Patents

Literature

200results about How to "Increase operating pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

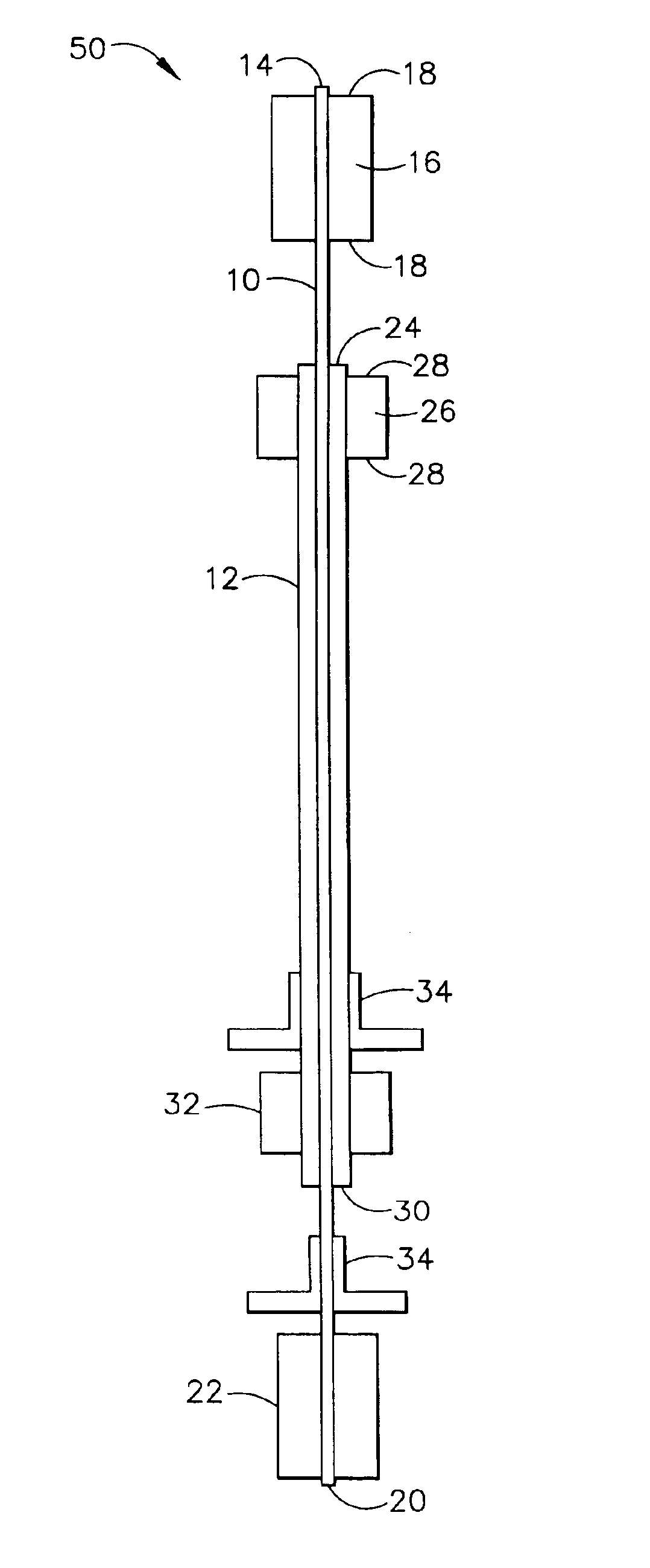

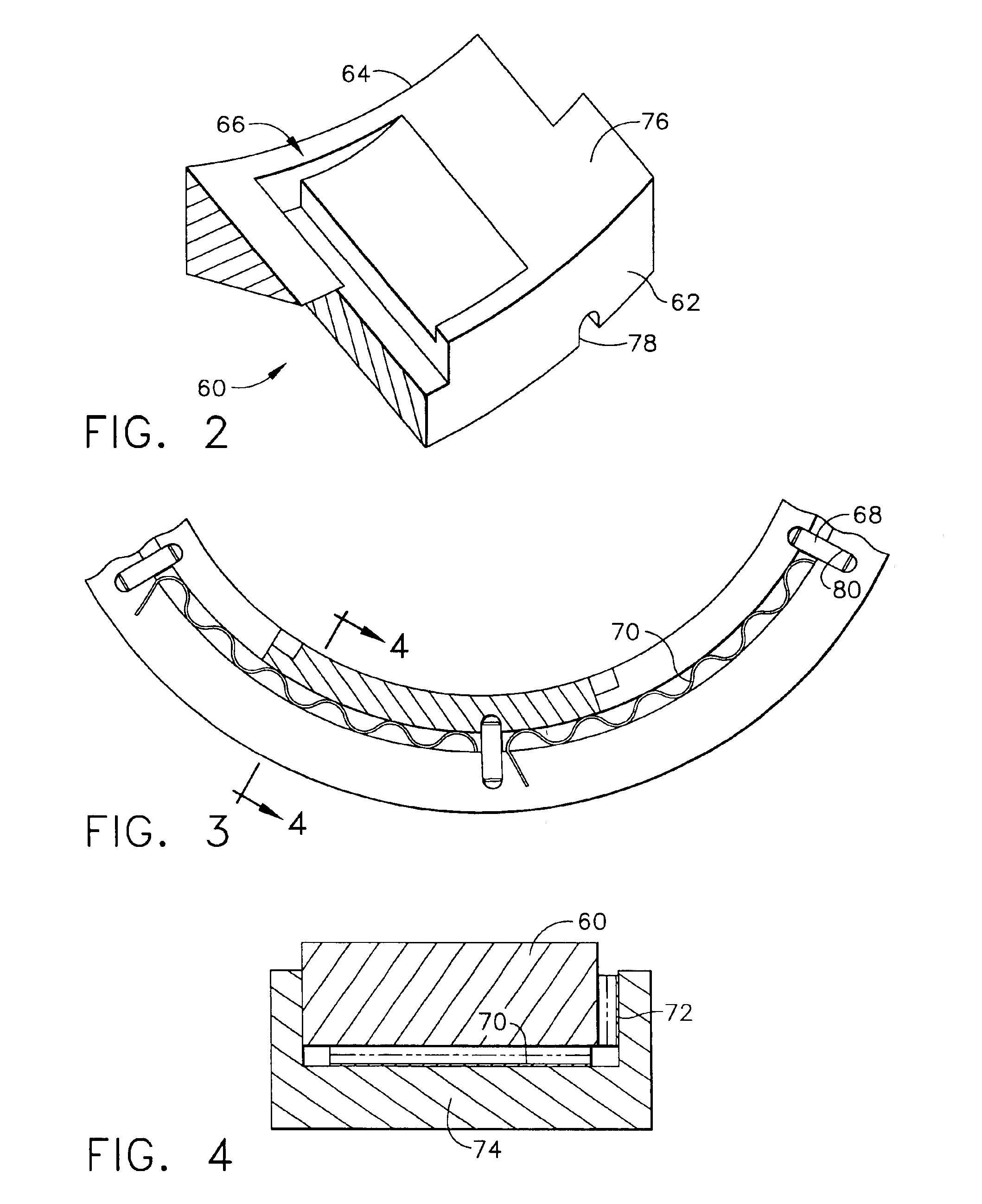

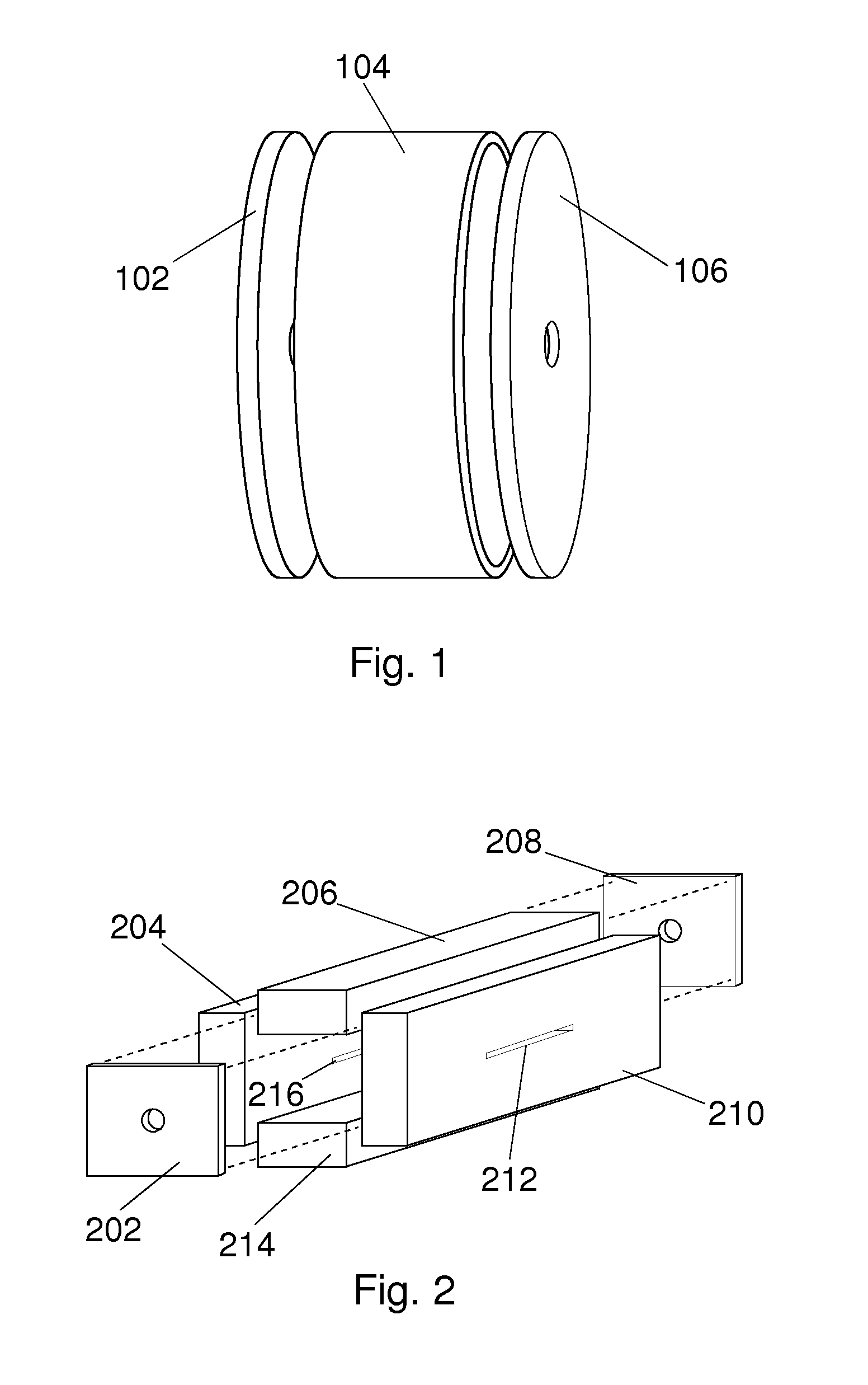

Gas-target neutron generation and applications

InactiveUS6922455B2Improve performanceMaximize productionNuclear energy generationX-ray tube electrodesHigh resistanceNeutron emission

