Patents

Literature

279results about How to "Prevent corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

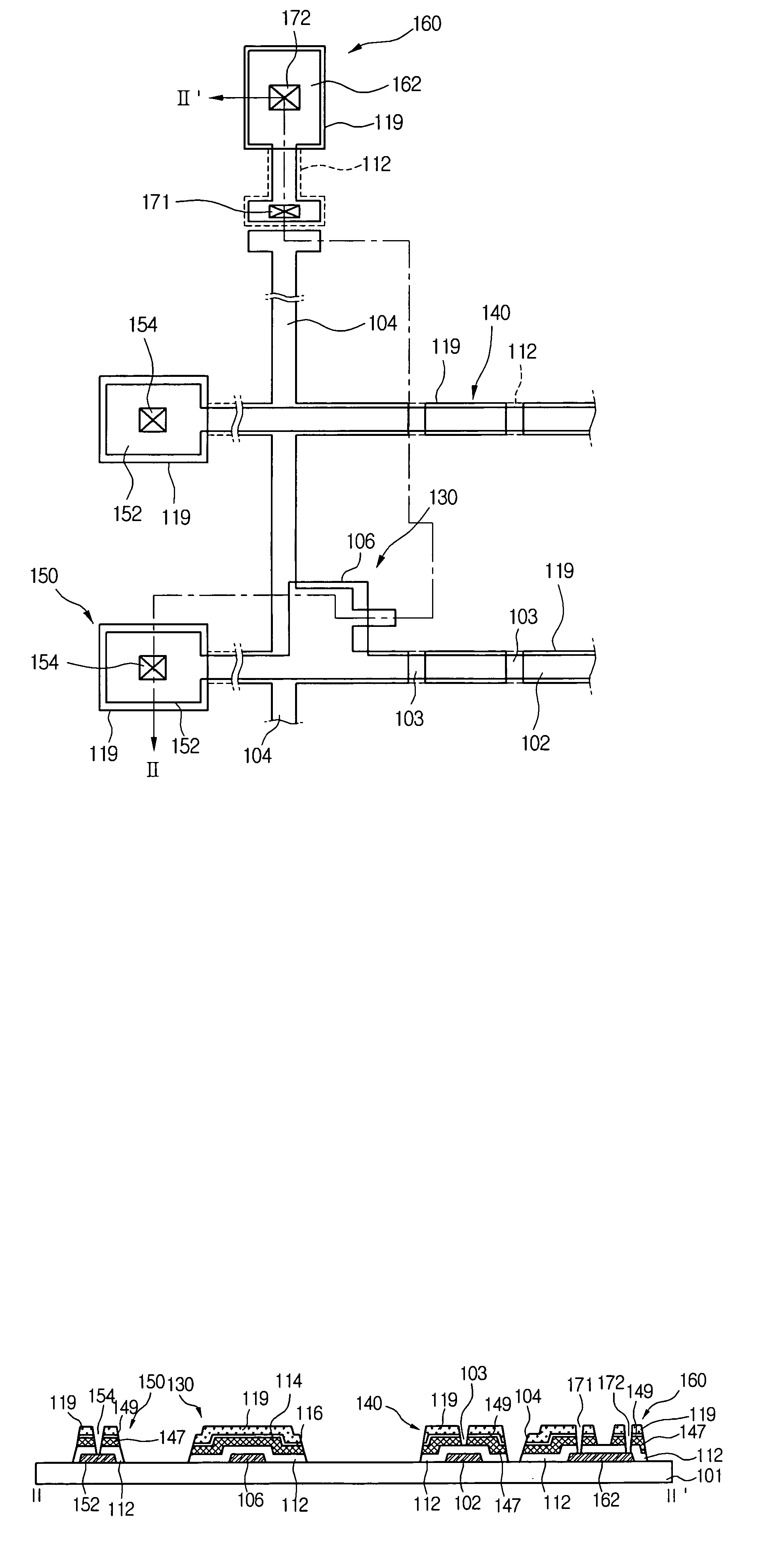

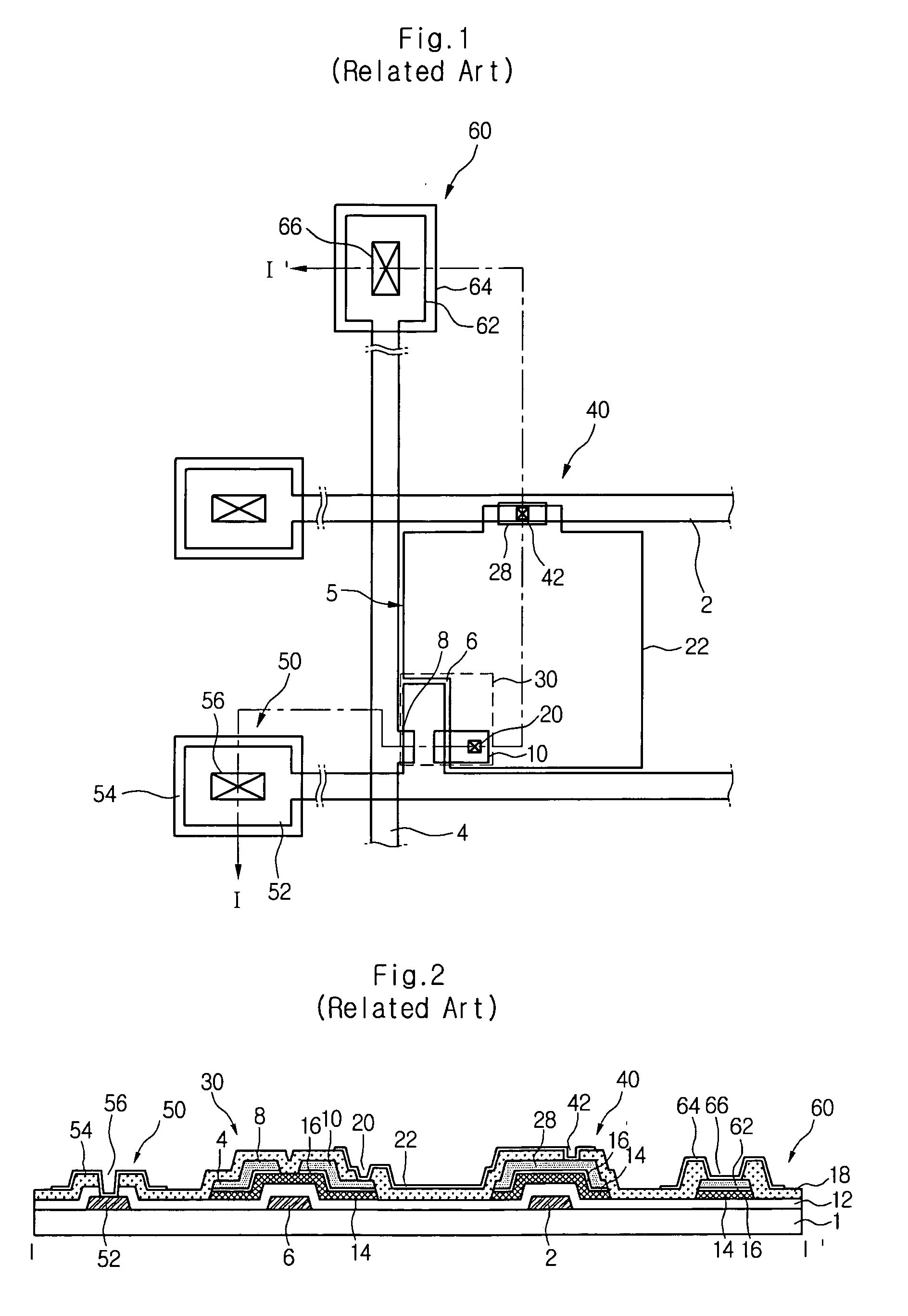

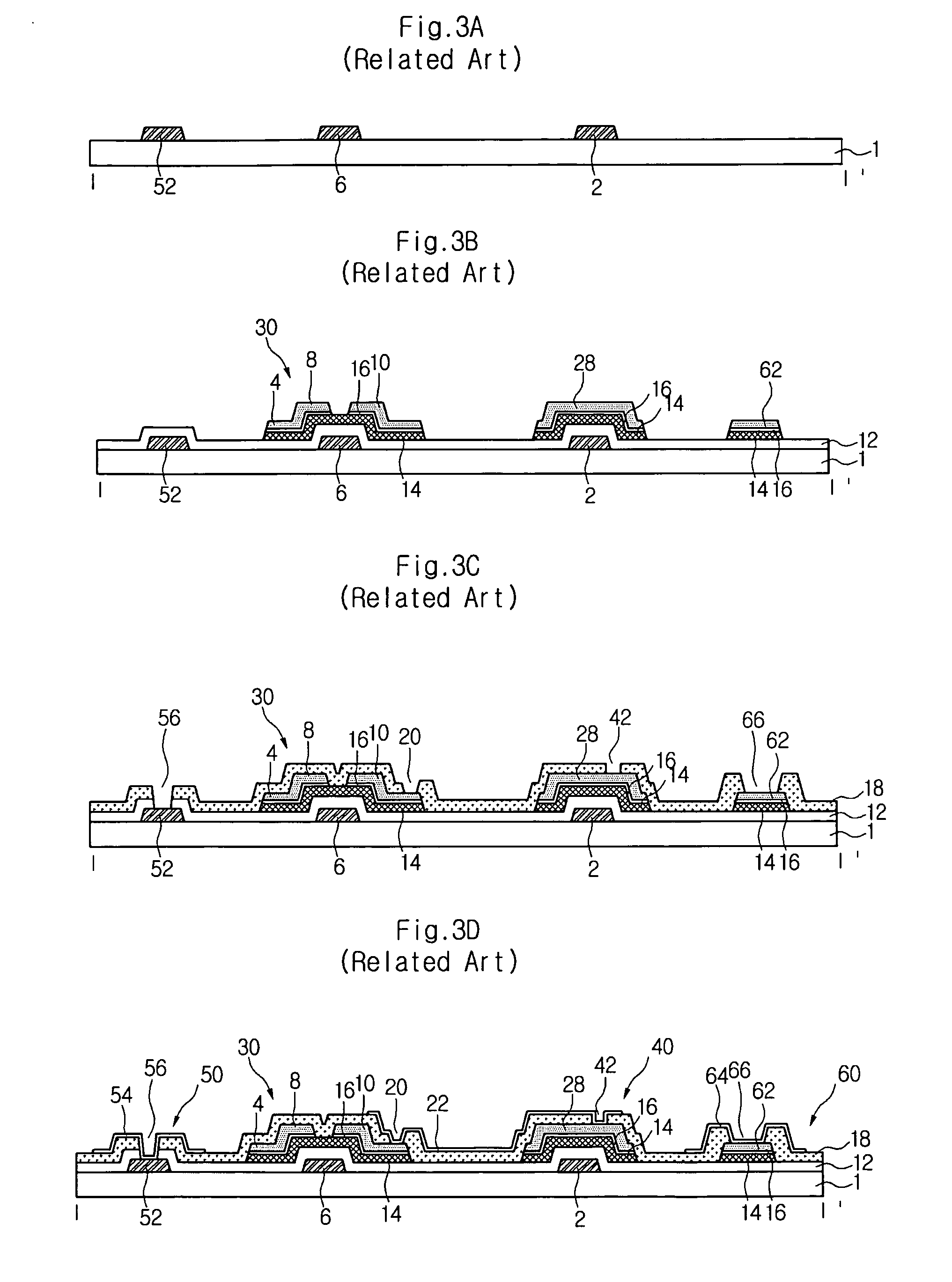

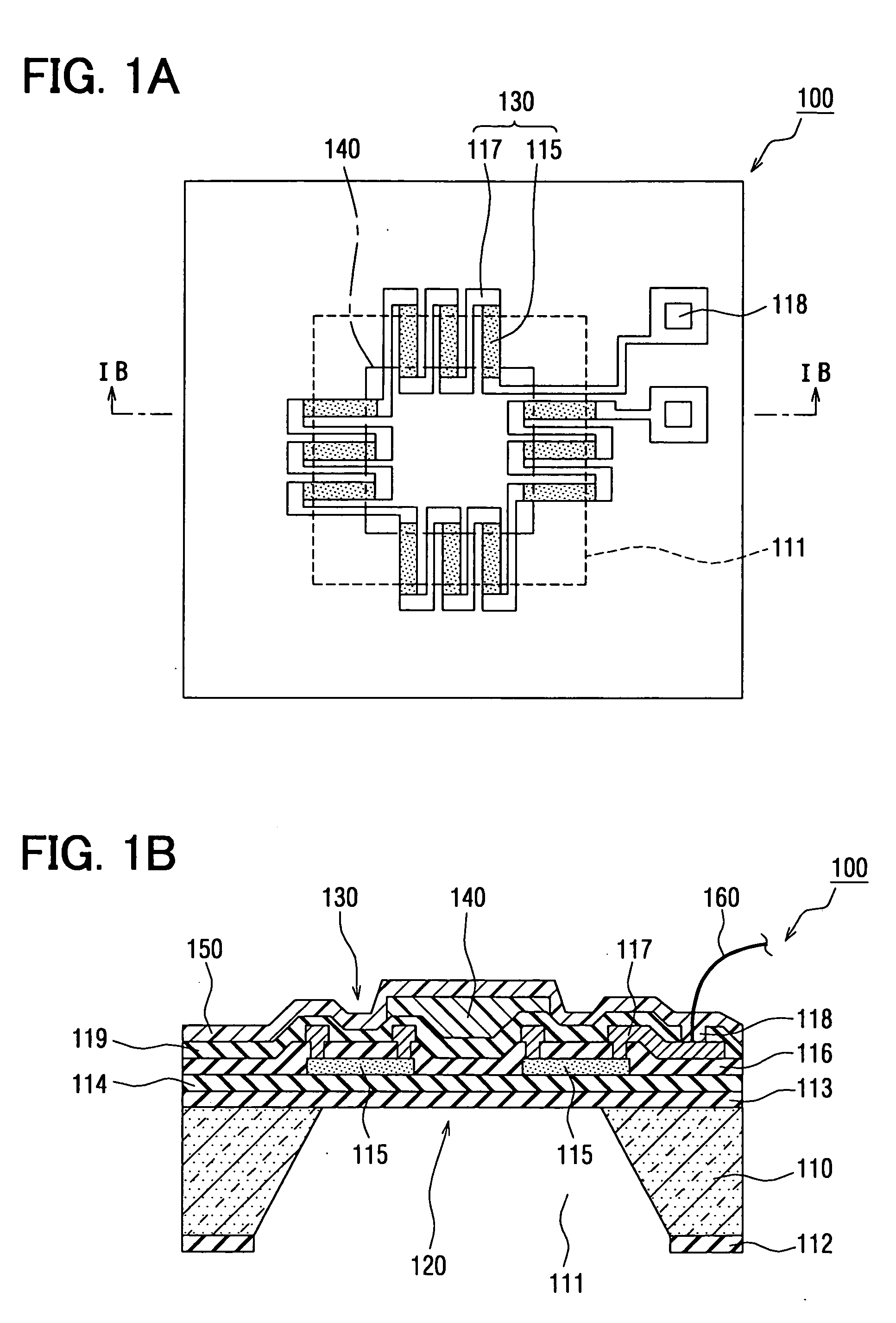

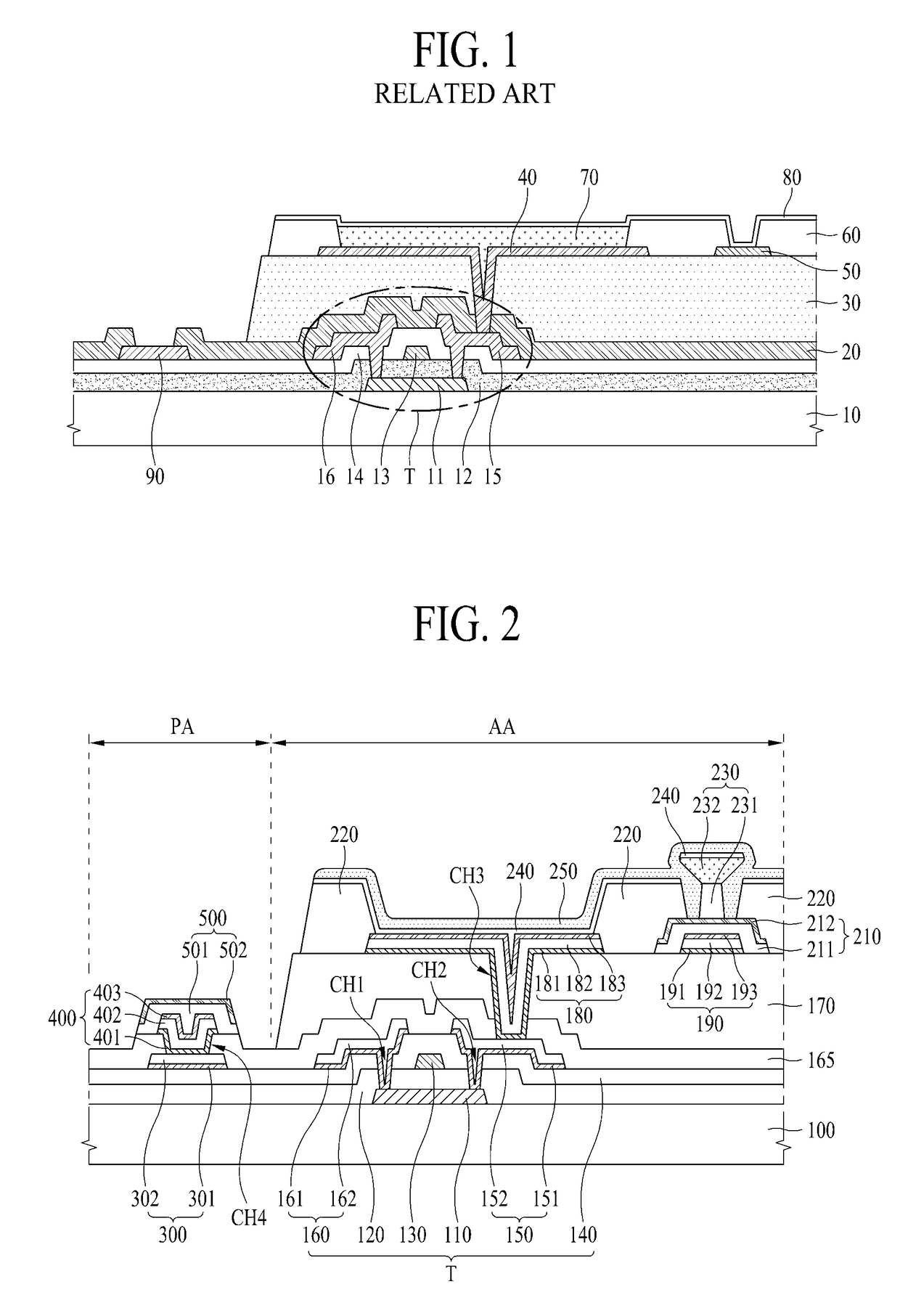

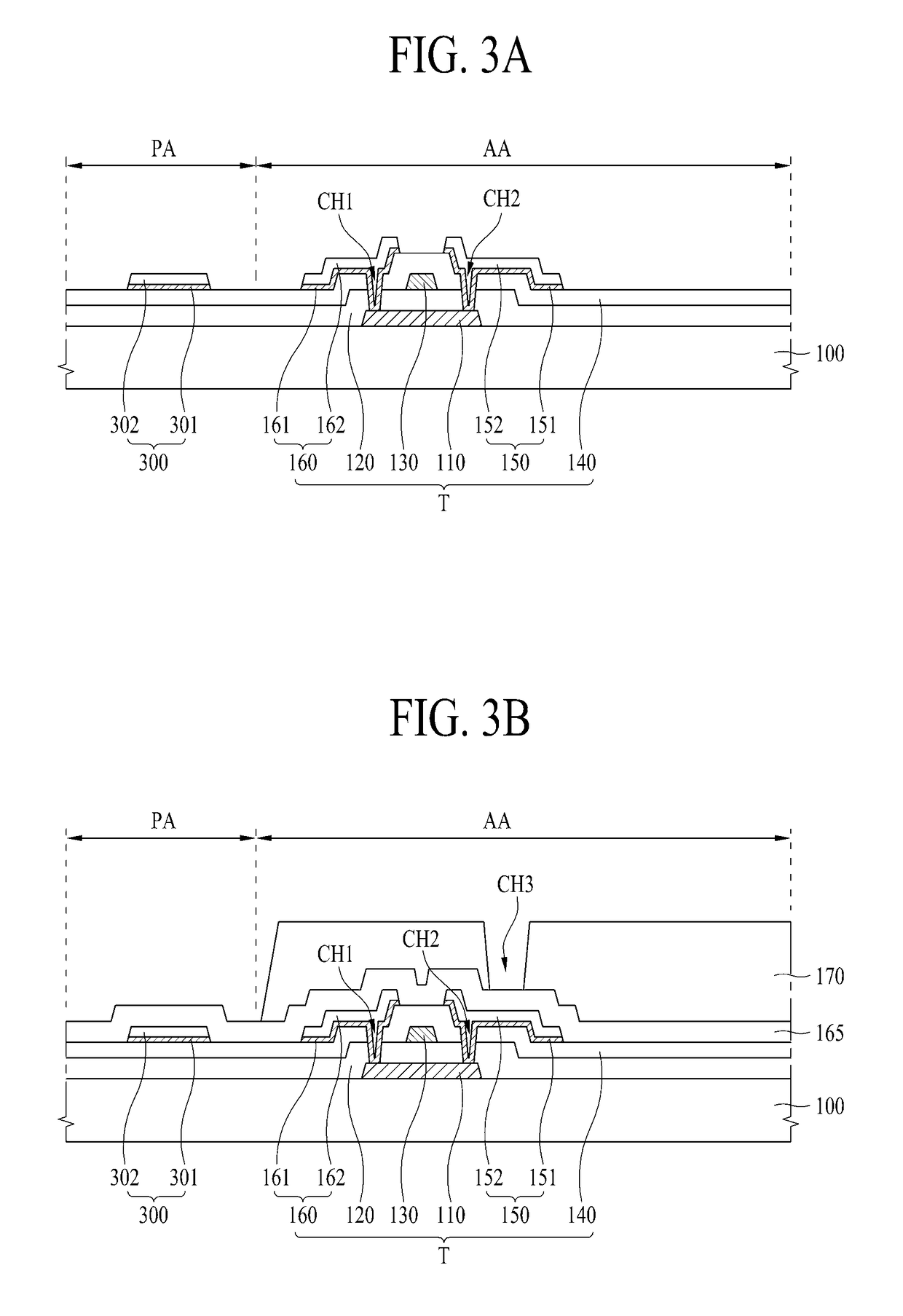

TFT array substrate and fabrication method thereof

InactiveUS20060145157A1Prevent corrosionReduce numberSolid-state devicesNon-linear opticsPhysicsData lines

A TFT array substrate is provided. The TFT array substrate includes a gate electrode connected to a gate line; a source electrode connected to a data line, the data line crossing the gate line to define a pixel region; a drain electrode facing the source electrode with a channel interposed therebetween; a semiconductor layer forming the channel between the source electrode and the drain electrode; a channel passivation layer formed on the channel to protect the semiconductor layer; a pixel electrode disposed in the pixel region to contact with the drain electrode; a storage capacitor including the pixel electrode extending over the gate line to form a storage area on a gate insulating layer on which a semiconductor layer pattern and a metal layer pattern are stacked; a gate pad extending from the gate line; and a data pad connected to the data line.

