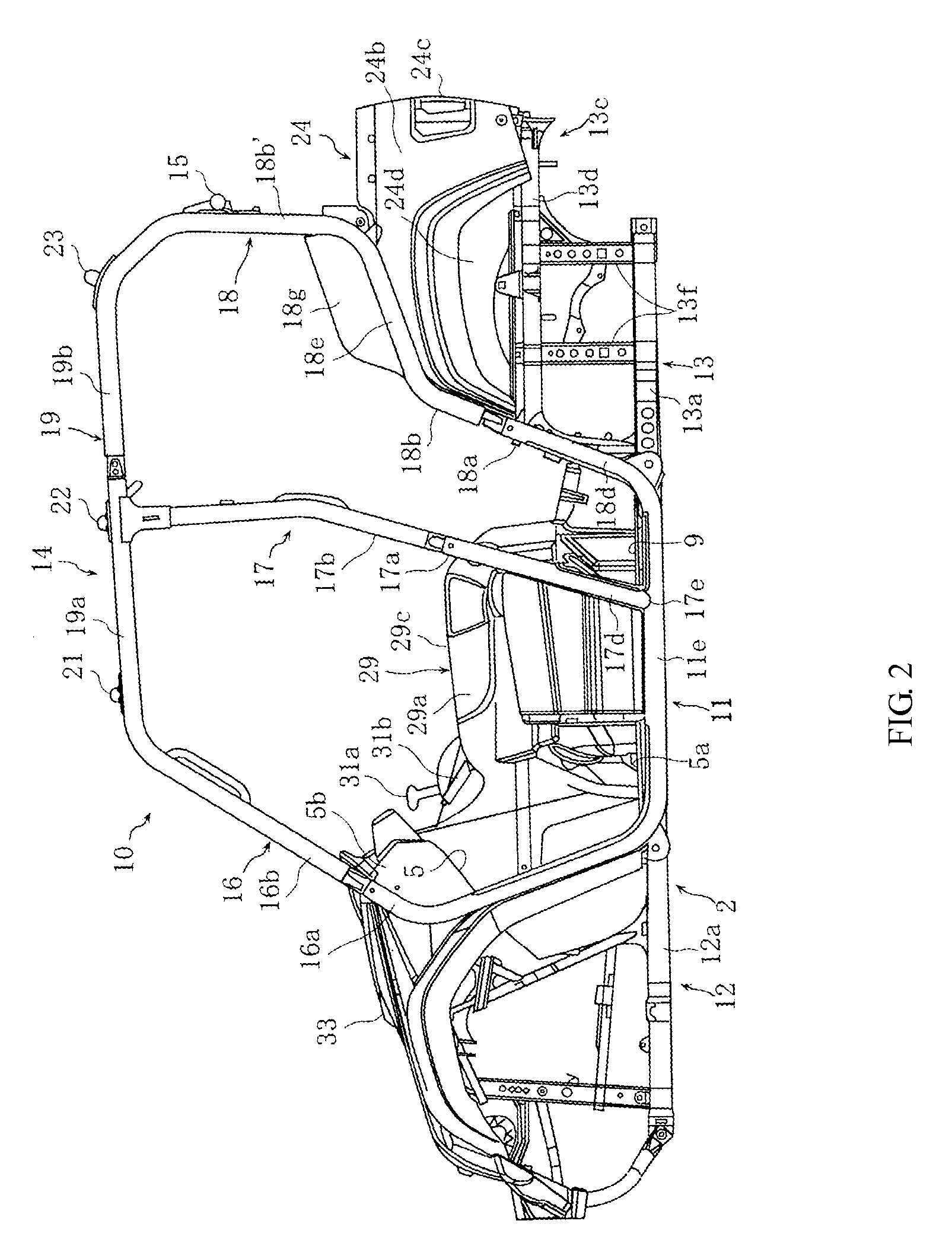

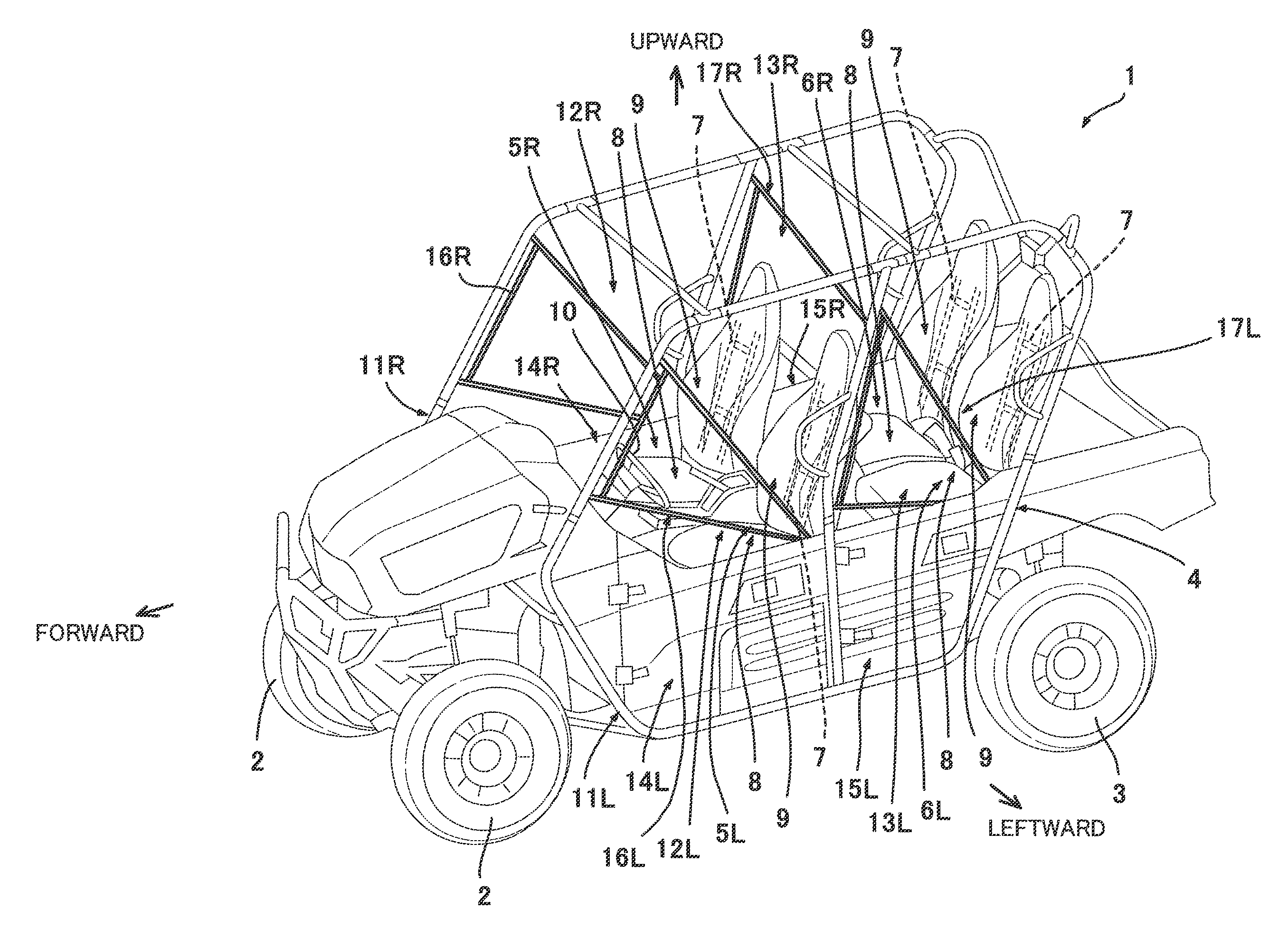

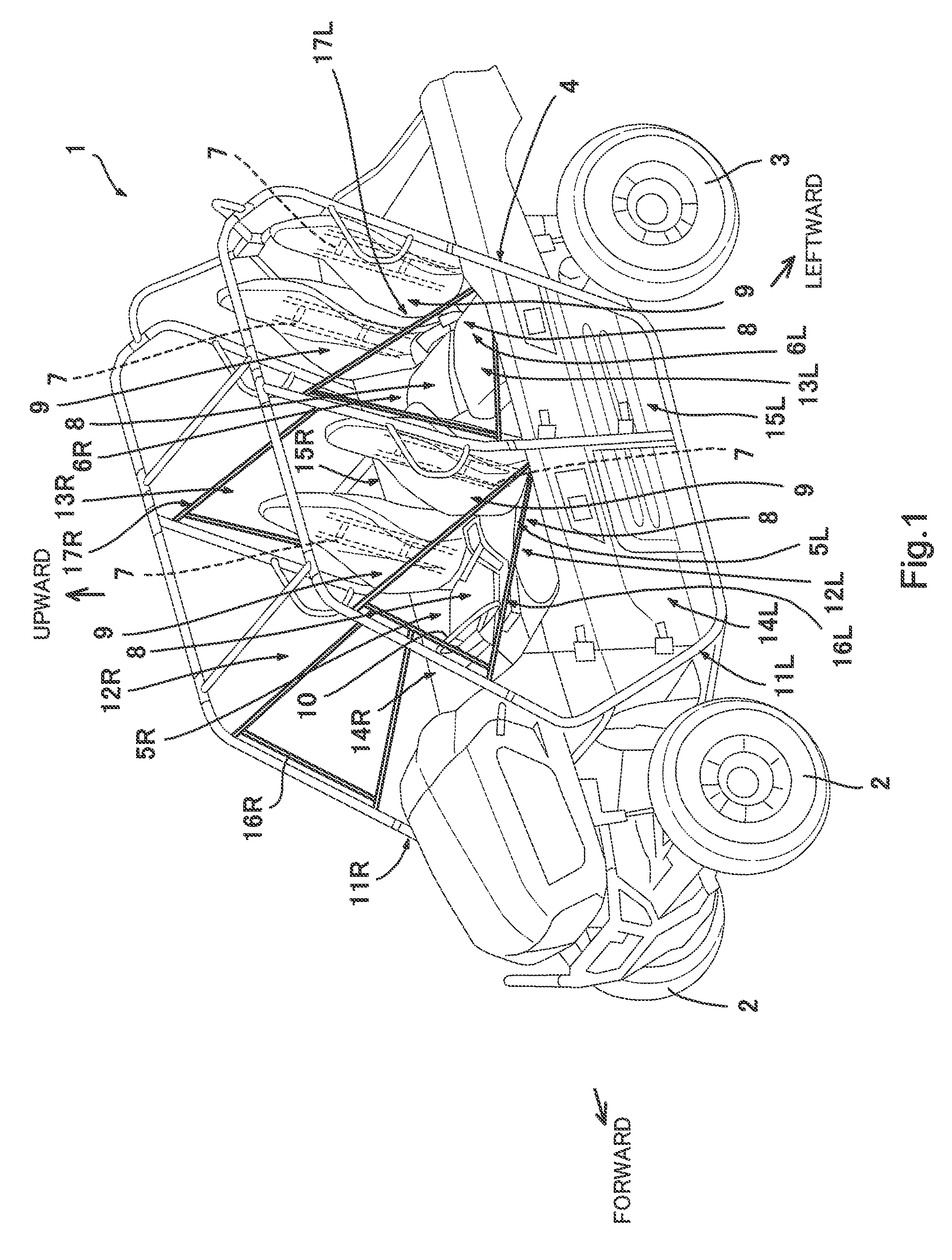

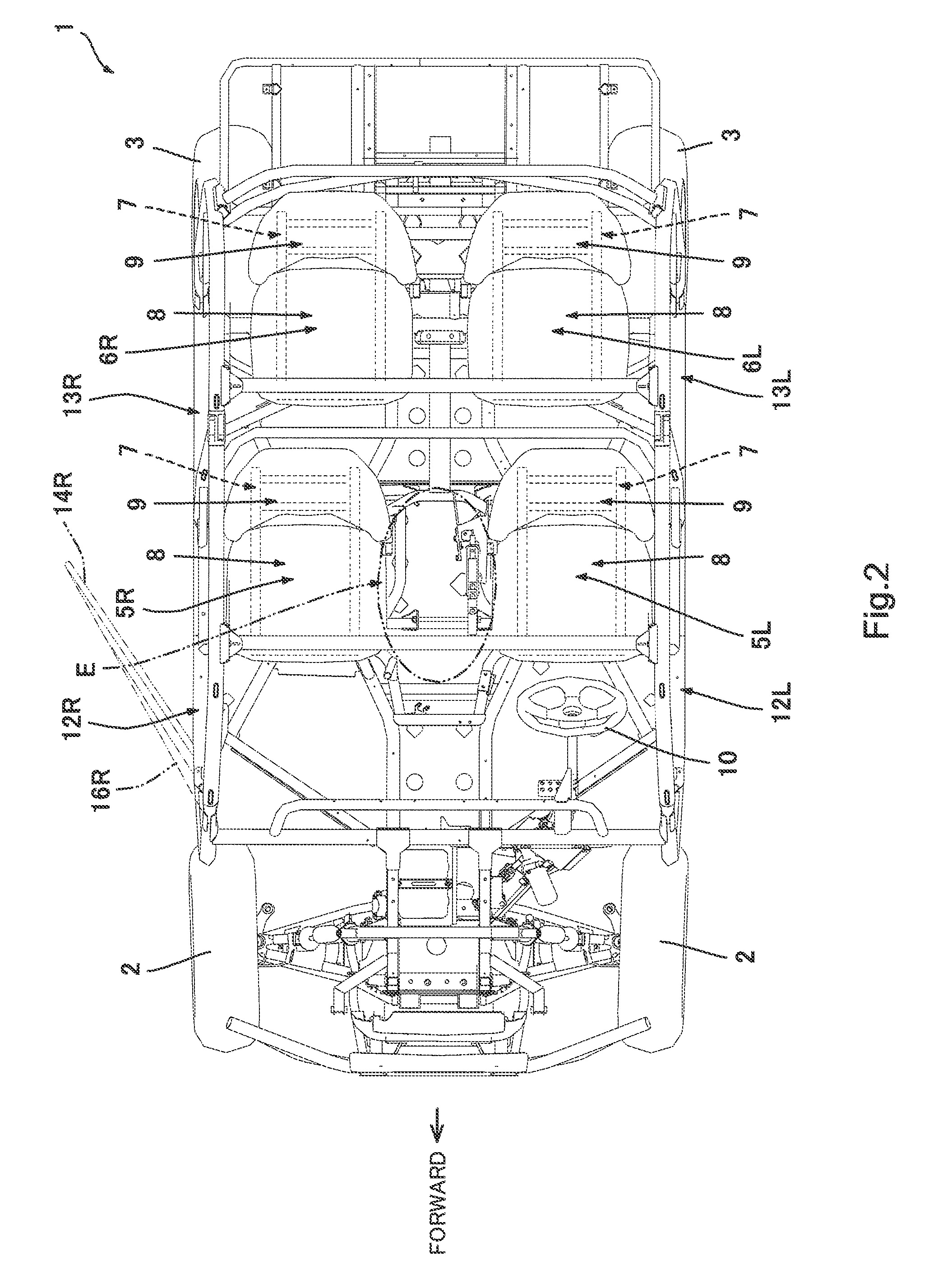

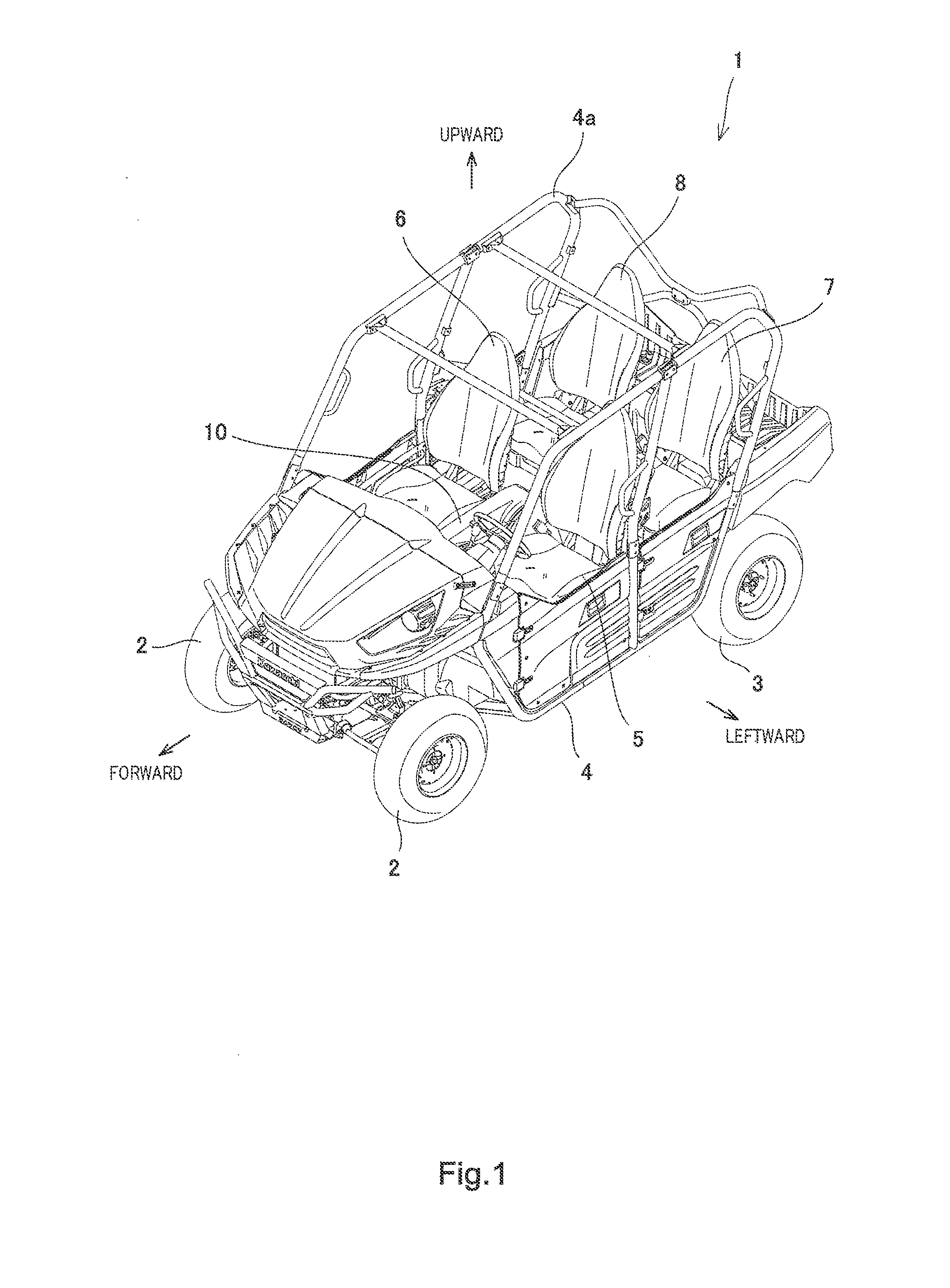

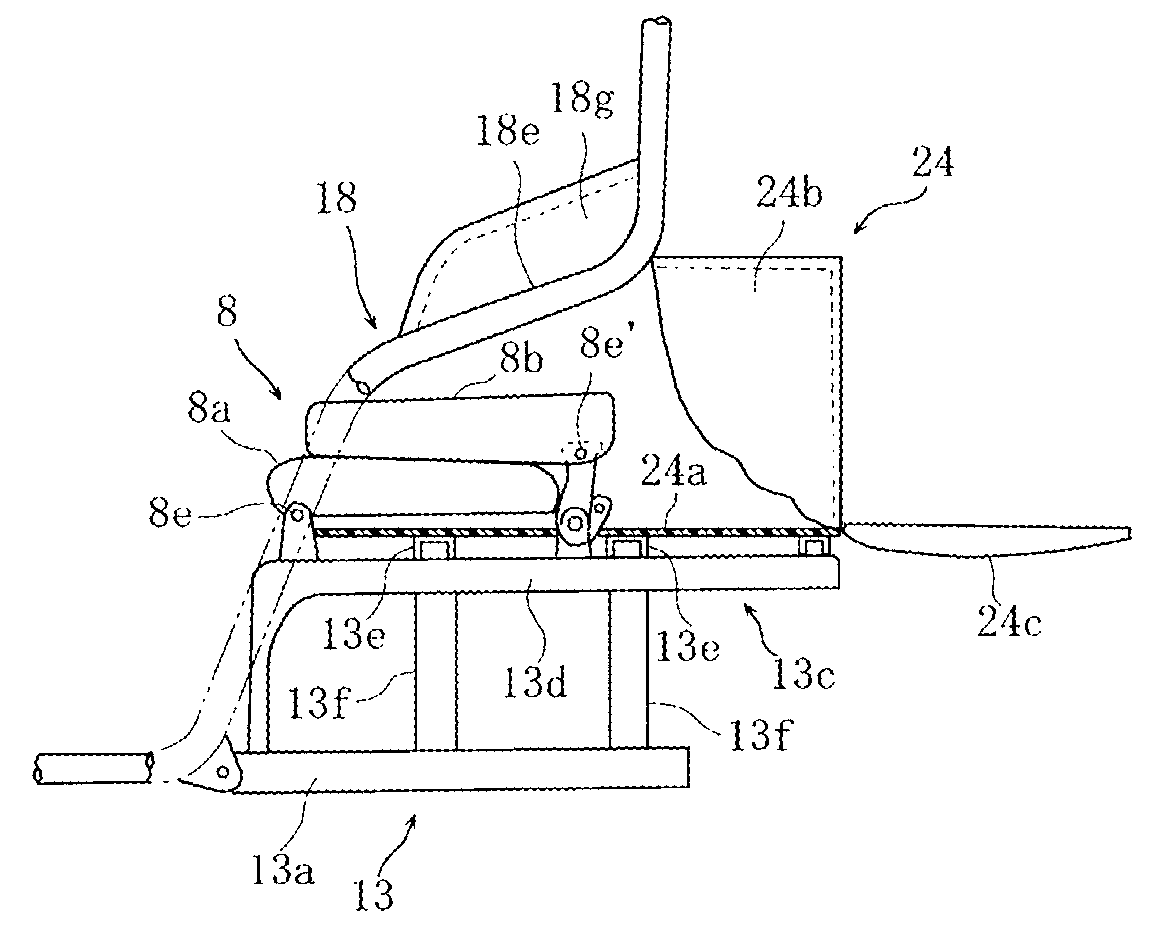

Utility vehicle

ActiveUS20090184531A1Easy to operateSimple structureUnderstructuresSuperstructure subunitsVehicle frameEngineering

A utility vehicle including: a vehicle body frame; a pair of left and right front wheels and at least a pair of left and right rear wheels that are supported on the vehicle frame; a front seat that is provided to the rear of the front wheels; a rear seat that is provided to the rear of the front seat having an in-use position, a transition position, and a non-use position; a cargo bed, disposed to the rear of the front seat including: a bottom wall portion whereon the seat cushion portion of the rear seat is provided movably; a left side wall portion and a right side wall portion that are provided on the left and right side portions of the bottom wall portion, wherein the left side wall portion and the right side wall portion extend forward to the rear seat in its non-use position; and a rear wall portion that is provided at the rear end portion of the bottom wall portion; and a rear floor provided between the front seat and the rear seat and lower than the bottom wall portion of the cargo bed.

Owner:YAMAHA MOTOR CO LTD +1

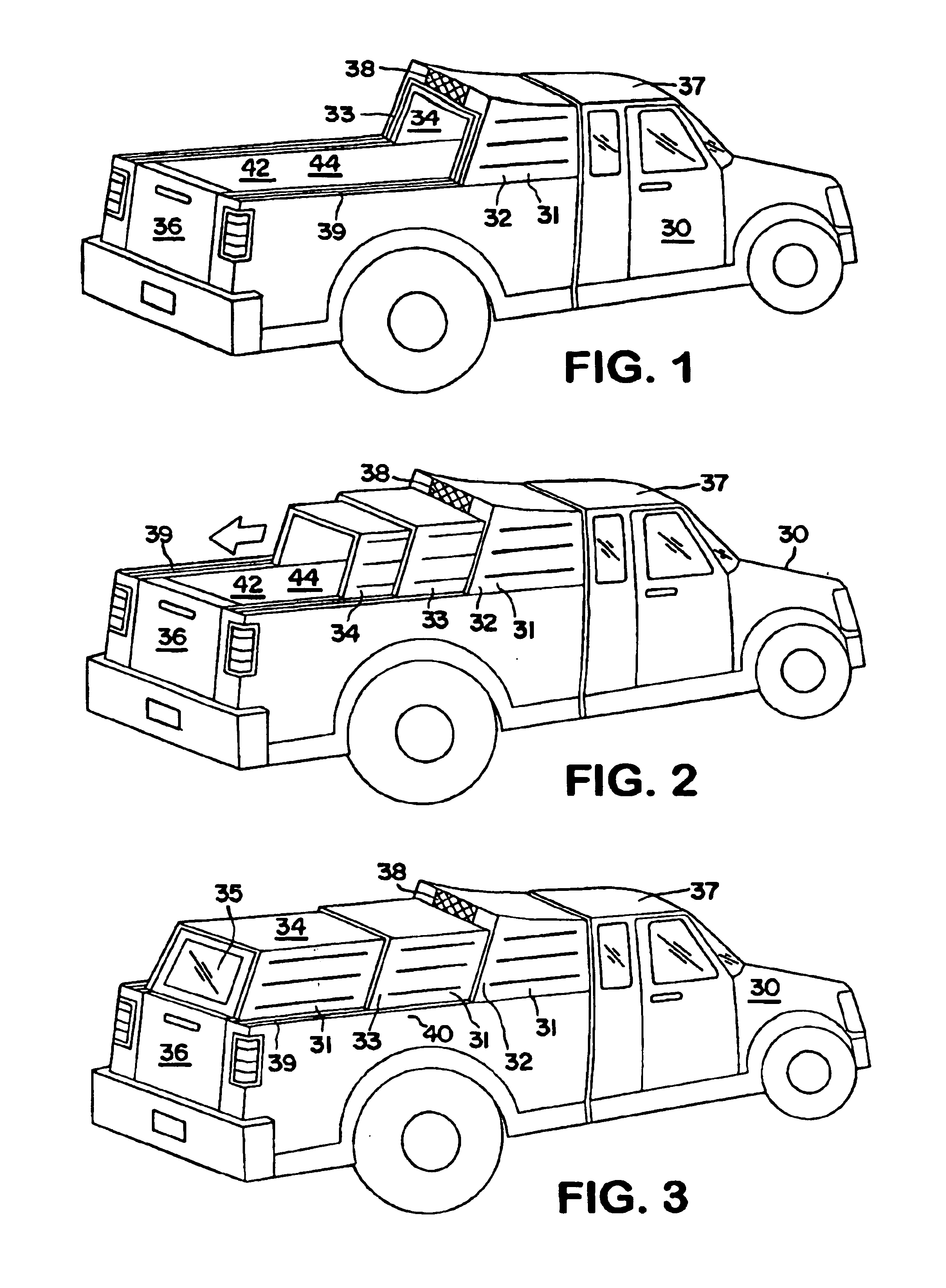

Vehicle with extendable cargo and/or passenger area

InactiveUS6851741B1Extending the length of a passenger areaSuperstructure subunitsItem transportation vehiclesPickup truckEngineering

Presented is a retractable substantially full passenger cab height cover for vehicle rear portions that renders the vehicle's rear portion open to transport cargo when the full cab height cover is retracted and covered at a full, or nearly so, passenger cab height when the full cab height cover is extended. It has application to all manner of vehicles such as pickup trucks or sport utility vehicles (SUV's) and may be designed in and sold as original factory equipment or sold as an aftermarket product. It is possible, by use of a fold down first tailgate disposed between the passenger cab and the rear portion of the vehicle and fold down rear passenger seat elements to have a very lengthy distance, from a second tailgate at the rear of the vehicle to just behind the driver's seat, for extra passenger seating, storage of cargo, carrying of small boats, or the like. A further refinement includes a multi-system sealing system disposed between elements of the retractable cargo bed cover.

