Patents

Literature

186 results about "Induction brazing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induction brazing is a process in which two or more materials are joined together by a filler metal that has a lower melting point than the base materials using induction heating. In induction heating, usually ferrous materials are heated rapidly from the electromagnetic field that is created by the alternating current from an induction coil.

High-strength aluminum alloy brazing filler metal with melting point being lower than 500 DEG C and preparation method thereof

InactiveCN102152024AAvoid overheatingAvoid eclipseWelding/cutting media/materialsSoldering mediaFiller metalShear strength

The invention discloses a high-strength aluminum alloy brazing filler metal with the melting point being lower than 500 DEG C and a preparation method thereof, belonging to the technical field of aluminum alloy welding. The brazing filler metal contains the following components in percentage by mass: 7.9-8.5 percent of Si, 14.0-16.0 percent of Cu, 7.0-8.0 percent of Ge, 2.0-4.0 percent of Ni, 2.0-3.0 percent of Sn, 0.5-1.5 percent of Mg, 0.55-0.65 percent of Sr, 0.1-0.3 percent of Bi, 0.5-1.0 percent of La and the balance of Al. The brazing filler metal is prepared by adopting a melt rapid cooling technology, has the melting point being lower than 500 DEG C and the brazing temperature from 520 DEG C to 530 DEG C, and is suitable for the brazing such as flame brazing, induction brazing, furnace brazing, gas-shielded brazing and the like of aluminum alloy with solidus curve of higher than 520 DEG C,. The brazing filler metal is in cooperation with QJ201 brazing LF21, and the shearing strength of a brazed joint is larger than 70MPa. The brazing filler metal has less content of Ge and lower cost.

Owner:ZHEJIANG UNIV

Method and device for soldering metal parts and components by adopting high-frequency induction brazing

ActiveCN102357695AThe steps are scientific and reasonableGood technical effectHeating appliancesWelding/cutting media/materialsRoom temperatureEngineering

The invention discloses a method for soldering metal parts and components by adopting high-frequency induction brazing, which can complete high-frequency brazing assembly molding of multiple soldering points of multiple soldering parts in one time. The method is dependent on a device, which comprises a high-frequency coil and a magnetic ring pressure lever, wherein the high-frequency coil and the magnetic ring pressure lever are connected with a high-frequency controller respectively, and are controlled uniformly by the high-frequency controller. By utilizing the device, the method comprises the following steps of: treating the surface of a part to be soldered; assembling the soldering device, and distributing the high-frequency coil and a magnetic head pressure lever; selecting a brazing filler metal to be matched with the part to be soldered, and preparing paste brazing flux FB303P; optimally allocating positions and quantities of the brazing filler metal and the brazing flux; setting corresponding process values by means of the high-frequency controller to perform heat soldering, preserving the temperature, switching off, and cooling by using cooling water to the room temperature. According to the method, one-time soldering molding can be realized by multiple soldering of multi-process multi-point and other processes.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

High-strength aluminum alloy solder for brazing at medium temperature and preparation method thereof

ActiveCN102513721ASmall tissueUniform compositionWelding/cutting media/materialsSoldering mediaSolution treatmentChemical composition

The invention discloses a high-strength aluminum alloy solder for brazing at medium temperature and a preparation method thereof. The chemical compositions of the solder include: by mass percentage, 5.0%-7.0% of Si, 10.0%-12.0% of Cu, 3.0%-4.0% of Ge, 2.0%-3.-% of Ni, and the balance Al. The solder is prepared by the melt quick-cooling technology with the melting temperature ranging from 514 DEG C to 538 DEG C and the brazing temperature ranging from 540 DEG C and 560 DEG C, is applicable to brazing of aluminum alloy with the solidus curve higher than 560 DEG C, is particularly suitable for heat-treatable strengthened aluminum alloy which requires solution treatment at the temperature not higher than 530 DEG C after being brazed, and can be adaptable to the brazing methods including brazing in protective gas, vacuum brazing, induction brazing, flame brazing and the like. With the solder, aluminum alloy 6063 is brazed in a soldering flux QJ201 gas protection furnace, soldered joints are subjected to T6 heat treatment, and the shearing strength of the soldered joints is higher than 91Mpa.

Owner:ZHEJIANG UNIV

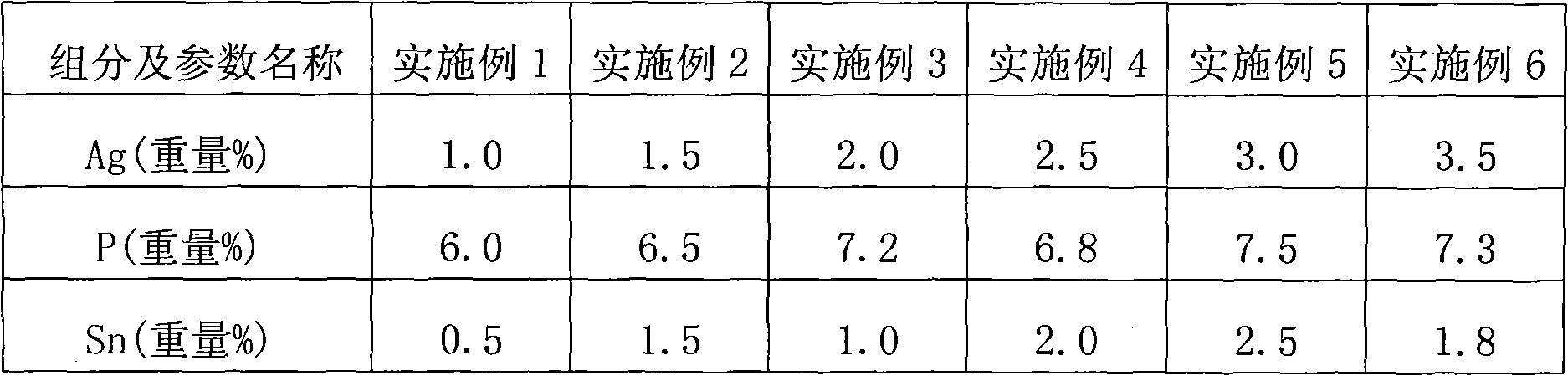

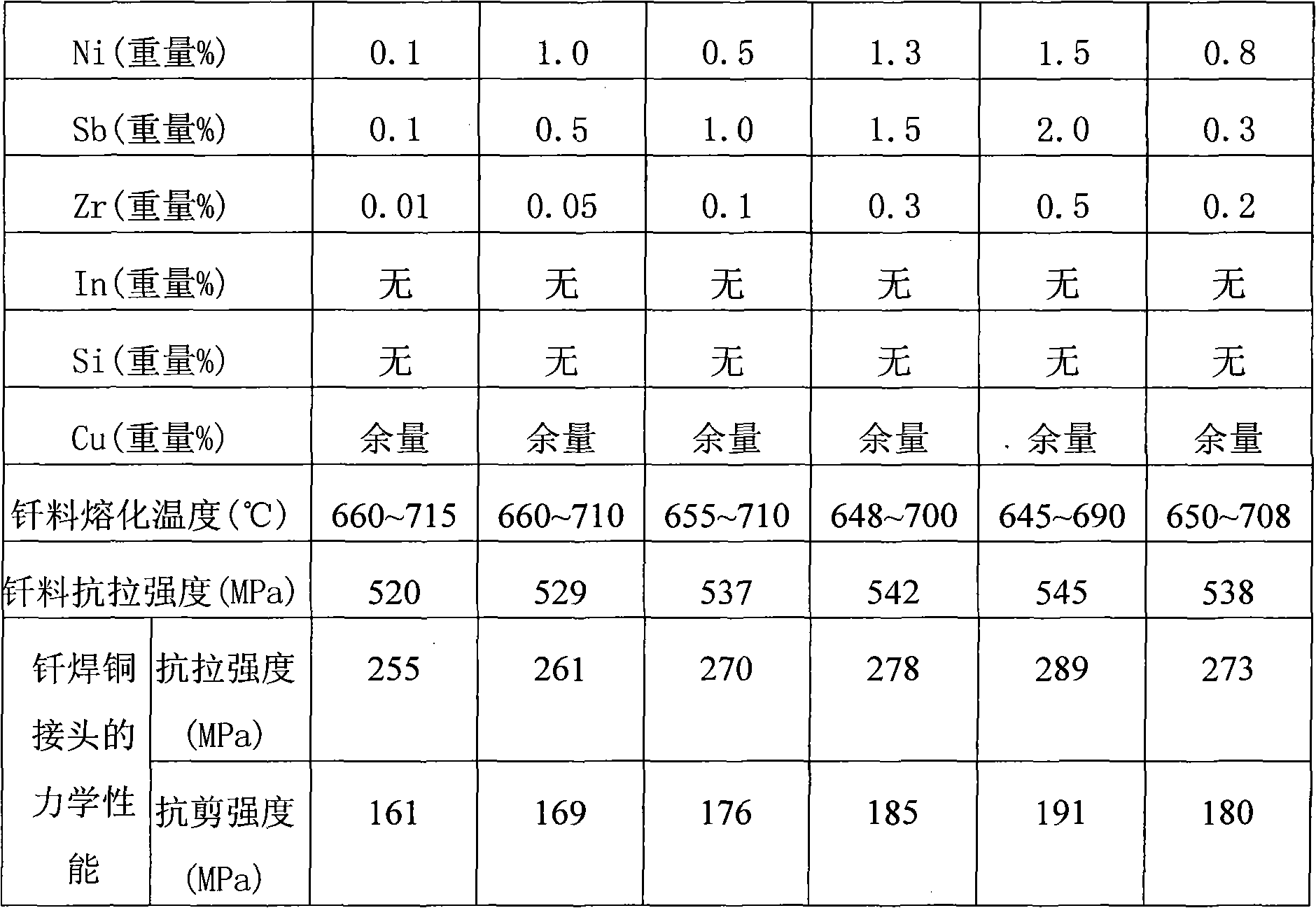

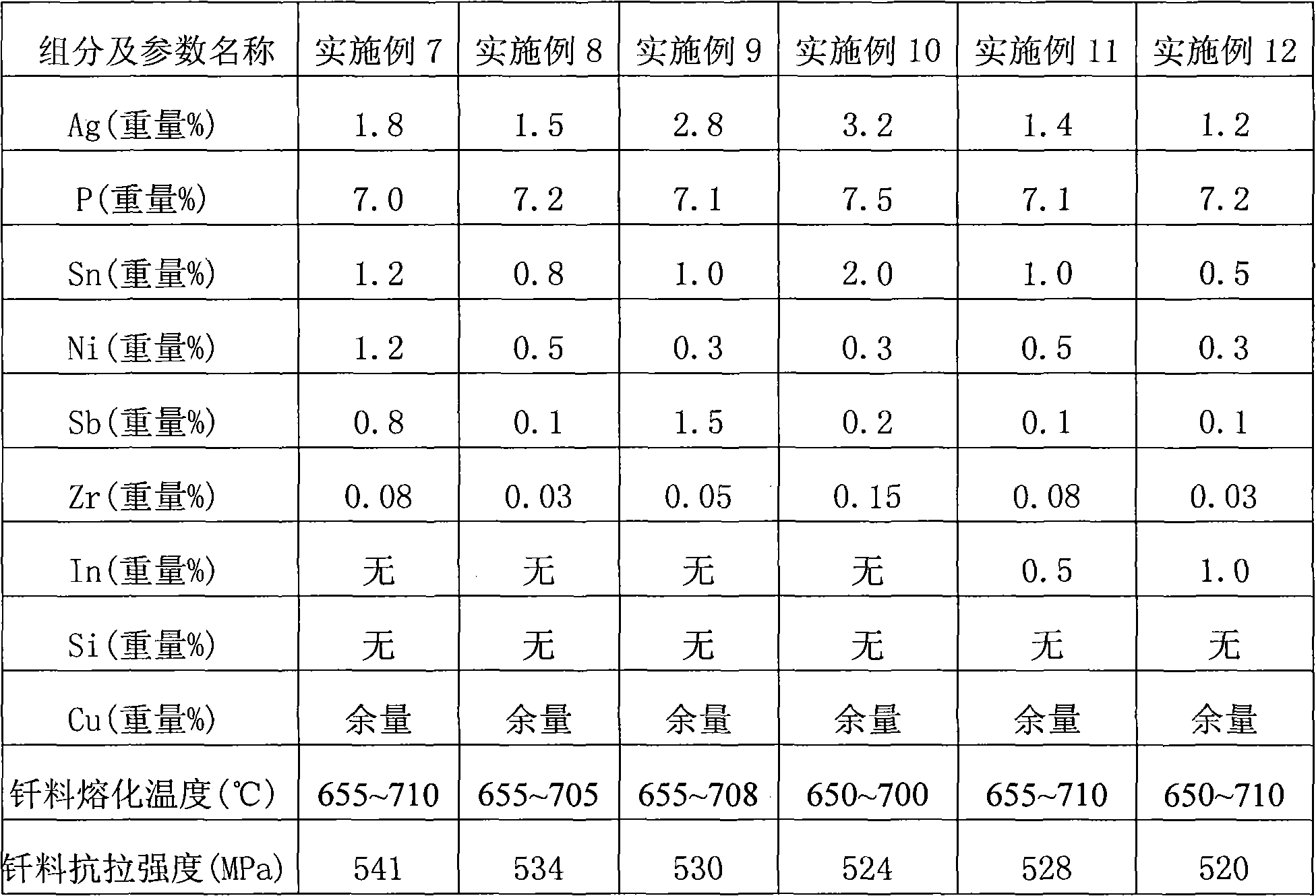

Novel active copper-phosphorus brazing alloy

ActiveCN101786208AReduce contentReduce dosageWelding/cutting media/materialsSoldering mediaElectromechanicsBraze alloy

The invention relates to a novel active copper-phosphorus brazing alloy, belonging to a medium-temperature brazing material. Currently, no copper-phosphorus brazing alloy with reasonable formulation design, low price and high performance-price ratio is presented. The novel active copper-phosphorus brazing alloy comprises the following components by weight percent: 1-3.5% of Ag, 6.0-7.5% of P, 0.5-2.5% of Sn, 0.1-1.5% of Ni, 0.1-2.0% of Sb, 0.01-0.5% of Zr and balance of Cu. The novel active copper-phosphorus brazing alloy has the advantages of reasonable formulation design, low price, high performance-price ratio, low melting temperature and good wettability, flowability and plasticity, can be processed to be a welding wire with the minimum diameter of 0.5mm, a welding ring with the minimum inner diameter of 3.0mm and a thin strip with the minimum thickness of 0.1mm and can be widely used for resistance brazing, flame brazing and high-frequency induction brazing in industries of refrigeration, machinery, electromechanics, electrical appliances and valve fittings.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

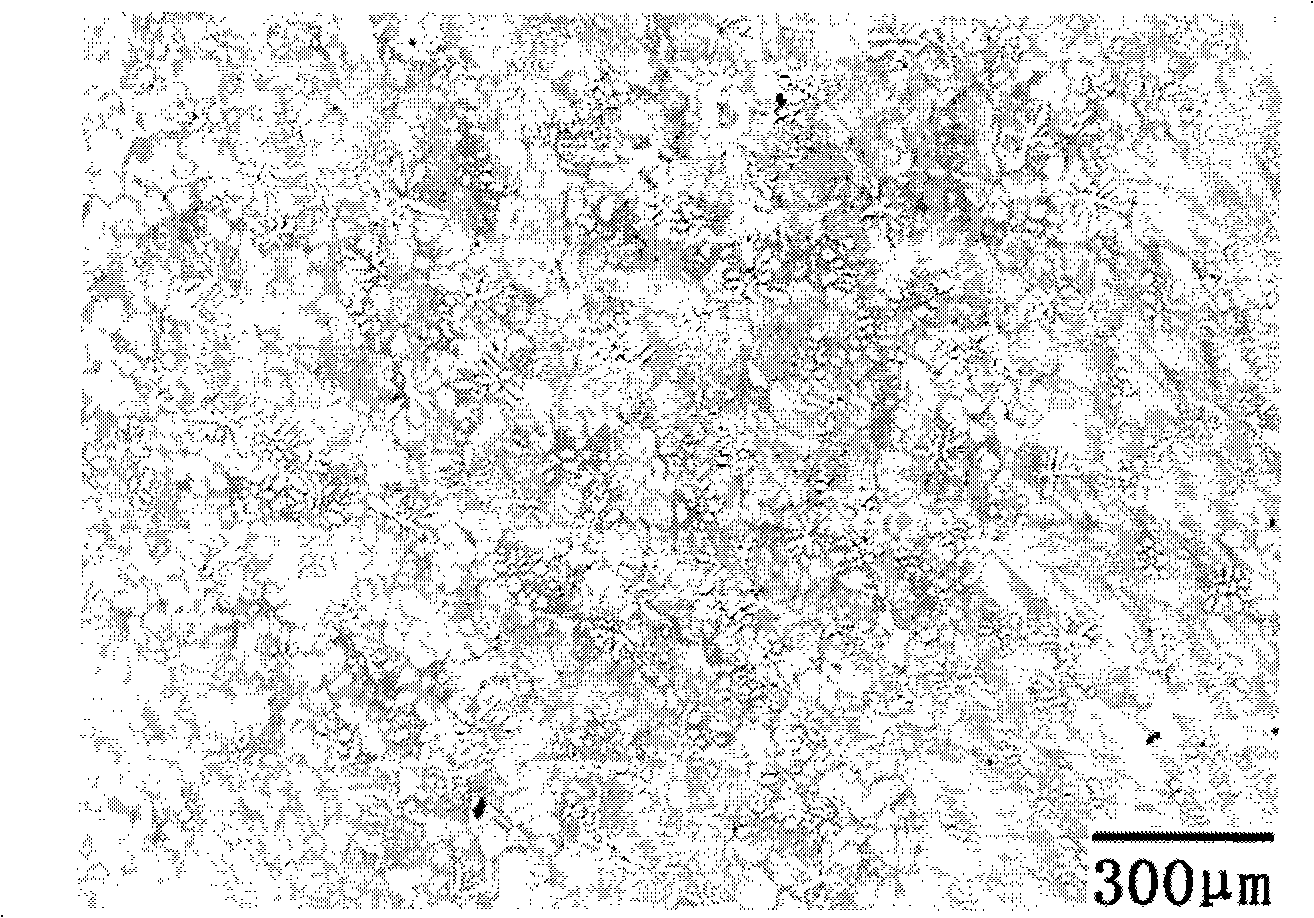

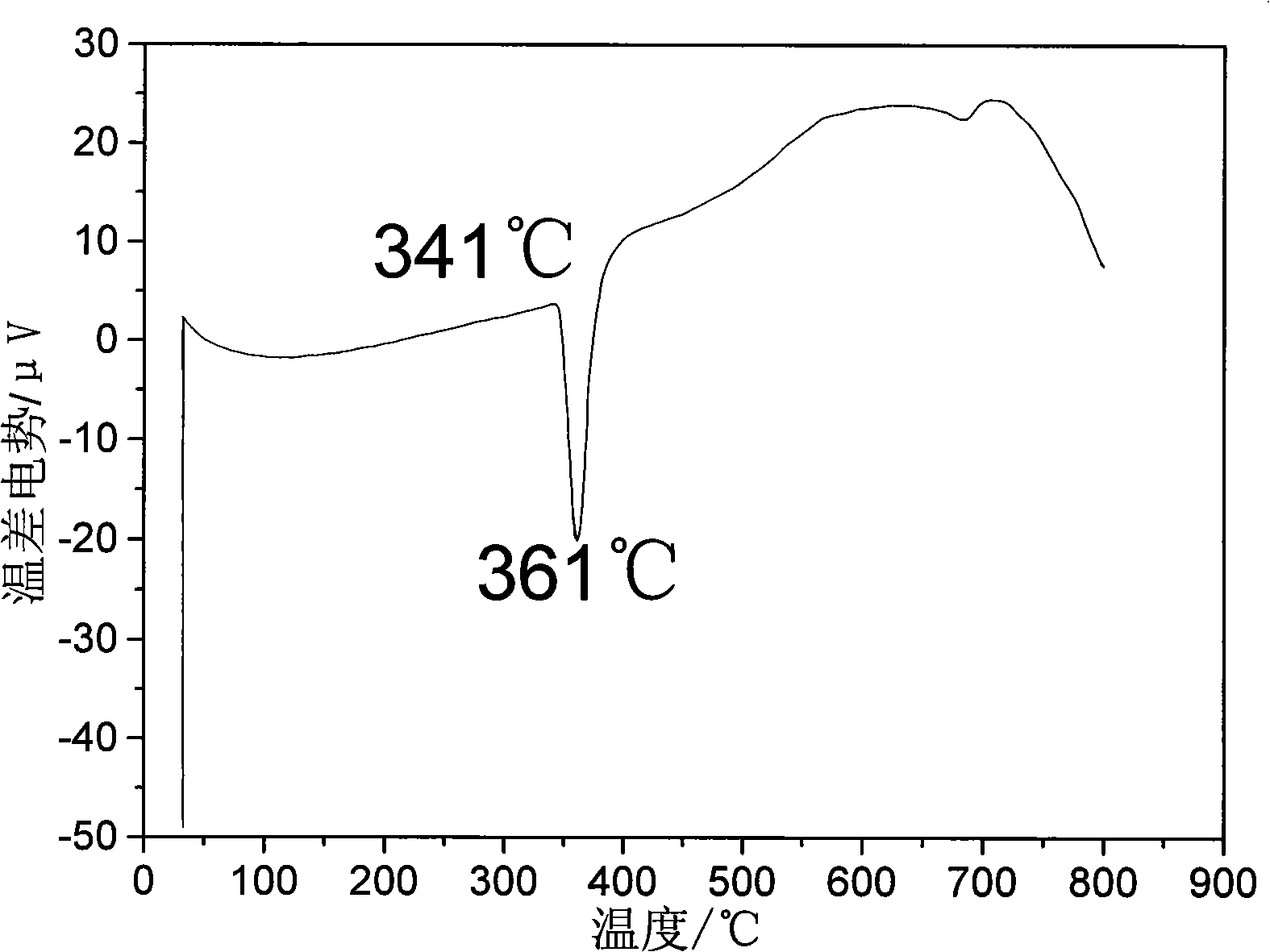

Magnesium alloy middle temperature brazing material

InactiveCN101323060AReduce brazing temperatureGood spreadabilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthMelting temperature

The invention relates to a magnesium alloy mid-temperature solder, belonging to the technical field of magnesium alloy welding. Most of the existing magnesium alloy solders have poor manufacturability, poor joint properties and other technical problems. The weigh percentage range of the components of the magnesium alloy mid-temperature solder of the invention is that: 1-2.5 percent of Al, 46-52 percent of Zn and the rest of Mg. The solder is smelted by a flux protection method; by using mechanical division, precision casting and a gas shielded ball milling method, the solders can be acquired in the forms of block, strip, powder and other forms. The melting temperature range of the solder is 336-361 DEG C; brazing temperature is low, which is 380-400 DEG C, and is suitable for magnesium alloy brazing having a solidus temperature over 400 DEG C. The solder of the invention has the advantages that brazing characteristics are good, and under the brazing temperature, spreading property and gap filling property are good; proper brazing methods include protective atmosphere brazing, induction brazing, furnace brazing and the like; the joint shear strength of brazing AZ31B magnesium alloy of the solder is more than 52 MPa, and the joint tensile strength is more than 72 MPa.