Owner:LG DISPLAY CO LTD

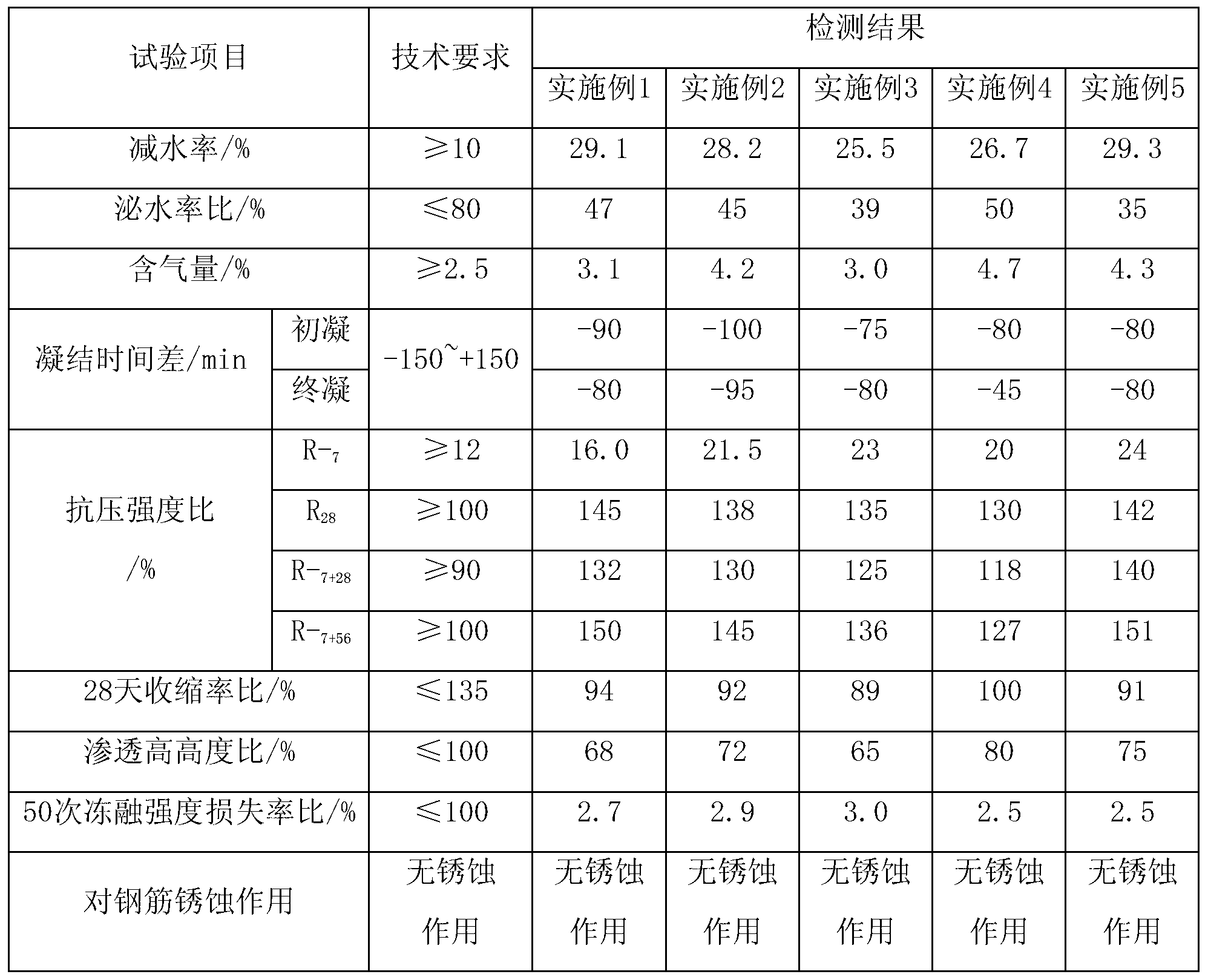

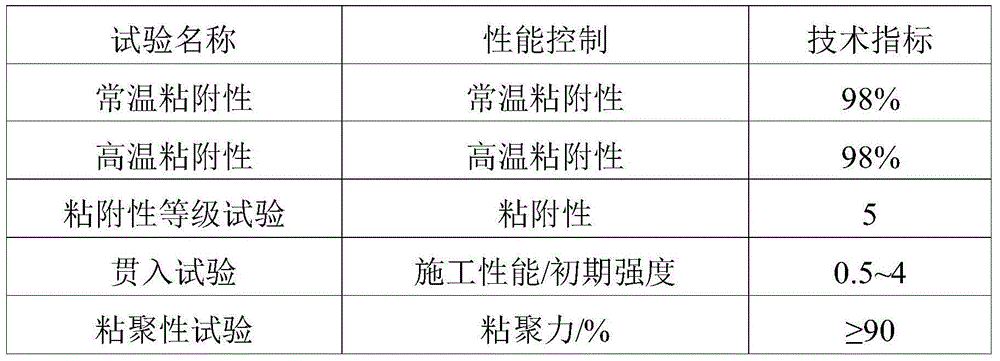

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

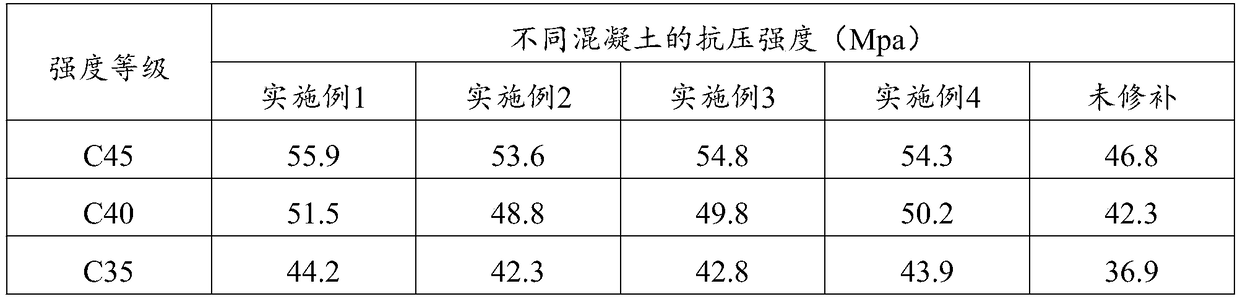

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Zinc-based double antiseptic powder coating and preparing method thereof

InactiveCN101033364AReduce dosageEnsure zinc contentAnti-corrosive paintsPowdery paintsHeavy dutyZinc

The invention discloses a kind of heavy-duty zinc-based powder coating and its preparation. The coating is prepared by the following share weight of raw materials through the melt extruderion-mixing or melt-mixing, and the raw materials are as follow: 50-75% of resin and its flow-curing system, 10-40% of zinc flake, 0.1-10% of nanomaterial, 0.1-20% of rust paint, 0-30% of filler, and 0.1-5% of other functional additives.

Owner:XUZHOU ZENITH COATING

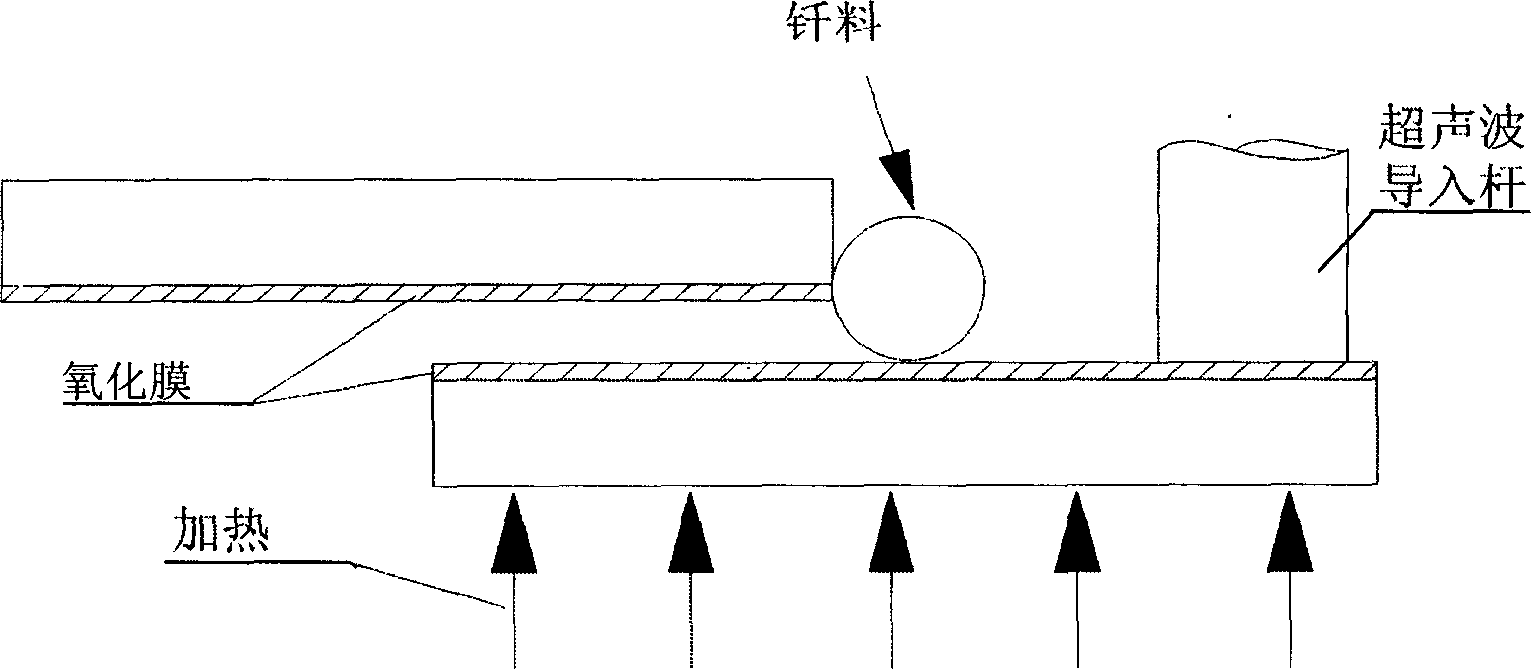

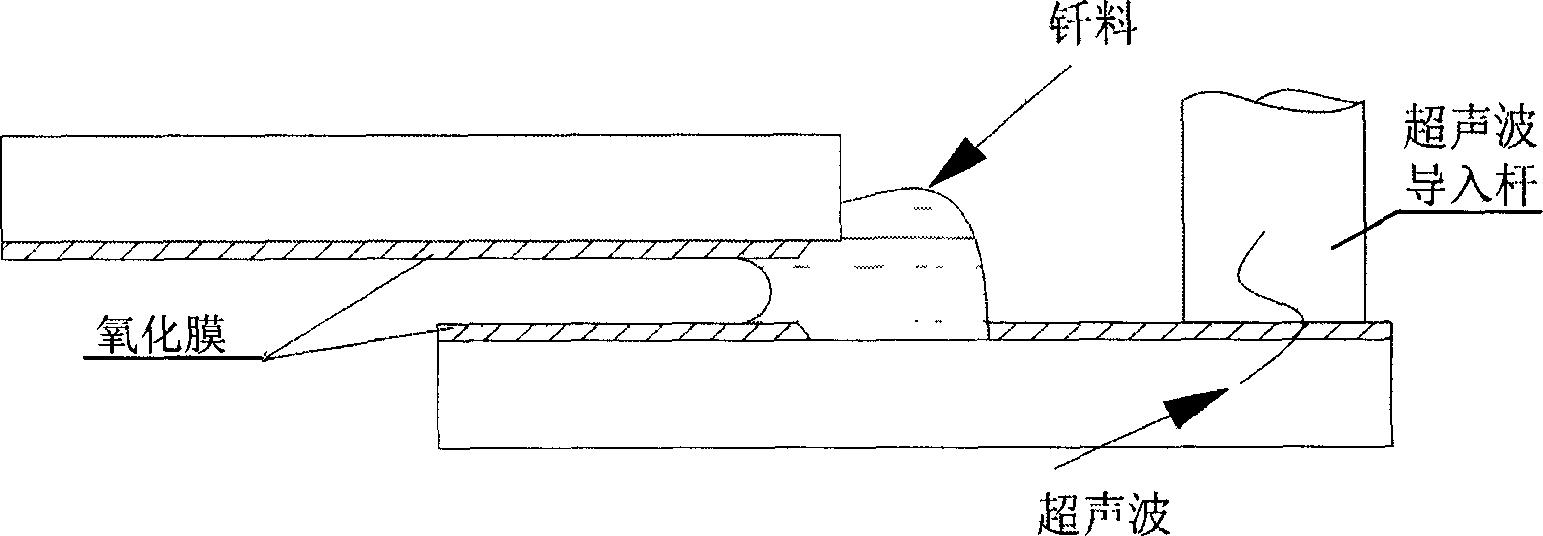

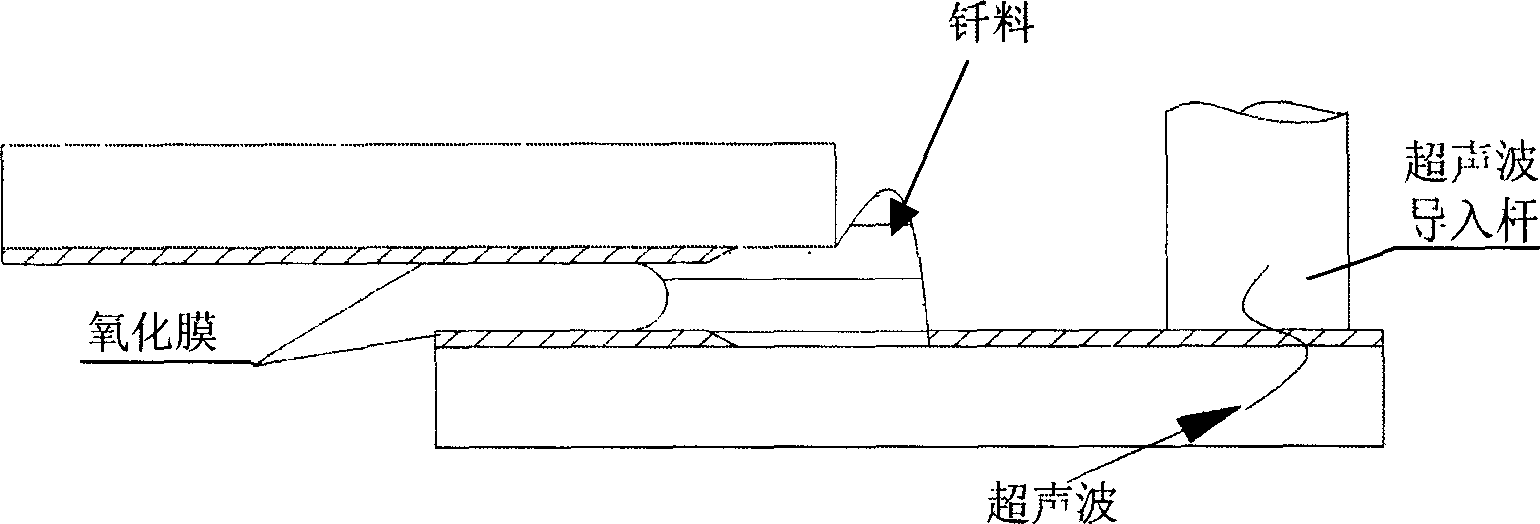

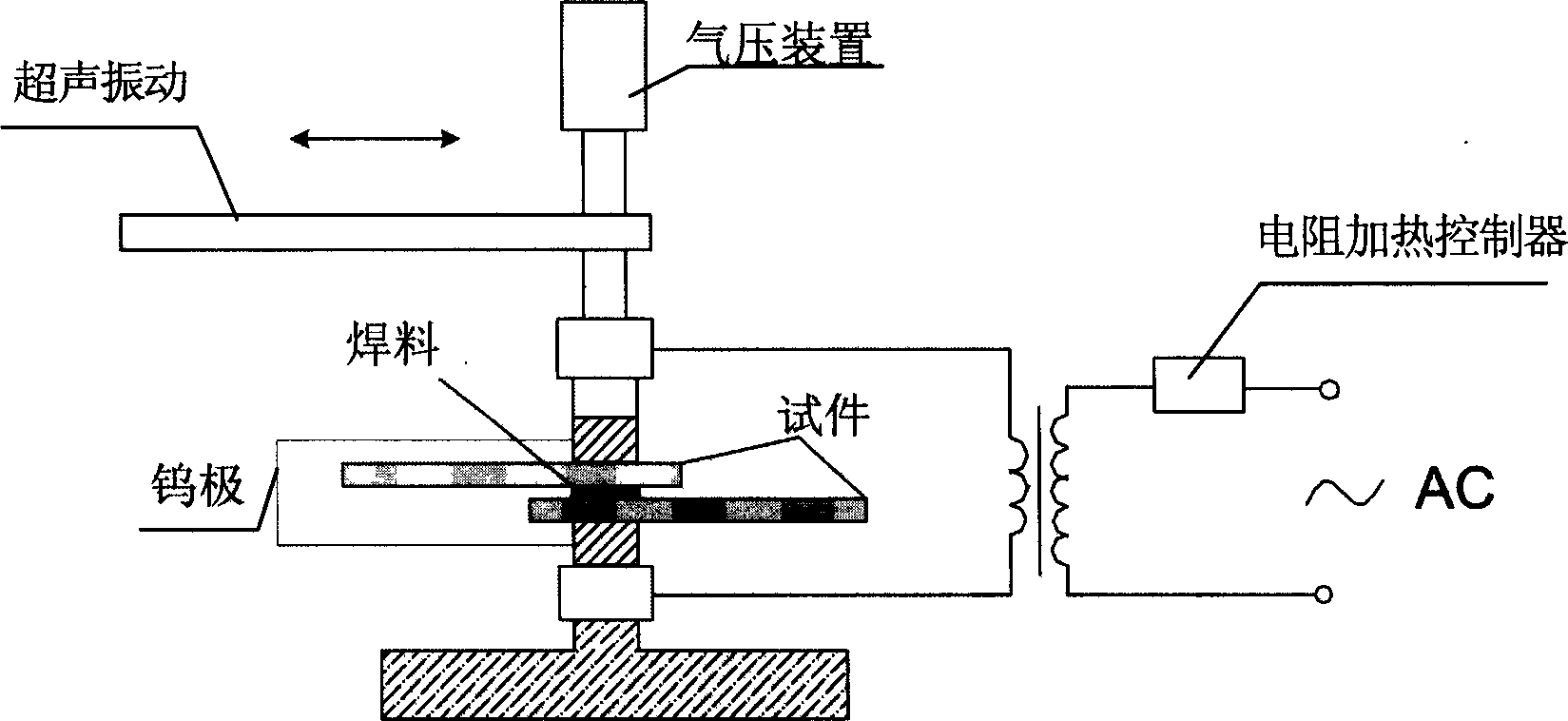

Aluminium base composite material ultrasonic wave fine welding method

InactiveCN1644291AAvoid WeldingEfficient weldingNon-electric welding apparatusUltrasonic vibrationMaterials science

An ultrasonic capillary welding method for the Al-base composite material includes such steps as arranging upper and lower parts to be welded in such manner that the gap between them is 10-300 microns, putting the flux close to lap end, heating to smelt the flux, holding the temp, pressing the ultrasonic head onto surface of the part to be welded, and applying ultrasonic vibration for 0.5-15 S. Its advantages are high welding quality, low welding temp, and high speed.

Owner:HARBIN INST OF TECH

Sludge composting method

ActiveCN101781131AEasy to getShort fermentation timeBio-organic fraction processingClimate change adaptationEcological environmentSludge compost

The invention provides a sludge composting method, and relates to a sludge treatment method which comprises the steps of preferable accessory selection, CK21 fungus spraying inoculation, heavy metal passivation and powder granulation, and then three-dimensional composite biological organic fertilizer with organic, inorganic and microbial active constituents is obtained. Mushroom compost and pig manure are used as accessories which are easily obtained and degraded, the stacker fermentation time is short, only one time of fermentation is needed, the C / N ratio can be effectively adjusted, and the water content of the sludge is reduced; and the efficient beneficial bio-fungus community CK21 is adopted. The microbial concentration is high, the secretion ability of the enzyme is strong, organic matters can be quickly decomposed so as to prevent the corruption of the organic matters, no odor exists, sludge is used for CK21 inoculation, fermentation starts fast, and the effect is good; and the product is inoculated with the CK21 fungus secondarily so as to further balance and activate nutrients, and the microbial natural reproduction is utilized to realize the is called flower dipping absorbing of the plants to nutrients. The invention has the advantages of optimizing the composting conditions, shortening the composting time, reducing energy consumption of turning, and reducing the damage of the heavy metal on the ecological environment.

Owner:厦门市政环境科技股份有限公司

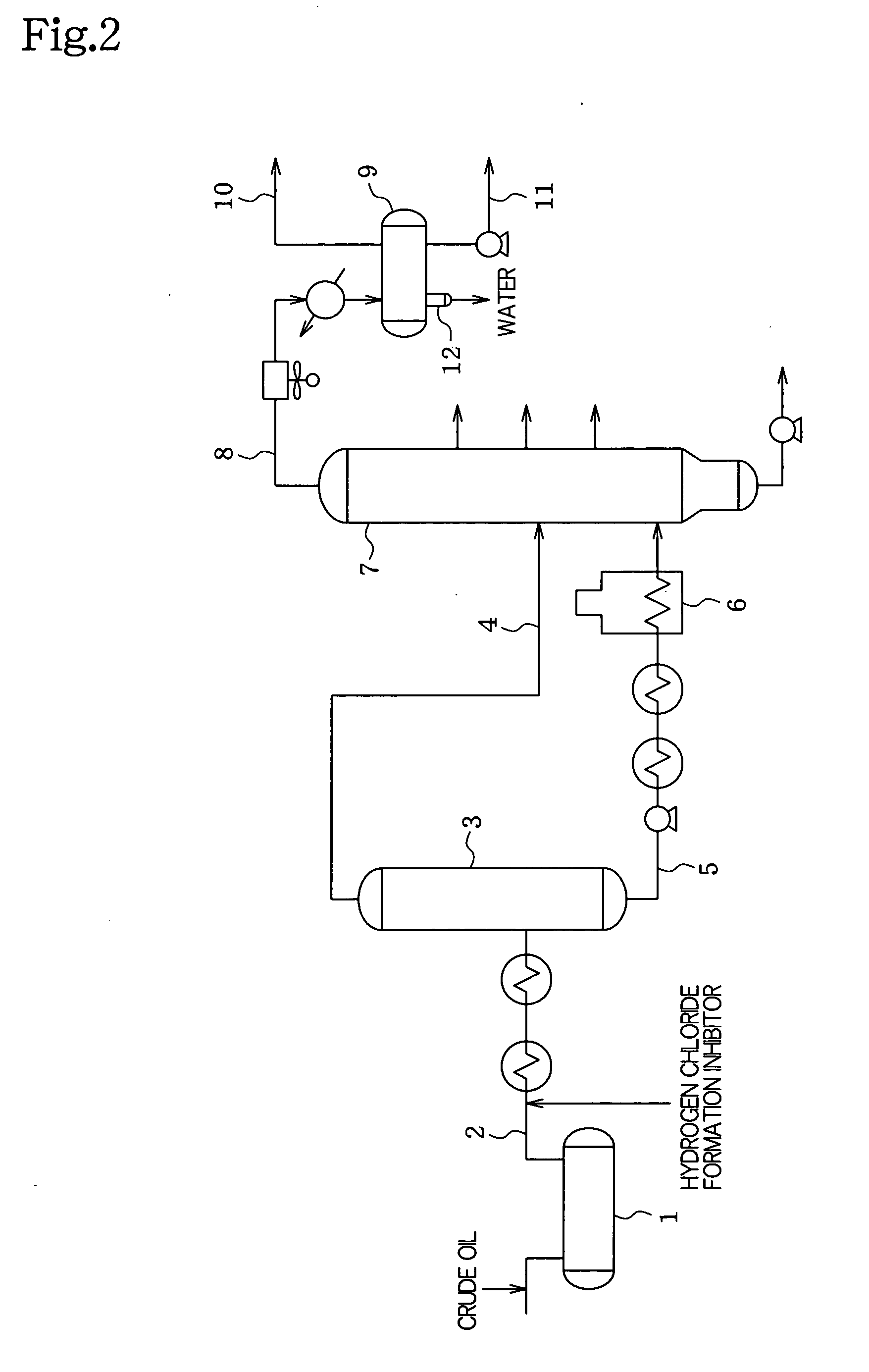

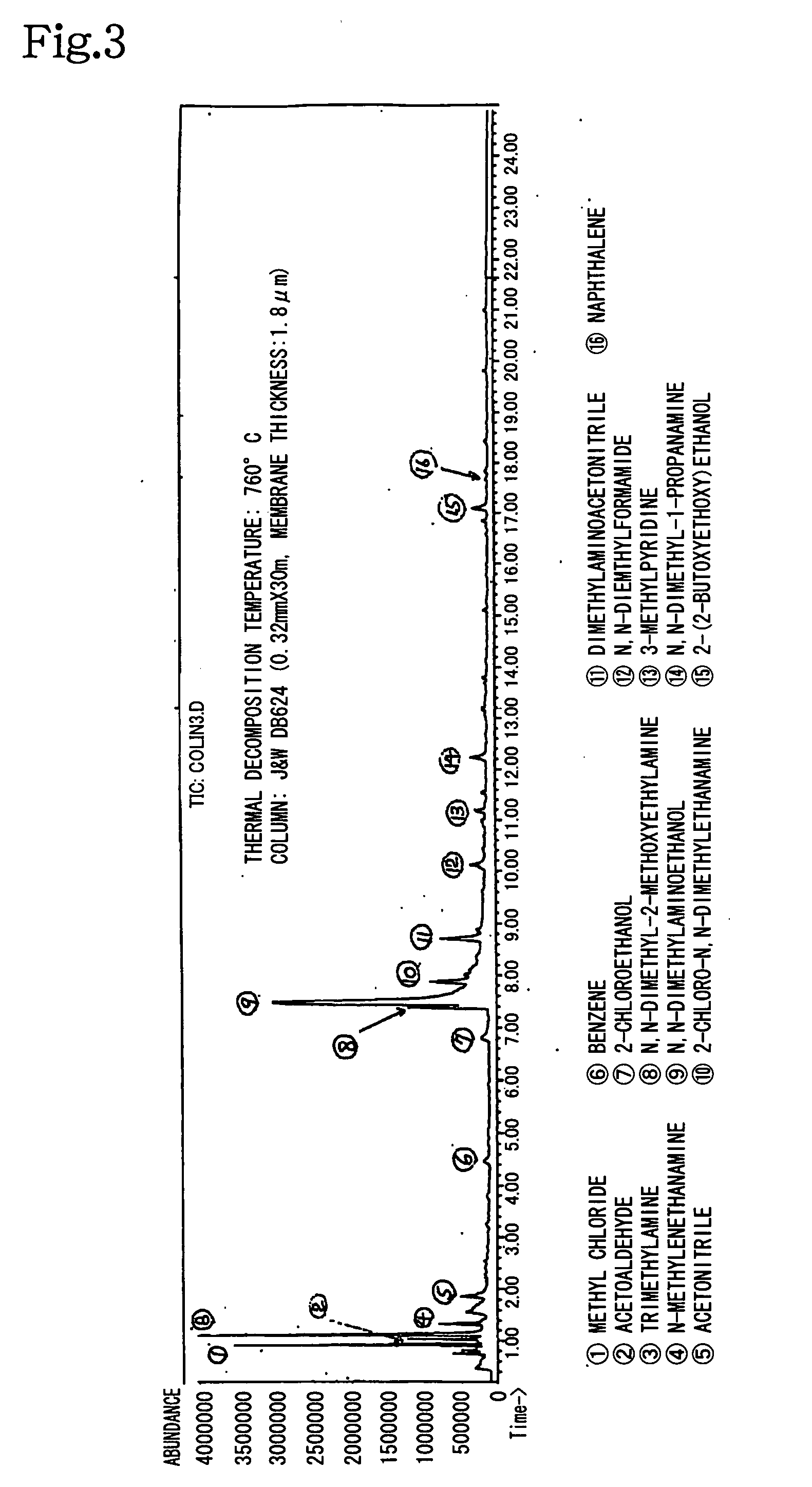

Metal corrosion inhibitor and hydrogen chloride formation inhibitor in a crude oil atmospheric distillation unit

ActiveUS20060043340A1Reduce riskPrevent corrosionDistillation corrosion inhibitionOther chemical processesAdverse effectPetroleum

The quaternary ammonium compound described by general formula 1 below (wherein R1, R2 and R3 are the same or different hydrocarbon radicals with 1 to 4 carbon atoms, and n is an integer between 1 and 10) is used as a metal corrosion inhibitor. With this metal corrosion inhibitor, it is possible even with the addition of small quantities to adequately prevent corrosion of metal in a steam generating unit or petroleum refining or petrochemical process unit. Moreover, (β-hydroxyethyl)trimethylammonium hydroxide is used as a hydrogen chloride formation inhibitor for a crude oil atmospheric distillation unit. With this hydrogen chloride formation inhibitor, it is possible to prevent the formation of hydrogen chloride itself in a crude oil atmospheric distillation unit without having any adverse effect on the catalyst.

