Patents

Literature

761results about How to "Short fermentation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

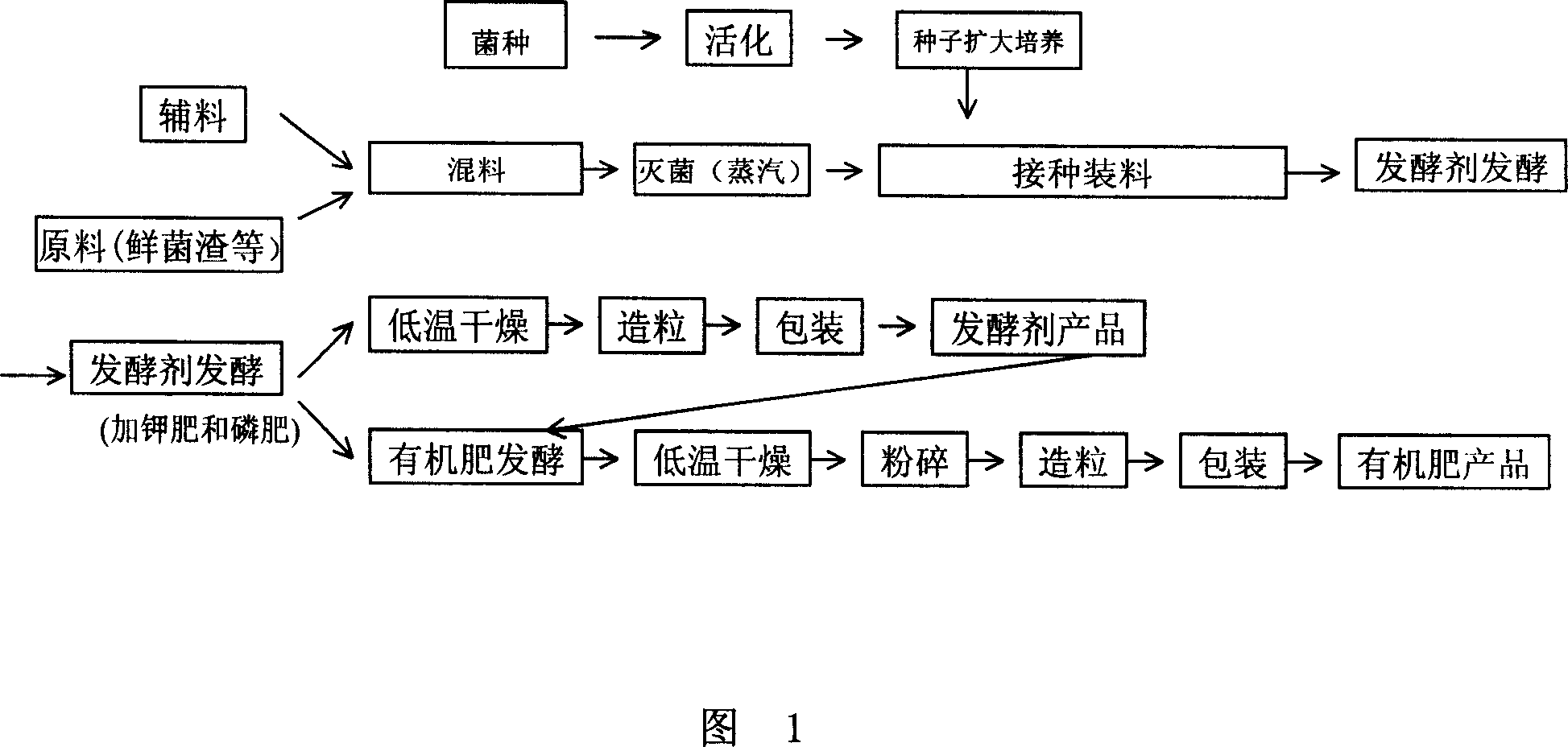

Fertilizer leaven and preparation method and application thereof

InactiveCN101041807ASimple processReduce manufacturing costFungiBacteriaBacillus licheniformisAzotobacter chroococcum

The invention discloses a method to prepare leaven of fertilizer and application, which is characterized by the following: allocating raw material with mass ratio at 10-80 wt industrial residue of ferment, 5-30 wt straw, 5-30 wt cake meal, 10-30 wt bran or rice bran, 1.5-2 wt aquacare, 0.5-1 wt NaCl and or amylaceum, and 1-30 wt brown ball Azotobacter (Azotobacter chroococcum), 1-30 wt bacillus megaterium (Bacillus megaterium), 1-30 wt bacillus licheniformis (Bacillus licheniformis), 1-30 wt plant lactobacillus (Lactobacillus plantarum) and 1-30 wt 1-5 strain of saccharomycopsis fibuligera (Saccharomycopsis fibuligera); producing the product.

Owner:北京世纪发展科技有限公司

Method for making fermented minced or cubed meat by utilizing fermenting agent

InactiveCN103704765AGood colorAdd flavorMeat/fish preservation using chemicalsFood ingredient for microbe protectionBiotechnologyFlavor

The invention provides a method for making fermented minced or cubed meat by utilizing a fermenting agent. The method comprises the steps of minced or cubed meat raw material pretreatment, preserving, fermenting, storing and the like, the above raw material selects cold meat or fresh meat, and a strain comprises one or more of lactic acid bacteria, Debaryomyces hansenii, Micrococcus Kristinae, Micrococcus varians and Staphylococcus xylosus. A fermented product obtained in the invention has the characteristics of fine texture, elasticity, rich and pure fragrance, possessing of the sour fragrance specially possessed by fermented meat products, good mouthfeel and unique flavor, and also has the advantages of high nutrition value, high safety, eating convenience, easy preservation, probiotic effect and the like.

Owner:胡永金

Process method for rapidly fermenting chopped hot peppers

InactiveCN101982104AShort fermentation timeReduce churnClimate change adaptationFood preparationAllium sativumWater content

The invention mainly relates to a process method for rapidly fermenting chopped hot peppers, and mainly relates to the field of food processing application. The process method comprises the following steps: washing, soaking and disinfecting the fresh hoppers; draining and removing the water content on the surface of the fresh hoppers; directly chopping by a chopper mixer; adding 2% of salt, 0.5% of calcium chloride, 0.05% of citric acid; inoculating 0.05% of lactobacillus plantarum, and 0.05% of lactobacillus fermentium cultured in high density, wherein, the number of the lactic acid bacteria is 1010cfu / g and the amount of the ester-producing yeast is over 107cfu / m; fermenting for 48h in a sealing mode at the temperature of 37 DEG C; filtering, wherein, the filter pulp can be used as the strain water of the next batch; adjusting the salt concentration of the filtered and fermented hot peppers according to the different tastes to 8%; adding spices, such as white wine, Liuyang brown bean and garlic and the like; encapsulating after evenly stirring; and pasteurizing to obtain the finished product.

Owner:HUNAN AGRICULTURAL UNIV

Method for producing probiotic feed for animals by fermenting high-fiber agricultural by-products with compound bacteria

A method for producing probiotic feed for animals by fermenting high-fiber agricultural and sideline products with complex bacteria. , and / or 0-1.0% calcium chloride and / or 0-1.0% magnesium sulfate) are mixed in proportion and then steamed with water; after the steaming is completed, cool to 20-40°C and inoculate Neurostria fortis and Lactobacillus plantarum is solid-state fermented at 20-40°C for 2-5 days; the fermented feed is dried at 40°C-70°C and crushed to obtain a probiotic feed product rich in carotenoids. The method has the advantages of high production efficiency, low cost and good benefit, and while solving the problem of environmental pollution, it also relieves the pressure of serious shortage of energy and protein feed sources.

Owner:NANCHANG UNIV

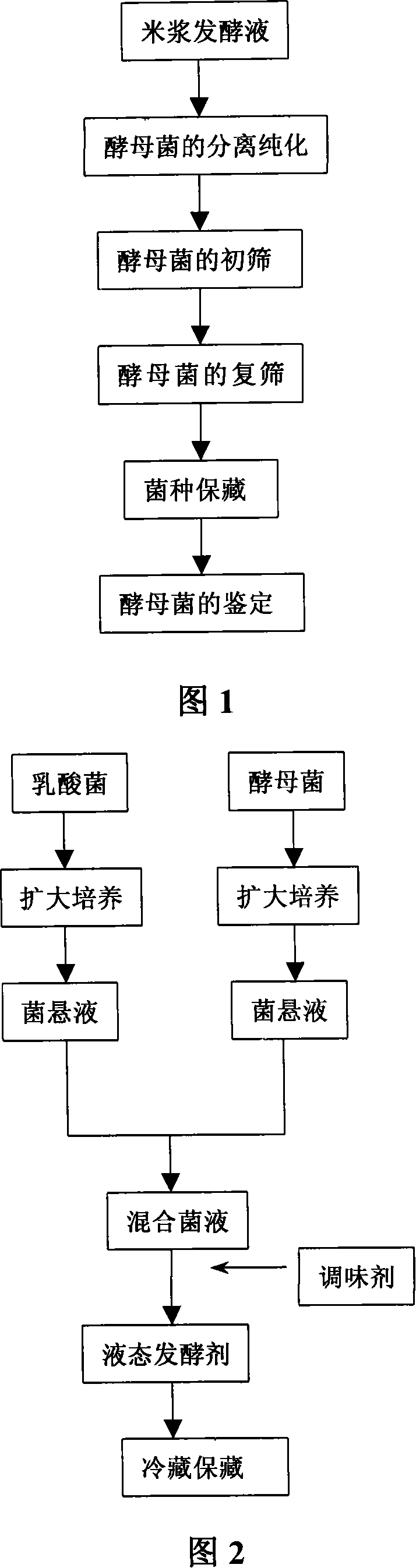

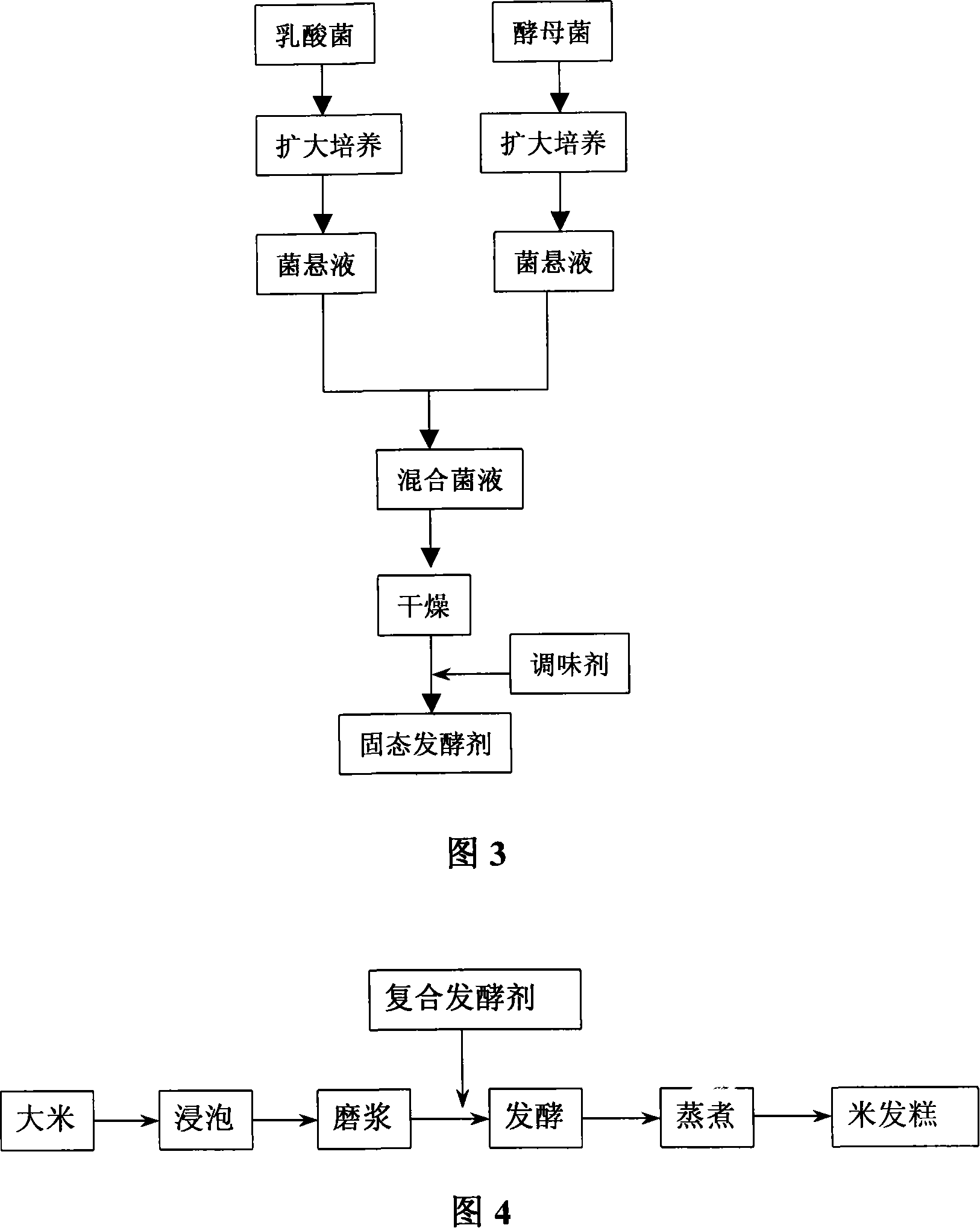

Mycopremna as microorganism leaven, composite leaven containing the mycopremna and application of the same