Owner:BEIJING UNIV OF TECH

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

Moisture absorption resisting aluminum alloy slit flux-cored wire and manufacturing method thereof

ActiveCN101920403AMoisture resistantWelding/cutting media/materialsSoldering mediaAl powderMoisture absorption

The invention relates to a moisture absorption resisting aluminum alloy slit flux-cored wire and a manufacturing method thereof. An alloy belt is used as the outer skin of the flux-cored wire, wherein the component of the flux-cored wire contains 5 to 90 wt.% of CsAlF4, 5 to 90 wt.% of Cs3AlF6, 1 to 45 wt.% of KALF4, 1 to 45 wt.% of K3AlF6, 0.001 to 2.0 wt.% of aluminum powder, 0.001 to 2.0 wt.% of silicon powder and 0.001 to 2.0 wt.% of Al-Mg alloy. By using the aluminum alloy belt sold on the market, based on the optimized proportion of the flux-cored wire component, the slit flux-cored wire is sewn as the slit having a stair so as to match with the edge of the flux-cored wire, thereby efficiently preventing water and other chemical materials from entering into the flux-cored wire through the slit and ensuring excellent moisture absorption resisting property. The flux-cored wire adopts torch soldering, induction brazing and furnace brazing to solder aluminum-aluminum alloy, aluminum-copper alloy and aluminum alloy-copper alloy. The slit metal not only has higher strength and air impermeability but also has excellent spreading property and permeating property.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

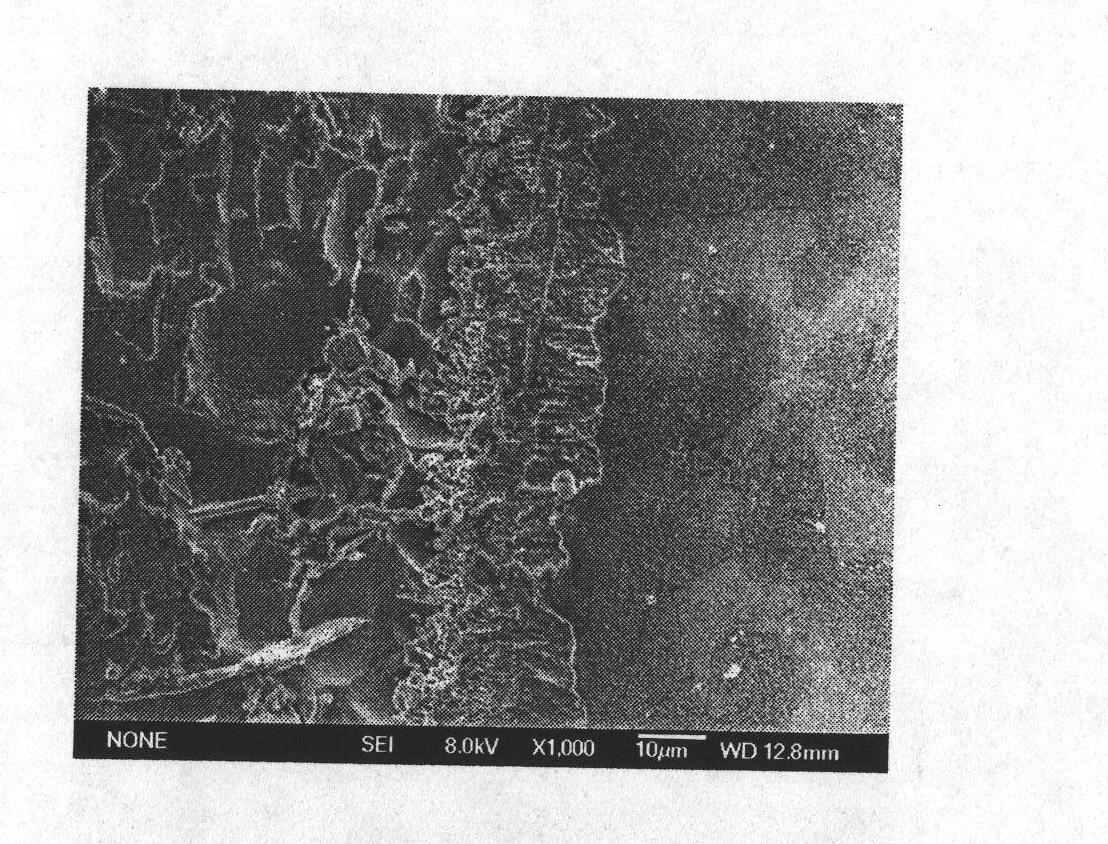

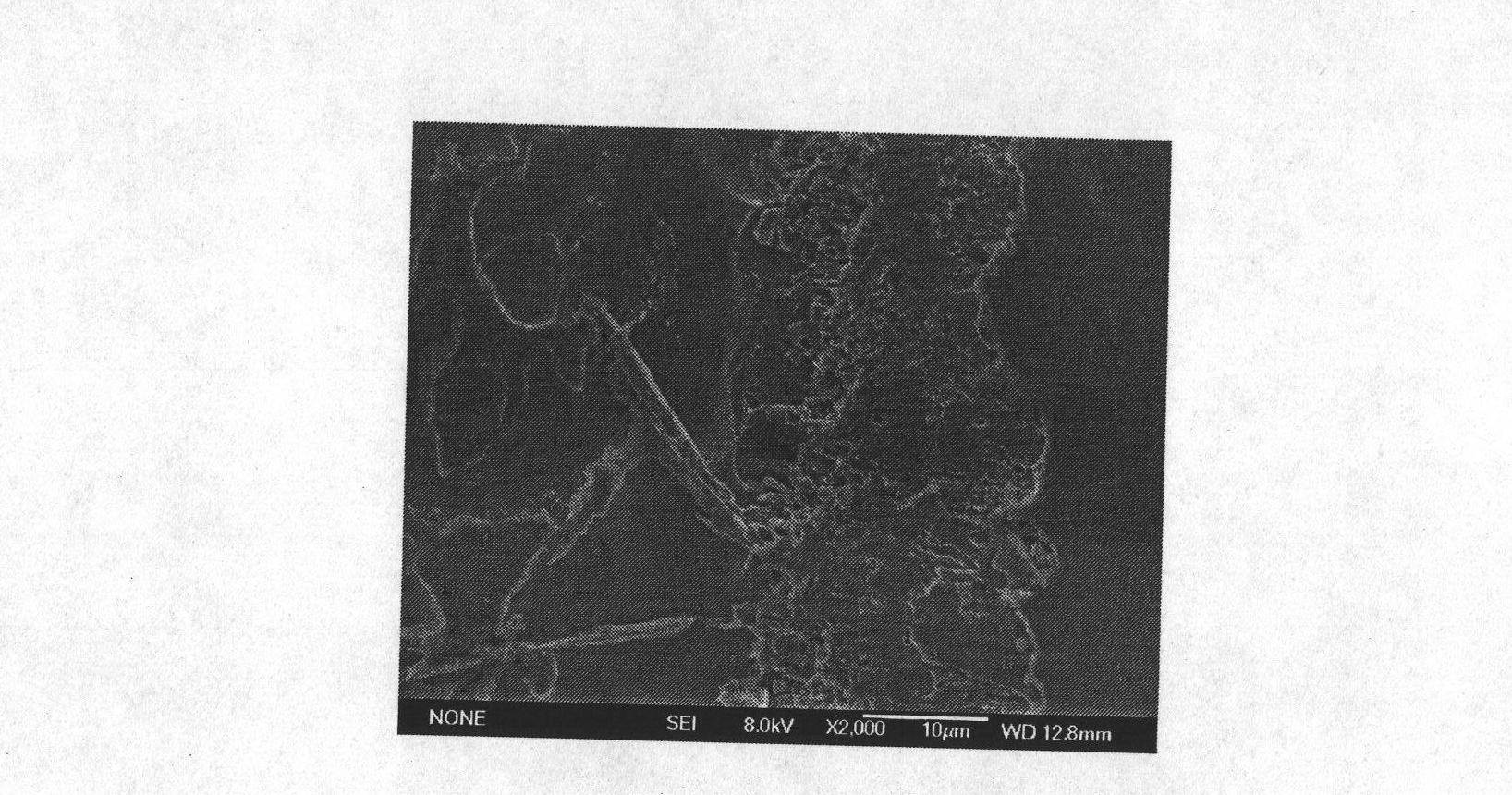

Brazing technology for diamond

InactiveCN101524779AImprove brazing qualitySuitable for industrial operationWelding/cutting media/materialsSoldering mediaArgon gasWelding torch

The invention relates to brazing technology for diamond. Firstly, a flame spraying method (an oxyacetylene welding torch) is used to plate solder alloy on a tool steel substrate, the diamond is arranged on the surface of a solder layer, then the high-frequency induction brazing is performed under the protection of argon at a temperature of 1,080 DEG C for 30 seconds to realize the combination of the diamond and the steel substrate, and main components of the solder alloy in percentage by mass comprise 72 percent of Ni, 14.4 percent of Cr, 3.5 percent of Fe, 3.5 percent of Si, 3.35 percent of B and 0.5 percent of O2. The technical proposal is adopted, so the brazing technology has high brazing quality and is suitable for industrialized operation.

Owner:JIANGSU YOUHE TOOLS CO LTD

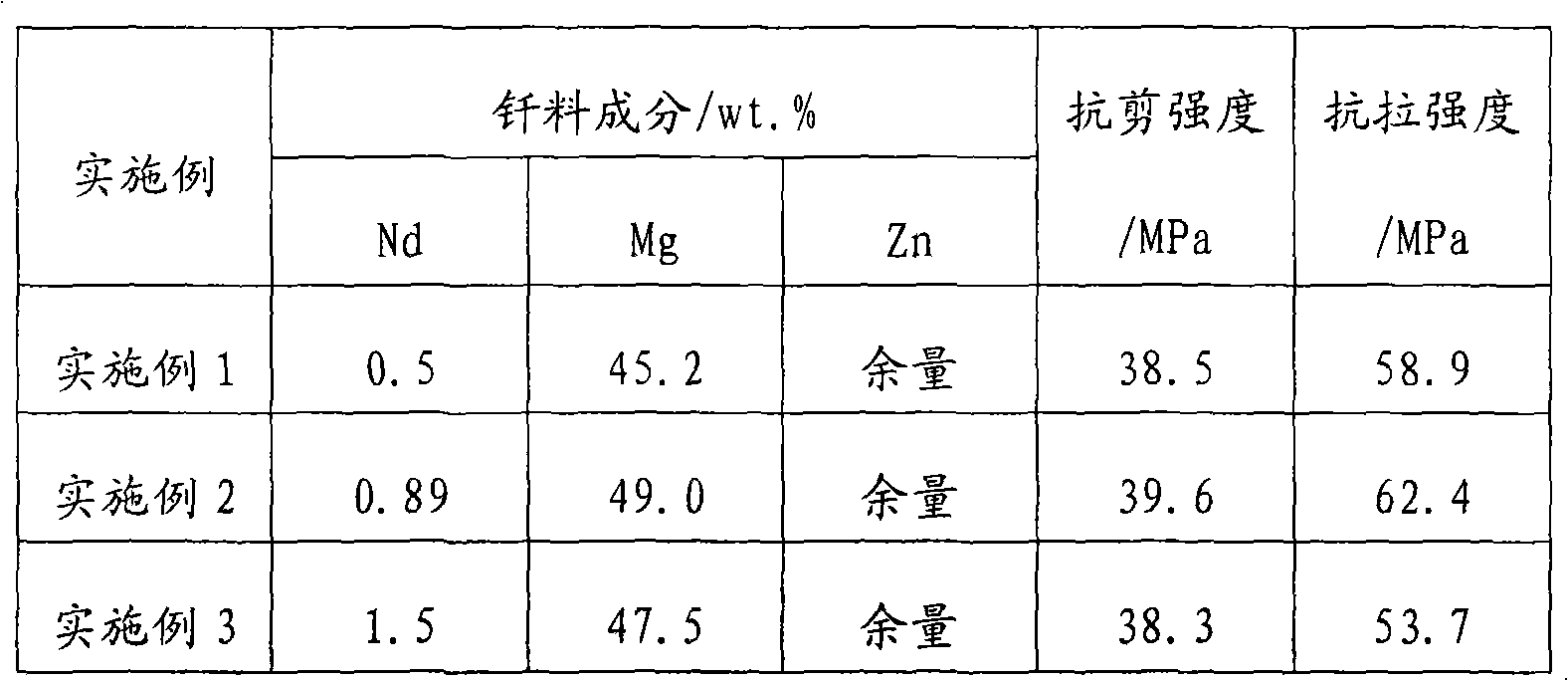

Magnesium alloy brazing solder containing rare earth

InactiveCN101658981AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaChemical compositionButt joint

The invention relates to a magnesium alloy brazing solder containing rare earth, belonging to the technical field of magnesium alloy welded connection. The chemical compositions and mass percent thereof of the magnesium alloy brazing solder containing rare earth are as follows: 0.5-1.5% of Nd,, 45-49% of Mg, and the balance of Zn. The melting temperature range of the magnesium alloy brazing soldercontaining rare earth is between 333 and 356 DEG C and the brazing temperature range thereof is between 400 and 430 DEG C, and the solder is applicable to the brazing of magnesium alloy with the solidus temperature higher than 430 DEG C. By using the solder to braze AZ31B magnesium alloy in the mode of high frequency induction brazing, the shearing strength of brazing overlapped joint is between38 and 39 MPa, and the tensile strength of the brazing butt joint is between 53 and 62 MPa. Compared with the AZ31B magnesium alloy joint brazed by magnesium alloy solder with the same components andwithout being added with rare earth, both the tensile strength and the shearing strength of brazing joints are improved by more than 30 percent.

Owner:BEIJING UNIV OF TECH

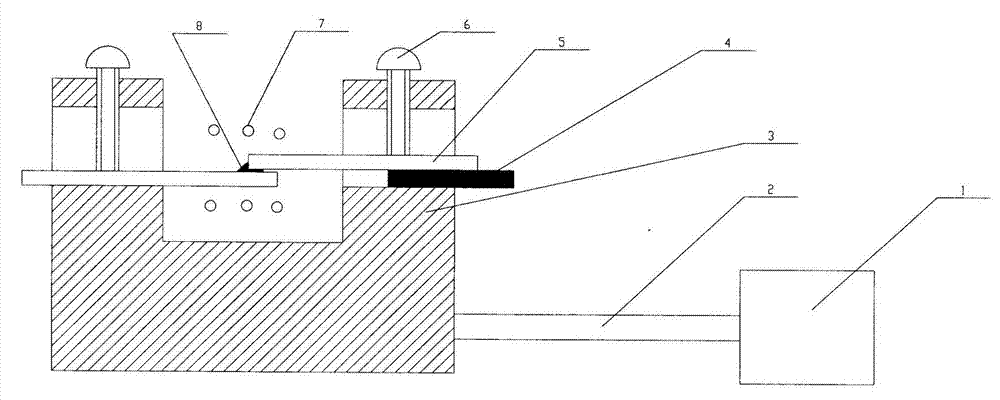

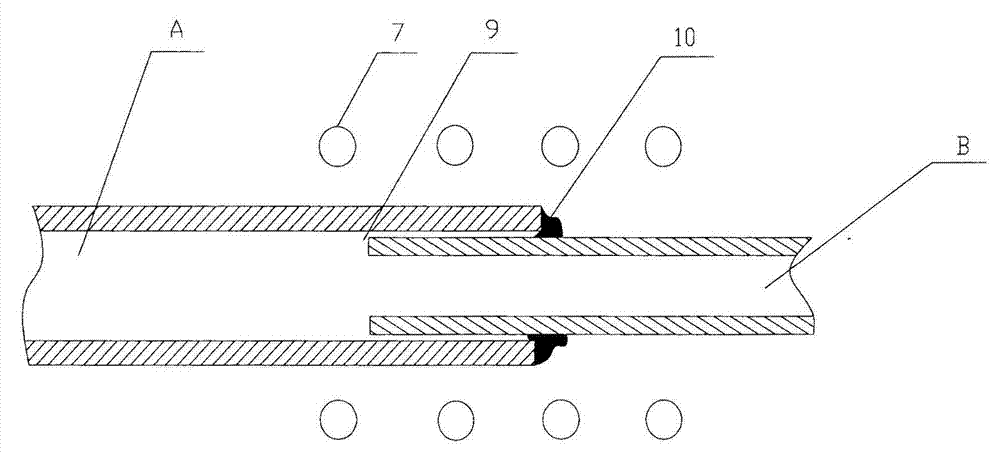

Method for vibration-assisted induction brazing

InactiveCN102784988AImprove compactnessImprove flow layingSoldering apparatusHigh frequency powerSlag

A method for vibration-assisted induction brazing includes the following steps that firstly, brazing flux is coated at a lap joint position of a clean work piece to be welded, and a brazing filler metal is preset at the lap joint position of the clean work piece to be welded; secondly, the work piece to be welded penetrates through an induction coil which is connected with a high-frequency power supply and located in the middle of a vibration table of a vibration-assisted high-frequency induction brazing machine, the work price to be welded is matched with a gasket with corresponding thickness to be horizontally placed on the vibration table, the lap joint position of the work piece to be welded is located at the center of the induction coil, and the work piece is horizontally fixed on the vibration table through fasteners at two ends of the vibration table; thirdly, the power supply of the high-frequency induction brazing machine and a water-cooling system are started, and the work piece to be welded is heated for 5-40s; fourthly, when the brazing filler metal is melted and spread, a mechanical vibration gauge is started to drive the vibration table to vibrate for 2-10s; fifthly, vibration is stopped, and heat preservation is performed for 5-30s to enable the brazing filler metal flows and spreads into gaps; and sixthly, the power supply of the high-frequency induction brazing machine is shut down, and the work piece is taken out when the work piece is cooled. The method for the vibration-assisted induction brazing is capable of obviously reducing defects that air holes, slag inclusion and poor gap filling exist in brazing seams and improving compactness of the brazing seams and mechanical performances of the joint.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