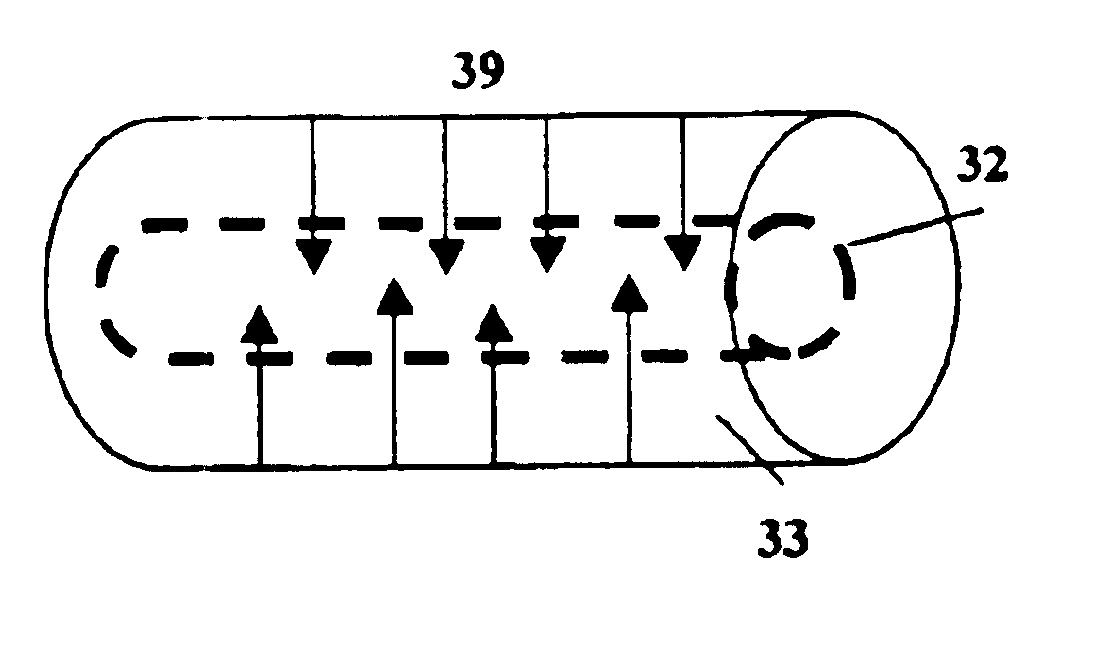

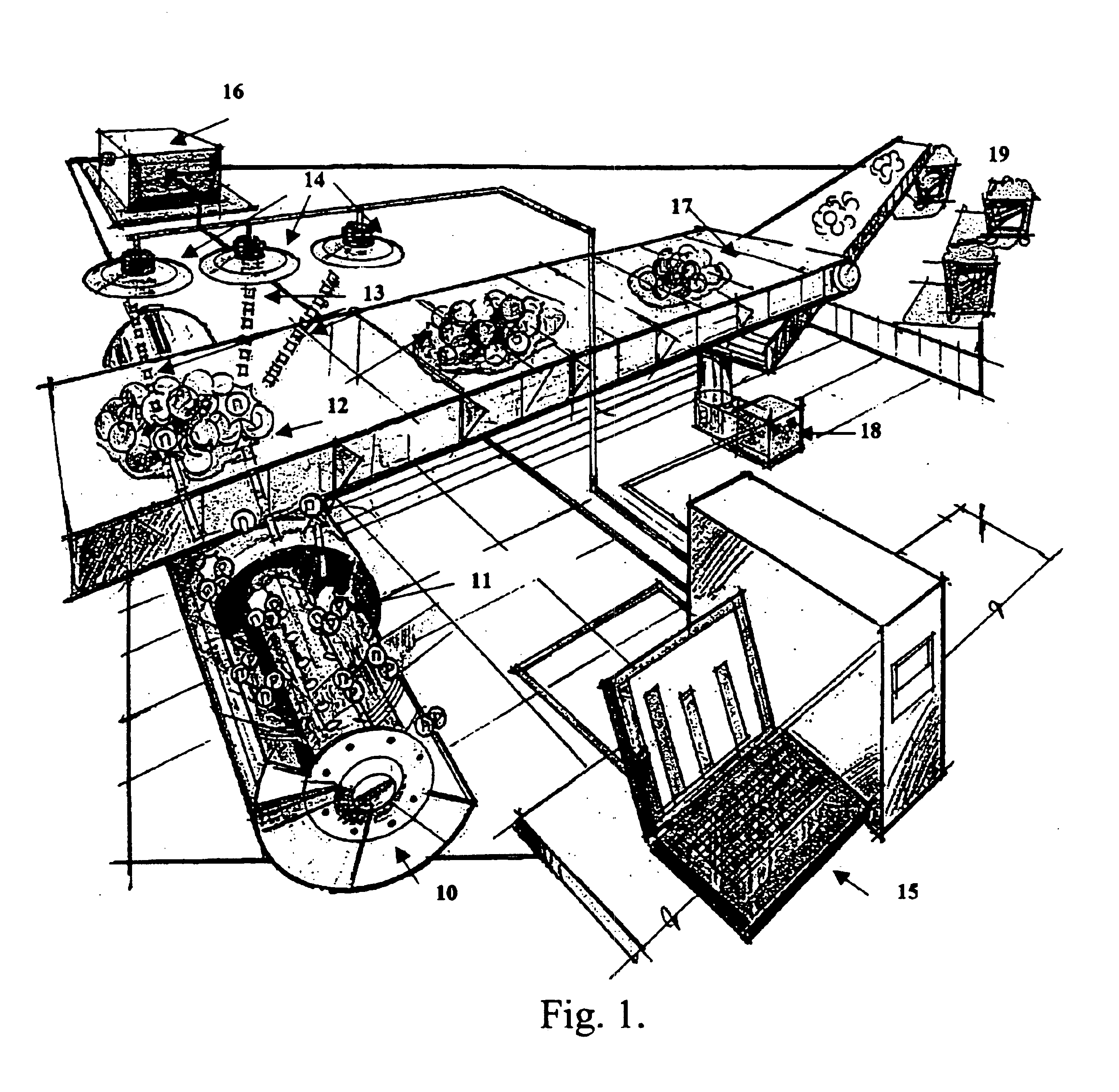

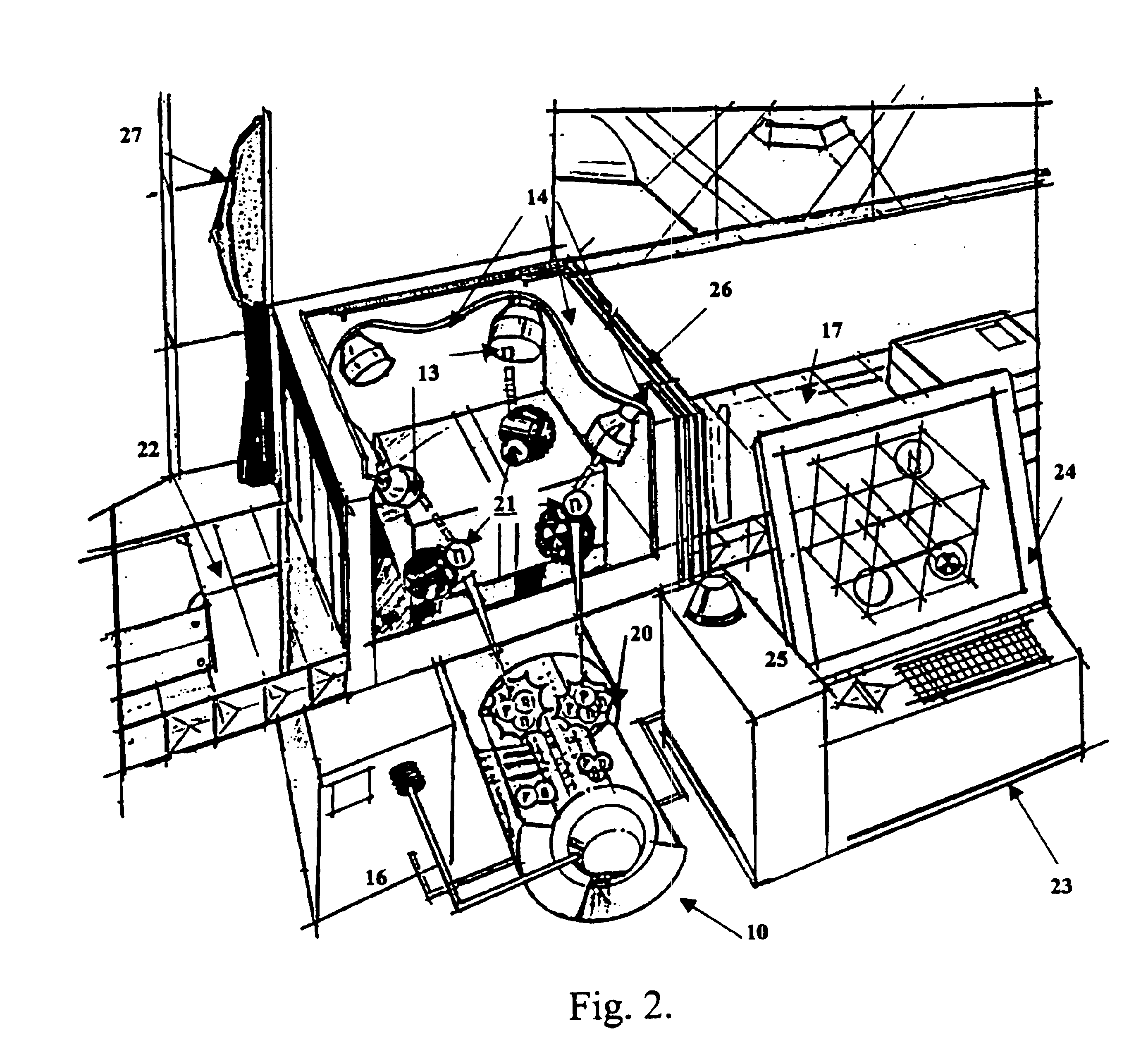

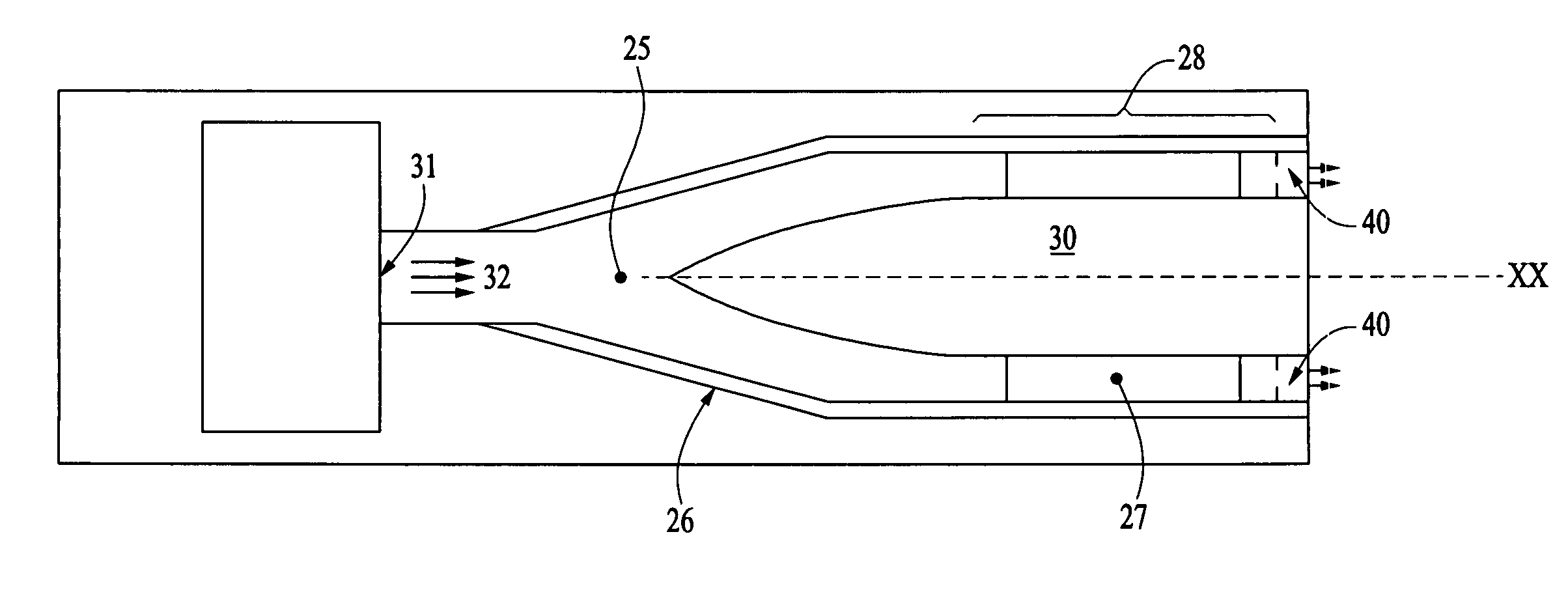

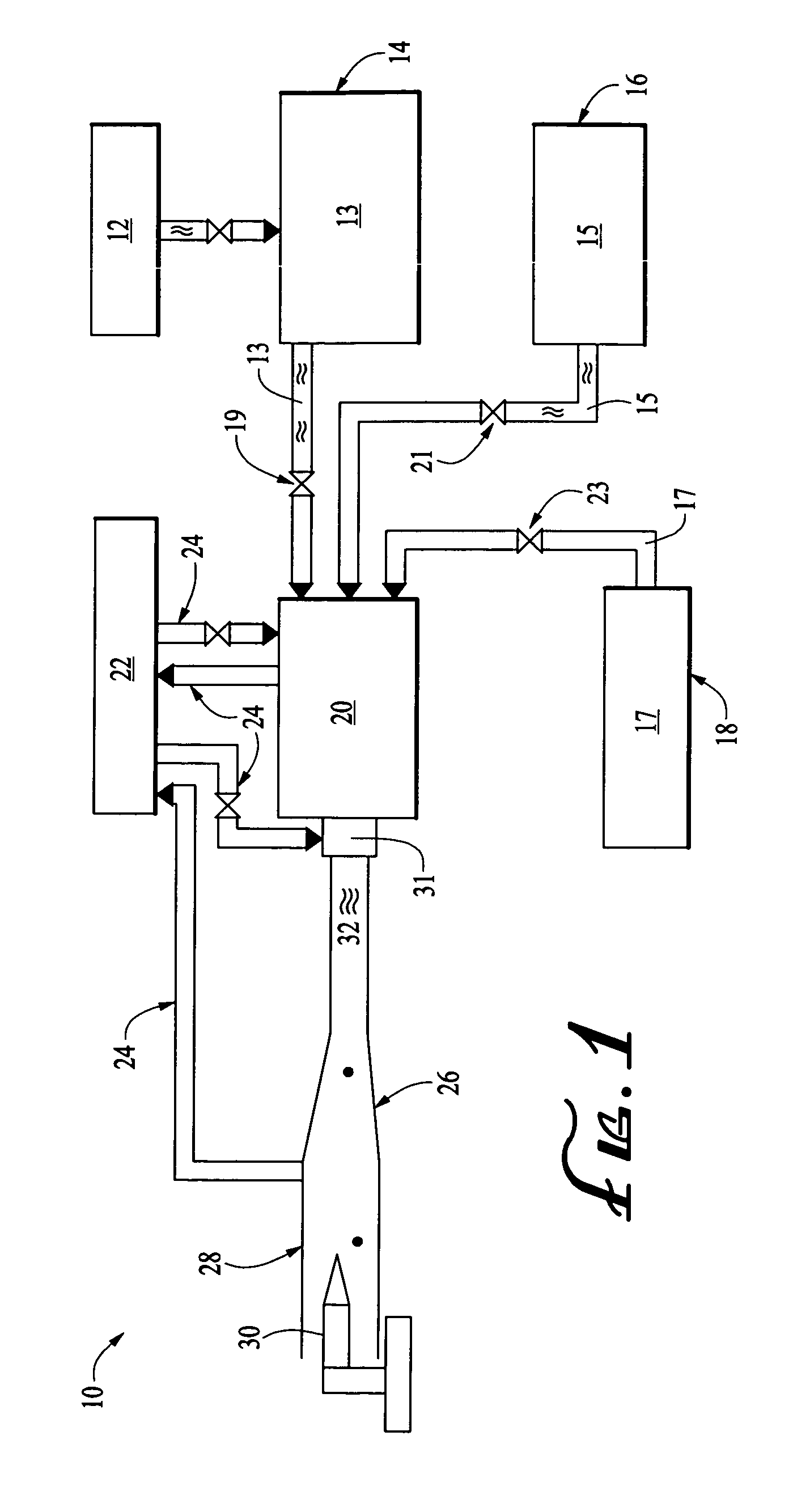

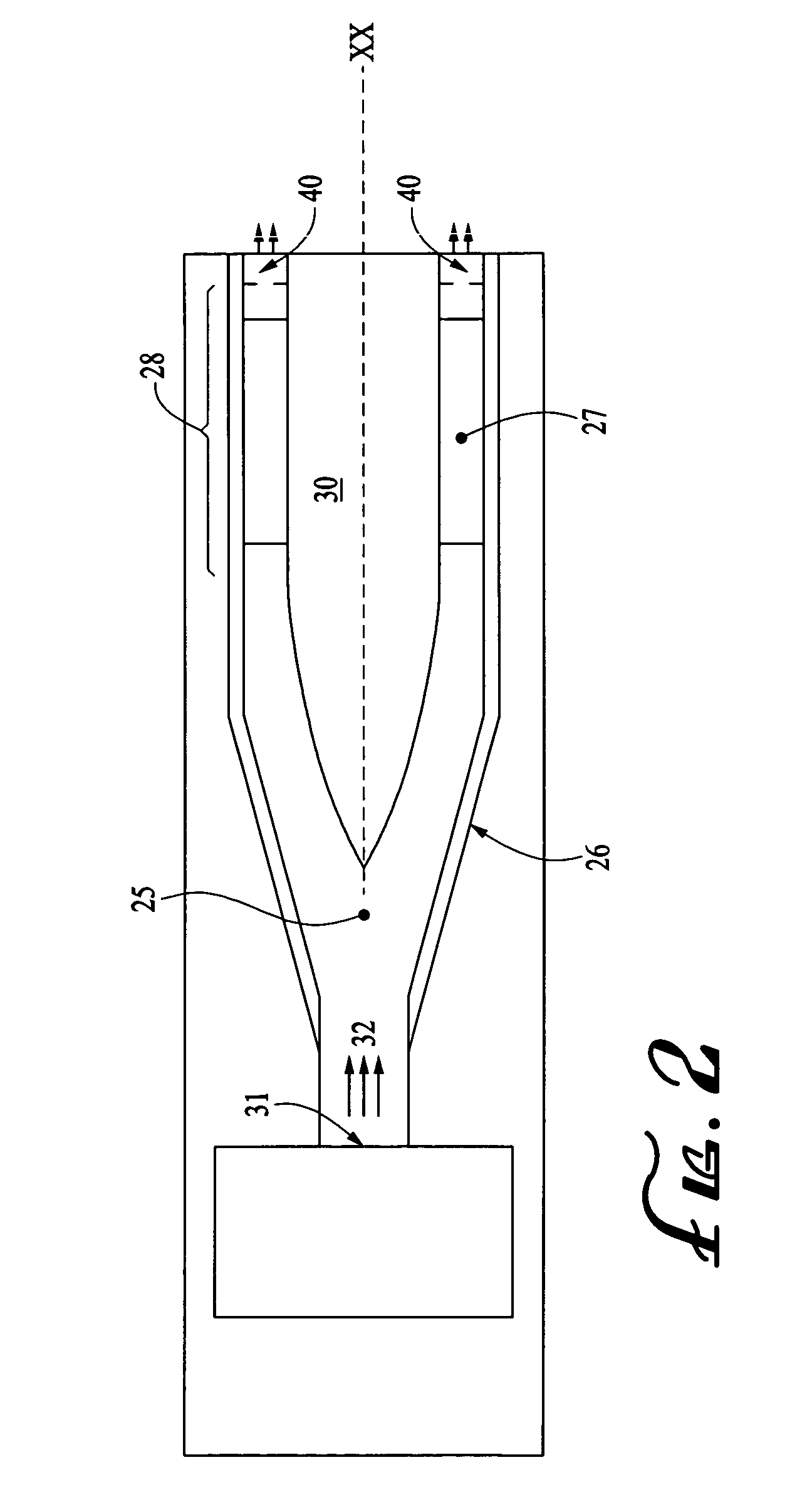

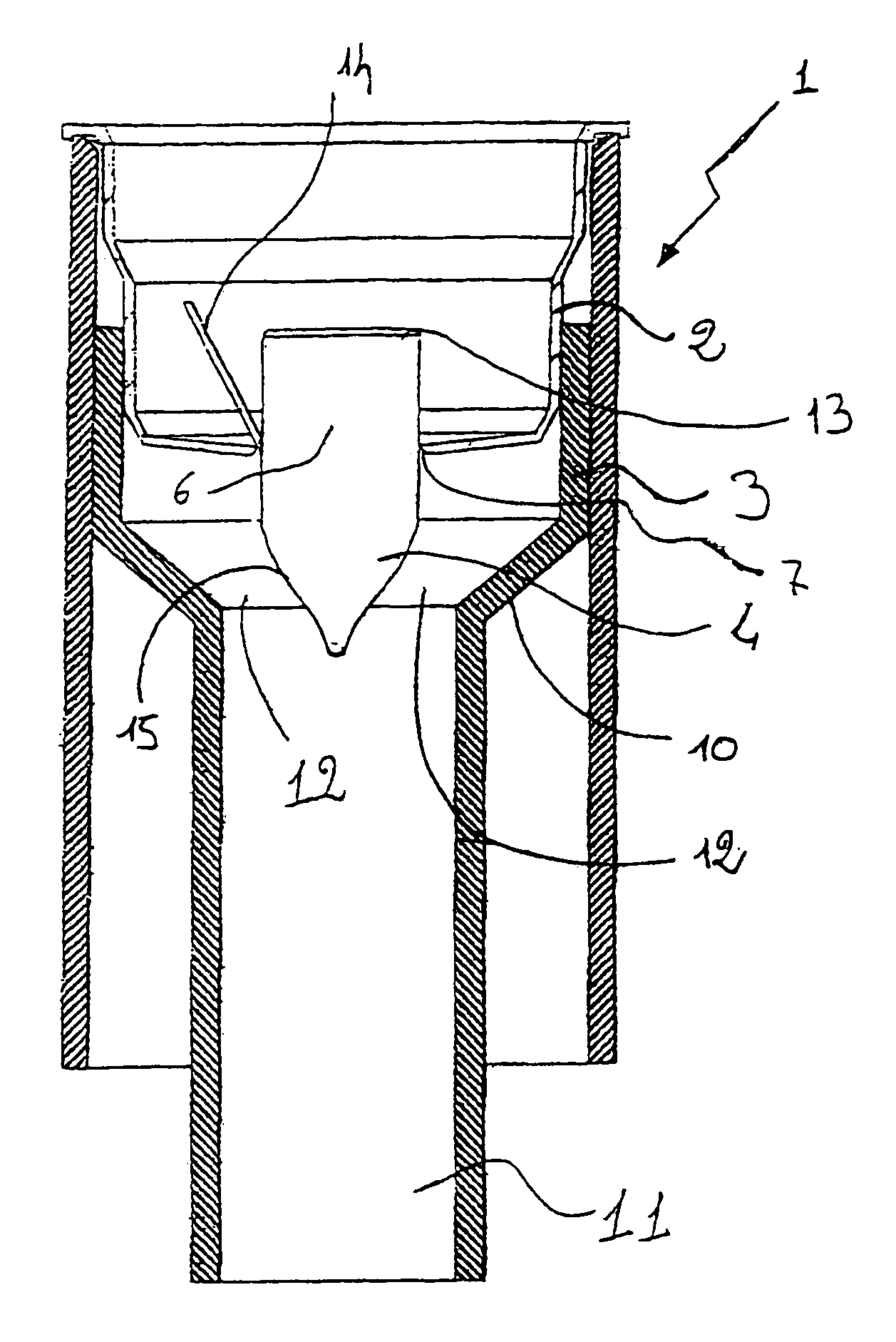

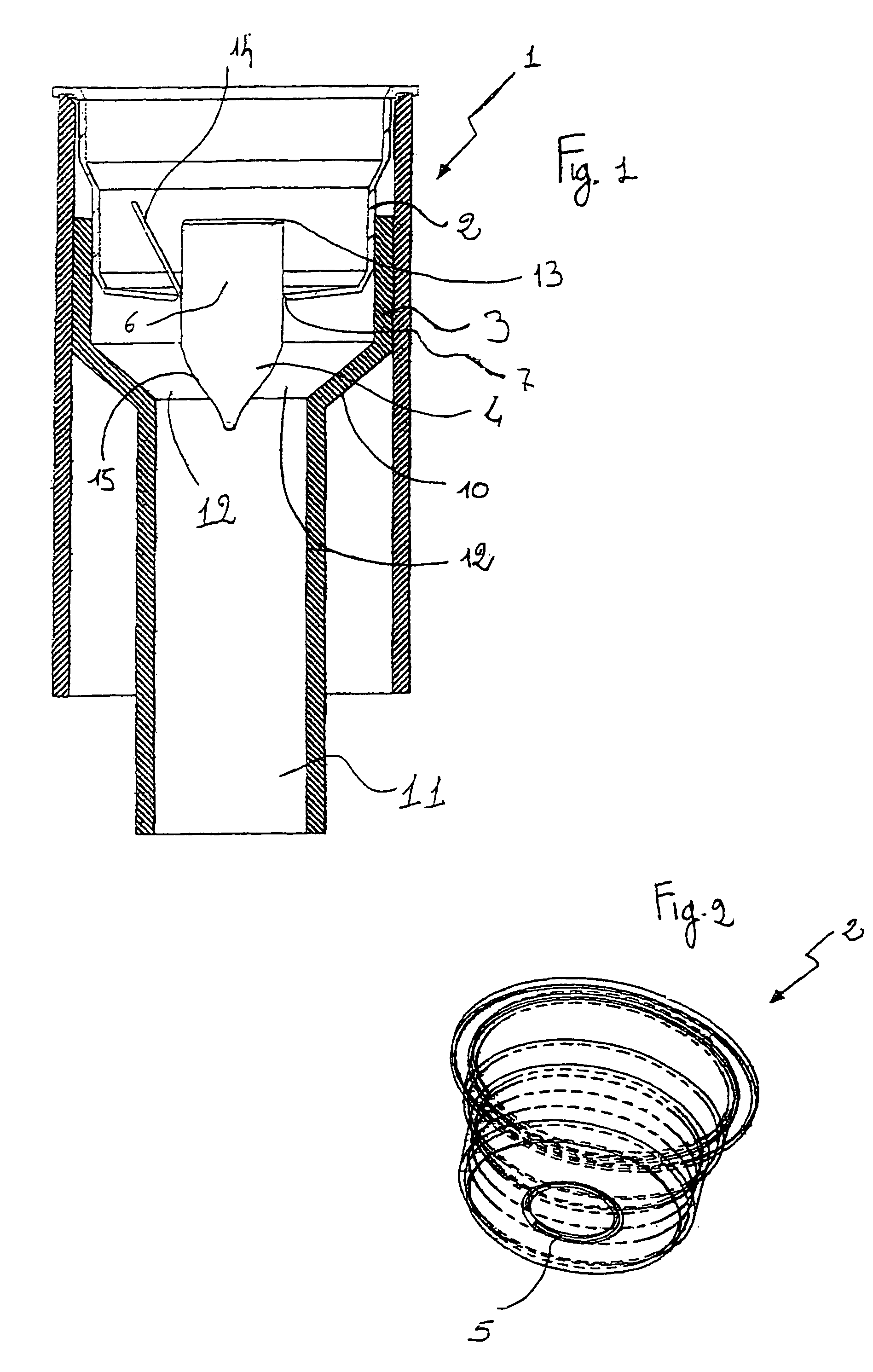

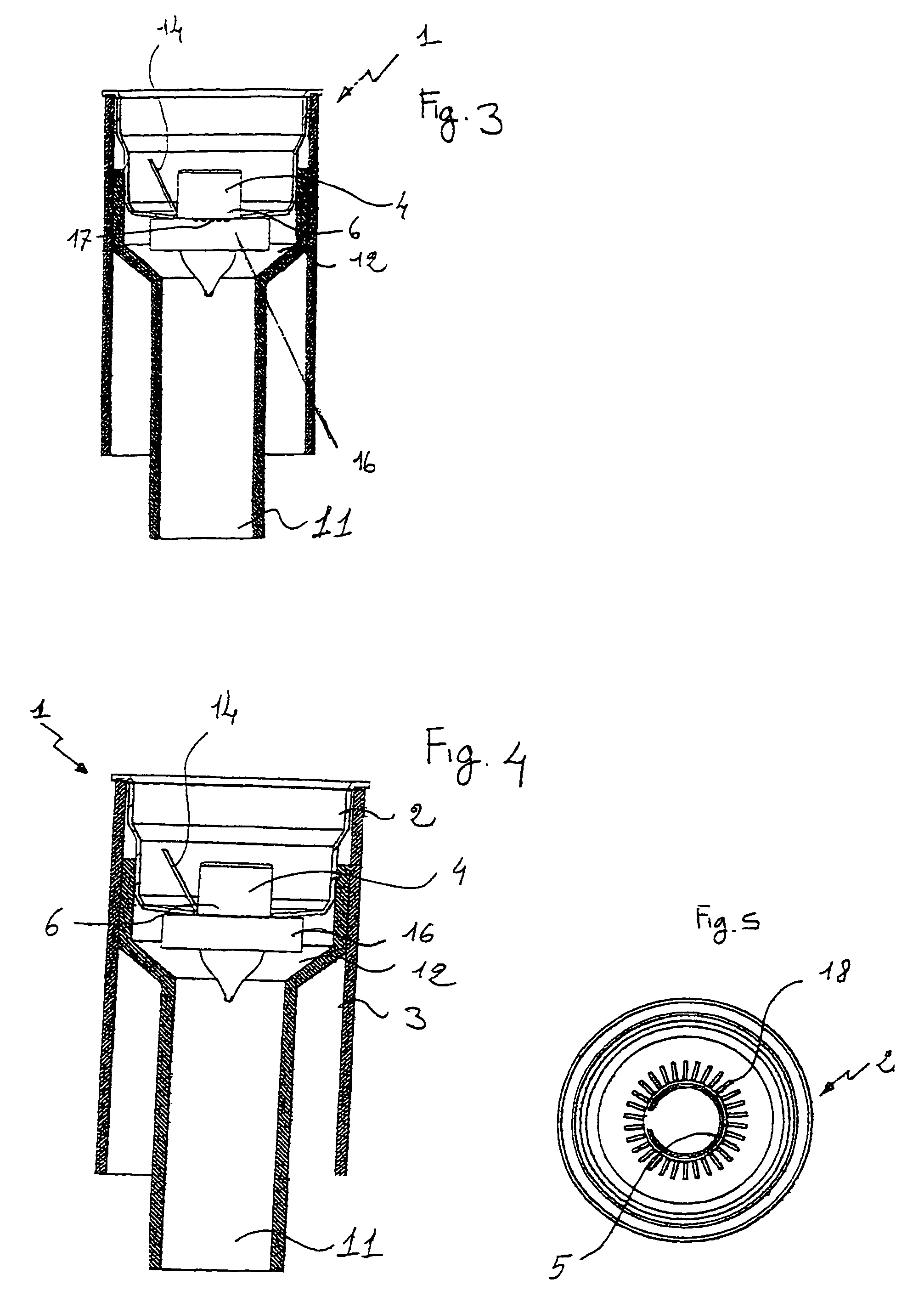

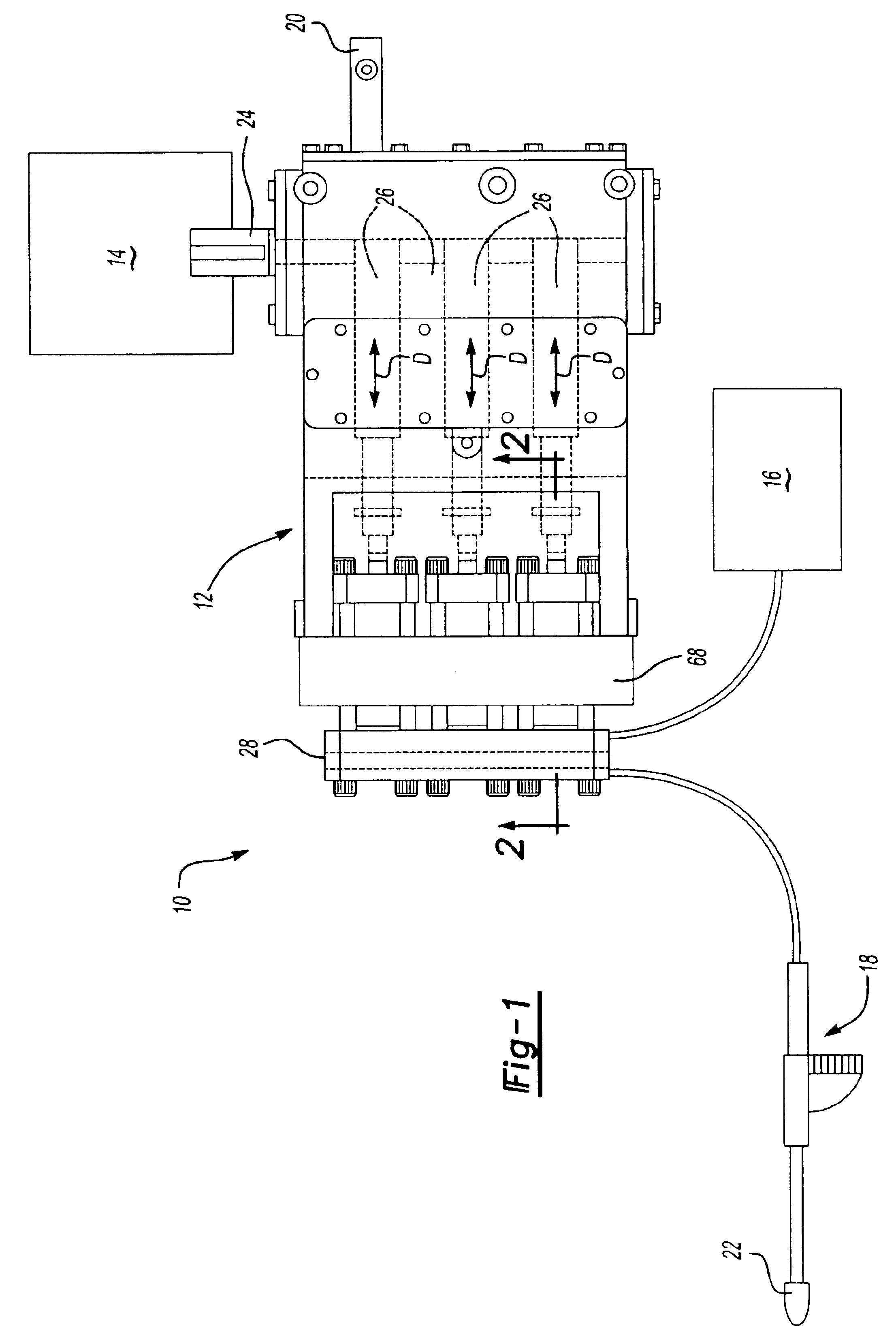

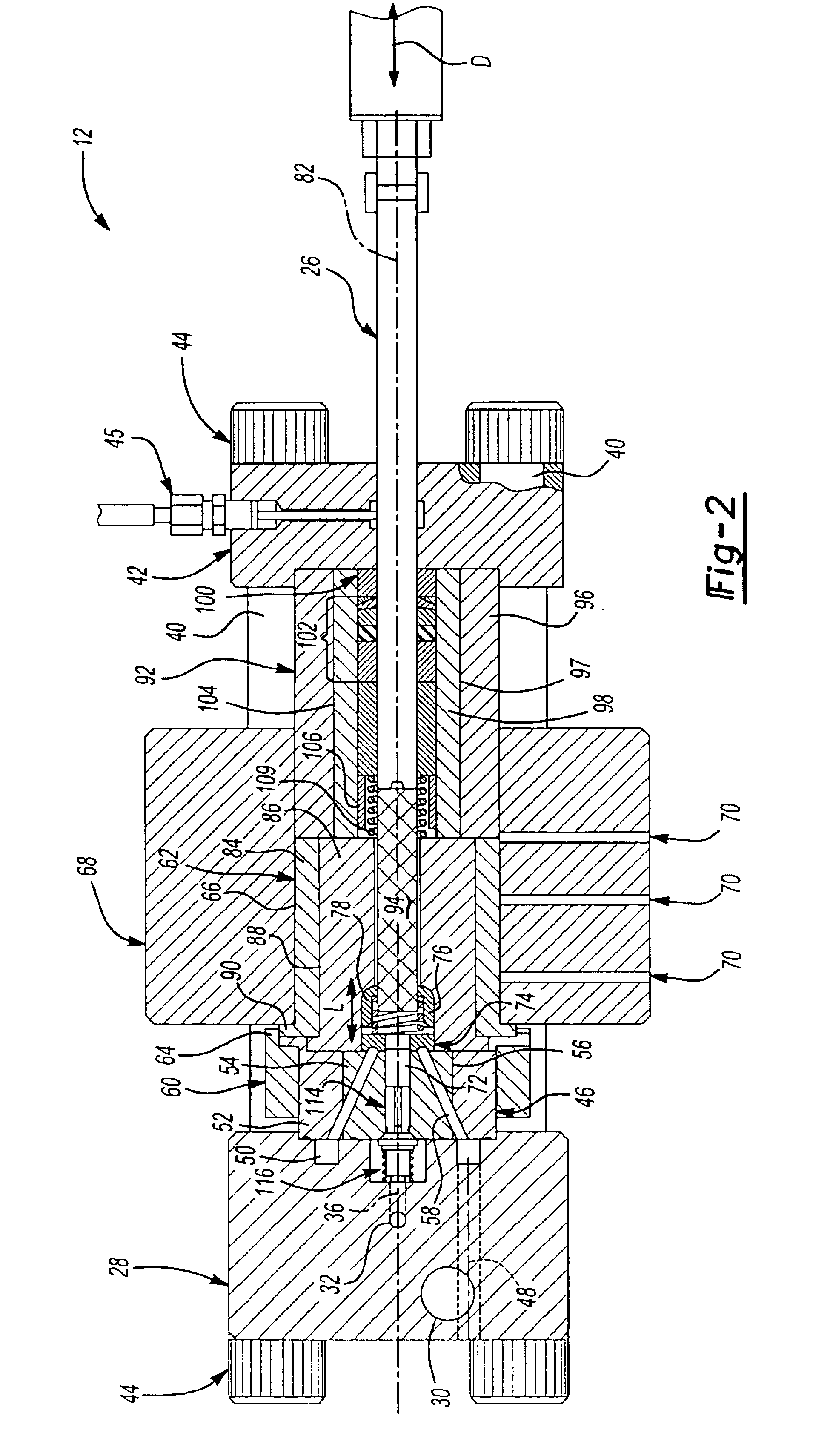

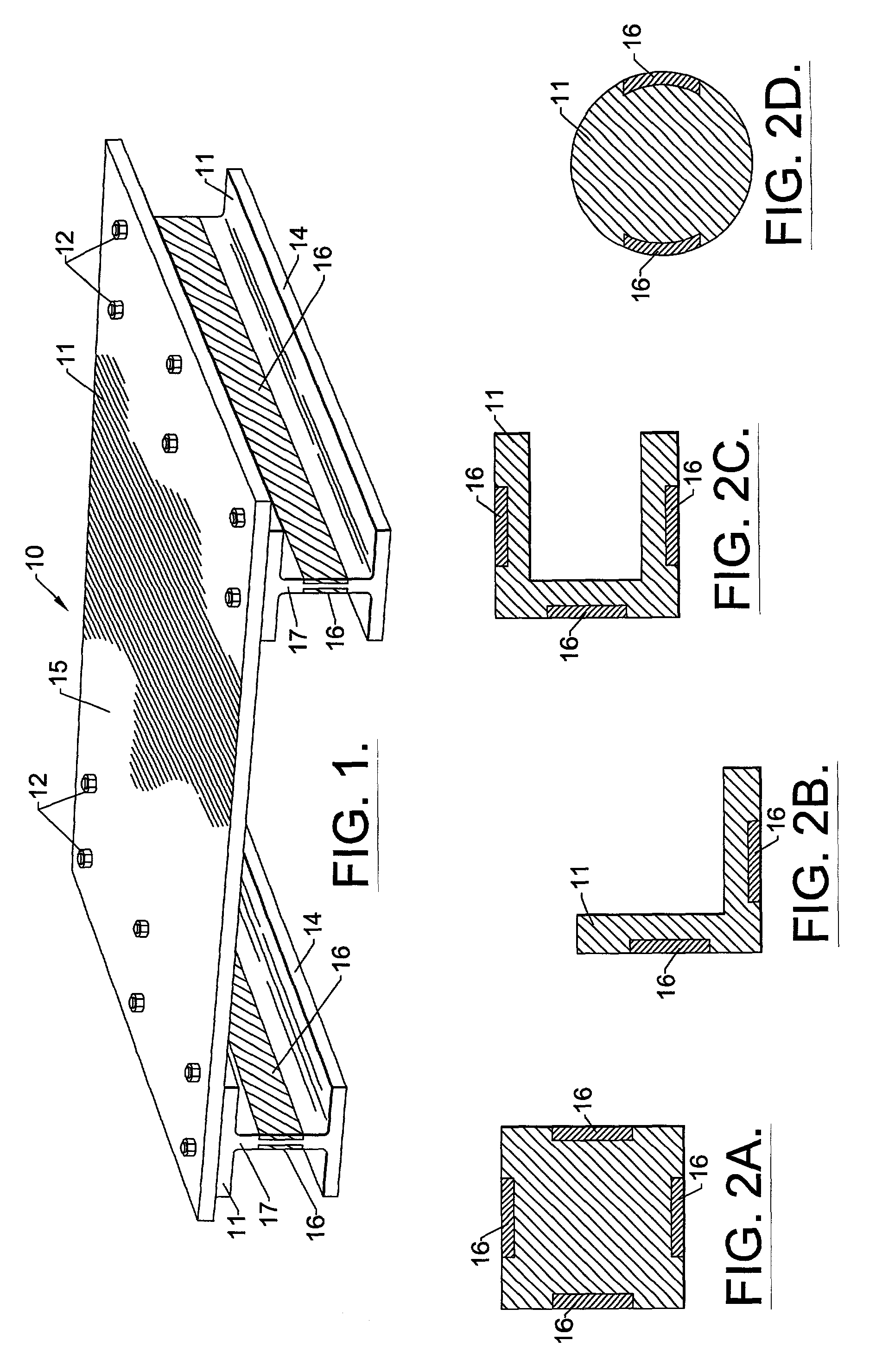

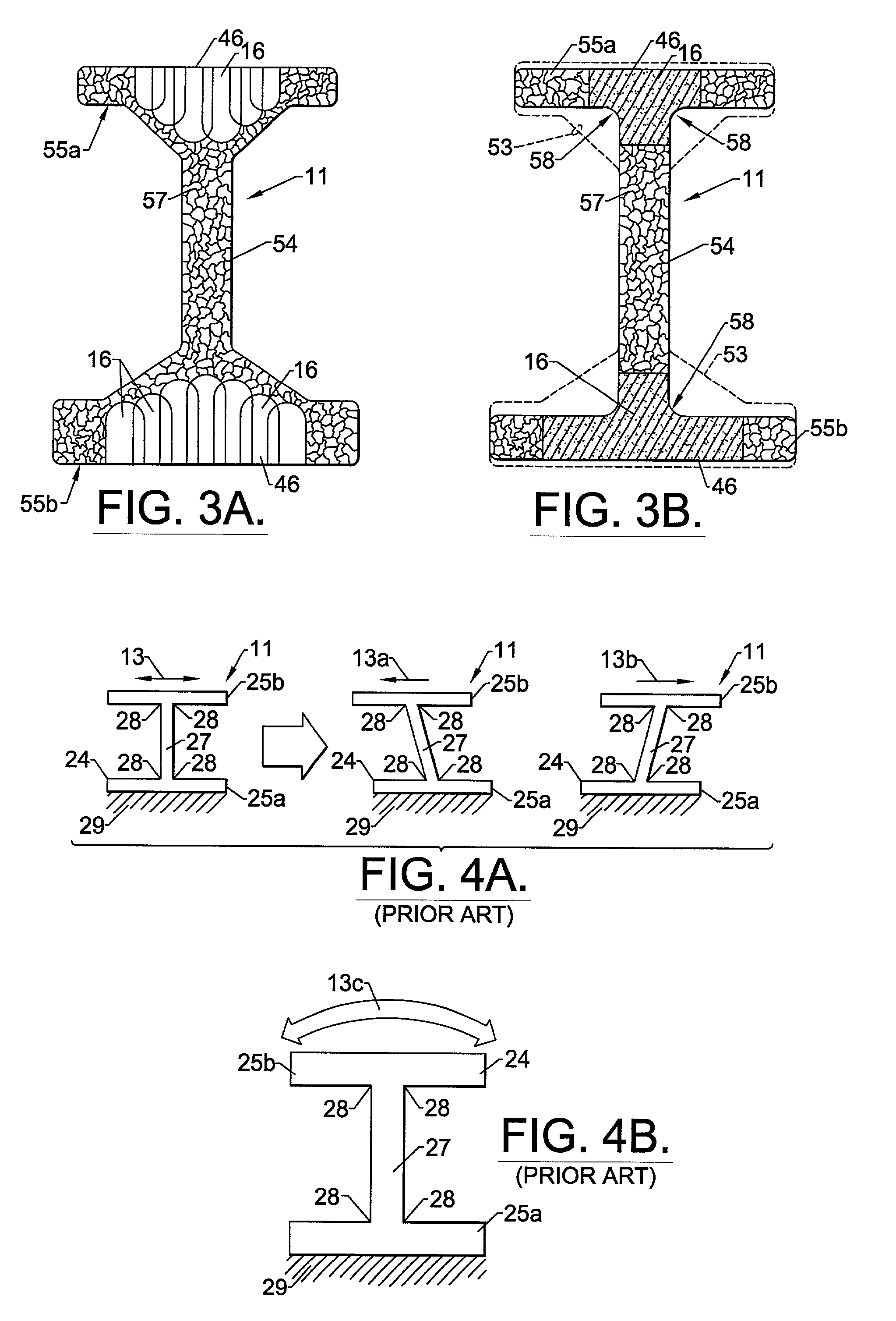

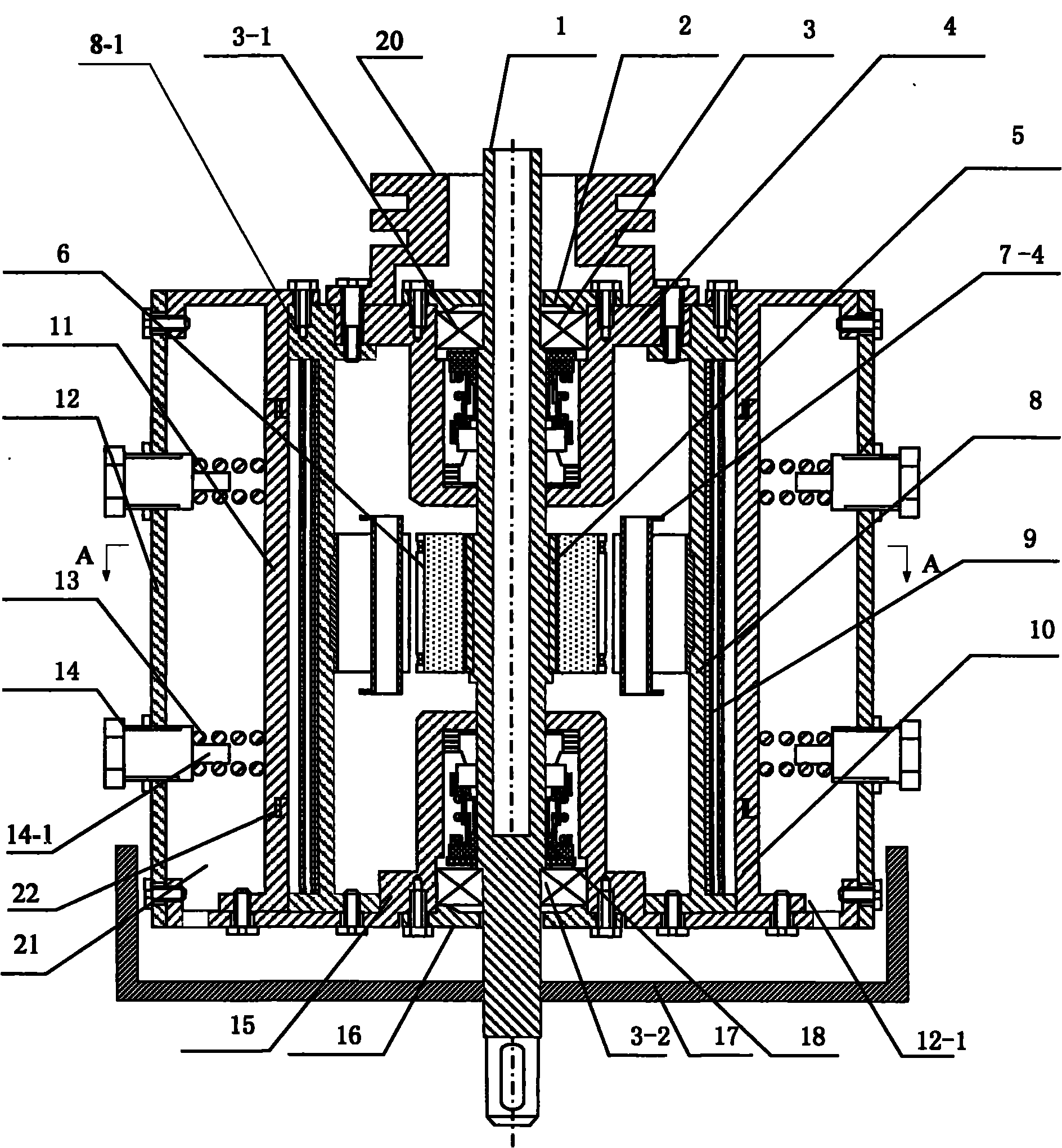

Described herein are integrated systems for generating neutrons to perform a variety of tasks including: on-line analysis of bulk material and industrial process control (as shown in FIG. 1), security interrogation (as shown in FIG. 2), soil and environmental analysis, and medical diagnostic treatment. These systems are based on novel gas-target neutron generation which embodies the beneficial characteristics of replenishable fusible gas targets for very long lifetime, stability and continuous operation, combined with the advantageous features common to conventional accelerator neutron tubes including: on / off operation, hermetically sealed operation, and safe storage and transport. Innovative electron management techniques provide gas-target neutron production efficiencies that are comparable or surpass existing sources. The high-pressure high-resistance gaseous discharge is presented as a favorable gas-target neutron generator embodiment, combining ion source regions, accelerator regions, gas-target regions and electron management components within a single simple cost-effective device that is adaptable to various geometric configurations that provide specific neutron emission profiles for greater analysis capacity.

Owner:STARFIRE INDS MANAGEMENT

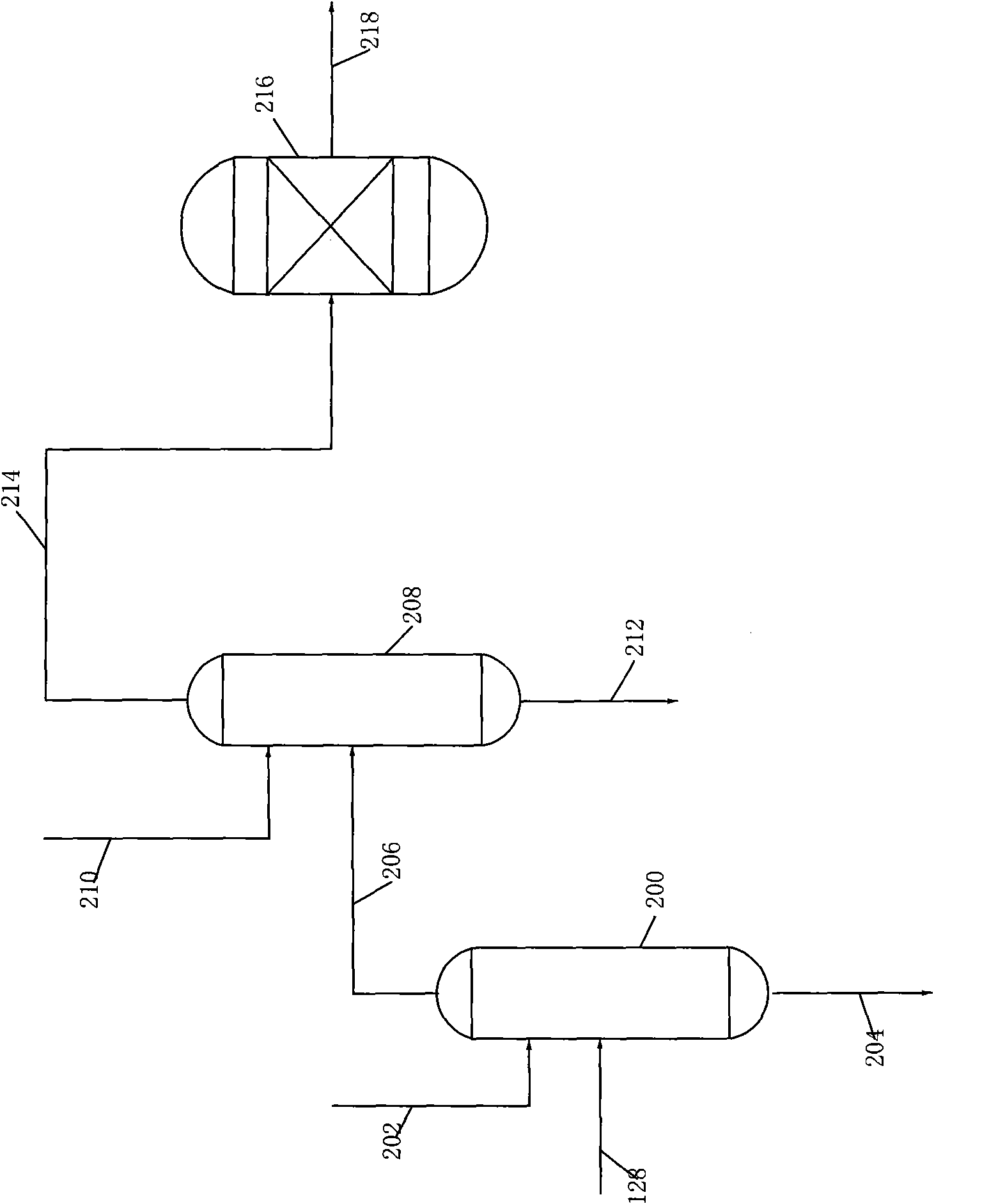

Method for concentrating water-soluble organic material

InactiveUS7594981B2Improve permeabilityIncrease operating pressureOrganic compound preparationDispersed particle separationDistillationWater soluble