InactiveCN101173223AShort fermentation timeGood fermentation propertiesFungiMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a strain used as hametz of microorganism, belonging to technical field of processing agricultural microorganism and food, which comprises the strain and the compound hametz ofplant lactocin as well as the application. The invention is characterized in that: the microzyme-Custer bouquet yeast strain can obtain by separating and filtering, which is suitable for fermenting the rice steamed sponge cake; the yeast strain is preserved in Chinese typical culturing and preserving centre and the preserved number is CCTCC NO: M207150. The microorganism compound hametz can be made by the ZSM-001 Custer bouquet yeast strain and AS1.510 plant lactocin (Lactobacillus plantarum), and can be used in rice fermented products, such as rice steamed sponge cakes. The invention has theadvantages of good fermenting performance and easy commercial process, and the products made by the invention have a typical sweet and sour perfume.

Owner:HUAZHONG AGRI UNIV

Sludge composting method

ActiveCN101781131AEasy to getShort fermentation timeBio-organic fraction processingClimate change adaptationEcological environmentSludge compost

The invention provides a sludge composting method, and relates to a sludge treatment method which comprises the steps of preferable accessory selection, CK21 fungus spraying inoculation, heavy metal passivation and powder granulation, and then three-dimensional composite biological organic fertilizer with organic, inorganic and microbial active constituents is obtained. Mushroom compost and pig manure are used as accessories which are easily obtained and degraded, the stacker fermentation time is short, only one time of fermentation is needed, the C / N ratio can be effectively adjusted, and the water content of the sludge is reduced; and the efficient beneficial bio-fungus community CK21 is adopted. The microbial concentration is high, the secretion ability of the enzyme is strong, organic matters can be quickly decomposed so as to prevent the corruption of the organic matters, no odor exists, sludge is used for CK21 inoculation, fermentation starts fast, and the effect is good; and the product is inoculated with the CK21 fungus secondarily so as to further balance and activate nutrients, and the microbial natural reproduction is utilized to realize the is called flower dipping absorbing of the plants to nutrients. The invention has the advantages of optimizing the composting conditions, shortening the composting time, reducing energy consumption of turning, and reducing the damage of the heavy metal on the ecological environment.

Owner:厦门市政环境科技股份有限公司

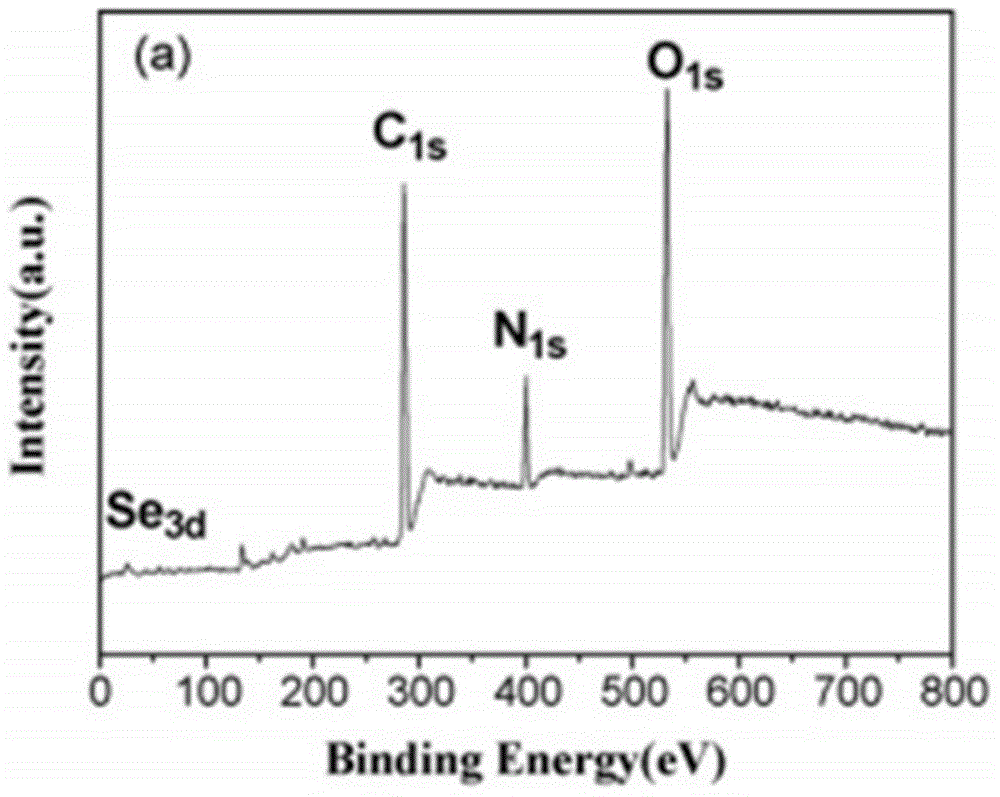

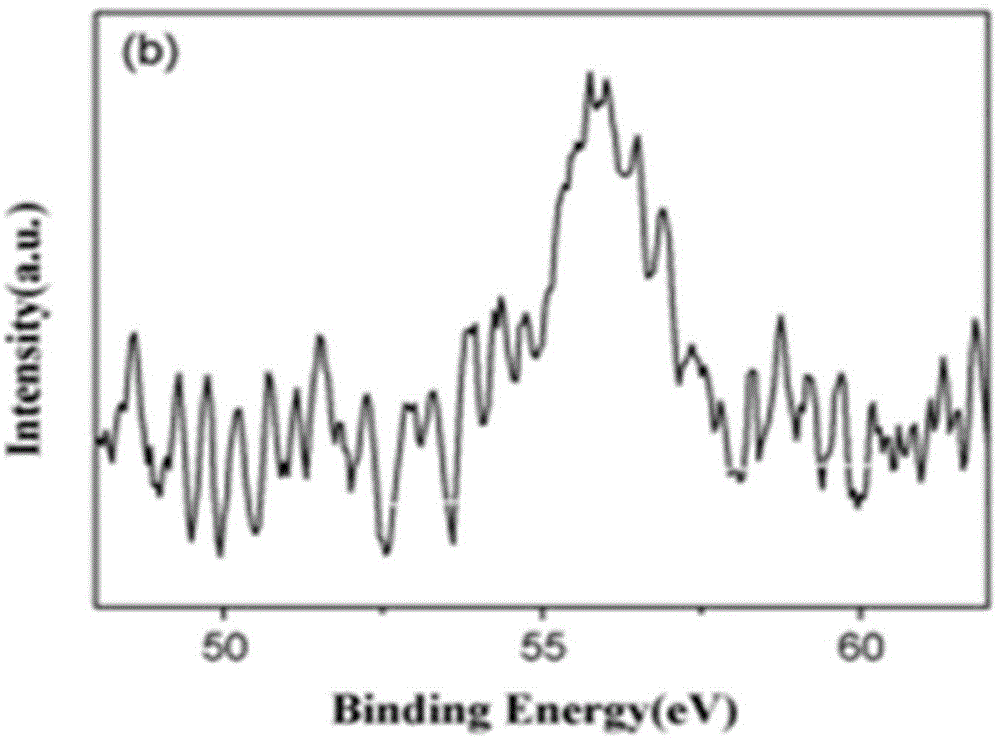

Selenium-rich chitosan nutritional microbial fertilizer and preparation method thereof

InactiveCN104447022AShort fermentation timeImprove efficiencyCalcareous fertilisersMagnesium fertilisersMicrobial agentHydrolysate

The invention relates to a selenium-rich chitosan nutritional microbial fertilizer. The selenium-rich chitosan nutritional microbial fertilizer is prepared from the following raw materials: sodium selenite, chitosan hydrolysate, compound trace elements, monopotassium phosphate, urea, peptone, yeast powder, NaCl, NaOH, NaNO3, NaCl, NH4Cl, K2HPO4, a beef extract, glucose, starch, calcium carbonate, amino acid, potassium nitrate, ferrous sulfate, magnesium sulfate, trisodium citrate, biochemical enzymes and a mixed bacterium liquid. Due to addition of the chitosan, the viable count of a microbial agent can be kept; the efficacy of the chitosan for keeping the viable count is put into an effective play; due to addition of the chitosan, the amount of bacteria of the microbial agent can reach 20,000,000,000 / mL; due to addition of the chitosan to a bacterial manure, the yield of commercial crops can also be increased by 10%-15%; and the nutritional microbial fertilizer has the efficacies of keeping moisture and slowly releasing fertilizer efficiency.