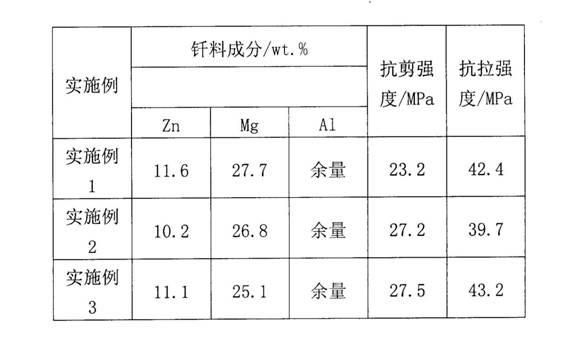

Brazing filler metal for brazing Al-Mg-Zn magnesium alloy

InactiveCN102069316AGood spreadabilityExcellent gap fillingWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to brazing filler metal for brazing an Al-Mg-Zn magnesium alloy, which is characterized in that the brazing filler metal comprises the following raw materials in percentage by weight: 10-12% of Zn, 25-28% of Mg and balance of Al. The melting temperature range of the brazing filler metal for brazing the Al-Mg-Zn magnesium alloy provided by the invention is 439-468 DEG C, the brazing temperature range is 500-510 DEG C; and under the brazing temperature, the brazing filler metal has good spreadability and gap filling property and can be suitable for brazing the magnesium alloy the solidus temperature of which is above 510 DEG C. Especially, when the brazing is carried out on an AZ31B magnesium alloy joint by adopting a high-frequency induction brazing process, only the joint part is heated and the residual part of a substrate is less heated, thereby effectively avoiding the matrix material of an AZ31B magnesium alloy from being oxidized and overburned, the shear strength of brazing an overlap joint is 23-28MPa, and the tensile strength of brazing a butt joint is 39-44MPa.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Single-layer high-temperature diamond grinding wheel brazing process

InactiveCN104889518AImprove wettabilityHigh bonding strengthSoldering apparatusGrinding devicesCarbideNi cr alloy

A single-layer high-temperature diamond grinding wheel brazing process is characterized in that Ni-Cr alloy layer with 1mm-1.5mm thickness is sprayed on a metal base body through gas welding firstly, then induction brazing is conducted on a workpiece sprayed with the Ni-Cr alloy layer in the argon at 1080 DEG C temperature till Cr in Ni-Cr alloy is separated and corresponding carbide of with 0.8mm-1mm thickness is gathered and generated on the surface of the workpiece. The alloy layer and the metal base body have good wettability, accordingly higher bonding strength can be obtained, operation is simple and convenient, a product is stable and reliable in quality, and the service life is long.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Medium-temperature aluminum-based foil strap brazing material and preparation method thereof

InactiveCN103008909AGood brazing processSimple preparation processWelding/cutting media/materialsSoldering mediaTorchShear strength

The invention discloses a medium-temperature aluminum-based foil strap brazing material and a preparation method thereof. The brazing material comprises the following components by mass percentage: 6.5-9.6 of Si, 16.0-20.0 of Cu, 8.0-10.0 of Ge, 2.0-6.0 of Zn, 0.5-1.0 of La and the balance of Al. The brazing material is prepared by rapid cooling of a melt, the melting point is lower than 495 DEG C, a foil strap is suitable for brazing of aluminum alloy with the solidus temperature higher than 520 DEG C, torch brazing, induction brazing, furnace brazing, gas protection brazing and the like can be performed, the brazing temperature is 510-520 DEG C, and the brazing material can be applied in brazing of precision components made of aluminum alloy. When the brazing material is used with 5083 aluminum alloy for QJ201 brazing, the shear strength of a brazed joint is higher than 80MPa.

Owner:ZHEJIANG UNIV +1

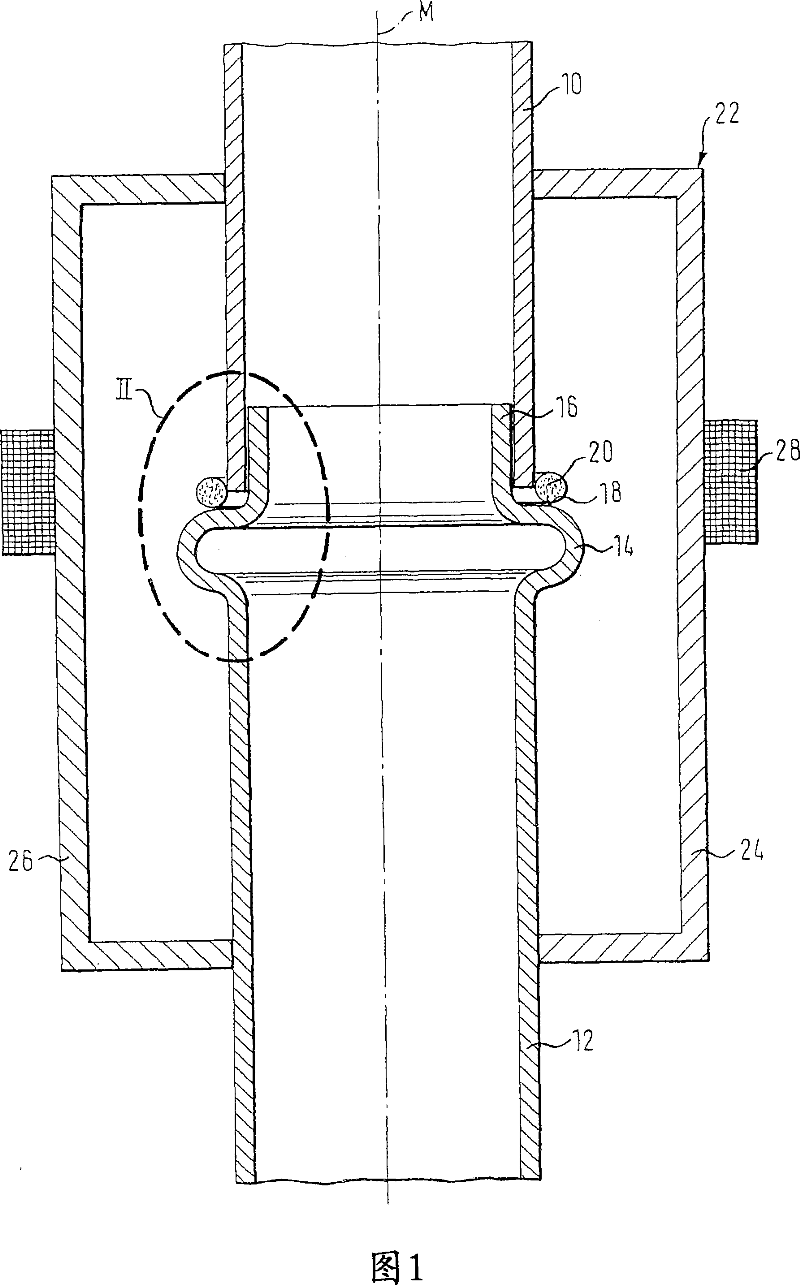

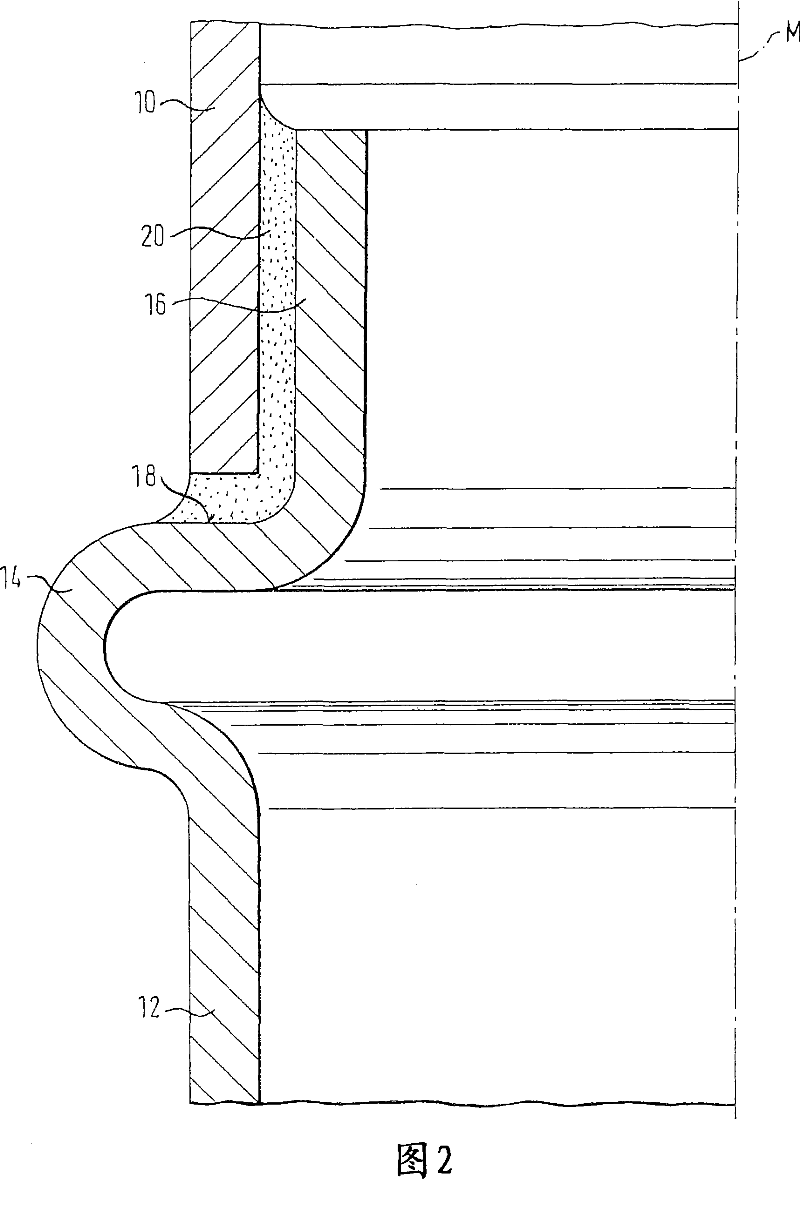

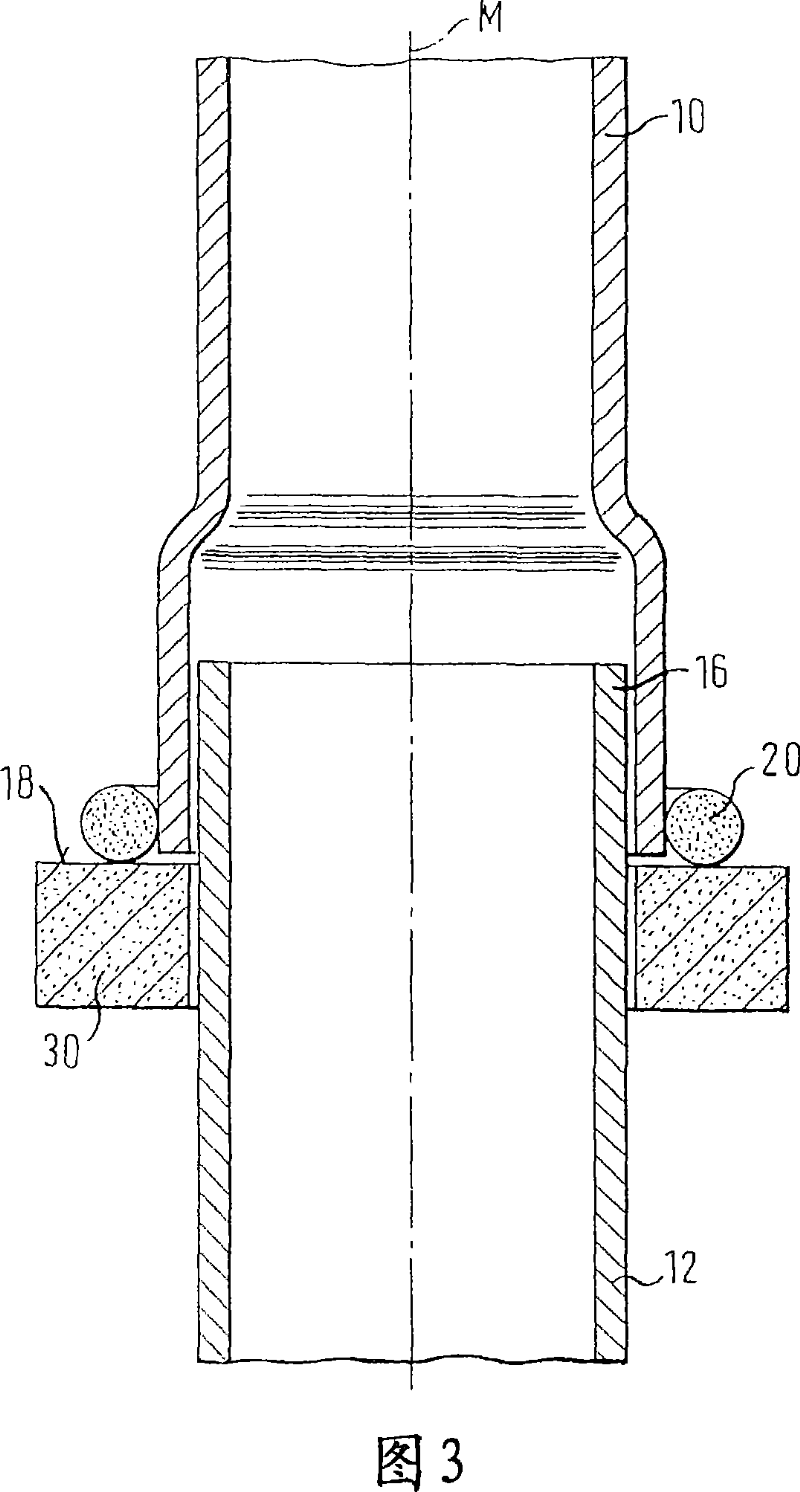

Exhaust system and method for joining components of an exhaust system

InactiveCN101044302ALow costSmall space requirementExhaust apparatusSoldering apparatusInductorSoldering

An exhaust system comprising a first component and a second component is characterized in that an induction soldered joint is provided between these two components (10, 12). According to a method for joining a first component of a motor vehicle exhaust system with a second component, the invention provides that two components, which are fitted together and provided with a high-temperature soldering material (20) are heated in the area of the soldering material by means of an inductor (28) to a temperature higher than the melting point of the soldering material (20).

Owner:ARVINMERITOR EMISSIONS TECH GMBH

Induction brazing welding method for metal part

The invention discloses an induction brazing welding method for a metal part. The method utilizes induction brazing welding equipment and then is implemented according to the following steps of: a step 1 of selecting the induction brazing welding equipment and determining related parameters; a step 2 of carrying out weldment surface processing, i.e. roughening the welding surface of a weldment, processing the metal-plated surface of the weldment, carrying out matched selection between the weldment and a soldering flux, a brazing filler metal, a welding temperature and a brazing clearance and selecting each process parameter of induction brazing; a step 3 of assembling and fixing the weldment; and a step 4 of implementing welding. According to the induction brazing welding method disclosed by the invention, the induction welding and the induction brazing welding of structures of different materials, pipe fittings, sheets, tube plates and the like are implemented, the sealing performance of a weld joint is improved, the intensity of the weld joint is reduced, the electrical conductivity is obviously improved, and the weld joint has a reliable quality.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

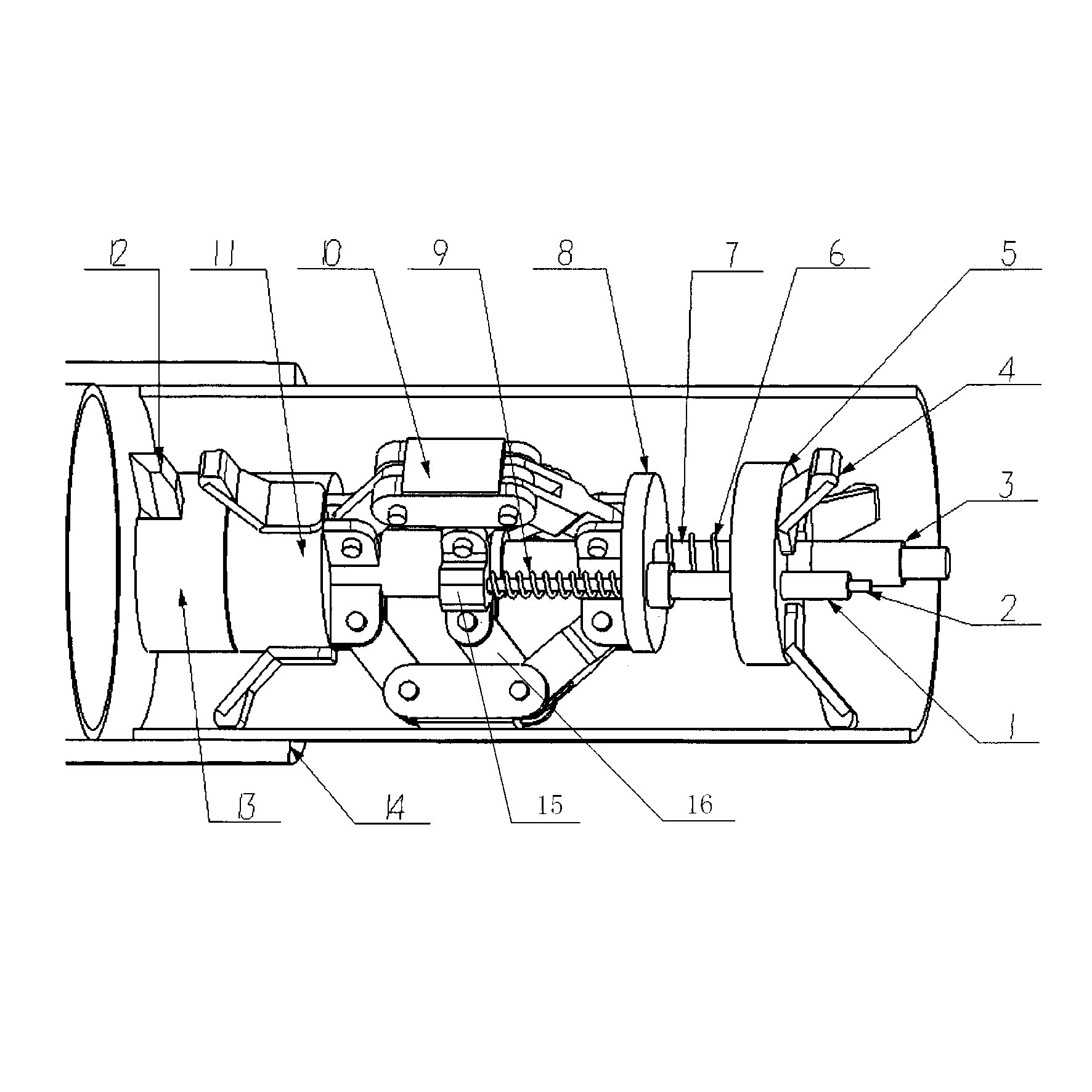

High-frequency induction brazing deep elbow pipe welding line polishing device

The invention relates to a high-frequency induction brazing deep elbow pipe welding line polishing device. One end of a bearing sleeve is connected with a soft shaft through a transmission shaft, the other end of the bearing sleeve is connected with a knife clamping disc, and a knife is arranged on the knife clamping disc. Three pairs of ear pieces which are distributed evenly in a periphery mode are arranged on a stepped shaft. A sliding block is in axial connection with the transmission shaft. Three pairs of ear pieces are distributed evenly on the inner surface of the sliding block. A supporting locating mechanism of a three-connecting-rod structure is connected between each sets of corresponding ear pieces of the sliding block and the bearing sleeve. A supporting sleeve is arranged on the bearing sleeve. Three pairs of ear pieces on the supporting sleeve are connected with connecting rods respectively. The other ends of the connecting rods are connected with connecting shafts above the supporting locating mechanism. A guiding pressing spring is arranged on the outer side surface of the sliding block. The other end of the guiding pressing spring is in contact with a supporting piece. A pulling wire penetrates through the supporting piece and the sliding block and then is connected with the support sleeve. A reset spring is arranged on the outer periphery of the pulling wire. The two ends of the reset spring are in contact with the supporting sleeve and the sliding block respectively. A pulling wire self-locking device is arranged on the end portion of the pulling wire. The polishing device can effectively polish a brazing overlap in an elbow pipe, using is convenient, maintaining is easy, and the polishing device is not limited by pipe models.

