Patents

Literature

214 results about "Engine configuration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The engine configuration describe the fundamental operating principles by which internal combustion engines are categorised. Piston engines are often categorised by their cylinder layout, valves and camshafts. Wankel engines are often categorised by the number of rotors present. Gas turbine engines are often categorised into turbojets, turbofans, turboprops and turboshafts.

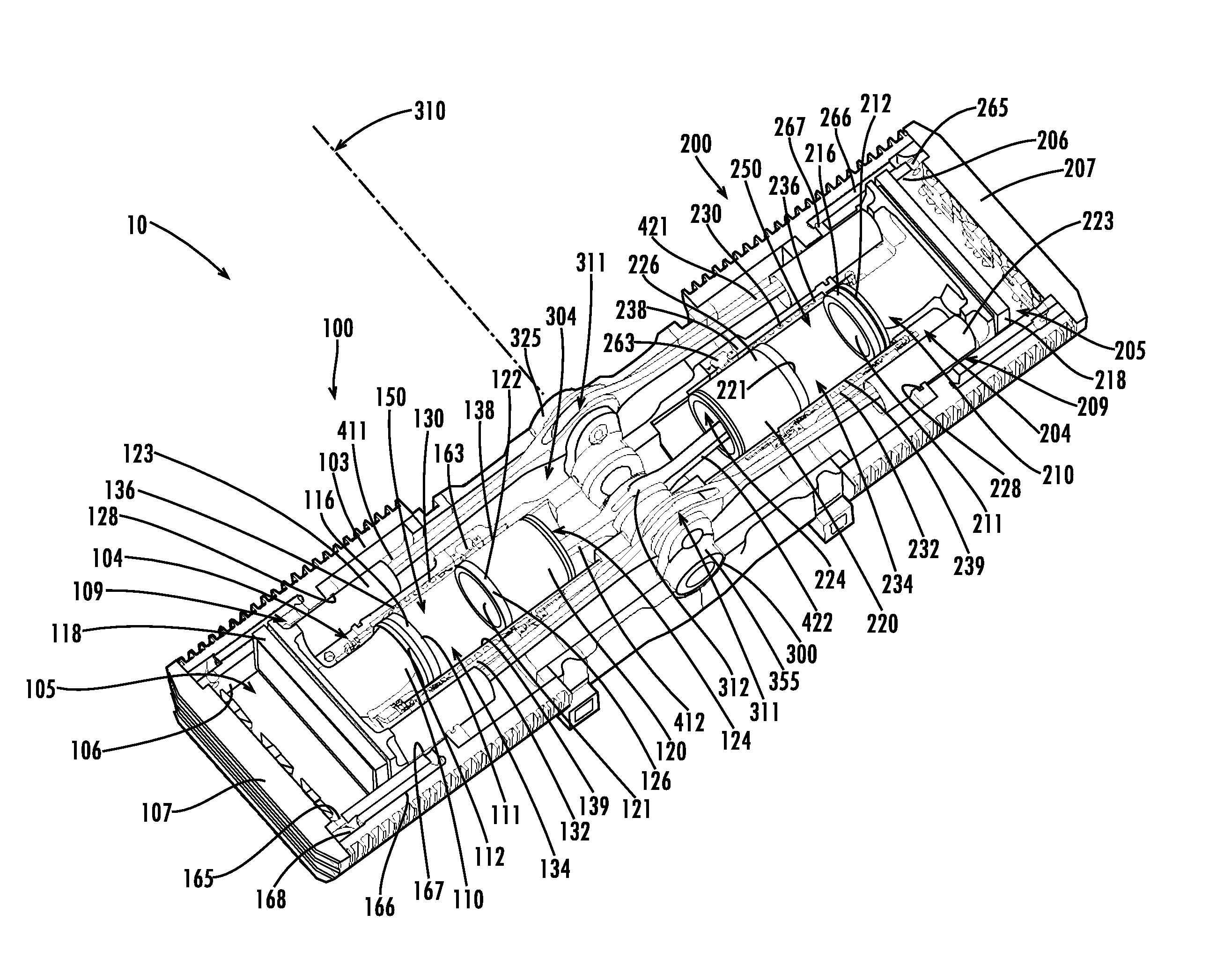

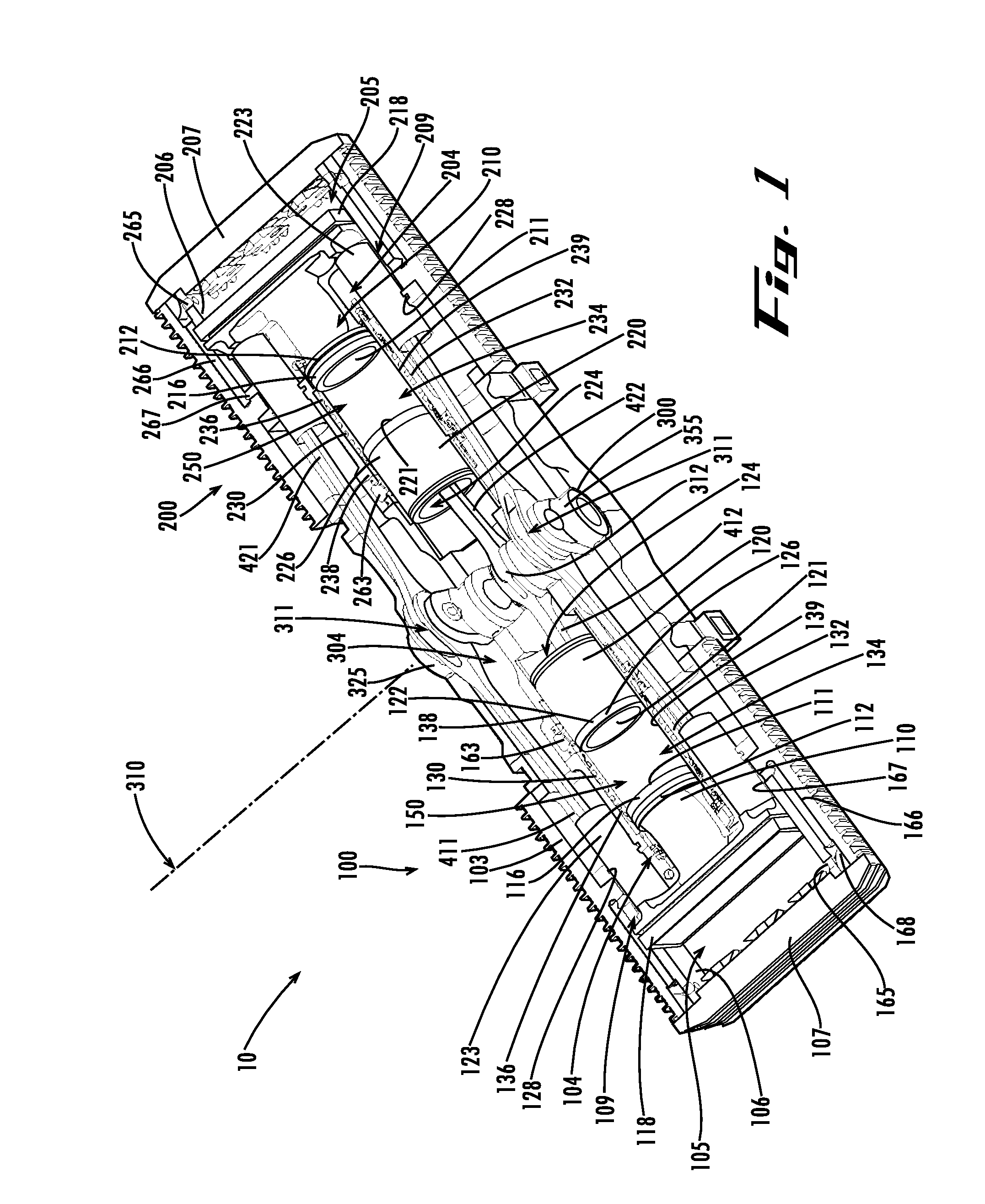

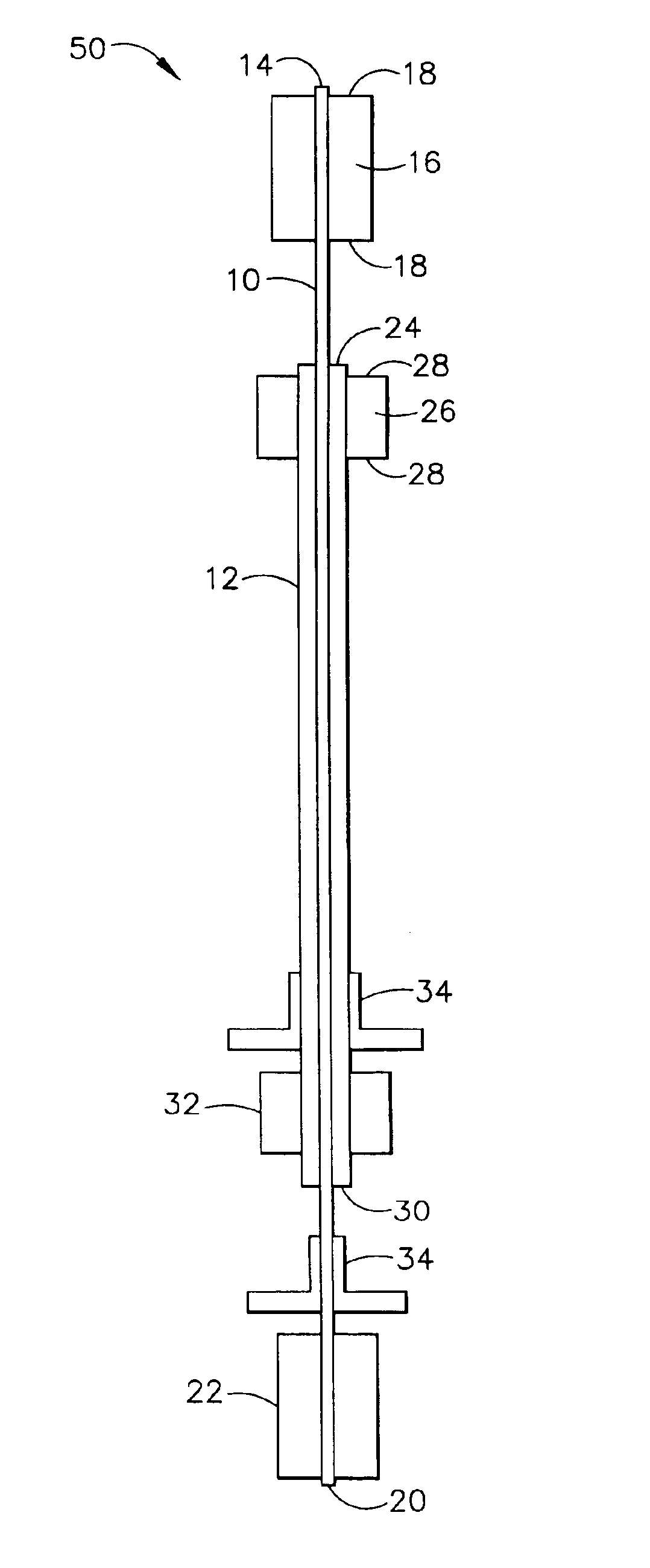

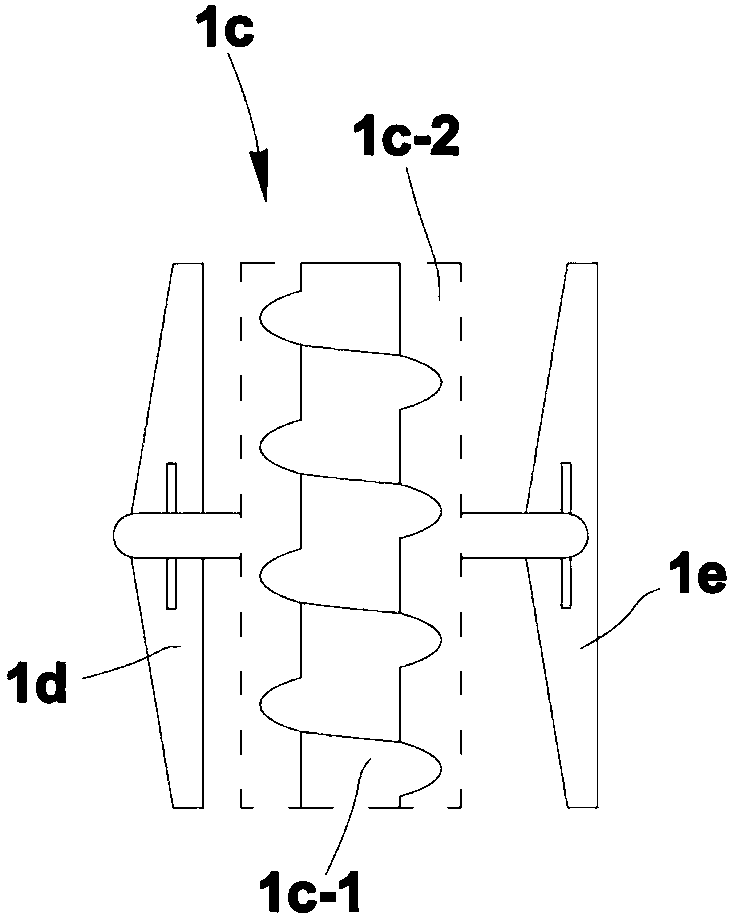

Internal combustion engine with a single crankshaft and having opposed cylinders with opposed pistons

InactiveUS6170443B1MiniaturizationEliminates dynamic imbalanceCombustion enginesReciprocating piston enginesExternal combustion engineEngineering