Owner:KURITA WATER INDUSTRIES LTD

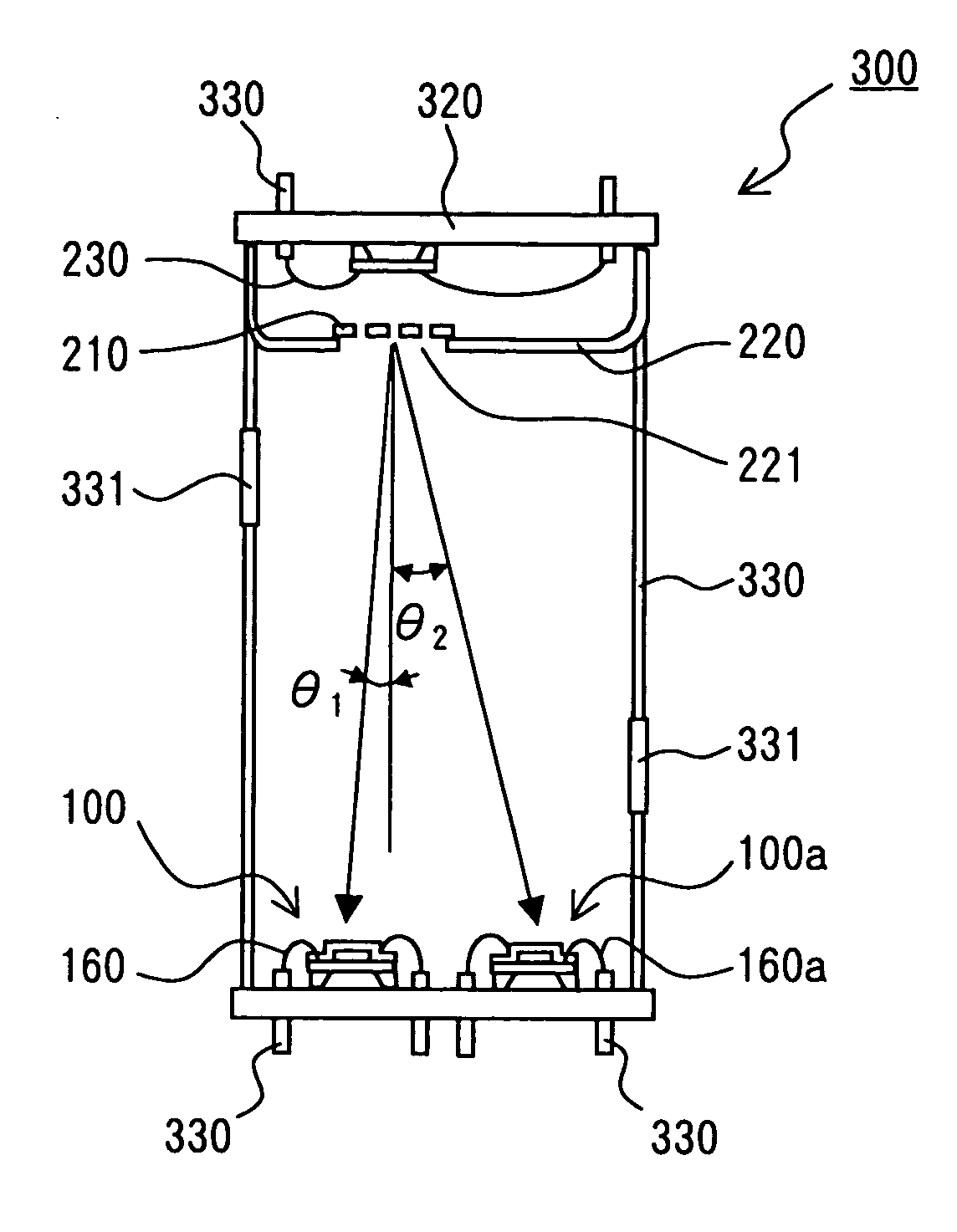

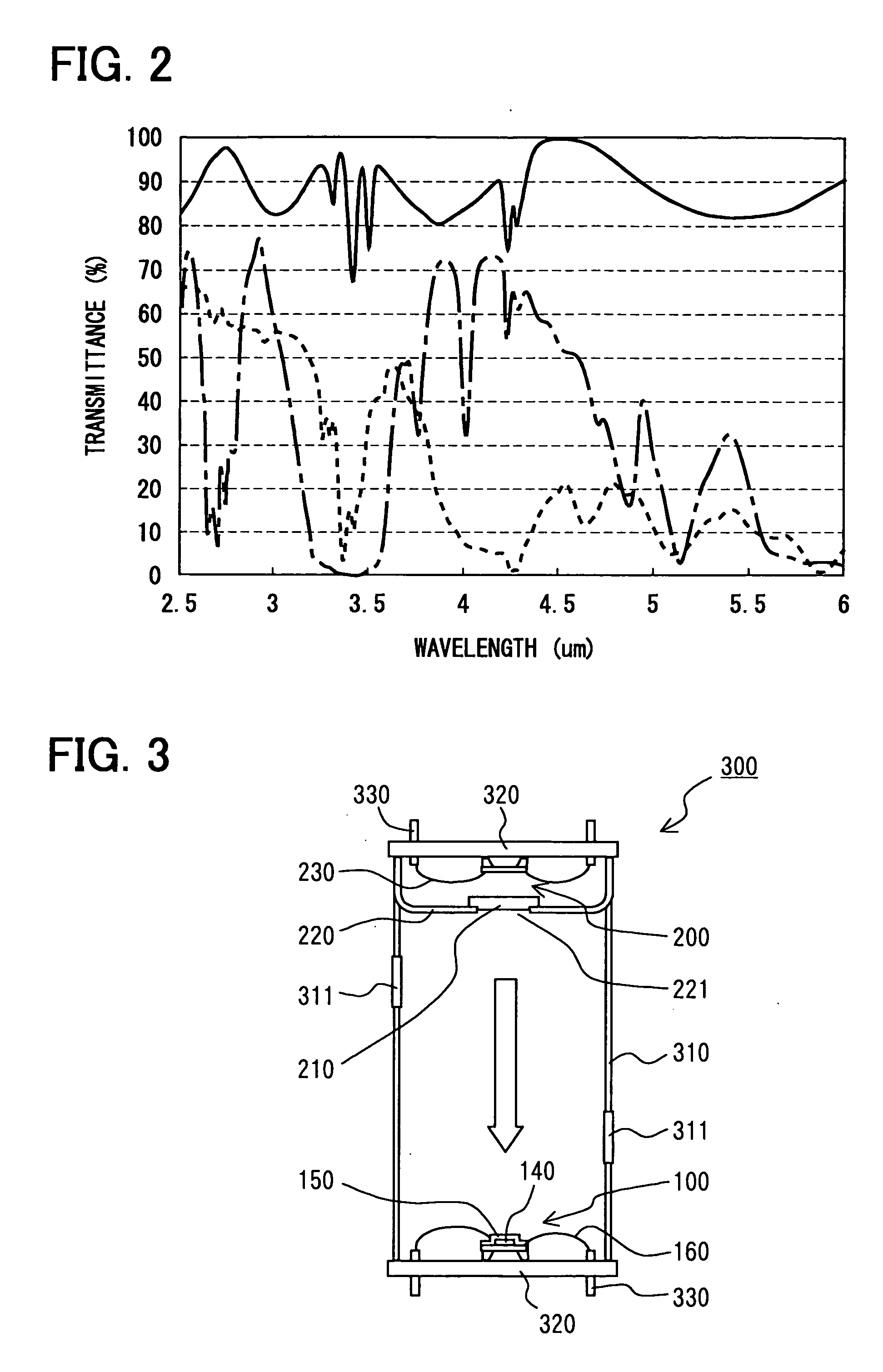

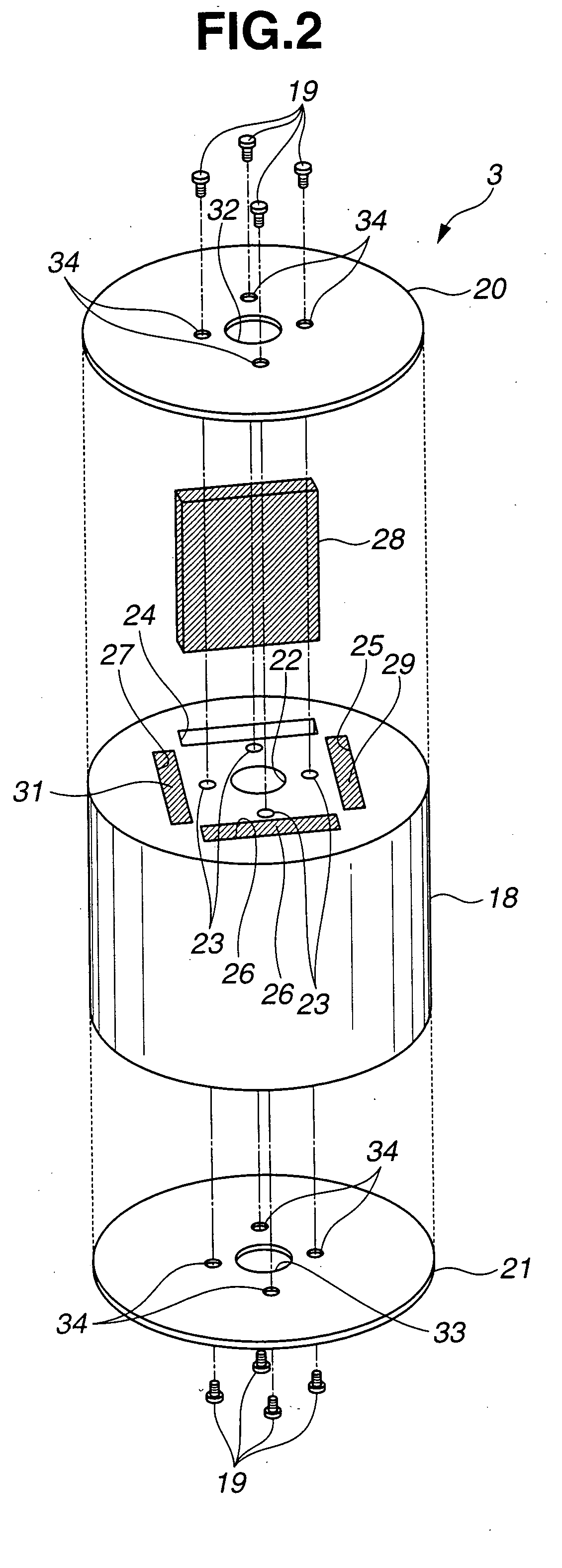

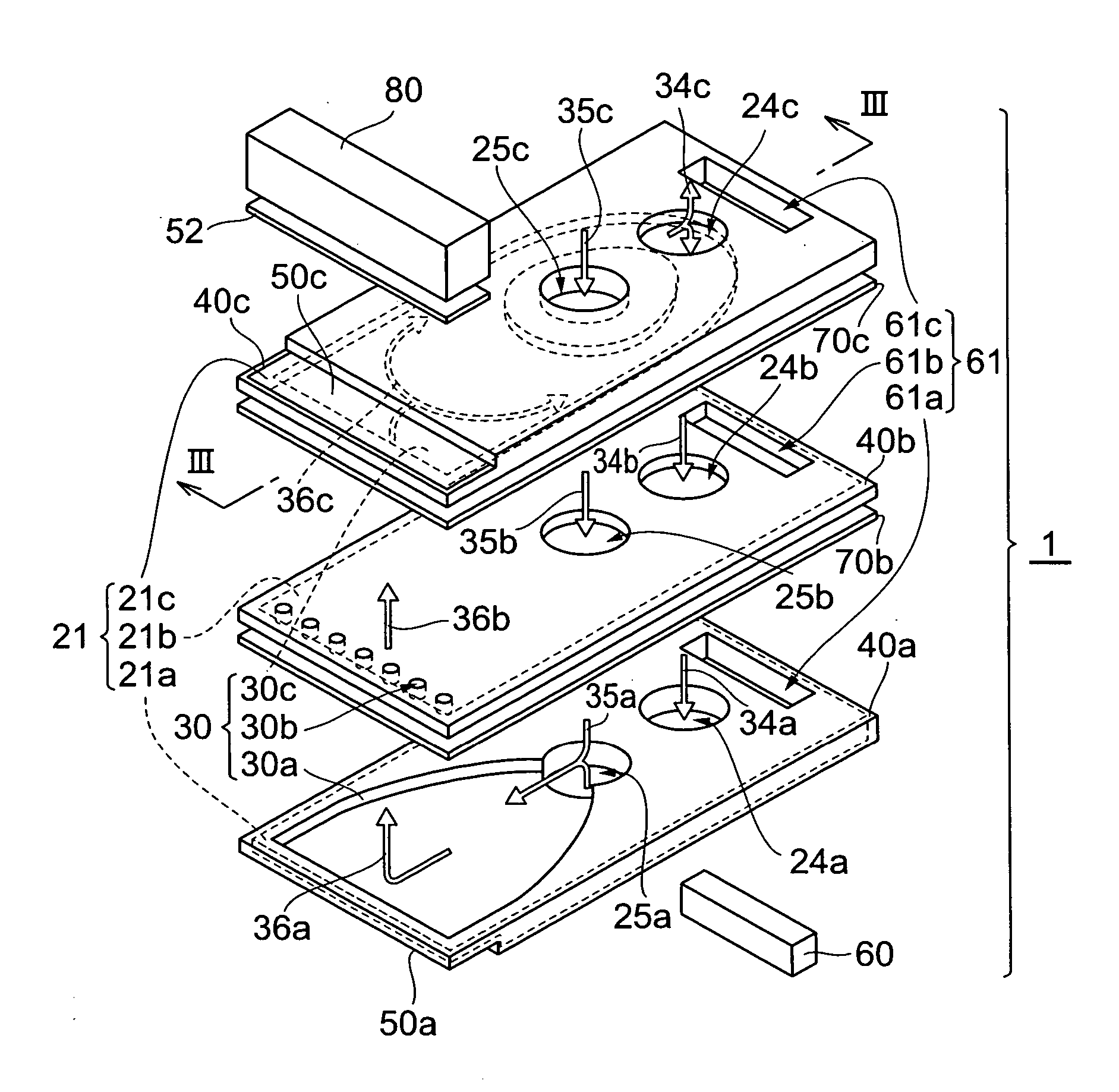

Infrared sensor, infrared gas detector and infrared ray source

InactiveUS20060060788A1Prevent corrosionSimplify constructionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSignal onPhysics

An infrared sensor includes a substrate, a membrane as a small-thickness portion formed on the substrate, a detecting element for generating a detection signal on the basis of temperature variation occurring when receiving infrared rays, at least a part thereof being formed on the membrane, and an infrared ray absorption film formed on the membrane so as to cover at least a part of the detecting element. The detecting element is externally electrically connected through a sensor pad portion provided at an end portion of the detecting element. A substrate surface including the sensor pad portion and the infrared ray absorption film is coated by a protection film made of parylene.

Owner:DENSO CORP +1

Additive used for monocrystalline silicon wafer alkaline flocking and application method thereof

InactiveCN102312294AExtended failure cycleIncrease contact rateAfter-treatment detailsTO-18Temperature control

The invention relates to an additive used for monocrystalline silicon wafer alkaline flocking and an application method thereof, belonging to the technical field of solar batteries. The additive is prepared by the following components: ethanolamine, polyphosphate, sodium dodecylbenzene sulfonate, sodium hydroxide and water. A flocking agent is prepared through the following steps: (1) dissolving sodium hydroxide in deionized water so as to obtain alkaline flocking liquid; (2) adding the additive motioned above into the alkaline flocking liquid to obtain the flocking agent. During flocking, monocrystalline silicon wafers used for solar batteries are immersed in the flocking agent with temperature controlled to be 75 to 85 DEG C and flocking time controlled to be 15 to 18 minutes. The additive used for monocrystalline silicon wafer alkaline flocking in the invention enables flocking reaction time to be shortened and productivity to be enhanced; prepared texture surface pyramids have a uniform size and low reflectivity; the additive is applicable to solar battery silicon wafer alkaline flocking of different specifications and meets the purpose of industrial production.

Owner:浙江向日葵聚辉新能源科技有限公司

Aluminium base composite material ultra sonic electrical resistance welding method

InactiveCN1686659AEasy to operateStrong designWelding apparatusElectrical resistance and conductanceMegasonic cleaning

An ultrasonic-resistance welding method for the Al-based composition includes grinding the surfaces of Al-based compositions, ultrasonic cleaning, putting the flux between two surfaces to be welded, heating by electric resistance, decreasing the thickness of liquid film between two surfaces, ultrasonic vibrating, pressing and natural cooling.

Owner:HARBIN INST OF TECH

Epoxy zinc-enriched antiseptic powdery paint and production thereof

InactiveCN1712473AEasy to produce and usePrevent corrosionEpoxy resin coatingsCorrosion preventionZinc

An epoxy resin and zinc-enriched heavy anti-corrosive powdery coating and its production are disclosed. The coating consists of epoxy resin, phenolic epoxy resin, zinc powder, curing agent, curing improver, leveling agent, toughening agent, degassing agent and flowing improver. The process is carried out by using filler as raw materials, preparing pre-disperse mixture from melt extrude mixing method or melt high-speed stir mixing method, mixing, extruding, breaking, screening and testing. It achieves non-toxic, no pollution and corrosion prevention.

