Patents

Literature

94 results about "Solvus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a physical or geochemical system, a solvus is a line (binary system) or surface (ternary system) on a phase diagram which separates a homogeneous solid solution from a field of several phases which may form by exsolution or incongruent melting. The line determines a solid solubility limit which changes as a function of temperature. It is a locus of points on the equilibrium diagram. An example is the formation of perthite when an alkali feldspar is cooled down. It defines the limit of solid solubility in an equilibrium diagram.

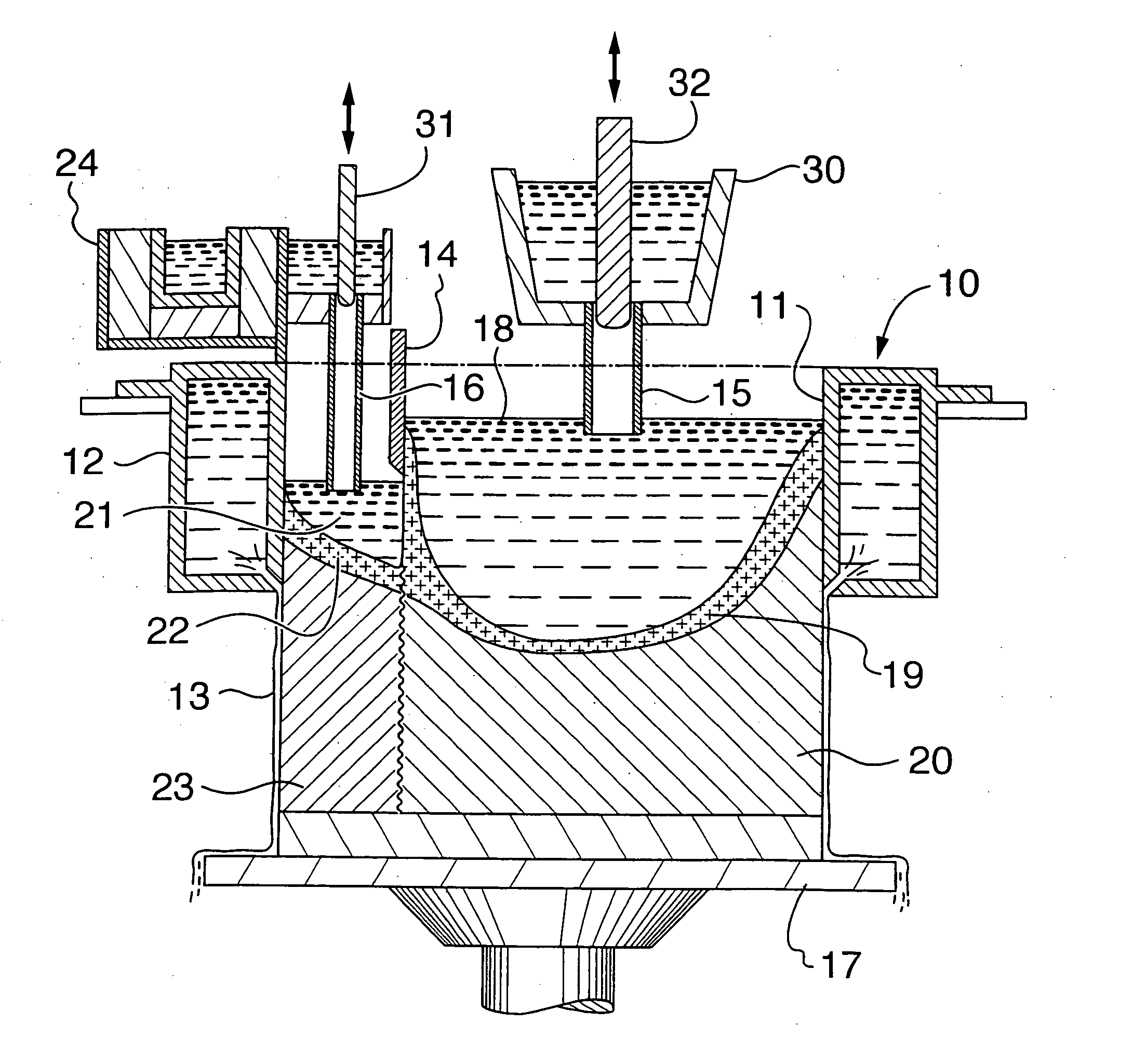

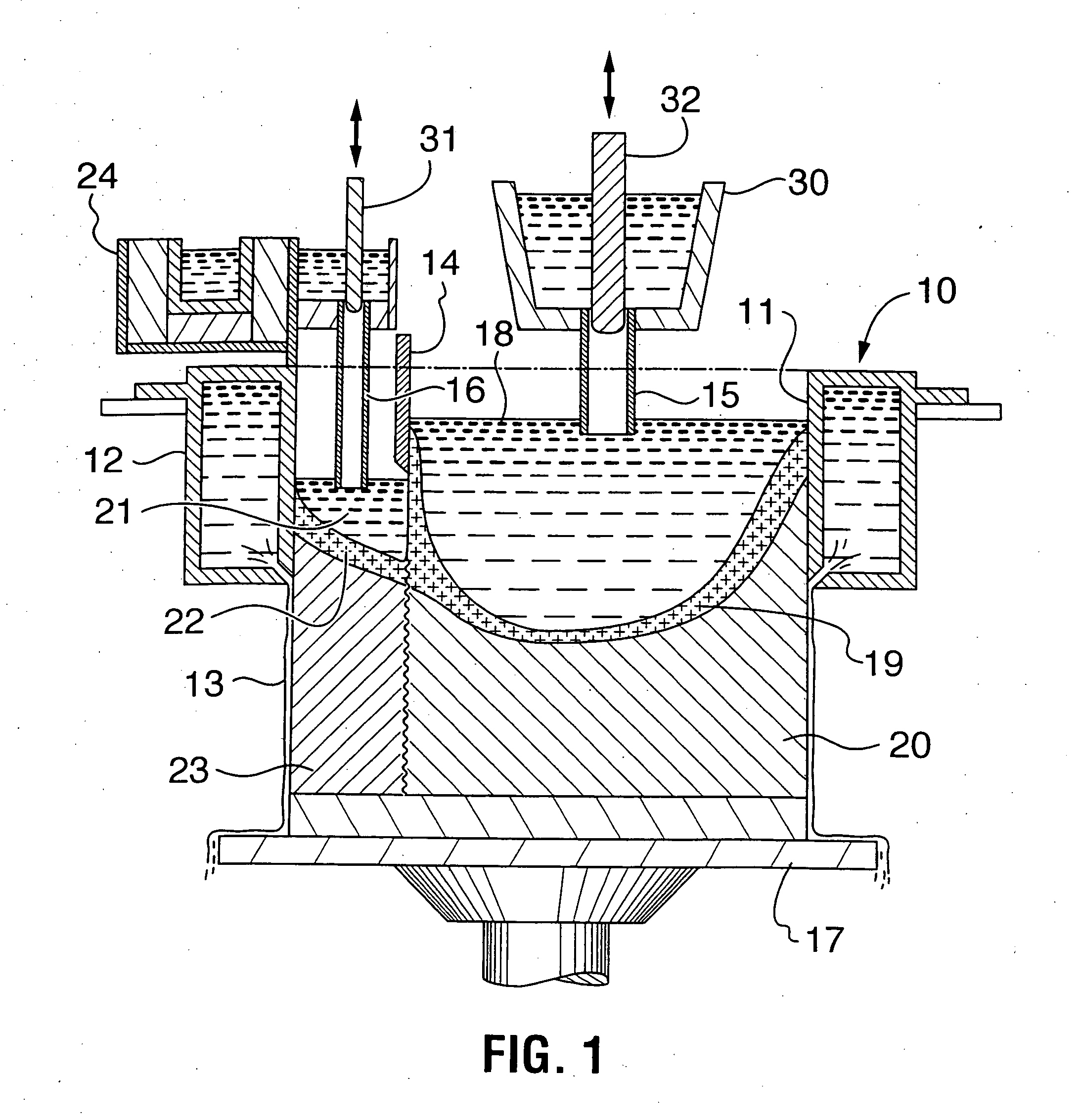

