Patents

Literature

3698results about How to "High yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

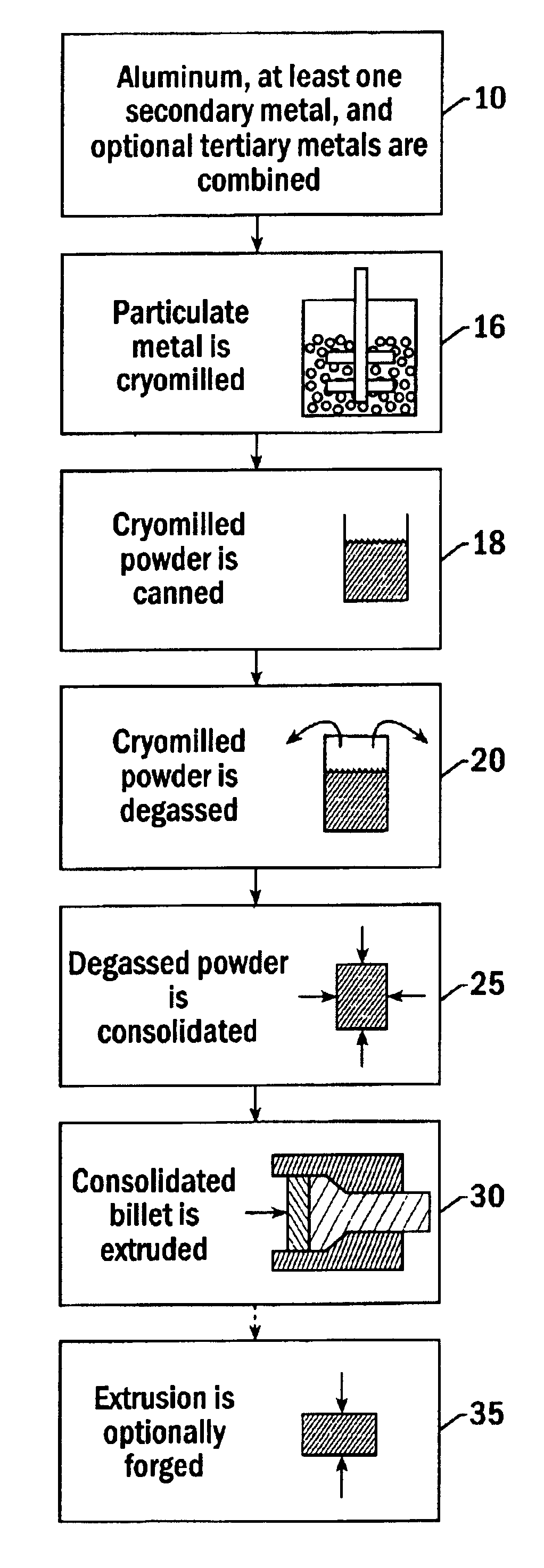

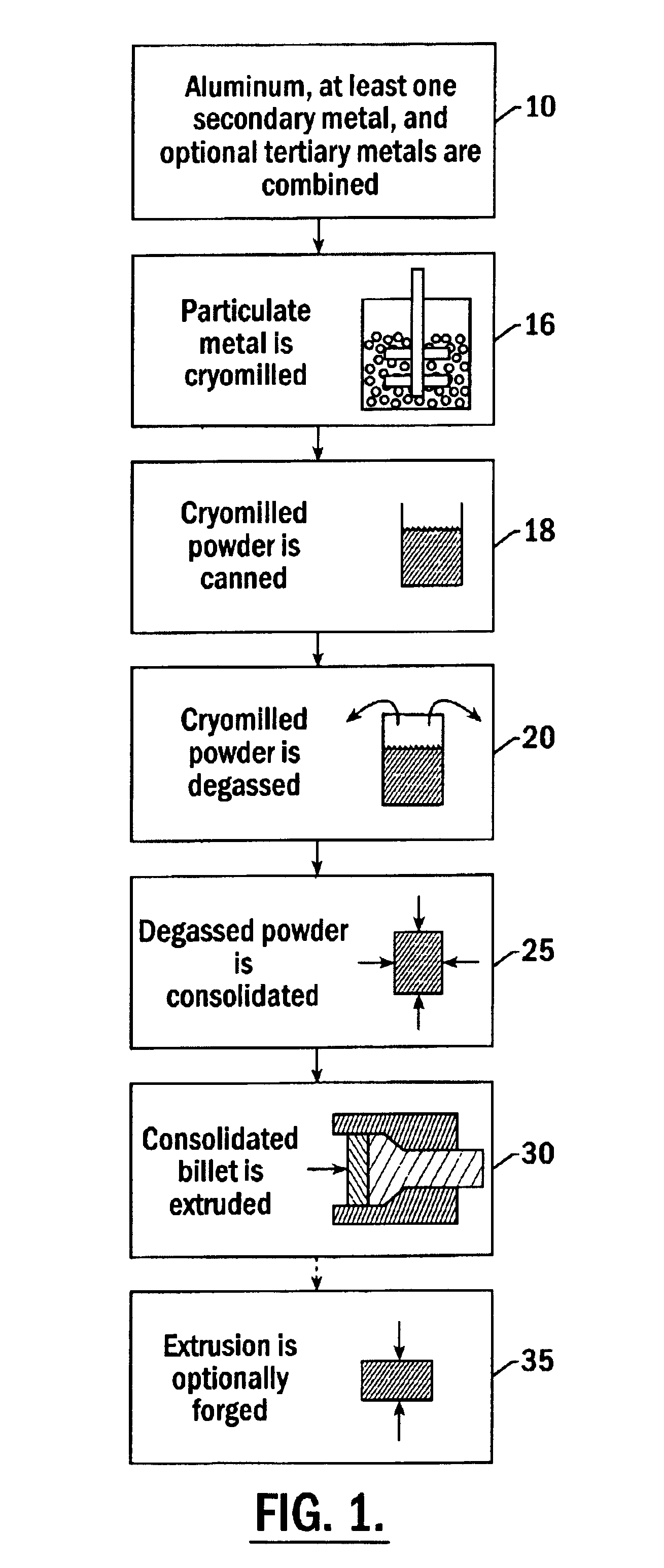

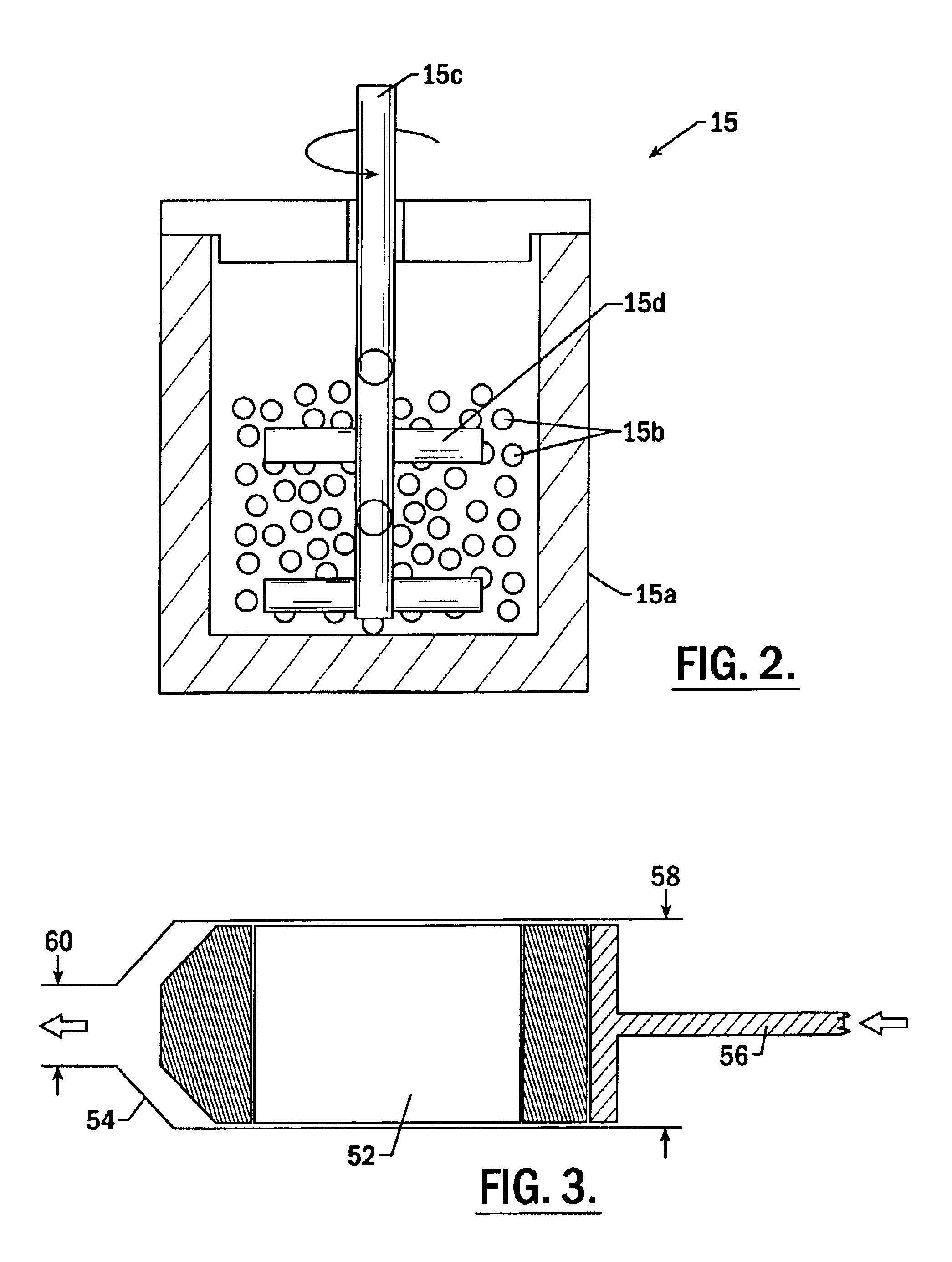

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

Method of making a product with improved material properties by moderate heat-treatment of a metal incorporating a dilute additive

InactiveUS6150186AStable mechanical propertiesImprove conductivitySemiconductor/solid-state device testing/measurementFinal product manufactureUltimate tensile strengthMechanical property

Deposition of metal in a preferred shape, including coatings on parts, or stand-alone materials, and subsequent heat treatment to provide improved mechanical properties. In particular, the method gives products with relatively high yield strength. The products often have relatively high elastic modulus, and are thermally stable, maintaining the high yield strength at temperatures considerably above 25 DEG C. This technique involves depositing a material in the presence of a selected additive, and then subjecting the deposited material to a moderate heat treatment. This moderate heat treatment differs from other commonly employed "stress relief" heat treatments in using lower temperatures and / or shorter times, preferably just enough to reorganize the material to the new, desired form. Coating a shape and heat treating provides a shaped deposit with improved material properties. Coating a shape with a portion connected to a base and a portion detached therefrom can provide a resilient, conductive contact useful for electronic applications.

Owner:FORMFACTOR INC

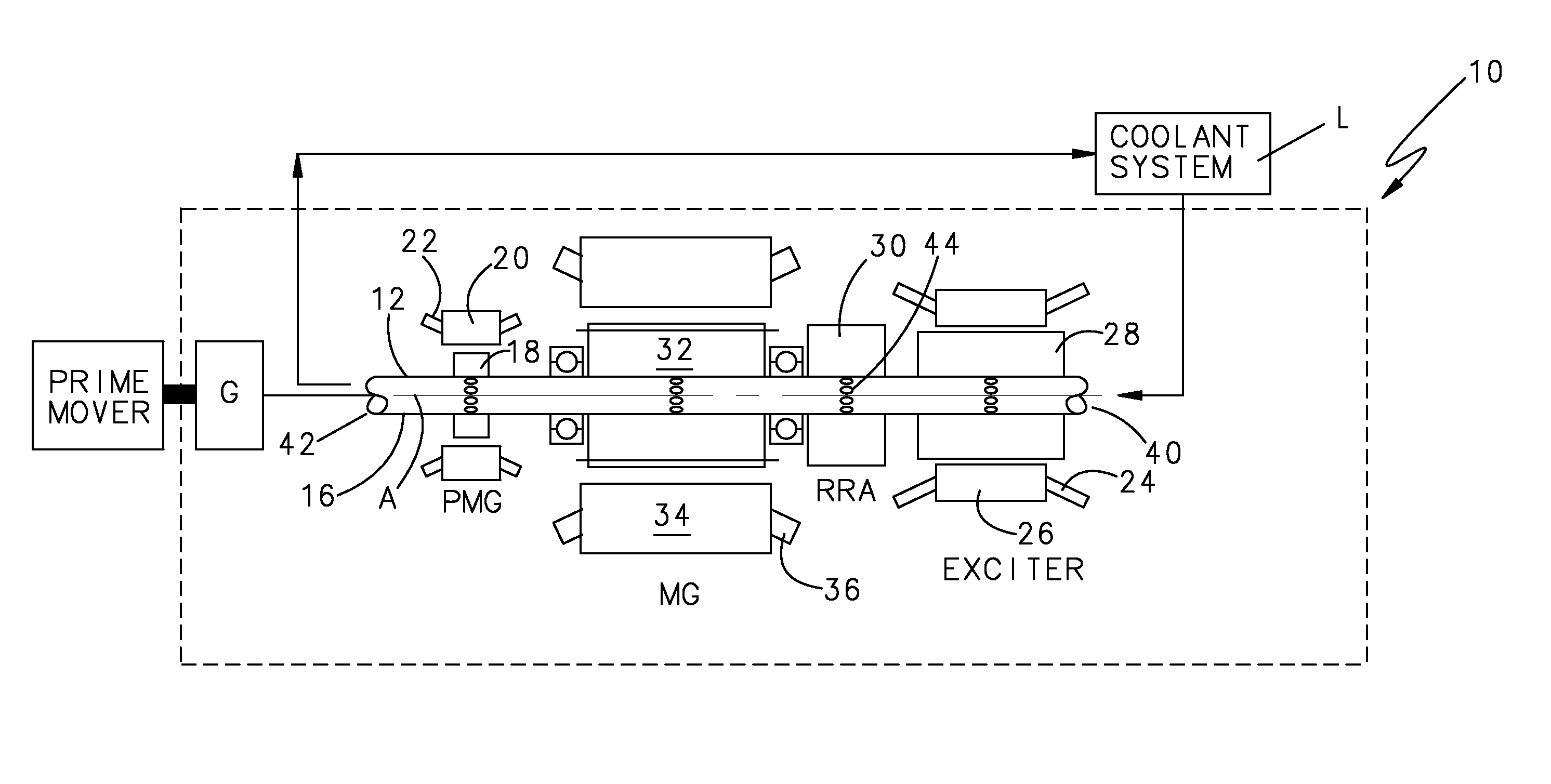

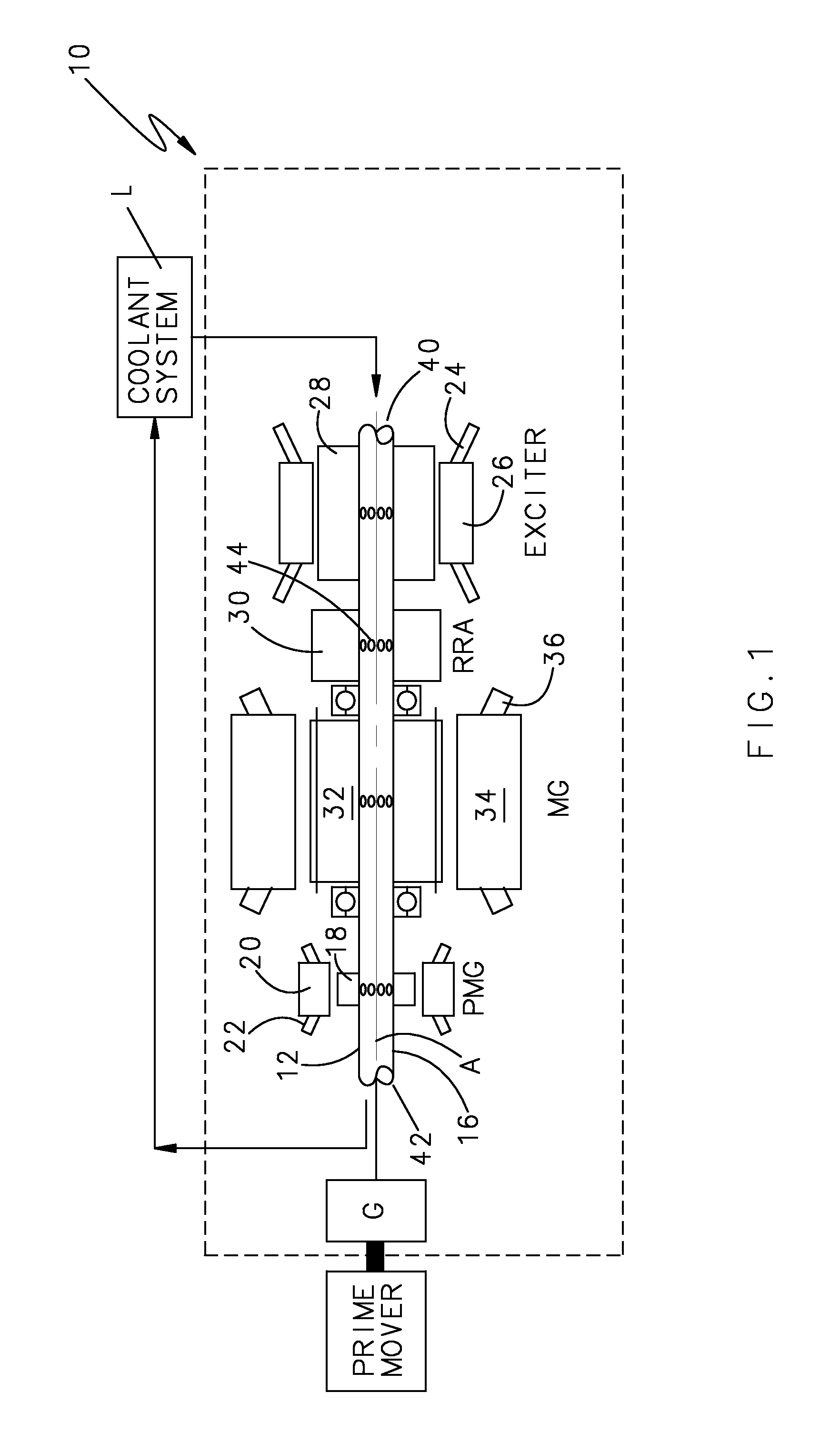

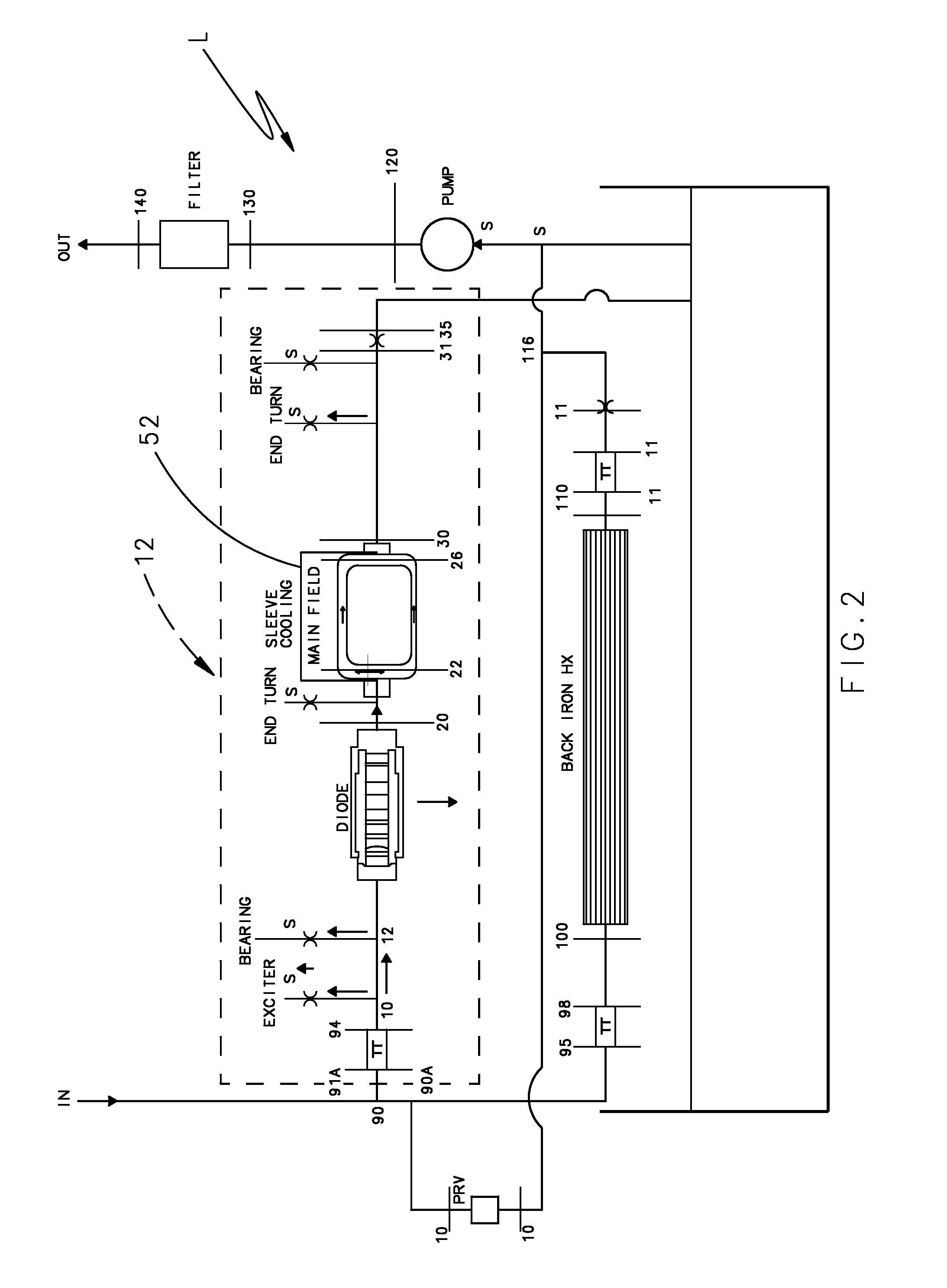

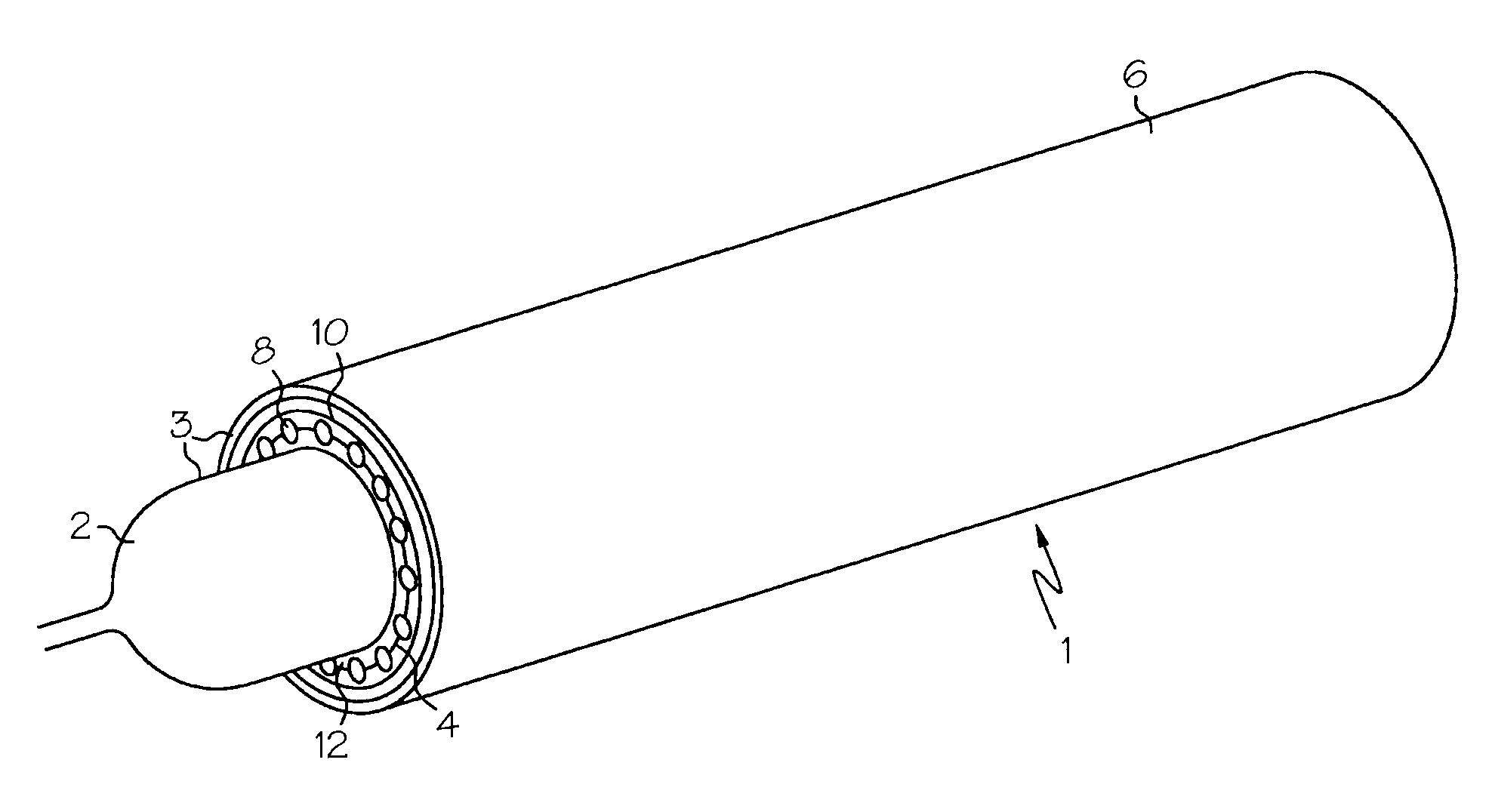

Rotor cooling system for synchronous machines with conductive sleeve

ActiveUS7208854B1Low operating temperatureThin constructionMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringElectrical and Electronics engineering

A wound field synchronous machine includes direct oil cooling along a conductive sleeve with elongated semi-arcuate shaped channels which alternate with damper bar channels containing tie-rod supports structures. With a reduction in sleeve thickness permitted by the direct cooling, the overall weight of the machine is reduced.