Owner:SHENYANG AIRCRAFT CORP

Medium-temperature high-strength aluminum alloy powder solder and preparation method thereof

ActiveCN102773630ASmall tissueUniform compositionWelding/cutting media/materialsSoldering mediaSolution treatmentChemical composition

The invention discloses medium-temperature high-strength aluminum alloy powder solder, comprising the following components by weight: 6.0-8.5% of Si, 10.0-12.0% of Cu, 3.0-4.0% of Ge, 3.0-4.0% of Ni, 0.5-0.8% of La and the balance of A1. The invention also discloses a method for preparing the medium-temperature high-strength aluminum alloy powder solder by adopting a melt rapid cooling technology. The melting temperature range of the solder disclosed by the invention is 515-539 DEG C, and the brazing temperature is 545-560 DEG C. The solder is suitable for the brazing the aluminum alloy of which a solidus is higher than 560 DEG C, especially suitable for the heat-treatable strengthening aluminium alloy which is subjected to a solution treatment after being brazed and is of the solution temperature no more than 545 DEG C. The solder is also suitable for furnace brazing, vacuum brazing, induction brazing, torch brazing, and the like. The solder disclosed by the invention is adopted to be matched with QJ201 brazing flux for brazing the 6061 aluminum alloy in a furnace; after being brazed, the 6061 aluminum alloy is subjected to a T6 heat treatment; and the shear strength of a brazing joint is more than 94MPa.

Owner:ZHEJIANG UNIV

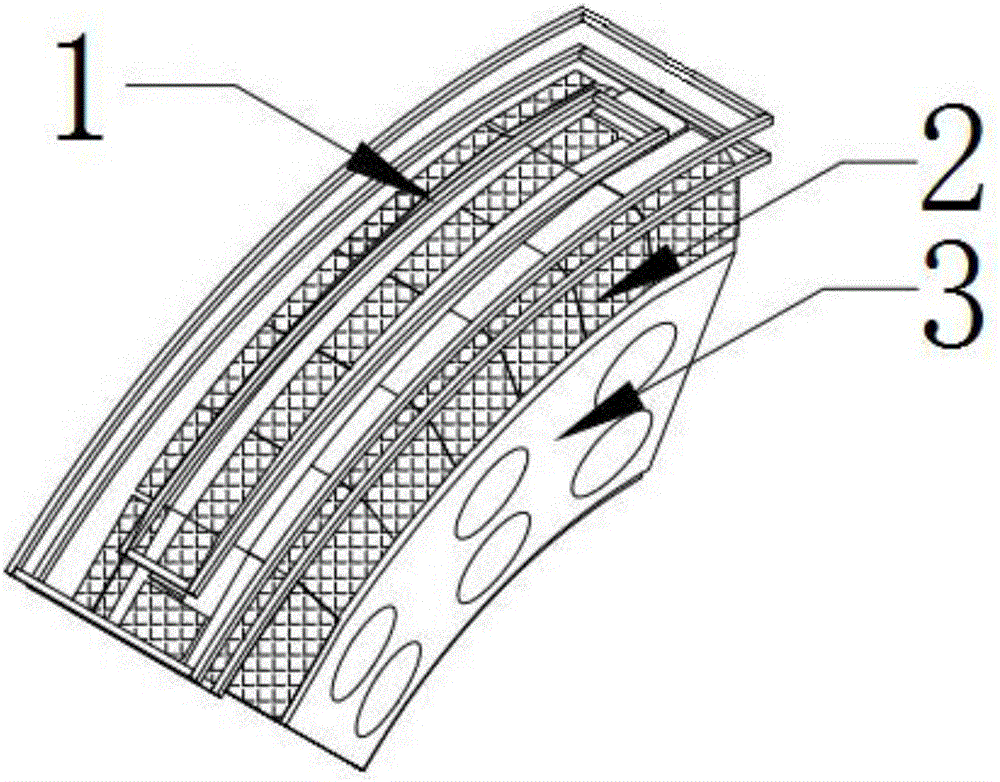

Gas protecting means for preparing superhard abrasive material tools through induction brazing

InactiveCN101176938APrevent oxidationAvoid heat damageMetal working apparatusSoldering auxillary devicesSuperhard materialShielding gas

The invention discloses a gas protection unit for making superhard grinding medium tools with induction heating brazing, which is suitable for the brazing of the superhard grinding medium (such as diamond, cubic boron nitride) tools. The invention comprises a rack, an induction heating system, a gas protection system, a workpiece lifting system, and a workpiece rotating system. When in use, one or two or more protection gases among hydrogen, nitrogen, carbon monoxide, argon, helium are filled to the quartz clock cover, and can also be vacuumized to prevent the oxidation of the solder and the base when high temperature brazing, the damage of superhard material and the graphitization of diamond. When brazing, the workpiece rotate, rise and fall in the protection room, which can realize the proper position for the workpiece in the induction heating ring, thus the uniformization of temperature in the brazing area of the workpiece surface is ensured.

Owner:徐州华谐科技发展有限公司

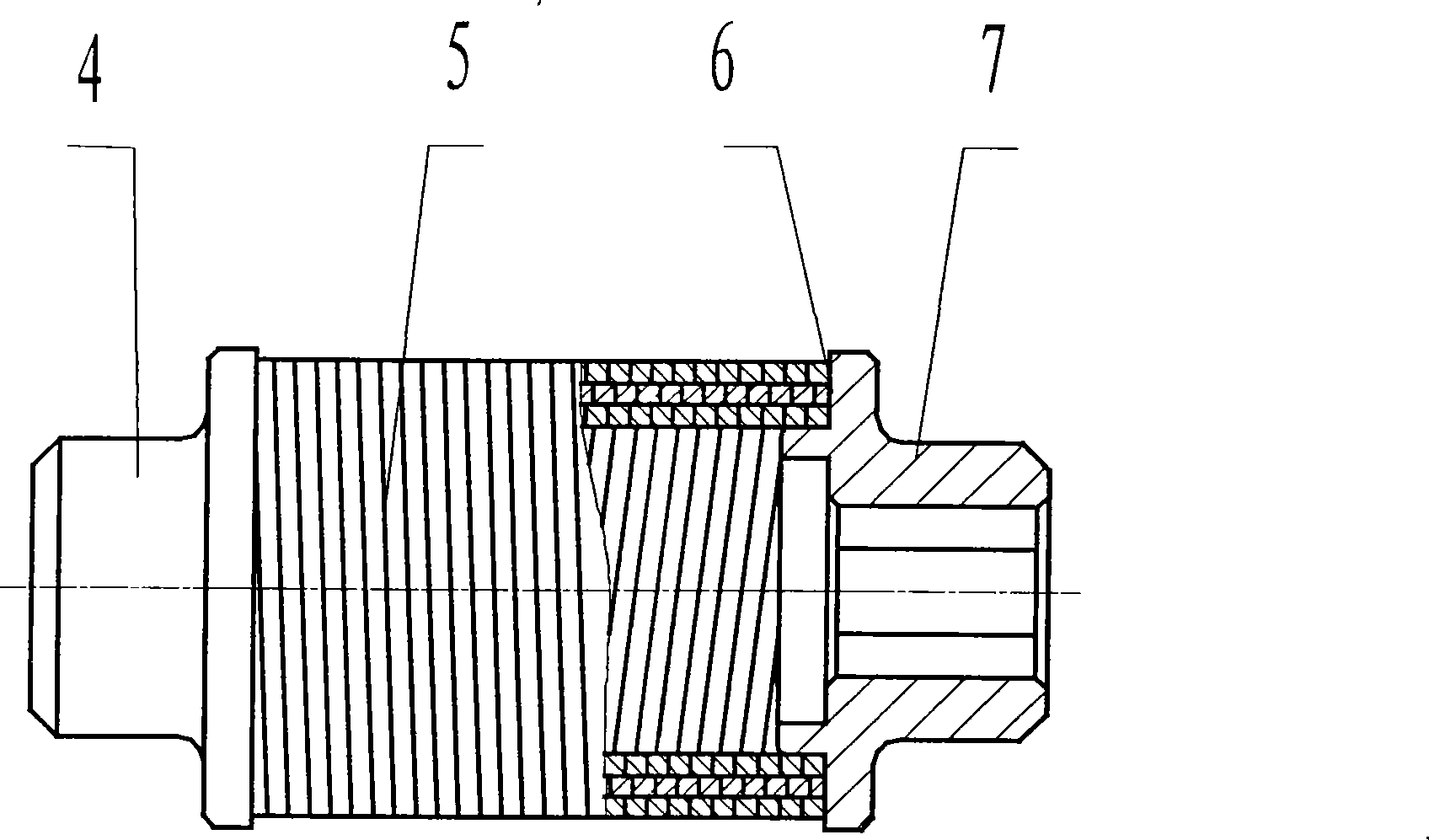

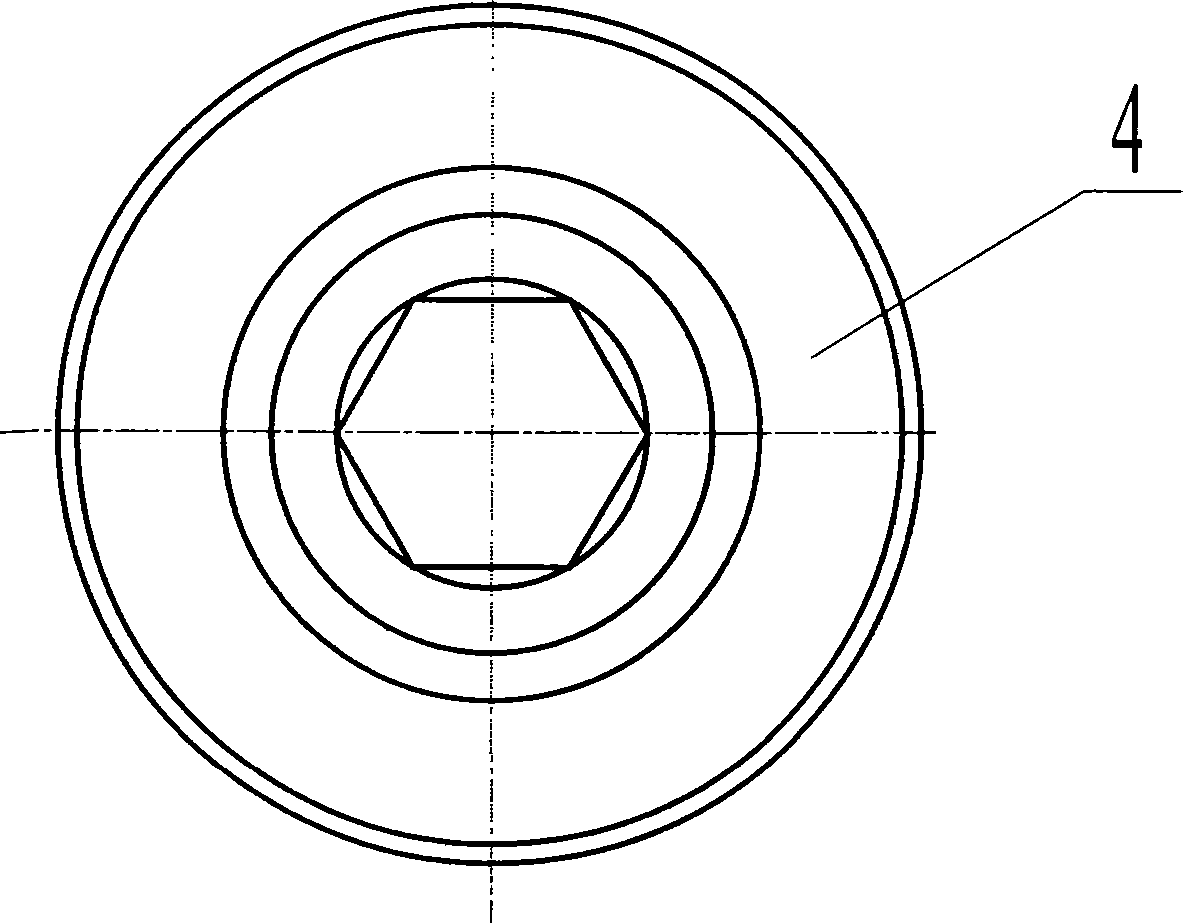

Composite spring type flexible clutch as well as welding method thereof

The invention relates to a compound spring type flexible shaft joint which comprises a first semi-shaft joint, a second semi-shaft joint and a compression spring connected between the first semi-shaft joint and the second semi-shaft joint; the invention is characterized in that: the compression spring is a compound spring which at least consists of one layer of more than two levo / dextral coil springs; two ends of the compound spring are fixed with one end of the first semi-shaft joint and one end of the second semi-shaft joint respectively. The invention also relates to a welding method of the compound spring type flexible shaft joint, which adopts the induction soldering technology and comprises the following steps that: flaky silver solders are punched and machined to two sheets of annular solders; firstly, one end of the compound spring is welded with the first semi-shaft joint, then the other end of the compound spring is welded with the second semi-shaft joint. The qualification rate of parts produced by the invention reaches 95 percent above; compared with the prior technology, the welding method of the compound spring type flexible shaft joint solidifies technological parameters, exists no problem of nonmetallic aging of the produced parts in the storage process, does not need to increase a mass of spare parts and reduces the cost.

Owner:CHONGQING WANGJIANG IND

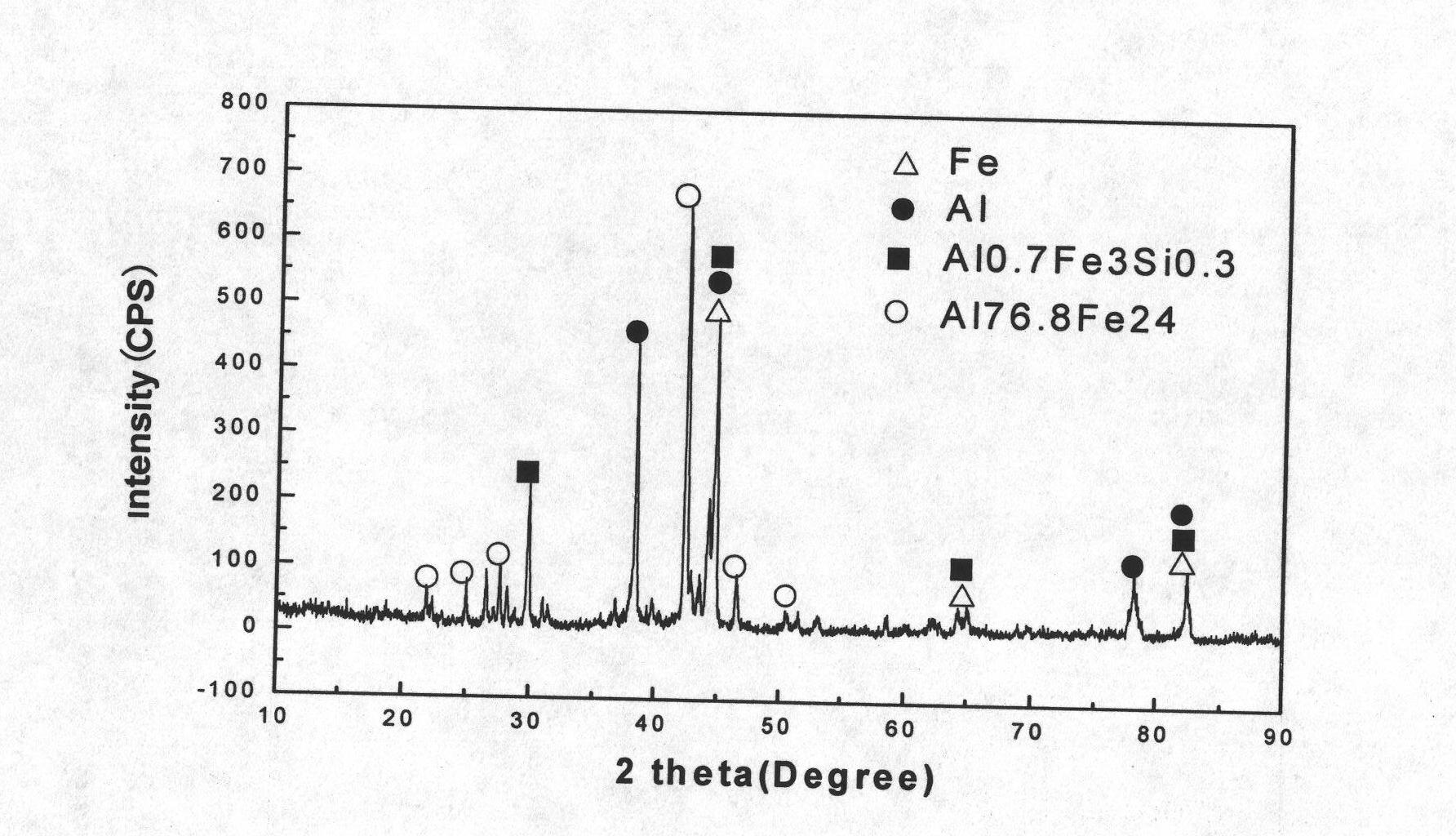

Brazing filler metal for high-frequency induction brazing of aluminum steel and brazing method of brazing filler metal

InactiveCN102152023AReduce adverse effectsImprove reliabilityWelding/cutting media/materialsSoldering mediaGranularitySodium potassium tartrate

The invention relates to a brazing filler metal for high-frequency induction brazing of aluminum steel and a brazing method of the brazing filler metal. In the brazing filler metal, Al-Si based alloy powder is used as a brazing filler metal component of a welding flux; the granularity of the brazing filler metal alloy is -150 to +300 meshes, and the melting point of the brazing filler metal alloy is 570 to 580 DEG C; three kinds of villiaumite, namely KF, NaF and AlF3, are used as a brazing flux in a ratio of (KF and NaF) to AlF3 of 1 to 10; sodium potassium tartrate is used as a bonding agent; and the content of the brazing filler metal in the welding flux is 60 percent, the content of the brazing flux is 38 to 39 percent, and the bonding agent accounts for 1 to 2 percent. The brazing method comprises the following steps of: preparing the components; making the components pasty by using absolute ethanol; removing oxidized membranes from the surfaces to be brazed of steel and aluminum workpieces, and washing by using acetone; uniformly coating the mixed welding flux on the surfaces to be brazed and pressurizing, placing the welding flux into high-frequency induction heating equipment and protecting by using argon; and under a voltage of 4.5kV, heating for 30 seconds and unloading the voltage, and taking the workpiece out if the temperature of the workpiece is below 50 DEG C.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