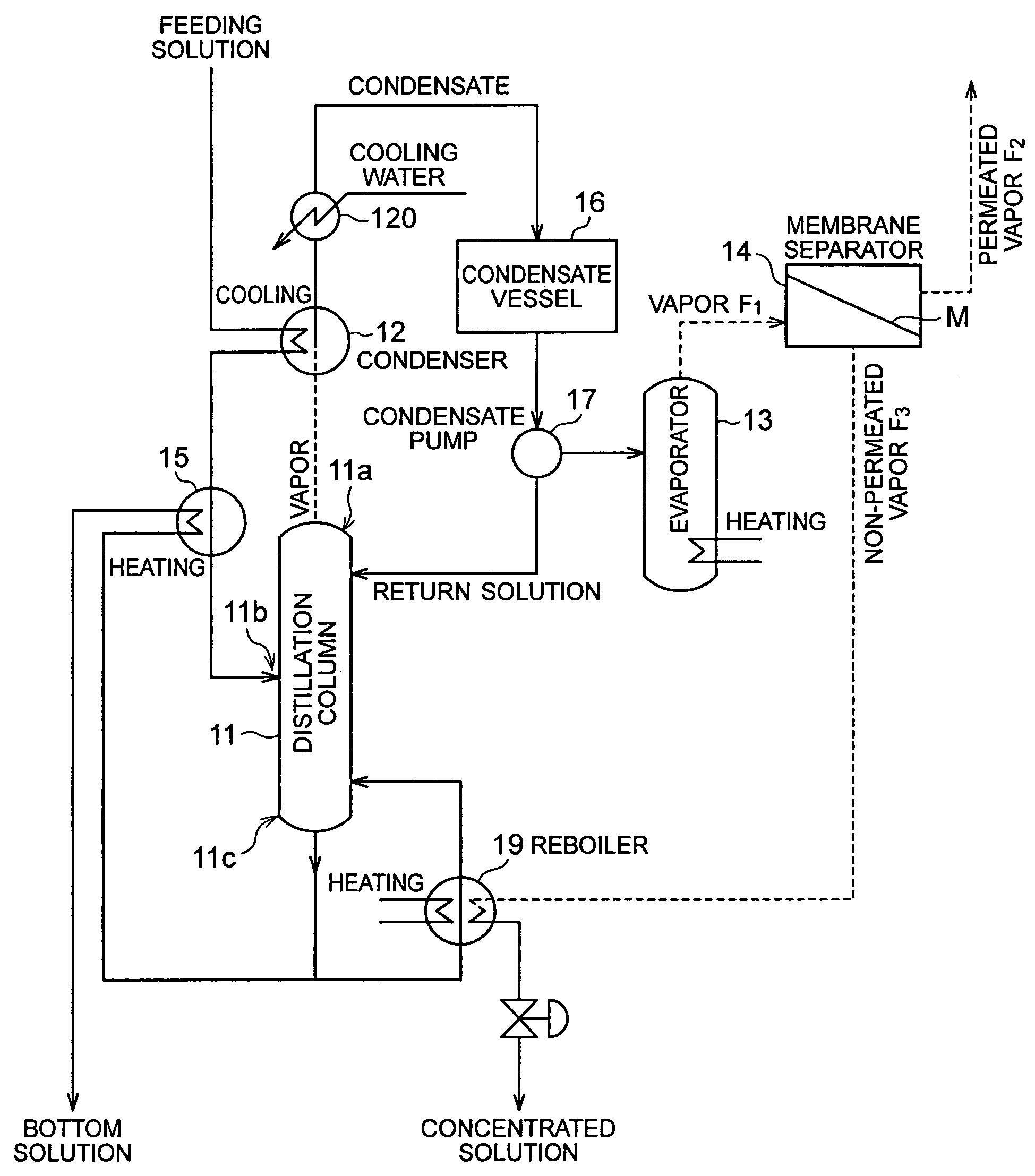

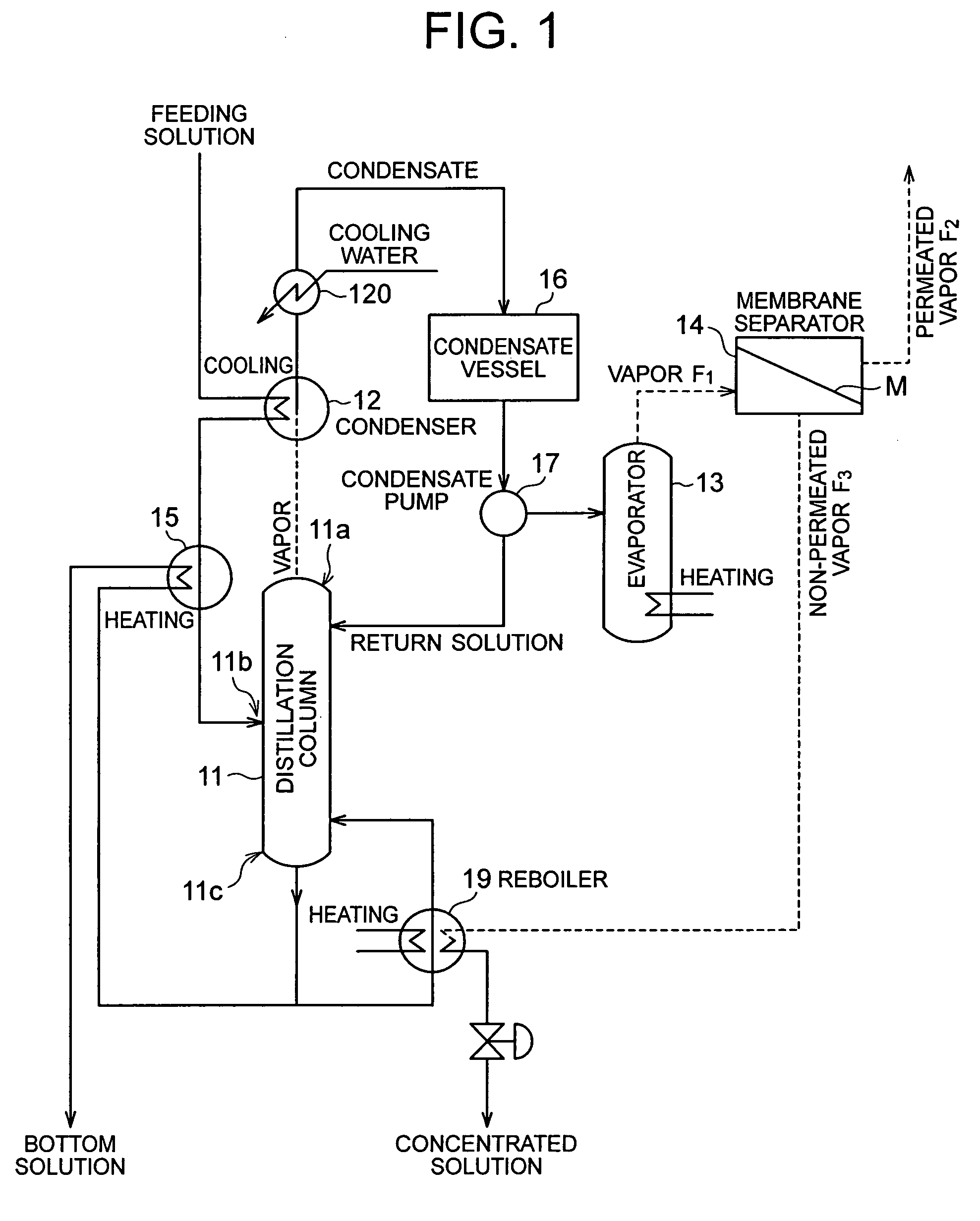

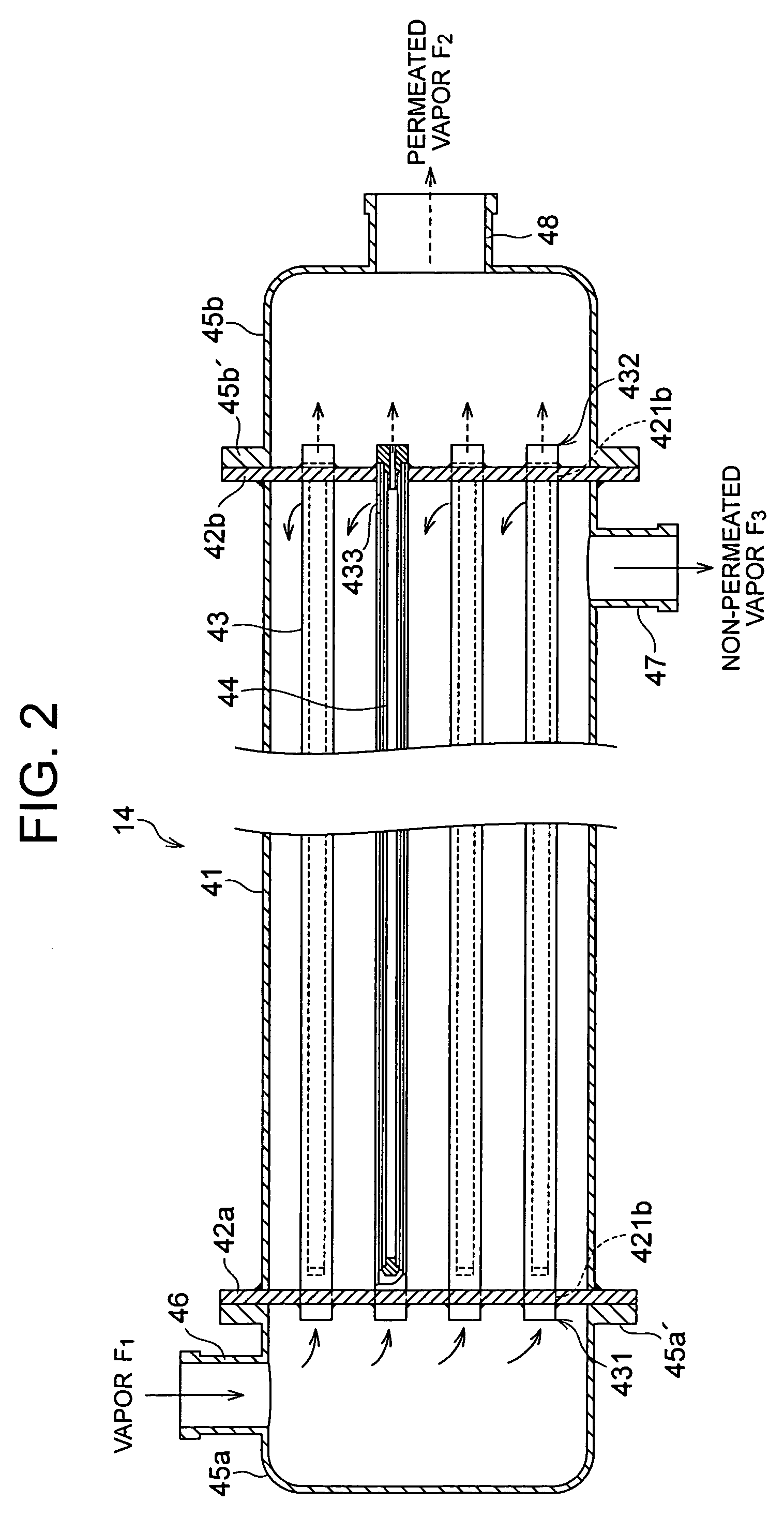

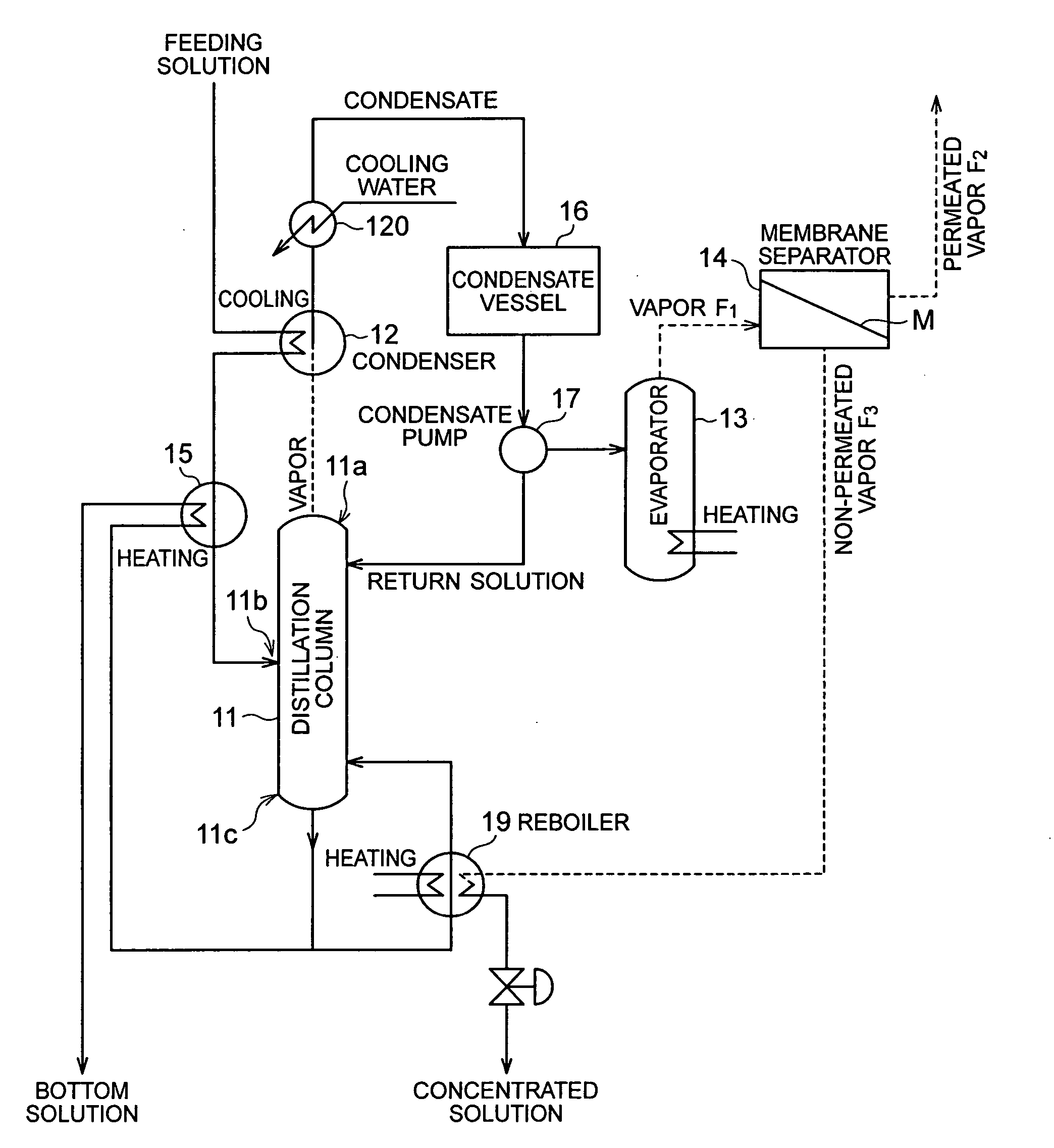

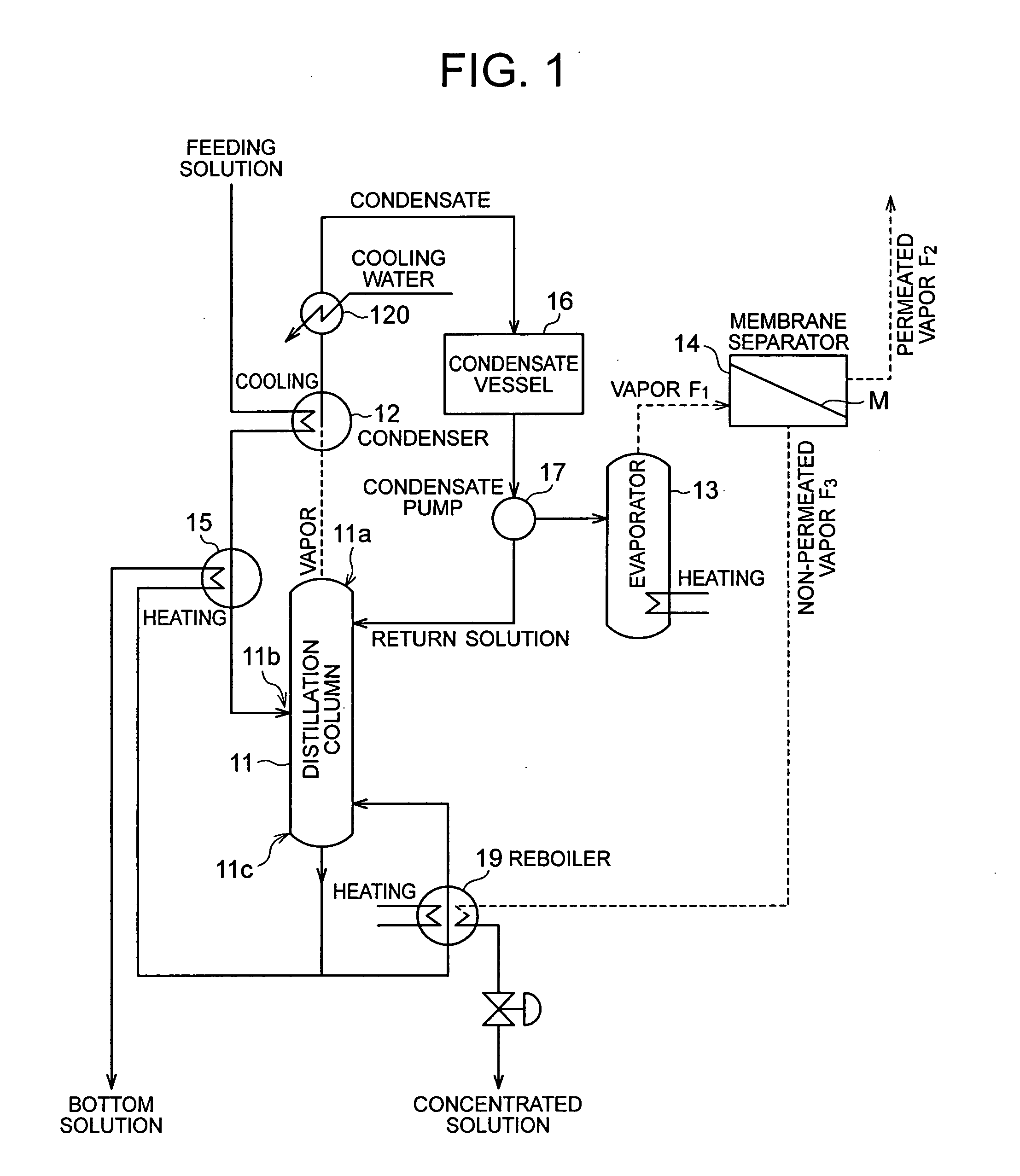

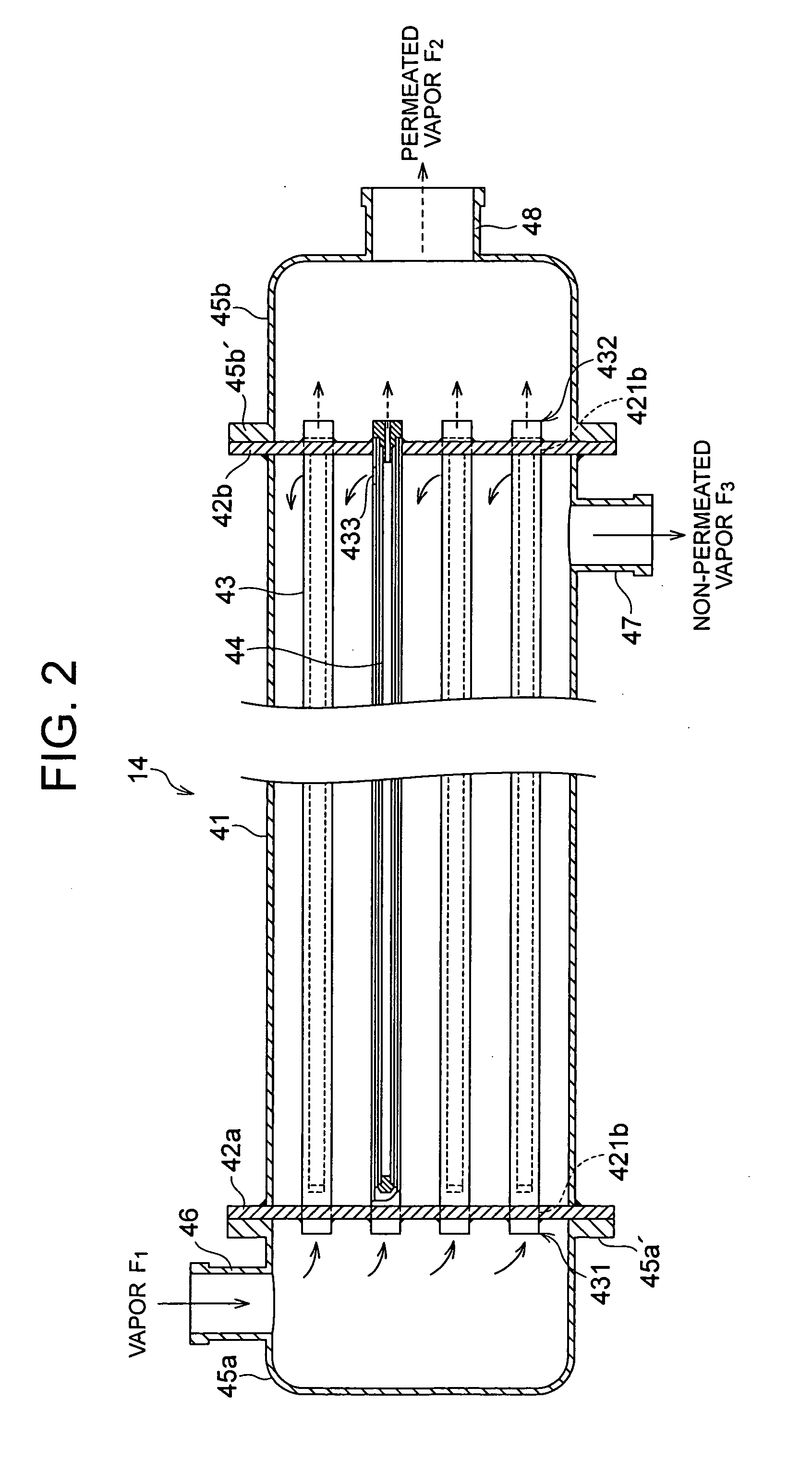

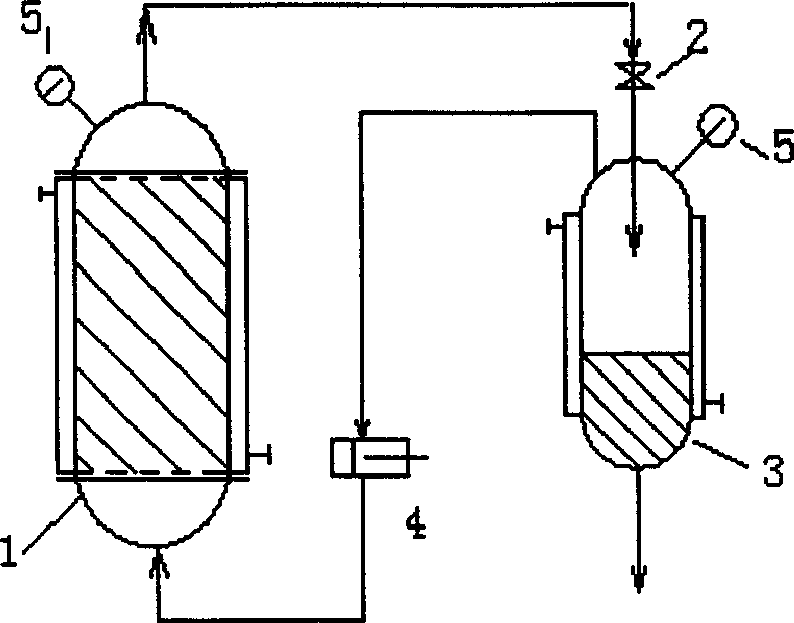

A method for concentrating a water-soluble organic material wherein a mixture of the water-soluble organic material with water is distilled in a distillation column (11), and the fraction from the top (11a) of the distillation column (11) is separated by the use of a membrane separator (14) into a permeated vapor (F2) and a non-permeated vapor (F3), which comprises once condensing the fraction to form a condensate, heating the condensate in an evaporator (13) to generate a vapor (F1) having a pressure higher than the operation pressure for the distillation column (11), and introducing the vapor (F1) to the membrane separator (14), thereby separating water from the mixture.

Owner:MITSUBISHI CHEM CORP

Low cost wind tunnel for supersonic and hypersonic aerothermal testing

The invention disclosed herein provides a subsonic wind tunnel capable for accurately maintaining a desired Mach number, pressure and temperature for use in aerothermal testing of materials. The invention allows the Mach number to be precisely controlled in the test section of the wind tunnel by employing a restricted outlet acting as a sonic throat for the wind tunnel. In the preferred embodiment, the restricted outlet is constructed to be variable in cross sectional area allowing a range of Mach numbers to be tested. The variable outlet is varied during the operation of the wind tunnel so that an actual trajectory with changing Mach numbers, pressure, and temperature is simulated.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Pressure sensor device including a diaphragm and a stopper member having a curved surface facing the diaphragm

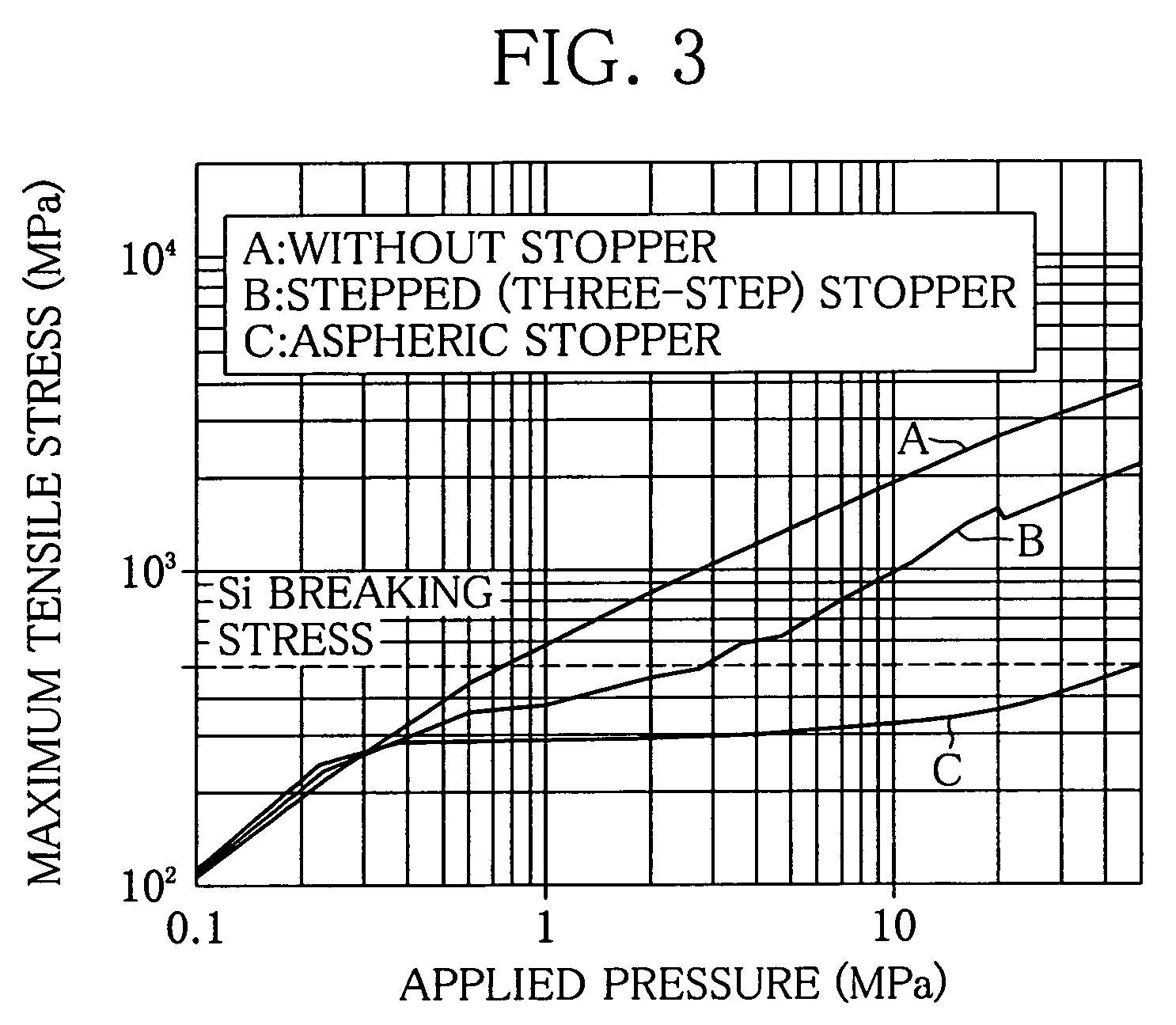

ActiveUS7360431B2Increase operating pressureSimple structureFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringMaximum pressure

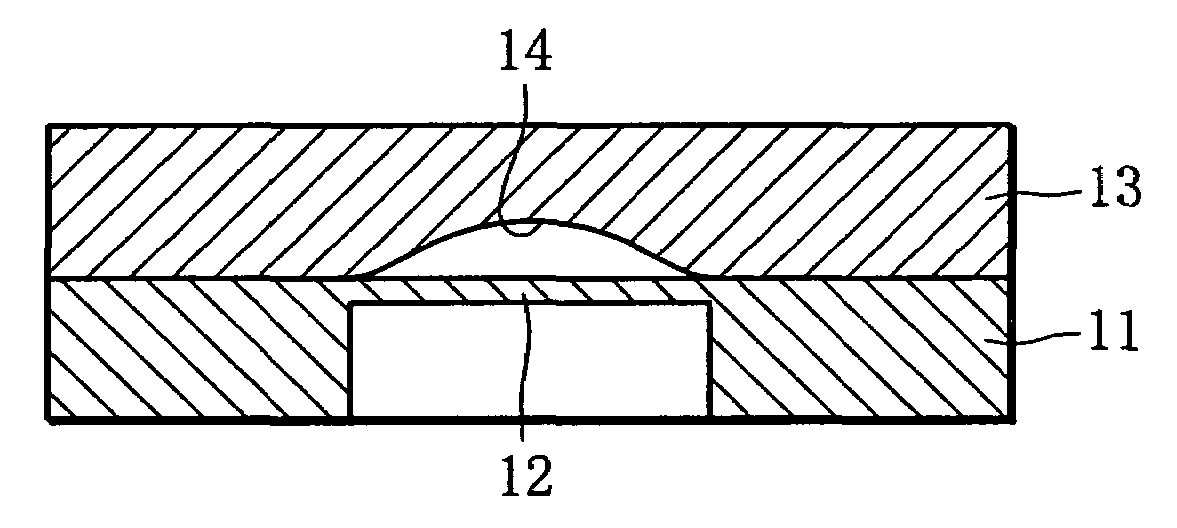

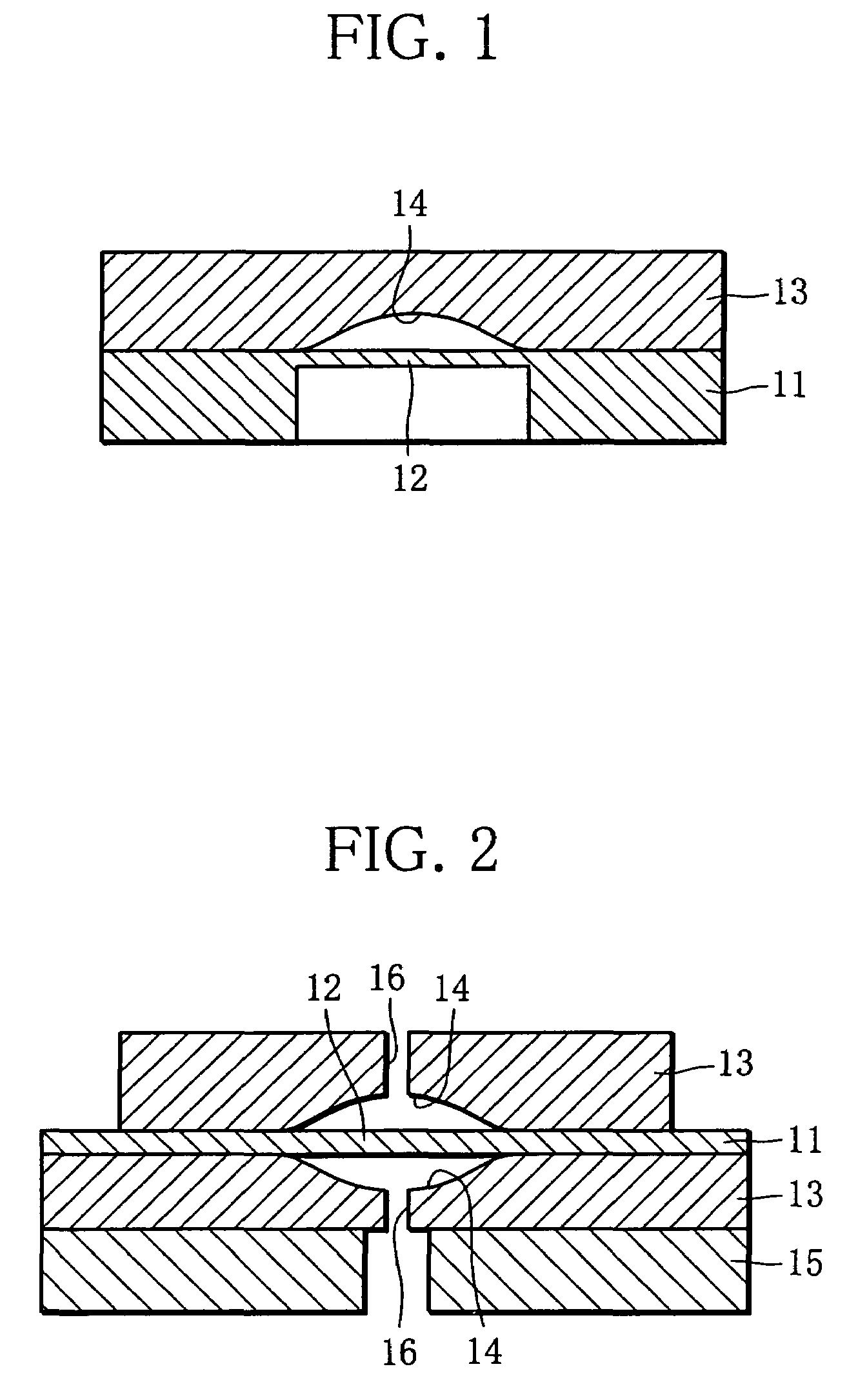

The pressure sensor device has a laminated diaphragm (12) in which a strain resistance gauge is formed in a surface and a stopper member (13) including a concave portion forming a curved surface parallel to a surface formed by displacement of the diaphragm, the concave portion being disposed to face the diaphragm. Specifically, the concave portion of the stopper member is formed into a curved surface in which depth y at a distance x from the center of the diaphragm is expressed by a quartic function [y=pr4(1−x2 / r2)2 / 64D] in relation to the operating pressure for protection against maximum pressure p when the diaphragm has a radius of r, a thickness of t, and a flexural rigidity of D.