Owner:XUZHOU ZENITH COATING

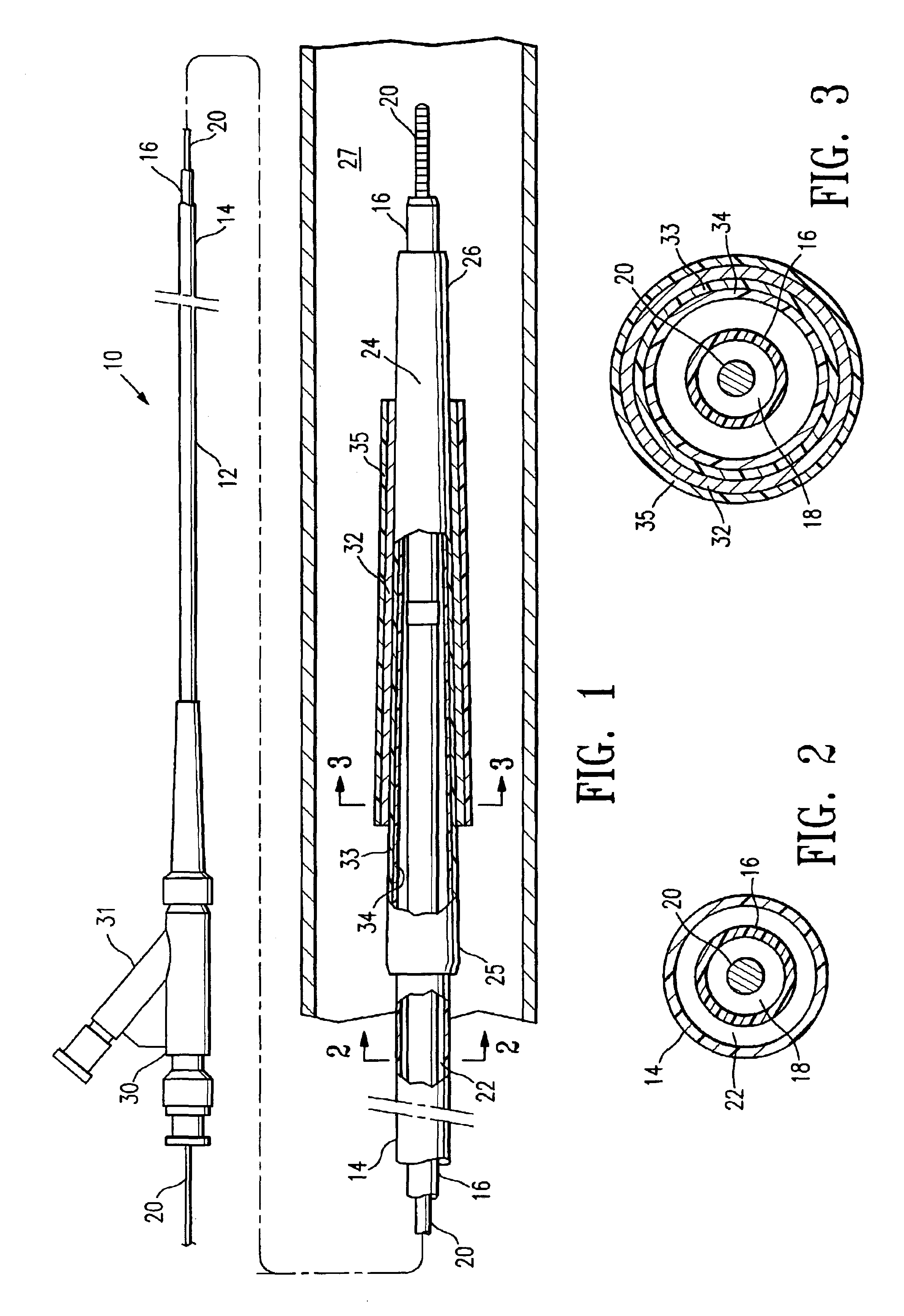

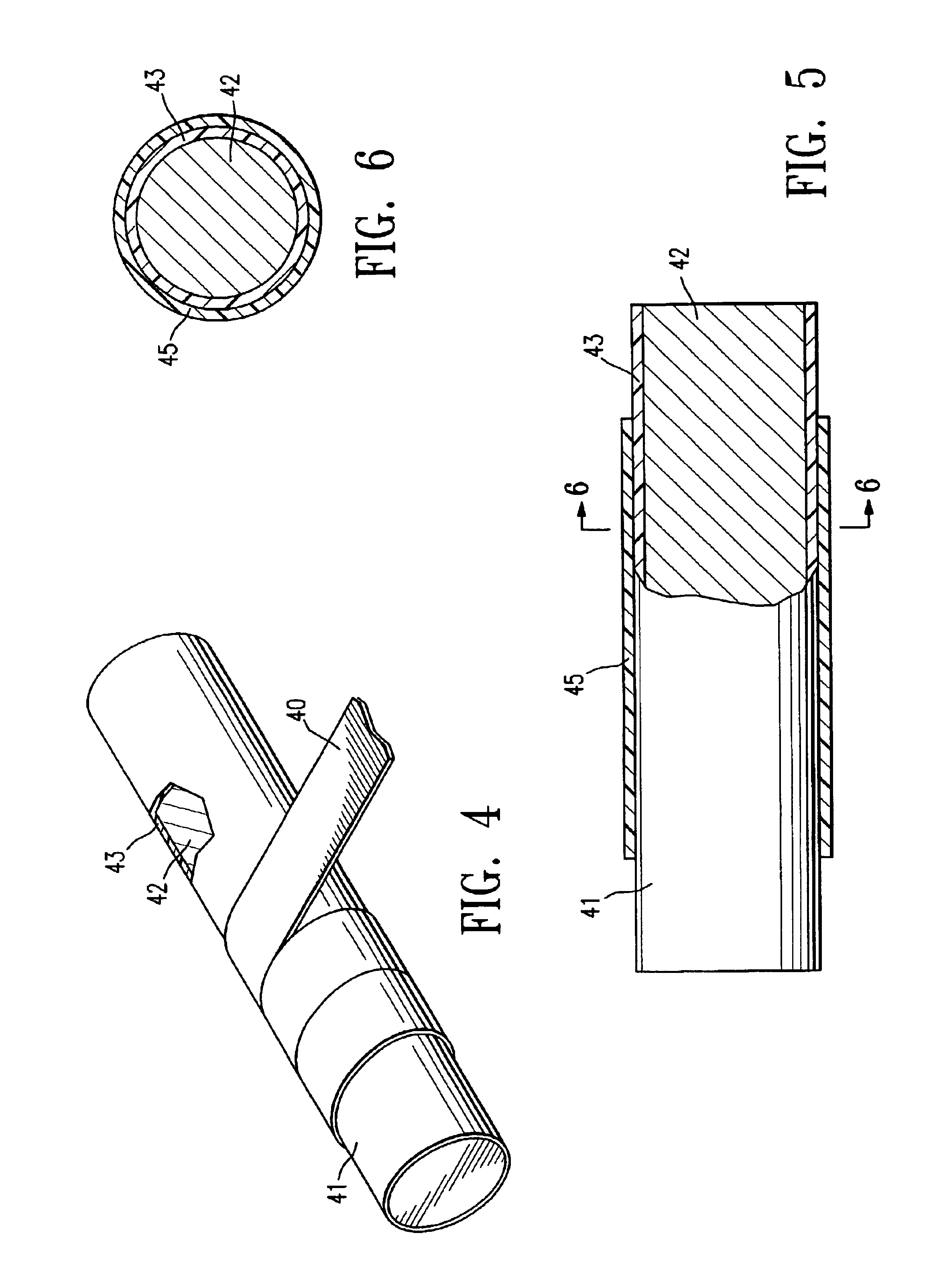

Method of making a catheter balloon using a polyimide covered mandrel

InactiveUS6878329B2Prevent corrosionFacilitate removalPaper/cardboard wound articlesMouldsPolyimideMedical treatment

A method of making a catheter balloon or other tubular medical device or component, in which a sheet of polymeric material is wrapped on a mandrel and heated to fuse sections of the wrapped sheet together to form a tube. The mandrel has a metallic core and a jacket on an outer surface of the metallic core, and the wrapped sheet of polymeric material is heated without corroding the metallic core of the mandrel. In a presently preferred embodiment, the sheet is formed of a fluoropolymeric material, and the resulting fluoropolymeric tube forms at least a layer of a catheter balloon.

Owner:ABBOTT CARDIOVASCULAR

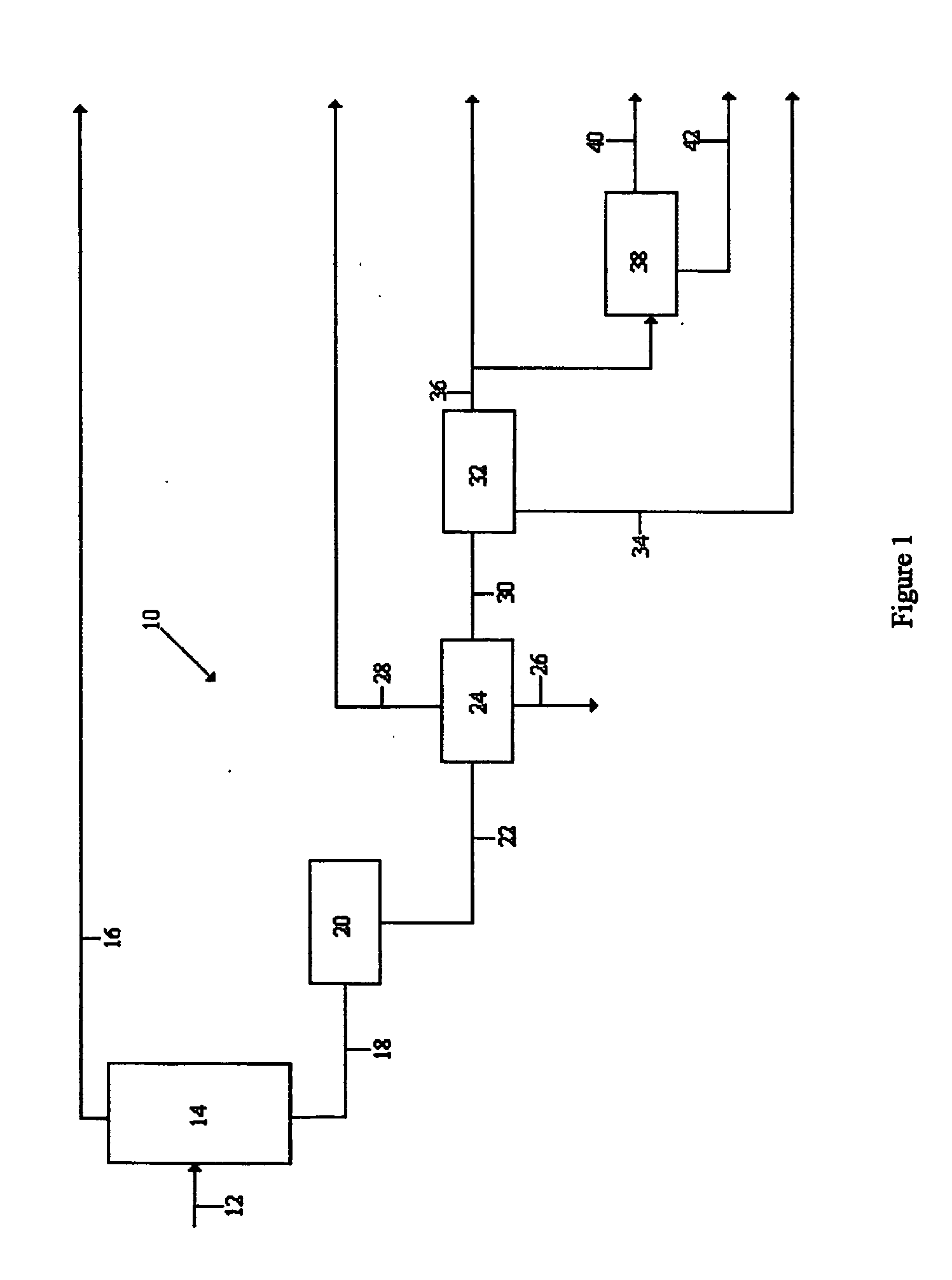

Method of purifying fischer-tropsch derived water

ActiveUS20050131085A1Prevent corrosionInhibitory effectTreatment using aerobic processesOxygen compounds purification/separationChemistryMembrane configuration

A process for the production of highly purified water from Fischer-Tropsch reaction water includes distillation as a primary treatment stage, evaporation as a secondary treatment stage, aerobic treatment as a tertiary treatment stage, solid-liquid separation as a quartic treatment stage, and membrane separation as a final treatment stage.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499AGood car frameFunction increaseLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

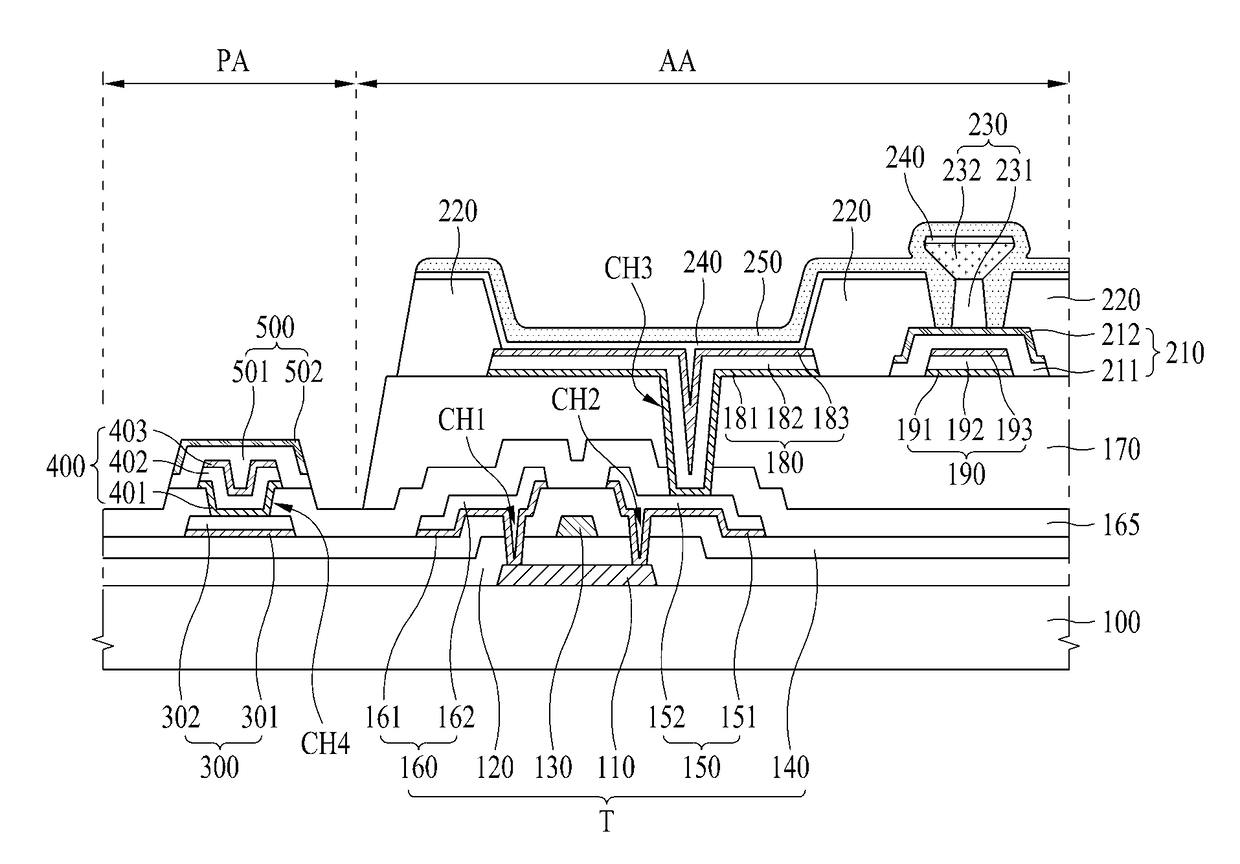

Organic Light Emitting Display Device and Method of Manufacturing the Same

ActiveUS20170141176A1Process be minimizePrevent corrosionSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsDisplay device

An organic light emitting display device is disclosed that includes a substrate including an active area and a pad area; a thin-film transistor (TFT) including a drain electrode, a source electrode, and a gate electrode; an anode electrode; an organic emitting layer; a cathode electrode; and a pad area of the substrate provided with a signal pad that is in a same layer as the drain electrode and the source electrode, the pad area including a first pad electrode on the signal pad, and a second pad electrode on the first pad electrode.

Owner:LG DISPLAY CO LTD

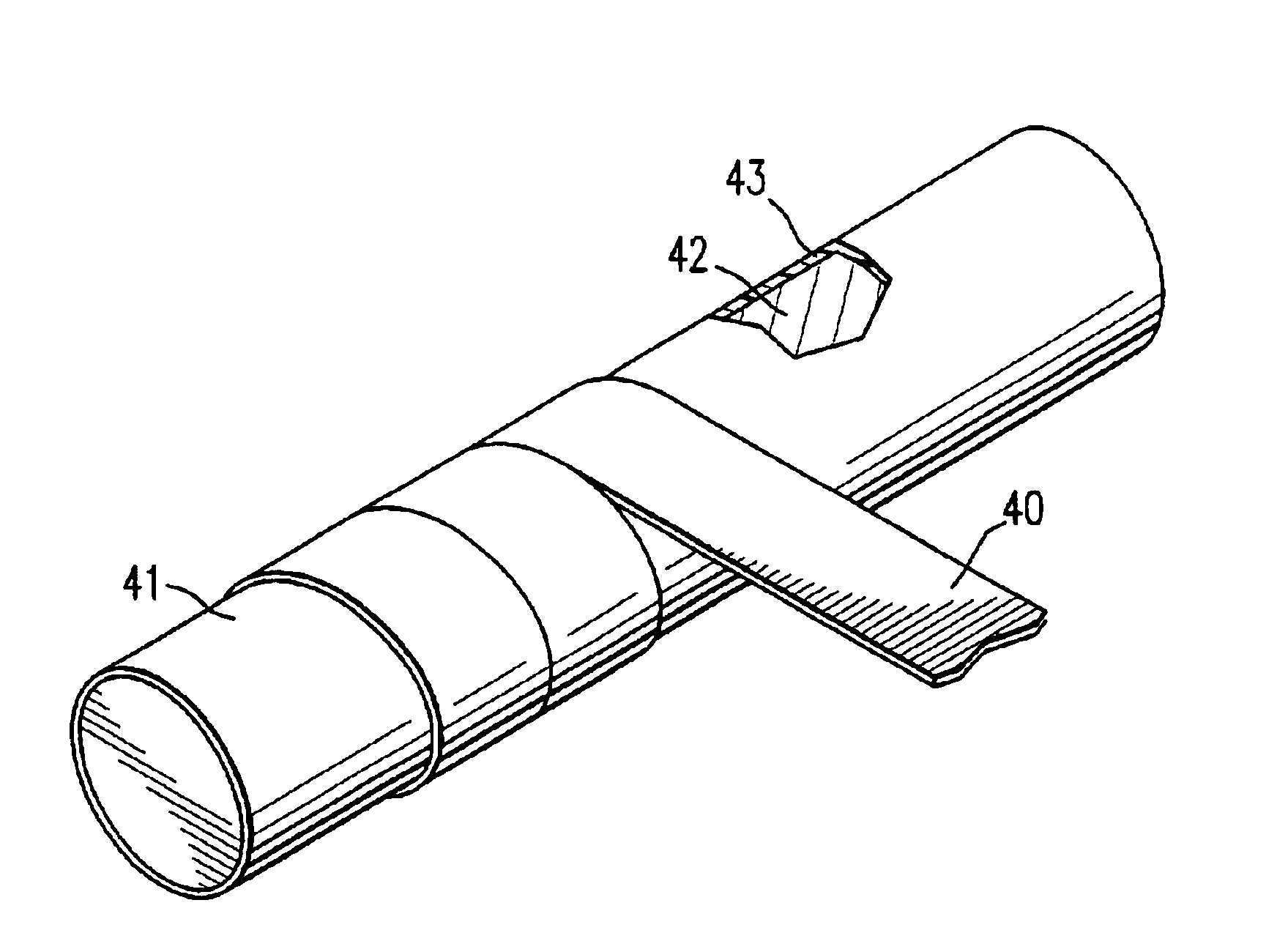

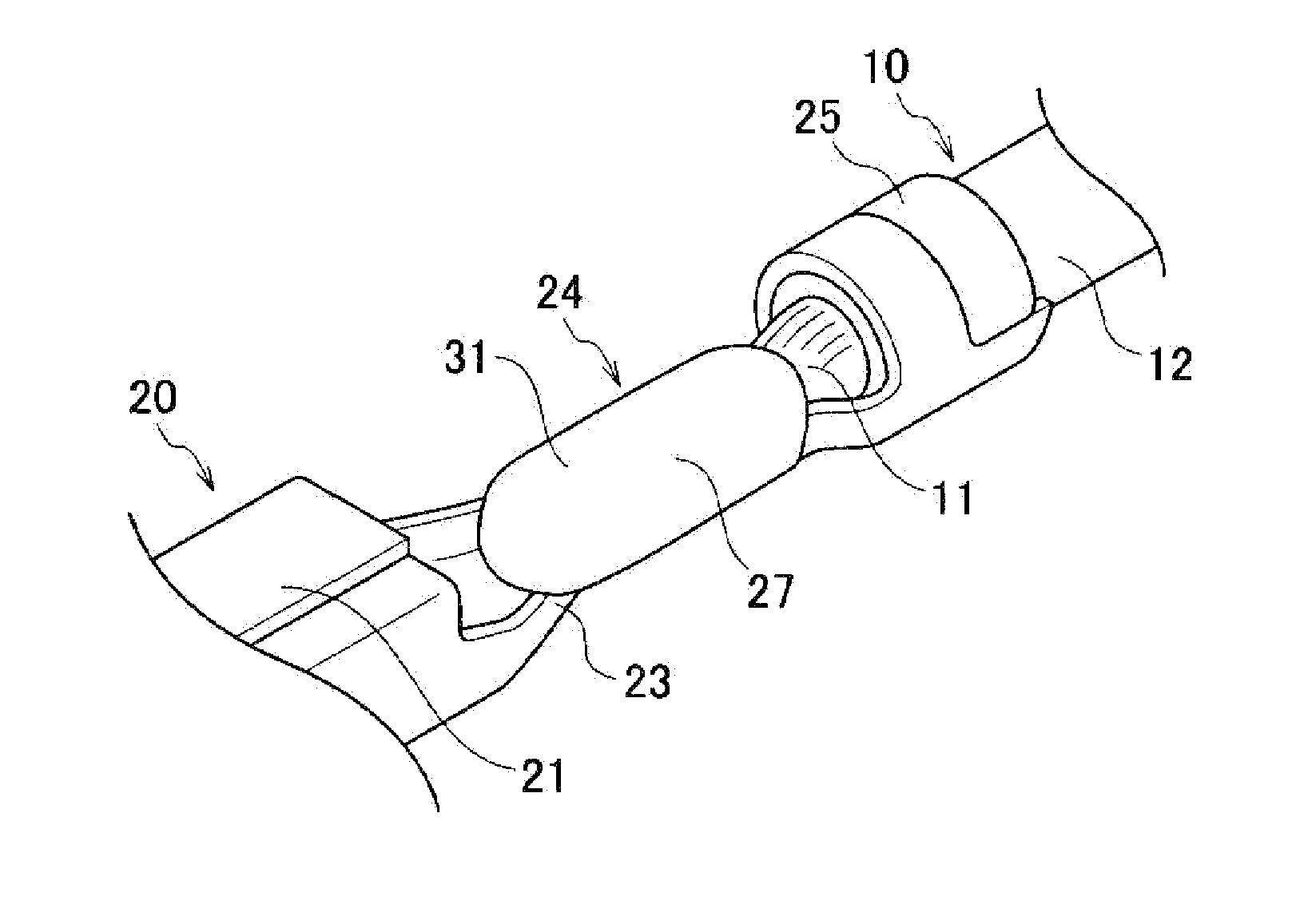

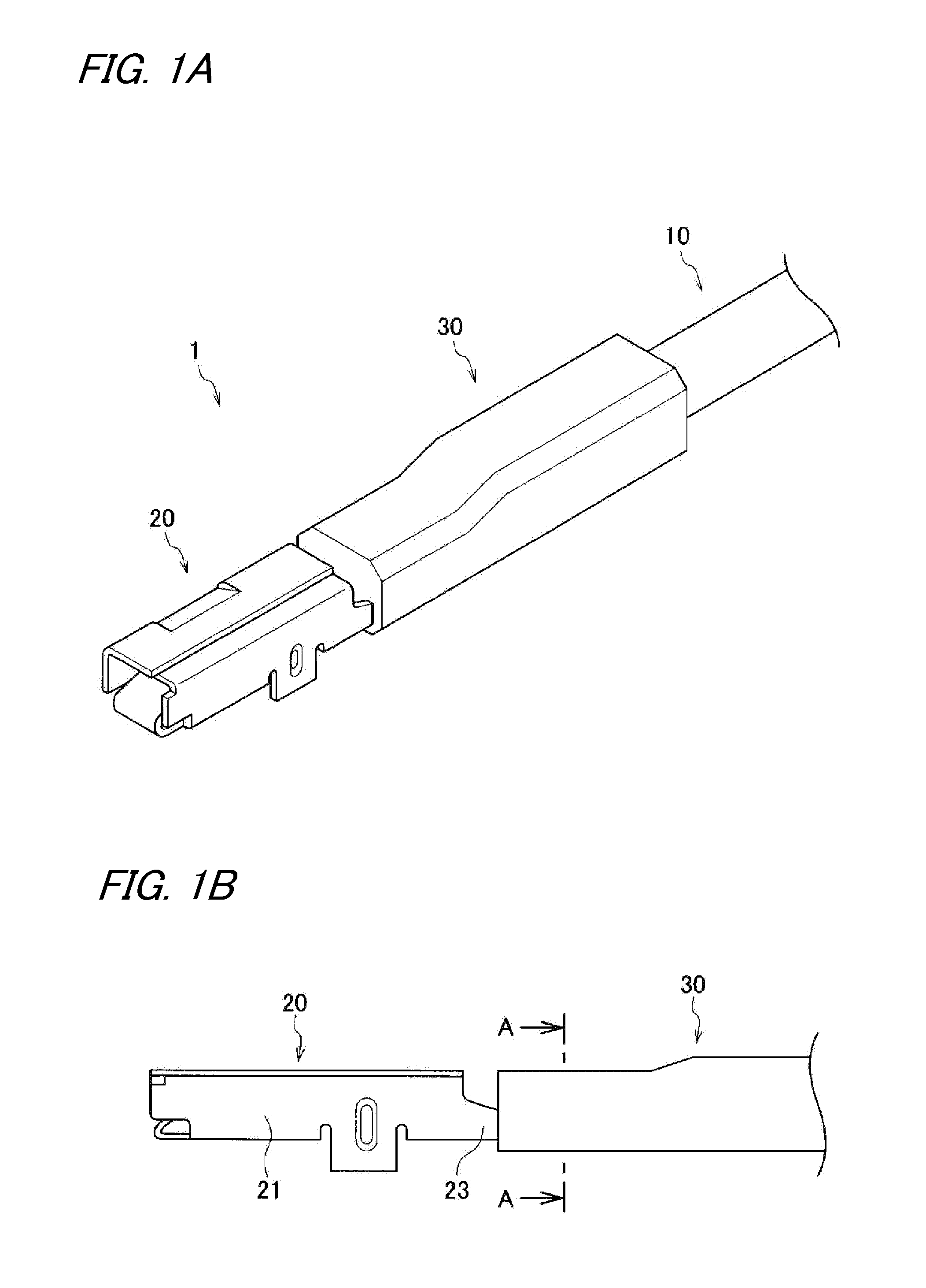

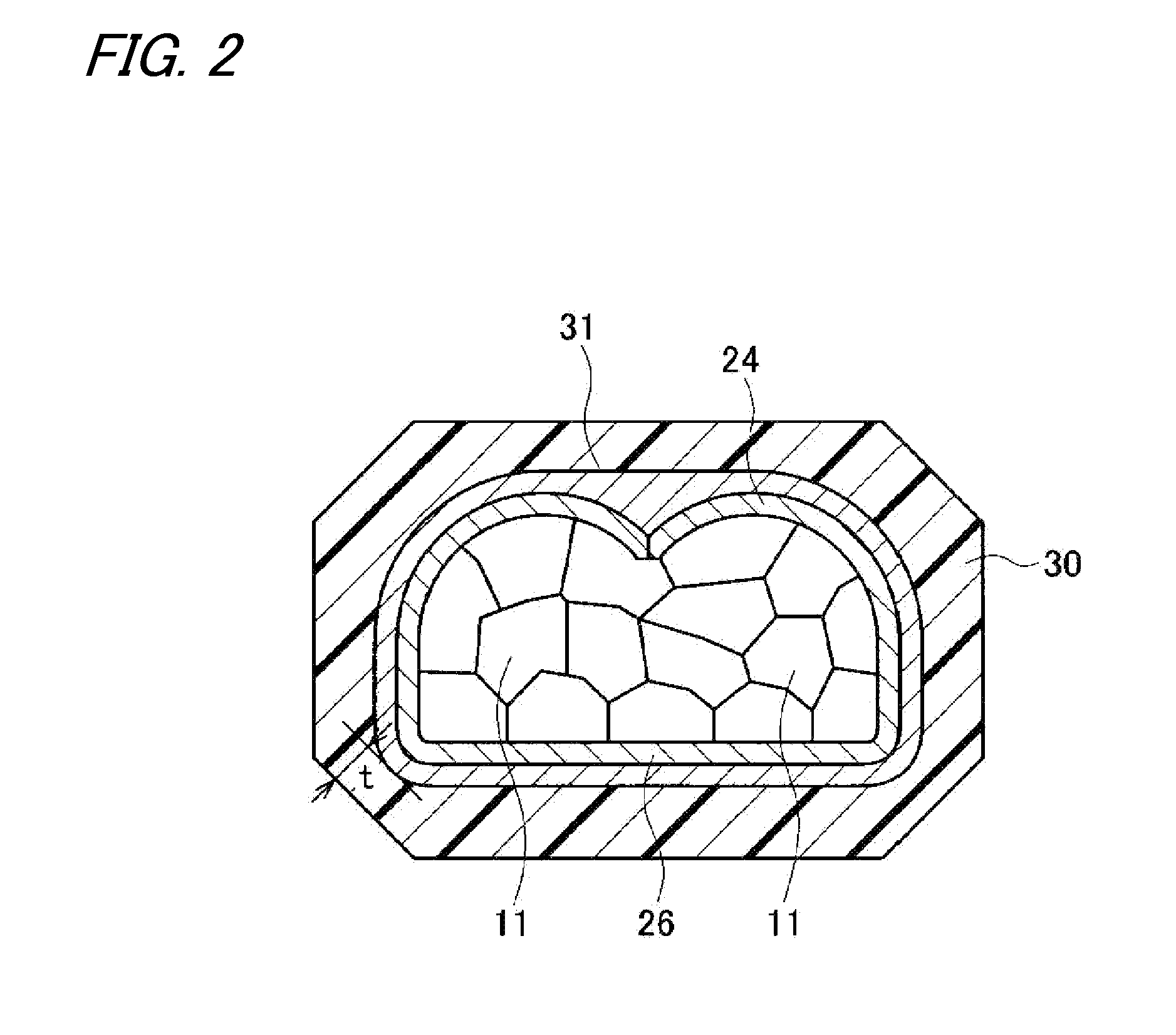

Crimped terminal wire for automobile

InactiveUS20130199842A1PreventPrevent corrosionVehicle connectorsCoupling device detailsAluminiumElectric wire