Owner:SHANDONG UNIV

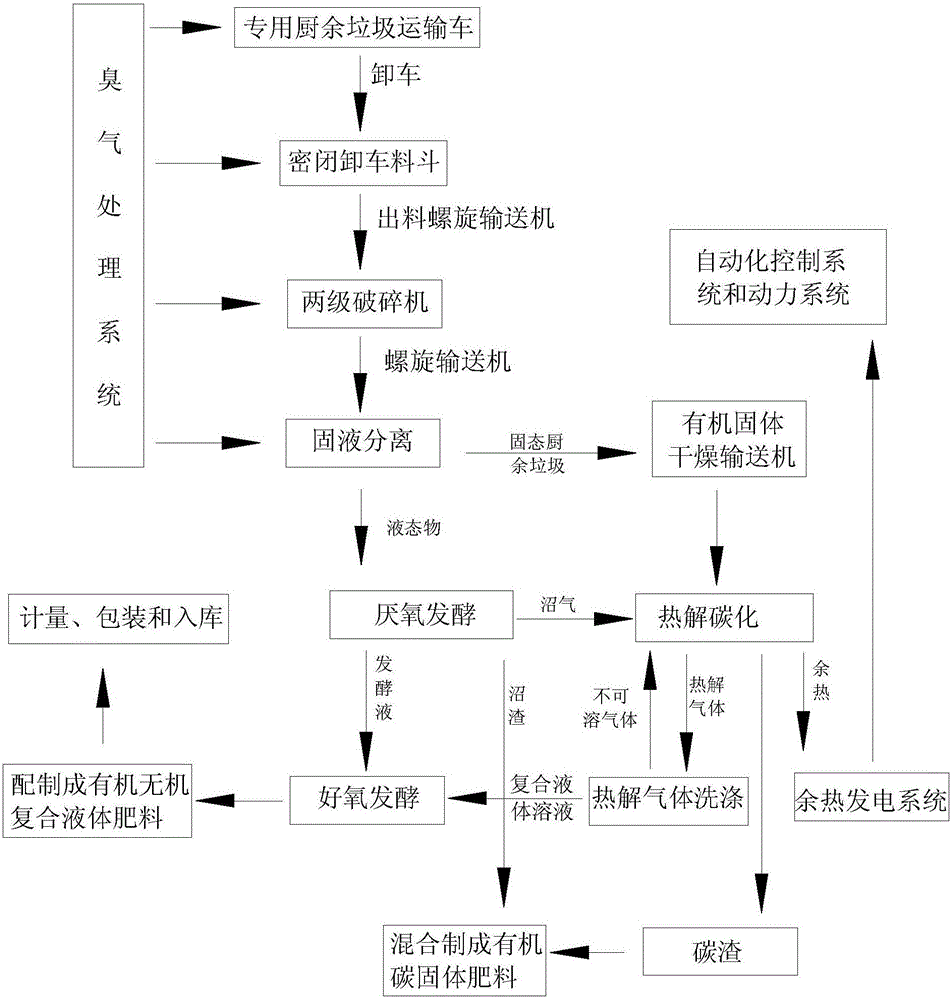

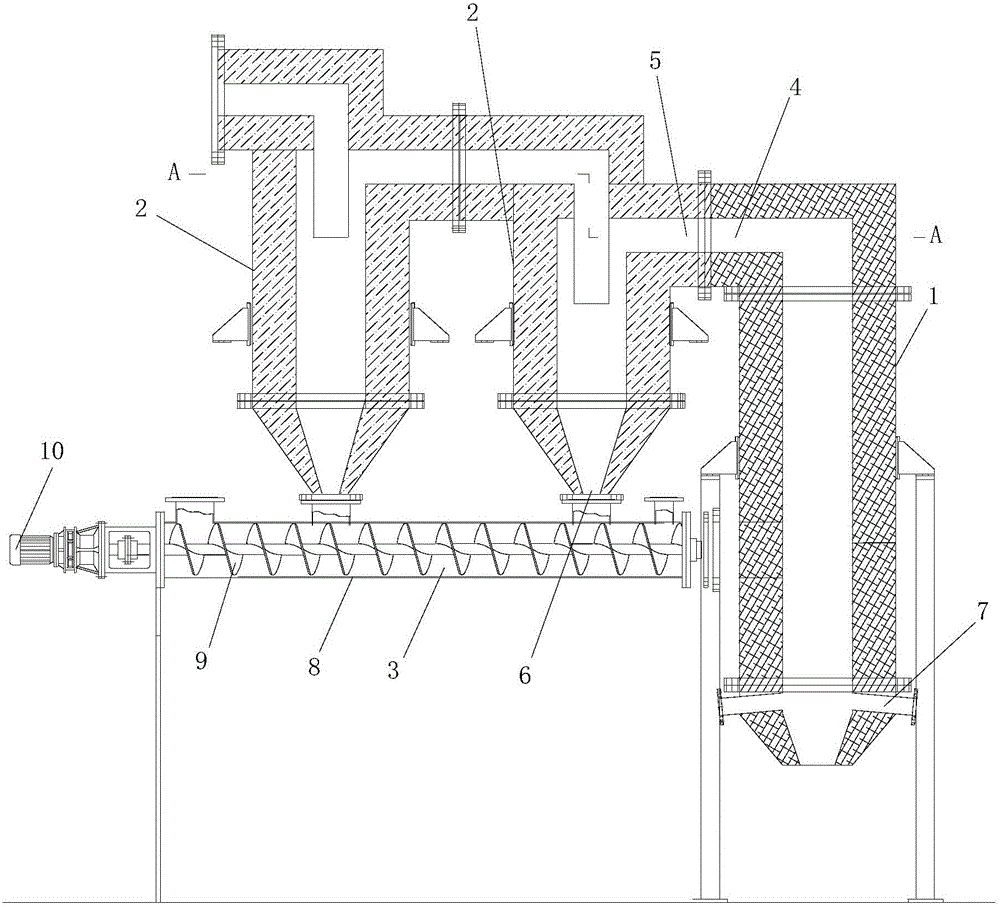

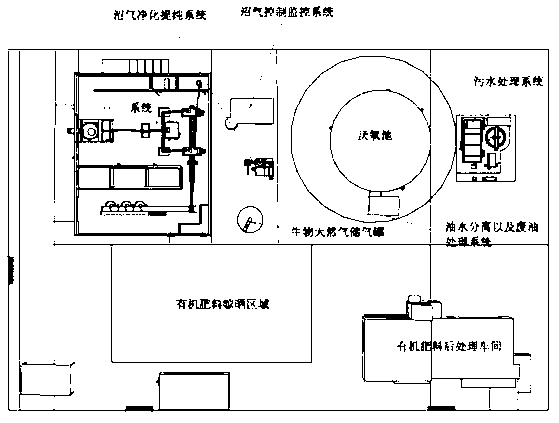

Method and device for preparing fertilizer from kitchen garbage

ActiveCN105060946AImprove efficiencySave spaceBio-organic fraction processingClimate change adaptationLitterOrganic liquids

The invention discloses a method and device for preparing fertilizer from kitchen garbage. The method comprises crushing kitchen garbage, carrying out solid-liquid separation, carrying out pyrolysis carbonization on the separated solid kitchen garbage to obtain pyrolysis gas and carbon residue, washing the pyrolysis gas, carrying out anaerobic fermentation on the separated liquid to obtain a broth, biogas residue and biogas, carrying out aerobic fermentation on the broth, then preparing organic-inorganic composite liquid fertilizer from the obtained liquid, mixing the biogas residue and the biogas residue obtained by the pyrolysis carbonization, adding composite microbe engineering bacteria into the mixture, and carrying out solid state fermentation to obtain the organic carbon solid fertilizer. The method and device respectively carry out resourceful treatment on the solid kitchen garbage and the organic liquid, the organic liquid is treated by a biotechnology so that the organic-inorganic composite liquid fertilizer is produced, and solid kitchen garbage is subjected to pyrolysis carbonization so that energy and biochar are produced.

Owner:GUANGZHOU YINGHAO ENVIRONMENTAL PROTECTION TECH CO LTD

Microbial decomposition agent for animal wastes and straws and preparation method thereof

InactiveCN105296394AFunction increaseHigh content of functional bacteriaFungiBacteriaDecompositionTrichoderma sp.

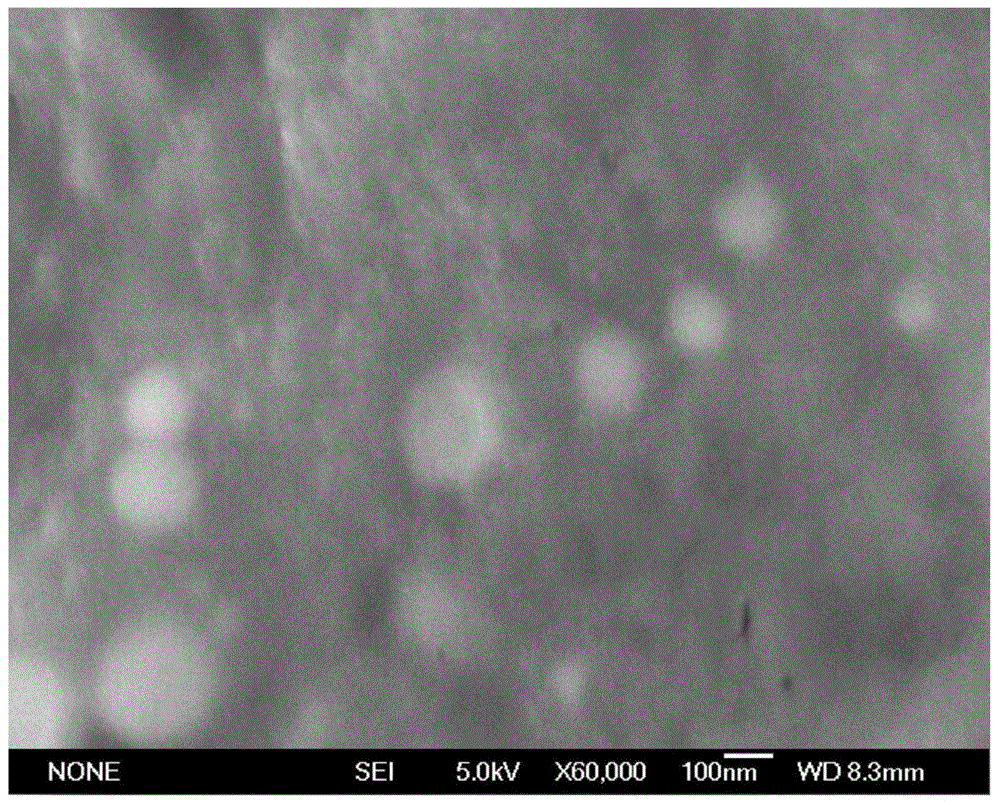

The invention discloses a microbial decomposition agent for animal wastes and straws and a preparation method thereof. The microbial decomposition agent comprises the following strains in parts by weight: bacillus, saccharomycetes, Aspergillus niger, Aspergillus oryzae, trichoderma sp, lactic acid bacteria, photosynthetic bacteria and actinomycetes. The decomposition agent has diversified functions, can be simultaneously used for composting straws and / or animal wastes, contains multiple functional bacteria and is high in microbe activity, the selected strains achieve a synergistic effect, do not generate antagonism, and the decomposition agent has the advantages of fast temperature rise and high temperature of fermented materials, complete decomposition, short decomposition time and the like. The preparation method of the microbial decomposition agent disclosed by the invention has the advantages of simplicity, feasibility, simple operation and low production cost.

Owner:广西多得乐生物科技有限公司

Selenium-enriched microorganism preparation prepared from fermentation of mixed bacterium liquid and preparation method of selenium-enriched microorganism preparation

InactiveCN104447021AImprove efficiencyShort fermentation timeCalcareous fertilisersMagnesium fertilisersMetaboliteMonopotassium phosphate

The invention discloses a selenium-enriched microorganism preparation prepared from fermentation of a mixed bacterium liquid. The selenium-enriched microorganism preparation consists of the following raw materials: sodium selenite, complex trace elements, monopotassium phosphate, urine, peptone powder, NaCl, NaOH, NaNO3, NaCl, NH4Cl, K2HPO4, a beef extract, glucose, starch, calcium carbonate, amino acid, potassium nitride, ferrous sulfate, magnesium sulfate, trisodium citrate, a biochemical enzyme and a mixed bacterium liquid; and the mixed bacterium liquid is a mixed liquid of the bacterium liquid of bacillus amyloliquefaciens, the bacterium liquid of bacillus subtilis, the bacterium liquid of bacillus licheniformis, the bacterium liquid of bacillus thuringiensis and the bacterium liquid of bacillus mucilaginosus. The mixed bacterium liquid applicable to the selenium-enriched microorganism preparation disclosed by the invention is conducive to microorganisms in soil, and can be used for increasing the quantity of the microorganisms in the soil and enhancing the activity of the microorganisms in the soil. Due to vital activity and metabolite, the strain is an agricultural product which can cause special fertilizer effect, growth regulating effect, effect of prevention and control of plant diseases and pests, soil bioremediation and the like to crops.

Owner:SHANDONG UNIV

Method for making fermenting bed for ecological pig breeding by using composite strain culture

InactiveCN101565684AShort degradation cycleStrong bacterial activityFungiBacteriaMicroorganismStart time

The invention discloses a method for making a fermenting bed for ecological pig breeding by using composite strain culture, in particular relates to a method for making the fermenting bed by using a plurality of microorganisms. The invention comprises the steps of preparing the culture and making the fermenting bed. In the invention, the culture is mainly prepared by microzyme, lactobacillus, actinomycetes, photosynthetic bacterium and mycelial fungus according to proportion. The culture after being activated is stirred uniformly with organic padding pro rata, piled, fermented, prepared into the fermenting bed, and then can be used for breeding live pigs. The method solves the problems of long fermenting starting time of the organic padding, unstable microbial inoculum, strict requirements on the fermenting conditions and materials as well as short service life in the existing ecological pig breeding method. The method uses the composite strain culture to build ecological colony house; the fermenting starting time of the organic padding is short, which can be 1 to 2 days in summer and 3 to 5 days in winter; the strain activity is strong; the decomposing process can be finished in 1 to 3 days; the effect lasts for long; and the fermenting bed can be continuously used for 5 to 8 years. Moreover, the method is green and environmental friendly.