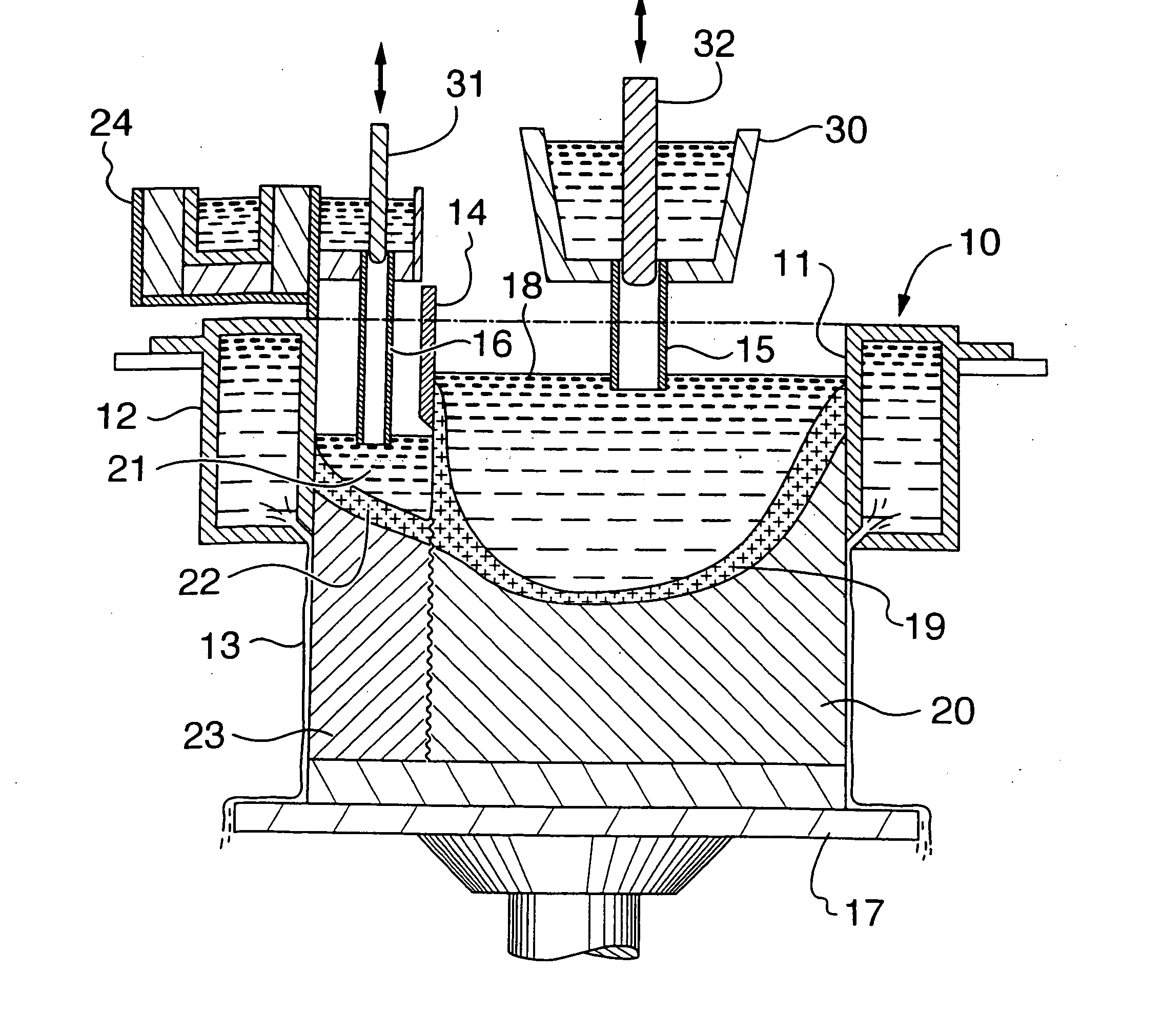

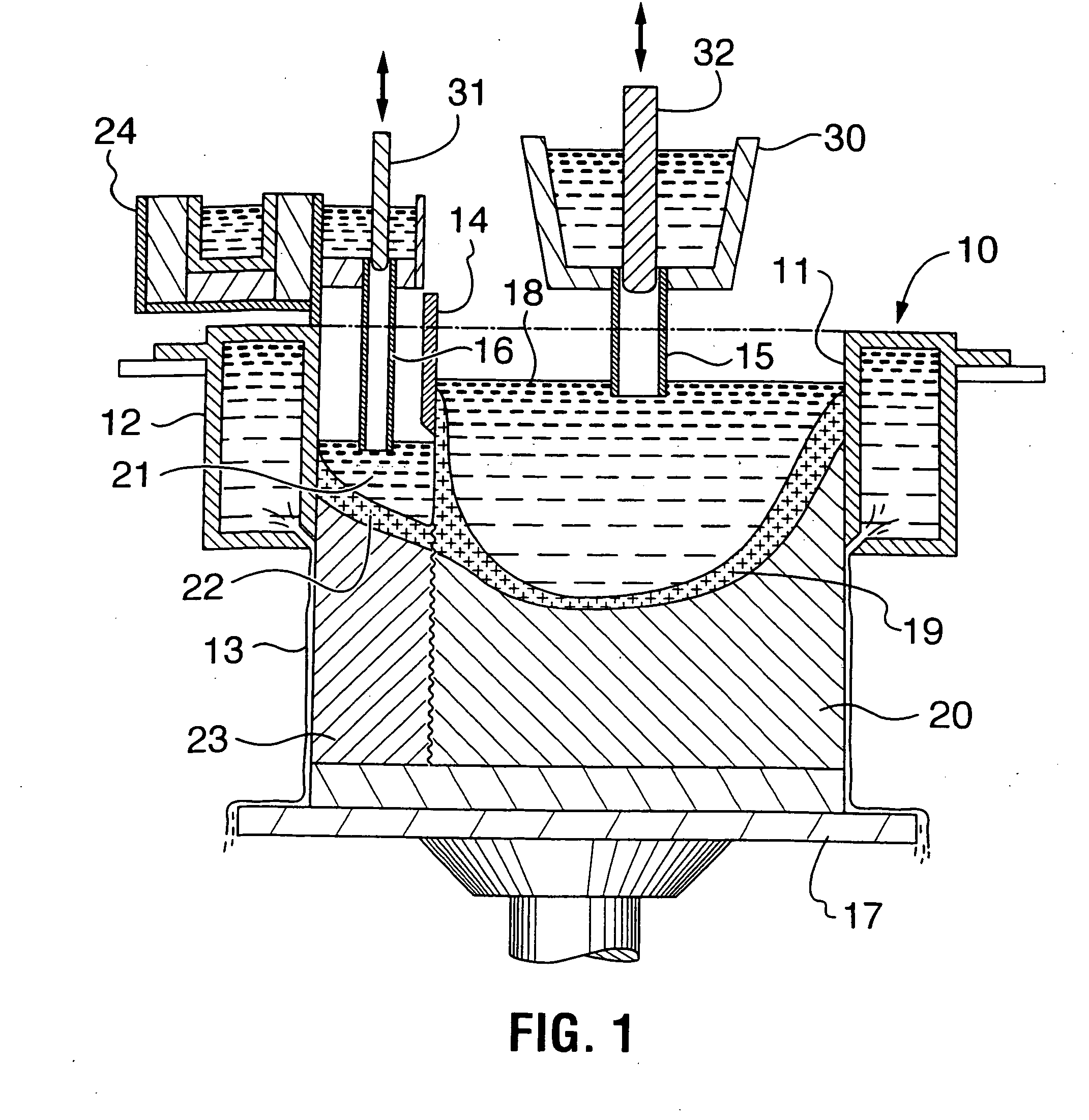

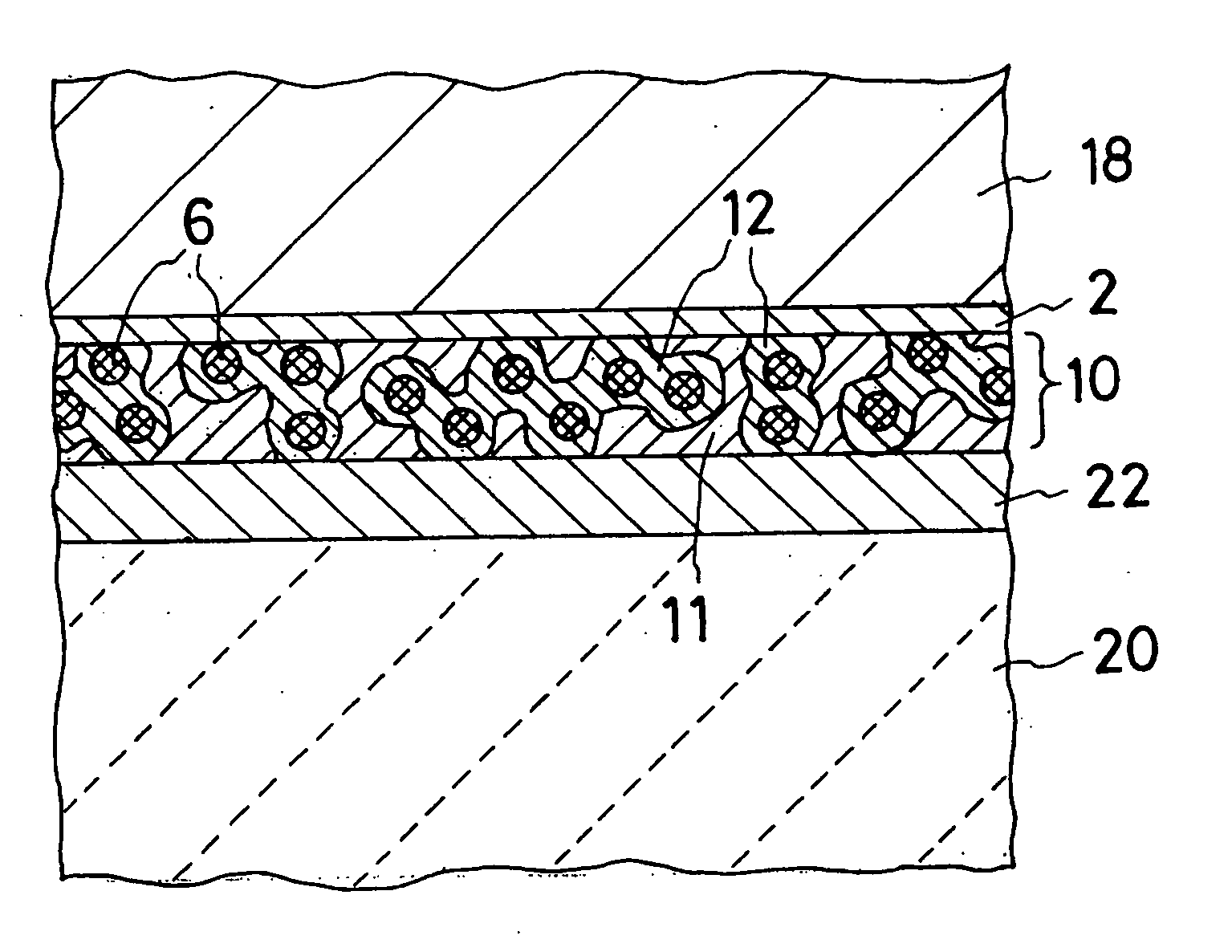

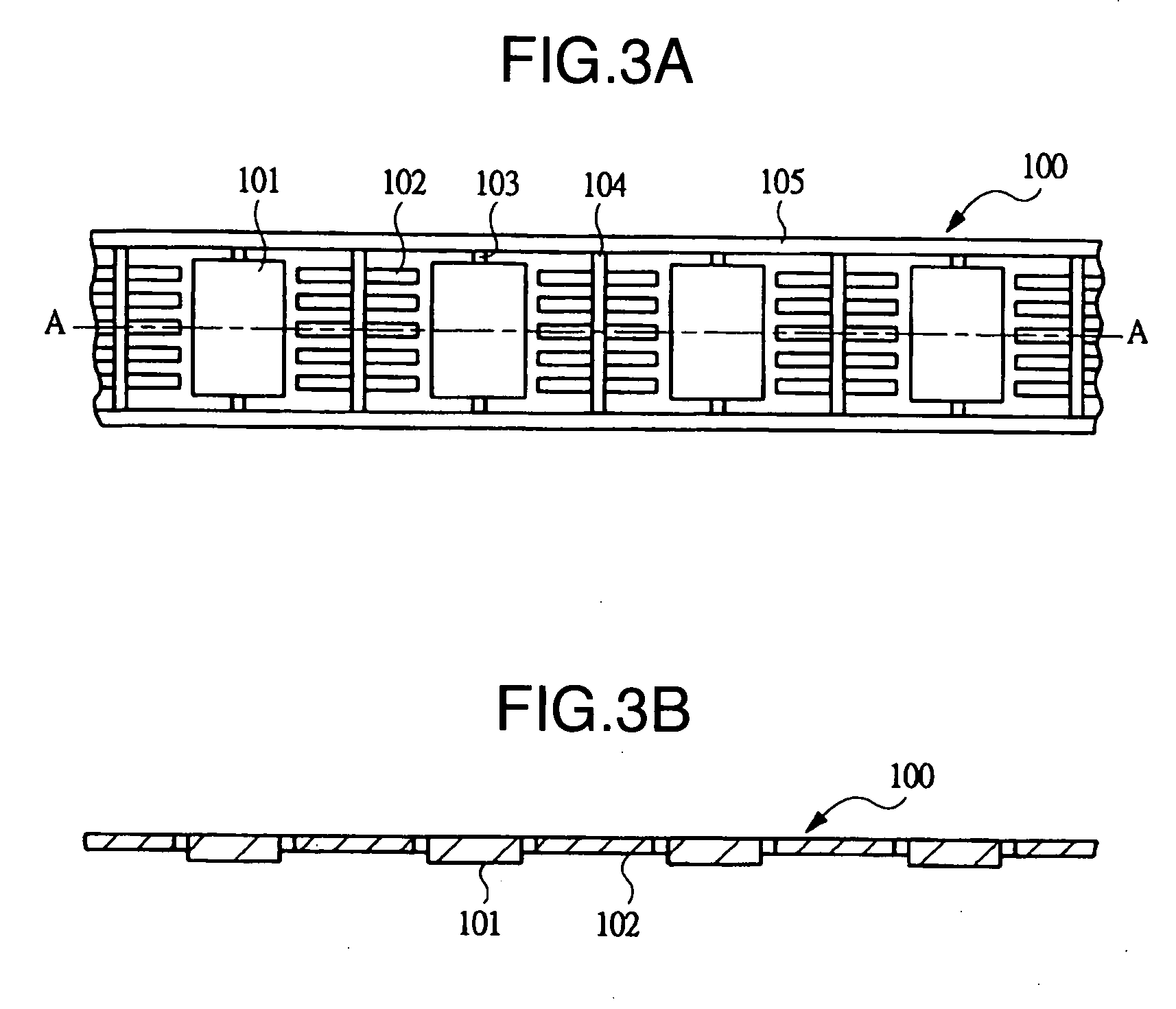

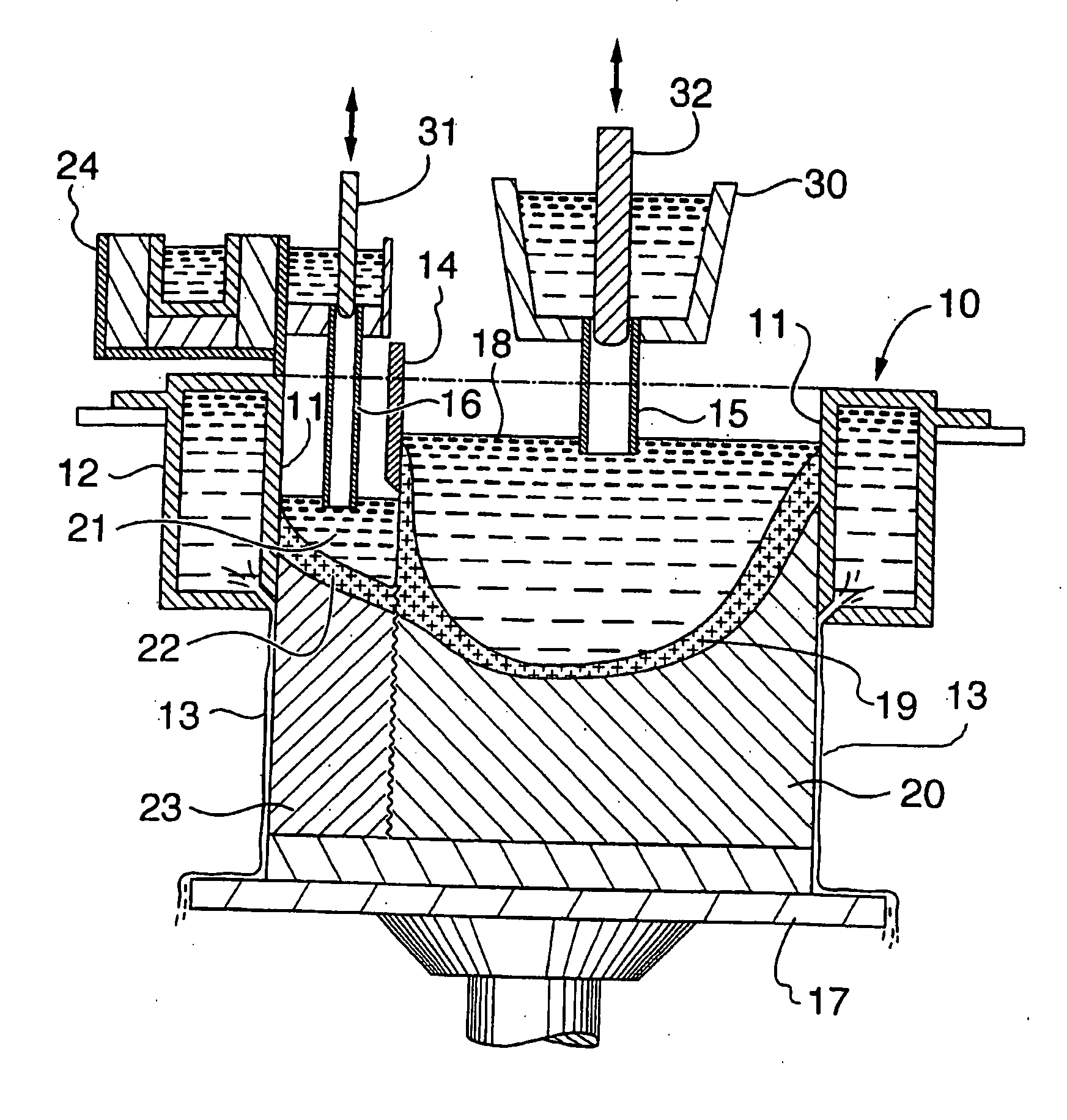

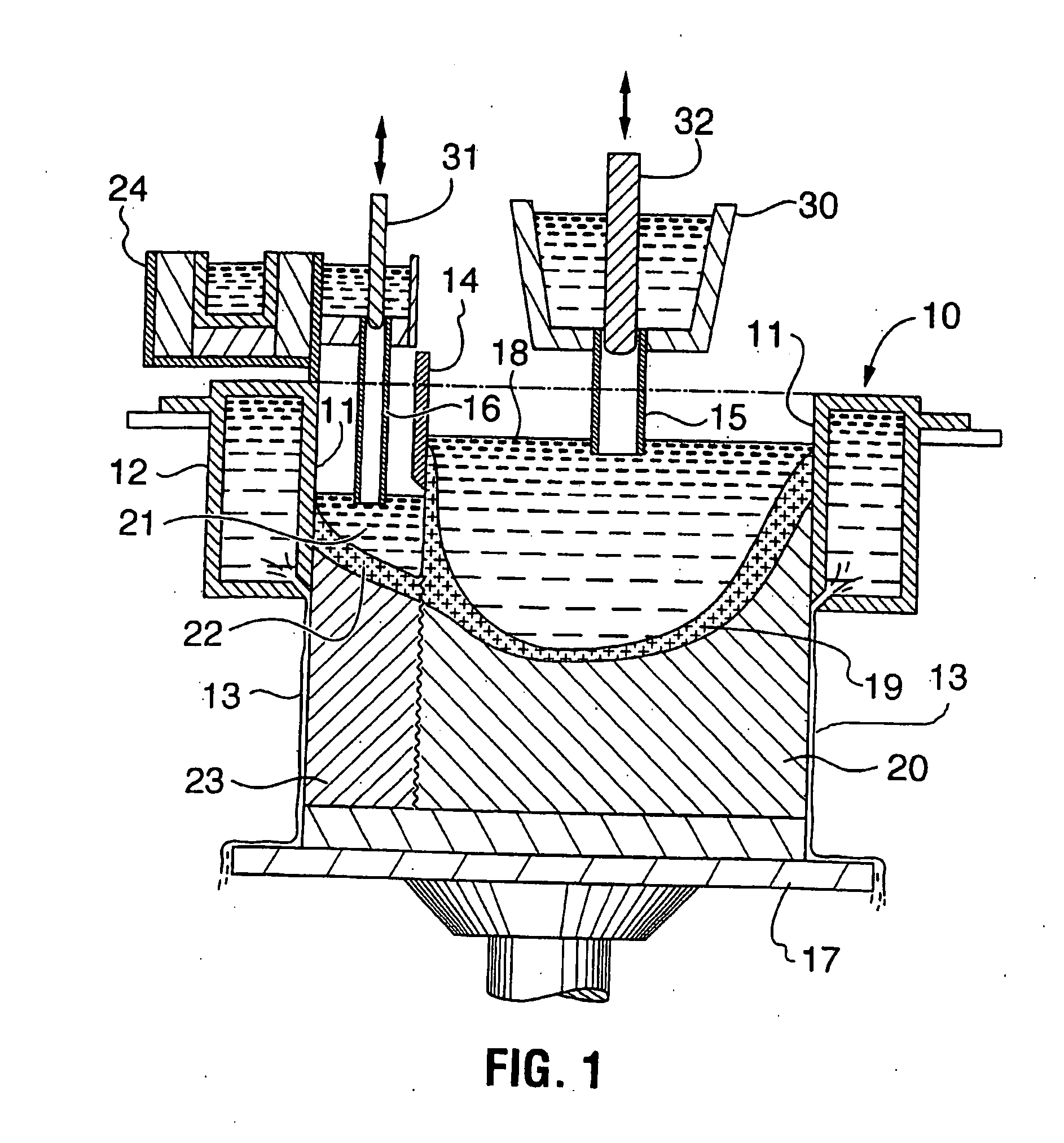

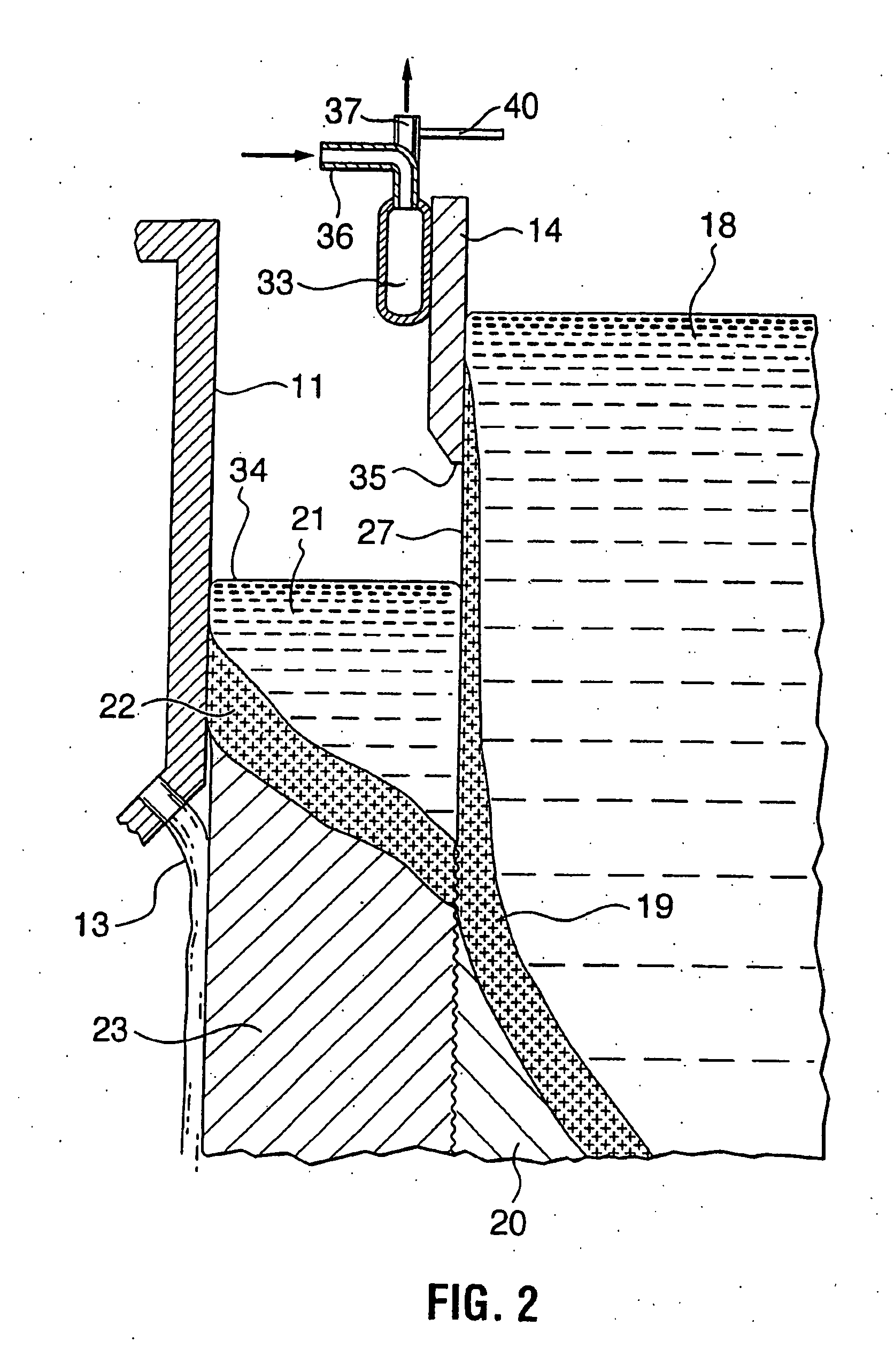

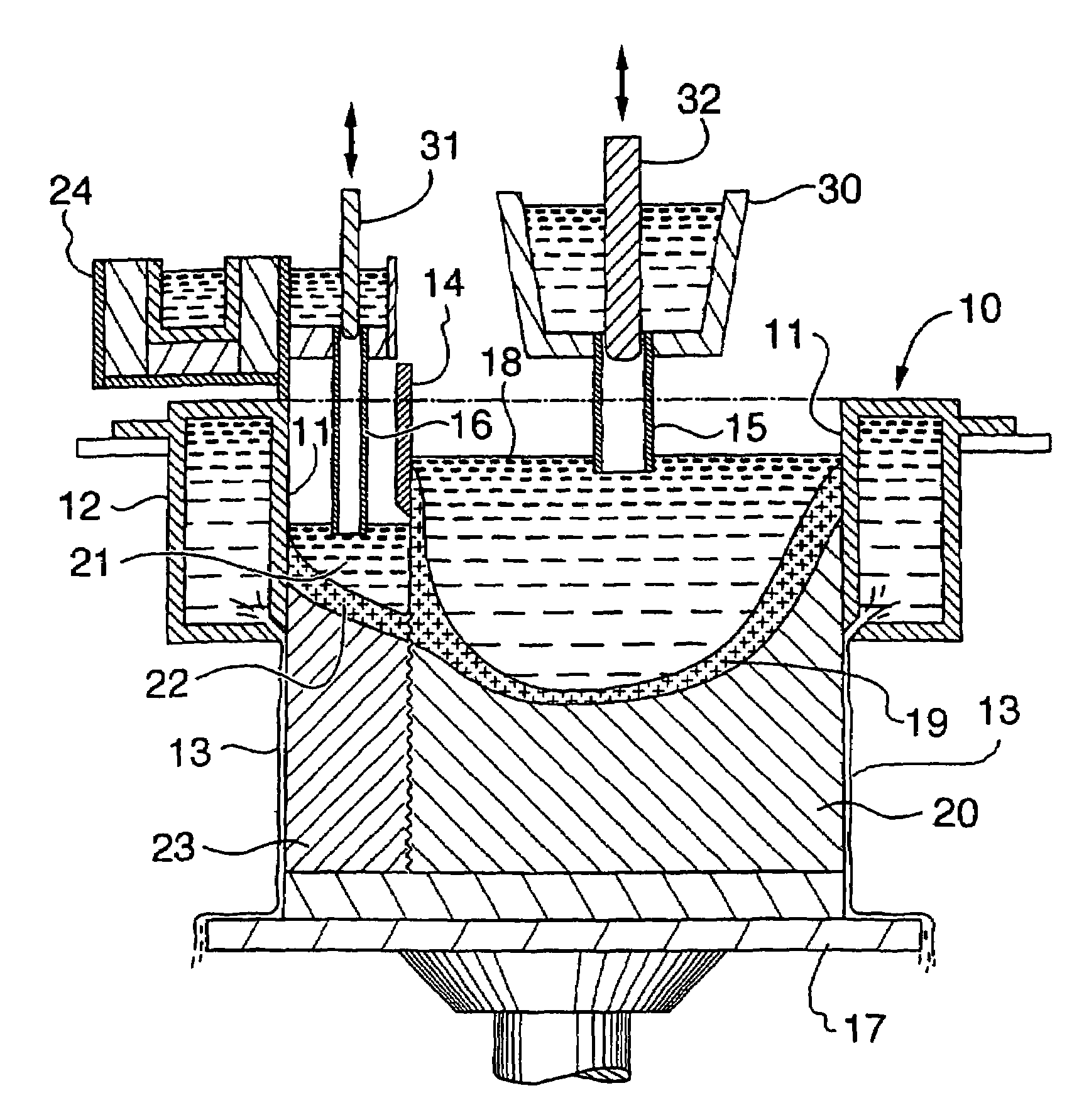

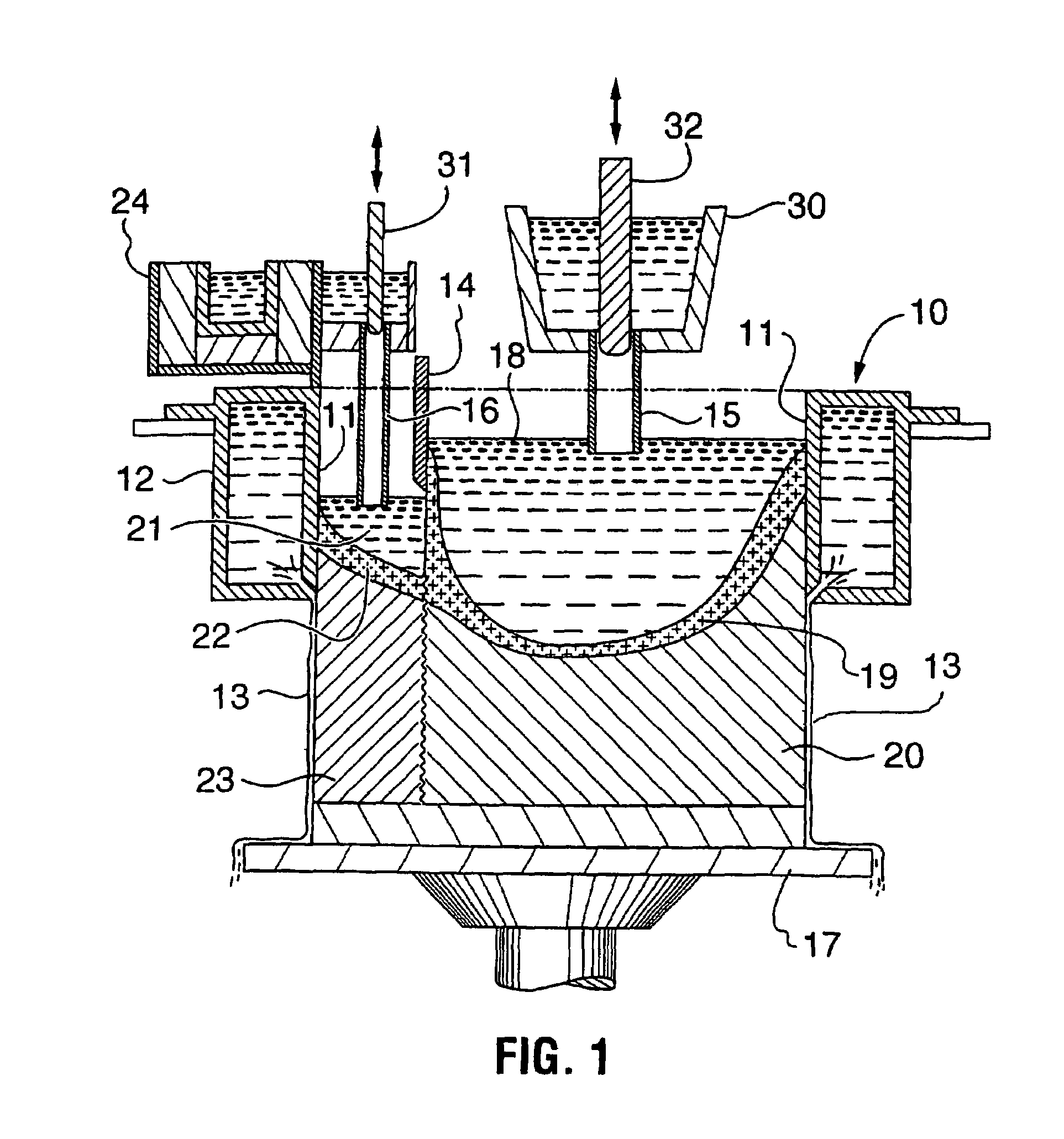

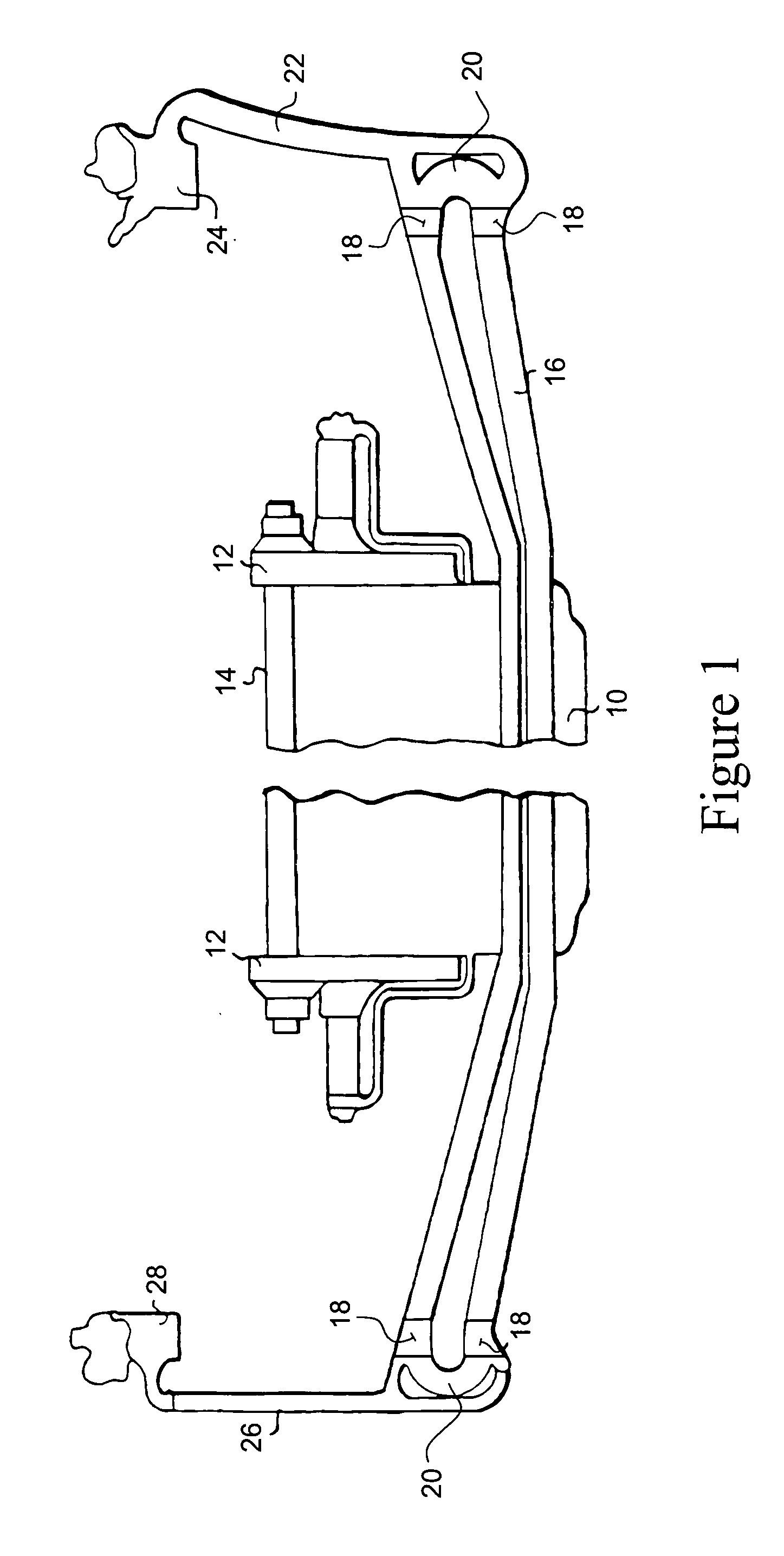

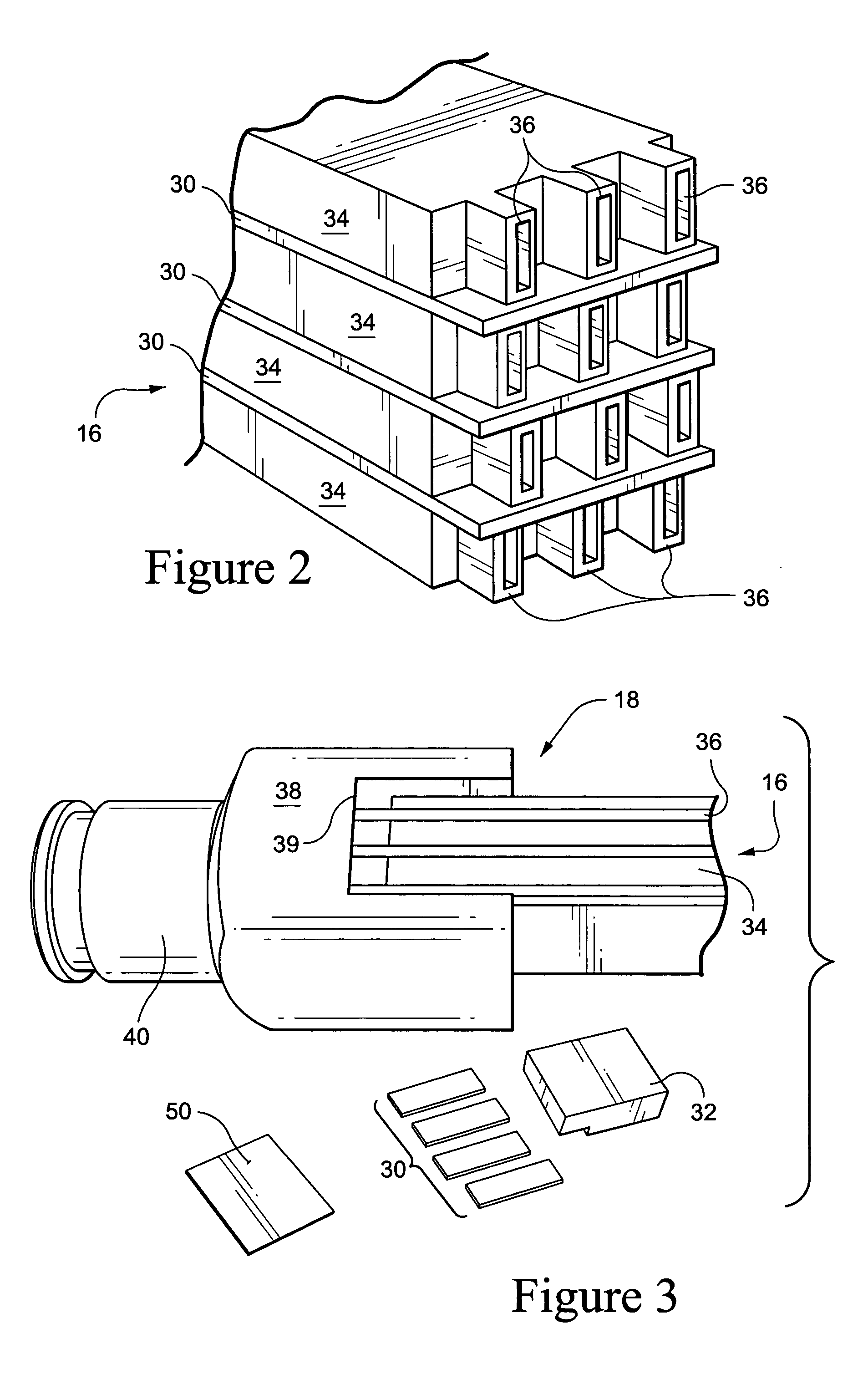

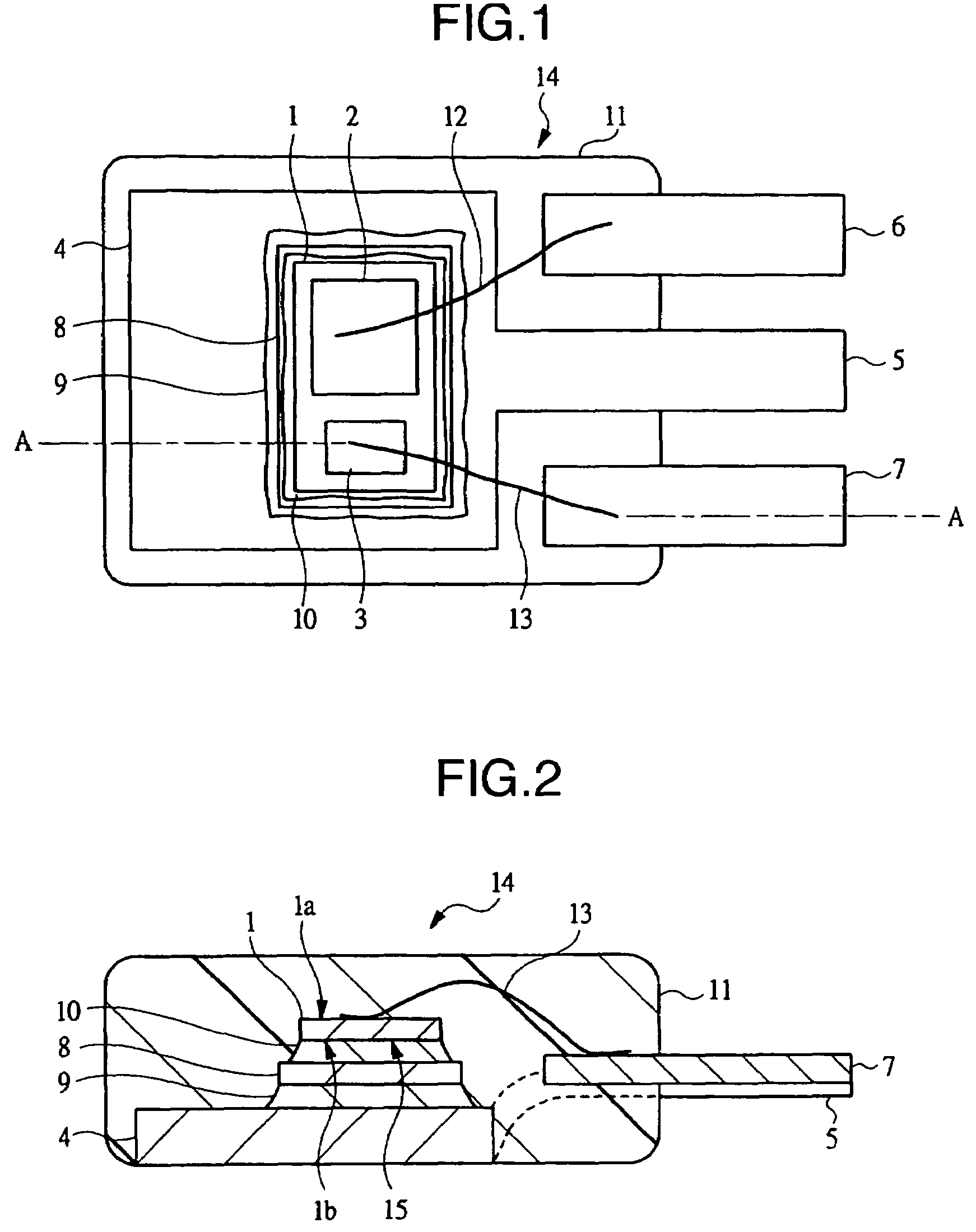

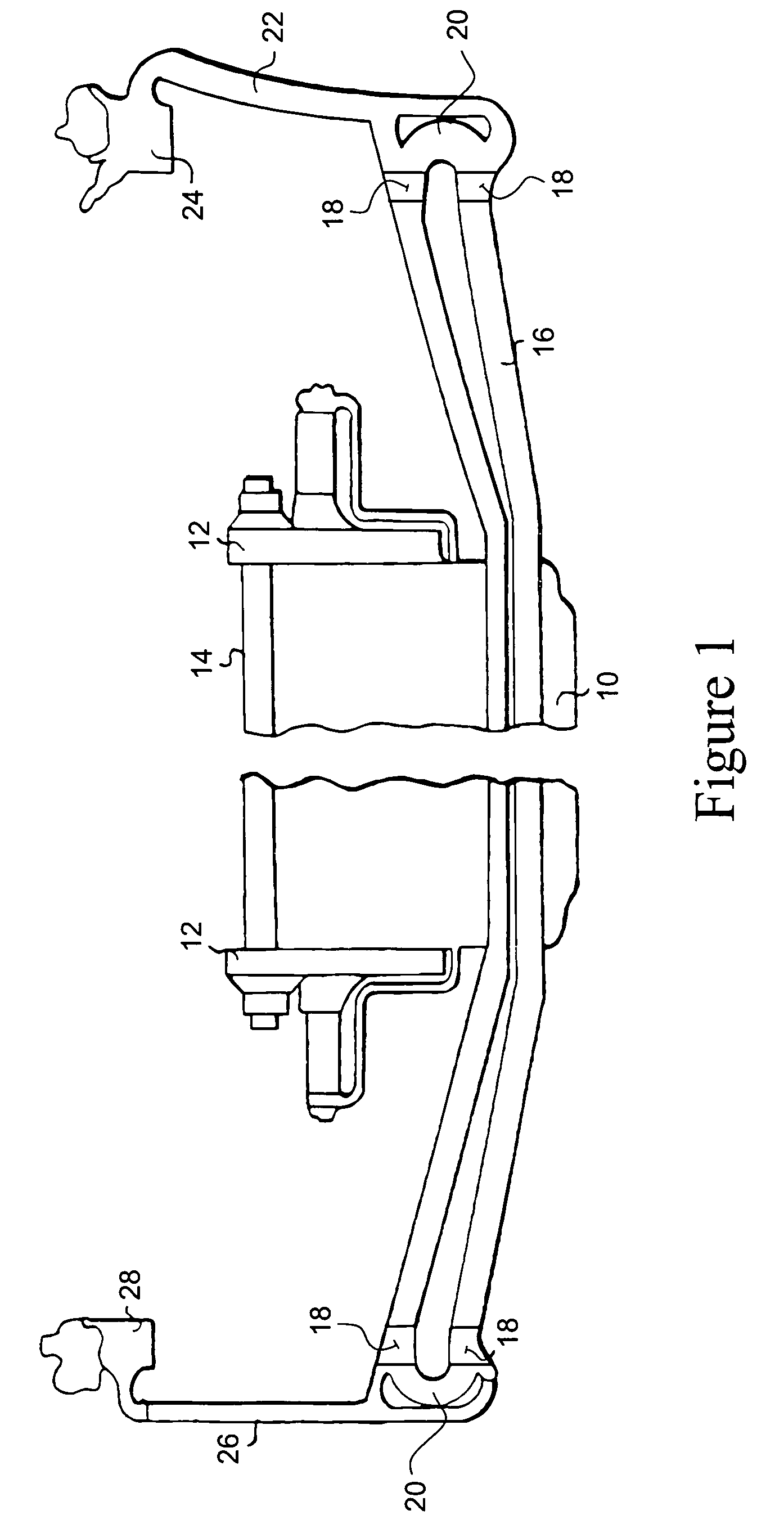

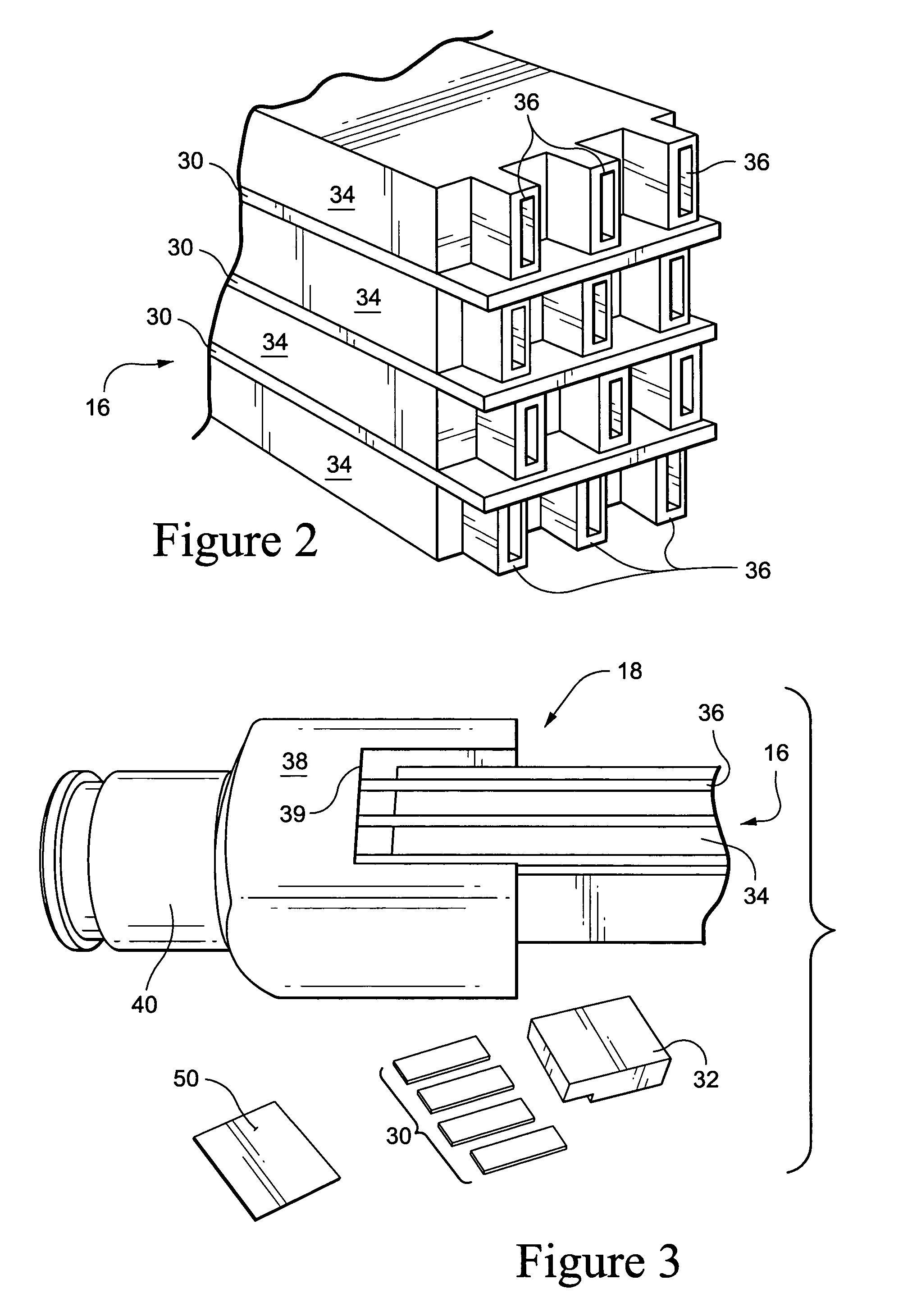

Method for casting composite ingot

ActiveUS20050011630A1Easy to controlImprove corrosion resistanceThin material handlingIngotMaterials science