Owner:YAMATAKE HONEYWELL CO LTD

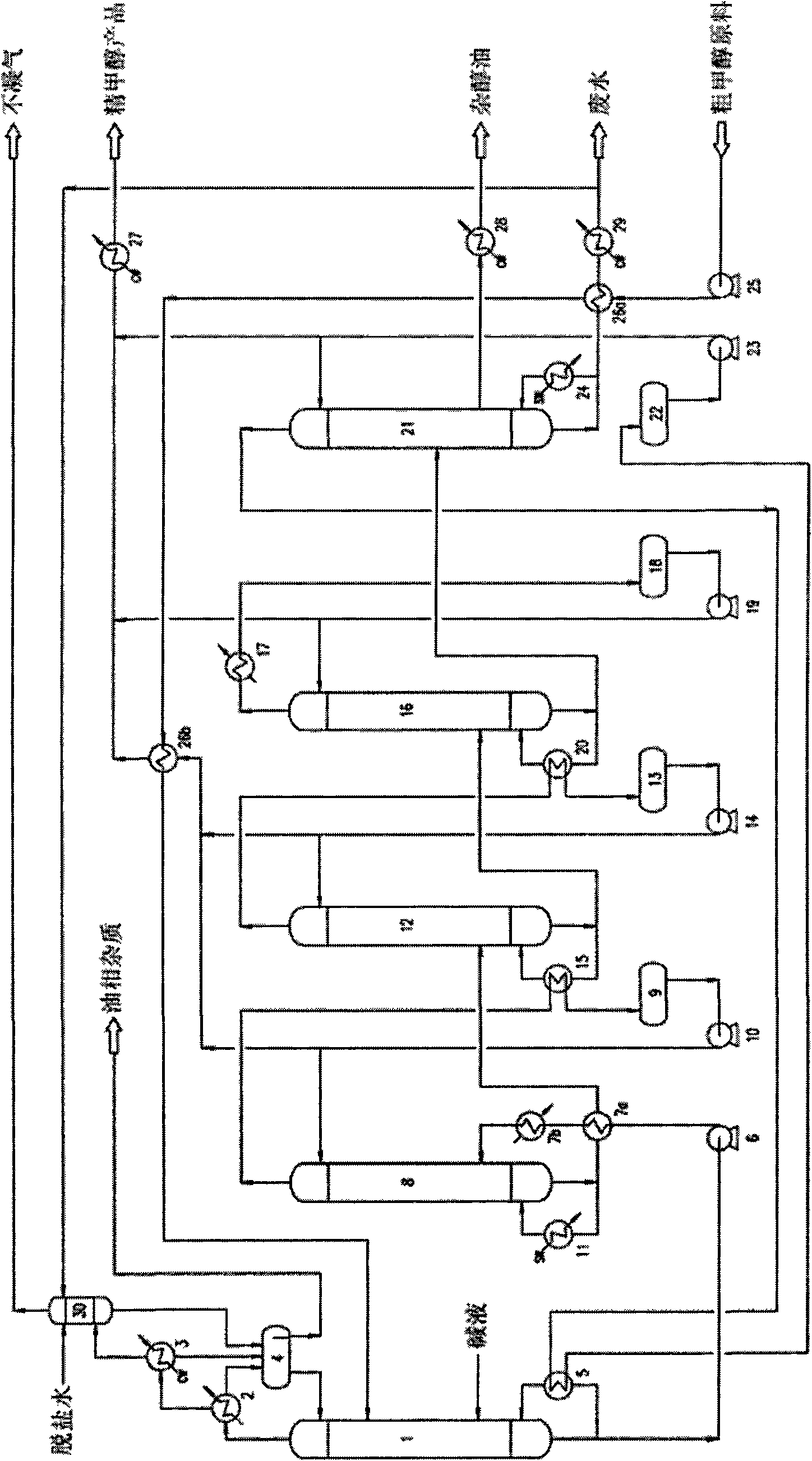

Multi-effect rectifying process of methanol

InactiveCN101570466AIncrease operating pressureIncrease productionOrganic compound preparationChemical industryChemistryReboiler

The invention relates to a multi-effect rectifying process of methanol, which belongs to the technical field of separation and purification of chemical products. In the process, a crude methanol raw material of coal-to-methanol is rectified by a pre-rectifying tower, a pressurizing tower I, a pressurizing tower II, an atmospheric tower and a recovery tower in turn at appropriate temperature and pressure so as to obtain a high-purity refined methanol product according with quality requirements. In the flow, methanol steam on the top of the pressurizing tower I is used for providing heat for a reboiler at the bottom of the pressurizing tower II, the methanol steam on the top of the pressurizing tower II is used for providing heat for a reboiler at the bottom of the atmospheric tower, and the pressurizing tower I, the pressurizing tower II and the atmospheric tower form multi-effect rectification; and simultaneously, the methanol steam on the top of the recovery tower is used for providing heat for a reboiler at the bottom of the pre-rectifying tower, and the recovery tower and the pre-rectifying tower form double-effect rectification. The invention provides an energy-saving methanol multi-effect rectifying process method which has the advantages of greatly reduced energy consumption, more stable production process, more easily controlled product quality, higher methanol recovery rate and basically equivalent investment compared with a three-tower rectifying process.

Owner:XI'AN PETROLEUM UNIVERSITY

Gearless/oilless gas turbine engine

InactiveUS6881027B2Increase operating pressureIncrease capacityEngine sealsPump componentsMagnetic bearingLubrication

The complex mechanical gear trains and lubrication systems of conventional engine configurations are eliminated by using combinations of hydrodynamic air foil bearings, hydrodynamic solid geometry carbon seals / bearings, magnetic bearings, and electrical starter / generators that can also act as bearings to support the high speed shafts of gas turbine engines. The various bearing types and the starter / generators are arranged in such a way as to share peak loads experienced by the engine shaft during maximum aircraft maneuvers. This results in a minimal bearing and engine size.

Owner:HONEYWELL INT INC

Method for concentrating water-soluble organic material

InactiveUS20060070867A1Improve permeabilityIncrease operating pressureSemi-permeable membranesOrganic compound preparationDistillationWater soluble

A method for concentrating a water-soluble organic material wherein a mixture of the water-soluble organic material with water is distilled in a distillation column (11), and the fraction from the top (11a) of the distillation column (11) is separated by the use of a membrane separator (14) into a permeated vapor (F2) and a non-permeated vapor (F3), which comprises once condensing the fraction to form a condensate, heating the condensate in an evaporator (13) to generate a vapor (F1) having a pressure higher than the operation pressure for the distillation column (11), and introducing the vapor (F1) to the membrane separator (14), thereby separating water from the mixture.

Owner:MITSUBISHI CHEM CORP

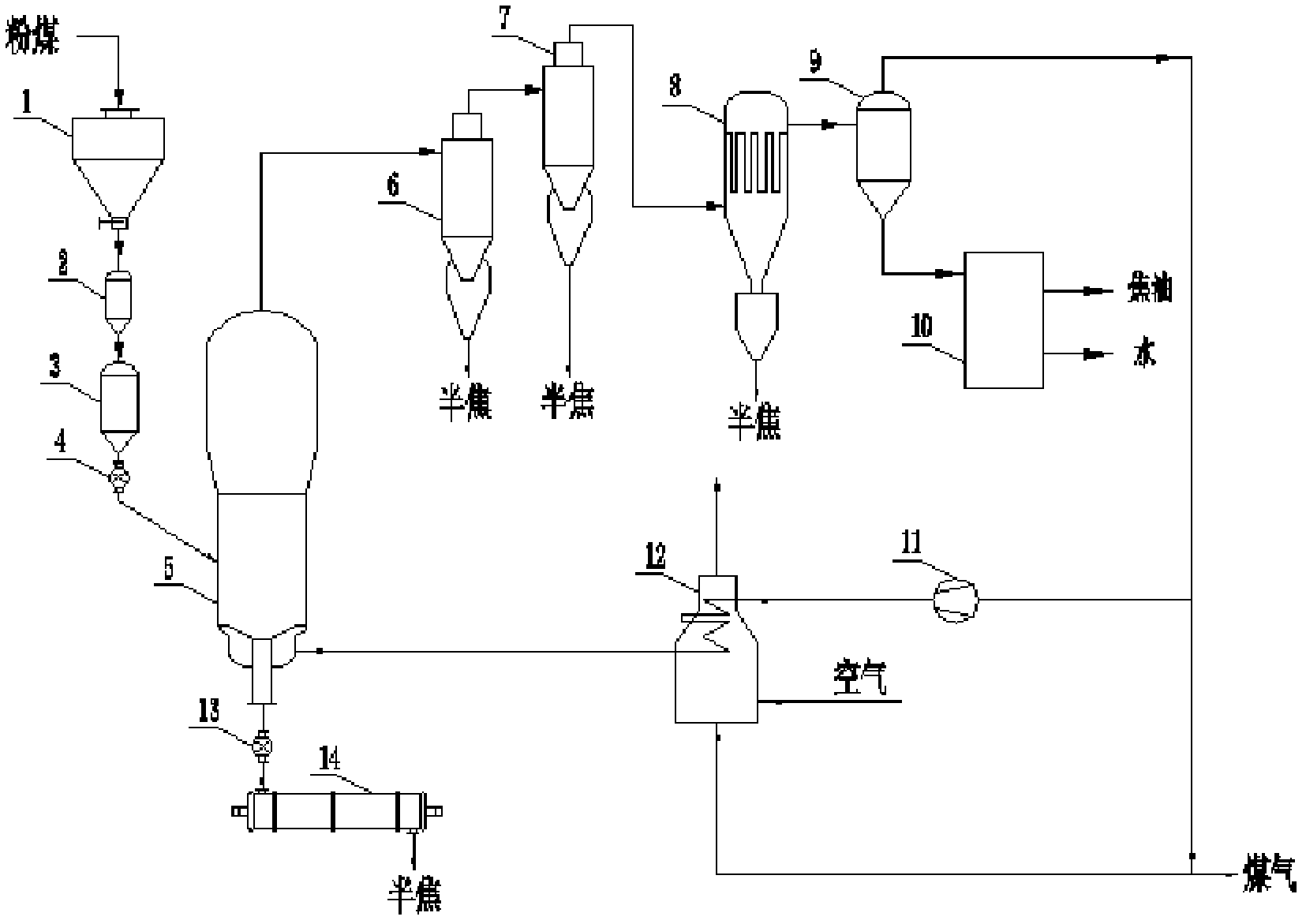

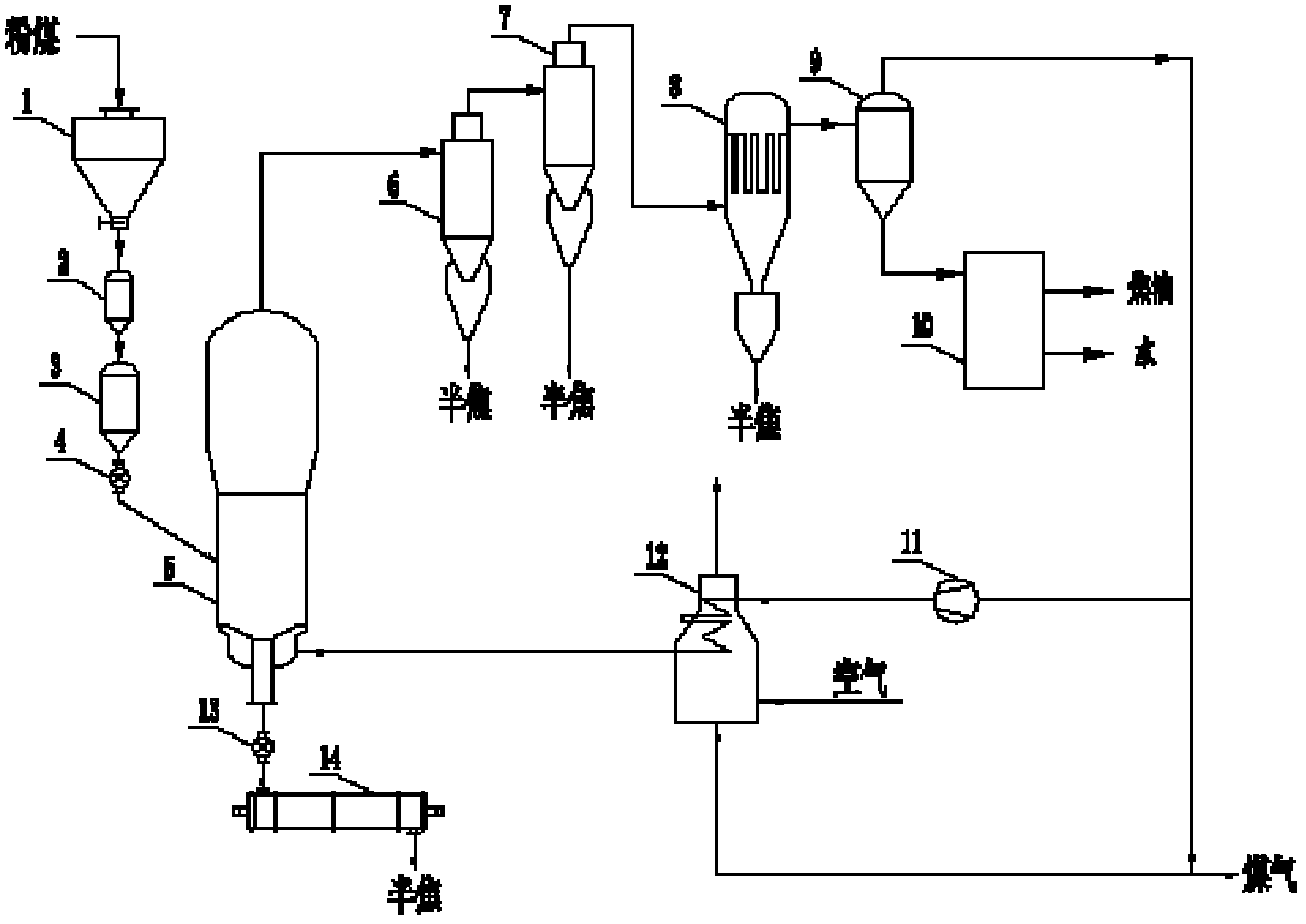

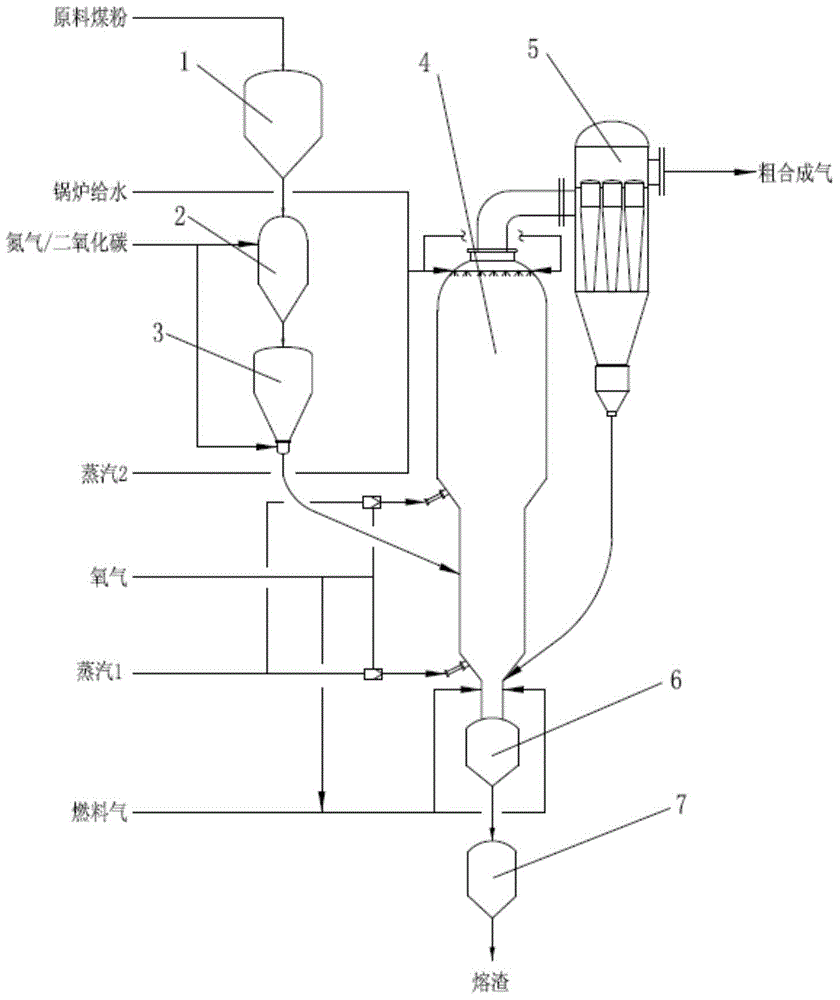

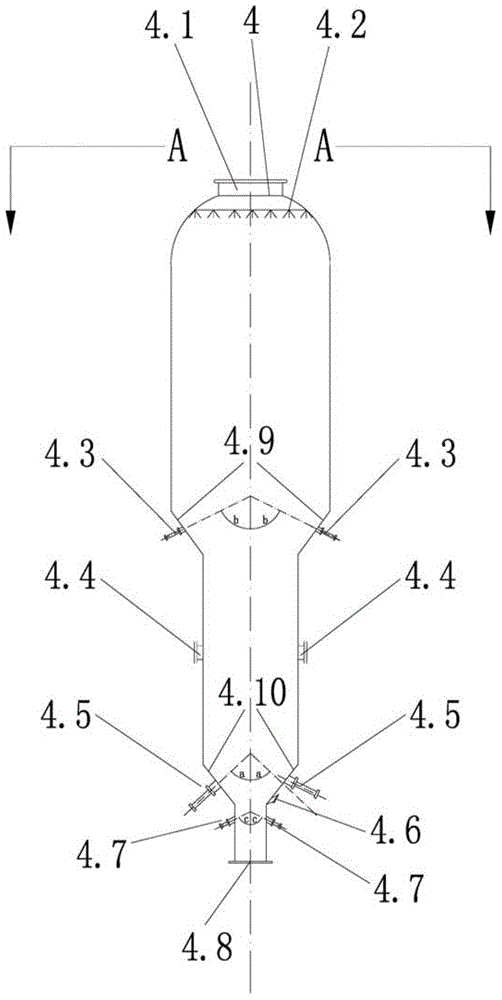

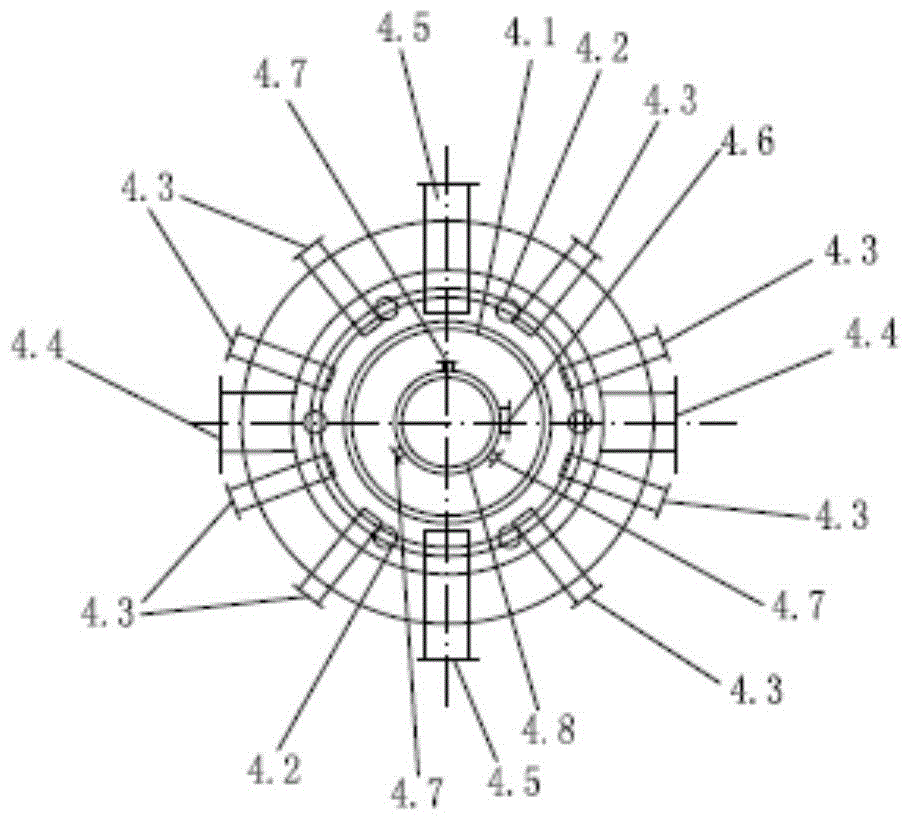

IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal

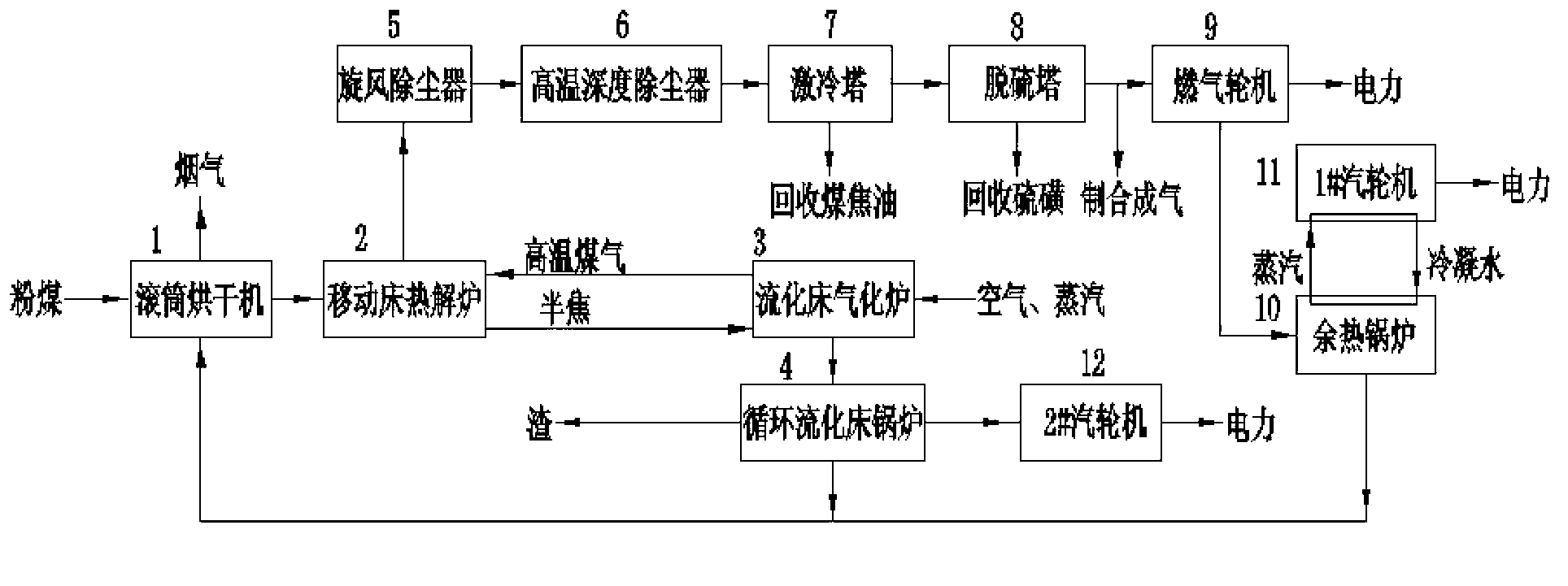

InactiveCN103013576ATake advantage ofAchieve integrationEnergy inputGas turbine plantsResource utilizationChemical products

The invention discloses an IGCC (Integrated Gasification Combined Cycle) poly-generation device and method based on pyrolysis and gasification of low metamorphic powdered coal. The device comprises a pyrolysis / gasification system, a coal gas purifying system, a circulating fluidized bed boiler and a gas turbine / steam turbine system. The method comprises the steps as follows: carrying out low temperature pyrolysis and partial air gasification on the low metamorphic powdered coal, grading and converting into coal gas, tar and semi-coke, and carrying out the IGCC poly-generation process by the semi-coke and the coal gas with high calorific value. According to the device and the method, the tar, sulphur and other chemical products can be produced while clean power is generated, the products obtained by grading and converting the low metamorphic powdered coal are fully utilized, the material conversion and energy conversion functions are integrated, the resource utilization rate is high, and the heat energy efficiency is high. The device and method are suitable for the low metamorphic powdered coal such as peat, brown coal, jet coal, non-sticking coal and the like, and the particle size of raw materials is 0-8 mm. The high-temperature coal gas generated in a fluidized bed gasification furnace contains a large amount of hydrogen, so that the powdered coal can be subjected to hydropyrolysis, and the tar recovery rate can reach more than 12%.

Owner:陕西华祥能源科技集团有限公司

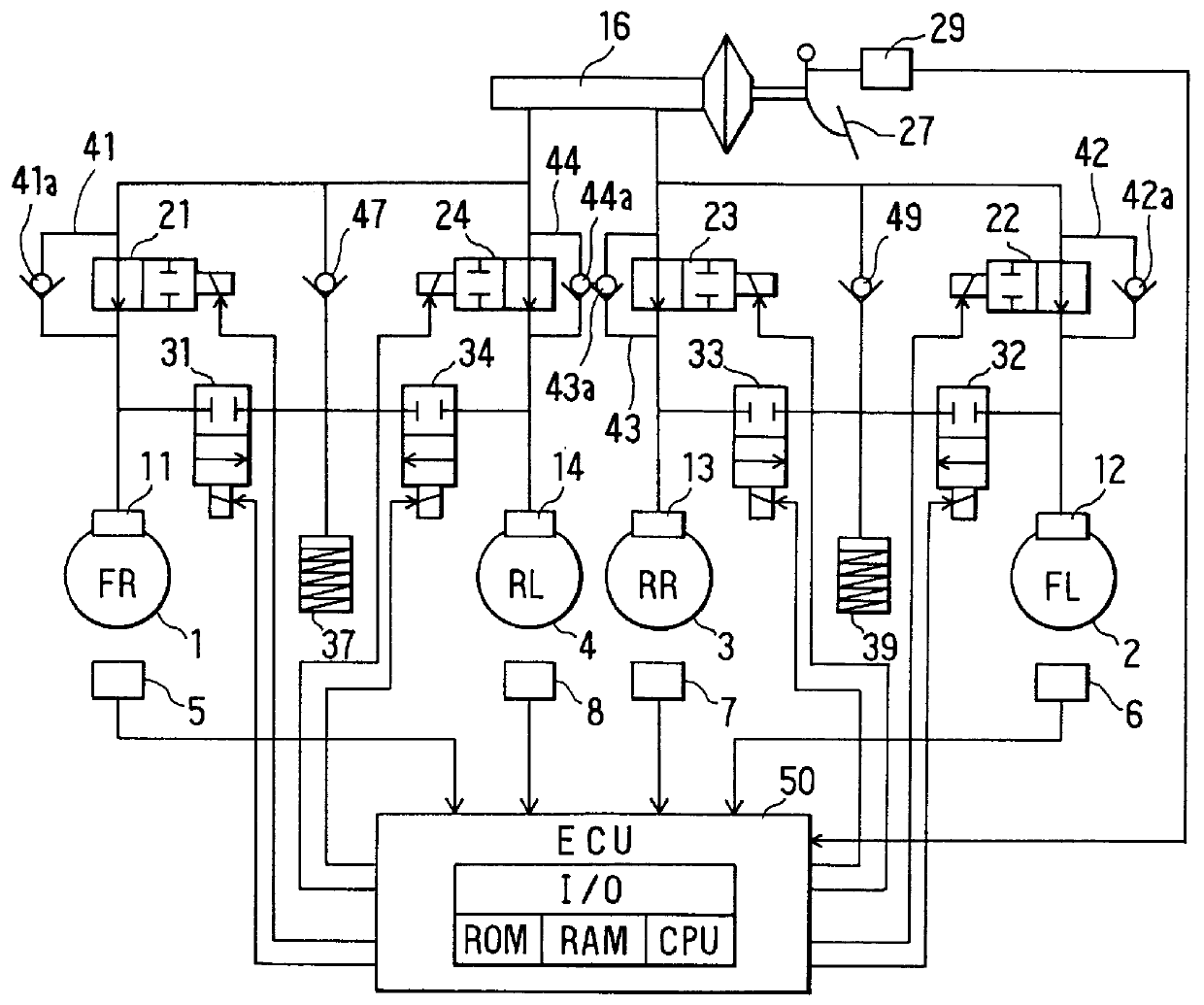

Brake apparatus

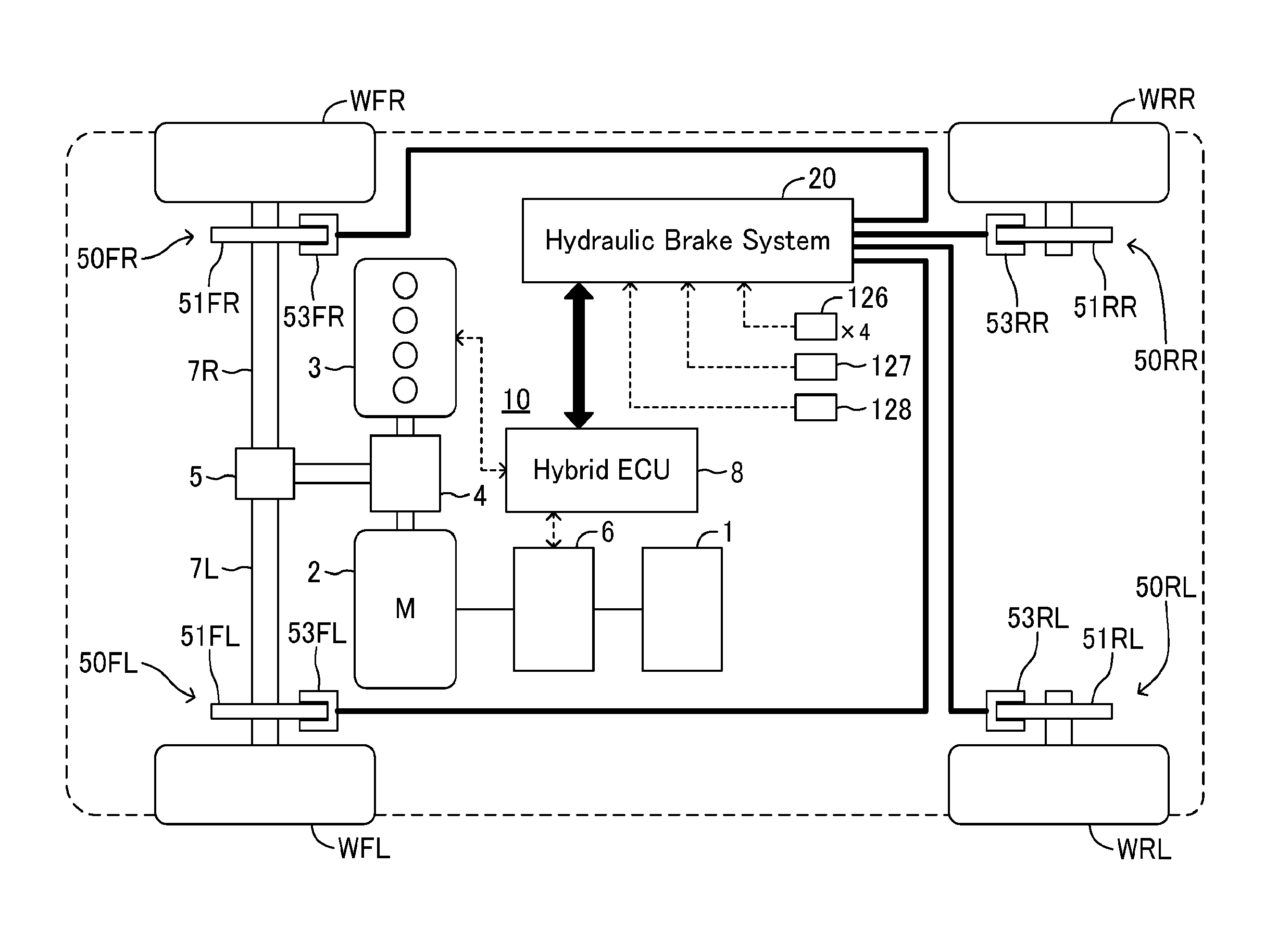

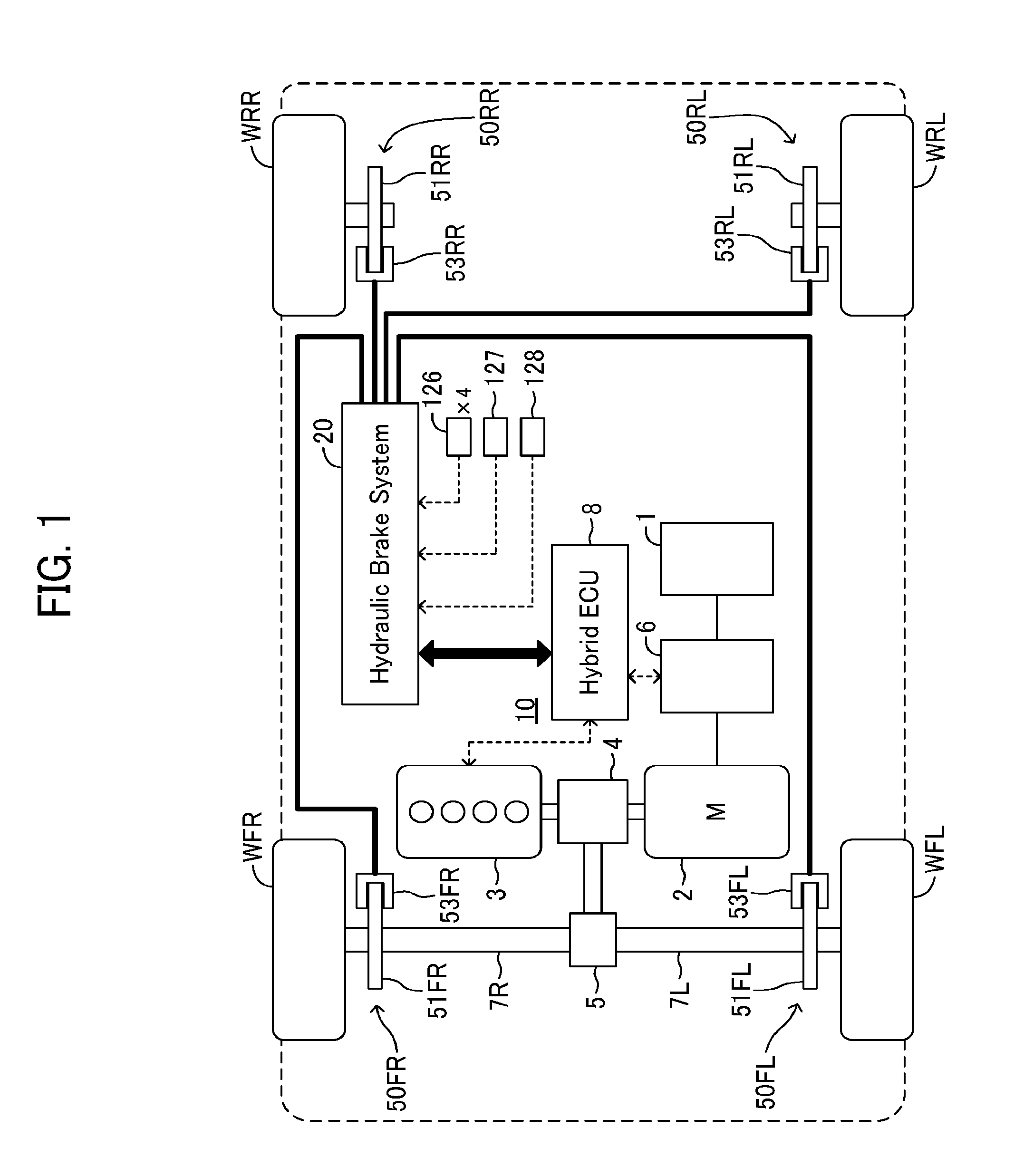

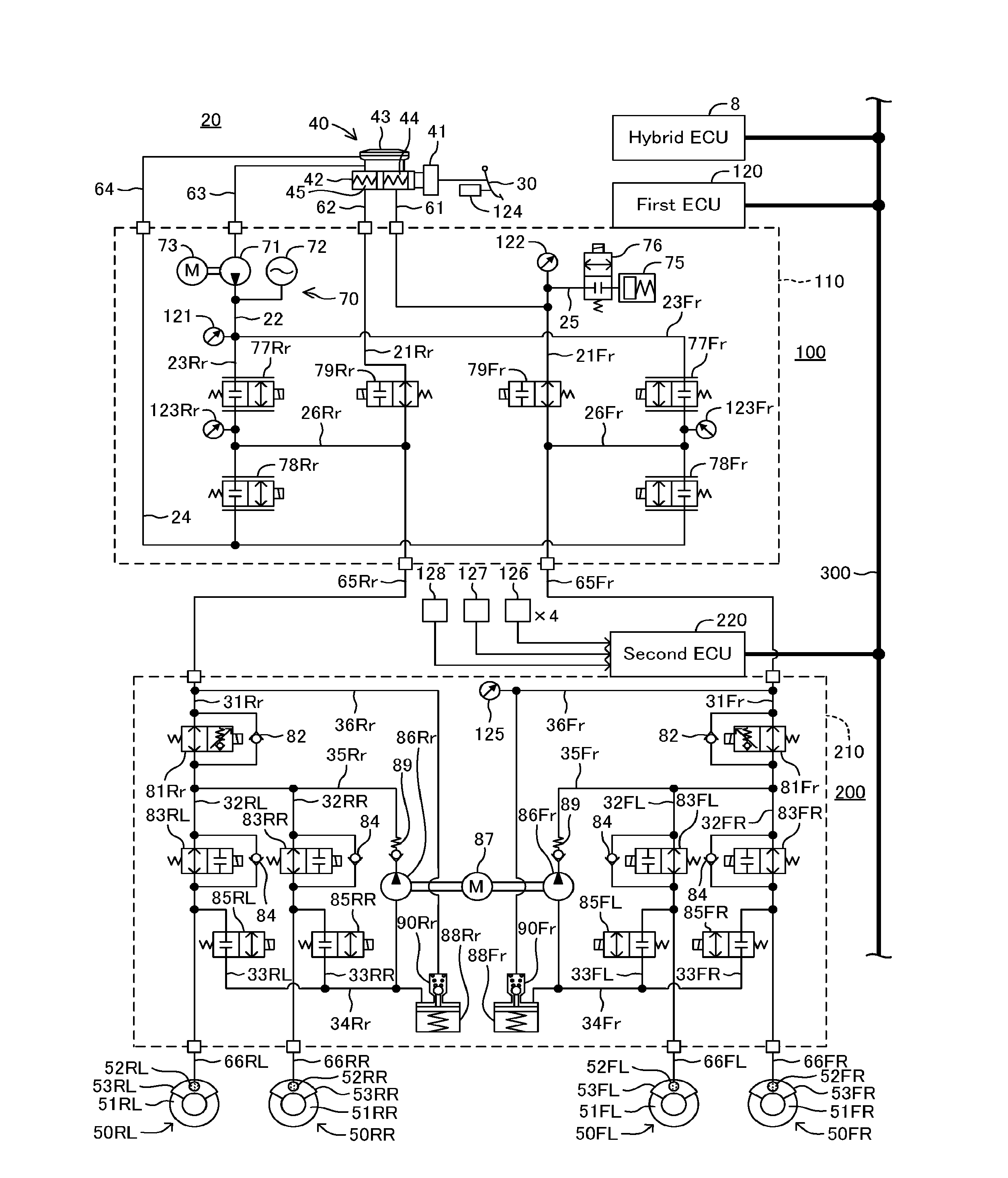

ActiveUS20160096434A1Reduce running noiseIncreased durabilityHybrid vehiclesDigital data processing detailsLinear controlOperation mode

A first ECU estimates whether the operation of a second actuator has been started, based on the variation of the hydraulic pressure with respect to the flow rate of hydraulic fluid outputted from a first actuator. Even in a case where the operation information of the second actuator is not received, the first ECU sets the control mode to a simultaneous operation mode, when it is estimated that the operation of the second actuator has been started. In the simultaneous operation mode, a controlled parameter of linear control valves on assumption that the second actuator is operating is set up, and a stop instruction of regenerative braking is transmitted to a hybrid ECU.