Owner:HAMILTON SUNDSTRAND CORP

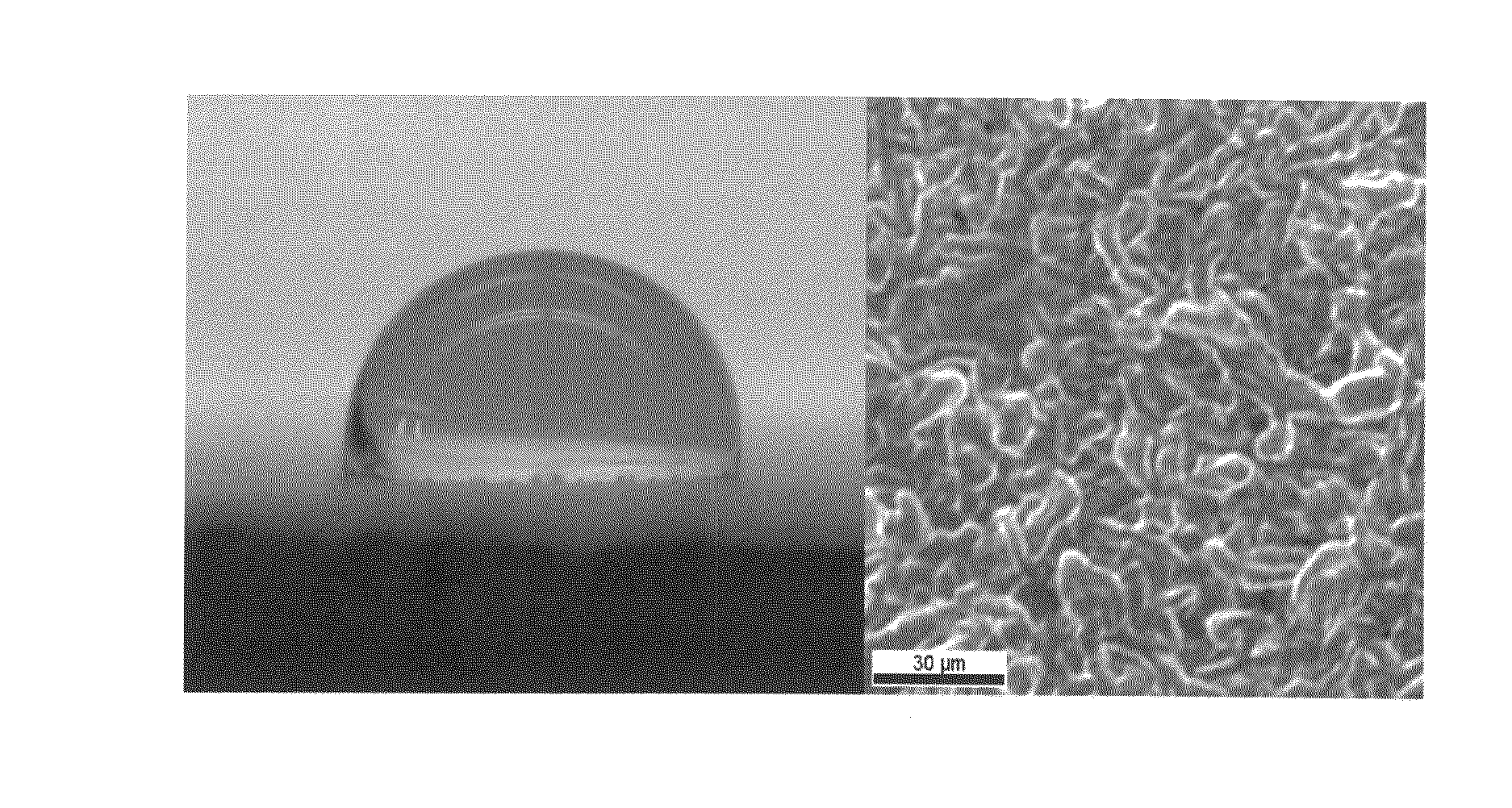

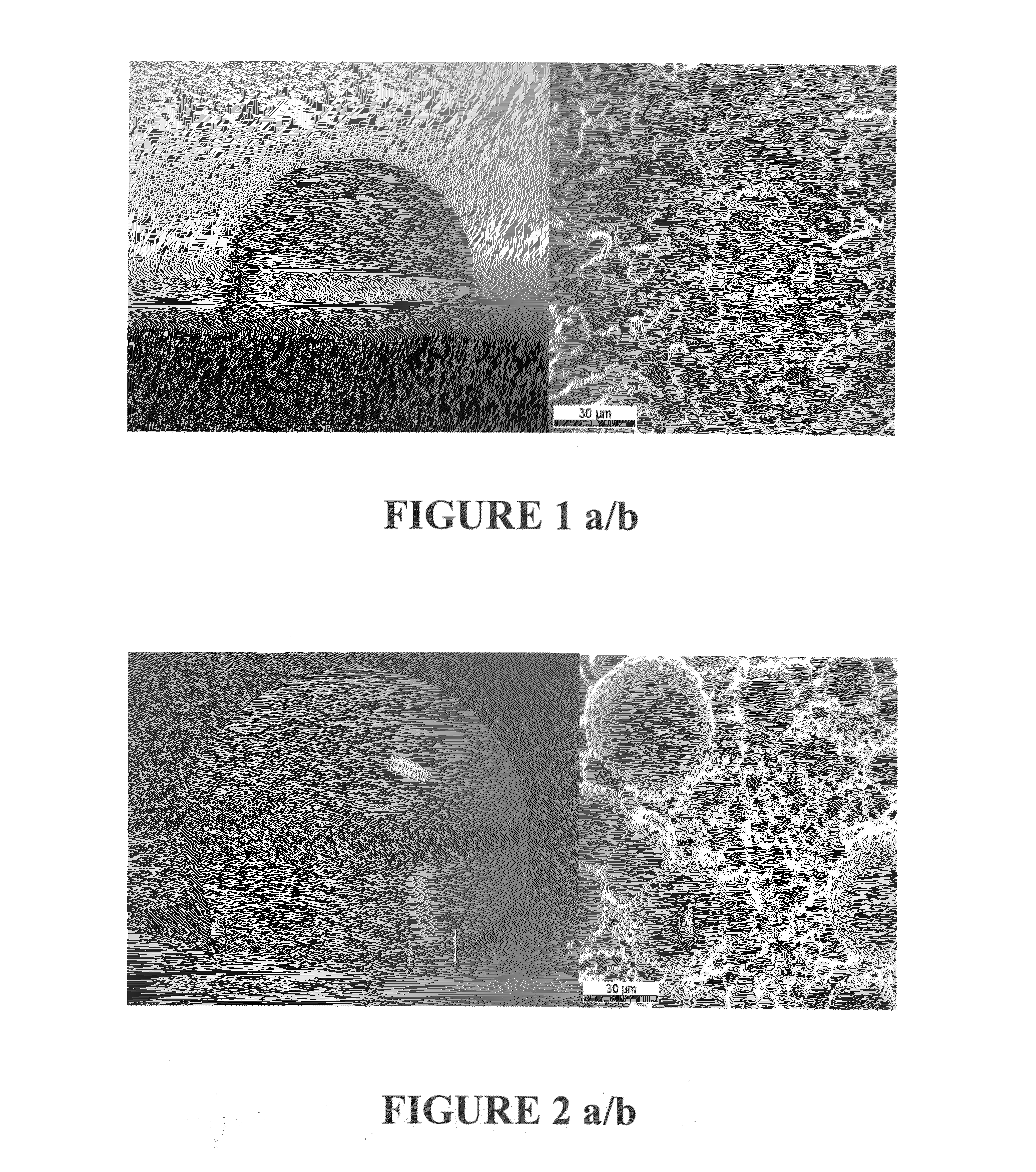

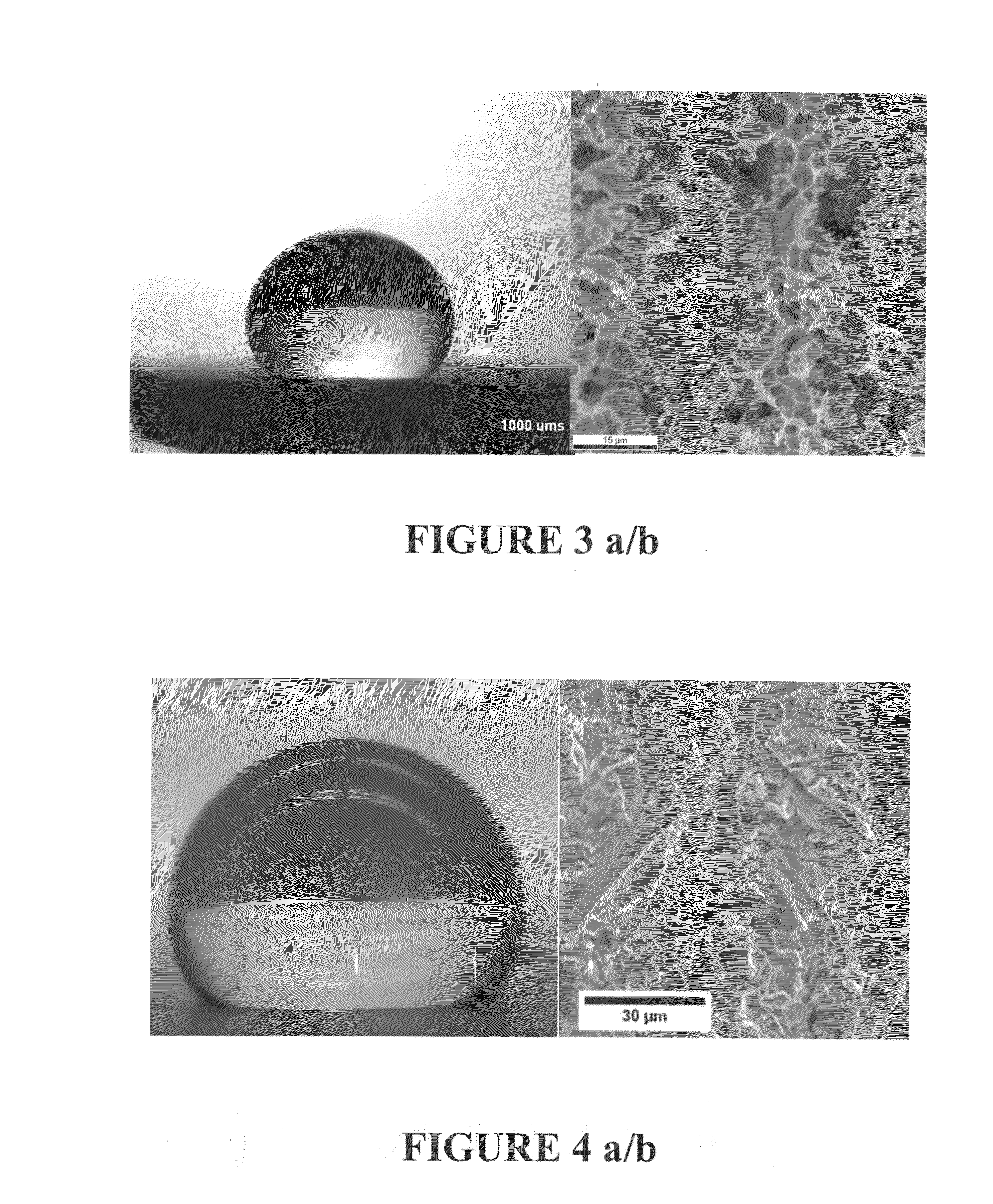

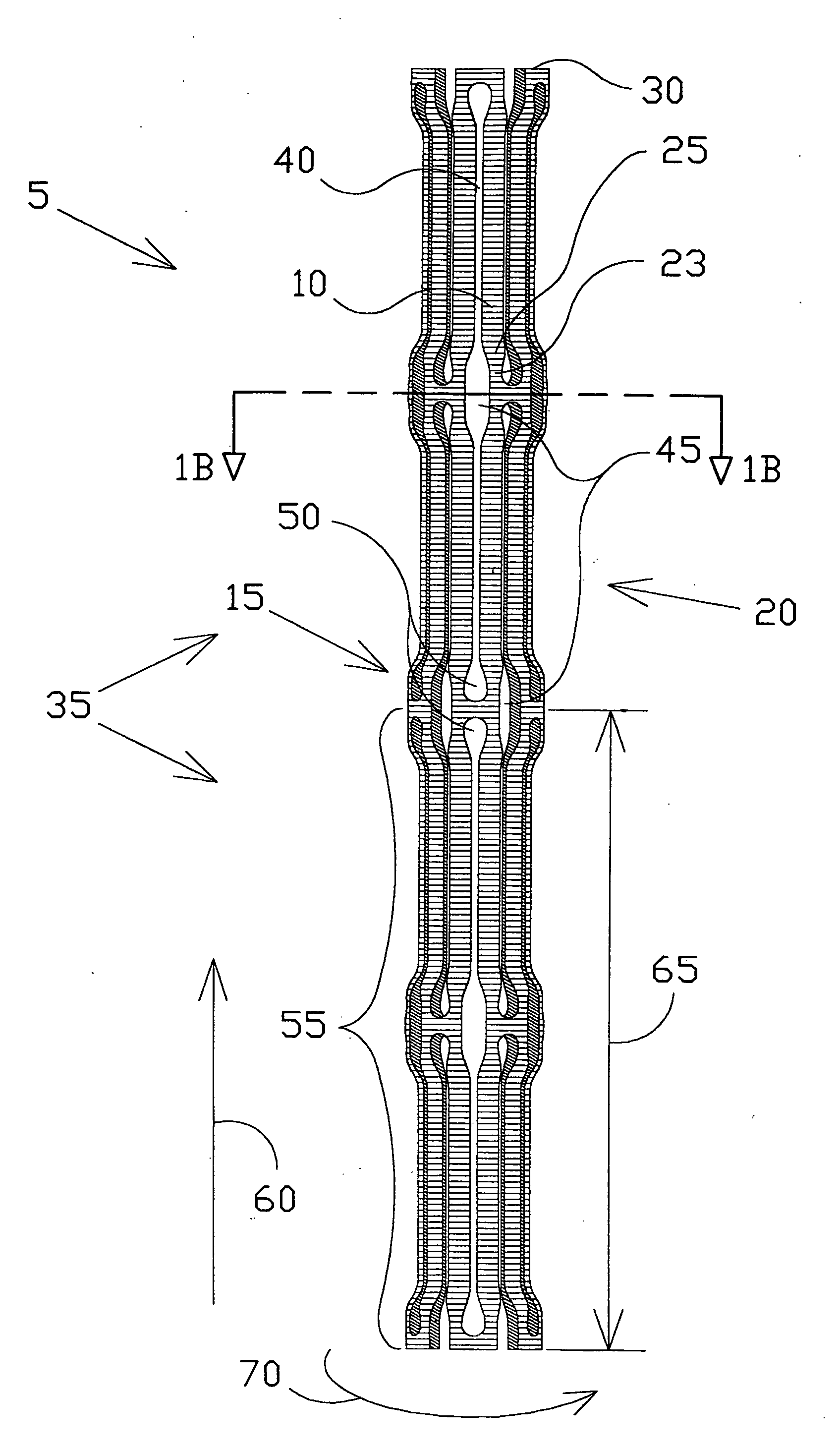

Metallic articles with hydrophobic surfaces

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

High-strength heat-resisting magnesium alloy and its preparing method

This invention is a high-intensive heat-fast magnesium alloy and its preparation method, and the magnesium alloy has the following components with their weight percentages: 6-15%Gd, 1-6%Y, 0.35-0.8%Zr, 0-1.5%Ca, and impurity elements Si, Fe, Cu and Ni with their gross less than 0.02%, and the rest percentage is Mg. while melting, add Gd, Y, Zr in the Mg melt in Mg-Gd, Mg-Y, Mg-Zr forms, then carry out solution treatment to the magnesium alloy under 450-500deg.C for 6-12 hours, squeeze in in 350-450deg.C, treat in time the squeezing stick for 10-16 hours in 225deg.C to improve its strength.