To provide a crimped terminal wire for automobile that includes an aluminum electric wire, a connecting terminal made from a copper-based material, and a resin-coated portion that is provided in a range capable of inhibiting crevice corrosion that builds up in a crevice between the connecting terminal and a resin from reaching a bimetal contact portion between the aluminum electric wire and the connecting terminal. A crimped terminal wire for automobile includes an aluminum electric wire, a connecting terminal made from a copper-based material, crimped onto an end of the wire and including a crimped member, a crimped portion where the terminal is crimped onto the wire, and a resin-coated portion disposed on the crimped portion, wherein the resin-coated portion is disposed on the crimped portion while an entire periphery of the crimped portion is coated with the resin-coated portion.

Owner:AUTONETWORKS TECH LTD +2

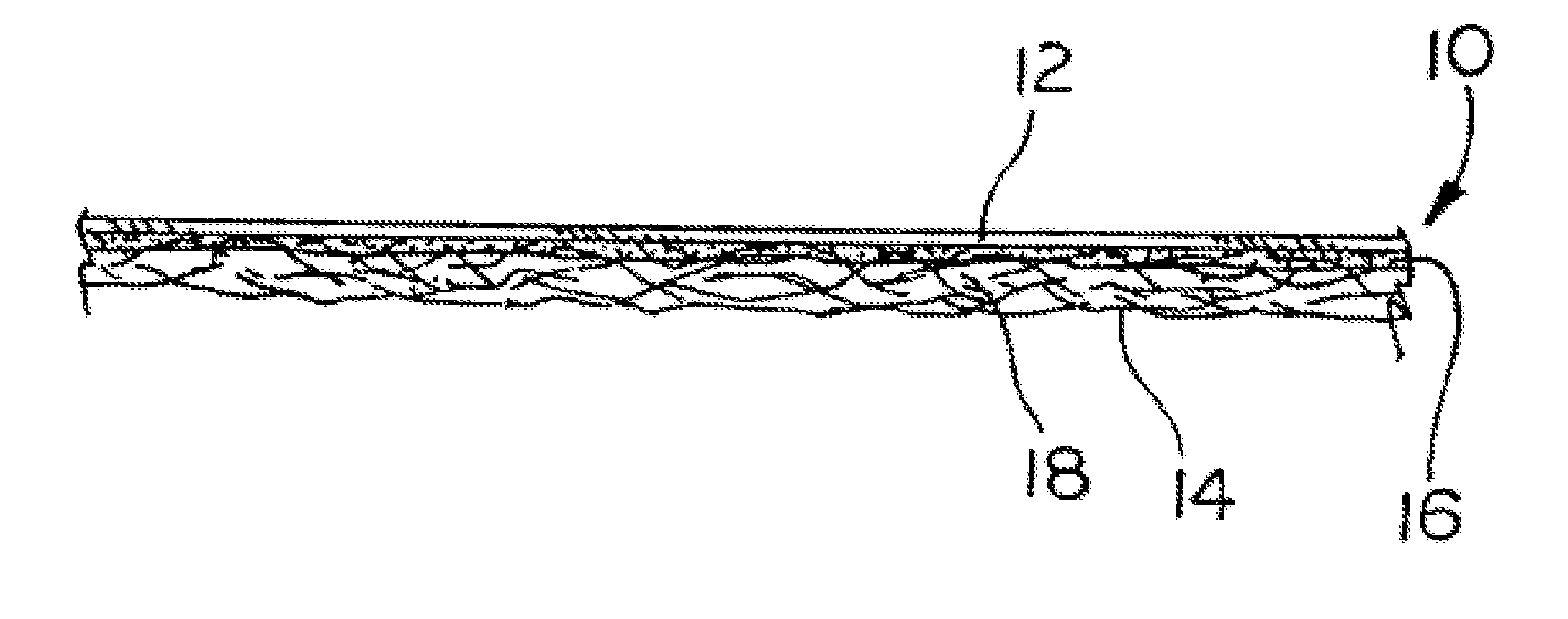

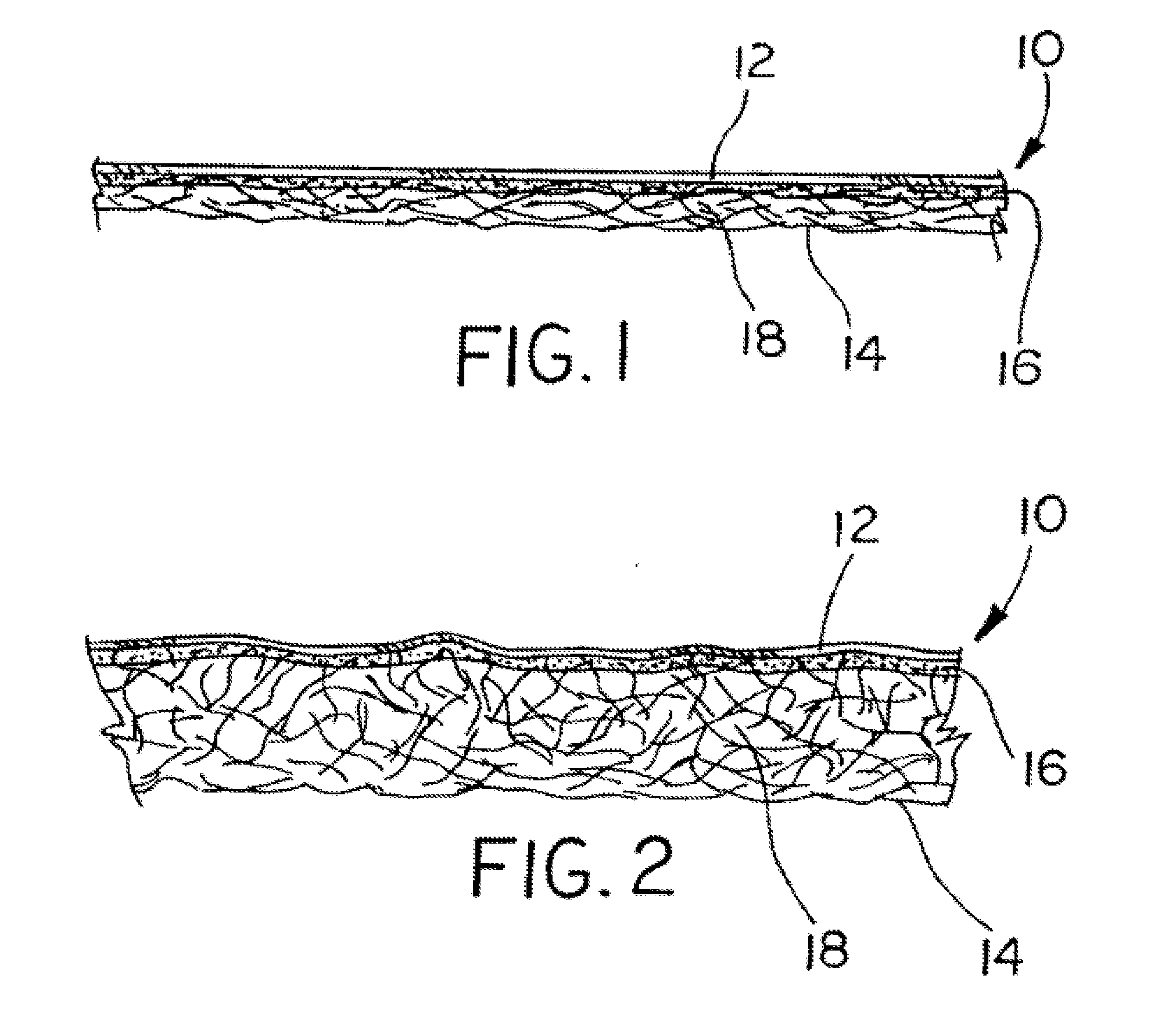

Adhesive composition and method

InactiveUS20110092120A1Prevent corrosionLow costNon-macromolecular adhesive additivesRotary stirring mixersMaximum dimensionTitanium

An adhesive composition contains a block copolymer hot melt adhesive and a vapor releasing vapor corrosion inhibitor mixed with the block copolymer hot melt adhesive, the vapor corrosion inhibitor being in the form of particles suspended in the adhesive composition, the particles preferably having a maximum dimension of less than about 30 microns. One improvement results from inclusion in the adhesive mixture of a titanium and / or zirconium containing coupling agent, either separately or as part of the VCI particles. Another improvement results from blending the adhesive mixture in a continuous process using for example a twin screw extruder. As a result, the adhesive mixture has better uniformity and superior viscosity properties during use.

Owner:TRANSHIELD INC

Terminal-attached electric wire

InactiveUS20150021090A1Prevent corrosionImprove adhesive propertyContact member cases/bases manufactureDustproof/splashproof/drip-proof/waterproof/flameproof connectionCorrosion resistantEngineering

A terminal-attached electric wire of the invention includes an electric wire having a conductor and an electric wire cover member covering the conductor, and a crimping terminal connected to the conductor of the electric wire. The terminal-attached electric wire further includes a corrosion resistant member integrally formed with a peripheral portion of a joint section interposed between the conductor and the crimping terminal and a peripheral portion of the electric wire cover member adjacent to the joint section. The corrosion resistant member contains a thermoplastic elastomer as a main component. A peel strength of bonded assemblies between the corrosion resistant member and a terminal member of the crimping terminal is equal to or greater than 0.2 N / mm, and a peel strength of bonded assemblies between the corrosion resistant member and the electric wire cover member is equal to or greater than 0.5 N / mm.