Owner:千智伟

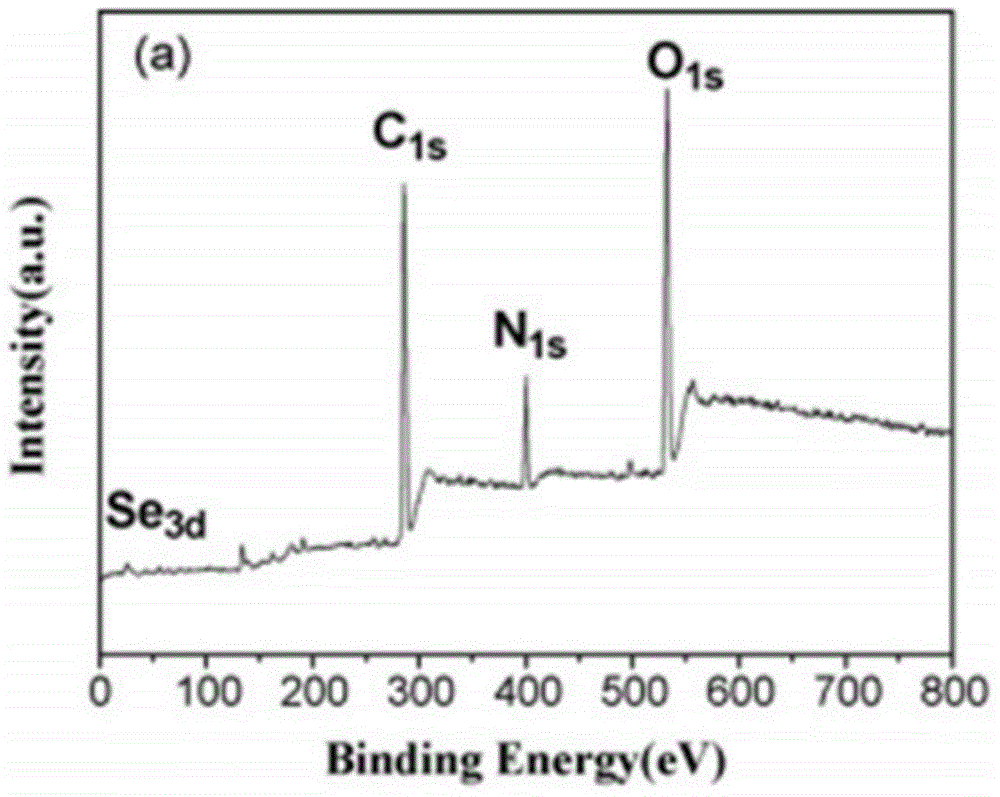

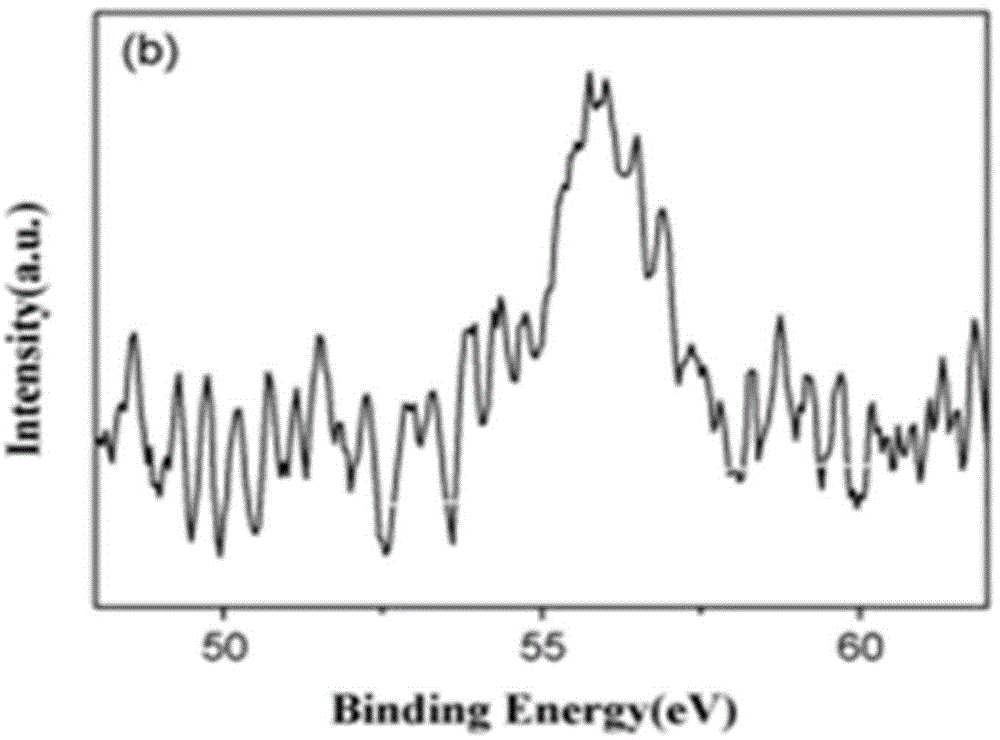

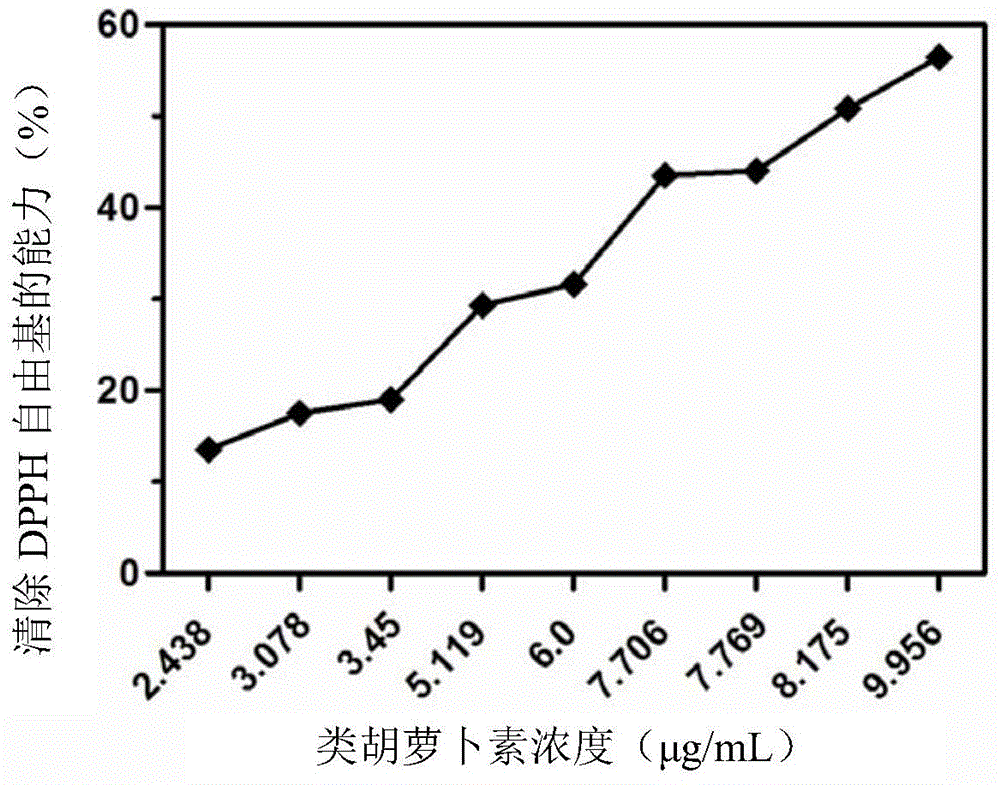

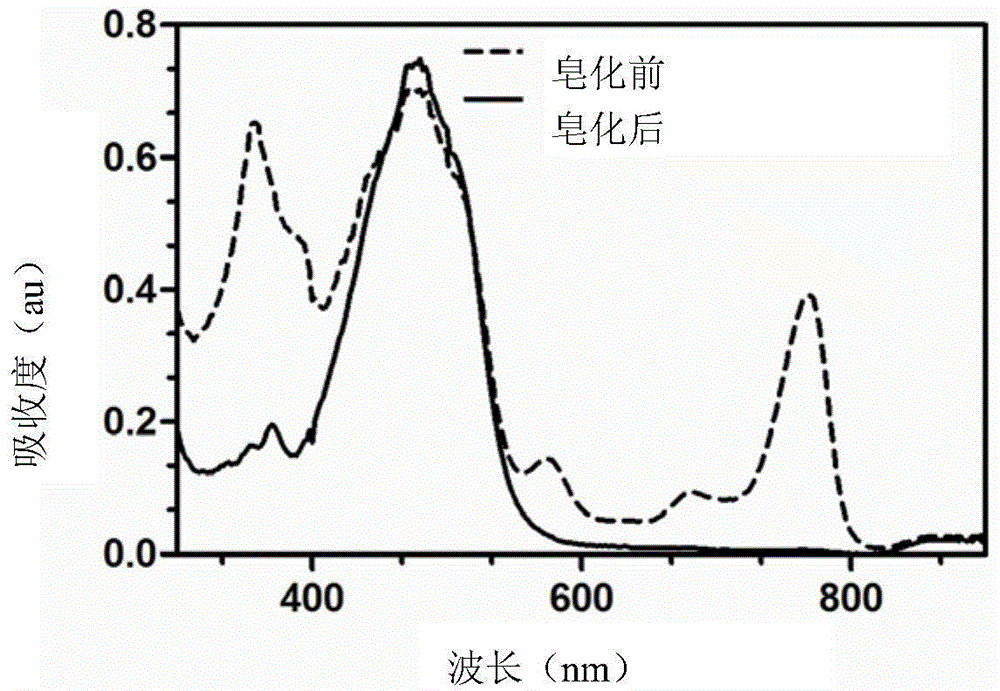

Method for quickly producing carotenoid by utilizing microaerobic fermentation of rhodobacter sphaeroides

ActiveCN104805168AIncrease production capacityShort fermentation timeMicroorganism based processesFermentationDPPHFermentation

The invention discloses a method for quickly producing carotenoid by utilizing microaerobic fermentation of rhodobacter sphaeroides. The method comprises the following particular steps that the activated rhodobacter sphaeroides is inoculated to an MMS (methylmercuric sulfate) culture medium; aerobic culture is performed until OD600 (optical density 600) is 0.6-0.8; a culture condition is adjusted to be microaerobic; the carotenoid is induced to be quickly and greatly synthesized; and then extraction and purification are performed. The time for producing the carotenoid by the method is short and only 36h; the yield of thallus is up to 6g / L; the yield and the productivity of the carotenoid are 8.287mg / L and 1911mug / g respectively; the carotenoid has good capacity for removing DPPH (1,1-diphenyl-2-picryl-hydrazyl) radicals; and IC50 (half maximal inhibitory concentration) is about 8mug / mL.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

