Carbon fiber reinforced plastic electric-smelting pipe fitting with strain self-monitoring function

A technology for electrofusion pipe fittings and reinforced plastics, which is applied in non-removable pipe connections, electrical/magnetic solid deformation measurement, pipe/pipe joints/pipe fittings, etc. Achieve the effect of improving intelligence and safety, high blasting pressure, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

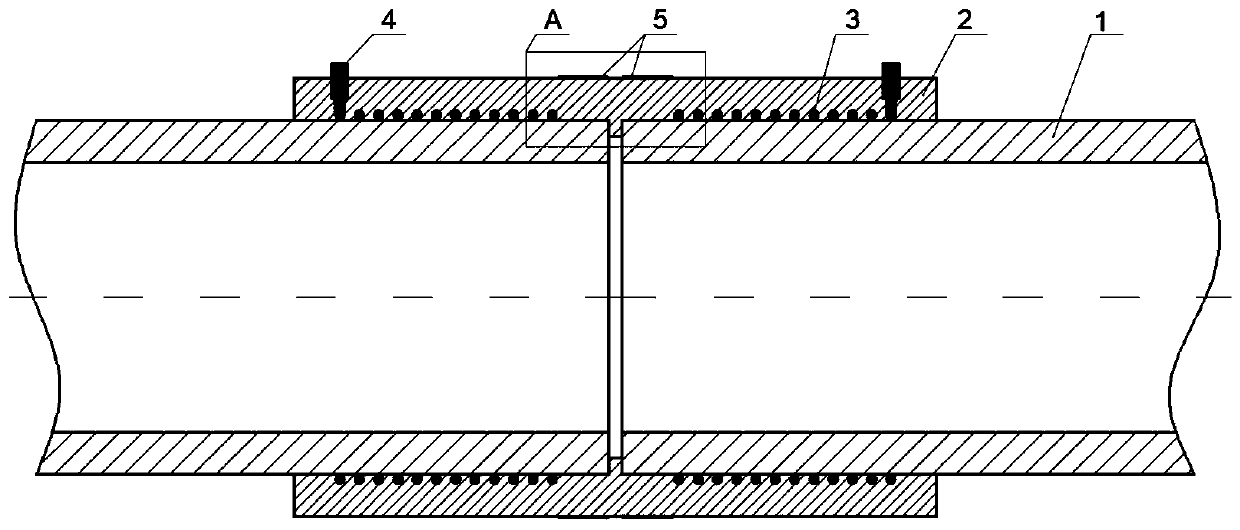

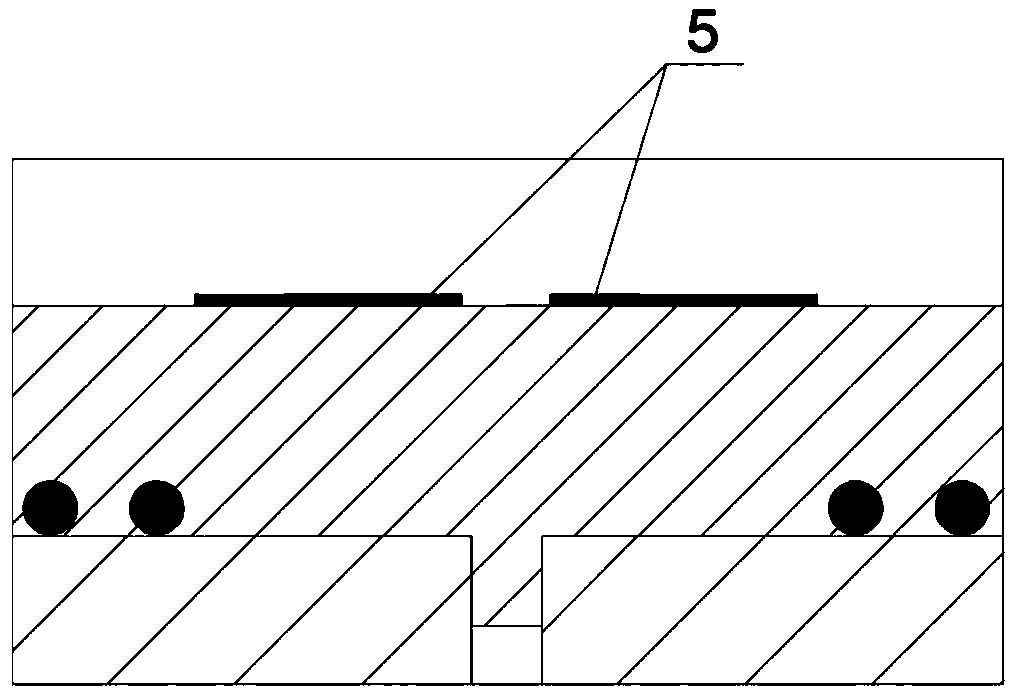

[0050] Such as Figure 1-2 As shown, the carbon fiber reinforced plastic electrofusion pipe fitting with strain self-monitoring function of the present invention includes an electrofusion pipe fitting body 2 embedded with a resistance wire, and two wires respectively connected to two ends of the resistance wire 3 are arranged on the electrofusion pipe fitting body 2 Column 4; the body 2 of the electrofusion pipe fitting is made of thermoplastic filled with carbon fiber; a pair of electrodes 5 are set on the surface of the electrofusion pipe fitting body 2, and the electrodes 5 will be used to monitor the temperature rise or internal pressure caused by heating during use. The change of resistance value caused by deformation can realize the strain monitoring of electrofusion pipe fittings. In the electrofusion pipe fitting body 2, the chopped carbon fiber accounts for 5-20% by mass. Electrofusion pipe fittings are usually made of polyethylene or polypropylene by separate inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com