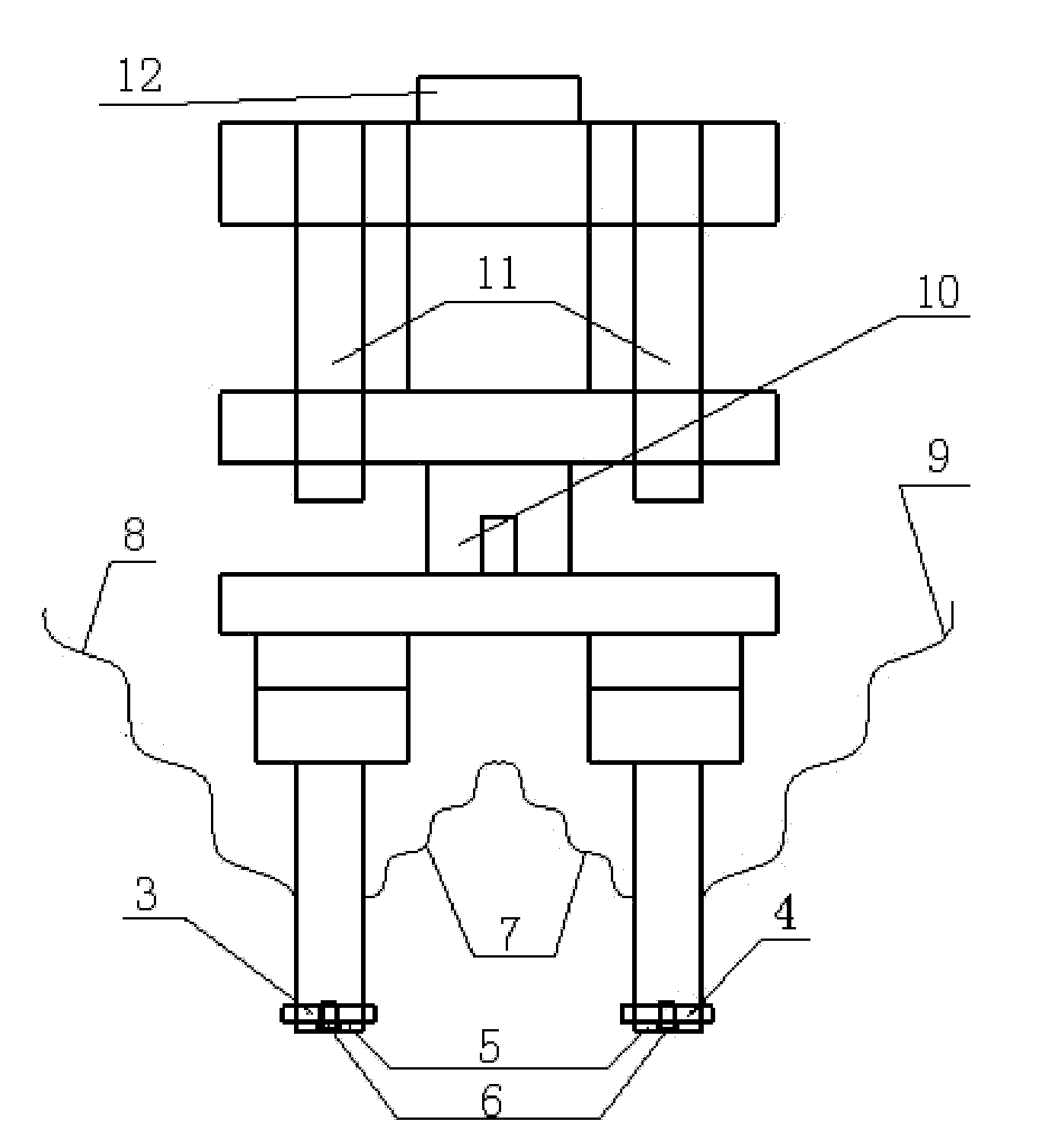

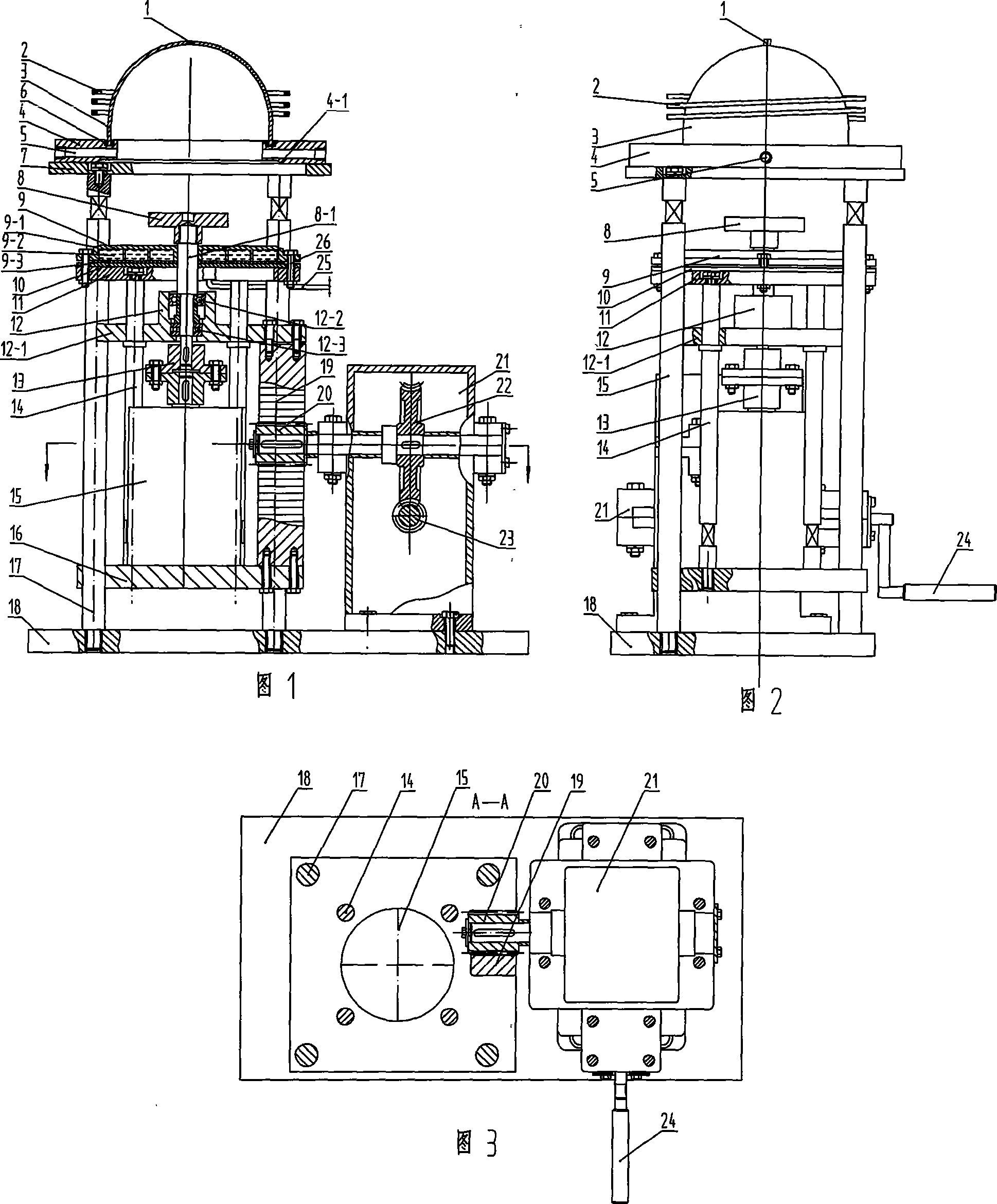

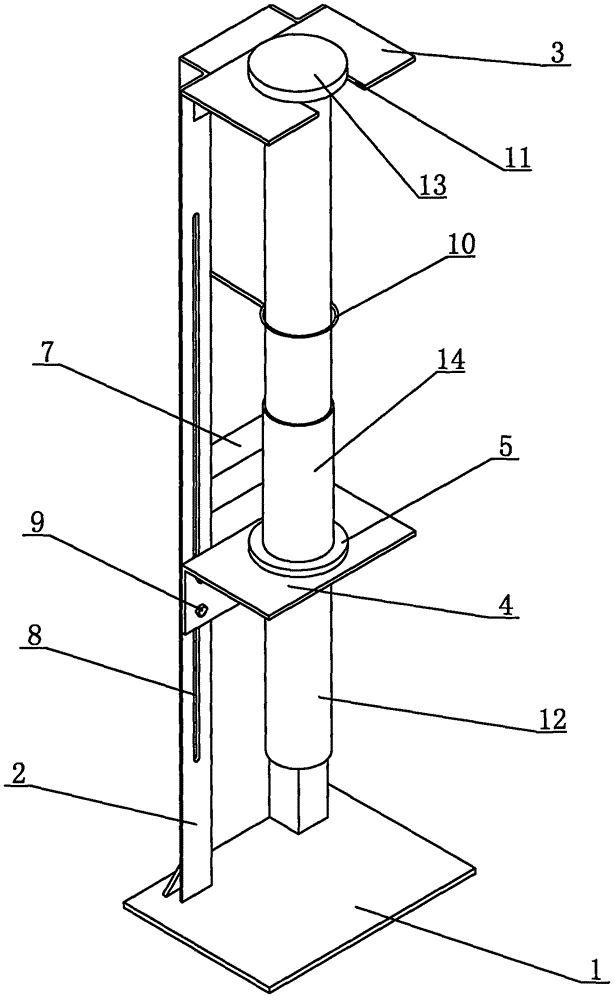

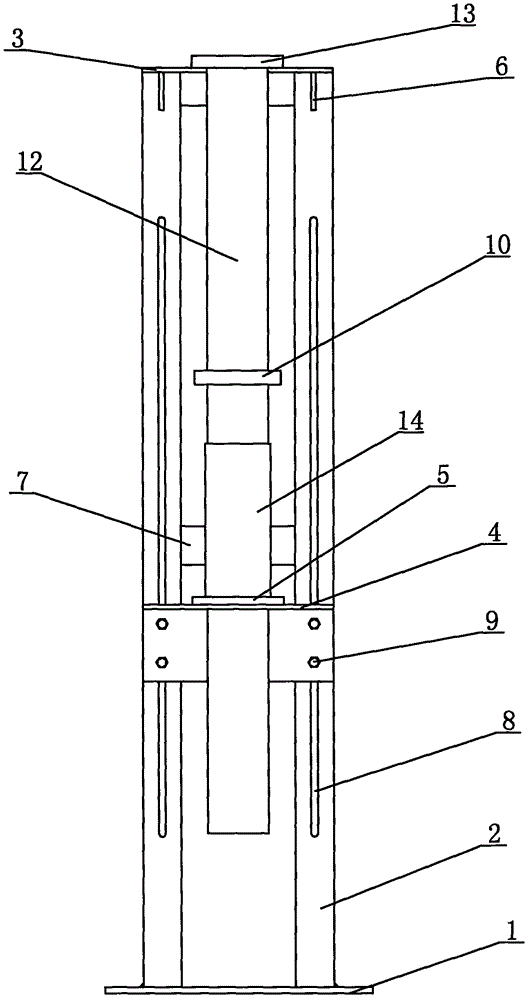

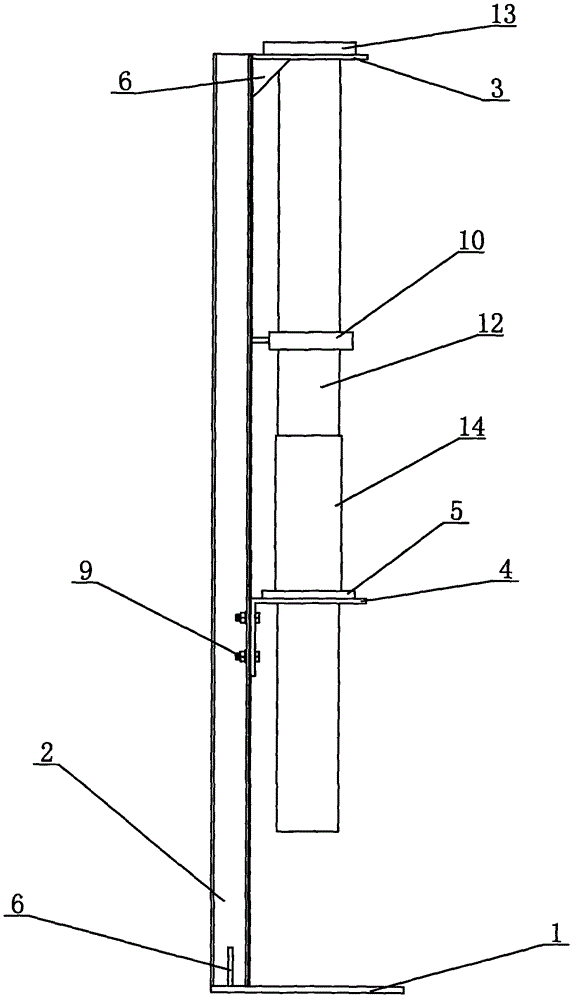

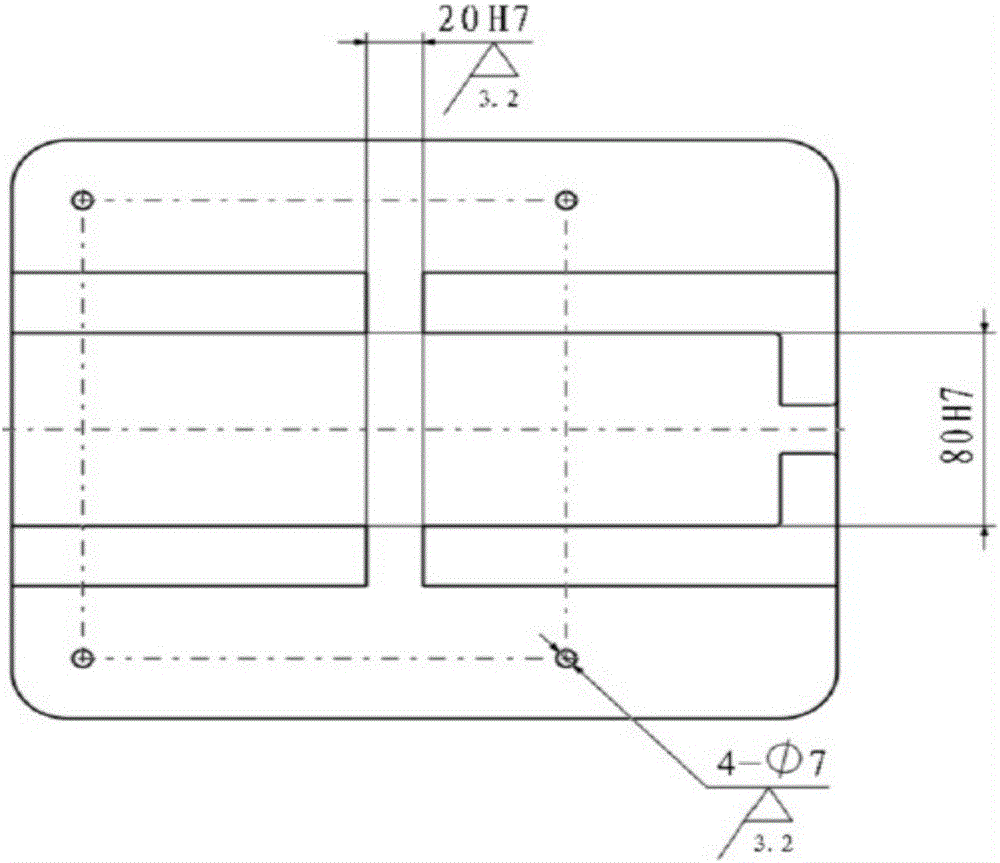

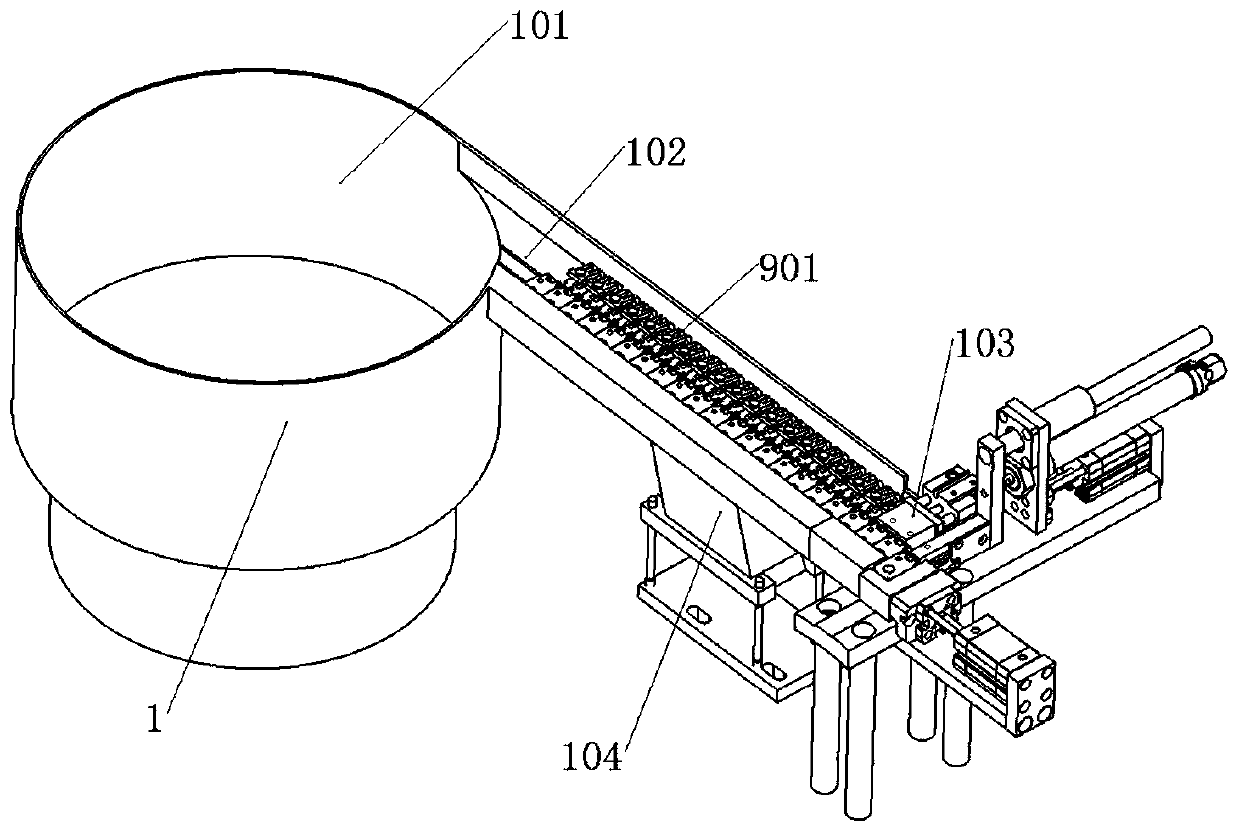

Welding tool for induction soldering pipe fittings

ActiveCN105127540ASimple structureEasy to operateTubular articlesSoldering auxillary devicesPipe fittingArchitectural engineering

The invention discloses a welding tool for induction soldering pipe fittings. The welding tool comprises a base plate, two stand columns, a supporting plate and a lifting table. The two stand columns are fixed to the base plate in parallel in a spaced mode. The supporting plate is fixed to the top ends of the two stand columns. The lifting table is arranged in the middles of the two stand columns in a height-adjustable mode. A through hole is formed in the lifting table. An induction coil of an induction soldering machine is arranged at the portion, between the two stand columns, above the lifting table. One end of the inner pipe fitting to be welded is connected to the supporting plate through a connecting assembly, and the other end of the inner pipe fitting to be welded penetrates through the induction coil, the outer pipe fitting to be welded and the through hole. The outer pipe fitting to be welded is arranged at the portion, outside the inner pipe fitting to be welded, of the lifting table through a limiting assembly. The welding tool for the induction soldering pipe fittings is simple in structure and convenient to operate, the welding efficiency is improved, and welding reliability and reliability are ensured.

Owner:无锡市创新低温环模设备科技有限公司

Germanium-contained (Ge-contained) corrosion-resistant aluminum-based solder

InactiveCN103008908AThe process is simple and easy to controlLow content of Ge elementWelding/cutting media/materialsSoldering mediaCeriumCopper

The invention discloses germanium-contained (Ge-contained) corrosion-resistant aluminum-based solder. The solder comprises the following components in mass percent: 6.5 percent of silicon (Si), 15.0 percent of copper (Cu), 0.1-8.0 percent of Ge, 6.0 percent of stannum (Sn), 1.0 percent of cerium (Ce) and the balance aluminum (Al). The solder is prepared by adopting the rapid cooling technique. The melting point of the solder is lower than 520 DEG C, and the brazing temperature is 540-550 DEG C. The Ge-contained corrosion-resistant aluminum-based solder is suitable for brazing of aluminum alloy of which the solidus is higher than 550 DEG C, such as flame brazing, induction brazing, furnace brazing and gas shield brazing. The solder is matched with a QJ201 brazing aluminum plate 3003, so that the shear strength of a brazed joint is higher than 82MPa. When the percentage composition of the Ge is 2.5, the corrosion resistance of solder alloy is optimal, and the corrosion current density is 3.562muAcm<-2>.

Owner:ZHEJIANG UNIV +1

Induction brazing method for edge scraper of shielding tunneling machine

ActiveCN105921838AExtended service lifeImprove wear resistanceHeating appliancesSoldering auxillary devicesTemperature differenceShield tunneling

The invention discloses an induction brazing method for an edge scraper of a shielding tunneling machine. An edge scraper body, silver-based brazing filler metal and a hard alloy tool bit which are well assembled are put in the lower end of a profiling coil and are tightly attached to the profiling coil, and then the welding work is completed after preheating, heating welding and post-welding thermal treatment. The adopted profiling coil is a self-made profiling coil. By means of the induction brazing method, the hard alloy at the middle part can be heated, the temperature differences of different positions of the edge scraper are reduced during welding, the same brazing filler metal can be conveniently used for brazing, and the phenomenon that because different types of brazing filler metal are used for brazing, mutual interference is caused is avoided. By means of the induction brazing method, brazing of the hard alloy tool bit and the edge scraper body can be completed at a time; and meanwhile, the weld joint brazed rate is increased, the shear strength is also improved, the service life of the edge scraper of the shield tunneling machine is prolonged, and wear resistance of the edge scraper of the shield tunneling machine is improved.