Owner:BURG PAULETTE RENEE

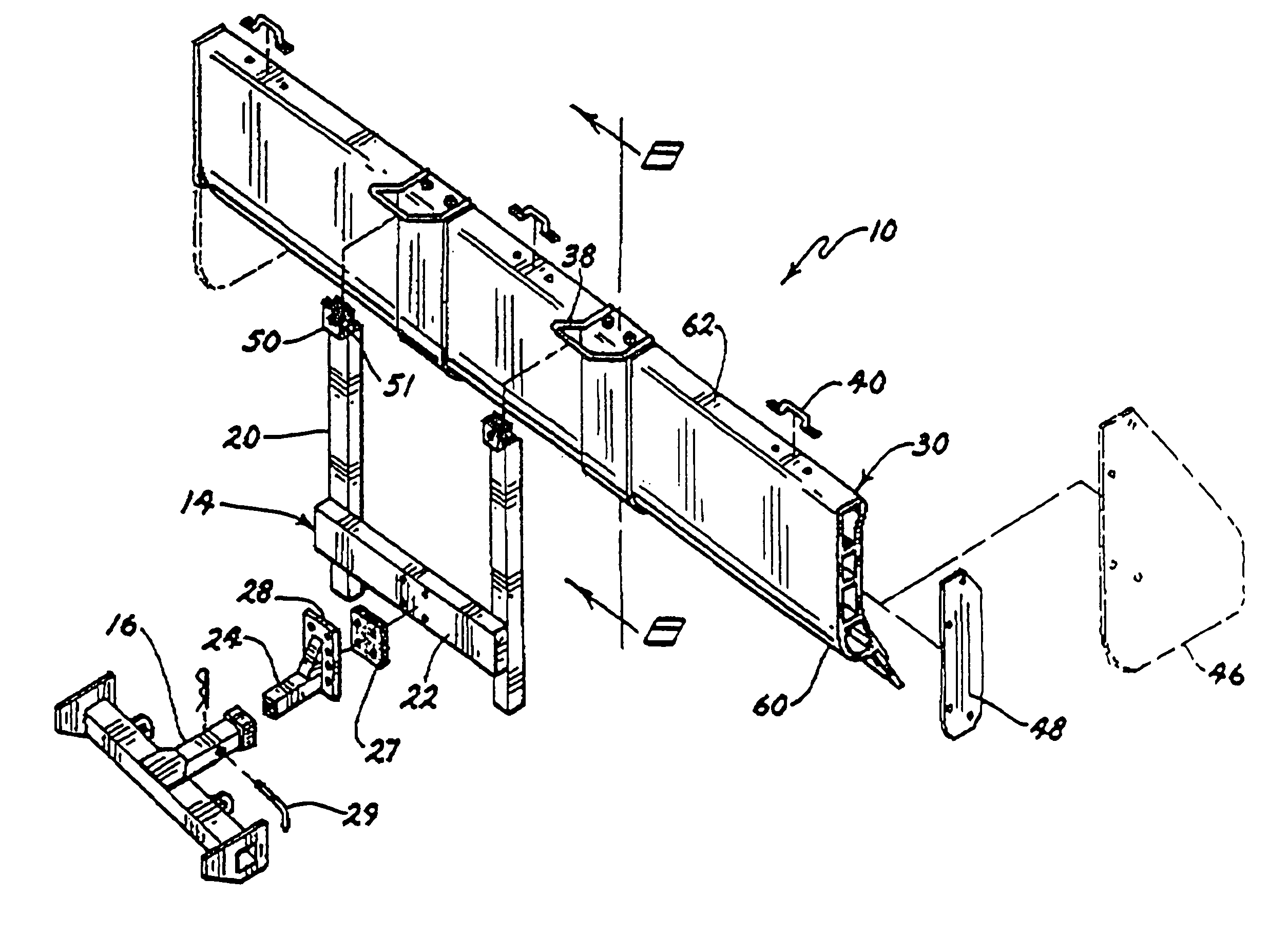

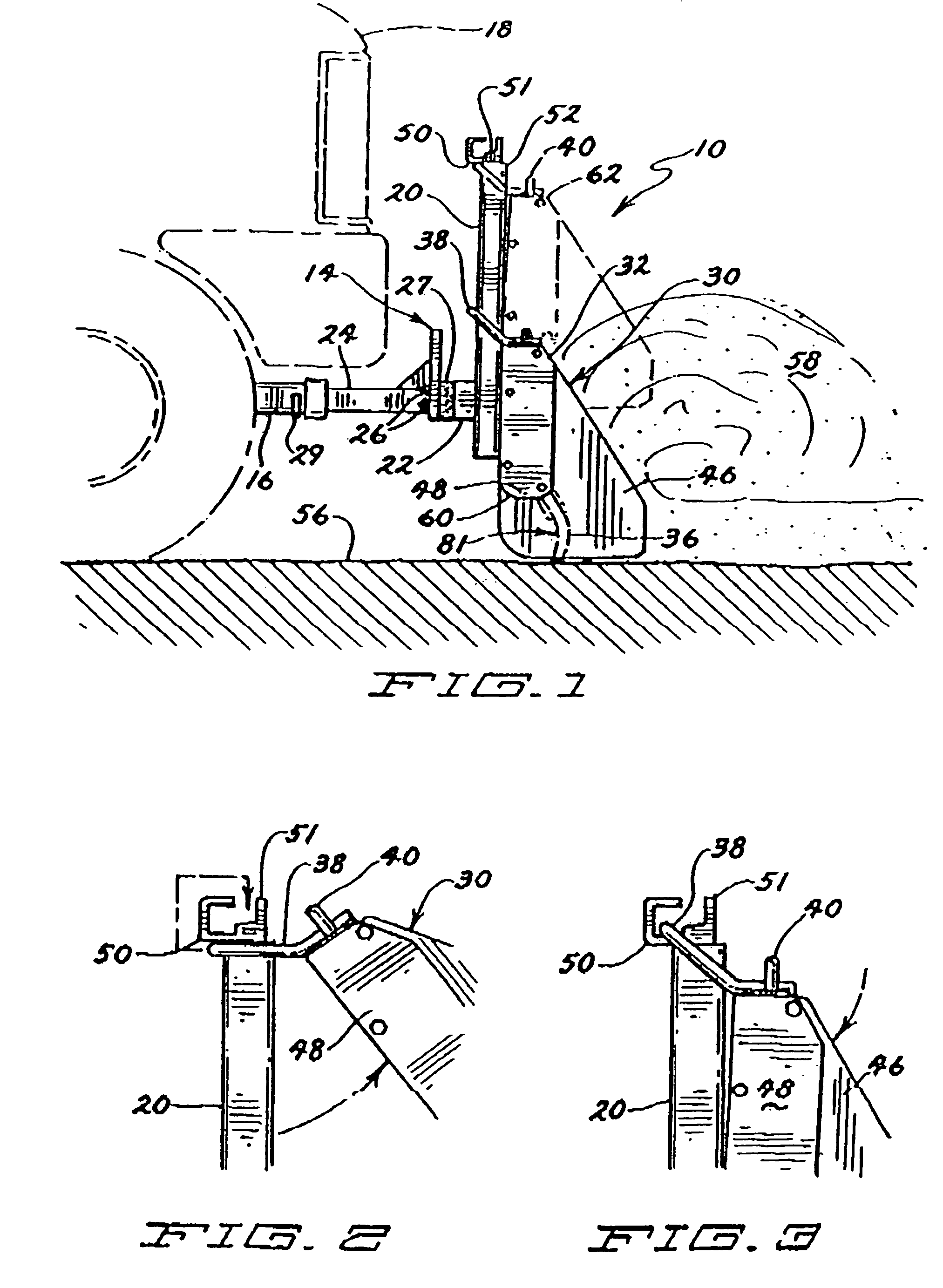

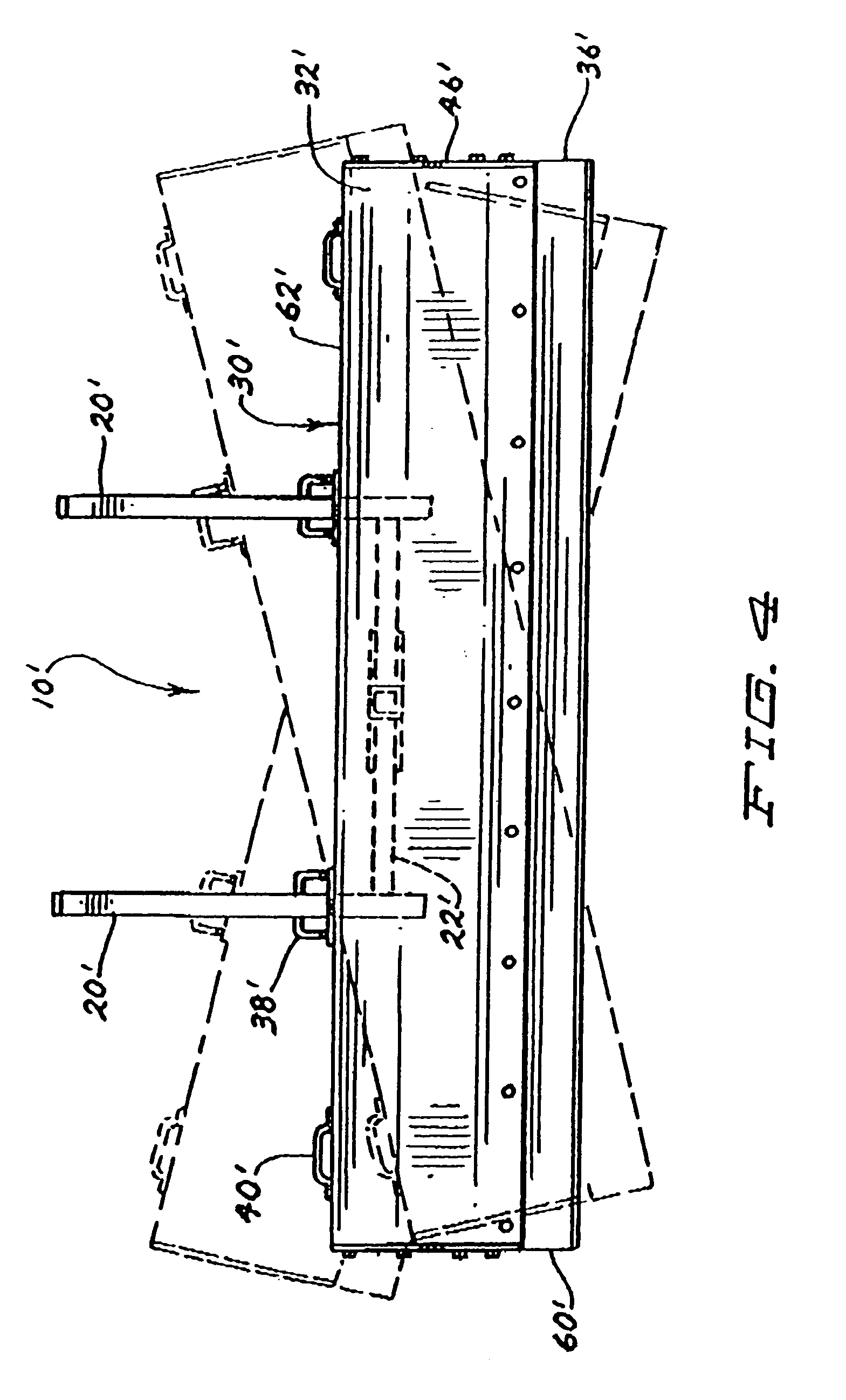

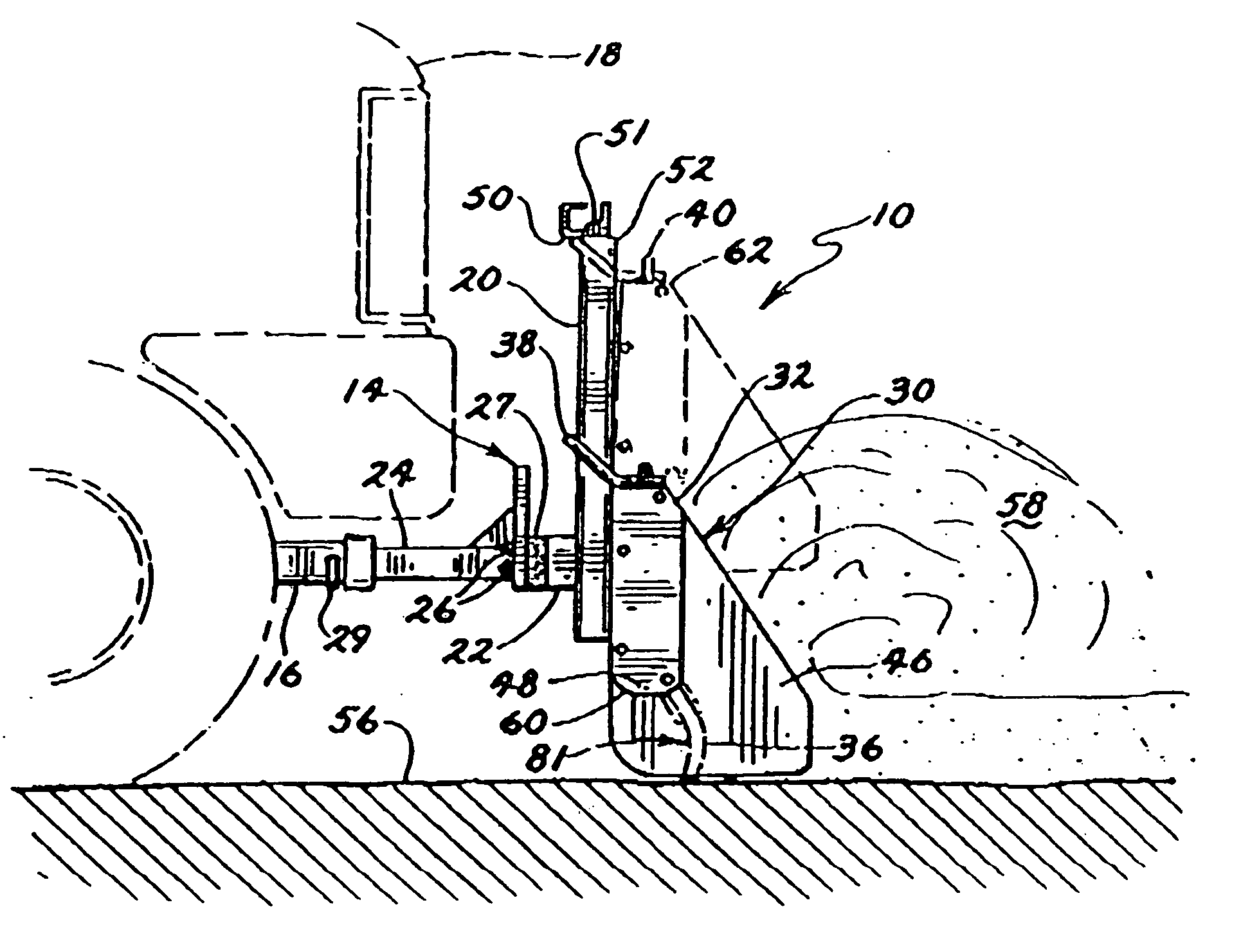

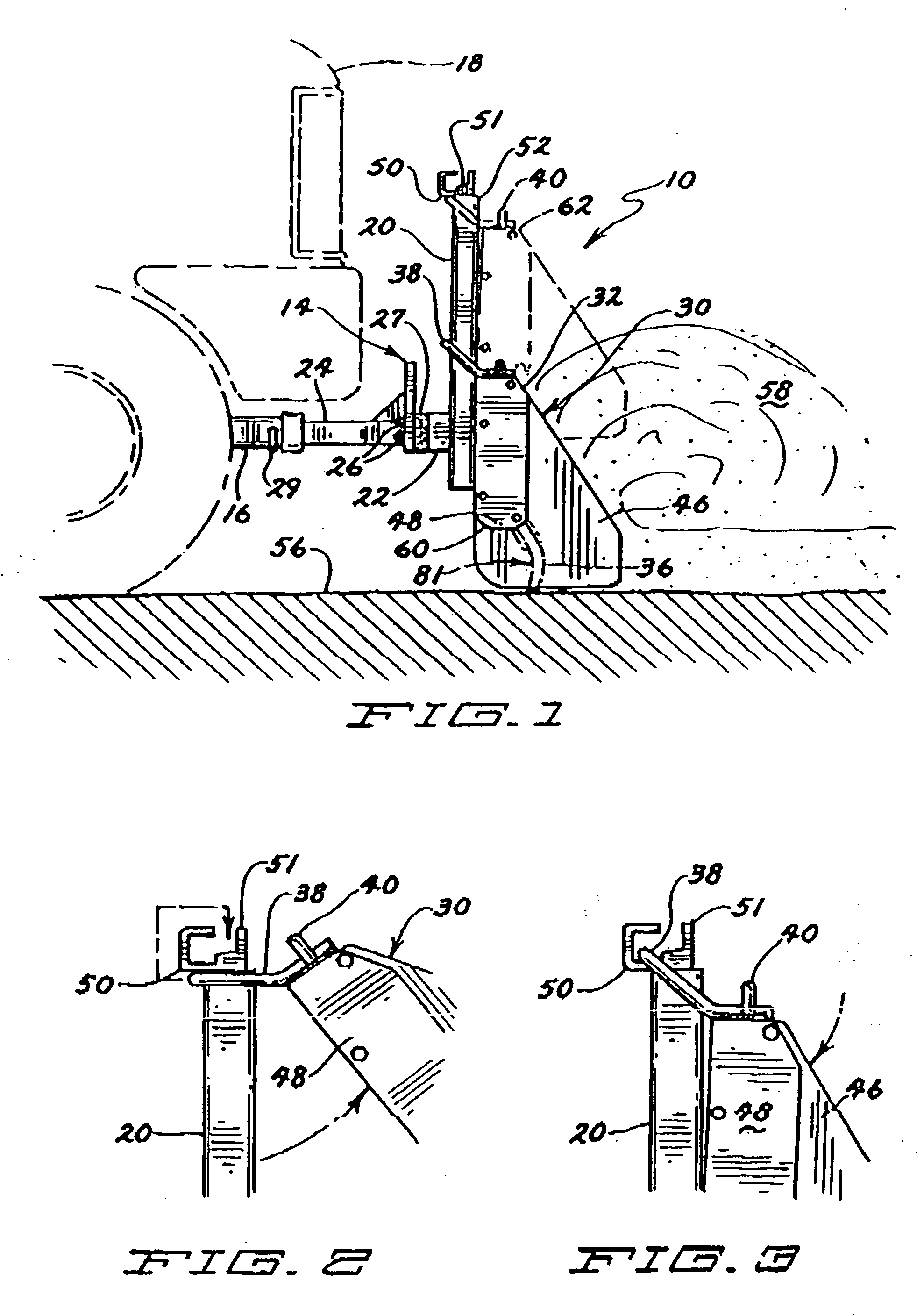

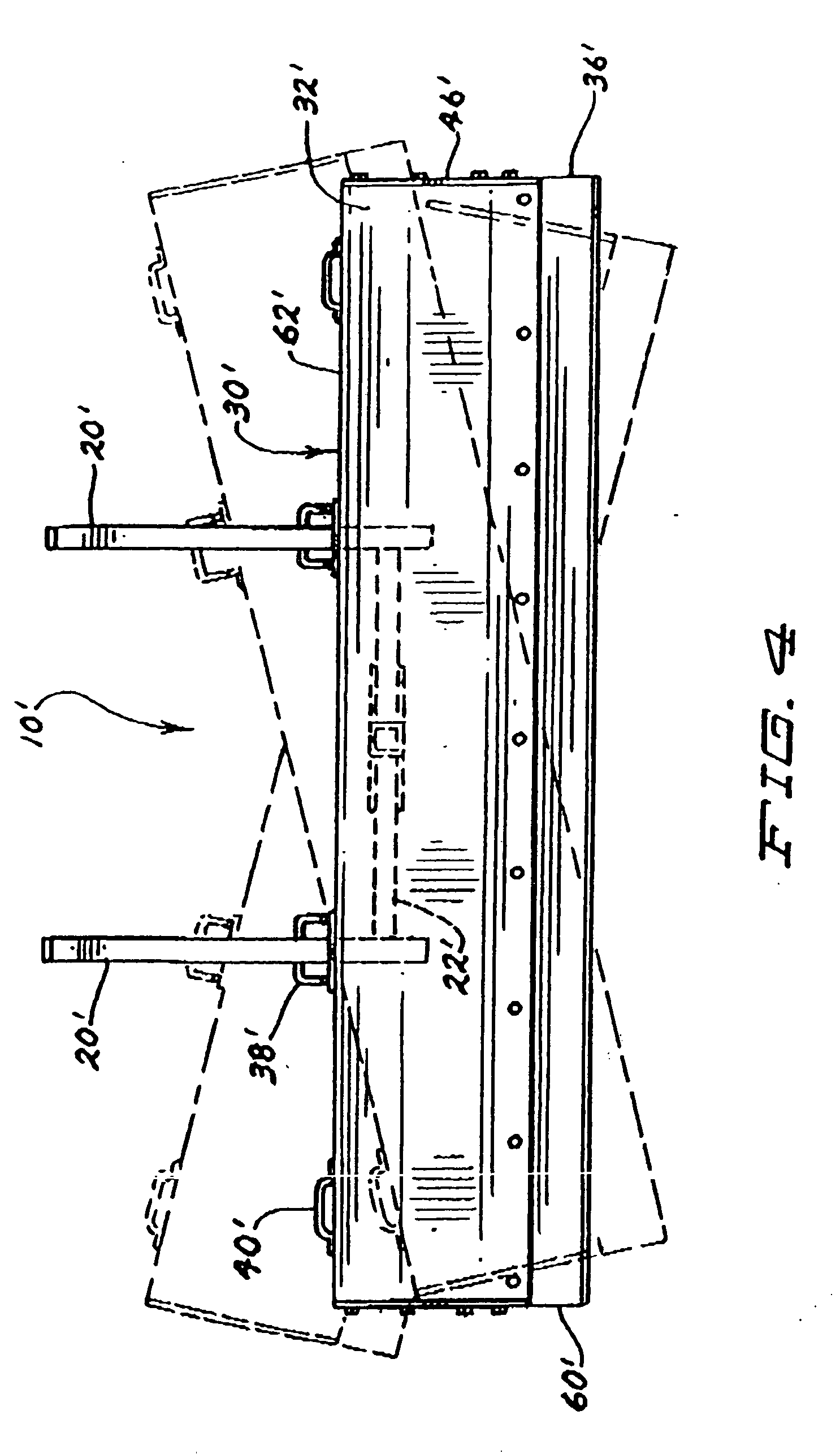

Self-adjusting snow plow

InactiveUS7131221B2Easy to mountEasy to removeMechanical machines/dredgersSnow cleaningPickup truckEngineering