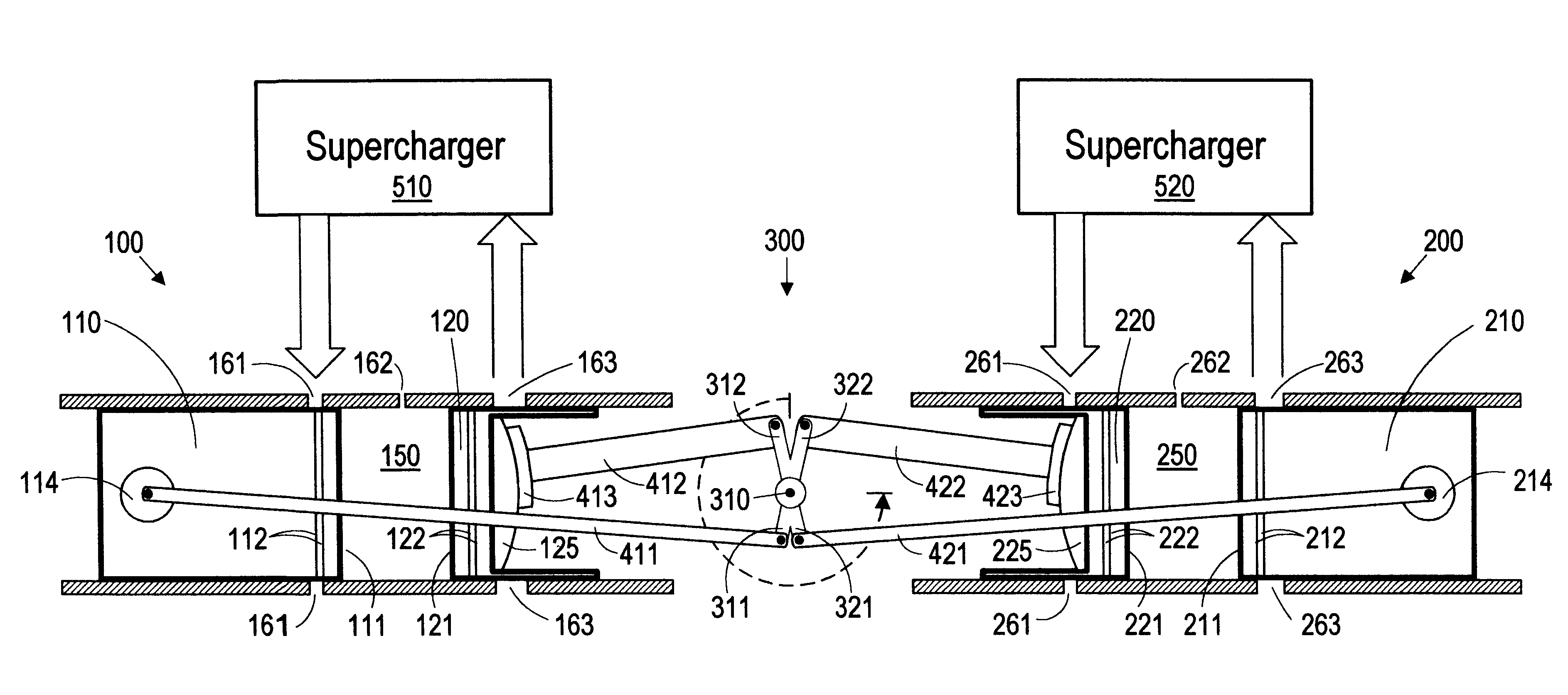

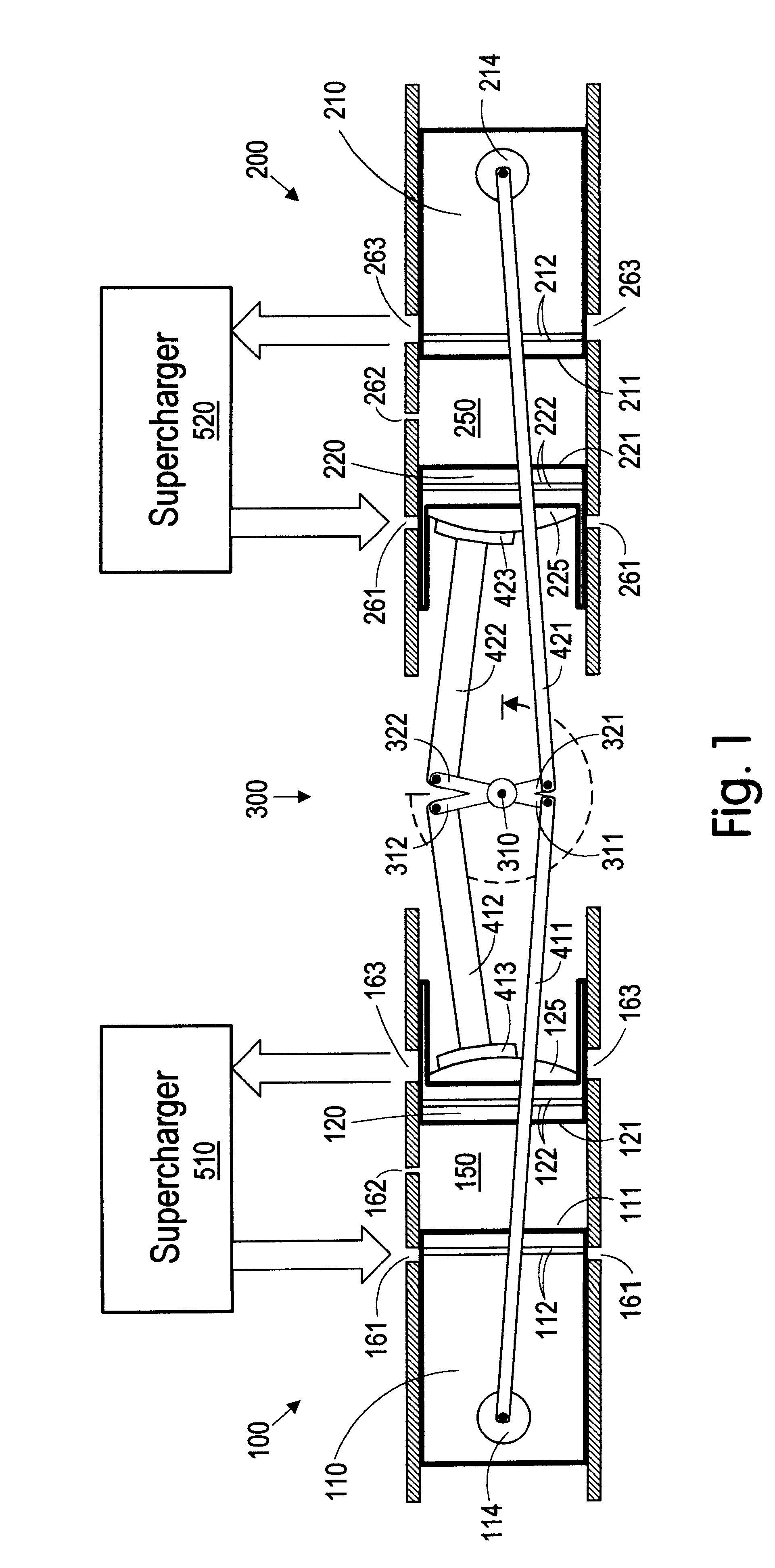

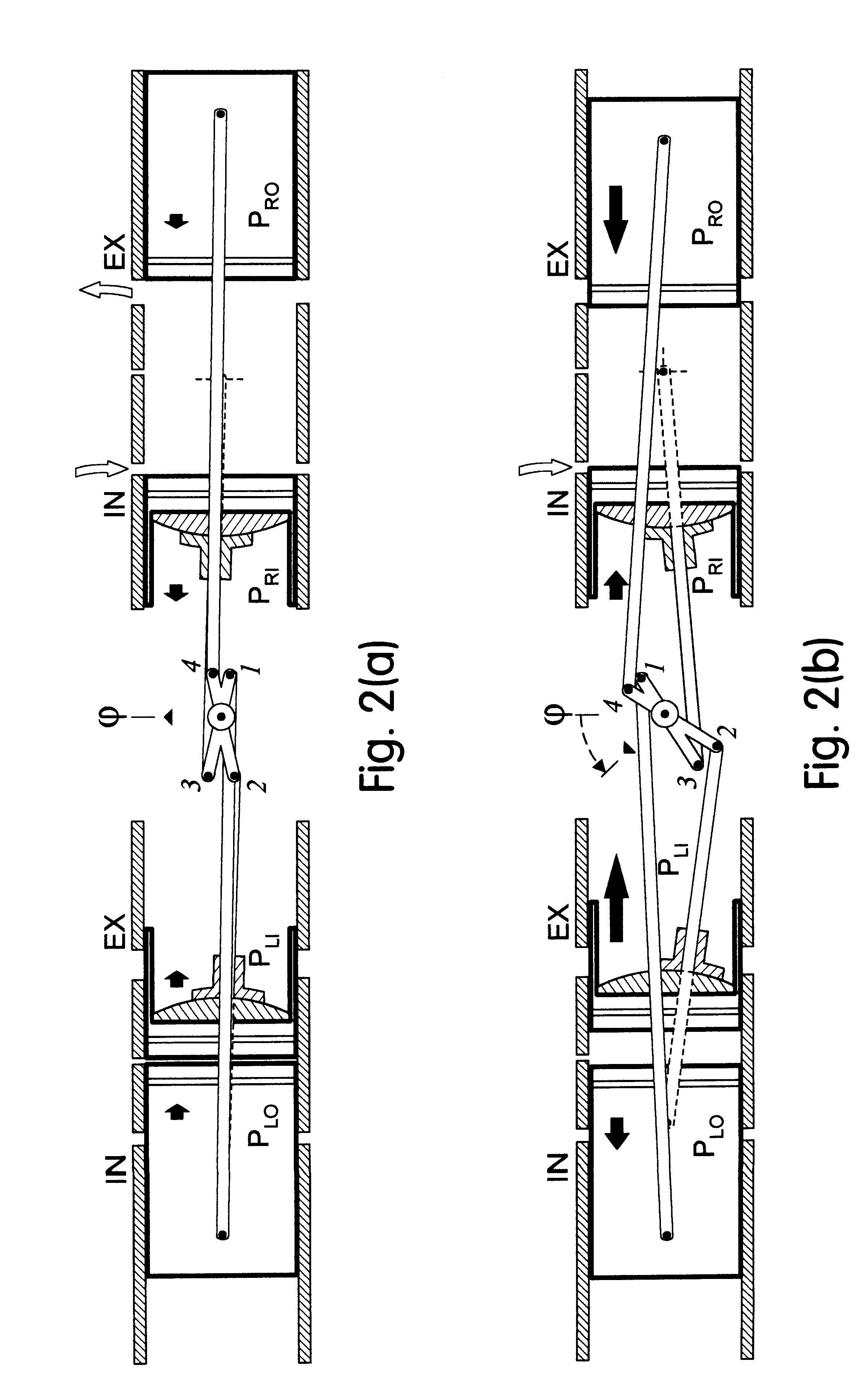

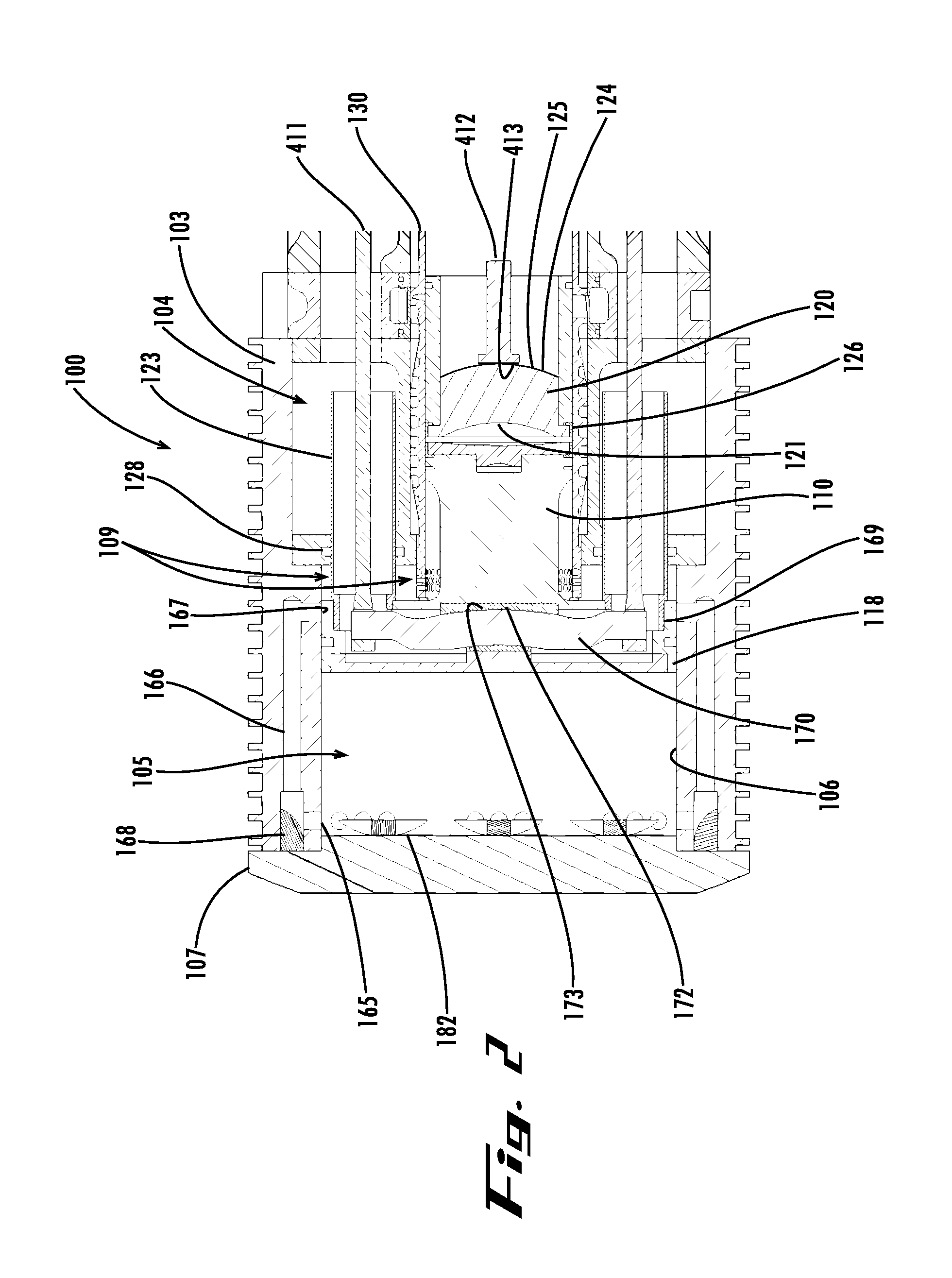

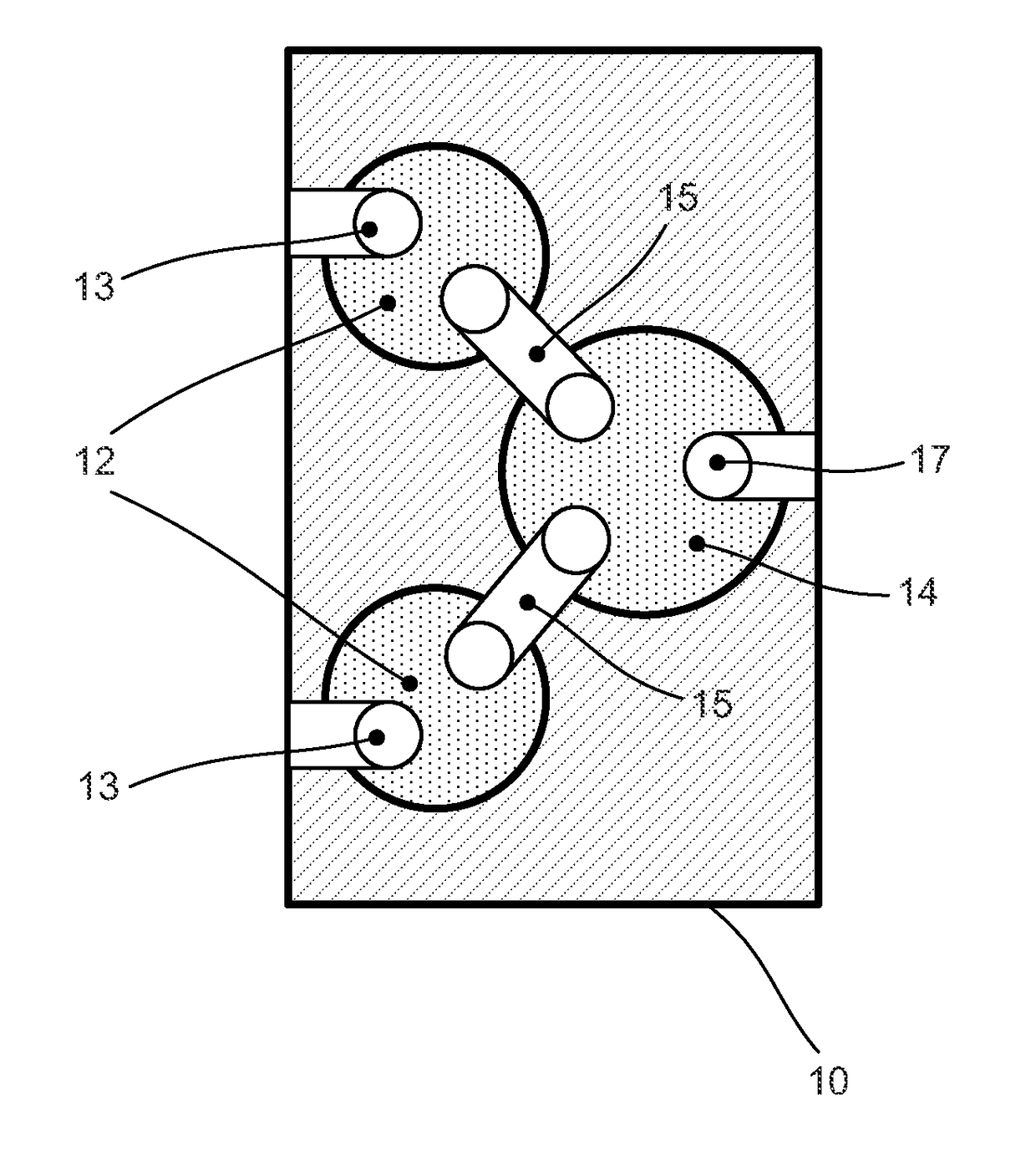

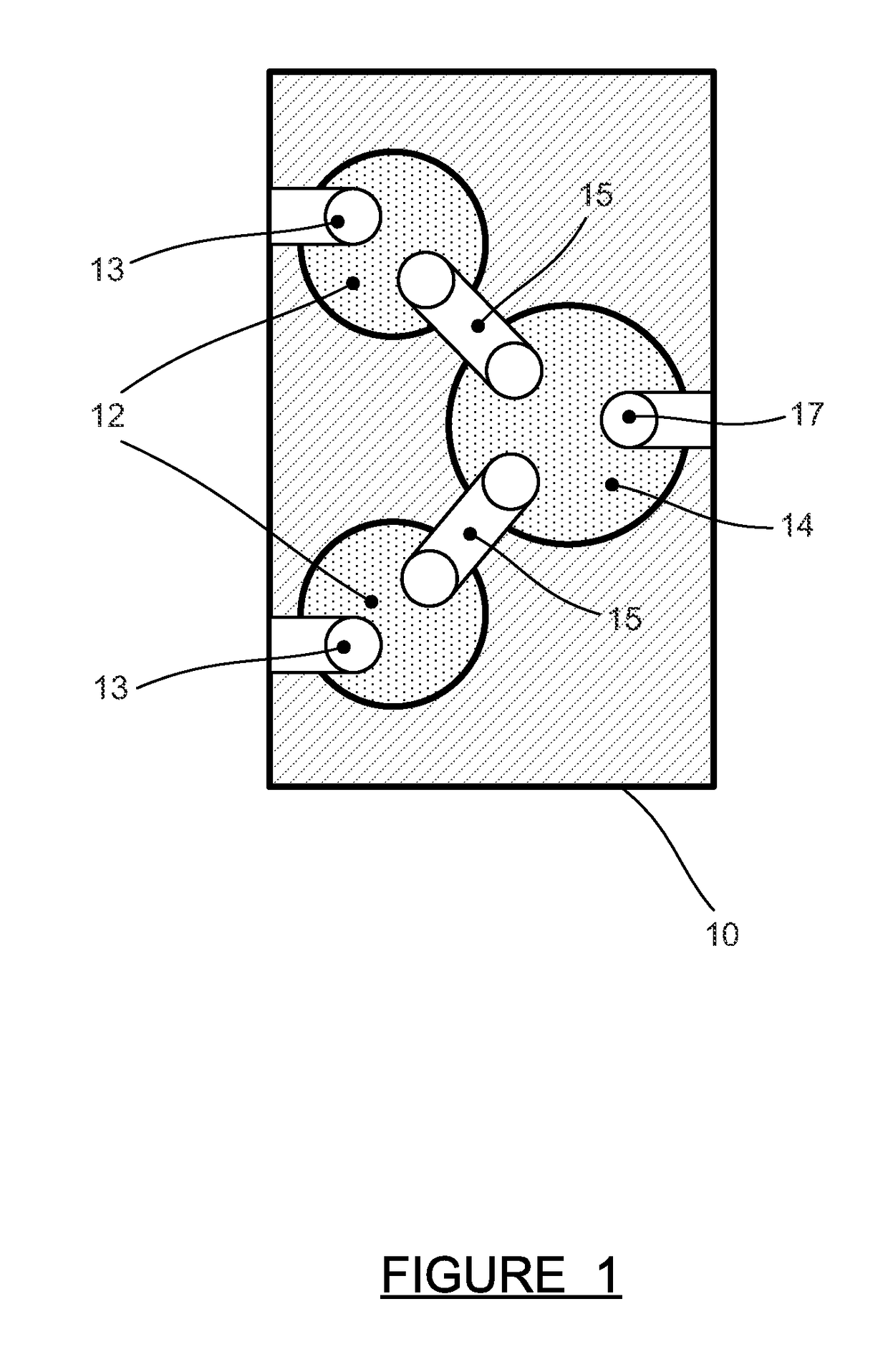

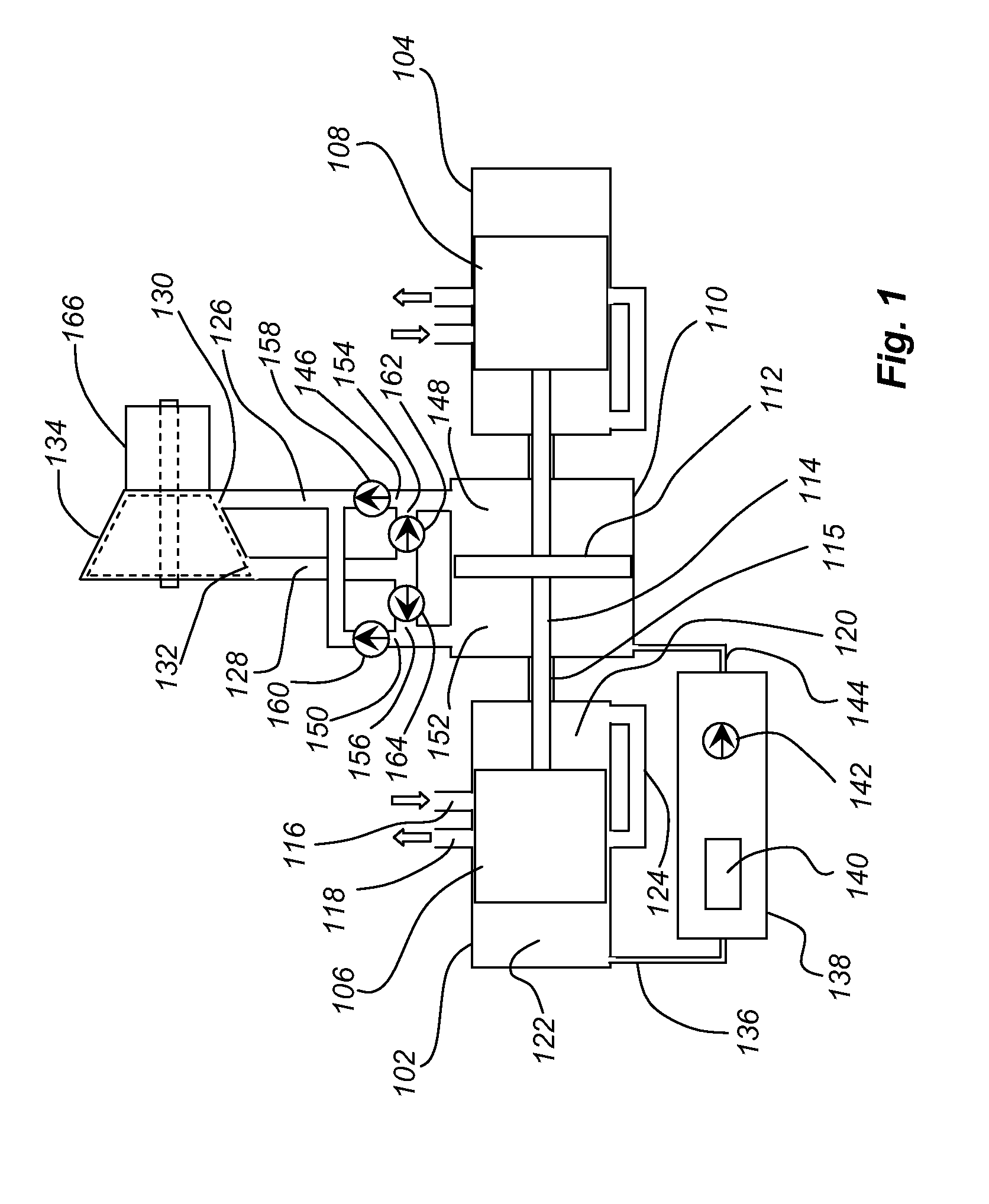

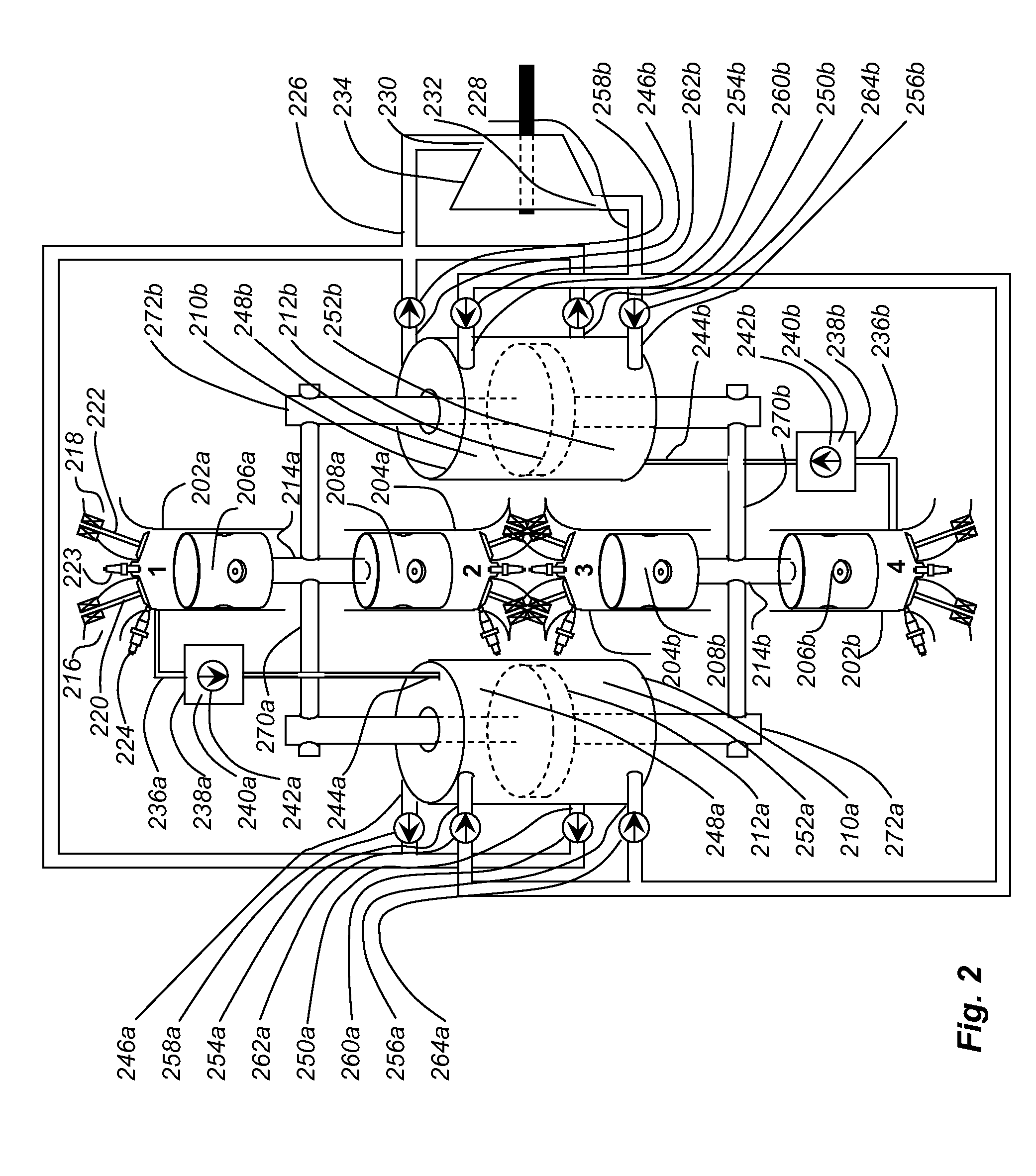

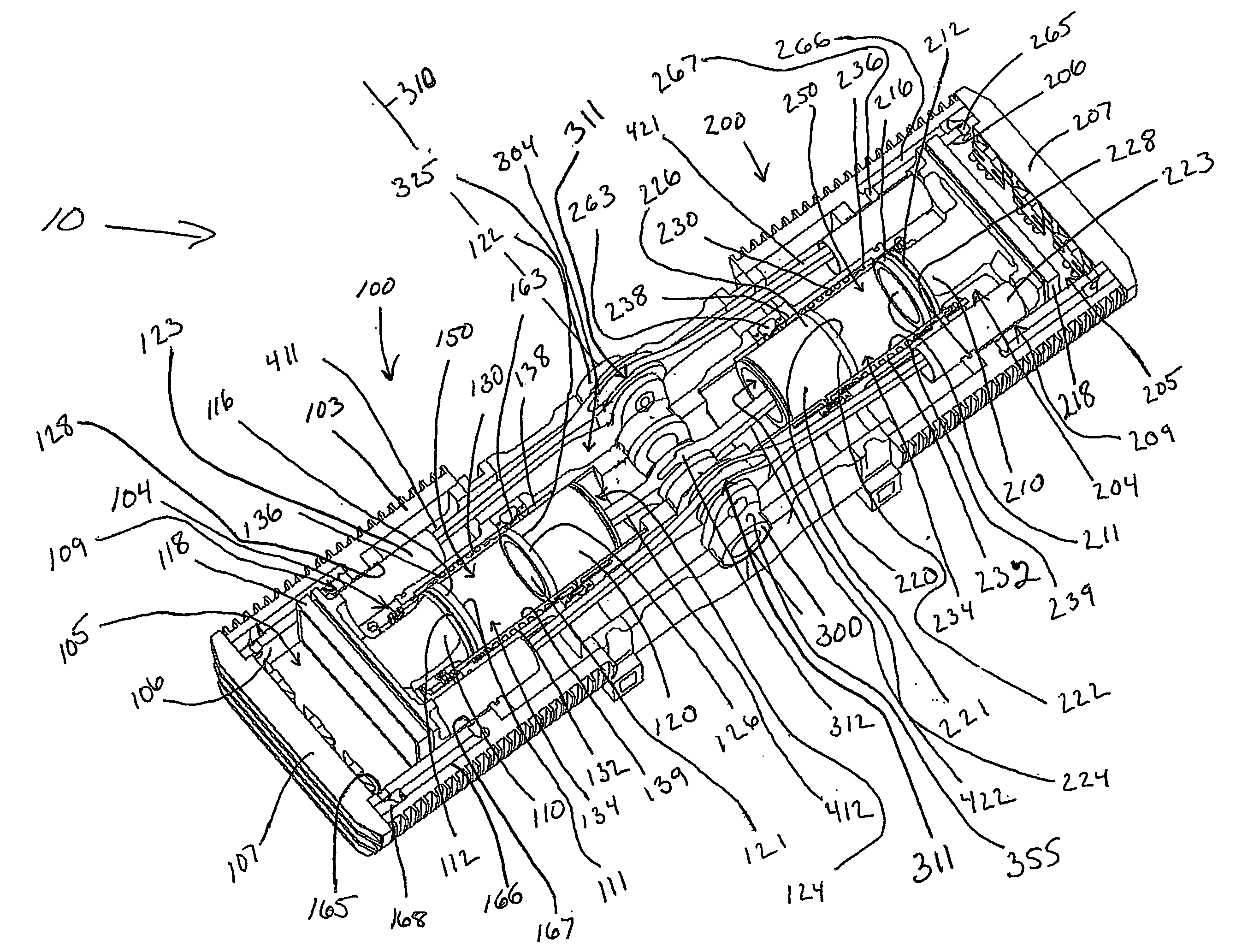

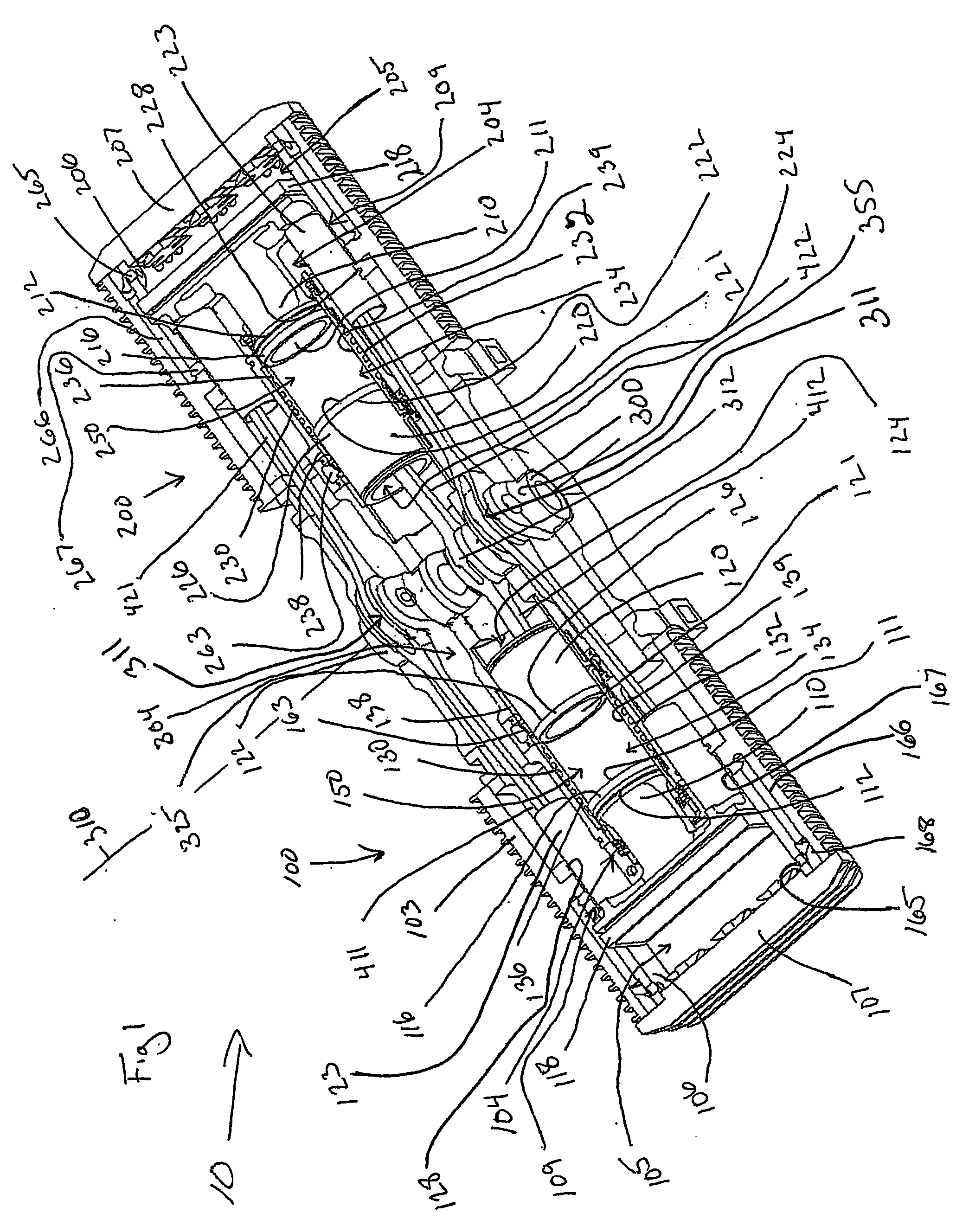

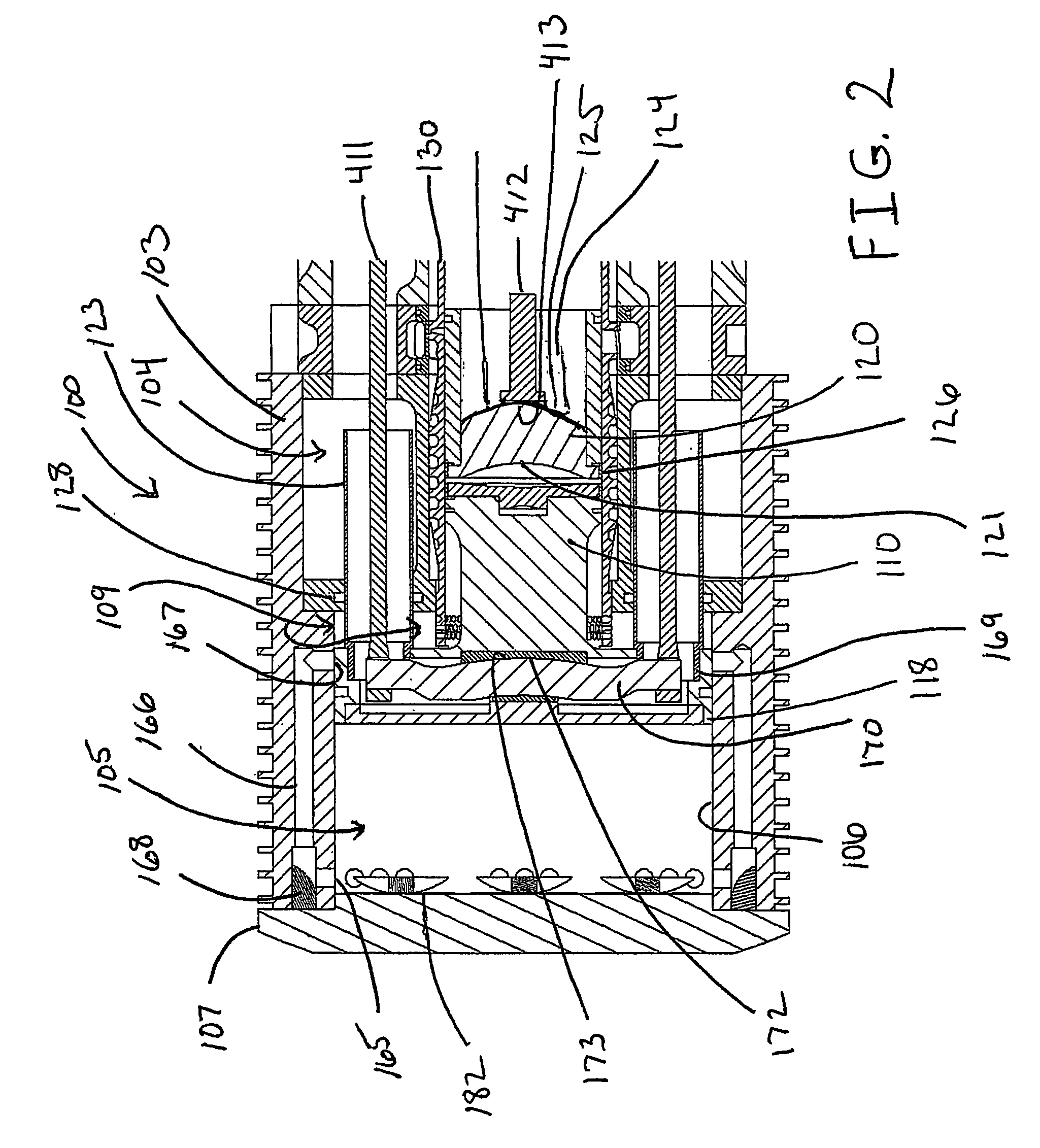

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. This configuration results in a compact engine with a very low profile, in which the free mass forces can be essentially totally balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through independent angular positioning of the eccentrics on the crankshaft, making the engine suitable for supercharging.

Owner:ADVANCED PROPULSION TECH +1

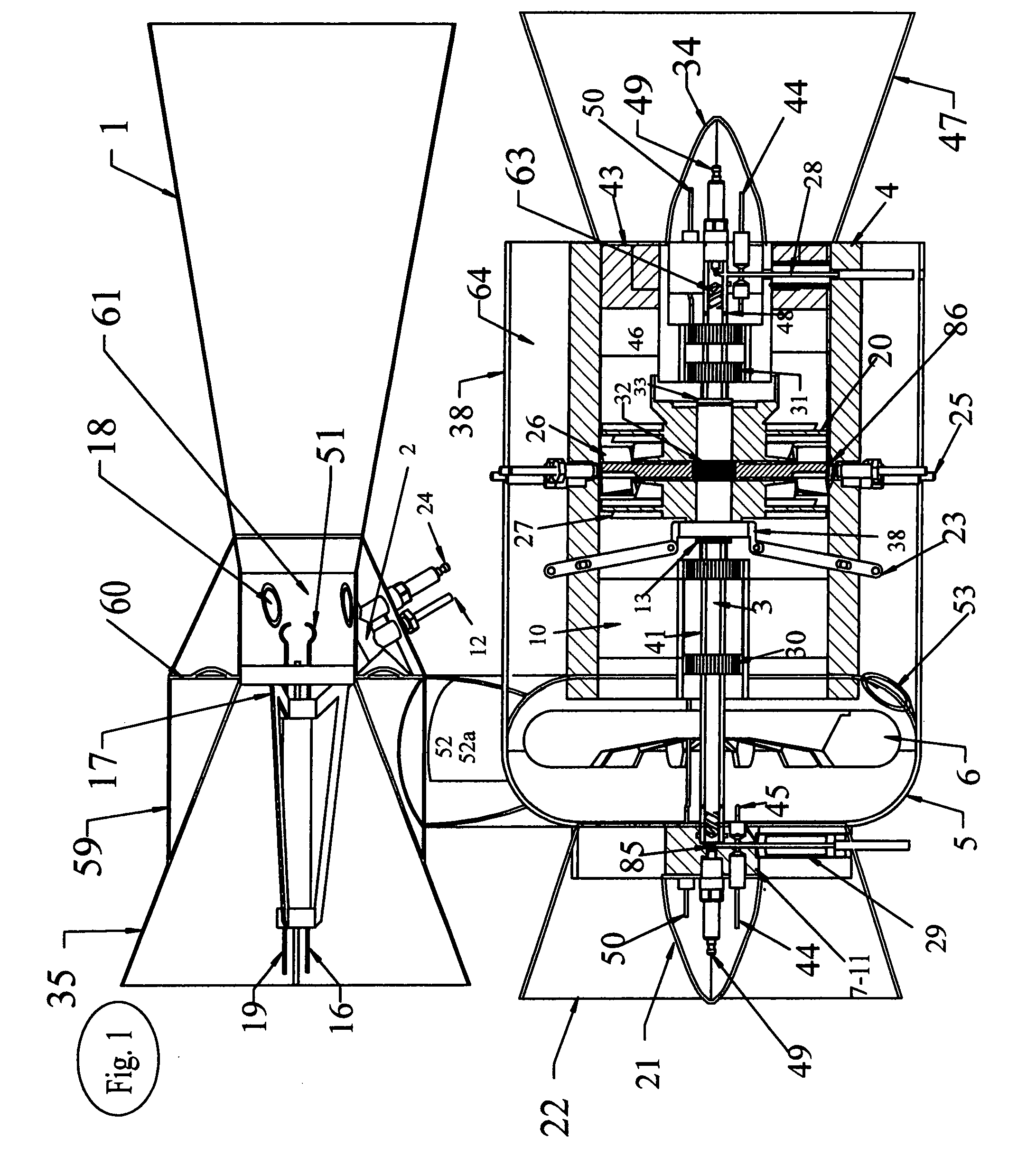

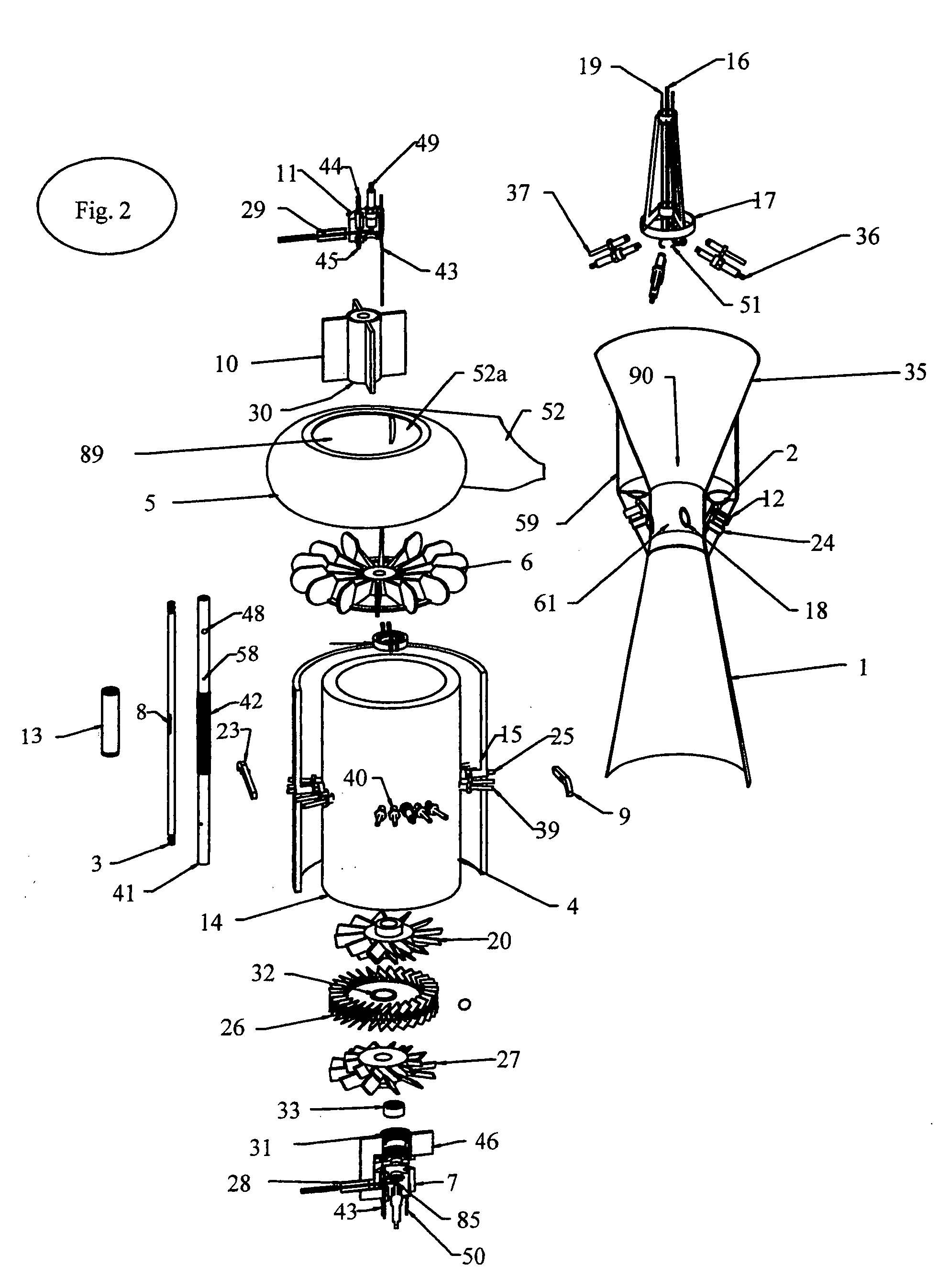

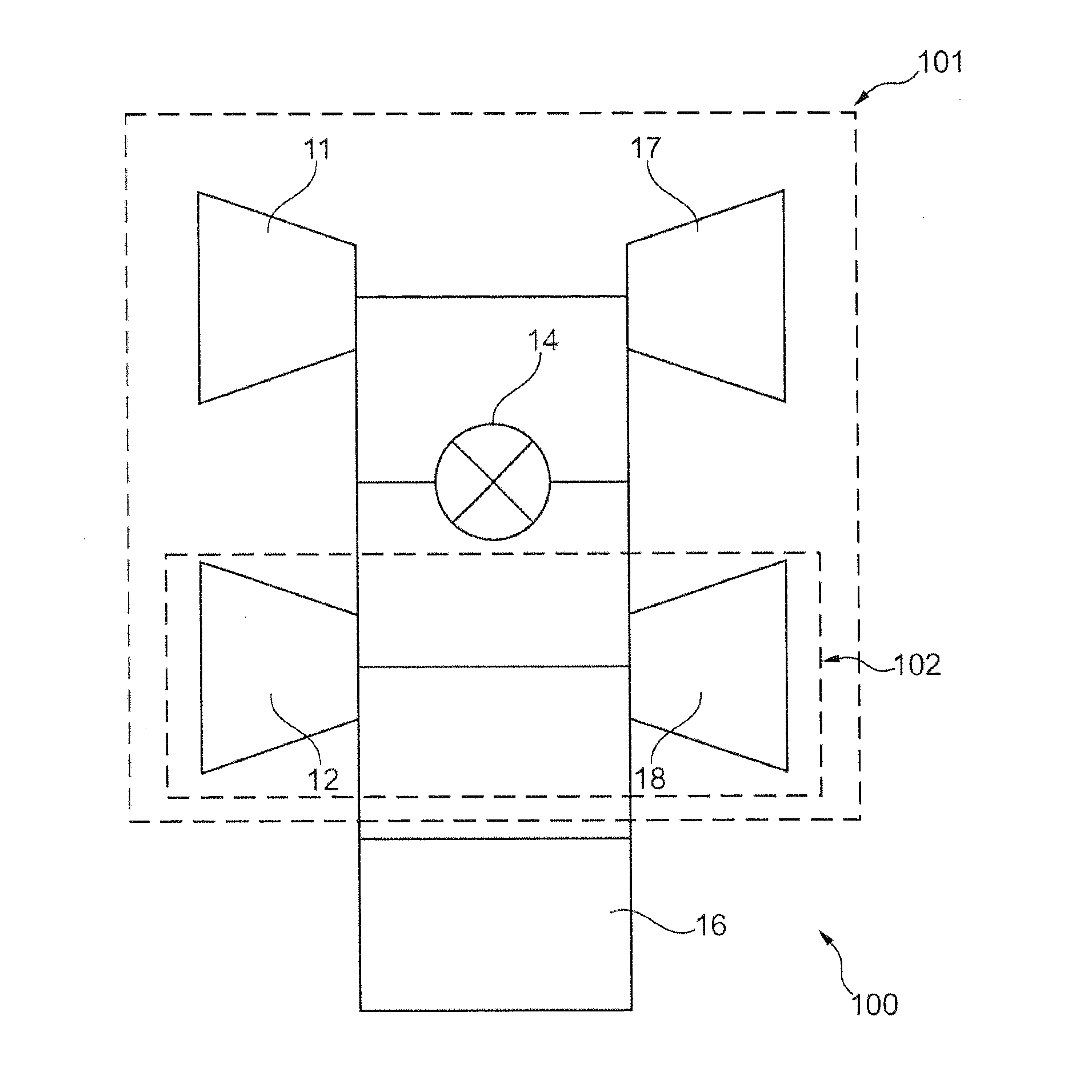

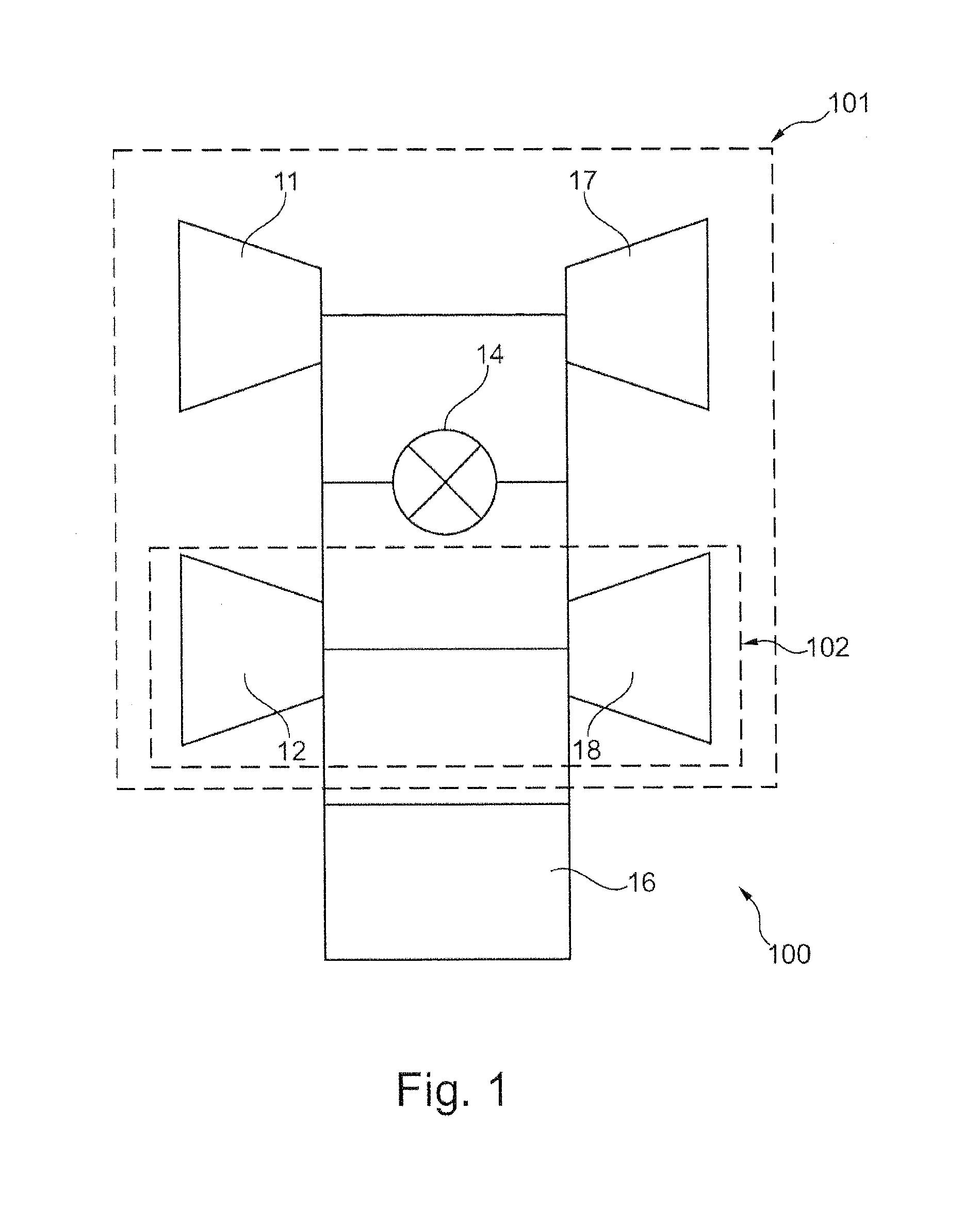

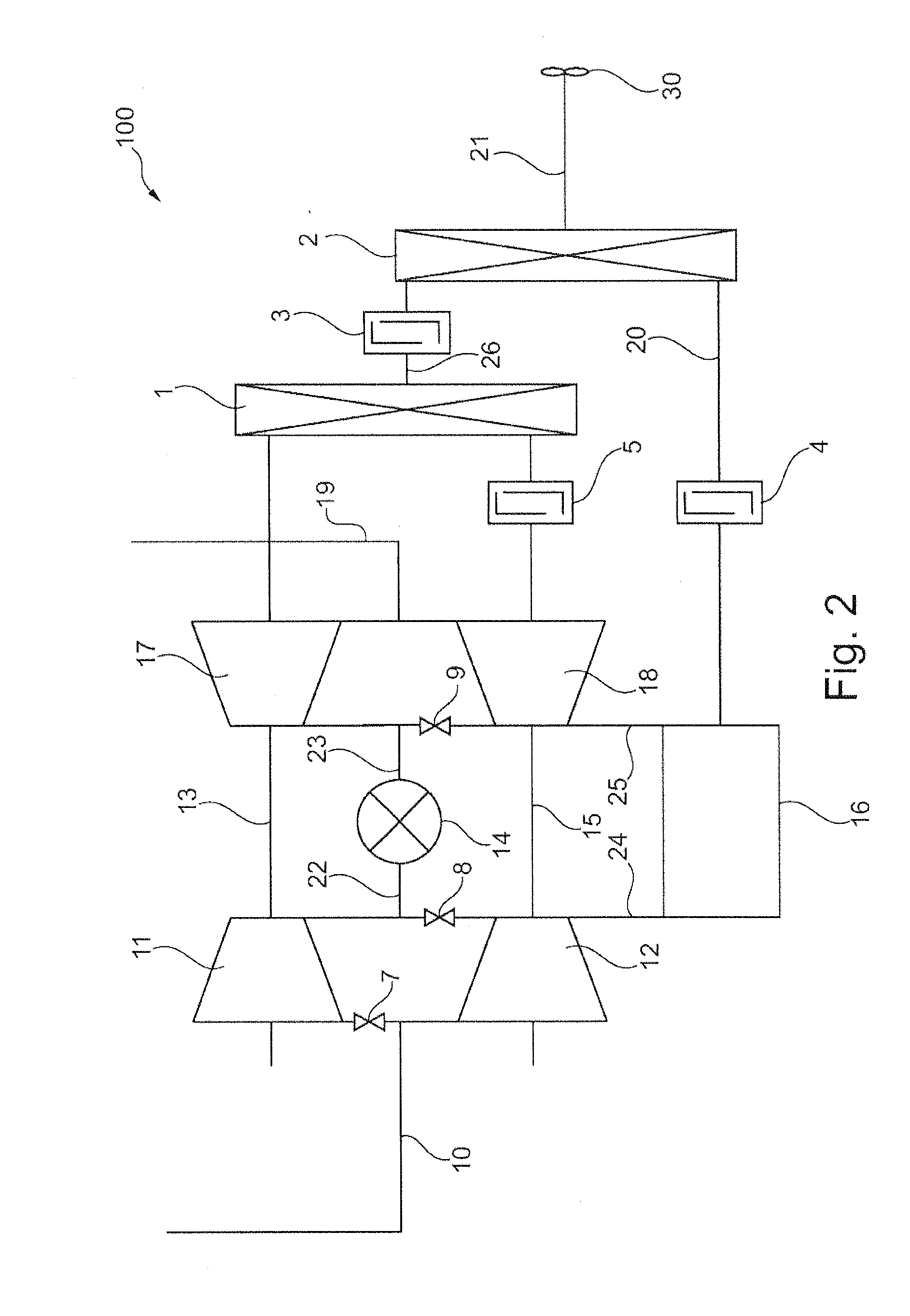

Methods of combining a series of more efficient aircraft engines into a unit, or modular units

InactiveUS20100251692A1More thermal capacityReduce environmental pollutionContinuous jet plantsRocket engine plantsRamjetFree-piston engine

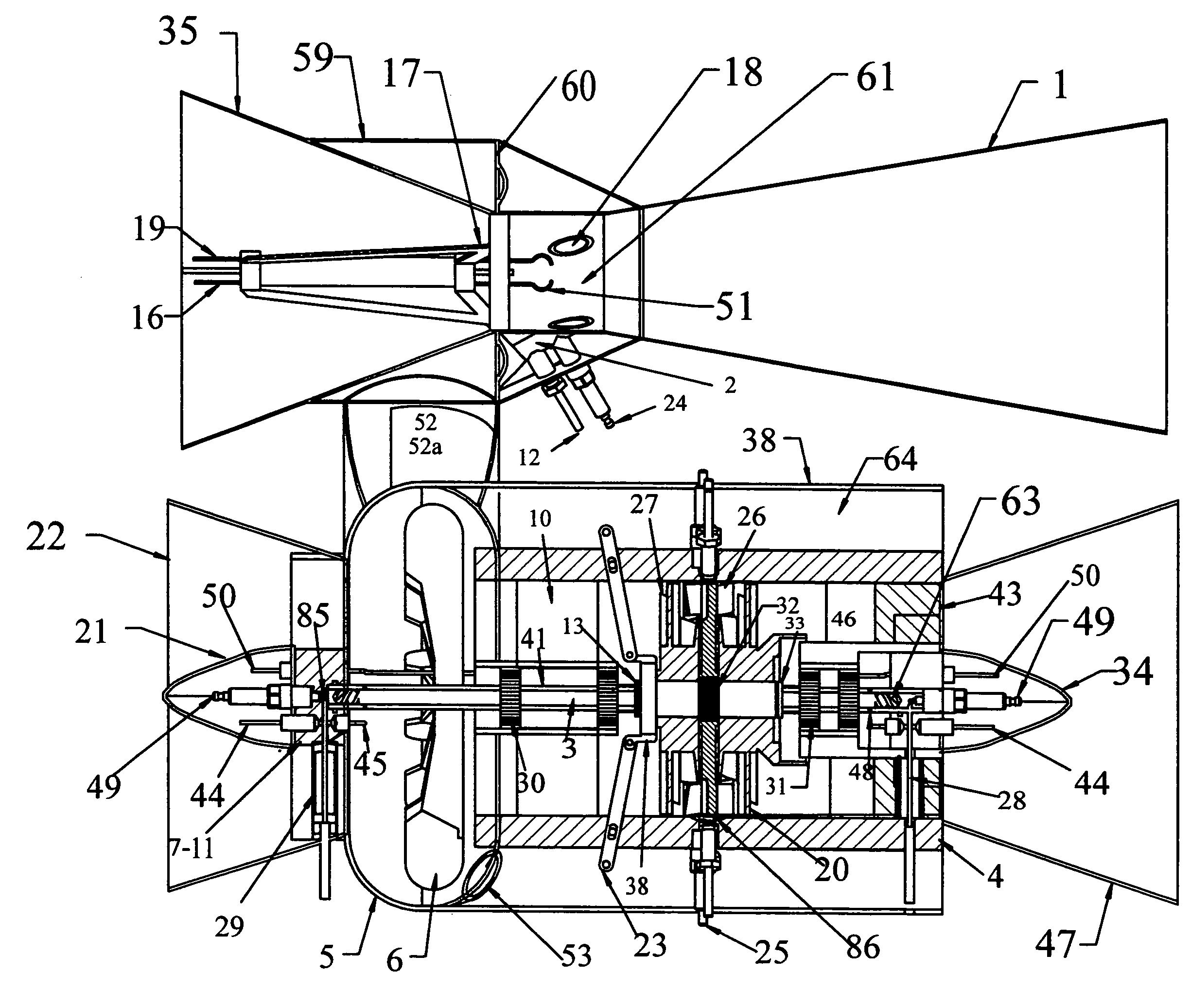

The present invention generally relates to units of engines and more particularly to units containing a unique combined-cycle (combustion-detonation) “counter-rotation, anti-gyration, gyroscopic,” turbine fan-jet / free-piston engine configuration for induced air supercharging and boosting the performance of novel Ramjet engines or Ramjet engine configurations by improving internal air-stream dynamics. These dynamics are the result of co-operative air stream intermixing through convergent, supercharge-attenuated, inducted, compressed, tuned, pre-heated ambient air. Achieved through the varying of the geometric structural form and the utilization of unique engines and air induction and propulsion conformations, aided with supplemental air, fuel, oxygen and optiomal water and electrolyte charging.

Owner:KINDE SR RONALD AUGUST

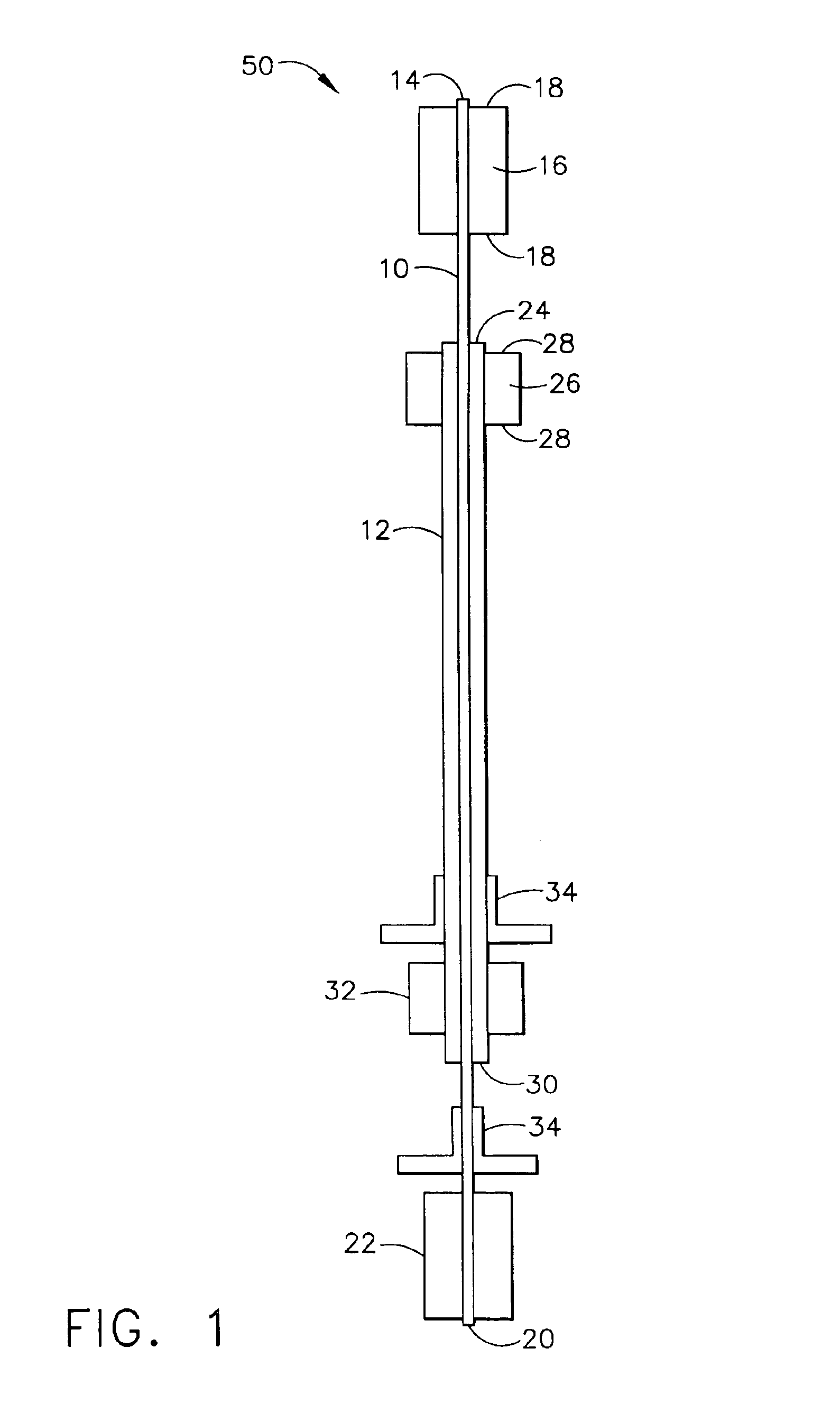

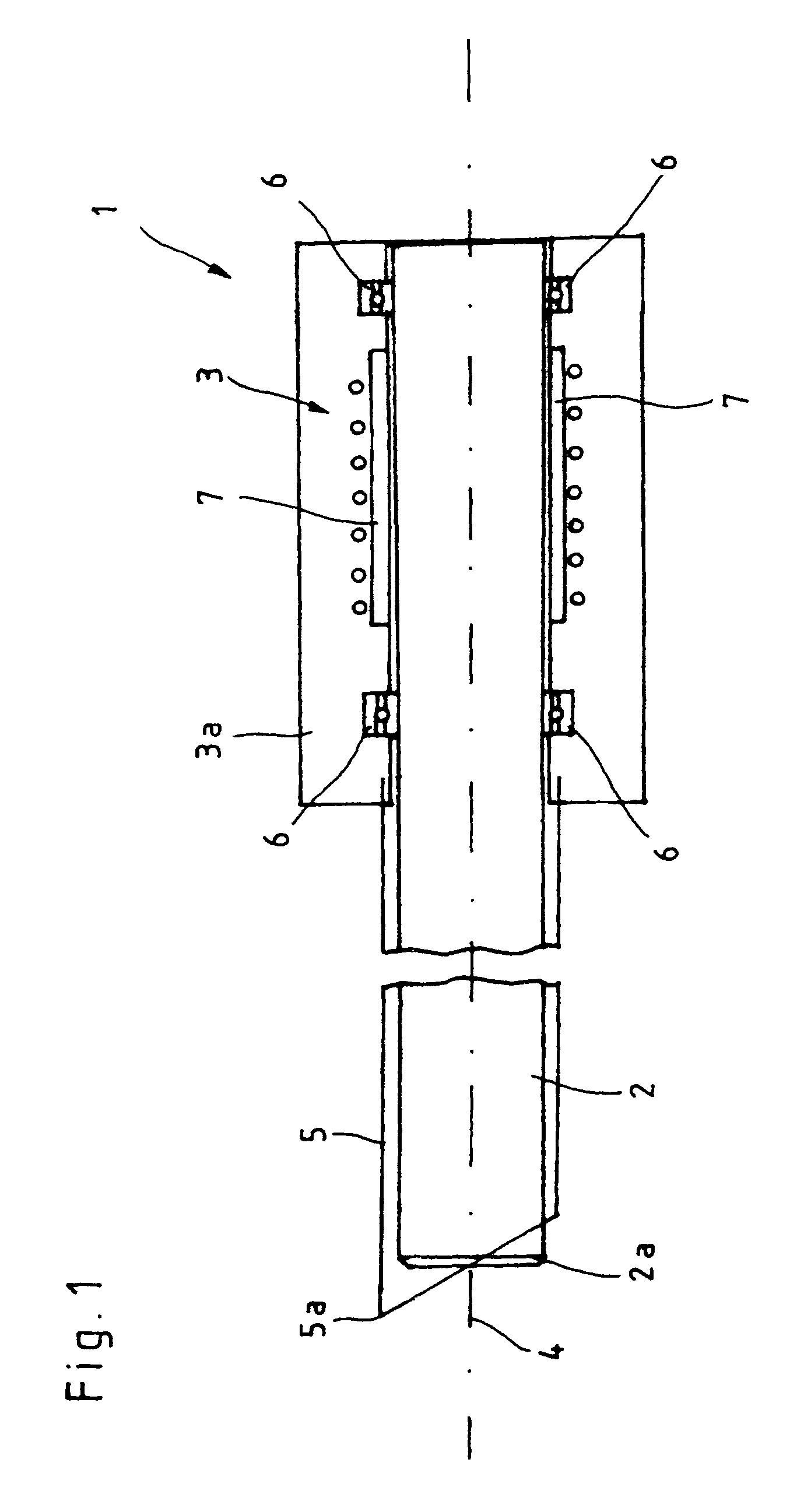

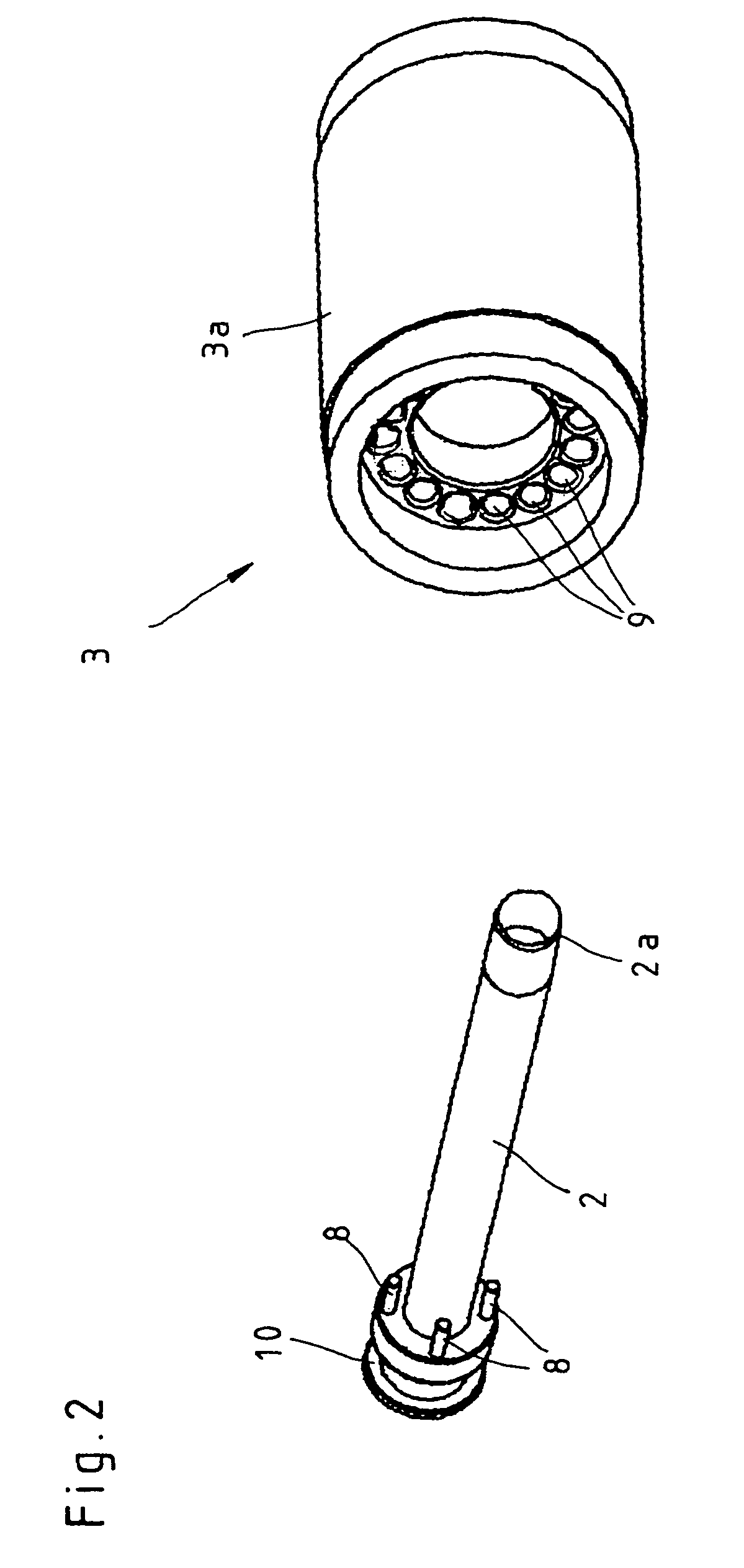

Internal combustion engine

InactiveUS7469664B2Reduce weightImprove efficiencyInternal combustion piston enginesOutput powerExternal combustion engineEngineering

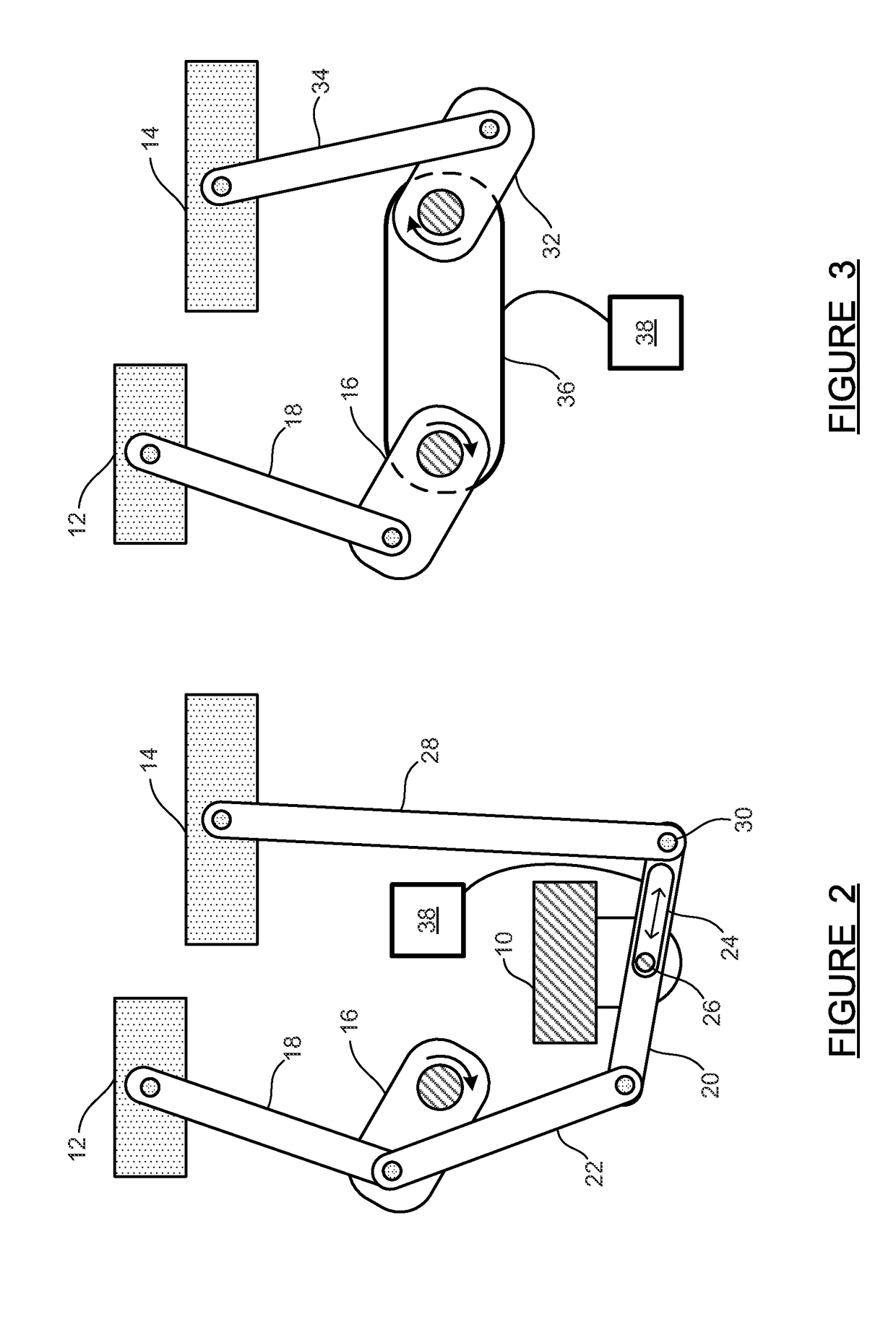

An internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons. All the pistons may be connected to a common central crankshaft. The inboard pistons of each cylinder may be connected to a common joint on the crankshaft with pushrods and the outboard pistons may be connected to a common joint on the crankshaft with pullrods. Each opposed cylinder may include an integrated scavenge pump for providing positive intake pressure. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through angular positioning of the journals on the crankshaft.