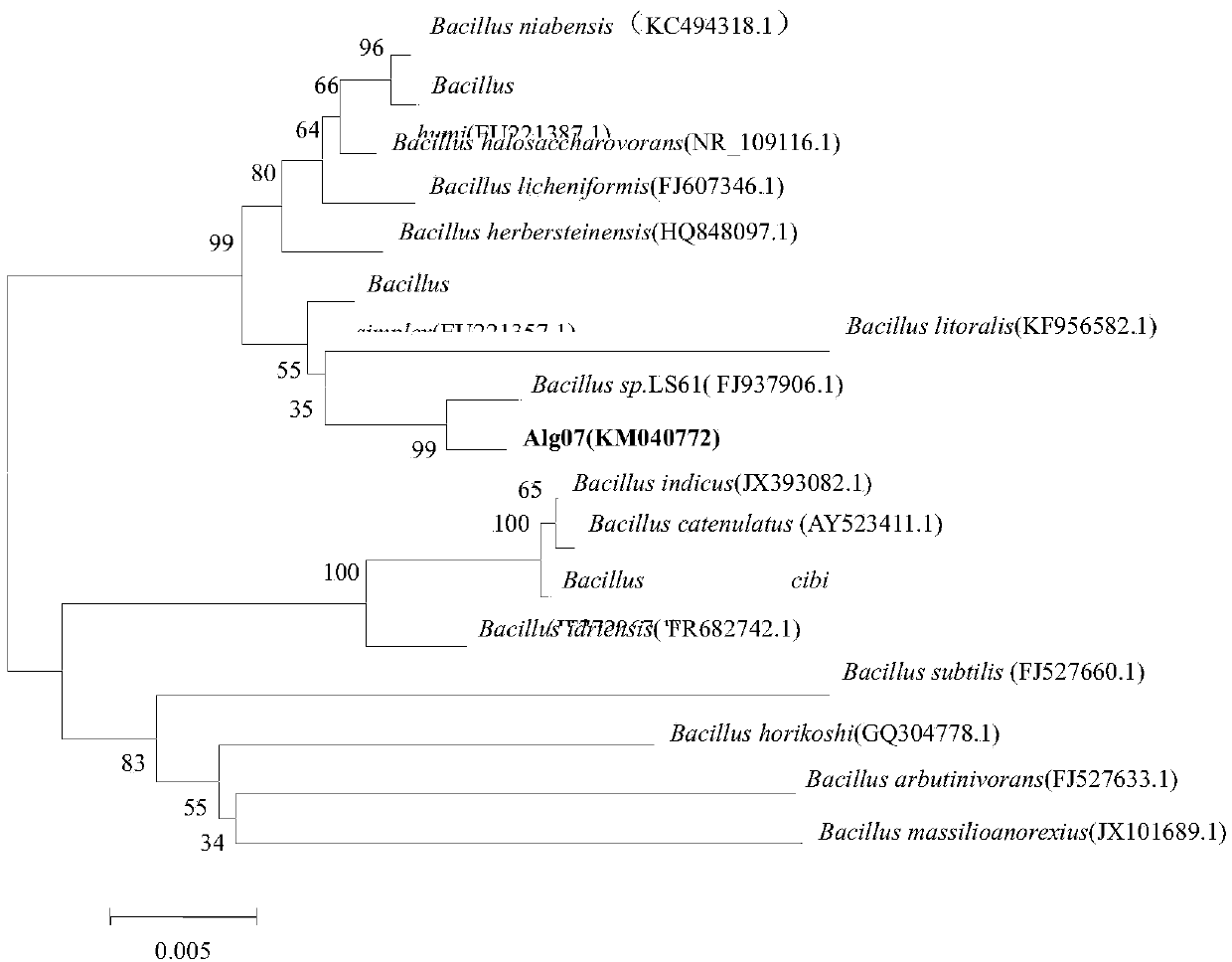

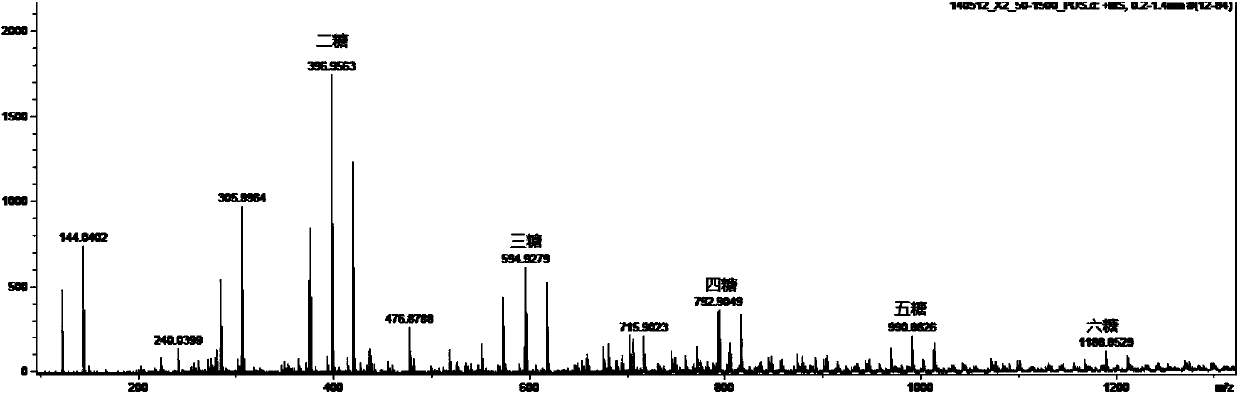

Bacillus sp capable of producing alginate lyase and application thereof

ActiveCN104195080AIncrease enzyme activitySimple nutritional requirementsBacteriaMicroorganism based processesSpecific enzymeAlginate lyase

The invention provides Bacillus sp Alg07 capable of producing an alginate lyase. The preservation number of the Bacillus sp Alg07 is CGMCC No.9391. The Bacillus sp Alg07 provided by the invention has the advantages that requirement on nutrition is low and fermentation time is short; a crude enzyme is easily prepared, and the crude enzyme can be obtained through centrifugation; the alginate lyase produced by the Bacillus sp Alg07 has high enzyme activity, the specific enzyme activity of an unpurified crude enzyme can reach 20000-40000 U / mg (563U / mL); the alginate lyase produced by the Bacillus sp Alg07 has good stability, is not obviously changed in enzyme activity after being preserved at 40 DEG C for 24 hours and is high and stable in enzyme activity at pH of 5.5-8.5; and the produced alginate lyase is capable of degrading sodium alginate to generate alginate-derived oligosaccharide with biological activity.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

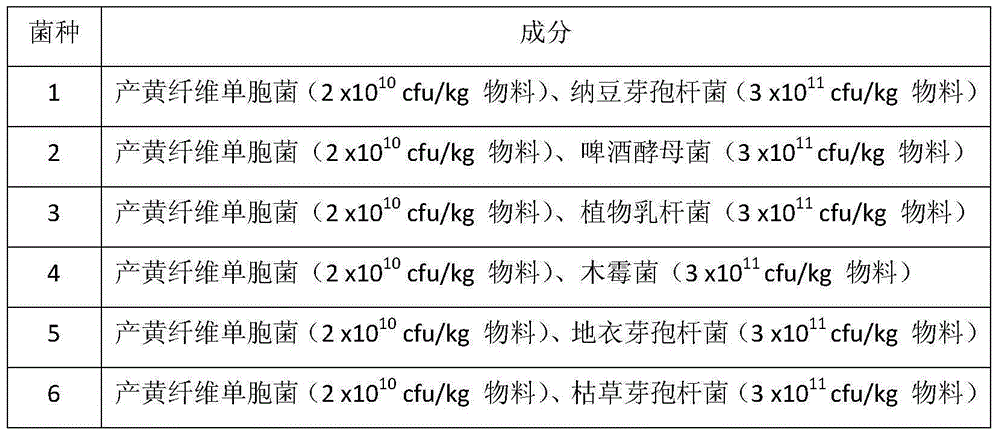

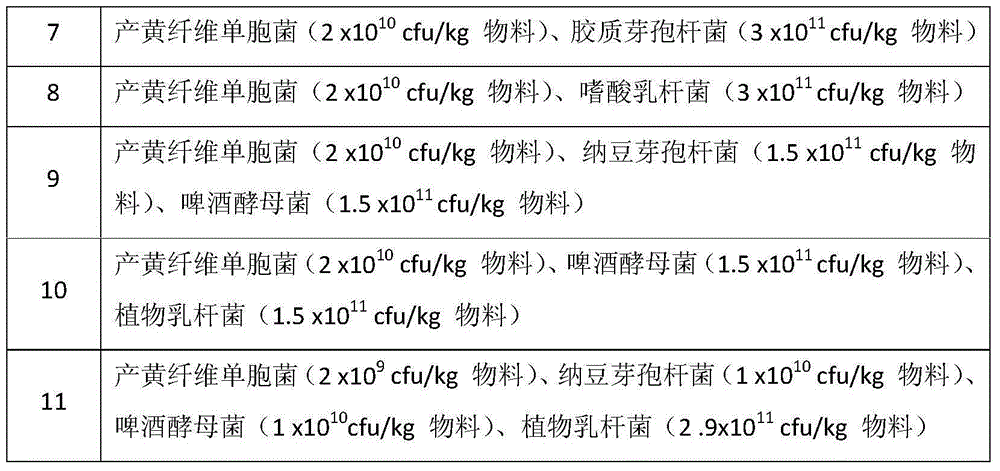

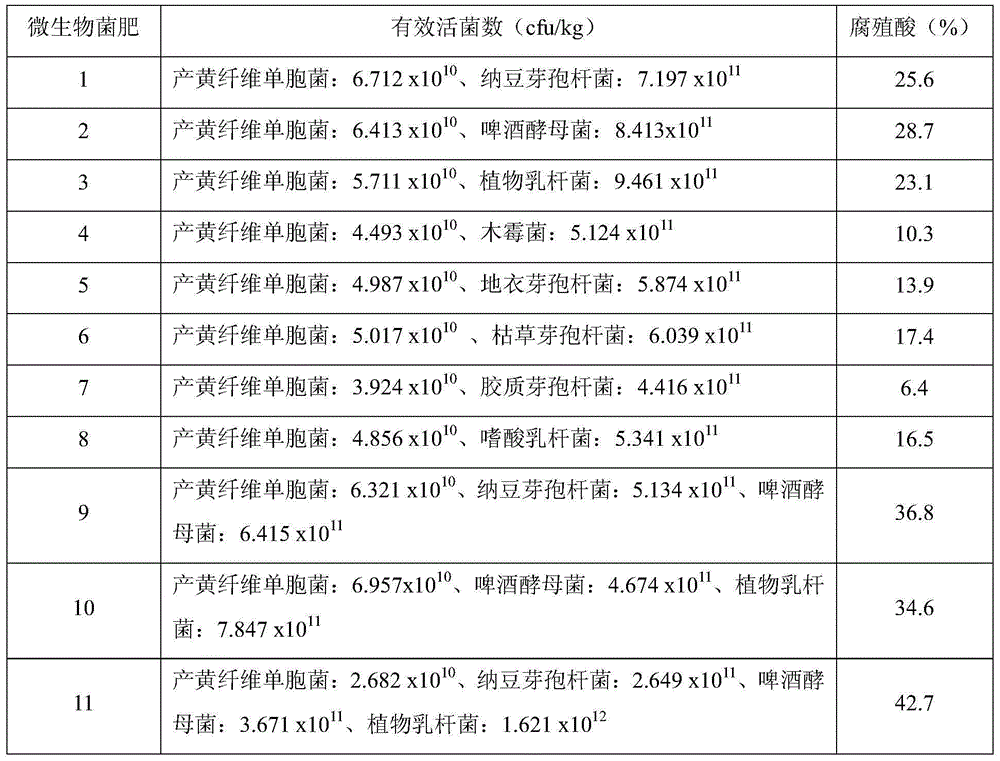

Microbial fertilizer manufacturing method, prepared microbial fertilizer and compound microorganism preparation

The invention provides a microbial fertilizer manufacturing method. Antibiotic fungus residue serves as a base material, and compound microorganisms are adopted to perform solid fermentation on materials, wherein the materials comprise waste rich in plant fiber and the antibiotic fungus residue. The compound microorganisms comprise cellulose decomposition bacteria and one or more of bacillus natto, saccharomyces cereviseae and lactobacillus plantarum. According to the microbial fertilizer manufacturing method, the problem that it is difficult to treat the fermented antibiotic fungus residue in a pharmaceutical factory at present can be solved. Furthermore, beneficial ingredients in the antibiotic fungus residue are can be utilized and converted into a microbial fertilizer, so as to solve the problem that at present, the soil hardening occurs and the fertility declines.

Owner:嘉兴市中正置业有限公司

Organic solid waste regeneration resource treatment method and apparatus system thereof

ActiveCN102921711AReduce moistureReduce salt contentBio-organic fraction processingSolid waste disposalEnvironmental engineeringEnergy supply

The invention provides an organic solid waste regeneration resource treatment method, which has a subcritical hydrolysis process and an anaerobic fermentation process, wherein the anaerobic fermentation process supplies energy for the subcritical hydrolysis process, and the subcritical hydrolysis process is an end treatment process, and comprises treatment of biogas residues generated by anaerobic fermentation. With the organic solid waste treatment method and the apparatus system thereof, energy self-circulation within the system can be achieved, wherein biogas generated by the anaerobic fermentation system is adopted as energy supply of the subcritical hydrolysis system, and the biogas residues generated by anaerobic fermentation can be treated into a fertilizer by the subcritical hydrolysis system, such that problems in the prior art are solved, energy consumption is substantially reduced, and environmental protection and pollution reduction are easily achieved, wherein the problems in the prior art comprise that: the biogas residues generated by anaerobic fermentation do not have a discharging way, and the subcritical hydrolysis system requires the external function.