Owner:SHANGHAI JIAO TONG UNIV

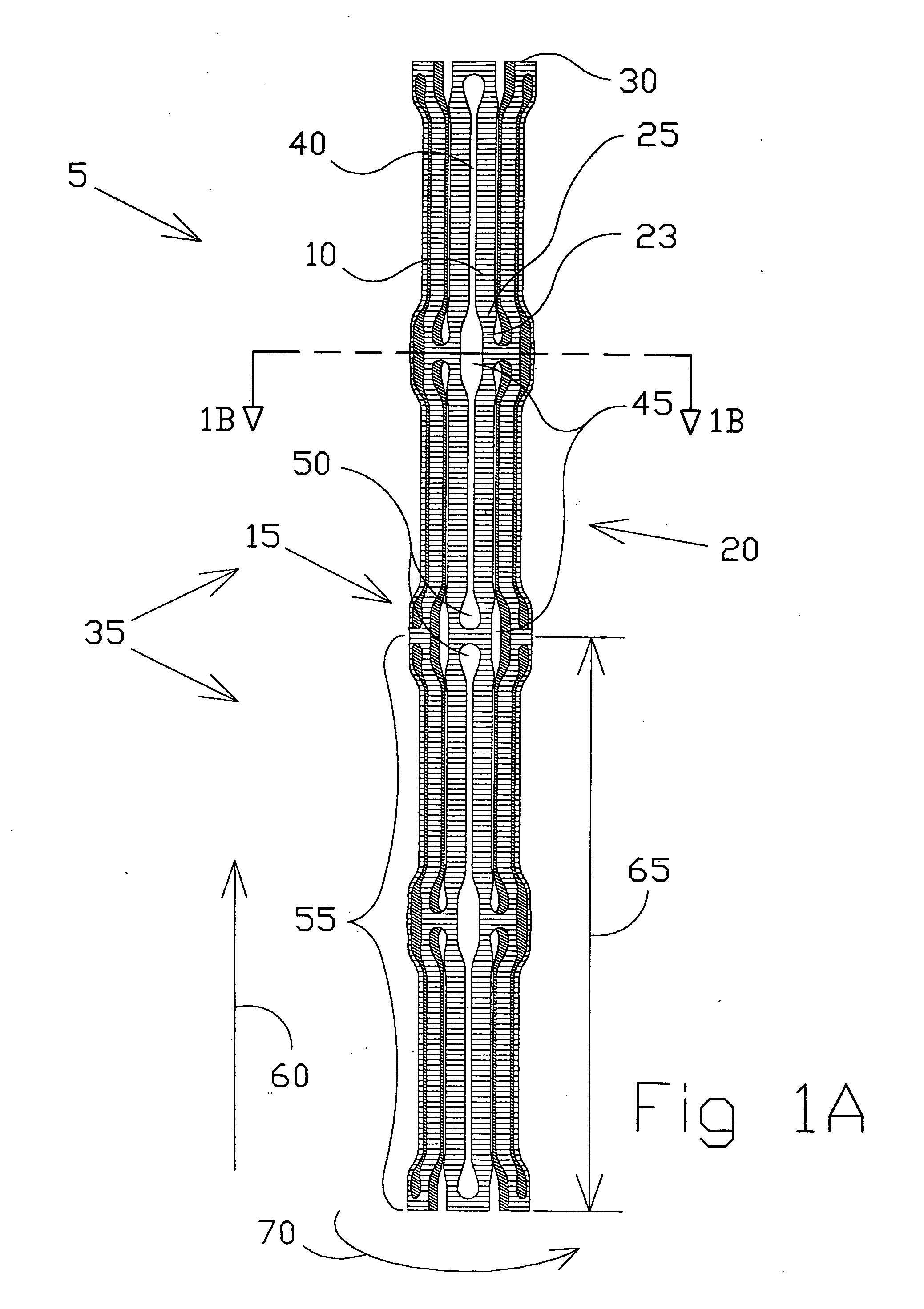

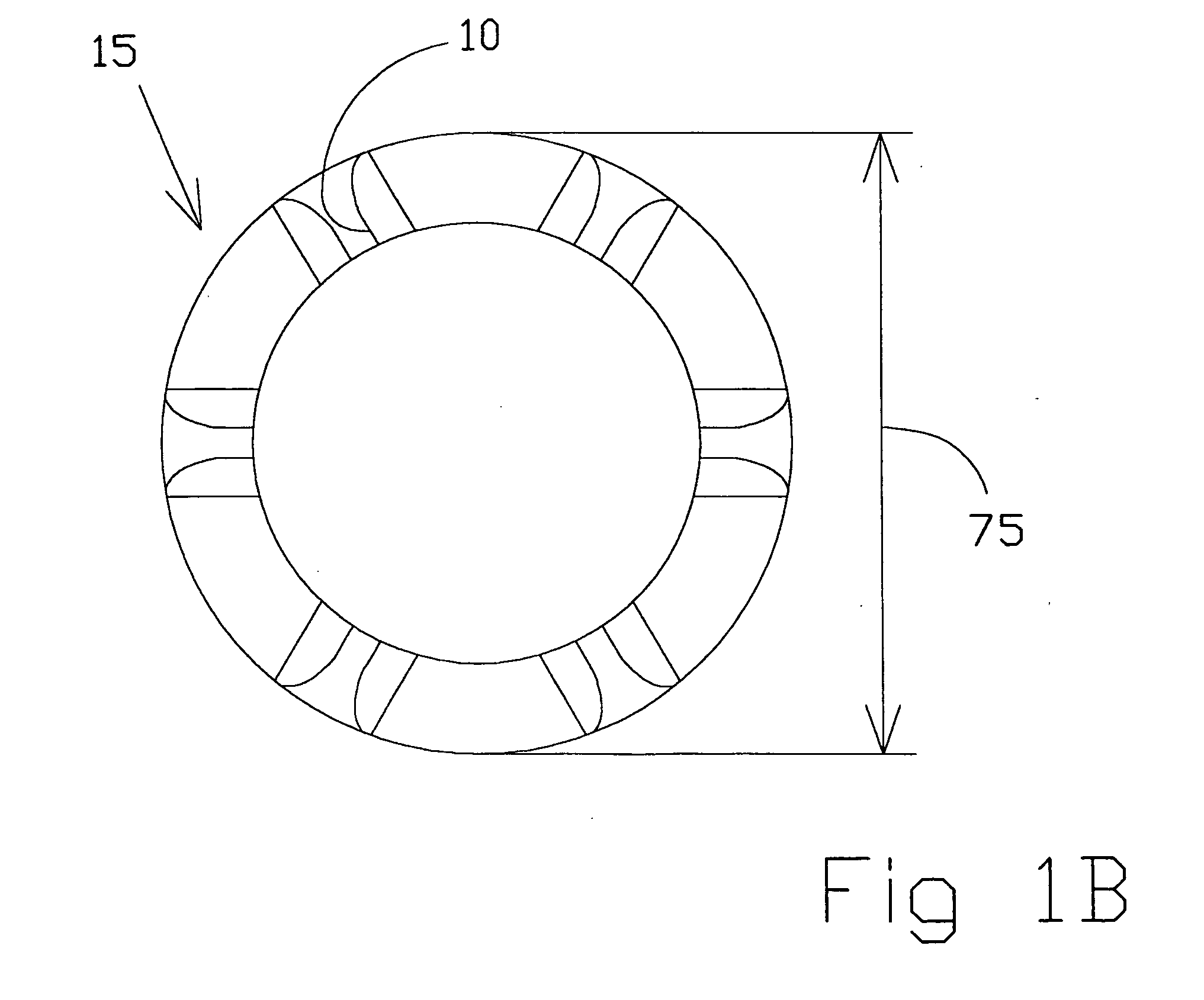

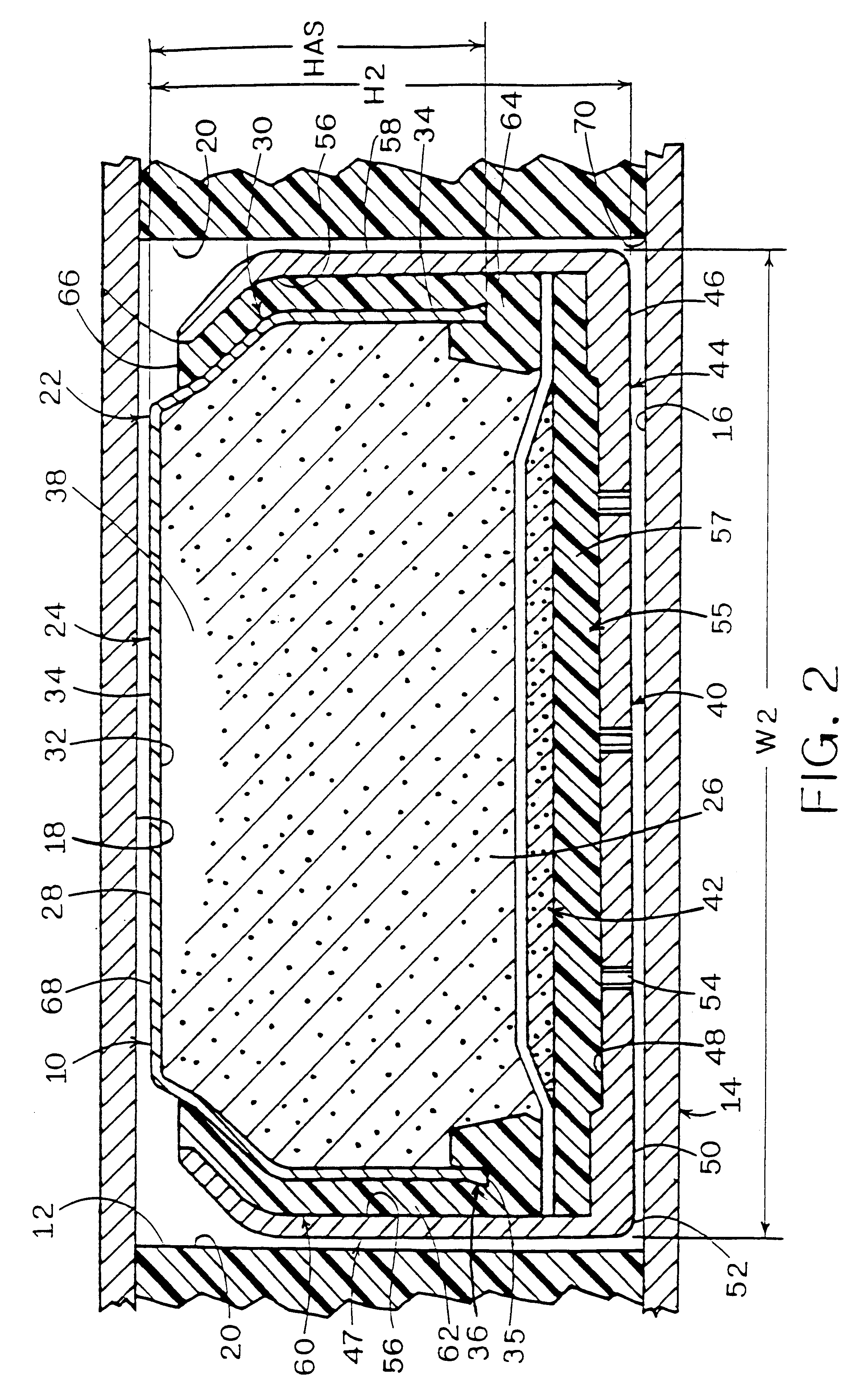

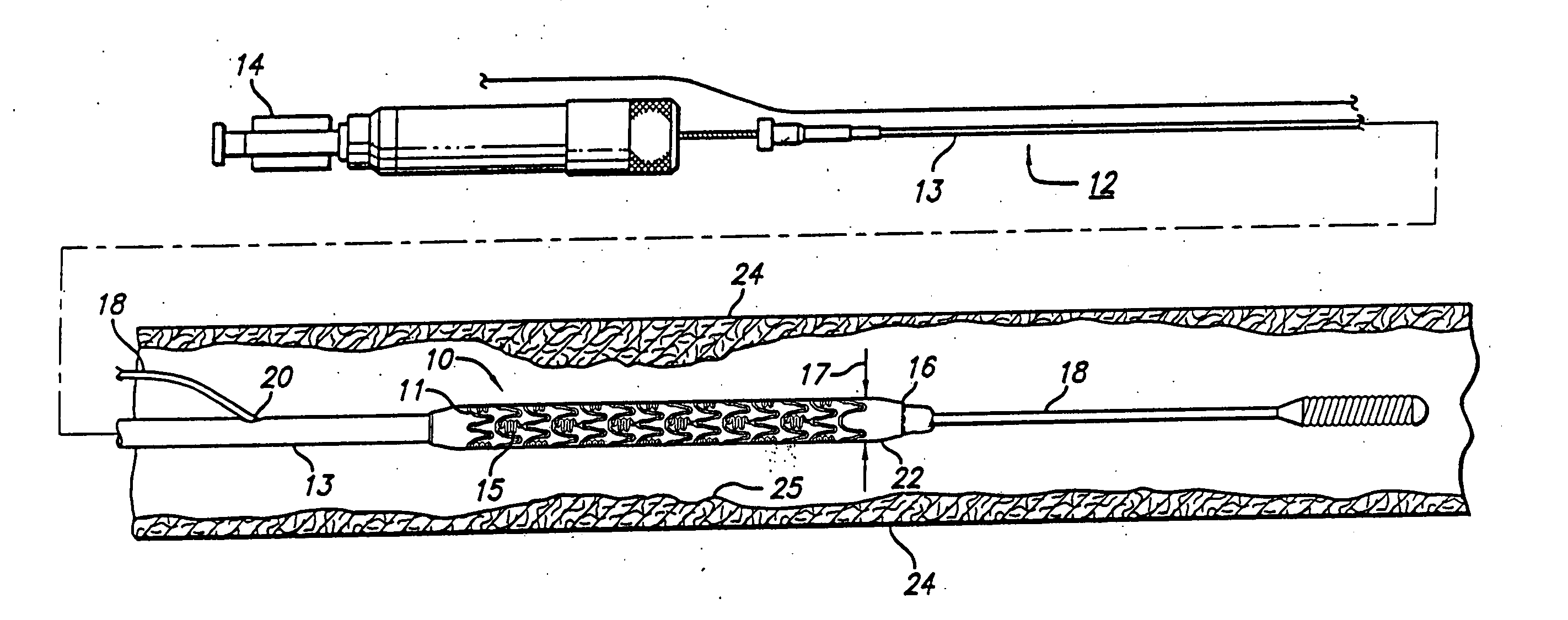

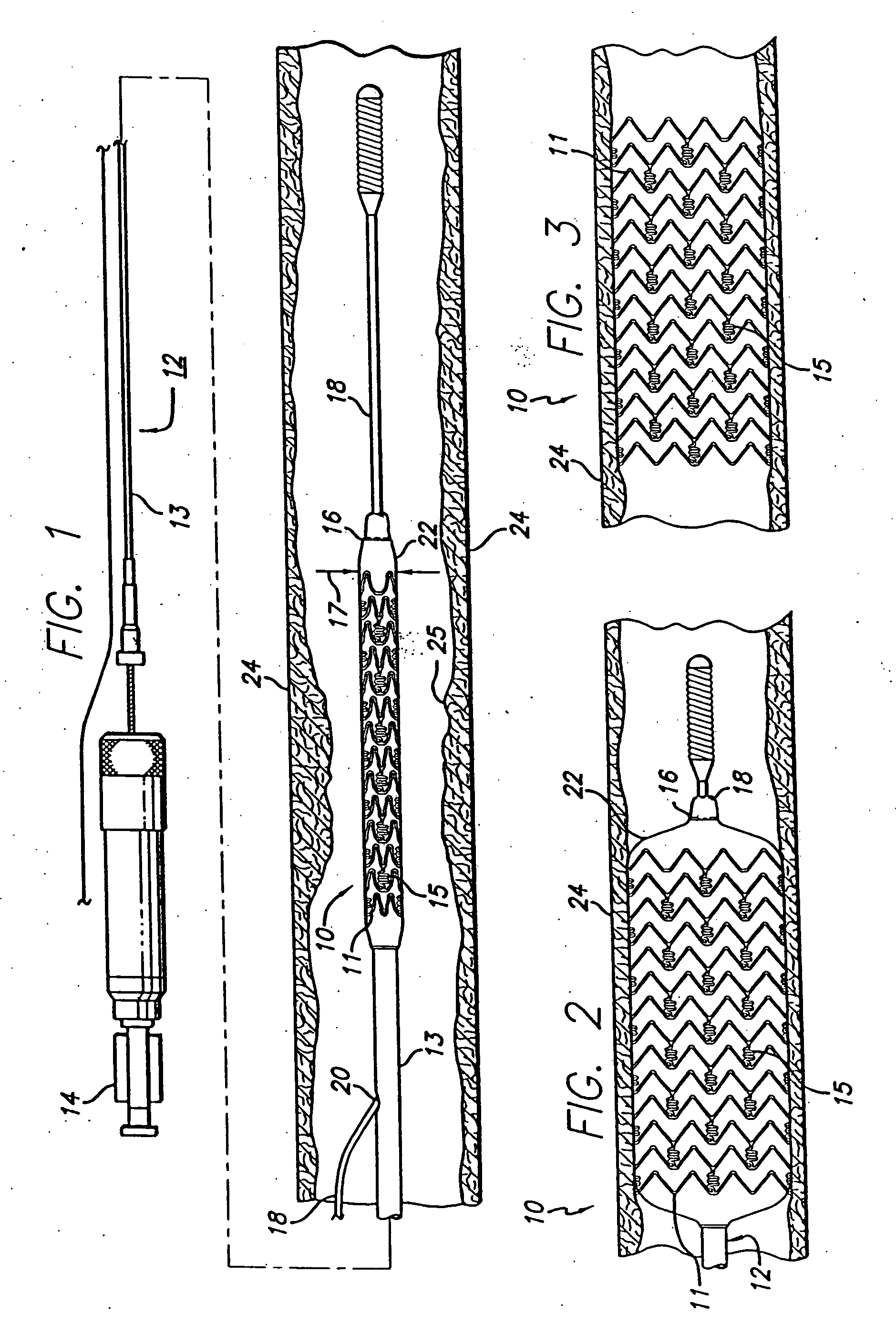

Intravascular hinge stent

A balloon or self expandable endoprosthesis formed of a single or multiple joined stent sections. Each section has a node and strut structure extending throughout in order to uncouple expansion forces of the stent to hold a blood vessel outward from crush forces that resist the formation of an oval shape during crush deformation. The hinge can bend in the direction of a uniformly curved surface of the stent but not in the radial direction. The strut can bend in the radial direction but not in the uniformly curved surface of the stent. The widths, lengths, and radial dimensions of the hinges and struts provide a balloon-expandable hinge stent that is non-crushable. For a self-expanding stent the hinge and strut dimensions provide expansion forces that are controlled independently from crush forces. Expansion properties are determined by the hinge dimensions and crush properties are determined independently by strut dimensions.

Owner:DRASLER WILLIAM JOSEPH +1

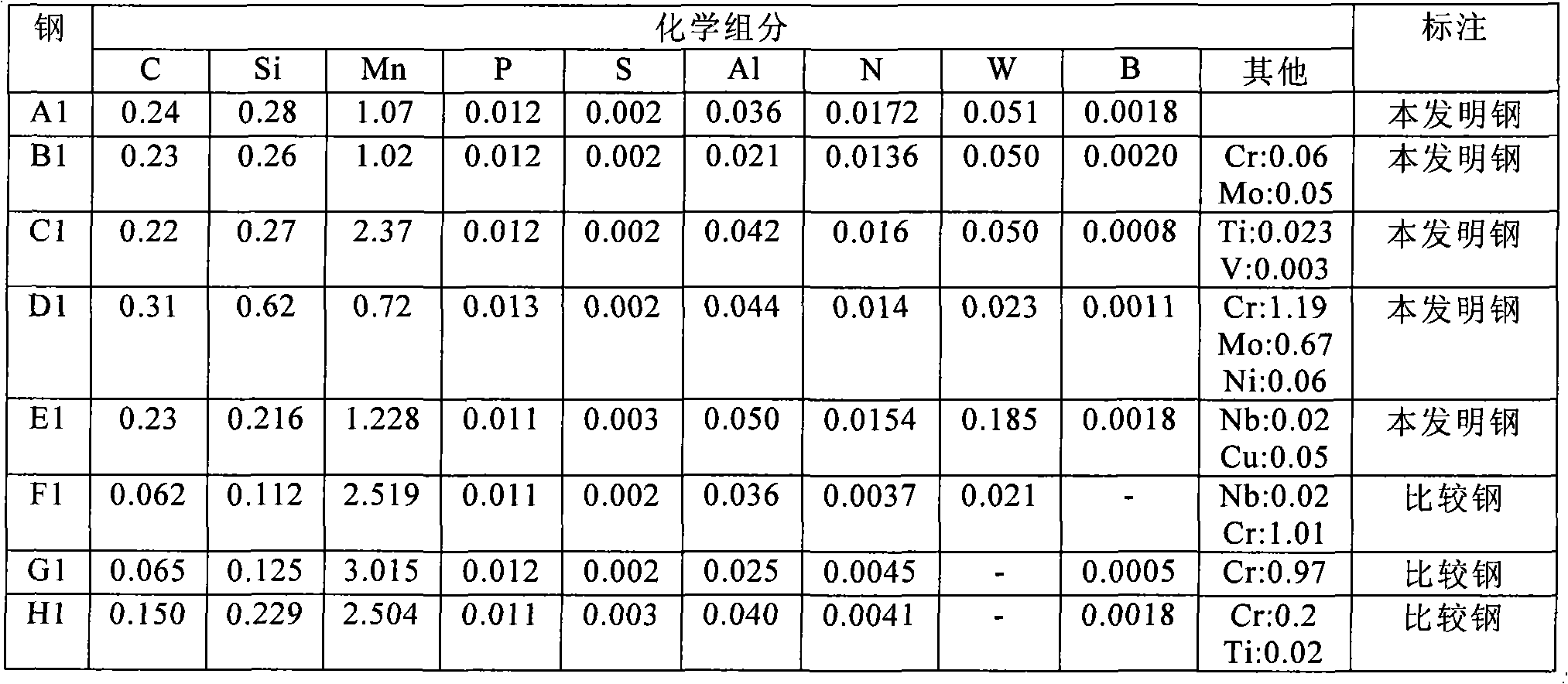

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

The invention provides high-strength and high-corrosion-resistance cast aluminum alloy and a pressure casting preparation method thereof. The alloy is prepared from, by a certain weight percent, Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al, wherein M is at least one element of Ti, Zr and V, or the element RE is added in M. After the high-strength and high-corrosion-resistance cast aluminum alloy is subjected to pressure casting, the room temperature tensile strength sigma b of alloy not subjected to heat treatment is larger than or equal to 315 MPa, the room temperature ductility sigma of the alloy not subjected to heat treatment is larger than or equal to 3.0%, and good corrosion resistance is achieved; and the alloy can be applied to automobile parts without ageing or solid solution heat treatment, and the requirement for light automobile development is met.

Owner:SHANGHAI JIAO TONG UNIV

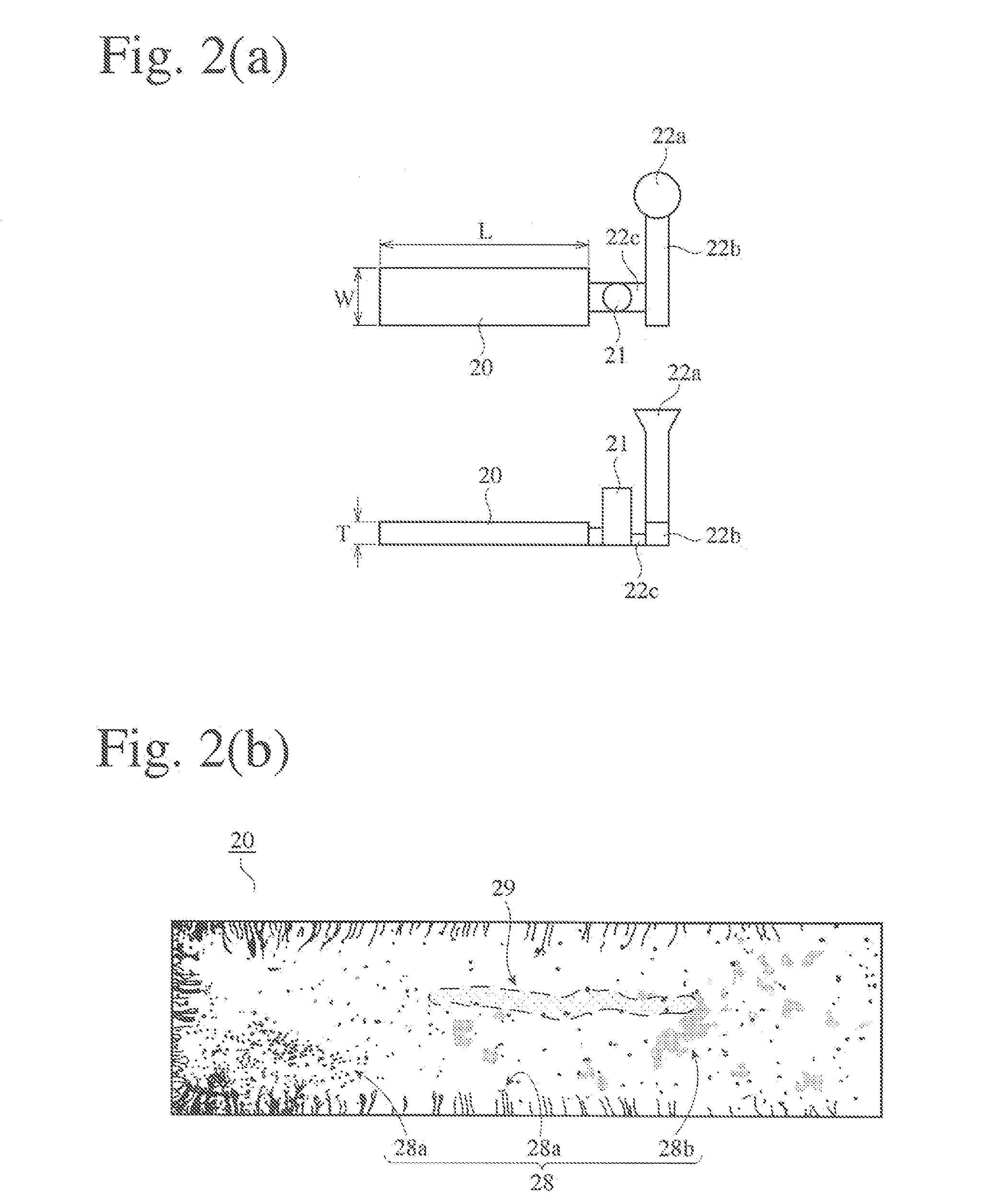

Extrusion casting method for aluminum alloy automobile speed changing box shell

ActiveCN102363211AImprove blank precisionSmall machining allowanceGearboxesThermal treatmentHardness

The invention discloses an extrusion casting method for an aluminum alloy automobile speed changing box shell. The method comprises the following steps of: preparing materials, smelting, preparing a die, performing extrusion casting and performing heat treatment. In the extrusion casting process, the manufactured aluminum alloy automobile speed changing box shell has higher tensile strength and yield strength and hardness by optimizing the design of aluminum alloy ingredients, process parameters of smelting and extrusion casting and a heat treatment system. By the extrusion casting method, the accuracy of blanks can be improved, machining allowance can be reduced, low consumption of resources and energy is realized, and the economic benefit is improved.

Owner:JIANGSU HIDA MARINE VALVE

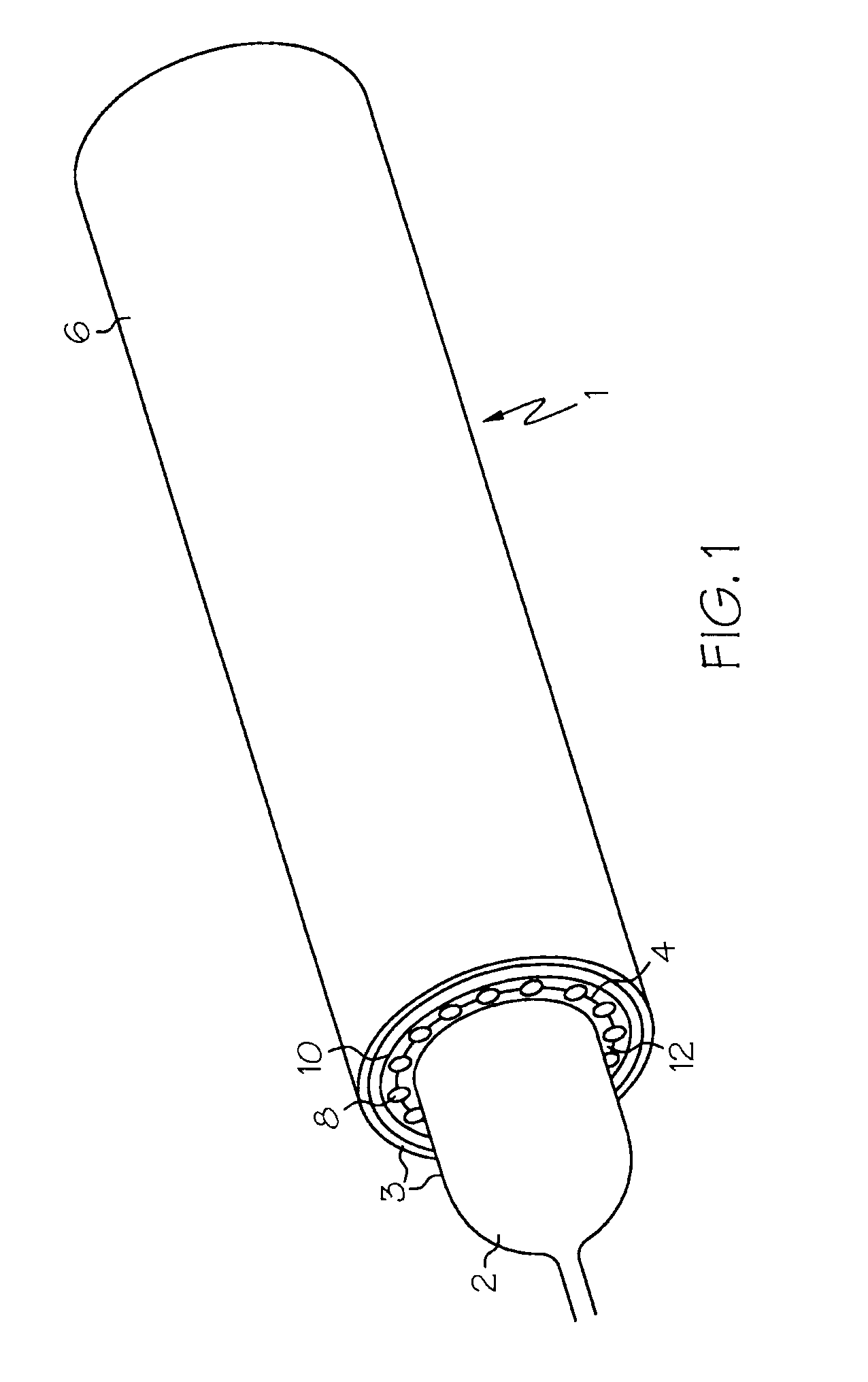

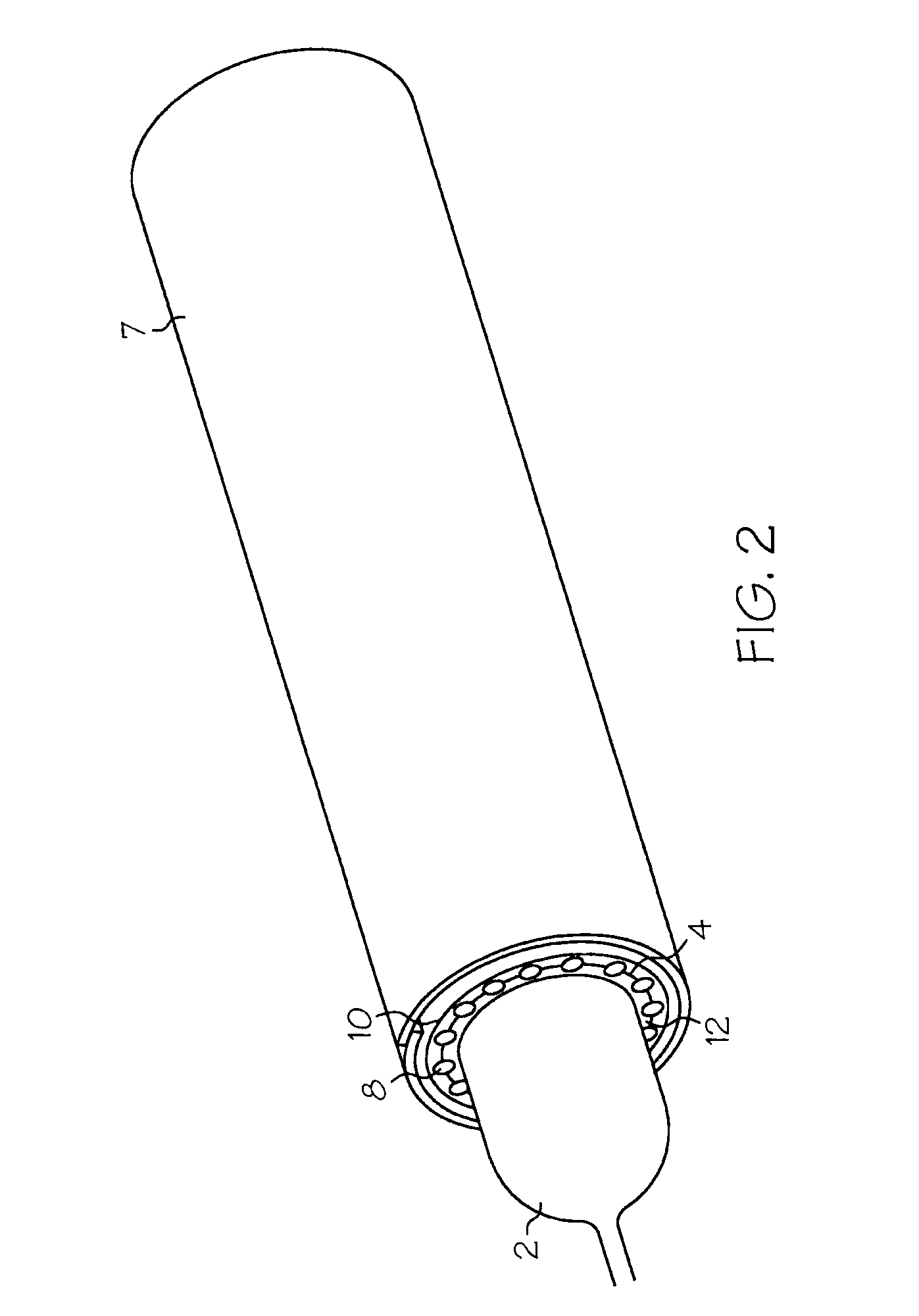

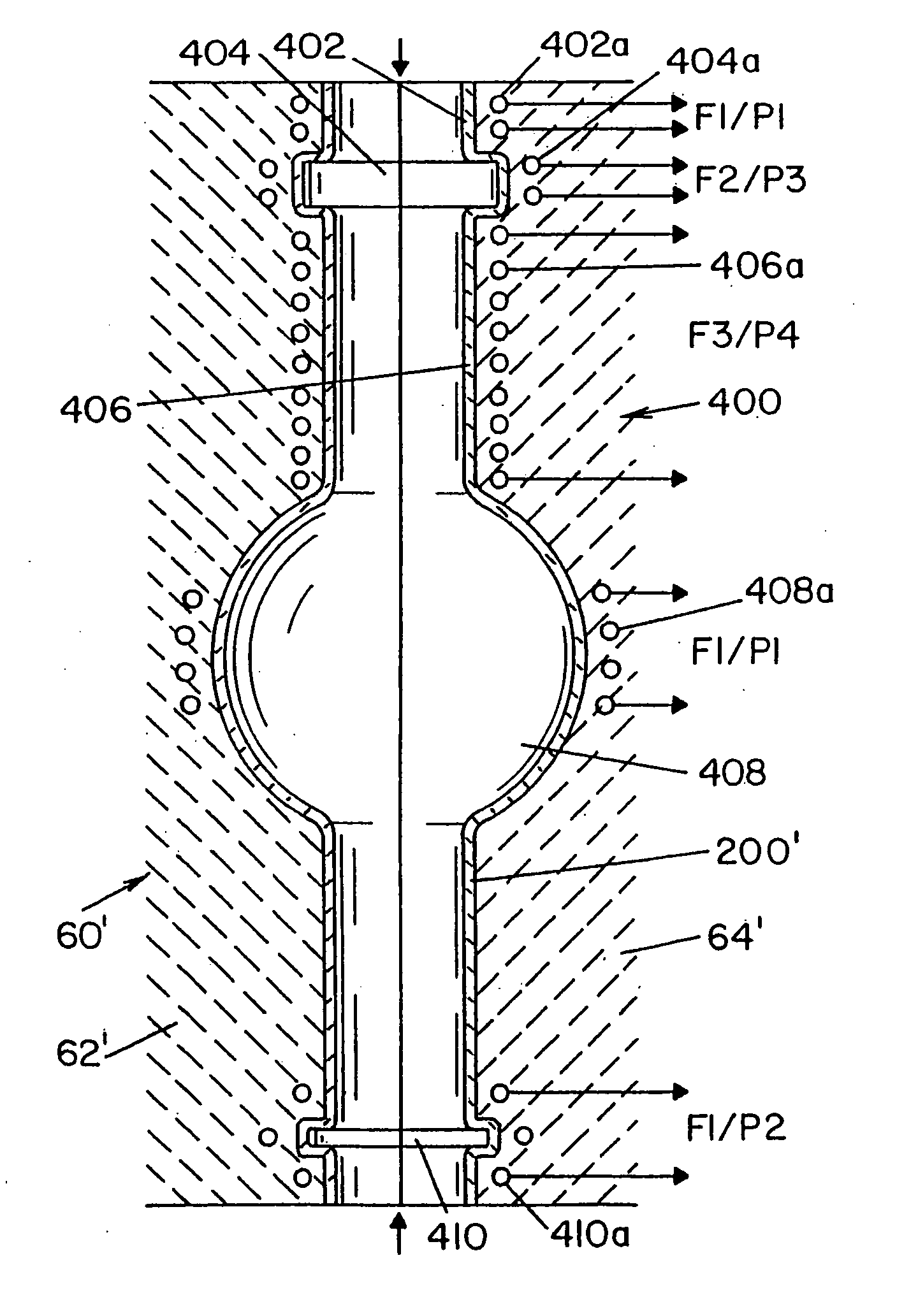

Medical device retaining sheath and medical device delivery system employing same

An endoluminal prosthetic delivery system provides a delivery sheath possessing a yield strength capable of allowing implantation of the prosthesis with increased efficiency. An endoluminal prosthesis is inserted in a body in a radially compressed condition, and expanded at an implantation site, whereby a delivery sheath or the prosthesis itself possesses a yield strength sufficient to allow radial expansion of the prosthesis. A method of implanting an endoluminal prosthesis is also herein provided.