Owner:AGRI COVER

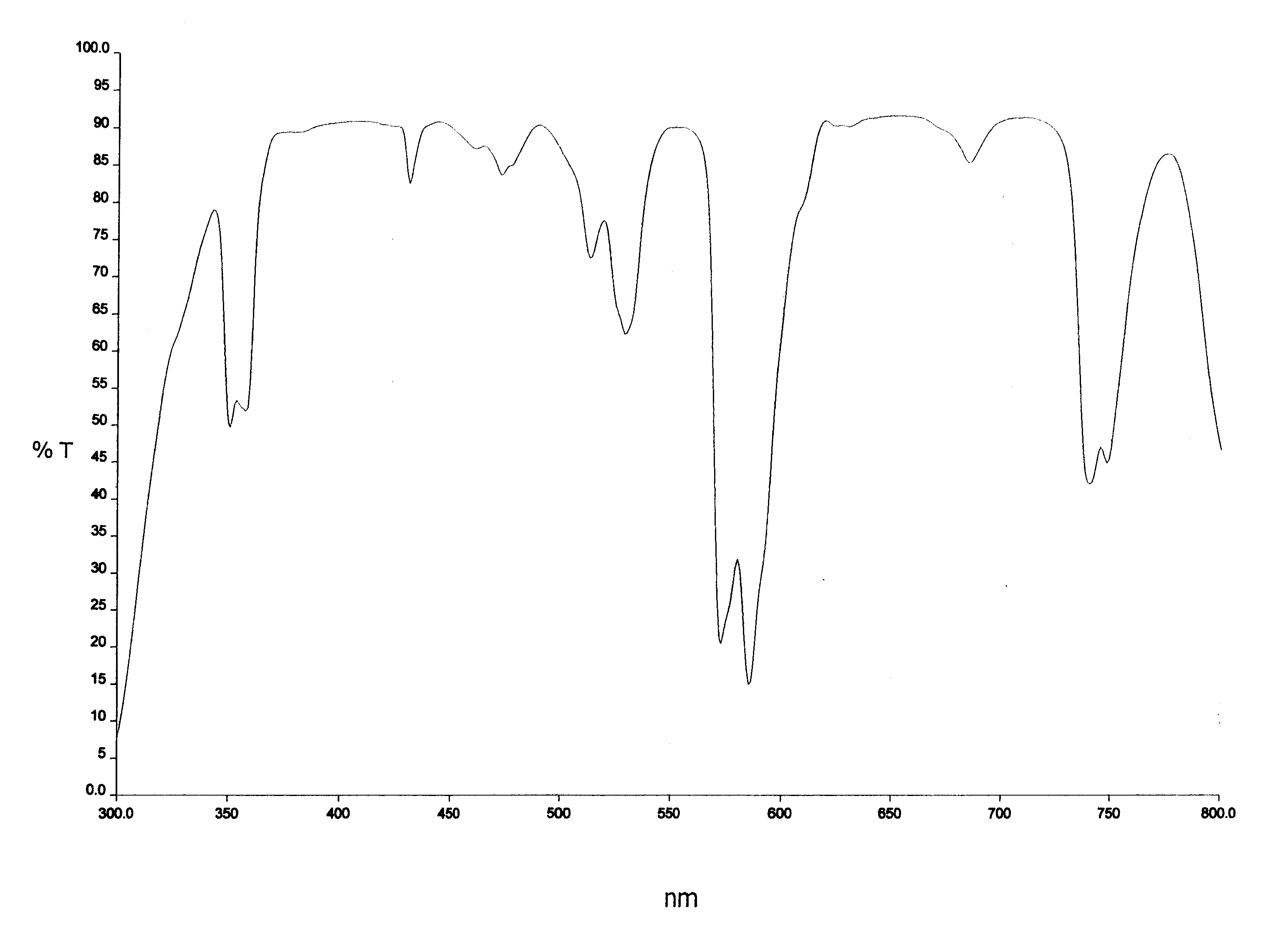

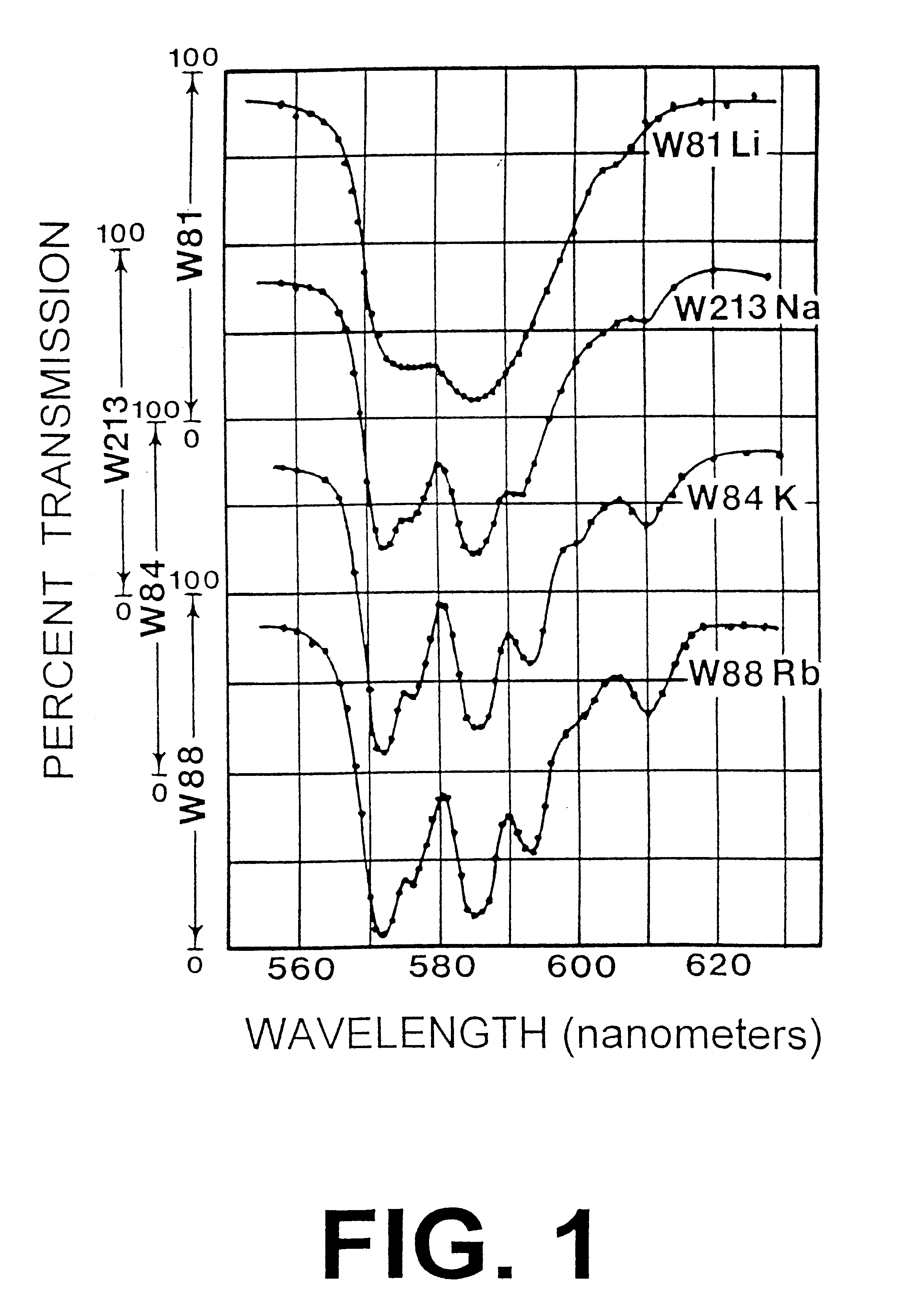

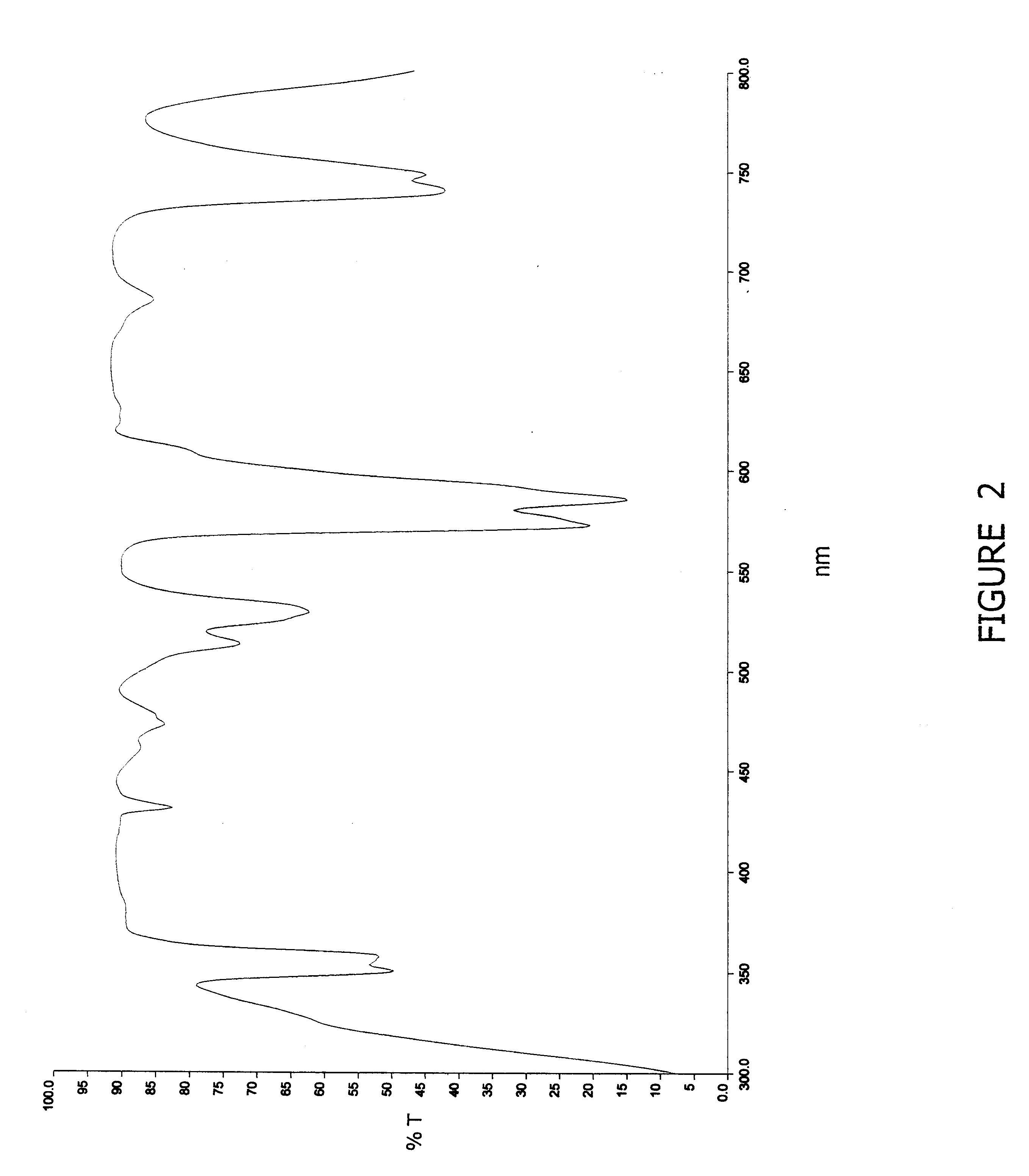

Neodymium oxide doped motor vehicle windshield and safety glazing material

Motor vehicle windshields and safety glazing material, suitable for use as motor vehicle windshields and safety glazing material for automobiles, trucks, buses, motorcycles, locomotives. sport utility vehicles, all terrain vehicles, and vans. The motor vehicle windshields and safety glazing material contains Neodymium Oxide, a rare earth compound. The Neodymium Oxide filters out the yellow portion of the spectrum, reducing glare. Incorporation of yellow light in the spectrum desaturates colors and reduces contrast. Improvement in contrast and a reduction in glare permits, for example, a motor vehicle driver to better discriminate the contrast of objects when there is no daylight and the only illumination is artificial. For drivers, in particular, elimination of the yellow light lessens eye strain currently resulting from light emitted by the conventional headlights of oncoming vehicles during hours of darkness. Neodymium Oxide can also be added to safety glazing materials for use in bullet resistant shields.

Owner:KARPEN DANIEL NATHAN

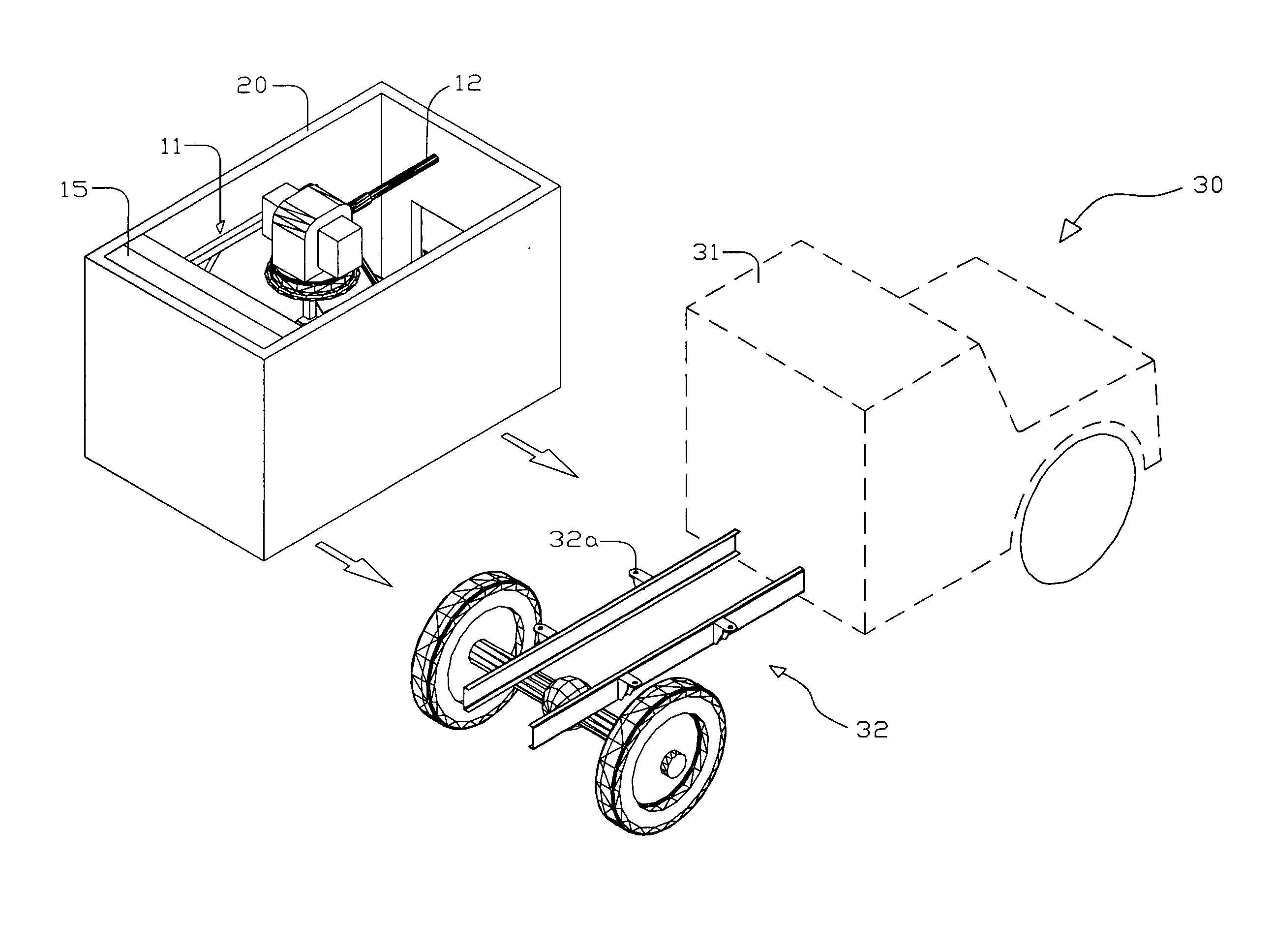

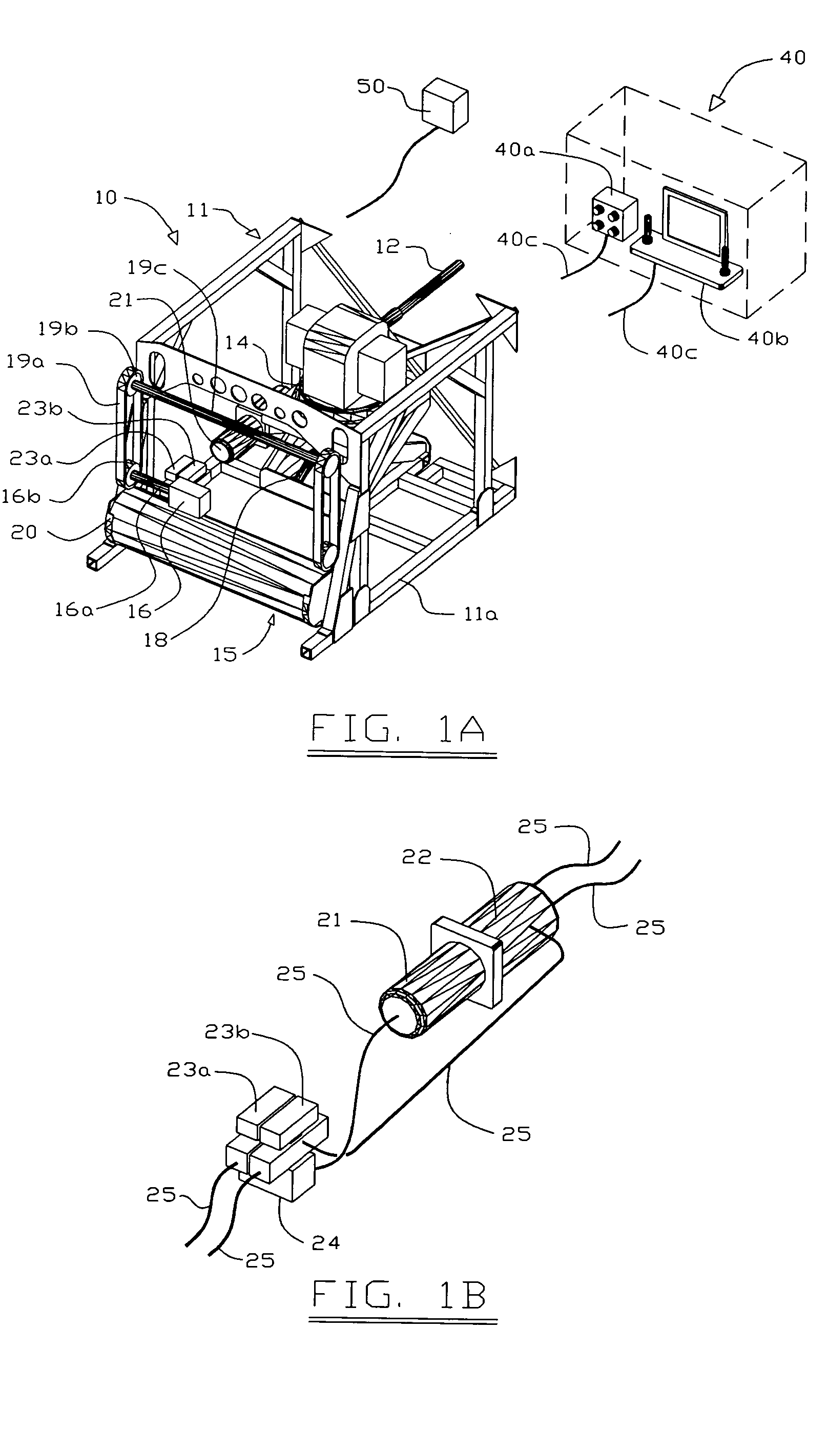

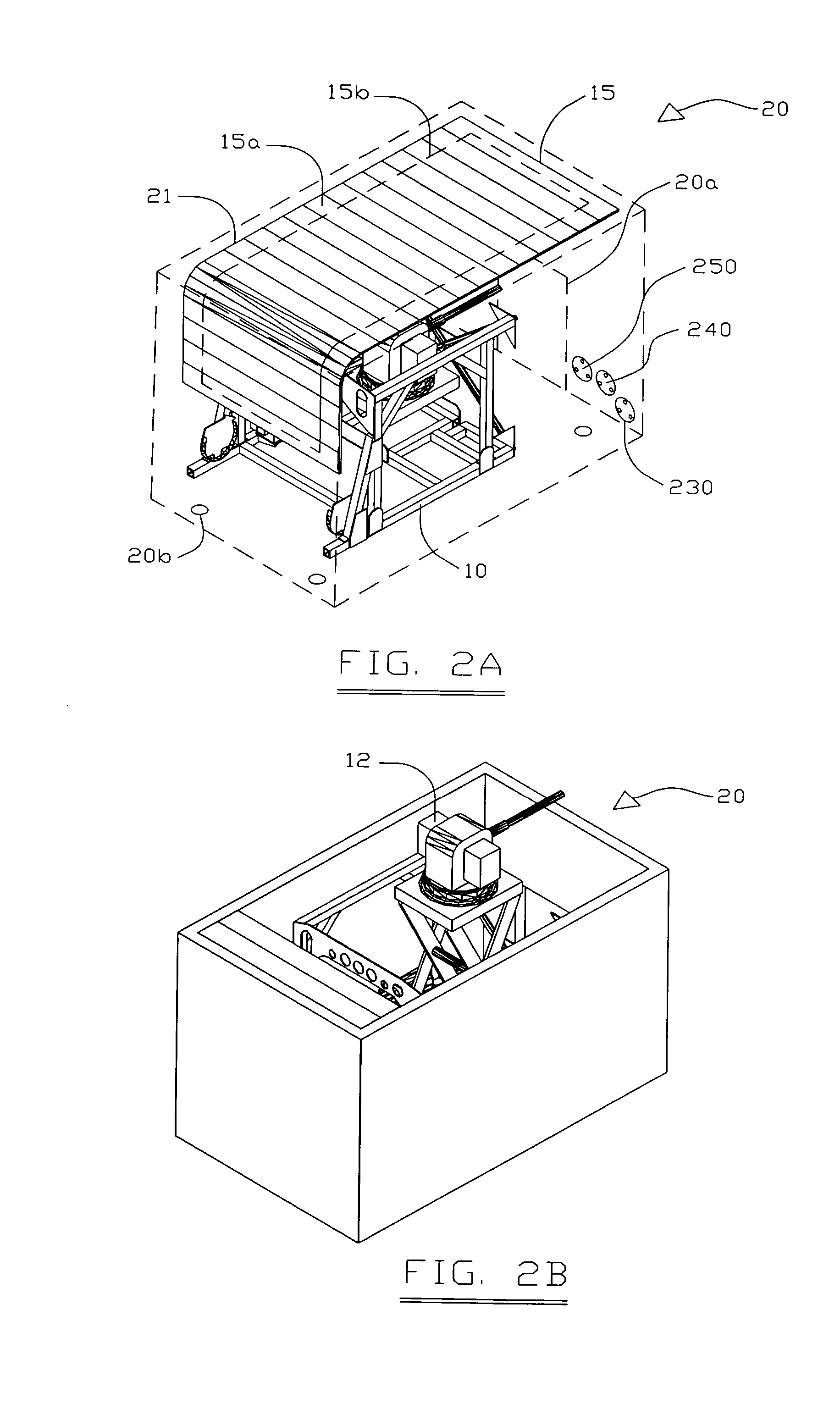

System and method for deploying a weapon from a stealth position

A stealth weapon module (10) including a weapon support cage (11) and a weapon (12), with the weapon module (10) able to be stowed beneath a retractable hard roof (15). The roof (15) is raised and lowered by a hydraulic motor (16), and includes a stabilizing cloth (15b) that keeps the roof (15), made of interconnected slats (15a), from pulling apart or otherwise changing shape as it is raised and lowered, even at rates of travel of several inches per second. The weapon module (10), with any of various different roof designs including the retractable hard roof (15), can be incorporated into either a transportable shell (20), able to be moved from one application to another, or can be built into (and so specially adapted to) a structure, such as the back / cab of a sports utility vehicle.

Owner:IBIS TEK

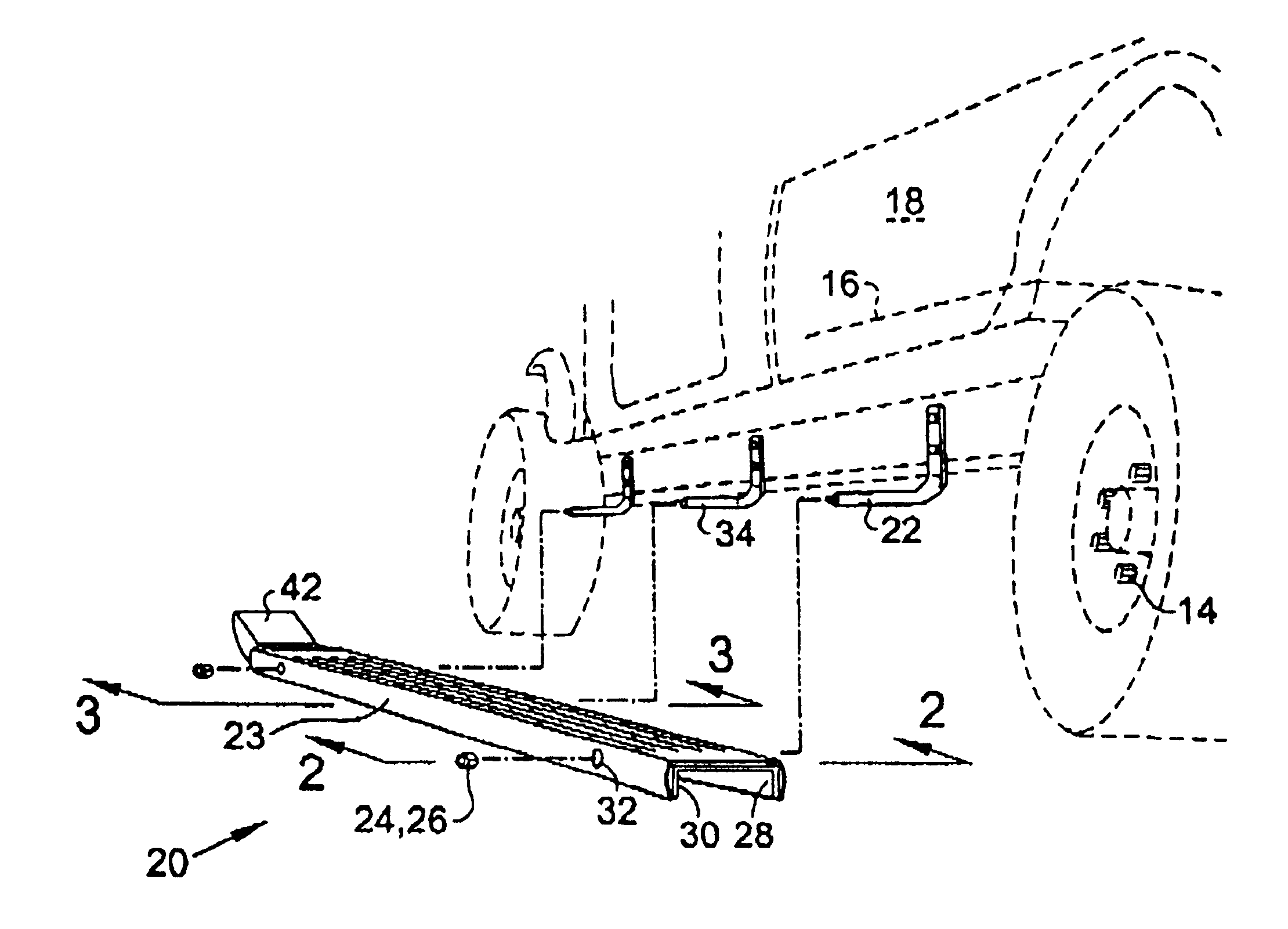

Vehicle running board detachable for use as loading ramp

InactiveUS6592135B2Convenient and inexpensive and reliableNeed can be availableVehicle arrangementsSuperstructure subunitsPick-up truckIn vehicle

A running board assembly for pick-up trucks, vans, and sport utility vehicles which has a detachable runner which used as a loading ramp when and wherever a loading ramp is needed to load the vehicle. The assembly not only provides the convenience of a running board which divides the long stretch when stepping into the vehicle; but additionally, it provides a convenient and unobtrusive means of carrying loading ramps in vehicles which typically lack the storage capacity, and particularly the length in their storage bed, to carry a loading ramp. The running board assembly comprises: a front and rear mounting bracket each secured to a lower central side portion of the vehicle; an elongate runner releasably engaging, and carried by the front and rear mounting brackets; and, releasable lock means to releasably lock the elongate runner board on the brackets.

Owner:HENDRIX THERON V

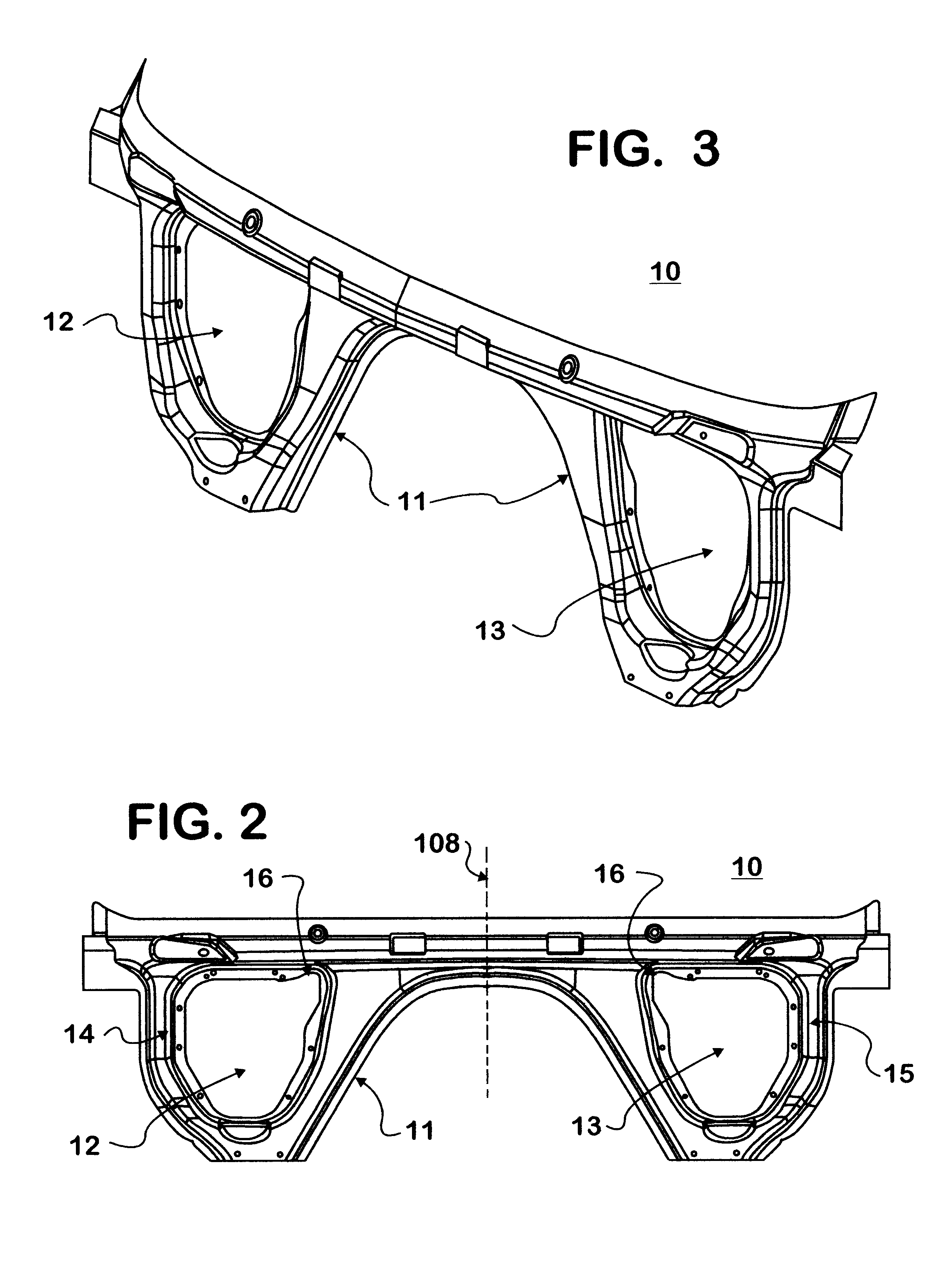

Symmetrical dash reinforcement

InactiveUS6260914B1Easy to shapeImprove rigidityVehicle seatsSuperstructure subunitsMobile vehicleHeavy duty

A dash reinforcement for a mobile vehicle with a passenger cab such as a sport utility vehicle, or medium or heavy-duty truck. The dash reinforcement may be a stamped sheet metal panel that strengthens the dash structure of the cab and provides for mounting of vehicle components. The dash reinforcement may be symmetrical about the centerline of the vehicle and this symmetry allows the panel to accommodate both left-hand drive and right-hand drive vehicle configurations. The dash reinforcement also includes "Y' shaped passages for a driver control module and for accessory equipment such as heating, ventilation, and air conditioning (HVAC) modules. The unique shape of these passages or openings adds strength to the overall dash structure and hence the cab. The dash reinforcement may be engaged to a dash panel to form a dash assembly. The dash panels made be manufactured by the same metal stamping dies moved to account for left-hand versus right-hand drive and conventional versus cab-over-engine or low front engine configuration.