Owner:国环电气科技(上海)有限公司

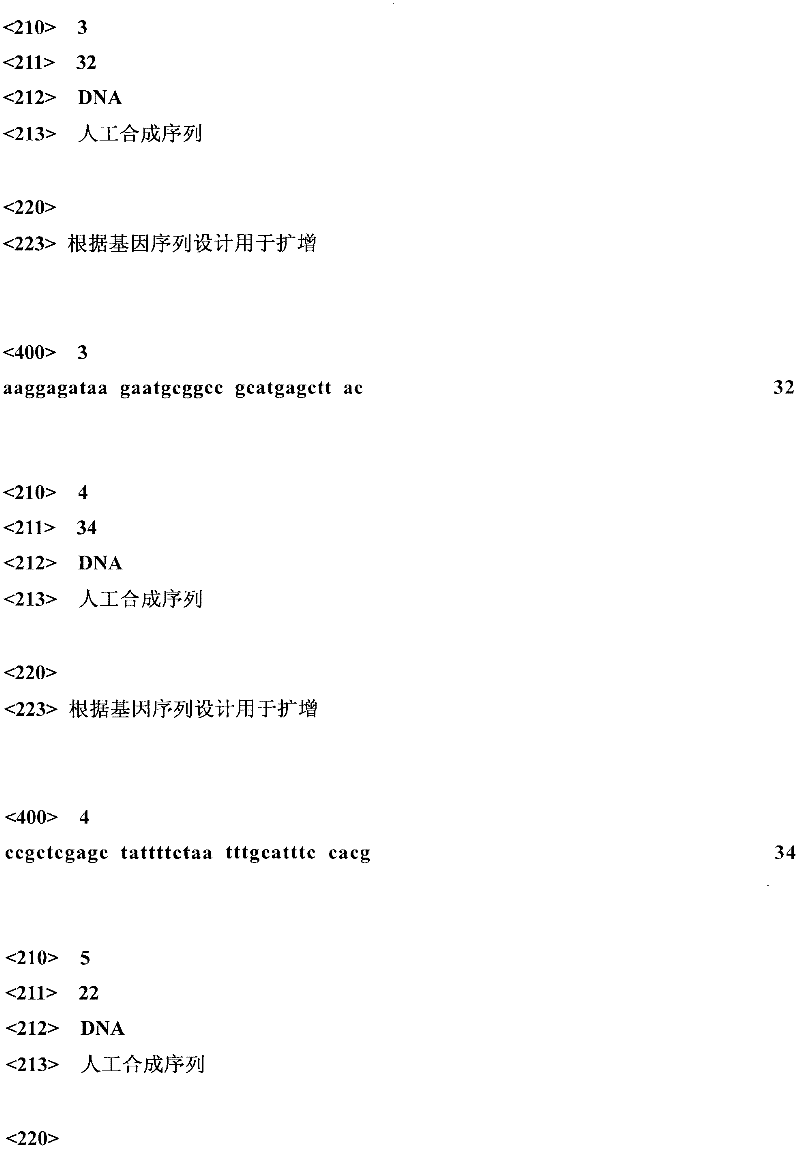

A high-yielding glucosamine engineering bacterium and its construction method through homologous recombination knockout nage

ActiveCN102268399AShort fermentation timeNo allergic reactionBacteriaMicroorganism based processesEscherichia coliHypersensitive response

The invention discloses a high-yield glucosamine gene engineering bacterium and an application thereof; the gene engineering bacterium E. coli-glmS-gnal-delta nagE is obtained by introducing a glucosamine synthase gene (glmS) and a glucosamine acetylase gene (gnal) into escherichia coli E. coli K-12, and knocking out an encoding gene nagE of an acetyl-glucosamine phosphate transport system; the bacterial strain is applicable to the fermentation production of glucosamine, has the advantages of high production intensity, low production cost, less environmental pollution, no allergic reaction, and the like; and the obtained glucosamine is widely applicable to fields such as medicin, food, etc.

Owner:衢州益康园生物科技有限公司

Agricultural organic fertilizer and preparation method thereof

The invention discloses agricultural organic fertilizer. The agricultural organic fertilizer consists of the following raw materials in percentage by weight: 30-45 parts of fowl manure, 15-25 parts of cow dung, 12-25 parts of pig manure, 10-13 parts of peat soil, 15-20 parts of straw ash, 8-10 parts of sawdust, 2-4 parts of formic acid, 5-8 parts of animal bone meal, 6-8 parts of egg shell powder, 3-5 parts of gypsum powder, 2-4 parts of calcium hydrogen phosphate and 0.5-0.8 part of an EM inoculant. Furthermore, the invention discloses a preparation method of the agricultural organic fertilizer. The agricultural organic fertilizer, compared with the prior art, has the following advantages that the agricultural organic fertilizer overcomes shortcomings of chemical fertilizer and conventional agricultural fertilizer, and realizes comprehensive treatment of waste to turn waste into wealth; and the agricultural organic fertilizer can protect soil. The organic fertilizer preparation method is simple and easy to operate, relatively short in fermentation time, wide in raw material source, low in cost, and quite remarkable in both social benefit and economic benefit.

Owner:合肥科友生物科技有限公司

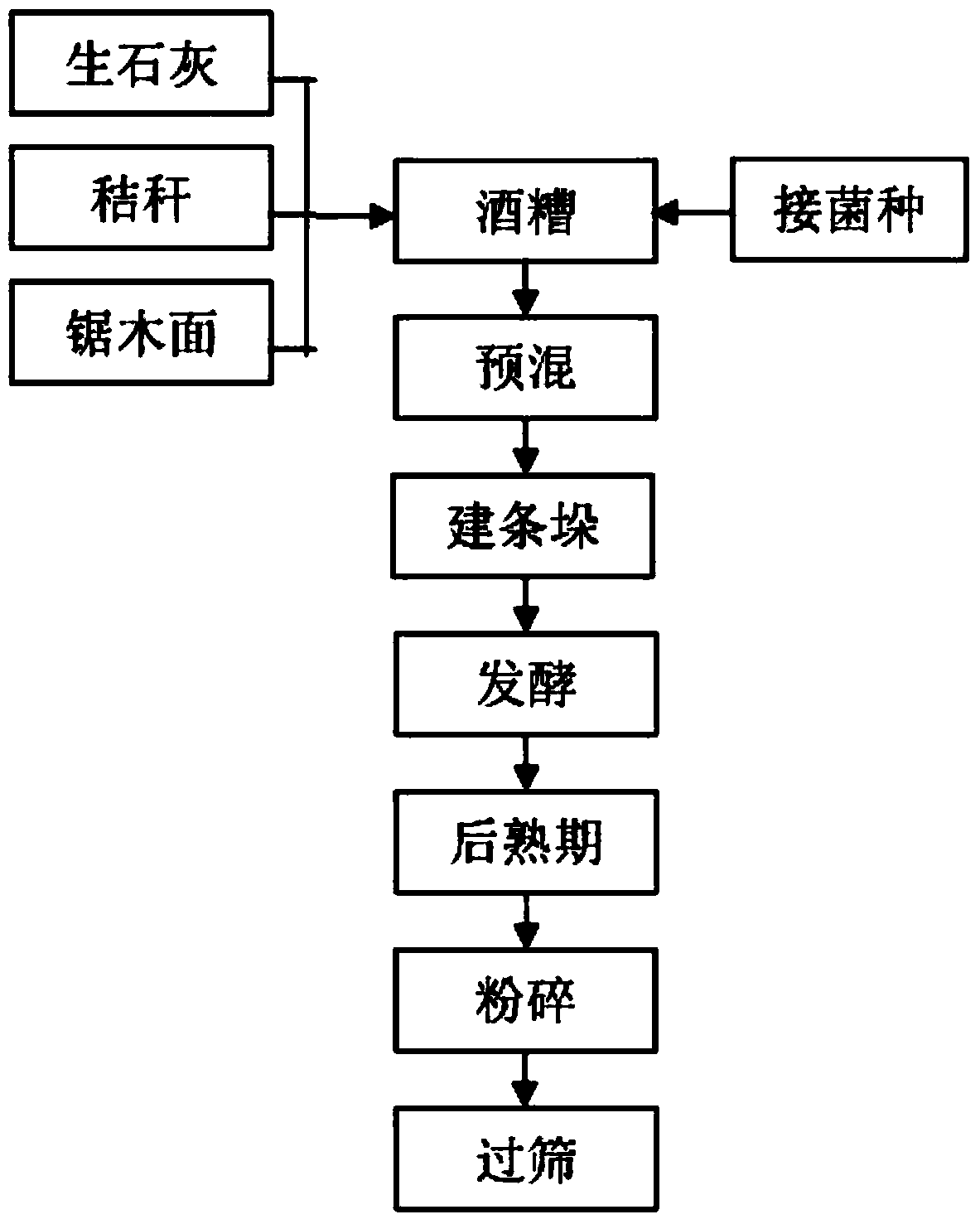

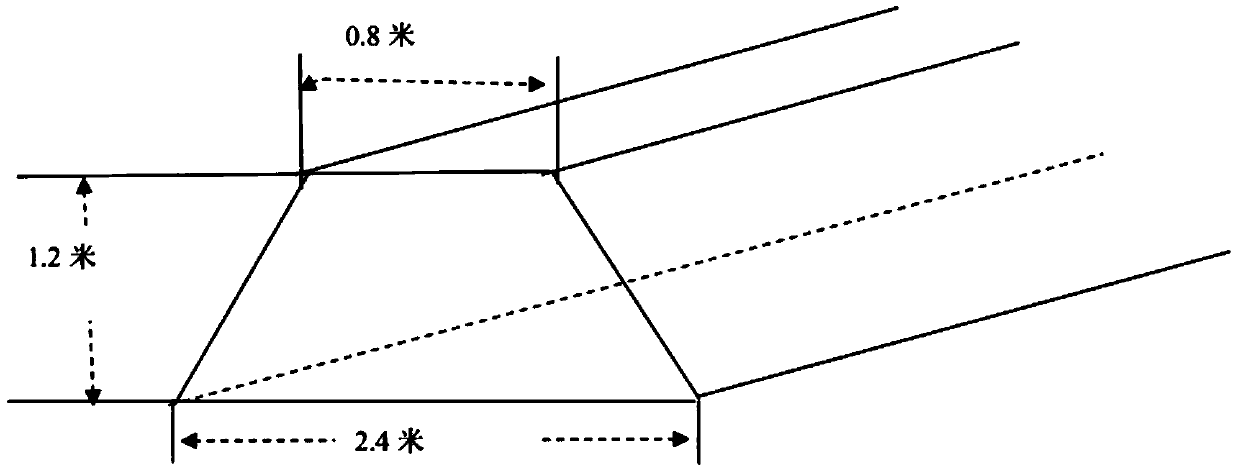

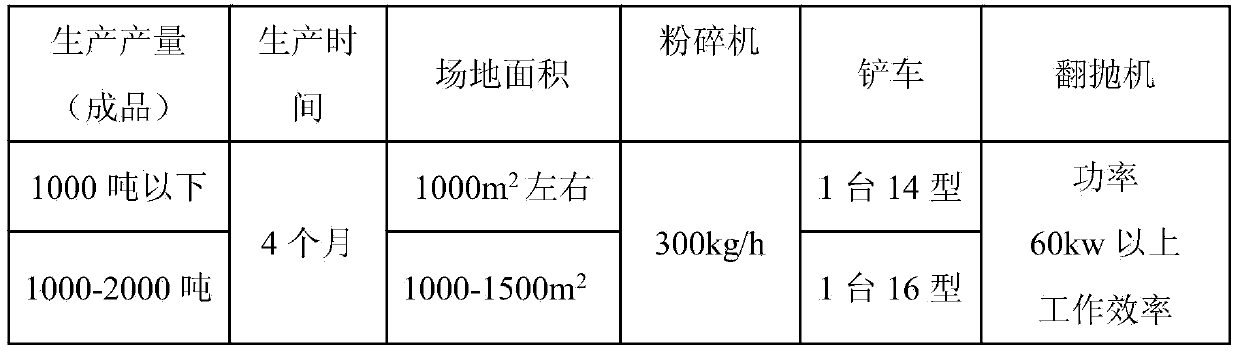

Distilled grain organic fertilizer and production method thereof

ActiveCN104151042AShort fermentation timeThe degree of fermentation is controllableBio-organic fraction processingOrganic fertiliser preparationNutrientChemistry

The invention discloses a distilled grain organic fertilizer and a production method of the distilled grain organic fertilizer. A fermentation material of the distilled grain organic fertilizer comprises the following components in parts by mass: 100 parts of distilled grains, 3-5 parts of straw, 1-2 parts of wood sawdust, 2-2.5 parts of quick lime and 0.2-0.3 part of a strain. The production method comprises the following steps: inoculating the fermentation material with the strain, uniformly mixing to construct a strip pile, and performing fermentation; heating the strip pile to 60-65 DEG C, and turning the pile; regulating the pile turning frequency under a principle of maintaining the temperature of the strip pile to be not more than 65 DEG C; naturally ventilating for 1-2 months after fermenting; further crushing and screening to obtain a distilled grain organic fertilizer final product. The method for producing the distilled grain organic fertilizer, disclosed by the invention, is short in fermentation time and controllable in fermentation degree; the obtained product comprises the following components in percentage by weigh: 76% of an organic matter, 4% of N, 2.18% of P2O5, 1.29% of K2O, 7.74% of total nutrients and 29% of moisture; the pH value of the product is 6.2; indicators of the mortality of roundworm eggs and the number of fecal coliforms of the product can meet the requirements of NY884.