Owner:TOYOTA JIDOSHA KK

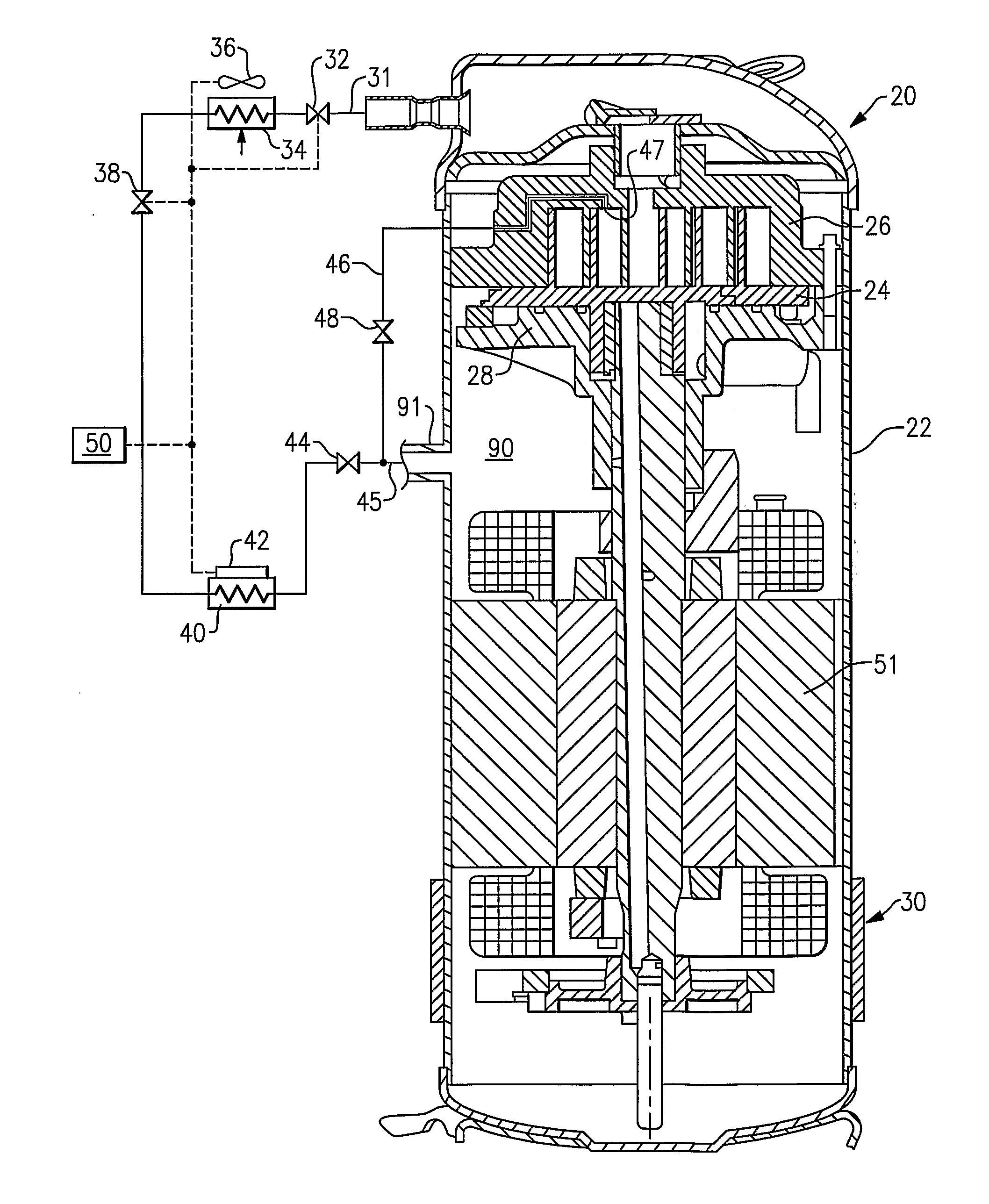

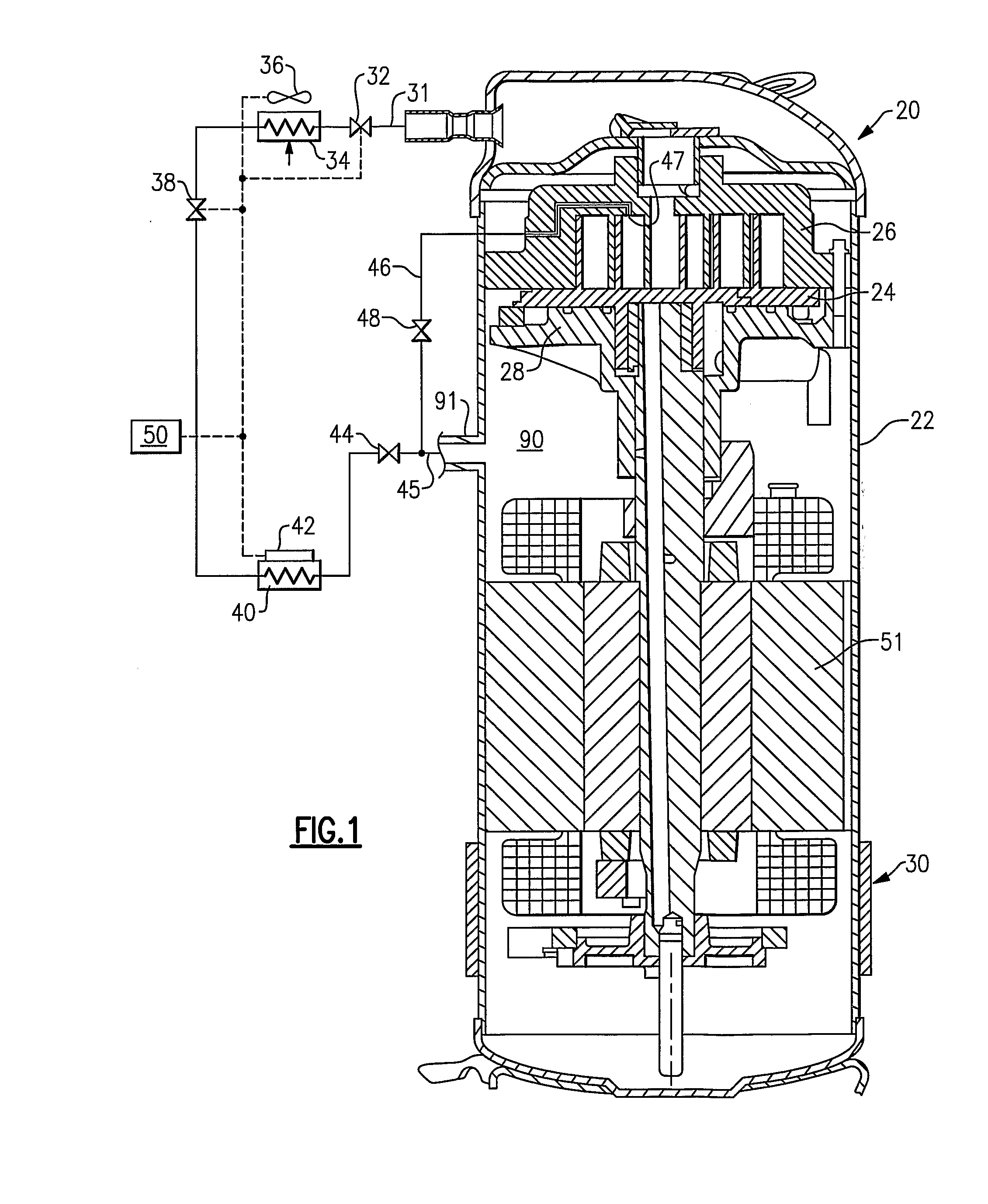

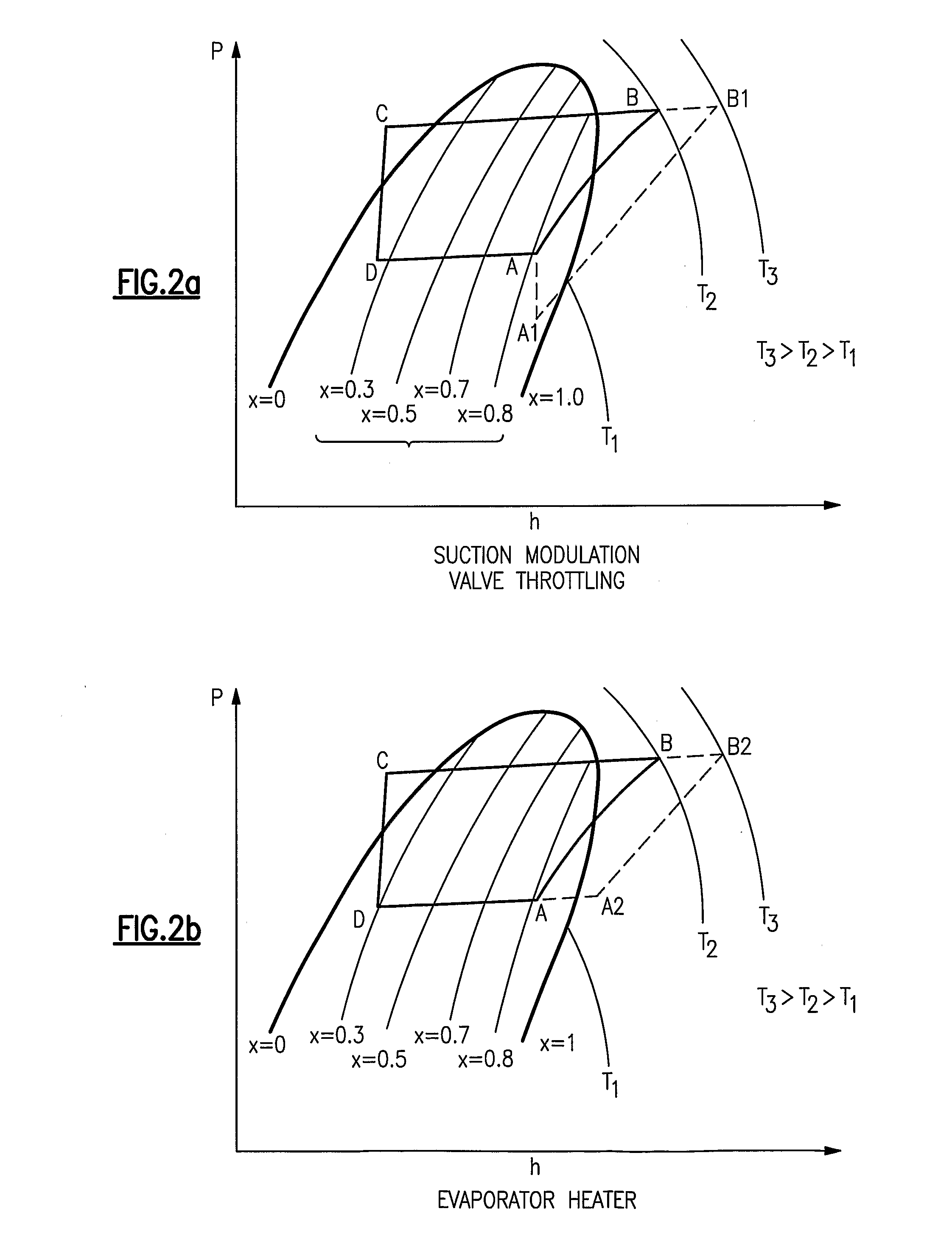

Refrigerant system with control to address flooded compressor operation

ActiveUS20090013701A1Reduce severityReduce the amount of solutionSampled-variable control systemsMechanical apparatusEngineeringRefrigerant

A suction modulation valve is throttled when conditions in a refrigerant system indicate that an undesirable amount of liquid refrigerant might otherwise be delivered to the compressor. As an example, the throttling would occur at start-up, among other conditions. Throttling the suction modulation valve reduces the amount of refrigerant reaching the compressor and thus ensures that any liquid refrigerant would be likely “boiled off” before raising any problems in the compressor. Other control steps can also be performed to alleviate flooded compressor operation with liquid refrigerant. Such steps, for example, can consist of: actuating heaters, discharge valve throttling, by-passing refrigerant from intermediate compression point back to suction, controlling the speed of the condenser fan can be performed independently or in combination including the suction modulation valve throttling.

Owner:CARRIER CORP

Circulated coal gas heat carrier fluidized bed ash coal pyrolysis device and method

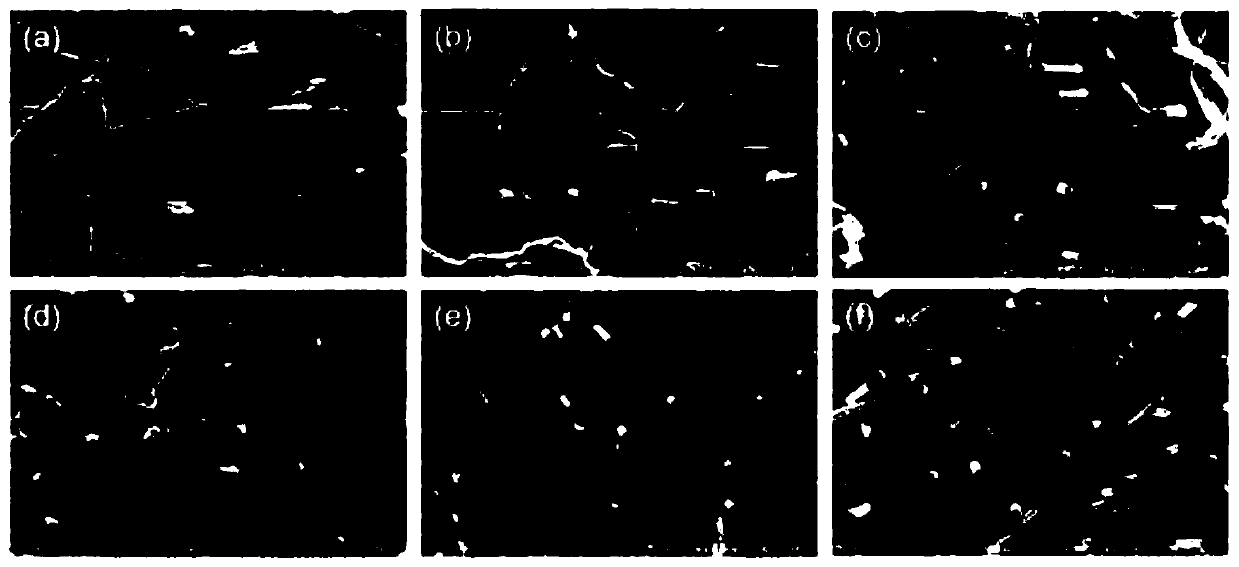

InactiveCN102352262ASimple processAchieving hydropyrolysisDirect heating destructive distillationSpecial form destructive distillationCycloneHeat carrier

The invention discloses a circulated coal gas heat carrier fluidized bed ash coal pyrolysis device and method. The device comprises a coal-adding system and a fluidized bed pyrolyzing furnace which is communicated with the coal-adding system and provided with a coke-discharging hole, wherein the gas distributor of the fluidized bed pyrolyzing furnace is communicated with a high temperature heating furnace, the coal gas outlet of the fluidized bed pyrolyzing furnace is communicated with a first-stage cyclone separator, a second-stage cyclone separator, a high temperature deep dust collector and a gas cooler in turn through a pipeline, the lower outlet of the gas cooler is communicated with a separator, and the gas outlet of the gas cooler is connected with the high temperature heating furnace and a coal gas delivering device respectively. The device has simple flow and does not require an air separation device; as the circulated coal gas contains a lot of hydrogen, the hydropyrolysis of coal is realized to a certain extent, the yield of oil is increased to above 12%; and the operating pressure can be increased to the medium / high level, and industrial clusters and polygeneration are applied on the basis of equipment scale expansion while the products such as coal gas with high calorific value, semicoke, tar and the like are prepared.

Owner:陕西华祥能源科技集团有限公司

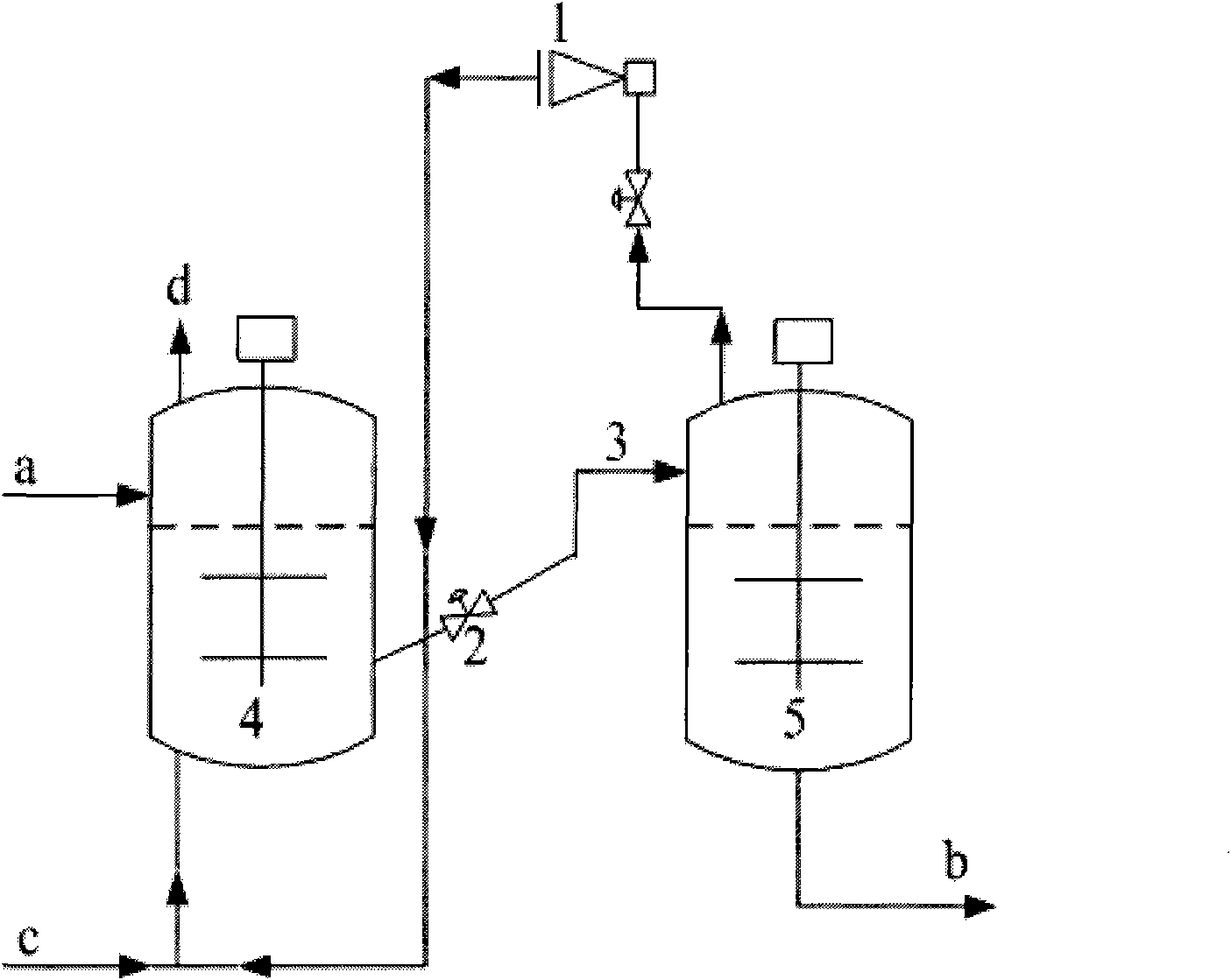

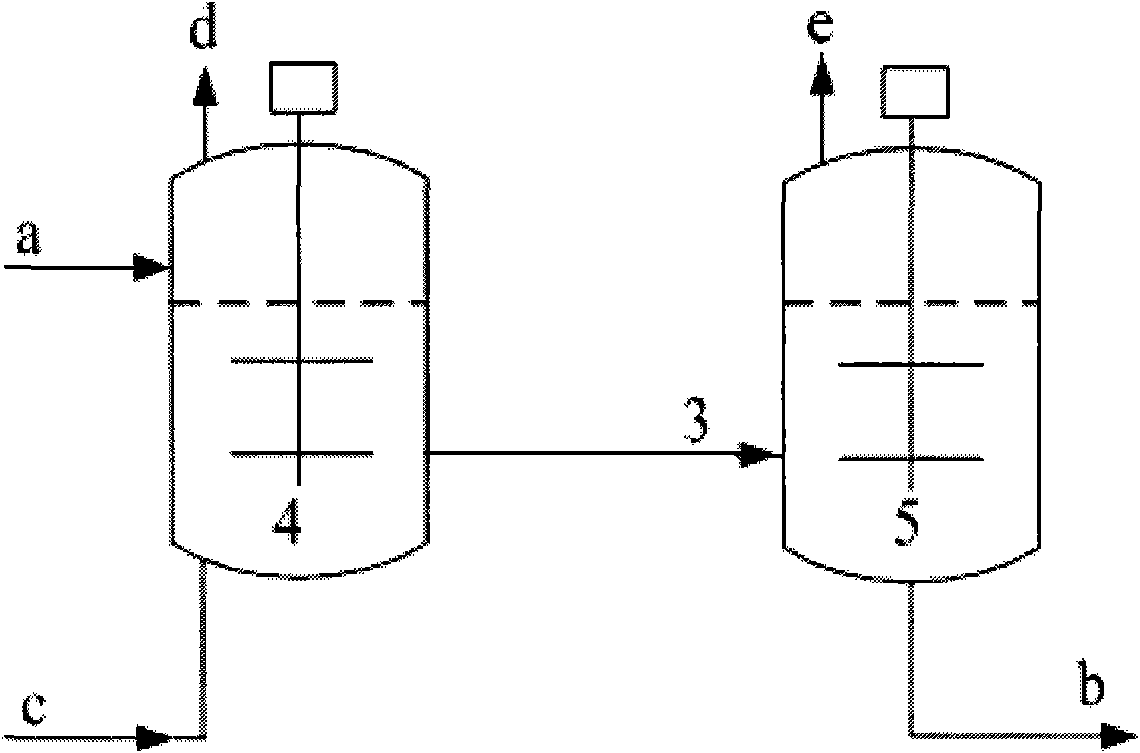

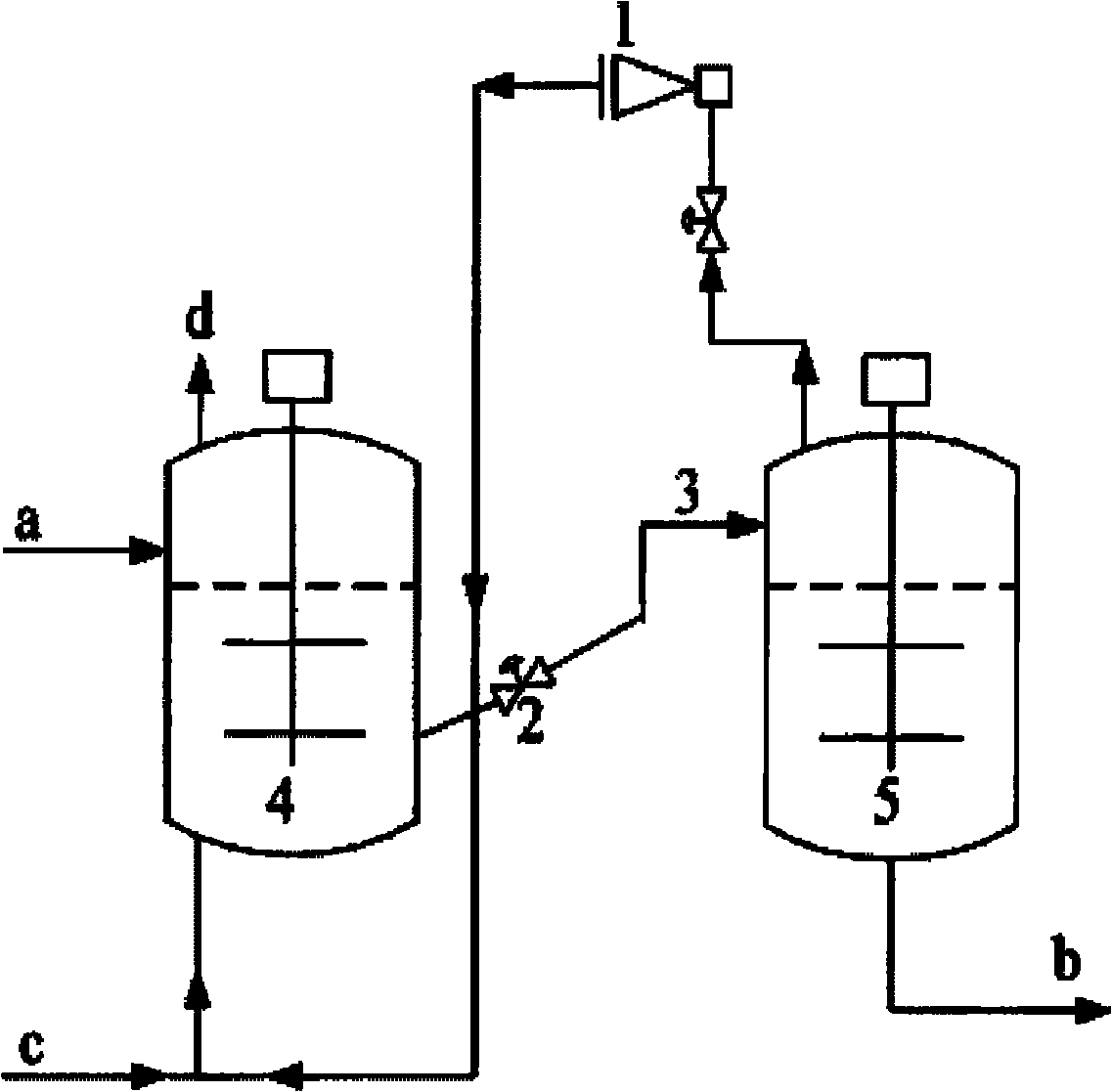

Method for depriving solvent for cis-polybutadiene

The invention relates to a method for depriving a solvent for cis-polybutadiene, which is mainly used for solving the problems of high consumption of solvent naphtha and large consumption of water vapor in the prior art. The technical scheme adopted by the invention comprises the following steps: a) injecting a material stream I containing rubber liquid cement and hot water from the upper part ofa first cohesion kettle, ejecting a material stream II containing water and solvent from the top of the first cohesion kettle, and ejecting a material stream III from an overflow pipe at the lateral part of the first cohesion kettle, wherein the flow capacity of the material stream III is controlled by a liquid level controlling system; b) feeding the material stream III from a gas phase spatial position in the second cohesion kettle, after the material stream containing water and solvent is drawn out by vacuum-pumping equipment, feeding the material stream containing water and solvent into the bottom of the first cohesion kettle together with the supplementary fresh steam, and carrying out cohesion, thus obtaining a material containing cis-polybutadiene at the bottom of the second cohesion kettle; and c) obtaining the solvent after the stream II containing water and solvent is subjected to separation. By utilizing the technical scheme provided by the invention, the problems in the prior art can be better solved; and the method for deprivating the solvent for cis-polybutadiene can be applicable to the industrial production for deprivating the solvent for the cis polybutadiene.

Owner:CHINA PETROLEUM & CHEM CORP

Method for removing oxy-compounds from olefin material flow

ActiveCN101993321AReasonable structureImprove general performanceDistillation purification/separationSorbentTower

The invention discloses a method for removing oxy-compounds from olefin material flow so as to overcome the defects that ethane and propylene are lost, the treated olefin material flow requires that the water content thereof is not more than 15,000wppm and the like. In the method, the olefin material flow containing the oxy-compounds passes through three oxide removing towers with different pressures in turn to fulfill the aim of removing the oxy-compounds from the olefin material flow, wherein the top operating pressure of the first oxide removing tower is 0.01 to 0.5MPa, the top operating pressure of the second oxide removing tower is 1.5 to 2.2 MPa, and the top operating pressure of the third oxide removing tower is 1.5 to 2.0 MPa. Through the method, under the condition of not adding any absorbent or adsorbent, the oxy-compounds are removed from the olefin material flow, so that oxy-compounds contained in components of the olefin product material flow are less than 1ppm, and the loss of the ethane and propylene is low.

Owner:CHINA PETROCHEMICAL CORP +1

Energy-saving water-saving organic silicon monomer rectifying method

ActiveCN101798322AImprove operational safetyIncrease operating pressureSilicon organic compoundsChemical industryWater vaporReboiler

The invention discloses an energy-saving water-saving organic silicon monomer rectifying method which adopts a cis cleavage multi-tower flow. In the rectifying method, the tower top material steam of a high-boiling component removing tower firstly enters a main distribution manifold, then heat is respectively supplied for tower bottom reboilers of a low-boiling component removing tower, a light component removing tower, a hydrogenous tower, an azeotropic tower, a trimethylchlorosilane separating tower, a methyl trichloro silicane separating tower and a dimethyldichlorosilane separating tower through the main distribution manifold, the tower top material steam of the high-boiling component removing tower after heat supply is condensed into liquid, is then cooled to the reflux temperature through an air cooler and enters a tower top reflux tank of the high-boiling component removing tower, a second reboiler is connected with the tower bottom of the dimethyldichlorosilane separating tower, and vapor is adopted for the heat exchange of the reboiler. By adopting the method, because the operating pressure and the operating temperature of the high-boiling component removing tower and the methyl trichloro silicane separating tower with larger cooling quantity requirements are increased, at least two towers in the flow have the condition of adopting air cooling, thereby reducing the circulating water quantity and decreasing the evaporation loss; and the energy-saving water-saving organic silicon monomer rectifying method has strong operation controllability, flexible mode, multiple control means, smaller pressure increasing amplitude and high operation security.