Owner:ADVANCED PROPULSION TECH

Exhaust compound internal combustion engine with controlled expansion

A piston compound internal combustion engine is disclosed with an expander piston deactivation feature. A piston internal combustion engine is compounded with a secondary expander piston, where the expander piston extracts energy from the exhaust gases being expelled from the primary power pistons. The secondary expander piston can be deactivated and immobilized, or its stroke can be reduced, under low load conditions in order to reduce parasitic losses and over-expansion. Two mechanizations are disclosed for the secondary expander piston's coupling with the power pistons and crankshaft. Control strategies for activation and deactivation of the secondary expander piston are also disclosed. In addition, six-cylinder engine configurations are defined by replicating groups of two power pistons and one expander piston.

Owner:GM GLOBAL TECH OPERATIONS LLC

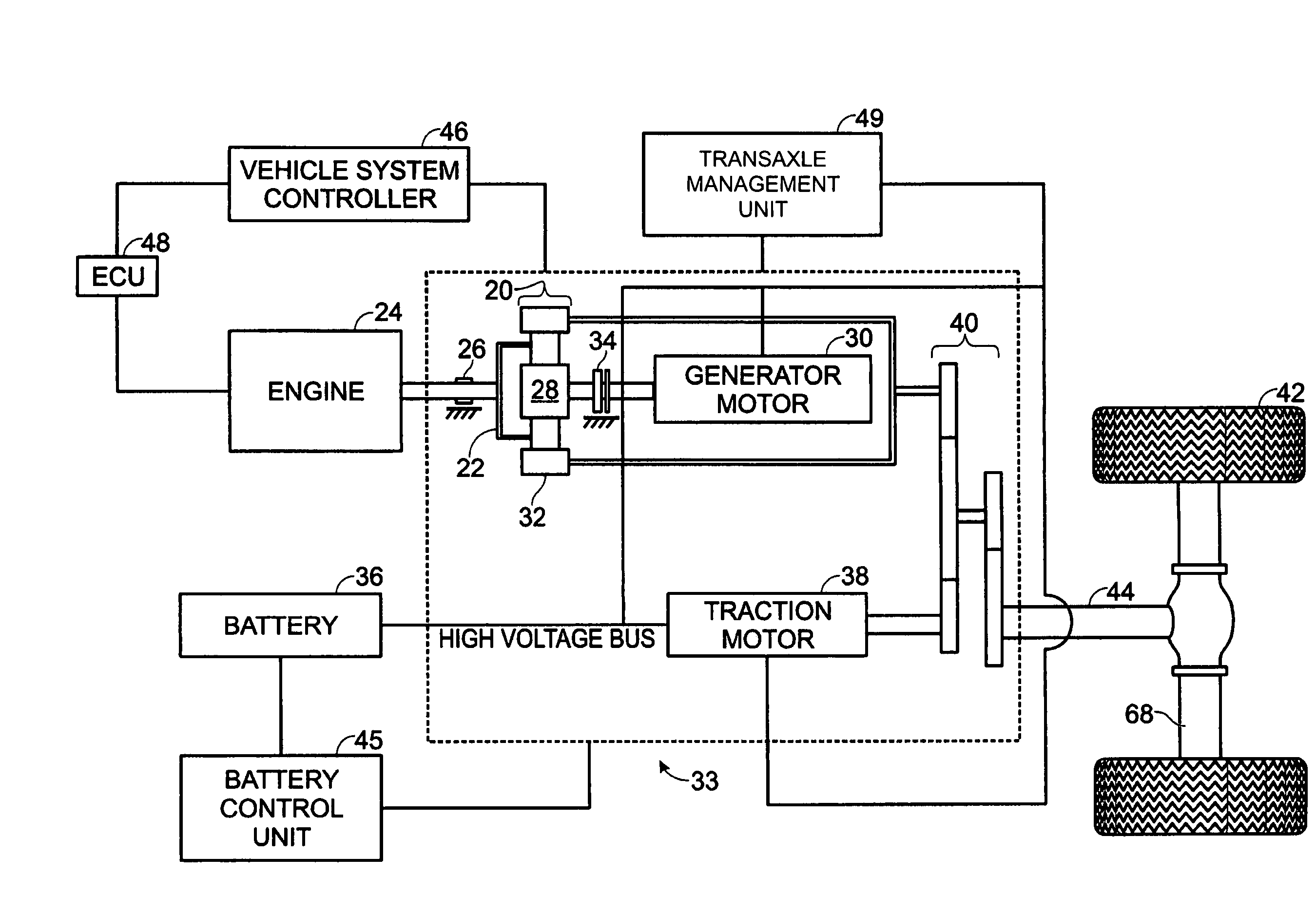

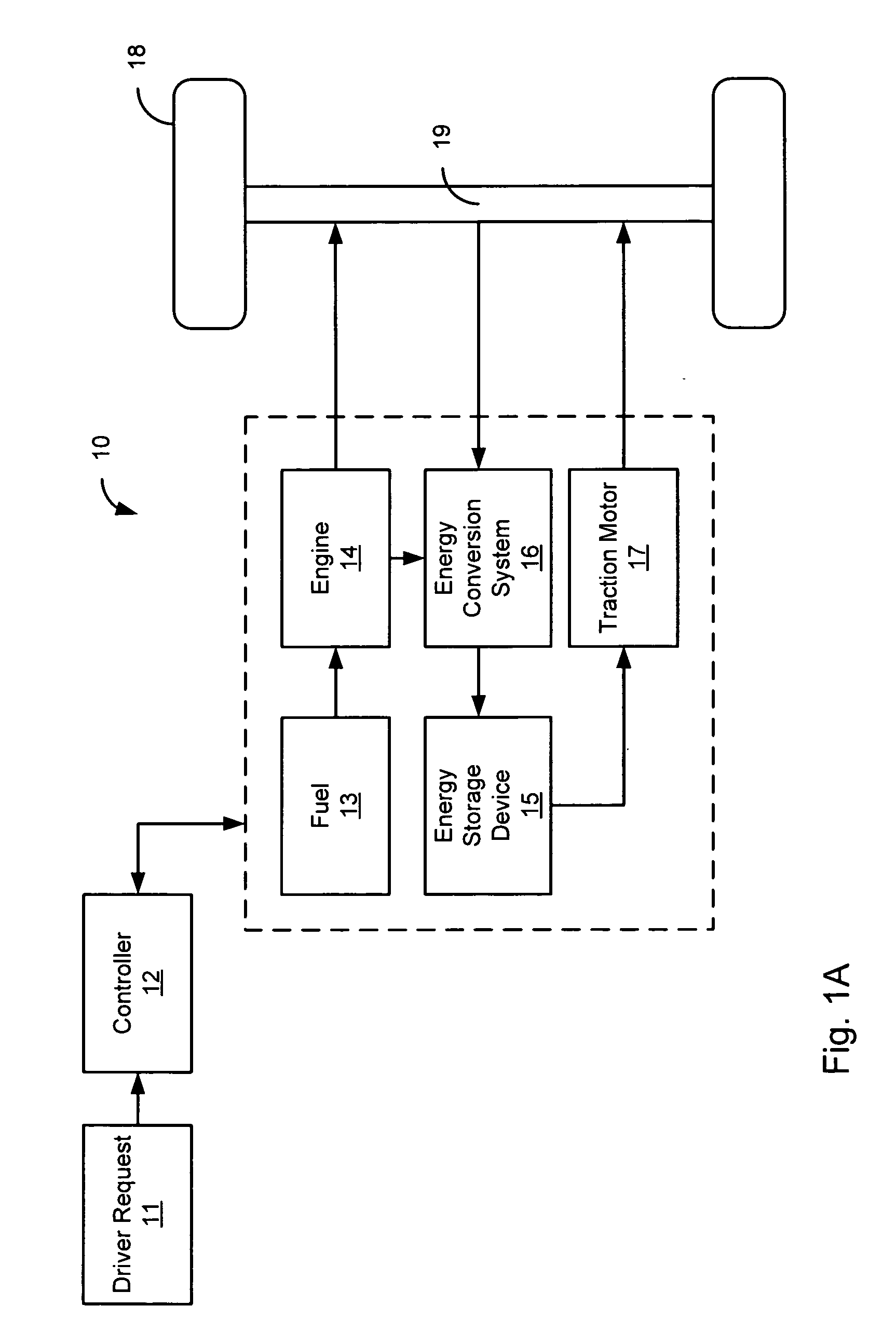

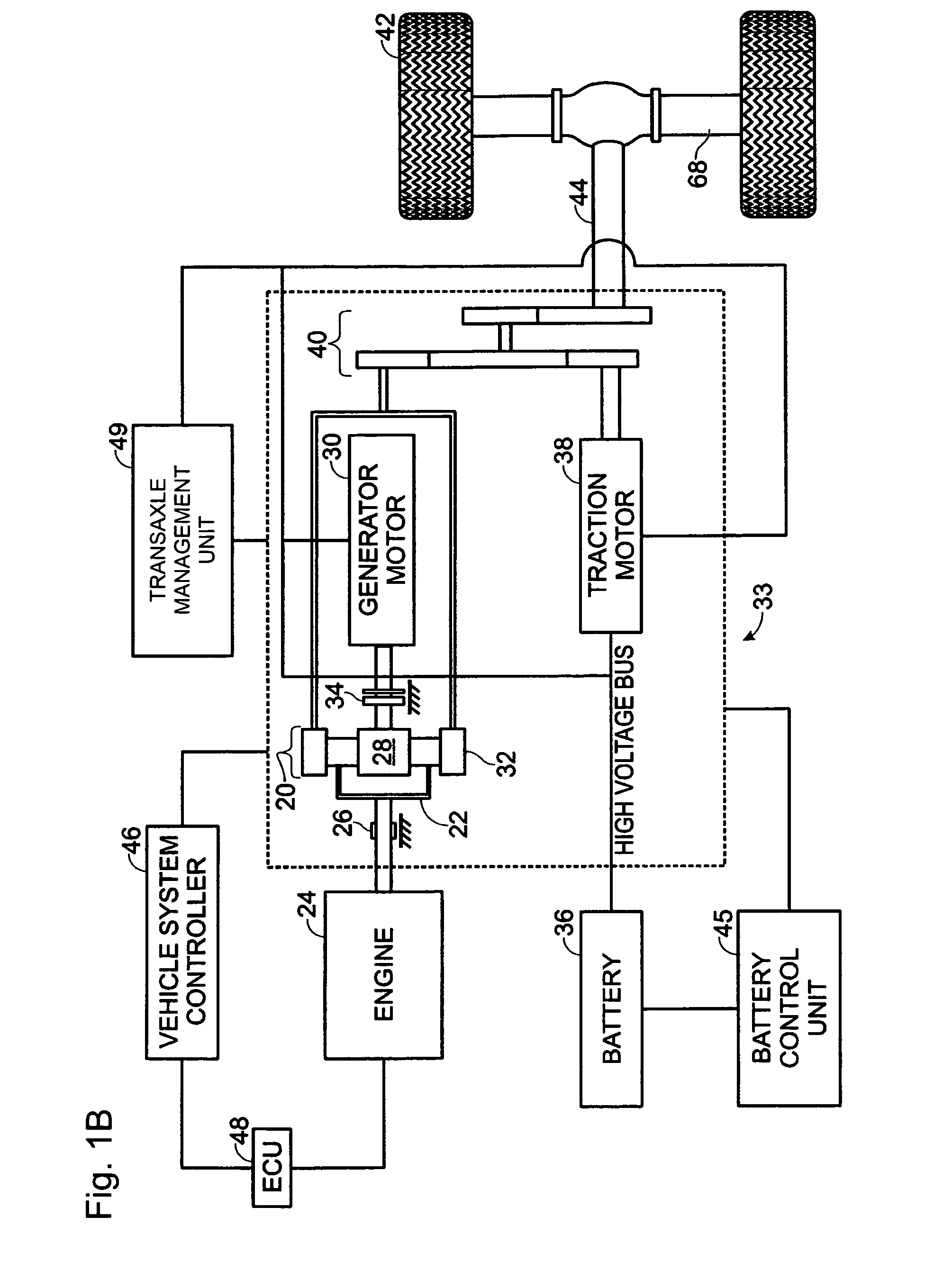

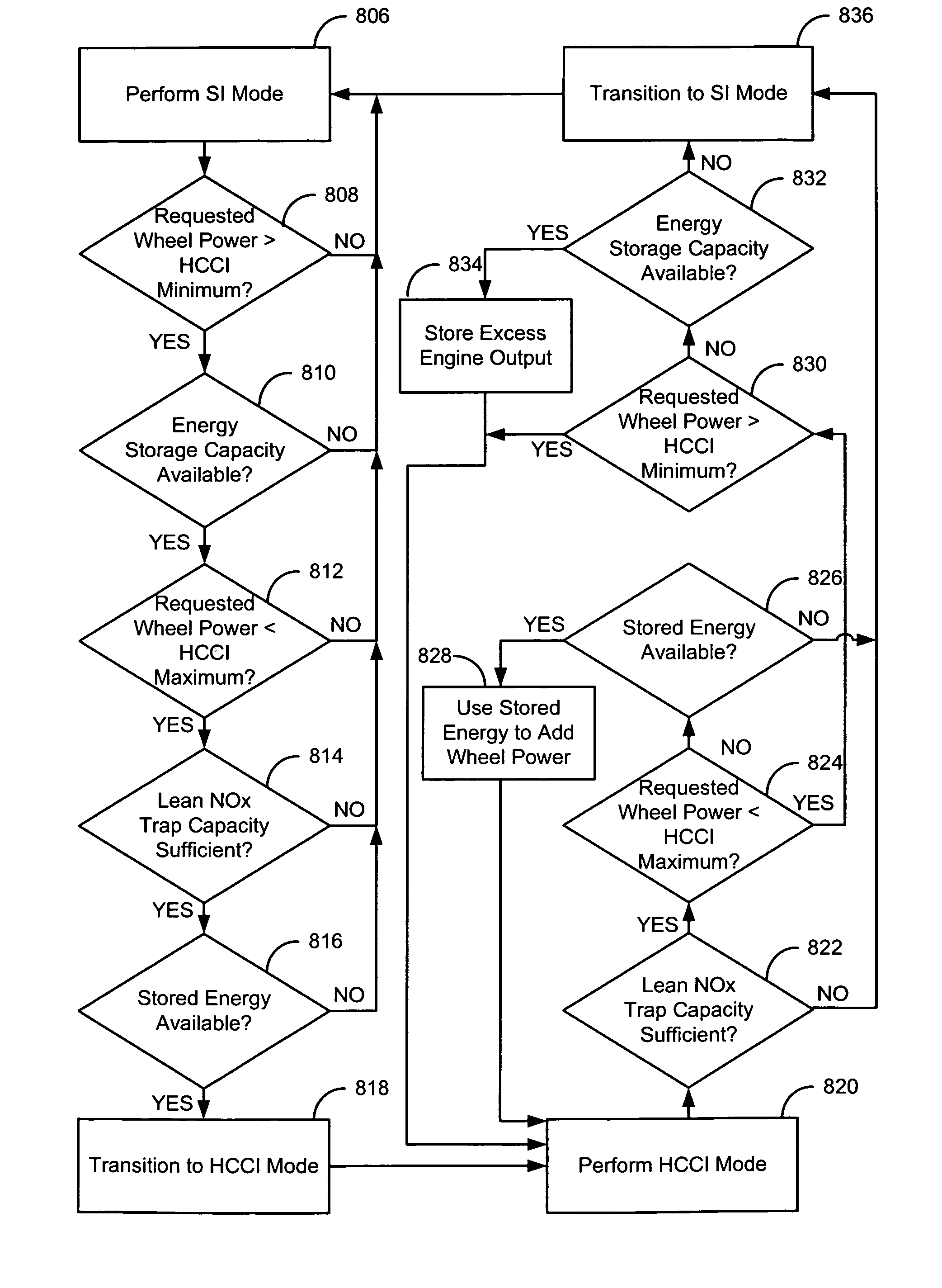

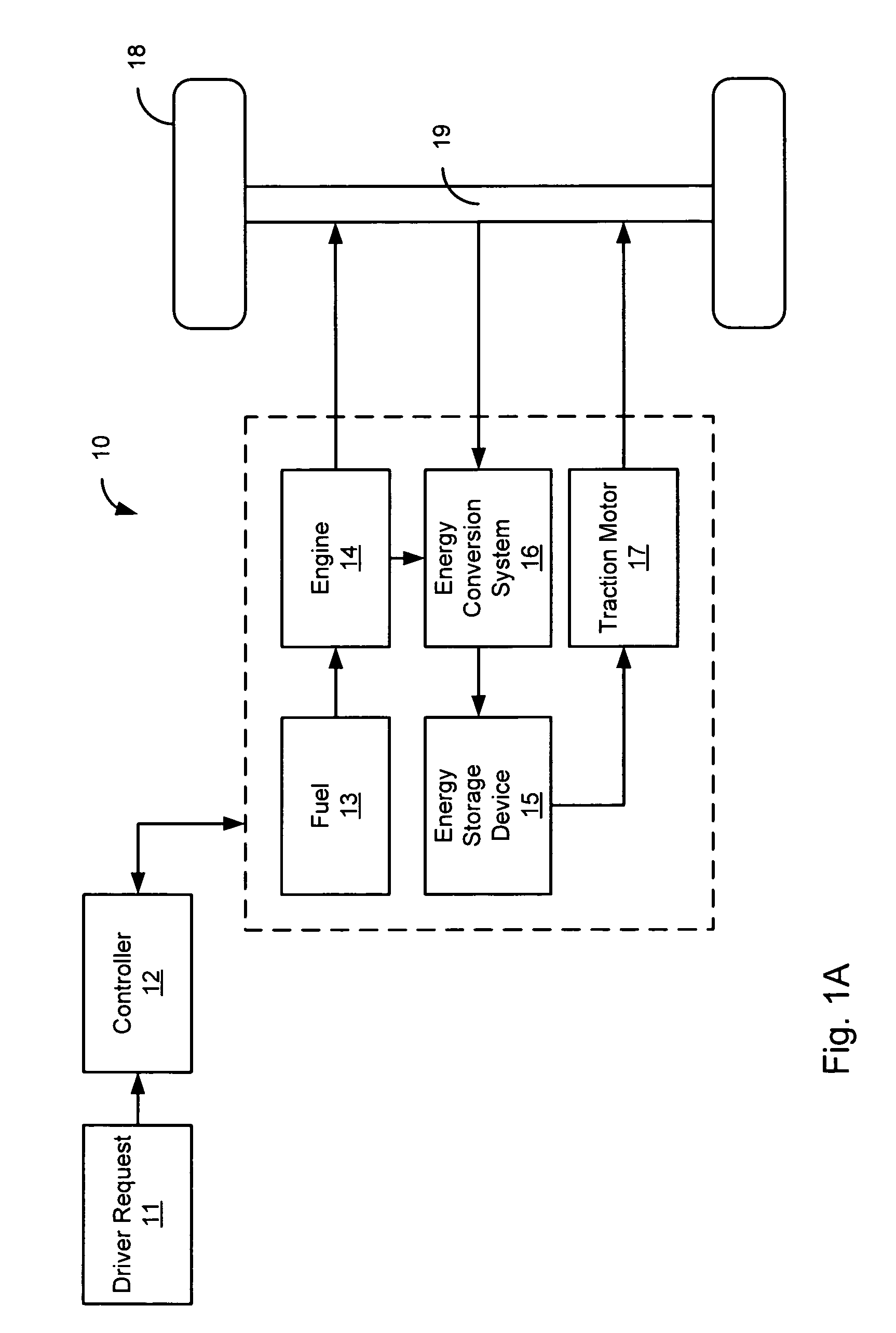

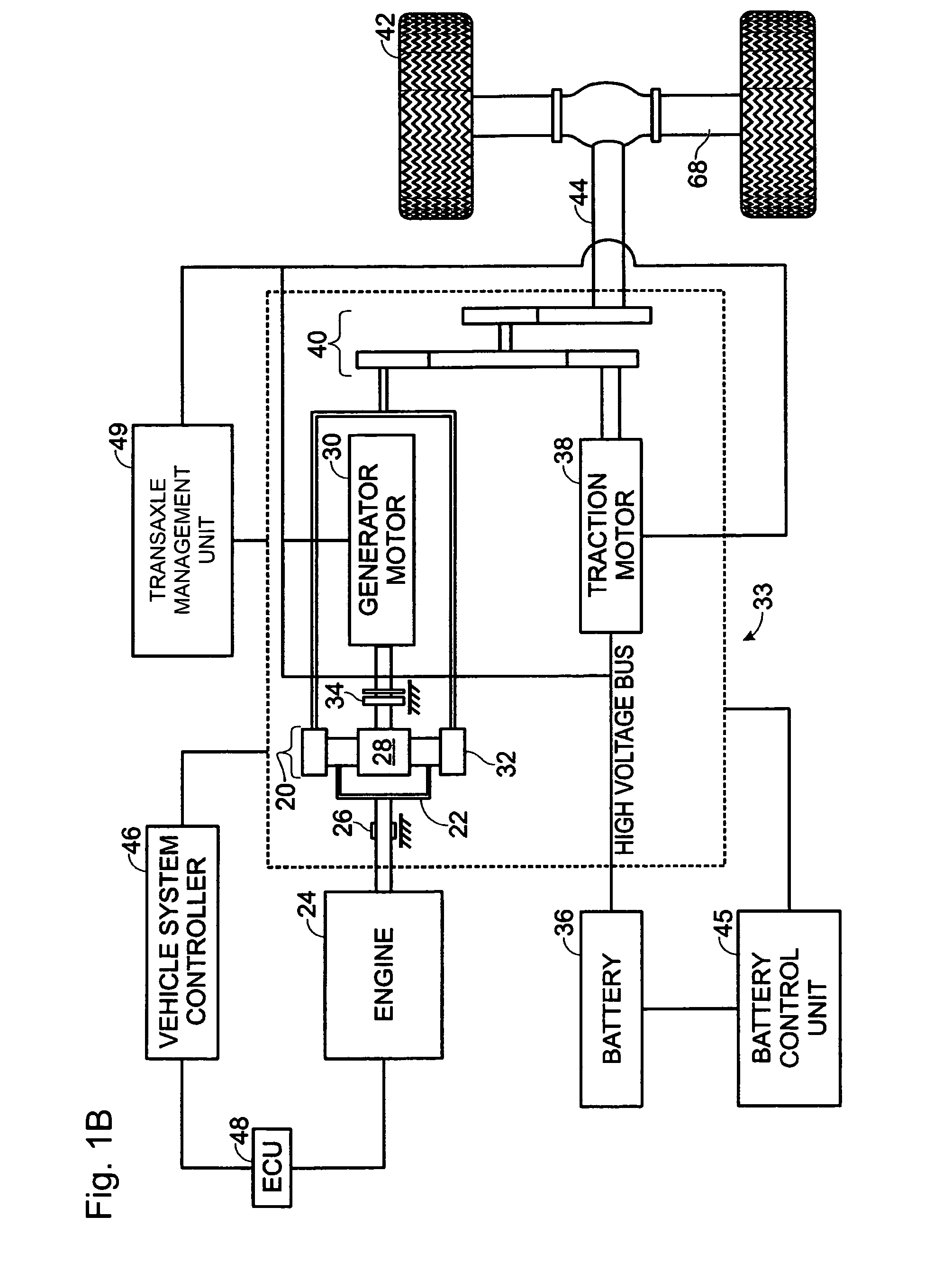

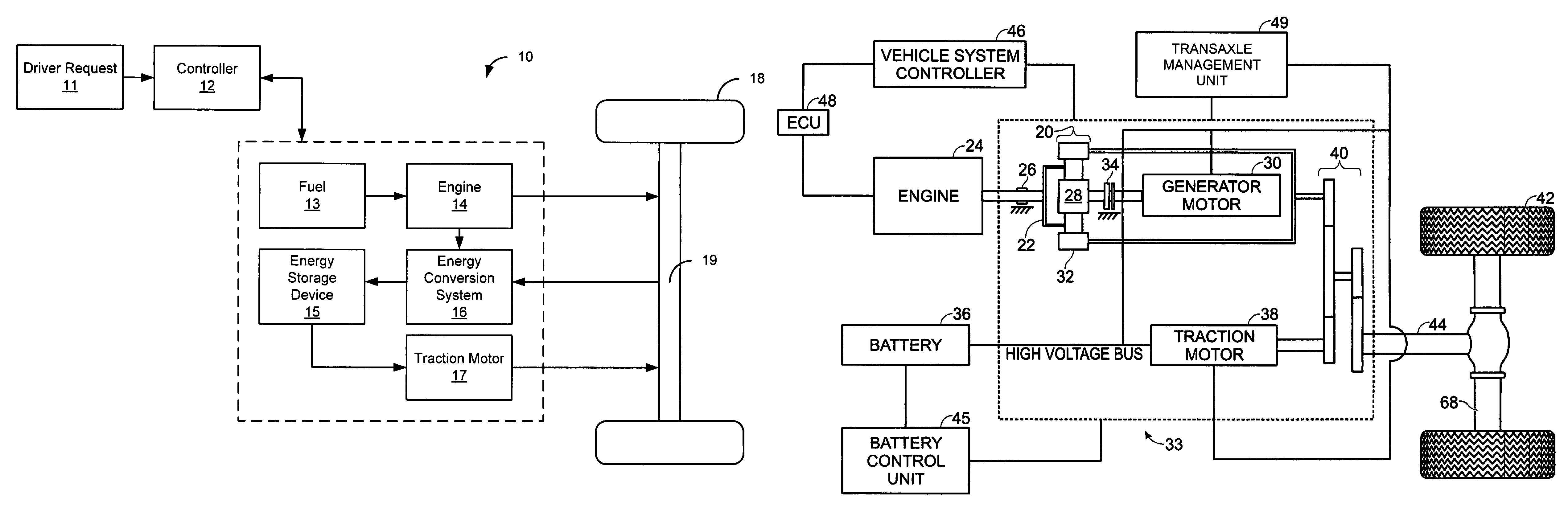

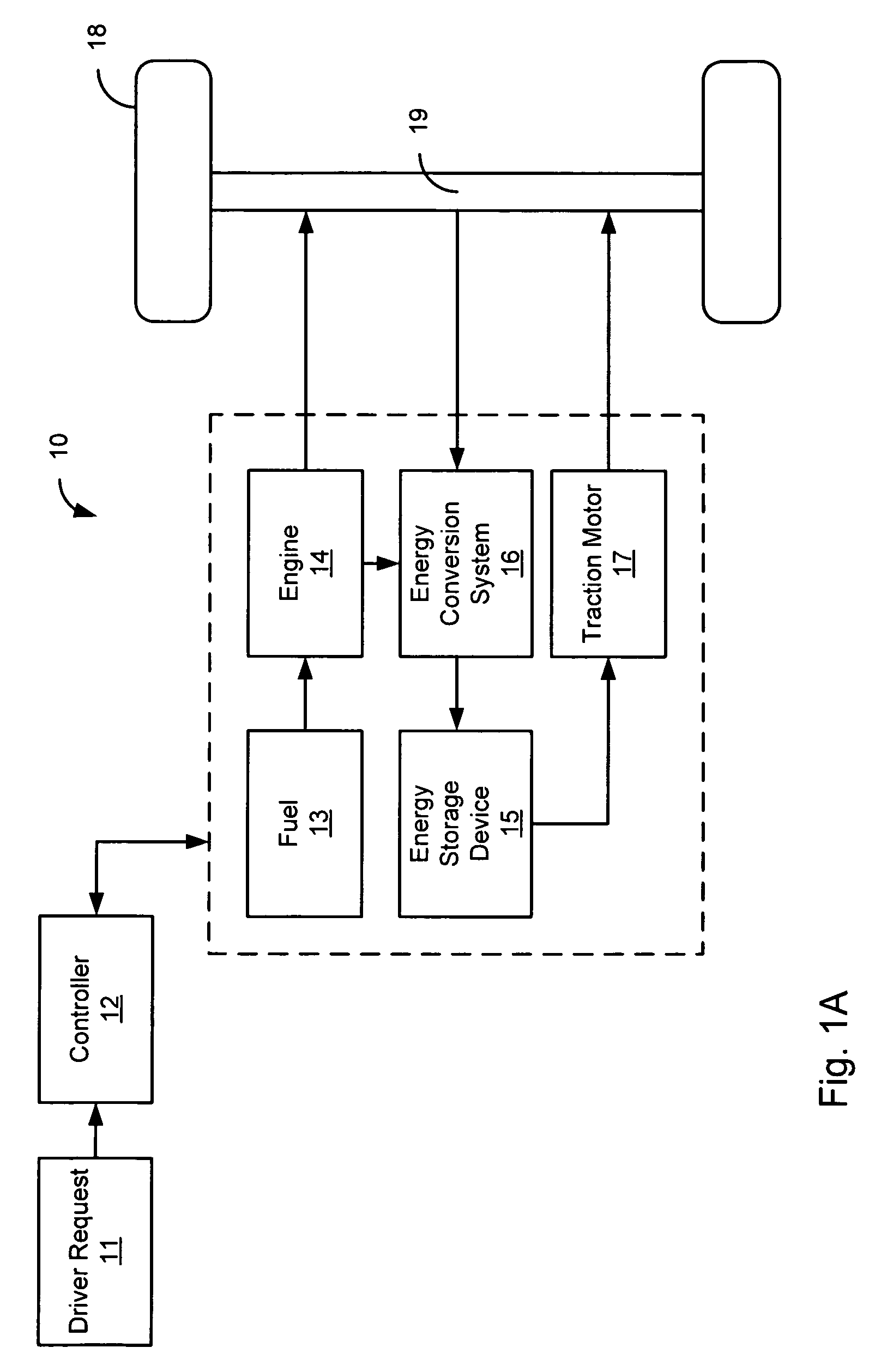

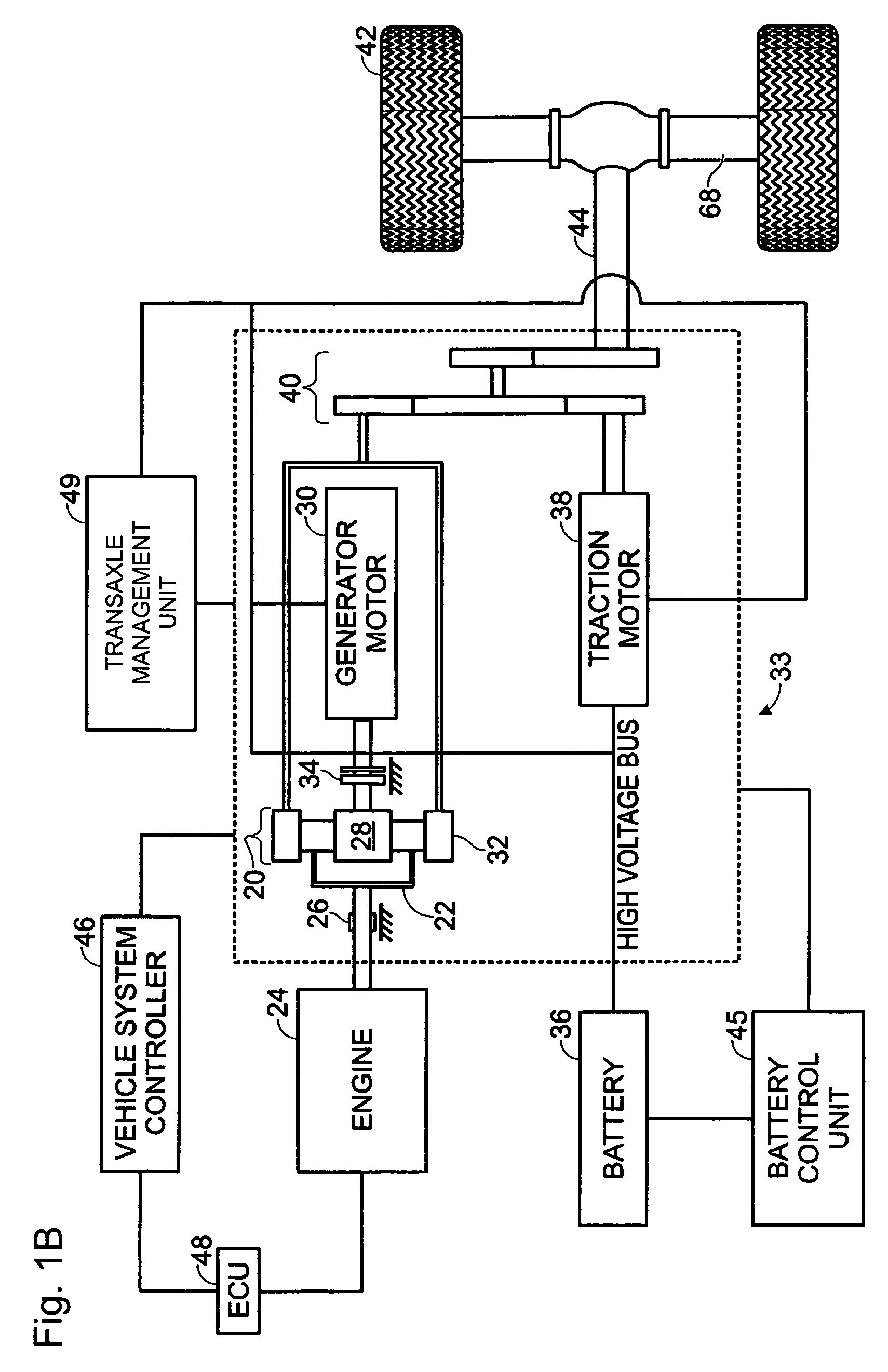

System and method for controlling vehicle operation

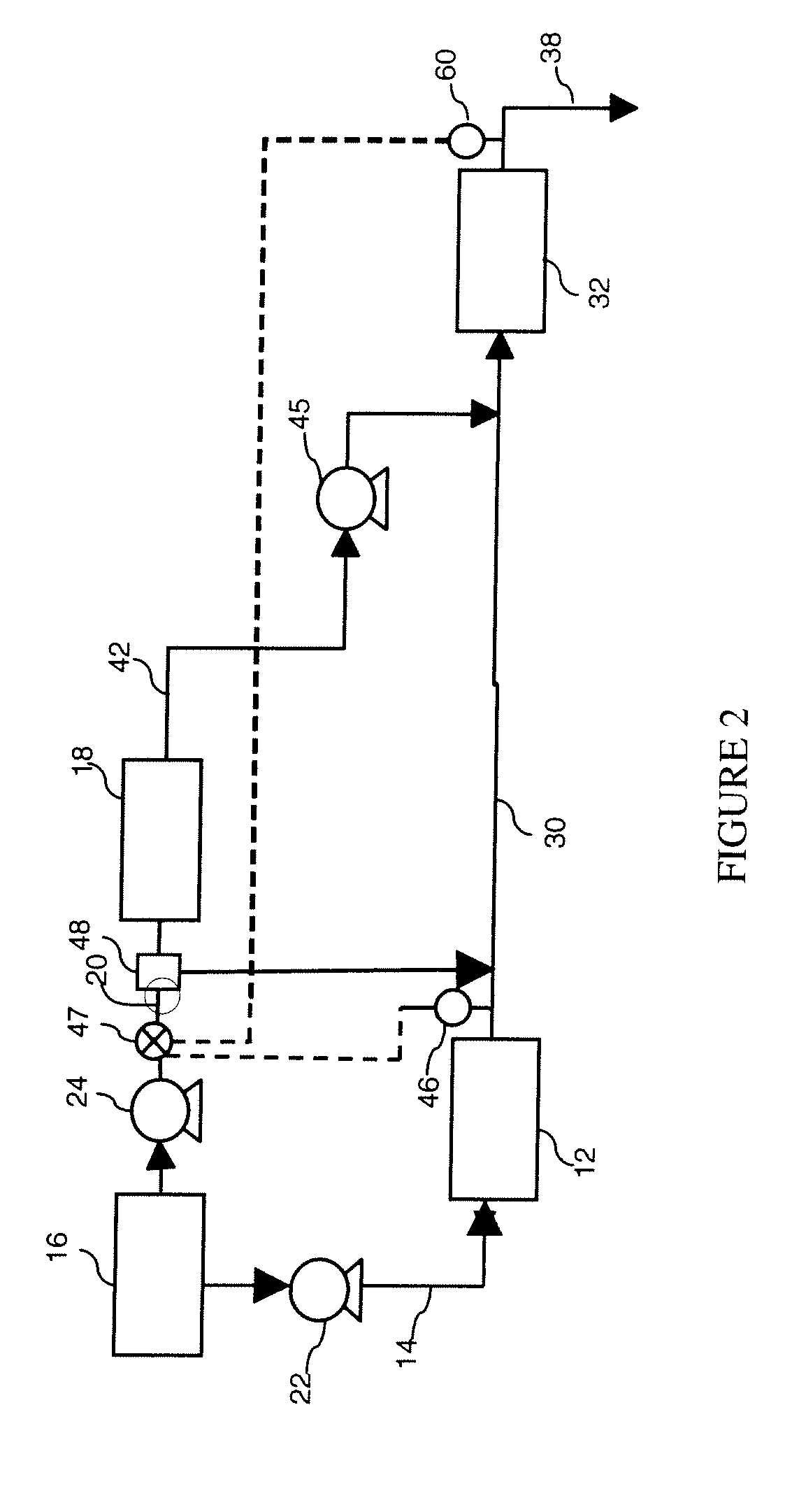

InactiveUS20070205029A1Improve fuel efficiencyReduce the production of nitrogen oxidesHybrid vehiclesAuxillary drivesHybrid vehicleEnergy storage

A hybrid vehicle propulsion system is disclosed comprising an engine having at least one combustion cylinder configured to operate in a first and a second combustion mode, wherein the first combustion mode is a spark ignition mode and the second combustion mode is a compression ignition mode, wherein the engine is configured to supply an engine output; a motor configured to selectively supply or absorb a secondary output; an energy storage device configured to selectively store at least a portion of the engine output and selectively supply energy to the vehicle; a lean NOx trap configured to store NOx produced by the engine; and a controller configured to control at least the engine, the motor, and the energy storage device, wherein the controller is configured to selectively operate said at least one combustion cylinder in one of the spark ignition mode and the compression ignition mode based on a condition of the lean NOx trap.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine driven turbo-generator for hybrid vehicles and power generation

InactiveUS20090179424A1Increased electrical system efficiencyLow costCombustion enginesVehicle sub-unit featuresExternal combustion engineEngineering

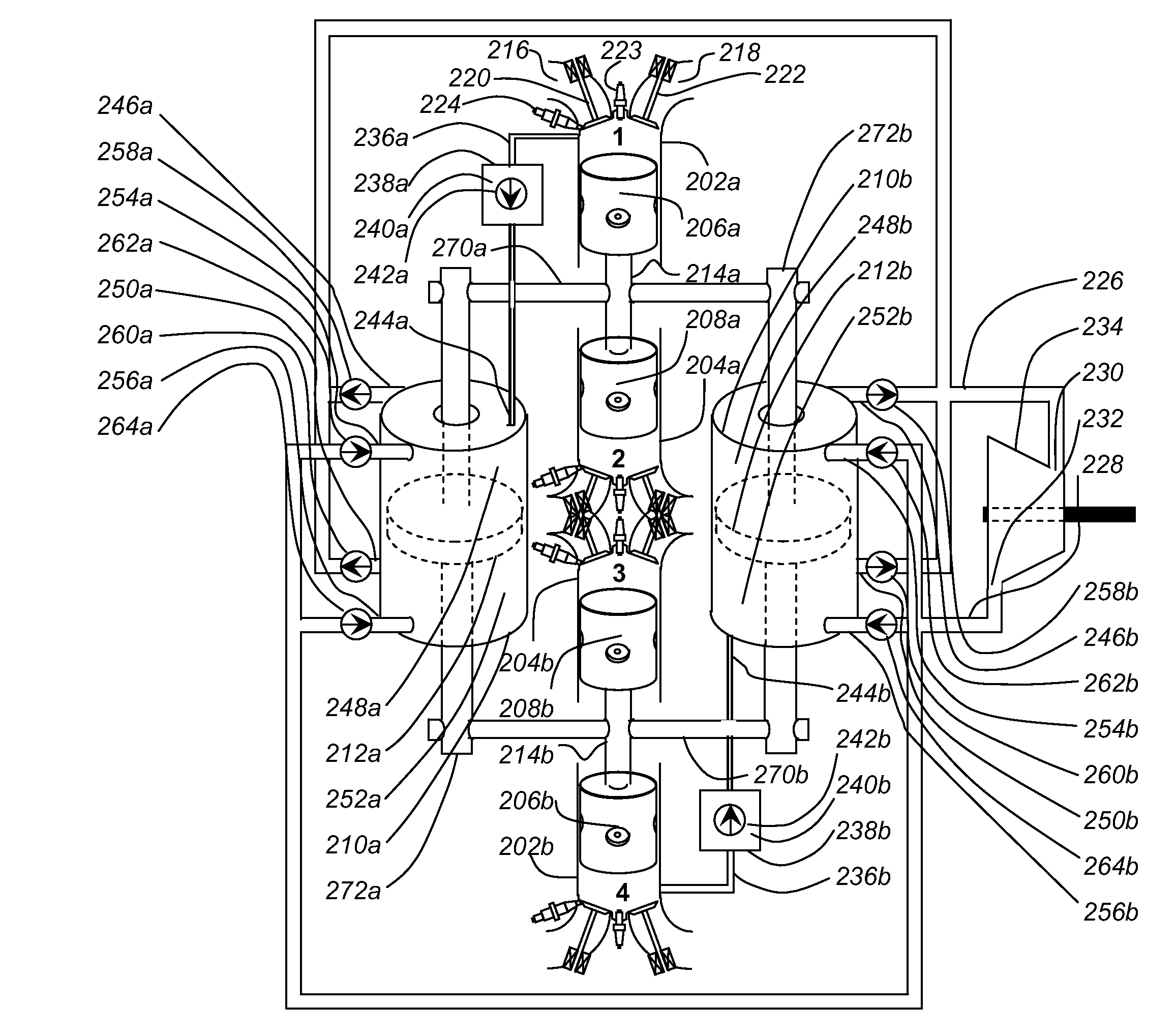

A piston compression system converts energy from a conventional combustion cycle engine driving a piston to displace a working gas for flow through a turbine for output power. The working gas is derived by diverting a portion of the charge during combustion at near peak combustion pressure (PCP) into a closed working volume. The working gas is maintained at high pressure within the working volume. The working volume has a first displacement compartment and a second displacement compartment, a supply manifold connected for receiving pressurized working gas alternately from the first and second compartments and connected to an inlet of the turbine, and a return manifold connected to an outlet of the turbine and alternately returning working gas to the second and first compartments. The engine is configured with first and second pistons housed in first and second combustion cylinders respectively powering a first displacing surface for displacement of working gas in the first compartment and a second displacing surface for displacement of working gas in the second compartment.