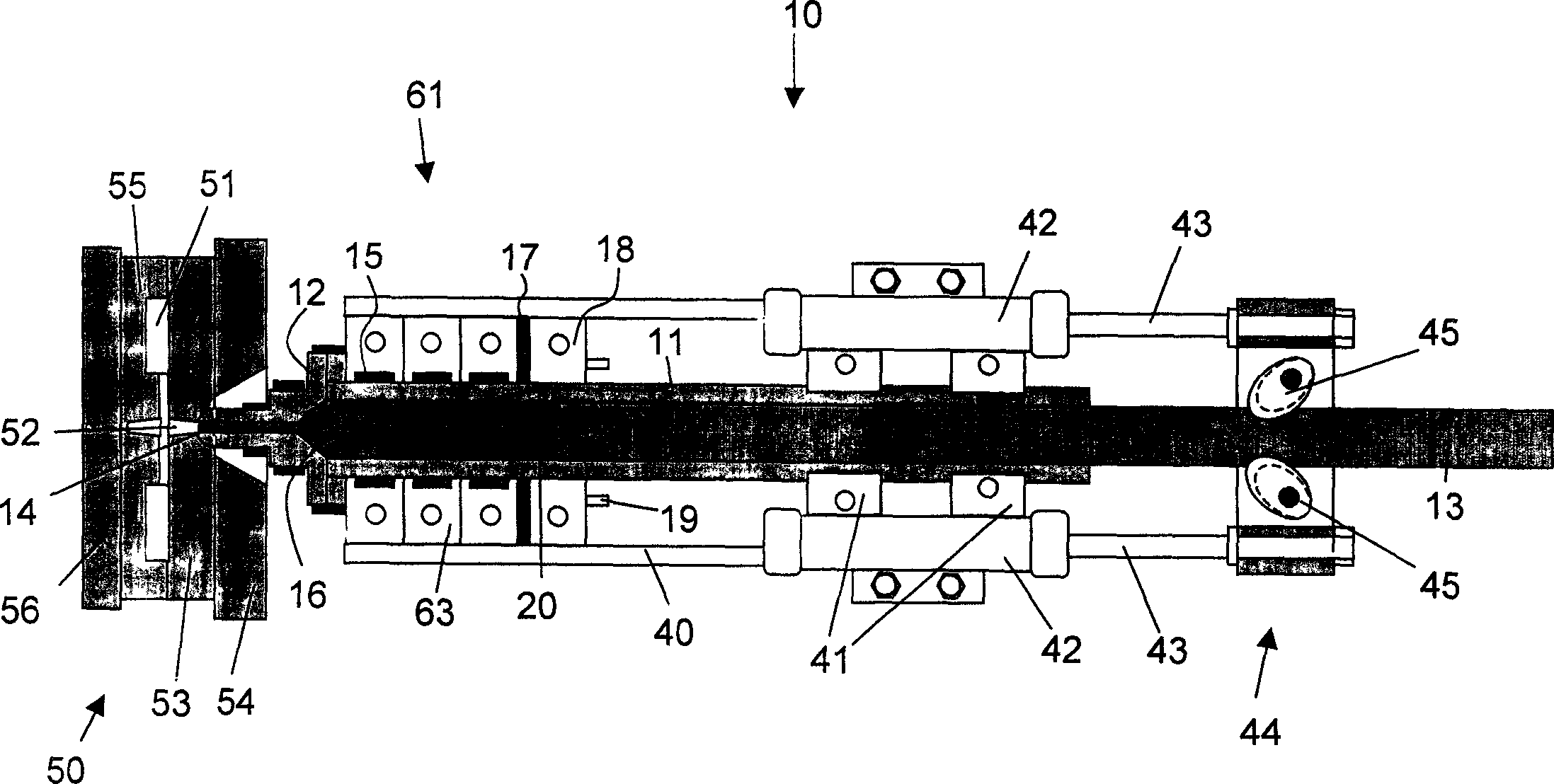

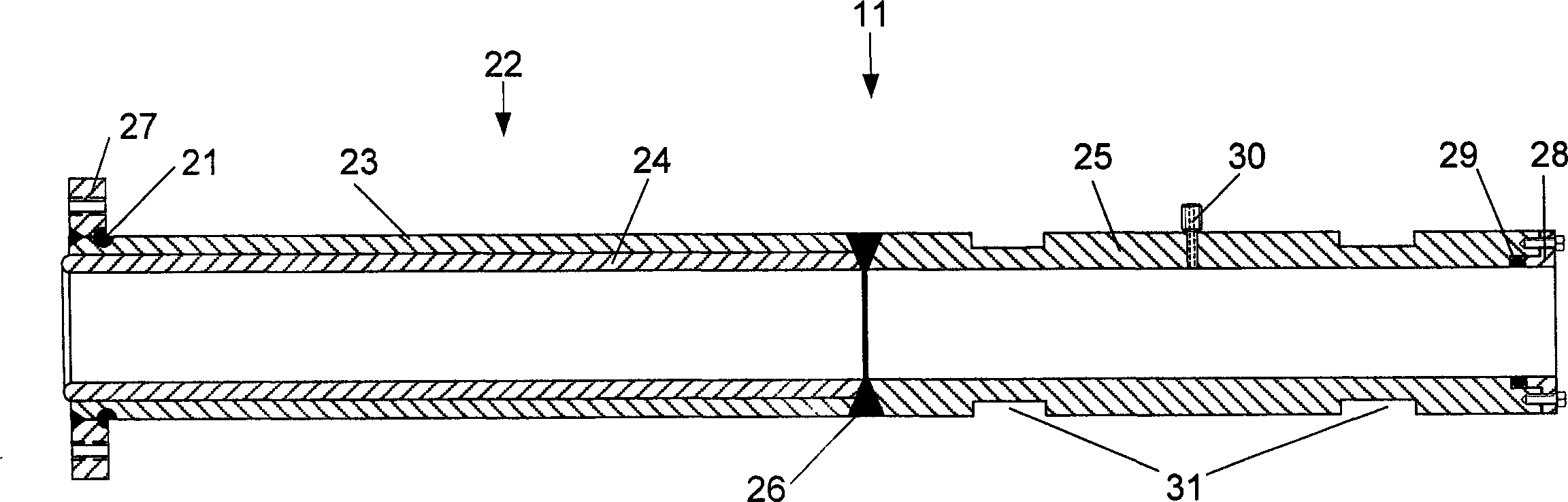

A method and apparatus are described for the casting of a composite metal ingot comprising at least two separately formed layers of one or more alloys. An open ended annular mould has a feed end and an exit end and divider wall for dividing the feed end into at least two separate feed chambers, where each feed chamber is adjacent at least one other feed chamber. For each pair of adjacent feed chambers a first alloy stream is fed through one of the pair of feed chambers into the mould and a second alloy stream is fed through another of the feed chambers. A self-supporting surface is generated on the surface of the first alloy stream and the second alloy stream is contacted with the first stream such that the upper surface of the second alloy stream is maintained at a position such that it first contacts the self-supporting surface where the self-supporting surface temperature is between the liquidus and solidus temperatures of the first alloy or it first contacts the self-supporting surface where the self-supporting surface temperature is below the solidus temperatures of the first alloy but the interface between the two alloys is then reheated to between the liquidus and solidus temperatures, whereby the two alloy streams are joined as two layers. The joined alloy layers are then cooled to form a composite ingot. This composite ingot has a substantially continuous metallurgical bond between alloy layers with dispersed particles of one or more intermetallic compositions of the first alloy in a region of the second alloy adjacent the interface.