Owner:BOSTON SCI SCIMED INC

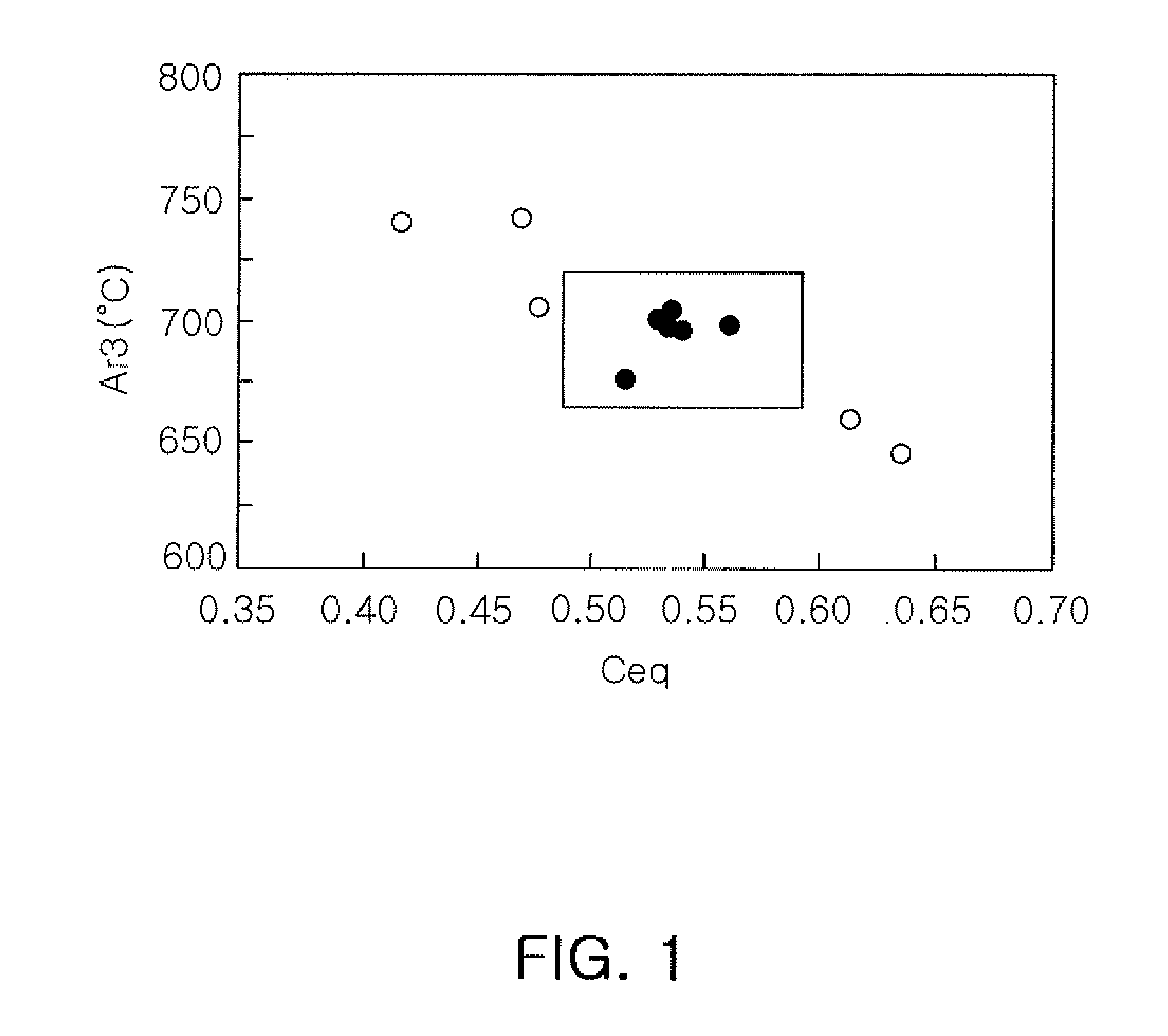

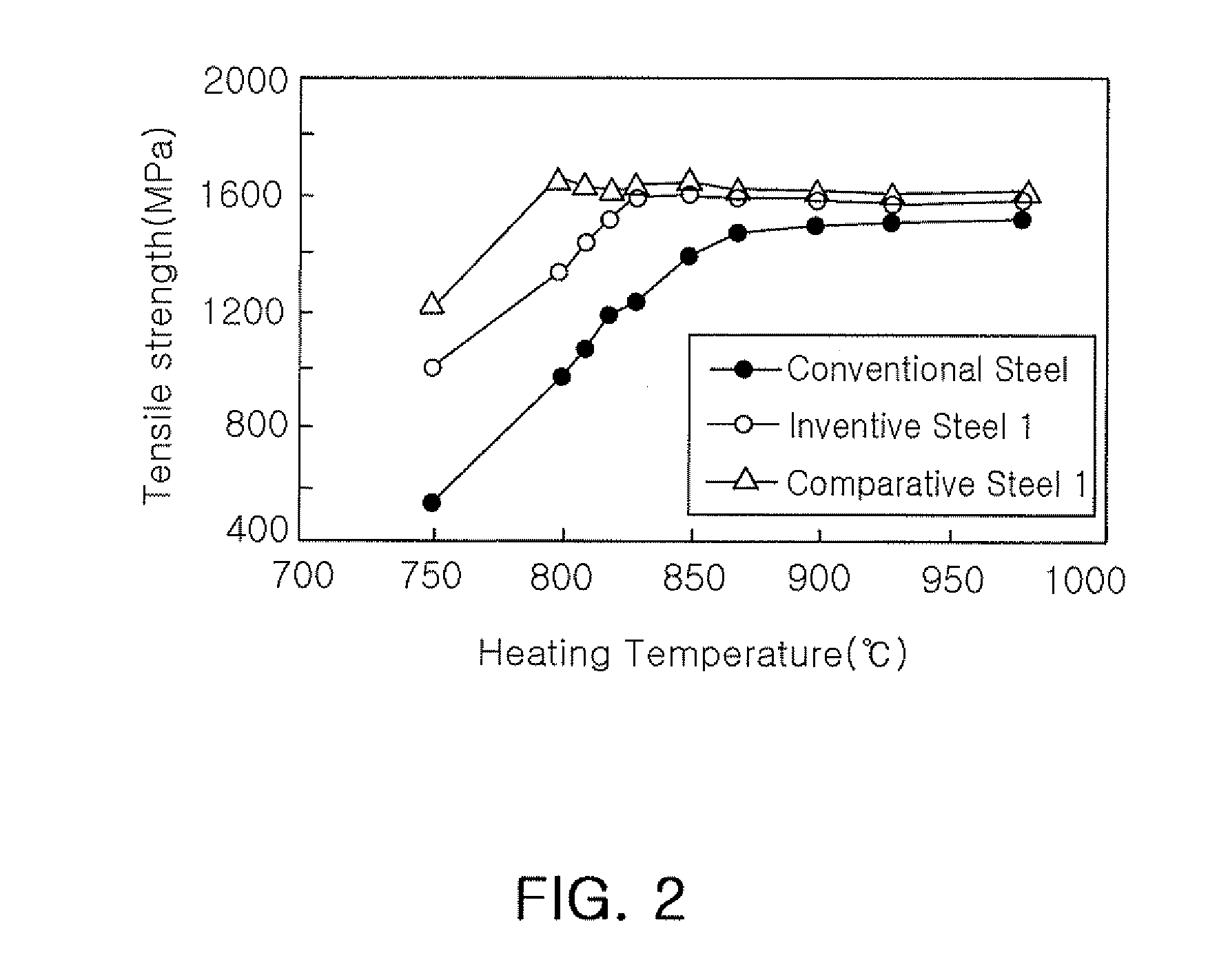

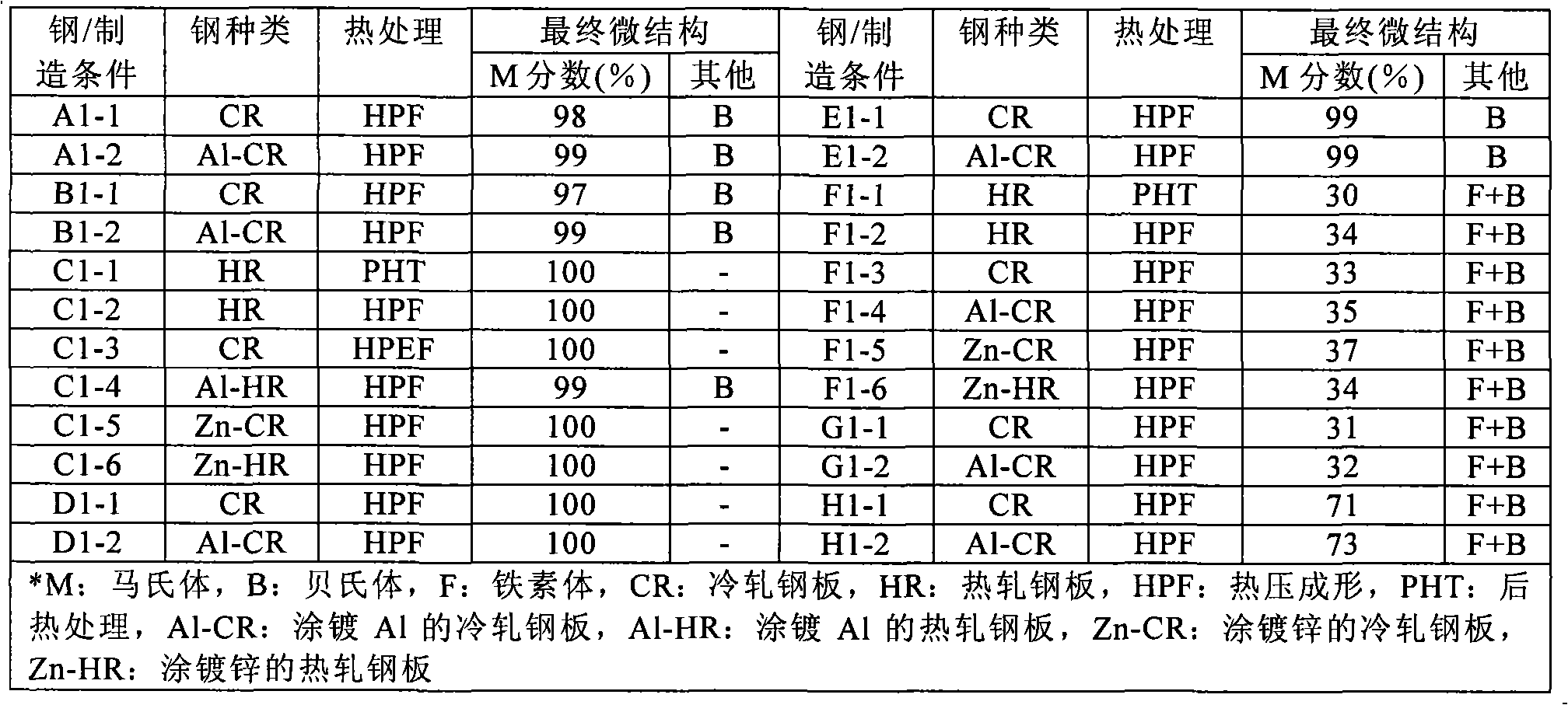

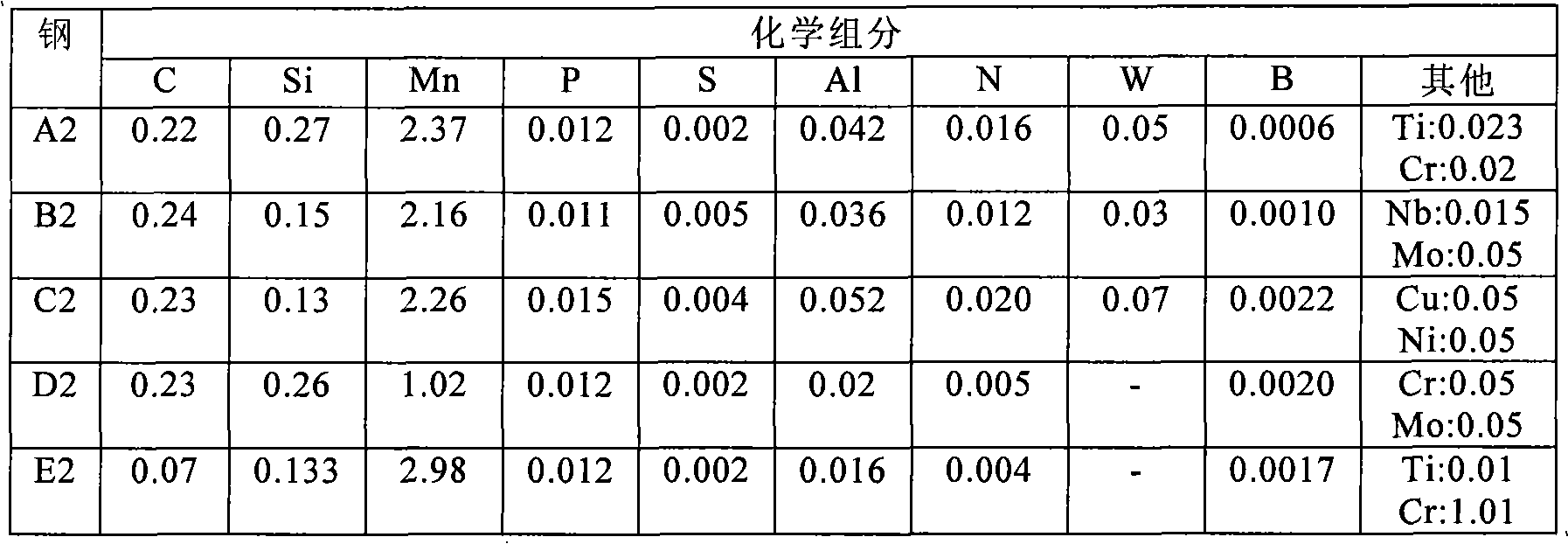

Steel sheet for hot press forming having low-temperature heat treatment property, method of manufacturing the same, method of manufacturing parts using the same, and parts manufactured by the same

ActiveUS20090238715A1Reduced strengthHigh yield strengthMetal rolling stand detailsFurnace typesManganeseHeat treated

A steel sheet for forming having low-temperature heat treatment property, in which heat treatment is performed within a range of lower temperature than a conventional steel sheet in the event of hot press forming or post-heat treatment after cold forming, a method of manufacturing the same, and a method of manufacturing parts using the same. The steel sheet has a composition of, by weight, carbon (C): 0.15 to 0.35%, silicon (Si): 0.5% or less, manganese (Mn): 1.5 to 2.2%, phosphorus (P): 0.025% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.01 to 0.05%, nitrogen (N): 50 to 200 ppm, titanium (Ti): 0.005 to 0.05%, tungsten (W): 0.005 to 0.1%, and boron (B): 1 to 50 ppm, wherein Ti / N: less than 3.4, where Ti / N is the atomic ratio of the corresponding elements, Ceq expressed by the following formula ranges from 0.48 to 0.58, and temperature Ar3 ranges from 670° C. to 725° C. Wherein Ceq=C+Si / 24+Mn / 6+Ni / 40+Cr / 5+V / 14 where C, Si, Mn, Ni, Cr and V indicate the contents (wt %) of the respective elements.

Owner:POHANG IRON & STEEL CO LTD

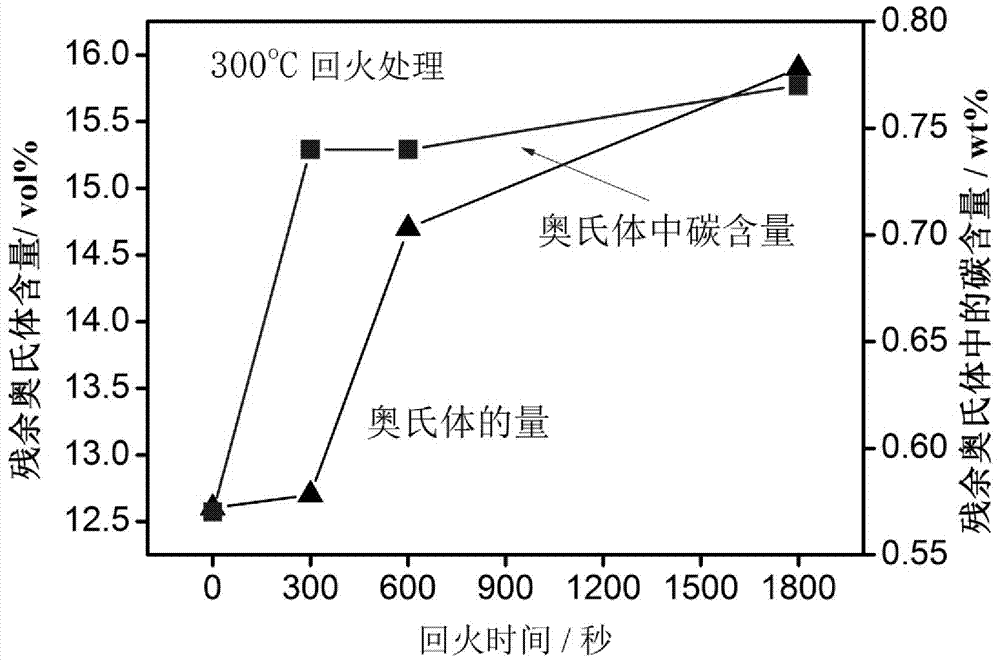

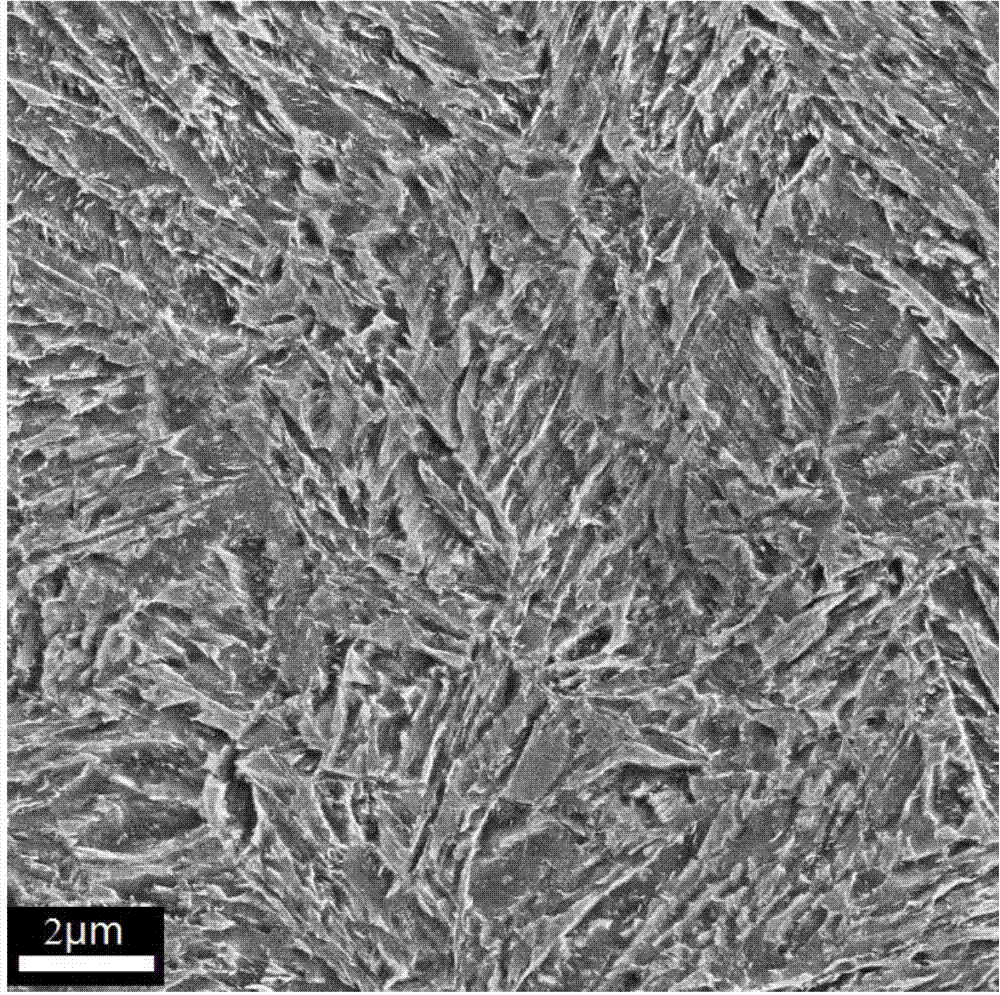

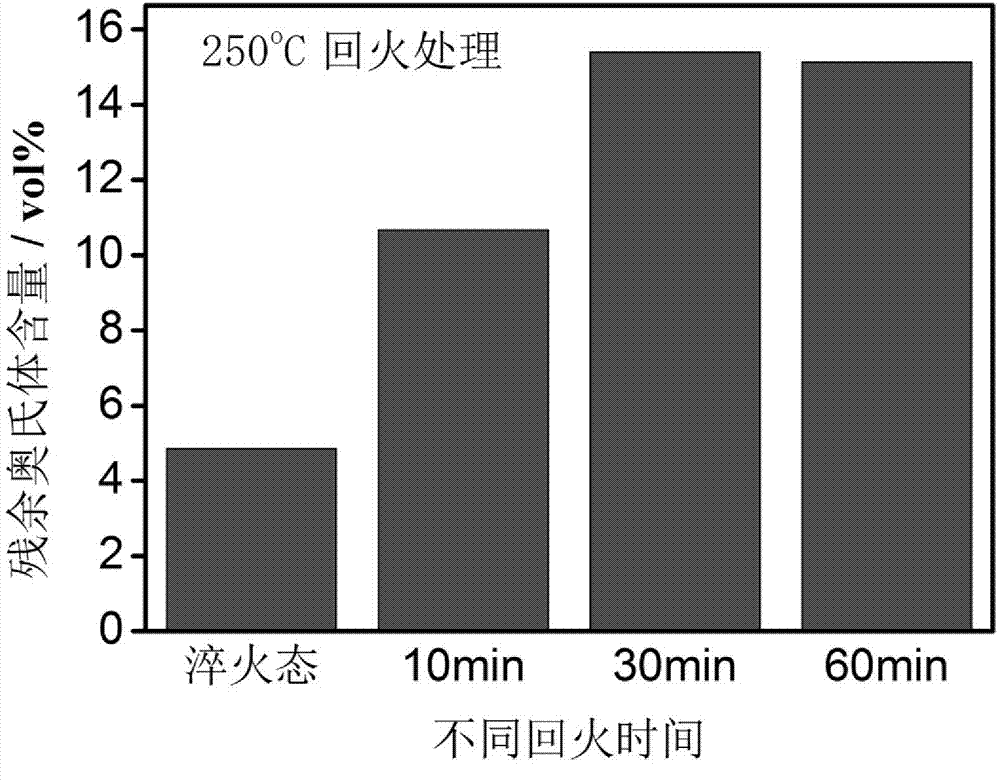

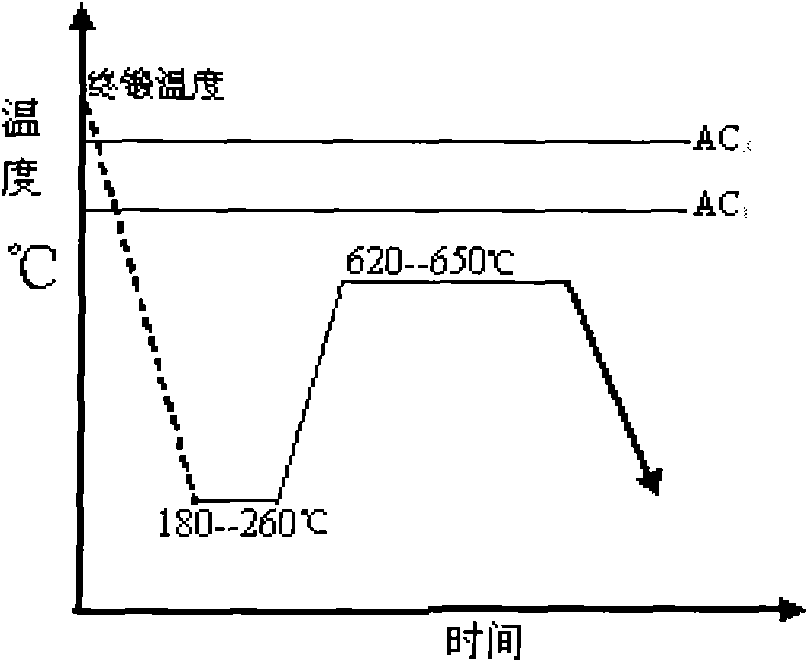

Steel plate for hot stamping, hot stamping process and hot-stamped member

ActiveCN104846274ALow austenitizing temperatureQuenching temperature is lowShaping toolsFurnace typesHot stampingMartensite transformation

The invention relates to a steel plate for hot stamping, a hot stamping process and a hot-stamped member. The steel plate for hot stamping is characterized by comprising, by weight, 0.18 to 0.42% of C, 4 to 8.5% of Mn and 0.8 to 3.0% of Si and Al, with the balance being Fe and avoidable impurities, wherein the alloy component of the steel plate satisfy the condition that the actual measured value of martensite phase transformation beginning temperature is no more than 280 DEG C. A manufacturing method for the hot-stamped member comprises the following steps: heating a material to 700 to 850 DEG C and carrying out stamping; then carrying out cooling in a die or air cooling or cooling in other manners to 150 to 260 DEG C below the martensite phase transformation beginning temperature; and heating the stamped member to 160 to 450 DEG C, maintaining the temperature for 1 to 100,000 s, carrying out tempering heat treatment and cooling the stamped member to room temperature. The hot-stamped member prepared in the invention has yield strength of no less than 1200 MPa, tensile strength of no less than 1600 MPa and total elongation percentage of no less than 10%.