Owner:YAZAKI CORP

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

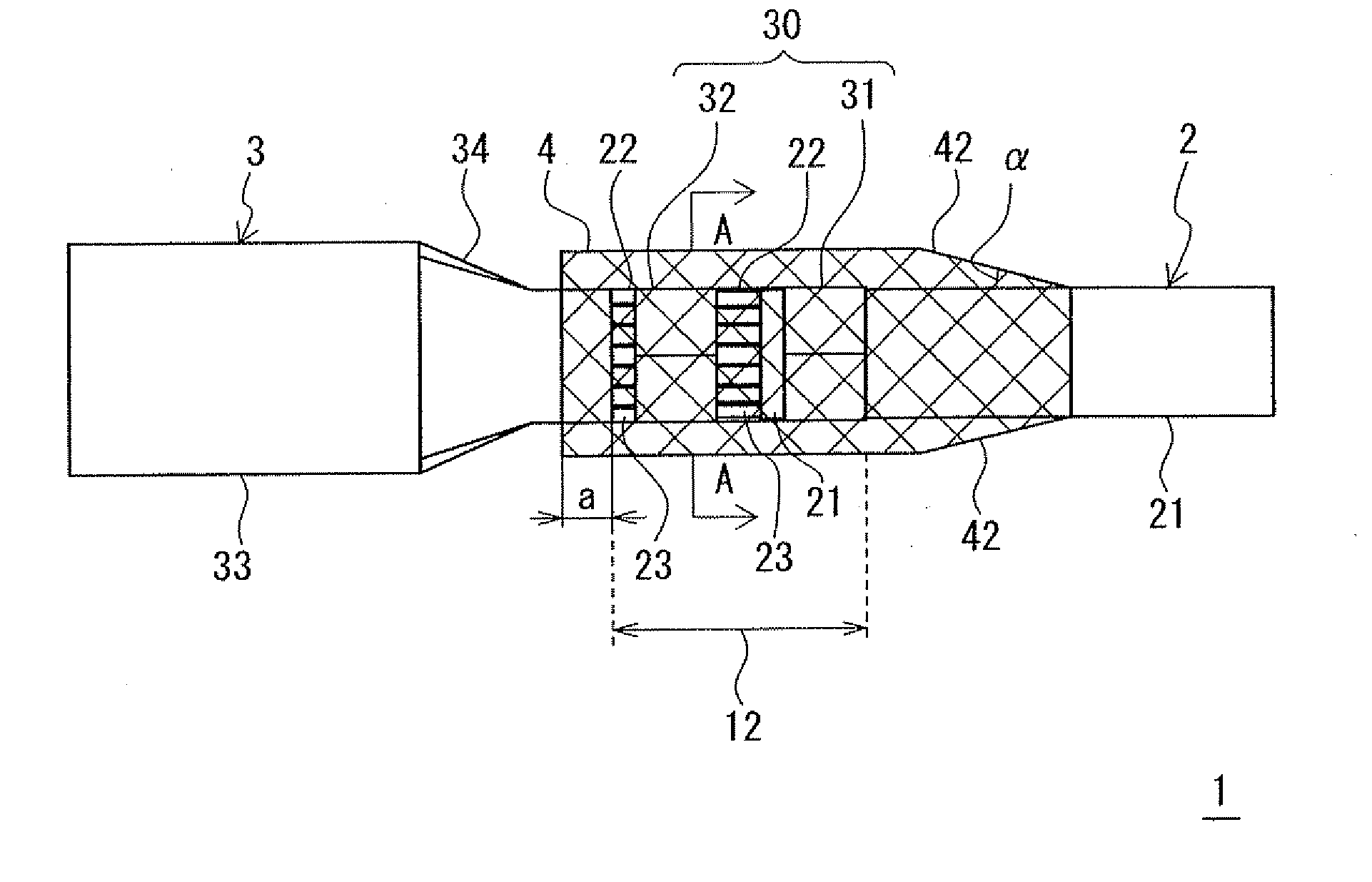

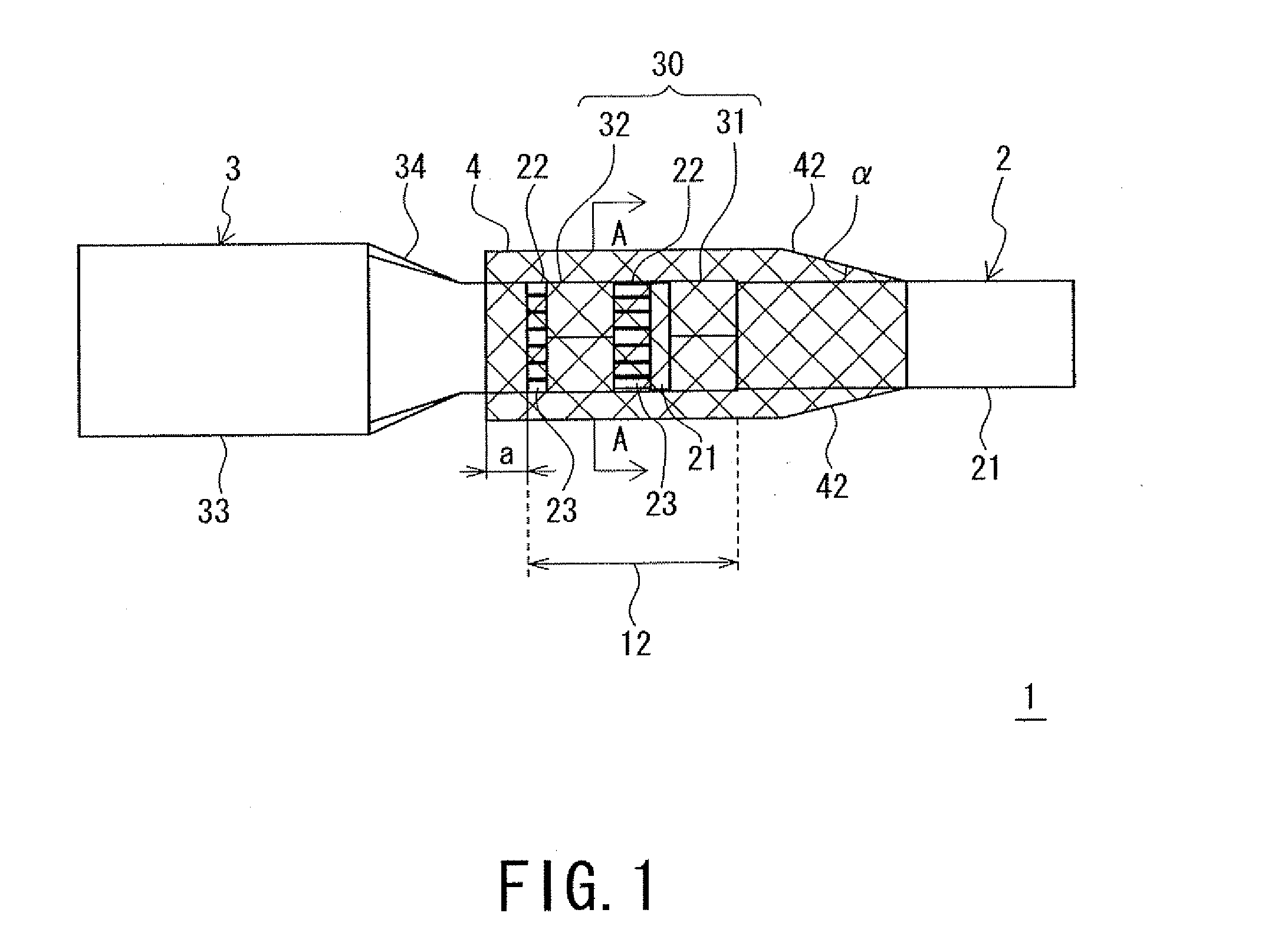

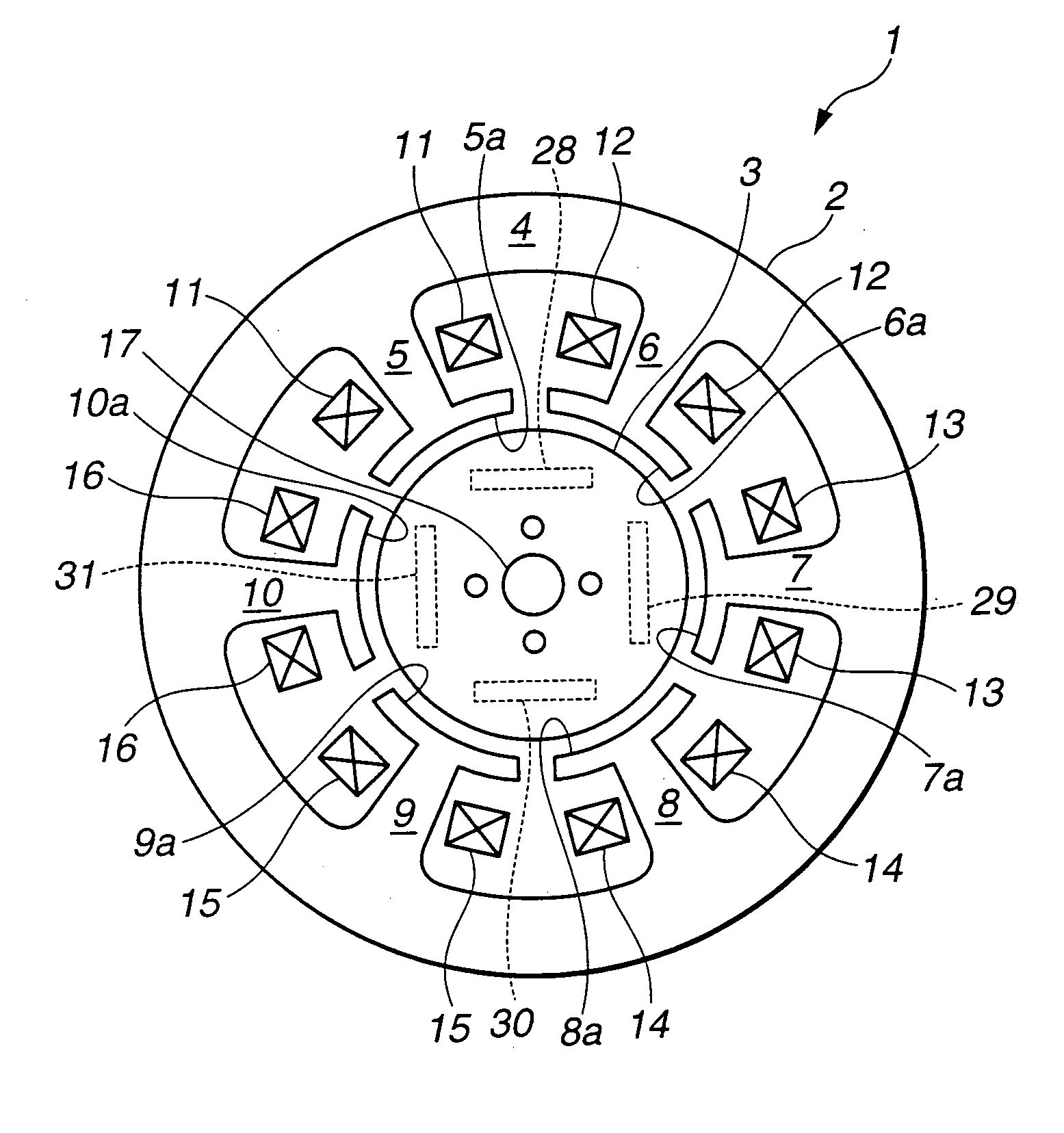

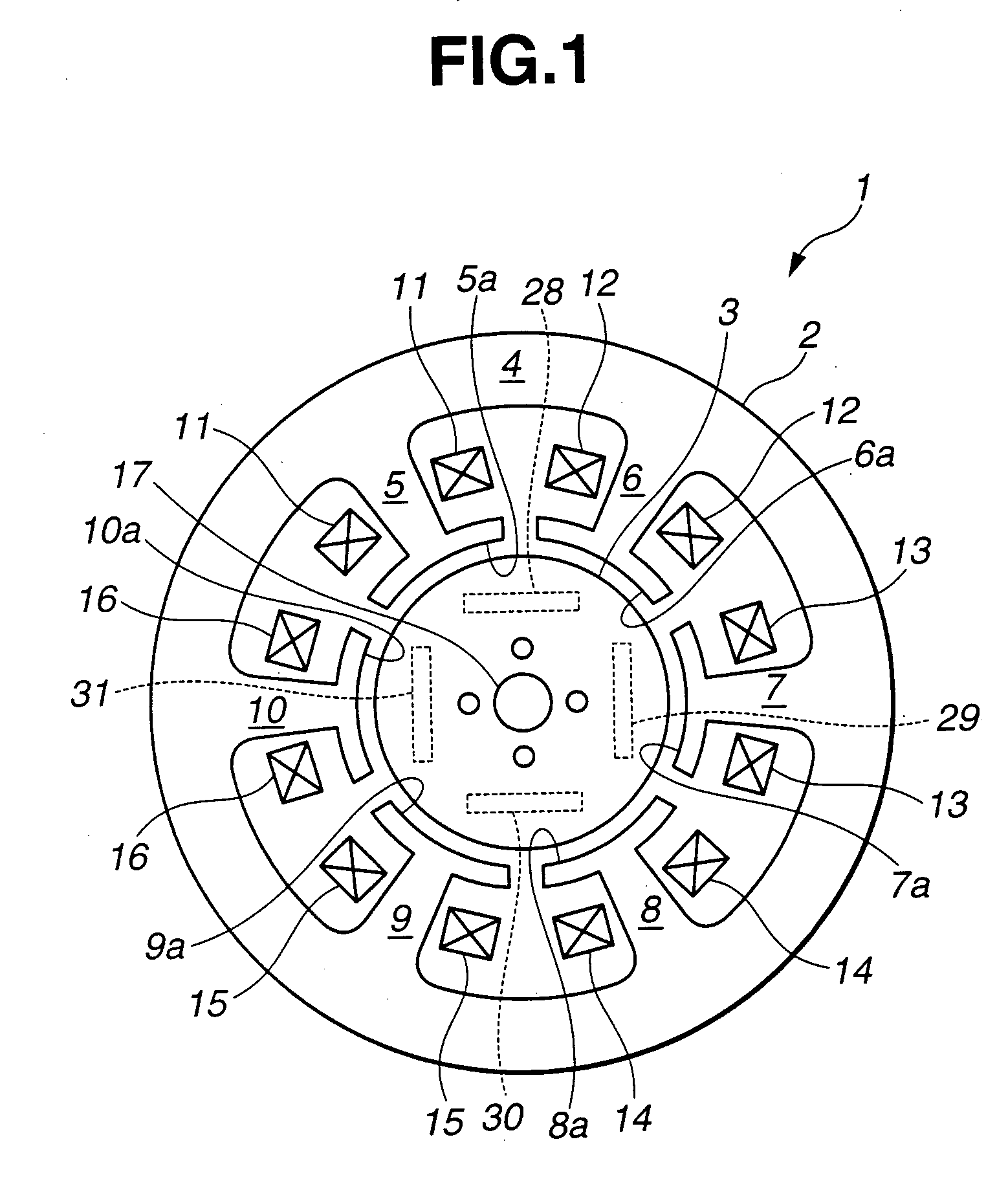

Rotating machine

InactiveUS20050156474A1Prevent corrosionAvoid corrosionSynchronous machine detailsMagnetic circuit rotating partsPhysicsMagnetic flux

A rotating machine is comprised of a rotor having permanent magnets and a stator disposed around the rotor. At least a surface of the permanent magnet, which faces the stator, is covered with a magnetic material whose thickness is determined on the basis of an electrical conductivity of the magnetic material, a magnetic permeability of the magnetic material and a frequency of a high-frequency magnetic flux act from the stator on the rotor.

Owner:JATCO LTD

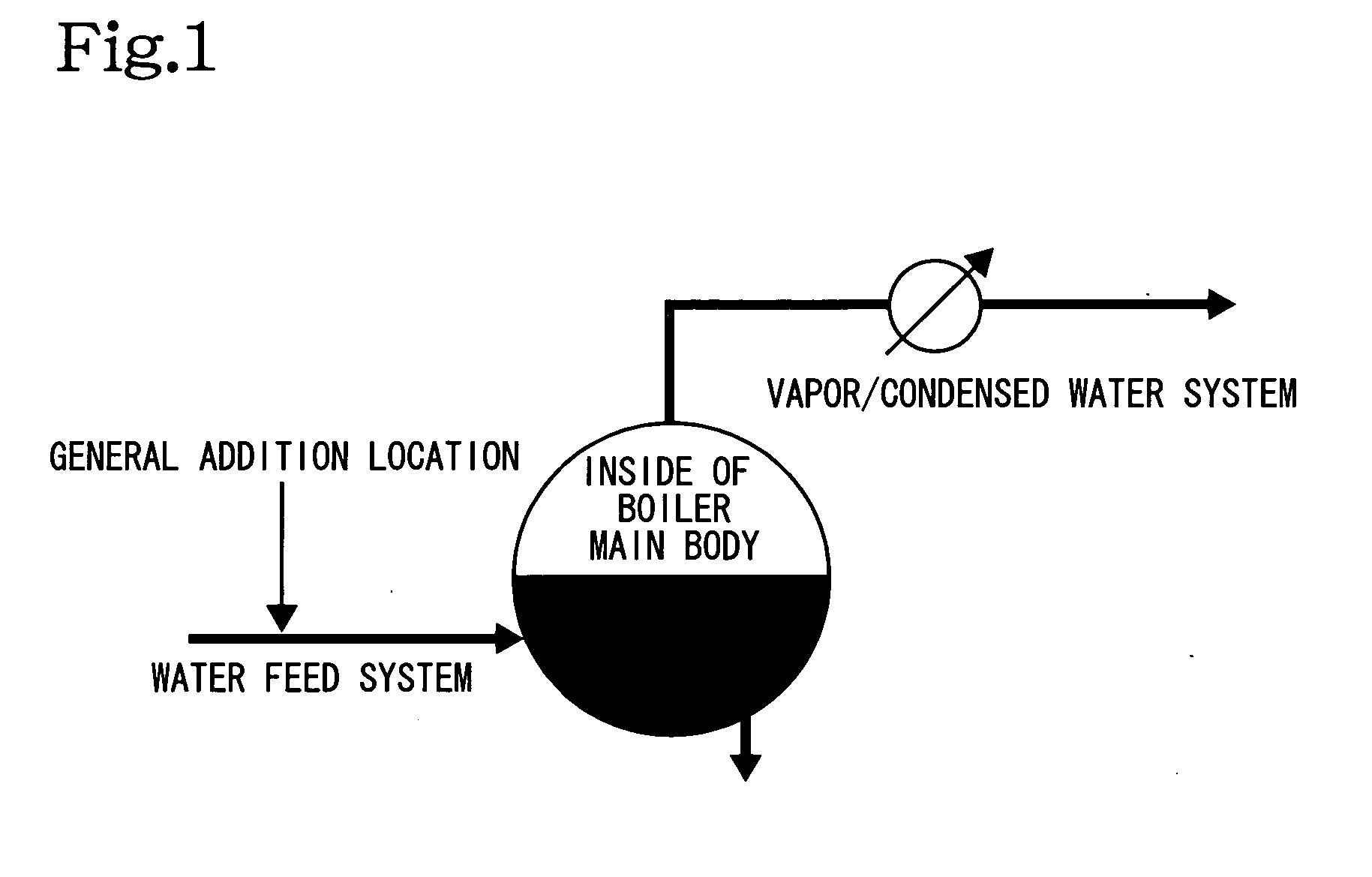

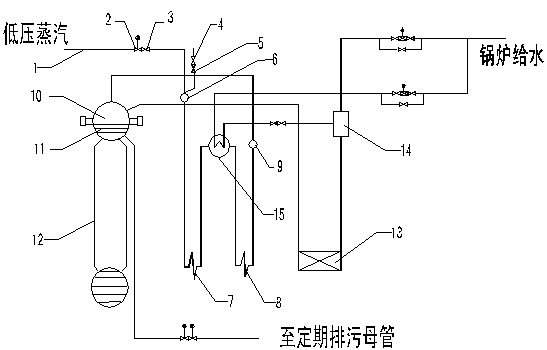

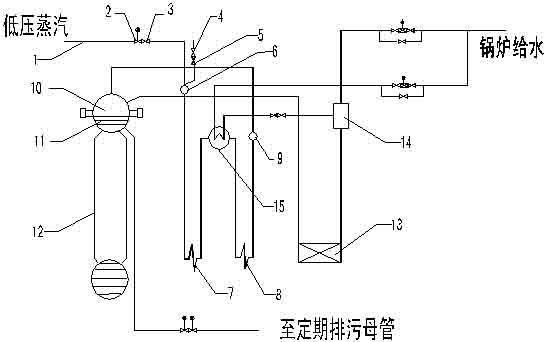

Maintaining and energy-saving method for blowout stand-by boiler

The invention relates to a maintaining and energy-saving method for a blowout stand-by boiler, which comprises the following steps: after the boiler steps out, reserving a fire bed; after the boiler is naturally cooled, when the exit temperature of the furnace chamber drops to 100 DEG C or so, the drum pressure is 0.05-0.1 MPa and the water level is kept within the range of drum central line + / -30mm, carrying out maintenance: carrying out water-side maintenance and vapor-side maintenance, and restarting the blowout stand-by boiler every 24 hours, wherein every time the restarting operation is finished, the opening of the fume outlet baffle is controlled at 10%, and the furnace chamber draft is adjusted to the minimum. The method provided by the invention well overcomes the defects in the prior art. The test proves that the method has favorable application effect and has the characteristics of quick start of the blowout stand-by boiler, favorable maintenance effect and obvious energy-saving effect.

Owner:KUNMING CELLULOSE FIBERS CO LTD

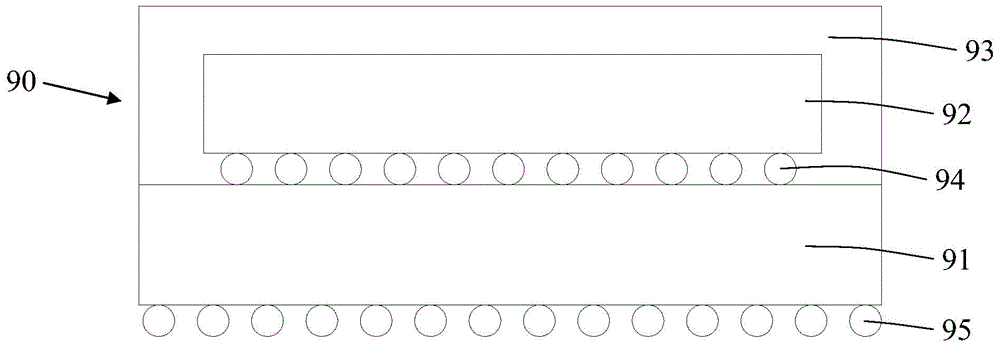

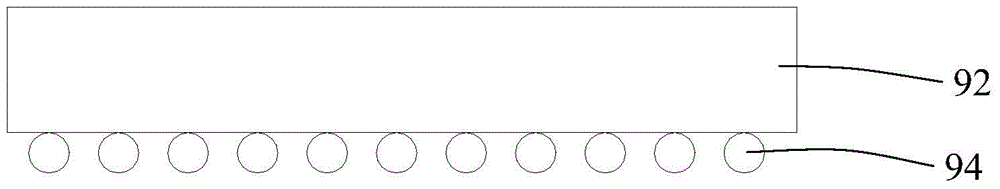

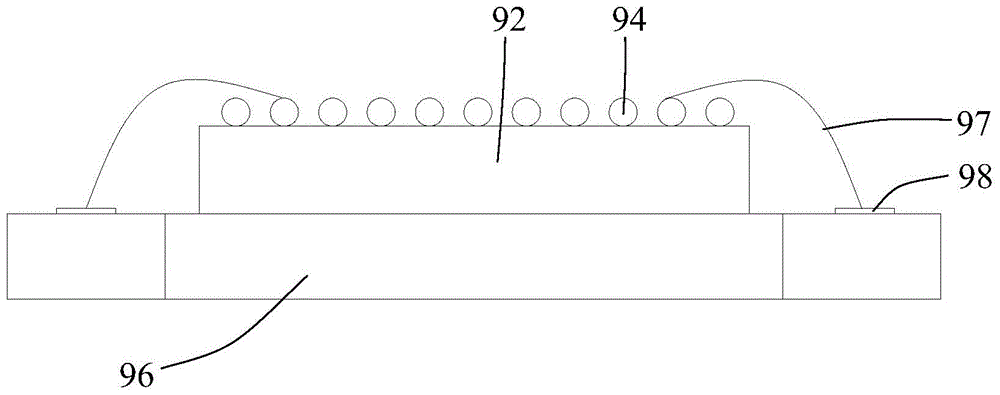

Flip chip failure analysis method and preparation method of detection sample in electric property positioning

ActiveCN105206546APrevent corrosionSemiconductor/solid-state device testing/measurementElectric propertiesSolder ball

The invention discloses a flip chip failure analysis method and a preparation method of a detection sample in electric property positioning. The preparation method includes the steps that a flip chip to be detected is provided, wherein the flip chip comprises a packaging substrate and a bare chip prepared on the packaging substrate, the bare chip is covered with a plastic package body, a gold bump is connected between the bare chip and the packaging substrate, and a solder ball is welded to the bottom of the packaging substrate; the plastic package body outside the bare chip is ground till the crystal back of the bare chip is exposed; the back face of the bare chip is combined to a glass base plate, and a conducting strip is arranged on the glass base plate; the conducting strip on the glass base plate is electrically connected with the solder ball at the bottom of the packaging substrate through a packaging binding wire, and then the detection sample is obtained. According to the preparation method of the detection sample for flip chip failure analysis, the plastic package body on the back face of the bare chip is ground away, then the back face of the bare chip is combined on the glass base plate for failure analysis, the plastic package body does not need to be corroded, the packaging substrate and the bare chip do not need to be separated, and therefore the probability that the gold bump is corroded in the bare chip taking process is avoided.

Owner:INTEGRA TED SERVICE TECH SHANGHAI CO LTD

Method for biologically treating industrial circulating water and stabilizing quality thereof

InactiveCN103204589AImprove water qualitySlightly corrodedFungiBiological water/sewage treatmentBiotechnologyMicrobial agent

The invention discloses a method for biologically treating industrial circulating water and stabilizing the quality thereof. The method is characterized by comprising a, separately breeding bacterial strains; b, performing acclimatization for the bacterial strains; c, culturing and preparing the bacteria; d, culturing the bacteria in an industrial expanding manner to produce medicinal products; and e, directly adding the produced medicinal products into a circulating water pond. The method has the advantages that the quality of the industrial circulating cooling water is stabilized by the aid of the biotechnology and method, in a circulating water system, currently preferred chemical corrosion and scale inhibitors, bactericides and other chemical agents are replaced by microbial agents; and the microbial agents are produced by a special process, and aerobic bacteria, anaerobic bacteria and facultative anaerobic bacteria which have biological reaction functions are optimized, are subjected to acclimatization and then are cultured in an industrial expanding manner to obtain the microbial agents (medicament or microbiological products in short).

Owner:付永全

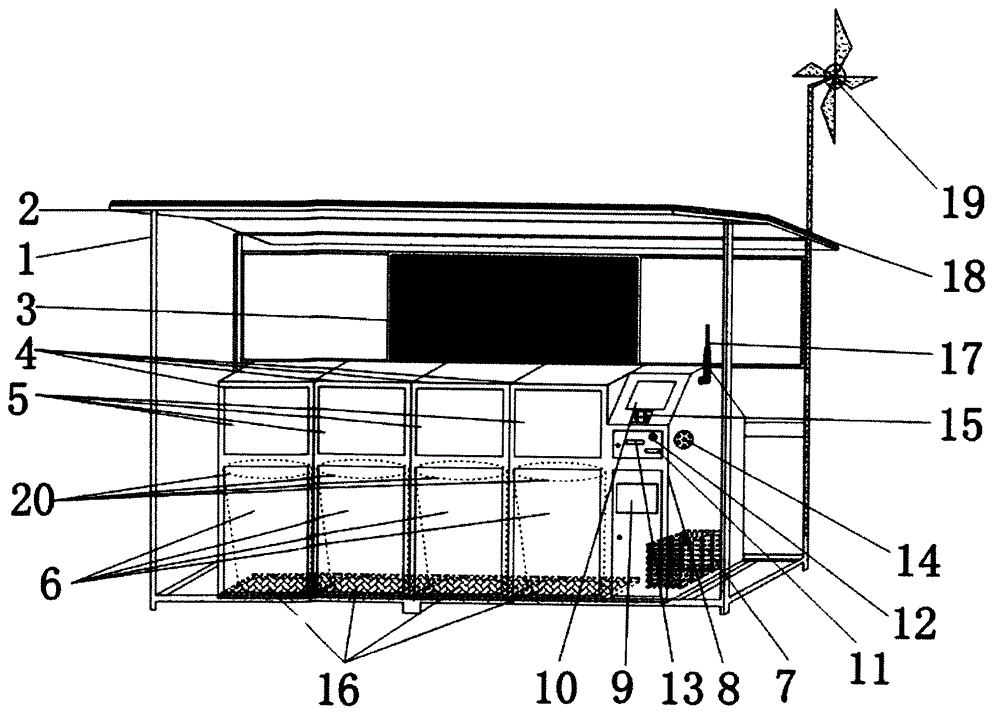

Intelligent garbage sorting and recycling equipment

InactiveCN104925417AAvoid direct physical impactPrevent corrosionWaste collection and transferRefuse receptaclesHeat sensitiveEngineering

The invention discloses intelligent waste classifying and recovering equipment which mainly comprises a waste type identification module used for identifying the types of wastes thrown by users and the identity information of the users, a waste classifying and throwing unit used for classifying and throwing the wastes by the users, a waste classifying and recovering unit used for classifying and recovering the wastes by waste recovery workers, a human body sensing module used for sensing pedestrians close to the equipment, a voice module used for playing an operation prompt voice and a publicity voice, an IC (integrated card) reading module used for reading user information, and a heat-sensitive printer used for printing the identity information of the users and the type information of the thrown wastes. Due to the adoption of the technical scheme, the equipment has the functions of sensing the pedestrians close to the equipment, making a voice prompt in the whole operation, intelligently identifying the waste types, automatically classifying and recovering the wastes and the like, and is easy and convenient to use and relatively high in waste classifying and recovering efficiency.