Owner:NOVELIS INC

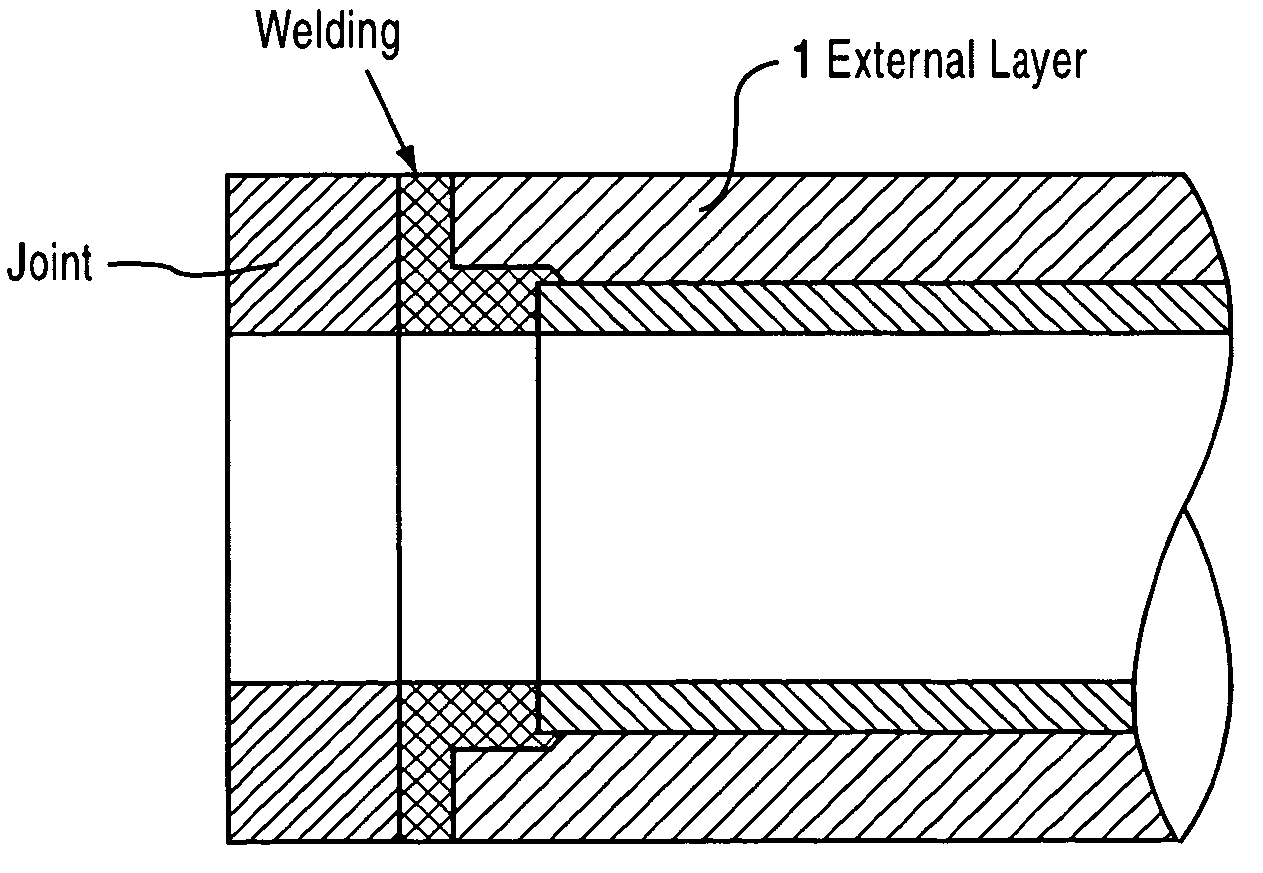

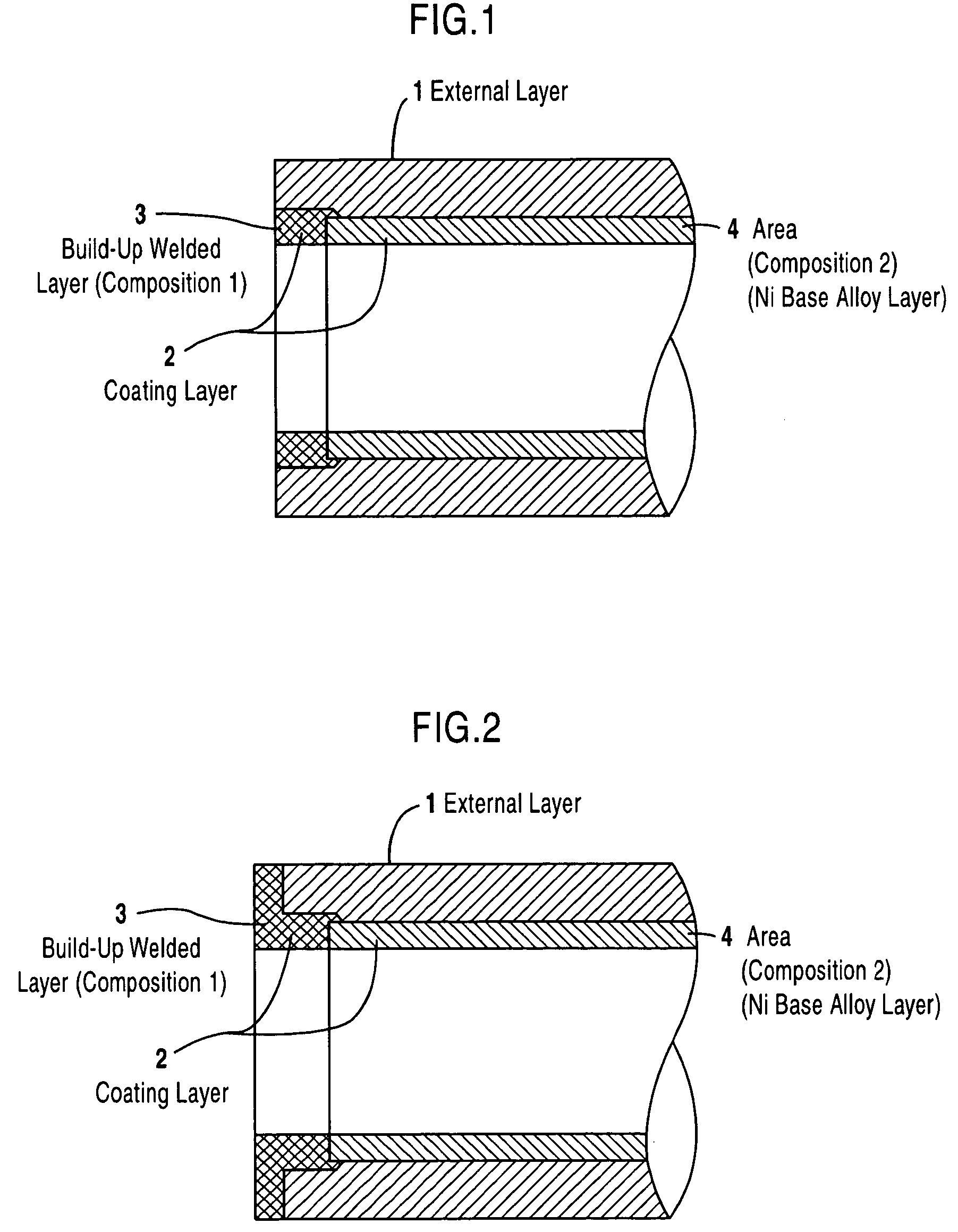

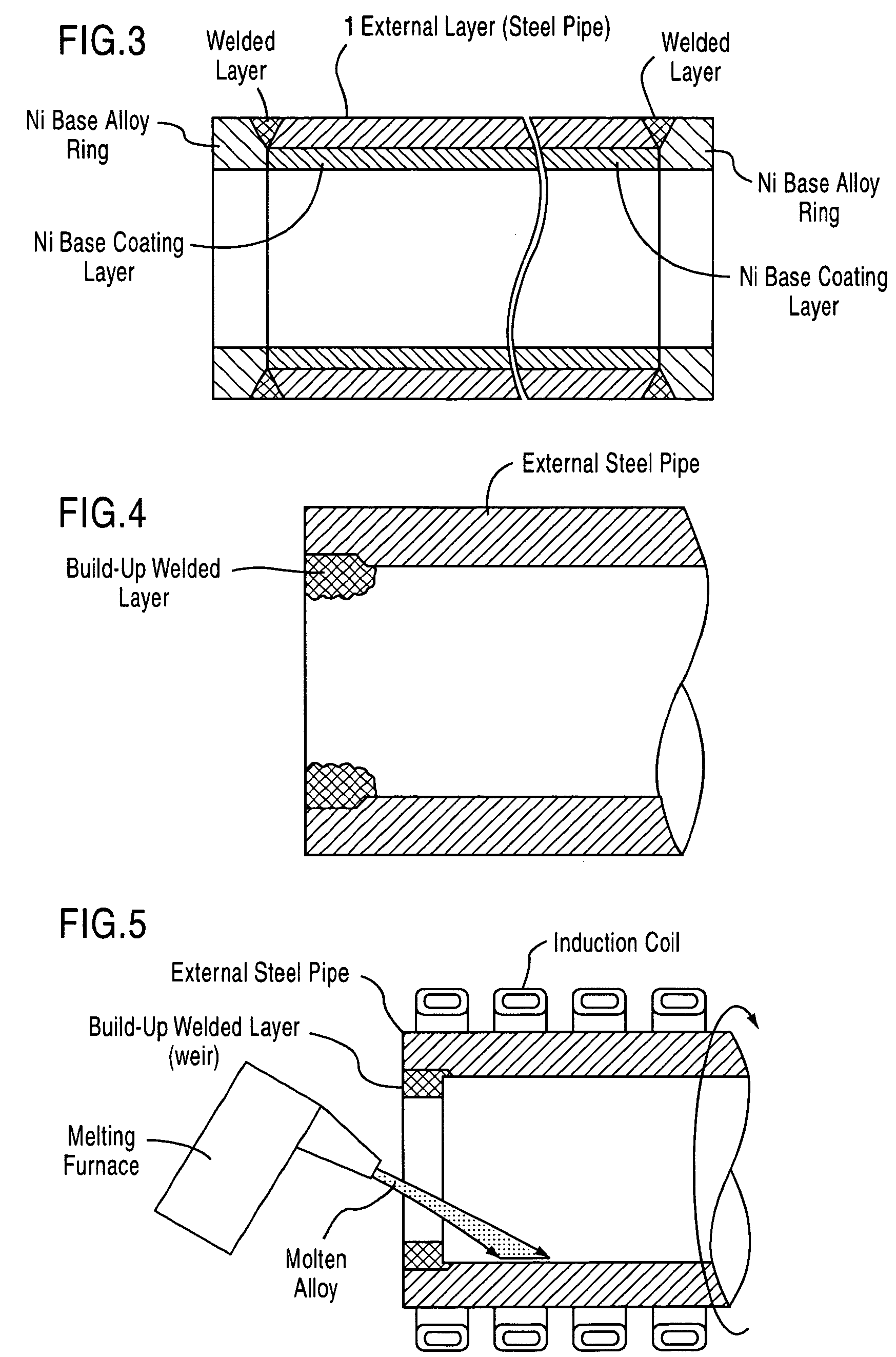

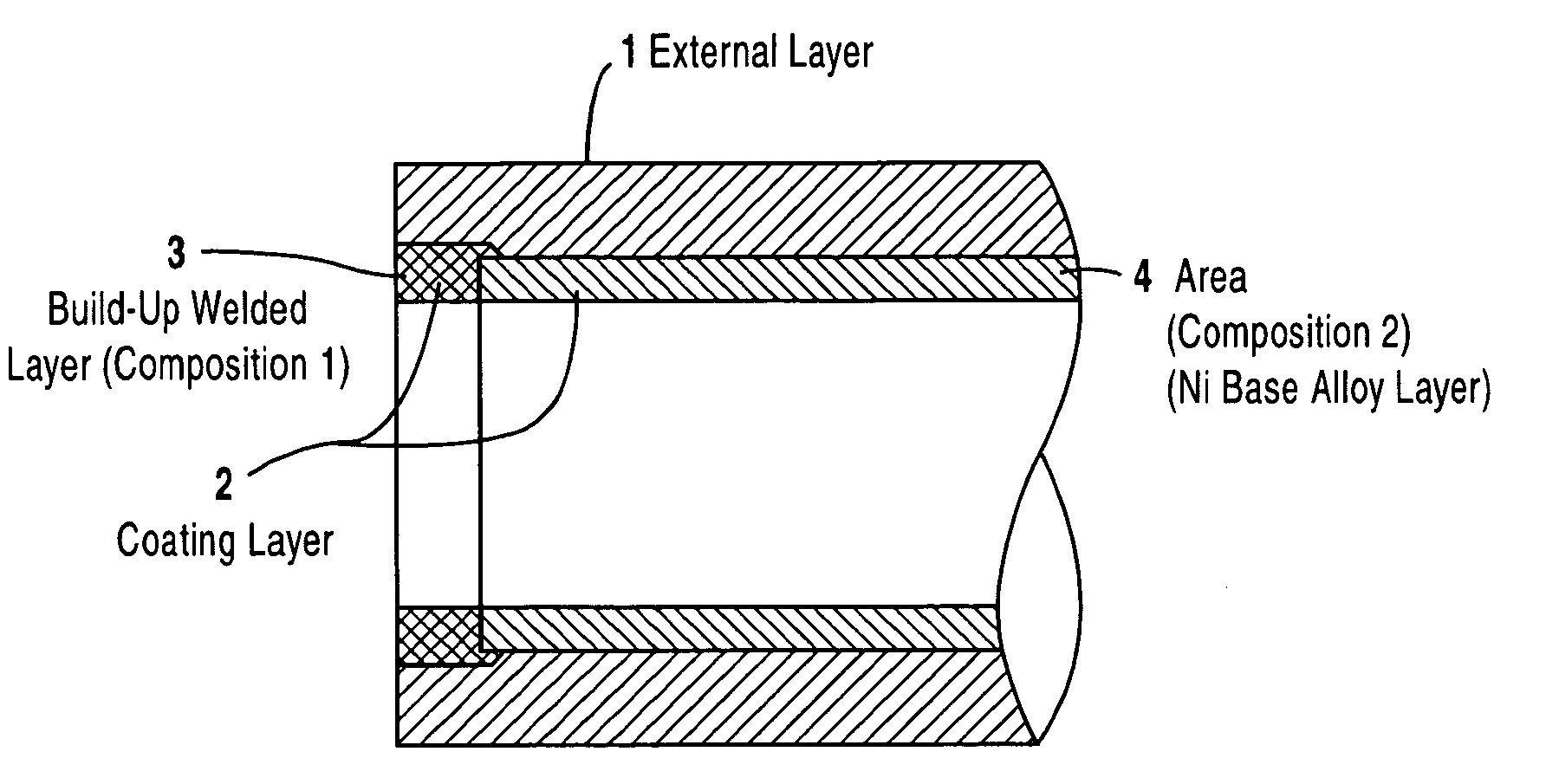

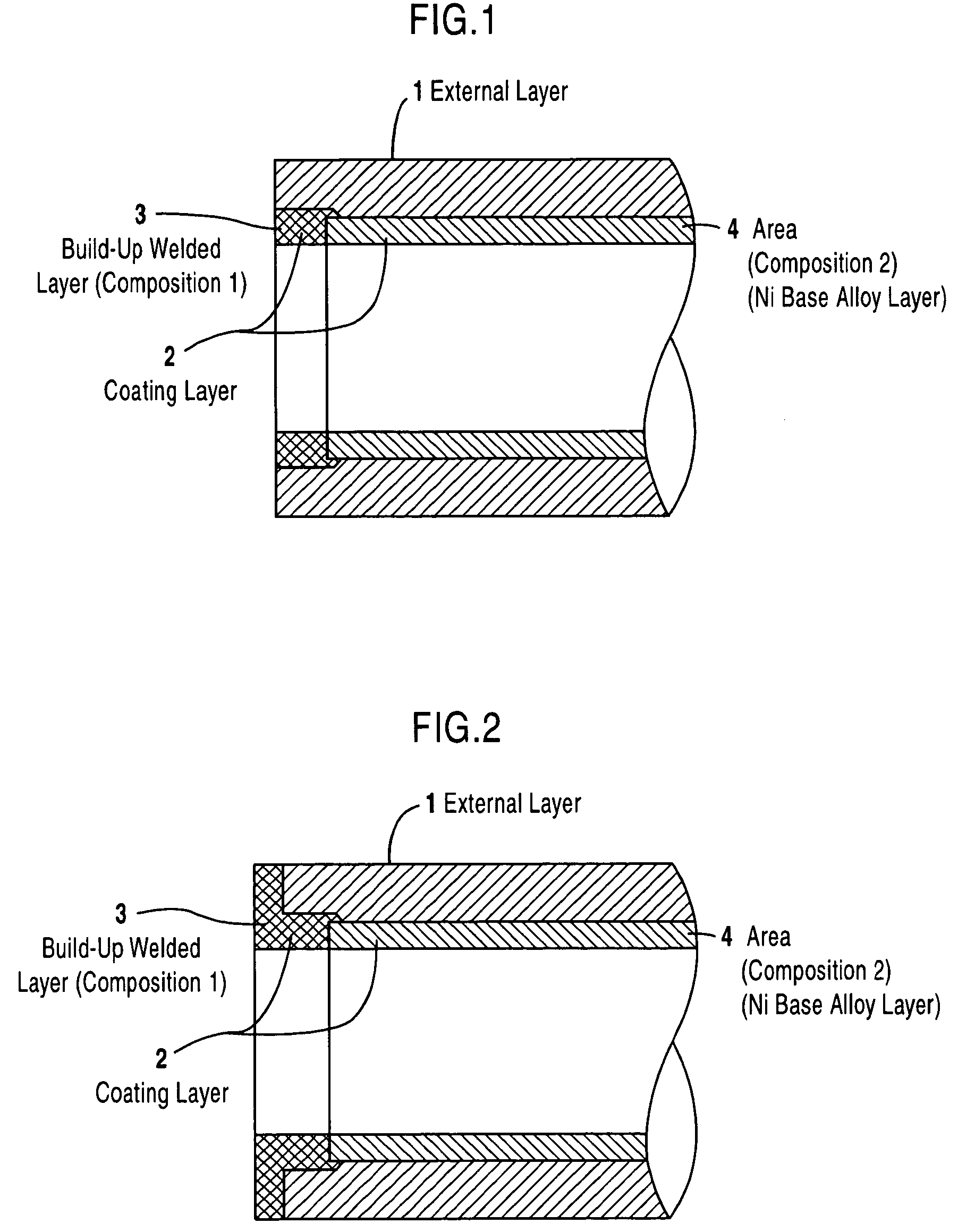

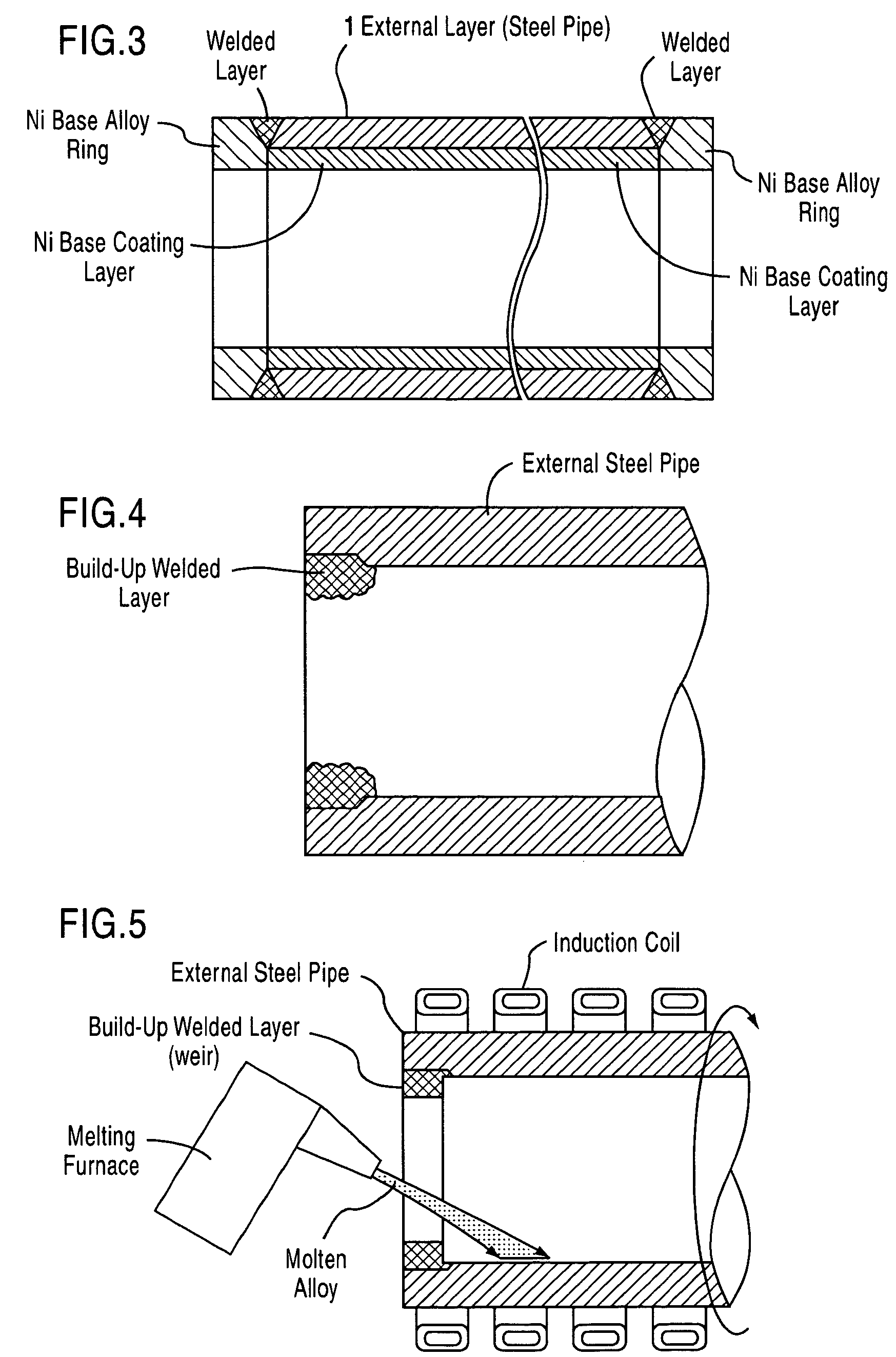

Clad pipe

InactiveUS20050166987A1Improve corrosion resistanceEasy to weldEnvelopes/bags making machineryMolten spray coatingMetallurgyAlloy

A clad pipe includes an external layer and a coating layer made of Ni base anticorrosion alloy. Both end portion areas of the coating layer are formed by a build-up welded layer (Ni base alloy of composition 1) on the inner surface of the external layer. Other areas are formed by a Ni base alloy layer (Ni base alloy of composition 2) fusion-bonded to the build-up welded layers and the inner surface of the pipe, a solidus-curve temperature of the Ni base alloy layer being 1300° C. or below and lower than a solidus-curve temperature of the Ni base alloy formed by build-up welding by 150° C. or more. Composition 1 and composition 2 are adjusted so that, in the same environment, corrosion resistance of the Ni base alloy of composition 1 is equivalent to or superior to that of the Ni base alloy of composition 2.

Owner:DAI ICHI HIGH FREQUENCY

High-strength aluminum alloy brazing filler metal with melting point being lower than 500 DEG C and preparation method thereof

InactiveCN102152024AAvoid overheatingAvoid eclipseWelding/cutting media/materialsSoldering mediaFiller metalShear strength

The invention discloses a high-strength aluminum alloy brazing filler metal with the melting point being lower than 500 DEG C and a preparation method thereof, belonging to the technical field of aluminum alloy welding. The brazing filler metal contains the following components in percentage by mass: 7.9-8.5 percent of Si, 14.0-16.0 percent of Cu, 7.0-8.0 percent of Ge, 2.0-4.0 percent of Ni, 2.0-3.0 percent of Sn, 0.5-1.5 percent of Mg, 0.55-0.65 percent of Sr, 0.1-0.3 percent of Bi, 0.5-1.0 percent of La and the balance of Al. The brazing filler metal is prepared by adopting a melt rapid cooling technology, has the melting point being lower than 500 DEG C and the brazing temperature from 520 DEG C to 530 DEG C, and is suitable for the brazing such as flame brazing, induction brazing, furnace brazing, gas-shielded brazing and the like of aluminum alloy with solidus curve of higher than 520 DEG C,. The brazing filler metal is in cooperation with QJ201 brazing LF21, and the shearing strength of a brazed joint is larger than 70MPa. The brazing filler metal has less content of Ge and lower cost.

Owner:ZHEJIANG UNIV

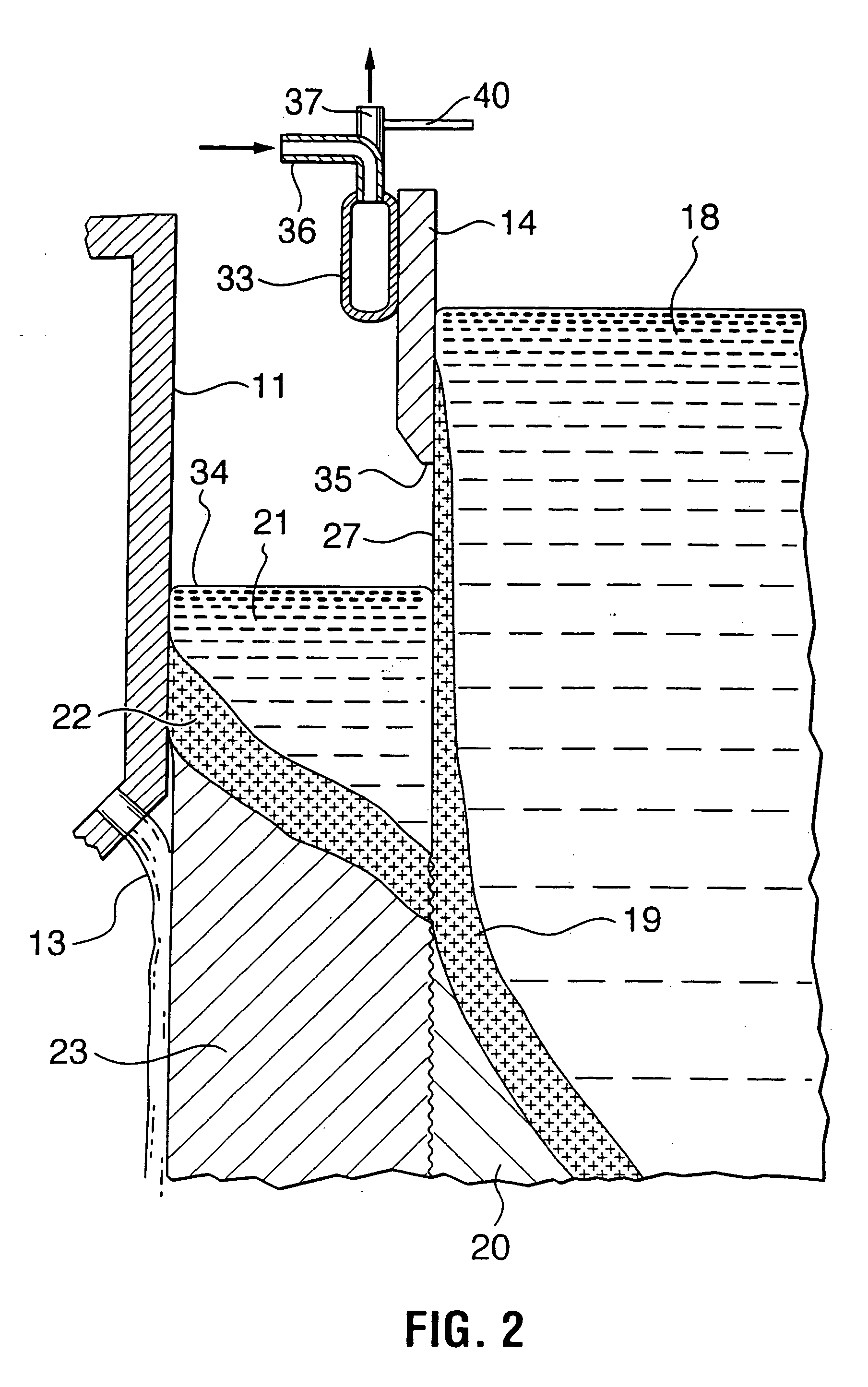

Method for casting composite ingot

InactiveUS20060185816A1Easy to controlImprove corrosion resistanceThin material handlingSurface layerIngot

A method and apparatus for the casting of a composite metal ingot comprising at least two separately formed layers of one or more alloys. An open ended annular mould has a feed end and an exit end and divider wall for dividing the feed end into at least two separate feed chambers, where each feed chamber is adjacent at least one other feed chamber. For each pair of adjacent feed chambers a first alloy stream is fed through one of the pair of feed chambers into the mould and a second alloy stream is fed through another of the feed chambers. A self-supporting surface is generated on the surface of the first alloy stream and the second alloy stream is contacted with the first stream such that the upper surface of the second alloy stream is maintained at a position such that it first contacts the self-supporting surface where the self-supporting surface temperature is between the liquidus and solidus temperatures of the first alloy or it first contacts the self-supporting surface where the self-supporting surface temperature is below the solidus temperatures of the first alloy but the interface between the two alloys is then reheated to between the liquidus and solidus temperatures, whereby the two alloy streams are joined as two layers. The joined alloy layers are then cooled to form a composite ingot. This composite ingot has a substantially continuous metallurgical bond between alloy layers with dispersed particles of one or more intermetallic compositions of the first alloy in a region of the second alloy adjacent the interface. The combination of an alloy of high strength bonded to a surface layer of higher ductility gives a sheet of improved bendability compared to the high strength alloy used alone.

Owner:NOVELIS INC

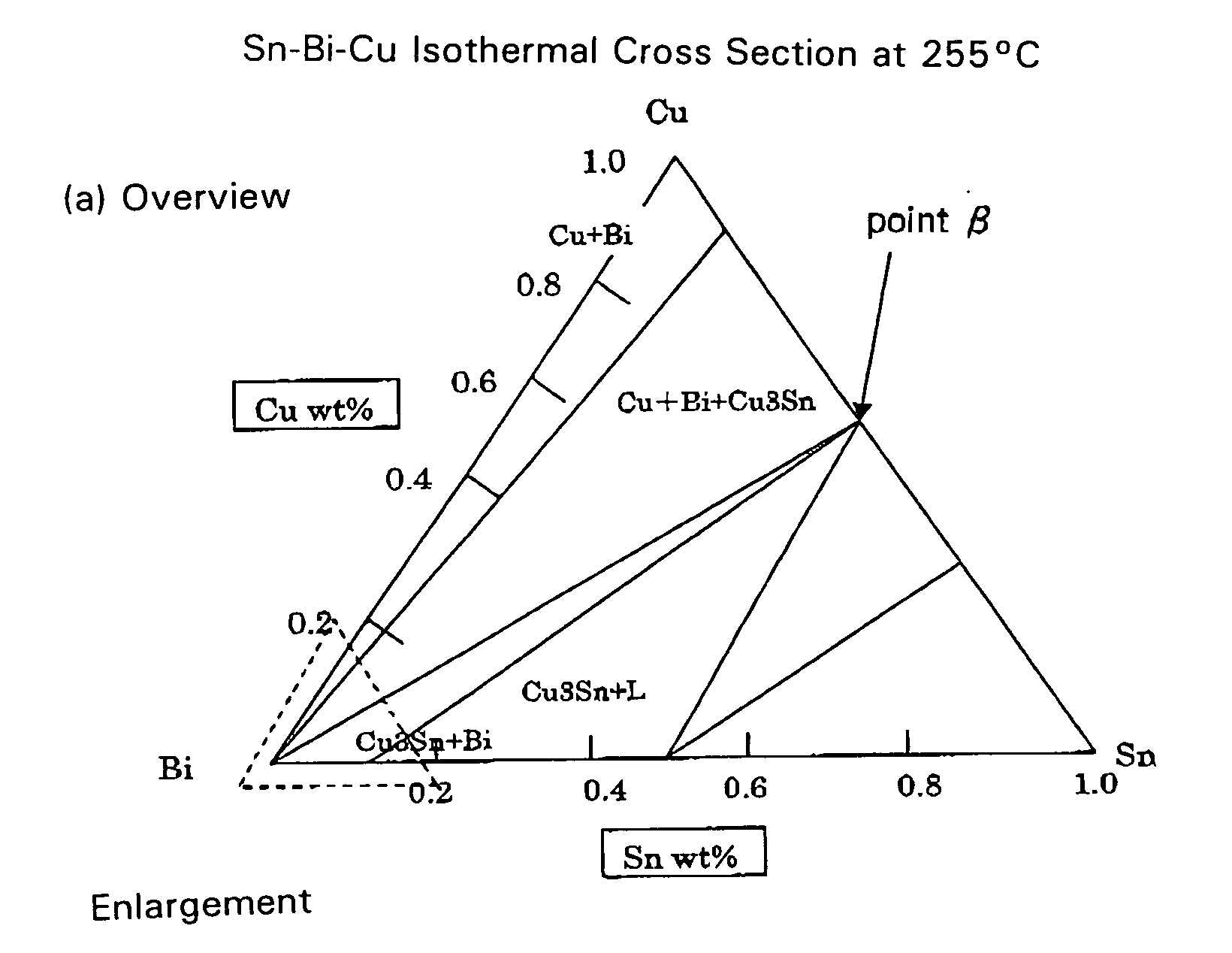

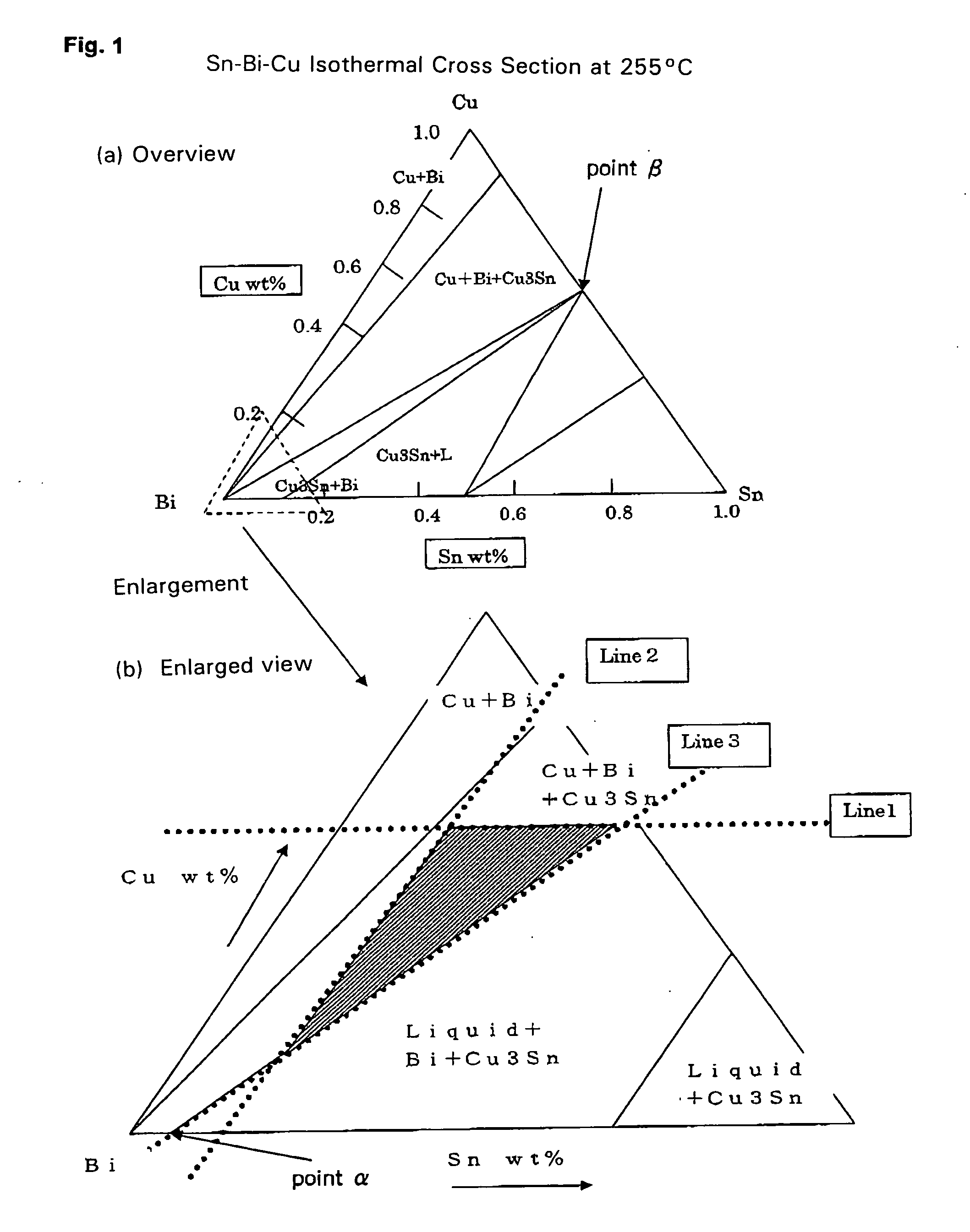

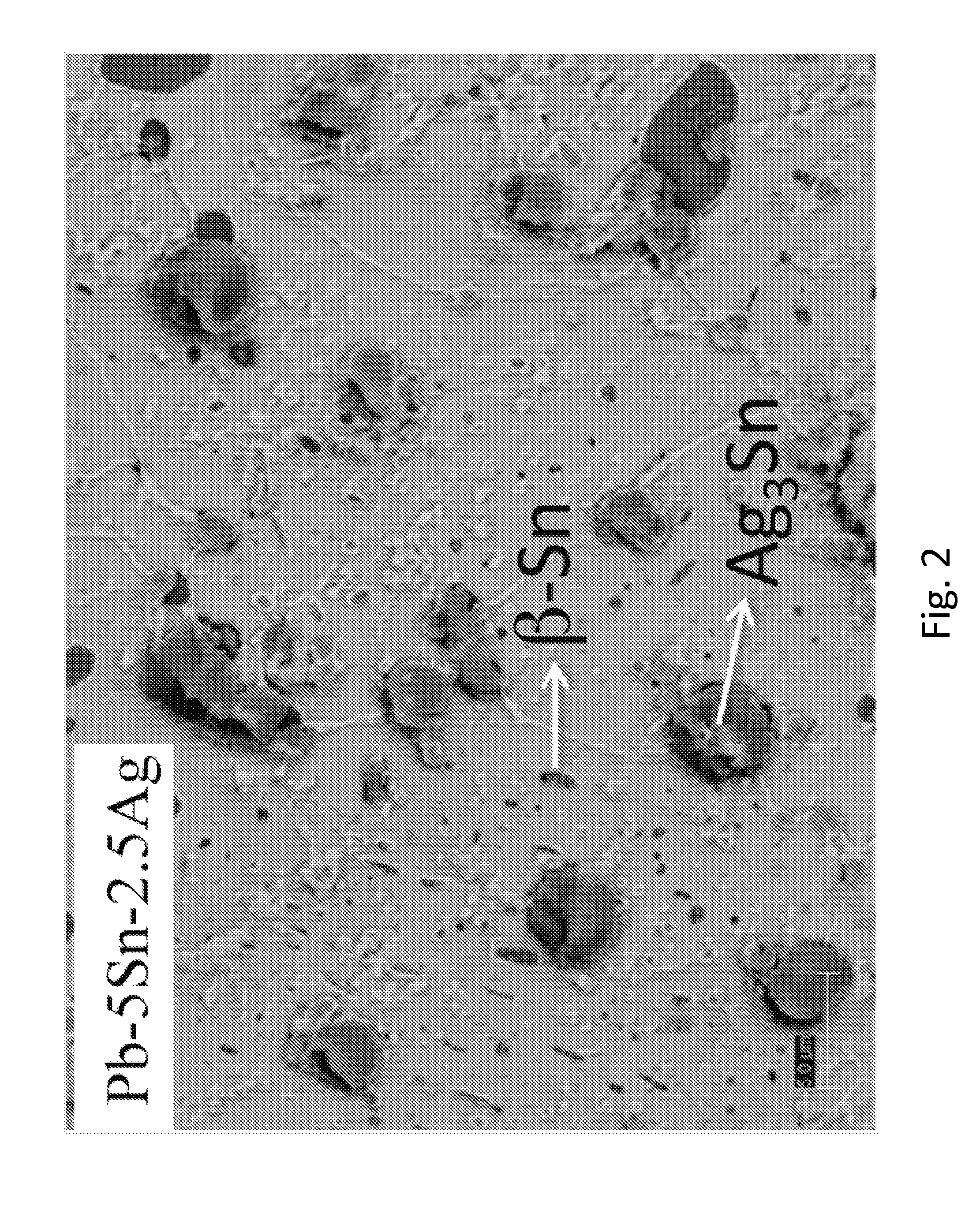

Solder Paste and Solder Joint

ActiveUS20090301607A1Improve wettabilityLow melting pointPrinted circuit aspectsPrinted circuit manufactureAlloyMetal powder

The invention provides a solder paste which has a solidus temperature of 255° C. or above and is improved in the wettability between Bi and Cu or Ag electrode to attain approximately equivalent wettability to those of Pb-containing high-temperature solders even in low-temperature soldering. The solder paste comprises a metal powder component consisting of Bi or a Bi alloy, a solidus temperature lowering metal for Bi, and a solid-phase metal capable of forming an intermetallic compound with the solidus temperature lowering metal, and a flux component.

Owner:SENJU METAL IND CO LTD +1

Lid for a functional part and a process for its manufacture

InactiveUS20100291399A1Easy to manufactureFunctionalHot-dipping/immersion processesSemiconductor/solid-state device detailsSolderabilitySolder paste

As a replacement for high-temperature solder having a solidus temperature of at least 250° C. for bonding a package and a lid of a functional part, a solder paste formed by mixing a Cu-based metal powder with a solidus temperature of at least 400° C. and an Sn-based solder powder is applied to a lid of a difficult to solder material which was previously subjected to plating having good solderability and heated to obtain a solder layer comprising the Cu-based metal powder, Cu6Sn5 intermetallic compounds, and lead-free solder on the plated surface. The intermetallic compounds are bonded to the difficult to solder material and the intermetallic compounds are connected to each other, so the solder layer functions as a high-temperature solder. The problem of poor solderability of high-temperature solders is avoided by the present invention.