Owner:SICHUAN GUANGZHENG TECH

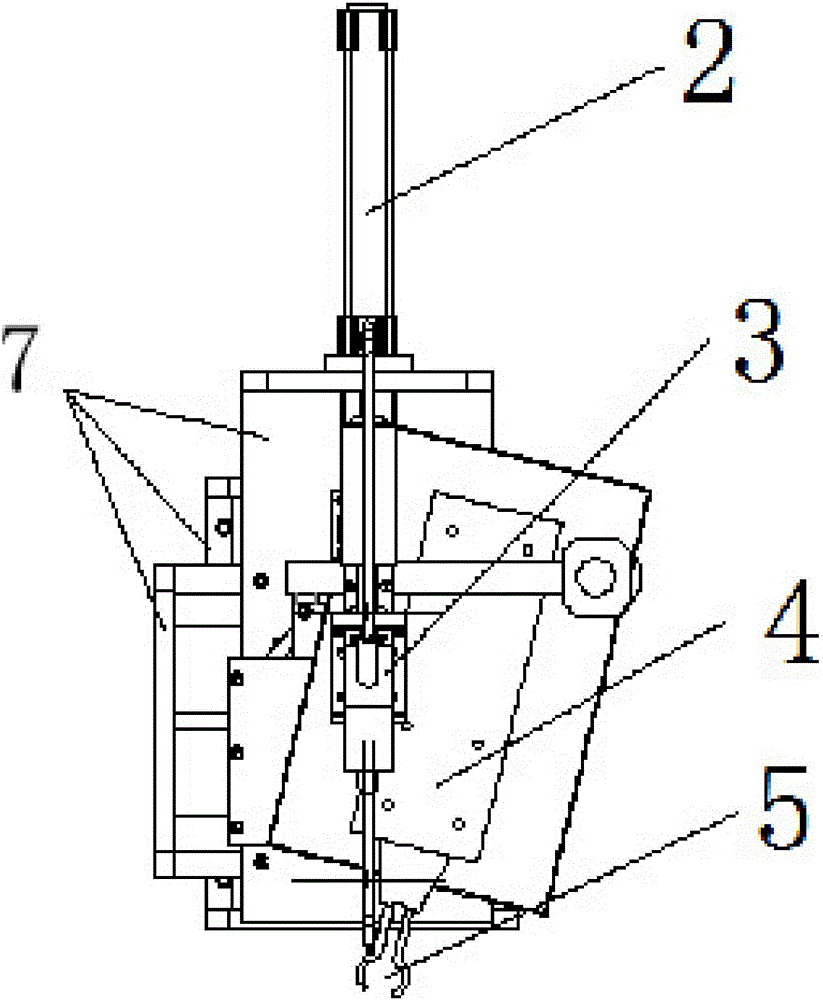

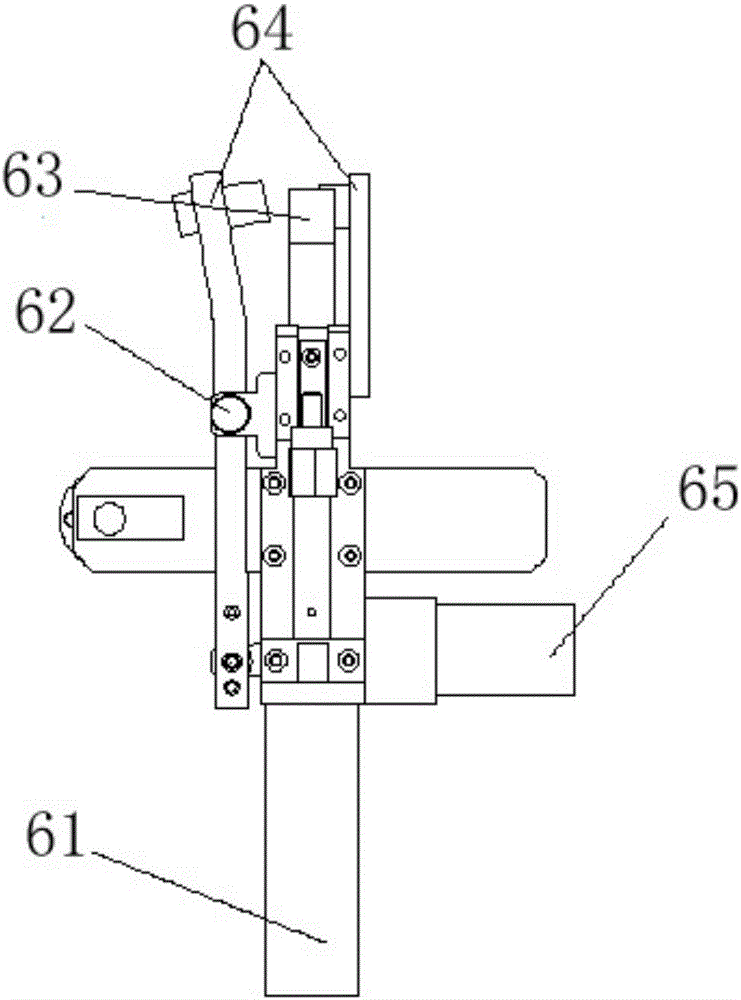

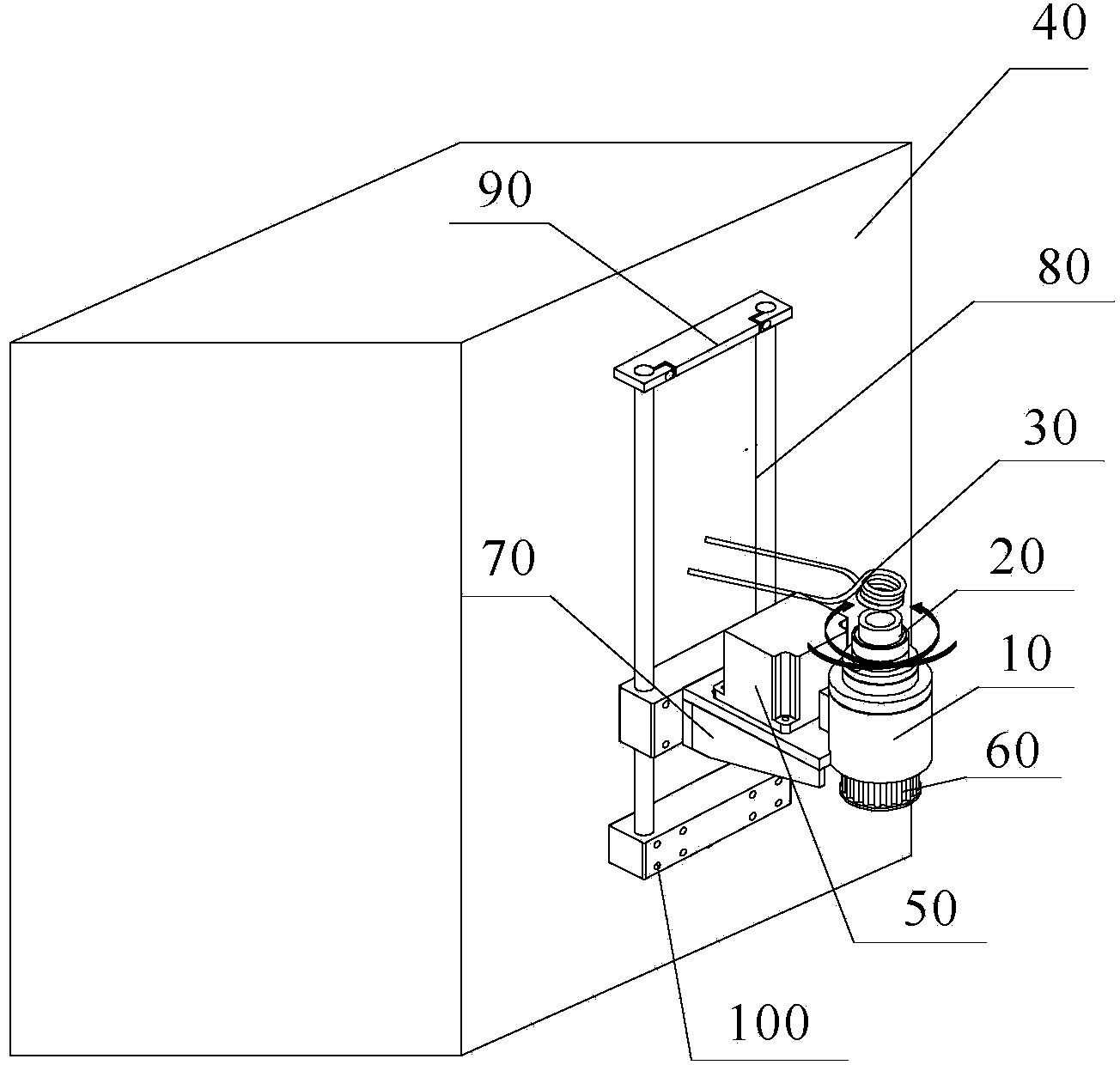

Induction brazing equipment and method

InactiveCN106392237AReduce the difficulty of position adjustmentImprove flexibilityHeating appliancesMetal working apparatusEngineeringMovement control

The invention provides induction brazing equipment which comprises a locating tool and a welding device. The locating tool is used for clamping a welding workpiece and feeding the welding workpiece to a preset position. The welding device is used for welding the welding workpiece when the welding workpiece is located at the preset position. The welding device comprises a motion control assembly, an induction heating assembly and an automatic wire feeding assembly. The induction heating assembly and the automatic wire feeding assembly are mounted on the motion control assembly. The induction heating assembly is used for heating the welding workpiece. The automatic wire feeding assembly is used for conveying welding flux to the welding workpiece. The motion control assembly is used for adjusting the position of the induction heating assembly and the position of the automatic wire feeding assembly so that the induction heating assembly and the automatic wire feeding assembly can cooperate to complete welding action. The invention further provides a corresponding induction brazing method. By means of the equipment and the method, the position adjusting difficulty of the induction heating assembly and the automatic wire feeding assembly is reduced, and the adjusting time is shortened.