Owner:GUIZHOU TOBACCO SCI RES INST +1

Brewing method of moso bamboo shoot wine

ActiveCN103409284AEfficient use ofHigh degreeAlcoholic beverage preparationMicroorganism based processesBamboo shootGeneral Appearance

The invention provides a brewing method of moso bamboo shoot wine. The brewing method comprises the following steps of (1) preparing materials and removing shells; (2) washing; (3) crushing; (4) distributing materials; (5) cooking; (6) saccharifying; (7) degrading cellulase and feeding sugar; (8) fermenting; (9) distilling; and (10) aging, mixing and packaging. The brewing method provided by the invention is simple in process and short in fermentation time; the general appearance of the brewed moso bamboo shoot wine is colorless, is bright and transparent and has no suspension matter and sediment; all tastes of the wine are coordinated and the wine is fragrant and pure, has a long-time sweet taste and is sweet and soft; the aftertaste is pure and cool.

Owner:HUNAN ACAD OF FORESTRY

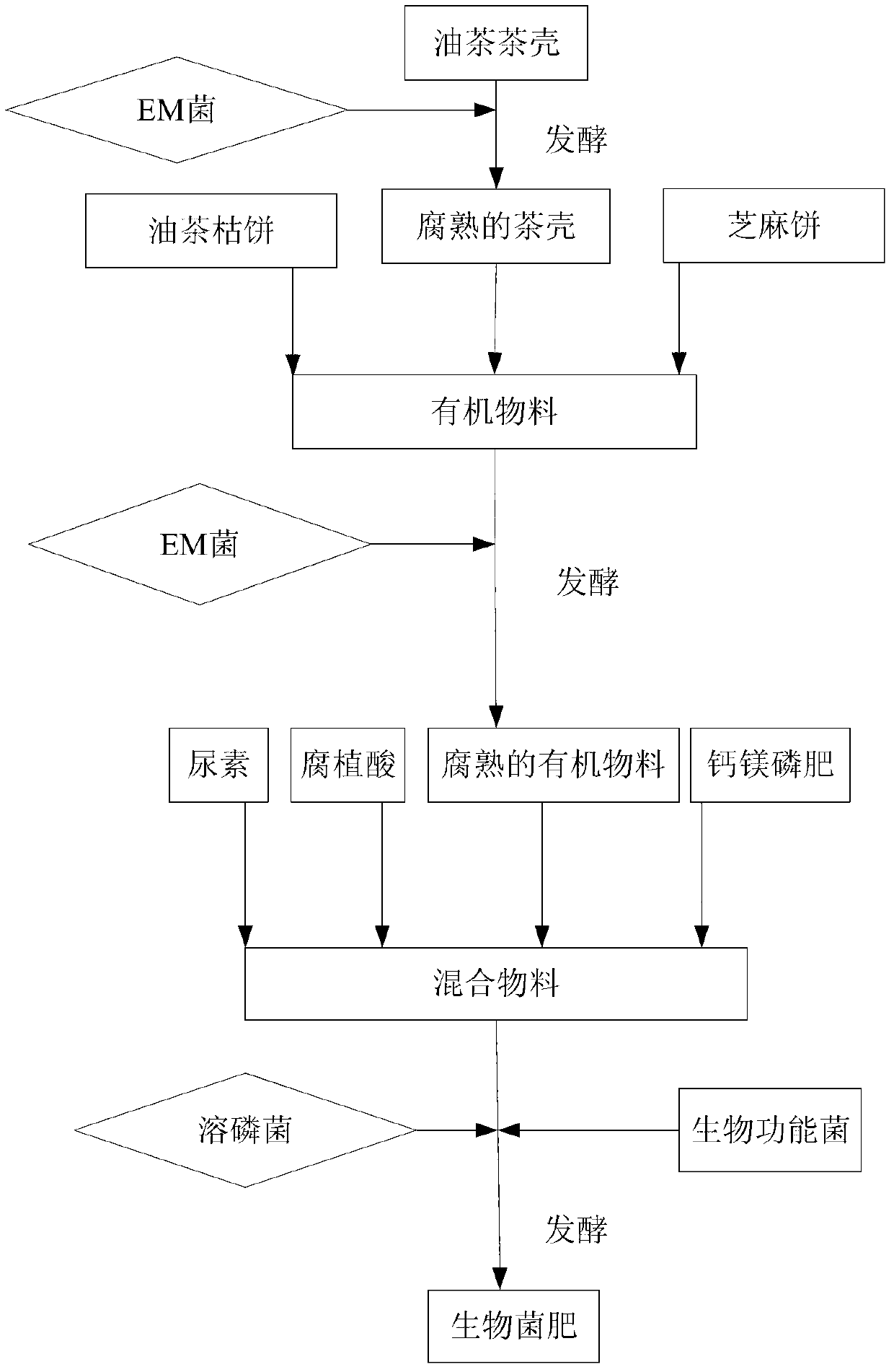

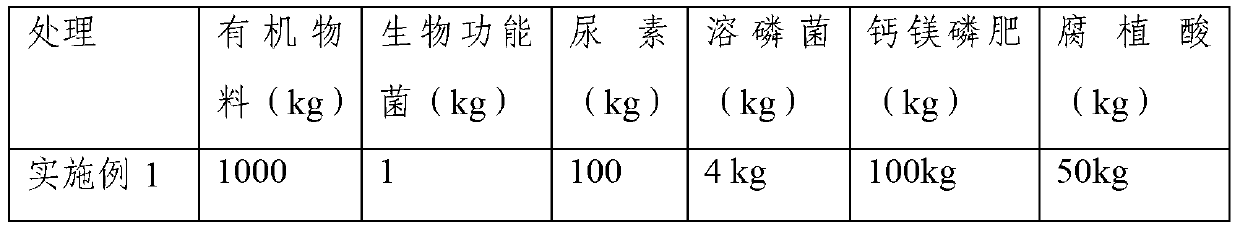

Special biological bacterial fertilizer for oil-tea camellia and production method thereof

ActiveCN103342592ALow utilization efficiencyProduction cost and equipment requirements are simpleBio-organic fraction processingOrganic fertiliser preparationCamellia oleiferaPhosphate solubilizing bacteria

The invention belongs to the field of organic fertilizer and relates to a method for producing special biological bacterial fertilizer for oil-tea camellia. The method comprises the following steps of: (1) adding smashed oil-tea camellia shells into an EM bacterium diluent for fermentation for 5-8 days to obtain rotted tea shells, (2) mixing the rotted tea shells, oil-tea camellia dried cakes and sesame cakes, adding the mixture into an EM bacterium diluent for fermentation for 10-15 days to obtain a fermented organic material, and (3) mixing the fermented organic material, urea, humic acid, biological functional bacteria and calcium magnesium phosphate fertilizer, and uniformly spraying a phosphate-solubilizing bacteria diluent for fermentation for 4-6 days. According to the method, the materials are readily available; production equipment is simple; the production time is short; the cost is low. The special biological bacterial fertilizer for oil-tea camellia can effectively improve the physical and chemical property of an oil-tea camellia land and promote the activation utilization of the fertilizer and soil phosphorous, so that the growth and the yield of oil-tea camellia are improved; the biological bacterial fertilizer is the first choice for high-efficiency ecological cultivation of oil-tea camellia in a red soil region and has wide application prospect.

Owner:邵阳县现代农业科技示范有限责任公司

Method for producing high-salt dilute fermented soybean sauce

InactiveCN103734668AQuality improvementShort fermentation timeFood preparationGeneration rateFermentation

The invention discloses a method for producing high-salt dilute fermented soybean sauce, and belongs to the field of liquid condiment production. By adopting the method, the soybean sauce which is stable in quality and good in color, fragrance, taste and smell can be brewed within 90 days, and the demands on the high-quality soybean sauce in market can be met. The method comprises the following steps: 1, screening non-transgenic defatted soybeans and subsequently steaming the screened non-transgenic defatted soybeans; 2, selecting starlatine wheat, frying and subsequently crushing; 3, mixing the defatted soybean with wheat; 4, propagating starter; 5, uniformly mixing the propagated starter so as to subsequently obtain fermented mash; 6, performing primary fermentation, aroma enhancement fermentation and later fermentation on the fermented mash in sequence; 7, sequentially extruding, blending and sterilizing so as to obtain the high-salt dilute fermented soybean sauce. The soybean sauce produced by using the method is not only good in quality, but also high in utilization rate of raw materials and high in amino acid generation rate, the fermentation time is shortened, the energy consumption is reduced because of heat preservation fermentation, the circulation of fermentation equipment is rapid, and the utilization rate of the equipment is increased by about one time.

Owner:哈尔滨正阳河调味食品有限公司

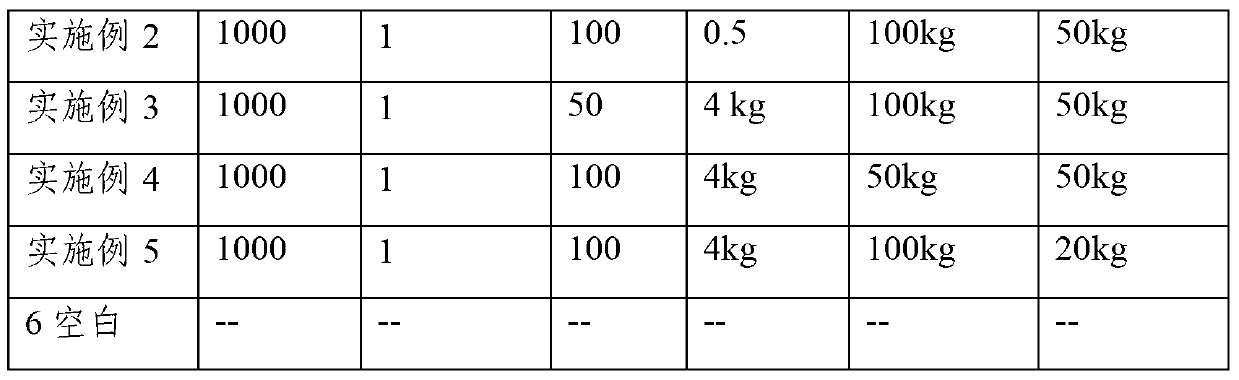

Hybrid paper mulberry tree leaf and shoot fermentation feed and preparation method thereof

InactiveCN105533160AIncrease crude protein contentReduce crude fiber contentAnimal feeding stuffAccessory food factorsAnimal feedPaper mulberry tree

The invention provides a preparation method of a hybrid paper mulberry tree leaf and shoot fermentation feed. The preparation method comprises the following steps of firstly crushing raw materials, performing soaking treatment with alkali, then performing high-temperature boiling, performing cooling and enzymolysis, and finally performing microbial fermentation so as to obtain finished products. The method disclosed by the invention is short in fermentation time, the obtained fermentation feed is high in the content of crude protein, reduced in the content of crude fibers, high in raising efficiency and environmentally-friendly, and animals fed with the fermentation feed grow quickly and are low in attack rate.

Owner:ANHUI ZHONGKE ANYUE FORESTRY TECH DEV CO LTD

Process for producing local flavor pickled vegetable juice

The present invention discloses preparation process of flavored pickle juice. The preparation process includes the following steps: 1. culturing lactic acid bacteria and yeast in certain conditions to obtain lactic acid bacteria culture solution and yeast culture solution and mixing the lactic acid bacteria culture solution and the yeast culture solution in the weight ratio of 1-3 to 1 to obtain mixed seed liquid; 2. boiling the mixture of salt 4-8 wt%, sugar 2-5 wt%, ginger 0.5-2 wt%, pricklyash 0.05-0.2 wt%, aniseed 0.05-0.2 wt% and water 86-92 % for 6-12 min to obtain mixed seasoning liquid; and 3. soaking cut fresh vegetable in the mixed seasoning liquid, adding mixed seed liquid in 8-15 wt%, fermenting first at 25-35 deg.c for 12-24 hr and then at 15-25 deg.c for 36-48 hr to obtain pickle, squeezing the pickle to obtain juice and vacuum concentrating to obtain flavored pickle juice.

