Microbial fertilizer manufacturing method, prepared microbial fertilizer and compound microorganism preparation

A technology of microbial bacterial fertilizer and compound microorganisms, applied in the field of biochemistry, can solve the problems of soil water retention, fertilizer retention capacity and permeability reduction, soil compaction, etc., so as to shorten the cultivation time, reduce the production cost and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

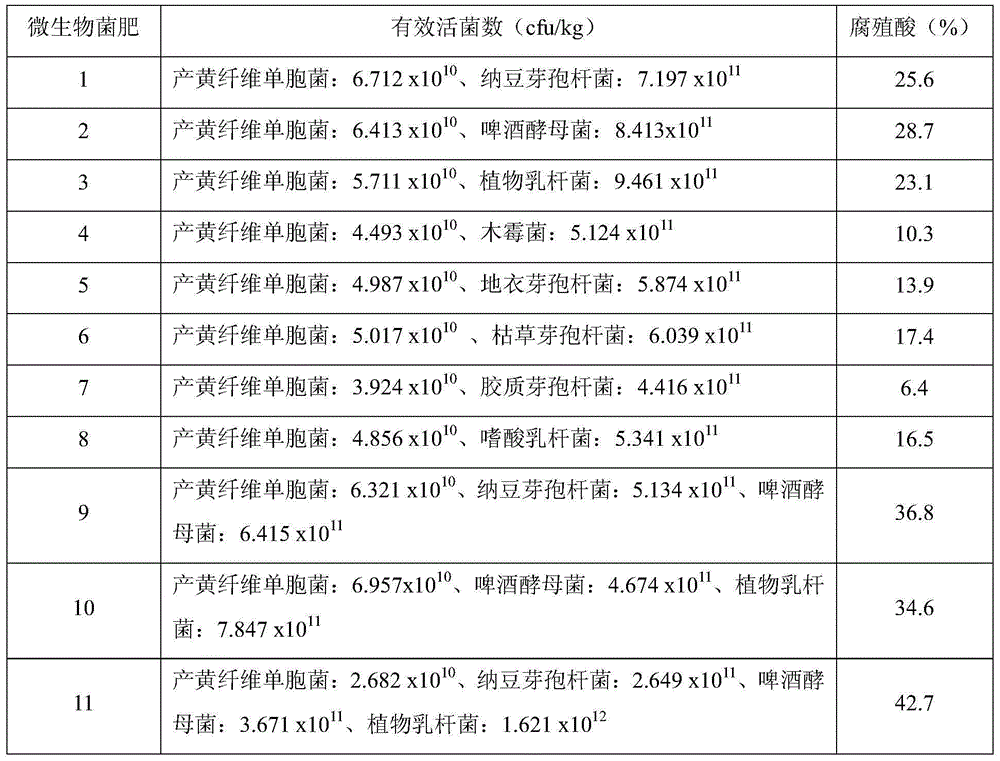

Examples

Embodiment 1

[0052] 1. Raw materials

[0053] Antibiotic residue: Penicillin G residue from a pharmaceutical factory, after testing, has a water content of about 75.9%, and the content of penicillin G in the residue is 2000ppm;

[0054] Wastes rich in plant fibers: residues after extraction of Houttuynia cordata and licorice;

