Special biological bacterial fertilizer for oil-tea camellia and production method thereof

A technology for biological bacterial fertilizer and camellia oleifera is applied in the field of organic fertilizers, which can solve the problems of no ecological environment protection, simple and practical, unfavorable for plants to absorb phosphorus, long fermentation time, etc., and achieves improved soil physical and chemical properties, low cost, and production equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

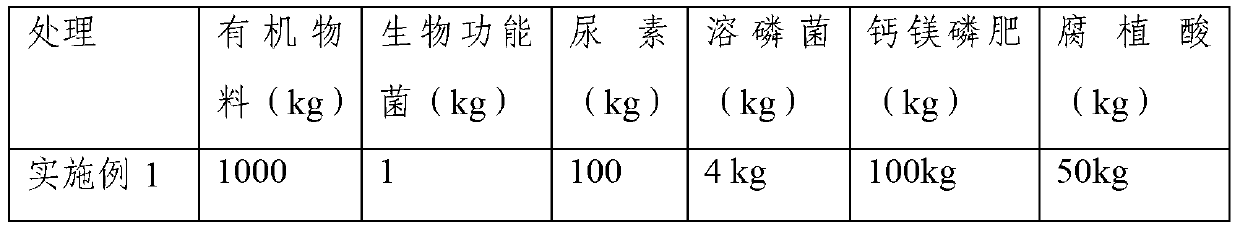

Embodiment 1

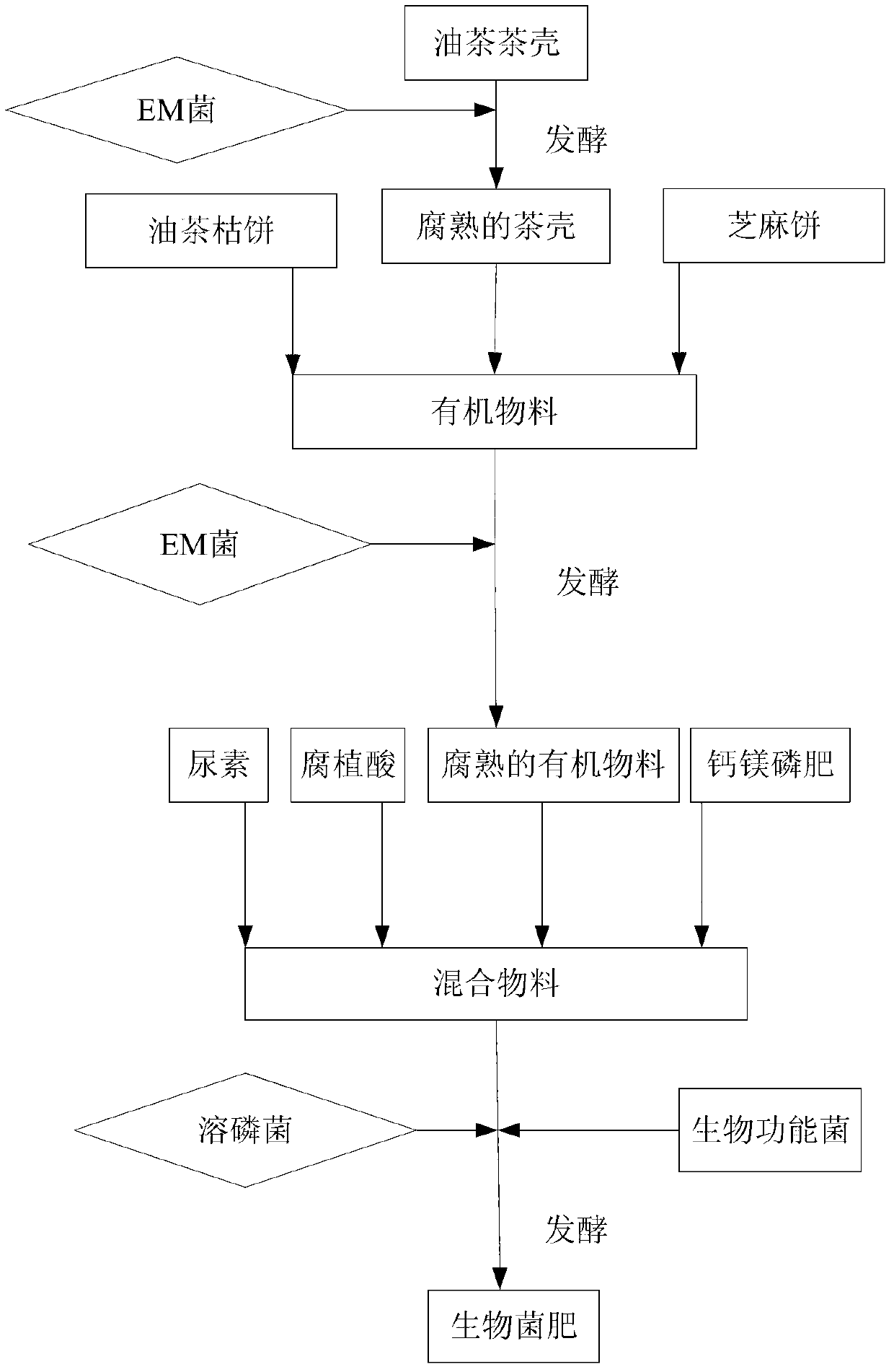

[0042] The process flow of preparation can be found in figure 1 .