Owner:INTERNAL COMBUSTION TURBINES

Accelerometer configuration

InactiveUS6909948B2Eliminate needVehicle testingRegistering/indicating working of vehiclesAccelerometerSignal conditioning

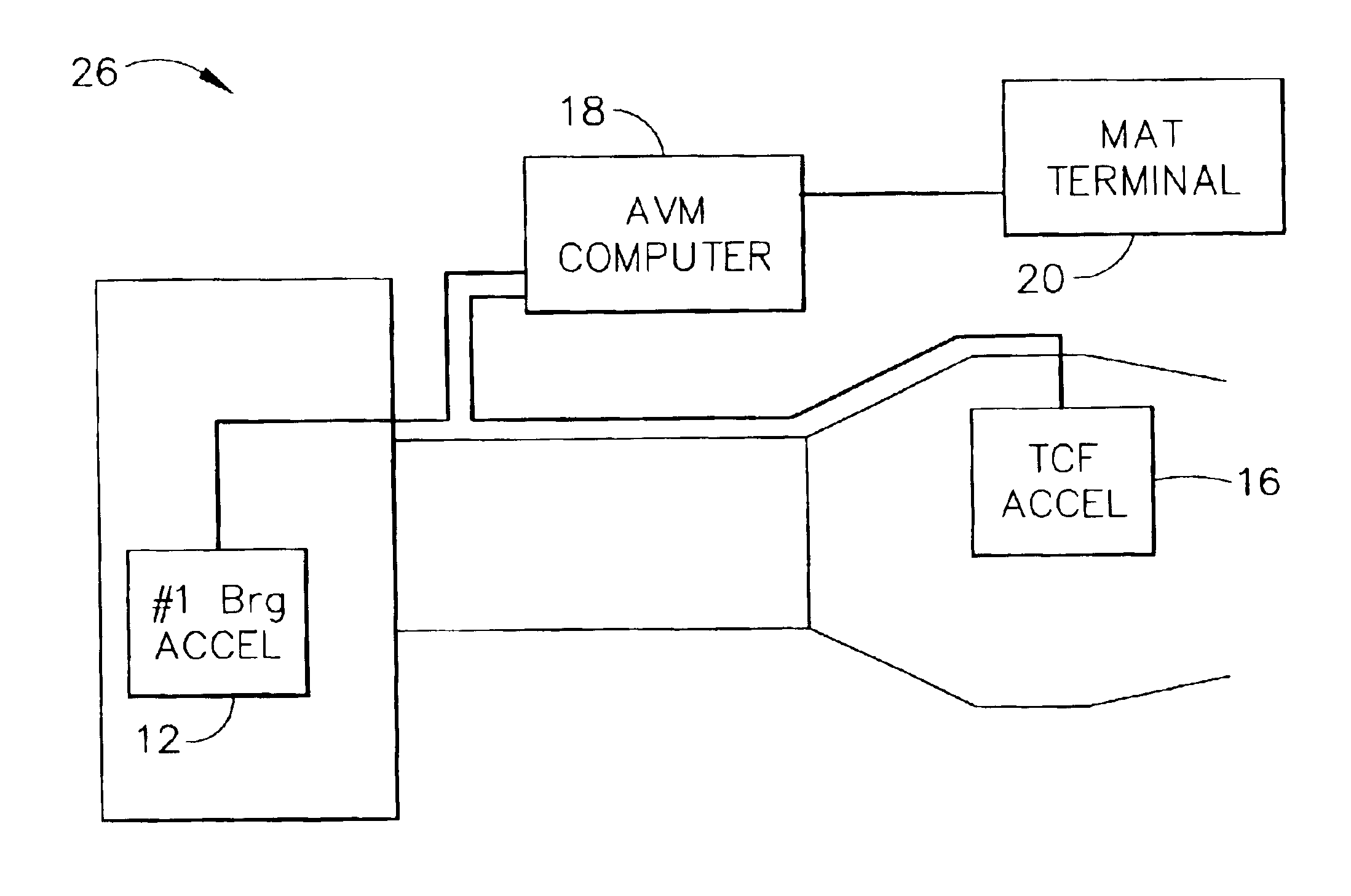

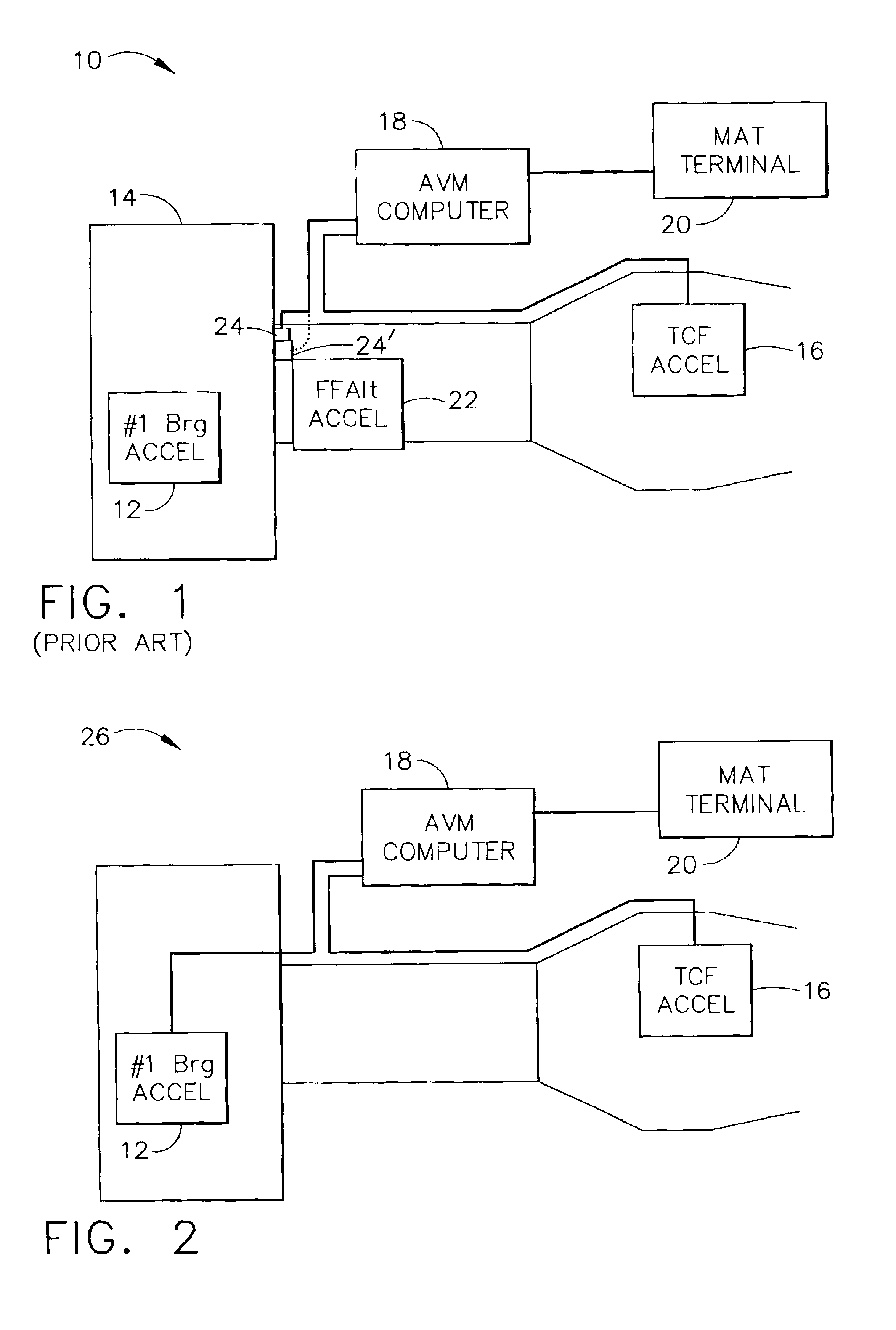

The present invention provides a system and method for using the external accelerometer in an aircraft engine configuration as a backup accelerometer, in the event the internally located production accelerometer fails. The sensor location of the external accelerometer has an acceptable sensitivity to fan imbalance, similar to the location of the former alternate accelerometer. The signal from this external accelerometer is duplicated using software in the signal conditioning hardware, creating the second, alternate signal. As an alternative embodiment, the signal may be duplicated by simply teeing or branching the original signal, using hardware rather than software.

Owner:GENERAL ELECTRIC CO

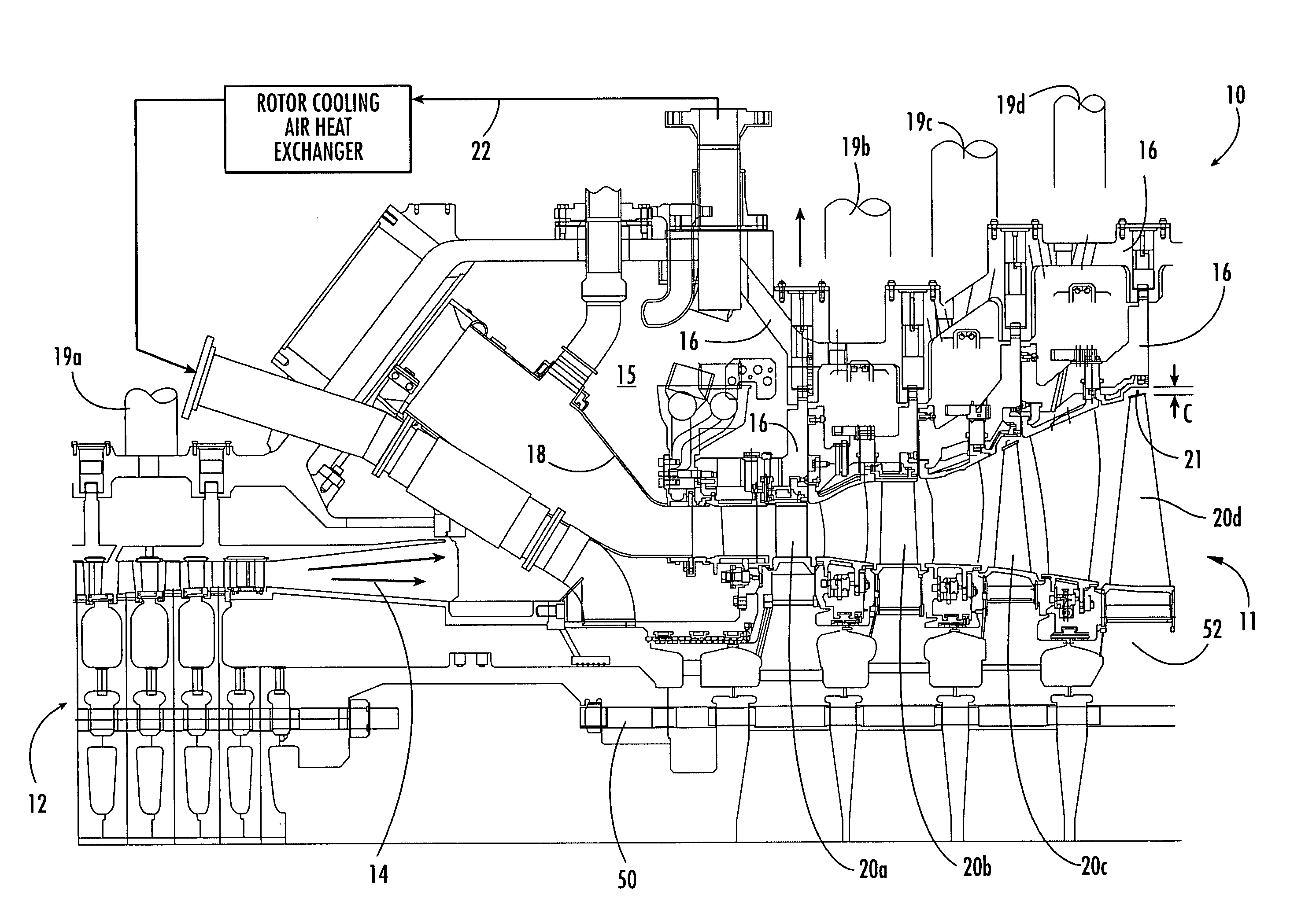

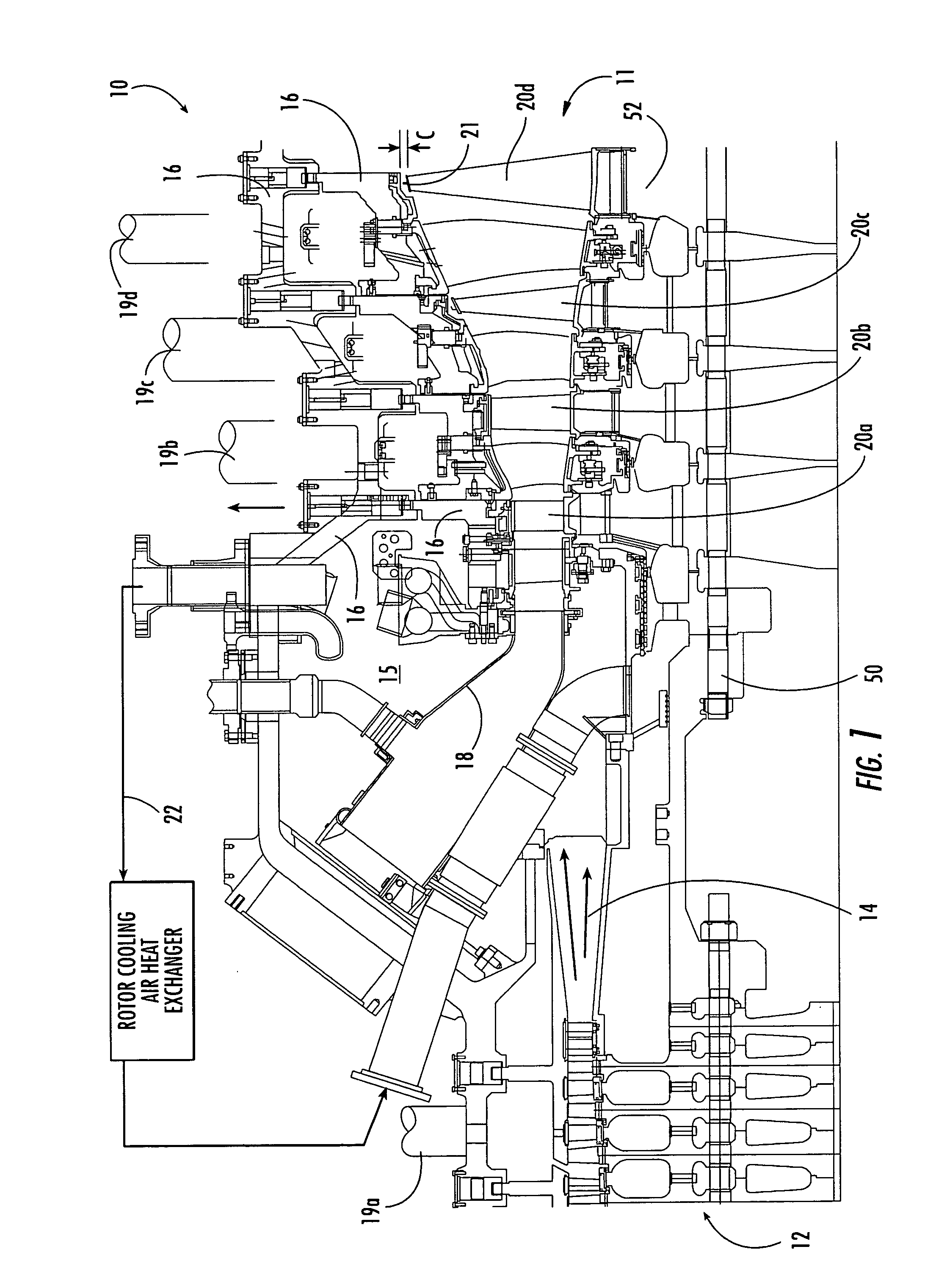

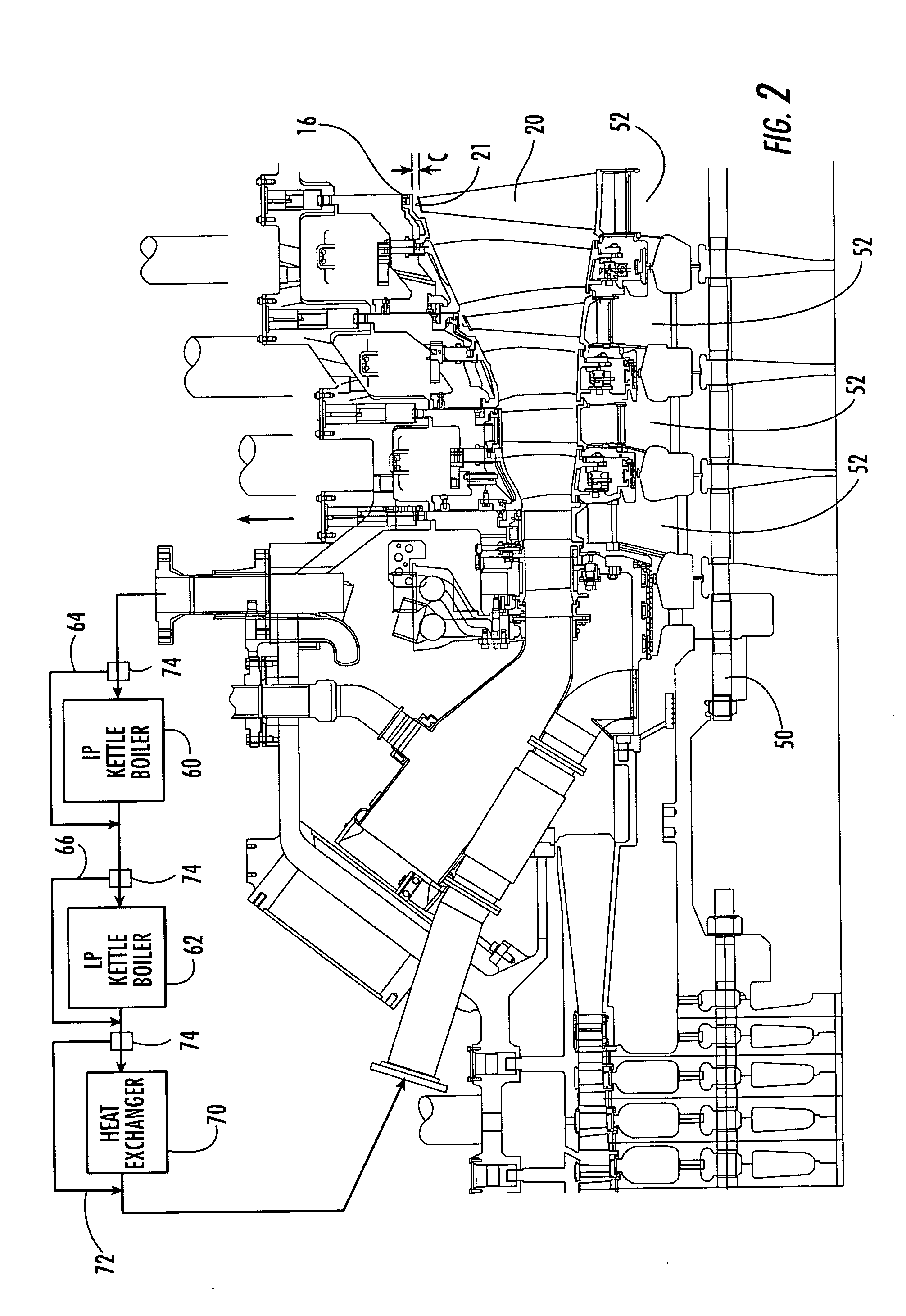

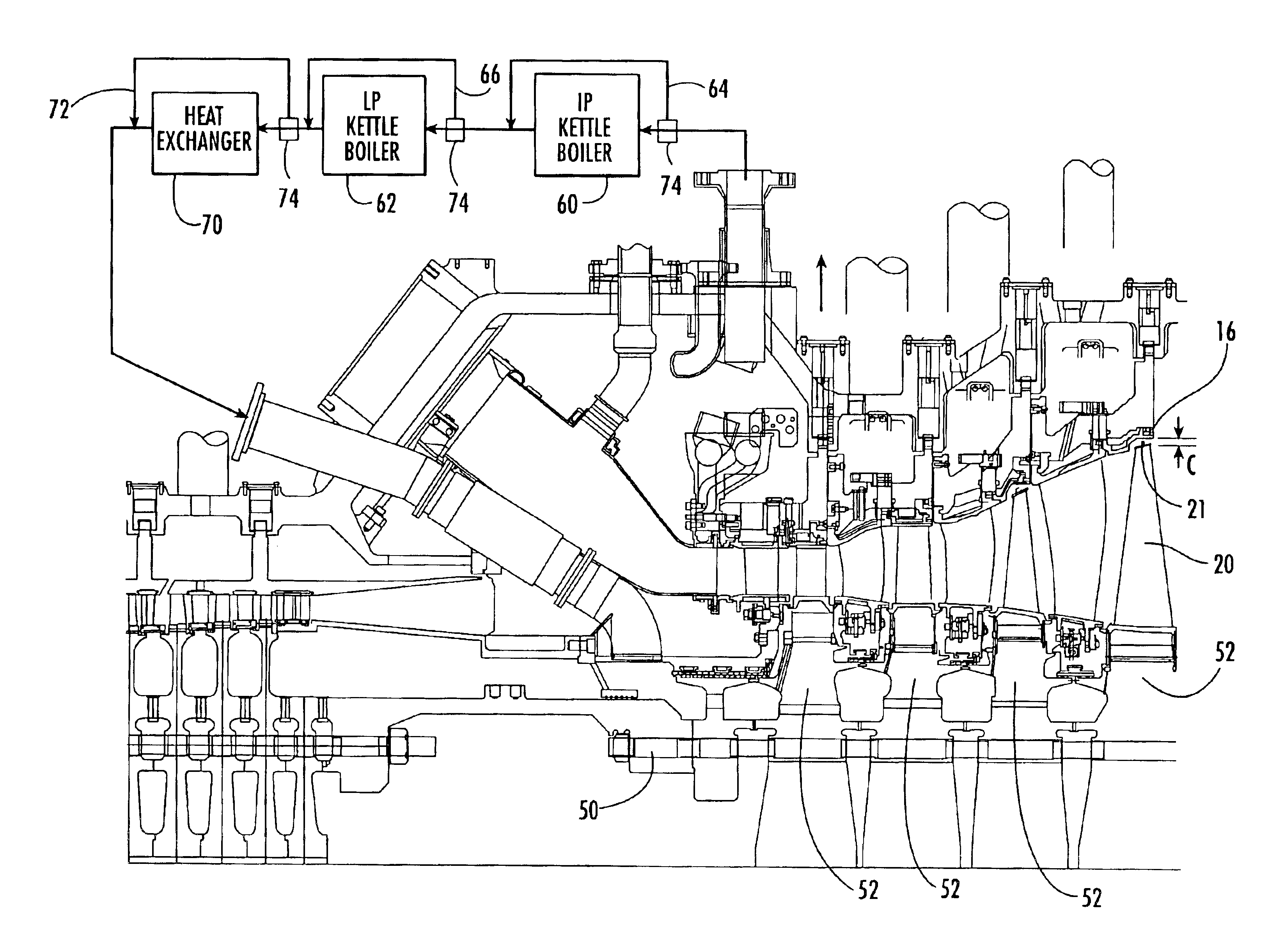

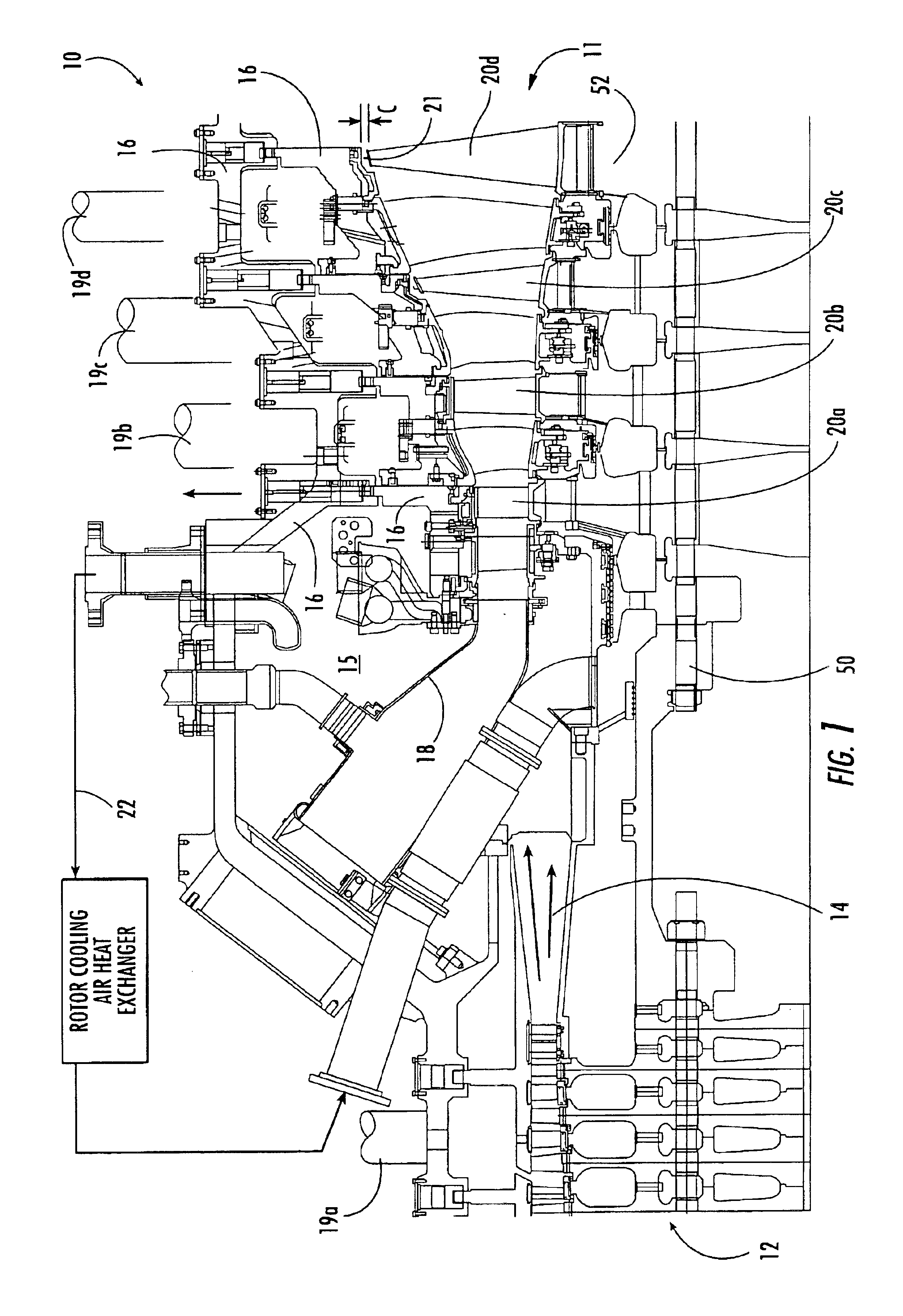

Part load blade tip clearance control

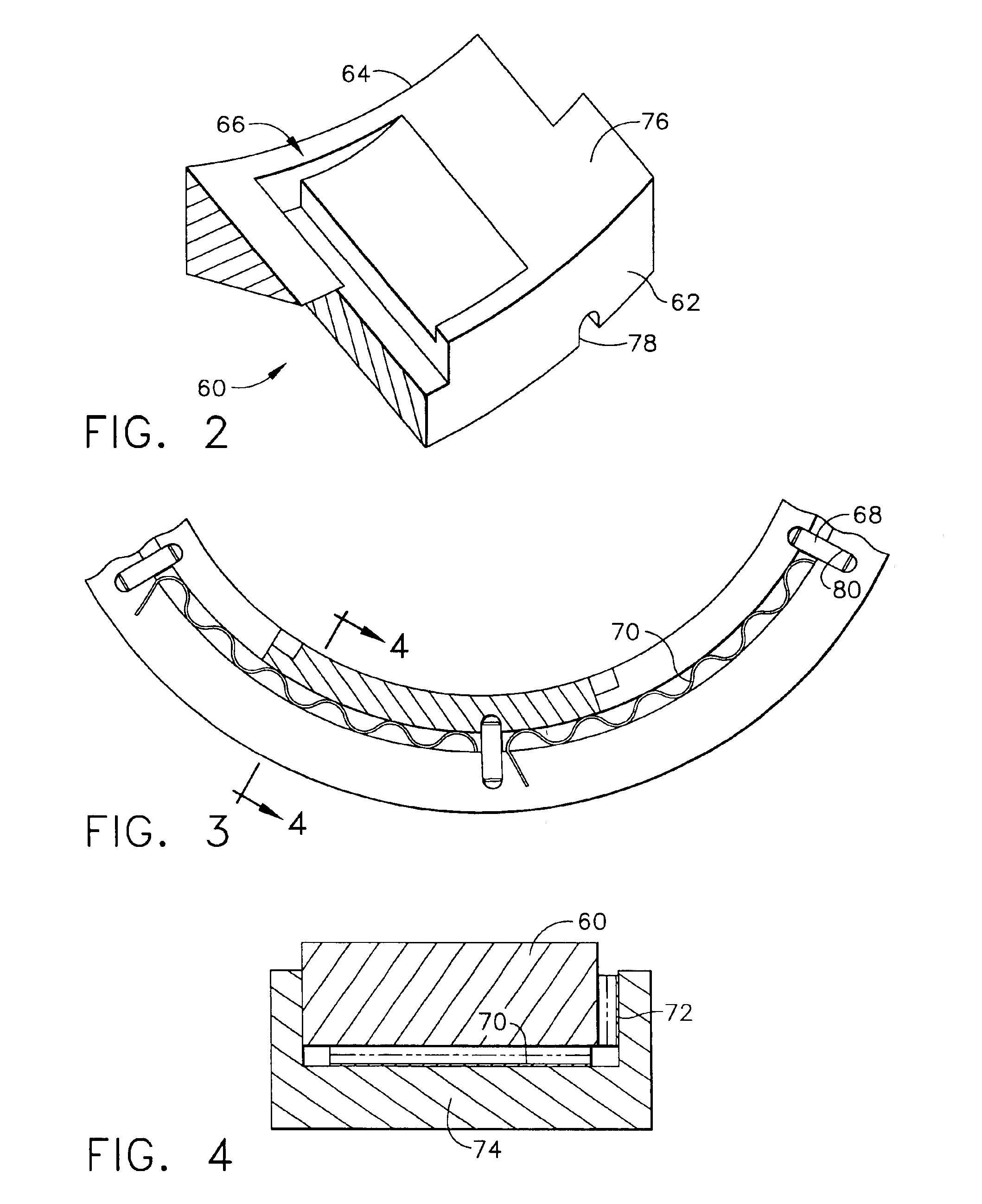

InactiveUS20050050901A1Reduce the temperatureLow cooling temperatureTurbine/propulsion engine coolingBlade accessoriesCircular discTurbine blade

Aspects of the invention relate to a turbine engine configuration and method for overcoming a turbine blade tip clearance problem that can arise when the turbine inlet temperature is maintained at a high level during part load operation of the turbine. Aspects of the invention relate to reducing rotor cooling air to a temperature below the design temperature level by using, for example, additional heat extraction devices or by reconfiguring or resizing existing heat exchanger devices. Upon exposure to the cooled air, the discs and blades of the turbine will shrink so as to provide a clearance between the blade tips and surrounding stationary support structure. The design rotor cooling air temperature can be from about 350 degrees Fahrenheit to about 480 degrees Fahrenheit. Aspects of the present invention can be used to decrease the rotor cooling air to about 150 degrees Fahrenheit at about 70 percent load.

Owner:SIEMENS ENERGY INC

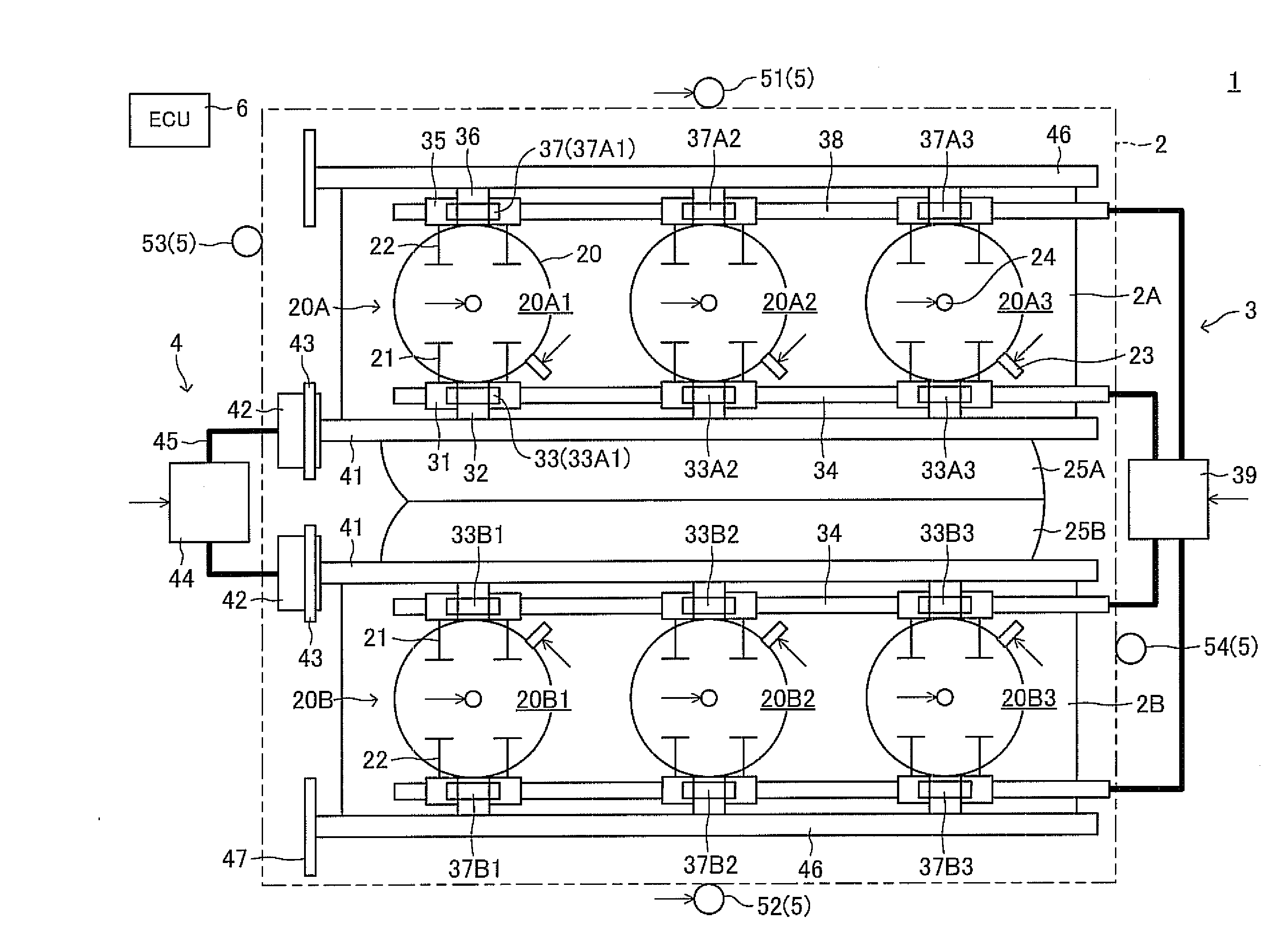

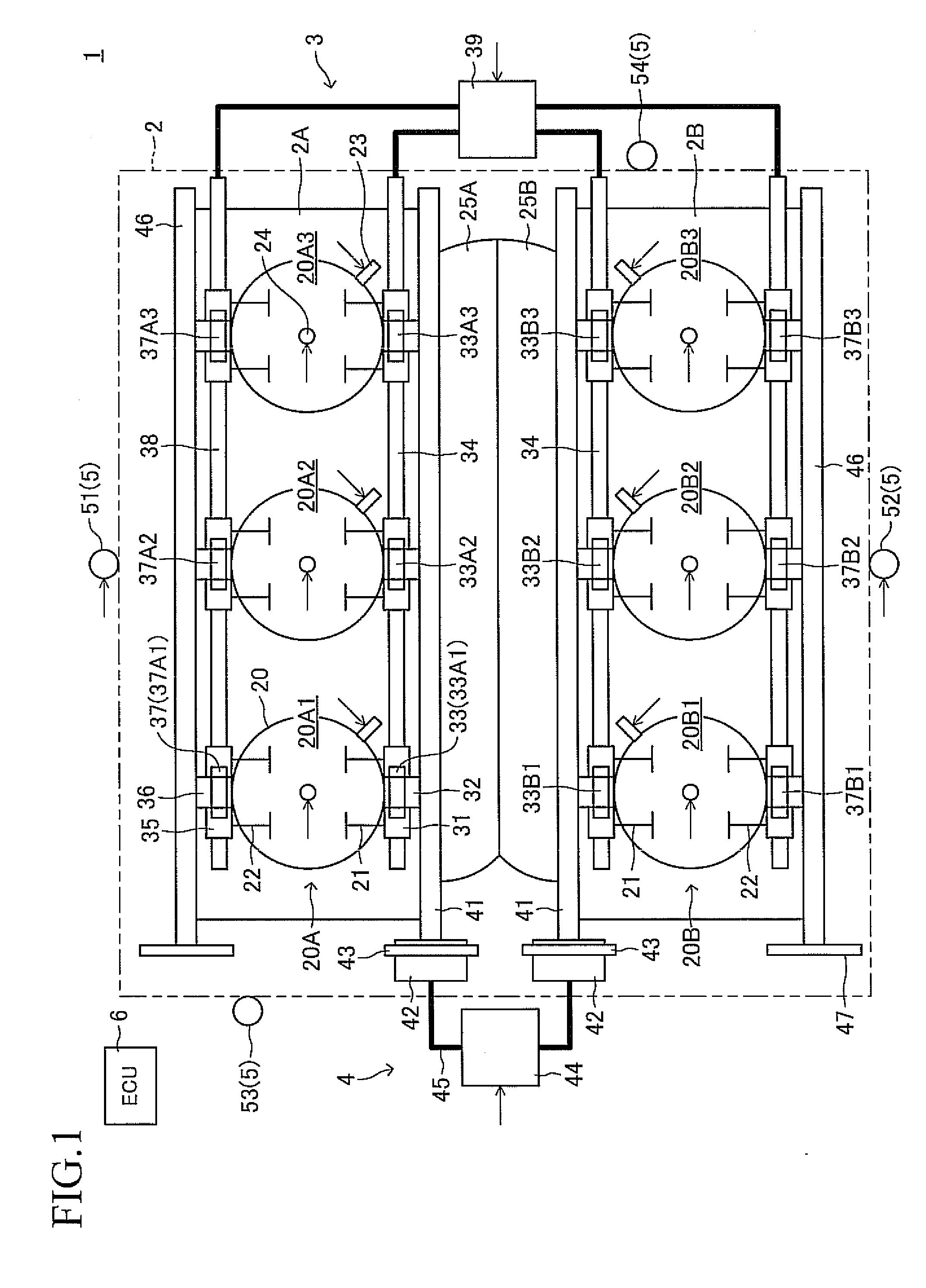

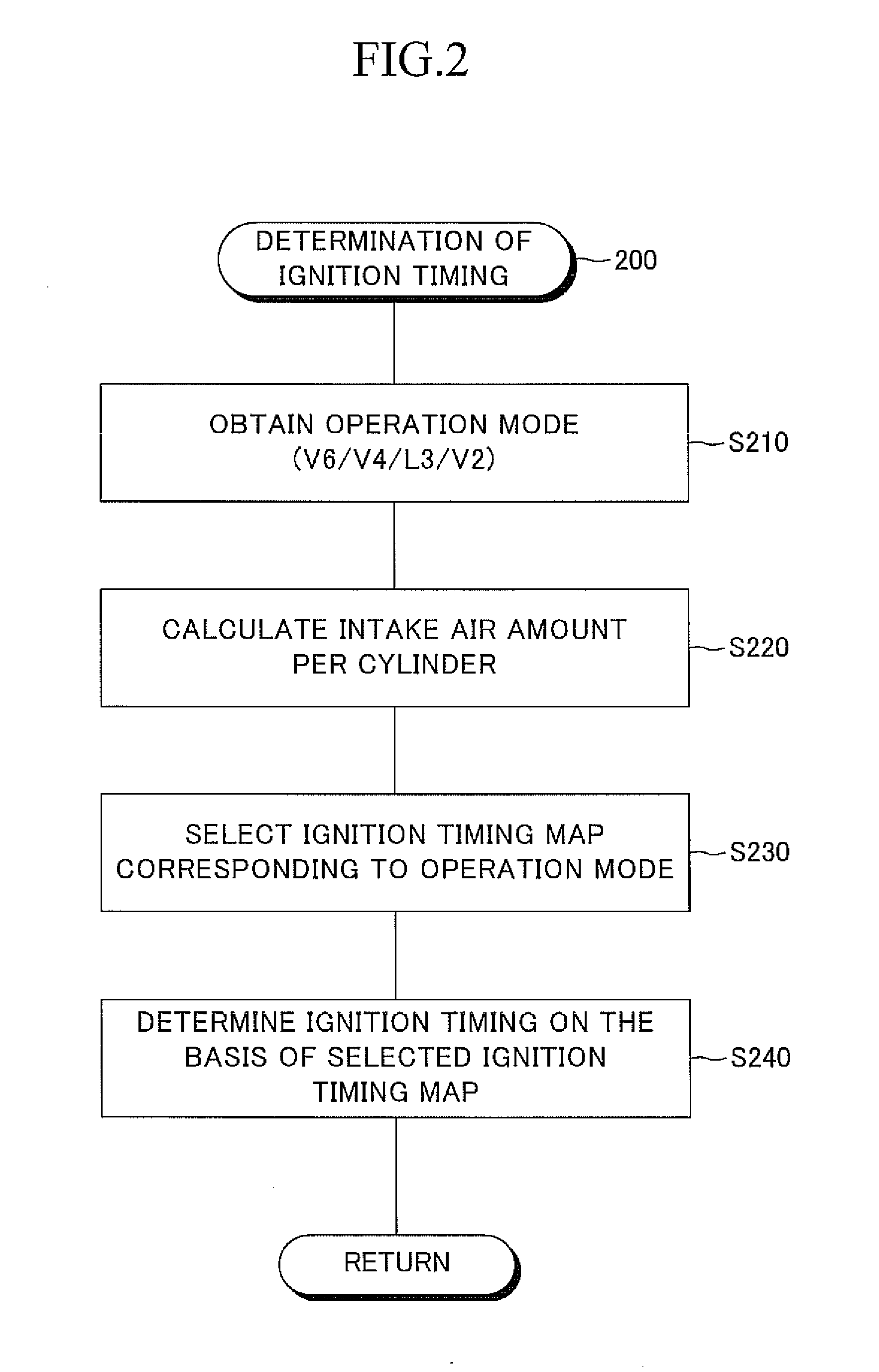

Multi-cylinder engine

InactiveUS20090248278A1Analogue computers for vehiclesElectrical controlInternal pressureEngineering

A multi-cylinder engine is configured to be able to perform a selected cylinder operation in which combustion is stopped in some cylinders. The multi-cylinder engine includes an ignition-timing adjustment section. This ignition-timing adjustment section retards ignition timing of each operating cylinder when the number of operating cylinders is small or when the engine operates in a selected cylinder operation mode in which explosion occurs at irregular intervals. In such a case, the peak of cylinder internal pressure is lowered by ignition timing retard. Thus, vibration and noise can be suppressed effectively.