Owner:SENJU METAL IND CO LTD

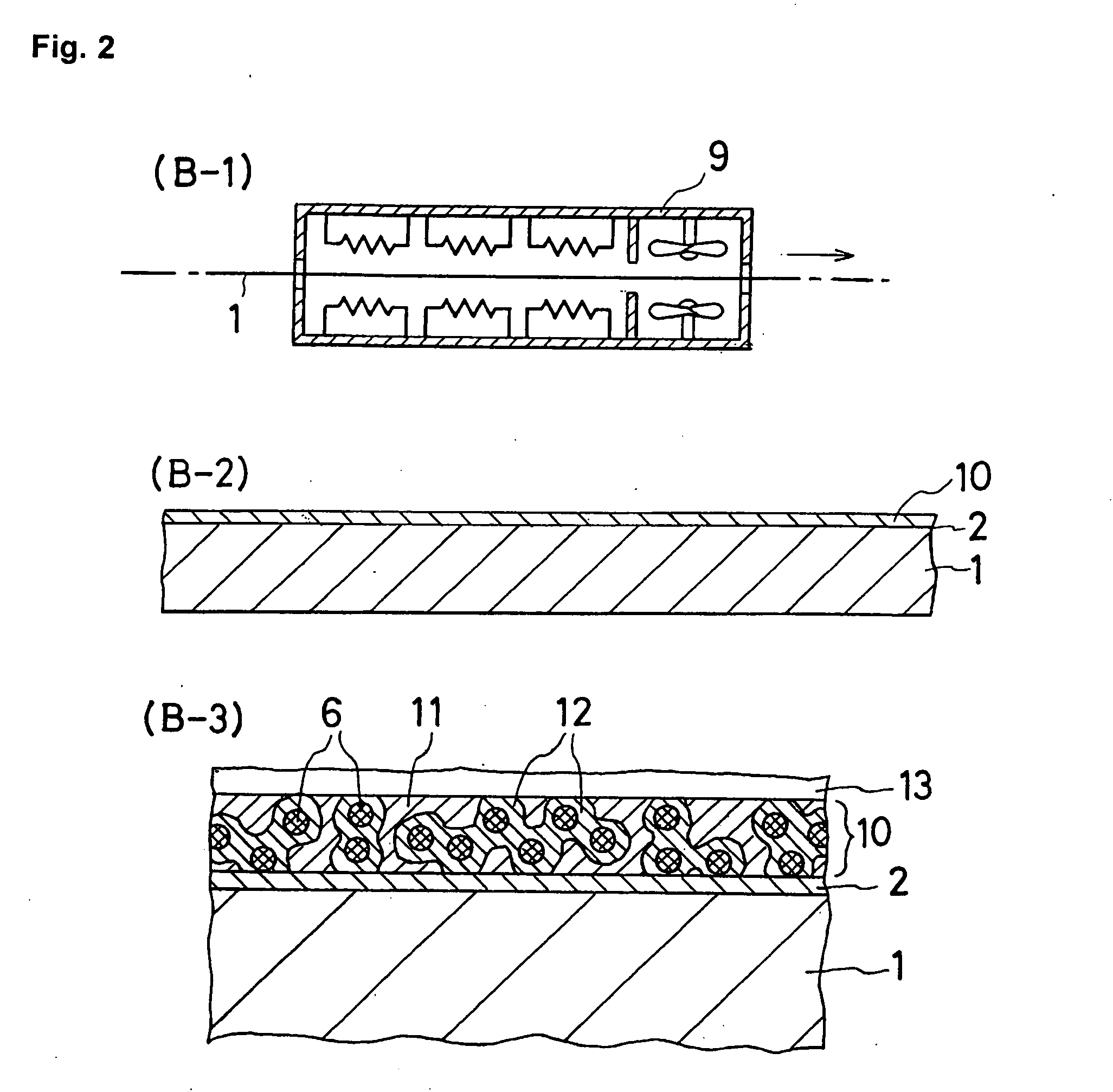

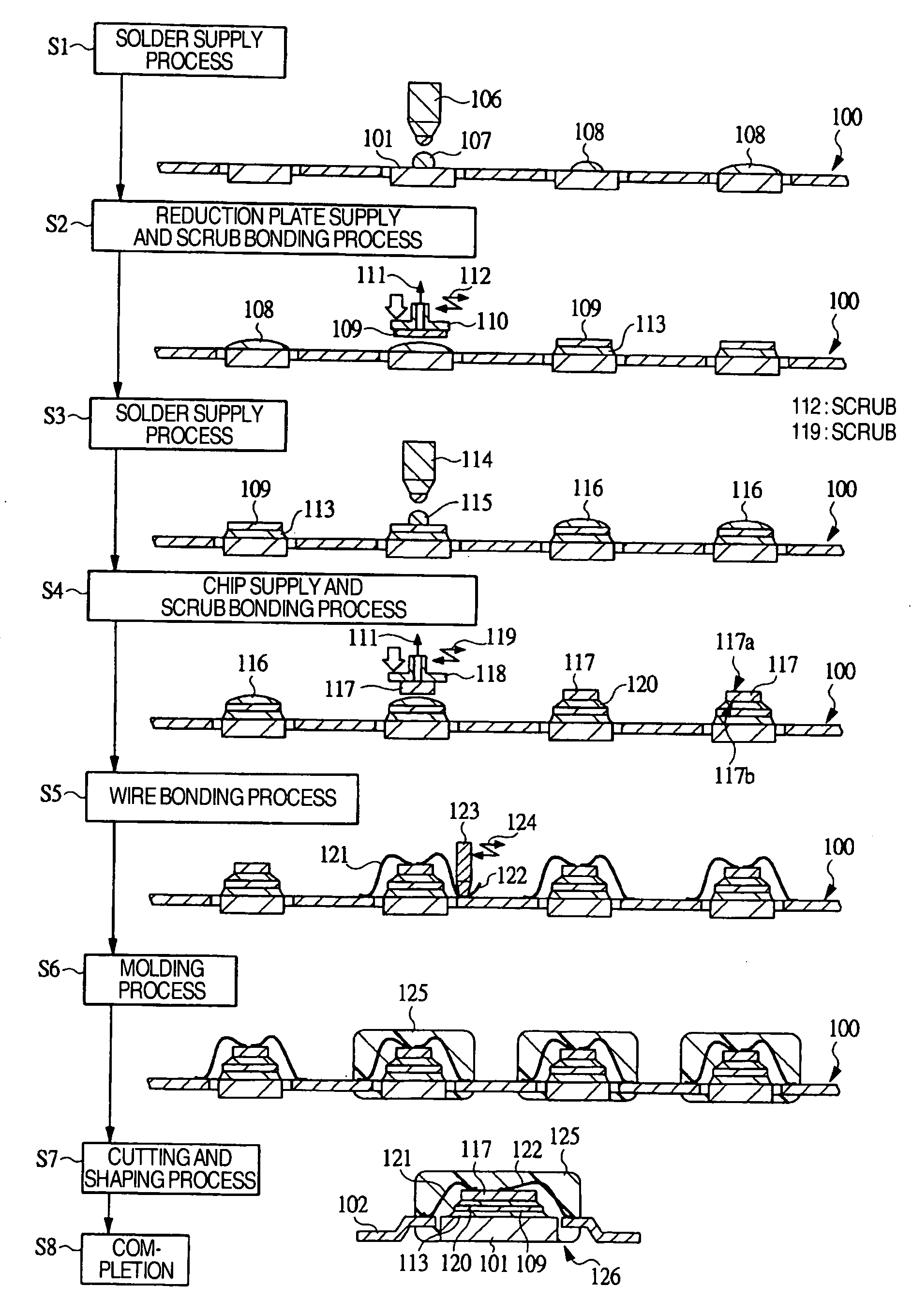

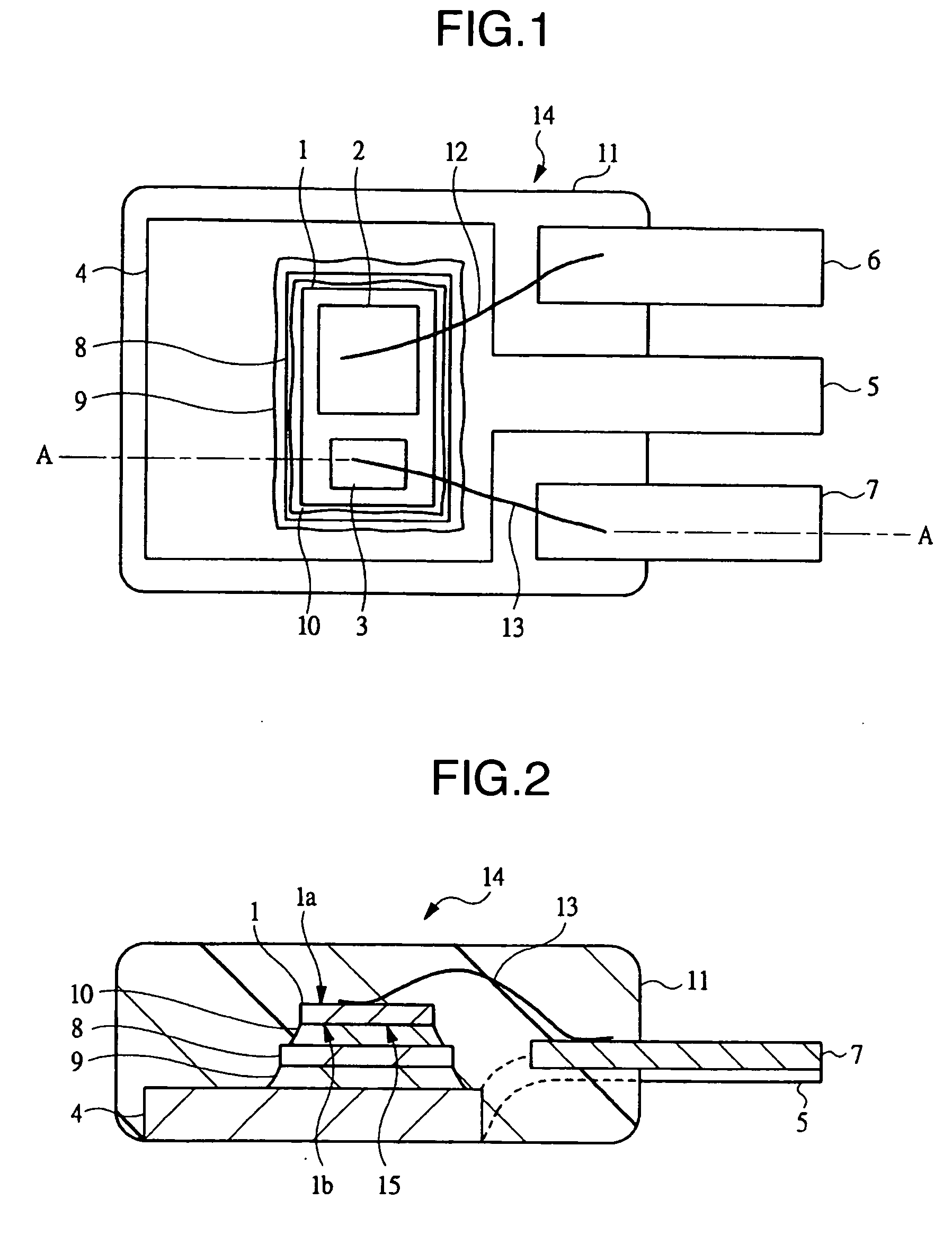

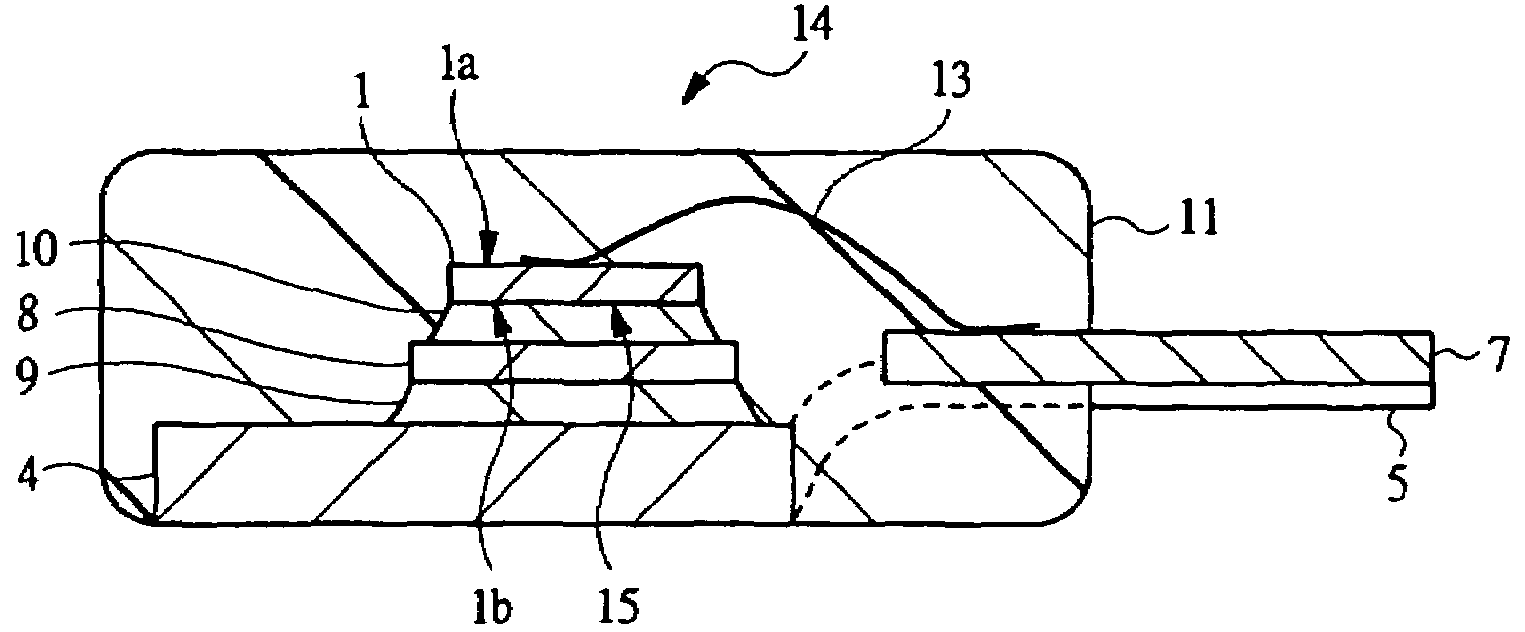

Semiconductor apparatus and manufacturing method

InactiveUS20060151889A1Preventing chip crackAvoid crackingTransportation and packagingRotary stirring mixersSemiconductor chipDie bonding

Pb free solder is used in die bonding. A thermal stress reduction plate is disposed between a semiconductor chip and a die pad made of a Cu alloy. The semiconductor chip and the thermal stress reduction plate are joined and the thermal stress reduction plate and the die pad are joined by a joint material of Pb free solder having Sn—Sb—Ag—Cu as its main constituent elements and having a solidus temperature not lower than 270° C. and a liquidus temperature not higher than 400° C. Thus, die bonding can be performed using the Pb free solder without generating any chip crack.

Owner:RENESAS ELECTRONICS CORP

Aluminum alloy intermediate temperature solder for braze welding

ActiveCN1970213ASolving Brazing ProblemsSimple processWelding/cutting media/materialsSoldering mediaSolderingUltimate tensile strength

It relates to an aluminum alloy solder with its components' mass percentage 16-20%Cu,5-8%Si,0.2-2.0%Mn,0-2%Mg, and the rest being Al. Small portion of Ti and B fine grains can be added to the solder to improve processing performance. The molten temperature of solder ranges 500-540DEG C, solder welding temperature 540-570DEG C, suitable for aluminum alloy soldering with the solids line temperature below 540DEG C. The solder can be made into different types like blocks, quick condensed strips or bars, suitable for vacuum soldering, protective solder and flame solder. The solder 6A02,2A5 alloy joint has tensile strength bigger than 100MPa, joint shearing force bigger than 80Mpa, without significant reduction of the joint strength after 200h salt fog corrosion.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

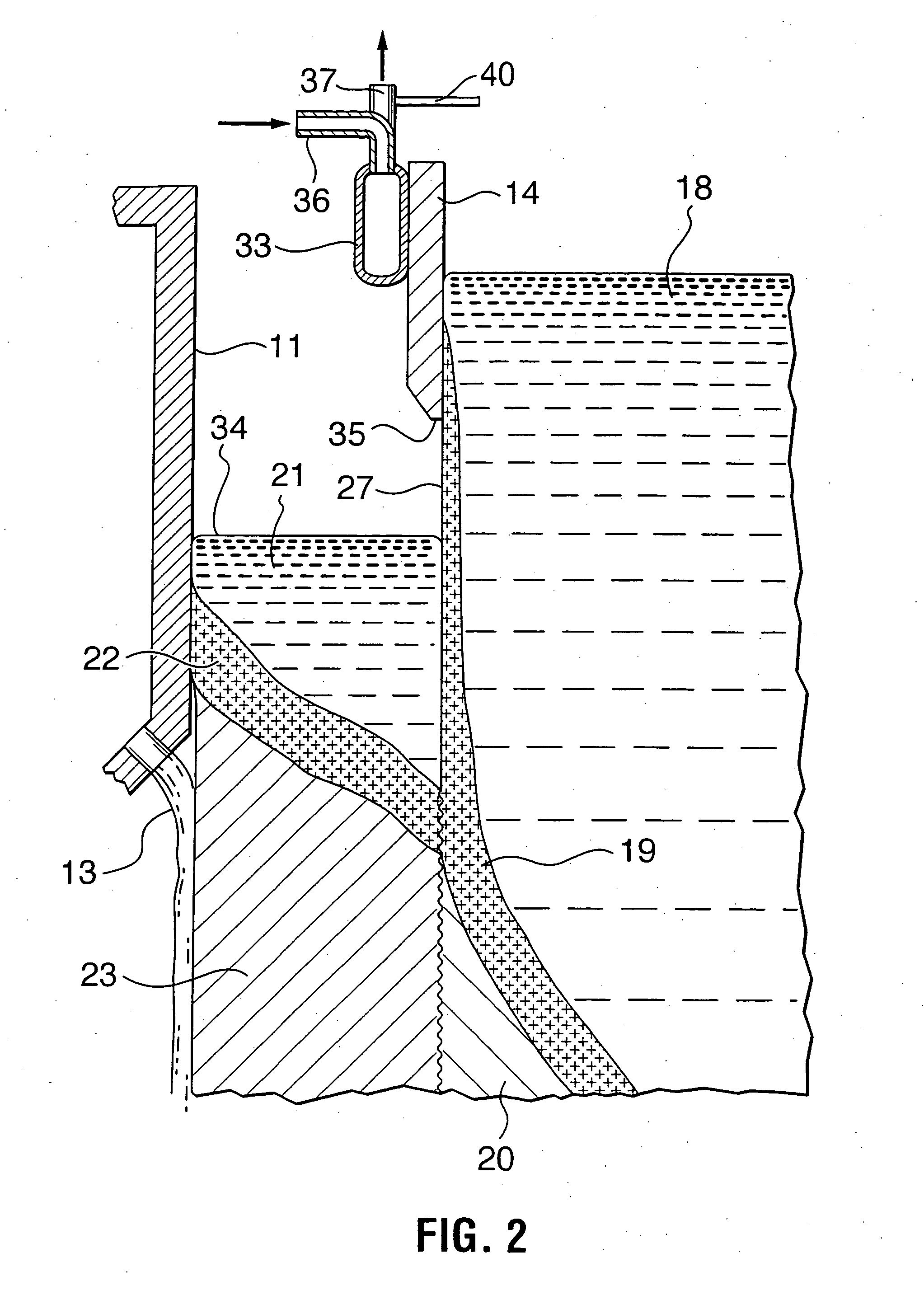

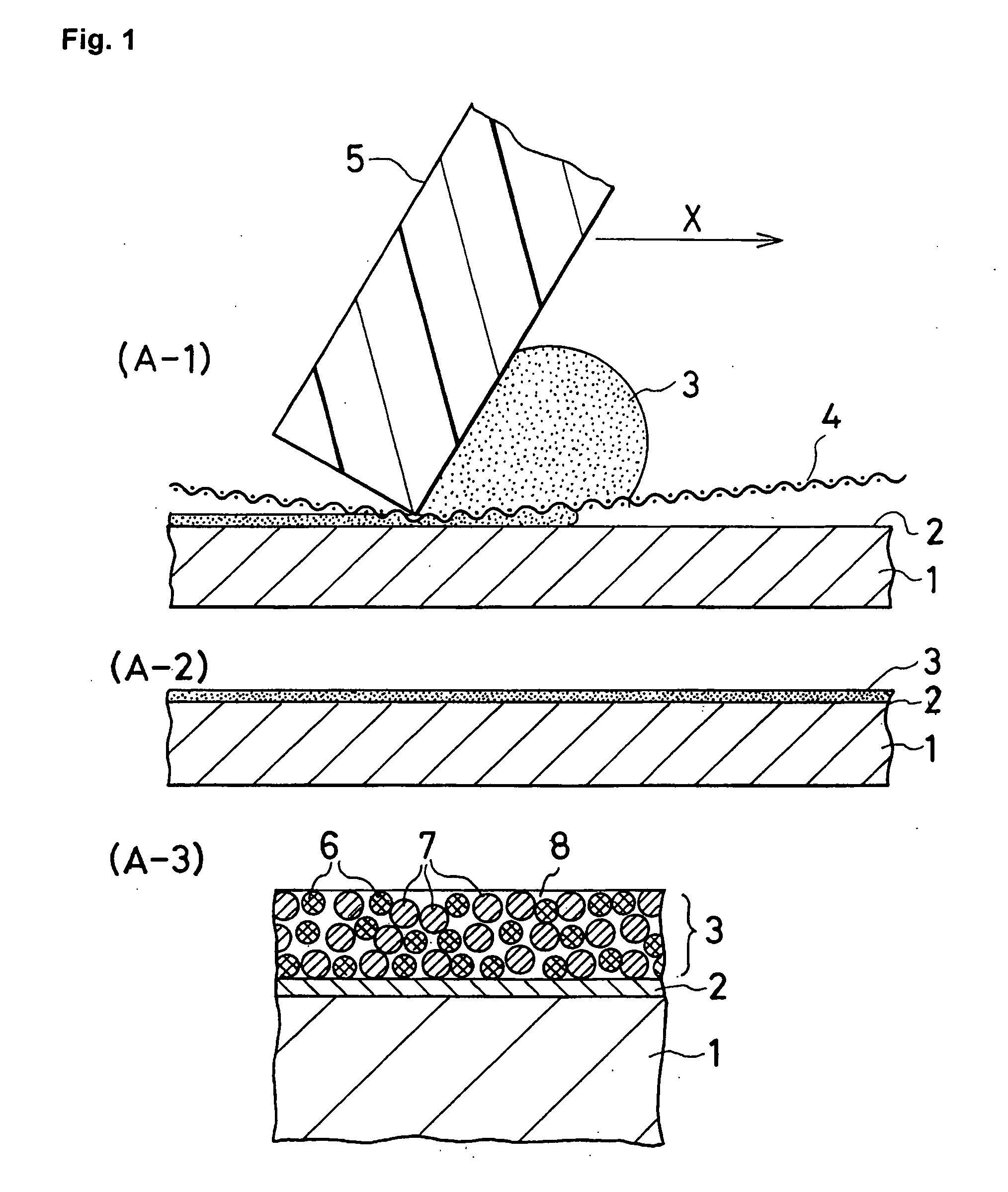

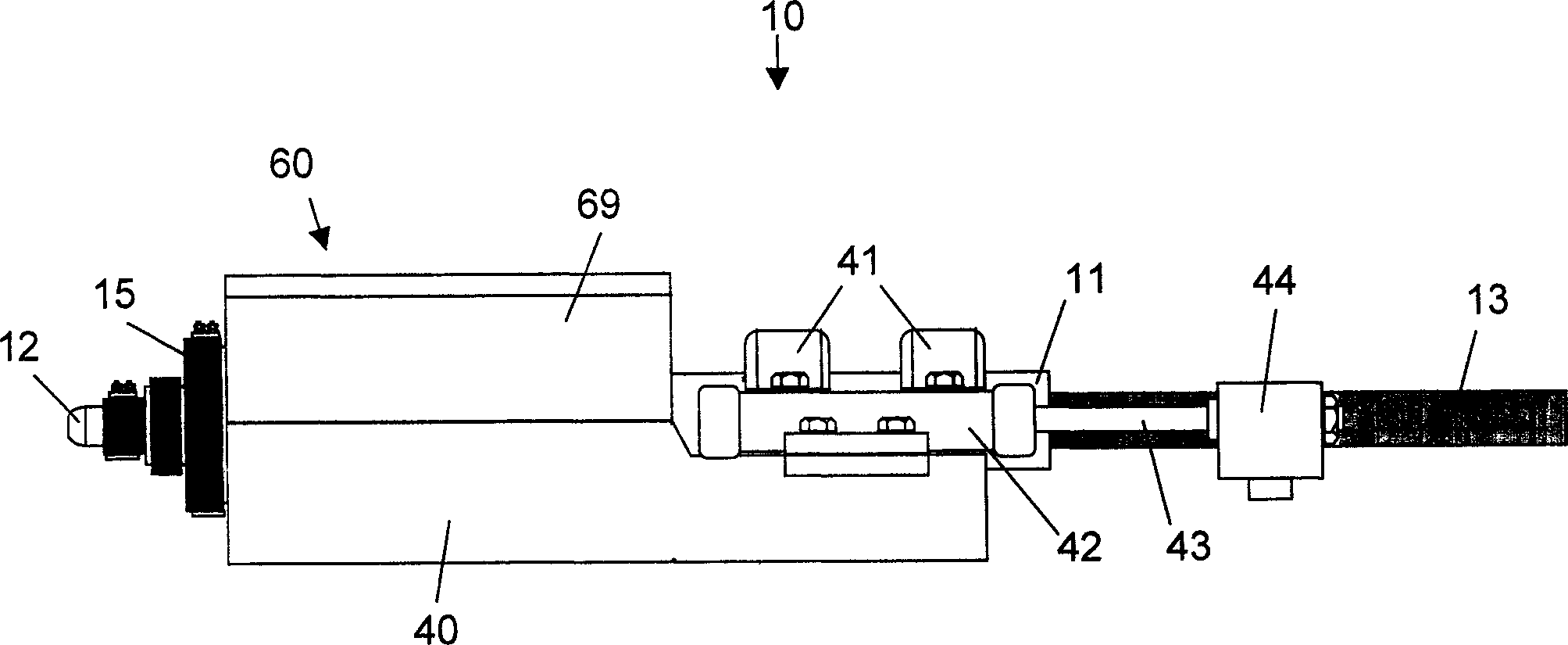

Cladding ingot to prevent hot-tearing

A method of casting an ingot of a metal having a susceptibility to hot-tearing while avoiding such hot tearing. The method involves co-casting a cladding metal on a surface of a metal core ingot as the ingot is being cast in a DC casting procedure. The cladding layer preferably contacts the core ingot at a position on the ingot surface where the metal of the ingot is incompletely solid, e.g. at a temperature between its solidus temperature and liquidus temperatures. The metal of the core ingot and the metal of the cladding layer are the same and, if they contain grain refiners, the are present in an amount of 0.005% by weight of the metal or less.

Owner:NOVELIS INC

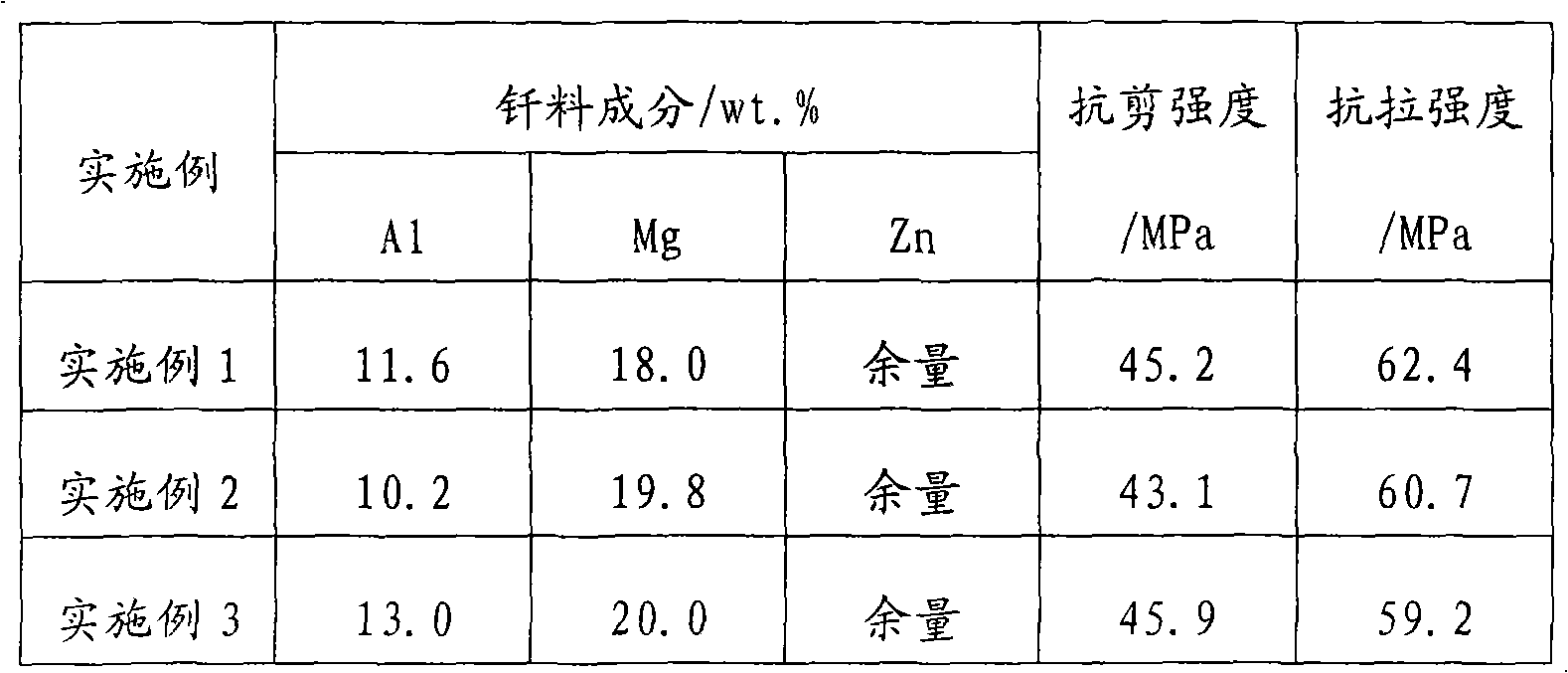

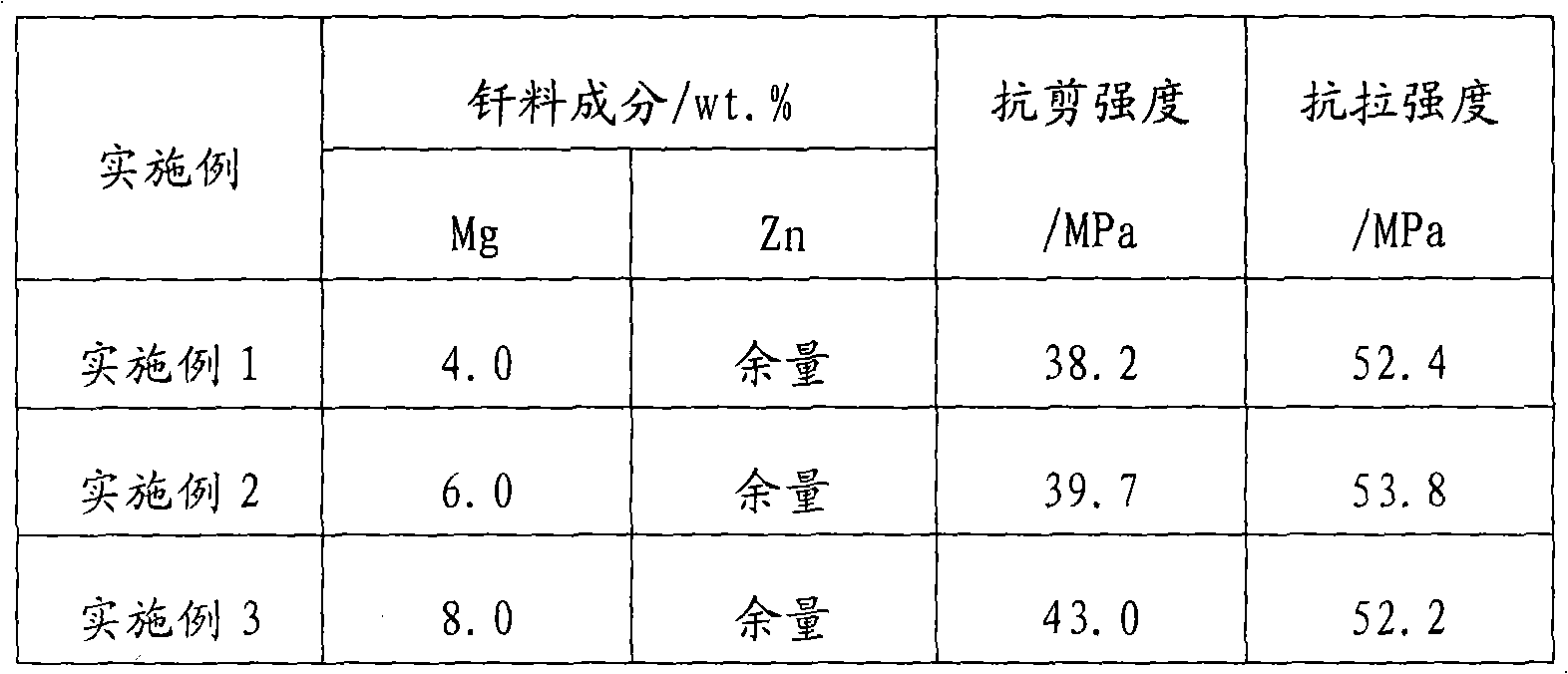

Zn-Mg-Al magnesium alloy solder

InactiveCN101653879AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaButt jointSoldering

The invention provides a Zn-Mg-Al magnesium alloy solder, belonging to the technical field of magnesium alloy welded joint. The components of the provided Zn-Mg-Al magnesium alloy solder contain 10% to 13% of Al, 18% to 20% of Mg and the remains are Zn. The melt temperature of the Zn-Mg-Al magnesium alloy solder is ranged from 379 DEG C to 488 DEG C and the soldering temperature is ranged from 500DEG C to 510 DEG C. The solder can be applied to the magnesium alloy solder with solidus temperature above 510 DEG C. The AZ31B magnesium can be soldered in the manner of high frequency induction welding. The slip resistance of the solder overlap joint is ranged from 43MPa to 45 MPa and the tensile strength of the butt joint is ranged from 59MPa to 62MPa.