Owner:EASYFORMING STEEL TECH CO LTD

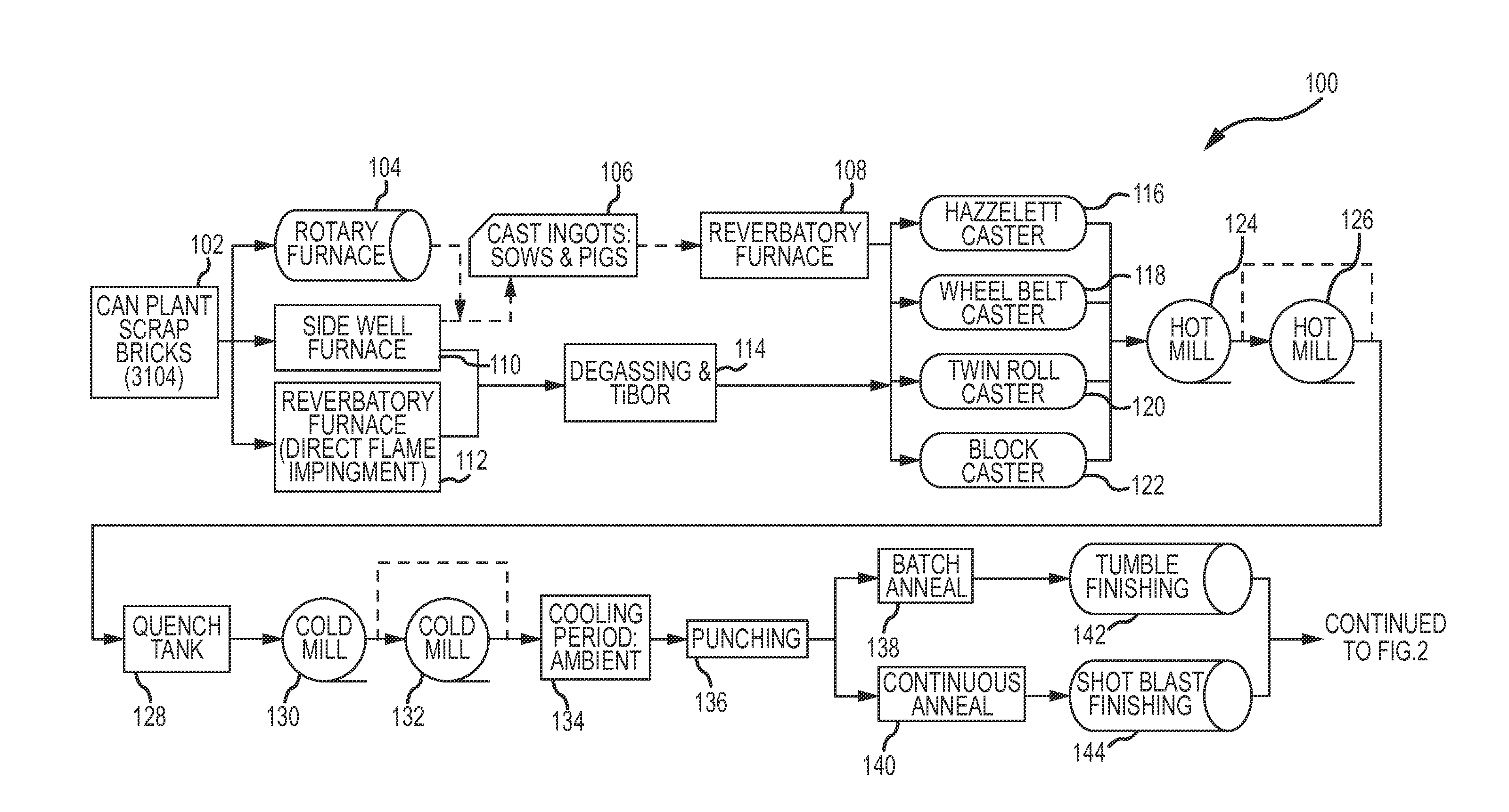

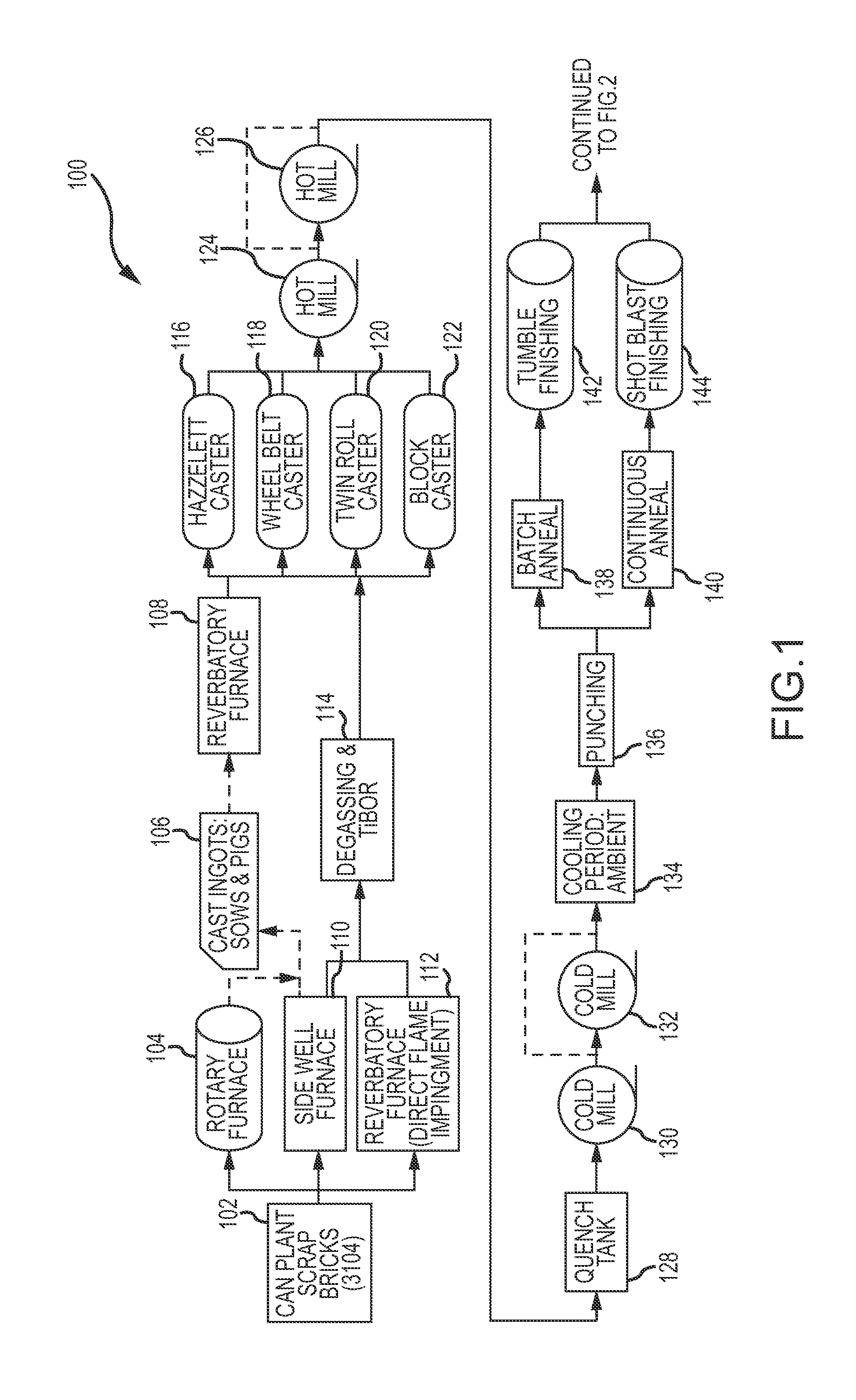

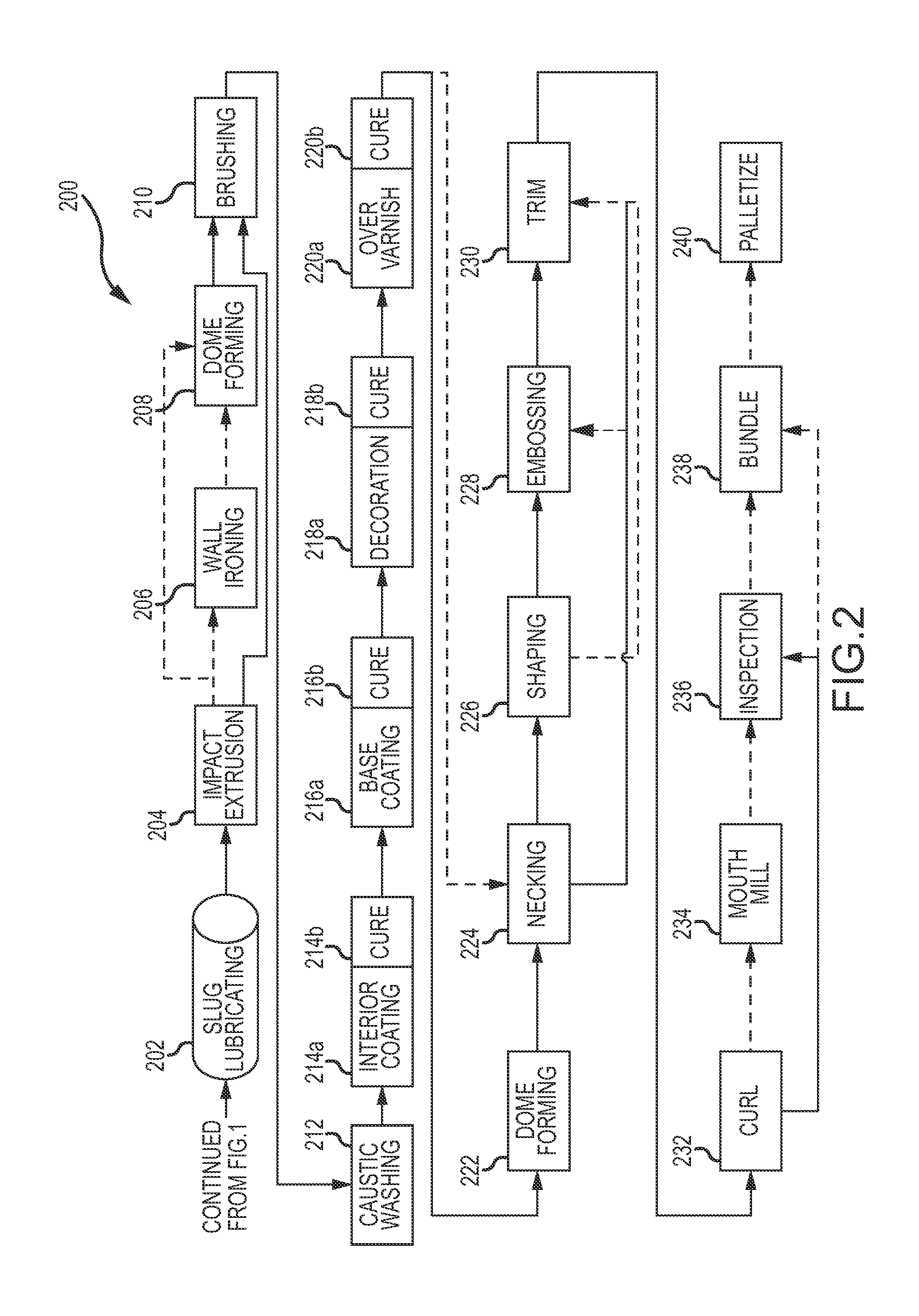

Impact extruded containers from recycled aluminum scrap

ActiveUS20130068352A1Increase resistanceReduction in weight and metal contentLiquid dispensingScrapEnvironmentally friendly

Novel aluminum alloys are provided for use in an impact extrusion manufacturing process to create shaped containers and other articles of manufacture. In one embodiment blends of recycled scrap aluminum are used in conjunction with relatively pure aluminum to create novel compositions which may be formed and shaped in an environmentally friendly process. Other embodiments include methods for manufacturing a slug material comprising recycled aluminum for use in the impact extraction process.

Owner:BALL CORP

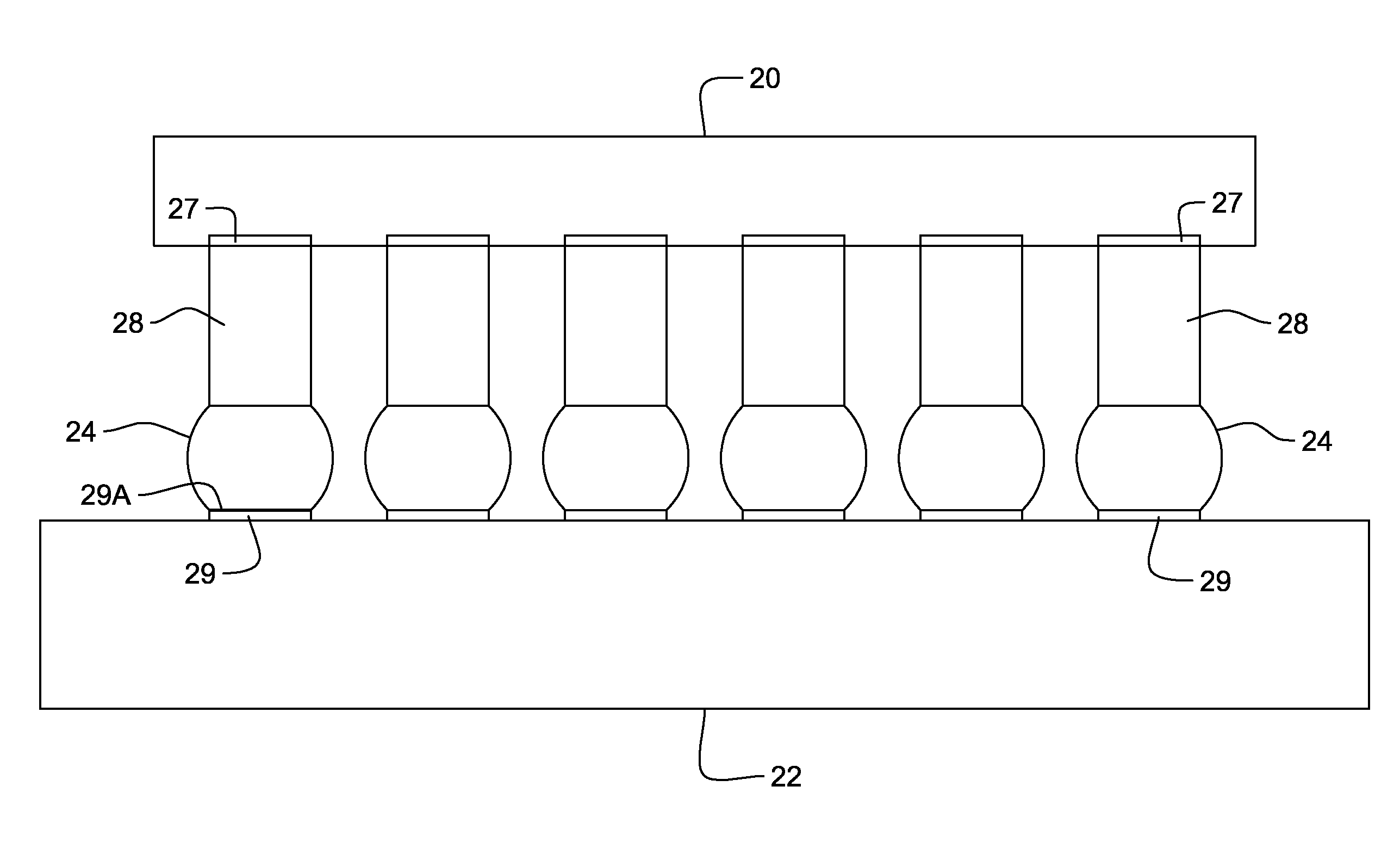

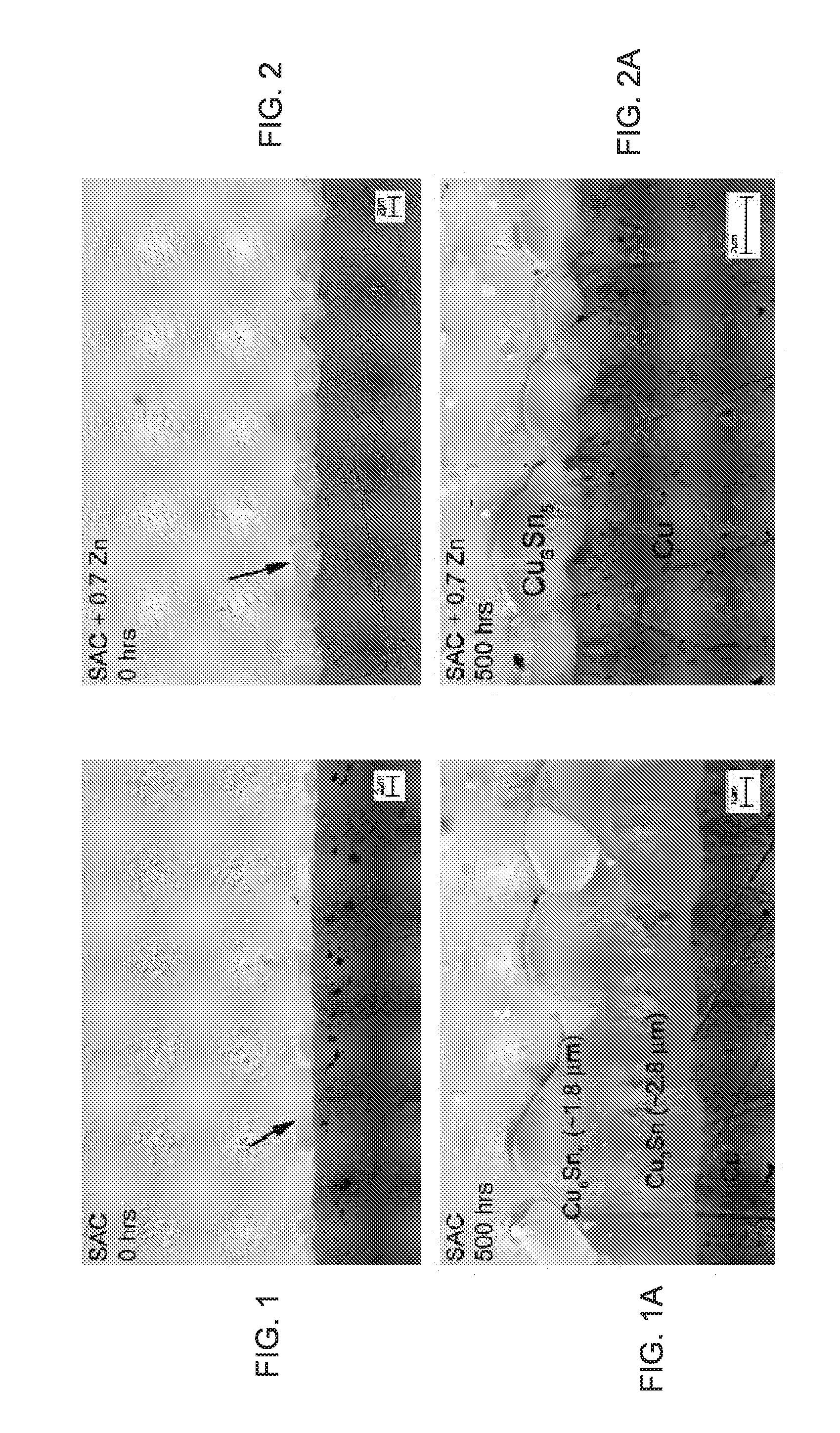

Modification of pb-free solder alloy compositions to improve interlayer dielectric delamination in silicon devices and electromigration resistance in solder joints

InactiveUS20090197114A1Good mechanical integrityImprove reliabilitySolid-state devicesPrinted circuit manufactureDielectricSilicon

A solder joint comprising a solder capture pad on a substrate having a circuit; and a lead free solder selected from the group comprising Sn—Ag—Cu solder and Sn—Ag solder adhered to the solder capture pad; the solder selected from the group comprising between 0.1 to 2.0% by weight Sb or Bi, and 0.5 to 3.0% Ag. Formation of voids at an interface between the solder and the solder capture pad is suppressed, by including Zn. Interlayer dielectric delamination is suppressed, and electromigration characteristics are greatly improved. Methods for forming solder joints using the solders.