Owner:TOYOTA JIDOSHA KK

System and method for controlling vehicle operation

A hybrid vehicle propulsion system is disclosed comprising an engine having at least one combustion cylinder configured to operate in a first and a second combustion mode, wherein the first combustion mode is a spark ignition mode and the second combustion mode is a compression ignition mode, wherein the engine is configured to supply an engine output; a motor configured to selectively supply or absorb a secondary output; an energy storage device configured to selectively store at least a portion of the engine output and selectively supply energy to the vehicle; a lean NOx trap configured to store NOx produced by the engine; and a controller configured to control at least the engine, the motor, and the energy storage device, wherein the controller is configured to selectively operate said at least one combustion cylinder in one of the spark ignition mode and the compression ignition mode based on a condition of the lean NOx trap.

Owner:FORD GLOBAL TECH LLC

Internal combustion engine

InactiveUS20060124084A1Improve efficiencyHeight profile of has been reducedInternal combustion piston enginesOutput powerControl theoryMechanical engineering

A two-stroke internal combustion engine is disclosed having opposed cylinders, each cylinder having a pair of opposed pistons, with all the pistons connected to a common central crankshaft. The inboard pistons of each cylinder are connected to the crankshaft with pushrods and the outboard pistons are connected to the crankshaft with pullrods. Each opposed cylinder further comprises an integrated scavenge pump for providing positive intake pressure. This configuration results in a compact engine with a very low profile, in which the free mass forces can be substantially balanced. The engine configuration also allows for asymmetrical timing of the intake and exhaust ports through angular positioning of the journals on the crankshaft.

Owner:ADVANCED PROPULSION TECH

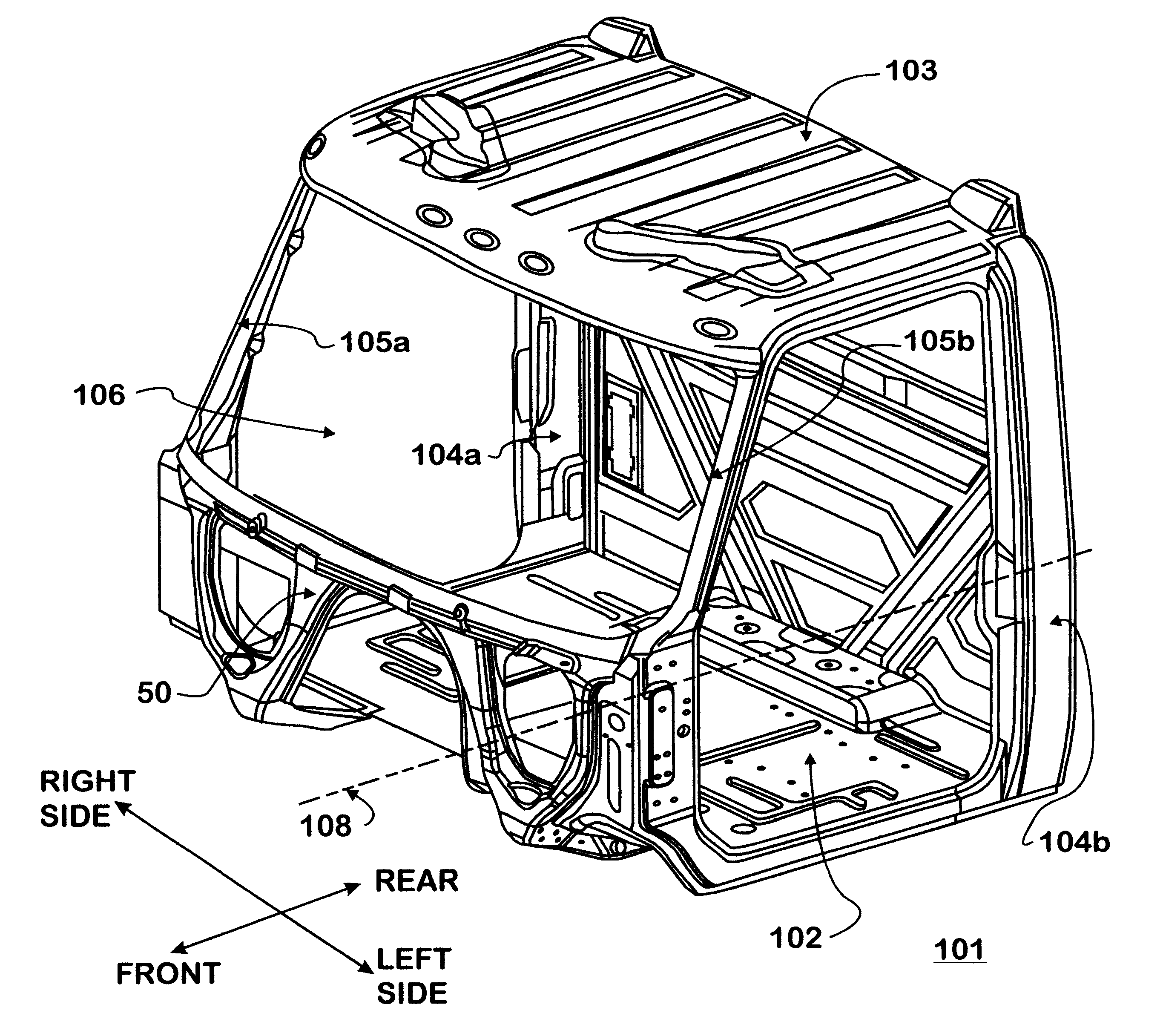

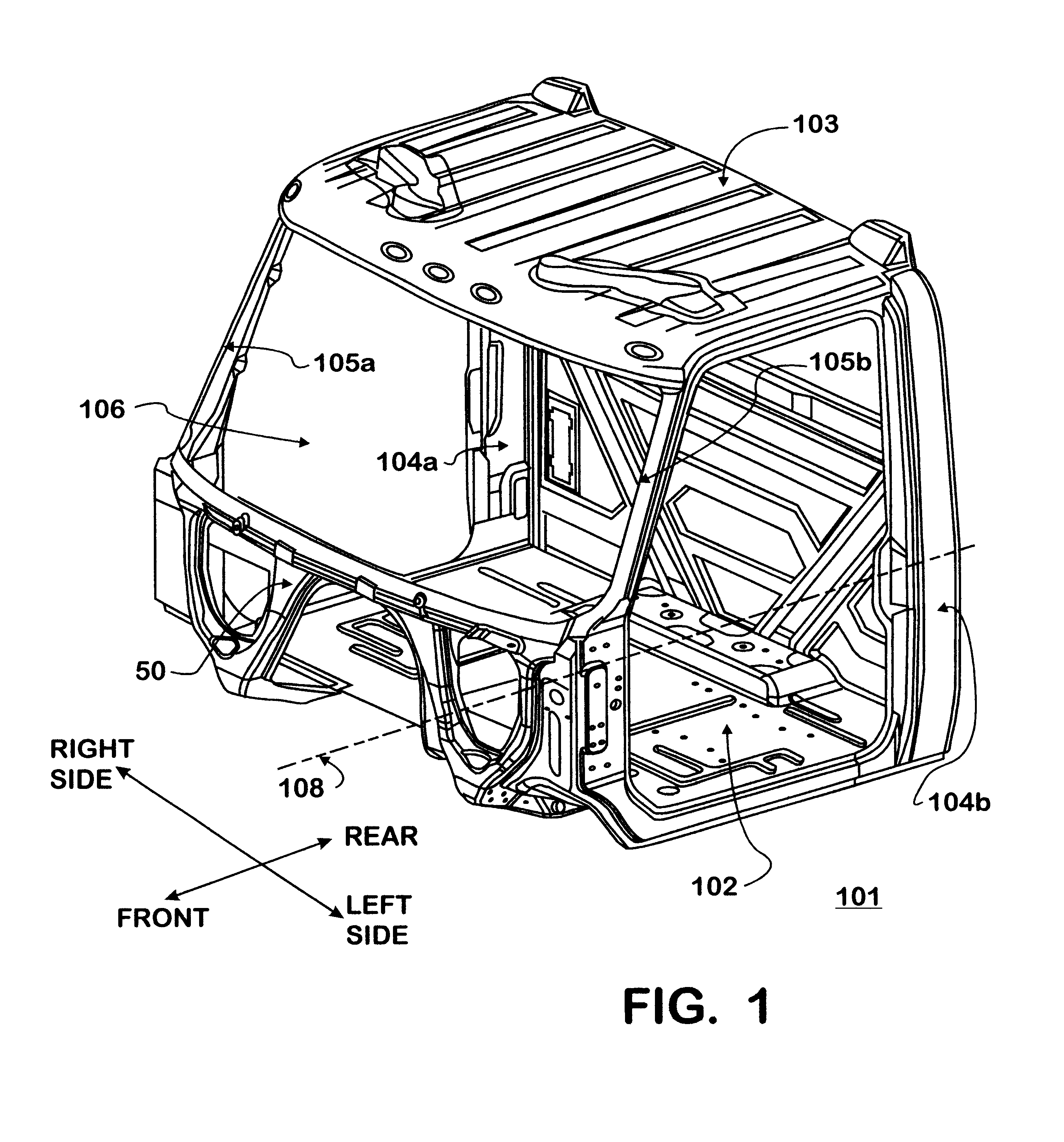

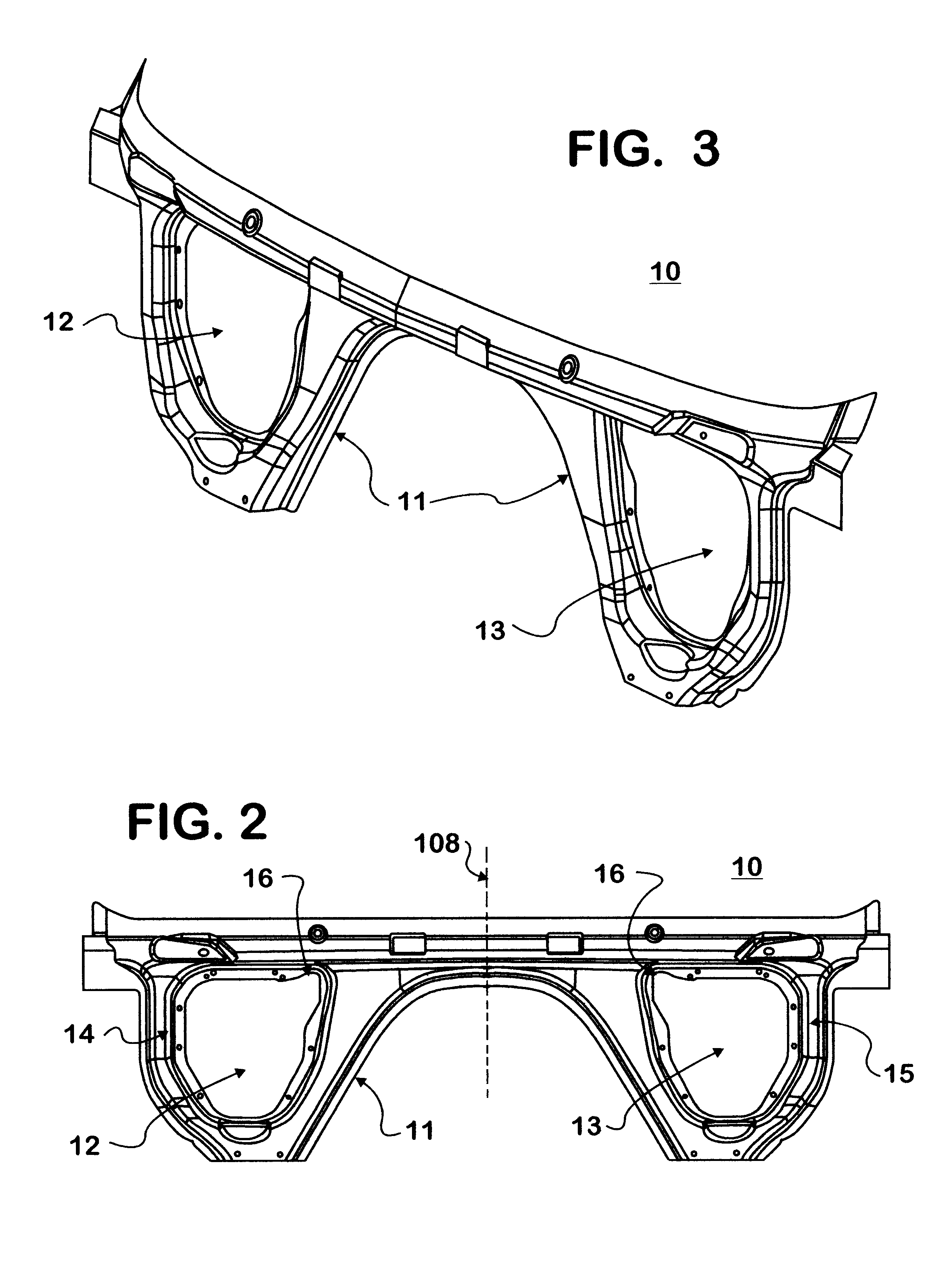

Symmetrical dash reinforcement

InactiveUS6260914B1Easy to shapeImprove rigidityVehicle seatsSuperstructure subunitsMobile vehicleHeavy duty

A dash reinforcement for a mobile vehicle with a passenger cab such as a sport utility vehicle, or medium or heavy-duty truck. The dash reinforcement may be a stamped sheet metal panel that strengthens the dash structure of the cab and provides for mounting of vehicle components. The dash reinforcement may be symmetrical about the centerline of the vehicle and this symmetry allows the panel to accommodate both left-hand drive and right-hand drive vehicle configurations. The dash reinforcement also includes "Y' shaped passages for a driver control module and for accessory equipment such as heating, ventilation, and air conditioning (HVAC) modules. The unique shape of these passages or openings adds strength to the overall dash structure and hence the cab. The dash reinforcement may be engaged to a dash panel to form a dash assembly. The dash panels made be manufactured by the same metal stamping dies moved to account for left-hand versus right-hand drive and conventional versus cab-over-engine or low front engine configuration.