Owner:BEIJING UNIV OF TECH

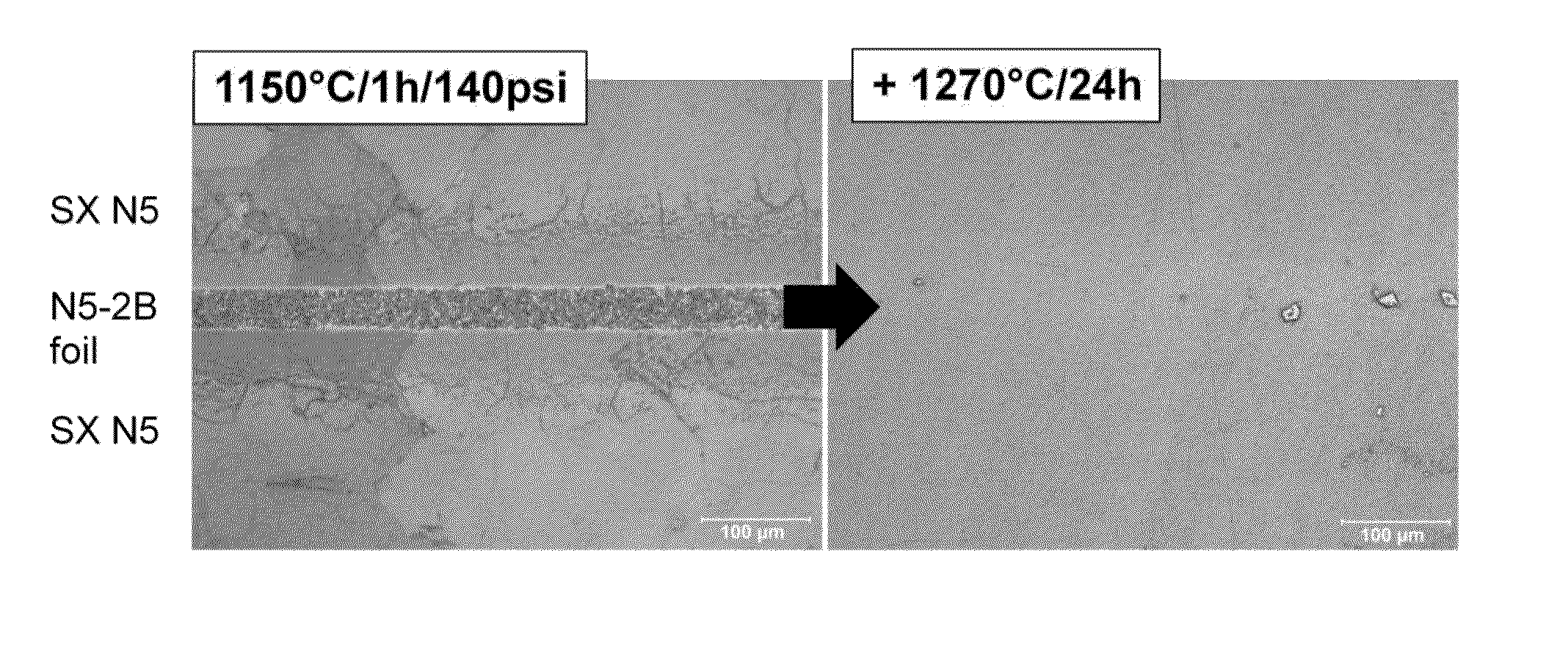

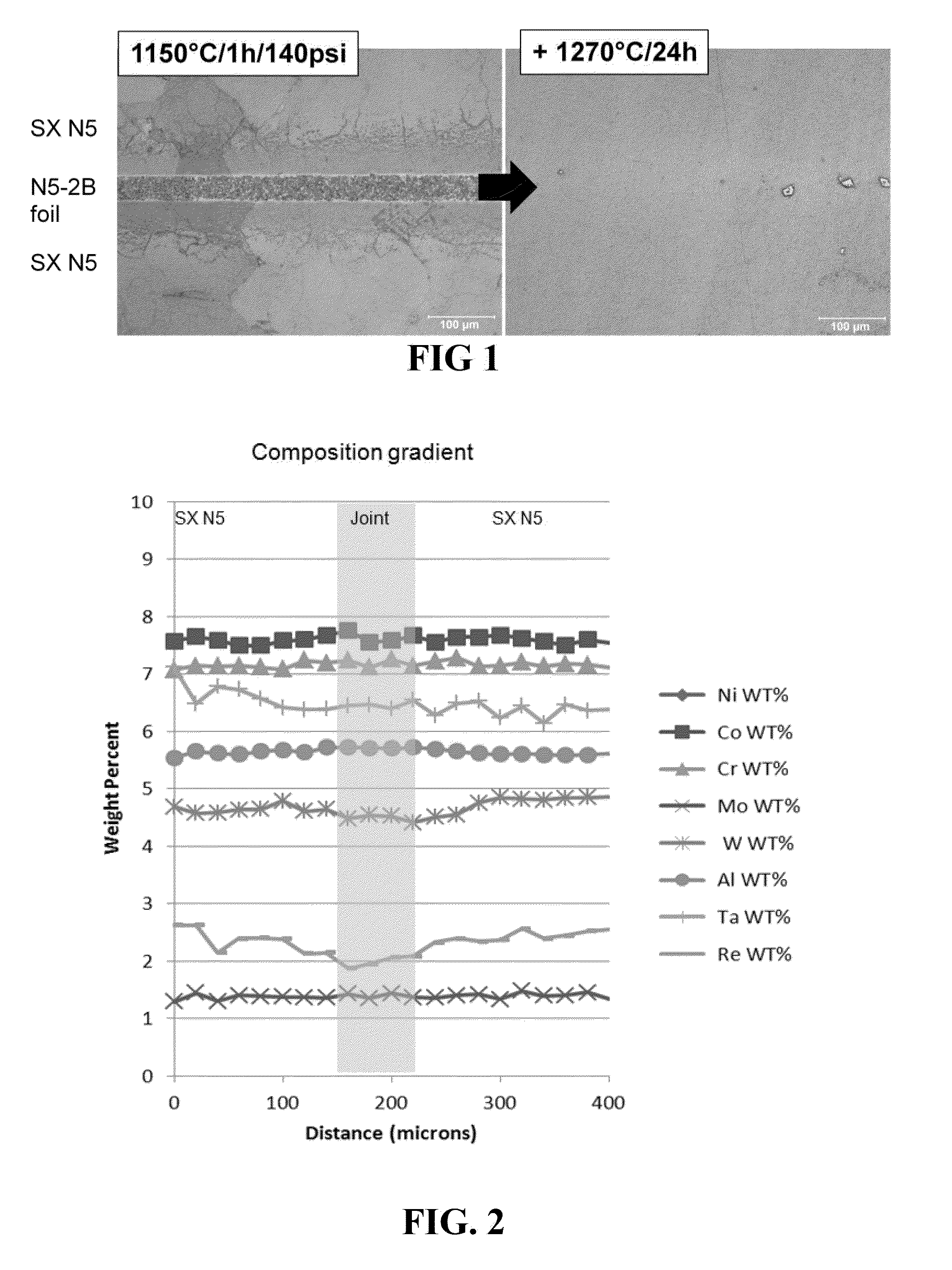

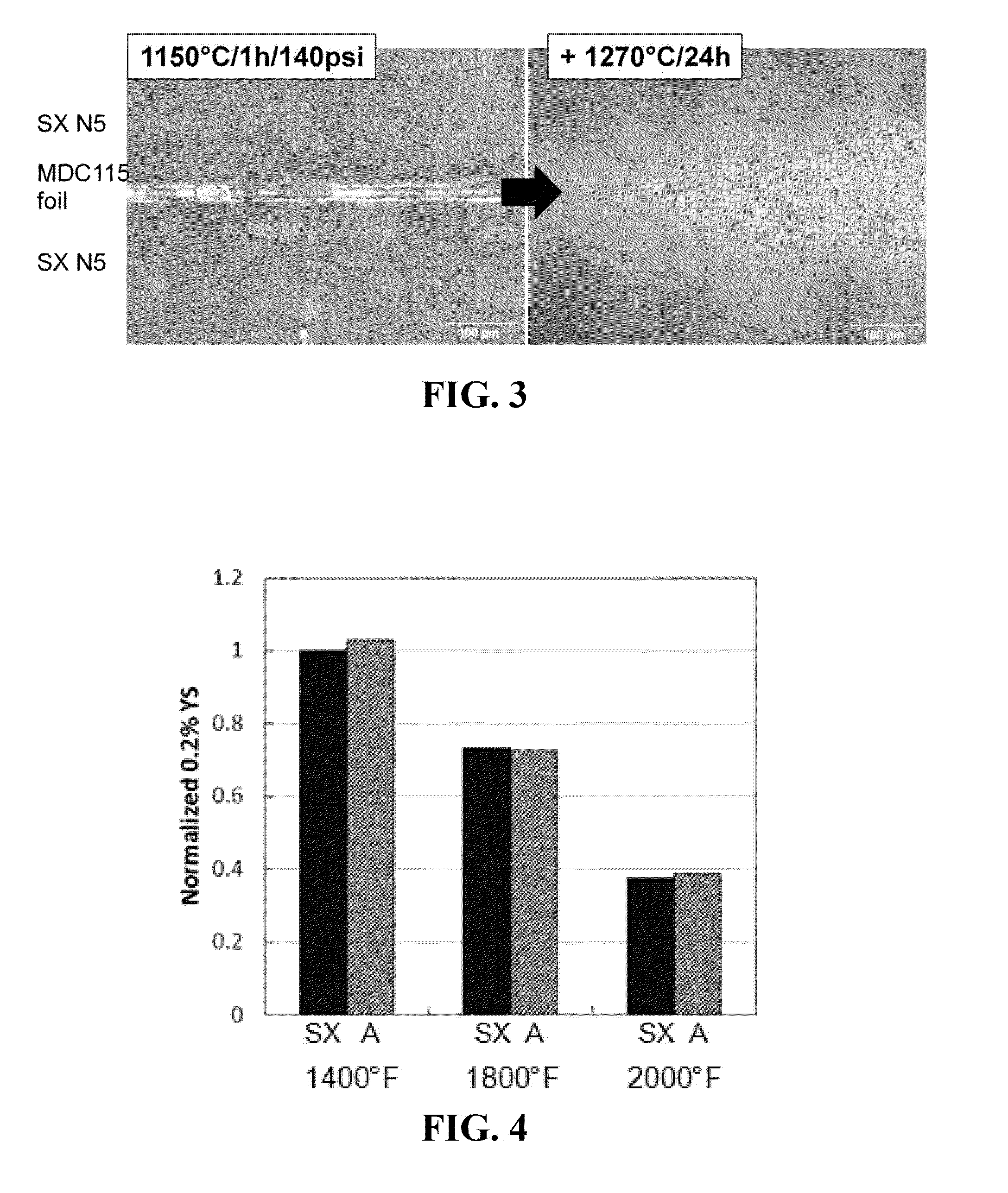

Joining process for superalloys

ActiveUS8925792B1Improve casting yieldHigh quality mechanical propertyWelding/cutting media/materialsSoldering mediaBoronHeat treated

A method of bonding superalloys is provided. The method includes: aligning a first superalloy subcomponent having a gamma-prime solvus g′1 and a second superalloy subcomponent having a gamma-prime solvus g′2, with a filler material that includes at least 1.5 wt % boron disposed between the first and second superalloy subcomponents; performing a first heat treatment at a temperature T1, where T1 is above the solidus of the filler material and below the liquidus of the filler material; and performing a second heat treatment at a temperature T2, where T2 is greater than T1, and where T2 is greater than or equal to the lower of g′1 and g′2.

Owner:GENERAL ELECTRIC CO

Previous particle boundary precipitation preventable high-temperature alloy powder hot isostatic pressing process

InactiveCN103551573AGuaranteed to dissolveIncrease profitTransportation and packagingMetal-working apparatusThermal insulationRoom temperature

The invention belongs to the field of powder metallurgy high-temperature alloy field, particularly relates to a previous particle boundary precipitation preventable high-temperature alloy powder hot isostatic pressing process and is applicable to preparation of powder metallurgy high-temperature alloy members formed through hot isostatic pressing directly. The process comprises that step one, the hot isostatic pressing temperature is higher than the initial melting temperature of low-melting-point phases of alloy powder and lower than 15 DEG C above the solidus of complete homogenization of alloy, the gas pressure is larger than or equal to 90 MPa, and time is longer than or equal to 20 minutes and shorter than or equal to 2 hours; step two, heating is stopped to subject materials to furnace cooling till the temperature of the materials is below the initial melting temperature of the low-melting-point phases to perform thermal insulation for 2 hours or longer after the first step is completed, so that the low-melting-point phases formed during cooling after the first step can be dissolved completely; the alloy is subjected to pressure maintaining and cooling with furnace till the room temperature after the second step is completed. By means of the process, precipitated phase such as carbides can be prevented from precipitating out along the powder previous particle boundaries, and accordingly, the compact alloy with microscopic structures as equiaxed grains is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

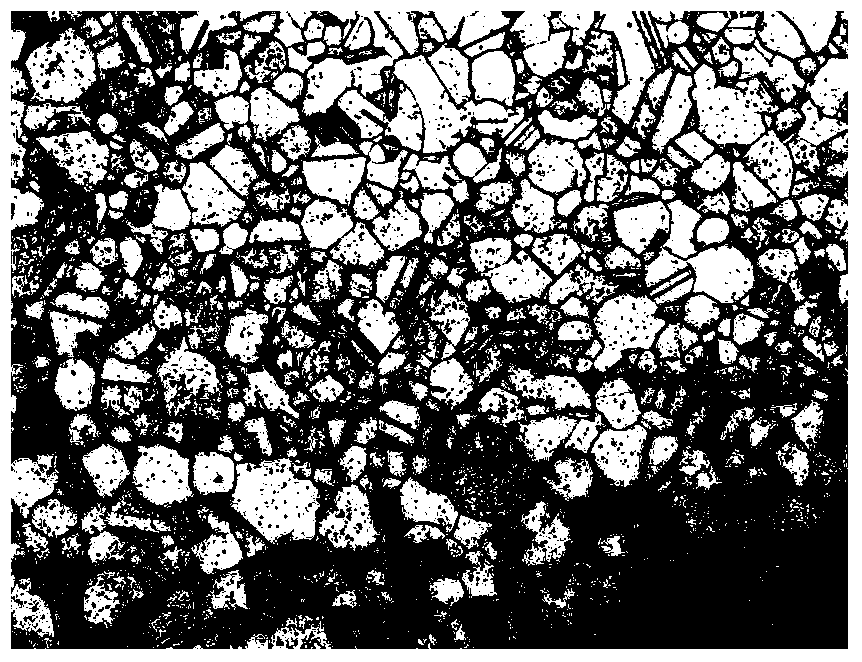

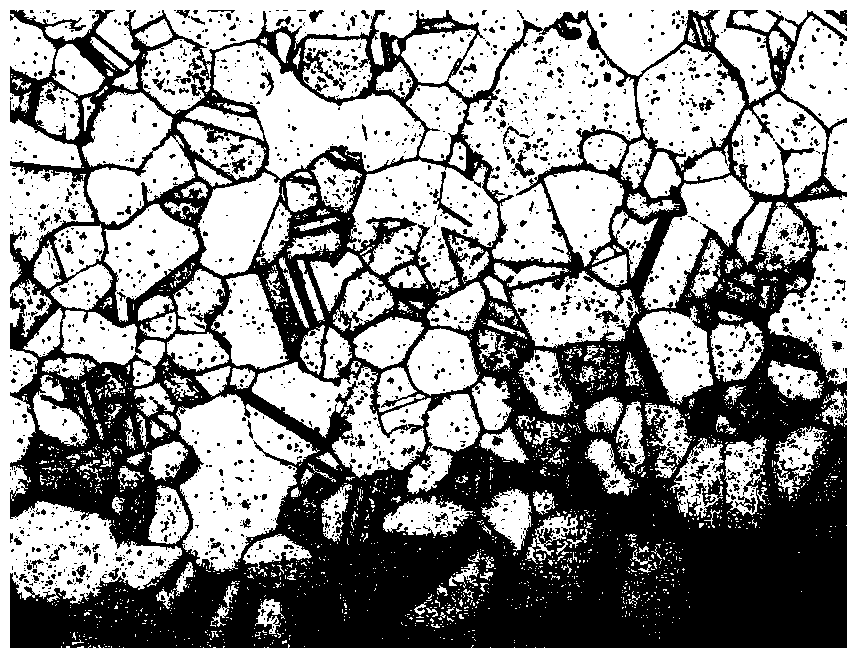

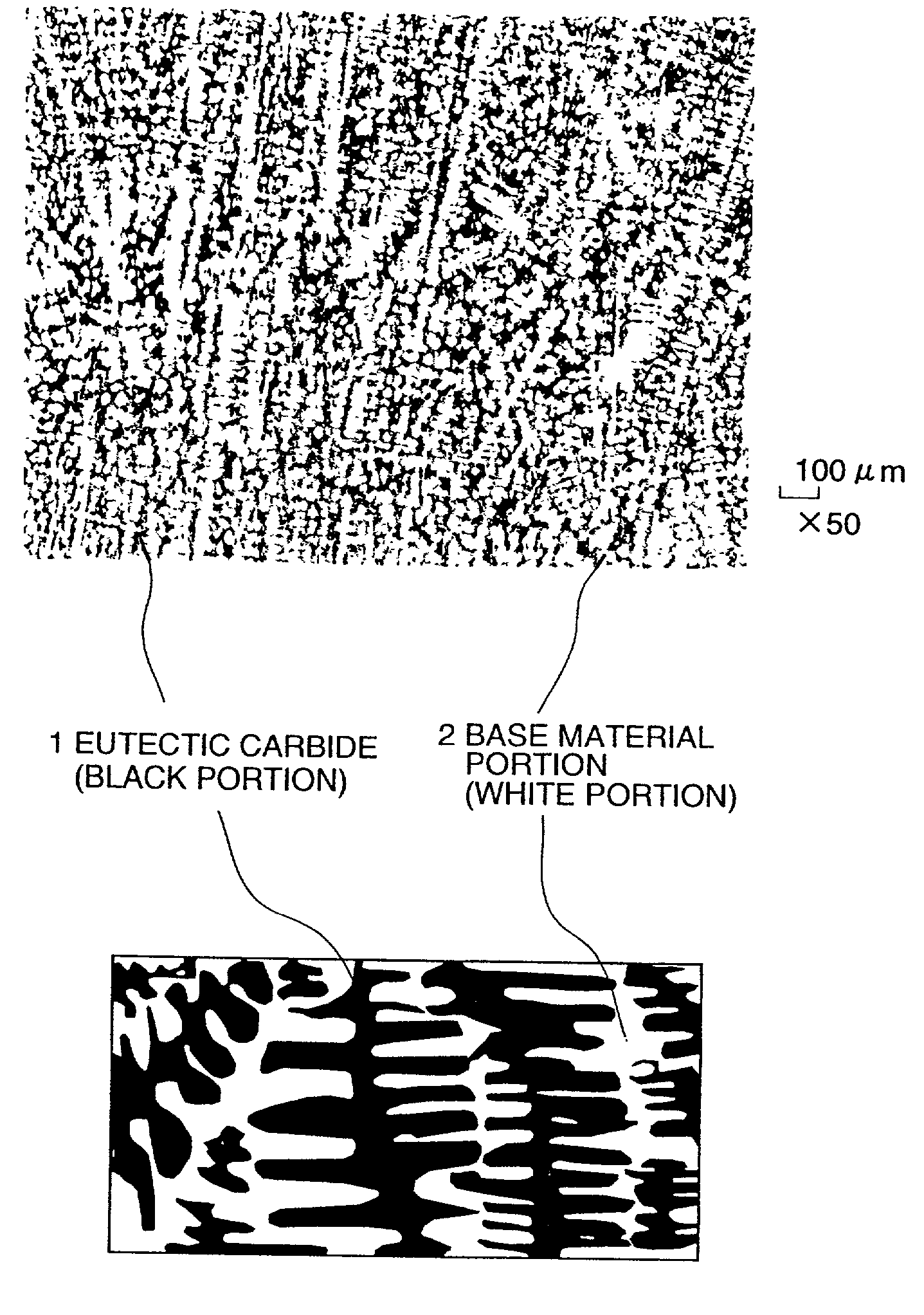

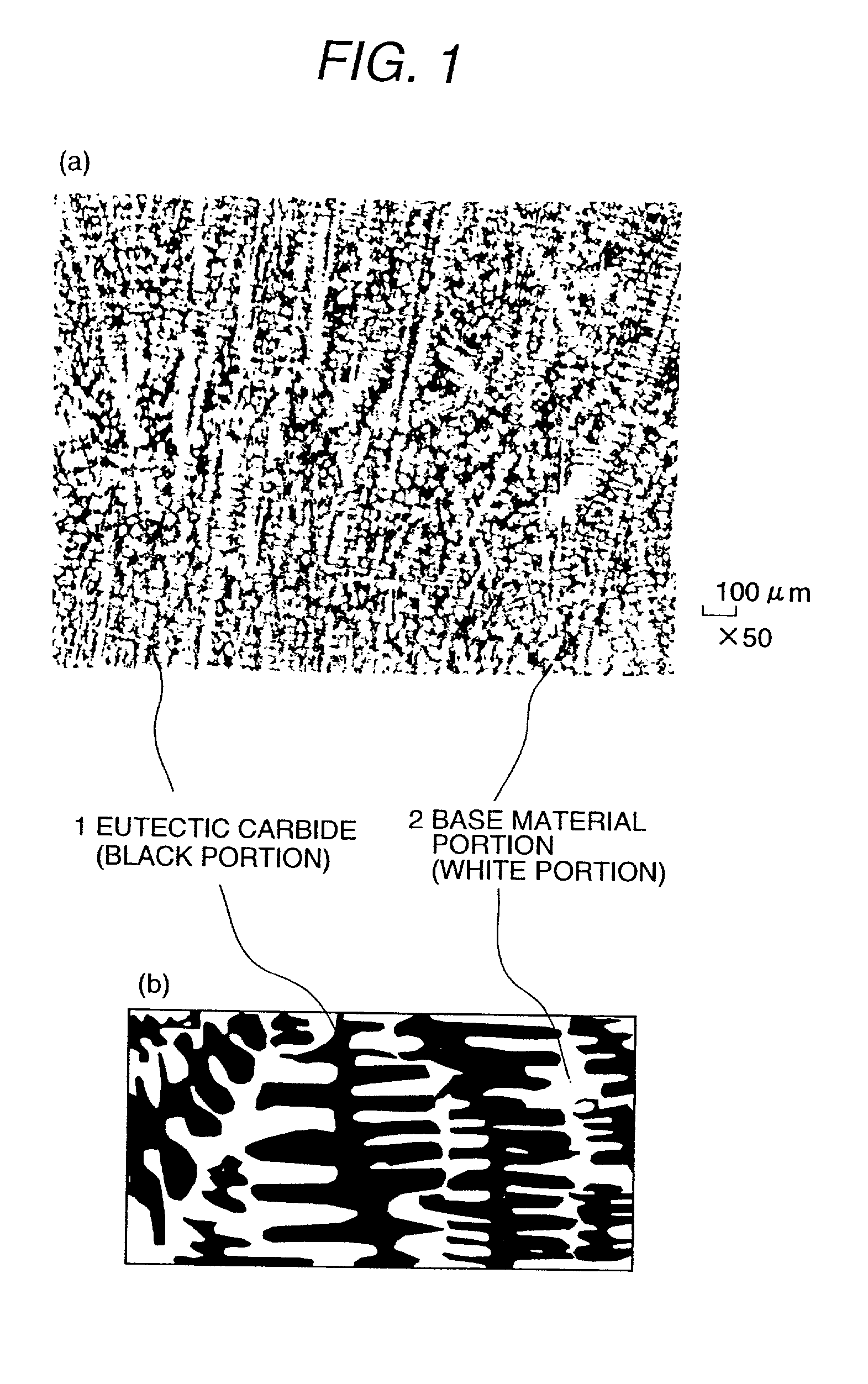

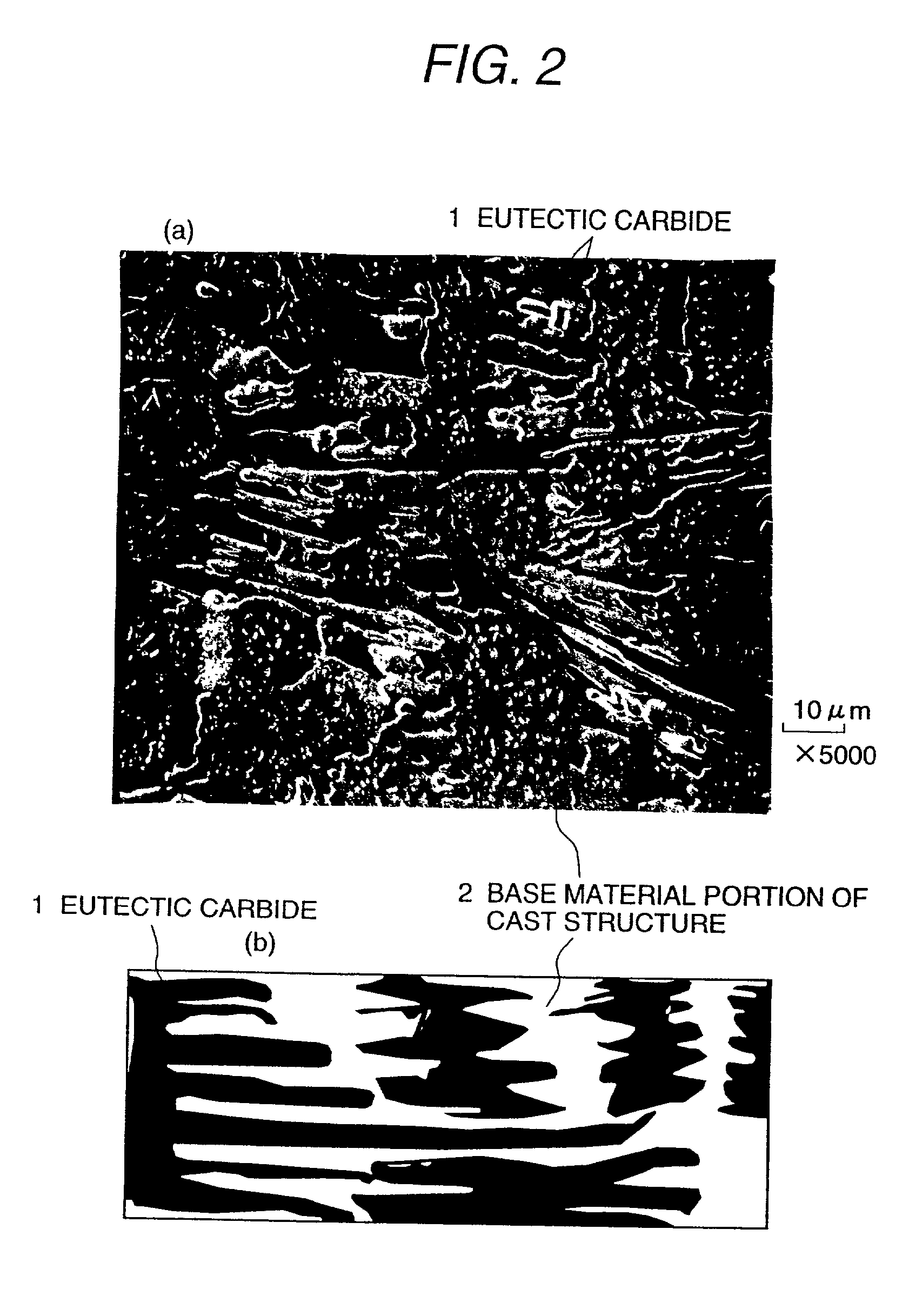

Corrosion-resisting and wear-resisting alloy and device using the same

InactiveUS20020064678A1High hardnessLow ductilityEngine sealsPositive displacement pump componentsOxygenCobalt

To provide a corrosion-resisting and wear resisting alloy including cobalt, nickel or iron as a base used for a sliding part or a valve seat for a machine, and restraining erosion and corrosion caused by eutectic carbide constituting the alloy in an atmosphere with dissolved oxygen. A material is selected from a cobalt base added with Cr and / or W, a nickel base added with Fe and / or Cr, and an iron vase added with Cr and / or Ni. The material is cast into an ingot or a slab to produce an intermediate material. The intermediate material comprises mesh-like eutectic carbide and a base material surrounded by the eutectic carbide. A heat plastic forming is applied to the intermediate material at a temperature 650° C. or more and the solidus temperature or less. The eutectic carbide is formed into multiple grains or clusters as a discontinuous distribution. A resulting corrosion-resisting and wear-resisting alloy has 0.1 to 0.5 of coefficient of friction, and 300 to 600 Hv of Vickers hardness without age-hardening process.