Owner:TIANJIN UNIV

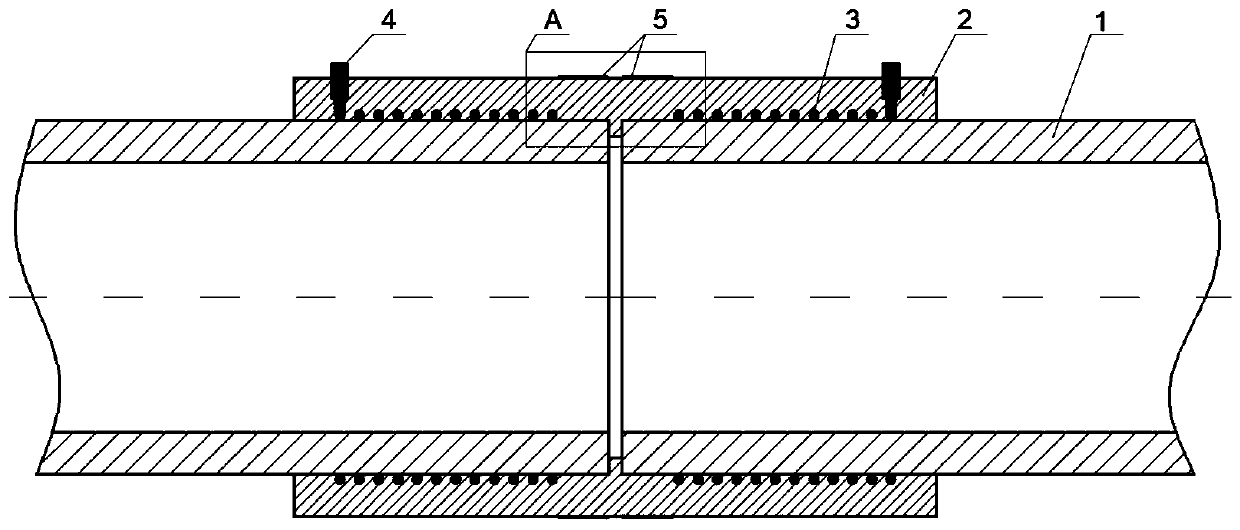

Carbon fiber reinforced plastic electric-smelting pipe fitting with strain self-monitoring function

ActiveCN109827014AIncrease elasticityHigh yield strengthElectrical/magnetic solid deformation measurementPipe connection arrangementsThermoplasticFiber

The invention relates to the field of thermoplastic plastic electric-smelting pipe fittings, and aims to provide a carbon fiber reinforced plastic electric-smelting pipe fitting with the strain self-monitoring function. The carbon fiber reinforced plastic electric-smelting pipe fitting comprises an electric-smelting pipe fitting body with a resistor wire buried, and two binding posts respectivelyconnected to the two ends of the resistor wire are arranged on the electric-smelting pipe fitting body. The carbon fiber reinforced plastic electric-smelting pipe fitting is characterized in that theelectric-smelting pipe fitting body is made of thermoplastic plastic filled with the carbon fiber, at least one set of paired electrodes is arranged on the surface of the electric-smelting pipe fitting body and used for monitoring the changes of the resistance values due to thermal temperature rising or internal pressure deformation in the suing process so as to achieve the strain monitoring of the electric-smelting pipe fitting. The carbon fiber reinforced plastic electric-smelting pipe fitting can improve the elastic modulus and yield strength of the material, has higher mechanical strength,higher blasting pressure, and can improve the operating pressure, the strain of the electric-smelting pipe fitting and the pressure inside the electric-smelting pipe fitting can be monitored, the additional equipment does not need, the intelligence and safety of the electric-smelting pipe fitting are improved, and the manufacturing process is simple, the stability is high, and the cost of the process is reduced.

Owner:ZHEJIANG UNIV

Unit for preparing beverages from soluble products

InactiveUS7100496B2Prevent outflowImprove solubilityTransportation and packagingBeverage vesselsComing outBiomedical engineering

The description concerns a unit for the preparation of a drink from a soluble mix contained in a disposable capsule, of the type comprising a collecting device with housing designed to contain the capsule, in which at least one choking arrangement is provided to ensure laminar flow of the drink as it comes out of the capsule.

Owner:TUTTOESPRESSO SPA (IT)

High pressure fluid cylinder system

InactiveUS6886832B2Increase operating pressureEfficient executionEngine sealsPositive displacement pump componentsDrive shaftEngineering

A high pressure fluid jetting system generally includes a fluid cylinder pump, a drive assembly, a pressurized liquid supply and an applicator gun. The drive assembly includes a diesel or electric powered motor which drives a rotatable drive shaft. The drive shaft drives a triple plunger which are reciprocally driven. The plungers communicate fluid from the supply to the gun to selectively jet water from the gun at a pressure of approximately 50,000 psi and 10.0 gallons per minute.

Owner:NEW LANTAO BUS

Supercritical extraction and drying method in preparation of ultrahigh molecular weight polyethylene fibre

InactiveCN1693545ALess investmentSimple processWet spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to a supercritical extracting and drying method in a process of preparing ultrahigh molecular weight polyethylene filber (UHMWPE), including: the fiber molded after cooled and solidified drops in an extraction kettle, and is arranged regularly; feeding extractant into the extraction kettle for supercritical extraction; after extraction complete, feeding hot gas in to dry; or drying in a vacuumizing mode; wherein the mentioned extractant is selected from one of methane, ethane, ethane, and propylene. The invention adopts supercritical extraction method to remove the first solution added in a solution preparing process, and the extracting and drying arts are completed in one device, simplifying the process.

Owner:BEIJING TEX STRONG NEW MATERIAL DEV

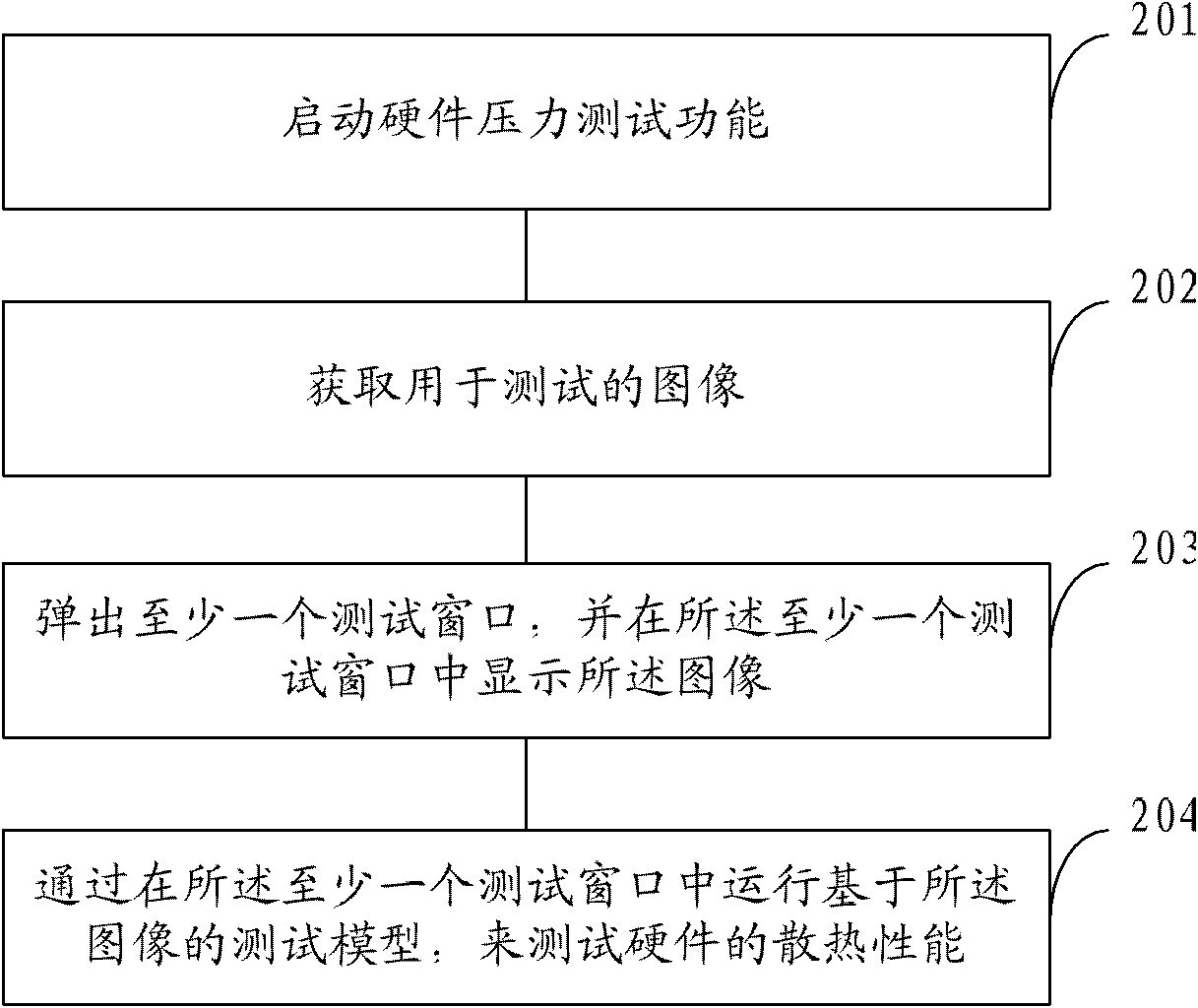

A hardware stress testing method and testing device

ActiveCN102279782AImprove cooling effectKnow about heat dissipation at any timeDetecting faulty computer hardwareComputer terminalTest fixture

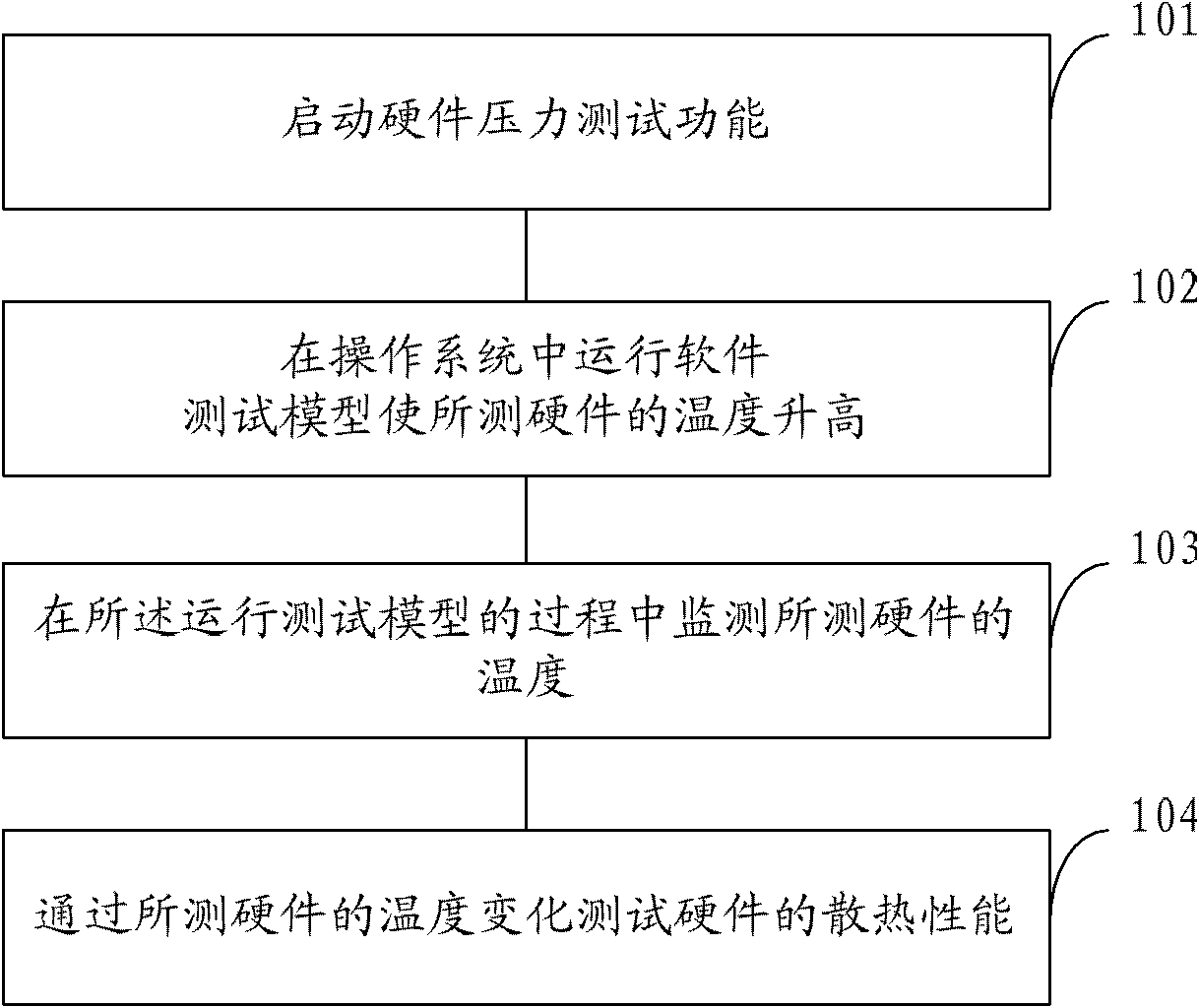

The invention provides a method and device for testing the hardware pressure, which can be used for easily and quickly helping an ordinary user test the performance of machine hardware such as computers, mobile terminals and the like. The method comprises the following steps of: starting a hardware pressure testing function; running a software testing model in an operating system to raise the temperature of tested hardware; and monitoring the temperature of the tested hardware in the running process of the testing model and testing the heat radiating performance of the tested hardware through the temperature change of the tested hardware. The method can be implemented without professional, an ordinary user can be helped to know the heat radiating performance of machine hardware (such as CPUs (Central Processing Units), display cards, hard disks, mainboards and the like) such as computers, mobile terminals and the like at any time, and the user is helped to perform performance testing in advance during purchase of machines such as computers, mobile phones and the like.

Owner:BEIJING QIHOO TECH CO LTD

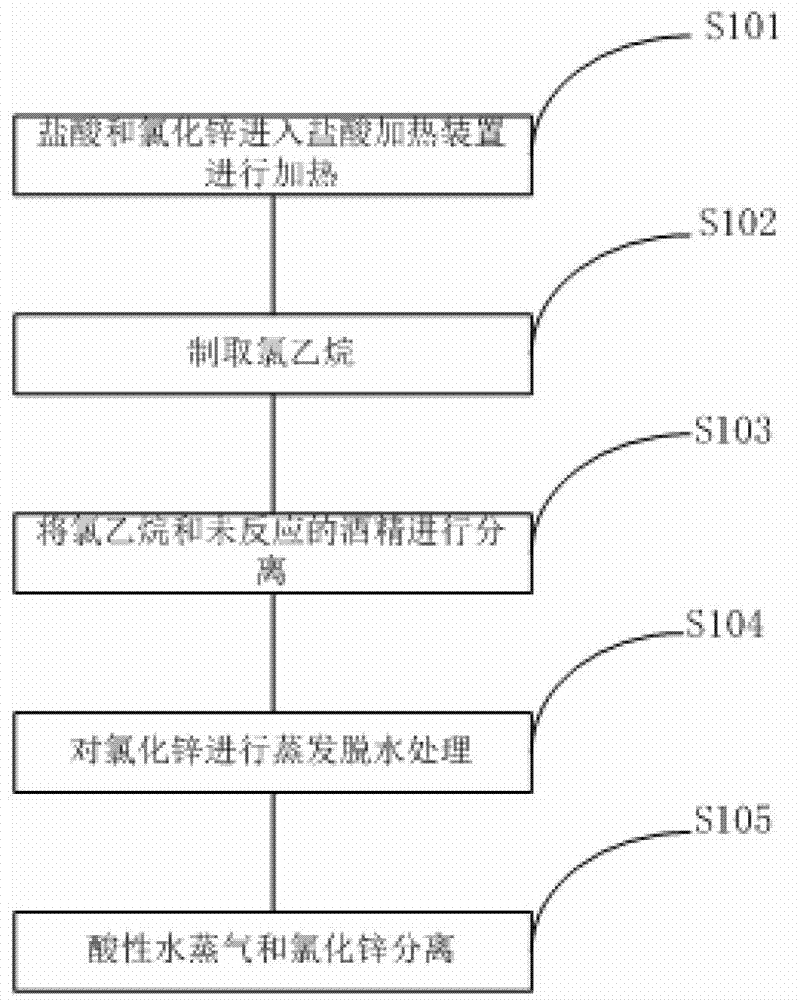

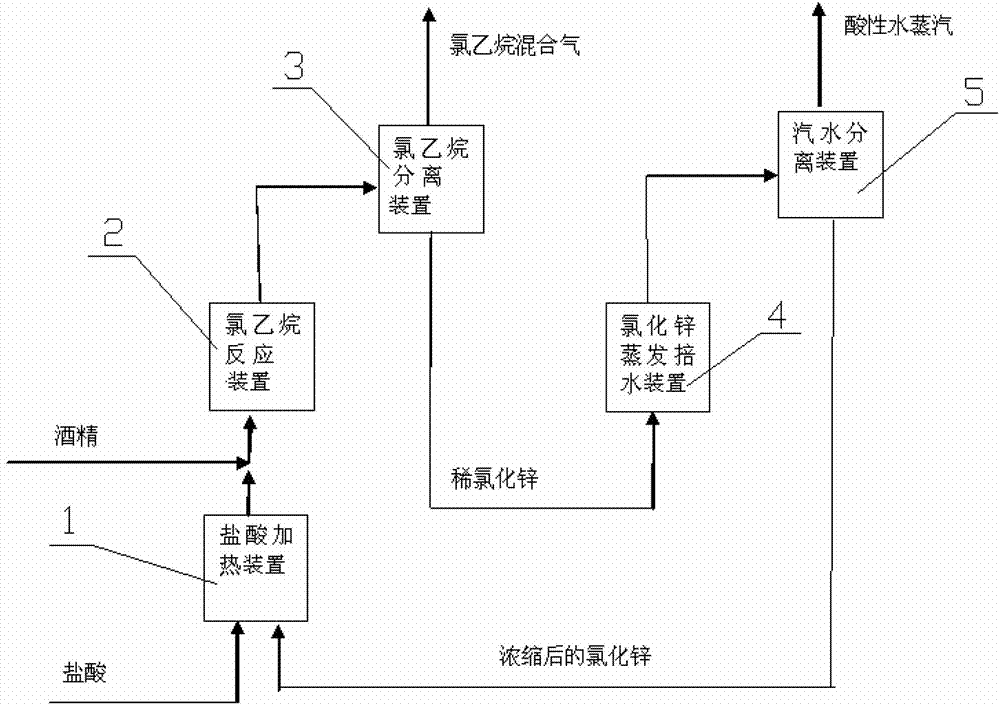

Method and system for producing ethyl chloride

InactiveCN103044187AIncrease productivityExpand the scope of operationChemical industryHalogenated hydrocarbon preparationHigh concentrationReaction rate

The invention discloses a method for producing ethyl chloride, which comprises steps as follows: hydrochloric acid and zinc chloride after concentration by evaporation enter a hydrochloric acid heating unit from the bottom to be heated, enter an ethyl chloride reactor, and are subjected to thermal separation of the ethyl chloride and mixed solution; the separated magnesium chloride enters an evaporation dehydrator to be heated; the zinc chloride solution is concentrated; and the high-concentration zinc chloride naturally flows to the lower part of a hydrochloric acid evaporator to be recycled. The invention can be matched with a climbing film graphite evaporator with larger heat transfer area to implement the large-size ethyl chloride reactor and enhance the level of the ethyl chloride industrialization device; the reaction rate and raw material conversion rate are enhanced; graphite is used as the distributor of the ethyl chloride reaction part, so the corrosion resistance is high; the steel liner polytetrafluoroethylene cylinder and pipeline are adopted, thereby resisting corrosion and enhancing the operating pressure and equipment utilization ratio; and in addition, the invention is convenient to operate, enhances the production efficiency of ethyl chloride, and has favorable application value.

Owner:JIANGSU YINZHU CHEM GROUP

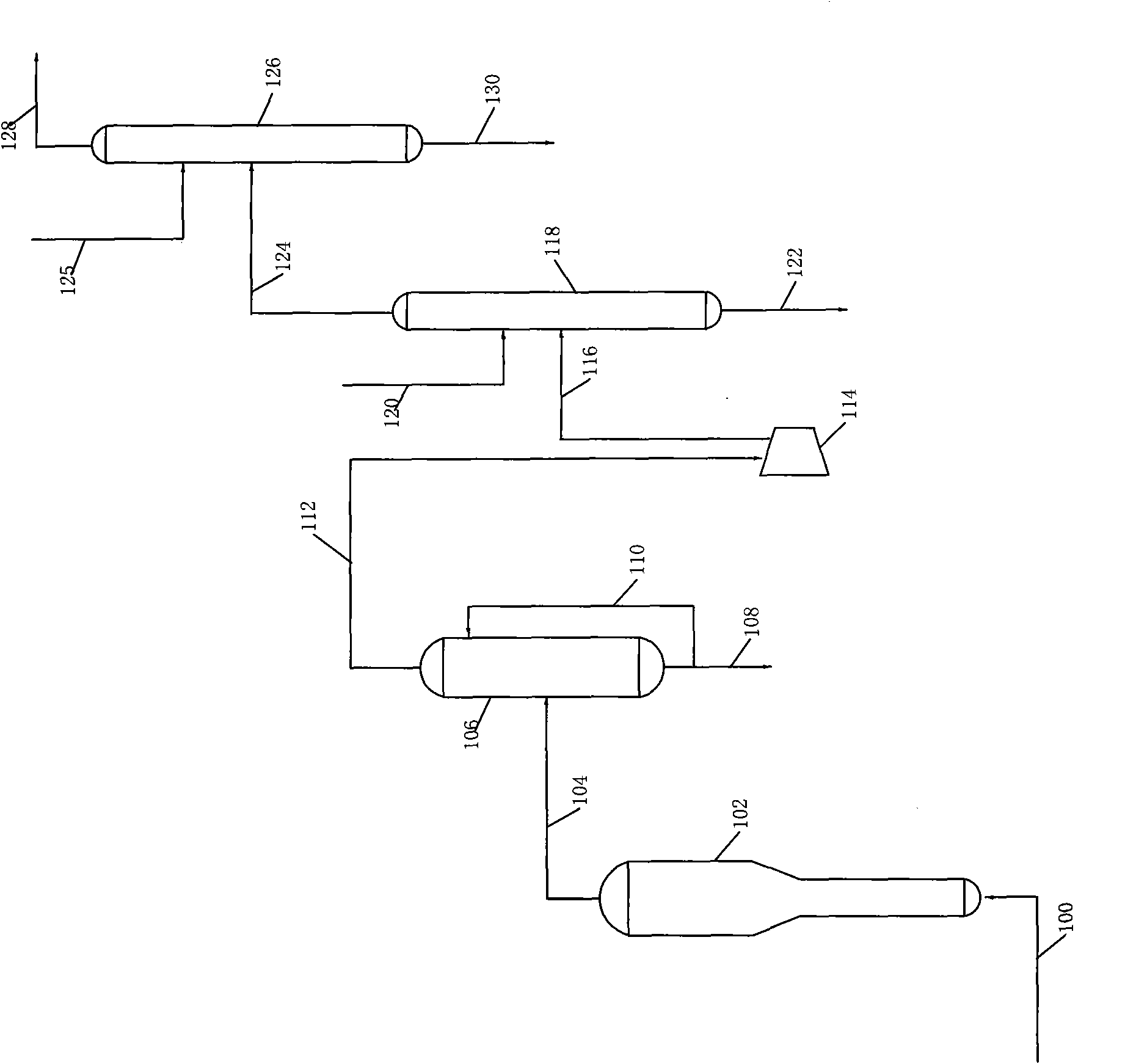

Nitrogen rejection method and apparatus

InactiveUS20040103687A1Facilitates operation of compressor and compressorReduce trafficSolidificationLiquefactionReboilerNitrogen

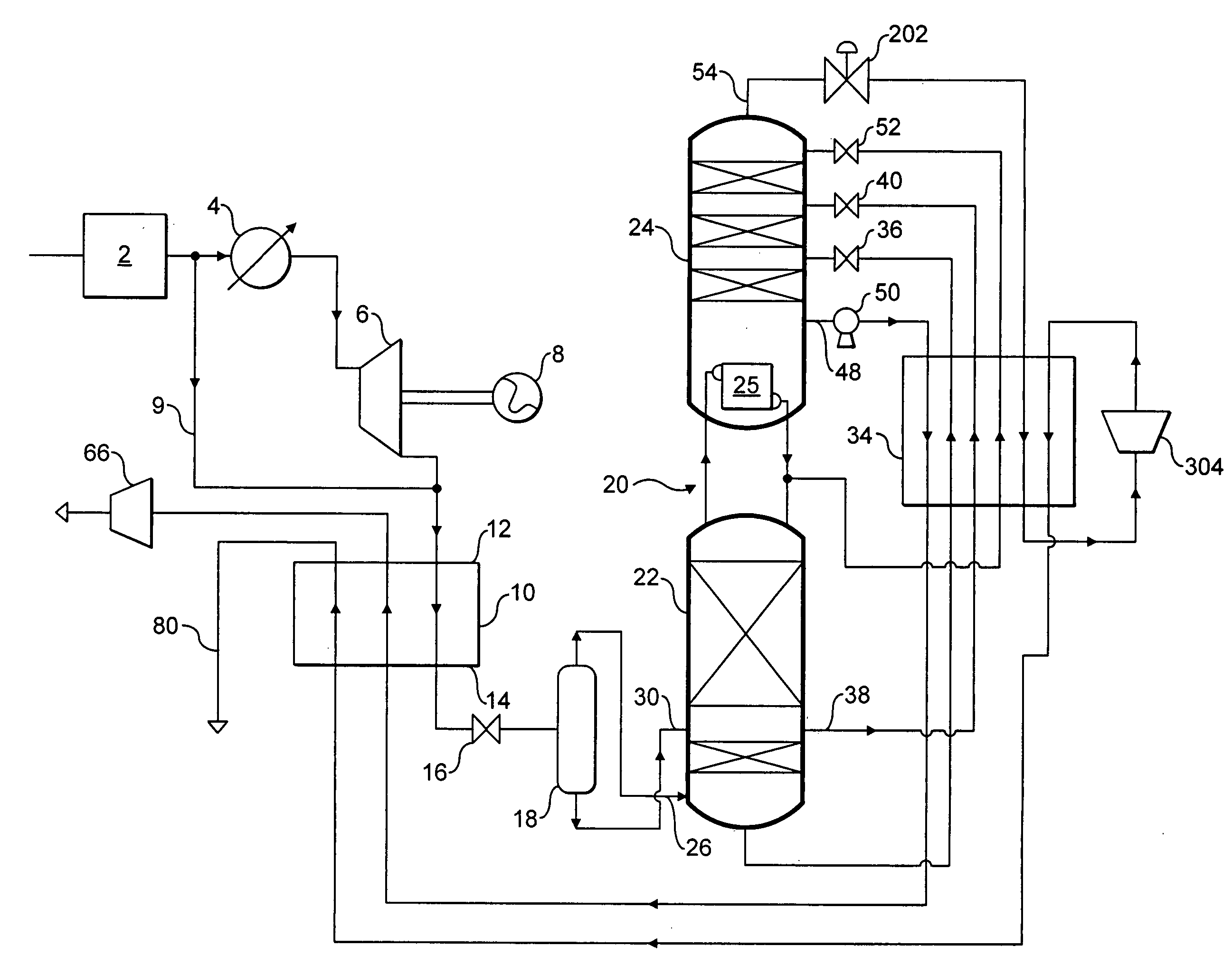

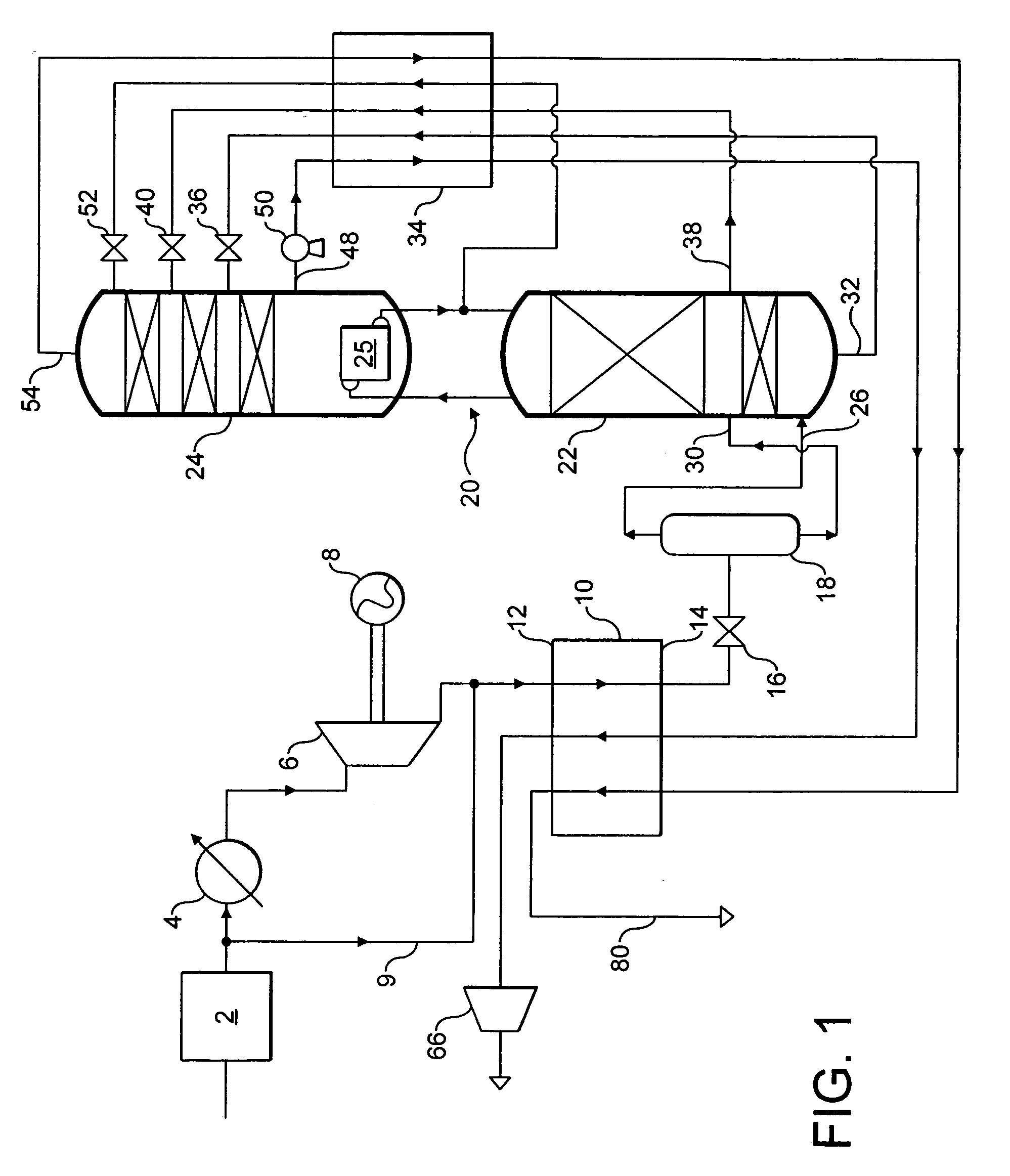

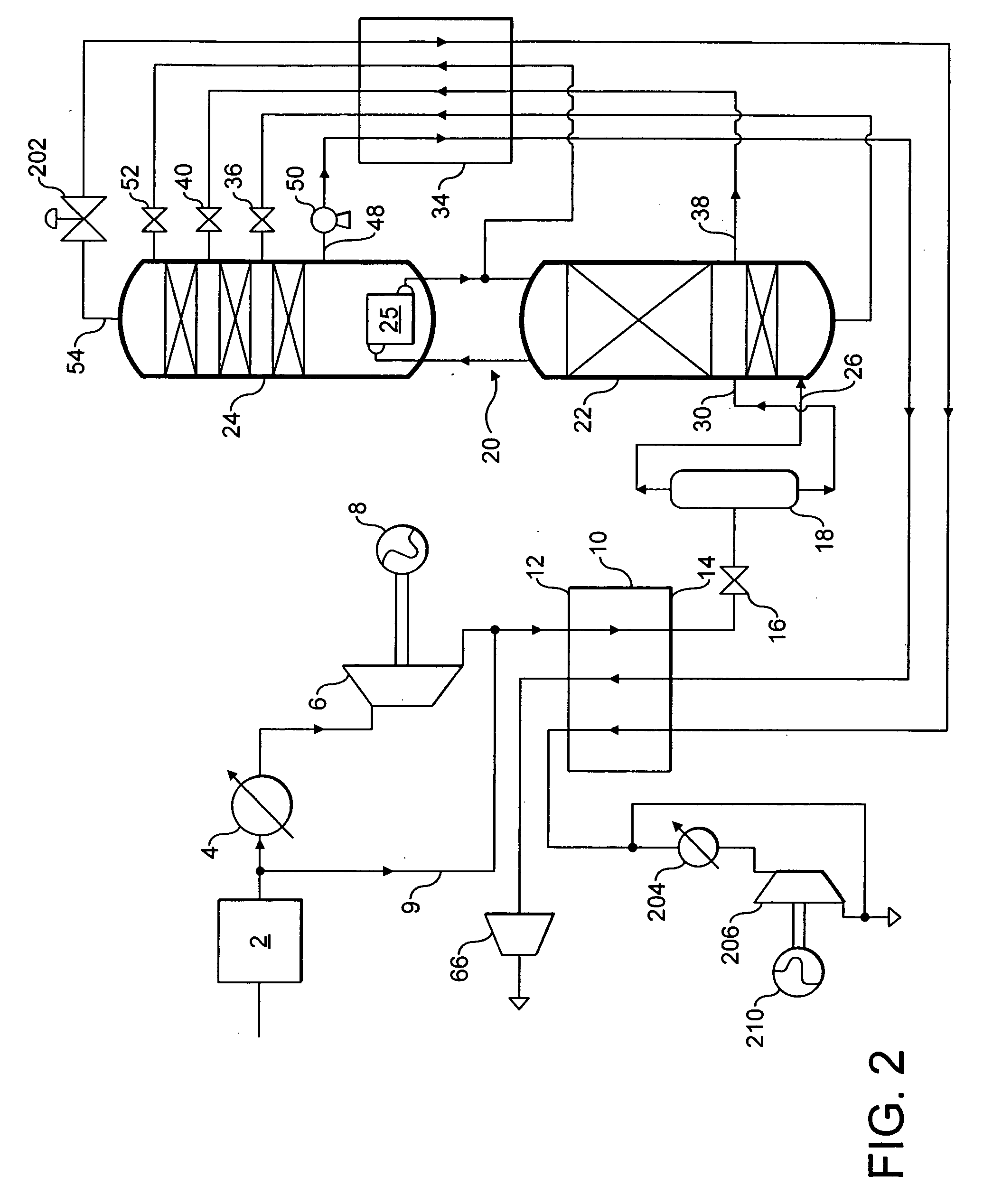

Nitrogen is rejected from a pressurised feed gas stream comprising methane and nitrogen by cooling the feed gas stream in a main heat exchanger 10 and rectifying the cooled feed gas stream in a double rectification column 20 comprising a higher pressure rectification column 22, a lower pressure rectification column 24, and a condenser-reboiler 25 placing the higher pressure column 22 in heat exchange relationship with the lower pressure column 24. A pump 50 withdraws a methane product stream from the column 24. The methane product stream is pressurised by the pump 50 and is vaporised in the main heat exchanger 10. The pressurised feed gas stream is expanded with the performance of external work in an expansion turbine 6 upstream of the main heat exchanger 10.