Owner:INT TRUCK INTPROP LLC

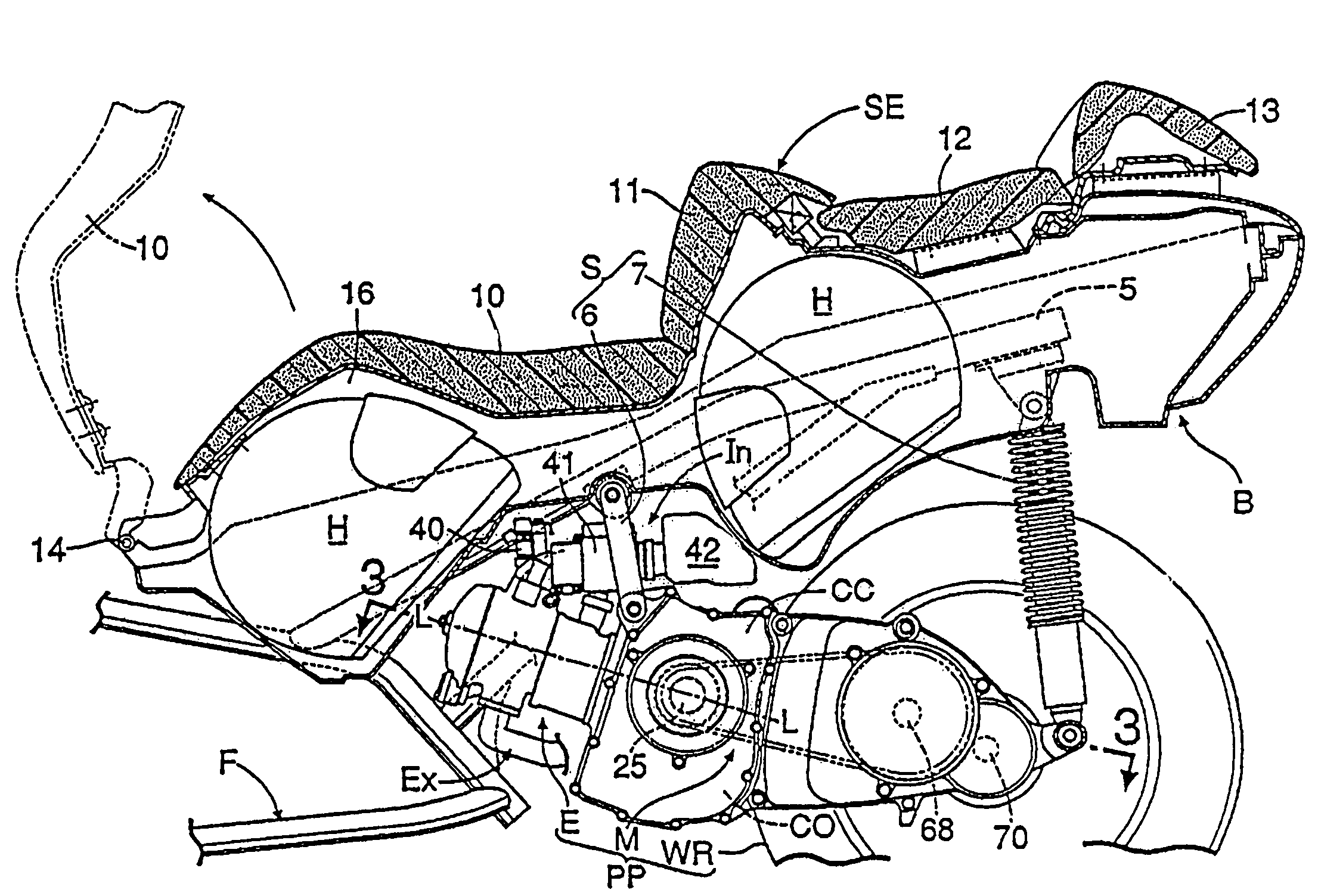

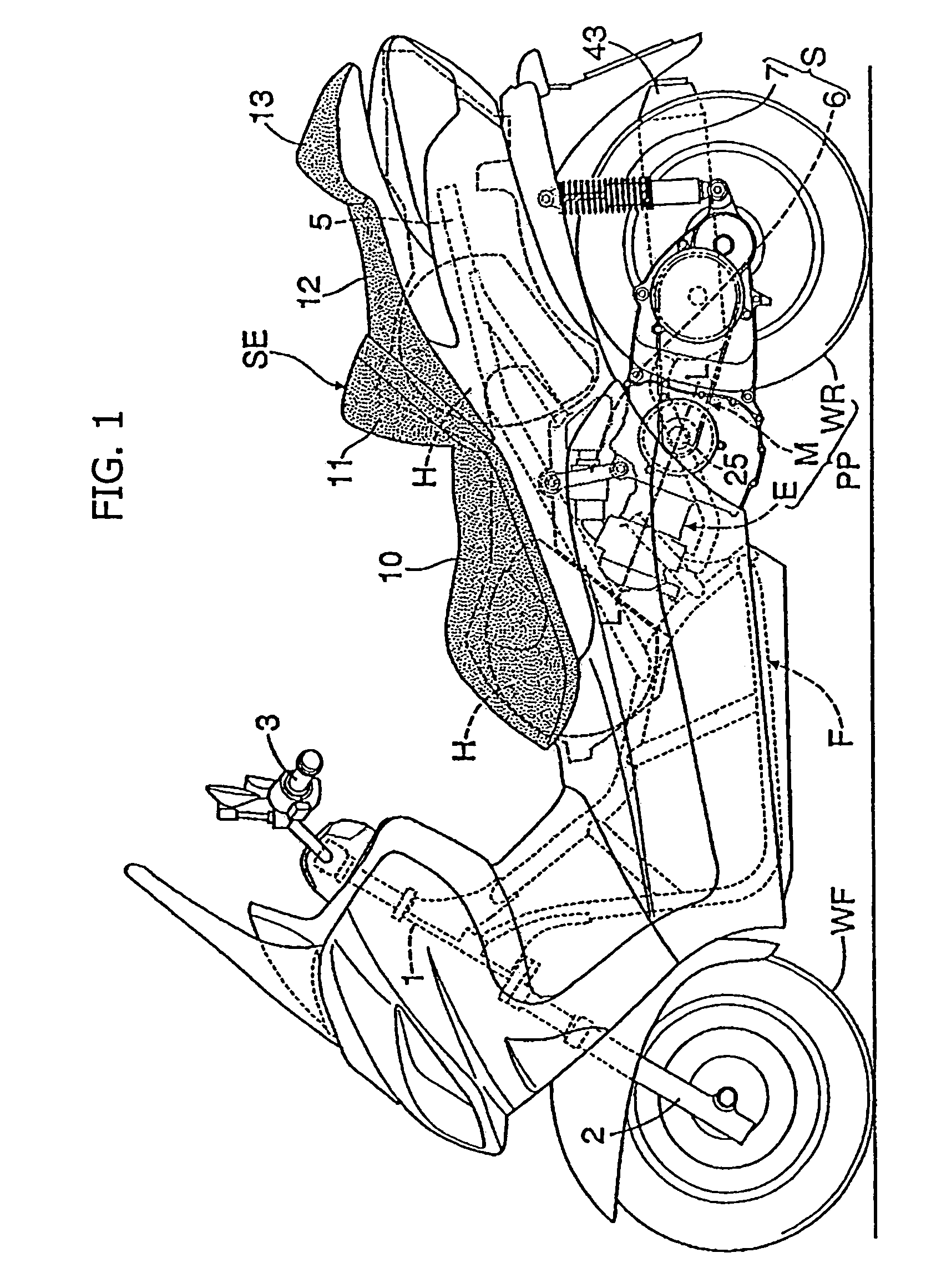

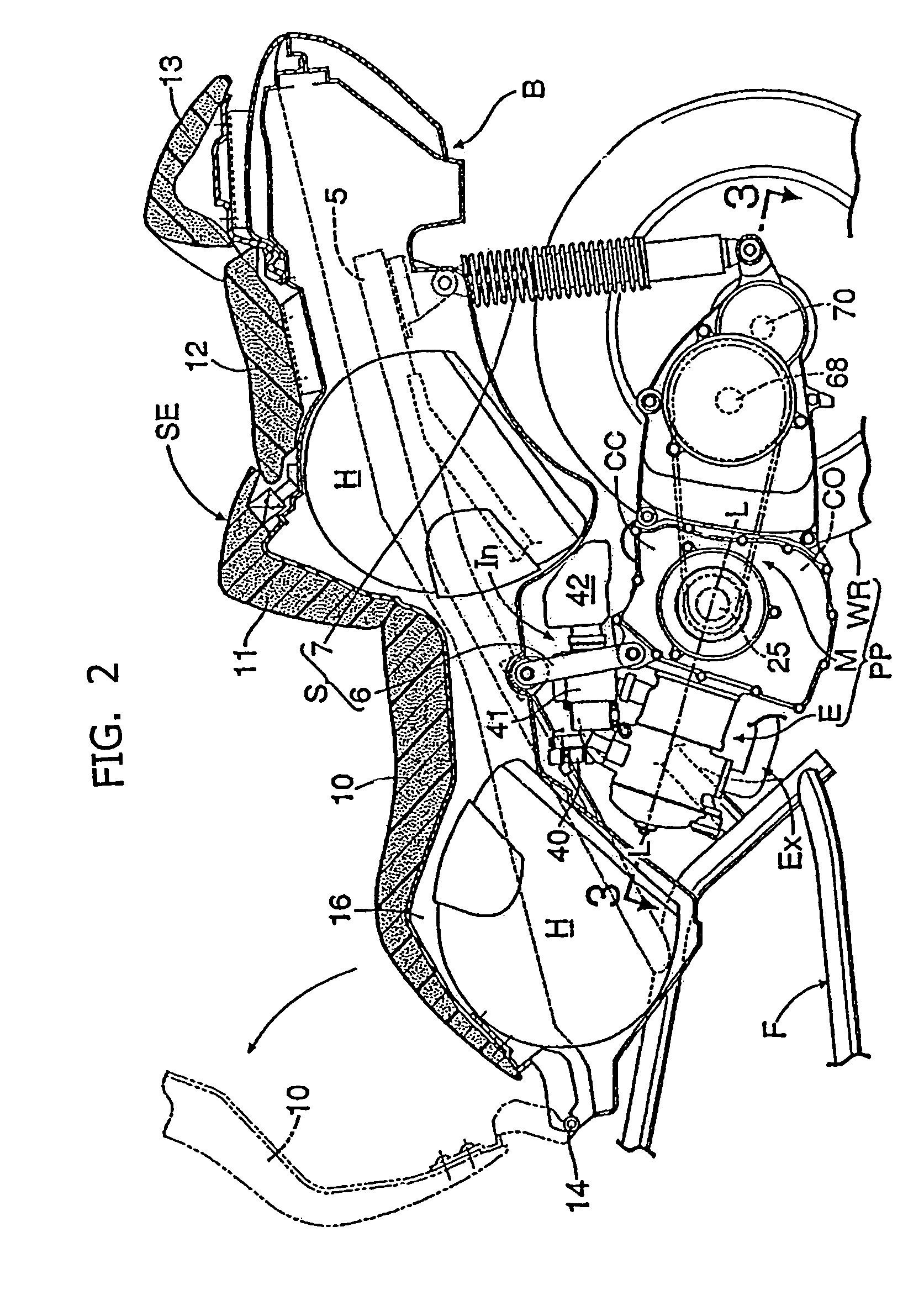

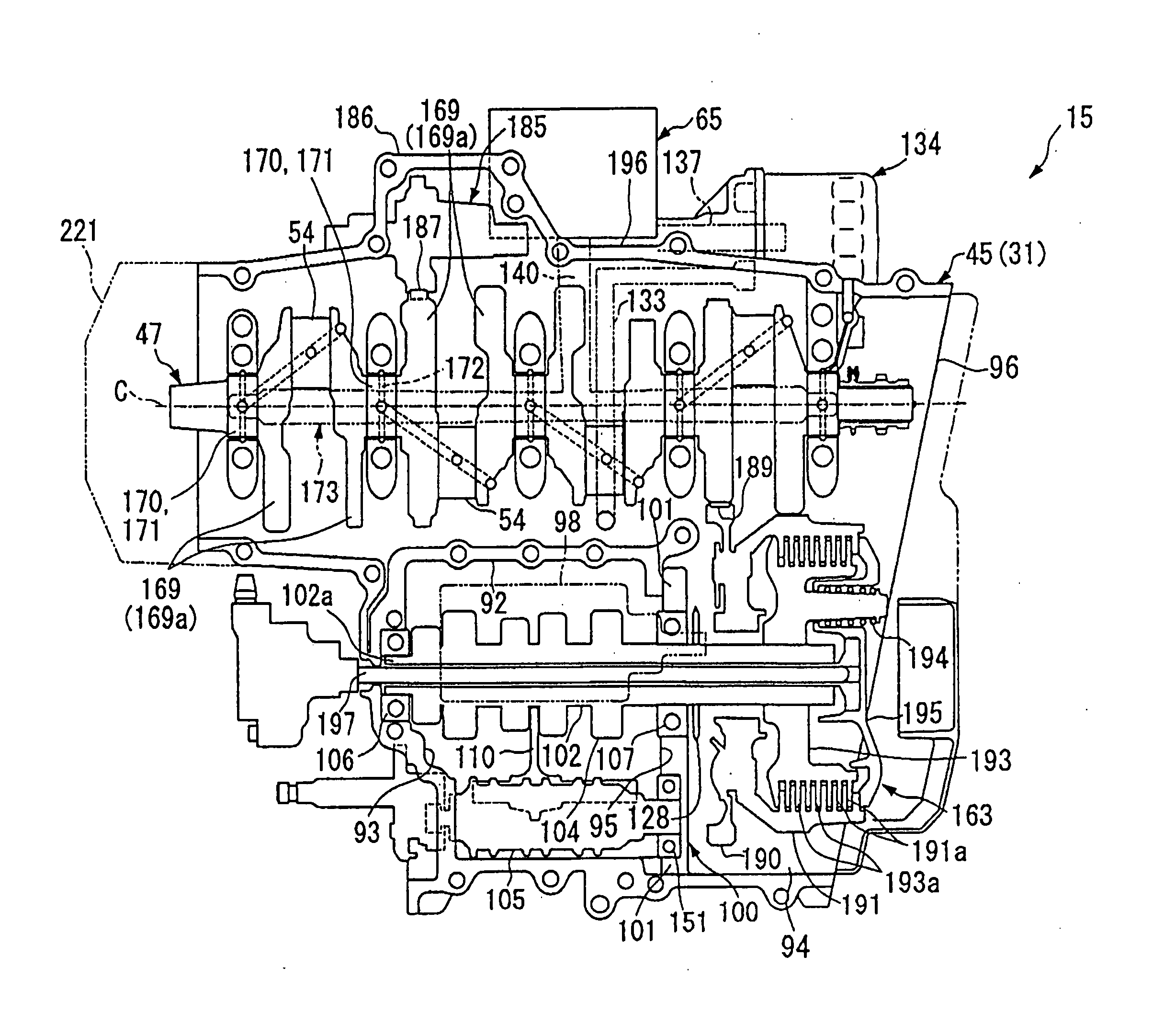

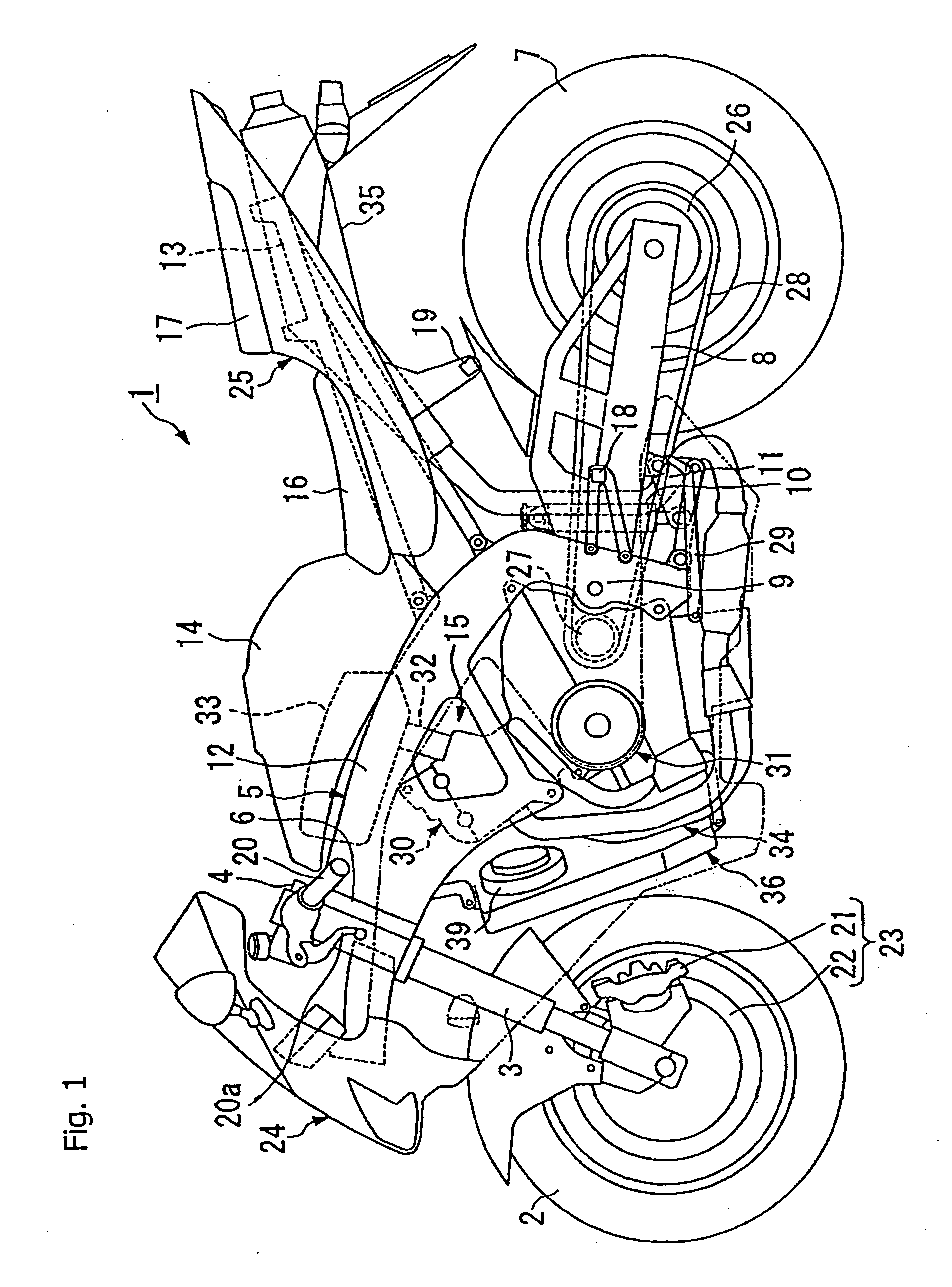

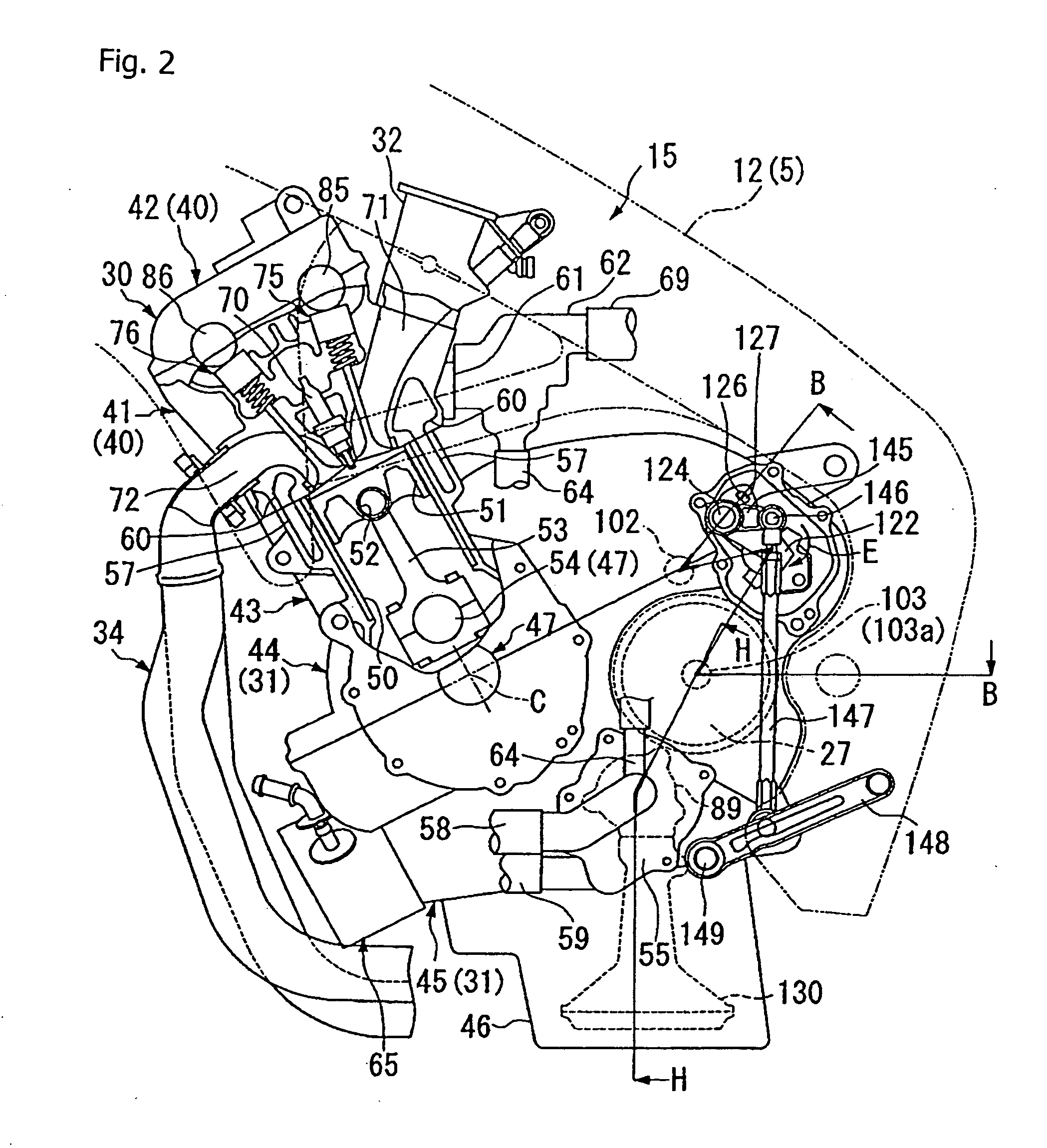

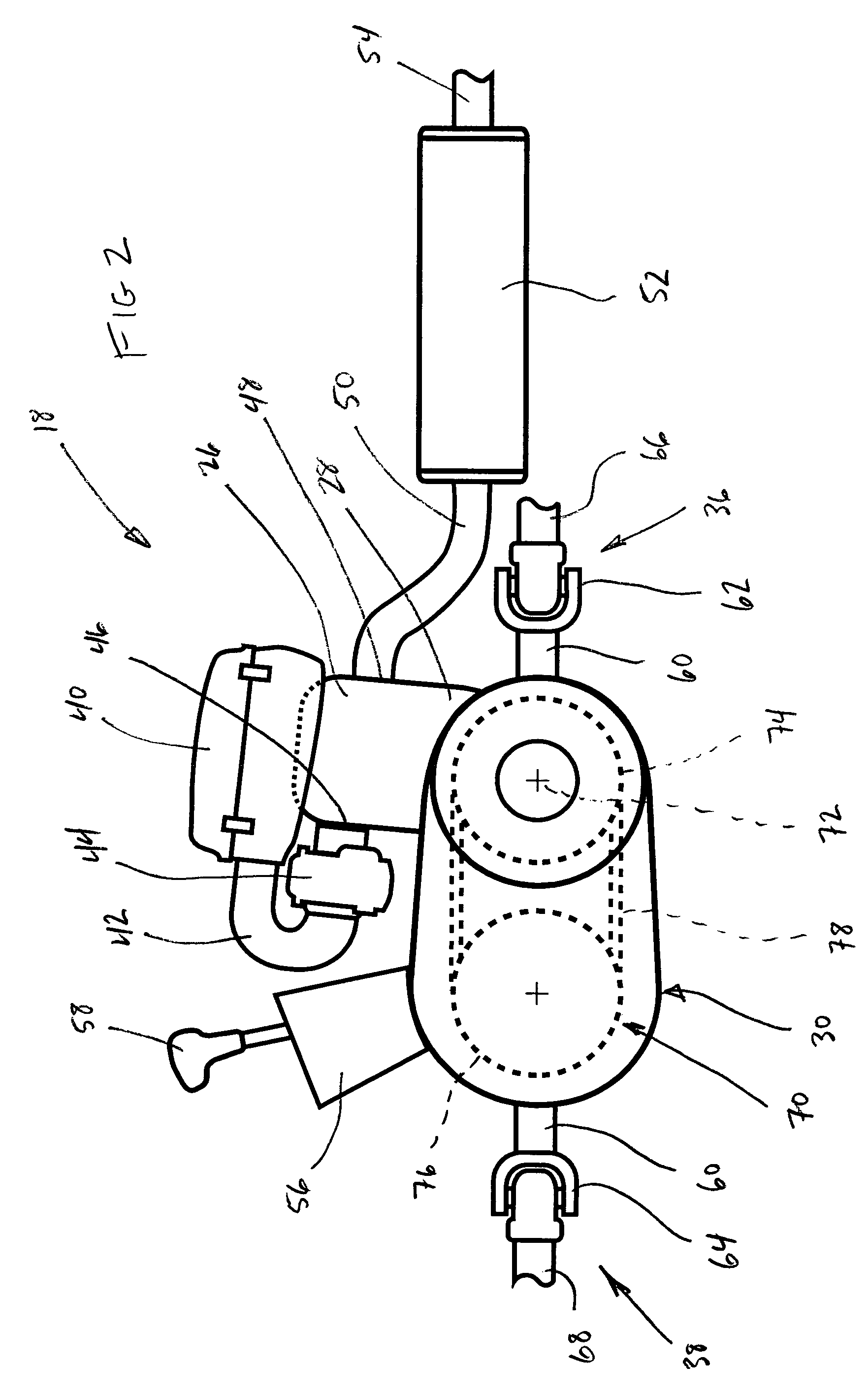

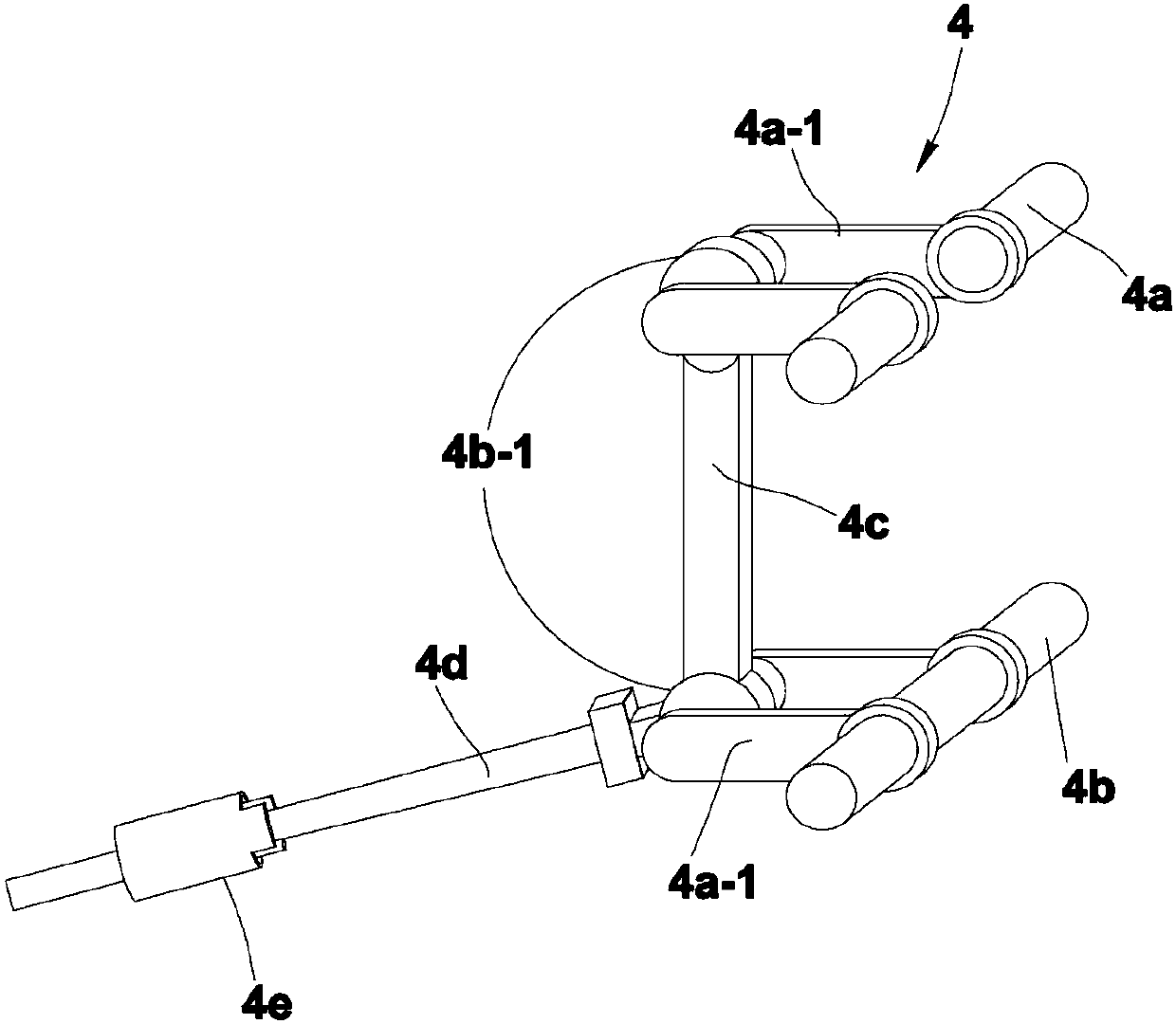

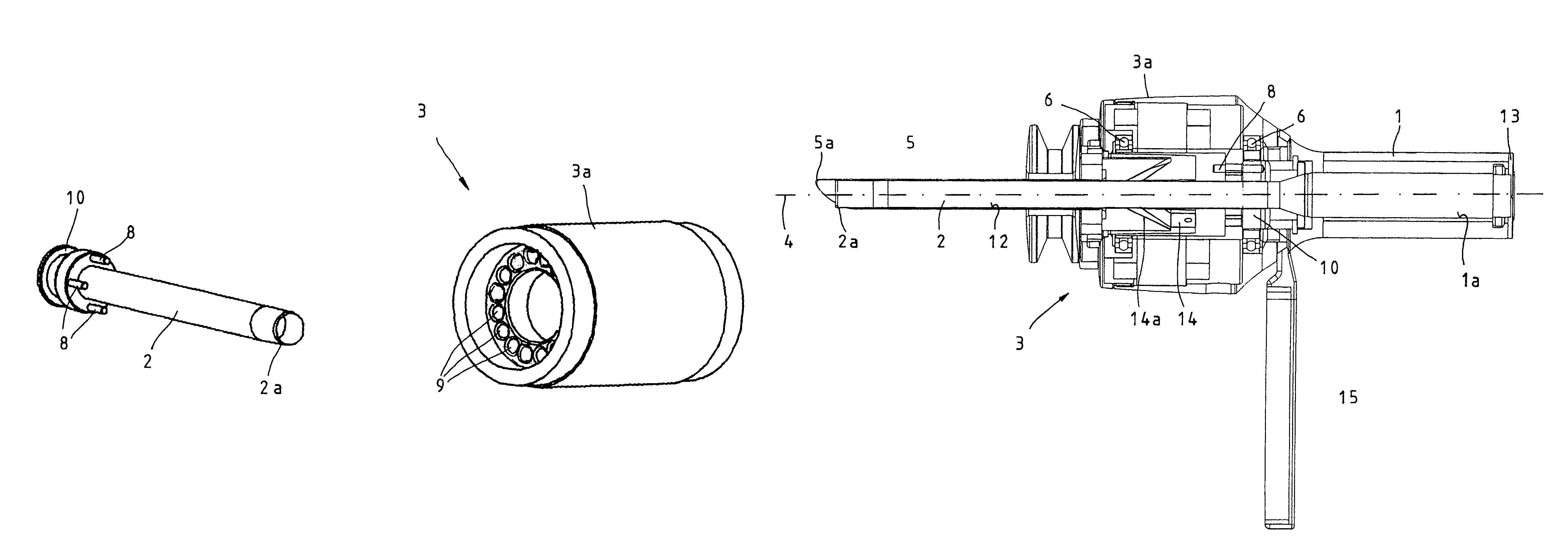

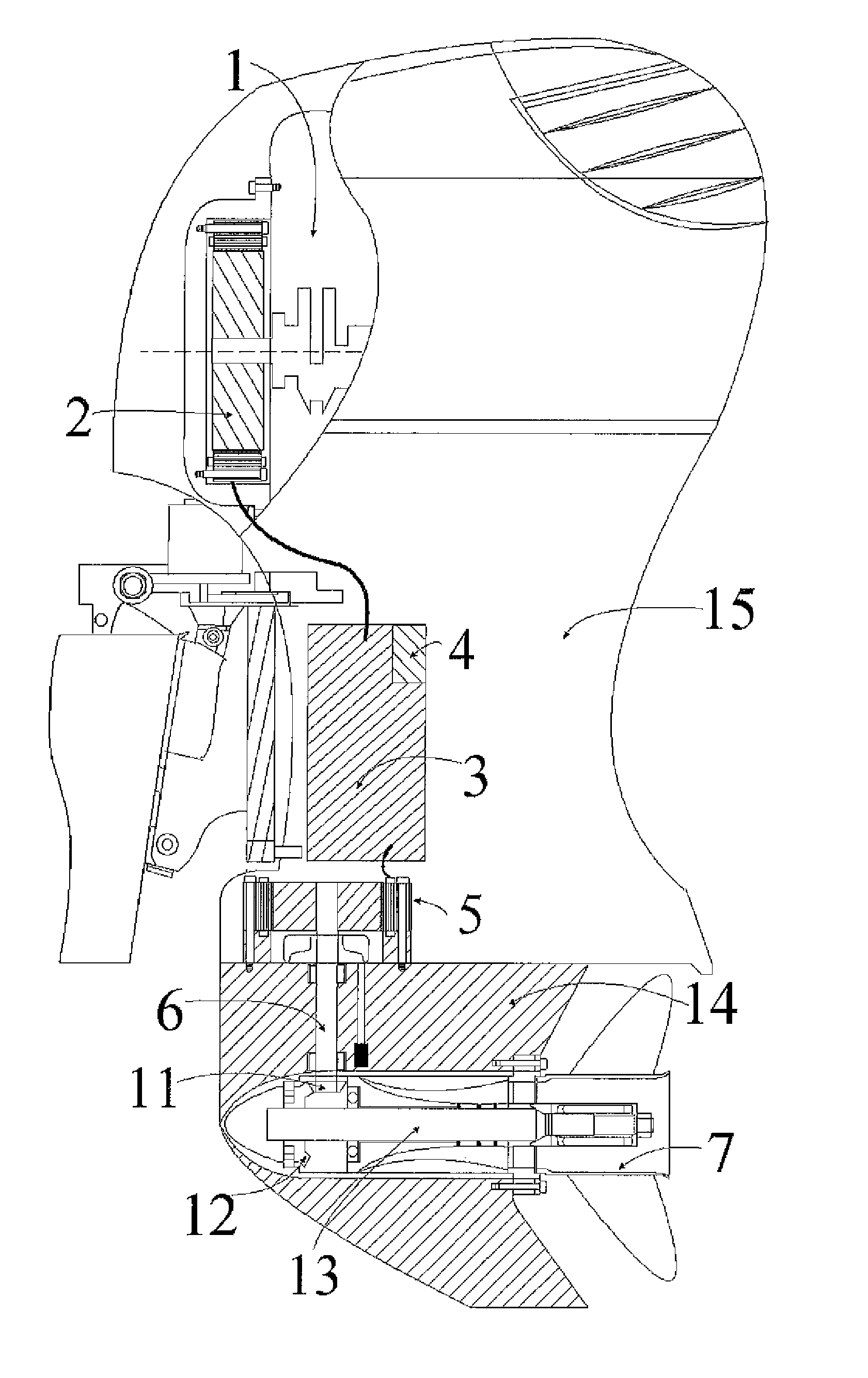

Engine configuration for a motorcycle

ActiveUS7334556B2Prevention of entrance of the lubricating oilEasy to processCasingsLubrication of auxillariesCrankcaseLubrication

A motorcycle is provided in which a seat and a storage box are arranged so as to be vertically stacked on each other in a rear portion of a body frame, and a pivotally mounted powertrain unit is suspended from the body frame under the storage box. The powertrain unit extends in the fore-and-aft direction of the body frame, and the engine has a crank chamber and a lubricant oil chamber provided separately from each other. A lubrication-oil passage structure for the engine is provided between each of a pair of journal bearing portions of a crankcase. The crankcase has an enclosed crank chamber and a crankshaft which is freely rotatably supported by the journal bearing portions with plain bearings. The journal bearing portions are provided with protrusion bosses for resisting entry of lubricating oil into the crank chamber from outside of the crankcase.

Owner:HONDA MOTOR CO LTD

Gearless/oilless gas turbine engine

InactiveUS6881027B2Increase operating pressureIncrease capacityEngine sealsPump componentsMagnetic bearingLubrication

The complex mechanical gear trains and lubrication systems of conventional engine configurations are eliminated by using combinations of hydrodynamic air foil bearings, hydrodynamic solid geometry carbon seals / bearings, magnetic bearings, and electrical starter / generators that can also act as bearings to support the high speed shafts of gas turbine engines. The various bearing types and the starter / generators are arranged in such a way as to share peak loads experienced by the engine shaft during maximum aircraft maneuvers. This results in a minimal bearing and engine size.

Owner:HONEYWELL INT INC

Powertrain assembly including modular transmission

A powertrain assembly having an improved engine configuration includes an engine and a transmission incorporated in a crankcase of the engine. The engine also comprises an oil pump and a water pump. The transmission is a cartridge-type shift drum transmission, which can be attached to or detached from a transmission attachment face which is a side face of the crankcase. The oil pump and the transmission attachment face are arranged in substantially non-overlapping relation in the side view of the engine. The water pump shaft is substantially coaxial with the oil pump shaft, and the water pump is positioned below a drive sprocket on the transmission countershaft so as to be overlapping while eliminating interference between them, allowing a close arrangement of components.

Owner:HONDA MOTOR CO LTD

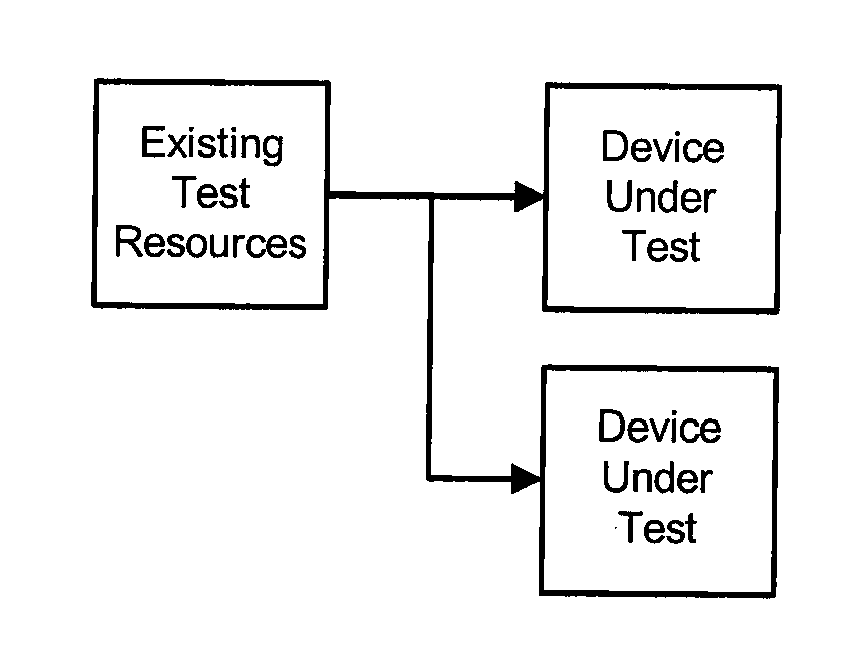

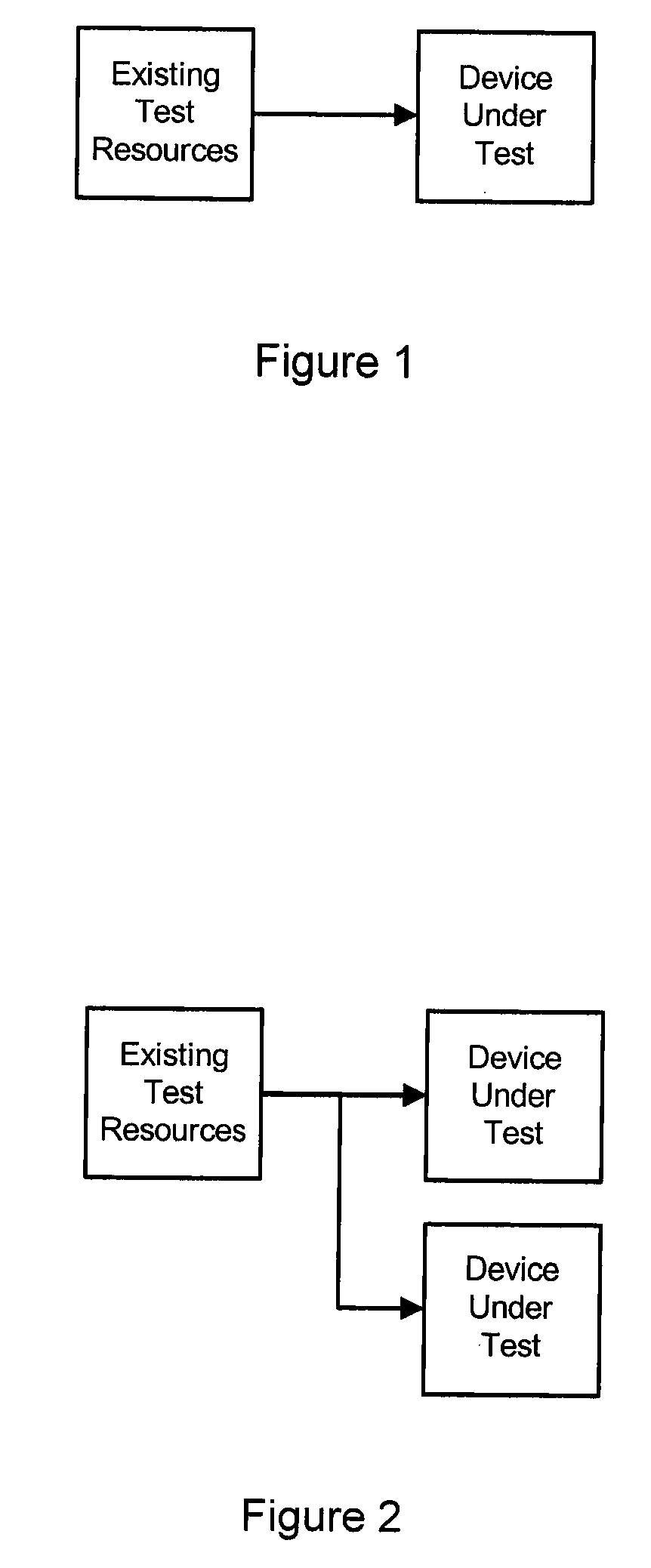

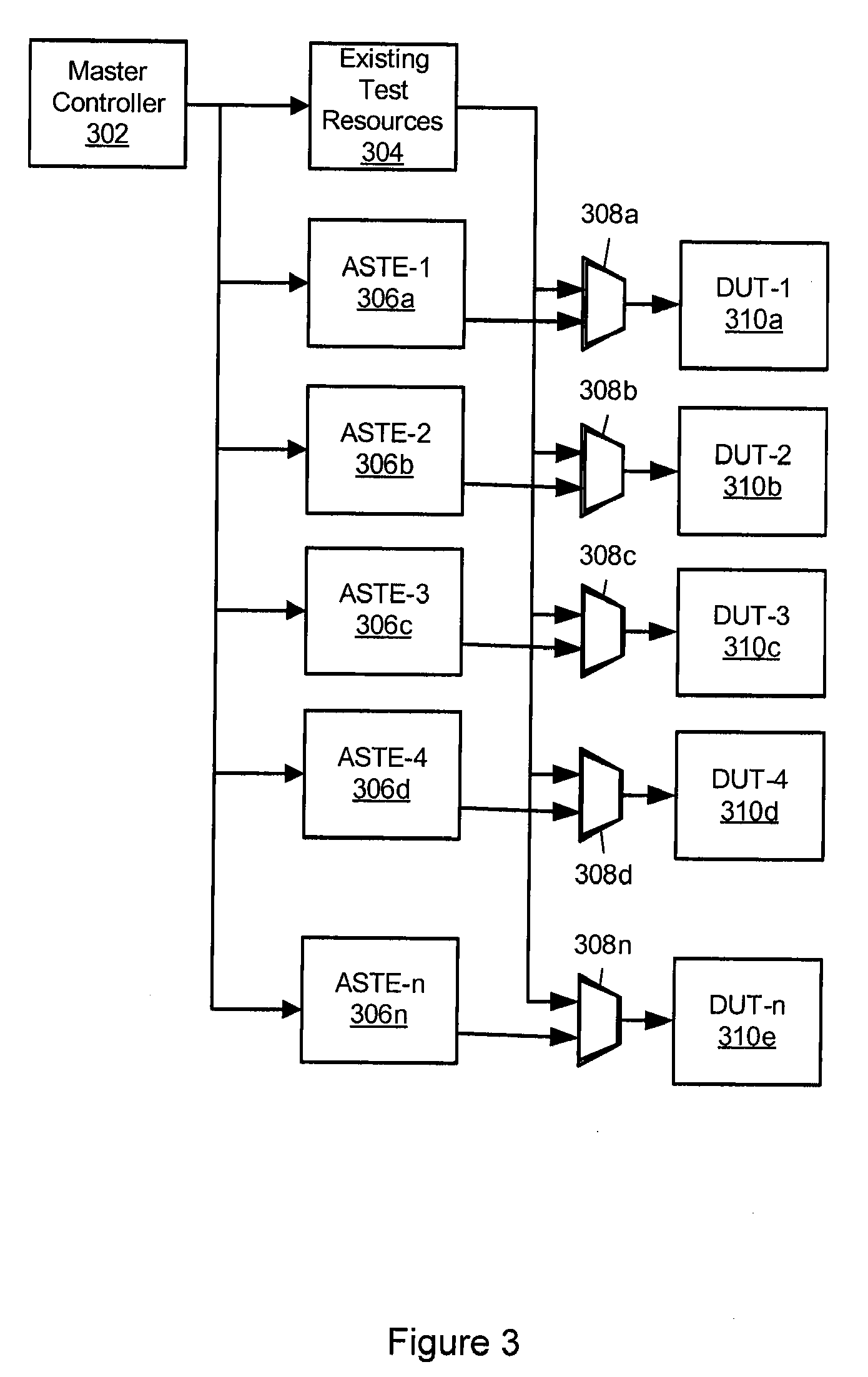

Application Specific Distributed Test Engine Architecture System And Method

InactiveUS20070245199A1Improve test throughputImprove overall utilizationElectronic circuit testingError detection/correctionDistributed testingTest requirements

An Application Specific Distributed Test Engine (ASDTE) that provides an optimized set of test resources for a given application. The test engine resources, configuration, functionality, and even the number of test engines can be changed as different devices are tested, or as different test methodologies are used with the system. This can be done by including the test engine configuration as a part of the application files that are loaded during the system set-up. This approach differs from conventional testing systems which limit testing to a fixed, limited, or standard stimulus / response engine configuration intended to test a variety of devices. Some of the benefits of the Application Specific Distributed Test Engine Architecture include: (1) a very high test throughput, (2) the ability to adapt system functionality and capabilities to meet different and new, unforeseen device test requirements on a lot-by-lot basis on a production test floor, and (3) the ability to change the number of test engines to optimize tester channels and system utilization.

Owner:POCHOWSKI ROBERT

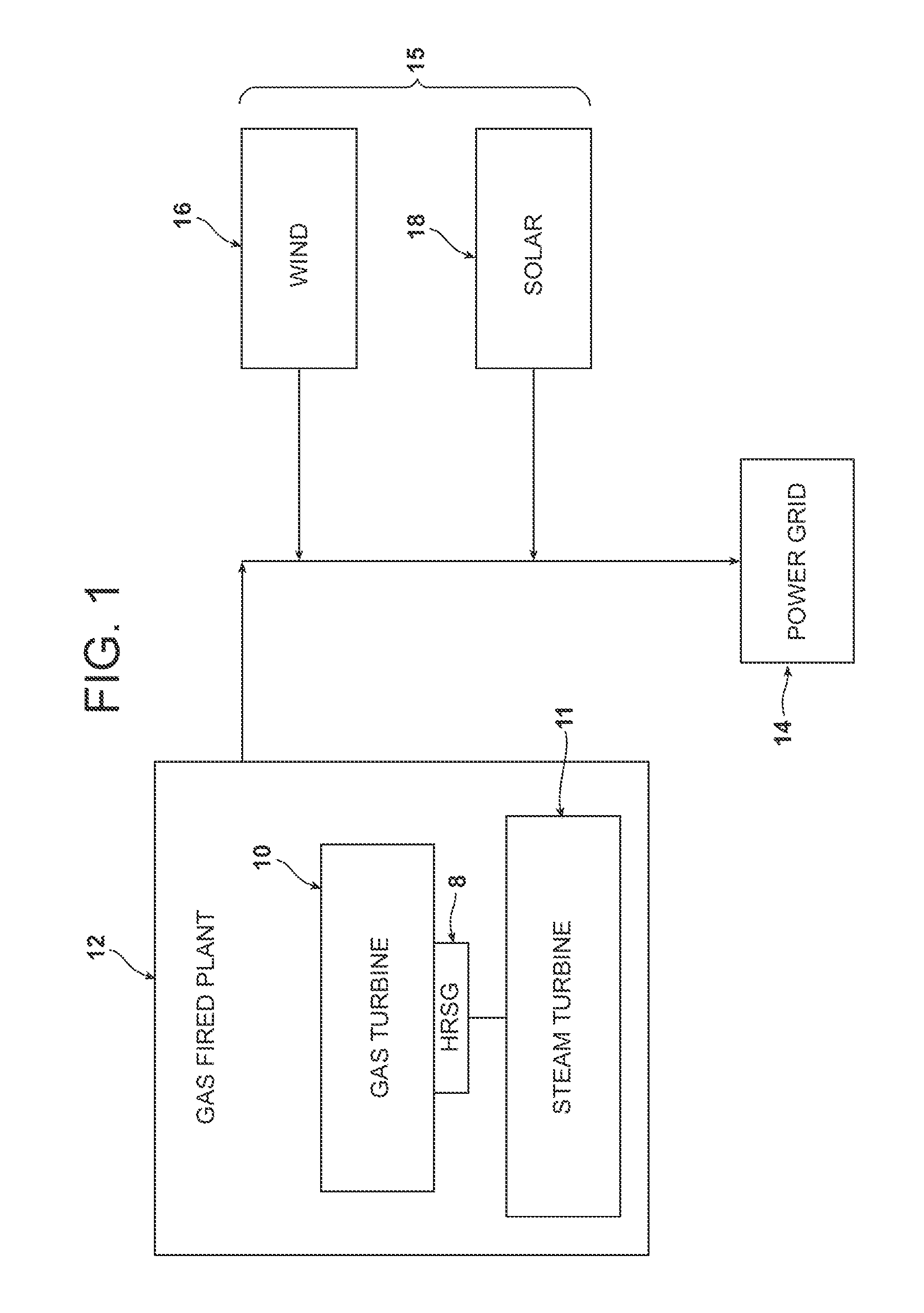

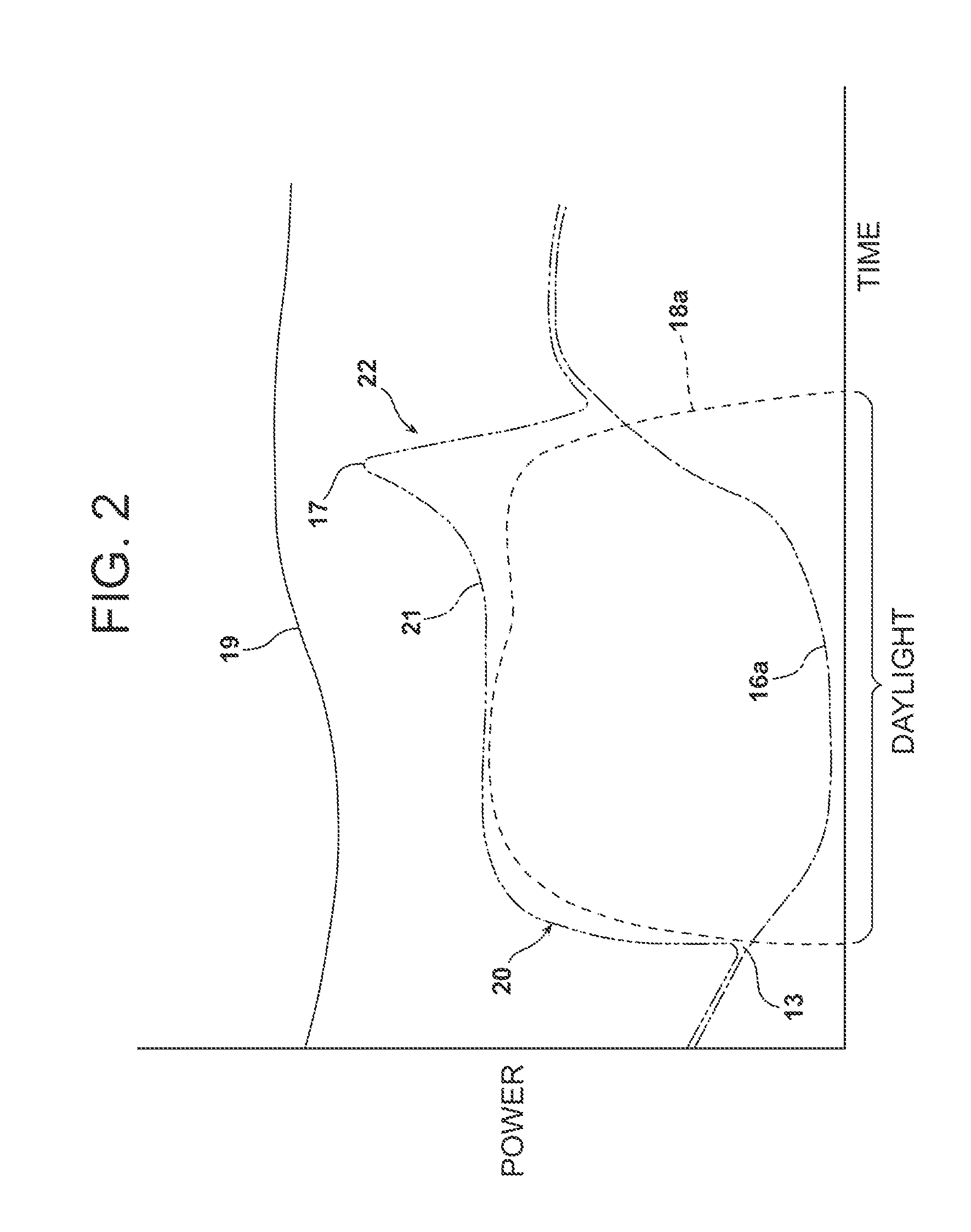

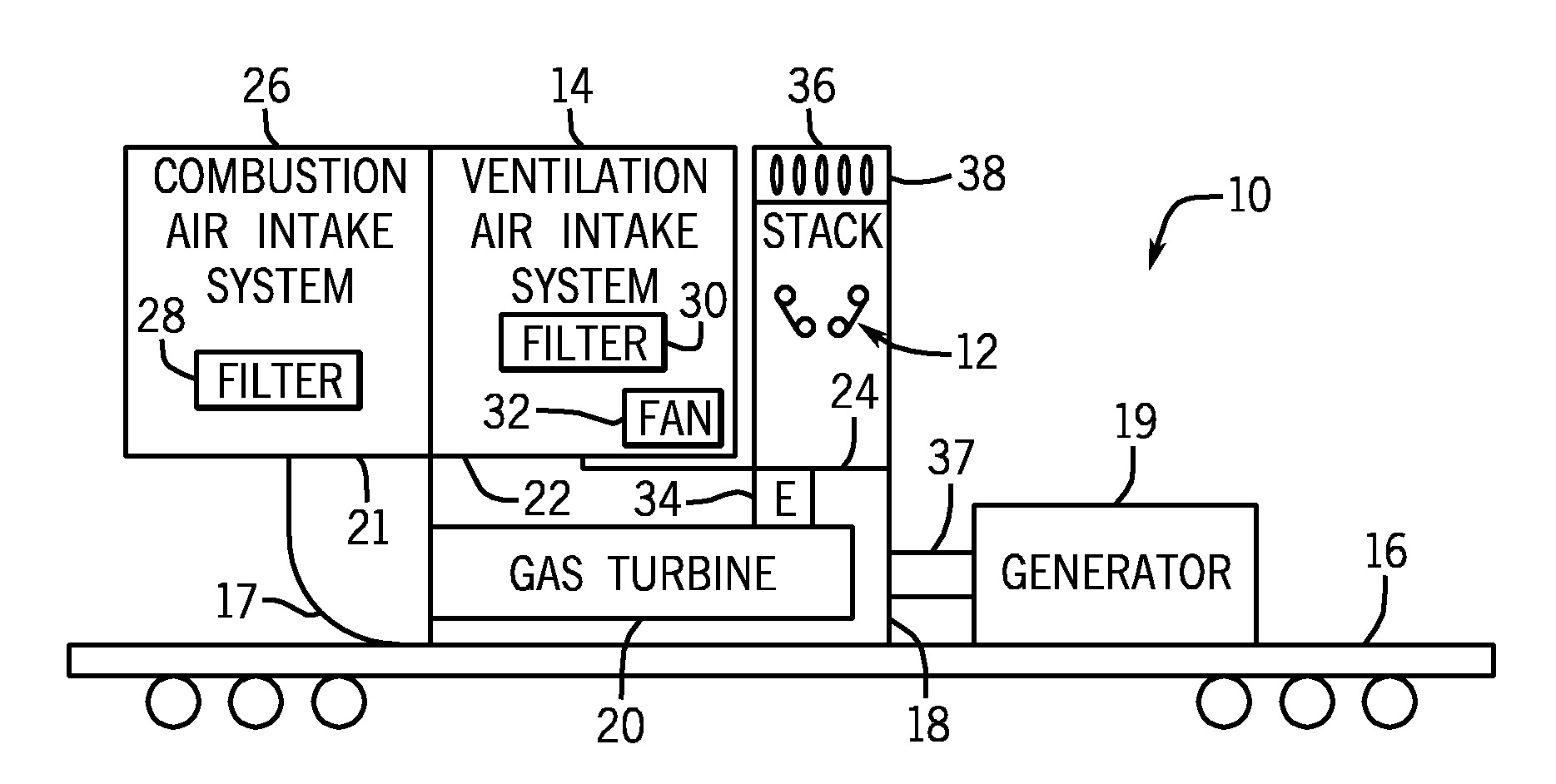

Gas turbine engine configured to shape power output

ActiveUS20130227954A1Reduce the total massReduce power outputGas turbine plantsTurbine/propulsion fuel controlPower gridPeak load

A gas turbine engine and method of controlling the gas turbine engine that may be utilized in a power grid having a plurality of additional power generation sources. The gas turbine engine is configured with a compressor having an enlarged mass flow volume. The gas turbine engine may be operated at a base load for supplying power to the power grid at a part load and optimum efficiency for the engine, and may be ramped up to a higher output to supply a peak load output to the power grid.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Part load blade tip clearance control

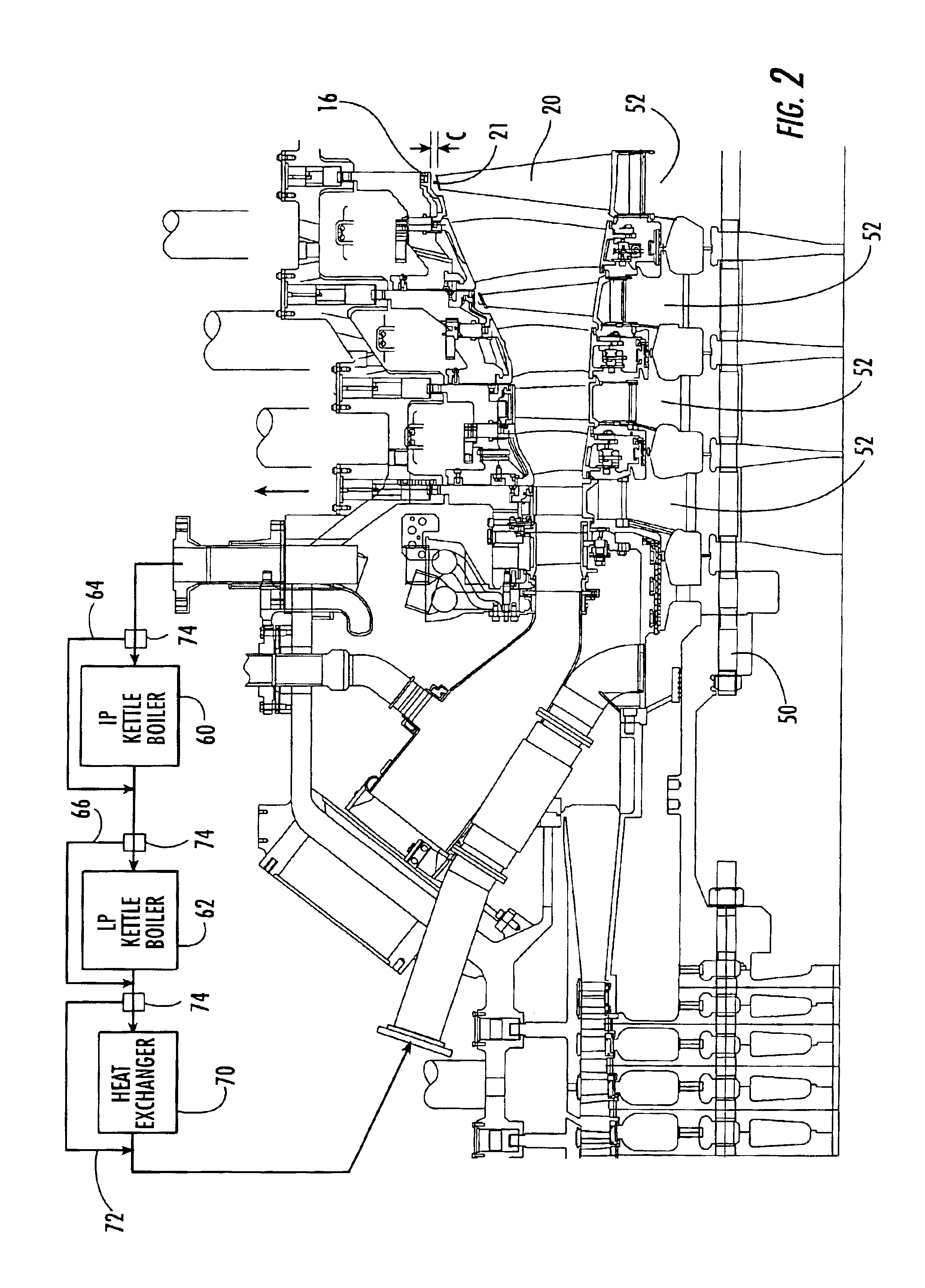

InactiveUS6968696B2Reduce the temperatureConstant cooling temperatureTurbine/propulsion engine coolingBlade accessoriesTurbine bladeDegree Fahrenheit

Aspects of the invention relate to a turbine engine configuration and method for overcoming a turbine blade tip clearance problem that can arise when the turbine inlet temperature is maintained at a high level during part load operation of the turbine. Aspects of the invention relate to reducing rotor cooling air to a temperature below the design temperature level by using, for example, additional heat extraction devices or by reconfiguring or resizing existing heat exchanger devices. Upon exposure to the cooled air, the discs and blades of the turbine will shrink so as to provide a clearance between the blade tips and surrounding stationary support structure. The design rotor cooling air temperature can be from about 350 degrees Fahrenheit to about 480 degrees Fahrenheit. Aspects of the present invention can be used to decrease the rotor cooling air to about 150 degrees Fahrenheit at about 70 percent load.