Owner:INT TRUCK INTPROP LLC

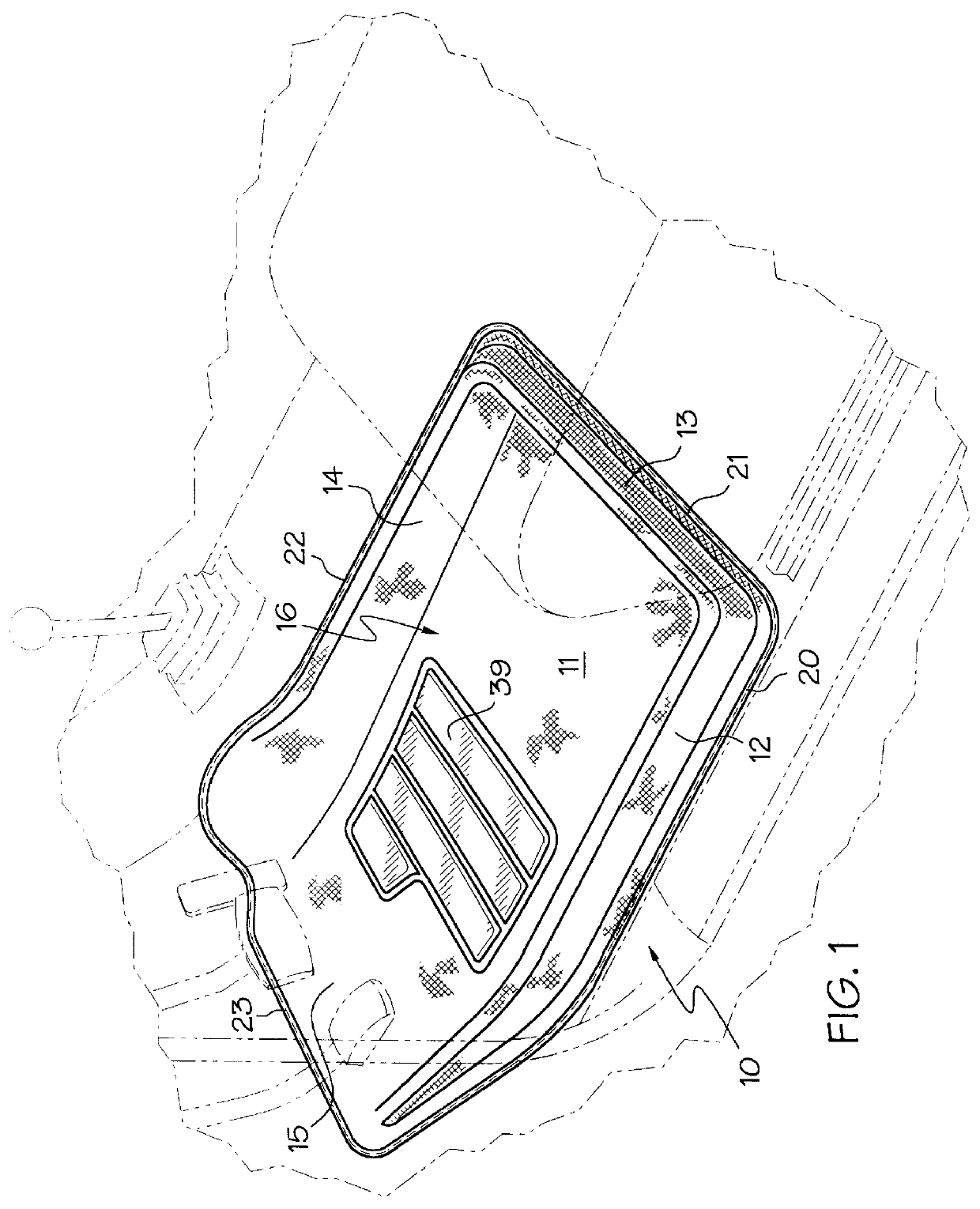

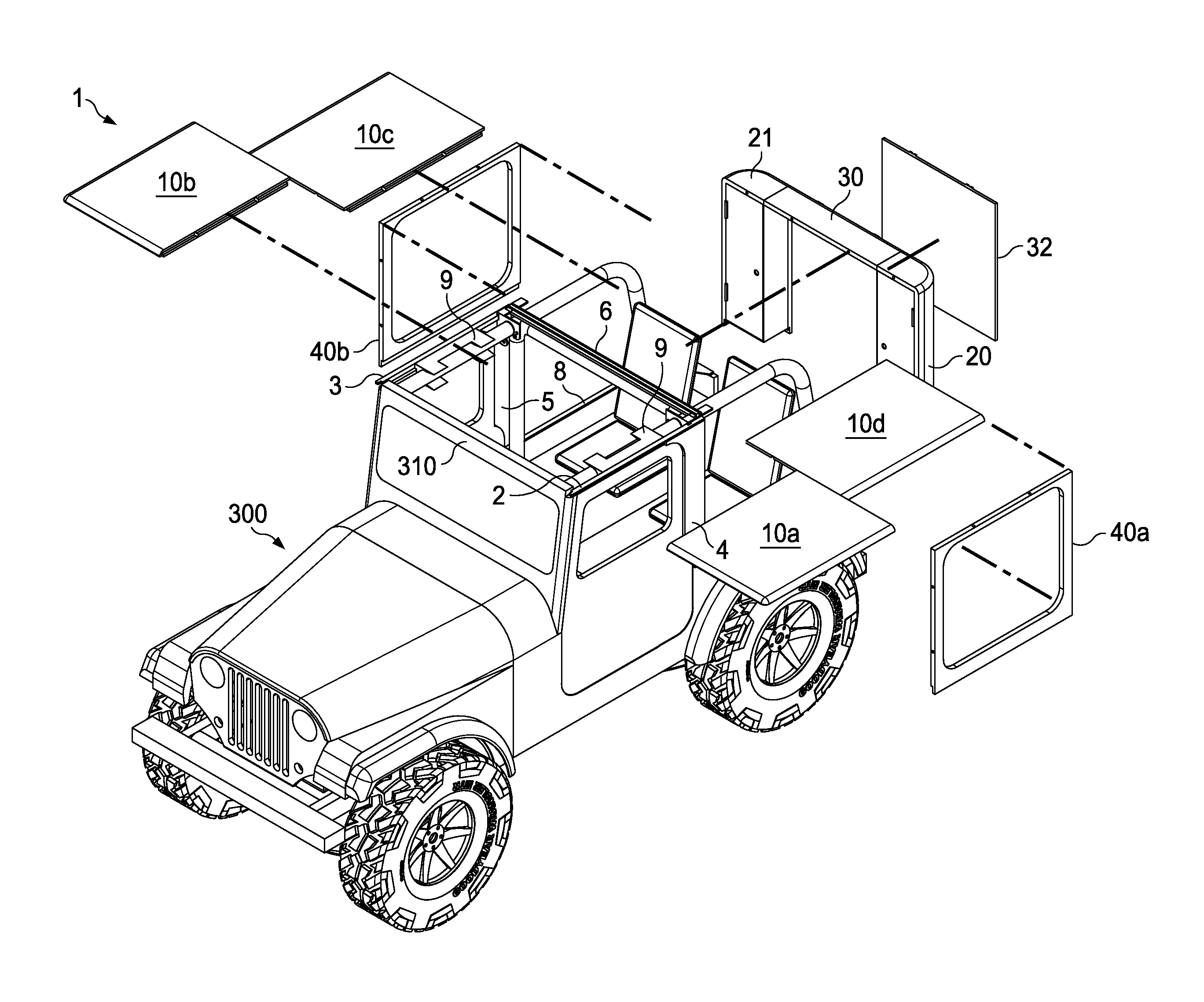

Collapsible hard top for sport utility vehicle

A removable hard top system for a convertible sport utility vehicle is described. The system comprises an adapter kit which is installed onto a vehicle and which remains in place on a semi-permanent basis. The system further comprises a removable hard top assembly which disassembles into component parts that may be fully stored in the vehicle to allow the user to install the hard top assembly on the vehicle at a time and place either at or remote from the home base of the vehicle. The system is modular so that the user can customize the coverage desired.

Owner:MECHANICAL HLDG

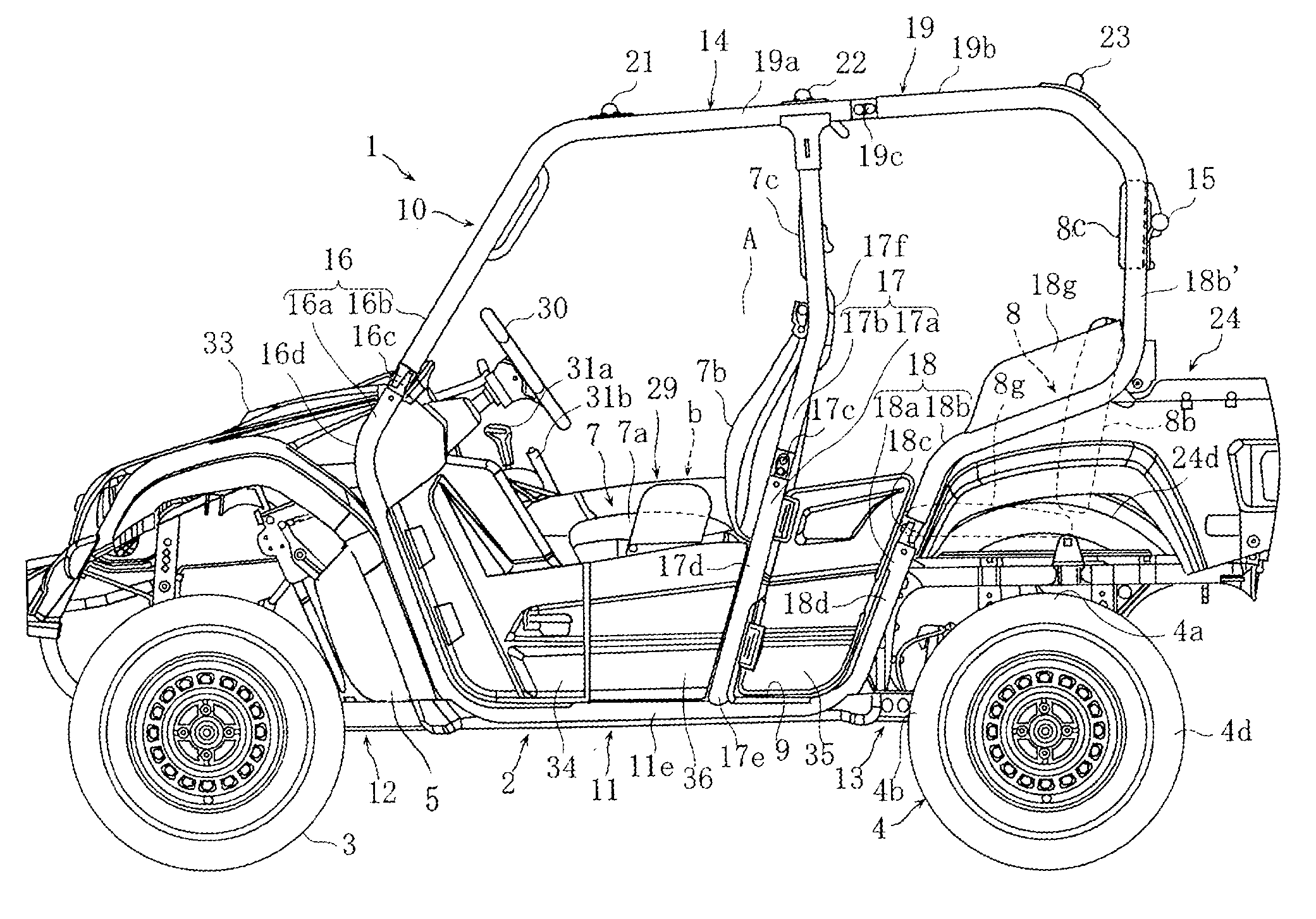

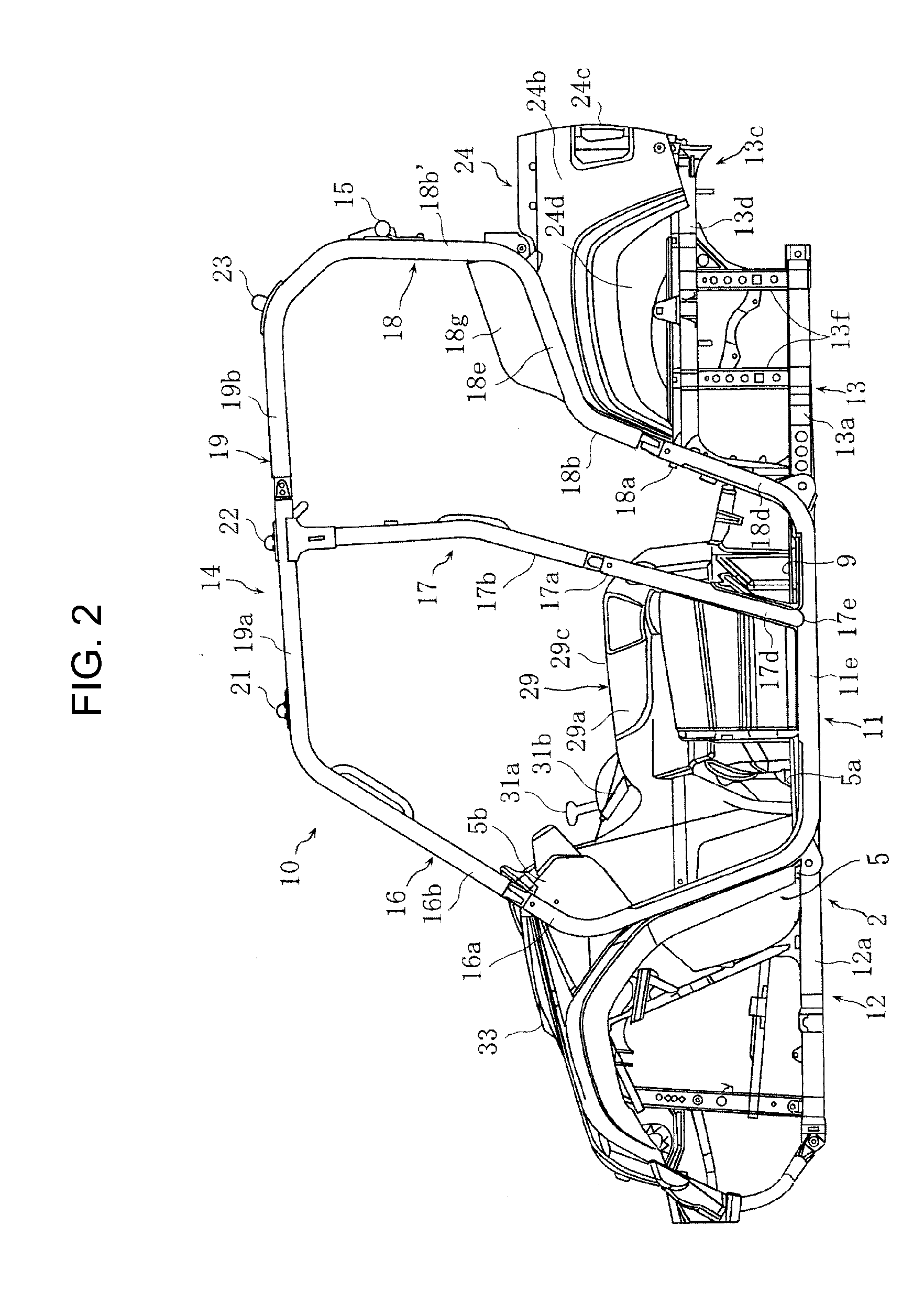

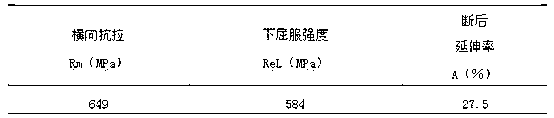

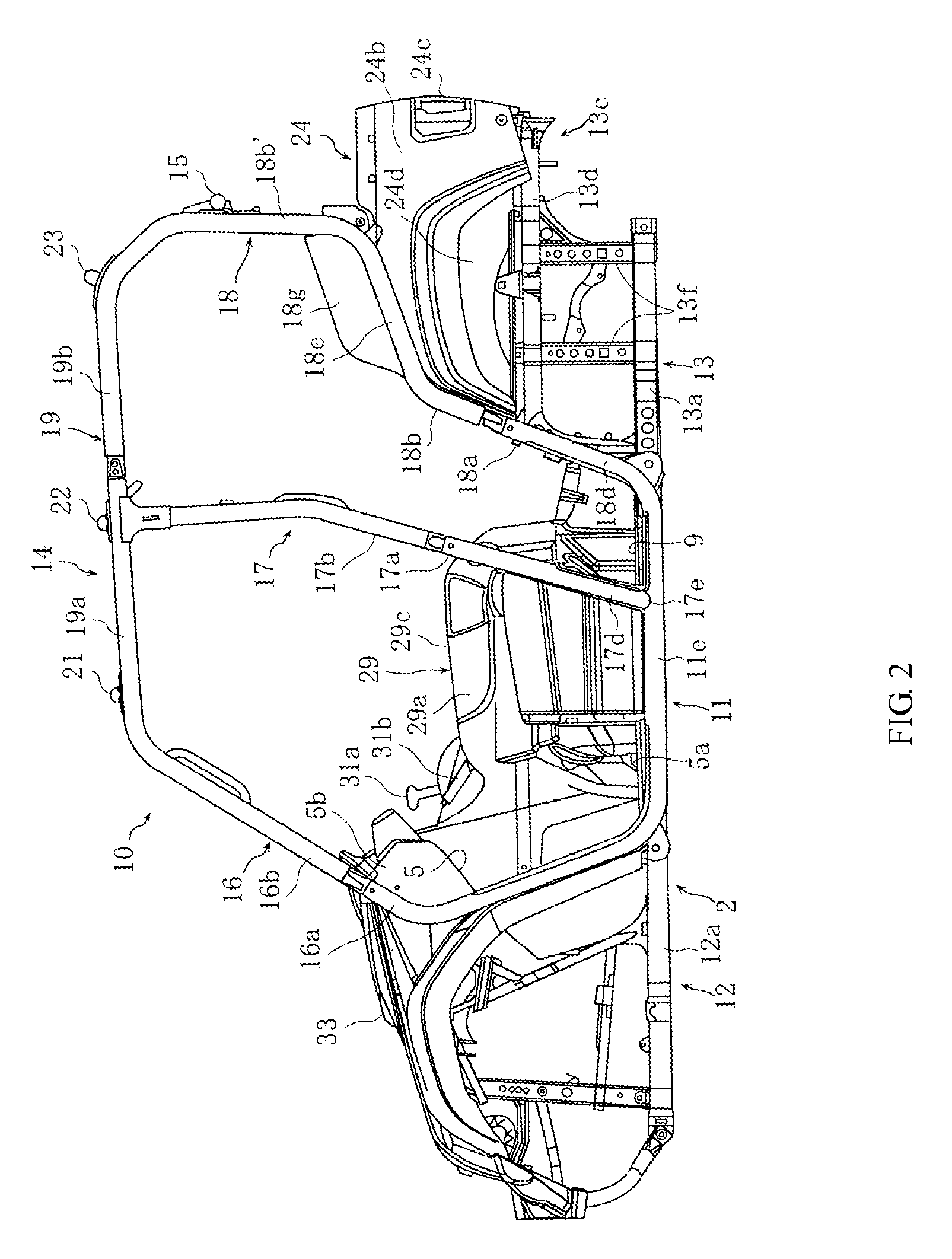

Utility vehicle

ActiveUS20090183938A1Increase in sizeEasy to useUnderstructuresPlural diverse prime-mover propulsion mountingEngineeringSport utility vehicle

A vehicle having a center console 29 provided with left and right walls 29a and 29b, and a top wall 29c, provided to the rear, in the front / back direction of the vehicle, from a front panel 5, extending rearward, in the front / back direction of the vehicle, from the center portion, in the direction of width of the vehicle, of the front panel 5 to at least the front end of a seat 7, wherein the top wall 29c is provided at a position that is higher than the bottommost end a of the front portion of a seating surface 7e of a seat cushion portion 7a of the front seat 7 and higher than the top end of an engine 6, and at a position that is lower than a top end 5b of the front panel 5.