Owner:GREE ELECTRIC APPLIANCES INC

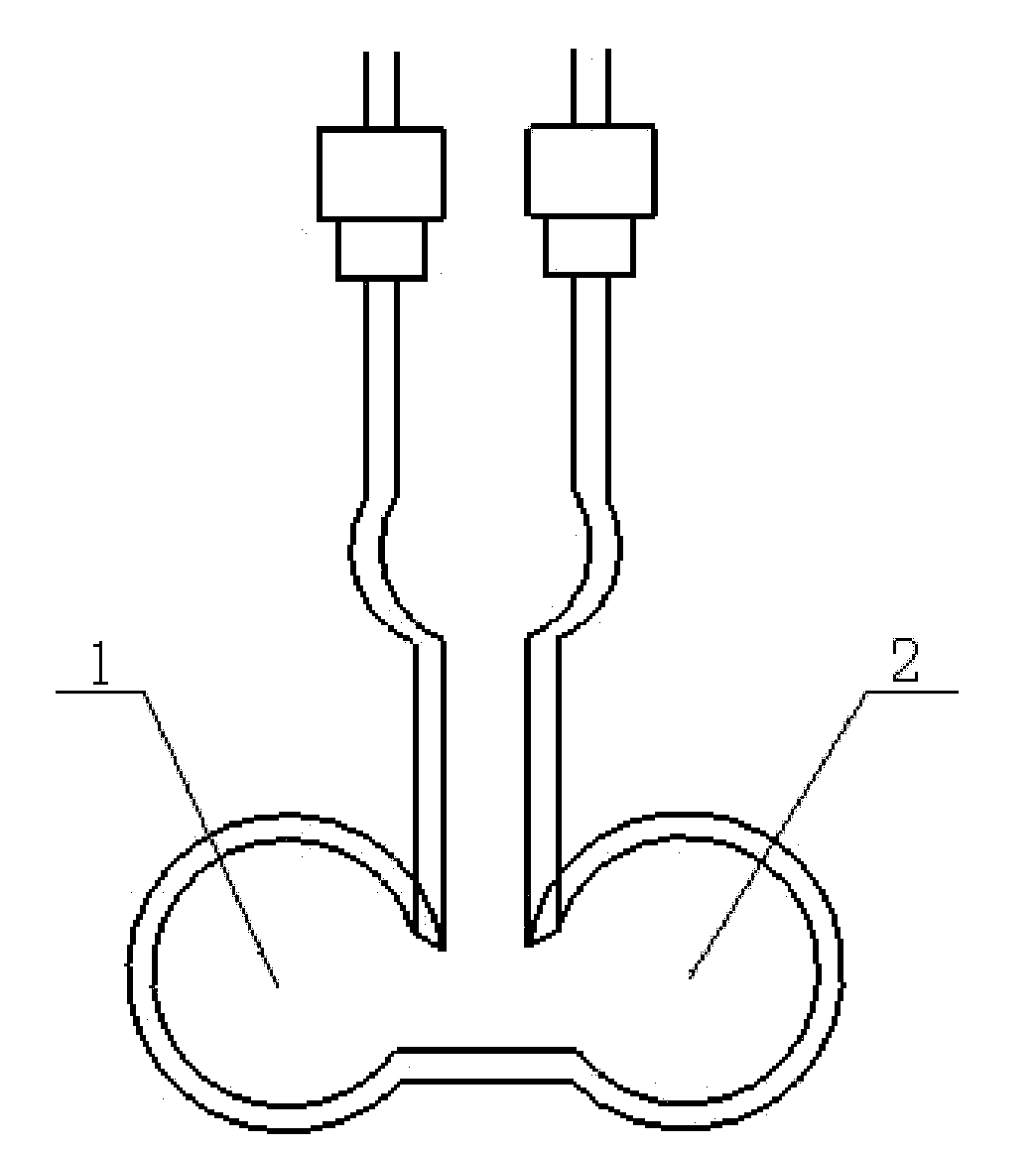

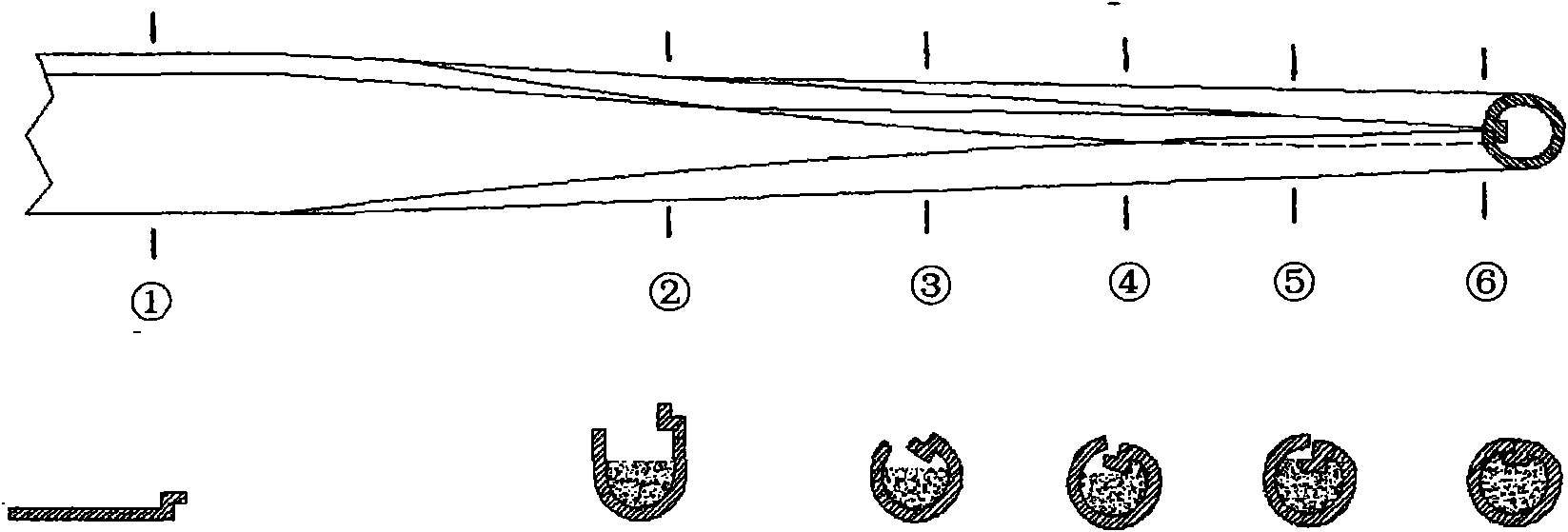

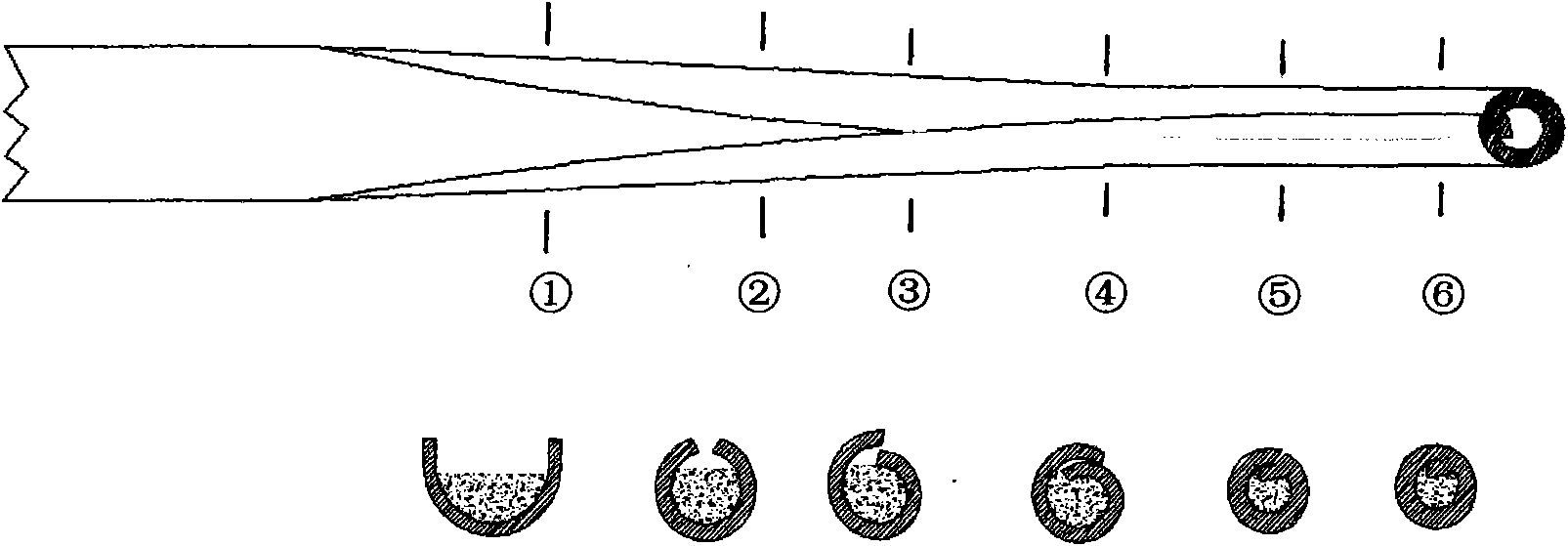

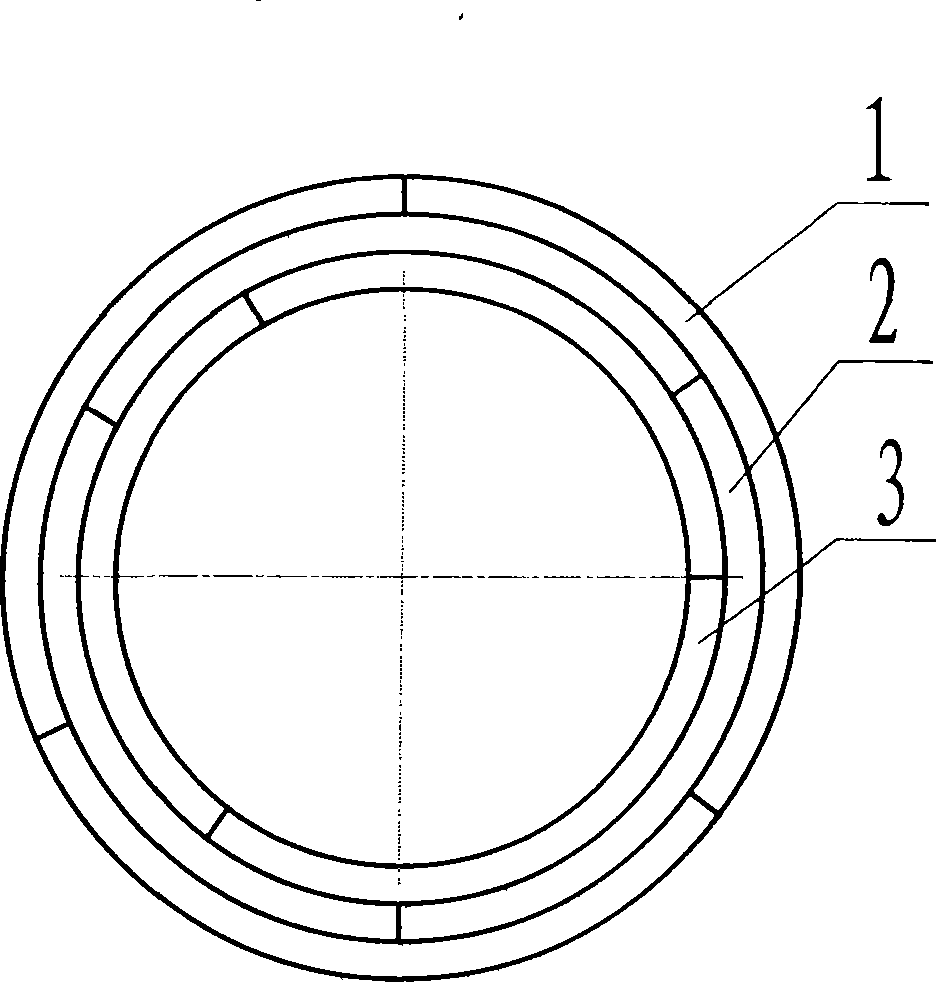

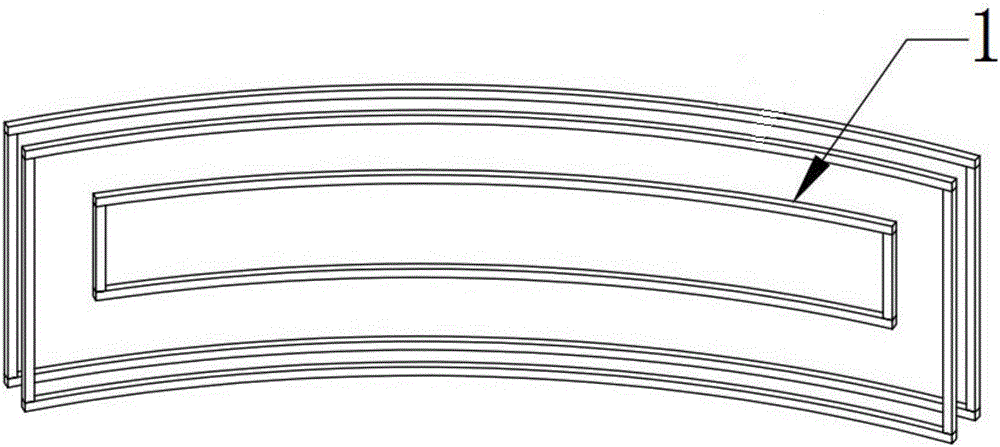

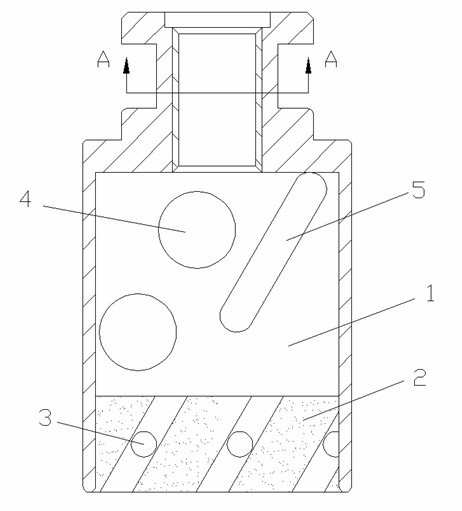

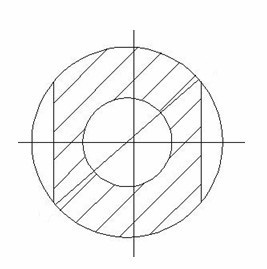

High-frequency induction brazed diamond drill bit

InactiveCN102205451AImprove work performanceExtended service lifeSoldering apparatusGranularityAlloy

The invention relates to a high-frequency induction brazed diamond drill bit. The high-frequency induction brazed diamond drill bit comprises a drill bit base body (1); tungsten and carbon (WC) powder is added into an alloy of the drill bit base body; first round heat dissipation chip removal slots (3), second round heat dissipation chip removal slots (4) and a third round heat dissipation chip removal slot (5) are formed on the drill bit base body (1); an inner layer of diamond particles and an outer layer of diamond particles are brazed on the surface, 0 to 15 millimeters away from the lower edge, of the drill bit base body (1) in a high-frequency induction manner; the granularity of the inner layer of diamond particles is 40 / 45, and the granularity of the outer layer of diamond particles is 45 / 50; and the inner layer of diamond particles and the outer layer of diamond particles are intermittently arranged on the surface of the drill bit base body in a strip manner, so a diamond working layer is formed. The high-frequency induction brazed diamond drill bit has good perforating effect, high perforating speed and long service life.

Owner:JIANGSU FUNLIN SUPER HARD TOOLS

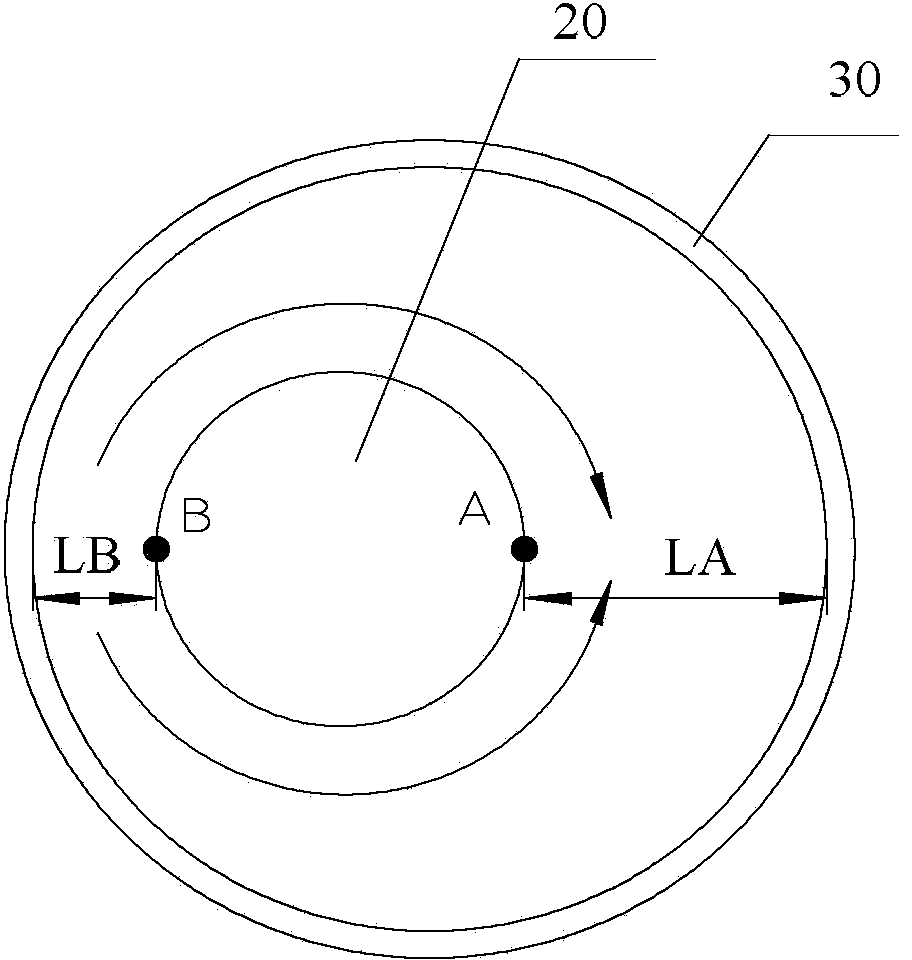

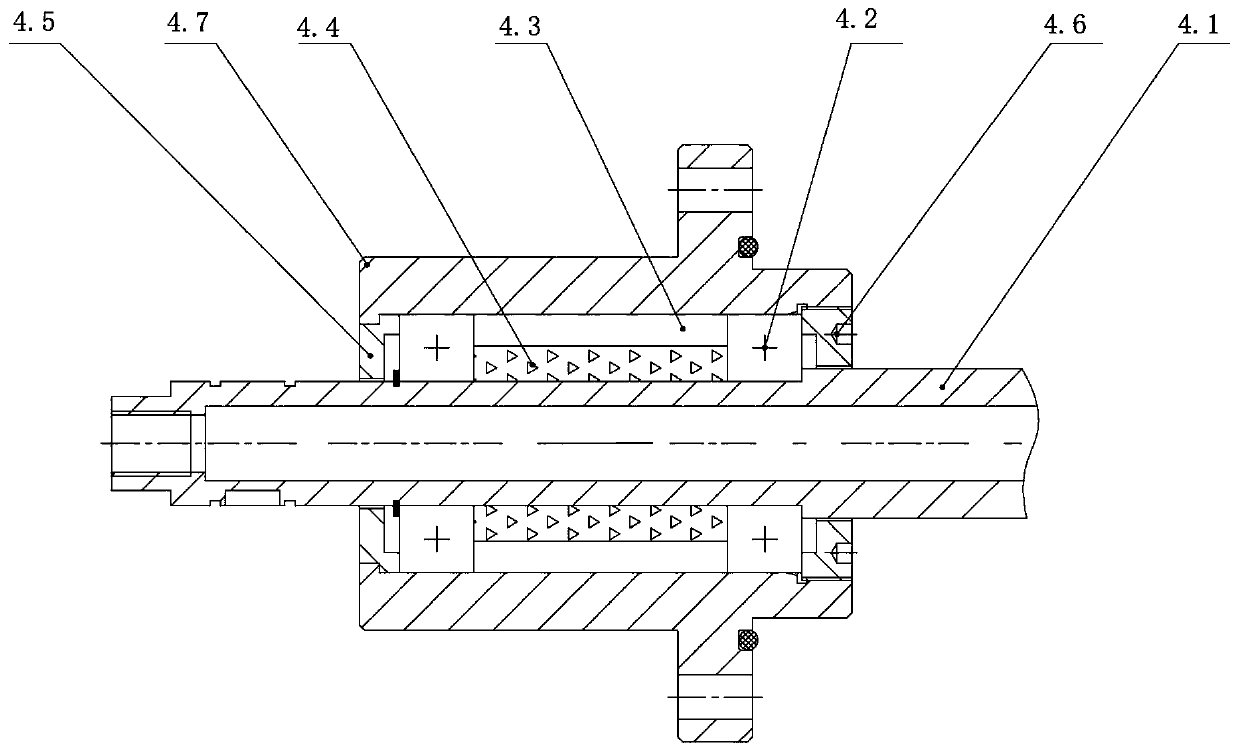

Induction brazing equipment

ActiveCN103909316AImprove brazing qualitySolve the phenomenon of uneven heatingHeating appliancesMetal working apparatusEngineeringElectrical and Electronics engineering

The invention provides induction brazing equipment which comprises a rotating mechanism, a positioning tool and an induction heating coil. The positioning tool is disposed on the rotating mechanism and concentrically rotates along with the rotating mechanism. The induction heating coil sleeves the outer side of the axis of the positioning tool. A mounting space is formed between the induction heating coil and the positioning tool. The induction brazing equipment has the advantages that a to-be-welded part is heated evenly through the induction heating coil, the problems of traditional flame brazing are solved, uneven heating caused by position deviation of tradition induction brazing is avoided, and brazing quality of workpieces is increased.

Owner:GREE ELECTRIC APPLIANCES INC

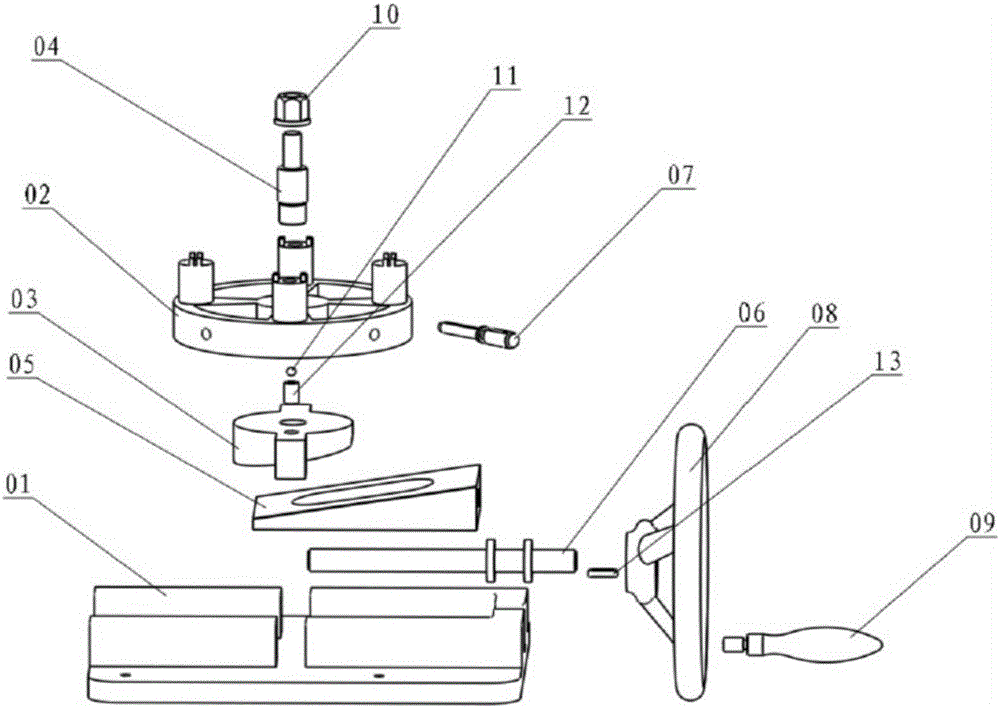

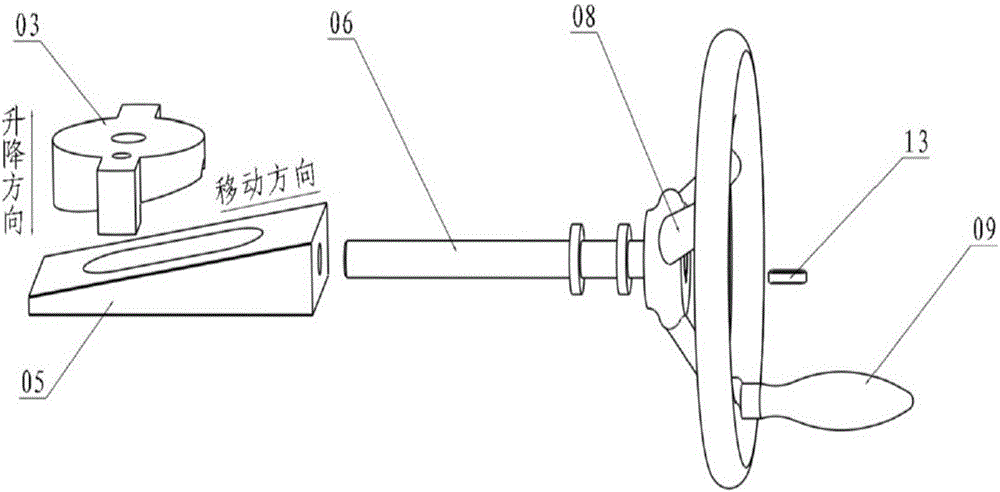

Device for high-frequency induction brazing machine

ActiveCN106077861AGuarantee welding qualityImprove life safetyWelding/cutting auxillary devicesAuxillary welding devicesProcess equipmentMechanical engineering

The invention discloses a device for a high-frequency induction brazing machine and belongs to the technical field of process equipment for aircraft part welding. According to the technical scheme of the device, a clamp main body part of the device is connected with the high-frequency induction brazing machine, rising and falling of a locating seat is achieved ultimately through a rotary curved handle, and then by rotating the locating seat, a cylinder convex block on the locating seat is located in a correct position during wielding of the high-frequency induction brazing machine. The device has the advantages that welding of aircraft parts is conducted on the device for the high-frequency induction brazing machine through the high-frequency induction brazing machine, four to-be-welded aircraft parts can be clamped at one time, clamping time is saved, meanwhile, welding time is shortened, and thus the production efficiency is improved. Locating is conducted through the cylinder convex block on the locating seat of the device, and thus welding quality of the aircraft parts can be ensured effectively. Due to the fact that ceramic is selected and used as the materials of the locating seat, the life safety of operating workers during welding is further improved.

Owner:SHAANXI AIRCRAFT CORPORATION

Brazing solder of diamond compacts and welding technology thereof

InactiveCN106141493AOther manufacturing equipments/toolsWelding/cutting media/materialsSolderingBinding force

The invention discloses brazing solder of diamond compacts and a welding technology thereof. A small quantity of Ni, Co and Mn are added into Ag-Cu-Zn brazing solder serving as a main body, a steel substrate is uniformly coated with the brazing solder after soldering flux is mixed, the cut PCD compacts are placed on the brazing solder, and then high-frequency induction brazing is carried out. According to the brazing solder, the ability of the soldering flux to wet substrate steel is high, a welding line of a tool is uniformly filled with the solder, and the binding force of the steel substrate and the compacts is high.

