Method for removing oxy-compounds from olefin material flow

A technology for oxides and compounds, applied in the fields of organic chemistry, distillation purification/separation, etc., can solve problems such as not given, and achieve the effects of reasonable structure, small loss and wide range of water weight content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

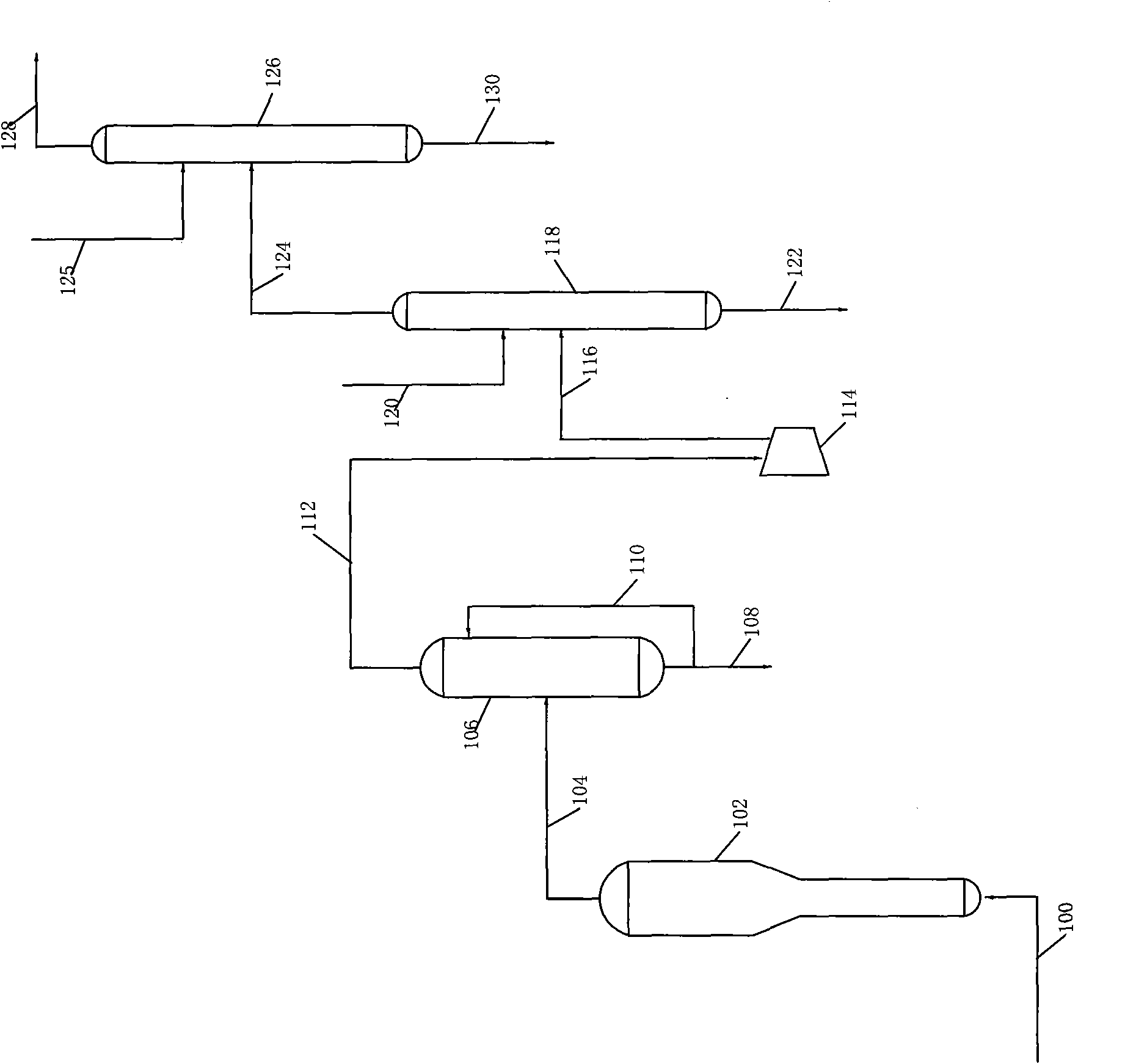

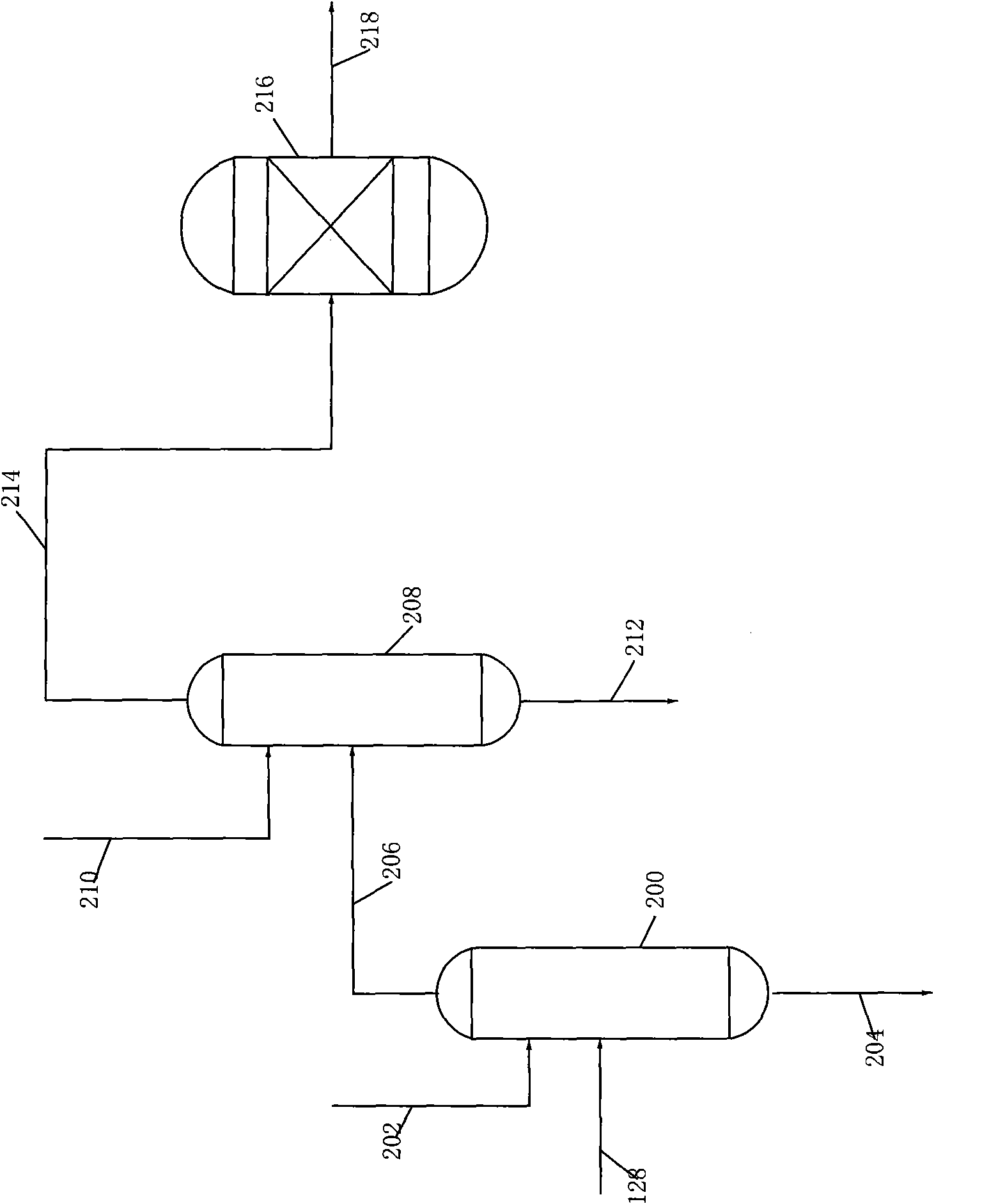

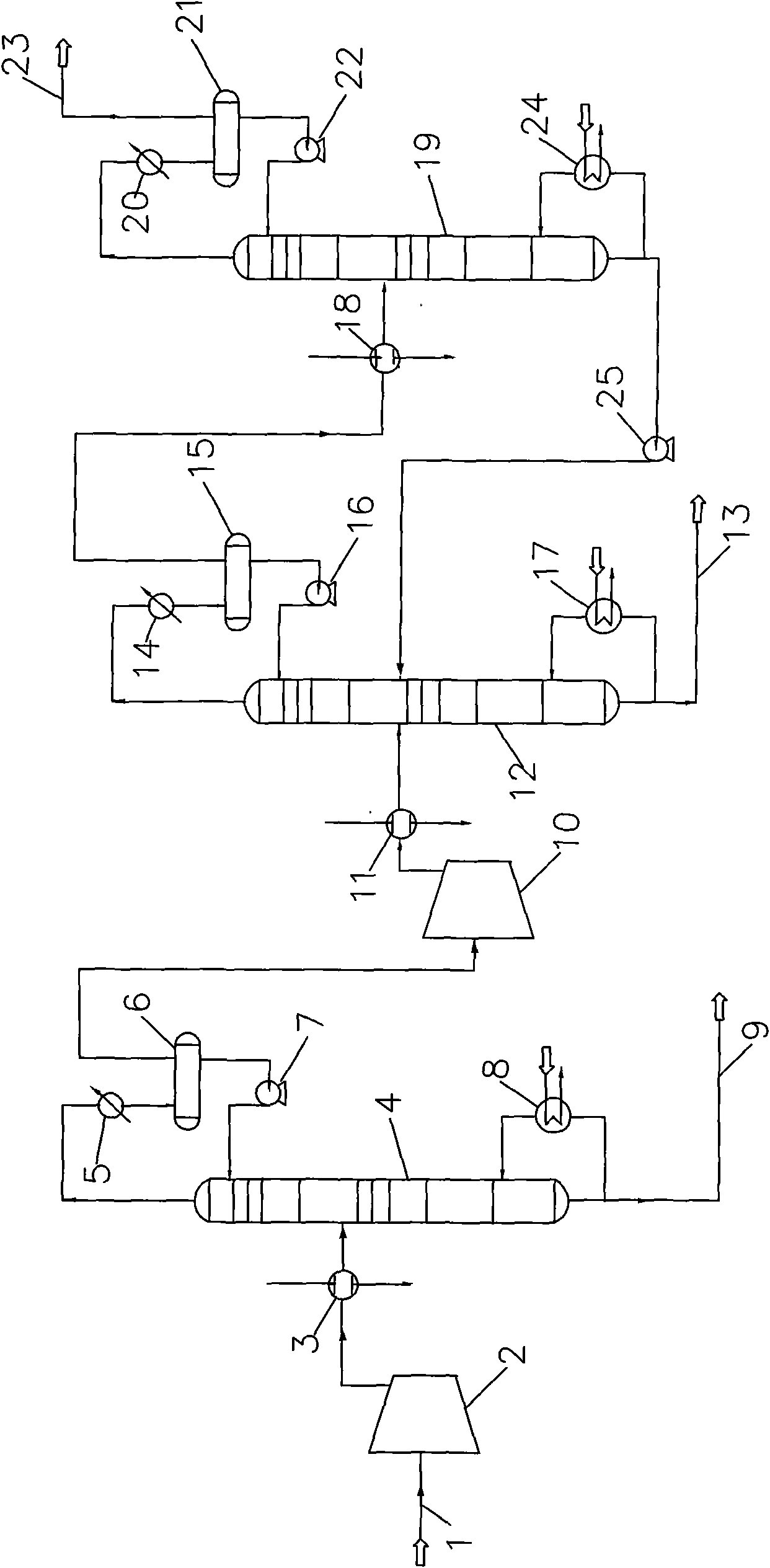

[0032] Such as image 3 As shown, the cooled stream of the reaction product of oxygenate to olefin is regarded as the olefin stream, or the stream of the reaction product of the reaction product of oxygenate to olefin is contacted with the quenching medium after passing through the quench tower and is regarded as olefin The stream, through the olefin stream line 1, is pressurized by the first compressor 2 and heat-exchanged by the first heat exchanger 3, and then enters the first deoxidation tower 4. The operating pressure at the top of the first deoxidation tower 4 is 0.01 to 0.5 MPa. Preferably 0.12-0.3Mpa, the bottom of the first deoxidation tower 4 can be heated through the first reboiler 8 with steam or other heating medium. The first deoxidation tower 4 overhead stream is a gas mixture containing ethylene, propylene and a small amount of water and oxygen-containing compounds, and enters the first deoxidation tower reflux tank 6 after being cooled and condensed by the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com