Owner:YAMAHA MOTOR CO LTD +1

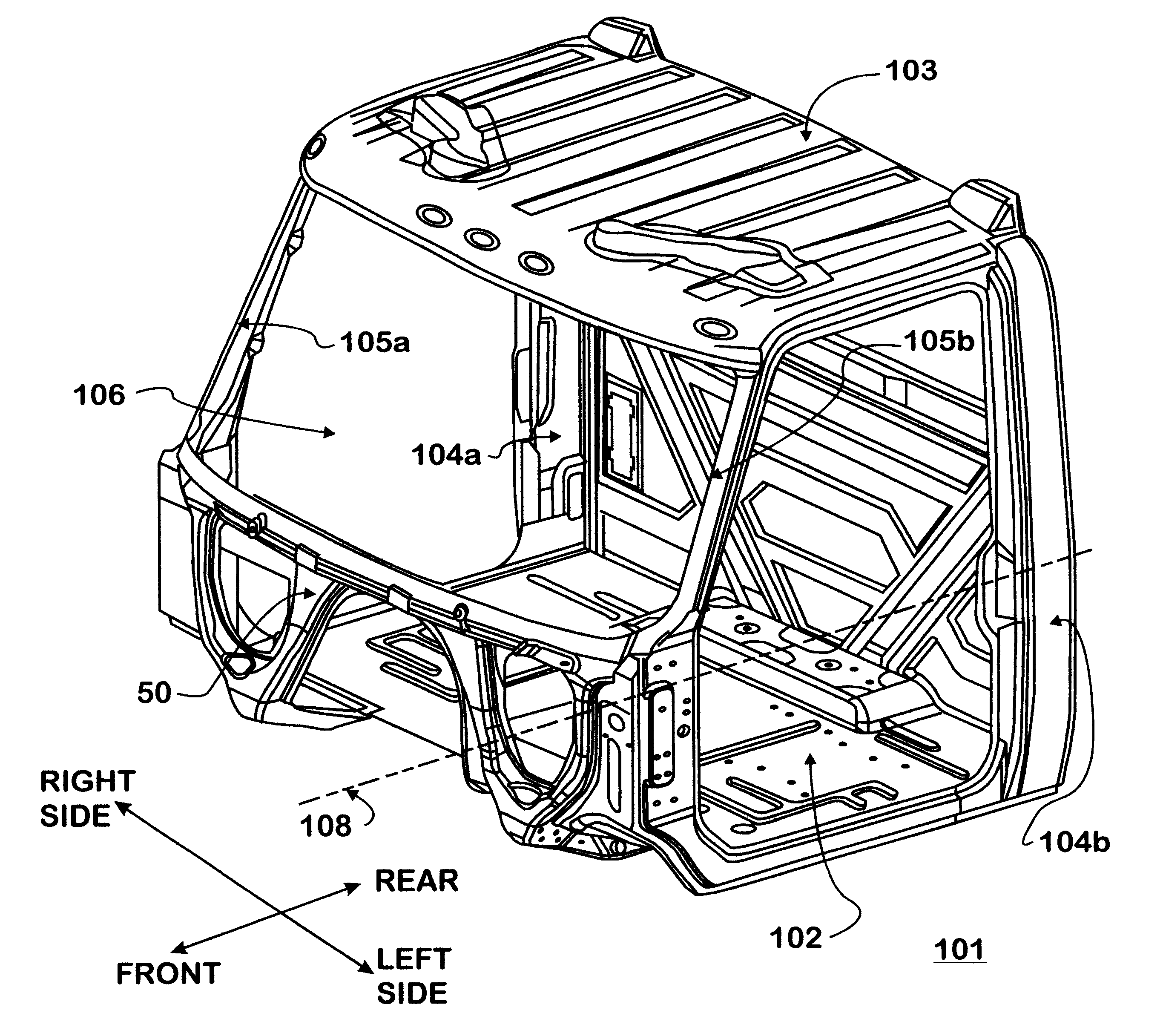

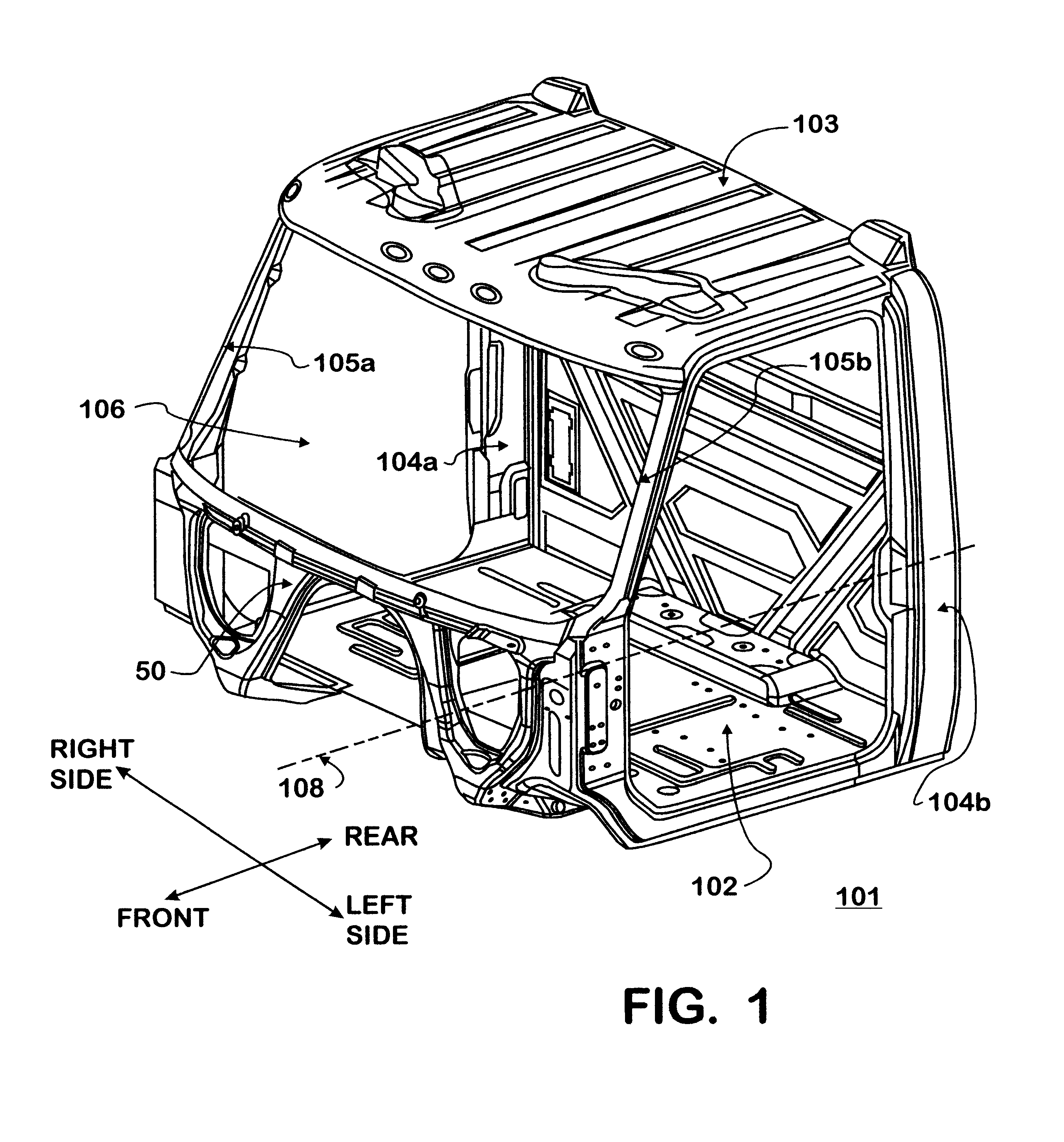

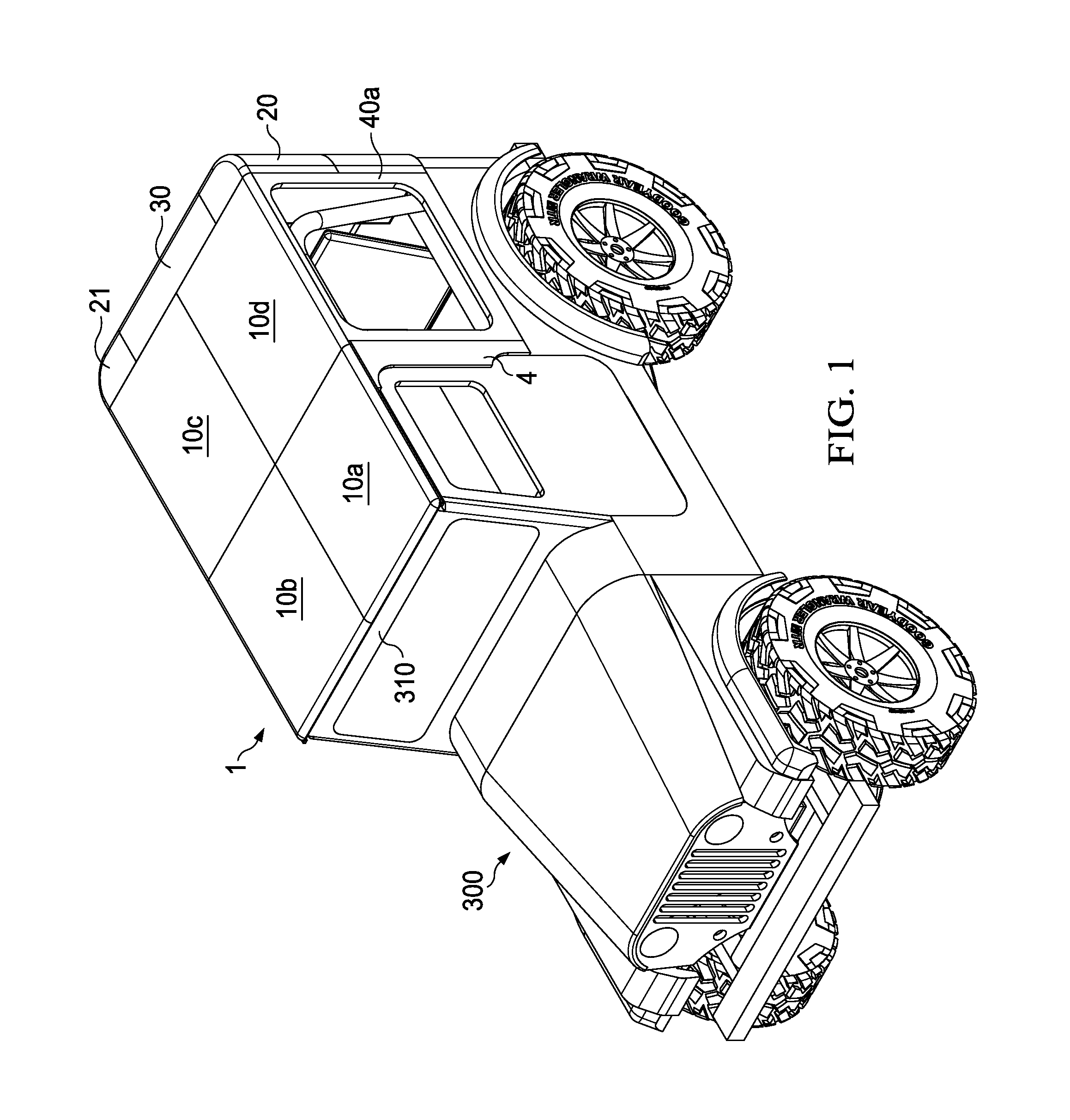

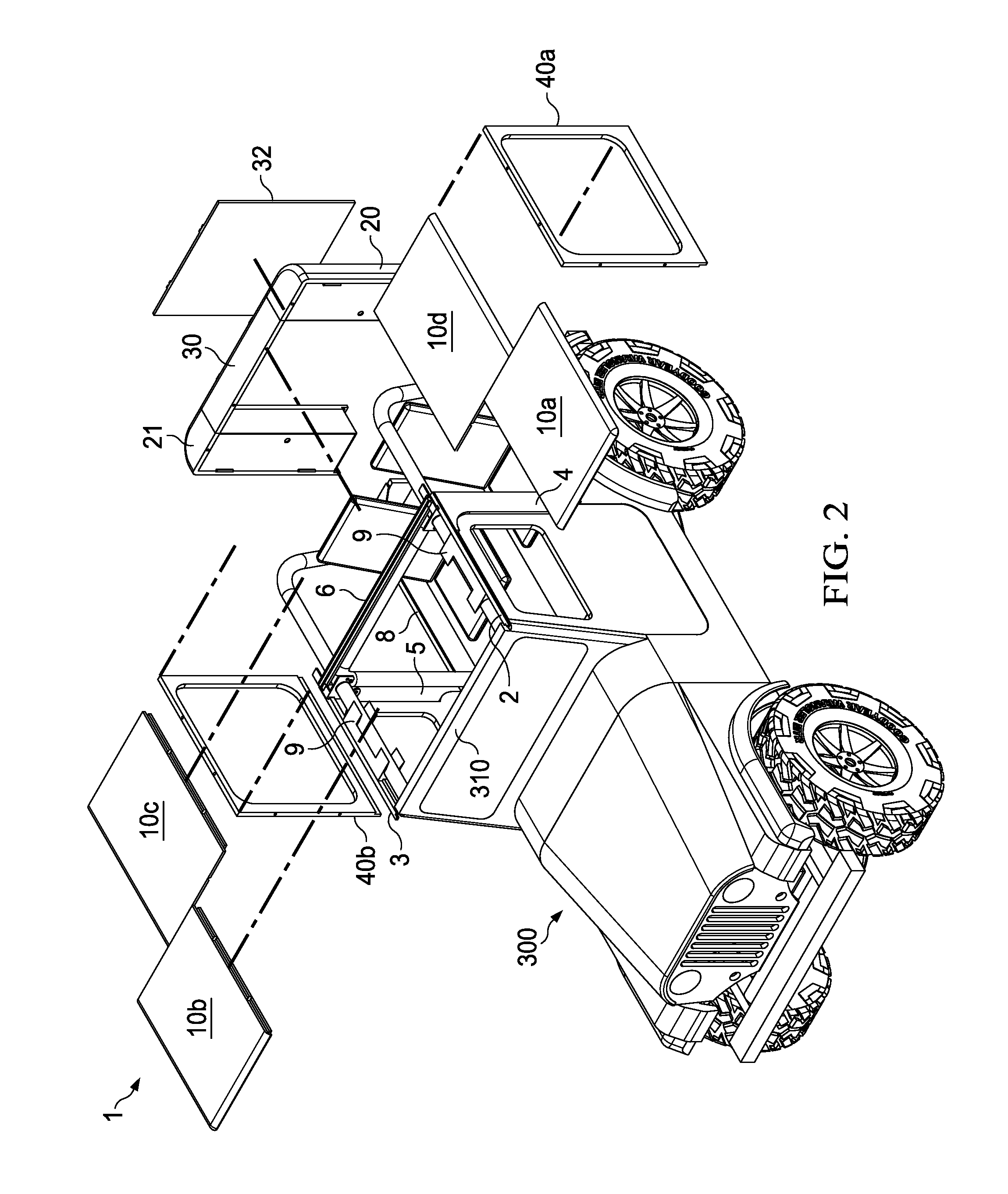

Utility Vehicle

ActiveUS20120161468A1Reduce kind of componentImprove production efficiencySuperstructure subunitsMonocoque constructionsEngineeringSport utility vehicle

A utility vehicle includes a vehicle body; a seat provided on the vehicle body; a pair of right and left entrances through which a user to be seated on the seat gets into and out of the vehicle, the entrances being provided at both sides of the vehicle body in a vehicle width direction; and a pair of right and left doors for opening and closing the pair of right and left entrances, respectively; each of the pair of right and left doors including a door body closing at least a portion of a corresponding entrance and a hinge for coupling the door body to the vehicle body such that the door body is rotatable around the hinge; and the door body including a door component which is substantially symmetric in shape in a rightward and leftward direction.