Owner:SIEMENS ENERGY INC

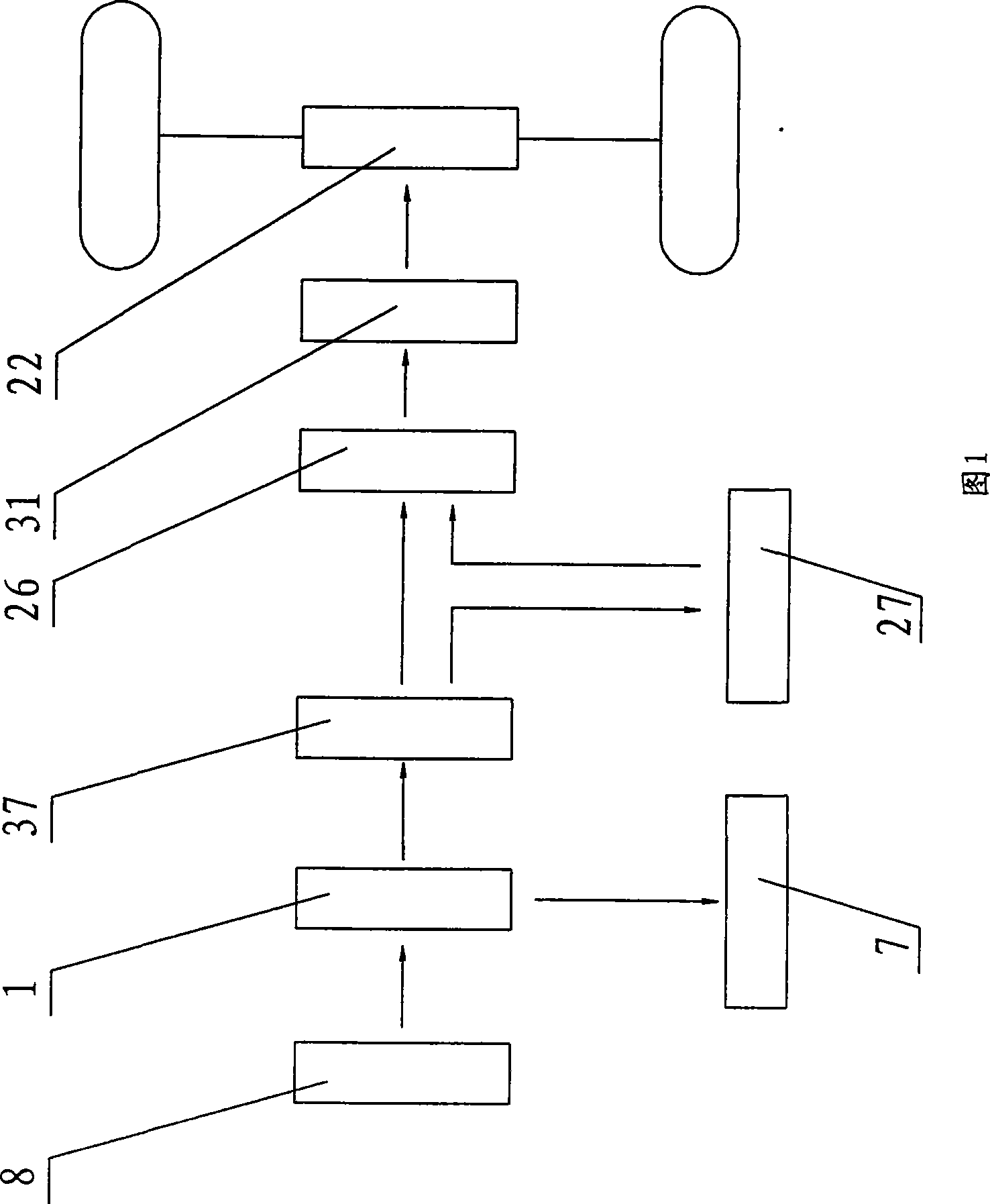

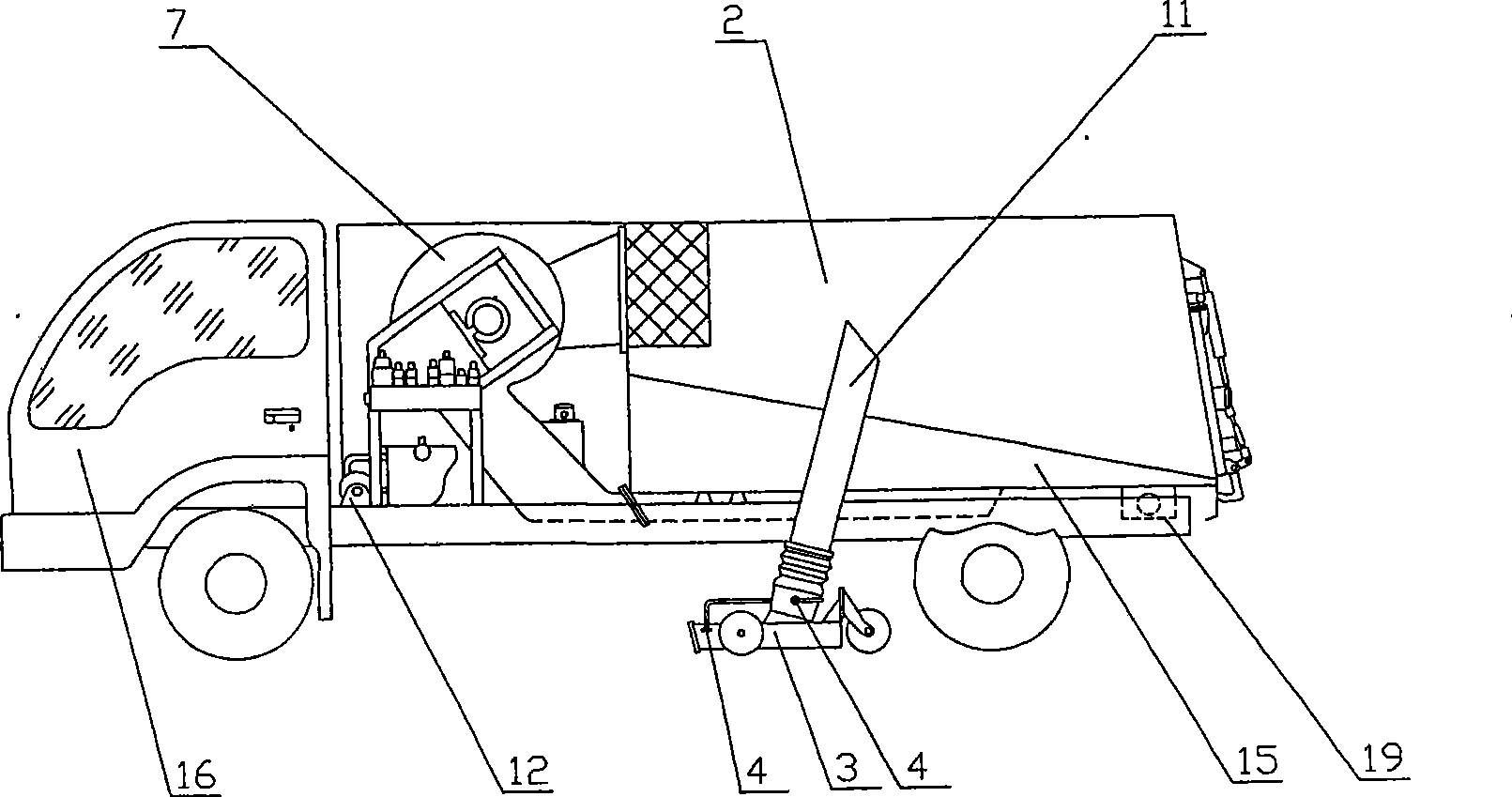

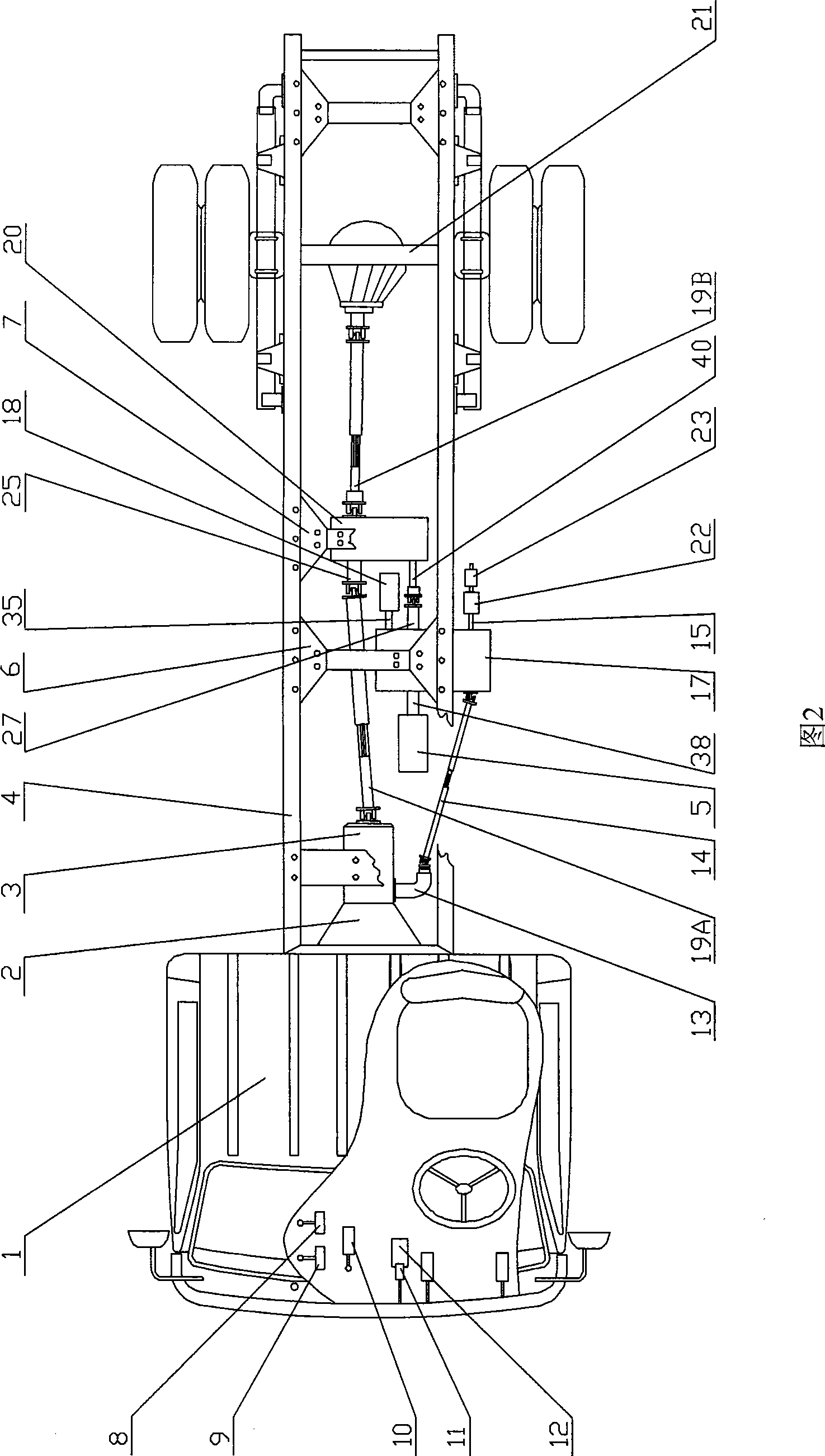

Hybrid dust absorption environmental sanitation vehicle and hybrid sweeping environmental sanitation vehicle

InactiveCN101392506AMeet the uncertain long-term continuous operation needsMeet power needsRoad cleaningTransfer caseVehicle frame

The invention relates to a hybrid vacuum sweeper. A chassis is provided with an engine, a gear transfer case, a silicon rectifying generator, a storage battery, a power converter, a motor, a dustbin, a suction tube, a suction cup, a fan, a water tank and a water pump. The engine drives the silicon rectifying generator and the fan respectively. The silicon rectifying generator is connected with the power converter and the storage battery to output generated electric current. The power converter is connected with the motor to drive a rear axle shaft to drive the vacuum sweeper to run. The fan sucks dust and garbage on the ground in front of the suction cup into the dustbin through the dustbin, the suction tube and the suction cup. The water pump pumps water from the water tank to control the dust in the suction tube and the suction cup by a wet method. In the invention, a hybrid drive technology is applied to a special urban environment sanitary vehicle with vehicle-mounted operating devices, and the special vehicle has an oil-saving effect due to the use of a single engine as well as good operation effects; and a hybrid drive mechanism continuously generates electricity and overcomes the drawback that an electrical vehicle can not work for a long time due to the limitation from the capacity of the storage battery.

Owner:赵国贵

System and method for controlling vehicle operation

A hybrid vehicle propulsion system is disclosed comprising an engine having at least one combustion cylinder configured to operate in a first and a second combustion mode, wherein the first combustion mode is a spark ignition mode and the second combustion mode is a compression ignition mode, wherein the engine is configured to supply an engine output; a motor configured to selectively supply or absorb a secondary output; an energy storage device configured to selectively store at least a portion of the engine output and selectively supply energy to the vehicle; and a control system configured to control at least the engine, the motor, and the energy storage device, wherein the control system is configured to selectively operate said at least one combustion cylinder in one of the spark ignition mode and the compression ignition mode based on a condition of the energy storage device.

Owner:FORD GLOBAL TECH LLC

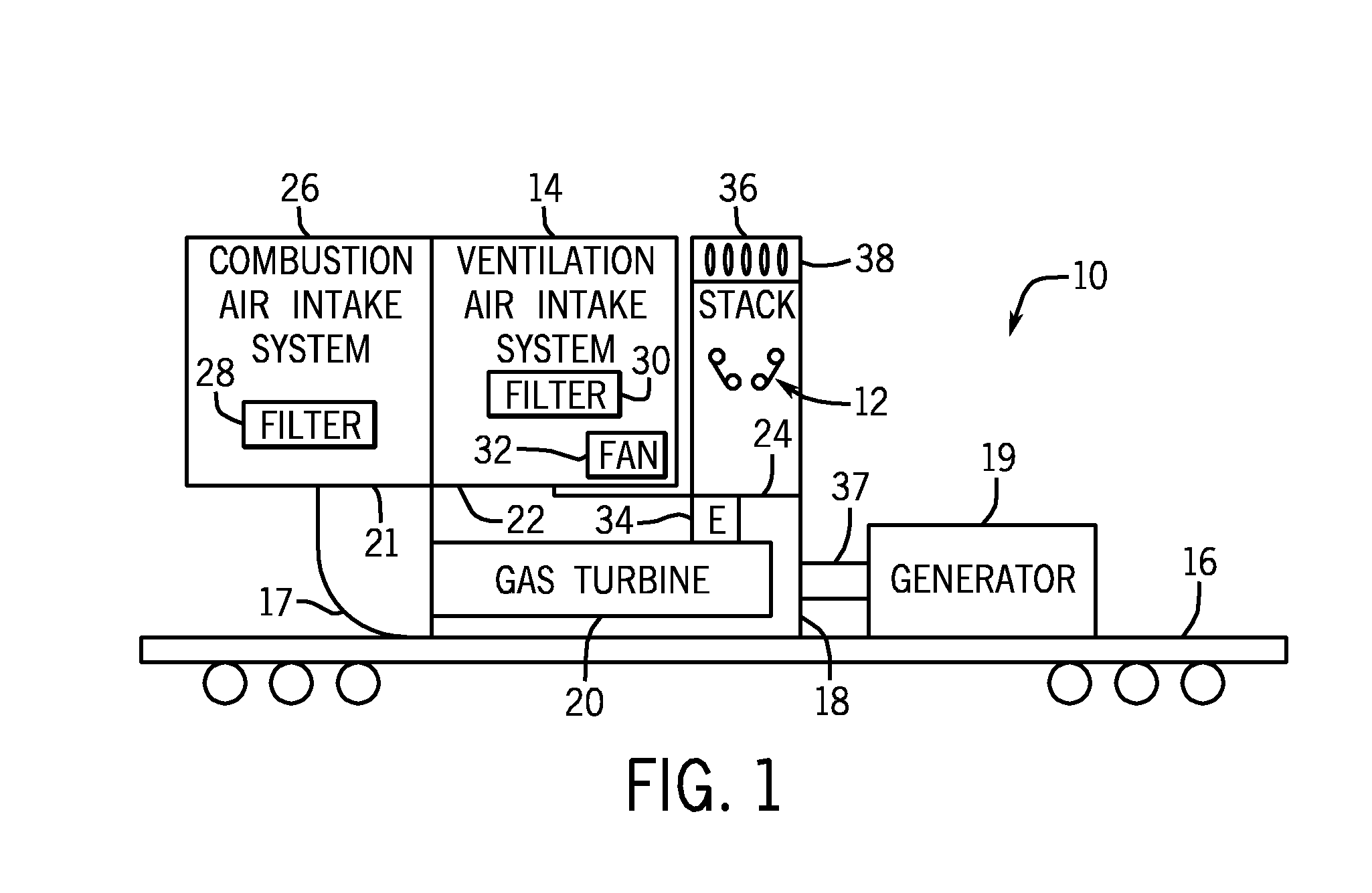

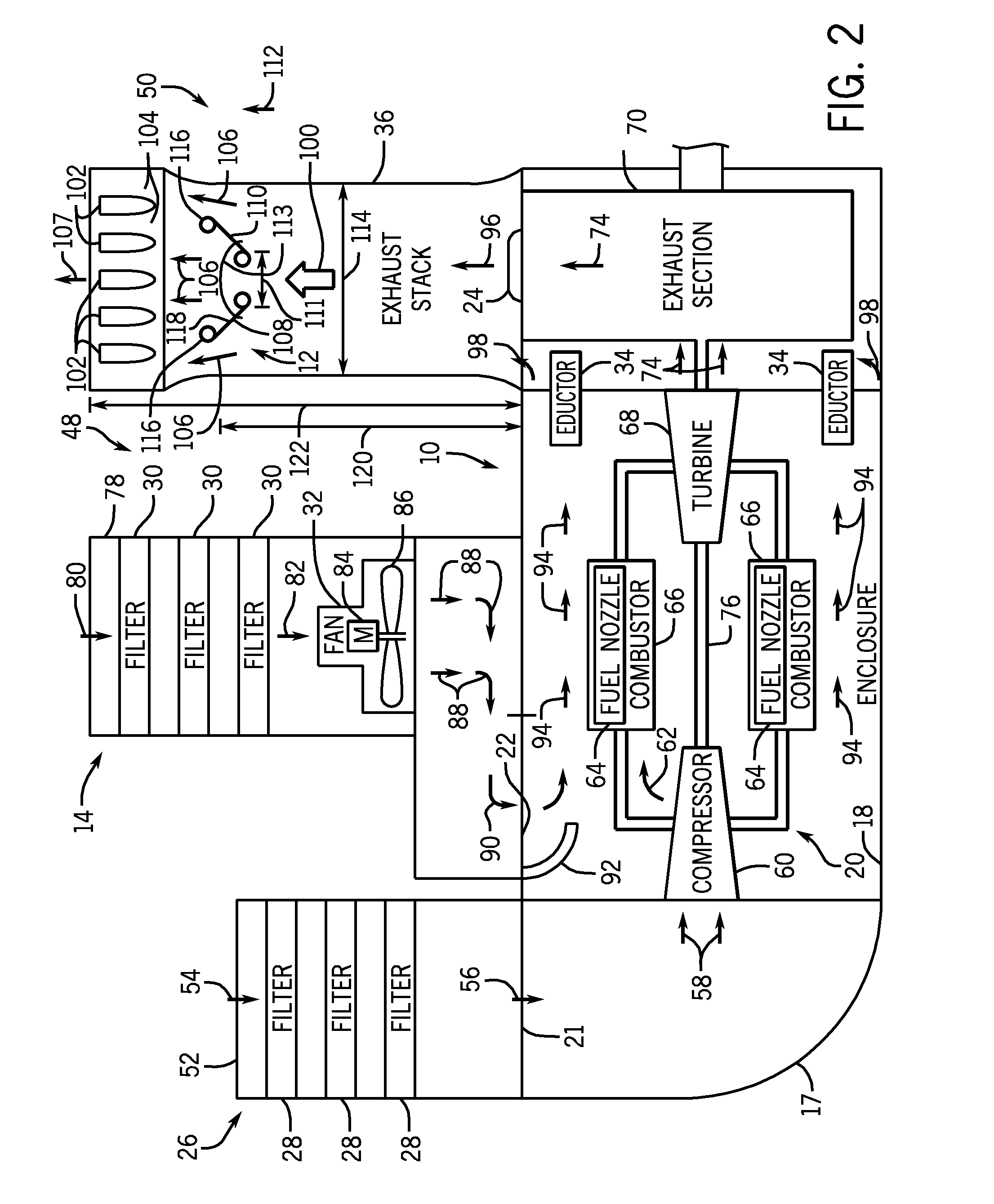

System for managing exhaust flow for a gas turbine

A system includes a gas turbine enclosure. The system also includes a gas turbine engine disposed in the gas turbine enclosure, wherein the gas turbine engine is configured to output an exhaust flow. The system further includes an exhaust driven eductor configured to draw an air flow through and out of the gas turbine engine enclosure using the exhaust flow. The system yet further includes an exhaust stack coupled to the gas turbine enclosure, wherein the exhaust stack is configured to output a mixed flow of the exhaust flow and the air flow. The system still further includes a diffuser plate disposed within the exhaust stack, wherein the diffuser plate is configured to provide a homogenous flow distribution for the mixed flow downstream of the diffuser plate.

Owner:GENERAL ELECTRIC CO

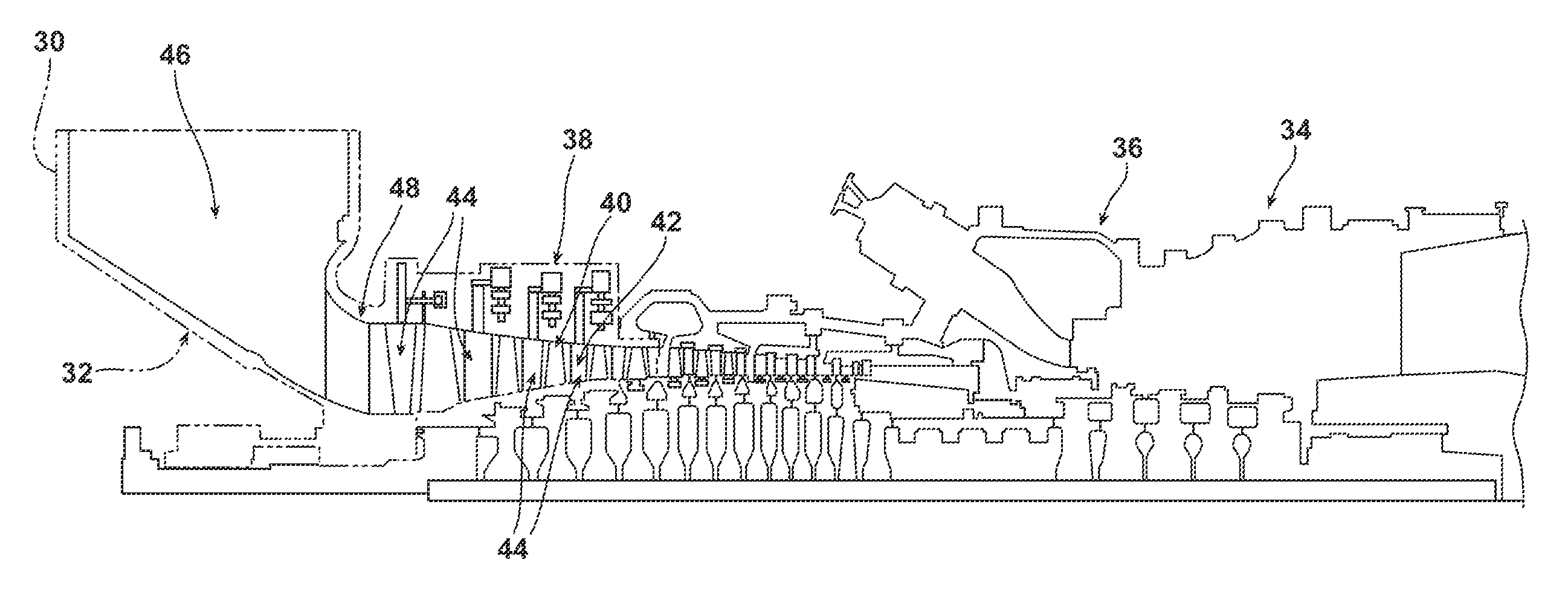

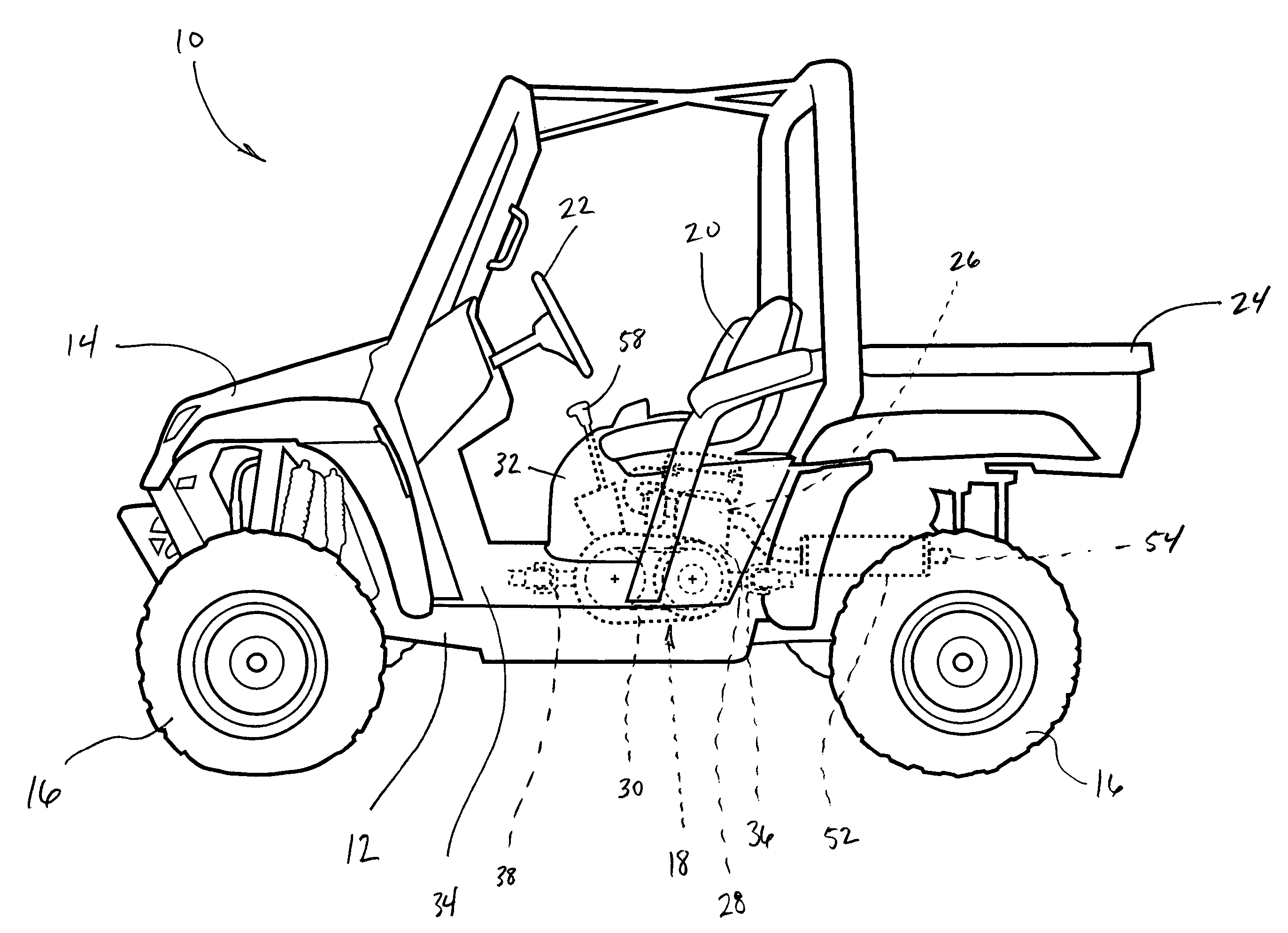

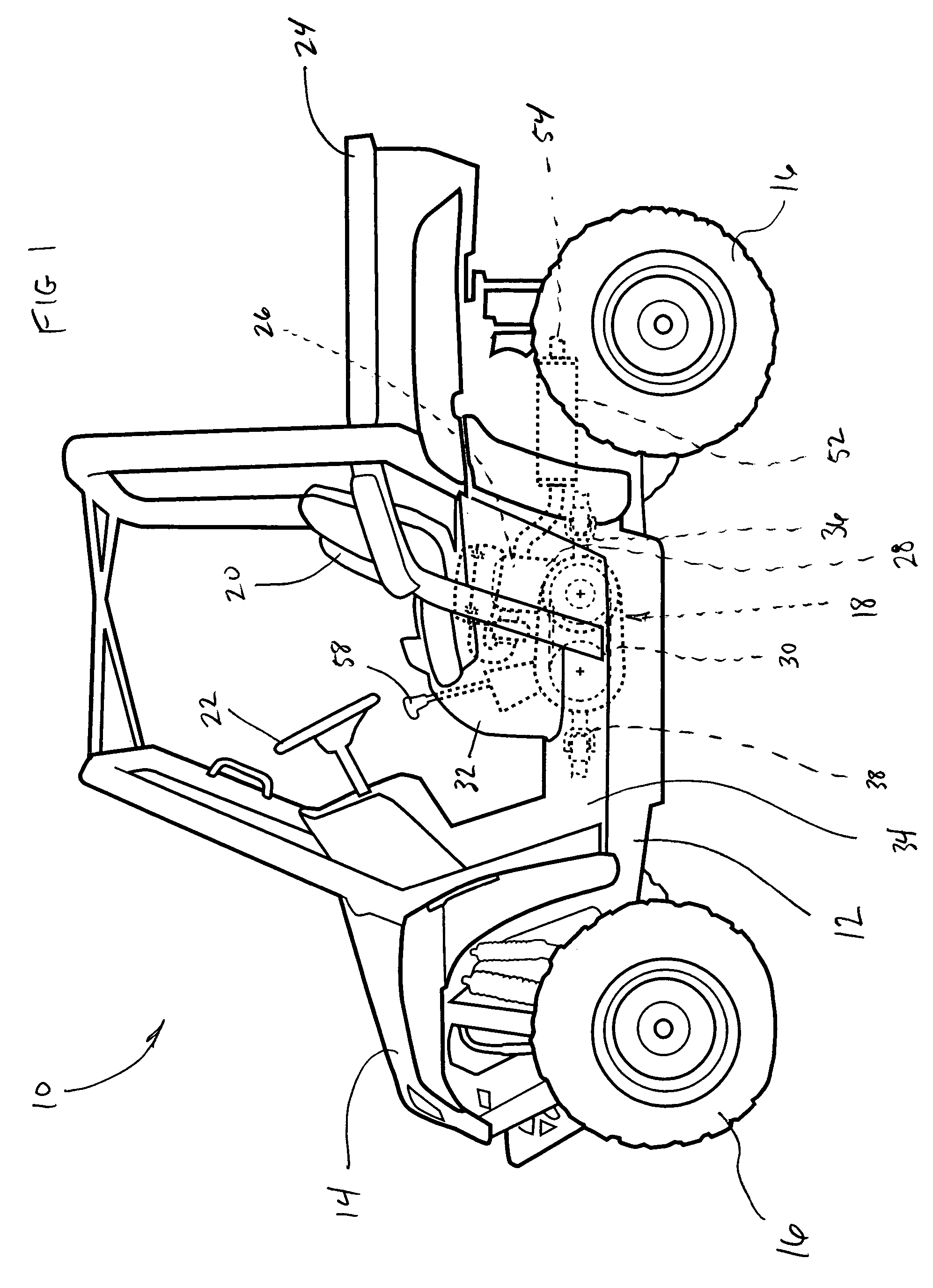

All-terrain vehicle engine configuration

ActiveUS7438153B2Adds to vehicle rider comfortReduce heatElectric propulsion mountingOff-road vehiclesCrankcaseEngineering

Owner:ARCTIC CAT

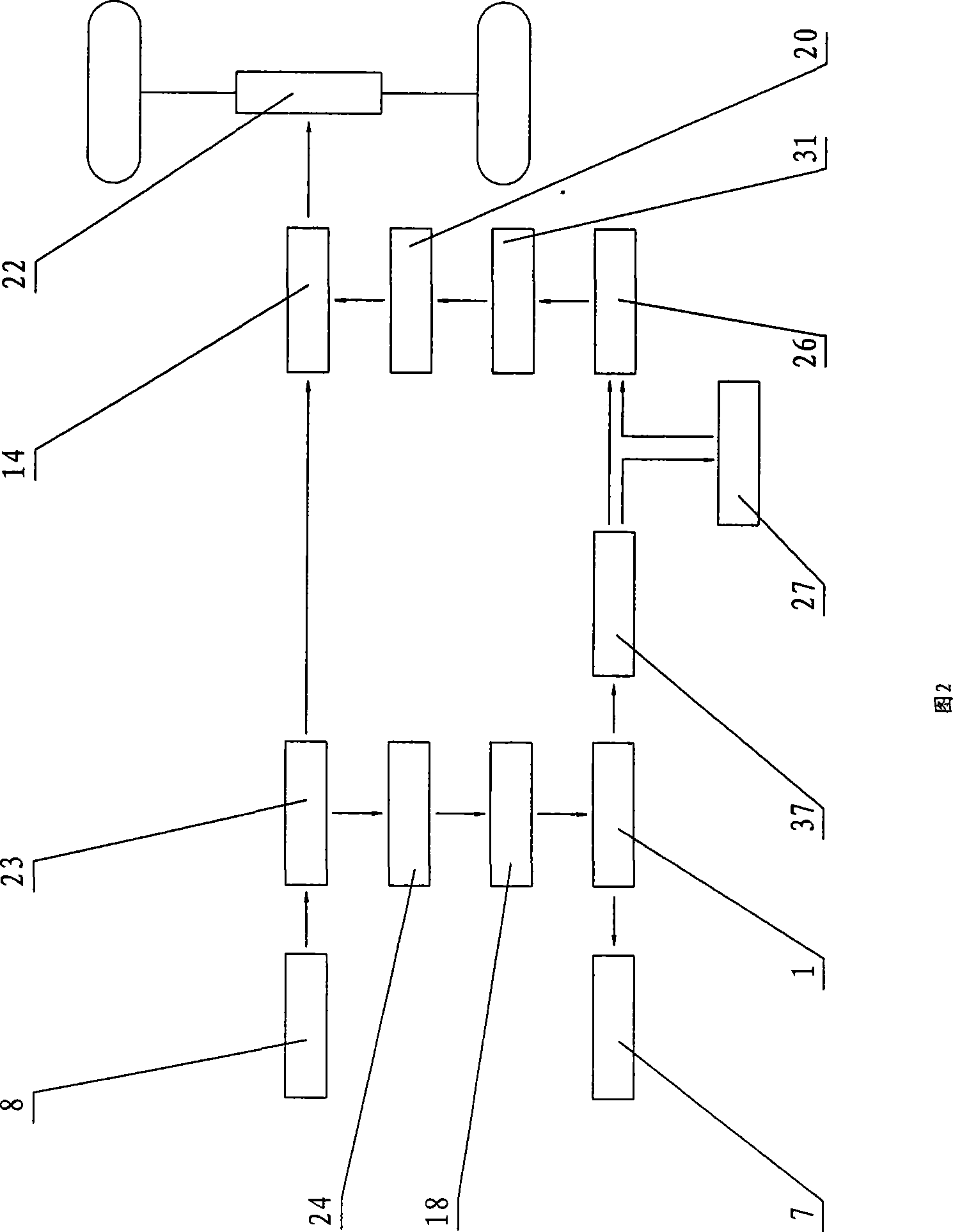

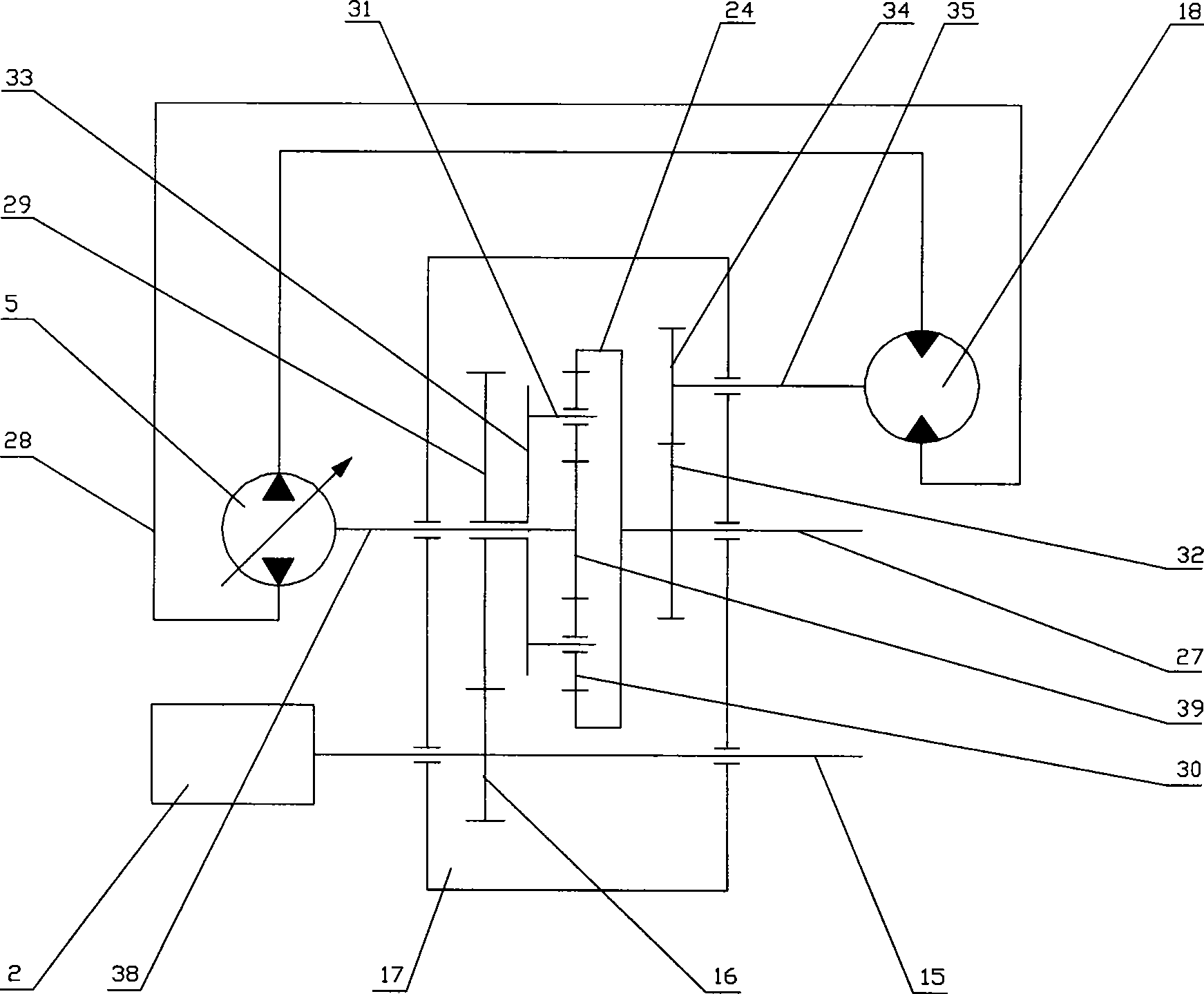

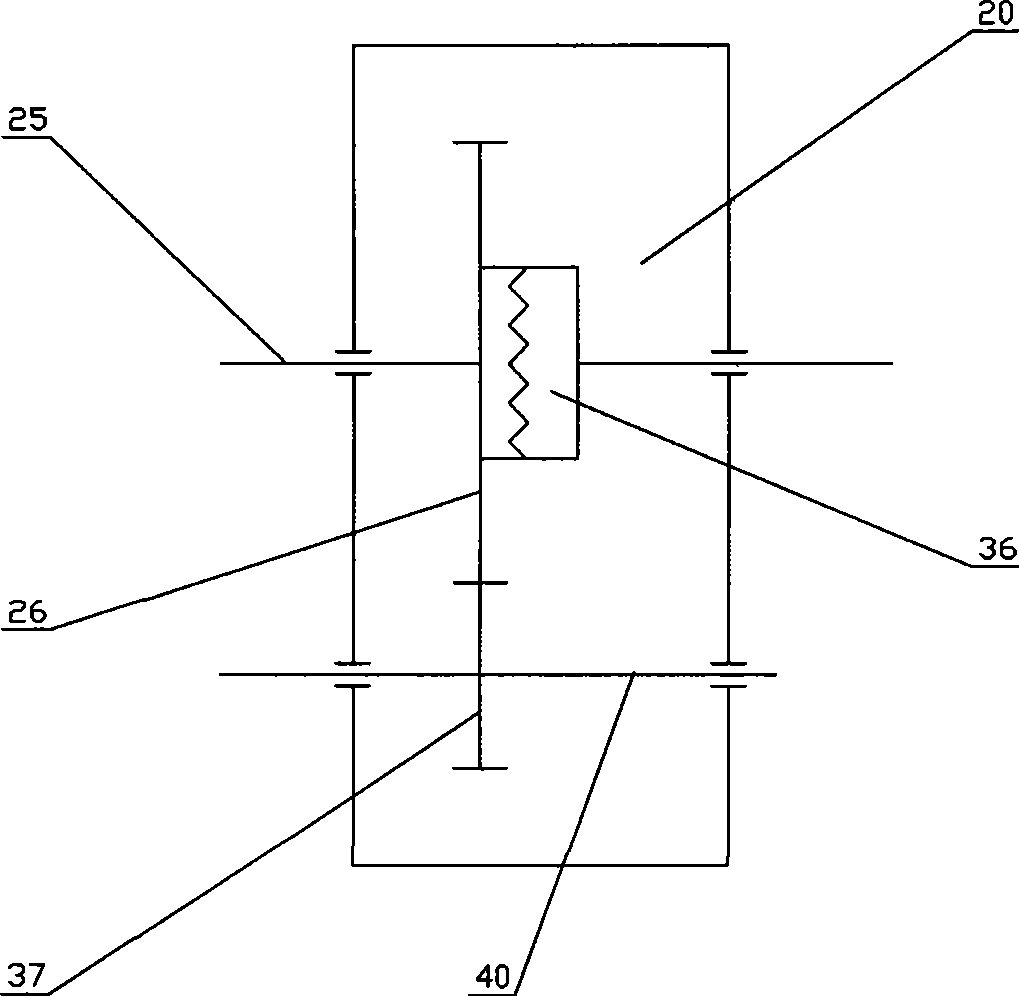

Mechanical and hydraulic combined transmission device

InactiveCN101413572AImprove transmission efficiencyReduce fuel consumptionFluid gearingsControl devicesHydraulic motorPower flow

The invention relates to a mechanical and hydraulic compound transmission device which comprises an engine, a speed changer, a planetary gear box, a hydraulic variable pump, a hydraulic motor and a reduction gearbox; the engine is sequentially connected with the transmission speed changer and the planetary gear box, and a planetary gear mechanism of the planetary gear box distributes the power driven by the motor to respectively drive the hydraulic variable pump and a center gear; the hydraulic variable pump is sequentially connected with a transmission hydraulic motor and a half shaft, the half shaft converges mechanical power flow driven by the center gear and hydraulic power flow driven by the hydraulic motor and protrudes outside the planetary gear box to output the power, and a transmission gear box is connected with the half shaft to redrive a rear shaft to drive a vehicle. A special vehicle refit by the technology with a single-engine configuration can run at a stepless variable speed in a mechanical and hydraulic compound transmission mode, meanwhile, the vehicle can drive a vehicle-mounted operating device in the mechanical transmission mode; during transition, the mechanical transmission mode can be adopted to cause the device to run quickly, the power system occupies little vehicle space, and has low emission, high transmission efficiency and low oil consumption.