Owner:SHIH YUAN +5

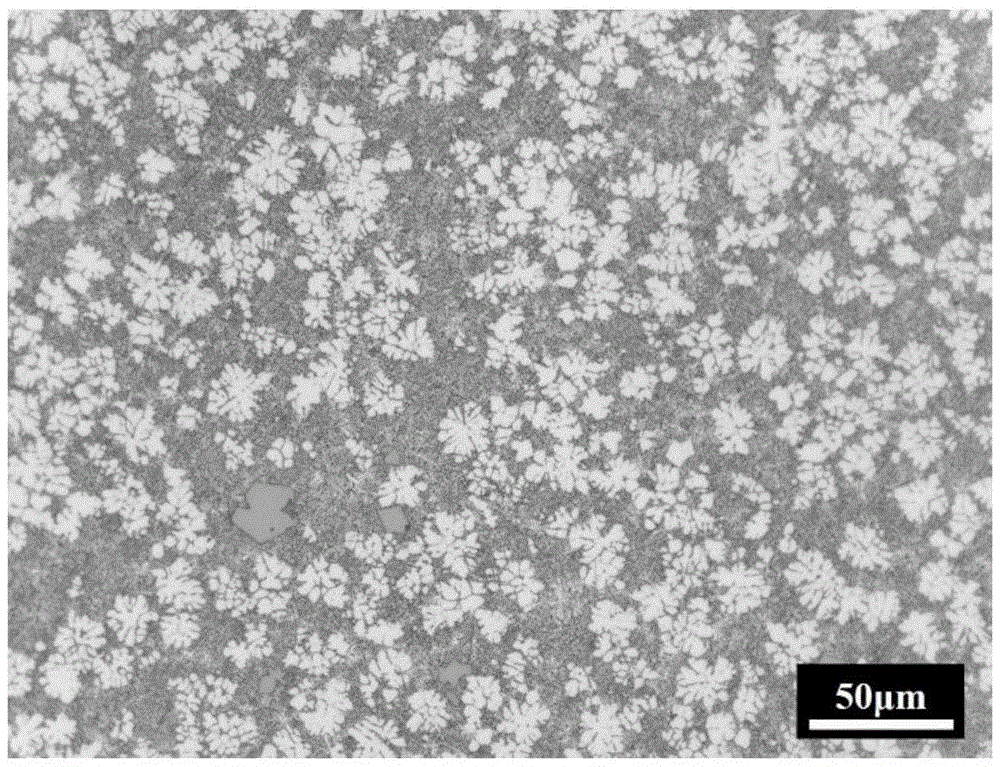

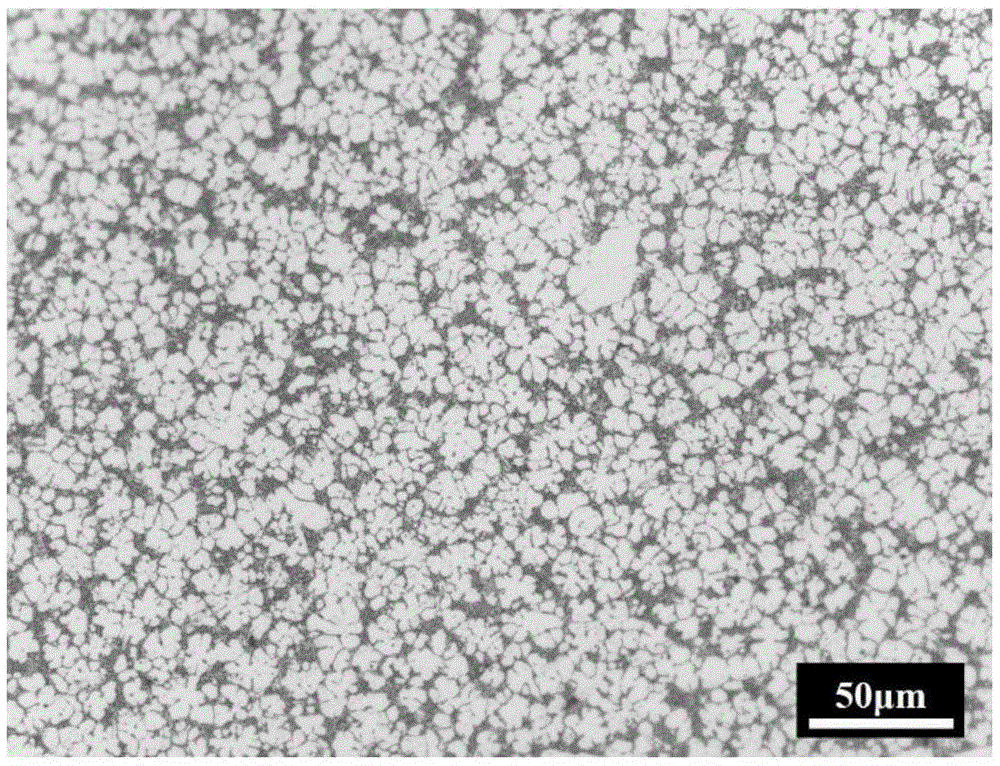

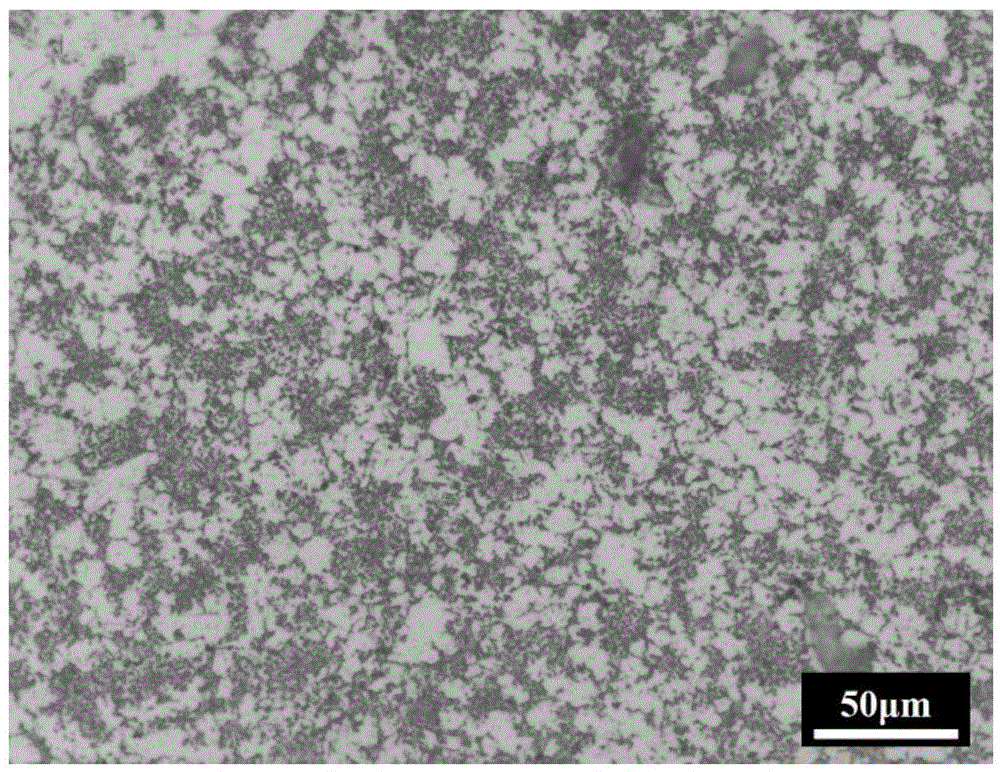

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

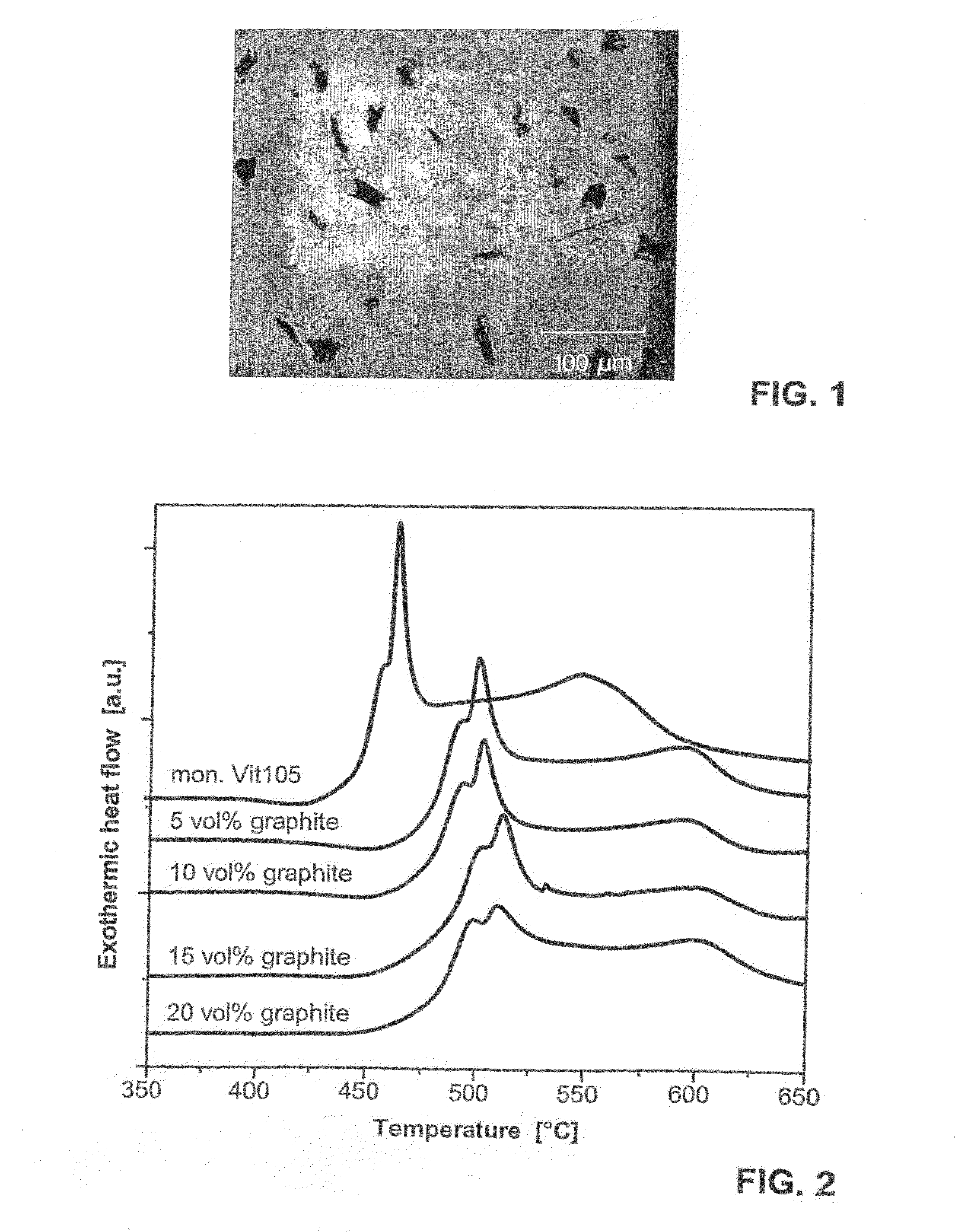

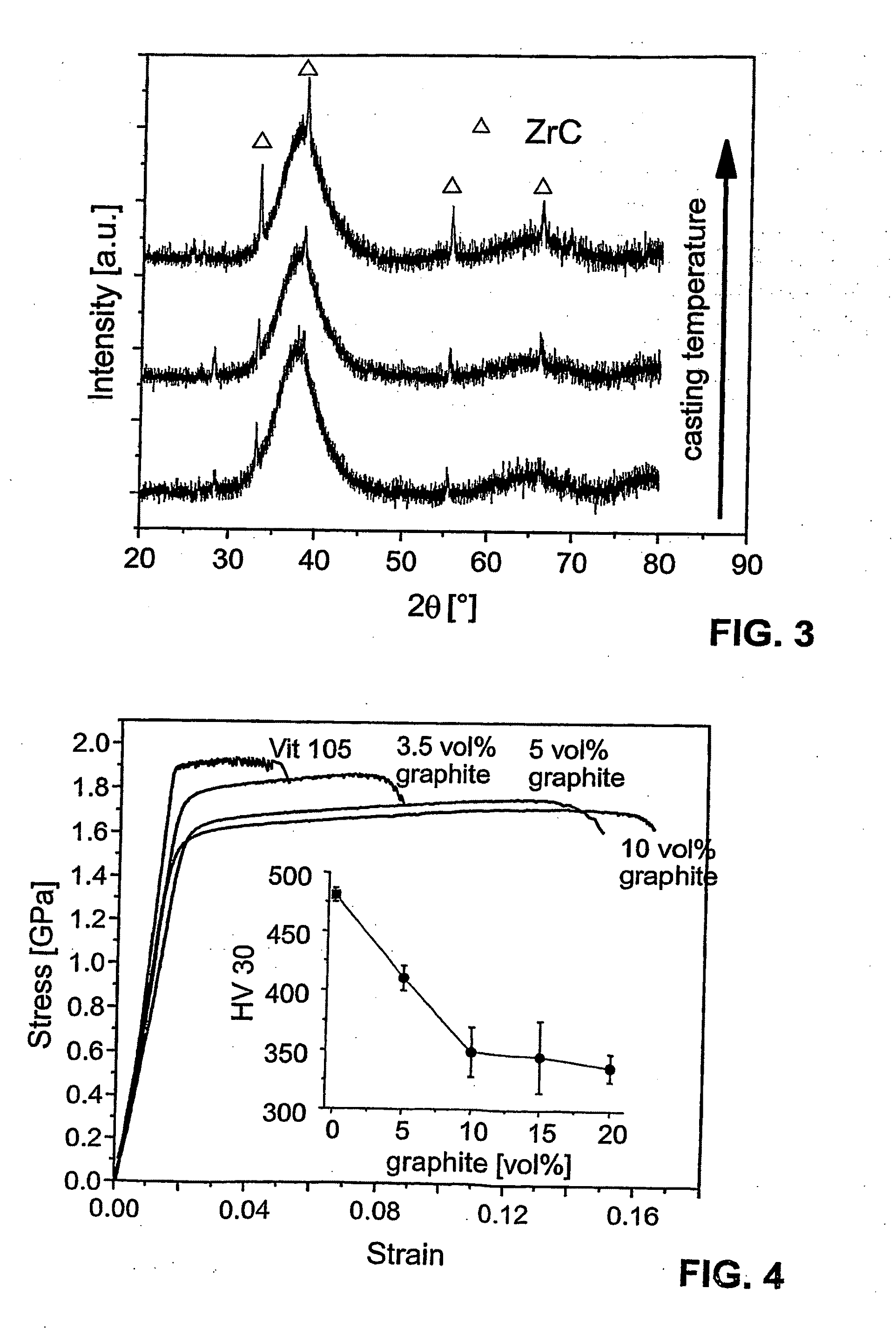

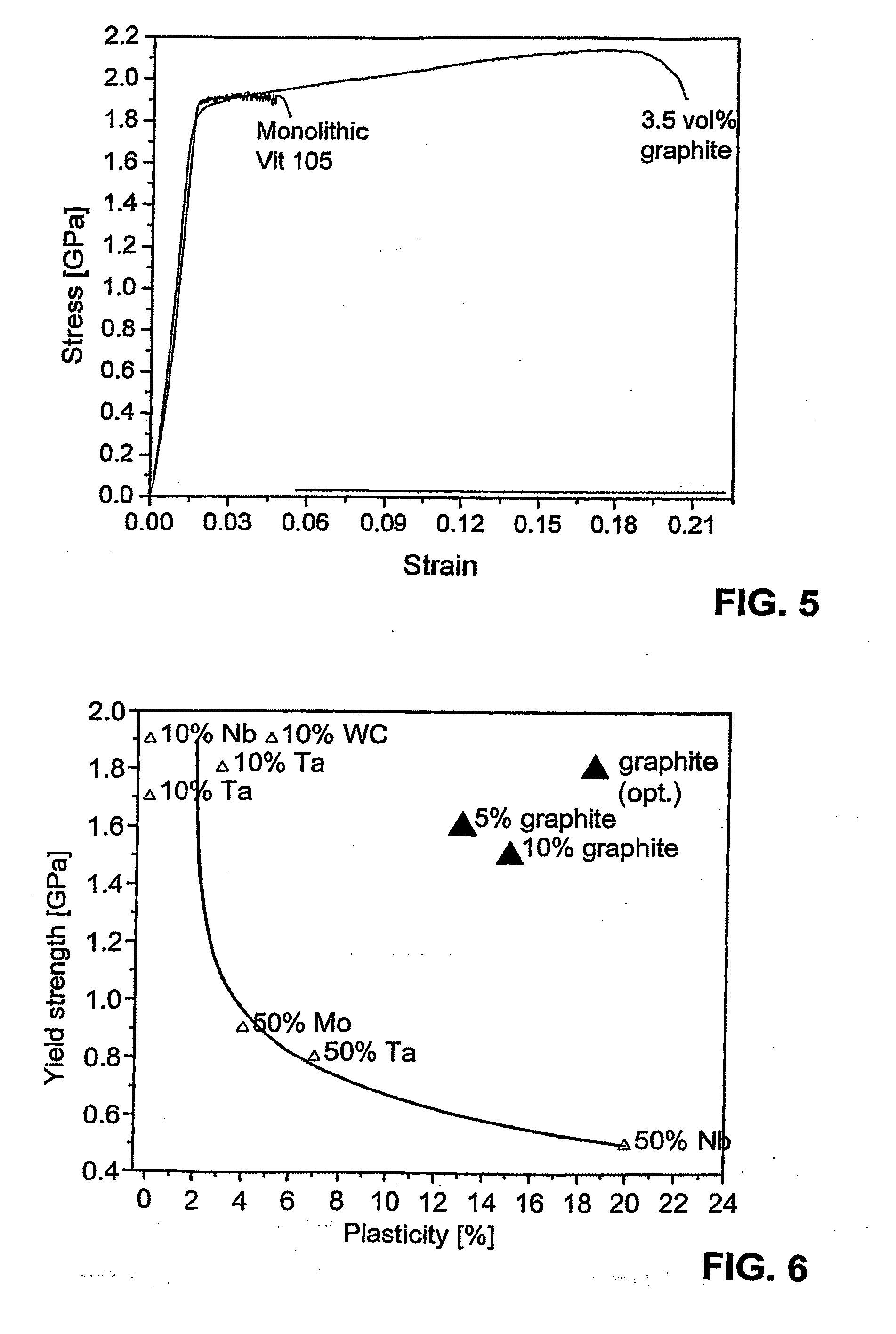

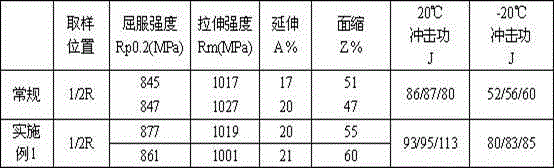

Bulk Metallic Glass/Graphite Composites

A composite material based on a bulk metallic glass is disclosed. In an amorphous alloy phase forming a substantially continuous matrix, a second phase comprising graphite particles is embedded. The alloy is preferably zirconium based. The particles may have a carbide surface layer, which may be formed phase comprising carbide particles may also be present. The composite material has high plasticity, high yield strength, good elasticity and low coefficient of friction, which renders it a good candidate for applications like joints, frictional bearings or Springs.

Owner:ETH ZZURICH

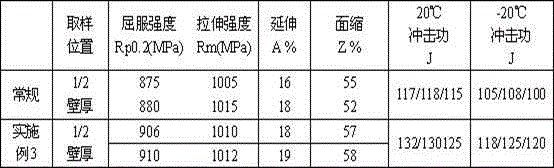

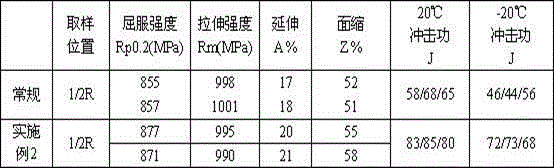

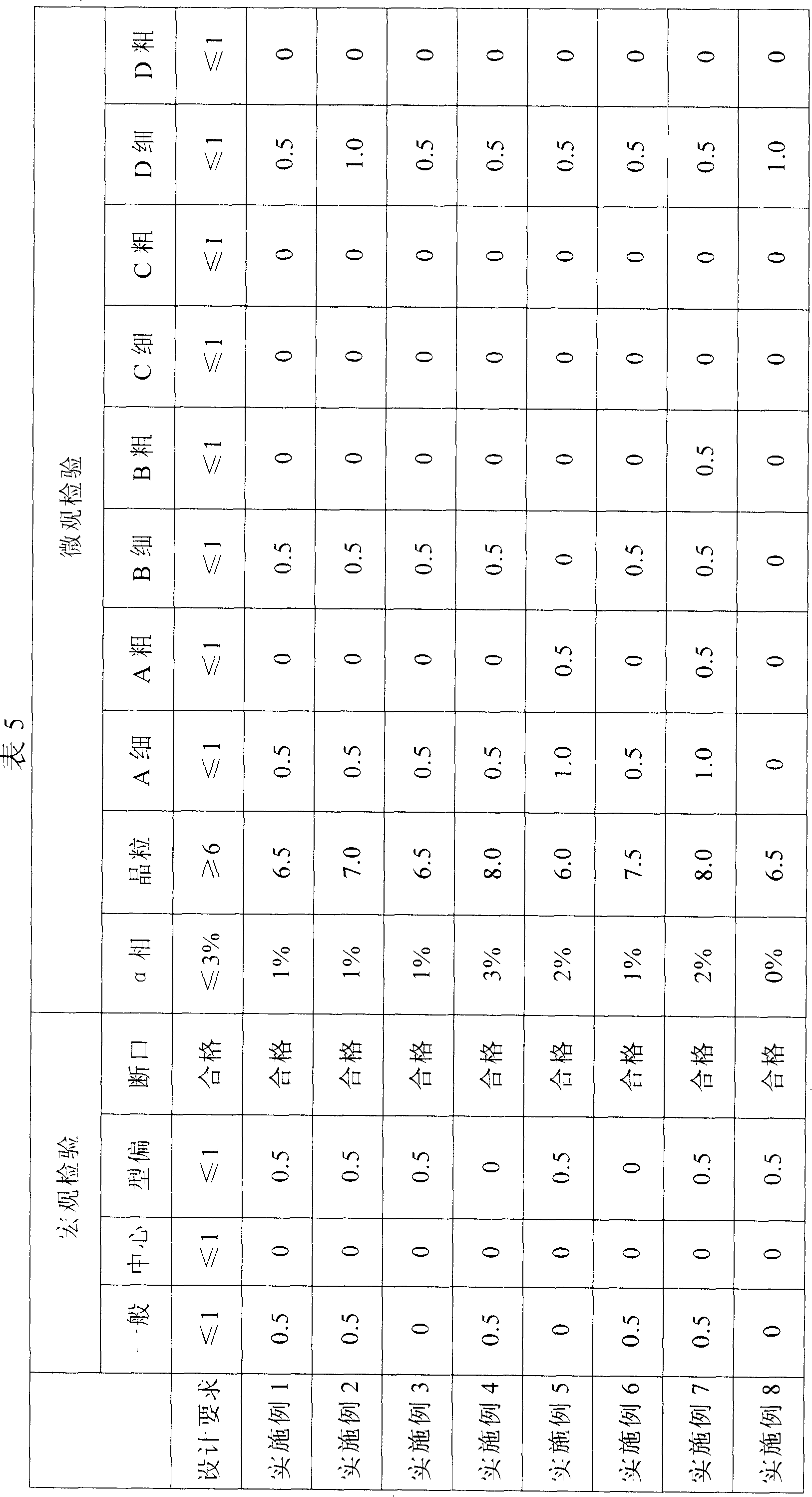

High-toughness medium-carbon quenched and tempered round steel of grade 120 KSI and manufacturing method thereof

The invention discloses high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI. The high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI comprises, by mass, 0.35%-0.50% of C, 0.15%-0.40% of Si, 0.60%-1.30% of Mn, equal to or less than 0.015% of P, equal to or less than 0.040% of S, 0.75%-1.30% of Cr, 0.15%-0.35% of Mo, equal to or less than 0.25% of Ni, equal to or less than 0.25% of Cu, 0.015%-0.040% of Alt, equal to or less than 0.10% of V, equal to or less than 0.10% of Nb, equal to or less than 0.05% of Ti, equal to or less than 0.008% of N, equal to or less than 0.0010% of B and the balance Fe and unavoidable impurity elements, wherein the content of V, the content of Nb and the content of Ti are not equal to or less than 0.010% at the same time. The round steel with the maximum specification reaching 260 mm is manufactured through Kanbara reactor (KR) pretreatment, basic oxygen furnace (BOF) smelting, ladle furnace (LF) refining, Ruhrstahl Heraeus (RH) vacuum degassing, continuous casting, heating, continuous rolling, and hardening and tempering, so that the requirements for high specifications and toughness are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