Owner:THE BOC GRP PLC

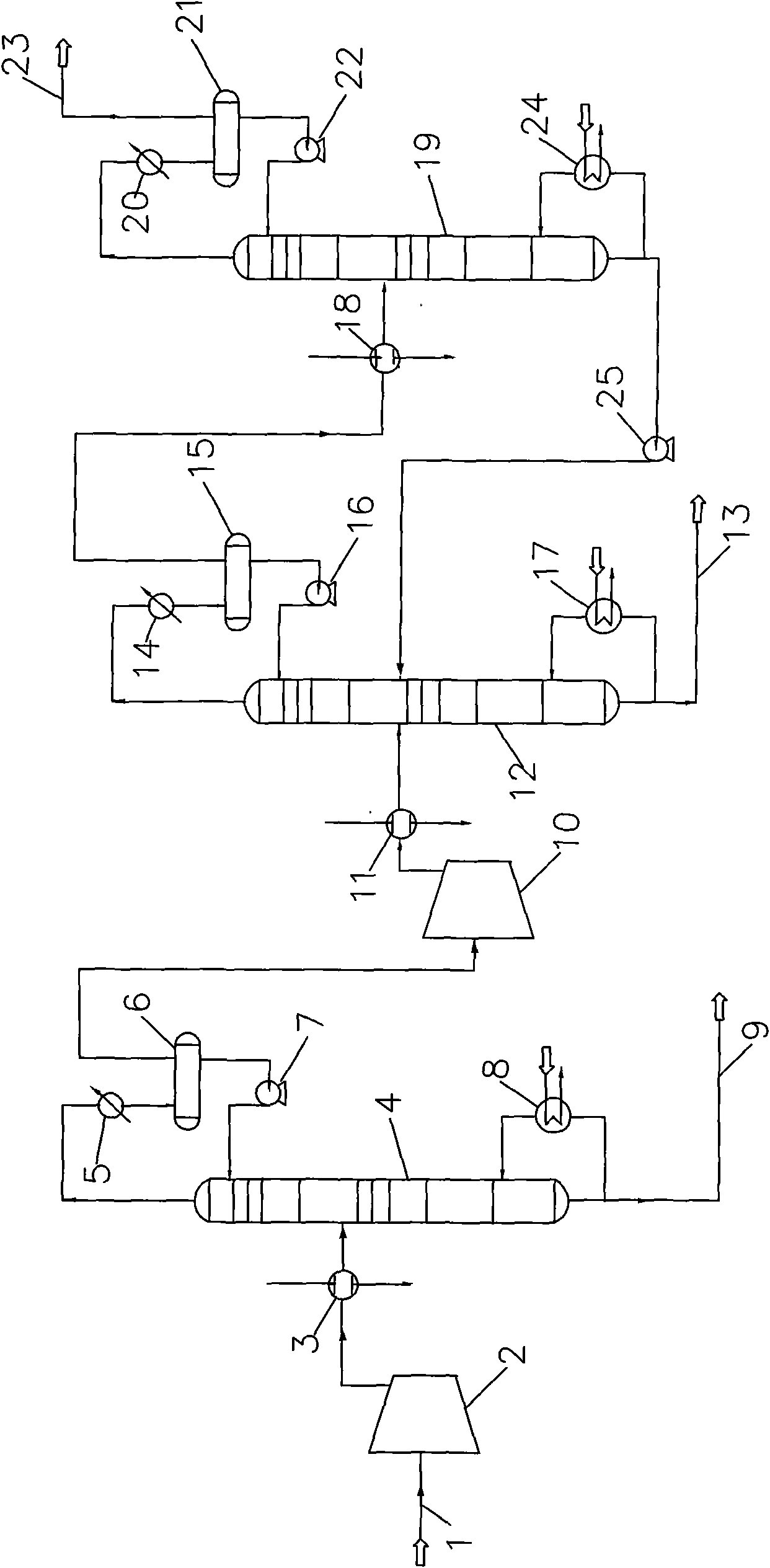

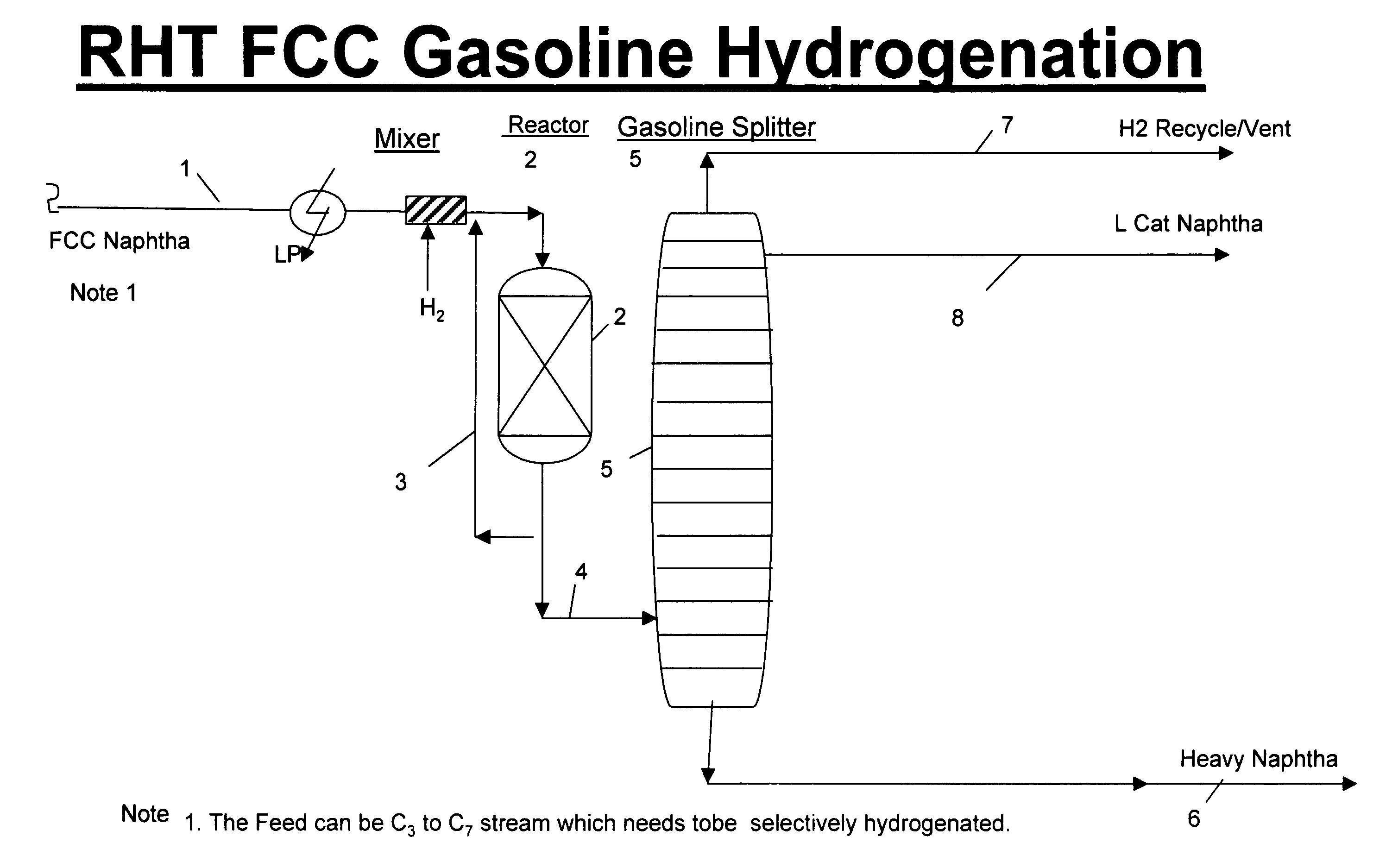

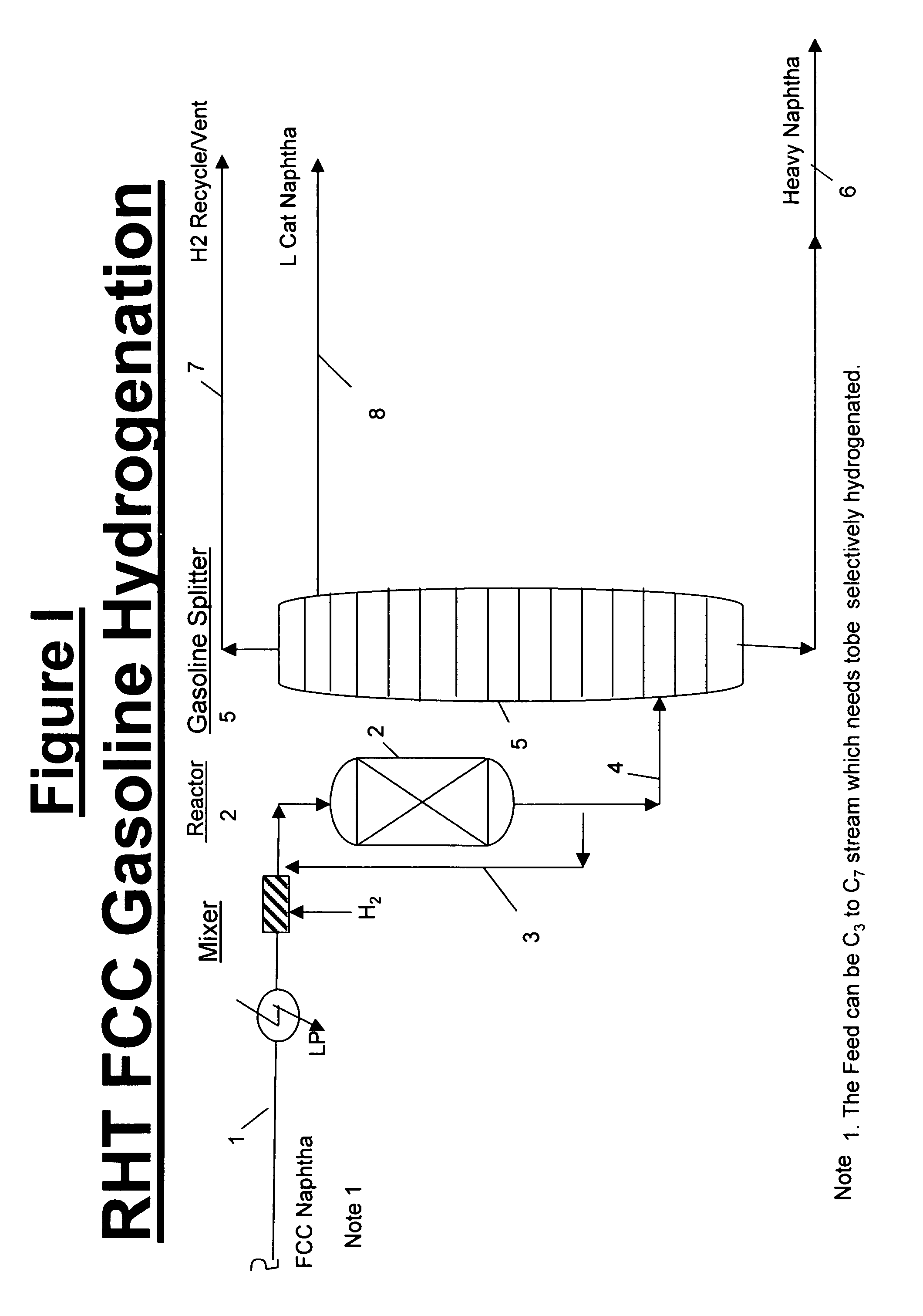

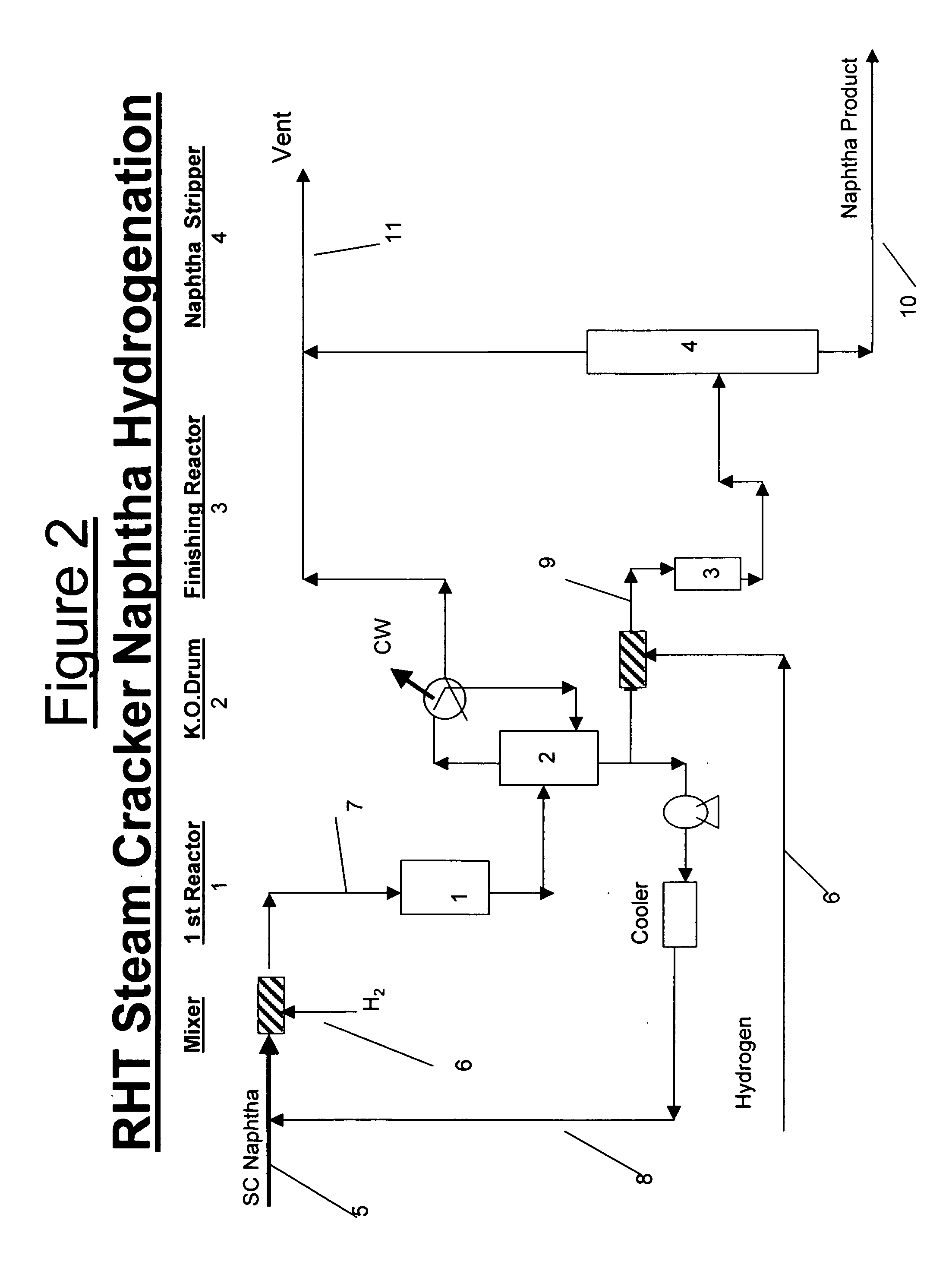

Optimum process for selective hydrogenation/hydro-isomerization, aromatic saturation, gasoline, kerosene and diesel/distillate desulfurization (HDS). RHT-hydrogenationSM, RHT-HDSSM

InactiveUS20080073250A1Simple configurationIncrease cetane numberHydrocarbon by hydrogenationHydrocarbon purification/separationIsomerizationDistillation

A process for selective hydrogenation of C3 / C4 / C5 / C6 / C7 and LCN, hydro-isomerization of olefins, benzene saturation and hydrodesulfurization of Gasoline, Kerosene and Diesel together with aromatic saturation of LCO is being provided so as to provide optimum technology at low cost with unique configuration. The technology is user friendly and uses conventional catalyst. These configurations cover both the options of installing the bulk catalyst in the distillation column with chimneys trays, hence essentially all the reaction takes place in the liquid phase in single or multiple beds or with fixed bed down flow or up flow reactor configuration. The configurations shown in the figures depicts that the fixed bed reactors are integrated with the Distillation Column and this art helps in lowering the Capital costs and the reactors are operating in single phase or two-phase conditions. The art is applicable to MAPD, vinyl acetylene, C3, C4, C5, C6, C7 mixed hydrocarbon stream, and LCN diolefin selective hydrogenation. It includes the process for hydro-isomerization of Butene-2 to Butene-1, or visa versa, removal of Isobutylene and Isobutane by distillation after hydro isomerization, benzene hydrogenation to Cyclohexane, hydrodesulfurization of FCC gasoline, coker gasoline or any other Naphtha stream together with hydrodesulfurization of Diesel / Kerosene from any of the refinery units.

Owner:REFINING HYDROCARBON TECH RHT

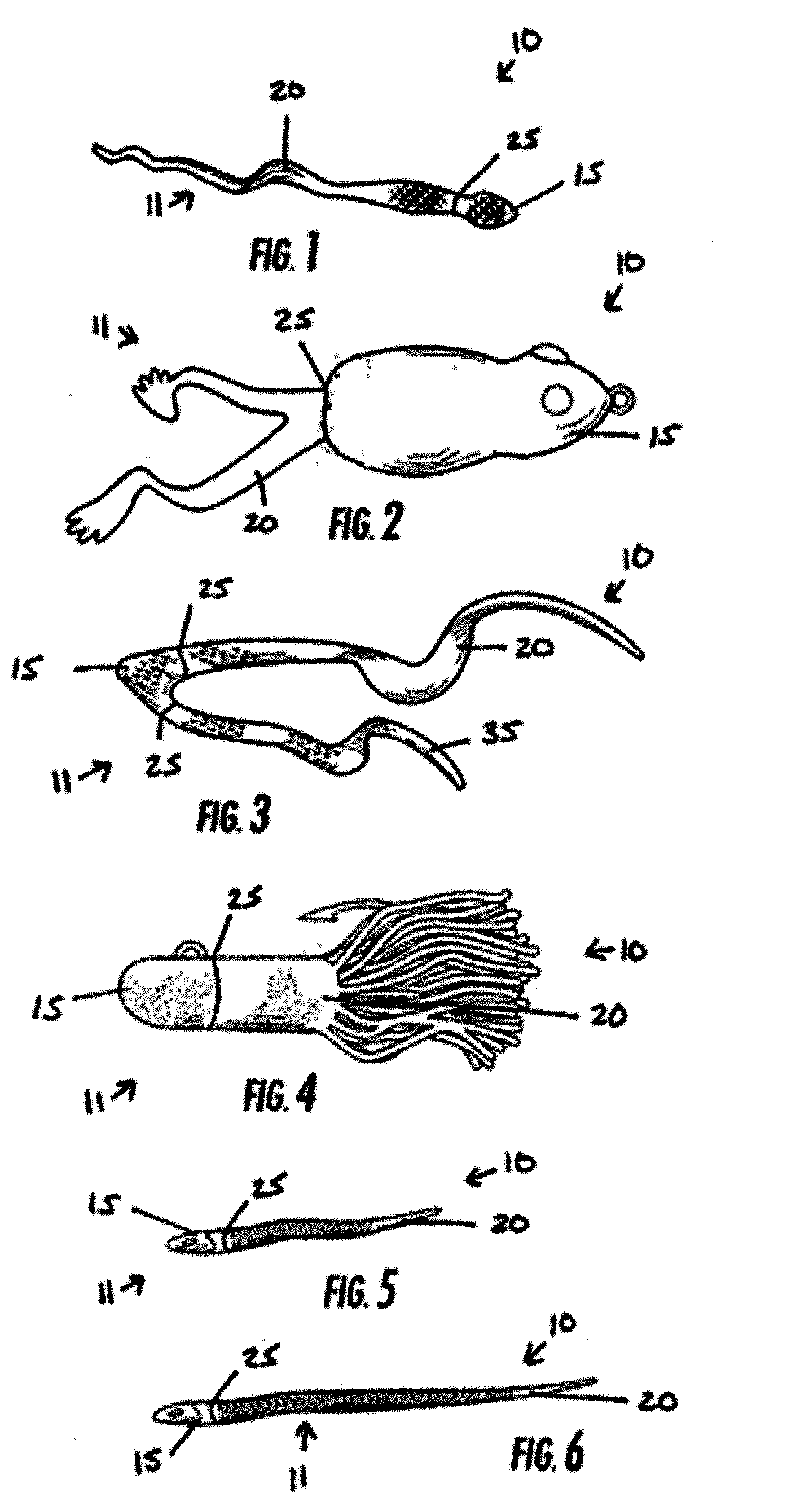

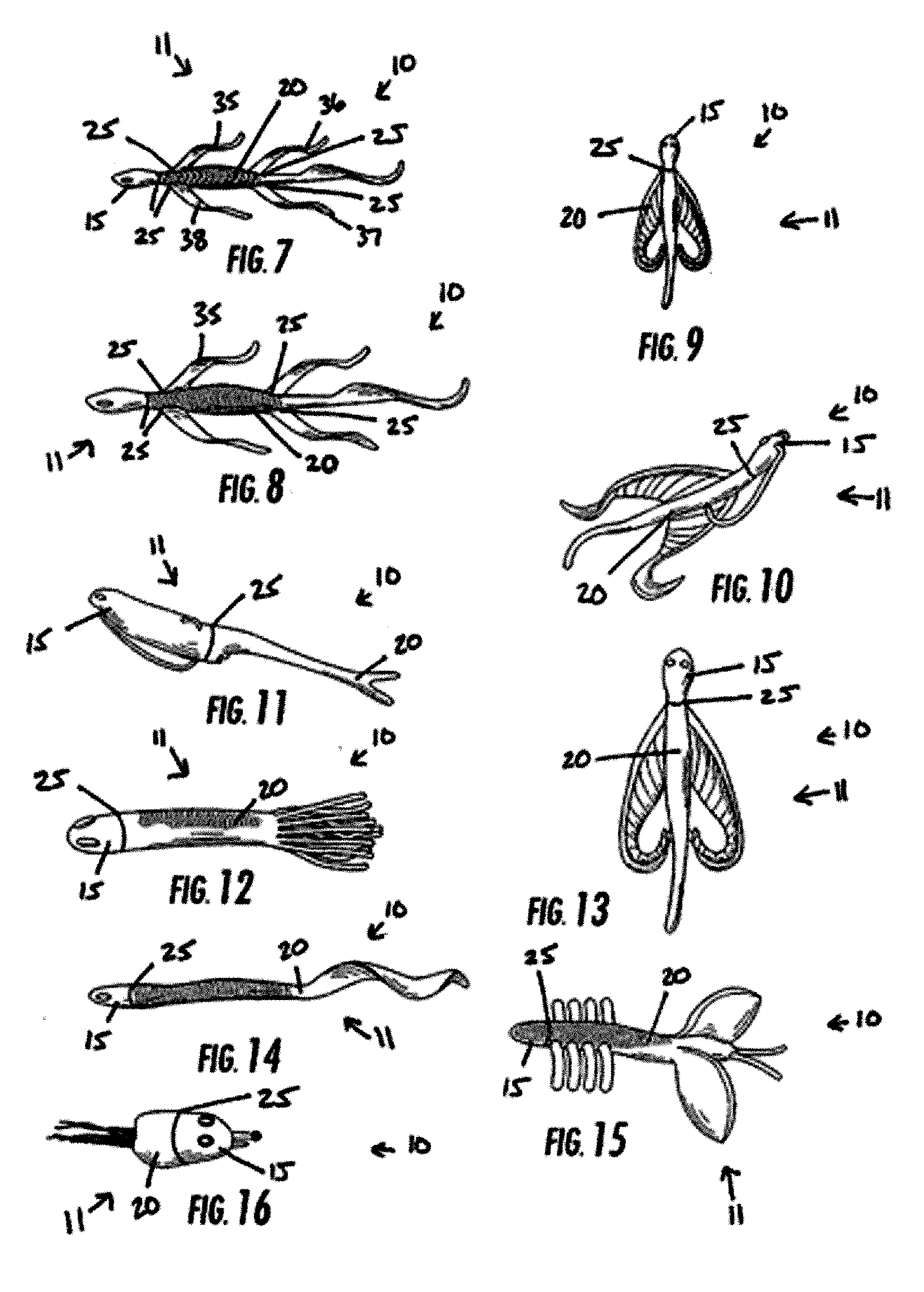

Fishing lures having elastomeric portions

InactiveUS20060037230A2Improve strength and toughness and fatigue resistanceIncrease operating pressureBaitElastomerHardness

Abstract of the DisclosureThe present invention provides a fishing lure comprising an elastomeric portion having at least first and second regions. Each region has a durometer hardness on the Shore A scale. At least a portion of the first region is characterized by comparatively high operational stress relative to the second region. The hardness of the first region exceeds the hardness of the second region to thereby selectively improve the strength, toughness and fatigue resistance of the first region.

Owner:MANNS BAIT

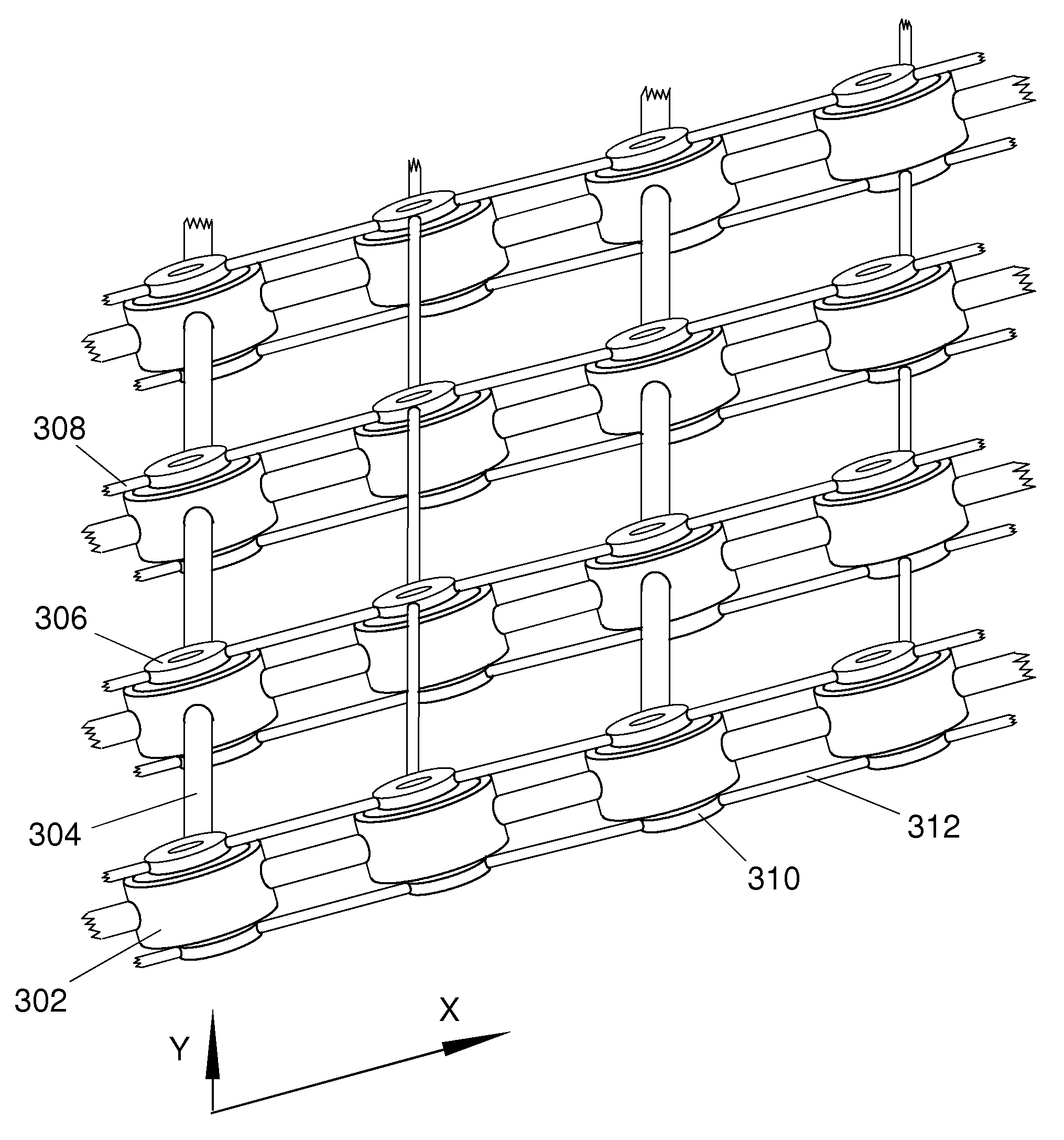

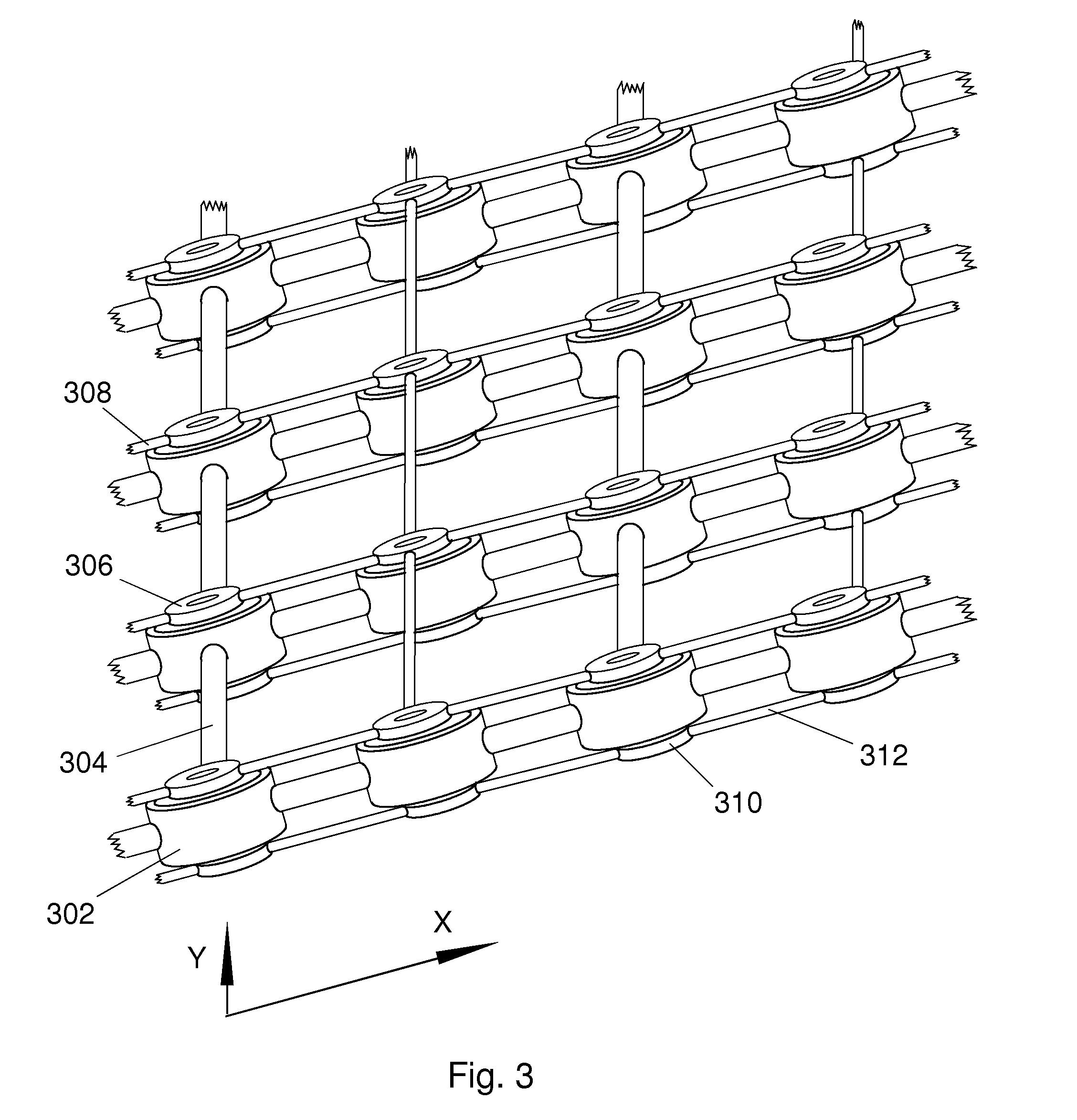

Apparatus and Methods for Controlling Miniaturized Arrays of Ion Traps

InactiveUS20160071709A1Performance maximizationImprove performanceElectron/ion optical arrangementsMiniaturised spectrometersVoltage amplitudeImage resolution

Apparatus and methods for controlling miniaturized arrays of ion traps, including cylindrical ion traps, rectilinear ion traps, and linear ion traps. Improved methods for applying supplemental AC signals to individual ion traps in an ion trap array. Methods of organizing ion trap arrays and operating the arrays in a manner to improve sensitivity, resolution and mass accuracy. Techniques for performing simultaneous detection of multiple compounds from ion trap arrays. Optimization of ion trap performance by dynamic optimization or adjustment of RF trapping frequency and voltage amplitude.