Owner:KAWASAKI MOTORS LTD

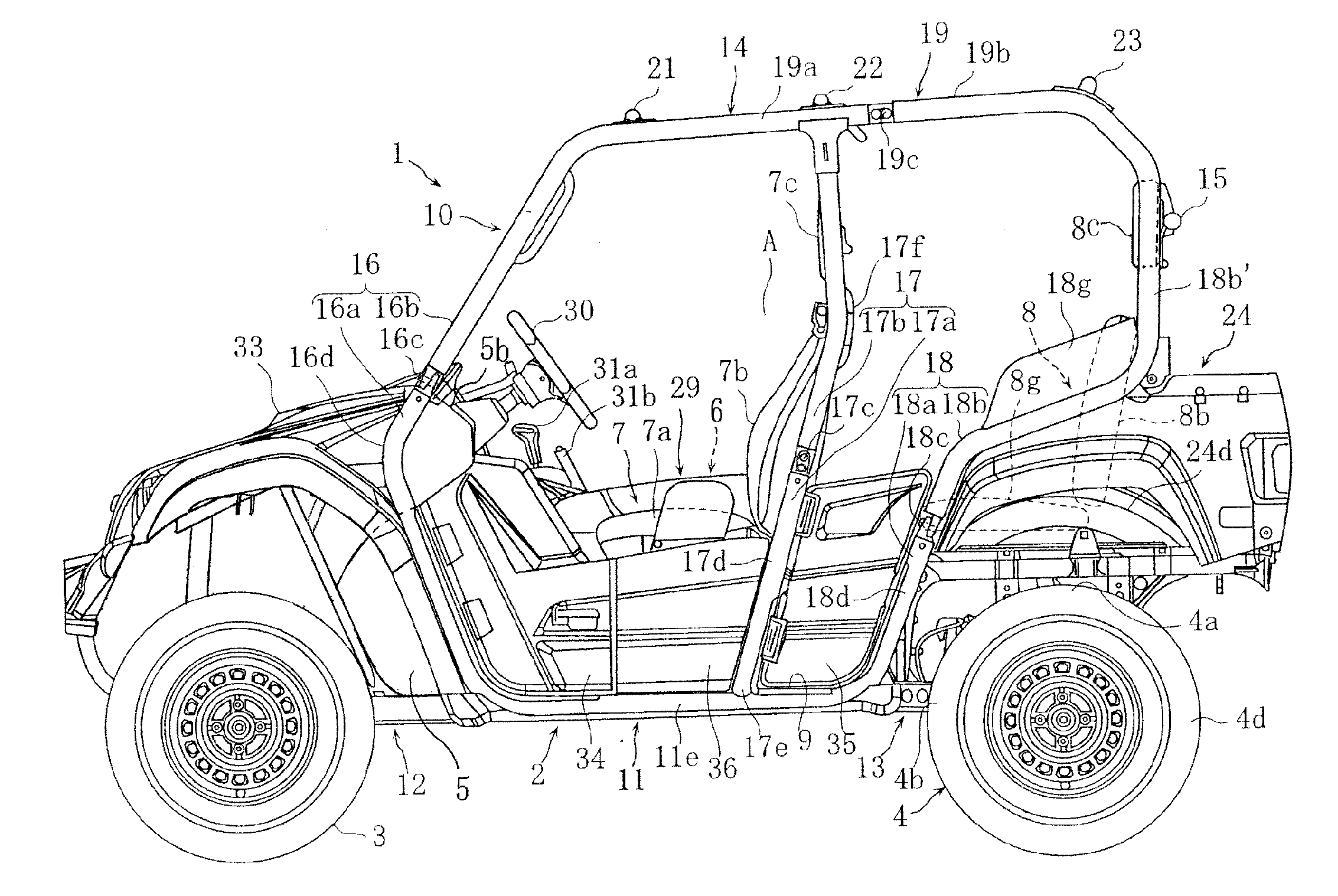

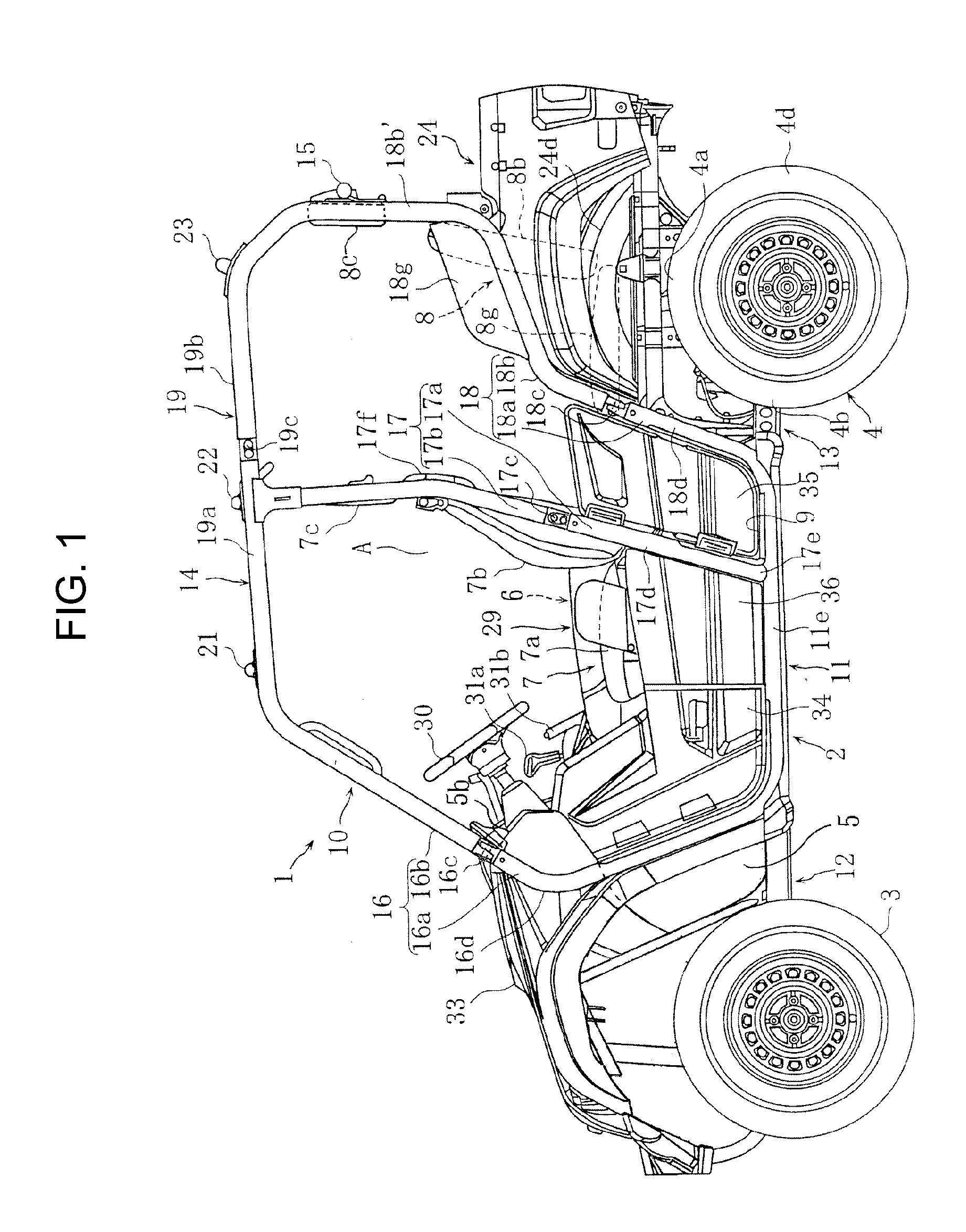

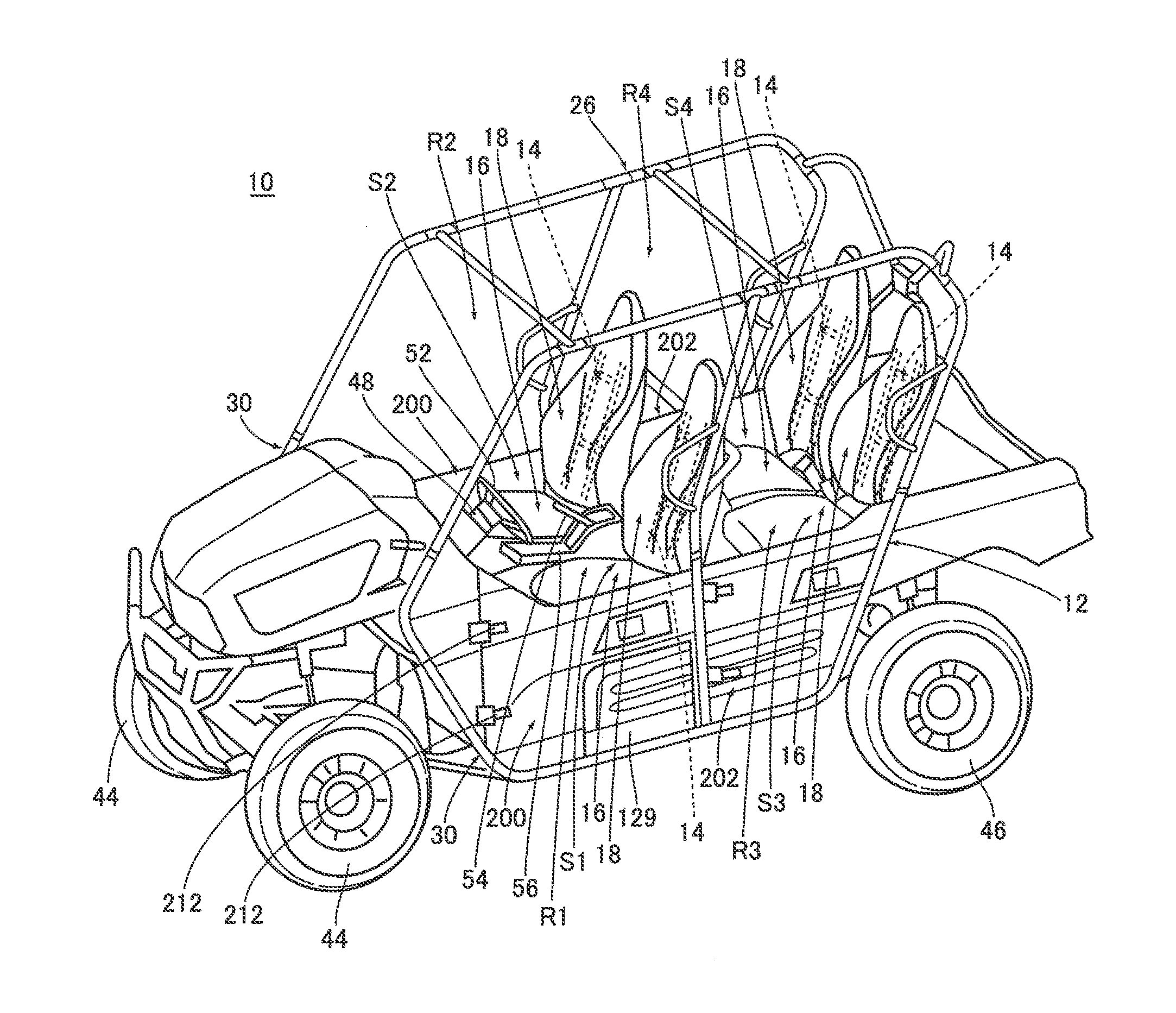

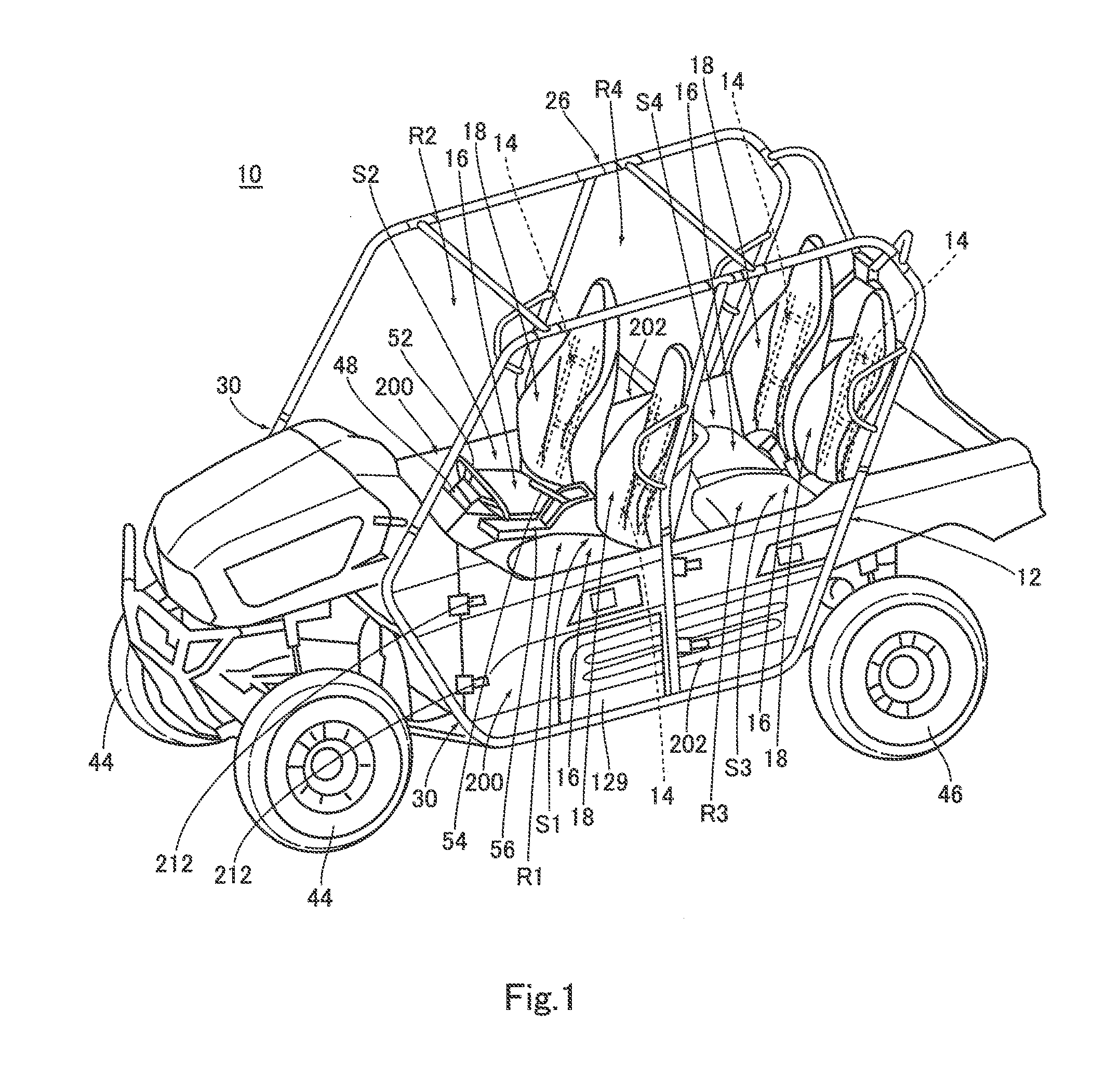

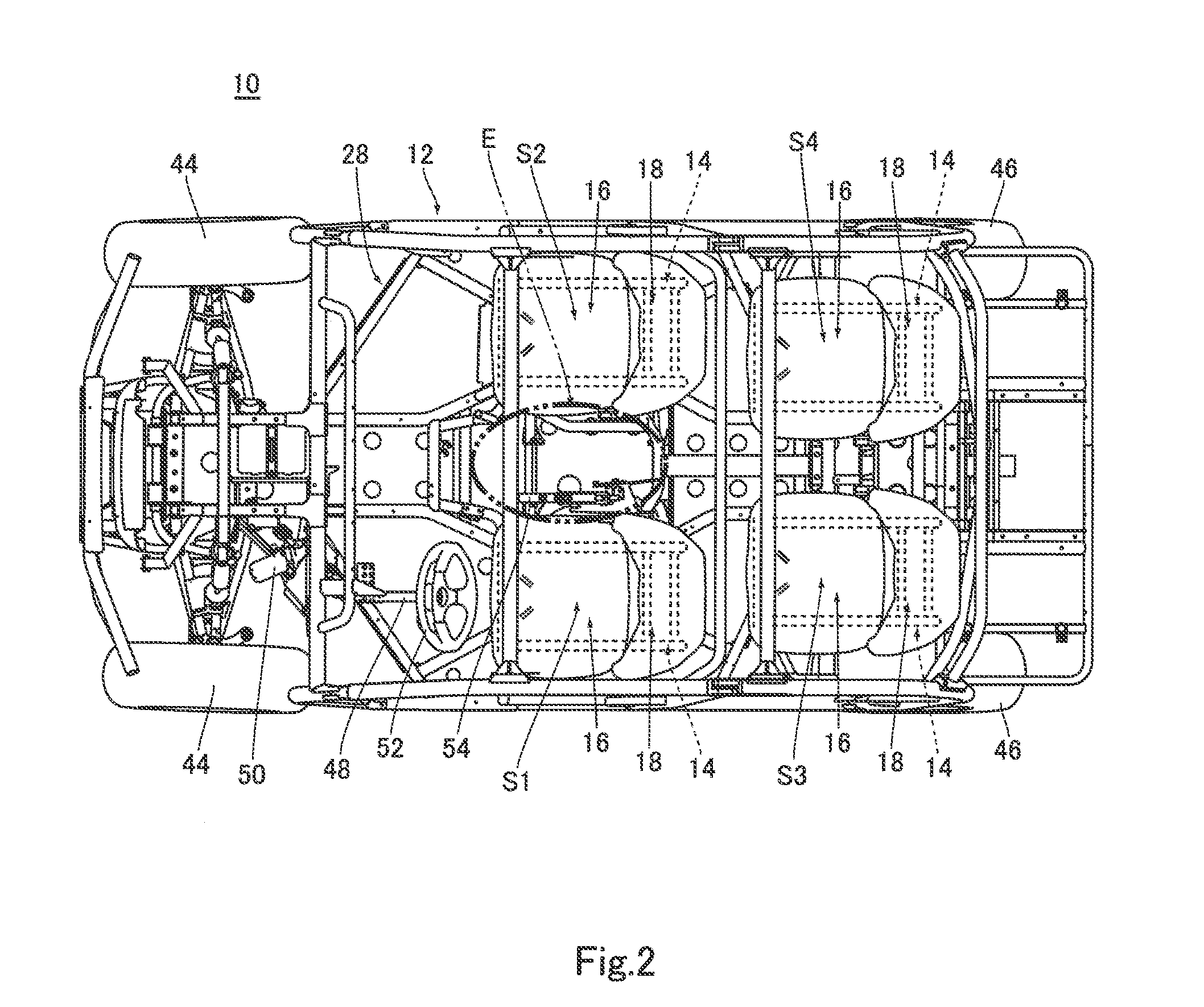

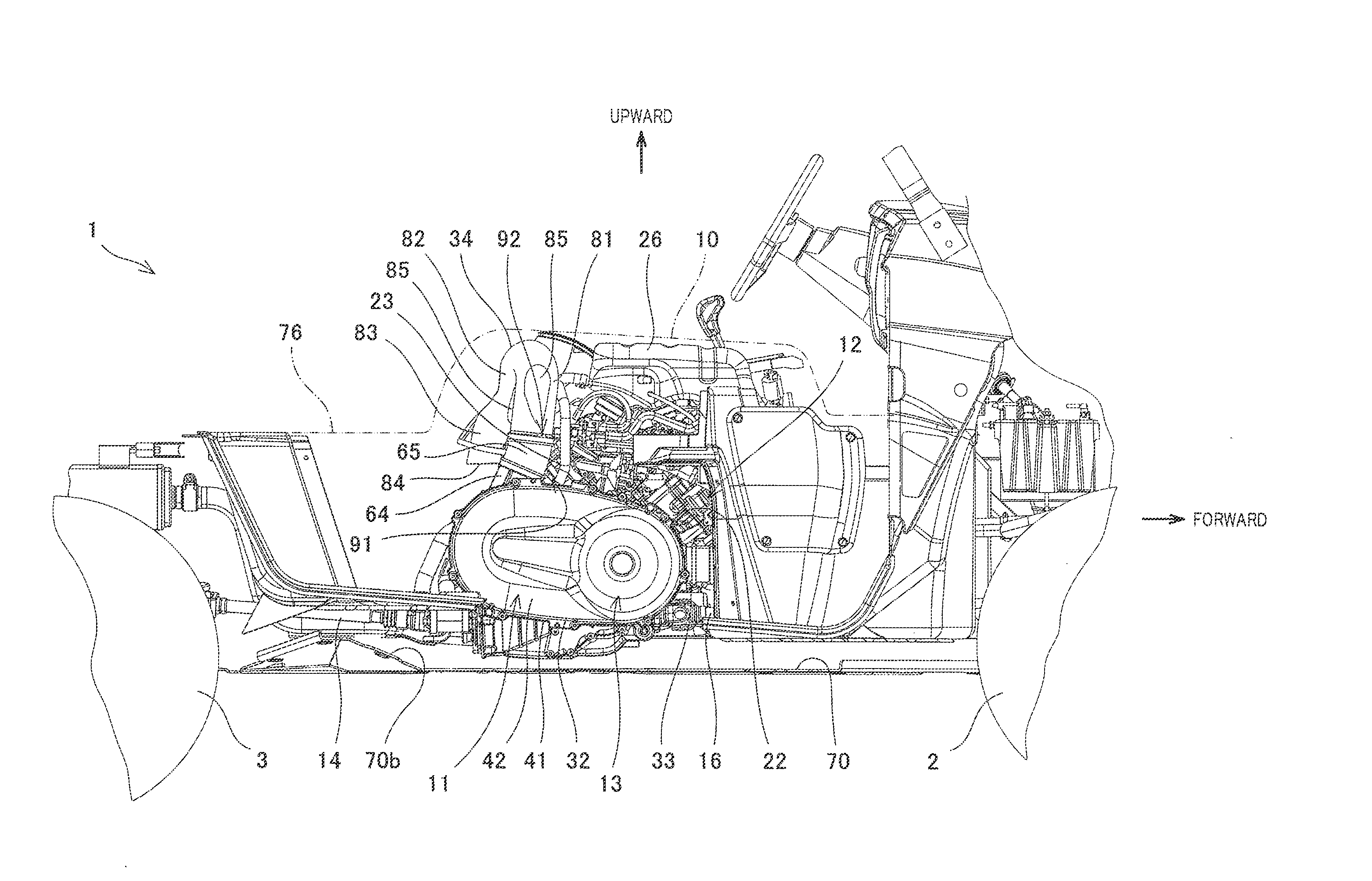

Utility vehicle

ActiveUS8292352B2Vehicle seatsPedestrian/occupant safety arrangementEngineeringSport utility vehicle

A utility vehicle includes a seat mounted to a vehicle body frame to seat a passenger thereon; a side member positioned outward in a vehicle width direction relative to the seat and forming a part of the vehicle body frame; an access opening defined by the side member, the seat being accessible by the passenger through the access opening; a door rotatably mounted to the side member to open and close a part of the access opening; and a protective cover provided between the door and the side member and coupled to the door and to the side member; the protective cover being rotatable with respect to the side member along with the door and closing at least a part of a portion of the access opening, which portion is above the door, in a state where the door is closed.

Owner:KAWASAKI MOTORS LTD

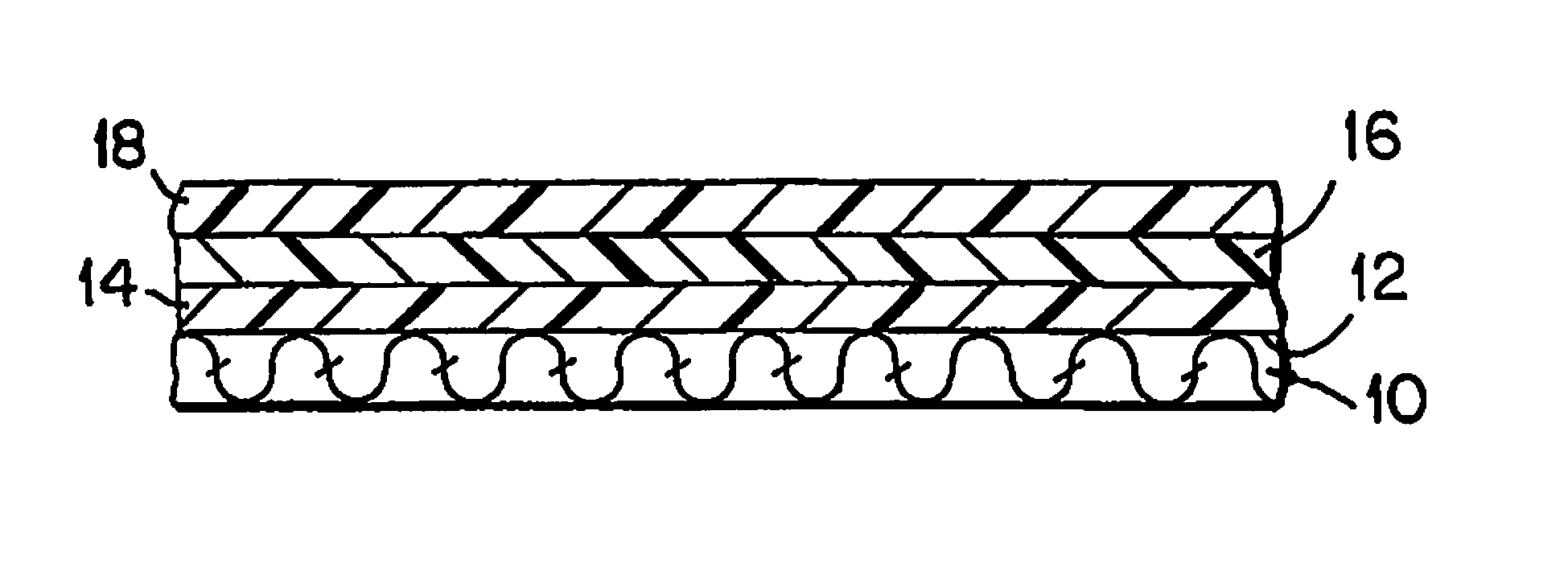

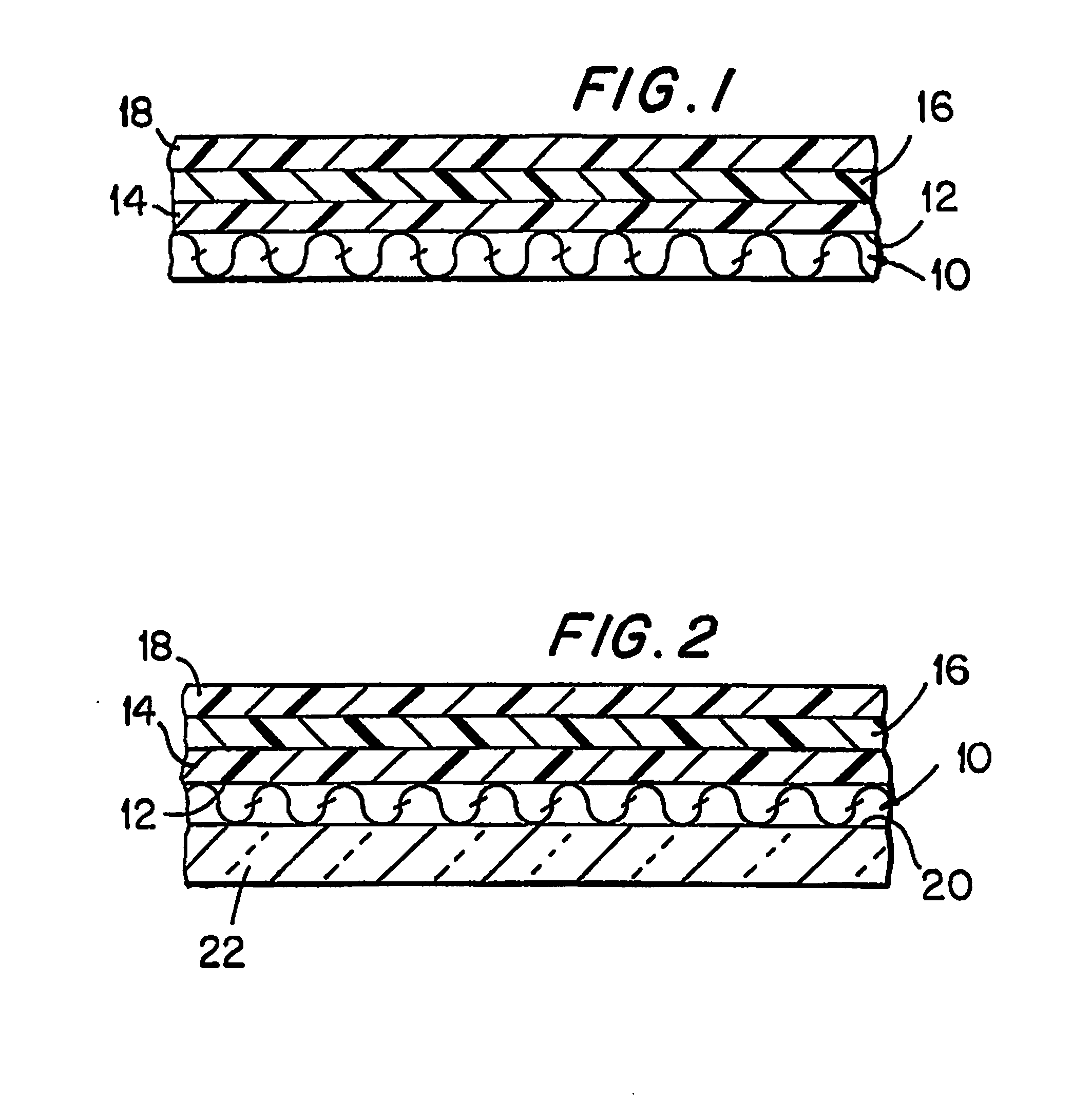

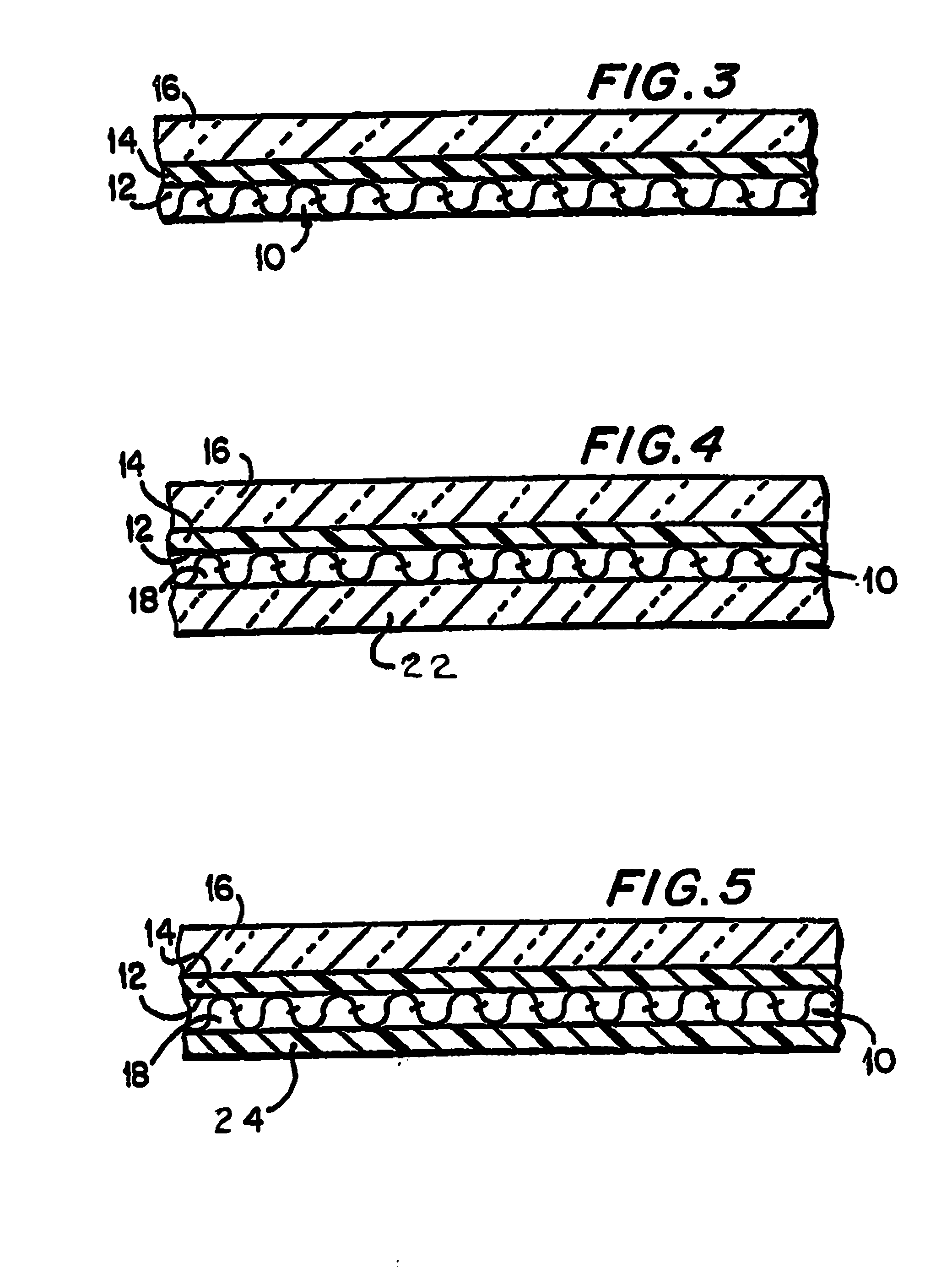

Polyvinyl chloride coated fabrics for use in air bags

InactiveUS20100129575A1Light weightExceptional air permeabilityPedestrian/occupant safety arrangementSynthetic resin layered productsElastomerPolyvinyl chloride

Textile fabrics for use in air bags and side curtains having at least one coating layer of polyvinyl chloride thereon, which may be a flat sheet, such as used in driver side air bags, or a multi-layered woven textile having preconfigured air-holding cavities therein for use in side curtains such as are installed in sport utility vehicles. Coating layers of elastomeric polyurethane may be applied to the textile fabric in addition to the coating layer of polyvinyl chloride. The textile fabrics may be coated on one side only, and may be coated on both sides (on opposed first and second surfaces). The polyvinyl chloride coatings, whether alone or in combination with other polymeric coatings, provide air bags or side curtains with superior air-holding characteristics. Means for adjusting the coefficient of friction of the air bag outer surface is also disclosed as an embodiment that includes a calendered coated textile fabric.

Owner:BRADFORD INDS

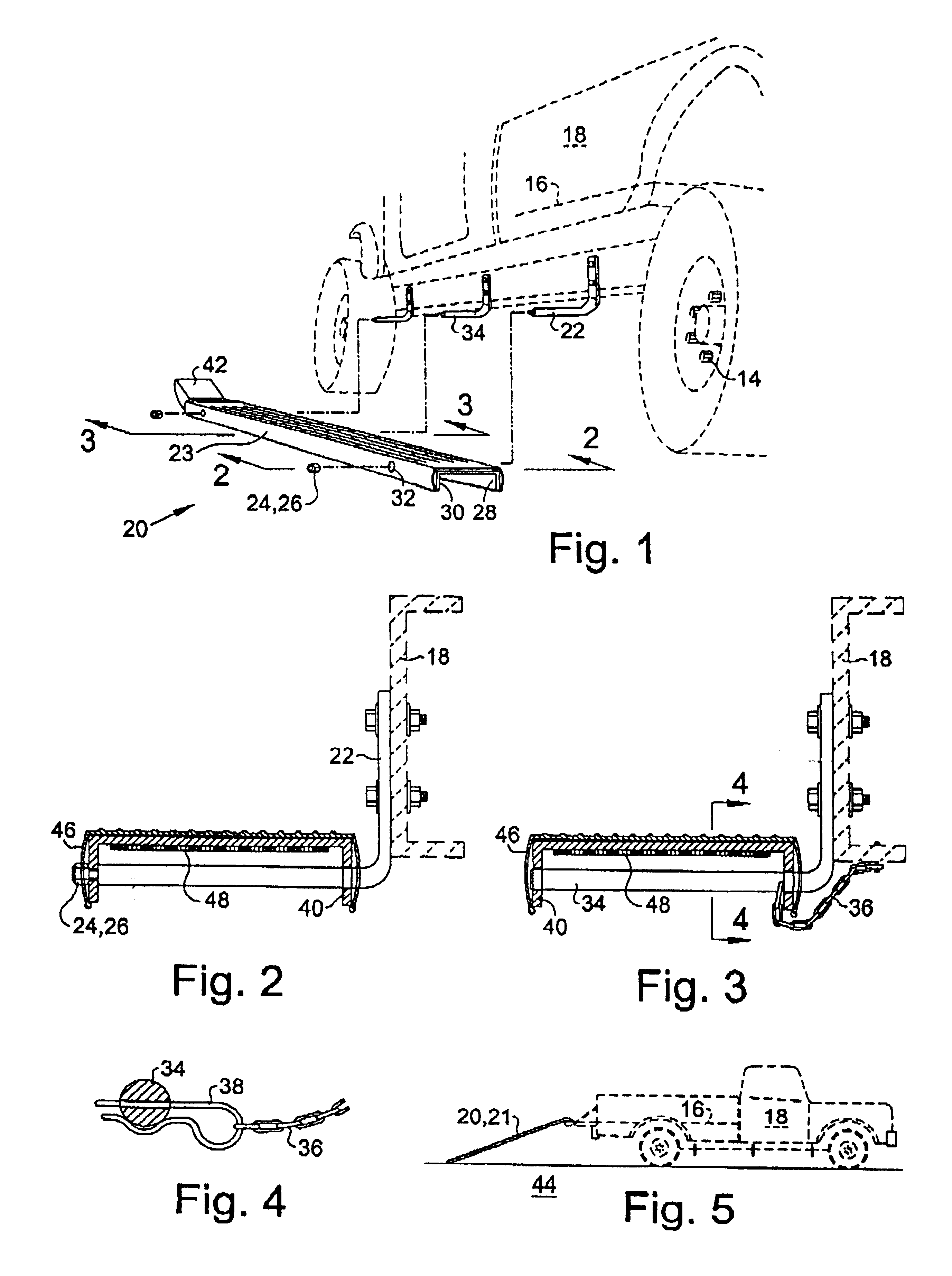

Self-adjusting snow plow

InactiveUS20050066554A1Easy to installSimple to useMechanical machines/dredgersSnow cleaningPickup truckSport utility vehicle

A self-adjusting snow plow for use with pickup trucks and sport utility vehicles is disclosed. The snow plow includes a mounting apparatus for attachment to a vehicle and a plow blade having first and second ends, a top, a bottom, a plurality of retention members and a rubber scraper. The mounting apparatus includes a pair of mounting uprights and a hitch tongue which is easily mounted in a hitch receiver which is secured to the front of a vehicle. The retention members are constructed and arranged to at least partially encircle and slideably engage one of the respective mounting uprights and the retention members allow the respective ends of the plow blade to slide upward relative to the mounting upright most proximate to that end of the plow while the other end of the plow remains generally in the same position relative to the mounting upright proximate that end of the plow blade. The retention members also permit the bottom of the plow blade to pivot away from the respective mounting uprights when the plow blade is engaged with the mounting apparatus in a working orientation and the vehicle is in motion in a direction rearward of the plow blade.