Owner:HITACHI LTD +1

Cladding ingot to prevent hot-tearing

A method of casting an ingot of a metal having a susceptibility to hot-tearing while avoiding such hot tearing. The method involves co-casting a cladding metal on a surface of a metal core ingot as the ingot is being cast in a DC casting procedure. The cladding layer preferably contacts the core ingot at a position on the ingot surface where the metal of the ingot is incompletely solid, e.g. at a temperature between its solidus temperature and liquidus temperatures. The metal of the core ingot and the metal of the cladding layer are the same and, if they contain grain refiners, the are present in an amount of 0.005% by weight of the metal or less.

Owner:NOVELIS INC

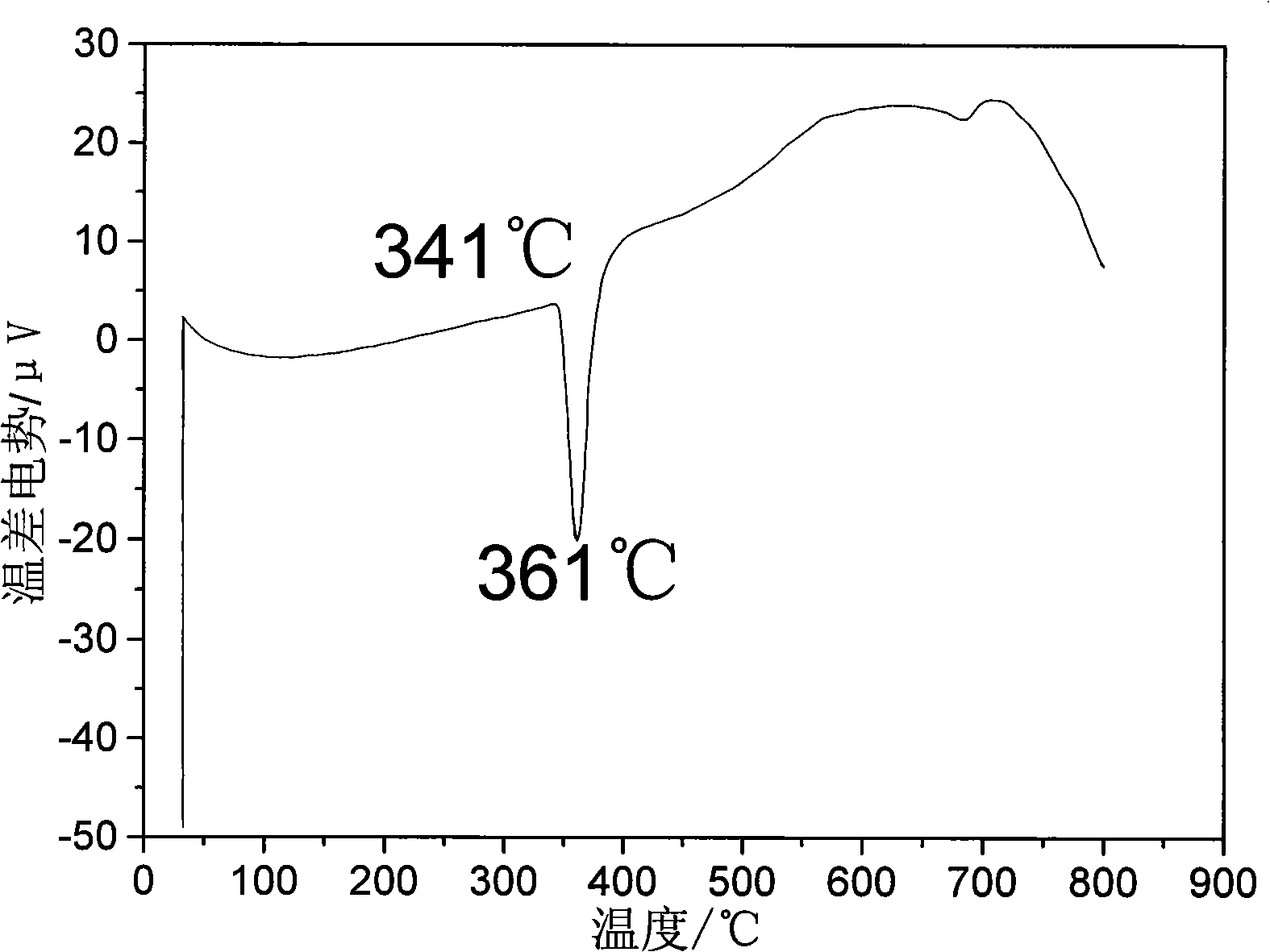

Magnesium alloy middle temperature brazing material

InactiveCN101323060AReduce brazing temperatureGood spreadabilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthMelting temperature

The invention relates to a magnesium alloy mid-temperature solder, belonging to the technical field of magnesium alloy welding. Most of the existing magnesium alloy solders have poor manufacturability, poor joint properties and other technical problems. The weigh percentage range of the components of the magnesium alloy mid-temperature solder of the invention is that: 1-2.5 percent of Al, 46-52 percent of Zn and the rest of Mg. The solder is smelted by a flux protection method; by using mechanical division, precision casting and a gas shielded ball milling method, the solders can be acquired in the forms of block, strip, powder and other forms. The melting temperature range of the solder is 336-361 DEG C; brazing temperature is low, which is 380-400 DEG C, and is suitable for magnesium alloy brazing having a solidus temperature over 400 DEG C. The solder of the invention has the advantages that brazing characteristics are good, and under the brazing temperature, spreading property and gap filling property are good; proper brazing methods include protective atmosphere brazing, induction brazing, furnace brazing and the like; the joint shear strength of brazing AZ31B magnesium alloy of the solder is more than 52 MPa, and the joint tensile strength is more than 72 MPa.

Owner:BEIJING UNIV OF TECH

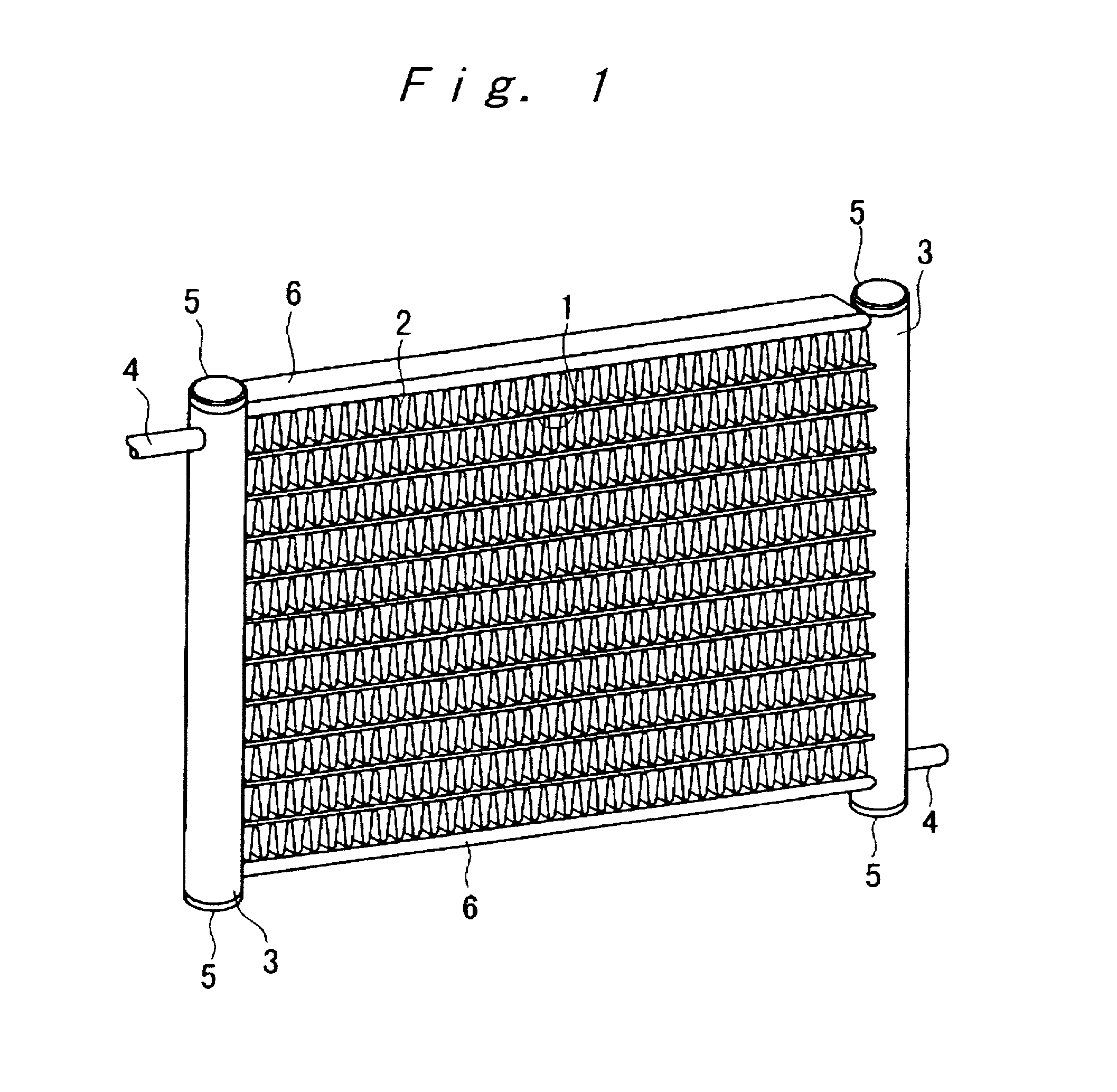

Method for brazing aluminum alloy-assembled articles within a short period of time and a filler alloy usable at low temperature

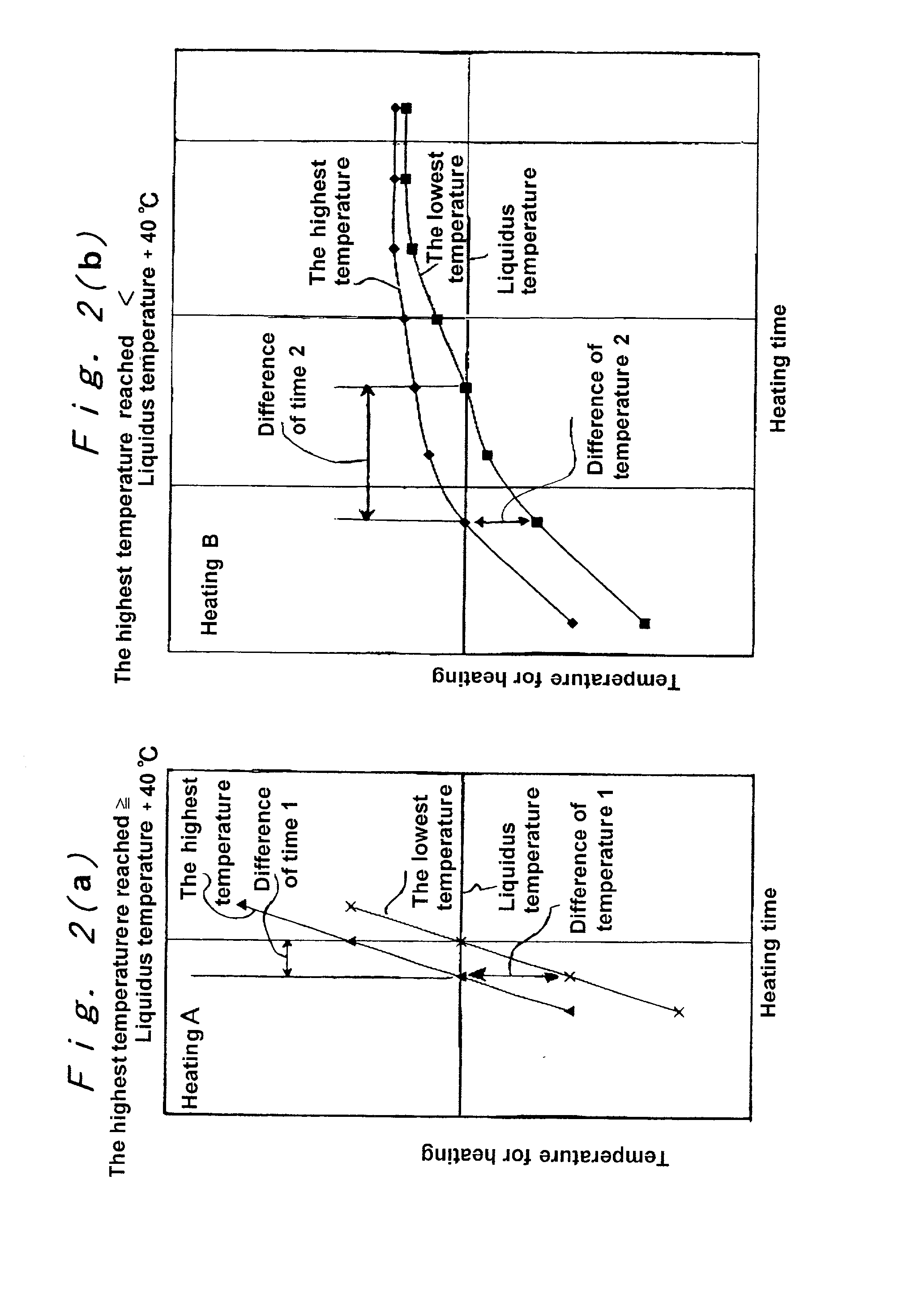

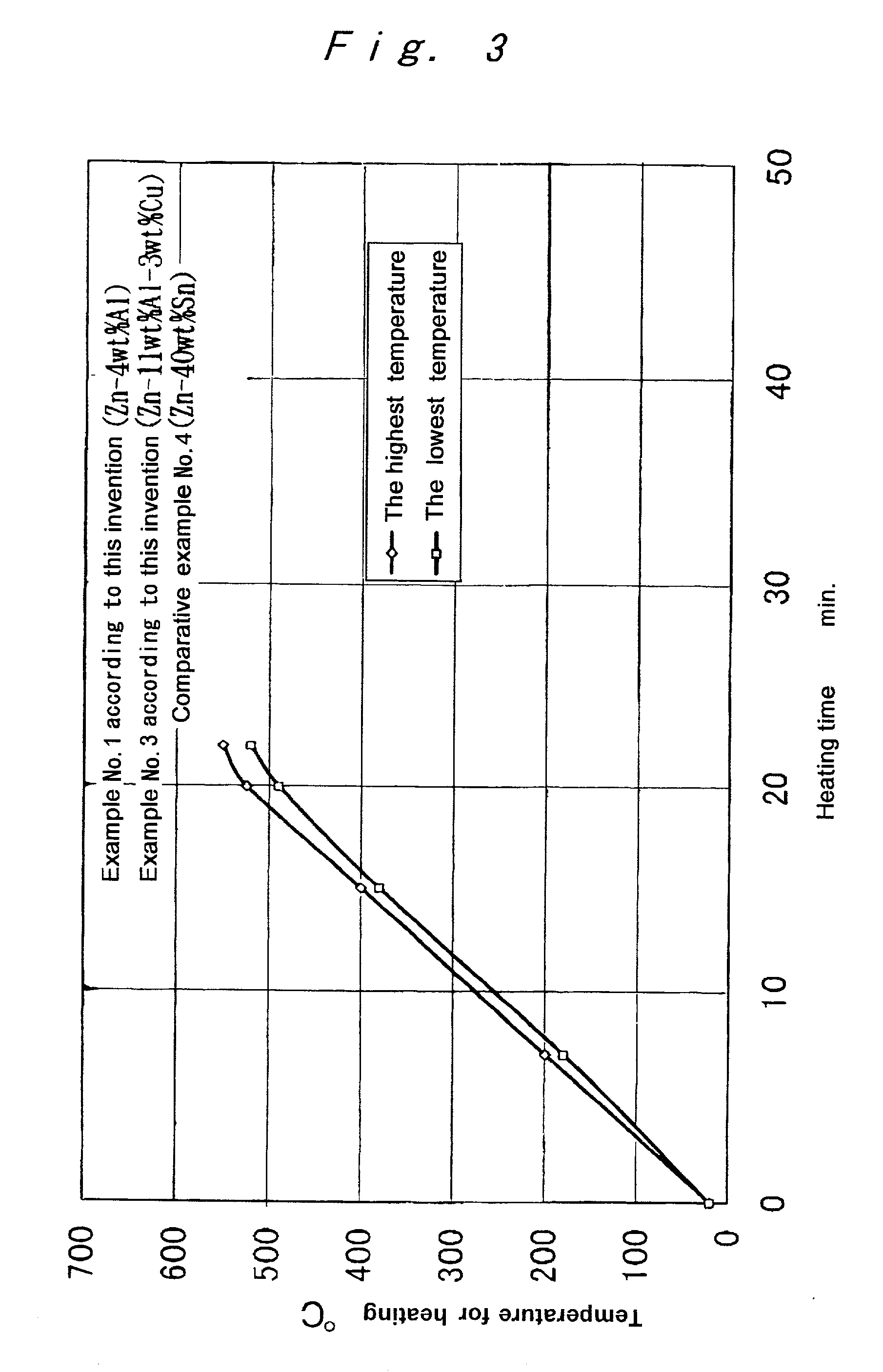

InactiveUS20020127135A1Welding/cutting media/materialsWelding/soldering/cutting articlesLiquidusAluminium alloy

A method for brazing aluminum alloy-assembled articles with a filler alloy having a liquidus temperature of 540.degree. C. or lower and a difference of temperature between the liquidus temperature and the solidus temperature being 100.degree. C. or lower, wherein the highest temperature reached in the assembled article at the time of heating for brazing being set 40.degree. C. or more higher than the liquidus temperature but 585.degree. C. or lower. An aluminum alloy-filler alloy usable at low temperature for brazing, which comprises Si in an amount of 4.0 wt % to 8.0 wt %, Zn in an amount of 7.0 wt % to 20.0 wt % and Cu in an amount of 10.0 wt % to 35.0 wt %, with the balance being made of aluminum.

Owner:DENSO CORP +1

Mixed alloy solder paste

ActiveUS20110268985A1Improved reaction chemistryWell-controlled IMC layer thicknessSolid-state devicesPrinted circuit manufactureSolder pasteMaterials science

A solder paste comprises an amount of a first solder alloy powder between about 60 wt % to about 92 wt %; an amount of a second solder alloy powder greater than 0 wt % and less than about 12 wt %; and a flux; wherein the first solder alloy powder comprises a first solder alloy that has a solidus temperature above about 260° C.; and wherein the second solder alloy powder comprises a second solder alloy that has a solidus temperature that is less than about 250° C.

Owner:INDIUM CORPORATION

Manufacture of composite components by powder metallurgy

A method for preparing an article is disclosed. The method comprises compacting a mixture of a first pre-alloyed powder and a lubricant to thereby form a green part having a green strength sufficient to permit mechanical handling; applying a slurry to a surface of the green part to thereby form a slurry coated green part, wherein the slurry comprises a second pre-alloyed powder, a binder, and a solvent; and heating the coated green part to a temperature below a solidus temperature of the first pre-alloyed powder and between a solidus temperature and a liquidus temperature of the second pre-alloyed powder to thereby solid state sinter the first pre-alloyed powder into a sintered core and to liquid state sinter the second pre-alloyed powder into a continuous alloy coating over the sintered core.

Owner:KENNAMETAL INC

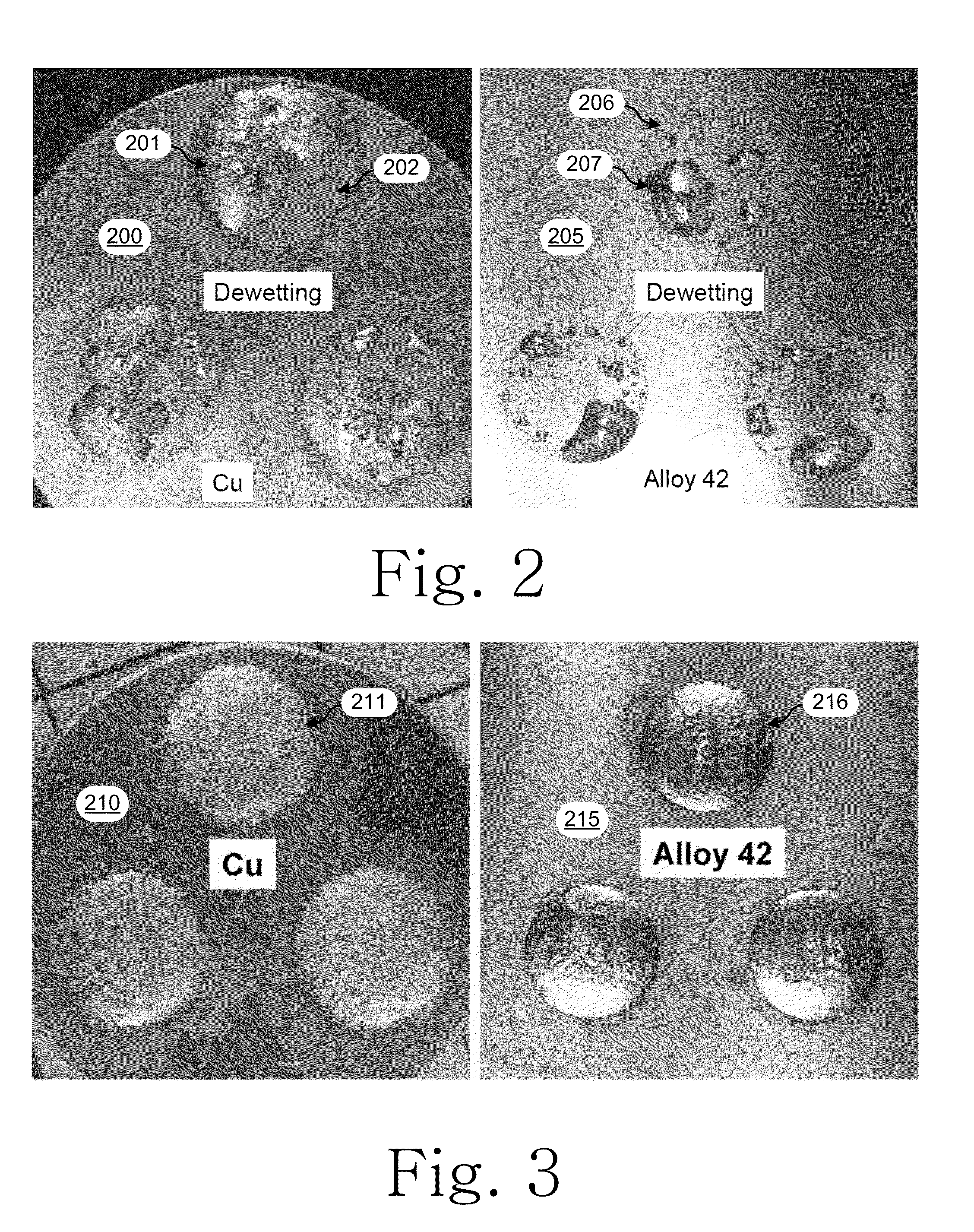

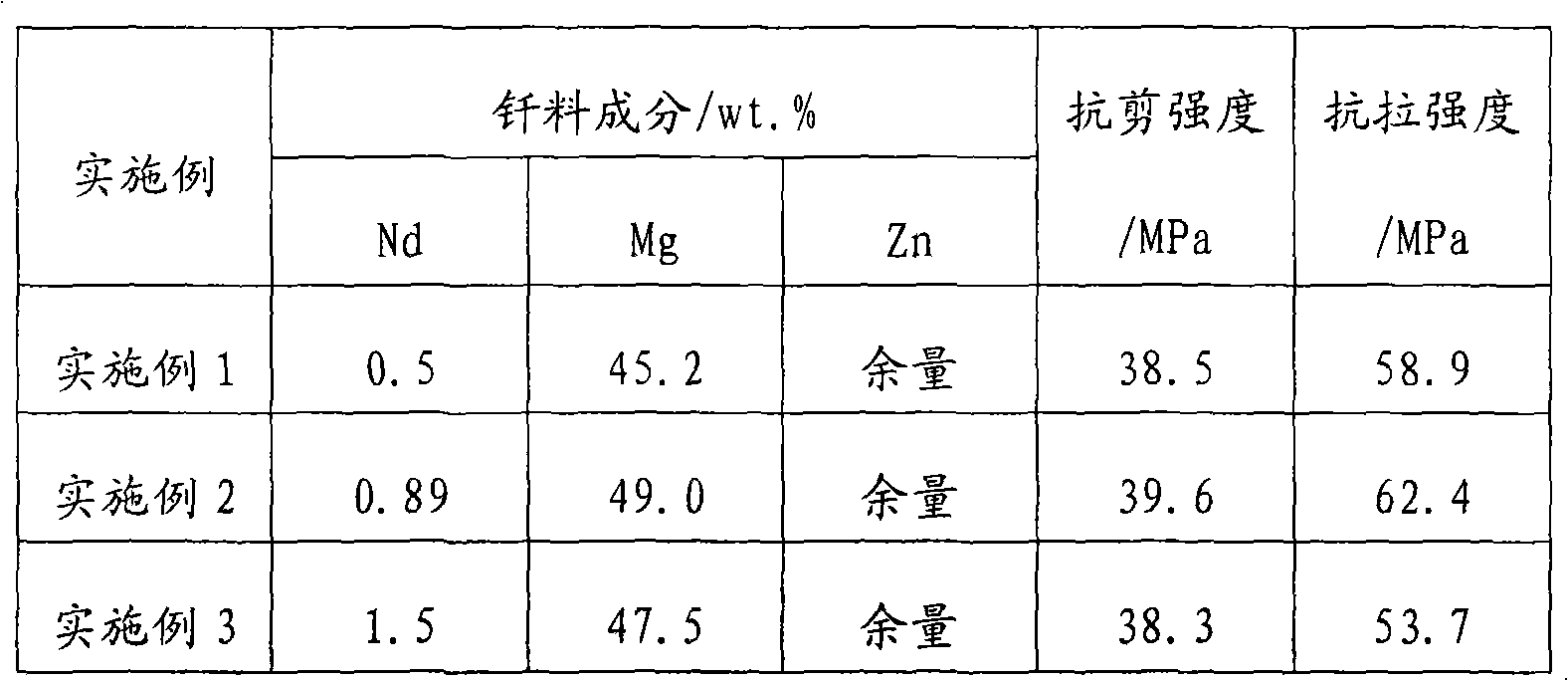

Magnesium alloy brazing solder containing rare earth

InactiveCN101658981AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaChemical compositionButt joint

The invention relates to a magnesium alloy brazing solder containing rare earth, belonging to the technical field of magnesium alloy welded connection. The chemical compositions and mass percent thereof of the magnesium alloy brazing solder containing rare earth are as follows: 0.5-1.5% of Nd,, 45-49% of Mg, and the balance of Zn. The melting temperature range of the magnesium alloy brazing soldercontaining rare earth is between 333 and 356 DEG C and the brazing temperature range thereof is between 400 and 430 DEG C, and the solder is applicable to the brazing of magnesium alloy with the solidus temperature higher than 430 DEG C. By using the solder to braze AZ31B magnesium alloy in the mode of high frequency induction brazing, the shearing strength of brazing overlapped joint is between38 and 39 MPa, and the tensile strength of the brazing butt joint is between 53 and 62 MPa. Compared with the AZ31B magnesium alloy joint brazed by magnesium alloy solder with the same components andwithout being added with rare earth, both the tensile strength and the shearing strength of brazing joints are improved by more than 30 percent.