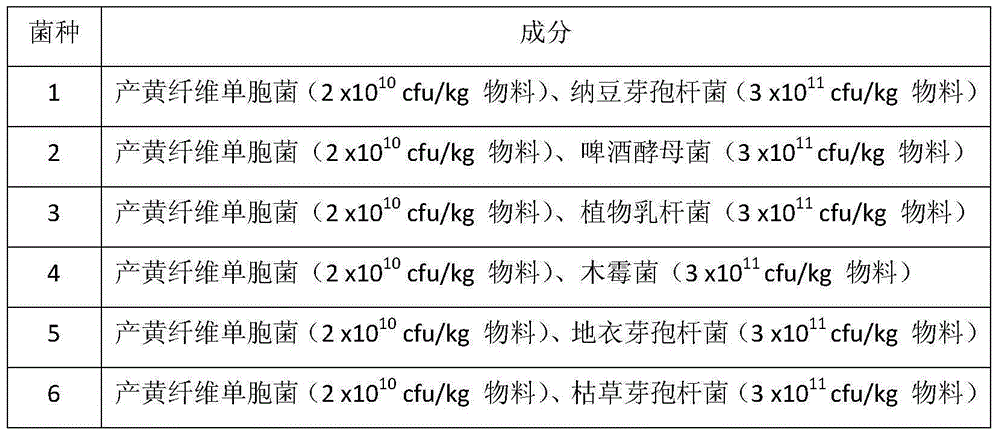

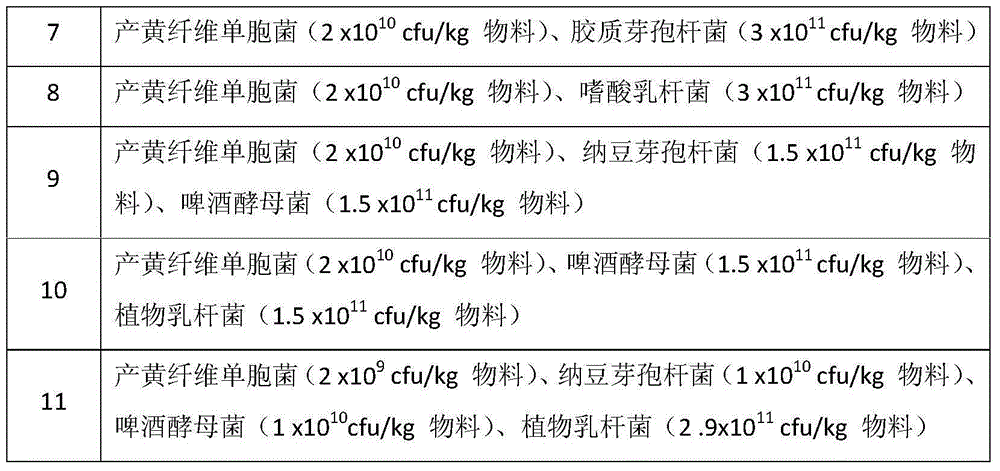

[0055] Composite microbial strains: Cellulomonas flavogenes, Bacillus natto, Saccharomyces cerevisiae, Lactobacillus plantarum;

[0056] Microbial culture medium: potato residue, distilled water, urea, KH 2 PO 4 、K 2 HPO 4 .

[0057] 2. Fermentation of microbial strains

[0058] The preparation of potato residue medium, potato residue 100g, distilled water 200g, urea 2g, KH 2 PO 4 0.2g, K 2 HPO 4 0.5g; Microbial strain inoculation, under sterile conditions, inoculate Cellulomonas flavinogenes, Bacillus natto, Saccharomyces cerevisiae, and Lactobacillus plantarum into potato dregs medium respectively, at 100rpm, the temperature is 25 ℃, pH is 6.8 under the...

Embodiment 2

[0067] 1. Raw materials

[0068] Antibiotic residue: Cephalosporin C residue from a pharmaceutical factory has been tested and found to have a water content of about 83.9%, and the cephalosporin content in the residue is 1800ppm;

[0069] Wastes rich in plant fibers: corn stover;

[0070] Composite microbial strains: Streptomyces, Bacillus natto, Saccharomyces cerevisiae, Lactobacillus plantarum;

[0071] Microbial culture medium: potato residue, distilled water, urea, KH 2 PO 4 、K 2 HPO 4 .

[0072] 2. Fermentation of microbial strains

[0073] The preparation of potato residue medium, potato residue 100g, distilled water 200g, urea 2g, KH 2 PO 4 0.2g, K 2 HPO 4 0.5g; microbial strain inoculation, under sterile conditions, inoculate Streptomyces, Bacillus natto, Saccharomyces cerevisiae, and Lactobacillus plantarum respectively in potato dregs medium, at 100rpm, the temperature is 25°C, and the pH is Under the condition of 6.8, culture on a shaking table for 2 days...

Embodiment 3

[0081] 1. Raw materials

[0082] Antibiotic residue: Tetracycline residue from a pharmaceutical factory, after testing, has a water content of about 80.4%, and the tetracycline content in the residue is 1600ppm;

[0083] Wastes rich in vegetable fibers: distiller's grains;

[0084] Composite microbial strains: Nocardia cellulose, Bacillus natto, Saccharomyces cerevisiae, Lactobacillus plantarum;

[0085] Microbial culture medium: potato residue, distilled water, urea, KH 2 PO 4 、K 2 HPO 4 .

[0086] 2. Fermentation of microbial strains

[0087] The preparation of potato residue medium, potato residue 100g, distilled water 200g, urea 2g, KH 2 PO 4 0.2g, K 2 HPO 40.5g; Microbial strain inoculation, under sterile conditions, inoculate Nocardia cellulose, Bacillus natto, Saccharomyces cerevisiae, and Lactobacillus plantarum into potato dregs medium respectively, at 100rpm, the temperature is 25 ℃, pH is 6.8 under the conditions, shaker culture 2d; obtain the enrichment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com