Owner:AGRI COVER

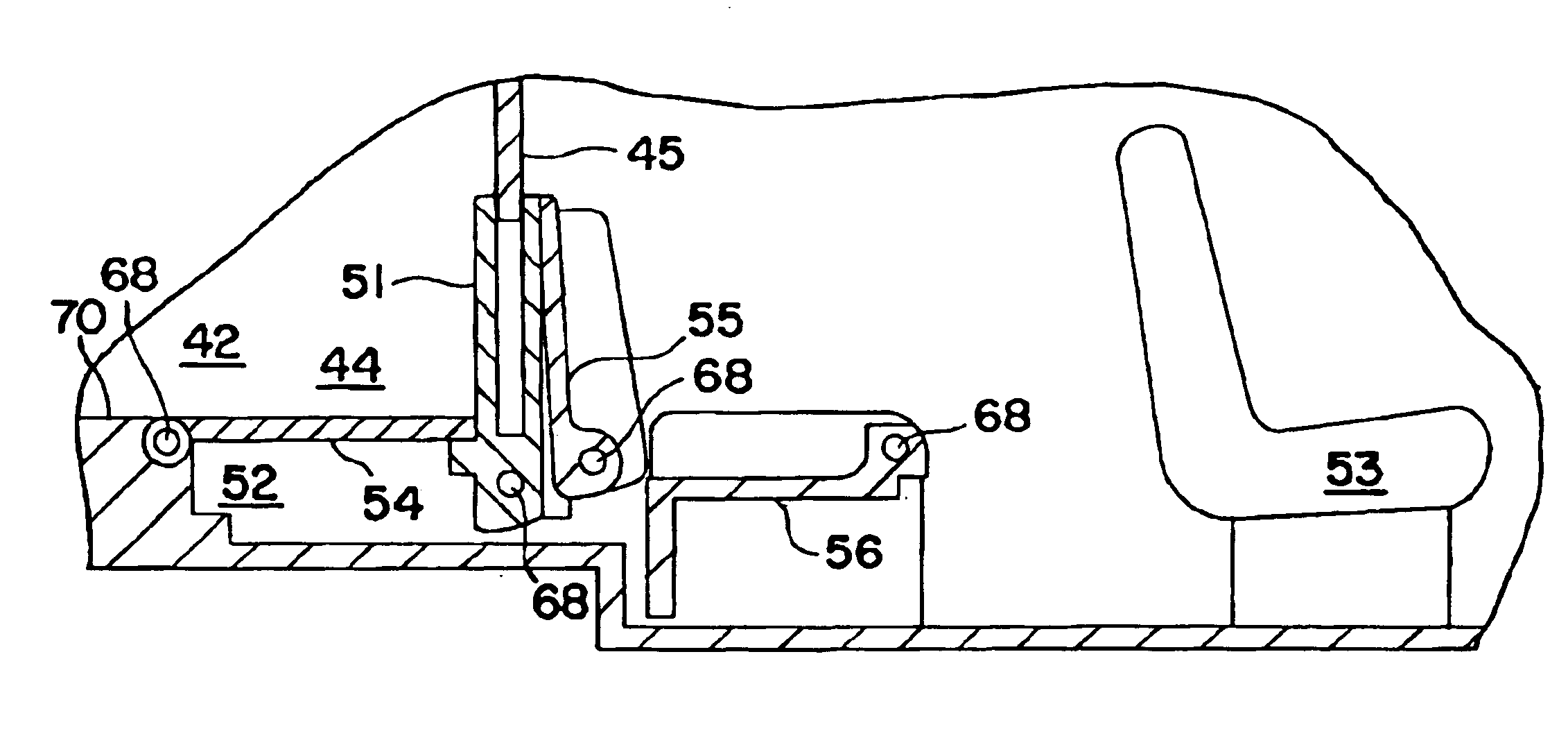

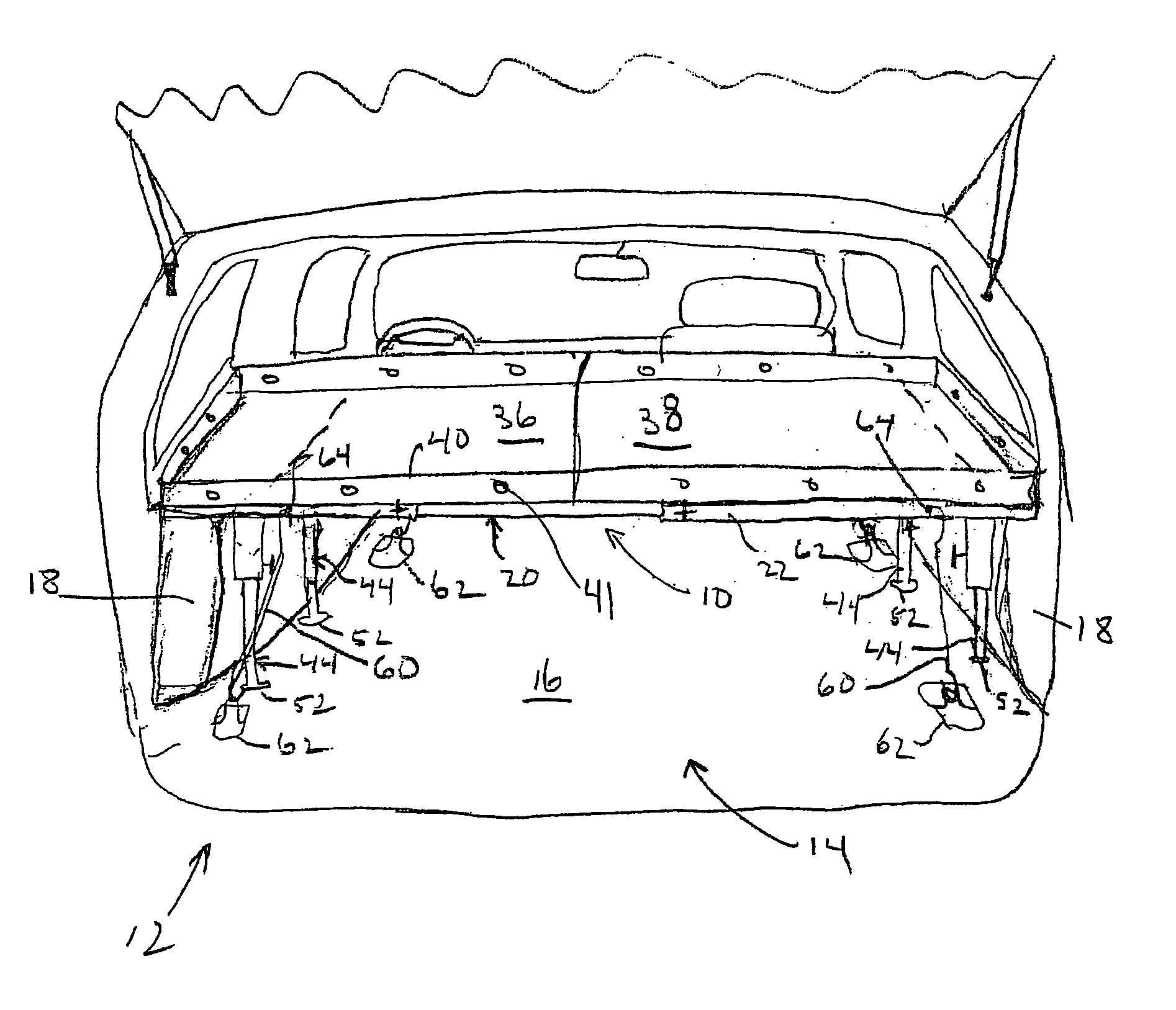

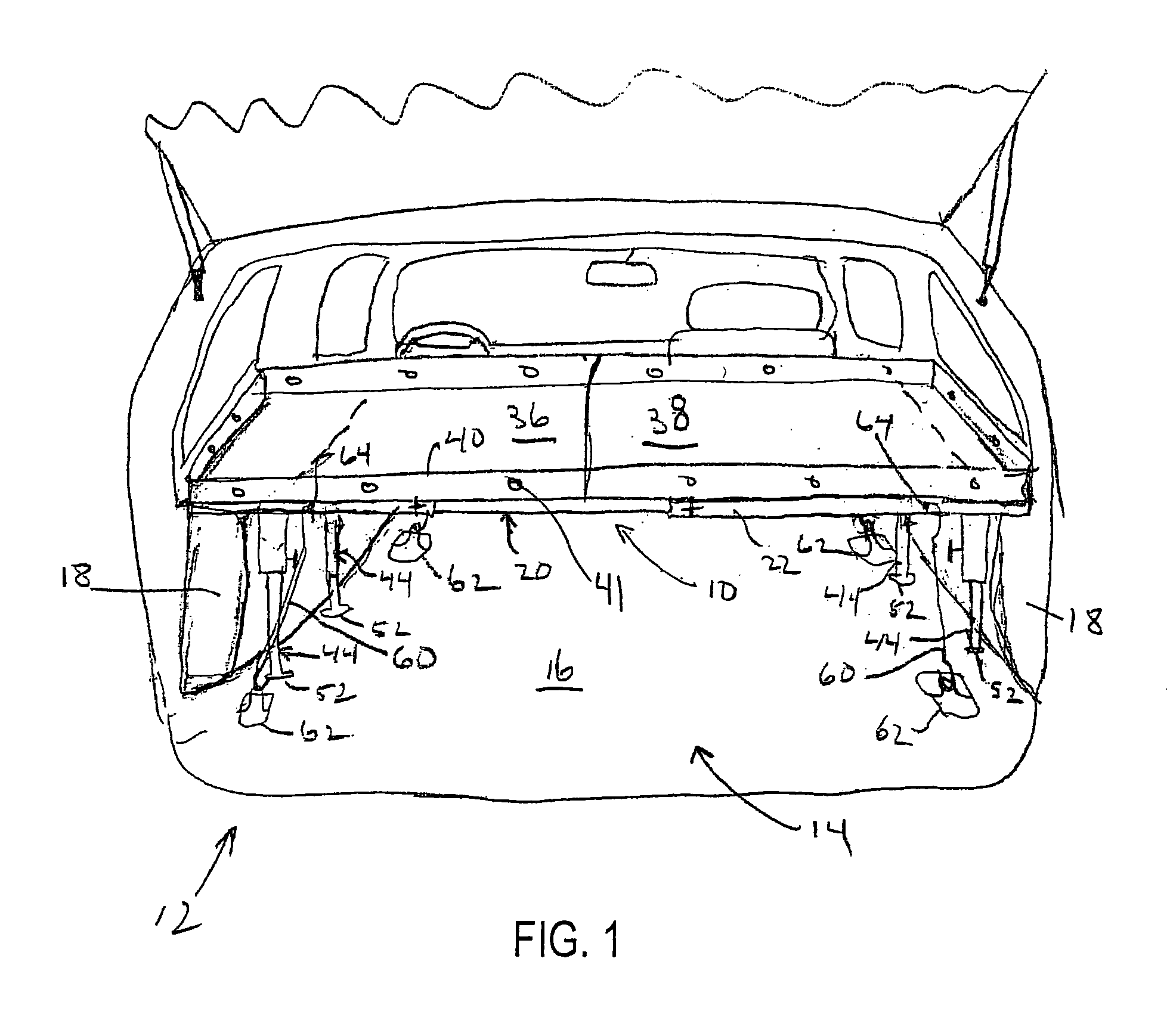

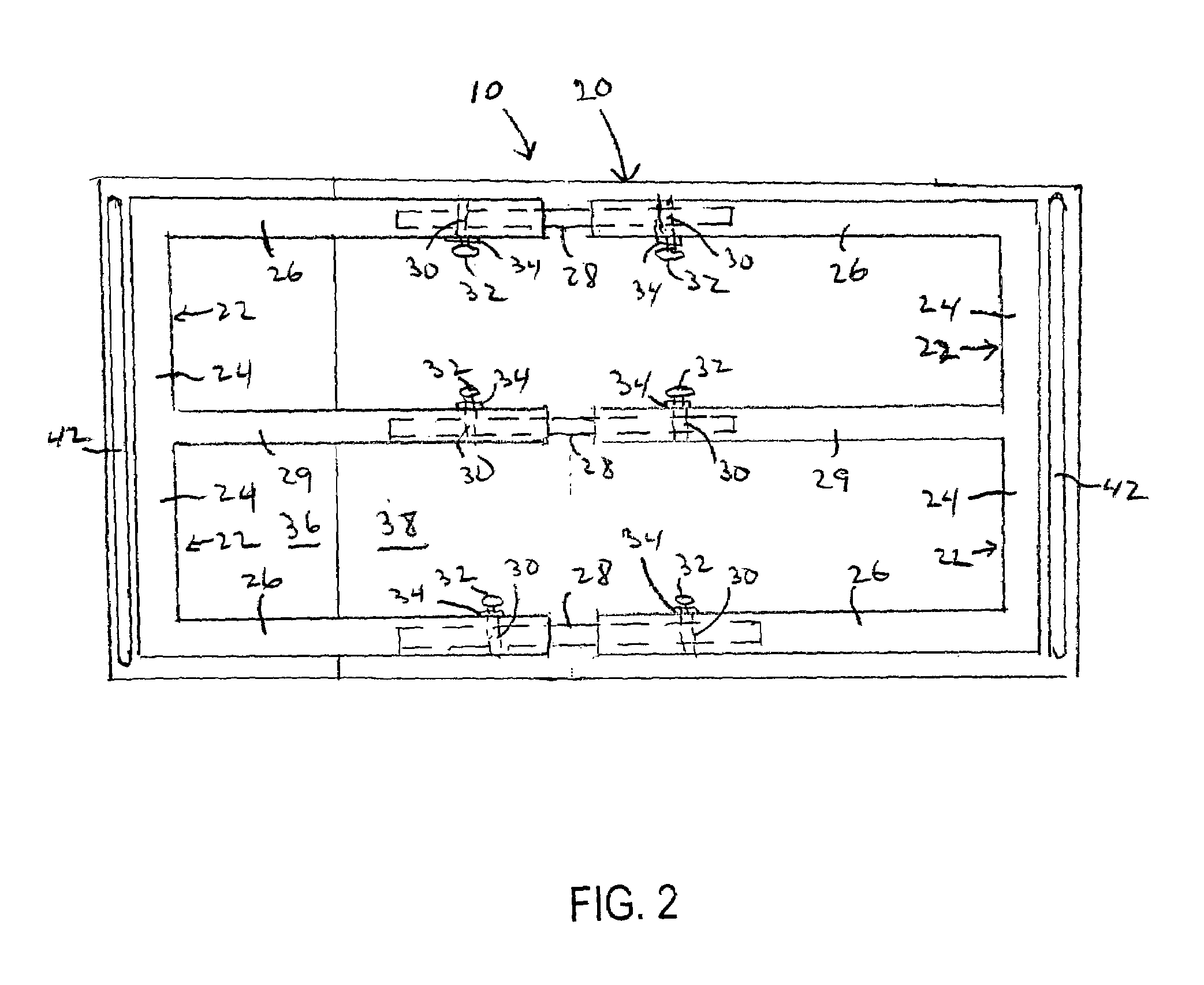

Removable storage shelf for a vehicle storage compartment

InactiveUS6942269B2Reduce exerciseIncrease storage capacityVehicle arrangementsStands/trestlesVehicle frameSport utility vehicle

A removable shelf assembly for vehicles (e.g., sport utility vehicles) to increase storage capacity in a generally flat rearwardly extending bed defined by a floor and pair of upwardly extending side walls, the shelf assembly comprising a frame composed of a plurality of U-shaped members, each member having a base and two spaced apart arms extending perpendicular to the base, a plurality of telescoping members associated with the arms, means for removably locking each arm of each the U-shaped member, whereby to adjustably fix the spaced apart bases; and, a first and second generally planar panel members positioned on the frame for receiving items to be transported thereon, the panel members associated with the frame to allow movement between the panel members. The frame preferably has a raised lip extending substantially around the frame so as to reduce movement of items placed on the frame. A downwardly depending leg which is able to pivot out of the way when needed provides additional load support. A plurality of locking thumbscrews are fitted within holes in the frame to removably lock the panels in a fixed relationship. A cushion material preferably is associated with the underside of a portion of the panels and provides cushioned support where the panels rest on the sidewalls. Preferably, a plurality of elastic tether cords are attachable to the shelf assembly and the floor tethers in the vehicle to provide further support.

Owner:KATIE KORP OF THE EMERALD COAST

Memory function for powered running boards

ActiveUS20050167941A1Convenient heightReliable constructionSteps arrangementEngineeringAltitude control

A control mechanism for a powered running board on an automotive vehicle, such as a sport utility vehicle, utilizes the memory function of the vehicle to store therein established operating positions for the running board. The user or occupant of the vehicle can manually position the powered running board to a convenient operating position within a range of available operating positions on the vehicle. By storing the selected position of the running board in the memory function of the vehicle, the control mechanism can return to that same operating height each time the occupant seeks to use the running board for entry or exit of the vehicle. The control mechanism is operable with different configurations of running boards and with different power devices for effecting the movement of the running board.