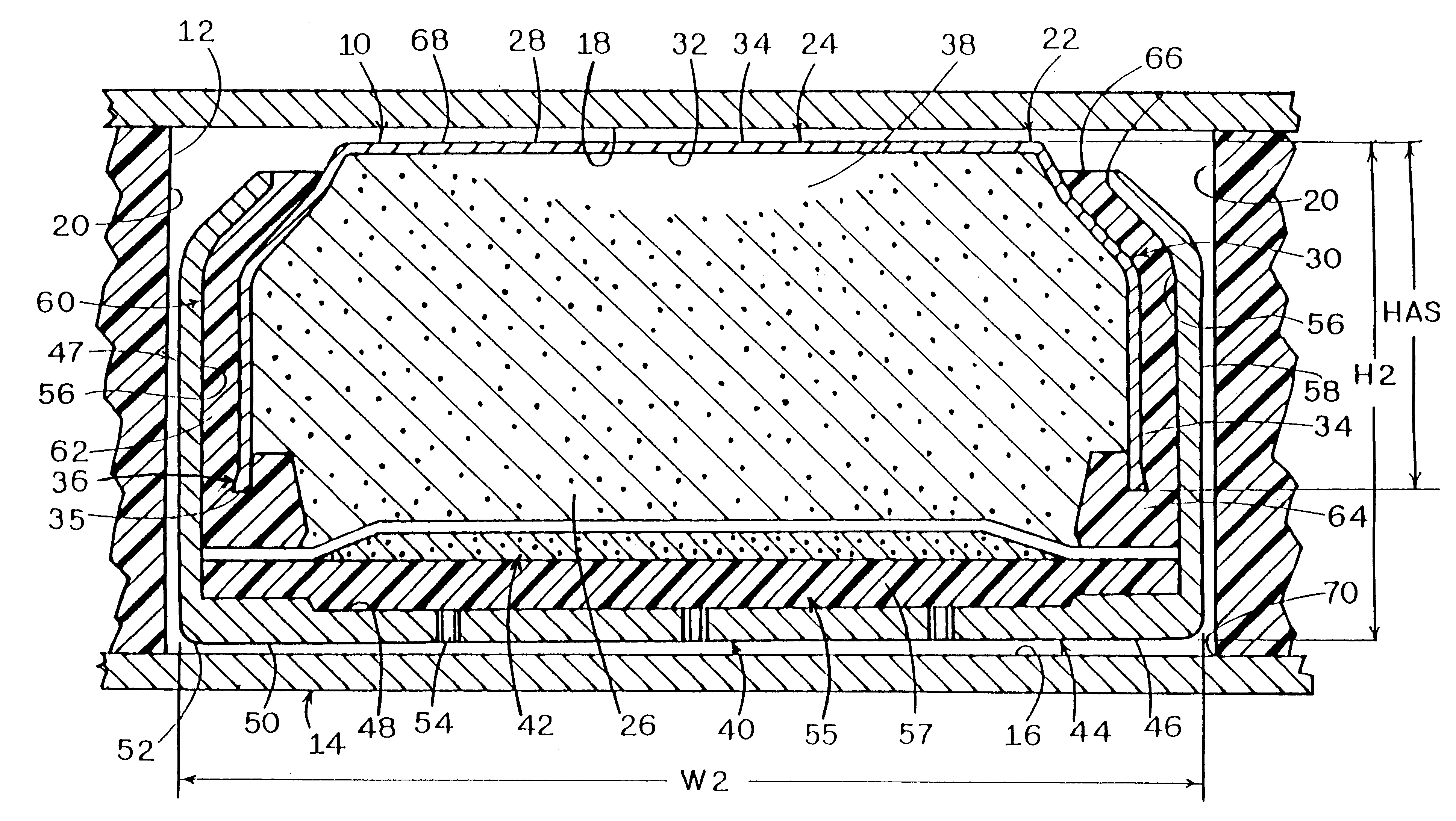

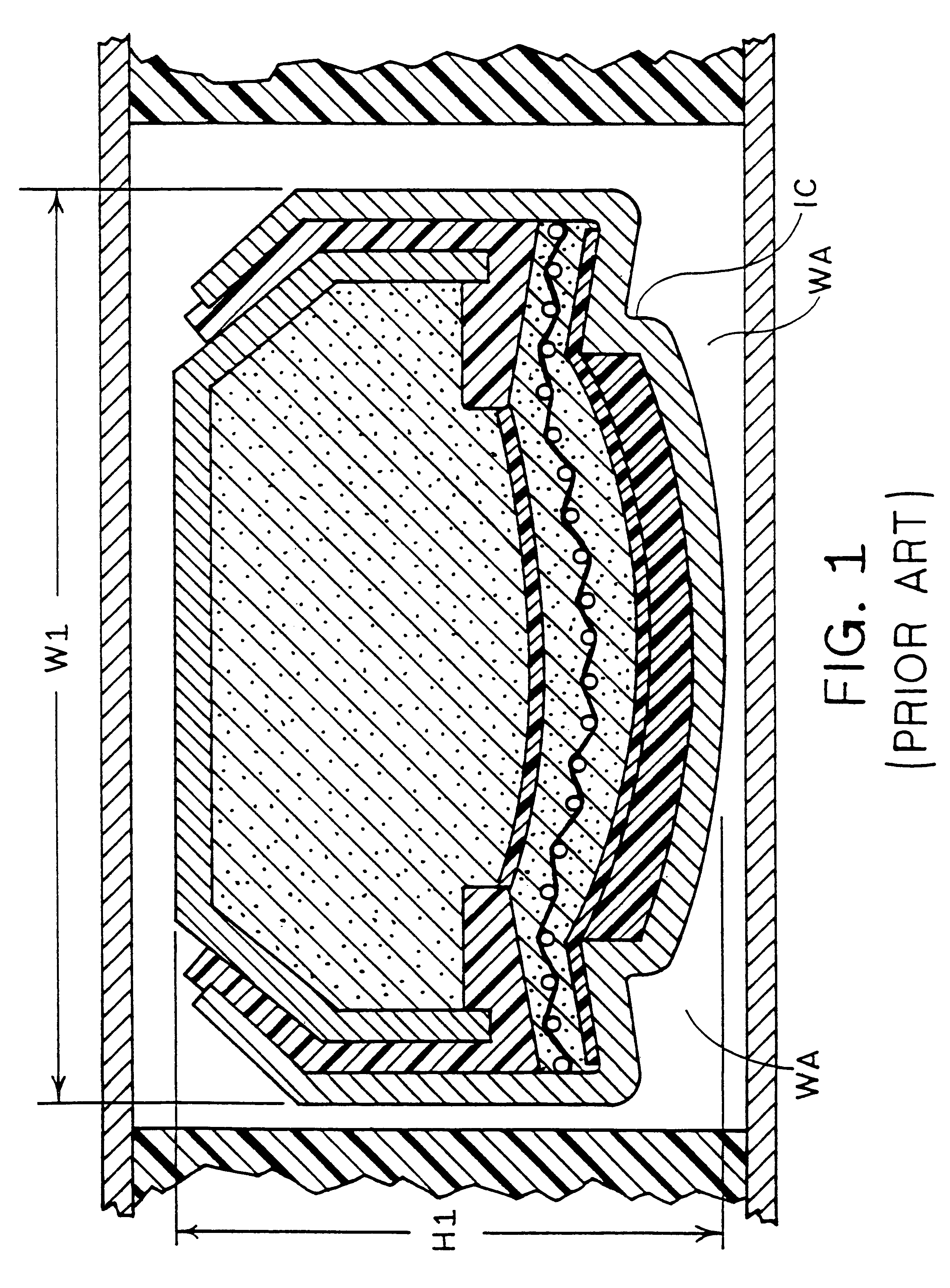

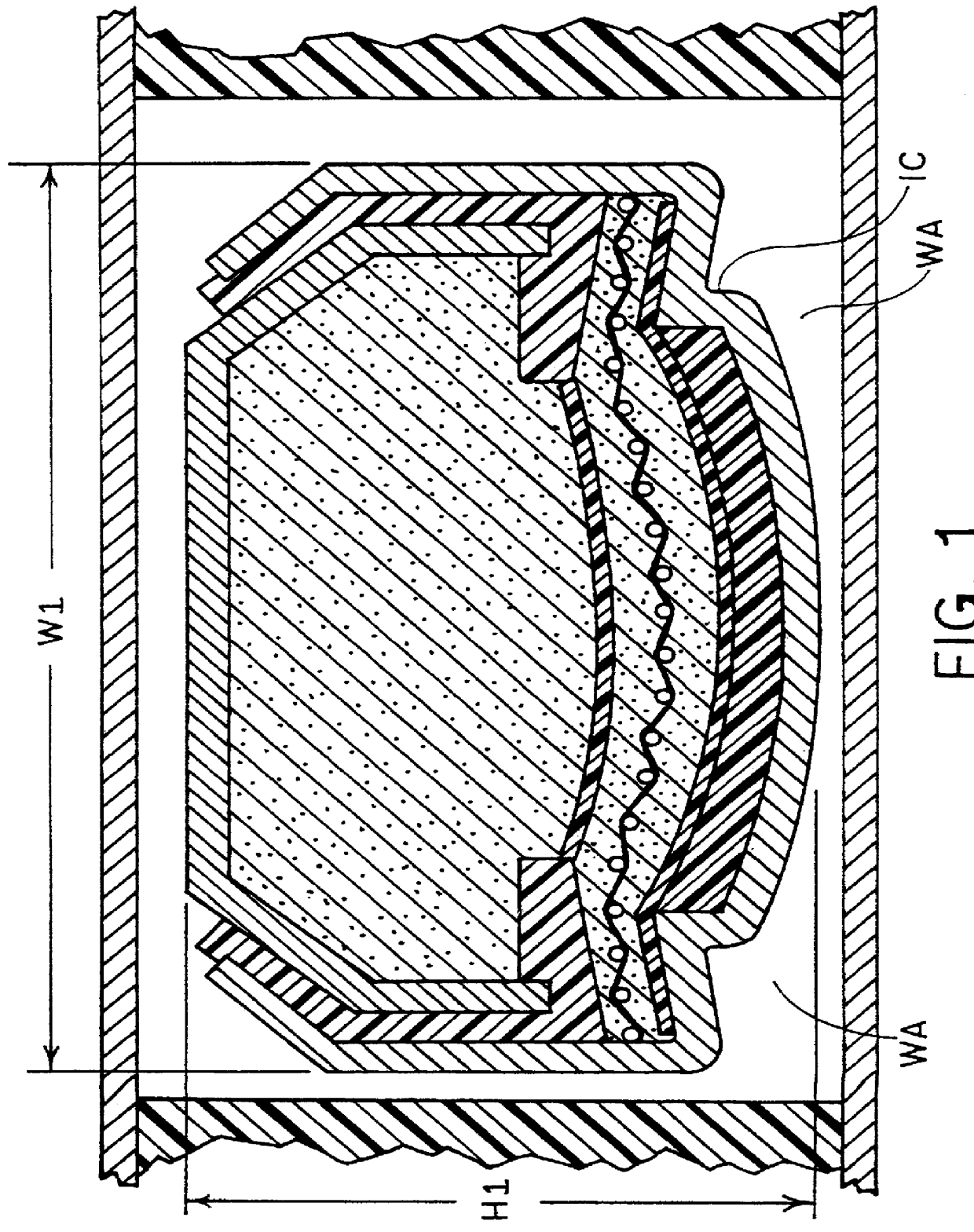

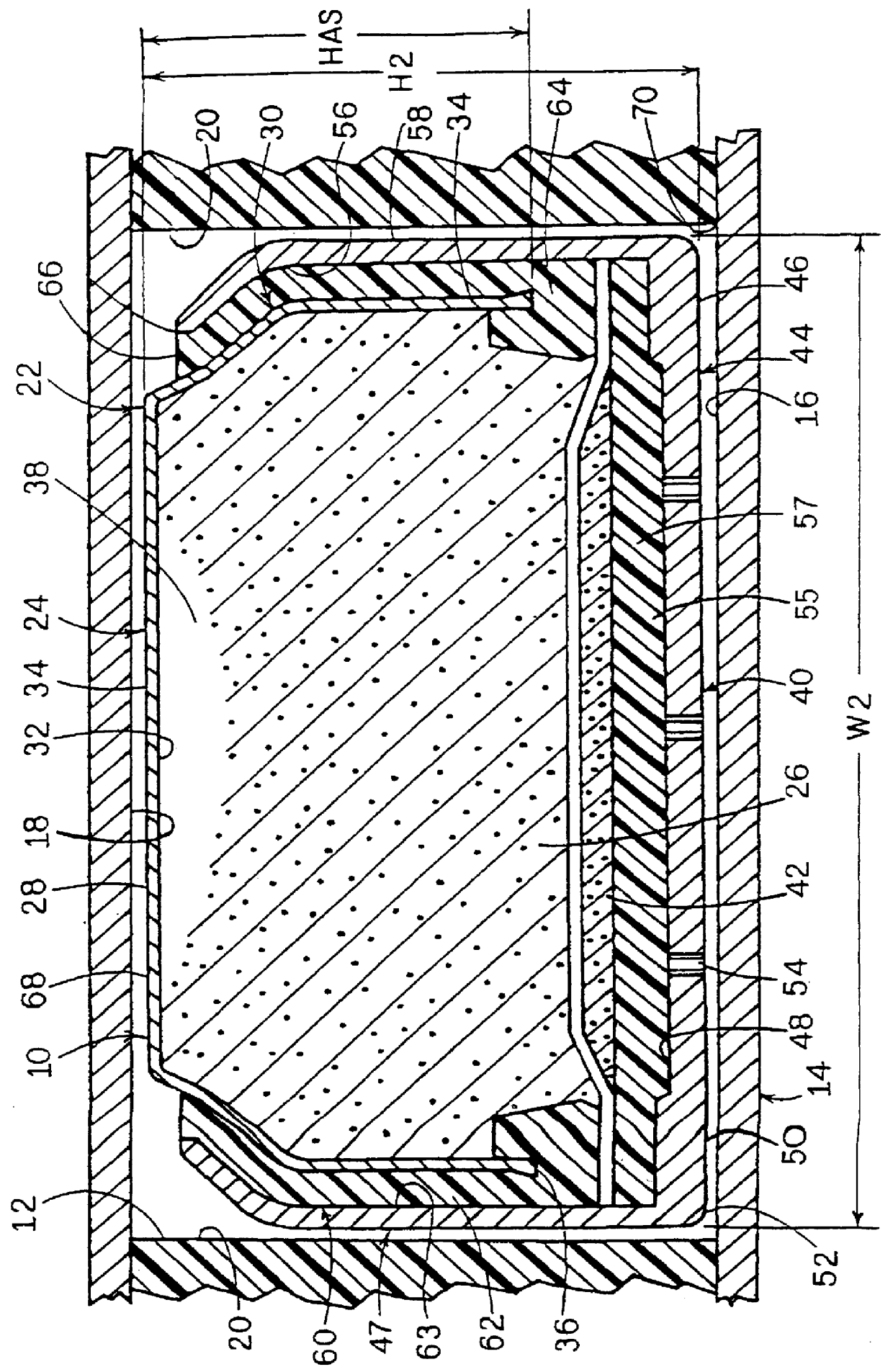

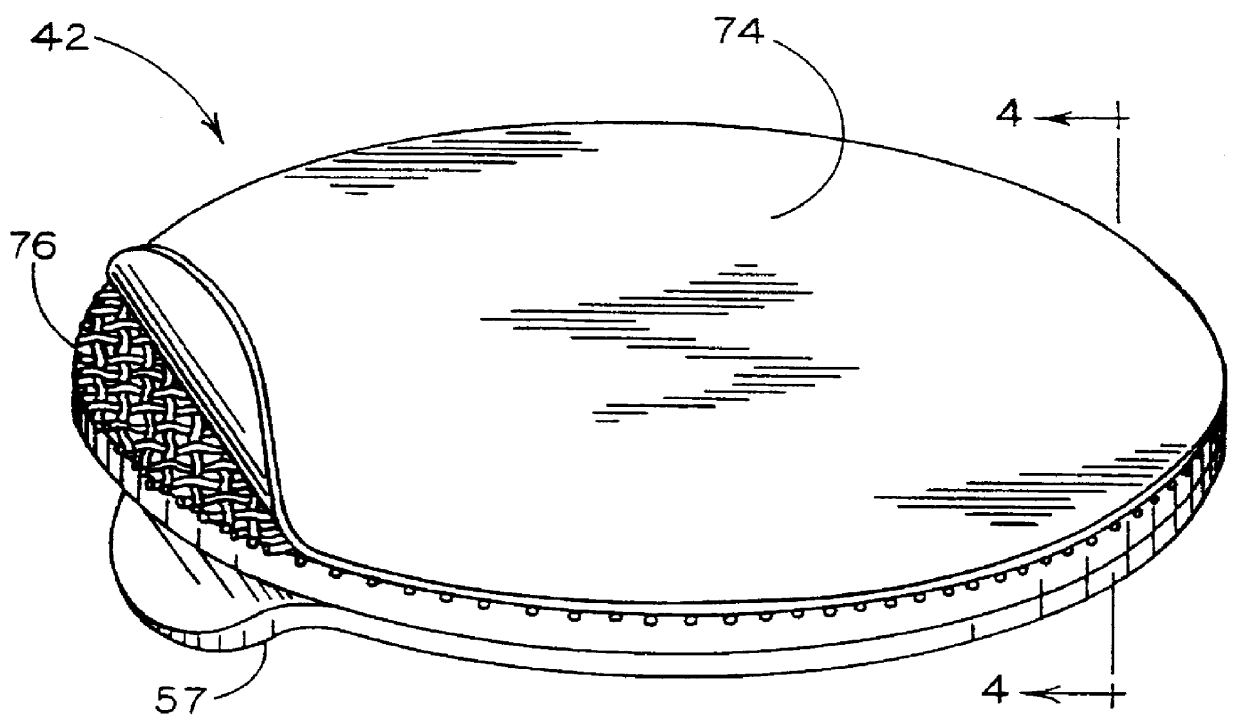

Electrochemical cells and components thereof

InactiveUS6245452B1Efficient fillingVolume maximizationFuel and primary cellsJackets/cases materialsElectrochemical responseElectrochemical cell

This invention pertains to electrochemical cells, typically to air depolarized cells of the button-type. Non-reactive elements of cells of the invention are thinner than corresponding non-reactive elements of prior art cells. Such elements can be made thinner because of improved structures of such elements. The anode can is made from a metal strip structure having a higher steel content. The cathode can preferably has improved stiffness and rigidity while retaining sufficient ductility to tolerate forming the cathode can. By so reducing the thicknesses of non-reactive elements of the cell, and thus the volume occupied by such non-reactive elements, the fraction of the cell devoted to holding electrochemically reactive anode material therein is increased, with corresponding increase in the milliampere hour capacity of the cell.

Owner:ROVCAL +1

High-strength high-corrosion-resistance cast aluminum alloy and gravity casting manufacturing method thereof

The invention provides high-strength high-corrosion-resistance cast aluminum alloy and a gravity casting manufacturing method of the high-strength high-corrosion-resistance cast aluminum alloy. The alloy is composed of Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al according to certain weight percentages, wherein the M is at least one of Ti, Zr and V or the RE element is added to the M. The cast aluminum alloy has the excellent cast performance and good mechanical property. The tensile strength, the yield strength and elongation are improved, good corrosion resistance is achieved, the aluminum alloy can be applied to automobile parts without solid solution heat treatment, and the requirement of low-weight development of automobiles is met.

Owner:SHANGHAI JIAO TONG UNIV

Steel sheet for hot press forming having excellent heat treatment and impact property, hot press parts made of it and the method for manufacturing thereof

Disclosed is a steel sheet that exhibits an ultra-high strength after hot press forming followed by rapid cooling, and an enhanced yield strength after painting. The steel sheet has a composition comprising 0.1% to 0.5% by weight of C, 0.01% to 1.0% by weight of Si, 0.5% to 4.0% by weight of Mn, 0.1 % by weight or less of P, 0.03% by weight or less of S, 0.1 % by weight of soluble Al, 0.01% to 0.1% by weight of N, 0.3% by weight or less of W, and the balance Fe and other inevitable impurities. Further disclosed are a hot-pressed part made of the steel sheet and a method for manufacturing the hot-pressed part. The hot-pressed part achieves a high increment in yield strength after heat treatment for painting while ensuring an ultra-high tensile strength. Furthermore, the hot-pressed part exhibits superior adhesion to a coatinglayer, good surface appearance and improved corrosion resistance after painting.

Owner:POHANG IRON & STEEL CO LTD

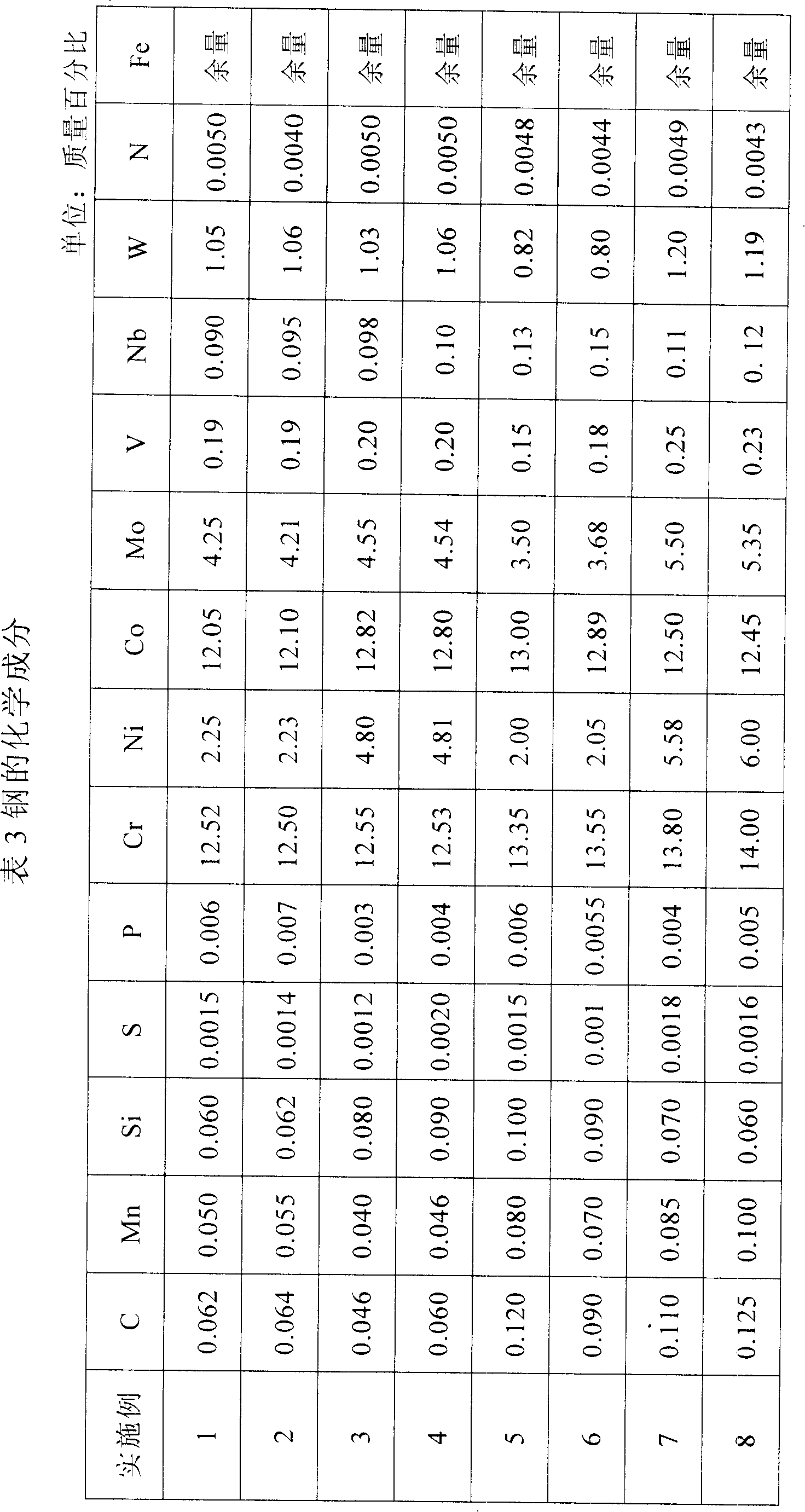

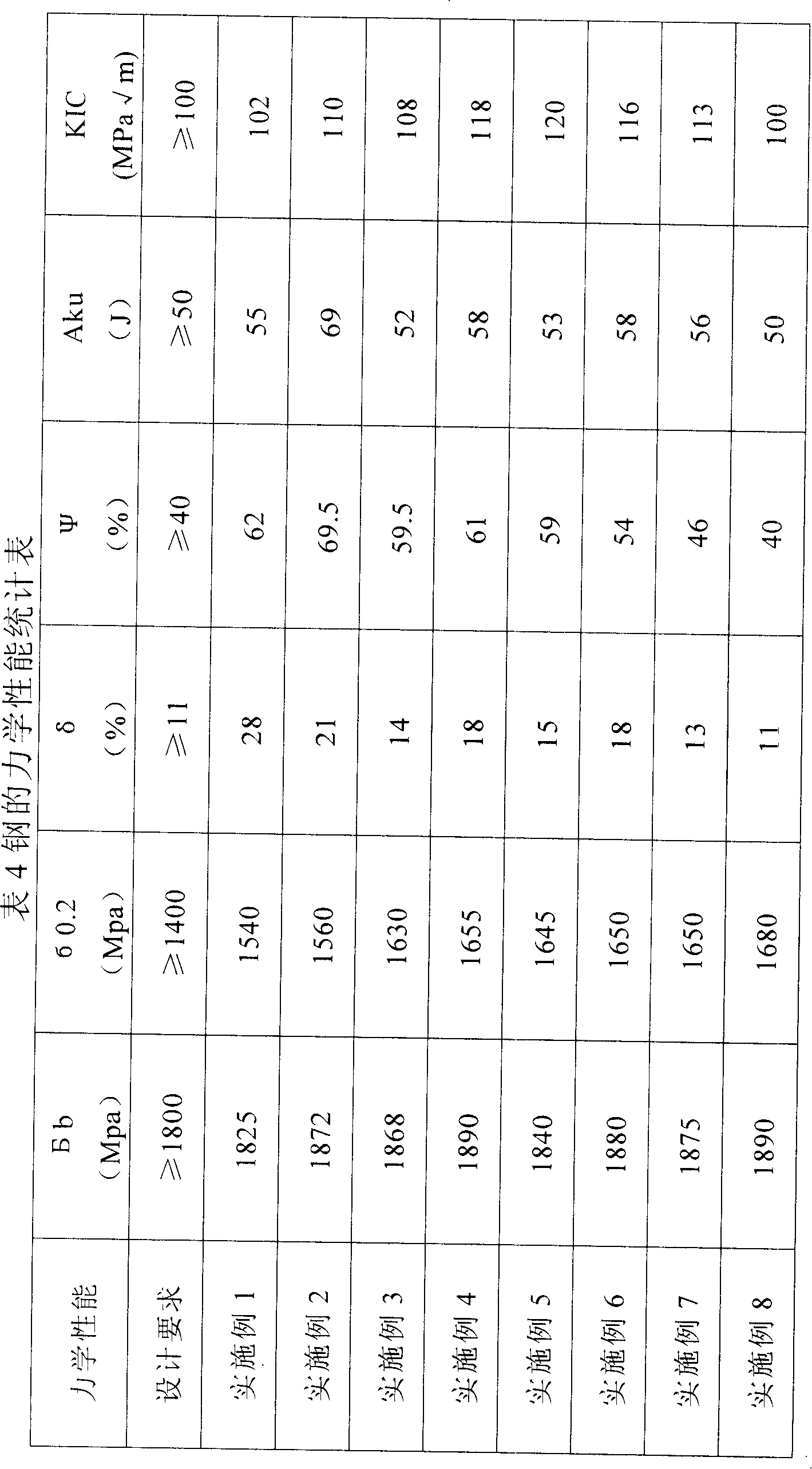

Tough ultra-strength stainless steel and method for manufacturing the same

InactiveCN101205595AHigh yield strengthImprove corrosion resistanceProcess efficiency improvementDuctilityNickel

The invention discloses a high-flexibility high-strength stainless steel and a method for making the same, wherein the method comprises the following steps of: 1) preparing parent alloy, the chemical compositions by weight percentage of which are: less than or equal to 0.03 percent of C, less than or equal to 0. 10 percent of Mn, less than or equal to 0.10 percent of Si, less than or equal to 0.002 percent of S, less than or equal to 0.006 percent of P, 6.0 to 13.0 percent of Cr, less than or equal to 0.05 percent of Al, less than or equal to 0.10 percent of Cu, less than or equal to 0.05 percent of Ti, the balance Fe and unavoidable impurities; 2) melting an electrode with a vacuum induction furnace, in which the parent alloy is prepared with pure iron, nickel, and other metal material for melting the electrode; 3) vacuum consumable remelting, at a melting speed of between 180 and 220 Kg / h; 4) forging, in which steel ingots are heated at a temperature of 1180+-20 DEG C, with the temperature maintained for 3 to 6 hours, and are upset and drawn twice, and the forging temperature is above 850 DEG C. The stainless steel of the invention has matched combination properties including 1800Mpa strength, 1400 Mpa yield strength, 50J impact ductility, more than 100 Mpa fracture toughness.

Owner:宝钢特钢有限公司

Bioabsorbable medical device

An implantable medical device is provided that degrades upon contact with body fluids so as to limit its residence time within the body. The device is formed of an iron carbon alloy that is subjected to DET heat treatment to impart high strength and high ductility in combination with an accelerated corrosion rate.

Owner:ABBOTT CARDIOVASCULAR

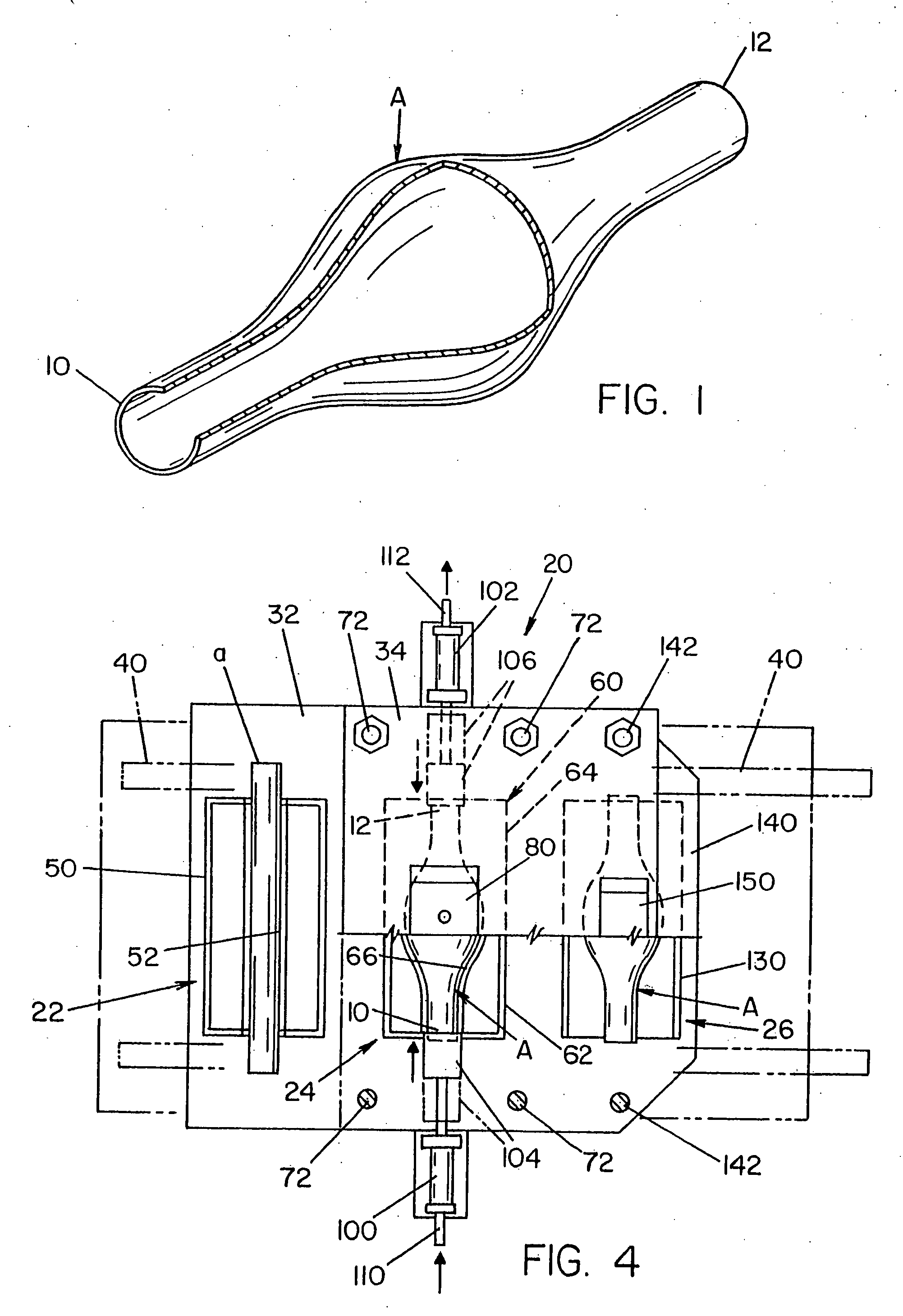

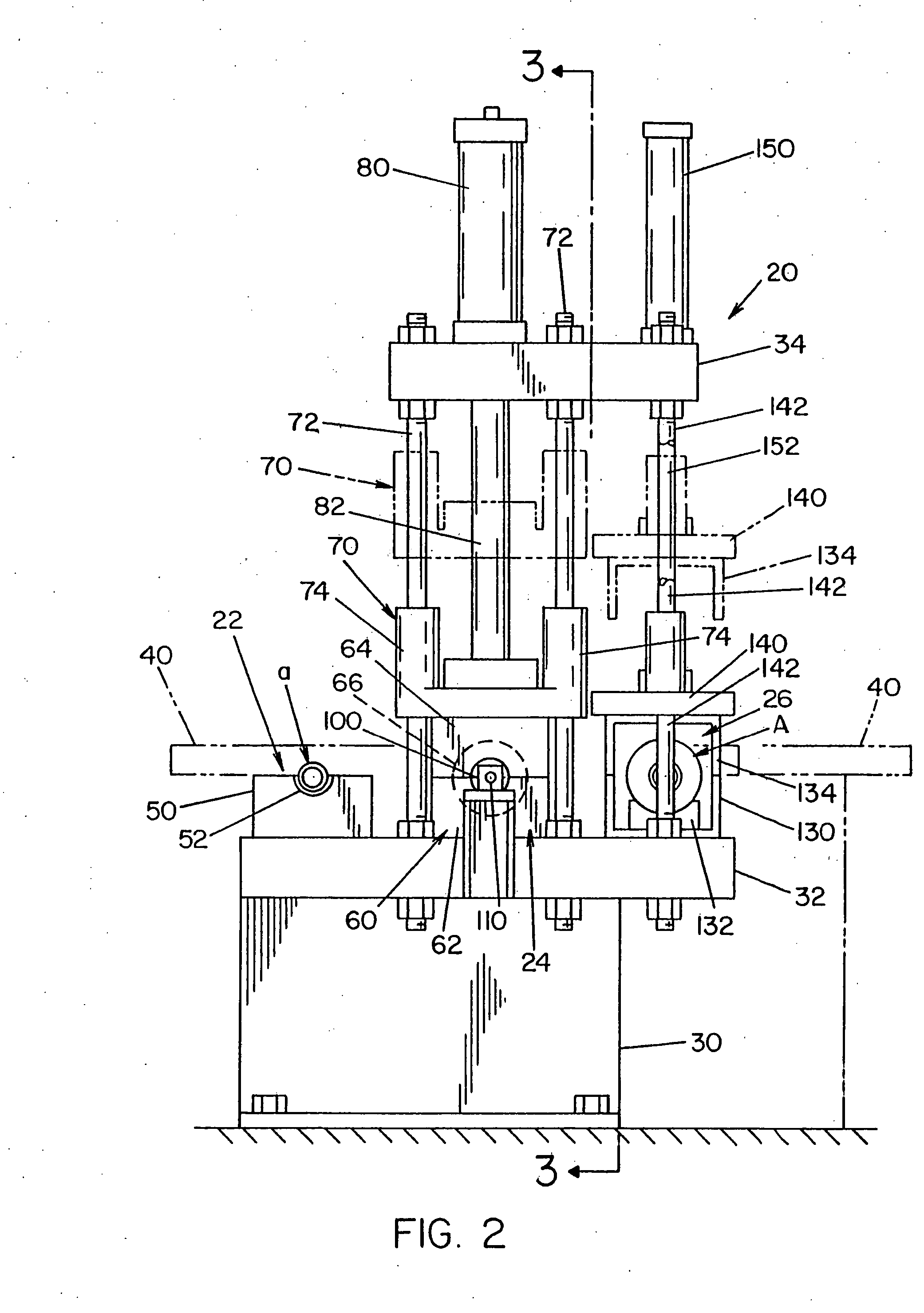

Method of forming a tubular blank into a structural component and die therefor

InactiveUS20040200550A1Reduce tooling costsImprove design flexibilityShaping toolsFurnace typesHigh pressureMetal