Owner:赵宏坚 +1

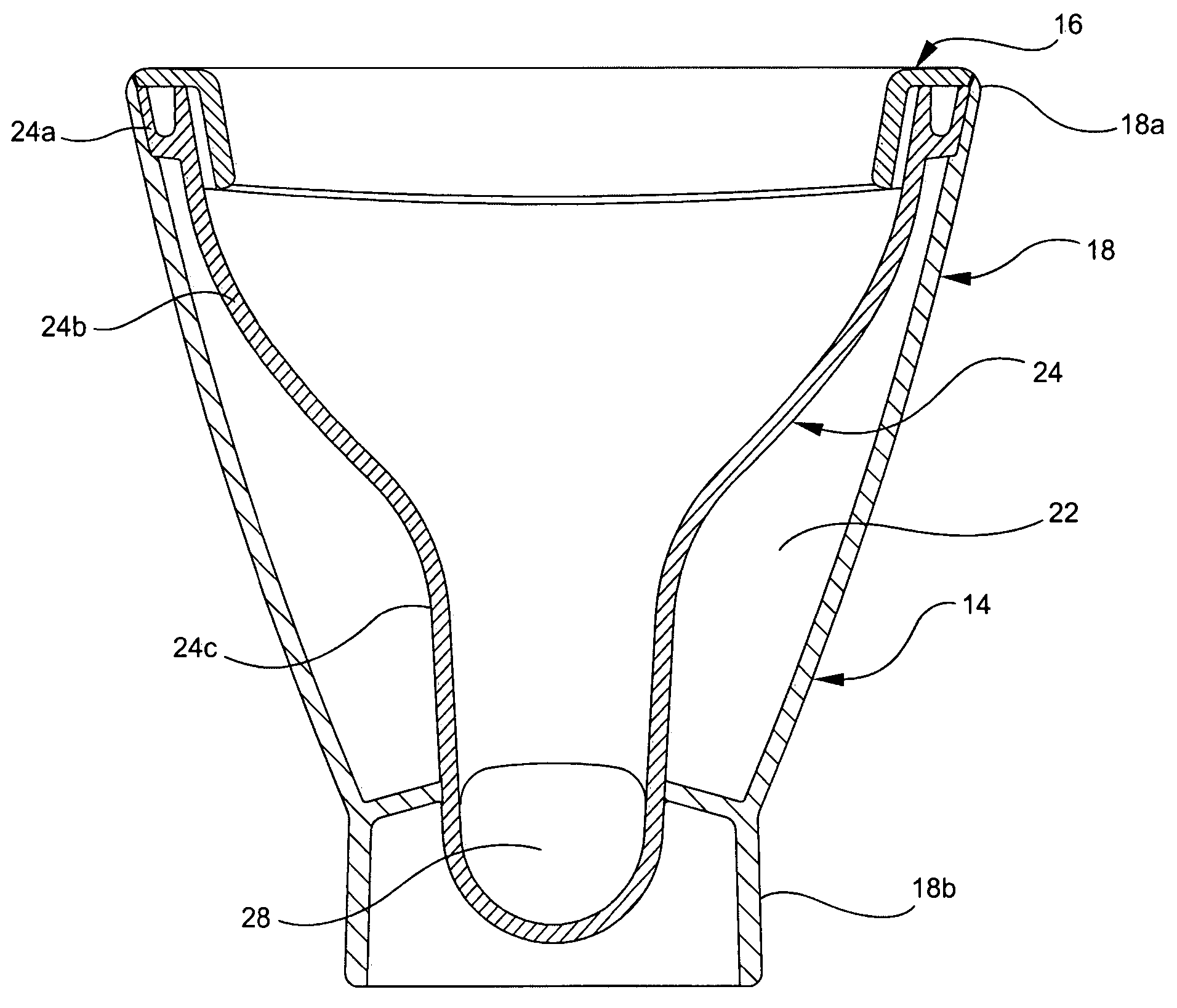

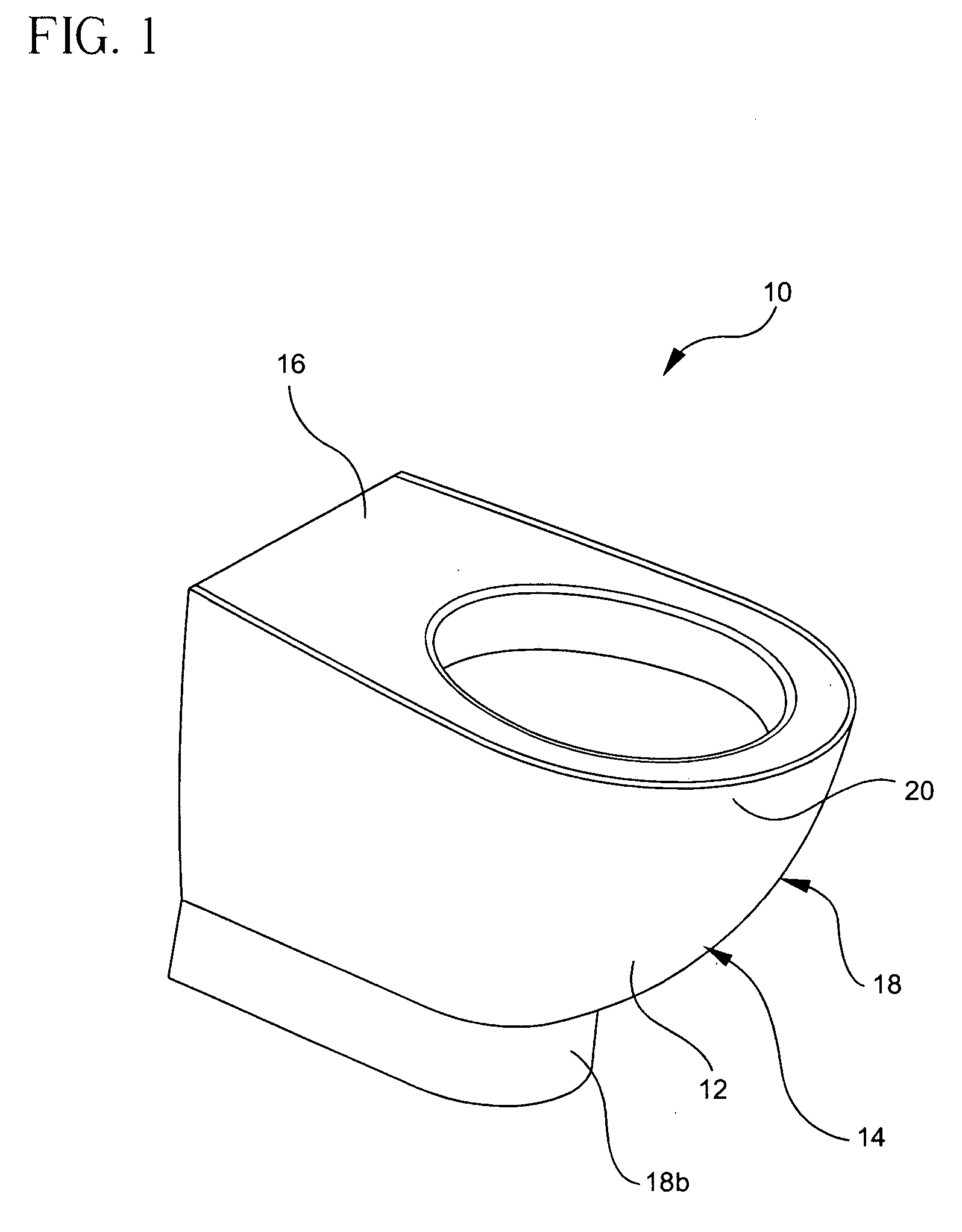

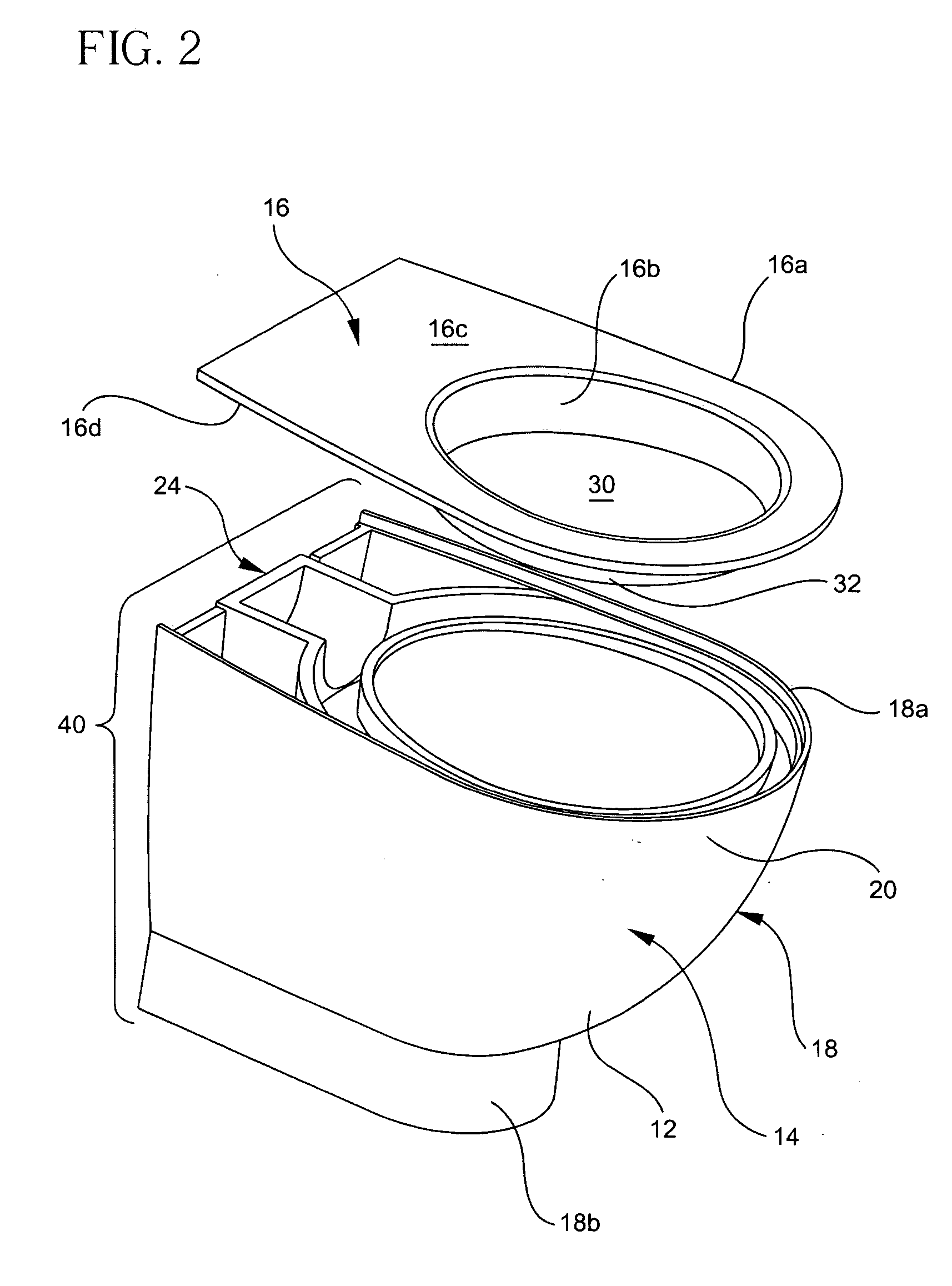

System and method for casting toilet bowls

ActiveUS20050115042A1Manufacturing can be simplified and expeditedIncrease choiceConfectionerySweetmeatsFlush toiletMechanical engineering

The present invention provides an improved system and method for casting toilets. In the disclosed method, at least one of a shell, engine and rim configuration for a toilet is provided, wherein the configuration is selected from a plurality of shell, engine and rim configurations defined by a corresponding plurality of shell, engine and rim molds. Each mold defines a casting space therewithin for casting the selected configuration therefrom. Each shell configuration includes a hollow housing space for disposition of a unique sanitaryware performance engine configuration therewithin. While still greenware, the cast engine is disposed in the shell housing space to form at least one shell and engine assembly thereby. Subsequently, and while also in a green state, the cast rim is assembled with the shell and engine assembly and the entire shell, engine and rim assembly is fired to form a single integral piece of sanitaryware. In the corresponding system, a series of casting stations is provided that defines a casting sequence, wherein each said station performs a specific casting step. The selected configuration is sequentially directed to at least one station selected from the series of stations where at least one casting step is performed. Sequential direction and casting steps are repeated until a predetermined number of toilets are produced.

Owner:AMERICAN STANDARD INC

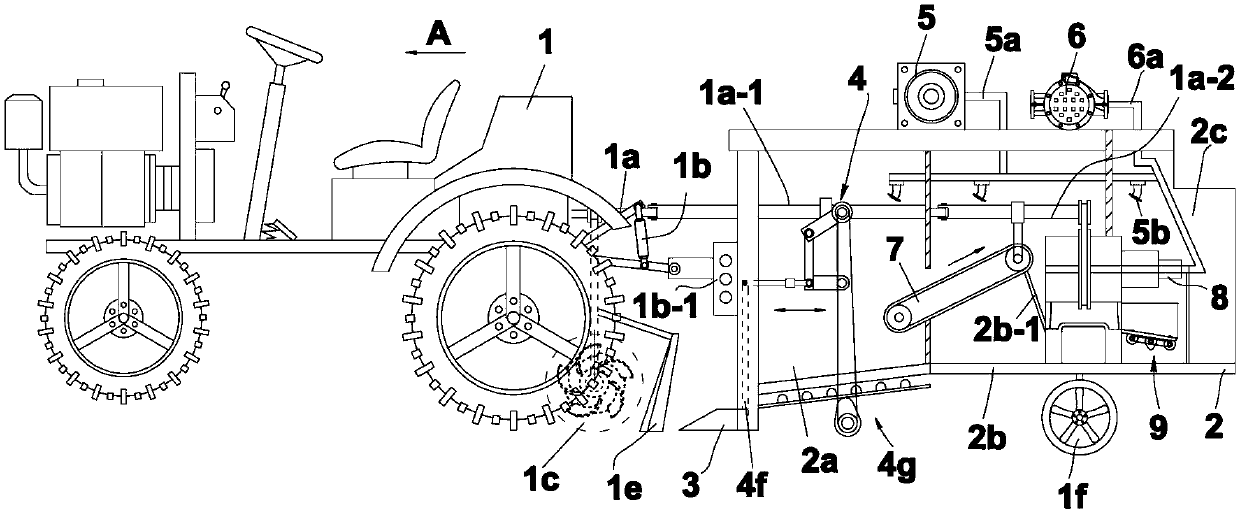

Integrated harvester of water chestnut

The invention relates to the technical field of agricultural machinery, in particular to an integrated harvester of water chestnuts. The integrated harvester of the water chestnuts is characterized inthat the integrated harvester of the water chestnuts comprises a walking machine and a frame; the walking machine is connected with a hydraulic suspension system which is connected with an engine ofthe same; the hydraulic suspension system comprises a transmission case and a hydraulic cylinder; a spindle I is fixed on a smashing mechanism behind the walking machine in drive connection; a shovelboard is arranged at the entrance of a front chamber and in active fit with the front chamber; a push plate vibration mechanism is installed in the front chamber; a mud pump and a high pressure air pump are mounted on the frame and powered by a generator configured by the engine; a water and gas mixing cleaning mechanism is installed in a transport warehouse; a compensatory cleaning mechanism is arranged just below the water and gas mixing cleaning mechanism; a water outlet of the mud pump is connected with a water pipe; a pluarlity of nozzles are mounted on the water pipe; an air outlet of the high pressure air pump is connected with an appendix. The integrated harvester of the water chestnuts has the advantages of being clean after five times of cleaning during work process of the wholemachine, greatly reducing damage during harvesting, improving harvesting efficiency and reducing farmers' harvesting costs.

Owner:惠安县德虹数控设备有限公司

Diesel engine/gas turbine compound engine for a means of transport

InactiveUS20130213048A1Low air mass flow rateSmall dimensionInternal combustion piston enginesGas turbine type power plantsTurbochargerDiesel engine

A compound engine for a means of transportation, includes a diesel engine and a gas turbine with at least one compressor and with at least one turbine. The diesel engine and the gas turbine are interconnected in such a manner that during continuous duty operation the compound engine is configured to be operated only by way of the diesel engine, and the diesel engine is optionally operated on its own or together with a compressor and a turbine of the gas turbine as a turbocharger for the diesel engine. The compound engine is configured to be operated by way of the diesel engine or the gas turbine.

Owner:AIRBUS OPERATIONS GMBH

Medical instrument for cutting biological and especially human tissue

InactiveUS7981130B2Simple and space-saving constructionReduce capacity lossSurgical needlesExcision instrumentsEngine mountHumans tissues

The invention relates to a medical instrument for cutting biological and especially human tissue, having a hollow cutting tube that can rotate by means of an engine around its longitudinal axis, on whose distal end at least one blade is mounted, as well as with a handle in which the cutting tube is mounted for control purposes. In order to produce a medical instrument for cutting biological and especially human tissue in which the powering of the cutting tube is of simple construction and involves minor losses of capacity, it is proposed with the invention that the engine is configured as a hollow-shaft engine mounted on the cutting tube.

Owner:KARL STORZ GMBH & CO KG

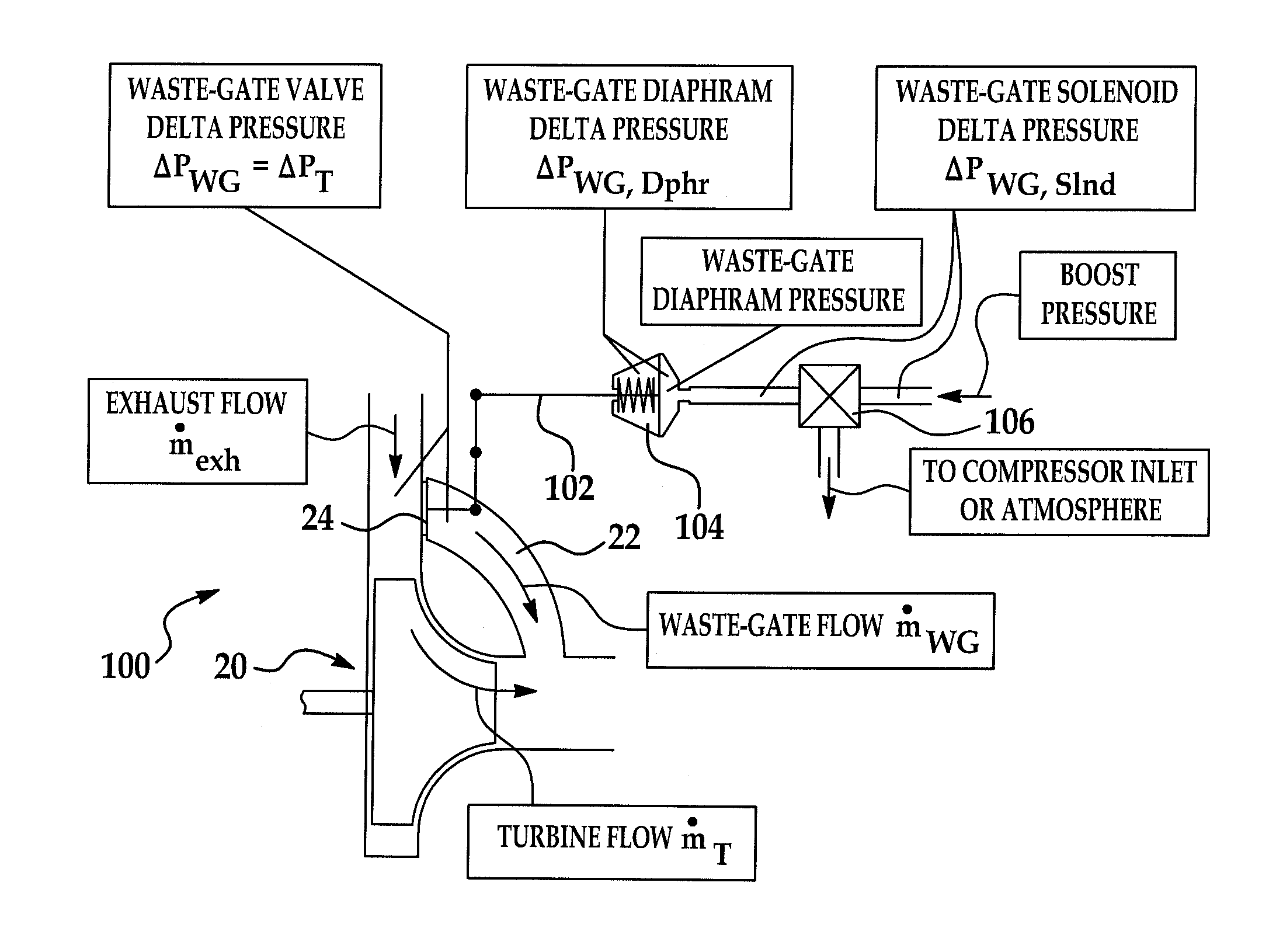

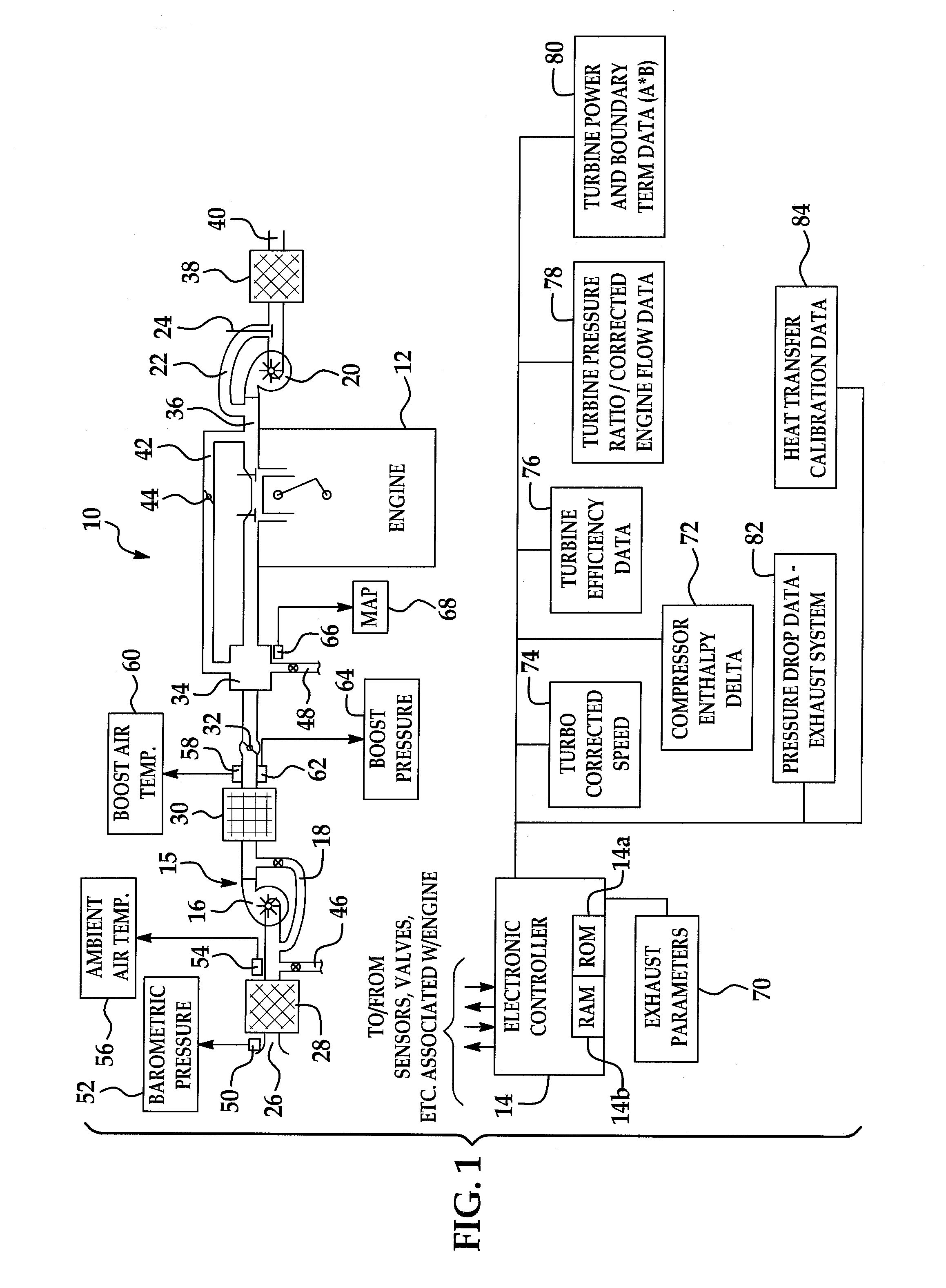

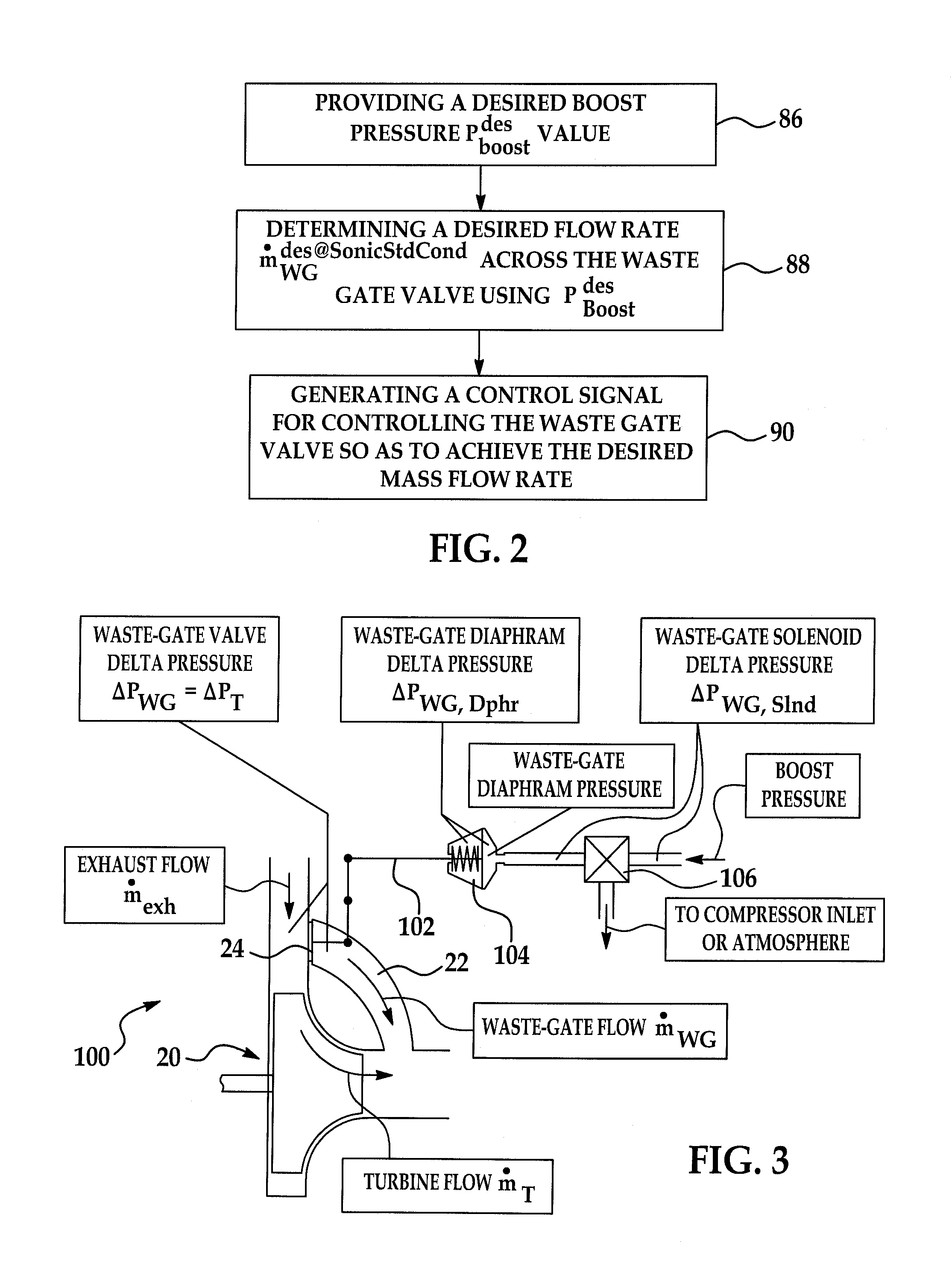

System and method for model based boost control of turbo-charged engines

ActiveUS7788922B2Improve engine efficiencyEasy to controlInternal combustion piston enginesNon-fuel substance addition to fuelWastegateControl signal

A system and method for controlling boost pressure in various turbo-charged engine configurations as well as variable geometry turbine (VGT) arrangements includes an electronic controller programmed to receive a predetermined desired boost pressure PBoostdes. A desired pressure delta ΔPWGdes across a waste-gate valve is determined using the desired boost pressure PBoostdes. A control signal is generated for controlling the waste-gate valve so as to achieve the desired pressure delta ΔPWGdes. In boost pressure and vacuum pneumatically-actuated waste-gate valve arrangements, the respective solenoid duty cycles are obtained through use of various data structures. Where a waste-gate valve position is controlled by an electrical motor, the valve position is determined using a data structure as a function of desired waste-gate valve flow at sonic standard conditions.

Owner:DELPHI TECH IP LTD

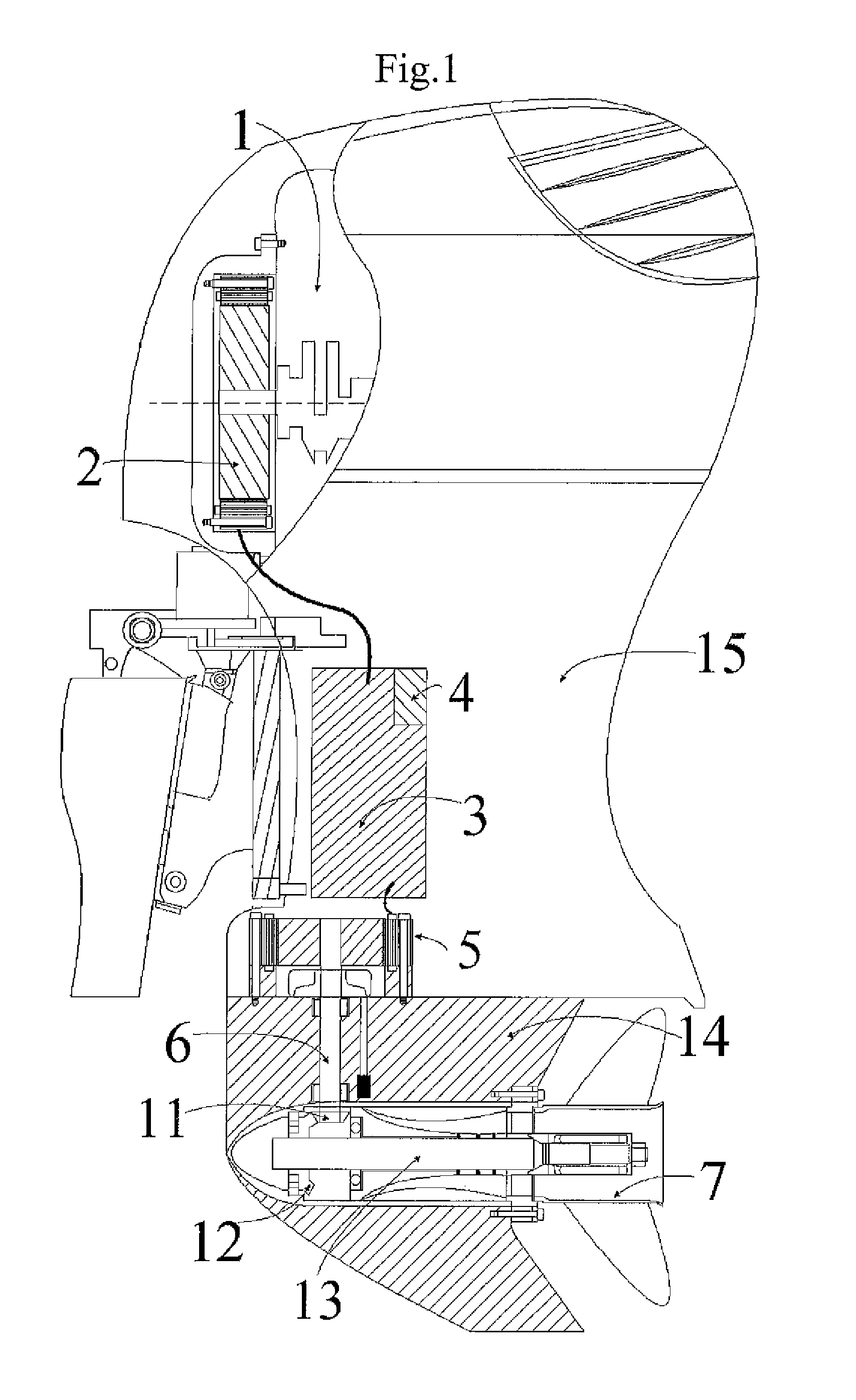

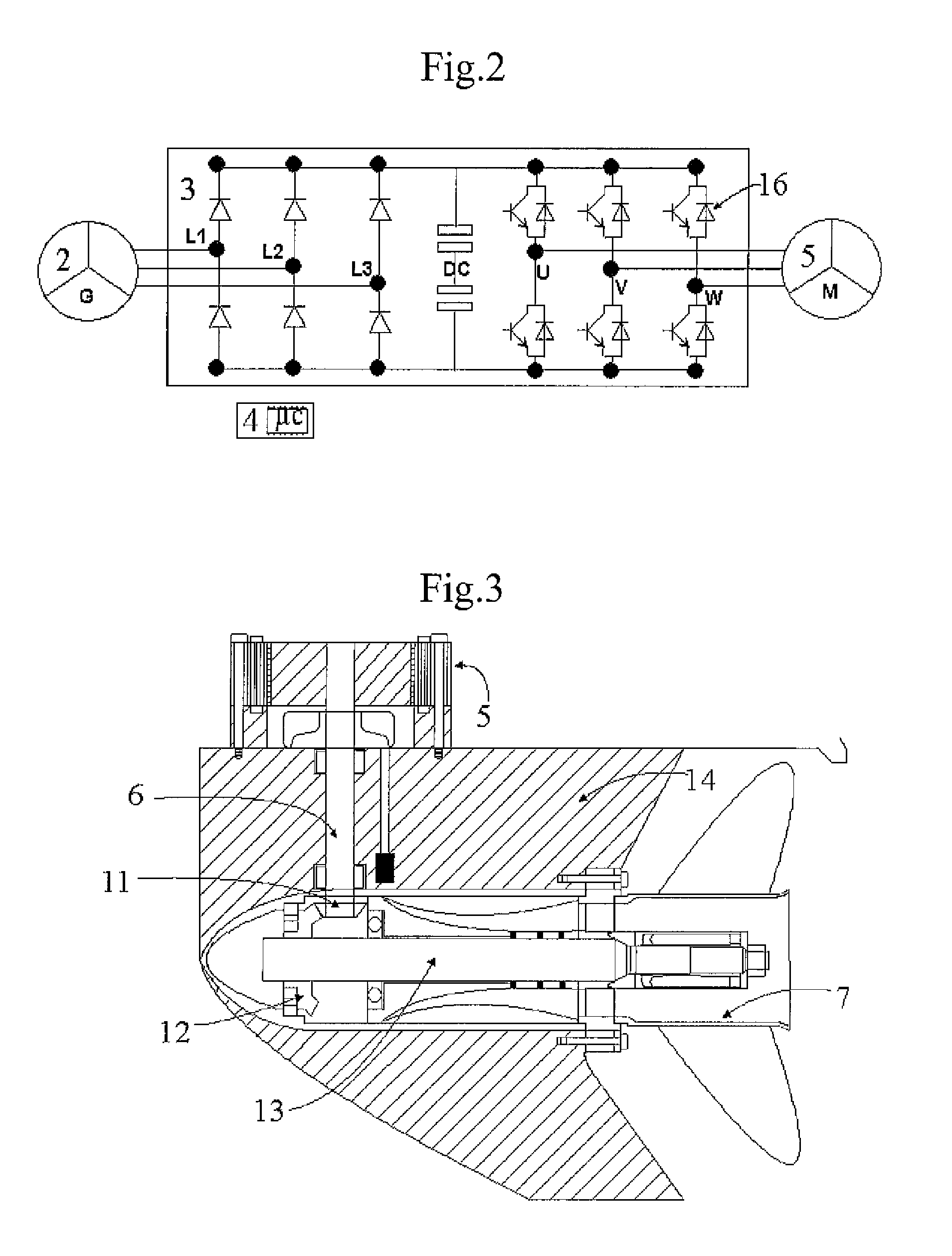

Outboard propulsion system for vessels

An outboard propulsion system is disclosed. In some embodiments, the outboard propulsion system includes a generator operable to produce a first electrical signal, an engine electrically coupled to the generator, an inverter electrically coupled with the generator to receive the first electrical signal, wherein the inverter is adapted to transform the first electrical signal into a second electrical signal, all electric motor electrically coupled to the inverter to receive the second electric signal, a shaft mechanically coupled to the electric motor and rotatable by the electric motor when the electric motor receives the second signal, and a thrust generation device mechanically coupled to the shaft. The engine is configured to operate the generator. The thrust generation device is adapted to rotate when the shaft rotates.

Owner:VOP SOLUTIONS CORP

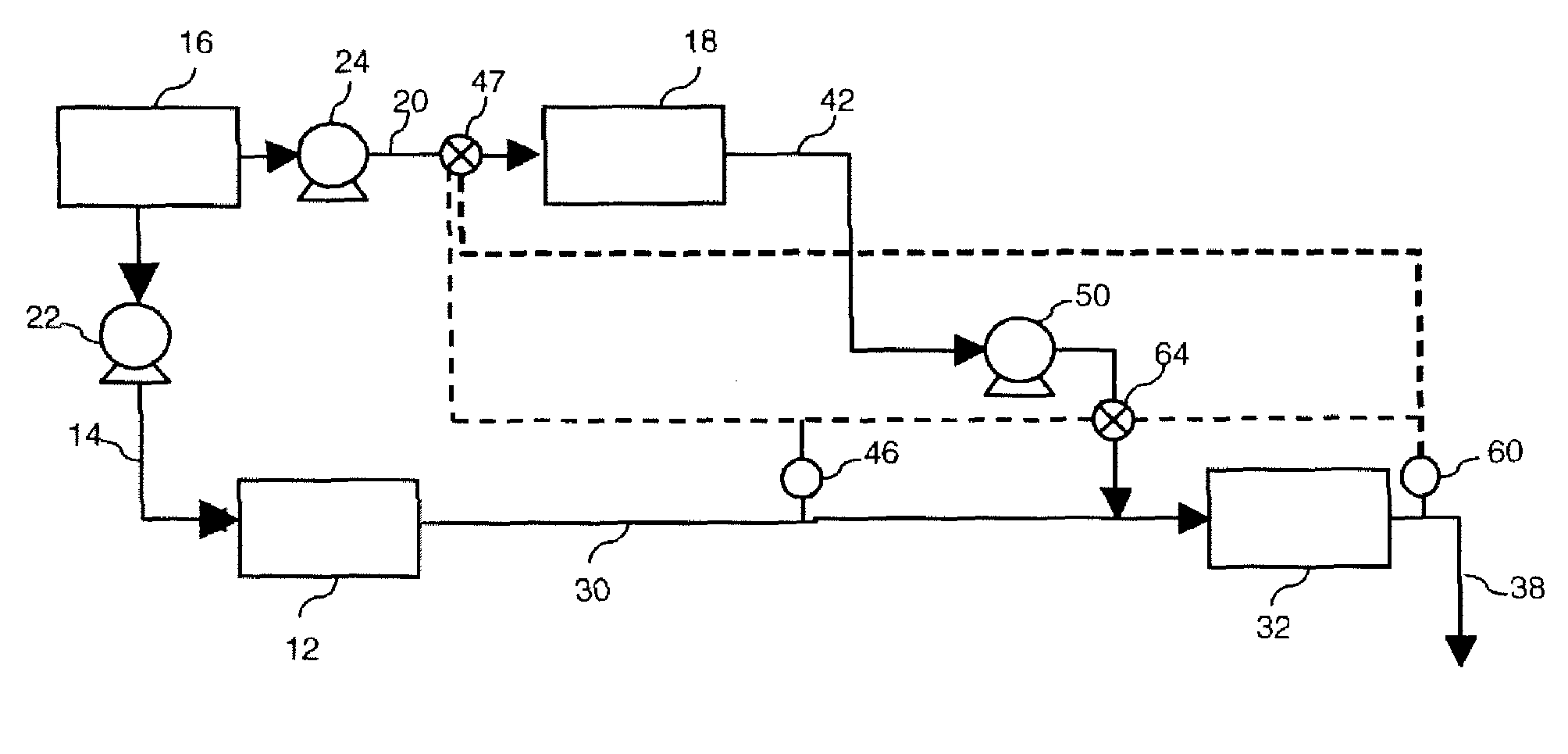

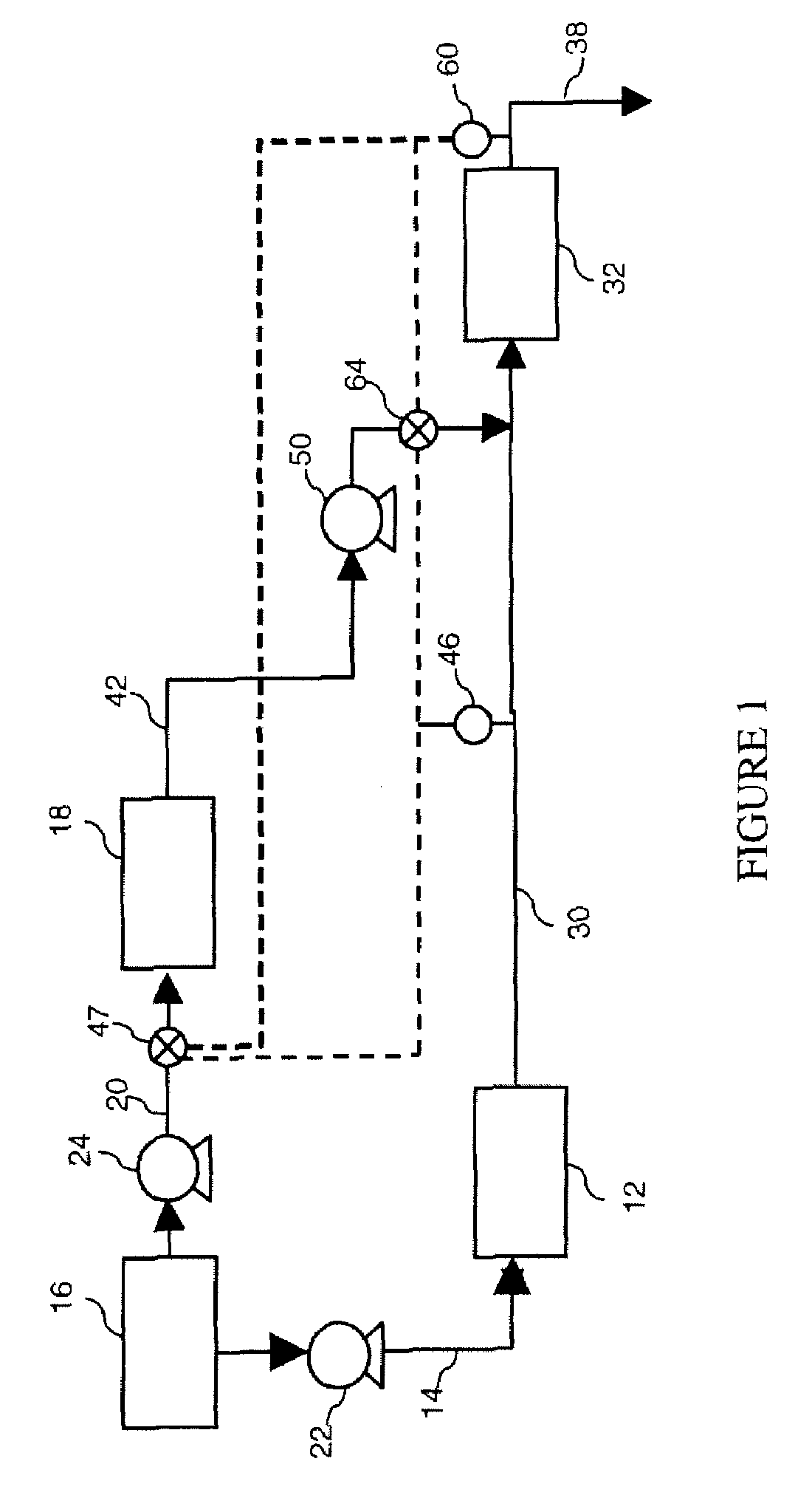

OPTIMIZED REDUCTION OF NOx EMISSIONS FROM DIESEL ENGINES

InactiveUS20090173061A1Improved emission controlReduce nitrogen oxide emissionsAnalogue computers for vehiclesInternal combustion piston enginesHigh concentrationTemperature control

A system is provided for operating a diesel engine with reduced emissions of NOx. The system comprises a fuel tank adapted to directly or indirectly supply a first premixed fuel stream and a second premixed fuel stream, wherein each fuel stream comprises a primary fuel component and a reductant component. An engine is in fluid communication with the fuel tank, whereby the engine is configured to receive the first premixed fuel stream and create an exhaust stream. The system includes an emission treatment unit to treat the exhaust stream, and a separation unit configured to receive the second premixed fuel stream. The separation unit is also configured to separate the second premixed fuel stream into a first fraction stream and a second fraction stream, and supply the first fraction stream to the exhaust stream. The first fraction stream comprises a higher concentration of the reductant component than the second fraction stream. A temperature sensor measures the temperature of the exhaust stream, whereby the concentration of the reductant component in the exhaust stream is controlled based on the measured temperature of the exhaust stream. The invention further provides a method for operating a diesel engine with reduced emissions of NOx. The method includes supplying a first premixed fuel stream to an engine, wherein the engine is configured to create an exhaust stream. A second premixed fuel stream is supplied to a separation unit, wherein the first and second premixed fuel streams each comprise a reductant component and a primary fuel component. At least a portion of the second premixed fuel stream is separated into a first fraction stream and a second fraction stream via the separation unit, wherein the first fraction stream comprises a higher concentration of the reductant component than the second fraction stream. At least a portion of the first fraction stream is supplied to the exhaust stream. The temperature of the exhaust stream is measured, and the concentration of the reductant component in the exhaust stream is controlled based on the measured temperature. The selective catalytic reduction of NOx present in the exhaust stream is performed.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com