Owner:BEIJING UNIV OF TECH

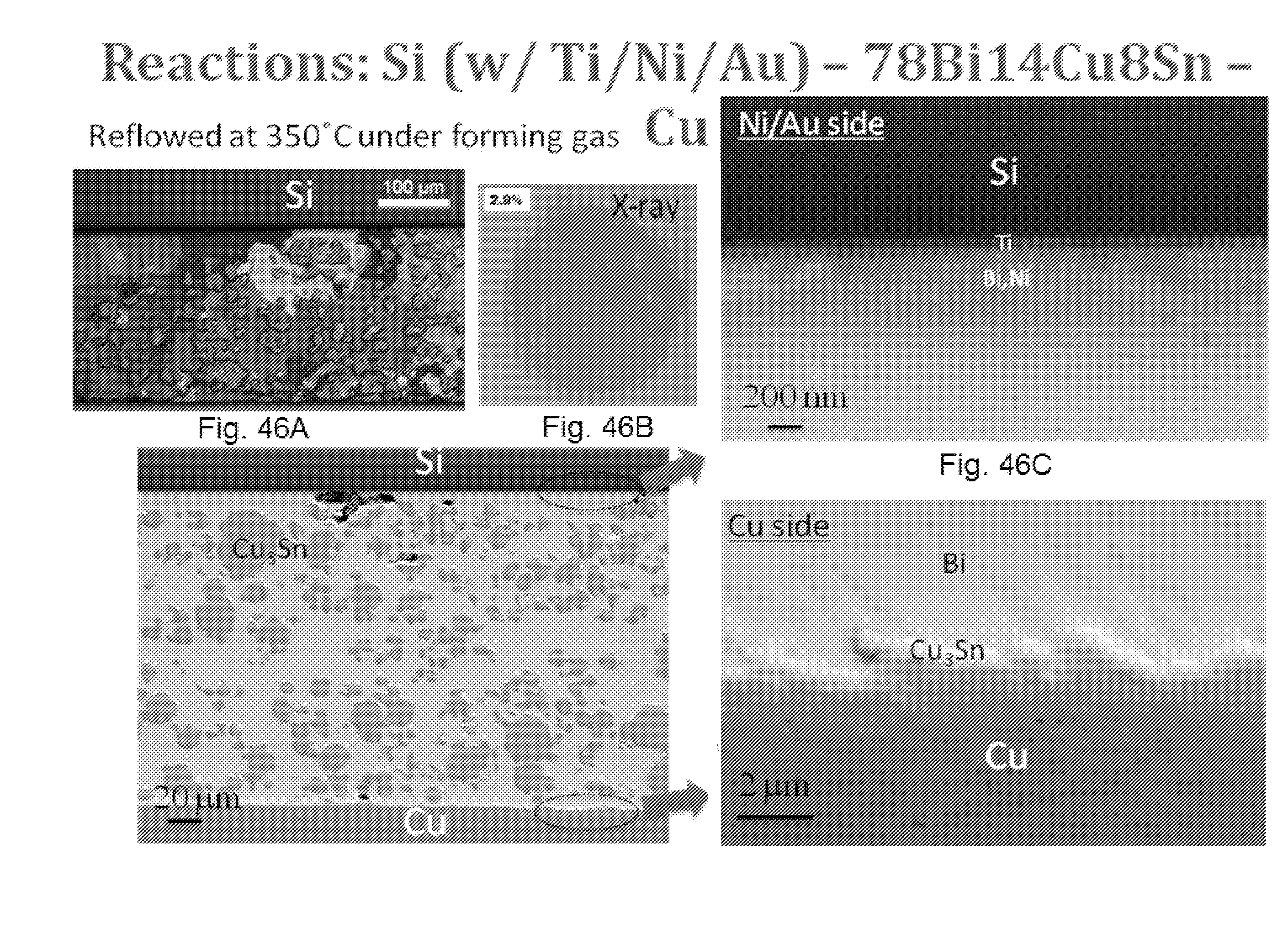

Solder alloys

InactiveUS20140361070A1Improve thermal conductivityLow thermal conductivityWelding/cutting media/materialsSoldering mediaCopperZinc

A solder comprising a bismuth matrix, between about 5-24% copper; and about 0.5-36% tin or antimony or zinc; having a solidus temperature of ≧271° C., a reflow temperature of ≦375° C., and at least one intermetallic composition precipitate comprising copper and at least one of tin, antimony and zinc substantially excluding bismuth formed within the solidus phase.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Medium-temperature aluminum-based foil strap brazing material and preparation method thereof

InactiveCN103008909AGood brazing processSimple preparation processWelding/cutting media/materialsSoldering mediaTorchShear strength

The invention discloses a medium-temperature aluminum-based foil strap brazing material and a preparation method thereof. The brazing material comprises the following components by mass percentage: 6.5-9.6 of Si, 16.0-20.0 of Cu, 8.0-10.0 of Ge, 2.0-6.0 of Zn, 0.5-1.0 of La and the balance of Al. The brazing material is prepared by rapid cooling of a melt, the melting point is lower than 495 DEG C, a foil strap is suitable for brazing of aluminum alloy with the solidus temperature higher than 520 DEG C, torch brazing, induction brazing, furnace brazing, gas protection brazing and the like can be performed, the brazing temperature is 510-520 DEG C, and the brazing material can be applied in brazing of precision components made of aluminum alloy. When the brazing material is used with 5083 aluminum alloy for QJ201 brazing, the shear strength of a brazed joint is higher than 80MPa.

Owner:ZHEJIANG UNIV +1

Method and system for applying an isolation layer to a brazed end of a generator armature winding bar

ActiveUS20060108355A1Soldering apparatusManufacturing dynamo-electric machinesIsolation layerEngineering

A method of forming a brazed joint between an armature bar and a hydraulic header clip including: assembling an end of the armature bar, hydraulic header clip and a substantially phosphorous-free braze material; positioning the assembly of the armature bar, hydraulic header clip and the braze material in a braze chamber, such that the clip is seated in an induction heating coil; heating the assembly to a first temperature within 200 degrees Fahrenheit of and below a solidus temperature of the braze material by applying electrical current to the induction heat coil; heating the assembly to a second temperature above the liquidus temperature of the braze material; pooling liquid braze material on ends of the armature bar, and cooling the assembly and thereby forming a braze layer on the end of the armature bar.

Owner:GENERAL ELECTRIC CO

Zn-Mg magnesium alloy solder

InactiveCN101653878AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaButt jointSoldering

The invention provides a Zn-Mg magnesium alloy solder, belonging to the technical field of magnesium alloy welded joint. The components of the provided Zn-Mg magnesium alloy solder contain 4% to 8% ofMg and the remains are Zn. The melt temperature of the Zn-Mg magnesium alloy solder is ranged from 365 DEG C to 396 DEG C and the soldering temperature is ranged from 420 DEG C to 450 DEG C. The solder can be applied to the magnesium alloy solder with solidus temperature above 450 DEG C. The AZ31B magnesium can be soldered in the manner of high frequency induction welding. The slip resistance ofthe solder overlap joint is ranged from 38MPa to 43 MPa and the tensile strength of the butt joint is ranged from 52MPa to 53MPa.

Owner:BEIJING UNIV OF TECH

Medium-temperature high-strength aluminum alloy powder solder and preparation method thereof

ActiveCN102773630ASmall tissueUniform compositionWelding/cutting media/materialsSoldering mediaSolution treatmentChemical composition

The invention discloses medium-temperature high-strength aluminum alloy powder solder, comprising the following components by weight: 6.0-8.5% of Si, 10.0-12.0% of Cu, 3.0-4.0% of Ge, 3.0-4.0% of Ni, 0.5-0.8% of La and the balance of A1. The invention also discloses a method for preparing the medium-temperature high-strength aluminum alloy powder solder by adopting a melt rapid cooling technology. The melting temperature range of the solder disclosed by the invention is 515-539 DEG C, and the brazing temperature is 545-560 DEG C. The solder is suitable for the brazing the aluminum alloy of which a solidus is higher than 560 DEG C, especially suitable for the heat-treatable strengthening aluminium alloy which is subjected to a solution treatment after being brazed and is of the solution temperature no more than 545 DEG C. The solder is also suitable for furnace brazing, vacuum brazing, induction brazing, torch brazing, and the like. The solder disclosed by the invention is adopted to be matched with QJ201 brazing flux for brazing the 6061 aluminum alloy in a furnace; after being brazed, the 6061 aluminum alloy is subjected to a T6 heat treatment; and the shear strength of a brazing joint is more than 94MPa.

Owner:ZHEJIANG UNIV

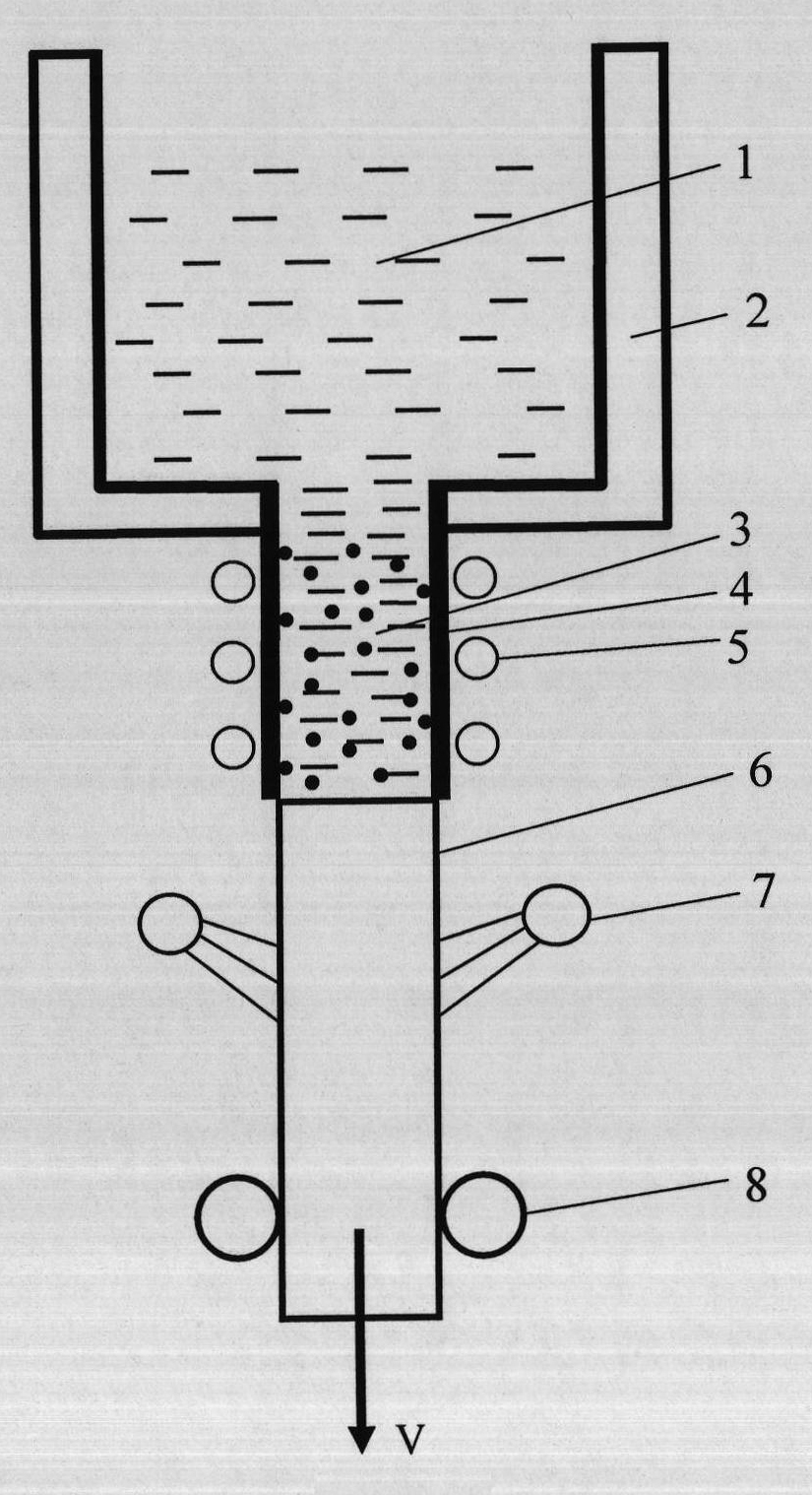

Casting equipment and method using solid-liquid two-phase region temperature as casting mold temperature

The invention discloses casting equipment and a casting method using solid-liquid two-phase region temperature as casting mold temperature, and belongs to the technical field of metal casting. The casting equipment is characterized by consisting of a crucible, two-phase region casting molds, a heater, a cooler and a traction mechanism, wherein one or more two phase region casting molds are arranged below, above or beside the crucible; the casting mold is insulated and heated through the heater or heated by using the heat which is conducted by the cast metal melt before entering the casting mold so as to keep the casting mold temperature between the solidus temperature and the liquidus temperature of the cast metal; the cast metal is forcibly cooled through the cooler which is arranged close to the outlet of the casting mold or a cooling device which is arranged at the outlet of the casting mold and can move along the casting direction; and the traction mechanism is used for drawing a metal casting blank. The equipment of the invention has the advantages of simple structure, convenient operation and repair, high production efficiency and wide application range and can industrially produce the high-quality metal casting blank with high strength, high plasticity, high surface finish, high dimensional accuracy, high compactness and low or no segregation in batches.

Owner:UNIV OF SCI & TECH BEIJING

Clad pipe

InactiveUS7169480B2Improve corrosion resistanceEasy to weldEnvelopes/bags making machineryMolten spray coatingAlloyCorrosion

A clad pipe includes an external layer and a coating layer made of Ni base anticorrosion alloy. Both end portion areas of the coating layer are formed by a build-up welded layer (Ni base alloy of composition 1) on the inner surface of the external layer. Other areas are formed by a Ni base alloy layer (Ni base alloy of composition 2) fusion-bonded to the build-up welded layers and the inner surface of the pipe, a solidus-curve temperature of the Ni base alloy layer being 1300° C. or below and lower than a solidus-curve temperature of the Ni base alloy formed by build-up welding by 150° C. or more. Composition 1 and composition 2 are adjusted so that, in the same environment, corrosion resistance of the Ni base alloy of composition 1 is equivalent to or superior to that of the Ni base alloy of composition 2.

Owner:DAI ICHI HIGH FREQUENCY

Semiconductor apparatus and manufacturing method

InactiveUS7528489B2Avoid crackingTransportation and packagingRotary stirring mixersSemiconductor chipDie bonding

Pb free solder is used in die bonding. A thermal stress reduction plate is disposed between a semiconductor chip and a die pad made of a Cu alloy. The semiconductor chip and the thermal stress reduction plate are joined and the thermal stress reduction plate and the die pad are joined by a joint material of Pb free solder having Sn—Sb—Ag—Cu as its main constituent elements and having a solidus temperature not lower than 270° C. and a liquidus temperature not higher than 400° C. Thus, die bonding can be performed using the Pb free solder without generating any chip crack.

Owner:RENESAS ELECTRONICS CORP

Repair method for propagating epitaxial crystalline structures by heating to within 0-100° f of the solidus

ActiveUS7784668B2Promote formationLow costPolycrystalline material growthFrom frozen solutionsCrystal structureGrain growth

A repair method of propagating epitaxial crystalline structures is provided. The repair method broadly comprises the steps of providing a substrate to be repaired, placing an additive material as a preformed shape onto an area of the substrate to be repaired, utilizing a heat source to heat an entire volume of the additive material and an area adjacent to the additive material to within 0-100° F. of their solidus temperatures, holding at the fusion temperature for a time sufficient to allow grain growth and orientation to occur, and ramping down the heat source at a predetermined controlled rate until solidification is complete.

Owner:RTX CORP

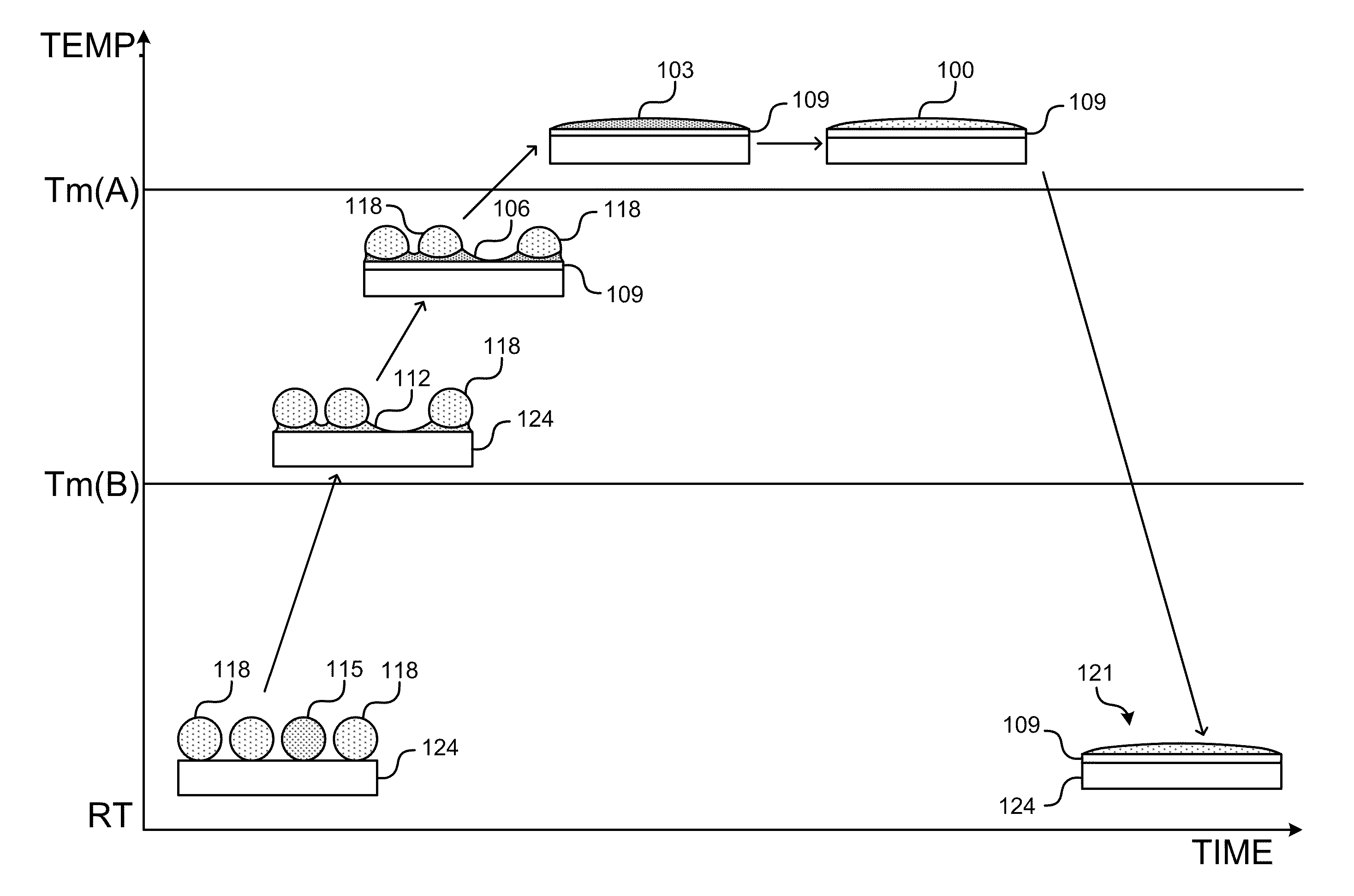

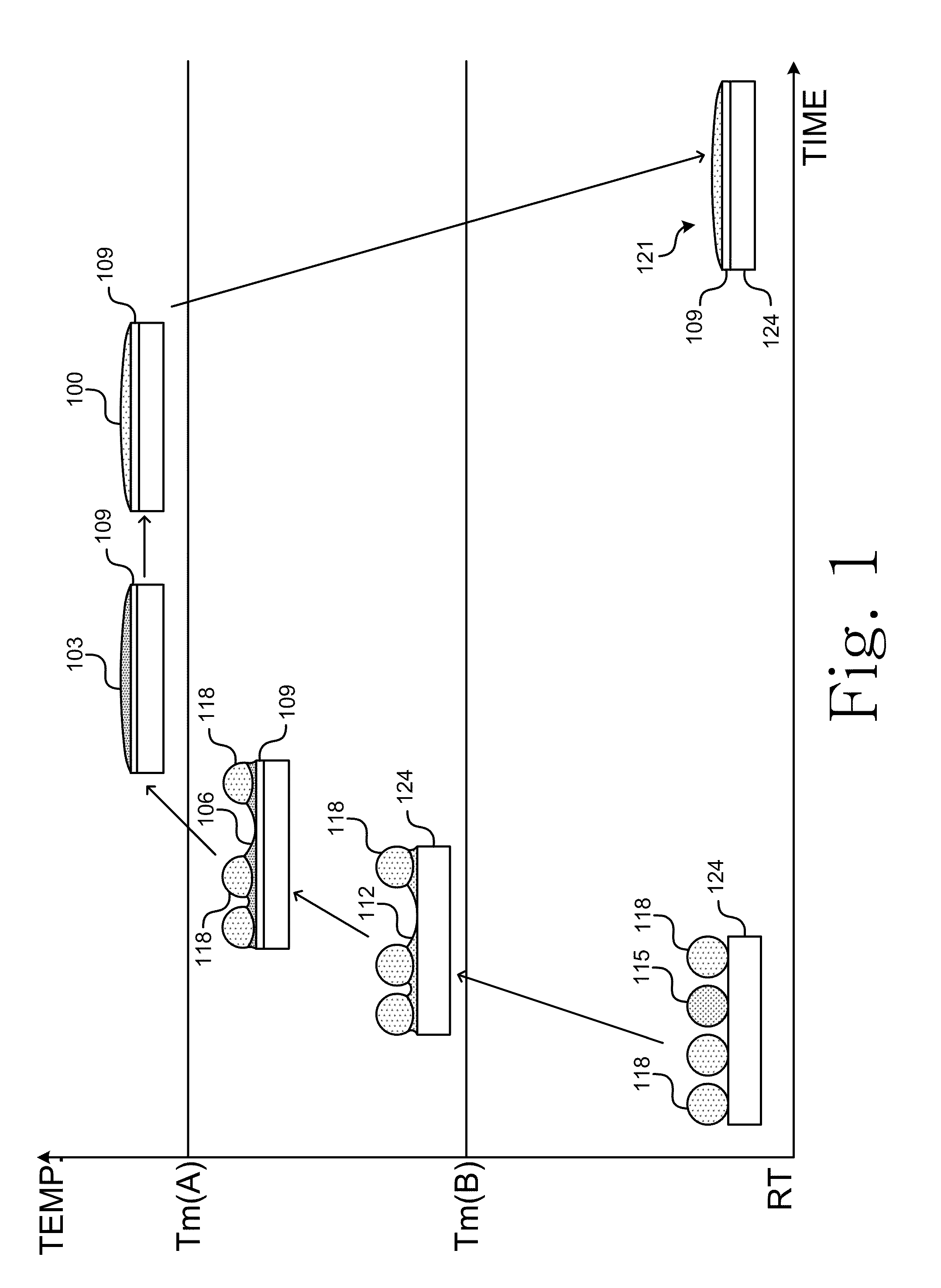

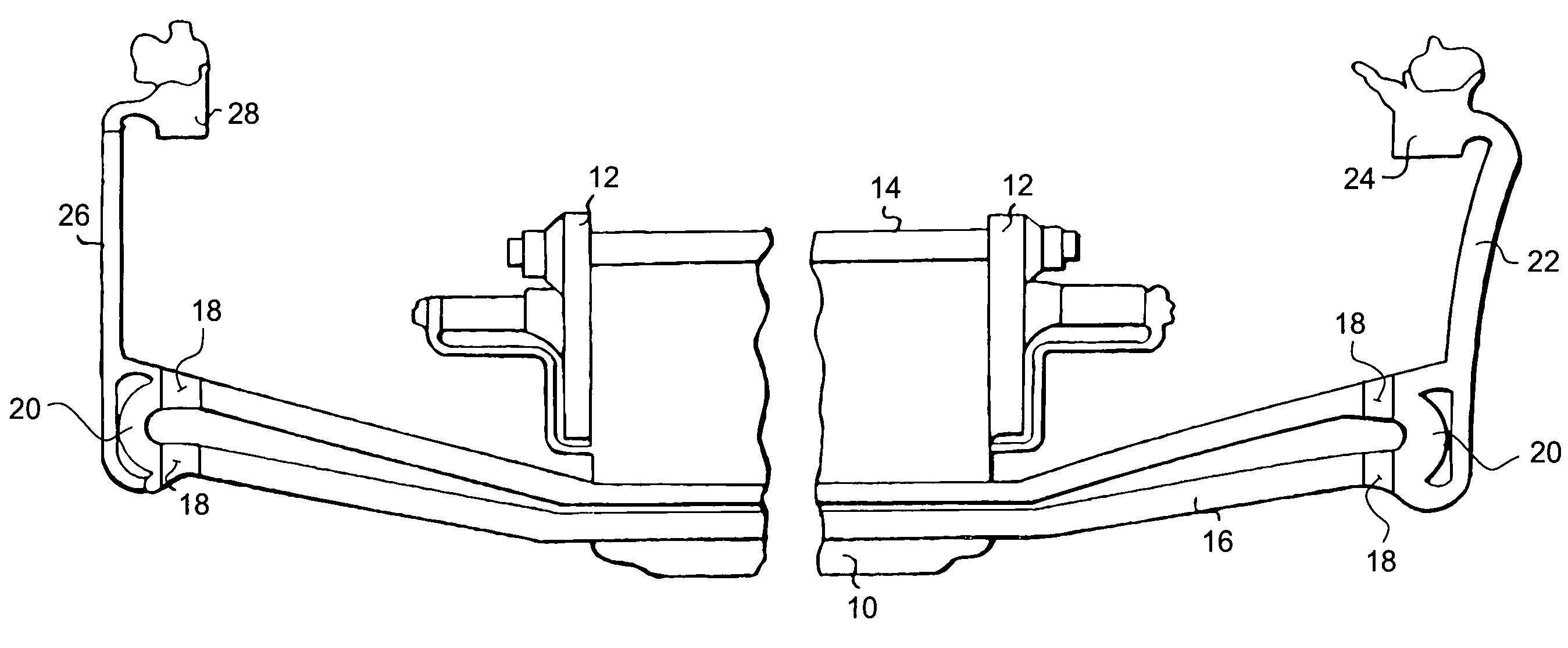

Method and apparatus for thixotropic molding of semisolid alloys

A method and apparatus for thixotropic molding of semisolid alloys are disclosed. The method comprises of feeding a dendritic-free feedstock bar into an extruder barrel, melting a terminal portion of the feedstock bar into a semisolid slurry by heating it to a temperature between its solidus and liquidus temperatures, and using the solid portion of the feedstock bar as an one-time 'plunger' to inject the semisolid slurry into a mold cavity. The apparatus based on the present method, which is equipped without a regular extruder screw or plunger, uses a feedstock bar as a one-time plunger to inject semisolid slurries formed from a terminal portion of the same feedstock bar.

Owner:刘伟杰

Method and system for applying an isolation layer to a brazed end of a generator armature winding bar

ActiveUS7199338B2Soldering apparatusManufacturing dynamo-electric machinesIsolation layerEngineering

A method of forming a brazed joint between an armature bar and a hydraulic header clip including: assembling an end of the armature bar, hydraulic header clip and a substantially phosphorous-free braze material; positioning the assembly of the armature bar, hydraulic header clip and the braze material in a braze chamber, such that the clip is seated in an induction heating coil; heating the assembly to a first temperature within 200 degrees F. of and below a solidus temperature of the braze material by applying electrical current to the induction heat coil; heating the assembly to a second temperature above the liquidus temperature of the braze material; pooling liquid braze material on ends of the armature bar, and cooling the assembly and thereby forming a braze layer on the end of the armature bar.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com