A method of forming an elongated metal blank into a structural component having a predetermined outer configuration. The method includes providing a shape imparting cavity or shell section formed from a rigid material which includes an inner surface defining the predetermined shape, placing the metal blank into the cavity or shell section, and forming the metal blank into the component by heating axial portions of the metal blank and forcing a fluid at a high pressure into the metal blank until the metal blank at least partially conforms to at least a portion of the inner surface of the cavity or shell section to form the structural component.

Owner:HOT METAL GAS FORMING IP2 INC +1

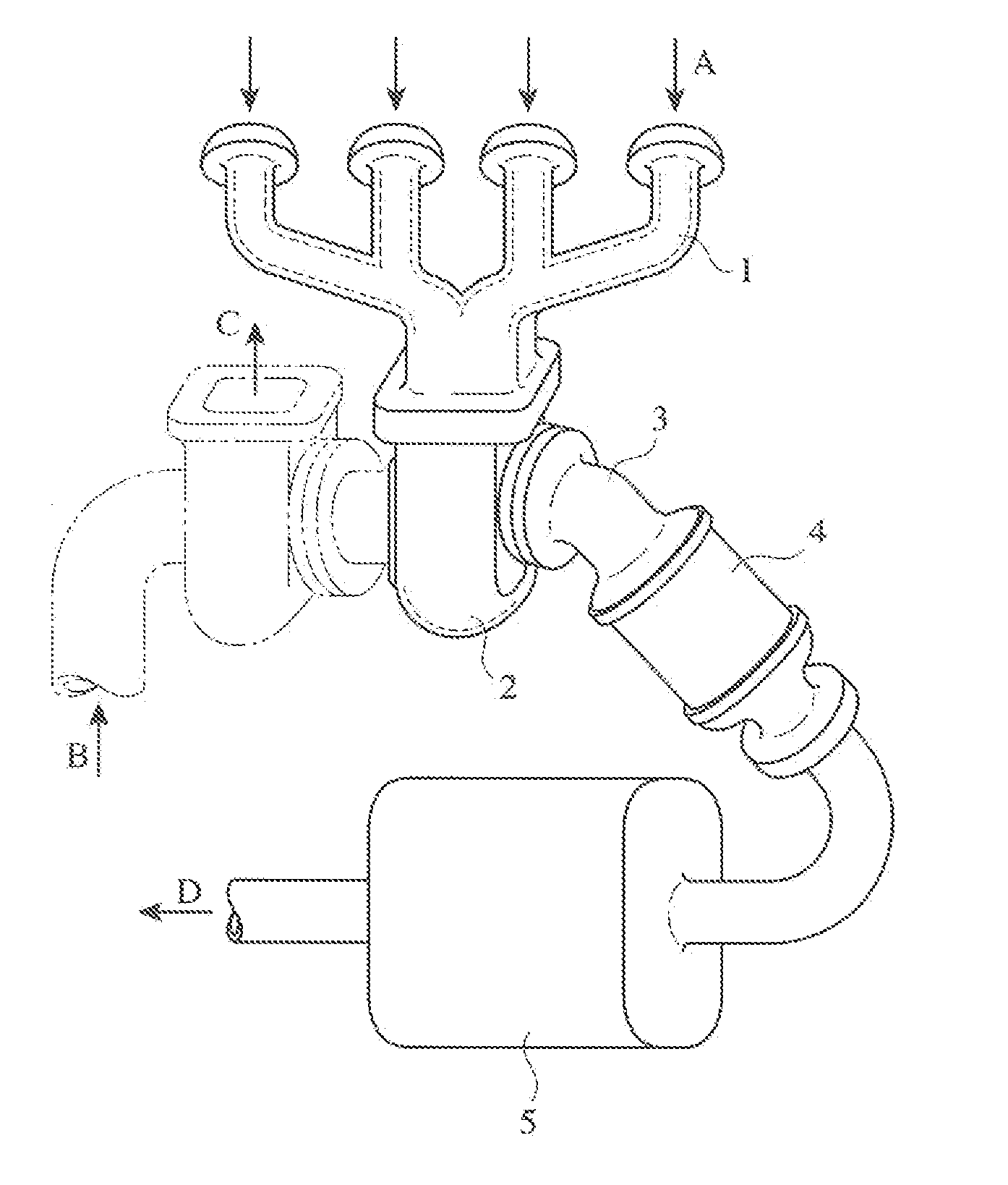

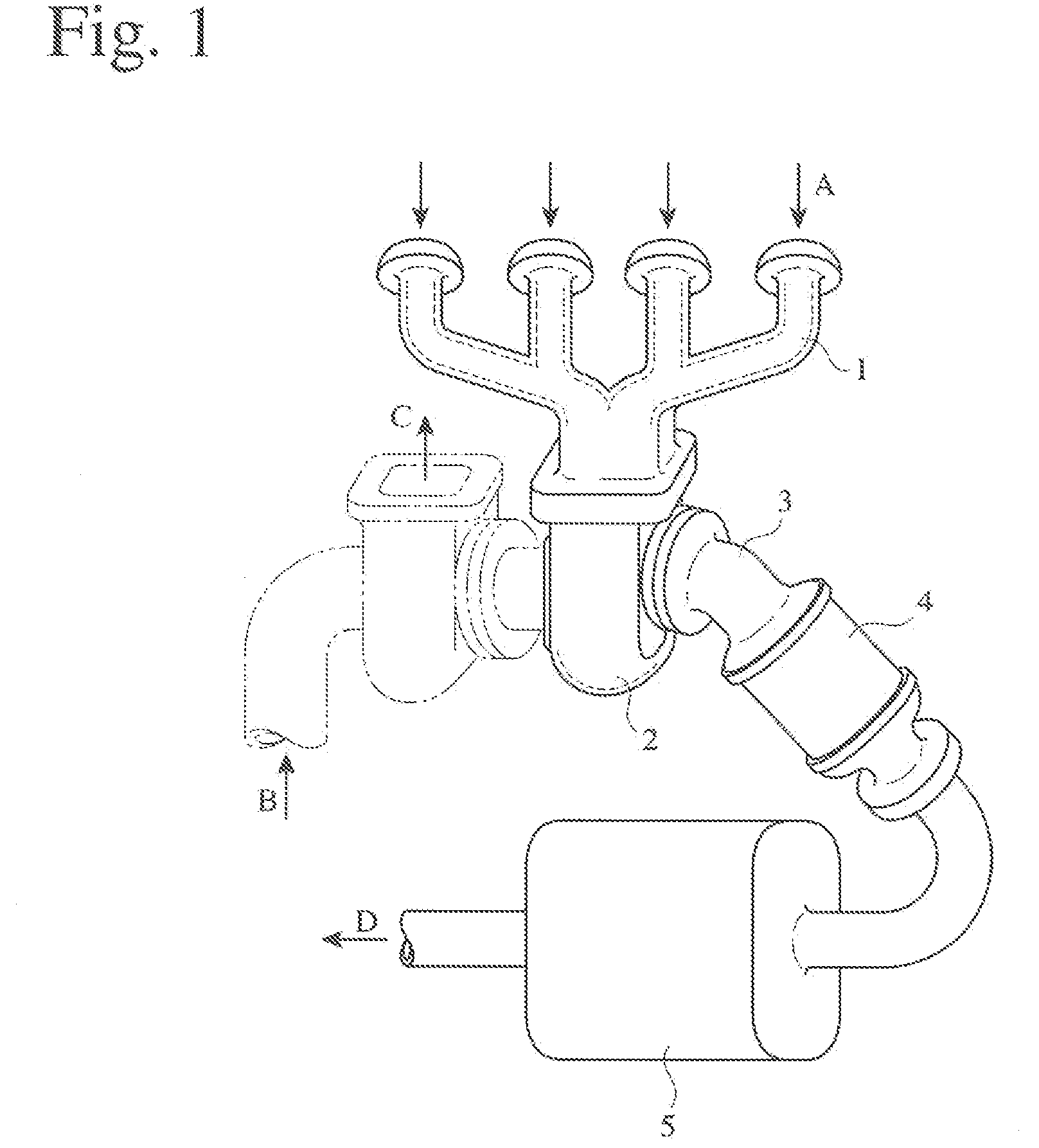

HIGH-Cr HIGH-Ni, HEAT-RESISTANT, AUSTENITIC CAST STEEL AND EXHAUST EQUIPMENT MEMBERS FORMED THEREBY

Owner:HITACHI METALS LTD

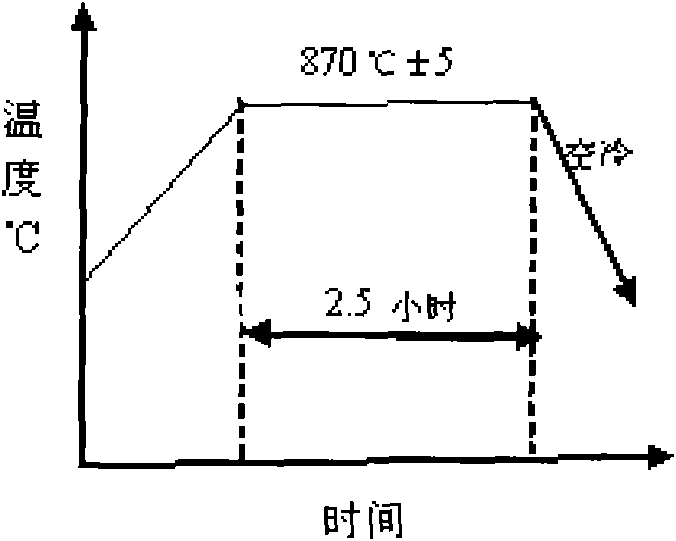

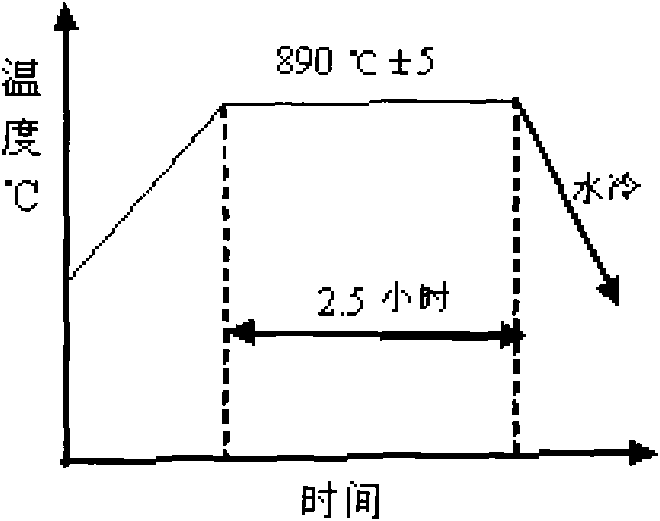

Wind power flange alloy steel and preparation technology of parts thereof

The invention discloses wind power flange alloy steel and a preparation technology of parts thereof. The alloy steel comprises the following chemical compositions: carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, nickel, copper, nitrogen, oxygen, hydrogen, rare earth and the balance of iron and the inevitable impurities. The preparation technology of the alloy steel parts comprises the following steps: pretreating molten iron, smelting in a converter, performing external refining, casting steel ingots, performing flame cleaning, heating, forging, slowly cooling, performing heat treatment, machining, performing flaw detection, inspecting, packaging and warehousing. Compared with the existing alloy steel used in the wind power generation at home and aboard, the alloy steel disclosed by the invention has higher tensile strength, yield strength, elongation after fracture and reduction of area, particularly higher low-temperature impact toughness. The atmosphere corrosion resistance and the sea atmosphere corrosion resistance are increased by two levels.

Owner:江阴同庆机械制造有限公司

High strength aluminium alloy brazing sheet

InactiveUS20050064226A1Good brazing propertyGood formability characteristicFurnace typesHigh frequency current welding apparatusSiluminHigh intensity

Disclosed is a high strength aluminium alloy brazing sheet, including an Al—Cu core layer and at least one clad layer, the core layer having the following composition (in weight percent): Cu: 1.2-4.0, Mn: 0.06-1.5, Mg: 0.06-1.5, Si: up to 0.5, Zn: <0.4, Zr: ≦0.25, Fe: ≦0.5, Ti: ≦0.25, Cr: ≦0.25; V≦0.25; the balance substantially aluminium and impurities, the clad layer including an Al—Si based filler alloy and being applied on at least one side of the core layer. Also disclosed is a brazed assembly including the brazing sheet and the use of the brazing sheet for a brazing application such as a heat exchanger.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

Thin walled electrochemical cell

InactiveUS6042957AHigh yield strengthLess elongationFuel and primary cellsActive material electrodesThin walledRelative stiffness

This invention pertains to alkaline electrochemical cells, typically to metal-air cells of the button-type. Non-reactive elements of cells of the invention are thinner than corresponding non-reactive elements of prior art cells. Such elements can be made thinner because of improved structures of such elements. The anode can is made from a metal strip structure having a higher steel content. The cathode can has a modified temper, which improves relative stiffness and rigidity while retaining sufficient ductility. By so reducing the thicknesses of non-reactive elements of the cell, and thus the volume occupied by such non-reactive elements, the fraction of the cell devoted to holding electrochemically reactive anode material therein is increased, with corresponding increase in the milliampere hour capacity of the cell.

Owner:THE BANK OF NEW YORK MELLON AS COLLATERAL AGENT

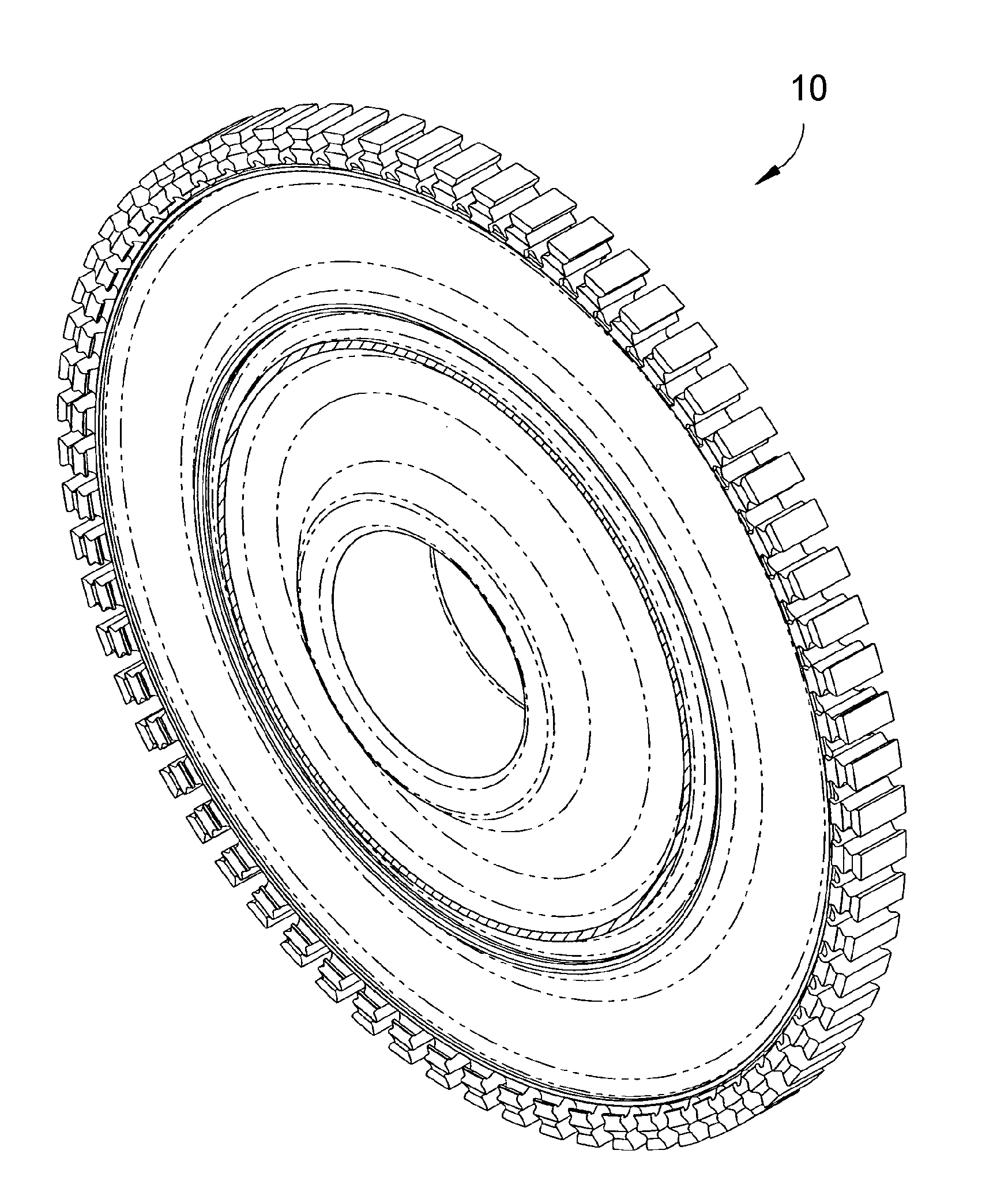

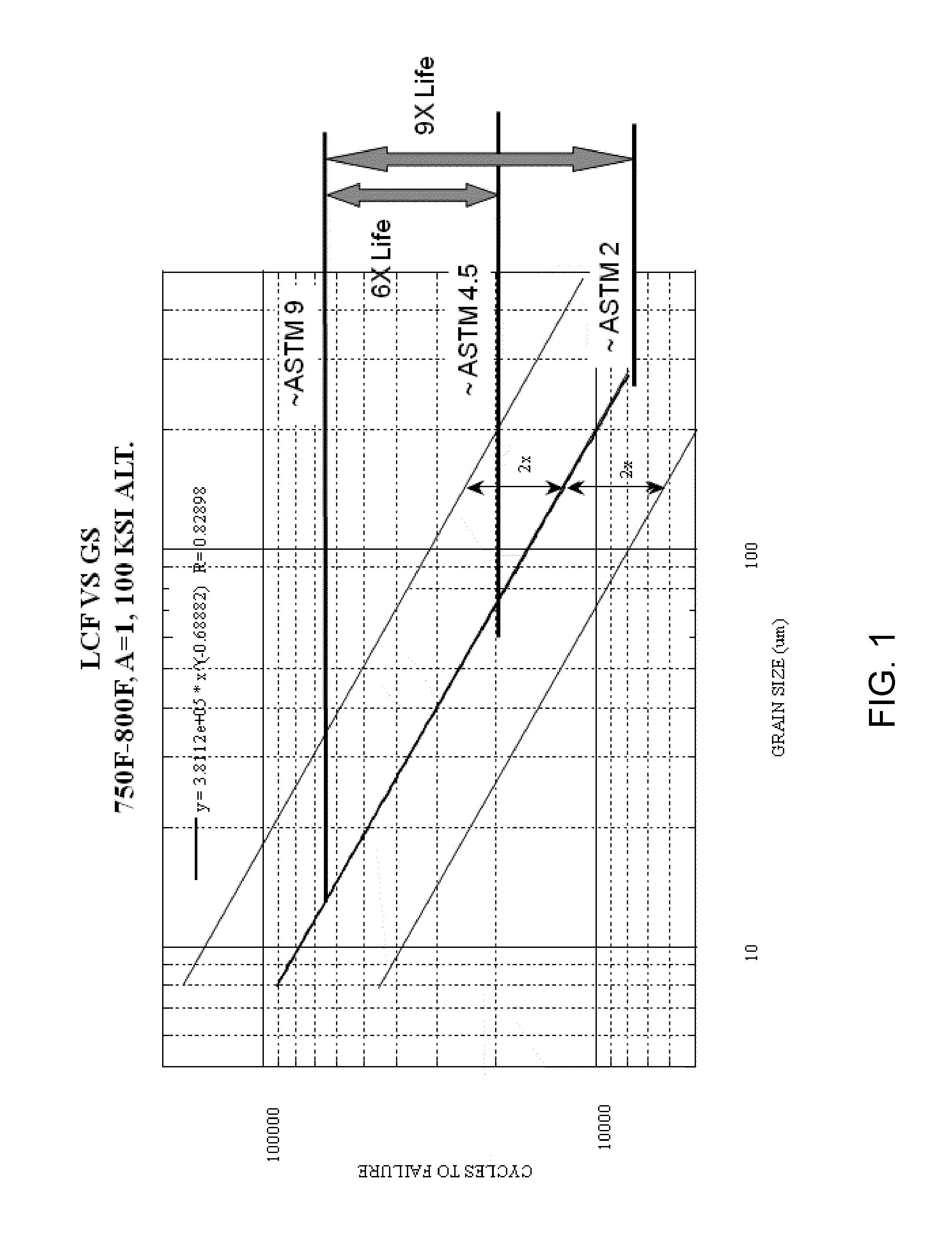

Method of controlling and refining final grain size in supersolvus heat treated nickel-base superalloys

InactiveUS20100329883A1Finer uniform grain sizeImproved low cycle fatigue behaviorPropellersEngine manufactureRheniumNiobium

A gamma prime precipitation-strengthened nickel-base superalloy and method of forging an article from the superalloy to promote a low cycle fatigue resistance and high temperature dwell behavior of the article. The superalloy has a composition of, by weight, 16.0-22.4% cobalt, 6.6-14.3% chromium, 2.6-4.8% aluminum, 2.4-4.6% titanium, 1.4-3.5% tantalum, 0.9-3.0% niobium, 1.9-4.0% tungsten, 1.9-3.9% molybdenum, 0.0-2.5% rhenium, greater than 0.05% carbon, at least 0.1% hafnium, 0.02-0.10% boron, 0.03-0.10% zirconium, the balance nickel and incidental impurities. A billet is formed of the superalloy and worked at a temperature below the gamma prime solvus temperature of the superalloy so as to form a worked article, which is then heat treated above the gamma prime solvus temperature of the superalloy to uniformly coarsen the grains of the article, after which the article is cooled to reprecipitate gamma prime. The article has an average grain size of not coarser than ASTM 7 and is substantially free of critical grain growth.

Owner:GENERAL ELECTRIC CO

Steel Sheet for Hot Press Forming Having Excellent Heat Treatment and Impact Property, Hot Press Parts Made of It and the Method for Manufacturing Thereof

InactiveUS20080286603A1High strengthHigh yield strengthHot-dipping/immersion processesPig casting plantsSheet steelUltimate tensile strength

Disclosed is a steel sheet that exhibits an ultra-high strength after hot press forming followed by rapid cooling, and an enhanced yield strength after painting. The steel sheet has a composition comprising 0.1% to 0.5% by weight of C, 0.01% to 1.0% by weight of Si, 0.5% to 4.0% by weight of Mn, 0.1% by weight or less of P, 0.03% by weight or less of S, 0.1% by weight of soluble Al, 0.01% to 0.1% by weight of N, 0.3% by weight or less of W, and the balance Fe and other inevitable impurities. Further disclosed are a hot-pressed part made of the steel sheet and a method for manufacturing the hot-pressed part. The hot-pressed part achieves a high increment in yield strength after heat treatment for painting while ensuring an ultra-high tensile strength. Furthermore, the hot-pressed part exhibits superior adhesion to a coating layer, good surface appearance and improved corrosion resistance after painting.

Owner:POHANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com