Owner:洛阳新巨能高热技术有限公司

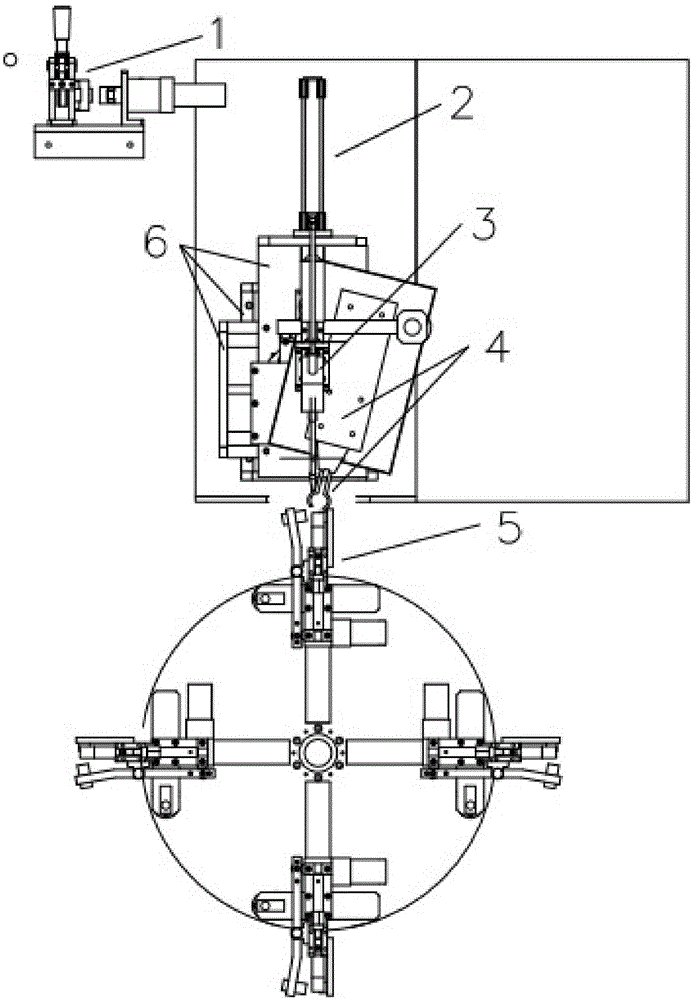

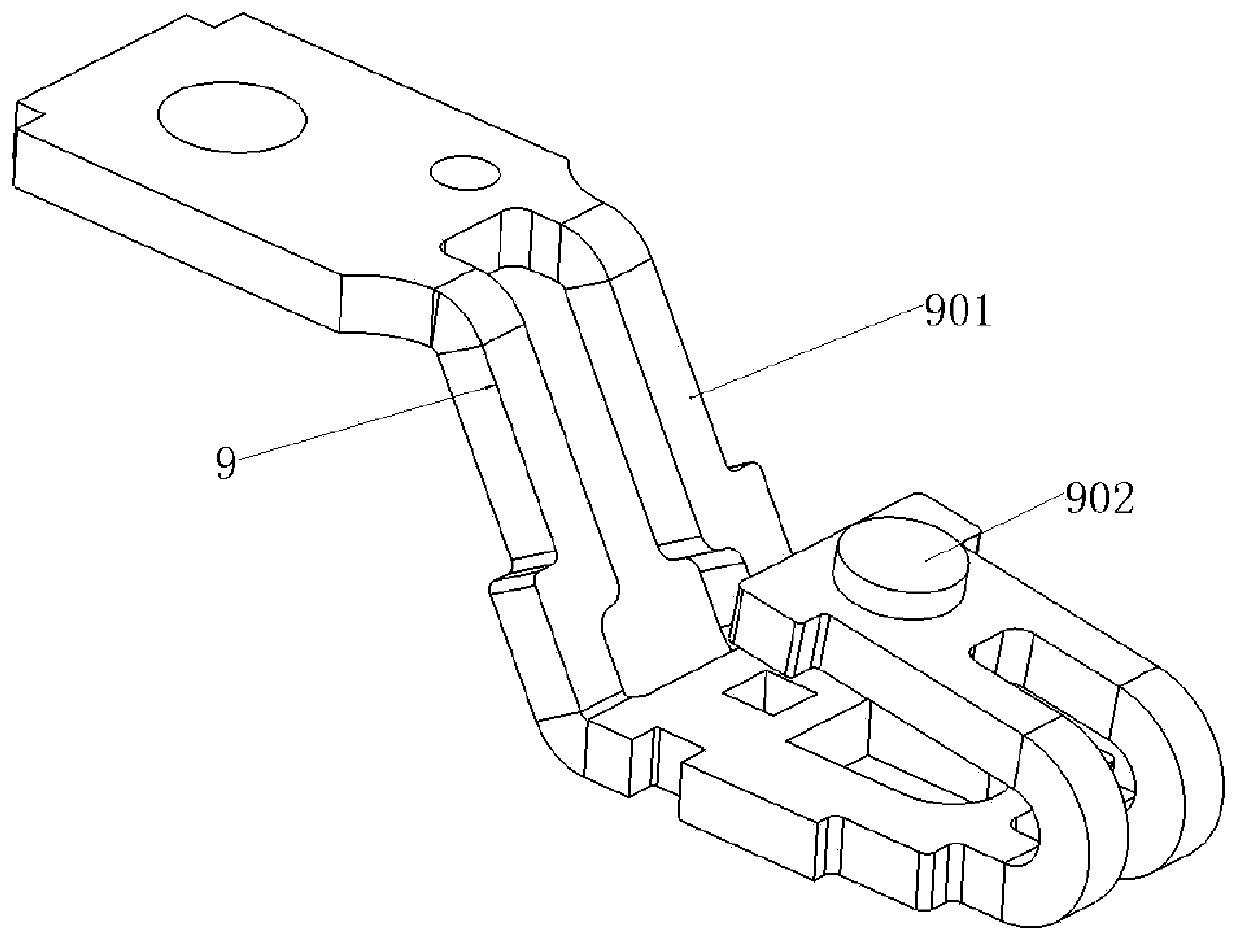

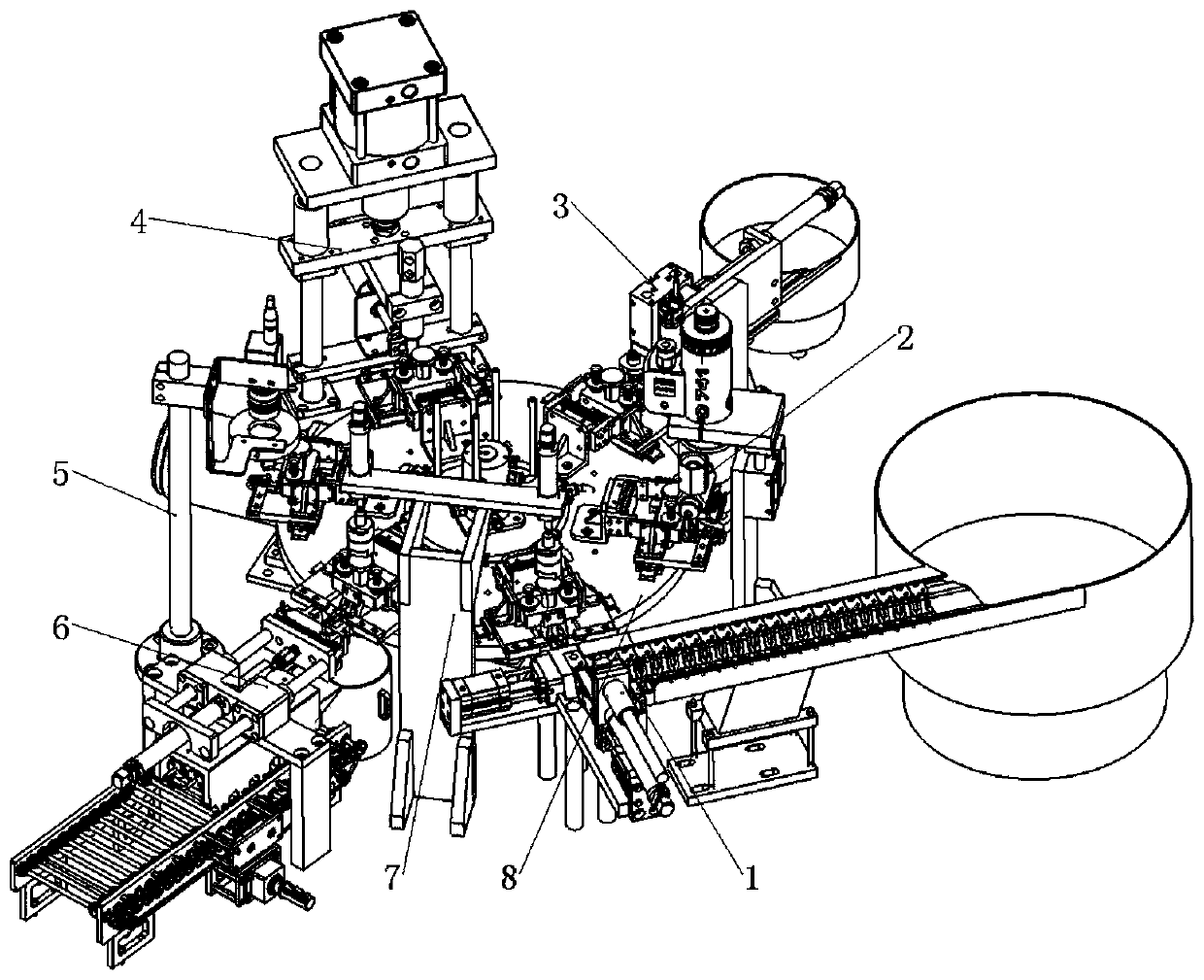

Electrical contact system ultrasonic-assisted high-frequency induction brazing device

ActiveCN110355437AImprove brazing rateImprove welding strengthMetal working apparatusSoldering auxillary devicesElectricityUltrasonic assisted

The invention provides an electrical contact system ultrasonic-assisted high-frequency induction brazing device. A body of the device adopts a six-index cam divider for driving, six assembling and machining stations are arranged on the periphery of a cam divider workbench in sequence, and a same positioning mould is arranged on each assembling and machining station. The electrical contact system ultrasonic-assisted high-frequency induction brazing device specifically comprises a contact bridge feeding assembly, a soldering paste dripping assembly, a contact feeding assembly, a high-frequency induction brazing assembly, a CCD industrial camera assembly, a discharging assembly, an electric chuck assembly 7 and a cam divider assembly. According to the device, through ingenious and reasonablestructural design, a high-frequency induction heat source and ultrasonic vibration double compound energy field is integrated in a compact space; through process procedure design, the welding positions are optimized before, during and after welding correspondingly; and the automation degree is high, and both the machining efficiency and the brazing quality are taken into consideration.

Owner:山东承坤信息科技有限公司

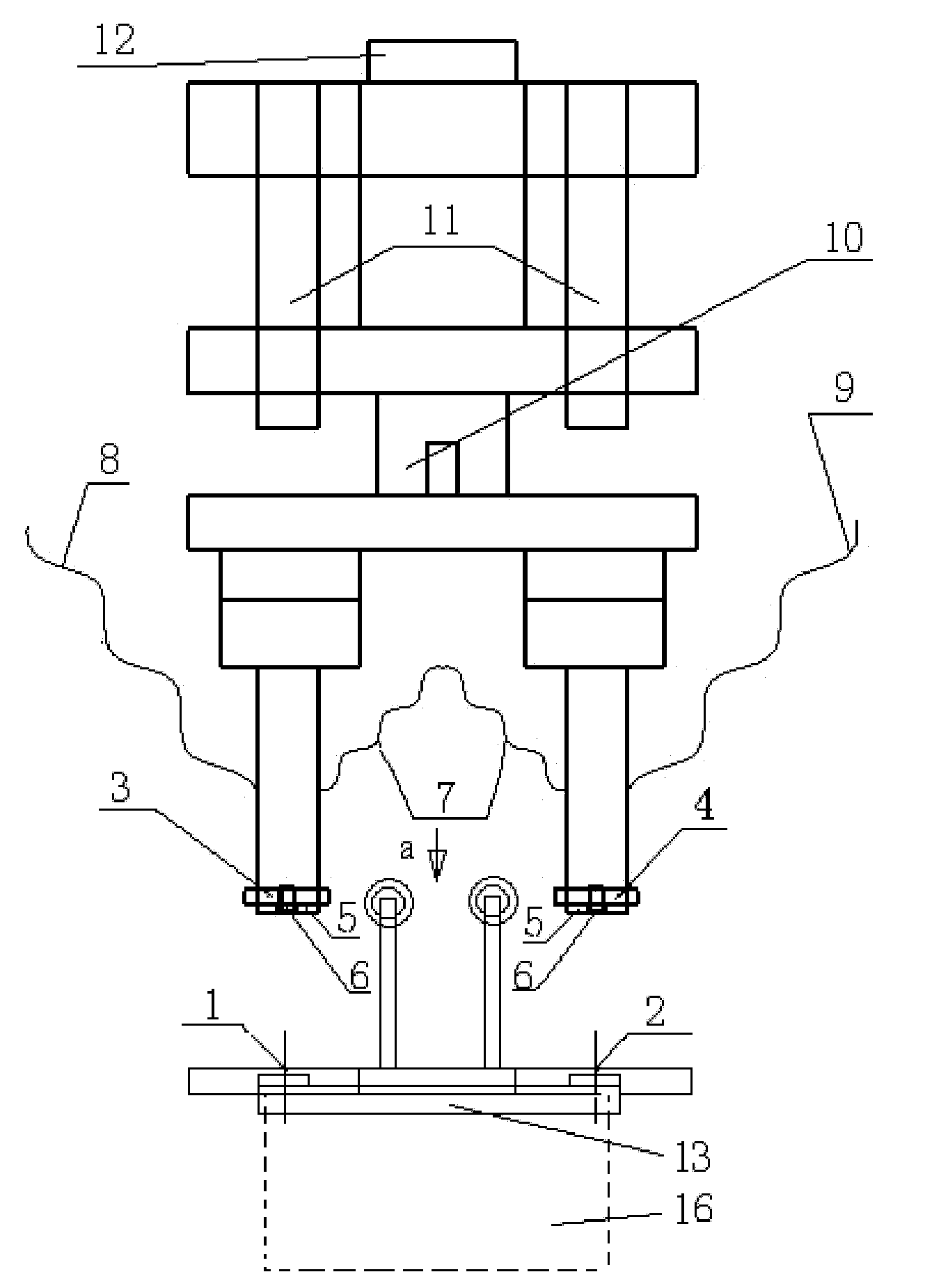

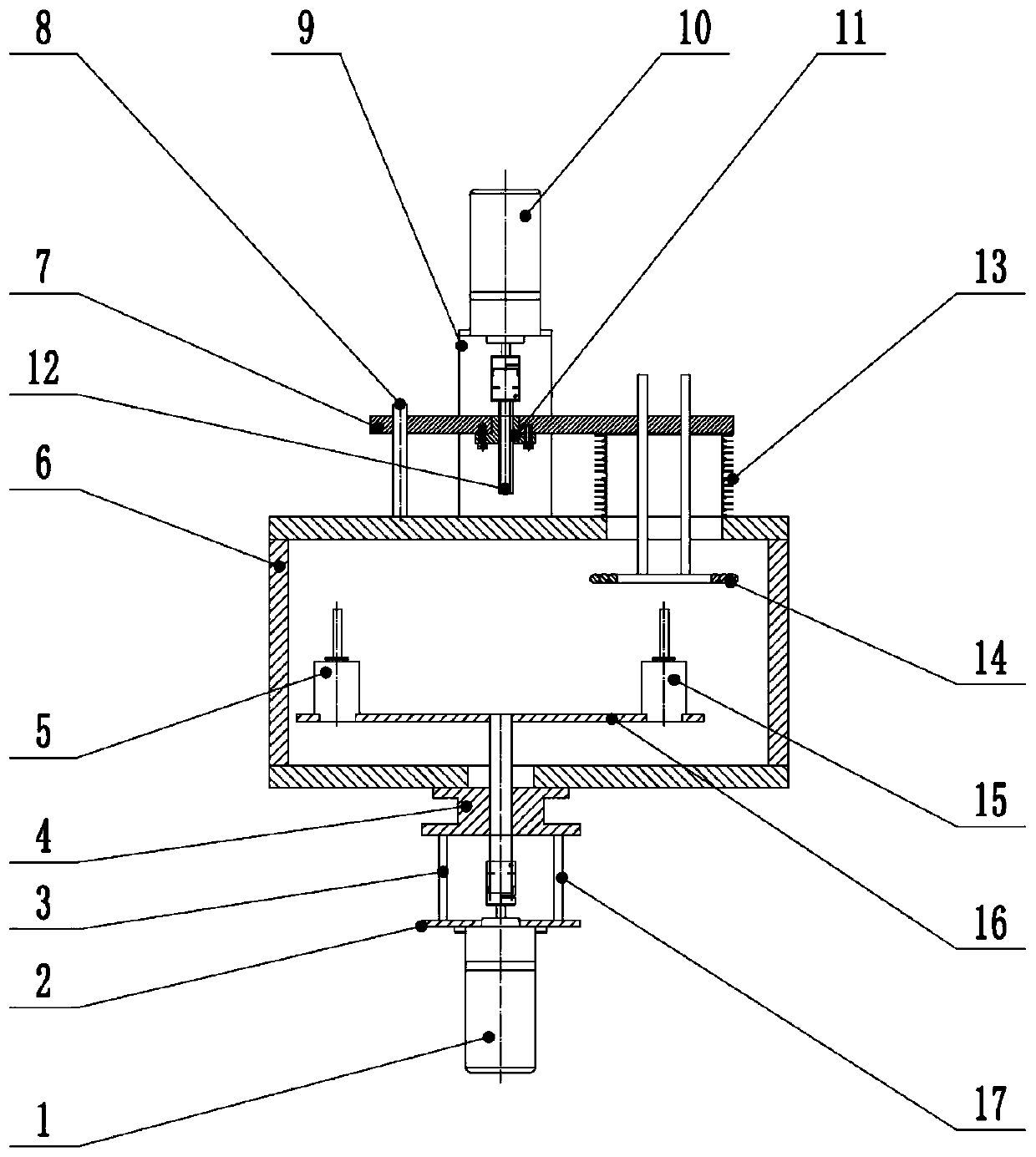

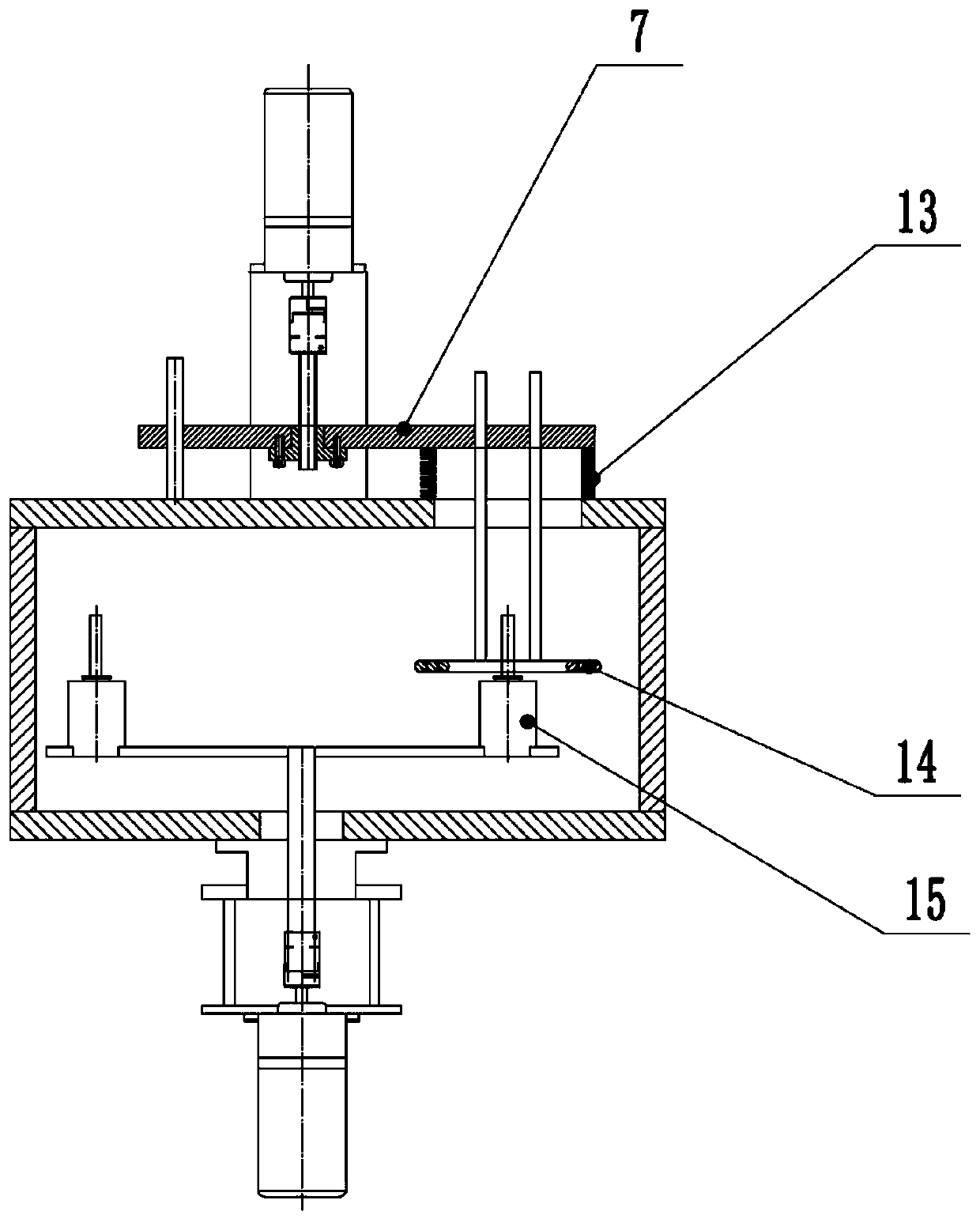

Vacuum induction brazing device and use method thereof

ActiveCN111468797AFast solderingReasonable structural designHeating appliancesSoldering auxillary devicesElectric machineVacuum chamber

The invention relates to a vacuum induction brazing device and a use method thereof. The device comprises a rotating motor, a rotating motor fixed plate, a supporting rod A, magnetofluid, a workpieceA, a vacuum chamber, a lifting adjusting plate, a guide rod, a lifting motor fixed plate, a lifting motor, a lifting nut, a screw, a welding corrugated pipe, an induction coil, a workpiece B, a rotating sample table and a supporting rod B, the rotating motor is fixedly mounted on the bottom face of the rotating motor fixed plate, the top face of the rotating motor fixed plate is connected with themagnetofluid through the supporting rod A and the supporting rod B which are arranged in parallel, the magnetofluid is fixed to the bottom of the vacuum chamber, the rotating sample table is fixed toa magnetofluid shaft and is located in the vacuum chamber, the screw is in transmission connection with an output shaft of the lifting motor, the induction coil is fixedly connected with the liftingadjusting plate and is located in the vacuum chamber, the device has the advantages of being reasonable in structural design, convenient to operate and use, and low in running cost, vacuum brazing andinduction brazing advantages are combined, defects of vacuum brazing and induction brazing are overcome, and workpiece rapid pollution-free welding is achieved.

Owner:磐石创新(江苏)电子装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com