Owner:TIANJIN CHUNFA BIO TECH GRP

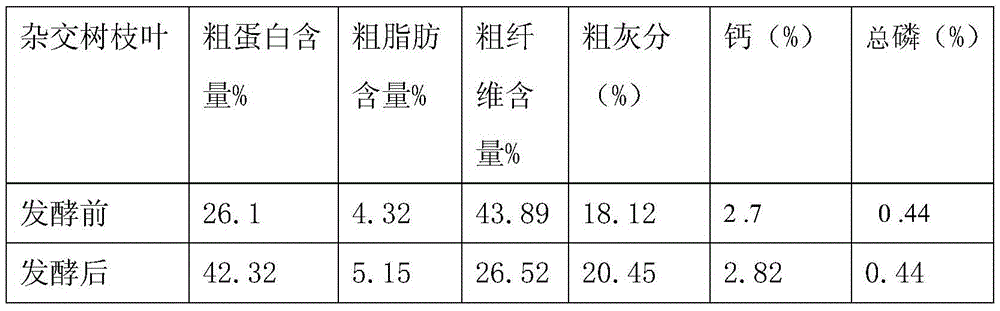

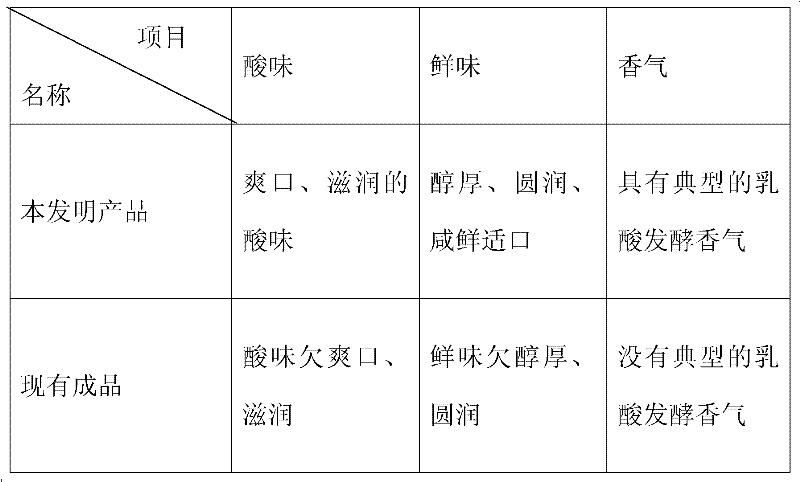

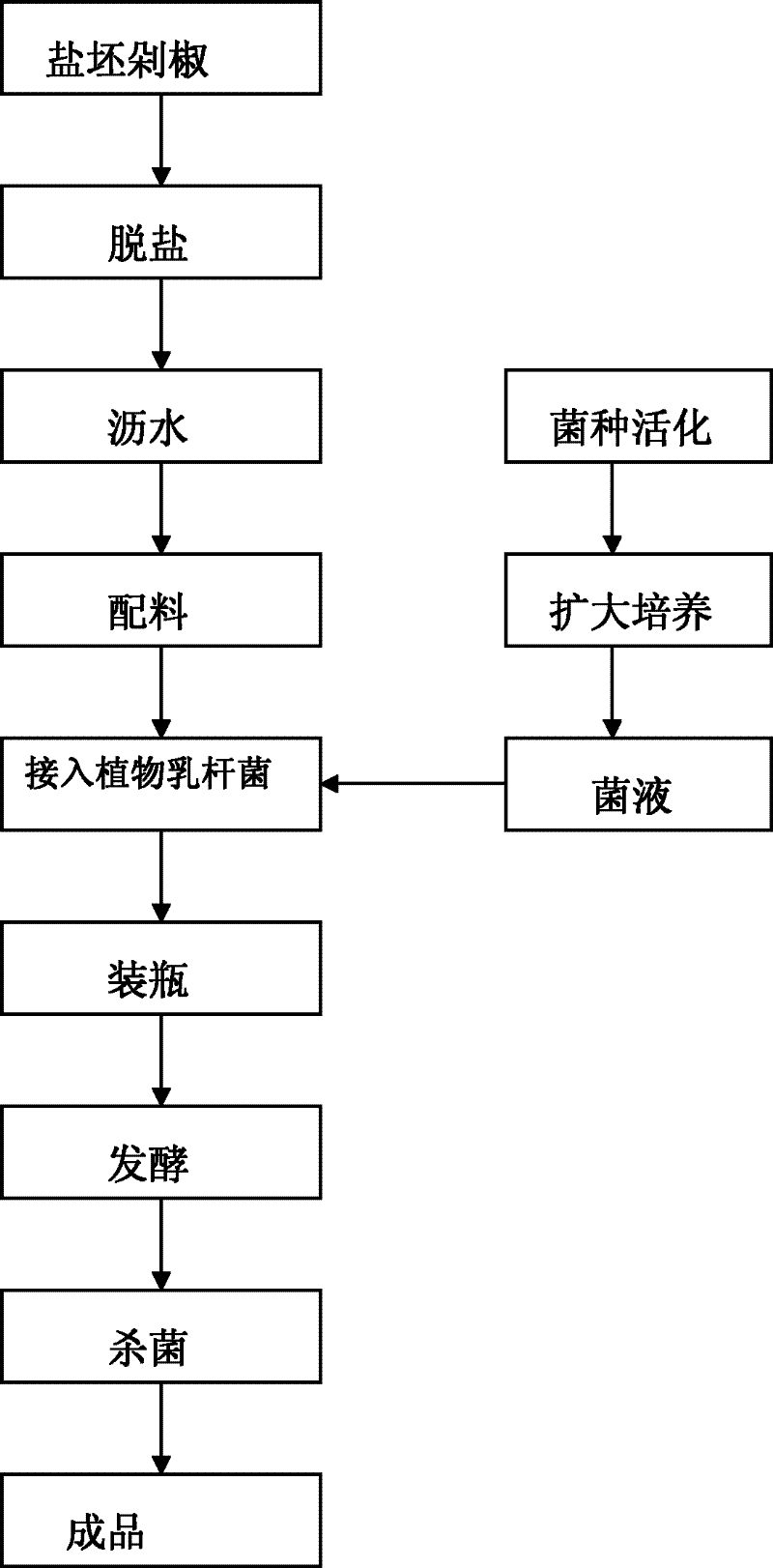

Method for bottling and fermenting chopped hot peppers

The method discloses a method for bottling and fermenting chopped hot peppers. The method mainly comprises the following steps of: desalting and draining salt blank chopped hot peppers used as raw materials; adding condiments, a preservative and a flavor agent; uniformly stirring to form a chopped hot pepper initial product; inoculating lactobacillus plantarum liquid, of which the bacterial number reaches 10<8> cfu / mL, into the chopped hot pepper initial product; uniformly stirring, bottling and fermenting; and sterilizing the fermented chopped hot pepper initial product and forming a finished product. The chopped hot pepper initial product prepared by the method is not only short in fermentation time, but also has thick fermentation fragrance and good flavor and quality; the fermentationof pure strains facilitates inhibiting the growth of hybrid bacteria, so that accumulation of nitrite during fermentation can be obviously reduced; and the edible safety of pure strain fermentation products is superior to that of natural fermentation products.

Owner:HUNAN AGRICULTURAL UNIV +1

Formula of zao pepper and processing method of zao pepper

InactiveCN103300337AShort fermentation timeExtended storage timeFood preparationBiotechnologyAllium sativum

The invention relates to a preparation method of zao pepper. The preparation method comprises the following materials in percentage by weight: 88-92% of red cluster pepper, 3-5% of salt, 2-3% ginger, 1.5-3% of garlic, 0.2-0.5% of pepper, 0.1-0.3% of cardamon, 0.1-0.3% of Chinese anise, 0.2-0.4% of sugar candy, 0.01-0.03% of yeast essence, and 0.01-0.03% of concentrating sweet wine medicine. The zao pepper with the preparation method is processed according to the following technological process: preparing a zao pepper food bag, preparing fresh pepper materials, preparing auxiliary materials, preparing the zao pepper, sterilizing, insepecting a product, packaging and placing in a bin. The preparation method provided by the invention is adopted to manufacture the zao pepper, the fermentation time is short, the holding time is long, the color can not fade, the vinegar-pepper taste is palatable, the taste is soft, the zao pepper has the functions of appetizing and tonifying spleen and increasing the appetite, and is an essential auxiliary material in a fried dish for all families in the southwest.

Owner:GUIZHOU ZUNYI COUNTY GUISANHONG FOOD

Microorganism solid leaven and preparing method thereof

InactiveCN1500862ANo pollution in the processShort fermentation timeBio-organic fraction processingBacteriaMicroorganismBiotechnology

The present invention relates to one kind of microbial solid fermenting agent and its preparing process. Microbial seeds are cultured compositely to obtain the microbial seed combination for treating waste as resource. The fermentation process is anaerobic process, and has the advantages of less consumption of nutritive components, short period, low power consumption and high conversion rate. During the fermentation, microbes and its produced physiological metabolic matters can kill various pathogenic bacteria, decompose and convert various organic pollutants and produce various fermented products, such as organic fertilizer obtained via converting animal excrement, protein feed obtained via converting straw, fermented protein feed obtained via converting different leftover, etc.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Method for preparing industrial fermentation pickled vegetable

ActiveCN101697751AAdd beneficial ingredientsGood antibacterial effectFruits/vegetable preservation using acidsSaline waterIndustrial fermentation

A method for preparing industrial fermentation pickled vegetable relates to a method for preparing fermentation pickled vegetable, solving the problems that pickled vegetable produced by the current large-scale factory is still prepared by traditional technique depending on natural fermentation and the cabbage in the fermentation jar can be easily damaged by other bacteria and be easily rotten and goes bad. The method comprises the following steps: 1, palletizing cabbages; 2, adding pickled vegetable fermentation engineering bacteria; 3, fully injecting brine to the fermentation jar; 4, carrying out fermentation to obtain the product of pickled vegetable. The method uses controllable industrial technique to ferment the pickled vegetable; the added components are known and controllable; thus, the method avoids the pollution of the cabbage by other bacteria, rot and metamorphism.

Owner:HEILONGJIANG UNIV

A kind of method for processing sludge fermentation to produce bio-organic fertilizer

InactiveCN102260104ANitrogen fixation, phosphorus and potassiumStrong for fatteningBio-organic fraction processingClimate change adaptationProcess equipmentBiochemical engineering

The invention discloses a method for producing a high-efficiency biological organic fertilizer by quickly fermenting sludge. The method comprises the following steps of: preparing a culture medium; fermenting; crushing; balling; drying; cooling and the like. The method has the advantages of wide raw material sources, simple process equipment, low cost, convenience in operation, and short fermentation time; and the fermented sludge can be used for producing the organic fertilizer, so that the technical problems of secondary environmental pollution and the waste of massive organic fertilizer sources in the prior art are solved.

Owner:YANTAI UNIV

Microorganism retting flax method for crudefiber crops

InactiveCN101285211AShort fermentation timeHigh rate of numbnessBacteriaMicroorganism based processesFiber cropMicroorganism

The invention provides a method for retting flax with microbe mild water for bast-fiber crops, belonging to a retting technology for the bast-fiber crops. The method comprises the following steps of: adding degumming bacteria into a retting vessel according to 0.5 to 1.0 per thousand of the total weight of aqueous solution; heating up to 30 to 40 DEG C after injecting water to 100 percent of the total weight of the aqueous solution; and finishing retting after 40 to 50 hours. The industrial production of the degumming bacteria is completed via primary strain culture, secondary strain culture and industrial production. The method has the characteristics of short retting fermentation period, high percentage of fiber extraction, high fiber stress, small water consumption, low energy consumption, retting water economization, zero drainage of retting water and no environmental pollution.

Owner:黑龙江省科学院亚麻综合利用研究所

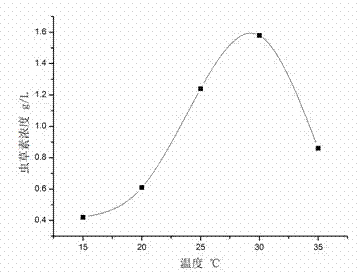

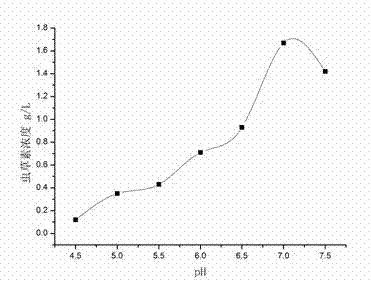

Cordyceps militaris strain for producing cordycepin with high yield

InactiveCN102876587AStable traitsShort fermentation timeFungiMicroorganism based processesBiotechnologyCordyceps

The invention discloses a cordyceps militaris strain for producing cordycepin with high yield and belongs to the technical field of bioengineering. The cordyceps militaris strain is named as cordyceps militaris JN168 by classification and is preserved with CCTCC No: M2011333 inChinaCenter for Type Culture Collection. The cordyceps militaris strain which is stable in character is obtained by isolation and screening of wild cordyceps militaris sporocarps collected from Antu, Jilin Province. The cordyceps militaris strain is capable of producing the cordycepin by liquid-state fermentation at the fermentation temperature of 30 DEG C, and the final concentration of cordycepin can be 6g / L after fermentation for 5 days.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com