Owner:FORD GLOBAL TECH LLC

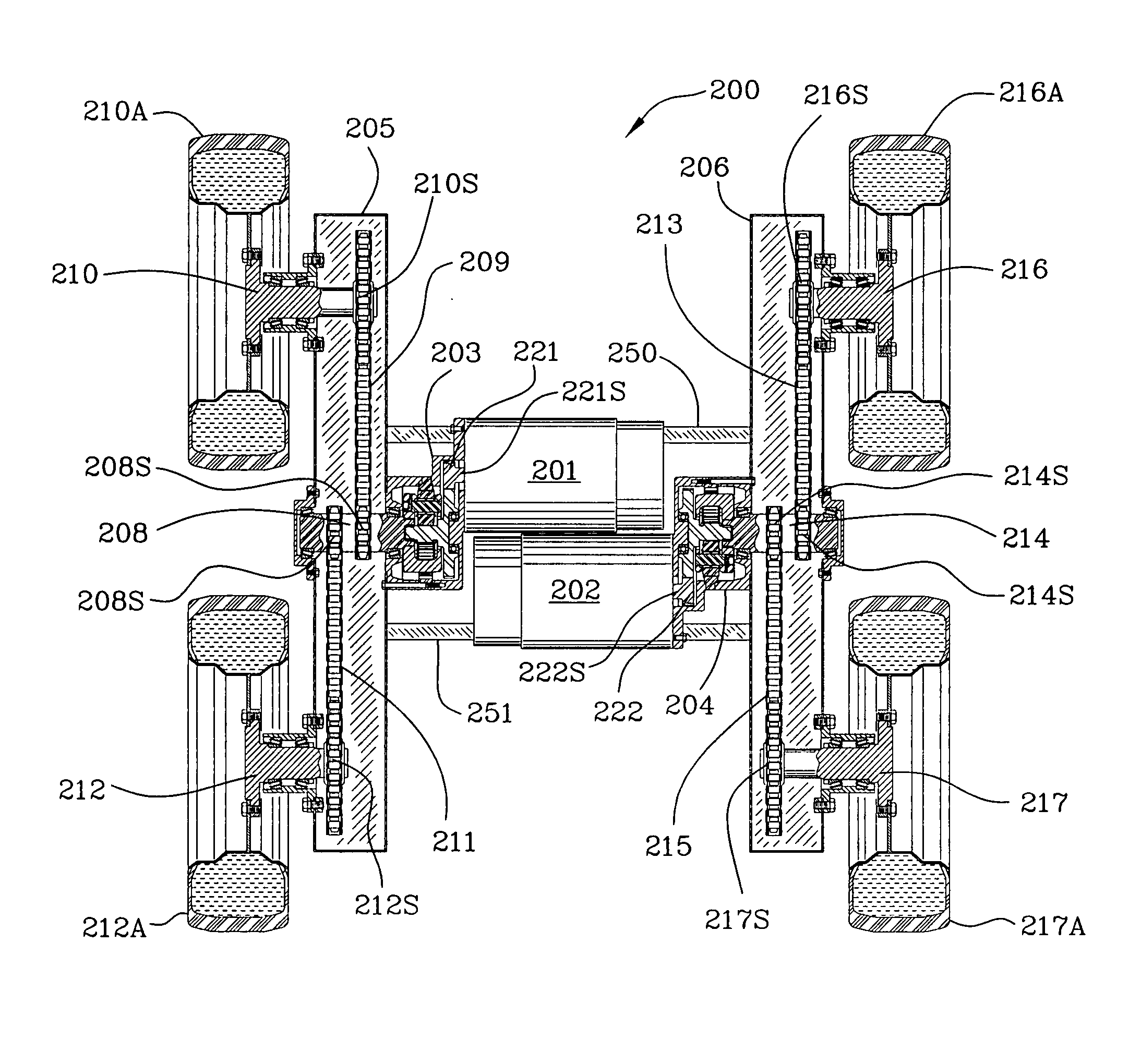

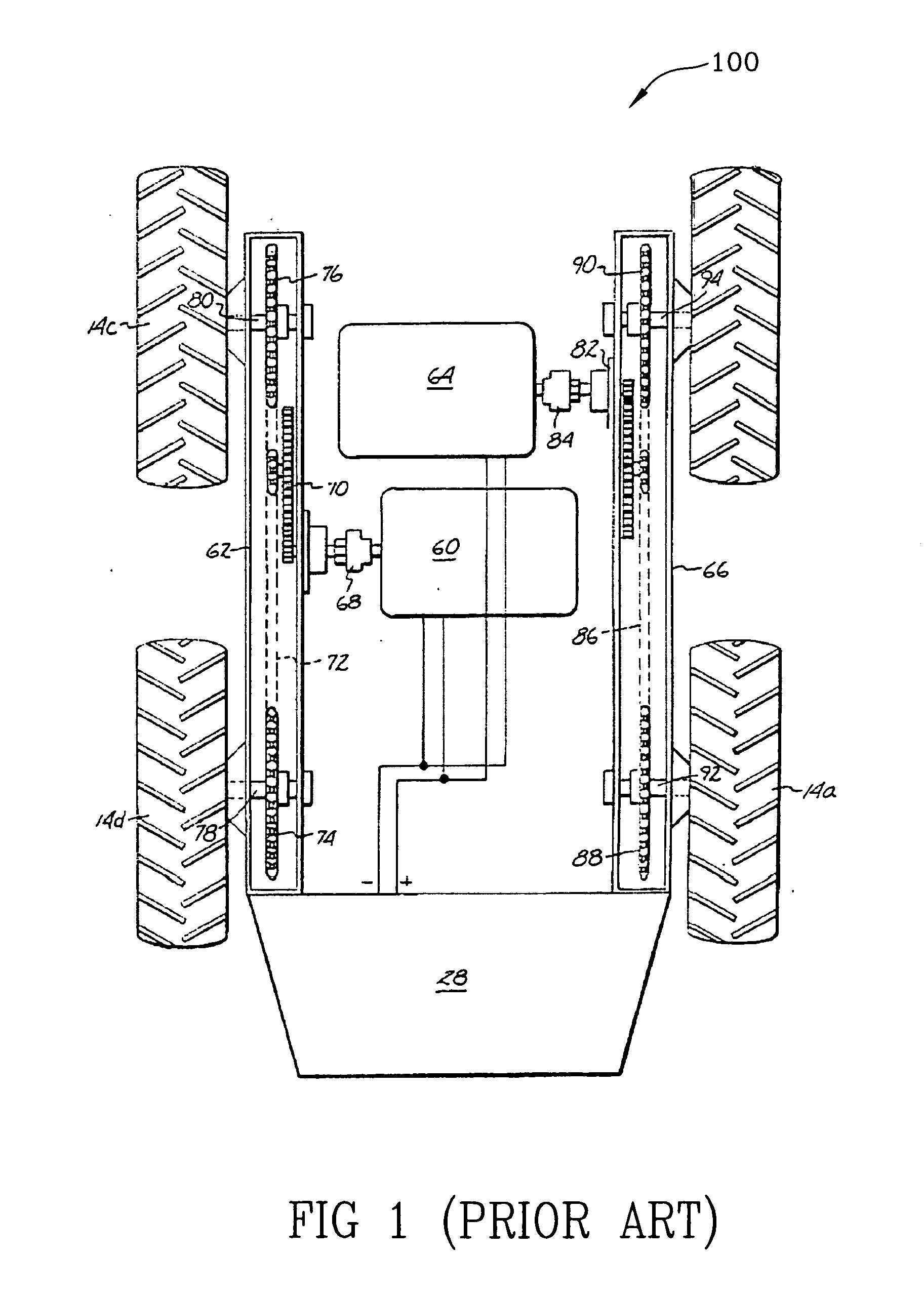

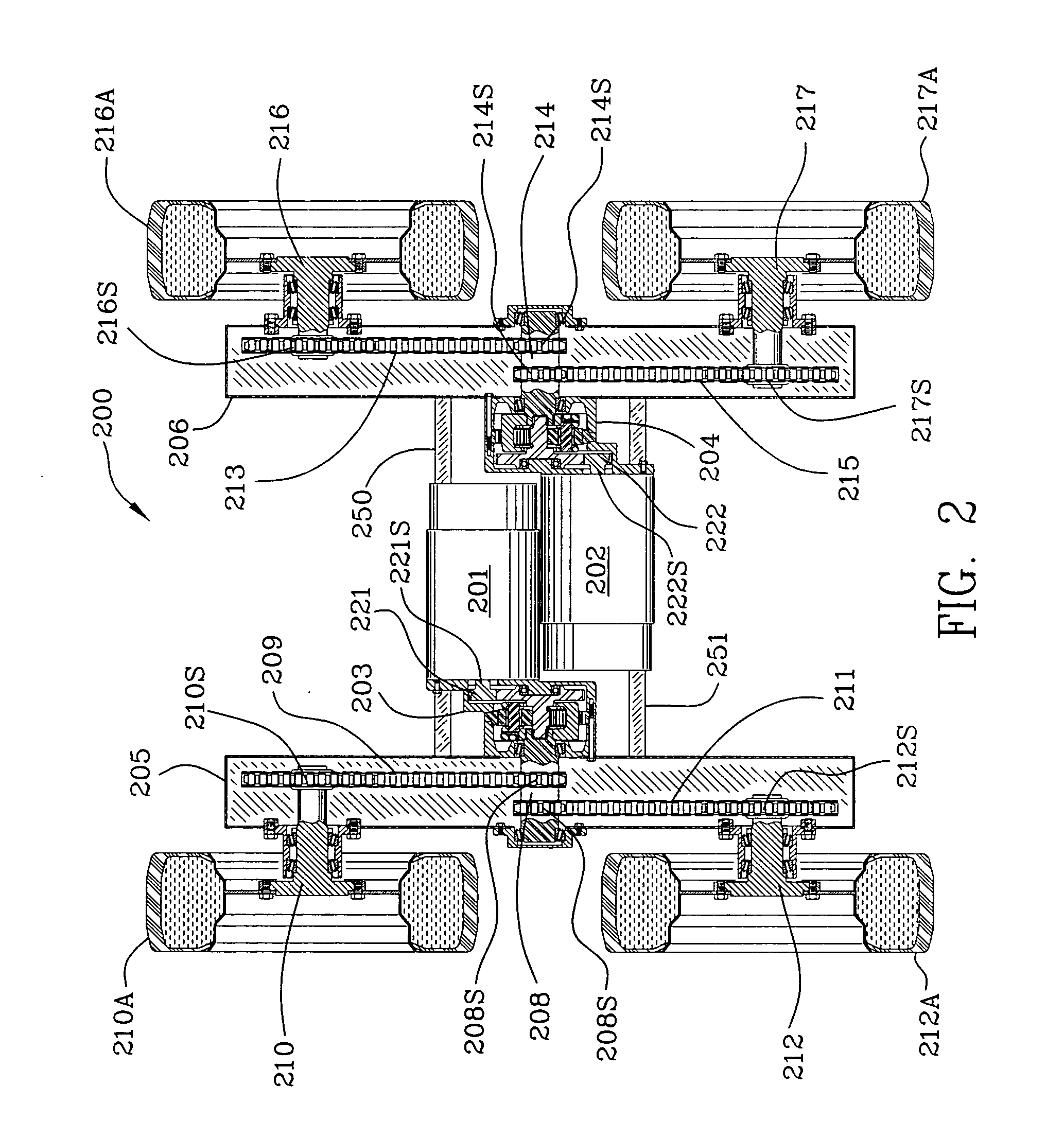

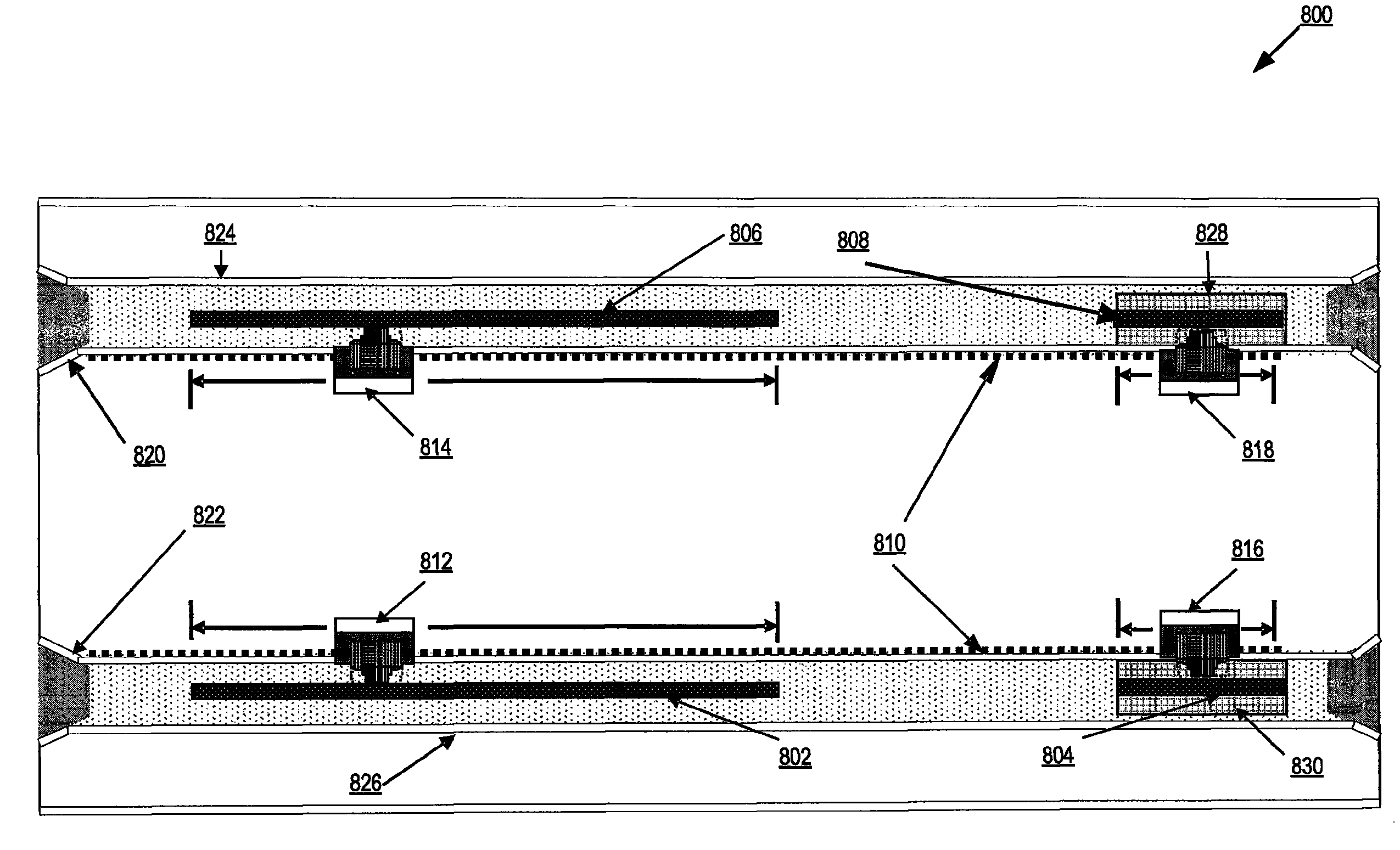

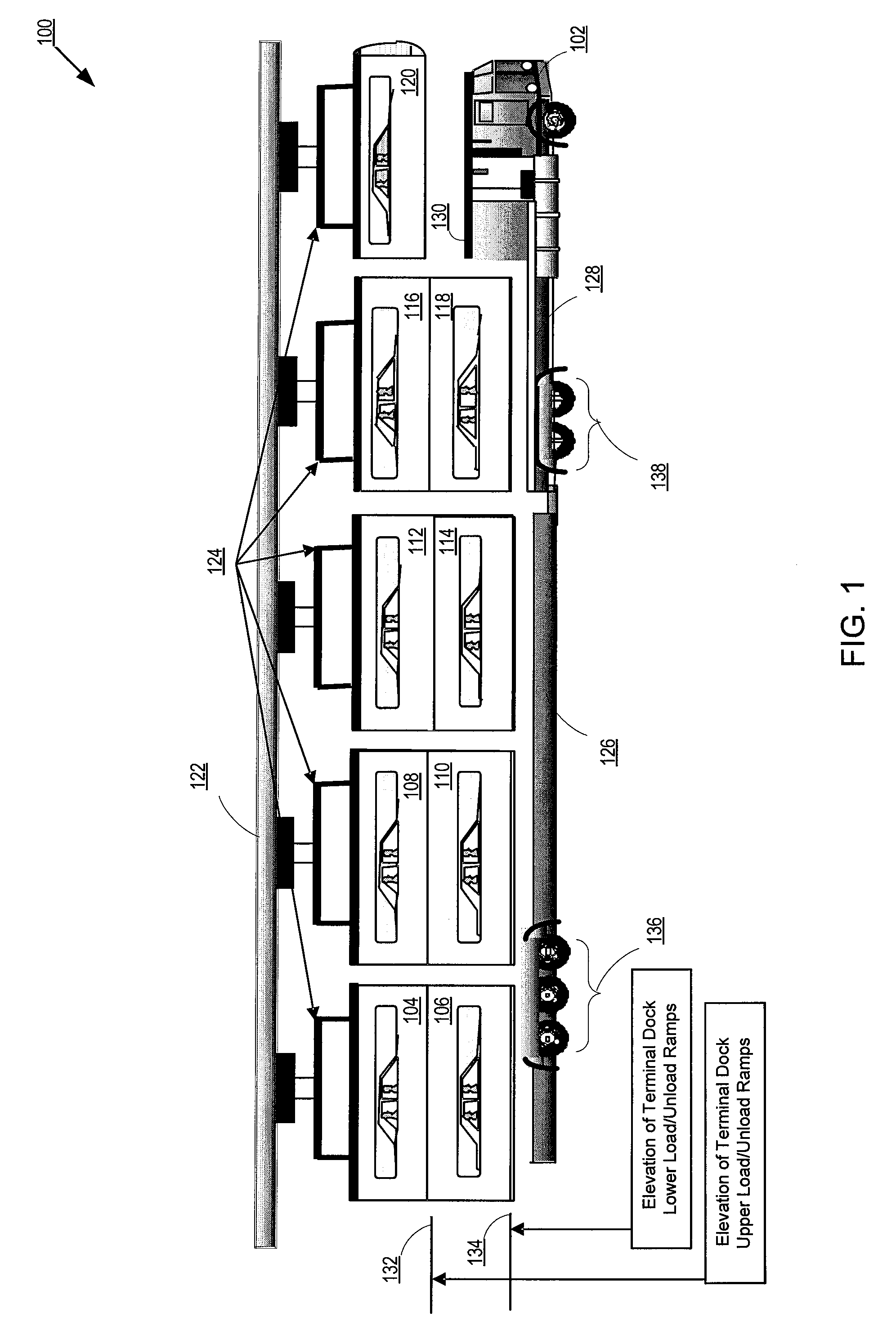

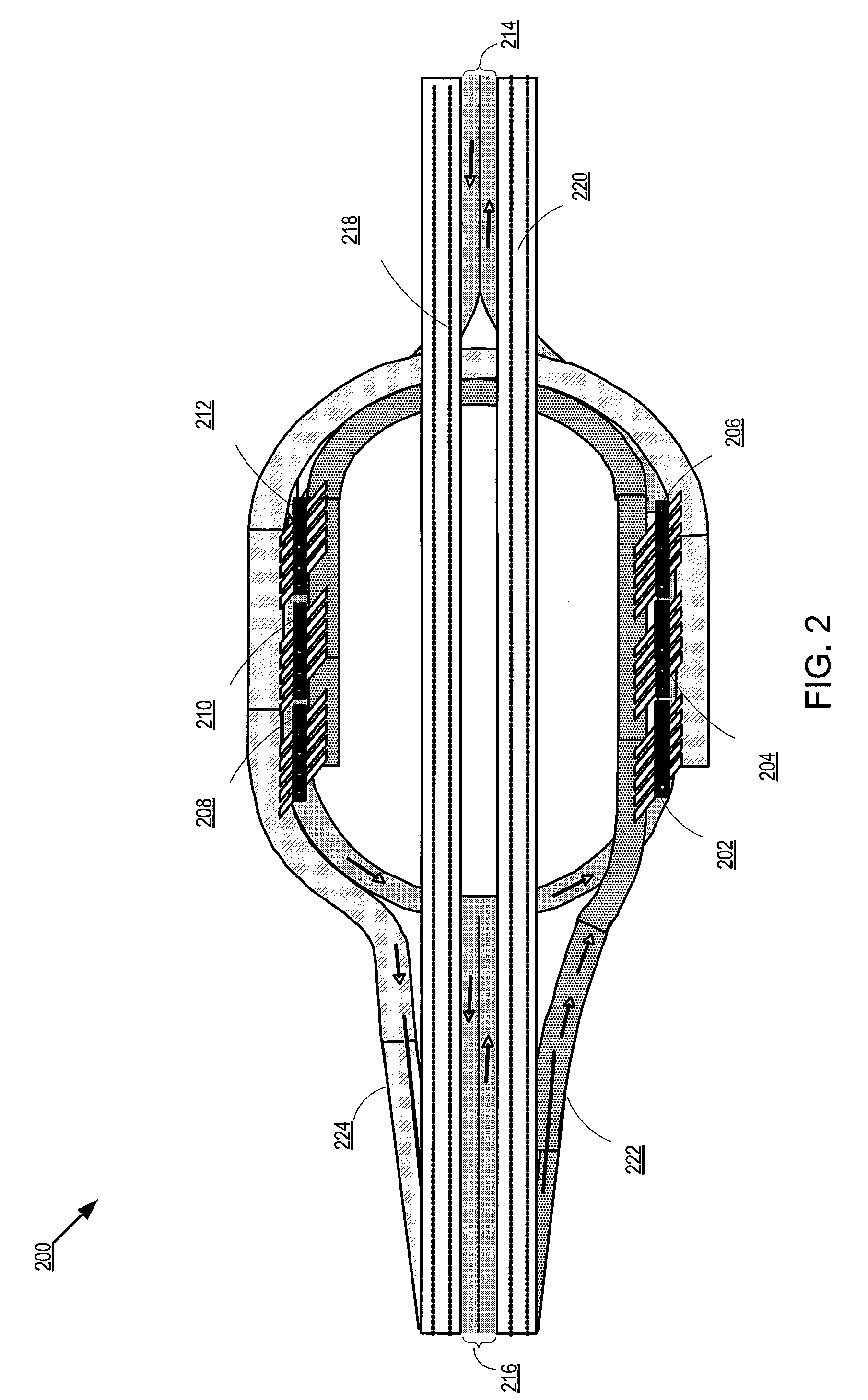

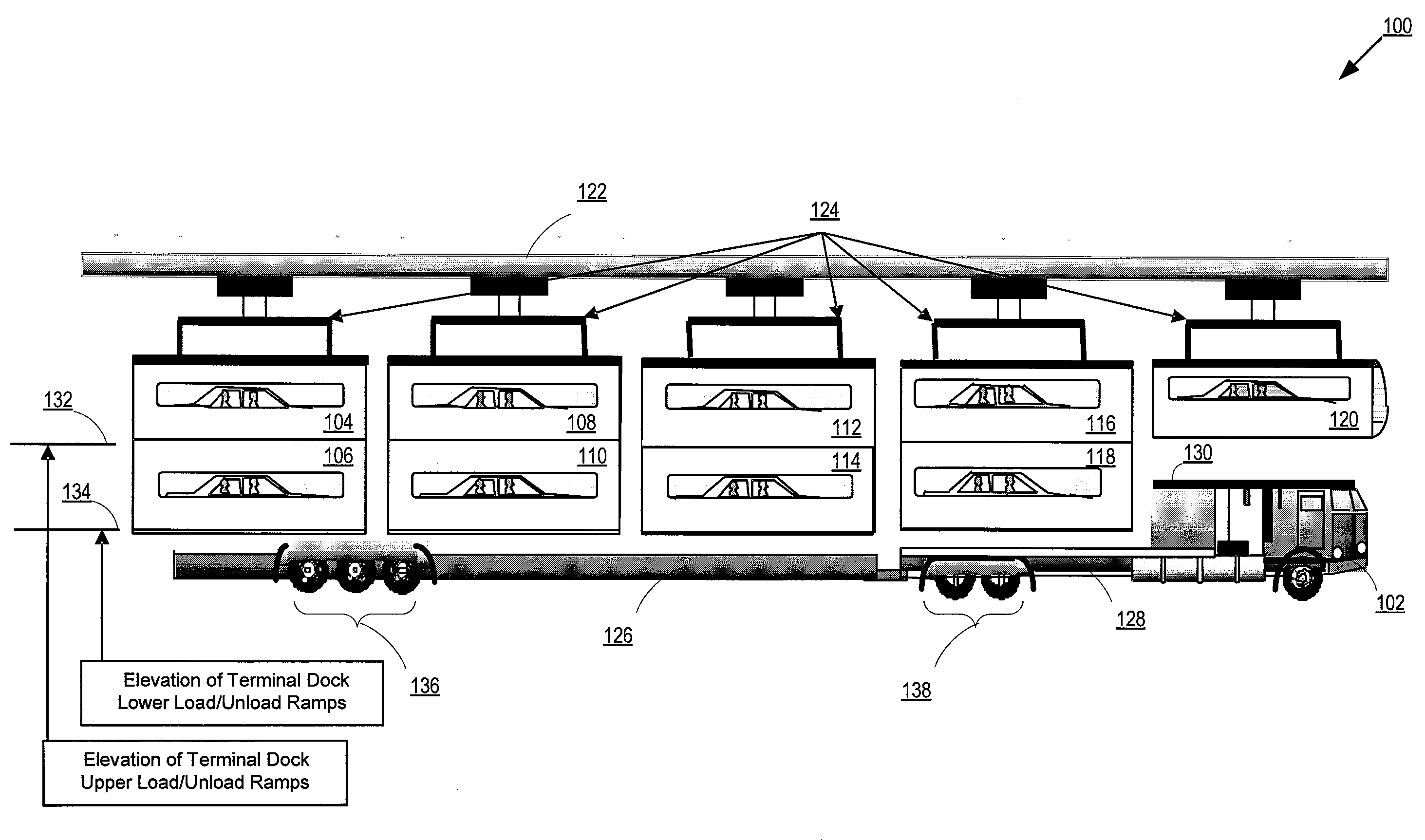

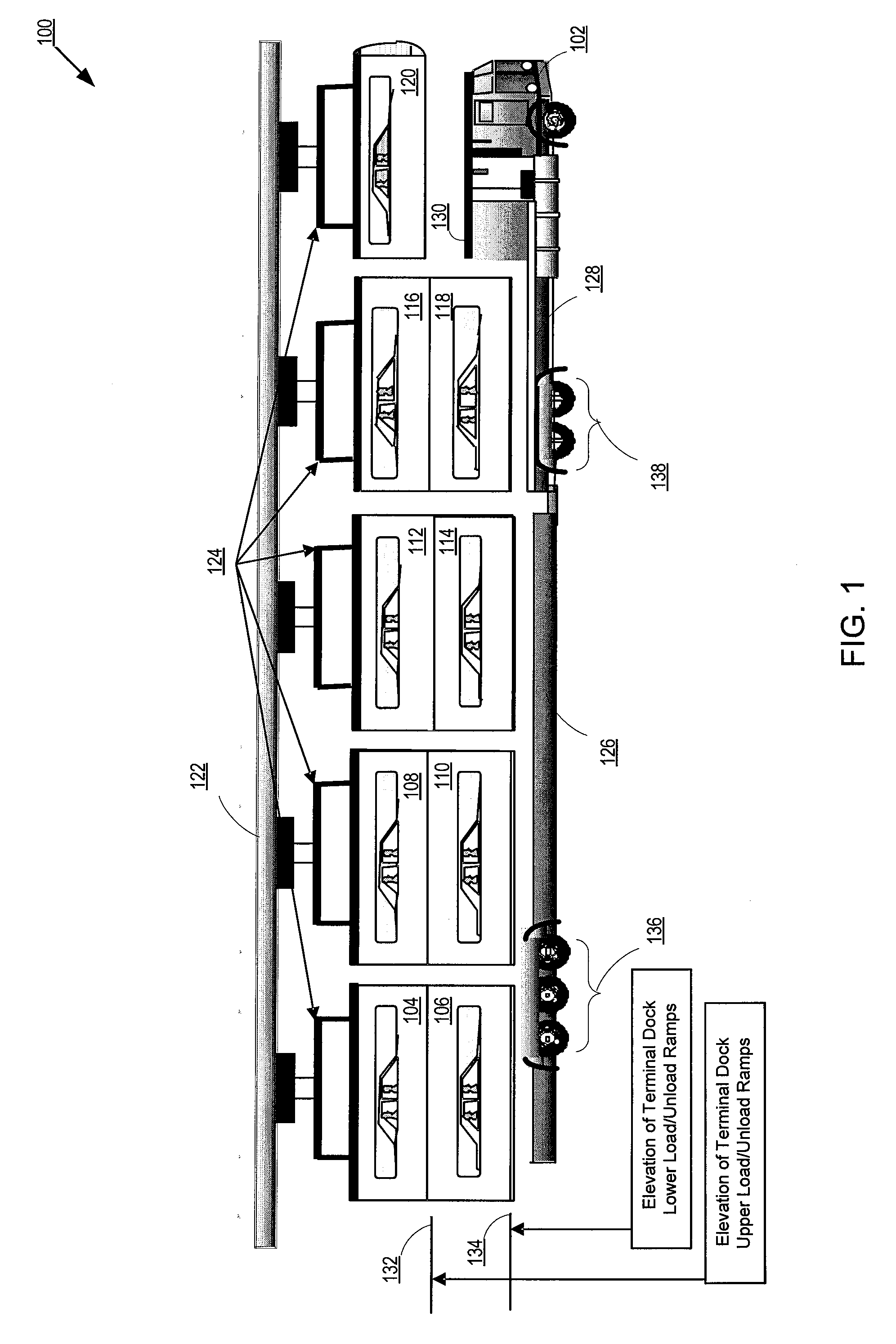

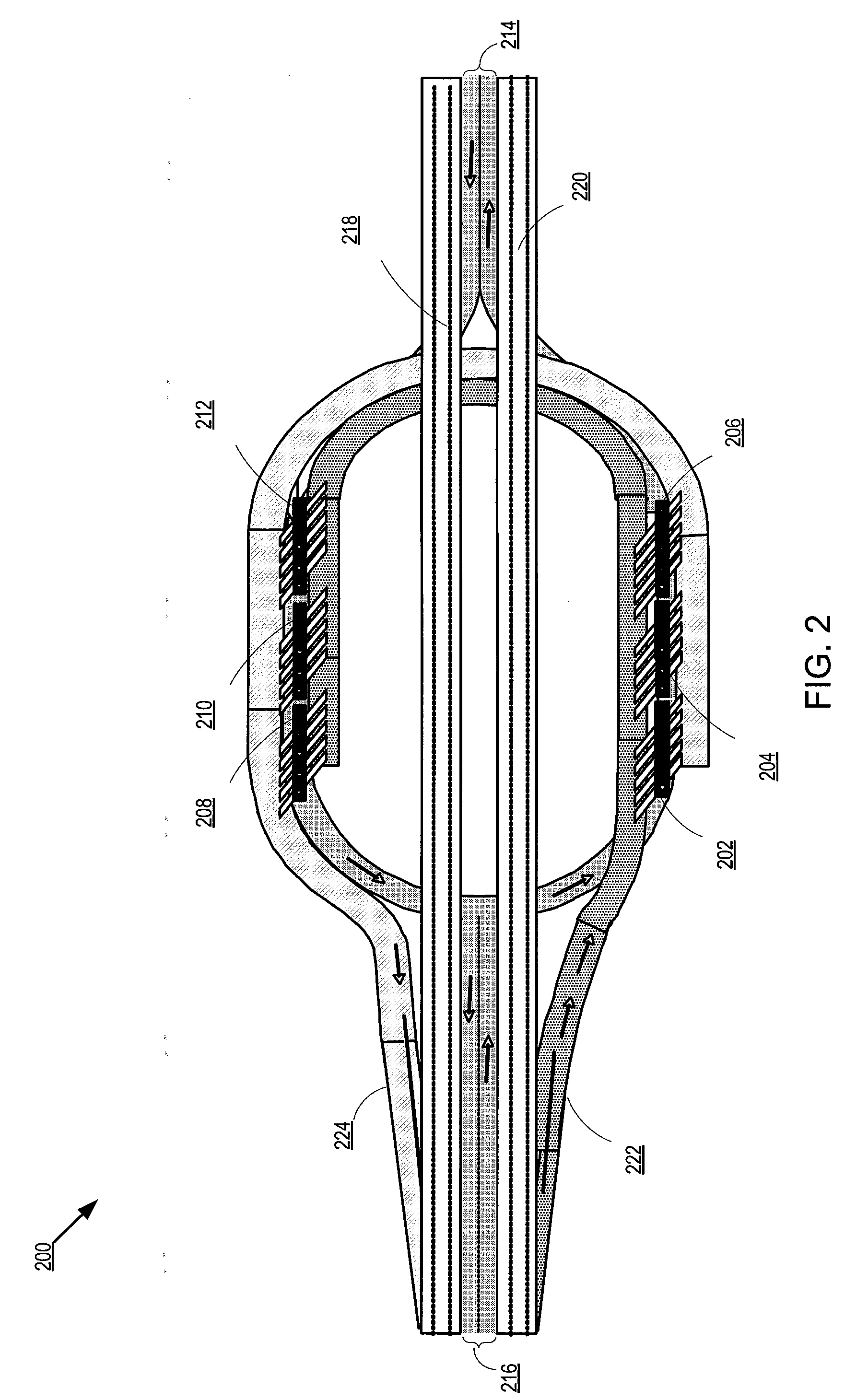

Multiple driver occupied passenger vehicles transporter system

InactiveUS8195382B2Increase flow rateTransportation safetyAnalogue computers for vehiclesAnalogue computers for trafficEngineeringTruck

The multiple driver occupied passenger vehicles transporter system (Autobus) provides a way to efficiently, economically and safely increase the highway vehicle flow rate of cars per lane per hour. Autobus employs a vehicle transporter, terminal, sensors and systems that provide a way to quickly load and unload driver occupied passenger vehicles on and off of the vehicle transporter. Autobus provides a way to safely transport multiple driver occupied passenger vehicles, including cars, sport utility vehicles (SUVs) and light trucks.

Owner:CLEAN TRANSPORT

Multiple driver occupied passenger vehicles transporter system

InactiveUS20100104392A1Increase flow rateTransportation safetyAnalogue computers for vehiclesAnalogue computers for trafficTraffic capacityDriver/operator

The multiple driver occupied passenger vehicles transporter system (Autobus) provides a way to efficiently, economically and safely increase the highway vehicle flow rate of cars per lane per hour. Autobus employs a vehicle transporter, terminal, sensors and systems that provide a way to quickly load and unload driver occupied passenger vehicles on and off of the vehicle transporter. Autobus provides a way to safely transport multiple driver occupied passenger vehicles, including cars, sport utility vehicles (SUVs) and light trucks.

Owner:CLEAN TRANSPORT

Vehicle side article transporter device

The present invention is a container for a light-duty automobile such as a light-duty pickup truck or sport-utility vehicle having at least one opening, operably associated with the quarter panel of an automobile, an inner wall operably associated with the container, and a cover having a closed position and an open position operably associated with the opening. The cover includes a door inner, and a door outer. The invention also includes a first rail positioned between the container and the quarter panel. The container is integrally formed with the first rail, and is located between the first rail and the inner wall. The first rail supports the container, and the cover can be moved from the open position to the closed position, allowing access to the container.

Owner:MAGNA INTERNATIONAL INC

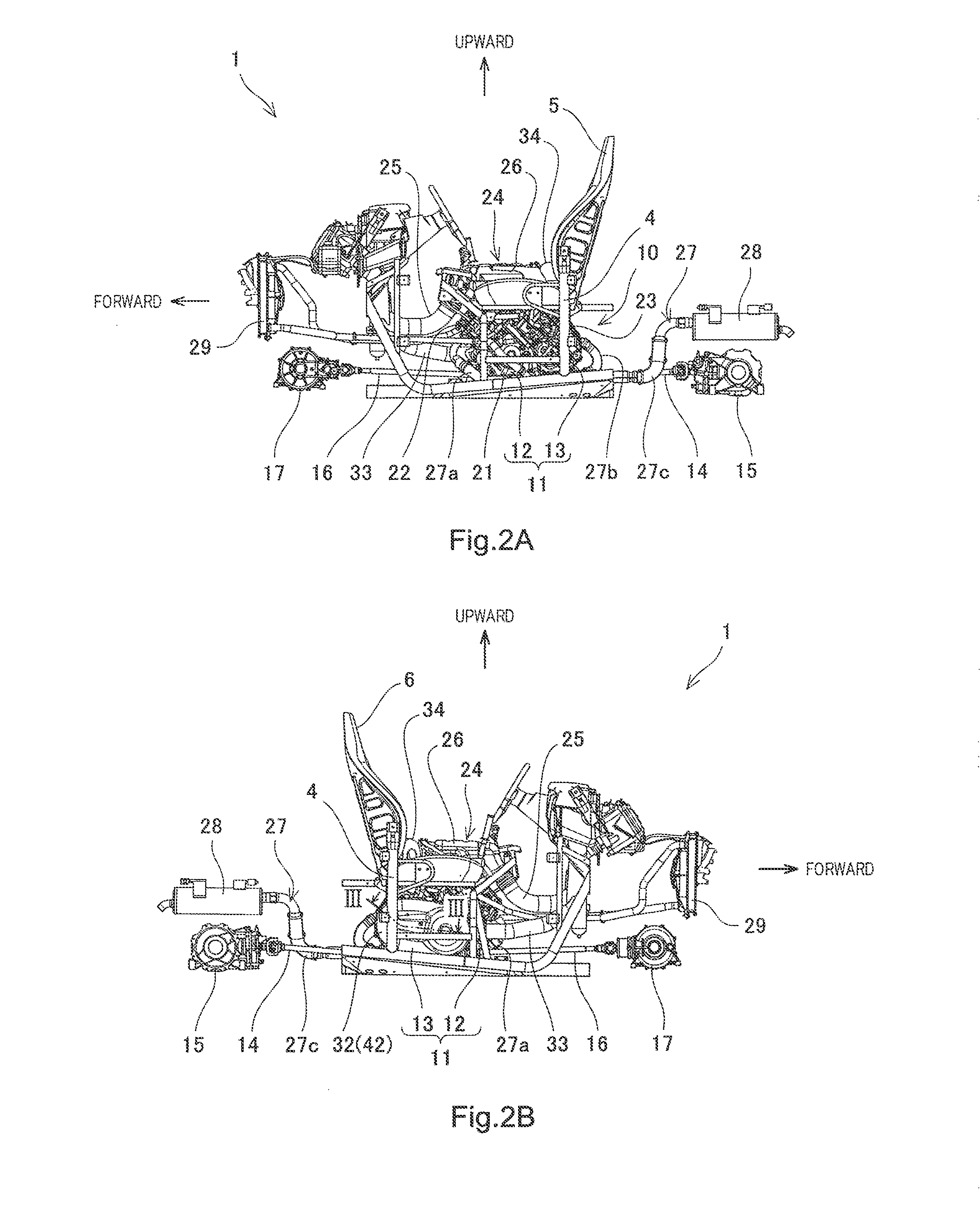

Utility vehicle

ActiveUS8596406B2Prevented from reachingAir-treating devicesRailway heating/coolingSport utility vehicleAerospace engineering

A utility vehicle is provided. The utility vehicle may include a transmission including a transmission mechanism and a transmission case assembly for accommodating the transmission mechanism; and an air discharge duct coupled to the transmission case assembly, to discharge air from inside the transmission case assembly; wherein the air discharge duct includes an upward extending portion extending substantially upward from the transmission case assembly, and a downward extending portion which is bent back at an upper end portion of the upward extending portion, and then extends substantially downward; and the upward extending portion and the downward extending portion partially overlap with each other in at least either a forward and rearward direction or a rightward and leftward direction.

Owner:KAWASAKI MOTORS LTD

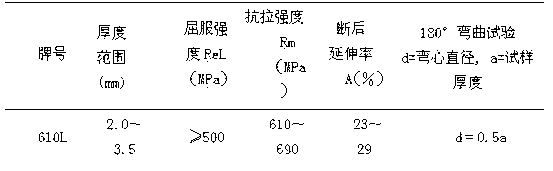

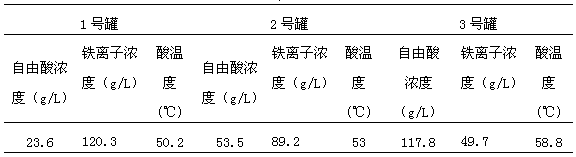

Process for producing hot-rolled acid-pickled 610 L automobile frame steel strip with thin gauge and high elongation

The invention relates to a process for producing a hot-rolled acid-pickled 610 L automobile frame steel strip with thin gauge and high elongation and belongs to the technical field of production processes of steel for automobiles. According to the technical scheme, the process specifically comprises a hot rolling production process and an acid pickling process of an automobile frame steel strip, wherein the hot rolling process comprises the steps of heating, rolling, cooling and the like; and the acid pickling process comprises the following steps of: performing three-section continuous hydrochloric acid pickling and five-section water rinsing on the automobile frame steel strip on a continuous acid pickling production line so that the acid-pickled automobile frame steel strip with gray or offwhite surface and metallic luster on the surface can be obtained; next, drying the surface of the acid-pickled automobile frame steel strip and electrostatically spraying anti-rust oil on both sides of the steel strip, and then coiling and packing the automobile frame steel strip to obtain the finished product. The thin-gauge 610 L automobile frame steel produced by using the process disclosed by the invention is used for substituting 510 L automobile frame steel, so that the thickness of a used steel plate as well as the weight of the whole automobile and fuel consumption of the automobile are reduced while the strengths of the frame and related parts are improved; and therefore, the hot-rolled acid-pickled 610 L automobile frame steel strip provided by the invention plays an important role in reducing the weight of vehicles such as SUV (Sport Utility Vehicle) vehicle and pickup truck. Besides, the acid-pickled surface has metallic luster and thereby has excellent electrophoretic paint coating performance.

Owner:HEBEI IRON AND STEEL

Utility vehicle

ActiveUS7874606B2Cargo bed is simpleConvenient spacingUnderstructuresSuperstructure subunitsVehicle frameEngineering

A utility vehicle includes a vehicle body frame, a pair of left and right front wheels and at least a pair of left and right rear wheels that are supported on the vehicle frame, a front seat that is provided to the rear of the front wheels, and a rear seat that is provided to the rear of the front seat and including an in-use position, a transition position, and a non-use position. A cargo bed, disposed to the rear of the front seat includes a bottom wall portion whereon the seat cushion portion of the rear seat is provided movably; a left side wall portion and a right side wall portion that are provided on the left and right side portions of the bottom wall portion, wherein the left side wall portion and the right side wall portion extend forward to the rear seat in its non-use position; and a rear wall portion that is provided at the rear end portion of the bottom wall portion. The utility vehicle further includes a rear floor provided between the front seat and the rear seat and lower than the bottom wall portion of the cargo bed.

Owner:YAMAHA MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com