[0043] Dilution of EM original bacteria: add 1kg of EM original bacteria whose main components are yeast, lactic acid bacteria and other flora with an effective viable count of 20 billion / ml, 1kg of brown sugar, and 100kg of well water, and mix well.

[0044] The tea husks purchased from Camellia oleifera production areas are crushed through a 10-mesh sieve, and then stacked and fermented with a height of 1.5 meters and a width of 5 meters at the bottom. : 40 spray EM diluent, then cover with plastic film, cover the surrounding soil and step on it, ferment for 6 days to get decomposed tea shell;

[0045] Use an excavator to excavate a fermentation tank of a suitable size. When digging the tank, tamp the surrounding area, and then put the decomposed tea shells, the dried camellia cake recovered from the oil factory using physical pressing, and the sesame cake recovered from the physical pressing factory accord...

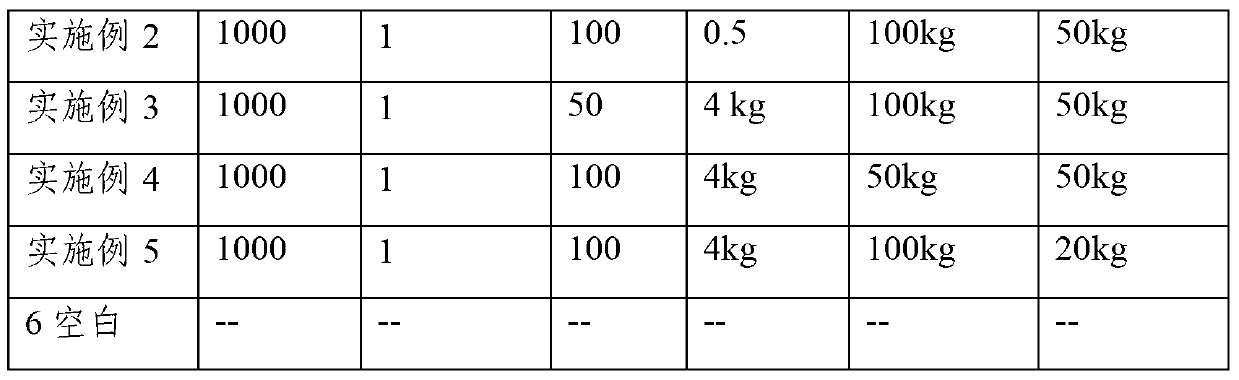

Embodiment 2

[0050] Dilution of EM original bacteria: add 1kg of EM original bacteria whose main components are yeast, lactic acid bacteria and other flora with an effective viable count of 20 billion / ml, 1kg of brown sugar, and 100kg of well water, and mix well.

[0051] The tea husks purchased from Camellia oleifera production areas are crushed through a 10-mesh sieve, and then stacked and fermented. The height of the stack is 1.5 meters, and the width of the bottom of the stack is 5 meters. Camellia oleifera husk: 1:40 dilution of EM bacteria, then cover with plastic film, surround the plastic film with soil and make it firm, ferment for 8 days to get decomposed tea husk;

[0052] In the central area of Camellia oleifera planting area, use an excavator to dig a fermentation tank of appropriate size. When digging the tank, tamp the surrounding area, and then put the decomposed tea shells, dried camellia cake and sesame cake recovered from the oil factory using physical pressing method a...

Embodiment 3

[0057] Add 50kg of urea (commercially purchased, total nitrogen content ≥ 46.4%), 50kg of humic acid (commercially purchased, humic acid ≥ 50%), and 1kg of biological functional bacteria (Guangzhou Nongguan Biotechnology Co., Ltd., agricultural Crown No. 15 complex bacteria, the number of effective viable bacteria ≥ 10 billion / g), calcium magnesium phosphate fertilizer 100kg (commercially purchased, effective phosphorus content ≥ 17%), mix with a mixer, add 4kg of phosphate-dissolving bacteria (Guangzhou Agricultural Crown Biotechnology Co., Ltd. company, No. 2 Phosphorus Solubilizing Bacteria of Agricultural Crown), the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com