Owner:BAYSPEC

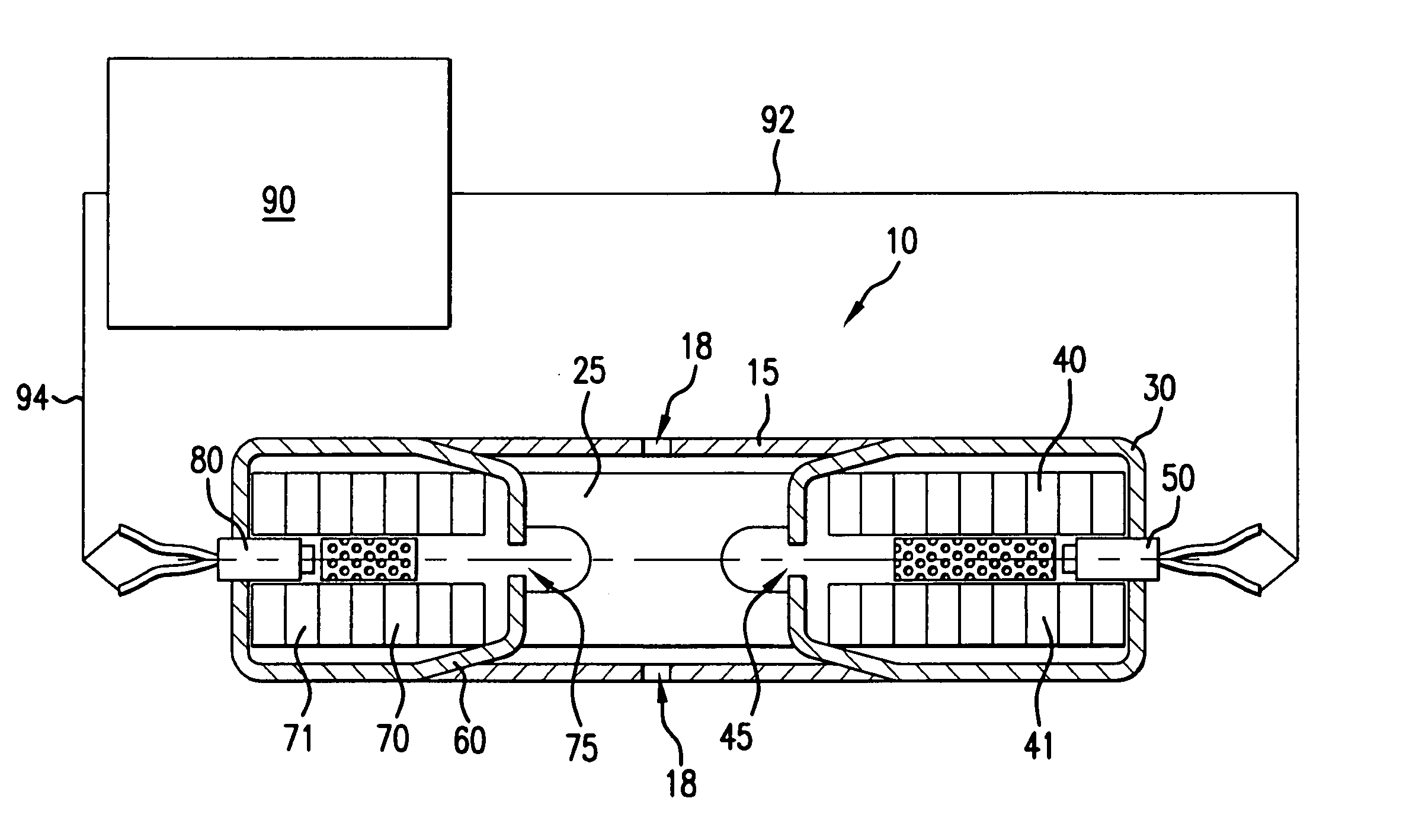

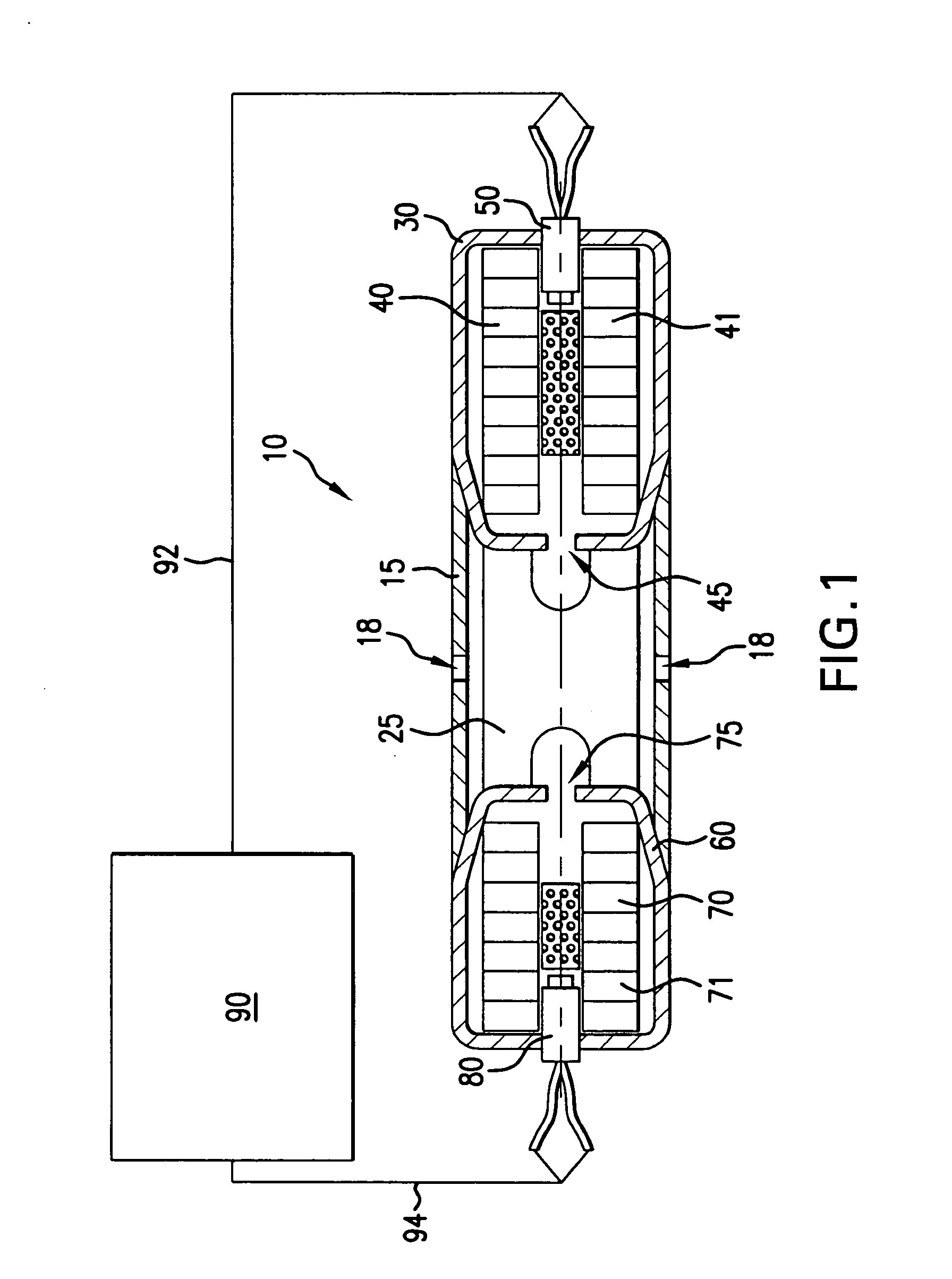

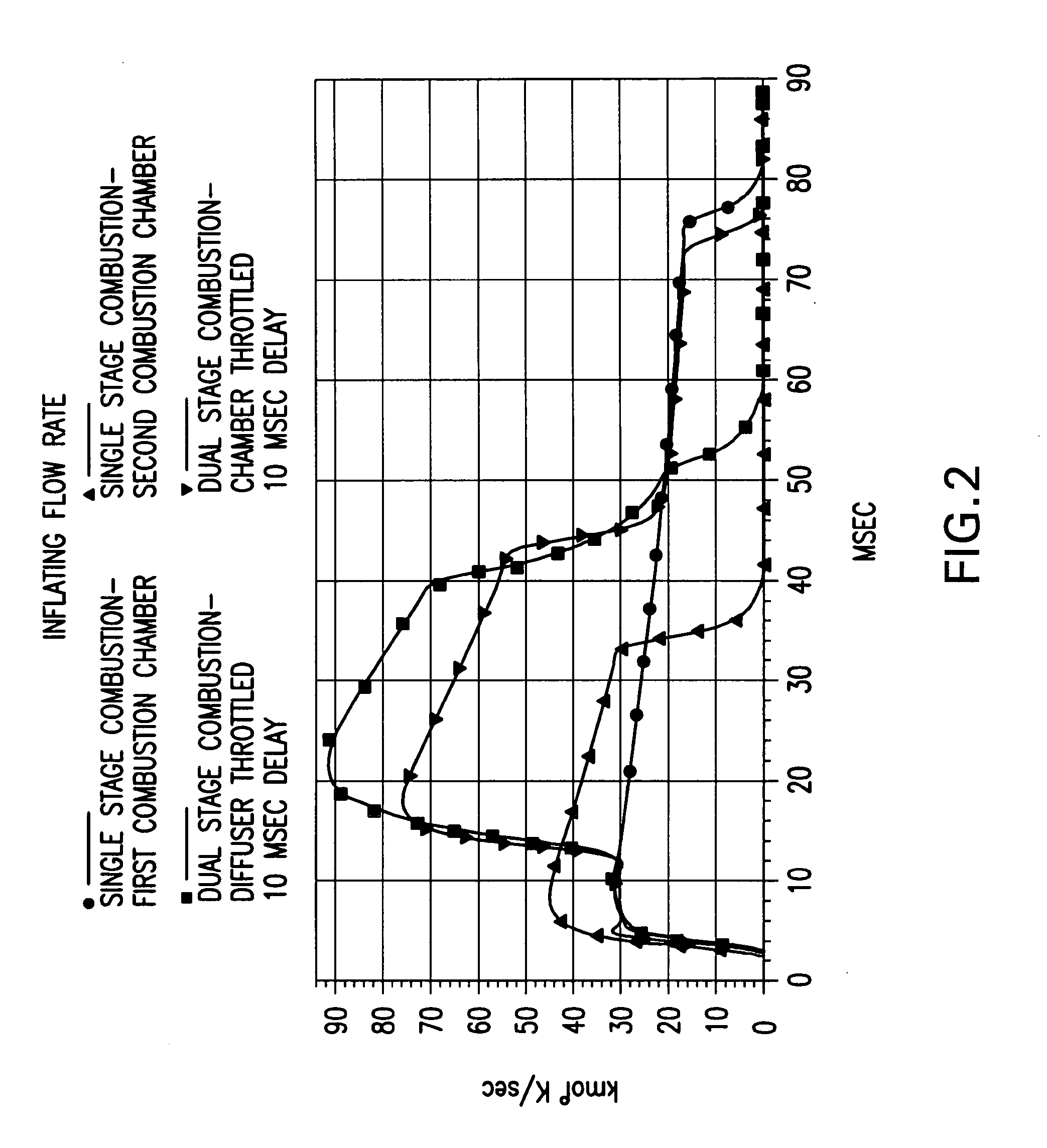

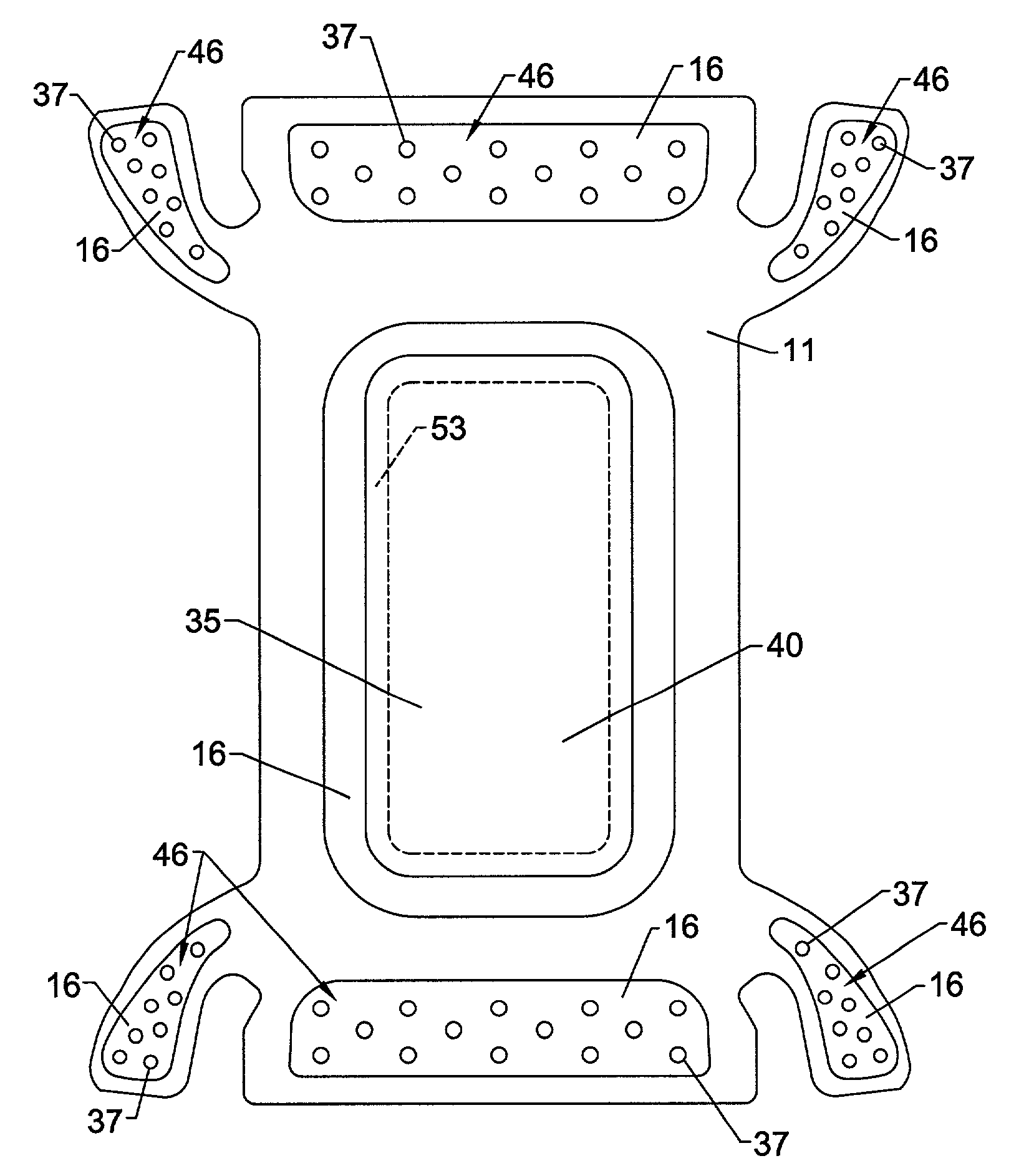

Pressure-enhanced, adaptive inflator device

InactiveUS20050098988A1Increase operating pressureImprove pressure resistancePedestrian/occupant safety arrangementPressure gas generationCombustion chamberSingle stage

An inflator device that includes a diffuser chamber with a first combustion chamber and a second combustion chamber each connected to the diffuser chamber. A supply of a first gas-generating pyrotechnic material having a burn rate that is pressure dependent is contained within the first combustion chamber. The first combustion chamber forms or includes an orifice providing independent fluidic communication between the first combustion chamber and the diffuser chamber. This orifice throttles a single stage combustion wherein the supply of the first gas-generating pyrotechnic material is selectively reactable to produce a first combustion chamber single stage combustion product gas. A supply of a second gas-generating pyrotechnic material is contained within the second combustion chamber. The second combustion chamber forms or includes an orifice that provides independent fluidic communication between the second combustion chamber and the diffuser chamber. This orifice throttles a single stage combustion wherein the supply of the second gas-generating pyrotechnic material is selectively reactable to produce a second combustion chamber single stage combustion product gas. The diffuser chamber forms or includes at least one exit orifice. This diffuser exit orifice throttles a dual stage combustion wherein the supply of the first gas-generating pyrotechnic material is reactable to produce a first combustion chamber dual stage combustion product gas and the supply of the second gas-generating pyrotechnic material is reactable to produce a second combustion chamber dual stage combustion product gas.

Owner:AUTOLIV ASP INC

Friction stir grain refinement of structural members

InactiveUS6994916B2Improve fatigue resistanceHigh strengthFuselage framesElongated constructional elementsEngineeringGrain structure

The present invention provides an improved structural assembly constructed of a plurality of structural members secured together. At least one of the plurality of structural members defines a first region characterized by comparatively high operational stress and a second region having a locally refined grain structure positioned such that the second region at least partially encompasses the first region to thereby enhance the strength, toughness and fatigue resistance of the at least one structural member in the first region. The present invention also provides a method for selectively improving the strength, toughness and fatigue resistance of a structural member in a region of high operational stress including the steps of casting the structural member in a pre-selected configuration. Regions of the structural member having comparatively high operational stress are identified. The structural member is secured to prevent movement. The region of the structural member having comparatively high operational stress is then mixed with a rotating friction stir welding probe to locally refine the grain structure of the structural member within the region of high operational stress to thereby improve the strength, toughness and fatigue resistance of the structural member in the region. The structural member can be secured to other structural members to form the frame of an aircraft. The improved structural assembly will have an increased operational life, as well as require less stock material with a corresponding decrease in the overall weight of the assembly.

Owner:THE BOEING CO

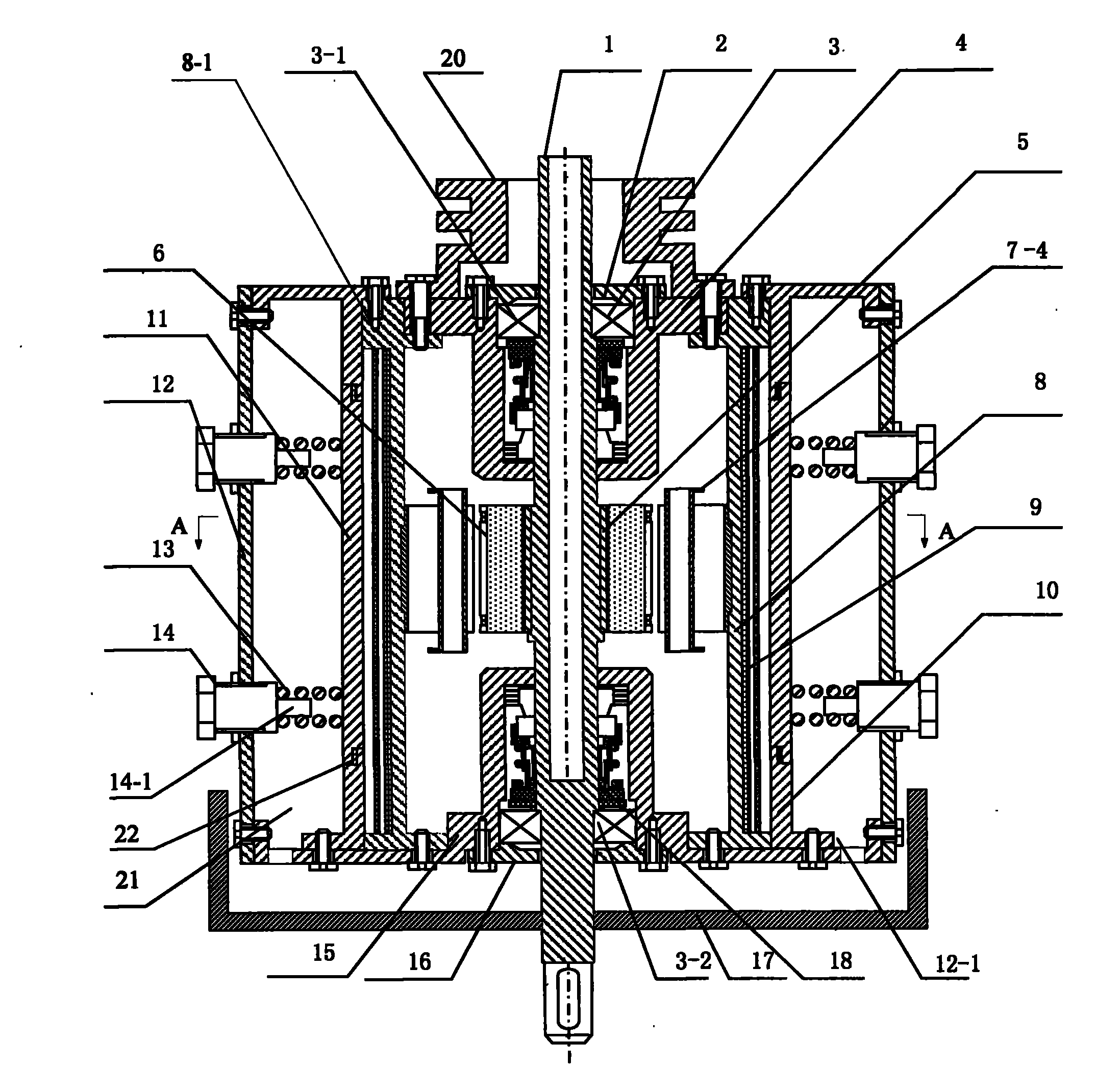

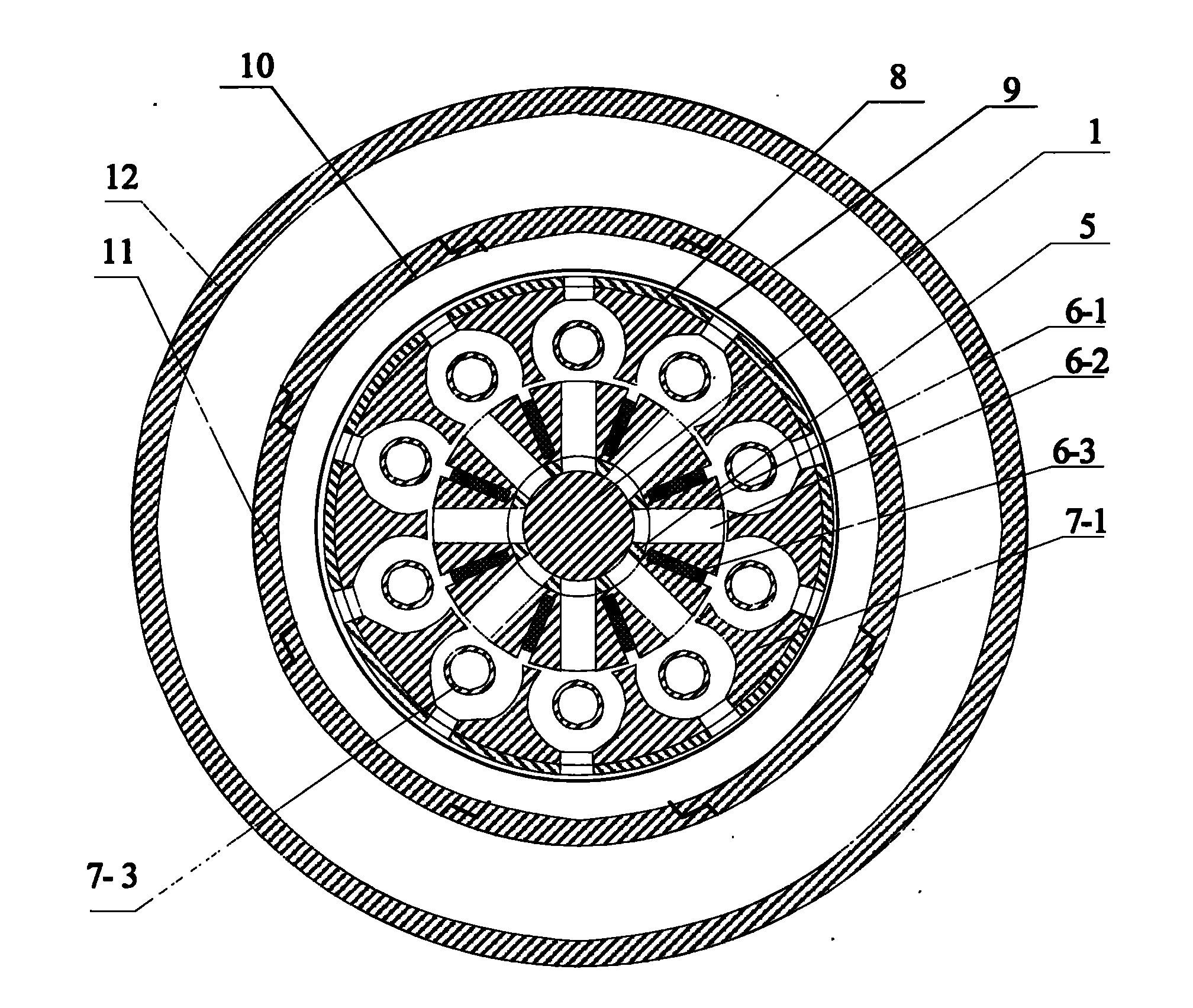

Seawater desalinator

InactiveCN101805041AIncrease temperatureImprove permeabilityGeneral water supply conservationSeawater treatmentSeawaterHigh energy

The invention relates to a seawater desalinator, in particular to a seawater desalination device which overcomes the defects of high energy consumption and low efficiency of the prior art and is used for desalinating seawater. The seawater desalination device comprises a hollow shaft, an upper bearing cover, an upper end bearing, a lower end bearing, an upper end cover, a stator part, a rotor part, a lower end cover, a lower bearing cover, a water-containing pan and two sealing sleeve assemblies. When the seawater desalination device is in work, seawater flows in the device from the hollow shaft and enters a cavity chamber with the stator part and the rotor part, external power drives the rotor part to rotate, the seawater is magnified by an electromagnetic reaction between the stator part and the rotor part and heated by generated heat, the rotating speed of the rotor part is increased after magnification is finished, a sealing pressure block is opened by utilizing centrifugal force which is generated by the high-speed rotation, the seawater enters a cavity of an outer cylinder body through a film and a film sealing sleeve, and fresh water flows in the water-containing pan. The invention changes the acting force between the solute and the solvent of an aqueous solution by a magnetic field, improves the flux of the film, increases the seawater temperature and enhances the water permeation capability.

Owner:HARBIN INST OF TECH

Nano-fiber material and salt rejection filtration material

ActiveUS20100219123A1Improve throughputIncrease operating pressureMembranesSemi-permeable membranesIonNanometre

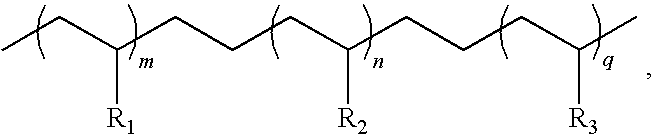

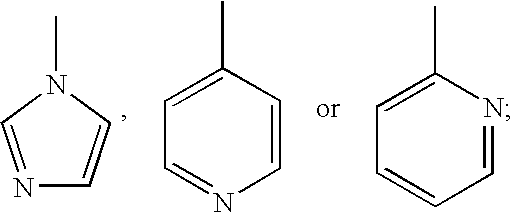

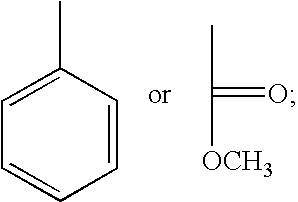

The invention discloses a nano-fiber material, wherein the nano-fiber material is formed by spinning an ionic polymer into a nano-fiber nonwoven, and the ionic polymer is represented by the formula:wherein:R1 includes phenyl sulfonate or alkyl sulfonate; R2 includesR3 includesand m / n is between 1 / 50 and 50 / 1, q≧0.

Owner:IND TECH RES INST

Clean coal pressurized fluidized bed slag gasification process and system

ActiveCN104531224AEffective coagulationEffective returnGasification processes detailsGasification apparatus detailsCycloneFluidized bed gasifier

The invention discloses a clean coal pressurized fluidized bed slag gasification process and system. By means of the gasification process and system, the problems that an existing pressurized fluidized bed industrial gasification process is complex, poor in coal applicability, low in gasification pressure, small in production capacity and low in gasification efficiency, the environment is polluted are solved. According to the technical scheme, the process includes the steps that raw material coal powder is pressurized and sent to a fluidized bed gasification furnace through a material inlet to react with a gasifying agent in a gasification mode, and crude synthesis gas and coal powder ash slag are obtained; the crude synthesis gad rises and is sent to a multi-pipe type cyclone separator through a top outlet of the fluidized bed gasification furnace to be dedusted, fluidizing agents are sprayed twice through a gasification spray nozzle to improve gasification efficiency, the coal powder ash slag is melt through a slag melting device, forms melt slag and then enters a slag quenching tank through a bottom outlet of the fluidized bed gasification furnace to be quenched and discharged through a slag locking hopper. The clean coal pressurized fluidized bed slag gasification process and system are simple in process, easy and convenient to operate, wide in coal applicability, high in gasification pressure, large in production capacity, high in gasification efficiency and environmentally friendly.

Owner:WUHUAN ENG +1

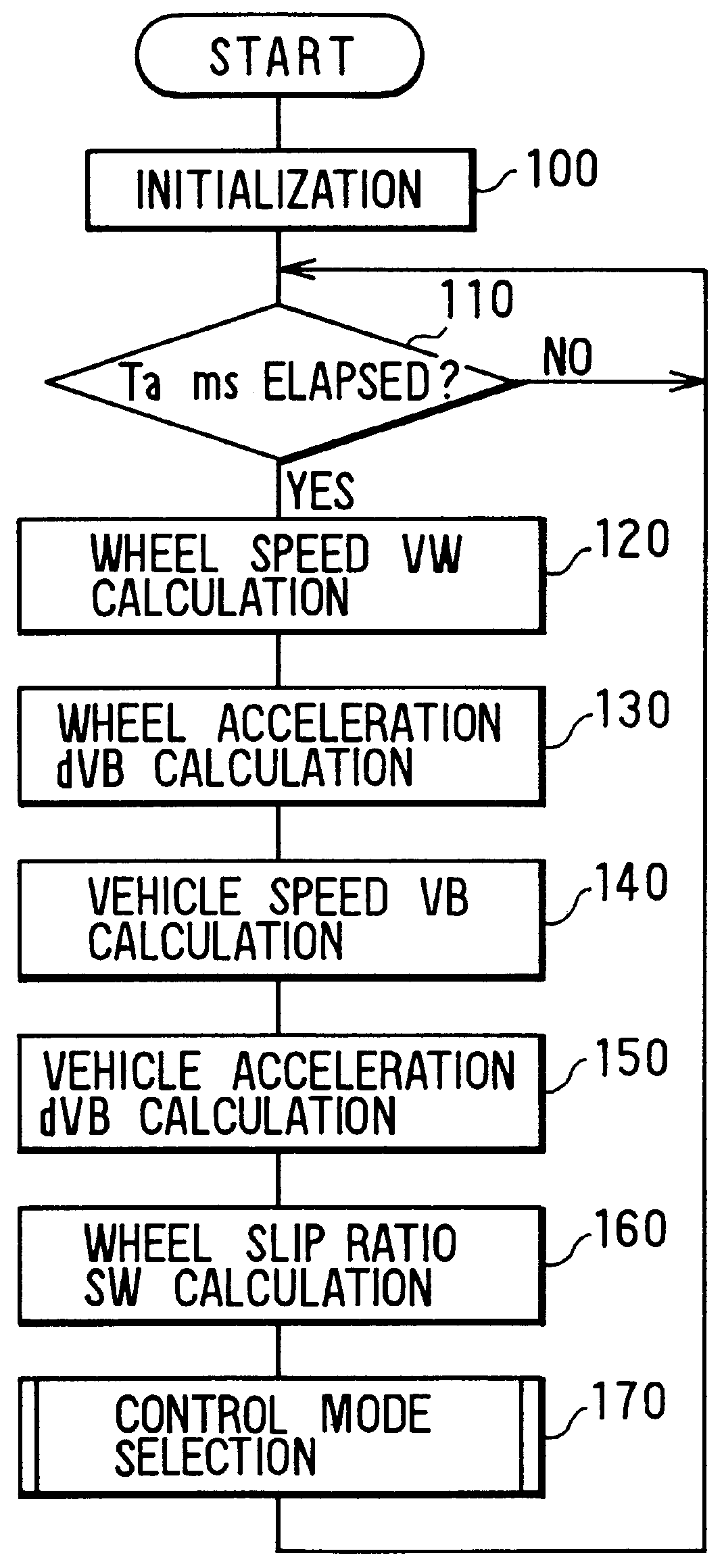

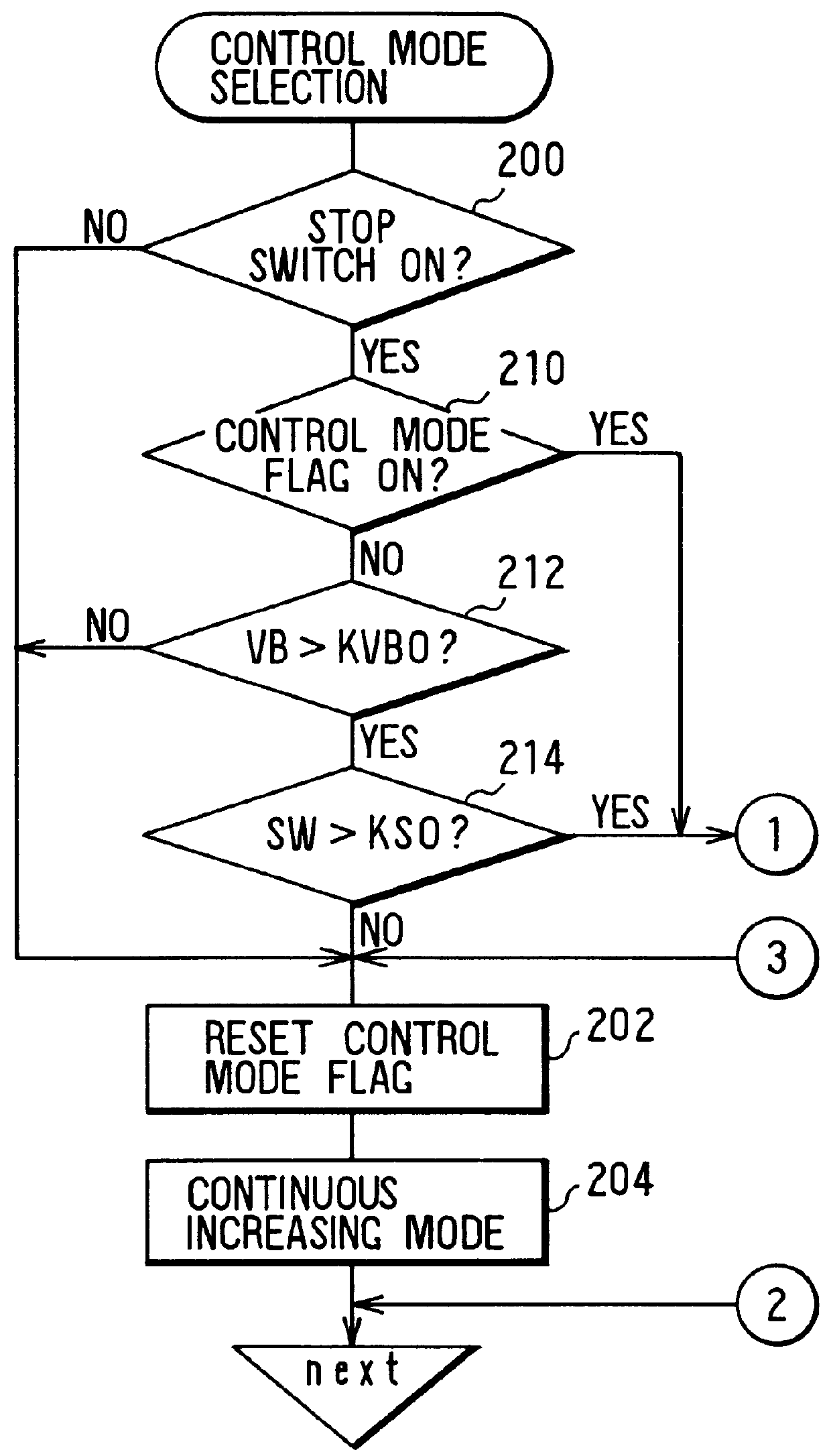

Antiskid control apparatus

InactiveUS6089681AImproving brake-pedal operationIncrease brake pressureApplication and release valvesMaster cylinderEngineering

In an antiskid control apparatus, brake pressures of a plurality of wheels are increased by using a hydraulic pressure generated by a master cylinder. When the running speed of a vehicle becomes lower than predetermined value due to a braking operation, a brake-pressure adjusting unit increases the brake pressures applied to the plurality of wheels with timings different from each other. In this way, it is possible to reduce changes with time in amount of fluid flowing out of the master cylinder.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com