Owner:张志勇

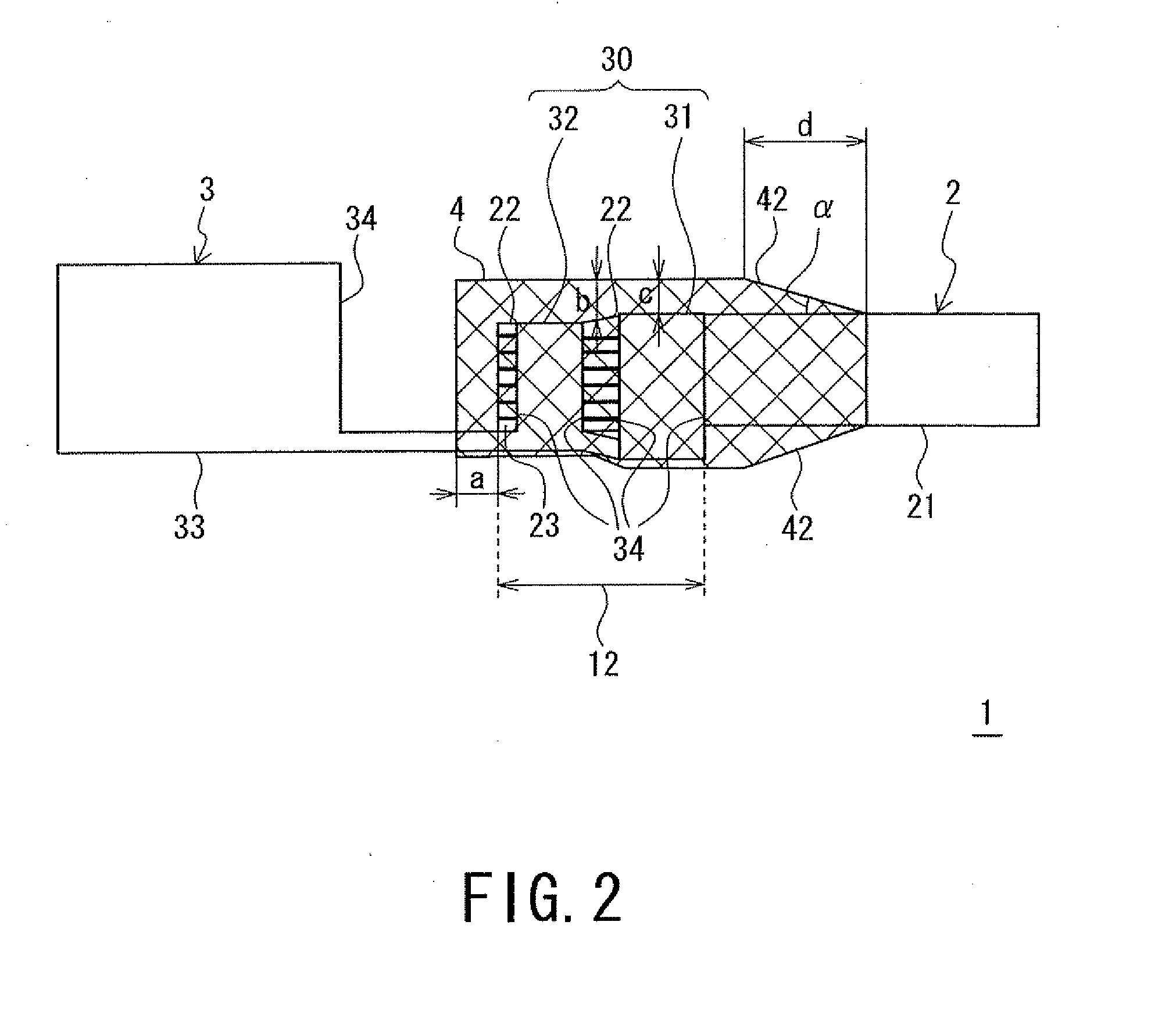

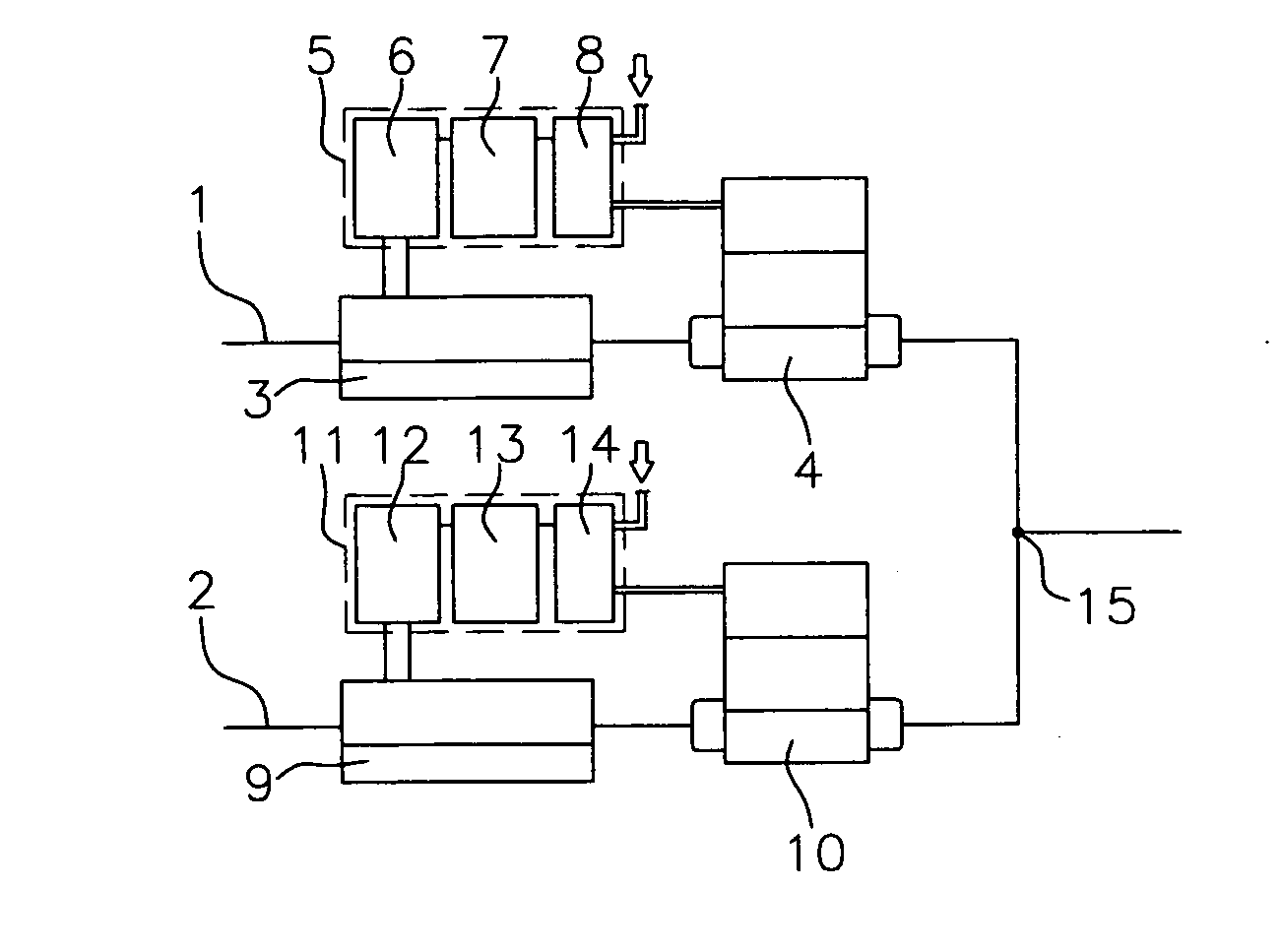

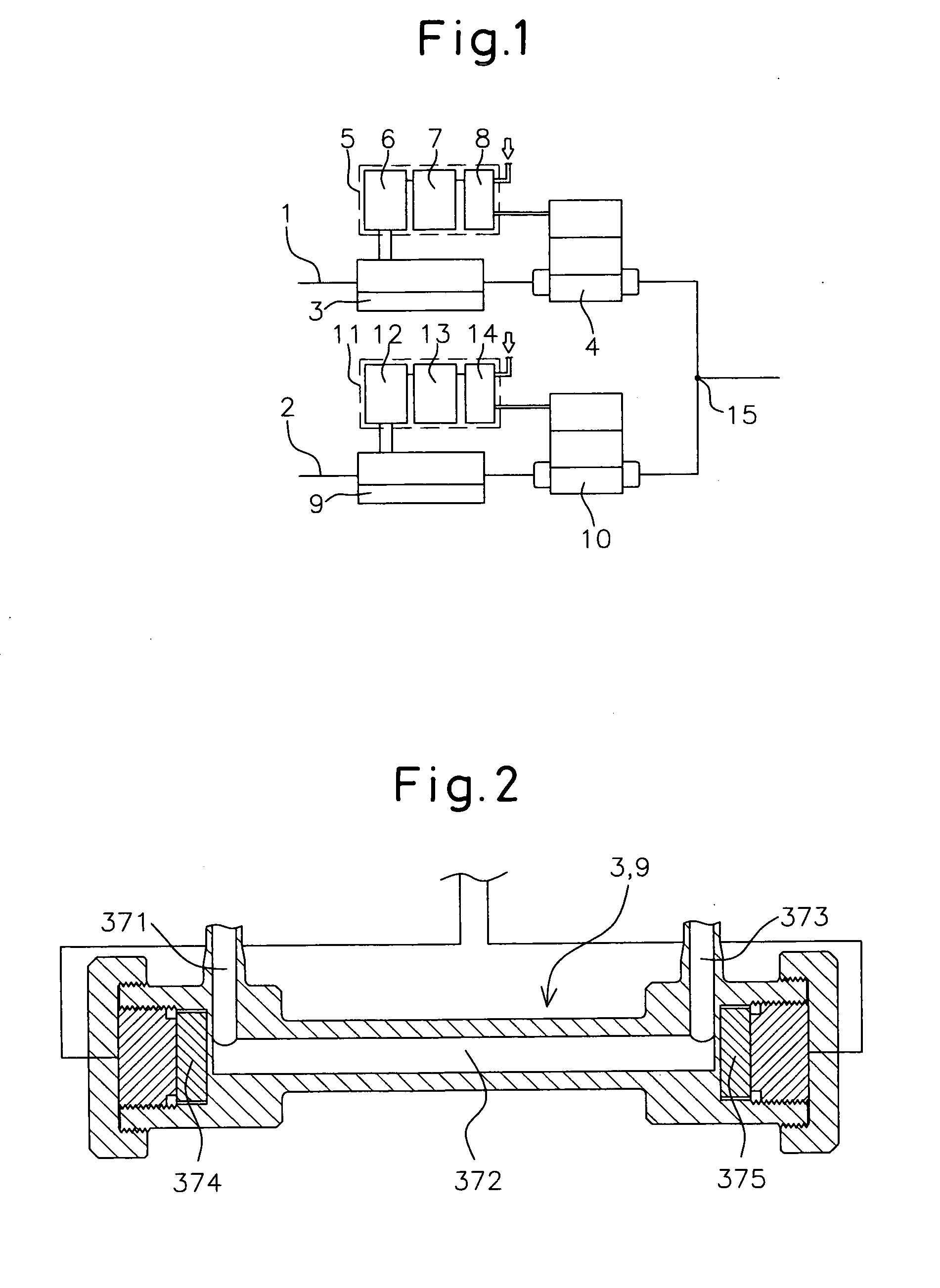

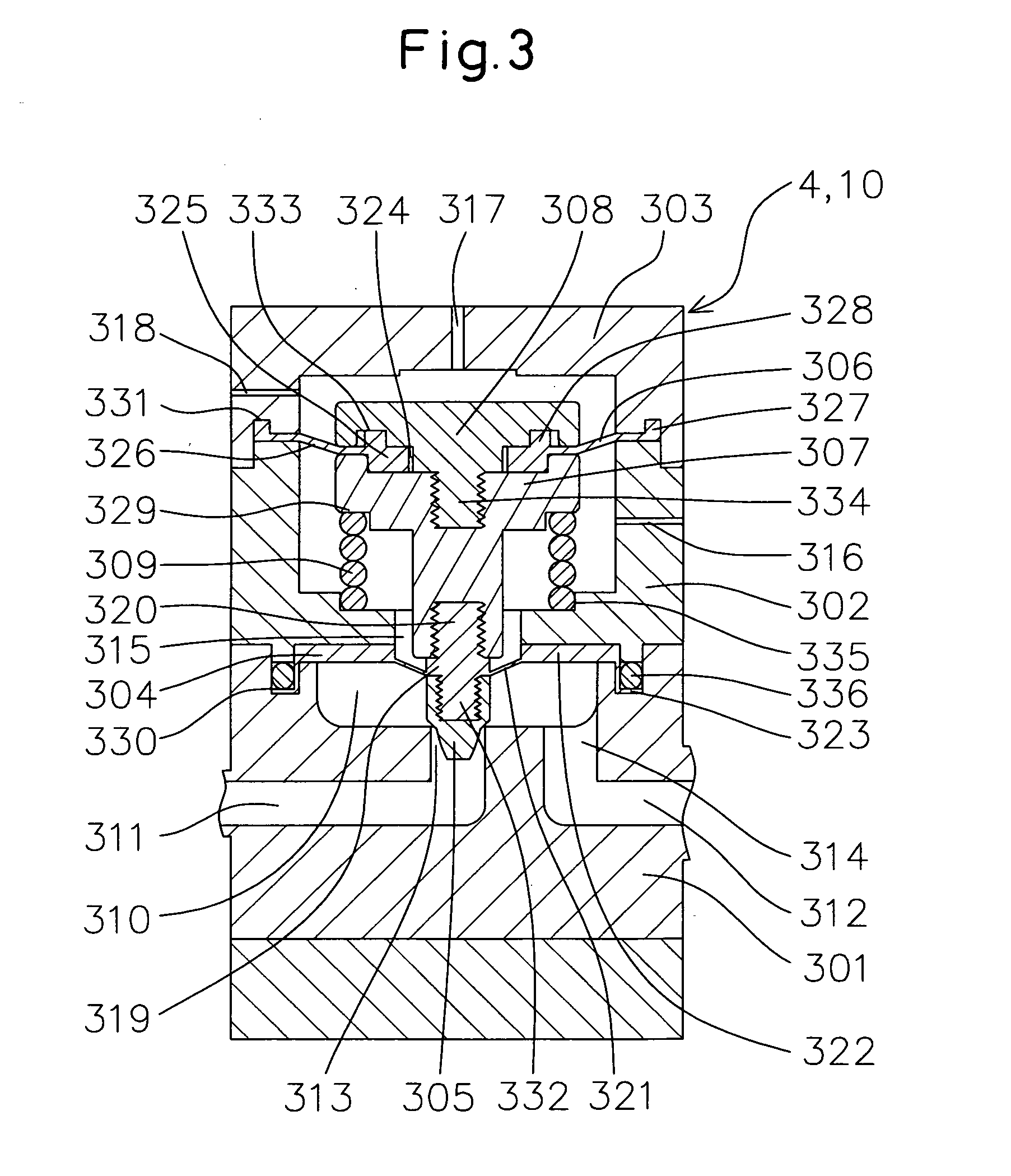

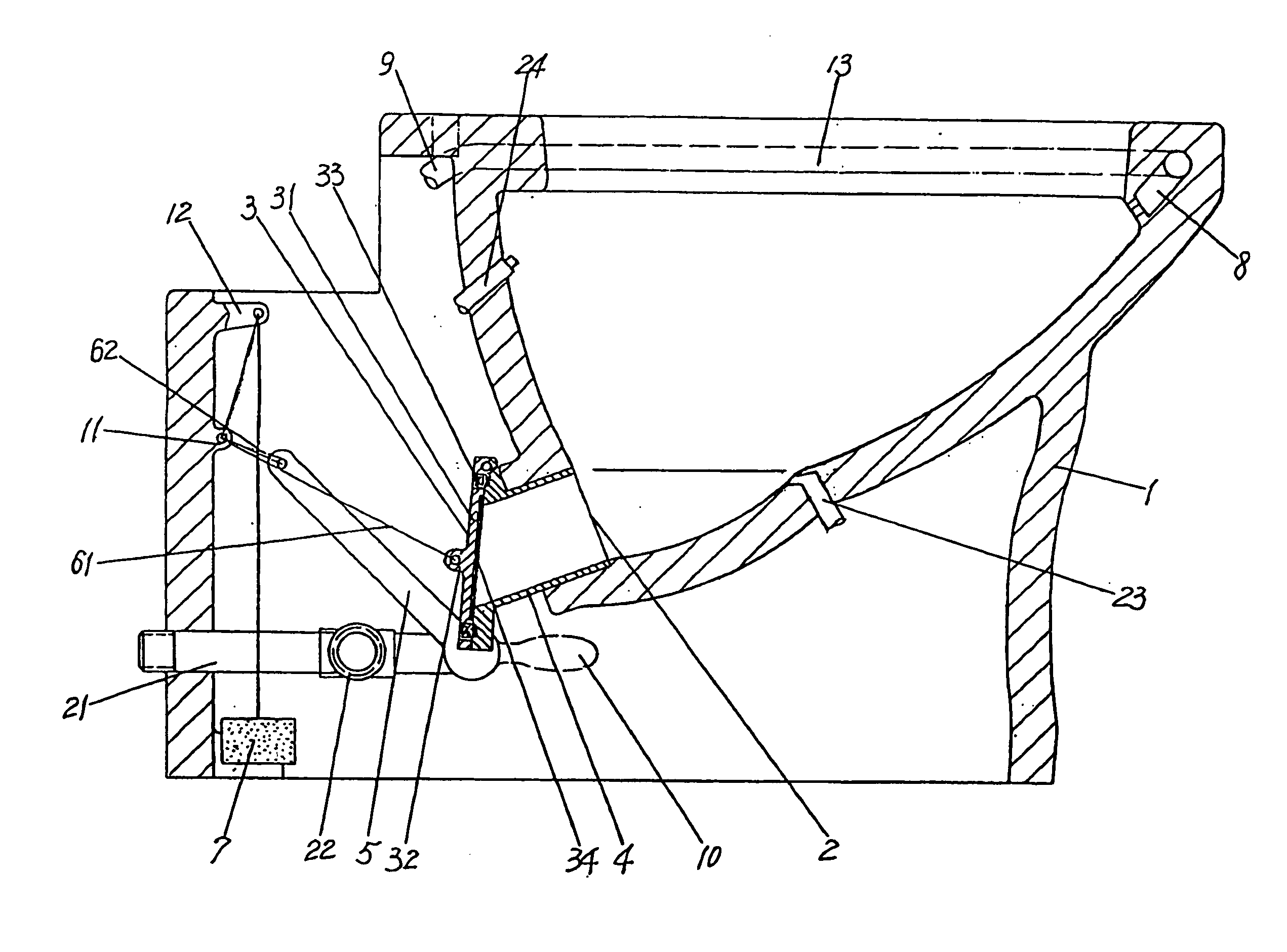

Fluid mixing system

InactiveUS20070204912A1Prevent corrosionGood responseOperating means/releasing devices for valvesFlow mixersHybrid systemEngineering

An object of the present invention is to provide a fluid mixing system able to control the flow rates of different lines of fluid to mix them in any ratio, able to control the flow rate of even a pulsating fluid without problem, compact in configuration and able to be installed in a narrow space, and enabling easy pipe laying and pipe connection at the time of installation.In the system of the present invention, its feed lines 1, 2 are provided with fluid control valves 4, 10 changing the opening area of the channels to control the flow rates of the fluids, flow rate measuring devices 3, 9 measuring the actual flow rates of the fluids and converting the measured values of the actual flow rates to electrical signals for output, and control units 5, 11 outputting command signals for controlling the opening areas of the fluid control valve to the fluid control valves or equipment operating the fluid control valves based on the error between the measured values of the actual flow rate and the flow rate setting. In the system of the present invention, for example, to obtain a washing solution for semiconductor production, hydrofluoric acid or hydrochloric acid is mixed with pure water by a ratio of 1 part to 10 to 200 parts.

Owner:ASAHI YUKIZAI KOGYO CO LTD

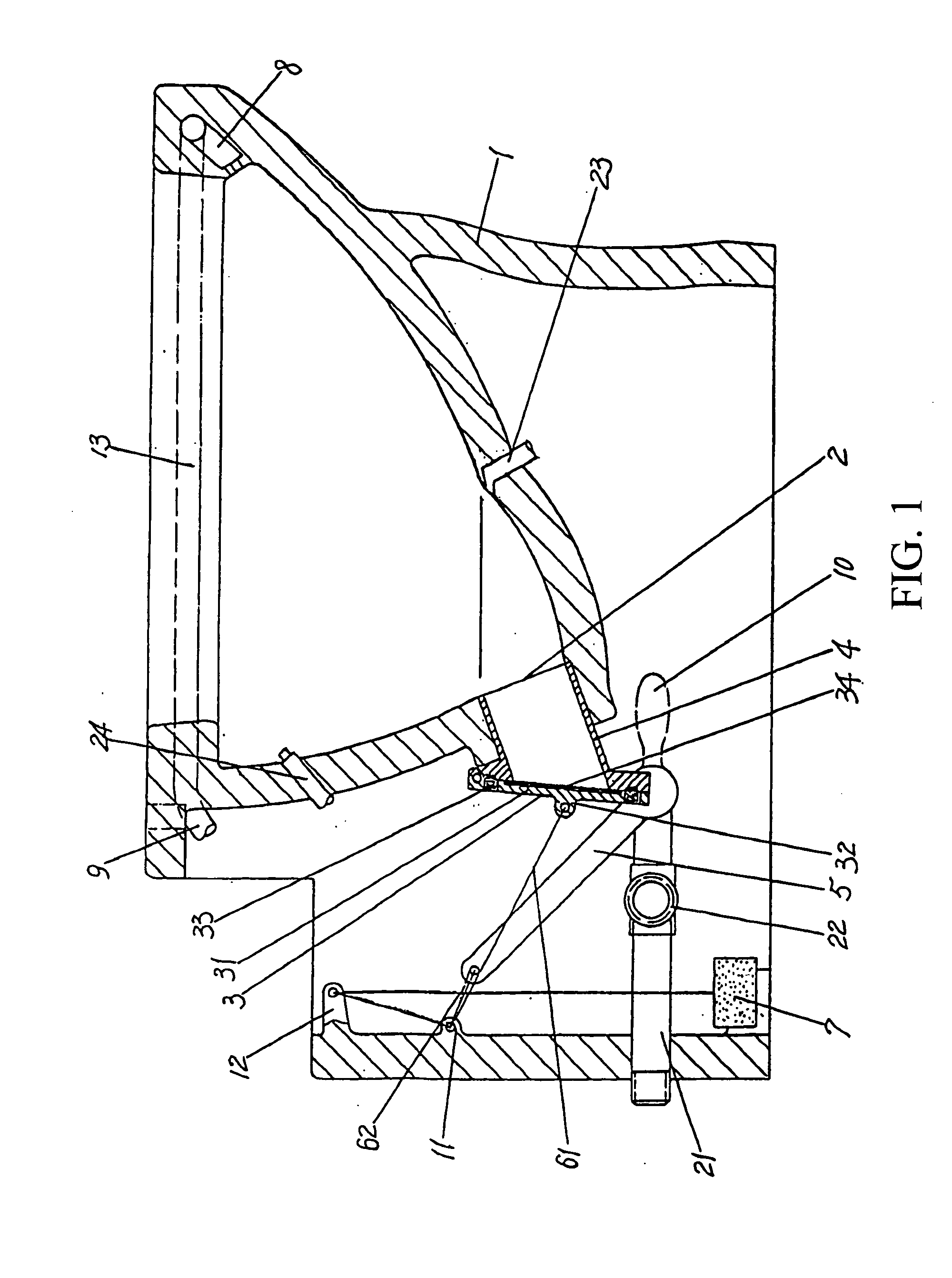

Water-saving flush toilet

This present invention relates to a water-saving flush toilet, comprising a bowl having a seat and a sewage discharge port, a siphon pipe is omitted at the rear of a sewage discharge pipe of the bowl. A discharge seal valve is arranged at the sewage discharge port, the discharge seal valve together with a valve cover are arranged at a valve seat. A water tap handle at the lower of the bowl is provided with a lever, a cord is connected between a handle of the valve cover and a joint of the bowl. Said cord is connected to hang a weight via another joint of the bowl. Another end of the lever is connected to another cord and also connected to said weight via said two joints. The upper of the bowl is arranged with a water channel and a sprinkler head, an open of said water channel connected to the water tap at the lower of the bowl via a connecting plastic tube, water pipes are arranged respectively at the upper and the lower of the bowl without any water tank. A water tank is omitted in this present invention and the cost is lowered as well as increasing the space of the cleaning room. The filling time of water tank in a traditional flush toilet is generally takes for 1 to 5 minutes, while the flushing time for the present water-saving flush toilet is only 2 seconds without the filling of water tank, which obviously saves time in flushing and save in water used.

Owner:CHU HUNGHING

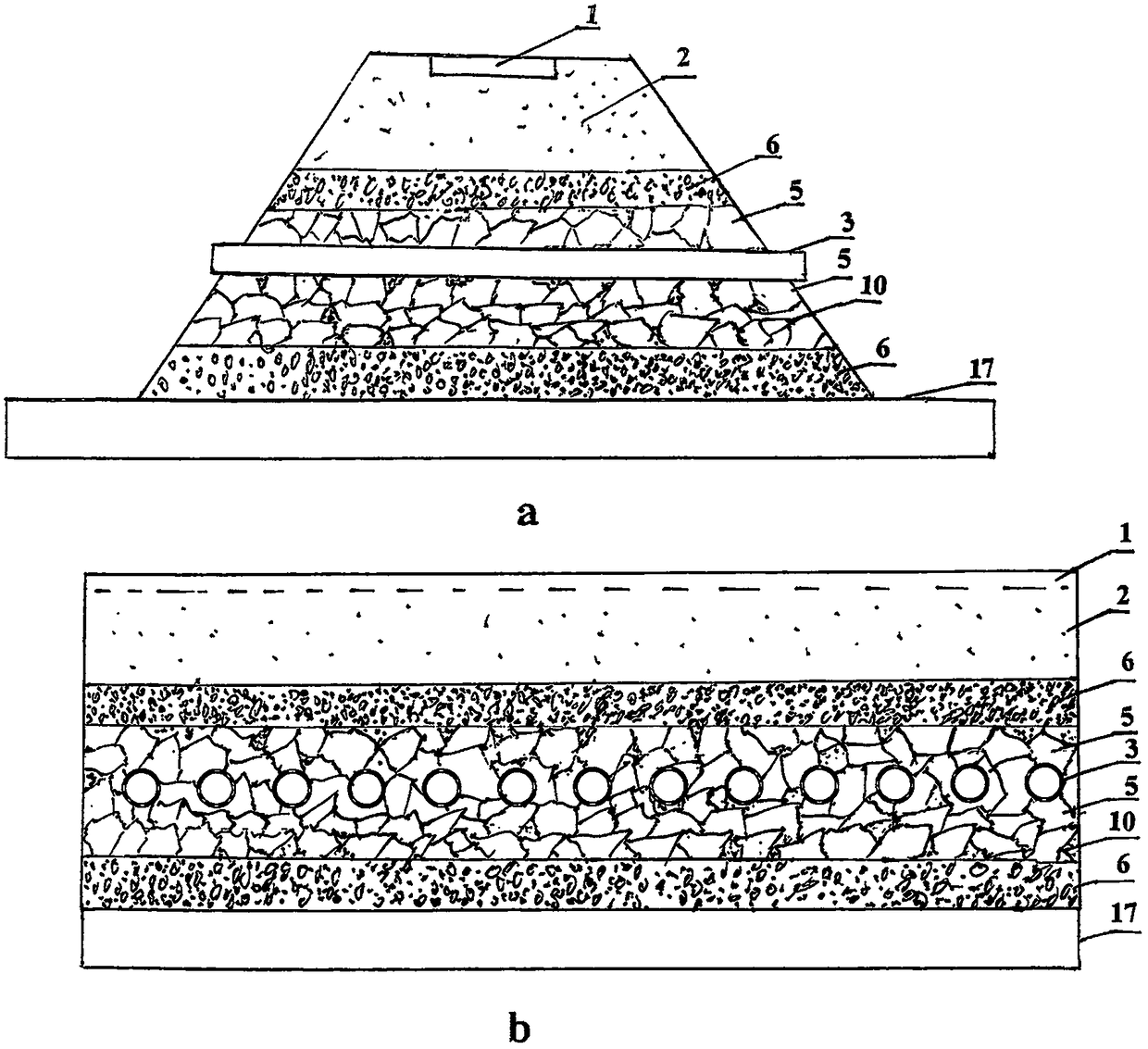

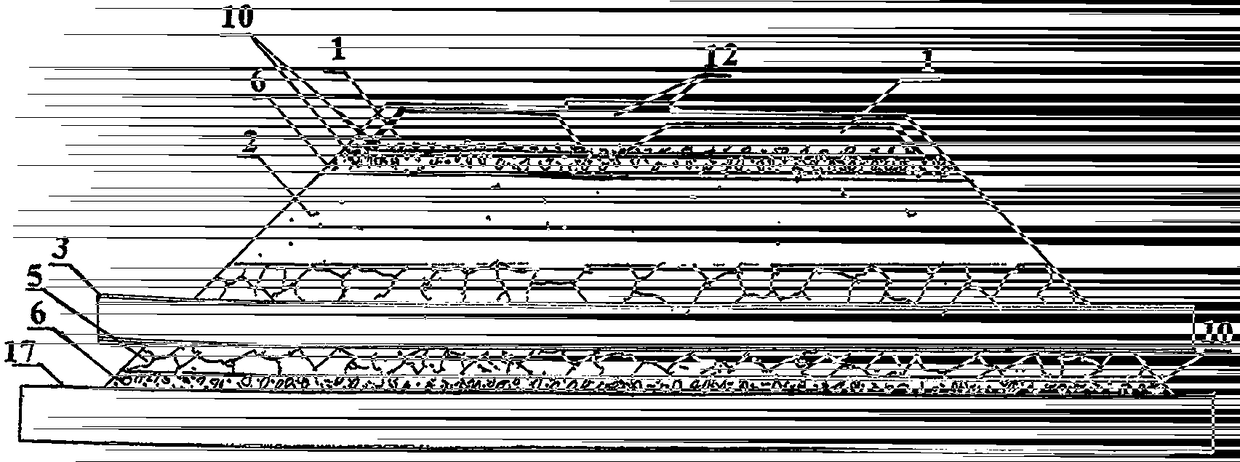

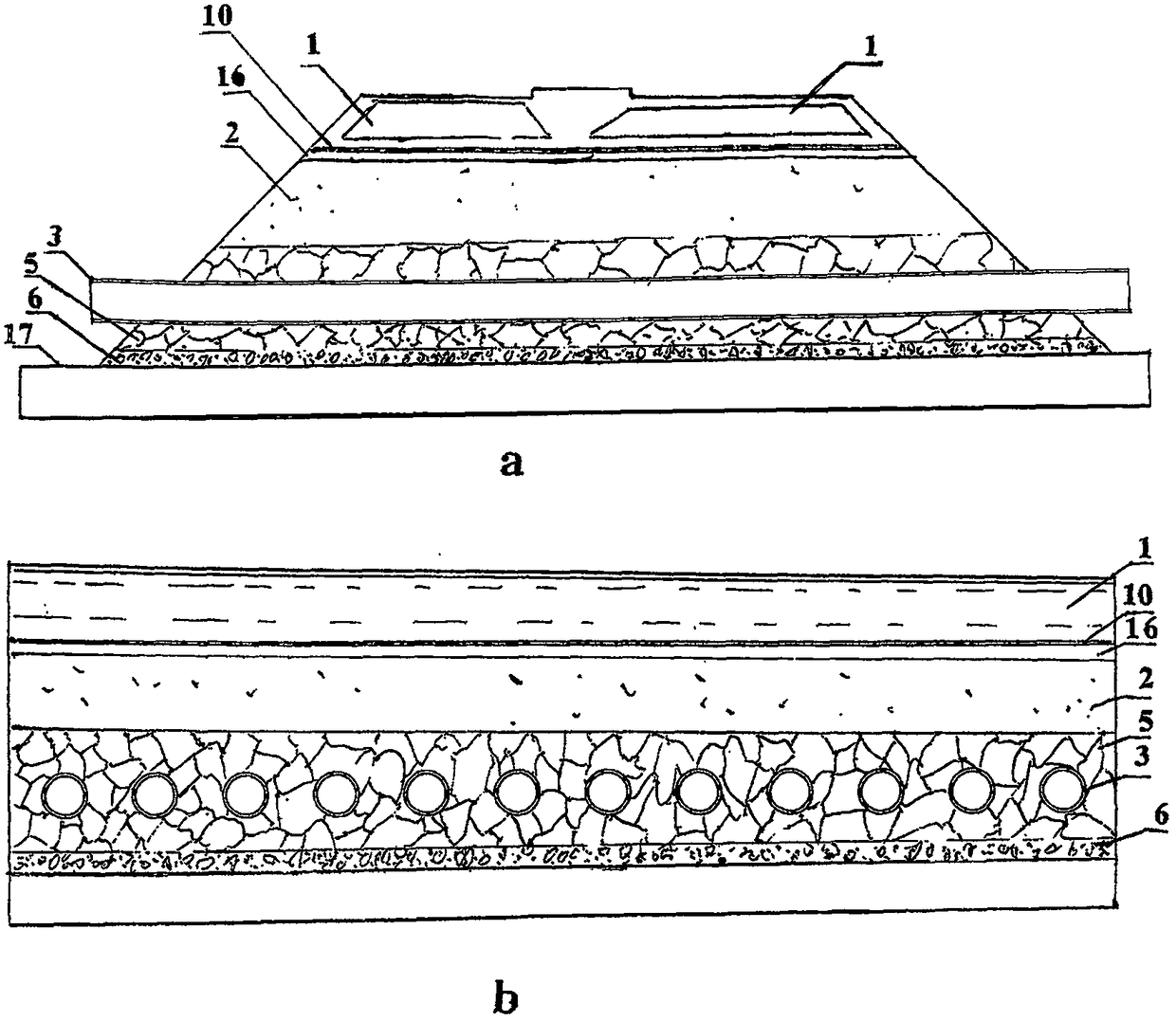

Anti-freezing expansion structural body of roadbed in seasonal frozen soil region and pavement method of structural body

InactiveCN108193575AReduce the temperatureReduce construction costsRoadwaysWeather resistanceAnti freezing

The invention discloses an anti-freezing expansion structural body of a roadbed in a seasonal frozen soil region and a pavement method of the structural body. The anti-freezing expansion structural body is characterized in that the anti-freezing expansion structural body comprises a perforated ventilation pipe, a chimney ventilation pipe, a hole-shaped ventilation plate, a heat insulation and cooling material, a roadbed construction and weather resistant paint. The pavement method comprises the steps of a double cloth isolation method, a chimney ventilation pipe method, a sun-proof and coolingbody method, a hole-shaped ventilation plate method and a coating method. The body is relatively simple and convenient in construction and higher in construction effect. Construction materials are low in cost, strong in weather resistance and long in service life. The body can be widely applied to newly constructed Sichuan-Tibet railway, permafrost railways and seasonal railways and highways, reduces the temperature of the roadbed comprehensively, prolongs a service life of the roadbed, and improves the stability of the roadbed and running safety of trains and automobiles.

Owner:张昆

Semiconductor Laser Device

InactiveUS20070297473A1Efficiently coolPrevent corrosionSolid-state devicesActive medium materialCorrosionSemiconductor

The present invention relates to a semiconductor laser apparatus having a metal body which efficiently cools a semiconductor laser element, in which joining of copper-made members coated with DLC layers and prevention of corrosion in the vicinity of joined portions are possible. The semiconductor laser apparatus has a metal body as a heat sink for cooling the semiconductor laser element. The metal body is constituted by a plurality of copper-made members, and the surfaces of each copper-made members are continuously coated with a diamond carbon layer except for regions corresponding to an exposed region in which the semiconductor laser element is mounted.

Owner:HAMAMATSU PHOTONICS KK

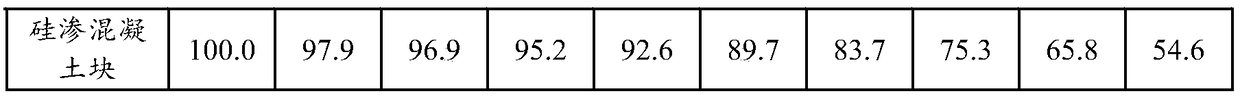

Hair-cracking repairing material for concrete and preparation method and application thereof

The invention provides a hair-cracking repairing material for concrete, and belongs to the technical field of sealing curing agents in the field of building materials. The provided hair-cracking repairing material for the concrete is prepared from, by weight, 20-50 parts of main agent, 0.1-0.4 part of stabilizing agent, 0.5-1.5 parts of dispersing agent, 0.2-0.8 part of curing agent, 0.2-0.8 partof complexing agent, 0.2-0.5 part of antifoaming agent, 0.3-1 part of penetrating agent and 50-70 parts of water, wherein the main agent comprises a mixture of one of sodium silicate and potassium silicate and lithium silicate, and the weight ratio of sodium silicate or potassium silicate to lithium silicate is (0.25-4):1. The provided hair-cracking repairing material for the concrete has the advantages that the curing effect is good, the wear of the concrete can be obviously reduced after the material is applied on the surface of the concrete, micro cracks are closed, etching of water is blocked, the durability of the concrete is improved, and the service life of an airfield runway is prolonged.

Owner:湖南峰航新材料科技有限公司 +1

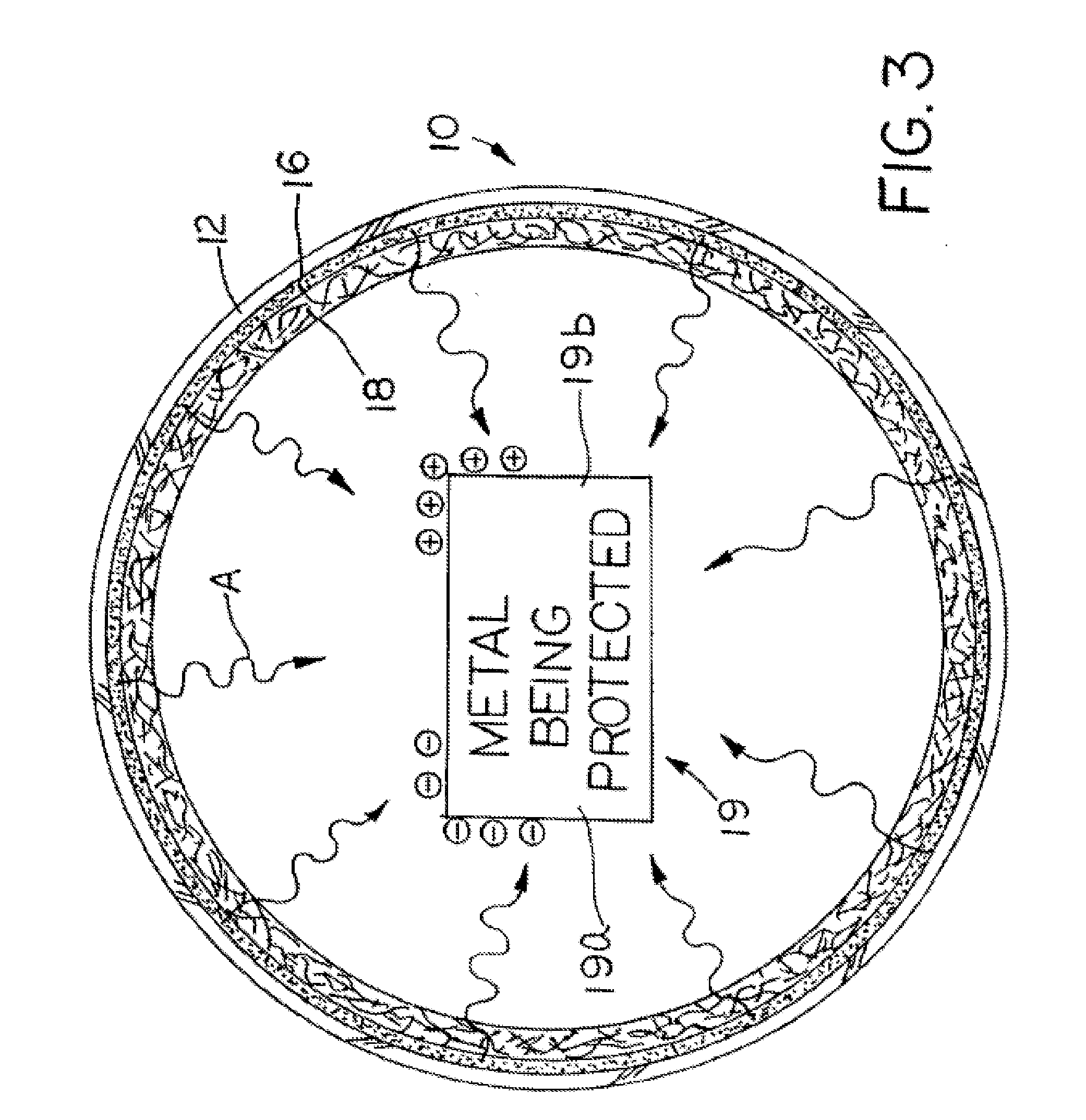

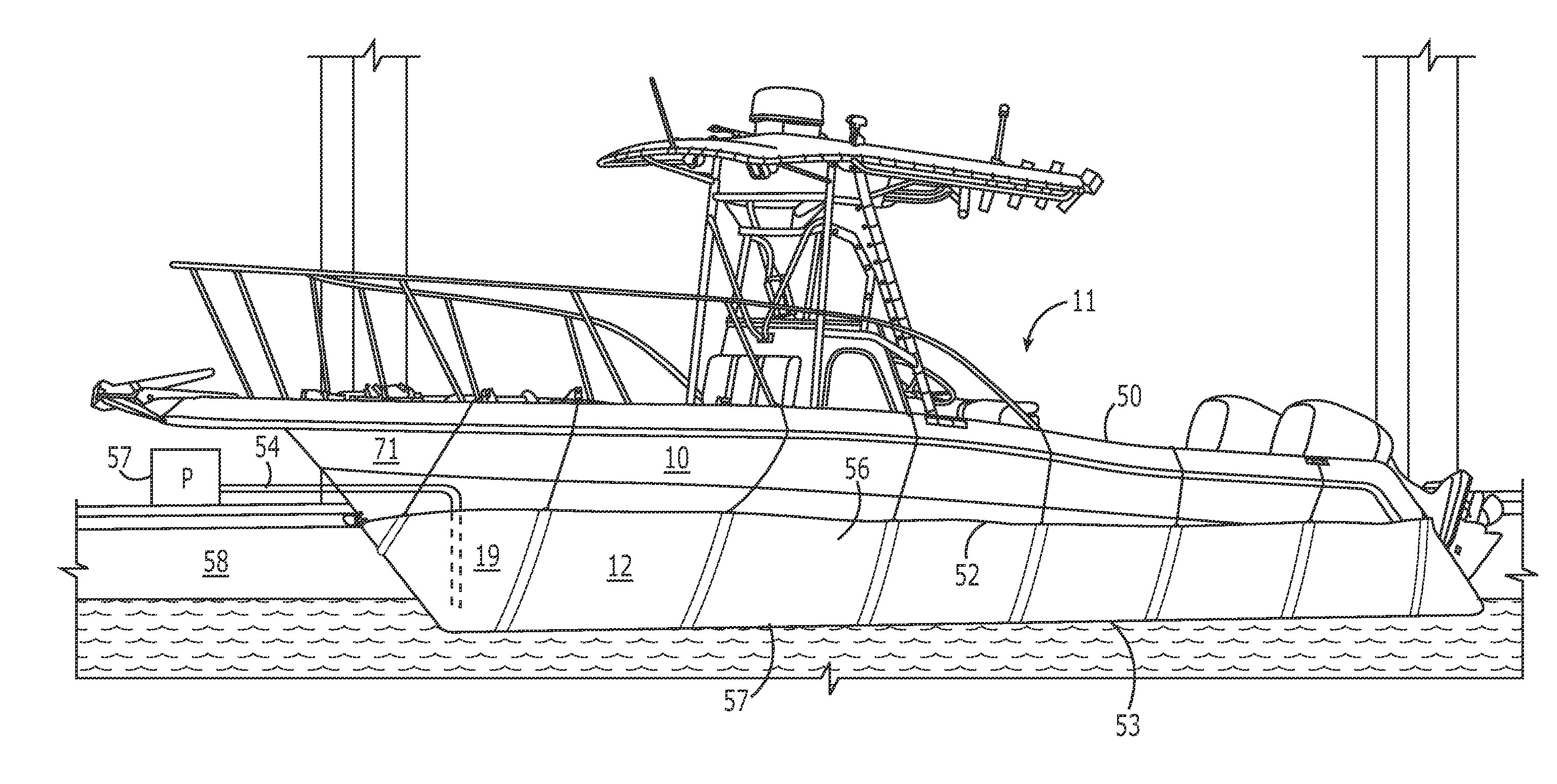

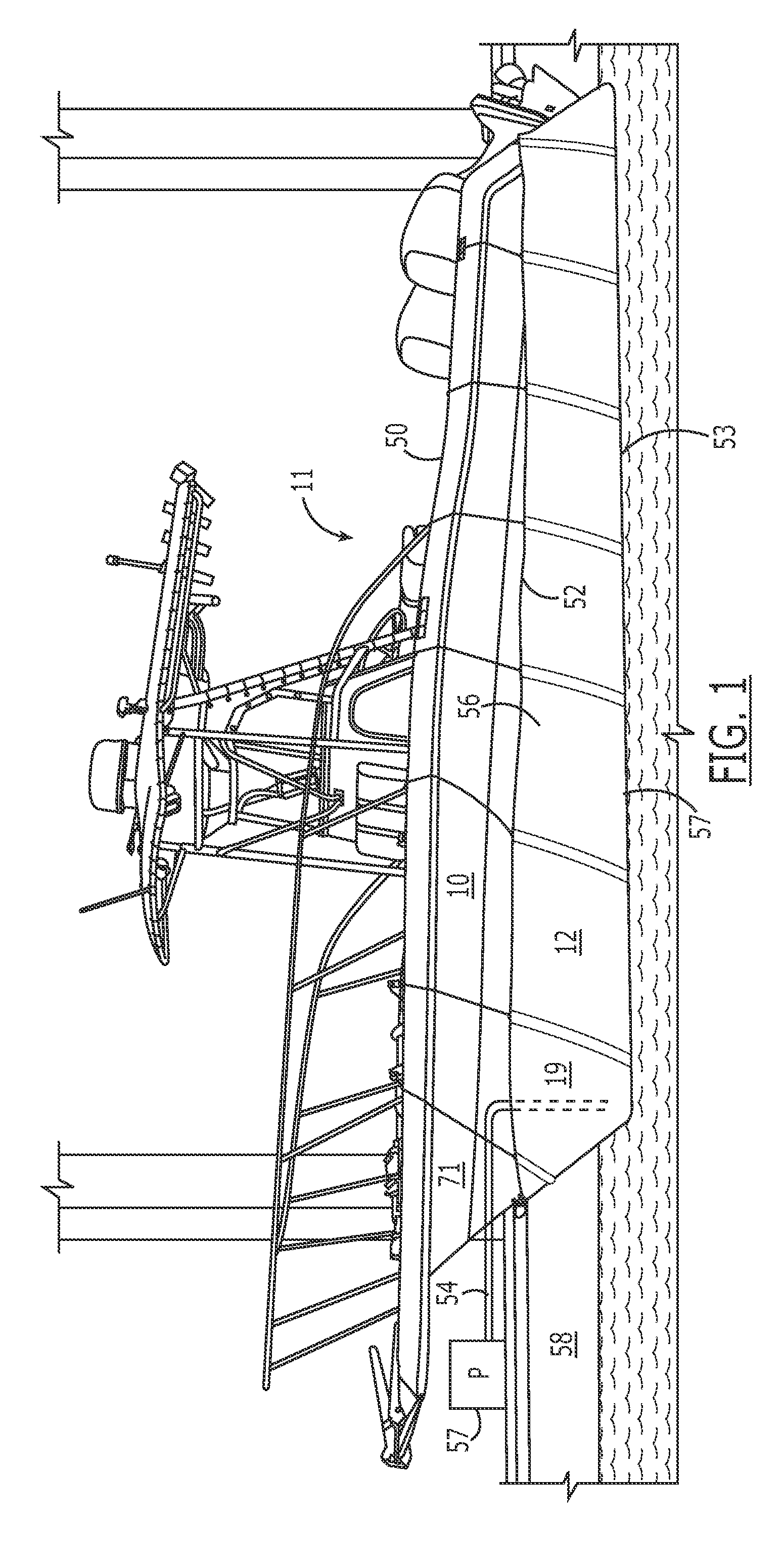

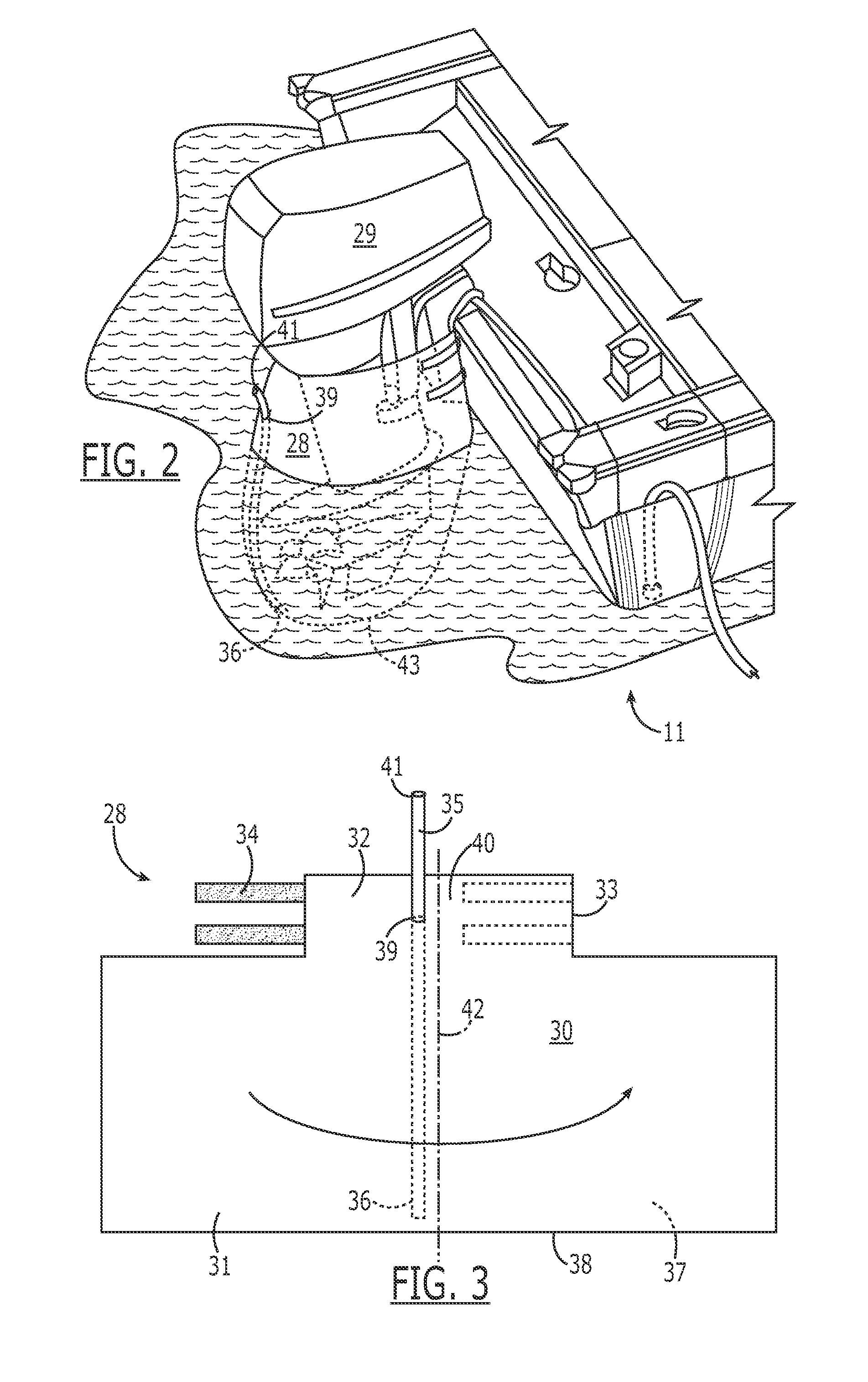

Marine Hull Protective Device and Associated Methods

InactiveUS20100006018A1Prevent corrosionAvoid damageVessel cleaningFlow propertiesPollutantMarine engineering

A device for protecting a hull of a marine vessel includes a cover of water-impermeable material dimensioned to conform to at least a water-contacting portion of a hull of a marine vessel. The cover is removably affixable to the hull, a top edge of the cover extending about the hull in spaced relation above a water line. A drain is positioned so as to lie adjacent a bottom of the hull when the cover is in place on the hull. In use, fresh water is transported into a space between the cover and the hull so as to displace ambient water therefrom. The ambient water can exit the space via the drain, leaving the fresh water within the space as a protective “jacket.” The fresh water serves to prevent galvanic corrosion, pollutant damage, and barnacle encrustation.

Owner:LATHEM MARK C

Cold repairing material for asphalt road surfaces as well as preparation method and application of cold repairing material

InactiveCN104929011AImprove stabilityExtended storage timeIn situ pavingsRoad surfaceMixed materials

The invention discloses a cold repairing material for asphalt road surfaces, as well as a preparation method and application of the cold repairing material. The cold repairing material is the mixture of a cold repairing binder and an aggregate material, wherein the mass ratio of the cold repairing binder to the aggregate material is 4-8:100. The cold repairing material for the asphalt road surfaces relies on the slow release technique of the cold repairing binder, so that the stability of asphalt can be improved, and the cold repairing material can be stored for a longer time; besides, the flexibility of the cold repairing material can be improved, so that the cold repairing material can be applicable under low-temperature weather conditions in winter. The cold repairing material is an oily material, has stable properties, is undissolved in water, and is insensitive to maneuvering impact, static electricity and the like. The components of the formula of the cold repairing material are environment-friendly materials, and do not generate any volatile substances polluting the environment during storage and use, so that the cold repairing material totally conforms to the environmental protection requirements.

Owner:江苏燕宁新材料科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com